Patents

Literature

1102 results about "UF - Ultrafiltration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrafiltration (UF) is a variety of membrane filtration in which forces like pressure or concentration gradients lead to a separation through a semipermeable membrane.

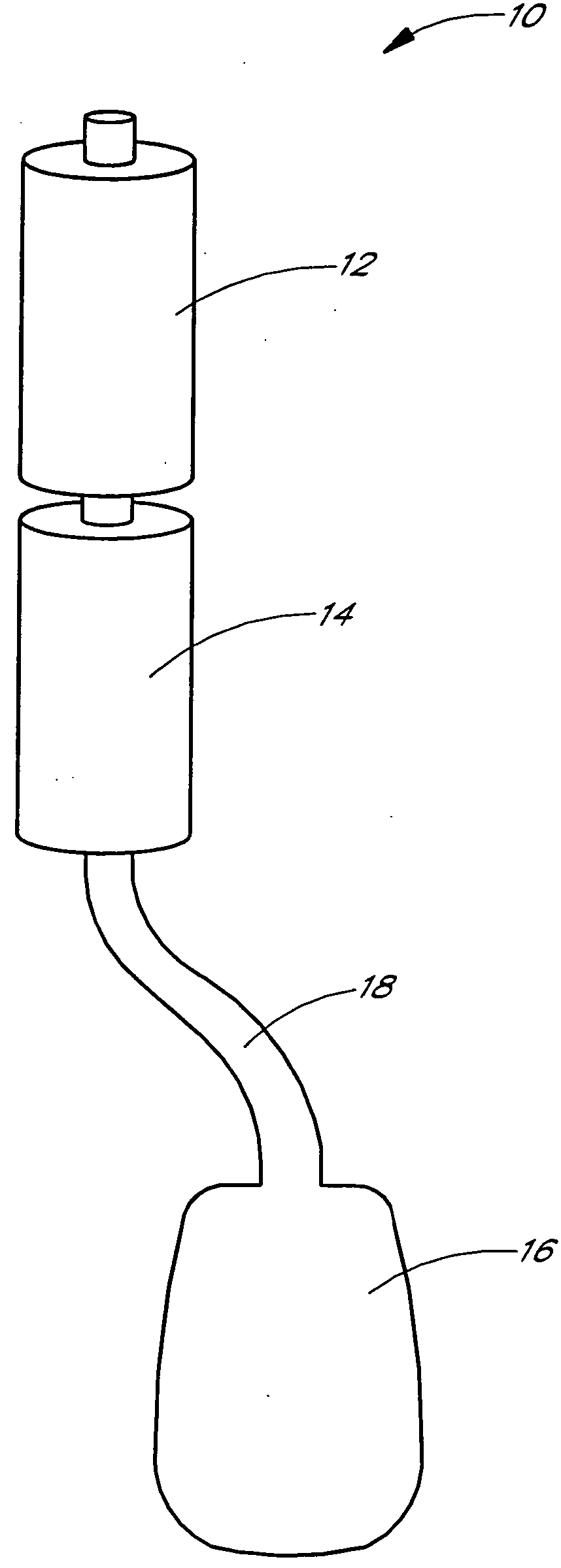

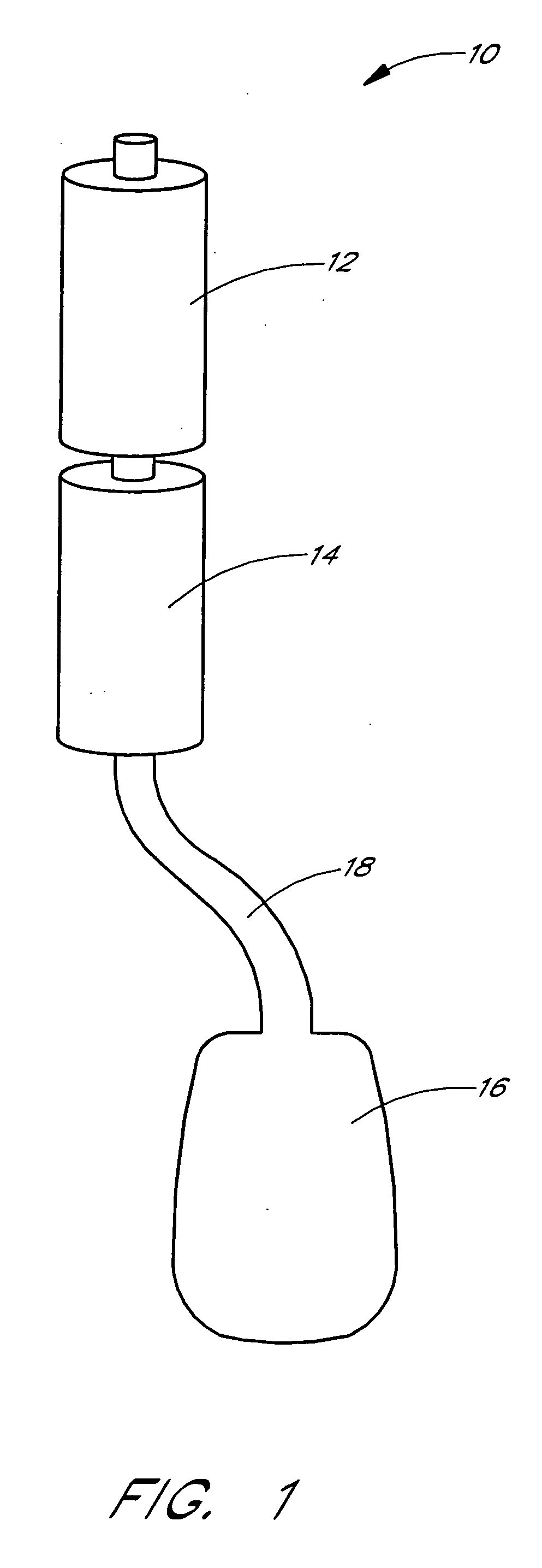

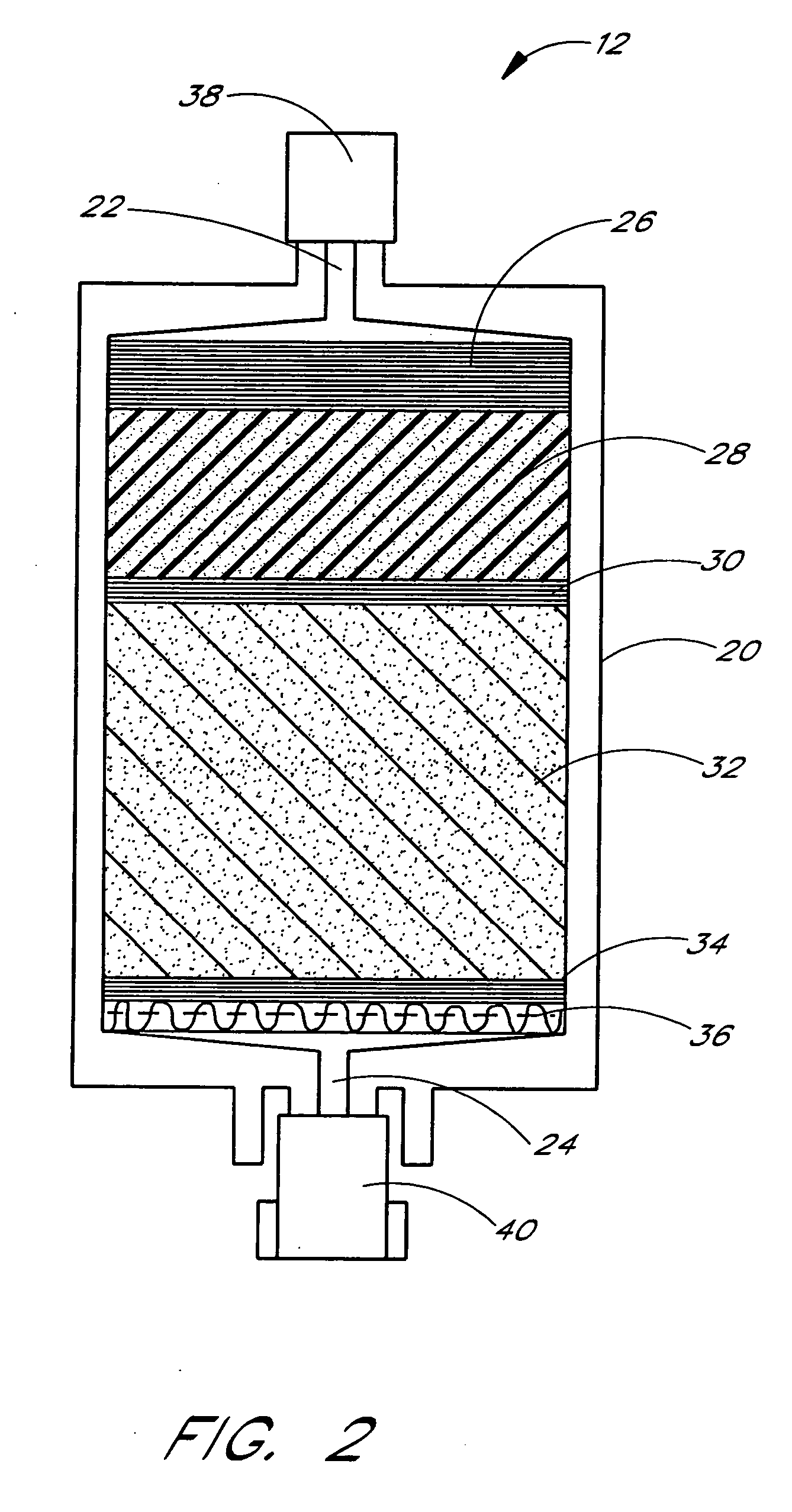

Water purification pack

InactiveUS20050113796A1General water supply conservationTransportation and packagingHuman bodyQuality level

An apparatus and methods are disclosed for purifying fluid, such as potable water, to quality levels suitable for medical application, particularly to applications involving injection of the fluid into a human body. The apparatus comprises a portable purification pack constructed for a single use. The pack houses depth filtration, activated carbon, mixed bed ion exchange resins and terminal filtration stages in series. The terminal filter comprises a fine (microfiltration or ultrafiltration), permeable membrane, treated with an endotoxin-binding chemistry. In contrast with semi-permeable osmotic membranes, the permeable membrane produces high flow rates at relatively low pressures, while still safely purifying fluid to injection quality.

Owner:TAYLOR MICHAEL A

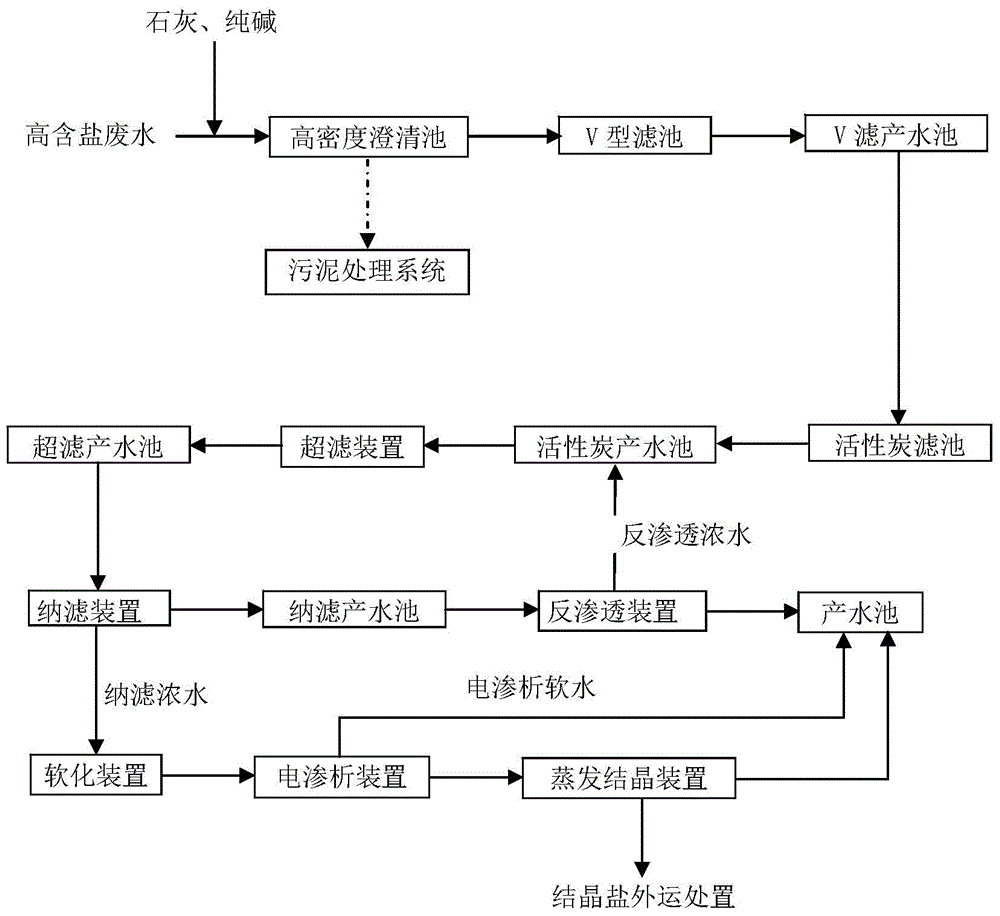

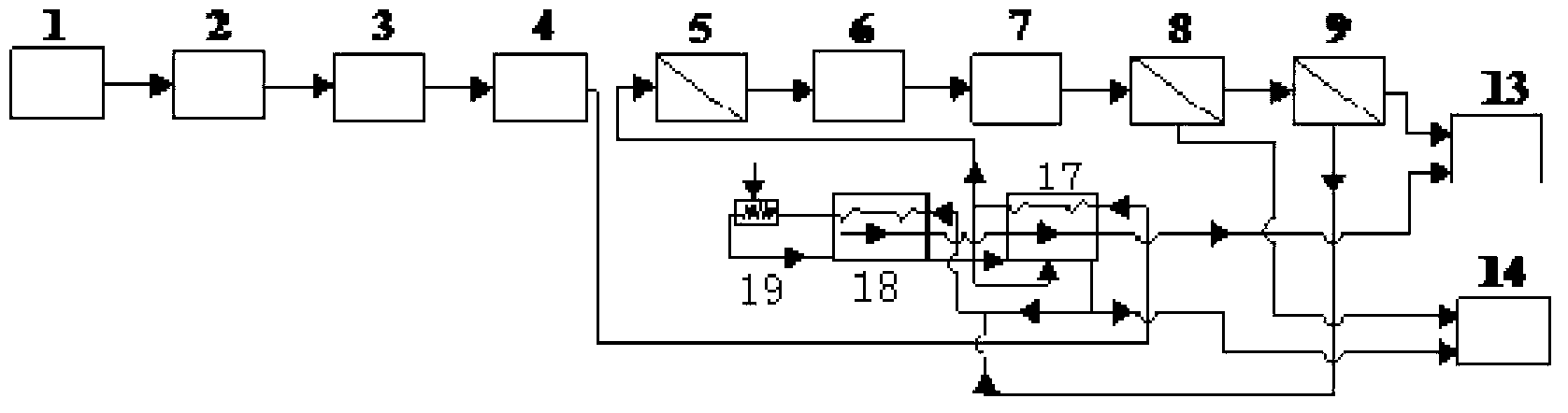

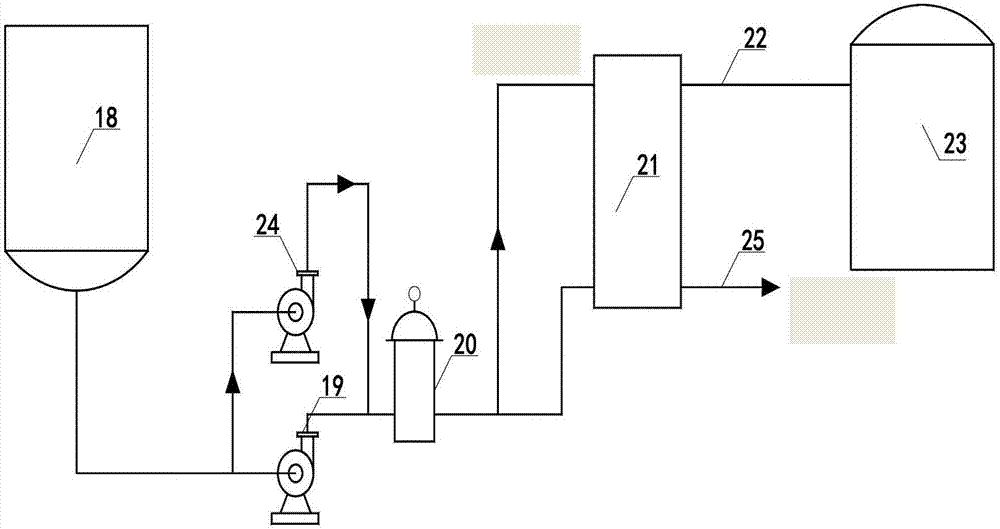

Zero-emission integrated process for treatment and reuse of high-salinity wastewater

ActiveCN104445788AHigh filtration precisionEasy to handleGeneral water supply conservationMultistage water/sewage treatmentSoftened waterEvaporation

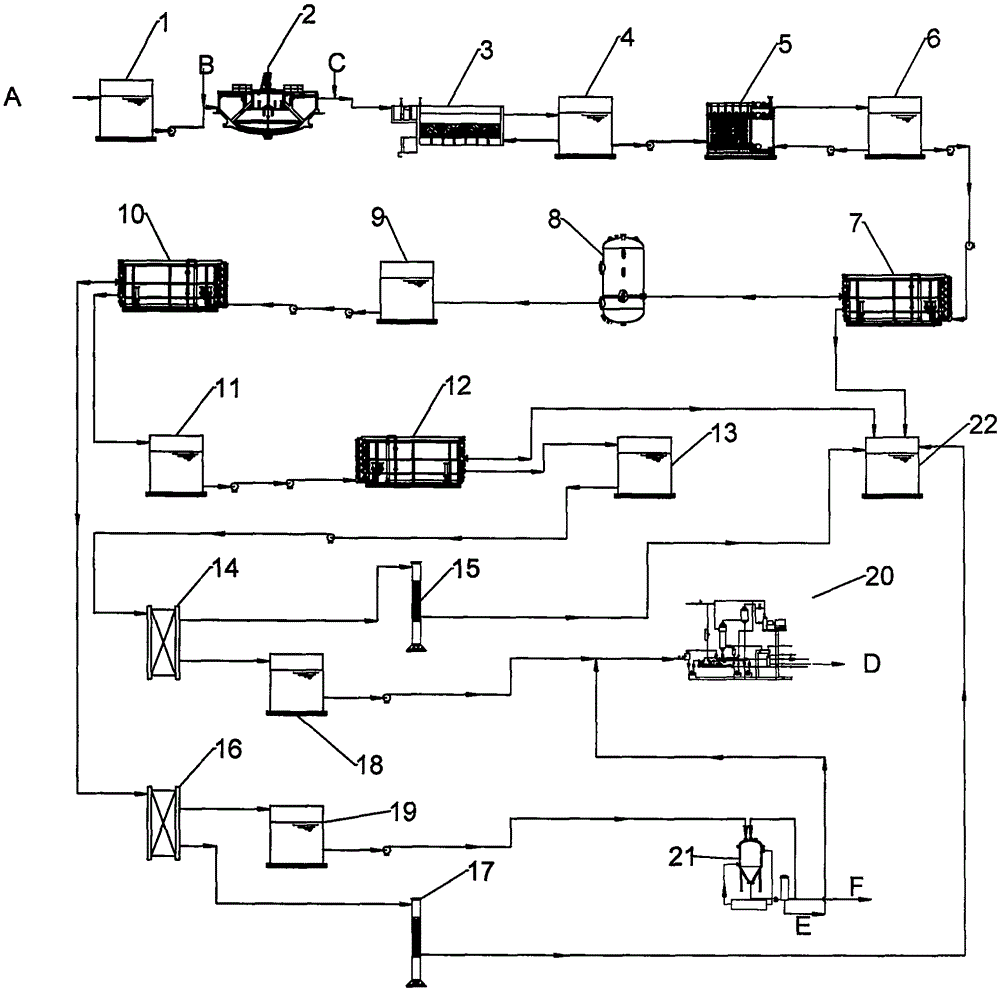

The invention discloses a zero-emission integrated process for treatment and reuse of high-salinity wastewater. The invention relates to a softening desalination treatment technology of water and particularly relates to a reuse treatment system for reverse osmosis concentrated water containing low-concentration organic matters which can achieve the requirement of 'zero emission'. The integrated process comprises the following steps: (1) firstly softening and pre-treating the high-salinity wastewater; (2) acquiring pre-treated water by virtue of activated carbon adsorption and an ultrafiltration device; (3) acquiring nanofiltration softened water and nanofiltration concentrated water by virtue of a nanofiltration device; (4) acquiring reverse osmosis softened water and reverse osmosis concentrated water by virtue of a reverse osmosis device; (5) acquiring electrodialysis softened water and electrodialysis concentrated water by virtue of an electrodialysis device; and (6) carrying out evaporation crystallization treatment on the electrodialysis concentrated water by virtue of an evaporation-crystallization device, regularly outwards transporting salts generated by the evaporation crystallization, feeding generated salt into a water-producing tank to enter a reuse system and finally completing the treatment and reuse of high-salinity wastewater. The integrated process is mainly used for the integrated treatment of the high-salinity wastewater.

