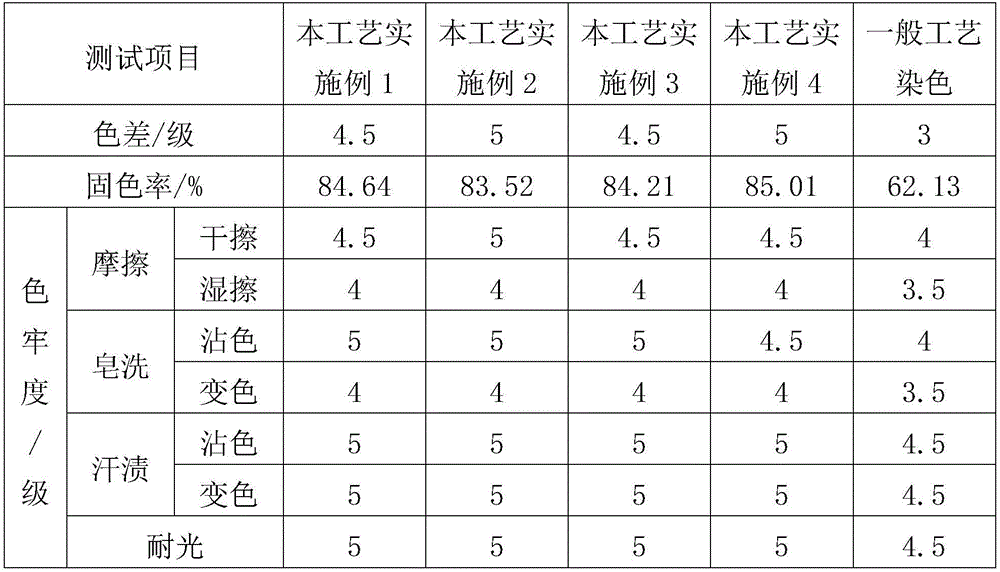

Patents

Literature

696results about How to "High color fixing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

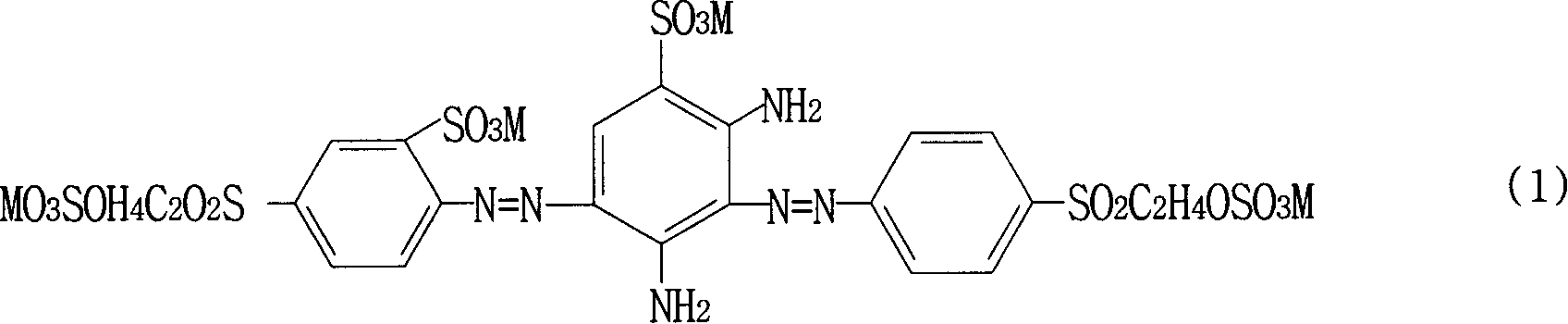

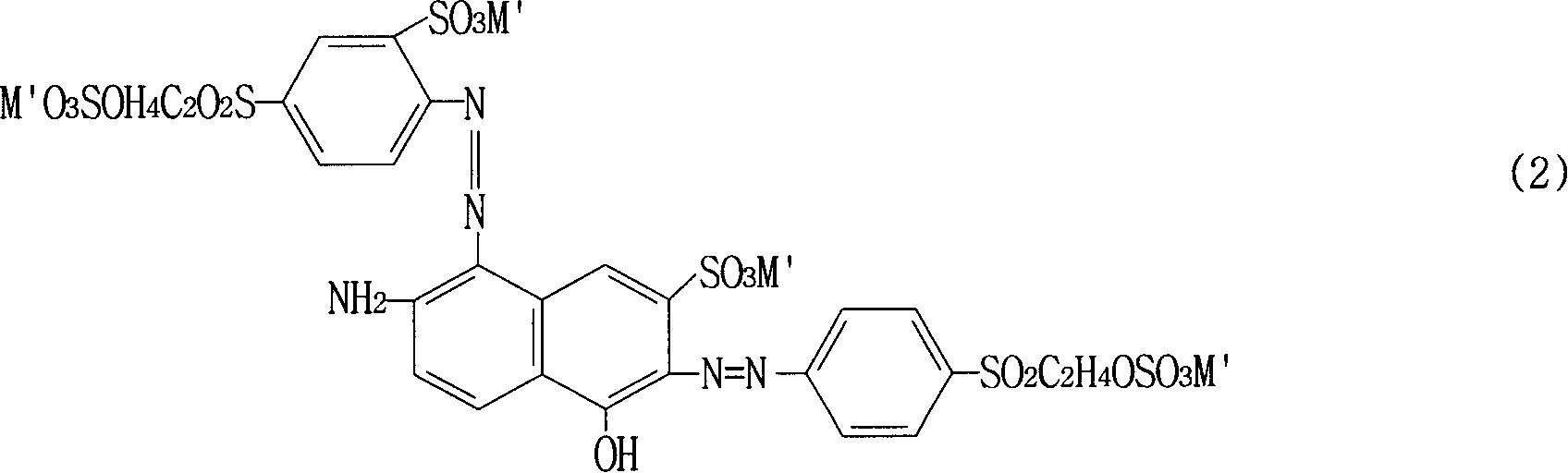

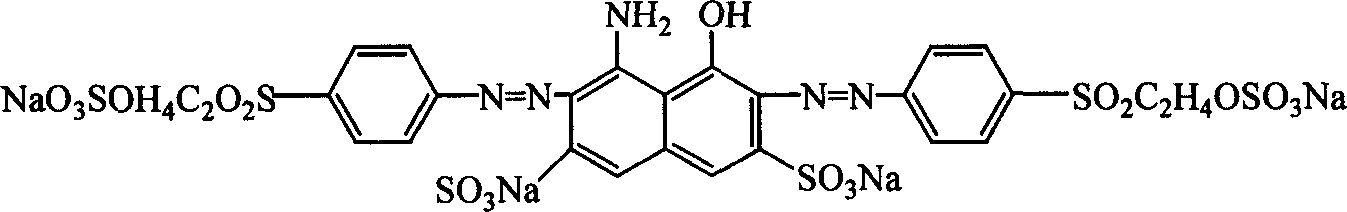

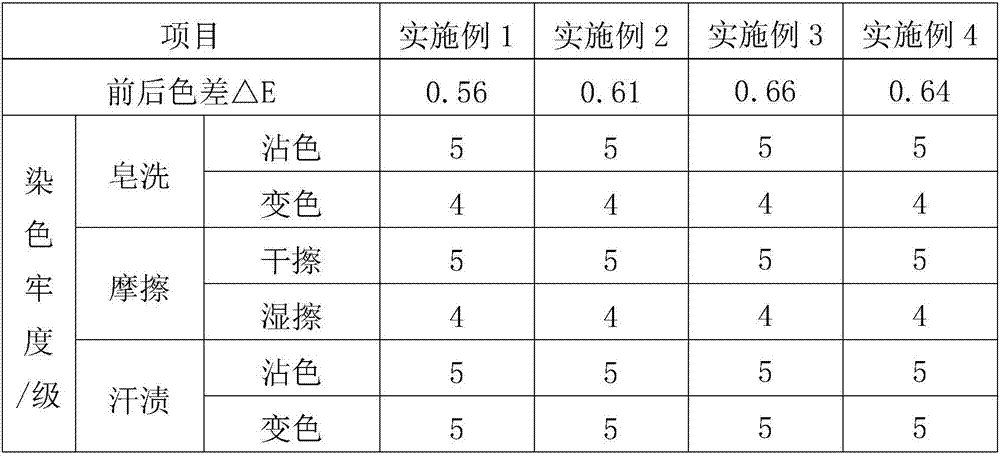

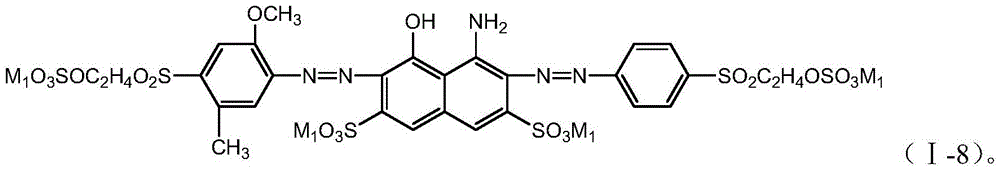

Compound active black dye

ActiveCN101037546AGood level dyeingHigh color fixing rateOrganic dyesDyeing processFiberPhotochemistry

