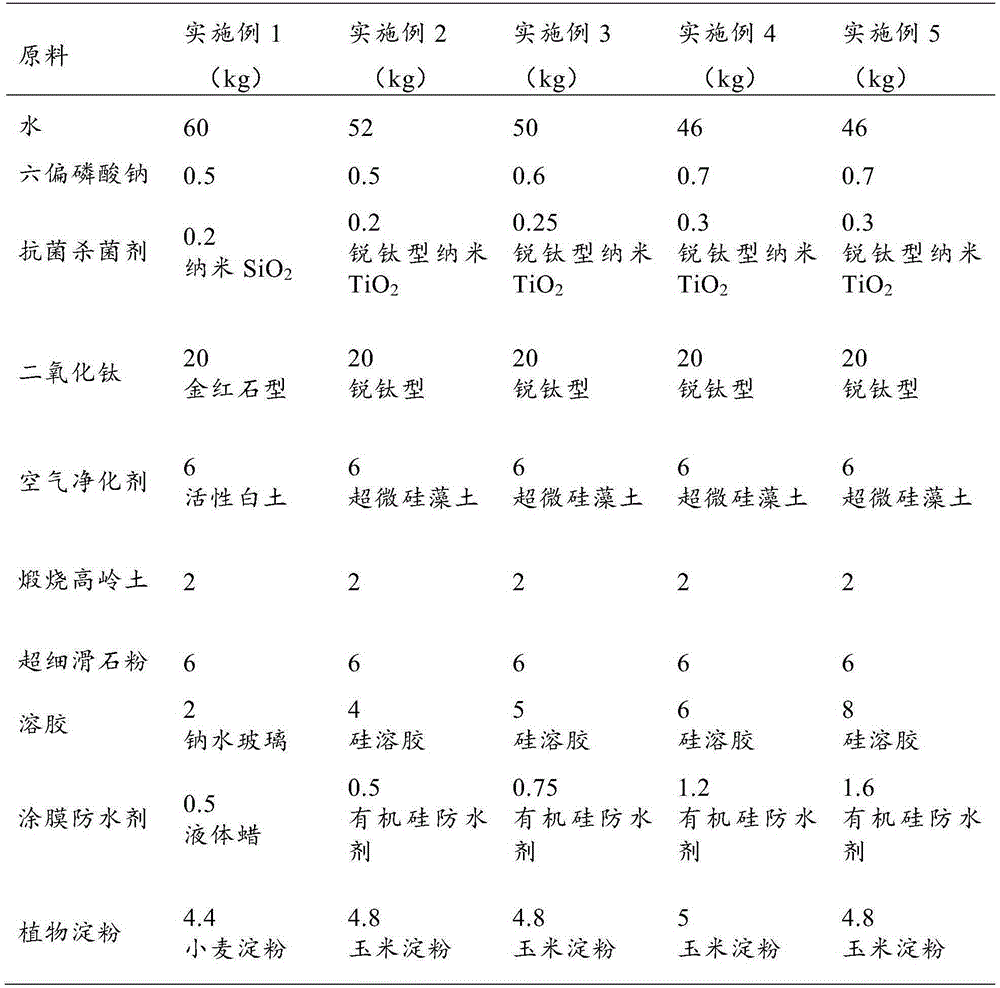

Patents

Literature

548results about How to "High film strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

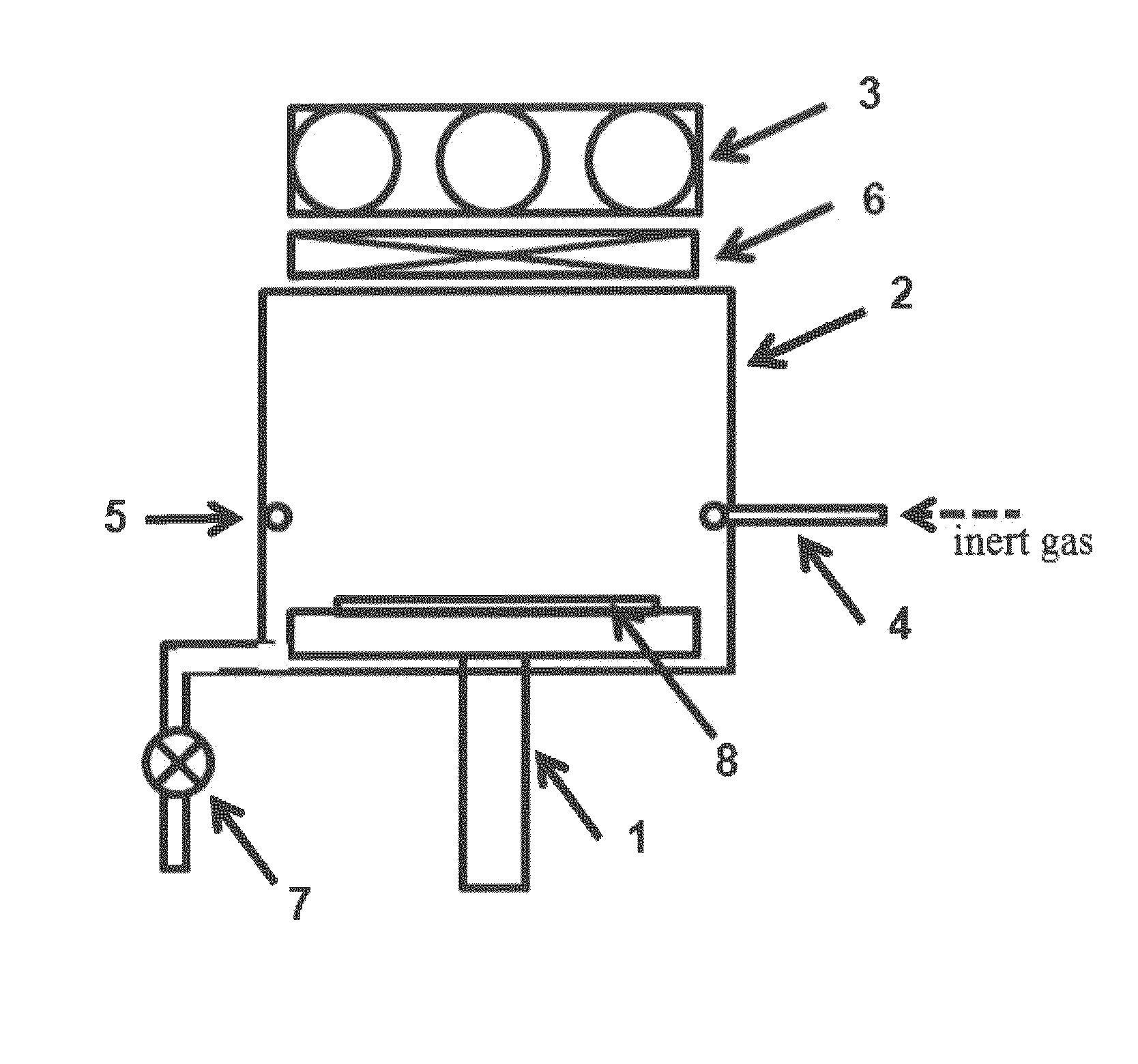

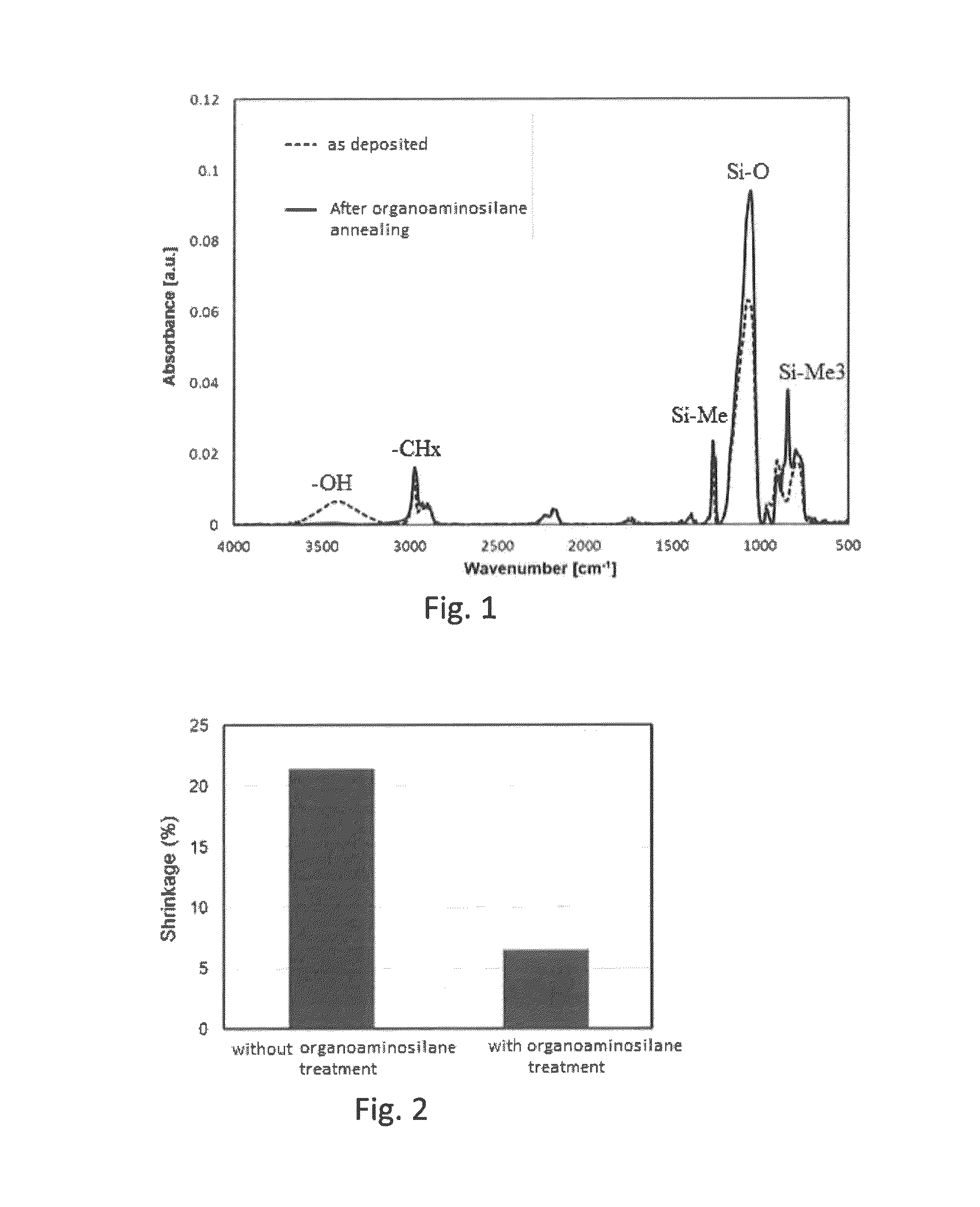

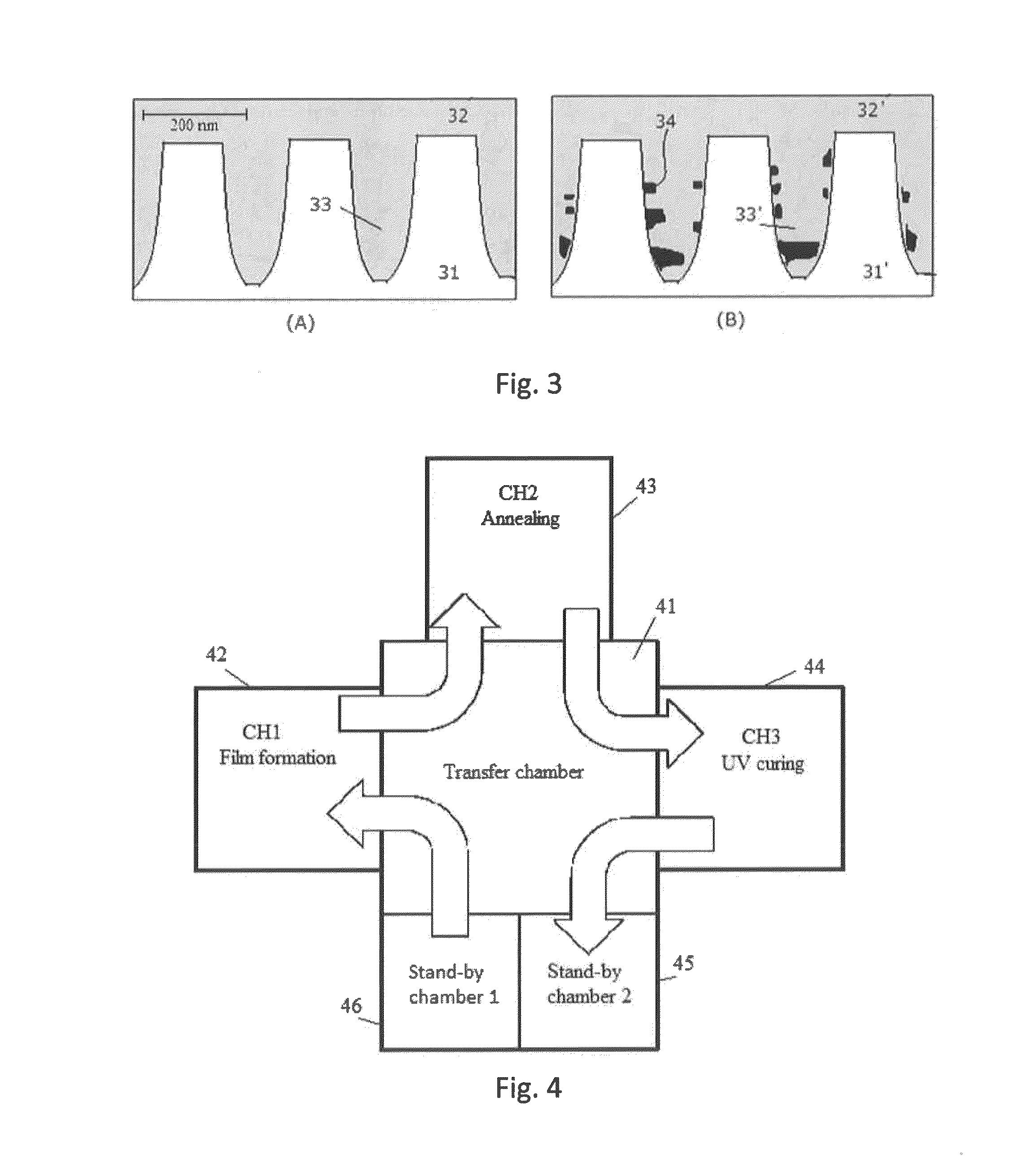

Method for forming SiOCH film using organoaminosilane annealing

ActiveUS9190263B2Improve liquidityReduce the amount requiredSemiconductor/solid-state device manufacturingPolymer scienceSilanes

Owner:ASM IP HLDG BV

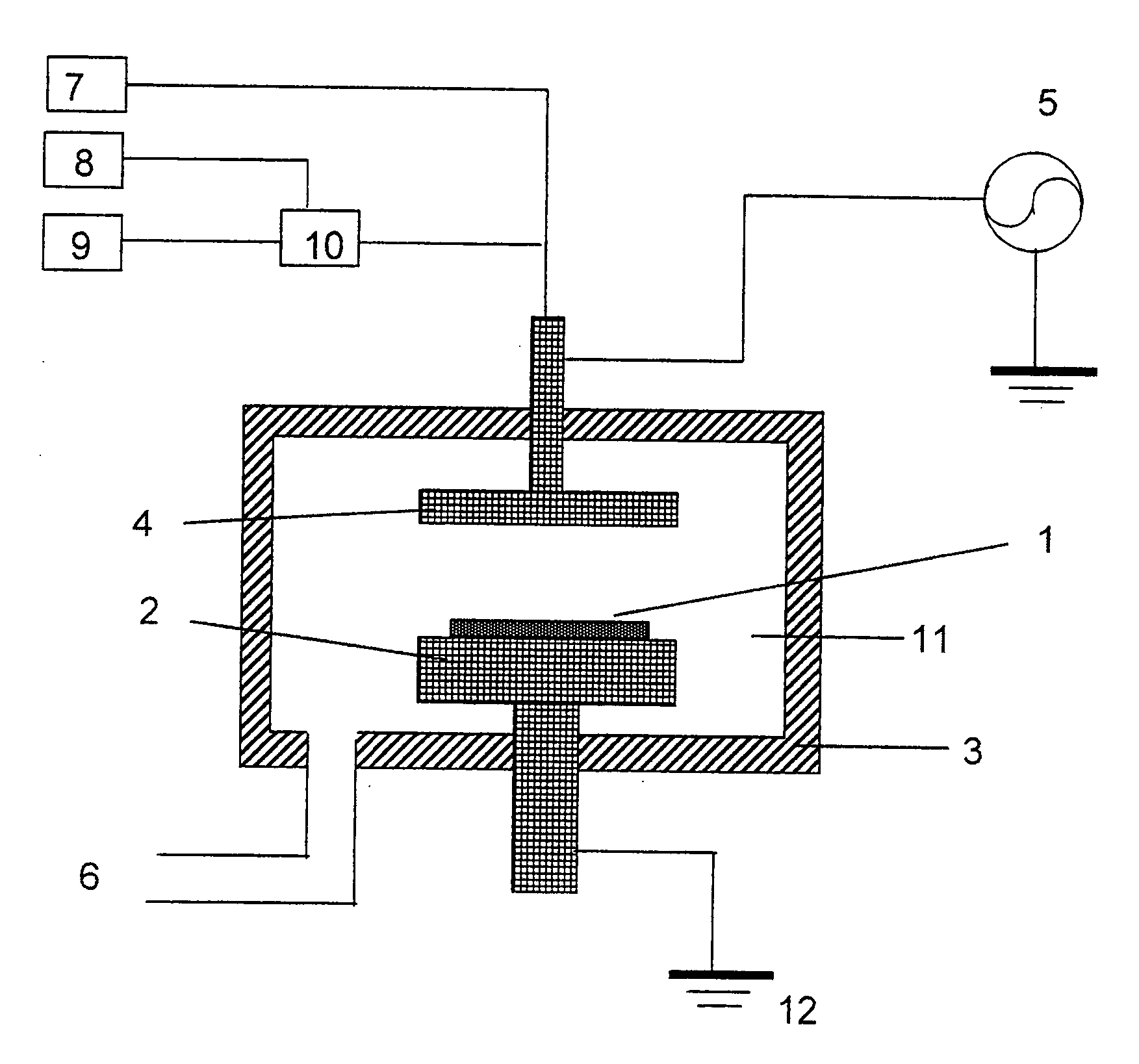

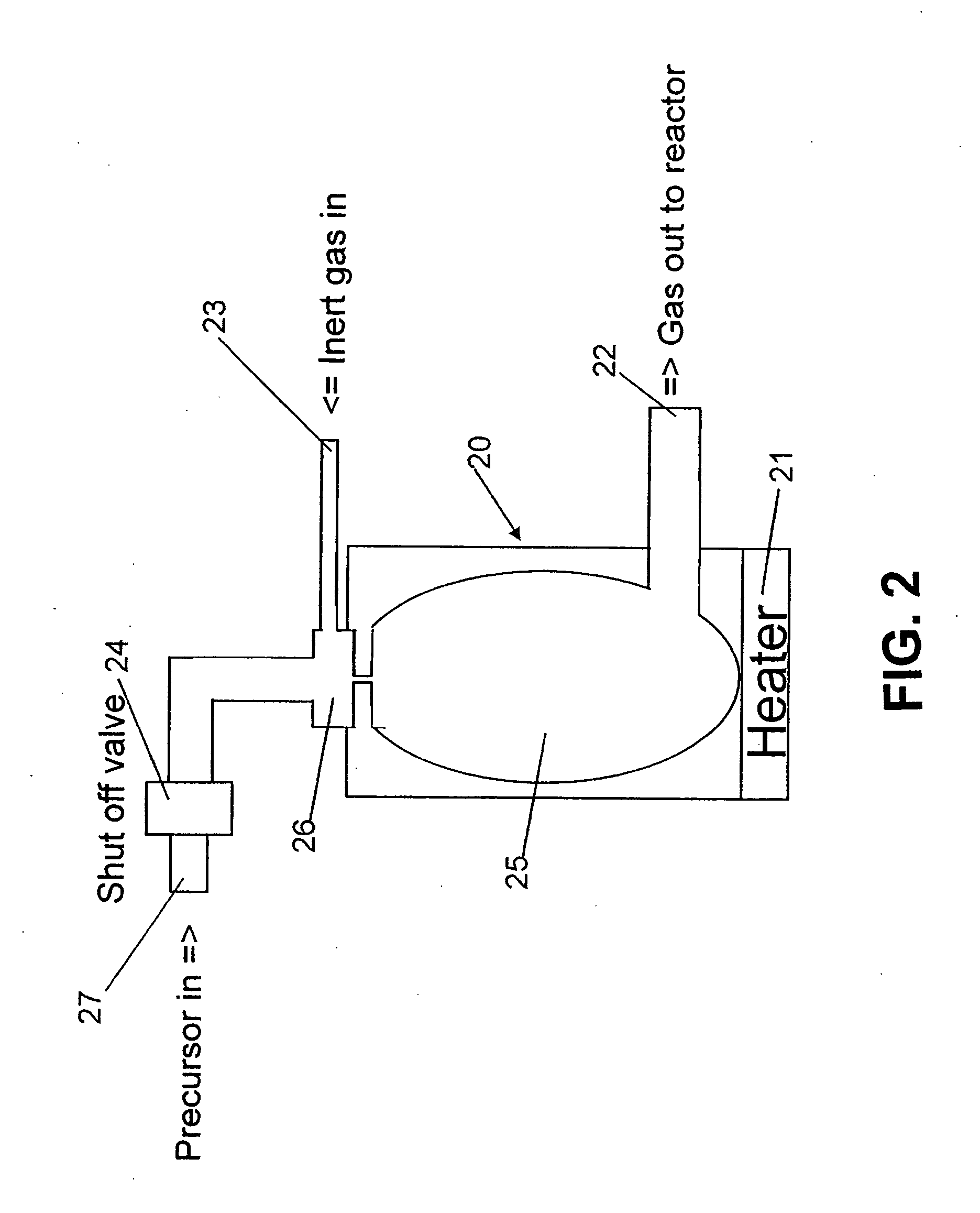

Method of forming carbon polymer film using plasma CVD

ActiveUS20070224833A1High film strengthReduction factorLiquid surface applicatorsSemiconductor/solid-state device detailsBoiling pointCapacitance

A method of forming a hydrocarbon-containing polymer film on a semiconductor substrate by a capacitively-coupled plasma CVD apparatus. The method includes the steps of: vaporizing a hydrocarbon-containing liquid monomer (CαHβXγ, wherein α and β are natural numbers of 5 or more; γ is an integer including zero; X is O, N or F) having a boiling point of about 20° C. to about 350° C. which is not substituted by a vinyl group or an acetylene group; introducing the vaporized gas and CO2 gas or H2 gas into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-containing polymer film on the substrate by plasma polymerization of the gas, thereby reducing extinction coefficient (k) at 193 nm and increasing mechanical hardness.

Owner:ASM JAPAN +1

Film for a separator of electrochemical apparatus, and production method and use thereof

InactiveUS6096456AHigh film strengthEasily and uniformly processedElectrolytic capacitorsSolid electrolyte cellsElectrolytic agentCarbamate

This invention provides a film comprising a cross-linked polymer having an oxyalkylene group or a cross-linked polymer having an oxyalkylene group through a urethane bond, as a constituent component, a production method of the film, and an electrochemical apparatus using the film as a separator. The film for separator of an electrochemical apparatus can be easily and uniformly processed, can include an electrolytic solution, exhibits good film thickness and ensures excellent safety and reliability. The electrochemical apparatus is free of leakage of the solution.

