Patents

Literature

463results about How to "Lower evaporation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

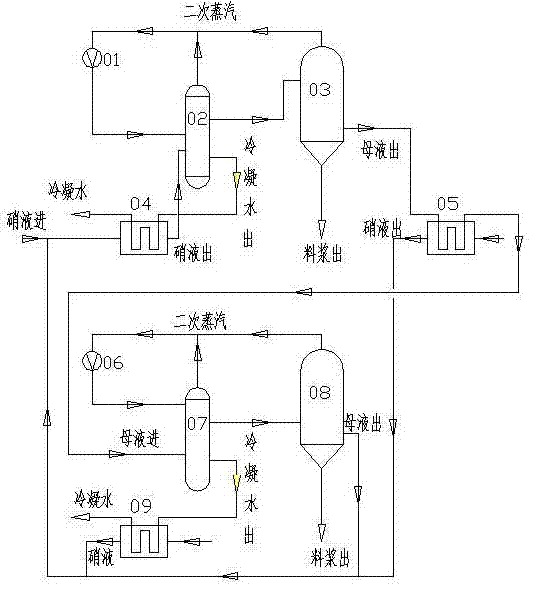

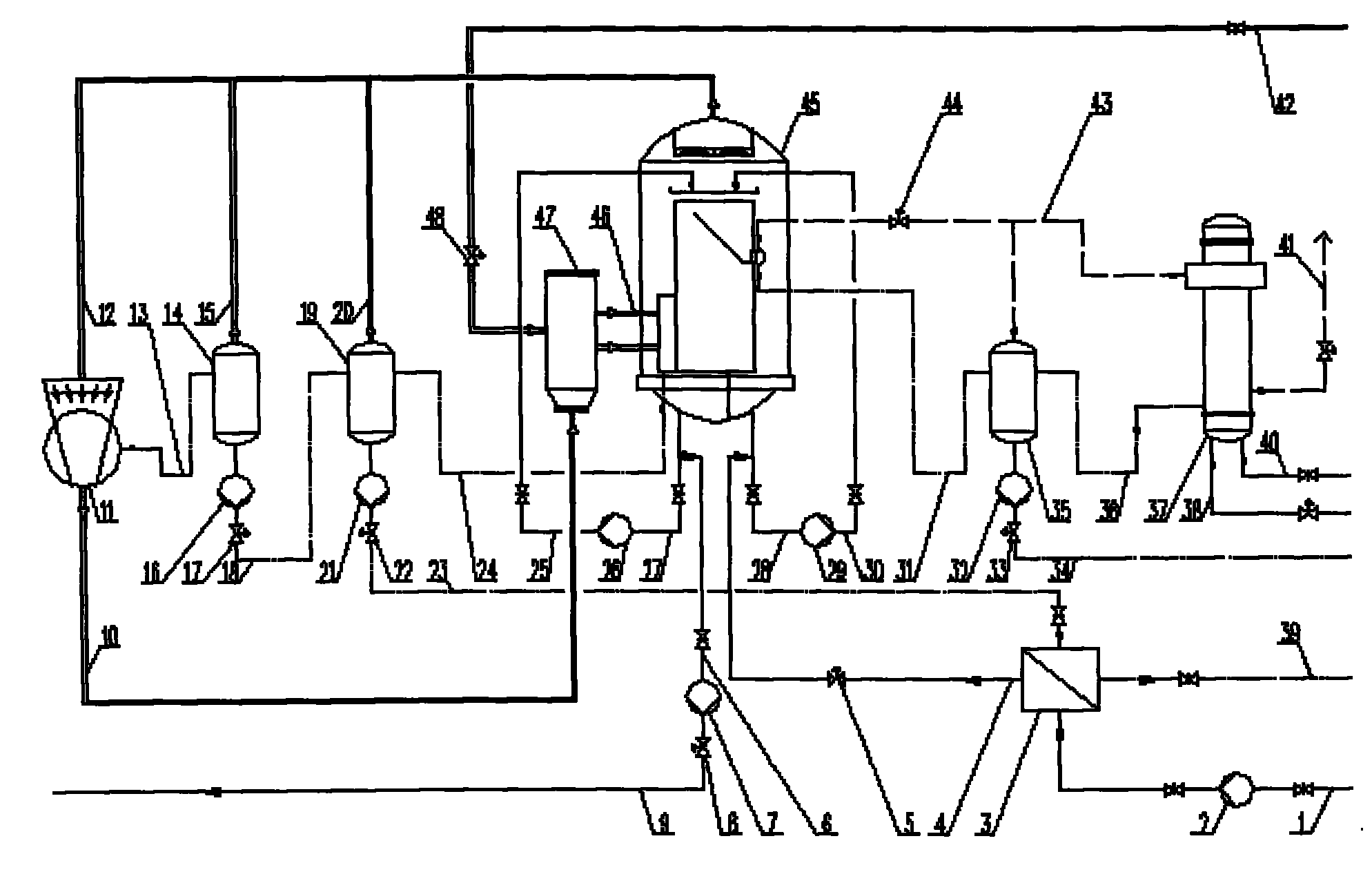

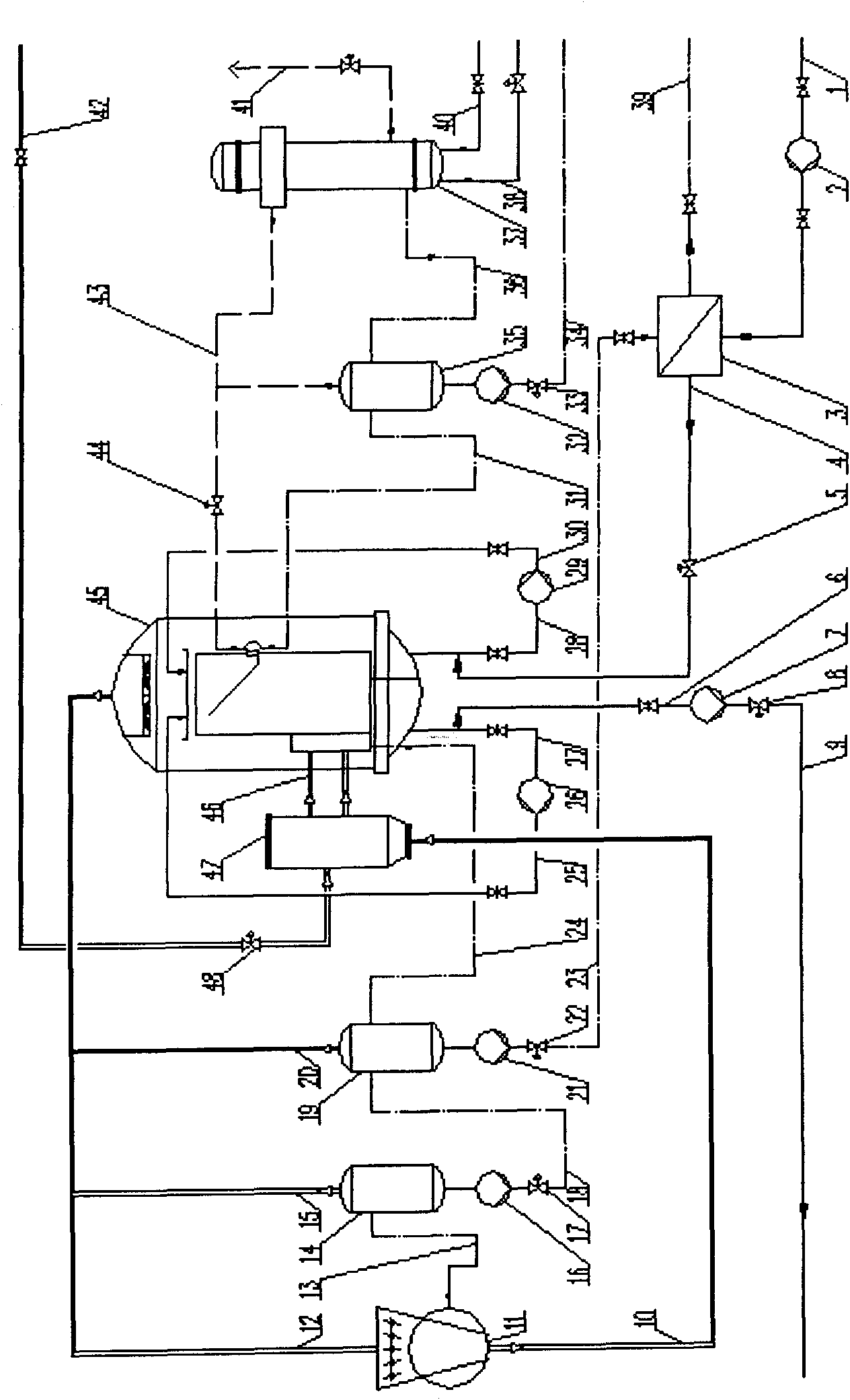

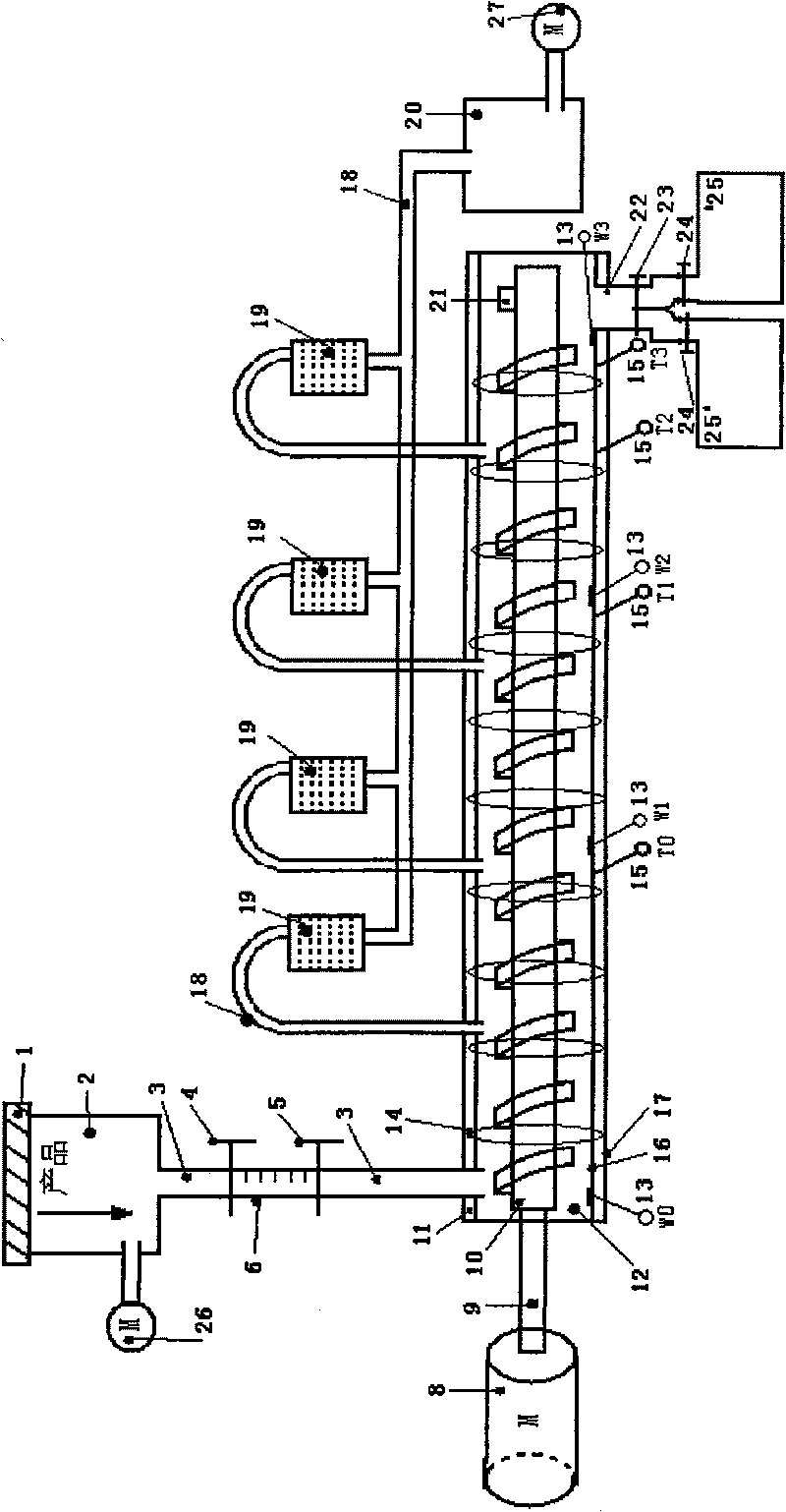

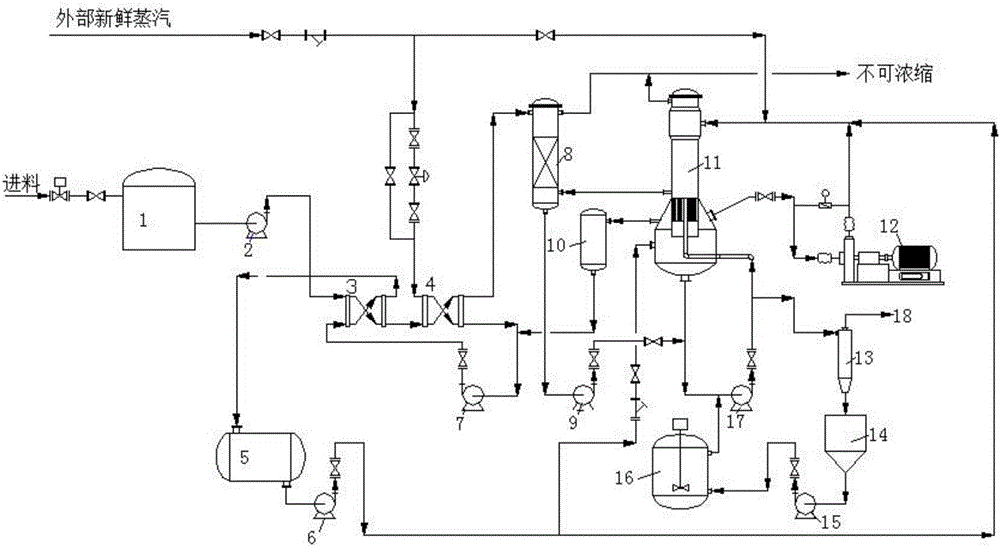

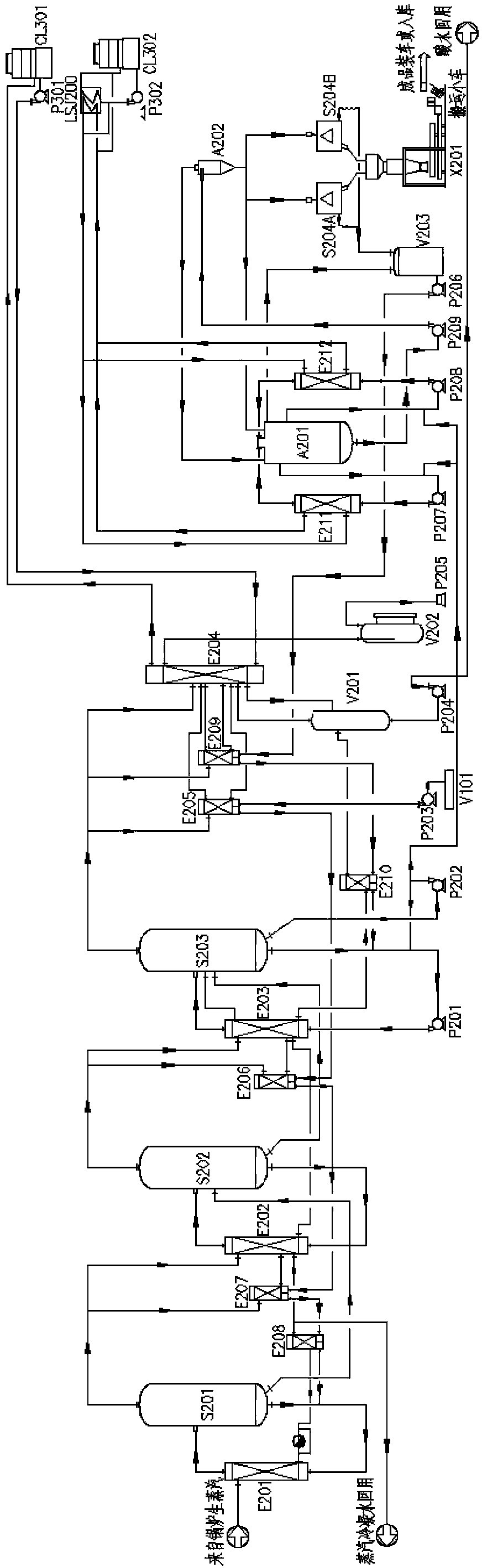

Application of MVR (mechanical vapor recompression) crystallizing evaporator in sodium sulfate and sodium chloride separation technology

InactiveCN103172088AImprove thermal efficiencyReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal chloridesPhysical chemistryExhaust fumes

The invention discloses an industrial application of an MVR (mechanical vapor recompression) crystallizing evaporator technology in the production of sodium sulfate and sodium chloride in Huaian, Jiangsu, and relates to an improvement of a salt and sodium sulfate coproduction evaporation technology, belonging to the technical field of chemical three-waste treatment and utilization, and in particular to an application of an MVR crystallizing evaporator in a sodium sulfate and sodium chloride separation technology. The application is mainly technically characterized in that sodium sulfate liquid is concentrated by the MVR crystallizing evaporator, the sodium sulfate is produced at high temperature, and the sodium chloride is produced at low temperature. According to the invention, the mechanical re-compressed vapor is evaporated, concentrated and crystallized at 90-100 DEG C to obtain sodium sulfate, and the re-compressed vapor at a low temperature of 55 DEG C is concentrated and crystallized to obtain sodium chloride. According to the invention, the application of the MVR technology to the concentration of sodium sulfate liquid is realized, the sodium sulfate is produced at high temperature, and sodium chloride is produced at low temperature. The application disclosed by the invention is an environmental protection project which saves energy, reduces emission and avoids waste gas, waste water and waste residue.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

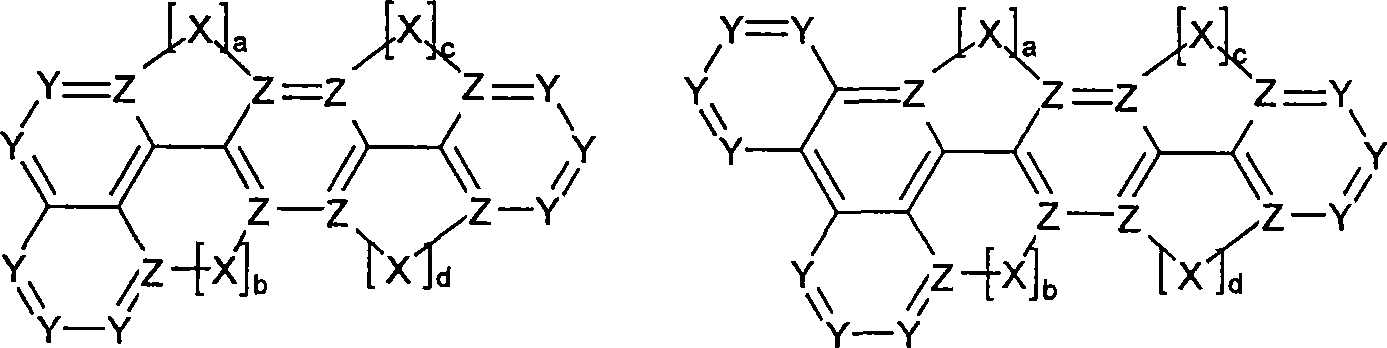

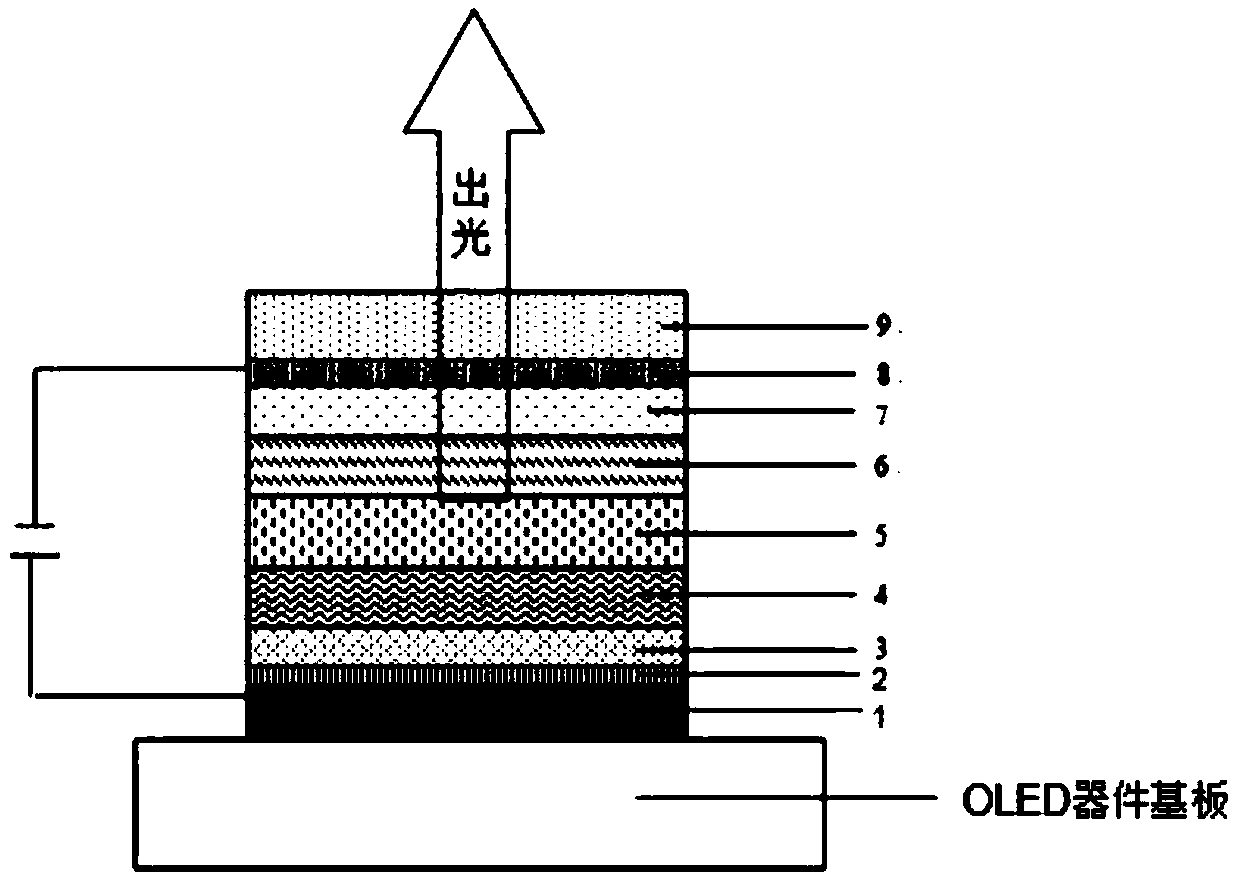

Novel materials for organic electroluminescent devices

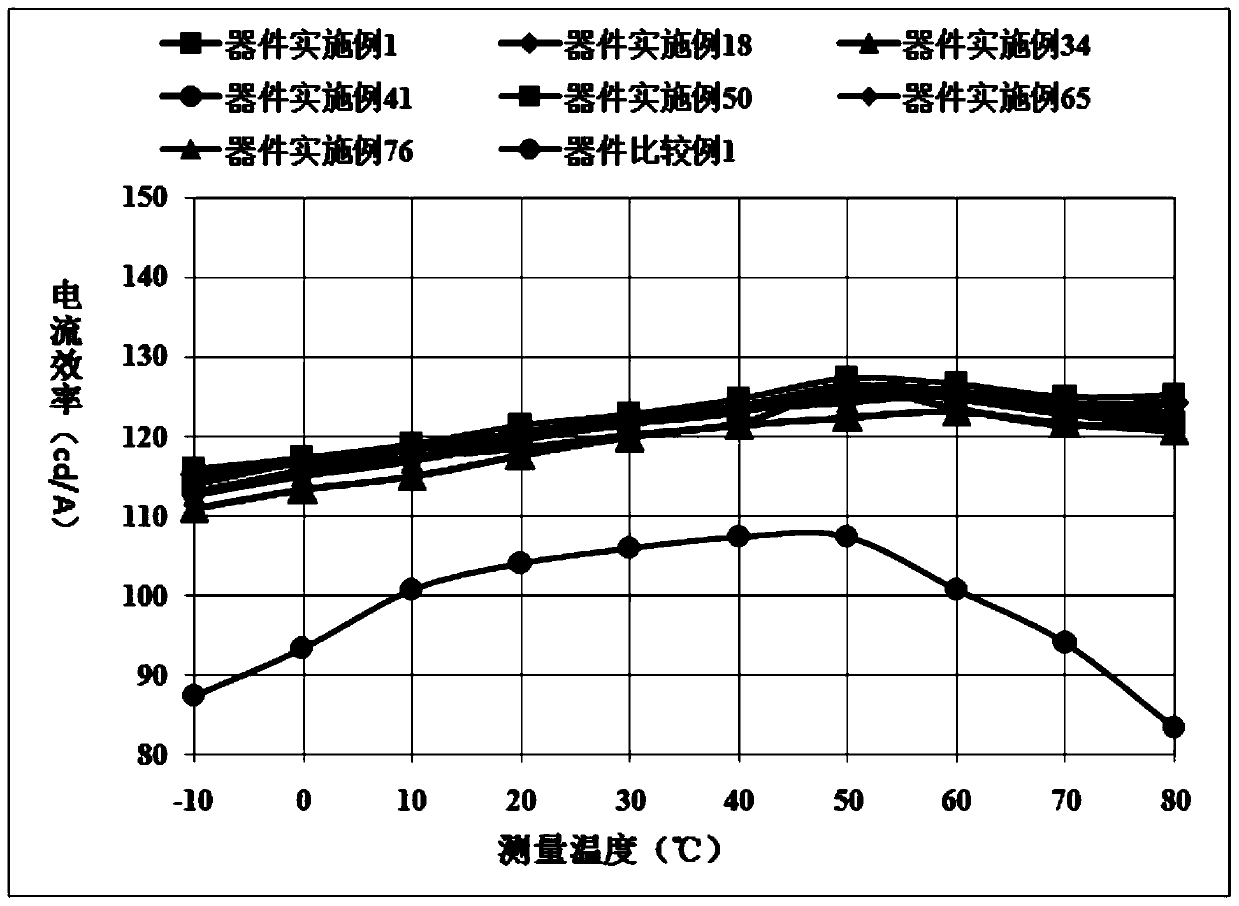

ActiveCN101490207ALow LUMOFacilitates electron injectionStyryl dyesGroup 4/14 element organic compoundsHost materialOrganic electroluminescence

