Patents

Literature

1035 results about "Effective power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

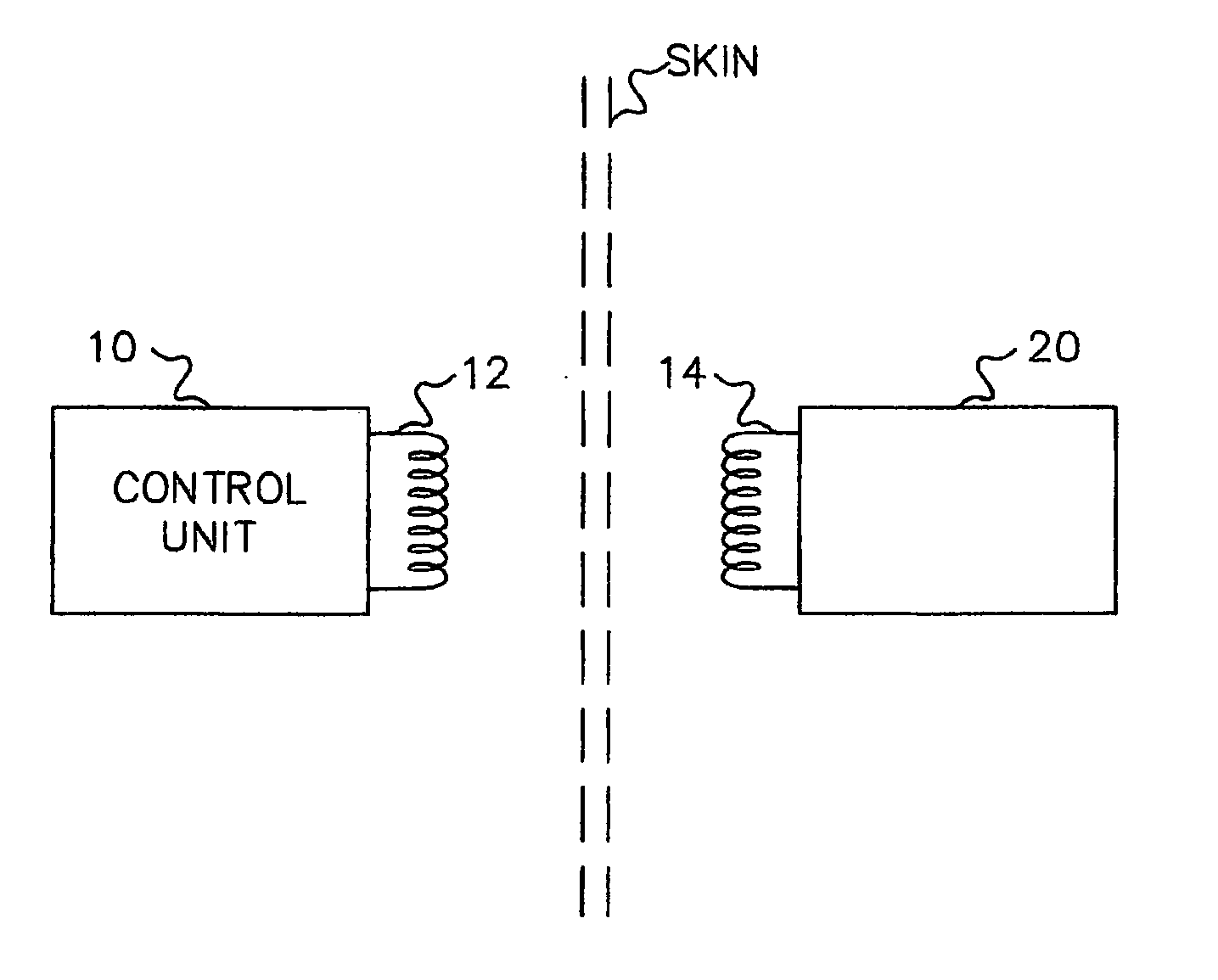

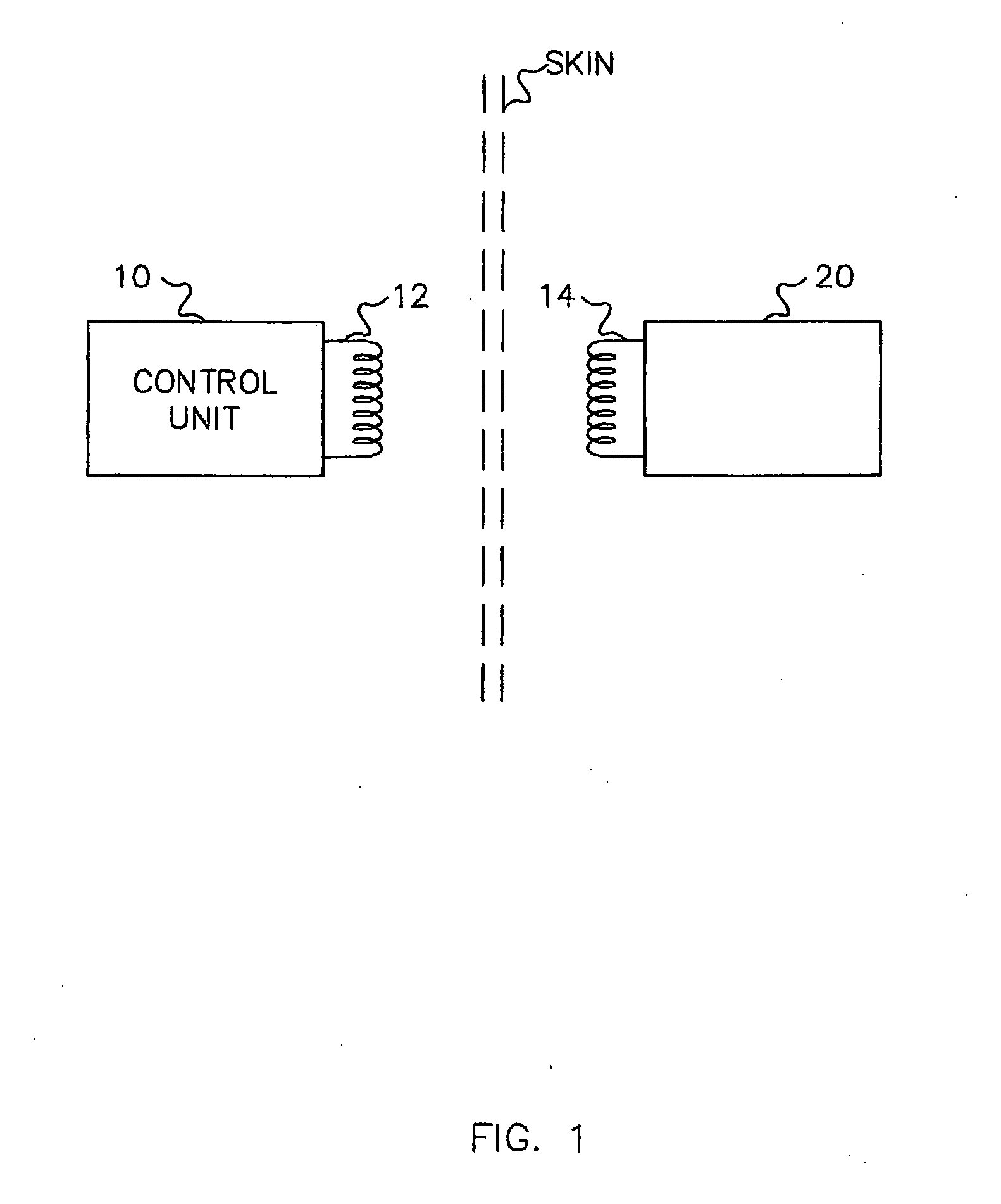

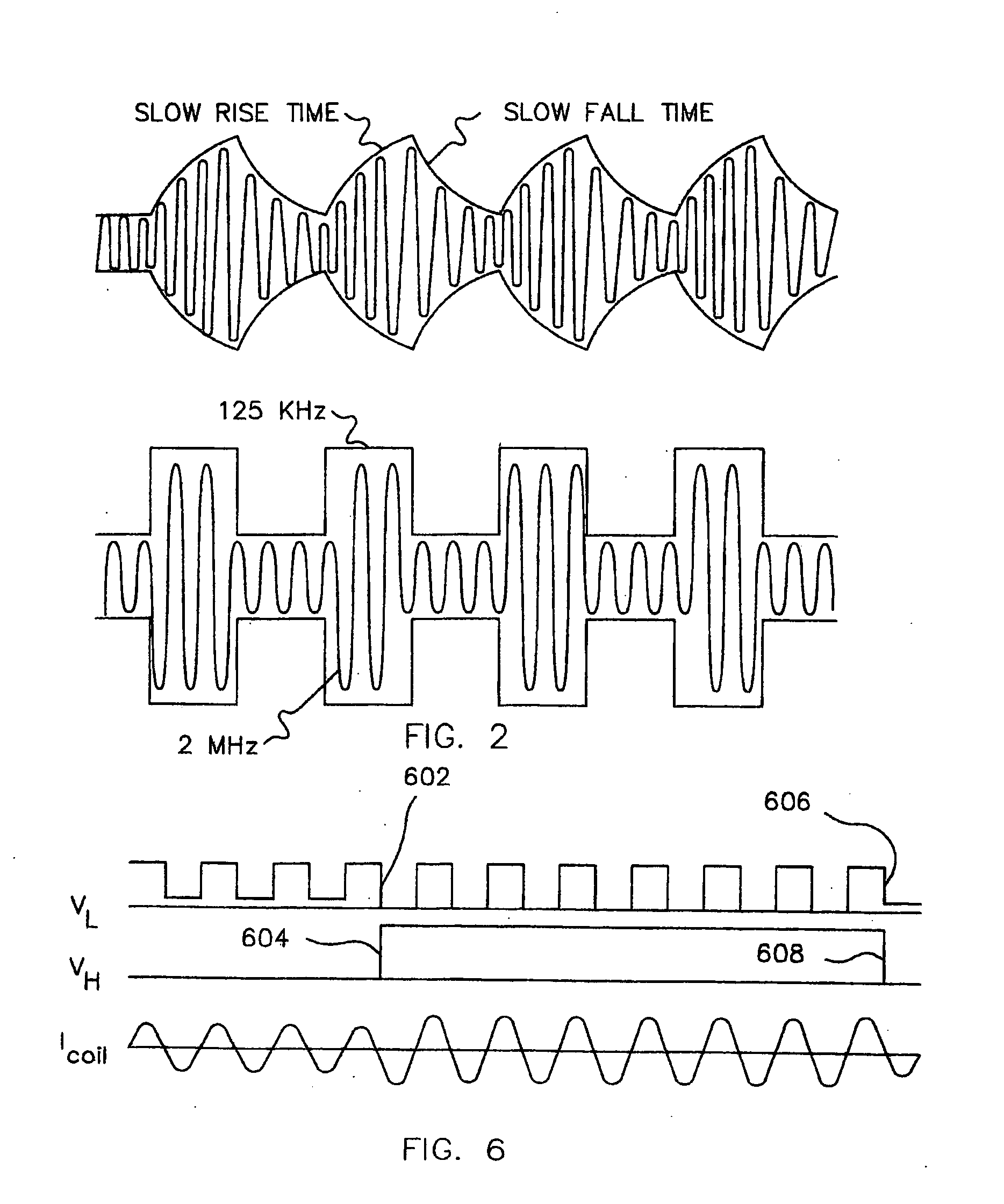

Method and apparatus for efficient power/data transmission

A system, method and power / data transmission device comprising a coil having a high Q, a low-voltage driver and a high-voltage driver switchably coupled to the coil. The low-voltage driver and the high-voltage driver are controlled by a microcontroller and switch at about the same time thereby providing a modulated data signal for transmission. Furthermore, the system includes at least one implantable microstimulator coupled to the transmission device.

Owner:ALFRED E MANN FOUND FOR SCI RES

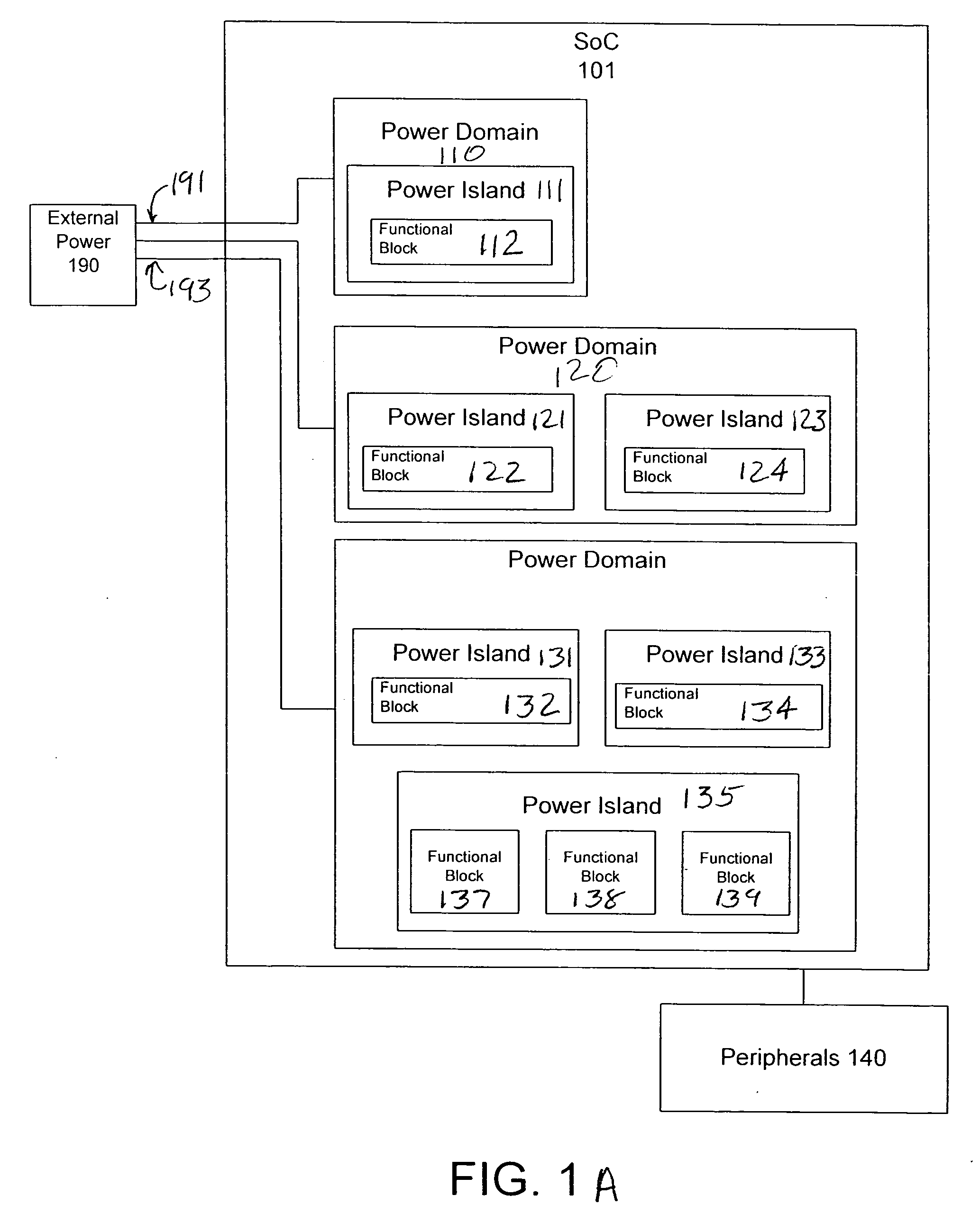

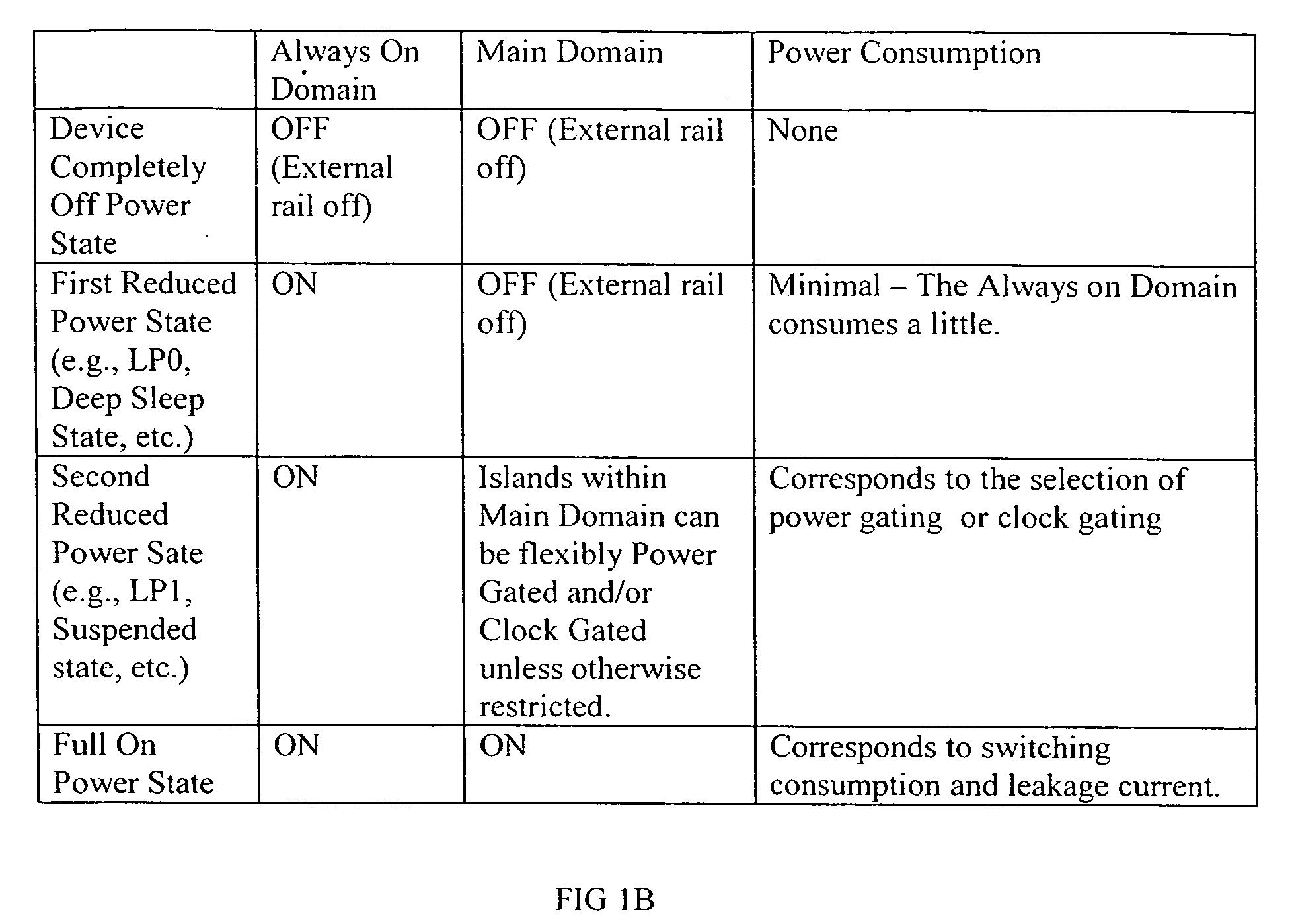

Power control system and method

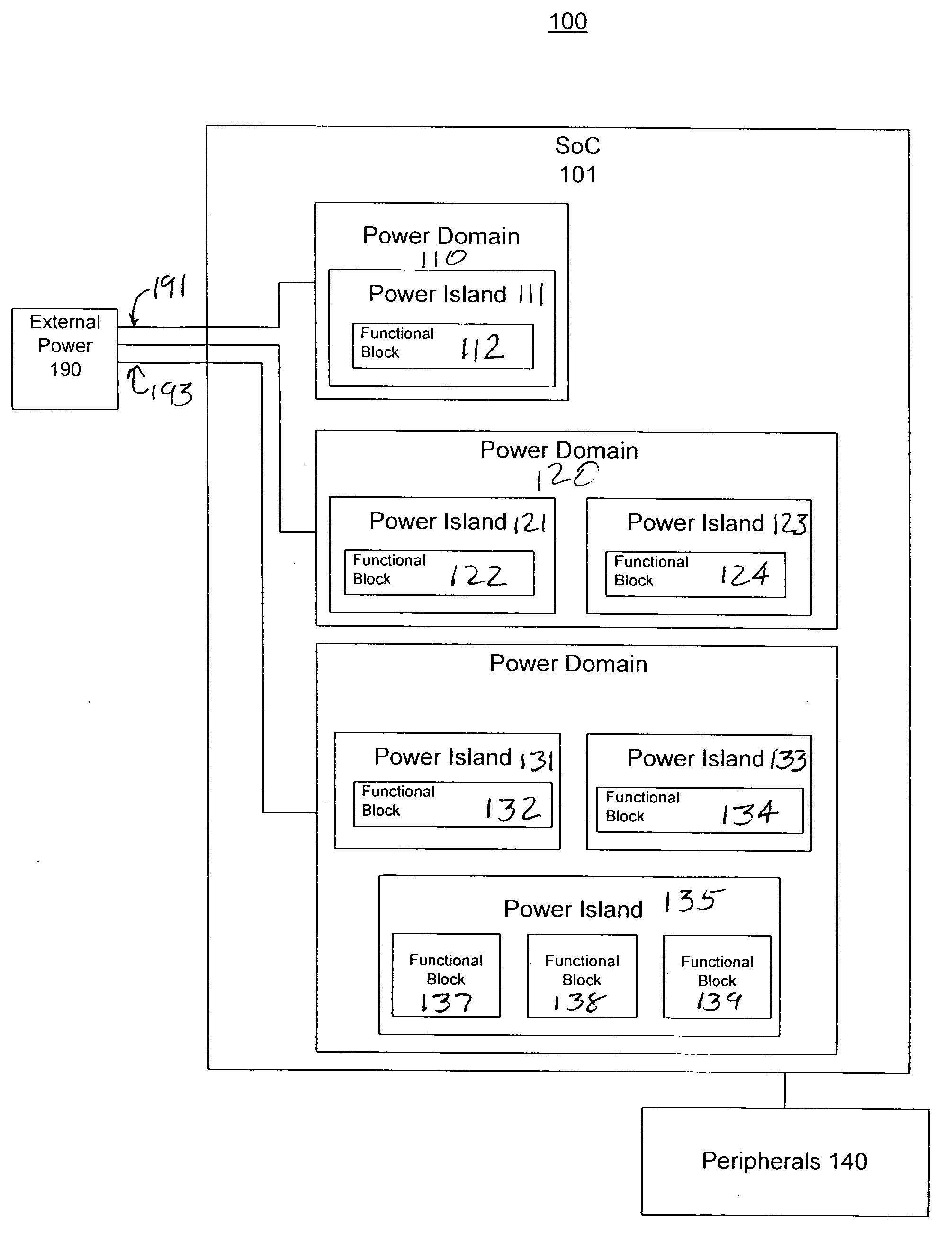

An efficient and effective power control system method are described with expedited recovery from a reduced power state. In one embodiment, a present invention power control system includes performing a reduced power detection process for detecting a reduced power state, wherein the reduced power state is associated with an expedited recovery; performing a reduced power state entry process; performing a recovery detection process for detecting a recover indication event; and performing an expedited recovery process in accordance with detection of a recovery indication event. The reduced power state entry process comprises saving an expedited recovery information in registers of an always on domain and putting an external memory in self refresh mode to preserve a system context while a chip is turned off. The expedited recovery process comprises determining whether to proceed with the expedited recovery process; initializing memory controller registers and directing memory controller to exit self refresh; validating system context recovered from memory using keys stored in an always on domain; jumping to recovery instructions in memory; restoring operating system information and returning to operating system control.

Owner:NVIDIA CORP

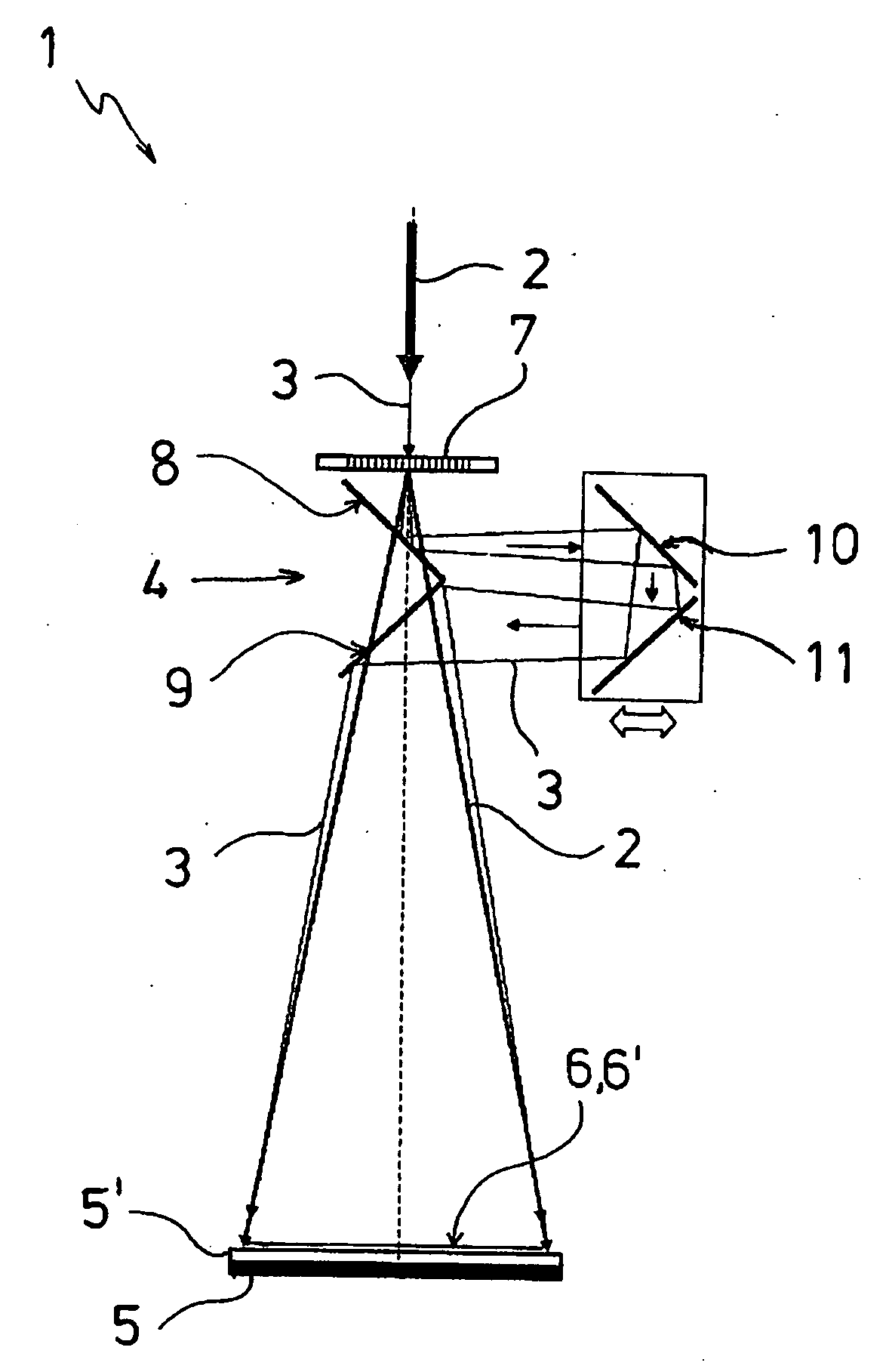

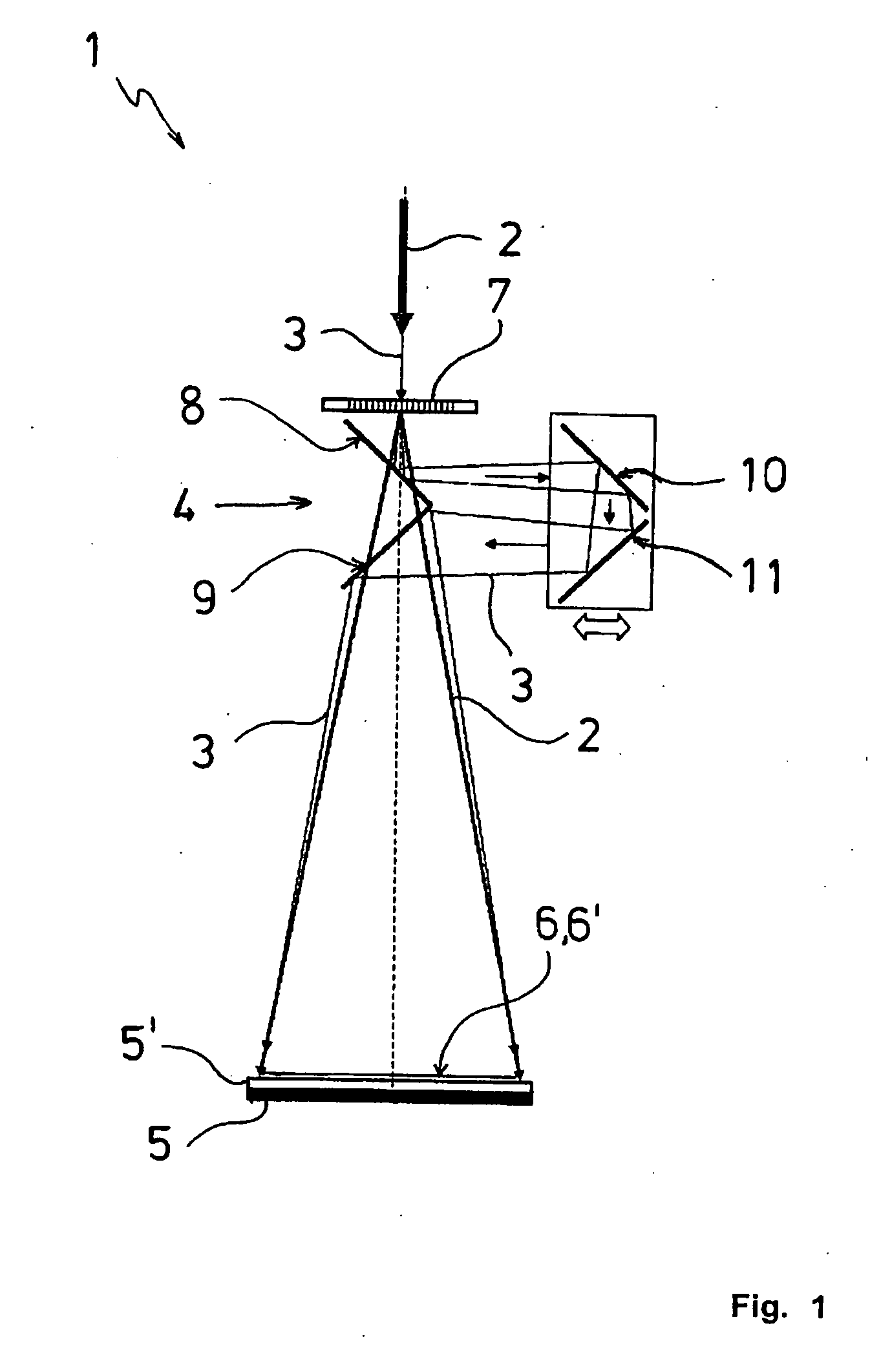

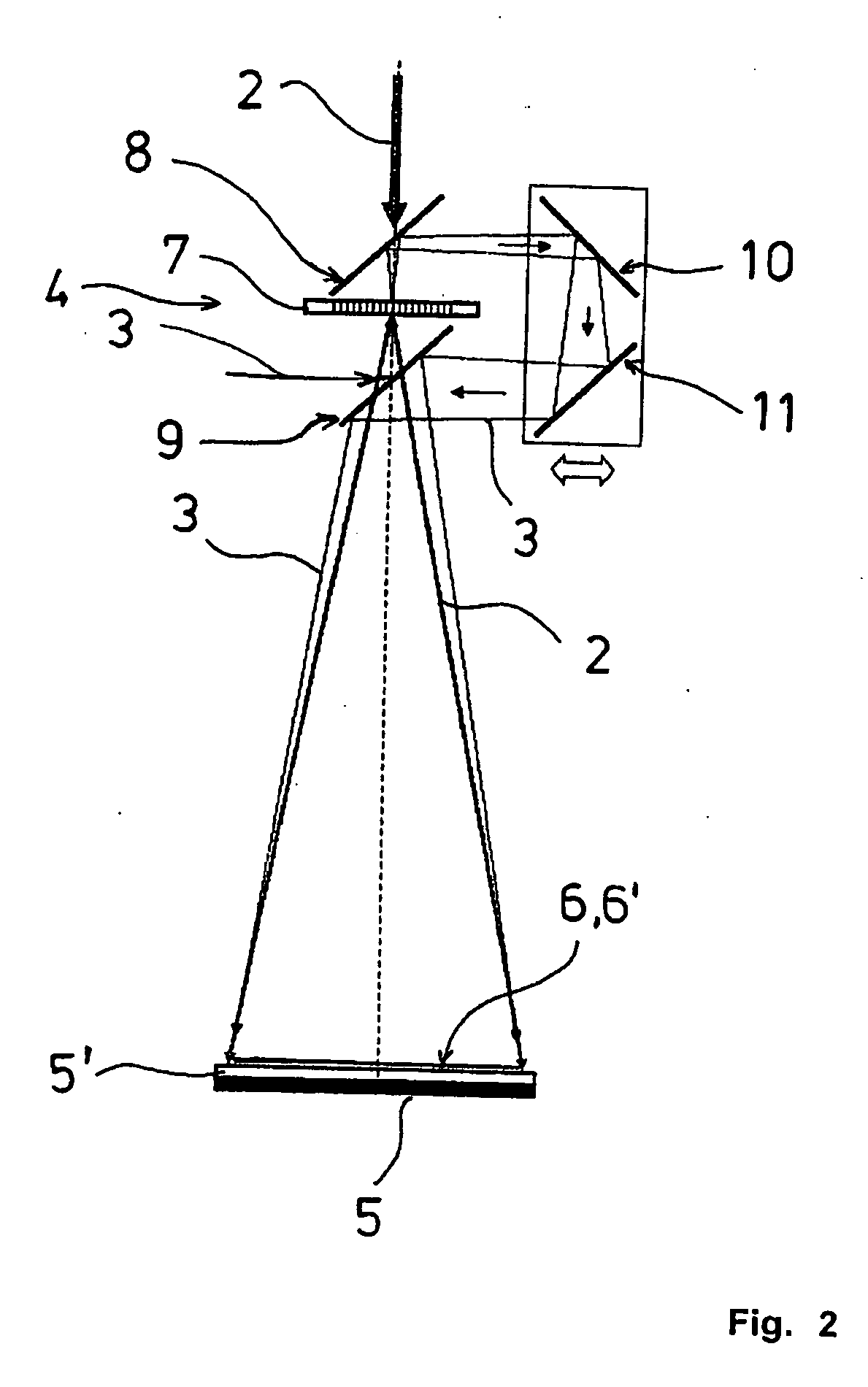

Laser operating process and laser device

InactiveUS20090272724A1Improve pronunciationSimple and flexible wayLaser beam welding apparatusEffective powerPath length

A device and a process for processing and / or joining work pieces via laser radiation, with an effective power laser and a pilot target laser that emit laser beams of different wavelengths, with the laser beams being directed at the work pieces by laser optics. Regarding the laser beams, by the laser optics that comprise at least one diffractive optical element (DOE) as a masking system, the beam pattern of the pilot target laser is adjusted to match the beam pattern of the effective laser beam. This is accomplished preferably by removing the pilot laser beam from the effective laser beam for part of the path length by dichroic mirrors, and by expanding the diverging pilot laser beam on said part of the path length by deflecting mirrors whose distance from the dichroic mirrors is variable.