Owner:SHOWA DENKO KK

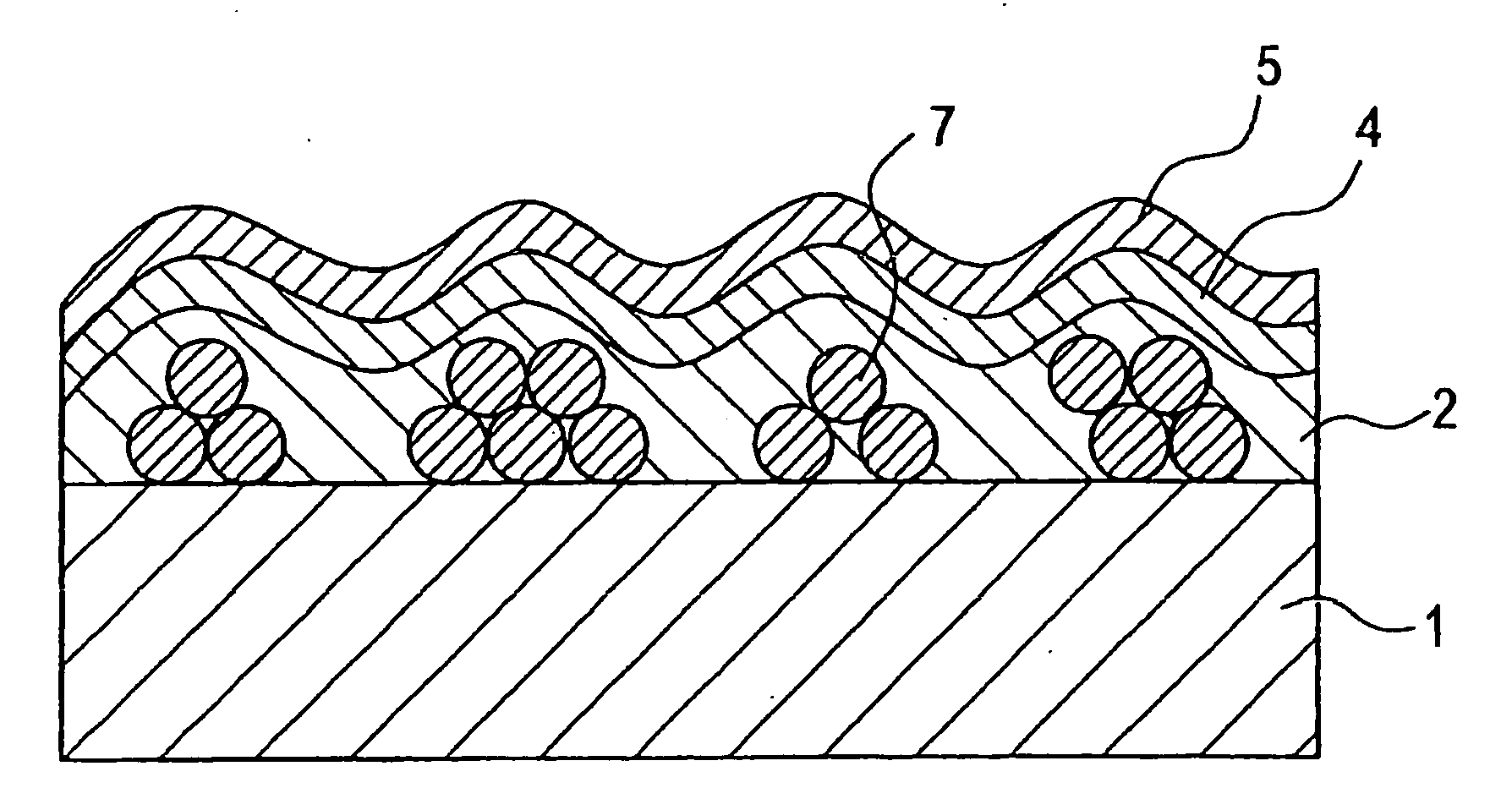

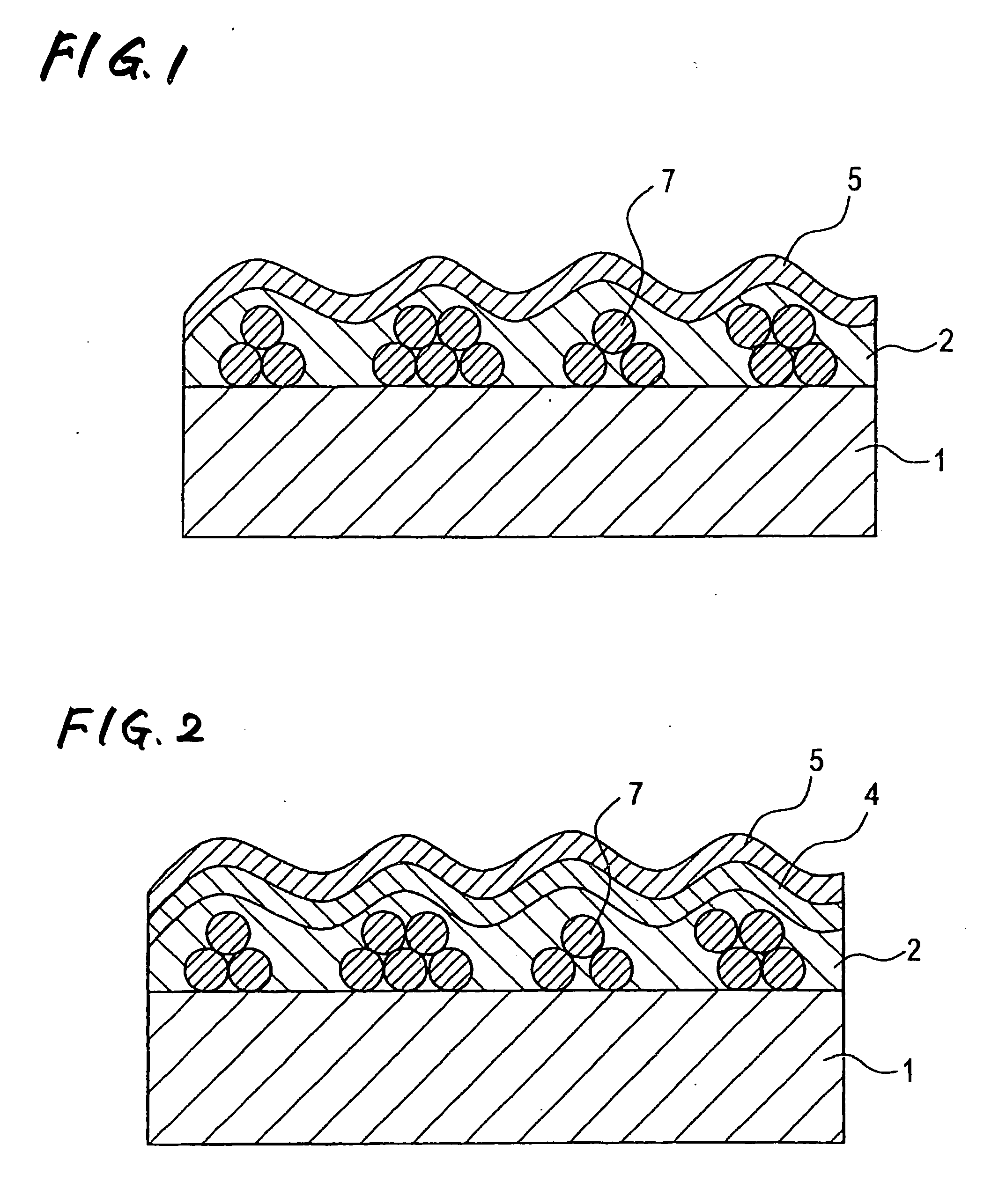

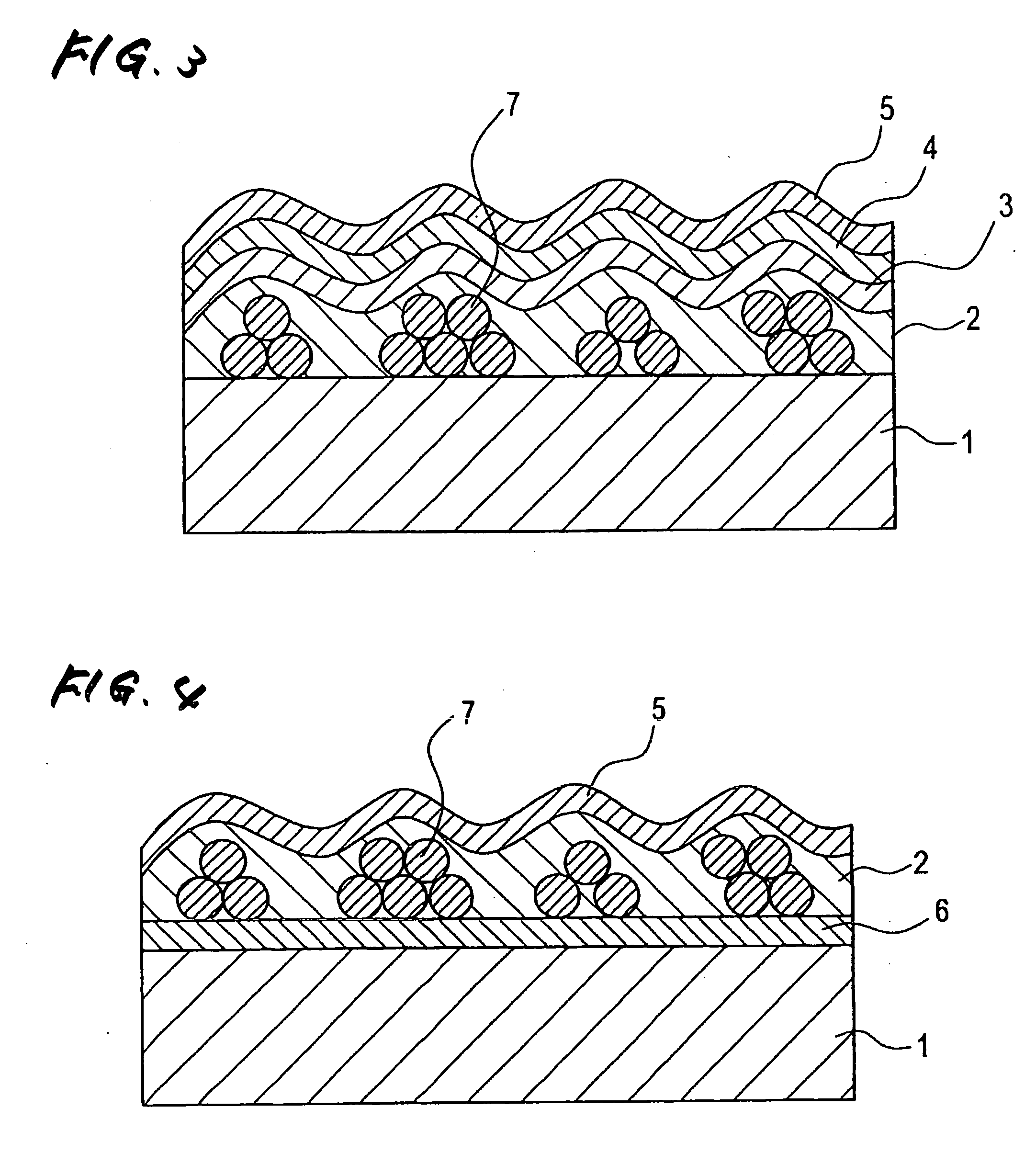

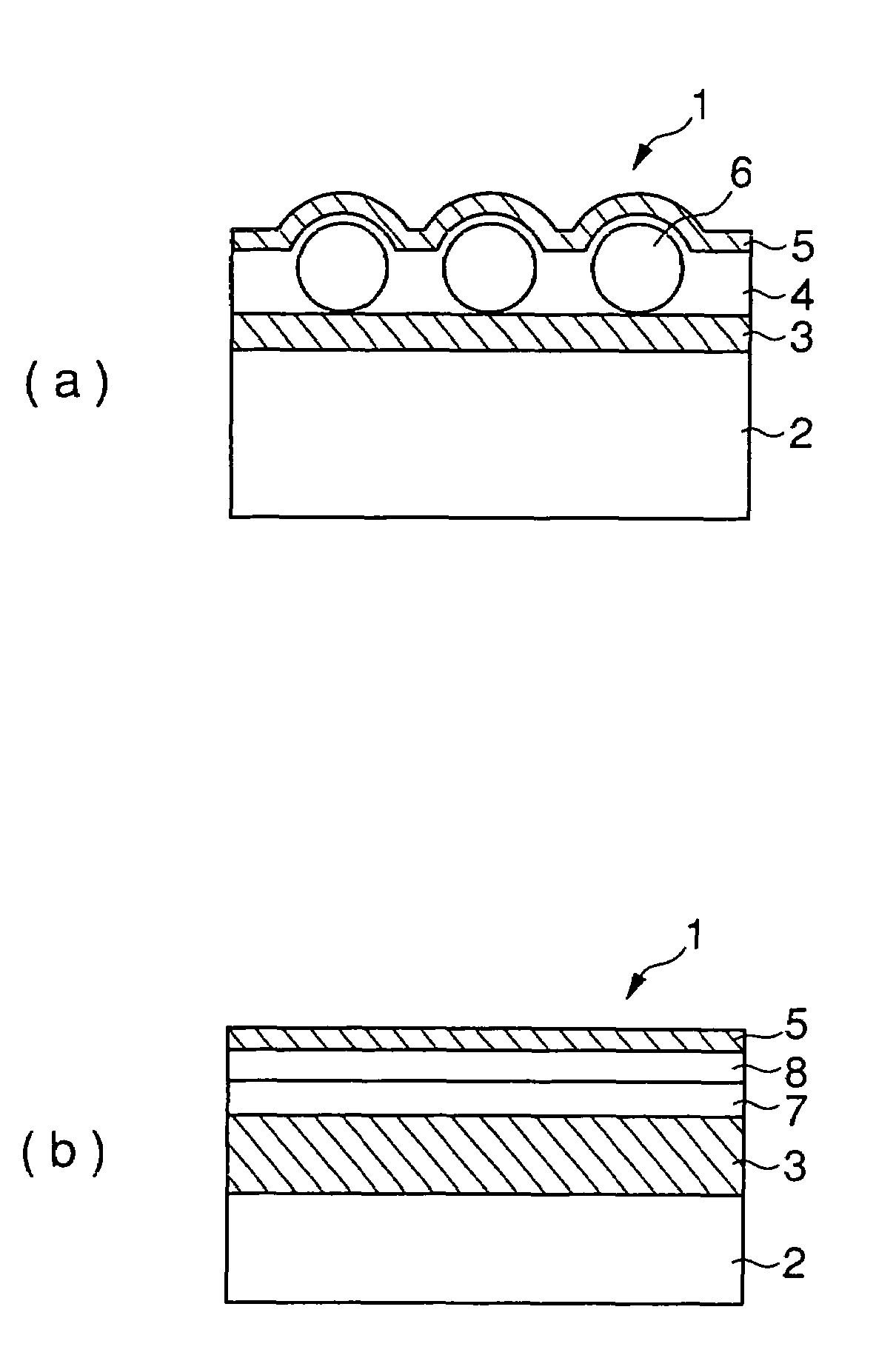

Optical film, antireflection film, polarizing plate and image display device

ActiveUS20070195431A1High film strengthExcellent optical propertiesDiffusing elementsDisplay deviceDiffusion layer

An optical film is provided and includes: a transparent support; and a light diffusion layer containing light-transmitting particles and a binder. The light diffusion layer has an average thickness of from 7.5 to 30 μm, and the average thickness of the light diffusion layer is from 1.4 to 3.5 times as large as an average particle diameter of the light-transmitting particles.

Owner:FUJIFILM CORP

Sliding member and manufacturing method thereof

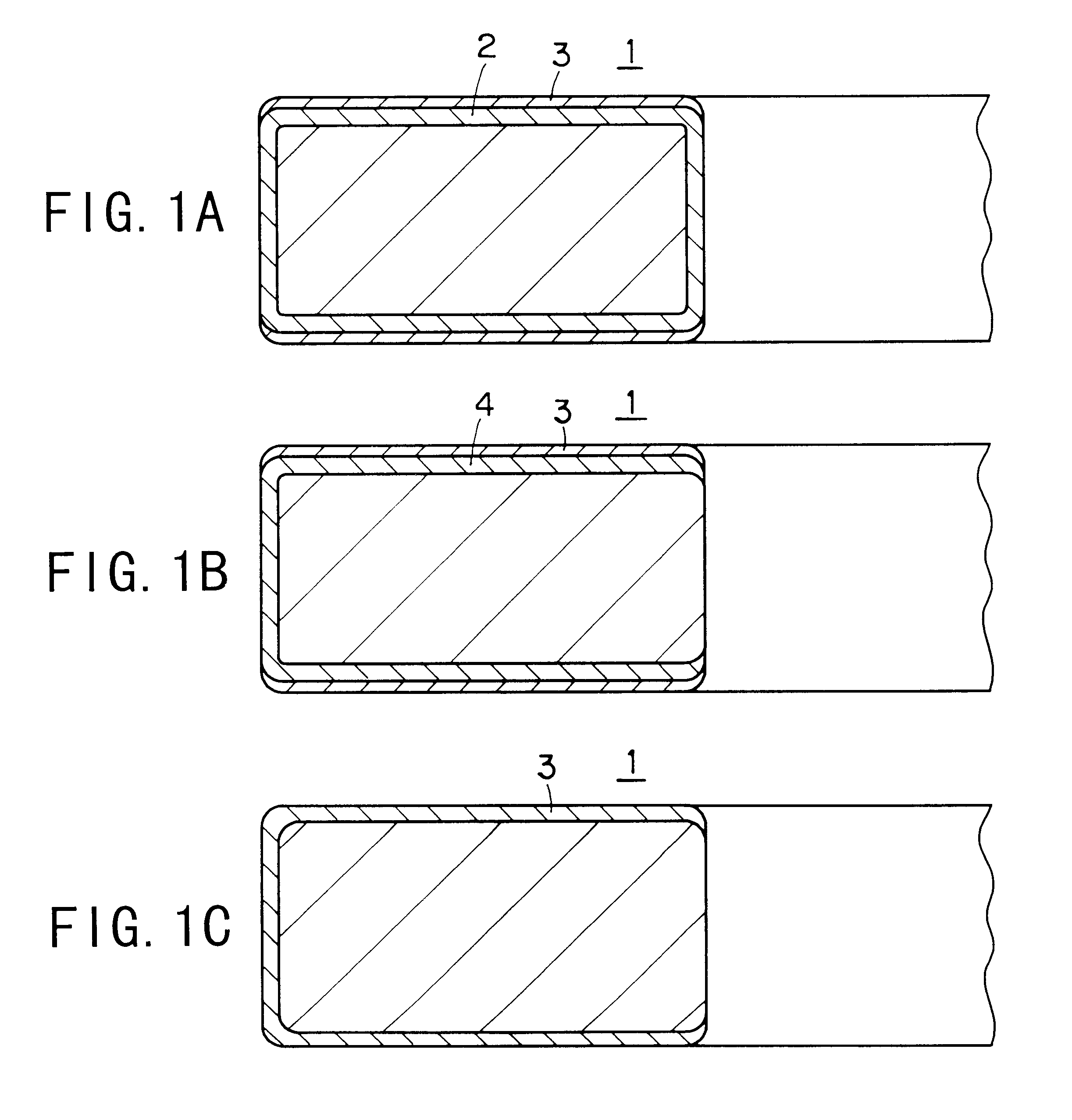

InactiveUS6279913B1Improve the immunityHigh bonding strengthPiston ringsBraking action transmissionCarbon filmDiamond-like carbon

A piston ring is formed over the entire surface with a gas nitrided layer. A diamond-like carbon film is formed in a thickness of 0.5 to 30 micrometers over the gas nitrided layer at the upper and lower surfaces. The diamond-like carbon film has a surface structure in which diamond-like carbon has been deposited in nodular shapes in sizes of 0.5 to 5 micrometers. The diamond-like carbon is configured with any one of an amorphous carbon structure, an amorphous carbon structure having partly a diamond structure, or an amorphous carbon structure having partly a graphite structure.

Owner:TEIKOKU PISTON RING CO LTD

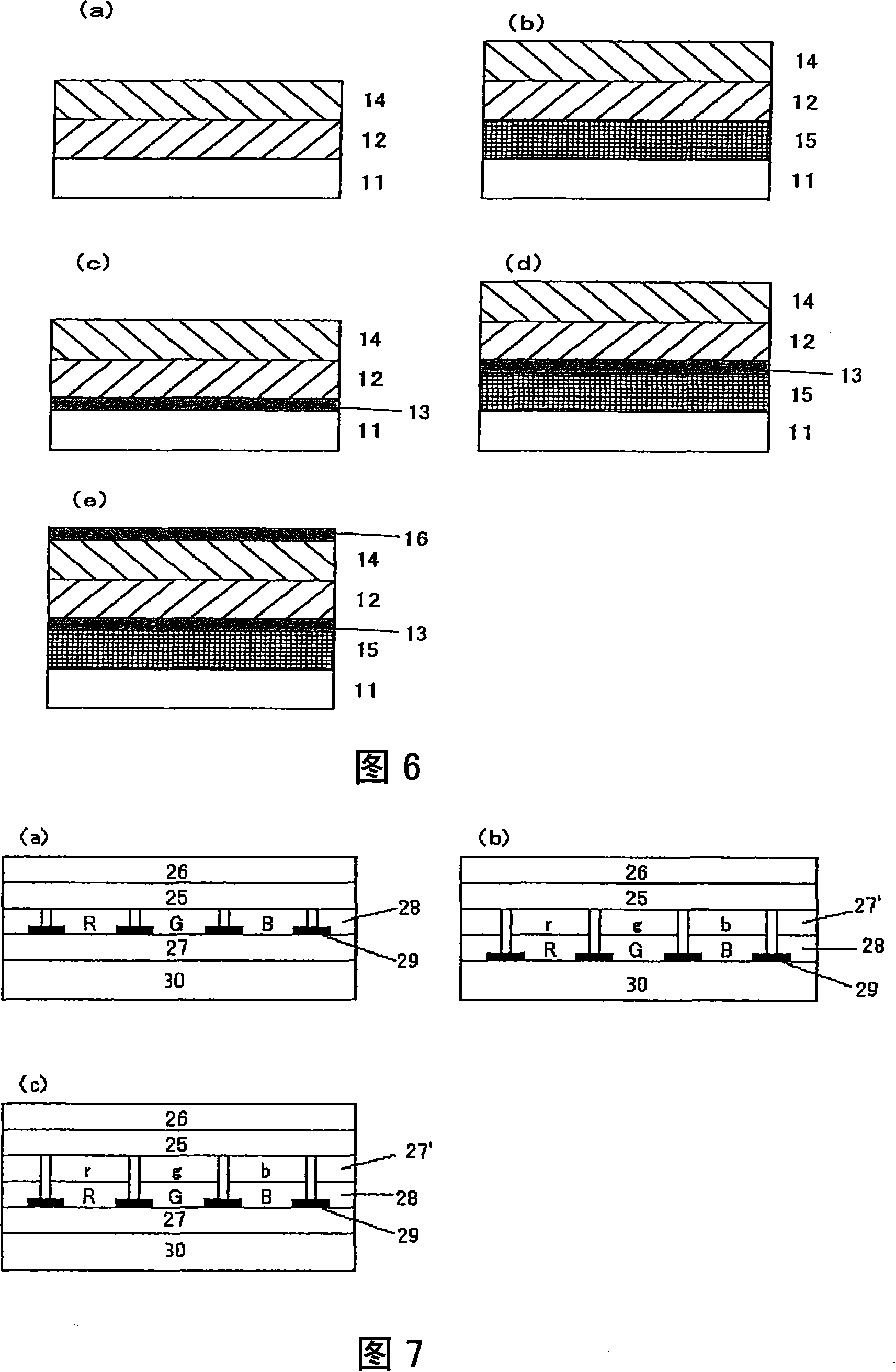

Method of producing optical film, optical film, polarizer plate, transfer material, liquid crystal display device, and polarized ultraviolet exposure apparatus

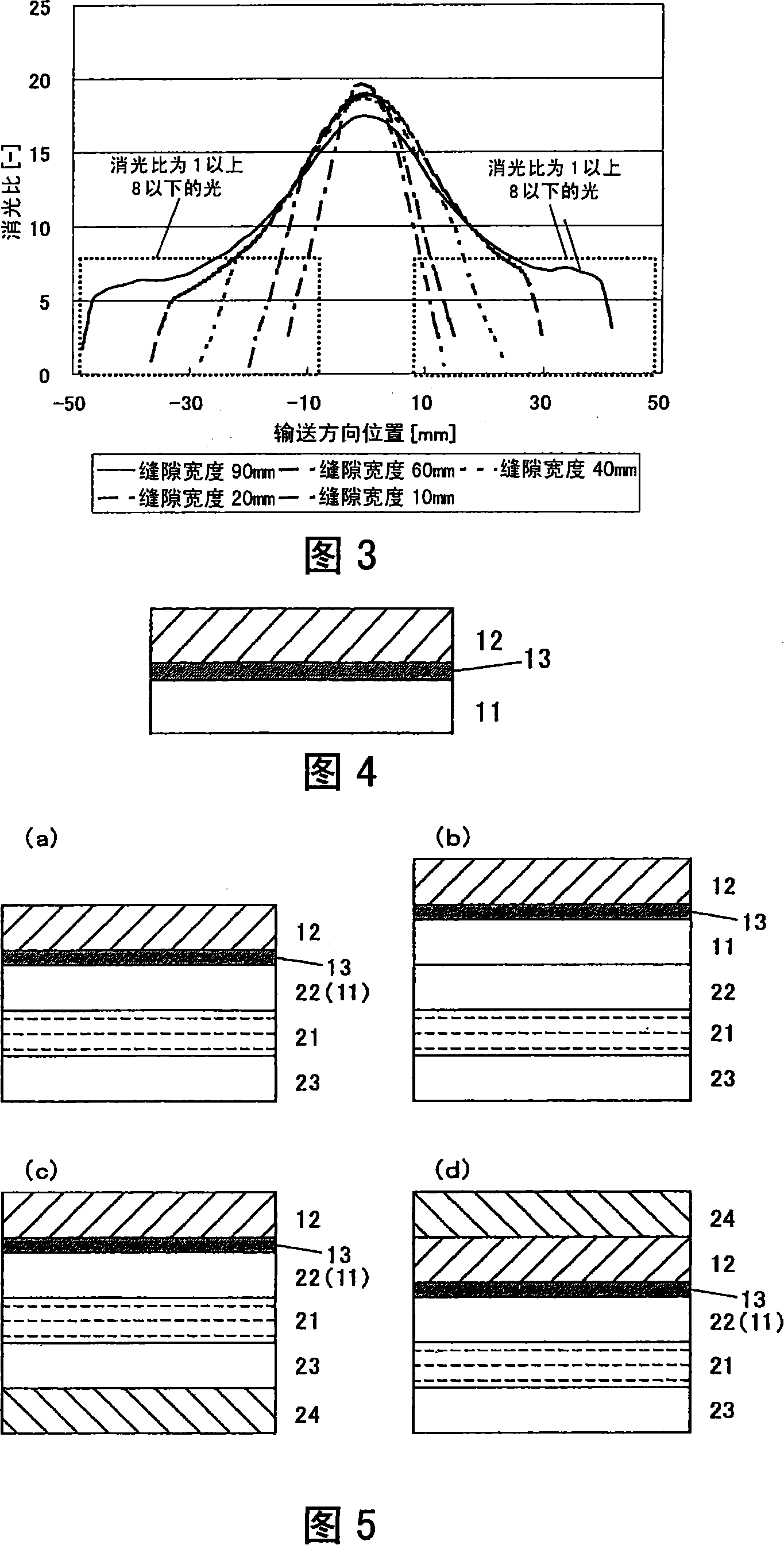

InactiveCN101131436AExcellent optical propertiesHigh film strengthPolarising elementsNon-linear opticsUltraviolet lightsPolarizer

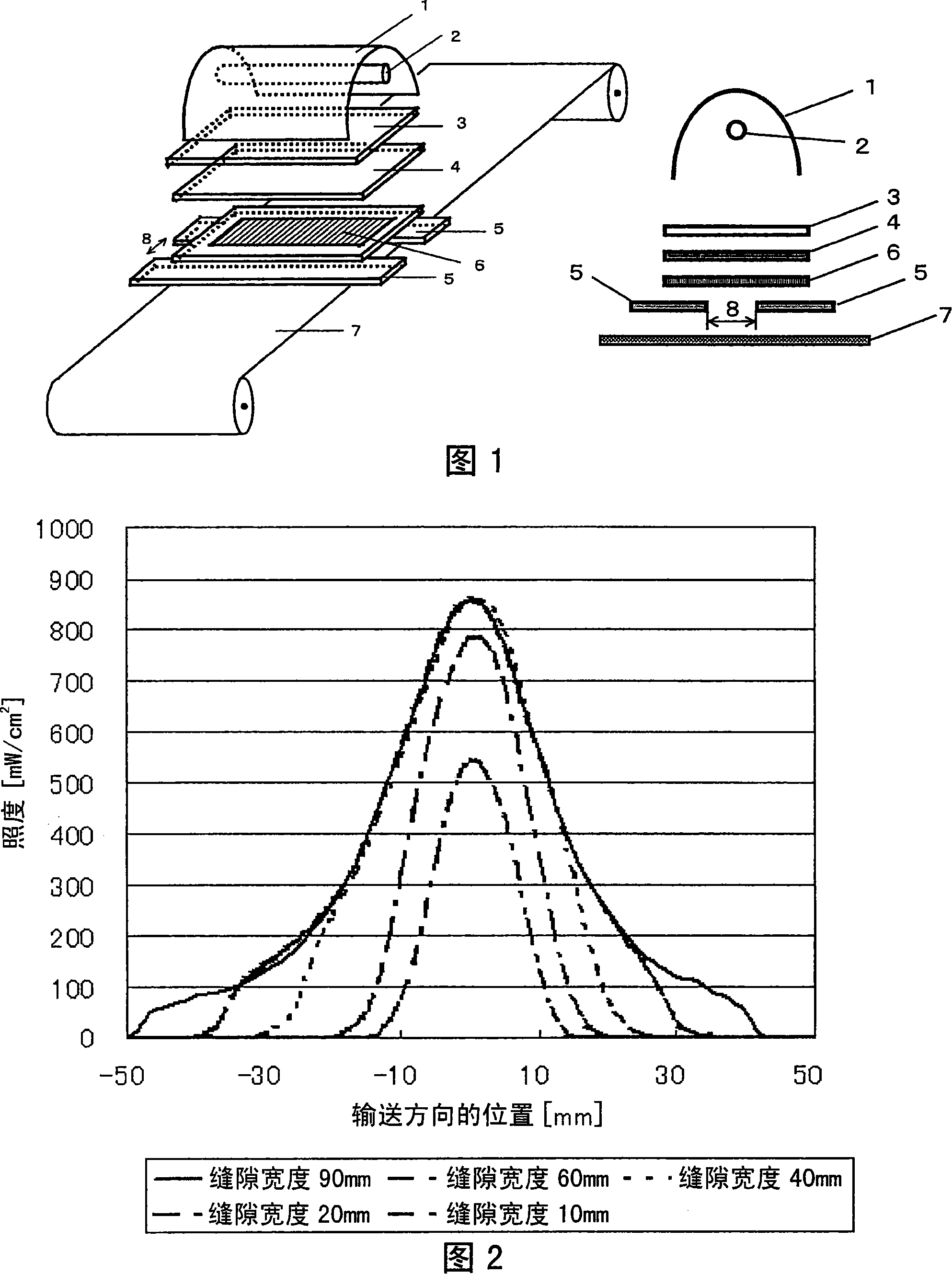

The present invention provides a method for producing an optical film exhibiting excellent optical characteristics and film strength with high productivity in a production method of an optical film including a step of irradiating polarized ultraviolet rays. The method for producing an optical film is characterized in that it is a method for producing an optical film comprising the following steps (1) to (3) in the order of (1) to (3): (1) A layer composed of a polymerizable composition containing a polymerizable liquid crystal compound and a dichroic polymerization initiator is formed on the surface; (2) the molecules of the polymerizable liquid crystal compound in the layer are formed into a first alignment state; (3) The layer is irradiated with polarized ultraviolet rays to polymerize the polymerizable liquid crystal compound, and fix the molecules of the polymerizable liquid crystal compound in the second alignment state to form an optically anisotropic layer. Exposure to area (J / cm 2 ), the proportion of polarized ultraviolet rays with an extinction ratio of 1 to 8 is 15% or less.