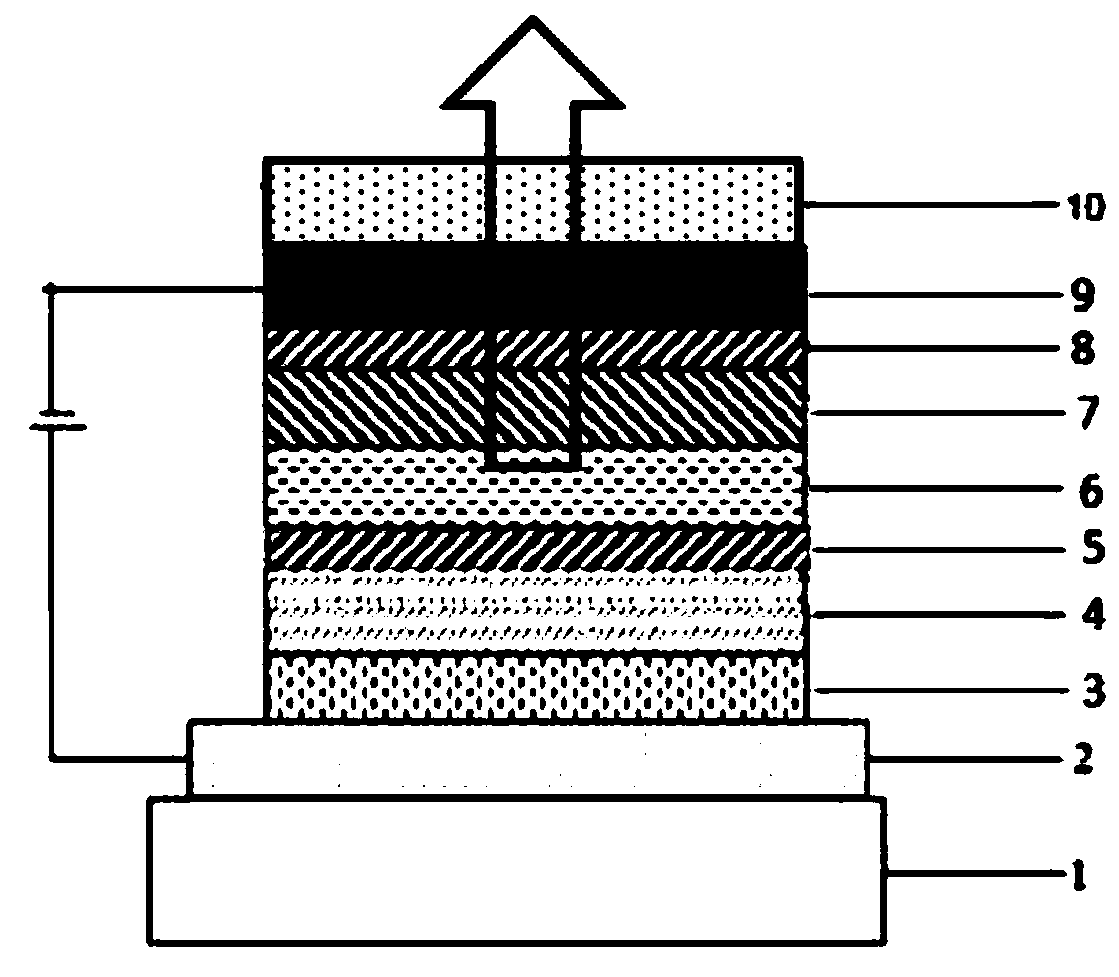

The invention relates to the compounds of formulae (1) to (6) and to organic electroluminescent devices, especially blue-emitting devices, in which these compounds are used as the host material or doping agent in the emitting layer and / or as the hole transport material and / or as the electron transport material.

