Patents

Literature

179results about How to "Reduce construction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray-coating high-strength elastic waterproof paint of polyurea and construction thereof

ActiveCN1817989AImprove construction efficiencyReduce construction efficiencyAntifouling/underwater paintsPaints with biocidesLacquerDiluent

A high-elasticity lacquer-spraying waterproof pigment of polyurea and its construction are disclosed. The procedure is carried out by adding counted diluent and polyether polylol into reactor, depress dewatering at 90-100DEG C for 1-2hrs, sampling to determine water content, stopping dewatering when reaching water content below 0.08%, cooling to 80-85 DEG C while retaining the temperature range, agitating while dripping polyisocyanate into reactor, accounting the weight of polyisocyanate by n-oH / n-NCO=1.05, reacting for 2hrs at 80-85 DEG C continuously, retaining at 80-85 DEG C, agitating while dripping residual polyisocyanate into reactor, keeping temperature, reacting for 2hrs continuously, cooling, discharging to obtain A component and mixing A component with B component in proportion of 1:1. The B component consists of amino resin, amine-chain reinforcer and active filler. It has excellent waterproof performance.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

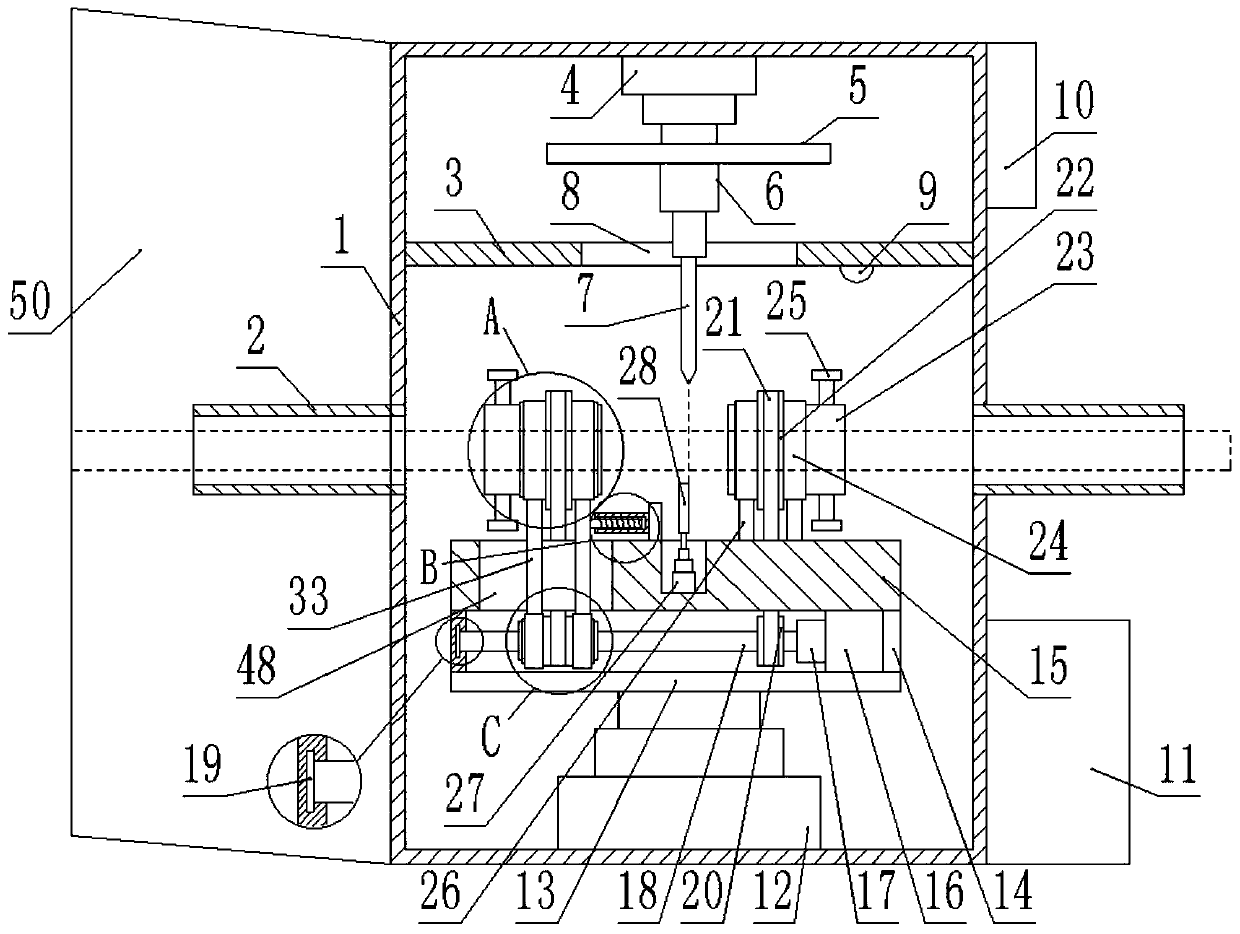

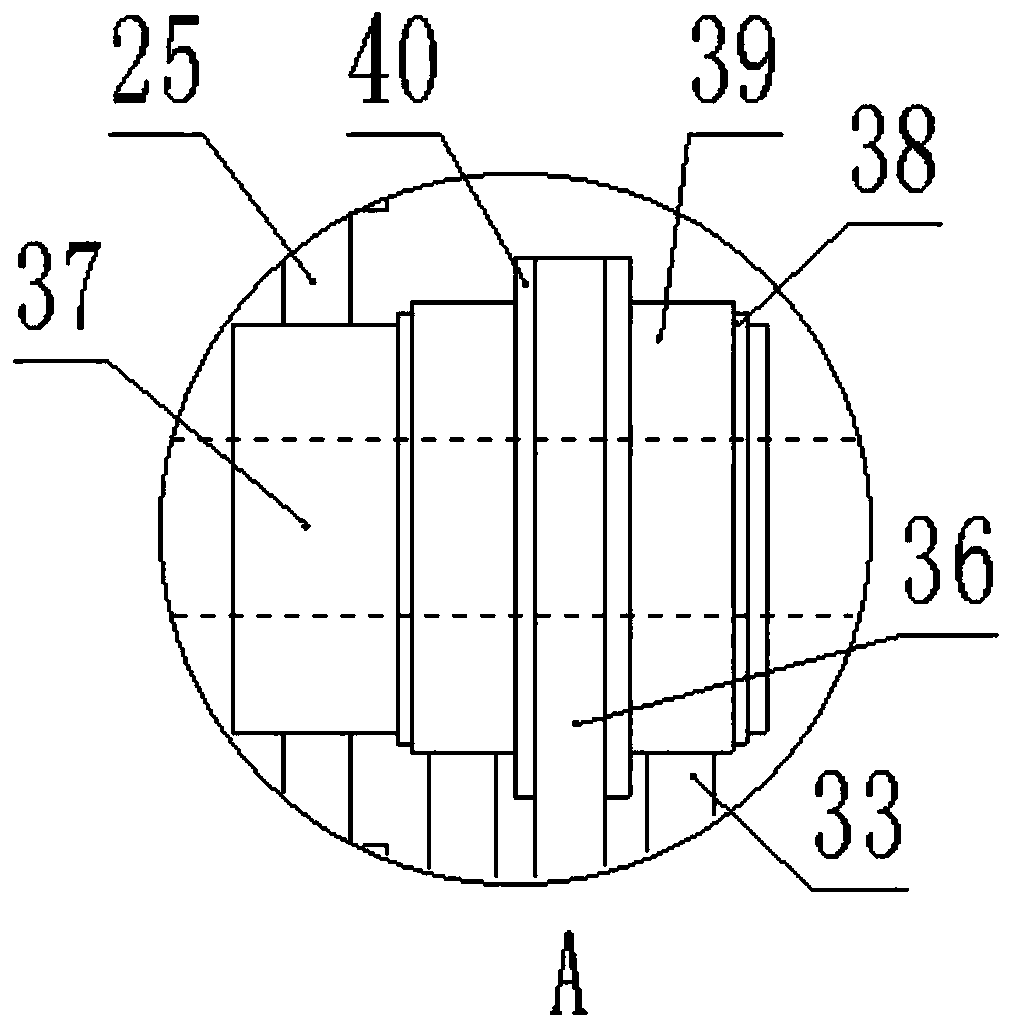

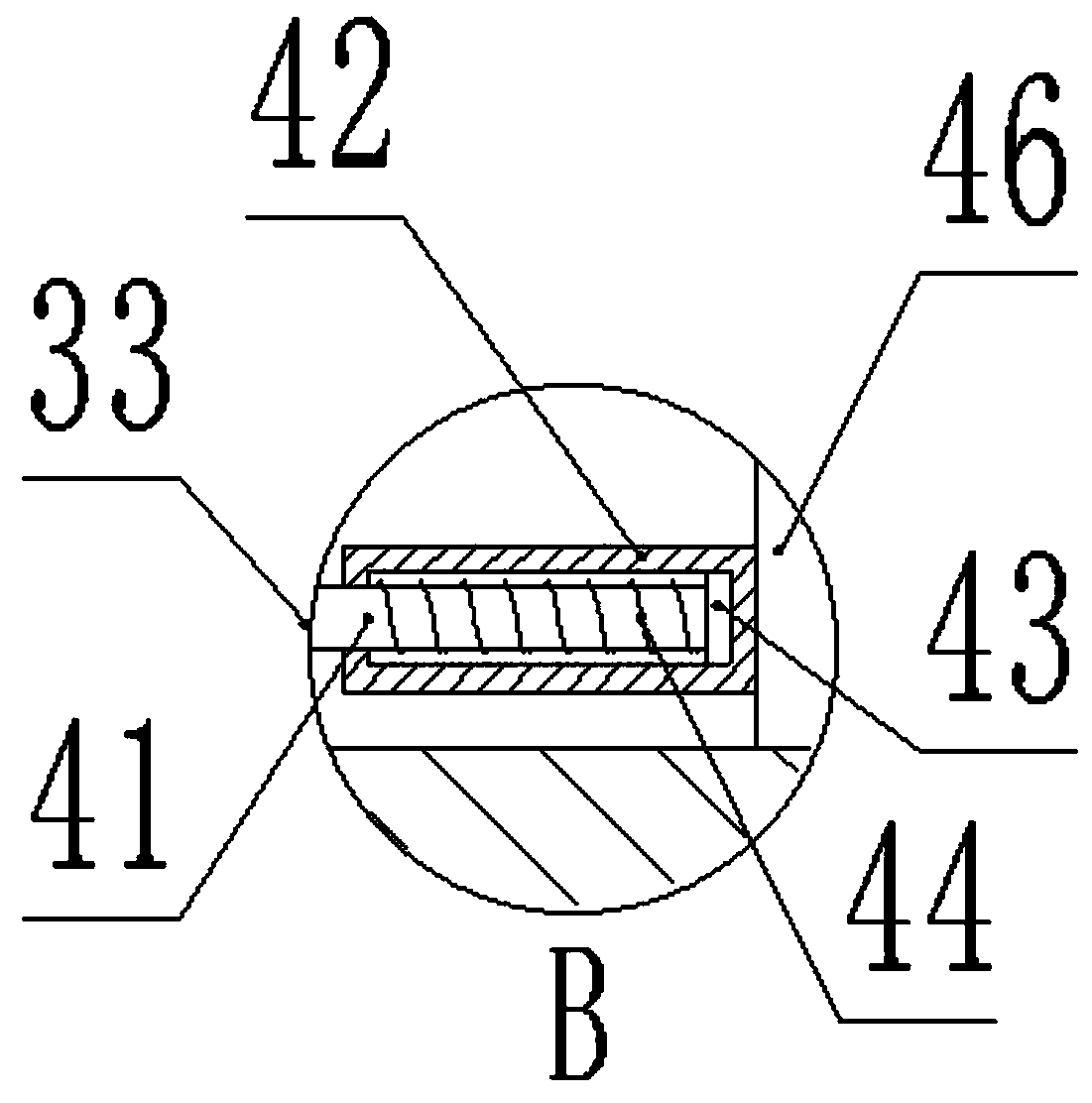

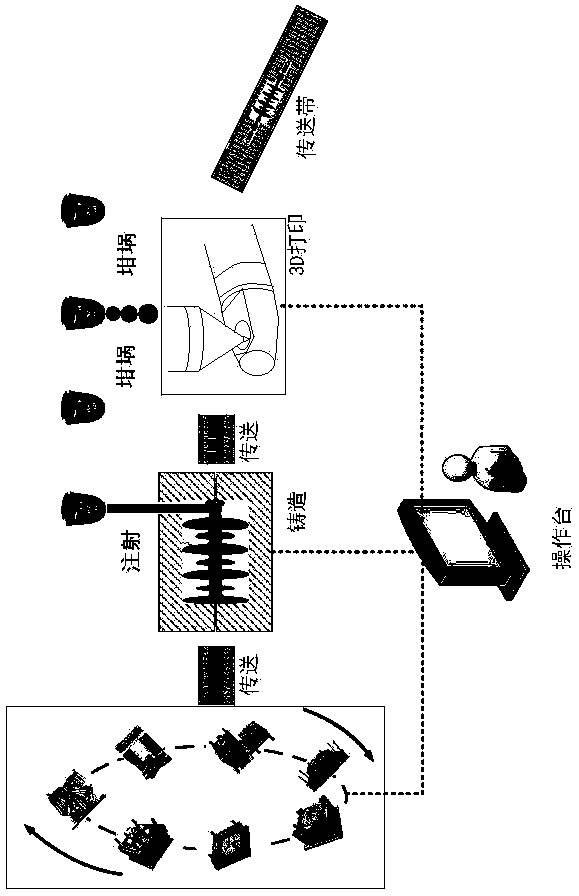

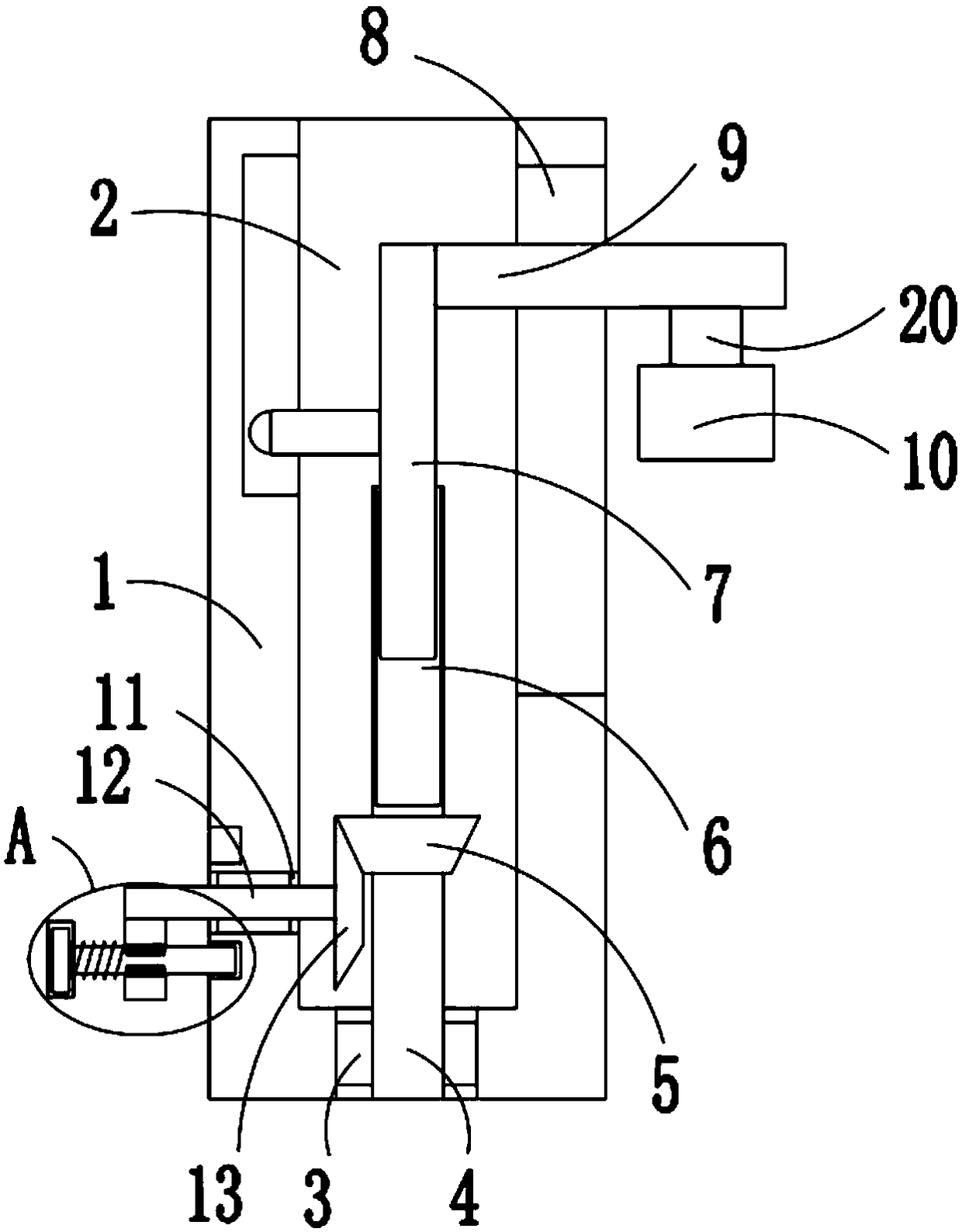

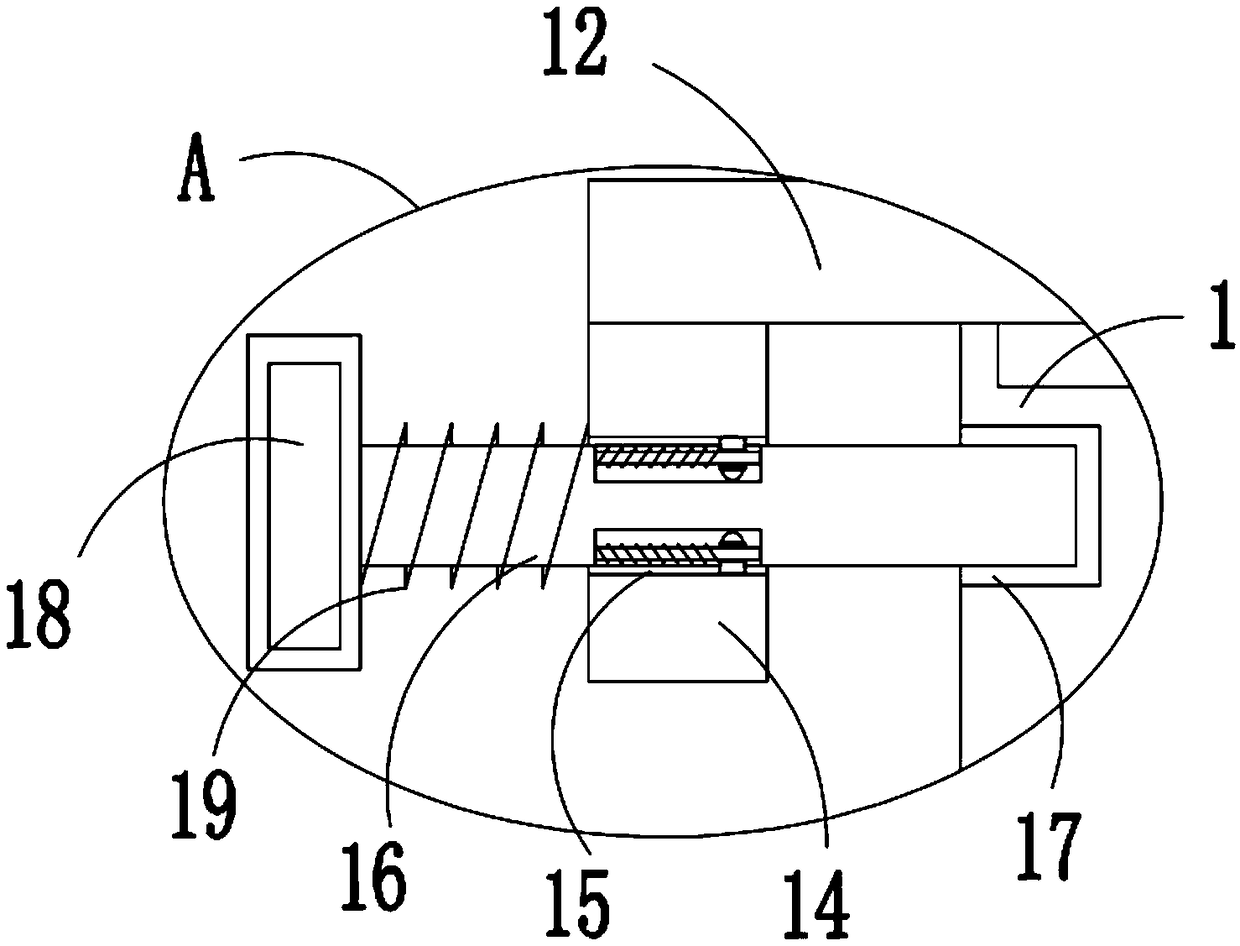

Steel thin-wall sounding pipe automatic welding device for bored concrete pile

InactiveCN109986278AGuaranteed supply and demandSolve the problem that the straightness does not meet the demandFoundation testingWelding/cutting auxillary devicesArchitectural engineeringMaterial supply

The invention discloses a steel thin-wall sounding pipe automatic welding device for a bored concrete pile. The welding device comprises a box body, feeding cylinders are symmetrically and fixedly mounted on the two sides of the box body, axes of the two feeding cylinders are oppositely arranged, a first hydraulic lifting device is fixedly mounted on the inner top face of the box body, a baffle isfixedly mounted on a piston rod on the bottom end of the first hydraulic lifting device, the bottom end of the baffle is fixedly provided with an automatic telescopic rod, a partition board is arranged on the top in the box body, and an opening is fixedly formed in the center of the partition board. When the device is used for welding a large batch of steel pipes, traditional manual welding is avoided, work efficiency is increased, time is saved, the whole construction efficiency is improved, the material supply needs are ensured, meanwhile, the problem that the straightness degree after welding of two steel pipes cannot meet the needs is solved, the yield is improved, many resources are saved, through welding in the box body, dangerousness during welding by a worker is reduced, work burdens of workers can be reduced, and the work can be more efficiently finished.

Owner:薛飞

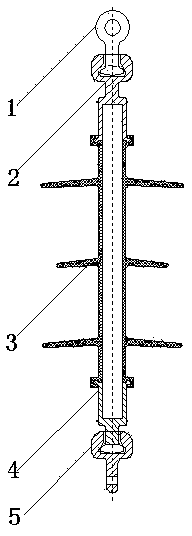

Overhung composite insulator string and method for printing same by using 3D

ActiveCN104103385AHigh degree of manufacturing flexibilitySave timeSuspension/strain insulatorsComputer Aided DesignComposite insulators

The invention discloses an integrated overhung composite insulator string and a method for printing a composite insulator string connecting metal tool by using 3D. The method comprises the following steps of: firstly, generating a three-dimensional CAD (Computer-Aided Design) model of a part in a computer, and printing the three-dimensional CAD model by utilizing a 3D molten-drop printing machine; then slicing up and layering the model according to a certain thickness, converting the three-dimensional information of the part into a series of two-dimensional profile information; melting down metal by using a crucible, and enabling the molten metal to flow out of a nozzle to form molten drops; then accumulating the molten drops layers by layer according to the two-dimensional profile information under the control of the computer so as to obtain a three-dimensional entity part or a part in similar shape. After the method is adopted, a ball-socket series of metal tools is shaped for once directly through the molten-drop 3D printing machine, the connecting cooperation is more reliable and more stable, secondary installation is unnecessary, and the production efficiency is improved; meanwhile, the efficiency of the site construction is provided, and a great influence to the construction of a high-voltage overhead power line is generated.

Owner:STATE GRID CORP OF CHINA +3

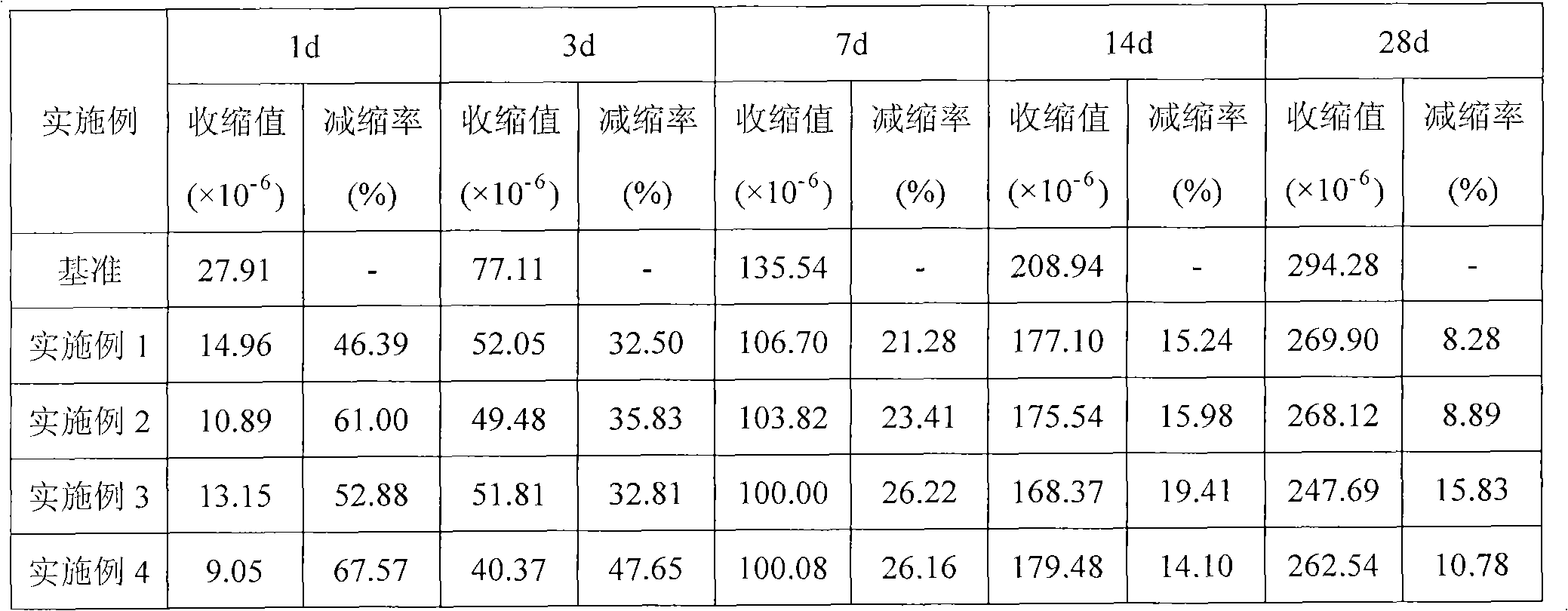

Multifunctional anti-leakage shrinkage type concrete surface layer reinforcer

The invention relates to a multifunctional anti-leakage shrinkage type concrete surface layer reinforcer which is prepared from the following components in percentage by weight: 10-20 percent of high polymer, 1-7 percent of film forming aided compound, 5-10 percent of surface layer active agent compound, 1-4 percent of leakage aided compound, 1.5-4.5 percent of active compound and the balance of water. The invention has good concrete surface layer enhancement effect, can obviously reduce the shrinkage of surface layer concrete, obviously improves the carbonization resistance and the medium leakage resistance of surface layer concrete, has convenient construction and obvious economic benefit and can be widely applied to the strengthening treatment operations on the surface layers of cement and concrete pouring components, concrete components under corrosion environment conditions such as piers, dams, and the like and deformed concrete components difficult to be strengthened by adopting a conventional method.

