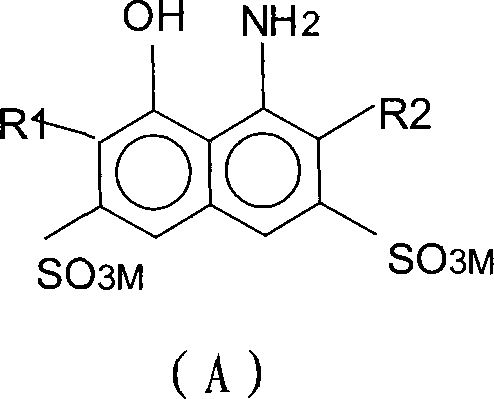

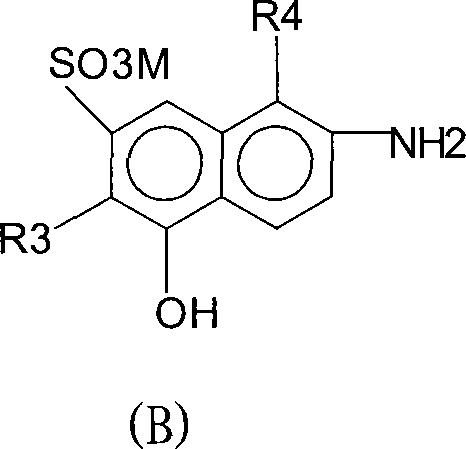

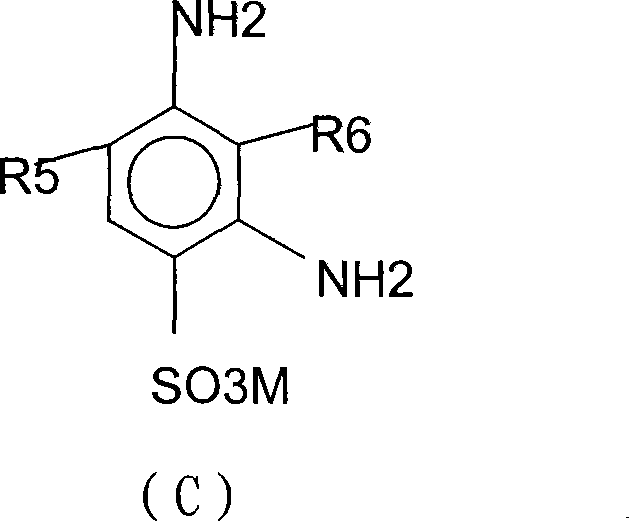

Reactive dye composition and preparing process and application thereof

A technology of reactive dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of increased dyeing cost for customers, unsatisfactory washing fastness, low alkali resistance stability, etc., and achieves excellent color fixing rate. , good washing fastness, improving the effect of chlorine fastness and light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Prepare dyes in the following proportions:

[0058]60% A1, 12% B1, 11% C2, 3% D1, and the rest are additives, and the prepared composition is P1. The preparation method is to grind (A1) compound, (B1) compound, (C2) compound, (D1) compound and 8% sodium sulfate, 5% dispersant MF and 1% dustproof agent AC-805, and then Use a mixer for mixing. The mixer can be cone-shaped, drum-type, or pear-knife-type. After mixing evenly, test and analyze the qualified package.

Embodiment 2

[0060] Prepare dyes in the following proportions:

[0061] 60% A1, 6% B2, 13% C2, 3% D1, and the rest are additives (10% sodium bicarbonate, 5% dispersant MF, 1% dustproof agent AC-805 and 2% urea). The composition is P2, and the preparation method is the same as in Example 1.

Embodiment 3

[0063] Prepare dyes in the following proportions:

[0064] 54% A1, 12% B3, 19% C1, 3% D1, and the rest are additives, and the prepared composition is P3. The preparation method is to produce the compound slurry of formula (A1), formula (B3), formula (C1) and formula (D1) and 8% dye accelerator sodium sulfate, 3.5% dispersant MF and 0.5% dustproof The agent AC-805 is poured into the color storage tank with stirring in proportion, and the mixer is started to stir evenly. After passing the test, it is directly packaged to make a liquid product, or dried through a spray tower, drying room, flash evaporation, etc. to obtain a granular or powder product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com