Owner:MERCK PATENT GMBH

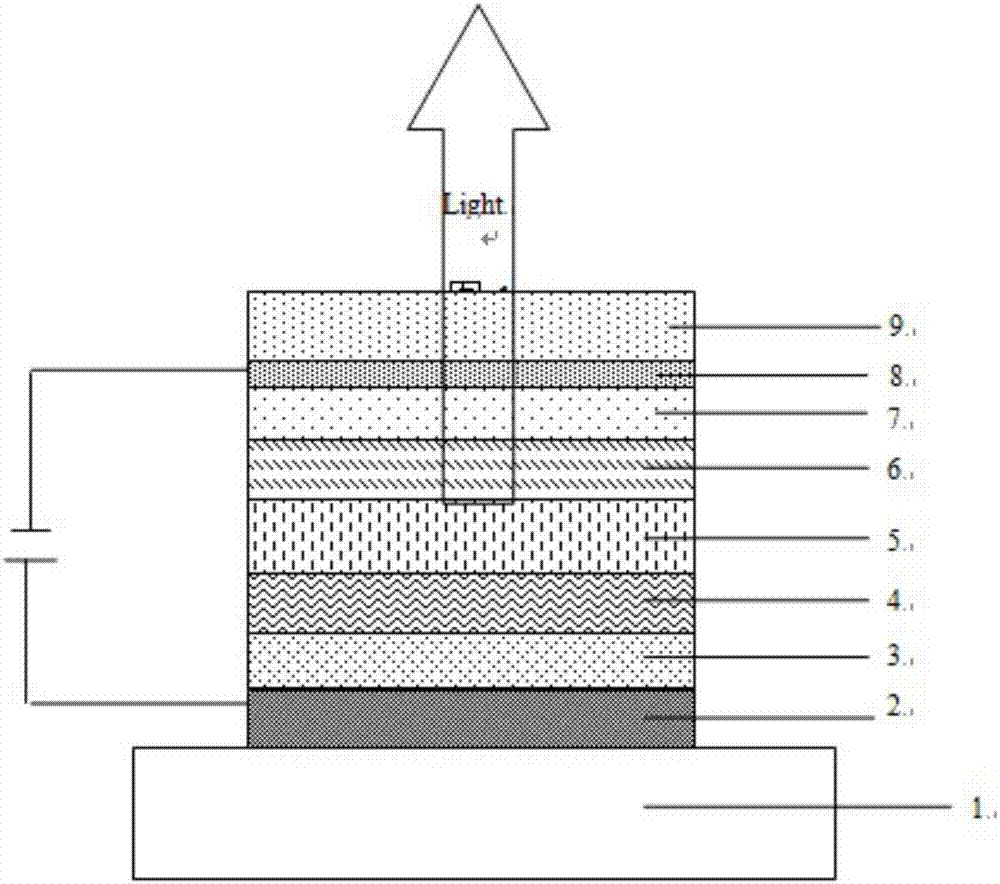

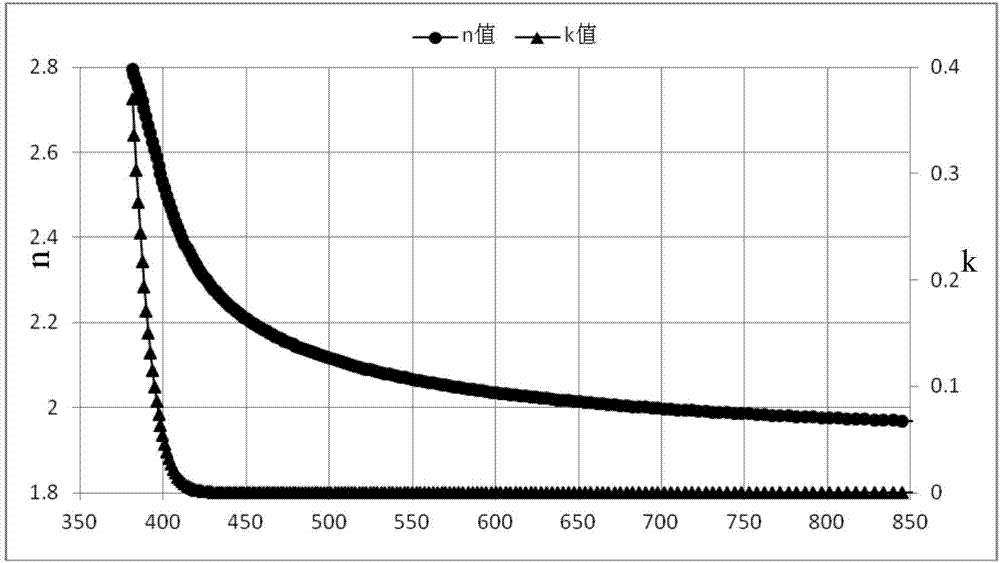

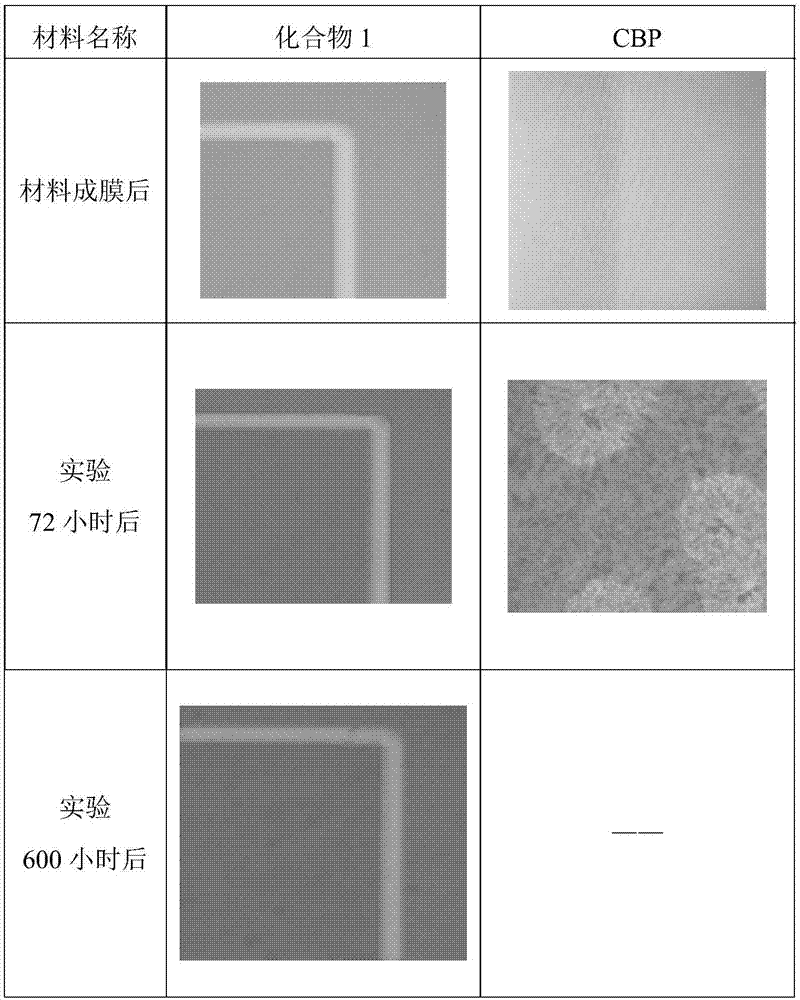

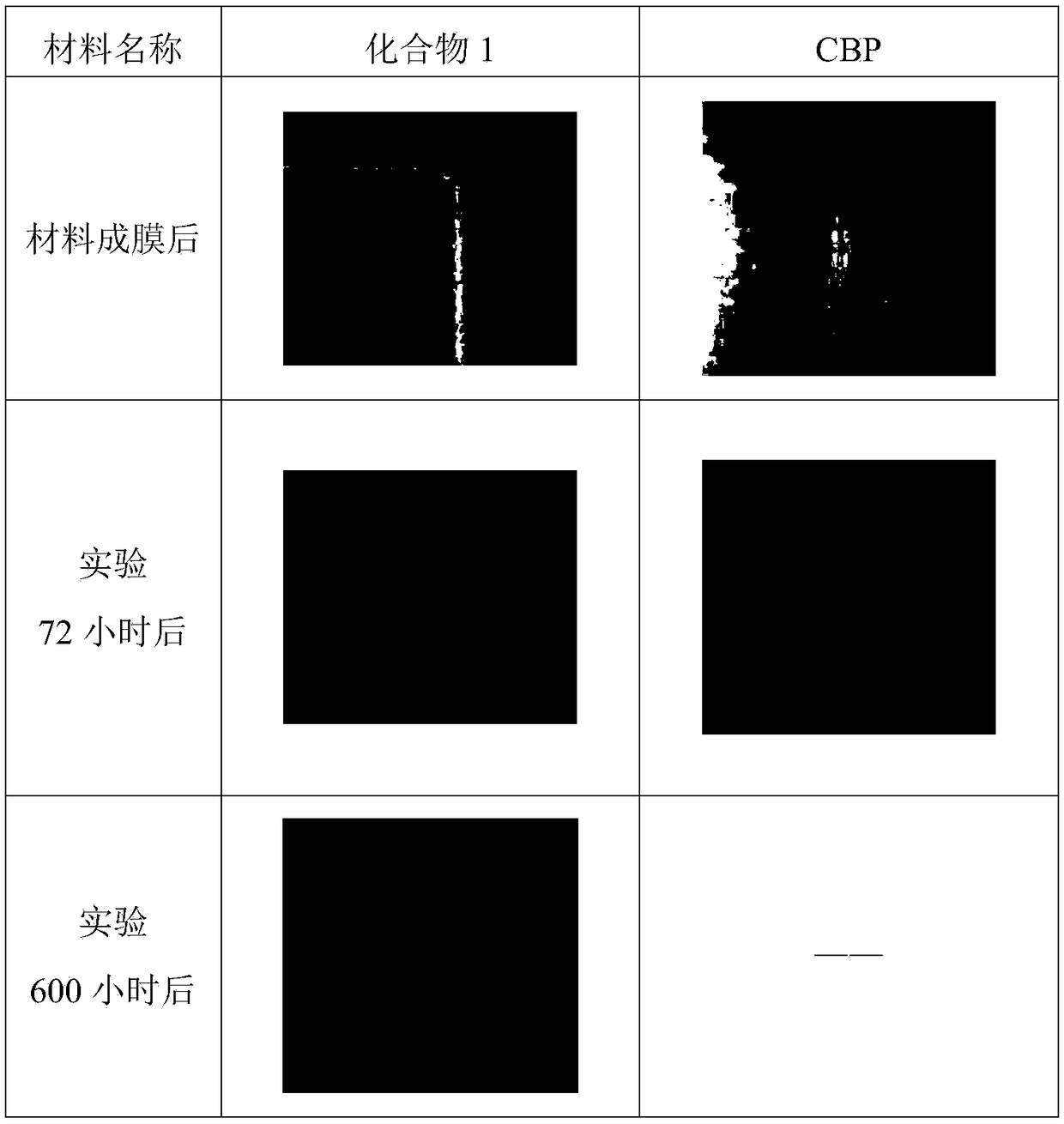

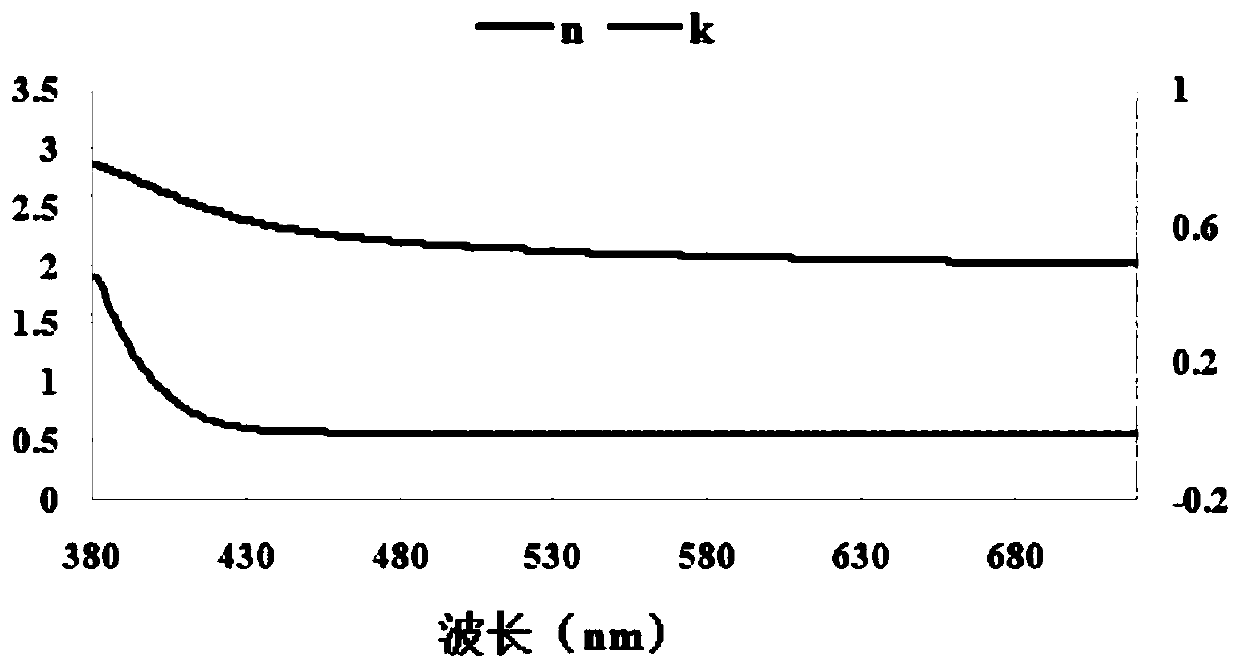

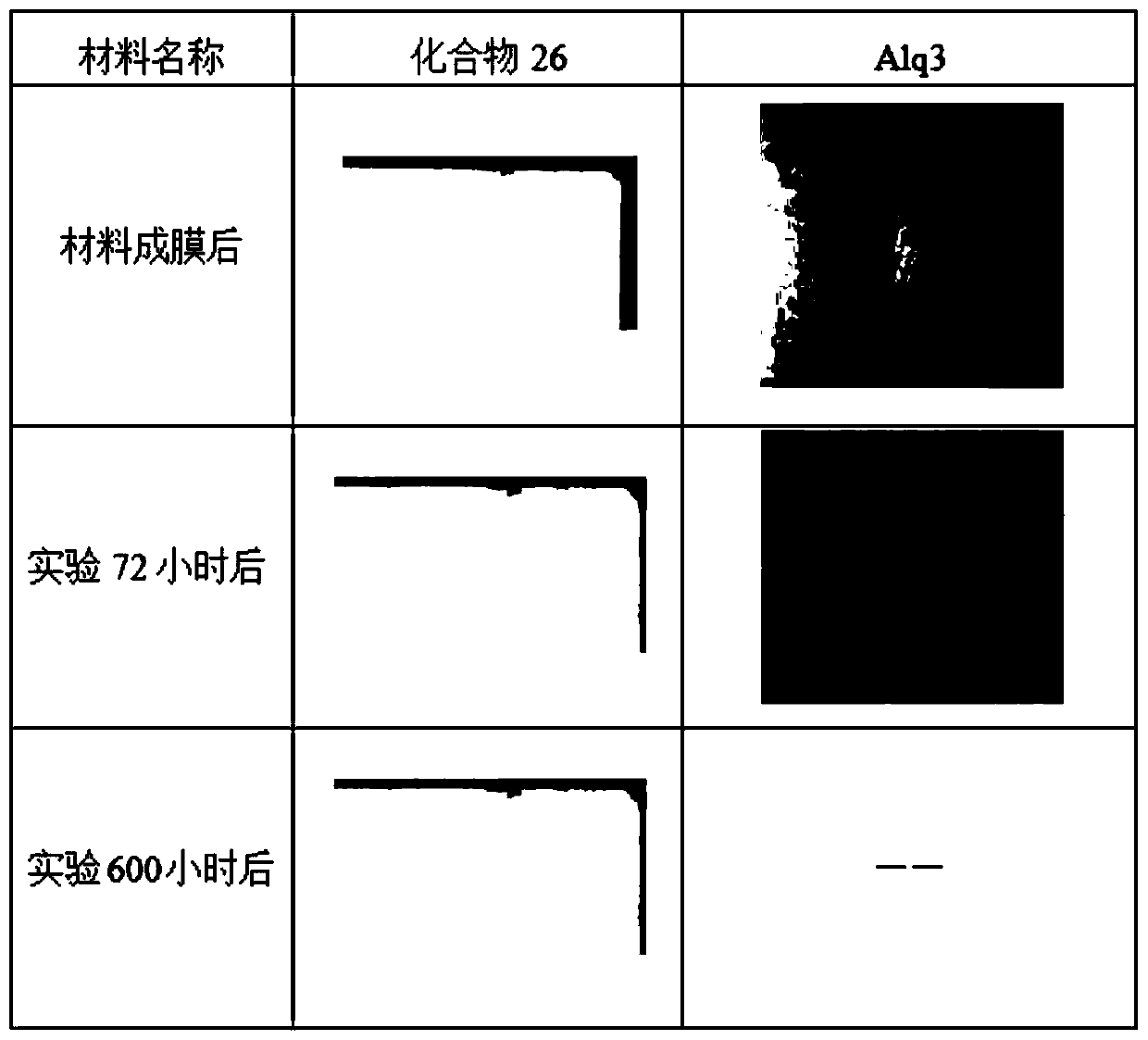

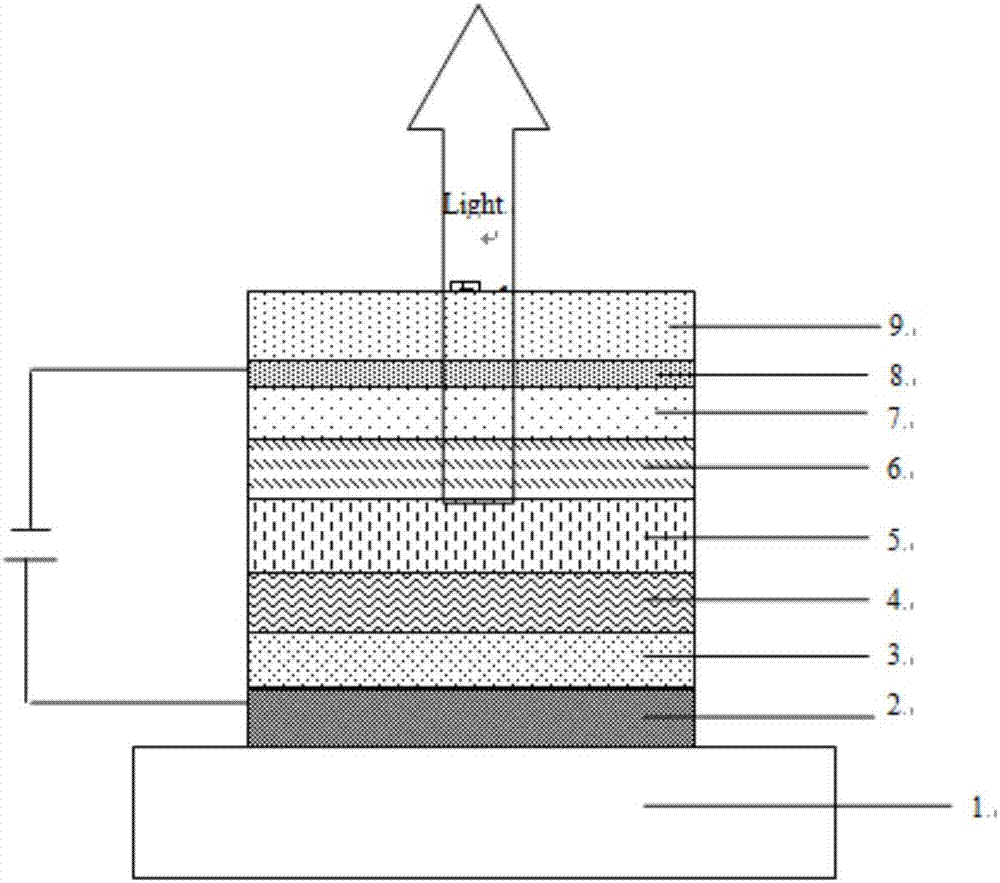

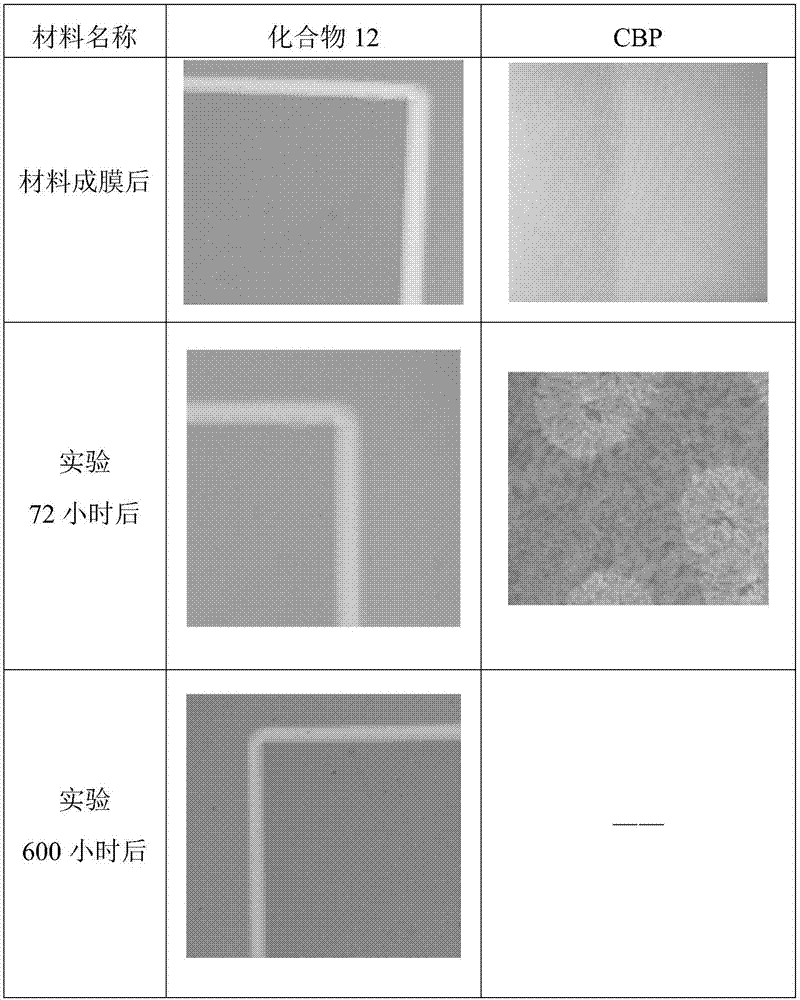

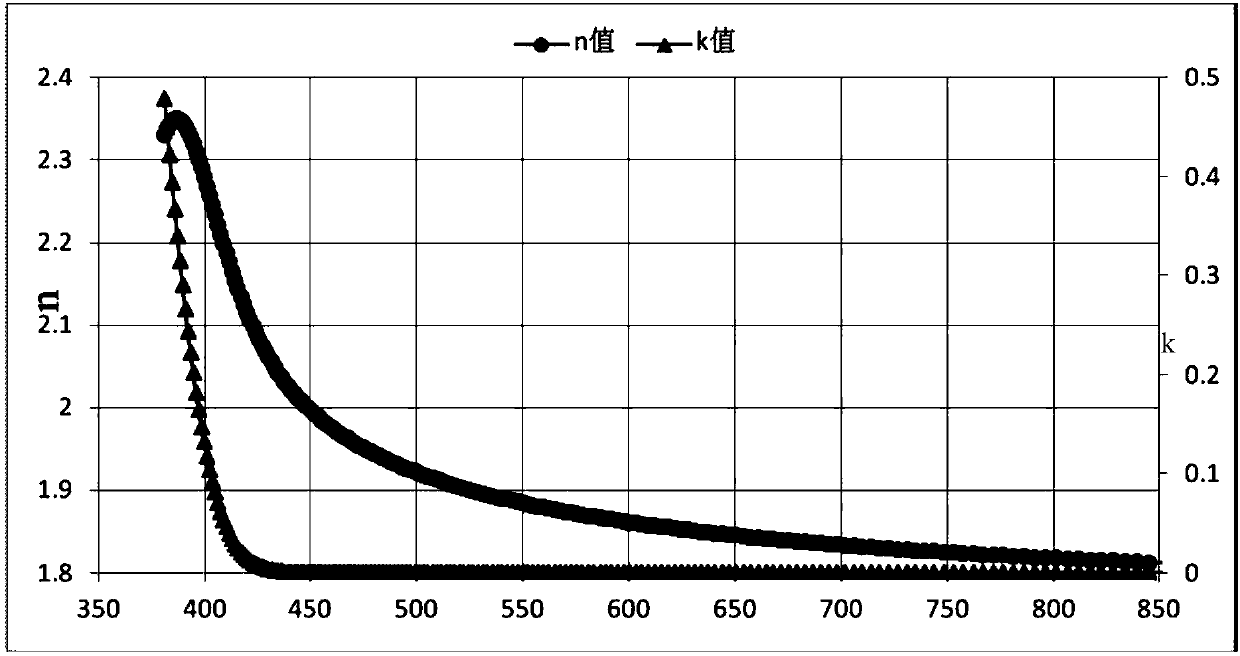

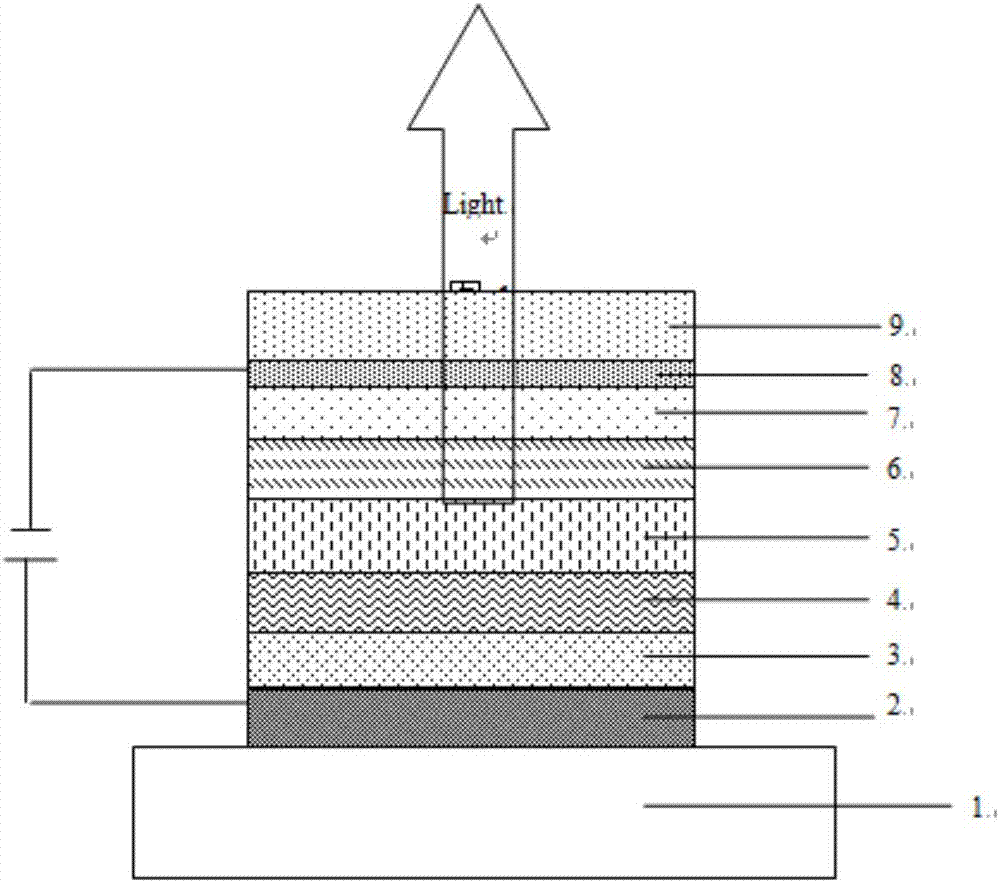

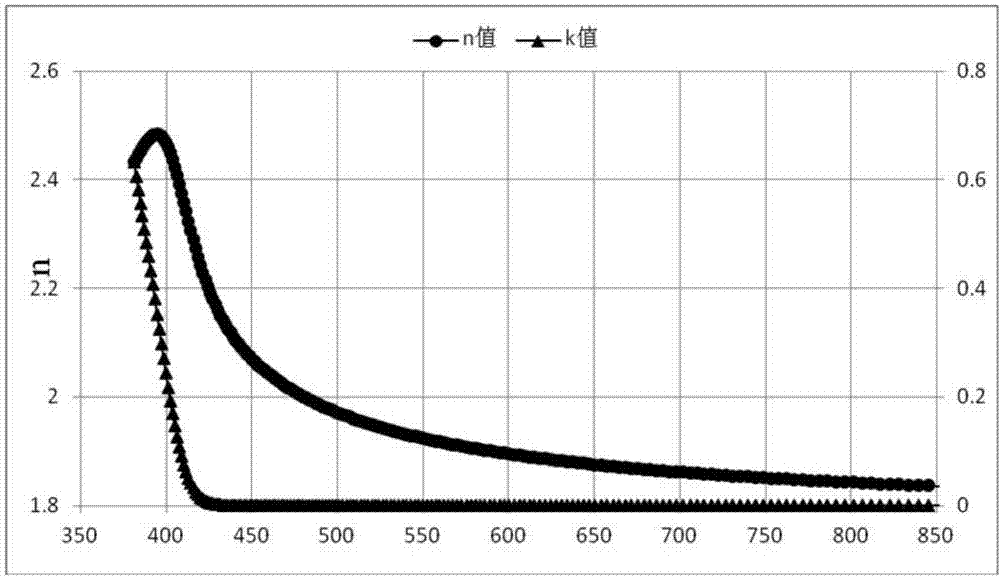

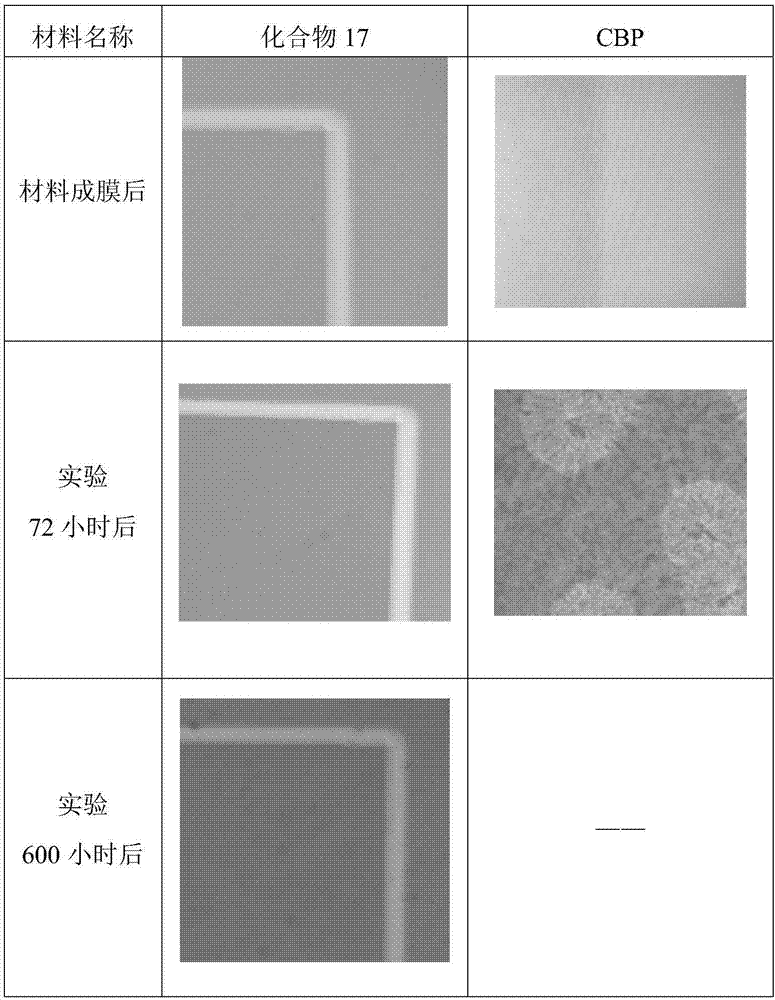

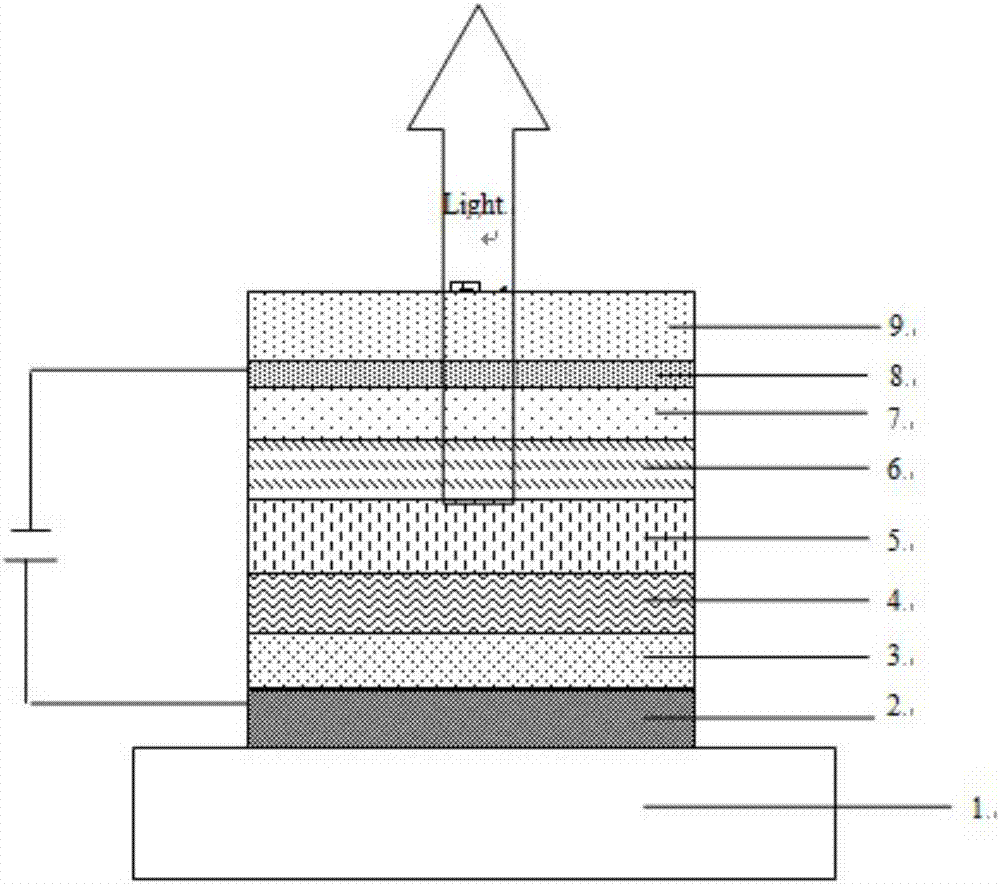

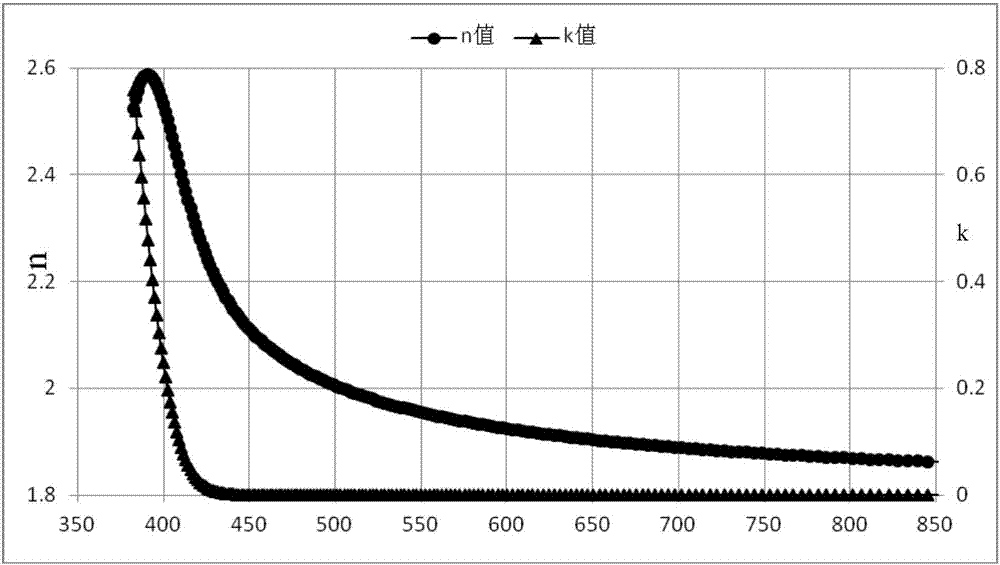

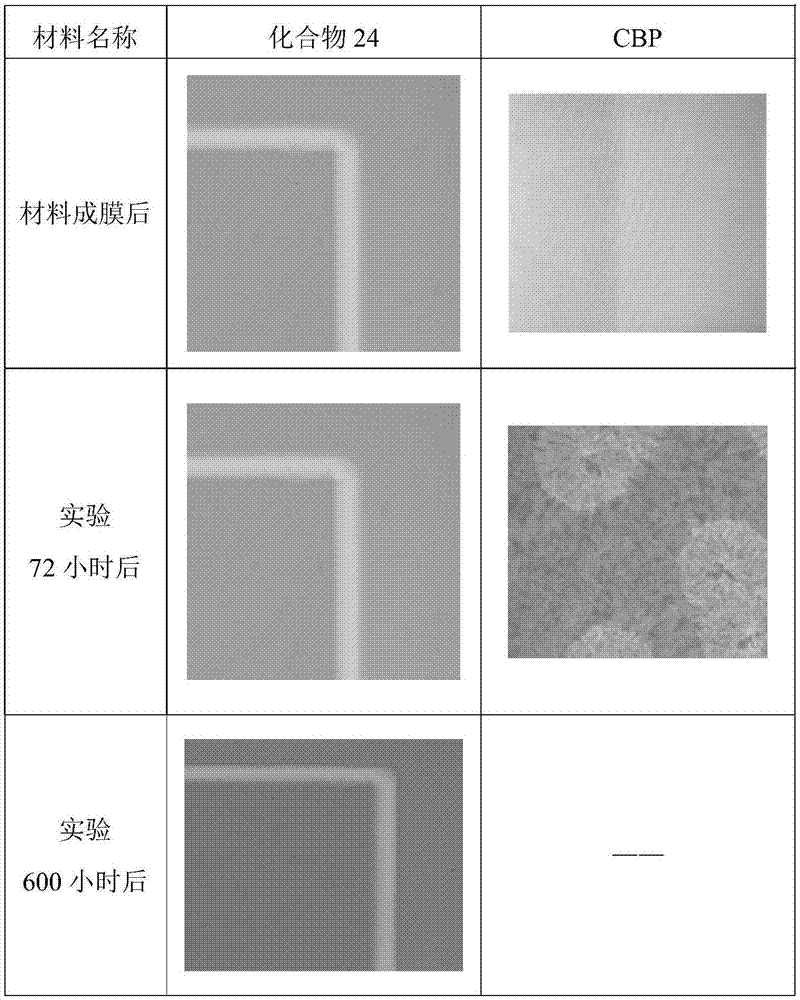

Organic compound based on heteroaryl amine structure and application thereof to OLED (Organic Light Emitting Diode)