Owner:XINJIANG DELAND

High-water-flux forward-osmosis composite membrane and preparation method thereof

ActiveCN103977718AHigh selectivityImprove hydrophilicitySemi-permeable membranesConcentration polarizationPolysulfone membrane

The invention relates to a high-water-flux forward-osmosis composite membrane and a preparation method thereof. The forward-osmosis composite membrane is a polysulfone-sulfonated polysulfone-inorganic filler blended / polyamide composite membrane. A traditional osmosis membrane is generally applied to a reverse-osmosis system, and if the traditional osmosis membrane is used in a forward-osmosis process, the water flux of osmosis is far lower than a theoretical value since the traditional osmosis composite membrane is large in thickness, the hydrophilicity of a supporting layer of a polyamide layer is poor so as to cause serious inner concentration polarization. The preparation method comprises the following steps: blending a polymer with a modifier to form film casting liquid; after scraping or leveling, performing non-solvent coagulating bath with water; by a phase-inversion method, preparing a polysulfone ultrafiltration membrane with good hydrophilicity, high porosity, uniform surface pore structure and narrow pore diameter distribution; and in a clean environment and at room temperature, airing the polysulfone membrane till the surface is dry, and growing a polyamide active layer on the surface of the polysulfone membrane by an interfacial polymerization method, thereby obtaining the forward-osmosis composite membrane with good hydrophilicity, high porosity, low thickness and high mechanical strength. The high-water-flux forward-osmosis composite membrane disclosed by the invention has the advantages that not only the osmosis flux is high, but also the reverse leakage of an extraction medium is low, and the selective permeability is good.

Owner:UNIV OF SCI & TECH OF CHINA

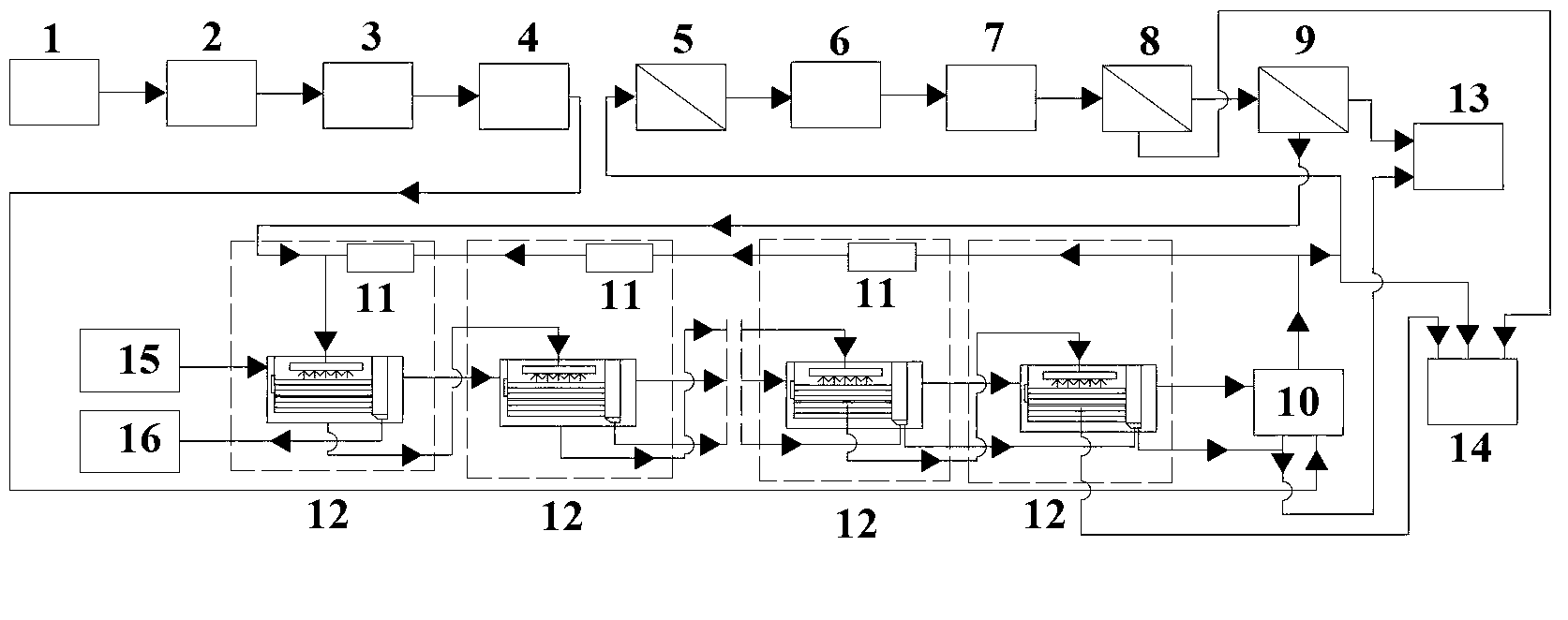

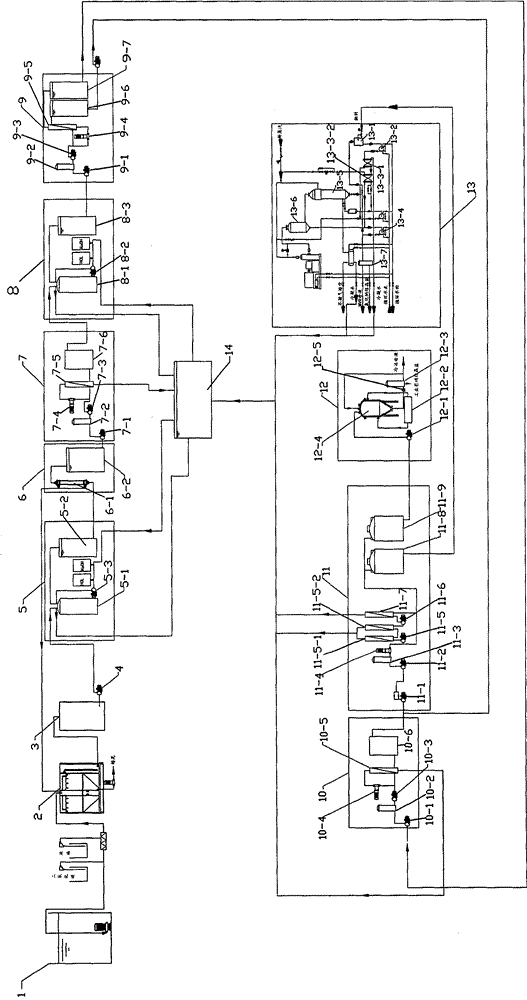

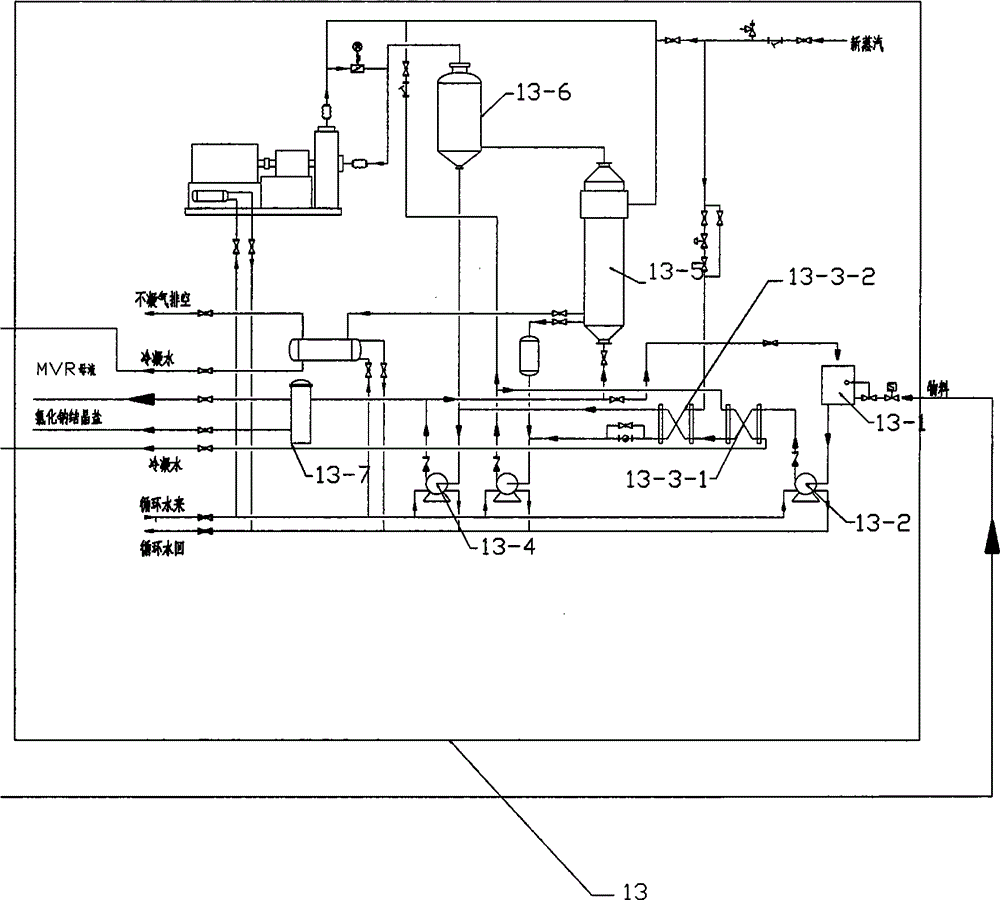

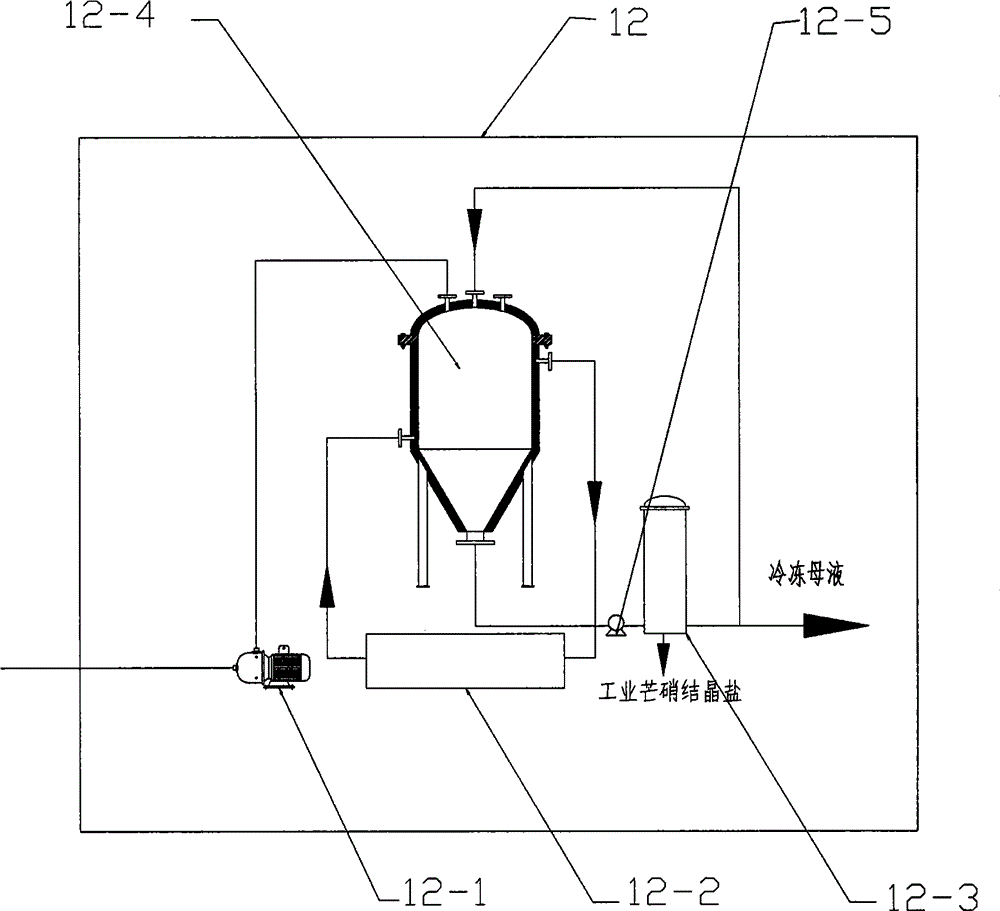

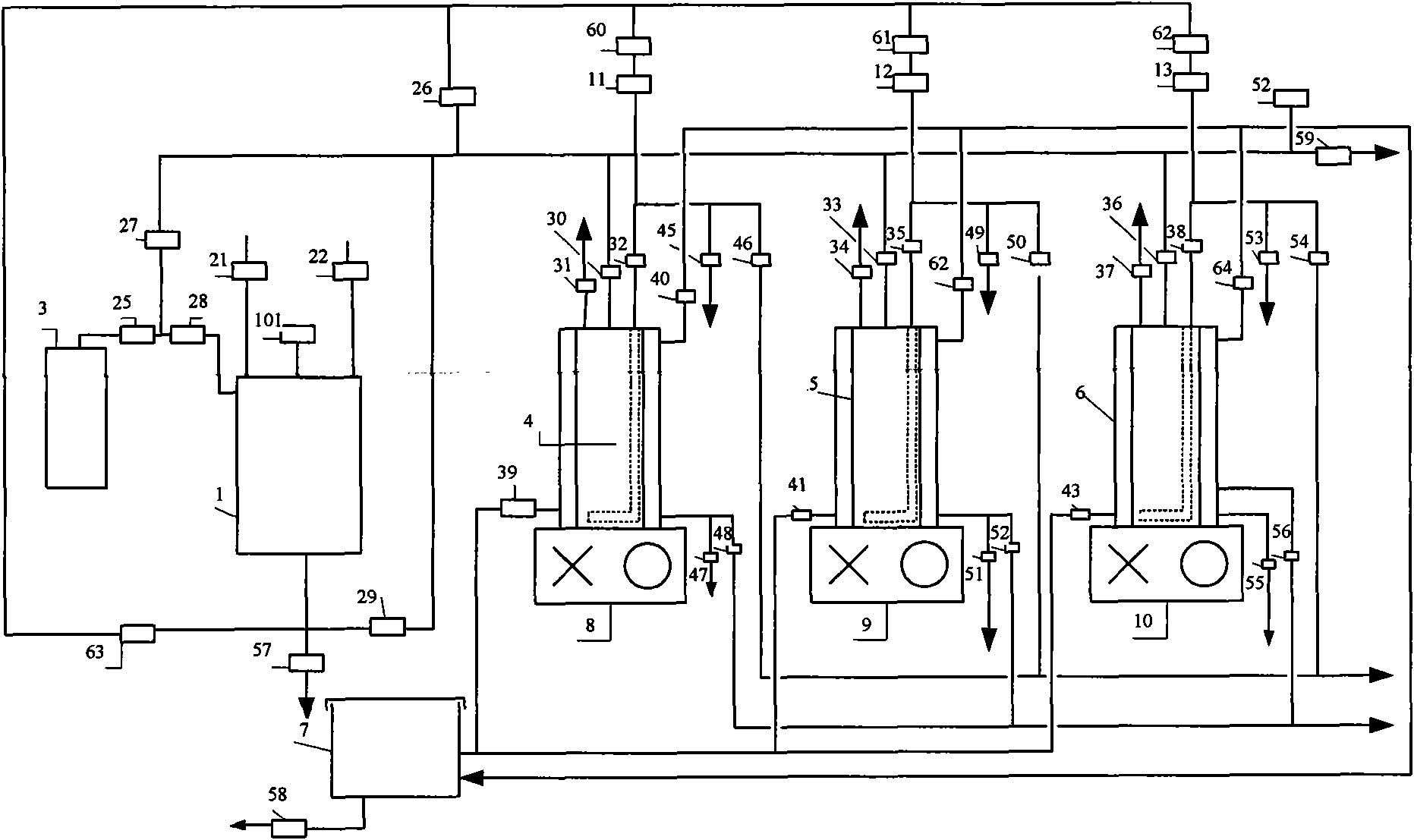

Intensified deep concentration system for high-salt-content industrial wastewater and technology thereof

InactiveCN105565569ARemove hardnessAlkalinity removalTreatment involving filtrationWater/sewage treatment by ion-exchangeHigh pressureIon-exchange resin

The invention discloses an intensified deep concentration system for high-salt-content industrial wastewater and a technology thereof and belongs to the field of water treatment. The high-salt-content industrial wastewater is adjusted through an adjusting tank, settled through a softening settling pond, filtered through a V-type filter tank, filtered through an ultrafiltration device in an intensified mode and concentrated through a first-stage reverse osmosis device, then the hardness is removed through an ion exchange resin device, and salt separation is performed through a nanofiltration device; thick water of the nanofiltration device is concentrated through a frequent electrode transfer electrodialysis device, produced water is oxidized through an advanced oxidization device and then enters a general produced water tank, and thick water is crystallized through a freezing crystallization system and crystallized with sodium sulfate; produced water of the nanofiltration device is concentrated through a second-stage reverse osmosis device and concentrated again through the frequent electrode transfer electrodialysis device, produced water is oxidized through the advanced oxidization device and enters the general produced water tank, and thick water is crystallized through an MVR evaporative crystallization device and crystallized with sodium chloride. The intensified deep concentration system has the advantages that potential safety hazards caused by high-pressure operation are effectively reduced; the problem that the COD content is high after thick salt water is highly concentrated is effectively solved, the purity of crystallized salt is improved, and the using value of the crystallized salt is improved; the system is high in automation degree, easy to operate, low in operation pressure, stable in operation, high in purity of the crystallized salt, low in operation cost and the like.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Method for cleaning ultrafiltration membrane

ActiveCN102397752AEliminate pollutionRestore performanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisInlet pressureSewage

The invention provides a method for cleaning an ultrafiltration membrane, which comprises a physical cleaning method and a chemical cleaning method. The physical cleaning method comprises a process of air scrubbing of ultrafiltration membrane components and a process of backwashing of the ultrafiltration membrane components. The process of air scrubbing of the ultrafiltration membrane comprises the following steps: ultrafiltration membrane components discharges concentrated water when compressed air is introduced, wherein the air inlet pressure of the ultrafiltration membrane components is less than 2.5 bar and more than 1.5 bar, compressed air is introduced for 1 minute, sewage in the ultrafiltration membrane components is exhausted after air scrubbing is completed, backwashing for once is carried out according to the backwashing process of the ultrafiltration membrane components. The chemical cleaning method comprises the following steps: carrying out forward cleaning circulation ofthe ultrafiltration membrane components; preparing an alkaline cleaner, carrying out forward cleaning circulation of the ultrafiltration membrane components; immersing the ultrafiltration membrane components. The method for cleaning the ultrafiltration membrane is capable of eliminating the pollution of the ultrafiltration membrane components, recovering the performance of the ultrafiltration membrane components, ensuring the normal operation of the ultrafiltration membrane components and prolonging the usage life of the ultrafiltration membrane components as long as possible.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Seawater desalting method

ActiveCN102849887APrevent scalingAvoid pollutionGeneral water supply conservationSeawater treatmentSoftened waterDistillation

The invention belongs to the technical field of desalting of seawater, and relates to a seawater desalting method. The seawater desalting method comprises the following steps of: charging filtering water which is obtained by the pretreatment of seawater into a heat exchanger of a heat discharge section of a seawater desalting system for condensing the steam and recovering the heat energy of the heat discharge section to obtain the heat-exchanged warm seawater with higher temperature; transporting the warm seawater into an ultrafiltration device by a low-pressure pump, transporting the ultrafiltration produced water into a nanofiltration device by a high-pressure device, selectively removing the scaled ions in seawater to obtain nanofiltration softened water, and inputting into a reverse osmosis device through the high-pressure pump to obtain reverse osmosis produced water and reverse osmosis concentrated water; recovering the energy of the reverse osmosis concentrated water to be directly taken as the charged water of a heat recovering section of an MED (multi effect distillation) device or an MSF (multi stage flash) device; mixing the desalting produced water and the reverse osmosis produced water through the MED device or the MSF device to be taken as drinking water; and recovering the energy of nanofiltration concentrated water, and mixing with the concentrated water to be discharged or comprehensively utilized. The method is simple in technology, low in energy consumption, high in desalting efficiency, good in effect, simple in device structure, reliable in principle, stable in production process, and environment-friendly.

