Low-temperature vacuum evaporation source

A low-temperature vacuum, evaporation source technology, applied in vacuum evaporation coating, ion implantation coating, metal material coating process and other directions, can solve the problems of difficult evaporation, difficult to achieve special material coating technology, etc., to achieve low cost, structure and Simple operation and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

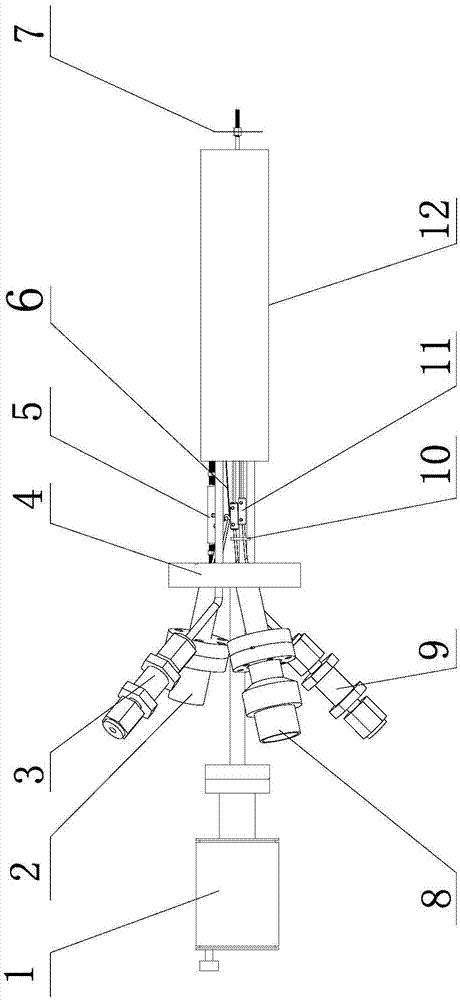

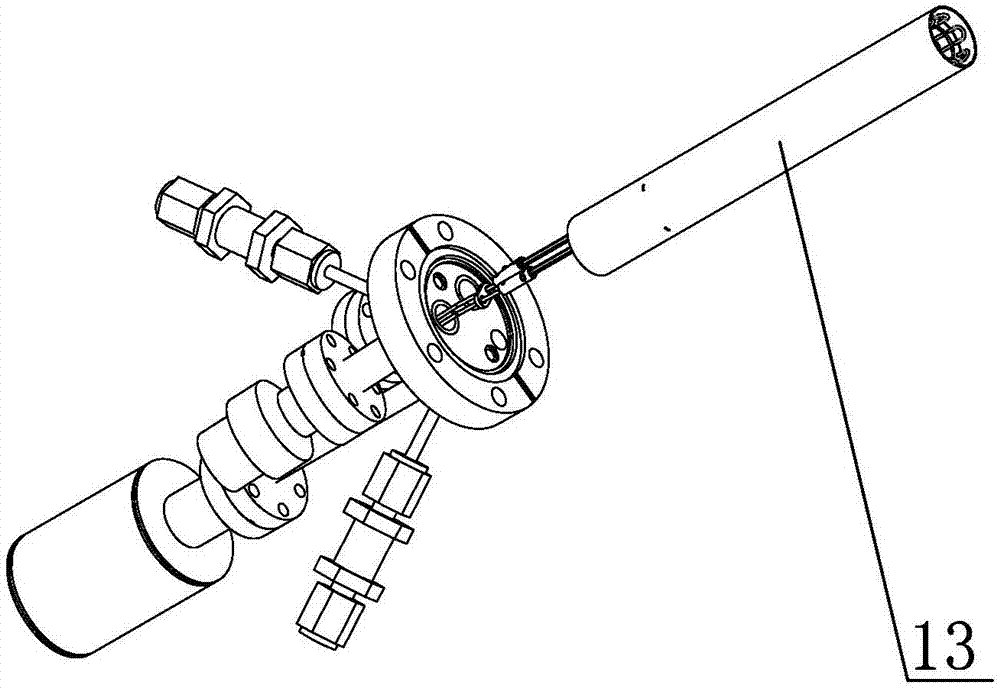

[0042] Such as figure 1 , figure 2 , image 3 with Figure 4 A low-temperature vacuum evaporation source shown, including: a heating system, a cooling system, a temperature measurement system, a control system, and connecting components;