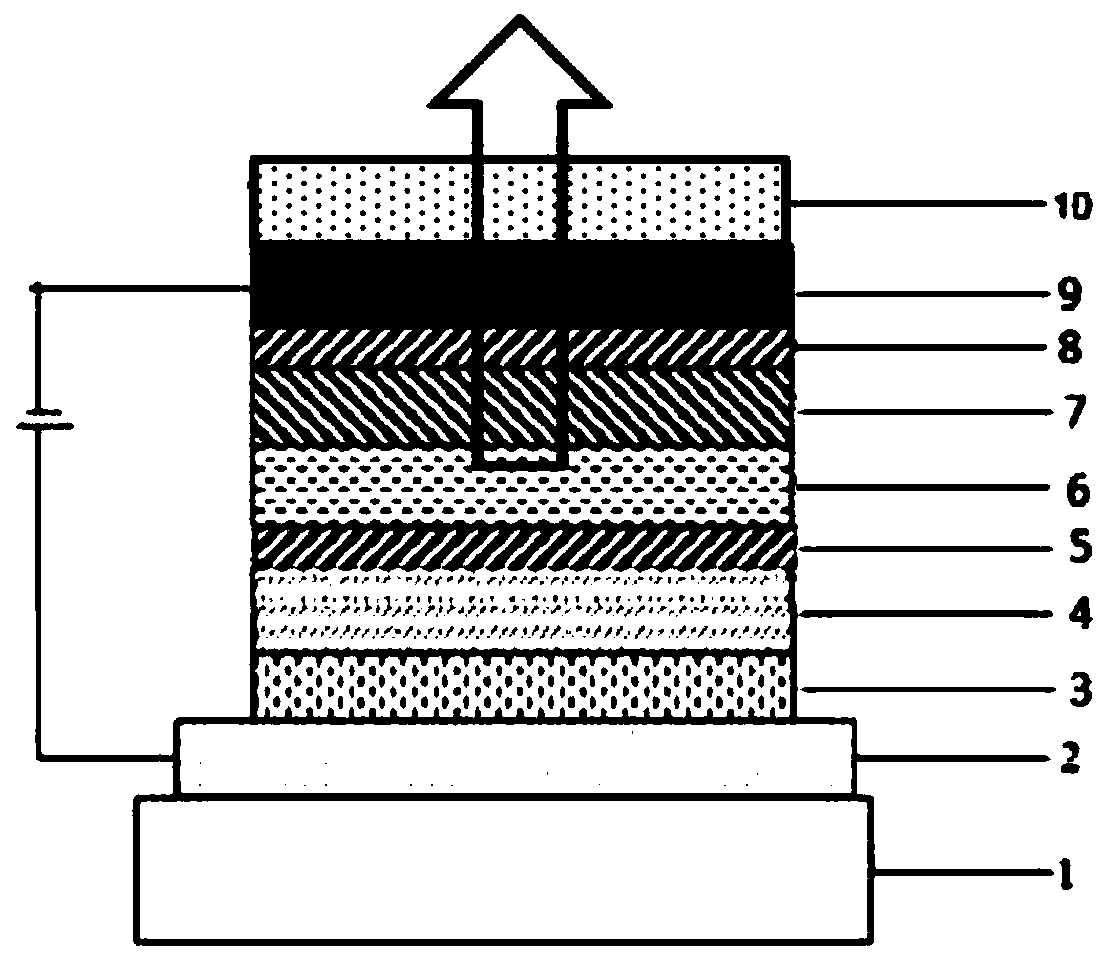

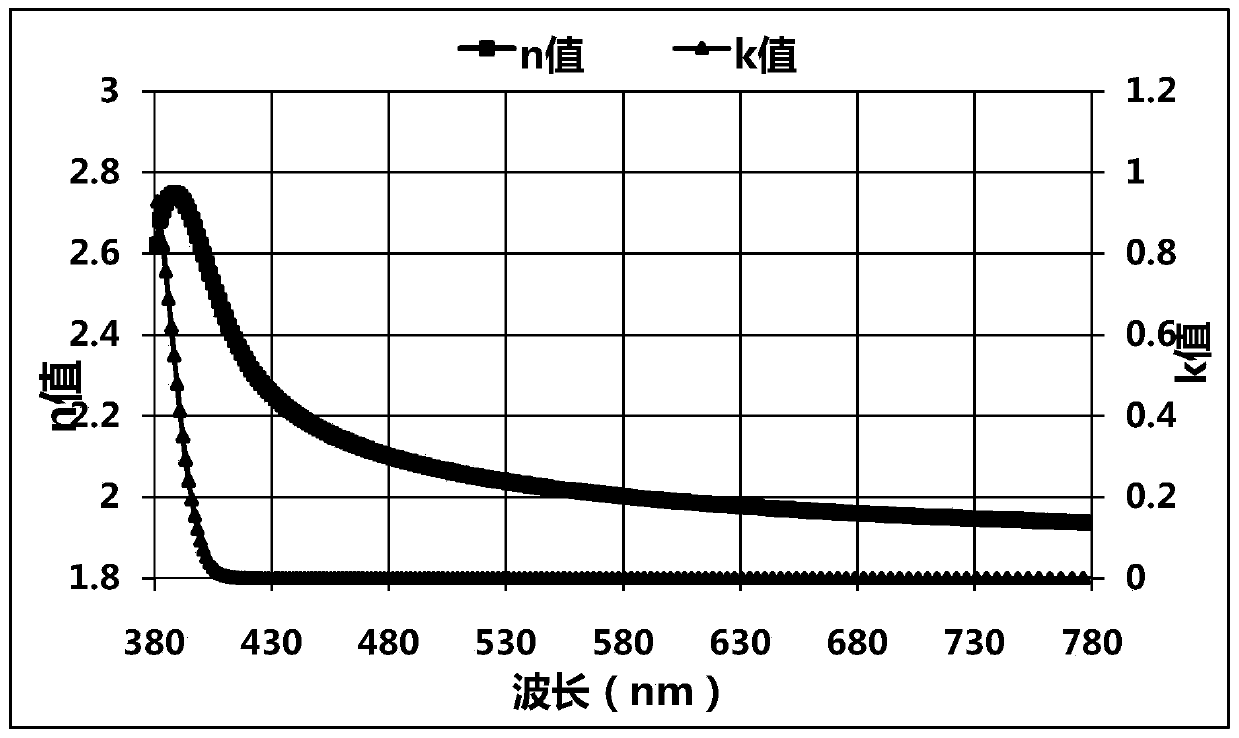

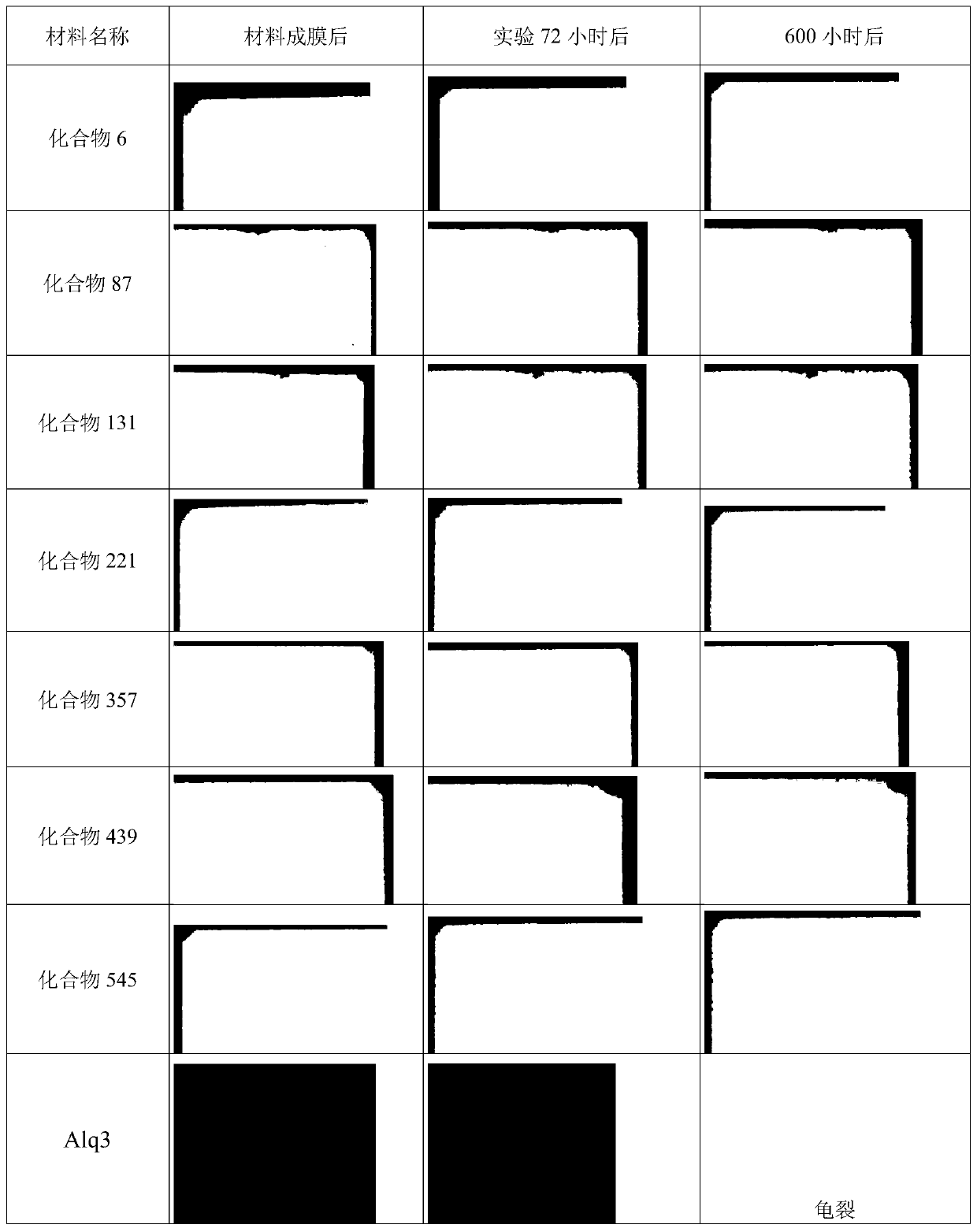

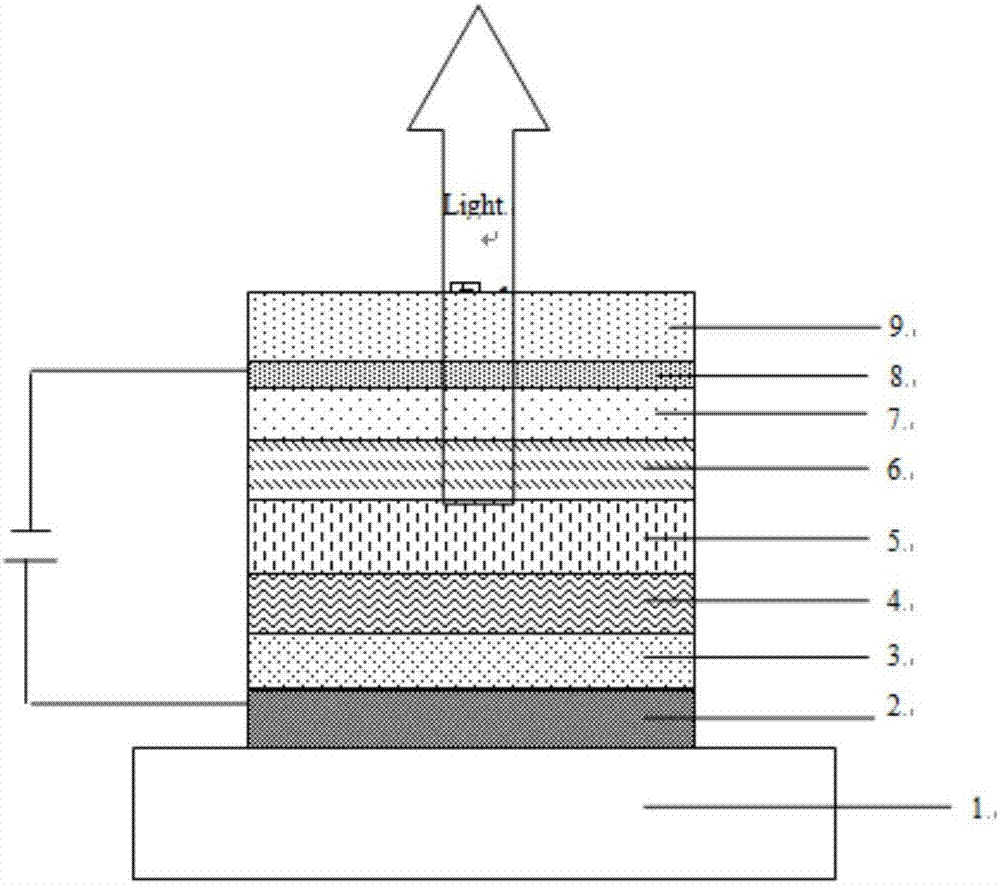

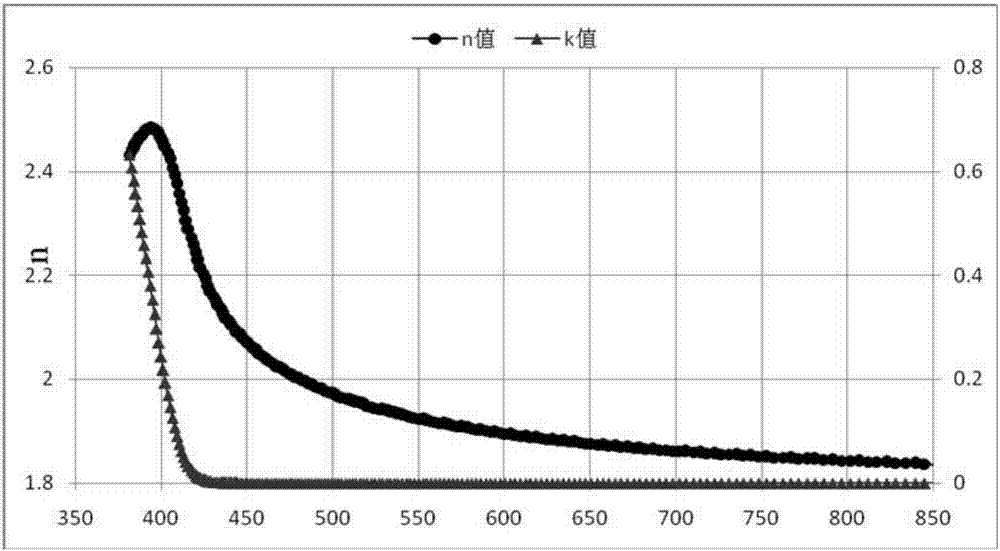

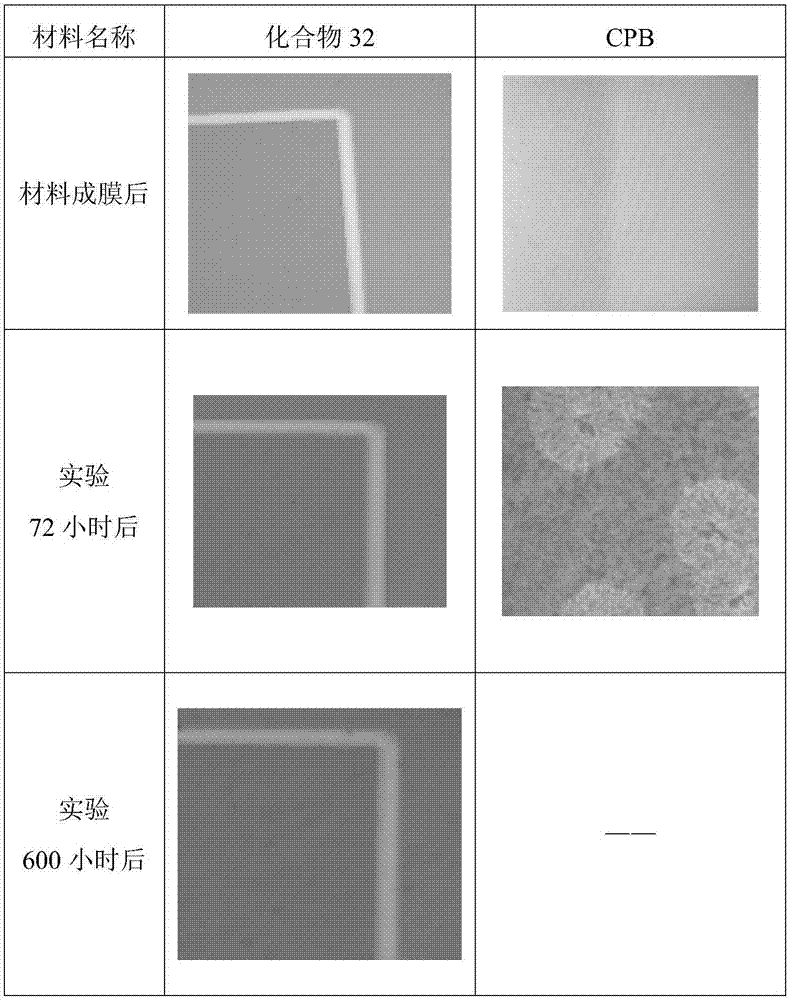

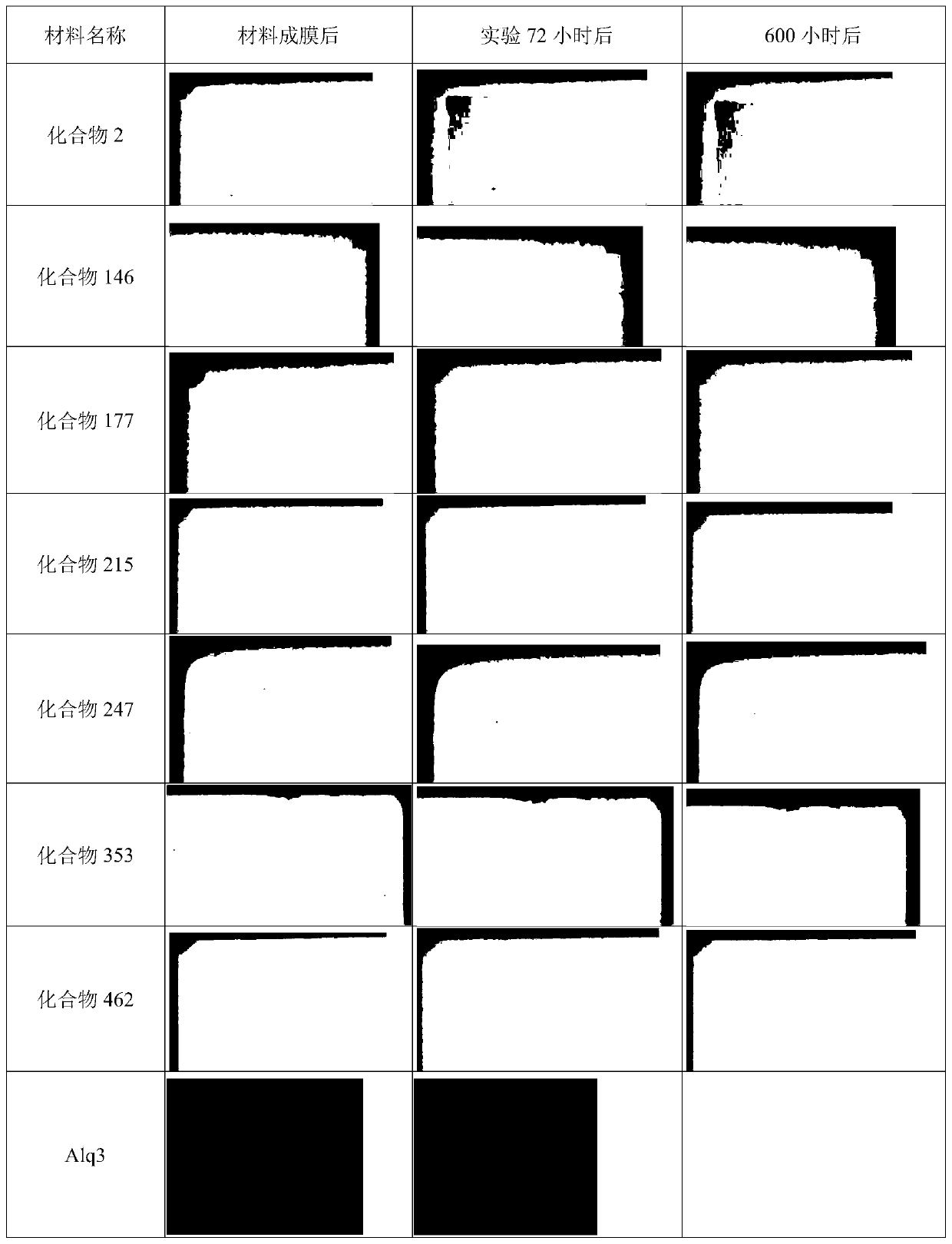

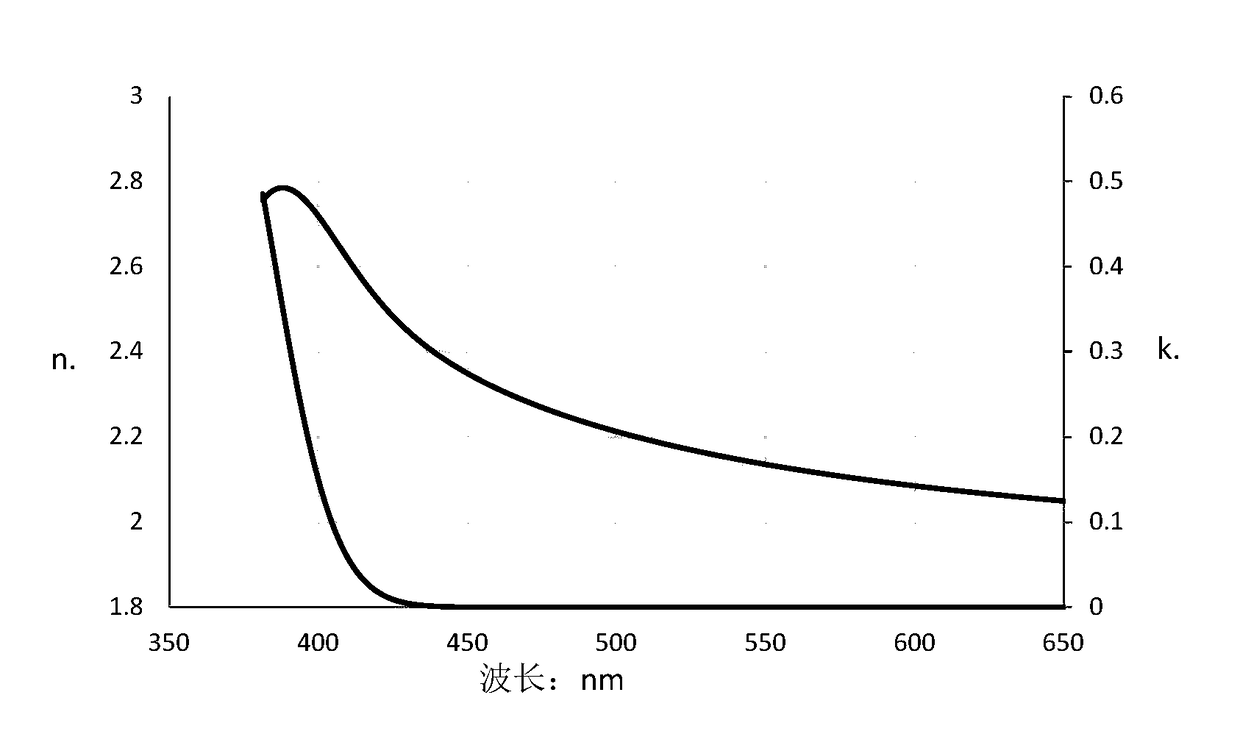

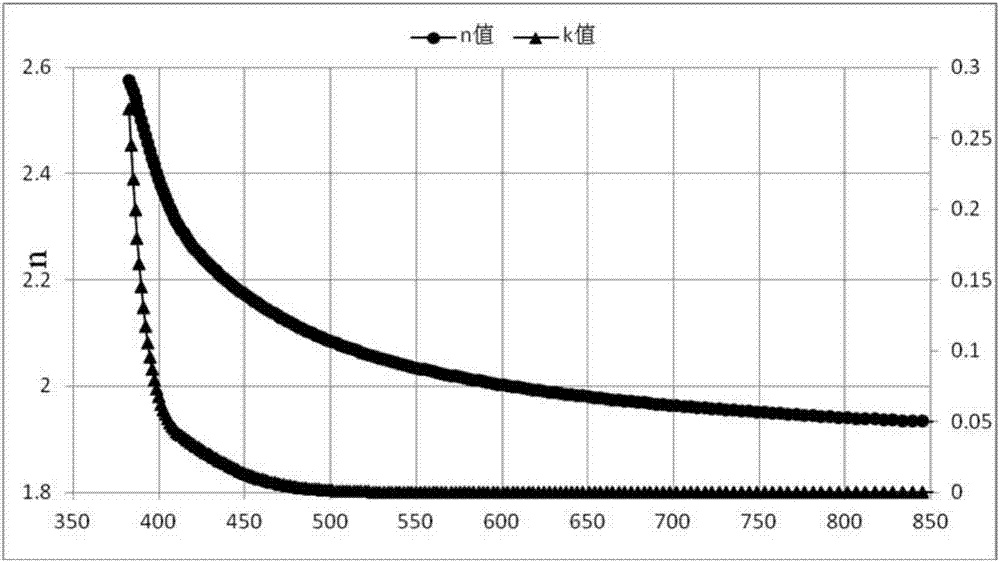

ActiveCN109761967AImprove stabilityHigh refractive indexOrganic chemistrySolid-state devicesFlexible organic light-emitting diodeAryl

The invention discloses an organic compound based on heteroaryl amine structure and application thereof to an OLED (Organic Light Emitting Diode). The compound structurally contains heteroaryl and benzo-heteroaryl amine structures at the same time, has relatively shallow LUMO energy stage, relatively high glass transition temperature and molecular thermal stability; the absorption in the visible light field is low; the refractive index is high; after the organic compound is applied to the CPL layer of the OLED device, the light extraction efficiency of the OLED device can be effectively improved.

