Patents

Literature

55results about How to "Reduce nucleation density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

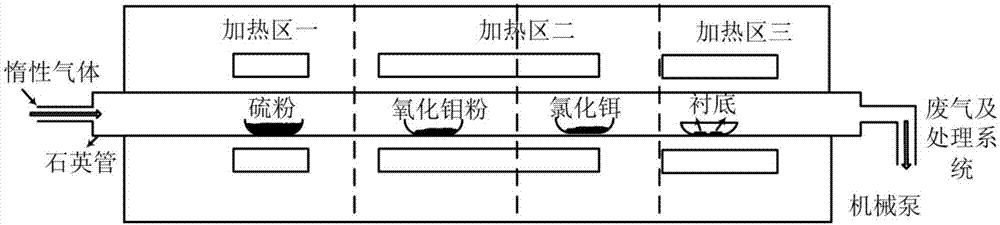

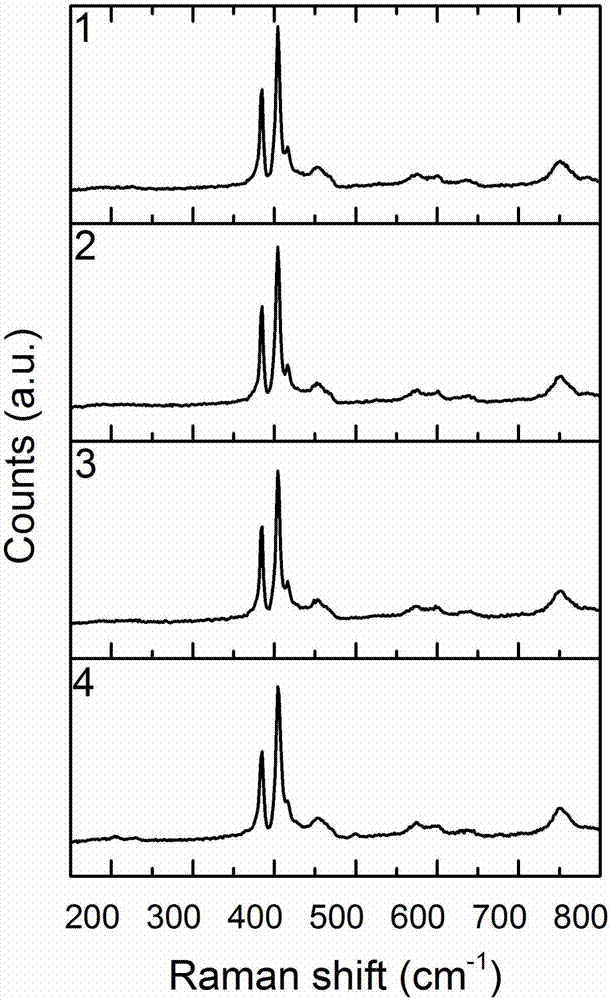

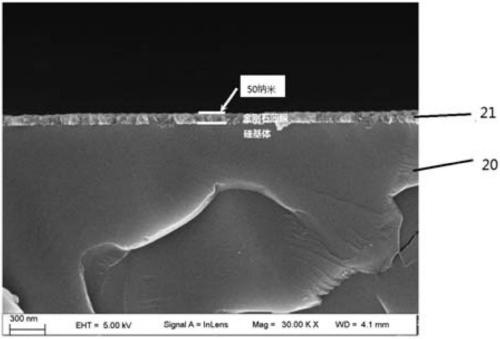

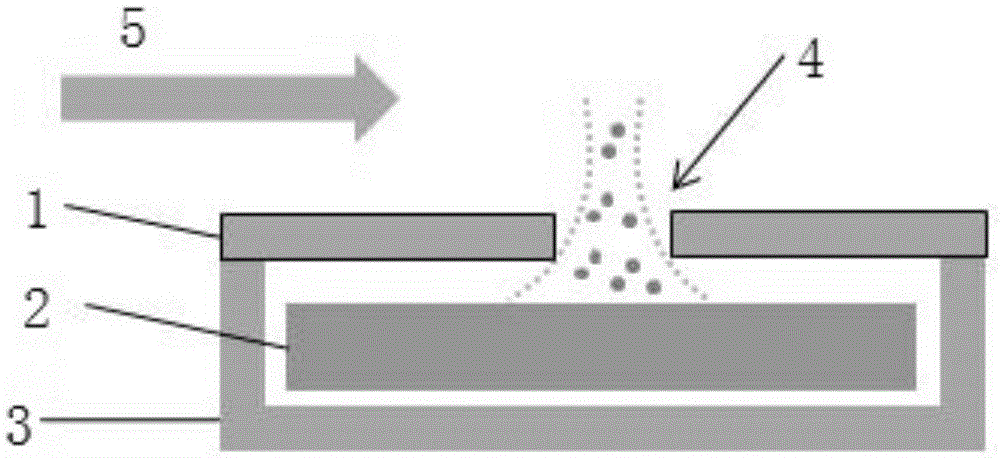

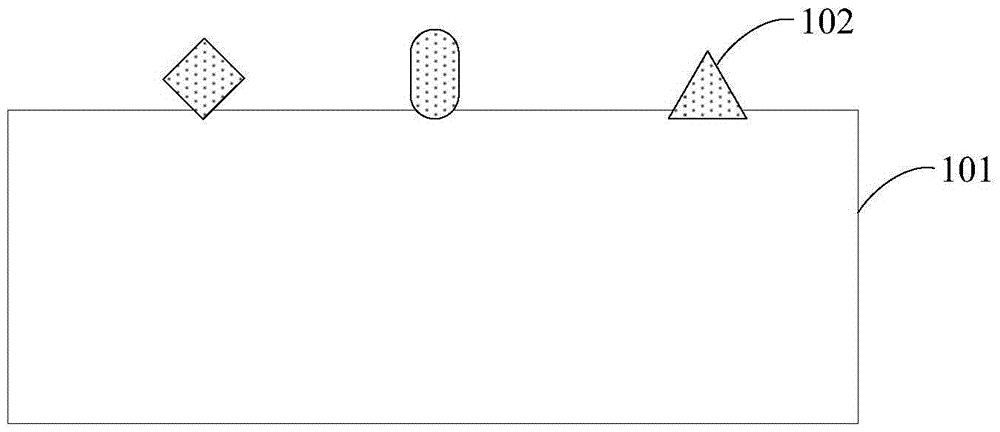

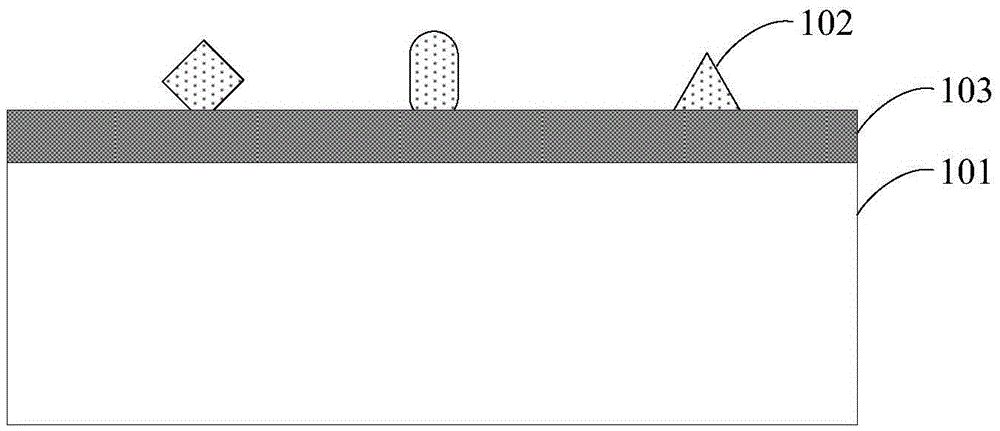

Preparation method of monolayer molybdenum disulfide thin film

ActiveCN107299333AAvoid too high a nucleation densityReduce nucleation densityChemical vapor deposition coatingTube furnaceMolybdenum disulfide

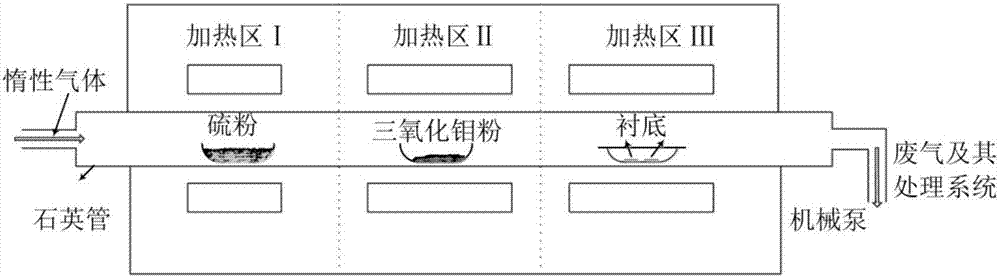

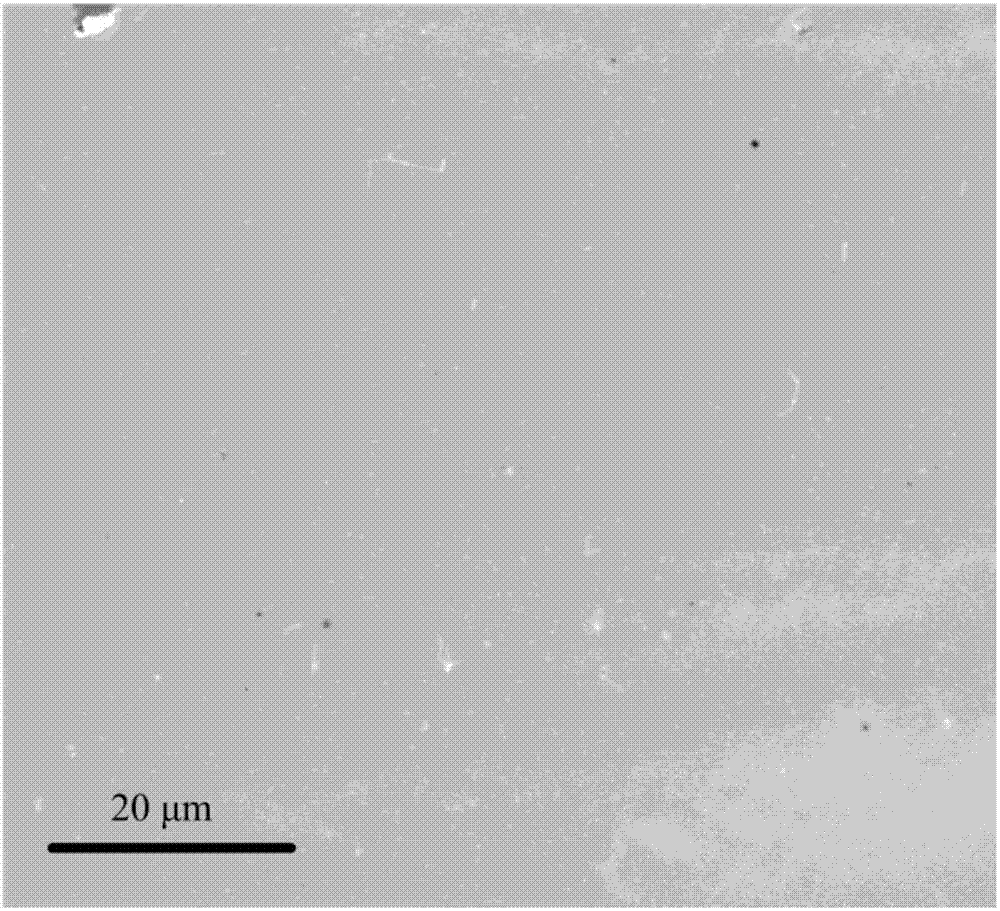

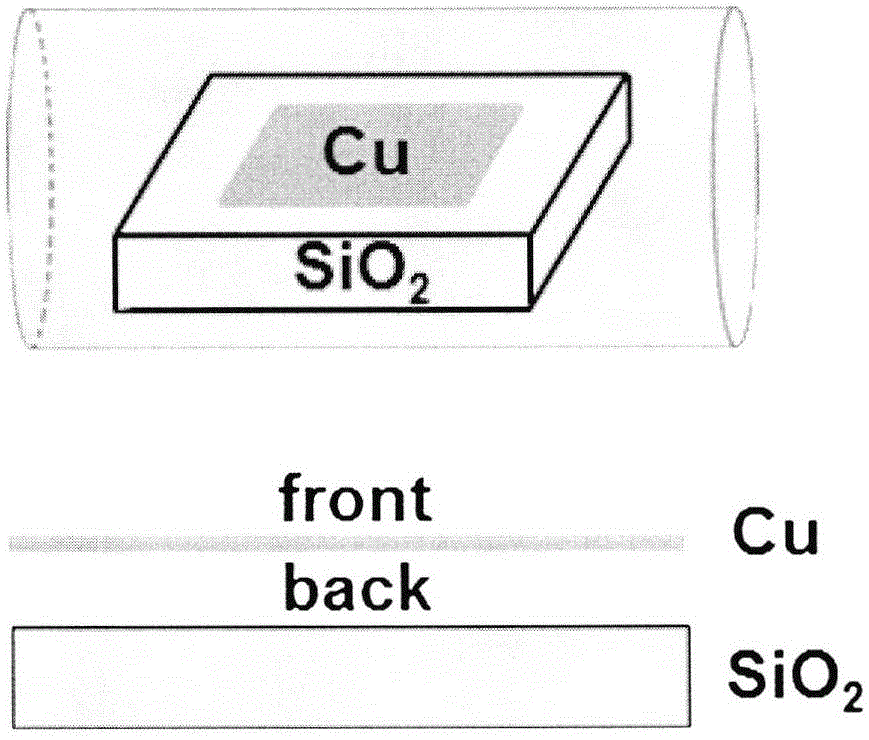

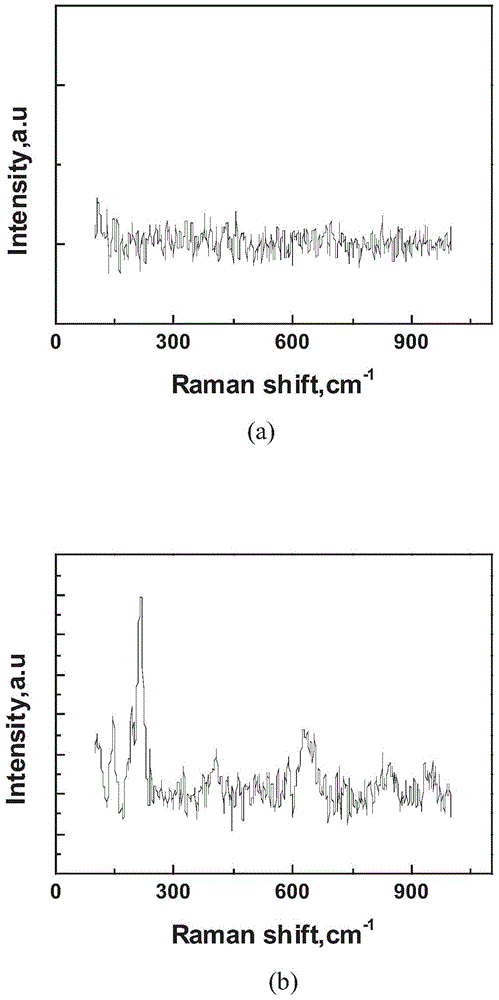

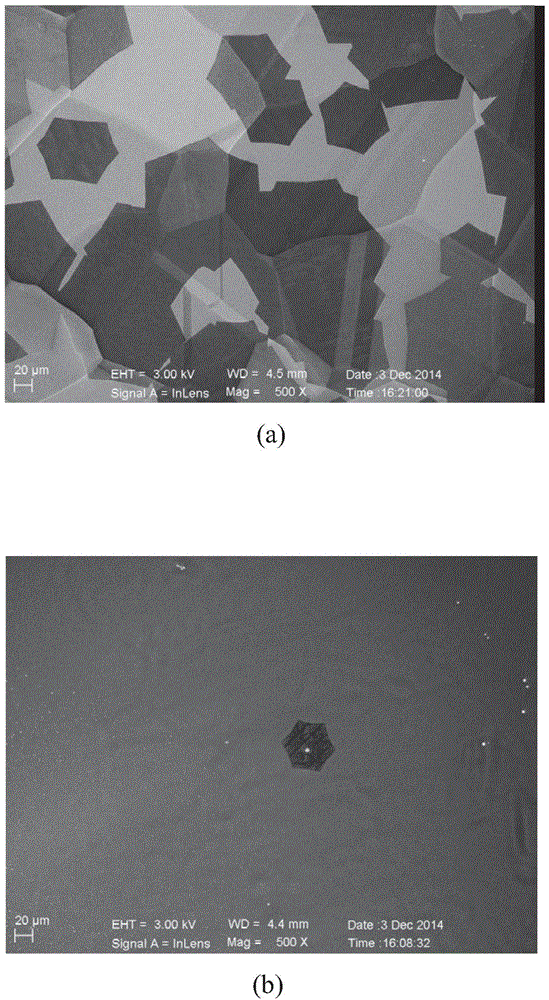

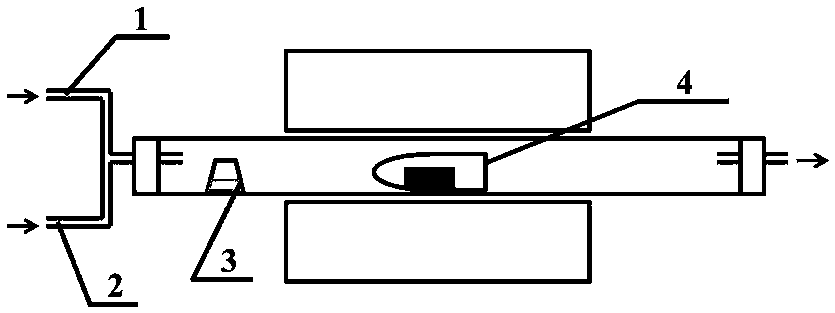

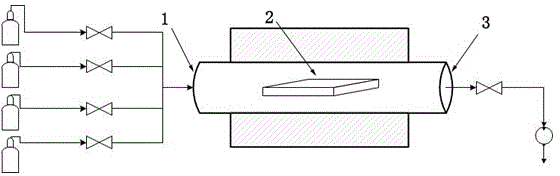

The invention discloses a preparation method of a monolayer molybdenum disulfide thin film. The preparation method comprises the following steps: step 1, arranging three temperature zones by using a vacuum tube type furnace, putting powdered sulfur in the temperature zone I, putting nolybdenum trioxide powder in the temperature zone II, putting a substrate at the bottom of a crucible with a cover and then putting the crucible in the temperature zone III; step 2, introducing carrier gas into the vacuum tube type furnace; step 3, heating the temperature zone II to 150-350 DEG C and heating the temperature zone III to 150-350 DEG C; step 4, heating the temperature zone II to 580-800 DEG C to obtain gaseous MoO3-x, wherein x is more than 0 but less than or equal to 1; heating the temperature zone III to 550-750 DEG C; step 5, heating the temperature zone I to 130-220 DEG C to obtain sulfur vapor; heating the temperature zone II to 800-950 DEG C and heating the temperature zone III to 750-900 DEG C; adjusting the flow rate of the carrier gas, carrying the sulfur vapor and the gaseous MoO3-x into a reaction chamber of the crucible through the carrier gas and forming the monolayer molybdenum disulfide thin film on the surface of the substrate. The preparation method disclosed by the invention has the advantage that the substrate is put in the quasi-enclosed crucible, so that the nucleation density of a reaction source is reduced, and the monolayer molybdenum disulfide thin film is obtained.