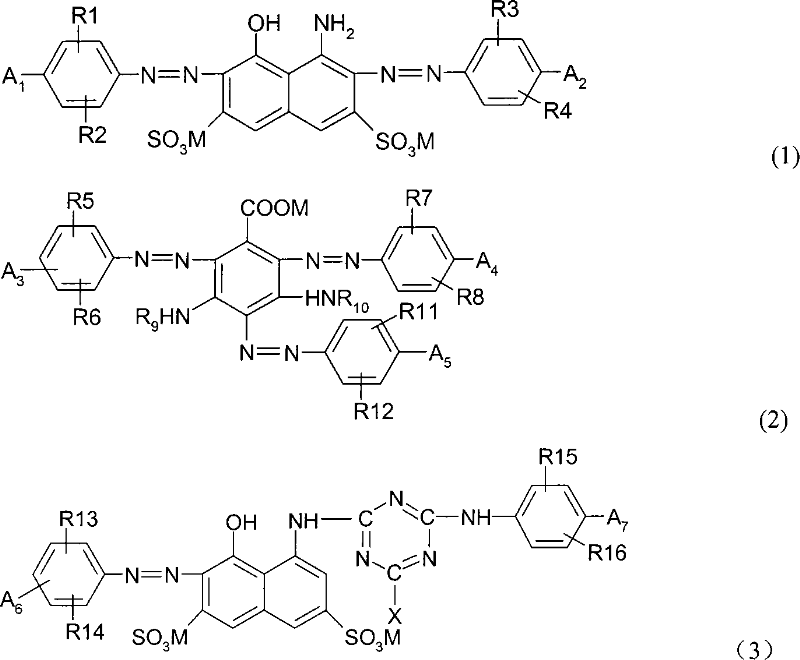

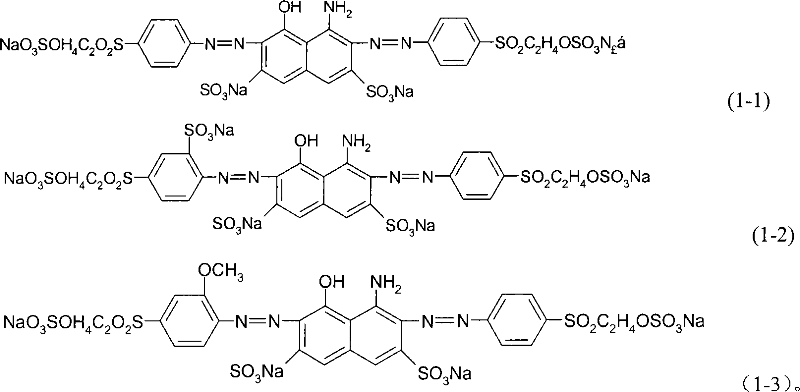

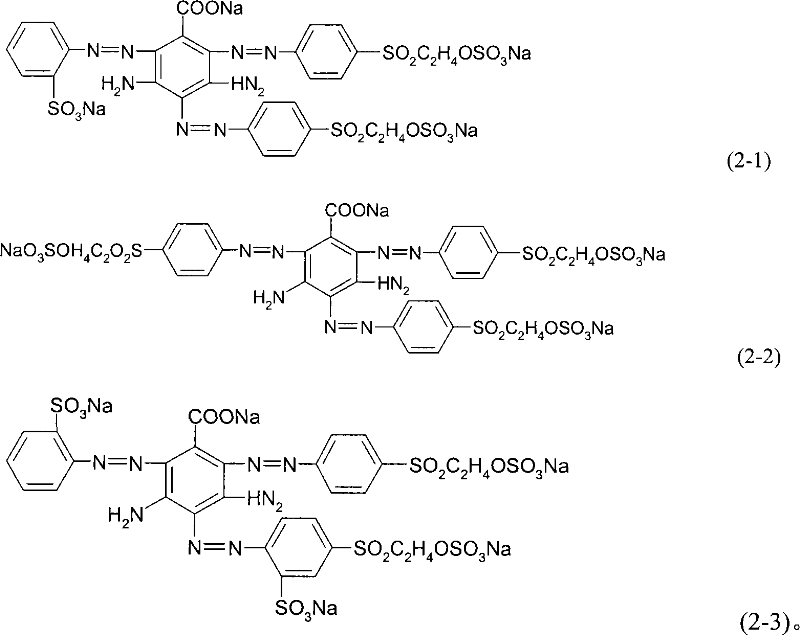

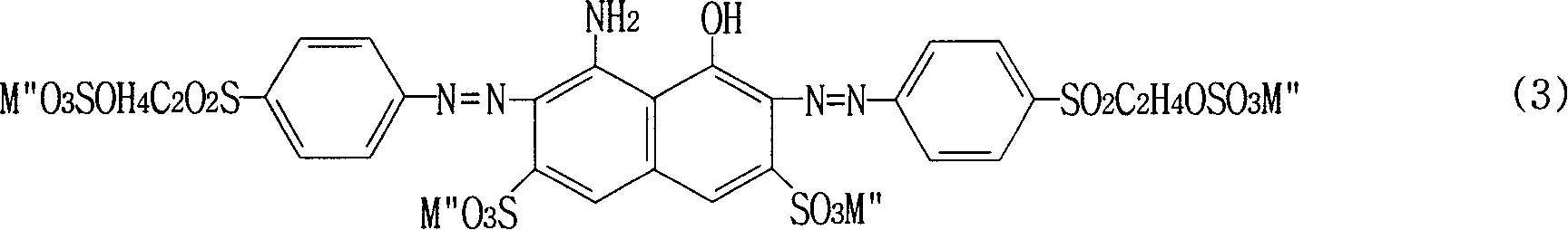

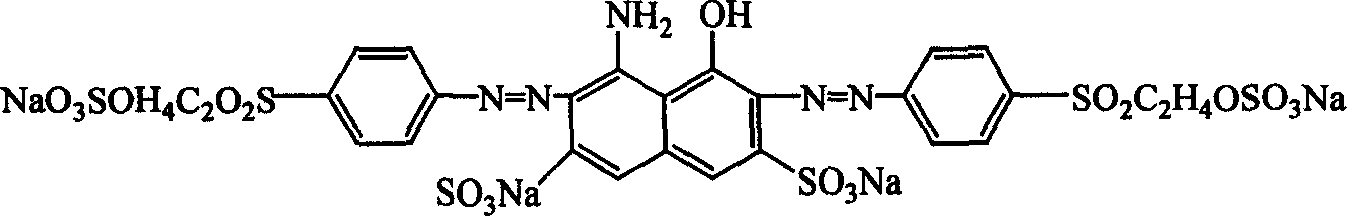

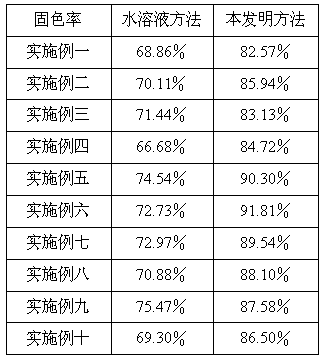

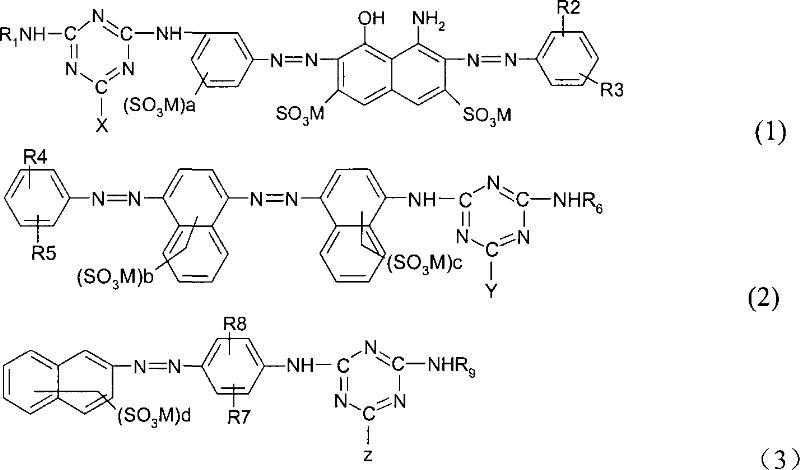

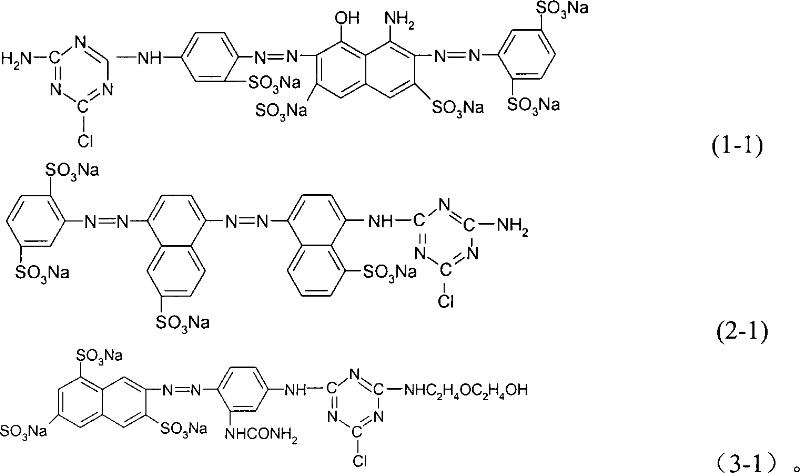

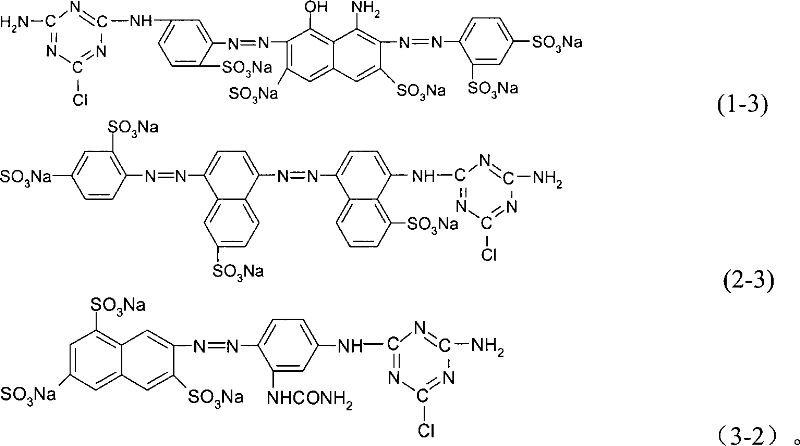

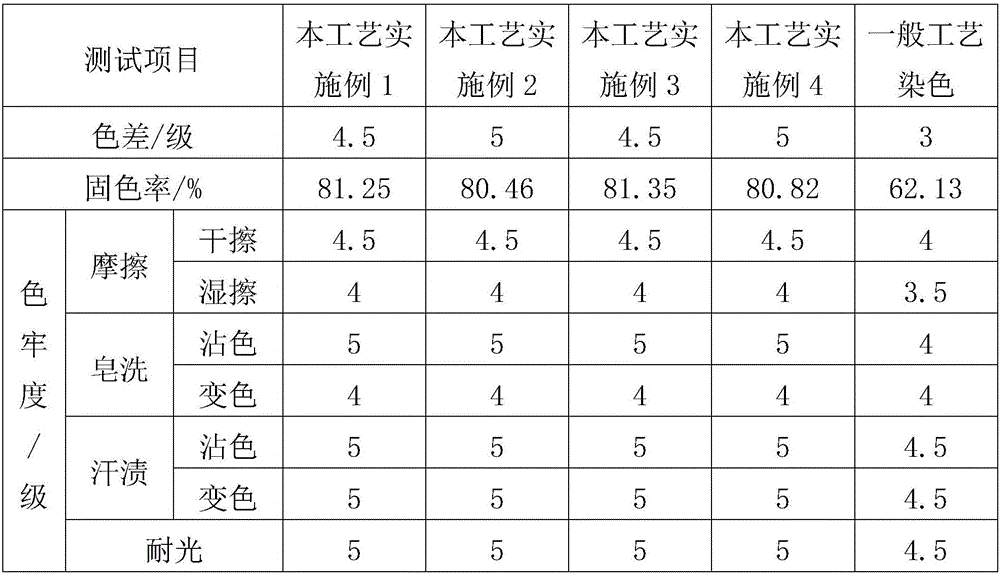

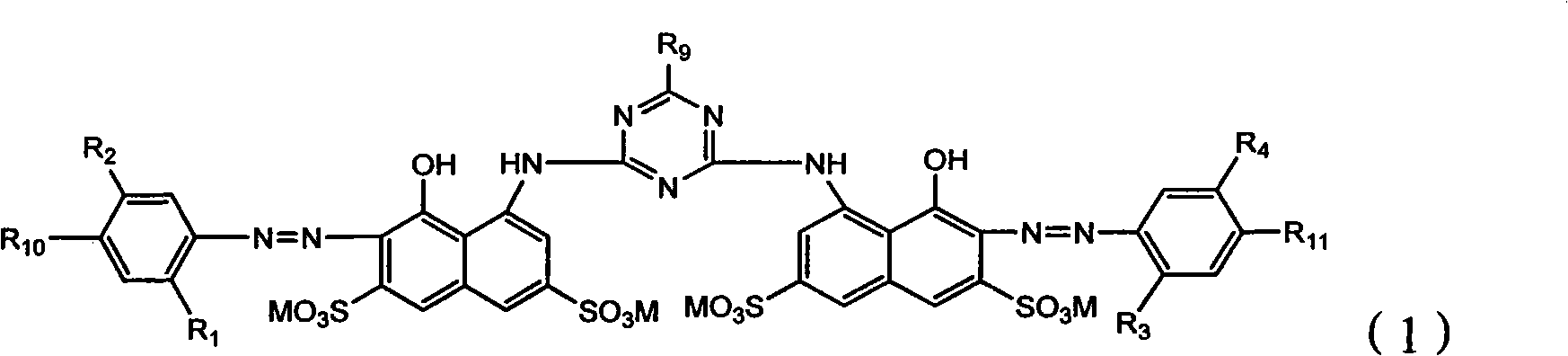

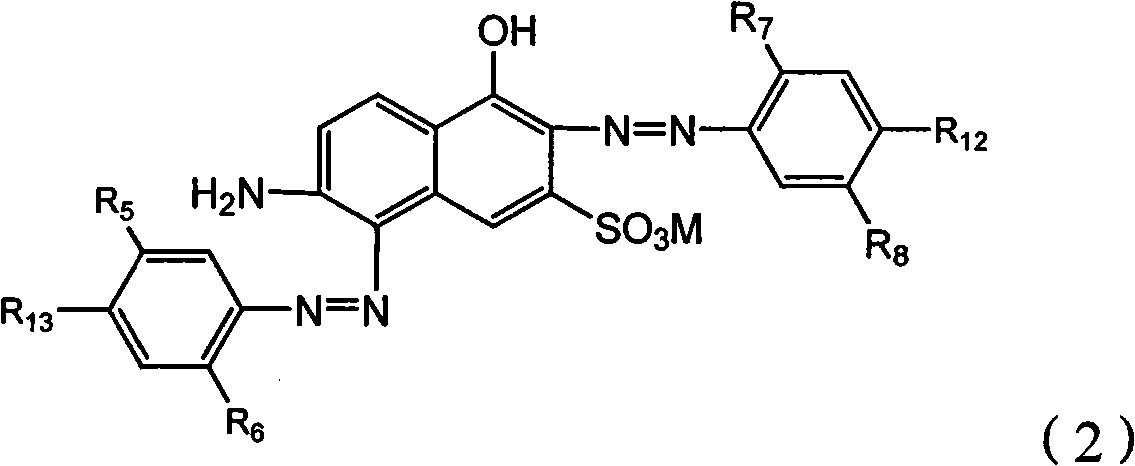

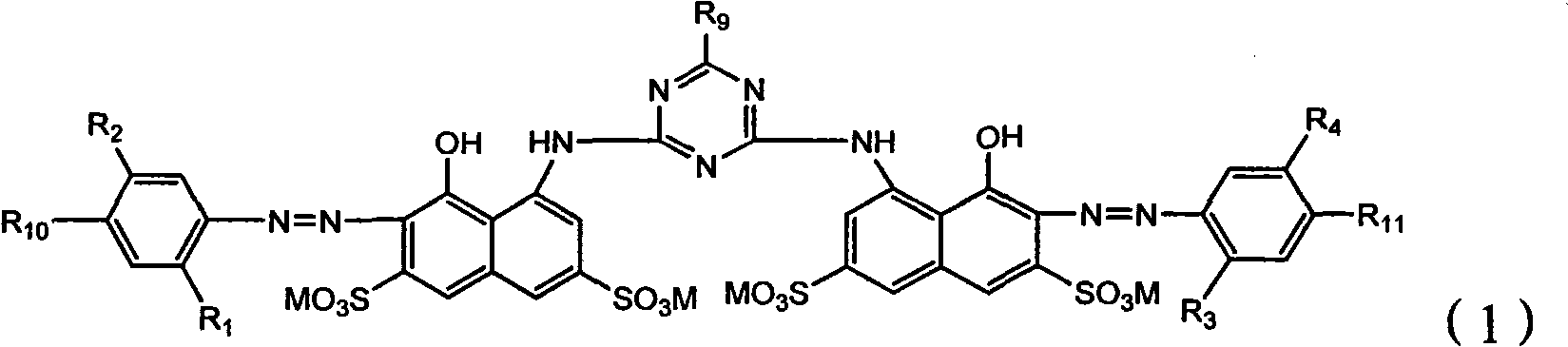

The invention provides a composite reactive black dye, which is confected by (counted by weight quotient): dye shown by formula (1) of 50-80 quotient, dye shown by formula (2) of 15-40 quotient and dye shown by formula (3) of 5-10 quotient. Advantages of the dye are: level-dyeing property and fixation yield is high, quantity of the dye for dyeing fibrous material is small, and not fixed dye is easy to clean.

