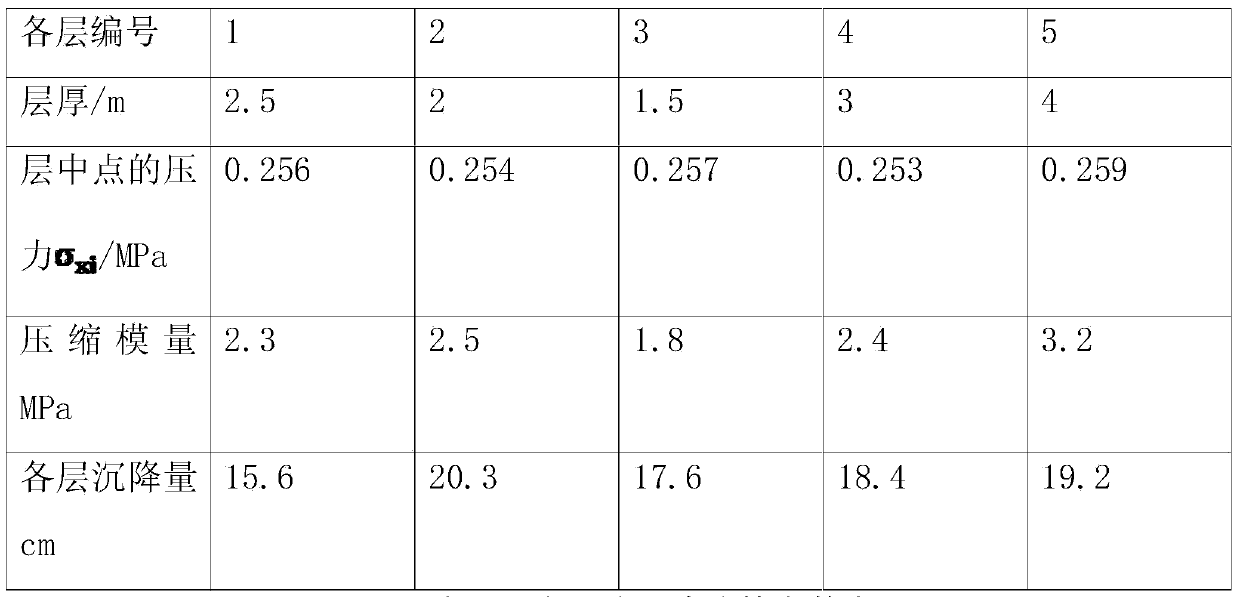

Patents

Literature

673 results about "Pile cap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pile cap is a thick concrete mat that rests on concrete or timber piles that have been driven into soft or unstable ground to provide a suitable stable foundation. It usually forms part of the foundation of a building, typically a multi-story building, structure or support base for heavy equipment. The cast concrete pile cap distributes the load of the building into the piles. A similar structure to a pile cap is a "raft", which is a concrete foundation floor resting directly onto soft soil which may be liable to subsidence.

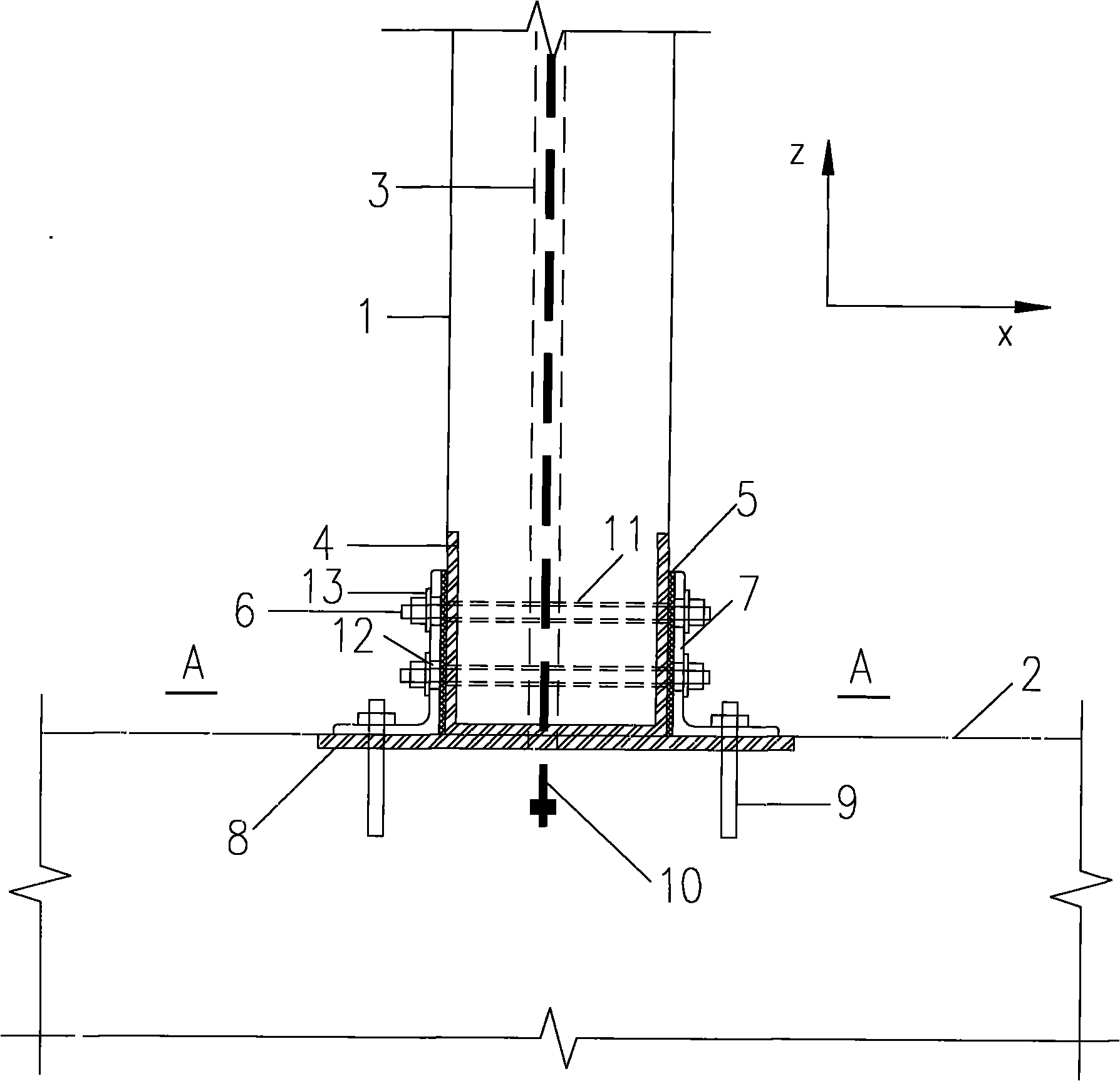

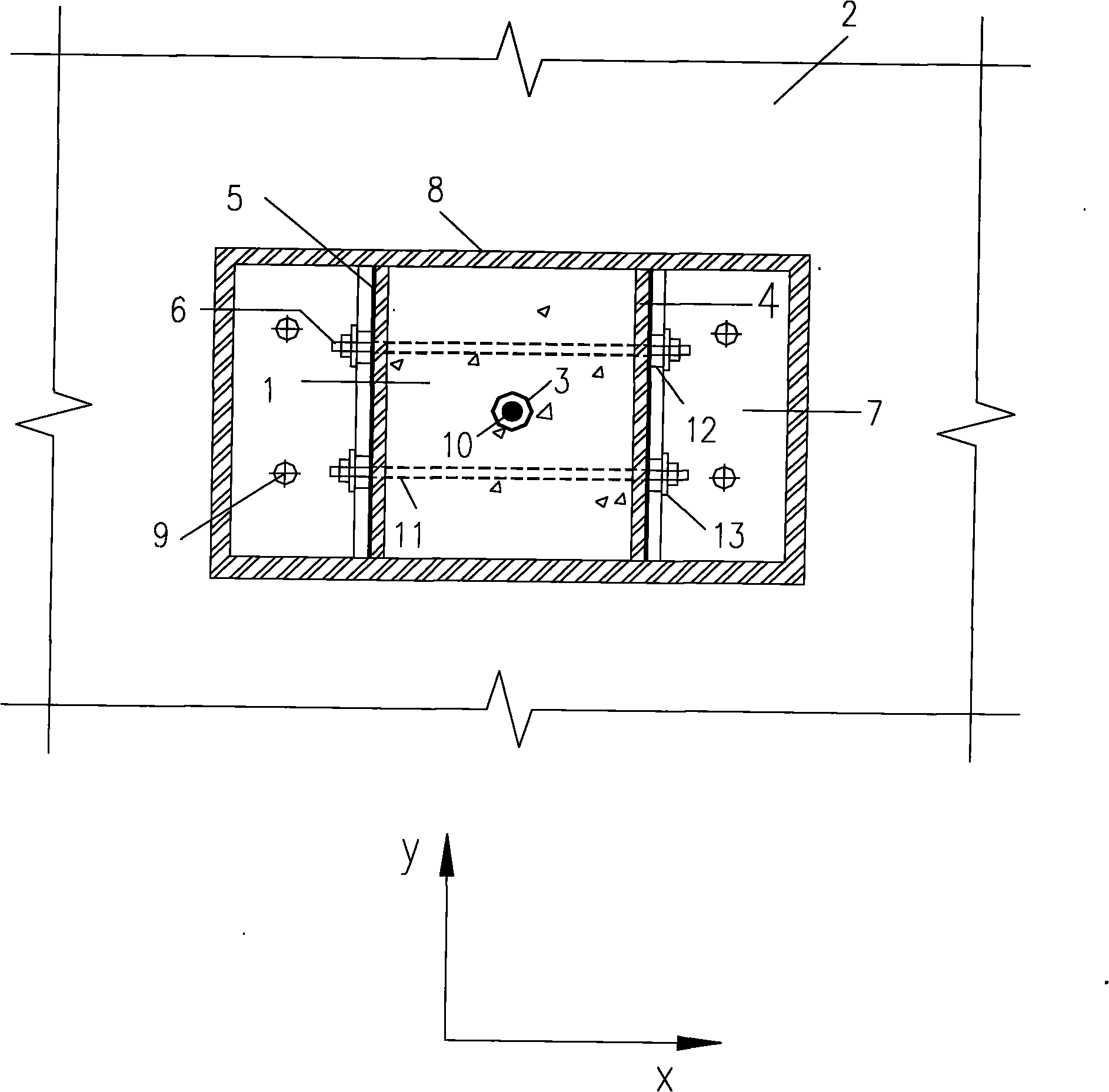

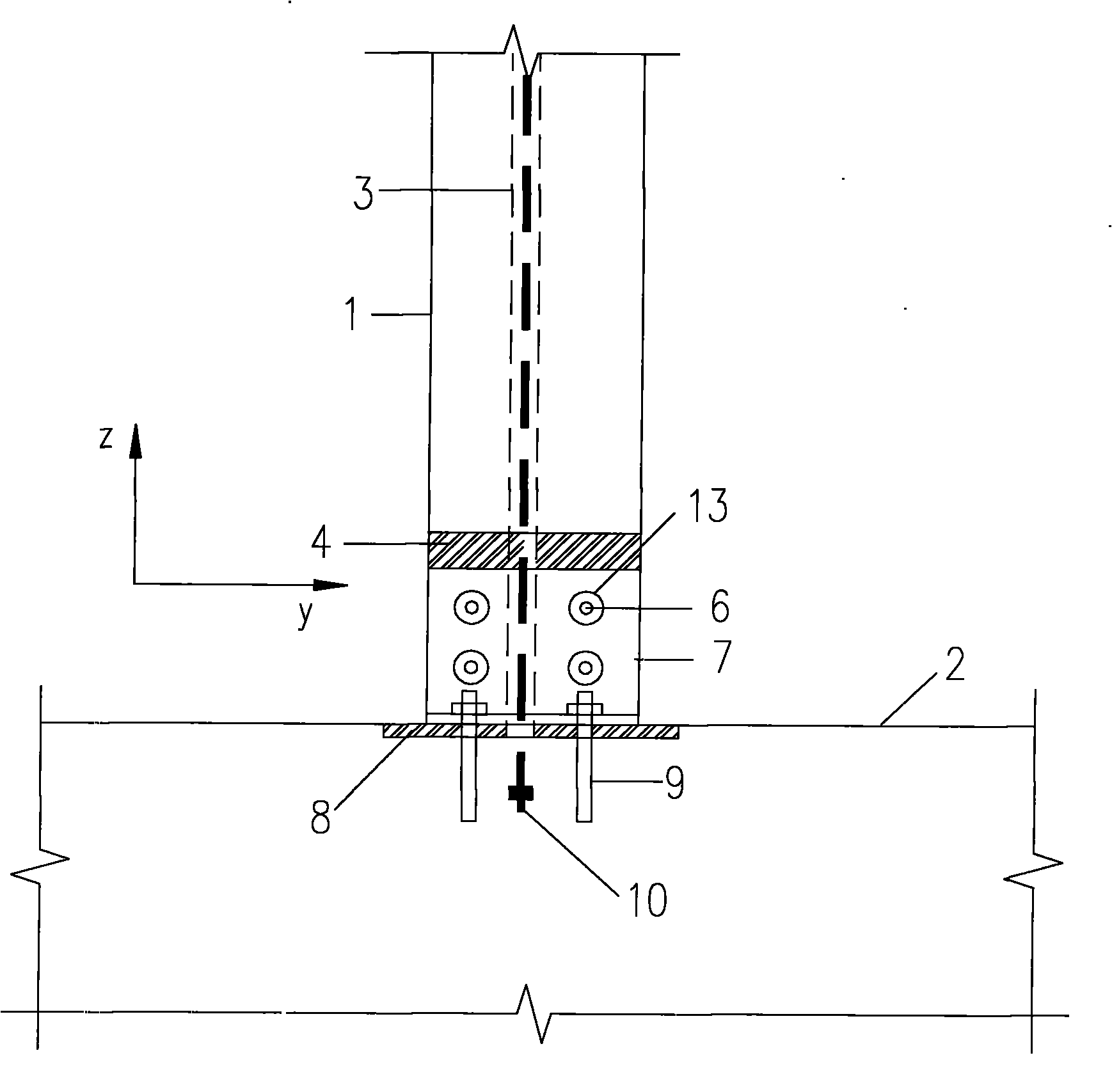

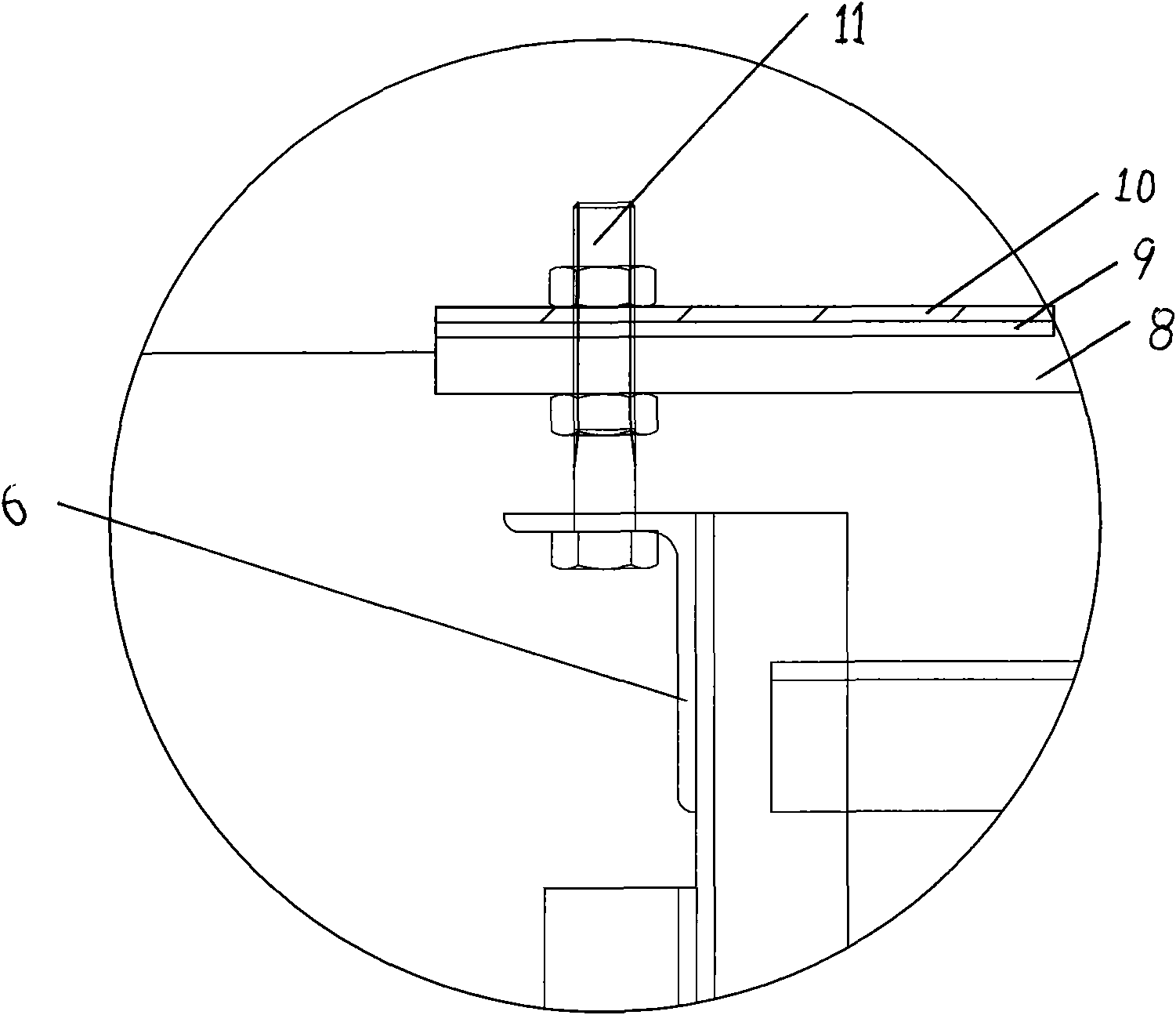

Friction energy consumption type node connection device for self-centering pier column structure

InactiveCN101936043AImprovement of local pressure problemsImprove performanceShock proofingPile capResidual deformation

The invention relates to a friction energy consumption type node connection device for a self-centering pier column structure, which is a device used for connecting a bridge pier or a frame column with a pile cap (a foundation), so as to improve the energy consumption of the pier column structure under the action of earthquake and eliminate or reduce the residual deformation and the injuries of the structure. The device comprises a pier column strengthening steel plate, a foundation pre-embedded steel plate, an angle steel, a friction bolt, a friction plate, unbonded prestressed tendons, an anchor bolt and the like. The device can connect a concrete pier column and the foundation into a whole through the unbonded prestressed tendons which are vertically arranged. When the earthquake strength achieves a certain degree, the pier column-foundation contact surface is open, and the pier column can produce a certain rotation relative to the foundation. A friction device can dissipate earthquake energy through friction at this time, and the prestress provided by the prestressed tendons can recover the structure to the initial position after the earthquake. A pre-embedded part at the end part of the pier column is used for improving the local bearing pressure of the concrete when the pier column rotates relatively.