Owner:LEISTER TECHNOLOGIES

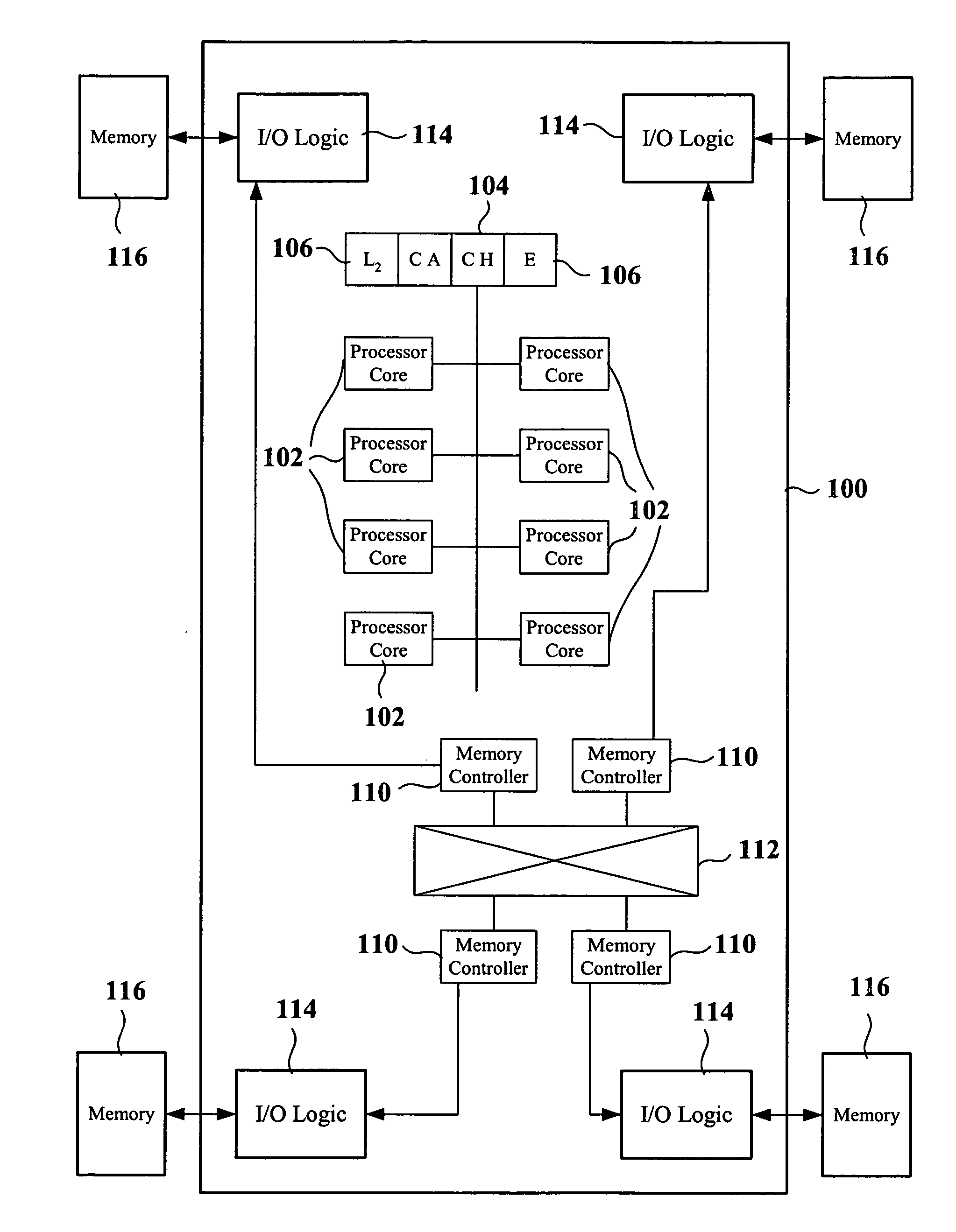

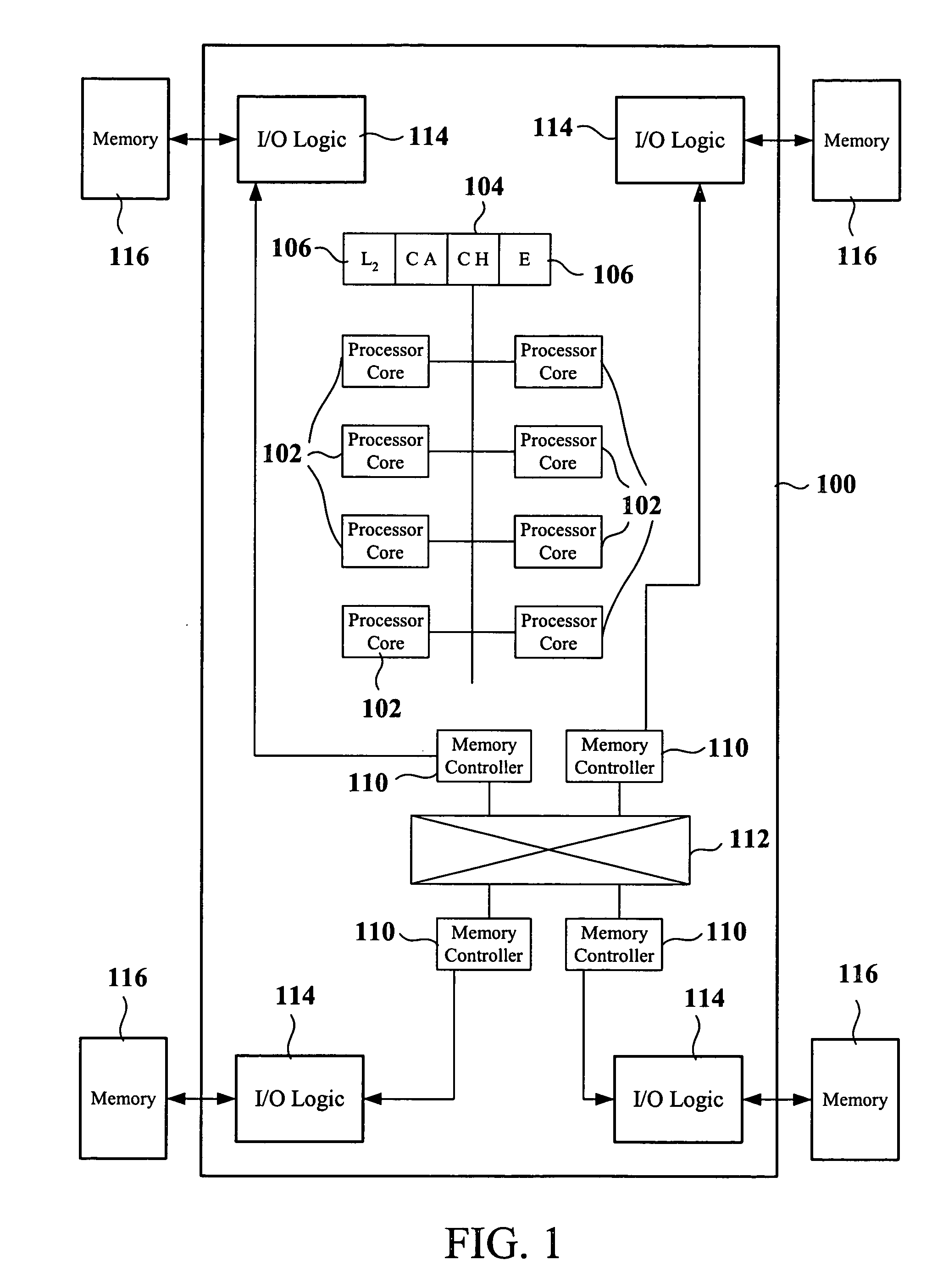

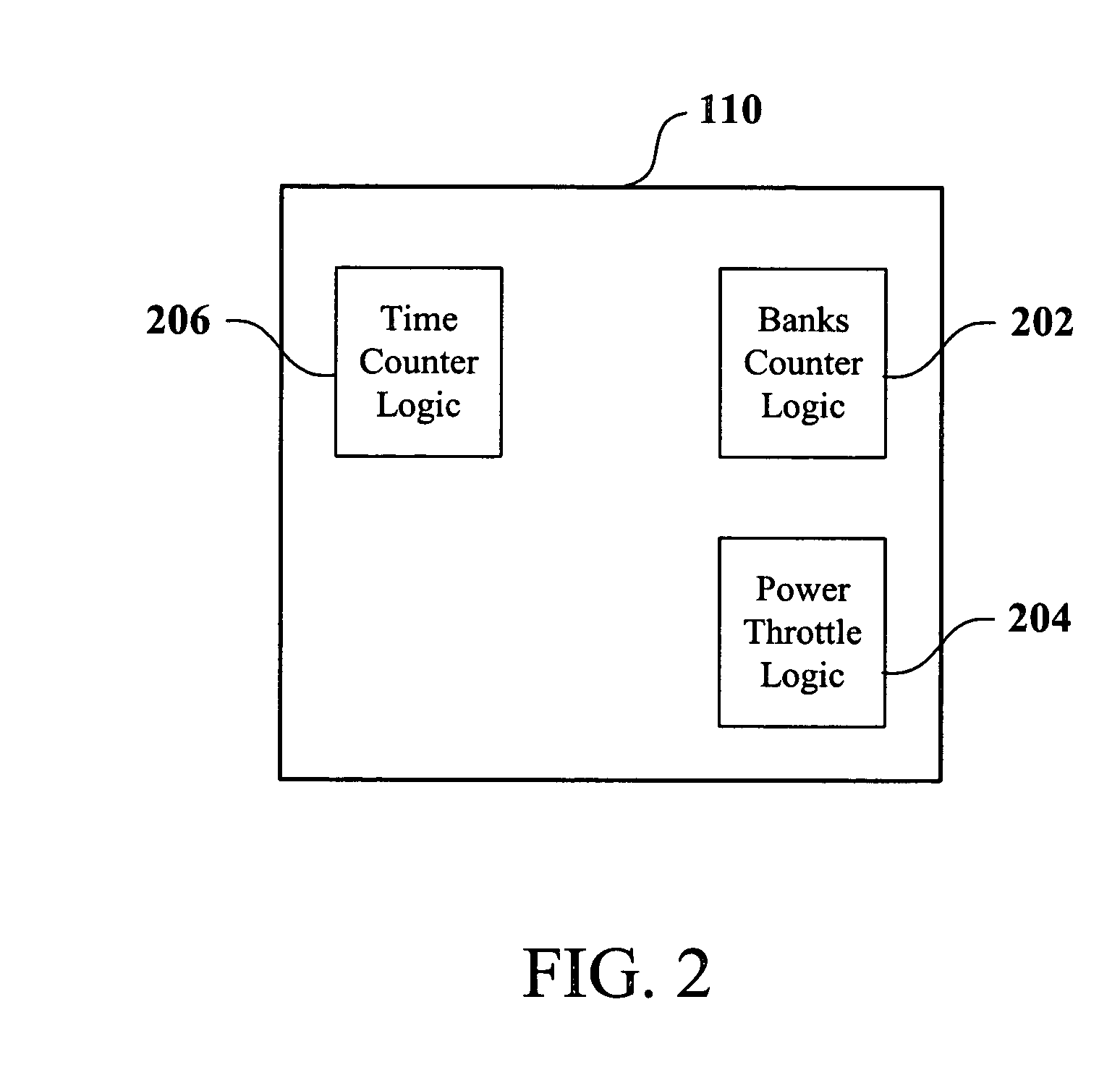

System and method for efficient power throttling in multiprocessor chip

ActiveUS7596707B1Control power consumptionEnergy efficient ICTVolume/mass flow measurementEffective powerMulti processor

A method for limiting power consumption in a multiprocessor chip is provided. In this method, a read or write request is received by the memory controller, which controls a memory that is external to the multiprocessor chip. The memory controller includes a bank counter that keeps track of the number of read or write requests received by the memory controller. At every clock cycle, the bank counter value is compared with a threshold value to determine whether the counter value is equal to the threshold value. If the bank counter value is determined to be equal to the threshold value, then any subsequent incoming read or write requests are blocked. The bank counter value is incremented each time a read or write request is sent to the memory.

Owner:ORACLE INT CORP

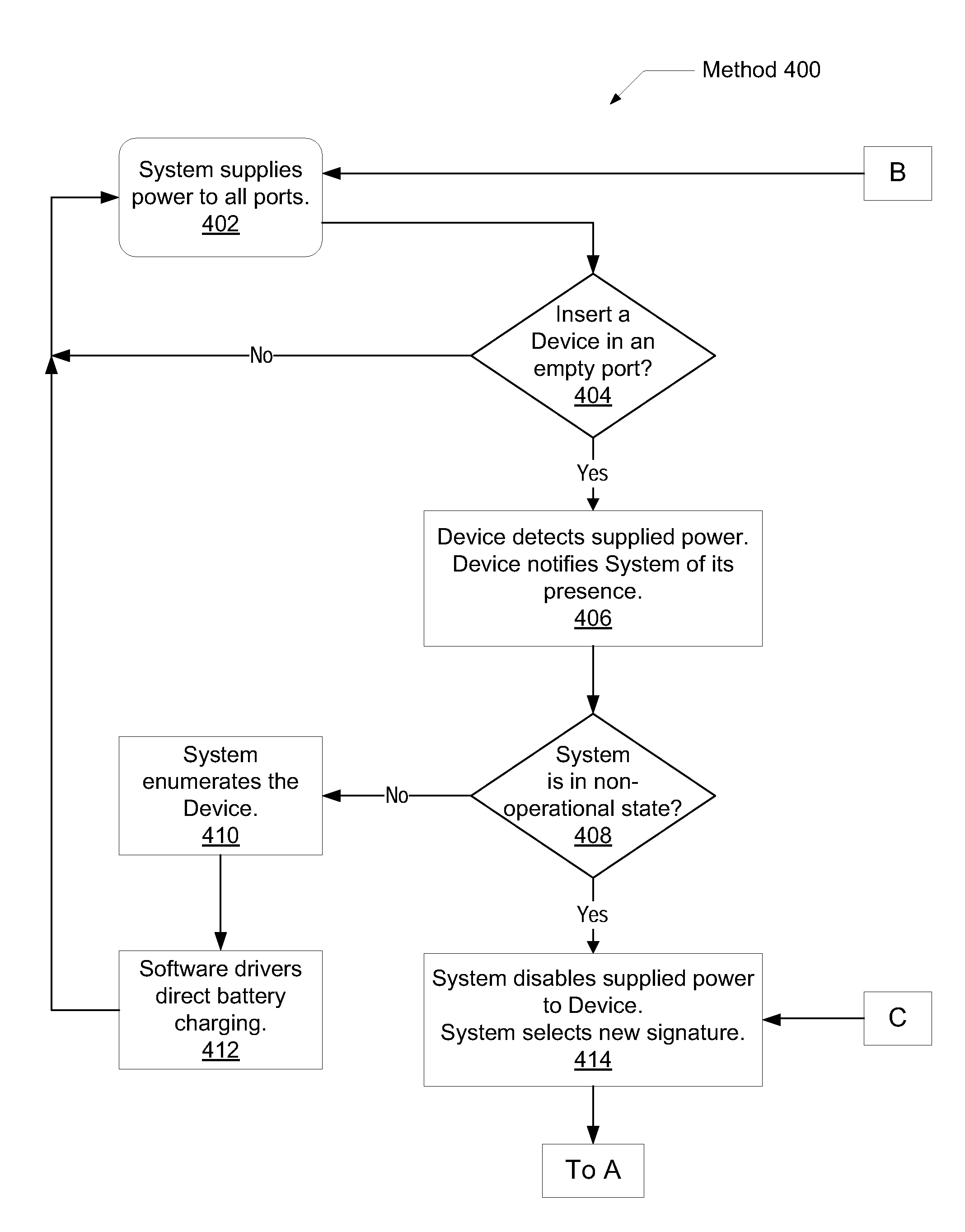

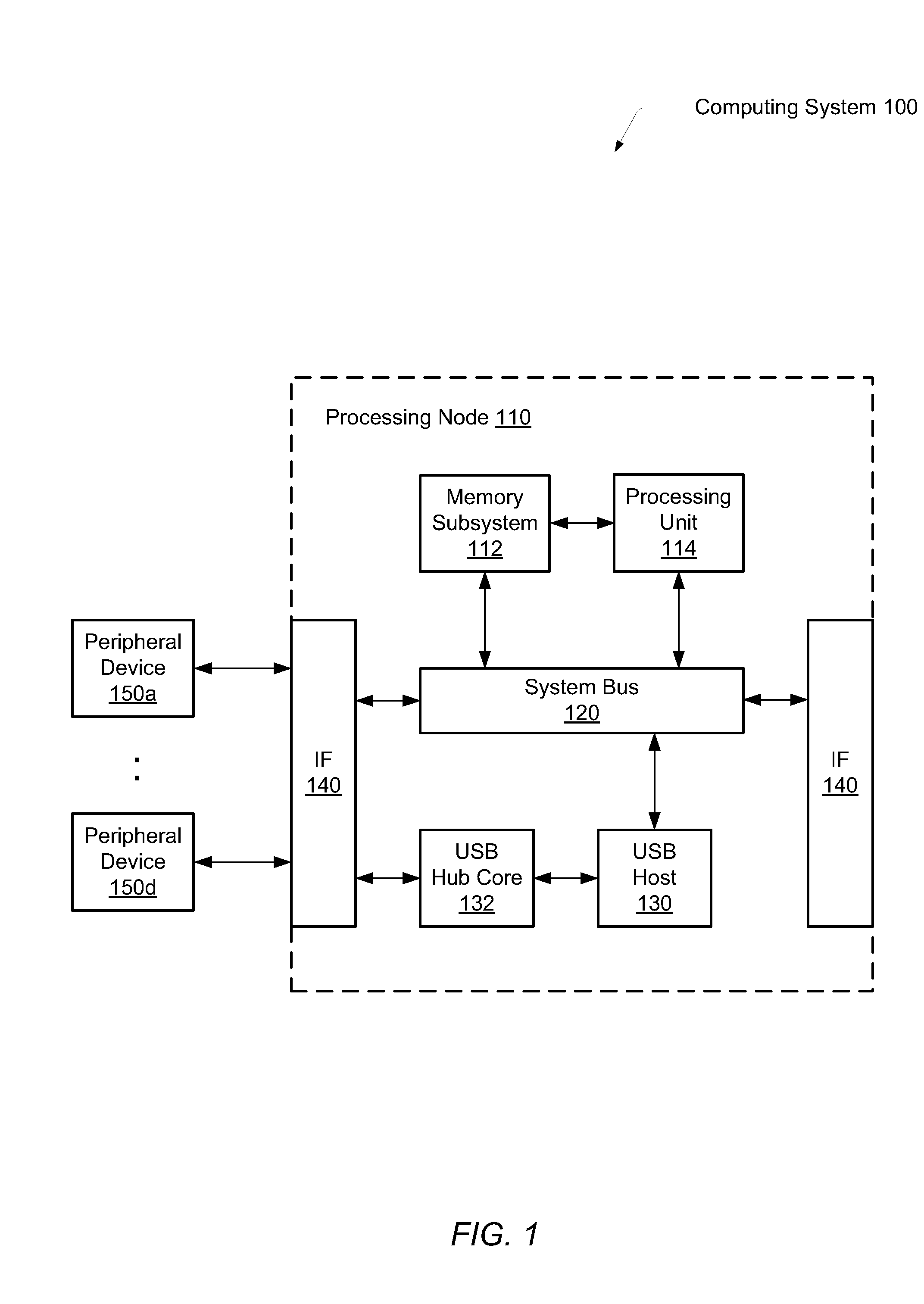

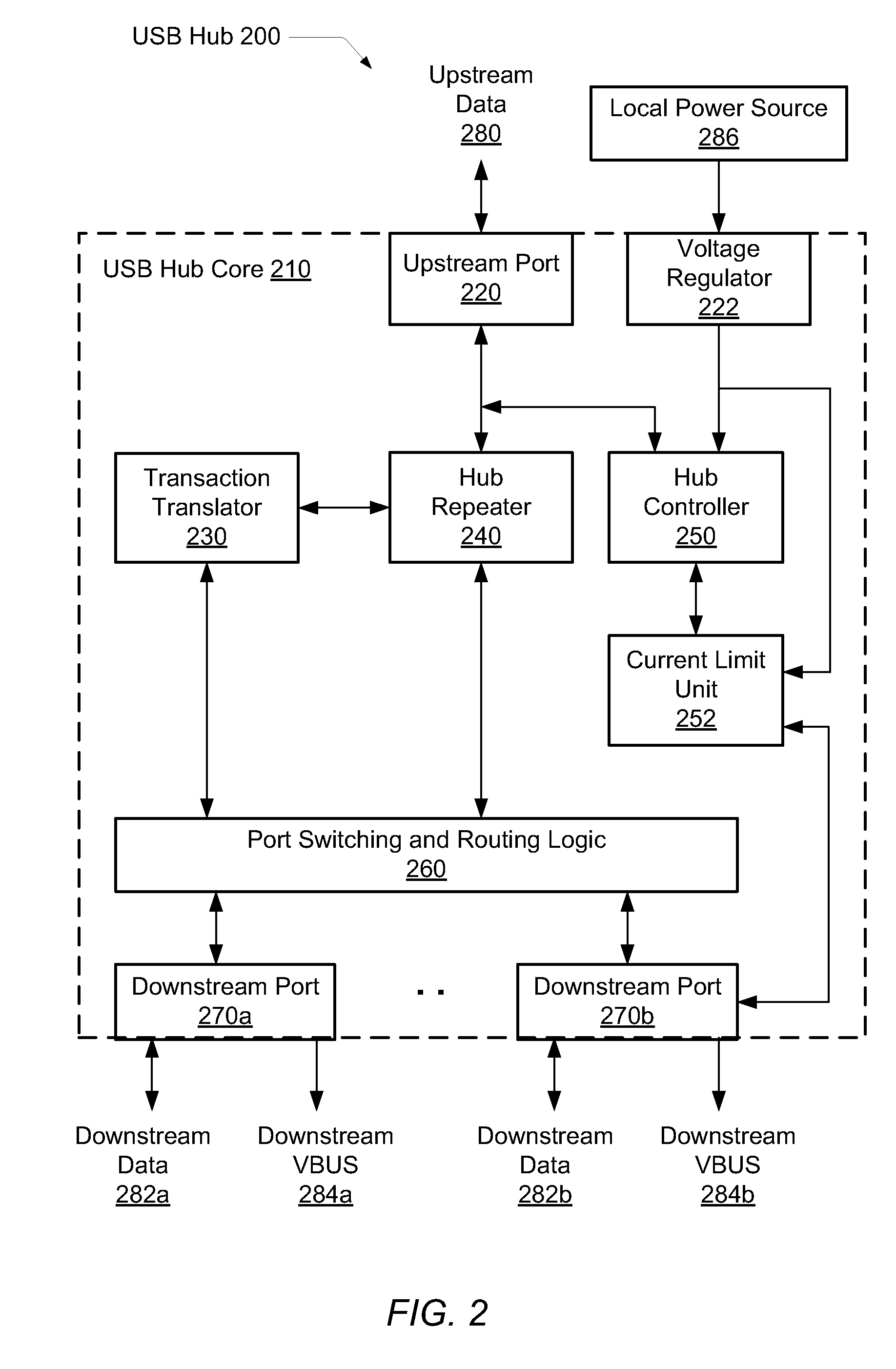

Bistone port power controller for USB hubs with legacy battery charge support

ActiveUS20100205463A1Digital data processing detailsSubstation equipmentPower controllerEffective power

A system and method for efficient power management of peripheral port connections. A USB hub core is configured to detect the presence of a legacy peripheral device on a downstream port when a corresponding USB host is in a non-operational state. The USB hub core chooses a battery charger signature for the peripheral device and subsequently directs an external port power controller to simulate disconnection / reconnection of the peripheral device. The chosen signature is presented to the peripheral device. If the signature matches the expected value of the peripheral device, then the peripheral device charges its battery. Otherwise, the process of choosing a different signature and simulating disconnection / reconnection is repeated.

Owner:MICROCHIP TECH INC

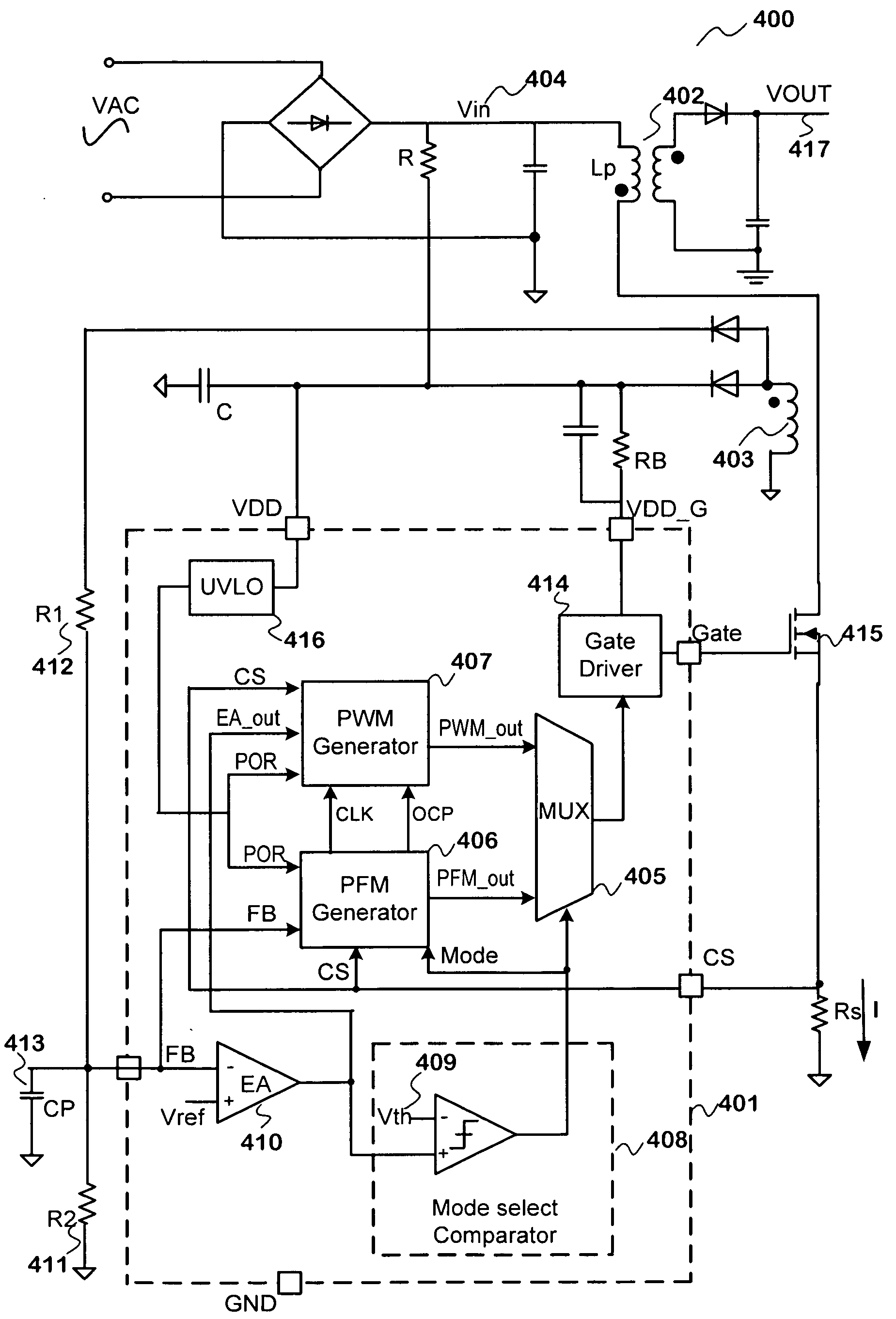

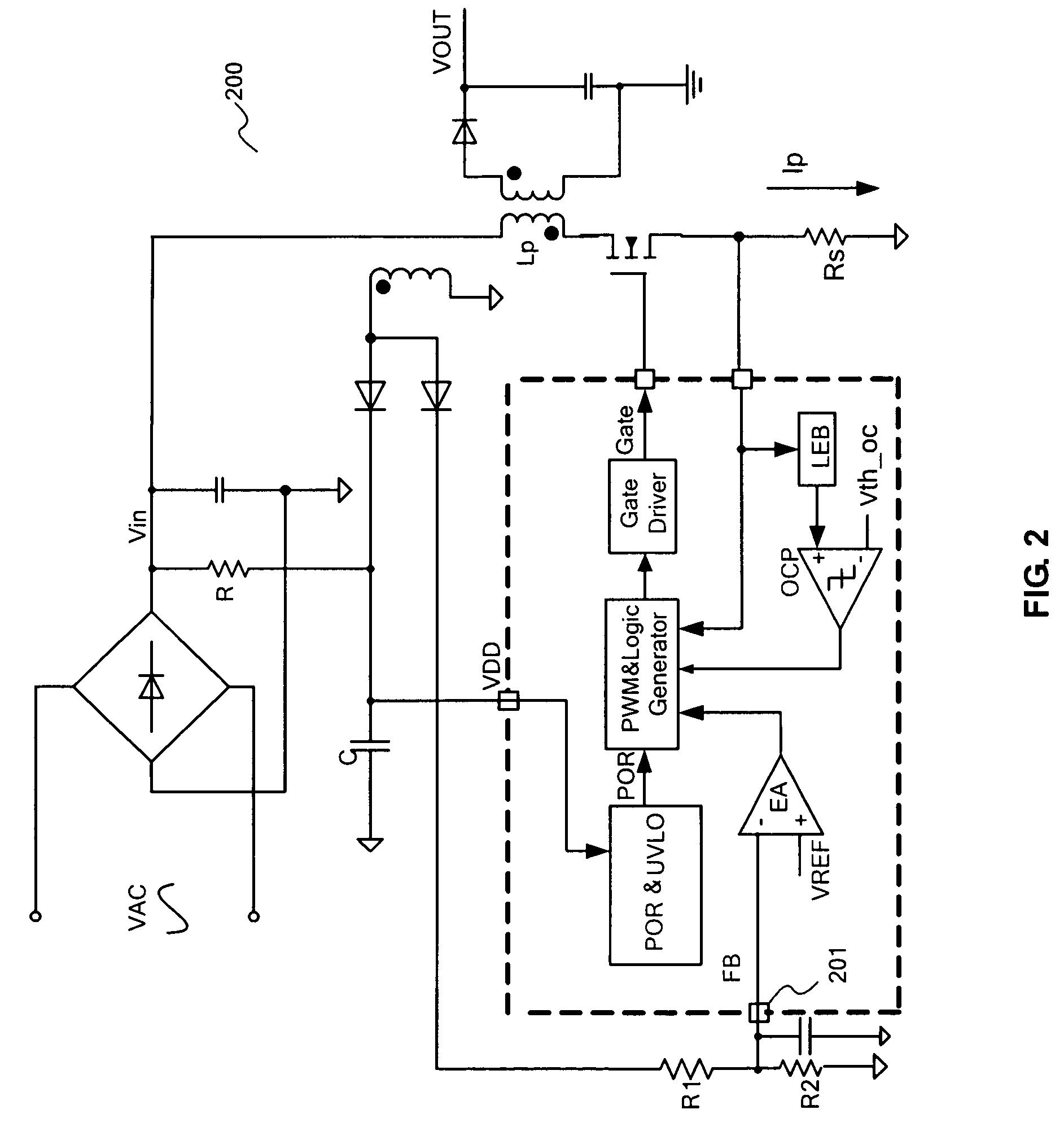

Method and system for efficient power control with multiple modes

InactiveUS20090206814A1Improve performanceImprove stabilityEfficient power electronics conversionDc-dc conversionEffective powerPower mode

Method and system for efficient power control with multiple modes. According to an embodiment, the present invention provides a power system with selectable power modes. The power system includes a first terminal for outputting energy, and the first terminal is electrically coupled to a load. The system also includes a pulse-frequency modulation (PFM) component that is configured to adjust a pulse frequency based on the load. The system additionally includes a pulse-width modulation (PWM) component that is configured to adjust a pulse width based on the load. The system further includes a switch that is electrically coupled to the first terminal. Also, the system includes a control component, the control component being configured to provide a control signal that is capable of causing the switch to be turned on or off. The control signal is associated with an output of the PWM component and the pulse width if an output is greater than a predetermined value. The control signal is associated with an output of the PFM component and the pulse frequency if an output is lower than a predetermined value.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

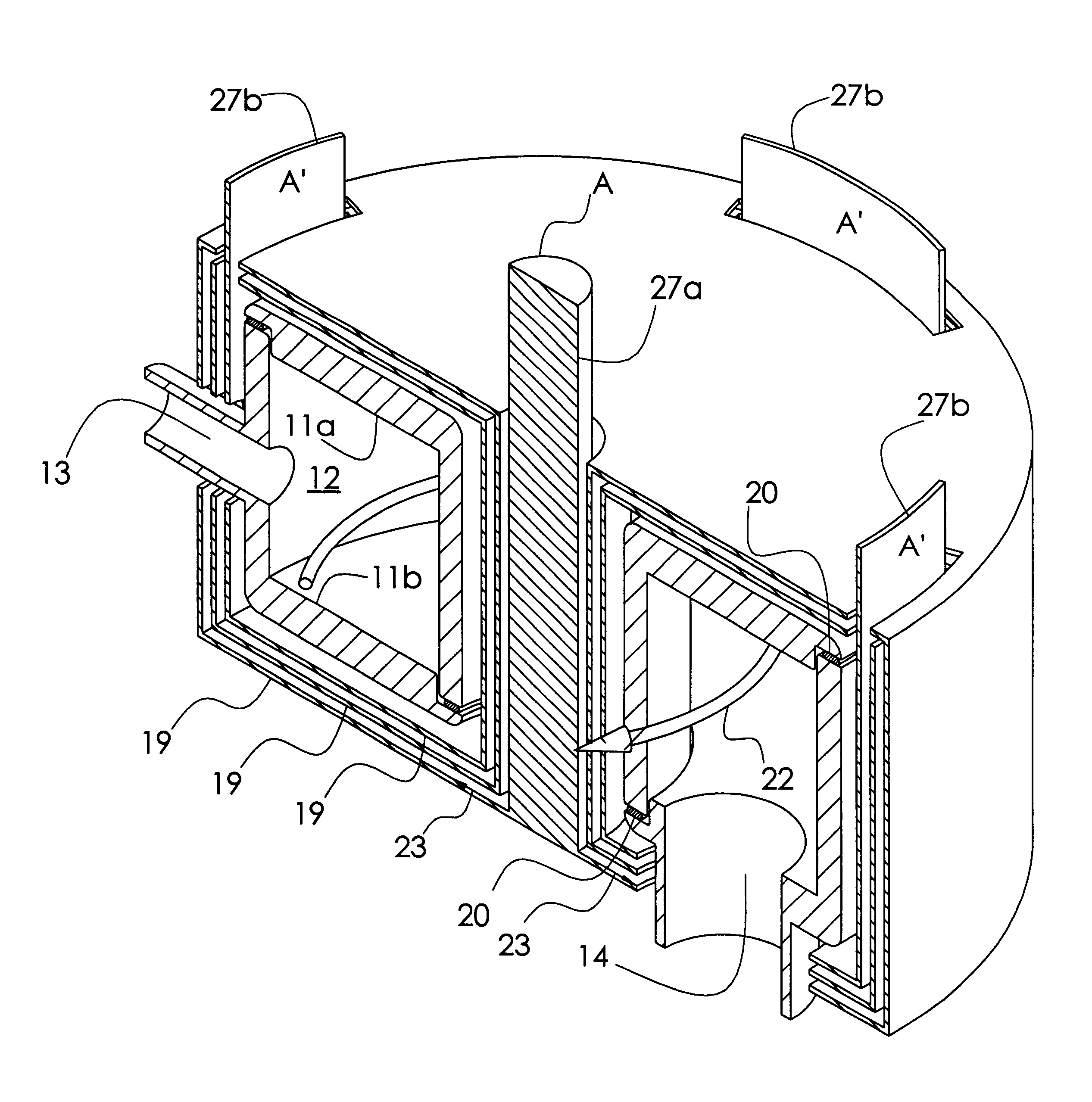

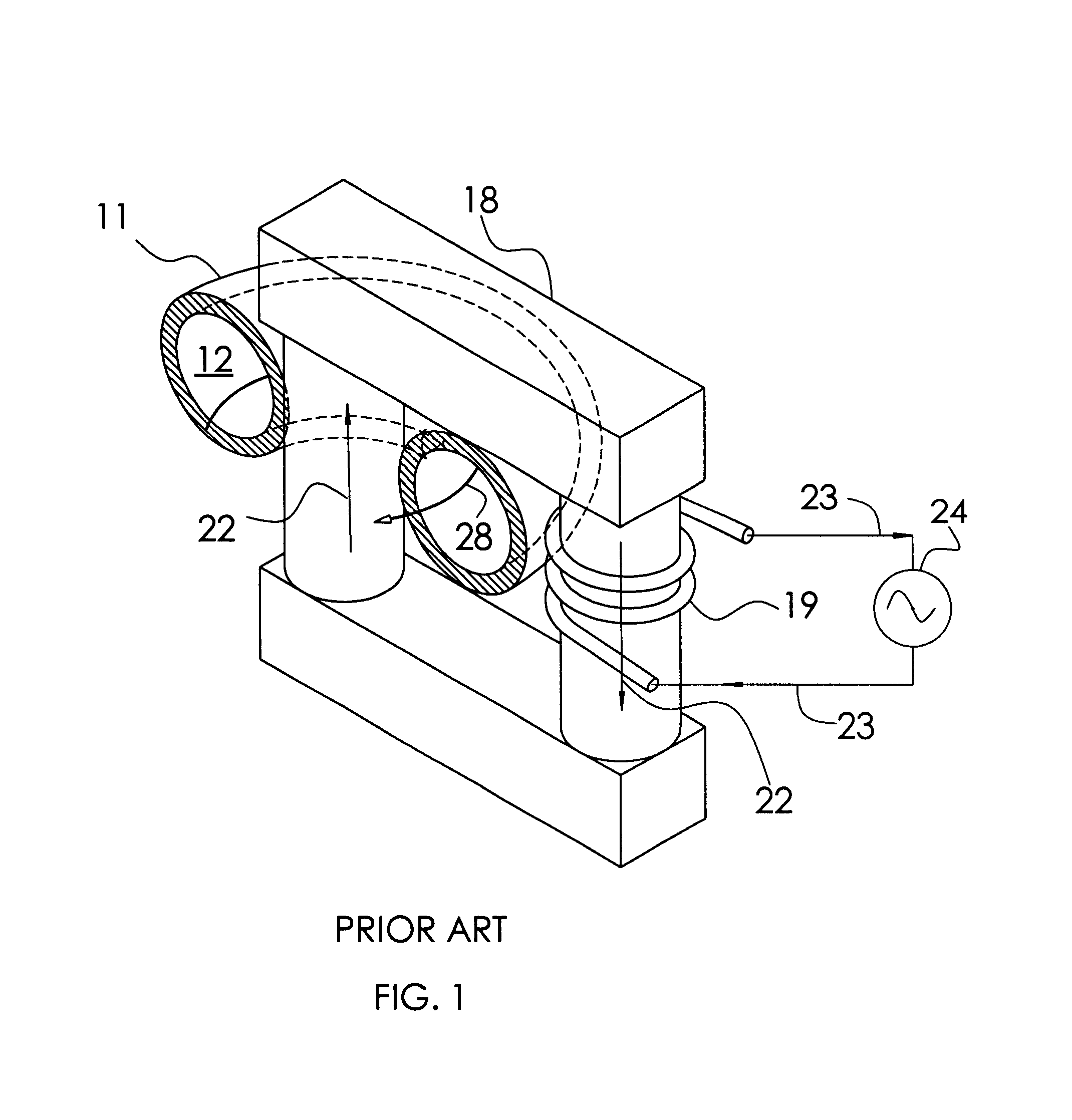

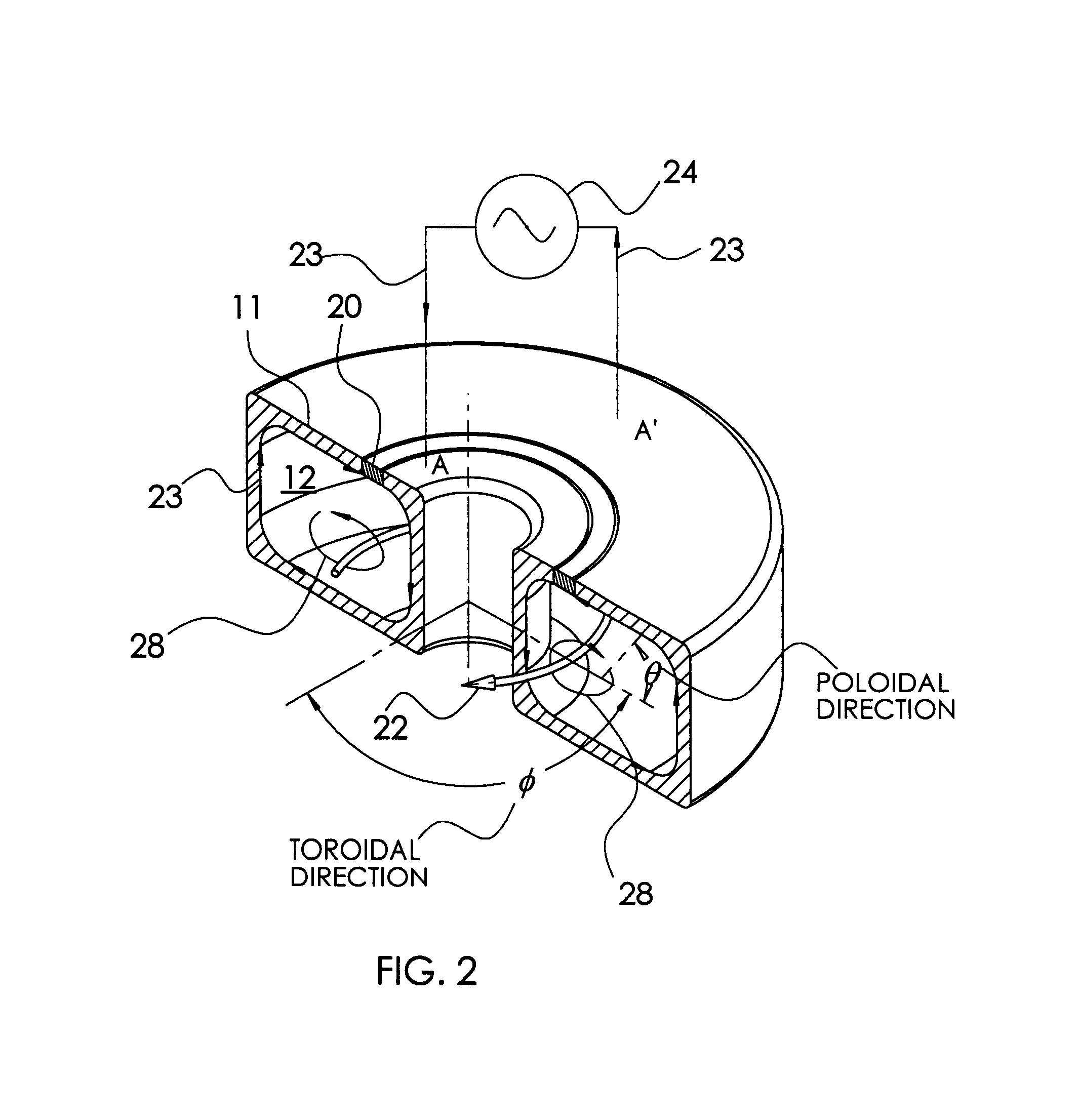

Induction plasma reactor

InactiveUS6855906B2Increase plasma densityImprove productivityCoil arrangementsSemiconductor/solid-state device manufacturingEffective powerElectricity

The invention is a plasma-generating device useful in a wide variety of industrial processes. The plasma is formed in a chamber having a toroidal topology, and is heated inductively. As with all inductive plasmas, a primary coil carries an applied AC current, which, in turn, generates a corresponding applied AC magnetic flux inside the plasma. This flux induces current to flow through the plasma in closed paths that encircle the flux, thereby heating and maintaining the plasma. In this invention, the applied AC current flows through the primary coil around substantially the short poloidal direction on the torus. Accordingly, the applied magnetic flux is caused to circulate through the plasma along the larger toroidal direction. Finally, the current induced within the plasma will flow in the poloidal direction, anti-parallel to the applied primary current. The plasma chamber wall is preferably made of metal such as aluminum and includes one or more electrical breaks that extend fully around the chamber wall in the toroidal direction. This prevents poloidal currents from being induced in the chamber wall, ensuring effective power transfer to the plasma. Elastomeric seals made from electrically insulating material seal the breaks.