Owner:HUBEI COLOR ROOT TECH CO LTD

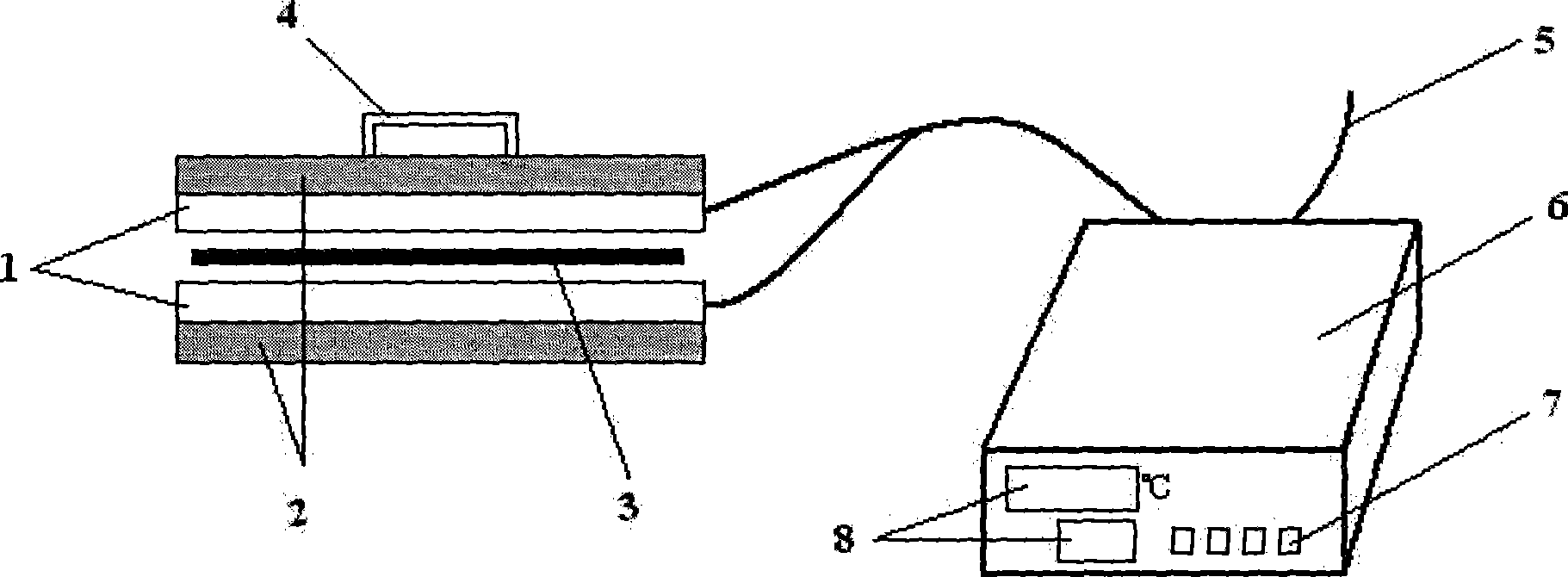

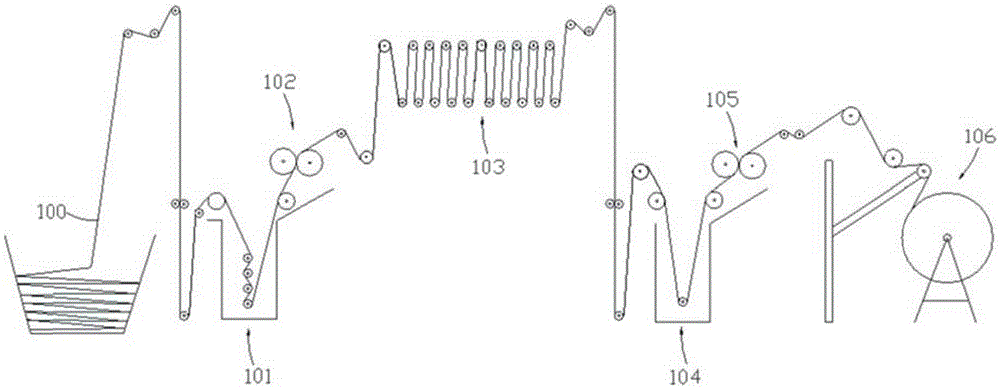

Fixation method and apparatus for inking and printing on cotton with active ink

InactiveCN101381934AHigh color fixing rateImprove color vividnessHeating/cooling textile fabricsDyeing processEngineeringDry heat

The invention relates to a method and a device for fixing cotton fabric reactive ink inkjet printing. The method comprises the following: (1) a step of pretreating fabric, which is to make thickener into stock thickener, dissolve alkaline agent, urea and antifoaming agent in water, add the alkaline agent, the urea and the antifoaming agent to the stock thickener, evenly mix the mixture so as to form a pretreatment solution, pad the fabric with the pretreatment solution and then dry the fabric; (2) a step of performing inkjet printing, which is to adopt reactive dye ink to perform inkjet printing to the pretreated fabric on a digital inkjet printing machine; and (3) a step of after-treating the fabric, which is to adjust humidity of the jet-printed fabric for 4 hours, adopt a contact-type dry-heat fixation device, regulate the temperature of a heating plate to be between 150 and 160 DEG C, set the treatment time to be between 40 and 80 seconds, complete fixation through contact-type dry-heat treatment, wash and dry or air the fabric, so as to obtain a finished product. The invention has the advantages of convenient operation of technological process, strong flexibility and high fixation rate, and solves the problems existing in small-batch steaming fixation.