Owner:OCEAN UNIV OF CHINA

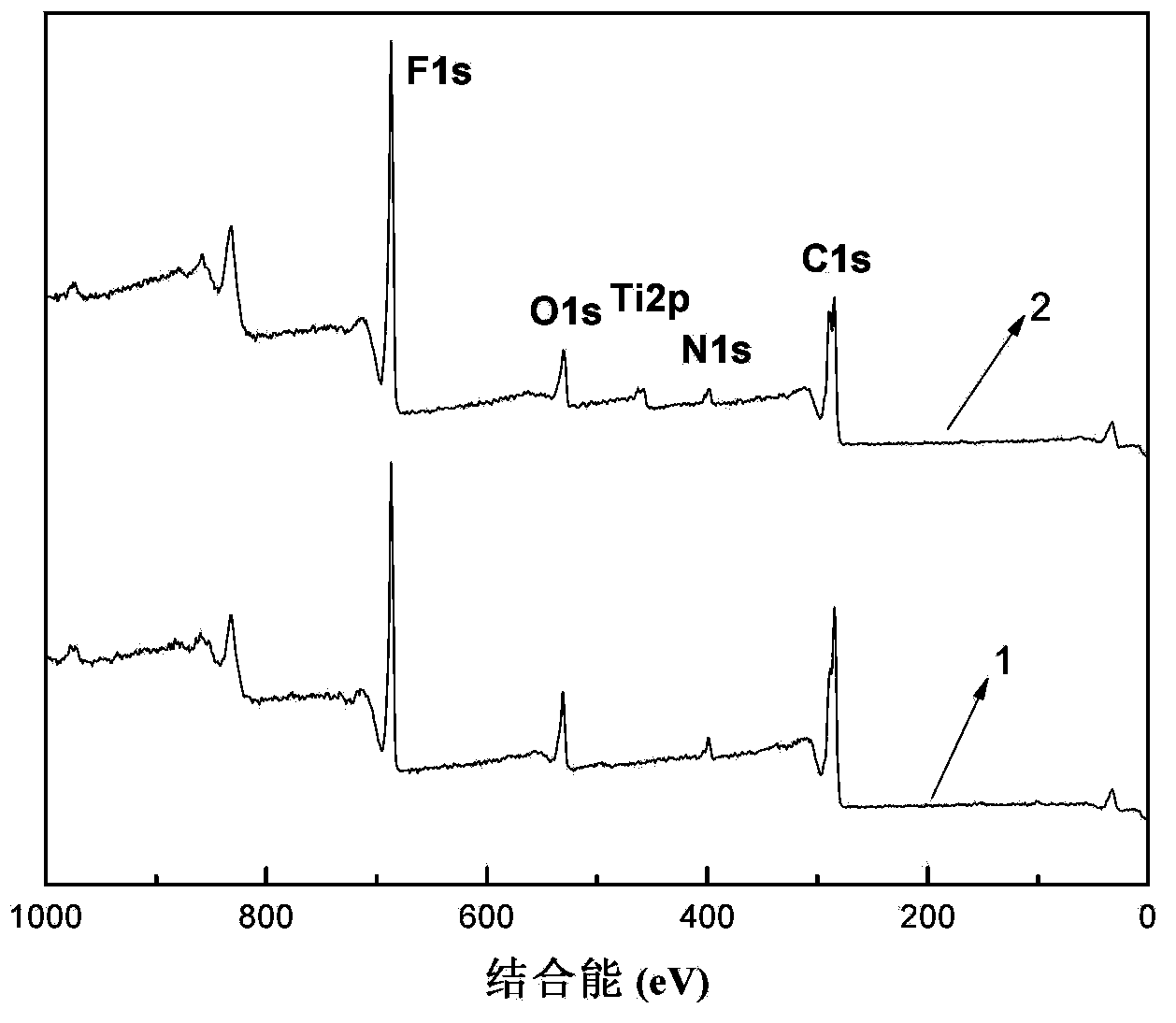

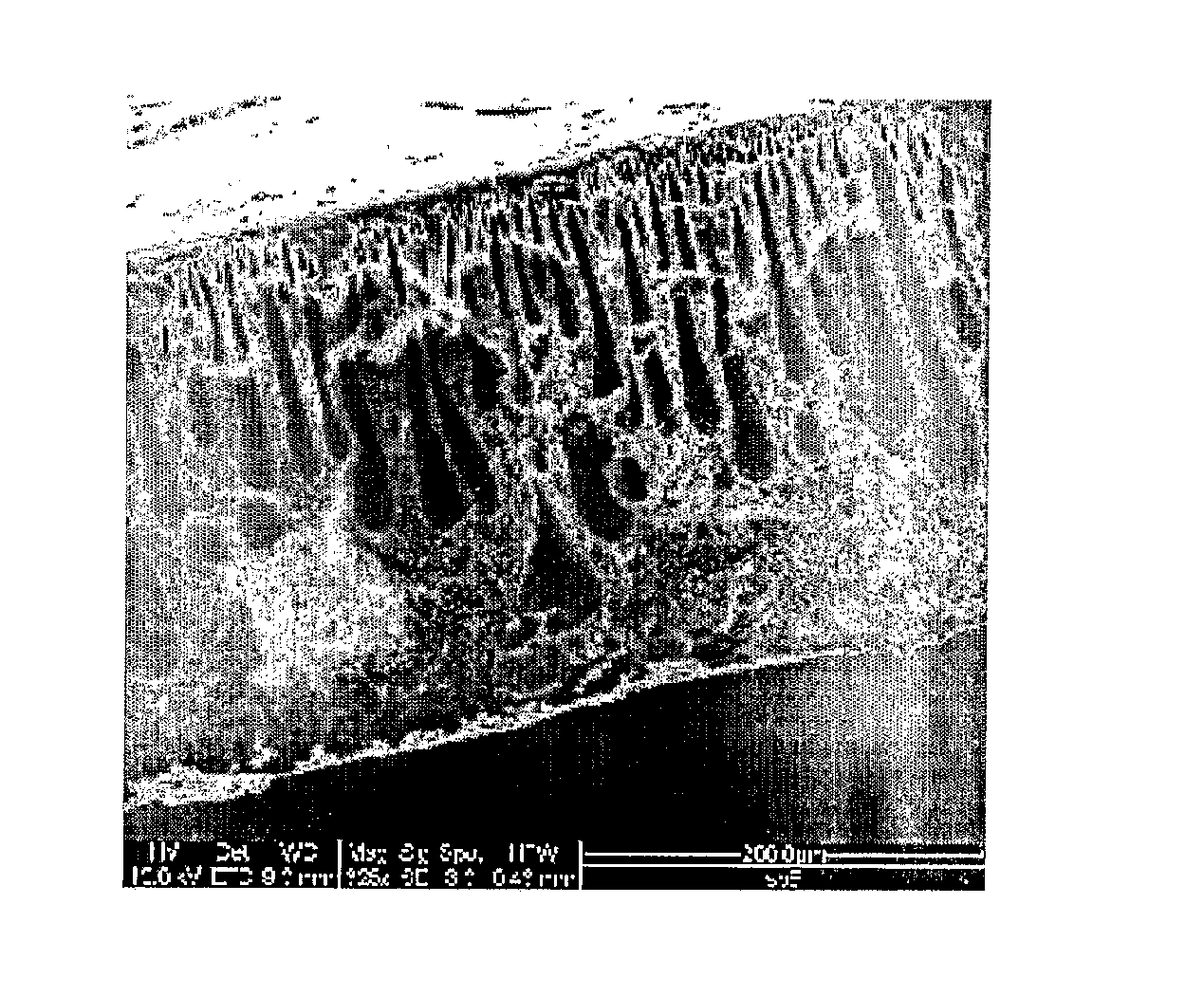

Preparation method of high-performance PVDF composite ultrafiltration membrane with surface loaded with TiO2 thin membrane

InactiveCN103394294AImprove stabilityEasy to manufactureSemi-permeable membranesThin membraneRejection rate

A preparation method of a high-performance PVDF composite ultrafiltration membrane with the surface loaded with a TiO2 thin membrane is provided. The invention is used for solving the problems of complex process, high membrane preparing cost, and difficult industrialized production existing in a conventional method for improving membrane hydrophilicity so as to improve membrane flux, anti-fouling performance and the like. The preparation method comprises the steps: 1, preparing a PVDF polymer membrane casting solution, and preparing an ultrafiltration basement membrane by an immersion-precipitation method; 2, preparing an auxiliary agent solution; 3, soaking the basement membrane in the auxiliary agent solution, taking out and swashing with water, and soaking in deionized water; 4, preparing a titania precursor solution; 5, immersing the basement membrane in the titania precursor solution, hydrolyzing a precursor, taking out and swashing with water, and thereby obtaining the high-performance ultrafiltration membrane with the surface firmly loaded with the TiO2 thin membrane. The method of the invention has the advantages of simple operation and low cost; and the obtained ultrafiltration membrane has large permeation flux, high rejection rate, strong hydrophilicity and outstanding anti-fouling performance. The preparation method is used for the membrane processing field.

Owner:HARBIN INST OF TECH

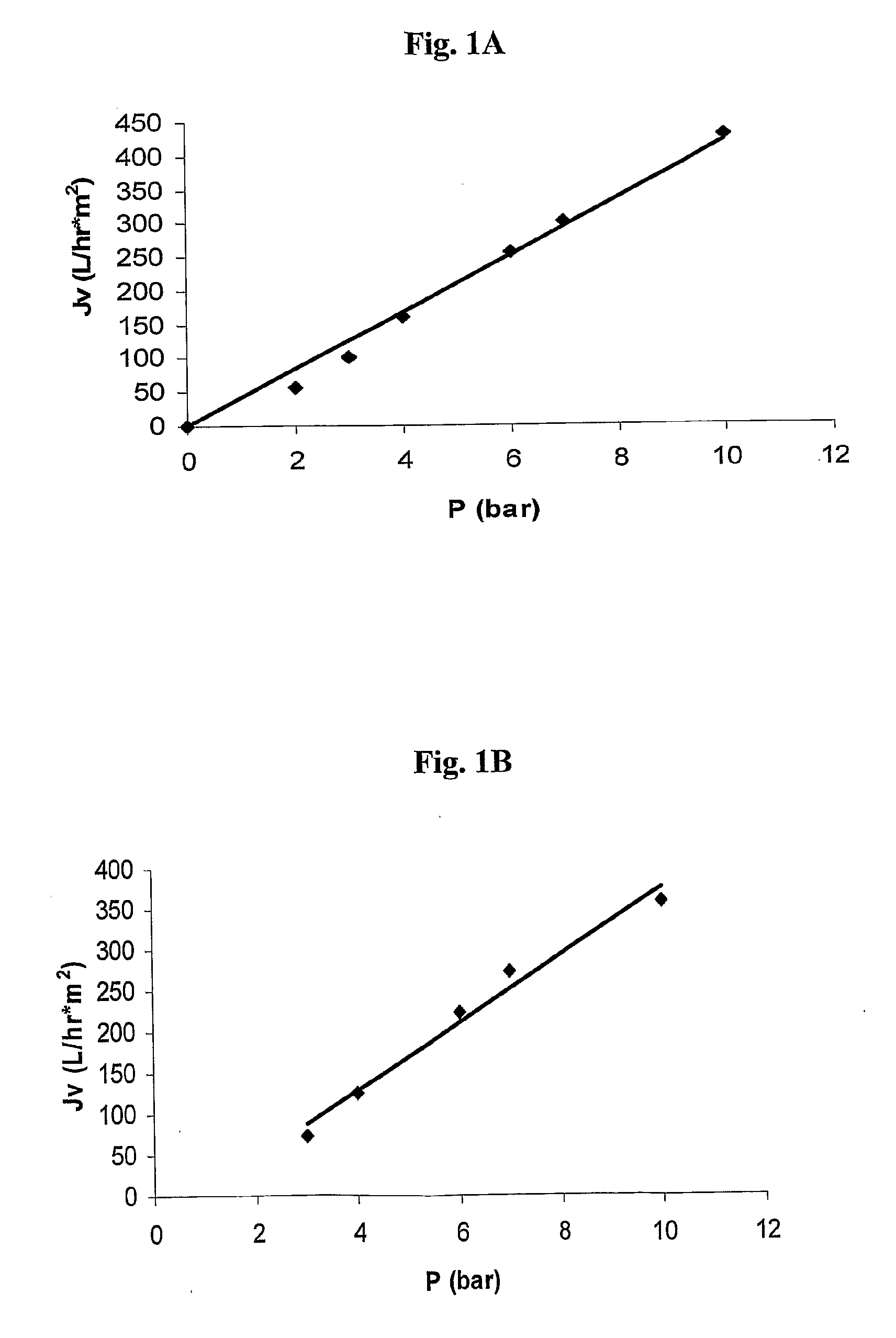

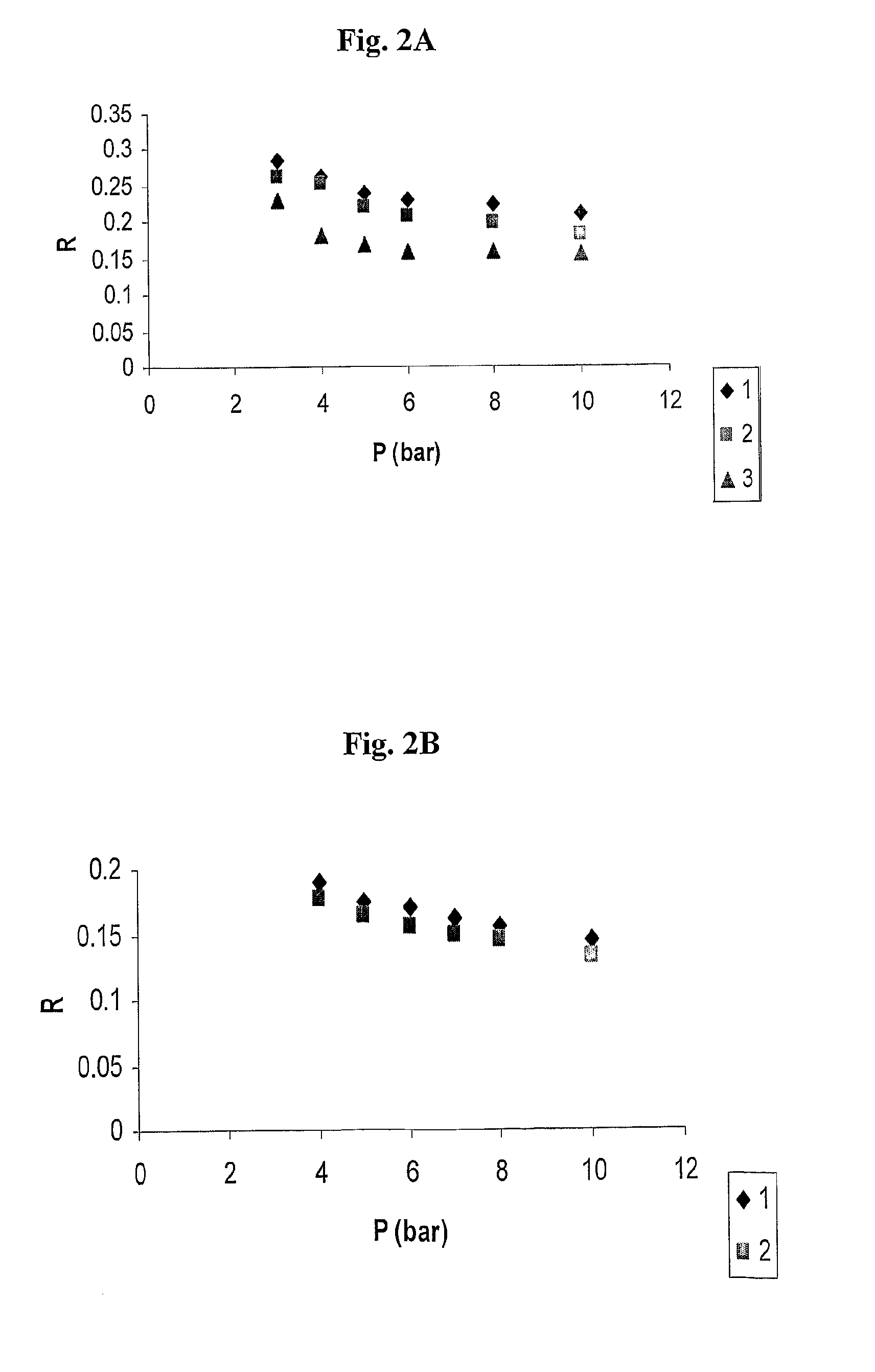

Polysulfone polymers and membranes for reverse osmosis, nanofiltration and ultrafiltration

The invention provides modified polysulfones substituted in one or more of the phenyl rings by functional groups and membranes composed of the modified polysulfones. Also provided are methods for the preparation of monodispersed nanoporous polymeric membranes. The membranes are useful for reverse osmosis, nanofiltration, and ultrafiltration, particularly for purification of water.

Owner:TECHNION RES & DEV FOUND LTD

A treatment system for high-salt waste water

InactiveCN104787951ARealize resource utilizationEfficient separationMultistage water/sewage treatmentSalt-wastingSmall footprint

The invention relates to a treatment system for high-salt waste water, and belongs to water treatment techniques. The treatment system comprises an adjusting tank, a high-density sedimentation tank, a V-type filter tank, a first-section ion exchange resin system, an ultrafiltration system, a first-section reverse osmosis system, a second-section ion exchange resin system, a high-pressure nanofiltration system, a second-section reverse osmosis system, a high-pressure flat sheet membrane system and an MVR system in order. The high-pressure nanofiltration system, the high-pressure flat sheet membrane system and a freezing crystallization system are connected in order. The ultrafiltration system is connected to the high-density sedimentation tank. The treatment system reasonably coupling ultrafiltration, nanofiltration, reverse osmosis and a high-pressure flat sheet membrane method and combining MVR crystallization and freezing crystallization techniques is adopted to treatment of the high-salt waste water, and is low in cost, low in running cost, free of secondary pollution, safe, compact in structure, small in occupied space and high in economic value.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

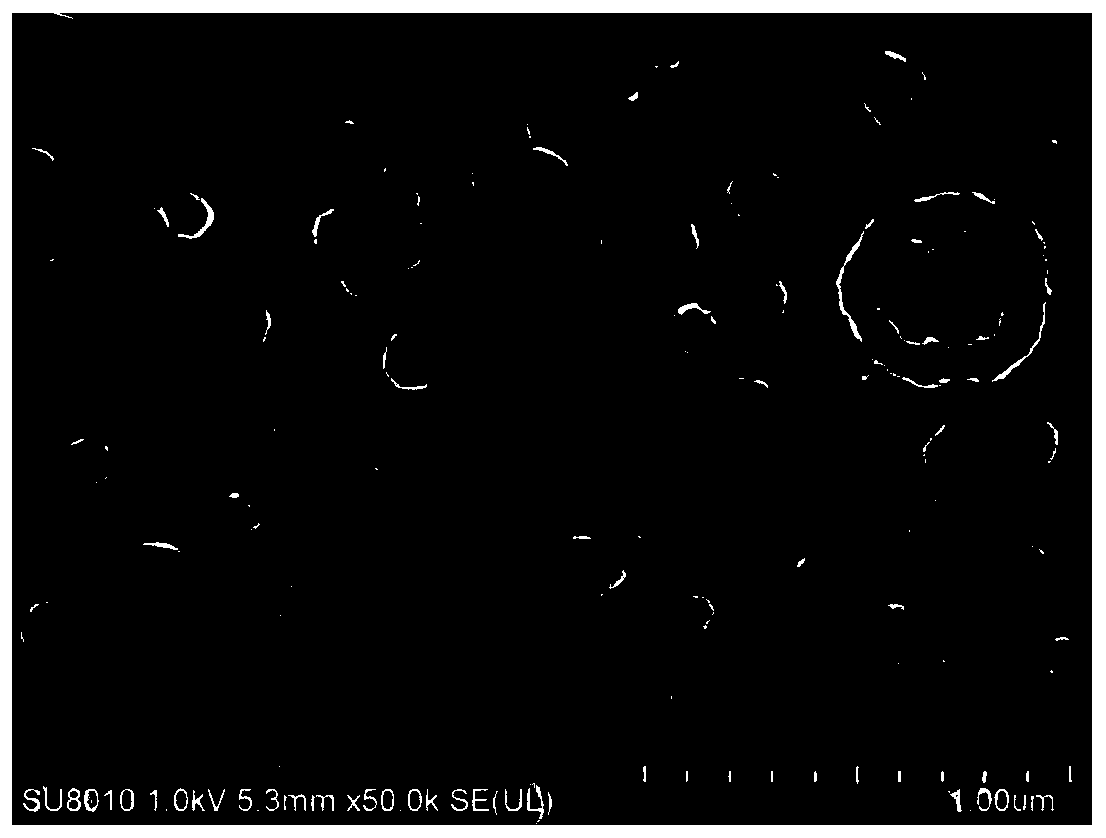

Preparation method of nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent

ActiveCN102239887AImprove antibacterial propertiesControl non-cohesiveBiocideDisinfectantsDisplacement reactionsZirconium oxychloride

The invention discloses a preparation method of a nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent. The preparation method comprises the following steps of 1, a nanoscale zirconium phosphate carrier preparation step specifically comprising that enough sodium dihydrogen phosphate aqueous solution is added into zirconium oxychloride aqueous solution to undergo areaction to produce nanoscale zirconium phosphate carriers, 2, an ultrafiltration step specifically comprising that the nanoscale zirconium phosphate carriers obtained from the step 1 are added into an ultrafilter membrane system for ultrafiltration and when a result of a detection adopting silver ions shows that there is not chloride ions in filtrate, the ultrafiltration is completed, 3, an antimicrobial metal ion adsorption and displacement step specifically comprising that nanoscale zirconium phosphate carrier sol precipitates are dissolved in pure water and then antimicrobial metal ion aqueous solution is added into the nanoscale zirconium phosphate carrier sol precipitate aqueous solution to undergo complete adsorption and displacement reactions, and 4, an inorganic antimicrobial powder preparation step specifically comprising that reaction products obtained from the step 3 are filtered by a pump and washed to form filter cakes and the filter cakes is dried by an oven, crushed slightly and calcined to form finished products. The preparation method removes an inorganic salt by-product from a zirconium phosphate synthesis process through adopting an ultrafilter membrane thus enables zirconium phosphate carriers to be utilized directly for adsorption and displacement of metal ions without high-temperature calcination.