Owner:BRAILOVE ADAM ALEXANDER

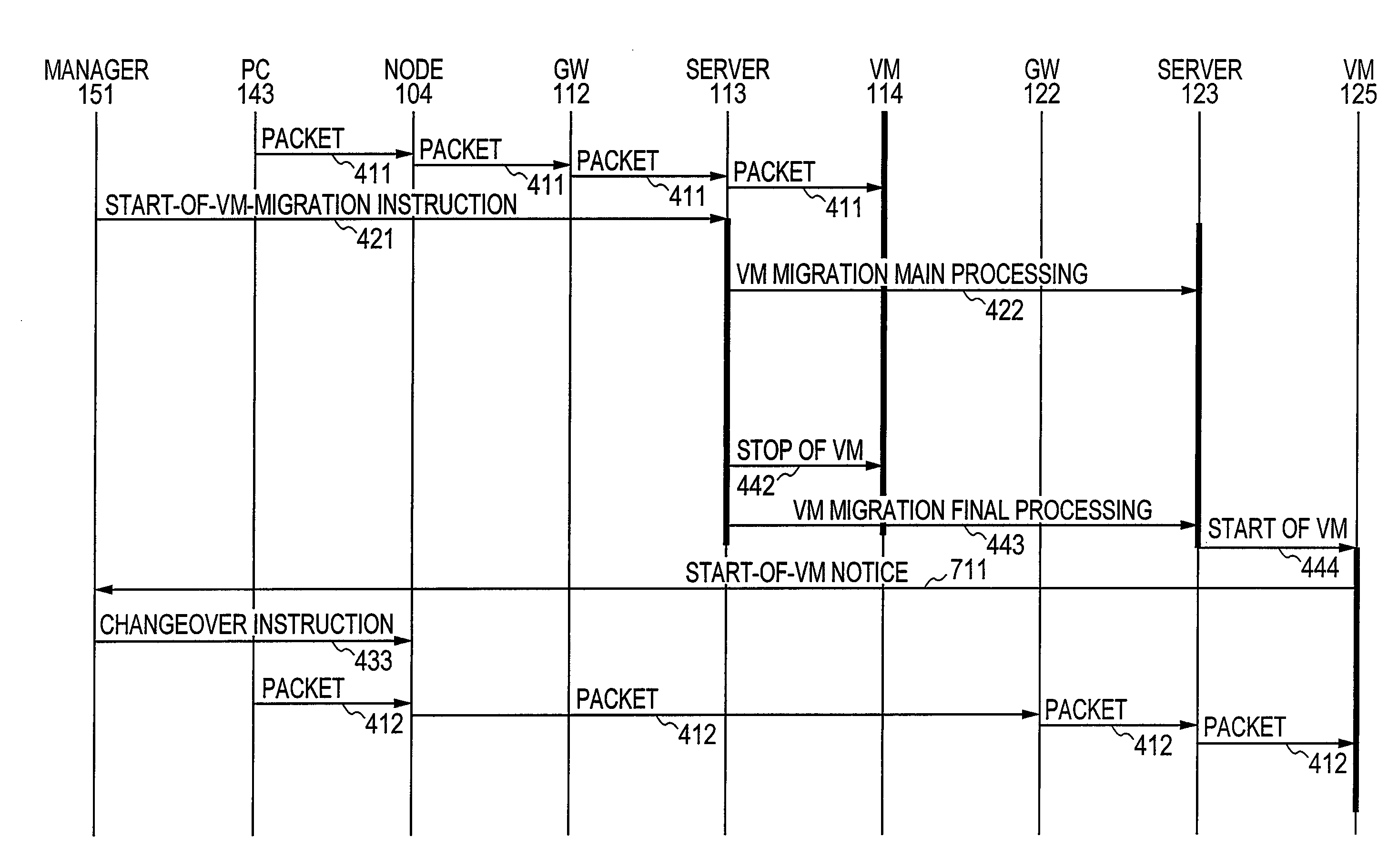

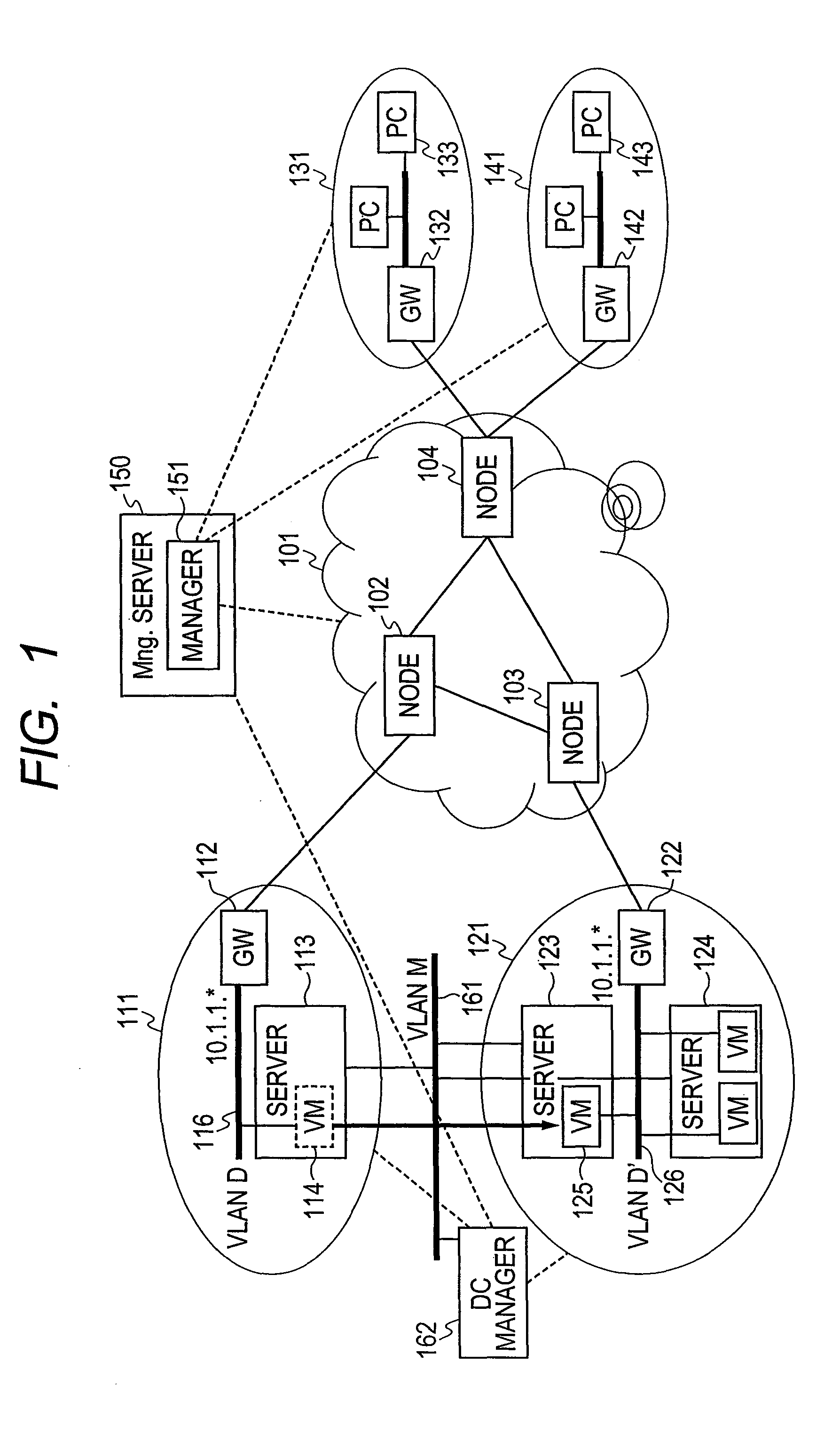

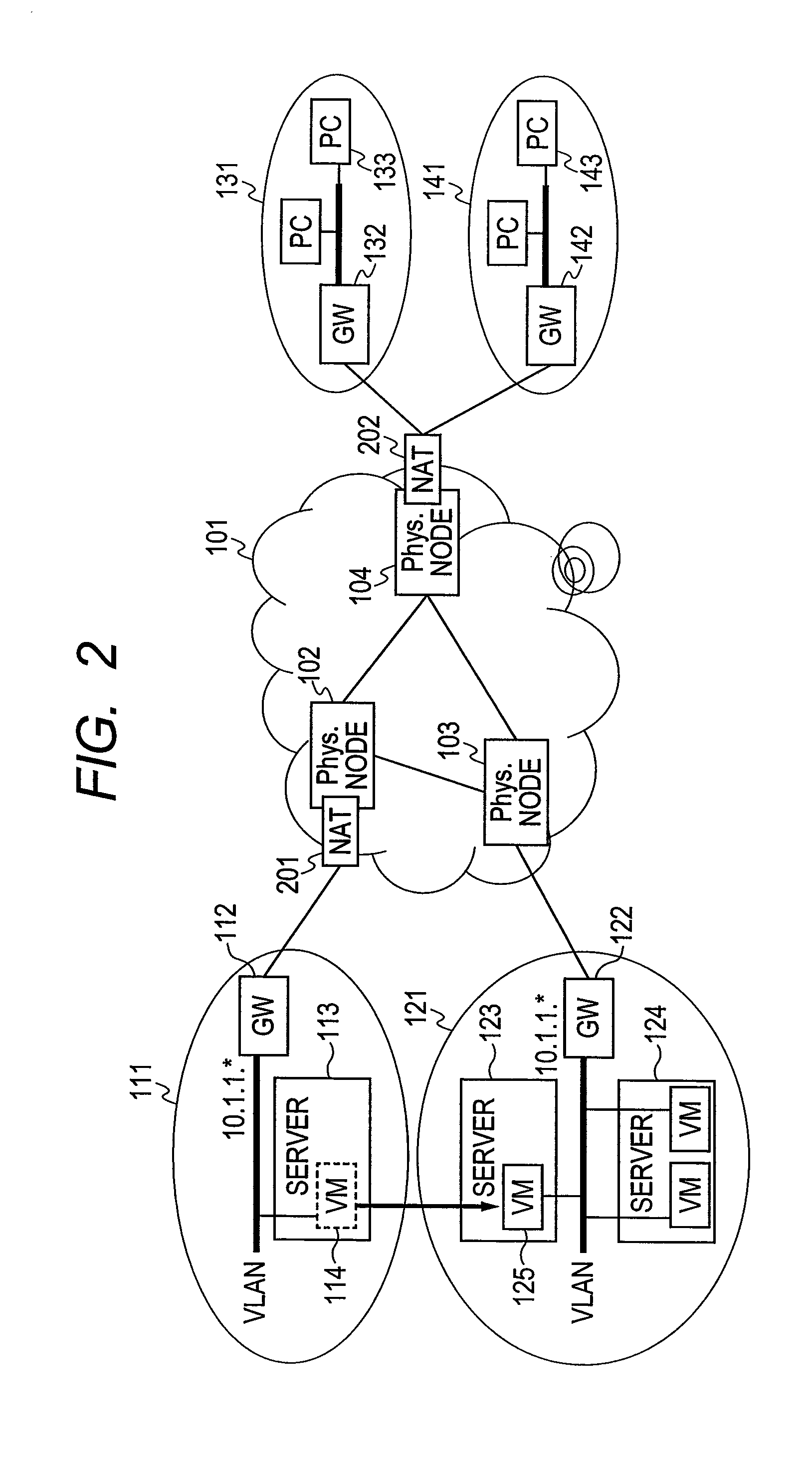

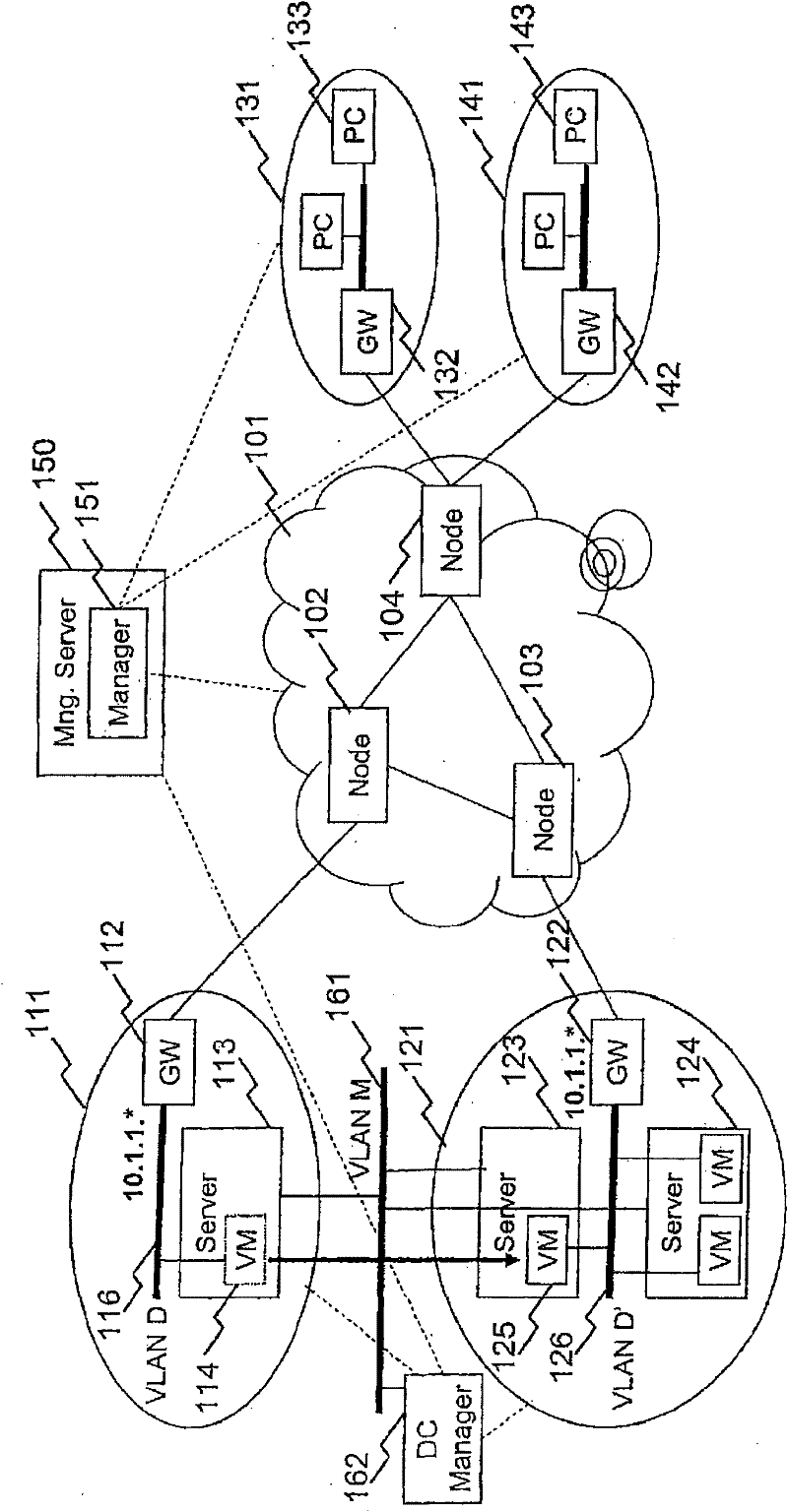

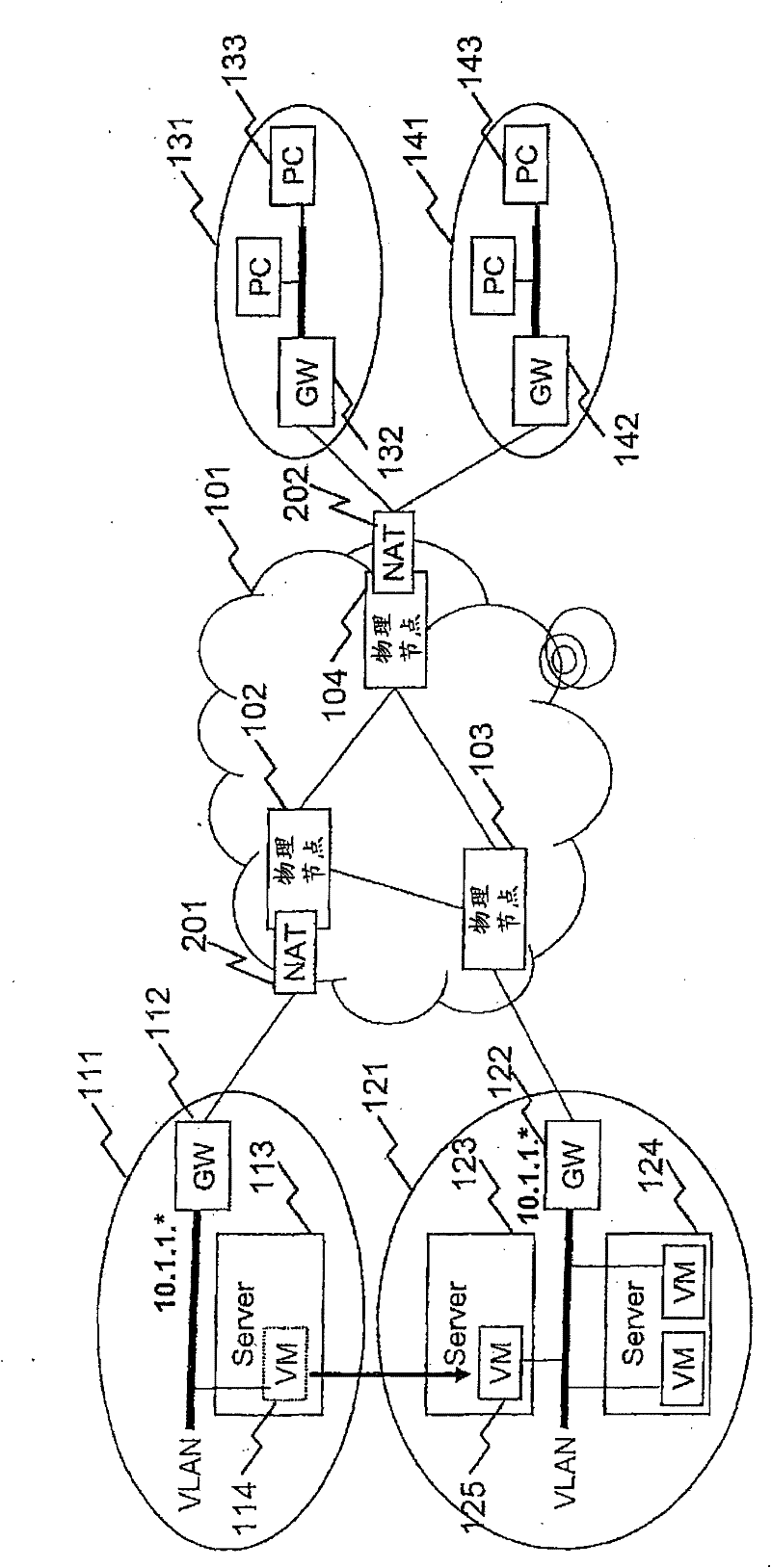

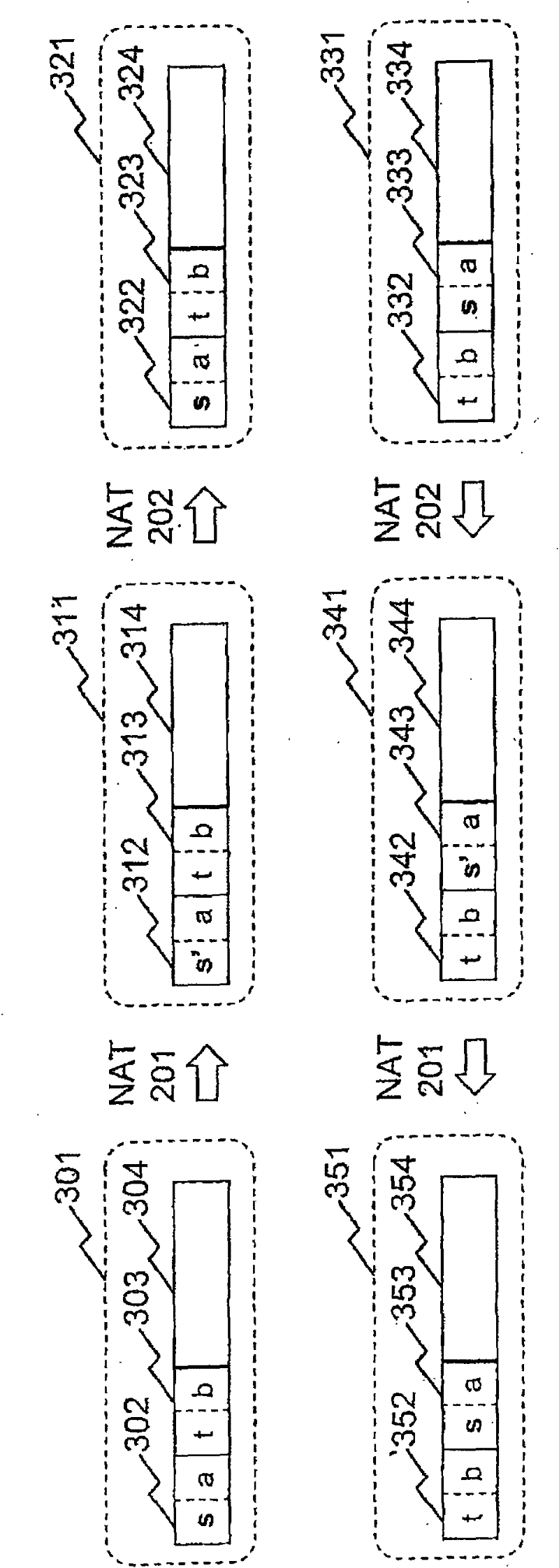

Method and system of virtual machine migration

ActiveUS8396986B2Reduce downtimeEnergy efficient ICTResource allocationEffective powerCountermeasure

In cooperation between each data center and a WAN, virtual machine migration is carried out without interruption in processing so as to enable effective power-saving implementation, load distribution, or fault countermeasure processing. Each node located at a boundary point between the WAN and another network is provided with a network address translation (NAT) function that can be set dynamically to avoid address duplication due to virtual machine migration. Alternatively, each node included in the WAN is provided with a network virtualization function; and there are implemented a virtual network connected to a data center for including a virtual machine before migration, and a virtual network connected to a data center for including the virtual machine after migration, thereby allowing coexistent provision of identical addresses. Thus, the need for changing network routing information at the time of virtual machine migration can be eliminated, and a setting change for migration accomplished quickly.

Owner:HITACHI LTD

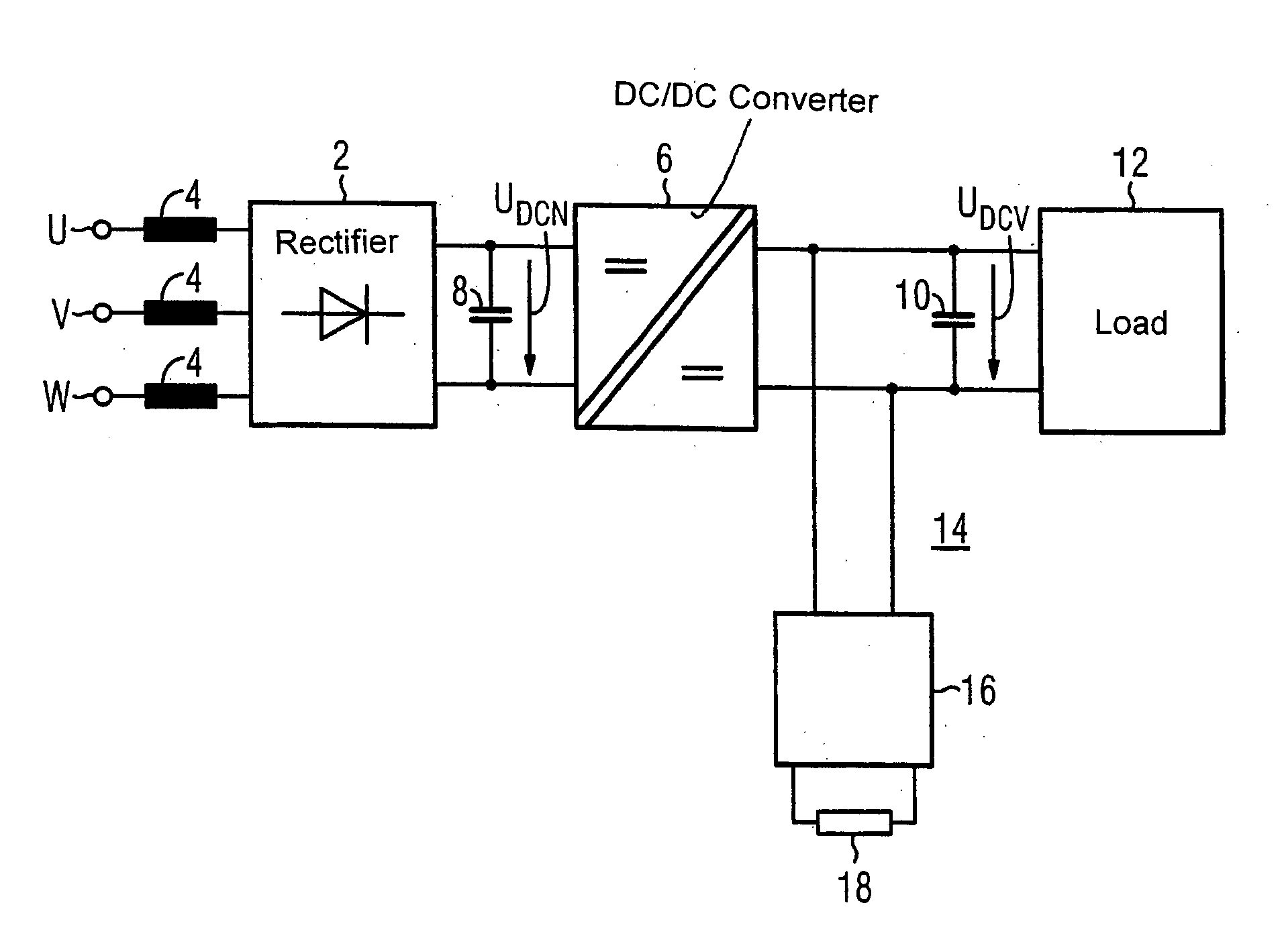

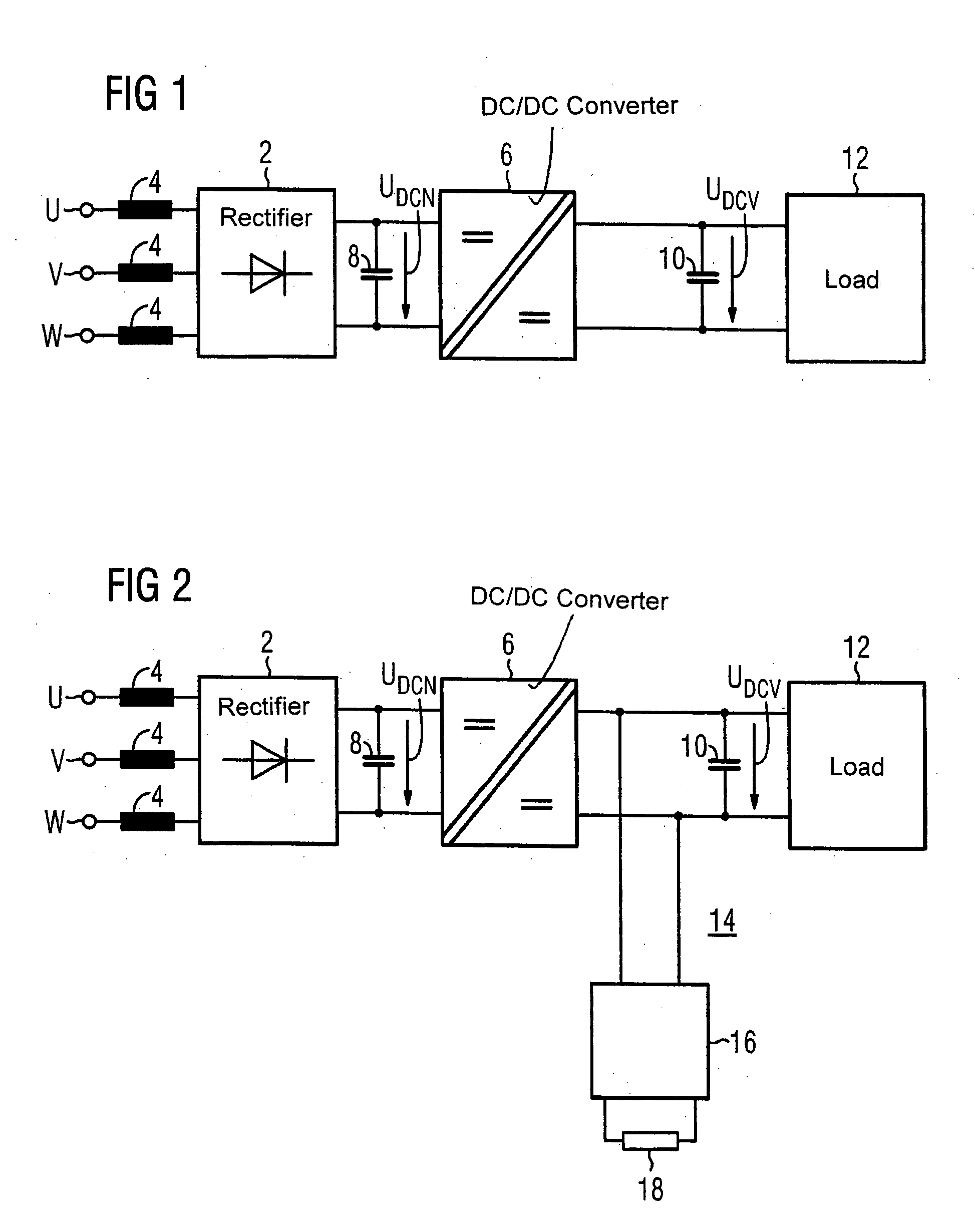

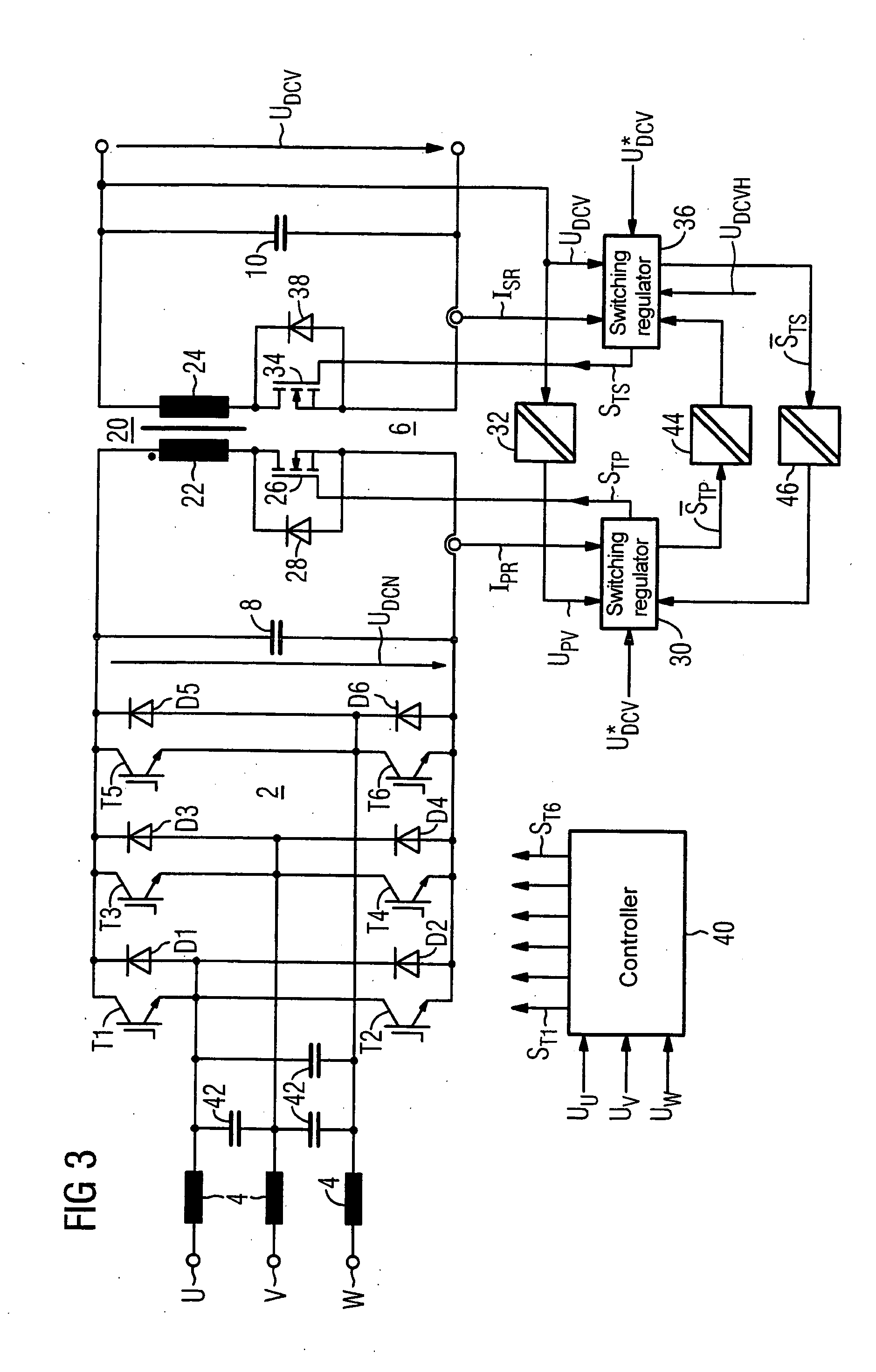

Power supply system

InactiveUS20050122747A1Improve energy balanceDissipate energy from the loadEfficient power electronics conversionAc-dc conversionSnubber capacitorEffective power

An electric power supply system includes a rectifier with an input connected to a power line and a DC output connected to a DC / DC converter. Two buffer capacitors are connected across the input and output, respectively, of the DC / DC converter. The output of the rectifier includes a plurality of diodes. An electronically controllable switch is electrically connected in parallel with a corresponding diode of the rectifier. A controller receives an input signal from a phase voltage of the power line and provides control signals to the controllable switches. The DC / DC converter is constructed symmetrically. This configuration results in a more cost-effective power supply system with an improved energy balance.

Owner:SIEMENS AG

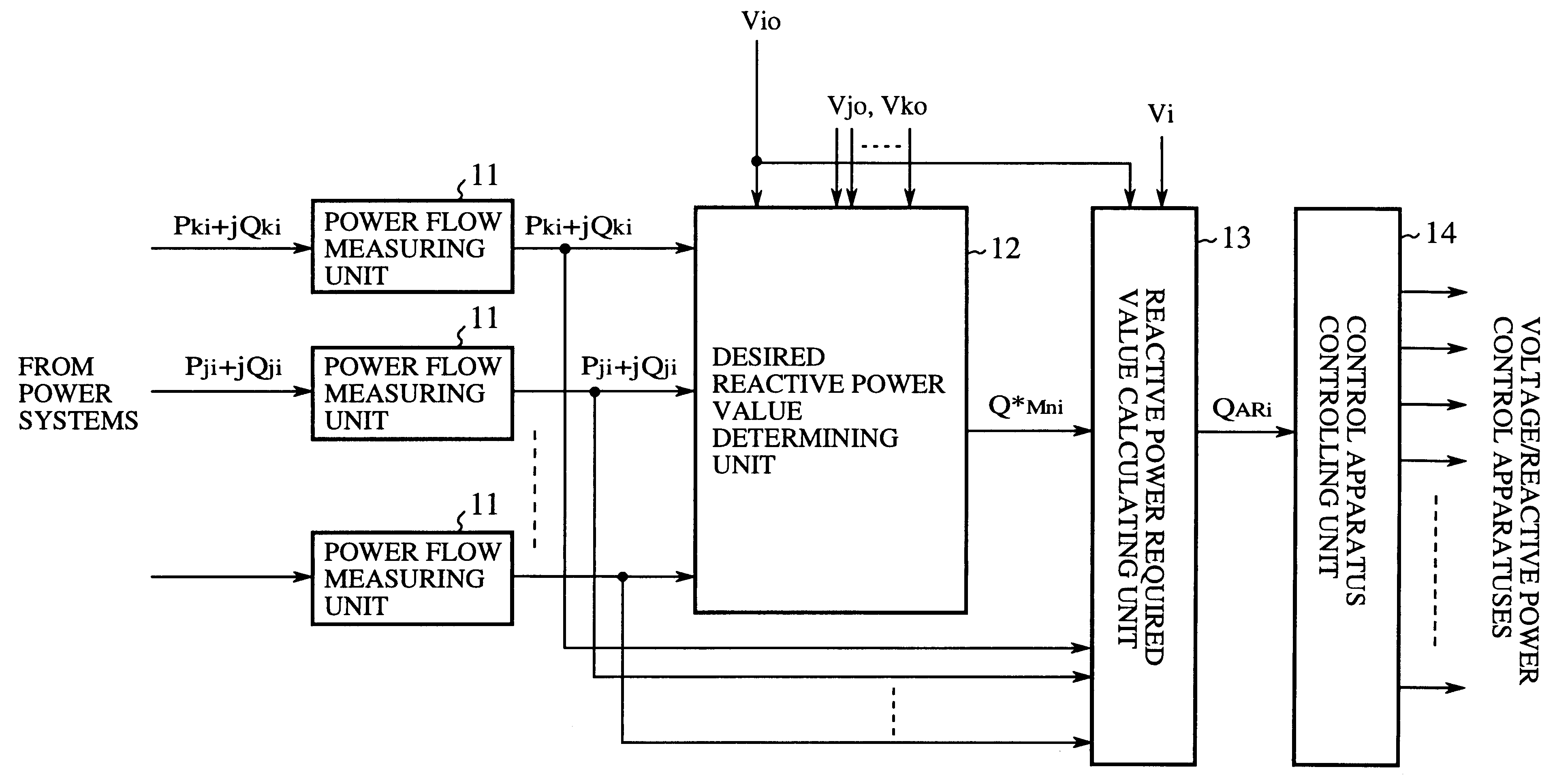

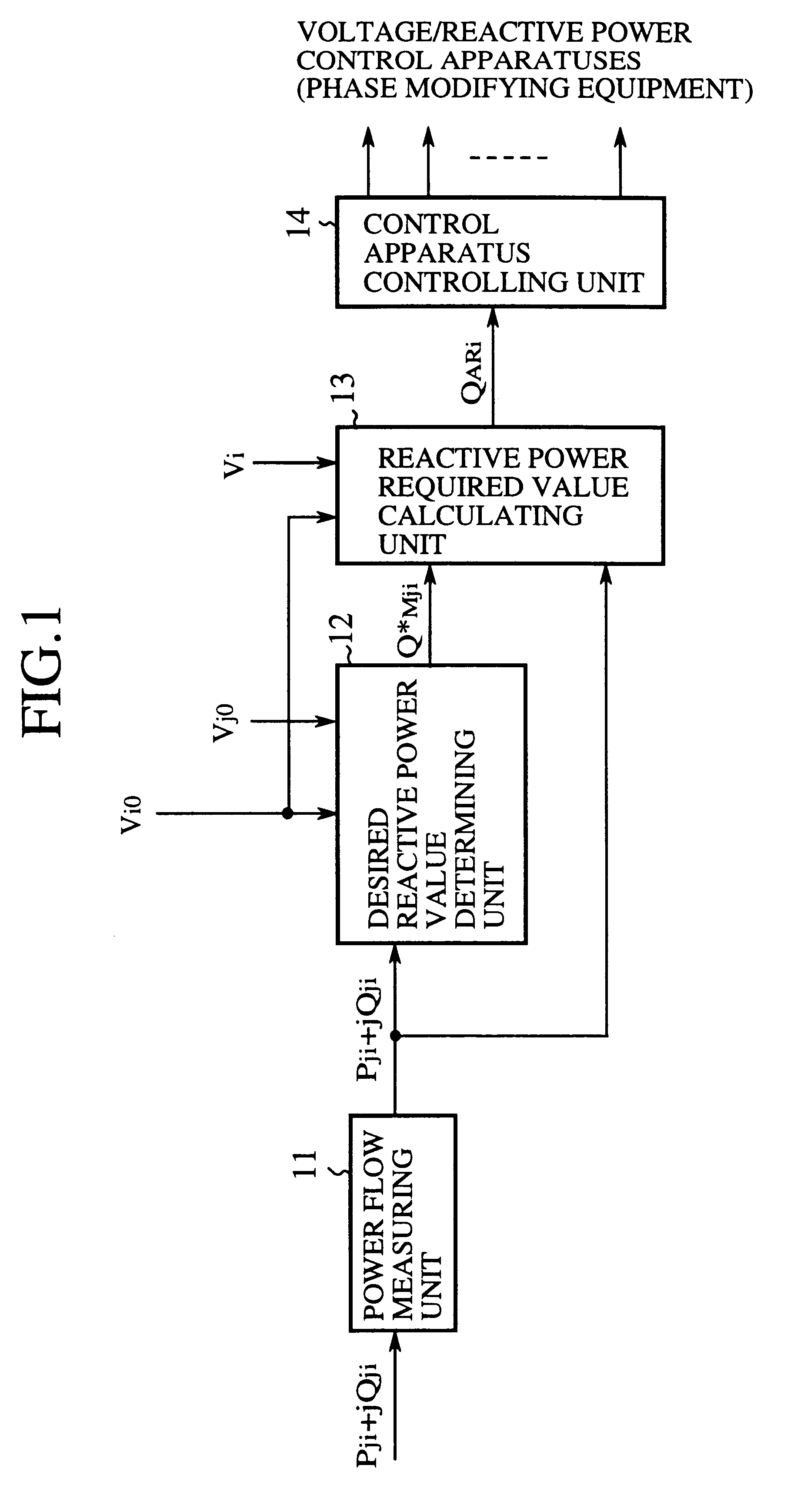

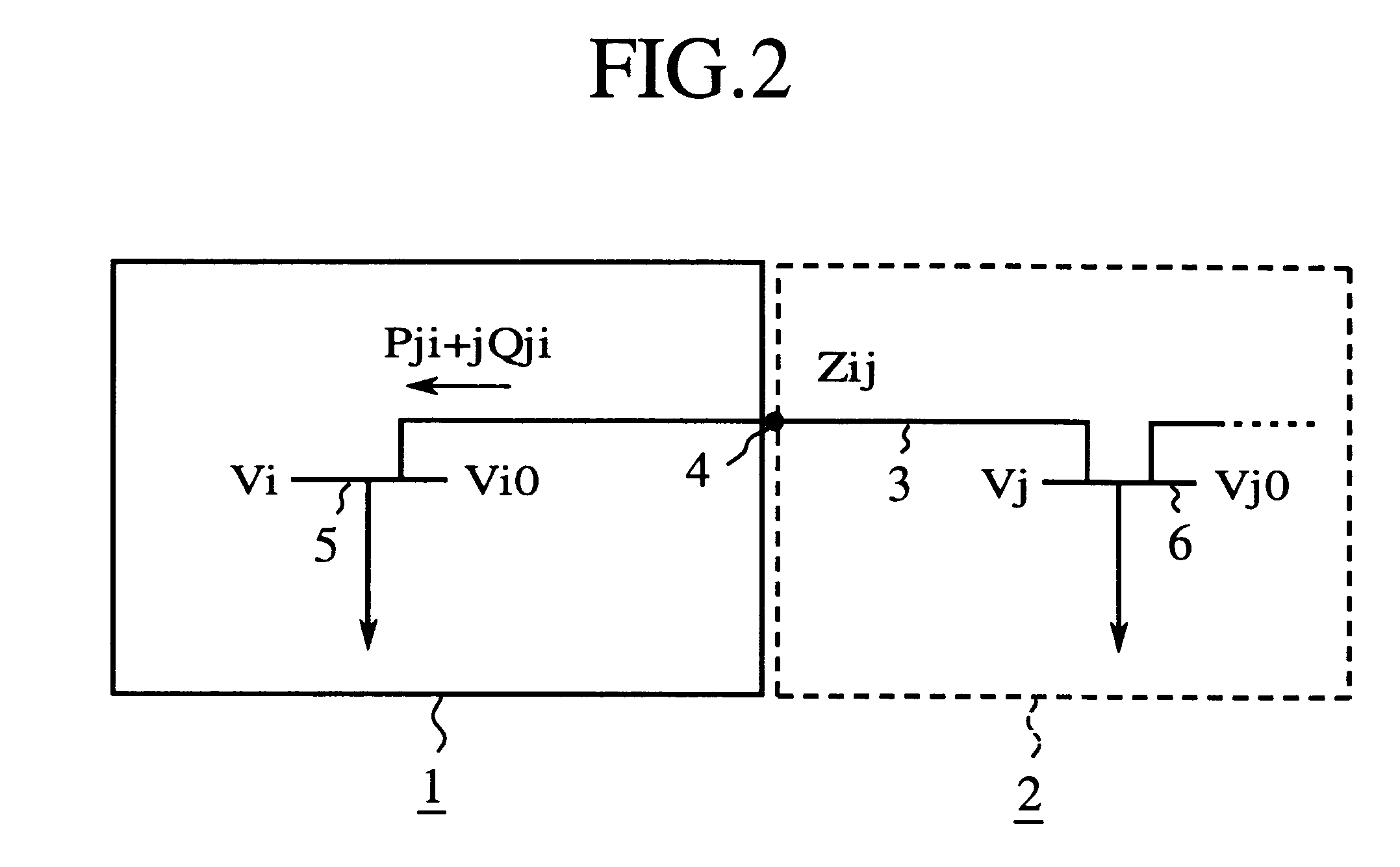

Power system control apparatus and power system control method

InactiveUS6188205B1Reduce the valueSuppresses voltage fluctuationsReactive power adjustment/elimination/compensationAc network voltage adjustmentEffective powerCapacitance

