Reactive black dye composition

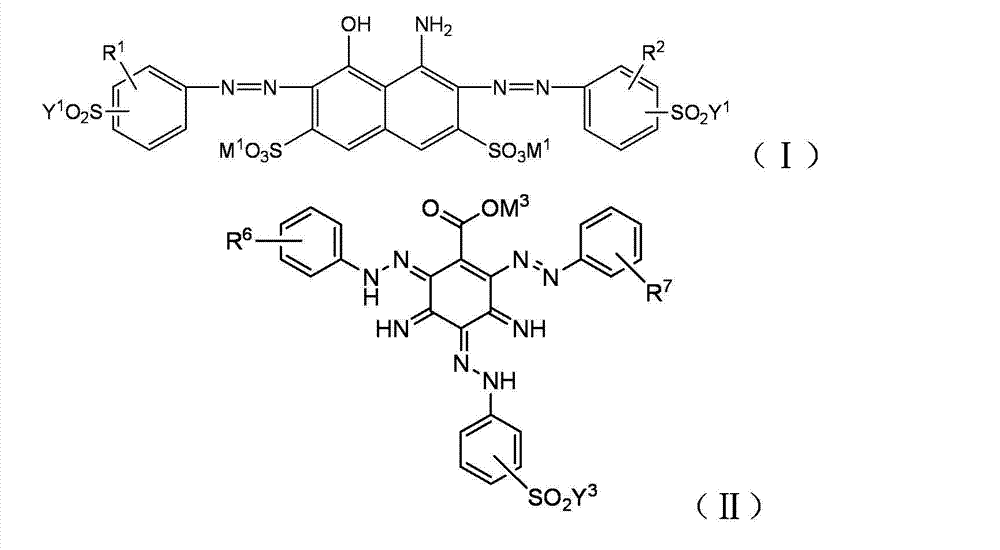

A dye composition and dye compound technology, applied in the field of reactive dye compositions, can solve the problems of weak dye depth, poor lifting power, insufficient blackness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

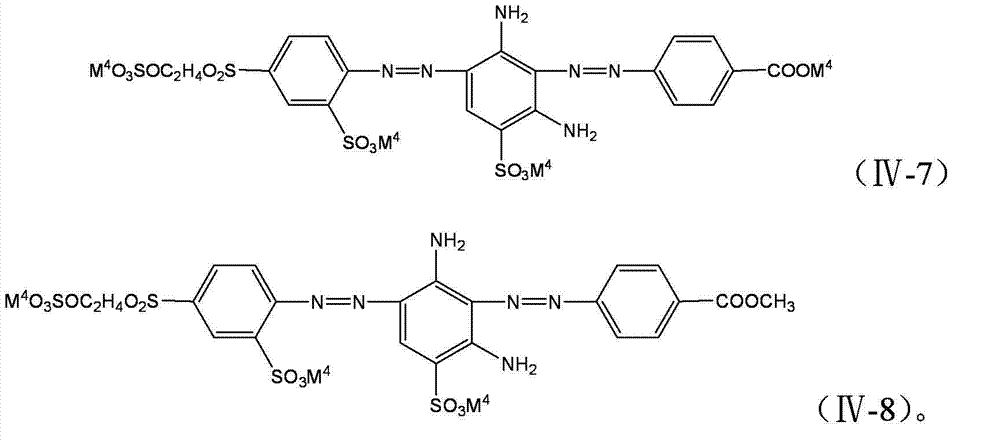

Method used

Image

Examples

Embodiment 1

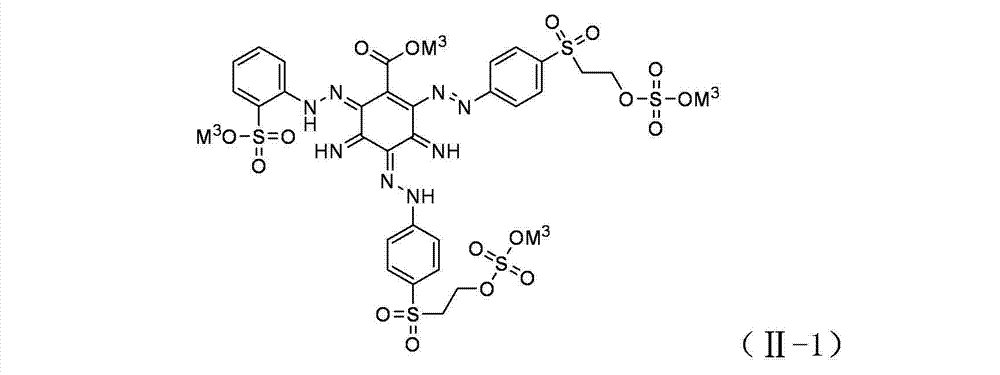

[0041] Embodiment 1: the preparation of formula (II-1) compound

[0042] (1) Diazotization: Add 17.3g of 2-aminobenzenesulfonic acid to 150mL of water and stir evenly, then cool to 0~5°C, add 12.5g of 31% (w / w) hydrochloric acid, maintain 0~5°C slowly Slowly add 24.5g of 30% (w / w) sodium nitrite aqueous solution dropwise, stir at this temperature for 1 hour, use sulfamic acid to eliminate excess sodium nitrite, and obtain diazonium solution of 2-amino-benzenesulfonic acid.

[0043] (2) Diazotization: add 56.2g of para-ester (i.e. p-(β-hydroxyethylsulfone sulfate) aniline) to 150mL of water and stir evenly, then cool to 0~5°C, maintain 0~5°C slowly Slowly add 21g of 31% hydrochloric acid and 48g of 30% sodium nitrite dropwise, stir at this temperature for 1 hour, use sulfamic acid to eliminate excess sodium nitrite, and obtain a diazonium solution of para-ester.

[0044] (3) Coupling: Add 15.2g of 3,5-diaminobenzoic acid into 100mL of water, after dissolving, add the diazonium...

Embodiment 2

[0047] Embodiment 2: the preparation of formula (II-2) compound

[0048] (1) Diazotization: add 26.0g of anthranilic acid to 280mL of water and stir evenly, cool to 0~5℃, add 18.7g of 31% hydrochloric acid, slowly add 36.7g of 30 % sodium nitrite aqueous solution, stirred at this temperature for 1 hour, and eliminated excess sodium nitrite with sulfamic acid to obtain diazonium solution of anthranilic acid.

[0049] (2) Diazotization: add 84g of para-ester (i.e. p-(β-hydroxyethylsulfone sulfate) aniline) to 250mL of water and stir evenly, then cool to 0~5℃, keep at 0~5℃ and slowly Add 30g of 31% hydrochloric acid and 72g of 30% sodium nitrite dropwise, stir at this temperature for 2 hours, use sulfamic acid to eliminate excess sodium nitrite, and obtain the diazonium solution of para-ester.

[0050] (3) First coupling: add 23.0g of 3,5-diaminobenzoic acid into 160mL of water, after dissolving, add the diazonium salt of step (1) into the solution, adjust the pH value to 5.7~6....

Embodiment 3~5

[0054] According to the preparation method described in Example 1 or a similar method, the difference is: the arylamine 1 and arylamine 2 in Table 1 are used to replace the arylamine in step (1) and step (2) respectively to carry out diazo The hydrazone dyes shown in Table 1 can be prepared, and the dyed fabrics appear bright yellow.

[0055] Table 1

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com