Patents

Literature

145results about How to "Improve wet fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid dye composition

An acid dye compound is prepared by taking weak acid dye, natural assistant and stabilizer as raw material and mixing to obtain final product. It has higher absorptive rate, better biological degradability and washing fastness.

Owner:DALIAN UNIV OF TECH

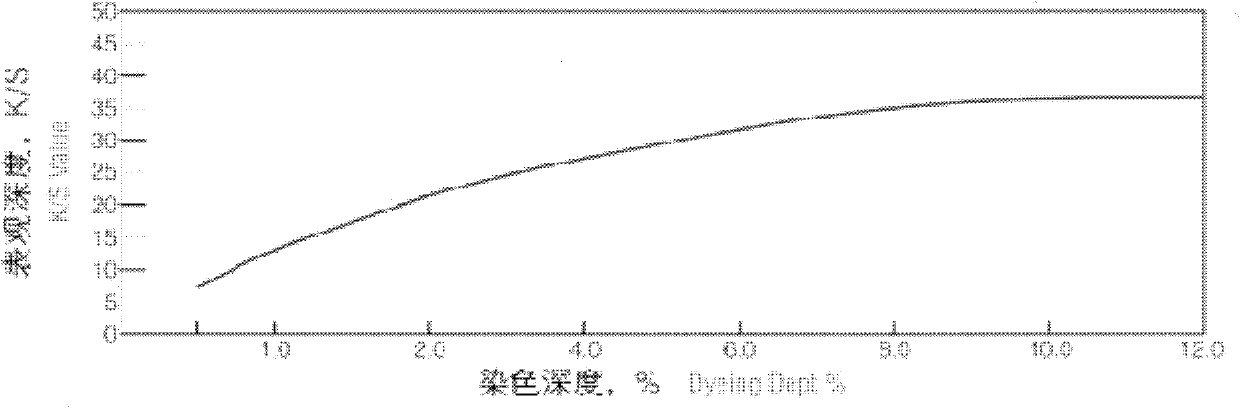

Digital ink-jet printing method of low-urea silk fabric

InactiveCN103952931AReduce dosageReduce the burden onDyeing processAnimal fibresTextile printerSewage treatment

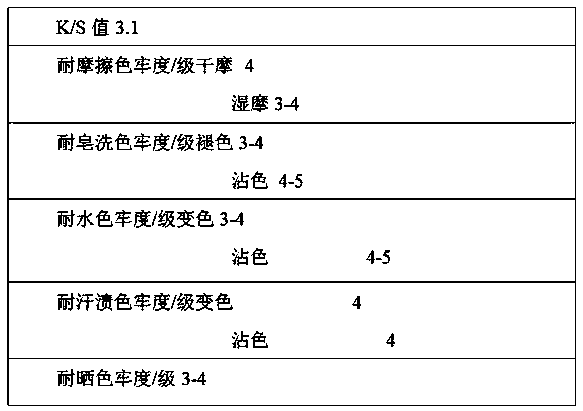

The invention relates to a digital ink-jet printing method of a low-urea silk fabric. The method comprises the following steps: firstly, carrying out a single-sided sizing pre-treatment on the silk fabric which is degummed and stentered by a sizing machine containing slurries such as a quaternary ammonium salt cationic modifier, guar gum and a low-urea wet absorption swelling agent; then, drying the fabric by an infrared drier at high frequency; then, jet-printing and steaming and fixing by regenerated active dye base ink; and finally, soaping by modified tea saponin, washing and drying to realize digital ink-jet printing of the low-urea silk fabric. According to the method provided by the invention, the silk fabric has good K / S value, fixation rate and wet-processing fastness, the use level of urea is reduced by 70-80%, and meanwhile, the utilization ratio of the active dye ink is increased, and finally, the burden of sewage treatment is alleviated. The method provided by the invention is a clean production method which satisfies the environmental requirement.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