Owner:湖州苏博特新材料有限公司

Drainage system used for drainage consolidation of high-water-content sludge and new dredger fill

ActiveCN104372789ASave sand resourcesReduce construction costsSoil preservationSludgePulp and paper industry

The invention relates to a drainage system used for drainage consolidation of high-water-content sludge and new dredger fill and belongs to the technical field of ultra soft soil. The drainage system comprises straw blankets and a straw roll, wherein the straw blankets are laid on the sludge or the new dredger fill, and the straw roll is inserted into the sludge or the new dredger fill. The straw blankets and the straw roll are fixedly connected to form the whole drainage system. The straw blankets are blanket type objects formed by weaving straw. The straw roll is a roll type object formed in the mode that a geotechnical cloth bag is wrapped on the straw. The novel drainage system can solve the problem of straw pollution in agricultural production, lower the construction cost for drainage consolidation of the ultra soft soil such as the high-water-content sludge and the new dredger fill and substantially improve the construction efficiency.

Owner:YANCHENG INST OF TECH

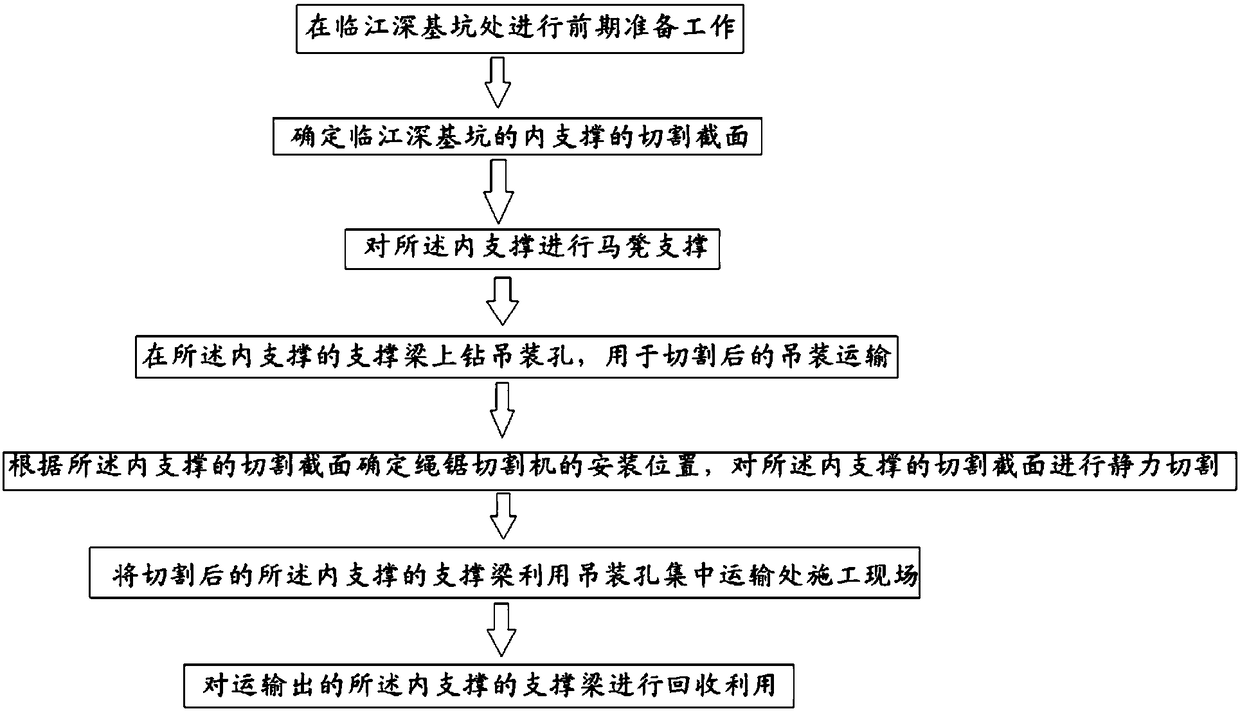

Method for cutting, removing and recycling deep foundation pit concrete near river

InactiveCN108166500AReduce the impactWill not affect normal lifeBuilding repairsExcavationsEnvironment effectEngineering

The invention discloses a method for cutting, removing and recycling deep foundation pit concrete near a river, and belongs to the technical field of building construction. The method for cutting, removing and recycling the deep foundation pit concrete near the river comprises the following steps that early-stage preparation work is carried out at a deep foundation pit near the river; the cuttingcross section of an inner support of the deep foundation pit is determined; supporting steel bars are used for supporting the inner support; hoisting holes are drilled in supporting beams of the innersupport, and are used for hoisting and transporting after cutting; the installation position of a rope saw cutting machine is determined according to the cutting cross section of the inner support, and static force cutting is carried out on the cutting cross section of the inner support; the supporting beams of the cut inner support are completely conveyed to a construction site through the hoisting holes; and the supporting beams, which are transported out, of the inner support are recycled. The method for cutting, removing and recycling the deep foundation pit concrete near the river is efficient, safe, environment-friendly, low in vibration, low in noise, free-dust, small in influence on surrounding environment, and low in environmental pollution, and can effectively reduce the construction waste.

Owner:WUHAN UNIV OF SCI & TECH

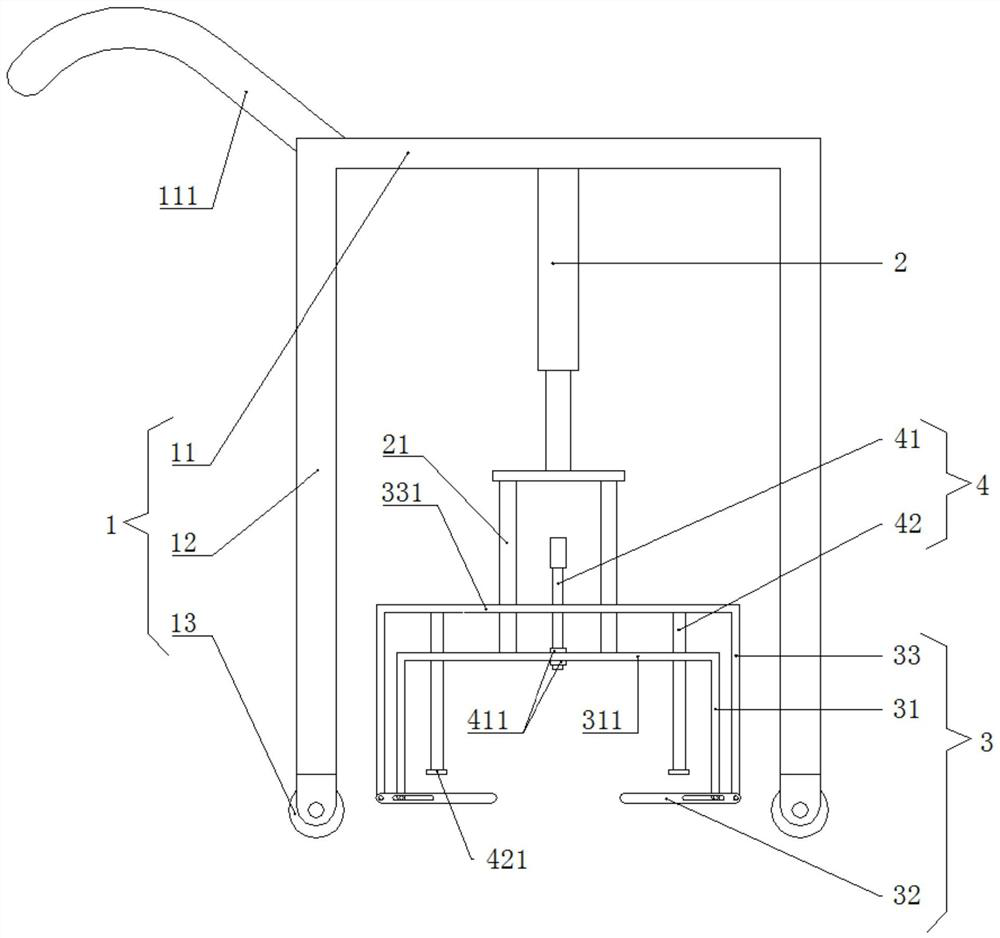

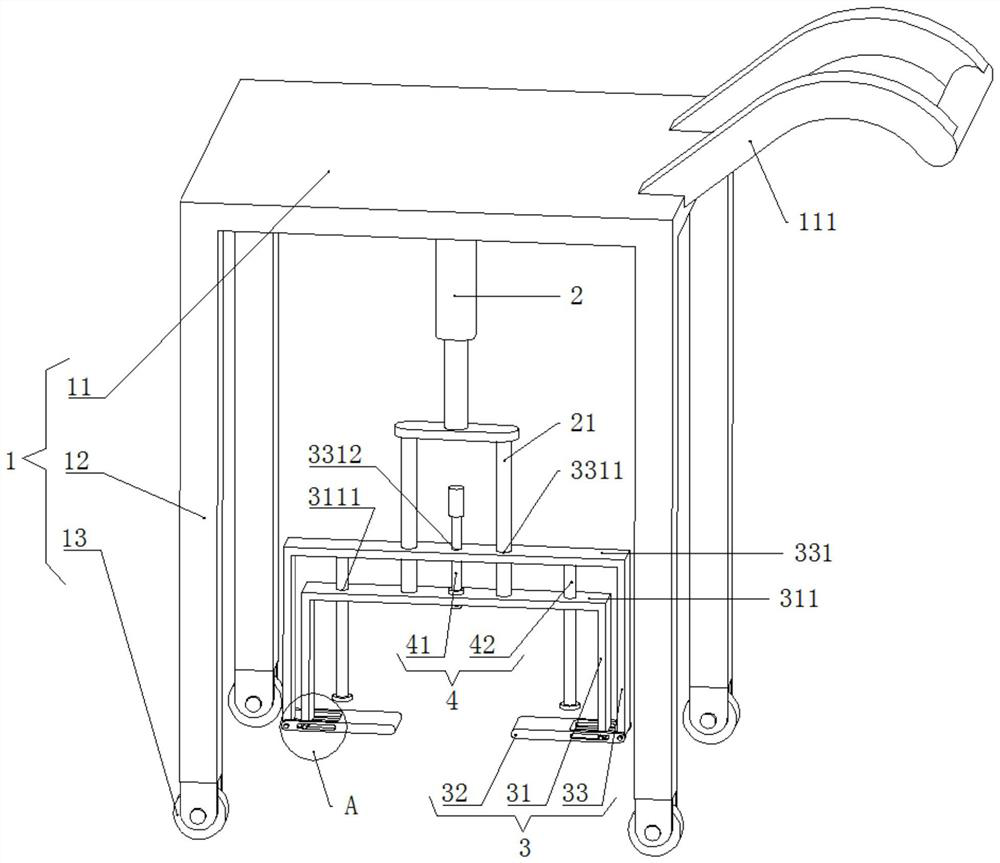

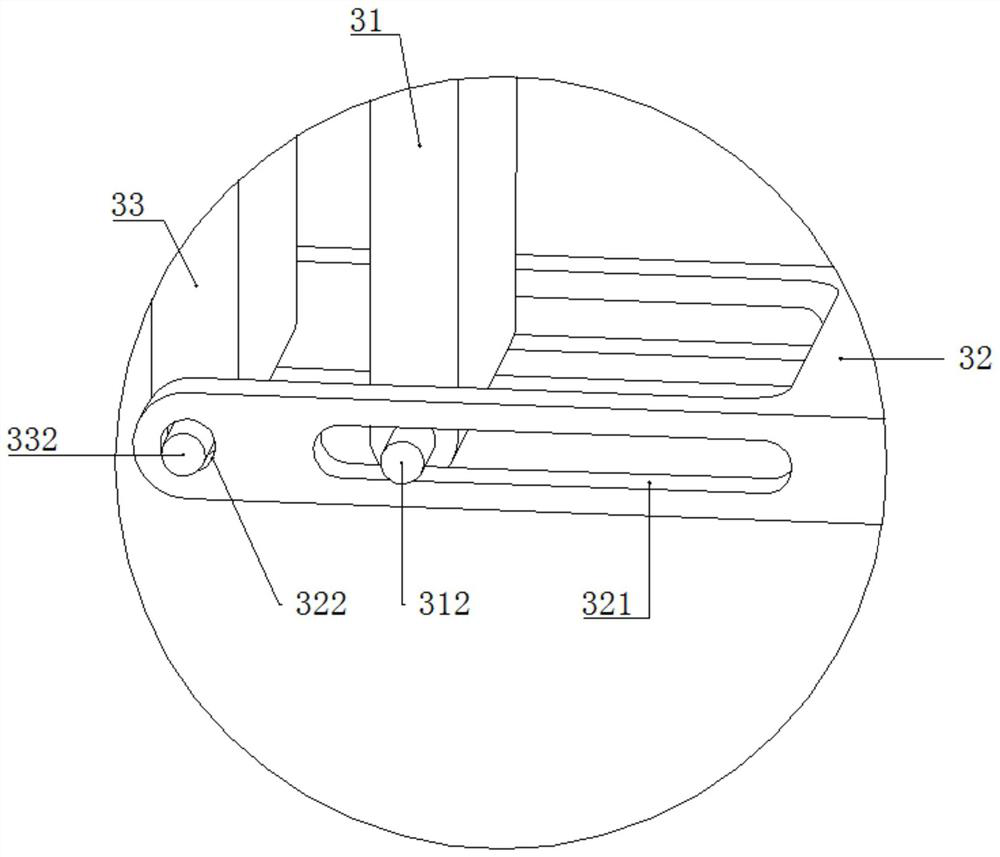

Cable trench cover plate prying and transporting device

ActiveCN111762696AReduce labor intensityAvoid smashingTrolley cranesTravelling gearStructural engineeringMechanical engineering

The invention discloses a cable trench cover plate prying and transporting device, and relates to the technical field of cable trench cover plate disassembly and assembly. The device comprises a moving frame, a lifting part and a prying mechanism, the prying mechanism comprises an inserting plate, a rotating plate and an adjusting plate, the moving frame is connected with the upper end of the lifting part, the lower end of the lifting part is connected with the upper end of the inserting plate, the lower end of the inserting plate is connected with the middle of the rotating plate, one end ofthe rotating plate is hinged to the lower end of the adjusting plate, and the adjusting plate is in sliding connection with the inserting plate; and when the lower end of the adjusting plate is flushwith the lower end of the inserting plate, the rotating plate rotates to a horizontal state of supporting a cable trench cover plate. According to the cable trench cover plate prying and transportingdevice, the labor intensity of constructors can be reduced, and the construction safety of the constructors is improved.

Owner:SHANDONG JIAOTONG UNIV

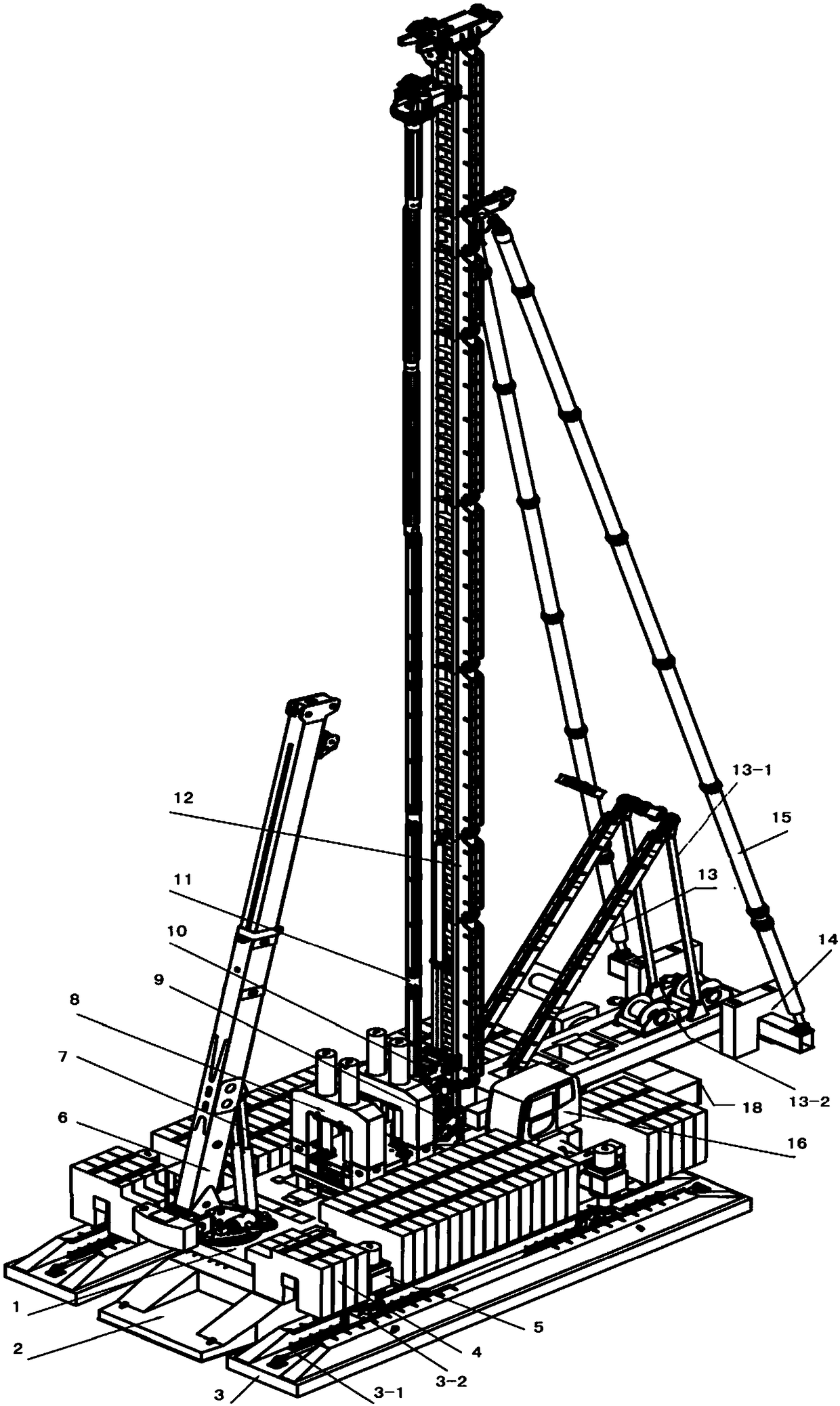

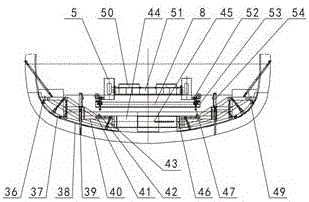

Mixing and pile-pressing integrated machine

The invention relates to a mixing and pile-pressing integrated machine. The mixing and pile-pressing integrated machine comprises two short boats, two long boats, a mixing and pile-drilling mechanismand a hydraulic pile-pressing mechanism. The mixing and pile-pressing integrated machine is characterized in that the mixing pile-drilling mechanism and the hydraulic pile-pressing mechanism are connected sequentially on the two short boats and the two long boats to form an integrated pile machine structure; the mixing pile-drilling mechanism is connected with the hydraulic pile-pressing mechanismthrough a rotary bearing to form a rotatable connection structure, and the mixing pile-drilling mechanism is connected with a lifting device to drive the mixing pile-drilling mechanism to lift or fall; the mixing pile-drilling mechanism and the hydraulic pile-pressing mechanism are connected to the long boats through a landing leg and on the short boats through a pin shaft; long ship oil cylinders and wheel sets are arranged on the long boats to form a transverse translation structure; short ship oil cylinders and wheel sets are arranged on the short boats to realize the longitudinal movementand steering of a whole machine; and the mixing pile-drilling mechanism and the hydraulic pile-pressing structure are connected into an integrated structure through a rotating bearing to form an integrated pile machine with the mixing pile-drilling and the hydraulic pile-pressing structure. The mixing and pile-pressing integrated machine has the characteristics of preventing cement mortar from being prone to solidifying, simple construction procedure and good piling quality.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

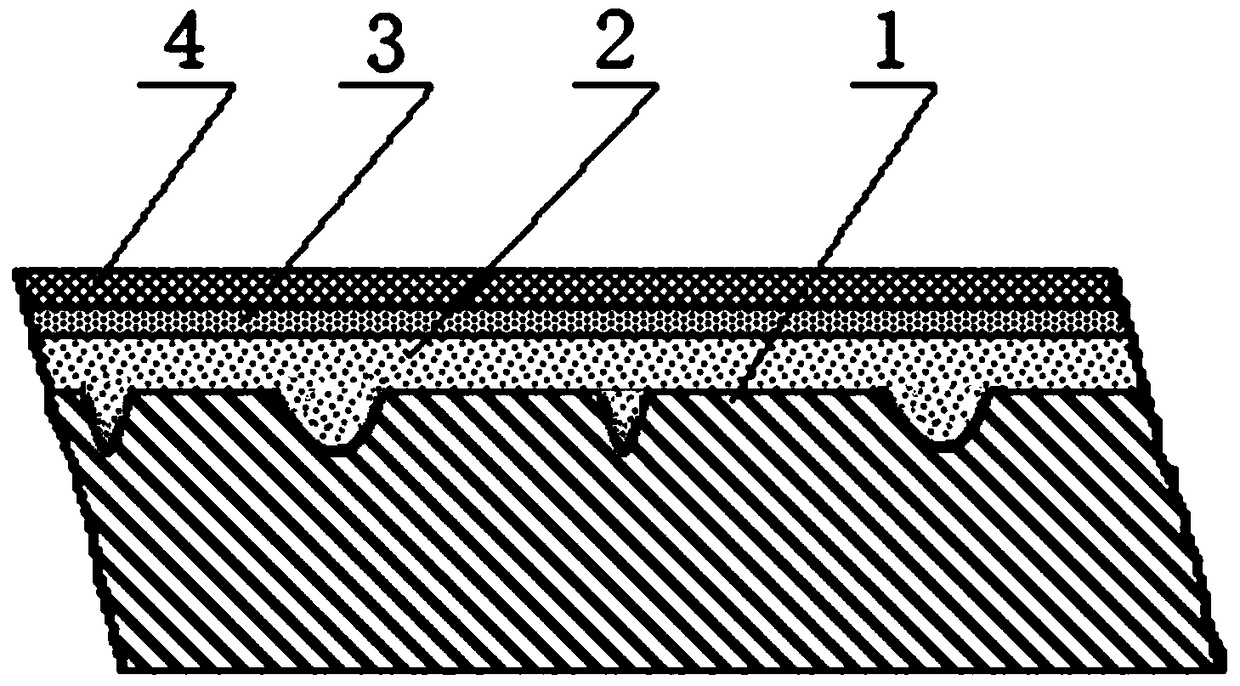

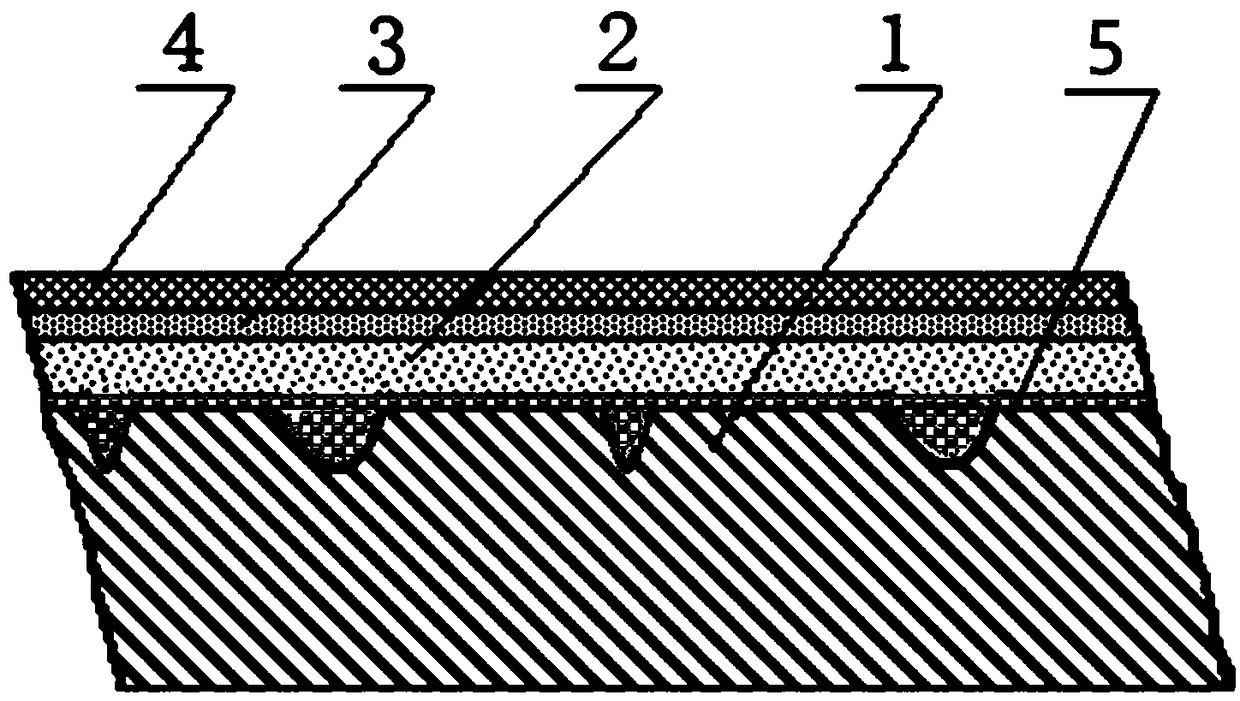

Plastic floor laying structure and construction method thereof

The invention discloses a plastic floor laying structure and a construction method thereof, and relates to the field of buildings. The plastic floor laying structure comprises a plastic floor laying structure body, and the plastic floor laying structure body is provided with a rough pitted surface layer, a self-leveling layer, a bonding layer and a plastic floor layer sequentially from bottom to top; and the rough pitted surface layer is formed by roughly polishing a surface layer of a ground structure. The construction method of the plastic floor laying structure comprises the following specific process that the surface layer of the original ground structure is polished into the rough pitted surface layer through matching of a cutting machine and an impact drill; the self-leveling layer is laid on the surface layer of the rough pitted surface layer; after being dried completely, the self-leveling layer is painted with the bonding layer; and the plastic floor layer is laid on the bonding layer. According to the plastic floor laying structure obtained through the construction method, original tiles do not need to be removed, construction is directly conducted on the basis of the original ground structure, manpower can be saved greatly, a large amount of construction waste is avoided, the construction cost is lowered, and the project construction period is shortened.

