Preparation method of graphene monocrystal

A graphene and single crystal technology, applied in the field of graphene single crystal preparation, can solve the problem of low efficiency of graphene single crystal preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

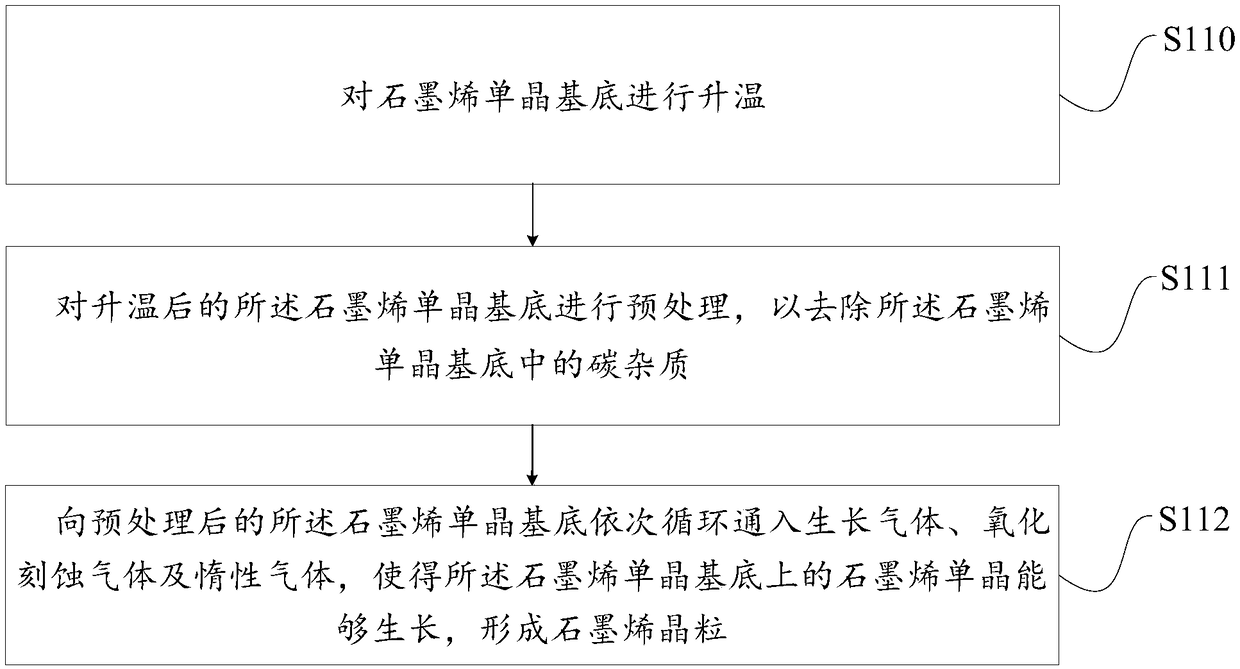

[0026] The present embodiment provides a kind of preparation method of graphene single crystal, such as figure 1 As shown, the methods include:

[0027] S110, heating the graphene single crystal substrate;

[0028] In this embodiment, first determine the material of the graphene single crystal substrate, the graphene single crystal substrate can include: copper Cu substrate, nickel Ni substrate, platinum Pt substrate, silicon Si substrate, germanium Ge substrate, silicon dioxide SiO 2 Any one of the substrate, the sapphire Sapphire substrate, and the zinc oxide ZnO substrate may also be any one or more alloy substrates of Cu, Ni, Pt, Si, and Ge. Preferably, it is a Cu substrate.

[0029] After confirming, put the graphene single crystal substrate into a chemical vapor deposition chamber (CVD, Chemical VaporDeposition), heat up the graphene single crystal substrate, and raise the temperature of the graphene single crystal substrate to 600-1083°C, preferably The ground is 800...