Owner:FUJIFILM CORP

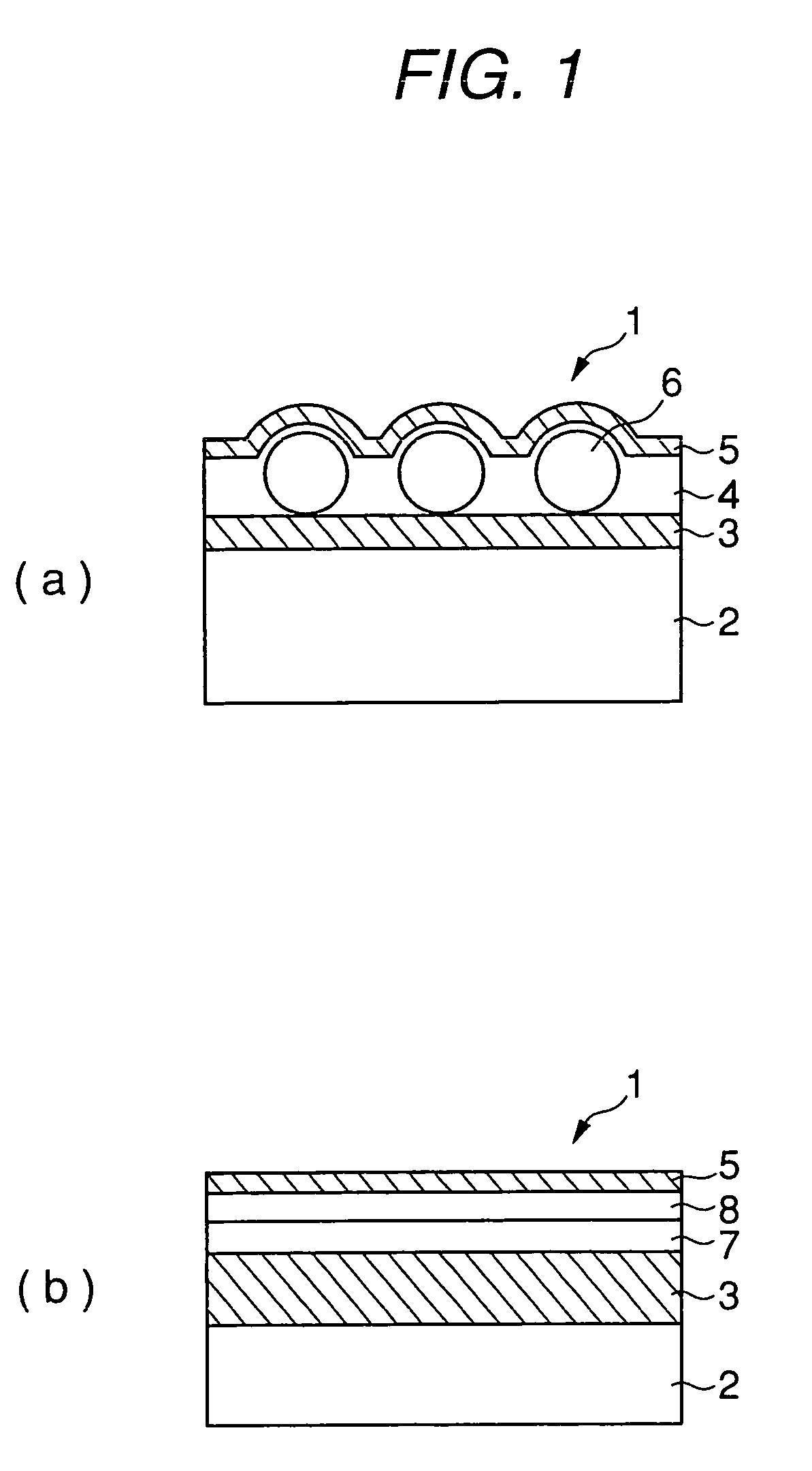

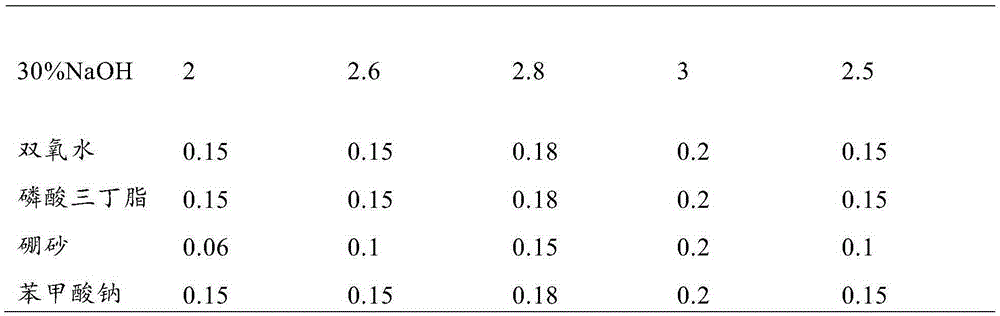

Antireflection film, polarized plate and image display device

ActiveUS20060057307A1Improve scratch resistanceImprove anti-reflection effectLiquid crystal compositionsDiffusing elementsTectorial membraneDisplay device

The present invention can provide an antireflection film improved in the scratch resistance while having a sufficiently high antireflection property, and a polarizing plate and a display device using the antireflection film, the antireflection film antireflection film comprising: a transparent support; and as an outermost layer, a low refractive index layer containing a fluorine-containing polymer, wherein the low refractive index layer comprises at least one inorganic fine particle having an average particle size of 30 to 100% of the thickness of the low refractive index layer; the polarizing plate using the antireflection film for one of two protective films of a polarizer in the polarizing plate; and the image display device using the antireflection film or polarizing plate for the outermost surface of the display.

Owner:FUJIFILM CORP

Coating liquid for forming transparent conductive film, substrate with transparent conductive film, and display device

InactiveUS20040016914A1Decreased electrical conductionReduce surface resistanceConductive layers on insulating-supportsCathode-ray/electron-beam tube vessels/containersSilica particleDisplay device

Disclosed is a coating liquid for forming a transparent conductive film, comprising conductive fine particles having an average particle diameter of 1 to 200 nm, silica particles having an average particle diameter of 4 to 200 nm and a polar solvent. The silica particles are in the form of chain silica particles having 2 to 10 silica particles on an average being connected. The content of an alkali in the silica particles is not more than 1000 ppm in terms of an alkali metal M. Also disclosed is a substrate with a transparent conductive film, comprising a substrate, a transparent conductive fine particle layer formed on the substrate and containing conductive fine particles having an average particle diameter of 1 to 200 nm and silica particles having an average particle diameter of 4 to 200 nm and / or chain silica particles having 2 to 10 silica particles on an average being connected, and a transparent film provided on the transparent conductive fine particle layer and having a refractive index lower than that of the transparent conductive fine particle layer. A display device using the substrate with a transparent conductive film is further disclosed. The coating liquid for forming a transparent conductive film is capable of forming a transparent conductive film having low surface resistance, excellent antistatic properties, excellent electromagnetic blocking properties, high film strength and excellent adhesion to a substrate.

Owner:CATALYSTS & CHEM

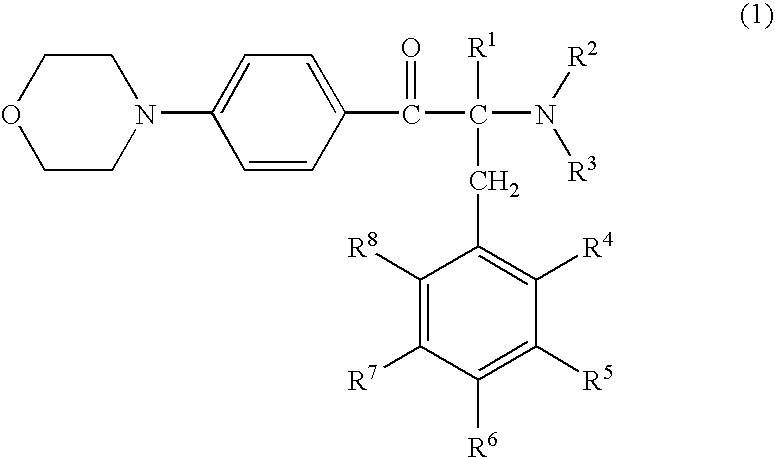

Energy ray-curable inkjet printing ink

InactiveUS20090118388A1Low viscosityHigh sensitivityMixing methodsDuplicating/marking methodsPrinting inkKetone

An energy beam curable type ink jet printing ink comprising (A) a colorant, (B) a compound having at least one ethylenically unsaturated bond which can be polymerized by the application of an energy beam and (C) a photopolymerization initiator, whereinthe component (B) is a compound having at least one methacryloyl group as a sole polymerizable unsaturated group and the component (C) is a 2-alkyl-2-amino-2-benzyl-1-(4-morpholinophenyl)ethan-1-one.This ink has low viscosity, high sensitivity and sufficiently high film strength after curing.

Owner:JSR CORPORATIOON

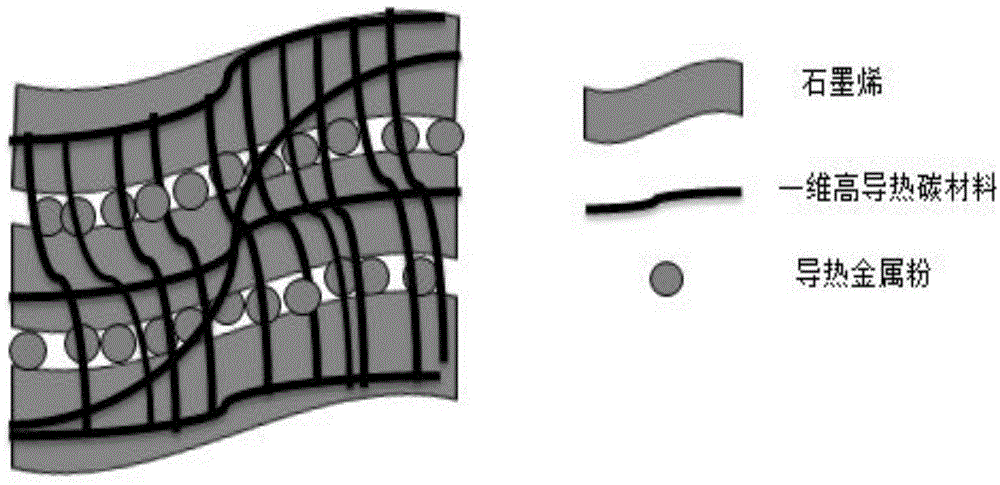

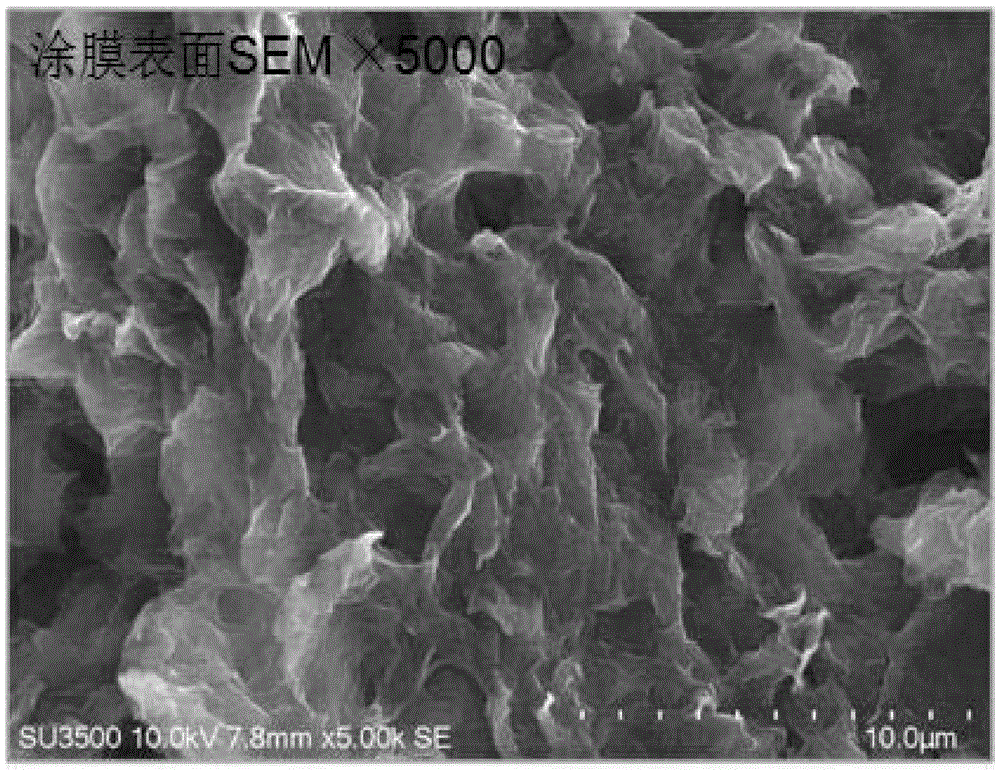

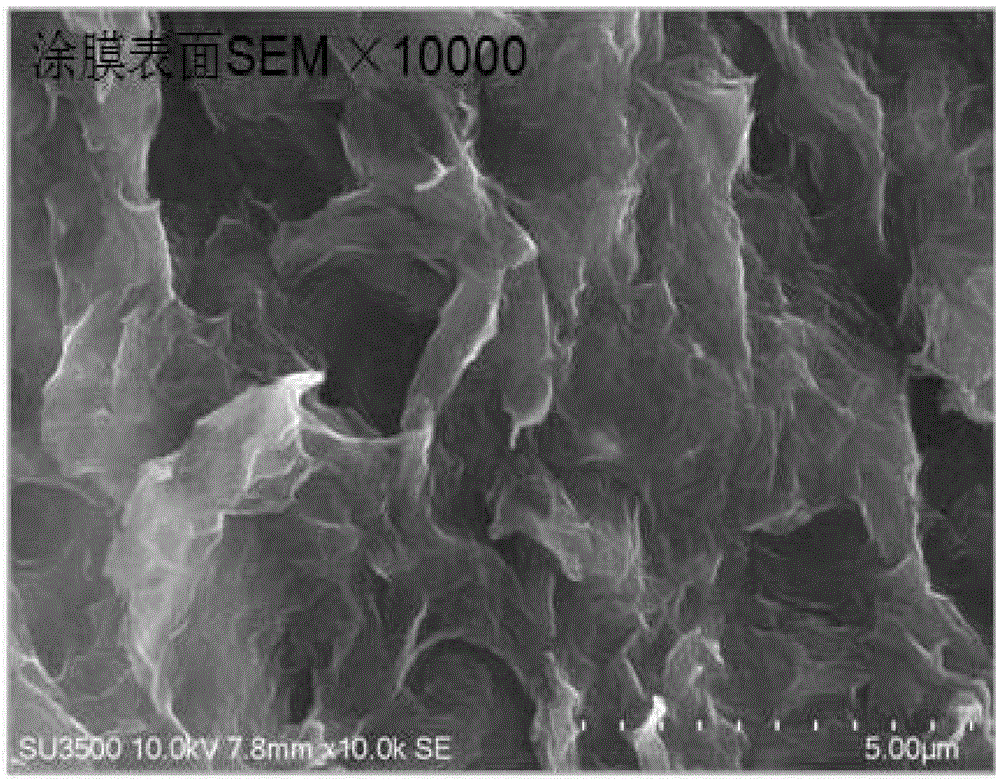

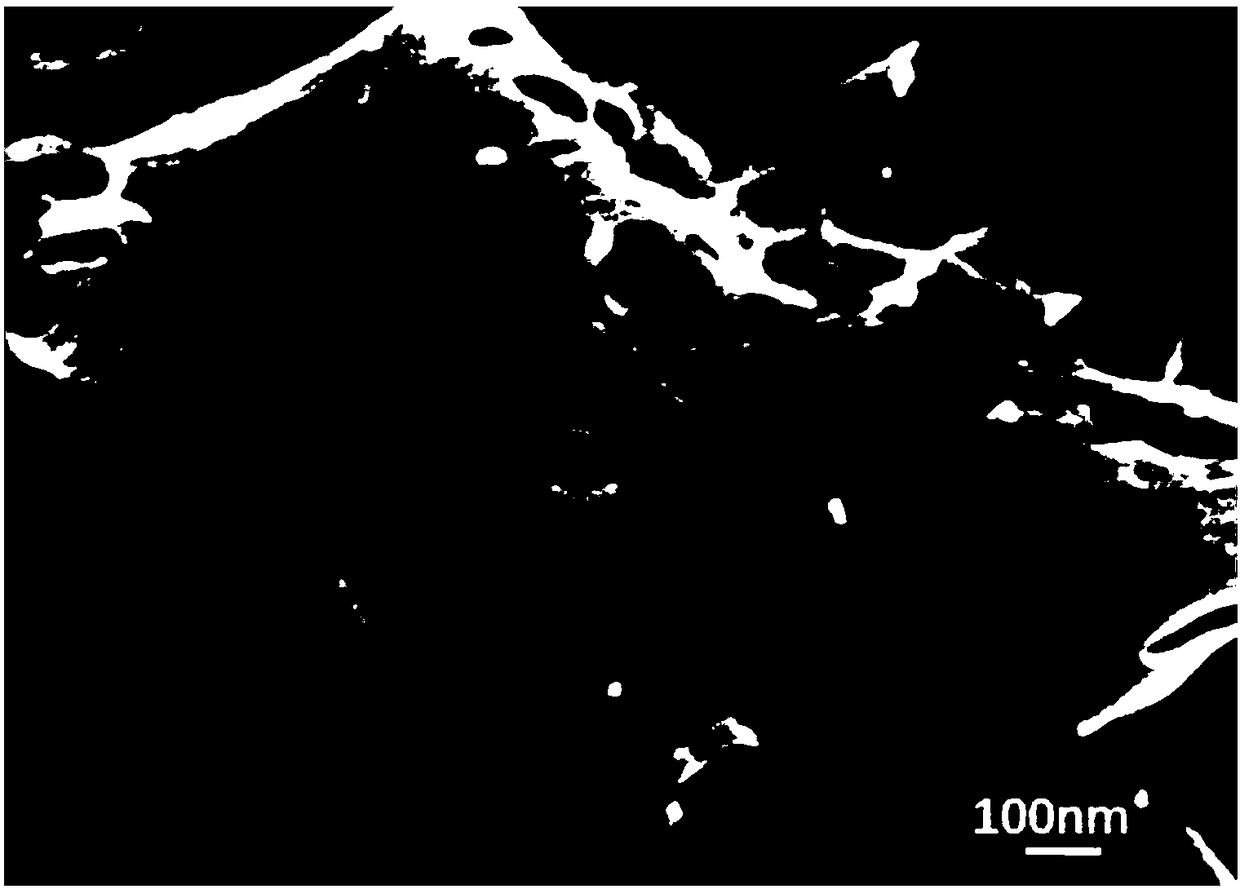

Graphene heat radiation paint, preparation method and applications

ActiveCN105273540ALight in massHigh film strengthEpoxy resin coatingsPolyester coatingsSolventRadiation

The invention discloses graphene heat radiation paint. The graphene heat radiation paint comprises the following ingredients, by weight, 40-80 parts of high-molecular resin, 5-15 parts of graphene, 1-8 parts of one-dimensional nanomaterials, 1-8 parts of heat conduction metal powder, 0.5-5 parts of dispersing agents, 0.5-5 parts of antifoaming agents and 100-200 parts of inert solvent. The heat conduction metal powder is at least one selected from silver powder, copper powder and aluminum powder and the granularity is 1-20 micrometers. The above paint has good heat radiation and heat conduction functions. The invention also discloses a preparation method for the graphene heat radiation paint. The preparation method mainly comprises processes of stirring, grinding and reblending. Operation is simple, and the cost is low. The graphene heat radiation paint is mainly applied in heat radiation of daily electronic products and also can be applied in spaceflight electronic devices with high requirements because of good heat conduction and heat radiation functions.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

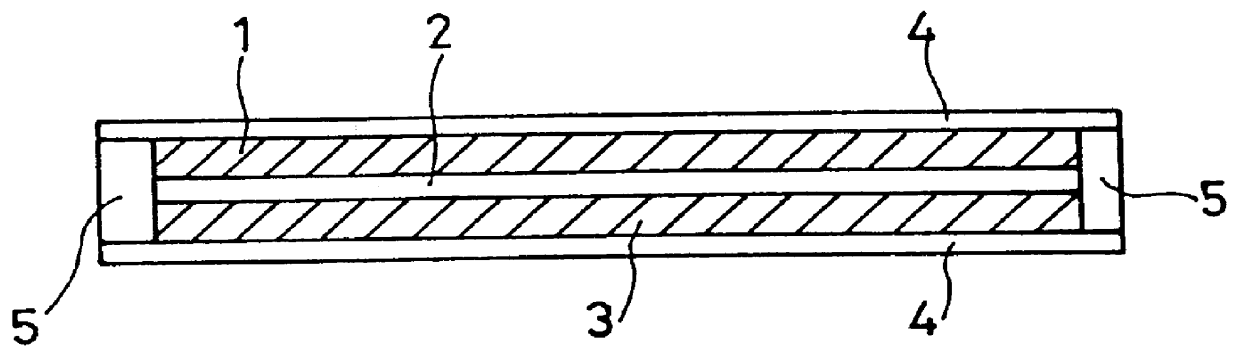

Water-proof sound-transmitting membrane, method for producing water-proof sound-transmitting membrane, and electrical appliance using the membrane

ActiveUS20100206660A1Ensure strengthGood transmittanceSynthetic resin layered productsLaminationPorous membraneBinding force

A water-proof sound-transmitting membrane 10 includes a polytetrafluoroethylene porous membrane 1 and has a surface density of 1 to 20 g / m2. The polytetrafluoroethylene porous membrane 1 includes a first porous layer 1a, and a second porous layer 1b stacked on and integrated with the first porous layer 1a by a binding force acting between polytetrafluoroethylene matrices.

