Preparation method for blending modification of ultrafiltration membrane by using nano cellulose crystal

A nanocellulose, blending modification technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of expensive nanomaterials, poor material dispersibility, insufficient hydrophilicity, etc. Achieve the effect of strong operability, reduction of complex processes and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: In this embodiment, the preparation method of ultrafiltration membrane modified by blending nanocellulose crystals is carried out according to the following steps:

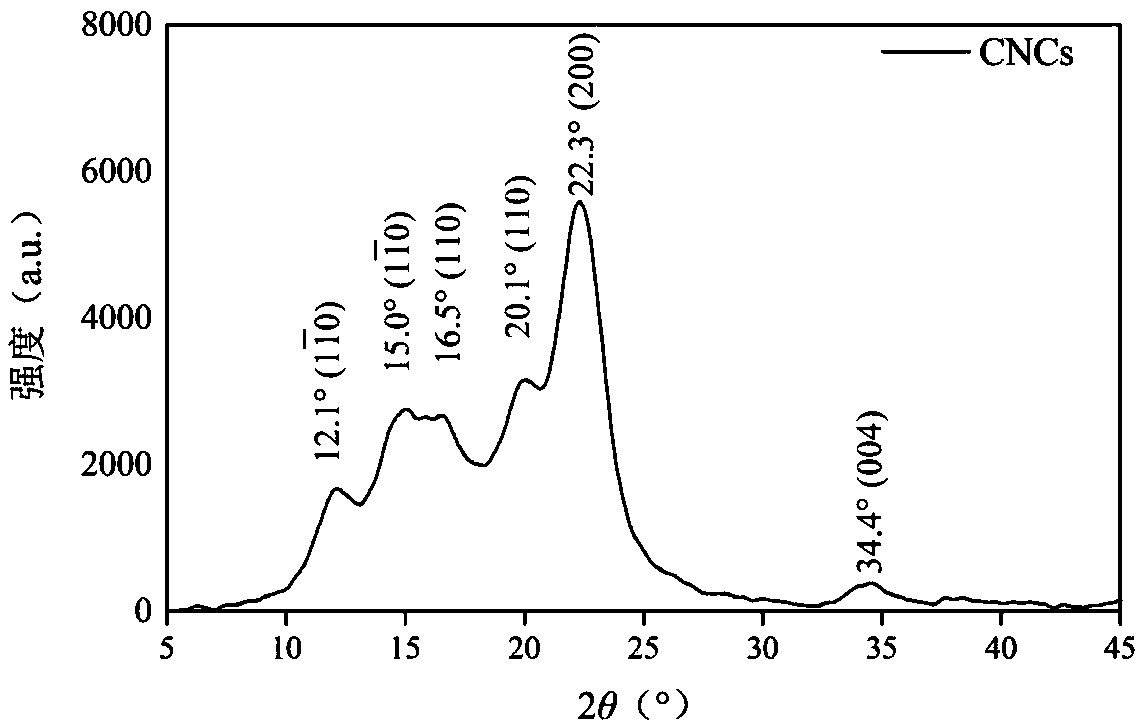

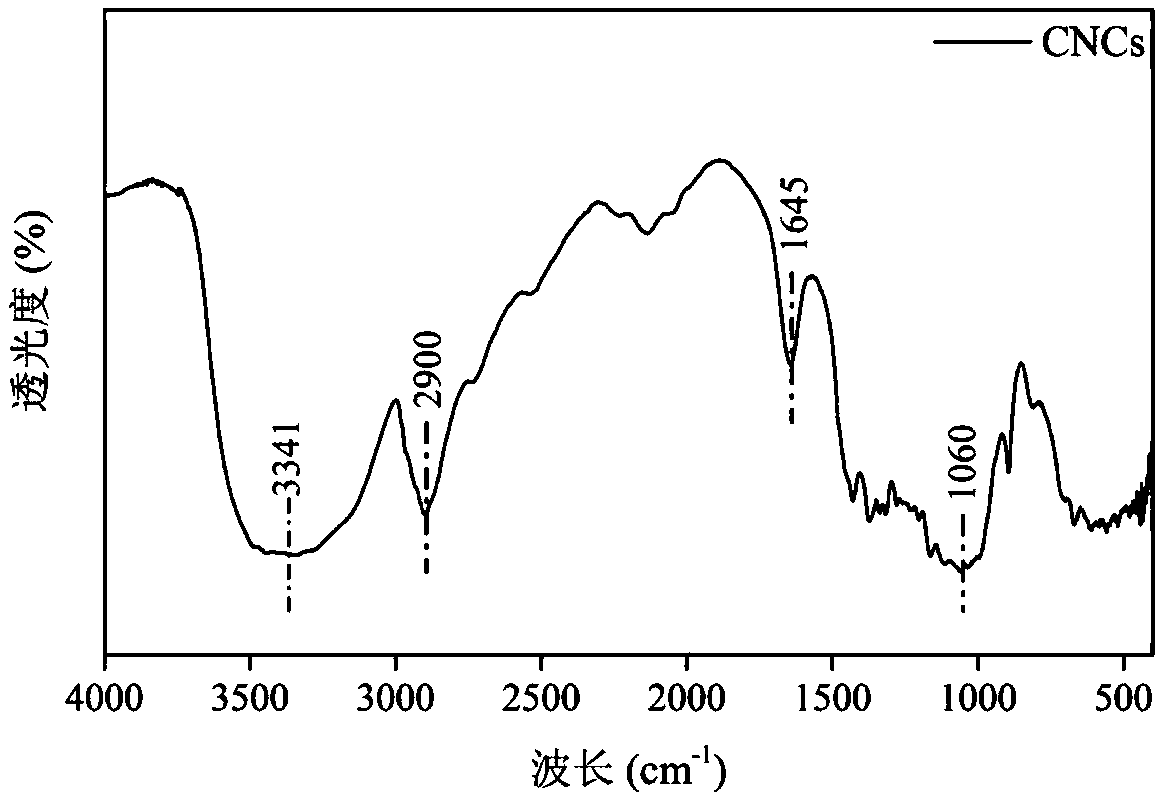

[0030] Step 1, in 250mL conical flask, add 0.5g nanocellulose crystal ( figure 1 , 2 and 3) and 83.5g of N,N-dimethylformamide, ultrasonically dispersed for 30min, added 12g of polysulfone and 4g of PEG200, sealed with plastic wrap, and then placed on a magnetic heating stirrer, at 60 ° C, 400r / After heating and stirring at 1 min for 8 hours, let it stand for degassing at room temperature for 24 hours, and the casting solution after degassing is a homogeneous and transparent colloidal solution, forming a homogeneous casting solution;

[0031] Step 2, then slowly pour the casting solution formed in Step 1 on the glass plate with PET non-woven fabric at a temperature of 25±0.5°C and a humidity of 30%-40%, and adjust the height of the doctor blade to 80 μm , scrape the film evenly on the non-w...

Embodiment 2

[0035] Embodiment 2: In this embodiment, the preparation method of ultrafiltration membrane modified by blending of nanocellulose crystals is carried out according to the following steps:

