Offshore wind power plant draught fan single pile foundation and construction method

A single-pile foundation and wind farm technology, which is applied in the field of marine engineering building structures and fixed structures, can solve problems such as low construction efficiency, poor adaptability of offshore construction windows, and protracted construction periods, so as to save construction costs and improve the efficiency of rock-socketed construction , to solve the effect of slow rock-socketed construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

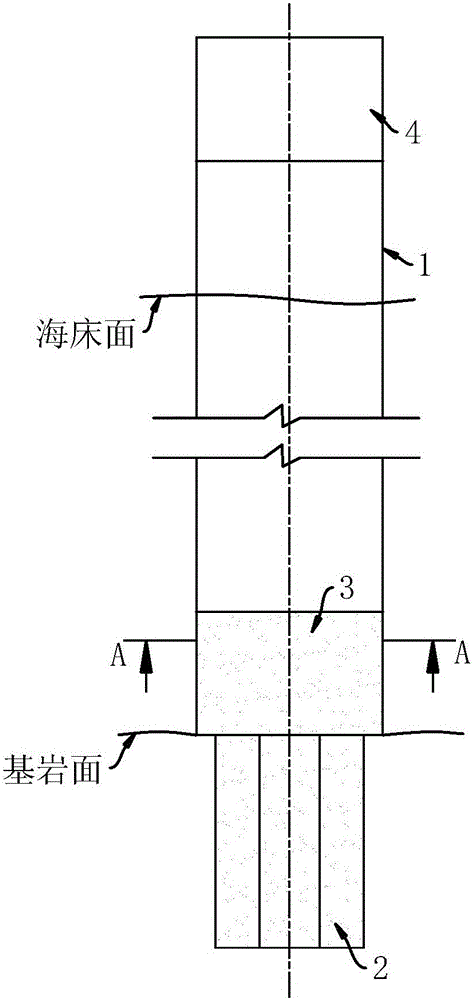

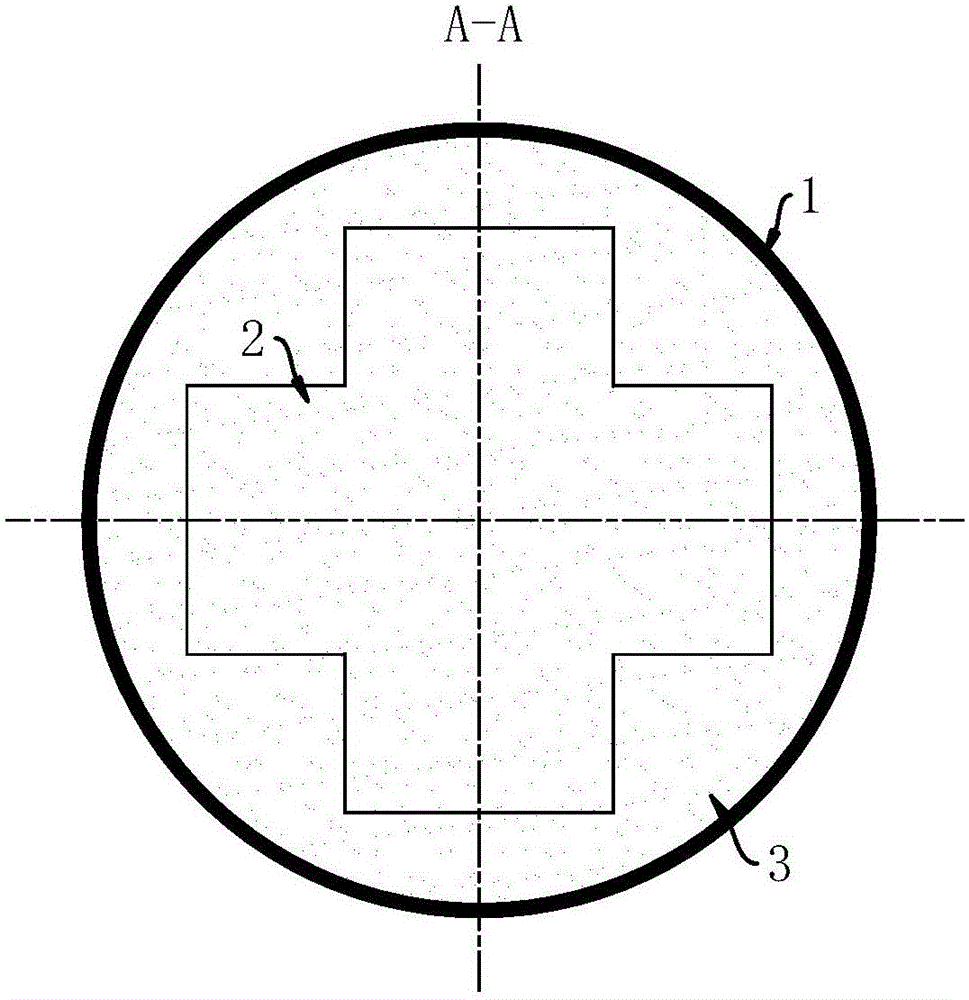

[0037] Such as figure 1 As shown, this embodiment provides a single pile foundation for a fan in an offshore wind farm, including steel pipe piles 1 and cast-in-situ piles 2, a wind turbine tower 4 is installed on the top surface of the steel pipe pile 1, and the steel pipe pile 1 passes through the seabed surface. And stand vertically on the top surface of the underwater bedrock, the inner lower end of the steel pipe pile is provided with a concrete