Embodiment 2

[0043] In practical applications, when a copper substrate is used to prepare a graphene single crystal, the specific implementation is as follows:

[0044] Put the graphene single crystal substrate 1 into the CVD chamber, raise the temperature of the graphene single crystal substrate, and raise the temperature of the graphene single crystal substrate to 750°C. Wherein, the air pressure in the CVD chamber is normal pressure: 720 Torr.

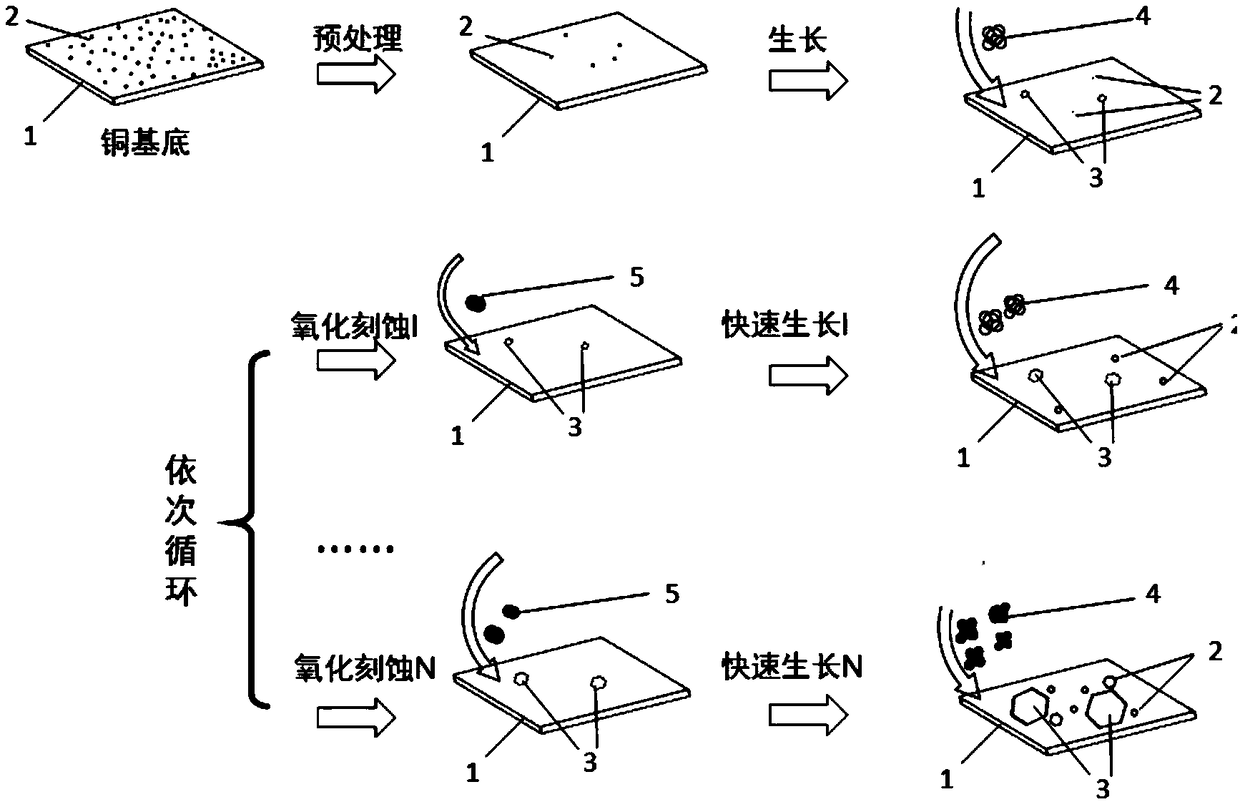

[0045] see figure 2 , pretreating the heated graphene single crystal substrate to remove carbon impurities 2 in the graphene single crystal substrate and reduce the nucleation density of graphene.

[0046] The pretreatment of the heated graphene single crystal substrate includes: annealing the heated graphene single crystal substrate in an oxidizing gas, a reducing gas or an inert gas. Wherein, the oxidizing gas may include: O 2 Mixed gas with Ar, the reducing gas can include H 2 A mixed gas with Ar, the inert gas may include: argon Ar.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com