Owner:JIANGSU SUNERA TECH CO LTD

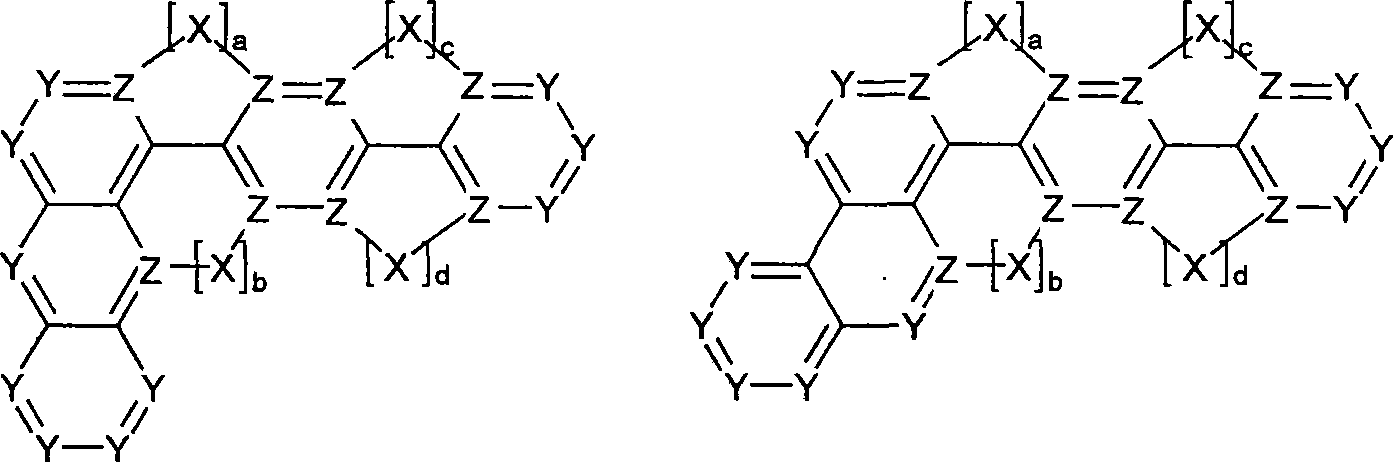

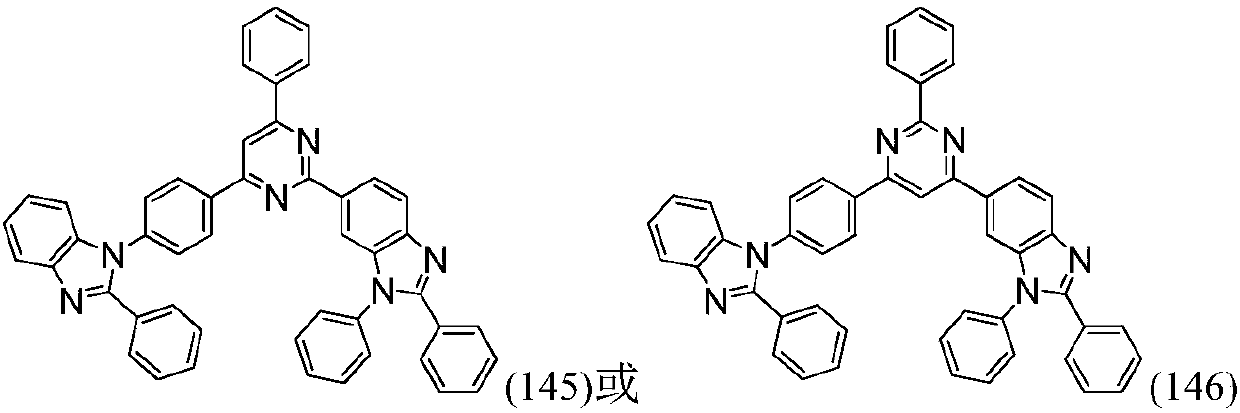

Organic compound taking triazine and benzimidazole as cores and application thereof to organic electroluminescent device

ActiveCN106946859AImprove structural stabilityHigh densityOrganic chemistrySolid-state devicesRefractive indexGlass transition

The invention relates to an organic compound taking triazine and benzimidazole as cores and application thereof to an OLED (Organic Light Emitting Diode) device. The compound provided by the invention has relatively high glass transition temperature and molecule thermal stability; the compound has low absorption and high refractive index in the field of visible light; after the compound is applied to a CPL (Circular Polarizing Filter) layer of an OLED device, the light extraction efficiency of the OLED device can be effectively improved; the compound also has a deep HOMO energy level and high electron mobility and can be used as a hole-blocking / electron transferring layer material of the OLED device; and the compound can be used for effectively stopping a hole or energy from being transmitted to one side of an electron layer from a light emitting layer, so that the compounding efficiency of the hole and electrons on the light emitting layer is improved, and furthermore, the luminous efficiency of the OLED device is improved and the service life of the OLED device is prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

Heteroaryl amine structure based organic compounds and applications thereof

ActiveCN109824659AShallow LUMO levelImprove stabilityOrganic chemistrySolid-state devicesRefractive indexThermal stability

The invention discloses heteroaryl amine structure based organic compounds and applications thereof. The structure of the organic compounds simultaneously comprises different types of heteroaryl groups and amino groups. The organic compounds have a low LUMO energy level, a high glass transition temperature, and high molecular thermal stability, have low absorption and a high refractive index in the visible light range, and can effectively improve the light emission efficiency of an OLED device, after being applied to the CPL layer of the OLED device.

Owner:JIANGSU SUNERA TECH CO LTD

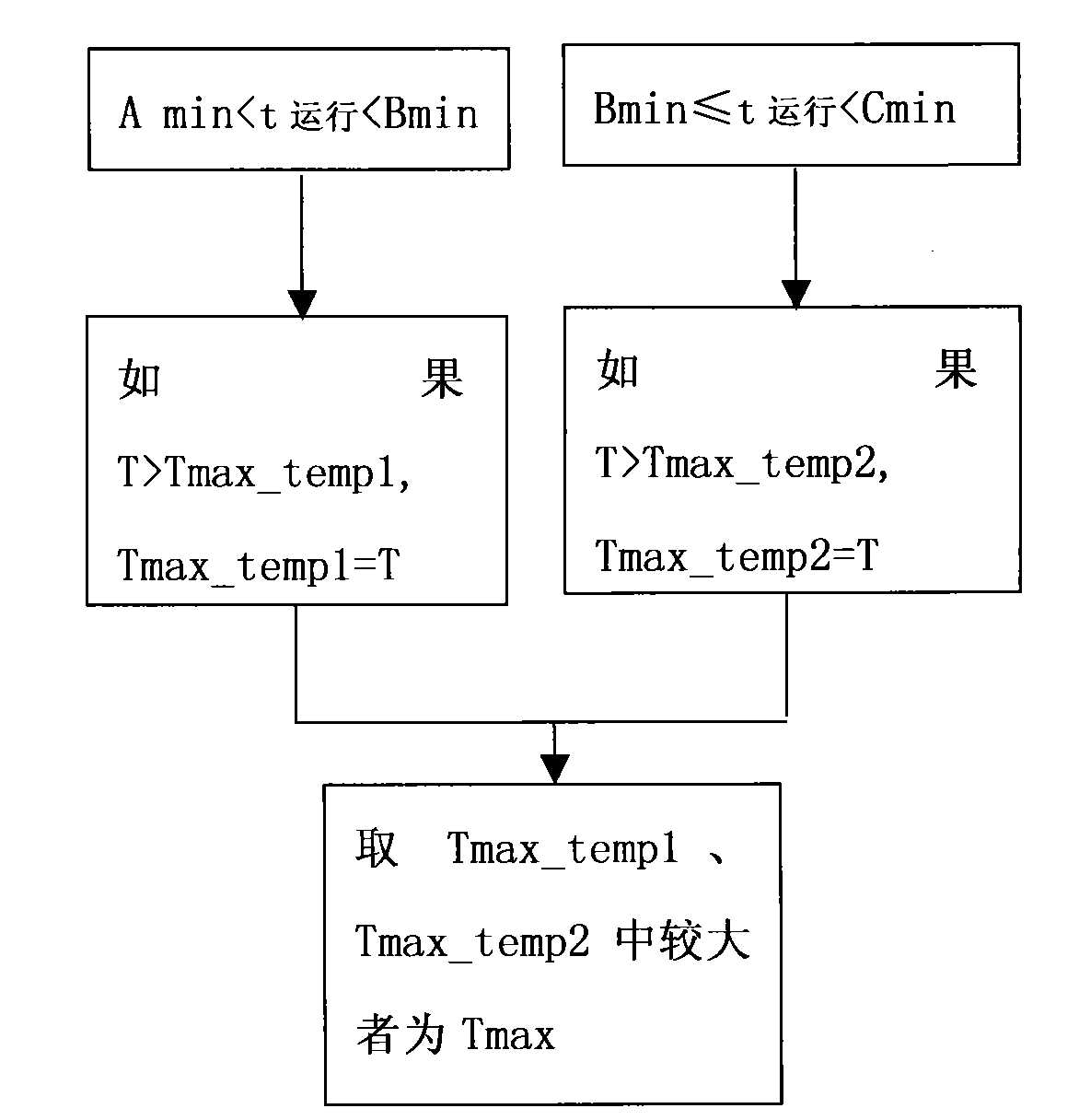

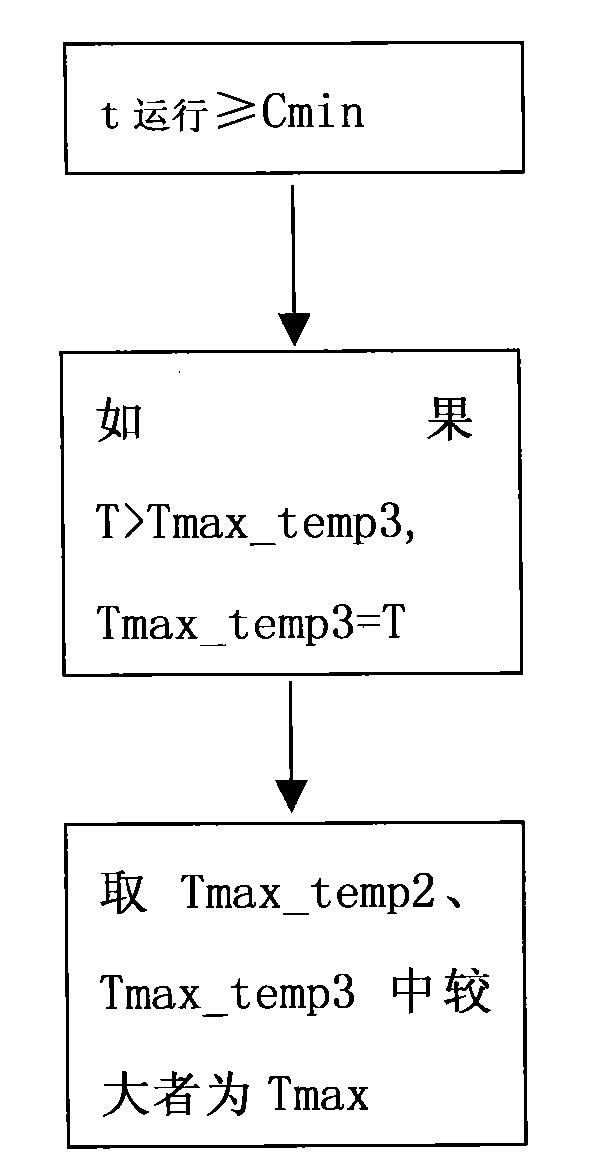

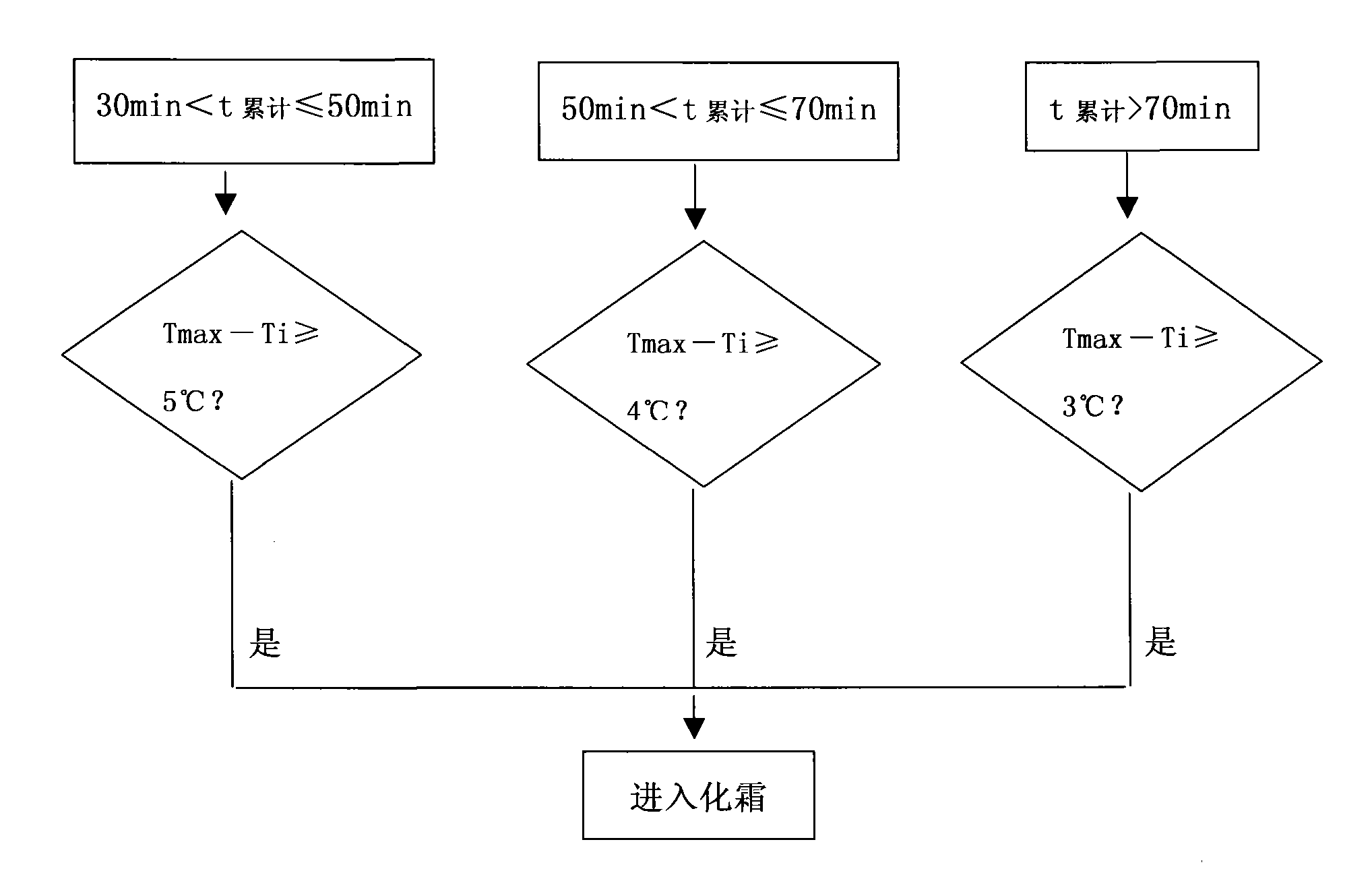

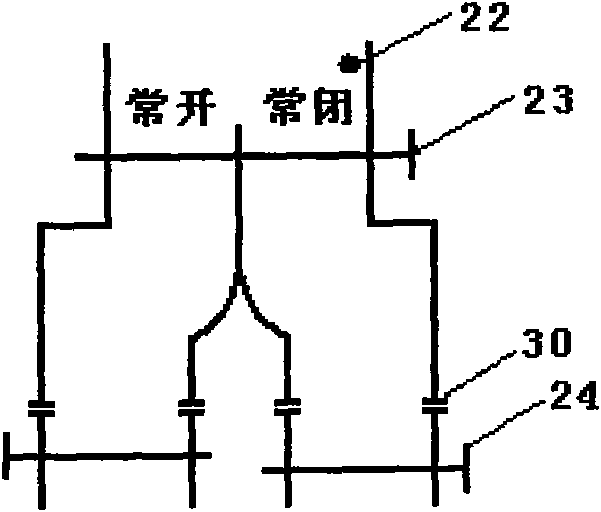

Defrosting control method of air-conditioner

ActiveCN101551183ALower evaporation temperatureControl defrost statusCorrosion preventionRefrigeration safety arrangementEngineeringHeat exchanger

The invention discloses a novel judging method of defrosting conditions of an air-conditioner, which cancels an environment temperature sensor and judges if an outdoor heat exchanger needs to be defrosted according to the temperature variation situation of an outdoor evaporator in the heating process, thereby simplifying the design and a manufacturing method of products, reducing the development cost and enhancing the heating efficiency of the air-conditioner. The defrosting control method is as follows: after the air-conditioner is started to carry out heating operation, a control device records an initial value of the temperature of the outdoor heat exchanger and then dynamically records and judges a temperature signal of the outdoor heat exchanger, which is sent by a pipe temperature sensor of the outdoor heat exchanger, so as to obtain a maximum value Tmax of the temperature of the outdoor heat exchanger and store the maximum value Tmax; after the cumulative time of the heating operation of the air-conditioner reaches a preset time quantum of the control device, the control device compares the current temperature T of the outdoor heat exchanger with the maximum value Tmax of the temperature of the outdoor heat exchanger, and when the Tmax-T is larger than or equal to M which is the set temperature, the air-conditioner is in a defrosting mode.

Owner:GREE ELECTRIC APPLIANCES INC

Organic compound based on triazine and benzimidazole and application thereof to organic light-emitting diode (OLED) device

ActiveCN106946853APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesRefractive indexAbsorption rate

The invention relates to an organic compound based on triazine and benzimidazole and application thereof to an organic light-emitting diode (OLED) device. The compound disclosed by the invention has a high vitrification temperature and high molecular thermal stability; the compound has a low absorption rate and a high refraction rate in the field of visible light, and can be applied to a CPL (Circular-Polarizing Filter) layer of the OLED device to effectively increase the light output efficiency of the OLED device; the compound also has a deep HOMO (Highest Occupied Molecular Orbital) energy level and a high electron mobility, can be taken as a hole-blocking / electron transport layer material of the OLED device, and can effectively block holes or prevent energy from being transported from a light-emitting layer to one side of an electron layer, so that the compound efficiency of the holes and electrons on the light-emitting layer is increased, and the light-emitting efficiency and the service life of the OLED device are increased and prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

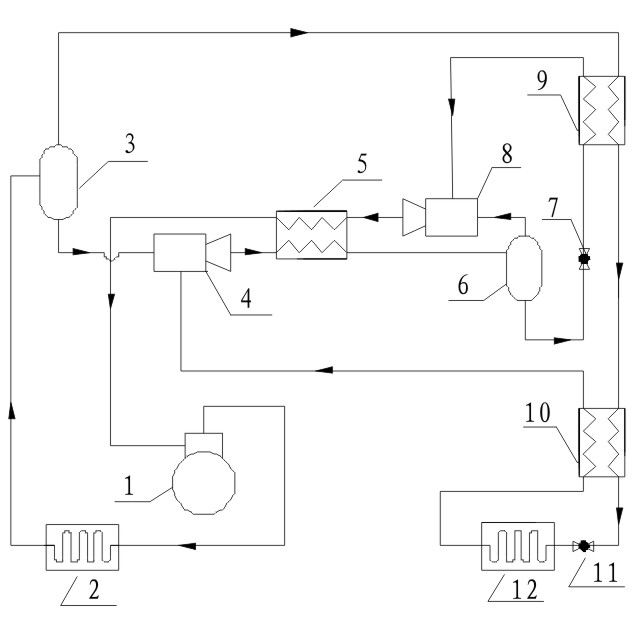

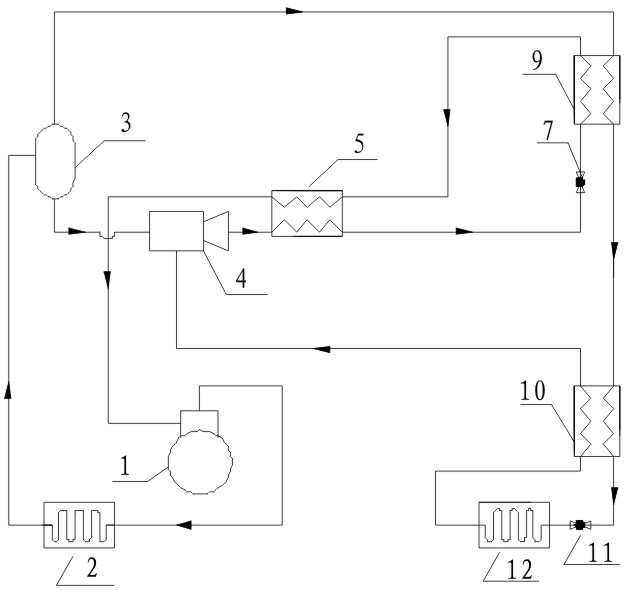

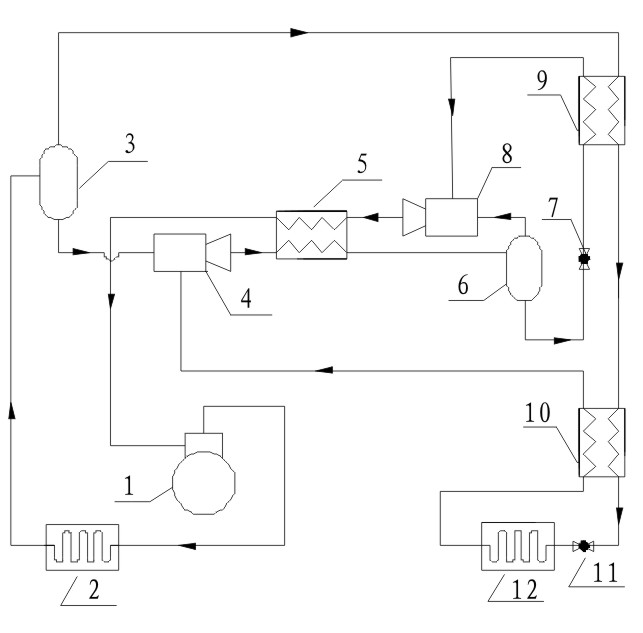

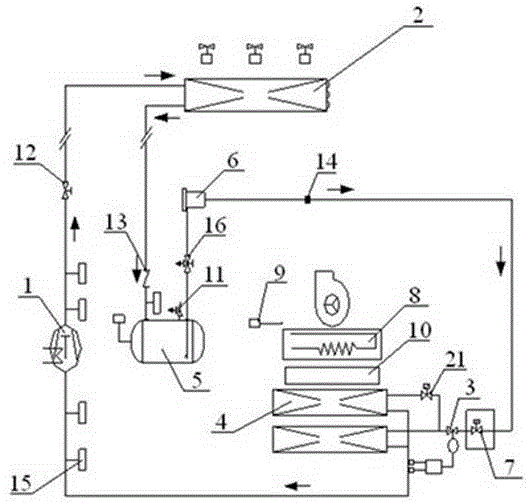

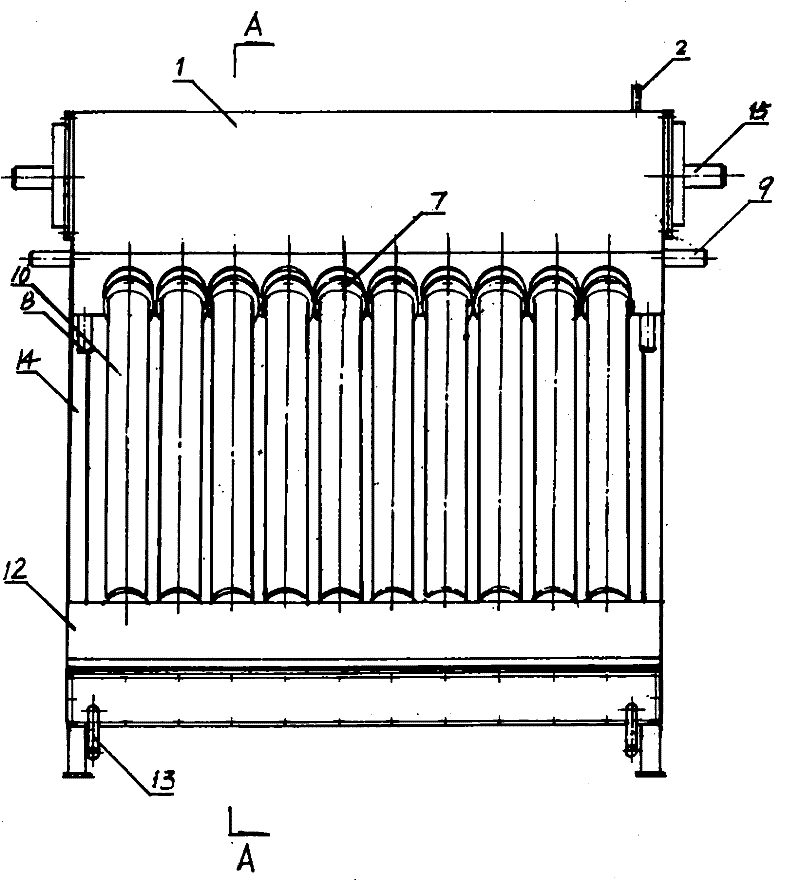

Ultra-low temperature circulation refrigeration method employing injectors

InactiveCN102003826AImprove cycle performanceIncrease inspiratory pressureCompression machinesFluid circulation arrangementVapor–liquid separatorWorking fluid

The invention relates to an ultra-low temperature circulation refrigeration method employing injectors. In the method, high-pressure mixed refrigerants compressed by a compressor (1) enter a condenser (2) and then enter a first gas-liquid separator (3) to realize gas and liquid phase separation, liquid refrigerants flowing out of the first gas-liquid separator (3) enter a first injector (4), gas and liquid two-phase mixed work media from an outlet of the first injector (4) are cooled by a first heat regenerator (5) and then enter a second gas-liquid separator (6) to be separated, work fluid of a second injector (8) is processed into low-pressure steam through a first throttling member (7) and a condensing evaporator (9), and the low-pressure steam is pressurized by the second injector (8), flows into the first heat regenerator (5) to be subjected to overheating and then flows back to the compressor (1); and gaseous refrigerants flowing out of the top of the first gas-liquid separator (3) flow into the condensing evaporator (9), are recooled through a second heat regenerator (10) and enter an evaporator (12) through a second throttling member (11) for refrigeration at low temperature, the ultra-low temperature can reach minus 40 DEG C to minus 170 DEG C, and the energy saving effect is good.