Owner:XIAN UNIV OF TECH

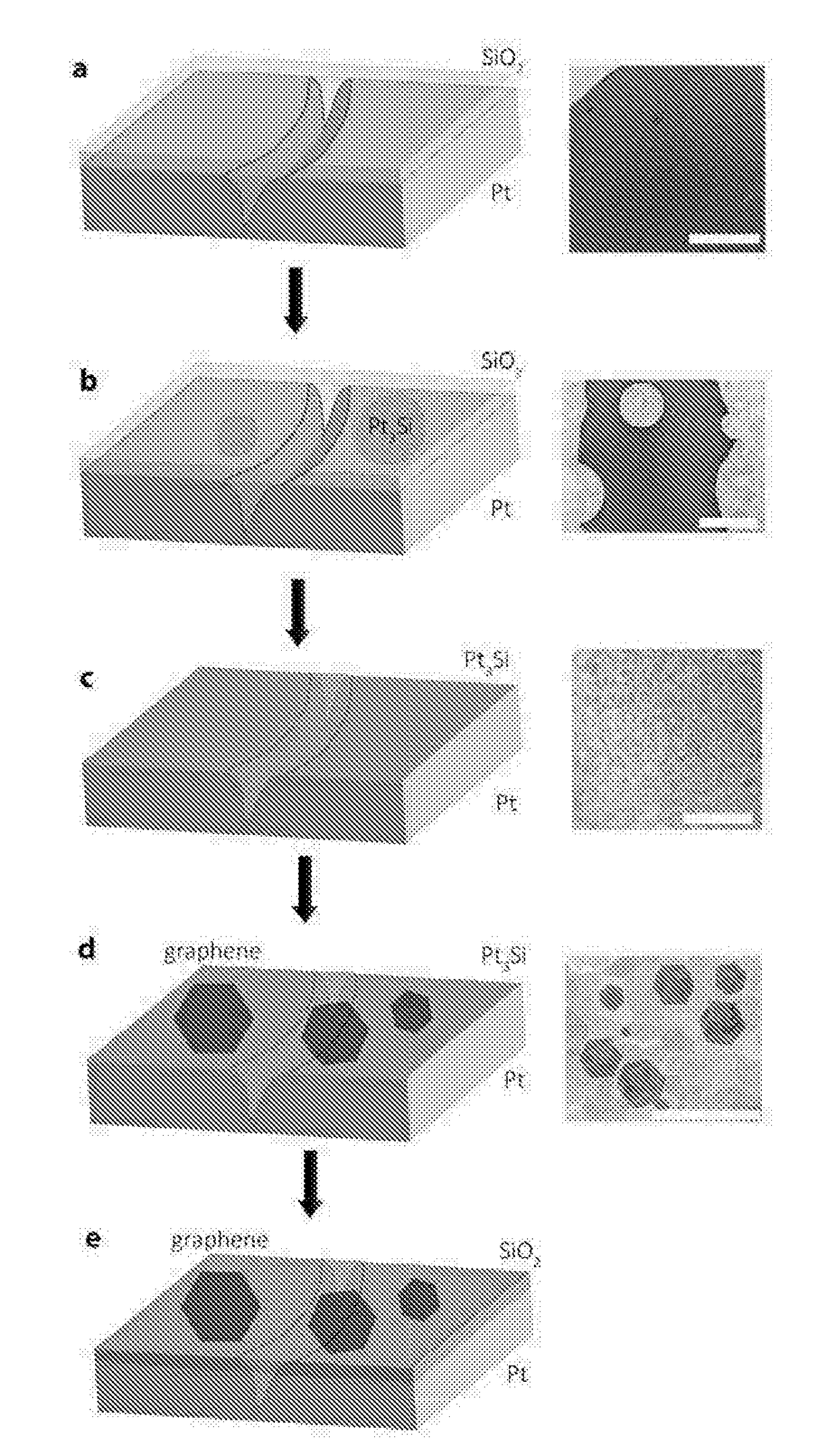

Oxide-substrate-assisted method for quickly preparing large-size single-crystal graphene

ActiveCN105112998ASimplify the growth processShorten the growth cyclePolycrystalline material growthFrom chemically reactive gasesMetal foilSingle crystal

The invention provides an oxide-substrate-assisted method for quickly preparing large-size single-crystal graphene, relating to a preparation method of single-crystal graphene. The method is mainly characterized in that metal foil is used as a catalyst and growth substrate, oxide is used as a substrate to closely contact the metal foil, and a normal-pressure chemical vapor deposition (CVD) process is utilized to quickly obtain the large-size high-quality single-crystal graphene. The method solves the technical problems of substrate surface treatment, long growth cycle and the like in the CVD process for preparing large-size single-crystal graphene by using the common single crystal as the substrate, and quickly prepares the high-quality large-size single-crystal graphene sample by using the very simple process.

Owner:PEKING UNIV

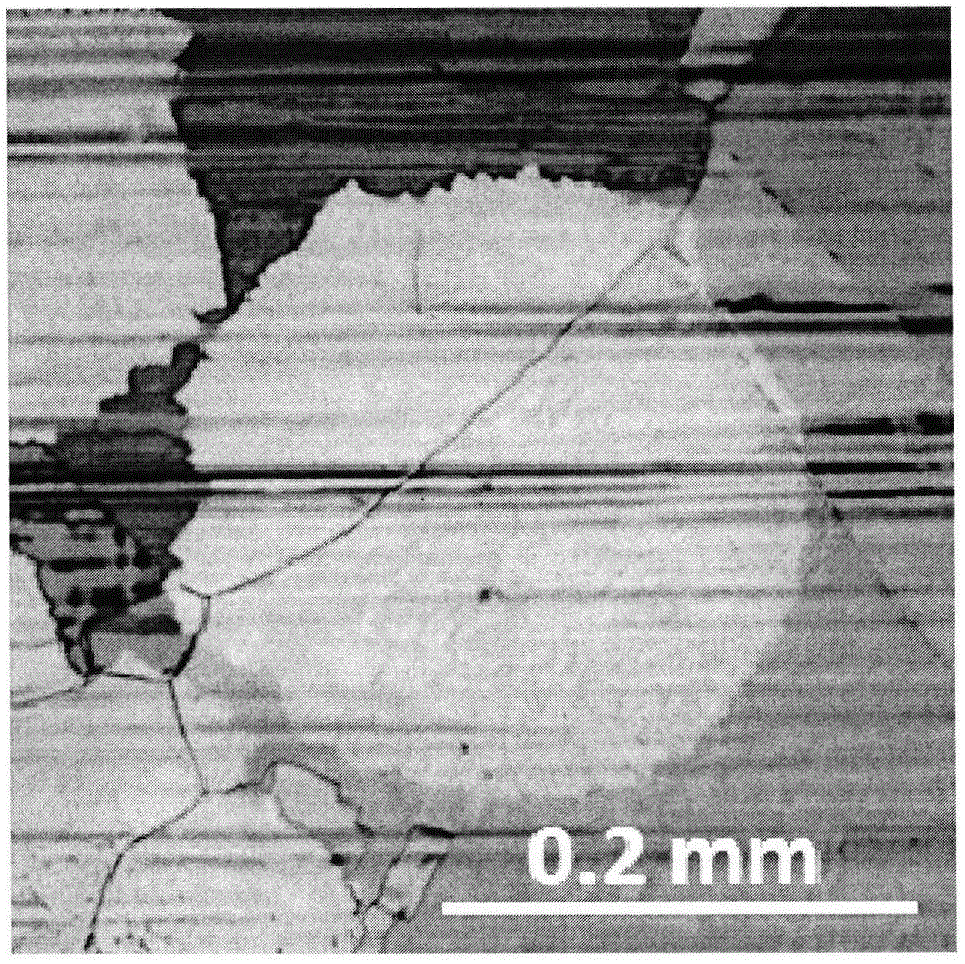

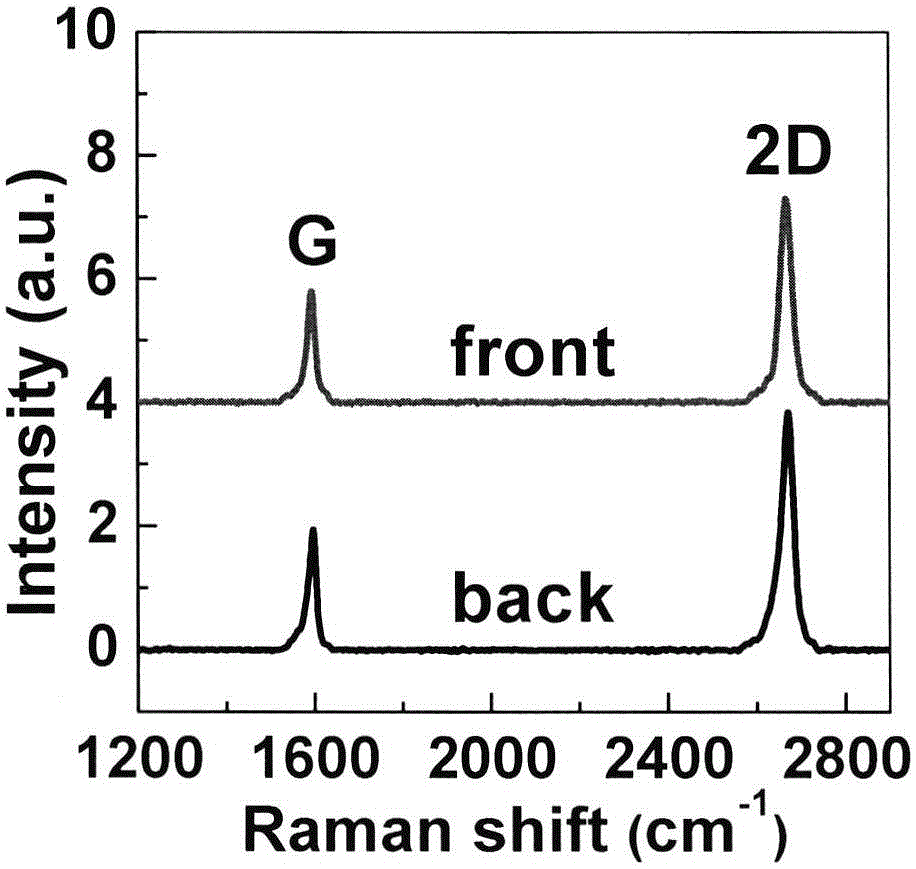

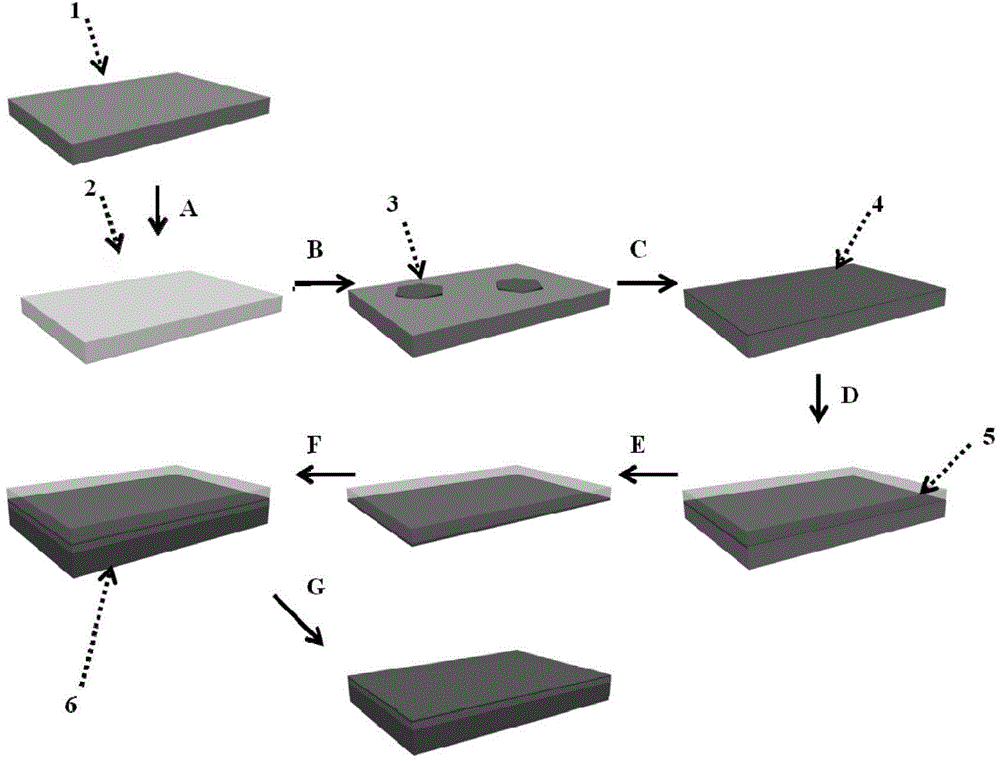

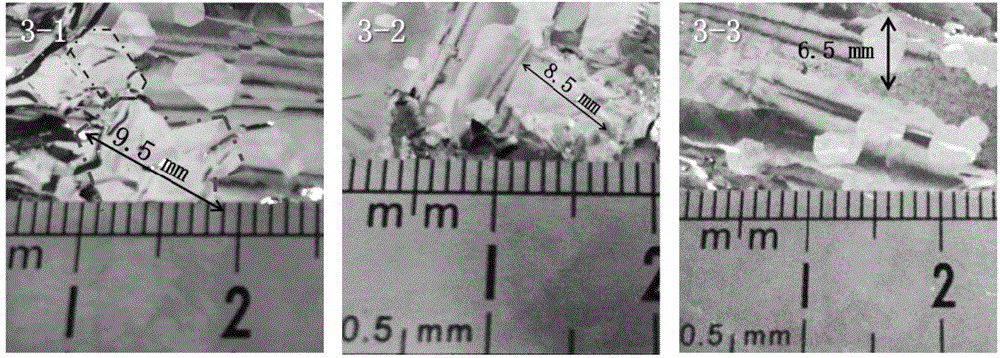

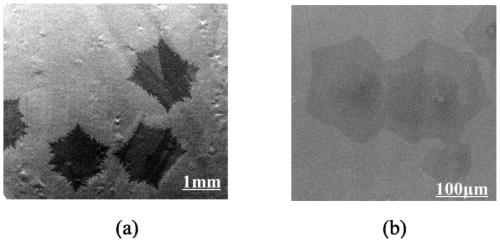

Large single crystal graphene and preparation method thereof

ActiveCN104674343AEasy to prepareReduce nucleation densityPolycrystalline material growthFrom chemically reactive gases1,3,5-TriazineSingle crystal

The invention relates to a large single crystal graphene and preparation method thereof. The preparation method comprises the following steps: 1) annealing a copper base under reducing atmosphere to obtain annealed copper base; 2) under triazine derivative steam atmosphere, treating the copper base annealed after the annealing treatment in the step 1) to obtain the copper base after the triazine derivative treatment, wherein the triazine derivative is selected from at least one of tripolycyanamide, 2,4-diamino-6-methyl-1,3,5-triazine, and 2-amino-4-methyl-6-methoxy-1,3,5-triazine; 3) depositing graphene on the surface of the copper base subjected to triazine derivative biological treatment by adopting a chemical vapor deposition method to obtain the large single crystal graphene. The preparation method is simple and suitable for large-scale production, the single crystal domain size achieves sub-centimeter level, and the single crystal quality is high and can be applied to the electronics.