Owner:SOUTHEAST UNIV

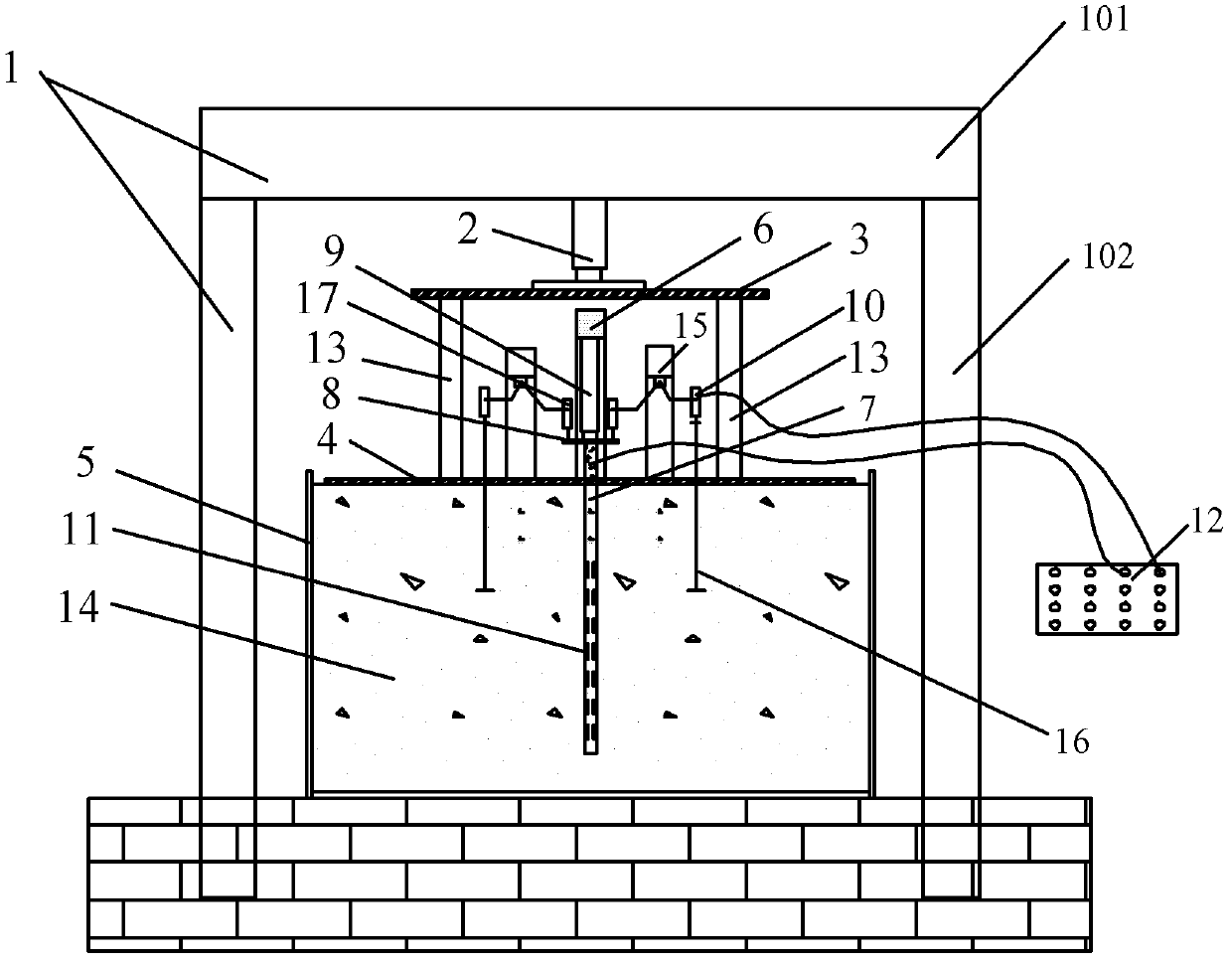

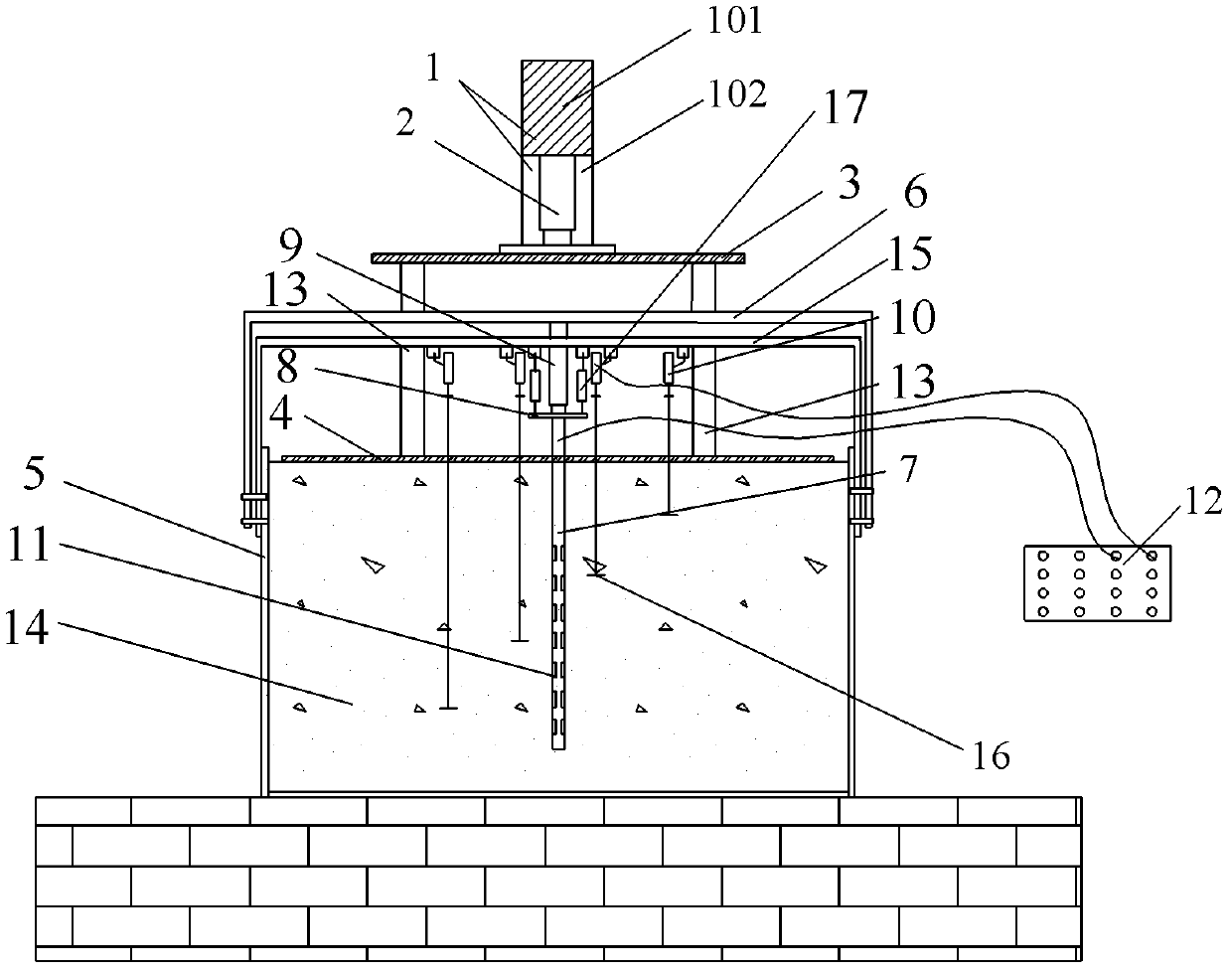

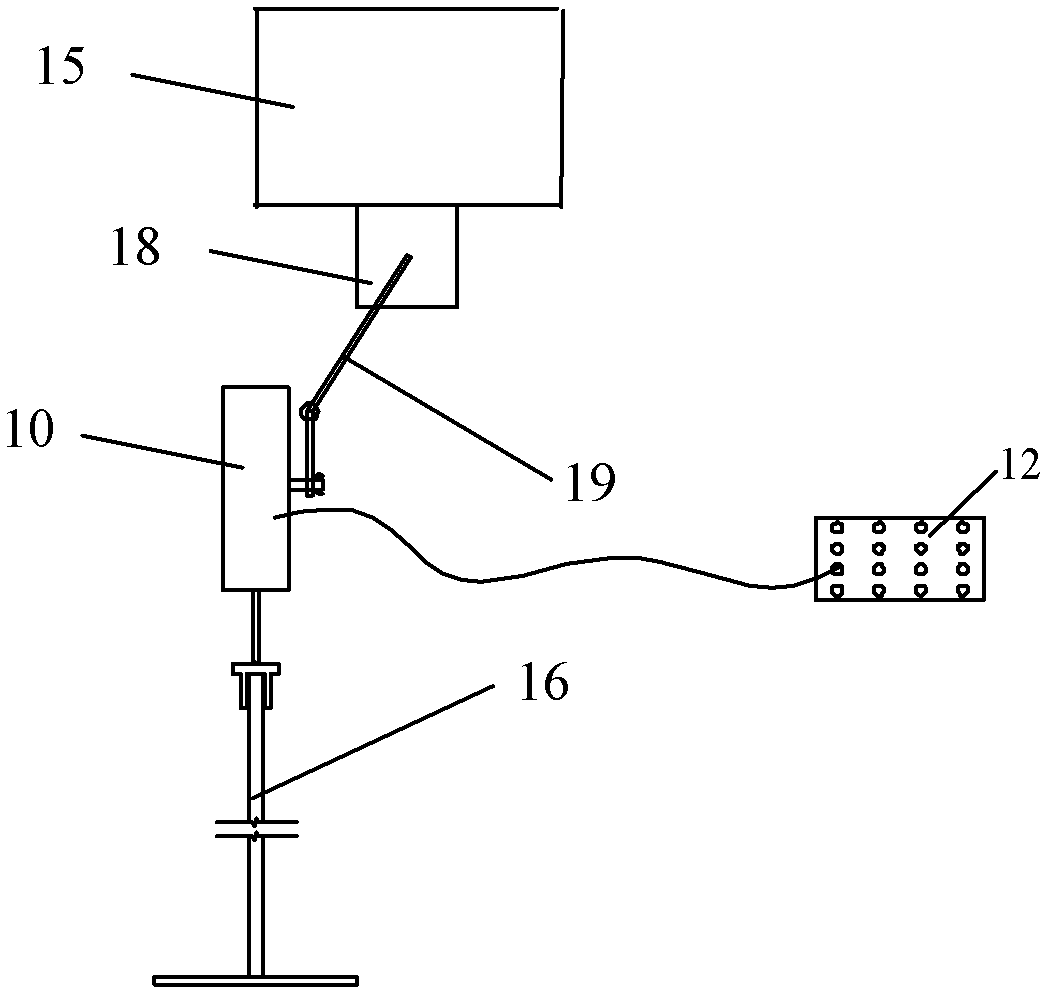

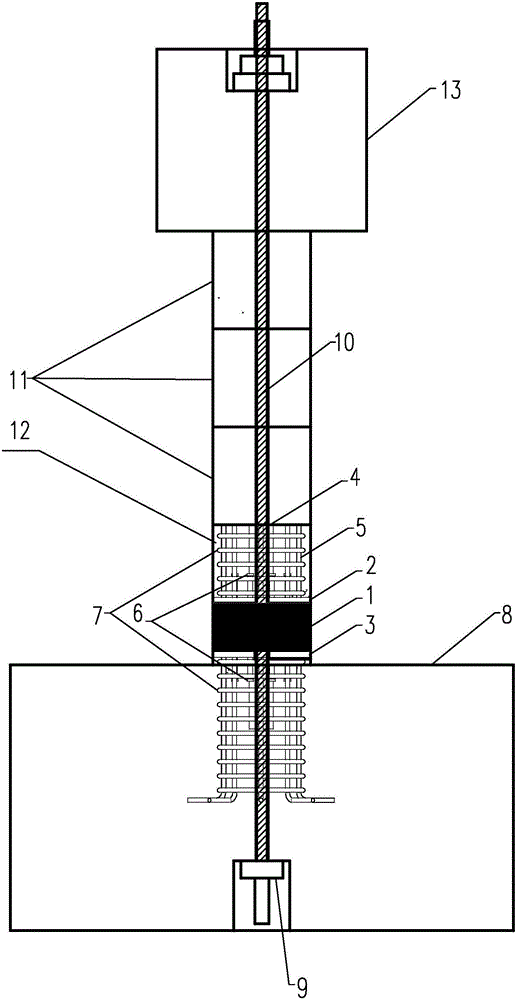

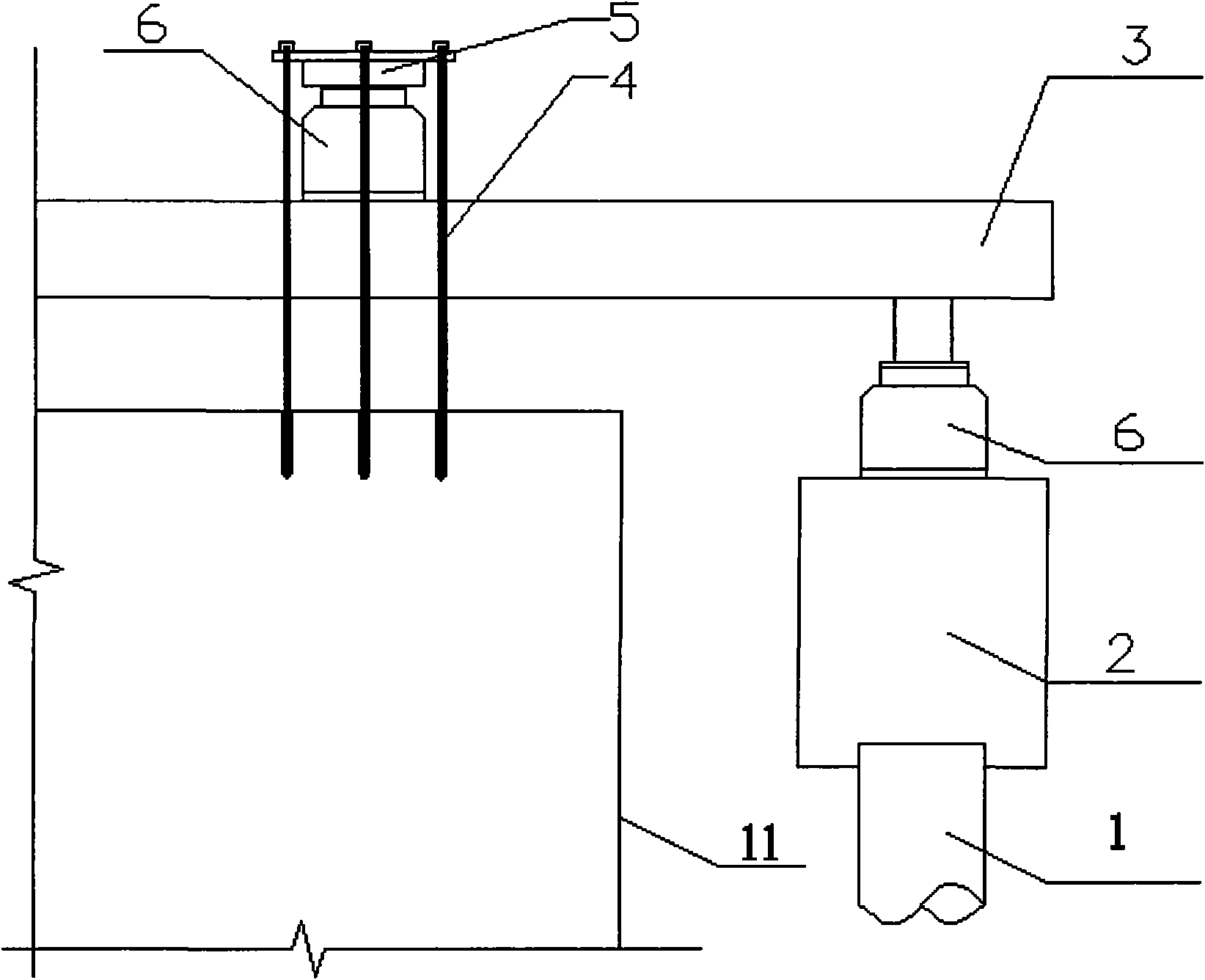

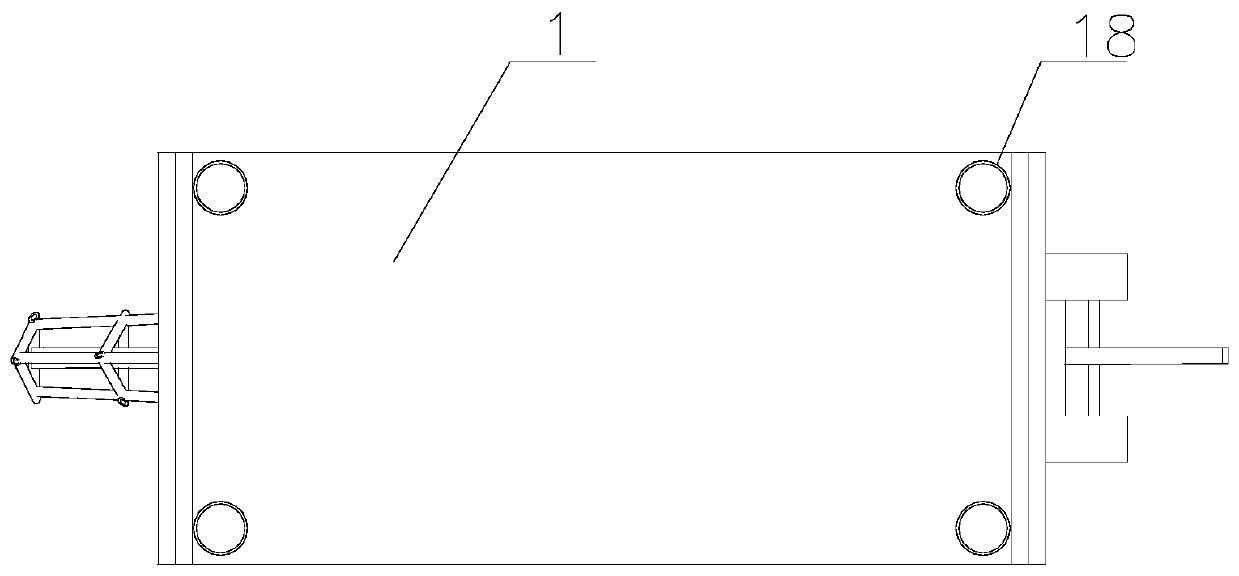

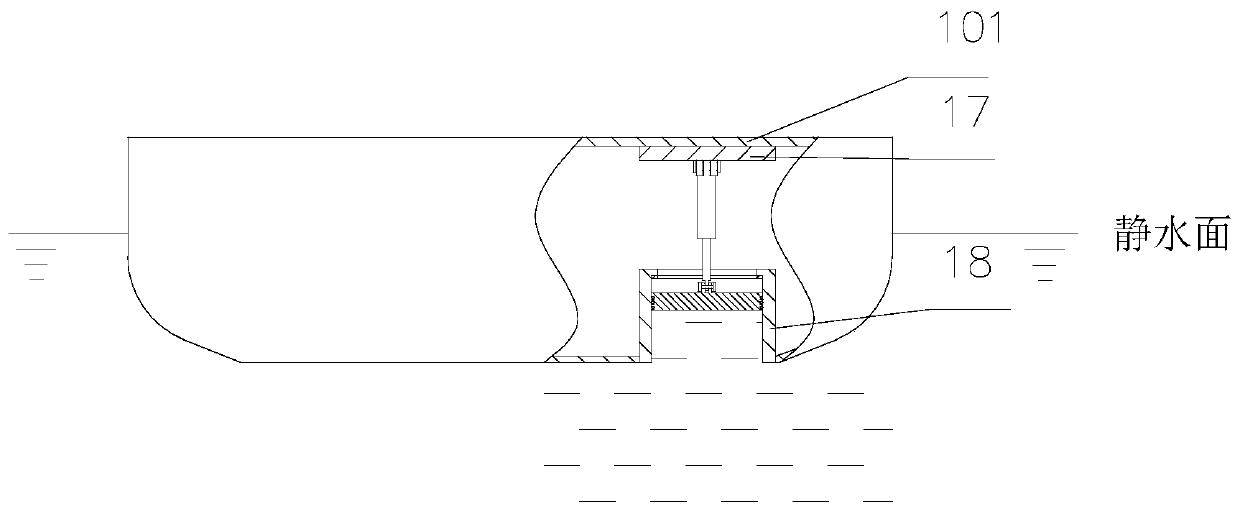

Device for measuring negative skin friction of pile soil

InactiveCN102607754AEasy to settleObvious negative frictionApparatus for force/torque/work measurementSoil sciencePile cap

The invention discloses a device for measuring negative skin friction of pile soil. The device comprises a first counter-force device, an upper jack, an upper loading plate, a lower loading plate, a test box body, a second counter-force device, a model pile, a pile cap, a lower jack, a first displacement sensor, a strain foil, a strain acquisition instrument, a balance beam, a subsidence mark and a second displacement sensor, wherein the lower loading plate is located on an upper surface of a soil body of the test box body; the top end of the model pile penetrates out of a through hole of the lower loading plate; the pile cap is located above the model pile; the lower jack is fixedly arranged on the top face of the pile cap; the upper loading plate is located above the second counter-force device; the upper jack is fixedly arranged on the top face of the upper loading plate; the subsidence mark is located in the soil body of the test box body; the first displacement sensor is located on the top end of the subsidence mark; the second displacement sensor is located on the top face of the pile cap; and the strain foil is attached to the surface of the model pile and is connected with the strain acquisition instrument. According to the measuring device, the jacks are utilized to load the soil body and the model pipe, so that a loading value is obtained, and the accuracy of negative skin friction measurement is ensured.

Owner:SOUTHEAST UNIV

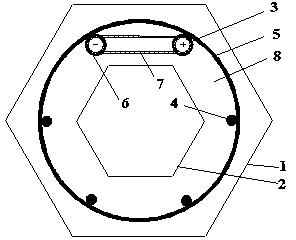

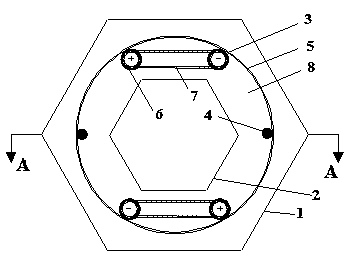

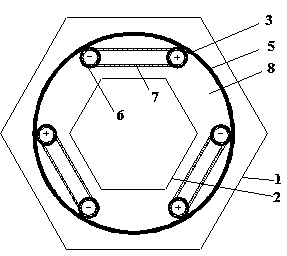

Method for constructing road swivel bridge and railway swivel bridge by using turnplate spherical hinge

ActiveCN101818482AConstruction safetySimple and fast operationBridge erection/assemblyPile capThree stage

The invention relates to a method for constructing a bridge, in particular to the method for constructing a road swivel bridge and a railway swivel bridge by using a turnplate spherical hinge, which aims to solve the problems of the complex process, inconvenient construction, high requirements on construction sites, and the like of the conventional swivel bridge construction. The method specifically comprises the following steps of: machining the turnplate spherical hinge; constructing a lower pile cap and mounting a lower spherical hinge and an endless track, wherein the concrete of the lower pile cap is poured in three stages; constructing an upper pile cap and mounting an upper spherical hinge and a support steel cylinder; and after the upper pile cap and the lower pile cap are swiveled in place under the action of the turnplate spherical hinge, pouring rear sealed concrete between the upper pile cap and the lower pile cap. The method has the advantages of the capacity of changing overhead barrier operation into operation on the coast or near the ground, safe and reliable construction, simple and convenient operation, fast implementation and construction cost reduction, is suitable for both straight bridges and curved bridges, and compared with the conventional construction methods, also has the advantages of shortening construction period, saving a part of big construction machinery and labor force and greatly saving construction cost.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

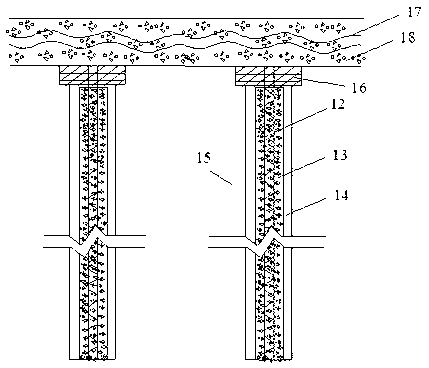

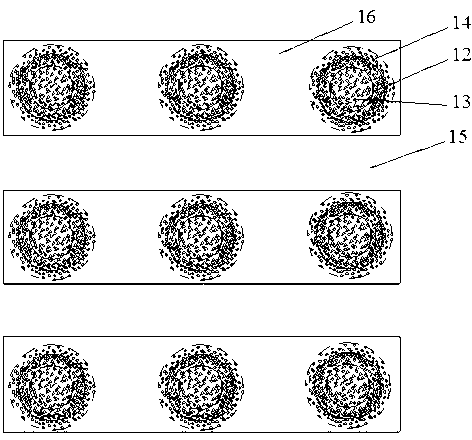

Construction method for precast energy pile

ActiveCN103485332ASolve the loss of densitySolve stacking problemsHeat pumpsBulkheads/pilesPile capArchitectural engineering

A construction method for a precast energy pile is characterized in that a heat transfer tube is embedded into a hollow steel tube, the hollow steel tube replaces a traditional solid reinforcement and serves as a main reinforce ement of the precast pile, and for being connected with the heat transfer pipe in the precast pile, a heat transfer elbow and a heat transfer tube joint are embedded into a precast pile shoe and a precast pile cap. As the heat transfer tube is embedded into the hollow steel tube, the technical problems of mutual interference, poor concrete compactness, reinforcement corrosion, effect on the overall bearing capacity of a pile foundation and the like caused by binding and embedding of the heat transfer tube and the main reinforcement are effectively solved. Moreover, the embedded tube is higher in survival rate, a large number of piles are conveniently stacked and safely transported, construction period is short, and underground space and construction cost are saved.

Owner:HOHAI UNIV

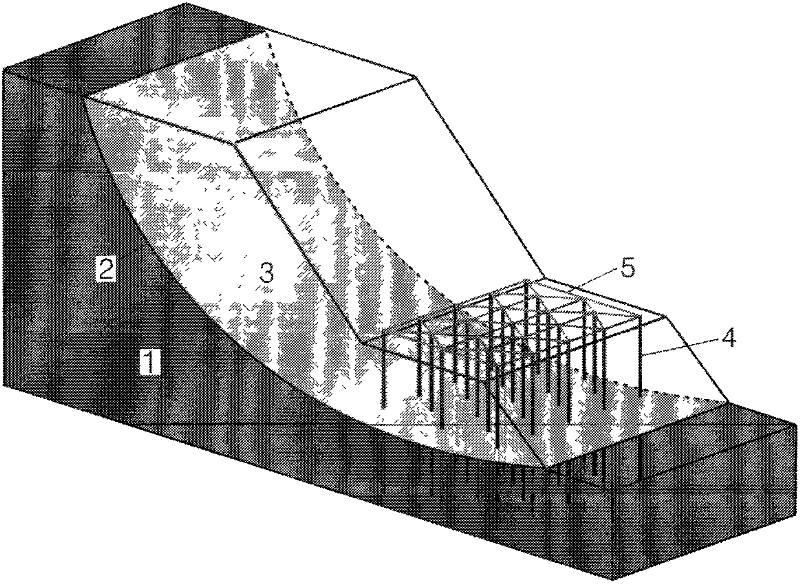

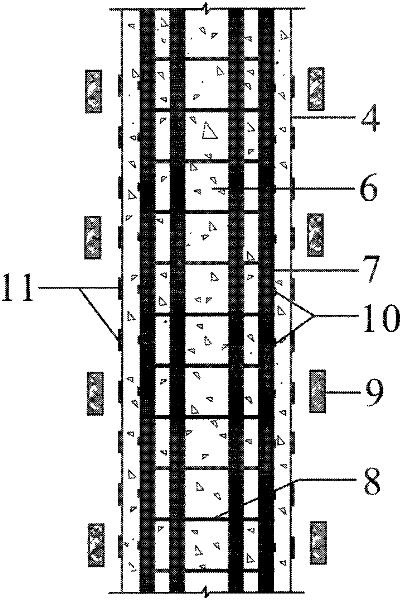

Method for treating soft soil roadbed by artificial composite crust layer

InactiveCN101368383AHigh strengthLow compressibilitySoil preservationPile capArchitectural engineering

The invention discloses a method for processing a soft roadbed through artificial composite crusts, including the following steps: first, constructing micro-piles; second, constructing a construction waste cushion layer; third, constructing pile caps and paving steel-plastic geotechnical grilles; fourth, filling and building a soillime layer; fifth, filling and building a compact clay-doped construction waste layer; and sixth, filling and building a road embankment. The micro-piles is connected with a plastic or hard plastic claypan and a soft plastic claypan; pile caps are arranged on the piles and the steel-plastic geotechnical grilles are connected on the pile caps; the undersides of the steel-plastic geotechnical grilles are connected with the construction waste cushion layer, and the upsides are connected with the soillime layer; and the soillime layer is connected with the compact clay-doped construction waste layer which is finally connected with the road embankment. The method reduces construction cost and environment pollution, realizes utilization of a large amount of construction waste, and remarkably improves the bearing strength and uneven settlement resistance of soft roadbeds. The method is also applicable for soft roadbed treatment in large area in other municipal projects.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

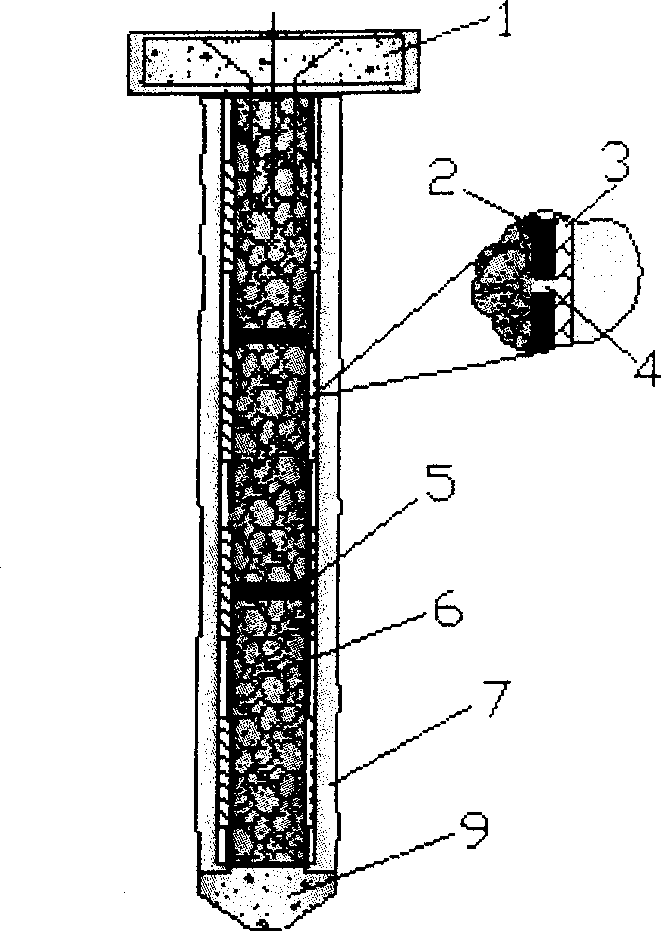

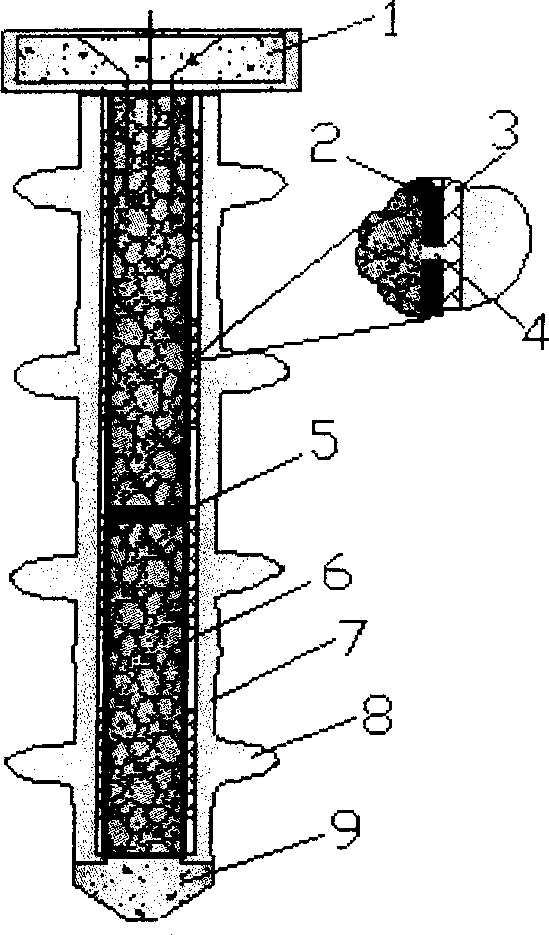

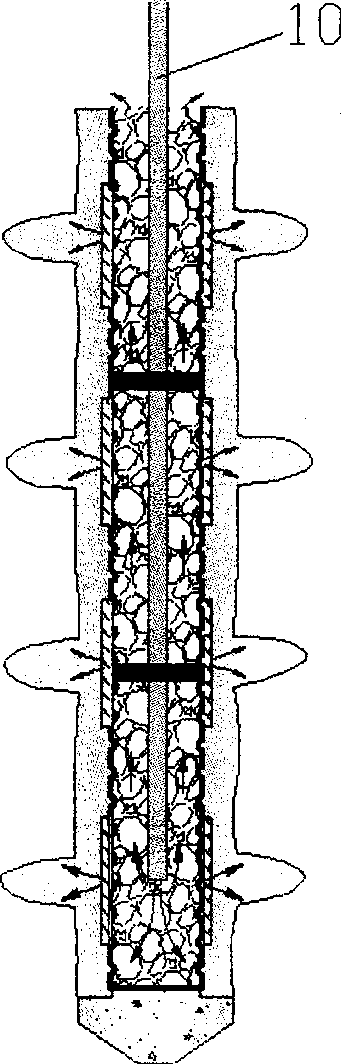

Granule grouting pile of ripple plastic sleeve with hole for strengthening soft soil foundation and strengthening method

The invention discloses a grouting pile of a plastic sleeve for strengthening a soft soil foundation and a pile-forming strengthening construction method thereof. The pile consists of a pile cap, a thread sleeve, an earthwork cloth, a joint, a pile body and a pile tip; the top of the sleeve is connected with the pile cap and the bottom of the sleeve is connected with the pile tip, the side wall of the sleeve is provided with an opening hole, the outside of the sleeve is packed by the earthwork cloth, each section of the sleeve is connected by the joint, and the sleeve is filled with granules and grouted with slurry inside so as to form the pile body and a pile periphery as a slurry spreading zone. The pile-forming strengthening method comprises: connecting the sleeve to the depth of the pile length by the joint and then to the pile tip, placing the sleeve and the pile tip into an immersed tube together, beating the sleeve into a foundation by a beating machine, leaving the sleeve and the pile tip in the foundation, feeding the granules into the sleeve and grouting the sleeve to form a slurry scattered material column, spreading a slurry liquid on the pile periphery to form a spreading zone under the grouting pressure or expanding the earthwork cloth outwards to form a gourd pile body, pouring the pile cap on the pile top, and paving a reinforced material and a gravel cushion after the pile body and the pile cap are dried so as to form a composite foundation. The pile type can strengthen the contact action between the pile and the soil, can improve the bearing capacity of the pile body greatly, and is an ideal pile type for strengthening the soft soil foundation.