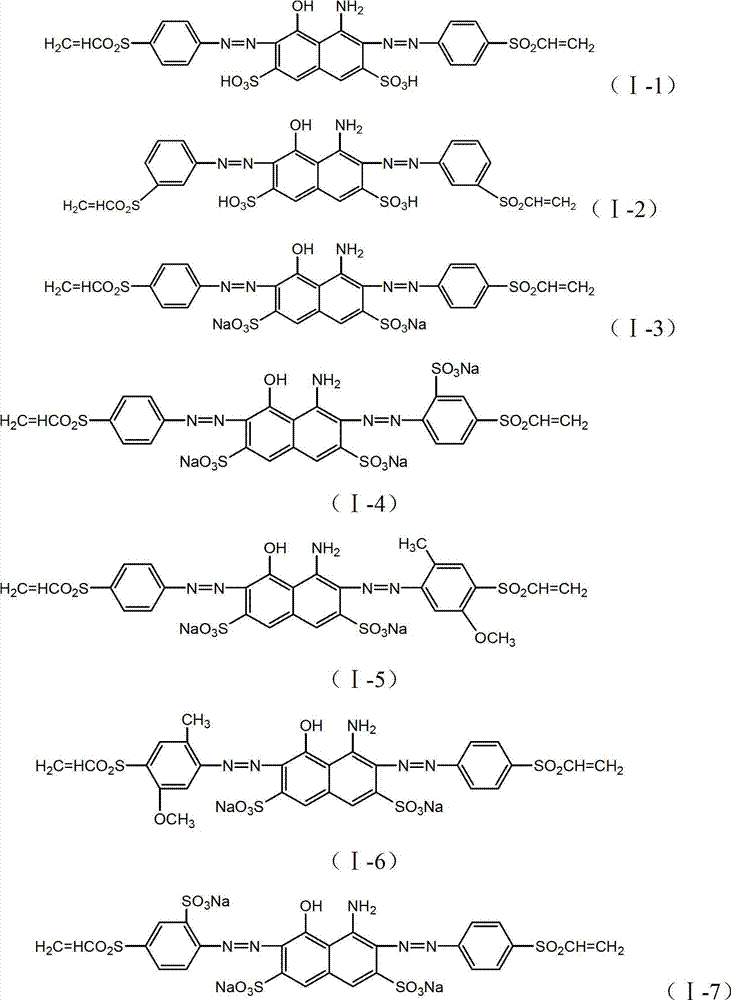

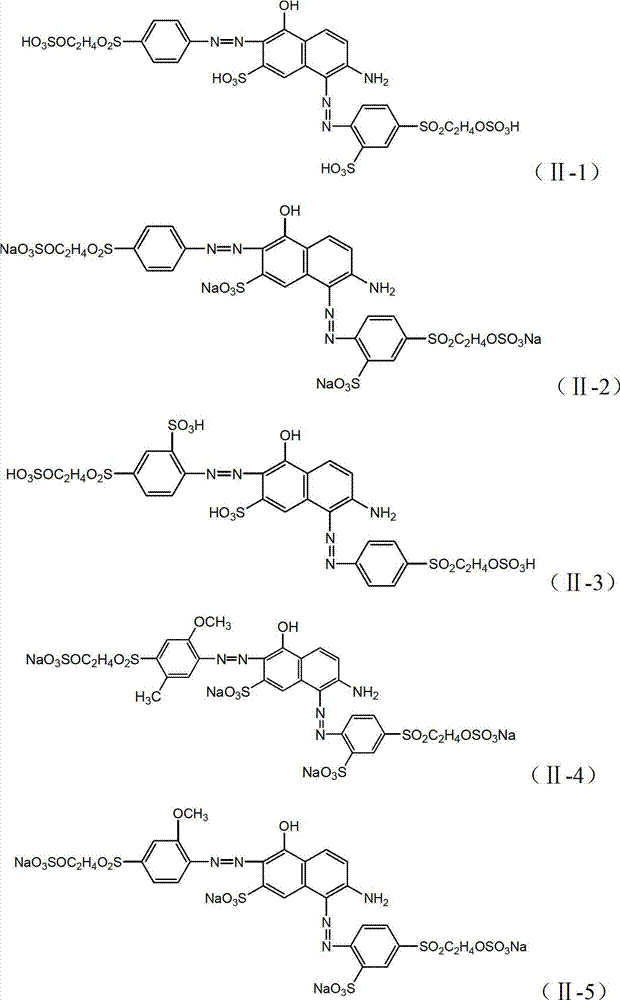

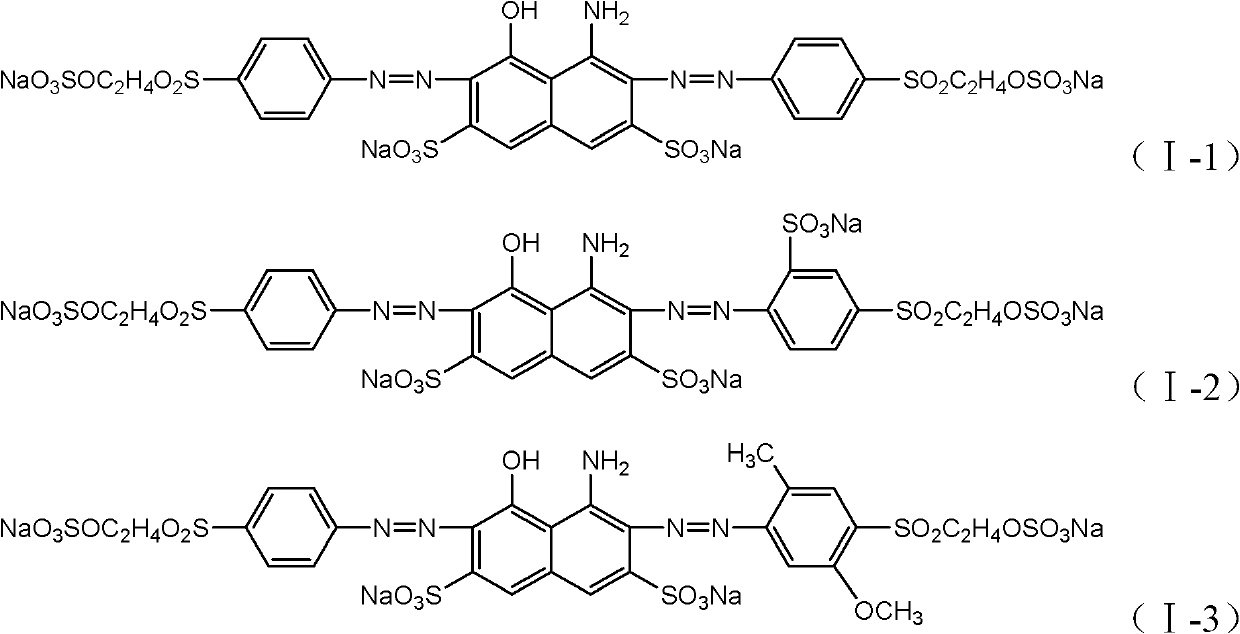

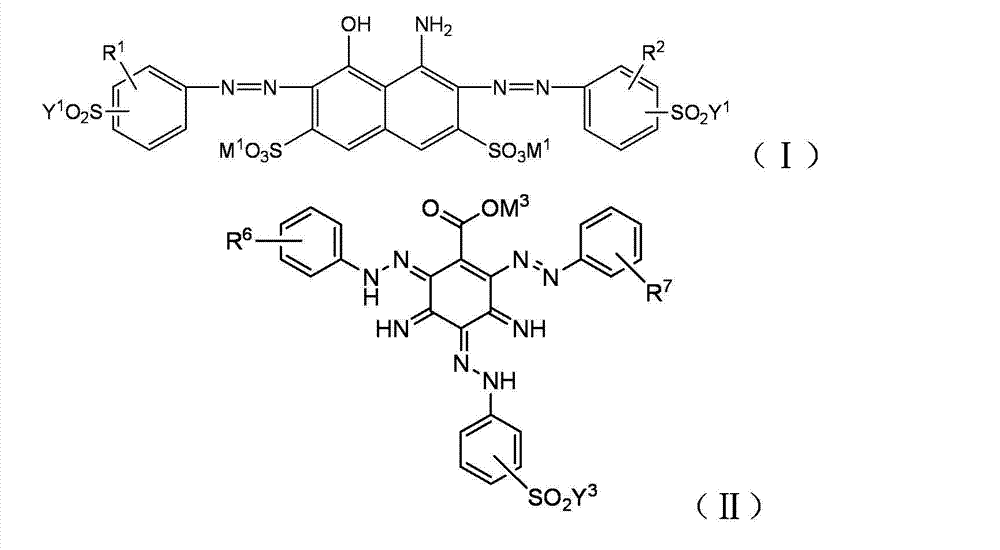

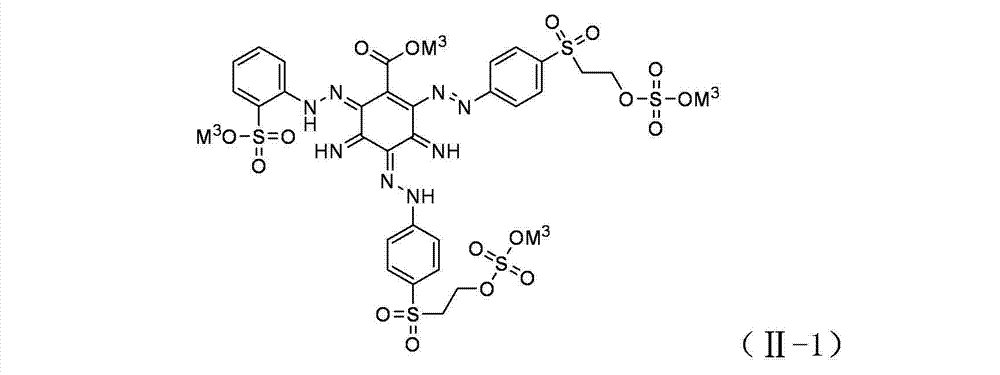

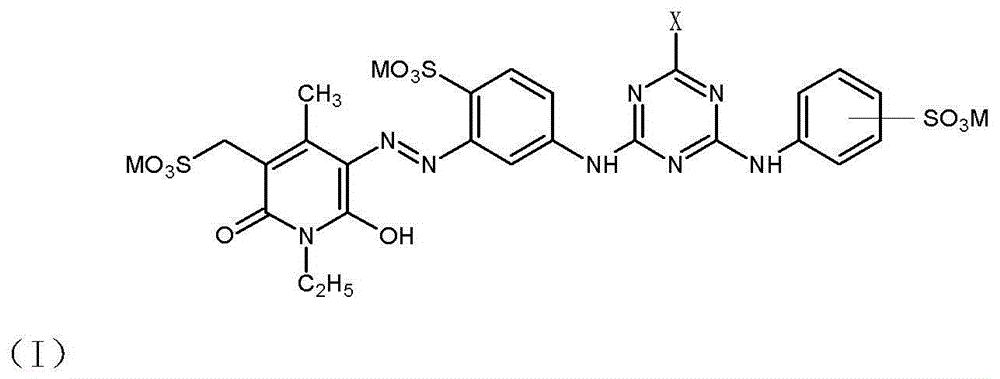

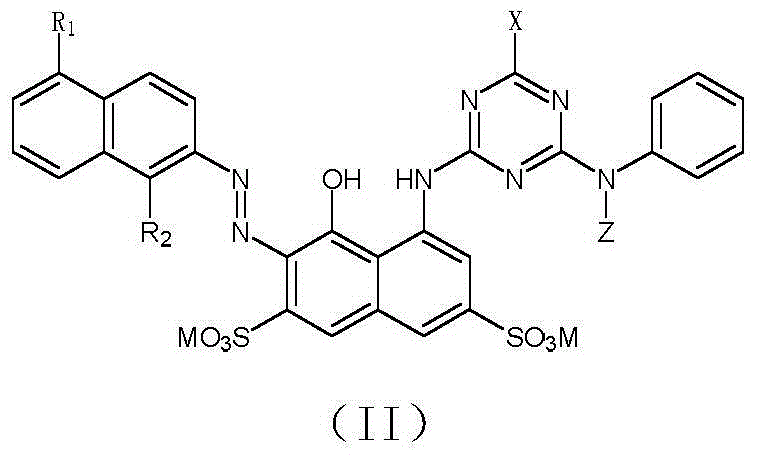

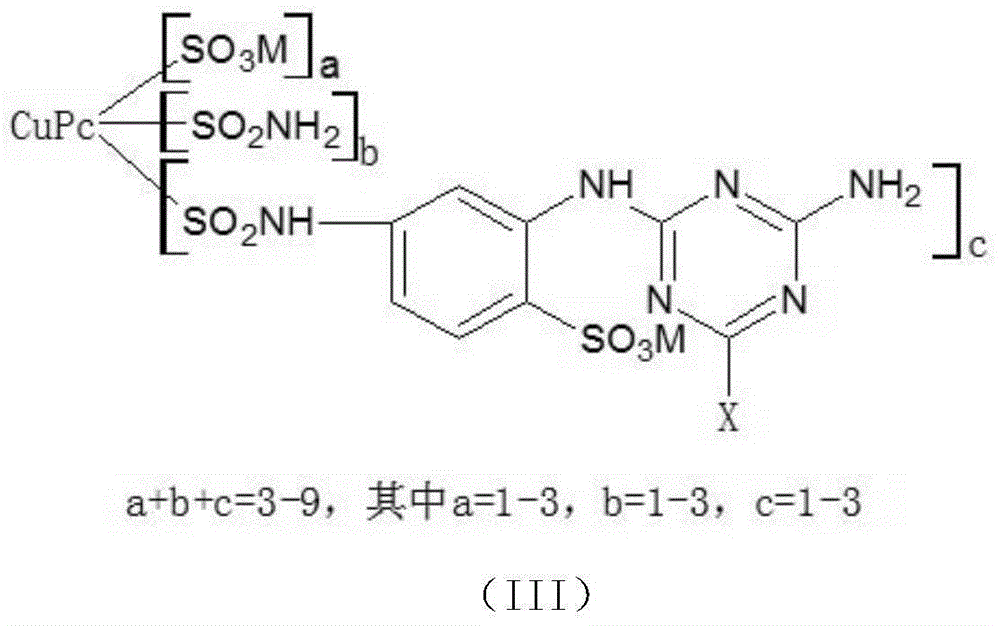

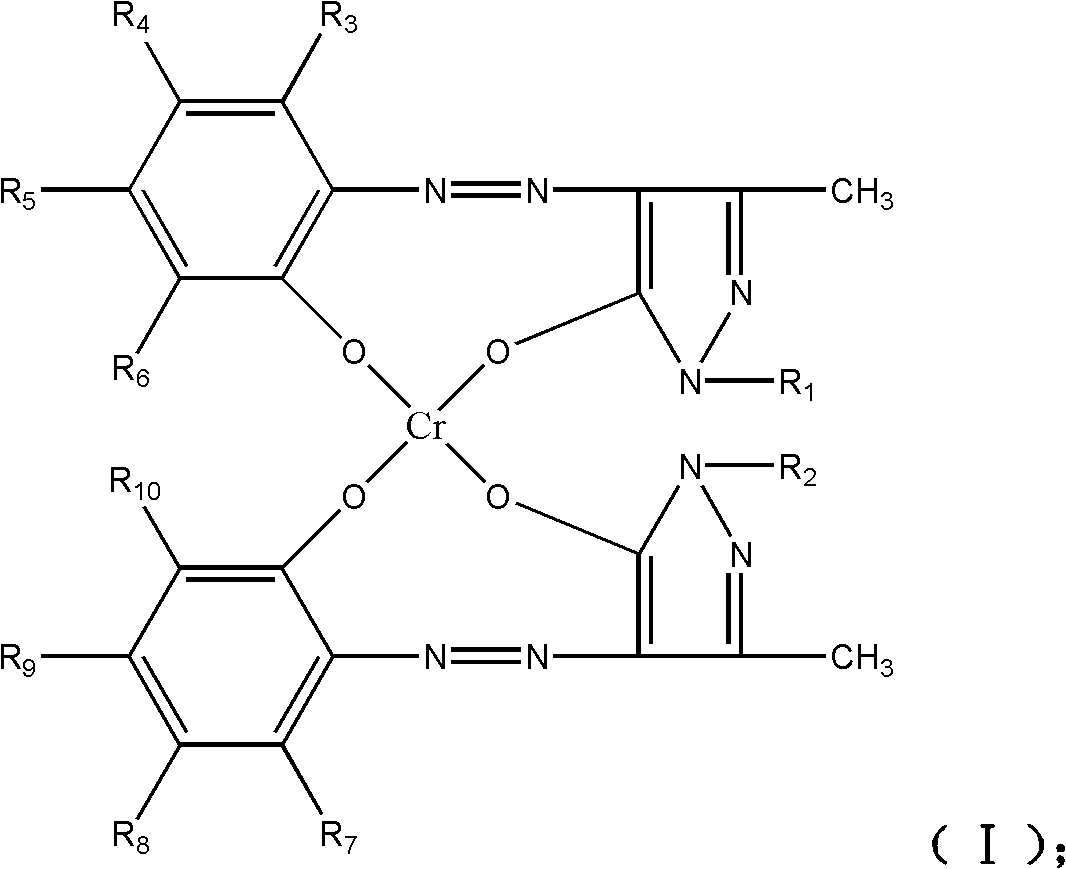

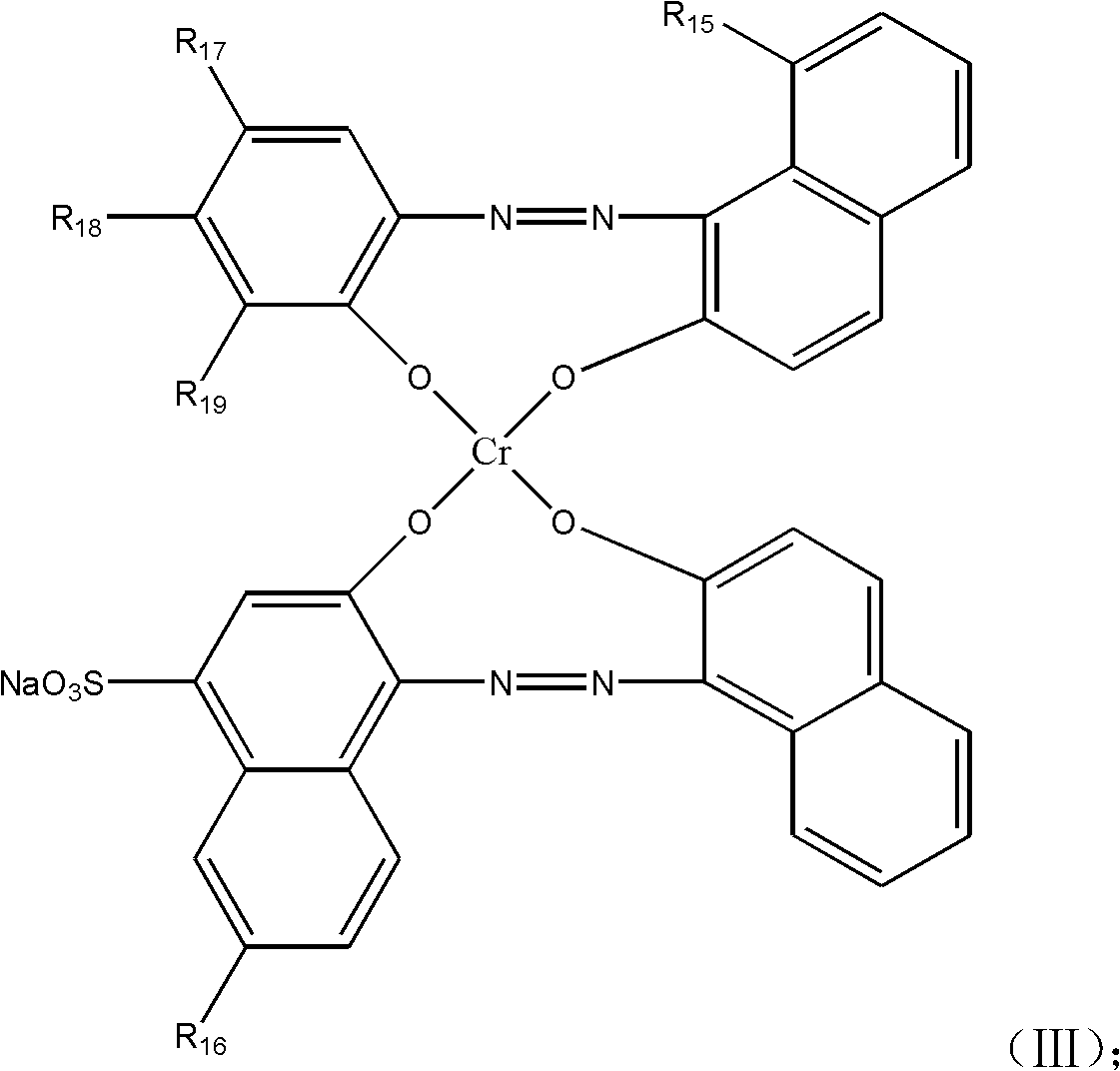

Active black dye composition

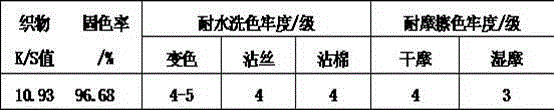

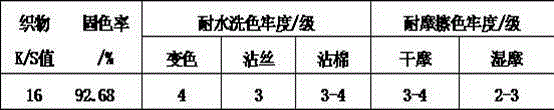

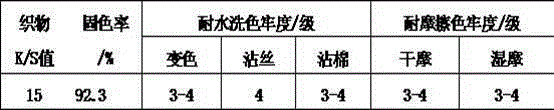

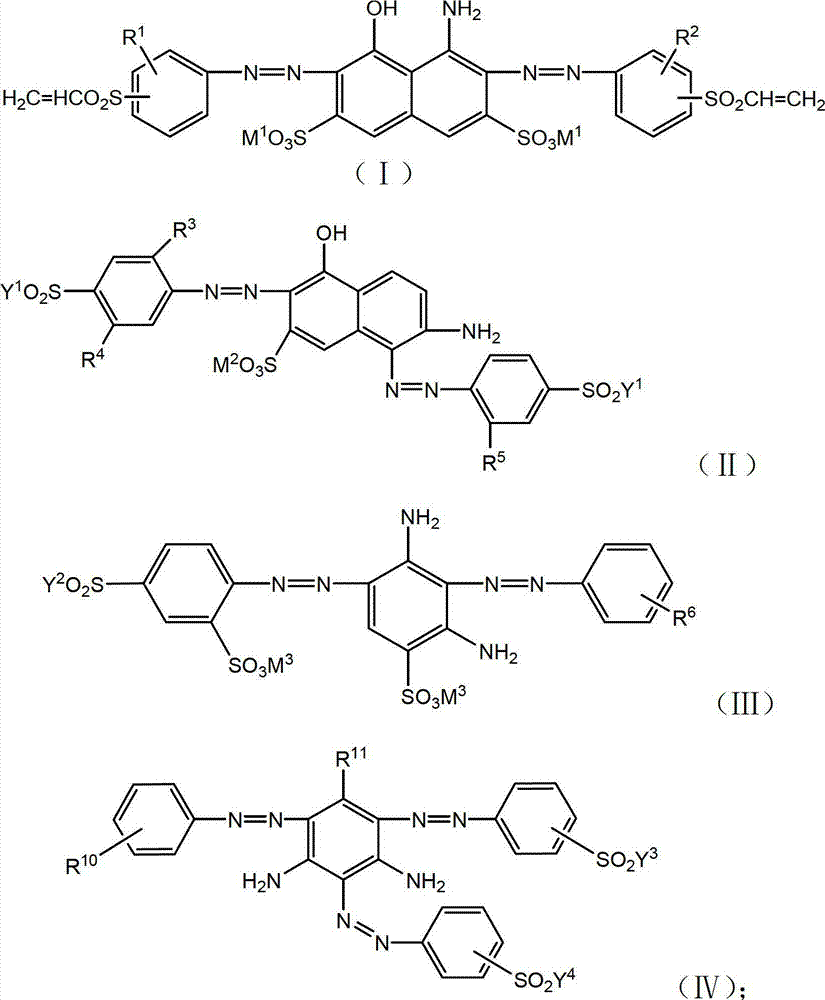

ActiveCN102964870AGood lifting effectHigh color fixing rateOrganic dyesDyeing processTextile printerPhotochemistry

The invention provides an active black dye composition, which comprises 45-90 weight parts of at least a component shown as a formula (I), 1-30 weight parts of at least a component B shown as a formula (II), and 1-40 weight parts of at least as a component C shown as a formula (III) and / or 1-40 weight parts of at least a component D shown as a formula (IV). The reactive black dye composition provided by the invention can be used for textile printing and dyeing, has advantages of good promotion performance, strong salt tolerance, easiness for washing and excellent wet-processing fastness, and is a rare economical black dye.