Owner:HENAN UNIV OF SCI & TECH

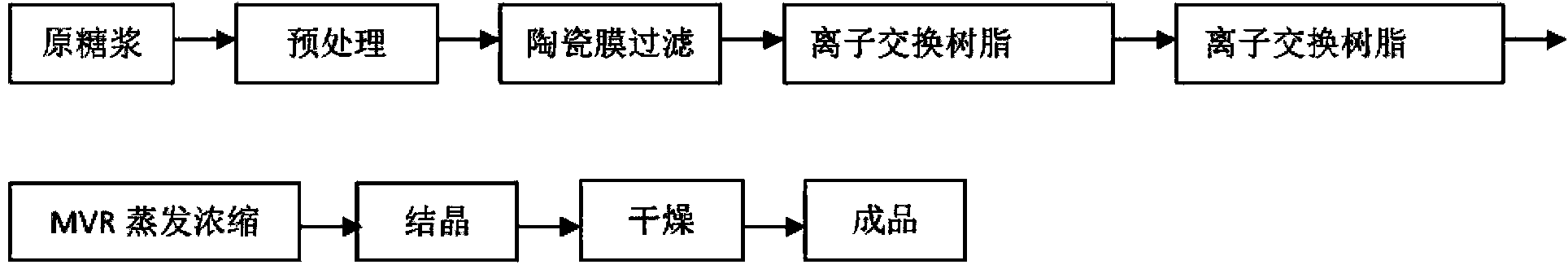

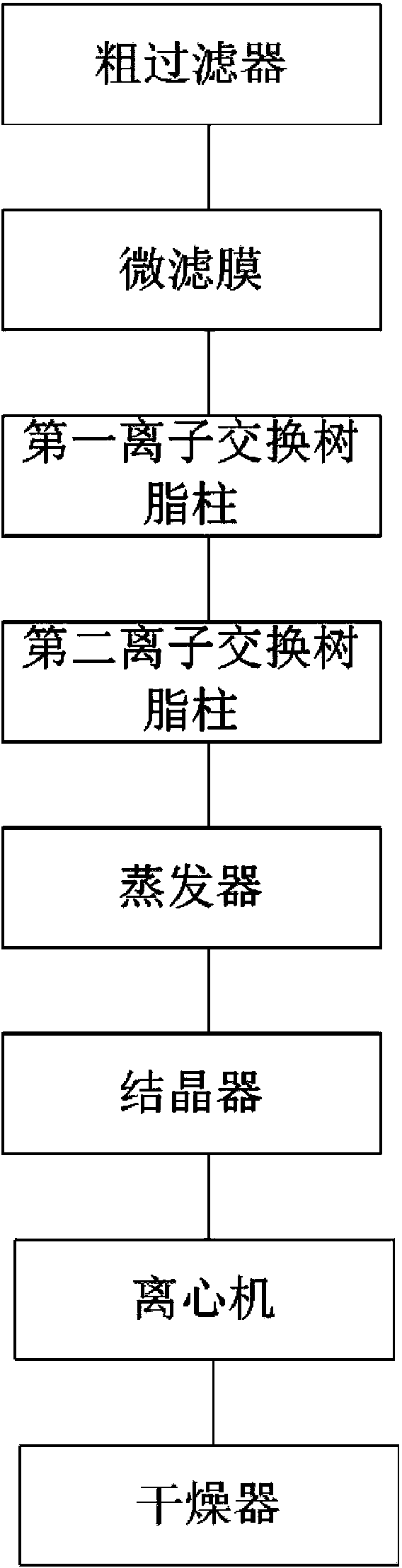

Process for preparing sugar by two-step method and device thereof

ActiveCN103710470ANo color reversionOptimal production process parametersSugar productsSucroseIon exchange

The invention discloses a process for preparing sugar by a two-step method and a device thereof. The process comprises the following steps: adding water into crude sugar for dissolving to obtain crude syrup; feeding the crude syrup into a primary filter and a micro-filtration membrane in sequence for filtering to obtain filtrate; feeding the filtrate into a first ion exchange resin tower to obtain a first penetrating fluid, wherein the first ion exchange resin refers to macroporous strong-basicity anion exchange resin; feeding the first penetrating fluid into a second ion exchange resin tower to obtain a second penetrating fluid, wherein the second ion exchange resin refers to strong-acidity cation exchange resin, weak-acidity cation exchange resin or a mixing bed of anion and cation exchange resin; feeding the second penetrating fluid into an evaporator for concentrating to obtain sucrose concentrated liquor; and crystallizing, centrifuging and drying to obtain a sucrose finished product. The process disclosed by the invention can be used for producing high-purity refined sucrose in batch, wherein a pigment removal rate reaches 99.9%, a salt removal rate reaches 98%, and sucrose component of the product reaches 99.9% which reaches the standard of national senior sugar.

Owner:JIANGSU JIUWU HITECH

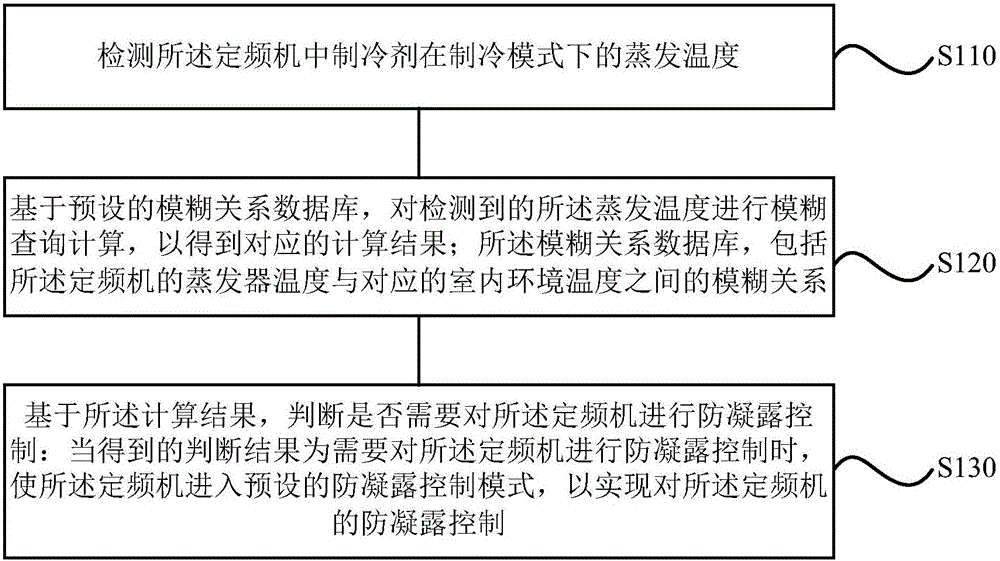

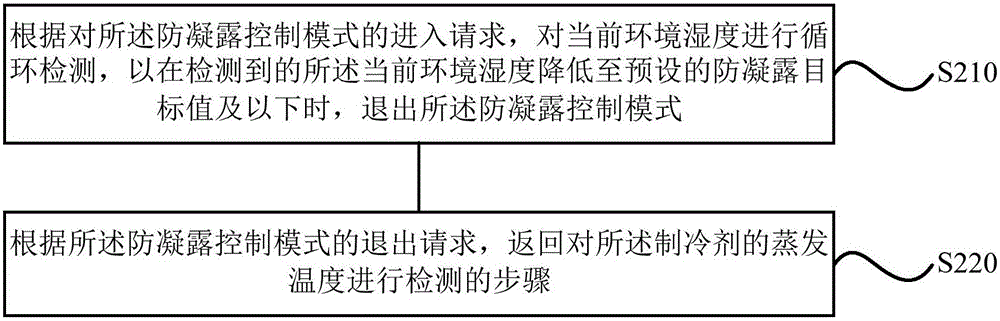

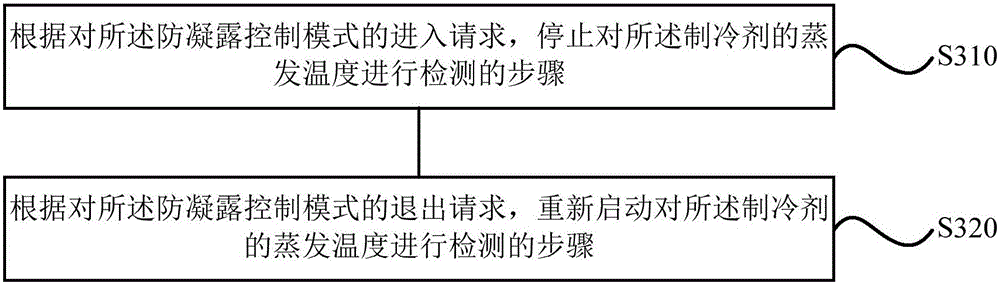

Anti-condensation control method, device and air condition system used for fixed frequency unit

ActiveCN105910174AReduce humidityLower evaporation temperatureMechanical apparatusCondensate preventionState of artFuzzy relational databases

The invention discloses an anti-condensation control method, device and air condition system used for a fixed frequency unit. The method includes detecting the evaporation temperature of a refrigerant agent in the fixed frequency unit in a refrigerating mode; performing fuzzy inquiry calculation on the detected evaporation temperature based on a pre-set fuzzy relation database so as to obtain a corresponding calculation result, wherein the fuzzy relation database includes the fuzzy relation between the evaporator temperature of the fixed frequency unit and the corresponding indoor environmental temperature; judging whether to perform anti-condensation control over the fixed frequency unit based on the calculation result; enabling the fixed frequency unit to enter a predetermined anti-condensation control mode when the judgment result shows that anti-condensation control over the fixed frequency unit is needed so as to realize the anti-condensation control over the fixed frequency unit. The scheme provided by the invention can overcome shortcomings of use inconvenience, large potential safety hazards and poor user experience and the like of the prior art and can achieve beneficial effects of use convenience, small potential safety hazards and good user experience.

Owner:GREE ELECTRIC APPLIANCES INC

Organic compound based on triazine and application thereof to organic electroluminescence device

ActiveCN109206420APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesElectronic transmissionRefractive index

The invention relates to an organic compound based on triazine and application thereof to an OLED (Organic Light Emitting Diode) device. The compound has high glass transition temperature and molecular thermal stability; in the visible light field, the absorption is low; the refraction index is high; after the compound is applied to a CPL layer of the OLED device, the light taking-out efficiency of the OLED device can be effectively improved. The compound also has deep HOMO energy level and high electronic mobility and can be used as a hole blocking / electronic transmission layer material of the OLED device; holes or energy can be effectively blocked from being transmitted from the luminescent layer to one side of the electronic layer, so that the compounding efficiency of holes and electrons in the luminous layer is improved; further, the luminous efficiency of the OLED device is improved; the service life of the OLED device is prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

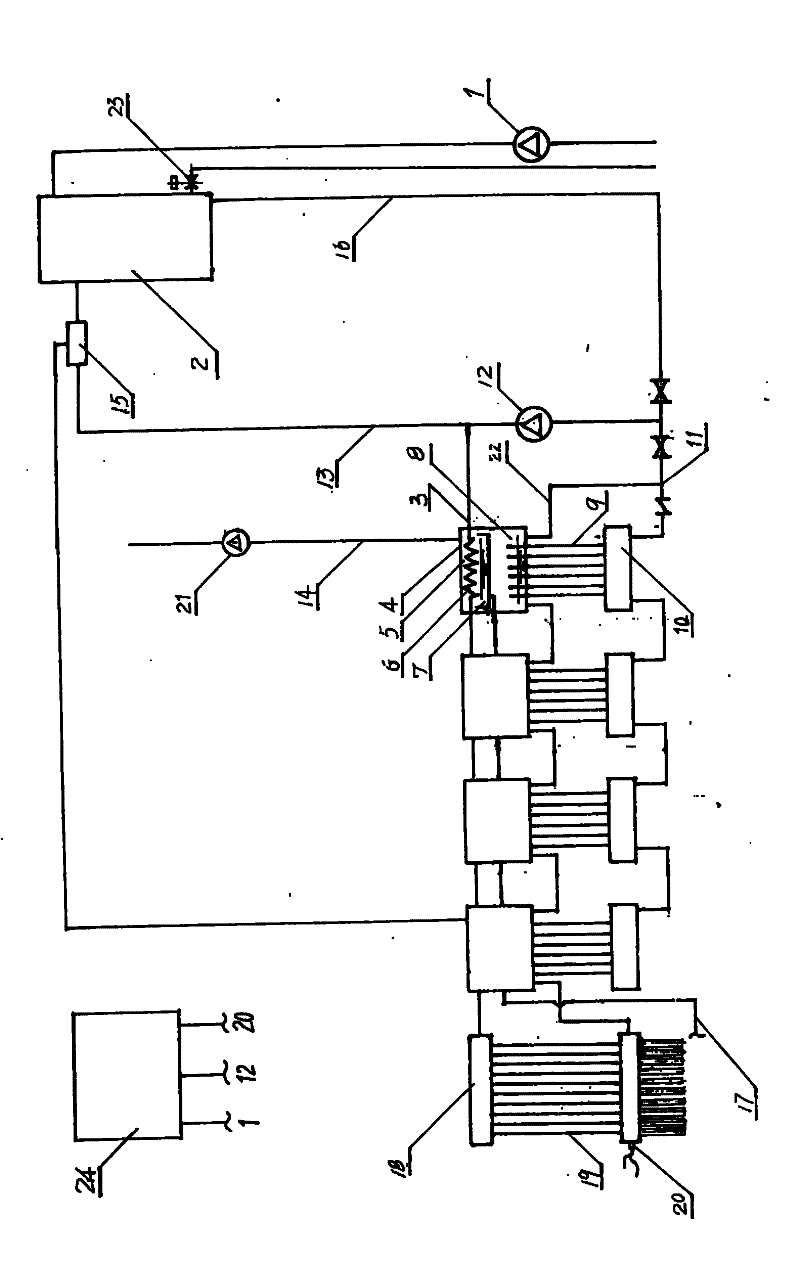

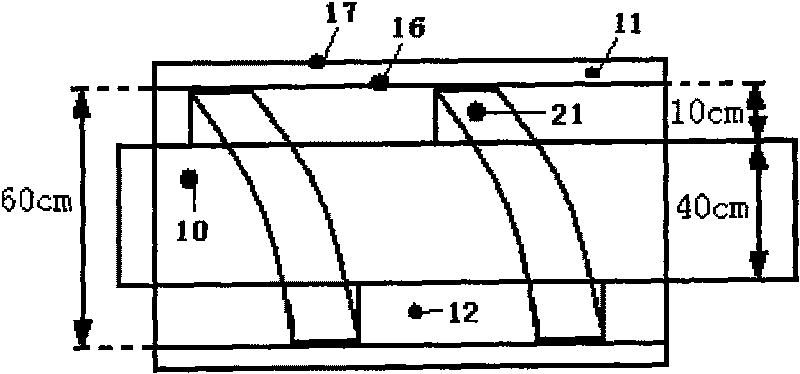

Circulation evaporator

InactiveCN101811743ANon-deterministicLower evaporation temperatureWater/sewage treatment by heatingPapermakingSewage

The invention discloses an evaporator for performing innocent treatment on sewage in industries of papermaking and the like. In an existing device, a secondary steam pipe is connected to an inlet of a compressor; an outlet of the compressor is connected with a steam inlet of a steady head tank; the other steam inlet pipe of the steady head tank is connected with a fresh steam pipe of a boiler; a steam outlet of the steady head tank is connected with a falling-film evaporator which is at least provided with one circulating pipe connected with a circulating pump; an outlet of a stripper plant of the falling-film evaporator is communicated with a non-condensable air pipe and a heavily-polluted condensate water outlet pipe which is communicated with a water inlet of a heavily-polluted condensate water tank; a water outlet of the heavily-polluted condensate water tank is communicated with a heavily-polluted condensate water delivery pipe; and a condensation water outlet pipe of a condenser is communicated with the water inlet of the heavily-polluted condensate water tank.

Owner:兰州节能环保工程有限责任公司 +1

Variable frequency air conditioning unit

InactiveCN102878615AAvoid wear and tearExtended service lifeCompressorSpace heating and ventilation safety systemsLiquid storage tankEngineering

The invention discloses a variable frequency air conditioning unit which solves the problem that in the prior art, the control over temperature and humidity precision by an air conditioner is lower. The variable frequency air conditioning unit comprises a compressor, a condenser, an expansion valve and an evaporator which are sequentially connected. The compressor is further connected with the evaporator. A condensing fan is further arranged above the condenser. An evaporating fan is further arranged above the evaporator. The compressor is a variable frequency compressor, the expansion valve is an electronic expansion valve, and a liquid storage tank is arranged between the condenser and the expansion valve. A humidifier and an electric heater are respectively arranged at an air supply outlet of the evaporating fan. A dehumidifying electromagnetic valve is further arranged between the expansion valve and the evaporator. The variable frequency air conditioning unit provided by the invention has the advantages of high precision control and energy-saving and the like, and is suitable for application.

Owner:YIMIKANG TECH GRP CO LTD

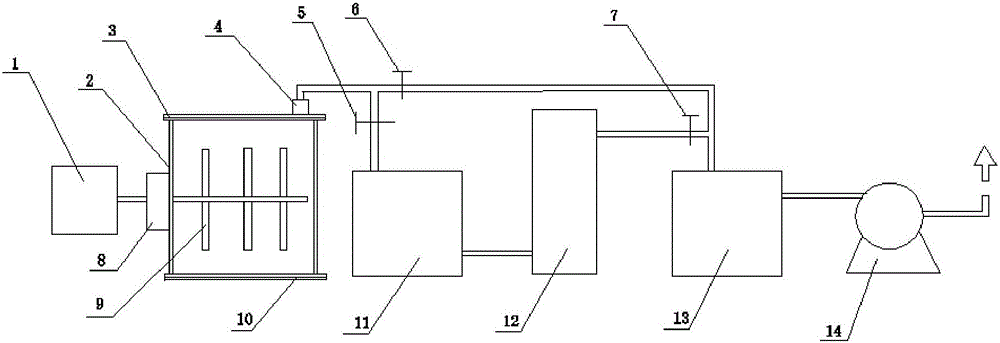

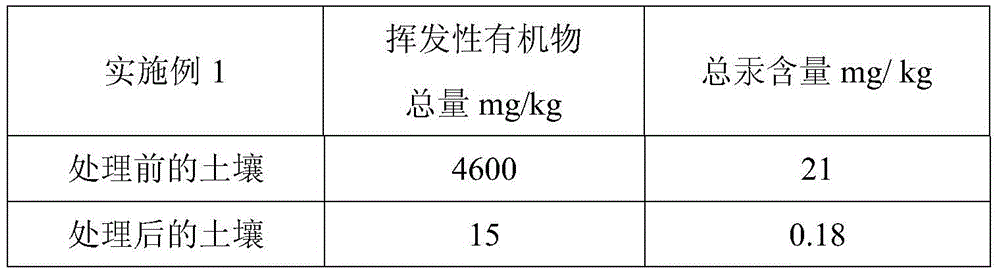

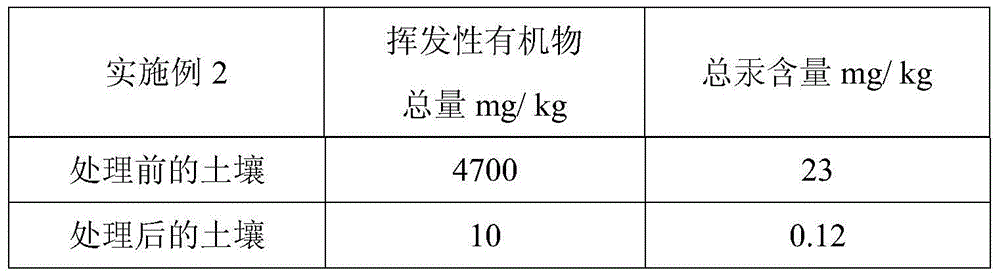

Method for remediation of volatile organic compound and mercury compound contaminated soil

The invention relates to a method for remediation of volatile organic compound and mercury compound contaminated soil, and belongs to the technical field of soil contamination remediation. The method comprises the steps that the contaminated soil is firstly excavated out of a contaminated land parcel, and breaking and screening treatment is carried out; then ferric chloride powder is added into soil particles according to the proportion of 1 g / kg-10 g / kg, after even mixing and stirring are carried out, vacuum heat treatment is carried out, the temperature is firstly controlled to range from 250 DEG C to 300 DEG C, and mercury and a small quantity of volatile organic compounds in the soil particles are removed; then the temperature is controlled to range from 500 DEG C to 600 DEG C, the volatile organic compounds in the soil are removed, and condensed air is supplied into the atmosphere through a vacuum pump; and the treated clean soil is taken out of a vacuum reactor. According to the method, remediation of the volatile organic compound and mercury compound contaminated soil is achieved, and the technological process is simple, efficient and free of secondary contamination.

Owner:博川环境修复(北京)有限公司

Multistage double effect distillation seawater desalination technology with heating seawater by solar energy

InactiveCN102190340AIncrease productionRelieve pressureGeneral water supply conservationSeawater treatmentDistillationEngineering

The invention relates to a multistage double effect distillation seawater desalination technology with heating seawater by solar energy. The technology comprises the following steps: seawater is delivered to a high cistern by a seawater pump; the seawater in the high cistern is delivered to a system for water supply through a water supply tube and a condenser inlet tube; the seawater is heated to a certain temperature by adsorbing latent heat of steam in an evaporator through all condensers of the system, and enters the evaporator after being heated to a designed temperature by a rapid heater with solar energy; the seawater enters the evaporator, becomes superheated water and is gasified rapidly and partially because a pressure in the evaporator is controlled to be lower than a saturation vapor pressure corresponding to a temperature of hot seawater; and a part of ungasified hot seawater enters a next stage evaporator and a part enters heat-collecting tubes at two sides of the evaporator. The heat-collecting tubes are provided with annular imbibition films, and the hot seawater flows from top to bottom after entering the heat-collecting tubes. In a flow process, the hot seawater is delivered to upper half parts of inner cavities of the heat-collecting tubes because of capillary imbibition actions of the imbibition films. The hot seawater is evaporated to steam because the heat-collecting tubes have a high temperature under the sunlight, the steam rises along the inner cavities of the heat-collecting tubes and enters the condenser to obtain fresh water which flows into a fresh water tank and then is output by a fresh water tube. Unevaporated concentrated seawater enters a concentrated water tank and is ouput by an inlet / outlet tube.

Owner:孙元新

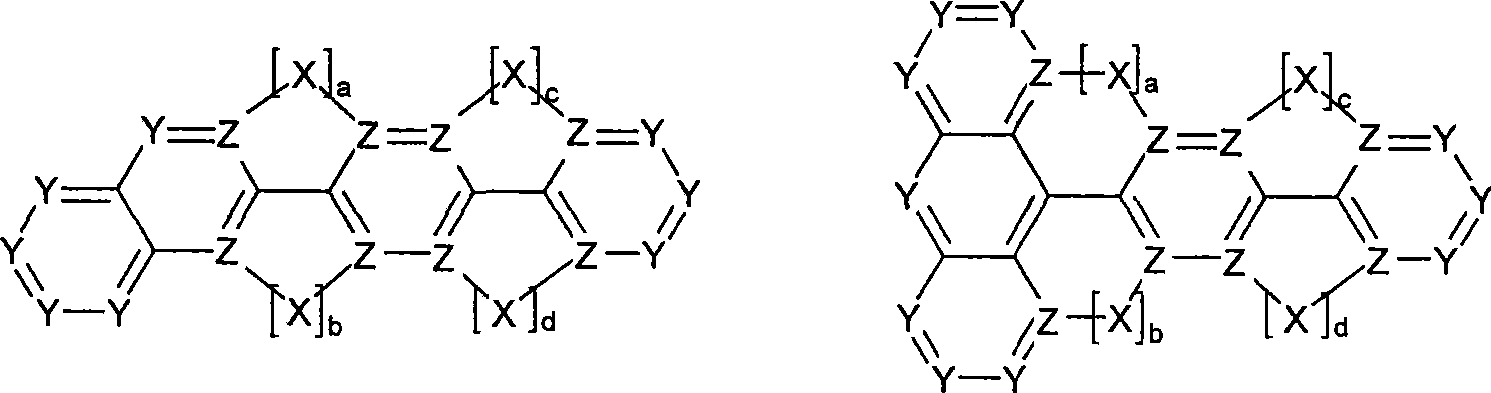

Organic compound based on pyridine and benzimidazole and application thereof in organic light emitting diodes (OLED)

ActiveCN107417668APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesHeat stabilityRefractive index

The invention relates to an organic compound taking pyridine and benzimidazole as a core and application thereof in organic light emitting diode (OLED) devices. The compound disclosed by the invention has higher glass transition temperature and molecular heat stability; the compound has low absorption and high refractive index in the field of visible light; after being applied to CPL layers of the OLED devices, the compound can effectively improve light extraction efficiency of the OLED devices. The compound disclosed by the invention further has a deep HOMO energy level and high electronic mobility, can serve as a cavity blocking / electron transfer layer material of the OLED devices and can effectively prevent cavities or energy from being transmitted to one side of an electronic layer from a luminescent layer; thus, composition efficiency of the cavities and the electrons in the luminescent layer is improved, and further luminous efficiency and service life of the OLED devices are improved.