Owner:SANDA FILM SCI & TECH XIAMEN

Preparation method and application of separation film with nano composite cortical layer

ActiveCN102908906AImprove throughputImprove interception effectSemi-permeable membranesDesalinationNanofiltration

The invention provides a preparation method and application of a separation film with a nano composite cortical layer. The separation film comprises a non-woven fabric layer, two porous support layers and a desalination layer, and is characterized in that the lower layer of the two porous support layers is a porous body layer containing polymers and / or nano particles, and the upper layer of the two porous support layers is a porous cortical containing polymers and nano particles. The preparation method includes coating the upper layer and the lower layer of the non-woven base material by means of a double-layer coating technology. An ultrafilter support layer of the composite separation film prepared by the preparation method is good in surface evenness, hight water flux is kept in the meantime of keeping higher cutoff rate, and the separation film can be directly used as an ultrafiltration film or can be used as a basic porous support layer to further prepare a composite forward osmosis, reverse osmosis and nanofiltration film. The preparation method can be applied to preparing the reverse osmosis film and the nanofiltration film which are good in performance, and a composite ultrafiltration film with low molecular weight cutoff.

Owner:VONTRON TECH CO LTD

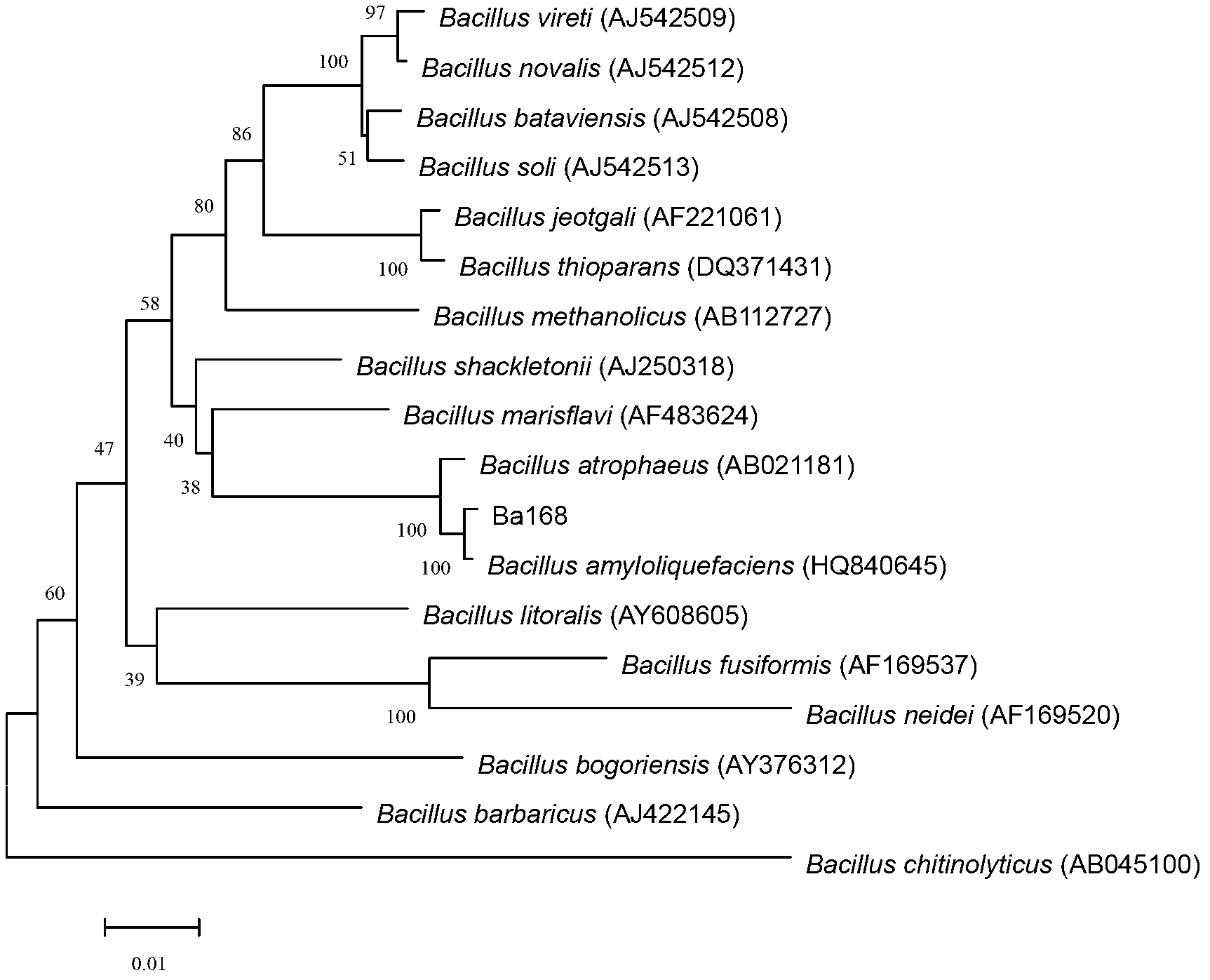

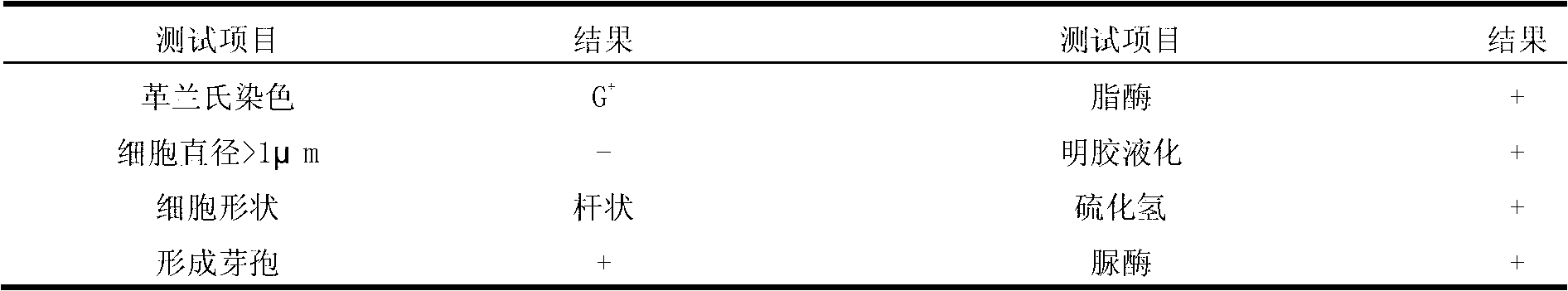

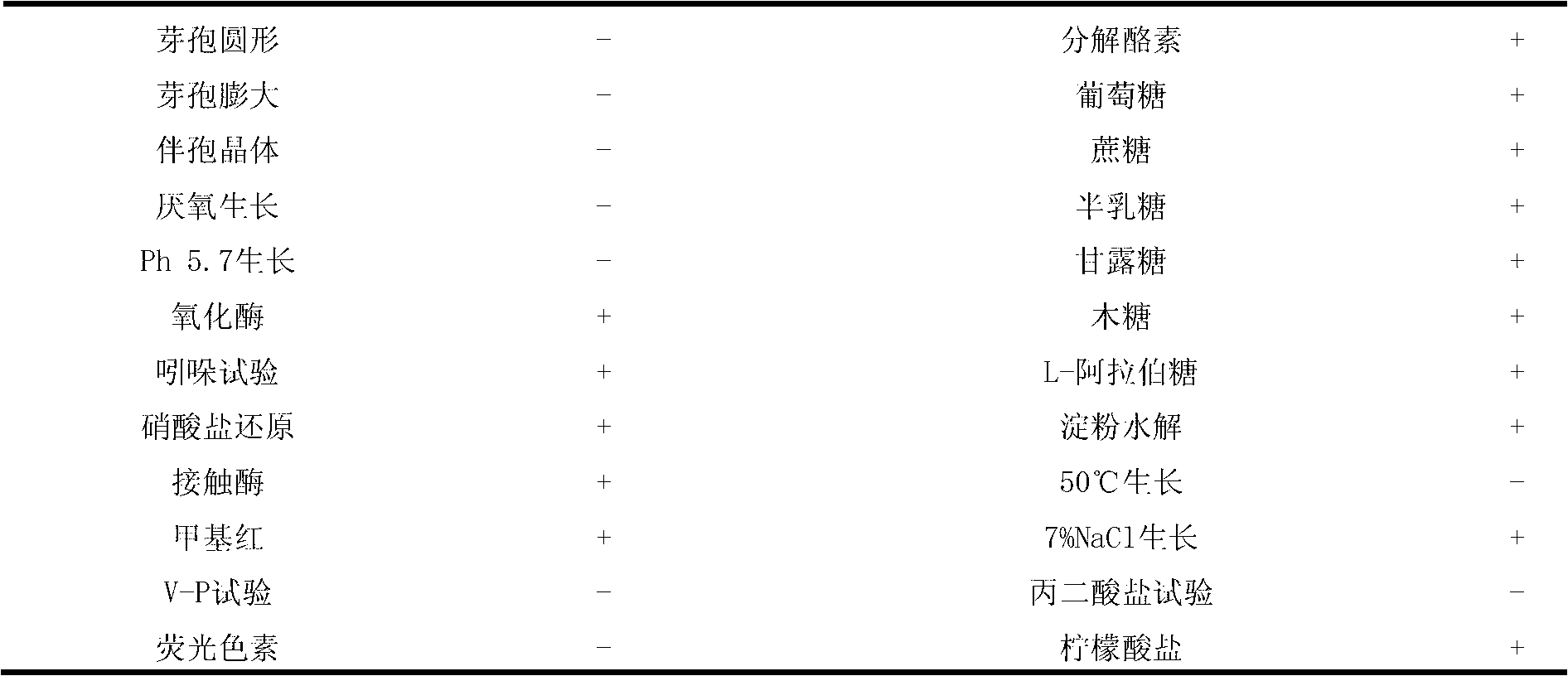

Bacillus amyloliquefaciens (Ba 168) and fermenting culture method and application of bacillus amyloliquefaciens

ActiveCN102839142AGood prevention effectGood environmental compatibilityBiocideBacteriaFiltrationBiological activation

The invention discloses bacillus amyloliquefaciens (Ba 168) and a preparation method and an application of the bacillus amyloliquefaciens, and aims at providing a biological control method of phytopathogens. The bacterial strain is preserved in the China General Microbiological Culture Collection Center (CGMCC), and the preservation number is CGMCC No.6462 on August 21, 2012. The bacterial strain is separated and obtained from soil in the Qinling Mountain virgin forest, and subjected to bacteria activation, shake-flask fermentation, seed liquid fermentation and large tank fermentation to obtain fermentation liquid; and the fermentation liquid is subjected to filtration and concentration, ultrafiltration membrane separation, and spray drying and packaging to be prepared into bactericide. The bacillus amyloliquefaciens has the advantages that the bacillus amyloliquefaciens can well prevent and cure bighead atractylodes rhizome root rot, American ginseng root rot, pseudo-ginseng root rot and other root rot caused by fusarium oxysporum.

Owner:杨凌绿都生物科技有限公司

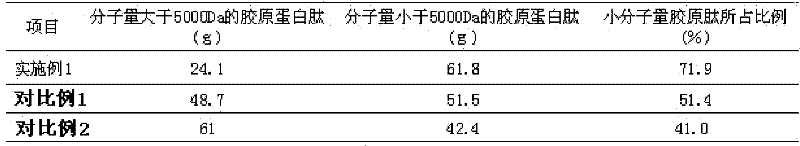

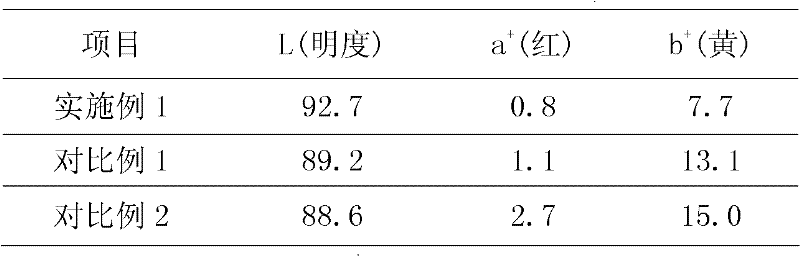

Preparation method of low molecular weight aquatic collagen peptide

InactiveCN102260727ALow Molecular Weight Collagen ContentLow molecular weight collagen content High molecular weight collagen contentPeptide preparation methodsFermentationFiltrationFreeze-drying

The invention discloses a method for preparing low-molecular-weight aquatic collagen peptides. Fresh fish scales are delimed with hydrochloric acid, fat and impurities are removed with caustic soda, and then hot water extraction is carried out to obtain a collagen solution, and three kinds of enzymes are used to separate enzyme Decompose collagen, then carry out activated carbon filtration and macroporous resin treatment, collect decolorization liquid, filter through ultrafiltration membrane, freeze-dry, the effective method of preparation molecular weight concentration, high recovery rate, good decolorization effect fish scale low molecular weight collagen, not only can Obtain high-content low-molecular-weight collagen peptides from fish skin and fish scales, remove pigments that affect the appearance of collagen products, and reduce the unique fishy smell of collagen, which can improve the product value of fish collagen products.

Owner:申铉日

Preparation method for improved polyvinylidene fluoride-based nanofiltration film

InactiveCN108097071AGuaranteed stabilityAvoid pollutionSemi-permeable membranesOil phasePolyvinylidene difluoride

The invention provides a preparation method for an improved polyvinylidene fluoride-based nanofiltration film, belonging to the technical field of films. The preparation method comprises the followingsteps: preparation of a polyvinylidene fluoride ultrafiltration base film by using a phase inversion process: mixing polyvinylidene fluoride, a solvent, an additive, a pore forming agent, and a compound having an amino, carboxyl, sulfonic acid, or hydroxyl function group, successively carrying out heating to 50-90 DEG C, uniform mixing under stirring and standing for deaeration in a vacuum environment so as to obtain a film casting solution, and then carrying out film scraping with a scraping knife and soaking in a coagulation bath for film formation or allowing the film casting solution to flow out from a spinneret to the coagulation bath for film formation so as to obtain the polyvinylidene fluoride ultrafiltration base film; and preparation of the polyvinylidene fluoride-based nanofiltration film by using an interfacial polymerization process: successively coating the surface of the polyvinylidene fluoride ultrafiltration base film with an aqueous solution of a water-phase monomerand an organic solution of an oil-phase monomer by using a quantitative injection process and then carrying out heat treatment so as to obtain the polyvinylidene fluoride-based nanofiltration film. The prepared the polyvinylidene fluoride-based nanofiltration film is stable and more cost-effective, and can avoid environmental pollution.

