Samarium cobalt permanent magnetic material and preparation method thereof

A permanent magnet material, samarium cobalt technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of not meeting the requirements of use, low temperature coefficient of remanence, low coercive force of magnets, etc., to save raw material costs, The effect of high magnetic properties and uniform distribution of alloy elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh raw materials: mix raw materials according to mass percentage: samarium 25.5%, cobalt 52%, iron 10.5%, copper 8%, zirconium 4%;

[0025] (2) Alloy smelting: Melt the prepared raw materials in an intermediate frequency induction furnace, then heat and refine them at a temperature of 1400°C to 1500°C for 10min to 15min, and then pour the molten samarium cobalt alloy liquid into a water-cooled copper mold for rapid cooling , to obtain a samarium-cobalt alloy ingot;

[0026] (3) Preparation of magnetic powder: coarsely crush the alloy ingot into 100 μm coarse particles with a vibration mill, and further crush the coarsely crushed magnetic powder into 3 μm to 5 μm with a planetary ball mill;

[0027] (4) Orientation forming: the magnetic powder is oriented and pressed under a magnetic field of 1.5T-2.0T, and then subjected to cold isostatic pressing under a pressure of 200Mpa-300Mpa to obtain a samarium-cobalt blank;

Embodiment 2

[0034] Raw materials: samarium, cobalt, iron, copper, zirconium;

[0035] The above raw materials are batched according to mass percentage: 24.5% samarium, 54.5% cobalt, 12% iron, 6.5% copper, 2.5% zirconium;

[0036] The preparation method of samarium cobalt permanent magnet material of the present invention is the same as embodiment 1.