Owner:安徽智恒信科技股份有限公司

Pretensioned prestressed superposed frame beam and construction method

The invention provides a pretensioned prestressed superposed frame beam and a construction method, and relates to the technical field of construction engineering. A superposed beam component includesa reinforcing cage, steel strands, anti-seismic casing pipes and precast concrete, the reinforcing cage is composed of stirrups and beam longitudinal rebar, the prestressed steel strands are located on the lower part of the superposed beam, arranged in the longitudinal direction of the superposed beam and be pretensioned and fixed through special equipment, and concrete poured by a factory can bereleased from the fixing equipment after reaching a certain strength; and the anti- seismic casing pipes are located on the prestressed steel strands and have a certain distance from the beam end of asuperposed beam, and the pouring range of the precast concrete is located in the lower middle part of the superposed beam. After the superposed beam component is hoisted on site in place, the steel strands on the lower part of the superposed beam and the extension parts of the longitudinal rebar form an effective connecting joint with frame columns by pouring the concrete on site. According to the scheme, the economic property is high, the quality is good, the site formwork amount is greatly reduced, the construction efficiency is improved, construction of the connecting joint is convenient,the performance of the structure is equivalent to that of cast-in-place concrete structure.

Owner:SANY CONSTR TECH CO LTD

Assembly type integral installation device for building electromechanical engineering

InactiveCN109058681AEasy to adjustReduce working at heightsStands/trestlesGear wheelArchitectural engineering

The invention discloses an assembly type integral installation device for building electromechanical engineering. The assembly type integral installation device for building electromechanical engineering comprises an installation seat, wherein a groove is formed in the top part of the installation seat; a rotating groove is formed in the inner wall of the bottom part of the groove; a rotating column is rotatably arranged in the rotating groove; a first conical gear fixedly sleeves on the outer side of the rotating column; a threaded groove is formed in the top end of the rotating column; a screw rod is in threaded connection into the threaded groove; a first sliding chute is formed in one side of the installation seat and communicates with the groove; and a first sliding block is fixedly arranged on one side of the screw rod and is slidably connected with the first sliding chute. The assembly type integral installation device for building electromechanical engineering provided by the invention is simple in structure and convenient to operate, the height of a main body of the installation device can be quickly and conveniently adjusted, the construction efficiency and the construction quality are improved, the construction period is shortened, the aerial work of workers is reduced, the safety of the construction process is improved, and the demands of the workers are met.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

High-speed railway roadbed uneven settlement reinforcement lifting and leveling method

ActiveCN110241662APrevent proliferationLifting speed is fastRailway tracksSoil preservationEngineeringOperability

The invention relates to a high-speed railway roadbed uneven settlement reinforcement lifting and leveling method. The high-speed railway roadbed uneven settlement reinforcement lifting and leveling method comprises the following steps: S1, a reinforcement area is formed, specifically, the reinforcement area is formed in an embankment below a railway track through static pressure grouting; S2, curtain walls are formed, specifically, the curtain walls are formed on the positions, close to the slope toe, of the two sides of the embankment through static pressure grouting; and S3, lifting and leveling are conducted, specifically, an area between the reinforcement area and the curtain walls serves as an acting force pushing area, a static pressure grouting method is adopted, and by grouting the acting force pushing area, the upward grouting pressure is generated to evenly lift the embankment reinforcement area. The high-speed railway roadbed uneven settlement reinforcement lifting and leveling method has the advantages that a technology is simple, operability is high, interference is avoided, and the construction efficiency is high.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

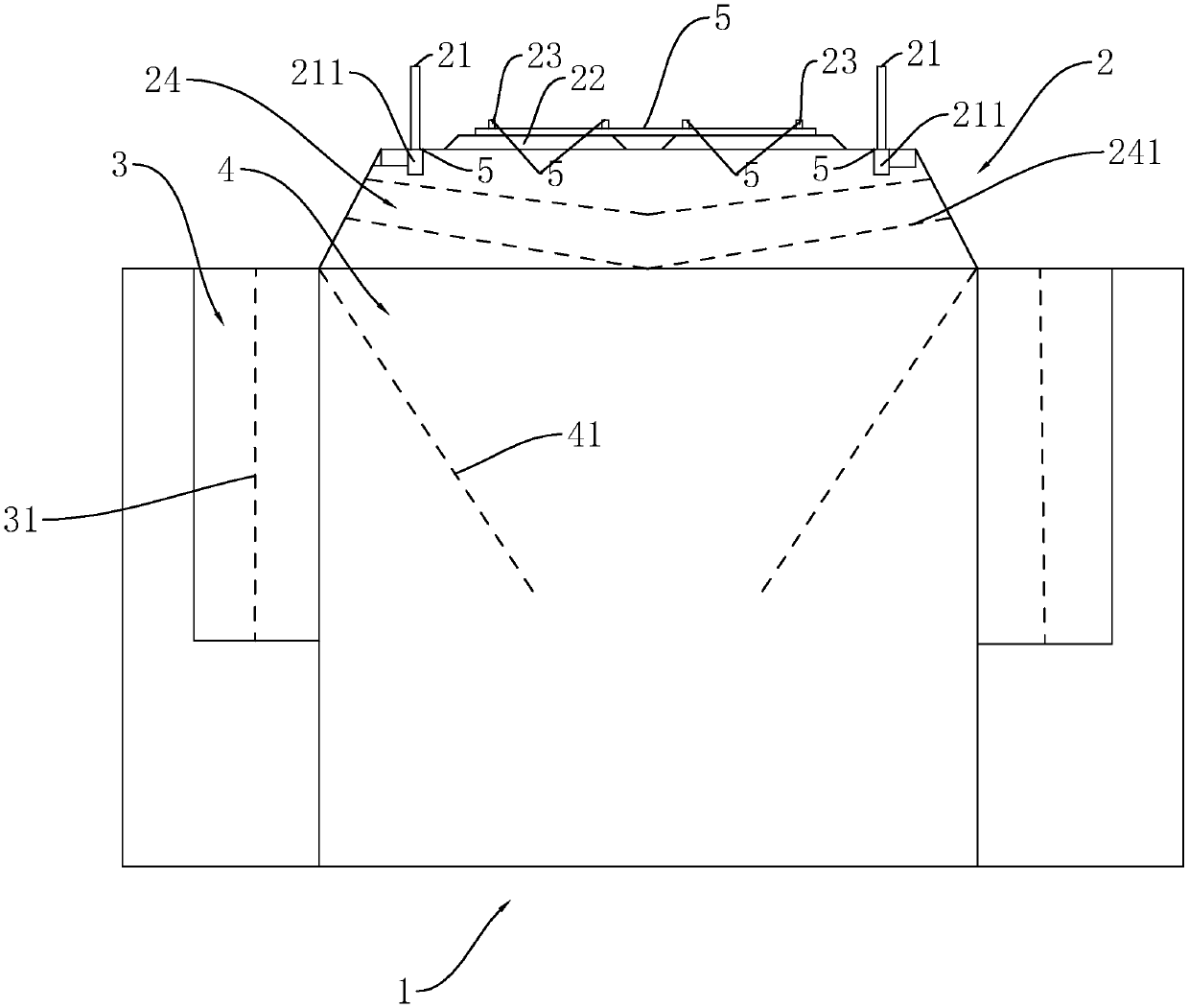

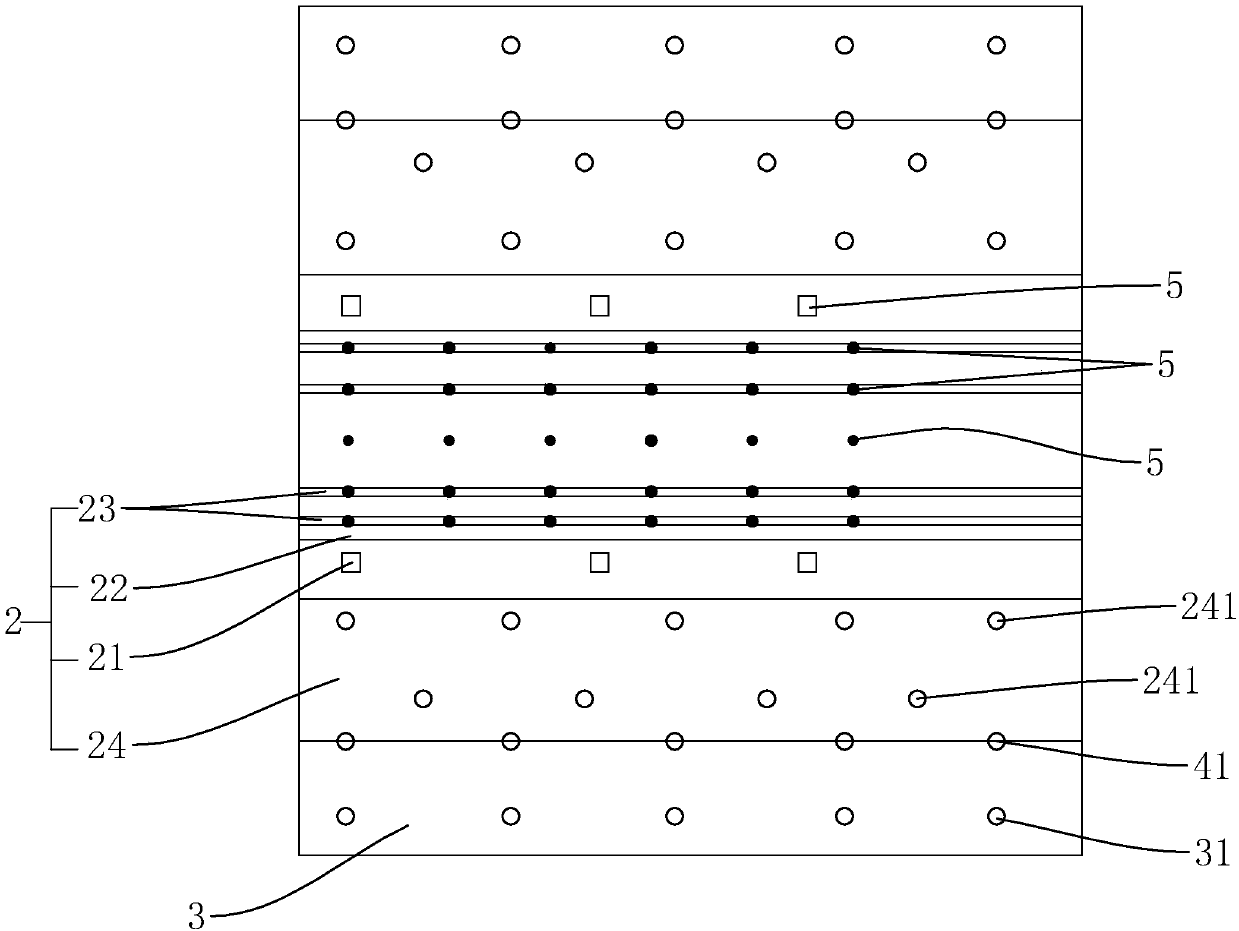

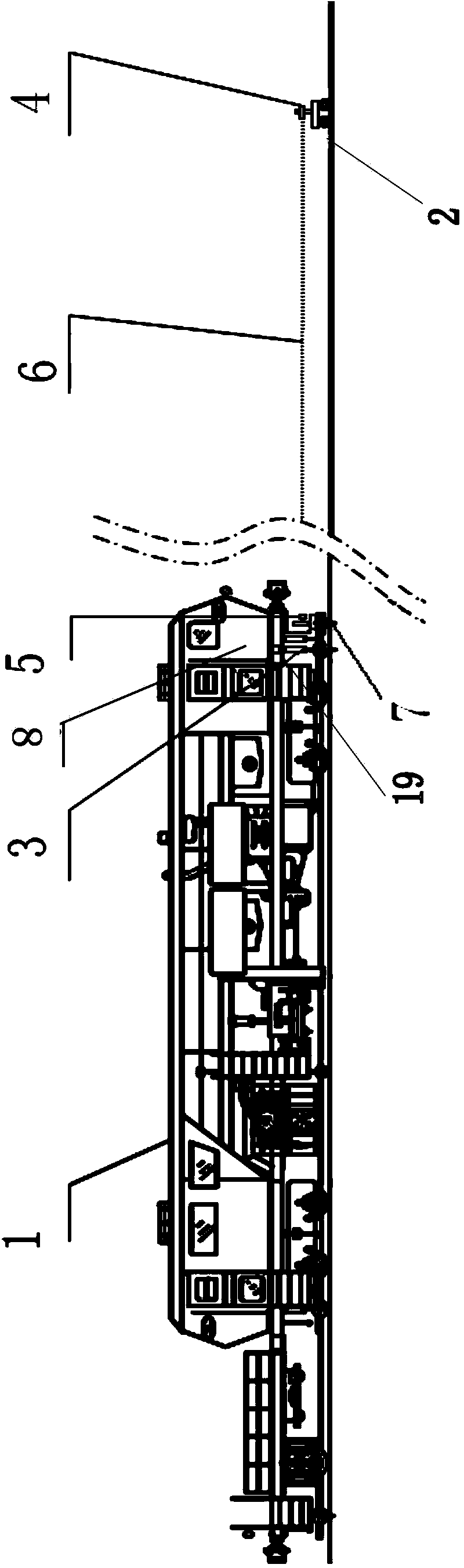

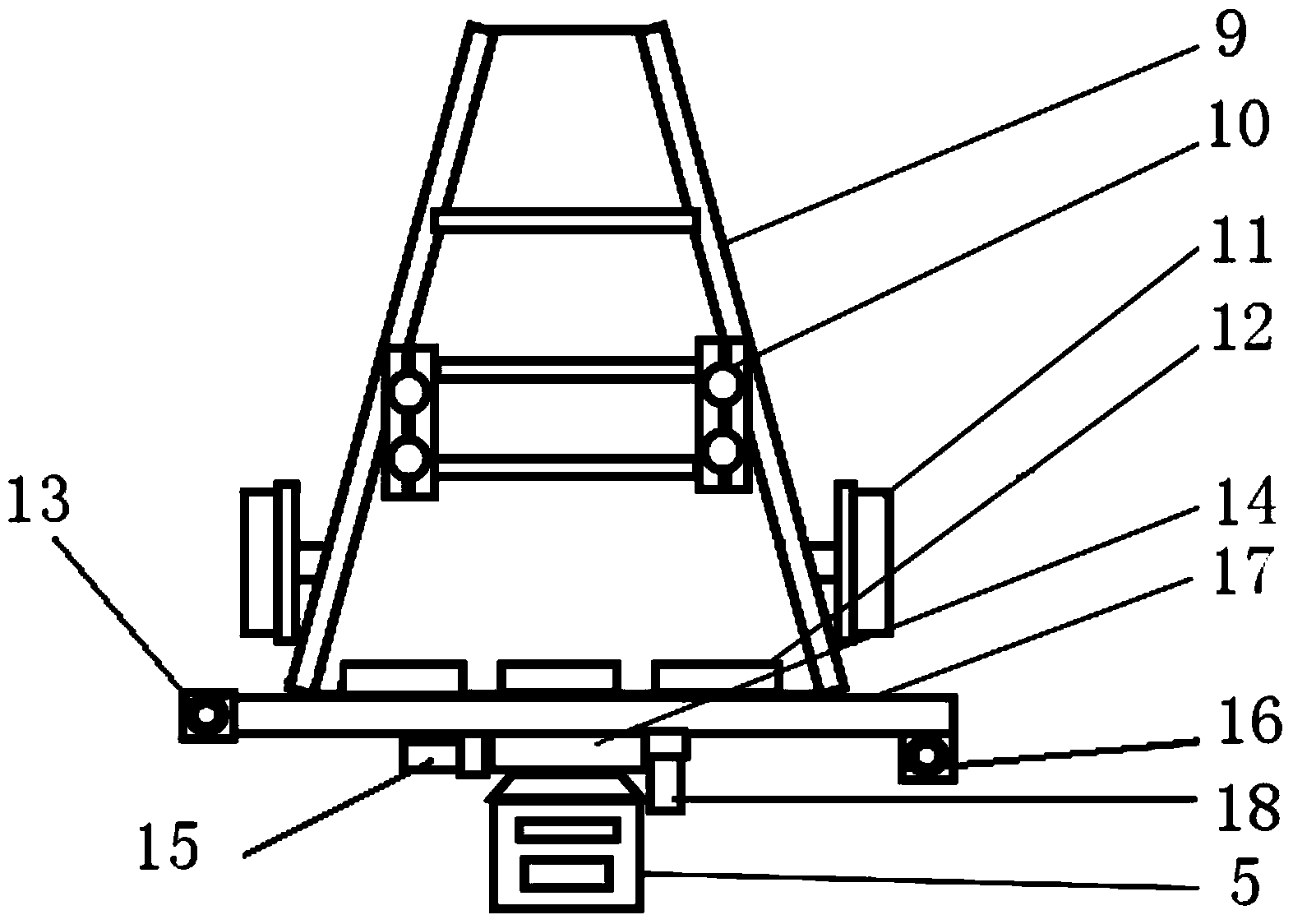

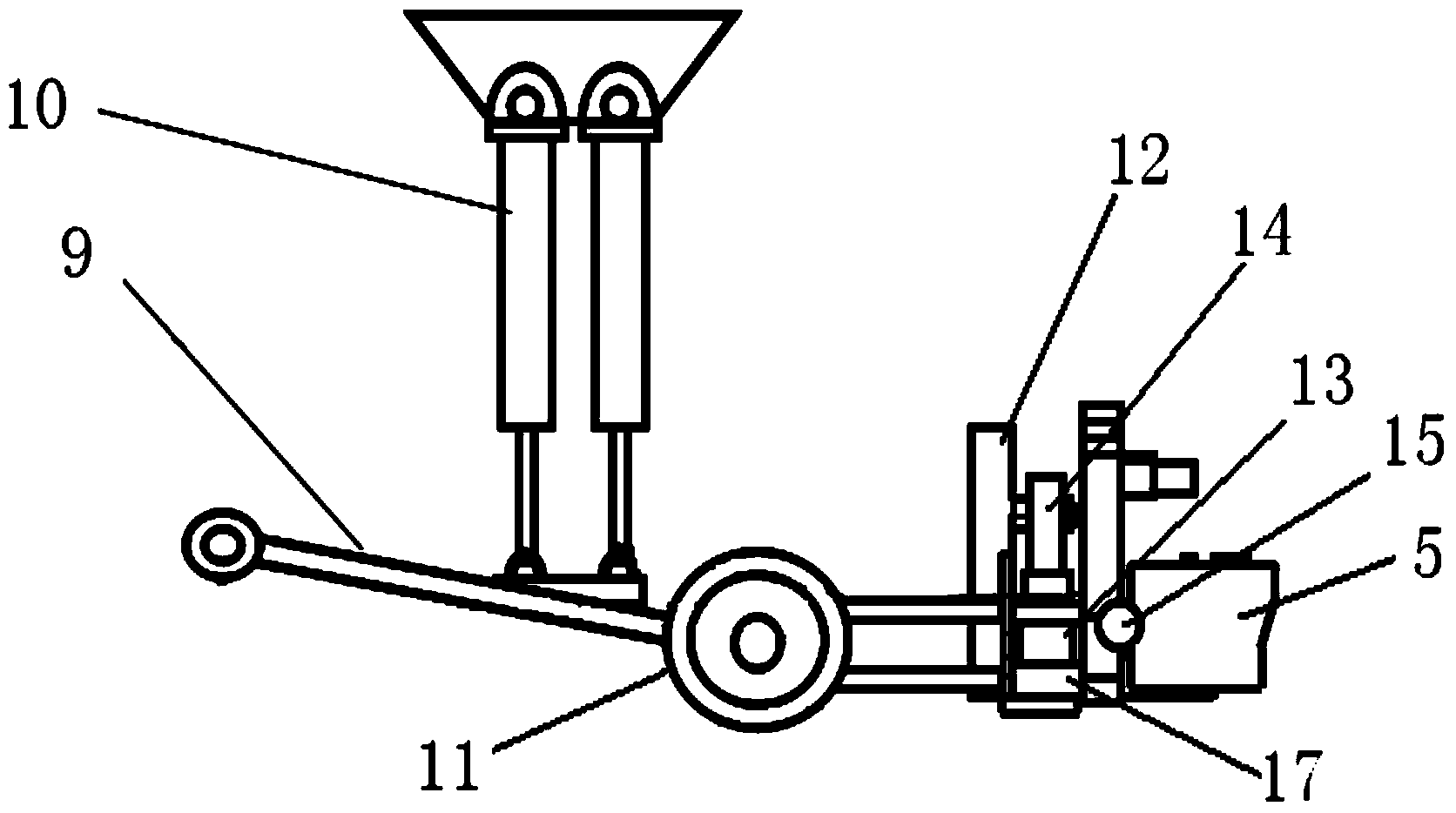

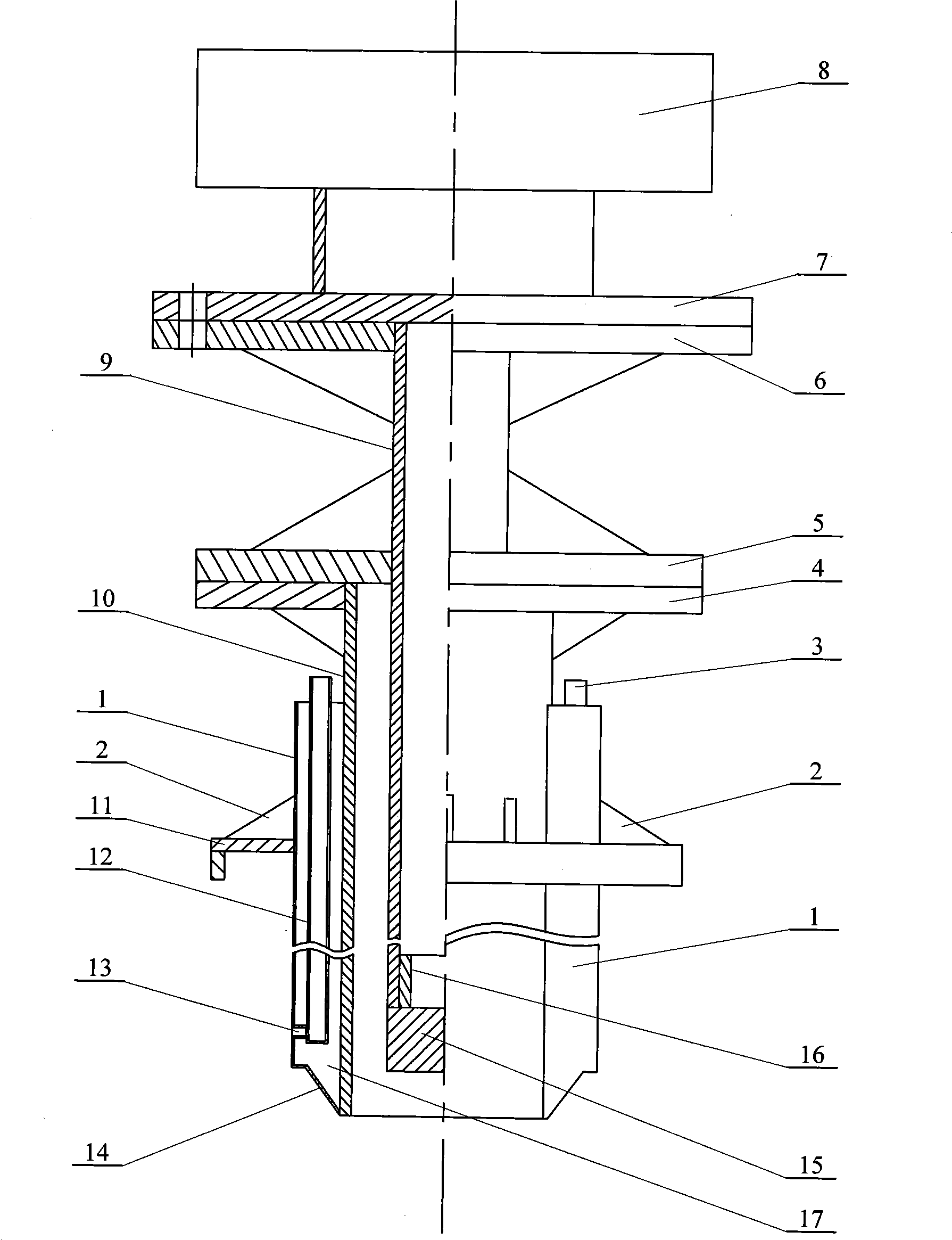

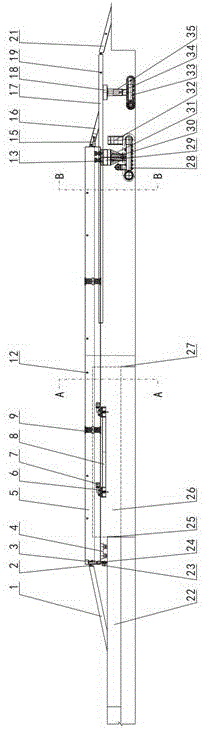

Ballast track laser intelligent track lifting and lining system and construction method

InactiveCN104060509AHigh degree of intelligenceReduced measurement workloadBallastwayRailway track constructionElectrical controlSet distance

The invention discloses a ballast track laser intelligent track lifting and lining system. The ballast track laser intelligent track lifting and lining system comprises a track lifting and lining tamper (1) and is characterized by further comprising an integrated full-route measurement device, the full-route measurement device comprises a laser transmitting device (4) and an image receiving device (5), the image receiving device (5) is arranged on a front end image receiving trolley (7), and the laser transmitting device (4) is arranged on a laser transmitting movable trolley (2) in a distance. The image receiving device (5) is provided with a two-dimensional automatic tracking mechanism. A construction method includes the steps that route geometrical shape parameters are input, and track lifting and lining are conducted; each time the ballast track laser intelligent track lifting and lining system advances by a set distance, an electrical control system collects front end lifting and lining quantity data, a gva system outputs track lifting and lining quantity data control operation of an operation position, and the gva system feeds back track lifting and lining quantity data of an operation process. By means of the ballast track laser intelligent track lifting and lining system and the construction method, ballast track accurate track lifting and lining measurement workloads are greatly reduced, construction accuracy is improved, the advantages of the full-route measurement system and a large track maintenance machine are given into full play, and the problem of man-made errors occurring in the connection between the measurement procedure and the track lifting and lining construction procedure is thoroughly solved.