Owner:PEKING UNIV

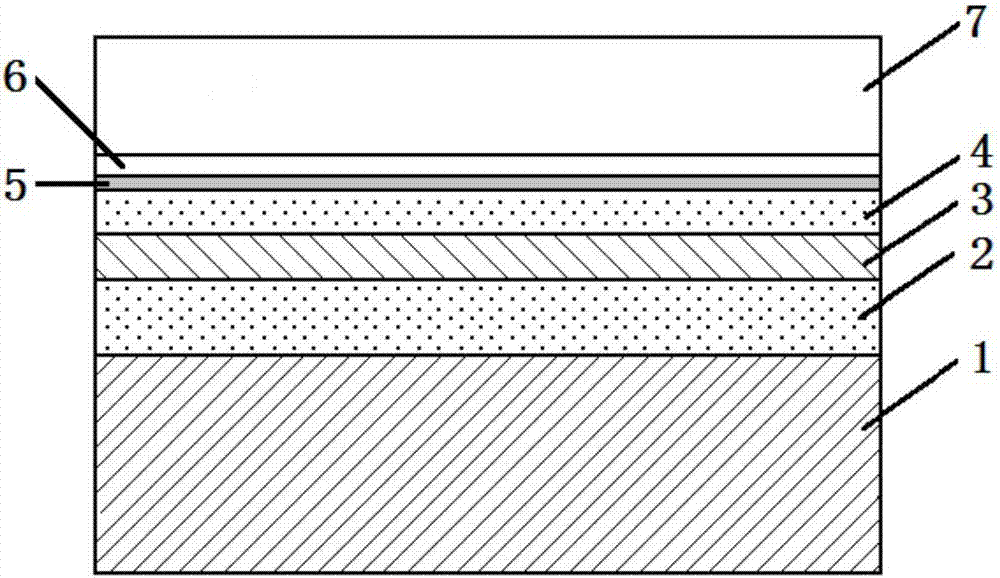

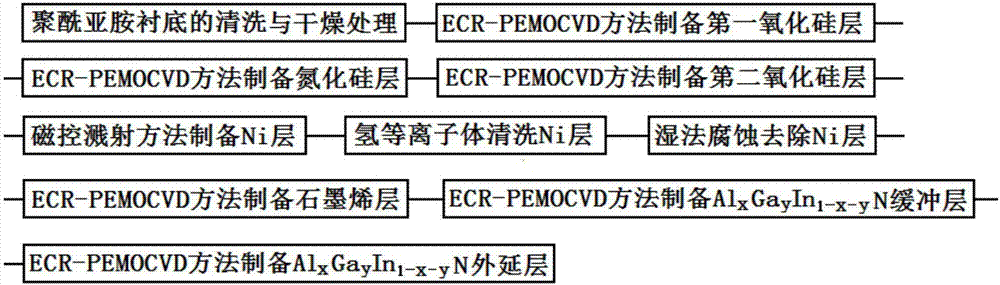

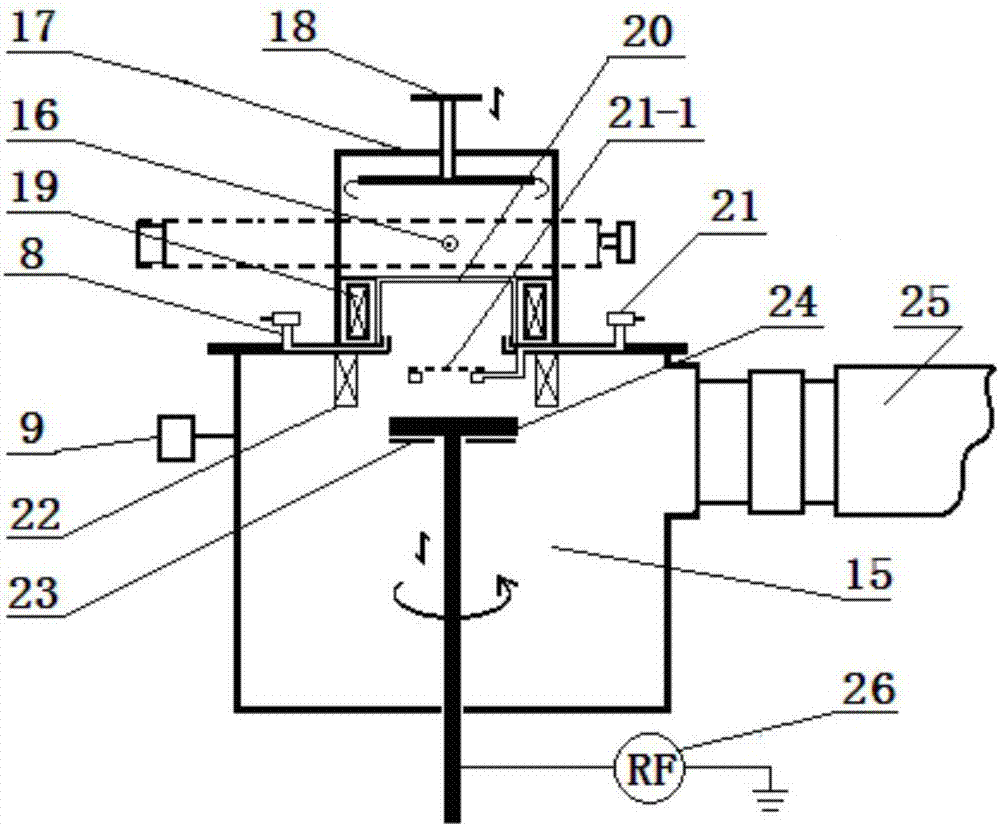

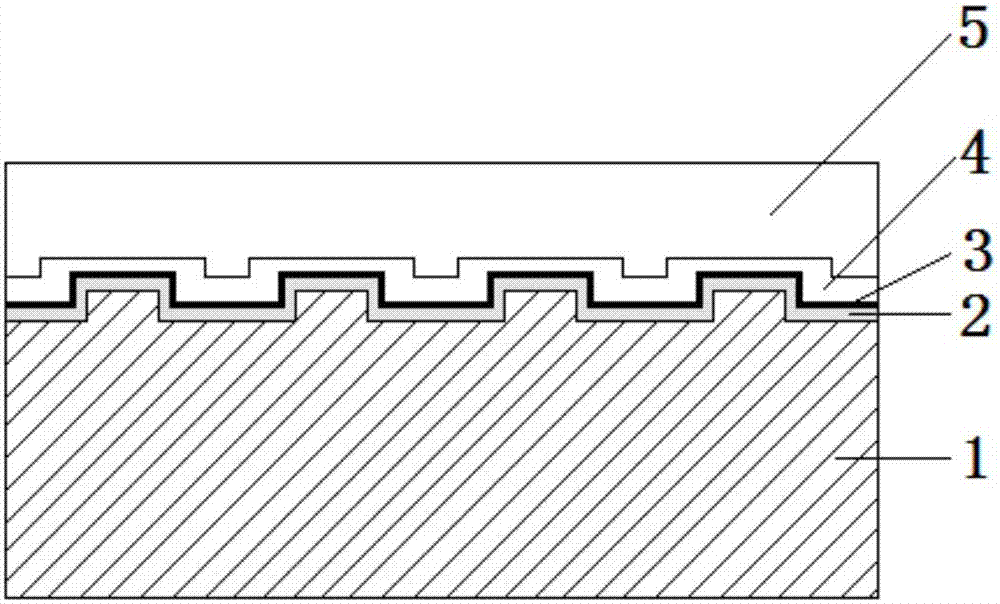

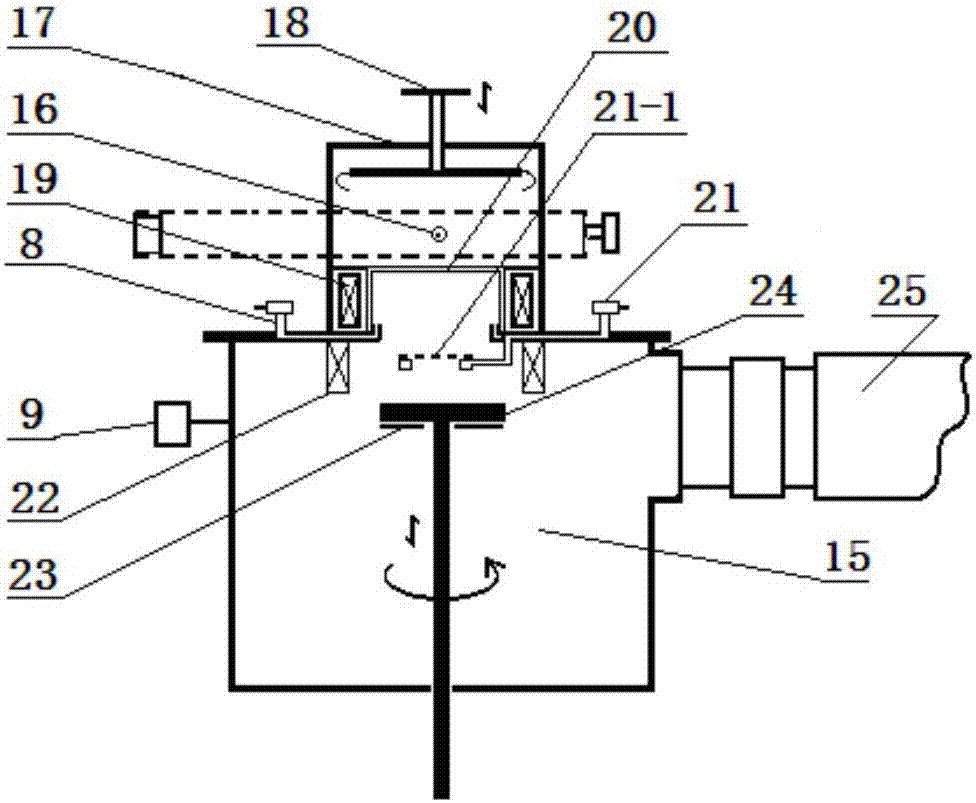

Gallium nitride base film on flexible polyimide substrate and preparing method of gallium nitride base film

ActiveCN107083540AReduce nucleation densityUniform large areaSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPolyimide substrateEtching

The invention belongs to the field of III group nitride film and device manufacturing, and provides a gallium nitride base film on a flexible polyimide substrate and a preparing method of the gallium nitride base film. Specifically, polyimide serves as the substrate, a first silicon oxide layer, a silicon nitride layer and a second silicon oxide layer are sequentially prepared on the polyimide substrate through an ECR-PEMOCVD method, then a Ni layer is prepared on the second silicon oxide layer through a magnetron sputtering method, a graphene layer is prepared on the interface of the Ni layer and the second silicon oxide layer through the ECR-PEMOCVD method, then, the Ni layer is removed through a wet etching method, and finally, an AlxGayIn1-x-yN buffering layer and an epitaxial layer are sequentially prepared on the graphene layer through the ECR-PEMOCVD method. A prepared AlxGayIn1-x-yN film can be used for preparing InGaN solar cells, AlGaN ultraviolet detectors, GaN film thin film transistors and other flexible devices.

Owner:DALIAN UNIV OF TECH

Process for the production of two-dimensional nanomaterials

ActiveUS20170114450A1Minimize impactChemical kinetics of the synthesis may also be changedMaterial nanotechnologyNitrogen compoundsLiquid surfacesChemistry

Owner:OXFORD UNIV INNOVATION LTD

Gallium-nitride-based film on graphene-modified patterned metal substrate and preparation method

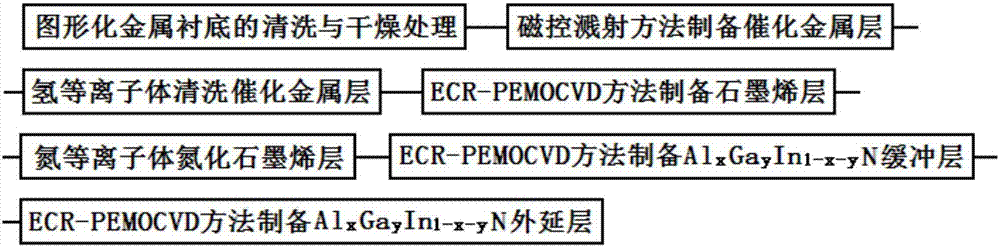

InactiveCN107083535AUniform large areaThickness is easy to controlVacuum evaporation coatingSputtering coatingDislocationCvd graphene

The invention belongs to the technical field of manufacturing of gallium-nitride-based films and gallium-nitride-based devices and provides a gallium-nitride-based film on a graphene-modified patterned metal substrate and a preparation method of the gallium-nitride-based film on the graphene-modified patterned metal substrate. Patterned metal is used as the substrate; a catalytic metal layer is prepared on the metal substrate through a magnetron sputtering method firstly; and then, an electron cyclotron resonance-plasma enhanced metal organic chemical vapor deposition method is adopted to sequentially conduct nitrogen plasma cleaning on the catalytic metal layer, prepare a graphene layer, prepare an AlxGayIn1-x-yN buffering layer and prepare AlxGayIn1-x-yN epitaxial layer. The gallium-nitride-based film which is low in dislocation density and high in crystalline quality can be prepared on a low-cost non-monocrystal metal substrate. The prepared gallium-nitride-based film can be directly used as a template substrate and the like of the gallium-nitride-based devices and has a broad application prospect.

Owner:DALIAN UNIV OF TECH

Preparation method of erbium-doped molybdenum disulfide film

ActiveCN107313023AReduce gas phase concentrationAchieve preparationChemical vapor deposition coatingSulfurTube furnace

The invention discloses a preparation method of an erbium-doped molybdenum disulfide film. The method comprises the following steps that (1), powdered sulfur is placed in a first temperature area, molybdenum trioxide powder and erbium chloride powder are placed in a second temperature area, a substrate is placed on the surface of crucible, and then the crucible is placed in a third temperature area; (2), a vacuum tube furnace is internally subjected to vacuumizing, and the carrier gas is introduced into the vacuum tube furnace to clean the vacuum tube furnace; (3), the carrier gas is introduced continuously, the second temperature area is heated to be 150-350 DEG C, and the third temperature area is heated to 150-350 DEG C; (4), the vacuum tube furnace for pre-evaporation and pre-nucleation of the third temperature area is set to be minus 150-150 DEG C, and gaseous MoO3-x is obtained, wherein x is larger than zero and smaller than or equal to one; (5), the first temperature area is heated to be 130-220 DEG C, sulphur vapor is obtained, the second temperature area is heated to be 800-900 DEG C, and the third temperature area is heated to be 700-850 DEG C; and (6), the first temperature area, the second temperature area and the third temperature area are cooled to the room temperature, and the molybdenum disulfide film is obtained. Control over the appearance of the molybdenum disulfide film is achieved through control over the temperature gradient between the pre-evaporation temperature and the pre-nucleation temperature.

Owner:XIAN UNIV OF TECH

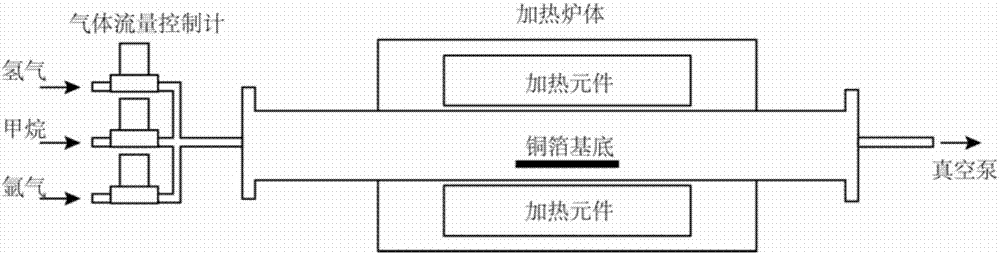

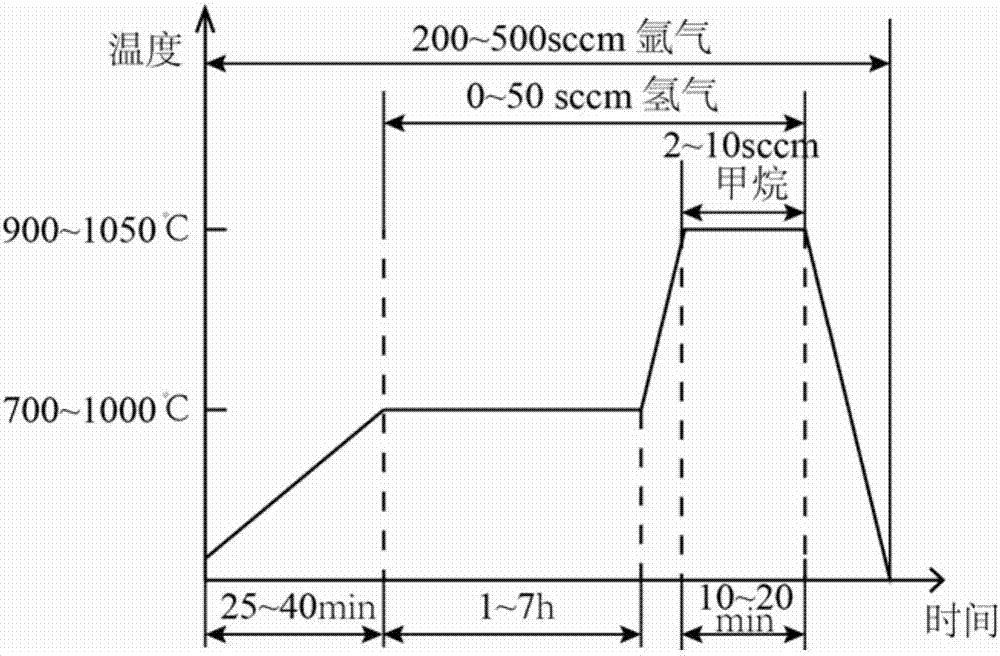

Method for improving electrical conductivity of graphene thin films prepared by normal-pressure chemical gas-phase sedimentation method

InactiveCN107217239AInhibits heterogeneous nucleationReduce nucleation densityChemical vapor deposition coatingGas phaseSurface cleaning

The invention belongs to the technical field of grapheme material preparation and discloses a method for improving the electrical conductivity of graphene thin films prepared by a normal-pressure chemical gas-phase sedimentation method. The method for improving the electrical conductivity comprises the steps that (1) copper foil is subjected to surface cleaning treatment; (2) the treated copper foil is subjected to high-temperature heat treatment, and the conditions of high-temperature heat treatment are that the flow speed of argon is 200-500 sccm, the flow speed of hydrogen is 0-50 sccm, and constant-temperature treatment is conducted at the temperature of 700-100 DEG C for 5-7 hours; (3) the copper foil subjected to high-temperature treatment is heated till the temperature is 900-1050 DEG C, and methane is led in for growth; and (4) leading-in of the methane and the hydrogen is stopped, leading-in of the argon is kept, cooling is conducted, and then the graphene thin films grown to copper piece substrates are obtained. According to the for improving the electrical conductivity of the graphene thin films prepared by the normal-pressure chemical gas-phase sedimentation method, operating is easy, extra equipment do not need to be additionally arranged, the cost is low, operating is easy, the purposes that sheet resistance of the graphene thin films is greatly reduced, and the electrical conductivity of the graphene thin films is improved can be achieved.

Owner:SOUTH CHINA UNIV OF TECH +1

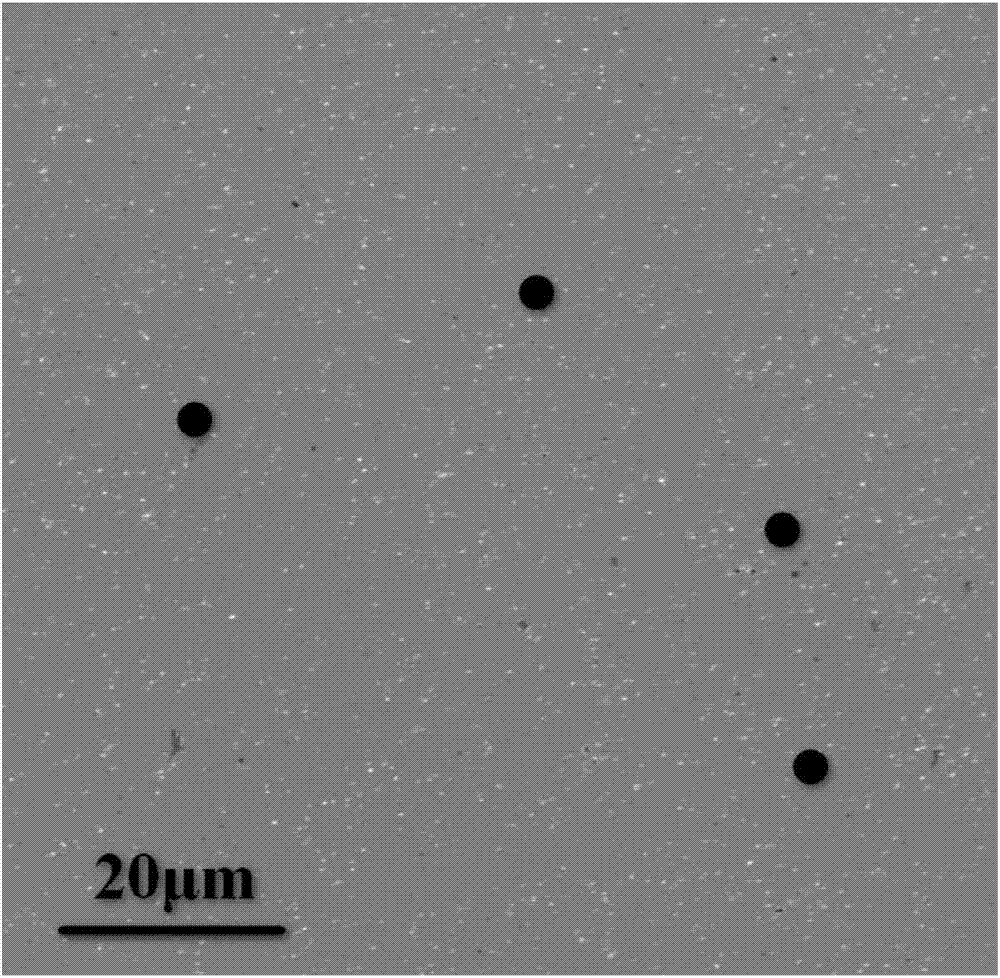

Low nucleation density graphene single crystal preparation method based on cuprous oxide film substrate

InactiveCN104975344AThe effect is obviousGood repeatabilityPolycrystalline material growthFrom chemically reactive gasesSingle crystalLow density

The present invention relates to a low nucleation density graphene single crystal preparation method based on a cuprous oxide film substrate. The low nucleation density graphene single crystal preparation method is characterized in that the low nucleation density graphene single crystal is directly prepared through the cuprous oxide film substrate. The specific preparation steps comprise: (1) preparing a cuprous oxide film; and (2) preparing a low-density graphene single crystal. According to the present invention, the preparation process is provided, such that the single crystal density of the CVD graphene is easily controlled, and the graphene nucleation density of the treated copper surface is substantially reduced so as to increase the single crystal size, and reduce the influence of the graphene grain boundary on the electrical property of the film; and the preparation method has high repeatability, and is simple and easy to perform.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

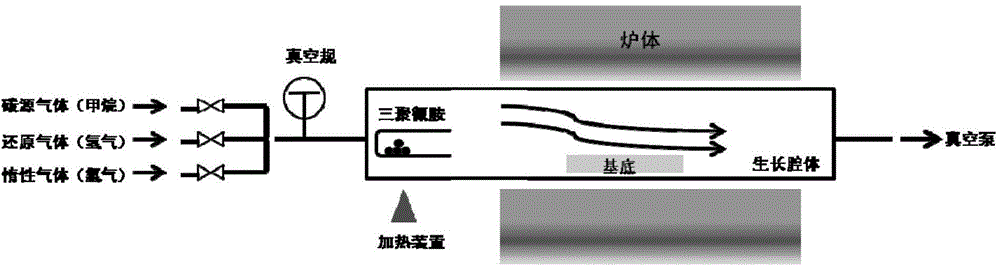

Preparation method of monolayer and mono-crystal graphene

The invention provides a preparation method of monolayer and mono-crystal graphene. The preparation method comprises the following steps: putting a semi-sealed quartz test tube filled with a copper-based catalyst into a tubular furnace; putting a weighing bottle filled with a solid carbon source into one end, close to a gas inlet, of the tubular furnace; introducing inert gas; continuously introducing the inert gas and heating the copper-based catalyst to raise the temperature to 600 DEG C to 800 DEG C; then keeping constant temperature for 30min to 120min; stopping introducing the inert gas and starting to introduce reducing gas; heating the copper-based catalyst and raising the temperature to 1000 DEG C to 1050 DEG C; then keeping the constant temperature for 60min to 120min; rapidly cooling to obtain the monolayer and mono-crystal graphene on the surface of the copper-based catalyst. The preparation method provided by the invention has the advantages of convenience for operation, simplicity and feasibility, safety and reliability, relatively low cost and strong controllability; the monolayer and mono-crystal graphene can be used for high-end electronic devices and integrated circuits and technical supports are provided for realizing an industrialized road of the monolayer and mono-crystal graphene.

