Stainless steel plate fin type heat exchanger core body high-temperature brazing jig and manufacturing process thereof

A technology of finned heat exchanger and stainless steel plate, applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of misalignment of assembly components, loss of elasticity of fixtures, and reduction of yield, so as to reduce stress and increase weld strength , Improve the effect of welding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

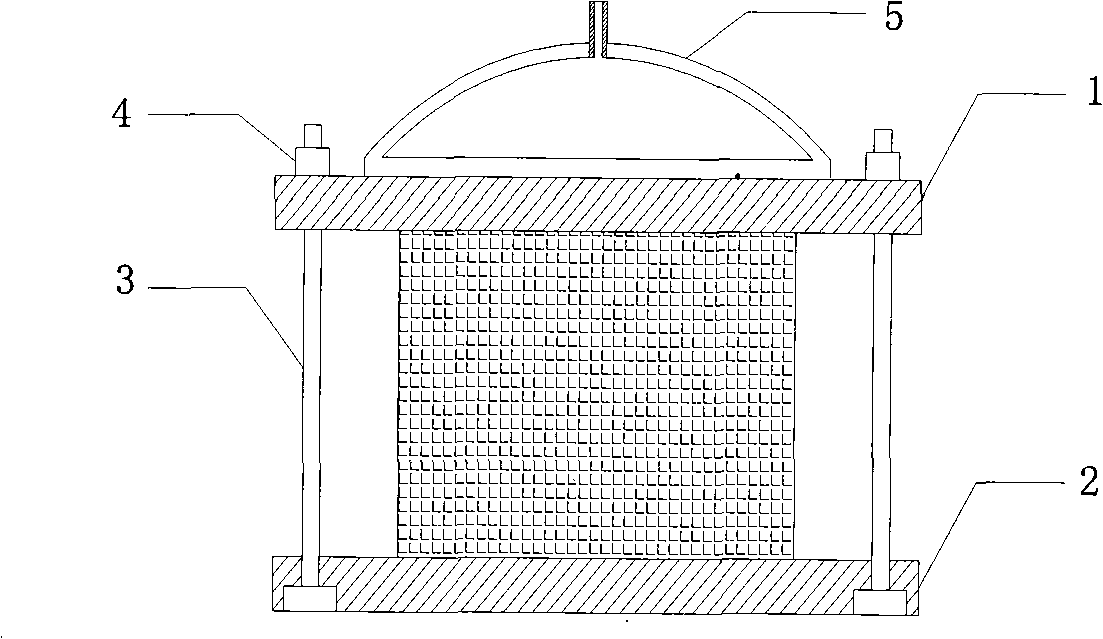

[0056] Example: such as figure 1 As shown, a fixture for high-temperature brazing of the core of a stainless steel plate-fin heat exchanger is composed of an upper splint 1, a lower splint 2, bolts 3, nuts 4 and a spherical crown pressure vessel 5. The upper and lower splints, bolts and nuts are made of high-temperature alloy KHR SA, and the lower splint is a whole piece with a rectangular "Tian" skeleton structure to increase the rigidity of the lower splint. The inside of the container is filled with argon gas at a certain pressure (0.1-1.0MPa), and the expansion of the gas at high temperature will generate pressure, so that the core body can obtain uniform pressure during the whole brazing process.

[0057] The special fixture for high temperature packaging of the stainless steel plate-fin heat exchanger core can be manufactured by the following method, which includes the following steps:

[0058] 1. Select the high temperature resistant alloy KHR SA (30Cr-48Ni-13W) to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com