Workpiece with high-density nano-diamond thin film on surface, and preparation method of high-density nano-diamond thin film

A nano-diamond and workpiece technology, applied in the field of nano-diamond, can solve the problems of many film defects and poor bonding force, and achieve the effects of high film quality, low cost, and improved nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

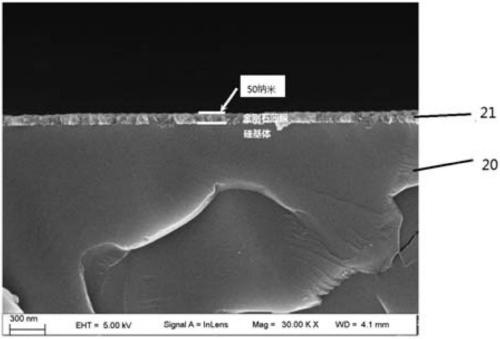

[0041] A preparation method of high-density nano-diamond film, comprising the following steps:

[0042] Step 1, take the silicon wafer substrate for surface pretreatment, so that the surface of the silicon wafer is negatively charged; first, the substrate is immersed in a temperature of 92°C and a ratio of NH 3 H 2 O:H 2 O:H 2 O 2 =10:50:10 (volume ratio) solution for 10 minutes, then the matrix was taken out, and ultrasonically cleaned in deionized water for 3 times, each time ultrasonic for 5 minutes;

[0043] Step 2: Prepare a nano-diamond suspension with positive charges on the surface of the diamond particles: add lysine to the water to prepare a lysine concentration of 5×10 -6 mol / L, the lysine solution of pH 7, adding the nano-diamond powder purchased on the market to the above-mentioned lysine solution, and ultrasonically dispersing to obtain a nano-diamond suspension with a mass concentration of 0.005% of the nano-diamond particles ;

[0044] Step 3, put the sub...

Embodiment 2

[0050] A preparation method of high-density nano-diamond film, comprising the following steps:

[0051] Step 1, take the silica substrate for surface pretreatment, so that the surface of the substrate is negatively charged: first, the substrate is immersed in a temperature of 82 ° C and a ratio of NH 3 H 2 O:H 2 O:H 2 O 2 =10:50:10 (volume ratio) solution for 10 minutes, then take out the matrix, ultrasonically clean it in deionized water for 3 times, each time ultrasonic for 5 minutes;

[0052] Step 2: Prepare a nano-diamond suspension with positive charges on the surface of the diamond particles: add lysine to the water to prepare a lysine concentration of 5×10 -6 mol / L, the lysine solution of pH 4, adding the nano-diamond powder purchased on the market to the above-mentioned lysine solution, and ultrasonically dispersing to obtain a nano-diamond suspension with a mass concentration of 0.005% of the nano-diamond particles ;

[0053] Step 3, put the substrate pretreated...

Embodiment 3

[0057] A preparation method of high-density nano-diamond film, comprising the following steps:

[0058] Step 1, take a silicon carbide substrate for surface pretreatment to make the surface of the substrate negatively charged: ultrasonically clean the substrate in acetone, alcohol and deionized water for 15 minutes in sequence.

[0059] Step 2: Prepare a nano-diamond suspension with positive charges on the surface of the diamond particles: add lysine to the water to prepare a lysine concentration of 5×10 -6 mol / L, a lysine solution with a pH of 3, adding the nano-diamond powder purchased on the market to the above-mentioned lysine solution, and ultrasonically dispersing to obtain a nano-diamond suspension with a mass concentration of 0.05% of the nano-diamond particles ;

[0060] Step 3, put the substrate pretreated in step 1 into the nano-diamond suspension prepared in step 2, ultrasonically vibrate for 30 minutes, and the power is 280W, so that the nano-diamond particles ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com