A desired value of reactive power flow between a to-be-controlled power system and an adjoining power system is determined according to measured values of the reactive power flow and an effective power flow and desired voltage values of the to-be-controlled power system and of the adjoining power system. Thereafter, a required value of a reactive power of the to-be-controlled power system is calculated according to the desired value of the reactive power flow, the measured values of the reactive power flow and the effective power flow, and the desired voltage value and a measured voltage value in the to-be-controlled power system. Thereafter, a control apparatus having an electric capacity near to the required value of the reactive power is selected from control apparatus arranged in the to-be-controlled power system to make the selected control apparatus adjust a voltage of the to-be-controlled power system. Therefore, cooperation of the to-be-controlled power system with the adjoining power system can be performed by collecting locally-existing-information, and a voltage fluctuation and / or a reactive power fluctuation in the to-be-controlled power system can be immediately suppressed.

Owner:MITSUBISHI ELECTRIC CORP +1

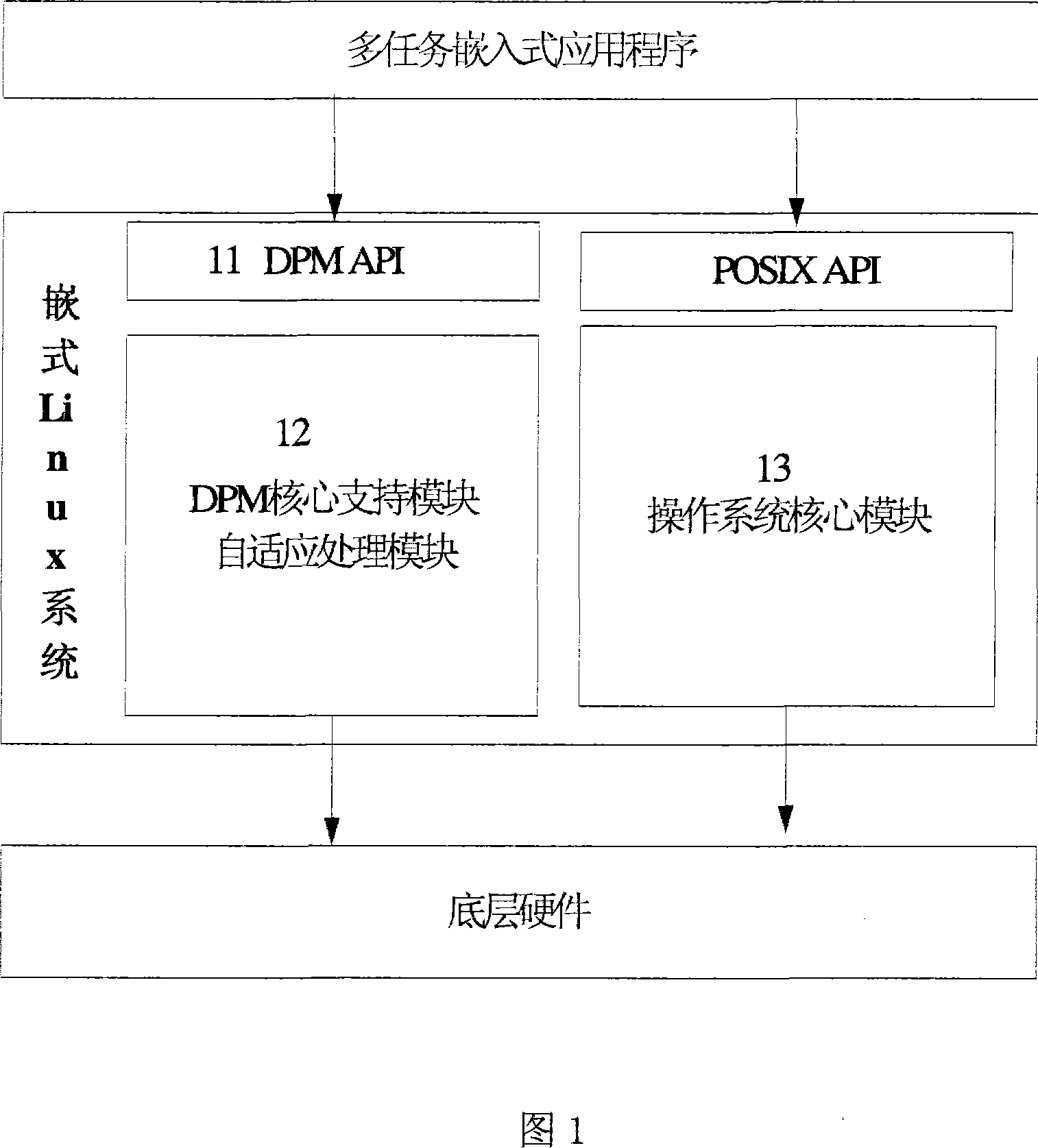

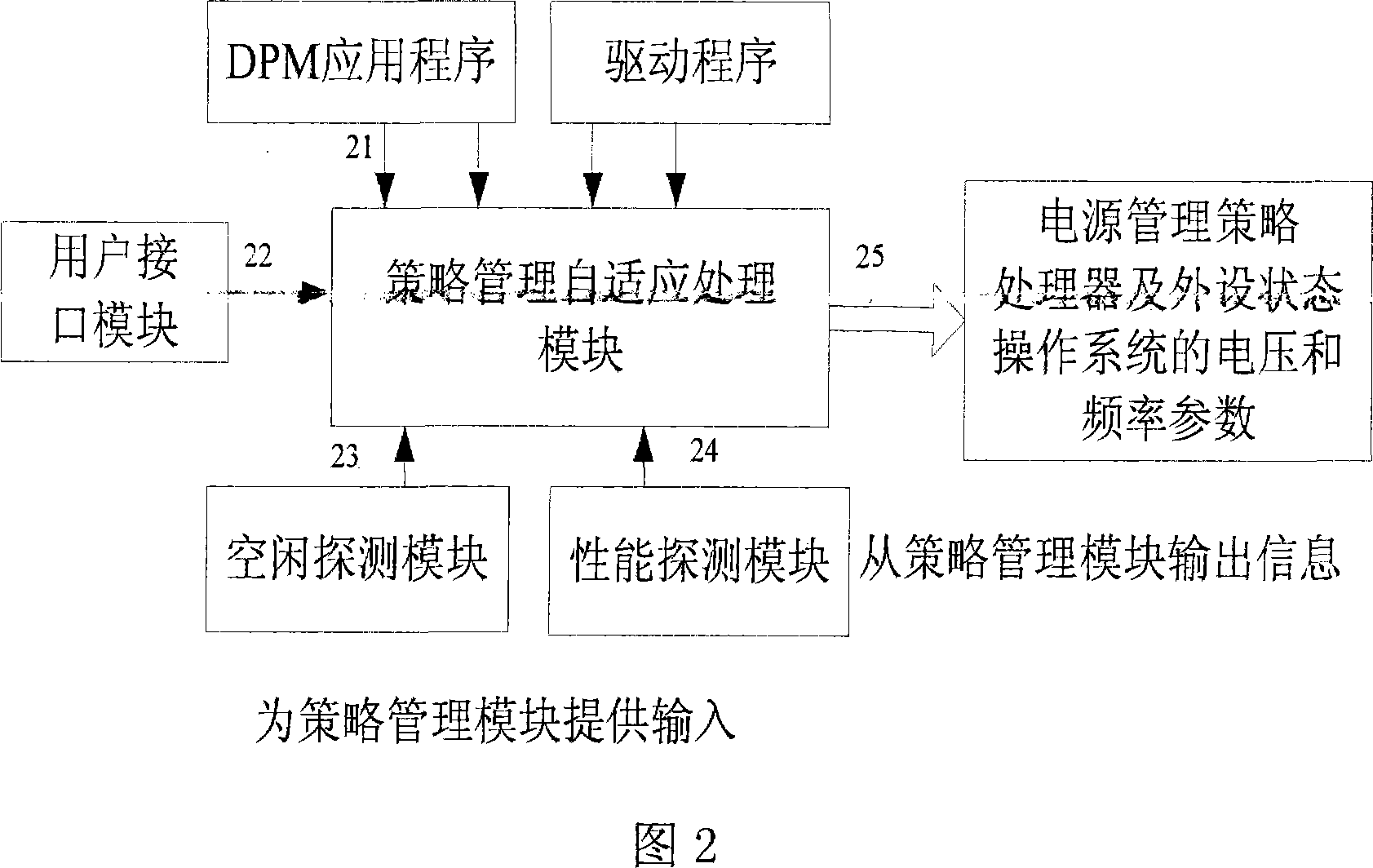

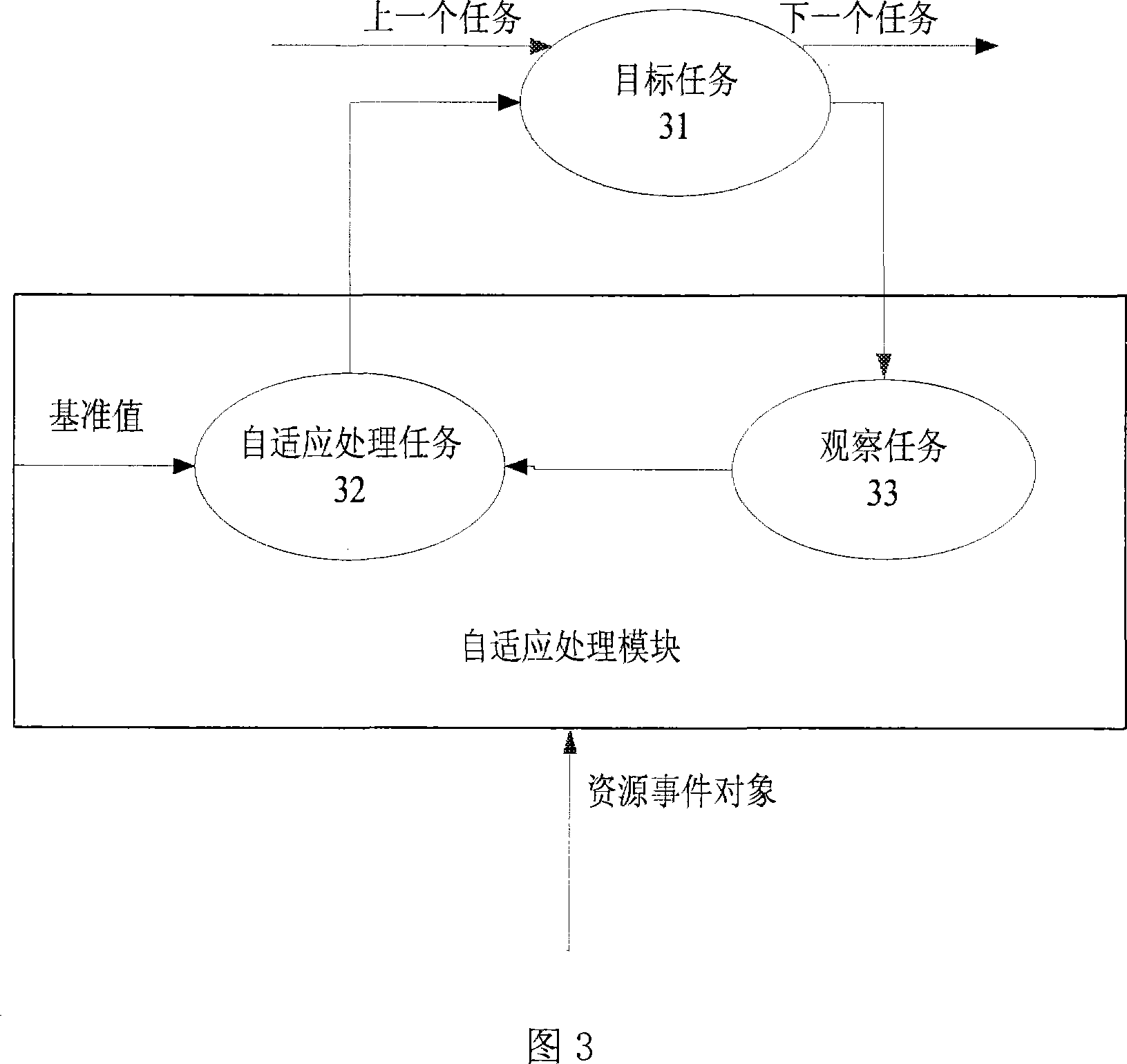

Energy consumption management method for inserting system

InactiveCN101067758AReduce power consumptionPower supply for data processingEffective powerOperational system

The invention provides an energy consumption management method for an embedded system, implemented by dynamic power supply management support module, comprising: policy management module, idle detection module, and performance detection module, where the policy management module makes effective power supply management at system layer so as to implement system performance and power saving, and gives attention to idle state and executed load of system, and self-adaptively regulates equipment idle time according to system task executing state and makes the system enter a corresponding low-power state when the idle time continues to a certain extent; the idle detection module provides idle information of CPU and operating system and monitors the idle thread or activity of a given working load in the operating system and provides policy-making parameter information for the policy management module; and the performance detection module monitors CPU utilization ratio and utilization conditions of main memory and provides accurate executed load information for the policy management module.

Owner:SOUTH CHINA UNIV OF TECH +1

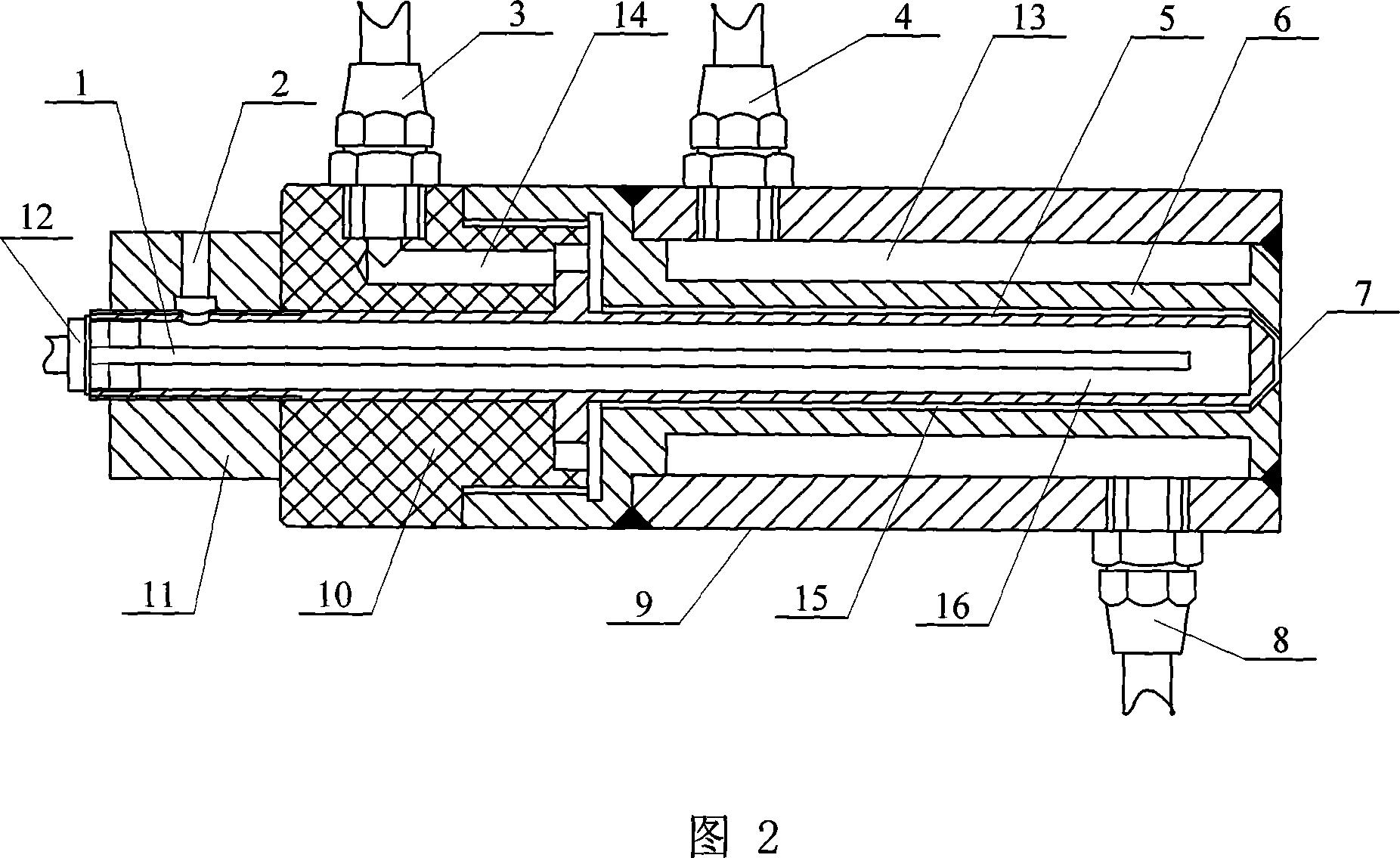

Method of polishing normal pressure plasma

The normal pressure plasma polishing method is provided. The normal pressure plasma polishing method includes providing plasma gas and reaction gas in the volume ratio of 4-1000; and starting RF power source and increasing power gradually while controlling the reflected power to zero, with the initial effective power being 180-240 W, normal power being 400-1200 W, and maximum power being 1500 W. The present invention realizes super smooth surface machining by means of plasma chemical reaction at normal pressure, and has no need of vacuum chamber, low cost, wide application range, high machining efficiency, no surface damage and contamination, and high surface smoothness up to 1nm Ra.

Owner:HARBIN INST OF TECH

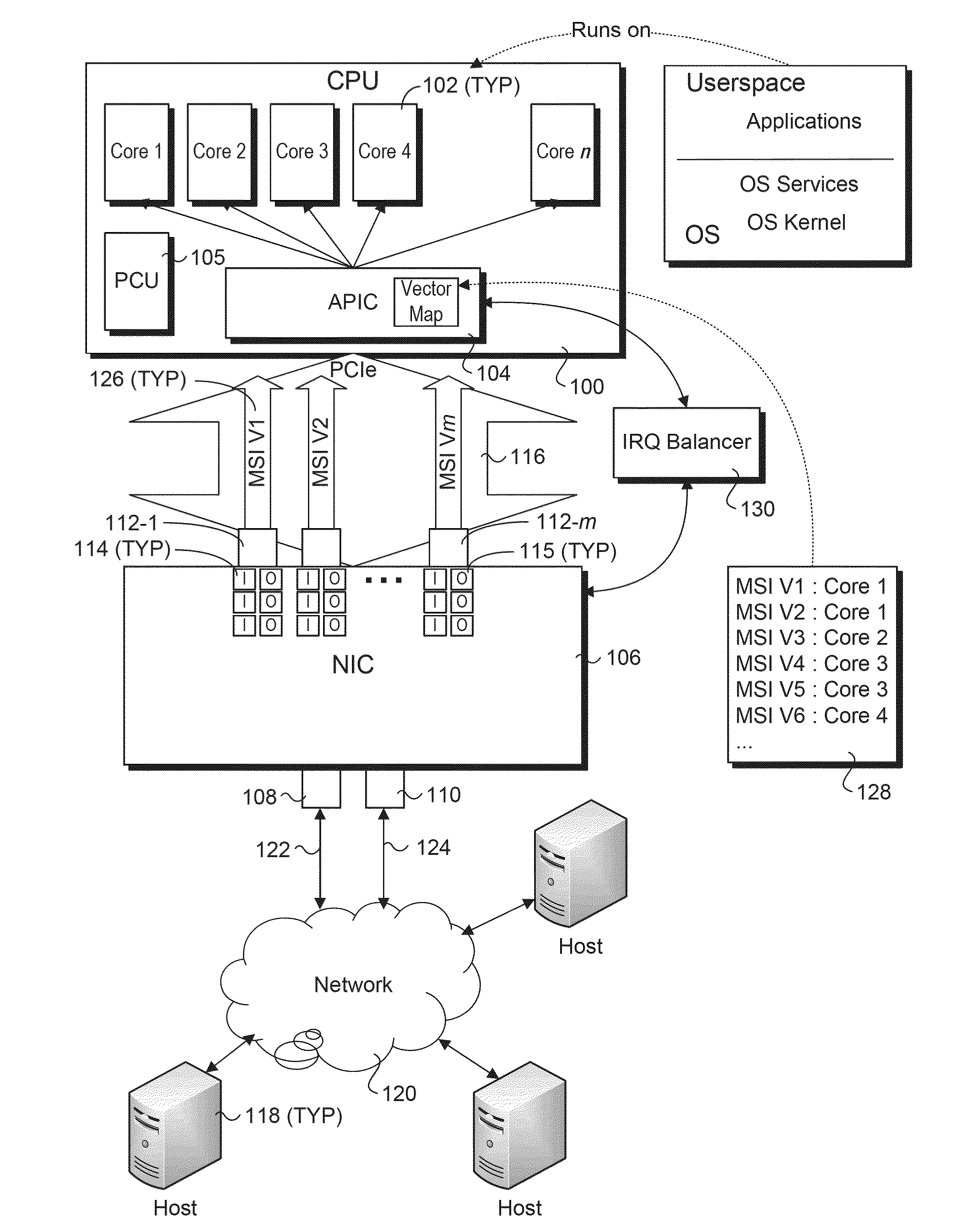

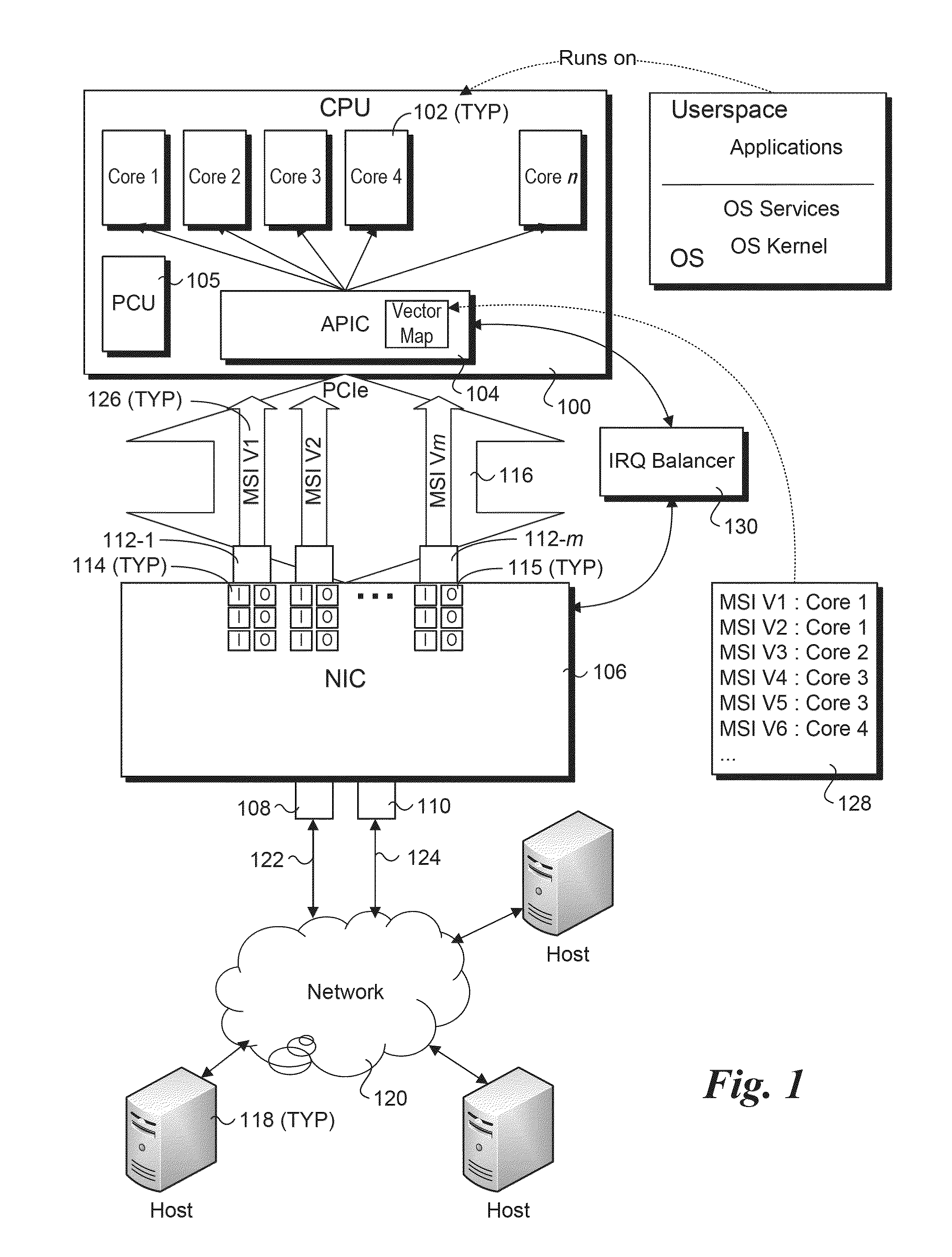

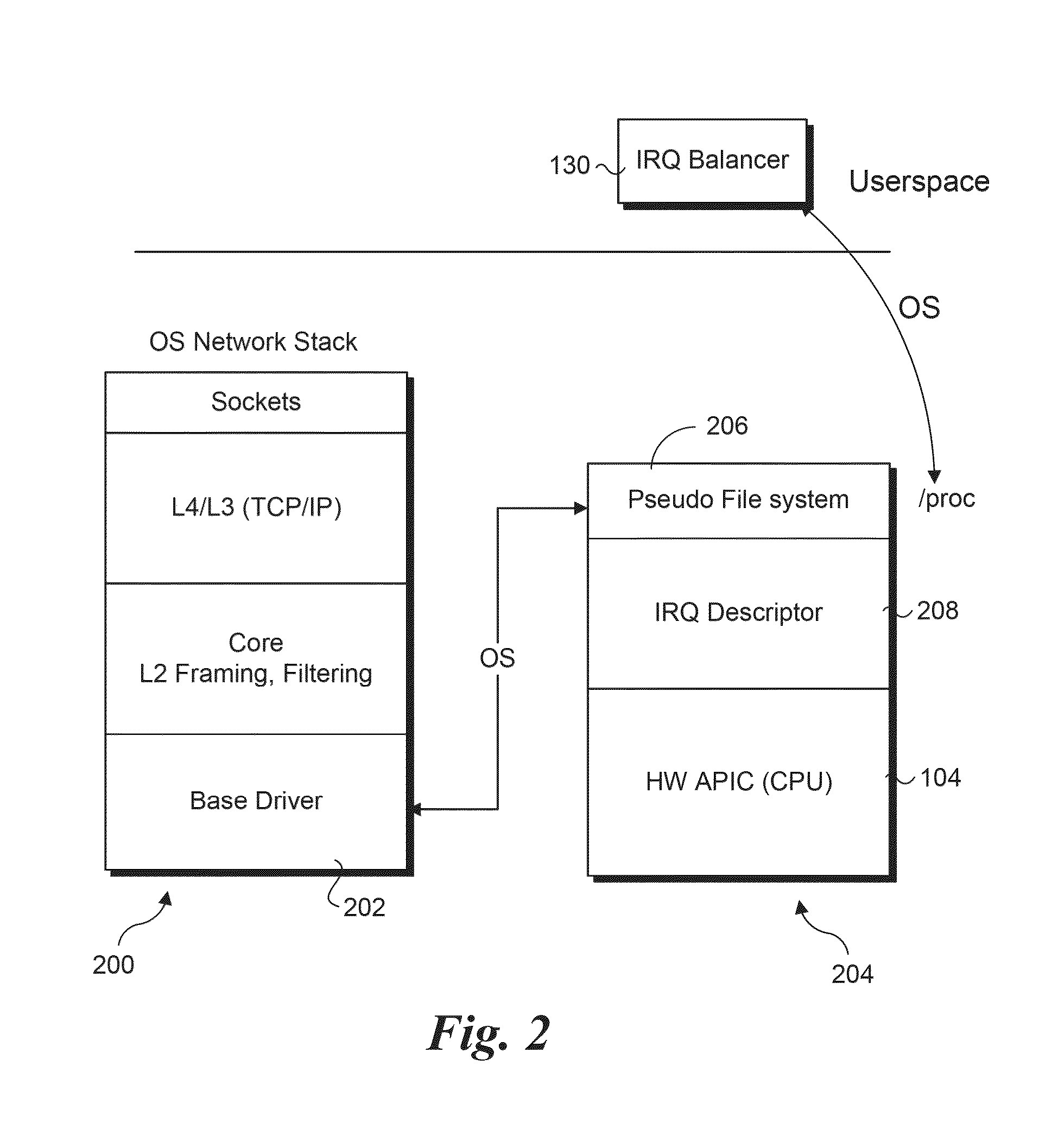

Dynamic interrupt reconfiguration for effective power management

ActiveUS20130318334A1Digital computer detailsConcurrent instruction executionEffective powerActive core

Methods, apparatus, and systems for facilitating effective power management through dynamic reconfiguration of interrupts. Interrupt vectors are mapped to various processor cores in a multi-core processor, and interrupt workloads on the processor cores are monitored. When an interrupt workload for a given processor core is detected to fall below a threshold, the interrupt vectors are dynamically reconfigured by remapping interrupt vectors that are currently mapped to the processor core to at least one other processor core, such that there are no interrupt vectors mapped to the processor core after reconfiguration. The core is then enabled to be put in a deeper idle state. Similar operations can be applied to additional processor cores, effecting a collapsing of interrupt vectors onto fewer processor cores. In response to detecting cores emerging from idle states, reconfiguration of interrupt vectors can be performed to rebalance the assignment of the vectors across active cores by remapping a portion of the vectors to those cores.

Owner:TAHOE RES LTD

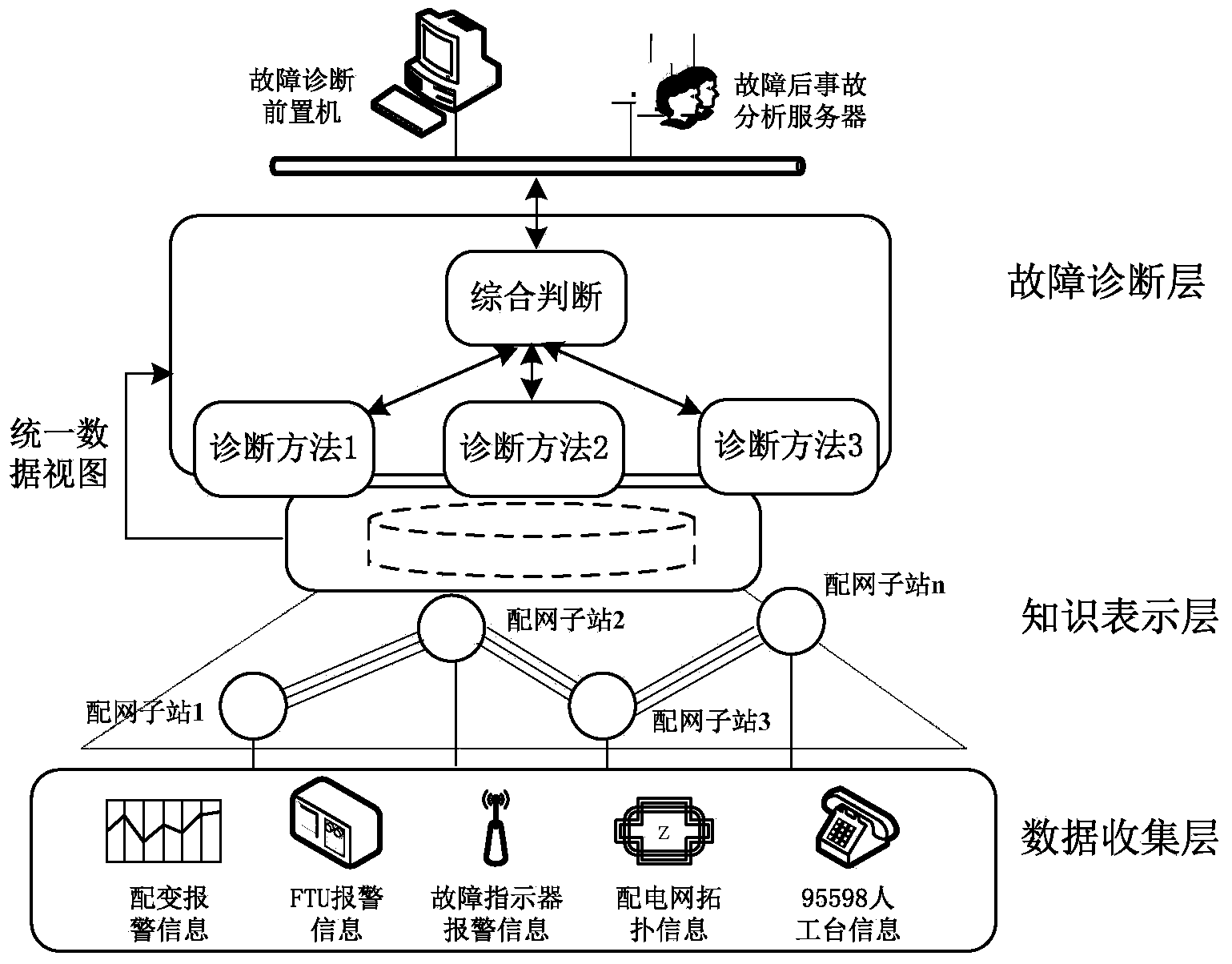

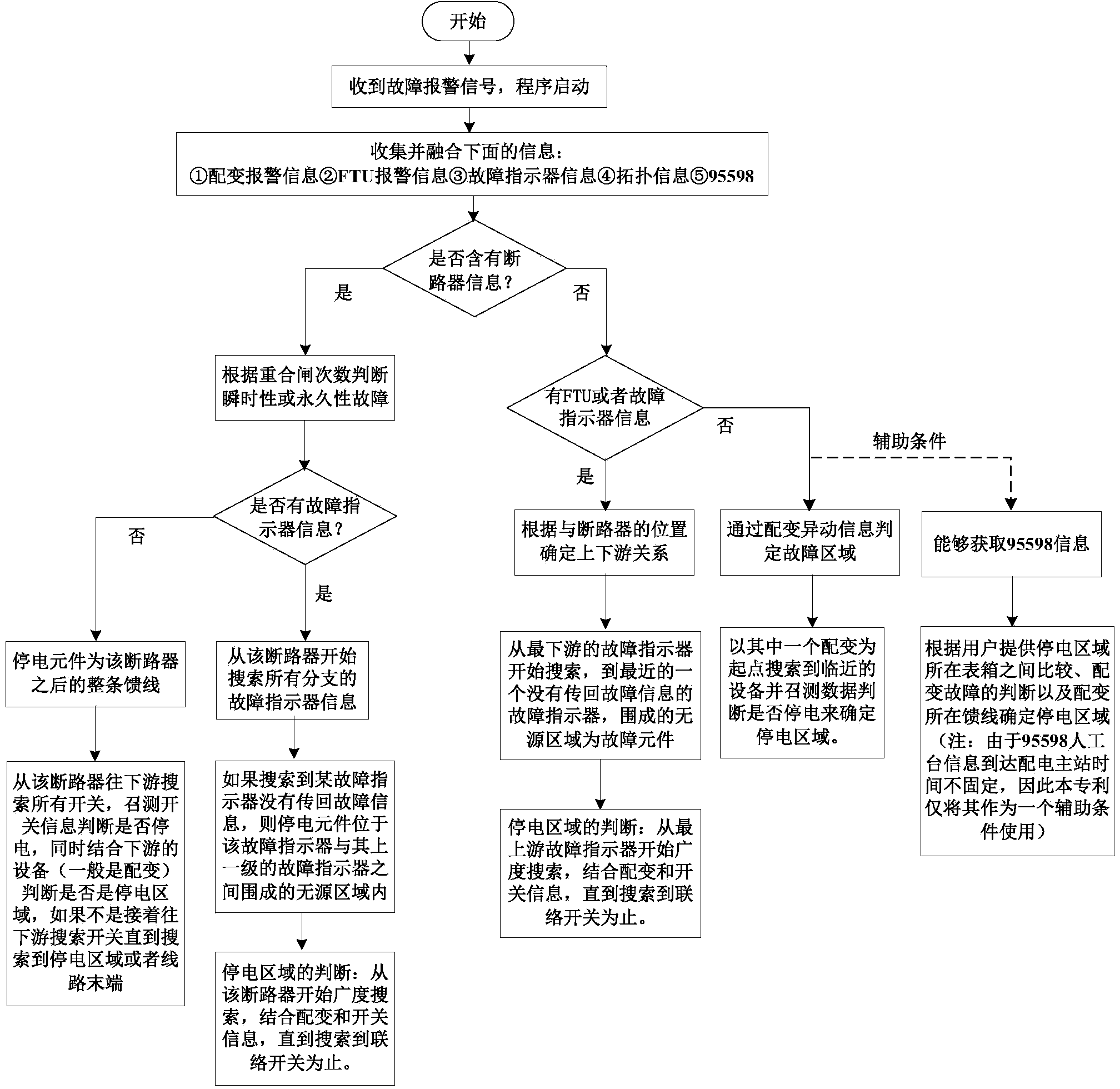

Power distribution network fault diagnosis system and method based on multi-source information

InactiveCN103941158AIncrease profitImprove power supply reliabilityFault locationSpecial data processing applicationsDiagnostic systemKnowledge representation and reasoning

The invention discloses a power distribution network fault diagnosis system and method based on multi-source information. The system comprises a data collection layer, a knowledge representation layer and a fault diagnosis layer, wherein the data collection layer collects fault warning information in each power distribution substation and provides the collected information for the knowledge representation layer in time sequence; the knowledge representation layer describes and buffers data of all kinds of data sources of the information and provides all kinds of heterogeneous data for the fault diagnosis layer in a unified data view mode; the fault diagnosis layer makes different diagnosis methods according to the different data sources, a fault result is comprehensively judged finally, and the diagnosis result is used for analysis after an accident. The utilization rate of the fault information is improved, the reliability of the fault diagnosis is ensured, the fault reason, the fault influence degree and the like are analyzed preliminarily after a fault happens, the analysis result can assist operating personnel in building a timely and effective power distribution network fault repairing strategy, and the power supply reliability of a power distribution network is improved.