Owner:ZHEJIANG LONGSHENG GROUP +2

Method for performing complete cotton knitted fabric dyeing post treatment using immobilization laccase

InactiveCN101302716AIncrease temperatureImprove stabilityBiochemical fibre treatmentOn/in organic carrierEcological environmentPolyethylene glycol

The invention discloses a post processing method for the dyeing of all-cotton knitted fabrics that applies an immobilized laccase, belongs to the technical field of the application of the dyeing and finishing treatment of the knitted fabrics in the printing and dyeing industry, and aims at solving the technical problems that traditional post processing of the knitted fabric dyeing has high soaping temperature, large water consumption and residual washing water with deep chromaticity and achieving the goal for optimizing the post processing effect of the dyeing. The post processing method of the invention adopts calcium alginate and gelatinum as carriers so as to implement the imbedding of the laccase, improves the immobilization efficiency of the laccase in the carriers through glutaraldehyde crosslinking, improves the heat and pH stability of the laccase in the carriers by adding polyethyleneglycol, and realizes the circulation of the immobilized laccase in the post enzyme-washing treatment of the dyeing of the all-cotton knitted fabrics by adding carmowax to improve the thermal stability and the pH stability of the laccase in the carriers. By adopting the post processing method of the invention, the enzyme-washing technique with the immobilized laccase can replace traditional chemical soaping techniques, can not only effectively remove superficial loose color of the dyed all-cotton knitted fabrics and improve the wet processing fastness of the fabrics, but also effectively lower the chromaticity of the post processing residual liquid and release the burden of the sewage treatment of the printing and dyeing, and the post processing method of the invention is favorable for protecting ecological environment.

Owner:JIANGNAN UNIV

New green synthesizing process for ketocoumaran compound

The invention discloses a new green synthesizing process for a ketocoumaran compound. The synthesizing process comprises the following steps: in the absence of a solvent, performing condensation reaction of a mandelic acid compound and hydroquinol under the action of a little amount of acid catalyst to obtain a full condensed intermediate, wherein the acid catalyst is selected from one of 10 to 37 percent concentrated hydrochloric acid, 60 to 98 percent concentrated sulfuric acid, fuming sulfuric acid, 80 to 98 percent phosphoric acid, polyphosphoric acid, p-toluenesulfonic acid, trifloromethanesulfonic acid, benzoic acid, ammonium acetate, ammonium chloride, KF, TiC14, NiCl2, CuSO4, Cu(OAc)2, ZnCl2, AlCl3, Fe(NO3)3, FeCl3 and SnCl2; and performing oxidation reaction of full condensed intermediate under the action of an oxidant to obtain a final product ketocoumaran compound. The synthesizing process of the invention is simple, and has low energy consumption and little environmental pollution.

Owner:ZHEJIANG UNIV OF TECH

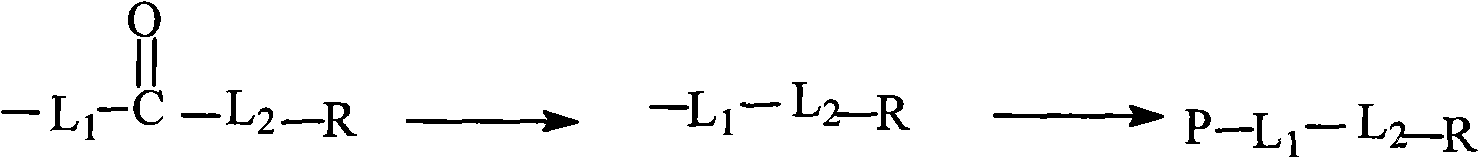

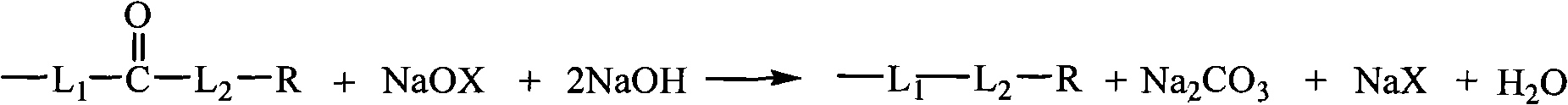

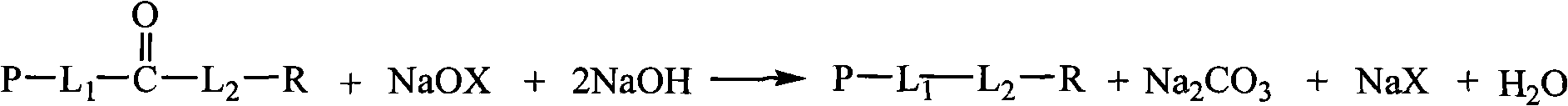

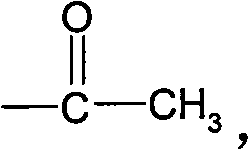

Positive image thermosensitive lithographic plate forebody and plate-making method thereof

InactiveCN102114725AIncreased sensitivityHigh developing latitudePhotosensitive materials for photomechanical apparatusForme preparationAcrylic resinSide chain

The invention discloses a positive image thermosensitive lithographic plate forebody. A thermosensitive layer is coated on a supporting body with hydrophilic surfaces and comprises alkali-soluable resin, an infrared absorbent and a dissolution inhibitor, and the alkali-soluable resin contains acrylic resin with a side chain structure of -L1-L2-R, wherein one of L1 and L2 is -HN- and the other one is -CH2-; and R is any one of H, alkyl, phenyl or substituted phenyl. The positive image thermosensitive lithographic plate forebody containing the alkali-soluable resin has the advantages of high sensitivity, high developing tolerance and high wet fastness.

Owner:LUCKY HUAGUANG GRAPHICS

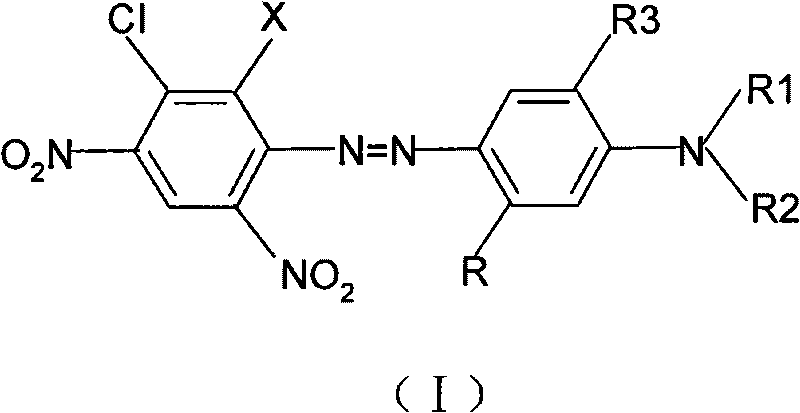

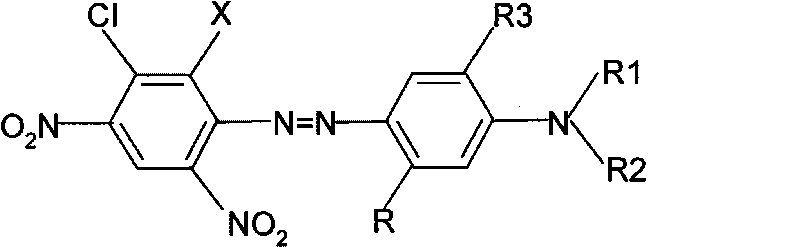

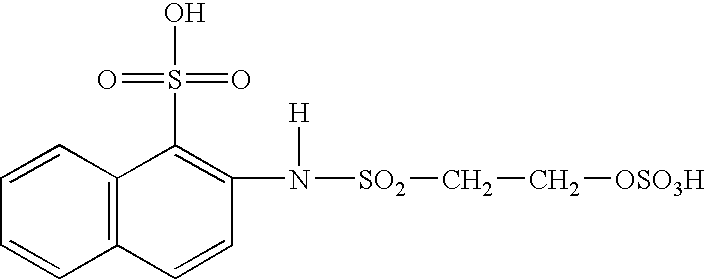

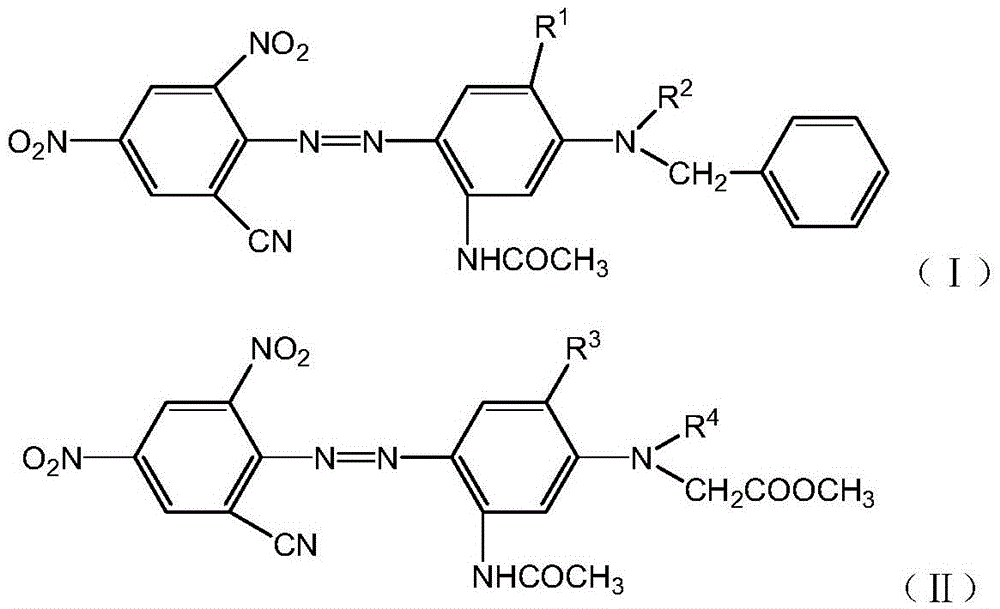

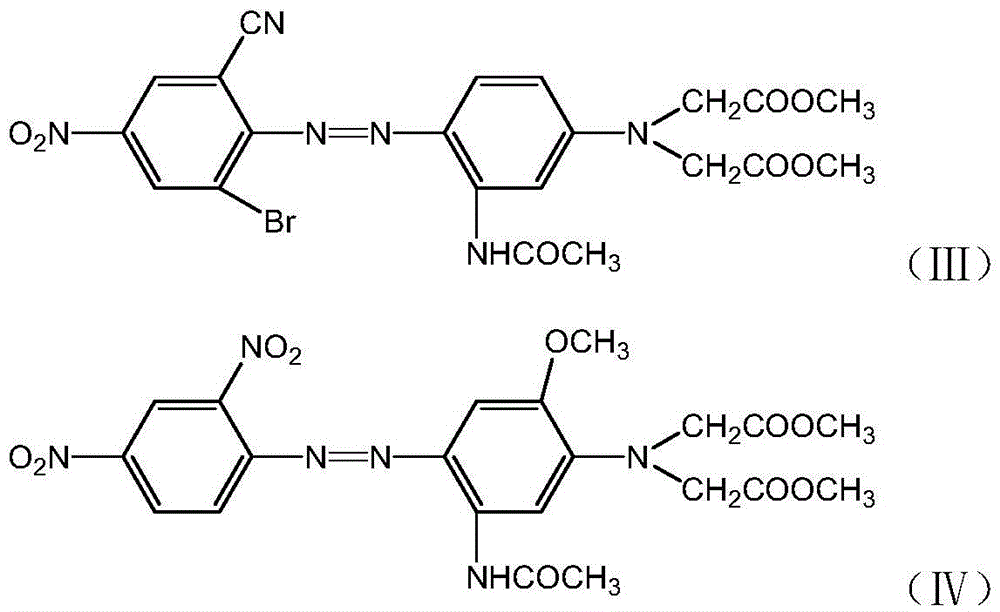

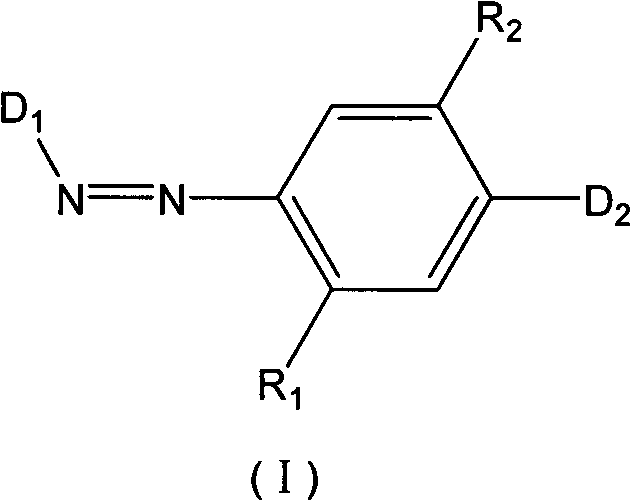

5-chloronitroaniline-containing azoic disperse dyes and preparation method and application thereof

InactiveCN101735665AImprove wet fastnessGood sublimation fastnessMonoazo dyesDyeing processDisperse dyeHydrogen

The invention provides 5-chloronitroaniline-containing azoic disperse dyes and a preparation method thereof. The structural general formula of the disperse dyes is shown in a formula (I), wherein X is hydrogen or bromine; R is hydrogen, methyl or -NHCO-C1-C4 alkyl; R1 is ethyl, cyanoethyl, phenmethyl, allyl or -CH2CH2OR4, wherein R4 is methyl, ethyl or carbonyl; R2 is independent of R1 but has the definition of the R1; and R3 is hydrogen, methoxyl or ethyoxyl. The 5-chloronitroaniline-containing azoic disperse dyes are characterized in that: a diazonium component contains 2,4-binitro-5-chloroaniline or bromide thereof. The dyes have the advantages of excellent wet fastness and sublimation fastness, are suitable for dyeing terylene and blend fabrics thereof, and have low cost and wide application prospect.

