Rock-socketed construction technology for large-diameter steel pipe inclined pile of offshore wind power high-rise pile cap foundation

A technology for high pile caps and offshore wind power, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems that affect the construction progress of high pile cap foundations, long construction periods, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with accompanying drawing.

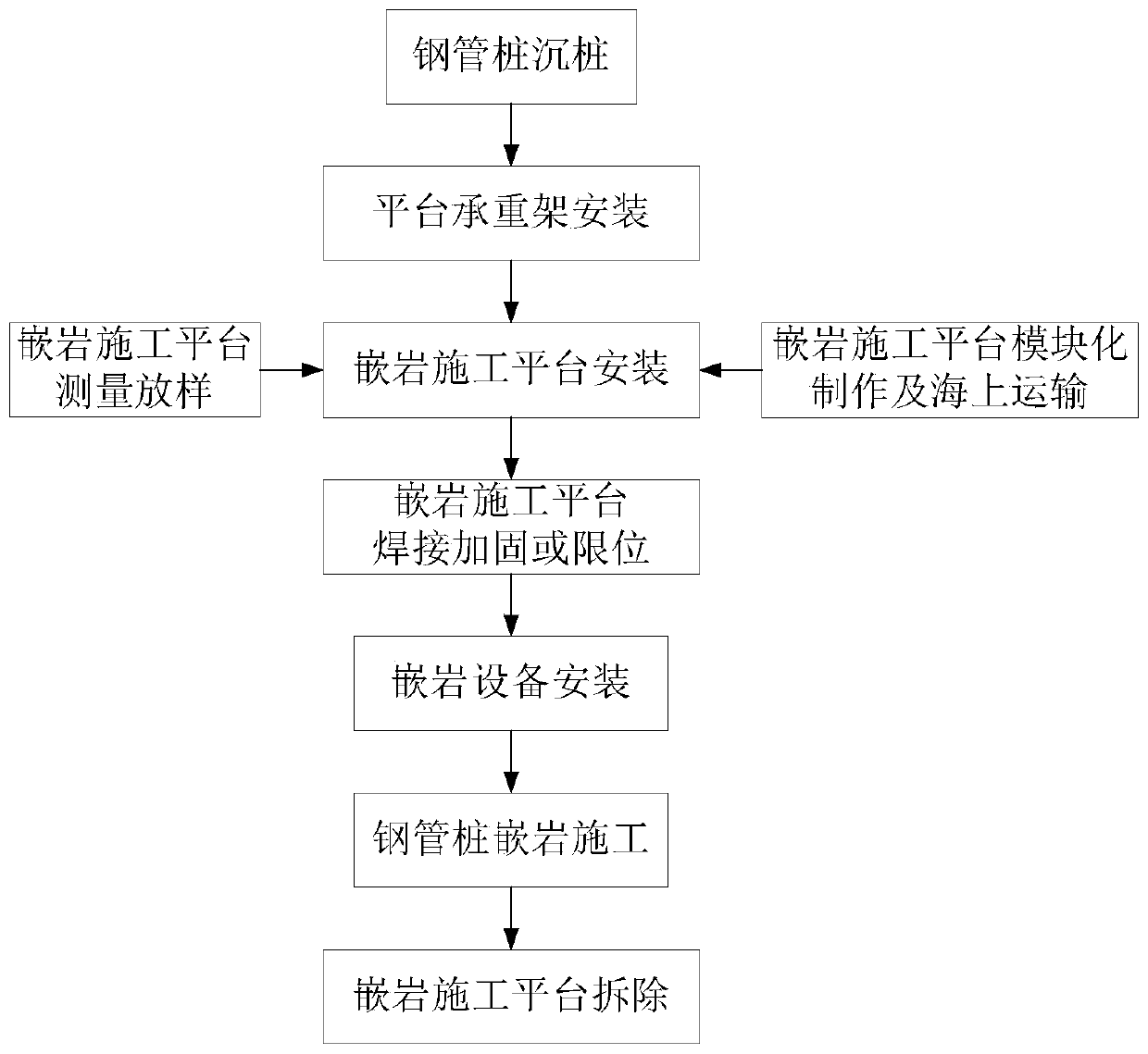

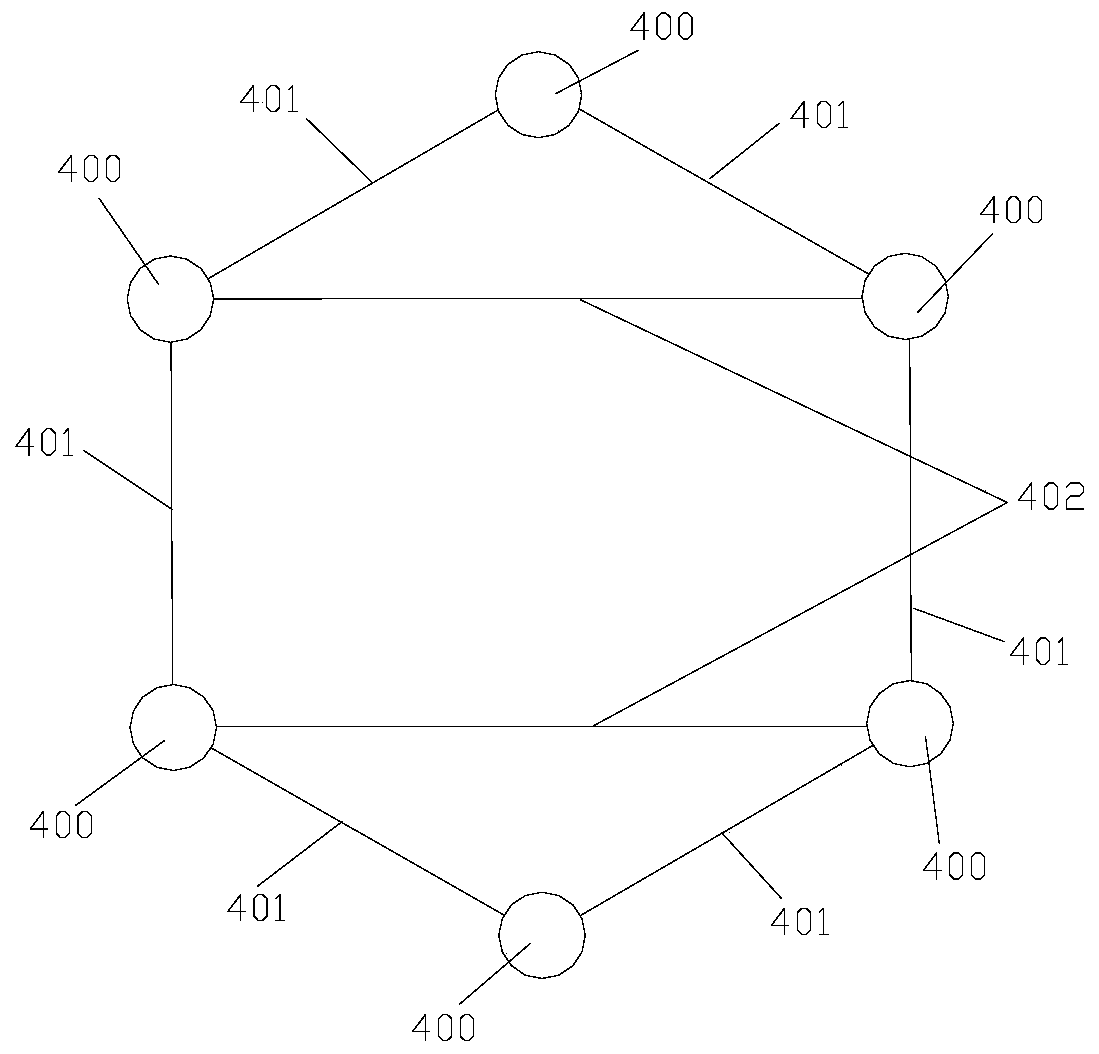