Owner:BEIJING E & E TECH

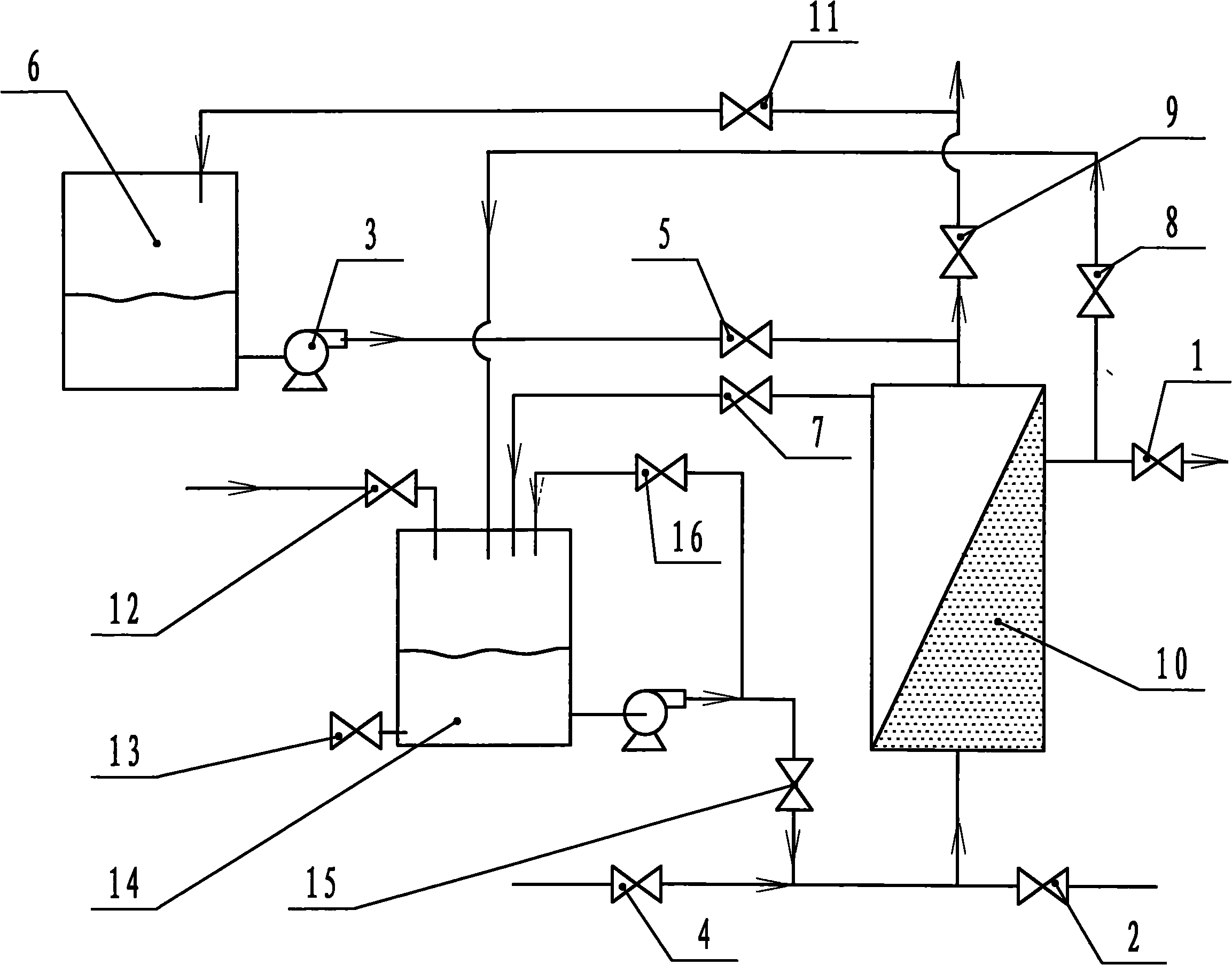

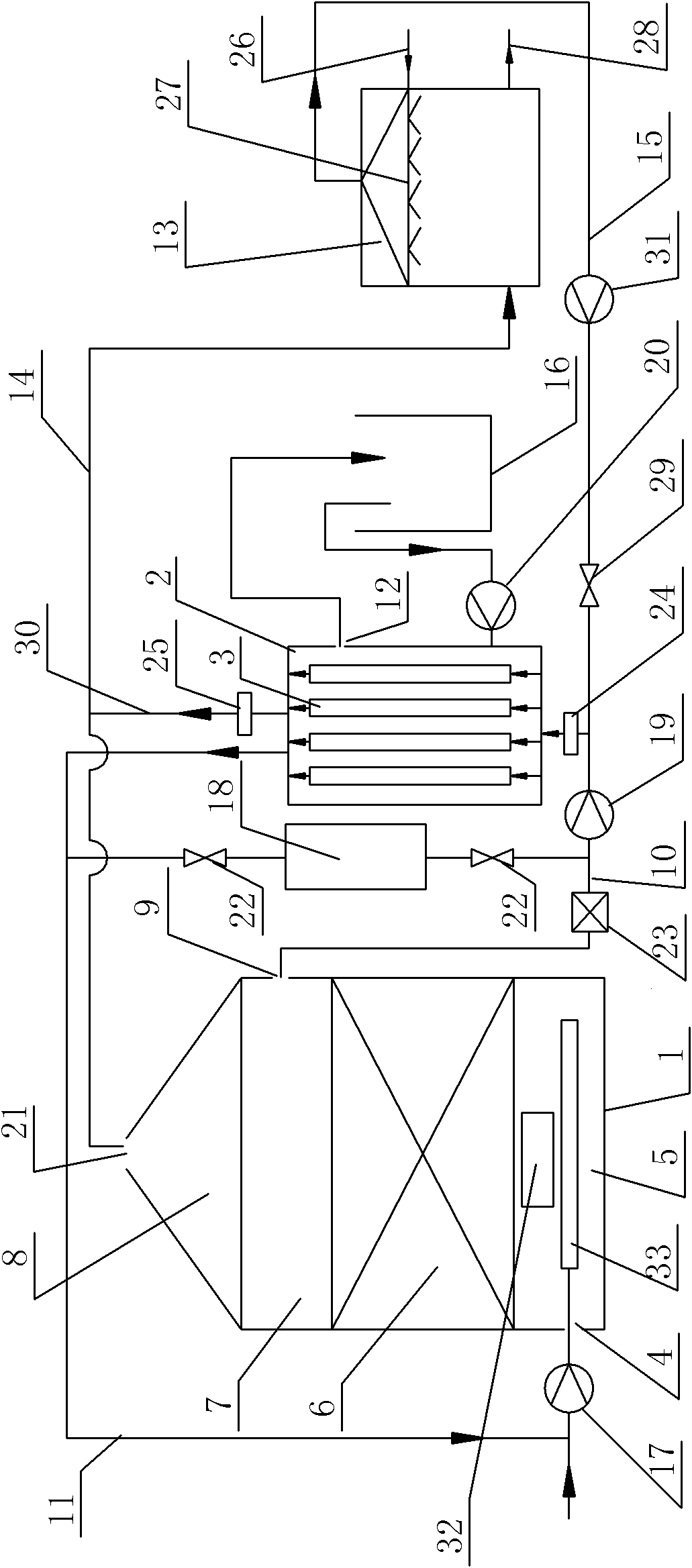

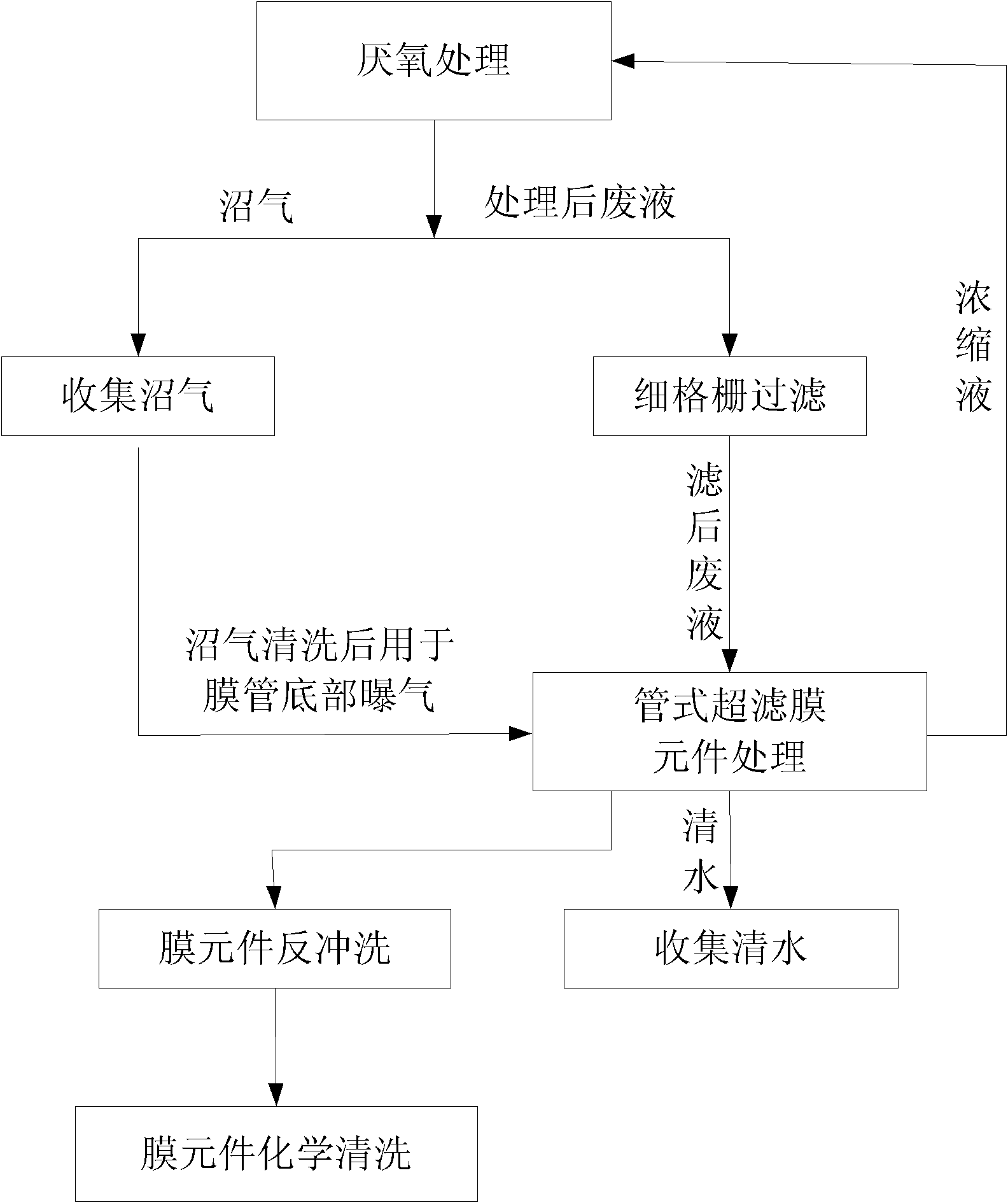

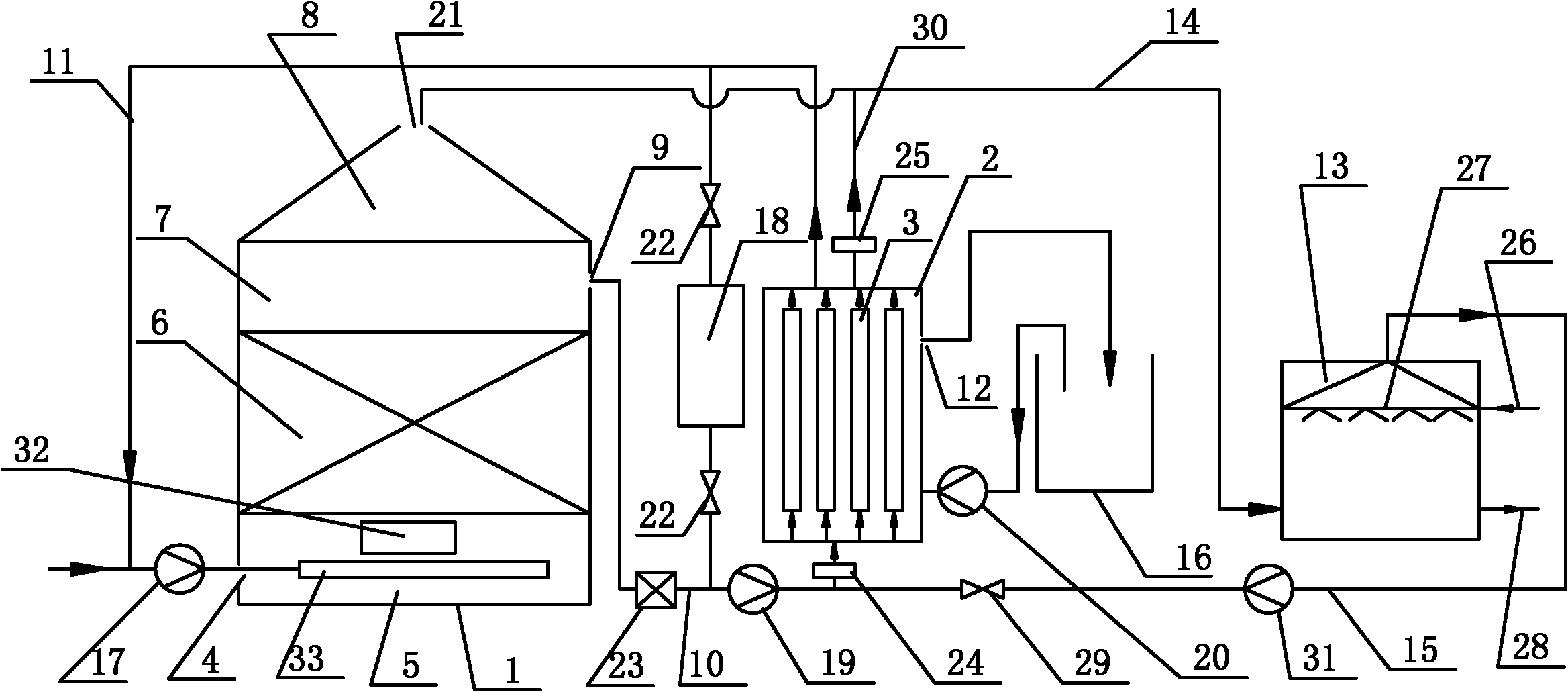

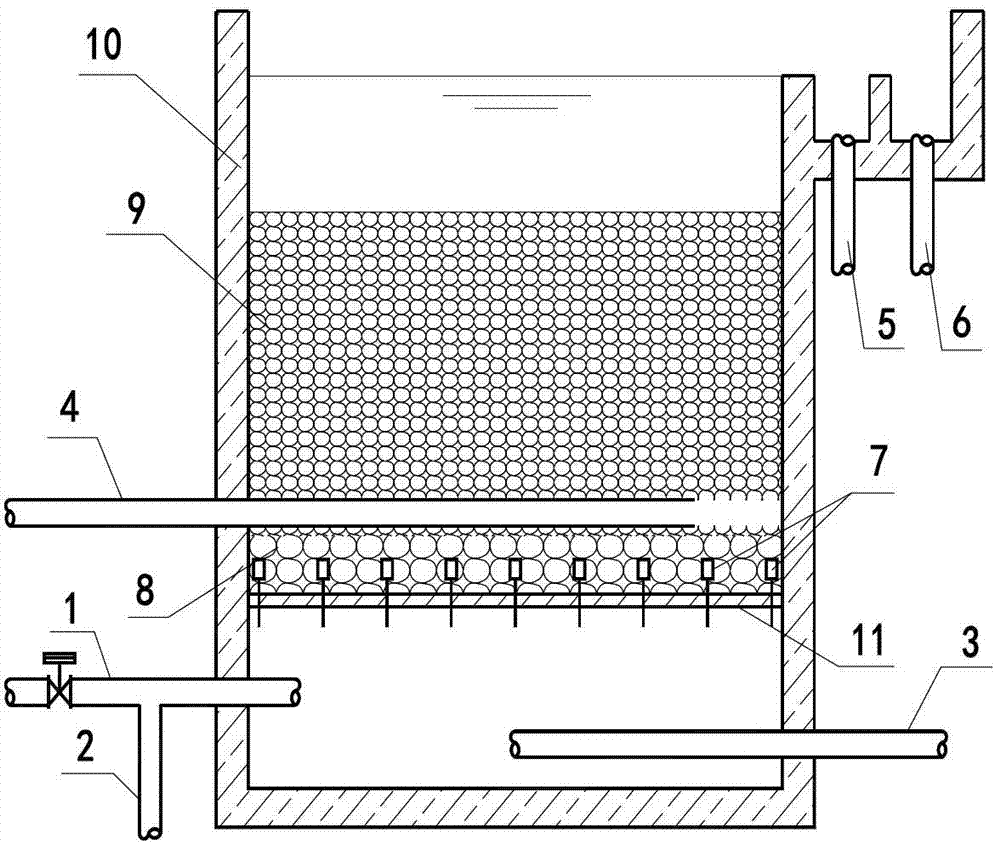

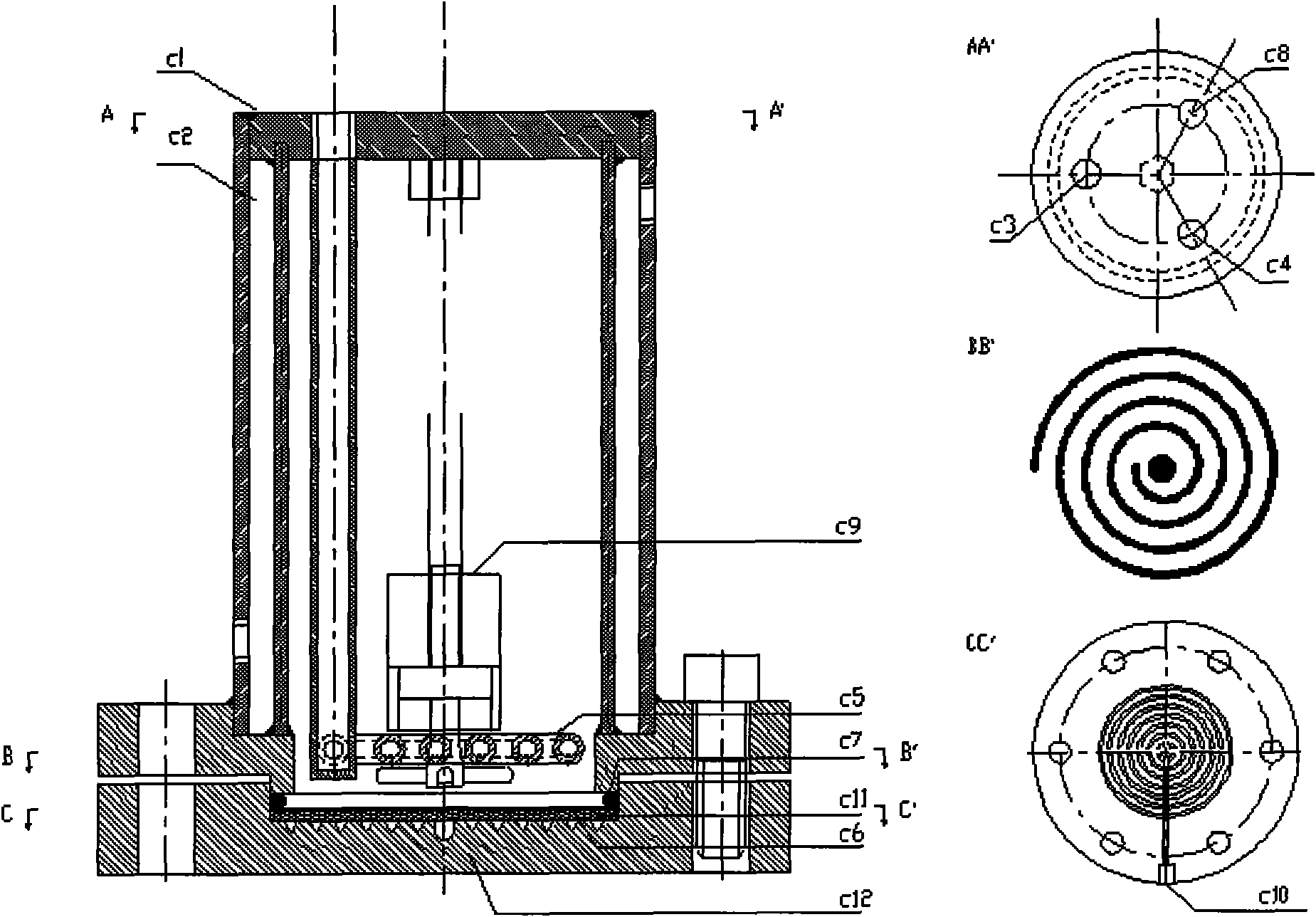

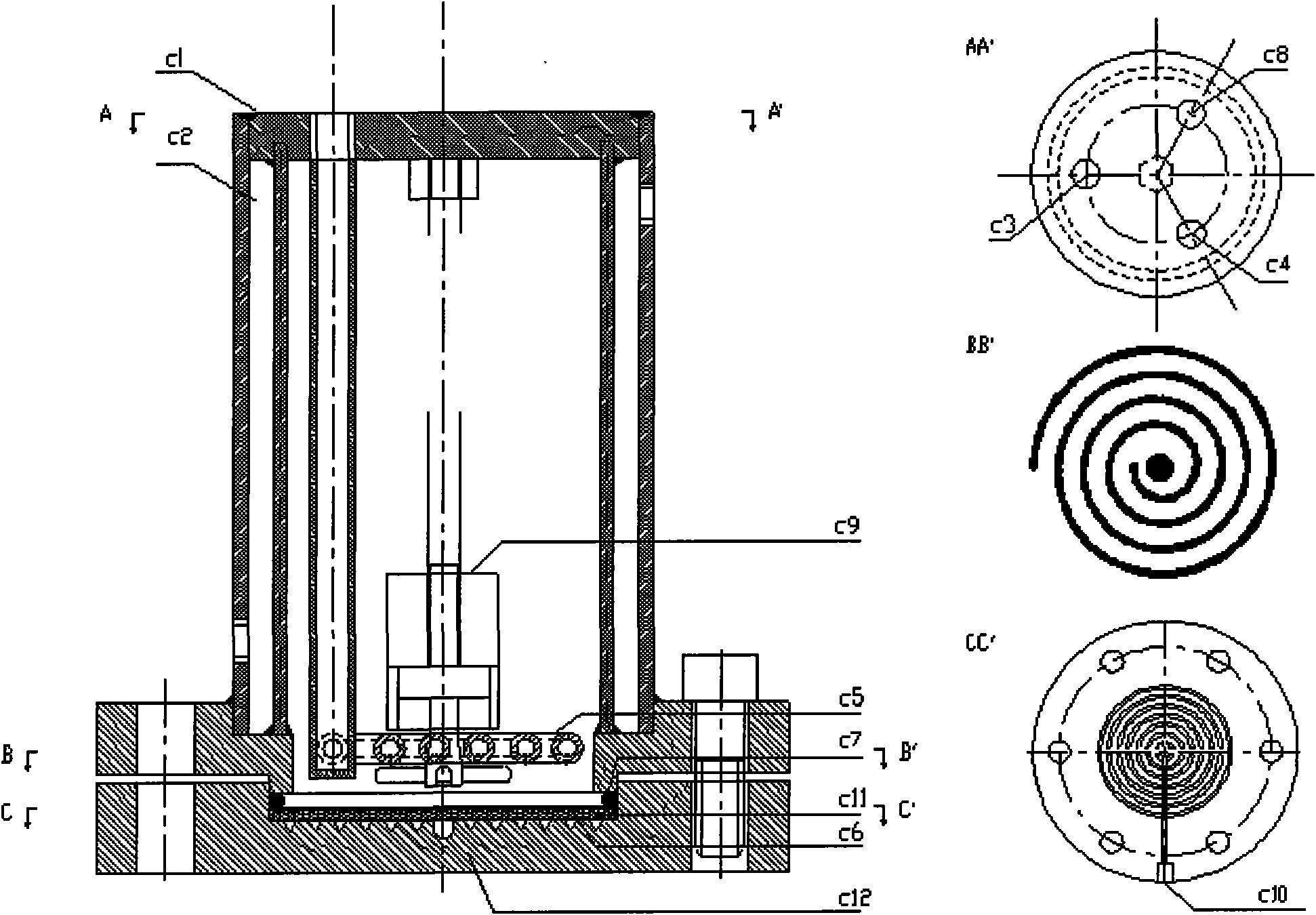

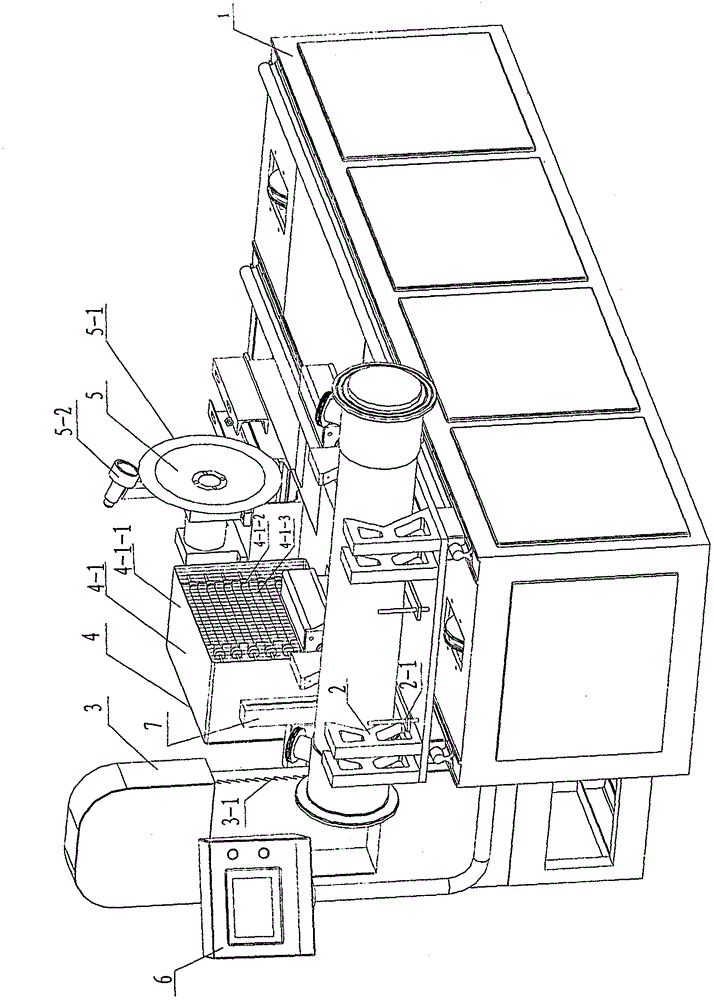

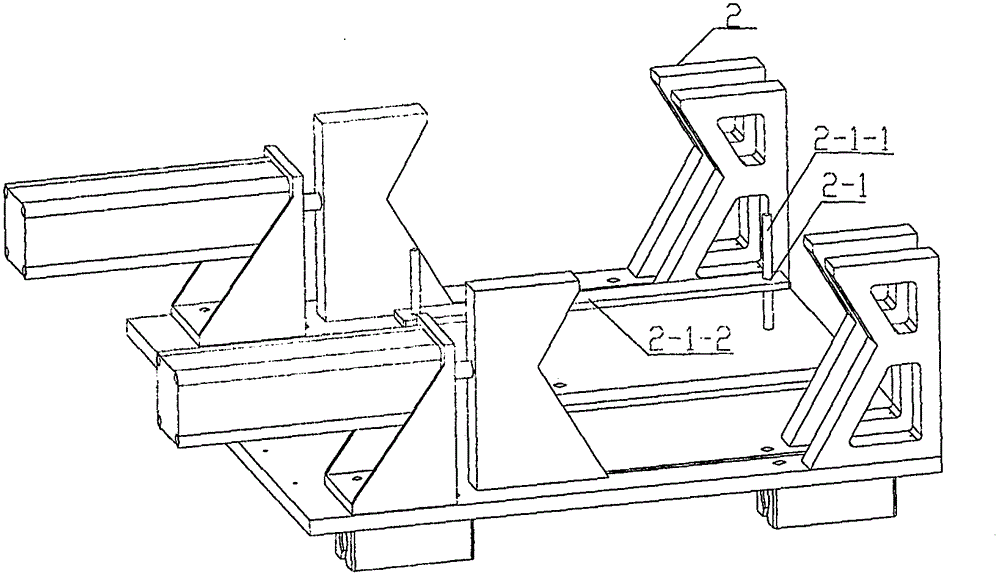

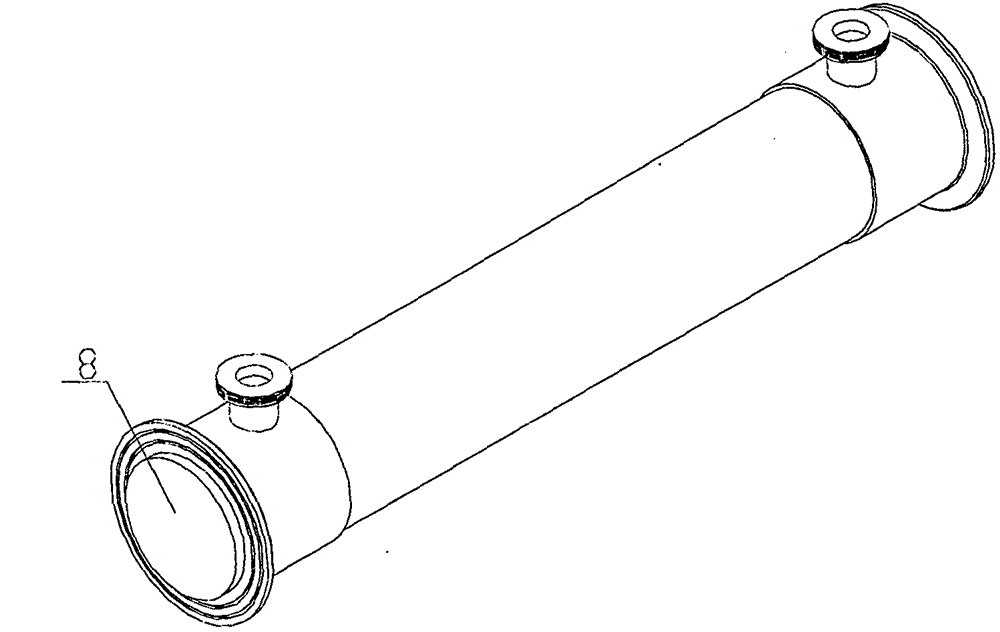

External anaerobic membrane bioreactor and waste water purification technology thereof

InactiveCN102153251AReduce operating energy consumptionImprove degradation efficiencyWaste based fuelTreatment with anaerobic digestion processesGratingAfter treatment

The invention provides an external anaerobic membrane bioreactor comprising an anaerobic tank, a tubular membrane component, tubular ultrafiltration membrane elements and a clear water tank, wherein the tubular ultrafiltration membrane elements are vertically arranged in parallel in the tubular membrane component. The invention also provides a corresponding waste water purification technology of the external anaerobic membrane bioreactor. The waste water purification technology includes the steps as follows: firstly conducting purification treatment on waste water to be treated in the anaerobic tank, collecting biogas which is generated after treatment, filtering and separating the treated waste water in sequence by a fine grating and the tubular ultrafiltration membrane elements, at last leading out the leached clear water, backwashing and chemically washing the tubular ultrafiltration membrane elements at time intervals, drip-washing the collected biogas, and then pumping the biogas together with sewage into the tubular ultrafiltration membrane elements, so that the washing effect of the inner walls of the tubular ultrafiltration membrane elements can be improved. As for the external anaerobic membrane bioreactor and the waste water purification technology thereof, the energy consumption in operation is low, the quality of effluent is good, and blockage does not happen easily.