Owner:烟台澳土复合材料有限公司

Method for providing protective treatment to nylon fibers

InactiveUS6719810B1Increased durabilityIncreased longevityMonocomponent protein artificial filamentReactive dyesResistDisperse dye

Owner:KELLY DAVID R +2

Alkali-fast aldehyde-free colour stabilizer and method for preparing the same

InactiveCN101492888AImprove wet fastnessImprove the composite fastness to sweat and lightDyeing processEpoxyAdditive ingredient

The invention relates to a color fixing agent and a preparation method thereof. An alkaline-resisting aldehyde-free color fixing agent is a cationic polymer formed by the polymerization reaction of acrylamide, butyl acrylate and epoxy chloropropane. A method for preparing the alkaline-resisting aldehyde-free color fixing agent comprises the ingredients as follows: 10%-35% of acrylamide, 15%-45% of butyl acrylate, 10%-40% of epoxy chloropropane, 5%-13% of hydrochloric acid and 0.1%-1.5% of an initiating agent; and comprises the following steps: adding acrylamide and butyl acrylate under normaltemperature and raising the temperature; adding epoxy chloropropane at 60 DEG C and maintaining the temperature for 10-18 minutes; raising the temperature to 80 DEG C to add the initiating agent and maintaining the temperature for 30 minutes; raising the temperature to the range from 120 DEG C to 130 DEG C, and persistently reacting for 3-4 hours; adding hydrochloric acid for acid cleaning, temperature reduction, neutralization and discharging to obtain the alkaline-resisting aldehyde-free color fixing agent. The invention is quite strong in resisting alkaline and high temperature, is free from color variation when treating the fabrics, and has no influence on chlorine fastness, light fastness and perspiration-light fastness.

Owner:上海德桑精细化工有限公司

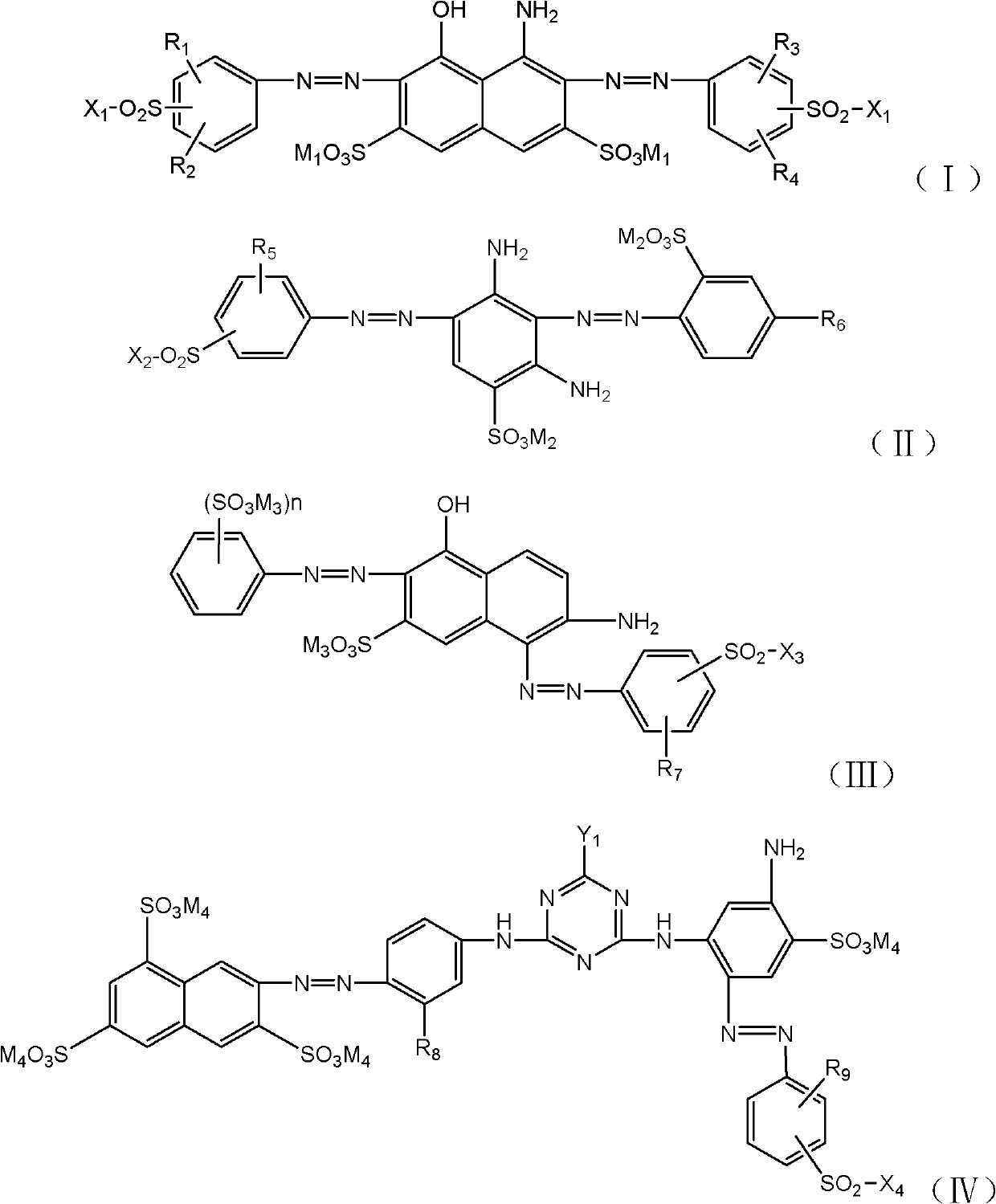

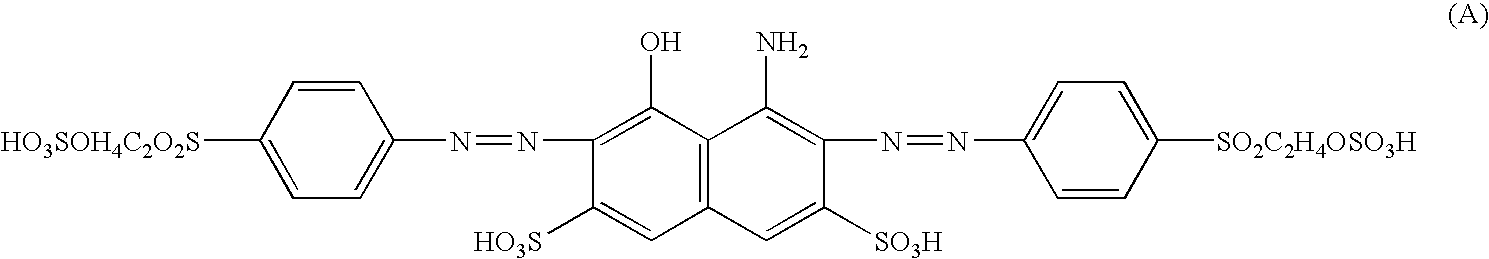

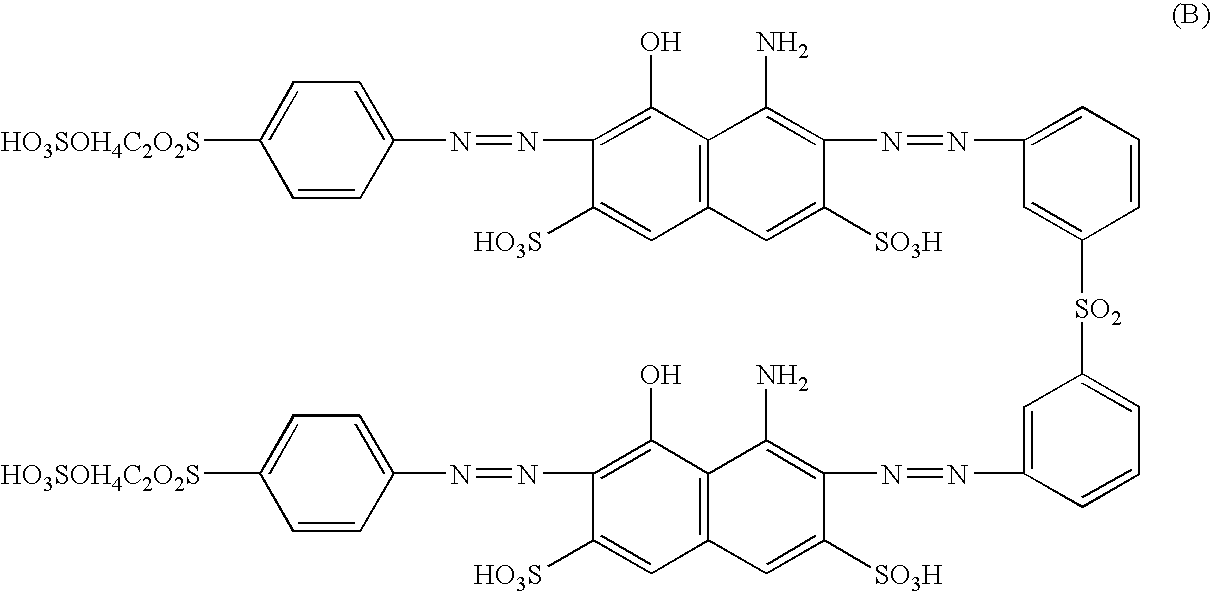

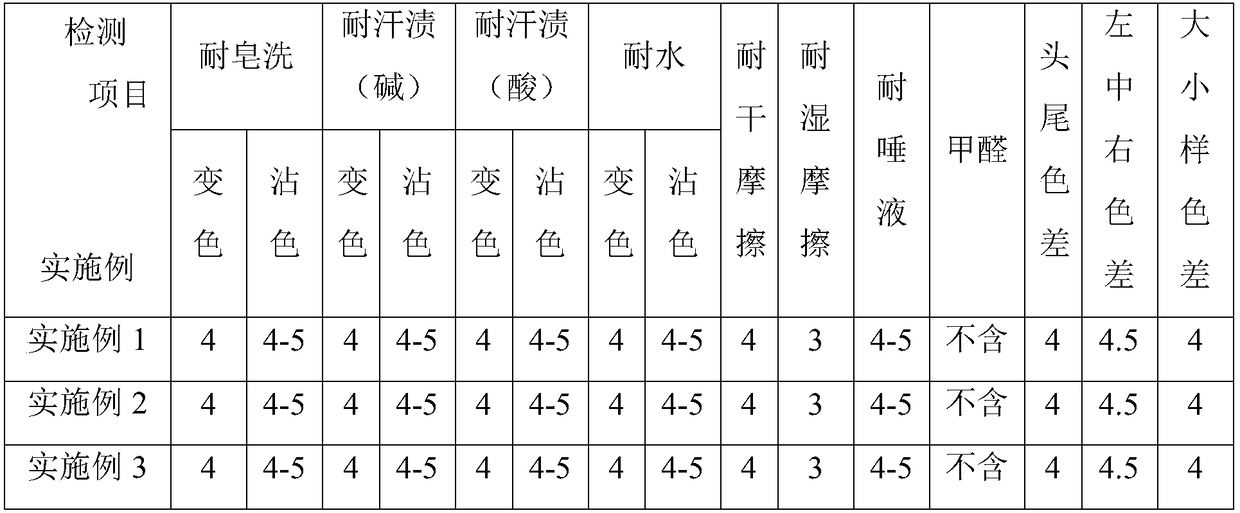

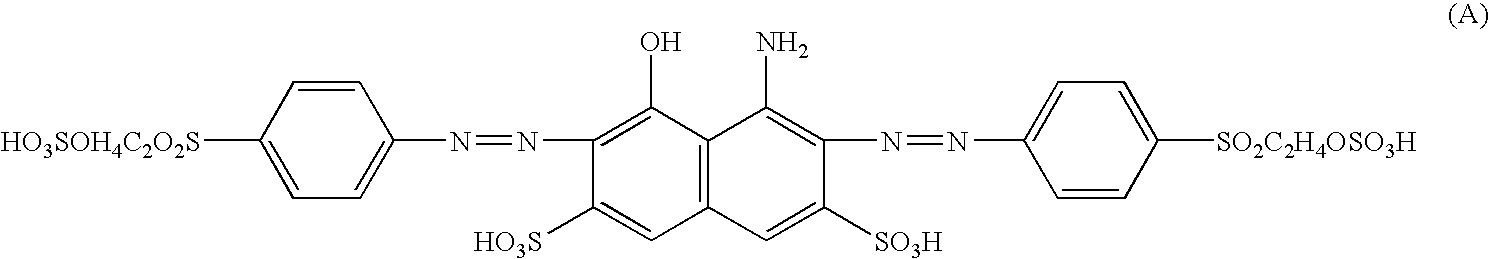

Compound active black dye composition

ActiveCN102558907AImprove solubilityGood lifting effectOrganic dyesDyeing processTextile printerPhotochemistry

The invention provides a compound active black dye composition, mainly comprising one or more than one component A with a structure shown as a formula (I), one or more than one component B with a structure shown as a formula (II) and one or more than one component C with a structure shown as a formula (III) and / or a formula (IV), wherein on the basis of the component A, the component B and the component C, the percent by weight of the component A is 45-90%, the percent by weight of the component B is 1-30%, and the percent by weight of the component C is 5-40%. The compound active black dye composition provided by the invention has high dissolvability, good lifting performance, high alkali resistance, excellent wet-processing fastness and good drawing performance and is easy to wash when being used for textile printing and is a rare economical dark black dye.