Owner:XINYANG NORMAL UNIVERSITY

Method for preparing molybdenum sulfide two-dimensional material by adopting MOCVD equipment

ActiveCN110655111AThickness is easy to controlControl nucleation densityChemical vapor deposition coatingMolybdenum sulfidesPhysical chemistrySulfidation

The invention discloses a method for preparing a molybdenum sulfide two-dimensional material by adopting MOCVD (Metal Organic Chemical Vapor Deposition) equipment, and the method is used for growing the MoS2 two-dimensional material on a Sapphire substrate in multiple steps, and comprises the following steps of: adopting Sapphire as the substrate; conveying the Sapphire substrate into an MOCVD (Metal Organic Chemical Vapor Deposition) equipment; introduced N2 gas into a MOCVD cavity; raising the temperature to a constant-temperature growth temperature, wherein the initial pressure in the cavity is 90Torr; introducing H2S as a sulfur gas source; introducing MO (CO) 6 as a molybdenum gas source for nucleation; reducing the pressure intensity in the cavity step by step, and promoting nucleation crystal grains to transversely grow so as to obtain the MoS2 two-dimensional material growing on the Saphire substrate. The preparation method provided by the invention has the advantages of simplegrowth process, controllable material thickness, high quality and the like. Through the preparation method provided by the invention, the MoS2 two-dimensional material which is adjustable in forbidden band width and can be used for flexible chip application is grown.

Owner:ZHEJIANG UNIV

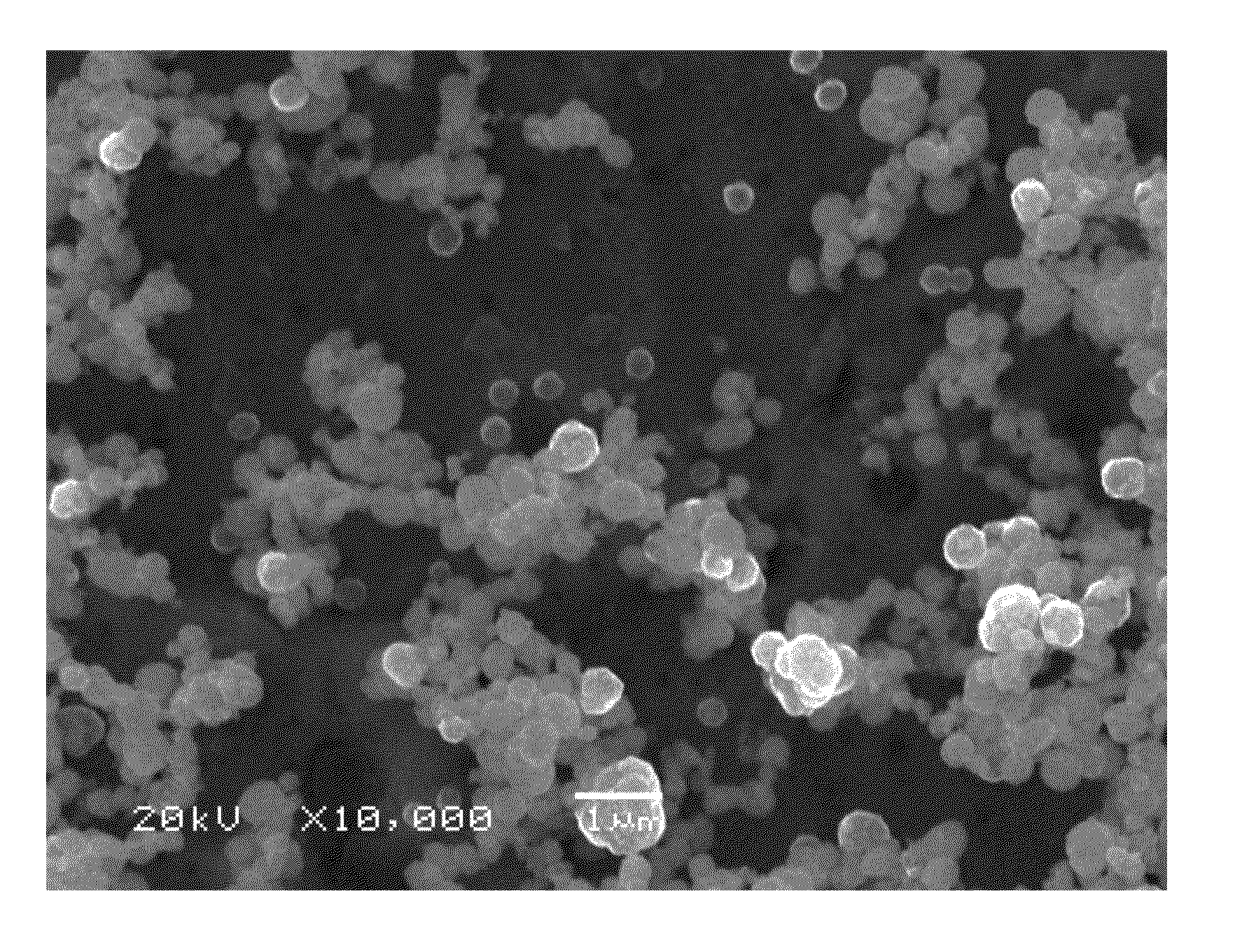

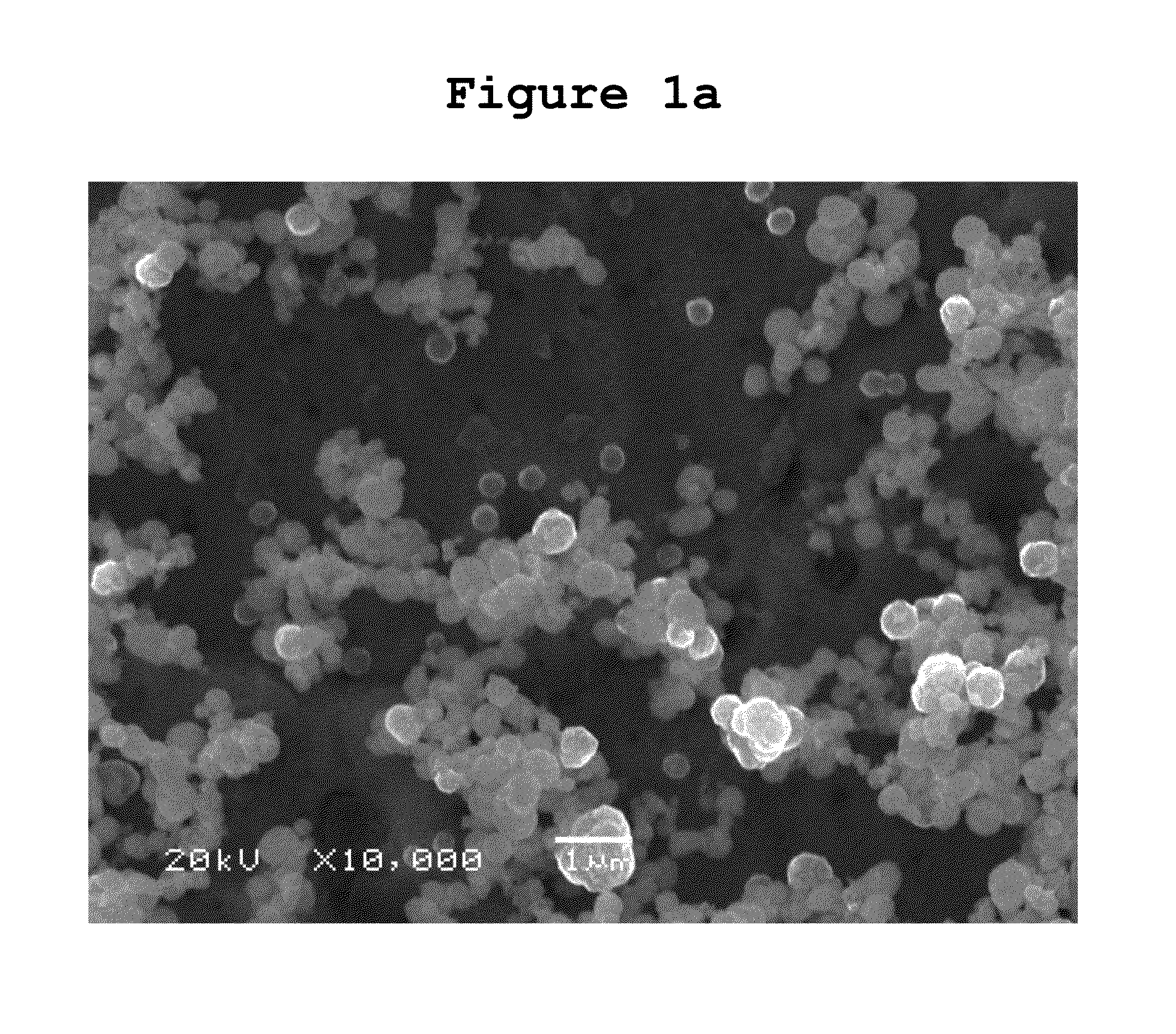

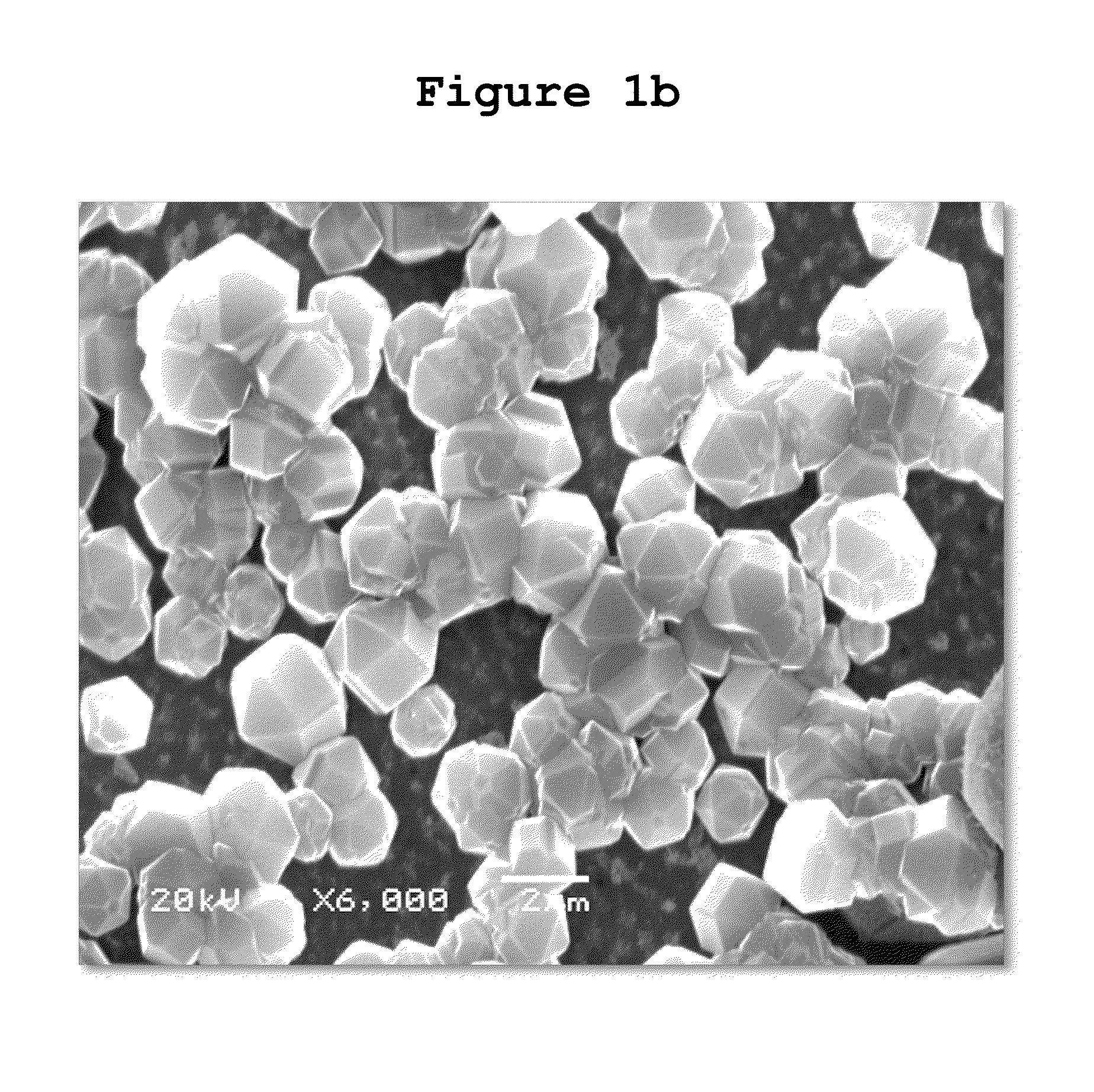

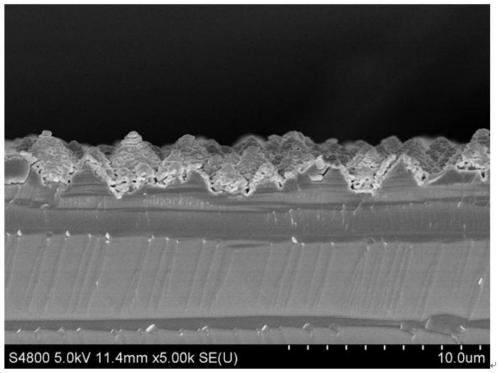

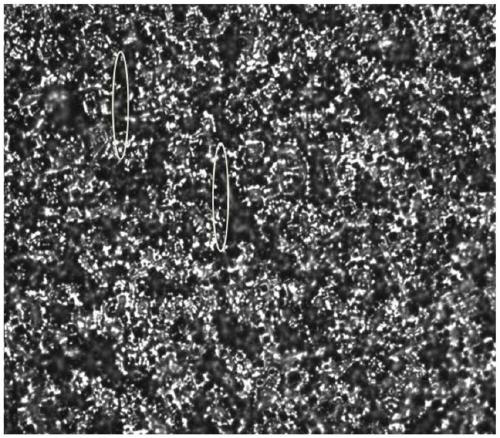

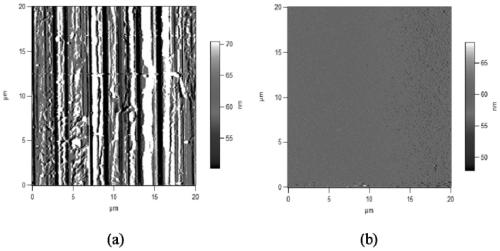

Workpiece with high-density nano-diamond thin film on surface, and preparation method of high-density nano-diamond thin film

PendingCN109097754ASolve the problem of low nucleation densityReduce nucleation densityChemical vapor deposition coatingHigh densityNitrogen

The invention provides a preparation method of a high-density nano-diamond thin film. The preparation method comprises the steps that a workpiece substrate is subjected to surface pretreatment to enable the surface of the workpiece substrate to be positively charged or negatively charged; lysine is added into water to obtain a lysine solution, then nano-diamond powder is added into the lysine solution, and nano-diamond suspension liquid with the positively or negatively charged nano-diamond particle surface is obtained after ultrasonic dispersion; the workpiece substrate subjected to surface pretreatment is immersed into the nano-diamond suspension liquid with the opposite charge to the workpiece substrate, and ultrasonic oscillation is conducted, so that nano-diamond particles are adsorbed on the surface of the workpiece substrate; and after adsorption is completed, the workpiece substrate is taken out, cleaned and blow-dried through nitrogen, and then the diamond thin film is grown on the workpiece substrate through chemical vapor deposition equipment. According to the preparation method, the large-area nanometer-thickness high-density nano-diamond thin film can be prepared on acomplex workpiece, the thin film is high in quality and high in bonding force, the technology is simple, the cost is low, and the preparation method has broad application prospects in a nano-electromechanical system.