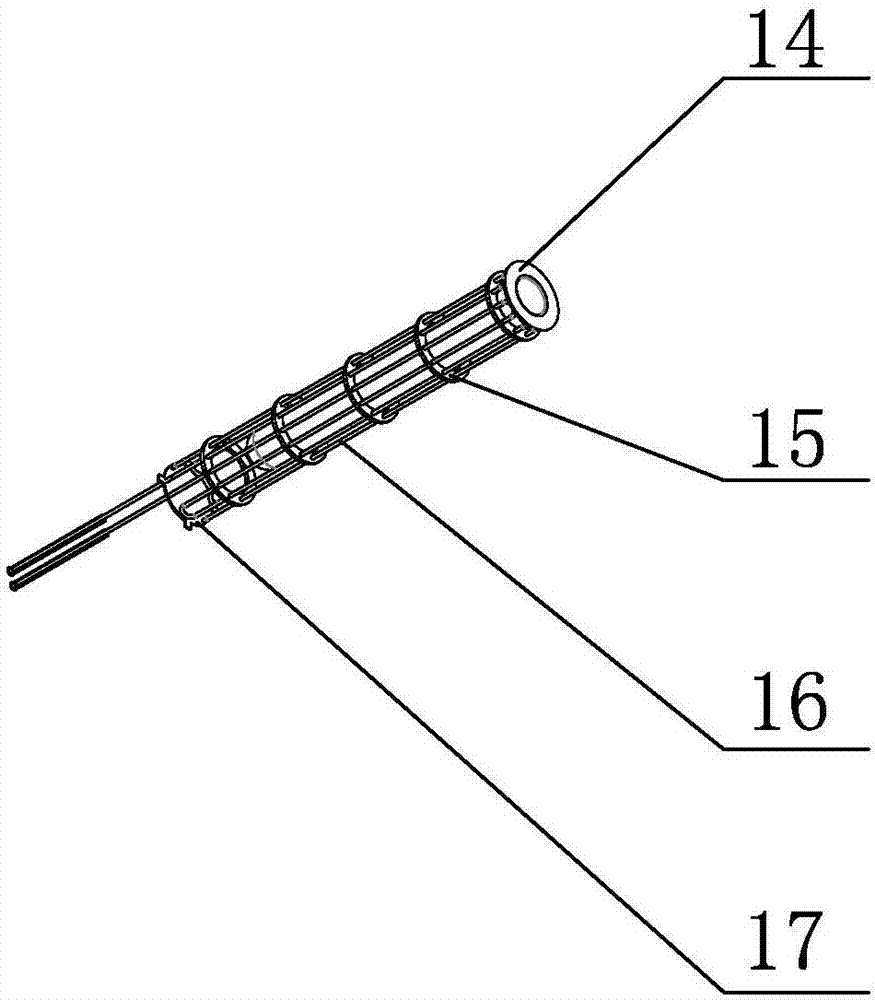

[0043] The heating system includes:

[0044] Electrode port 8, heating filament 16, shielding cover 13, crucible 14, fixing ring 15, negative plate 17 and electrode connector 11;

[0045] Among them, the heating filament 16 and a plurality of fixing rings 15 form a hollow cylindrical heating core, the shielding cover 13 covers the outside of the heating core, the crucible 14 is embedded in the top of the heating core, the bottom plate 17 is fixed at the bottom of the heating core, and the heating filament 16 protrudes The power supply joint of the electrode connector 11 is connected with the power supply line extending from the electrode port 8;

[0046] The cooling system includes:

[0047] Cooling cover 20, water inlet pipe 18, wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com