Owner:HOHAI UNIV

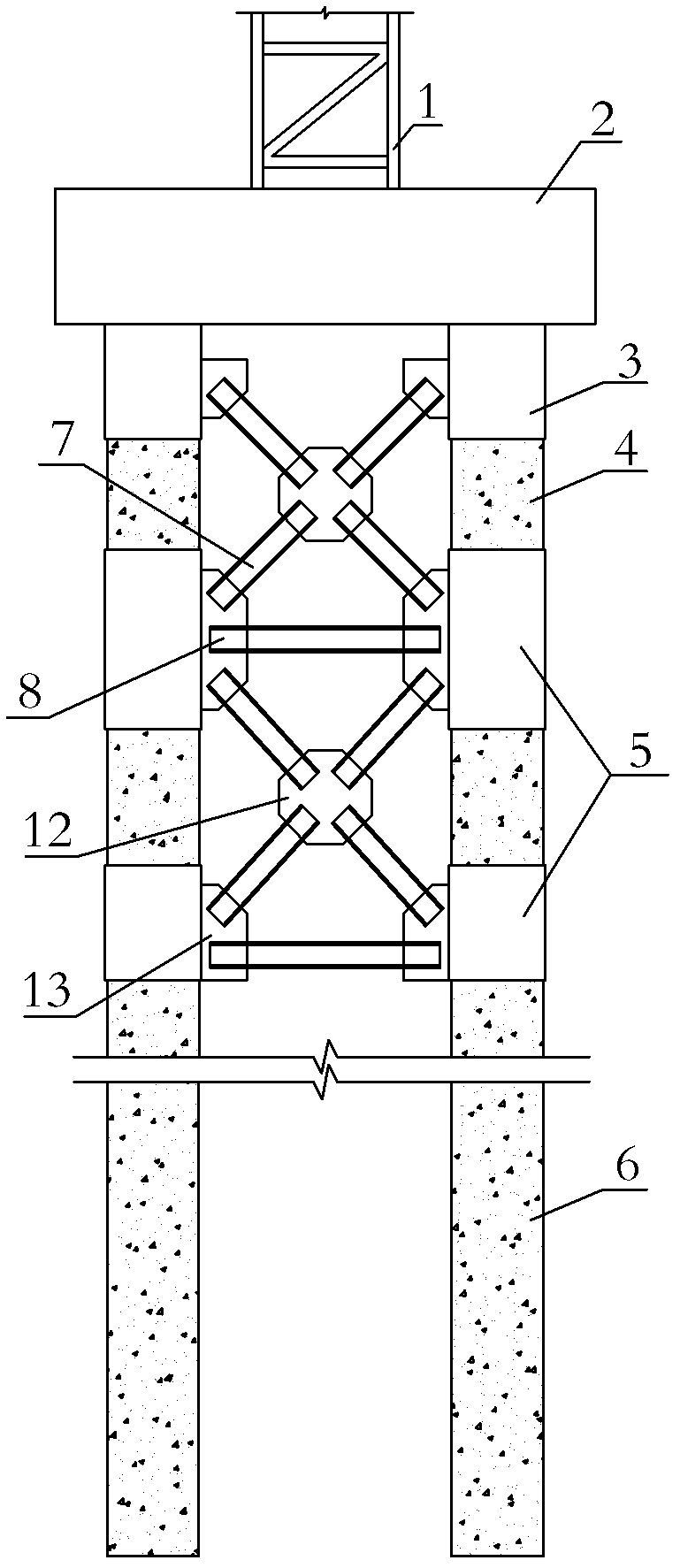

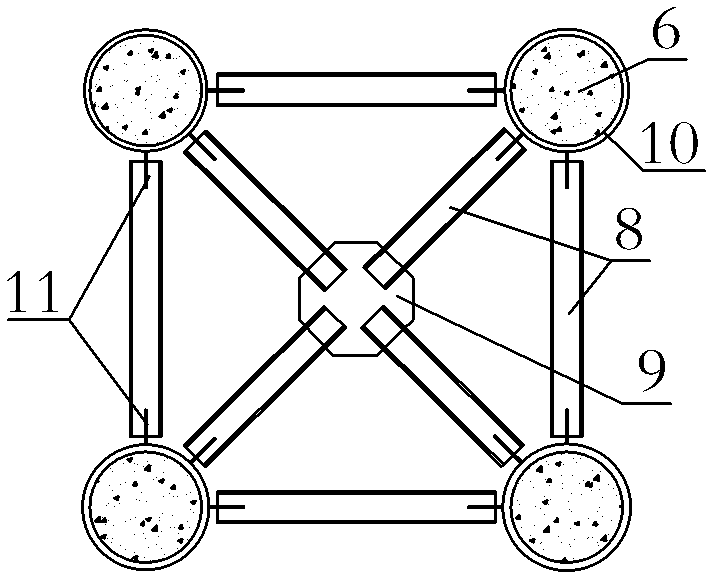

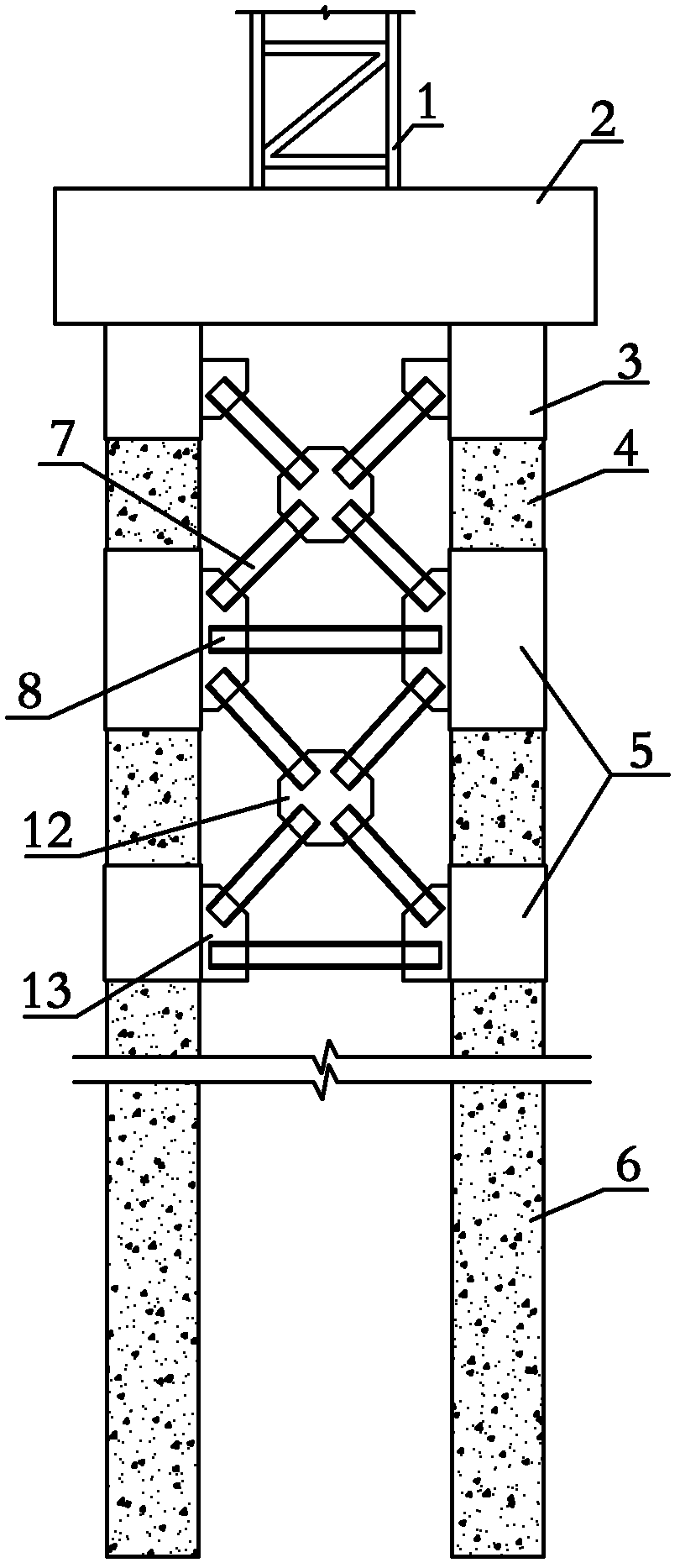

Assembled type pier column member with steel-concrete composite structure

InactiveUS20170356144A1Improve construction progressReasonable and convenient to constructBridge structural detailsBridge erection/assemblyPile capPre stress

A segment-assembled type pier column member with a steel-concrete composite structure includes a reinforcement tube embedded in a pile cap, wherein the reinforcement tube is connected with a bottom of a lower segment of a hollow steel tube pier and is poured with concrete, and pier columns in upper and lower segments are reinforced by means of segment connecting and being embedded with local reinforcing meshes. A steel cross beam is connected with an upper segment of the hollow steel tube pier in an assembled way. A pre-stressed tensioning duct is reserved between the steel cross beam and the pier column in the upper segment.

Owner:HOHAI UNIV

High polymer material slurry filled discrete material pile composite foundation and construction method thereof

The invention discloses a high polymer material slurry filled discrete material pile composite foundation and a construction method thereof. A discrete material pile is filled in a soft soil foundation through a vibrating immersed pipe, a rigid injection pipe is embedded in advance in the middle of the discrete material pile, a barrel-shaped cover plate is embedded on the top of the discrete material pile, and high polymer material slurry is sprayed to the discrete material pile at high pressure through a slurry injection system. The high polymer material slurry is filled in the clearance of the discrete material pile and splits to permeate into pile soil, so that the discrete material pile body is engaged and contacted with the soil around the discrete material pile, and the friction coefficient of the pile-soil contact surface is effectively increased. Bar pile caps are poured on the top which is formed by a high polymer material slurry filled discrete material pile body, a high polymer material slurry filled soil body and the pile soil. A high polymer material is insoluble and has certain expansibility. In the process of spraying at high pressure, water in a part of the soil body is discharged through a passage of the discrete material pile. The high polymer material slurry filled discrete material pile composite foundation has the advantages of simple construction process, strong operability, convenience in quality control, good engagement effect of the pile-soil contact surface, obvious economic benefit and significant effect for reinforcing the soft soil foundation.

Owner:HOHAI UNIV

Active pile foundation underpinning structure and constructing method thereof

The present invention provides one kind of active pile foundation underpin structure, which includes a new underpin pile with pile cap and an underpin beam slab, and has a lifting jack on the pile cap for pre-lifting and unloading the underpin beam slab so as to transfer the load from the pile to be underpinned to the newly constructed underpin structure and realize force conversion. The present invention also provides the construction process of the active pile foundation underpin structure. The present invention makes it possible to control actively the deformation of the upper building to be underpinned, and is suitable for pile foundation underpin with great axial force.

Owner:铁道第二勘察设计院 +1

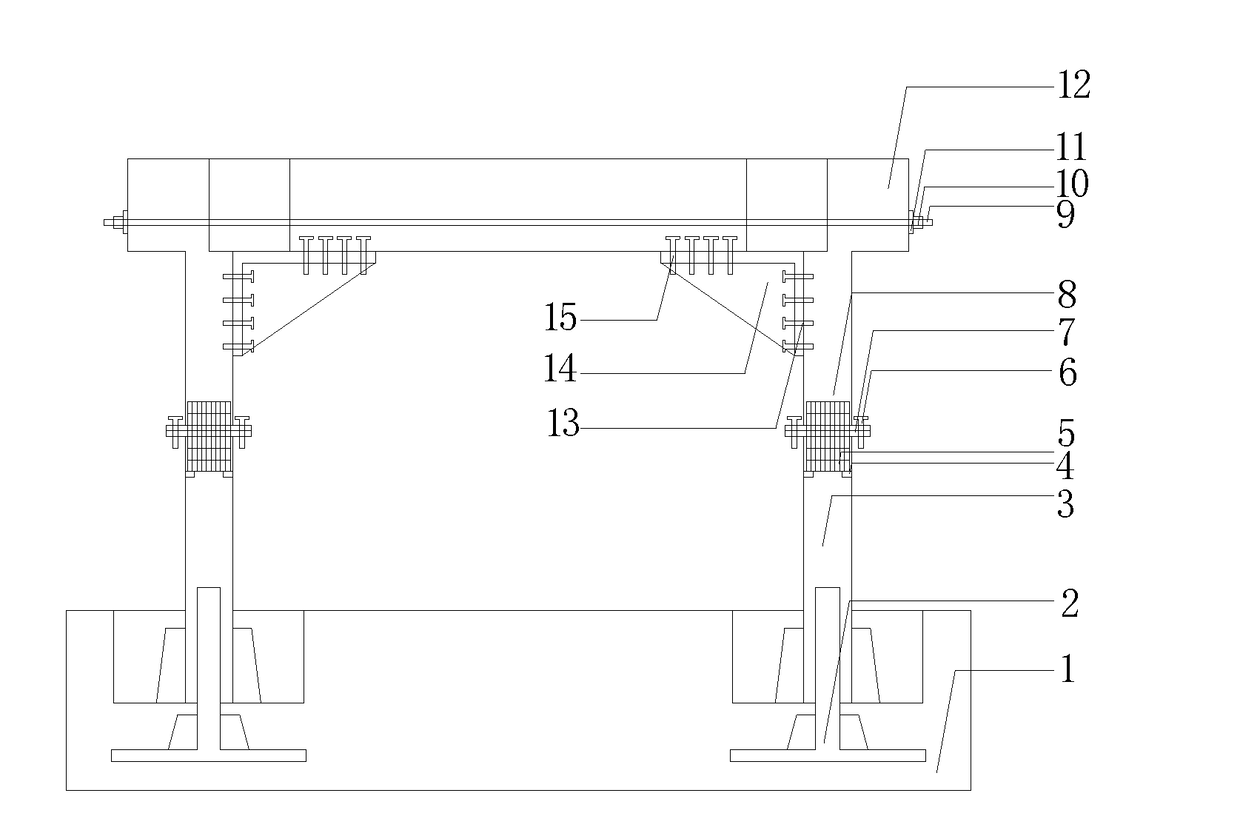

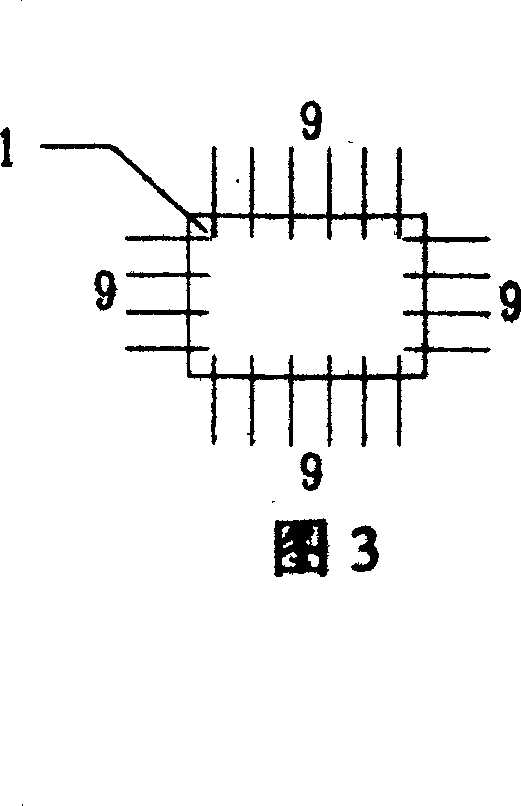

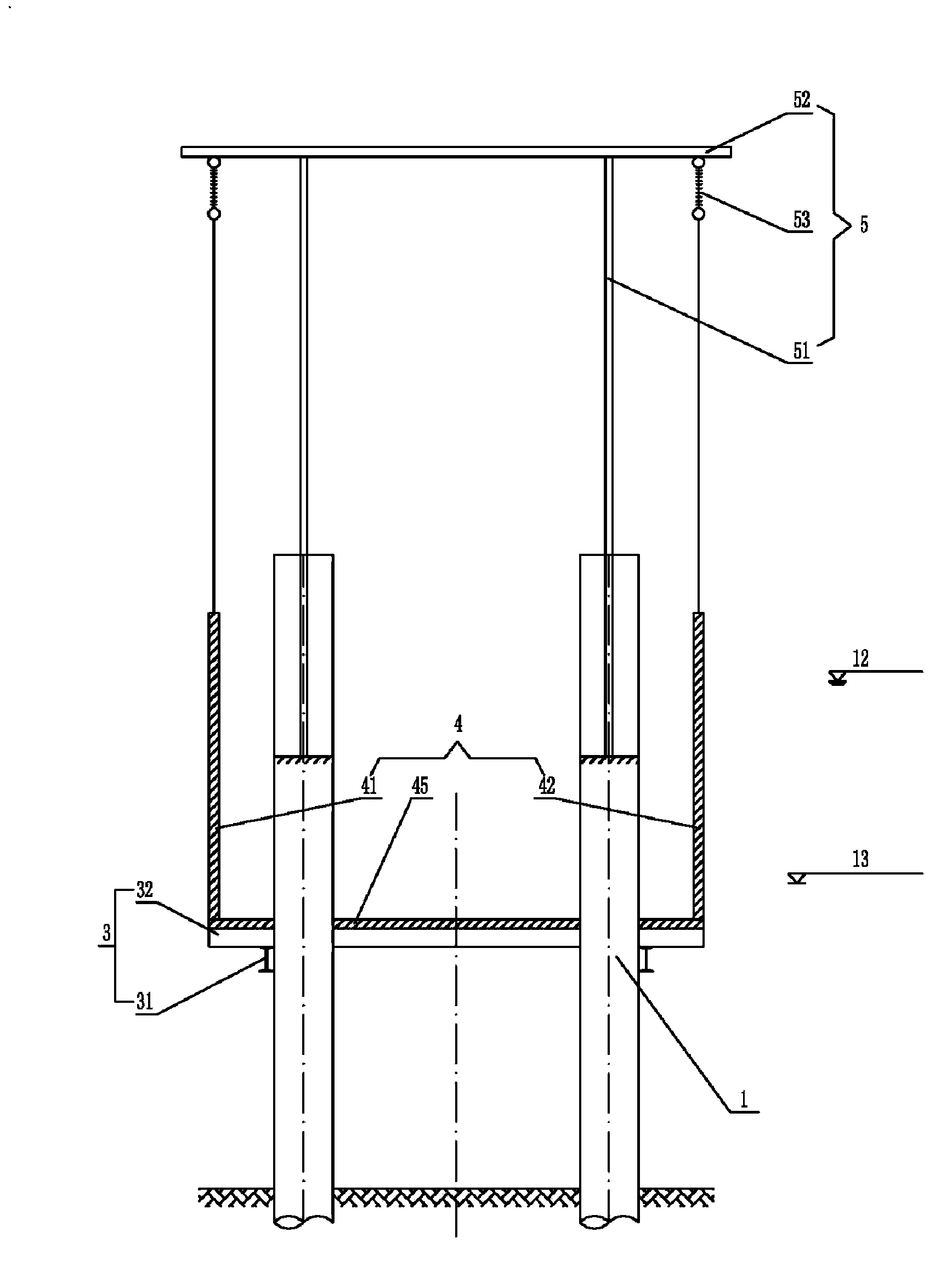

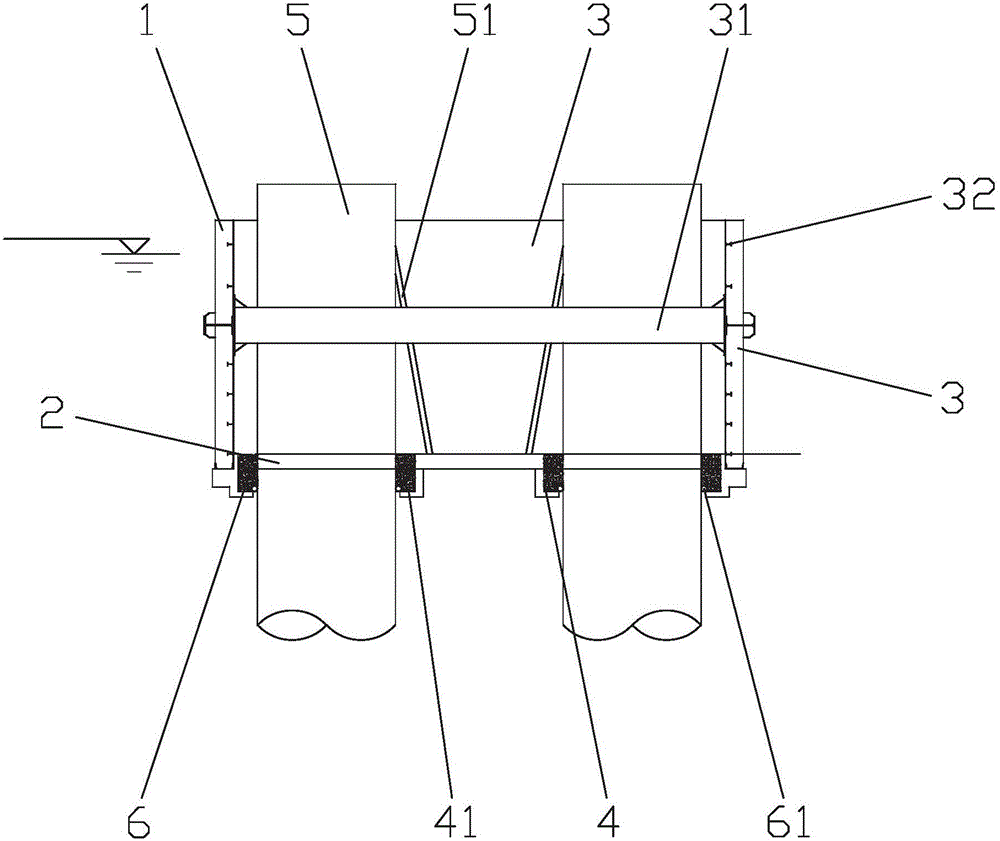

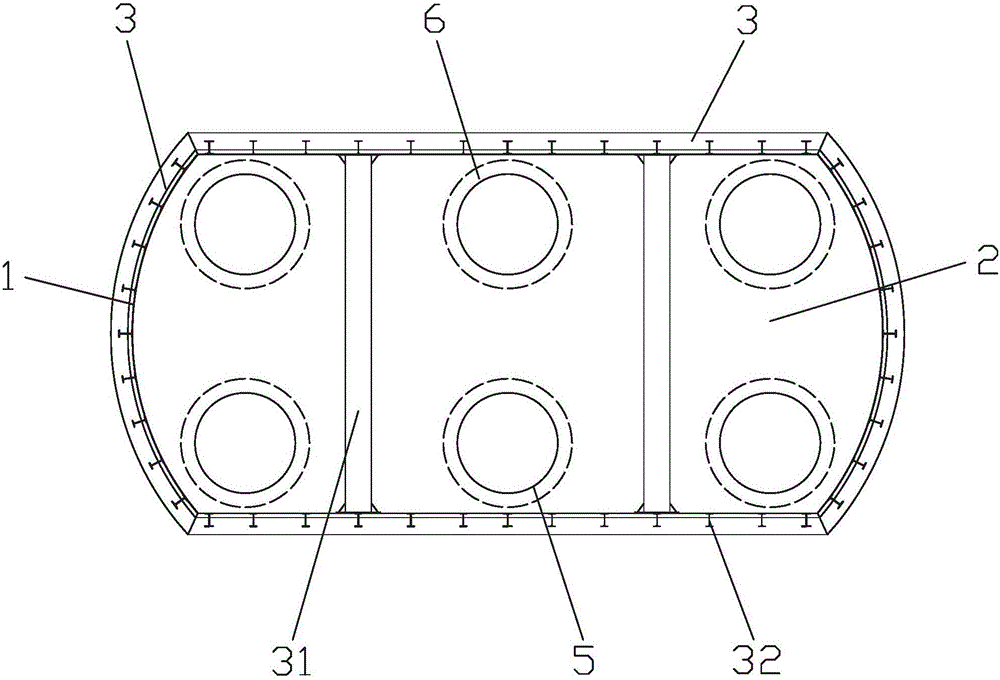

Steel hanging box system for underwater high-rise pile cap construction and construction technology thereof

ActiveCN103510529AReduce construction costsImprove construction progressBridge erection/assemblyCaissonsPile capWater level

The invention relates to a steel hanging box system for underwater high-rise pile cap construction and a construction technology thereof. The steel hanging box system is composed of a load-bearing beam component, a steel hanging box, a suspension system and brackets. The first brackets are welded on the positions above a normal water level of four bored pile steel pile casings, and the first brackets are used for supporting to splice the steel hanging box. The steel hanging box is hung through the suspension system which is supported on the inner pile tops of the bored pile steel pile castings, the supporting first brackets are cut off, the steel hanging box is sunk to a designed elevation, a bottom seal concrete layer is poured in the steel hanging box, water in the steel hanging box is pumped completely, in the state of being free of water, the second brackets are welded to the four bored pile steel pile castings again, the load-bearing beam component, a bottom plate of the steel hanging box and the bottom seal concrete layer are fixedly combined with the second brackets through bolts and bear loads, and at last the concrete layer, a bearing platform and a bridge pier are leveled through construction. According to the steel hanging box system for the underwater high-rise pile cap construction and the construction technology thereof, loads of splicing, lifting and bearing of the steel hanging box are all transmitted to engineering bored piles, the number of auxiliary equipment is reduced, operating is convenient and simple, and cost is saved.