Owner:NITTO DENKO CORP

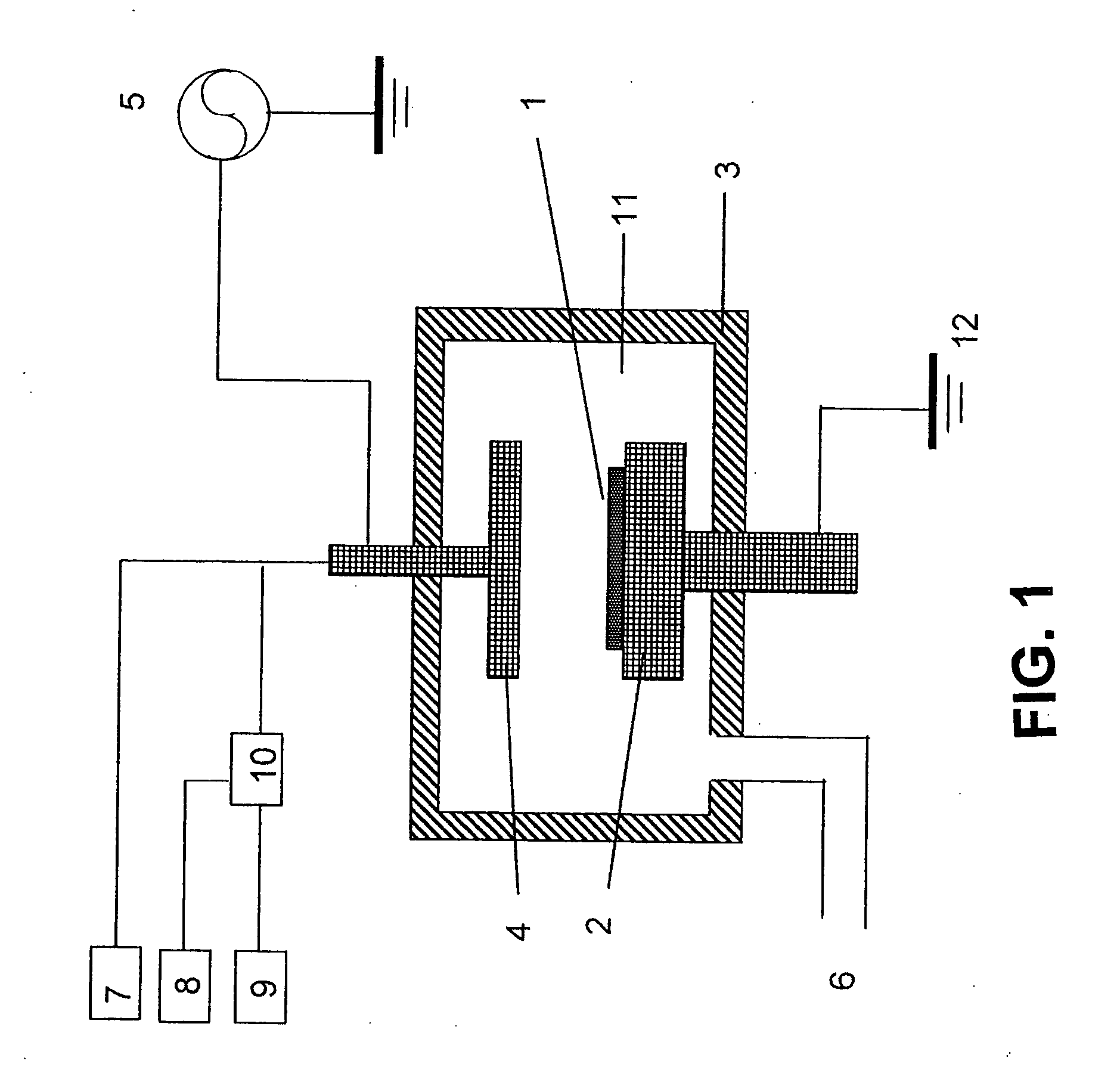

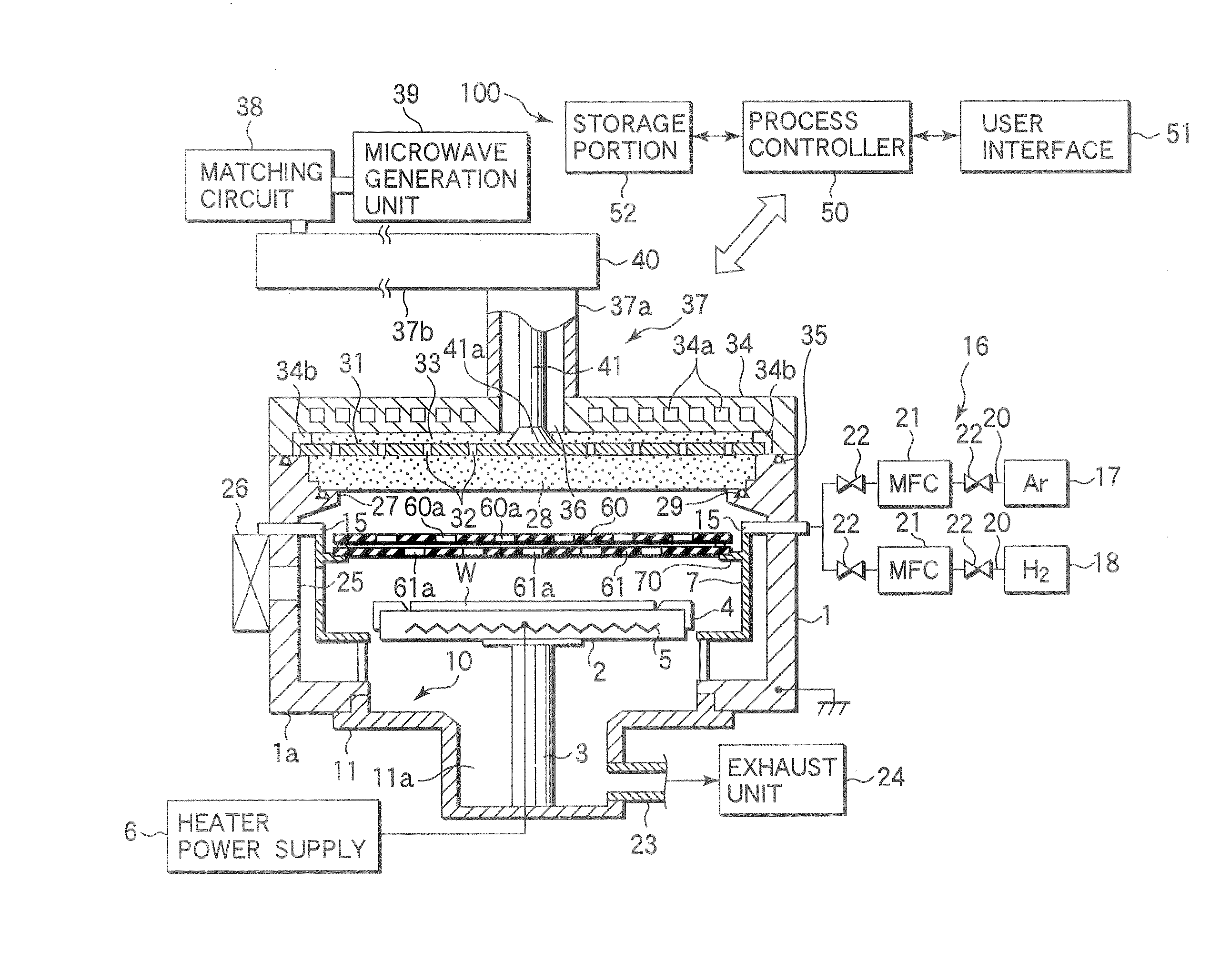

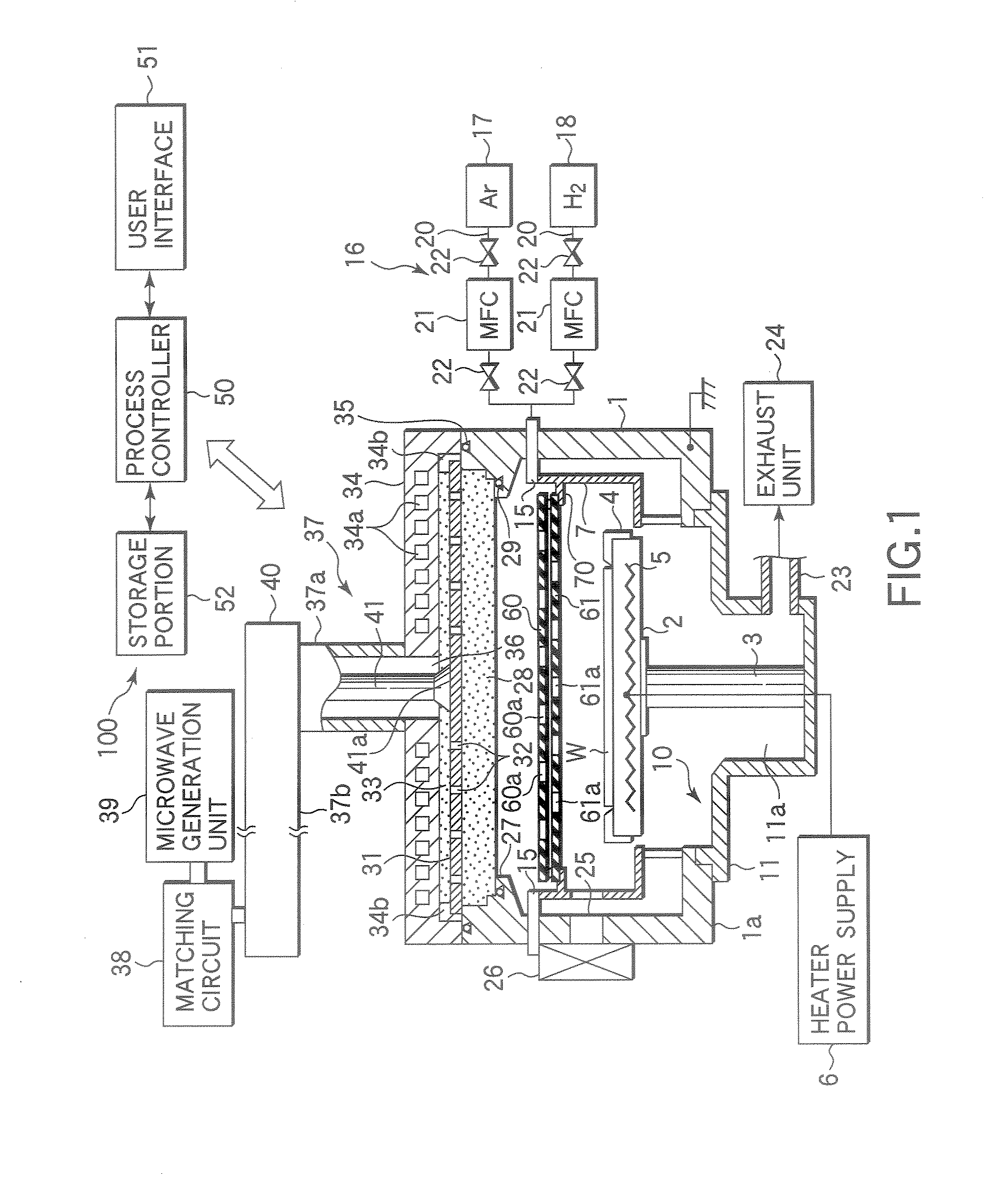

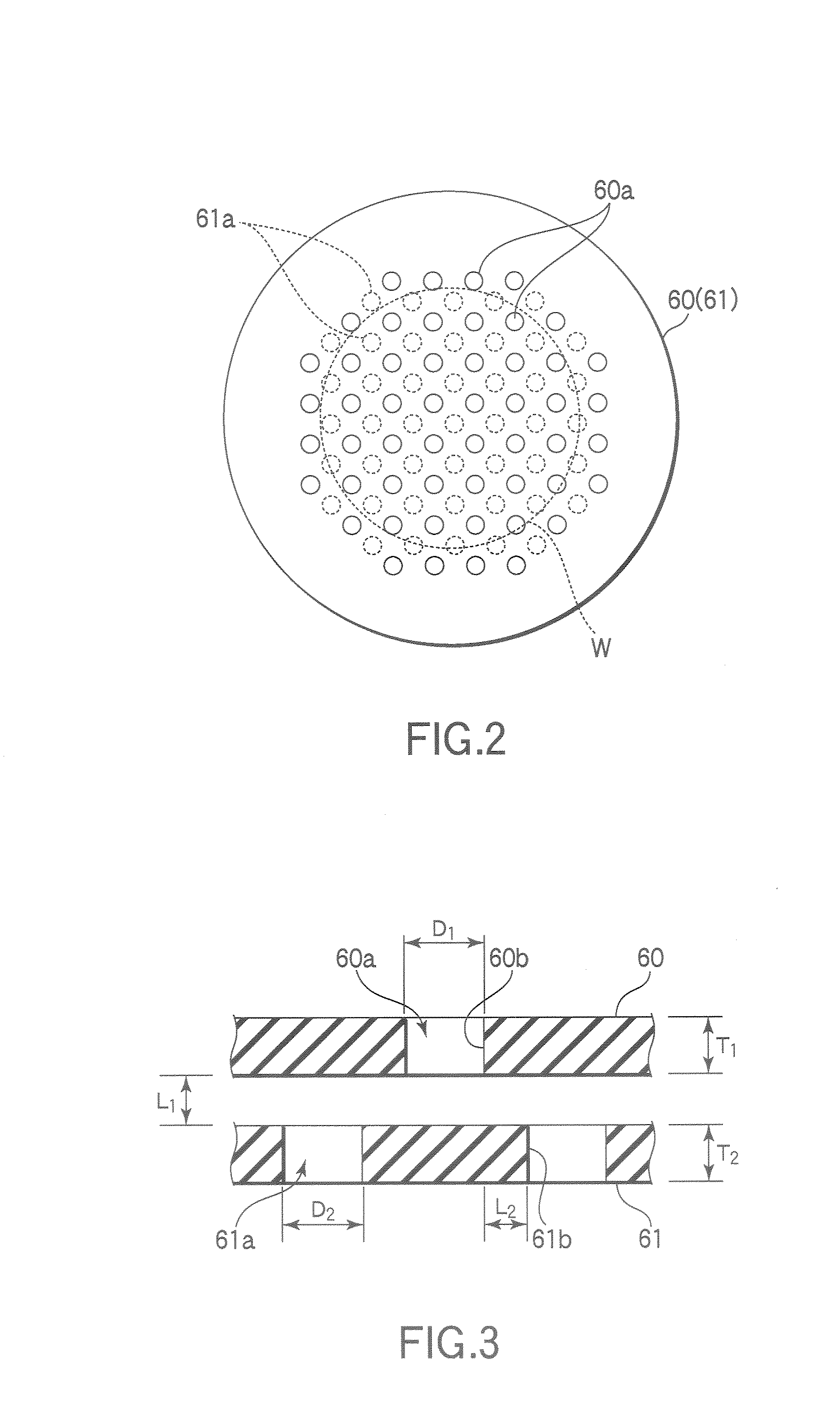

Plasma processing apparatus and plasma processing method

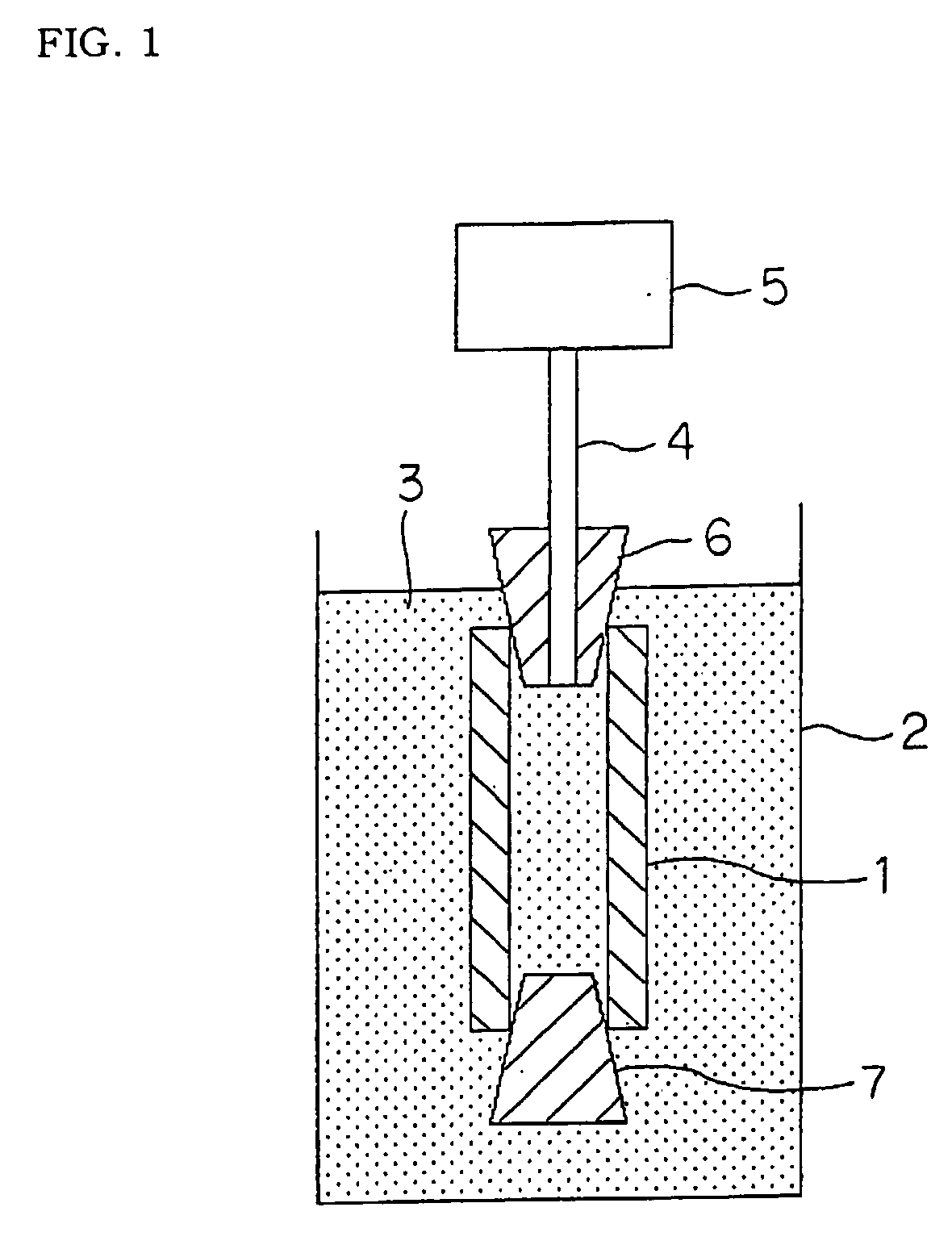

InactiveUS20070286967A1Reliably curing processHigh film strengthElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma processingMechanical engineering

A plasma processing apparatus 100 includes an upper plate 60 and a lower plate 61 disposed above a susceptor 2. The upper plate 60 and lower plate 61 are made of a heat resistant and insulative material, such as quartz. The two plates are disposed in parallel with each other with a predetermined gap of, e.g., 5 mm interposed therebetween. The two plates have a plurality of through holes 60a and 61a formed therein and positionally shifted from each other. The two plates are disposed in an overlapped state such that the through holes 61a of the lower plate 61 are not aligned with the through holes 60a of the upper plate 60.

Owner:TOKYO ELECTRON LTD

Solid dust suppressant

InactiveCN104817997AHigh bonding strengthGuaranteed moisture contentOther chemical processesBursting strengthMoisture absorption

A solid dust suppressant is prepared by mixing 40-90% of a water-soluble high molecular polymer, 5-40% of water-soluble high molecular glue, 0-25% of a moisture absorption humectant, 0.5-5% of a flexibilizer, 1-5% of an antiseptic and 3-10% of an osmotic agent, and has the characteristics of high film forming strength, low brightness and moderate viscosity. The viscosity (at 25DEG C), the pH value, the wind loss rate (under 30mm / s wind speed 5mins, %), the cured layer thickness, the film tensile strength, the film elongation at break and the material bursting strength of the solid dust suppressant are not lower than 8.0mPa.s, 6.0-7.0, not greater than 0.40, not lower than 11.25mm, greater than 11mpa, greater than 13% and greater than 0.05mpa respectively, and the solid dust suppressant realizes difficult brittle rupture after film formation, has a long effective dust suppression time and an ideal dust suppression effect.

Owner:INNER MONGOLIA BORAN TECH CO LTD

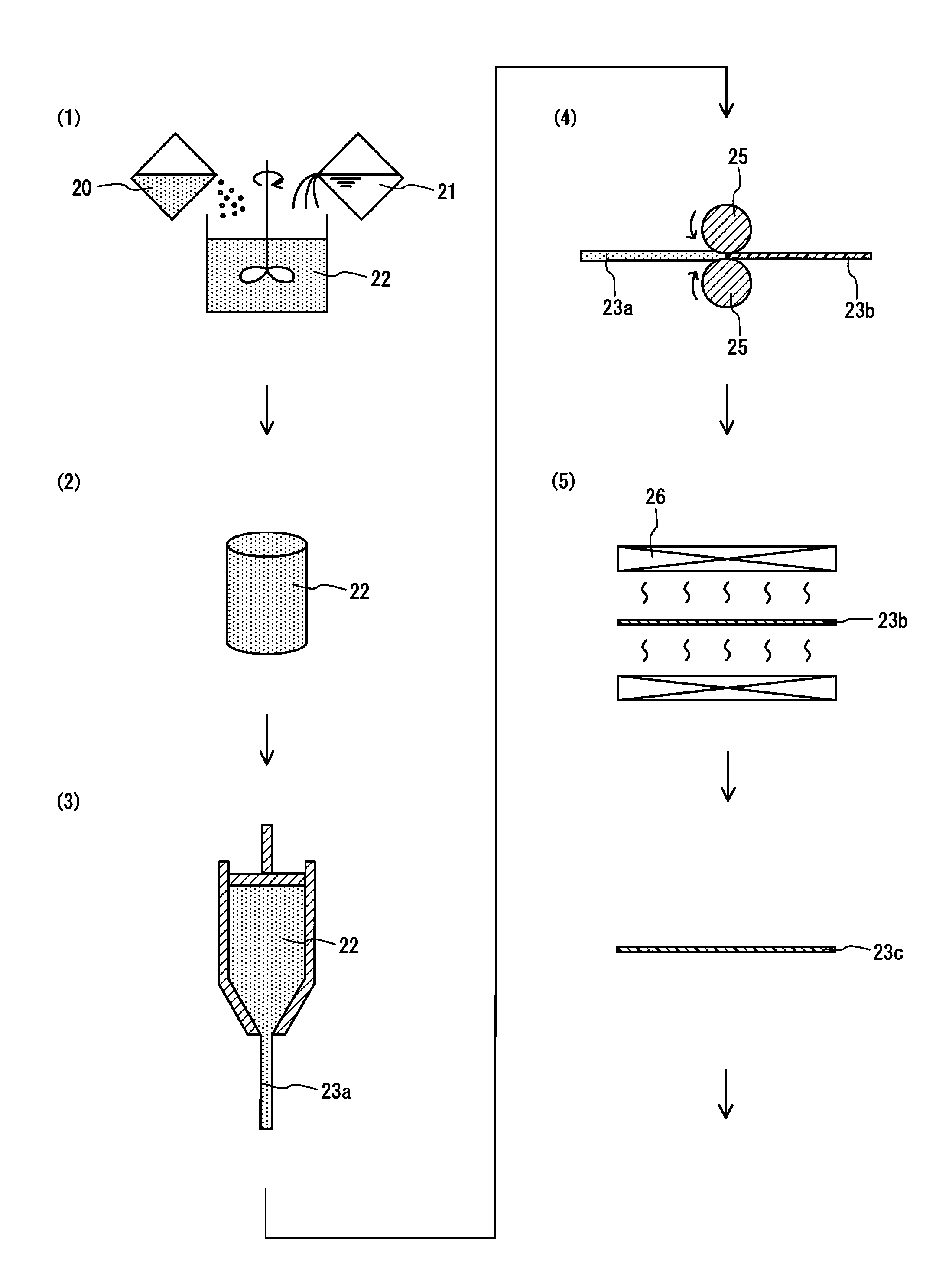

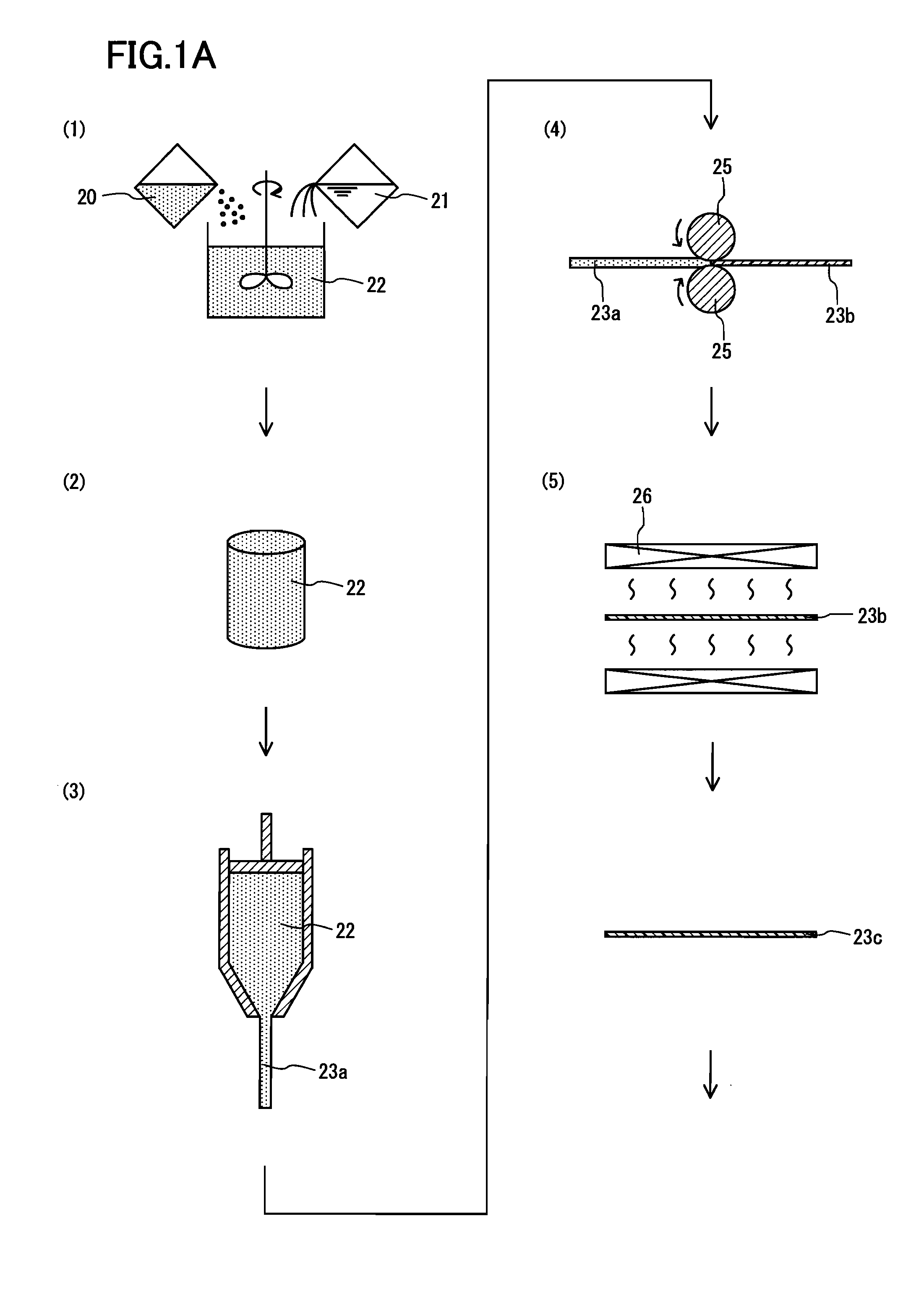

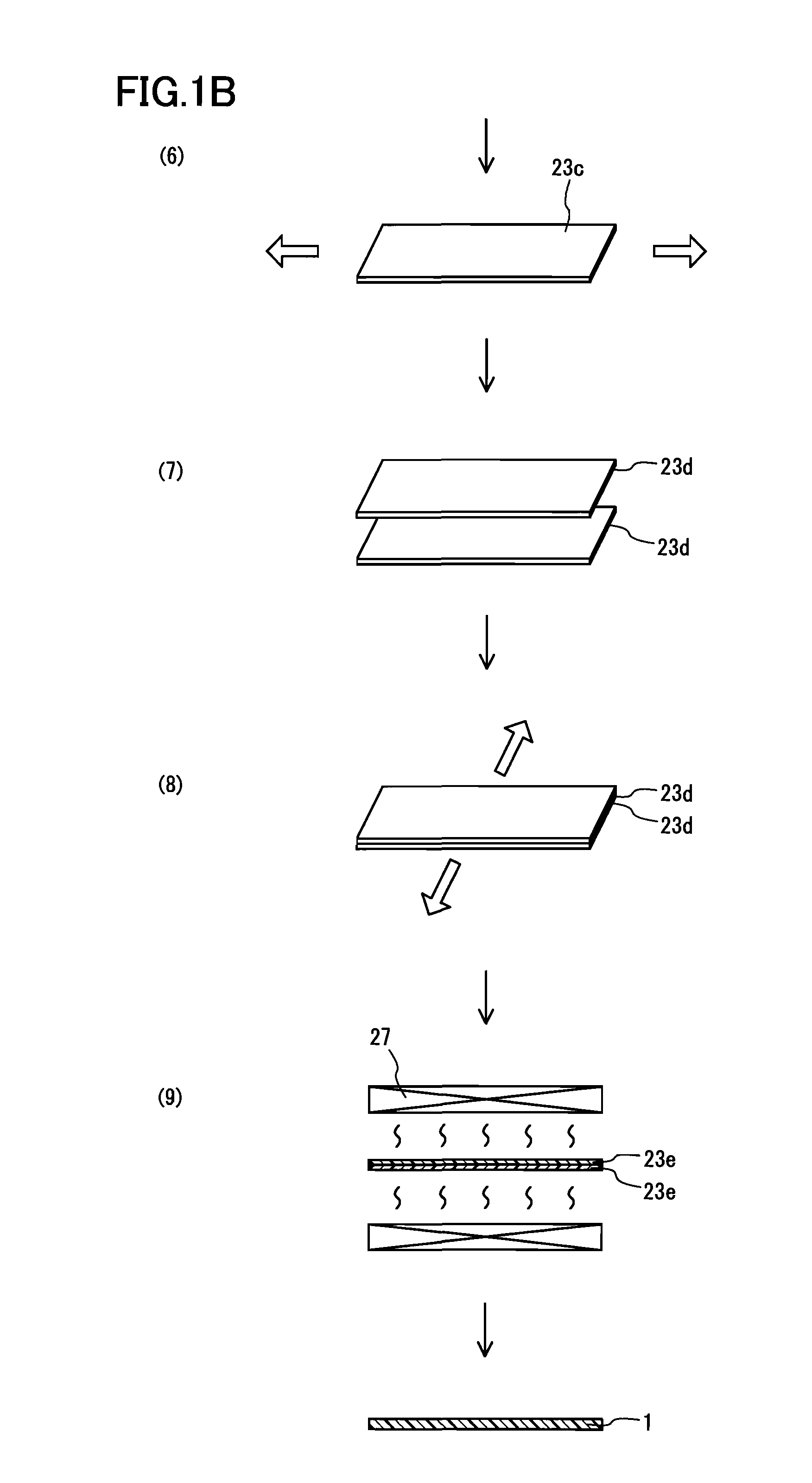

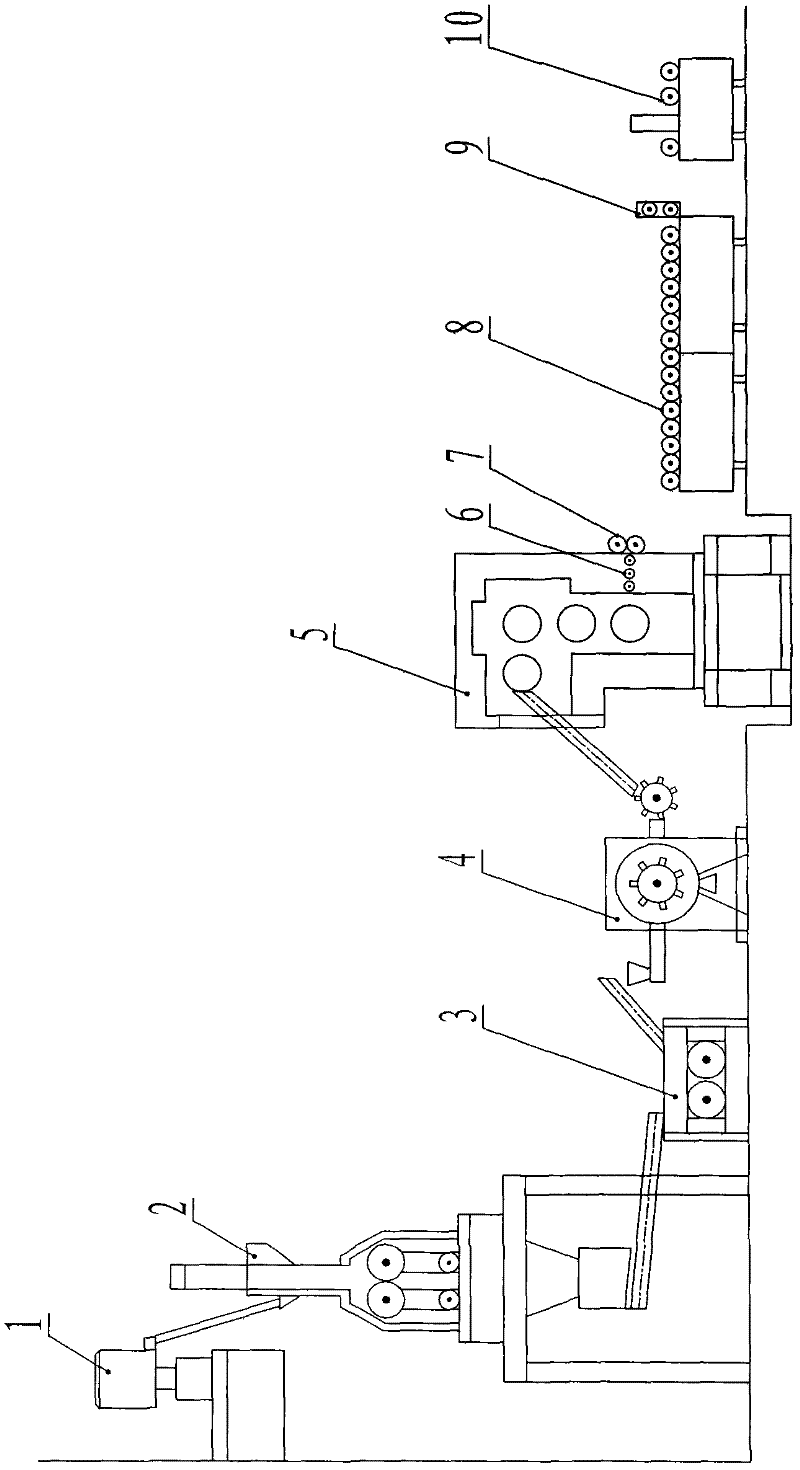

Manufacture method of high-strength TPU (thermoplastic polyurethane) compound fabric

ActiveCN102390152AUniform thicknessHigh film strengthLamination ancillary operationsSynthetic resin layered productsThermoplastic polyurethaneHigh intensity

The invention discloses a manufacture method of a high-strength TPU (thermoplastic polyurethane) compound fabric, which solves the problems of uneven film, low yield and high cost of the TPU compound fabric produced by adopting the traditional production method of the TPU compound fabric. A TPU film is produced with high production efficiency and low cost by adopting a process of calendering with a four-roller calendar. Because the produced TPU film has uniform thickness, the produced high-strength fabric has the advantages of uniform cloth, good compound fabric, high coating strength, high airtightness and high abrasive resistance, and can be widely applied to the fields of airships, surface-effect ships, oil containment booms, lifesaving devices, supplementary restraint systems and the like.