[0036] Step 1, in 250mL conical flask, add 0.5g nanocellulose crystal ( figure 1 , 2 and 3) and 83.5g N-methylpyrrolidone, ultrasonically disperse for 30min, add 12g polyether ether ketone and 4g PVPk30, seal the bottle mouth with plastic wrap, then place it on a magnetic heating stirrer, and heat it at 60°C and 400r / min After stirring for 8 hours, stand at room temperature for degassing for 24 hours, and the casting solution after degassing is a homogeneous and transparent colloidal solution, forming a homogeneous casting solution;

[0037] Step 2, then slowly pour the casting solution formed in Step 1 on the glass plate with PET non-woven fabric at a temperature of 25±0.5°C and a humidity of 30%-40%, and adjust the height of the doctor blade to 80 μm , scrape the film evenly on the non-wo...

Embodiment 3

[0038] Embodiment 3: In this embodiment, the preparation method of ultrafiltration membrane modified by blending nanocellulose crystals is carried out according to the following steps:

[0039] Step 1, in 250mL conical flask, add 0.5g nanocellulose crystal ( figure 1 , 2 and 3) and 83.5g N, N-dimethylacetamide, ultrasonic dispersion for 30min, add 12g polyethersulfone and 4g ethylene glycol, seal the bottle mouth with plastic wrap, then place it on a magnetic heating stirrer, at 60 ℃, After heating and stirring at 400r / min for 8 hours, let it stand at room temperature for degassing for 24 hours, and the casting solution after degassing is a homogeneous and transparent colloidal solution, forming a homogeneous casting solution;

[0040] Step 2, then slowly pour the casting solution formed in Step 1 on the glass plate with PET non-woven fabric at a temperature of 25±0.5°C and a humidity of 30%-40%, and adjust the height of the doctor blade to 80 μm , scrape the film evenly on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com