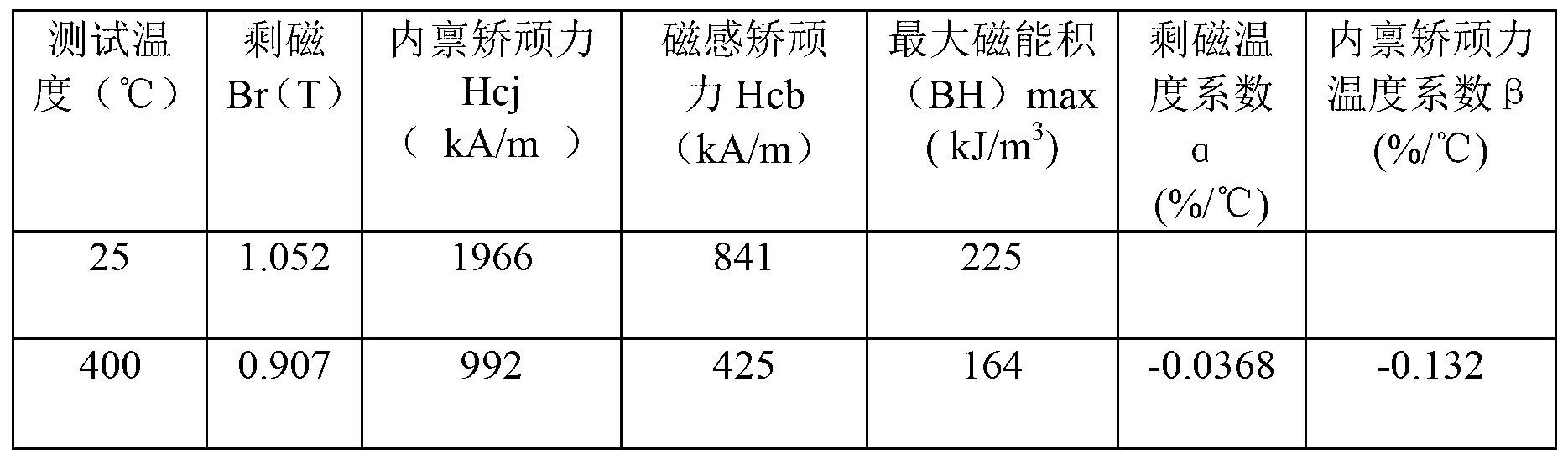

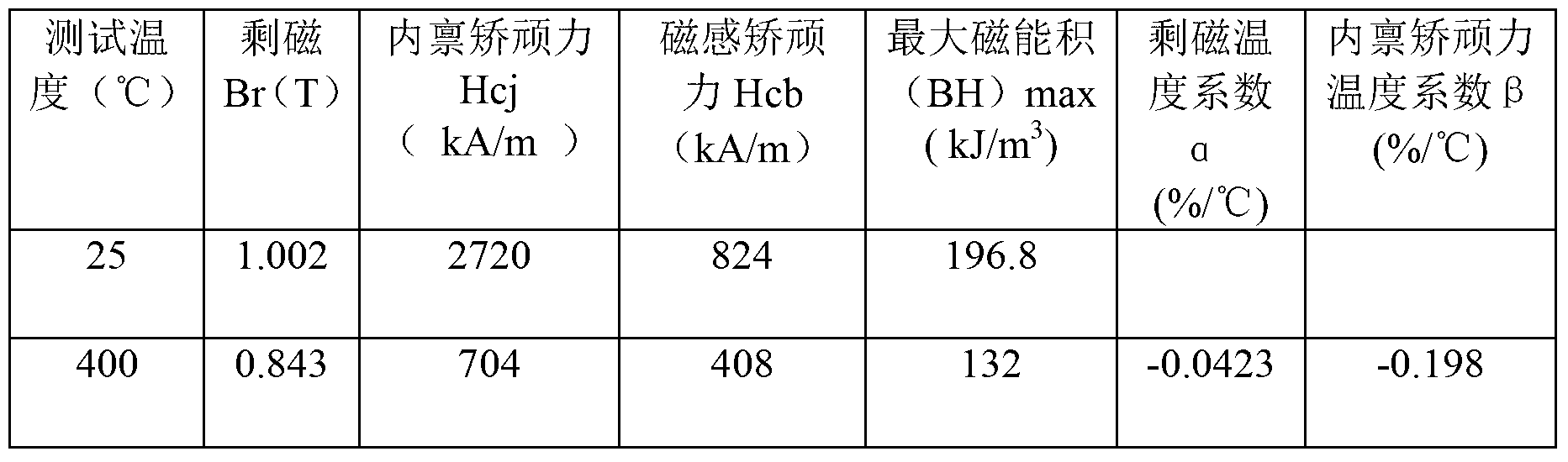

[0037] The magnetic properties of the samarium cobalt permanent magnet sample test prepared by the present embodiment are as shown in table 2:

[0038] Table 2

[0039]

Embodiment 3

[0041] Raw materials: samarium, cobalt, iron, copper, zirconium;

[0042]The above raw materials are batched according to mass percentage: samarium 25%, cobalt 56%, iron 7.5%, copper 8%, zirconium 3.5%;

[0043] The preparation method of samarium cobalt permanent magnet material of the present invention is the same as embodiment 1.

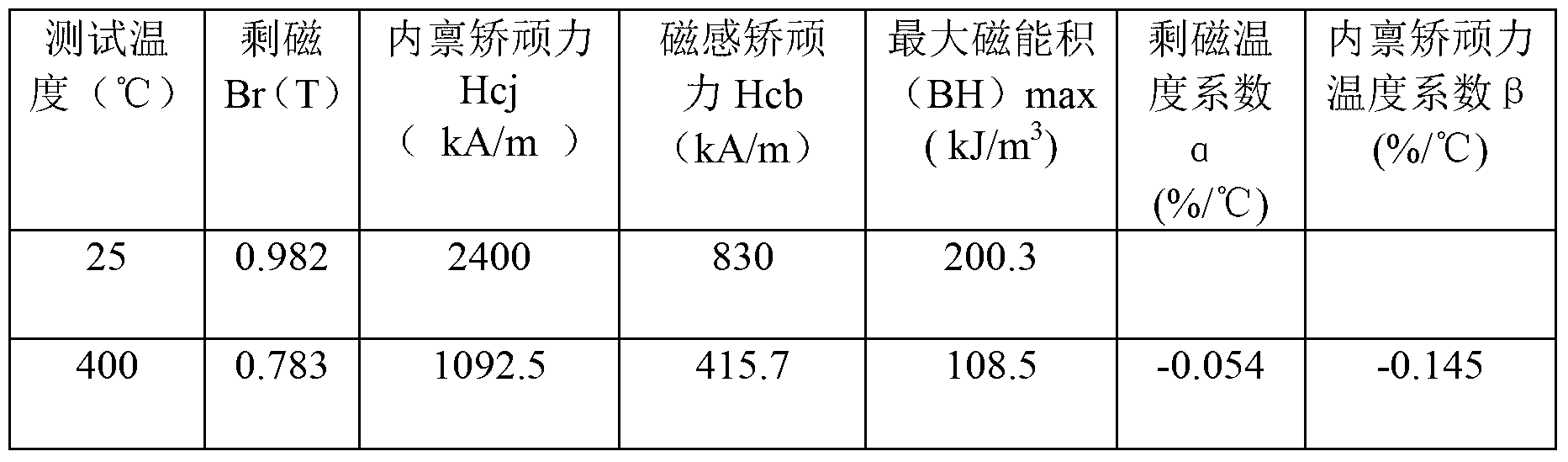

[0044] The magnetic properties of the samarium cobalt permanent magnet sample test prepared by the present embodiment are as shown in table 3:

[0045] table 3

[0046]

[0047] It can be seen from the samples prepared in the above examples that the samarium cobalt permanent magnet material of the present invention has high coercive force and low temperature coefficient while reducing the production cost, and the demagnetization curve at 400° C. to 450° C. is a straight line, satisfying High temperature use requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanence | aaaaa | aaaaa |

| Intrinsic coercive force | aaaaa | aaaaa |

| Remanence temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com