Owner:STATE GRID CORP OF CHINA +1

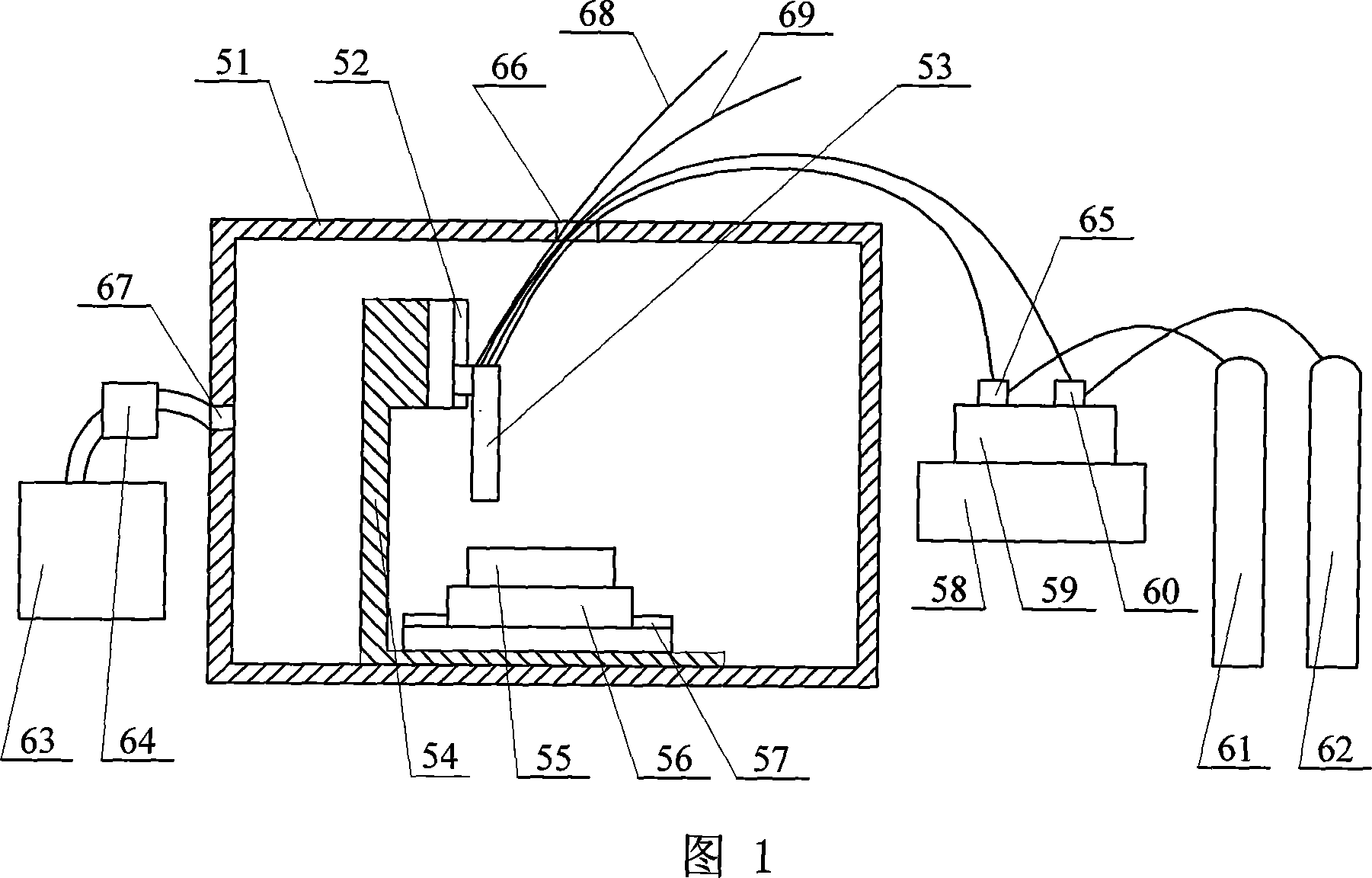

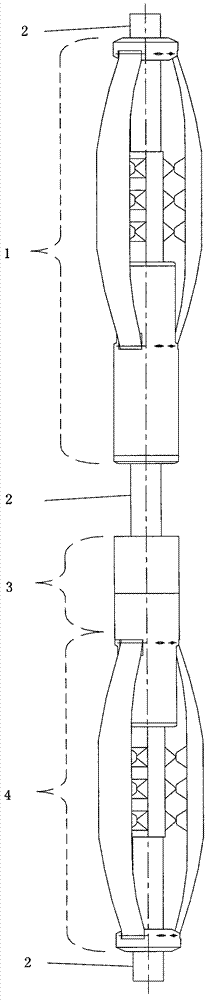

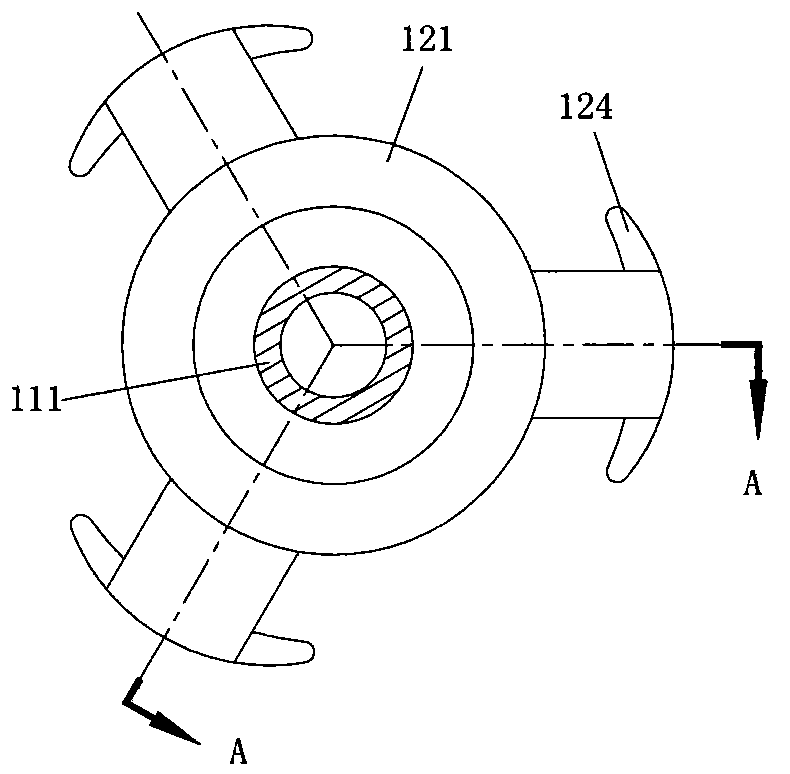

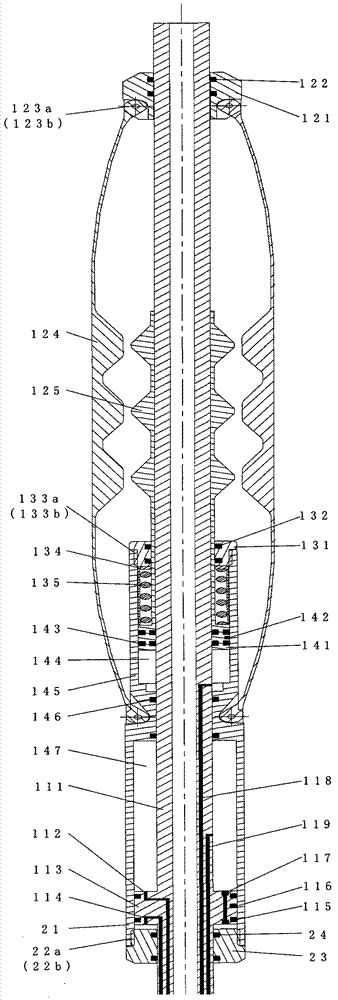

Electric control fluid drive coiled tubing downhole retractor

ActiveCN102777145AIncrease flexibilityReduce complexityBorehole/well accessoriesEffective powerSupporting system

The invention belongs to the field of oil gas development, and particularly relates to an electric control fluid drive coiled tubing downhole retractor. The electric control fluid drive coiled tubing downhole retractor comprises an upper slip support and traction system, a center slip pipe assembly, a control system and a lower slip support system, wherein the upper slip support and traction system is sleeved on the upper part of the center slip pipe assembly in a sliding manner, and can slide along the center slip pipe assembly up and down; and the control system and the lower slip support system are fixed on the lower part of the center slip pipe assembly. The retractor provided by the invention has the advantages that the control flexibility is better, the retractor is suitable for small hole downhole traction operation, the normal downhole fluid cycle is ensured in a traction process, the flexible winding adaptive ability is strong in the traction process, and the retractor can realize two-way traction; and most of retractors in China only can realize a single direction traction motion, the retractor provided by the invention can smoothly drag a pipe column to realize taking-out and putting-down operations, the flexibility is good, and the retractor can realize effective power-off protection.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

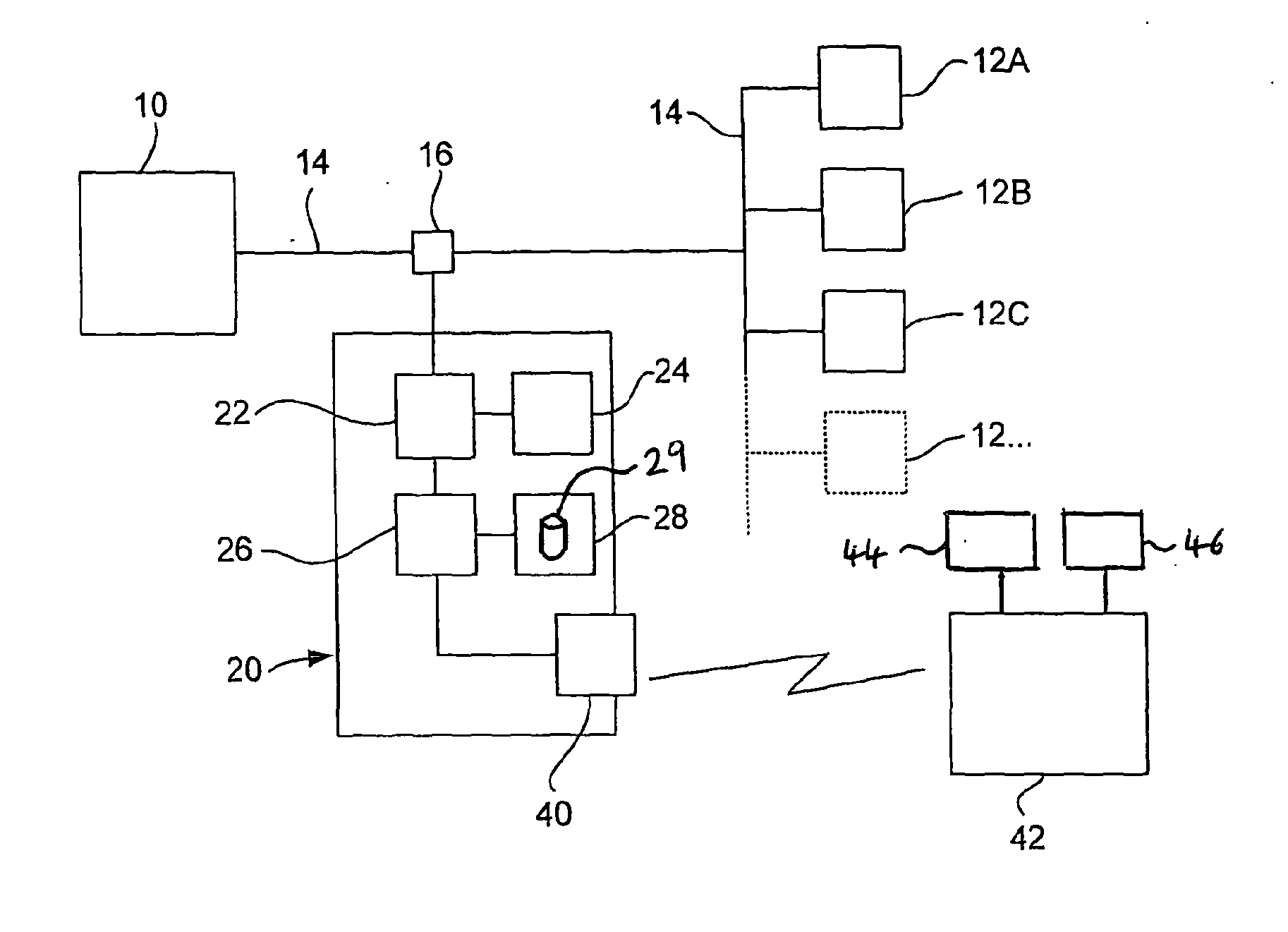

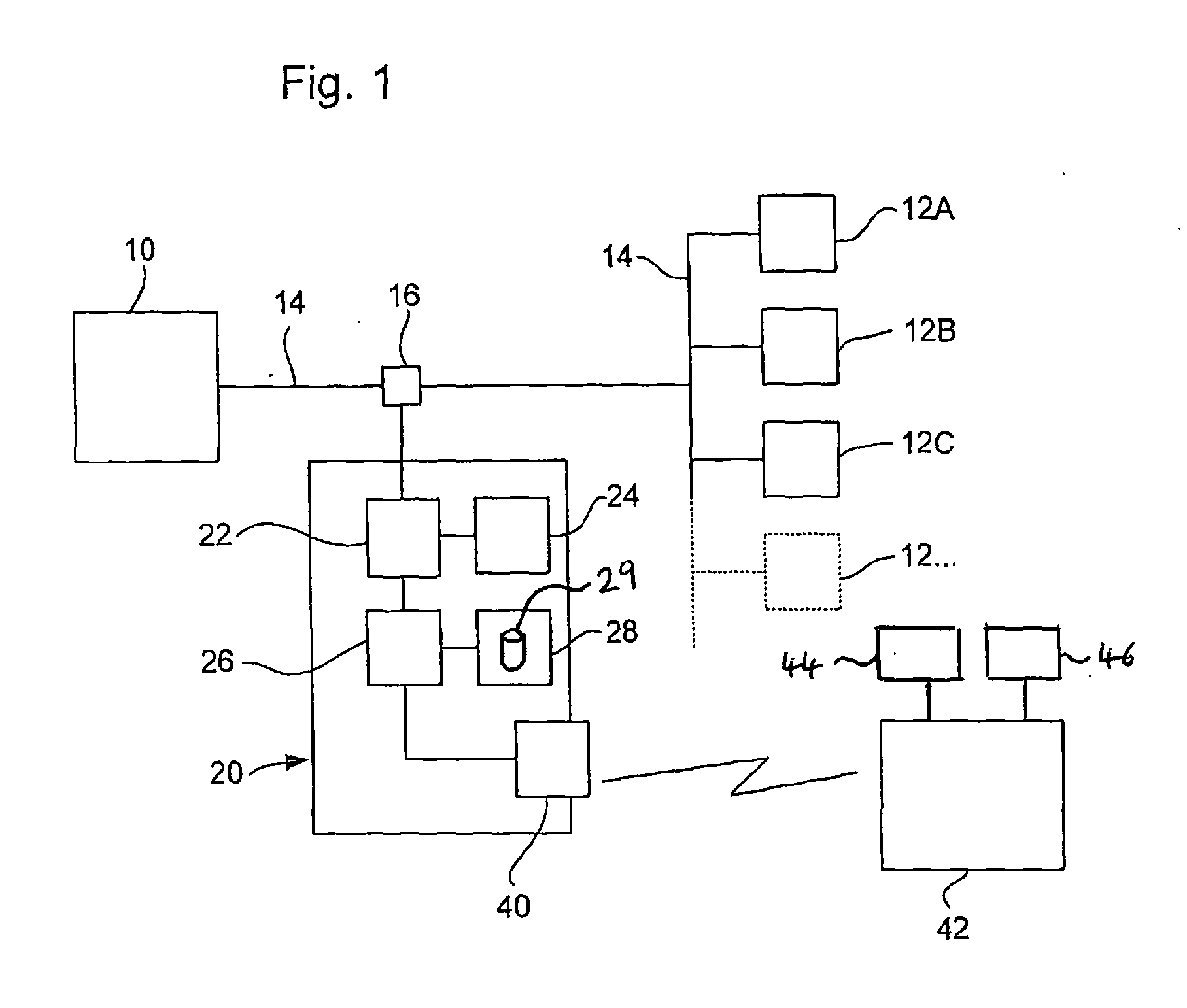

Method and system of virtual machine migration

InactiveCN102209024AReduce downtimeImprove the effect of energy savingEnergy efficient ICTResource allocationEffective powerCountermeasure

The invention provides a method and a system of virtual machine migration. In cooperation between each data center and a WAN, virtual machine migration is carried out without interruption in processing so as to enable effective power-saving implementation, load distribution, or fault countermeasure processing. Each node located (102, 104) at a boundary point between the WAN (101) and another network (111, 131, 141) is provided with a network address translation (NAT, 201, 202) function that can be set dynamically to avoid address duplication due to virtual machine migration. Alternatively, each node (102, 103, 104) included in the WAN (101) is provided with a network virtualization function; and there are implemented a virtual network connected to a data center (111) for including a virtual machine before migration, and a virtual network connected to a data center (121) for including the virtual machine after migration, thereby allowing coexistent provision of identical addresses. Thus, the need for changing network routing information at the time of virtual machine migration (114, 125) can be eliminated, and a setting change for migration accomplished quickly.

Owner:HITACHI LTD

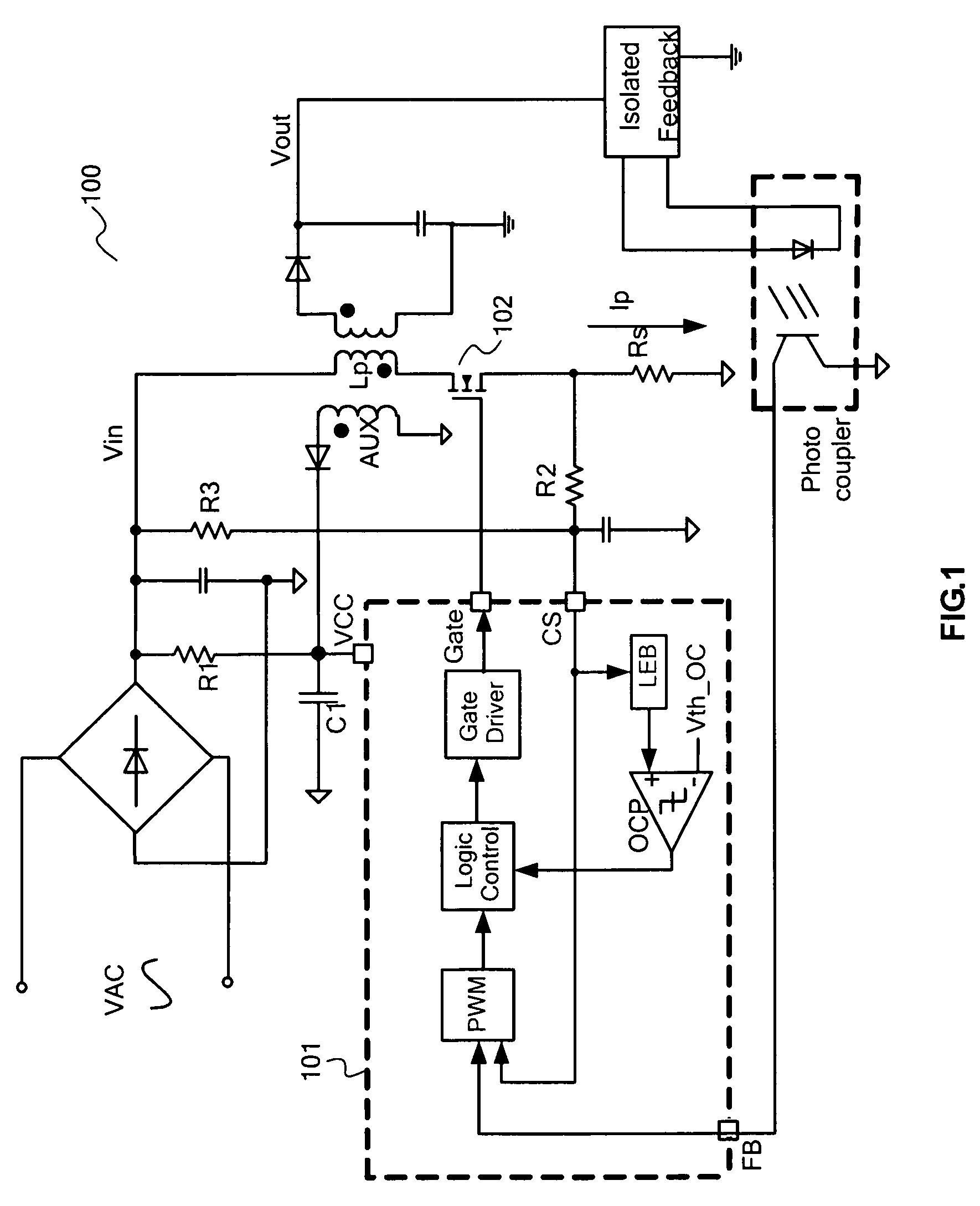

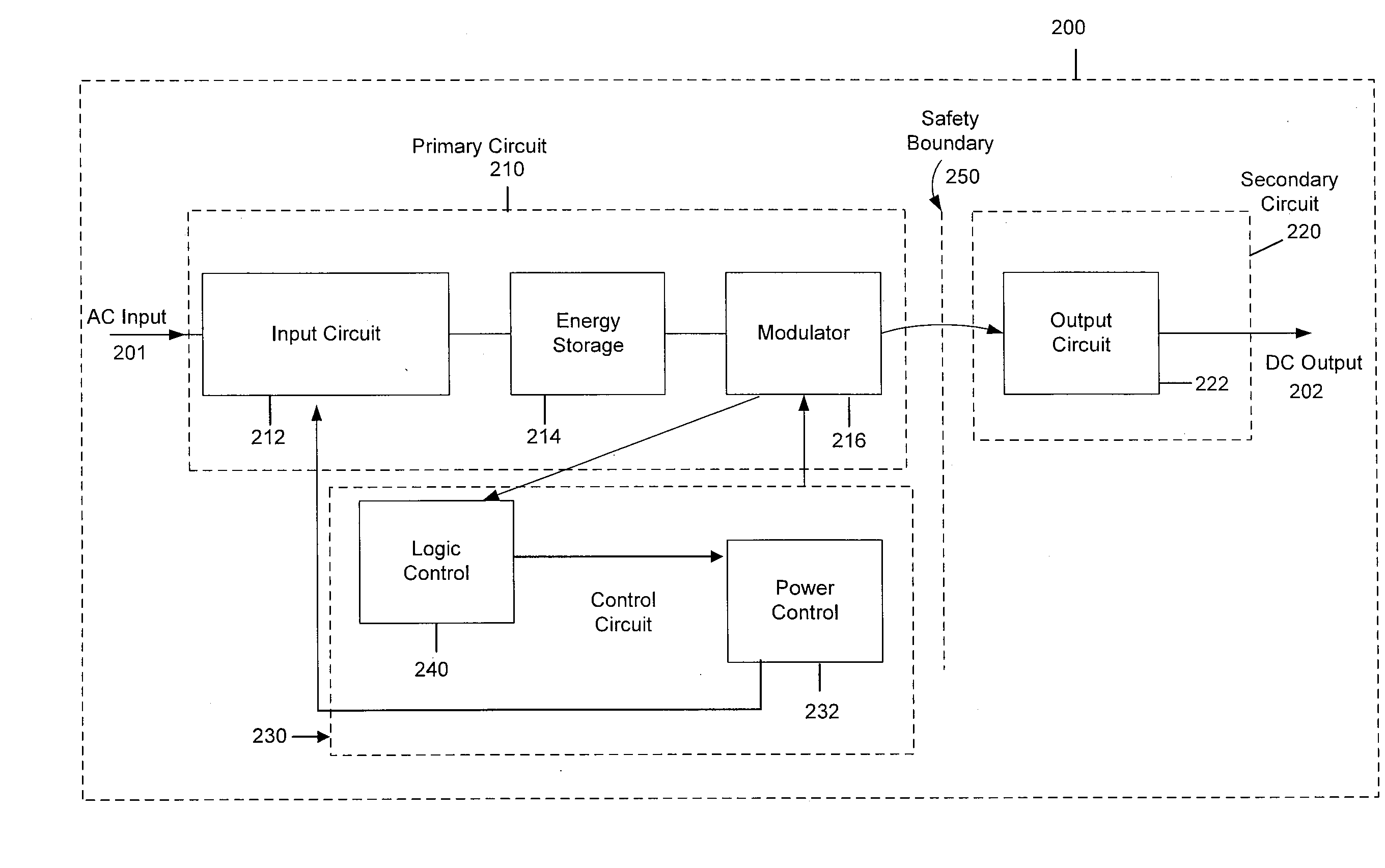

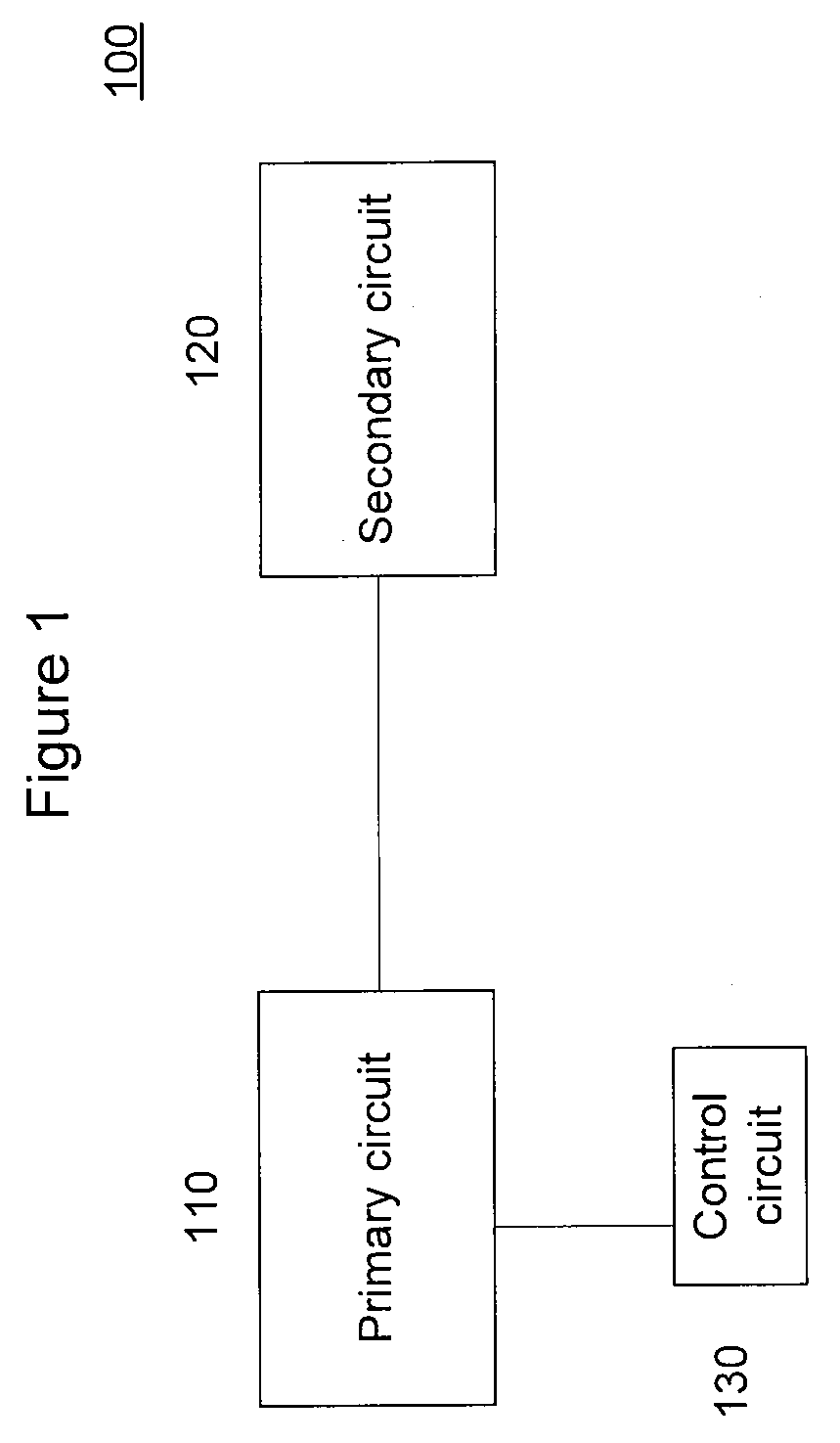

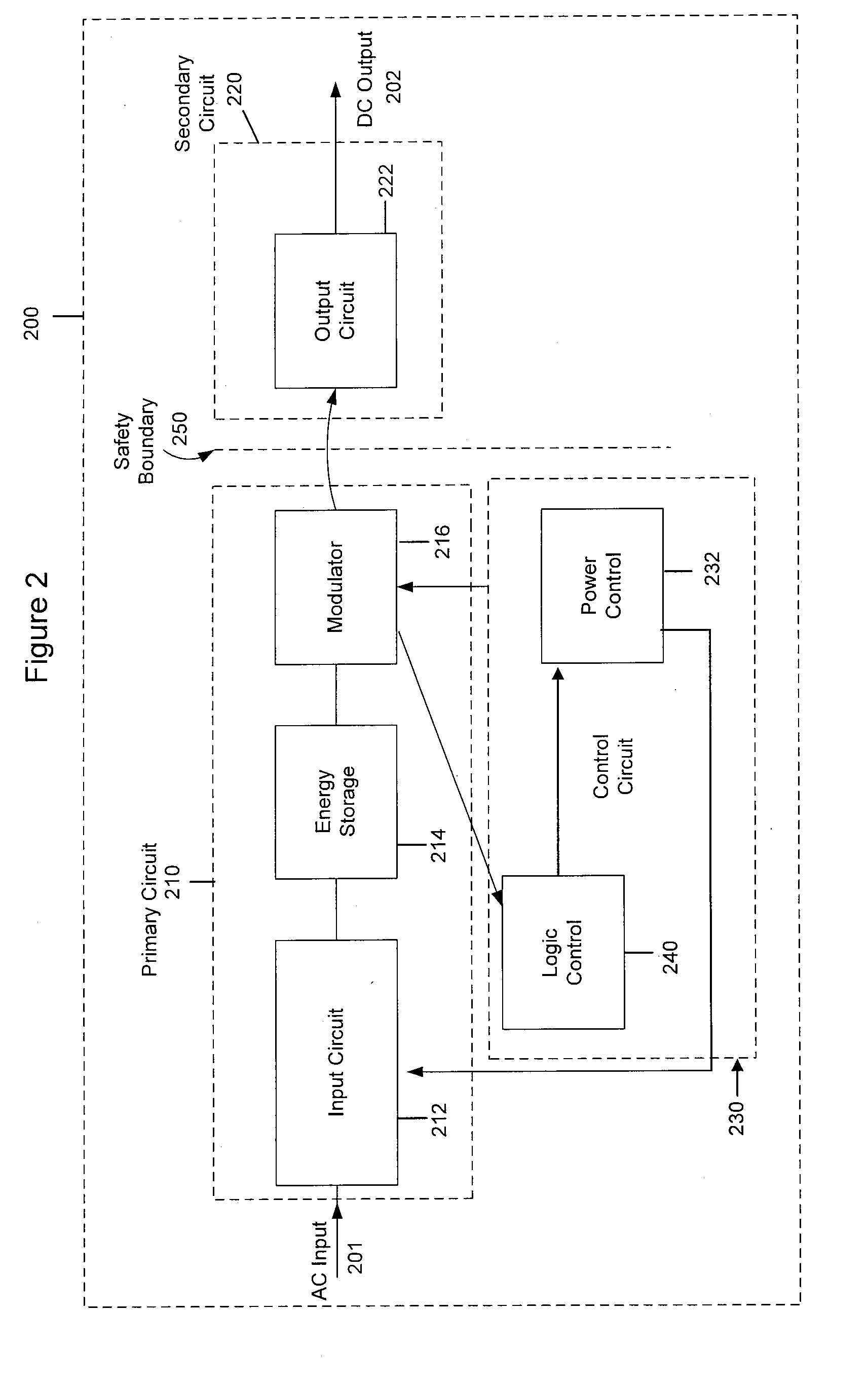

Primary side control circuit and method for ultra-low idle power operation

InactiveUS20090300400A1Reduce power consumptionLess of active powerVolume/mass flow measurementDc-dc conversionEffective powerSecondary circuit

A method and circuit for reducing power consumption during idle mode to ultra-low levels, such as about 1 / 10th to 1 / 1000th or less of active power is disclosed. An ultra-low idle power supply comprises a primary circuit, a secondary circuit and a control circuit. The control circuit monitors behavior of the primary circuit and determines whether an idle state or no load condition exists, and if so the primary circuit is disengaged. By disengaging the primary circuit, the power consumption of the ultra-low idle power supply is reduced to ultra-low levels.