Owner:DONGHUA UNIV

Dyeing process of pure cotton fabric

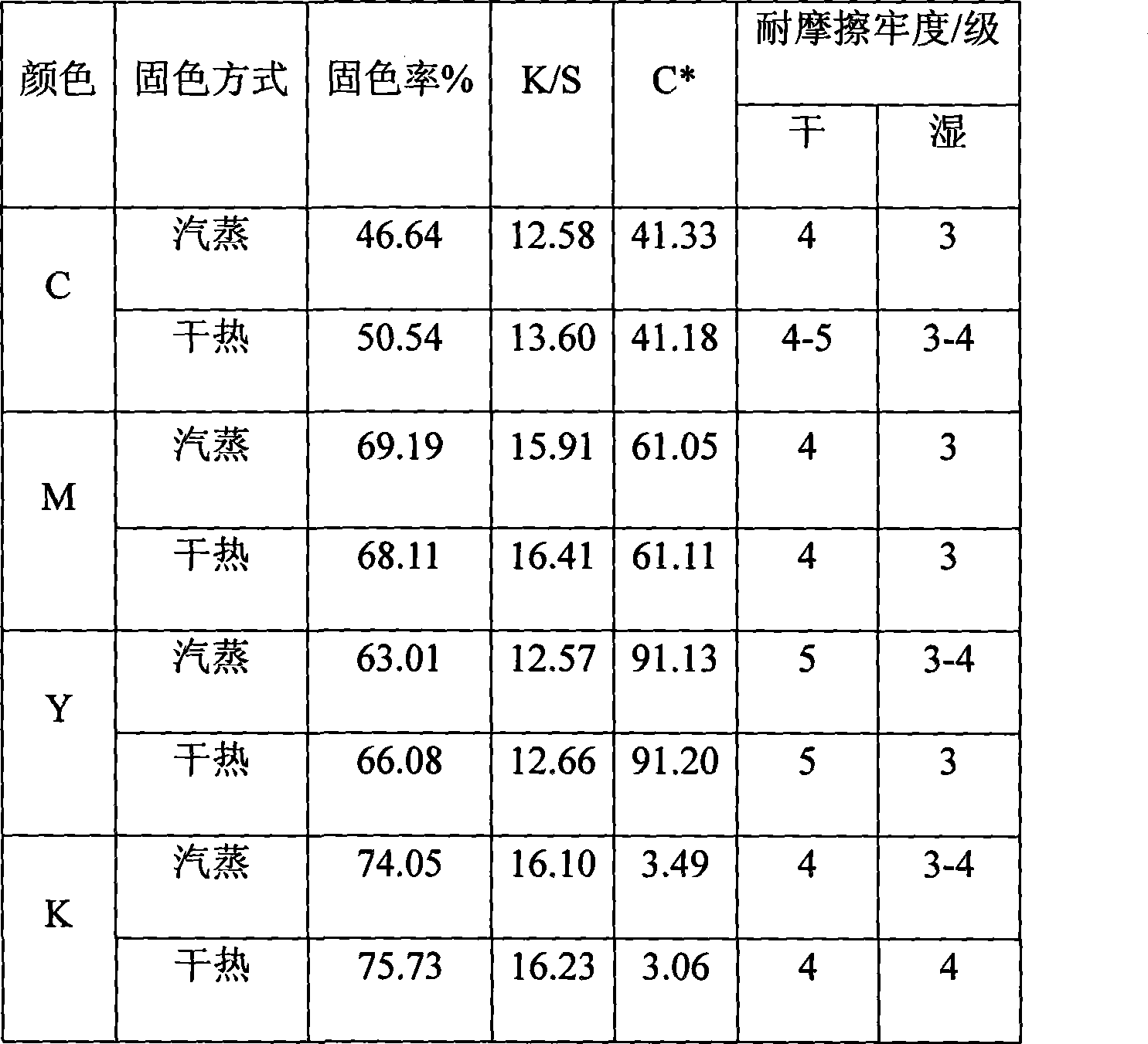

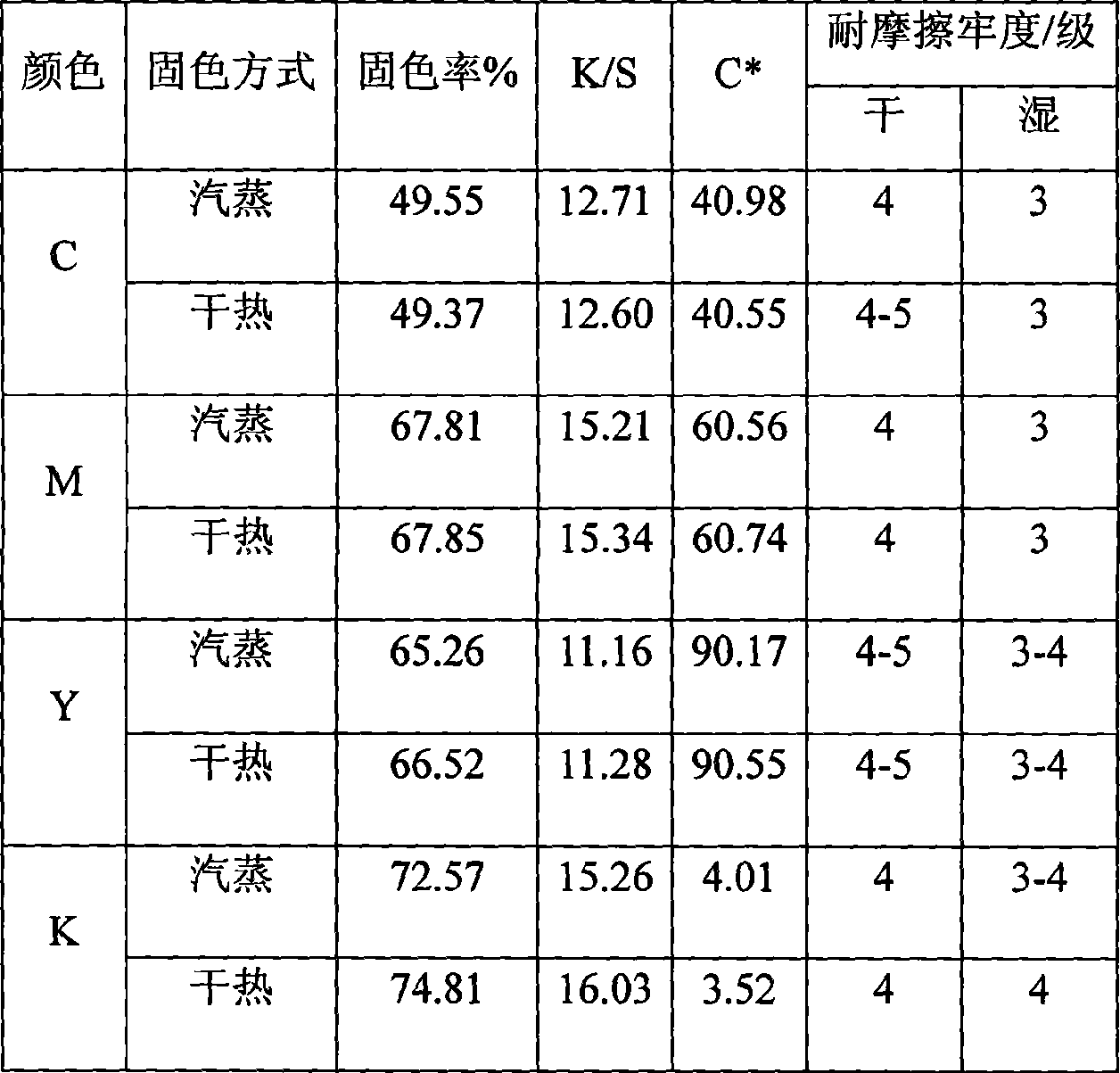

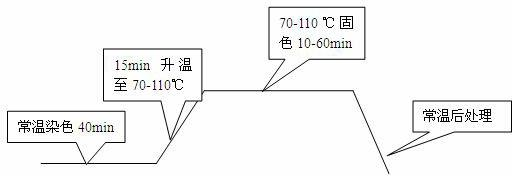

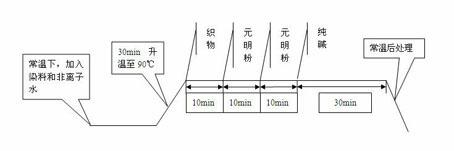

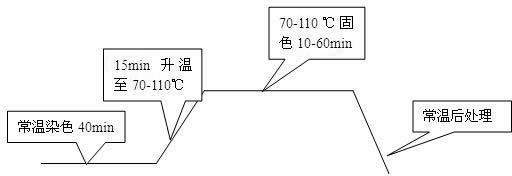

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

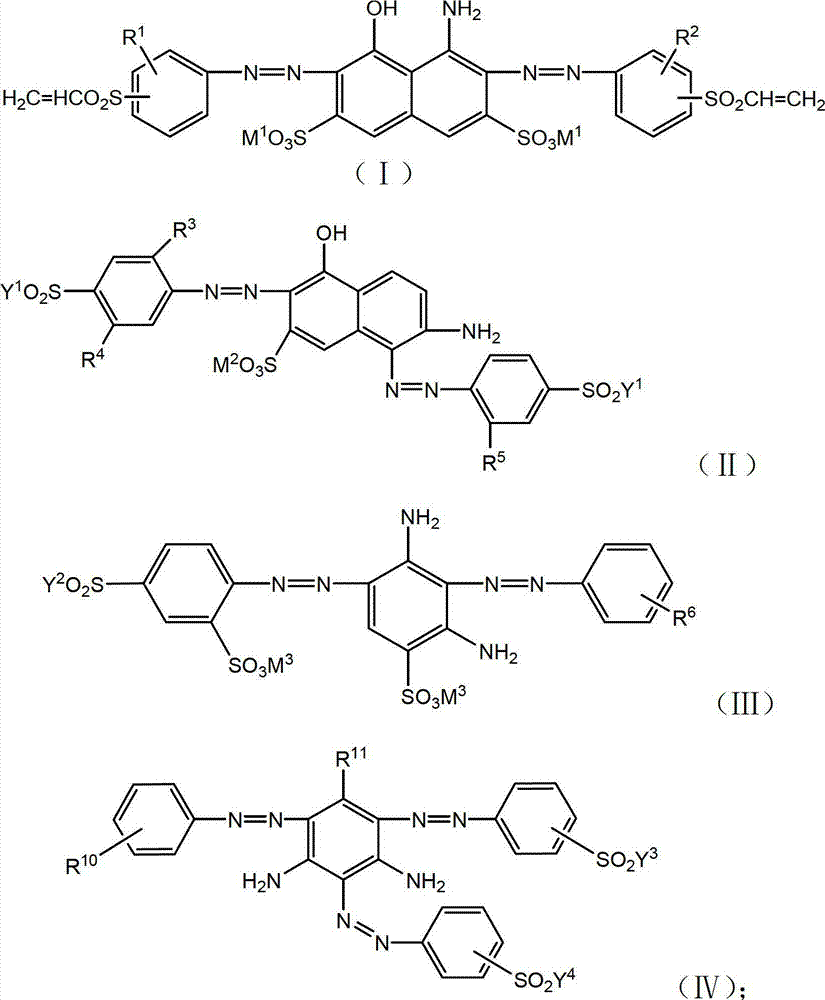

Active black dye

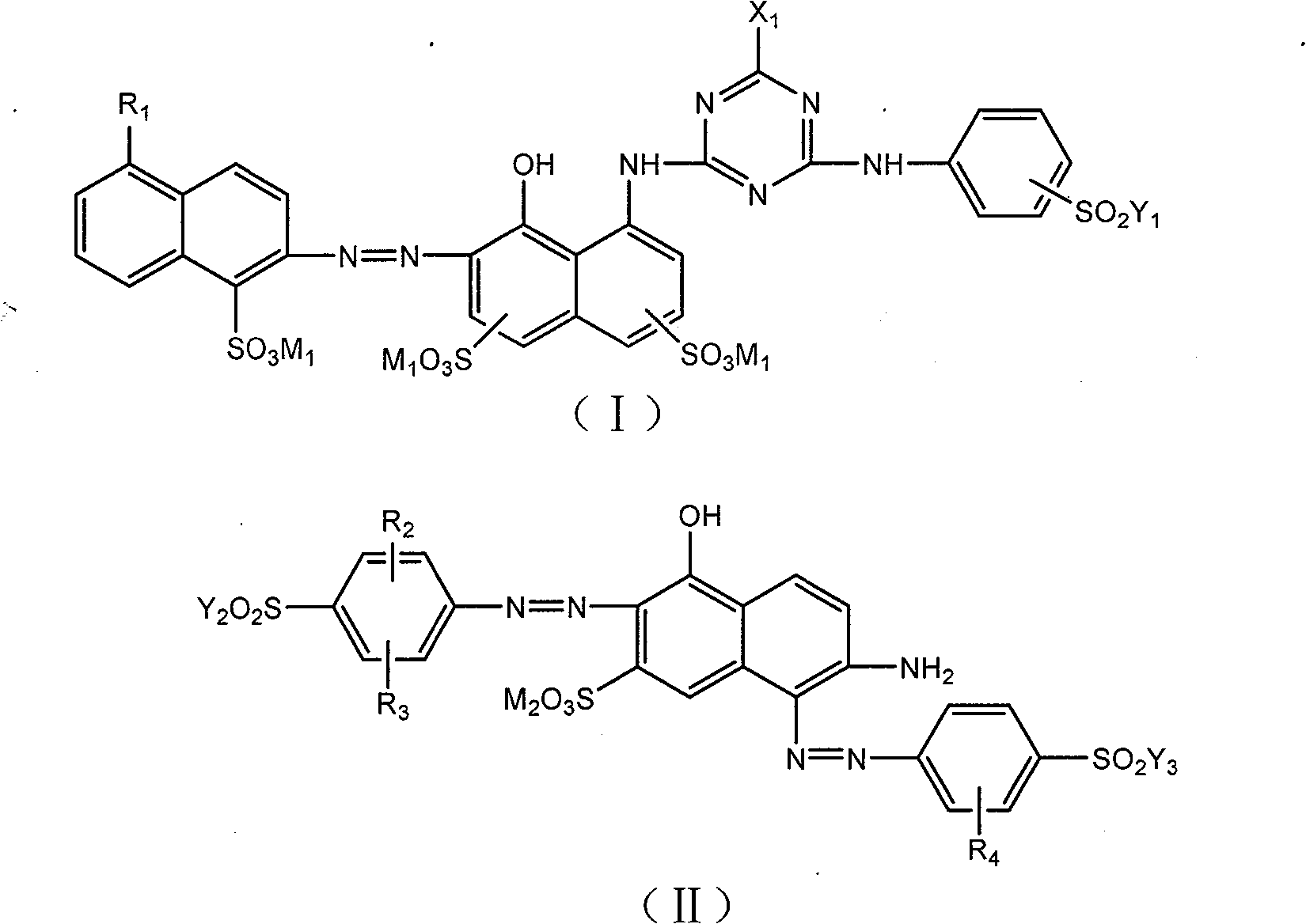

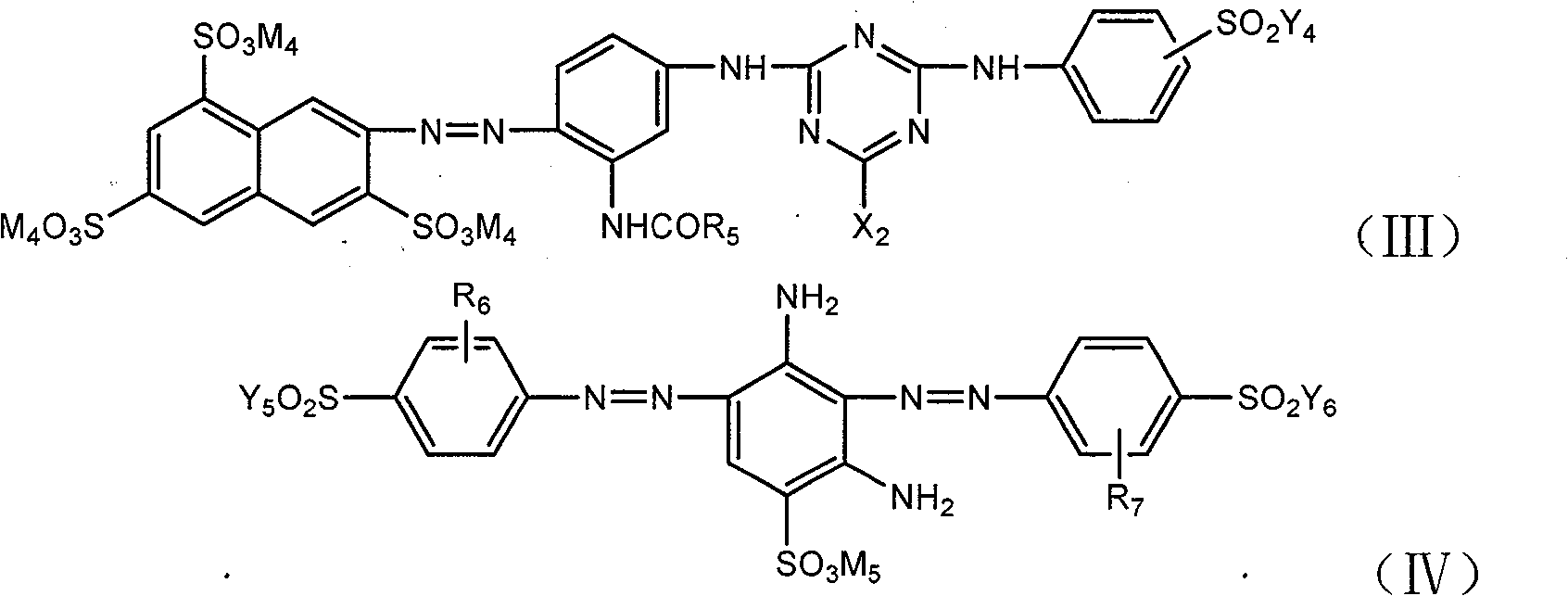

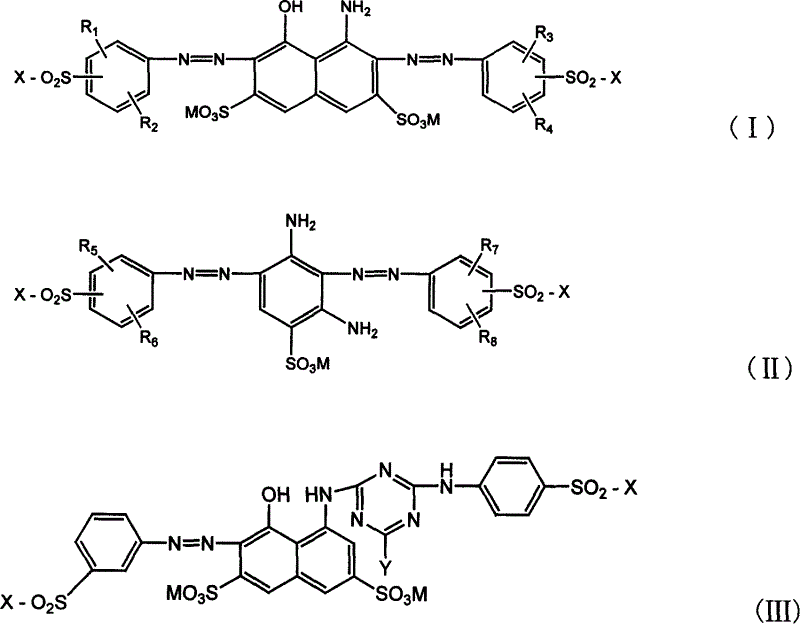

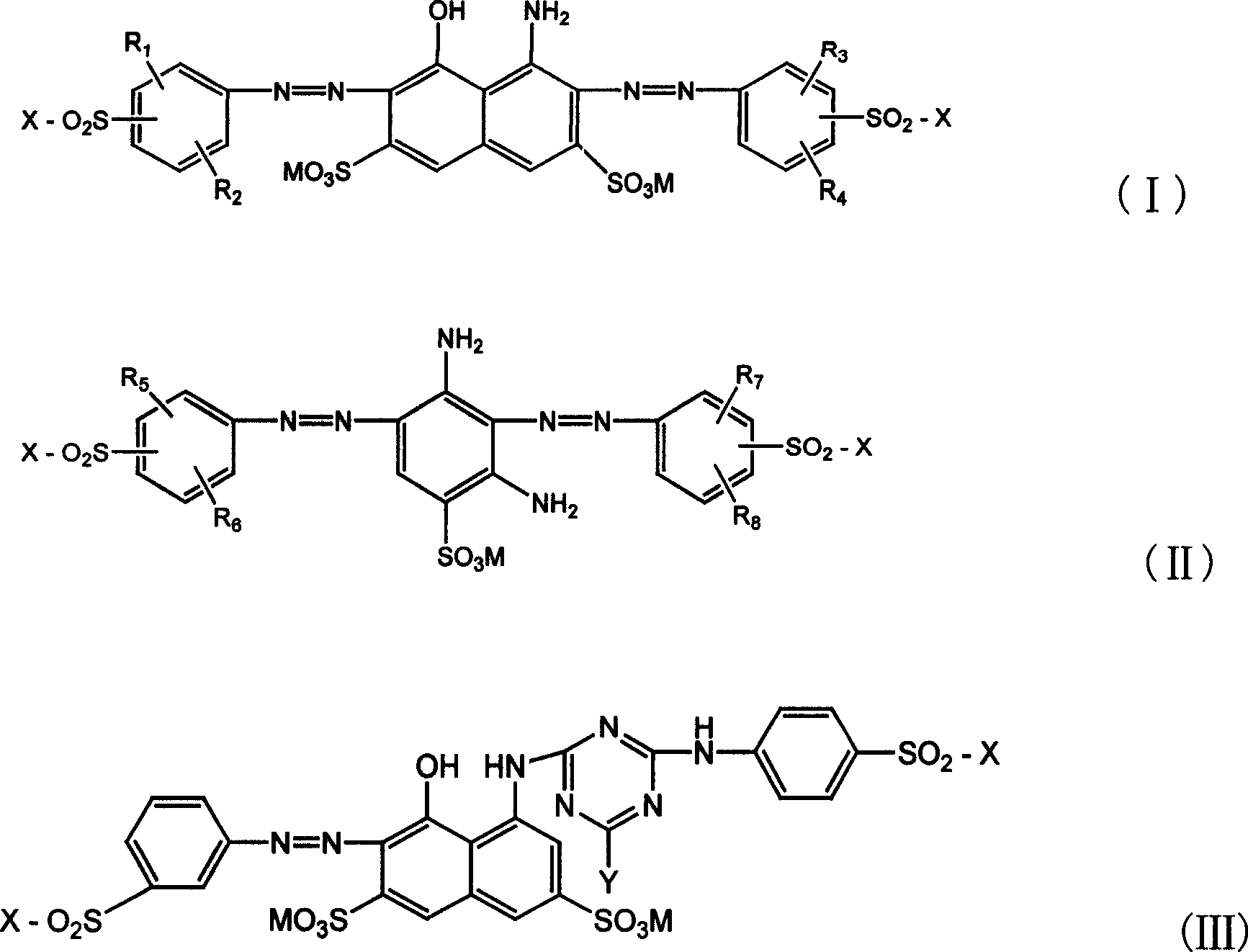

The invention relates to active black dye which essentially comprises fuchsine component A, orange yellow component B and navy component C, and is based on the component A, the component B and the component C; the weight percentage of the component A is 1 to 25 percent, the weight percentage of the component B is 1 to 25 percent, and the weight percentage of the component C is 50 to 95 percent; and the component A comprises at least a dye shown as formula (I) and a dye shown as formula (II), the component B comprises at least a dye shown as formula (III) and a dye shown as formula (IV), and the component C comprises at least a dye shown as formula (V). The active black dye has the advantages of high product solubility, strong salt and alkali resistance, high uptake date and color fixing rate, excellent dyeing fastness and environmental protection.

Owner:ZHEJIANG LONGSHENG GROUP +1

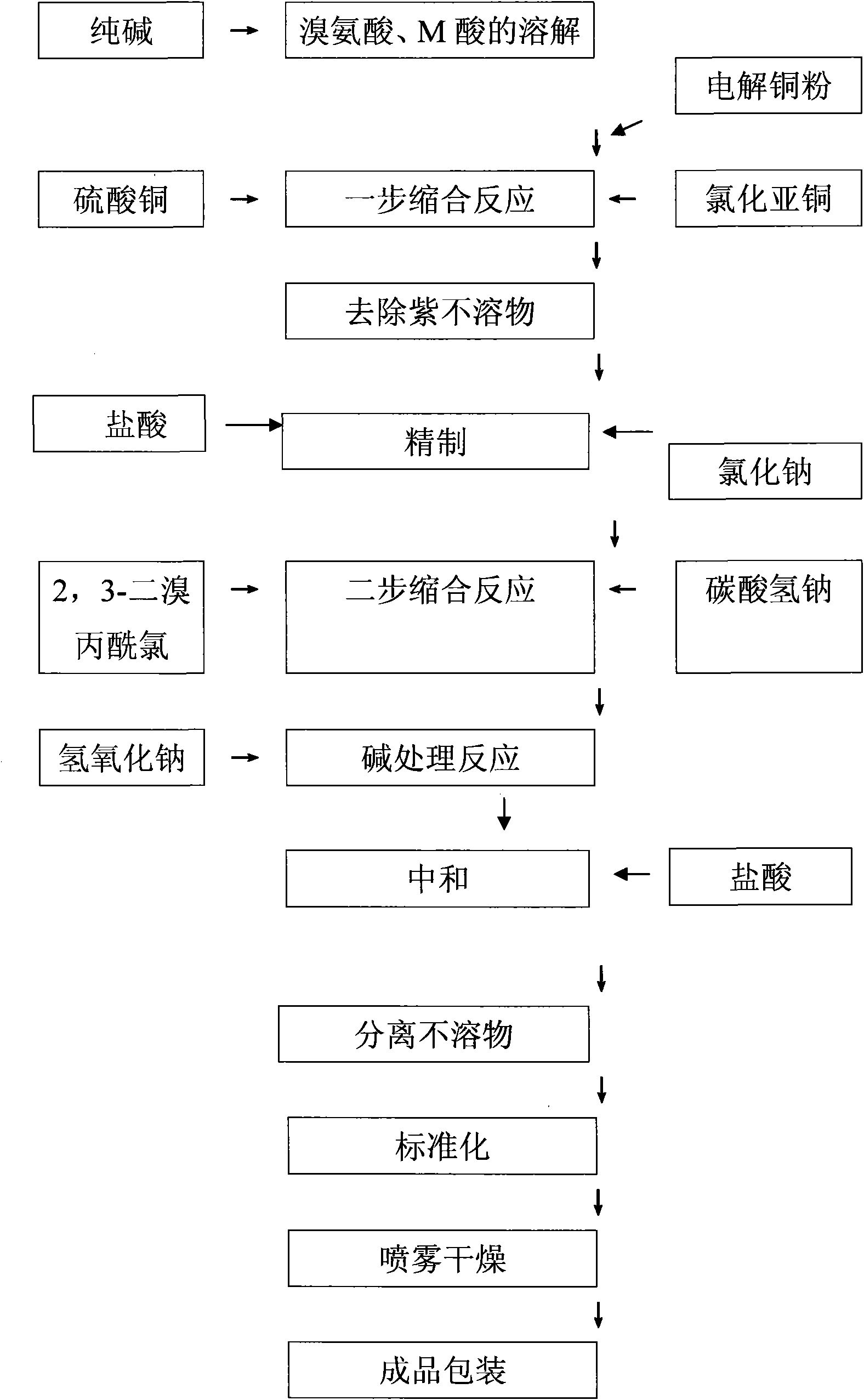

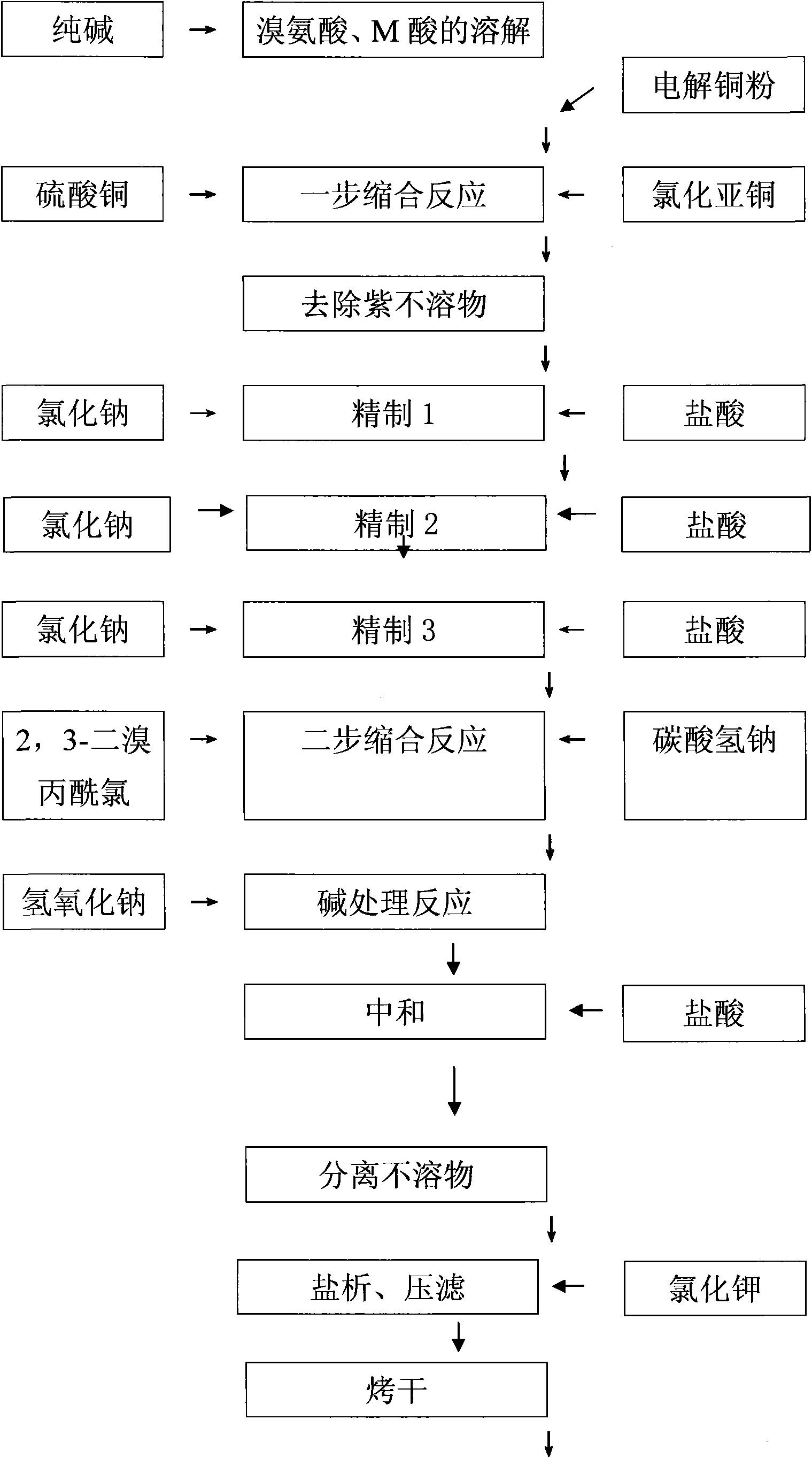

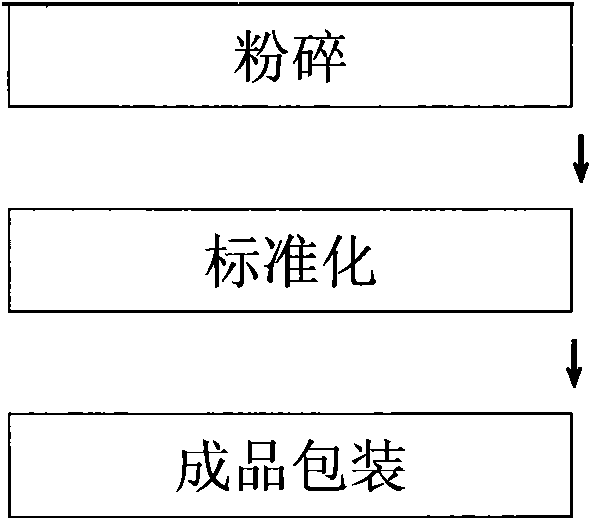

Method for preparing wool reactive-dye brilliant blue

ActiveCN101585974AReduce adverse effectsReduce consumption of raw materialsReactive dyesChemistryWool

The invention provides a method for preparing wool reactive-dye brilliant blue 4R. The method comprises the steps of condensing bromamine acid with M acid under the action of a catalyst, removing purple insoluble substances, condensing with 2,3-dibromo propionyl chloride, performing alkali treatment, neutralizing and blending. The method is characterized by removing the purple insoluble substancesat a temperature between 30 and 45 DEG C, thereby reducing a refining link in the prior art, for example, changing three times of refining in the prior art into one time of refining. More preferably,the method changes the steps of salting-out, filter-pressing, baking, grinding and blending in the prior technical method into the steps of directly blending neutralized color paste solution and thenperforming spray-drying.