Owner:CCCC THIRD HIGHWAY ENG +1

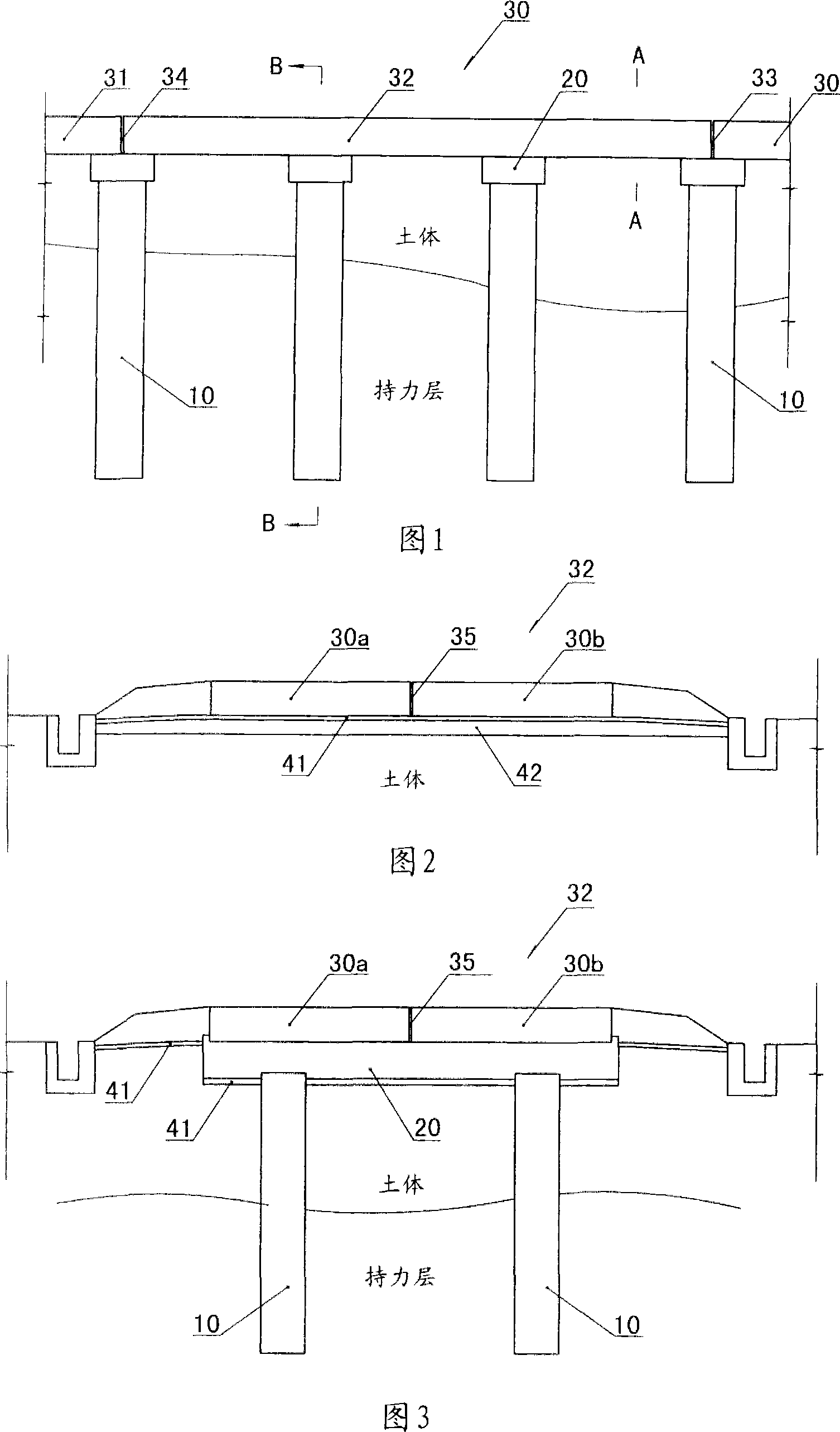

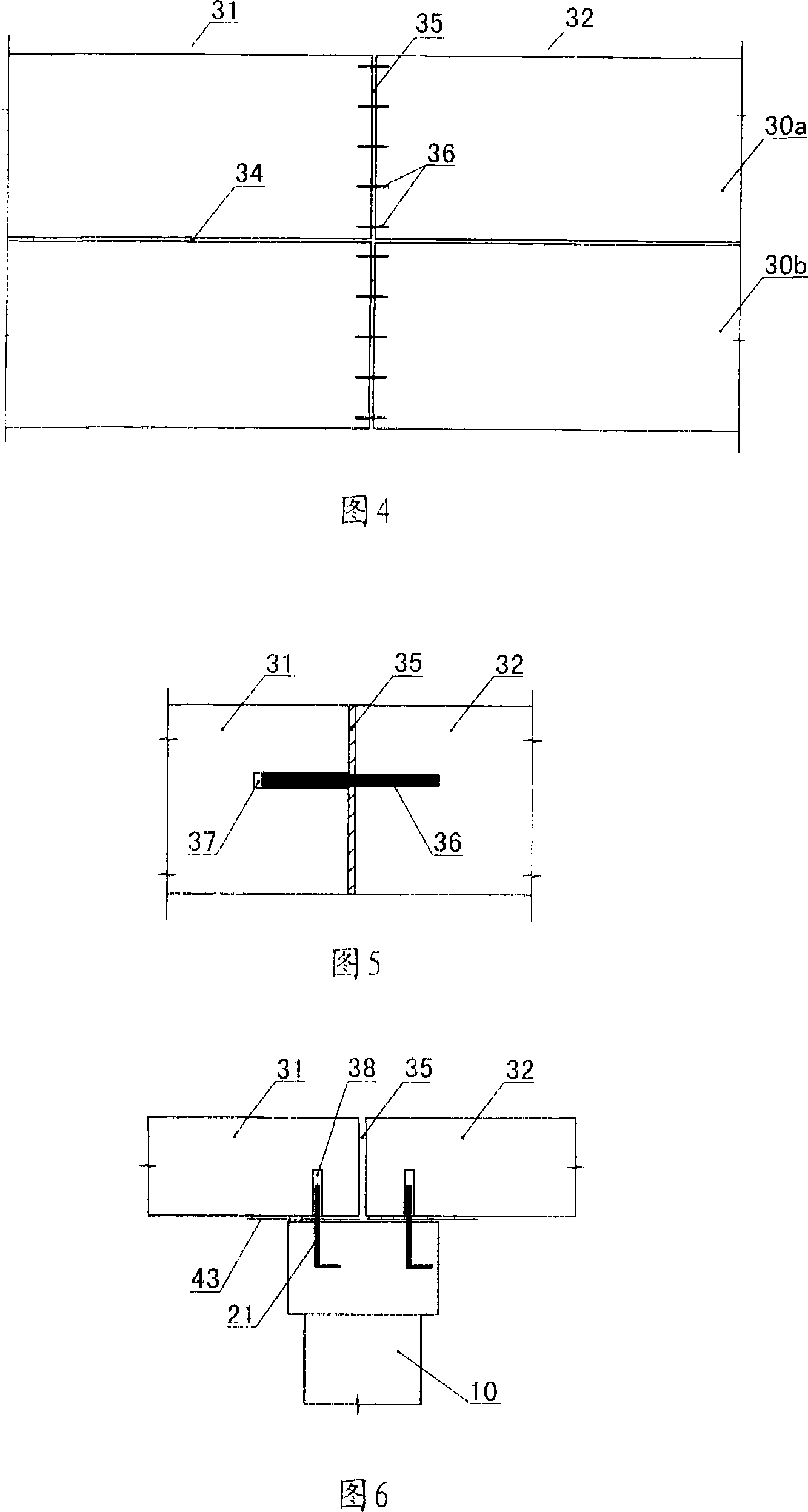

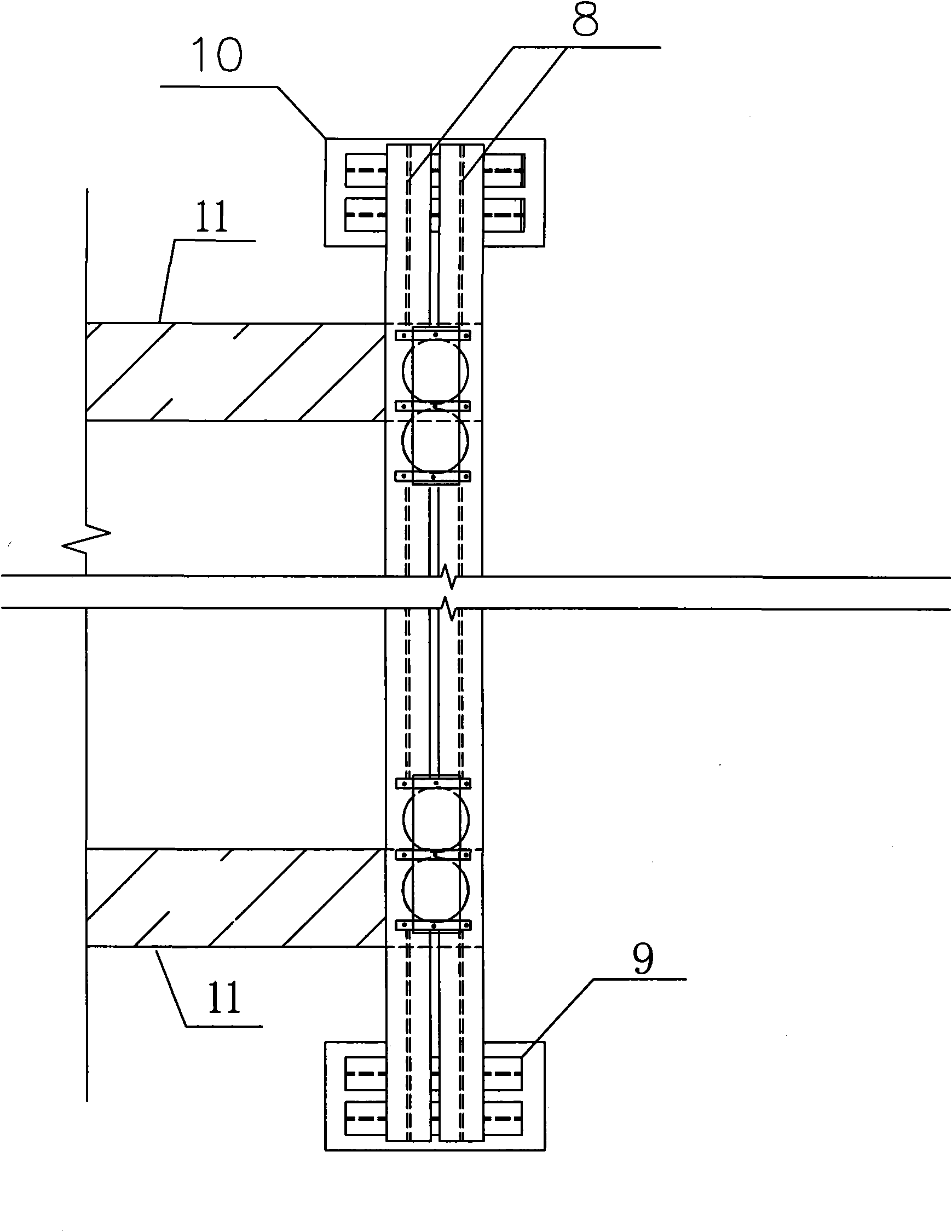

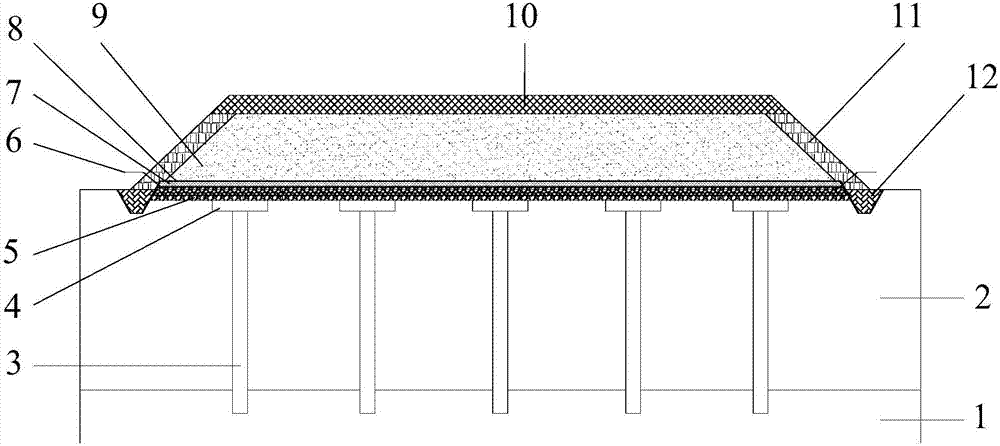

Thick collapsible loess subgrade groundwork structure

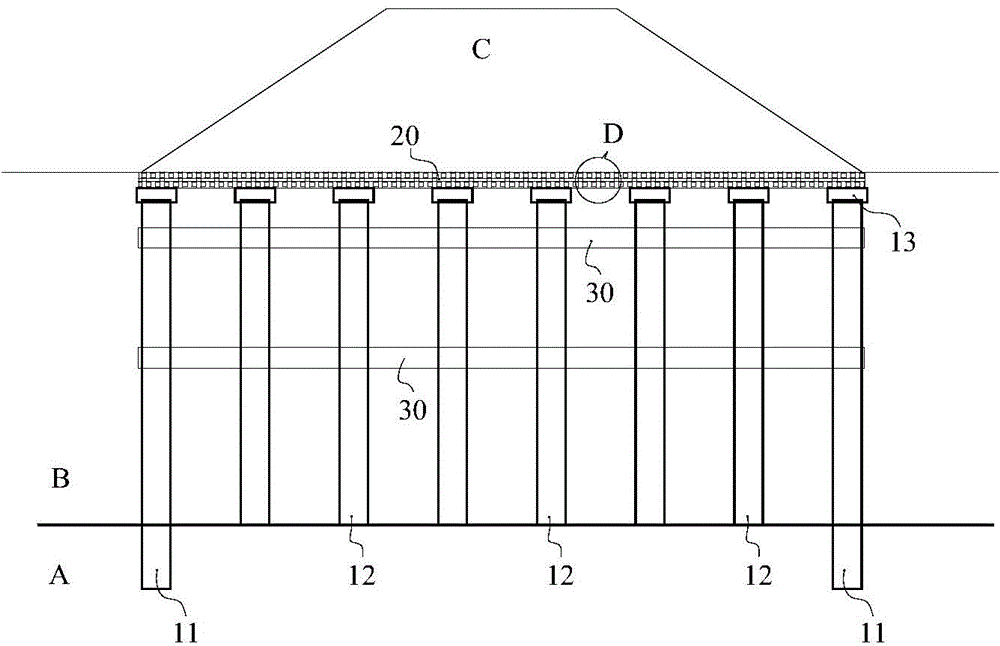

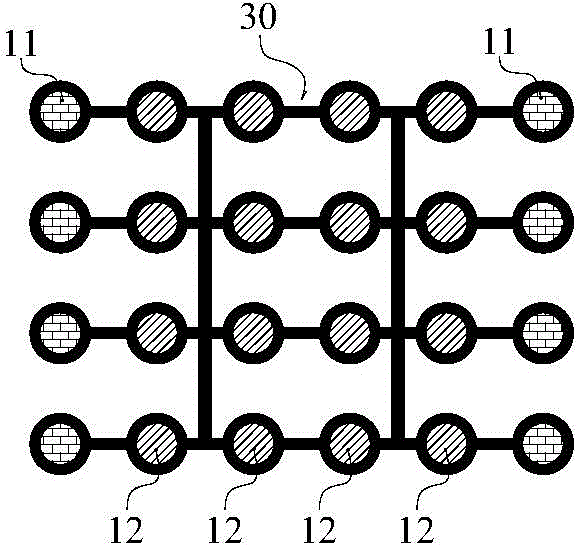

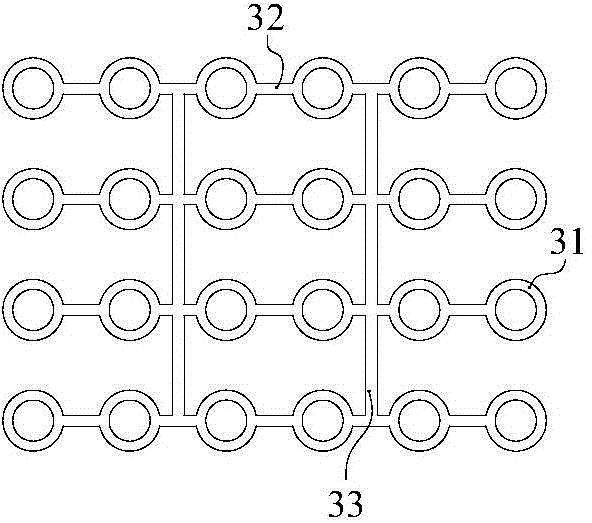

The invention discloses a deep collapsible loess subgrade structure, which can strictly control the post-construction settlement and differential settlement of the collapsible loess and the deep collapsible loess foundation. It includes reinforced concrete pile foundations (10), which are arranged in groups at intervals along the longitudinal direction of the foundation, and the pile bodies are consolidated with the bearing layer after penetrating the soil vertically; The top of the foundation (10) is rigidly connected thereto; the reinforced concrete cap slab (30), extending longitudinally along the foundation, is supported on and connected to the reinforced concrete joist (20). The invention uses the pile-slab system as a reinforcement structure, which has the characteristics of strong adaptability, good overall performance, high rigidity, small deformation, large depth of untreated soil, and convenient construction, and successfully solves the problems of uneven settlement caused by collapsing The technical problem of excessive settlement can well meet the design requirements of passenger-dedicated railways with a design speed of 300-350 kilometers per hour.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

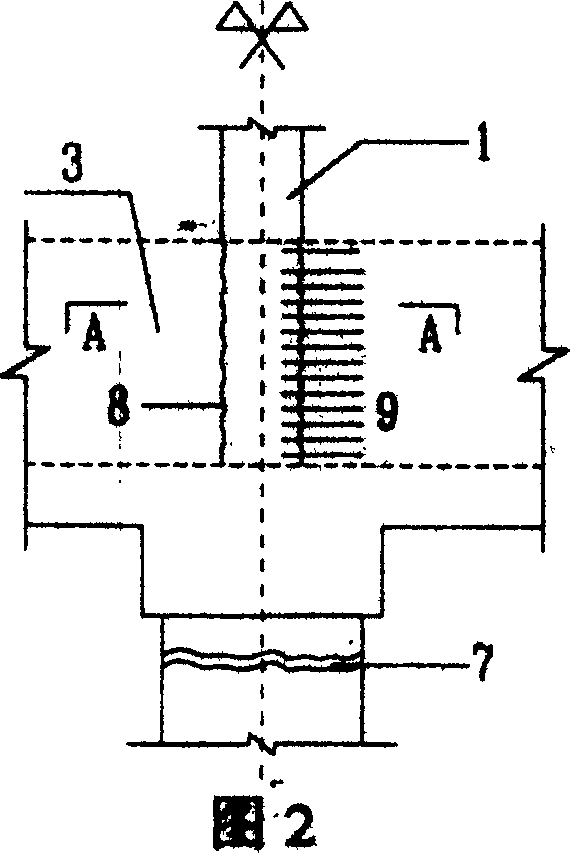

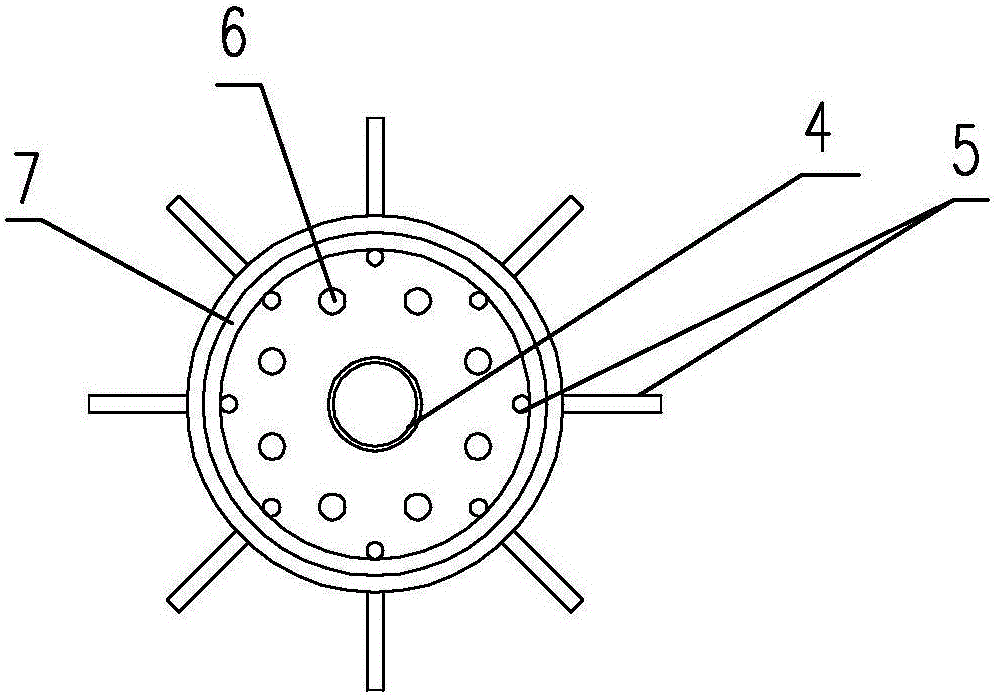

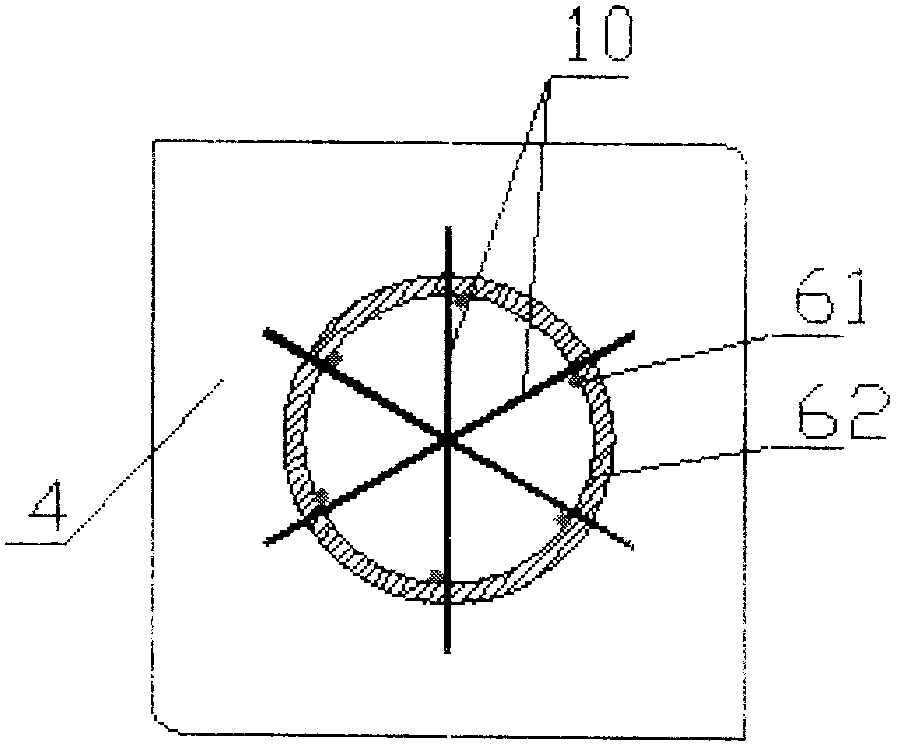

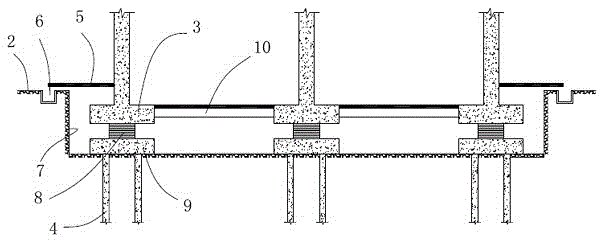

Embedded elastic rubber bearing device and construction method of applying bearing device to connection between prefabricated concrete bridge pier and pile cap

ActiveCN105755952AImprove ductilityConstruction occupies less landBridge structural detailsBridge erection/assemblySheet steelPile cap

The invention provides an embedded elastic rubber bearing device. The embedded elastic rubber bearing device comprises an elastic rubber bearing, an upper reinforcement steel plate and a lower reinforcement steel plate; a post-tensioning pre-stressing penetration steel tube hole is formed in the center of the elastic rubber bearing, and energy-consumption reinforced bar holes for allowing penetration of energy-consumption reinforced bars are formed in the circumference of the elastic rubber bearing; steel tube penetration holes and energy-consumption reinforced bar holes, positions and forms of which are in one-to-one correspondence with steel tube penetration holes and energy-consumption reinforced bar holes in the elastic rubber bearing, are respectively formed in the upper reinforcement steel plate and the lower reinforcement steel plate; in use, a post-tensioning pre-stressing penetration steel tube and energy-consumption steel tubes respectively and sequentially penetrate through the steel tube penetration holes and the energy-consumption reinforced bar holes formed in the upper reinforcement steel plate, the elastic rubber bearing and the lower reinforcement steel plate; the upper reinforcement steel plate and the lower reinforcement steel plate are respectively closely adhered to the upper surface and the lower surface of the elastic rubber bearing; shear studs are annularly welded between the penetration steel tubes and the energy-consumption reinforced bars of the upper reinforcement steel plate and the lower reinforce steel plate, and stirrups are annularly arranged on the outer sides of the energy-consumption reinforced bars. The construction method, which is provided by the invention, provides an anti-seismic energy-consumption connection method for cast-in-place reinforced concrete pile caps and piers.

Owner:LIUZHOU OVM MASCH CO LTD

Process method for rectifying deviation of open caisson by jacking balance of jack

The invention provides a process method for rectifying the deviation of an open caisson by the jacking balance of jack, which comprises the following steps: knocking pre-stressed tubular piles into the four corners of a concrete box at the short-direction side as stress points; preventing the lower end of the concrete box from sinking in digging by an unloading device which comprises a pile cap, a steel truss, hydraulic jacks and a replaceable component; digging the subsoil at the high end of the concrete box to cause the lower foundation of the concrete box to have new inverse and non-uniform sinking; slowly sinking the concrete box to a designed elevation by adjusting the jack stroke and the replaceable component of the unloading device step by step; and replacing all the jacks by the replaceable component. The method can effectively solve the problem of non-uniform sinking of an open caisson in rectifying the deviation of the open caisson, and dynamically control the sinking of open caissons. The method is especially suitable for rectifying the deviation of open caissons in flow plastic muddy soil.

Owner:GUANGZHOU NO 2 MUNICIPAL ENG CO LTD

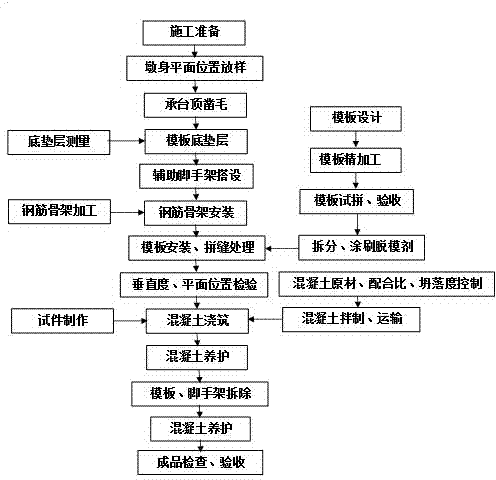

Construction method for pouring and forming urban viaduct curve type pier stud in one-off mode

InactiveCN104846744AQuality improvementHigh precisionBridge structural detailsBridge erection/assemblyFalseworkPile cap

The invention discloses a construction method for pouring and forming an urban viaduct curve type pier stud in a one-off mode. The construction method includes the following steps of 1 positioning pier stud pre-buried main reinforcement, 2 chiseling the combined portion of a pier body and a pile cap, 3 staking out in survey, 4 putting up a scaffold, 5 machining and installing reinforcement, 6 machining and installing a formwork, 7 pouring concrete, 8 disassembling the formwork and curing, and 9 removing the scaffold. According to the construction method for pouring and forming the urban viaduct curve type pier stud in the one-off mode, the pier stud has the advantages of being fast to construct, reasonable in structure, economical, practical and the like and is widely applicable to an urban high-pier bridge, particularly an urban high-pier landscape bridge.