Owner:无锡翔隆高分子面料有限公司

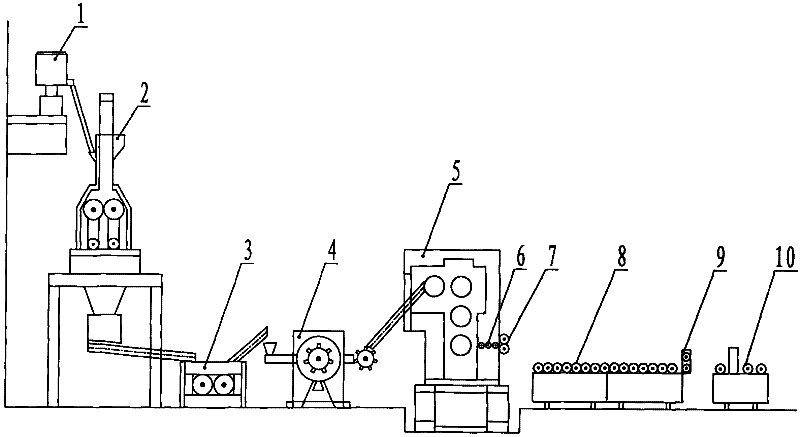

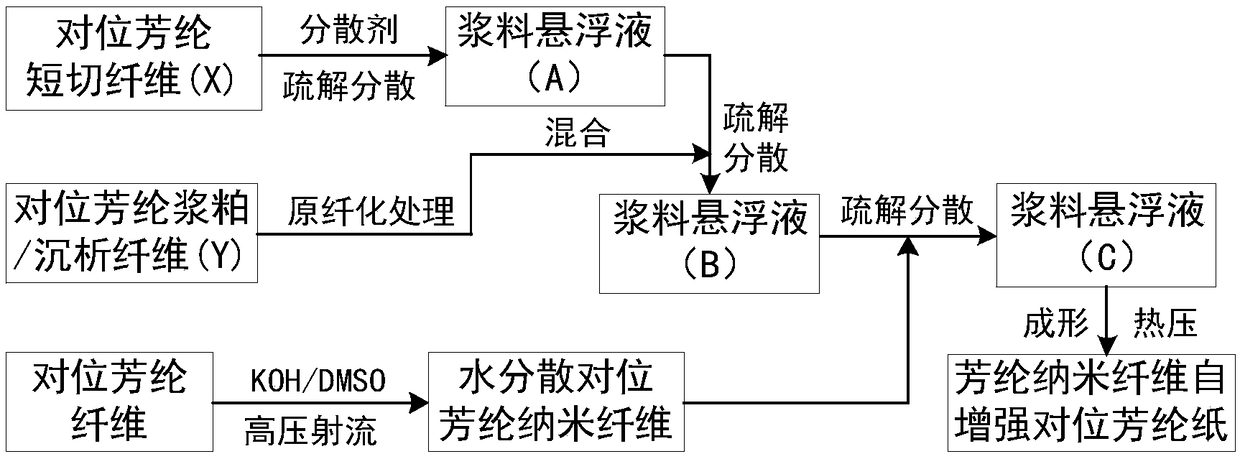

PPTA paper using aramid nanofiber for self-reinforcement and preparation method thereof

ActiveCN108265566AUnique nanoscale structureLarge aspect ratioSpecial paperPaper/cardboardNano structuringHigh surface

The invention discloses a PPTA paper using aramid nanofiber for self-reinforcement and a preparation method thereof. The preparation method includes: utilizing para-aramid paper nanofiber with the advantages of special nano-structure, small fiber diameter, large length-diameter ratio, high surface activity, excellent heat resistance and the like as the self-reinforcement material of para-aramid paper, conducting mixing, defibering and dispersion on aramid chopped fiber, pulp or fibrid and aramid nanofiber to make a uniform suspension, carrying out papermaking shaping, squeezing and drying, andfurther performing hot-pressing on a hot press to obtain aramid paper. The introduced aramid nanofiber enables nanoscale aramid fiber and an aramid nanofilm formed thereby to reach the good interfacefilling, coating and enhancement effects, provides more binding sites for the combination of components, at the same time reduces the pores and holes between components, significantly improves the bonding strength between the aramid paper components, and greatly enhances the mechanical and insulation properties.

Owner:SHAANXI UNIV OF SCI & TECH

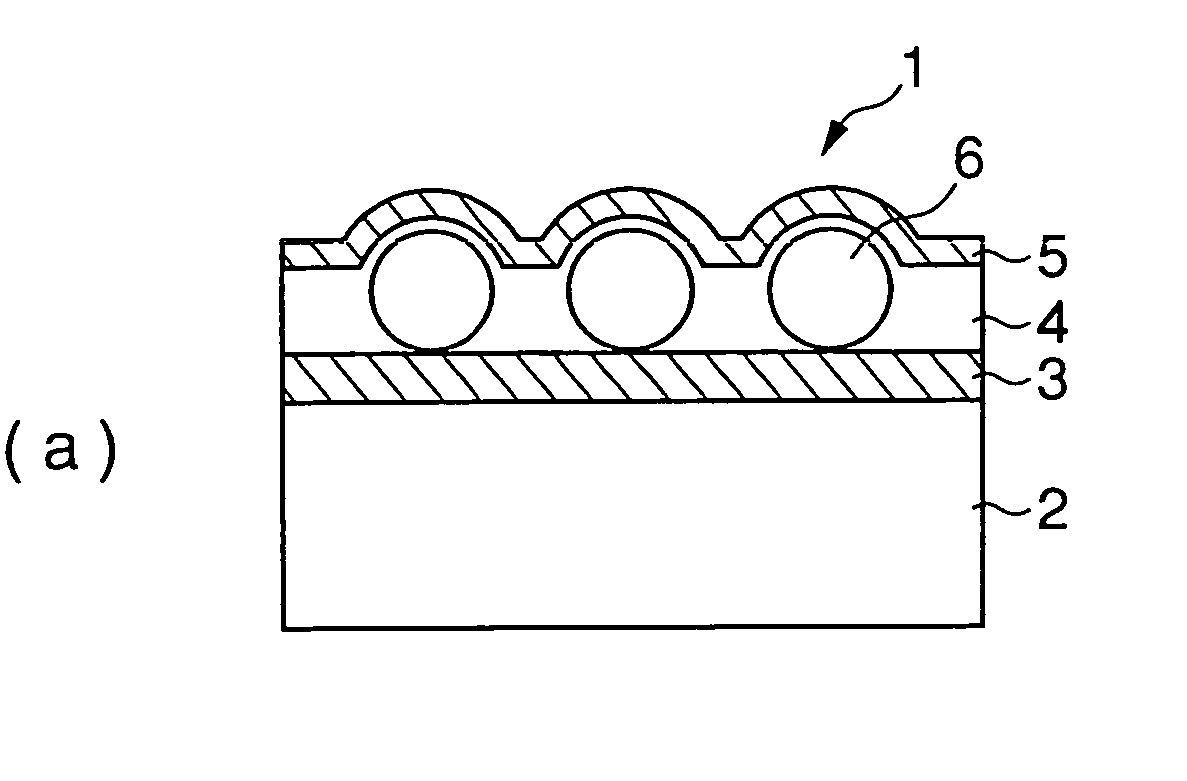

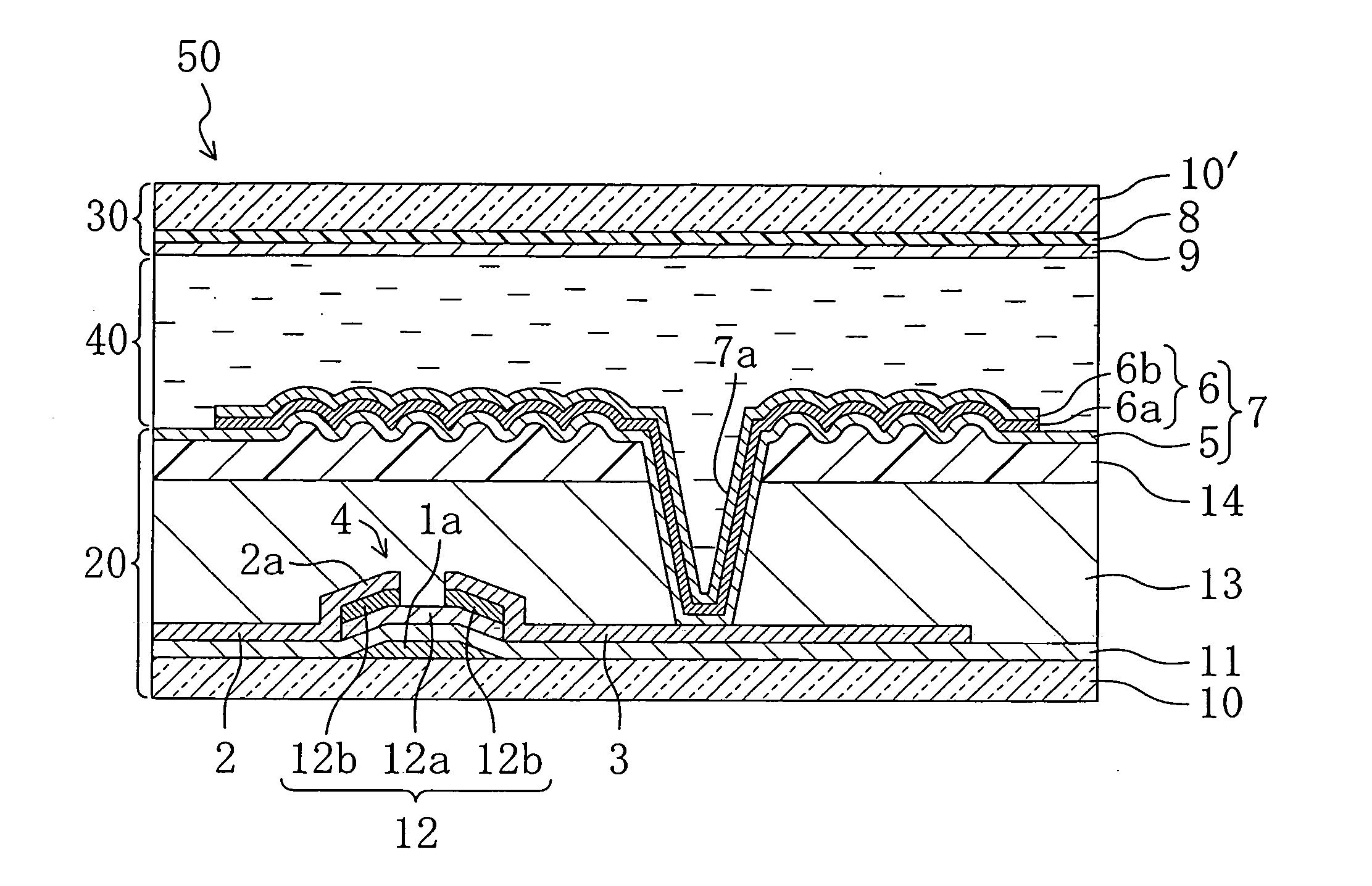

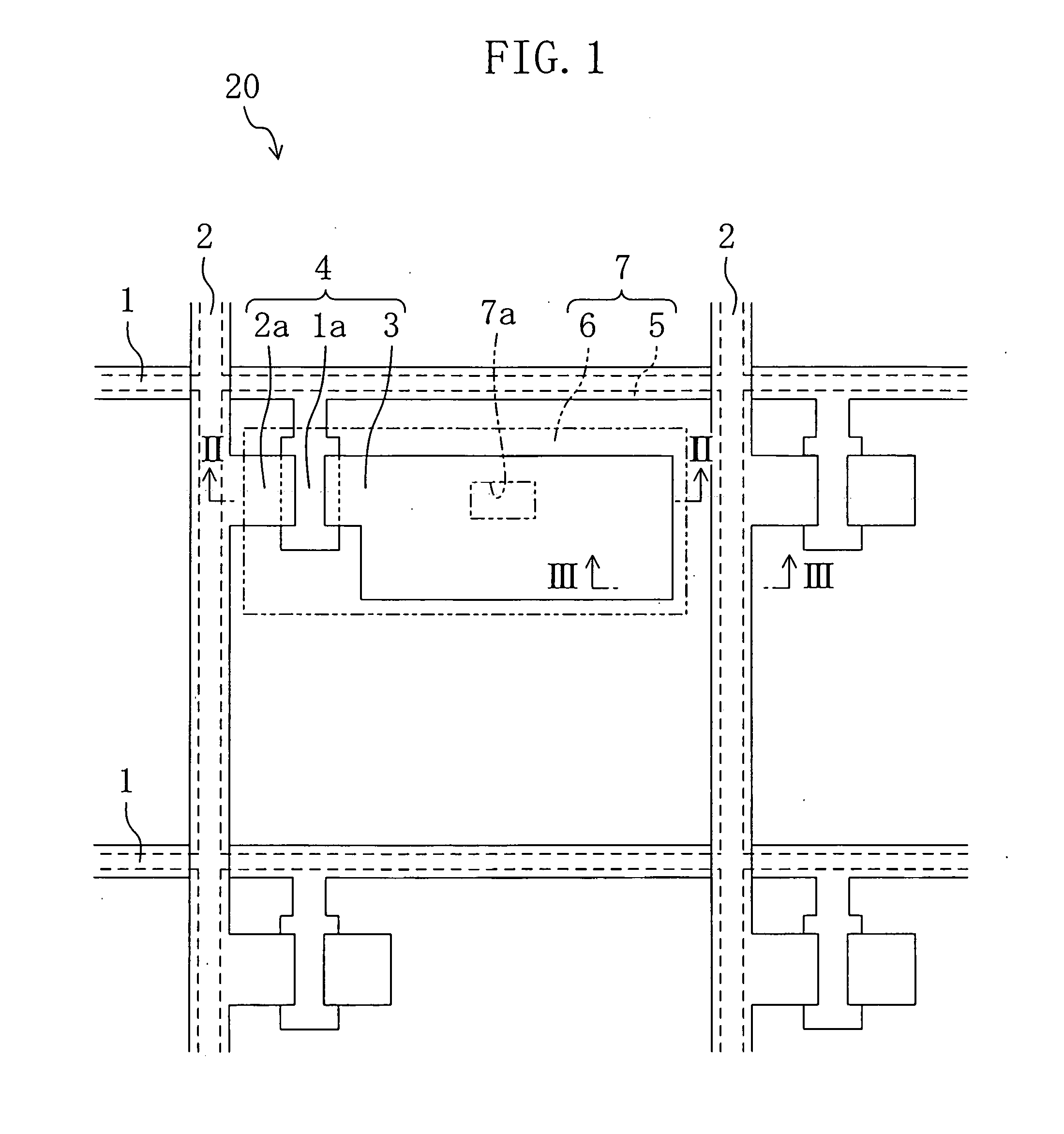

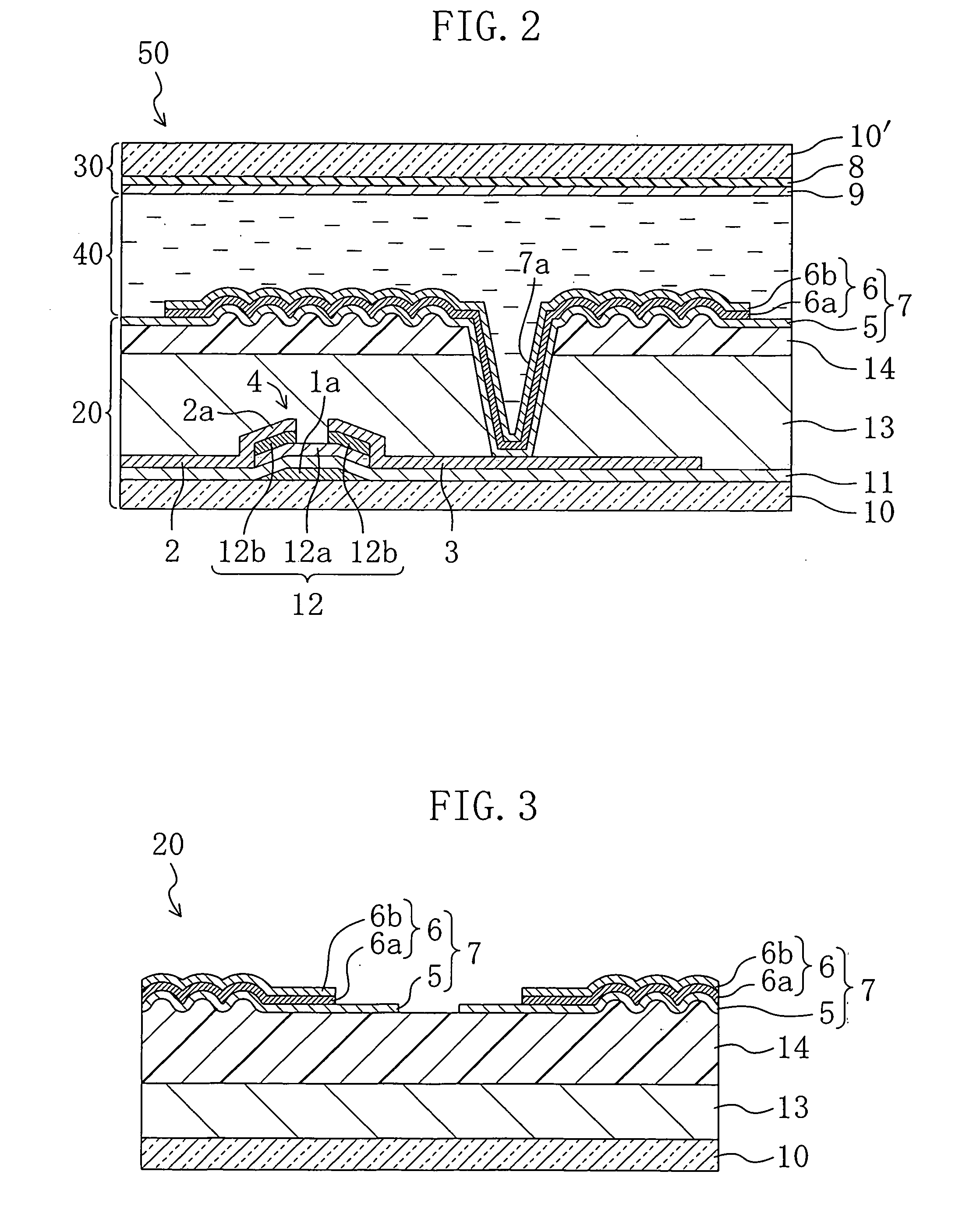

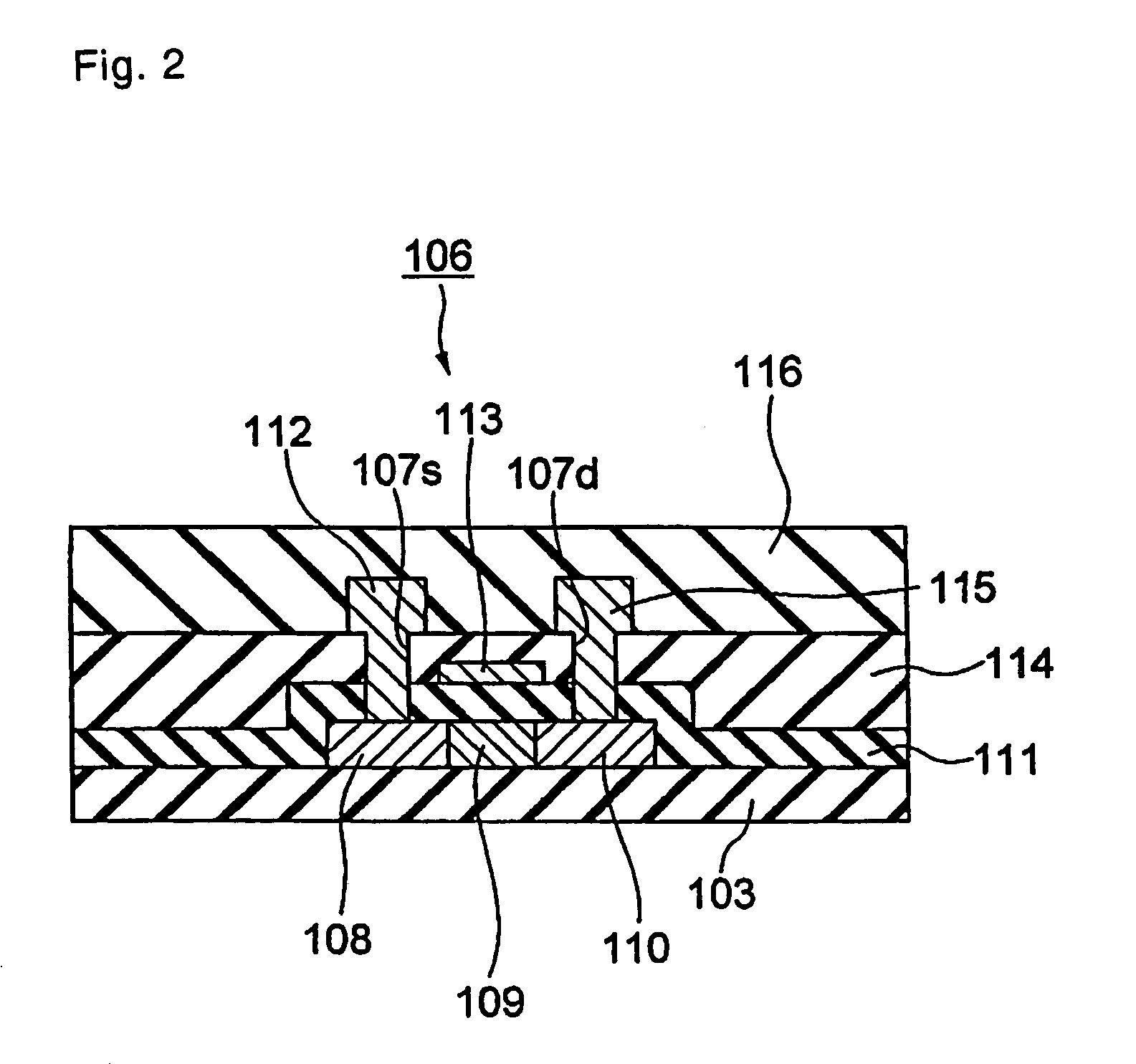

Method for manufacturing conductive element substrate, conductive element substrate, method for manufacturing liquid crystal display, liquid crystal display and electronic information equipment

InactiveUS20050186359A1High film strengthReduce etch rateLiquid crystal compositionsAdjusting/maintaining mechanical tensionLiquid-crystal displayActive matrix

A method for manufacturing a liquid crystal display which employs an active matrix substrate including a plurality of pixels arranged in matrix on a substrate and reflecting electrodes formed in the pixels, respectively. The method comprises (a) a laminated conductive film formation step of sequentially forming a conductive metal film and an amorphous transparent conductive film on a substrate to form a laminated conductive film and (b) a reflecting electrode formation step of patterning the laminated conductive film into a reflecting electrode, wherein the step (b) includes a first etching step of etching the conductive metal film and the amorphous transparent conductive film simultaneously and a second etching step of etching the amorphous transparent conductive film only.