Owner:TIANJIN DEK CHEM

Reactive dye cosolvent staining method for cellulose fabric

The invention relates to a reactive dye cosolvent staining method for a cellulose fabric. The method comprises the following steps of: adding a solvent into an aqueous solution of a reactive dye, thus obtaining a cosolvent solution of the dye; soaking the cellulose fabric in the dyeing solution under room temperature, and raising the temperature to the dyeing temperature of 40-100 DEG C; and adding the solvent and sodium carbonate, raising the temperature to the fixation temperature of 40-100 DEG C, keeping the temperature for 30-60 minutes, taking the fabric out, and washing, soaping and washing to obtain the product. The method is simple, is easily industrialized, can obtain higher dye-uptake and higher fixation rate compared with the traditional reactive dye staining process, and has high leveling property.

Owner:DONGHUA UNIV

Method for cation modification and salt-free dyeing of cellulose fabric through one bath

InactiveCN106638036AReduce processSimple processDry-cleaning apparatus for textilesDyeing processReactive dyeSoft water

The invention discloses a method for cation modification and salt-free dyeing of a cellulose fabric through one bath. The method comprises the following steps: (1) preparation of a modified dyeing liquid, including uniformly dissolving a reactive dye and sodium hydroxide in soft water, uniformly mixing the reactive dye and sodium hydroxide, adding a modifier in the obtained mixture, and performing uniform mixing to obtain the modified dyeing liquid; and (2) modification dyeing of a fabric, including performing dip padding treatment of a cellulose fabric with the modified dyeing liquid prepared in the step (1), winding the fabric into a roll after one dip and one padding, covering the roll with a film, putting the obtained roll at the room temperature, and performing room-temperature washing, acid washing, soaping, hot water washing, room-temperature washing and drying to the obtained fabric to obtain the salt-free dyed fabric. Cation modification and salt-free dyeing are carried out in one bath. The method is less in process, simple in technology and easy to operate. Acid washing and multiple water washing before dyeing in a two-bath method is not required, so that the method is less in water consumption and the process is easy to control. Modification and dyeing are carried out at the room temperature, and hydrolysis of the modifier and dye is reduced.

