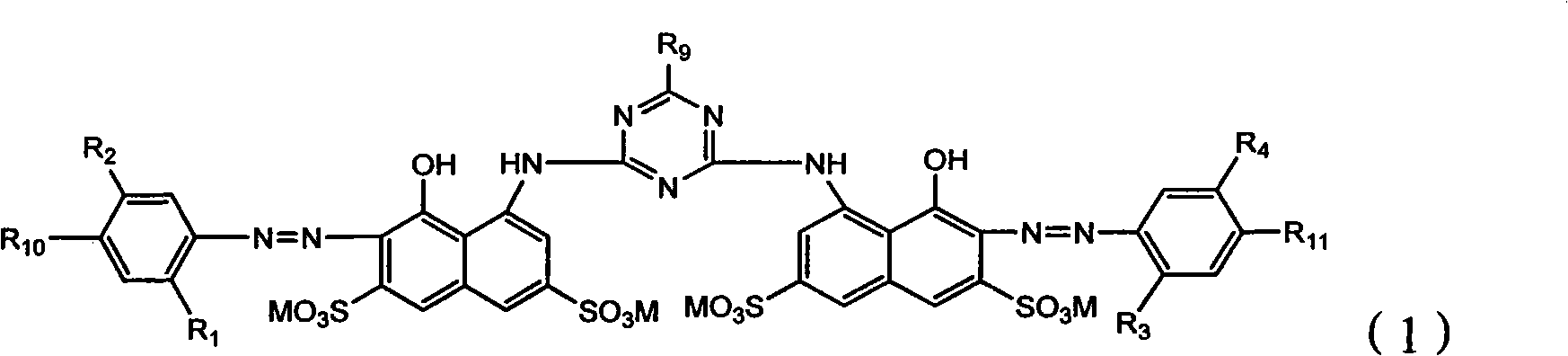

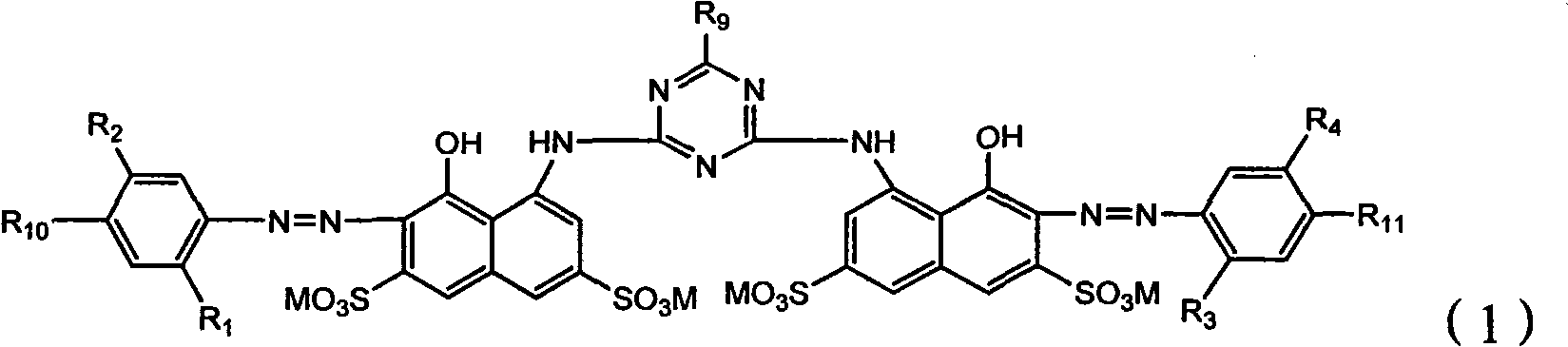

Composite active red dye

A technology of reactive red dye and dye monomer, applied in the field of reactive dyes, can solve the problems of difficult cleaning, poor fastness, thermal stability and alkali resistance, large dust, etc., to achieve high utilization rate, improve color fixing rate, increase The effect of solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

[0024] According to the data in Table 1-1, Table 1-2 and Table 2, after mixing dye monomer A, dye monomer B, co-solvent and water, grind and disperse with a sand mill, and then spray dry.

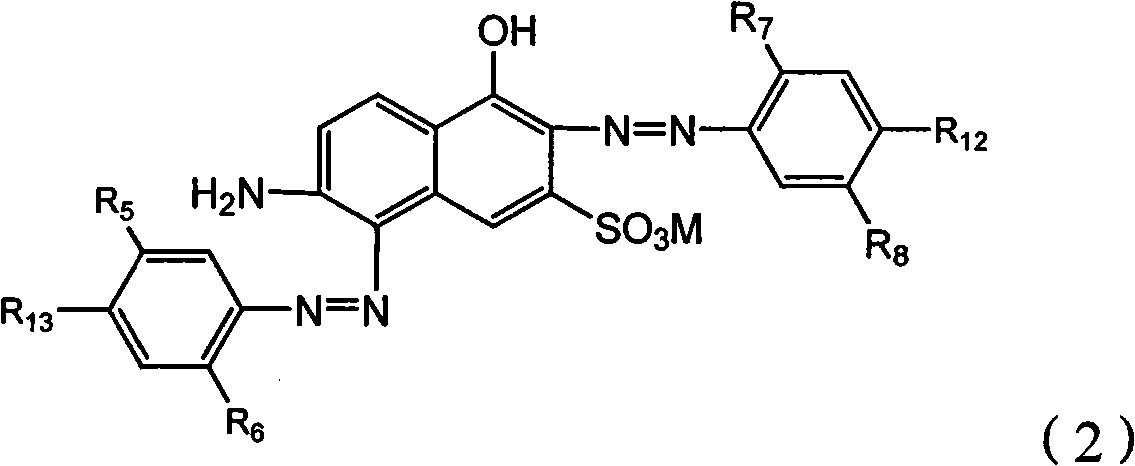

Embodiment 5

[0026] The preparation process of the dye monomer B in Example 5 is: add sodium nitrite to the para-ester in hydrochloric acid to carry out diazotization reaction, add J acid after the diazotization is completed, and perform a coupling under acidic conditions. After the completion of the dye intermediate product; beat the calculated amount of clixidin para-ester in the diazo pot, add hydrochloric acid to cool down, and then add sodium nitrite to carry out the diazotization reaction. After the diazotization reaction is completed, add the diazonium solution The secondary coupling is carried out in the dye intermediate, and the desired dye monomer B is obtained after the secondary coupling is completed.

[0027] Table 1-1

[0028]

[0029]

[0030] Table 1-2

[0031]

[0032] Table 2

[0033]

[0034]

[0035] The reactive dyes prepared in the above examples were dyed with standard reactive dyes to obtain their corresponding performance data, as shown in Table 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com