Owner:上海膜达克环保工程有限公司

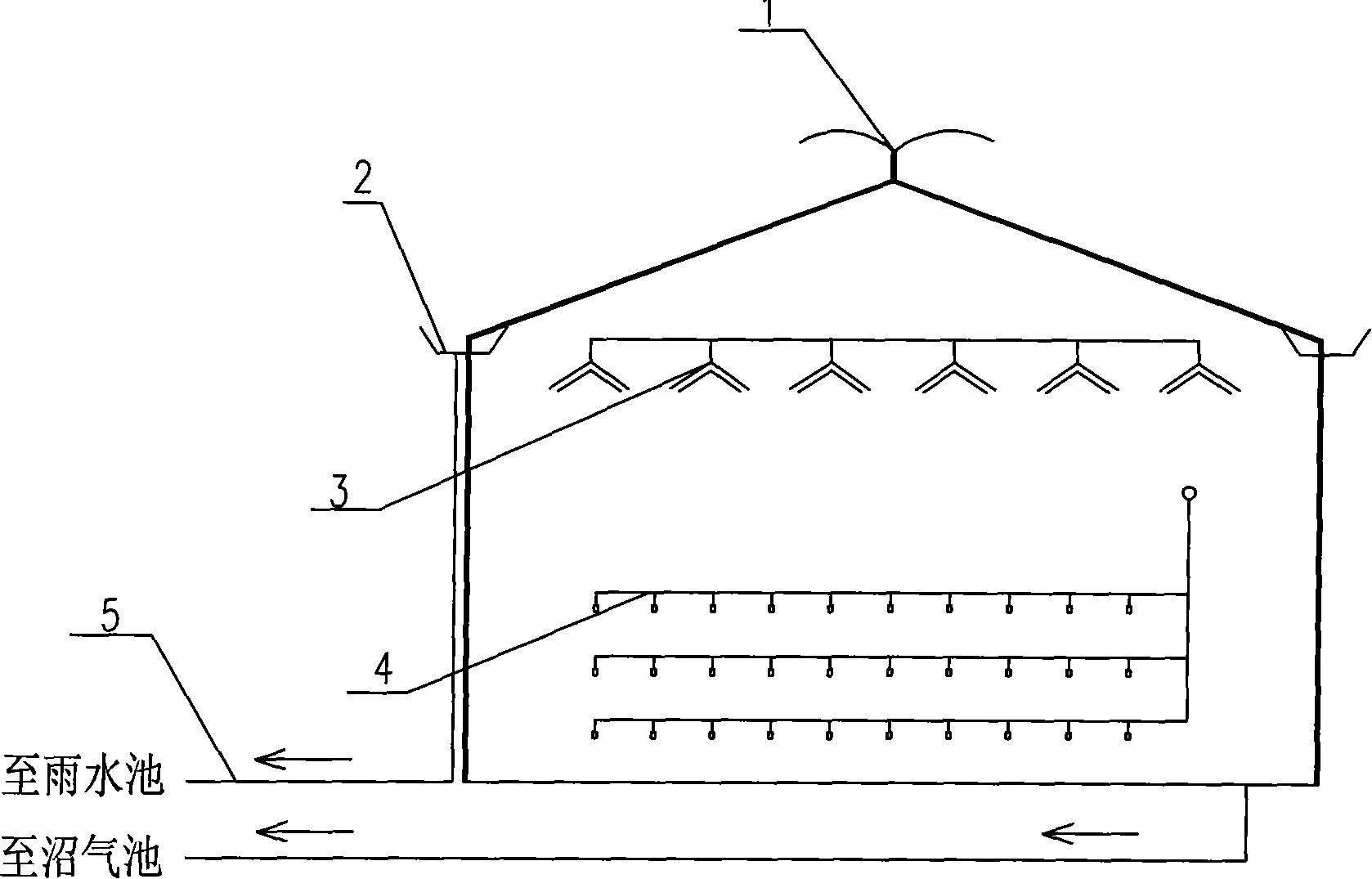

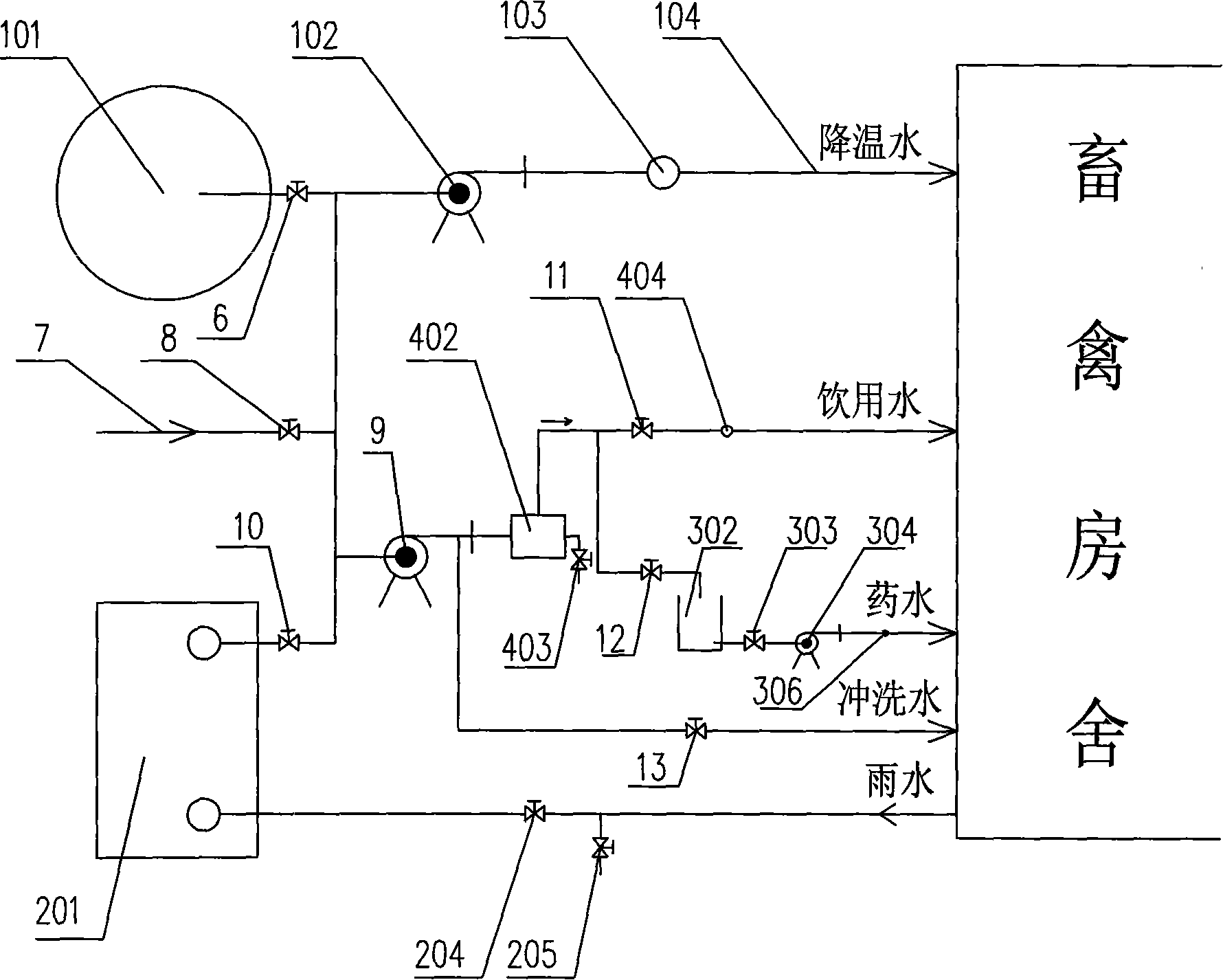

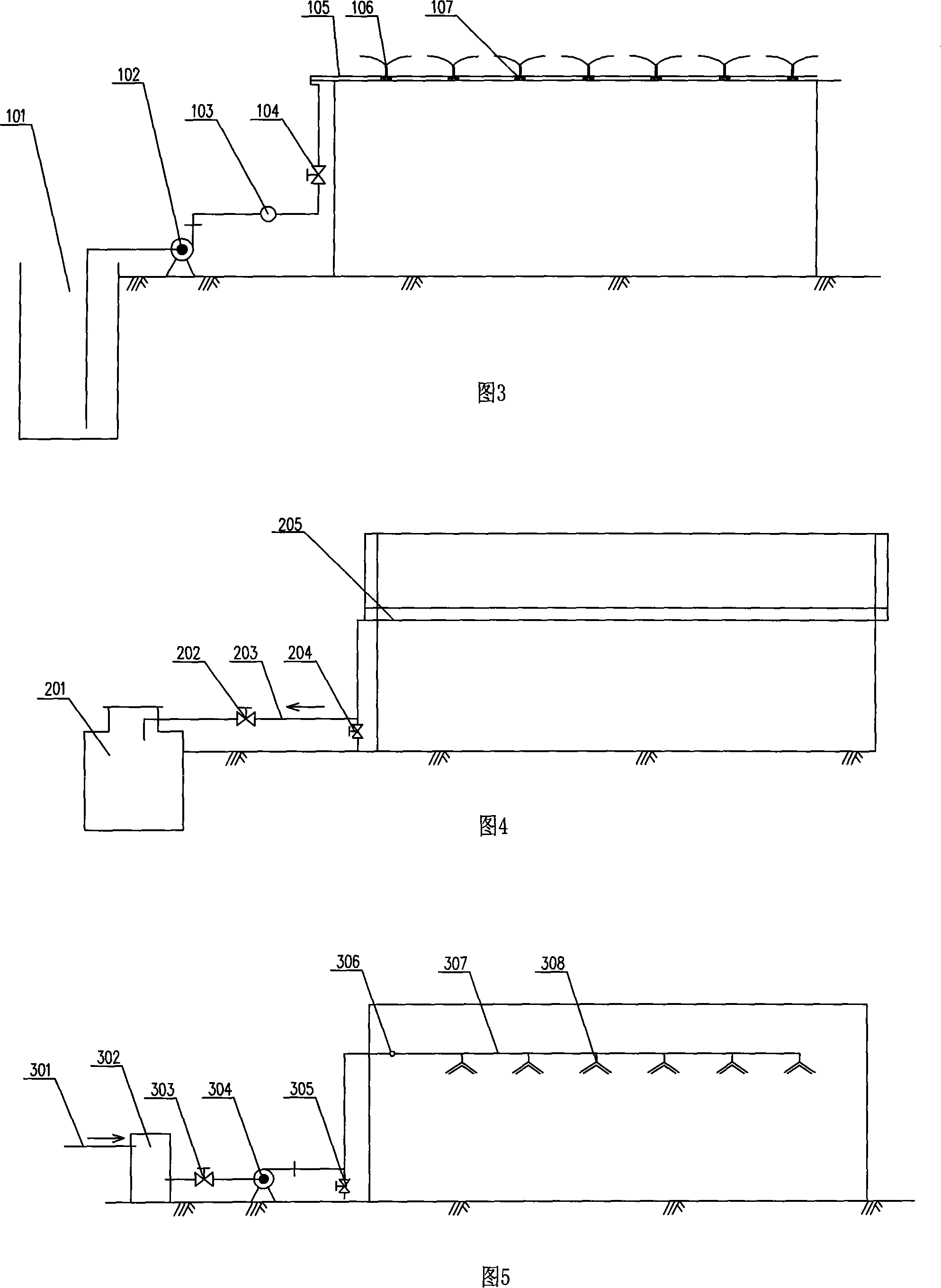

Water supply and drainage system of livestock and poultry farms

InactiveCN101248776AEnsure safetyTo achieve the purpose of sterilizationBio-organic fraction processingClimate change adaptationSlurryEngineering

The invention relates to a livestock and poultry farm water supply and drainage system, which is designed for water resource recycling of the scale livestock and poultry farm. The system consists of five parts including a cooling device, a rain water harvesting device, a medicine spraying device and a sewage disposal system. The design of the system is mainly characterized in that the system adopts well water or rain water for cooling the livestock and poultry houses, the cooling sewage and the rain water are colleted to rain water pools through rain water grooves, and the rain water or tap water is processed by a ultrafiltration membrane water processor to provide drinking water for the houses. The tap water or the rain water processed by the ultrafiltration membrane water processor is used for diluting the liquid medicine and the well water or the rain water is used for washing the livestock and poultry houses; the methane and the biogas slurry generated after the biological treatment of the house-washing sewage is used for fertilizing after being biologically treated. The water supply and drainage system is characterized in reasonable design, water conservation, water resource recycling, ecological virtuous circle and low production cost, which is applicable to the modernized management of the scale livestock and poultry farm water supply and drainage facility.

Owner:奕永庆 +2

Preparation method of oxidized grapheme/silver particle nanometer compound and application thereof

InactiveCN103250739AImprove responseMild conditionsBiocideDisinfectantsSolubilityUF - Ultrafiltration

The invention provides a preparation method of oxidized grapheme / silver particle nanometer compound and application thereof, and an oxidized grapheme solution is prepared by an improved Hummers method, and silver nitrate solid powder is added and boiled, and trisodium citrate is added as reducing agent and stabilizing agent, and the solution is boiled for 1 hour continuously and washed out for 3 times by a ultrafiltration pipe. Compared with the prior art, the preparation method provided by the invention is simple and fast, and the prepared nanometer compound has the advantages of stable structure, good water-solubility and good antibiosis activity, and the product can be used as antibiosis material with high efficiency and safety.

Owner:SUZHOU UNIV

Method for preparing composite flat ultrafiltration membrane

The invention discloses a method for preparing a composite flat ultrafiltration membrane. According to the invention, immersion-precipitation phase transformation method is used in the preparation method, a supporting layer used herein is a PET fiber braided fabric, and a high-molecular polymer casting solution is coated on the supporting layer. The preparation method comprises the following steps: (1) mixing high-molecular polymer, organic solvent, and additives in proportion to prepare a homogeneous casting solution; (2) putting the PET fiber braided fabric in an NaOH solution with a certain concentration, and removing residual oil stains and dirt on the fabric; (3) carrying out surface modification on the PET fiber braided fabric; and (4) uniformly coating the casting solution obtainedby the step (1) on the surface of the modified fiber braided fabric, then putting the coated fiber braided fabric in a gel bath to carry out phase-inversion film forming to obtain the composite flat ultrafiltration membrane which has the advantages of high flux, high strength, pollution resistance, and hydrophilicity, wherein the supporting layer and the coating layer are not easy to be separated.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

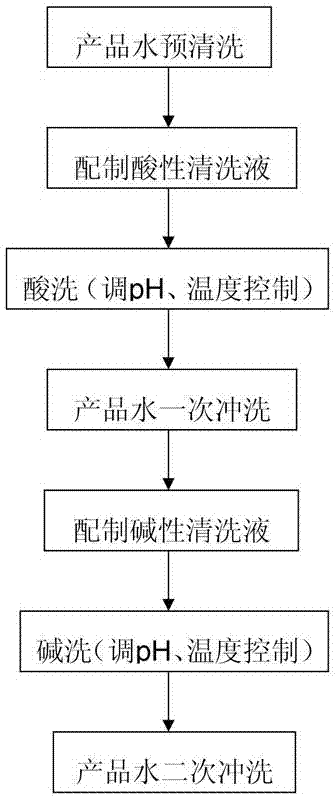

Cleaning method of ultrafiltration membrane

ActiveCN107297147AEfficient removalIncrease permeate flowUltrafiltrationCleaning methodsOrganic matter

The invention discloses a cleaning method of an ultrafiltration membrane. The cleaning method is used for mainly treating the pollution form of the ultrafiltration membrane with inorganic scales coated with organic scales. The method comprises the following steps: (1) preparing an acid cleaning solution; (2) carrying out acid pickling: carrying out circulating cleaning on the ultrafiltration membrane by using the acid cleaning solution, controlling the pH value of the cleaning solution to be 1.5-3 and controlling the cleaning temperature to be 38-41 DEG C; (3) carrying out primary flushing and removing residual acid cleaning solution in the ultrafiltration membrane; (4) preparing an alkaline cleaning solution; (5) carrying out alkaline washing: carrying out circulating cleaning on the ultrafiltration membrane by using the alkaline cleaning solution, controlling the pH value of the cleaning solution to be 10.5-11.5 and controlling the cleaning temperature to be 38-41 DEG C; and (6) carrying out secondary flushing and removing the residual alkaline cleaning solution in the ultrafiltration membrane. According to the method, various organic matters intercepted on ultrafiltration membrane pores can be efficiently removed, the water yield of the ultrafiltration membrane is increased, the operation pressure of the ultrafiltration membrane is reduced and stable operation of a landfill leachate ultrafiltration membrane treatment system is ensured.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