Owner:SOUTH CHINA UNIV OF TECH +1

Middle-temperature type disperse dye compound and preparation method and application thereof

ActiveCN102604413ABright colorHigh color fixing rateMonoazo dyesDyeing processDisperse dyeHigh pressure

The invention discloses a middle-temperature type disperse dye compound and a preparation method and application thereof, relating to the technical field of a disperse dye. In order to solve the problem that the traditional middle-temperature types disperse dye is fewer in varieties, the invention provides the monoazo disperse dye compound and the preparation method and application thereof. The general formula of the middle-temperature type disperse dye compound is shown in (I); and the middle-temperature type disperse dye compound is used for dyeing polyester fibers, has the advantages of good dyeing effect at a high temperature and a high pressure, high fixation rate, low cost, high color yield, good fastness and simple production technology.

Owner:ZHEJIANG JIHUA GROUP +1

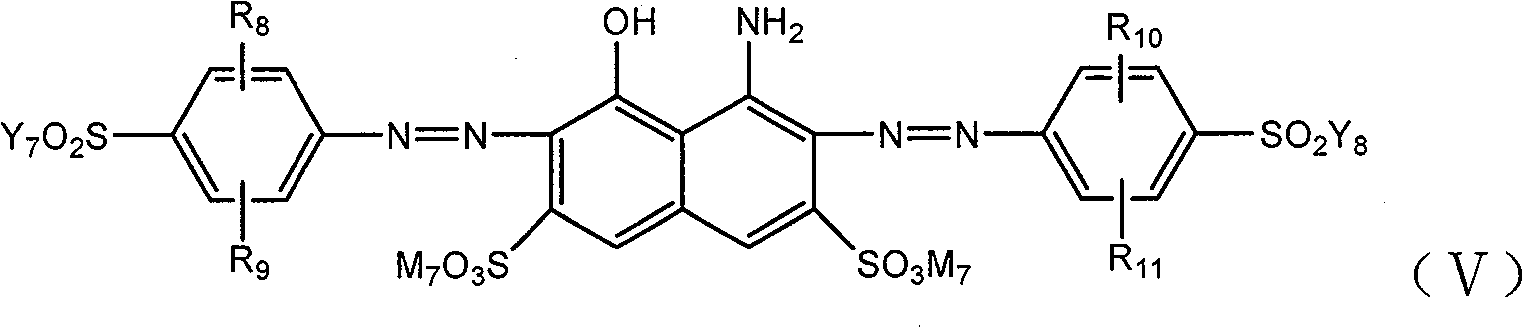

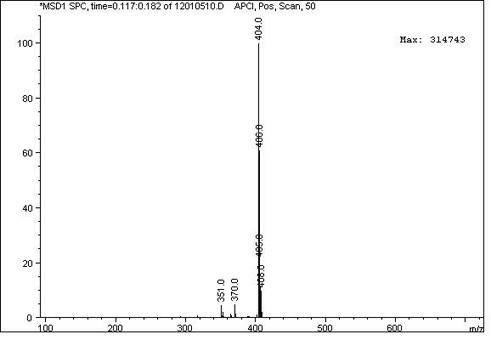

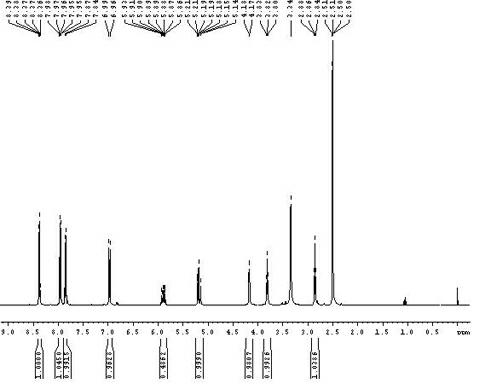

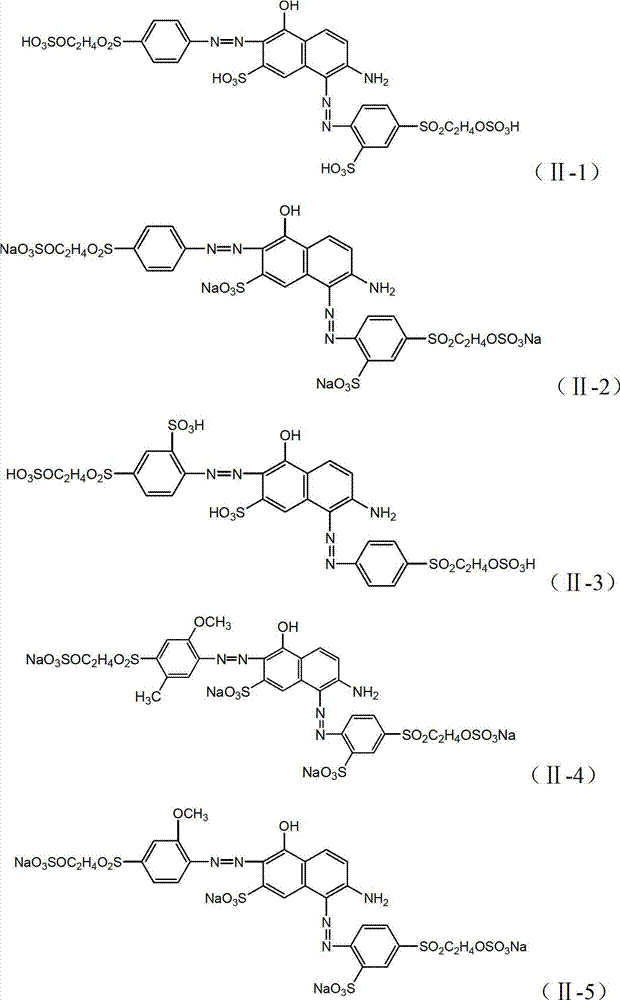

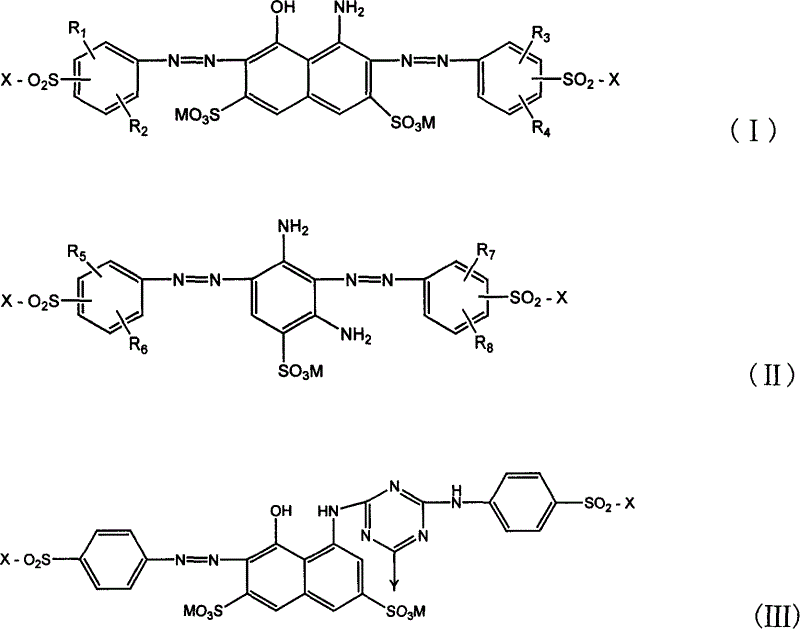

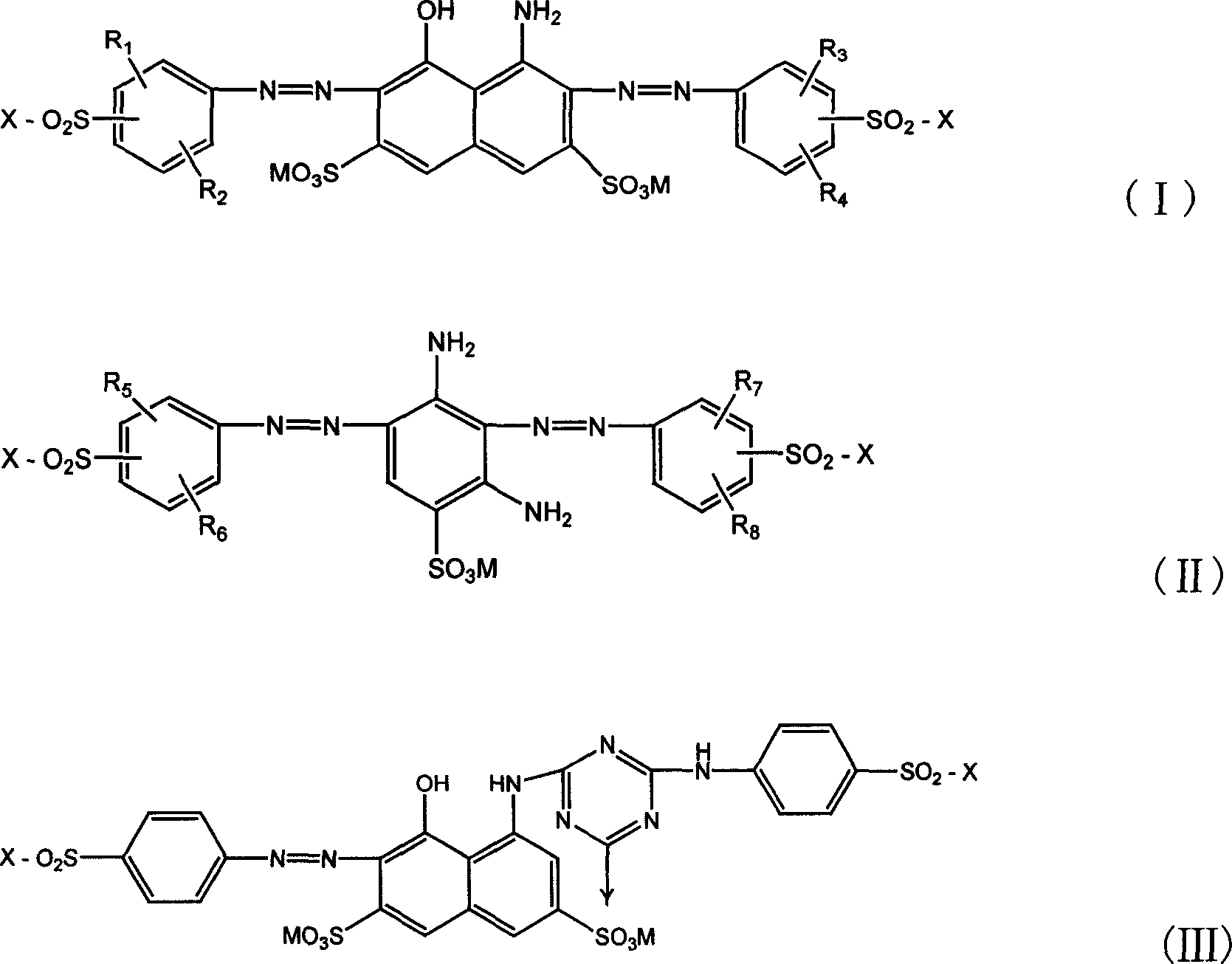

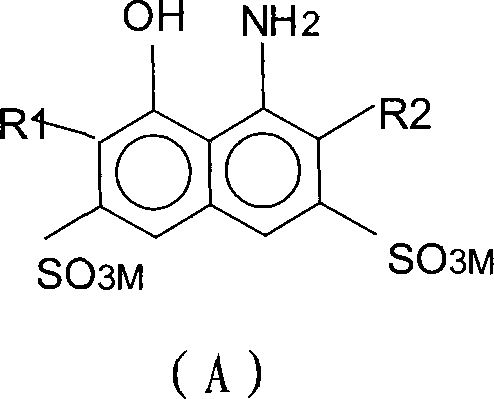

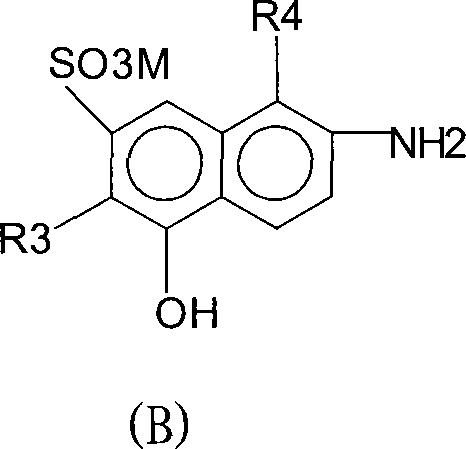

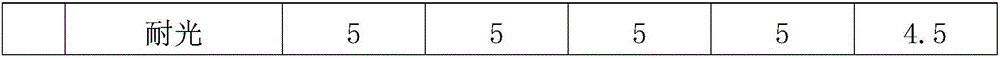

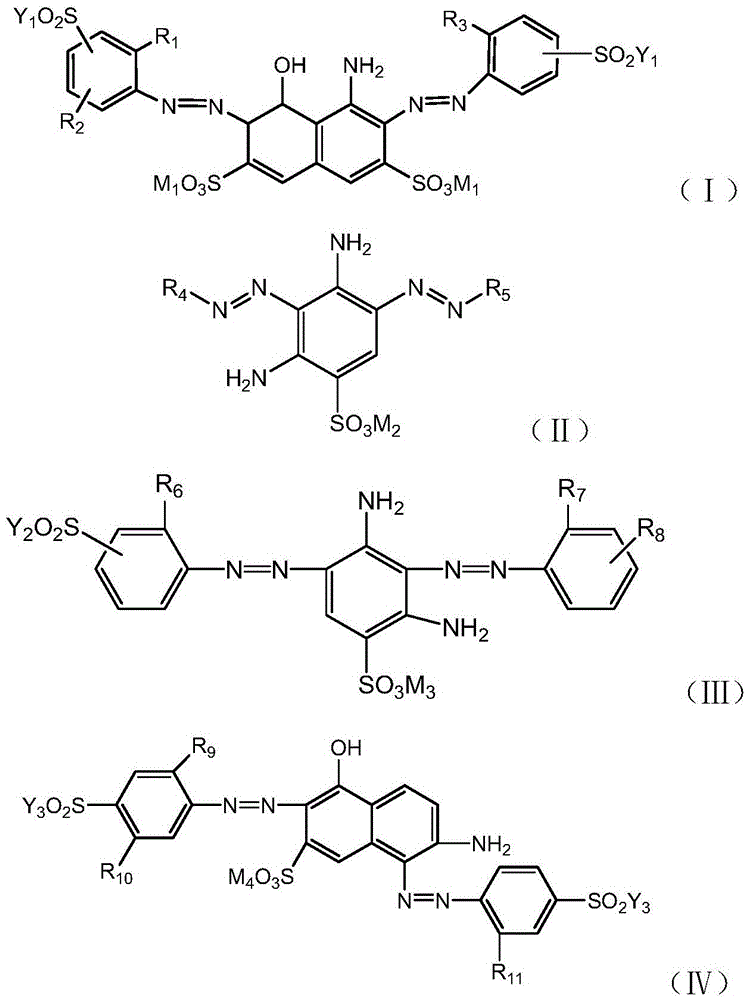

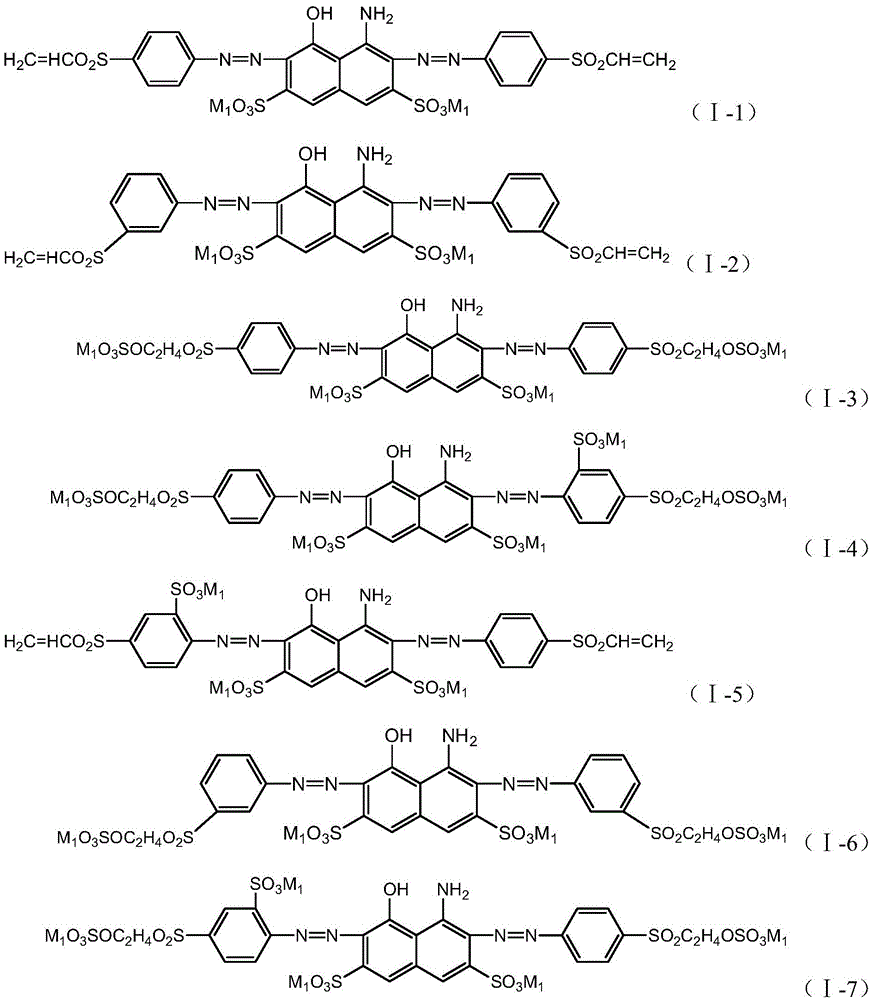

Active black dye composition

ActiveCN102964870AGood lifting effectHigh color fixing rateOrganic dyesDyeing processTextile printerPhotochemistry

The invention provides an active black dye composition, which comprises 45-90 weight parts of at least a component shown as a formula (I), 1-30 weight parts of at least a component B shown as a formula (II), and 1-40 weight parts of at least as a component C shown as a formula (III) and / or 1-40 weight parts of at least a component D shown as a formula (IV). The reactive black dye composition provided by the invention can be used for textile printing and dyeing, has advantages of good promotion performance, strong salt tolerance, easiness for washing and excellent wet-processing fastness, and is a rare economical black dye.

Owner:ZHEJIANG LONGSHENG GROUP +2

Active composite dye

ActiveCN1858118AGood synchronization of dyeingGood level dyeingOrganic dyesDyeing processCelluloseCompound c

The active composite dye includes at least one of compound A, at least one of compound B and at least one of compound C, with the compounds A, B and C being shown. The active composite dye is suitable for dyeing cellulose or protein fiber, and has the composition meeting the environmental and ecological requirement of Oeko-Tex Standard 100. The active composite dye has high build-up, good level dyeing property, good color reproduction, high dye uptake and other excellent performance.

Owner:ZHEJIANG RUIHUA CHEM

Composite active black dye

InactiveCN1616551AHigh color fastnessHigh blacknessOrganic dyesDyeing processSynthetic fiberHydroxyl radical

The composite active black dye includes dye A in 40-70 wt%, dye B in 15-35 wt% and dye C IN 8-30 wt%. The composite active black dye is especially suitable for dyeing fiber material containing hydroxyl radical or carboxyl radical, such as cellulose fiber, cotton fiber, synthetic fiber, etc. and is one kind of ecological active black dye with high color fastness, high blackness and other features.

Owner:SHANGHAI KEHUA DYESTUFF IND

Method for improving pad dyeing fixation rate of textile

The invention relates to a method for improving the pad dyeing fixation rate of a textile, and belongs to the field of textile printing and dyeing processing. According to the method provided by the invention, the proportioning of a dye solution and a fixation solution in a textile pad dyeing process is changed, the textile is pad-dyed and dye-fixed respectively using the dye solution or the fixation solution, which is prepared by mixing an alcohol organic solvent in high proportion, a little water, and a dye or a fixing agent, so that the pad dyeing fixation rate of the textile is improved. By adopting the method for improving the pad dyeing fixation rate of the textile provided by the invention, in the pad dyeing process of the textile, not only can the hydrolysis rate of the dye in the dye solution be reduced to improve the utilization rate, the dye-uptake rate, and the even dyeing rate of the dye and the fixation rate of the textile, but also the problem of high water consumption in the textile pad dyeing process can be greatly reduced, as well as the dosage of an auxiliary can be effectively reduced. The method provided by the invention is simple in process, and low in cost, and the alcohol organic solvent can be recycled, is safe, energy-saving, economic and environment-friendly.

Owner:WUHAN TEXTILE UNIV

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

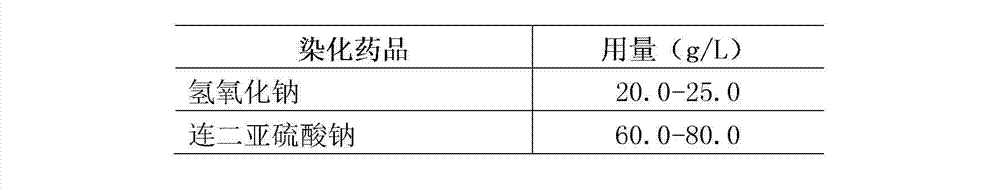

Novel dyeing method of reactive dyes