Owner:中铁二十二局集团第二工程有限公司 +1

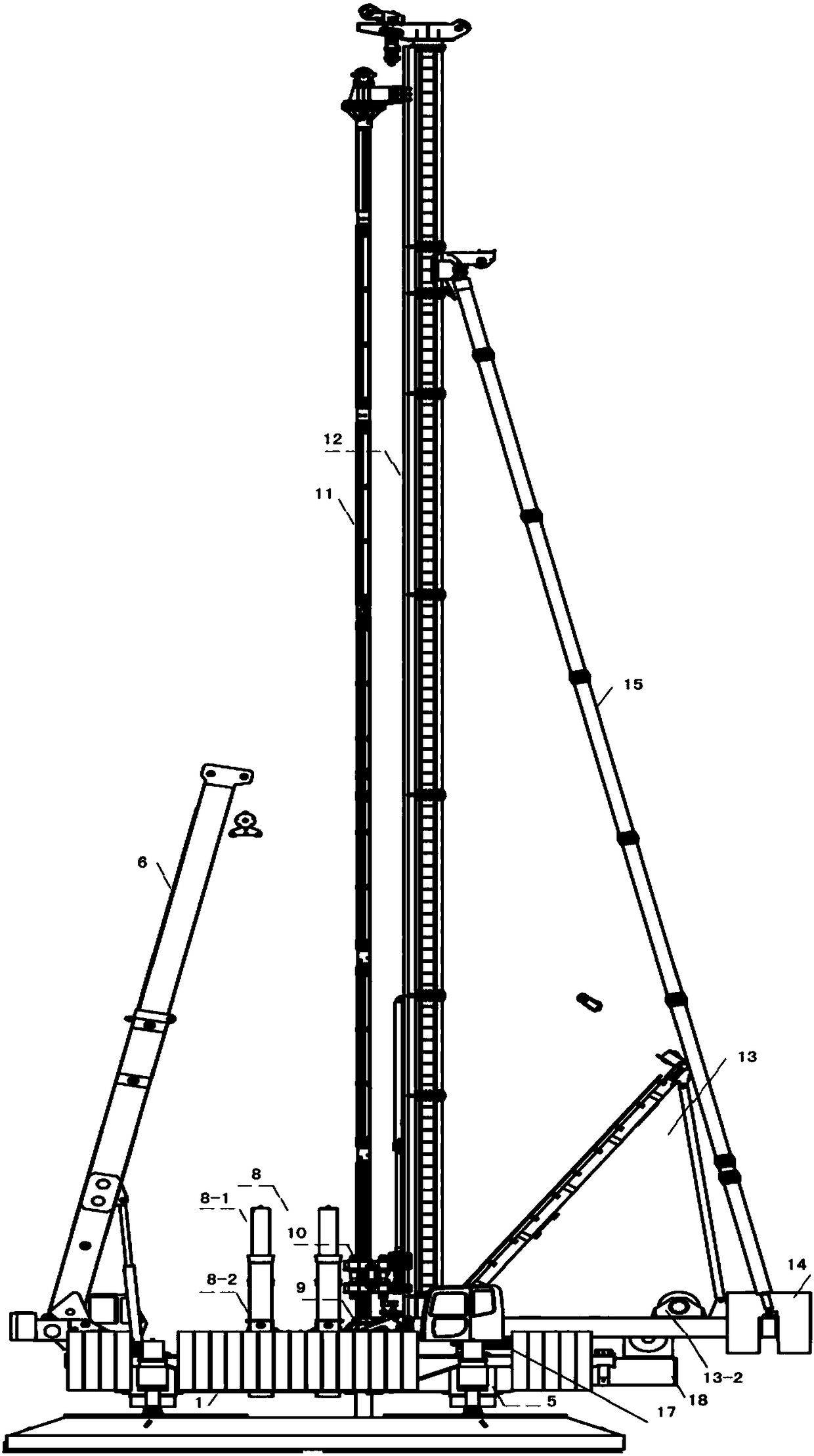

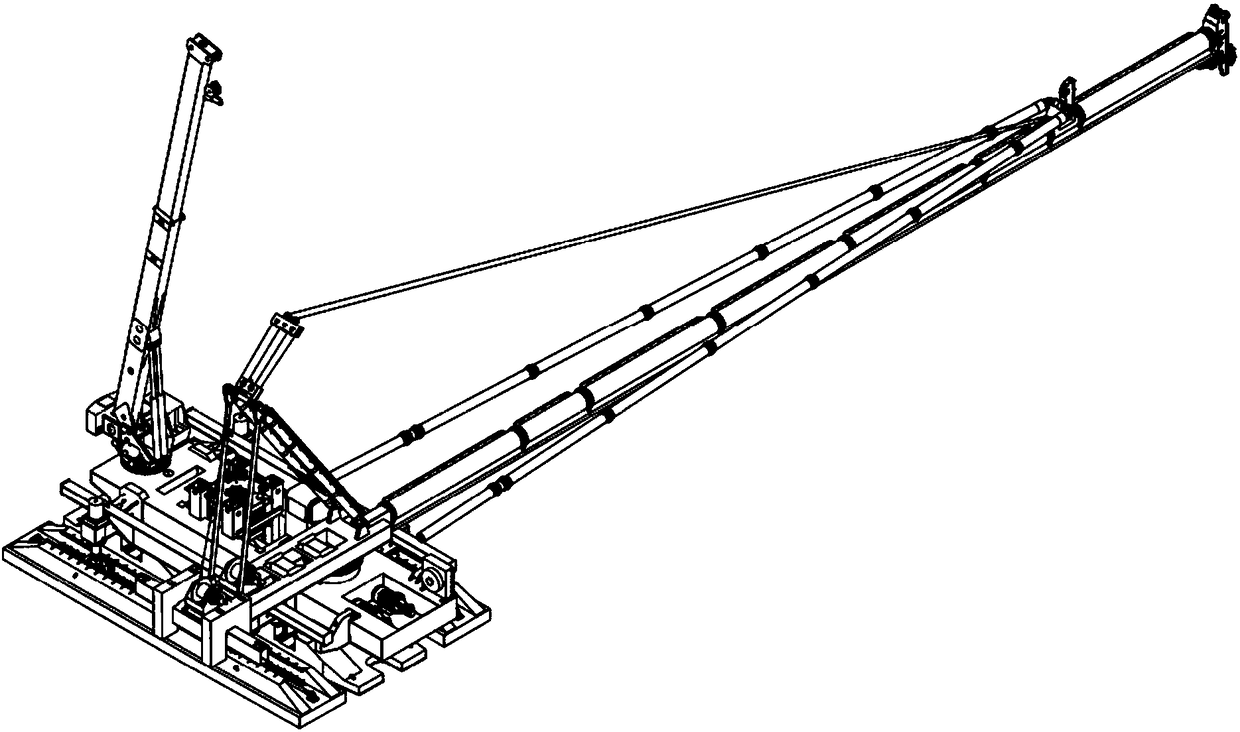

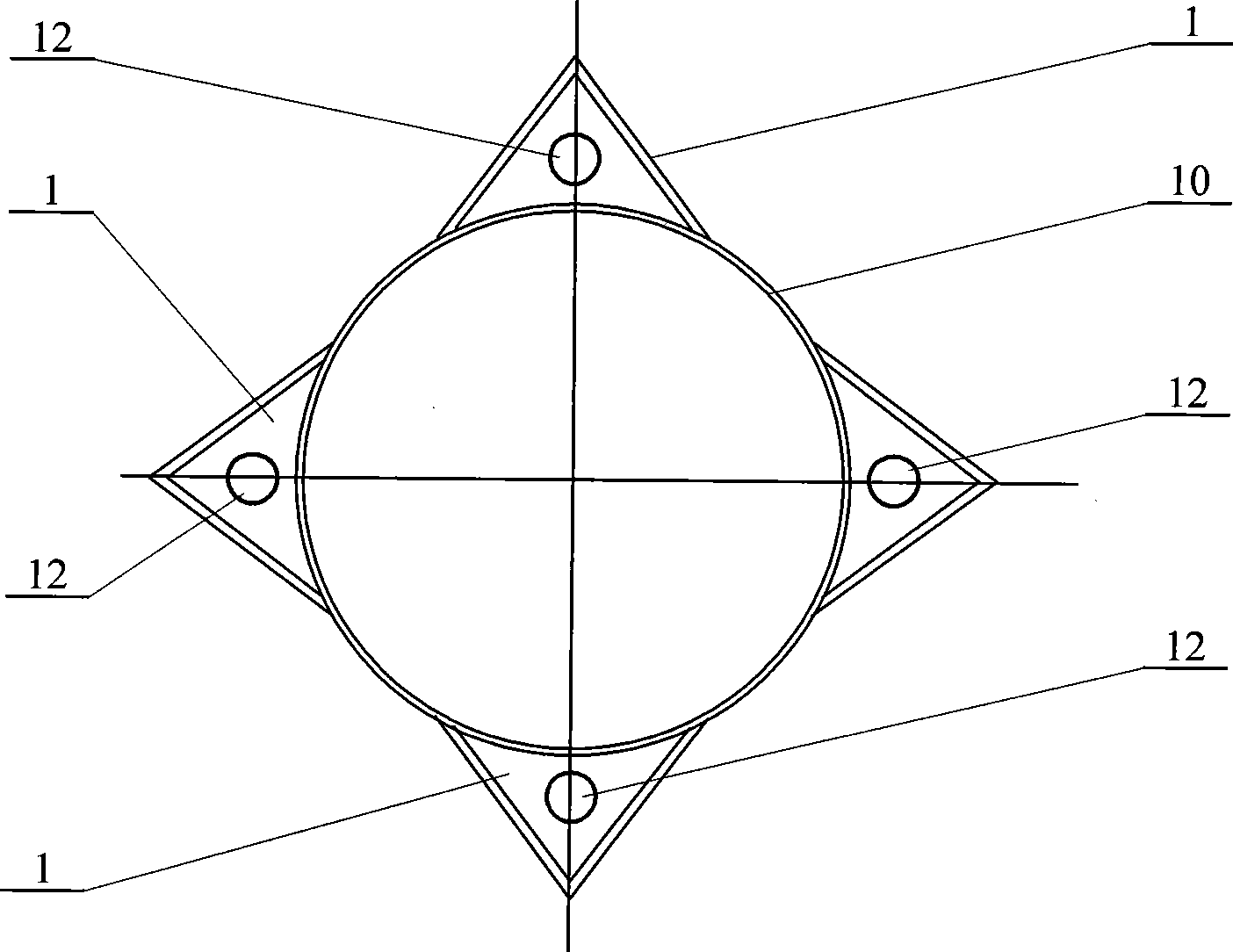

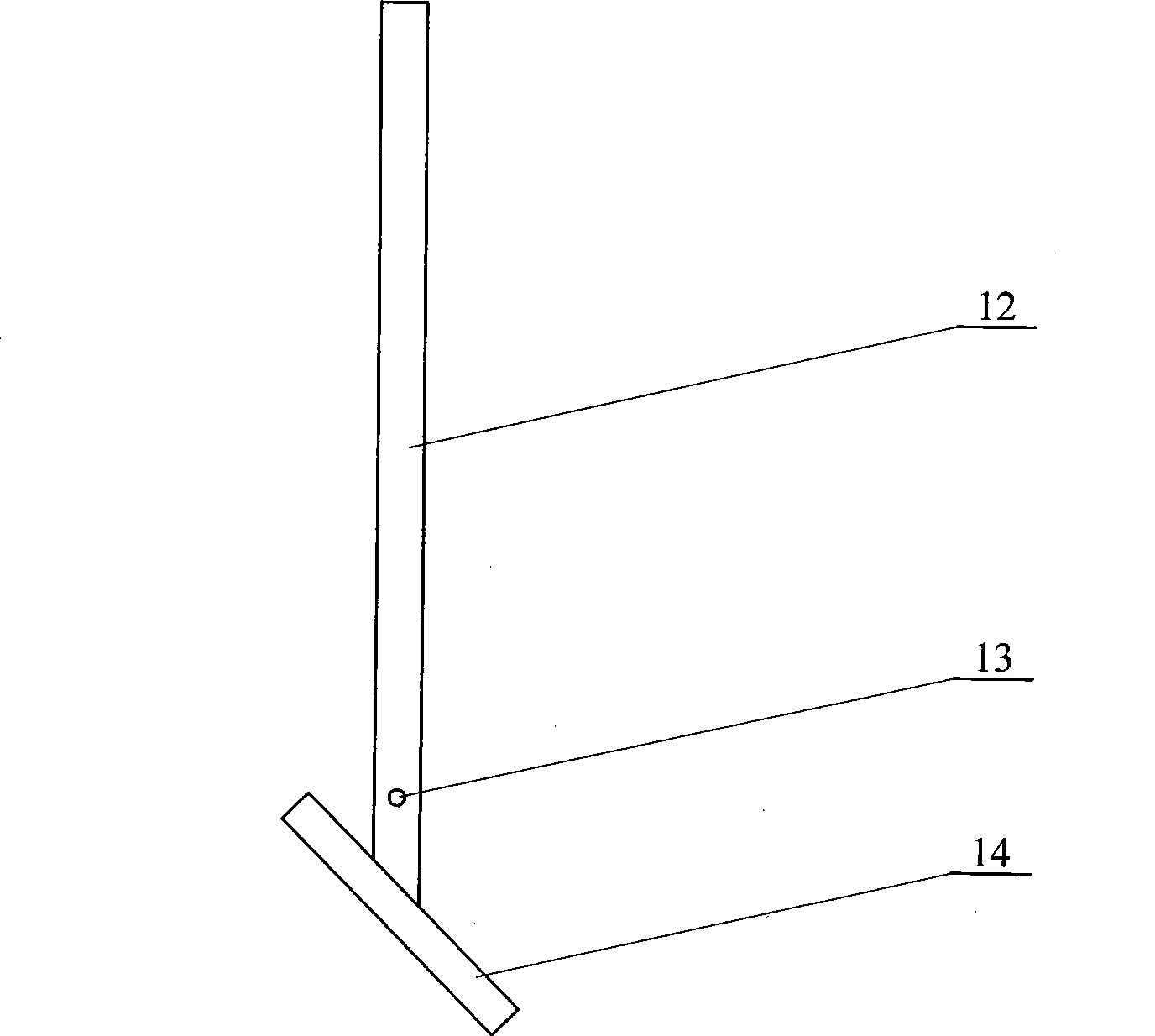

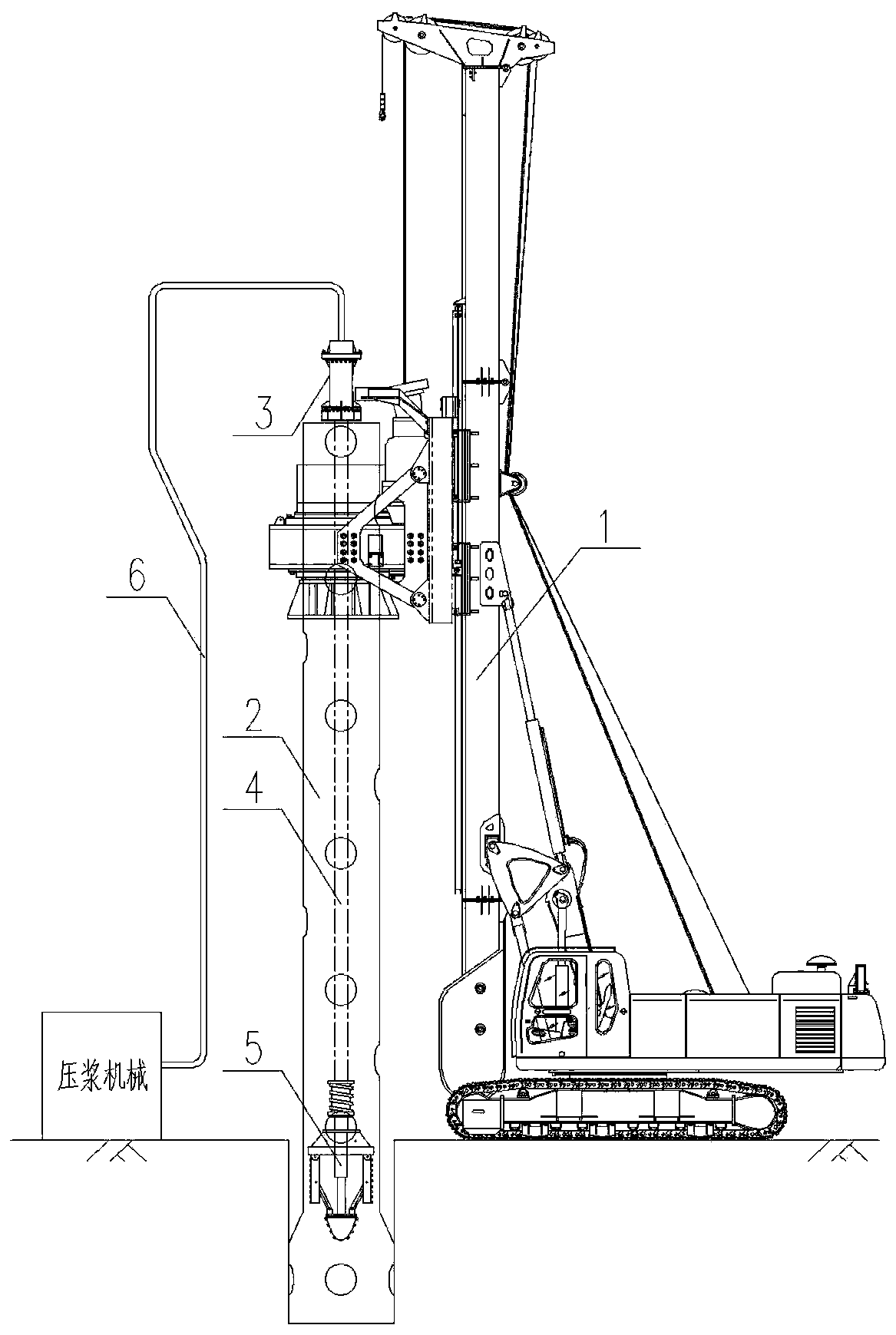

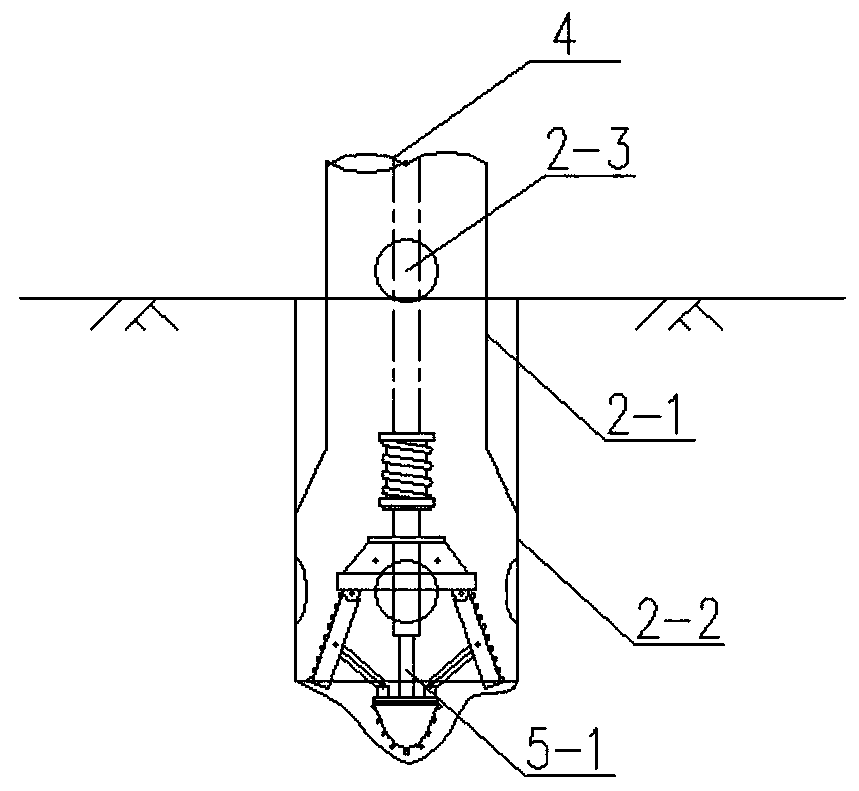

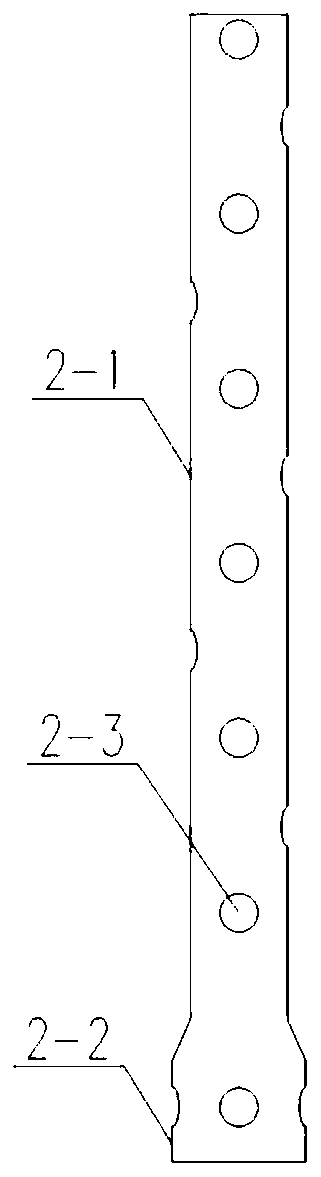

Pile forming apparatus and method for mud-jacking inner-ramming pedestal pile

The invention provides a pile-forming device for a grouting internal-ramming pedestal pile and a pile-forming method thereof, relating to a pile-forming device and a method. The device and the method aim at solving the problems that the existing internal-ramming pile has bad side friction and anti-pulling capability, is easy to generate the necking and breaking problem and has low construction efficiency. The injection pipe of the device is fixed in an external steel plate with a sealed cavity; the bottom end of the external steel plate with the sealed cavity is fixedly provided with a lower sealing plate with a sealed cavity; the invention is provided with four methods as follows: method one: an external pipe is impacted by a hammer, meanwhile, the grout is injected into the injection pipe by a pump, with the injection pressure of 0.3-10MPa; method two: an internal pipe is impacted by a diesel hammer, a hydraulic hammer or a vibration hammer and the filling material is impacted; method three: the external pipe and a pre-fabricated pile are impacted to a design depth by the diesel hammer, the hydraulic hammer or the vibration hammer; method four: the pre-fabricated pile is impacted into the pile hole, wherein, the diameter of the external pipe is less than or equal to the maximum internal tangent round of the pre-fabricating pile. The device has high construction efficiency and is suitable for various soil qualities. The method reduces the generation of necking and breaking, and improves the bearing capability by more than 30%.

Owner:李永刚

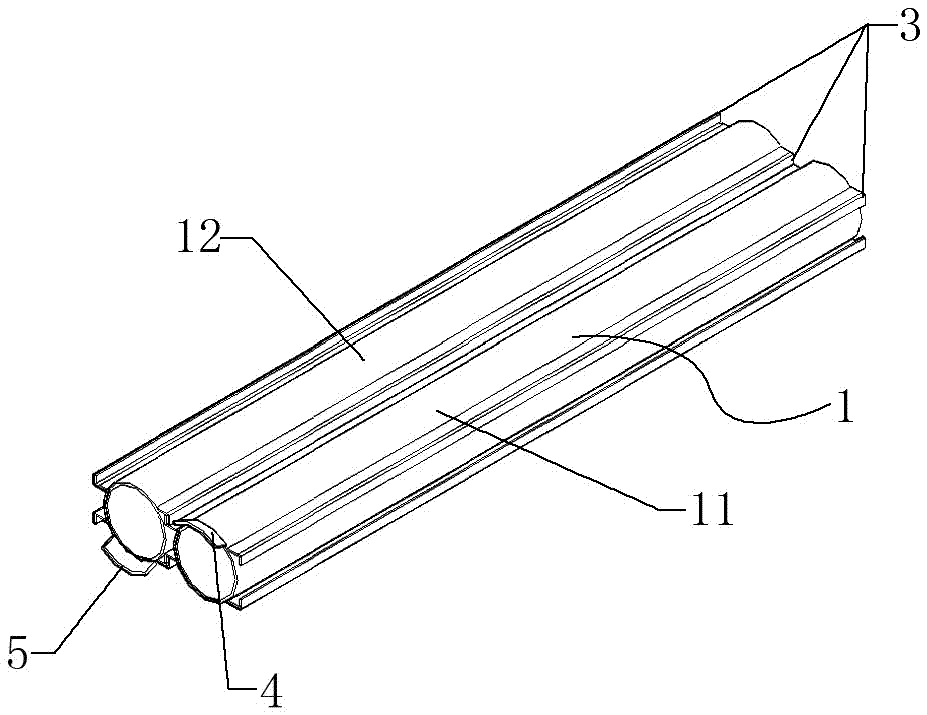

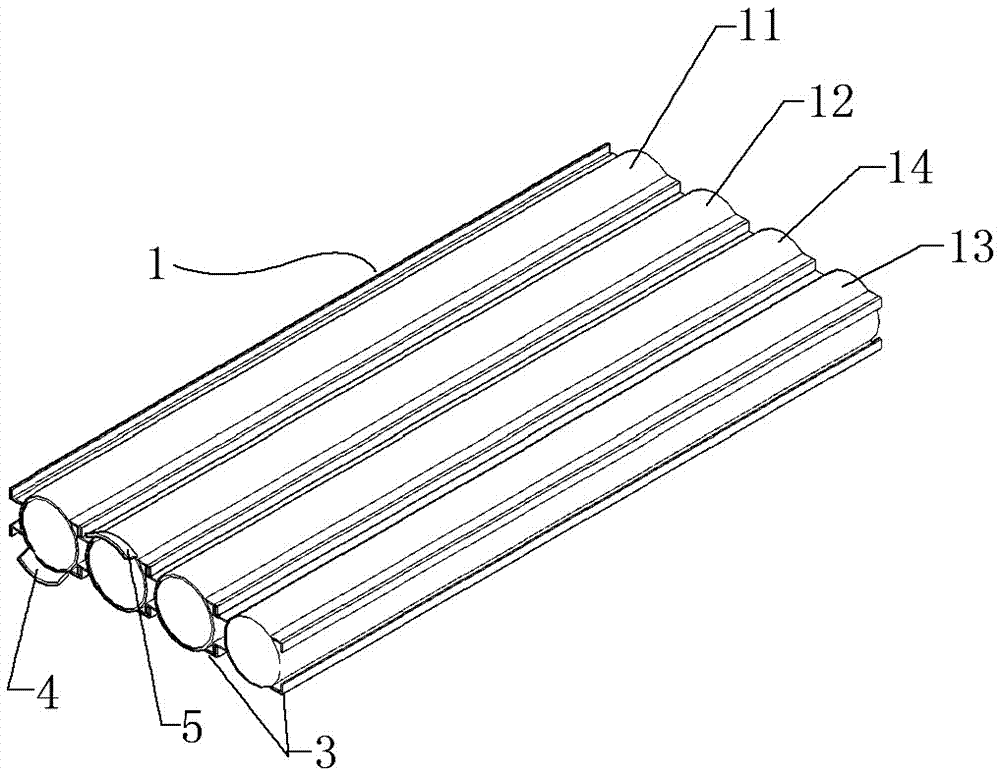

Pipe curtain construction method based on pipe banks

ActiveCN107190775ASimple construction methodFlexible construction methodArtificial islandsUnderwater structuresArchitectural engineeringUnderground space

The invention relates to the technical field of underground space construction, and discloses a pipe curtain construction method based on pipe banks. According to the pipe curtain construction method based on the pipe banks, the pipe banks are used as the construction unit and jacked at the same time for constructing a pipe curtain structure, each pipe bank is formed by arranging a set of steel pipes side by side, every two adjacent steel pipes are connected through a connecting component, and the number of the steel pipes in each set is not smaller than two. By adoption of the pipe curtain construction method based on the pipe banks, the construction efficiency is high, the jacking tendency can be controlled highly, jacking deviation can be rectified easily, and the construction precision is high.