Owner:SHENZHEN INST OF ADVANCED TECH

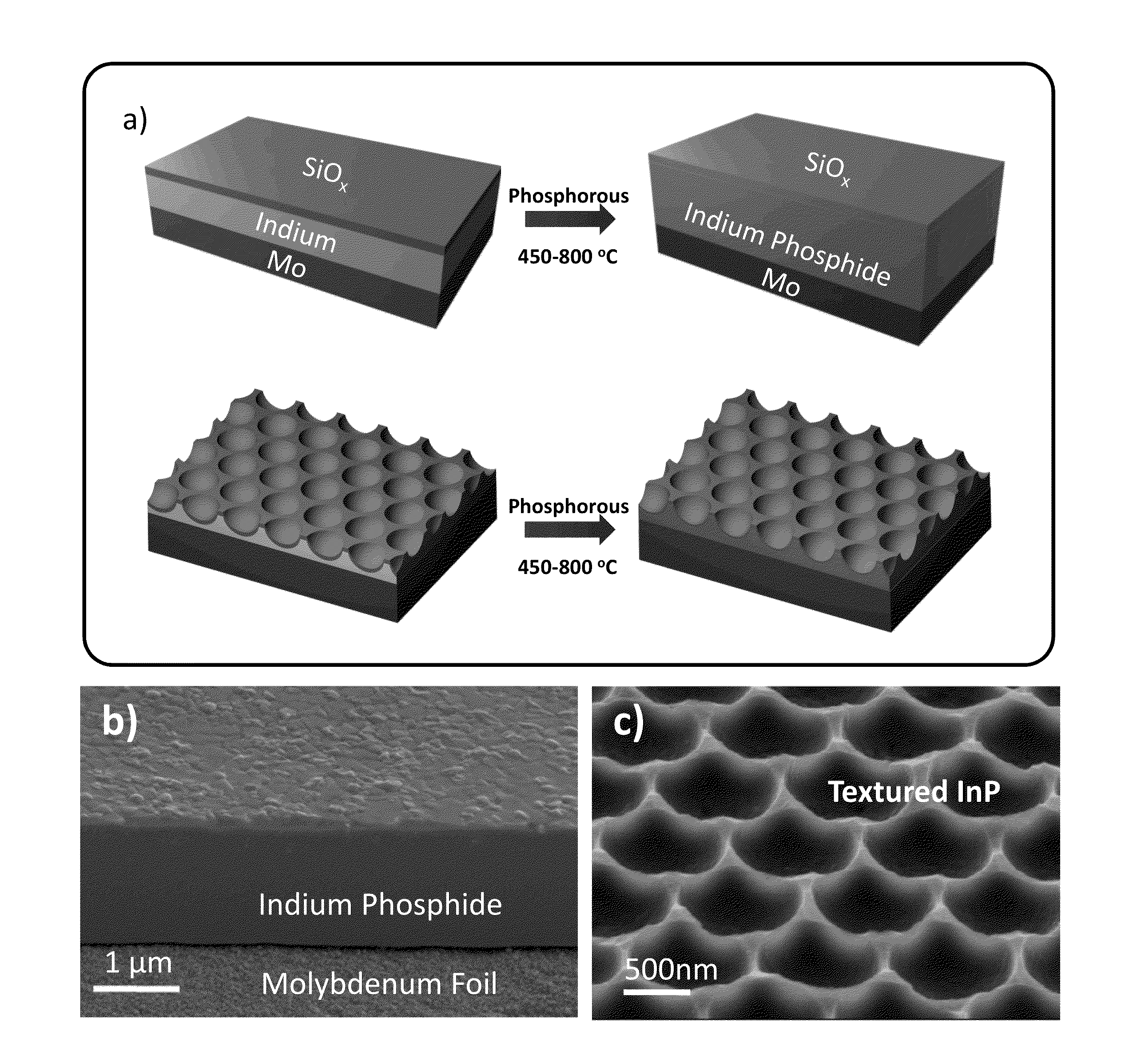

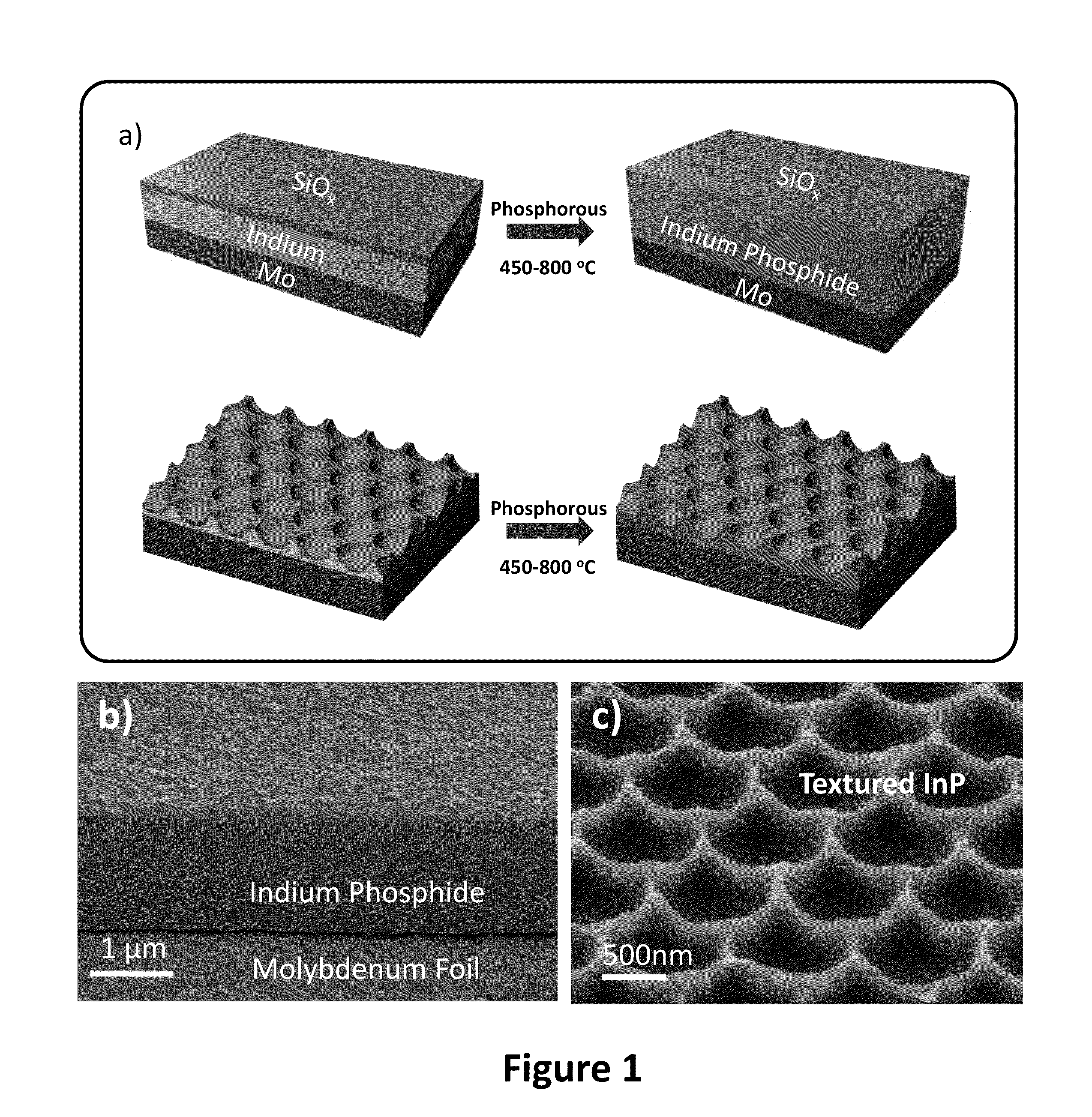

Thin film vls semiconductor growth process

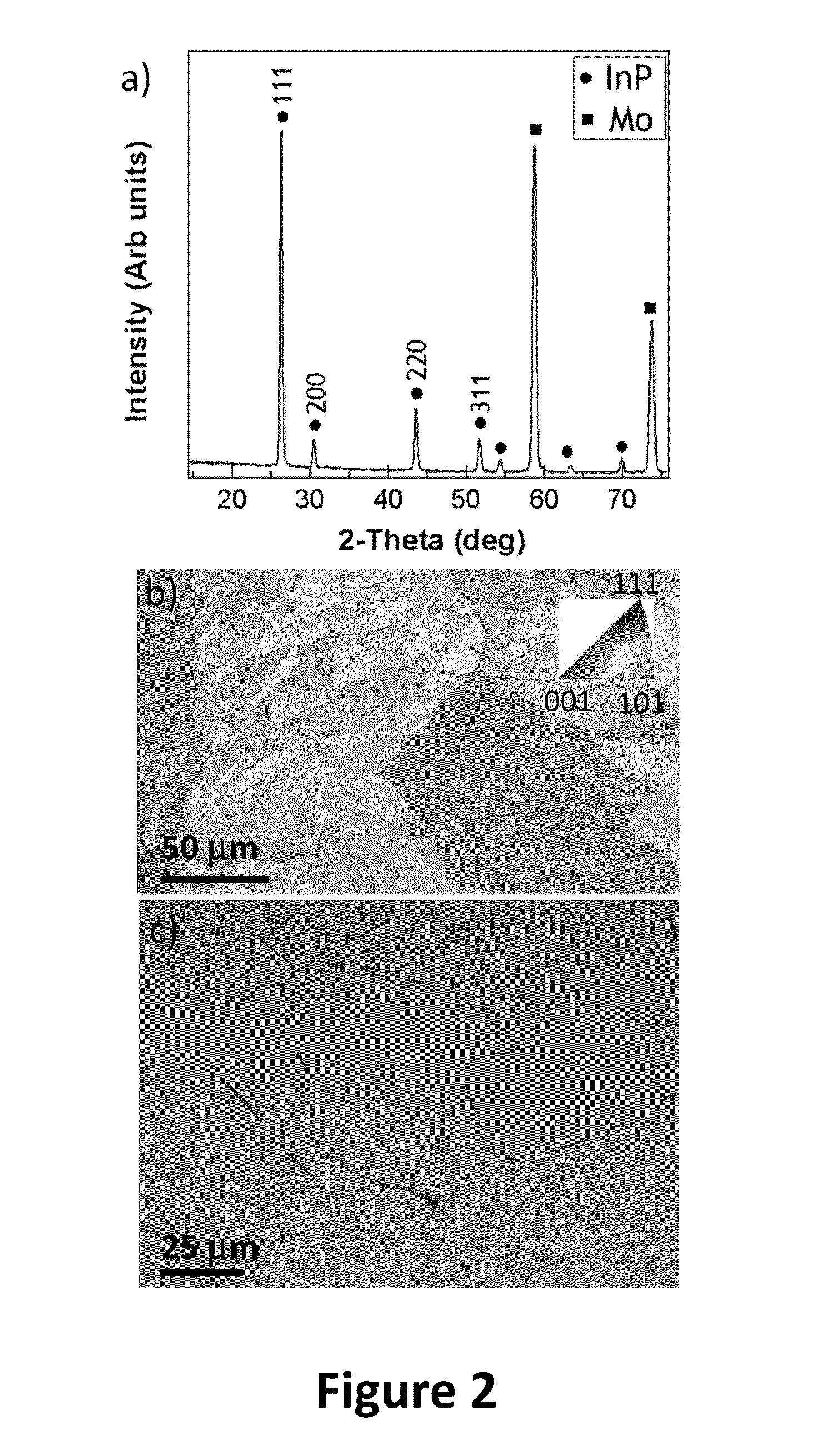

InactiveUS20140290737A1Reduce morbidityReduce nucleation densityFinal product manufactureSemiconductor/solid-state device manufacturingThin oxideIndium

A composition comprising a substrate, a polycrystalline III-V semiconductor layer, and an oxide layer disposed above the polycrystalline III-V semiconductor layer is described. A growth method that enables fabrication of continuous thin films of polycrystalline indium phosphide (InP) directly on metal foils is described. The method describes the deposition of an indium (In) thin film (up to 20 microns thick) directly on molybedenum (Mo) foil, followed by the deposition of a thin oxide capping layer (up to 1 micron thick). This capping layer prevents dewetting of the In from the substrate during subsequent high temperature processing steps. The Mo / In / Capping Layer stack is then heated in the presence of phosphorous precursors, causing supersaturation of the liquid indium with phosphorous, followed by precipitation of InP. These polycrystalline III-V films have grain sizes 100-200 microns, minority carrier lifetimes >2 ns and hall mobilities of 500 cm̂2 / V-s.

Owner:RGT UNIV OF CALIFORNIA

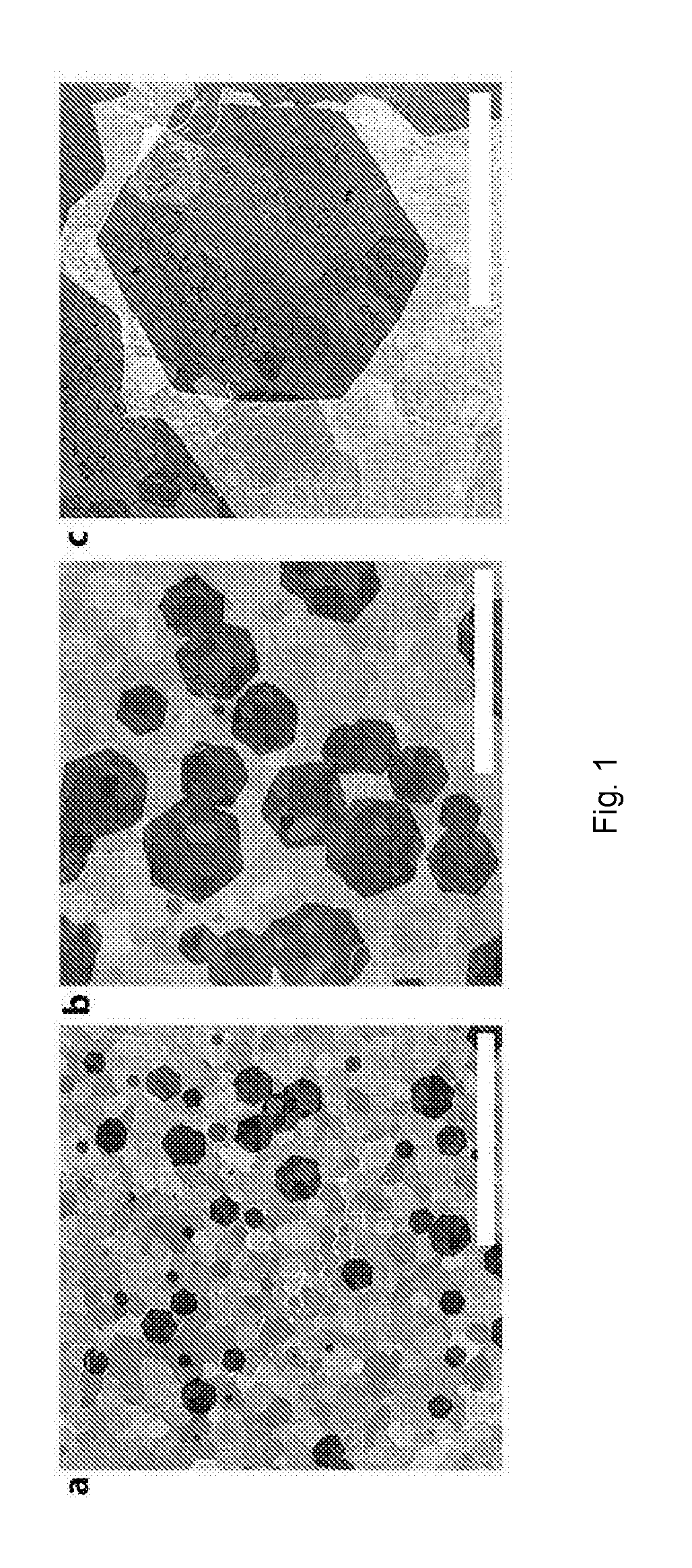

Preparation method of large-size single-crystal graphene

InactiveCN105986315AGrow fastGood crystal formPolycrystalline material growthFrom chemically reactive gasesReactive gasSingle crystal

The present invention relates to a graphene material and its chemical vapor deposition (CVD) preparation technology, specifically a method for preparing large-size single crystal graphene. The method adopts chemical vapor deposition technology and uses copper foil with a certain oxygen content as a growth substrate. And the copper foil is made into a cavity structure. Under the protection of non-reactive gas, the copper cavity structure is first heat-treated, and hydrocarbons are used as the carbon source, and the carbon source gas is used to catalyze cracking at high temperature to grow large-scale monolayers. crystalline graphene. The invention has the advantages of simple technological process, easy operation, low cost, high product quality, large and uniform size, good repeatability and the like.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Diamond nucleation using polyethene

ActiveUS8491964B1High nucleation densityPoor nucleation densityChemical vapor deposition coatingSubstrate surfaceMaterials science

The invention presents a simple, non-destructive and non-abrasive method of diamond nucleation using polyethene. It particularly describes the nucleation of diamond on an electrically viable substrate surface using polyethene via chemical vapor deposition (CVD) technique in a gaseous environment.

Owner:PUERTO RICO UNIV OF

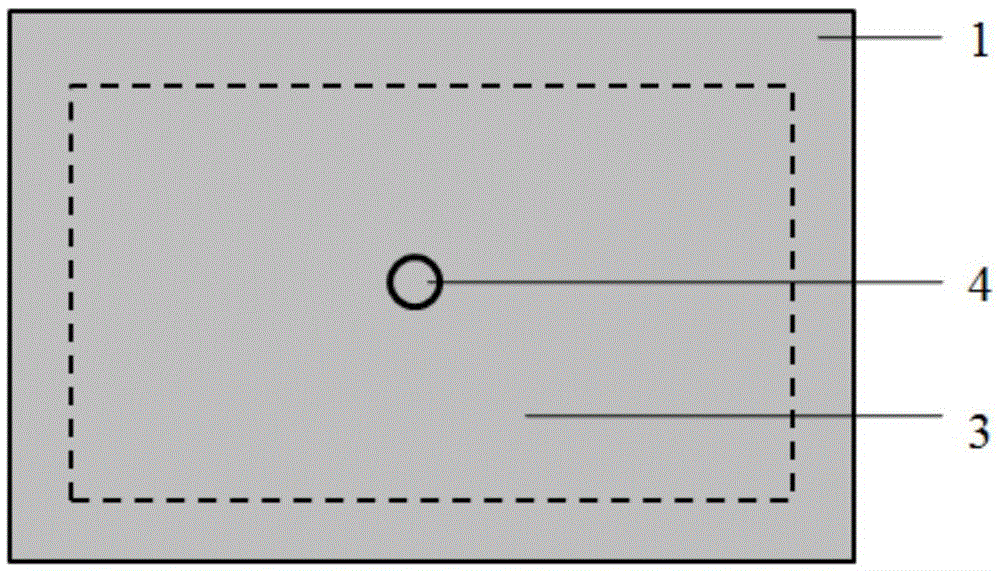

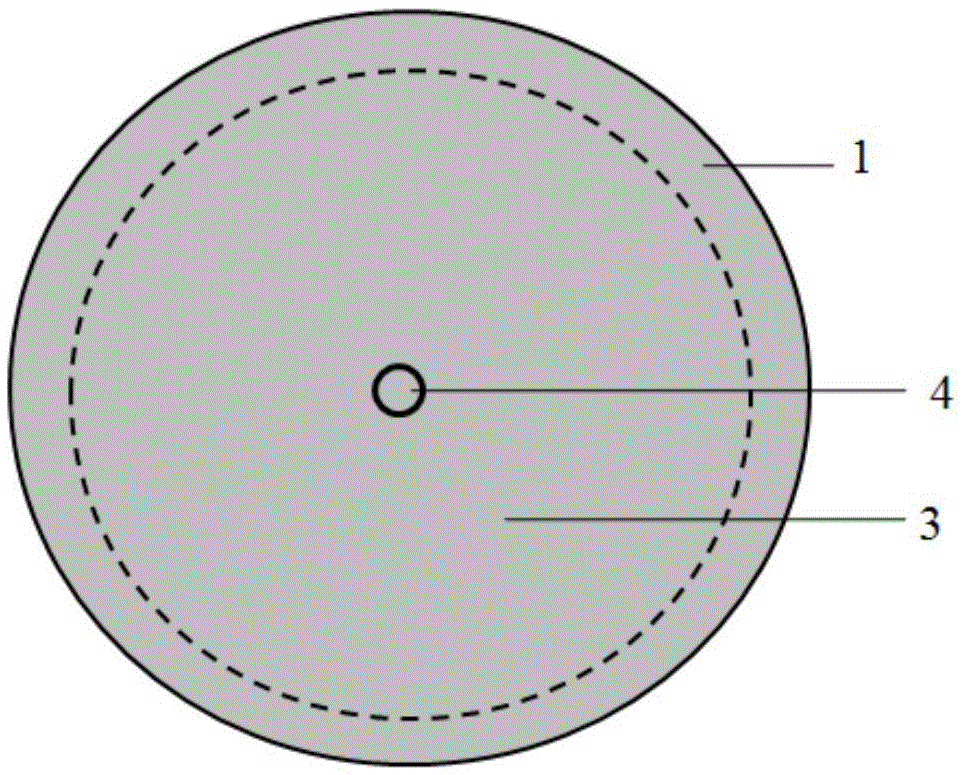

Carrier for controlling graphene crystal nucleus growth

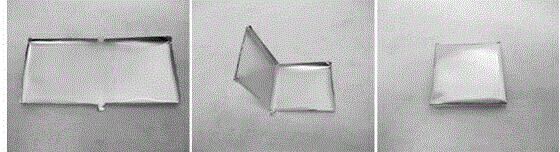

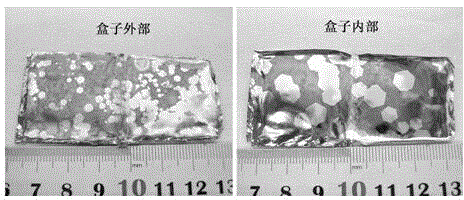

The invention discloses a carrier for controlling graphene crystal nucleus growth. The carrier comprises an upper cover, a box and a straight metal substrate for graphene growth, wherein a small hole is formed in the upper cover, and both the upper cover and the box are made of high-temperature-resistant materials such as graphite, quartz, silicon nitride or silicon carbide and the like with melting points higher than 1,000 DEG C; the distance between the metal substrate and the lower surface of the upper cover covering the box is smaller than or equal to 2mm after the metal substrate is placed on a base of the box. A using method of the carrier comprises processes including pretreatment of the metal substrate, annealing of the metal substrate, graphene nucleation, cooling and oxidation. The hole size of the carrier plays a current limiting role for reactant gas at the nucleation stage, and the nucleation area and the nucleation density of graphene on copper foil can be controlled; the nucleation density of graphene is decreased through control on the hole size and various growth parameters, so that preparation of large single-crystalline graphene is realized; the single-crystalline or polycrystalline area of graphene is increased through control on the gas proportion and pressure by a CVD (chemical vapor deposition) tube furnace.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