The invention provides a novel dyeing method of reactive dyes. The method includes the steps of conducting preprocessing, wherein loose fiber or yarn or fabric is preprocessed; conducting dyeing, wherein the preprocessed loose fiber or yarn or fabric is dyed in the reactive dyes through a water-saving dyeing method; conducting color fixing, wherein the dyed loose fiber or yarn or fabric is directly soaked in color fixing liquid to be subjected to color fixing and is then baked so that the dyeing process of the reactive dyes can be completed. In the dyeing step, the structure of the reactive dyes at least contains three active groups. According to the technical scheme, operation is easy, no salt is used in the dyeing process, and the good dyeing and color fixing effects can be achieved with a smaller volume of water; in addition, water used in the dyeing process can be directly evaporated in the subsequent operation process, no washing operation is needed after color dyeing and fixing, and therefore no dyeing wastewater can be produced after operation is ended, and clean production is achieved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Black dye mixer and preparation method and application thereof

The invention provides a black dye mixture, which is mixed by (counted by weight quotient): dye shown by formula (1) of 50-80 quotient, dye shown by formula (2) of 9-30 quotient and dye shown by formula (3) of 4-20 quotient. The black dye mixture owns property of high level-dyeing property, high fixation yield and high jet black degree, and can combine with cotton, hemp, yarn, thread, hair and polyamide to form covalent bond. Moreover, the black dye contains no harmful arylamine and heavy metal element and does not decompose harmful matter to human body during using process.

Owner:佛山市焱基化工染料有限公司 +1

Application of quaternary ammonium salt organic compound as natural fibre and fabric accelerant

InactiveCN101725058AImprove dye uptakeHigh color fixing rateOrganic compound preparationDyeing processWastewaterNatural fiber

The invention discloses an application of quaternary ammonium salt organic compound as a natural fibre and fabric accelerant. In the traditional dyeing technology of natural fibre and fabric thereof, a small quantity of quaternary ammonium salt organic compound is added to serve as accelerant to ensure that the mass percent concentration thereof is 0.1-0.5%; thus, the dye-uptake rate and the color fixation rate of dye can be greatly improved; salt is not used during dye-uptake, the dye-uptake rate can reach 95.0-99.5%, and the color fixation rate can be above 90%. The application not only can greatly improve the utilization ratio of dye, but also can lower dying waste water pollution.

Owner:SOUTHWEST UNIVERSITY

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

Polyester-cotton disperse dye, and reactive dye one-bath process dyeing method

ActiveCN106245368AHigh color fixing rateAvoid hydrolysisDry-cleaning apparatus for textilesDyeing processDisperse dyePh buffering

The invention discloses a polyester-cotton disperse dye, and a reactive dye one-bath process dyeing method. The reactive dye one-bath process dyeing method comprise following steps: a dyeing solution is prepared at normal temperature; pH value of the dyeing solution is adjusted to 4 to 6; polyester-cotton fabric is immersed; the temperature is increased to 95 to 105 DEG C at a rate of 2 to 3 DEG C / min, and then is increased to 130 to 150 DEG C at a rate of 1 to 2 DEG C / min; suction filtration of the dyeing solution and isolation of disperse dye microcapsules are carried out, and continuous dyeing is carried out for 15 to 25min; the temperature is reduced to 85 to 95 DEG C at a rate of 1.5 to 2.5 DEG C / min; and primary water washing, soaping, afterwashing, and drying are carried out. The dyeing solution comprise, 0.5 to 1.5%owf of a reactive dye, 30 to 40g / L of anhydrous sodium sulfate, 1.5 to 3.5g / L of a pH buffering agent, 0.5 to 5%owf of disperse dye microcapsule, and 0.1 to 3g / L of a dyeing auxiliary. The reactive dye one-bath process dyeing method is simple; period is short; fixation rate is high; and levelling properties are excellent.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Composite active black dye

InactiveCN1616552AHigh color fastnessHigh blacknessOrganic dyesDyeing processCarboxyl radicalCellulose fiber

The composite active black dye includes dye A in 40-70 wt%, dye B in 10-30 wt% and dye C IN 15-40 wt%. The composite active black dye is especially suitable for dyeing fiber material containing hydroxyl radical or carboxyl radical, such as cellulose fiber, cotton fiber, synthetic fiber, etc. and is one kind of ecological active black dye with high color fastness, high blackness and other features.

Owner:SHANGHAI KEHUA DYESTUFF IND

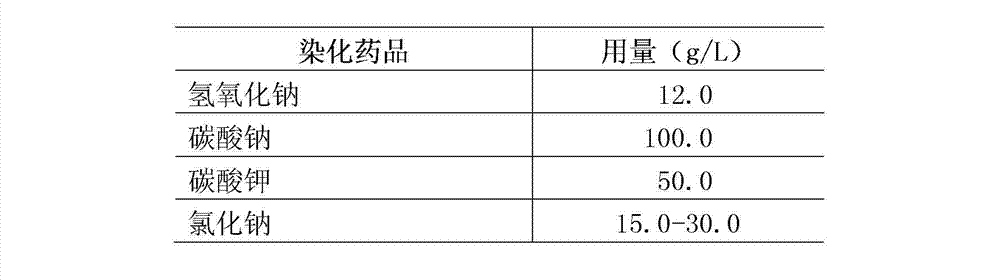

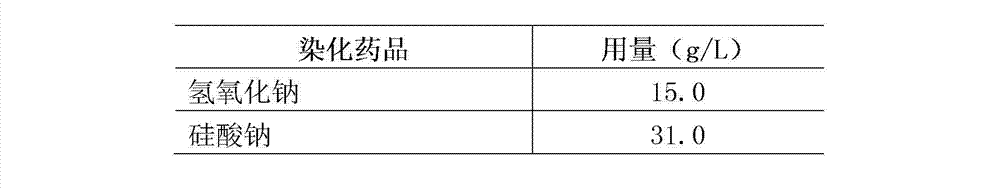

Cold pad batch (CPB) dyeing method of pure cotton knitted fabric

InactiveCN102061611AOvercome chromatic aberrationOvercome the black air on the clothDyeing processVegetal fibresSodium silicateSodium hydroxide

The invention relates to a cold pad batch (CPB) dyeing method of a pure cotton knitted fabric. The invention provides a pure cotton knitted fabric pretreatment liquor comprising sodium peroxide, sodium hydroxide and sodium silicate for CPB dyeing of the pure cotton knitted fabric, a dye comprising reactive dye, an alkali agent and a penetrating agent and a method for CPB dyeing by applying the pretreatment liquor and the dye. The method solves the problems of color difference, cloth cover black gas, color dot, dyeing speck, and the like to a certain extent, and has the advantage of high color fixation of reaching higher than 85 percent.