Owner:BEIJING SHOUER ENG TECH

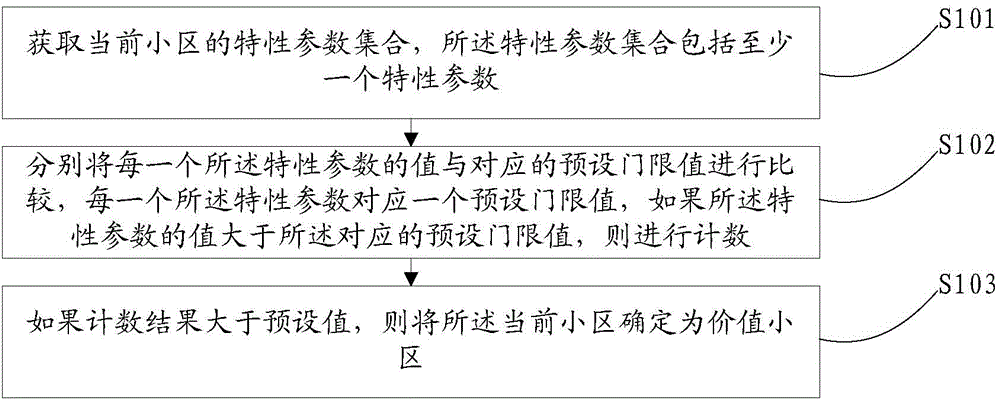

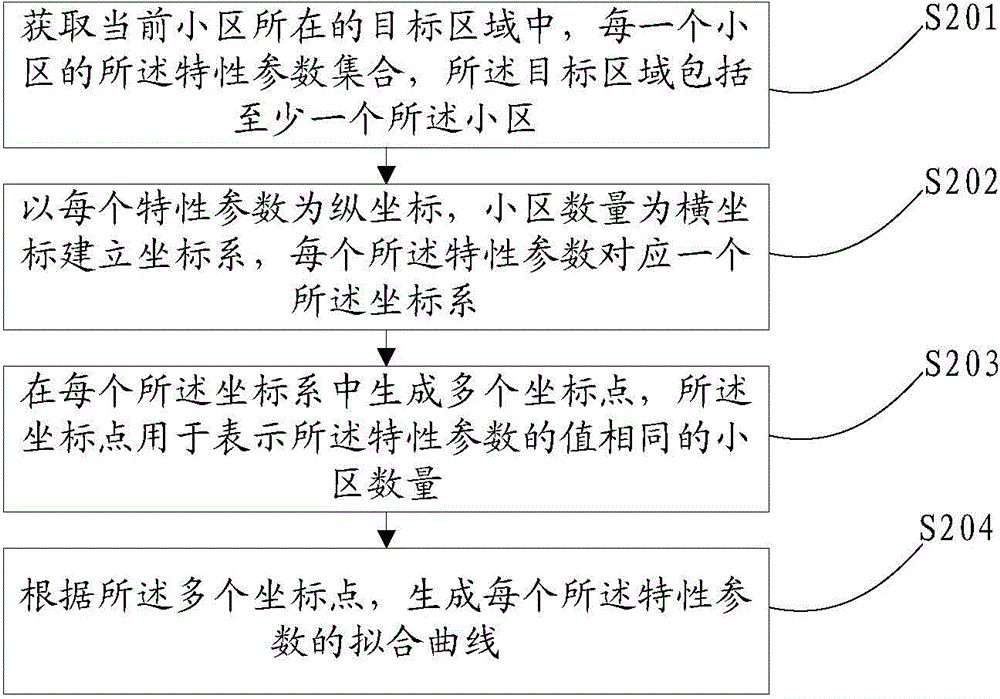

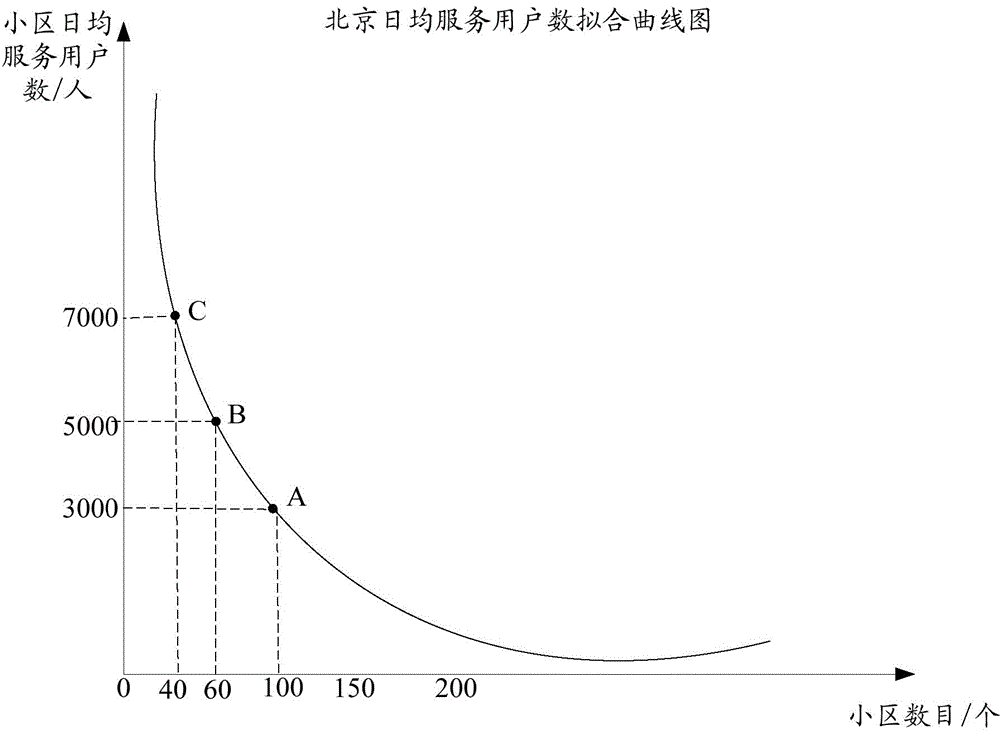

Method and device for selecting valuable cell

ActiveCN104486769AReduce construction efficiencyImprove construction efficiencyNetwork planningCurrent cellMachine learning

The invention discloses a method and a device for selecting a valuable cell, relates to the technical field of communication, and aims at solving the problem in the prior art that the network construction efficiency is relatively low due to the fact that the focus of network construction is not prominent in an existing network construction process. The method comprises the following steps: obtaining a characteristic parameter set of a current cell, wherein the characteristic parameter set comprises at least one characteristic parameter; respectively comparing the value of each characteristic parameter with a corresponding preset threshold value, wherein each characteristic parameter corresponds to one preset threshold value; if the value of one characteristic parameter is greater than the corresponding preset threshold value, counting; if the counting result is greater than a preset value, determining the current cell to be the valuable cell. The method and the device are applied to a construction process of a mobile communication network.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

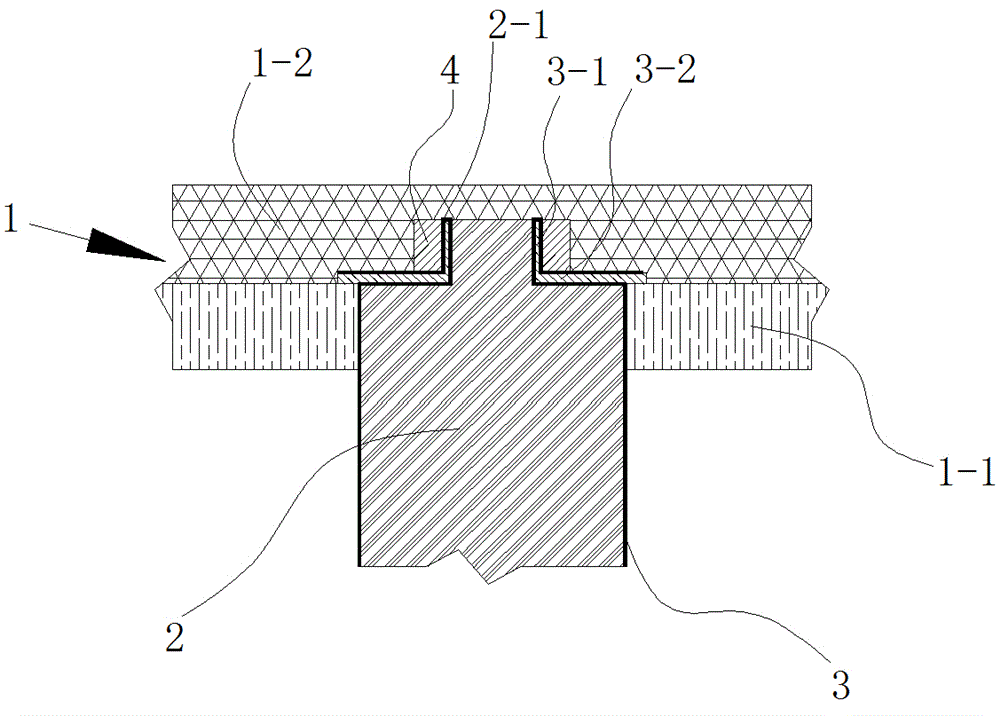

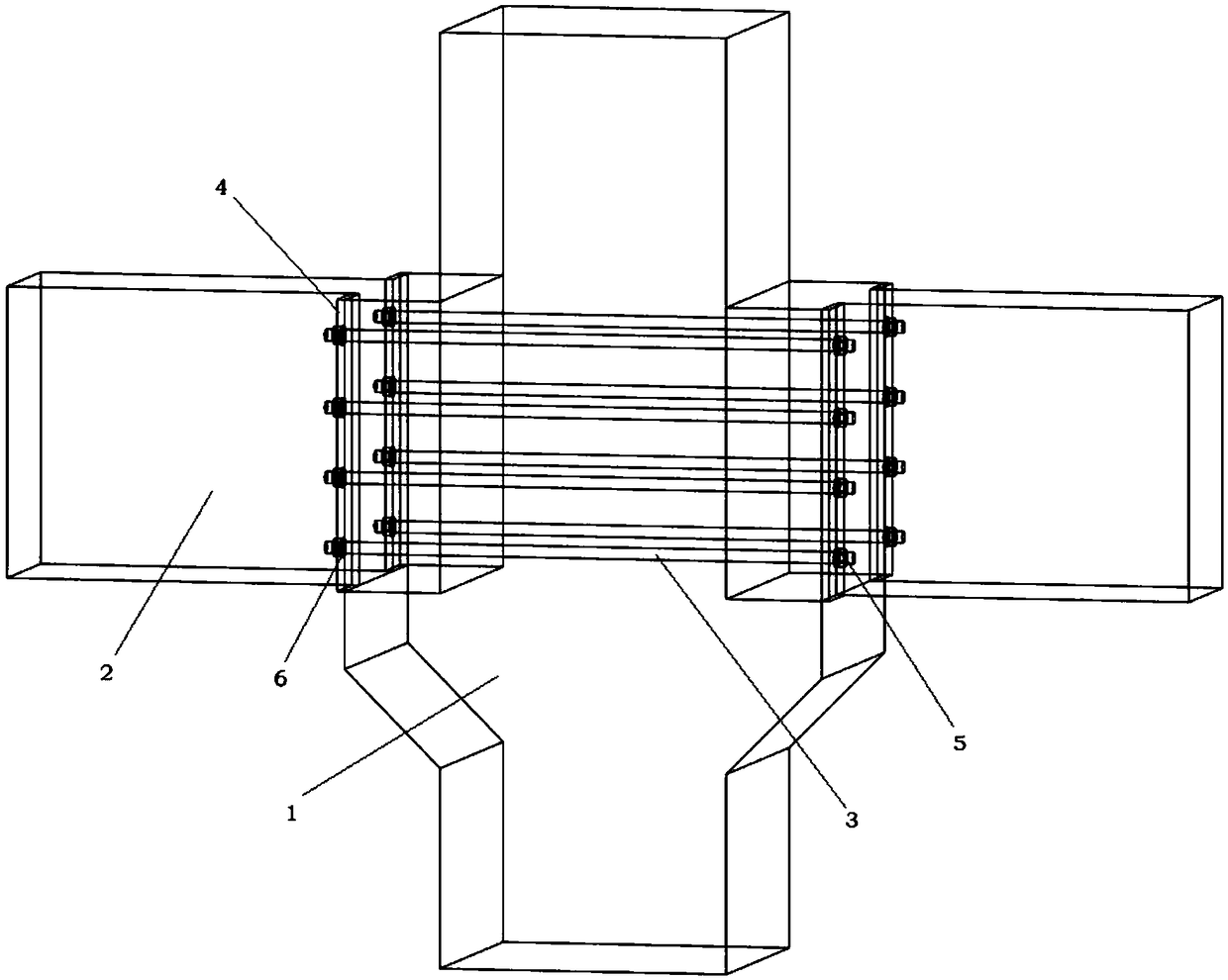

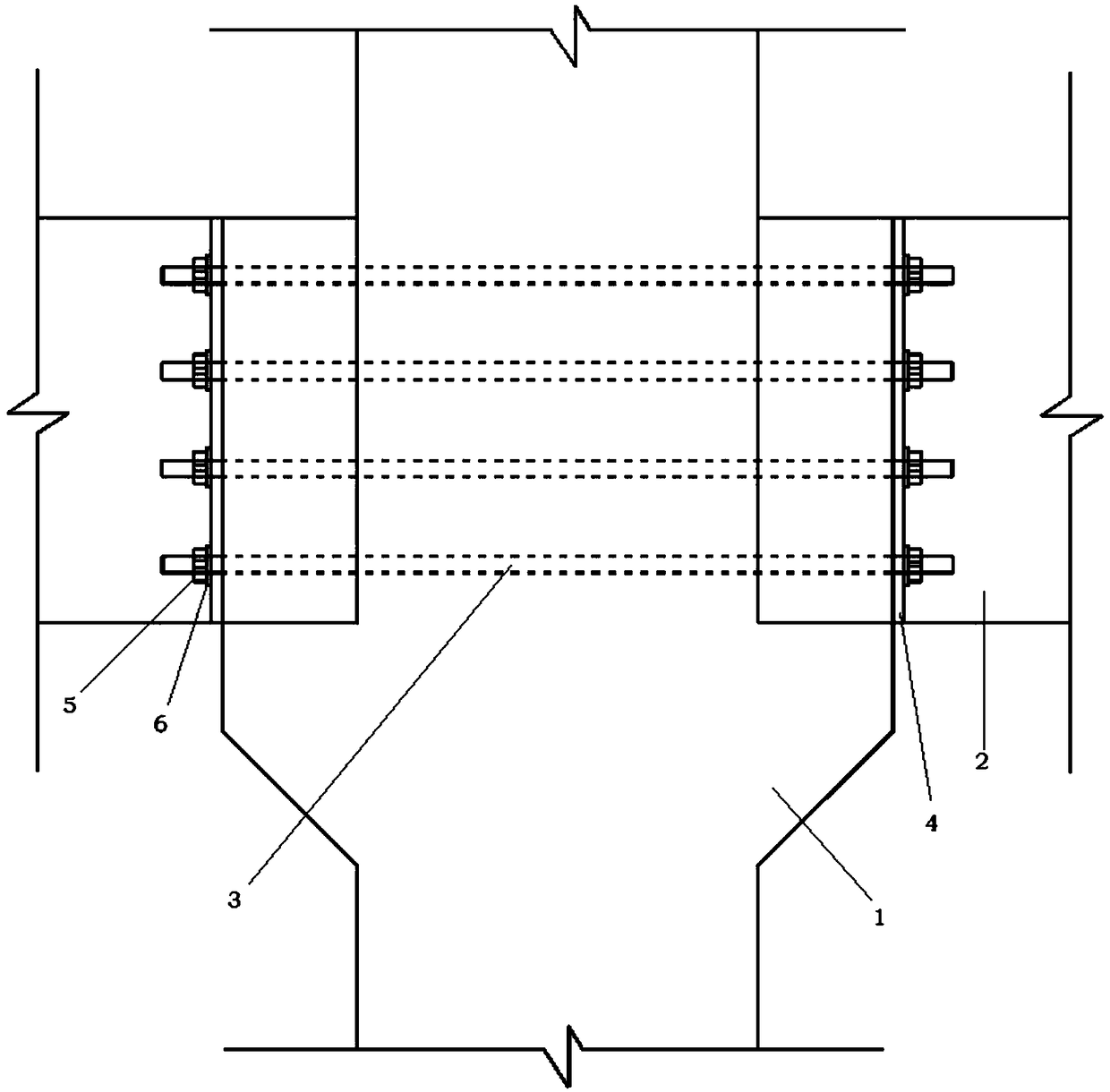

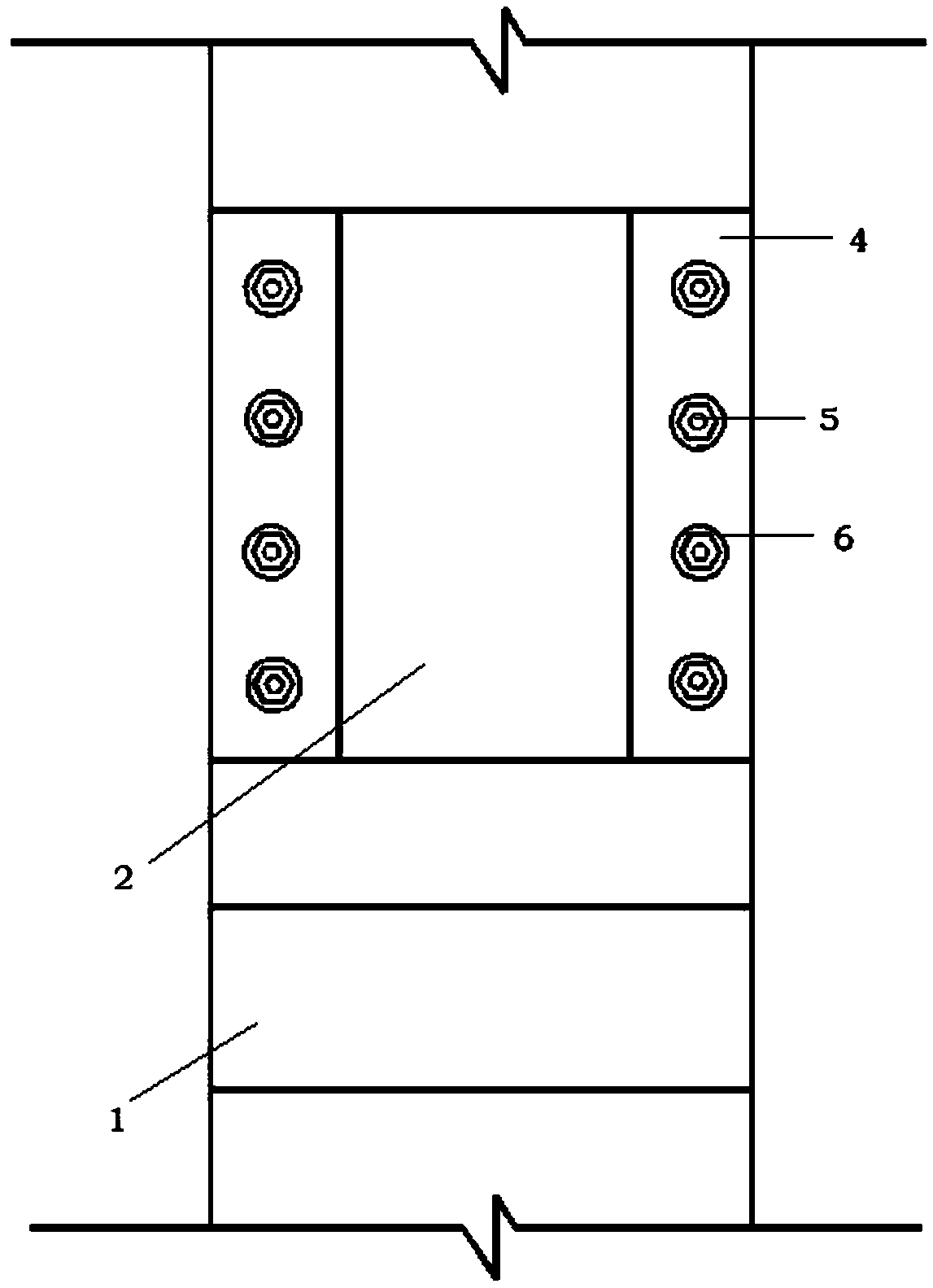

Fabricated frame structure beam-column connection node and construction method

PendingCN109183986AImprove deformation abilityImprove earthquake resistance and energy dissipation capacityBuilding material handlingEngineeringEnergy consumption

The invention discloses a fabricated frame structure beam-column connection node and a construction method and relates to the structural engineering field. The beam-column connection node includes a prefabricated cow-leg pillar, a prefabricated beam, a high-strength bolt, a pressure bearing steel plate and a nut, wherein the prefabricated beam includes a main body and a connecting portion, the connecting portion is located at an end portion of the main body and is integrally formed with the main body, the cross-sectional area of the connecting portion is larger than the main body, a force applying surface opposite to an end surface of the prefabricated beam is formed on the connecting portion, the pressure bearing steel plate is disposed on the force applying surface, the connecting portion is supported by cow legs on both sides of the cow-leg pillar, the connecting portion and the cow-leg pillar are connected through the high strength bolt, and an end portion of the high-strength boltpenetrates through the pressure bearing steel plate and is tightened by the nut. The beam-column connection node is advantaged in that through the prefabricated cow-leg pillar and the prefabricated beam, in a direct field splicing mode, construction of the beam-column connection node is completed, construction efficiency is effectively improved, energy saving and environmental protection are achieved, later maintenance difficulty is low, deformation capacity of the node is further greatly improved, and anti-vibration energy consumption capacity of the node is enhanced.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

