Reactive black dye composition and dye product

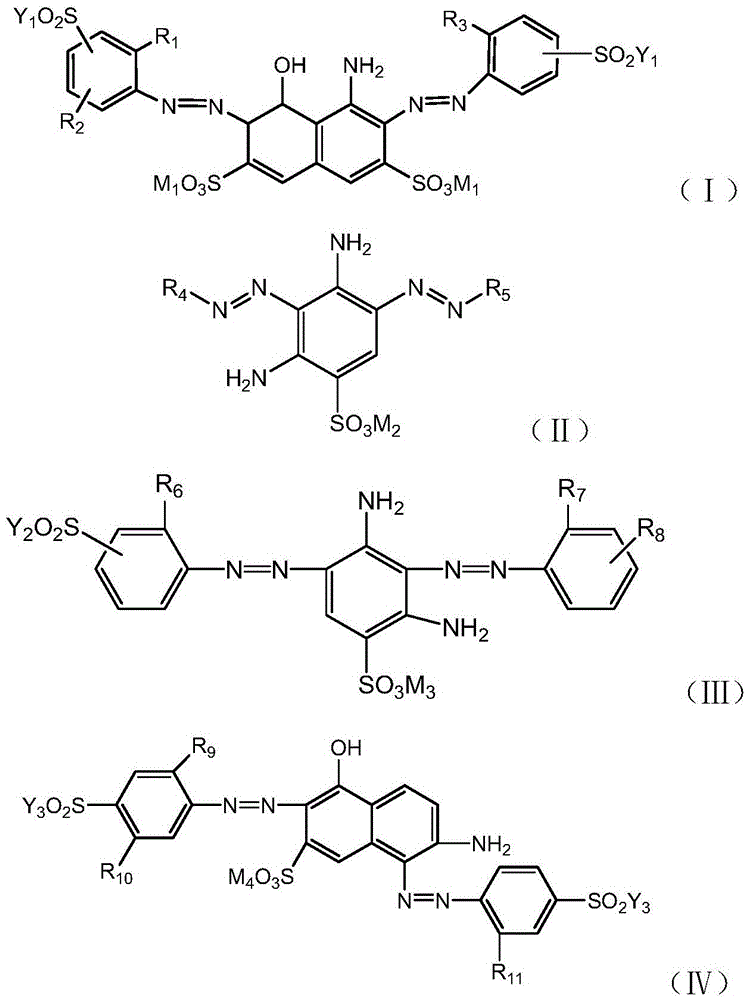

A technology of dye composition and reactive black, which is applied in organic dyes, dyeing methods, textiles and papermaking, and can solve the problems of poor dyeing depth, affecting the wet fastness of dyed fabrics, and poor dyeing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