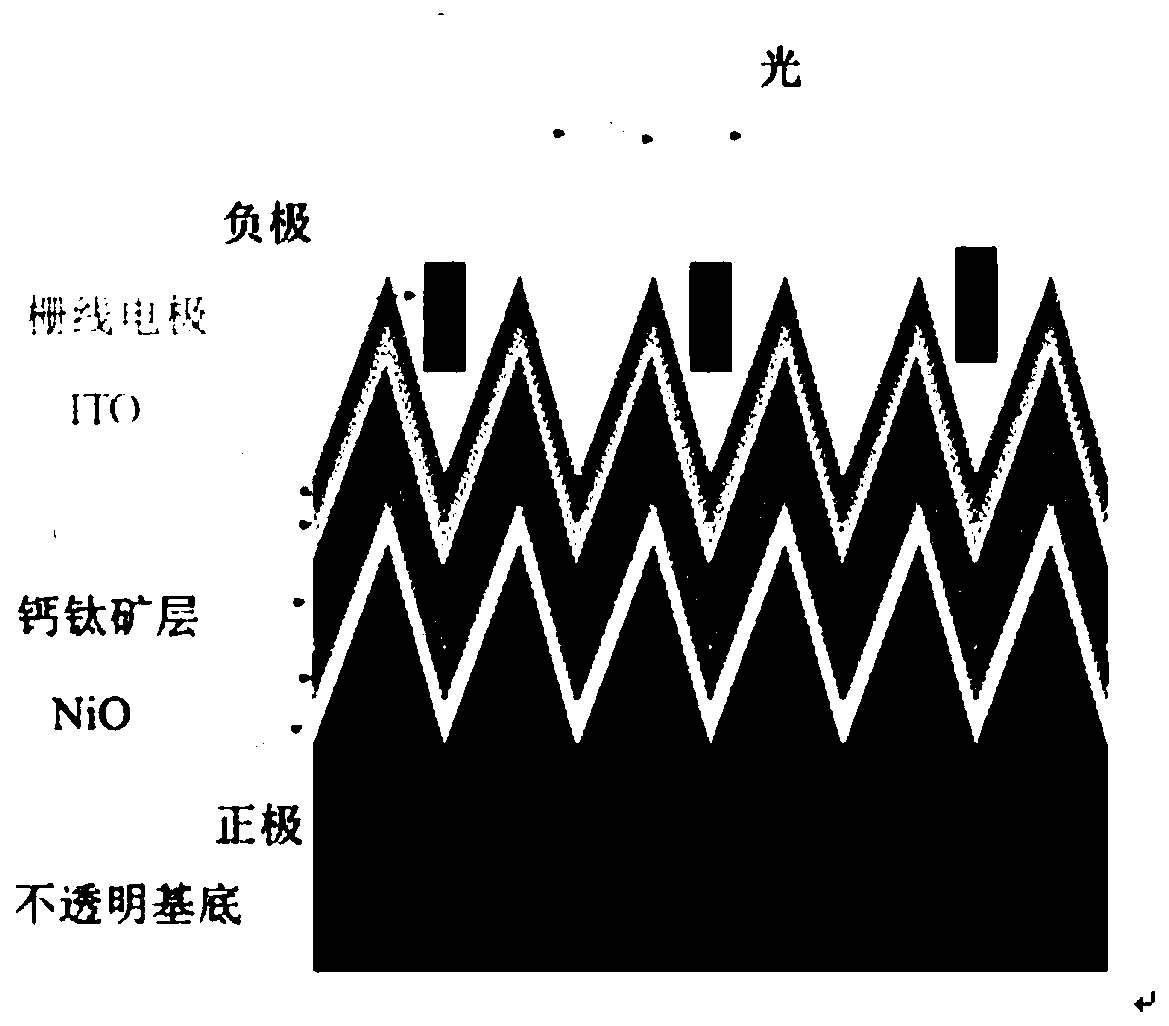

Method for preparing perovskite solar cell on micron-sized large suede

ActiveCN111370582ASlow reaction rateImprove qualitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellLead chloride

The invention relates to the technical field of solar cells, in particular to a method for preparing a perovskite solar cell on a micron-sized large suede. The method comprises the following operationsteps: S1, preparing an electrode, a hole or an electron transport layer on a micron-sized suede substrate; S2, preparing a lead iodide / lead chloride film on the hole transport layer; S3, treating the lead iodide-lead chloride film in ligand steam, and cooling to N DEG C on a cooling table to obtain a ligand-lead iodide-lead chloride film; S4, coating the ligand-lead iodide-lead chloride thin film obtained in the step S3 with an organic salt solution, and then annealing in dry and clean air at 150 DEG C; S5, preparing an electron or hole transport layer; S6, preparing an electrode or a grid line electrode; wherein 5 < = N < = 15 DEG C. According to the method for preparing the perovskite solar cell on the micron-sized large suede, the quality of the perovskite thin film is improved, and uniform coverage of the large suede is realized.

Owner:CHANGZHOU UNIV

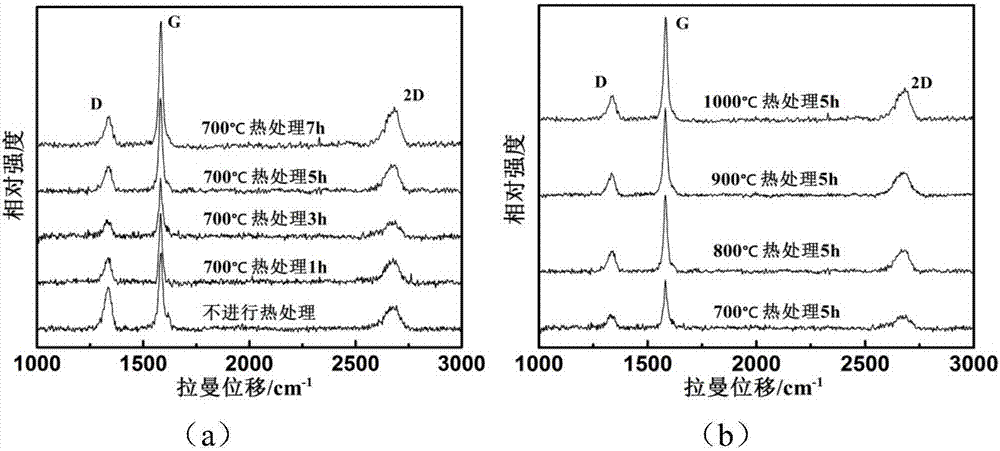

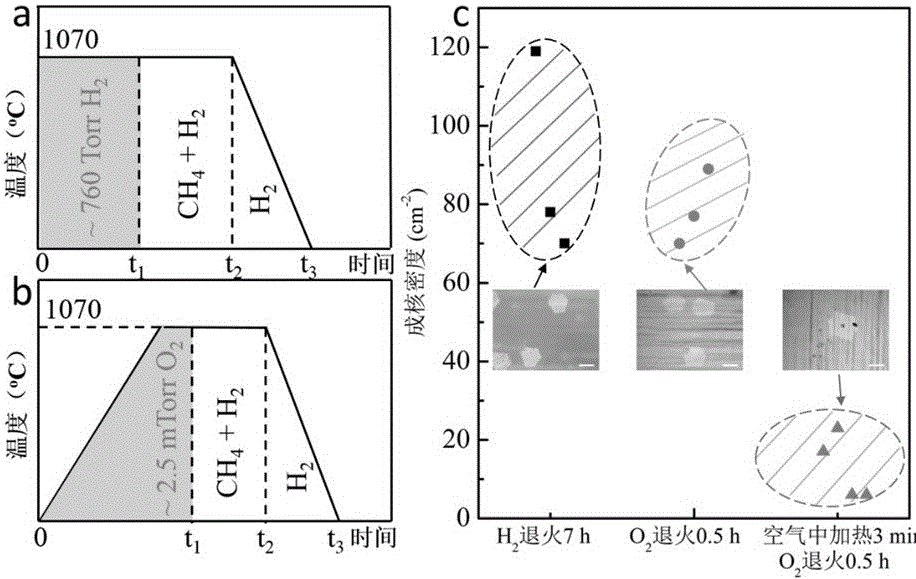

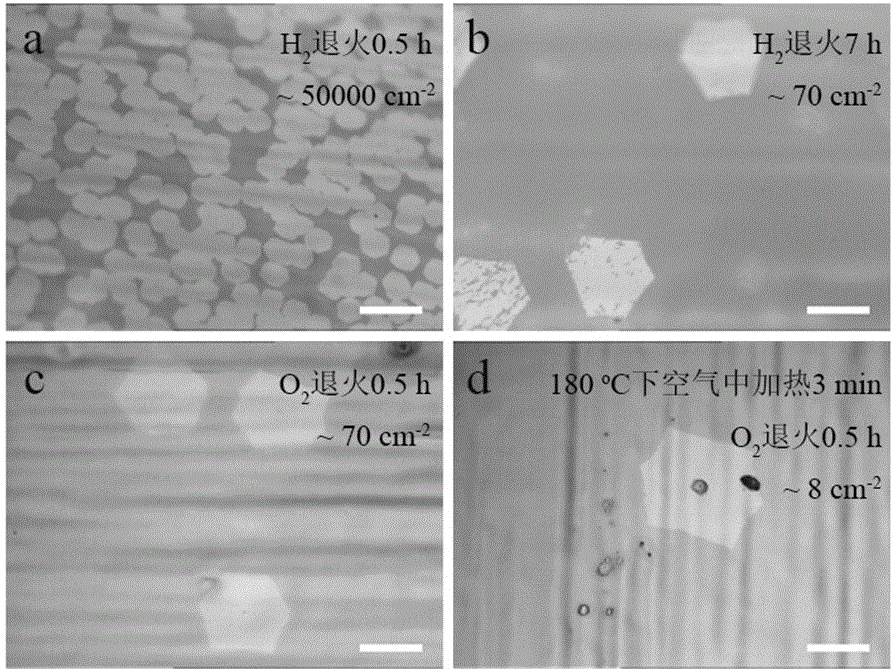

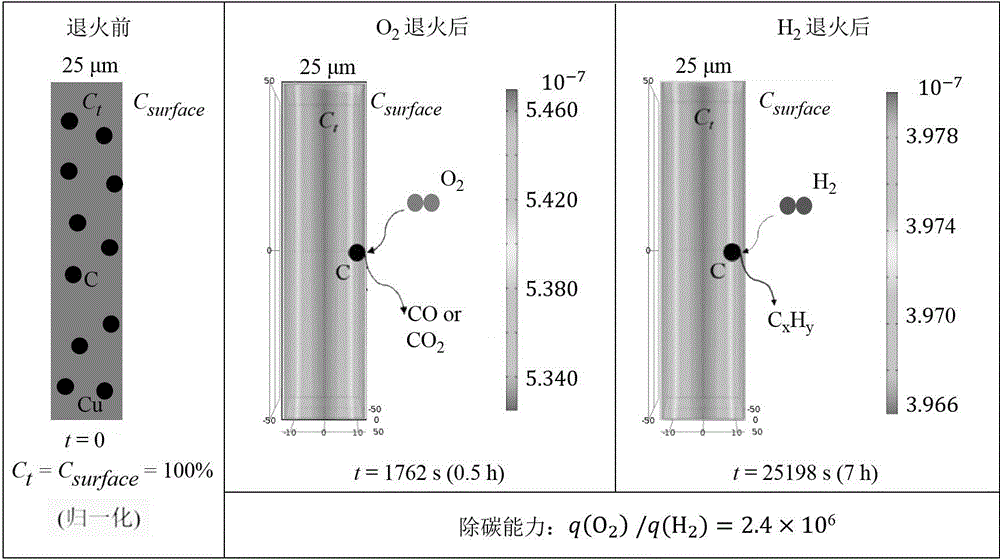

Method for reducing nucleus density in procedures for synthesizing single-crystal graphene by aid of chemical vapor deposition processes

InactiveCN106637391ASuitable for preparationReduce nucleation densityPolycrystalline material growthFrom chemically reactive gasesHydrogen atmosphereSingle crystal

The invention belongs to the field of technologies for synthesizing graphene, and particularly discloses a method for reducing the nucleus density in procedures for synthesizing single-crystal graphene by the aid of chemical vapor deposition processes. The nucleus density is an important factor for determining the sizes of single crystals in procedures for industrially synthesizing the large graphene single crystals, and the large single crystals can be increasingly advantageously obtained along with decrease of the nucleus density. High-temperature annealing treatment is carried out on metal growth substrates for the graphene in oxygen or hydrogen atmosphere under controlled pressures, evolution of the contents of carbon on the surfaces of metal and inside the metal is jointly computed and simulated, annealing conditions are optimized, and metal substrates which are suitable for industrial standard production and have low nucleation density can be ultimately obtained.

Owner:FUDAN UNIV

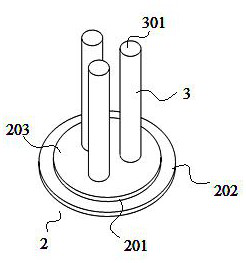

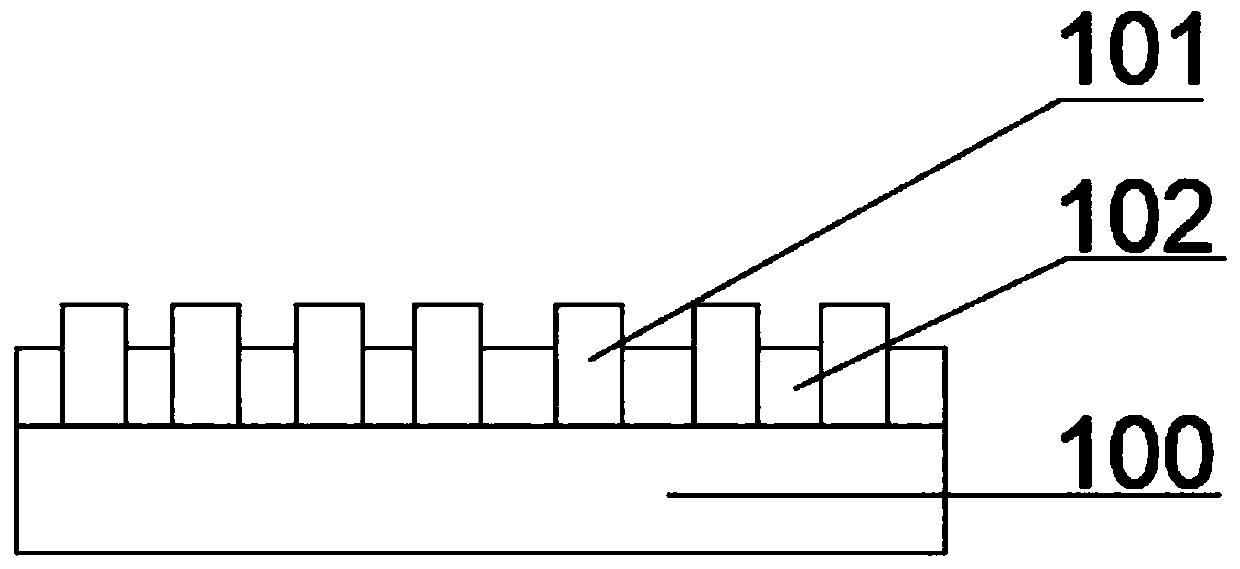

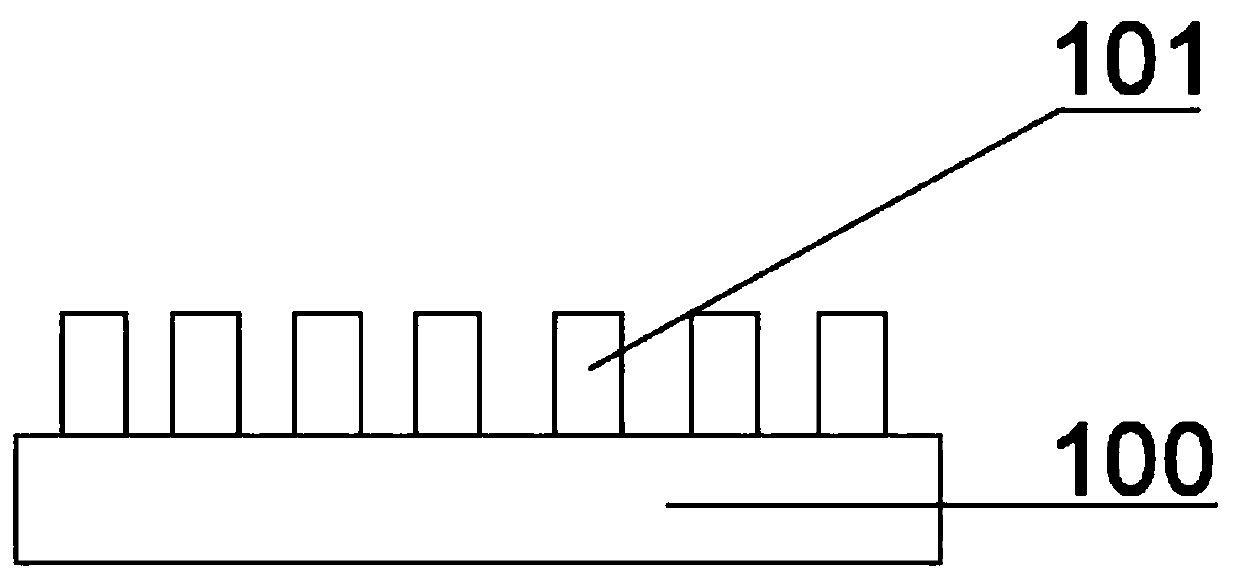

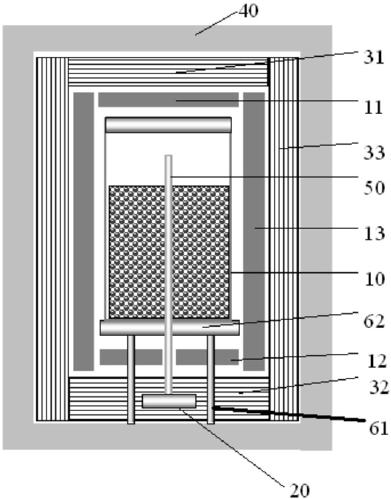

AlN crystal material preparation method based on size and shape control

ActiveCN114855281AReduce nucleation densityIncrease in sizePolycrystalline material growthFrom condensed vaporsSeed crystalShape control

The invention belongs to the field of semiconductors, and particularly relates to an AlN crystal material preparation method based on size and shape control, according to the method, AlN powder is used for preparing AlN crystals in an AlN crystal material preparation system, the preparation system comprises an outer crucible and an inner crucible arranged in the outer crucible, and the inner crucible comprises an inner crucible body and an outer crucible body arranged in the inner crucible body. The shell is provided with an internal space and extends in the vertical direction; the upper cover is located at the upper end of the shell, and the upper cover comprises a first surface extending in the horizontal direction; the lower cover is located at the lower end of the shell and used for bearing aluminum nitride powder, and the lower cover comprises a second surface extending in the horizontal direction; the column is arranged in the inner space of the inner crucible; a plurality of columns are arranged, and the plurality of columns are arranged at preset intervals; each column is provided with a third surface extending in the horizontal direction; the aluminum nitride seed crystal with the particle size larger than 20 mm is obtained on the third surface of the column through multiple times of growth through the charging step, the heating step, the growth step and the cooling step.

