Assistant device for graphene preparation, graphene and preparation method thereof

An auxiliary device, graphene technology, applied in the field of semiconductors, can solve the problem of graphene growth rate reduction and achieve the effect of reducing the nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

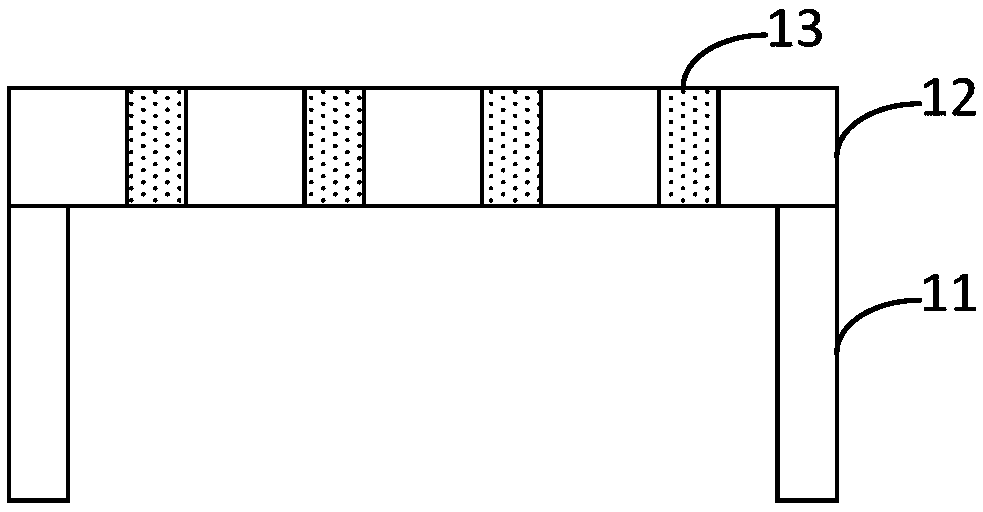

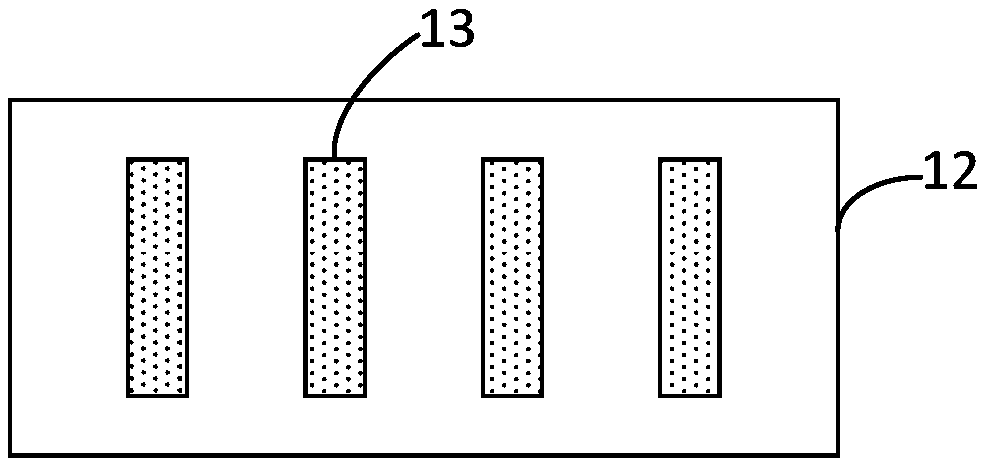

[0034] Please refer to figure 1 with figure 2 , figure 1 with figure 2 It is a schematic structural view of the graphene auxiliary device provided by Embodiment 1 of the present invention, the device includes: a support body 11 and a buffer layer 12, the buffer layer 12 is arranged on the upper surface of the support body 11, and the buffer layer 12 is provided with one or more The hole 13 runs through the buffer layer 12 .