Owner:ZHEJIANG KEYONG CHEM CO LTD

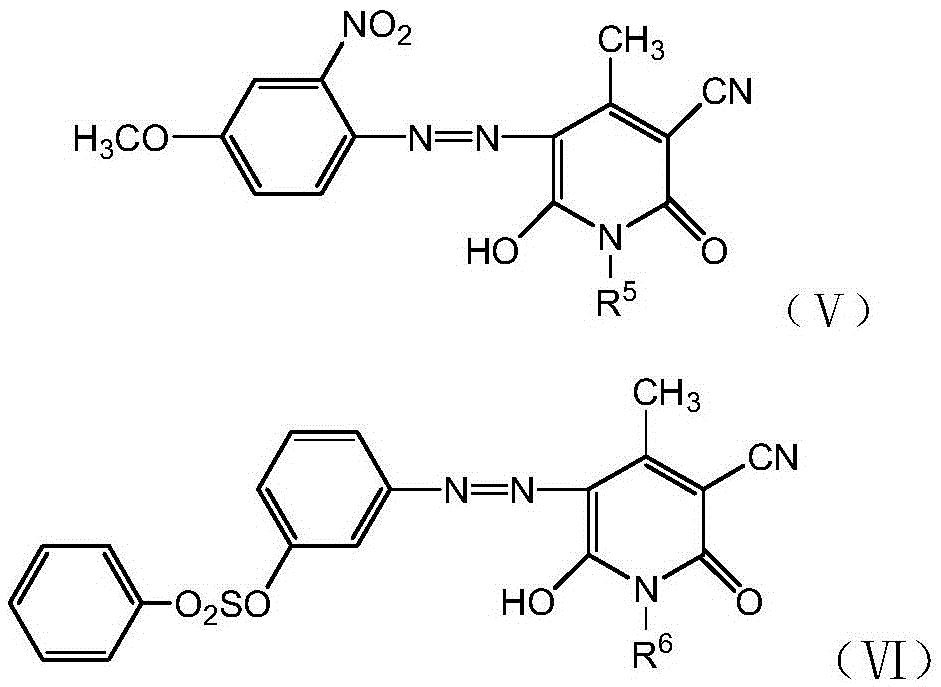

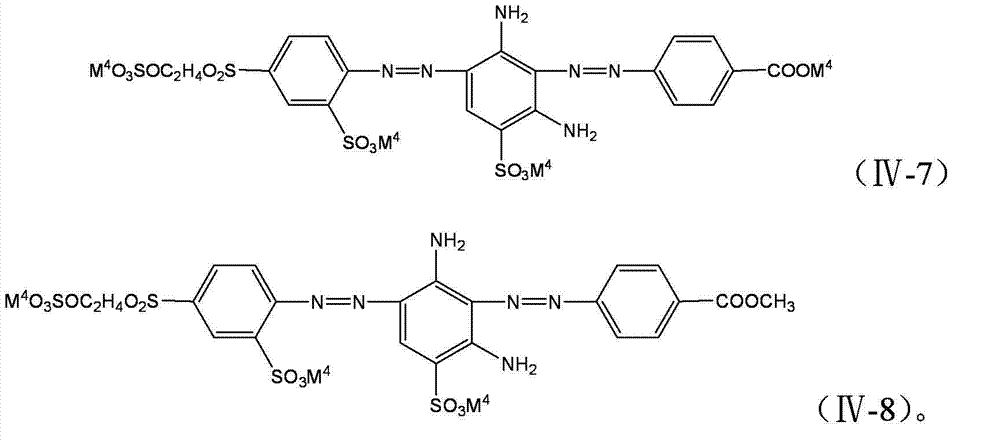

Disperse blue to black dye composition, dye product and applications thereof

ActiveCN105566947AGood wet fastness and fastness to crockingMeet the needs of ecological and environmental protectionOrganic dyesDyeing processChemistryDyeing

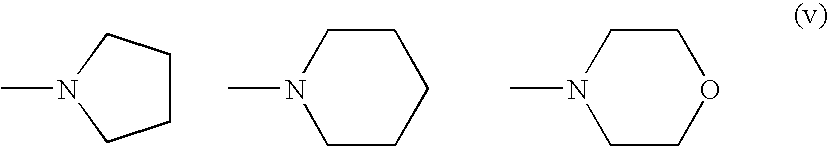

The invention discloses a disperse blue to black dye composition, a dye product, and applications thereof. The disperse blue to black dye composition comprises the following components in percentage by weight: 30 to 80% of blue component A, 5 to 40% of purple component B, 5 to 40% of yellow component C, and 5 to 40% of red component D; wherein the blue component A is a mixture of a compound represented by the formula (I) and a compound represented by the formula (II) according to any ratio, the purple component B is a mixture of a compound represented by the formula (III) and a compound represented by the formula (IV) according to any ratio, the yellow component C is one or more of compounds represented by the formula (V) and / or formula (VI), and the red component D is at least one of the compounds represented by the formula (VII). The disperse blue to black dye product contains the disperse blue to black dye composition and auxiliary agents. The invention also provides the applications of the disperse blue to black dye composition and dye product in printing and dyeing of hydrophobic fiber materials.

Owner:ZHEJIANG LONGSHENG GROUP

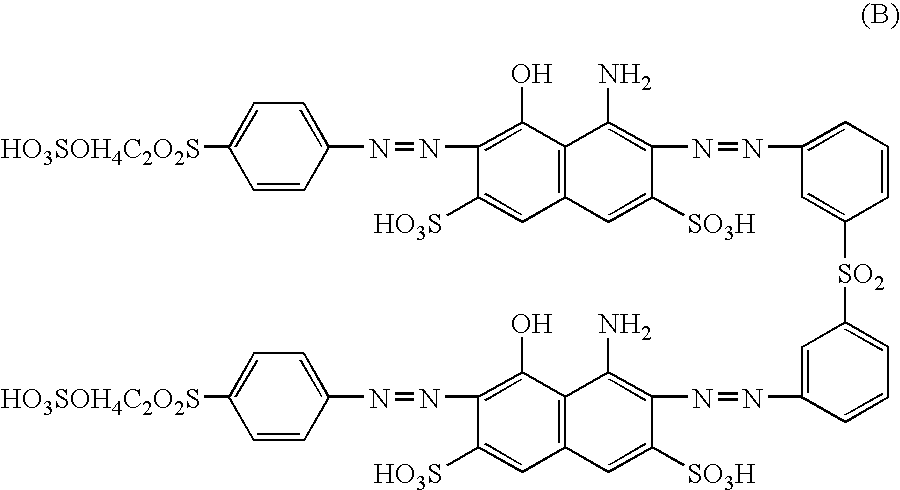

Reactive black dye composition

InactiveCN103073920AGood lifting effectHigh color fixing rateReactive dyesDyeing processSalt resistancePhotochemistry

The invention provides a reactive black dye composition. The reactive black dye composition mainly comprises 45-99 parts of at least one component A shown in formula (I) and 1-55 parts of at least one component B shown in formula (II) by mass. The reactive black dye composition has the advantages of good upgrading performance, high color fixing rate, high dyeing rate, easy washing, clear dyeing residual liquid, stable salt resistance and alkali resistance and excellent wet fastness when used in fabric printing and dyeing, and is a rare deep black economical dye.

Owner:ZHEJIANG LONGSHENG CHEM RES

Formula of reactive dye

The invention relates to a formula of reactive dye, and belongs to the technical field of printing dye. The formula comprises the following constituents in parts by weight: 20 to 40 parts of 2,4-difluoro-5-chloropyrimidine dye, 30 to 50 parts of vinyl sulfone dye, 20 to 40 parts of alpha-bromo-acrylic amide dye, 1 to 8 parts of dye leveller peregal O, 1 to 10 parts of sodium sulfate, 1 to 10 parts of sodium chloride, 2 to 8 parts of disodium hydrogen phosphate, 10 to 20 parts of sodium dihydrogen phosphate, 5 to 15 parts of sodium hydroxide, 1 to 20 parts of sodium carbonate, and 5 to 15 parts of urea. The dye has relatively high fastness and wet fastness, bright color, excellent performance and high applicability, and both the color and the performance of the dye can meet the requirements on fiber and apparel fabric by the market.

Owner:GUANGDONG JINCHAO GRP

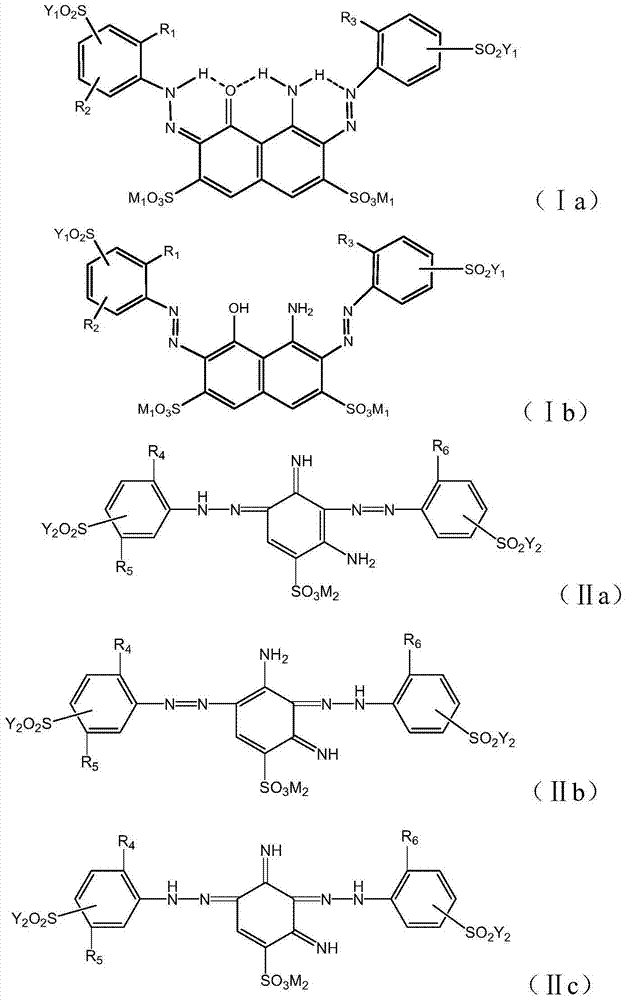

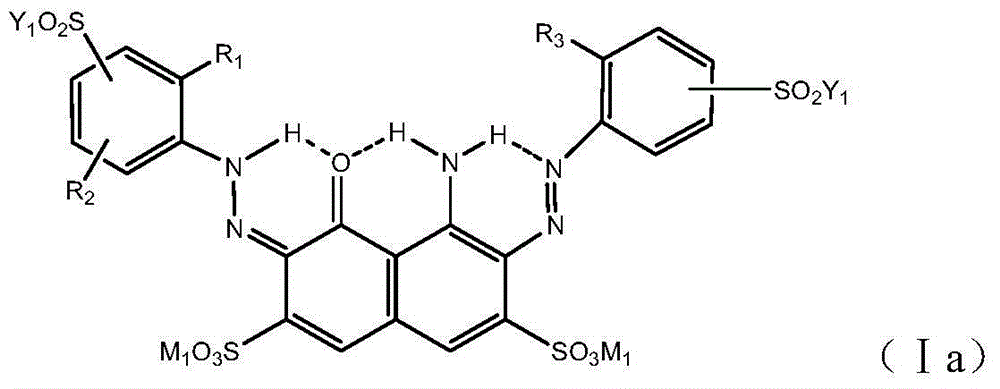

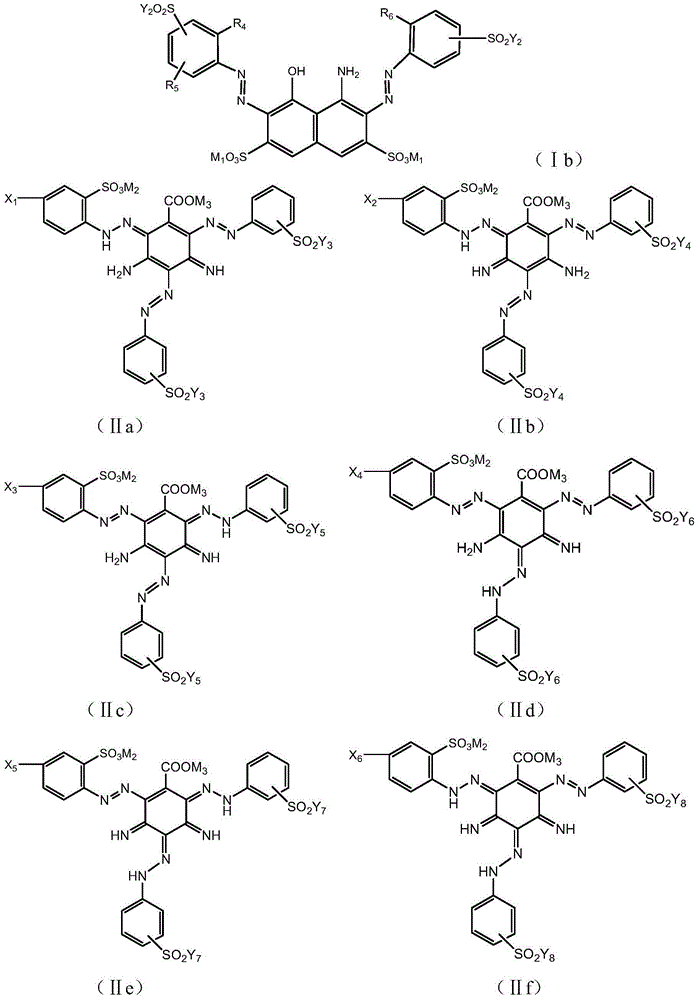

Reactive black dye composition

InactiveCN104513497AGood lifting effectHigh color fixing rateOrganic dyesDyeing processTextile printerHigh color

The present invention provides a reactive black dye composition, which mainly comprises 45-99 parts by mass of a component A and 1-55 parts by mass of a component B, wherein the component A is selected from one or a plurality of materials represented by formulas (Ia)-(Ib), and the component B is selected from one or a plurality of materials represented by formulas (IIa)-(IIc). According to the present invention, when the reactive black dye composition of the present invention is used for textile printing dyeing, advantages of good build-up property, high color fixation rate, high dye uptake, easy water washing, clear dyeing residue liquid, stable saline-alkaline tolerance, and excellent wet treatment fastness are provided, and the reactive black dye composition is a cheap and rare deep black dye. The formulas are defined in the instruction.

