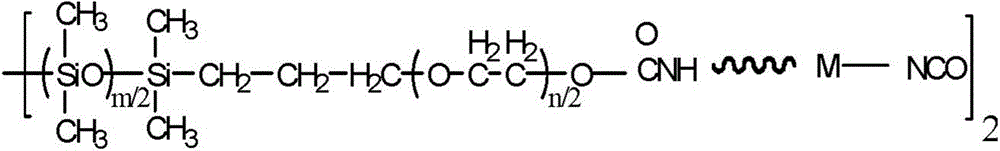

Preparation method of blocked organosilicone waterborne polyurethane anti-fluffing-and-pilling agent

A pilling agent, silicone water-based technology, applied in the field of preparation of anti-pilling agent, can solve the problems of modified polyurethane such as limited adaptability, easy yellowing, affecting hand feel, etc., to improve hand feel and water resistance, and not easy to yellow change, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

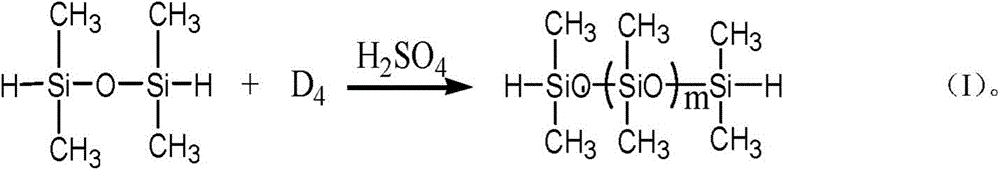

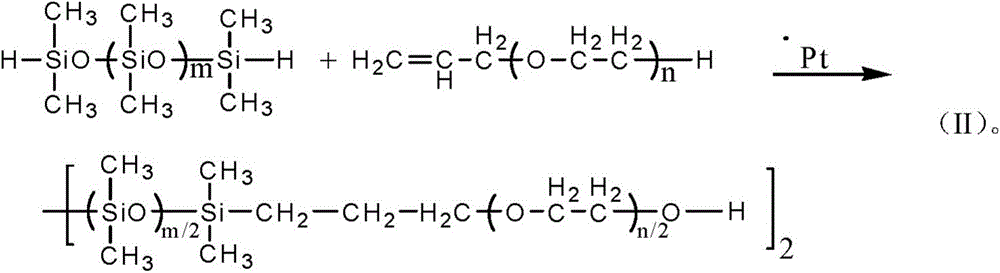

Method used

Image

Examples

specific Embodiment 1

[0036] A block organosilicon water-based polyurethane anti-pilling agent, the block organosilicon water-based polyurethane anti-pilling agent is composed of the following components in parts by weight: hydroxyl-terminated silicone oil: 20 parts, Isophor Ketone diisocyanate: 7 parts, dimethylolpropionic acid: 1.5 parts, 1,4-butanediol: 0.2 parts, dibutyltin dilaurate: 0.20 parts, triethylamine: 1 part, acetone: 10 parts , water: 90 parts.

[0037] A preparation method according to the described block organosilicon water-based polyurethane anti-pilling agent, adding the dehydrated hydroxyl-terminated silicone oil, dibutyltin dilaurate and isophorone diisocyanate into the reaction kettle, Heating and reacting for 1 hour, then adding dimethylol propionic acid and 1,4-butanediol, reacting for 1.5 hours; adding an appropriate amount of acetone to adjust the viscosity, adding triethylamine to neutralize after cooling down, stirring rapidly for 30 minutes, and finally adding water for...

specific Embodiment 2

[0042] A block organosilicon water-based polyurethane anti-pilling agent, the block organosilicon water-based polyurethane anti-pilling agent is composed of the following components in parts by weight: hydroxyl-terminated silicone oil: 30 parts, Isophor Ketone diisocyanate: 15 parts, dimethylolpropionic acid: 2.5 parts, 1,4-butanediol: 0.5 parts, dibutyltin dilaurate: 0.24 parts, triethylamine: 2 parts, acetone: 20 parts , water: 120 parts.

[0043] A preparation method according to the described block organosilicon water-based polyurethane anti-pilling agent, adding the dehydrated hydroxyl-terminated silicone oil, dibutyltin dilaurate and isophorone diisocyanate into the reaction kettle, Heating and reacting for 1 hour, then adding dimethylol propionic acid and 1,4-butanediol, reacting for 1.5 hours; adding an appropriate amount of acetone to adjust the viscosity, adding triethylamine to neutralize after cooling down, stirring rapidly for 30 minutes, and finally adding water ...

specific Embodiment 3

[0048] A block organosilicon water-based polyurethane anti-pilling agent, the block organosilicon water-based polyurethane anti-pilling agent is composed of the following components in parts by weight: hydroxyl-terminated silicone oil: 27 parts, Isophor Ketone diisocyanate: 12 parts, dimethylolpropionic acid: 1.9 parts, 1,4-butanediol: 0.3 parts, dibutyltin dilaurate: 0.22 parts, triethylamine: 1.4 parts, acetone: 17 parts , water: 107 parts.

[0049] A preparation method according to the described block organosilicon water-based polyurethane anti-pilling agent, adding the dehydrated hydroxyl-terminated silicone oil, dibutyltin dilaurate and isophorone diisocyanate into the reaction kettle, Heating and reacting for 1 hour, then adding dimethylol propionic acid and 1,4-butanediol, reacting for 1.5 hours; adding an appropriate amount of acetone to adjust the viscosity, adding triethylamine to neutralize after cooling down, stirring rapidly for 30 minutes, and finally adding wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com