Owner:山西中科潞安半导体技术研究院有限公司

Pretreatment method of graphene growth substrate

PendingCN111188021AReduce nucleation densityReduce surface roughnessPolycrystalline material growthFrom chemically reactive gasesCopper nickel alloyTube furnace

The invention discloses a pretreatment method of a graphene growth substrate. The method comprises the following steps of by using a copper foil or a copper-nickel alloy foil as a substrate, preliminarily polishing the substrate, annealing the substrate in a tube furnace, taking the annealed substrate out of the furnace, polishing the substrate again, and heating and oxidizing the substrate on a heating table to complete the pretreatment, wherein the pretreated substrate can be used for chemical vapor deposition growth of graphene. According to the pretreatment method, the roughness of the copper or copper-nickel alloy substrate can be reduced, the purity of the substrate is improved, active sites on the surface of the substrate are reduced, finally the effect of reducing the nucleation density of graphene is achieved, so that preparation of large single crystal graphene and large-area few-layer graphene with uniform thickness within the range of 2-5 layers is realized.

Owner:NANJING UNIV

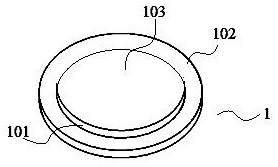

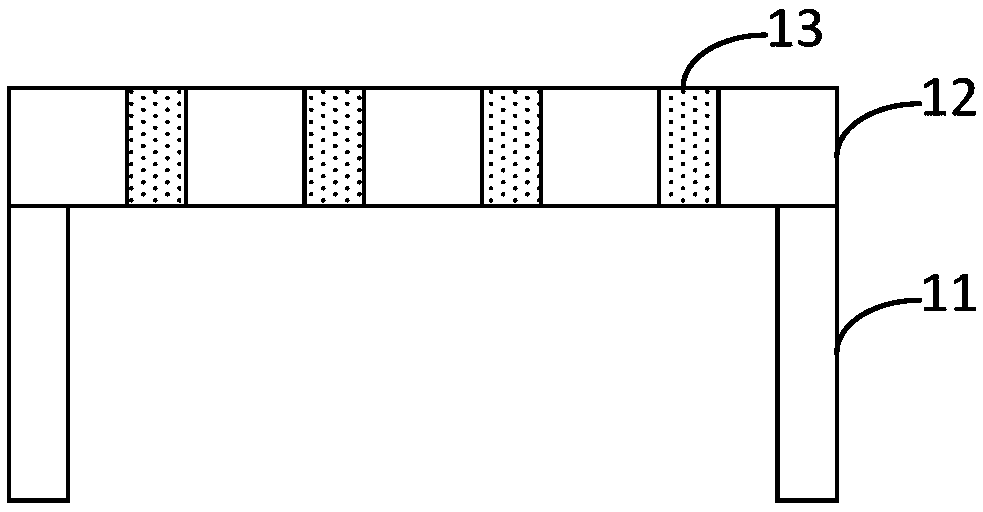

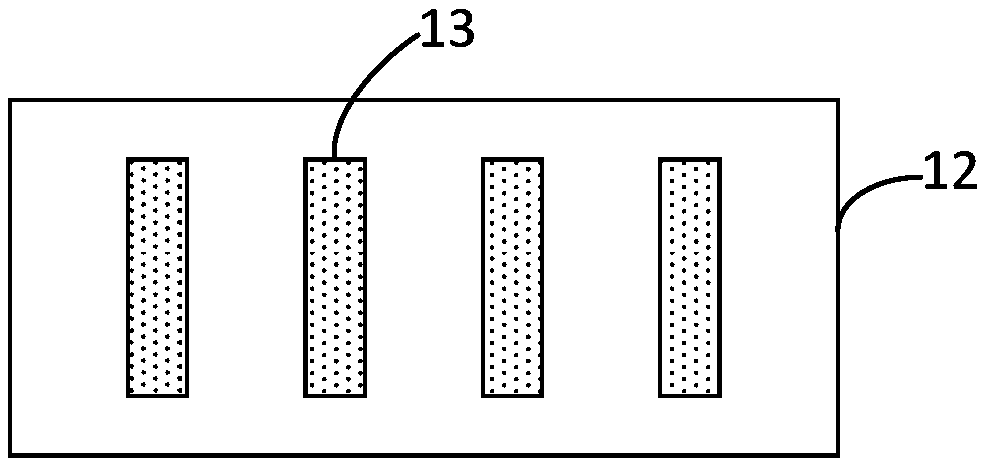

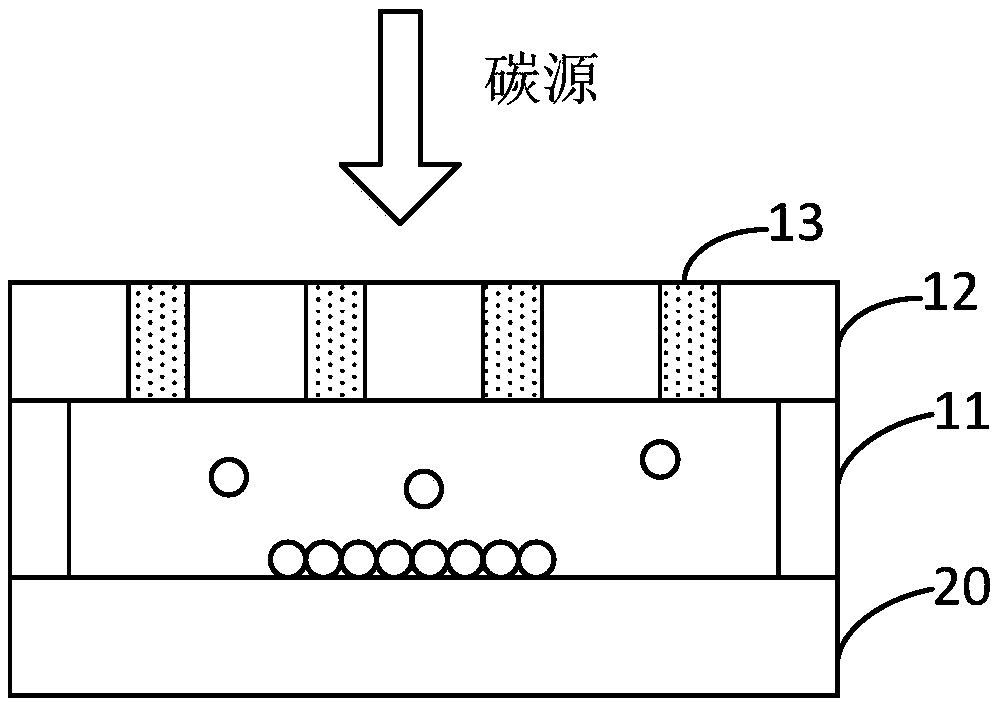

Assistant device for graphene preparation, graphene and preparation method thereof

InactiveCN108892132AReduced nucleation densityReduce nucleation densityGrapheneCarbon sourceSemiconductor

The invention is suitable for the technical field of semiconductors and provides an assistant device for graphene preparation, graphene and a preparation method thereof. The preparation method includes: putting the assistant device on the upper surface of a substrate, and putting the substrate in a cavity of chemical vapor deposition equipment, wherein the assistant device comprises a supporting body and a buffering layer arranged on the upper surface of the supporting body and provided with a plurality of holes penetrating the buffering layer, and the supporting body contacts with the substrate; heating the cavity to preset temperature, and discharging air in the cavity; feeding a carbon source into the cavity, and maintaining temperature of the cavity at the preset temperature; stoppingfeeding the carbon source after preset time, feeding protective gas into the cavity, and lowering the temperature of the cavity. Nucleation density of graphene can be lowered without lowering growth speed of the same.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

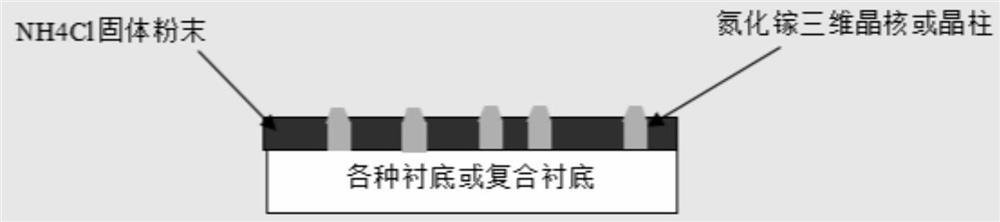

Self-supporting gallium nitride single crystal based on HVPE and preparation method thereof

InactiveCN111501102AEasy to peelLow process temperaturePolycrystalline material growthAfter-treatment detailsPhysical chemistrySingle crystal

The invention provides a preparation method of a self-supporting gallium nitride single crystal based on HVPE, and the method comprises the following steps: (1) providing a substrate, and carrying outthe in-situ cleaning of the surface of the substrate; (2) growing a GaN crystal nucleus on the surface of the substrate at a low temperature, and forming NH4Cl solid from HCl and NH3 at the same timeto compete with the GaN crystal nucleus to cover the substrate; (3) increasing the temperature to 1000 DEG C or above for annealing treatment, and improving the GaN crystal nucleus quality; (4) growing a GaN layer on the GaN crystal nucleus in a medium-high temperature two-dimensional manner; and (5) continuously growing GaN single crystals on the GaN layer at a high temperature; and cooling, andstripping the GaN single crystal from the substrate to form the self-supporting crystal. High-quality nucleation points are provided for growth of self-supporting gallium nitride through HVPE, warping is reduced due to the fact that gaps release stress, cracking is eliminated when growth is finished and cooling is conducted, and the growth yield of the self-supporting gallium nitride is increased.

Owner:WUXI WUYUE SEMICON CO LTD

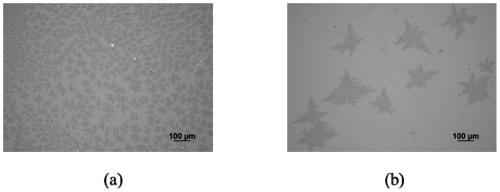

Preparation method of molybdenum sulfide two-dimensional material growing on Sappire substrate

InactiveCN110670125ASmall sizeUniform thicknessPolycrystalline material growthFrom chemically reactive gasesPhysical chemistrySulfidation

The invention discloses a preparation method of a MoS2 two-dimensional material growing on a Sappire substrate. The method comprises the following steps: 1, preparing the substrate: adopting the Sappire substrate without any pretreatment; 2, preparing a raw material: conveying the Saphire substrate to a quartz table in an MOCVD cavity, controlling the pressure in the cavity to be 20 Torr, and introducing N220 slm into the cavity all the time; and 3, reacting by a chemical vapor deposition technology: raising the temperature in the cavity to the growth temperature, sequentially introducing a H2S gas source and Mo(CO)6, carrying out constant-temperature growth, reducing the temperature to the room temperature, and taking out the obtained sample to obtain the MoS2 two-dimensional material growing on the Saphire substrate. The method has the advantages of effectiveness in control of the nucleation density, uniformity and grain orientation of MoS2, and high feasibility.

Owner:ZHEJIANG UNIV

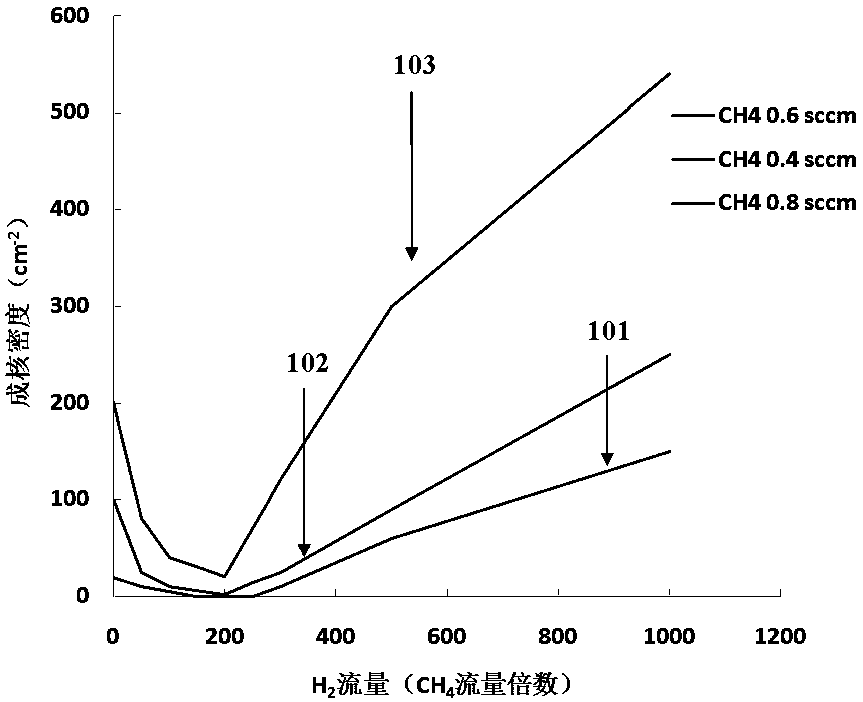

Method for synthesizing gaphene by carbon oxide-assisted chemical vapor phase deposition

The invention belongs to the technical field of graphene preparation and particularly relates to a method for synthesizing gaphene by carbon oxide-assisted chemical vapor phase deposition. The methodcomprises the following steps: tentative experiment and graphene synthesis; the tentative experiment comprises the following processes: substrate polishing and oxidation and loading a substrate into achemical vapor phase deposition system; growing the grapheme under preset reaction conditions; recording the nucleation density, drawing a 'nucleation density-H2 flow' curve and determining nucleation conditions and extension conditions; finally synthesizing the gaphene according to the determined nucleation conditions and extension conditions. The method provided by the invention can realize thesynthesis of large-scale single crystal graphene, can be duplicated in different systems and has better applicability to the different systems.

Owner:FUDAN UNIV

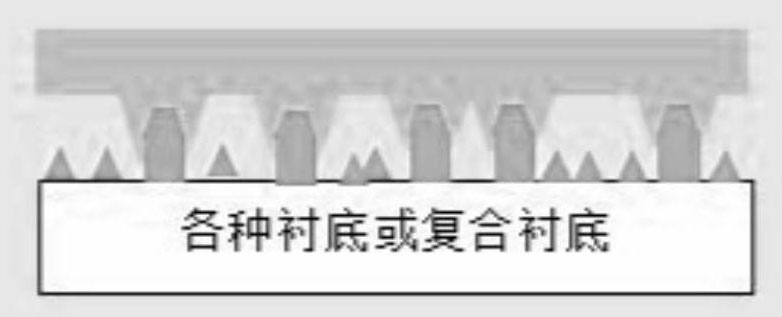

Method of implementing one or more void buried interposers in HPVE growth

InactiveCN112575378AConvenience to mergeEffective lateral growthPolycrystalline material growthFrom chemically reactive gasesPhysicsThin membrane

The invention relates to the related technical field of gallium nitride production and preparation methods, and discloses a method for realizing one-time or multi-time hole burying of an insertion layer in HPVE growth, which comprises the following steps: (1) preparing one of the following substrates or composite substrates, comprising (I) Al2O3, SCAM, Si and SiC substrates, (II) preparing an Al2O3 substrate, an SCAM substrate, an Si substrate and an SiC substrate which are provided with Spring AlN, and (III) an Al2O3 substrate, an SCAM substrate, an Si substrate and an SiC substrate which areprovided with MOCVD GaN thin films; and placing the substrate or the composite substrate into an HVPE device for processing. The method for realizing the one-time or multi-time hole burying of the insertion layer in the HPVE growth comprises the following steps: firstly, forming a low-density and low-coverage gallium nitride crystal nucleus at a low temperature, and heating and annealing to forma high-quality small crystal; and then carrying out two-dimensional growth to form a gap layer in the interface and for absorbing stress during growth; in such a way, one or more layers are inserted to provide a template for the growth of self-supporting gallium nitride with high quality, low warpage and automatic interface stripping.