Owner:JIANGSU SUNERA TECH CO LTD

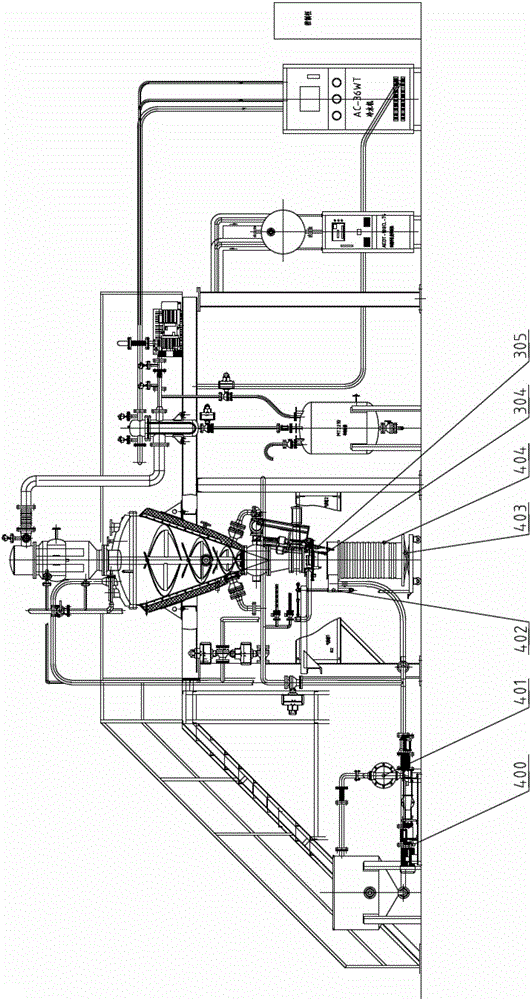

Vacuum dryer for screw to convey materials and method thereof

InactiveCN101762146AIncrease temperature differenceImprove qualityDrying using combination processesHeating arrangementElectrical resistance and conductanceSteam pressure

The invention discloses a vacuum dryer for a screw to convey materials and a method thereof. The dryer comprises a vacuum drying device and a controller; the controller mainly comprising PLC and an upper computer, timely controls the rotate speed of a screw and the heating power of a ten-section resistance according to the detection data of the temperature and the humidity of the materials. The invention adopts a subsectional heating and drying control strategy giving consideration to both the drying quality and the production efficiency, comprises PID and predictive control, and a drying control strategy of the heating control and the linkage of the screw rotating speed; and the drying precision can be 98.8%. The invention is characterized by drying the inflammable and explosive materials and materials easy to be decomposed at a high temperature and no-air contacted materials. Furthermore, the vacuum operation reduces the steam pressure and the temperature, improves the temperature range between heating elements and the dried materials; the screw conveying increases the drying area, is benefit to evenly heating; a mechanism of screw rotating speed linkage based on the subsectional drying control strategy can not only ensure the high quality of the dried materials but also has high production efficiency.

Owner:ZHEJIANG UNIV

Organic compound based on azabenzene and application thereof in OLED

ActiveCN110229145APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesRefractive indexHigh electron

The invention relates to an organic compound based on azabenzene and an application thereof in an OLED device. The compound has relatively high glass transition temperature and molecular thermal stability; the compound has low absorption and high refractive index in the visible light field, and light extraction efficiency of the OLED device can be effectively improved after the compound is appliedin a CPL layer of the OLED device; and the compound also has deep HOMO energy level and high electron mobility, and can be used as a hole blocking / electron transport layer material of the OLED device, transmission of holes or energy from a luminescent layer to the side of an electron layer can be effectively blocked, and thus composite efficiency of holes and electrons in the luminescent layer isimproved, and luminescent efficiency and service life of the OLED device are improved.

Owner:JIANGSU SUNERA TECH CO LTD

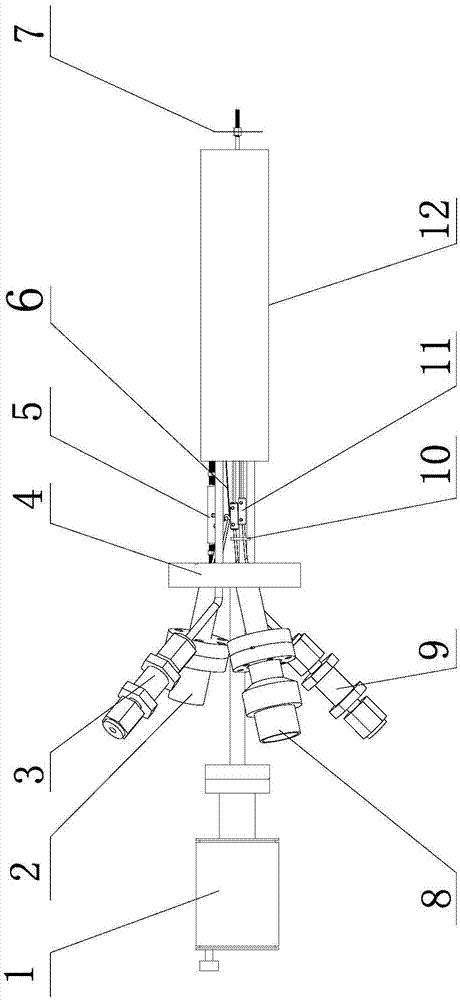

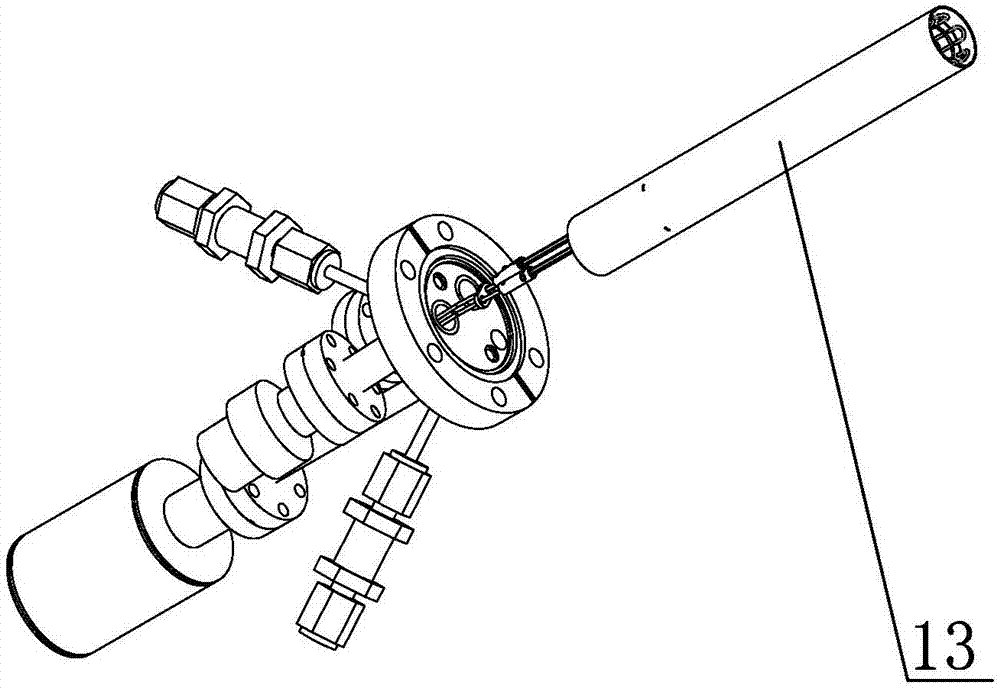

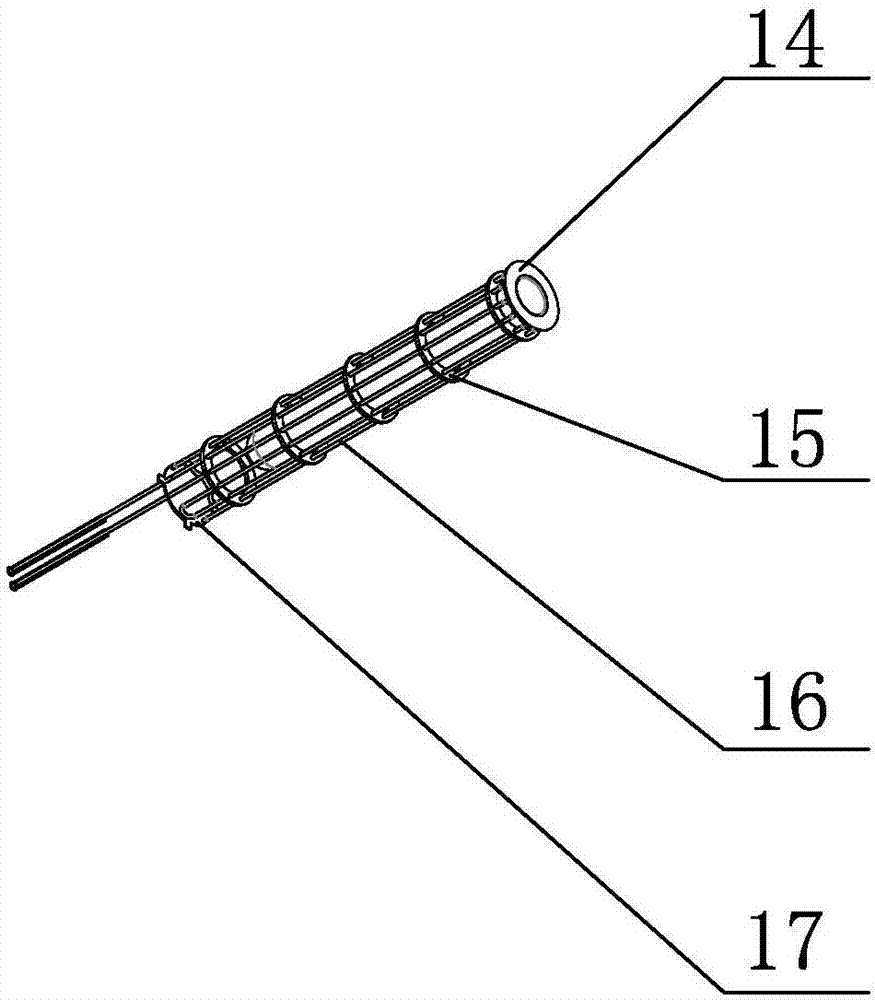

Low-temperature vacuum evaporation source

PendingCN107217236AEfficient exclusionTo achieve the purpose of coolingVacuum evaporation coatingSputtering coatingWater circulationOrganic compound

The invention discloses a low-temperature vacuum evaporation source. The low-temperature vacuum evaporation source comprises a heating system, a cooling system, a temperature measuring system, a control system and a connecting assembly. An electrode in the device is electrified to heat a lamp filament of the heating system, and when the temperature of the lamp filament reaches the sublimation temperature of substances in a crucible, a source substance starts to be evaporated, gas molecules obtained through evaporation are transmitted to a to-be-coated base body in a vacuum cavity, and evaporation of alkaline metal and an organic compound can be achieved. A real-time evaporation temperature of a thermocouple of the temperature measuring system is conducted and detected through an electric couple wire. Cooling water is led into a water inlet pipe of the cooling system, the crucible is cooled through water circulation in a cooling cover, and the low-temperature evaporation effect is achieved. A rotation baffle on a crucible opening can adjust and control whether the substances obtained through evaporation conduct coating on the base body or not through a manual rod.

Owner:DALIAN JIAOTONG UNIVERSITY

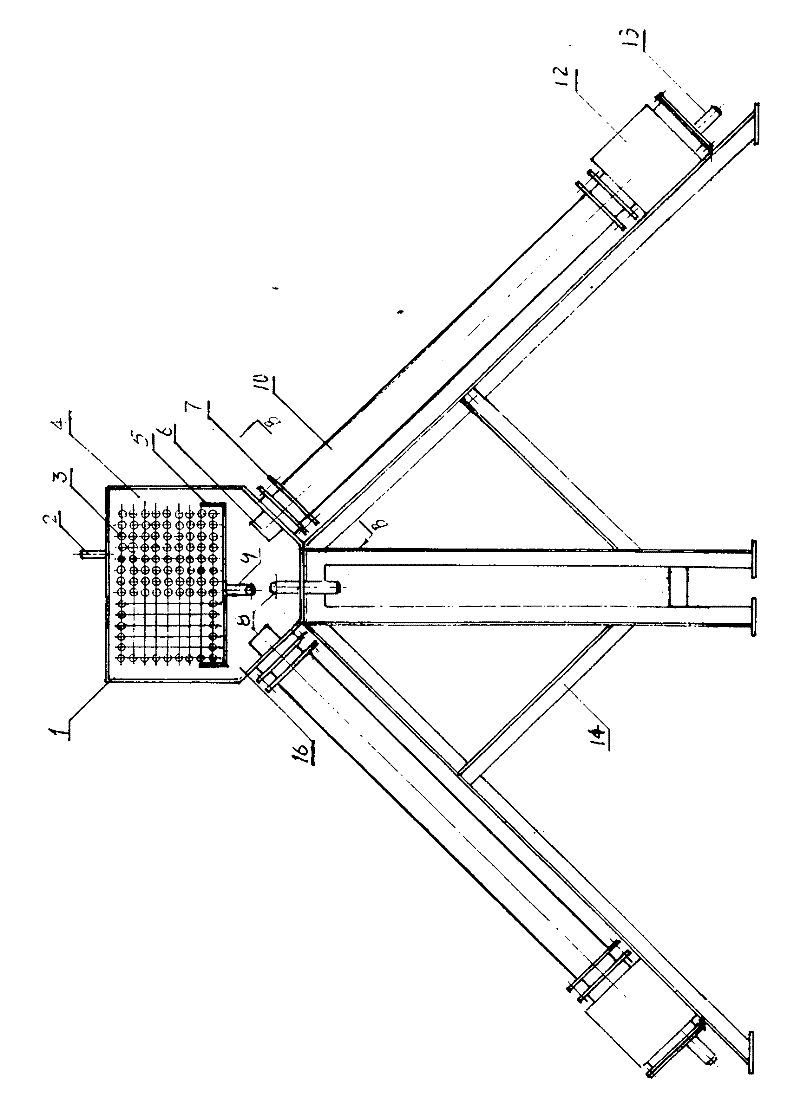

Mechanical steam recompression falling film evaporation process method and system

ActiveCN104986910AImprove thermal efficiencySave energyMultistage water/sewage treatmentSteam pressureSteam condensation

The invention provides a mechanical steam recompression falling film evaporation process method comprising the following specific steps: (1) high-salt wastewater pretreatment is carried out, wherein a material is delivered into a preheater through a feeding pump; condensate water of falling film evaporator secondary steam condensation is adopted as a heat source of the preheater, and the material is preheated; the preheated material is delivered into a liquid mixing device, and is mixed with liquid from an evaporation chamber of the falling film evaporator; and the mixture is delivered into the falling film evaporator; (2) a falling film evaporation system is established, wherein after the material enters the falling film evaporator, with indirect heating of evaporator shell-side steam, the material absorbs heat and the temperature is increased; the material enters the evaporation chamber; with the negative pressure in the evaporation chamber, the material is instantly evaporated, and most of water is converted into secondary steam and is discharged from a secondary steam outlet; and (3) a steam compression recycling system is established, wherein secondary steam from the evaporation chamber enters a steam compressor; with the compression of the steam compressor, steam pressure and temperature are both increased; and the steam is returned to the shell-side of the falling film evaporator again and is reused.

Owner:JIANGSU DUBLE ENG

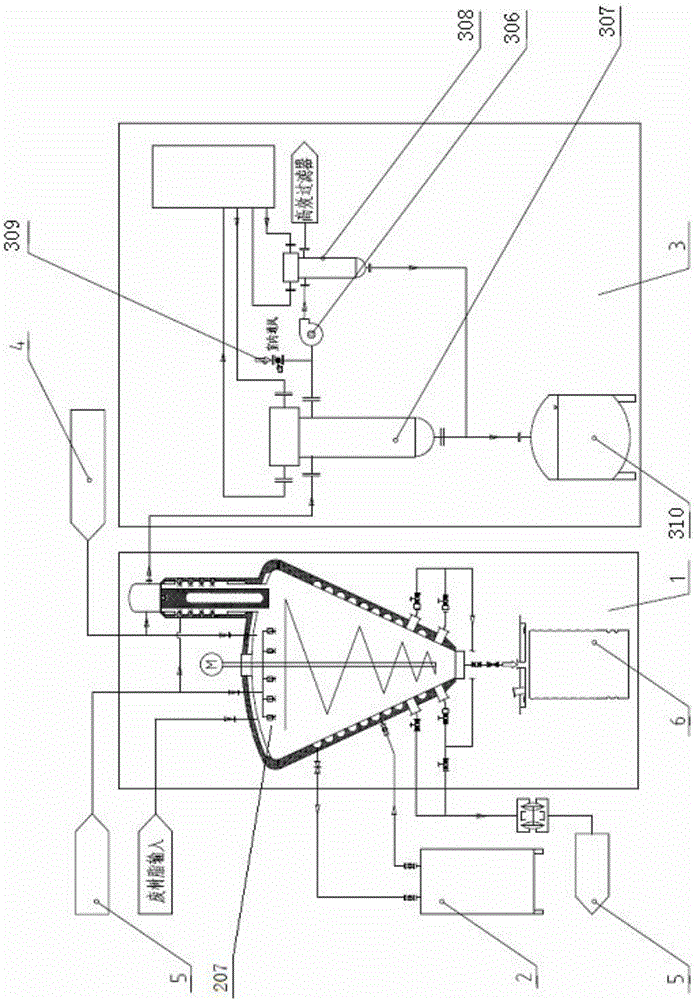

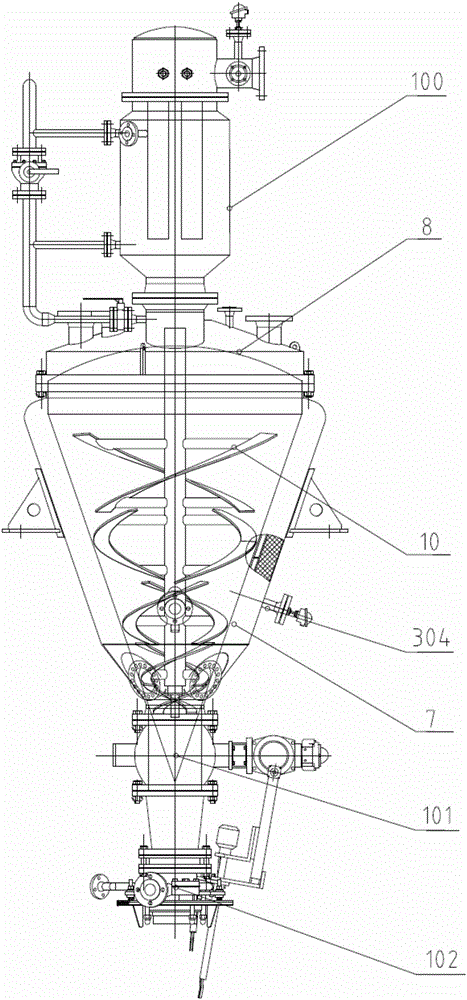

Conic nuclear power plant waste resin drying device

ActiveCN106558352AEvenly heatedReasonable structureDrying solid materials without heatDrying chambers/containersNitrogenEngineering

The invention discloses a conic nuclear power plant waste resin drying device. The conic nuclear power plant waste resin drying device comprises conic dryer body equipment used for waste resin vacuum drying, a hot oil unit used for heating and cooling a conic dryer, an air exhausting and condensation system used for maintaining the vacuum degree in a dryer body and condensing steam, a nitrogen purging system used for protecting the system and washing a washable filter, a washing and dewatering system used for dewatering waste resin and washing system pipelines, and a resin barreling system used for simulating a nuclear island SRTF station. The provided conic nuclear power plant waste resin drying device is safe, reliable, easy to operate and control, reasonable in structure configuration, high in drying efficiency and large in resin volume reduction ratio.

Owner:AEROSUN CORP +1

Organic compound taking triazine and benzimidazole as cores and application thereof to OLED (Organic Light Emitting Diode)

InactiveCN106946852ABlock free spinsImprove structural stabilityOrganic chemistrySolid-state devicesRefractive indexOrganic compound

The invention relates to an organic compound taking triazine and benzimidazole as cores and application thereof to an OLED (Organic Light Emitting Diode) device. The compound provided by the invention has relatively high glass transition temperature and molecule thermal stability; the compound has low absorption and high refractive index in the field of visible light; after the compound is applied to a CPL (Circular Polarizing Filter) layer of an OLED device, the light extraction efficiency of the OLED device can be effectively improved; the compound also has a deep HOMO energy level and high electron mobility and can be used as a hole-blocking / electron transferring layer material of the OLED device; and the compound can be used for effectively stopping a hole or energy from being transmitted to one side of an electron layer from a light emitting layer, so that the compounding efficiency of the hole and electrons on the light emitting layer is improved, and furthermore, the luminous efficiency of the OLED device is improved and the service life of the OLED device is prolonged.