Owner:SHARP KK

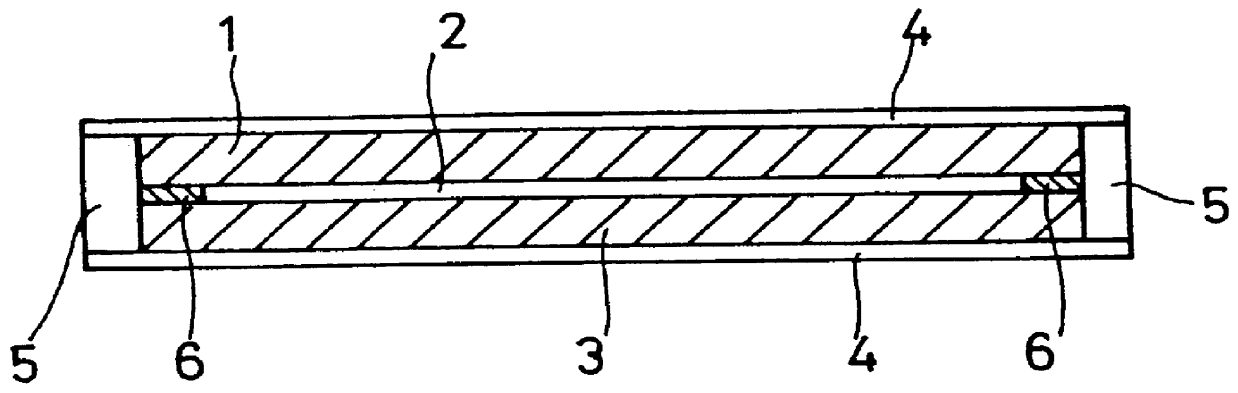

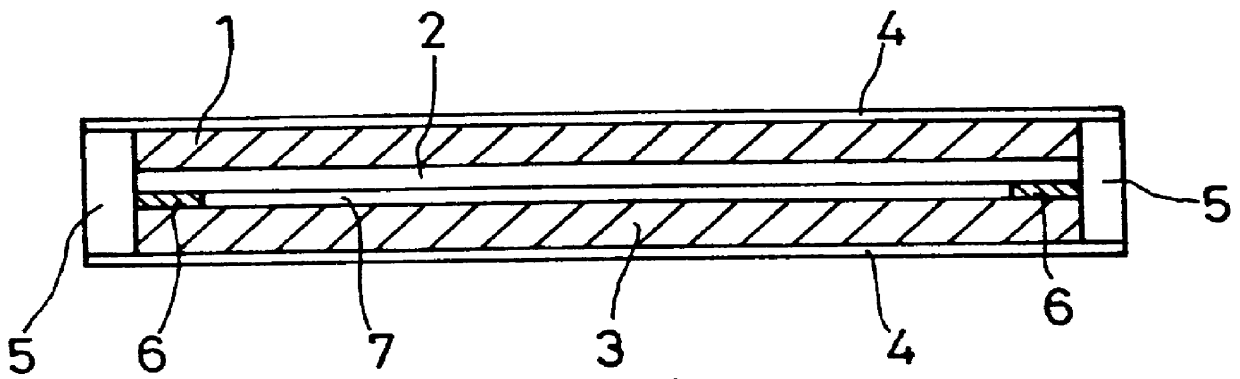

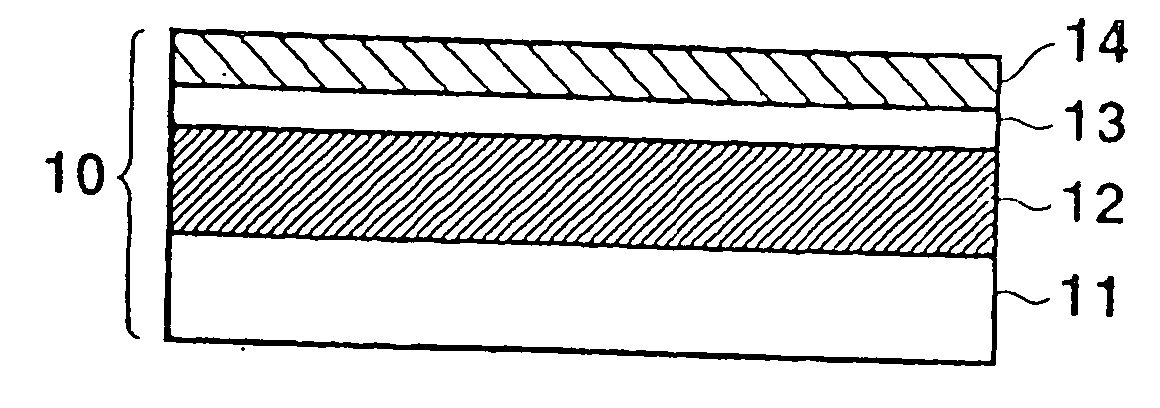

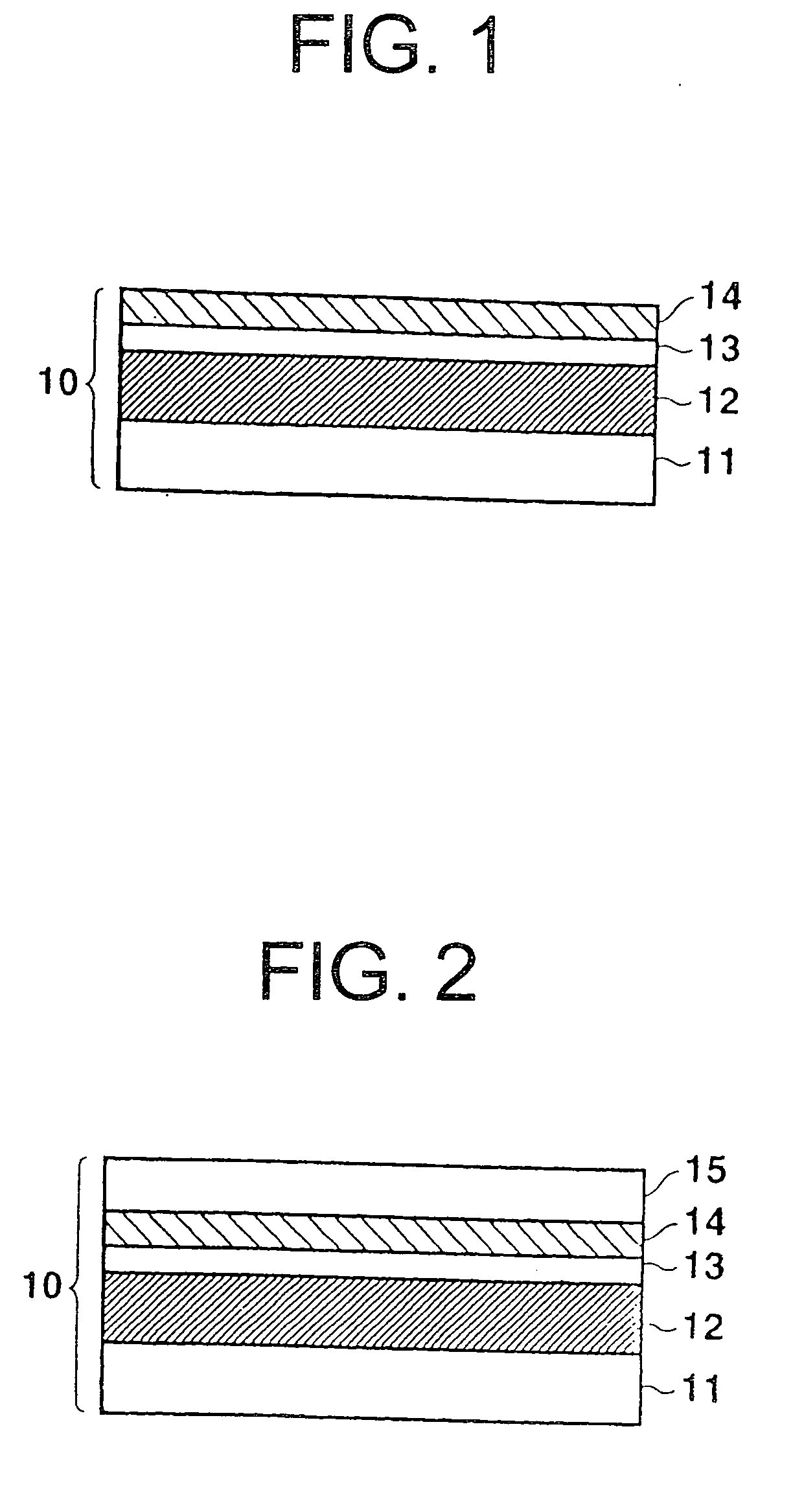

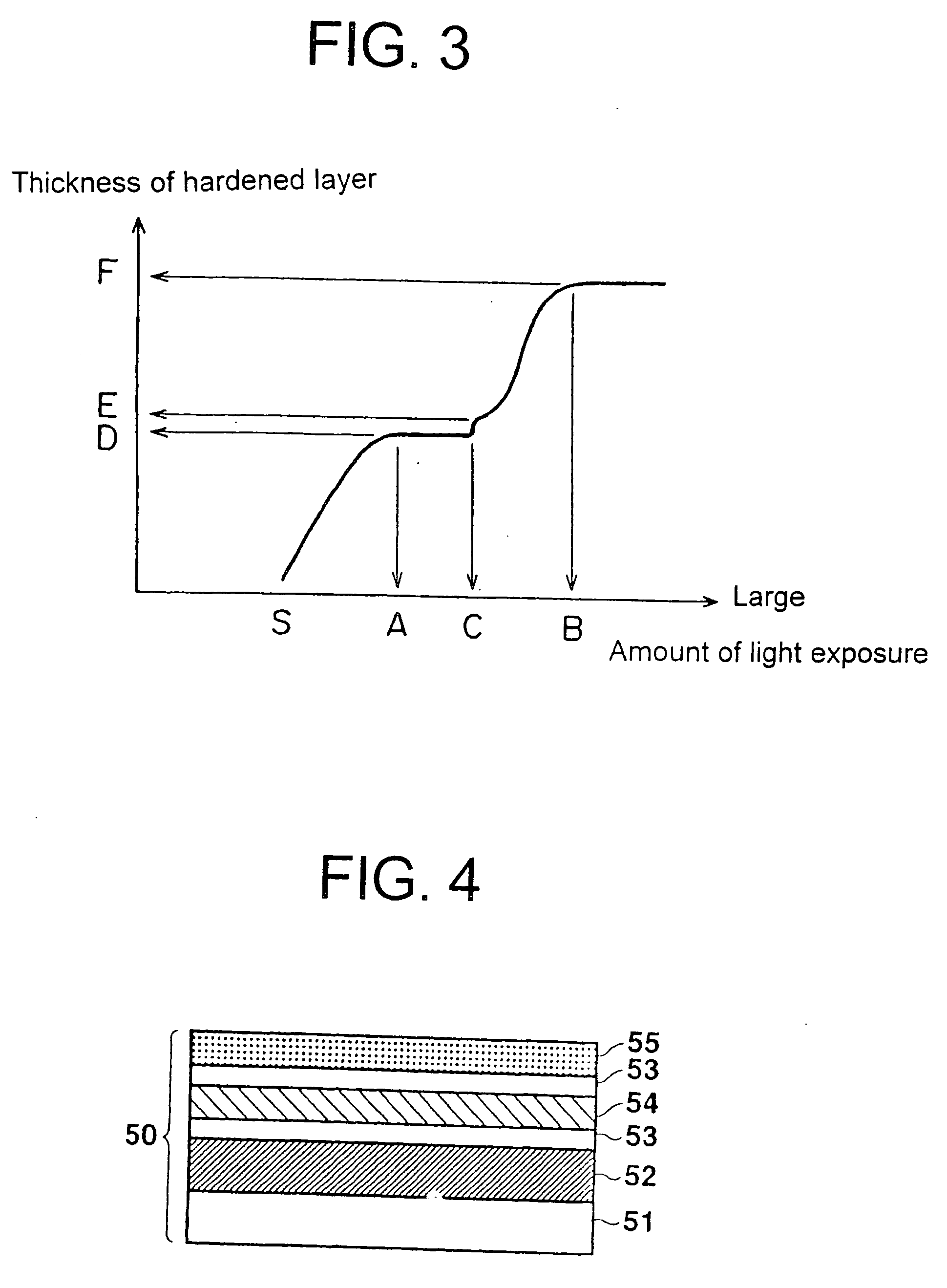

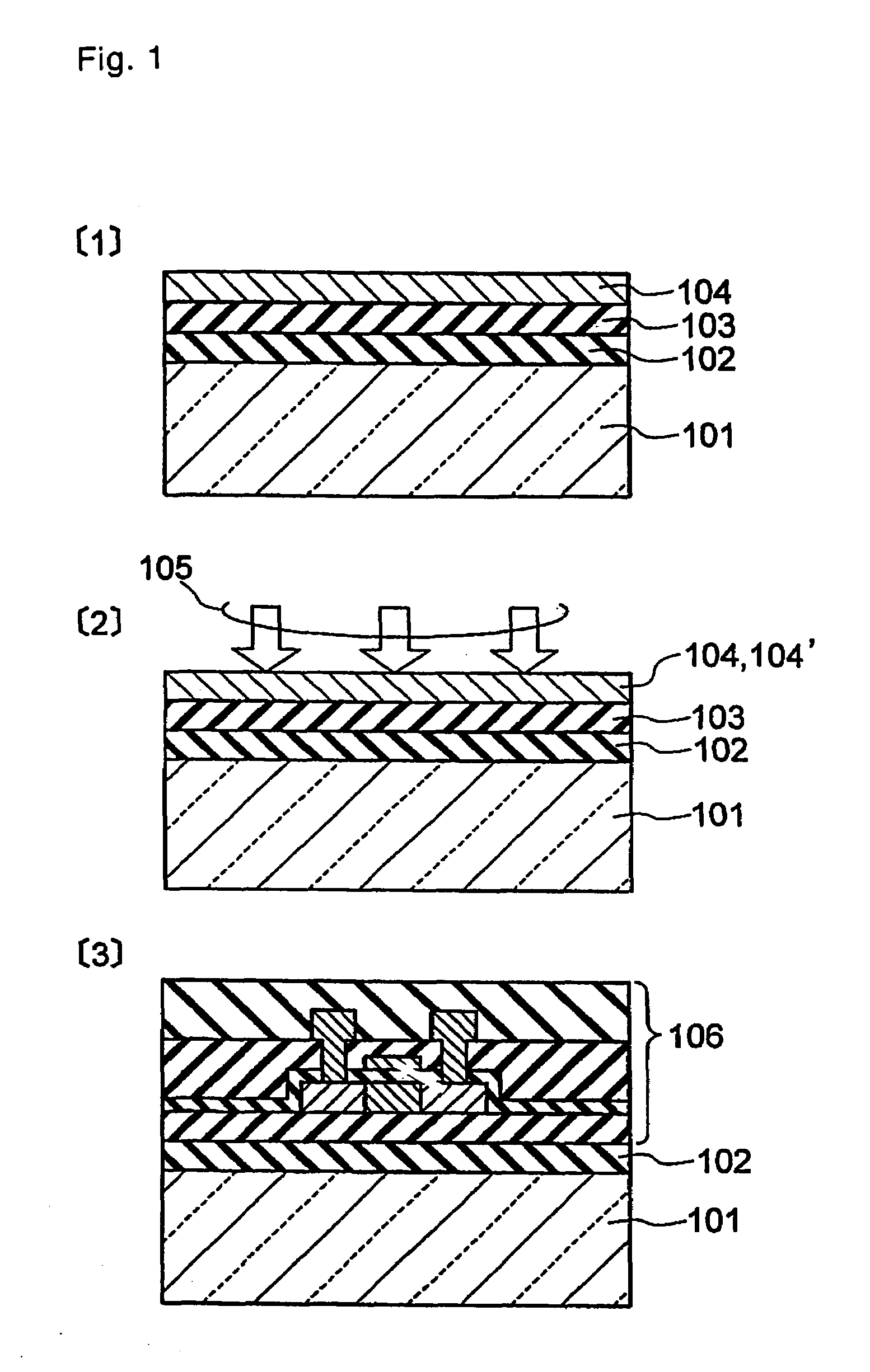

Light-sensitive sheet comprising support, first and second light-sensitive layers and barrier layer

ActiveUS20050037281A1High film strengthHigh resolutionRadiation applicationsSemiconductor/solid-state device manufacturingPolymerizationChemistry

A light-sensitive sheet comprises a support, a first light-sensitive layer, a barrier layer and a second light-sensitive layer in this order. Each of the first and second light sensitive layers independently contains a binder, a polymerizable compound and a photo-polymerization initiator. The second light-sensitive layer is more sensitive to light than the first light-sensitive layer. A light-sensitive laminate comprises a substrate, the second light-sensitive layer, the barrier layer and the first light-sensitive layer in this order.

Owner:FUJIFILM CORP +1

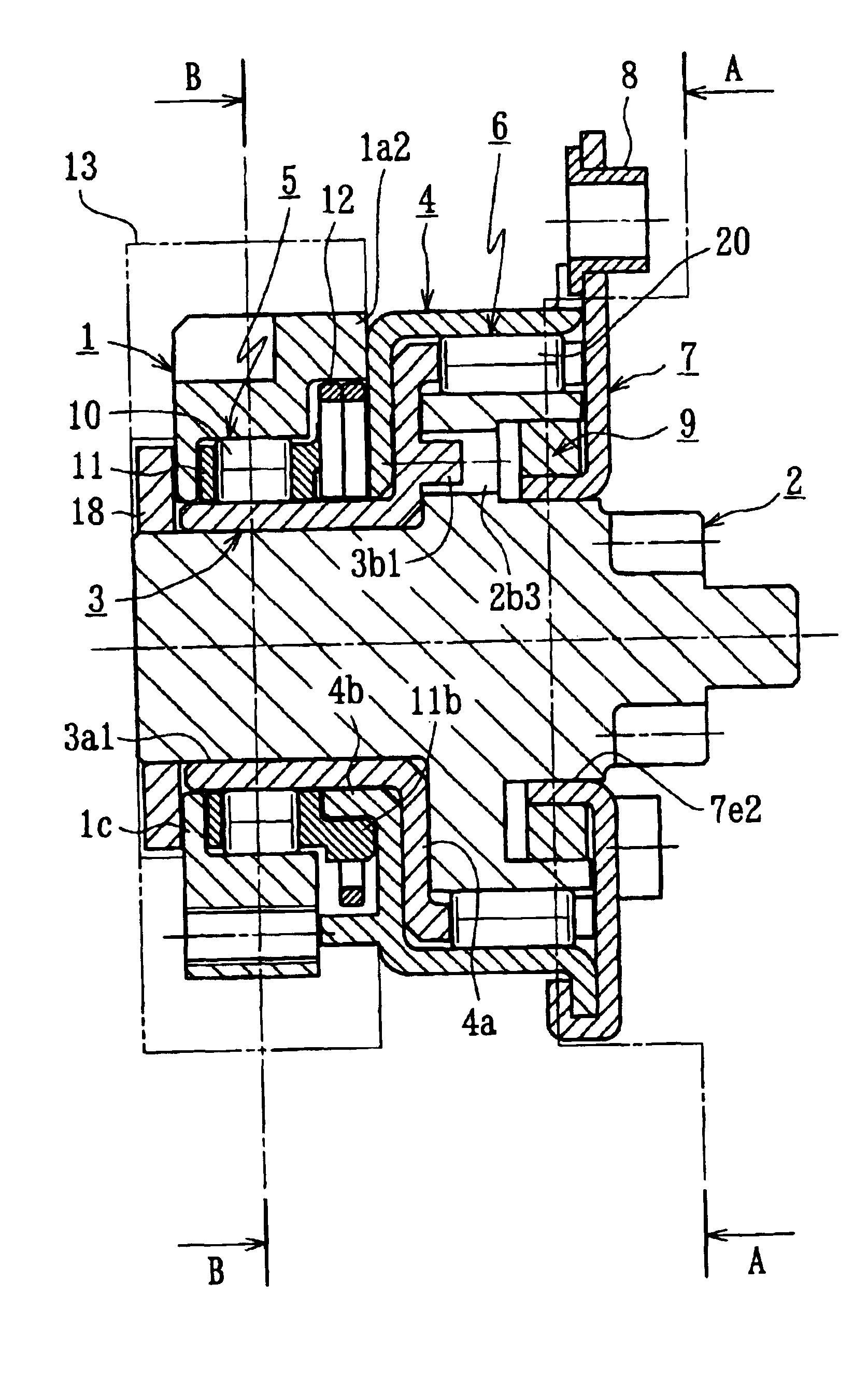

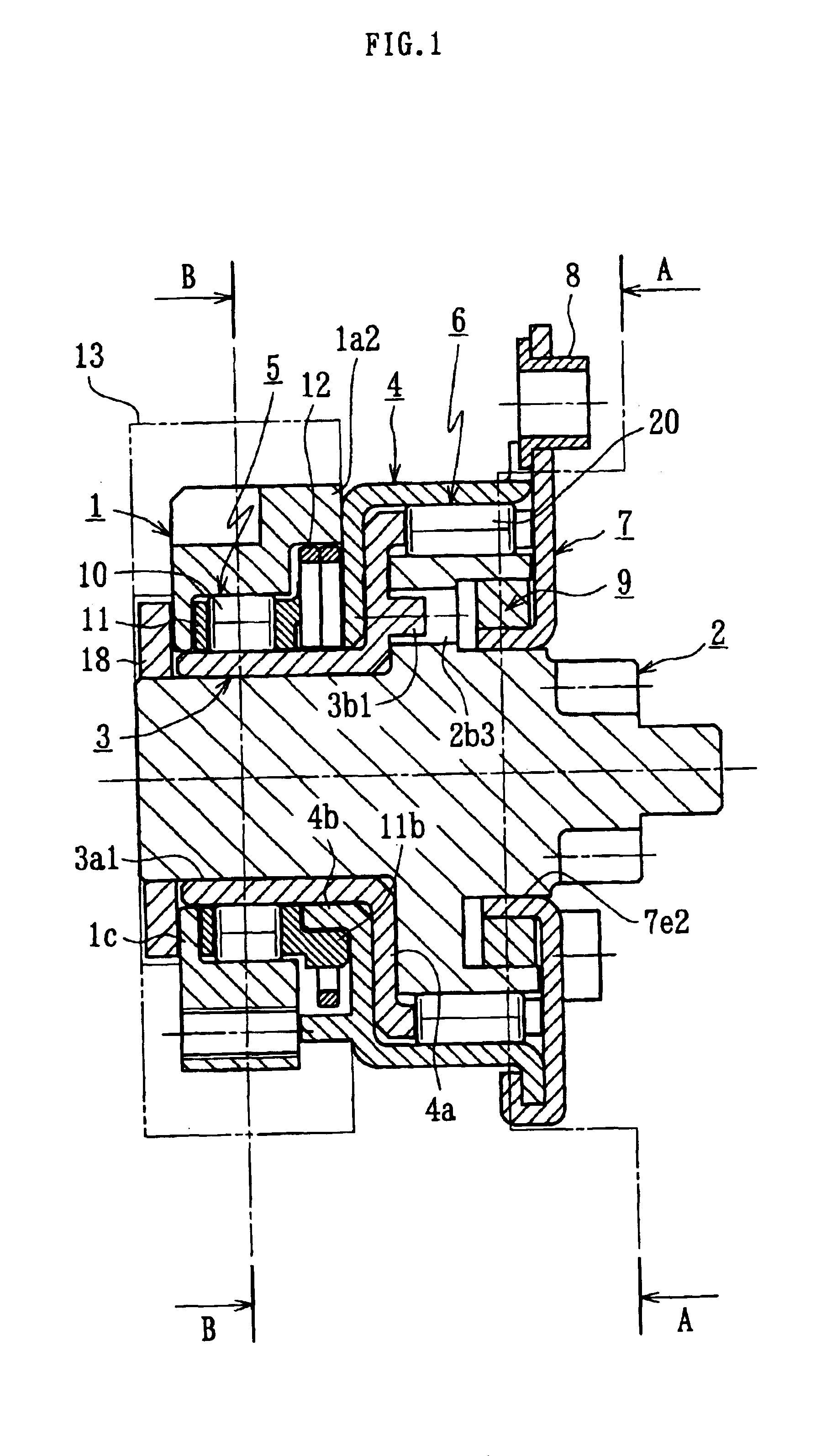

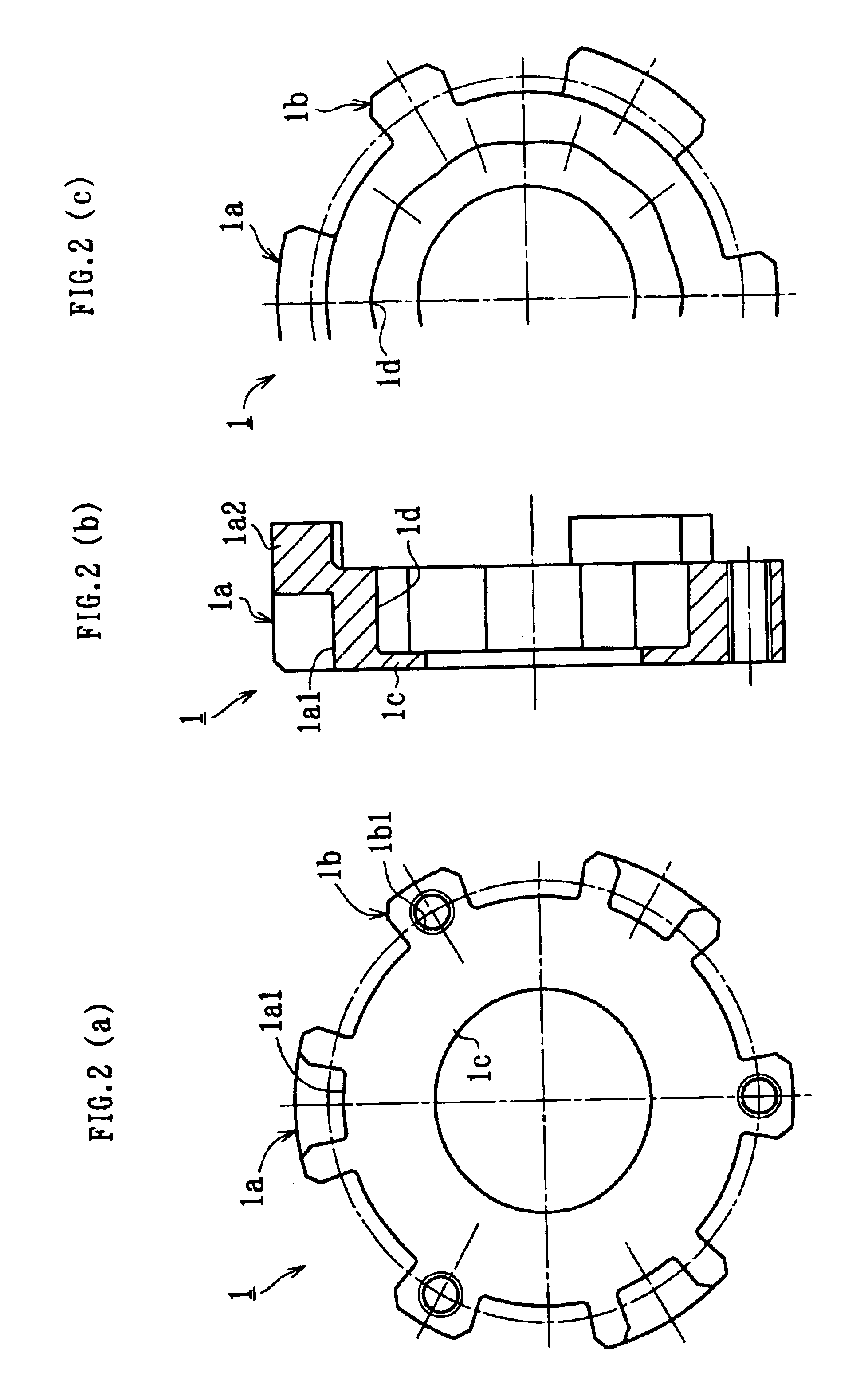

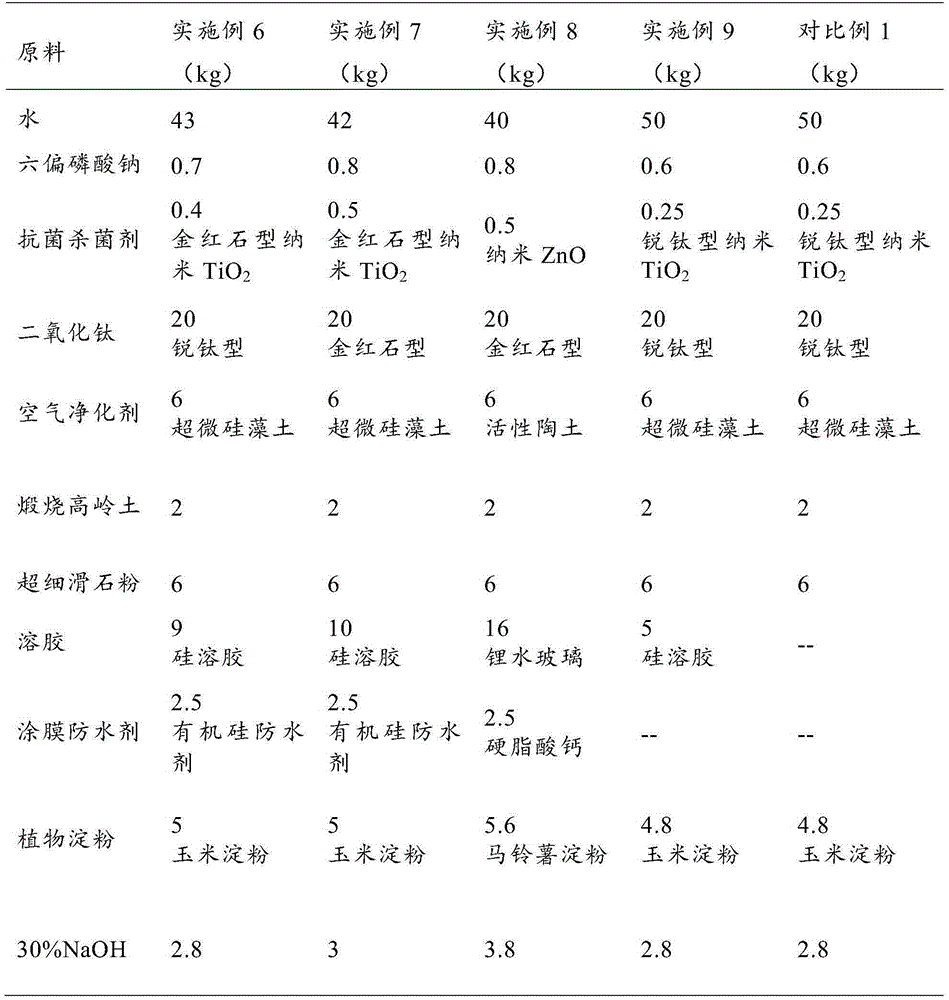

Clutch unit

InactiveUS6955251B2Increase powerReduce frictional resistanceStoolsCoupling-brake combinationControl theoryClutch

A clutch unit comprises an outer ring 1 as an input-side member, an output shaft 2 as an output-side member, an inner ring 3 as a control member, an outer ring 4 as a stationary-side member, a first clutch part 5 interposed between the outer ring 1 and the inner ring 3m, and a second clutch part 6 interposed between the outer ring 4 and the output shaft 2. Input torque input from an operation lever 13 is transmitted in the path of the outer ring 1→the first clutch part 5→the inner ring 3→the output shaft 2. Reverse input torque input from the output shaft 2 is locked with the outer ring 4 through the second clutch part 6.