Owner:ZHEJIANG KEYONG CHEM CO LTD

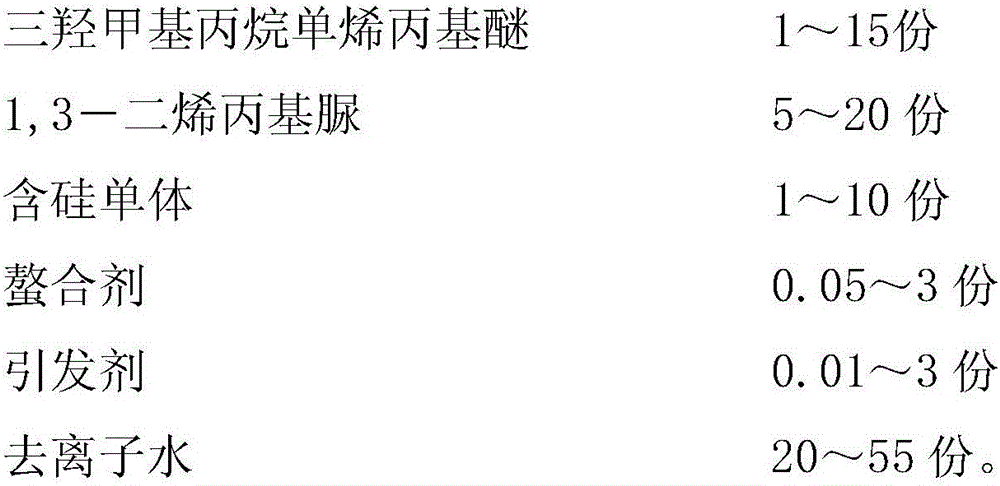

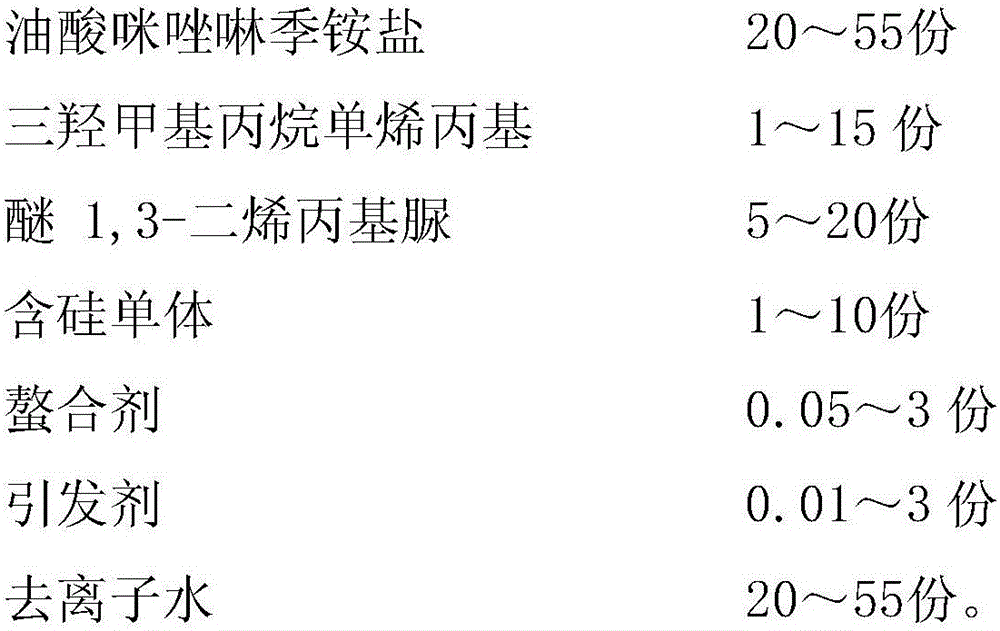

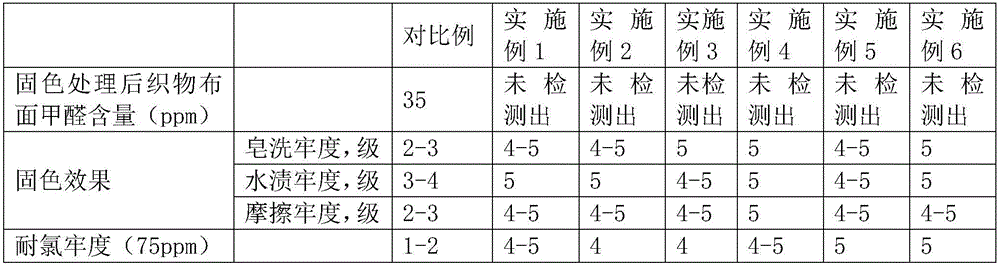

Formaldehyde-free activated dye color fixing agent and preparation method thereof

The invention provides a formaldehyde-free activated dye color fixing agent and a preparation method thereof. The preparation method comprises the following steps of 1, sequentially adding oleic acid imidazoline quaternary ammonium salt, trimethylolpropane monoallylether, 1-3-diallylurea, silicon-containing monomer, a chelating agent and deionized water into a reaction kettle provided with a thermometer, a stirrer and a reflux condenser, then starting reflux condensation, conducting stirring, and starting heating for raising the temperature; 2, when the temperature is raised to 85-100 DEG C, starting dropwise adding an initiator solution with the mass percentage concentration ranging from 1% to 10%, wherein the initiator solution is prepared from initiator and part of deionized water, the dropwise adding time is controlled to be 0.5-4 hours, and the temperature in the dropwise-adding process is controlled to be 85-100 DEG C; 3, after the initiator solution is added completely, conducting a reaction for 1-5 hours with the temperature preserved, subsequently adding the balance water, stirring the materials for 0.5 hour, and then discharging the materials, so that the color fixing agent is obtained.

Owner:山东艾文生物科技有限公司

Printing discharge dyeing paste for coating material to discharge dye silk broadcloth, and discharge printing technique of extracting activity of coating material

This is the discharging paste of real silk discharging dye printing and its discharging dye printing technics of coating active discharge. The discharging slurry of real silk coating discharging dye printing of the present invention is a mixture of special mulriple slurry and discharging agent. Thereinto the special mulriple slurry contains components represented by weight shares: the natural modified cataplasm of 8% solid containing rate 30 - 50, the complex thickening agent of 2% solid containing rate 20 - 40, the bond 6 - 18, the moist penetrant 4 - 10, softening agent 1 - 2, macromolecular weight dye printing accessorial agent 0.5 - 2, nanometer silicon dioxide sol 1 - 5, water 2 - 10; the discharging agent is common use discharging agent whose weight shares are 5 - 20% of special mulriple slurry or 5 - 20% weight shares of common use discharging agent and 1 - 3% weight shares of discharge-proof dope. Therefore it will realize the discharging dye printing technics of coating active discharge, to make the discharging dye printing real silk have good color, light and heat stability, up to 4 - 5 rank of color firming intensity, and keep the inherent style of silk fabric. Besides its level dyeing capability is good and its color and luster are more vivid.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

Alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent and preparation method thereof

InactiveCN105755870AImprove wet fastnessGood alkali and chlorine resistanceFibre treatmentDyeing processIonCardanol

The invention discloses an alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent which comprises the following components in parts by weight: 5-10 parts of an organic silicon monomer, 12-15 parts of acrylic acid, 8-13 parts of butyl acrylate, 6-10 parts of butyl diphenyl ether sodium disulfonate, 1-4 parts of cardanol polyoxyethylene ether, 7-10 parts of polyethylene glycol, 1.5-2 parts of carbon nanotubes, 2-3 parts of calcium silicate, 0.5-1 part of an initiator and 10-20 parts of deionized water. The invention further discloses a preparation method of the alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent. The alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent is good in alkali resistance, high in chlorine solidness and good in water scrubbing resistance, free of influence to appearance and property of a textile, free of toxic substance release in the preparation and use process, and beneficial to environment protection.

Owner:SUZHOU SANHE KAITAI COLORED THREAD WEAVING CO LTD

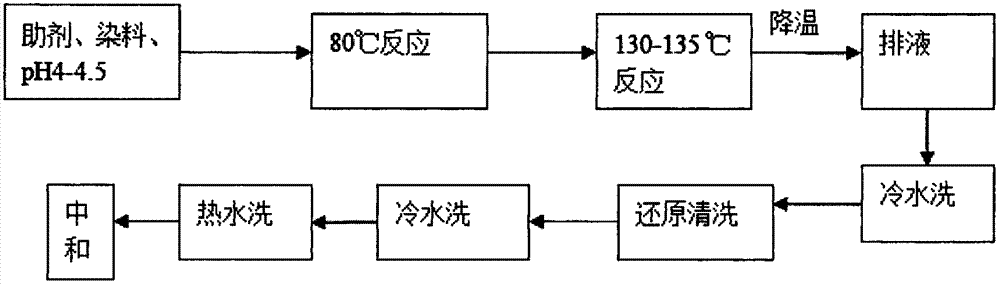

Reactive silk printing method

InactiveCN106087479AProcess environmental protectionGood K/S valueDyeing processTemperature controlPulp and paper industry

The invention discloses a reactive silk printing method, which comprises the following steps: (1) pretreatment; (2) treatment with a maintenance solution: preparing the maintenance solution from silk proteins, trehalose, glycine and aloe vera juice, and performing impregnation pretreatment on a pre-treated silk fabric for 60 to 80min at temperature controlled to be 30 DEG C; (3) sizing: performing single-sided sizing on the silk fabric subjected to maintenance treatment on a sizing machine; (4) drying: performing low-temperature drying at drying temperature of 60 DEG C by adopting infrared drying equipment; (5) document making; (6) spray printing; (7) steaming drying: performing reaction for color fixation for 30 to 50min under the condition of 100 to 110 DEG C saturated steam; (8) washing: performing washing with cold water; (9) tenter drying.