Owner:NANTONG UNIVERSITY

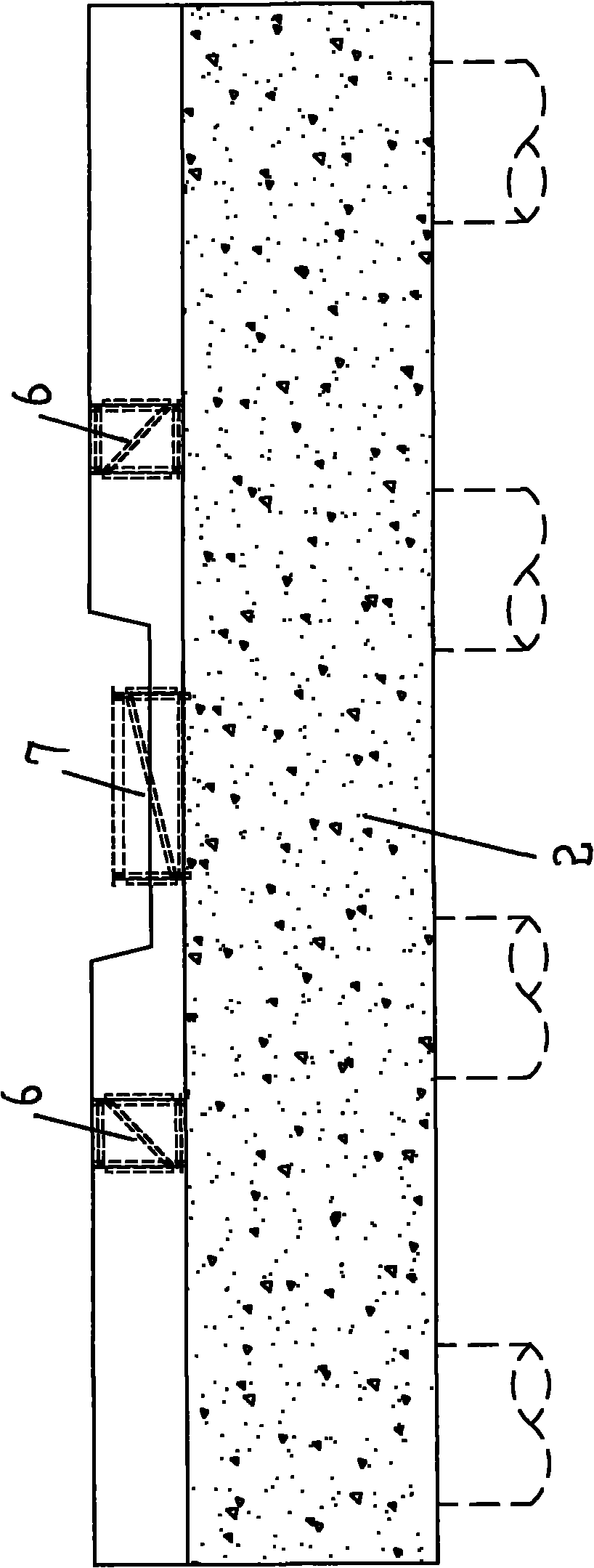

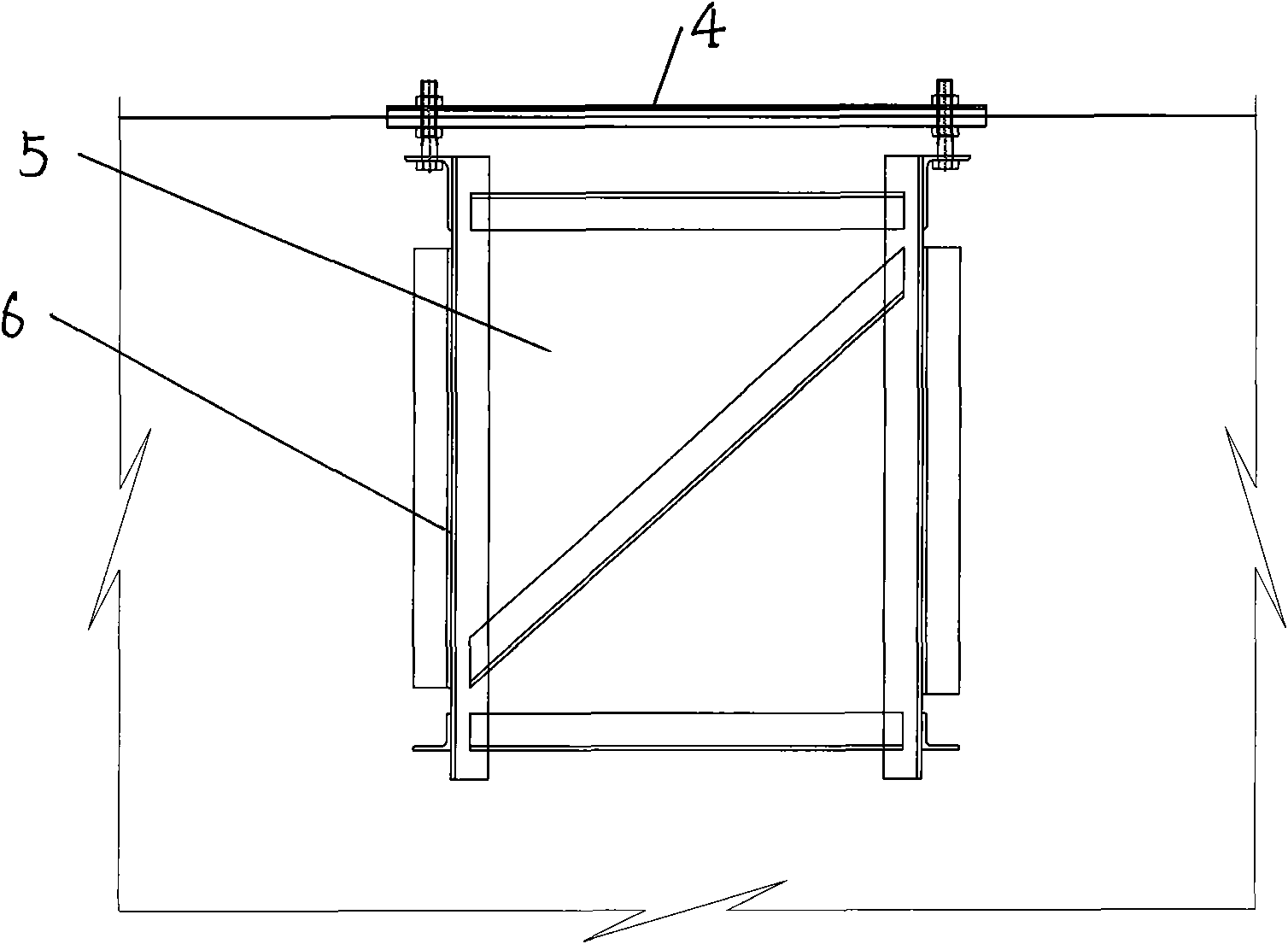

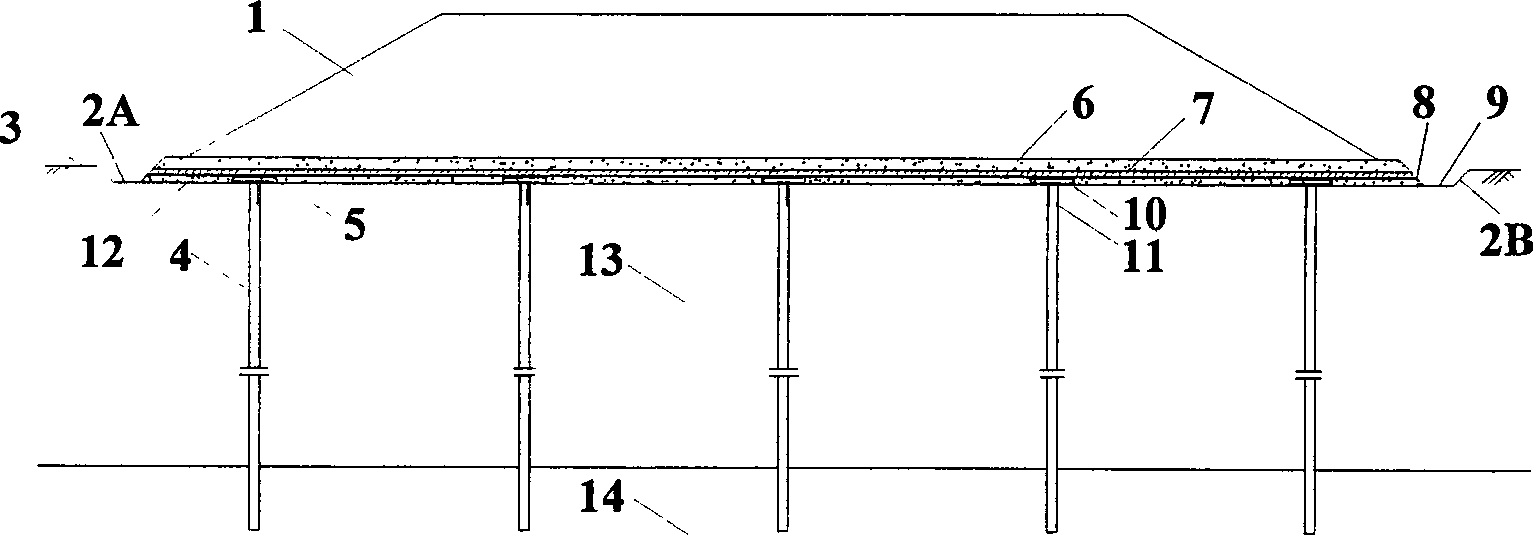

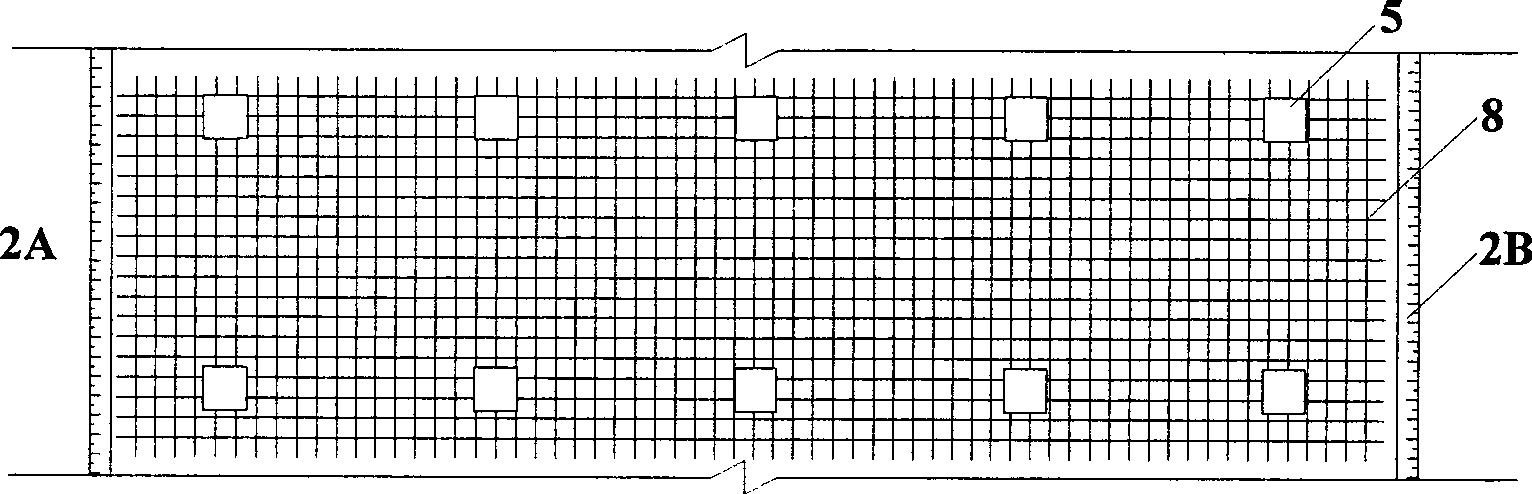

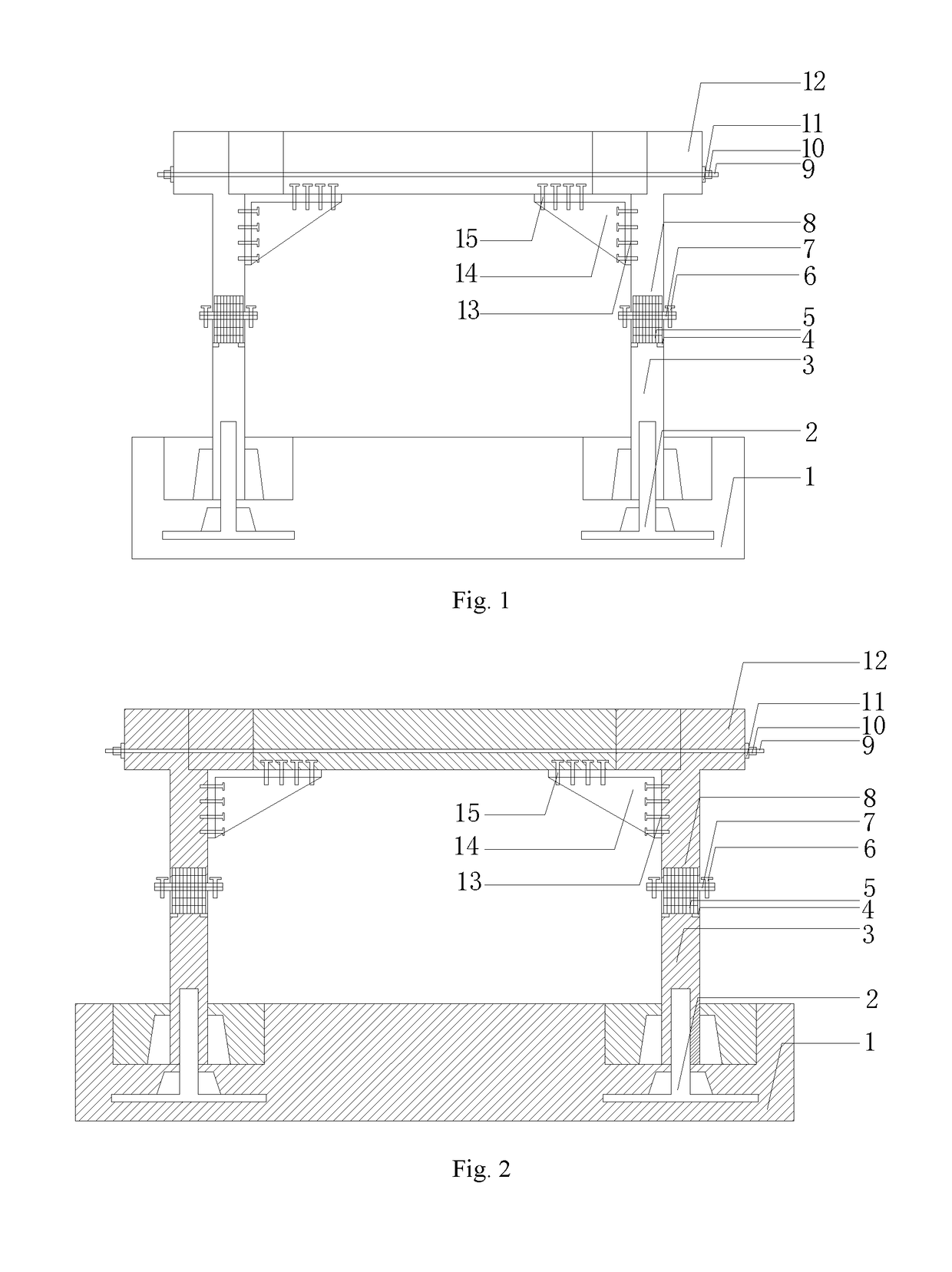

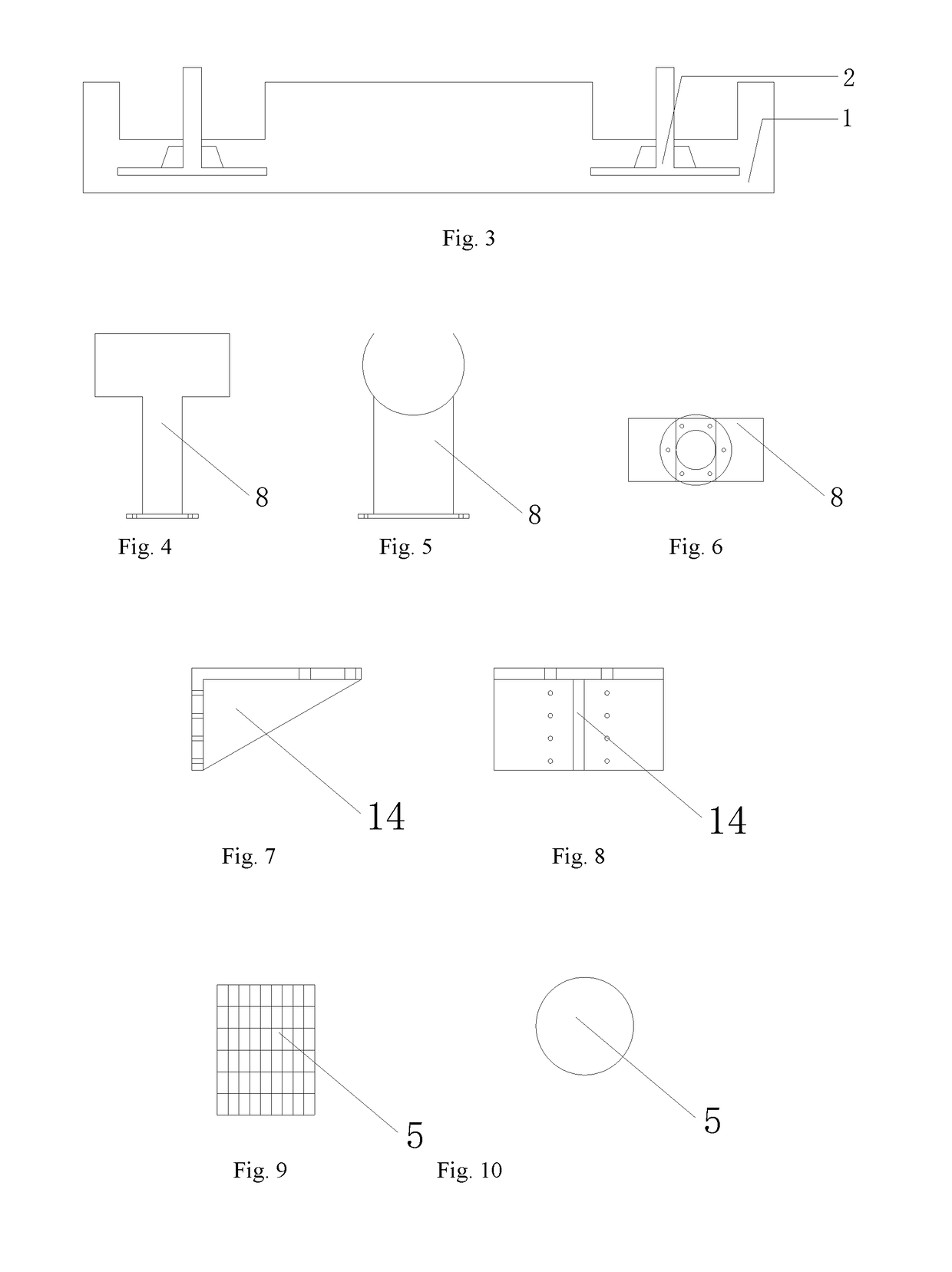

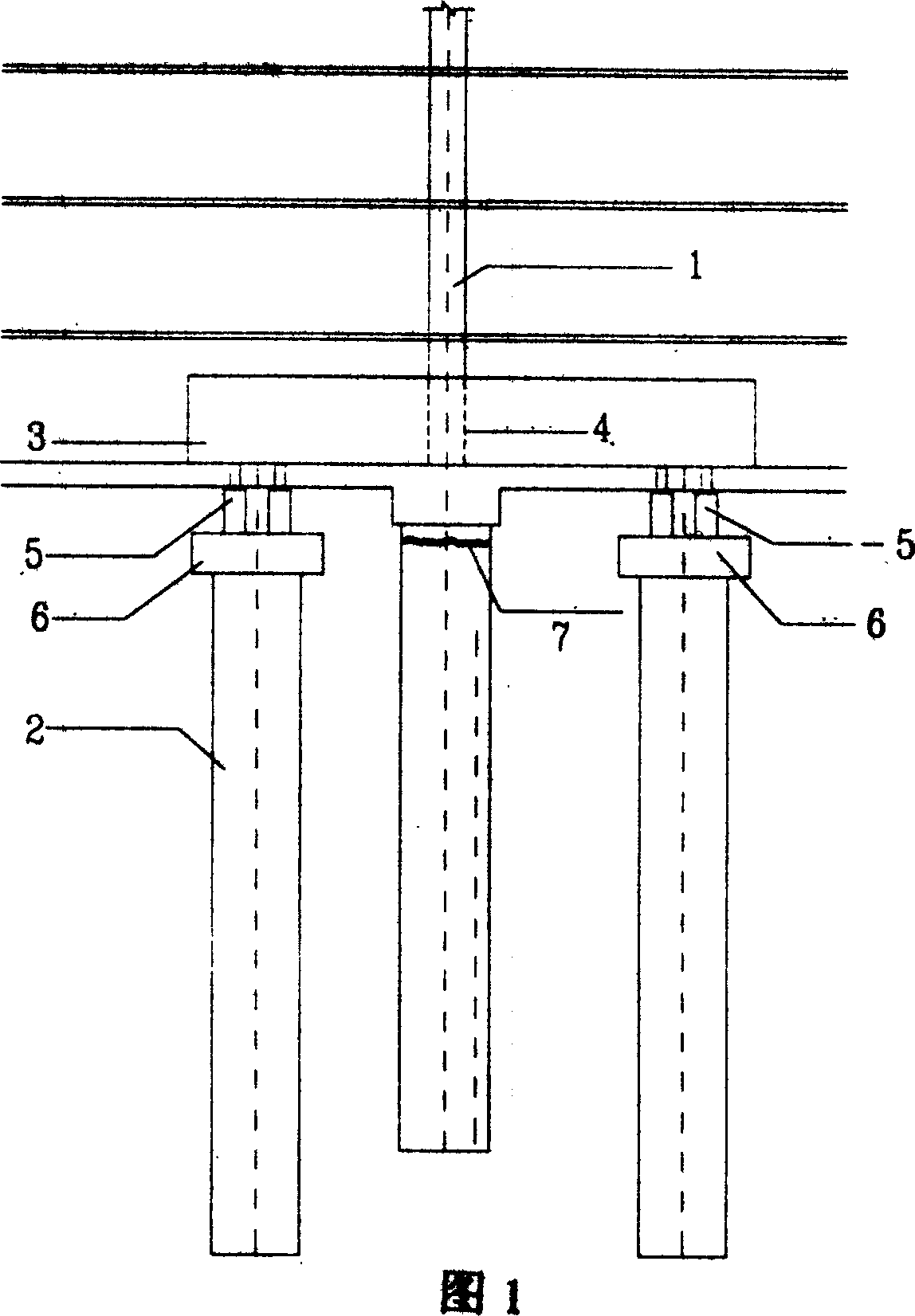

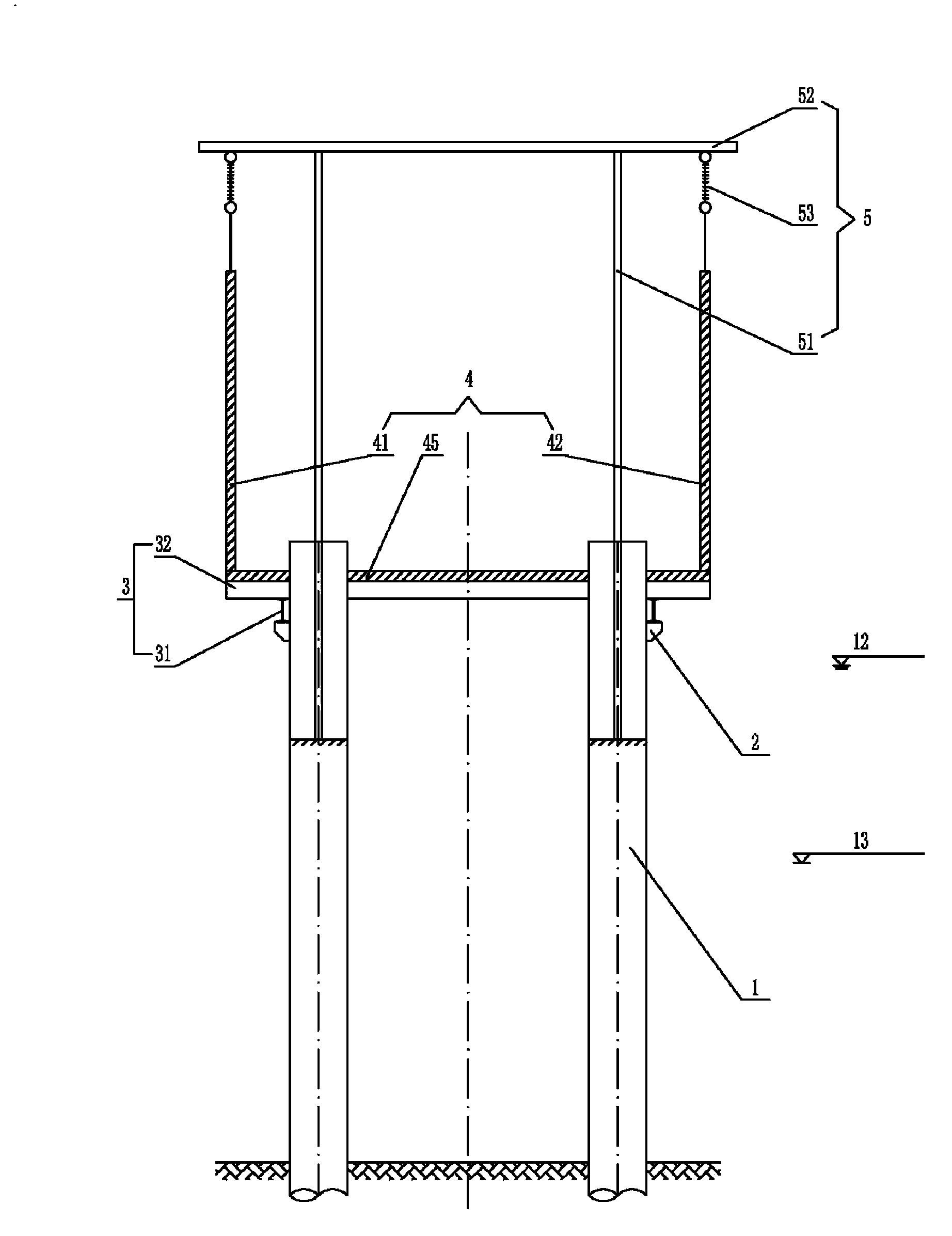

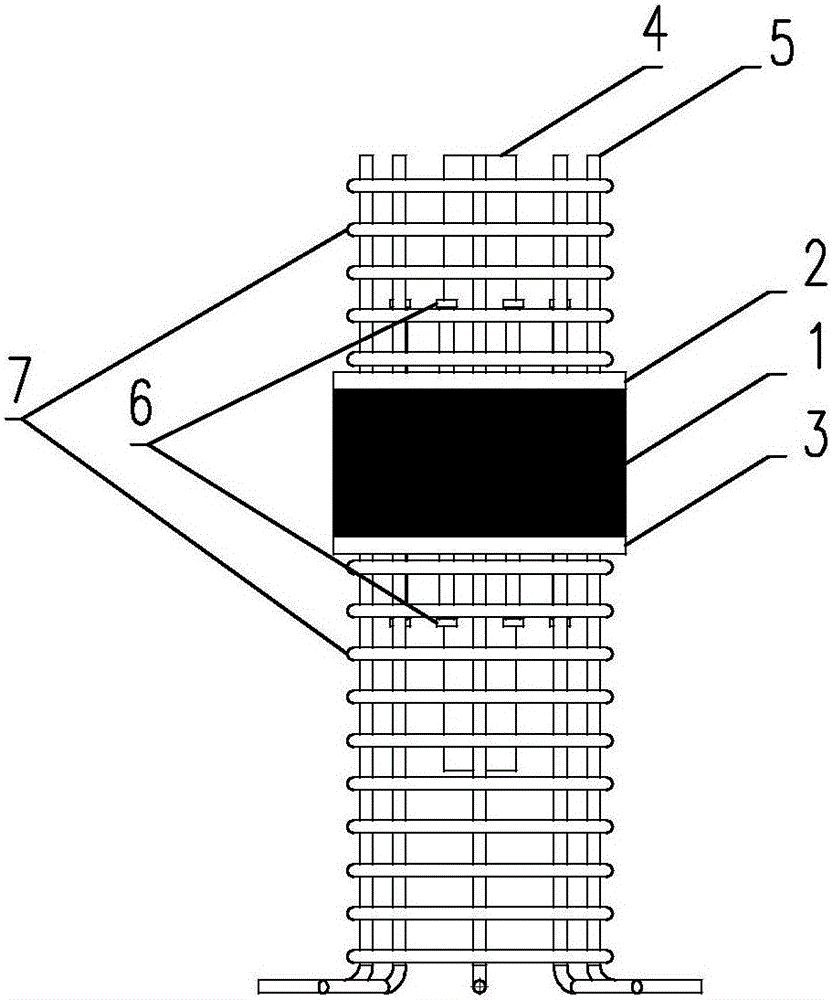

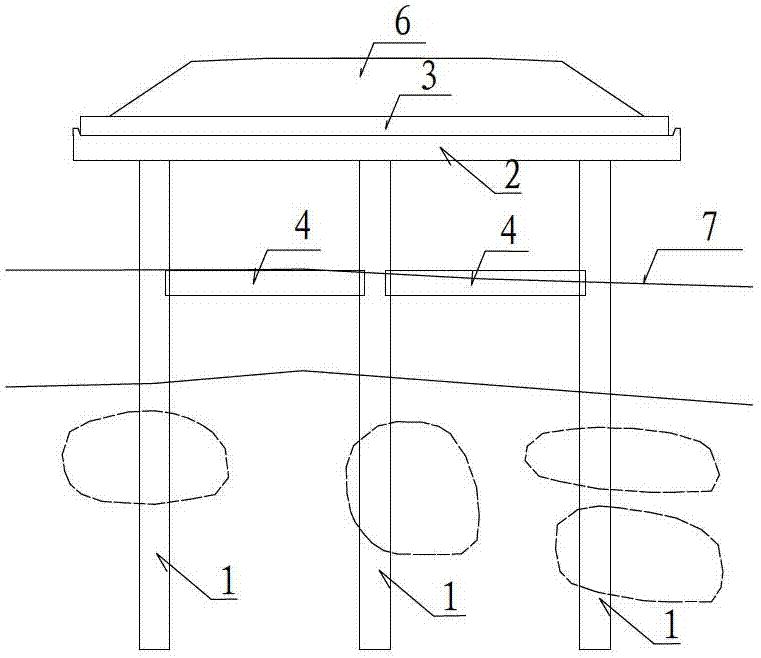

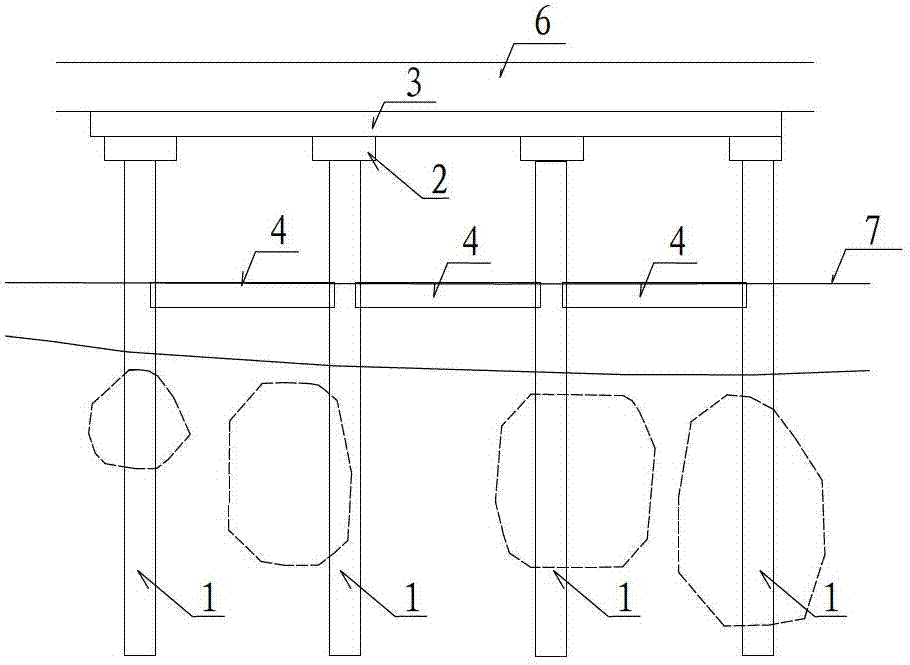

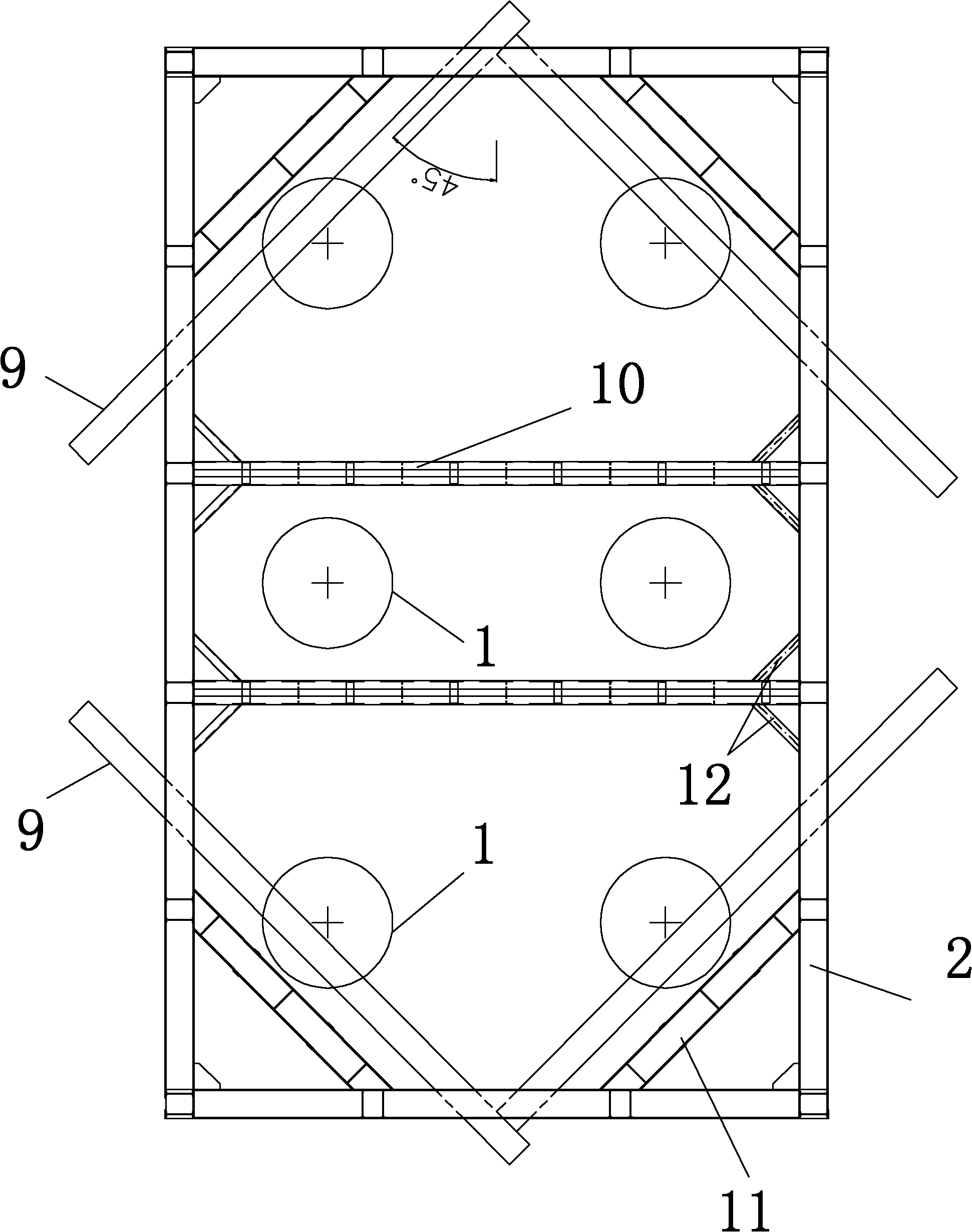

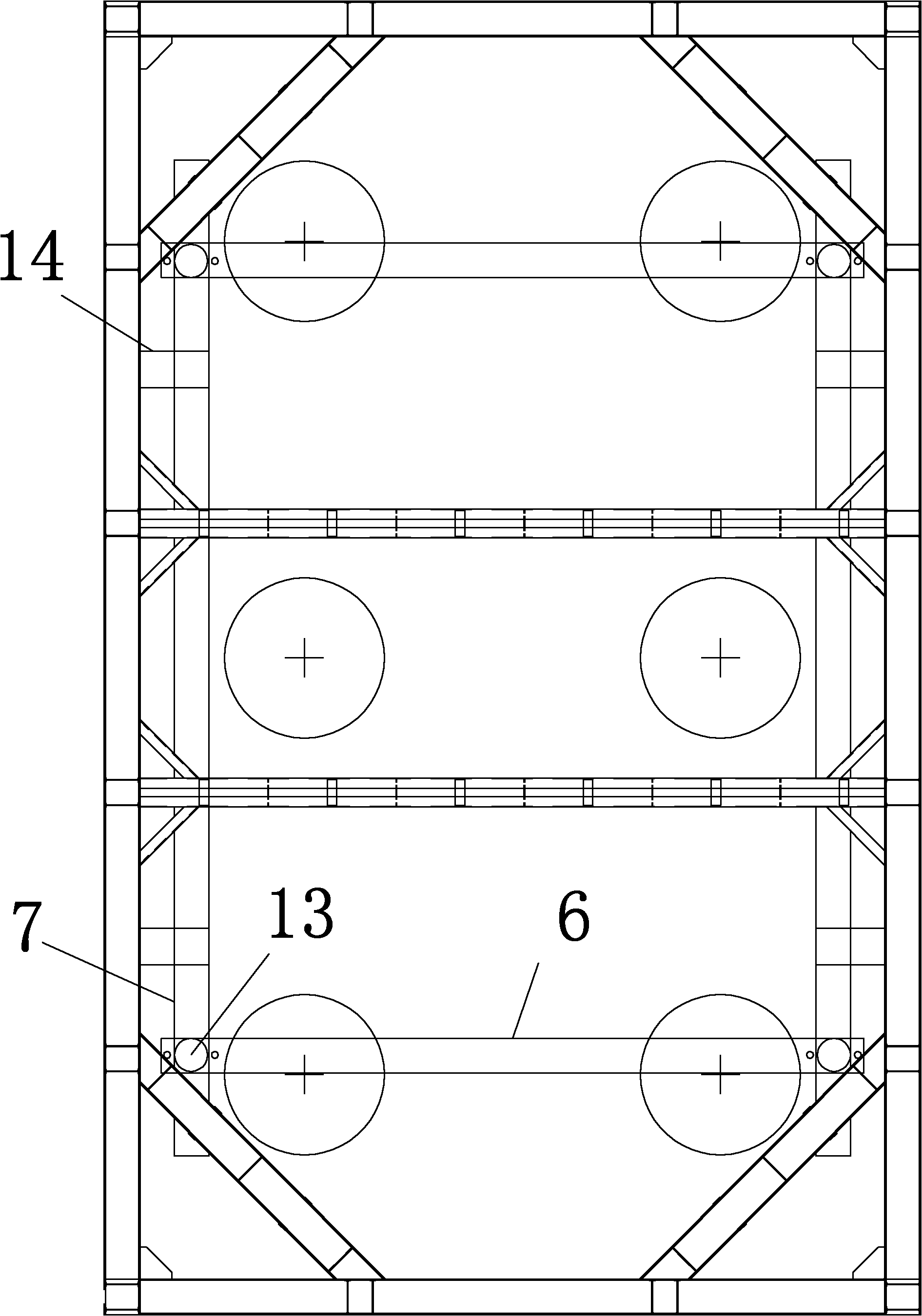

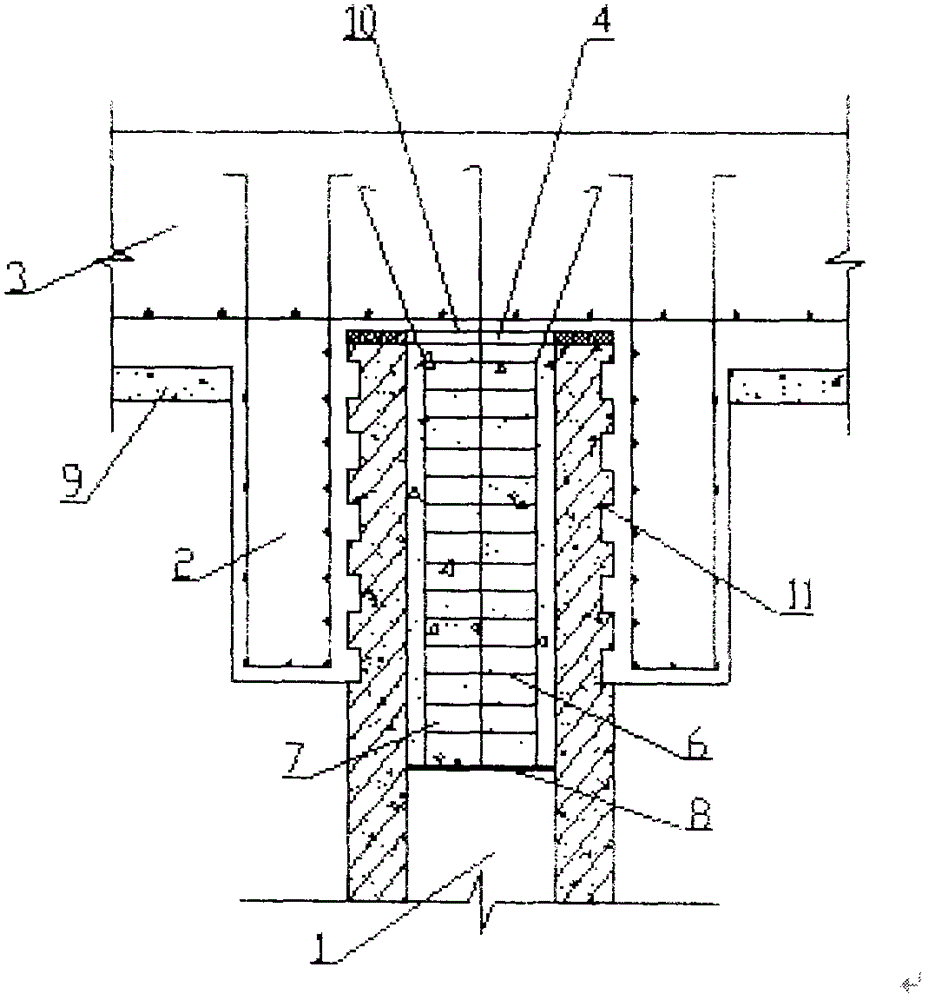

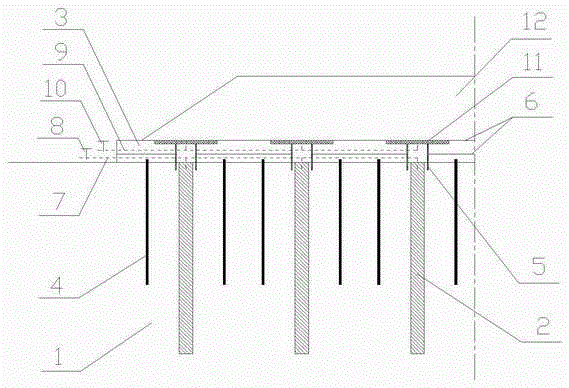

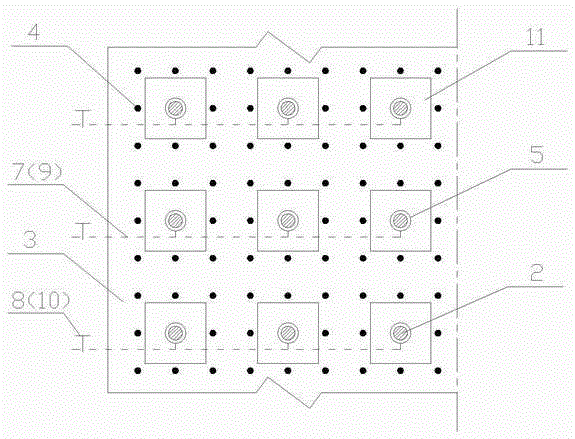

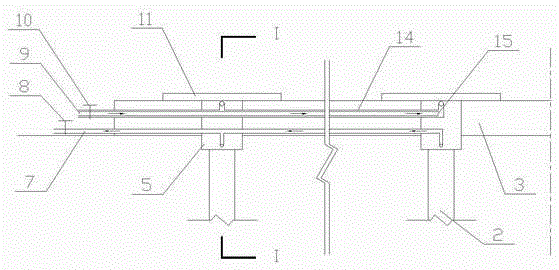

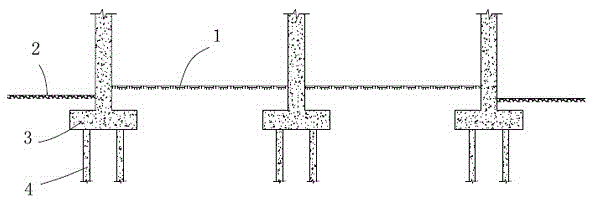

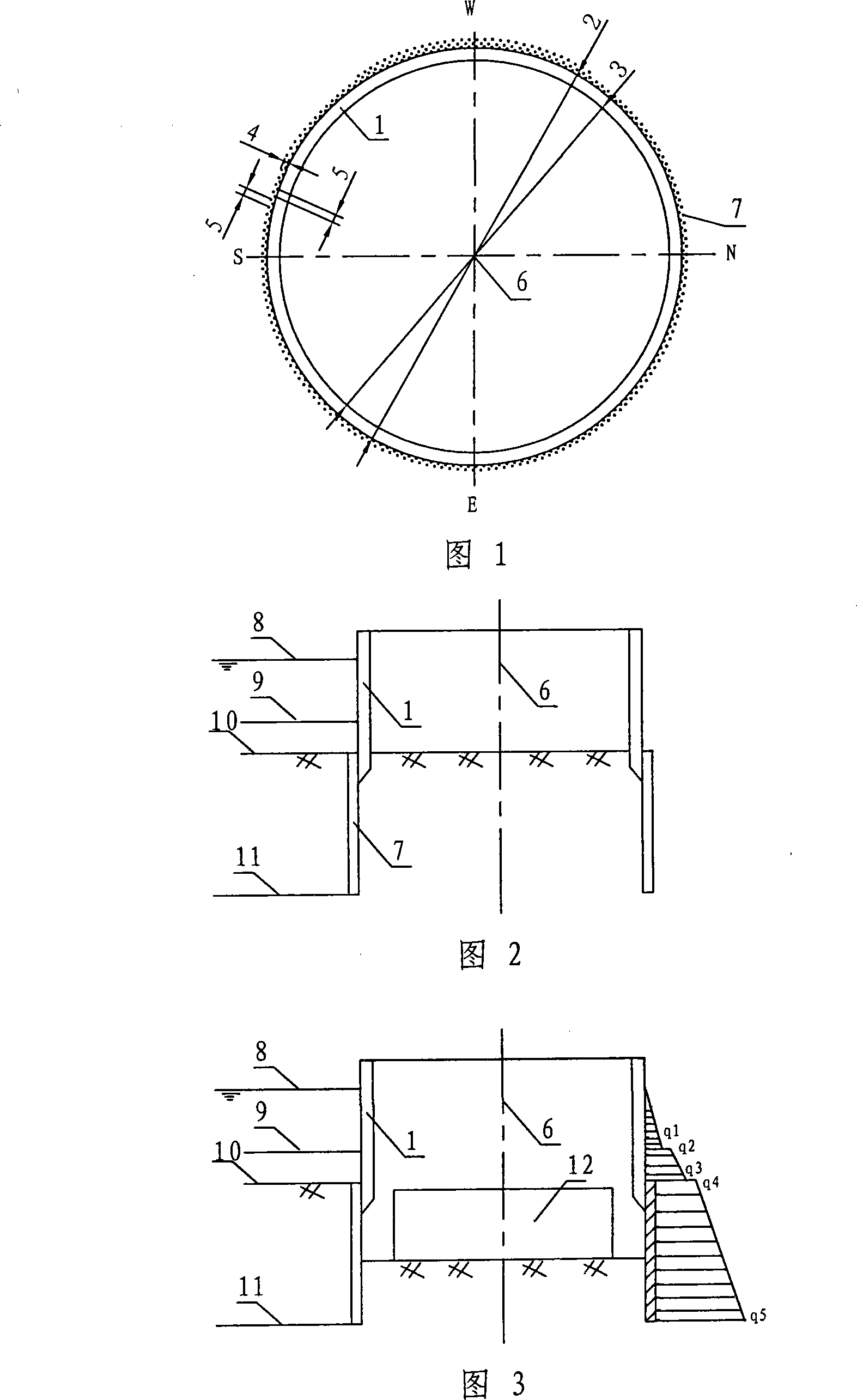

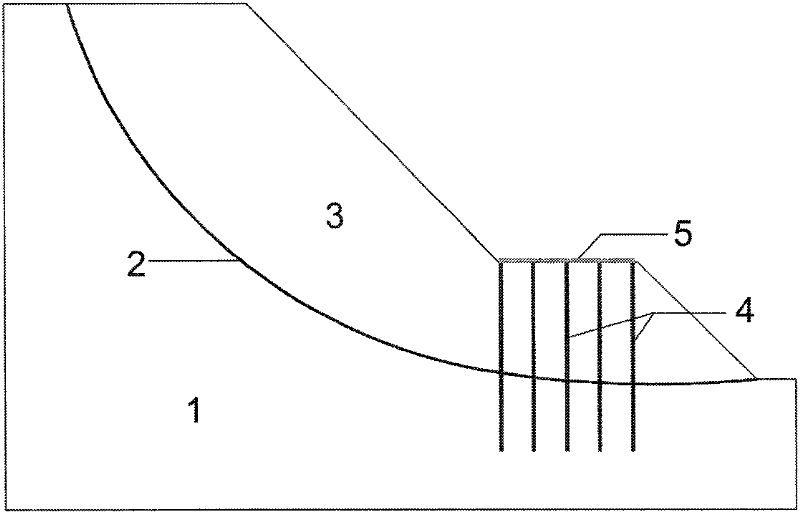

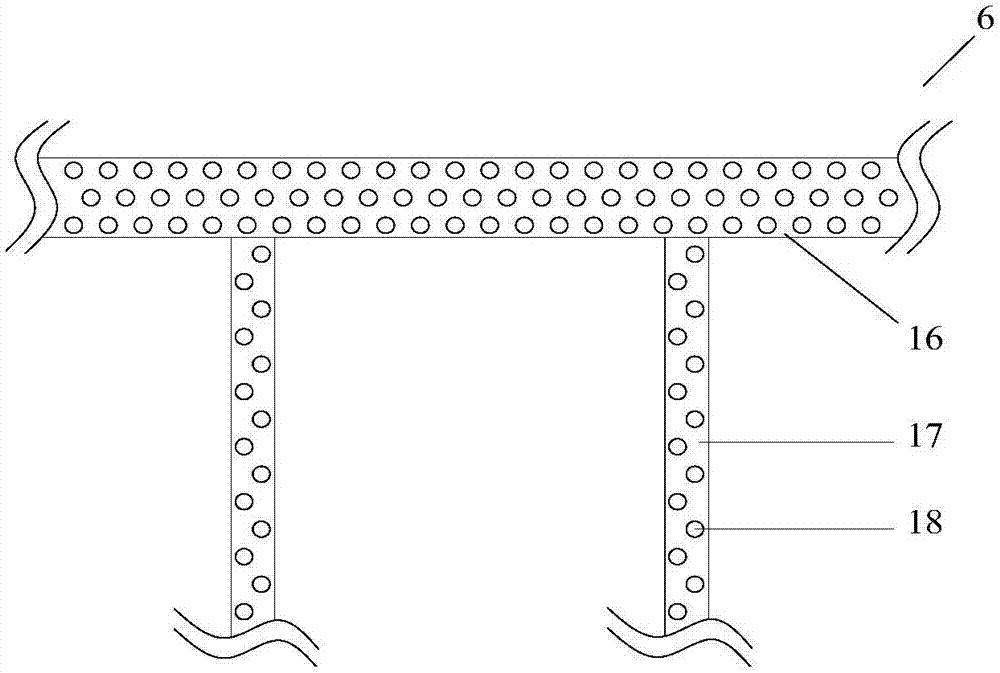

Light frame-subgrade pile-board structure in karst areas

InactiveCN102787534ASettle settlementFix stability issuesRailway tracksFoundation engineeringPile capJoist

A light frame-subgrade pile-board structure in karst areas aims to solve the problems of subsidence and poor stability of high-speed railway subgrades in the karst areas and overcome the defects of difficulty in treating and detecting karst groundwork. The light frame-subgrade pile-board structure comprises foundation piles (1), joists (2), a pile cap (3), transverse tie beams (4) and longitudinal tie beams (5), wherein the foundation piles (1) are arranged in rows at intervals transversely and in columns at intervals longitudinally; the joists (2) are transversely arranged at the tops of the foundation piles (1) and in rigid connection with the same; the pile cap (3) is arranged at the tops of the foundation piles (1) or the joists (2) and in rigid connection with the foundation piles (1) or the joists (2); the transverse tie beams (4) are arranged among the foundation piles (1) in the same rows and in rigid connection with the same; and the longitudinal tie beams (5) are arranged among the foundation piles (1) in the same columns and in rigid connection with the same.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Soft soil foundation combined pile net structure