Owner:IGO INC

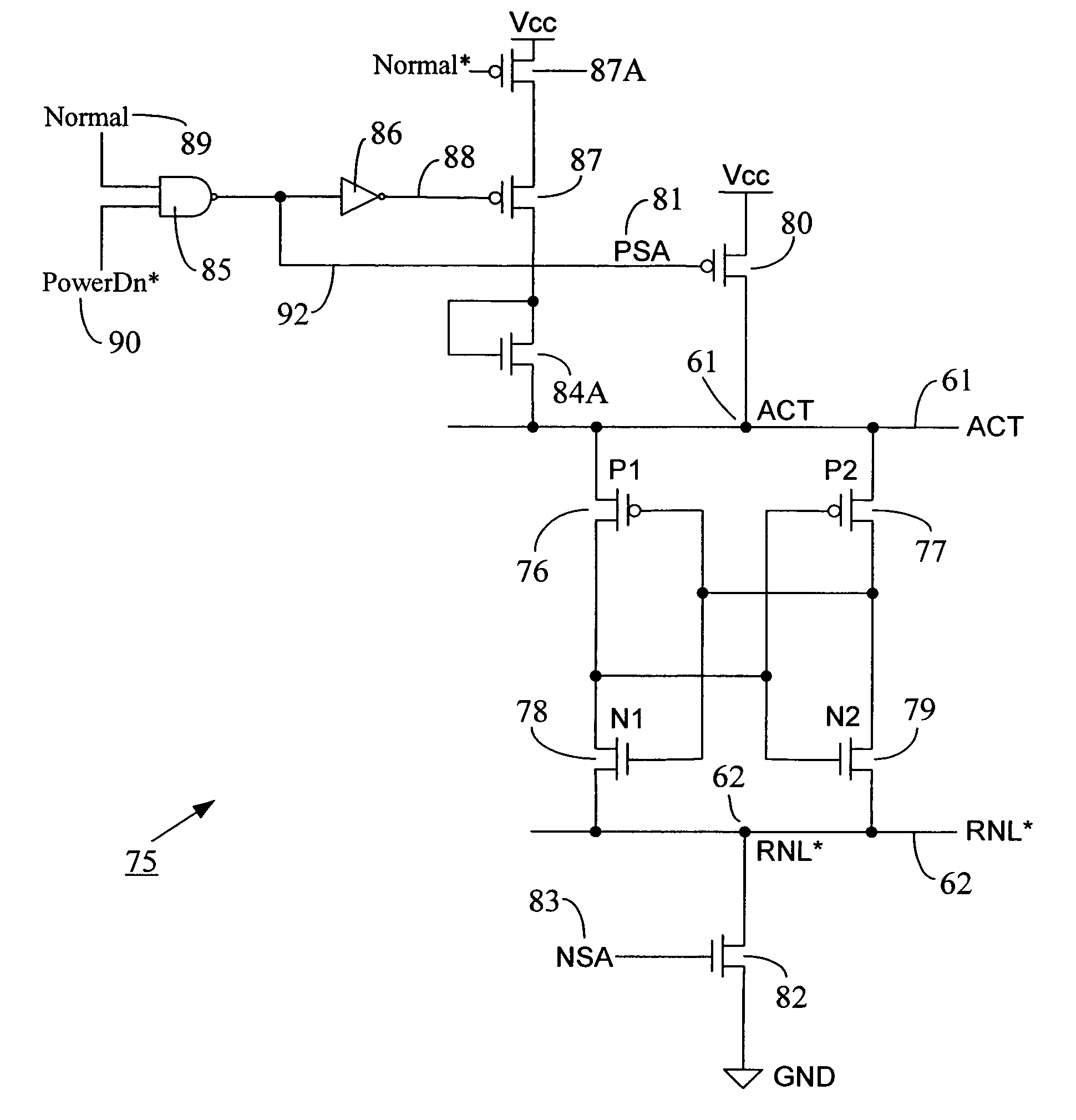

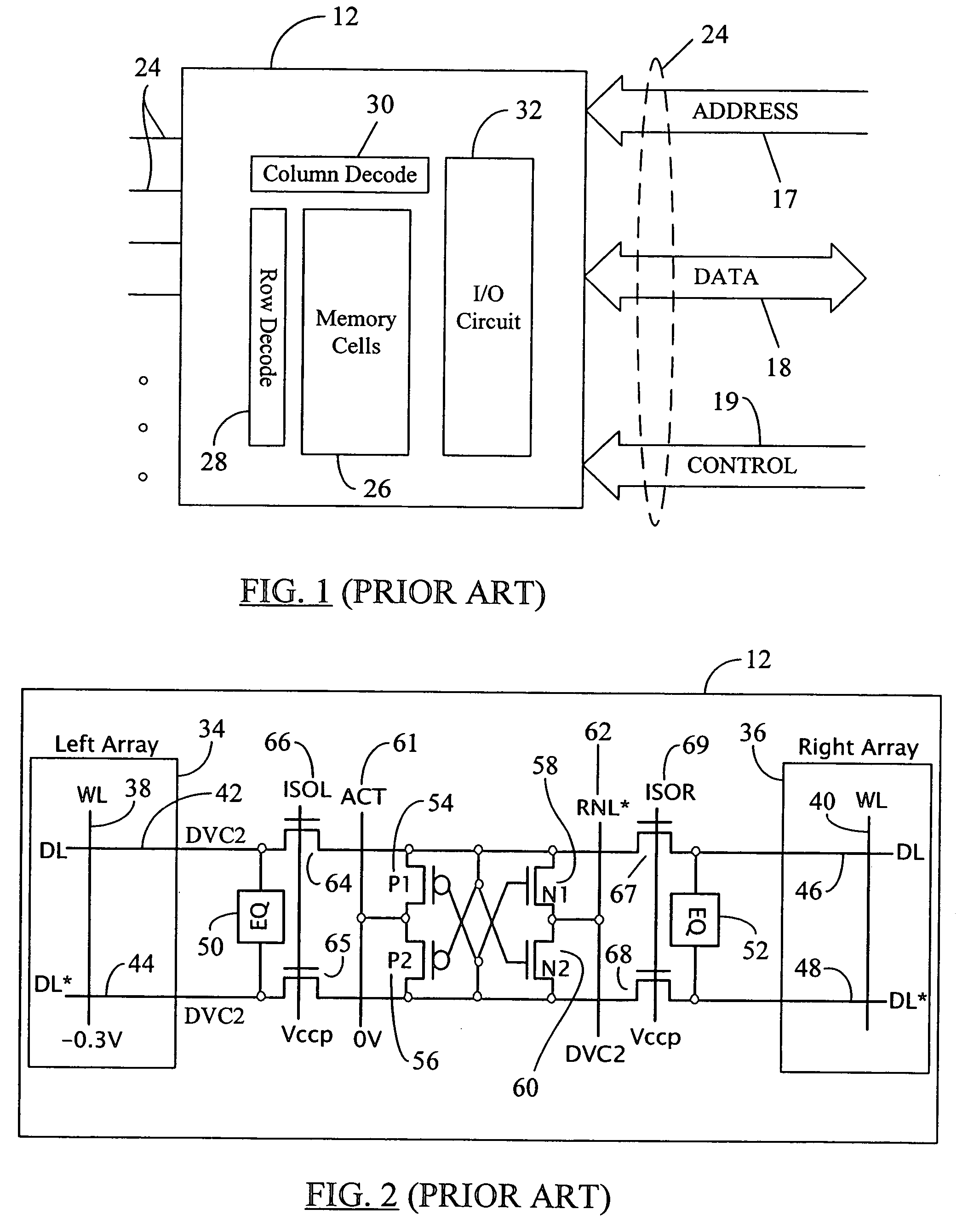

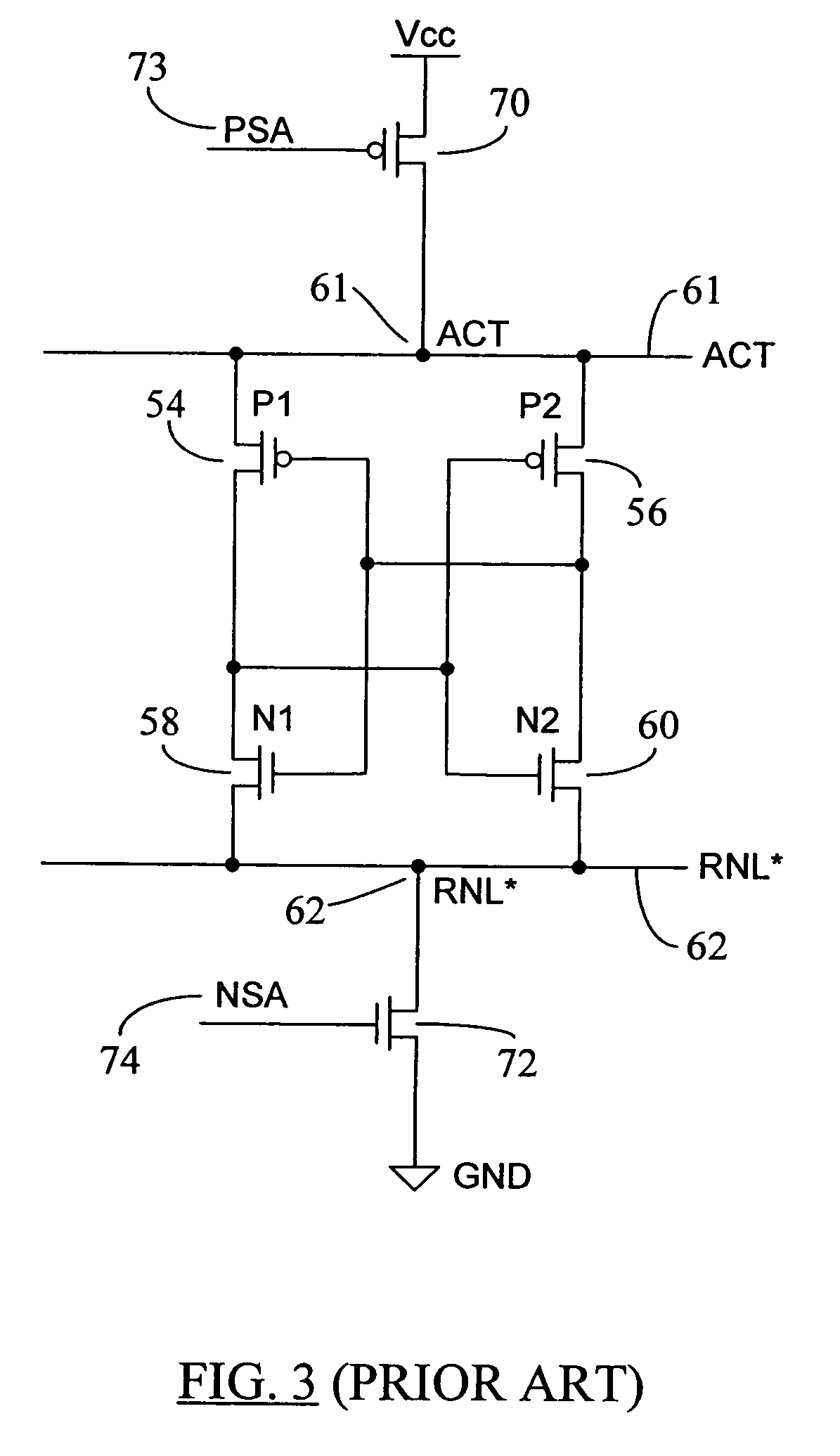

Low voltage sensing scheme having reduced active power down standby current

ActiveUS7372746B2Reduces active power down standby leakage currentReduce voltageDigital storageControl lineEngineering

A low voltage sensing scheme reduces active power down standby leakage current in a memory device. During memory's active power down state, the leak current may increase because of the use of P and Nsense amplifiers having low threshold voltages (Vth) for low Vcc sensing of data signals. A clamping device or diode is used between a Psense amplifier control line (e.g. ACT) and Vcc and / or between an Nsense amplifier control line (e.g. RNL*) and Vss (ground potential). The clamping diode is not enabled during normal memory operations, but is turned on during active power down mode to reduce leakage current through ACT and / or RNL* nodes. The clamping device connected to the ACT node may reduce the voltage on the ACT line during power down mode, whereas the clamping device connected to the RNL* node may increase the voltage on the RNL* line during power down mode to reduce sense amplifier leakage current through these nodes.

Owner:MICRON TECH INC

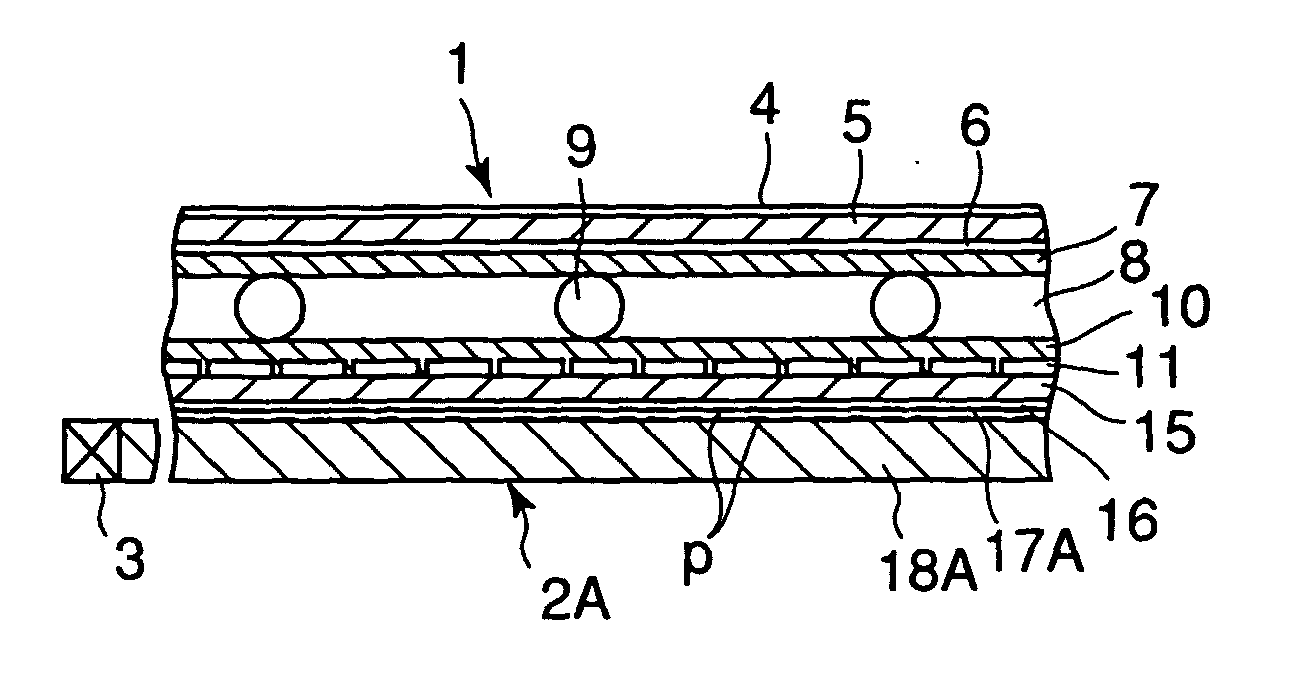

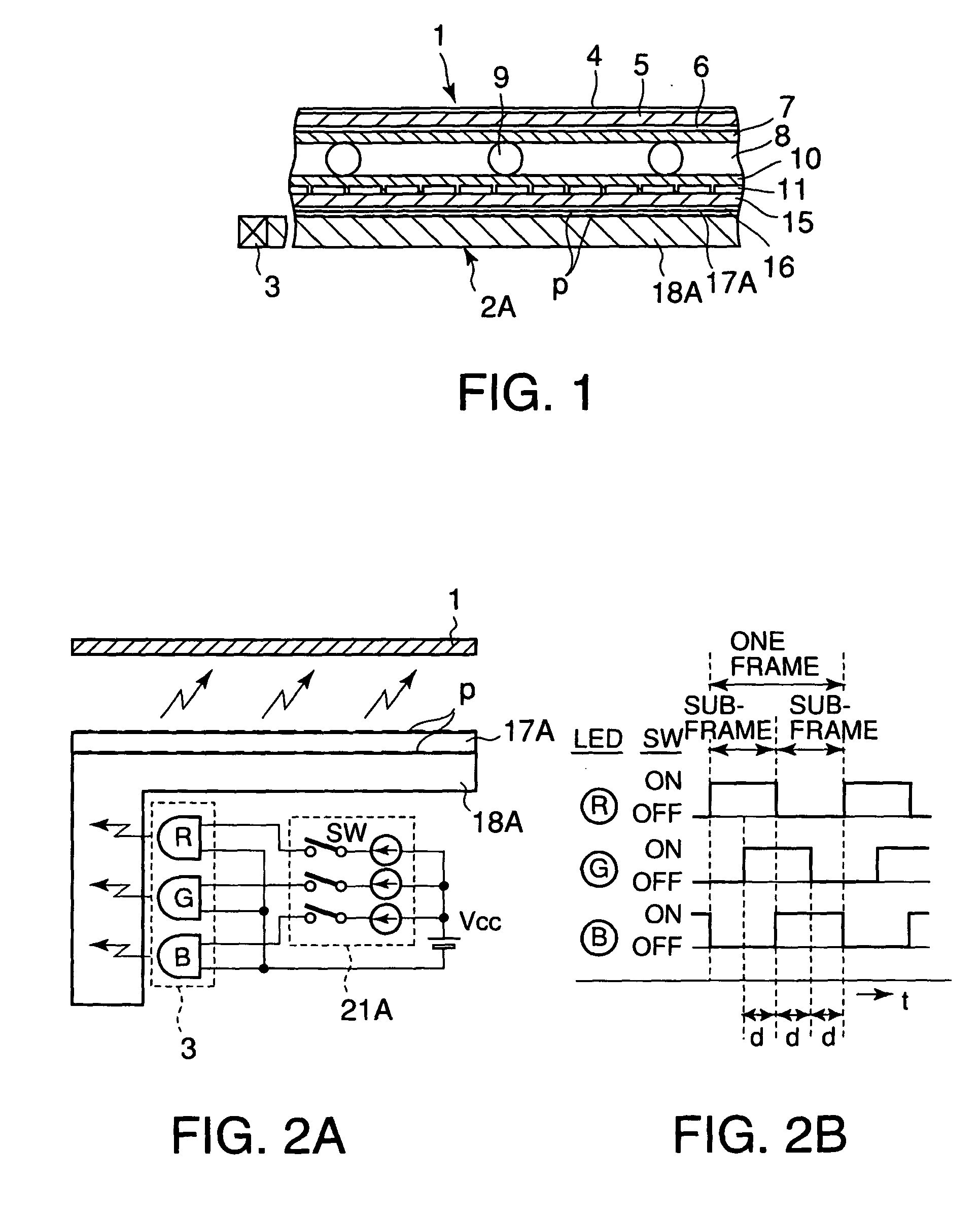

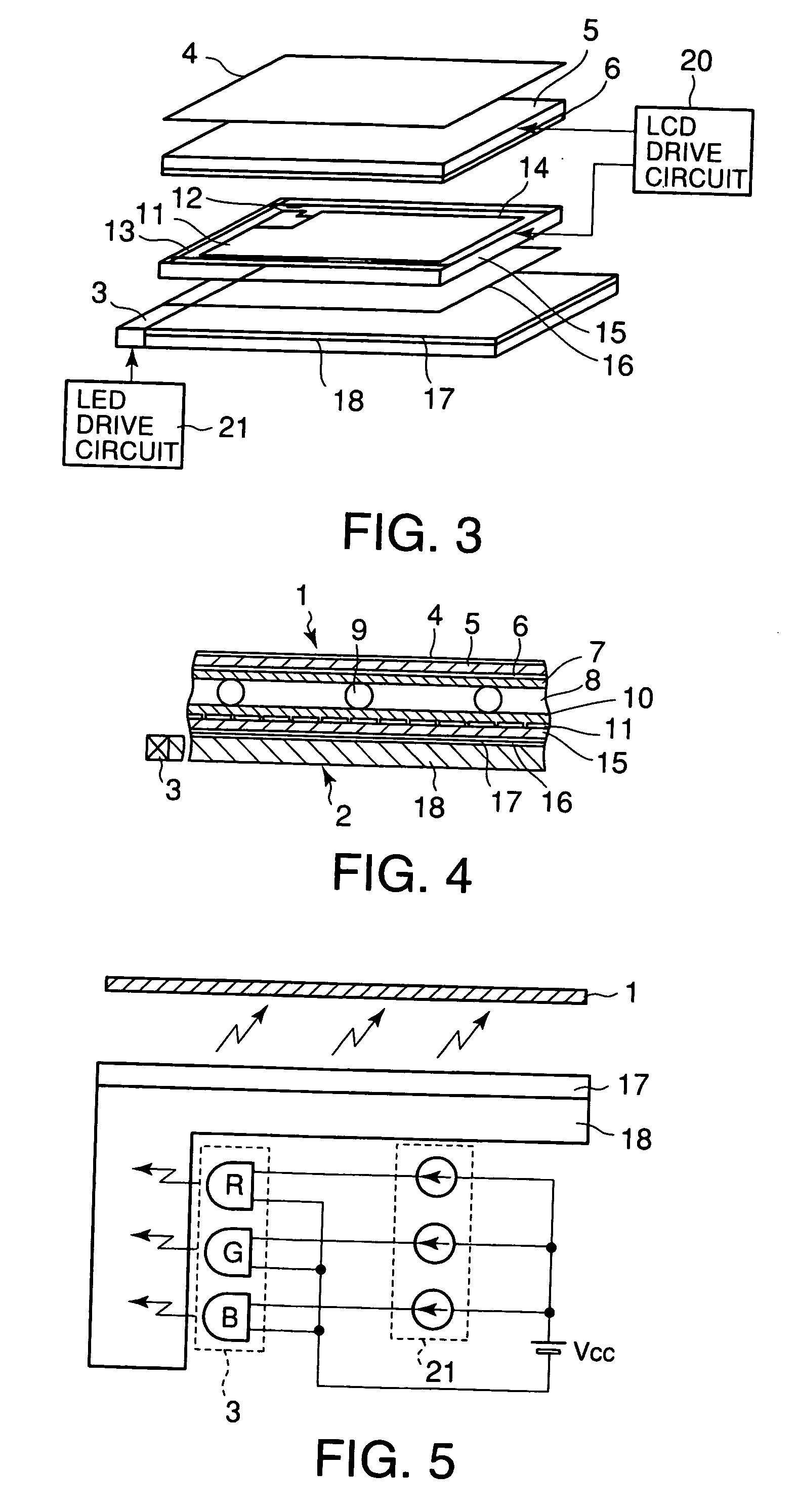

Backlight device

A backlight device obtains white light by mixing and synthesizing the three primary colors, the white light appearing as bright to the human eye as conventional white light; in addition, the backlight device is highly economical, in that it reduces power consumption by reducing the effective power input to the light-emitting diodes, and lengthens the lives of the light-emitting diodes. In a backlight device comprising self-luminous-sources in the colors of red, green, and blue, the device mixing and synthesizing the three primary colors from the self-luminous sources into white light, in order to light a liquid crystal display device using a light-conducting plate and / or a light-scattering plate, the self-luminous-sources of the three primary colors are illuminated sequentially at different timings for each color, so that the light-generating timings partially overlap, achieving time-division light-emission.

Owner:TOKO KABUSHIKI KAISHA

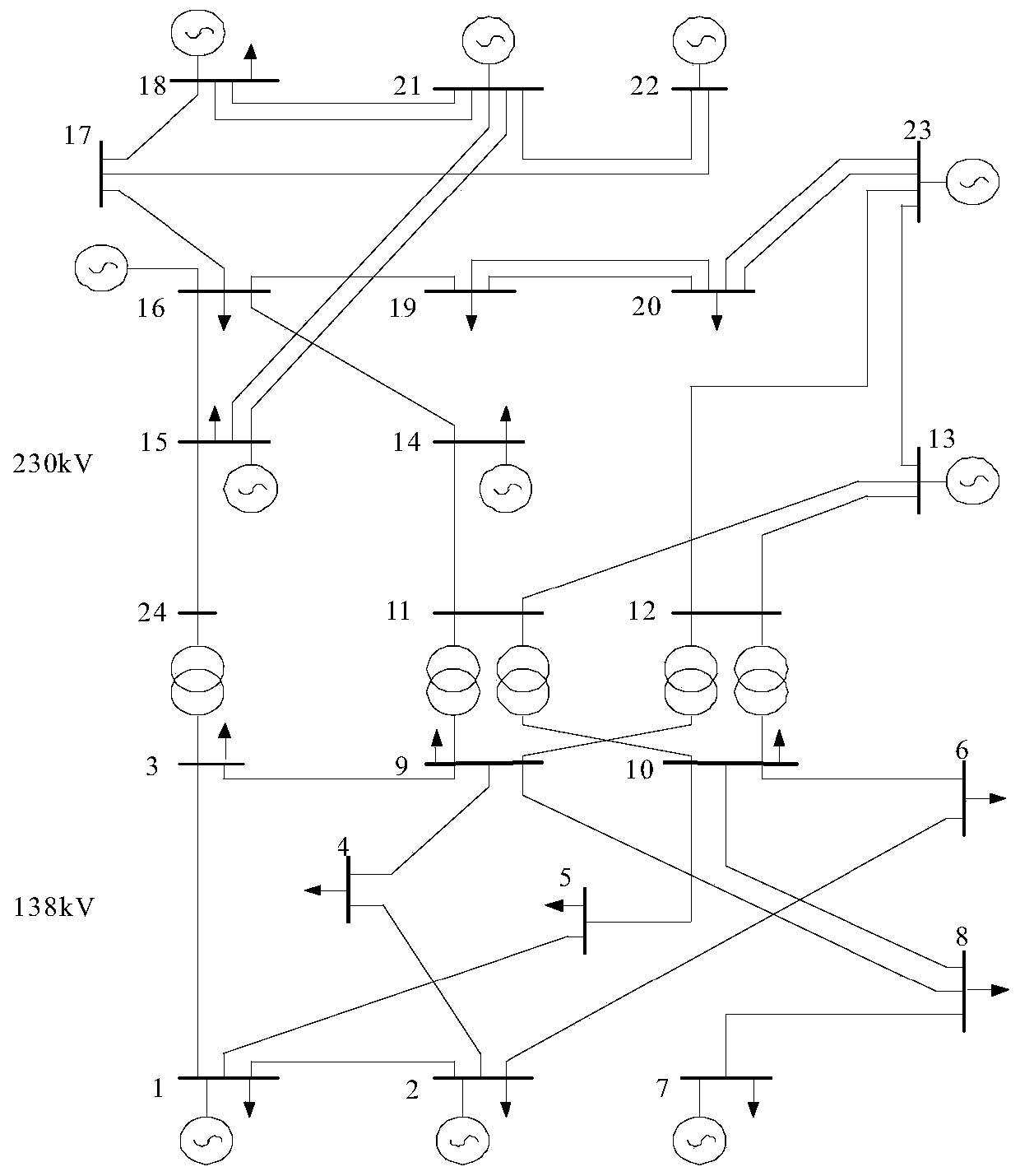

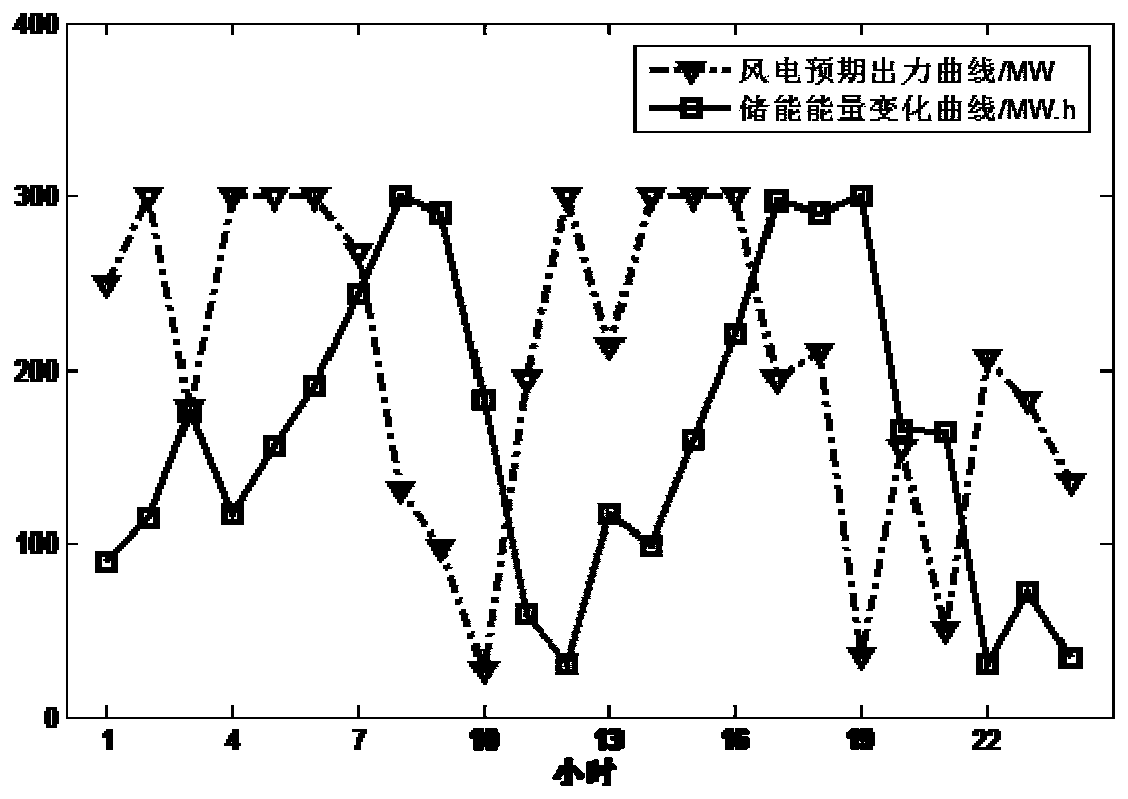

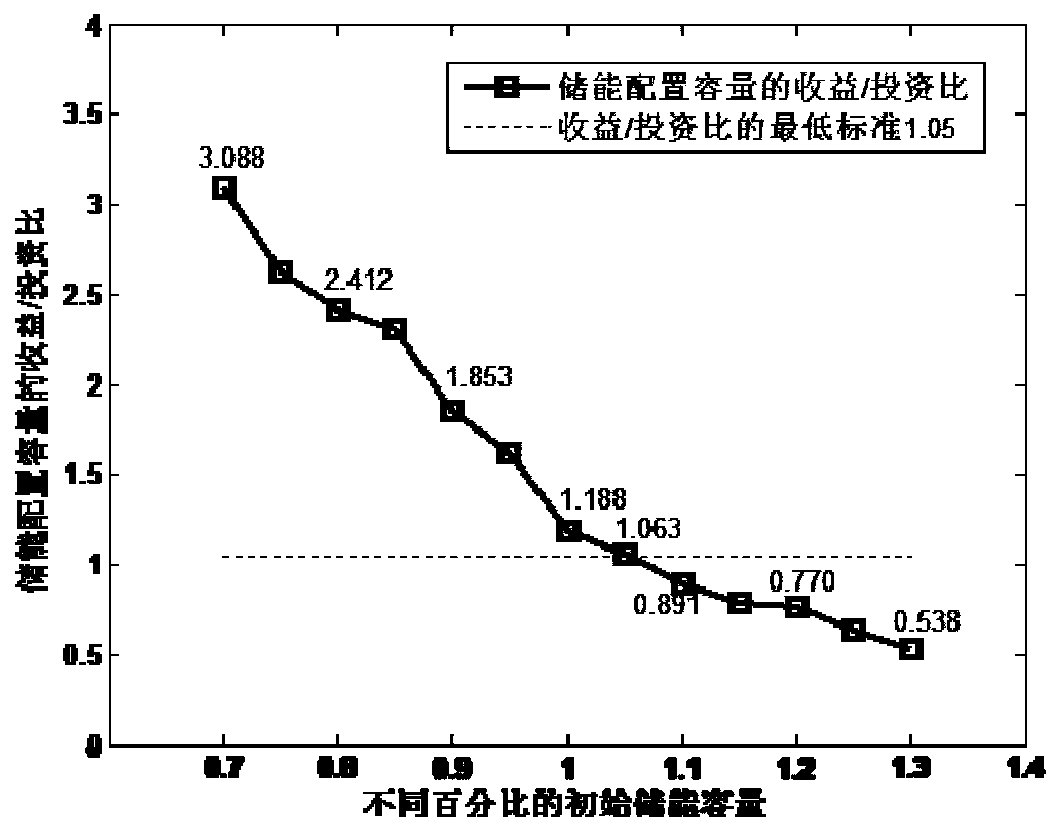

Power transmission network expansion and energy storage configuration combined planning method based on large-scale wind power access

ActiveCN110071505AReduce congestionImprove utilization efficiencySingle network parallel feeding arrangementsEnergy storageNew energyPlanning method

The invention provides a power transmission network expansion and energy storage configuration combined planning method based on large-scale wind power access, and belongs to the field of power grid planning considering new energy power generation and consumption. According to the method, by combining multi-scene random planning and operation simulation, a hybrid optimization method considering wind power uncertainty and energy storage life loss is provided; a random output scene of full-year wind power-load can be considered, and the influence of the energy storage life loss on a combined planning result can be considered; and finally, solving is performed to obtain a reasonable and effective power transmission network expansion and energy storage configuration scheme. The method can be applied to the field of combined planning of power transmission network expansion and energy storage configuration under the large-scale wind power access; and an obtained configuration result can notonly effectively relieve the problem of difficulty in grid connection of wind power generation but also improve the utilization efficiency of a power transmission line, thereby relieving line blockage.

Owner:TSINGHUA UNIV +3

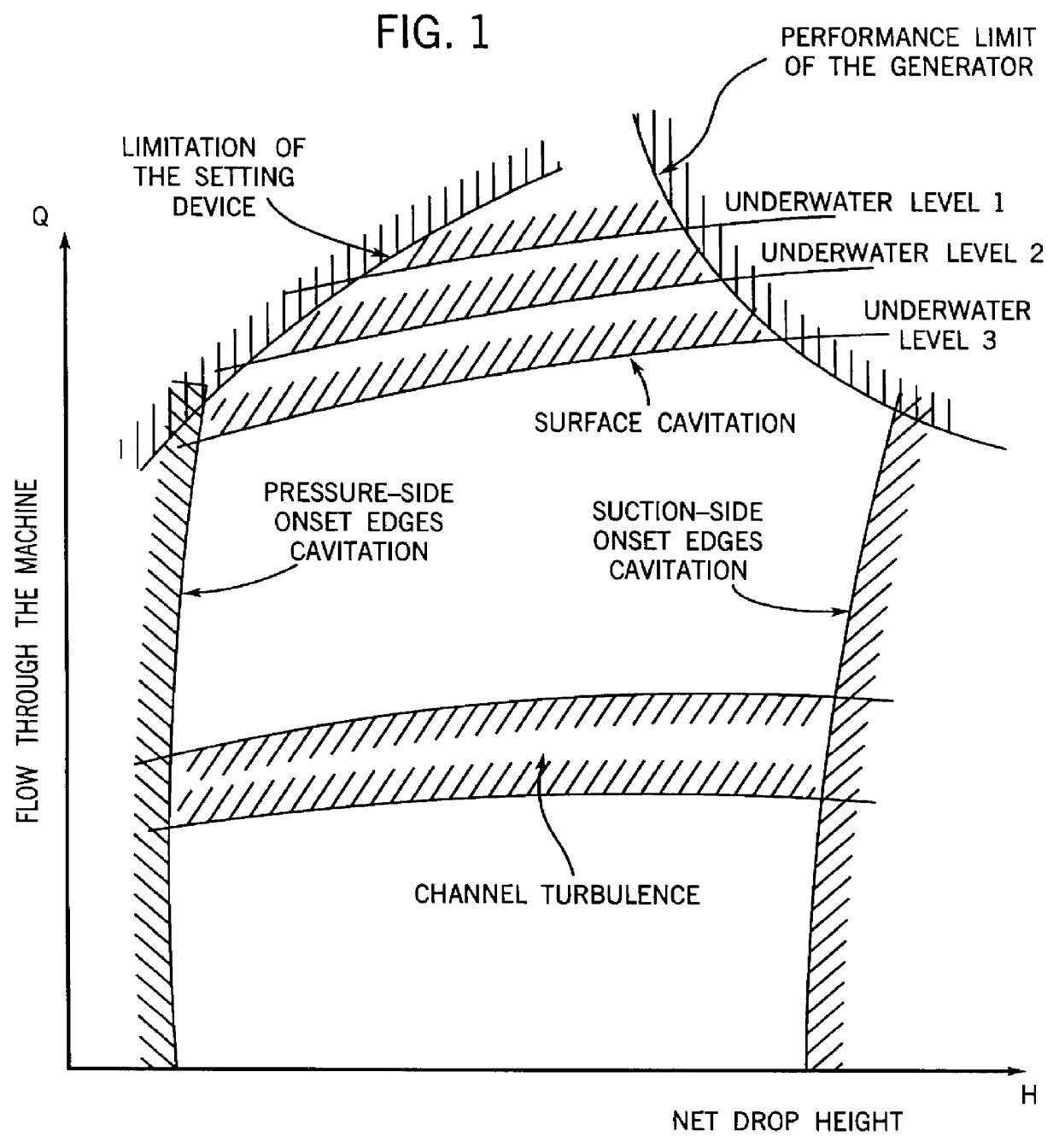

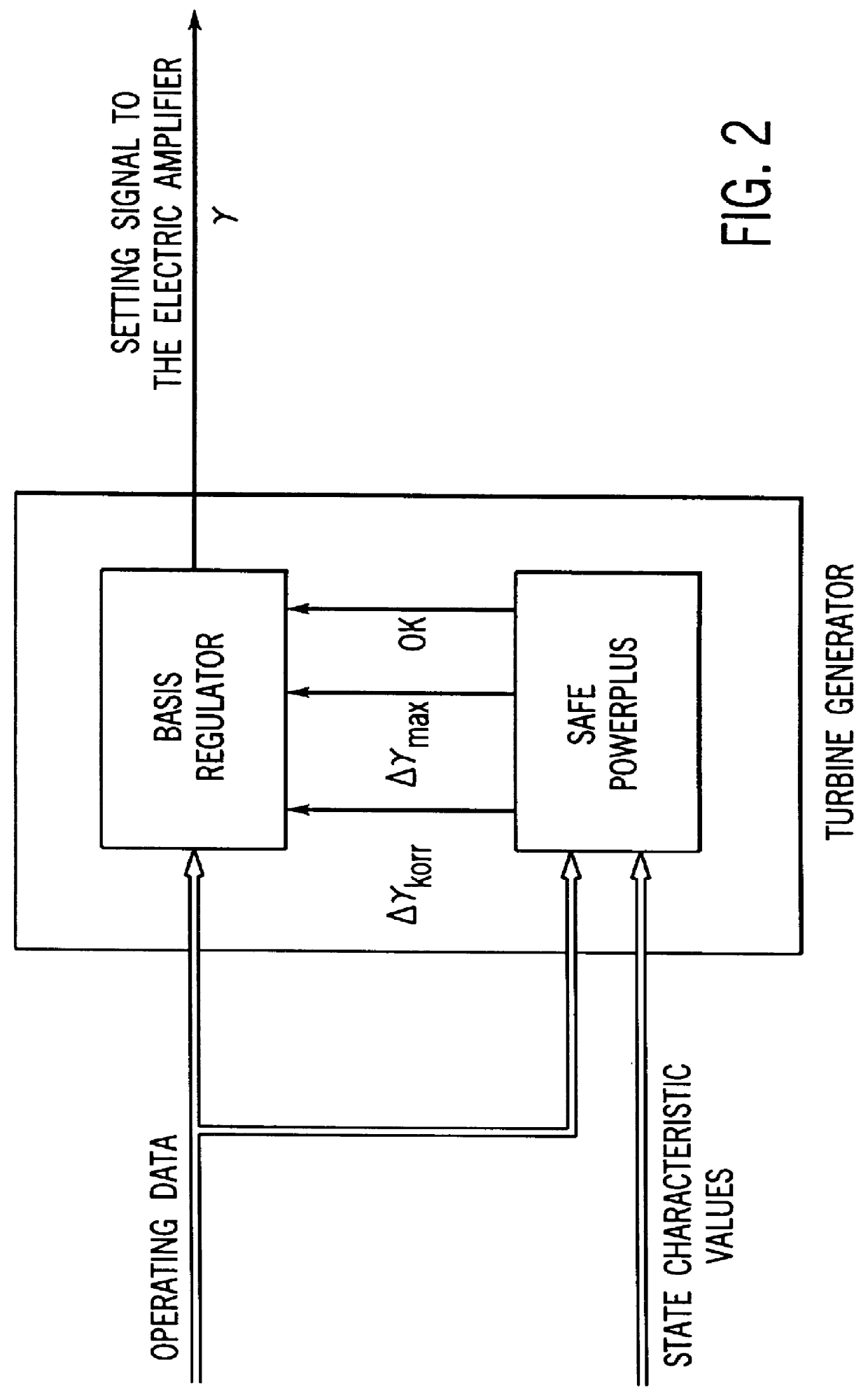

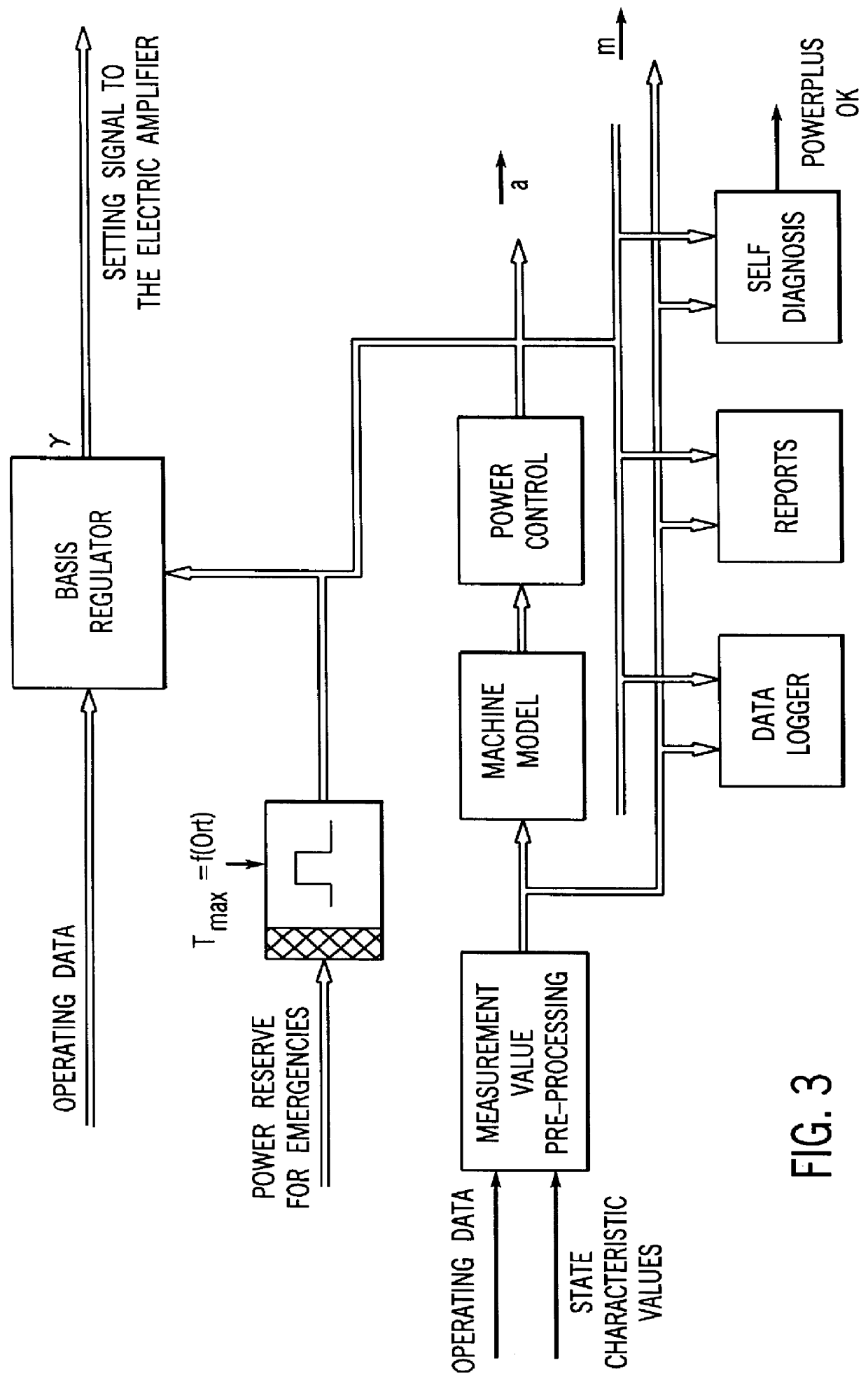

Method for operation of hydraulic turbine

InactiveUS6152684ASignificant utilityCavitation safety is givenWind motor controlHydro energy generationOperating pointCavitation

A process for operating a hydraulic machine, especially a hydro-turbine, includes the step of detecting an actual machine state during operation of the machine by ascertaining operating data. The ascertained operating data includes flow through the turbine (if present), effective and reactive power fed into the electric mains, guide vane opening, pressure before the machine and at the suction pipe exit, headwater level, and tailwater level. The method further includes the step of processing at least one state characteristic values of a first cavitation characteristic value (indicative of cavitation intensity), a second cavitation characteristic value (indicative of an abrupt rise in cavitation manifestations), vibration characteristic values, suction pipe pressure, sand concentration, air pressure, water temperature, and generator temperature (for example winding temperature). The method also includes the step of altering an operating point of the machine based on the at least one processed characteristic value to reduce cavitation and / or quiet running.

