Light frame-subgrade pile-board structure in karst areas

A technology of pile-slab structure and karst areas, which is applied in the direction of infrastructure engineering, roads, buildings, etc., can solve the problems of difficult handling and detection of karst foundations, and achieve the goal of avoiding difficult handling and detection, simple construction technology, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

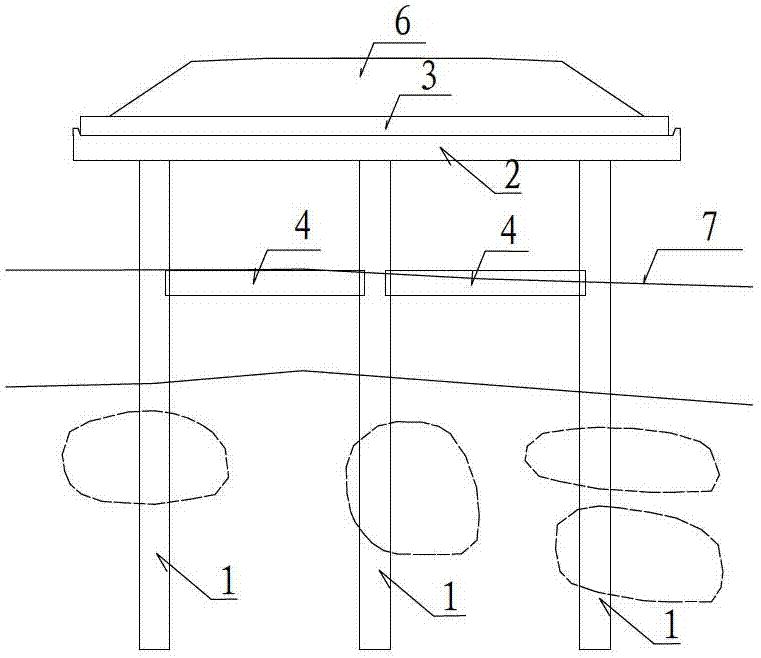

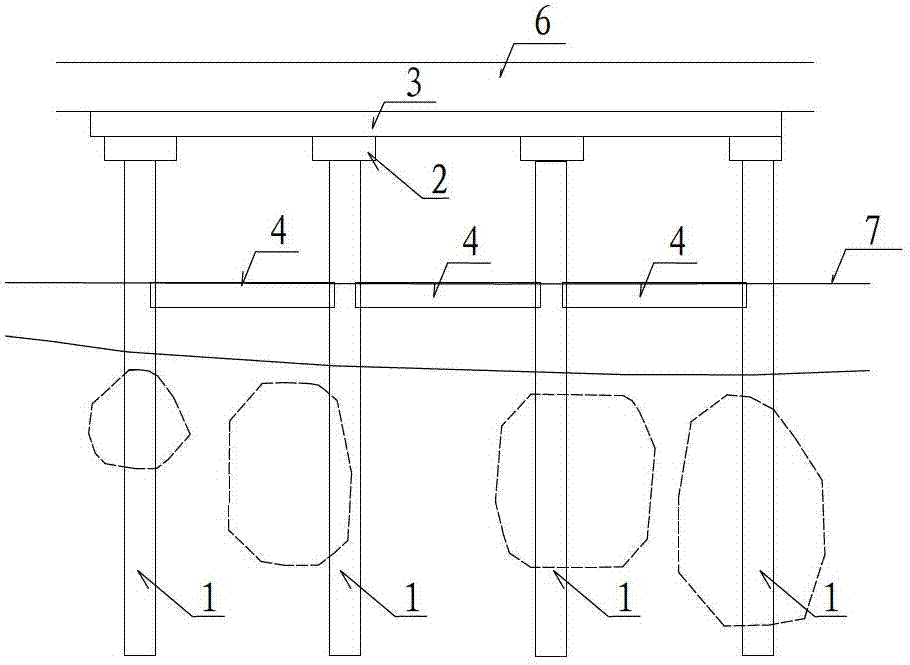

[0012] refer to figure 1 and figure 2 , the light frame subgrade pile-slab structure structure in karst area of the present invention, it comprises: foundation pile 1, arranges in row along the horizontal interval of railway, longitudinal interval arranges in column; Rigid connection; platform cap 3, placed on top of foundation pile 1 or joist 2 and rigidly connected with it; transverse tie beam 4, set between foundation piles 1 in the same row and rigidly connected with it; longitudinal tie beam 5, set It is between and rigidly connected with foundation piles 1 in the same row. The present invention bears the vertical gravity generated by the subgrade filling soil 6, the train and the track structure through the foundation pile 1, and bears the horizontal load and temperature load of the train through the space frame system composed of the foundat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com