The invention discloses a soft soil foundation combined pile net structure, aims at effectively improving reinforcing effect and saving project investment and comprises cast-in-place piles, pressed piles, pile caps, guide fixing frame lattices and a cushion body. The cast-in-place piles are arranged around the boundary of a filling body at intervals, bottoms of the cast-in-place piles enter a bedrock layer below a soft soil layer by certain depth, the pressed piles are arranged in the soft soil layer within a range of the cast-in-place piles at intervals, bottoms of the pressed piles are pressed in the top surface of the bedrock layer, the pile caps are arranged at the tops of the cast-in-placed piles and the pressed piles and fixedly connected with the cast-in-placed piles and the pressed piles, the guide fixing frame lattices are positioned in the soft soil layer and transversely restrain the cast-in-place piles and the pressed piles, and the cushion body is laid between the tops of the piles caps and the undersurface of the filling body.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

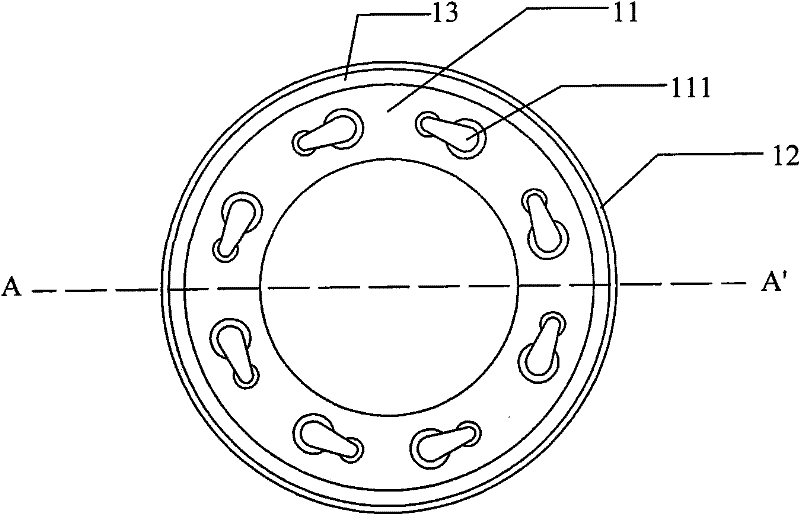

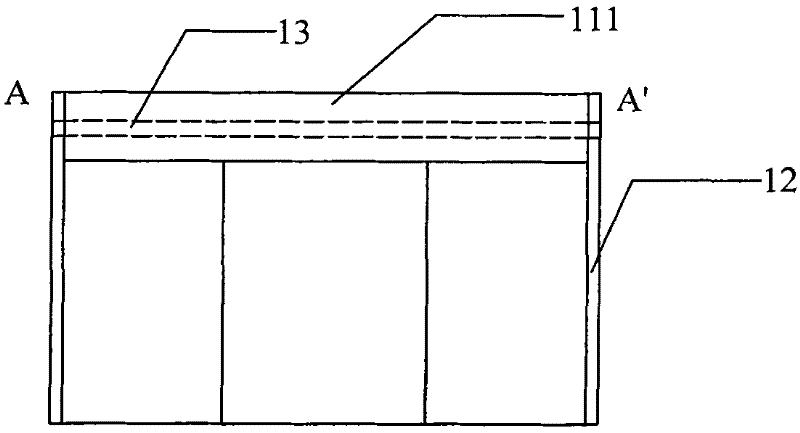

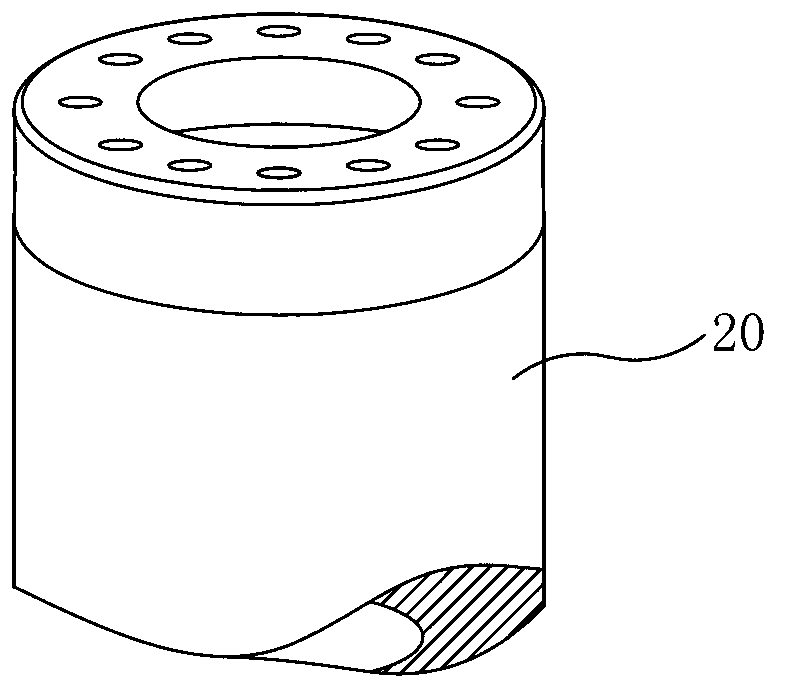

Method for strengthening and repairing tubular pile head

The invention provides a method for strengthening and repairing a tubular pile head. The method comprises the following steps: cleaning broken and loose concrete, exposing main reinforcement for 3 to 4cm, regulating the main reinforcement to ensure that the main reinforcement is vertical to the ground; sawing off the broken pile head, and flat sawing the pile head; washing float ash and dust on the surface of the concrete, drying the concrete, and covering a pile cap with the same specification on the pile head; connecting the exposed main reinforcement with the pile cap, and placing a pallet matched with the pile cap in an inner cavity of the tubular pile; connecting the pallet with the pile cap; and finally, filling epoxy resin concrete in a cavity formed by the pallet, an annular end plate and the inner wall of the tubular pile, and continuously connecting the epoxy resin concrete with a sunk pile after curing in 4 hours. The pile cap comprises the annular end plate, wherein a cylindrical steel hoop is sleeved on the annular end plate; the surface of the annular end plate and the end surface of the cylindrical steel hoop are coplanar, and the annular end plate and the cylindrical steel hoop are connected; the annular end plate is provided with end plate screw holes; and the connection of the exposed main reinforcement and the pile cap is to weld the exposed main reinforcement onto the end plate screw holes one by one.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Steel sheet pile coefferdam structure and topdown construction method thereof

ActiveCN102191777ARealize intermittent decentralizationHigh positioning accuracyLifting devicesFoundation engineeringPurlinPile cap