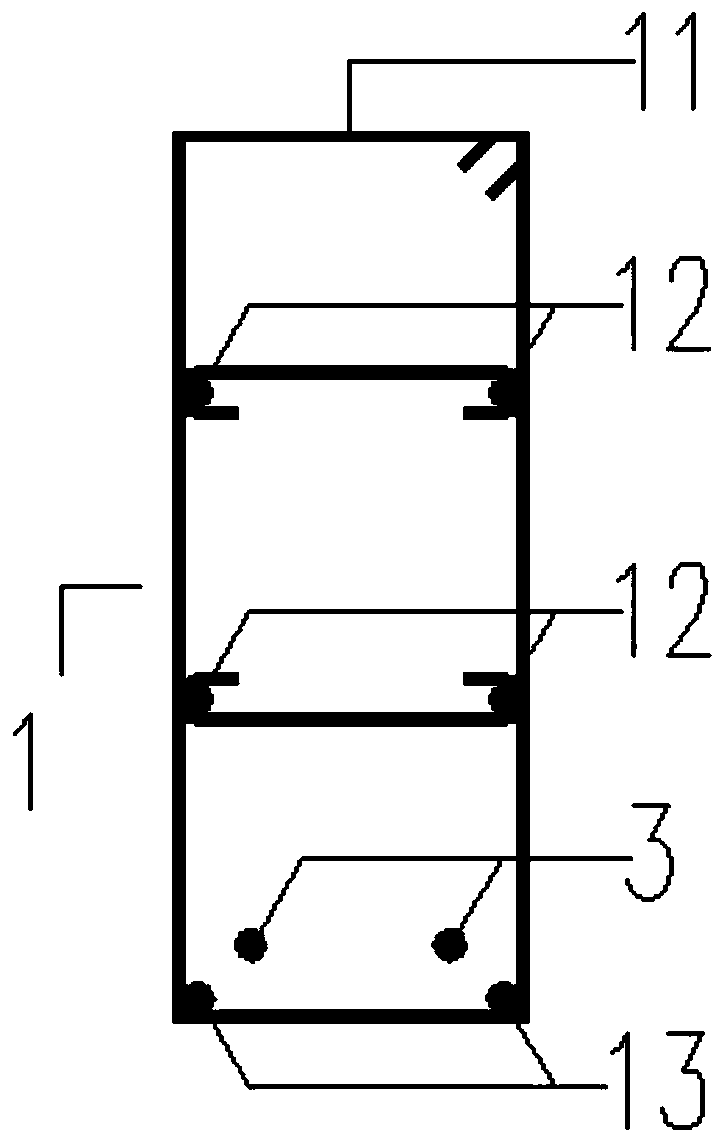

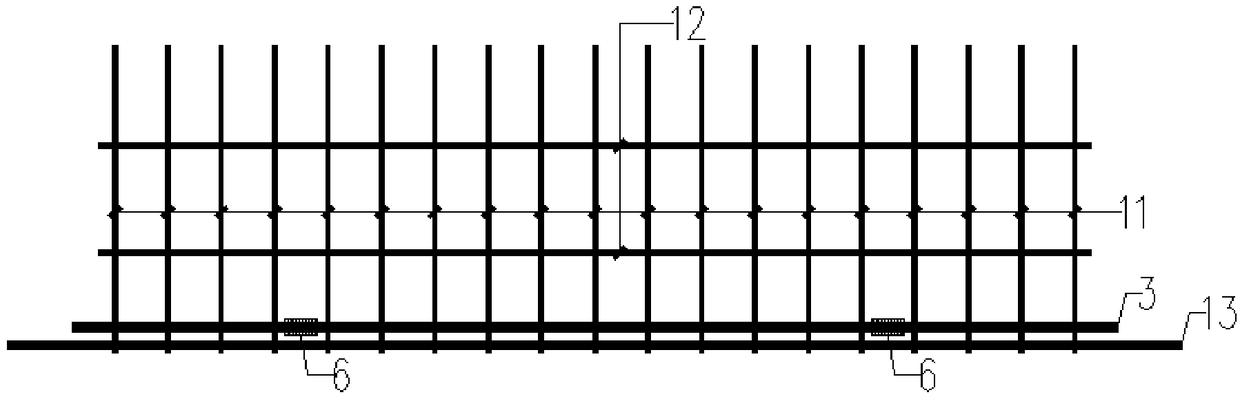

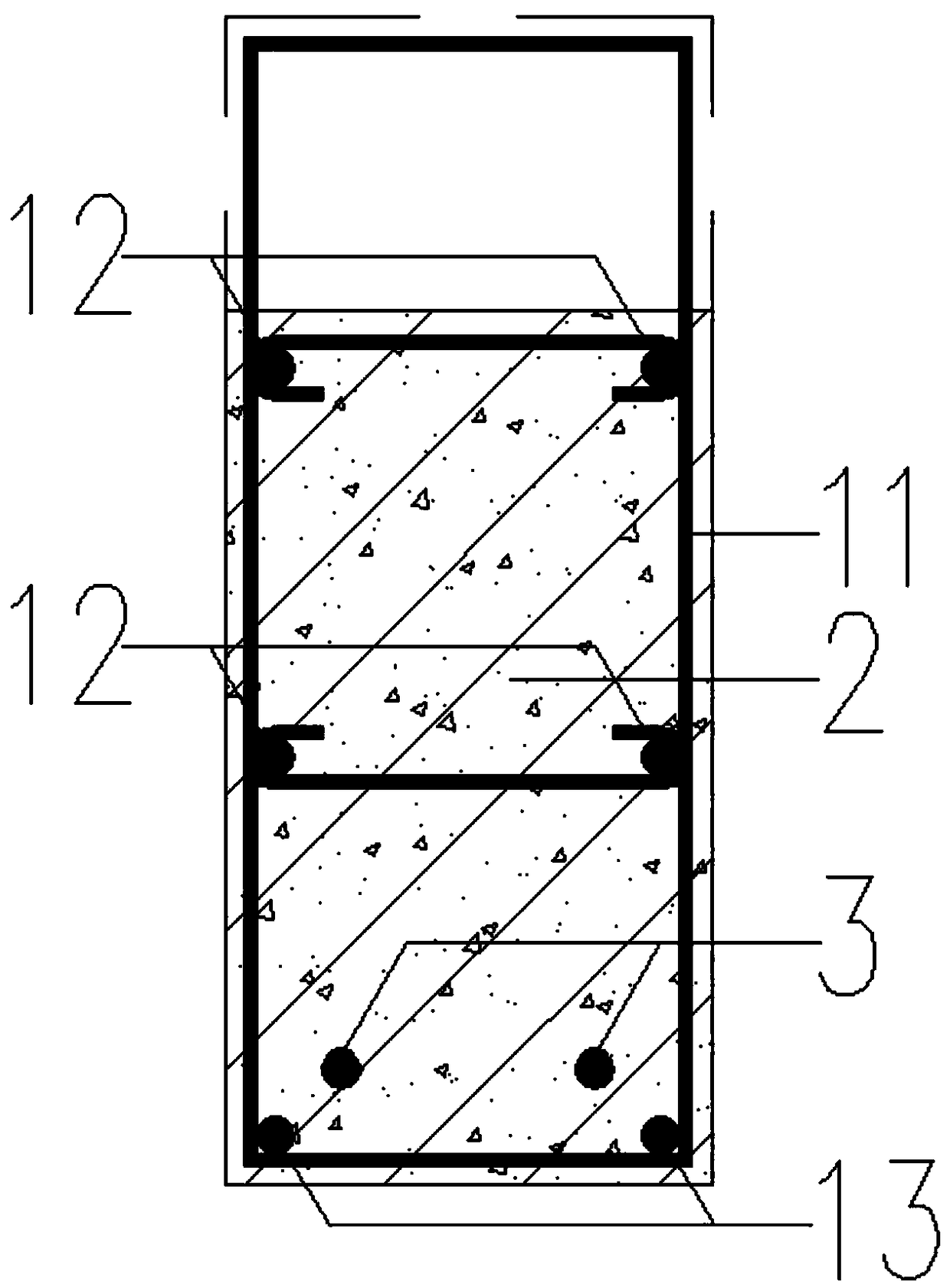

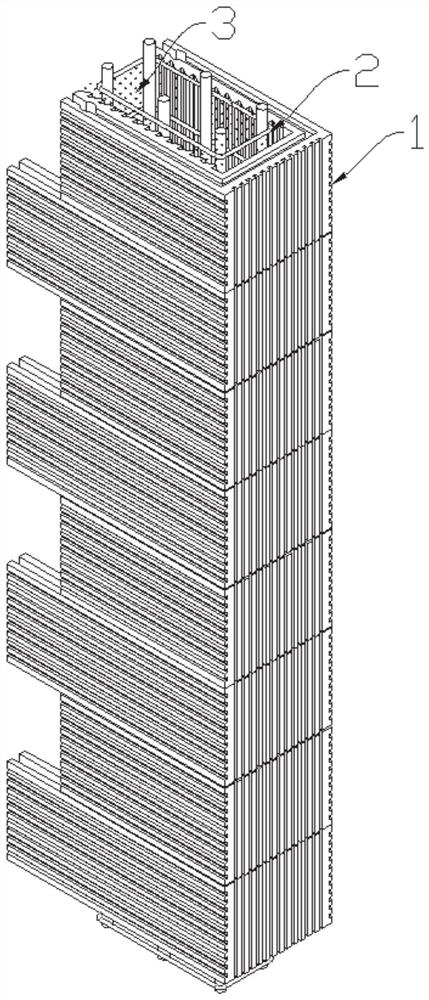

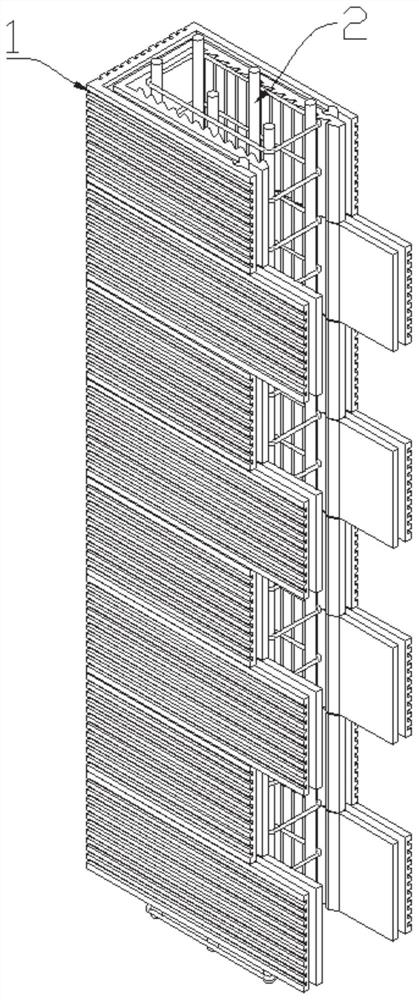

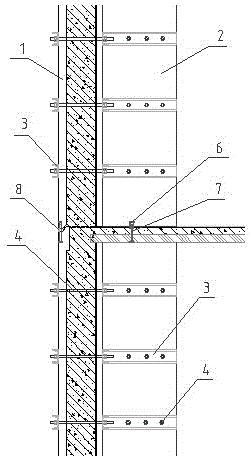

Construction equipment and method for fabricated non-dismantling formwork constructional column and ring beam

ActiveCN113846802ASave the installation and disassembly processImprove construction qualityStrutsWallsBrickArchitectural engineering

The invention relates to the technical field related to buildings, in particular to construction equipment and method for a fabricated non-dismantling formwork constructional column and a ring beam. The fabricated non-dismantling formwork constructional column comprises a plurality of U-shaped brick bodies which are different in length and connected in a staggered mode to form a formwork groove; a steel bar column is placed in the formwork groove, and a concrete pouring layer is poured between the steel bar column and the formwork groove. According to the construction equipment and method for the fabricated non-dismantling formwork constructional column and the ring beam, the design is novel, a U-shaped brick body is adopted to replace a wood formwork, a formwork mounting and dismounting procedure is omitted, the construction quality of the constructional column and the ring beam is improved, the construction efficiency is improved, the construction period is effectively shortened, the construction cost is saved, and the safety risk of edge work of the constructional column and the ring beam is greatly reduced. According to the construction equipment and method for the fabricated non-dismantling formwork constructional column and the ring beam, for the super high-rise edge constructional column, the formwork supporting and disassembling process is omitted, the construction risk is greatly reduced, a large amount of high-altitude edge operation is reduced, and the practicability is high.

Owner:CHINA RAILWAY URBAN CONSTR GRP

Reclamation area ultra-deep concrete diaphragm wall structure and construction method thereof

InactiveCN110512593AIngenious designImprove construction efficiencySoil-shifting machines/dredgersBulkheads/pilesImportance factorWell control

The invention discloses a reclamation area ultra-deep concrete diaphragm wall structure and a construction method thereof. The concrete diaphragm wall structure is in a ring shape, the concrete diaphragm wall structure comprises I type concrete diaphragm walls and II type concrete diaphragm walls which are arranged at intervals, the I type concrete diaphragm walls comprise I type groove sections,reinforcement cages arranged in the I type groove sections and cast-in-situ concrete, and the II type concrete diaphragm walls comprise II type groove sections, reinforcement cages arranged in the IItype groove sections and cast-in-situ concrete. Groove grasping technology construction can be conducted in advance, the construction main line time is not occupied, the construction efficiency is greatly improved, and the construction time is shortened. A reclamation area belongs to soft soil ground, soil reinforcement is conducted by using three-axis mixing before concrete diaphragm wall construction. Perpendicularity is well controlled, the width of sleeve connection is guaranteed, and later stage leakage is avoided. The formed concrete diaphragm wall structure is firm and durable, the safety level of a foundation pit support structure is the first level, and the importance factor is 1.1. The service life of the foundation pit temporary support structure is designed to be two years, andthe service life of the foundation pit support structure for permanent using is 50 years.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

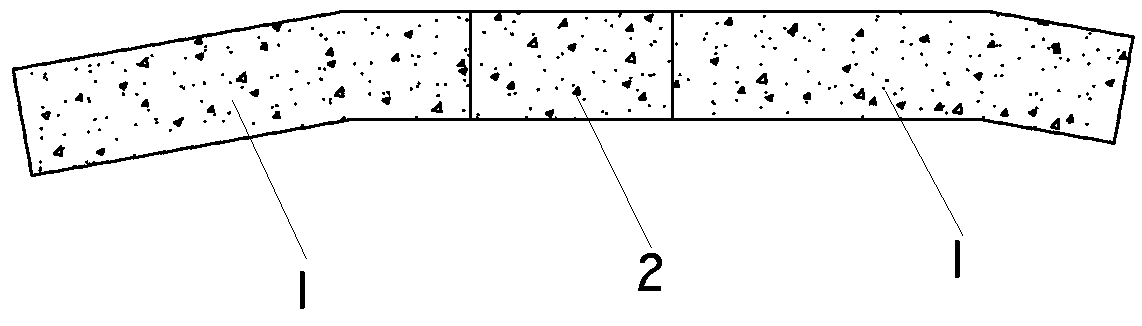

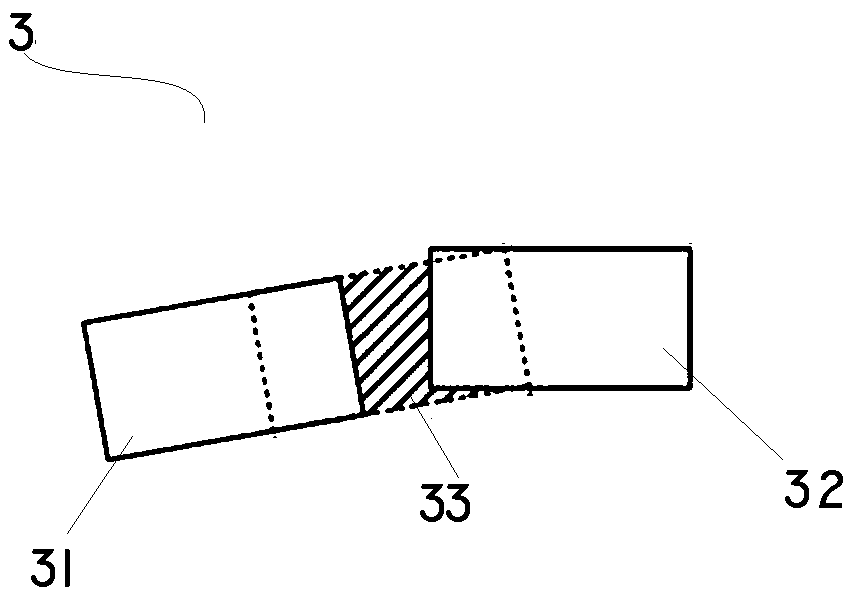

Closing construction method for steel bar-concrete superposed beam cable-stayed bridge

ActiveCN103147409AReduce control precision requirementsReduce waiting timeBridge erection/assemblyCable stayedSteel bar

A closing construction method for a steel-concrete superposed beam cable-stayed bridge comprises the following steps: manufacturing a handy elliptical hole tool splicing plate, closing at a fixed time, tool splicing plate temporarily fixing construction, construction of a permanent splicing plate replacing tool a splicing plate, and the like. According to the invention, the construction of the handy elliptical hole tool splicing plate is adopted for accomplishing timed closing construction to the steel-concrete superposed beam cable-stayed bridge, and then in-plant punching manufacture and on-site replacement construction are performed on the permanent splicing plate according to the position size of a blot hole of the closed tool splicing plate, so as to achieve midspan closing. The orderliness and the definitiveness of organization of closing construction procedures can be enhanced, the construction efficiency is improved, and construction quality and safety are ensured.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

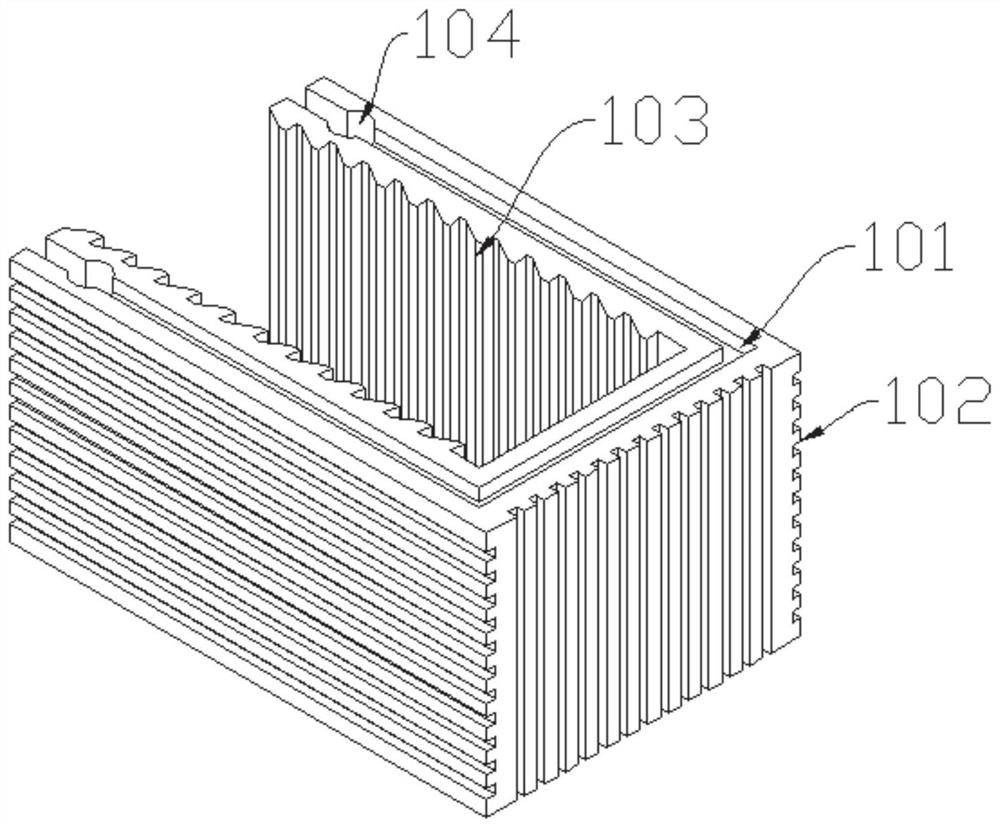

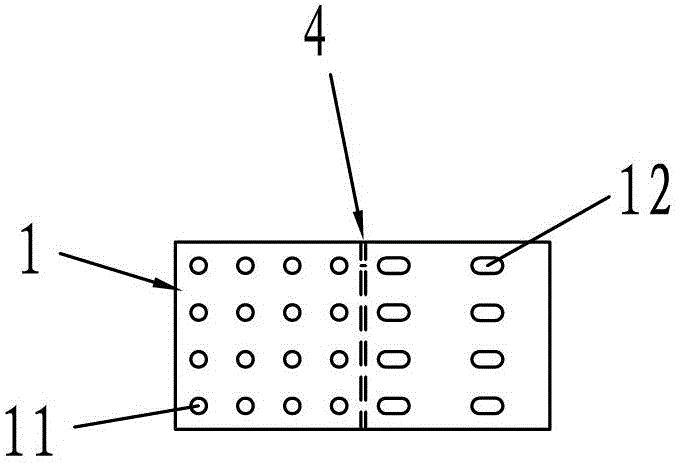

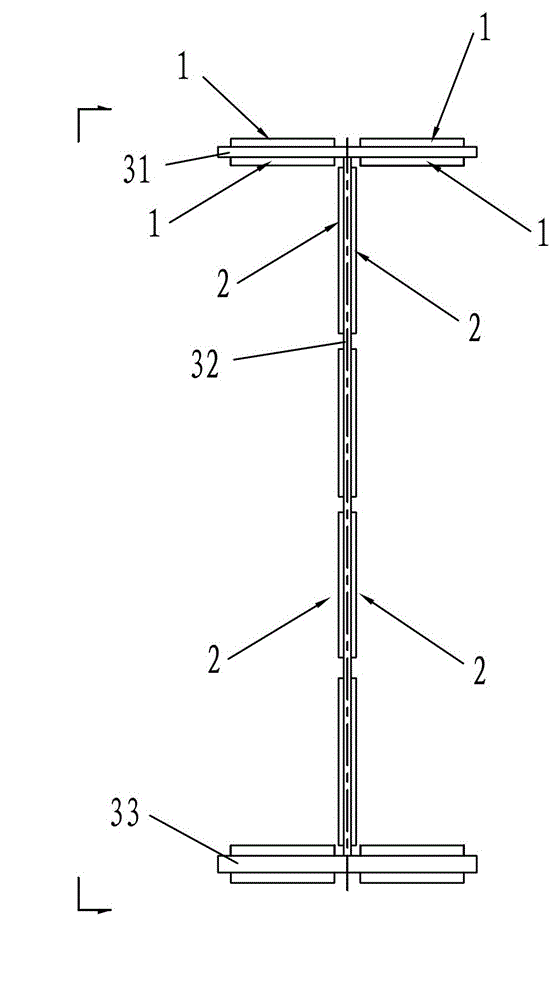

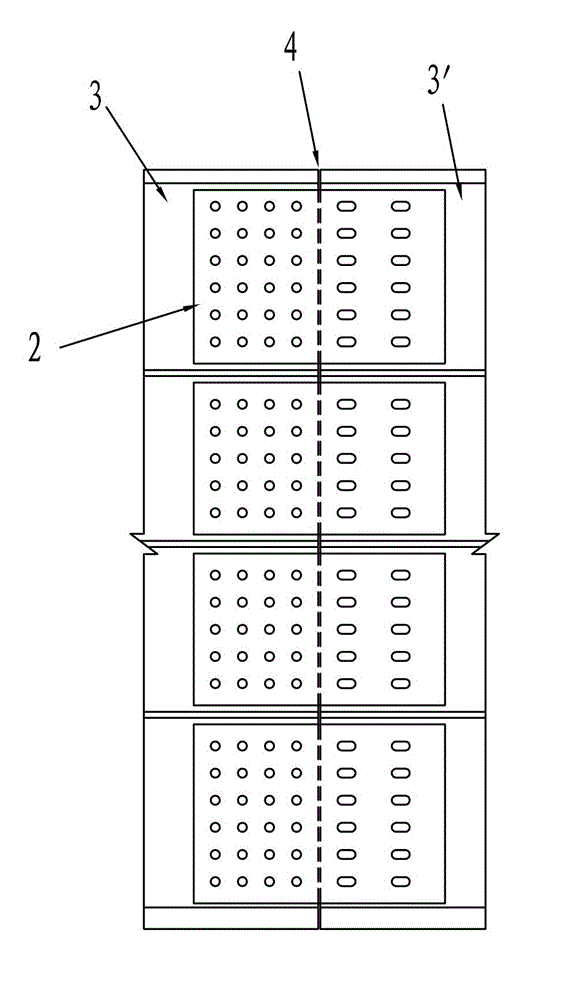

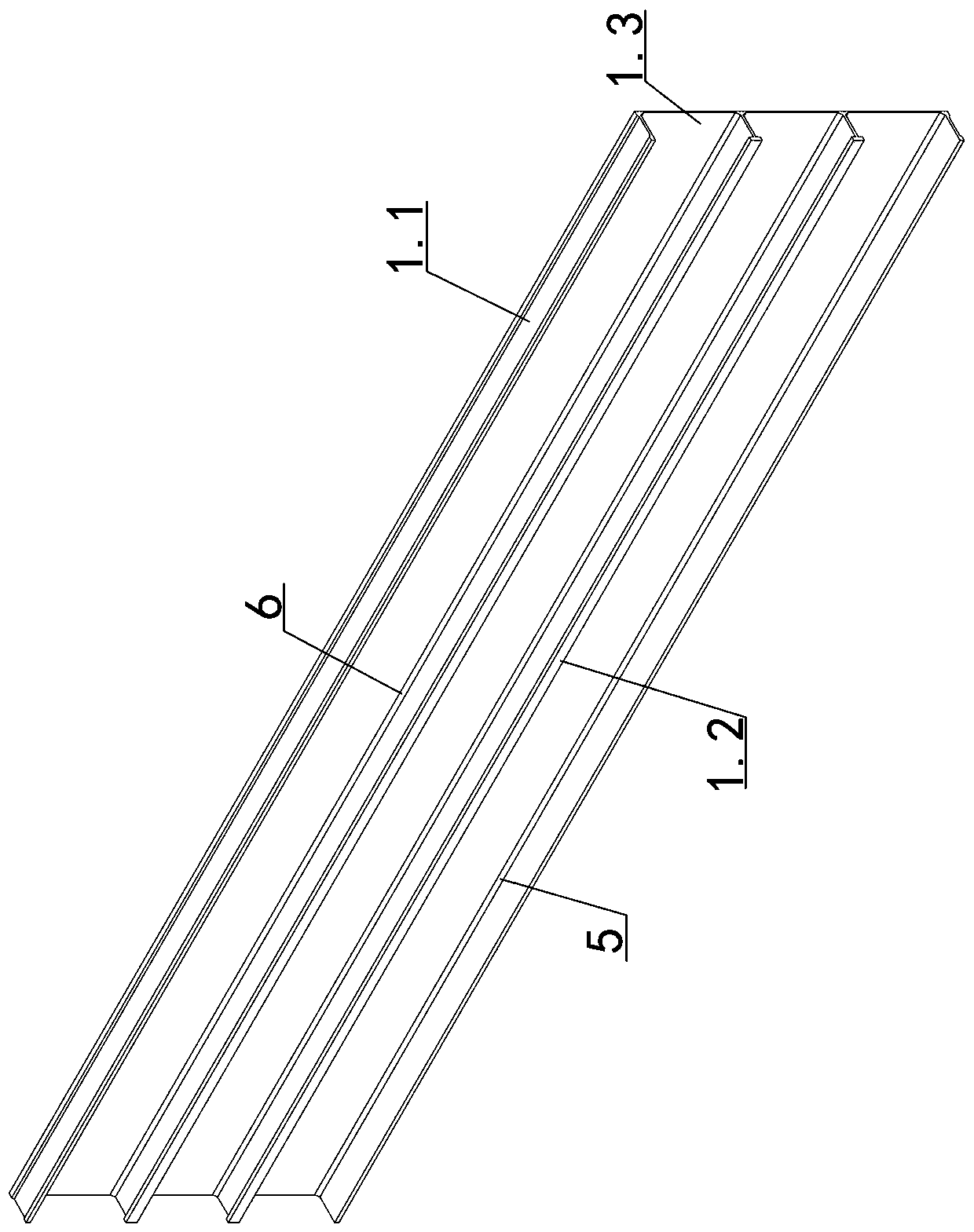

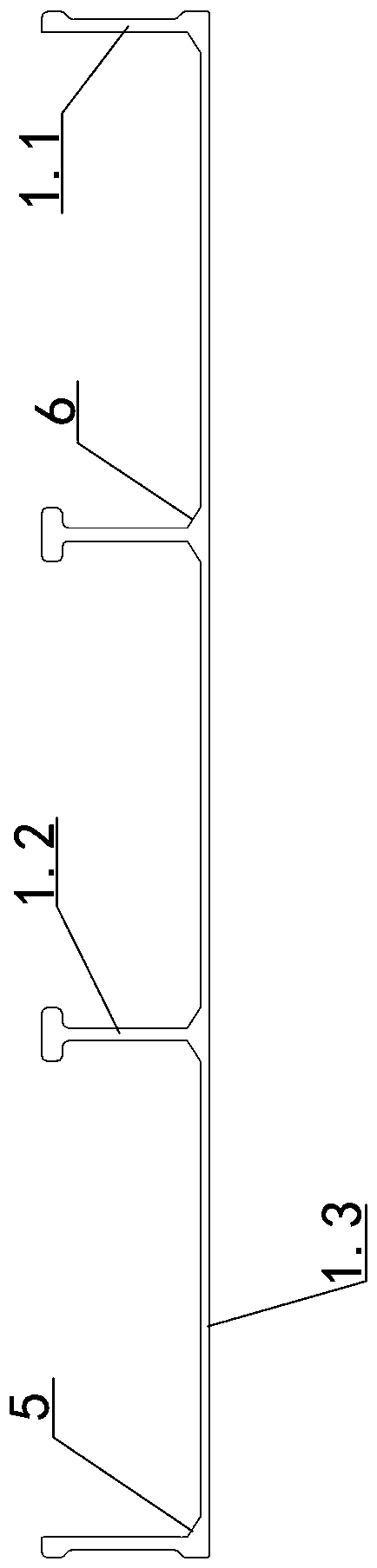

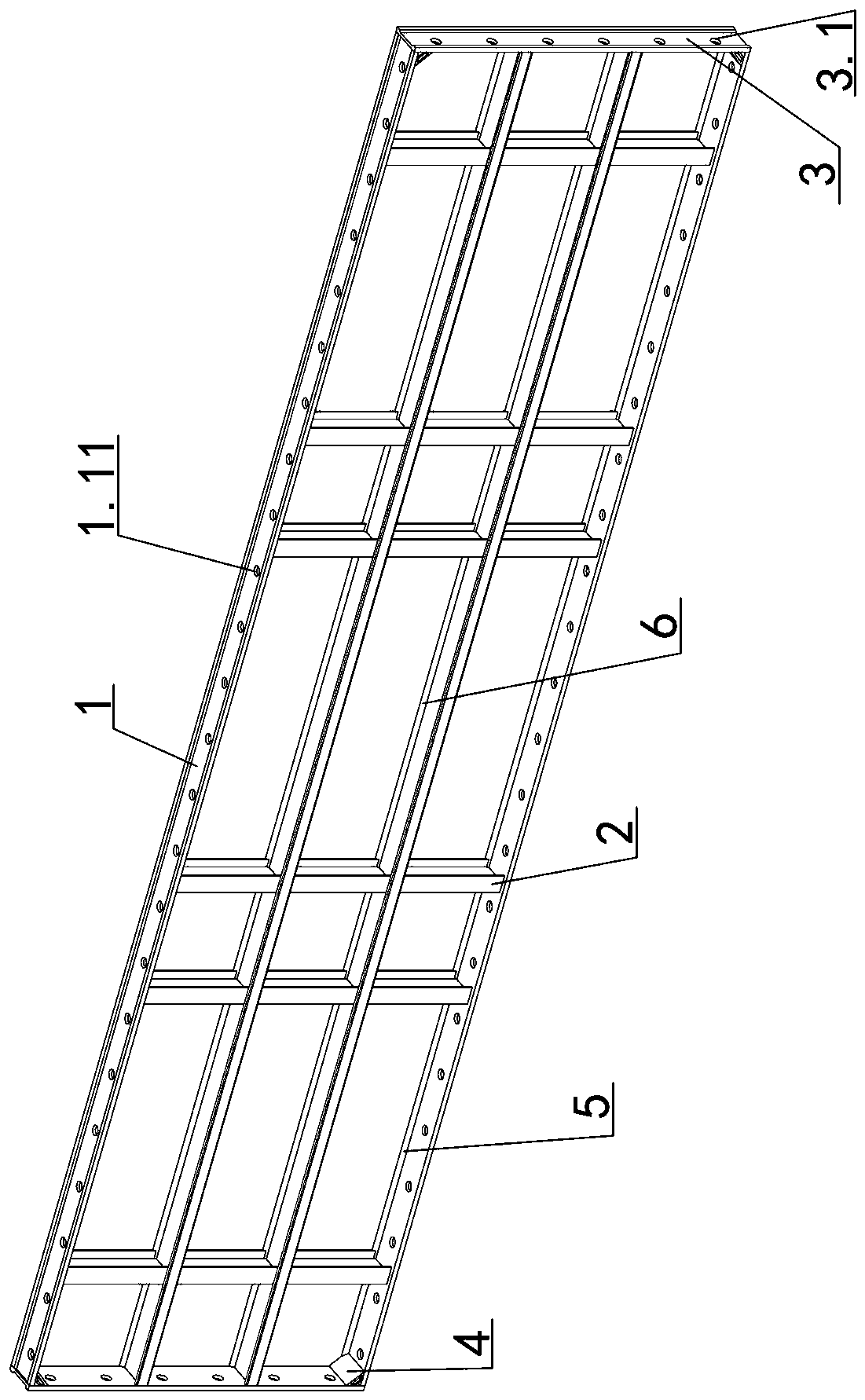

T-shaped section profile for aluminum alloy template and unit template structure of aluminum alloy template