Owner:VOITH HYDRO

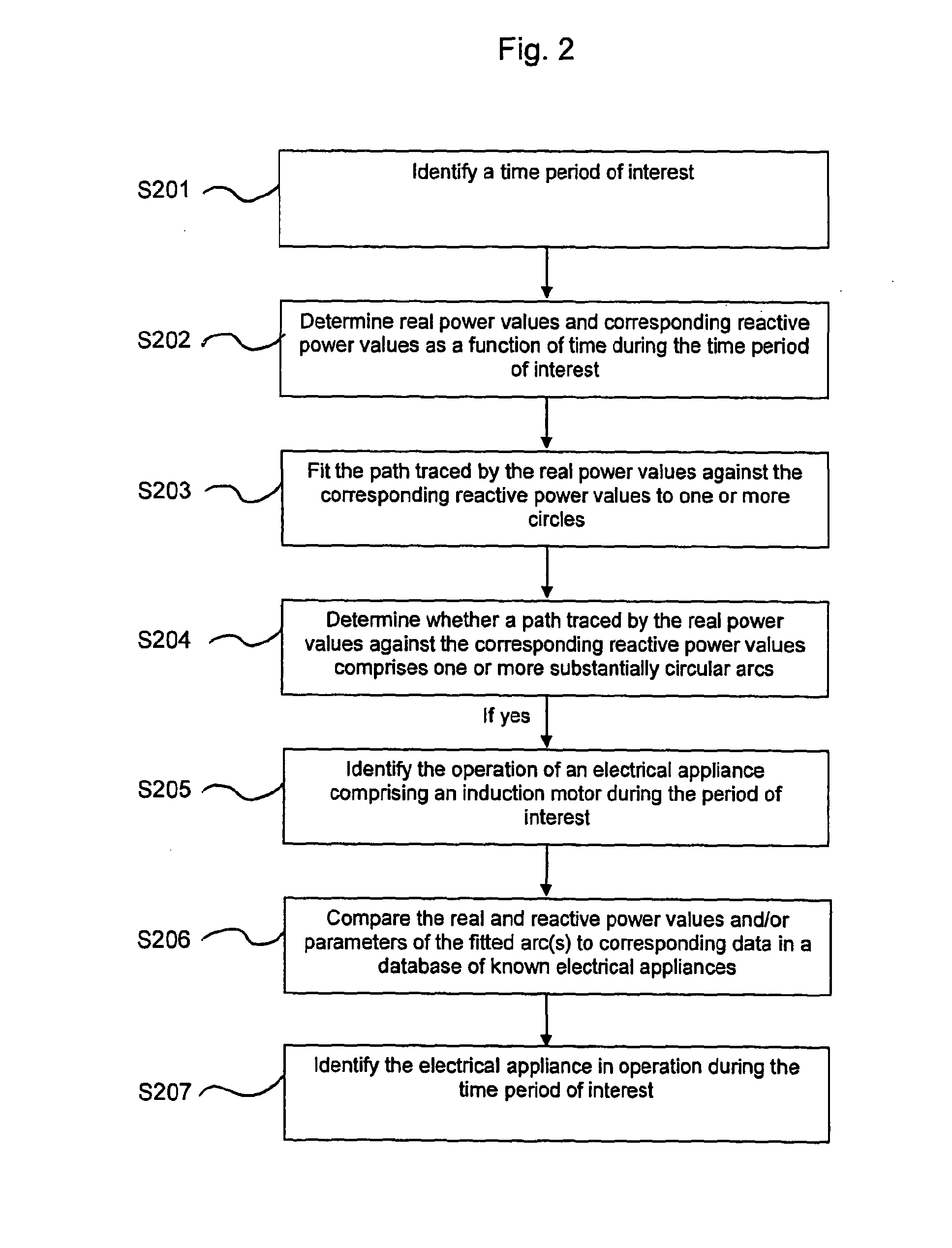

Identifying the operation of a specified type of appliance

ActiveUS20120136593A1Avoid identificationReduce in quantityElectric devicesTariff metering apparatusEffective powerElectricity

A method of identifying the operation of an electrical appliance comprising an induction motor is described. The method comprises identifying the operation of an electrical appliance comprising an induction motor when a path traced by real power values against corresponding reactive power values over a time period of interest comprises one or more substantially circular arcs. The real power values are related to the total real power supplied to one or more electrical appliances as a function of time, and the reactive power values are related to the total reactive power supplied to the one or more electrical appliances as a function of time.There is also described a related method of identifying the operation of a specified type of appliance, in which the operation of said specified type of appliance is dependent on a supply of at least one utility such as electricity, natural gas or water. Corresponding computer programs, computer-readable mediums, computer program products and apparatuses are also described.

Owner:SENSUS USA

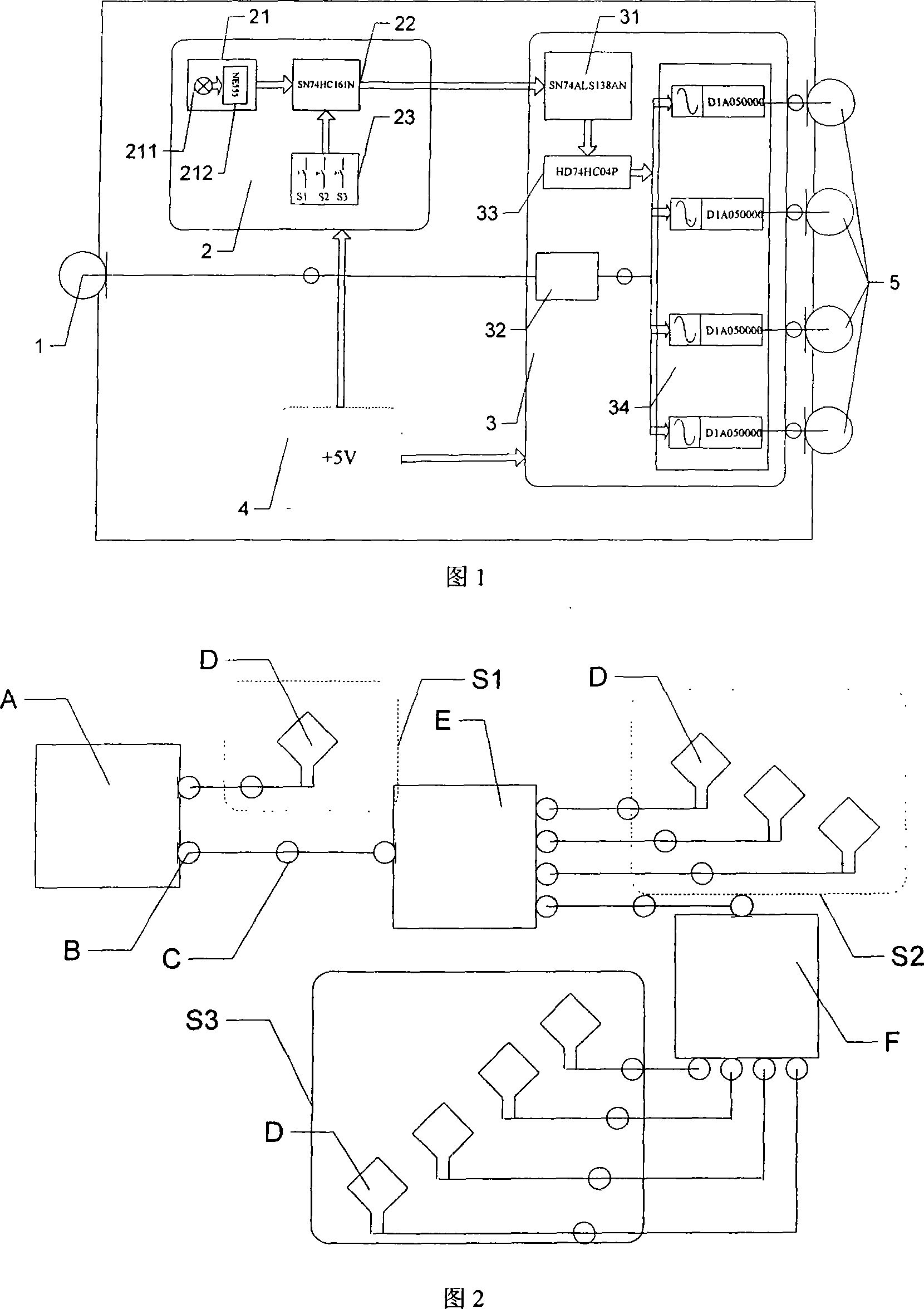

RFID antennae polling switching device

InactiveCN101236597ARealize series connectionIncrease the number of external antennasSensing record carriersEffective powerTime-sharing

The invention provides an RFID antenna polling switch device which ensures that a plurality of antennas simultaneously connect to a radio-frequency port of a reader-writer and realize the automatic polling of an antenna array in order to realize time-sharing drive of each antenna to read electronic tags in a coverage area. The invention realizes that one antenna polling switch device or a plurality of antenna polling switch devices are connected in series between the reader-writer and the antennas which are separate from each other; a periodic pulse signal is generated through a timing circuit of the device; a periodic communication and disconnection of at least one mechanical switch are driven so that the radio-frequency port of the reader-writer and a plurality of reader-writer antenna can be communicated in a cycle and time-sharing operation is carried out by each antenna; the invention can solve the problem of collision produced in controlling a processing module and can ensure that the effective power of the antenna is not reduced, thereby achieving a larger reading range and a better reading effect. The RFID antenna polling switch device has simple structure, reliable performance and low cost and can be applicable for the management of warehouses, libraries, etc, in particular for making a periodic inventory of goods or books in different positions of a goods shelf or a bookshelf.

Owner:BEIJING UNIV OF POSTS & TELECOMM

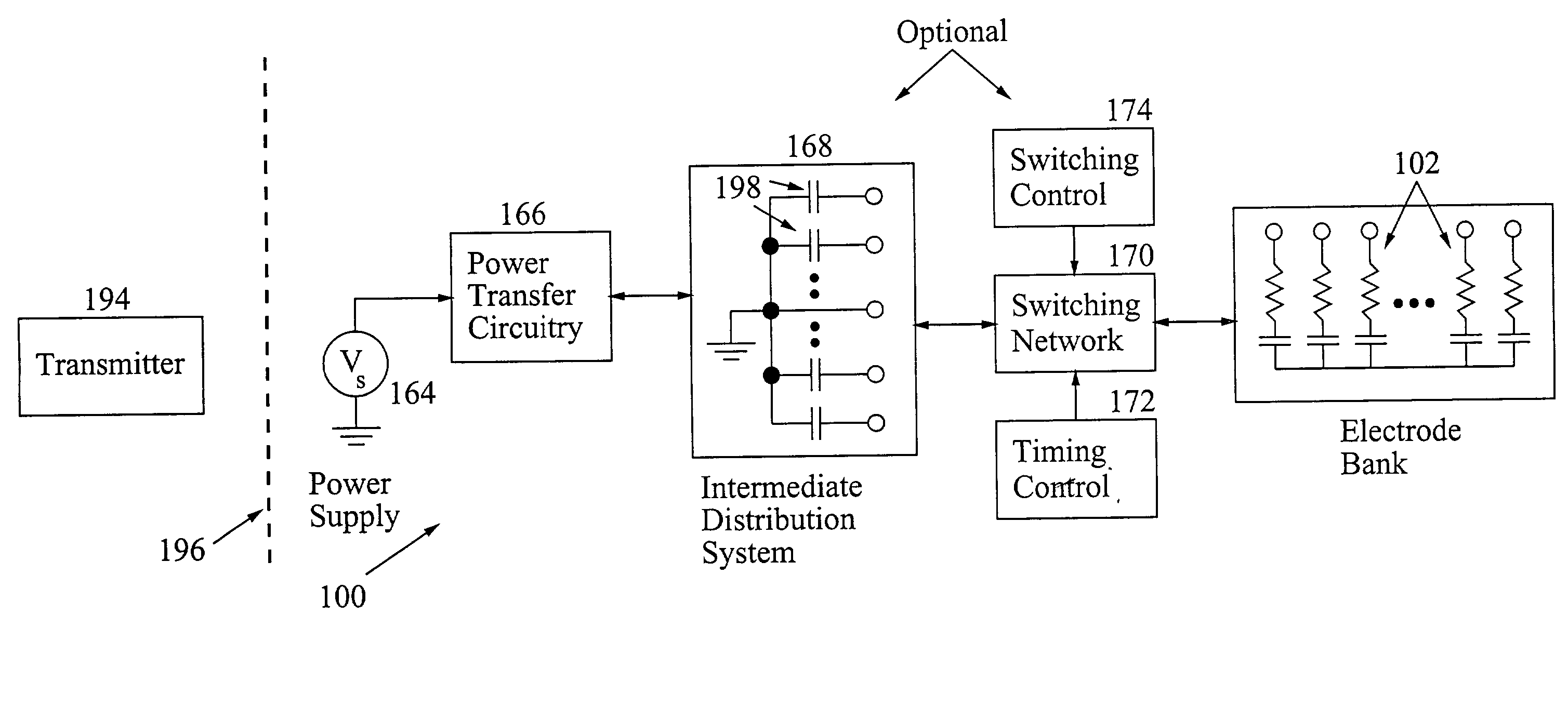

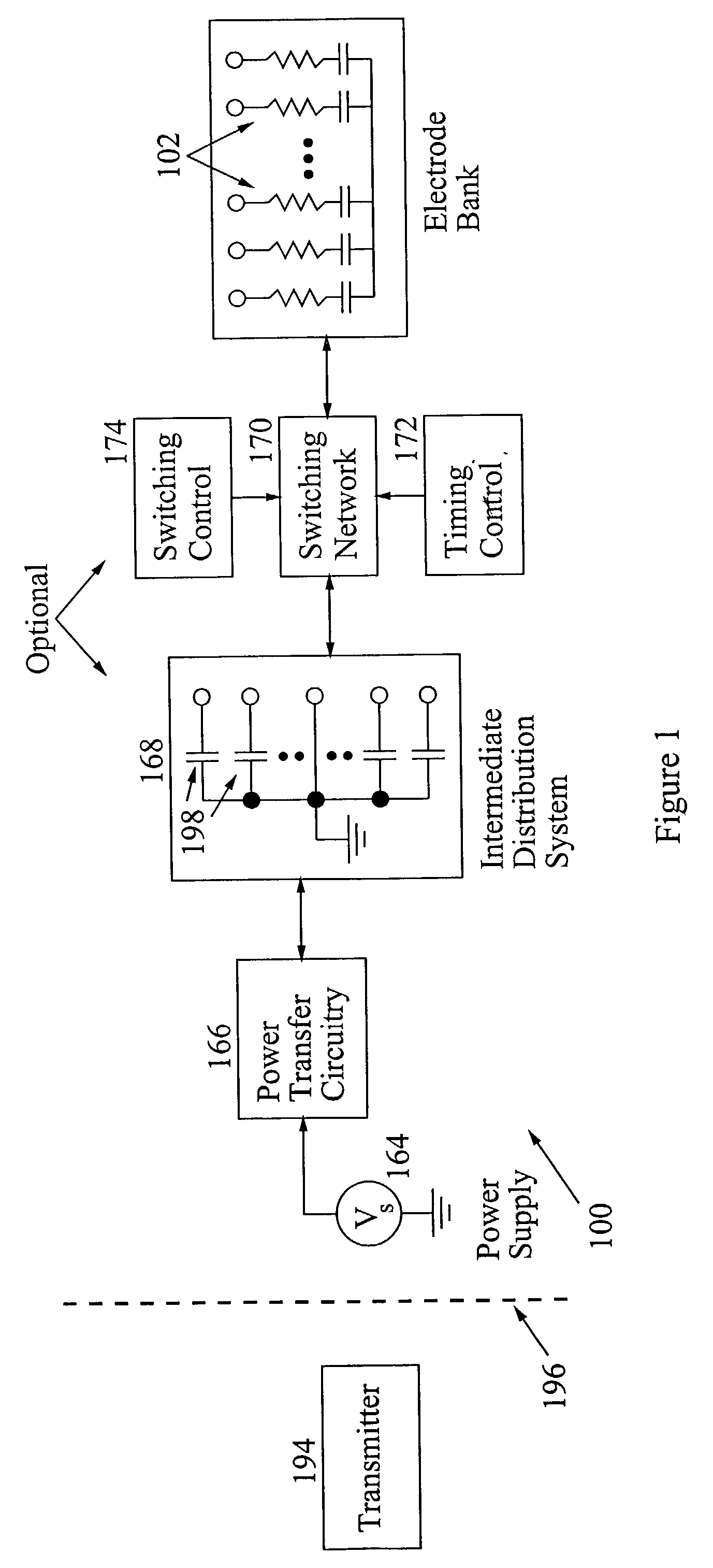

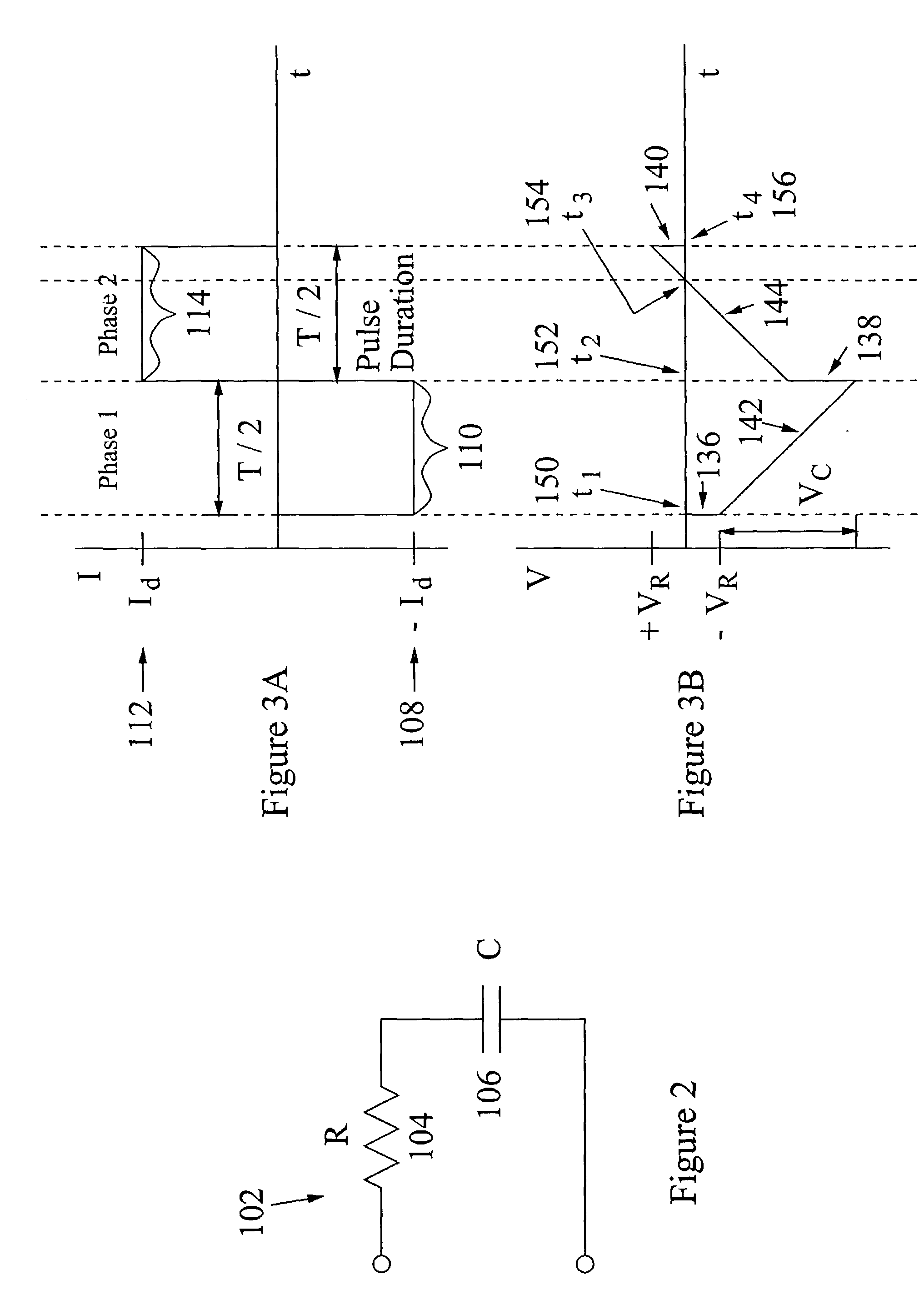

System for and method of power efficient electrical tissue stimulation

ActiveUS7295872B2Reduce the required powerRun energy savingHead electrodesArtificial respirationCapacitanceEffective power

Owner:MASSACHUSETTS INST OF TECH

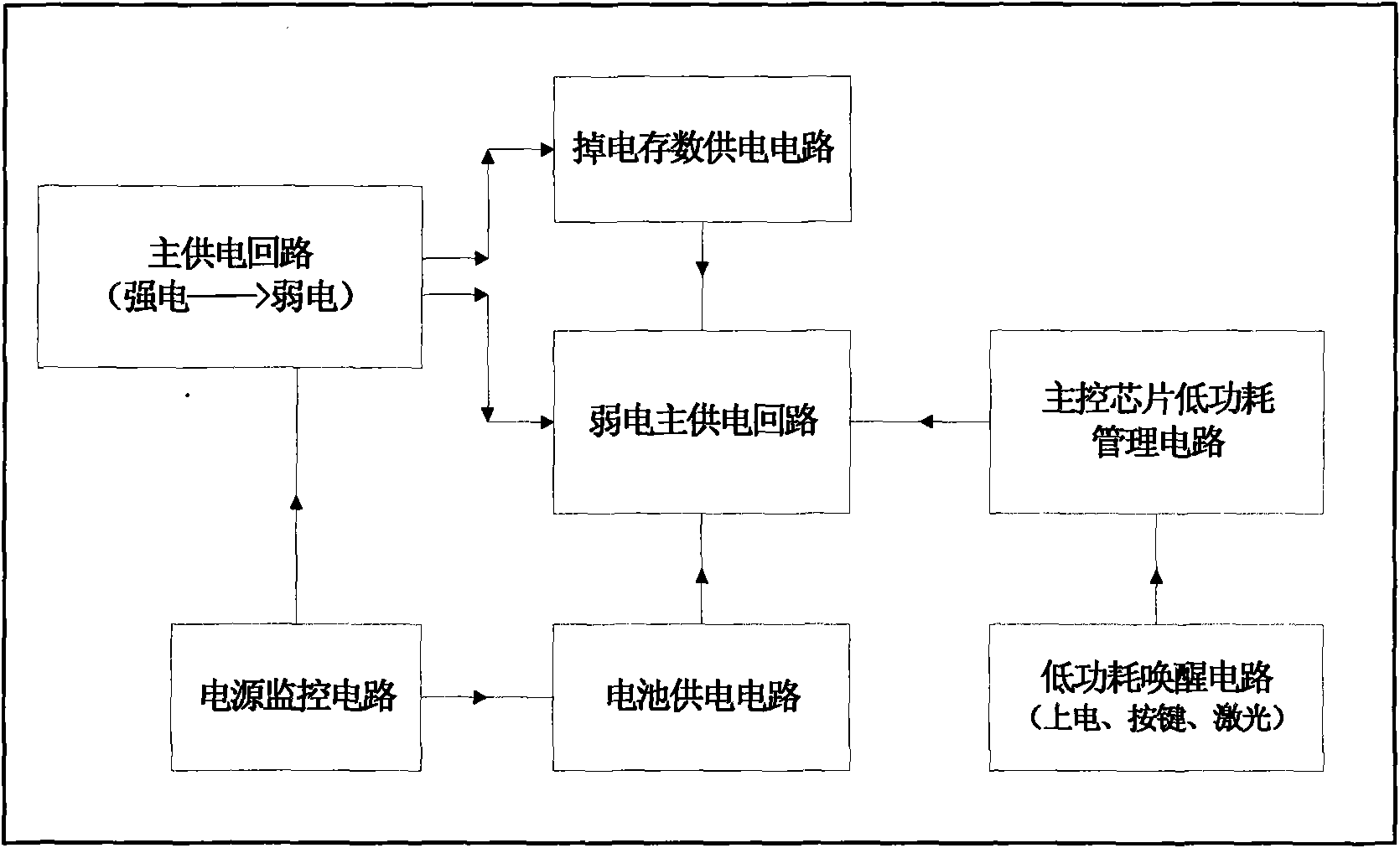

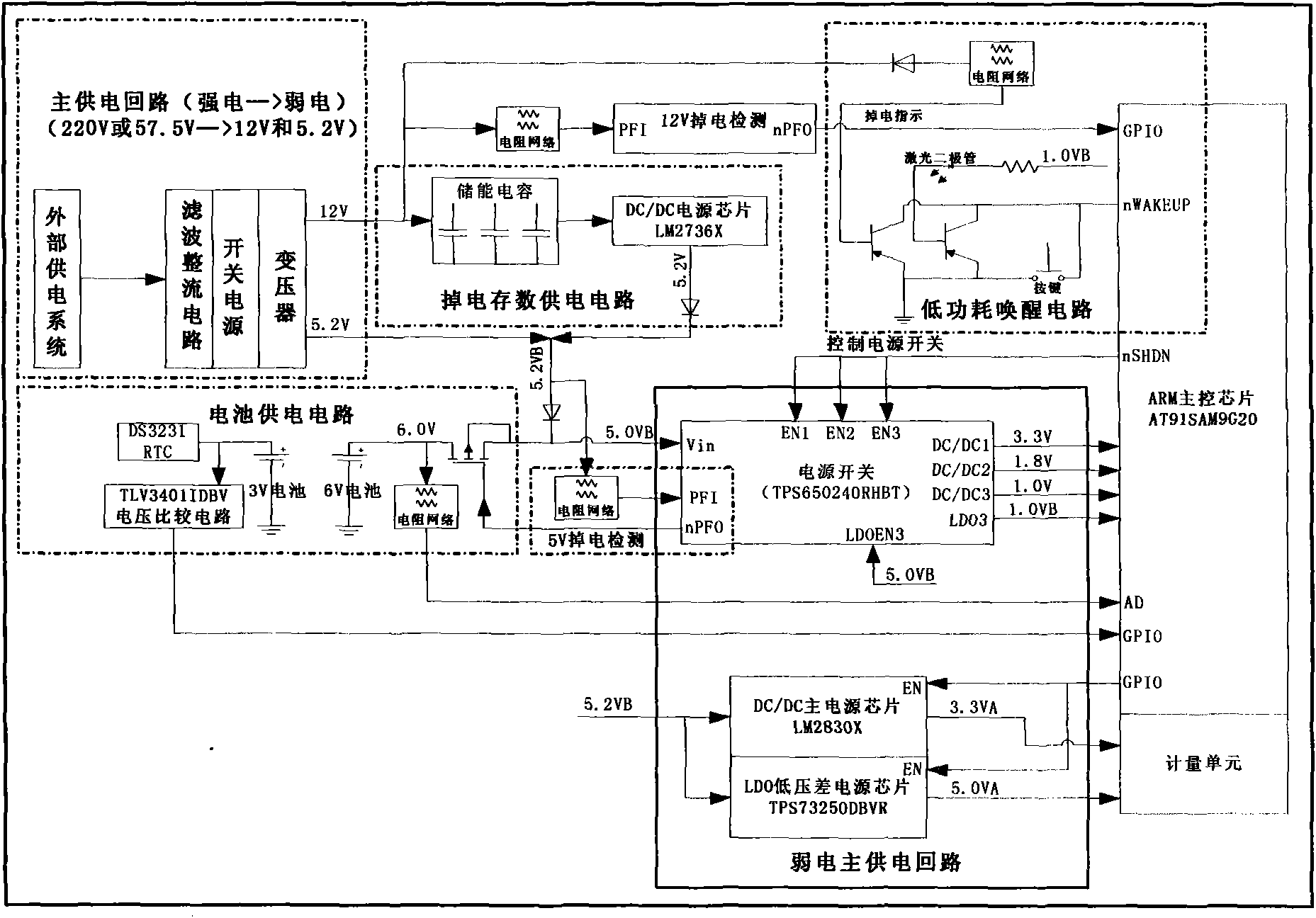

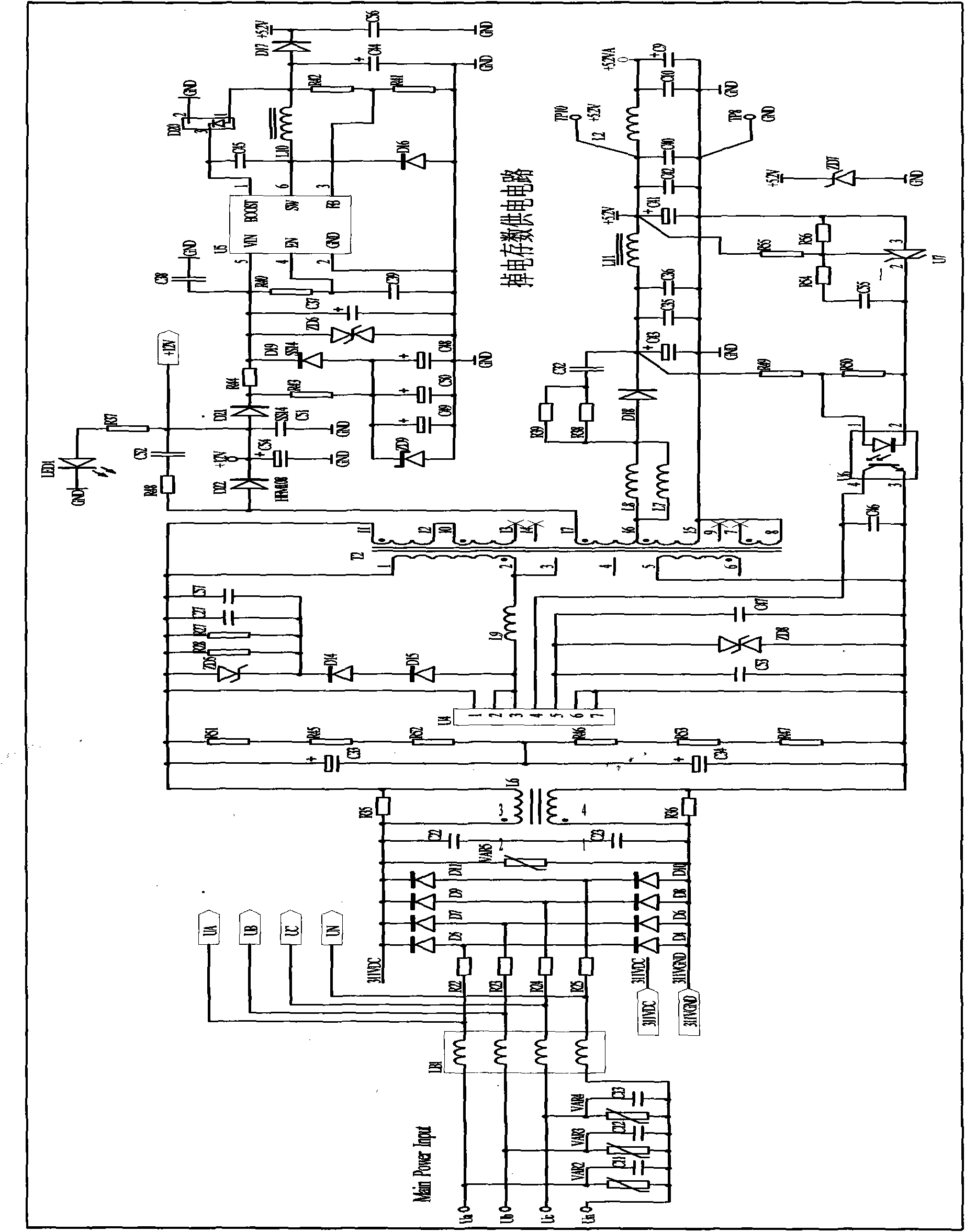

Power management power supply system for electronic electric energy meter

ActiveCN101841187AAdd sleep modeEfficient, safe and stable workPower network operation systems integrationInformation technology support systemEffective powerElectricity

The invention discloses a power management power supply system for an electronic electric energy meter. The system comprises a weak current main power supply loop, a power monitoring circuit, a power-down memory power supply circuit, a battery power supply circuit, a low power consumption wake-up circuit and a main control chip low power consumption management circuit, wherein the low power consumption wake-up circuit is connected with the main control chip low power consumption management circuit; the main control chip low power consumption management circuit is connected with the weak current main power supply loop; the power-down memory power supply circuit is connected with the battery power supply circuit and the weak current main power supply loop; a power management chip in the weak current main power supply loop is a multi-path output DC / DC high-efficiency power management chip; the main power chip is a DC / DC high-efficiency power chip; the power chip in the power-down memory power supply circuit is a DC / DC high-efficiency power chip; and finally, the weak current main power supply loop has a plurality of paths of effective power outputs all the time. Due to the adoption of the system of the invention, the high-performance chip can be applied to the electronic electric energy meter and the electronic electric energy meter can work stably in each power supply operating mode.

Owner:WASION GROUP HLDG

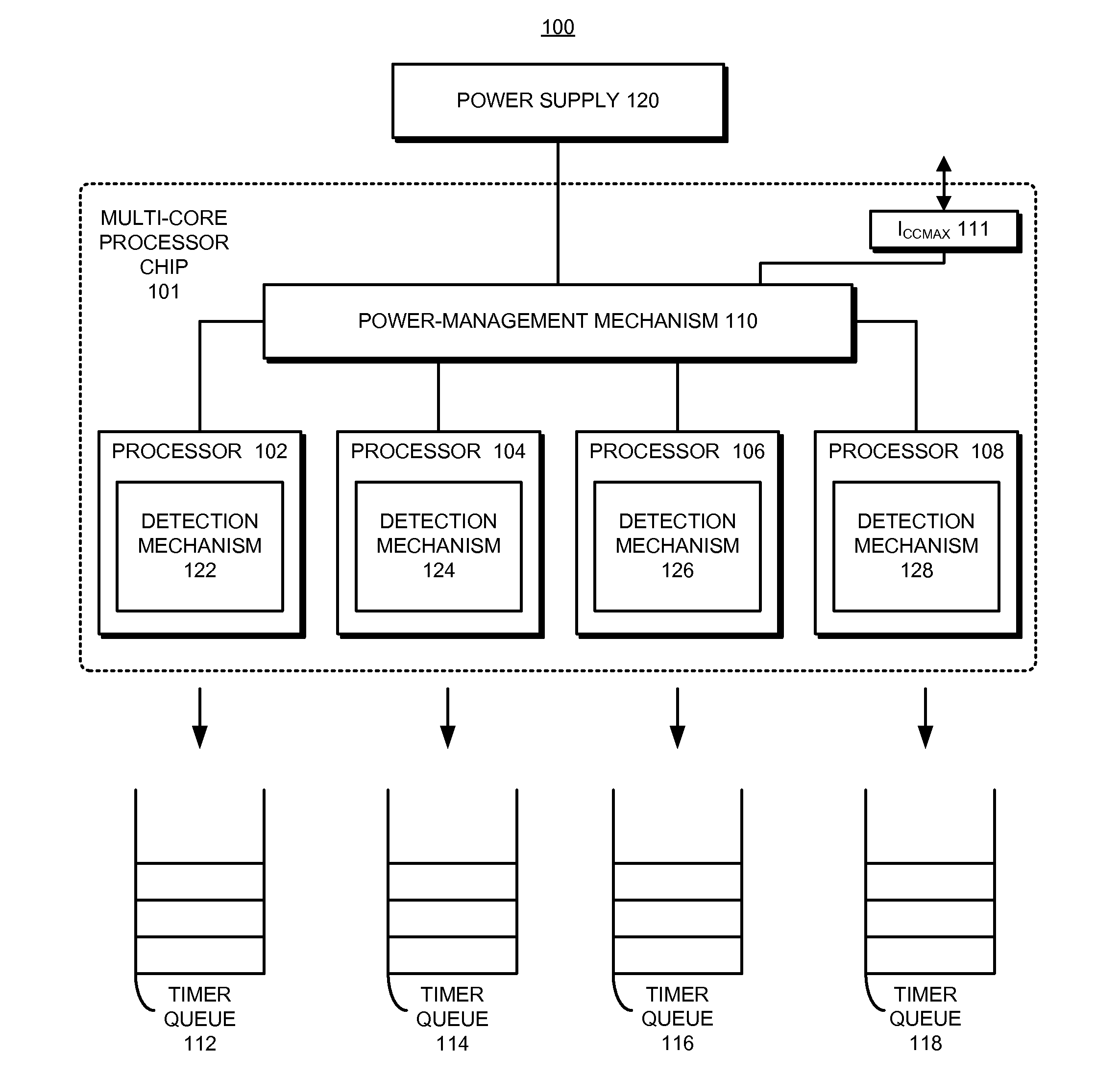

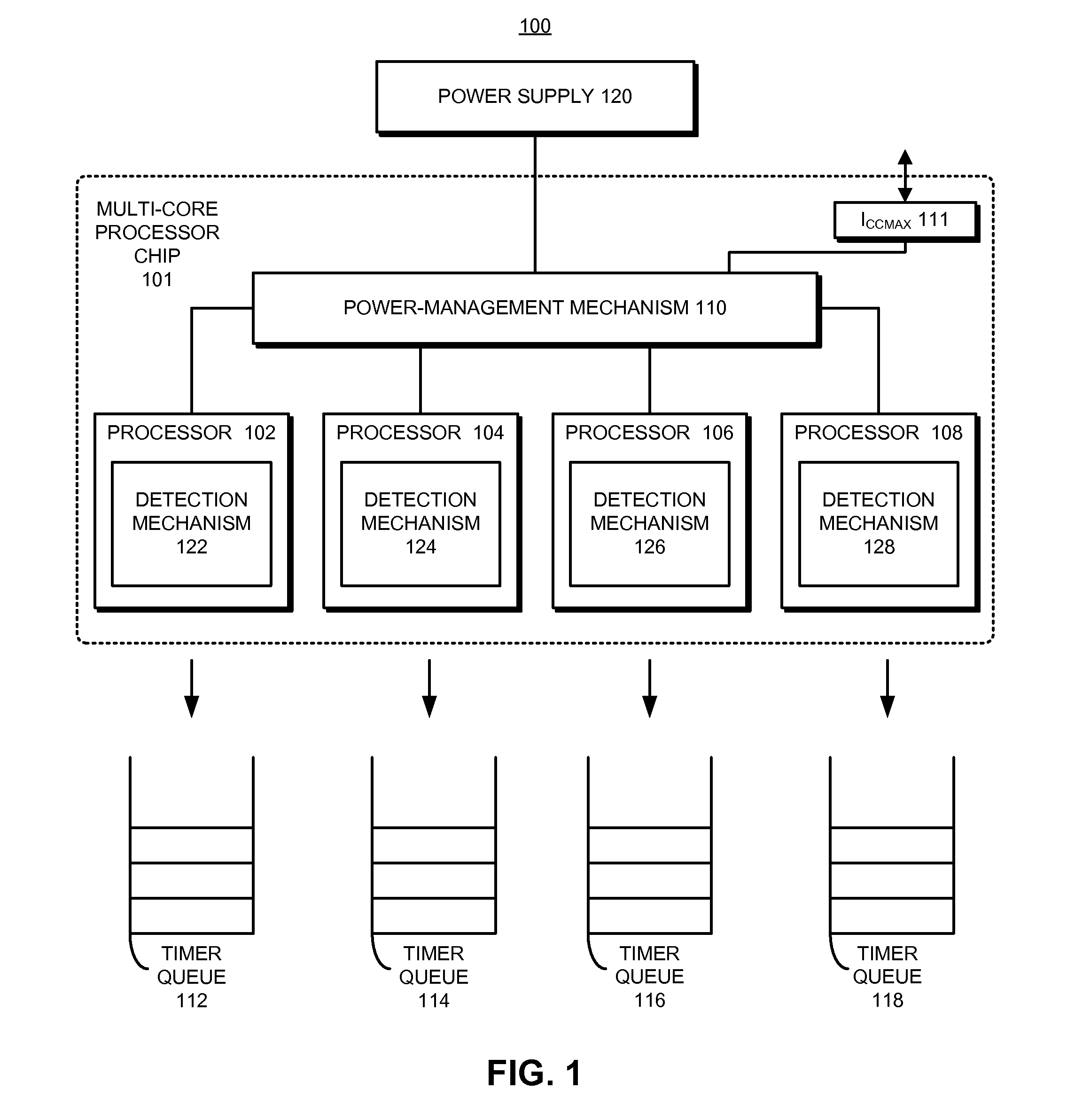

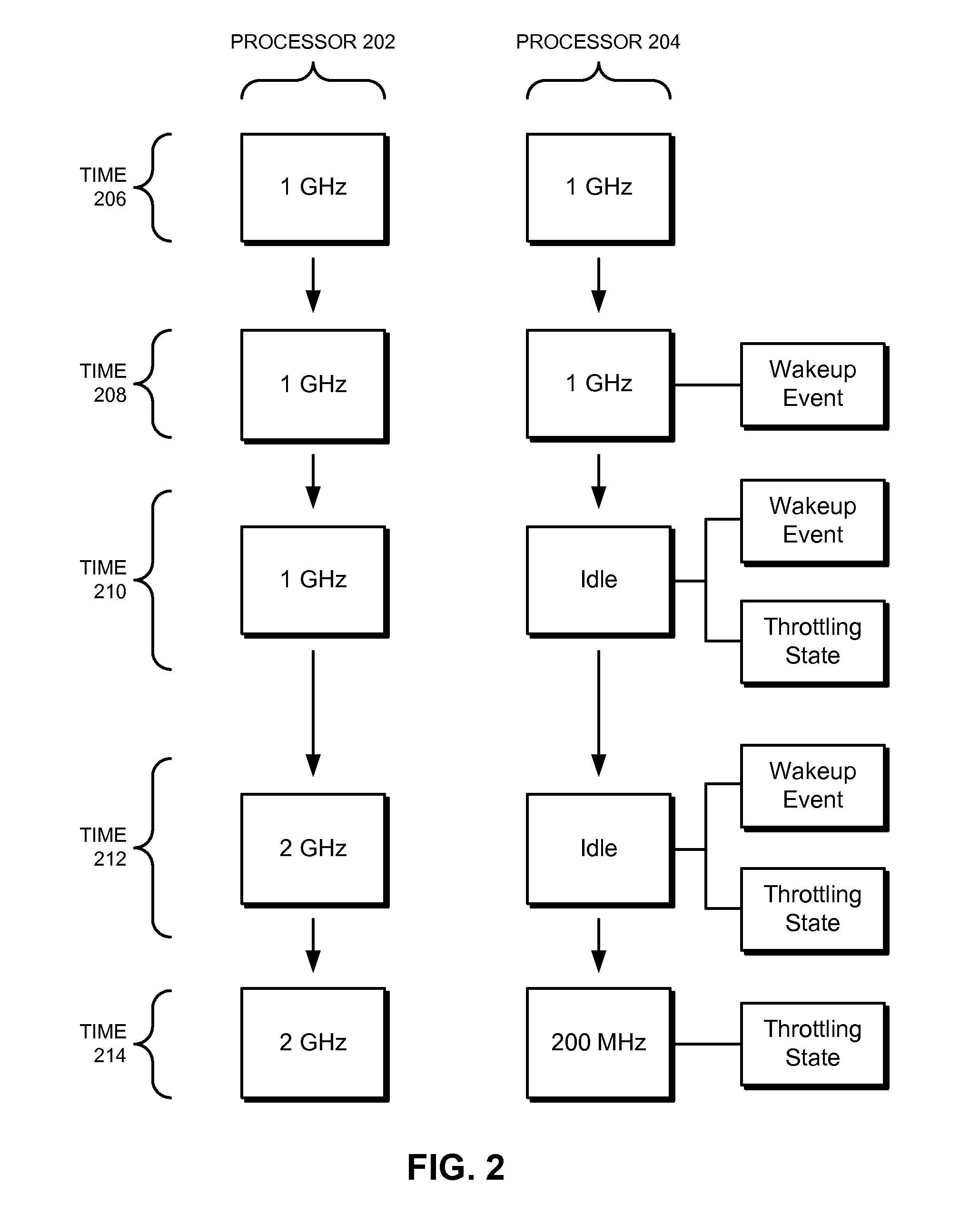

Facilitating power management in a multi-core processor

ActiveUS20120072746A1Convenient power managementSave powerEnergy efficient ICTVolume/mass flow measurementEffective powerActive state

The disclosed embodiments provide a system that facilitates power management in a multi-core processor. During operation, the system detects a change related to a number of active processor cores in the multi-core processor. (Within this system, a given processor core can reside in an active state, wherein the given processor core can draw an active power, or alternatively in a constrained state, wherein the given processor core can draw a constrained power, which is less than the active power.) In response to detecting the change, the system computes a new current limit ICCMAX for the multi-core processor based on the number of active and constrained processor cores. Finally, the system communicates ICCMAX to a power-management mechanism within the multi-core processor. This enables the power-management mechanism to use ICCMAX to account for power saved by the constrained processor cores when the multi-core system is subsequently determining whether to change its operating frequency.