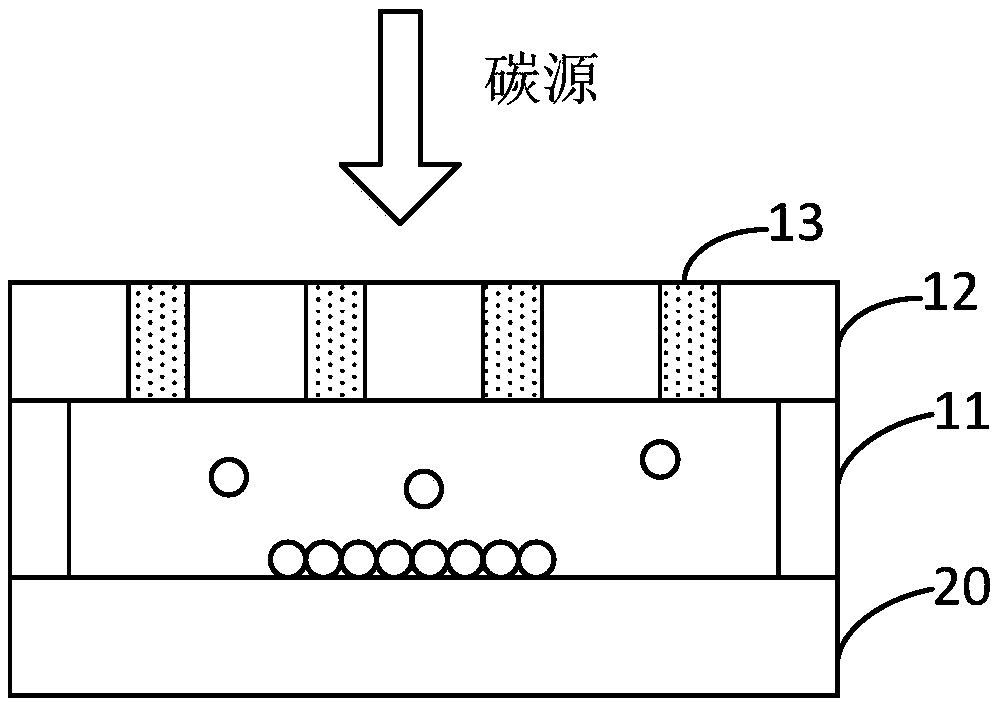

[0035] In the embodiment of the present invention, such as image 3 As shown, when preparing graphene by the CVD method, the device is placed on the upper surface of the substrate 20, the carbon source is buffered by the buffer layer 12, and reaches the surface of the substrate 20 through the hole 13, forming nucleation on the surface of the substrate 20 layer, through the buffering effect of the buffer layer, the speed at which the carbon source reaches the surface of the substrate 20 and the supersaturation of the carbon source on the surface of t...

Embodiment 2

[0046] Please refer to Figure 4 , Figure 4 It is a schematic flow diagram of the realization of the preparation method of graphene provided by the second embodiment of the present invention, and the method comprises the following steps:

[0047] Step S101, placing the auxiliary device for preparing graphene as described in Embodiment 1 of the present invention on the upper surface of the substrate, and placing the substrate in the cavity of the chemical vapor deposition equipment, wherein the support of the auxiliary device The body is in contact with the substrate.

[0048] In the embodiment of the present invention, such as image 3 As shown, the above-mentioned auxiliary device for preparing graphene is placed on the upper surface of the substrate 20, and the substrate is placed in the chamber of the CVD equipment.

[0049] Optionally, the substrate is a copper substrate. Before step S101, the method further includes: growing a copper oxide film on the surface of the ...

Embodiment 3

[0059] Embodiment 3 of the present invention provides a kind of preparation method of graphene, and this method comprises the following steps:

[0060] Step 1. Heat the copper substrate to 200° C. in air and maintain it for 20 minutes.

[0061] Step 2, placing the auxiliary device for preparing graphene as in Embodiment 1 of the present invention on the upper surface of the copper substrate, wherein the height of the support in the auxiliary device is 4 mm, and placing the copper substrate on the CVD equipment cavity.

[0062] Step 3. Raise the temperature of the chamber to 1030° C., control the pressure at 25 mbar, and feed argon into the chamber at a flow rate of 500 sccm, maintain it for 10 minutes, and discharge the air in the chamber.

[0063] Step 4. Introduce hydrogen and methane into the cavity, wherein the flow rate of hydrogen gas is 30 sccm, the flow rate of methane is 2 sccm, and the temperature of the cavity is set at 1030°C.

[0064] Step 5. After 60 minutes, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com