Owner:德清县新鑫达丝绸炼染有限公司

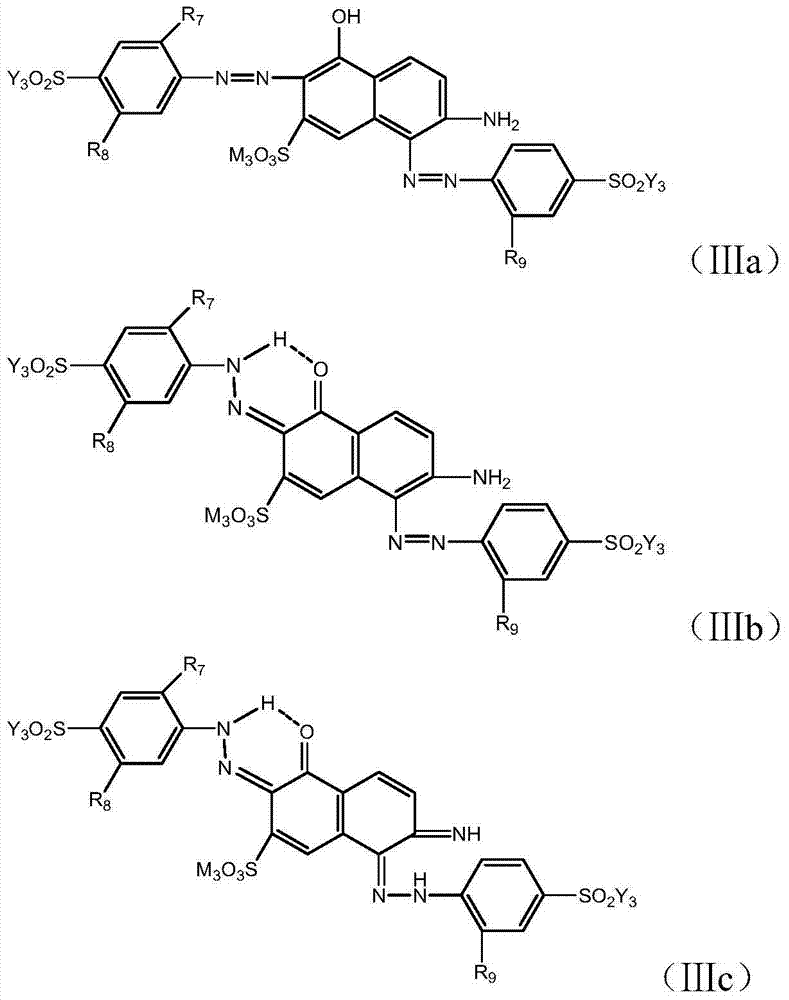

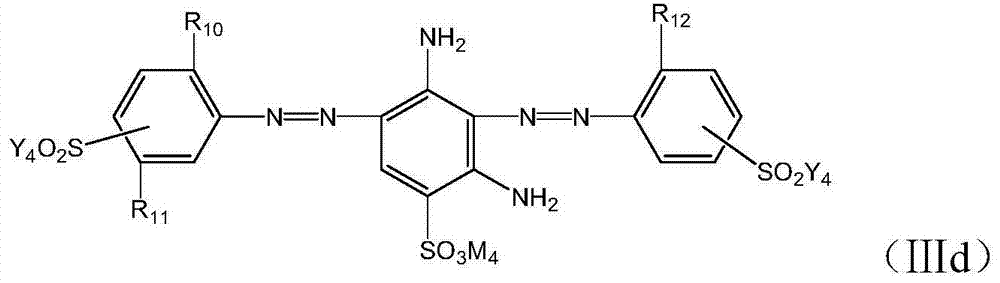

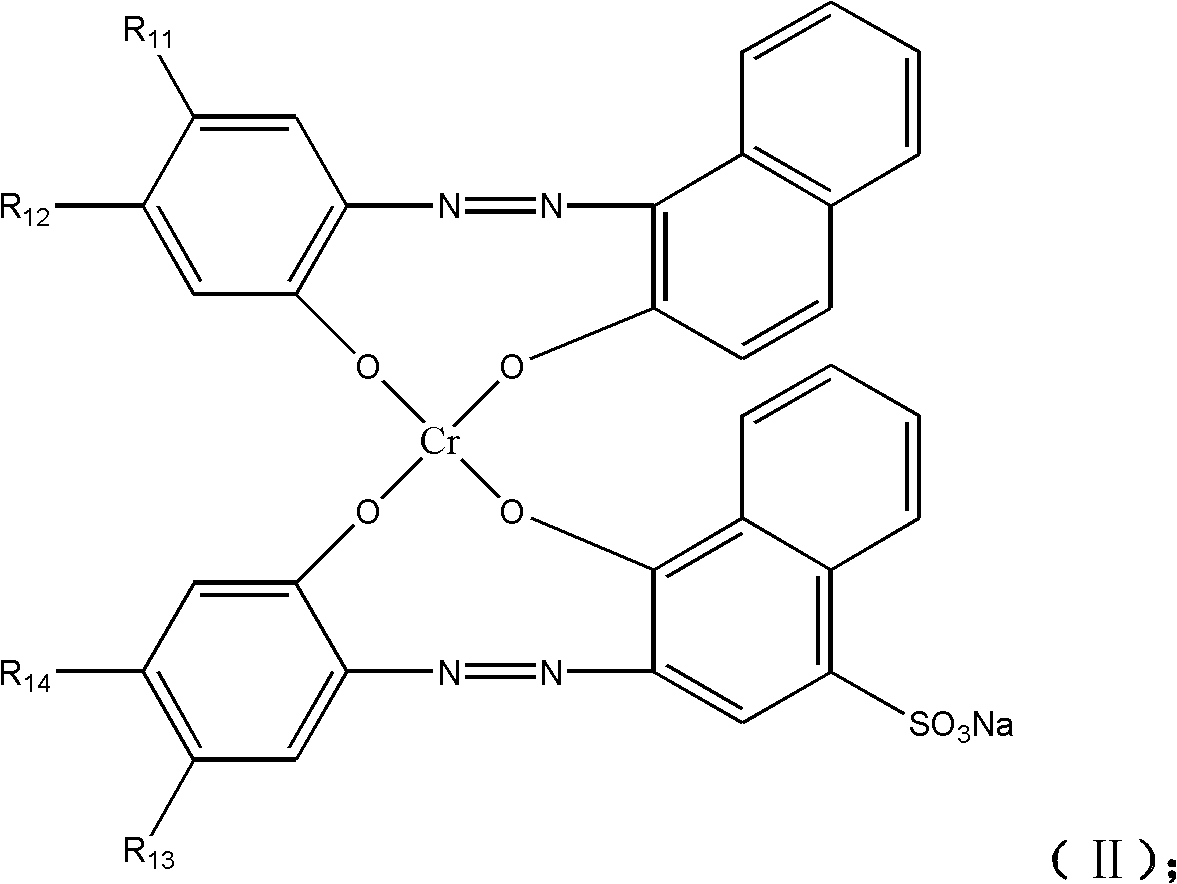

Reactive black dye composition

ActiveCN104804470AGood lifting effectHigh color fixing rateOrganic dyesDyeing processTextile printerDye uptake

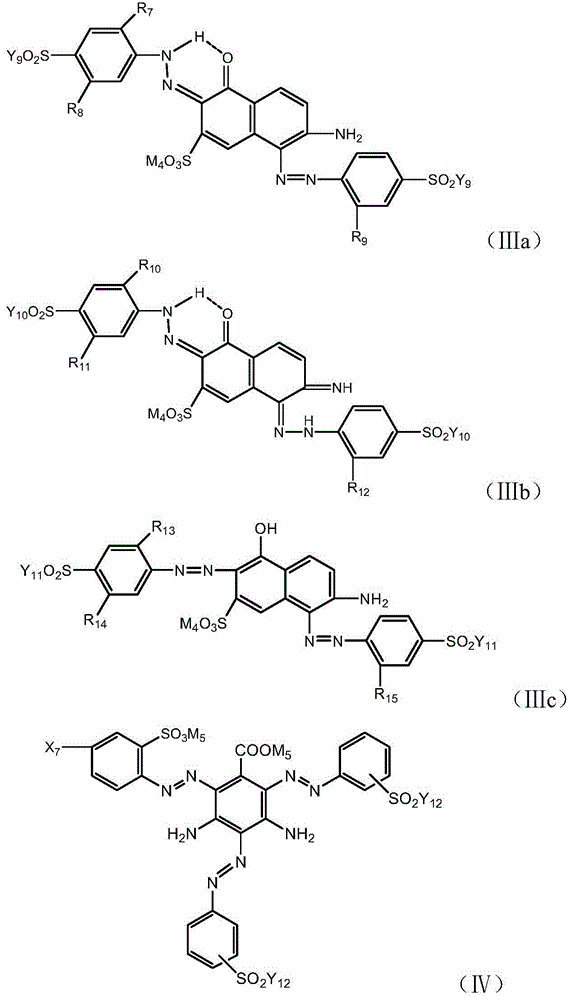

The invention provides a reactive black dye composition, comprising 95-45 parts by weight of a component A, 0-40 parts by weight of a component B, 1-40 parts by weight of a component C, and 0-40 parts by weight of a component D. The component A is one or more selected from the compounds (Ia)-(Ib); the component B is one or more selected from the compounds (IIa)-(IIb), the component C is one or more selected from of (IIIa)-(IIIe), and the component D is one or more selected from formula (IV). The reactive black dye composition provided by the invention can be used for textile printing and dyeing, has advantages of good promotion performance, high color fixing rate, high dye uptake, easiness for washing, clear dyeing raffinate, stable alkaline and salt tolerance, and excellent wet-processing fastness, and is a rare economical black dye.

Owner:ZHEJIANG KEYONG CHEM CO LTD

Acid dye mixture with good colourability

InactiveCN102408750AImprove wet fastnessHigh exhaustion rateOrganic dyesDyeing processFiberWastewater

The invention discloses an acid dye mixture with good colourability. The acid dye mixture has the following beneficial effects: as a natural auxiliary is added, the wet fastness of the acid dye after mixing is improved, the fiber handfeel can not be changed and the exhaustion of the dye is substantially improved; the wastewater generated after dyeing can be entirely degraded biologically; and the acid dye mixture is more suitable to dye nylons, silk, leathers, wool, paper, synthetic resins and other substances, simultaneously is quite suitable for various novel fibers and has uniform dyeing effect.

Owner:DAFENG QIANCAI FINE CHEM

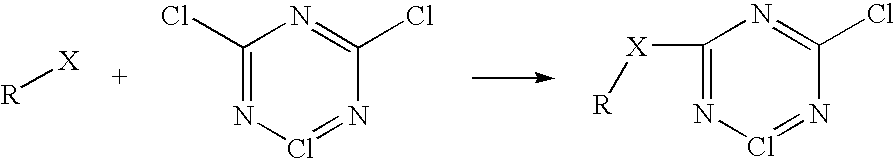

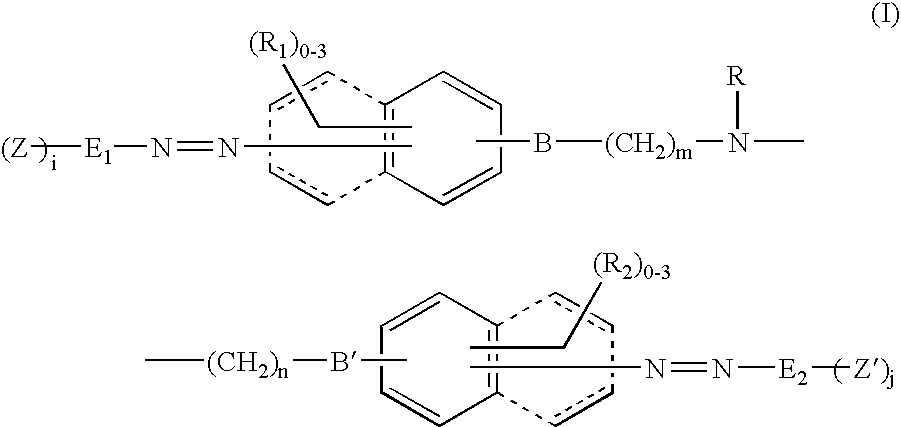

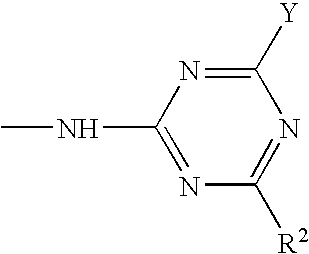

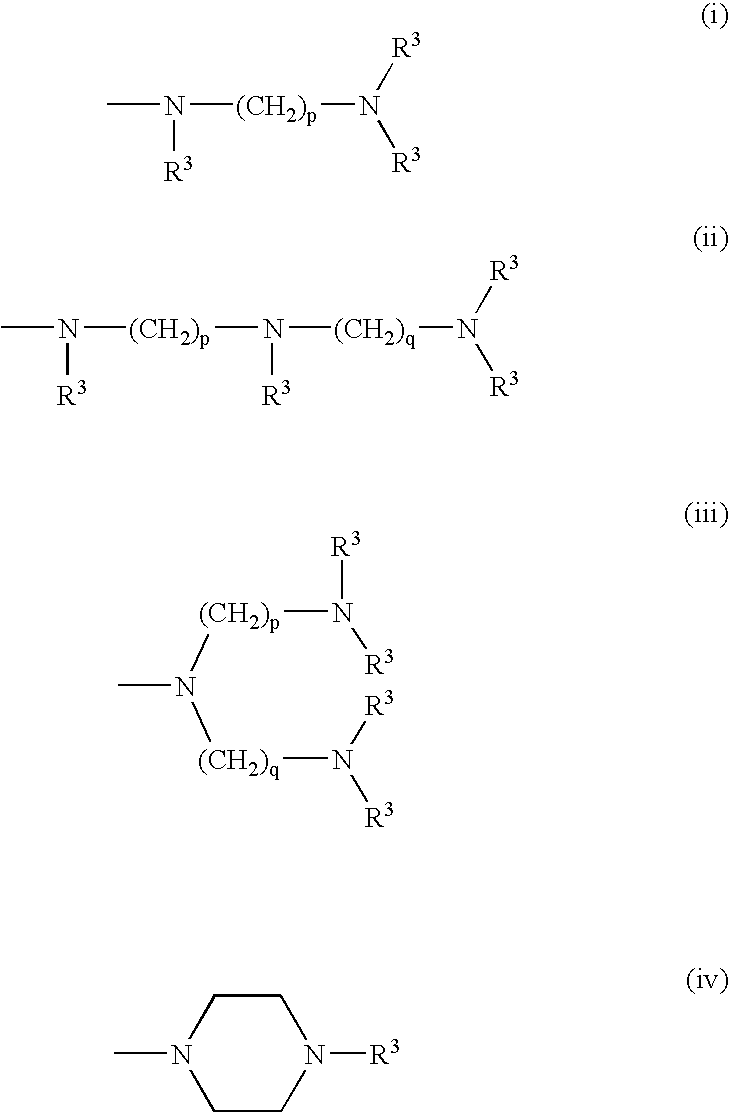

Novel reactive dyestuff with N,N-dialkylamino bridge group

InactiveUS20090176972A1High color yieldHigh fastnessDisazo dyesOrganic chemistryPolyaminePhotochemistry

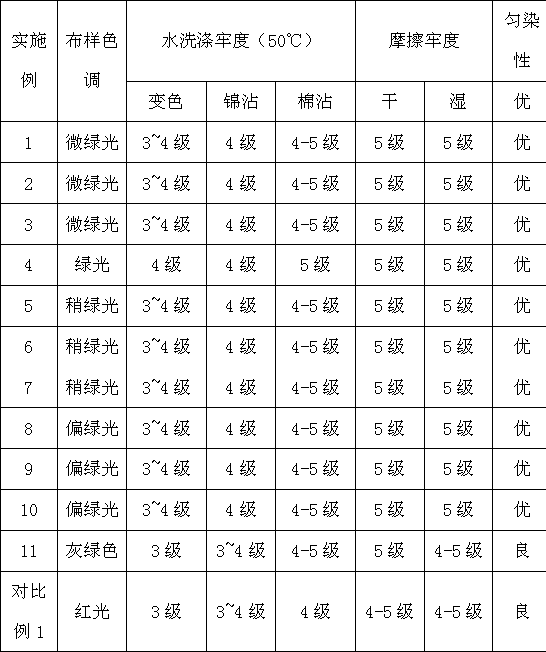

The present invention relates to a novel reactive dyestuff with an N,N-dialkylamino bridge group, represented by the following formula (I):wherein R, B, B′, E1, E2, Z, Z′, i, j, R1, R2, m and n are defined the same as the specification. The reactive dyestuff of the present invention is suitable for exhaust dyeing, cold batch-up dyeing, continuous dyeing, printing and digital spray printing materials that contain hydroxyl group or polyamine fibers.

Owner:EVERLIGHT USA INC

Novel activated printing ink and preparation method thereof as well as direct printing technology

The invention belongs to the printing and dyeing industry, particularly relates to composition of novel activated printing ink used for performing intaglio or flexible direct printing on a piece of dry alkali-slurry-containing cellulose fiber cloth and a preparation method of the printing ink, further relates to a set of production technological processes for using the novel activated printing ink for performing intaglio or flexible direct printing on the dry alkali-slurry-containing cellulose fiber cloth as well as technological conditions of the production technological processes, and provides the novel activated printing ink and the preparation method thereof as well as a direct printing technology. With the adoption of the preparation method, operations are simple, only an improved intaglio press or an improved flexible press is required to be bought additionally to be used as technological equipment, and other equipment can adopt existing technological equipment of a printing and dyeing factory for operation; the printing and dyeing factory equipped with activated printing ink cold transfer printing technological equipment can use the existing technological equipment for operation, and technological equipment is not required to be bought additionally.