connecting section 3, and the concrete connecting section 3 is extended downward with a cast-in-place pile 2, the lower end of the cast-in-place pile 2 is embedded in the bedrock, and the upper end is connected to the The concrete connecting section 3 is fixedly connected into one body. The lower end surface of the concrete connecting section 3 is flush with the lower end surface of the steel pipe pile 1, and the lower end surface of the concrete connecting section 3 is in close contact with the top surface of the underwater bedro...

Embodiment 2

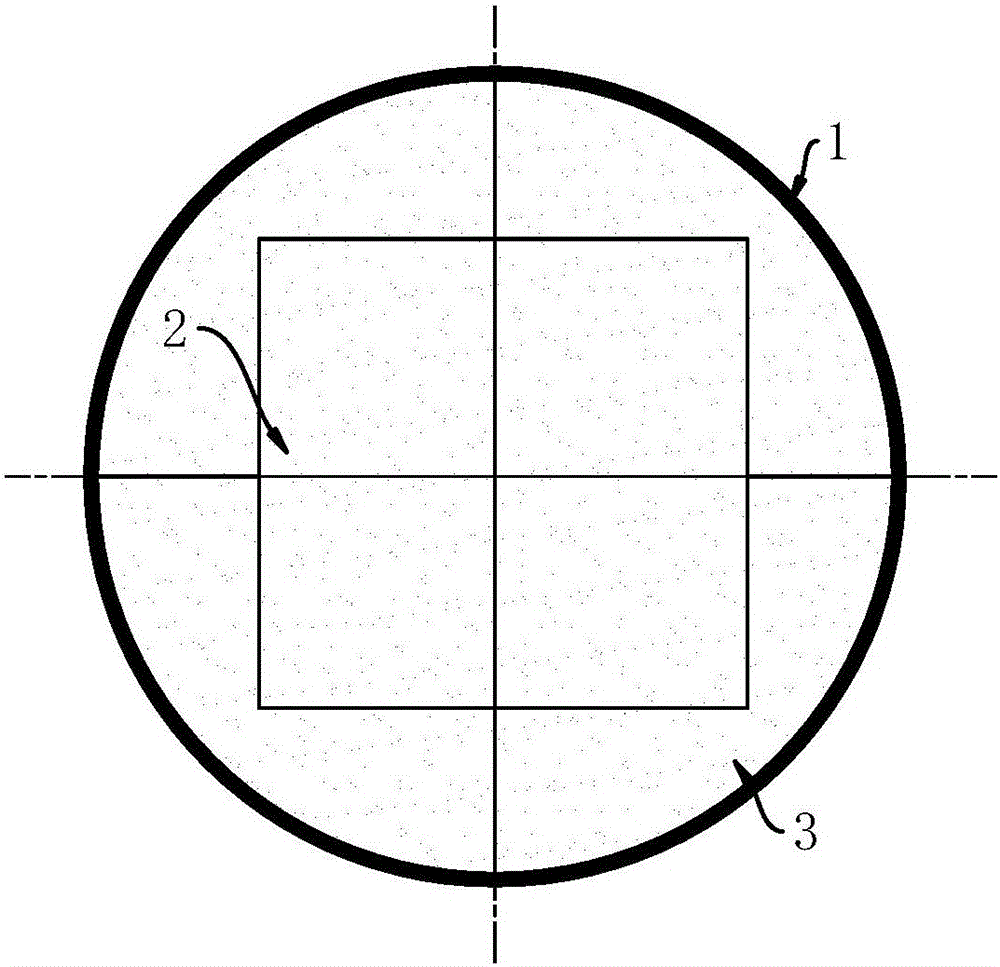

[0046] to combine image 3 As shown, based on Example 1, the cast-in-place pile 2 is composed of a support pile. The cast-in-place pile 2 is square, and the axis of the square cast-in-place pile 2 coincides with the axis of the concrete connecting section 3 . Construction method see embodiment 1.

Embodiment 3

[0048]combine Figure 4 As shown, based on Example 1, the cast-in-situ pile 2 is composed of a supporting pile. Construction method see embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com