Silane crosslinked polymer separation film and preparation method thereof

A technology of silane cross-linking and silane cross-linking agent, which is applied in the field of electrochemistry, can solve problems such as unsatisfactory thermal shrinkage, difference between membrane rupture temperature and closed cell temperature, and achieve excellent comprehensive performance, low closed cell temperature, and low The effect of mean pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

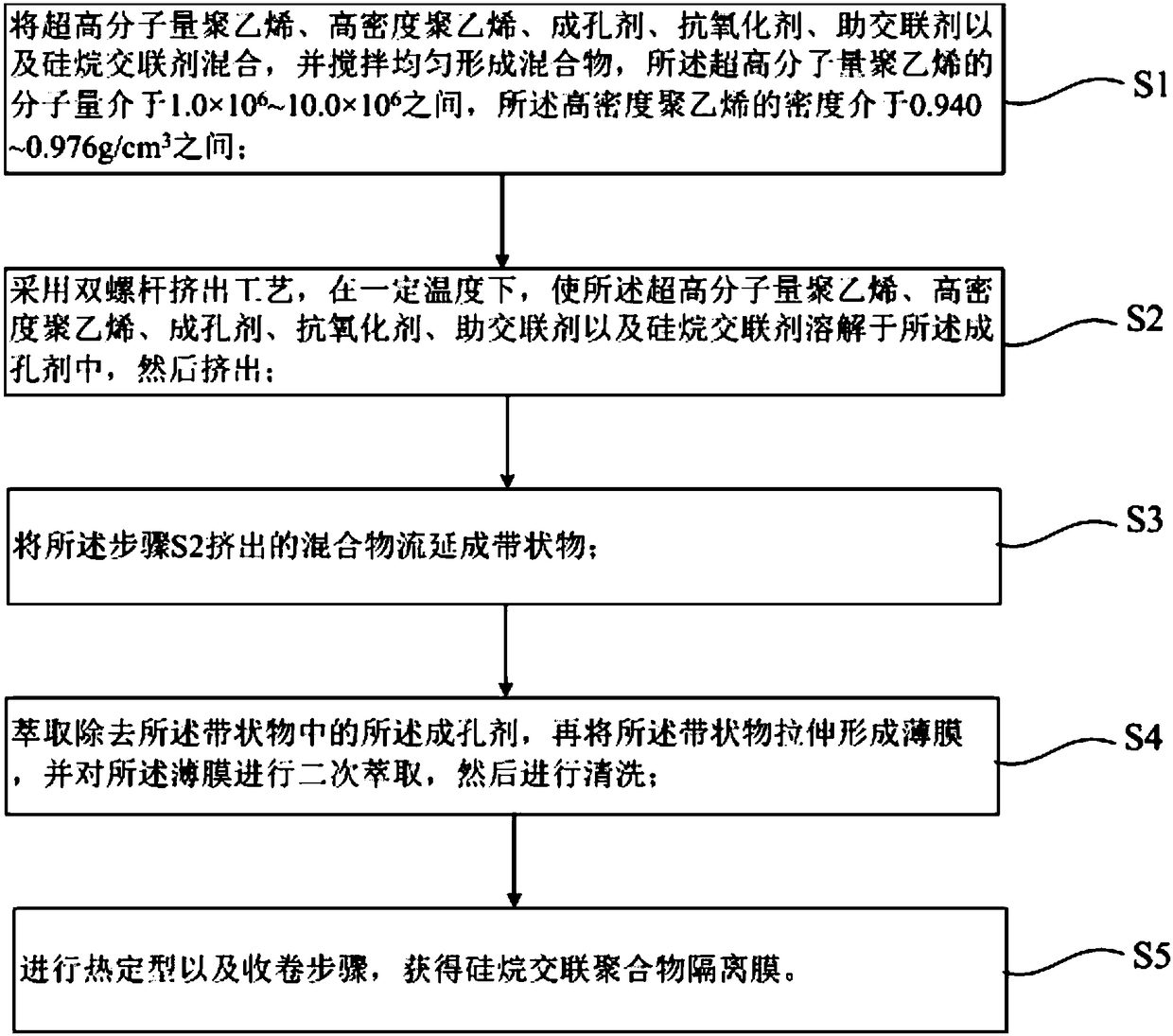

[0046] Such as figure 1 As shown, the present invention also provides a method for preparing the above-mentioned silane cross-linked polymer isolation film. The silane cross-linked polymer isolation film is prepared by chemical cross-linking. The preparation method is roughly as follows: raw material mixing, mixture extrusion, casting Making strips, extracting strips, washing to obtain films, heat-setting the obtained films, winding, etc. Specifically, at least include the following steps:

[0047] S1, mixing ultra-high molecular weight polyethylene, high-density polyethylene, pore-forming agent, antioxidant, auxiliary cross-linking agent and silane cross-linking agent, and stirring uniformly to form a mixture, the molecular weight of the ultra-high molecular weight polyethylene is between 1.0 ×10 6 ~10.0×10 6 Between, the density of the high-density polyethylene is between 0.940 ~ 0.976g / cm 3 between;

[0048] S2, using a twin-screw extrusion process, at a certain temper...

