Reactive black dye composition

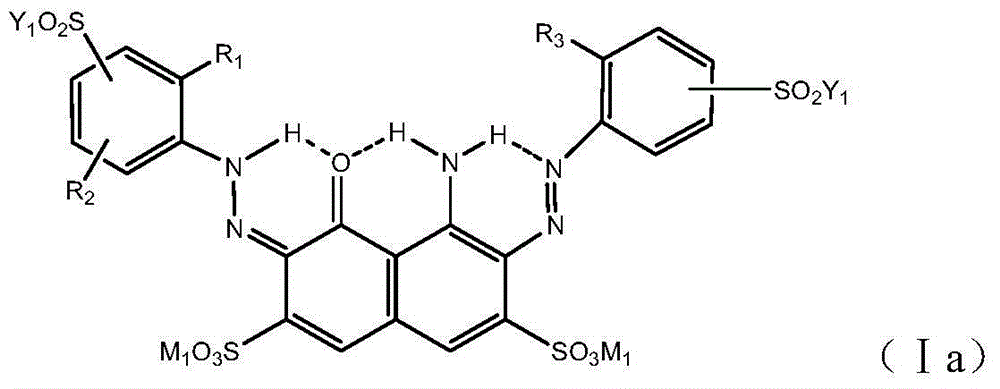

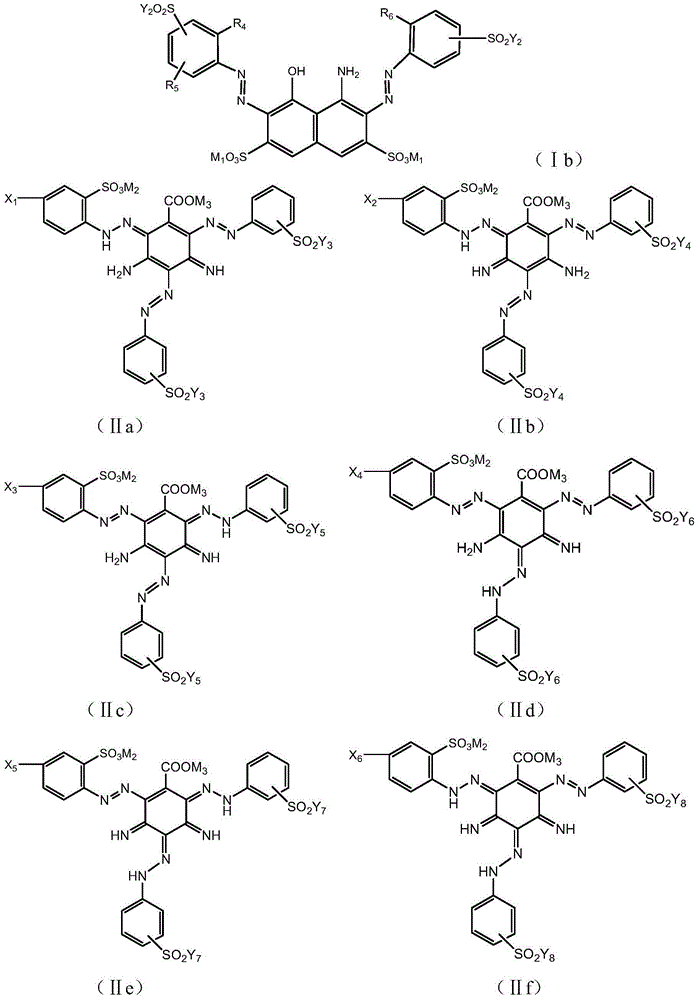

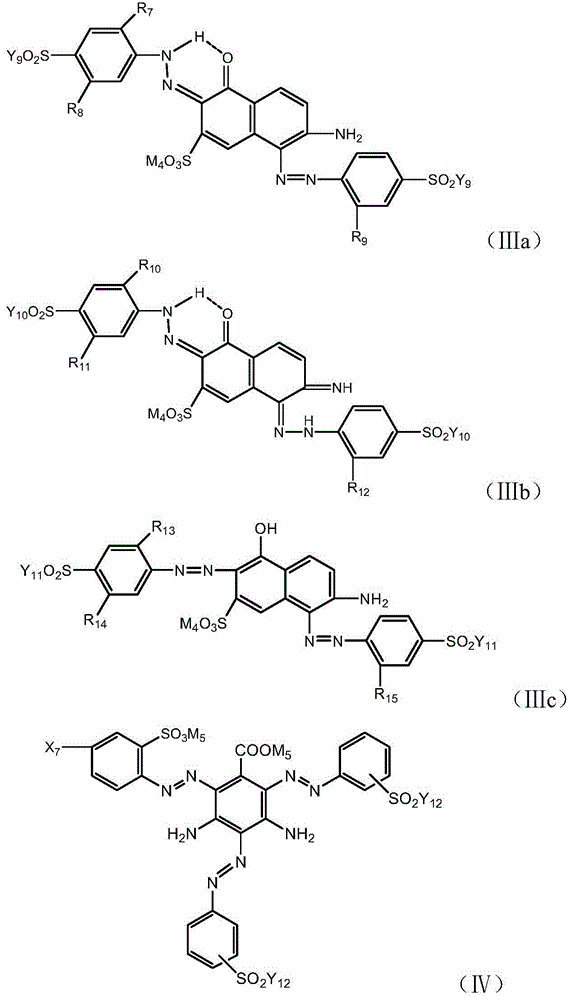

A technology of dye composition and reactive black, which is applied in organic dyes, dyeing methods, textiles and papermaking, and can solve problems such as poor dyeing depth, difficult cleaning of dyed fabrics, and insufficient blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Mechanically mix 80 parts of the dye of formula (Ia-1), 11 parts of the dye of formula (IIa-1), 9 parts of the dye of formula (IIIa-1) and 25 parts of sodium sulfate, and the obtained composite dyed cotton is deep black (M 1 ~ M 4 Both are H, that is, the dye compound is expressed in the form of free acid).

[0117]

[0118]

Embodiment 2

[0120] Mechanically mix 60 parts of the dye of the formula (Ia-3), 10 parts of the dye of the formula (IIa-1), 7 parts of the dye of the formula (IIIa-1) and 23 parts of sodium sulfate, and the obtained composite dyed cotton is deep black (M 1 , ~ M 4 Both are H, that is, the dye compound is expressed in the form of free acid).

[0121]

[0122]

Embodiment 3~120

[0124] Mechanically mix the dyes listed in Table 1 to dye cotton black (M 1 ~ M 5 Both are H, that is, the dye compound is expressed in the form of free acid).

[0125]

[0126]

[0127]

[0128]

[0129]

[0130]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com