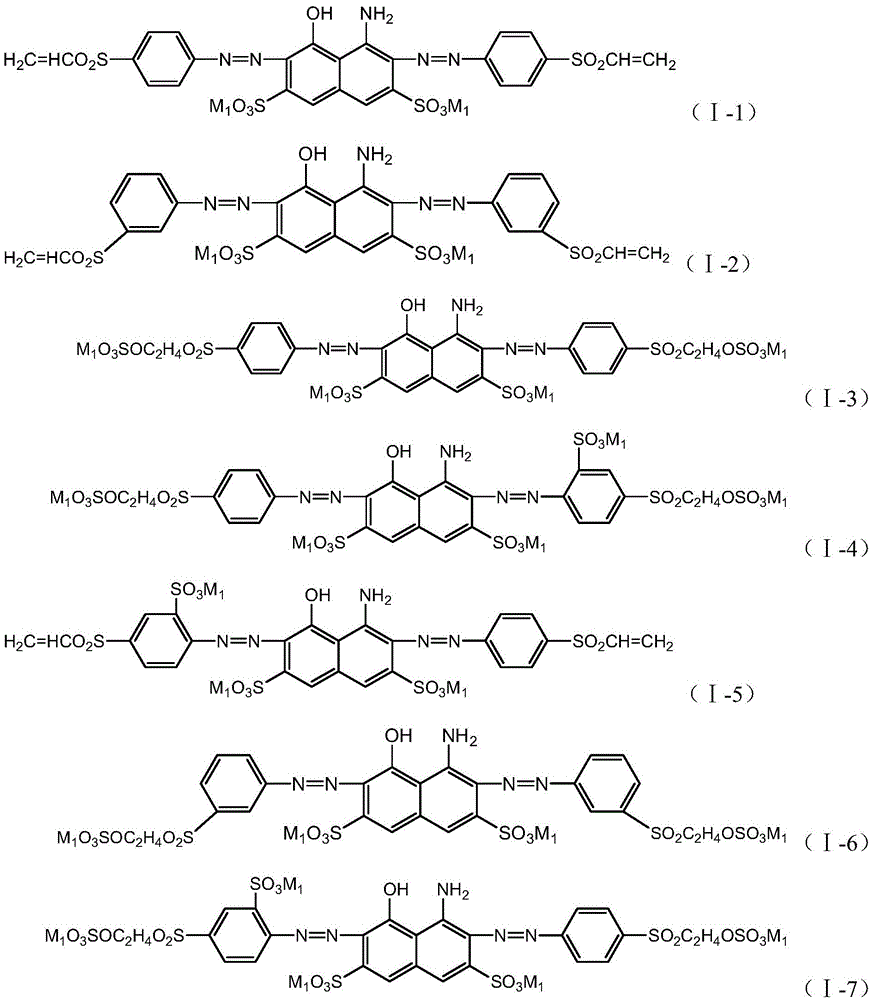

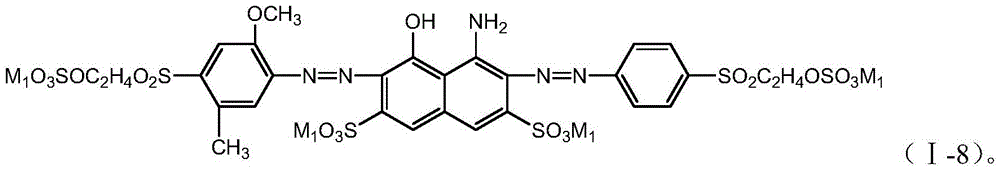

Examples

preparation Embodiment 1

[0065] 1. Weigh 14.6g (0.02mol) of sulfonated para-ester with a content of 53%, add water and beat for 0.5h, slowly add 5.06g of 30% sodium nitrite solution dropwise under the conditions of pH 0.8-1.4 and temperature 14-17°C (0.022mol) carry out diazonium reaction, every 0.5h judges whether sodium nitrate is excessive, reacts for 2h, the reaction terminal control amino reagent does not show yellow;

[0066] 2. Weigh 4.6g (0.02mol) of metaurea with a content of 65%, slowly add it to the above-mentioned diazo component, adjust the pH to 4.5-5.0, perform coupling reaction at 10-15°C for 2 hours, and measure the purity of the liquid phase Reaching 80% is the end of the reaction;

[0067] 3. Adjust the pH of the above coupling solution to 6.5-6.7, add 5.06g (0.022mol) of 30% sodium nitrite solution and stir evenly, and slowly add it dropwise to 5.9g (0.05mol) of 31% glacial hydrochloric acid within 40-60min. And keep stirring and reacting for 3 hours, and judge whether the sodium ...

Embodiment 23

[0083] 85 parts of the dyestuff of formula (Ⅰ-3), 15 parts of the dyestuff of formula (II-1) and 20 parts of sodium sulfate are mechanically mixed, and the composite dye dyed cotton that obtains is black (M 1~ M 2 Both are H, that is, the dye compound is expressed in the form of free acid).

[0084]

Embodiment 24

[0086] With 20 parts of dyes of formula (I-1), 45 parts of dyes of formula (I-3), 25 parts of dyes of formula (II-5), 10 parts of dyes of formula (III-1) and 30 parts of sodium sulfate Carry out mechanical mixing, the compound dyestuff dyeing cotton that obtains is black (M 1 ~ M 3 Both are H, that is, the dye compound is expressed in the form of free acid).

[0087]

[0088]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com