Owner:日冠(福建)针纺织机械有限公司

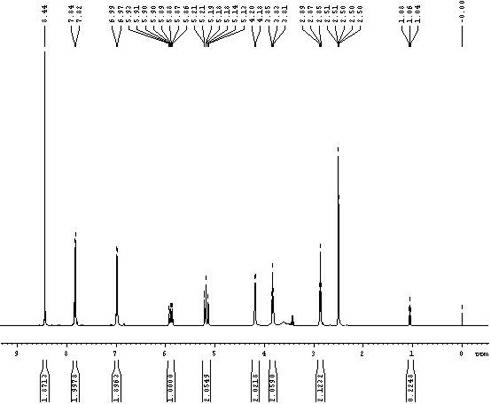

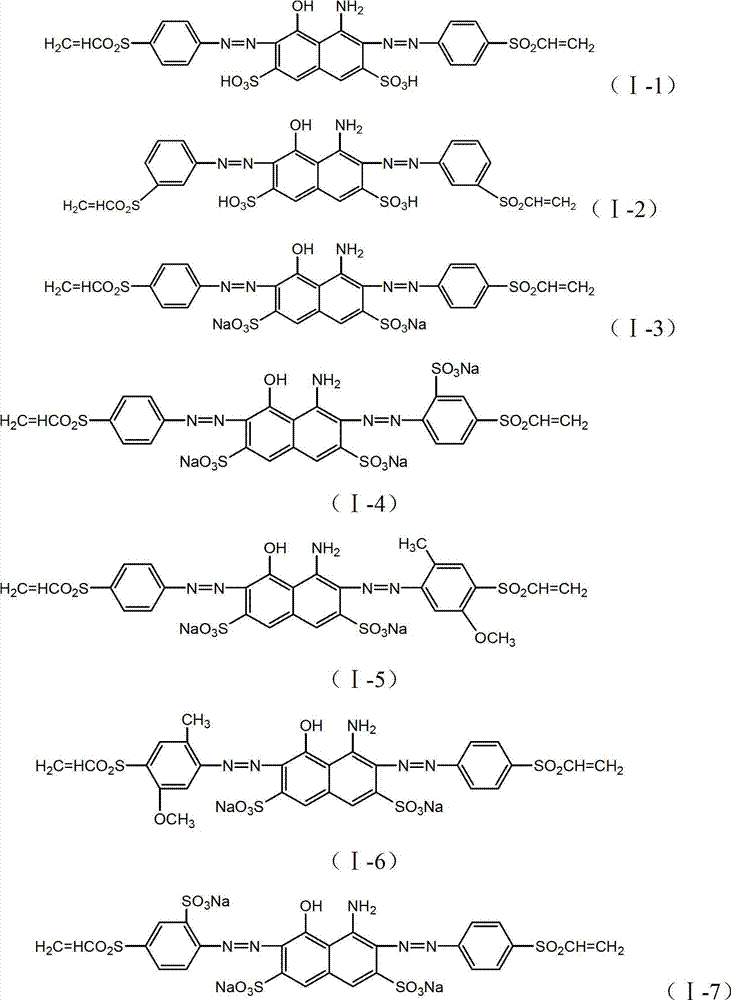

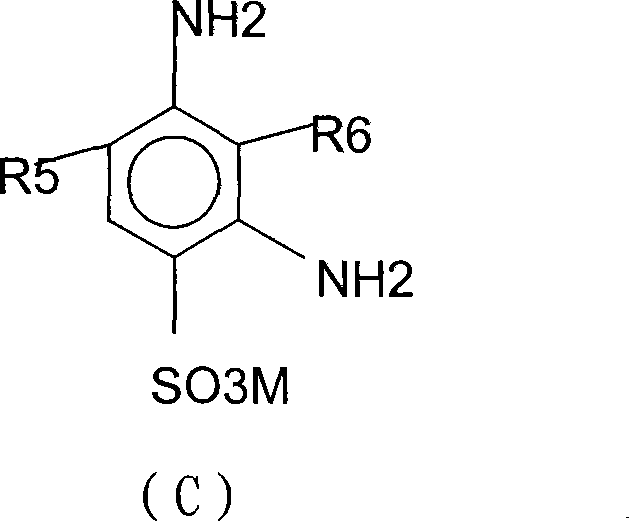

Reactive dye composition and preparing process and application thereof

InactiveCN101143972AHigh color fixing rateGood synchronization of dyeingOrganic dyesDyeing processCelluloseOil water

The invention discloses an active dye composition, which includes compound as showed in formula (A), formula (B), formula (C) and formula (D) and additive. 4 components of the active dye composition of the invention active dye composition are medium temperature dye, wherein the oil-water ratio, dye curve, affinity to cellulose, degree of dyeing, color fixing rate, sensitivity to salt and base, effect on bath ratio and sensitivity to temperature are very close. The composition has good dyeing synchronism and level dyeing property, and much higher color fixing rate, thereby being applicable for dip dyeing, continuous dyeing, cold dome, and printing and embossing of cellulose or protein fiber.

Owner:ZHEJIANG RUIHUA CHEM

Dyeing and finishing process for polyester interweaved fabric

ActiveCN107059384AGood removal effectHigh whitenessHeat resistant fibresBiochemical treatment with enzymes/microorganismsPhenolsPh buffering

The invention discloses a dyeing and finishing process for polyester interweaved fabric. The dyeing and finishing process comprises the following steps: S1) pre-treating: performing scouring and bleaching and enzyme washing treatment on the polyester interweaved fabric in turn; S2) pre-shaping: performing pre-shaping treatment on the polyester interweaved fabric; S3) dyeing: soaking the polyester interweaved fabric into a dye liquor at a liquor ratio of 1:(10-30), wherein the dye liquor comprises 1-3% of reactive dyes, 2-5% of rare-earth complex micro-encapsulation disperse dyes, 5-15g / L anhydrous sodium sulphate, 1.5-3.5g / L pH buffering agent, 0.1-0.3g / L organic phenol halide and 0.01-0.05g / L organic fluorinated surfactant; and S4) finishing: performing softening and flame-proof treatment on the fabric in turn. The dyeing and finishing process for polyester interweaved fabric, disclosed by the invention, not only can obviously improve the performances, such as, hand feel and elasticity, of the fabric but also can achieve the effects of uniform dyeing, high color fastness and abundant color and luster.

Owner:宣城加特林机械有限公司

Polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology

ActiveCN106245352AImprove adsorption capacityImprove dyeing uniformityDyeing processMicroballoon preparationDisperse dyeOrganic solvent

The invention discloses a polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology. The technology comprises the steps of: S1, polyester dyeing: dipping a to-be-dyed polyester-cotton fabric in a dye solution containing microcapsule disperse dye, conducting heat preservation at 65-75DEG C, then performing heat preservation at 110-130DEG C, and carrying out cooling to 30-40DEG C, using chitosan to serve as the carrier of the disperse dye, and then conducting crosslinking curing; S2. cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, carrying out stirring reaction, then adding a reactive dye, performing heat preservation at 55-65DEG C, adding an organic solvent, conducting heat preservation at 70-90DEG C, then adding organic amine and sodium carbonate, and performing heat preservation at 60-100DEG C; and S3, aftertreatment: performing cooling to room temperature, and then carrying out primary washing, soaping and after-washing. The polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology provided by the invention has the advantages of simple process, little pollution, wide dye applicability, uniform coloring, high color fixation rate and good level-dyeing properties.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Dyeing and finishing process of polyester and cotton blended fiber fabric

InactiveCN105063997AHigh whitenessAvoid damageSucessive textile treatmentsBiochemical fibre treatmentPolyesterFiber

The invention discloses a dyeing and finishing process of polyester and cotton blended fiber fabric. The process comprises pretreatment, presetting, modification treatment, dyeing, mordant removal, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Snailase and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the polyester and cotton blended fabric is modified fundamentally, and the dye-uptake of the fabric is increased; in the dyeing procedure, fewer alkaline substances and inorganic salt are used, a dye leveler, substitution alkali, a migration inhibitor and a diffusant are added, the dye leveling performance is improved, natural dye is used, environmental pollution is avoided, and the environment-friendly requirement is met; self-cleaning treatment is added during aftertreatment, and the self-cleaning capacity, the crease-resistant performance, the wash durability and color fastness are improved; silk fibroin and sericin are adopted for afterfinish, and the anti-pilling performance and the antistatic performance of the fabric are provided; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Low-temperature dyeing and finishing technology for bamboo fiber fabric

InactiveCN105019250AAvoid damageLower processing temperaturePhysical treatmentBiochemical fibre treatmentAmylaseFiber

The invention discloses a low-temperature dyeing and finishing technology for bamboo fiber fabric. The low-temperature dyeing and finishing technology includes the steps of pretreatment, preshaping, modification treatment, dyeing, mordant removal, soaping, color fixation, after finishing, drying, shaping, calendering and rolling. Helicase, scouring enzyme and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the performance of the bamboo fiber fabric is modified fundamentally, and the dye-uptake rate of the fabric is increased; as in the dyeing working procedure, alkaline substance and inorganic salts are not used in quantity, and a levelling agent is added, the dyeing levelness is improved; environment pollution is avoided by using natural dyestuff, which meets the requirement for environmental protection; as self-cleaning treatment is added in after treatment, the self-cleaning capacity, crease-resistant performance and wash-resisting firmness of the fabric are improved; crease-resistant finishing is added, and therefore the crease-resistant performance of the fabric is improved; the whole technology is environmentally friendly and free from pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Composite active red dye

The invention discloses a composite active red dye which comprises the following components in percentage by weight: 60-90 percent of dye monomer A shown as the formula (1), 10-40 percent of dye monomer B shown as the formula (2) and 0-10 percent of dispersing agent MF and / or diffusant NNO. The composite active red dye can obtain higher dyeing level and bright colors when being used for dyeing cotton, hemp and viscose glue, and the friction resistant fastness and the perspiration and soaping resistant fastness can meet the standard requirement.

Owner:ZHEJIANG JINGGUANG IND

Reactive dye cold pad-batch dyeing equipment and dyeing method

ActiveCN105256485AImprove solubilityIncrease dosageSucessive textile treatmentsTextile treatment machine arrangementsBiochemical engineeringDeoxygenation

The invention relates to the technical field of dyeing and provides reactive dye cold pad-batch dyeing equipment and a dyeing method. The dyeing equipment comprises a first dipping tank, a first padder, a ventilating device, a second dipping tank, a second padder and a rolling and piling device. The dyeing method comprises the following steps of primary padding, wherein fabric sequentially passes through the first dipping tank and the first padder, and the first dipping tank contains reactive dye and deoxygenation enzyme; ventilating treatment for 1-4 minutes; secondary padding, wherein the fabric sequentially passes through the second dipping tank and the second padder, and the second dipping tank contains alkaline agents; aftertreatment. According to the reactive dye cold pad-batch dyeing method, the reactive dye and the alkaline agents are padded in a separated mode, and the problems that because the reactive dye and the alkaline agents react before padding, diffusivity of the reactive dye is decreased, and dyeing is unstable are solved; the selection range of the reactive dye and the color fixing alkaline agents is enlarged, the requirement for the equipment is lowered, a proportioning pump is omitted, and operation is convenient.

Owner:新乡橄榄枝纺织化工有限公司

Disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric

ActiveCN106223076APreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Reactive black dye composition and dye product

ActiveCN105542510AGood lifting effectHigh color fixing rateOrganic dyesDyeing processHigh colorCompound c

Owner:SHANGHAI KEHUA DYESTUFF IND +1

Multi-color roller gravure printing production method of textile dye

ActiveCN102785495AExtended door widthShorten the printing processDuplicating/marking methodsOther printing apparatusFiberWastewater

The invention relates to a multi-color roller gravure printing production method of a textile dye. According to the traditional printing method, more floating colors exist in the washing process, and the excessive wastewater discharge is easily caused. The invention comprises the following steps that: (1) pre-treatment working solutions are selected according to textiles of different types of fibers; (2) the pre-treatment working solutions of different concentrations are padded under the conditions that the immersion time is 5-30 seconds, the expression is between 50% and 100% and the speed is 10 to 40m / min, and are dried; (3) a special dye ink for gravure printing is selected; (4) through an improved multi-color roller gravure printing machine with adjustable printing thickness, lengthened width, enhanced drying and the like, the special dye ink is printed to the textile which is padded with the pre-treatment working solutions and is dried at a speed of 10-40 m / min and is dried; (5) the printed textile enters steaming equipment for steaming fixation; and (6) after fixation, the printed textile is subjected to washing, drying and other treatment processes to complete the entire printing production process of the textile.

Owner:ZHEJIANG YIDE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com