InactiveCN105239771AReasonable section structureEasy to shapeForming/stuttering elementsStructural engineeringProcessing cost

The invention relates to a T-shaped section profile for an aluminum alloy template and a unit template structure of the aluminum alloy template. The T-shaped section profile is an integrally-molded aluminum alloy profiled plate and is composed of a groove body and a group of longitudinal reinforcing ribs, wherein the groove body is formed by a rectangular panel and two opposite longitudinal side frames on the back of the panel, and the longitudinal reinforcing ribs are uniformly distributed at the groove bottom of the groove body. The unit template structure comprises the T-shaped section profile of the aluminum alloy template, a transverse side frame, transverse reinforcing ribs and angle reinforcing blocks. The T-shaped section profile has the advantages of being definite in structure and simple in molding, little post processing of the template is required, the processing cost is reduced, and the light weight, safety in use and long service life of the template can be ensured; the construction efficiency is improved, and the standardized and systemized, industrialized production is easier; thus, the template has the advantages of being quick and convenient in disassembly and assembly, firm in mounting, high in construction efficiency and low in construction cost.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

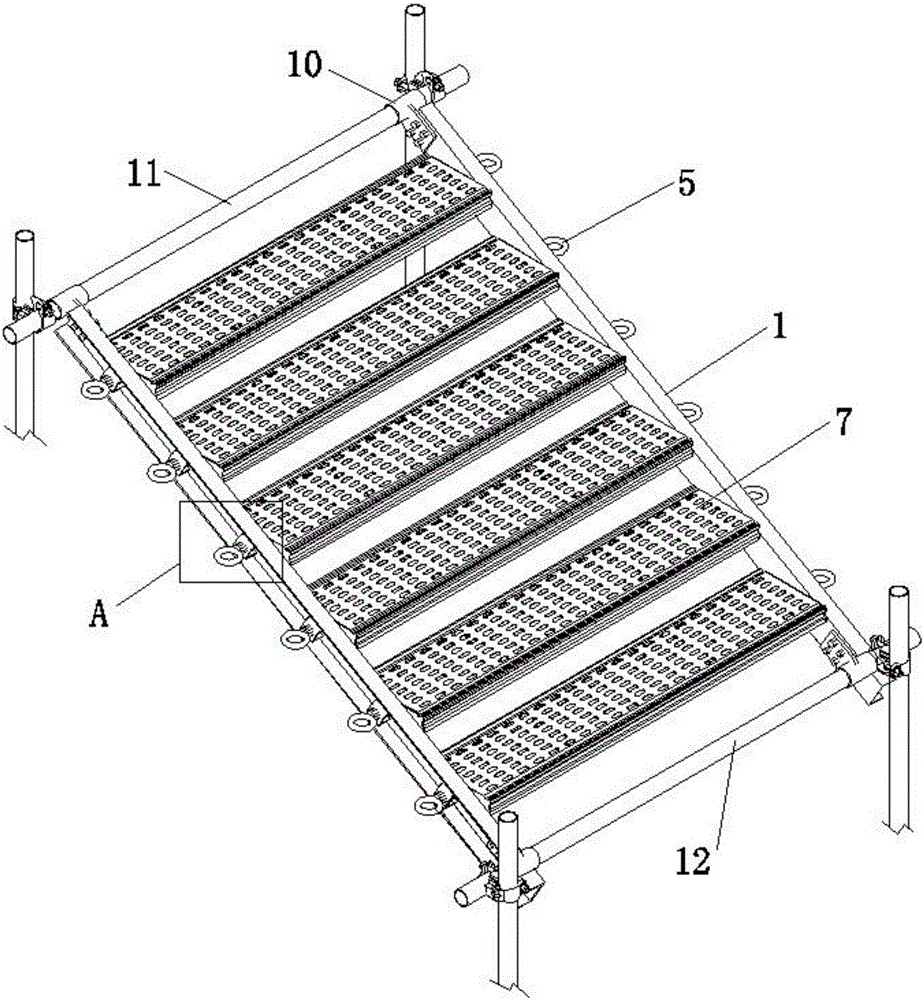

Building scaffolding stairs easy to detach and install and erection method thereof

ActiveCN104963500AImprove stabilitySimple structureScaffold accessoriesFalseworkArchitectural engineering

The invention discloses building scaffolding stairs easy to detach and install. The stairs comprise a first cross beam, a second cross beam and two side beams, the first cross beam and the second cross beam are fixed at different stair platforms respectively, one end of each side beam is connected with the first cross beam, and the other end of each side beam is connected with the second cross beam; horizontal pedals are arranged between the side beams at equal intervals in the height direction, and the two ends of each pedal are installed on the side beams at the two sides through connecting pieces respectively; each connecting piece comprises a hinge pin and a pulling ring, each hinge pin is a polygonal column, one end of each hinge pin is inserted into an installing hole formed in the corresponding side beam and a locating hole formed in the side face of the corresponding pedal, and each installing hole and each locating hole are matched with the corresponding hinge pin. The invention further discloses an erection method of the building scaffolding stairs easy to detach and install. According to the stairs, the components of the stairs are movably connected, the detachment and installation are convenient and fast, the construction efficiency is improved greatly, the accessories can be utilized repeatedly, the materials are saved, and the construction cost is saved greatly.

Owner:CHINA FIRST METALLURGICAL GROUP

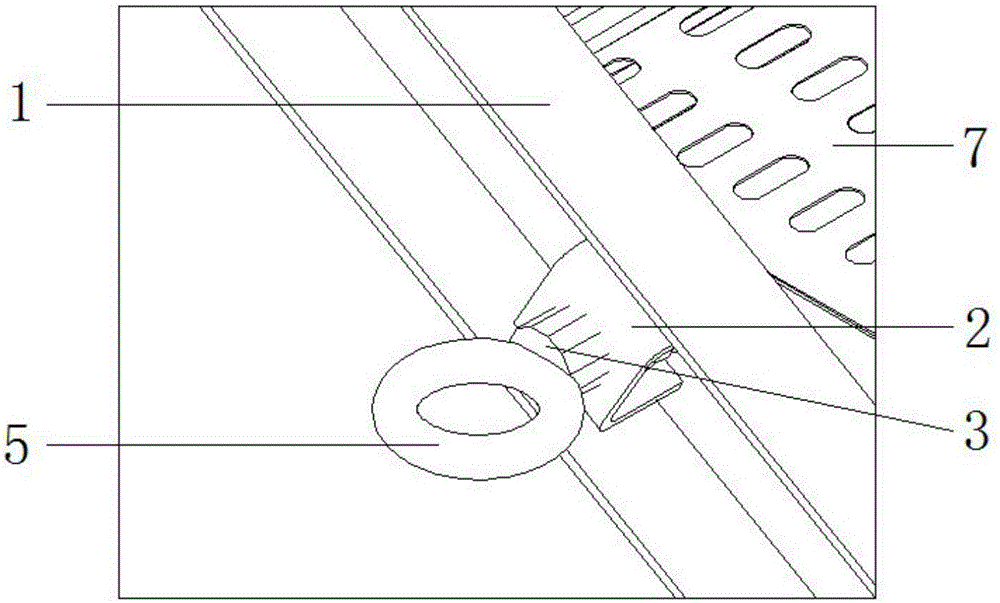

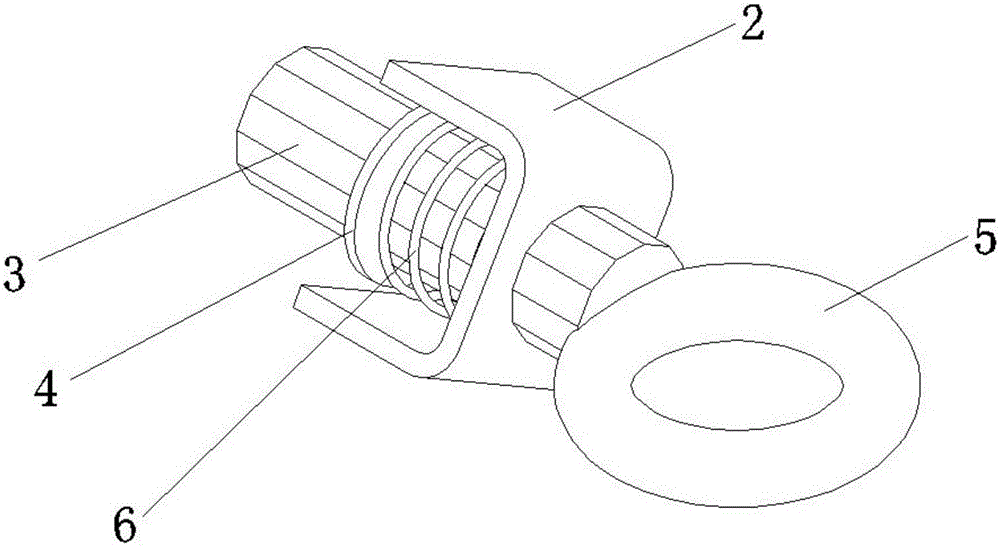

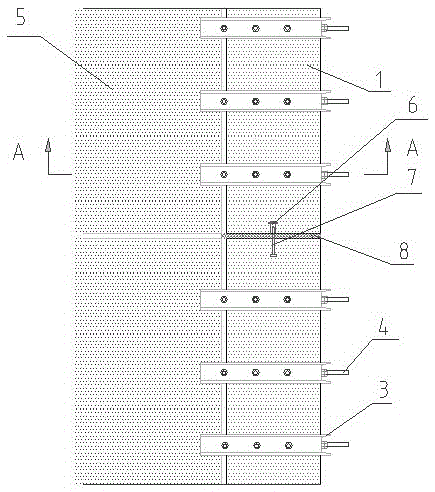

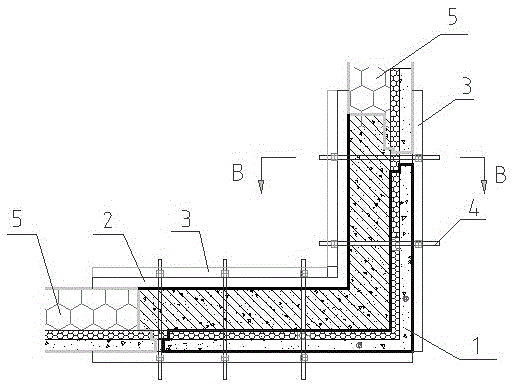

Formwork supporting device for wall corner portion construction and construction method

InactiveCN105544979ASpeed upReduce construction efficiencyAuxillary members of forms/shuttering/falseworksForming/stuttering elementsSteel tubeFastener

The invention relates to the technical field of building construction, in particular to a formwork supporting device for wall corner portion construction and a construction method. The formwork supporting device for wall corner portion construction comprises an outer formwork and an inner formwork, and further comprises a fixing device for supporting the outer formwork and the inner formwork. The fixing device comprises structural steel and a pull rod. The structural steel is symmetrically arranged on the inner formwork and the outer formwork. Installation holes matched with the pull rod in size are formed in the inner formwork, the outer formwork and the structural steel. The outer formwork is a PCF board. The formwork supporting device for wall corner portion construction is built through the structural steel and the pull rod, the problems that a construction period is long, working procedures are complex, and the cost is high due to that fact that a supporting frame built by materials such as a steel pipe and a fastener is used for supporting are effectively solved, the construction period is shortened, the construction working procedures are simplified, and the construction material is saved.

Owner:CHENGDU SIXTH CONSTR ENG

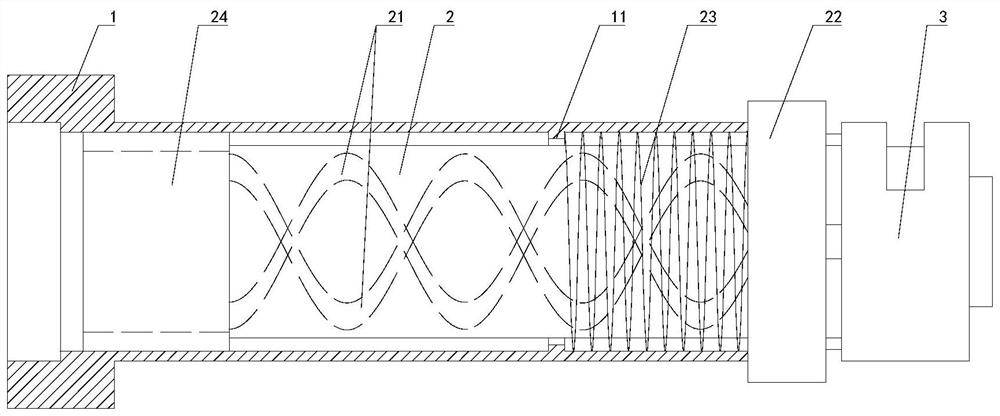

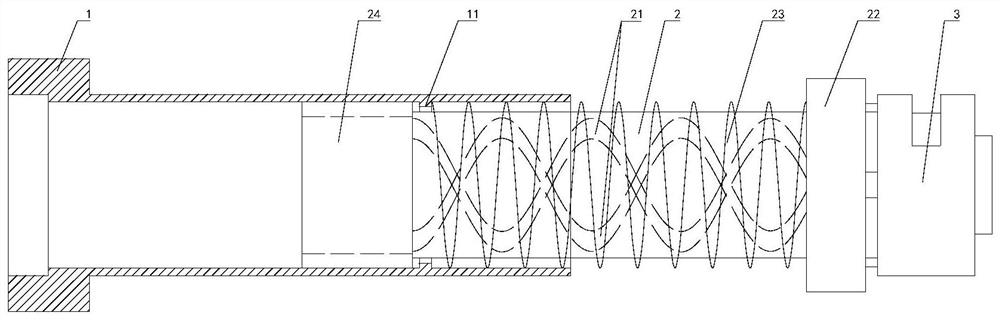

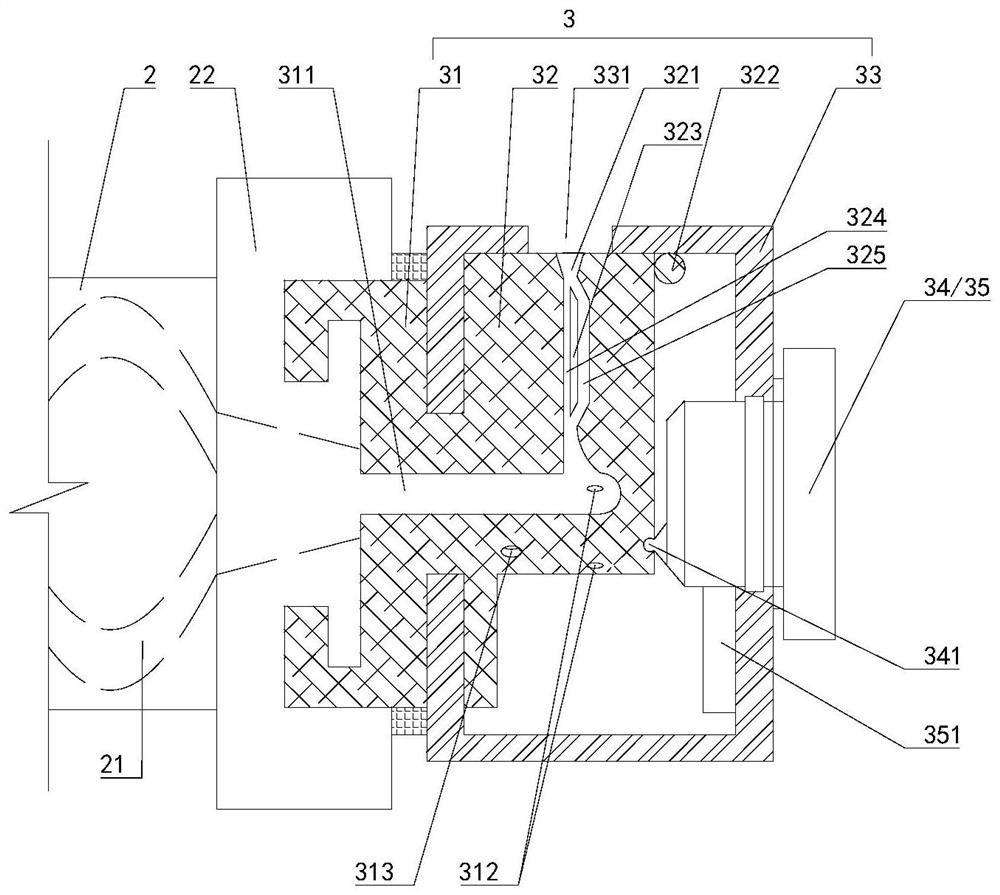

Spray maintenance telescopic spray head

ActiveCN111672647AReduce site occupancyReduce construction difficultyMovable spraying apparatusSpray nozzlesStructural engineeringWater supply

The invention provides a spray maintenance telescopic spray head. The spray maintenance telescopic spray head comprises a connecting pipe, the connecting pipe is connected with a water supply pipe, asliding body is slidably connected in the connecting pipe, under the action of water pressure, the sliding body partially extends out of the connecting pipe, under the action of no water pressure, thesliding body retracts in the connecting pipe, a water channel is arranged in the sliding body, a spray head device is rotatably connected to the tail end of the sliding body, the spray head device communicates with the water channel, and the spray head device swings left and right under the action of water pressure by taking a central shaft of the sliding body as a rotating shaft. According to the spray maintenance telescopic spray head, the technical effects that the site occupancy rate is greatly reduced, the construction difficulty and the construction cost are greatly reduced due to sitesaving, the telescopic swing spray head has no interference with formwork erecting and detaching of cast-in-place components, formwork erecting and detaching are conveniently and rapidly carried out,the construction efficiency is improved, the economic benefit is obvious, the spray area of the spray head is increased through the swing spray head, the spraying effect is better, the curing effect is improved, the strength of the components is guaranteed, and water resources are saved are achieved.

Owner:湖北省清江路桥建筑有限公司

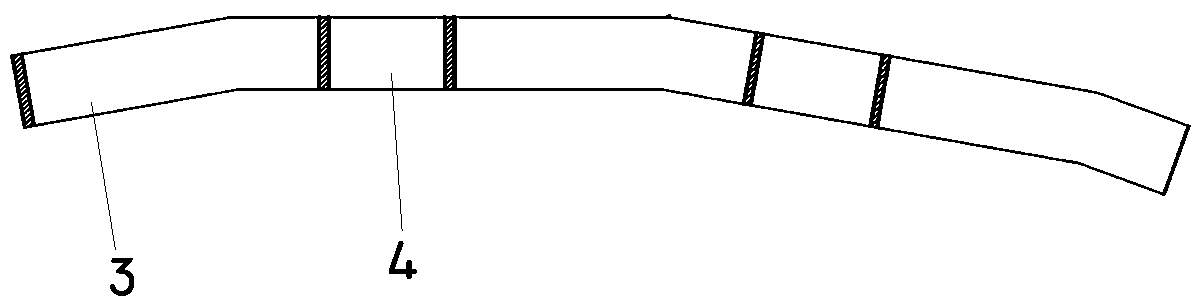

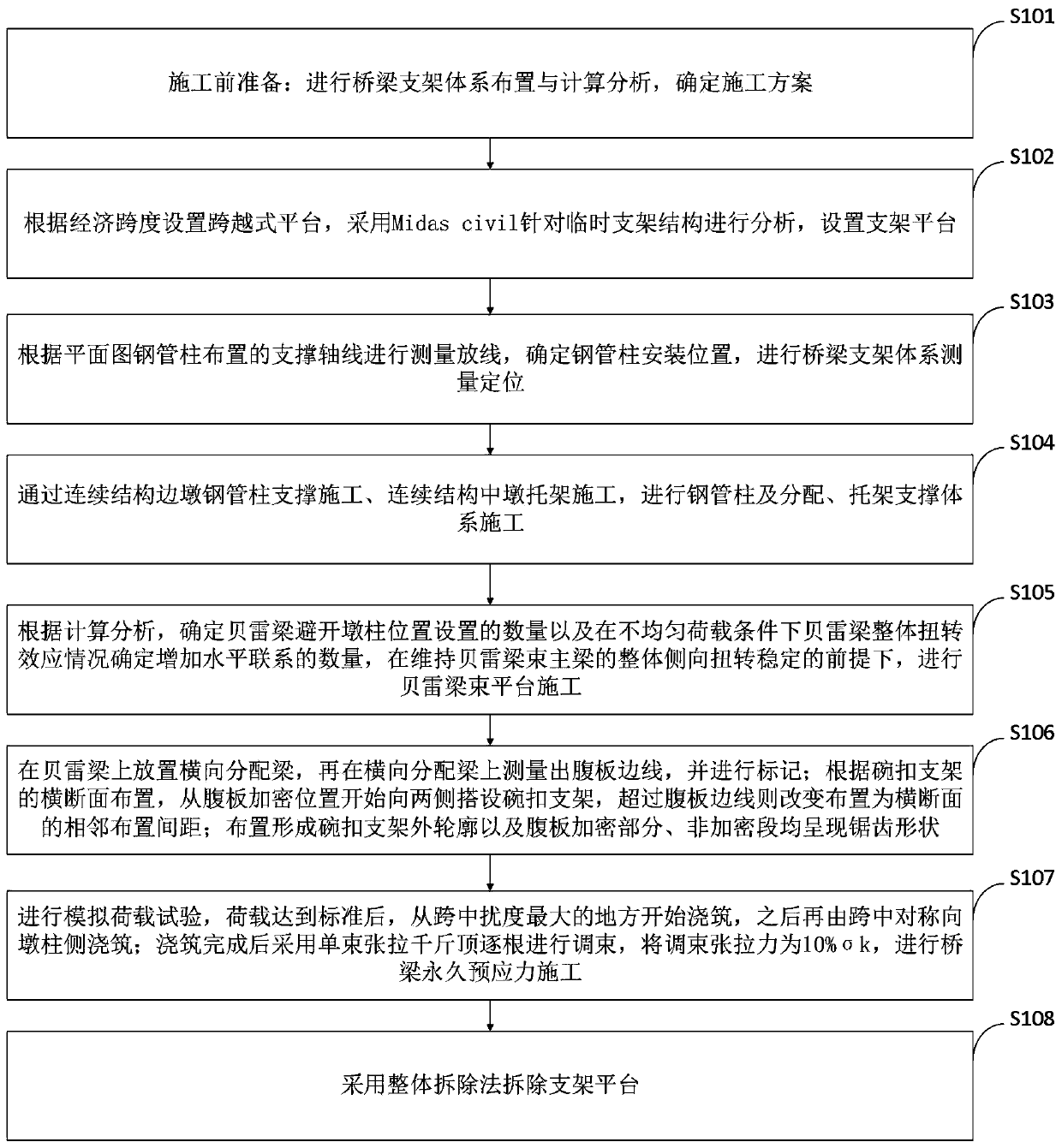

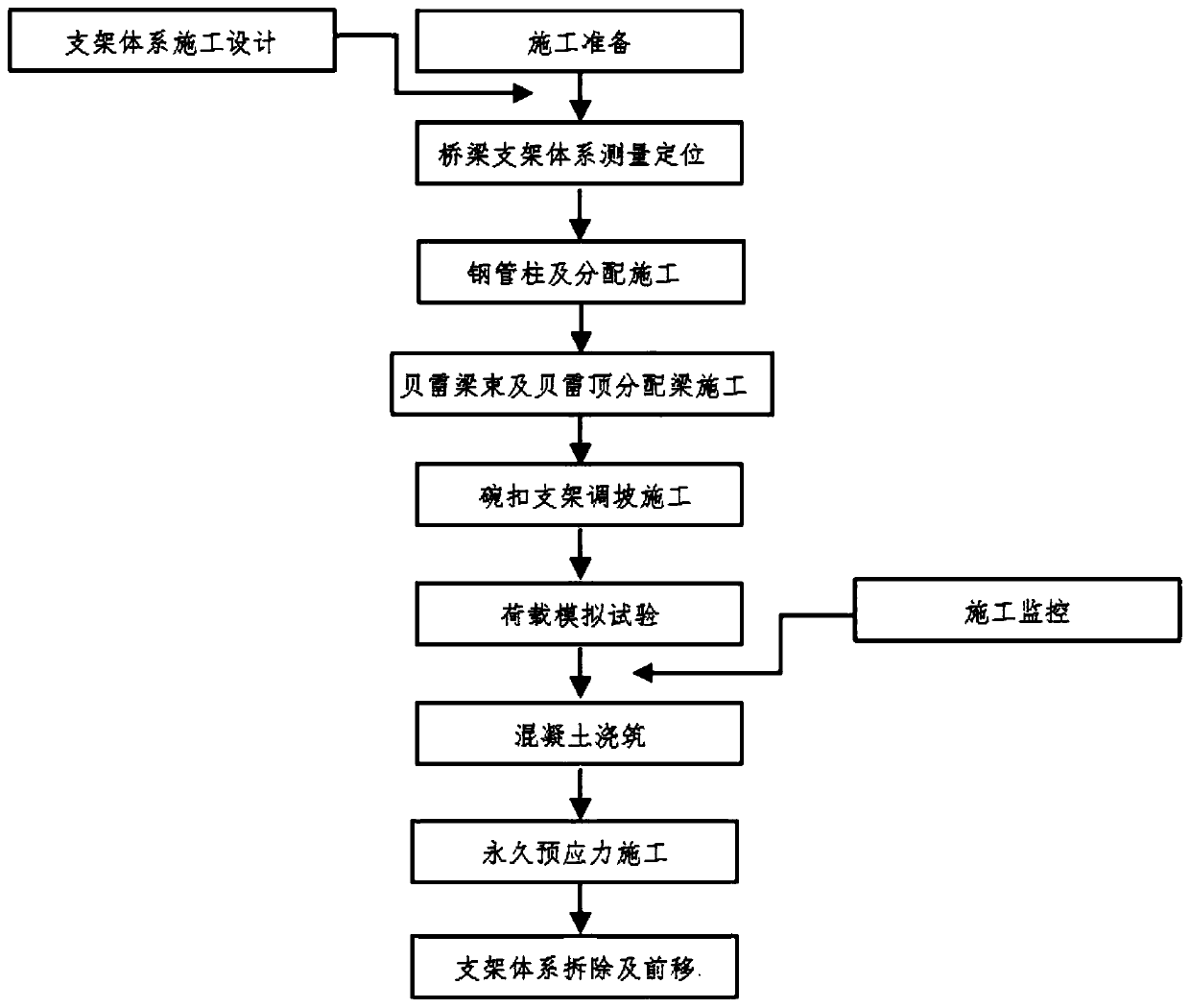

High-pier small-radius curve ramp bridge cast-in-place platform bailey beam bundle construction method