Owner:APPLE INC

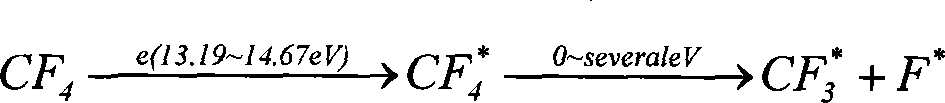

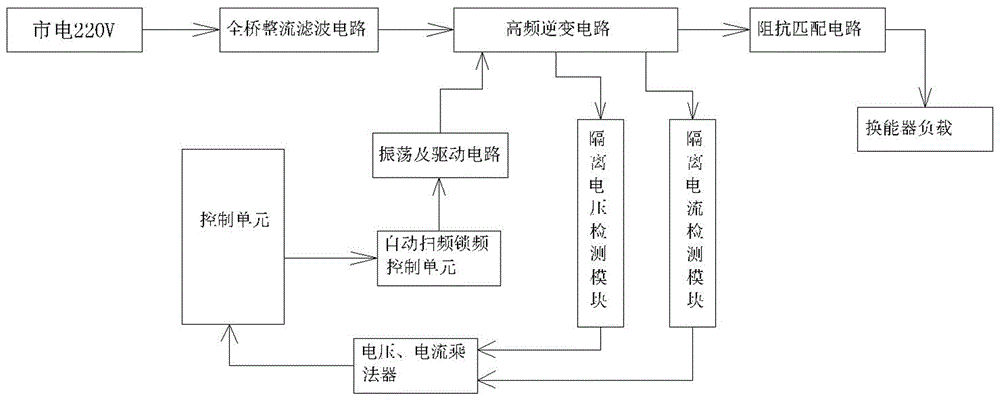

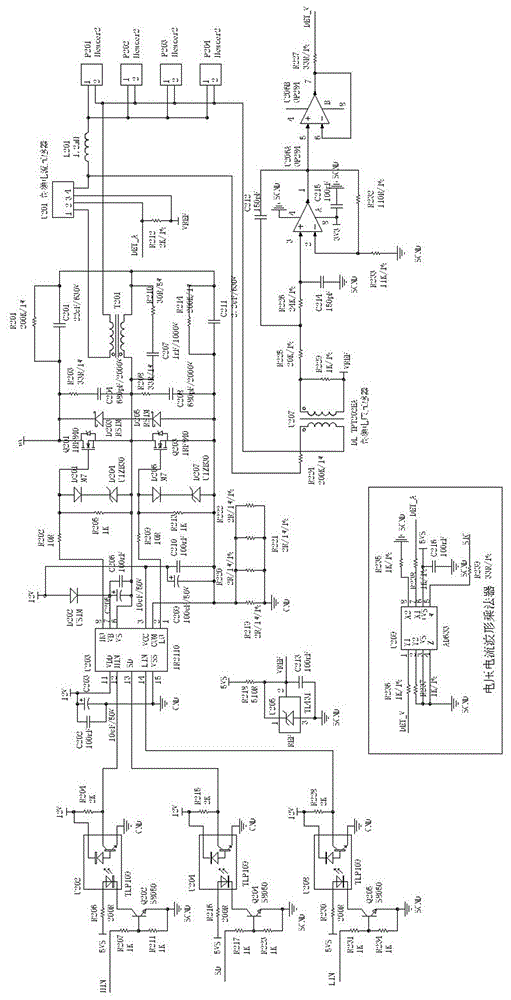

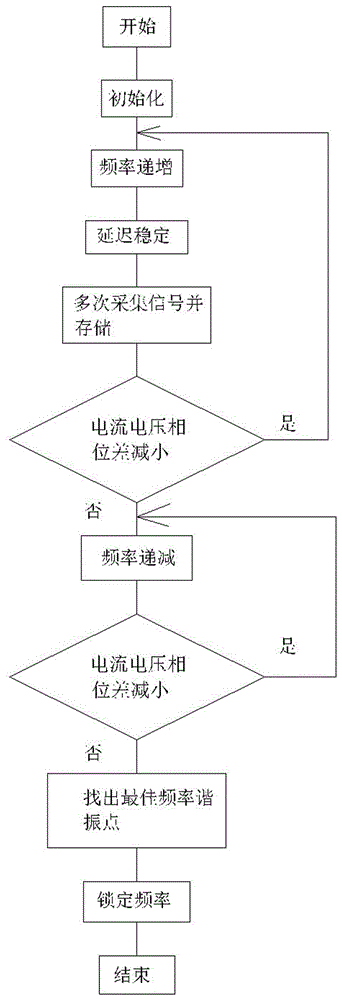

Digital ultrasonic generator and automatic frequency locking method thereof

ActiveCN106140592AImprove conversion efficiencyImprove stabilityMechanical vibrations separationTransformerPhase difference

The invention discloses a digital ultrasonic generator for measuring current wave forms and voltage wave forms at two ends of a transducer load in an isolation manner, acquiring current signals and voltage signals under effective power and automatically tracking frequencies through the signals to accurately find out resonant frequencies. The voltage wave forms and the current wave forms are calculated by multiplication; phase differences delta phi of the voltage and current wave forms are directly reflected through the obtained direct-current wave forms; and when delta phi is lower, a transducer is nearer a pure resistor, the conversion frequency of the transducer is higher, and the oscillation frequency thereof is nearer an optimal resonant point, so that the transducer load works in a resonant state, the conversion frequency of the ultrasonic transducer is improved, the heating capacity of an inductor and a transformer is reduced, and the current stability and efficiency are improved.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD

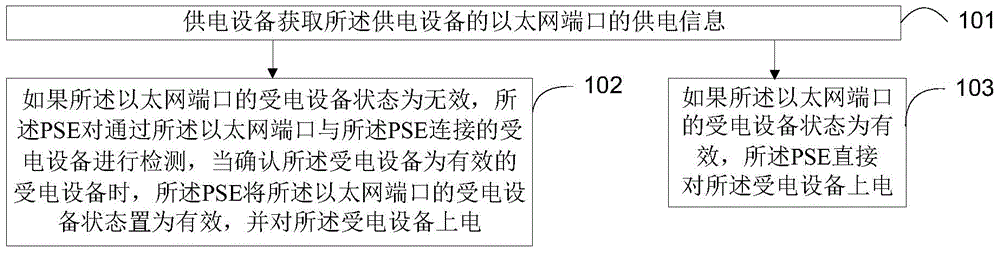

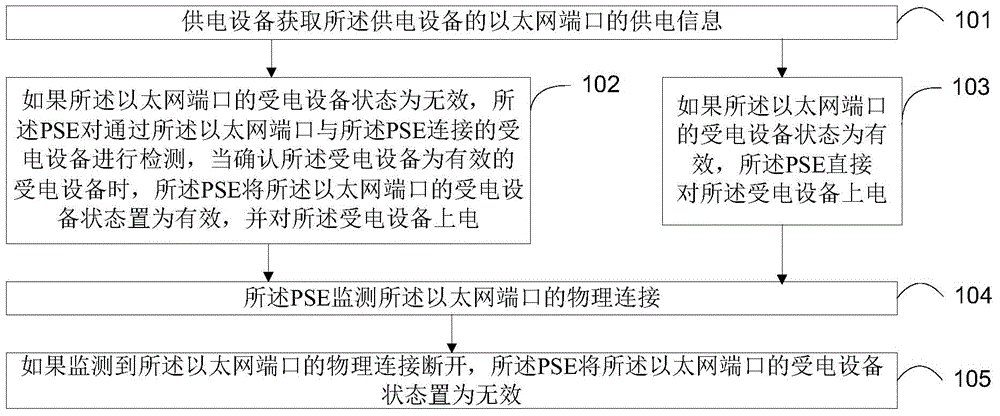

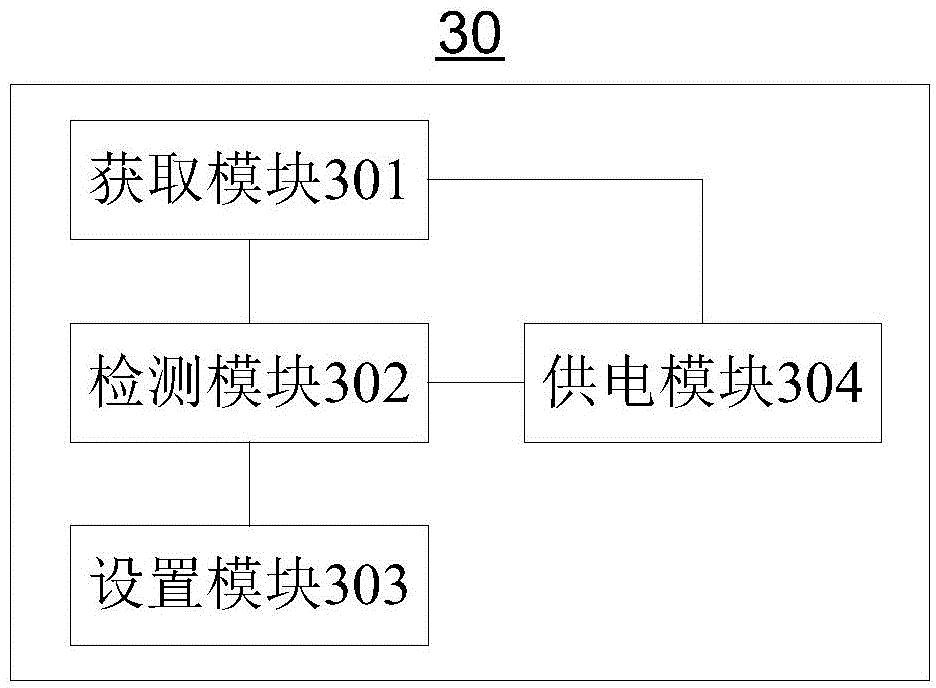

Method for power over Ethernet, power sourcing equipment and system for power over Ethernet

ActiveCN104954145AImprove reliabilityReduce power-on timeData switching current supplyElectricityEffective power

The invention discloses a method for power over Ethernet. Power sourcing equipment acquires power sourcing information of Ethernet ports, and the power sourcing information includes the state of powered devices; if the state of the powered devices of the Ethernet ports is ineffective, the powered devices connected with the power sourcing equipment via the Ethernet ports are detected, and when the powered devices are ensured to be effective powered devices, the state of the powered devices of the Ethernet ports is set to be effective and the powered devices are powered on; and if the state of the powered devices of the Ethernet ports is effective, the powered devices are directly powered on so that rapid power-on and starting of the powered devices can be realized. The invention also provides the power sourcing equipment and a system for power over Ethernet.

Owner:HUAWEI TECH CO LTD

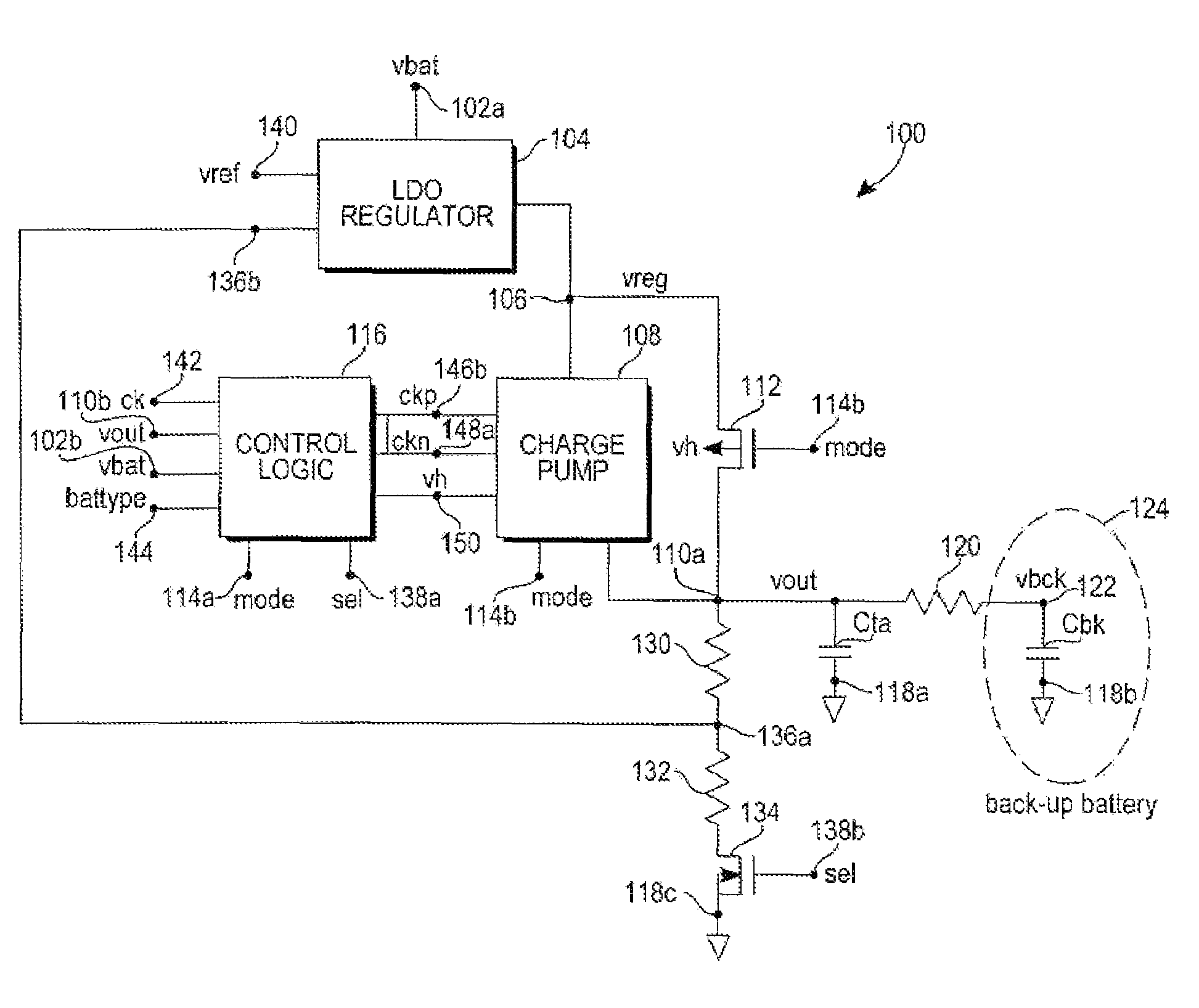

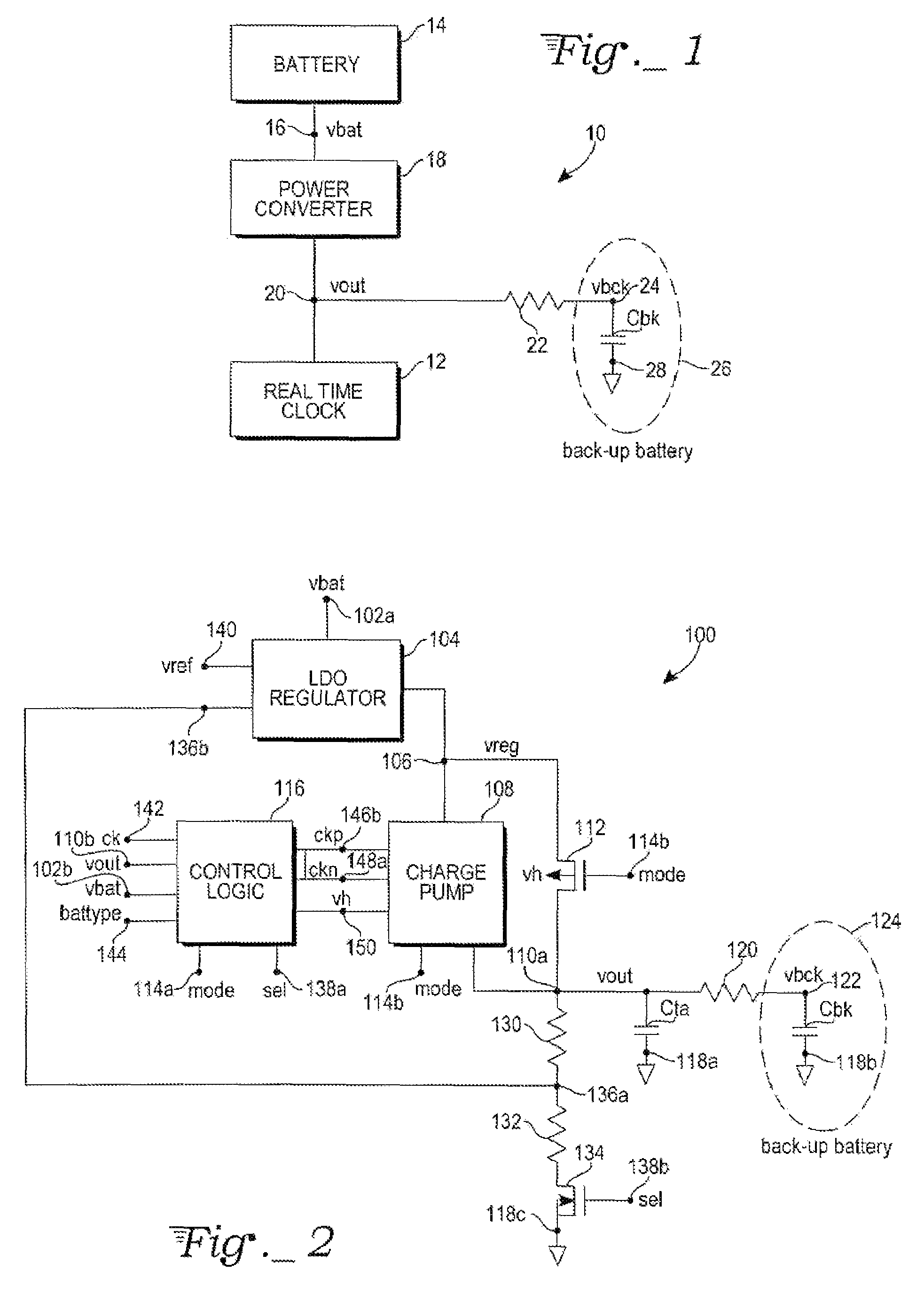

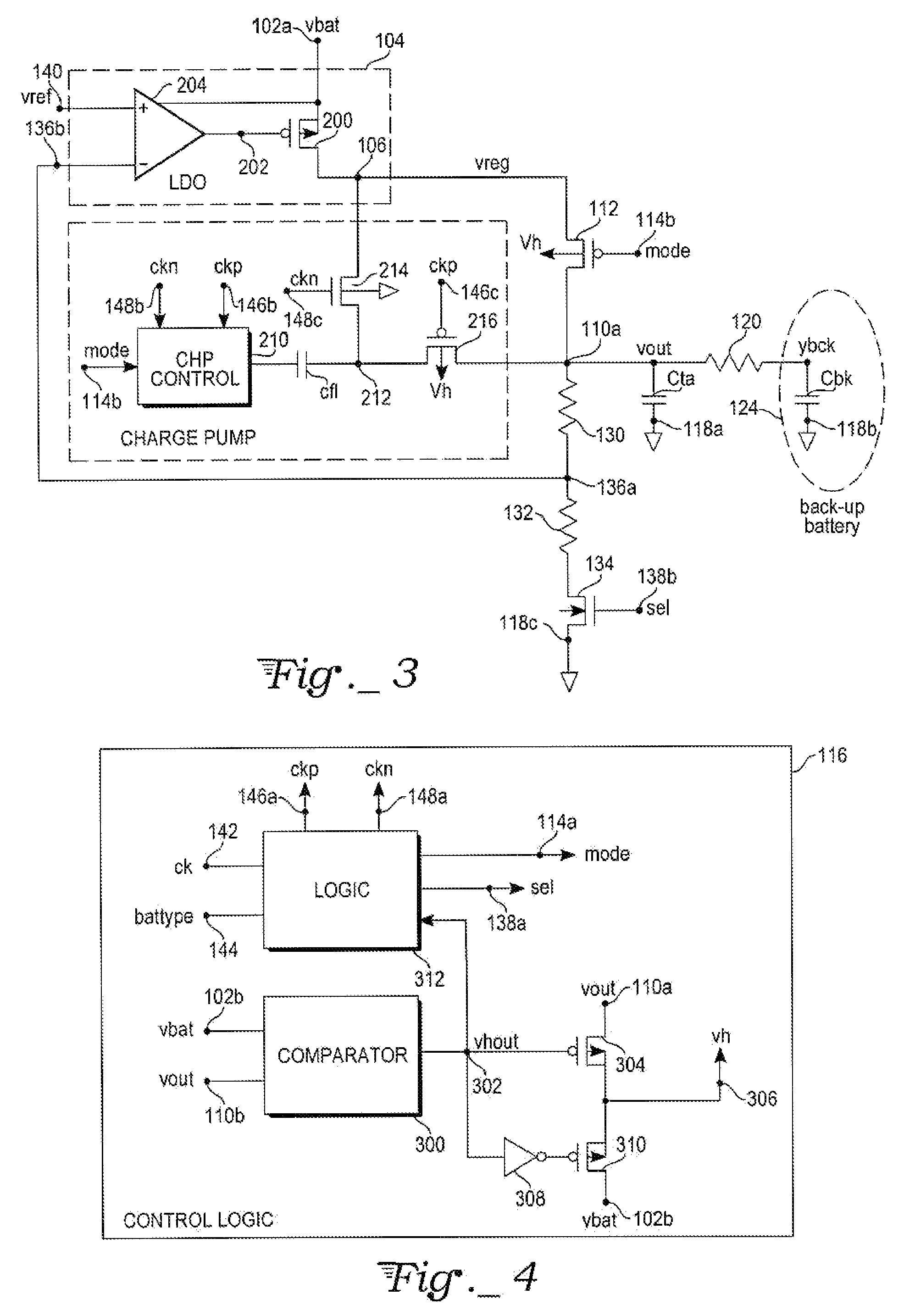

Method and circuit for a voltage supply for real time clock circuitry based on voltage regulated charge pump

ActiveUS7550954B2Efficient Power ConversionApparatus without intermediate ac conversionDc source parallel operationElectrical batteryLithium-ion battery

A versatile voltage regulator accommodates either an Alkaline or Lithium-Ion battery main battery and provides low-current power for a real time clock module and for charging a backup battery. Depending upon the battery power source that is used, the present invention provides a best circuit configuration for efficient power conversion. If the power converter according to the present invention provides a regulated output voltage that is greater than the main battery voltage of an Alkaline battery, a low drop-out-voltage (LDO) voltage regulator is used in feedback loop with a charge pump. Otherwise, for a Lithium-Ion battery, only a LDO voltage regulator is used. The voltage regulator includes a series low drop-out-voltage (LDO) voltage regulator that is coupled between the main external battery and the vout load terminal, when the voltage at the vout load terminal is less than the voltage of the main external battery. The voltage regulator also includes a charge pump circuit adapted to be connected in feedback loop with the LDO regulator and the vout load terminal, when the voltage at the vout load terminal exceeds the voltage of the main external battery.

Owner:ATMEL CORP

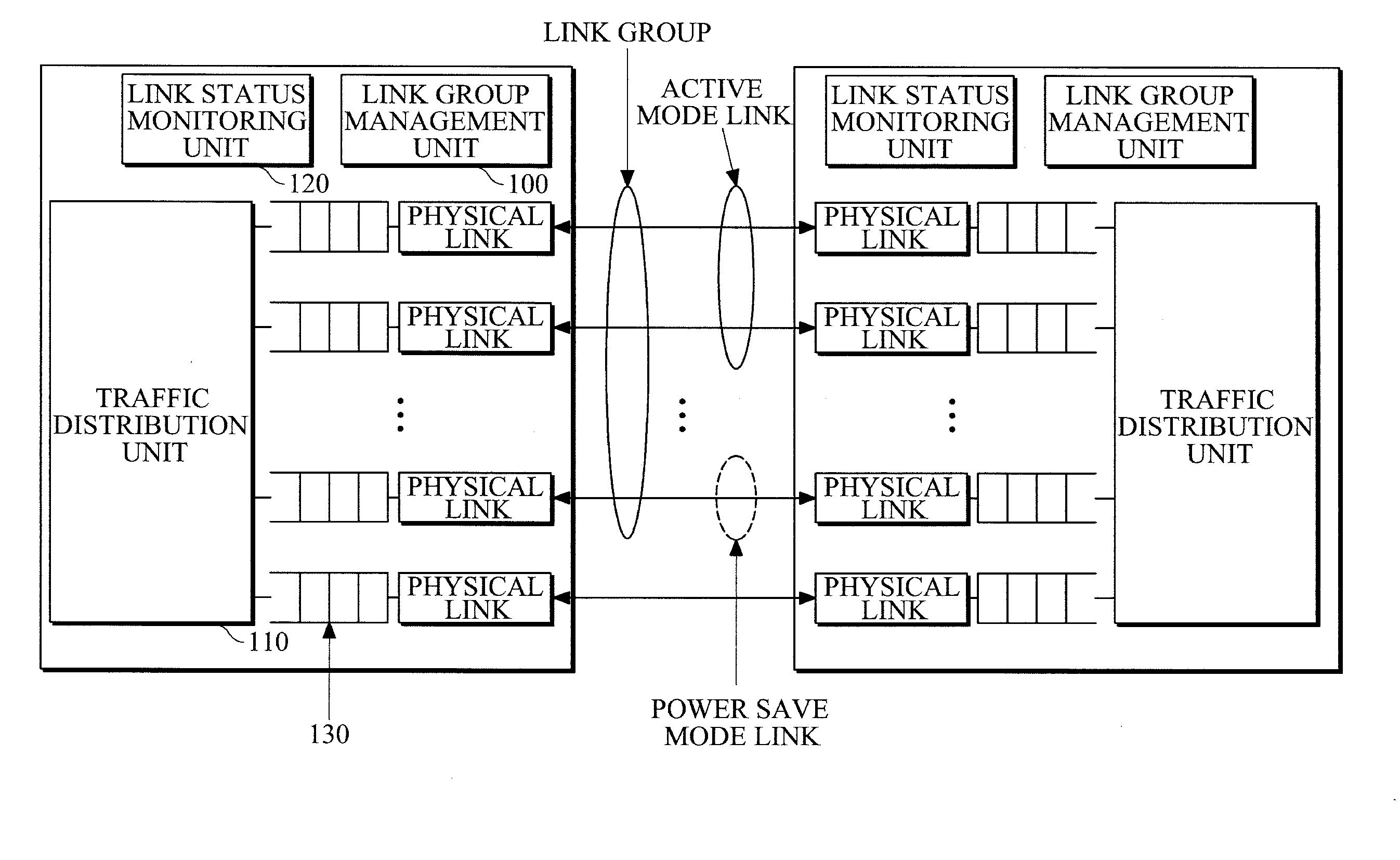

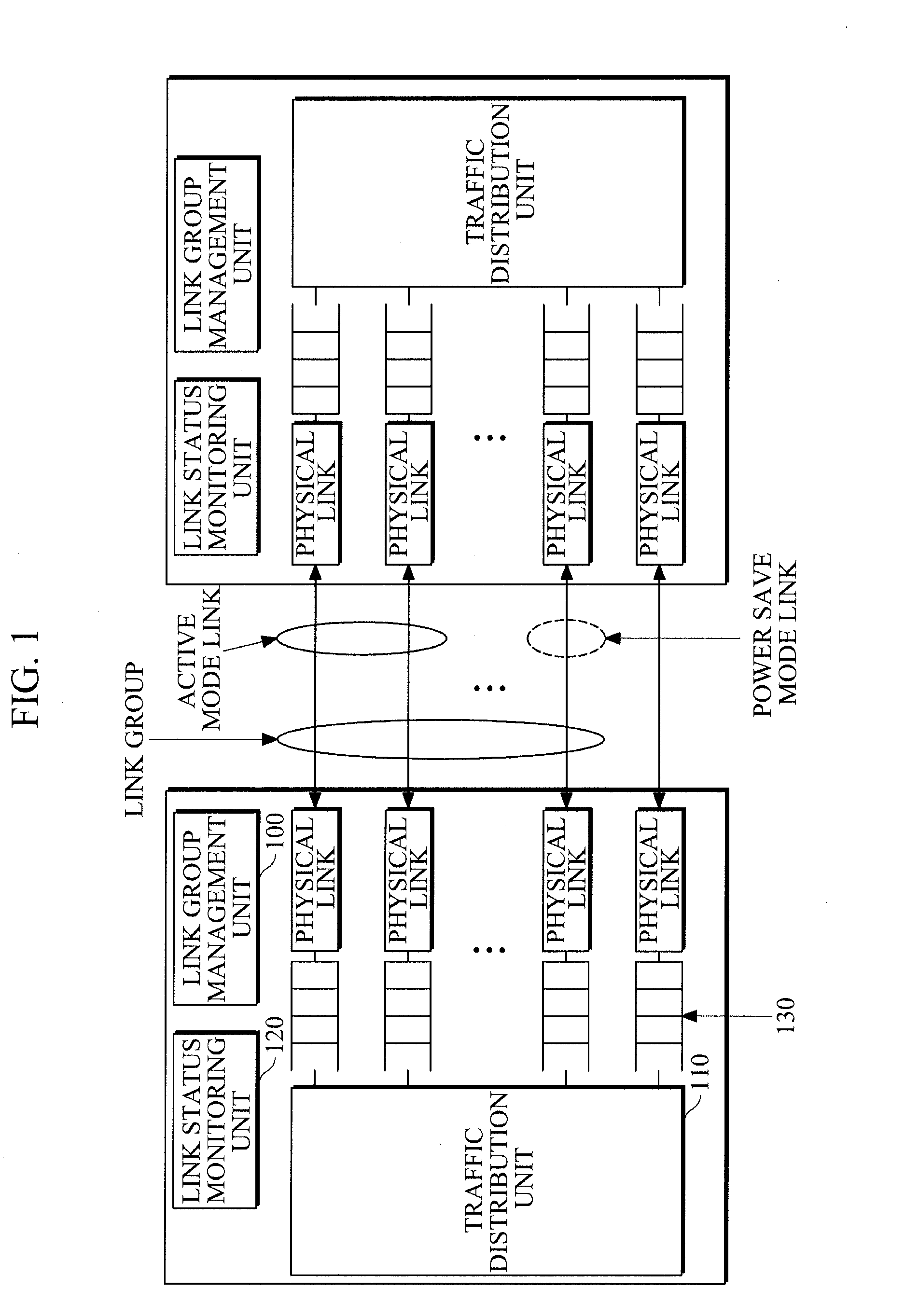

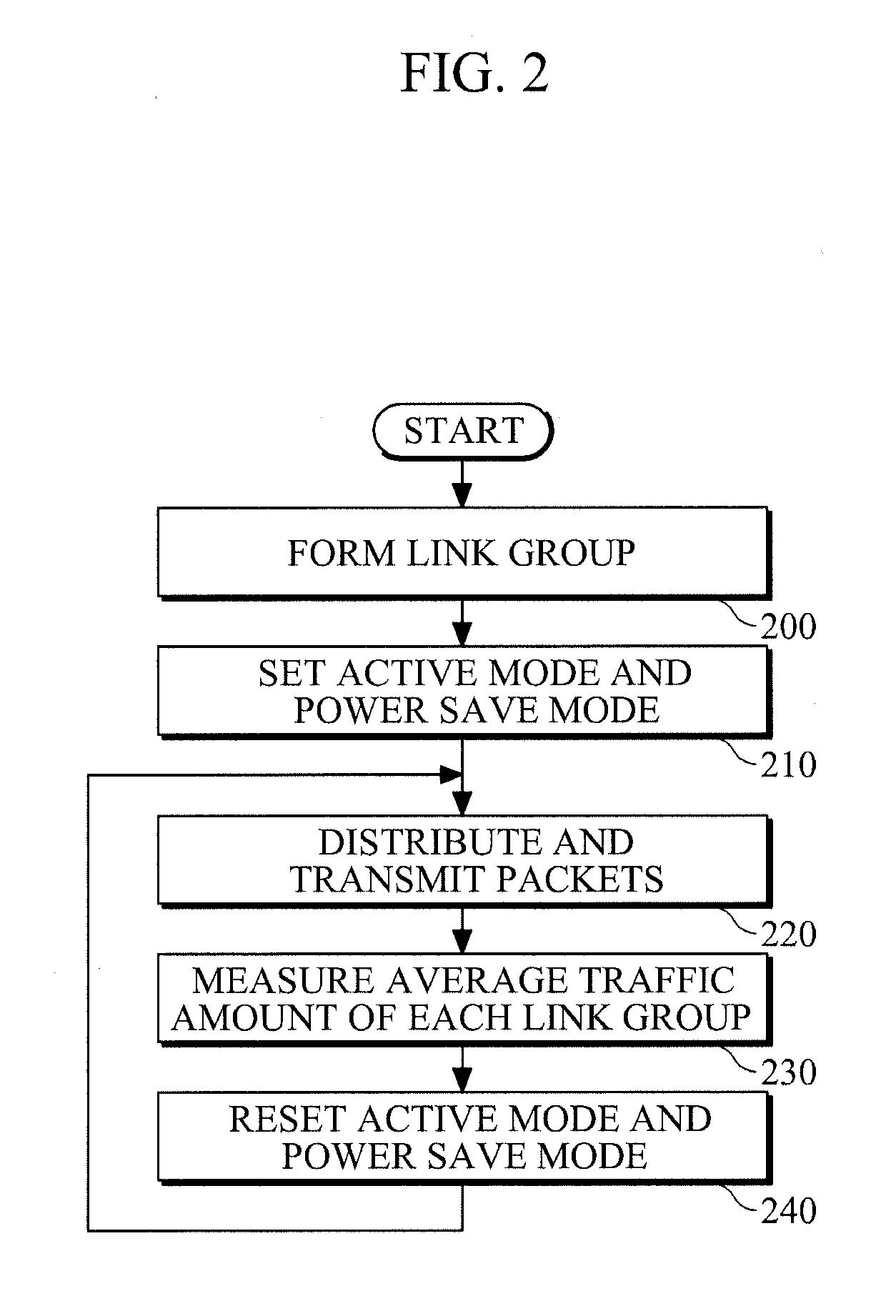

Power-efficient link group communication apparatus and method

A power-efficient link group-based communication system is provided. In link group-based communication, according to the amount of transmitted traffic, an appropriate number of links in a link group are set to active mode to be used for traffic transmission, and the rest of the links in the link group are set to power save mode, thereby not transmitting traffic. Thus, efficient power reduction in the link group-based communication can be realized.

Owner:ELECTRONICS & TELECOMM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com