Owner:NTN CORP

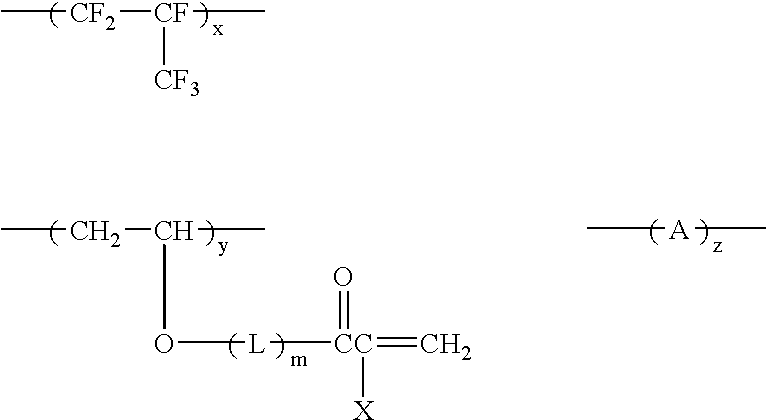

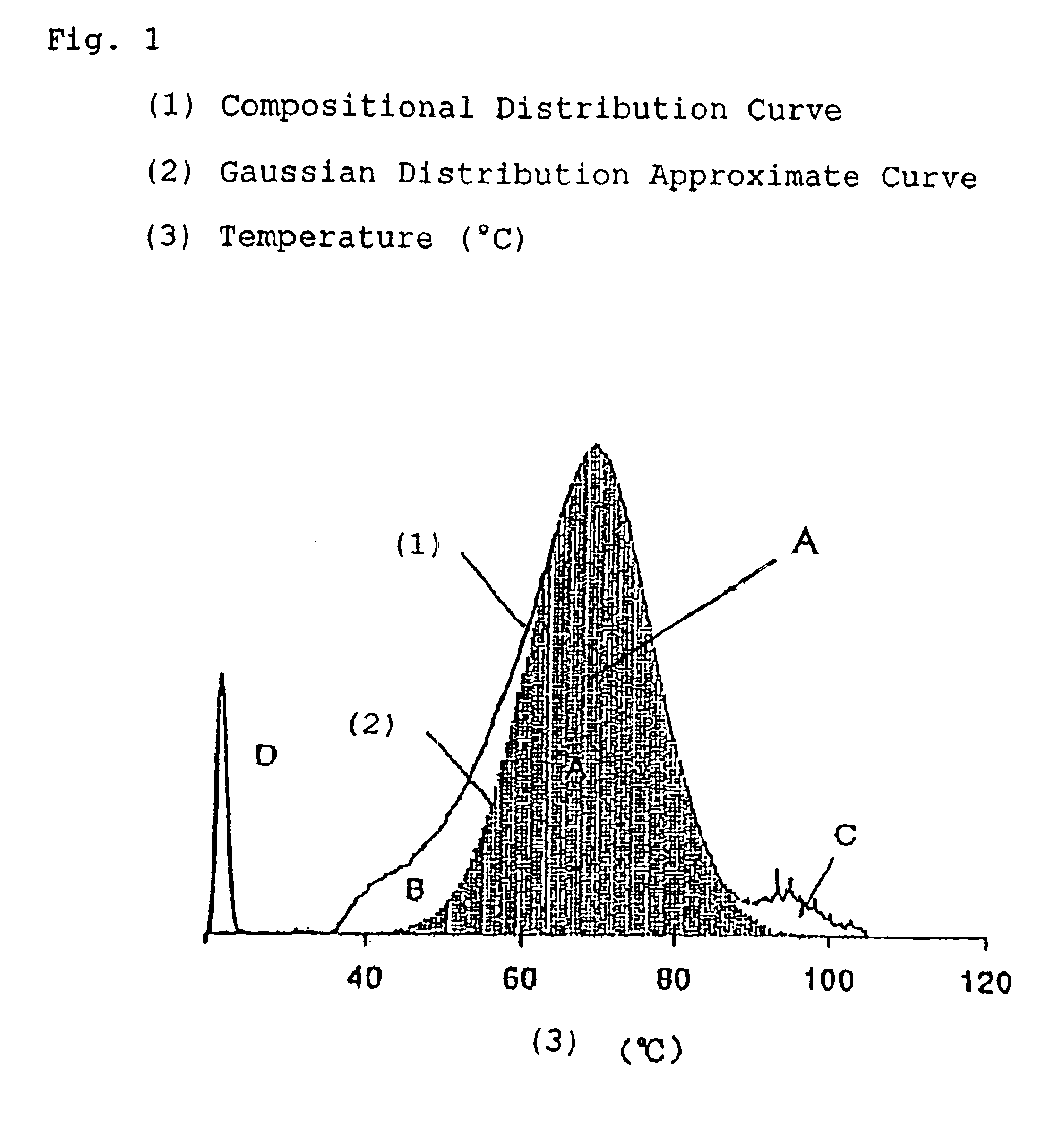

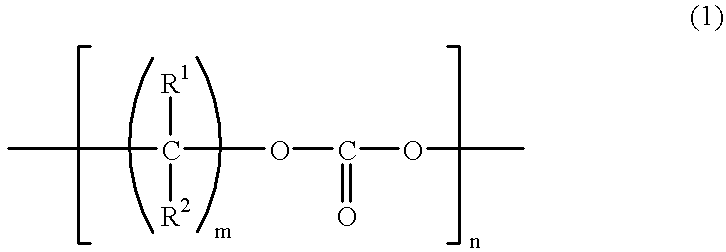

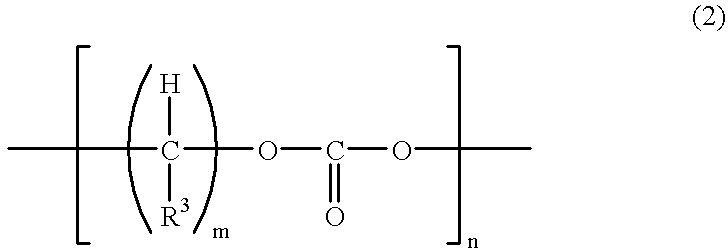

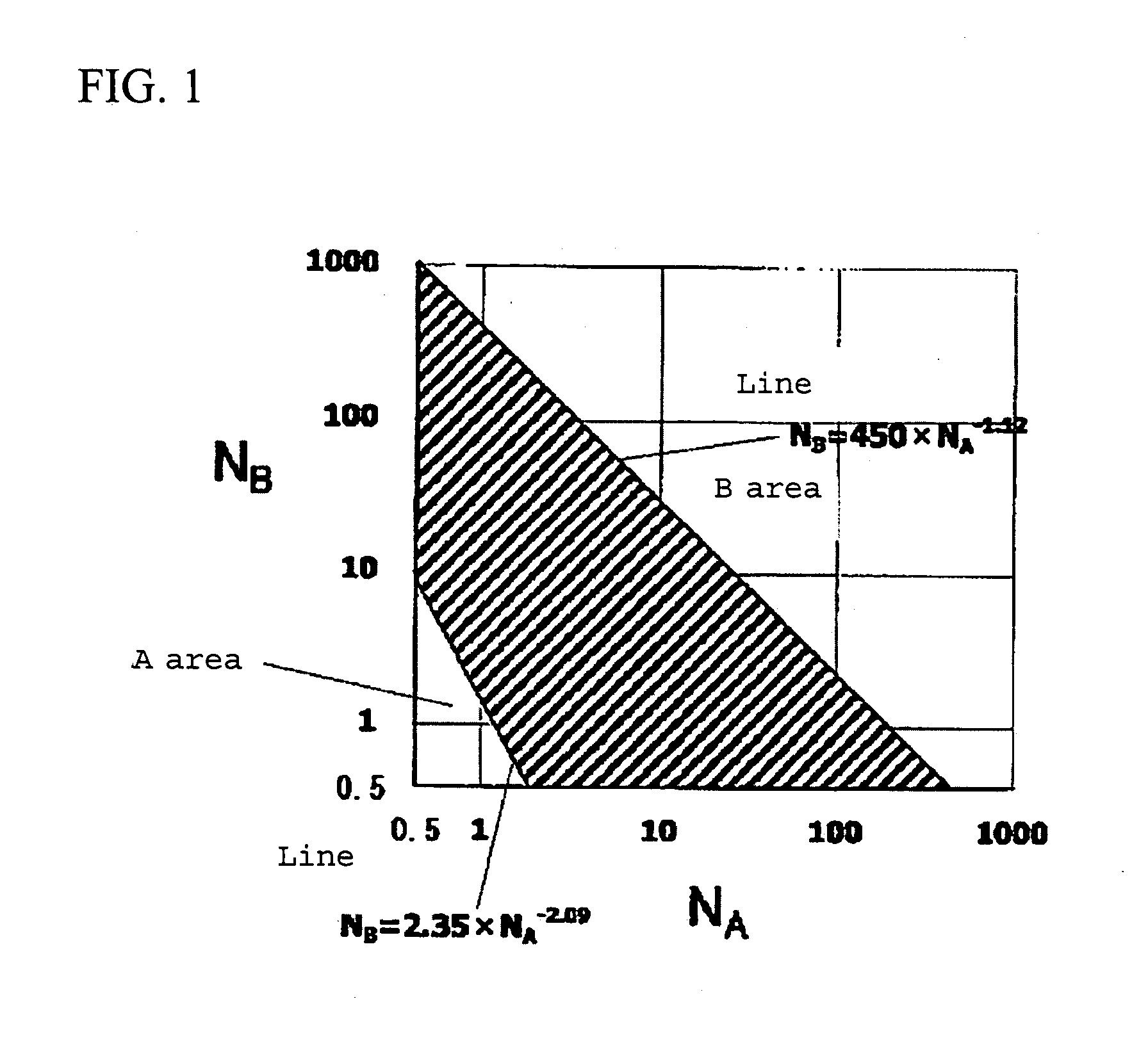

Ethylenic copolymer, composition containing said copolymer, and ethylenic copolymer film

An ethylenic copolymer composition including an ethylenic copolymer having Mw / Mn of 1.5 to 4, Mw of 3,000 to 1,000,000, and a resin density of 0.85 to 0.95 g / cm3. The relationship between the half width at the half maximum [W / 2] of the Gaussian distribution curve, and the average, n, of short-chain branches in the copolymer satisfies the equation,0.704+0.147n=W / 2=−0.055+0.577n. The ethylenic copolymer composition also includes an ethylenic copolymer having an Mw of 3,000 to 1,000,000 and a resin density of 0.85 to 0.95 g / cm3.

Owner:IDEMITSU KOSAN CO LTD

Antireflection film, polarizing plate and image display device

InactiveUS7371439B2Improve scratch resistanceHigh propertyLiquid crystal compositionsDiffusing elementsTectorial membraneRefractive index

The present invention can provide an antireflection film improved in the scratch resistance while having a sufficiently high antireflection property, and a polarizing plate and a display device using the antireflection film, the antireflection film antireflection film comprising: a transparent support; and as an outermost layer, a low refractive index layer containing a fluorine-containing polymer, wherein the low refractive index layer comprises at least one inorganic fine particle having an average particle size of 30 to 100% of the thickness of the low refractive index layer; the polarizing plate using the antireflection film for one of two protective films of a polarizer in the polarizing plate; and the image display device using the antireflection film or polarizing plate for the outermost surface of the display.

Owner:FUJIFILM CORP

Spray-coating high-strength elastic waterproof paint of polyurea and construction thereof

ActiveCN1817989AImprove construction efficiencyReduce construction efficiencyAntifouling/underwater paintsPaints with biocidesLacquerDiluent

A high-elasticity lacquer-spraying waterproof pigment of polyurea and its construction are disclosed. The procedure is carried out by adding counted diluent and polyether polylol into reactor, depress dewatering at 90-100DEG C for 1-2hrs, sampling to determine water content, stopping dewatering when reaching water content below 0.08%, cooling to 80-85 DEG C while retaining the temperature range, agitating while dripping polyisocyanate into reactor, accounting the weight of polyisocyanate by n-oH / n-NCO=1.05, reacting for 2hrs at 80-85 DEG C continuously, retaining at 80-85 DEG C, agitating while dripping residual polyisocyanate into reactor, keeping temperature, reacting for 2hrs continuously, cooling, discharging to obtain A component and mixing A component with B component in proportion of 1:1. The B component consists of amino resin, amine-chain reinforcer and active filler. It has excellent waterproof performance.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

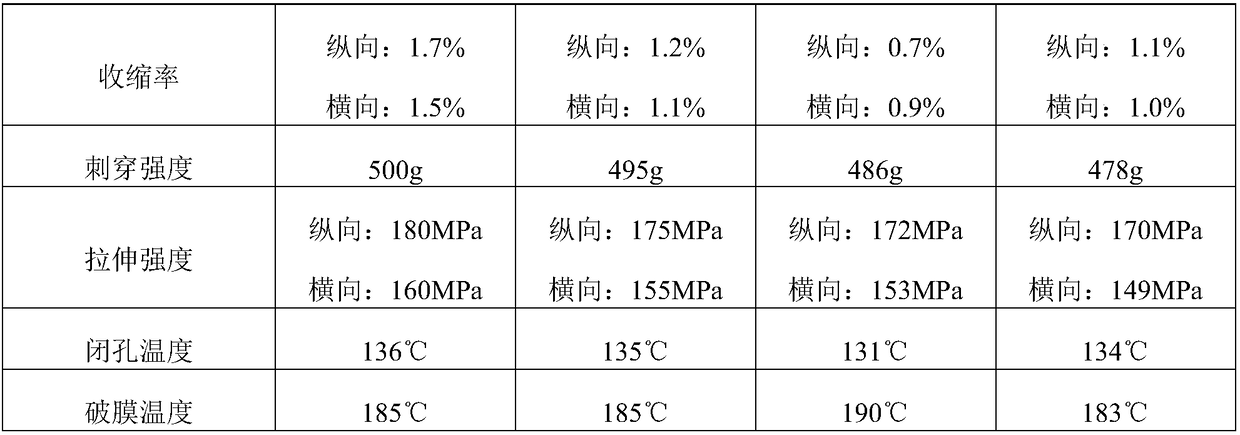

Porous structure with seed crystal-containing layer for manufacturing zeolite membrane, zeolite membrane, and method for manufacturing zeolite membrane

ActiveUS20080047432A1High film strengthEasy to handleSolid sorbent liquid separationIsotope separationForeign matterPorous substrate

A porous substrate with a seed crystal-containing layer for manufacturing a zeolite membrane includes: a ceramic porous substrate, and a seed crystal-containing layer containing a zeolite powder to function as a seed crystal for forming a zeolite membrane and a ceramic powder and being loaded on a surface of the ceramic porous substrate and fired to fix the seed crystal-containing layer on the porous substrate. The porous substrate with a seed crystal-containing layer used for manufacturing a zeolite membrane can inhibit a defect such as a crack from being generated in the zeolite layer upon manufacture or use by manufacturing a zeolite membrane by the use of the substrate and can be subjected to air-spraying, washing, and processing for the purpose of removing a foreign substance, etc., prior to hydrothermal synthesis.

Owner:NGK INSULATORS LTD

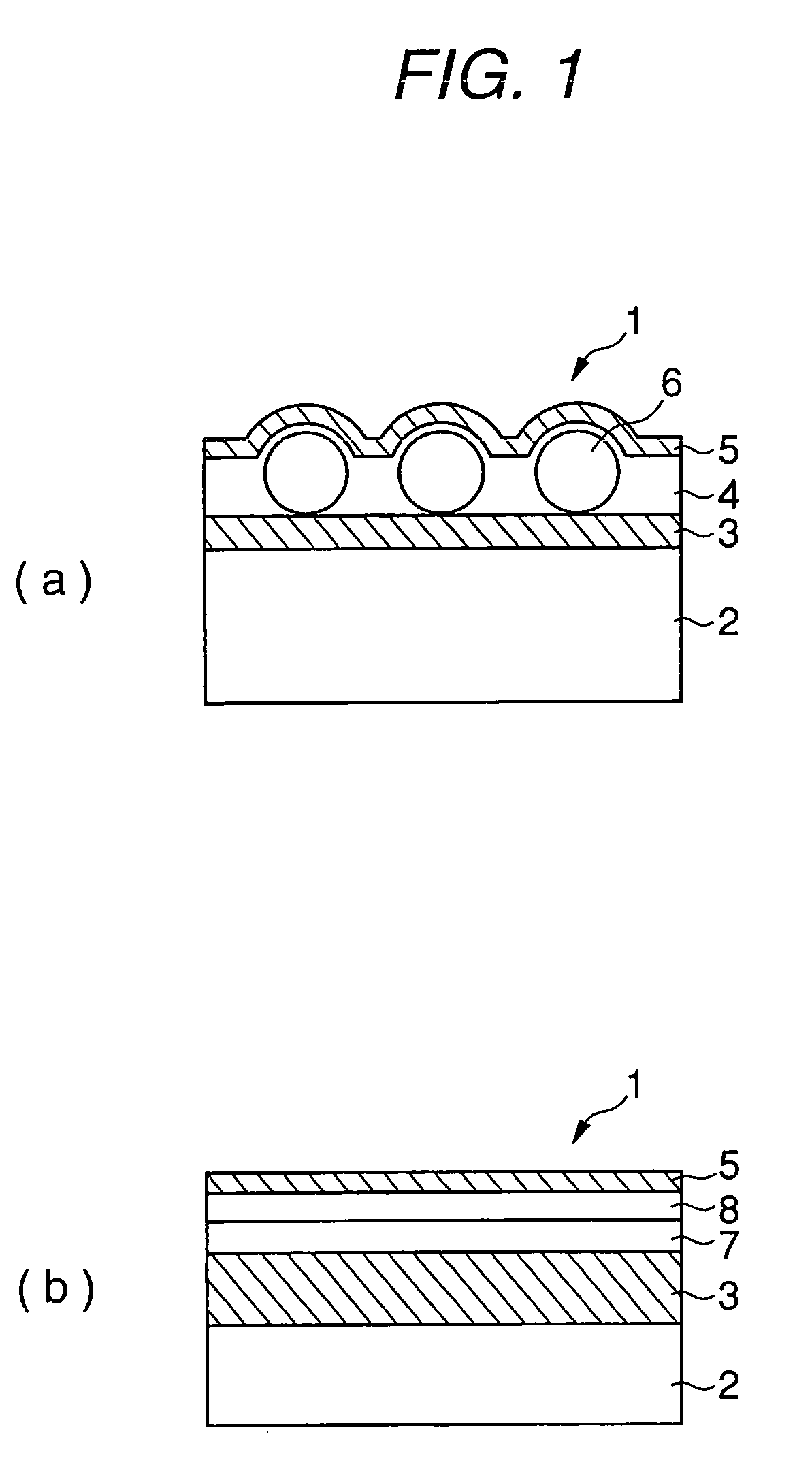

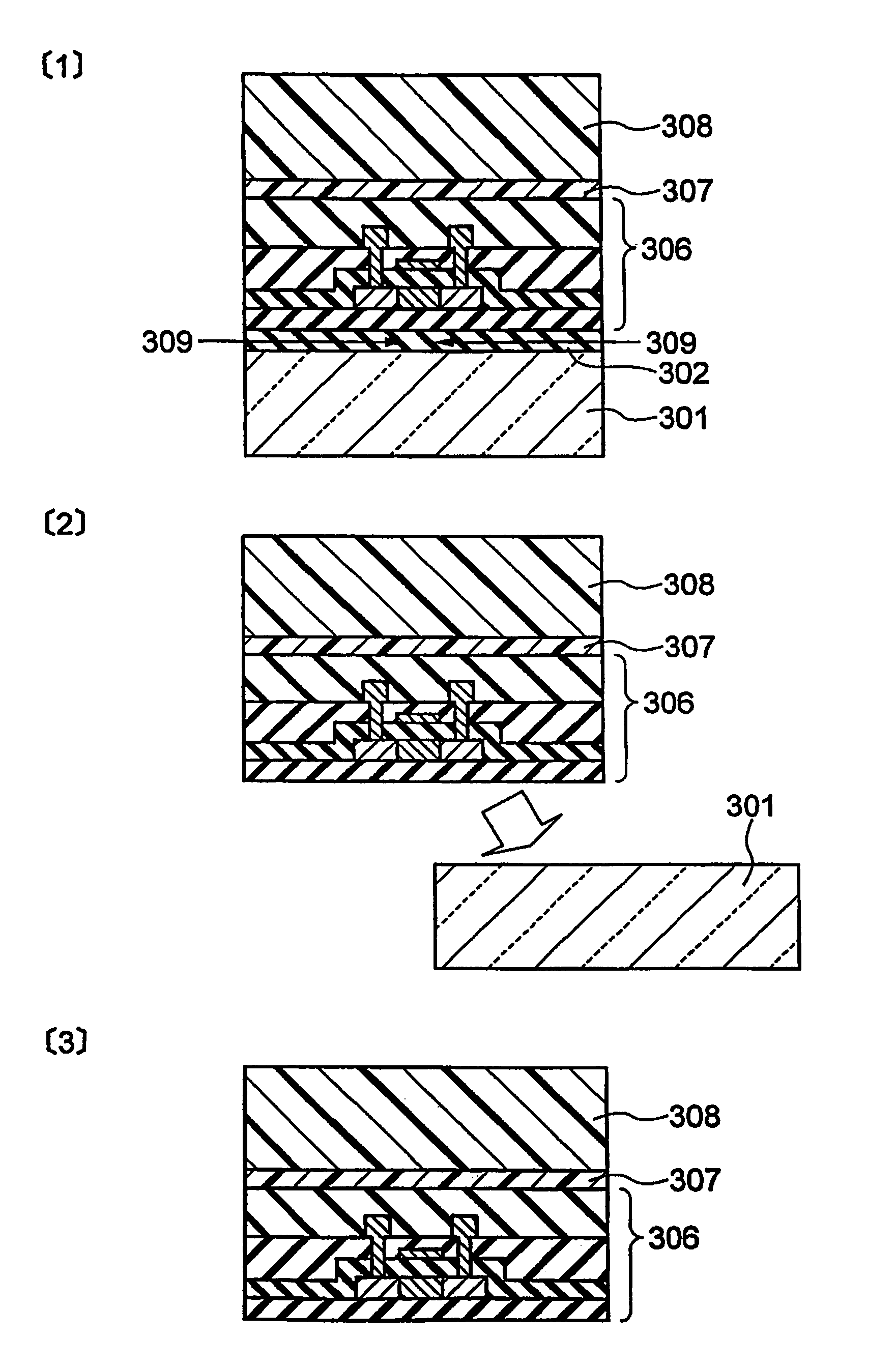

Manufacturing method of thin film device substrate

ActiveUS7256102B2Improve performancePrevent heat from spreadingTransistorSolid-state devicesDevice formAmorphous silicon

An object of the present invention is to prevent the thin film device formed by laser annealing from making, due to overheat, abnormal operations. Firstly, on a glass substrate 101. a heat insulating film, a silicon oxide film and an amorphous silicon film are formed in succession, and the amorphous silicon film is irradiated from above with a laser beam of an excimer laser. After being molten, the amorphous silicon film undergoes recrystallization to form a polycrystalline silicon film. Subsequently, using the polycrystalline silicon film as an active layer, a TFT is formed, and then a plastic substrate is bonded onto the TFT, and finally the glass substrate is peeled off by way of the heat insulating film, whereby a transfer of the TFT is completed. Because the heat insulating film is removed, abnormality caused by overheat at the time of operation is well prevented from occurring.

Owner:INNOLUX CORP

Optical film, antireflection film, and polarizing plate and display device using the same

ActiveUS20080131674A1Reduce curlingImprove brittlenessLiquid crystal compositionsSynthetic resin layered productsPolarizerChemistry

An optical film includes a transparent support; and a hardcoat layer that is a layer formed by curing a coating solution containing (A) an octa- to pentadeca-functional urethane (meth)acrylate-based compound having a molecular weight of 800 to 2,000 and having two or more urethane bonds in its molecule, and a photopolymerization initiator.

Owner:FUJIFILM CORP

Plant ecological interior wall coating and preparation method thereof

ActiveCN105368164ALow NaOH contentImprove water resistanceStarch coatingsEcological environmentBinding force

The invention discloses a plant ecological interior wall coating and a preparation method thereof. The plant ecological interior wall coating is characterized by being prepared from a titanium dioxide filler, a borax crosslinking agent, an oxidizing agent, water, plant starch serving as a binding agent and sol serving as a binding agent modifier. According to the plant ecological interior wall coating, the plant starch is utilized as the binding agent, no synthetic resin emulsion is contained, complete biodegradation can be achieved, and the coating is an ecological environment-friendly interior wall coating in the true sense; the sol is added to serve as the binding agent modifier, the higher film coating binding force and film coating strength are achieved, and the technical property can reach the GB / T9756-2009 standard of a qualified synthetic resin emulsion interior wall coating product and is obviously suprior to the JC / T423-91 technical requirements for a water-soluble interior wall coating.

Owner:烟台阳光新材料技术有限公司

Nitrogen foam gel profile control agent and preparation method and application thereof

ActiveCN108203579AHigh film strengthImprove the blocking effectFluid removalDrilling compositionCross-linkCarboxymethyl cellulose

The invention discloses a nitrogen foam gel profile control agent and a preparation method and application thereof and belongs to the field of oilfield chemistry. The profile control agent comprises afoam gel skeleton and nitrogen gas distributed in the foam gel skeleton. The foam gel skeleton is obtained through feeding nitrogen gas into the gel. The gel is prepared from 1.5%-2.5% by mass of polyacrylamide, 0.3%-1% by mass of a foaming agent, 1%-3% by mass of a foam stabilizer, 1.5%-2.5% by mass of an organic chromium cross-linking agent and the balance of water through a cross-linking reaction. The foam stabilizer comprises sodium carboxymethyl cellulose or soluble starch. A volume ratio of the nitrogen gas to the foam gel skeleton is 70-95: 1. The profile control agent can seal and profile the medium and low temperature oil layers at 30 to 70 DEG C. The nitrogen foam gel skeleton has good membrane strength and good sealing effects and can greatly improve the mining efficiency of the crude oil.