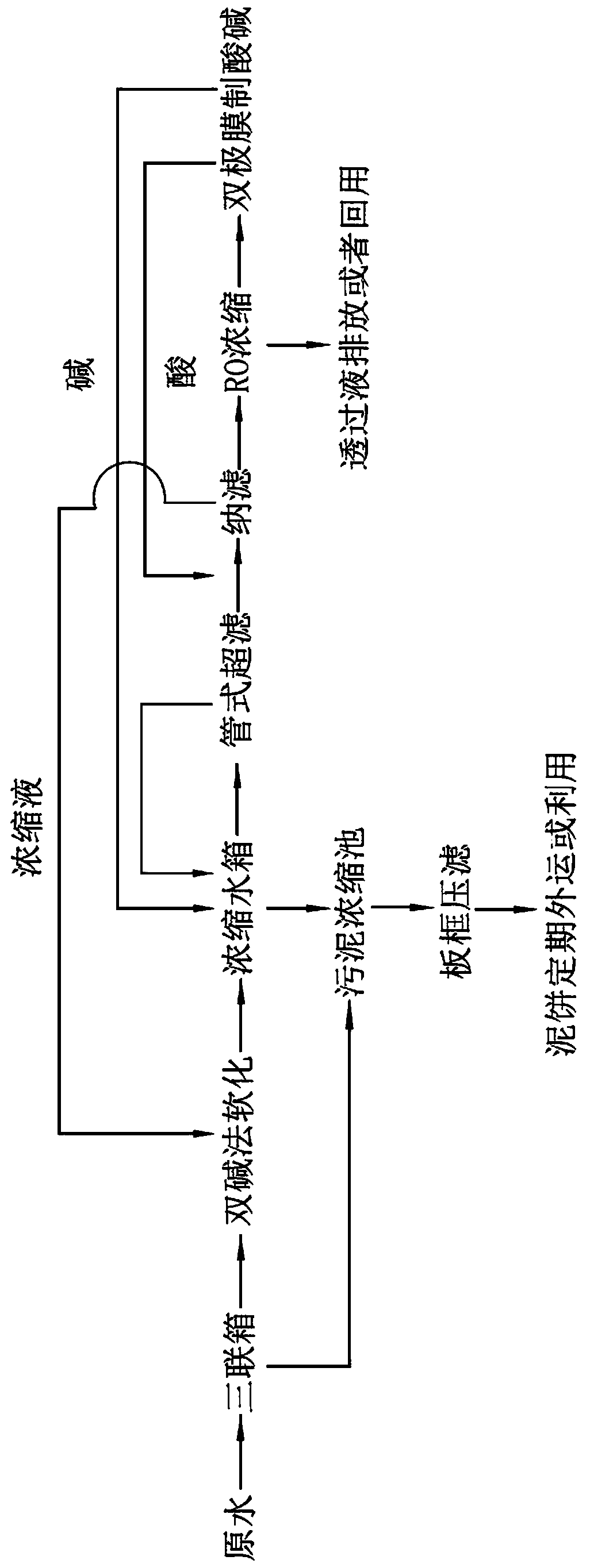

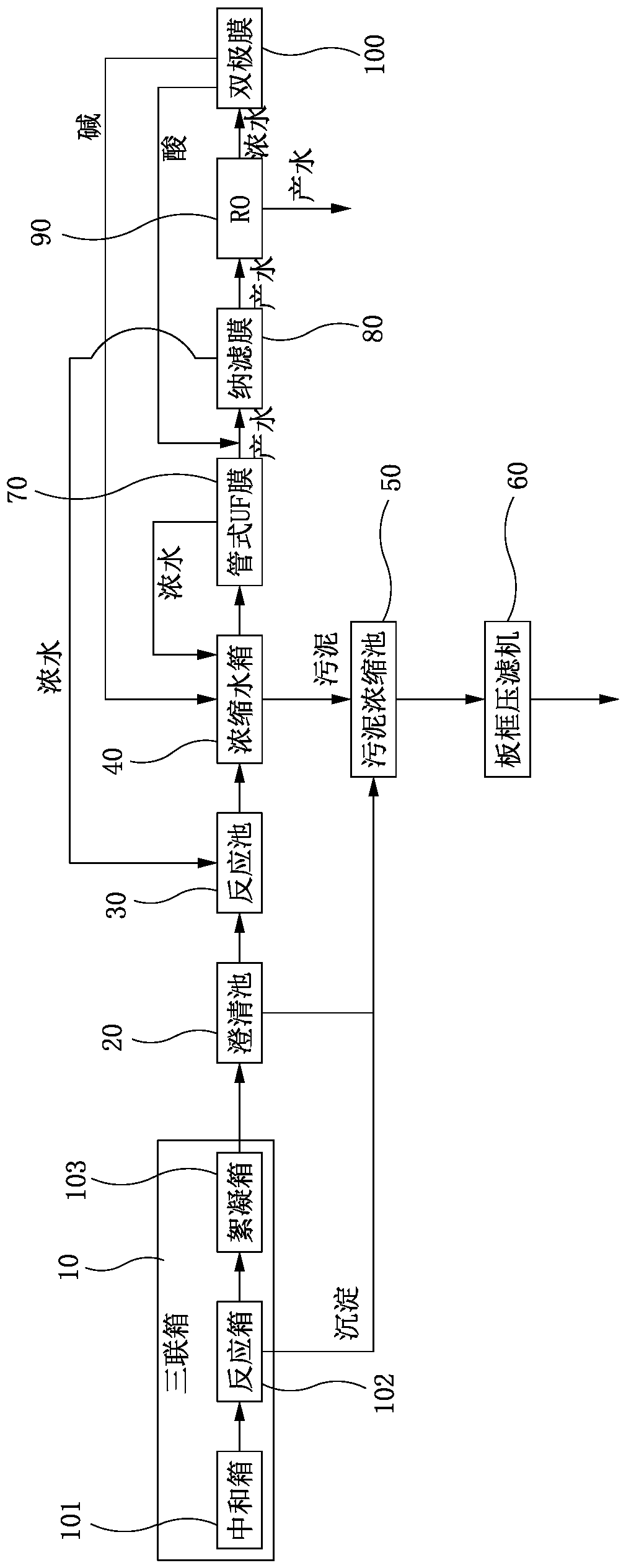

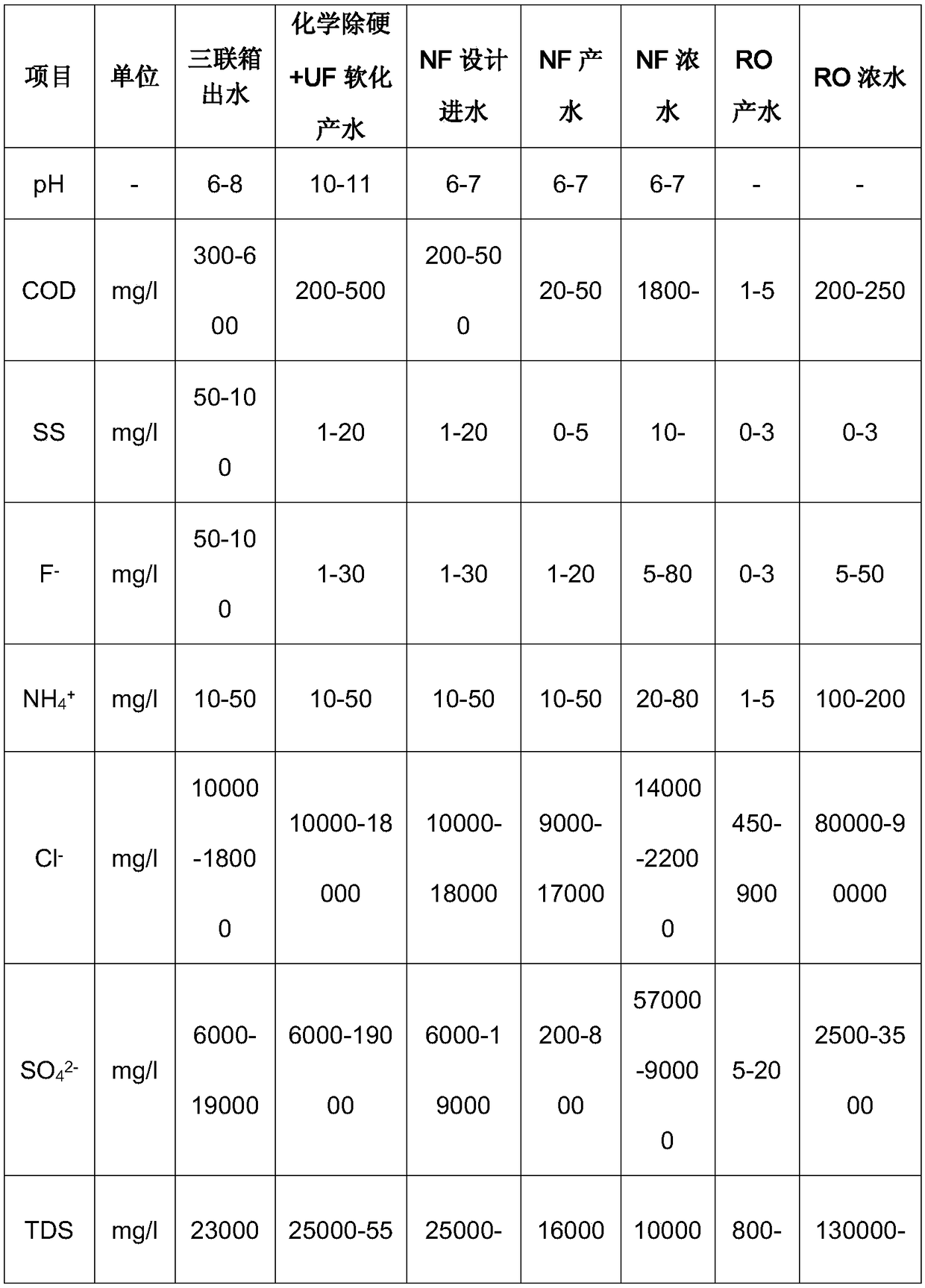

Resource-recyclable zero-discharge treatment technology and device for desulfurization wastewater in power plant

ActiveCN108249646AEasy to captureGood removal effectSludge treatment by de-watering/drying/thickeningGeneral water supply conservationResource recoveryWastewater

The invention discloses a resource-recyclable zero-discharge treatment technology for desulfurization wastewater in a power plant. The resource-recyclable zero-discharge treatment technology sequentially comprises triple-box pretreatment, double-alkali scale removal, tubular UF ultrafiltration, nanofiltration, reverse osmosis and acid and alkali recycling. Deep zero-discharge treatment of the desulfurization wastewater in the power plant is achieved, and sodium chloride contained in the wastewater is fully utilized and directly prepared into available acid / alkali so as to achieve resource recycling.

Owner:XIAMEN JIARONG TECH CO LTD

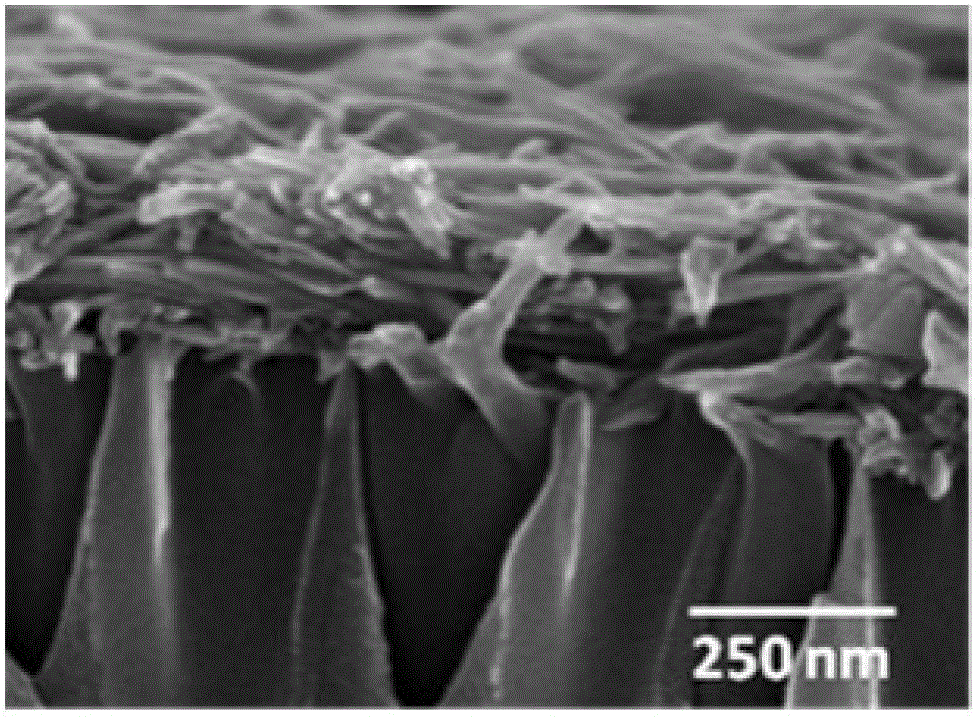

Method for preparing nanofiber-based composite filter membrane by hot-pressing incipient fusion method

ActiveCN104353369AControl thicknessControl UniformitySemi-permeable membranesFiberUF - Ultrafiltration

The invention relates to a method for preparing a nanofiber-based composite filter membrane by a hot-pressing incipient fusion method. The method comprises the following steps: preparing a spinning solution from functional macromolecules to carry out electrostatic spinning and using an obtained nanofiber non-woven fabric as a supporting layer of the composite filter membrane; preparing a solution from another functional macromolecules and spraying the solution to the surface of a base membrane of the non-woven fabric by an electrostatic spraying method to form a barrier layer of the composite membrane; carrying out processing on the barrier layer of the composite membrane by adopting the hot-pressing incipient fusion method which gives suitable temperature, pressure and hot-pressing time so as to obtain the complete barrier layer; finally, carrying out post processing on the barrier layer to obtain the required nanofiber-based separation composite membrane. The method for preparing the composite filter membrane, which is provided by the invention and is simple and easy to operate, can conveniently and accurately control the thickness and uniformity of the functional barrier layer and is easy to implement scale production; the obtained nanofiber-base composite membrane has a wide prospect in the fields of ultrafiltration, nanofiltration, reverse osmosis and the like.

Owner:DONGHUA UNIV

Preparation method of anti-pollution composite nanofiltration membrane

ActiveCN110052179AEasy to separateWater flux effectSemi-permeable membranesHydrophilic polymersSalt bridge

The invention provides a preparation method of an anti-pollution composite nanofiltration membrane. The preparation method includes subjecting a polysulfone ultrafiltration membrane to primary interfacial polymerization by a first aqueous phase solution and an oil phase solution, pouring a second aqueous phase solution containing nonionic hydrophilic polymers onto the surface of the ultrafiltration membrane to conduct secondary interfacial polymerization, removing the second aqueous phase solution, conducting heat treatment, and taking out the membrane for washing to obtain the composite nanofiltration membrane. The preparation method has the advantages that the nonionic hydrophilic polymers containing ether bonds in main chains are embedded in a polyamide layer through the secondary interfacial polymerization, the surface of the modified membrane is smooth, and the surface roughness is lowered; through introduction of nonionic hydrophilic groups, the number of residual carboxyl groupson the surface can be remarkably decreased, pollutant adsorption and salt bridge effect can be effectively reduced, and the anti-pollution performance of the nanofiltration membrane is improved; theoperation process is simple and convenient, and the preparation method is convenient for industrial production and has a broad application prospect in anti-pollution modification of the composite nanofiltration membrane.

Owner:WANHUA CHEM GRP CO LTD +1

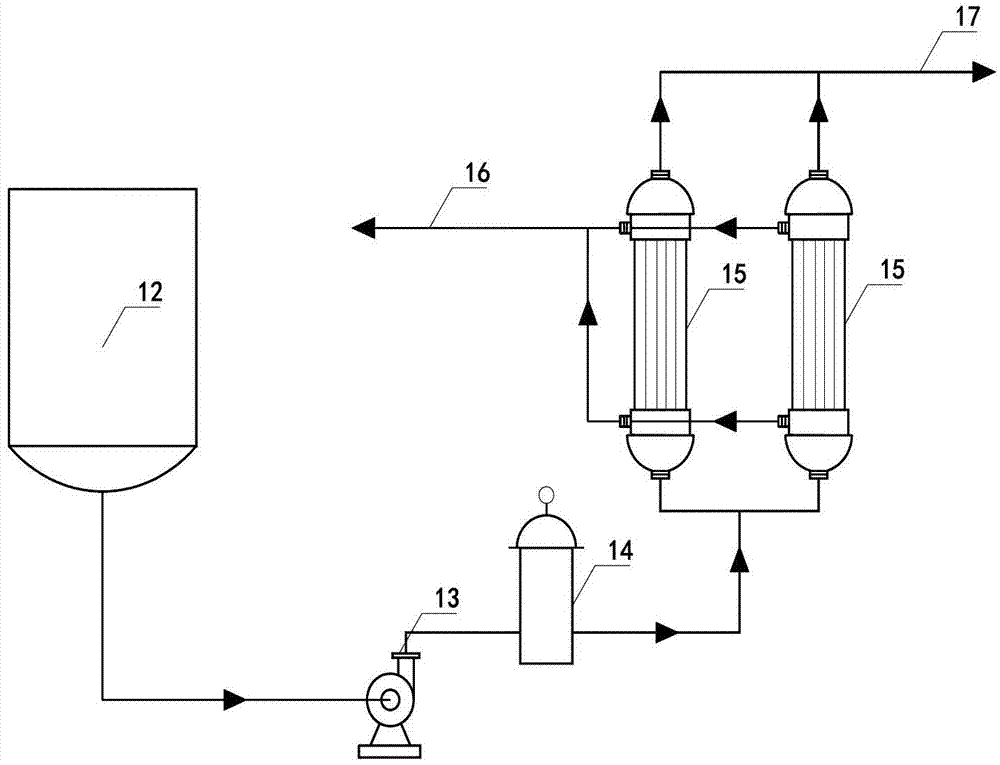

Method for advanced treatment and reuse of wastewater

InactiveCN103172216AReduce pollutionLow running costMultistage water/sewage treatmentWater dischargeWater production

The invention provides a method for advanced treatment and reuse of wastewater. The method is characterized in that a biochemical device adopting a biological aerated filter comprises a water inlet pipe, a backwashing water inlet pipe, a backwashing air inlet pipe, an aerator pipe, a backwashing drain pipe, a water outlet pipe, water distributors, supporting fillers, ceramic fillers, a cell body and a filter plate, wherein energy consumption is only 60% of that of a contact oxidation method after secondary wastewater is subjected to biochemical treatment in the biological aerated filter and organic pollutants are removed; a separation device of an ultrafiltration pressing film comprises a biological aerated filter water discharging tank, a lift pump, a safety filter, ultrafiltration films, an ultrafiltration water production pipe and an ultrafiltration concentrated water pipe, wherein the ultrafiltration films can be used for intercepting matters with molecular weights of 3*10000-1*10000 and removing most colloidal silicon and organic matters in the water; and an electric-absorption desalting device comprises an ultrafiltration device water discharging tank, a water supply pump, a filtering device, an electro-adsorption module, a water production pipe, a reuse water tank, a regenerative pump and a regenerative water outlet, wherein raw water lifted by the regenerative pump is flushed by a short-circuited and standing module so as to regenerate an electrode, and a pollution discharge process is a backwashing process of the module.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

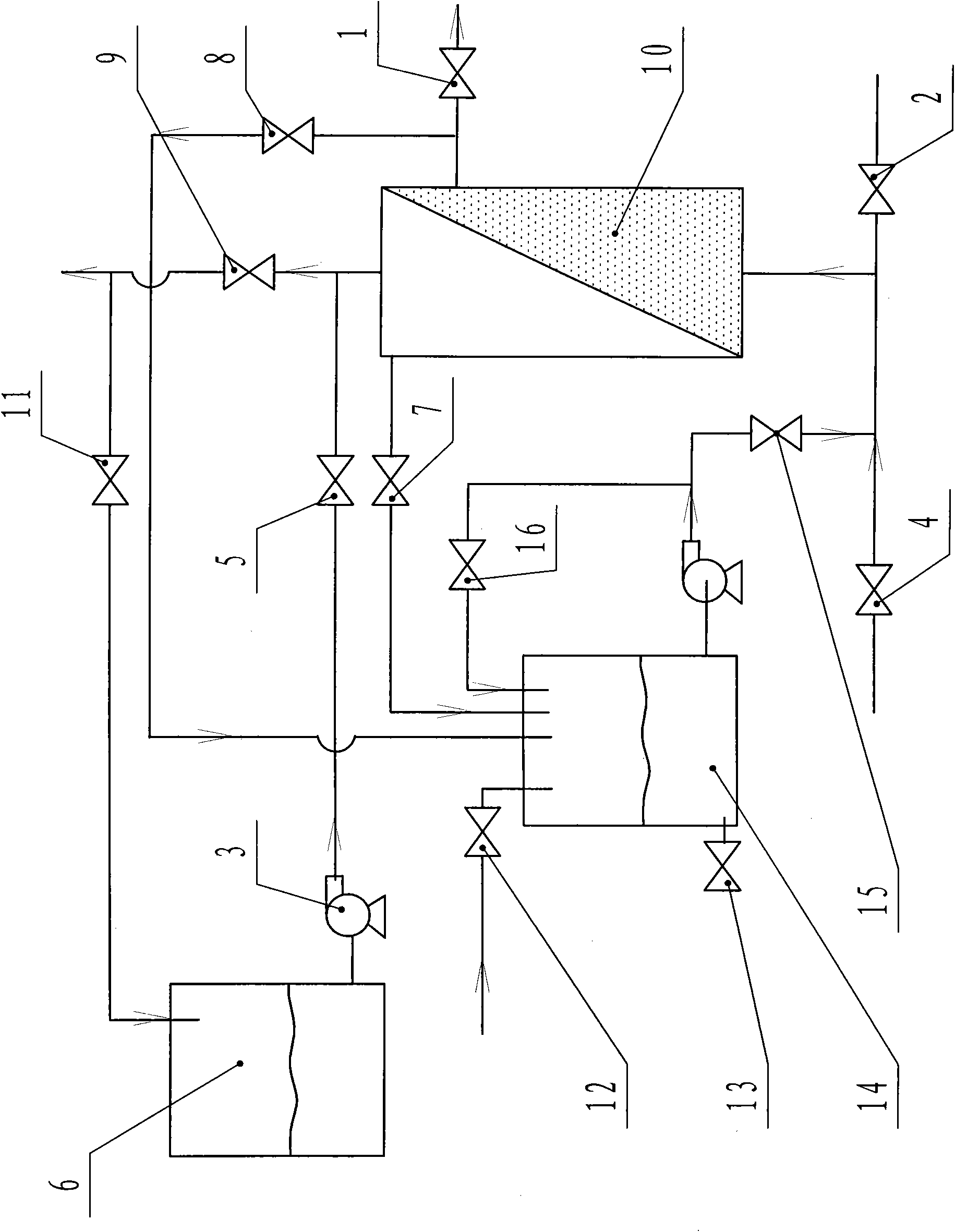

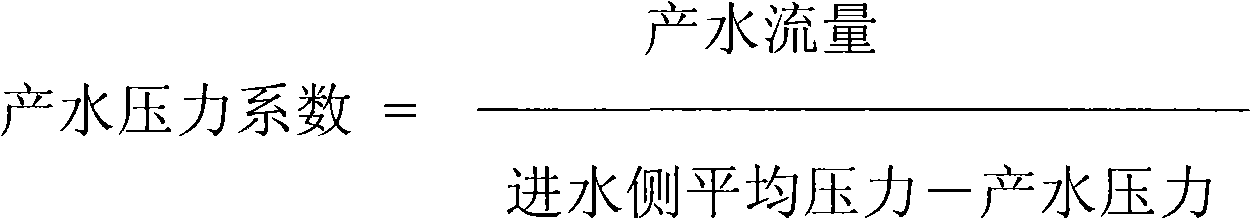

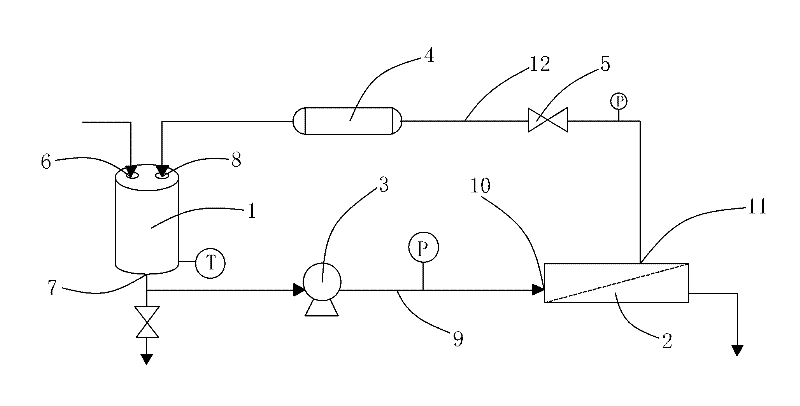

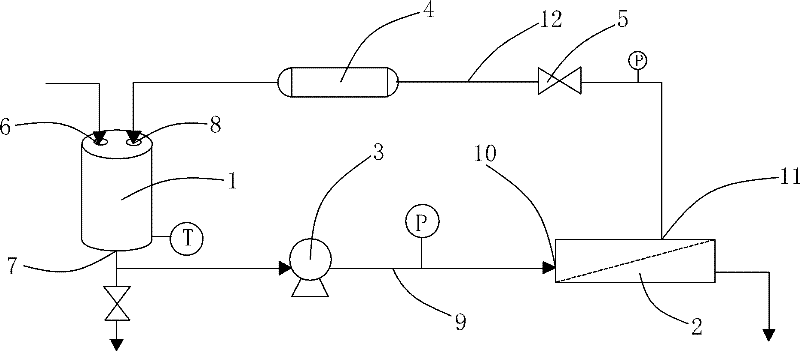

Membrane performance tester and application thereof

ActiveCN102049199AExtended stayStable temperature controlSemi-permeable membranesUltrasound attenuationWater baths