Owner:VALIANT CO LTD

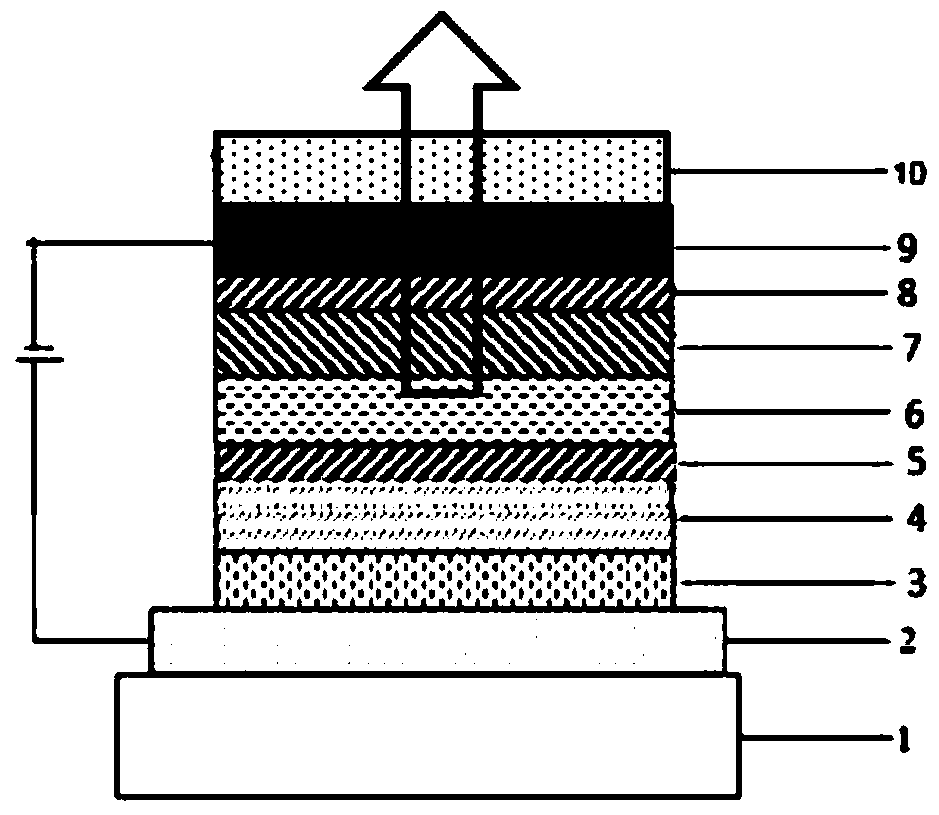

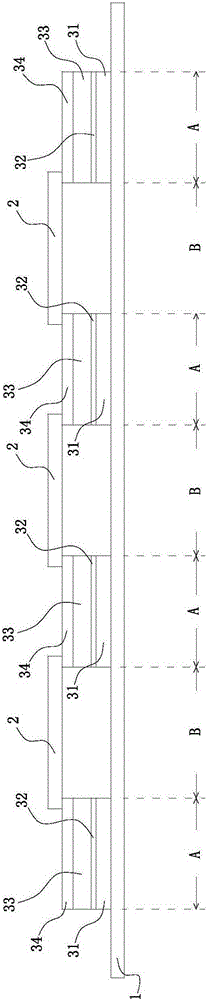

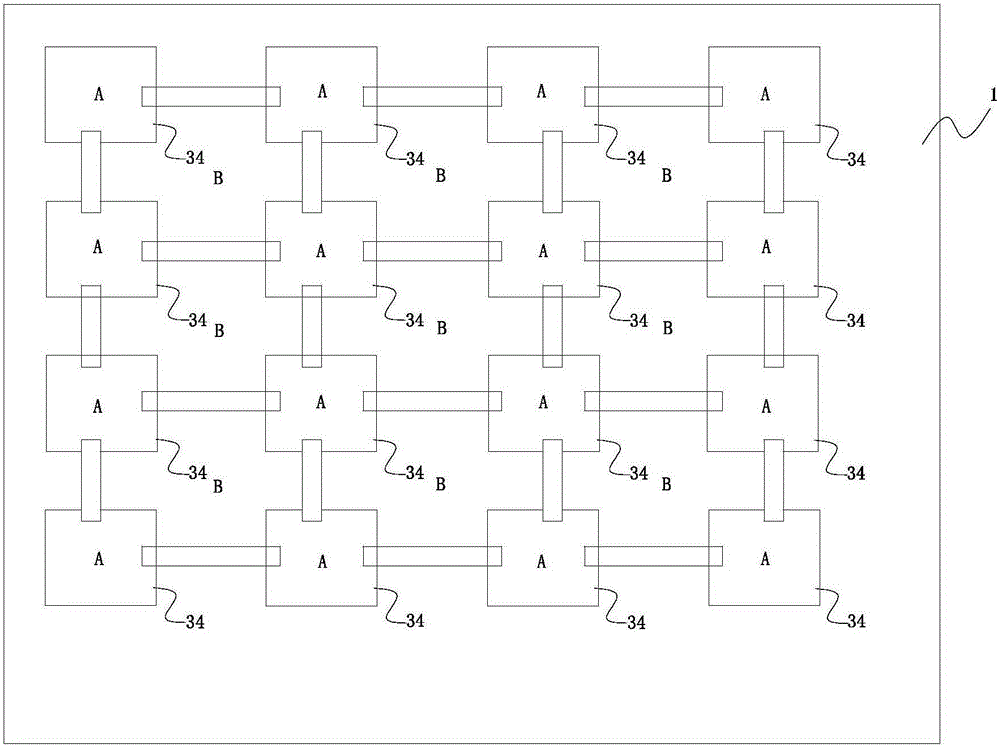

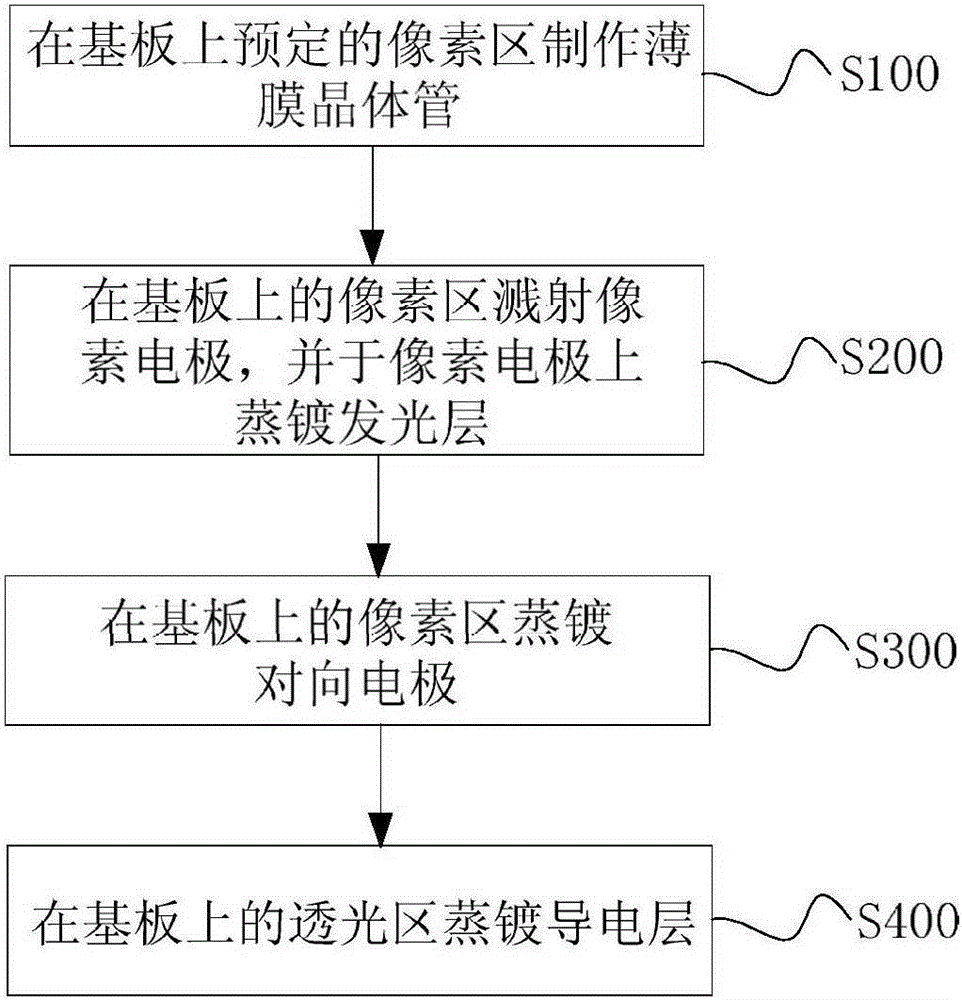

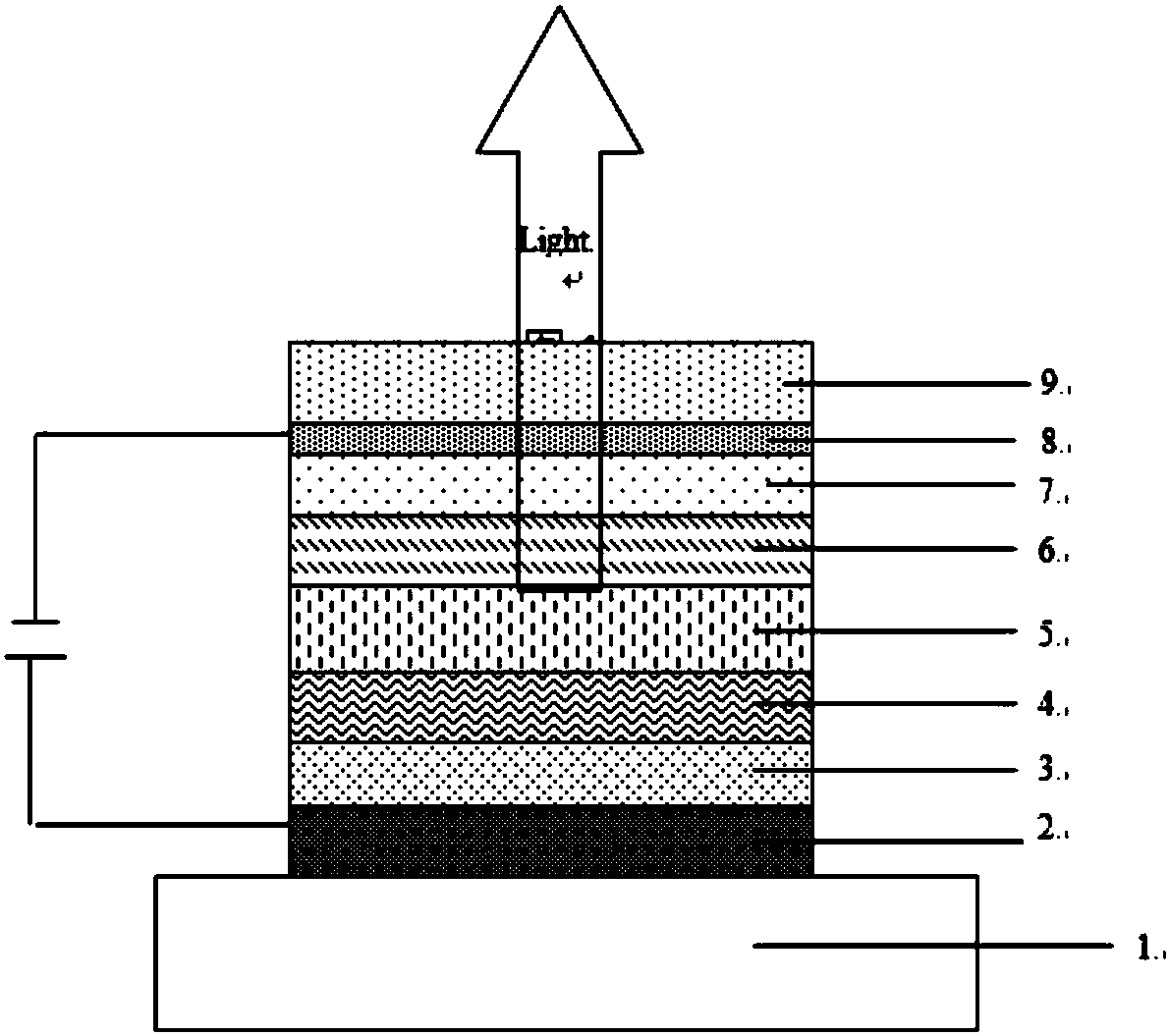

Transparent display panel and manufacturing method thereof

InactiveCN105206650AAchieve conductionLower evaporation temperatureSolid-state devicesSemiconductor/solid-state device manufacturingConductive materialsOrganic electroluminescence

The invention discloses a transparent display panel and a manufacturing method thereof. The transparent display panel comprises a substrate, organic electroluminescent devices, pixel electrodes, light-emitting layers, opposite-direction electrodes and a conductive layer, wherein the substrate comprises a plurality of pixel areas and a light transmitting area surrounding the pixel area; the organic electroluminescent devices are arranged on the substrate, correspond to the pixel areas of the substrate and comprise thin film transistors which are arranged on the pixel areas of the substrate; the pixel electrodes are arranged on the thin film transistors and electrically connected with the thin film transistors; the light-emitting layers are arranged on the pixel electrodes; the opposite-direction electrodes are arranged in the pixel areas of the substrate and located above the light-emitting layers; the conductive layer is arranged above the light transmitting area, located between the two opposite-direction electrodes and used for connecting the two adjacent opposite-direction electrodes; the conductive layer is made from conductive materials with the evaporation temperature lower than 600 DEG C.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

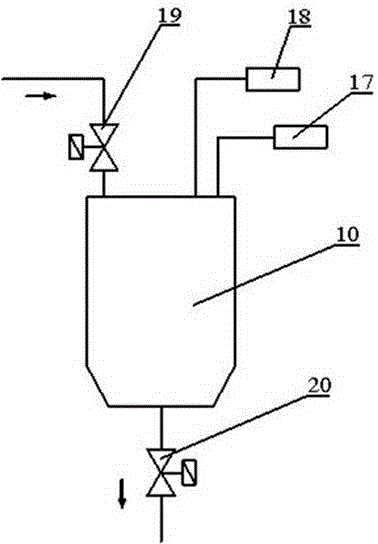

Method for concentrating high-salinity wastewater at low temperature

ActiveCN103819041ALower evaporation temperatureEnergy savingMultistage water/sewage treatmentWater/sewage treatment by heatingProcess engineeringEvaporator

The invention discloses a method for concentrating a high-salinity wastewater at low temperature. The method is characterized by comprising the following steps: feeding, single-effect evaporation, two-effect heat exchange, two-effect evaporation and separation. Especially, a steam machine recompression evaporator is adopted to carry out low-temperature evaporation concentration in the single-effect evaporation step, and the concentration effect is good. By adopting the method for concentrating the high-salinity wastewater at low temperature, the evaporation temperature of the high-salinity wastewater is reduced, energy is saved, the environment is protected, energy consumption for evaporating 1t of water is about 1 / 8 to 1 / 7 of that of the traditional evaporator, the method completely gets rid of dependence on a steam boiler, the MVR mainly consumes electric energy after consuming steam, an energy source is saved, the cost is reduced, the automatic degree is high, the work flow is full-automatic, and method is free of manual control.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

Organic compound based on pyridine and quinoxaline and application of organic compound to OLED (organic light emission diode) device

InactiveCN107602538APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesQuinoxalineHeat stability

The invention relates to an organic compound based on pyridine and quinoxaline and an application of the organic compound to an OLED (organic light emission diode) device. The compound has higher glass transition temperature and molecular heat stability, and is low in absorption and high in refractive index in the field of visible light, and light extraction efficiency of the OLED device can be effectively improved after the organic compound is applied to a CPL layer of the OLED device; the compound further has high HOMO energy level and high electron mobility and can be taken as a hole-blocking / electron transfer layer of the OLED device and can effectively prevent holes or energy from being transferred to one side of the electron layer from a luminous layer, so that composite efficiency of the holes and electrons in the luminous layer is improved, the luminous efficiency of the OLED device is improved, and the service life of the OLED device is prolonged.

Owner:VALIANT CO LTD

Process for recycling ammonium chloride waste water

InactiveCN102020389AReduce steam consumptionLow running costMultistage water/sewage treatmentAmmonium salt fertilisersTriple effectFertilizer

The invention provides a process for recycling ammonium chloride waste water, which comprises the steps of pre-heating ammonium chloride waste water and performing triple effect evaporation on feed liquid by using a plate type evaporator in turn. The process has the advantages that: triple effect downstream evaporation is adopted, pressure is kept between normal pressure and low vacuum, and evaporation temperature is lowered with the increase in the ammonium chloride concentration in waste water to reduce the corrosion of a medium by ammonium chloride, and the enough gas heat generated by steam-liquid separation at the previous effect evaporation is used as the heat source for later effect evaporation, so that the heating medium is fully utilized and steam consumption and operation cost are reduced; the first effect evaporation and second effect evaporation are falling film evaporation which has high evaporating capacity; the third effect evaporation is forced circulation evaporation; and the concentration of ammonium chloride solution after triple effect evaporation is controlled to be saturated, cooling and crystallizing can be performed subsequently, and the dried material can be used as a fertilizer directly and has a high commercial value.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

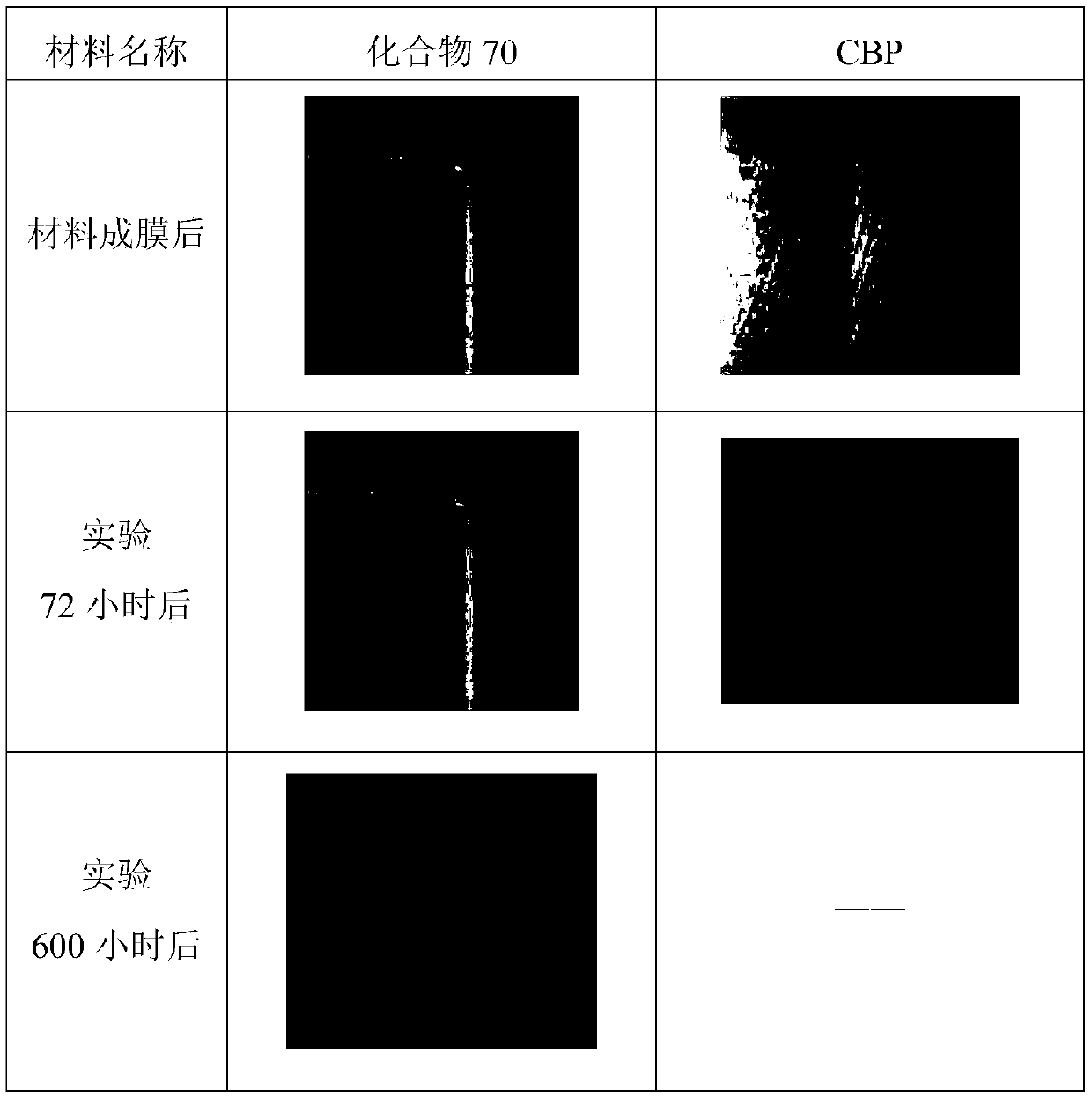

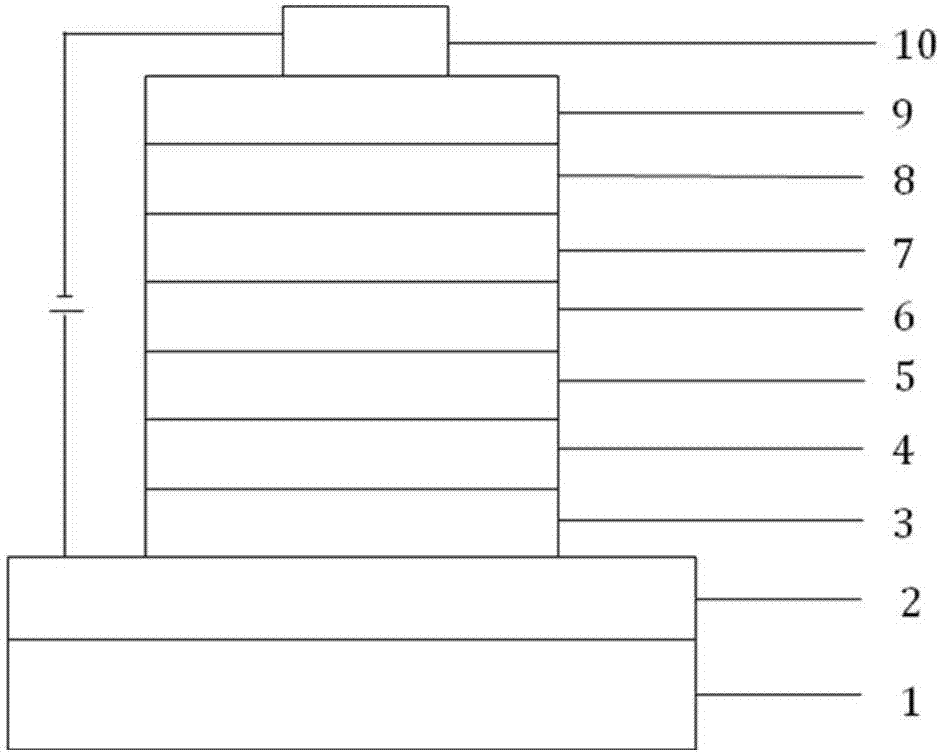

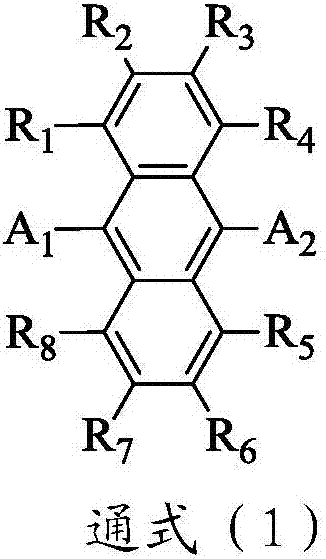

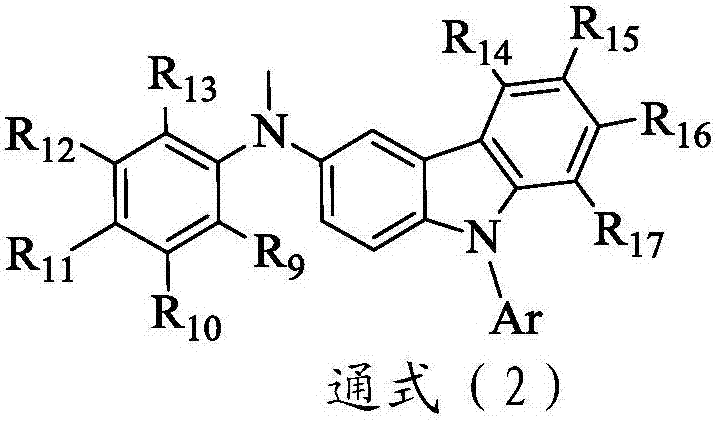

Organic electroluminescent device taking anthracene as core compound, and applications thereof

InactiveCN108003089ADestroy crystallinityInhibit aggregationOrganic chemistrySolid-state devicesAnthraceneChain structure

The invention discloses an organic electroluminescent device taking anthracene as core compound, and applications thereof. The organic electroluminescent device taking anthracene as core compound comprises a cavity transmission layer, a luminescent layer, and an electron transmission layer; and anthracene is taken as the core compound. Anthracene is combined with a branch chain structure represented by general structure (2), so that it is convenient for energy transmission among host and guest materials, and device high efficiency can be achieved easily; and in addition, the core compound possesses relatively high glass transition temperature and molecule heat stability, and appropriate HOMO and LUMO energy level, device structure optimization is capable of improving OLED device photoelectric properties and prolonging OLED device service life effectively.

Owner:VALIANT CO LTD

Organic compound taking triazine and benzimidazole as cores and application thereof

InactiveCN106946860AImprove structural stabilityHigh densityOrganic chemistrySolid-state devicesRefractive indexGlass transition

The invention relates to an organic compound taking triazine and benzimidazole as cores and application thereof to an OLED (Organic Light Emitting Diode) device. The compound provided by the invention has relatively high glass transition temperature and molecule thermal stability; the compound has low absorption and high refractive index in the field of visible light; after the compound is applied to a CPL (Circular Polarizing Filter) layer of the OLED device, the light extraction efficiency of the OLED device can be effectively improved; the compound also has a deep HOMO energy level and high electron mobility and can be used as a hole-blocking / electron transferring layer material of the OLED device; and the compound can be used for effectively stopping a hole or energy from being transmitted to one side of an electron layer from a light emitting layer, so that the compounding efficiency of the hole and electrons on the light emitting layer is improved, and furthermore, the luminous efficiency of the OLED device is improved and the service life of the OLED device is prolonged.

Owner:VALIANT CO LTD

High-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer

ActiveCN103394206AIncrease profitImprove economySolution crystallizationMultiple-effect evaporationLiquid wasteSolvent

The invention discloses a high-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer, belonging to the field of pickling waste liquoir treatment. The evaporation crystallizer disclosed by the invention comprises an evaporation concentration unit, a feed unit, a gas condensation unit, a cooling crystallization unit, a solid-liquid separation unit, a mother liquor circulating unit and a vacuum unit. The hydrochloric acid pickling waste liquor is heated in a vacuum state, so that volatile chlorine hydride and water in the solution are evaporated together, and are condensed through the gas condensation unit to form reusable clean hydrochloric acid; and the concentration of the nonvolatile metal salt in the solution is continuously increased to form a metal salt supersaturated solution, and the metal salt supersaturated solution is cooled by the cooling crystallization unit, so that part of metal salts are precipitated in the crystalline-state hydrous crystal, thereby achieving the goal of separating the solute and solvent in the solution. The invention mainly aims to provide a high-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer which has the advantages of favorable antiseptic property, high recovery ratio and low treatment cost.

Owner:常州泰特环境设备工程有限公司

Organic compound based on pyridine and benzimidazole and application of organic compound

InactiveCN106967052APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesElectronic transmissionHeat stability

The invention relates to an organic compound taking pyridine and benzimidazole as a core and an application of the organic compound on an OLED (organic light emitting diode) device. The compound has relatively high glass state temperature and molecular heat stability, low absorption and high refractive index in the field of visible light, and can effectively improve light extraction efficiency of the OLED device after the compound is applied to a CPL (circular-polarizing filter) layer of the OLED device. The compound further has an HOMO (highest occupied molecular orbital) energy level and high electron mobility, and can serve as a hole obstruction / electronic transmission layer material of the OLED device and effectively prevent a hole or energy from being transmitted to one side of an electronic layer from a light emitting layer, so that the combination efficiency of the hole and an electron on the light emitting layer is improved; and the light emitting efficiency and a service life of the OLED device are improved and prolonged.

Owner:VALIANT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com