Owner:WUXI WUYUE SEMICON CO LTD

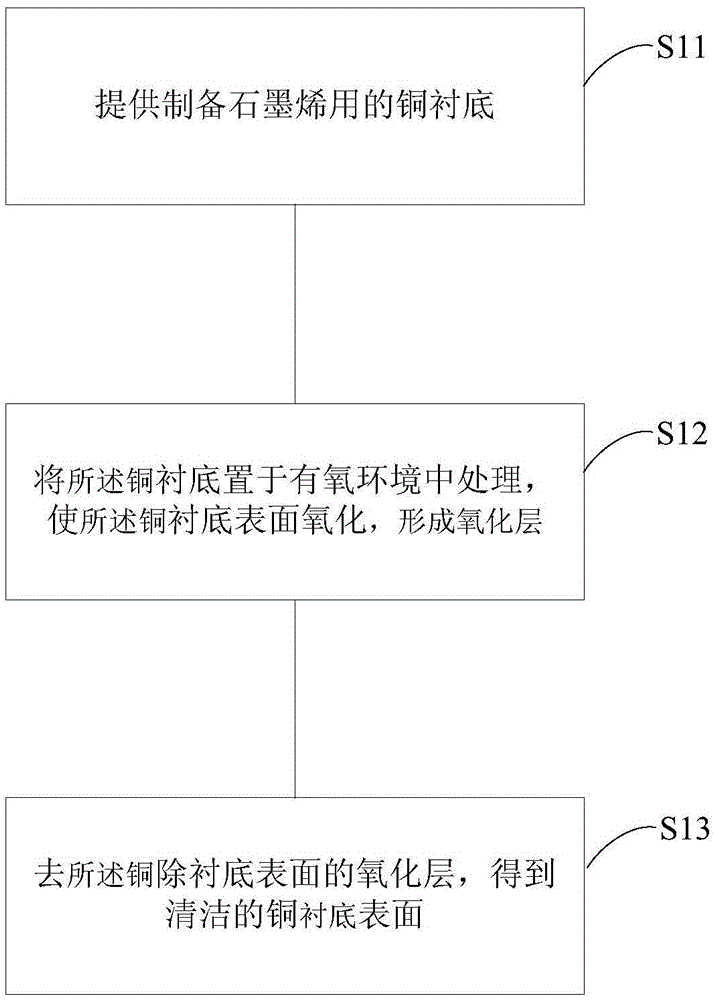

Method for preparing copper substrate based on dry method cleaning process

ActiveCN106884153AReduce defectsReduce nucleation densityPolycrystalline material growthFrom chemically reactive gasesSurface layerNucleation

The invention provides a method for preparing a copper substrate based on a dry method cleaning process. The method comprises the following steps: a step 1), the copper substrate for preparing graphene is provided; a step 2), the copper substrate is placed in an aerobic environment for treatment, so that the surface of the copper substrate is oxidized in order to form an oxidation layer; and a step 3), the oxidation layer on the surface of the copper substrate is removed in order to obtain a clean copper substrate surface. By means of oxidation of the copper substrate for growth of graphene, the surface layer of the substrate is oxidized and shed from the substrate, the clean copper surface for preparing graphene with a proper high quality is obtained, the copper substrate can obviously reduce nucleation density and reduce defects in graphene. The method has the advantages of good repeatability, simple and easy operation, and good controllability; and the method is suitable for batch treatment of industrial applications.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

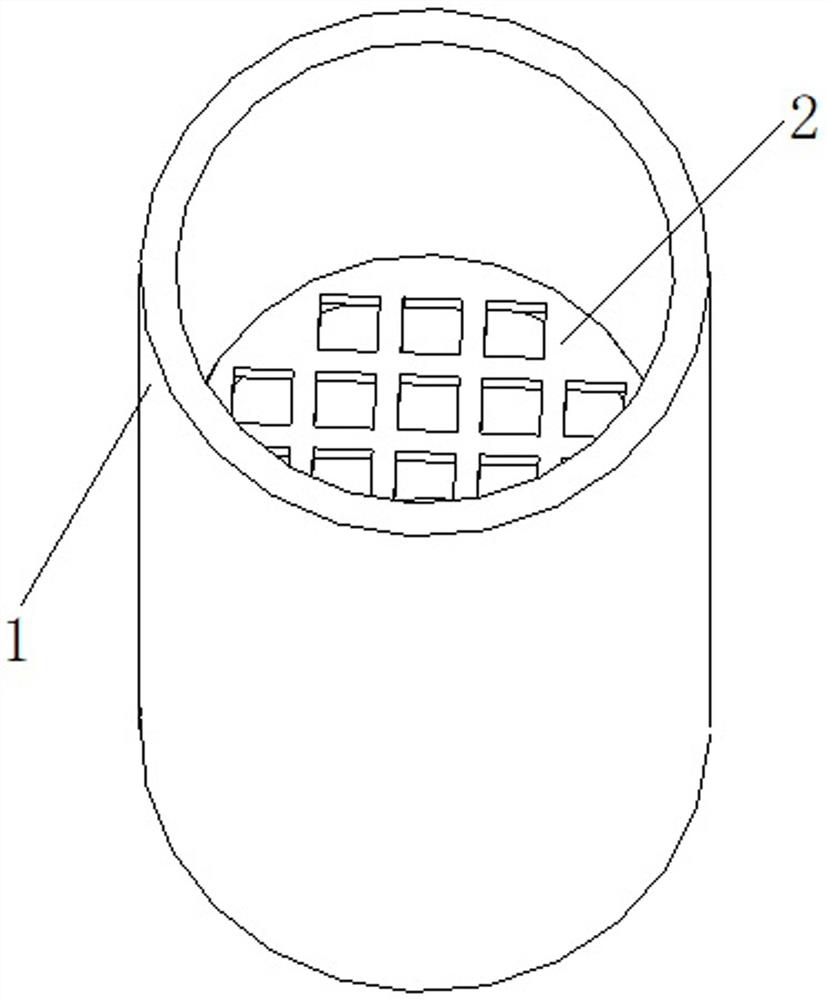

Method for preparing AlN crystal through spontaneous nucleation by PVT method

InactiveCN113789573AReduce supersaturationReduce nucleation densityPolycrystalline material growthFrom condensed vaporsPhysicsCrystallite

The invention relates to a method for preparing AlN crystal through spontaneous nucleation by a PVT method. The method comprises the following steps: 1) purifying AlN powder; and 2) putting the purified AlN powder into a crucible (1), putting a metal wire mesh (2) at a position which is 1 / 5-4 / 5 of the height of the interior of the crucible (1), enabling the AlN powder to be located below the metal wire mesh (2), then putting the crucible (1) into a graphite heating body, putting the graphite heating body into a single crystal growth furnace, vacuumizing the single crystal growth furnace to 10E-6mbar at normal temperature, and then under a pure nitrogen atmosphere of 100-1000mbar, conducting heating to 2000-2300 DEG C at the heating rate of 100-150 DEG C / h, keeping the temperature for 24-72 hours, and then conducting cooling to room temperature at the cooling rate of 100-150 DEG C / h, so as to grow AlN crystals on the surface of the metal wire mesh (2) in a spontaneous nucleation manner. The prepared AlN crystal is high in crystal grain quality and large in size.

Owner:山西中科潞安紫外光电科技有限公司

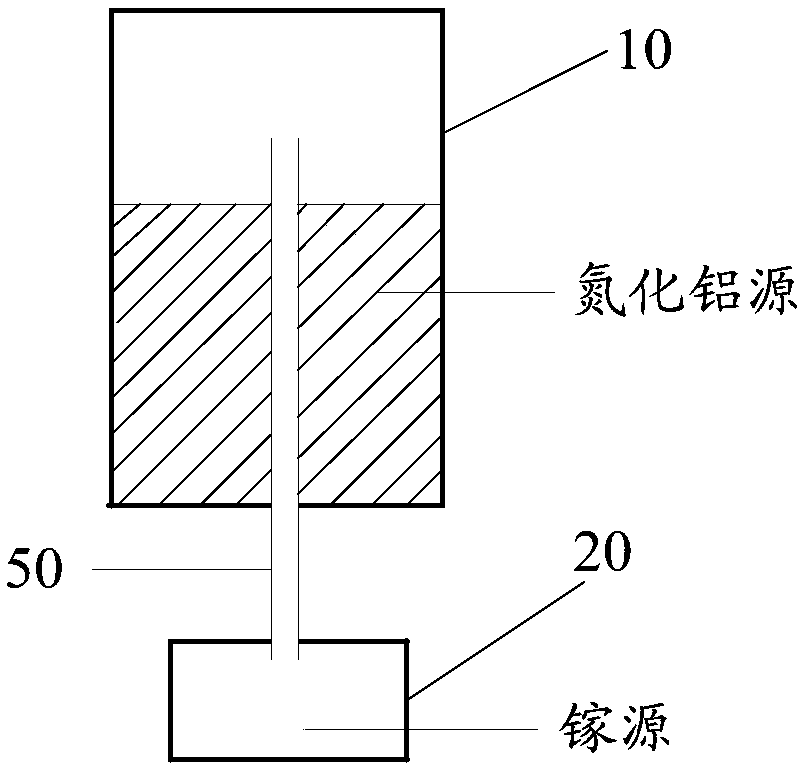

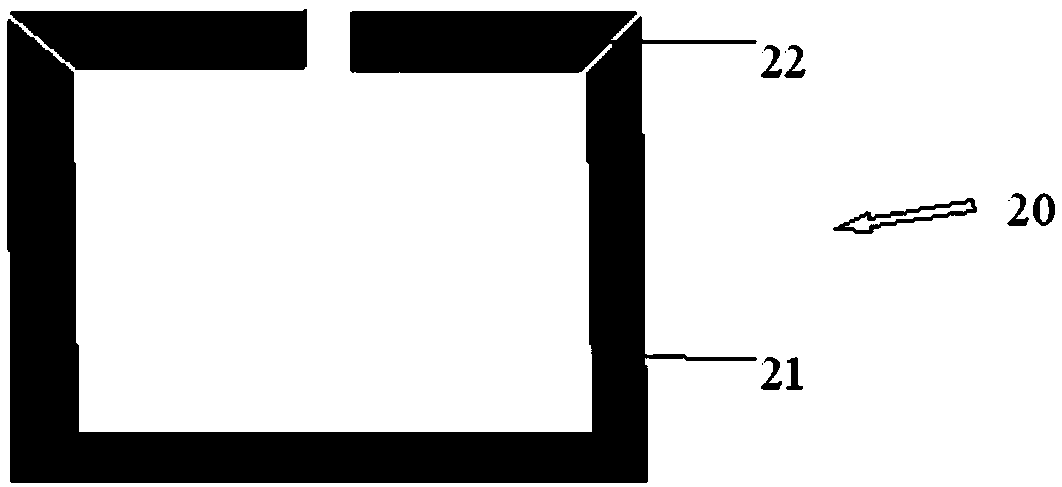

Crucible equipment and method for preparing aluminum nitride crystal

ActiveCN109112634AControlled nucleationControl expansion growthPolycrystalline material growthFrom condensed vaporsCrucibleSingle crystal

The invention discloses crucible equipment and method for preparing an aluminum nitride crystal. The crucible equipment comprises a first crucible, a second crucible and a connection pipe, wherein theinner part of the first crucible and the inner part of the second crucible are communicated through the connection pipe; the first crucible is used for containing an aluminum nitride source and the second crucible is used for containing a gallium source; the extending length of the connection pipe in the first crucible is greater than the thickness of the aluminum nitride source in the first crucible. Compared with the prior art, gallium steam generated by the gallium source in the second crucible can enter a reaction cavity of the first crucible; the gallium steam can be used for changing the crystallization property of the aluminum nitride crystal, and the nucleation and diameter-expanding growth of the aluminum nitride crystal are easy to control, so that the gallium steam is mixed into the reaction cavity of the first crucible in a process of preparing the aluminum nitride crystal, the nucleation density of the aluminum nitride crystal can be effectively reduced and the size of the aluminum nitride crystal also can be enlarged, and furthermore, a large-size aluminum nitride single crystal is obtained.

Owner:SHENZHEN UNIV

P-type phosphorus-doped two-dimensional tungsten selenide semiconductor material and preparation method thereof

InactiveCN109650352ALower evaporation temperaturePromote growthMetal selenides/telluridesBinary selenium/tellurium compoundsSelenideTungsten

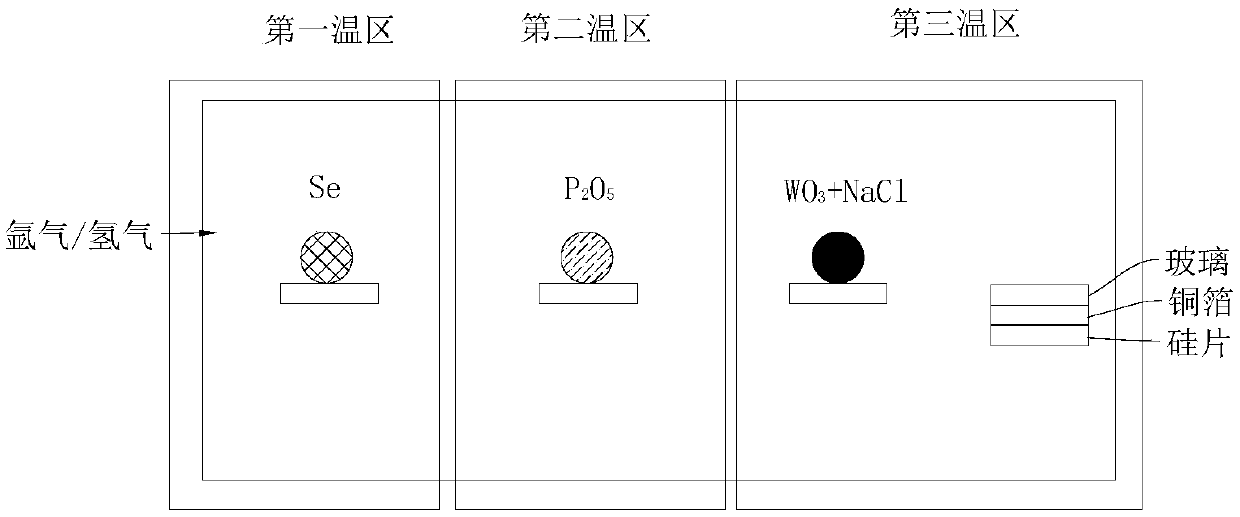

The invention discloses a p-type phosphorus-doped two-dimensional tungsten selenide semiconductor material and a preparation method thereof, and belongs to the technical field of semiconductor material preparation. The preparation method uses Se as a selenium source, a mixture of WO3 and NaCl as a tungsten source and P2O5 as a phosphorus doping source, and prepares the p-type phosphorus-doped two-dimensional tungsten selenide semiconductor material on a glass substrate by using a preparation mode of three temperature regions, wherein the Se, P2O5 and mixture of WO3 and NaCl are respectively placed in the first temperature region, second temperature region and third temperature region, and the substrate is placed in the third temperature region.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Preparation method of graphene monocrystal

InactiveCN109321973AGrow fastReduce nucleation densityPolycrystalline material growthFrom chemically reactive gasesCarbon impuritiesSingle crystal

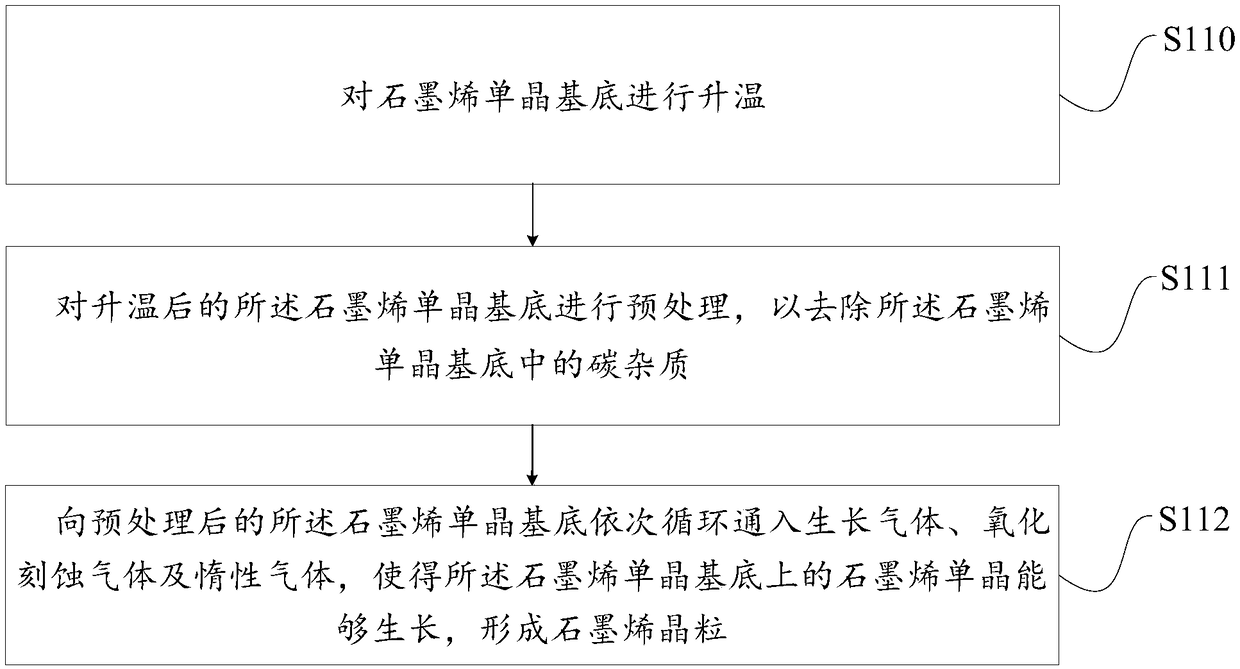

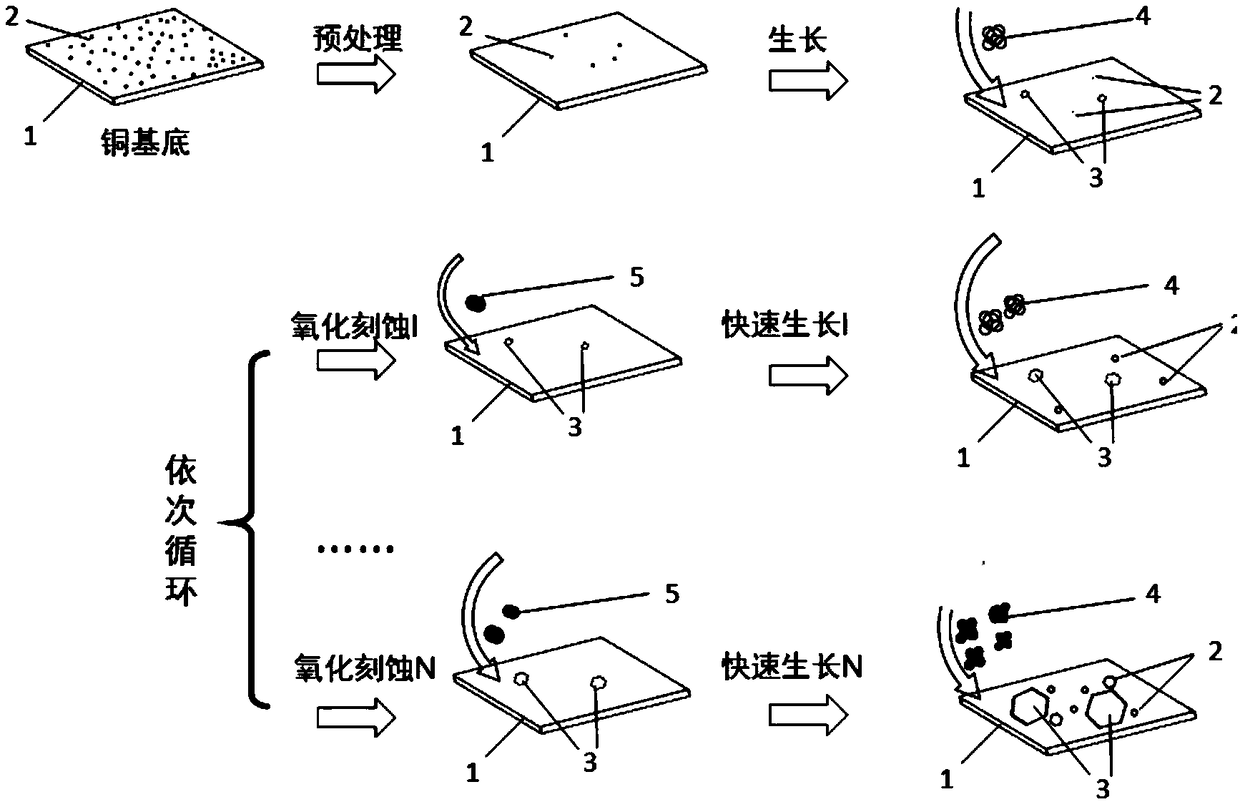

The invention provides a preparation method of a graphene monocrystal. The preparation method comprises the following steps: heating a graphene monocrystal substrate; pretreating the heated graphene monocrystal substrate so as to remove carbon impurities in the graphene monocrystal substrate; successively circularly introducing growth gas, oxidization etching gas and inert gas into the pretreatedgraphene monocrystal substrate, so as to enable the graphene monocrystal on the graphene monocrystal substrate to grow to form graphene crystal grains, wherein when the growth gas and the oxidizationetching gas are successively circularly introduced, the introduction amount of the growth gas and the oxidization etching gas can be gradually increased according to the preset gas increment amount; therefore, in the growth process, the nucleation density of the graphene can be reduced by successively circularly introducing the oxidization etching gas; the introduction amount of the growth gas isgradually increased according to the preset gas increment amount, so that in the growth process of the graphene monocrystal, sufficient growth gas can be provided, and the growth rate of the graphenemonocrystal can be increased.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com