Owner:PETROCHINA CO LTD

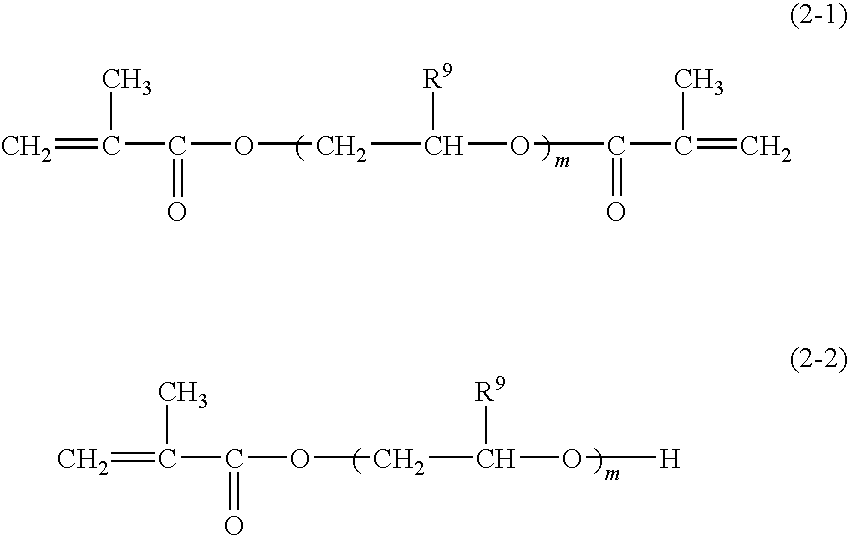

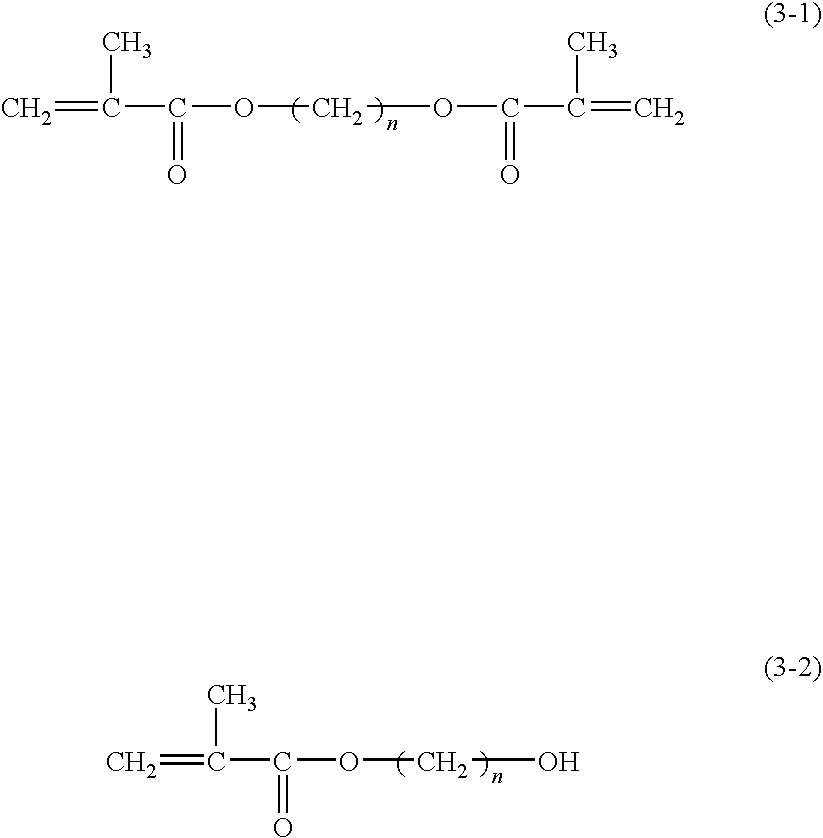

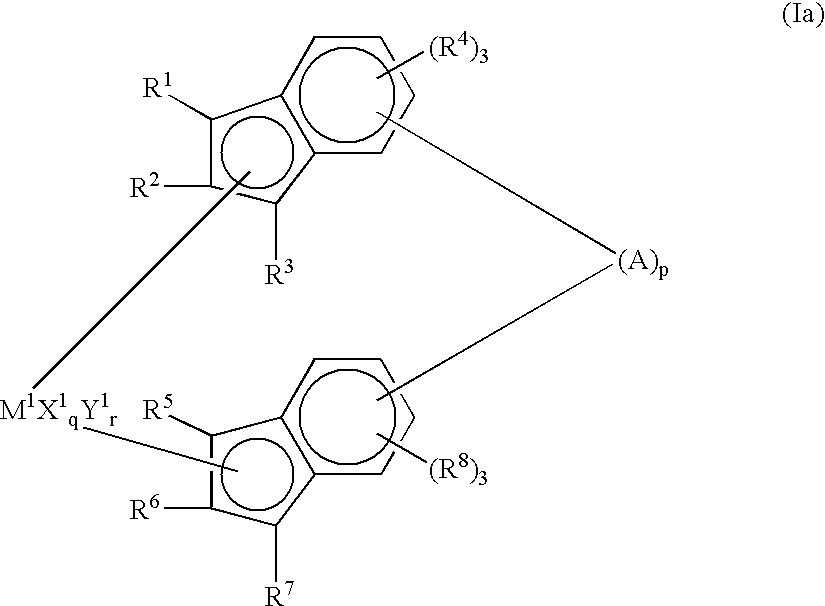

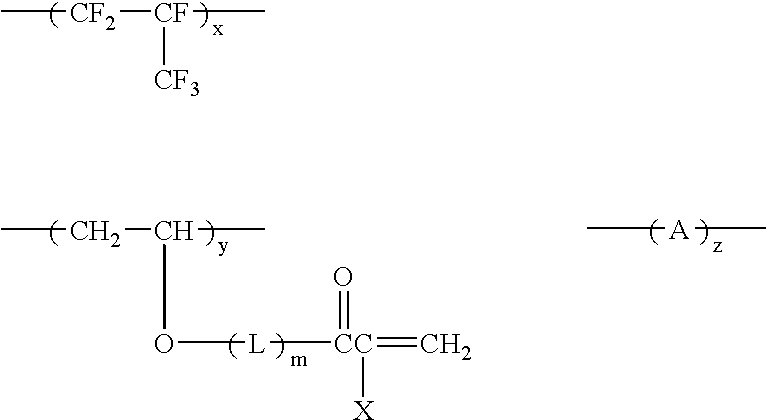

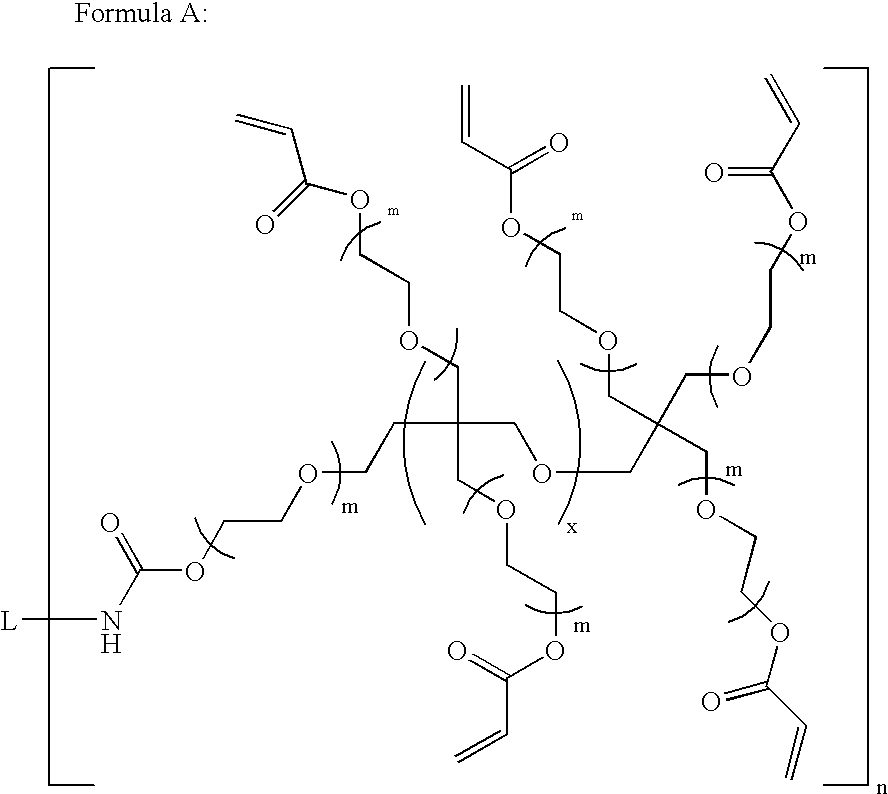

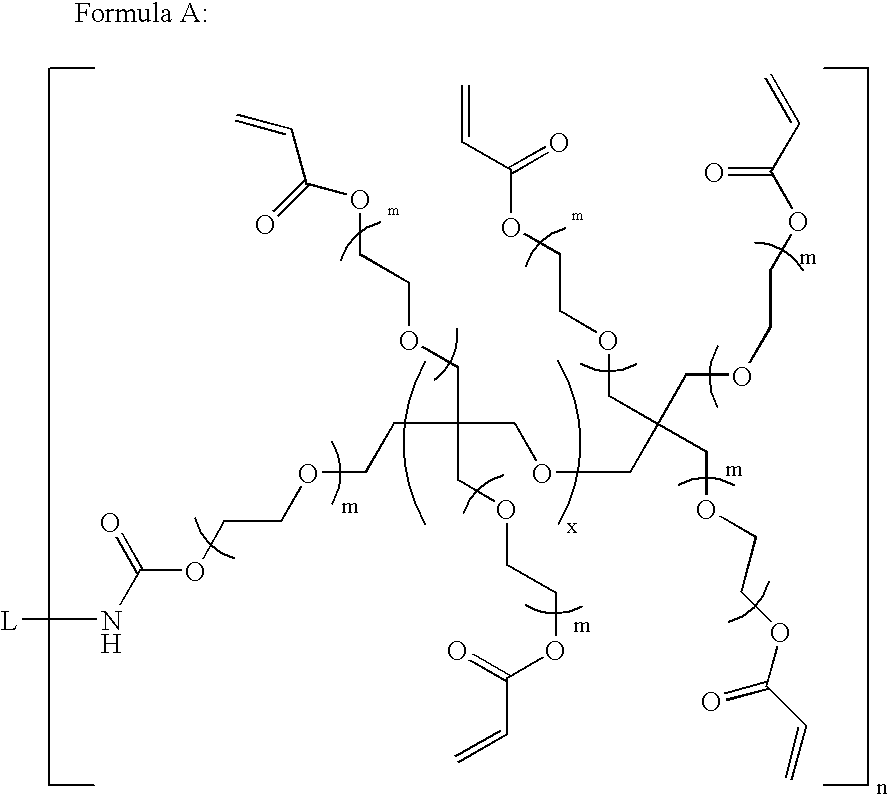

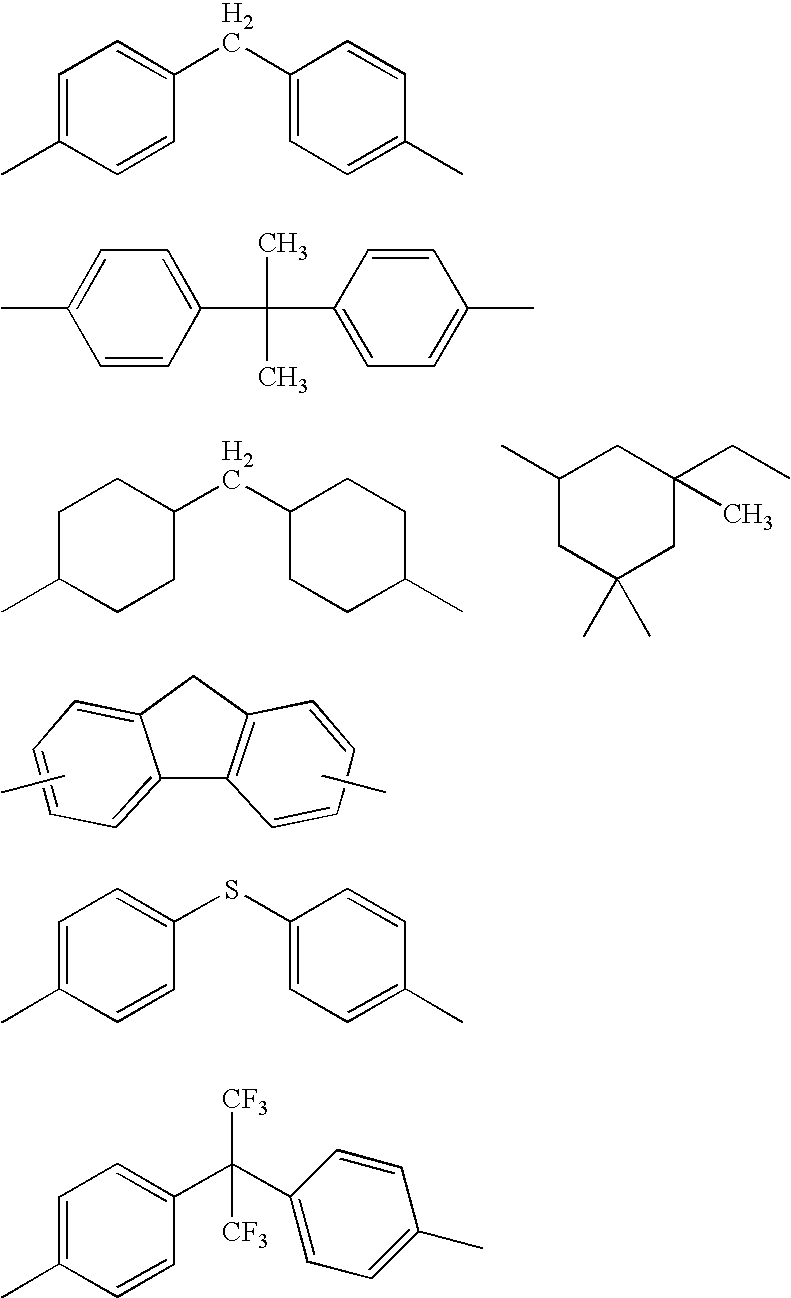

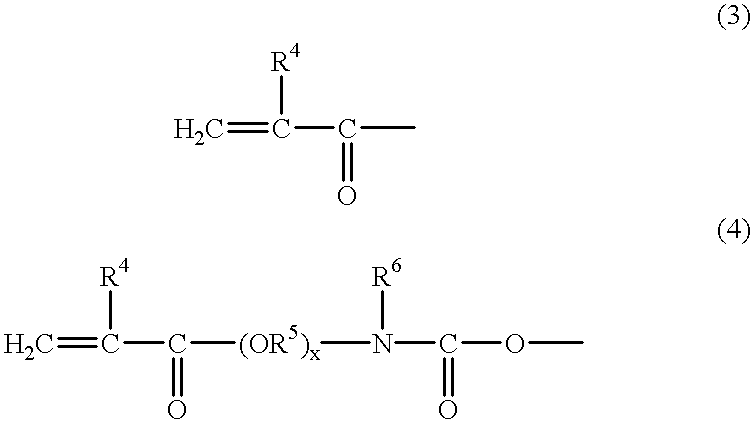

Polymerizable composition and use thereof

InactiveUS20020018938A1Improve ionic conductivityImprove polymerization effectLight-sensitive devicesOrganic chemistryPolymer electrolytesPolymer science

The present invention provides a solid polymer electrolyte; a polymerizable composition having low viscosity and excellent processability for obtaining the solid polymer electrolyte; and a polymerizable compound having low viscosity, and good polymerizability and stability for use in the polymerizable composition. The present invention also provides primary and secondary batteries capable of working with high capacity and current; an electric double-layer capacitor ensuring high output voltage, large takeout current, and good processability; and an electrochromic device favored with high response speed. Each thereof use the solid polymer electrolyte of the present invention and are ensured with long life, excellent safety free of liquid leakage, high reliability and production at a low cost. A solid polymer electrolyte, including a carbonate-based polymer in which a branched chain is introduced and having a high dielectric constant and a wide electrochemical stability range, having excellent processability, good safety and high ionic conductivity, is provided.

Owner:SHOWA DENKO KK

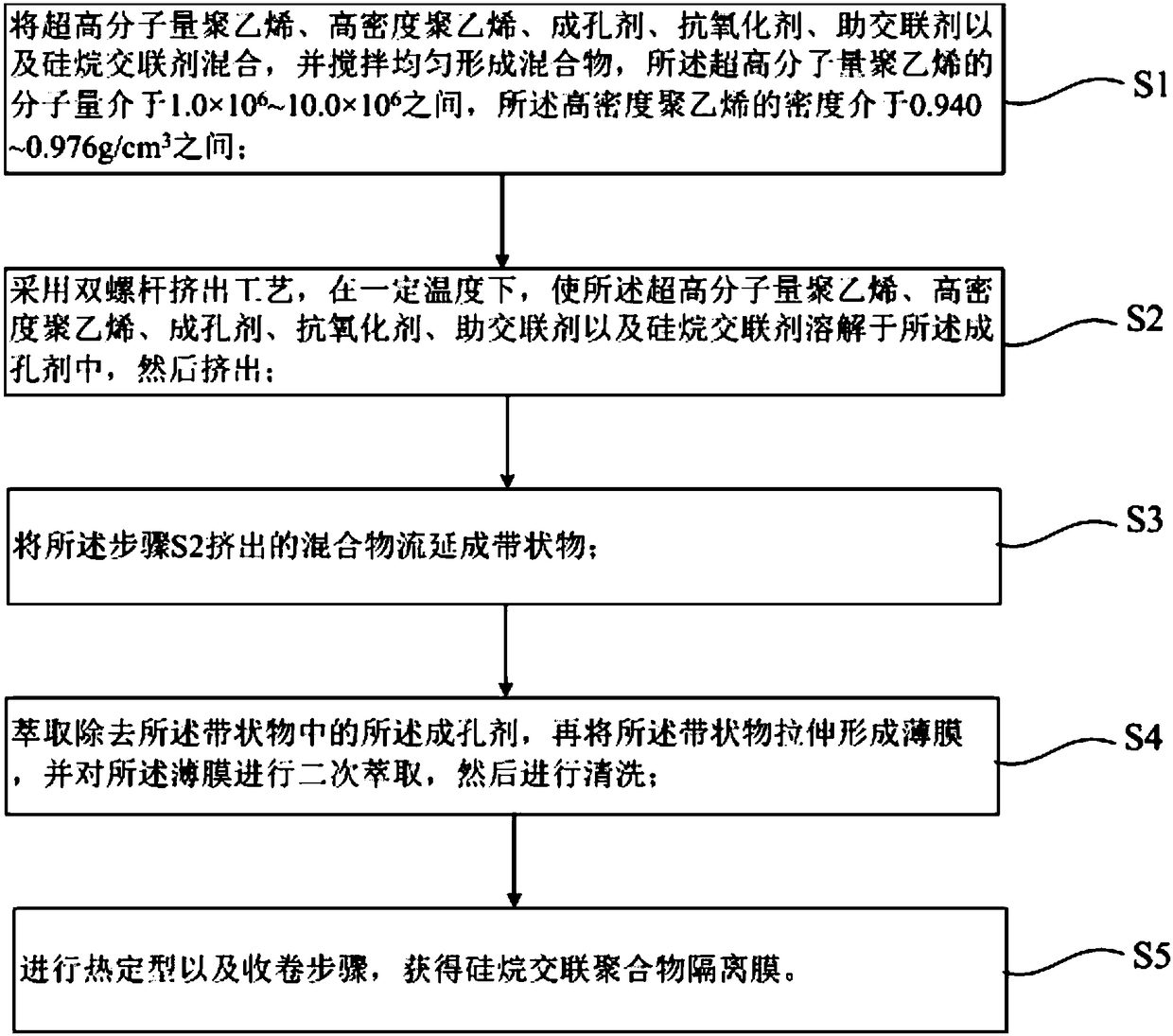

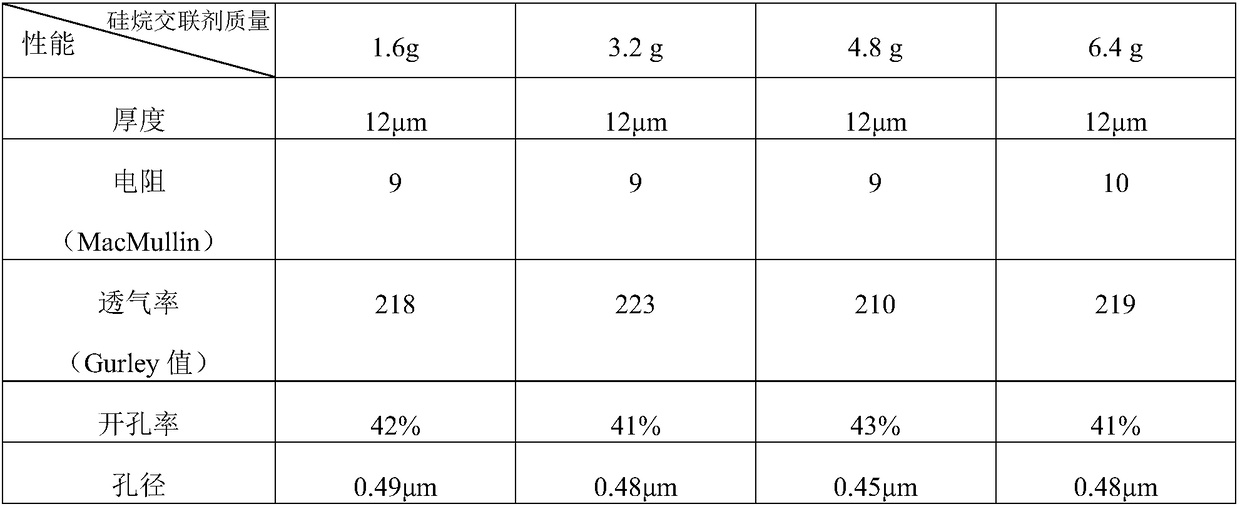

Silane crosslinked polymer separation film and preparation method thereof

InactiveCN108198986AReduce processing costsLow heat shrinkageCell seperators/membranes/diaphragms/spacersHigh densityAntioxidant

The invention provides a silane crosslinked polymer separation film, which comprises crosslinked polymerized ultrahigh molecular weight polyethylene, high-density polyethylene, an antioxidant, an assistant crosslinker and a silane crosslinking agent, wherein the molecular weight of the ultrahigh molecular weight polyethylene is 1.0*10<6> to 10.0*10<6>; the density of the high-density polyethyleneis 0.940-0.976g / cm<3>; and on the basis of 100 parts by weight of a mixture of the ultrahigh molecular weight polyethylene and the high-density polyethylene, the weight of the antioxidant is 0.5-20 parts, the weight of the assistant crosslinker is 0.1-10 parts and the weight of the silane crosslinking agent is 0.1-10 parts. The separation film is prepared through a chemical crosslinking method, sothat a difference value between the film rupture temperature and the obturator temperature of the prepared silane crosslinked polymer separation film and the hot shrinkage rate are improved and the safety performance of a battery is higher.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Transparent electric conductive base material, its mfg. method and coating liquid for forming transparent coating thereby and display device with said base material

InactiveCN1334588AImprove conductivityHigh film strengthTube/lamp screens manufactureConductive layers on insulating-supportsDisplay deviceMicroparticle

A transparent conductive layered structure which has the functions of preventing electrostatic charging or shielding an electric field, and preventing reflection, the two-layered film of which has an excellent scratch strength, and with which a reduction in production cost is expected and a method of producing the same, and a transparent coat layer forming coating liquid used in the method of producing the same, and a display device to which the transparent conductive layered structure is applied, are provided. A transparent conductive layered structure of the present invention, comprises a transparent substrate and a transparent two-layered film being composed of a transparent conductive layer and a transparent coat layer being formed in succession on the transparent substrate, wherein the transparent conductive layer comprises, as its main components, conductive microparticles having a mean particle diameter of 1 to 100 nm and a binder matrix of silicon oxide, and wherein the transparent coat layer comprises, as its main component, a binder matrix of silicon oxide including one or more types of alkyl groups selected from long chain alkyl groups containing 7 to 30 carbon atoms.

Owner:SUMITOMO METAL MINING CO LTD

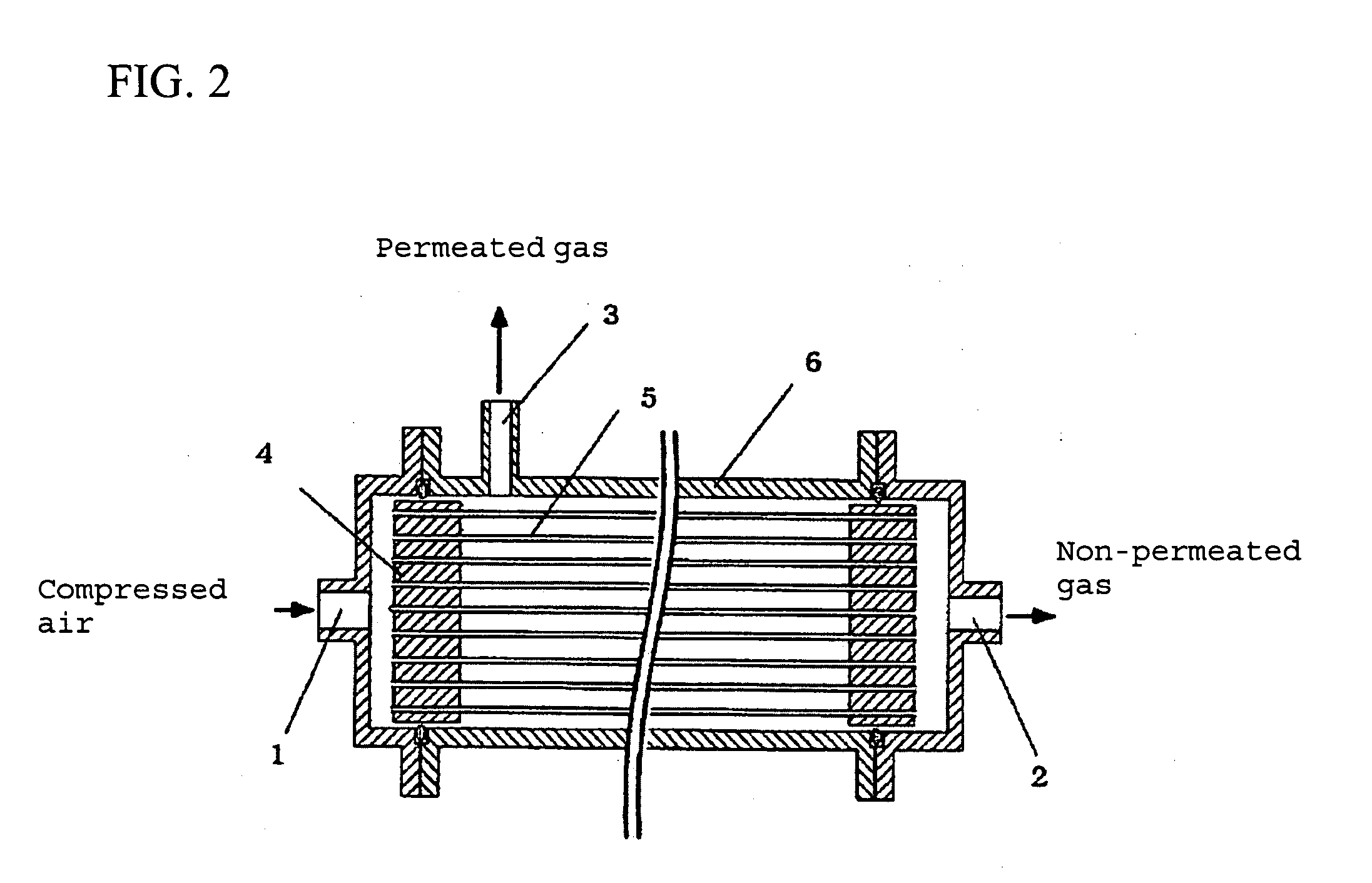

Asymmetric hollow-fiber gas separation membrane, gas separation method and gas separation membrane module

ActiveUS20080017029A1High mechanical strengthAdequate gas separation performanceSemi-permeable membranesMembranesFiberNitrogen gas

The present invention relates to an asymmetric hollow-fiber gas separation membrane made of a polyimide having a specific repeating unit, an improved tensile elongation at break of 15% or more as a hollow-fiber membrane itself, an oxygen gas permeation rate (P′O2) of 4.0×10−5 cm3 (STP) / cm2·sec·cmHg or more and a gas ratio of permeation rate of oxygen to nitrogen (P′O2 / P′N2) of 4 or more that are measured at 50° C., a gas separation method and a gas separation membrane module using the asymmetric hollow-fiber gas separation membrane. In addition, the present invention relates to an asymmetric hollow-fiber gas separation membrane obtained by heat-treating the asymmetric hollow-fiber gas separation membrane at a maximum temperature of from 350 to 450° C. The asymmetric hollow-fiber gas separation membrane has sufficient mechanical strength even after the heat-treatment at a maximum temperature of from 350 to 450° C.

Owner:UBE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com