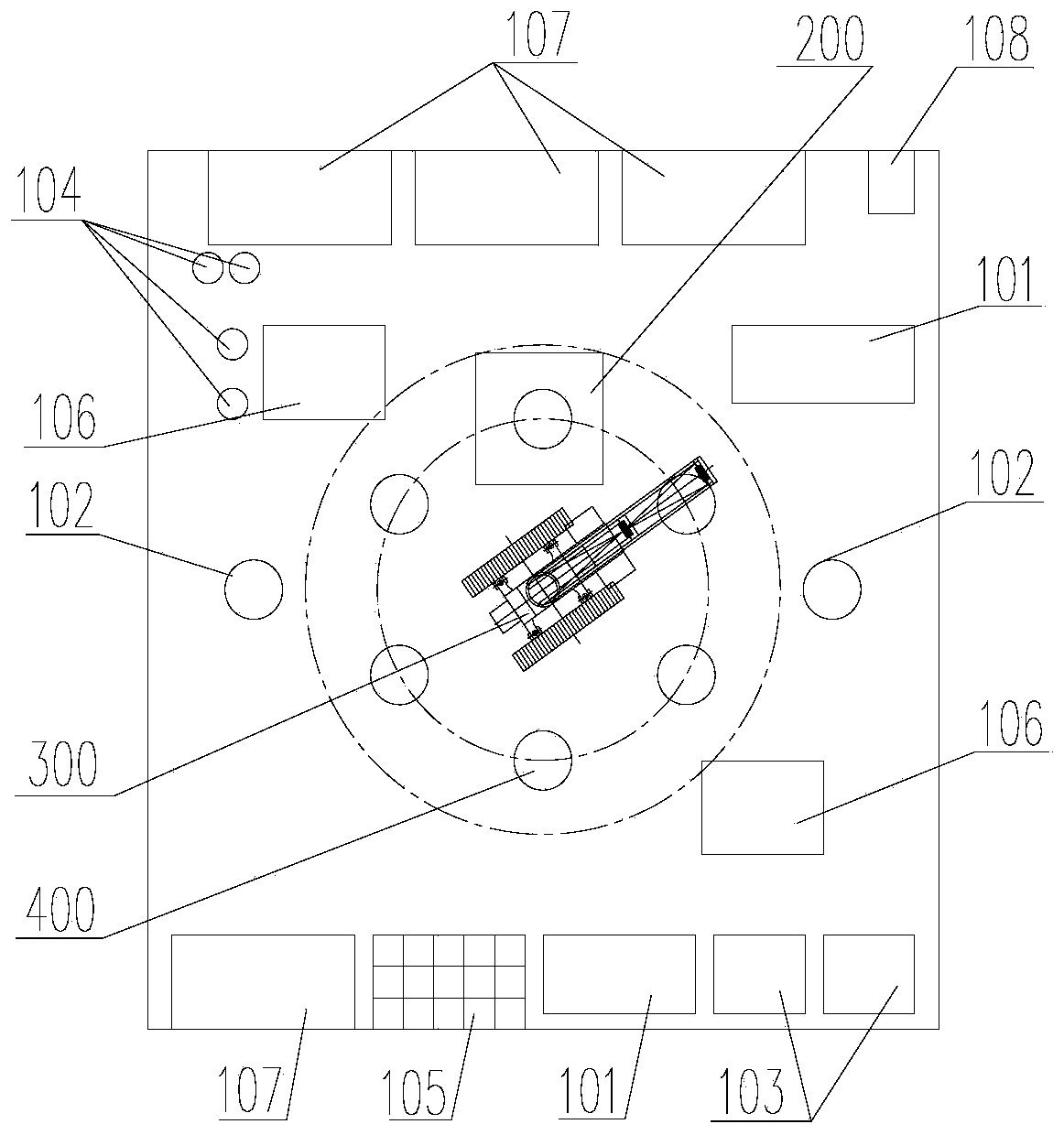

[0068] see first Figure 1 to Figure 5 , the rock-socketed construction process of large-diameter steel pipe inclined piles for offshore wind power high pile cap foundations of the present invention includes the following processes: steel pipe pile sinking, platform load-bearing frame installation, rock-socketed construction platform installation, rock-socketed equipment installation, steel pipe Pile rock-socketed construction and rock-socketed construction platform demolition.

[0069] Before the steel pipe pile sinking process, the steel pipe piles are transported to the steel pipe processing plant and transported to the construction site by a 5000t large barge equipped with a tugboat.

[0070] The pile sinking process of steel pipe piles includes the following steps: piling ship and piling barge station, steel pipe pile inspection and piling, pile lifting, GPS measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com