The invention discloses a steel sheet pile coefferdam structure comprising a steel protecting canister, a plurality of layers of circuit purlins and steel sheet piles, wherein the steel sheet piles are inserted into the peripheries of the circuit purlins; the lower part of the steel protecting canister is welded with a bracket to form a temporary supporting platform; the circuit purlins at the upper layer and the circuit purlins at the lower layer are connected through a vertical rid and a bridging at 45 degrees; the top of the steel protecting canister is fixedly provided with an upper outrigger; the upper outrigger is provided with lifting equipment; and a lower outrigger is welded below the circuit purlins at the lowermost layer and lifted by a lifting rope of the lifting equipment. The invention also discloses a topdown construction method of the steel sheet pile coefferdam structure. In the invention, the circuit purlins, the vertical ribs and the bridging at 45 degrees are installed by utilizing a lifting system under the preconditions without using large-size lifting equipment or utilizing a large-scale prefabricating field, and therefore the quality and the stability of a steel sheet pile coefferdam are ensured; and a highrise pile cap of a pier inside water is constructed with lowest cost and smallest construction risk, therefore the feasibility and the economy of a construction technology of the steel sheet pile coefferdam inside water are enhanced.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

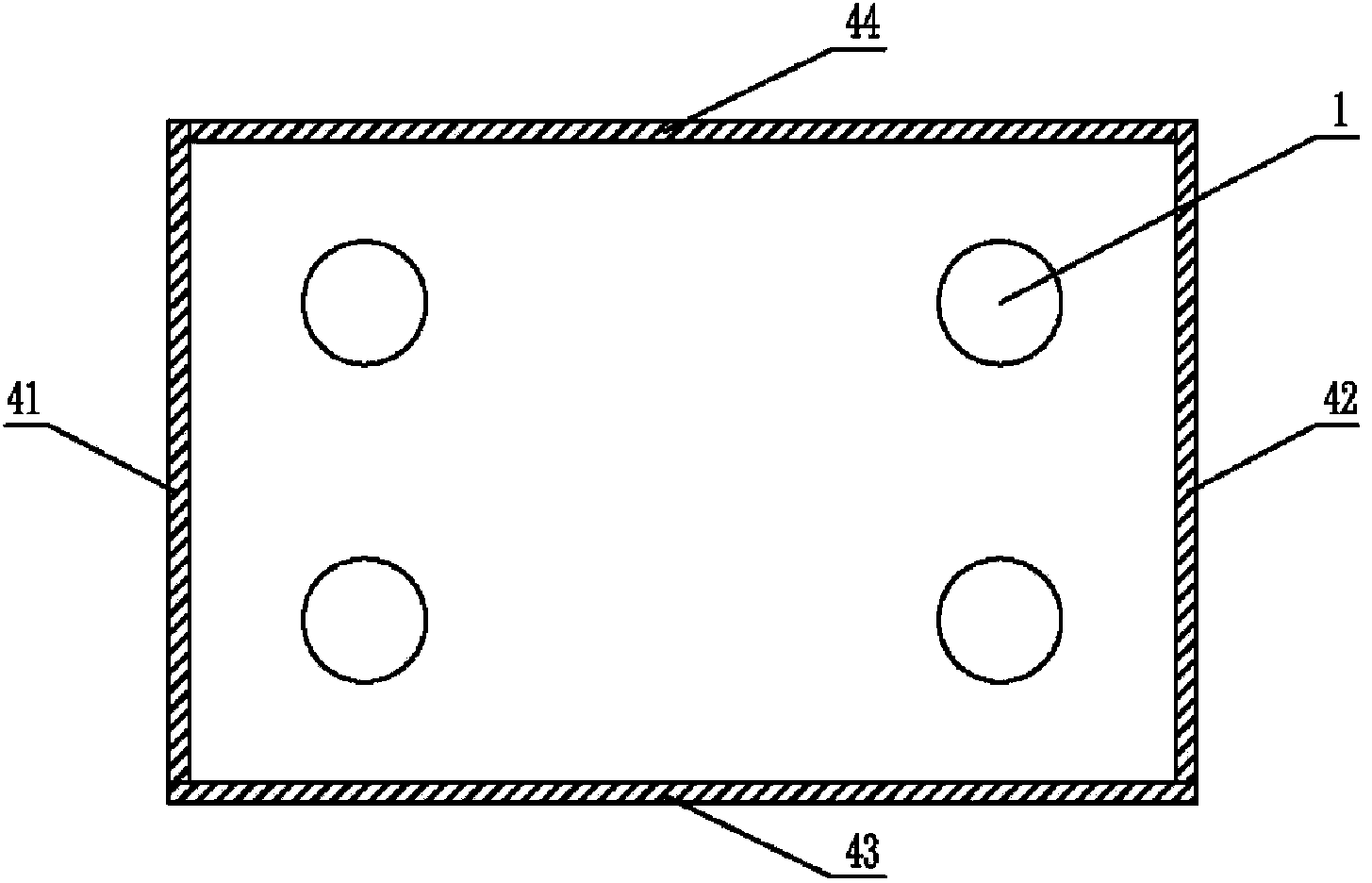

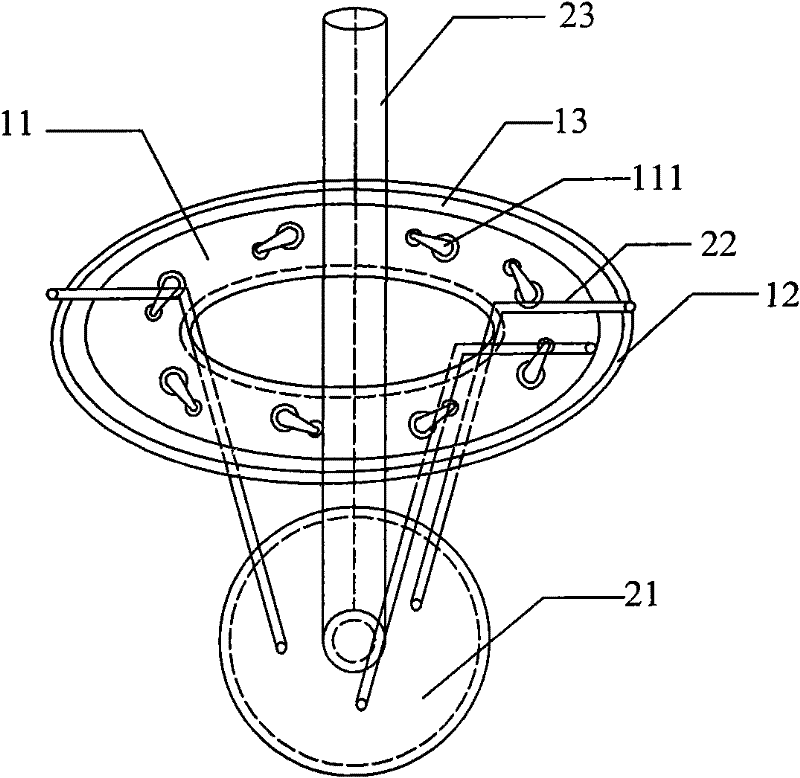

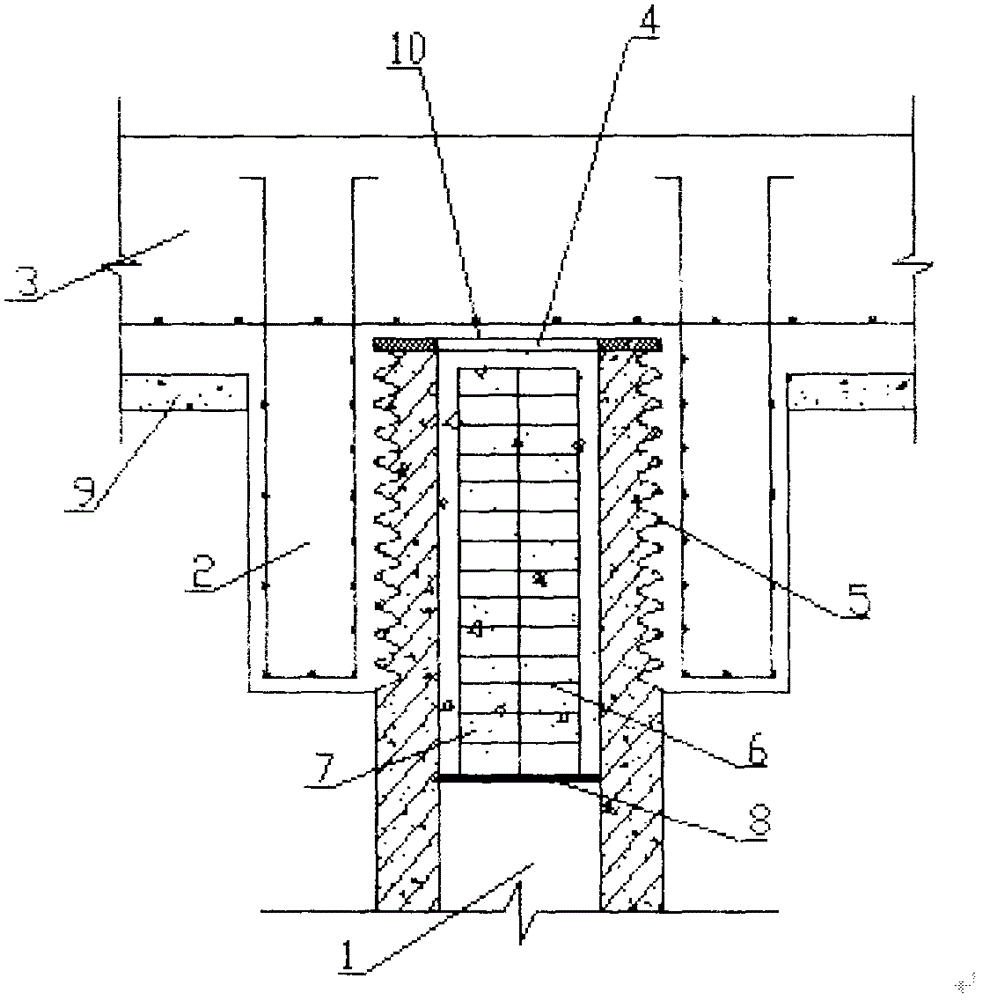

Novel connecting structure of prestressed concrete pile and cushion cap

InactiveCN102720206AFirmly connectedSolve the weak link of pull-out resistanceBulkheads/pilesPile capPre stress

The invention discloses a novel connecting structure of a prestressed concrete pile and cushion cap. The novel connecting structure is mainly characterized in that a pile cap is arranged around a pile body; a base cushion cap is connected with the pile body by the pile cap; an end plate is arranged at the top of the pile body and provided with a reinforcing steel bar; a thread is arranged on one end of the outer wall of the pile body; the pile body consists of a reinforcement cage and core concrete; the reinforcement cage is arranged in a cavity of the pile body; a round steel support plate is arranged at the bottom end of a longitudinal bar, and core concrete is poured in the cavity of the concrete pile above the round steel support plate; and a concrete cushion layer is positioned below the base cushion cap. The novel connecting structure of the prestressed concrete pile and the cushion cap changes the traditional mode of inward core extraction resistance, a pile top is connected with the base cushion cap by the pile cap, and the connecting structure ensures the connection of the prestressed concrete pile and the cushion cap to be safer and more reliable, thus greatly improving the connection strength of the cushion cap and the pile top, being simple in processing technique, saving manufacturing cost of the engineering, and being high in efficiency and wide in application range.

Owner:NANJING UNIV OF TECH

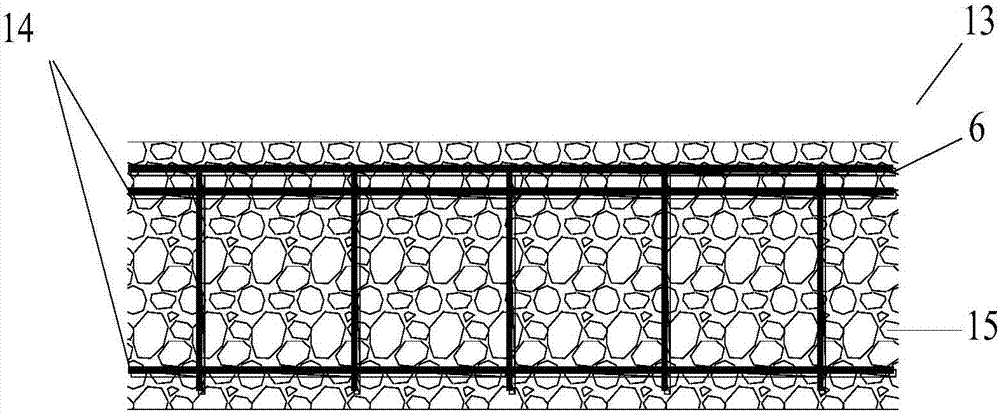

Combined-type composite foundation with controllable rigidity piles, drainage materials and reinforced cushion

ActiveCN106759223AImprove stabilityReduce differential settlementSoil preservationSupporting systemPile cap

Disclosed is a combined-type composite foundation with controllable rigidity piles, drainage materials and a reinforced cushion. The reinforced cushion is laid on the surface of a soft soil foundation. The vertical drainage materials and the rigidity piles with caps are arranged in the foundation. Grouting tubes are installed between pile tops and the pile caps to form a controllable supporting system. When grouting is not conducted on the grouting tubes, drainage consolidation is conducted through the soft soil foundation under the effect of an upper load so as to improve the bearing capacity. The bearing effect of the rigidity piles is difficult to play due to the fact that the rigidity piles are stabbed into the grouting tubes. When the grouting tubes are grouted and after slurry is hardened, the pile caps, the slurry and the rigidity piles form a rigidity support, and the goal that the load is undertaken by the piles and soil together to reduce settlement is realized. Meanwhile, the reinforced cushion has the effects of restraining the horizontal displacement of the piles and the soil, limiting the local deformation of a dyke and a dam and the like. According to the composite foundation, the bearing force of the foundation soil can be given full play; the using amount of the rigidity piles is reduced; the stability of the foundation is improved; the post-construction settlement and differential settlement are reduced; the construction period is shortened; and the composite foundation can be applied to projects such as highways, railways and earth-rock dams.

Owner:WUYI UNIV

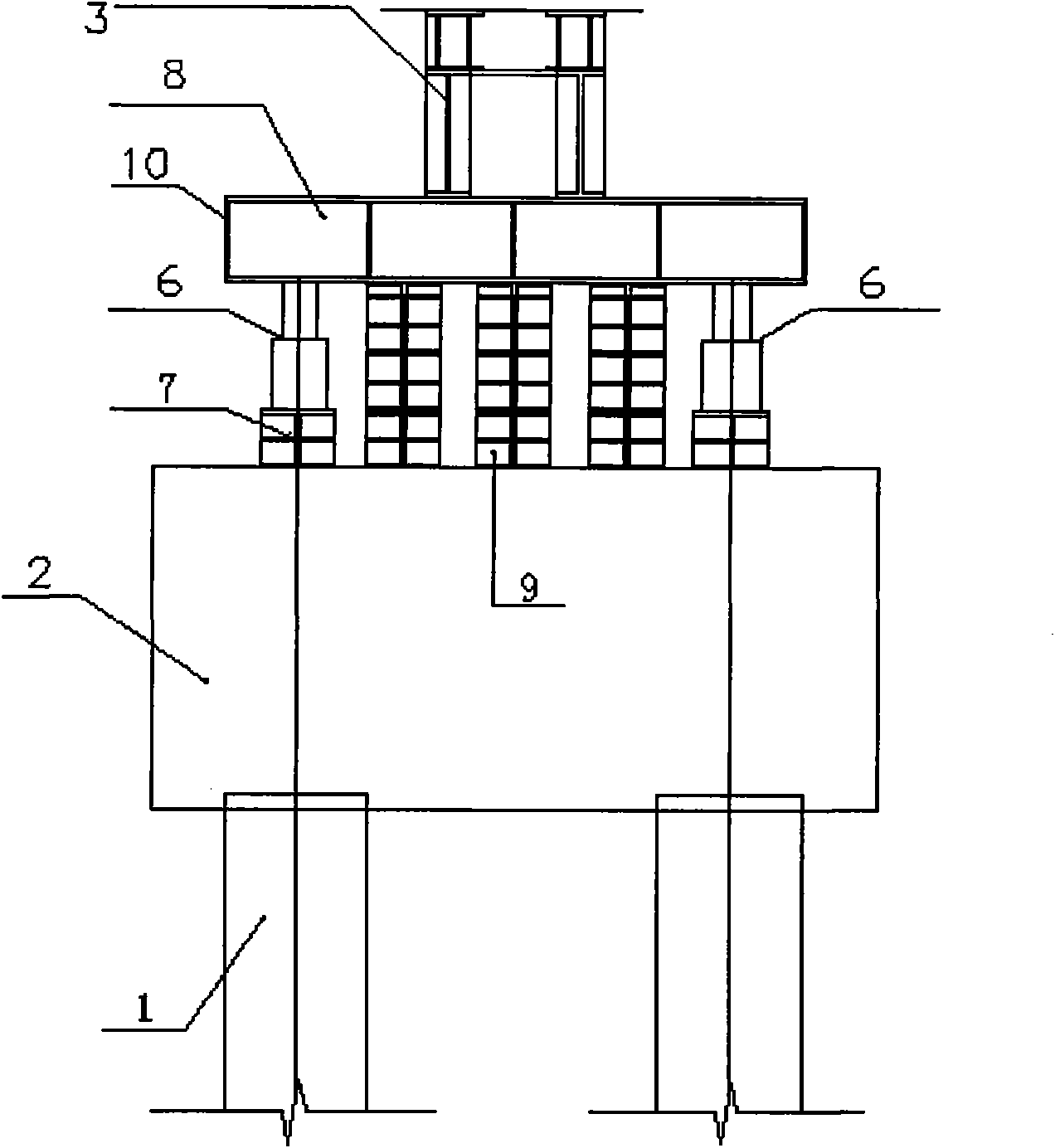

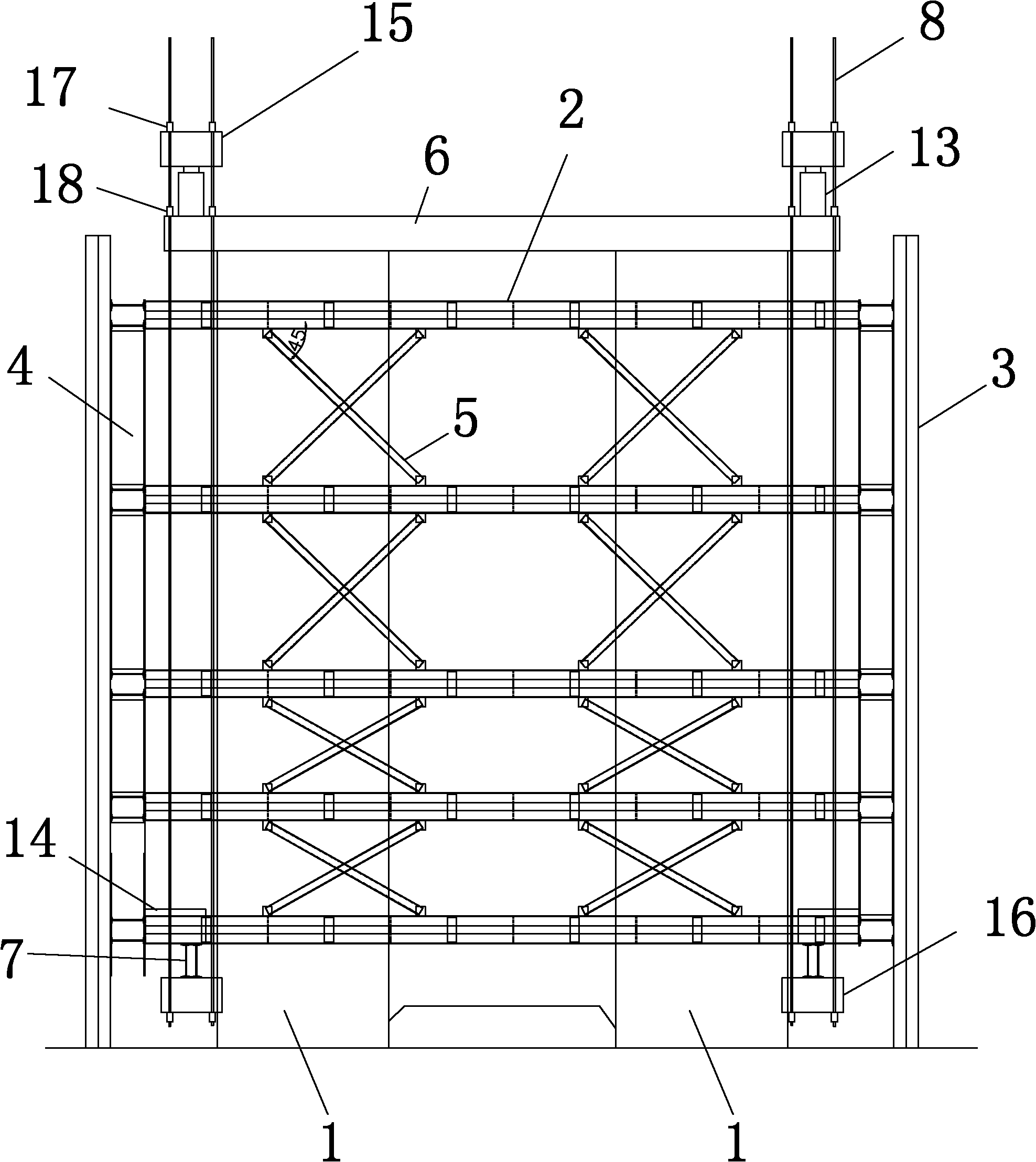

Steel hoop truss type elevated pile cap tower crane foundation construction method and structure

InactiveCN102561384ADecrease productivityImprove work efficiencyFoundation engineeringReinforced concreteTower crane

The invention discloses a steel hoop truss type elevated pile cap tower crane foundation construction method. The method comprises (1) constructing four cast-in-place concrete piles in a foundation pit before foundation pit earthwork excavation, the pile bottom elevation being below the foundation pit bottom elevation and the ratio of the length of the cast-in-place concrete pile below the foundation pit bottom face to the length of the cast-in-place concrete pile in the foundation pit being larger than or equal to 1.5; (2) pouring a reinforced concrete pile cap at the pile top and installing a tower crane on the pile cap; and (3) carrying out the foundation pit earthwork excavation, while forming a steel truss type hoop structure on the exposed sections of the four cast-in-place concrete piles in the foundation pit to connect them together. The invention also discloses a steel hoop truss type elevated pile cap tower crane foundation structure constructed by the method. The tower foundation adopting the invention has stable and firm structure, high safety, convenient construction, and low cost, and the steel components of the steel truss type hoop structure can be recycled.

Owner:ZHONGTIAN CONSTR GROUP

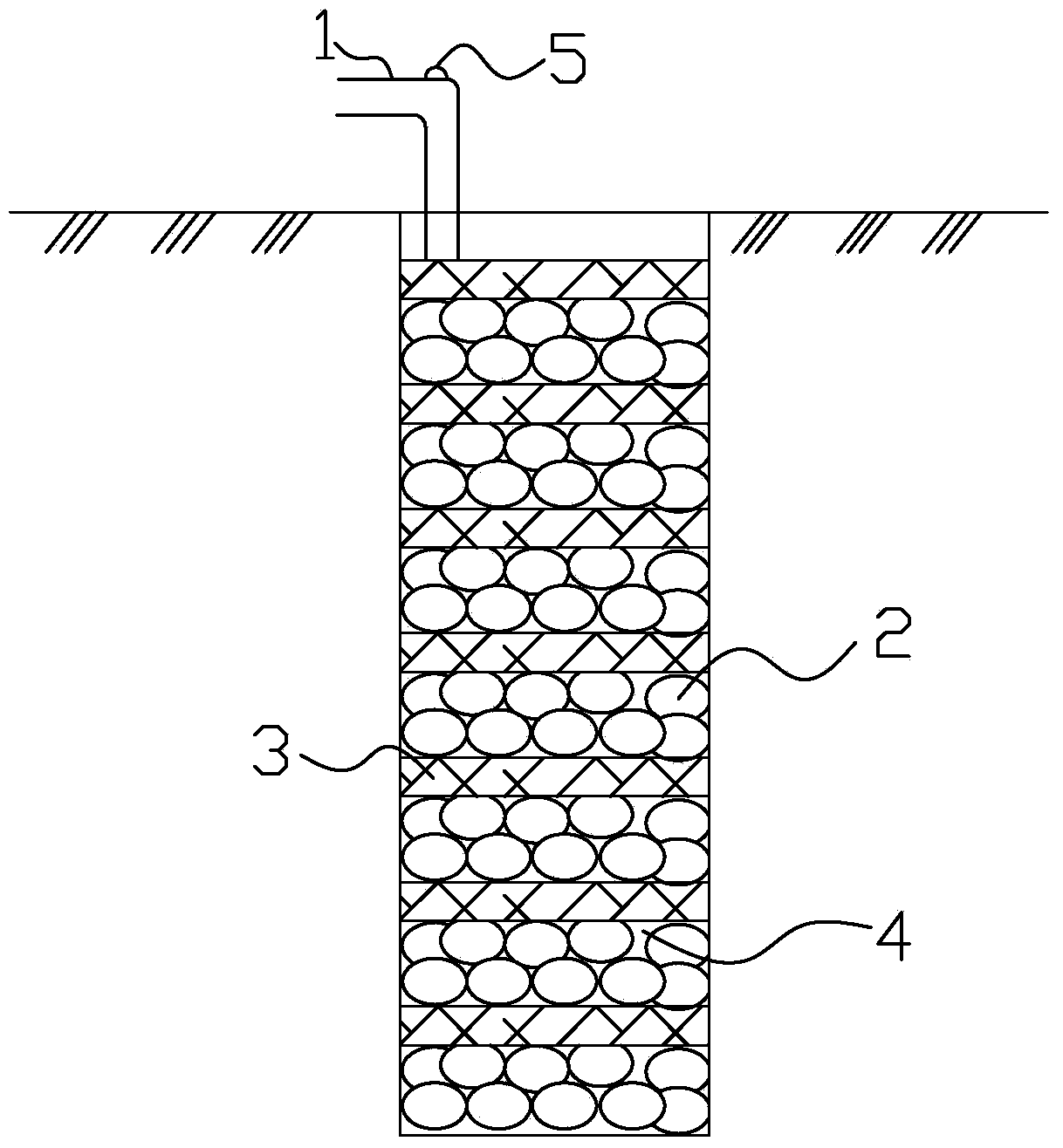

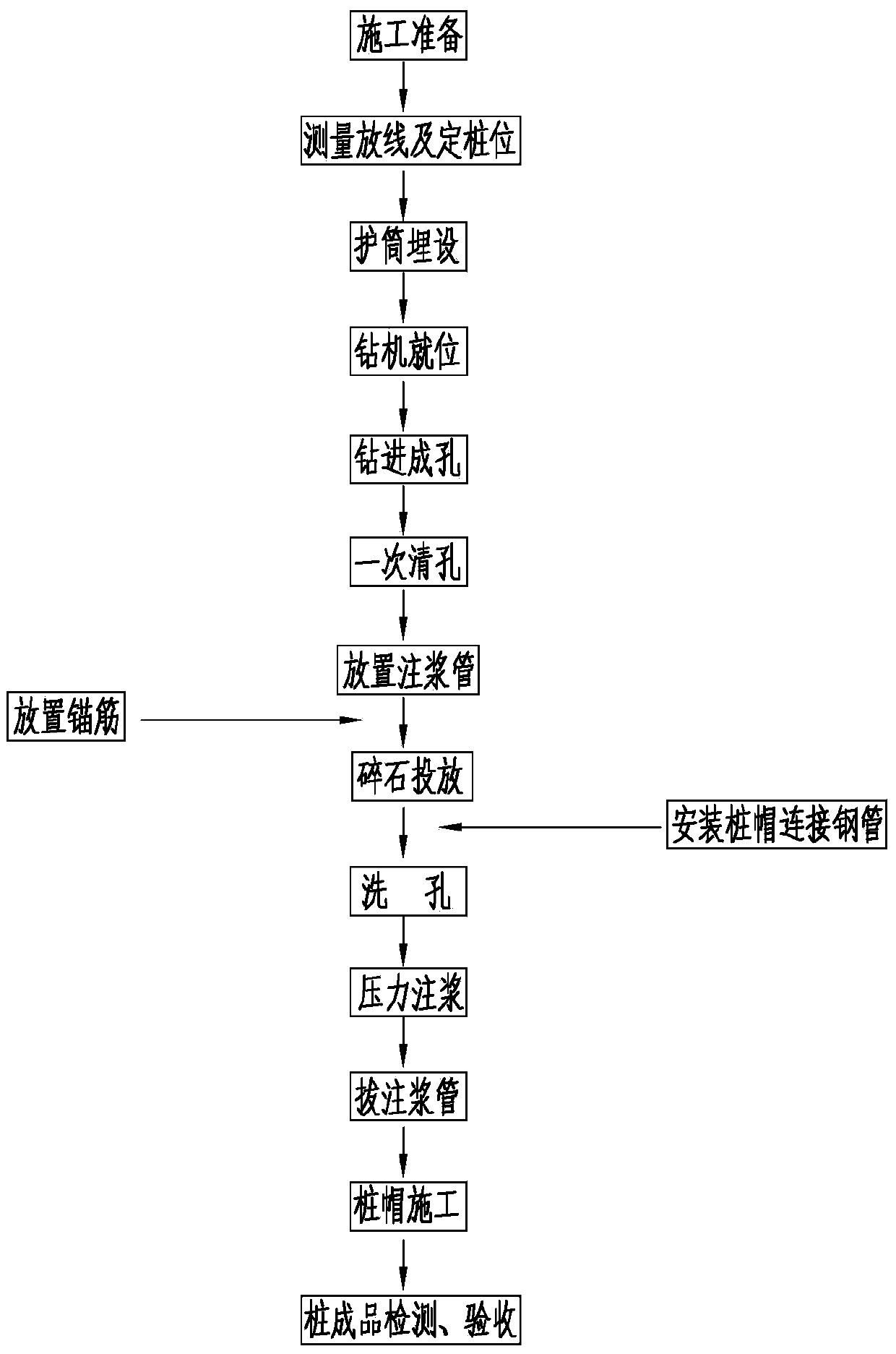

Construction method of gravel grouting pile

The invention discloses a construction method of a gravel grouting pile. The construction method comprises the following steps: (1) preparing for construction, (2) conducting measurement, paying off and positioning of the pile, (3) embedding a protective canister, (4) placing a drilling machine in place, (5) forming a hole by drilling, (6) cleaning the hole at a time, (7) placing a grouting pipe, (8) placing an anchor bar, (9) putting gravels in the hole, (10) installing a pile cap connecting steel pipe, (11) cleaning the hole, (12) conducting pressure grouting, (13) pulling the grouting pipe out, (14) constructing a pile cap, and (15) conducting detection and acceptance inspection on the finished pile. According to the construction method of the gravel grouting pile, the construction speed is high, the construction period is shortened, and compared with soft foundation treatment such as a prestressed pipe pile and a Y-type pile, the engineering investment is saved; the labor intensity is low, the construction is safe, and the construction method can be widely popularized and used; the gravel pile formed by cement and gravels is high in integrality and stability. The engineering drilling machine is adopted in a soft foundation to drill the hole in a rotating and cycling mode to form the pile, the disturbance to the foundation and the surrounding buildings is small, ground depression is controlled, and the construction method is small in vibration and low in noise during the construction and has good social benefits.