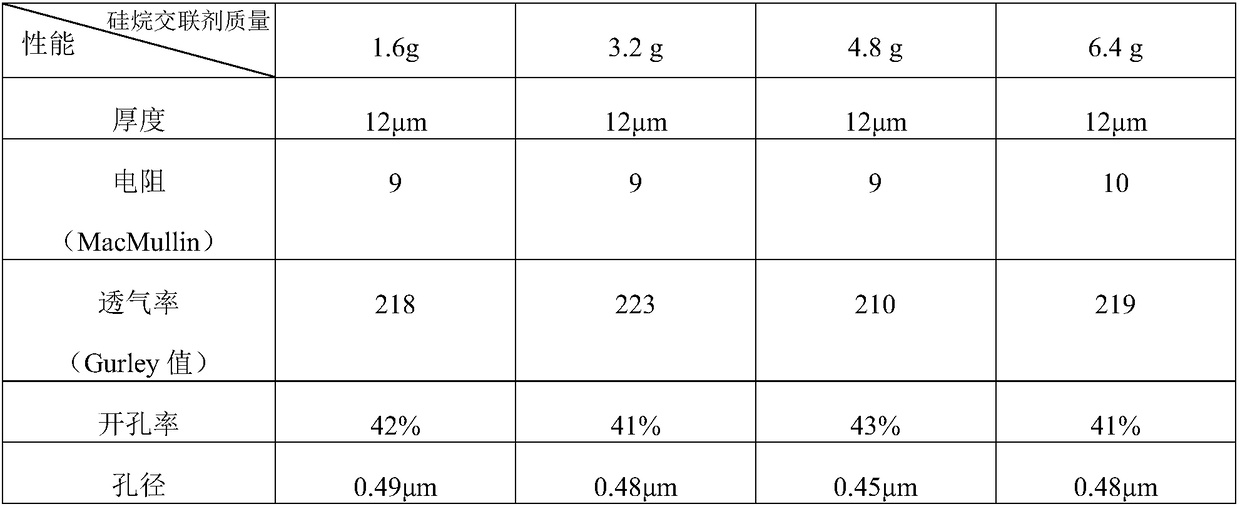

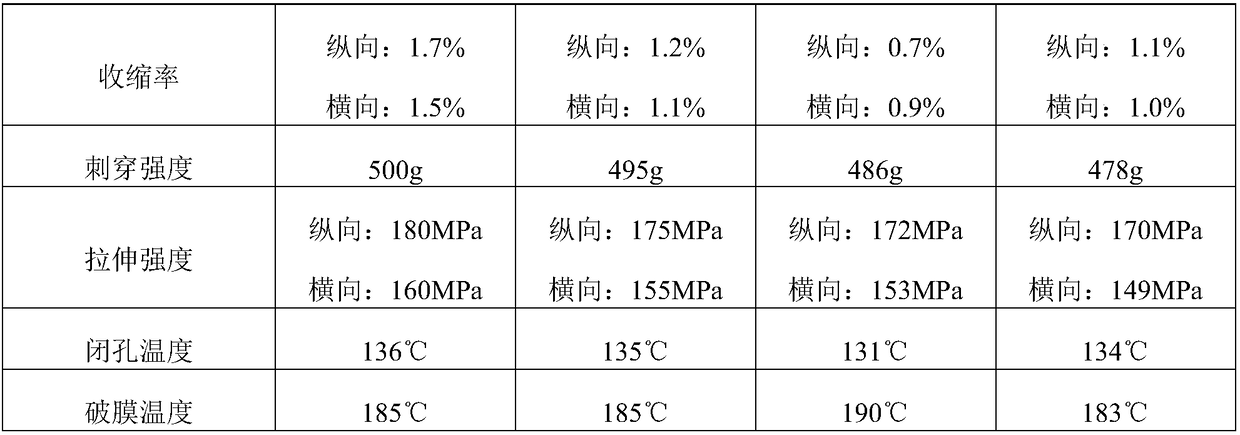

Embodiment 1

[0079] The density of 220 grams is 0.956g / cm 3 High-density polyethylene with a molecular weight of 5.0×10 in 100 grams 6 Ultra-high molecular weight polyethylene, 6.4 g antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate n-octadecanoate), silane crosslinker (vinyltrimethylsilane ), 4.3 grams of auxiliary cross-linking agent (triallyl isocyanurate), 2200 grams of mineral oil (i.e. pore forming agent, CAS8020-83-5, purchased from Lanzhou Petrochemical Company) adds in the continuous batching feed kettle, with Stir at a speed of 50 rpm to mix the ingredients evenly.

[0080] The mixture is continuously fed into the twin-screw extruder, and the ultra-high molecular weight polyethylene, high-density polyethylene, antioxidant, silane crosslinking agent and co-crosslinking agent are continuously dissolved in the twin-screw extruder under the condition of 180°C in mineral oil, and then extruded continuously by a twin-screw extruder at a speed of 200 rpm, the mixture conti...

Embodiment 2

[0086] The density of 220 grams is 0.956g / cm 3 High-density polyethylene with a molecular weight of 5.0×10 in 100 grams 6 Ultra-high molecular weight polyethylene, 6.4 grams of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate n-octadecanoate), 4.8 grams of silane crosslinking agent (vinyl trimethyl base silane), auxiliary crosslinking agent (triallyl isocyanurate), and 2200 grams of mineral oil are added in the continuous batching and feeding kettle, stirred at a speed of 50 rpm, and the raw materials are mixed evenly.

[0087] The mixture is continuously fed into the twin-screw extruder, and the ultra-high molecular weight polyethylene, high-density polyethylene, antioxidant, silane crosslinking agent and co-crosslinking agent are continuously dissolved in the twin-screw extruder under the condition of 180°C in mineral oil, and then extruded continuously by a twin-screw extruder at a speed of 200 rpm, the mixture continuously enters the slot die, and the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com