The invention belongs to the technical field of constructional engineering construction, and discloses a high-pier small-radius curve ramp bridge cast-in-place platform bailey beam bundle constructionmethod which comprises the steps that preparation is conducted before construction, and a support platform is arranged; a bridge support system is measured and positioned; steel pipe column and distribution and bracket supporting system construction is conducted; a bailey beam bundle platform is constructed; a transverse distribution beam is placed on the bailey beam, the side boundary of the webplate on the transverse distribution beam is measured and marked; according to the arrangement of the cross sections of the bowl buckle supports, the bowl buckle supports are erected from the web densification position to the two sides, and the adjacent arrangement distance of the cross sections is changed if the side lines of webs are exceeded; the non-encryption sections are arranged to form the outer contour of the bowl buckle support and the web plate encryption part and are in a sawtooth shape; a simulation load test is carried out, pouring is carried out, and the bridge permanent prestress construction is carried out; and the platform is detached. The cost can be effectively reduced, the temporary structure safety is ensured, the practicability is high, and the good application andpopularization value is achieved.

Owner:重庆建工建筑产业技术研究院有限公司 +2

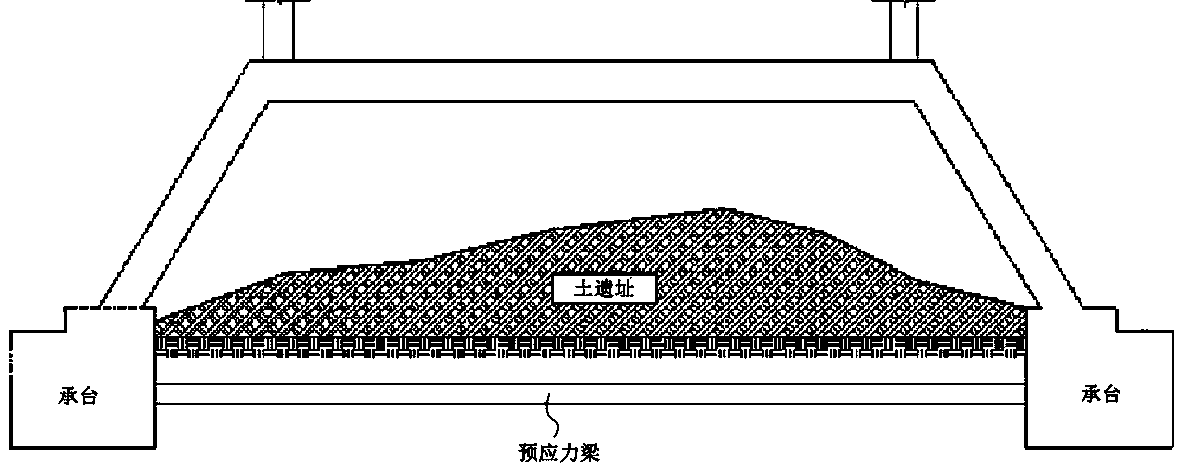

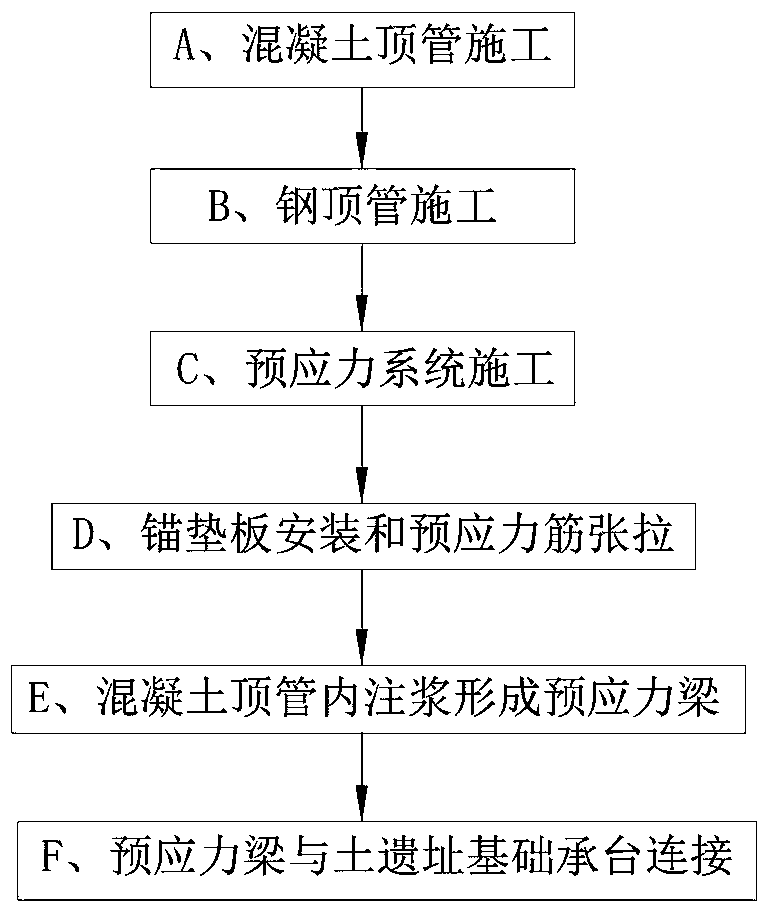

Construction method of non-excavation top pipe pre-stress beam

ActiveCN109854266AIntegrity guaranteedAvoid damagePipe laying and repairUnderground chambersPre stressPre stressing

The invention discloses a construction method of a non-excavation top pipe pre-stress beam. The construction method comprises the sequentially-executed steps of concrete top pipe construction, steel top pipe construction, pre-stress system construction, anchor bearing plate mounting and pre-stress tendon tensioning, pre-stress beam forming through concrete top pipe interior pouring, and connectionof the pre-stress beam and an earthen ruin foundation bearing table. On the basis of ensuring that pre-stress beam construction meets construction requirements, destruction of an excavation-type construction mode on ruin soil bodies is reduced, it is effectively ensured that the ruin soil bodies are complete, the good conditions are created for protection and research work of ruins, the influences of excavating a large amount of earthwork on the aspects such as earthwork transportation and dust raising pollution are reduced, and the impact on the environment is lowered.

Owner:河南六建建筑集团有限公司

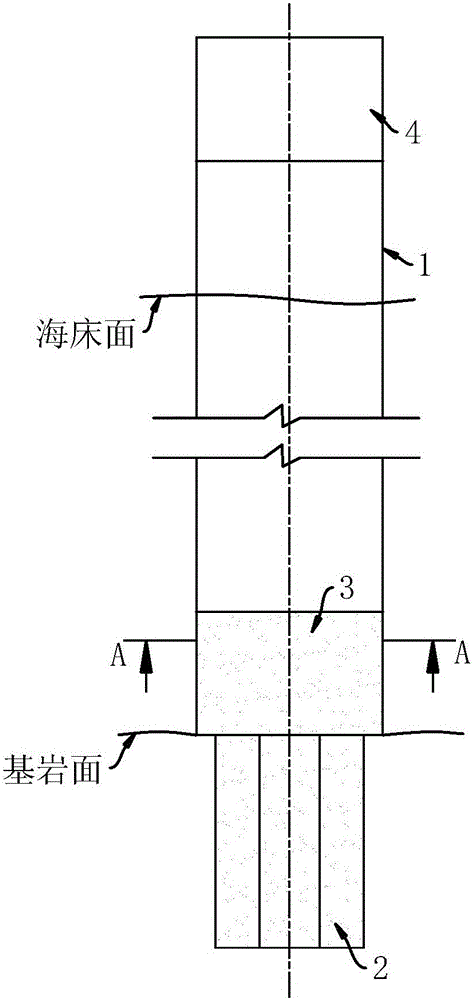

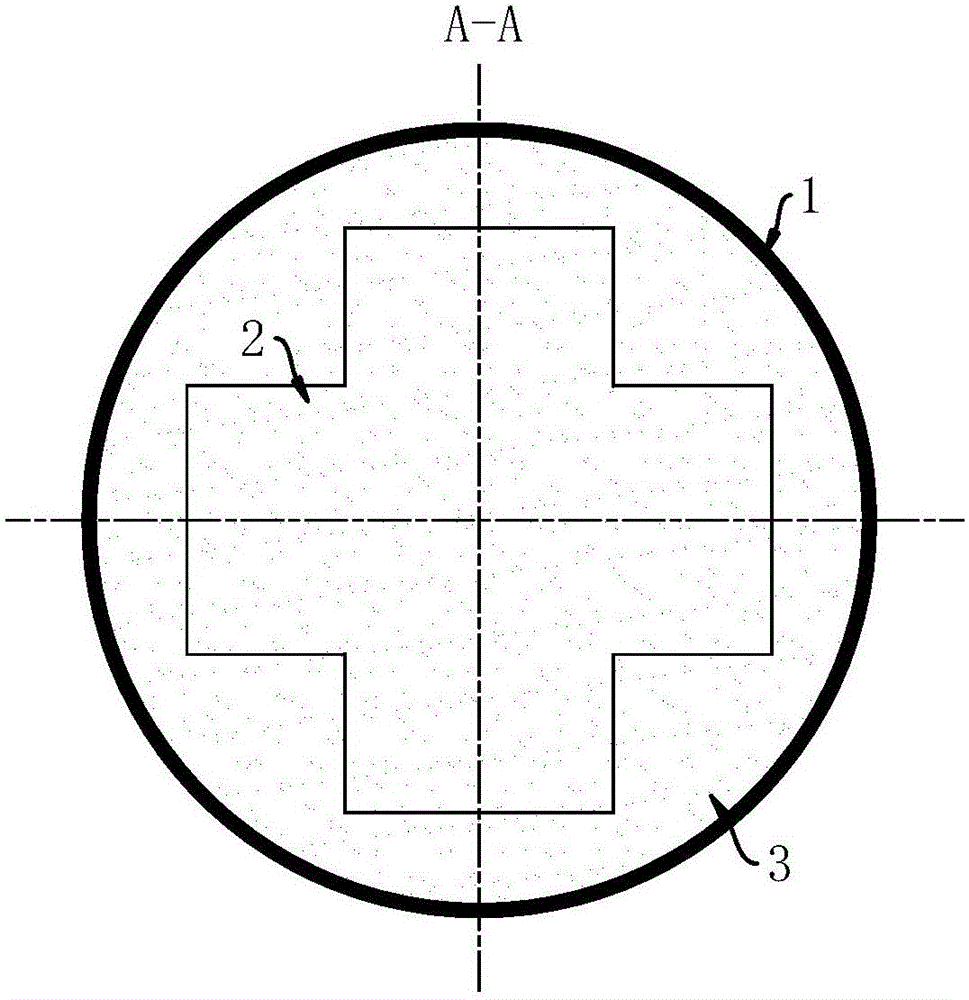

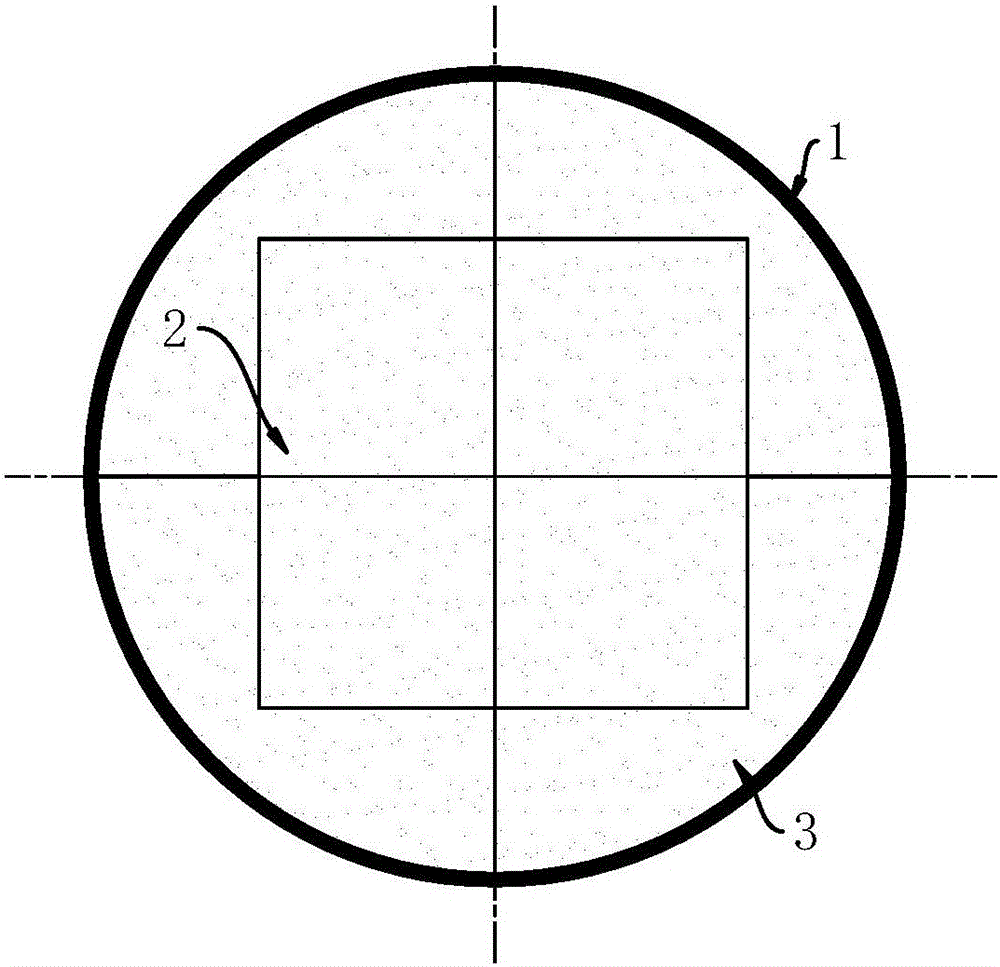

Offshore wind power plant draught fan single pile foundation and construction method

InactiveCN105862906AImprove the efficiency of rock-socketed constructionSolve the contradictions of slow rock-socketed construction and few construction windowsFoundation engineeringTowerOffshore wind power

The invention discloses a single pile foundation for a fan in an offshore wind farm, which includes a steel pipe pile and a cast-in-situ pile. The top surface of the steel pipe pile is installed with a wind turbine tower. On the top surface of the underwater bedrock, the inner lower end of the steel pipe pile is provided with a concrete connecting section, and the concrete connecting section extends downward to provide the cast-in-place pile, the lower end of the cast-in-place pile is embedded in the bedrock, and the upper end is connected to the cast-in-place pile. The concrete connecting section is fixedly integrated, and the cast-in-place pile is composed of at least one support pile, and the cross-section of the support pile is rectangular. The present invention also provides a construction method for the above-mentioned single pile foundation of the wind turbine in the offshore wind farm.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

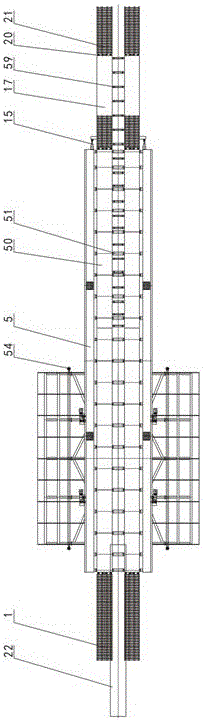

Multifunctional stretchable inverted-arch trestle

ActiveCN106640133AImplement resizingEasy to disassemble/assembleUnderground chambersTunnel liningHydraulic cylinderEngineering

The invention discloses a multifunctional stretchable inverted-arch trestle. The multifunctional stretchable inverted-arch trestle comprises a trestle girder, a front ladder stand, a back ladder stand, a walking cart, a stretchable trestle body, an inverted-arch formwork and a central furrow formwork; the walking cart is installed below the trestle girder, the stretchable trestle body is located at the front portion below the trestle girder, the front portion of the stretchable trestle body is arranged on a stretchable trestle body beam, the back portion of the stretchable trestle body is movably installed on the trestle girder through connecting plates, and the stretchable trestle body beam is installed on a walking auxiliary caterpillar band chassis through vertical auxiliary lifting hydraulic cylinders and auxiliary movable stand columns; the inverted-arch formwork and the central furrow formwork are sequentially installed in the middle and at the back portion below the trestle girder from front to back and move back and forth through the walking cart. According to the multifunctional stretchable inverted-arch trestle, the trestle girder, the stretchable trestle body, the inverted-arch formwork, the central furrow formwork and end sealing plates are designed into an integrated device, multiple working procedures can be carried out at the same time, the construction period is greatly saved, the construction efficiency is improved, the labor intensity of workers is reduced, the construction quality is guaranteed, and the construction cost is reduced.

Owner:四川省创力隧道机械设备有限公司

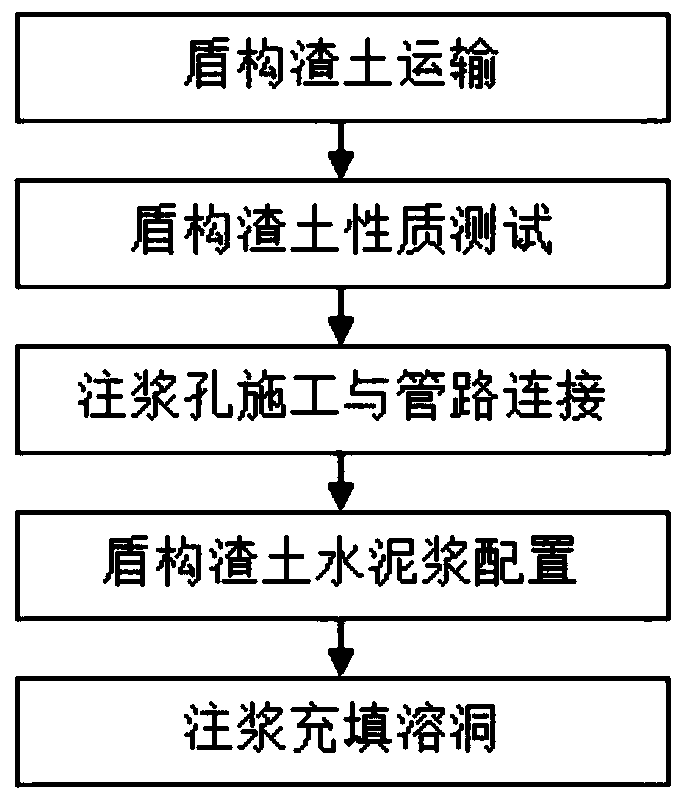

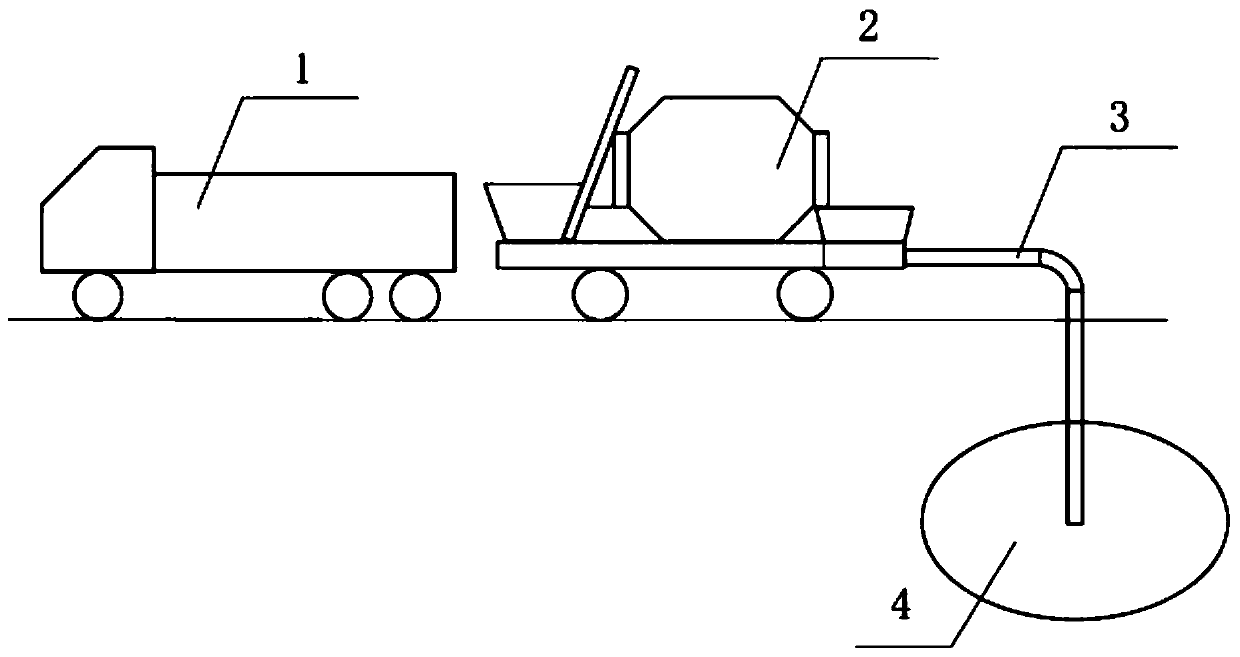

Shield tunnel karst cave filling method

The invention discloses a shield tunnel karst cave filling method, and relates to the technical field of shield tunnel karst cave filling. The shield tunnel karst cave filling method comprises the following steps that (1) shield muck transportation is carried out, wherein shield muck is transported from an adjacent subway tunnel section to a karst cave filling construction site; (2) shield muck property testing is carried out, wherein tested shield muck moisture content sampling and particle gradation are carried out; (3) grouting hole construction and pipeline connection are carried out, wherein a geological drilling machine is used for drilling holes in the top of a karst cave, grouting pipe embedding is carried out, and grouting pipe connecting is carried out; (4) shield muck cement paste configuration is carried out, wherein according to the shield muck property, pebbles with the particle size larger than 30 mm are screened out, cement and water are added, and a stirring trailer pump is used for configuring shield muck cement slurry; and (5) grouting filling of the karst cave is carried out, wherein the shield muck cement slurry is pumped for karst cave grouting construction, and the slurry is injected for karst cave filling. By means of the shield tunnel karst cave filling method, shield muck is used as a grouting material, the stirring trailer pump is used for configuringthe shield muck cement slurry, muck is absorbed while quick filling of the shield tunnel karst cave is carried out, and the grouting material is saved.

Owner:CENT SOUTH UNIV

In-situ mixing steel tube pile construction system and method for coral reef geology

PendingCN110777776AImprove bearing capacityImprove construction efficiencyBulkheads/pilesSteel tubeHollow core

The invention discloses a in-situ mixing steel tube pile construction system and method for coral reef geology. The in-situ mixing steel tube pile construction system for the coral reef geology comprises a steel tube pile, a rotating power device, a grouting pipeline and a base expanding drill bit, wherein the steel tube pile comprises an upper standard section and a lower diameter expanding section which are formed in an integrated manner, the side face of the steel tube pile is provided with multiple open holes, the rotating power device is connected with a drill stem which is a hollow rod.The in-situ mixing steel tube pile construction method for the coral reef geology comprises the steps that preparation is conducted; drilling is conducted, wherein when the base expanding drill bit drills into the diameter expanding section at the bottom of the steel tube pile, the diameter expanding drill bit expands the diameter and continues drilling; solidification slurry is poured into the hole base through the drill stem, the solidification slurry and coral reef sand are evenly mixed under the rotating and mixing action of the diameter expanding drill bit driven by rotation of the drillstem, and then the solidification slurry-coral reef sand mixture fills the inside and outside of the standard section through the open holes on the steel tube pile. The in-situ mixing steel tube pileconstruction method for the coral reef geology combines the construction methods of an in-situ mixing pile and a steel tube pile and integrates the three work procedures of drilling, pile driving andgrouting, and therefore the in-situ mixing steel tube pile construction system and method for the coral reef geology have the advantages that the bearing capacity is high, the construction efficiencyis high, and the construction cost of a project is low.

Owner:CCCC SECOND HARBOR ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com