Owner:NINGBO SHENGHONG CONSTR ENG

Construction method for mucky soft soil roadbase tubular pile

InactiveCN104894937ASolve widening and transformationComplete specificationsRoadwaysBulkheads/pilesPile capPre stress

The invention discloses a construction method for a mucky soft soil roadbase tubular pile. The construction method comprises the steps of preparatory work, construction for a roadbase soleplate, construction for a prestressed pipe pile, construction for a pile cap, construction for a cushion layer and the like. The construction method for the mucky soft soil roadbase tubular pile provides new thinking for governing differential settlement of a roadbase and solving bump at a bridge-head, freeway widening, etc. The problems of unmanageable construction quality of soft foundation at the bridge head in the soft foundation treatment and uneven settlement after being opening to traffic are solved.

Owner:成军

Seismic retrofit method for existing pile foundation buildings

The invention relates to a seismic retrofit method for existing pile foundation buildings. The seismic retrofit method solves the problem that potential safety hazards exist in the existing old buildings without the seismic performance when earthquakes occur and comprises the steps of cutting soil bodies downwards, constructing new supporting pile caps, arranging supporting devices, removing original pile foundations in a chiseling mode, installing seismic insulation supports and constructing a layer of beam plates. The seismic insulation supports are installed on the bottoms of upper structures of the existing buildings, and the seismic wave energy can be obviously prevented from being transmitted to the upper structures when the earthquakes occur; the layer of beam plates is poured on the top of a seismic insulation layer, the upper structures of the existing buildings keep integral, and therefore the overall coordination work ability of seismic insulation mechanisms is improved; the soil bodies are excavated one by one on original supporting pile caps, and therefore the supporting performance of the ambient soil bodies is guaranteed.

Owner:ZHEJIANG SCI-TECH UNIV

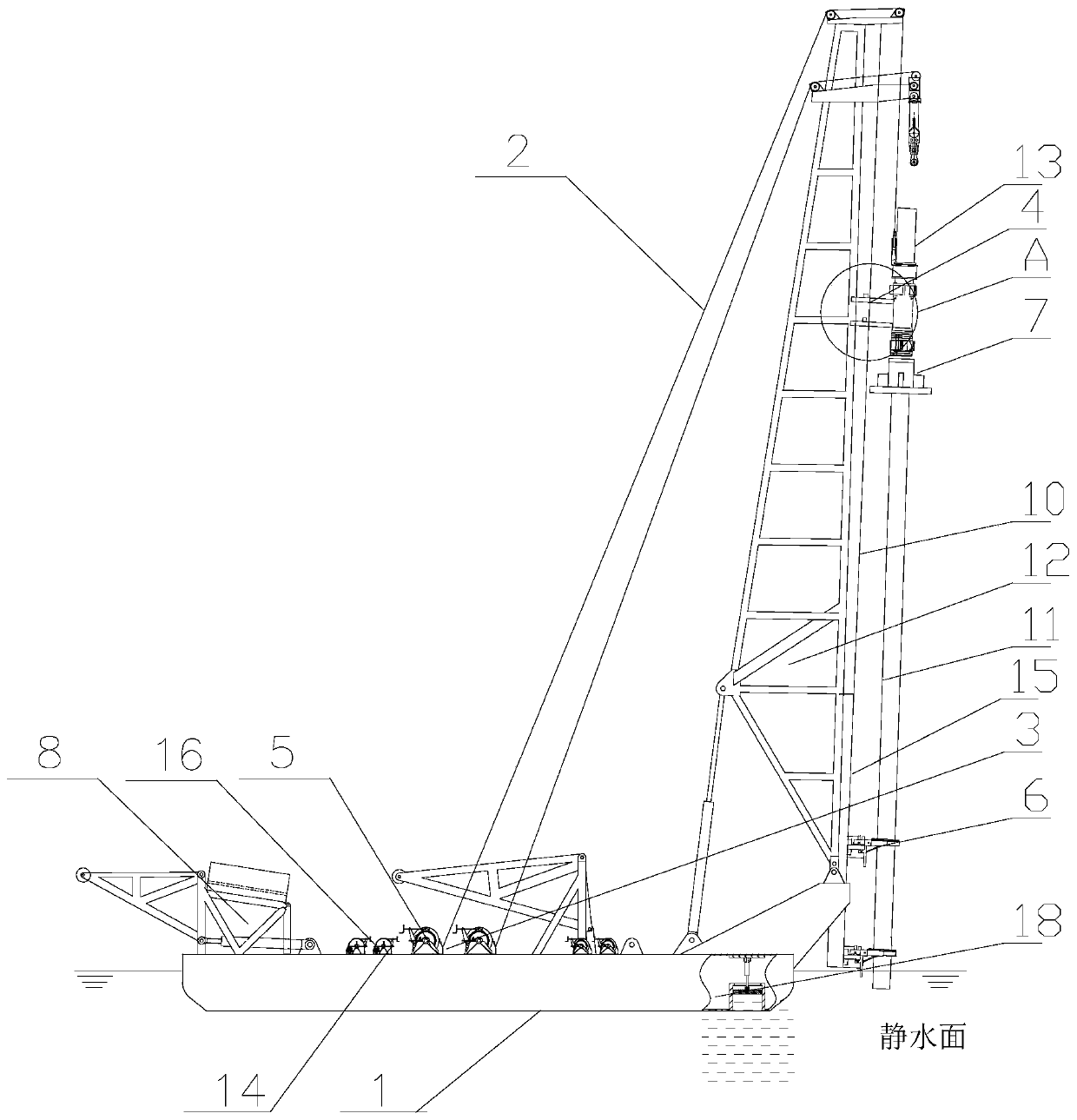

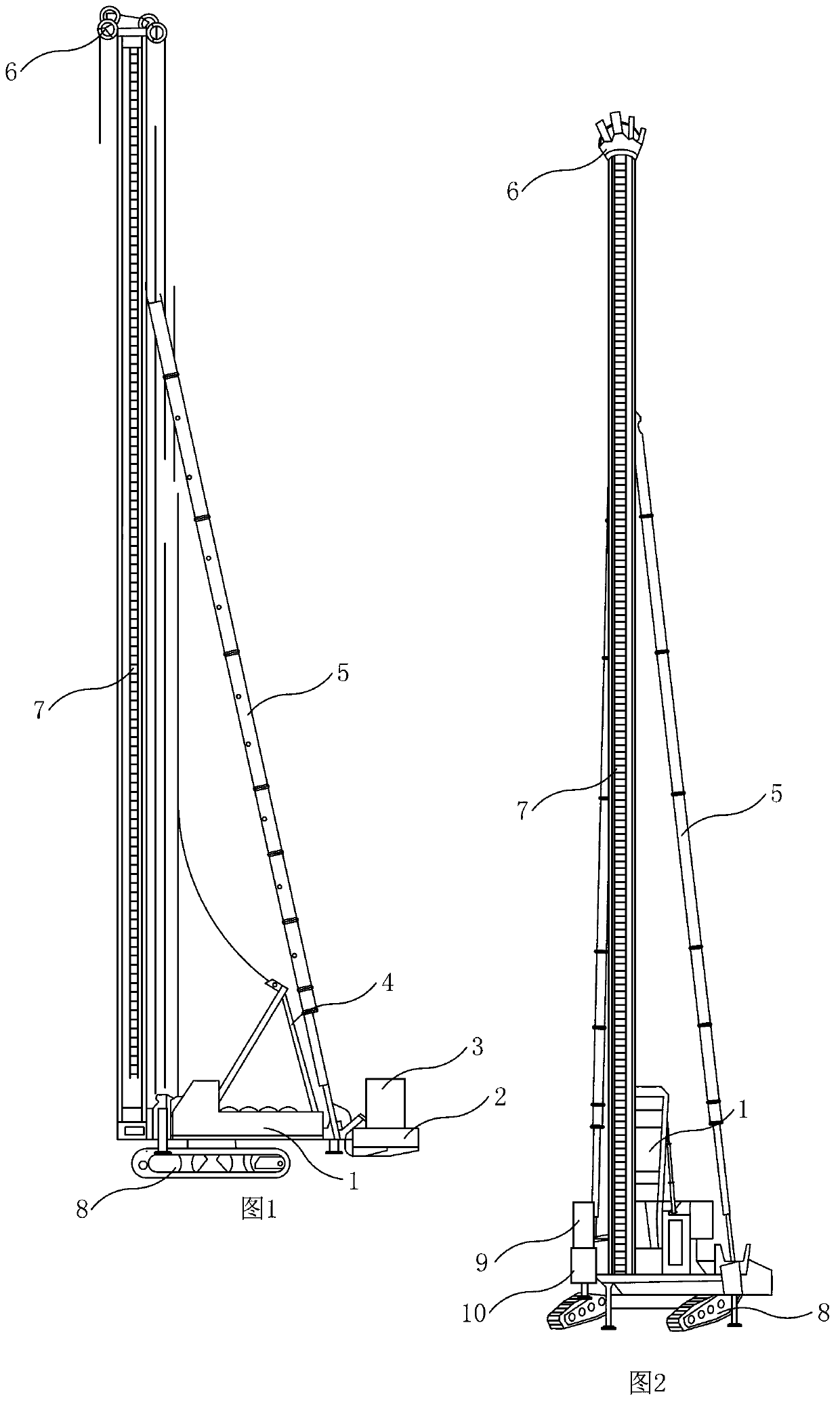

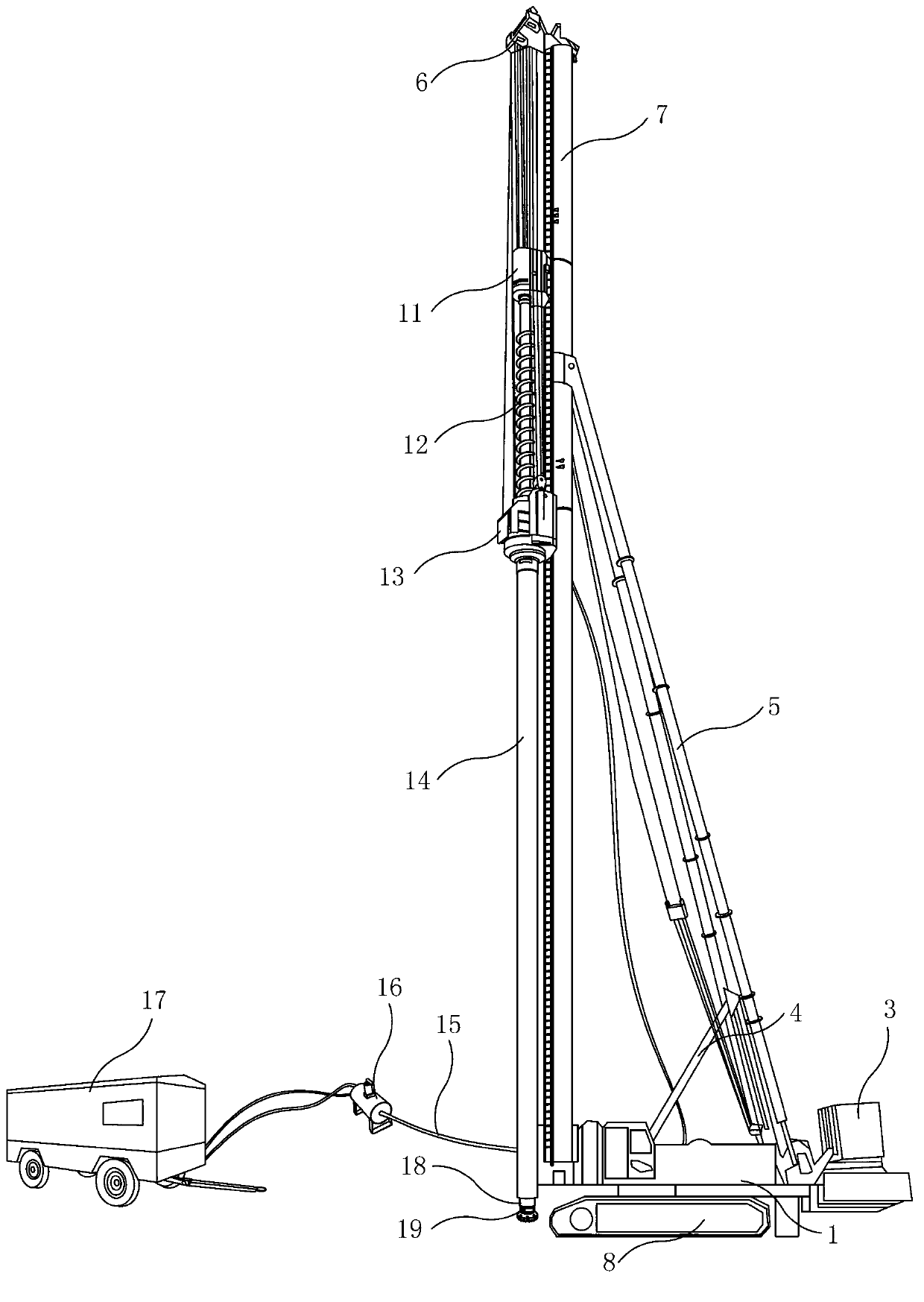

Pile driving barge and posture adjustment, positioning control and pile driving methods thereof

ActiveCN109914408AImprove efficiencyHigh precisionVessel movement reduction by mass displacementDesign optimisation/simulationPile capWinch

A pile driving barge comprises a barge body, buoyancy adjusting devices are arranged at four corners of the barge body respectively, an upper scanner and a lower scanner for scanning vertical piles are arranged on the barge body, and GPS signal receivers are arranged at two different positions of the barge body; anchor machines for anchoring at least four different positions are arranged on the barge body; a pile frame is rotationally arranged on the barge body; the barge body is provided with an automatic pile frame lying device; a piling guide rail is arranged on the pile frame; a pile hammer is movably arranged on the pile driving guide rail; a first brake device for limiting the position of the pile hammer on the pile driving guide rail is arranged on the pile hammer, a transition roller is arranged on the upper portion of the pile frame, the upper portion of the pile hammer is connected with a winch arranged on the barge body through a steel wire rope, and a second brake device for braking by braking a winch roller to control the steel wire rope to pull the pile hammer is arranged on the barge body; and a pile cap is arranged on the pile hammer, a pile gripper for gripping thevertical pile is arranged on the lower portion of the pile frame. The invention further discloses a posture adjusting method, a positioning control method and a pile driving method of the pile driving barge.

Owner:JIANGSU UNIV OF SCI & TECH +1

Method for surrounding water by combination of steel cofferdam and heavy-pressure rotary-spraying pile in deep-water low-pile cap construction

InactiveCN101205721ASolve the difficulty of sinkingBridge erection/assemblyBulkheads/pilesDouble wallEngineering

The invention discloses a construction method using a steel cofferdam to be combined with a high-pressure rotary jet grouting pile to surround water in the deep-water low-pile cap construction. A steel boxed cofferdam is conveyed to the position of a pier and is located through a location system; the water is filled between double walls to cause the steel cofferdam to go down below the riverbed surface under the action of self-weight; the top surface of the cofferdam is provided with a rotary jet grouting pile construction platform for placing a single-tube high-pressure rotary jetting jig and a high-pressure grouting pump; a rotary jet grouting pile is formed through guide-hole, blocking of vertical nozzles, mortar stirring and rotary jetting construction of the rotary jetting jig; the rotary jet grouting pile is constructed in a sequence from inner layers to outer layers around the cofferdam; a pile cap foundation pit in the cofferdam is made a water extraction and dug, then the pile cap is constructed. The invention has the advantages that: the steel cofferdam is settled to the soil layer of the riverbed and is used for the water surrounding structure in deep water, a vertical curtain is established in the soil layer by using the high-pressure rotary jet grouting pile and is mainly used for water stop and support excavation below the riverbed surface, the steel cofferdam is organically combined with the high-pressure rotary jet grouting pile, the settlement difficulty that the cofferdam runs through the thicker hard clay layer is solved, also the problems of water stop and support when the underwater pile cap digs to the sand layer and the sandy loam layer are overcome.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

Method for testing characters of micro piles in landslide control

InactiveCN102330438AAccurately obtain the whole process traitsIntuitive Destruction ModeFoundation testingPile capLandslide

The invention relates to a method for testing characters of micro piles in the landslide control. The method comprises the following steps of: manufacturing a landslide bed in a filling mode; excavating a plurality of micro pile grooves on the landslide bed and placing the micro piles with micro pile stress monitoring devices in the micro pile grooves, wherein one or a plurality of micro piles are arranged in each micro pile groove; filling the micro pile grooves in a layered mode and placing horizontal pressure monitoring devices at the position at a first distance from the corresponding micro piles in the layered filling process; placing a sliding film on a sliding surface of the landslide bed, filling the sliding film in a layered mode to form a slip mass, and placing the horizontal pressure monitoring devices at the positions at a second distance from the corresponding micro piles in the process of filling the slip mass; manufacturing a slope and arranging pile cap beams and pile top displacement monitoring devices on the slip mass; and loading and acquiring monitored data output by each monitoring device at the top of the slope. Due to the adoption of the method, the characters of the micro piles in the actual using process can be accurately acquired, so that the micro piles are beneficial for being popularized and applied in the landslide control.

Owner:INST OF GEOMECHANICS

Soft soil foundation high fill embankment for effectively controlling post-construction settlement and construction method

ActiveCN107419630AReduced settlement structureImprove integrityRoadwaysClimate change adaptationPile capEngineering

The invention relates to a soft soil foundation high fill embankment for effectively controlling post-construction settlement and a construction method. The soft soil foundation high fill embankment comprises a bearing layer, a soft soil foundation, a high fill light solidified silt embankment and an embankment settlement control structure embedded in the soft soil foundation. The upper surface and the two sides of the high fill light solidified silt embankment are paved with a pavement waterproof layer and slope protection waterproof layers correspondingly. The slope toe of each slope protection waterproof layer is provided with a concrete sealing ditch. The embankment settlement control structure comprises a rigid pile group, pile caps, a semi-rigid reinforced solidification cushion layer, a powdery fine sand inverse filtering layer and a waterproof geotextile. Rigid piles in the rigid pile group punch the soft soil foundation and are embedded in the bearing layer. The pile caps are arranged at the tops of the rigid piles. The waterproof geotextile, the powdery fine sand inverse filtering layer and the semi-rigid reinforced solidification cushion layer are sequentially paved at the tops of the pile caps from top to bottom. The high fill light solidified silt embankment is arranged on the upper surface of the waterproof geotextile. The waterproof geotextile is sealed at the bottoms of the concrete sealing ditches. According to the soft soil foundation high fill embankment for effectively controlling post-construction settlement and the construction method, the structure is reasonable, construction is convenient, and embankment settlement can be reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

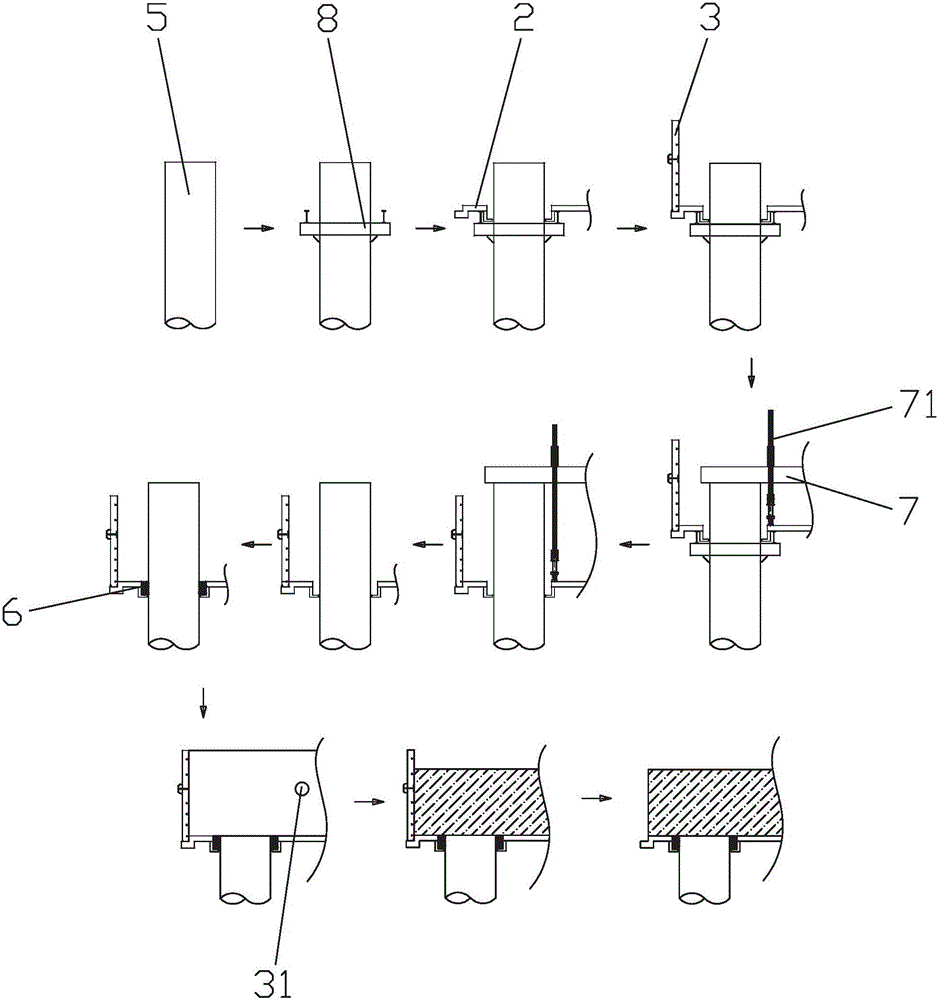

Construction method and structure of underwater reinforced concrete combined suspension-box cofferdam free of bottom-sealing concrete

ActiveCN105951856ALow level of operation requiredShorten the construction periodFoundation engineeringReinforced concreteUnderwater

The invention discloses a construction method and structure of an underwater reinforced concrete combined suspension-box cofferdam free of bottom-sealing concrete. The construction method comprises the following steps: after pile foundation construction is finished, manufacturing a suspension box; mounting carrying pole beams and continuous jacks on pile casings as lowering devices of the suspension box; slowly lowering the suspension box in place with the jacks; and pouring underwater undispersed concrete between a bottom board and annular stepped grooves of the pile casings. According to the technological method, the suspension box stops water by virtue of the reinforced concrete bottom board and the underwater undispersed concrete, which can thoroughly break through the conventional construction method in which bottom sealing is indispensable in construction of an underwater bridge / wharf pile cap suspension box cofferdam, saves a great amount of concrete and steel, reduces the construction cost, simplifies construction procedures and shortens the construction period; and the method is simple in process and convenient to operate, has a good water-stopping effect and a wide application range, has low requirements on ambient environment, corollary equipment and operation level of workers, and has high popularization and application values.

Owner:CRCC HARBOR & CHANNEL ENG BUREAU GRP

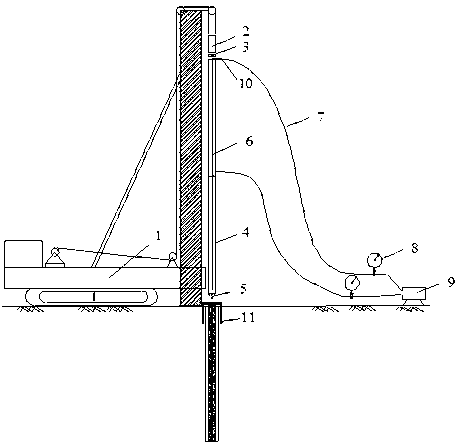

Device for drilling rock and embedding rock-socketed prestressed pipe pile by down-hole hammer and construction method of device

InactiveCN103132908ASolve the technical problem of poor effect of rock-socketed pile plantingBorehole drivesBulkheads/pilesPile capHigh pressure

The invention relates to a device for drilling rock and embedding a rock-socketed prestressed pipe pile by a down-hole hammer and a construction method of the device and aims to solve the problem that existing similar product structures and construction methods are poor. The device comprises a crawler-type pile driver, a casing pipe, an upper power head, a lower power head, a long spiral drill bar, the down-hole hammer, a rock drilling bit, an oil atomizer, an air compressor, an air duct and the like. The device is characterized in that the down-hole hammer is a pneumatic down-hole hammer, high-pressure blast generated by the air compressor sequentially passes through the air duct, the oil atomizer, the air duct and the upper power head and then passes through an air channel of inner holes of the long spiral drill bar to reach to the down-hole hammer, the casing pipe is driven by the lower power head to rotate anticlockwise to be pre-buried in a clay stratum, a gravel layer and a rock stratum, then the pipe pile is placed in the casing pipe, the pipe pile is embedded into the rock stratum, the casing pipe can be slowly pulled out by the crawler-type pile driver, a drop hammer is used for hammering a pile cap or a pile follower of the pipe pile till the pipe pile is fixed in a drill hole, and the pipe pile is organically combined with a rock surface of the rock stratum at the hole bottom. The device is applied to the construction of the rock-socketed prestressed pipe pile.

Owner:宁波市中乾建筑工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com