Owner:ZHEJIANG YIDE CHEM

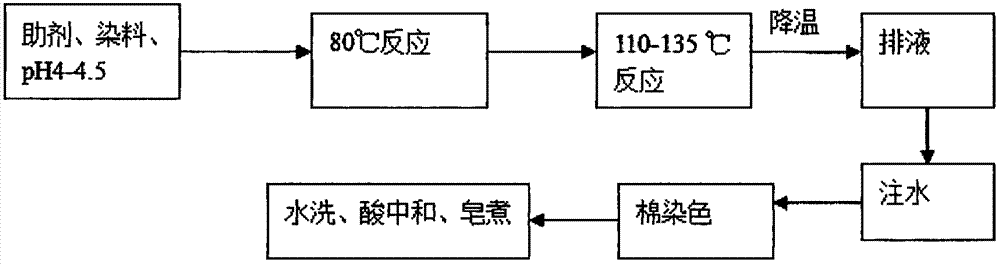

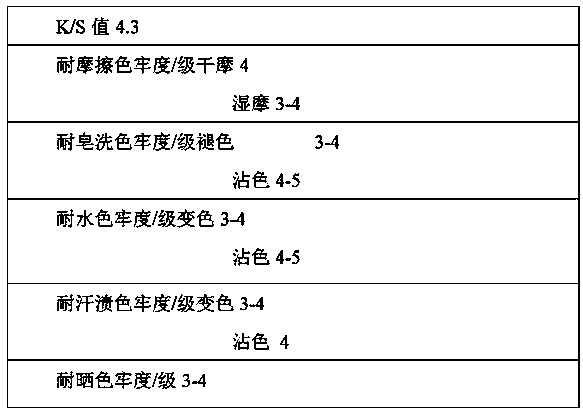

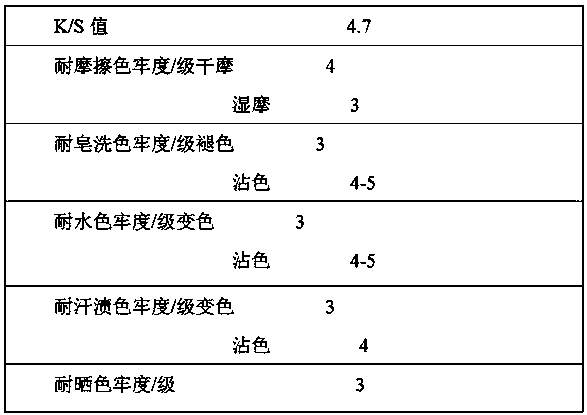

Disperse dye composition and applications thereof

ActiveCN102888129ASave energyIncrease productivityOrganic dyesDyeing processBenzoic acidDisperse dye

The invention relates to a disperse dye composition and an application method of the disperse dye composition. During dyeing polyester-cotton blended fabrics, the disperse dye composition can be adopted to remove traditional necessary technical step of reducing and cleaning after dyeing through the disperse dye, therefore, the energy is saved, the production efficiency is improved, and high color fastness can be ensured. The benzoic acid is added to the disperse dye composition to be served as a carrier, therefore, the disperse dye composition provided by the invention can be used for dyeing the polyester fiber at 110 to 120 DEG C without influencing the color fastness and degree of dyeing; meanwhile, the benzoic acid is served as a solid food additive; compared with a traditional carrier, the disperse dye composition can not harm a human body, and has high environmental-protection characteristics; and when the disperse dye composition is applied to pure terylene fabric, the residual dyeing temperature can be utilized for reducing and cleaning by adding sodium formaldehyde sulfoxylate composition without draining liquid, therefore, the resource consumption is reduced, and the production efficiency is improved.

Owner:SHANGHAI YILIAN CHEM TECH

Method for dyeing cotton fabric with green by means of natural pigments

The invention discloses a method for dyeing cotton fabric with green by means of natural pigments. The cotton fabric is dyed according to the technology of dyeing, post-mordant treatment and aftertreatment. In dye liquor, the mass ratio of a gardenia yellow pigment to a gardenia blue pigment ranges from 5:4 to 5:7, and the use amount of the gardenia yellow pigment ranges from 0.5% owf to 2.5% owf;the use amount of a myrobalan extract ranges from 0.5% owf to 1.5% owf; a neutral electrolyte is sodium chloride or sodium sulfate, and the use amount of the neutral electrolyte ranges from 10 g / L to30 g / L; and in mordant dyeing liquor, the use amount of a mordant dyeing agent ranges from 1% owf to 4% owf. According to the method, the wet treatment fastness of the dyed fabric can be effectivelyimproved through complexing of the natural pigments, the mordant dyeing agent and cellulose fibers by the aid of the post-mordant dyeing method. The cotton fabric is dyed by means of the natural pigments, the environment-friendly mordant dyeing agent is used, and the requirements for environmental protection and physical fitness of people are met. Zinc sulfate, lanthanum chloride, cerium chloride,alum and aluminum sulfate are used as the mordant dyeing agent, and thus the green cotton fabric can be obtained.

Owner:HENAN INST OF ENG

Cotton fiber gray fabric modifying and dyeing method

The invention relates to a cotton fiber gray fabric modifying and dyeing method. The method includes the steps of scouring a cotton fiber gray fabric, adding an enzyme and a biological modifying agentfor modification to obtain a modified cotton fiber gray fabric, washing the gray fabric with water, adding a light-color or neutral-color active dye for dyeing, conducting washing and softening to obtain a light-color or neutral-color cotton fabric dyed fabric, or adding a deep-color active dye for dyeing, conducting washing, adding a color fixing agent for color fixing, and then conducting washing and softening to obtain a deep-color cotton fiber dyed fabric. By means of the method, the cotton fiber gray fabric is refined and modified, fiber cationization is achieved, the affinity between fiber and dye molecules is increased, operation is simple, efficiency is improved, the dyeing rate reaches 90% or above, no soup washing is needed after dyeing, no salt or alkali needs to be added in dyeing for dyeing promoting, dyeing wastewater can be directly recycled, and zero emission is realized.

Owner:NINGBO GUANG YUAN FABRIC

Water soluble colorants for ink jet printing

In accordance with one embodiment of the present invention, a colorant in an ink jet ink formulation is disclosed. The colorant comprises an organic dye chromophore with at least one functional group Y containing one or more primary, secondary or tertiary amino groups, which in the presence of an acid provides a water soluble, cationic ink jet ink colorant with increased water fastness when applied to paper.

Owner:PITNEY BOWES INC

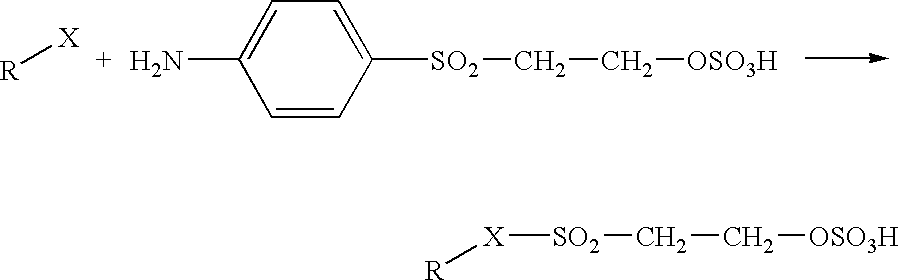

Compound type black acid dye

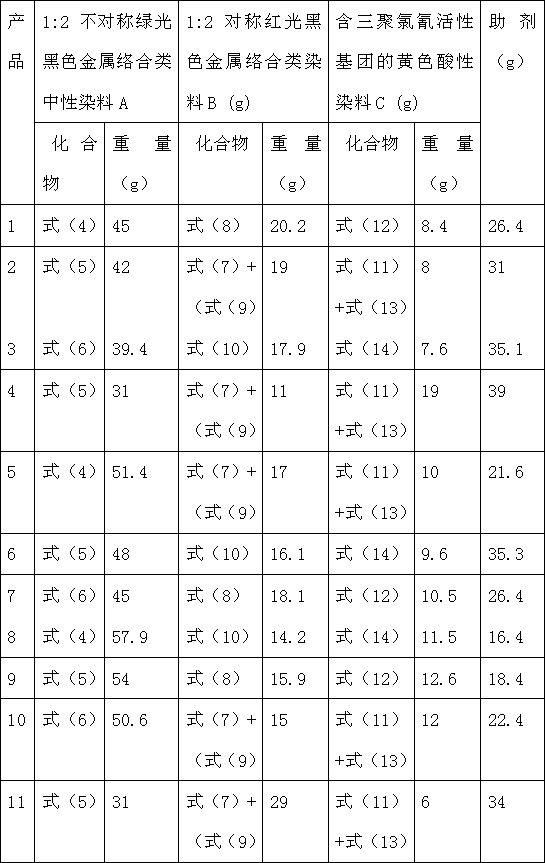

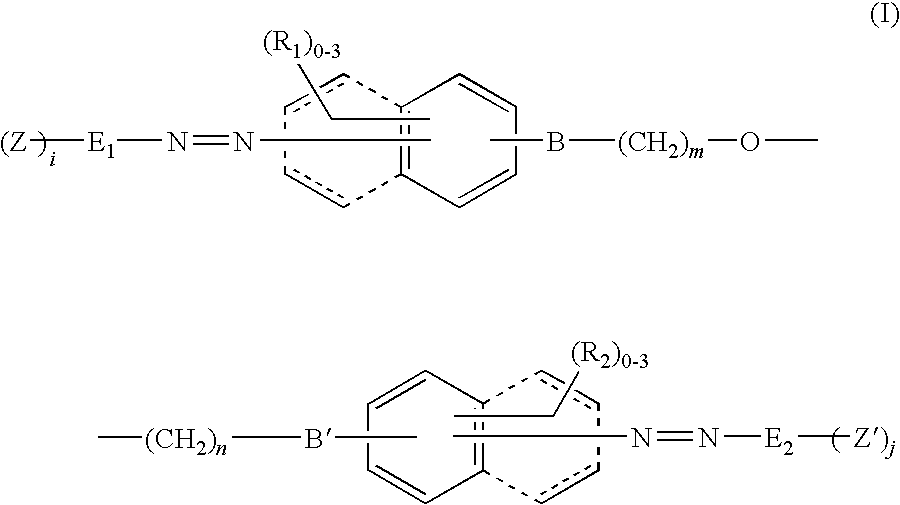

The invention relates to the field of printing and dyeing, and particularly relates to an acid dye, more particularly relates to a black acid dye. The invention aims to provide a compound type black acid dye which is formed by compounding a weak acid dye and an acid dye containing active groups so as to obtain excellent synchronism and levelling property as well as high wet color fastness during dyeing. The compound type black acid dye disclosed by the invention comprises a 1:2 asymmetric green light black metal complexation type neutral dye A, a 1:2 symmetric red light black metal complexation type dye B and a yellow acid dye C containing a cyanuric chloride active group. The compound type black acid dye disclosed by the invention not only effectively solves the problem of bad levelling property and bad reproducibility in traditional black dyeing but also achieves brighter coloring and better color saturation and expressivity, and simultaneously increases the quality of the product obtained.

Owner:HENGSHENG CHEM QIDONG

Reactive dyestuff with dialkylether bridge group

The present invention relates to a novel reactive dyestuff with dialkylether bridge group, represented by the following formula (I):wherein B, B′, E1, E2, Z, Z′, i, j, (R1)0-3, (R2)0-3, m and n are defined the same as the specification. The reactive dyestuff of the present invention is suitable for exhaust dyeing, cold batch-up dyeing, continuous dyeing, printing and digital spray printing materials that contain hydroxyl group or amino group fibers.

Owner:EVERLIGHT USA INC

Dyeing process for superfine fiber synthetic leather

InactiveCN104294684ASmall molecular weightGood diffusion performanceDyeing processColor toneColor matching

The invention discloses a dyeing process for superfine fiber synthetic leather. By means of a dispersed dye dyeing process, the color tone is adjusted and the level dyeing degree is enhanced. By means of a neutral dye dyeing process, a deep color, wet treatment fastness and light fastness can be obtained. According to a two-dye one-bath dyeing process, the proportions of different components in the mixed dye are adjusted to investigate the dyeing effect and different-index dyeing curves, dyes with similar dyeing properties are selected for compatibility, and at the same time a proper dyeing assistant is employed to strengthen similar compatible performance between dyes. The dispersed dye has the advantages of small molecular weight, good diffusion performance, simple dyeing method, good level dyeing property, excellent light fastness and good coverage, and can avoid uneven dyeing phenomenon caused by molecular size differences during chinlon polymerization or different stretching degrees during spinning. Dyeing with a neutral dye can achieve deep color, good wet treatment fastness and light fastness. Dyes have good color matching performance, few competitive phenomena exist, and the dye utilization rate is high. The dyeing process is relatively simple.

Owner:刘自忠

Neutral dye composition

InactiveCN102634235AGood same colorGood compatibilityOrganic dyesDyeing processPerspirationColor tone

The invention discloses a neutral dye composition which consists of a dye component and an auxiliary component. In the dye composition, three dyes are mixed in compatibility, and each of the three dyes is asymmetric 1:2 metal complex. The composition has better isochromatic property in dyeing wool, chinlon and chinlon-spandex blend fiber to obtain better color tone, better wet fastness, water logging fastness of level 5, rubbing fastness of level 5, light fastness of level 6, perspiration (alkali) of level 4-5, perspiration (acid) of level 4-5, consistent dyeing curve, high dyeing rate and good isochromatic property; and the composition can be widely applied to the dip dyeing for continuous dyeing.

Owner:河北永泰柯瑞特化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com