The invention provides a performance tester of a continuous flat ultrafiltration membrane and a reverse osmosis membrane and a use method thereof. The tester comprises a water supply unit, a drainage unit and a plurality of parallel infiltration ponds, wherein each infiltration pond comprises a substrate, a shell, a water inlet, a water outlet, an exhaust port, a bottom inserting tube, a stirrer and a constant-temperature water bath jacket. Produced water penetrating through a separation membrane to be measured is discharged out of the infiltration ponds via the water outlets. The tester can carry out constant-temperature and stable operation at higher temperature and can realize the functions of testing membrane separation performance and membrane flux attenuation, extracting key pollutants of the membrane, cleaning the membrane on line and testing membrane performance restore after cleaning.

Owner:CHINA PETROLEUM & CHEM CORP +1

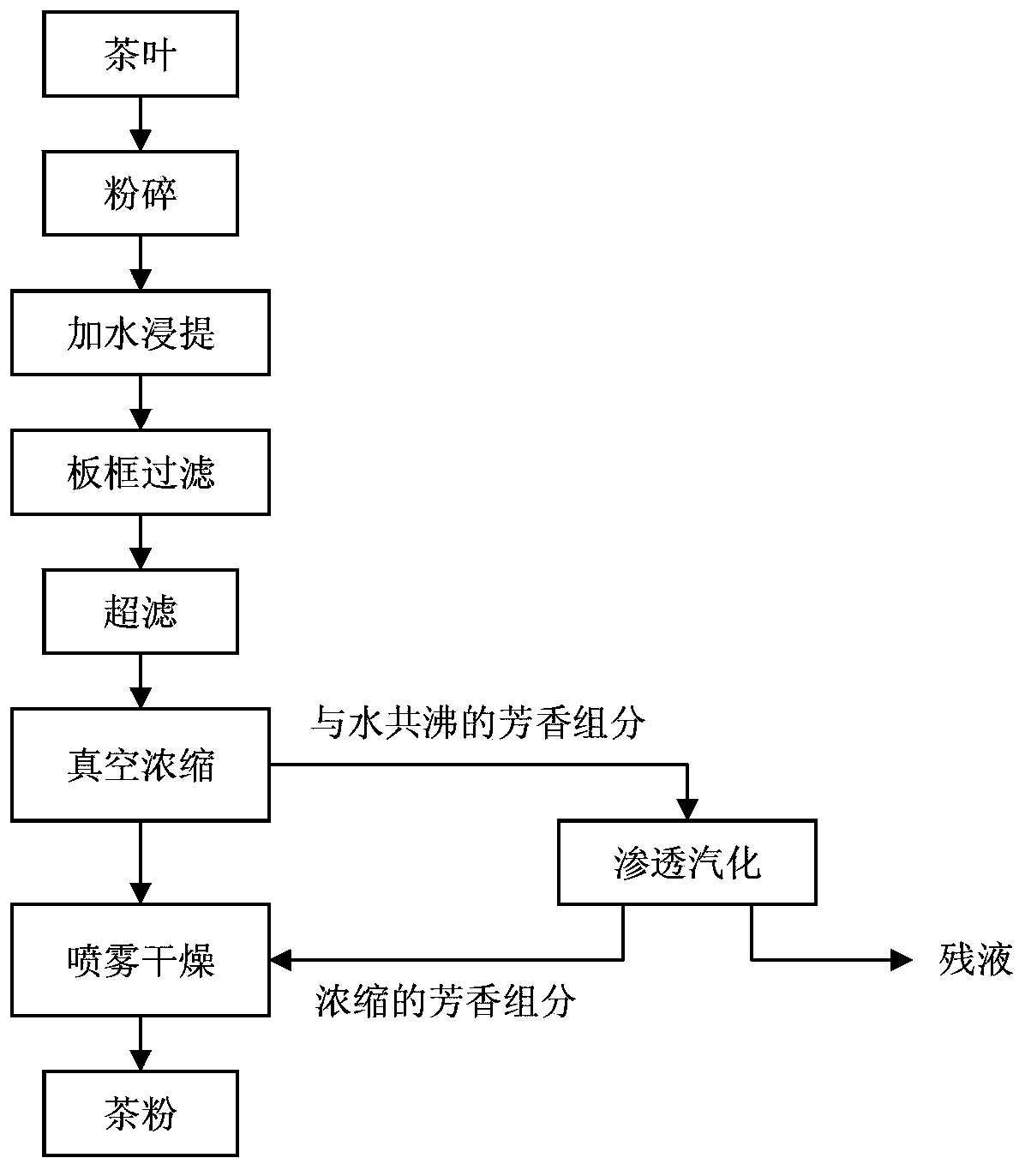

Recovery method for aroma components in production process for instant tea powder

The invention discloses a recovery method for aroma components in a production process for instant tea powder. The recovery method comprises the following steps: crushing tea into coarse powder by using a pulverizer, mixing the obtained tea powder with water and extracting aroma components in the tea; filtering tea soup obtained after extraction by using a multilayer plate and frame type filter press; subjecting a filtrate obtained after plate and frame type filtration to ultrafiltration so as to obtain a clear filtrate and subjecting the filtrate to vacuum concentration; subjecting a concentrate obtained after concentration to spray drying so as to obtain the tea powder, wherein solid content of the concentrate is 40 to 50 wt%; and with condensed water generated in the process of vacuum concentration as a material liquid for pervaporation, carrying out pervaporation membrane separation and subjecting concentrated aromatic substances in the tea to spray drying to recover the aromatic substances to the tea powder. According to invention, most aromatic substances in the tea can be recovered, the quality of the tea powder is improved, and the utilization rate of the tea is increased; compared with a traditional extractive distillation method and the like, the recovery method for the aroma components in the tea through pervaporation membrane separation has the advantages of high separability, low energy consumption, a mild operation temperature, no additive, etc.

Owner:NANJING UNIV OF TECH

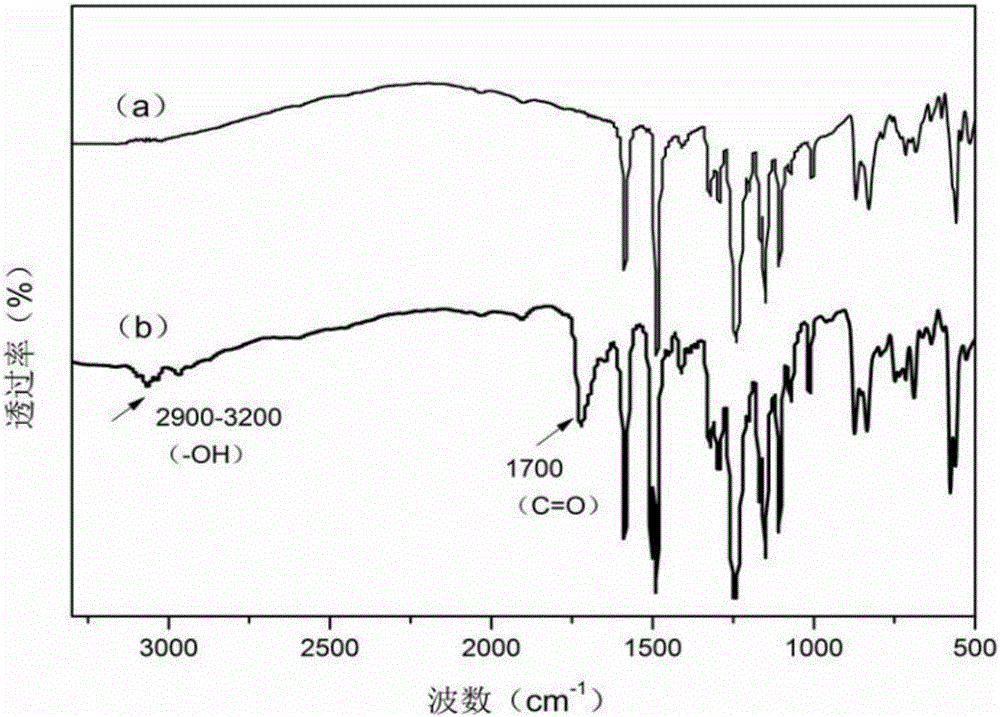

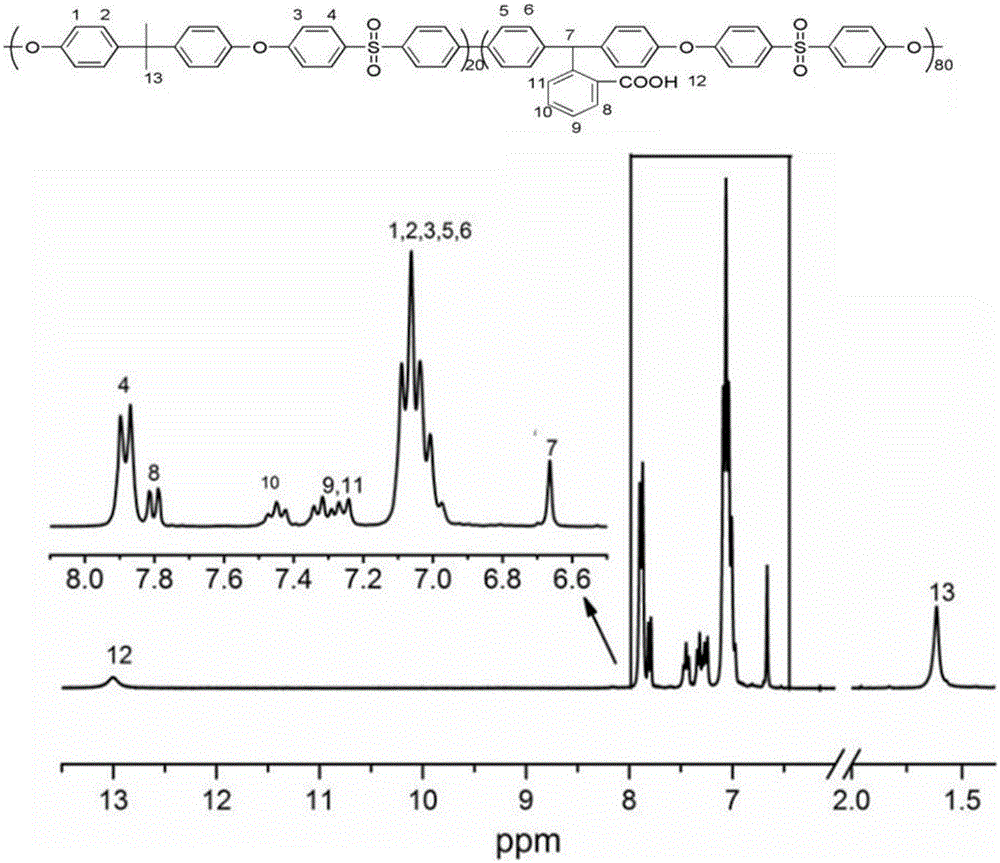

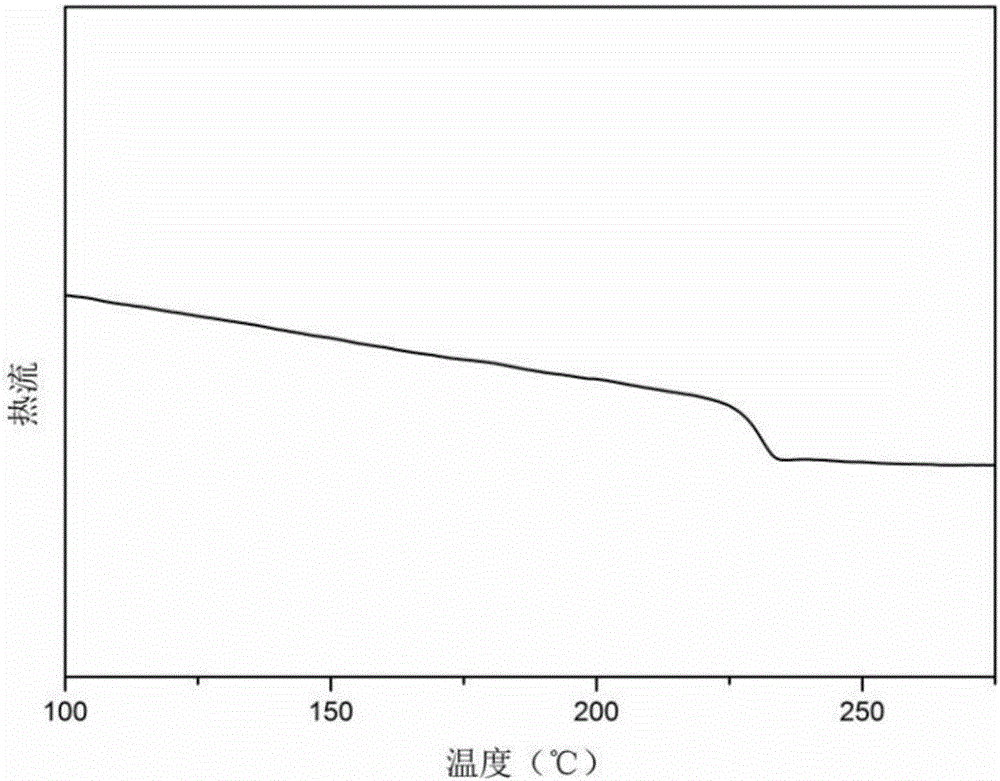

Carboxyl-side-group-containing polyarylether copolymers and preparation method thereof, and application of copolymers in aspect of ultrafiltration membrane hydrophilic modification

ActiveCN106008978AEasy to prepareImprove hydrophilicityMembranesReverse osmosisMaterials preparationPhase conversion

The invention relates to carboxyl-side-group-containing polyarylether copolymers and a preparation method thereof, and application of the copolymers in the aspect of ultrafiltration membrane hydrophilic modification, belonging to the technical field of ultrafiltration membrane preparation. By adopting nucleophilic polycondensation and one-step feeding, the mole ratio of the phenolphthalin bisphenol monomer to the total bisphenol monomer is changed to prepare a series of polyarylether copolymers with different carboxylation degrees; and the polyarylether copolymers are used as the membrane material preparation membrane casting solution to prepare a series of ultrafiltration membranes by an impregnation precipitated-phase conversion process. The hydrophilicity and water flux of the carboxyl-side-group-containing modified polyarylether ultrafiltration membranes are obviously enhanced. The modified monomer phenolphthalin can be obtained only by hydrolyzing / reducing phenolphthalein, so the experimental operation is simple, and the raw material price is low. In addition, the technique has the advantages of enduring chemical hydrophilic modification, high repetitiveness and the like, and is easy to operate.

Owner:JILIN UNIV

Multifunctional ultrafiltration membrane module cutter

InactiveCN102744742AImprove cutting efficiencyHigh speedMetal working apparatusBiochemical engineeringOperational safety

The invention relates to the technical field of ultrafiltration membrane machining equipment, in particular to a multifunctional ultrafiltration membrane module cutter. The multifunctional ultrafiltration membrane module cutter is provided with a frame with a slide rail; a movable clamping device used for clamping an ultrafiltration membrane module is arranged on the frame; and a rough cutting device, a heating device and a fine cutting device, which are capable of roughly cutting, heating and finely cutting the ultrafiltration membrane module in the clamping device in sequence when the clamping device advances to a certain position, are arranged on one side of the frame. Through the adoption of the technology, technical problems of low efficiency, uneven cutting end surface, easiness for plugging a hole, potential safety hazards in operation and so on of the traditional manual cutting are solved; high production efficiency, even cutting end surface, no blockage of the hole, good use effect and long service life of an ultrafiltration membrane as well as simplicity and convenience in operation are achieved; and the potential safety hazards in operation are lowered.

Owner:施吉中

Water-soluble Chitooligosaccharide preparation method

InactiveCN1544479AImprove anti-tumor activitySimple processSemi-permeable membranesUF - UltrafiltrationGlycosidic bond

The invention relates to a process for preparing water-soluble chitooligosacchrides, which is prepared by utilizing the difference of recognition capability and disengagement capability of enzymes to different glycosidic bonds and the inhomogeneous distribution of acetylaminos in chitosan raw material. The invention realizes simple process, wherein at the same time of preparing Chitosan oligosaccharide, 8-200 polymerization degree of water-soluble chitooligosacchride can be achieved simultaneously through the method of ultrafiltration membrane separation. The product obtained thereby has exhibites antineoplastic action and immunologic enhancement.

Owner:WUHAN UNIV

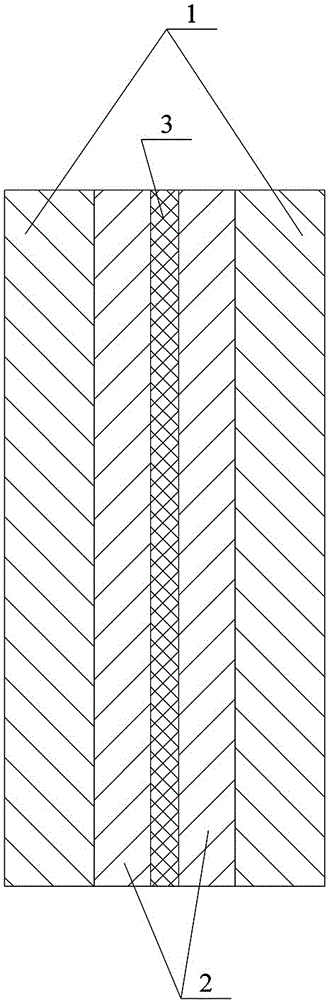

Multilayer composite ultrafiltration membrane and preparation method thereof

ActiveCN105032202AImprove antifouling performanceEnhanced water fluxUltrafiltrationSynthetic resin layered productsCellulosePolymer science

The invention discloses a multilayer composite ultrafiltration membrane and a preparation method thereof. The multilayer composite ultrafiltration membrane is characterized by being provided with five layers of structures, wherein each of the inner and outer surfaces of the ultrafiltration membrane is a PET or PP non-woven fabric base body, each of the inner and outer subsurfaces of the ultrafiltration membrane is a polymer nanofiber membrane layer, and the middle layer of the ultrafiltration membrane is a cellulose nanofiber membrane layer. A polymer in the polymer nanofiber membrane layer is selected from one of polyether sulfone, polysulfone, polyacrylonitrile and polyvinylidene fluoride film forming polymers, and then is processed to prepare a spinning solution, and electrostatic spinning dope forms the polymer nanofiber membrane layers on PET or PP non-woven fabrics serving as the base bodies for electrostatic spinning collection. The cellulose nanofiber membrane layers are prepared by selecting one of bamboo, wood, cotton and linen, dissociating fiber slurry and processing. The multilayer composite ultrafiltration membrane prepared by the method has good hydrophily, higher pollutant resistance and water flux, and better interception characteristic, and is more economical in use and longer in service life.

Owner:上海展恒环保科技有限公司

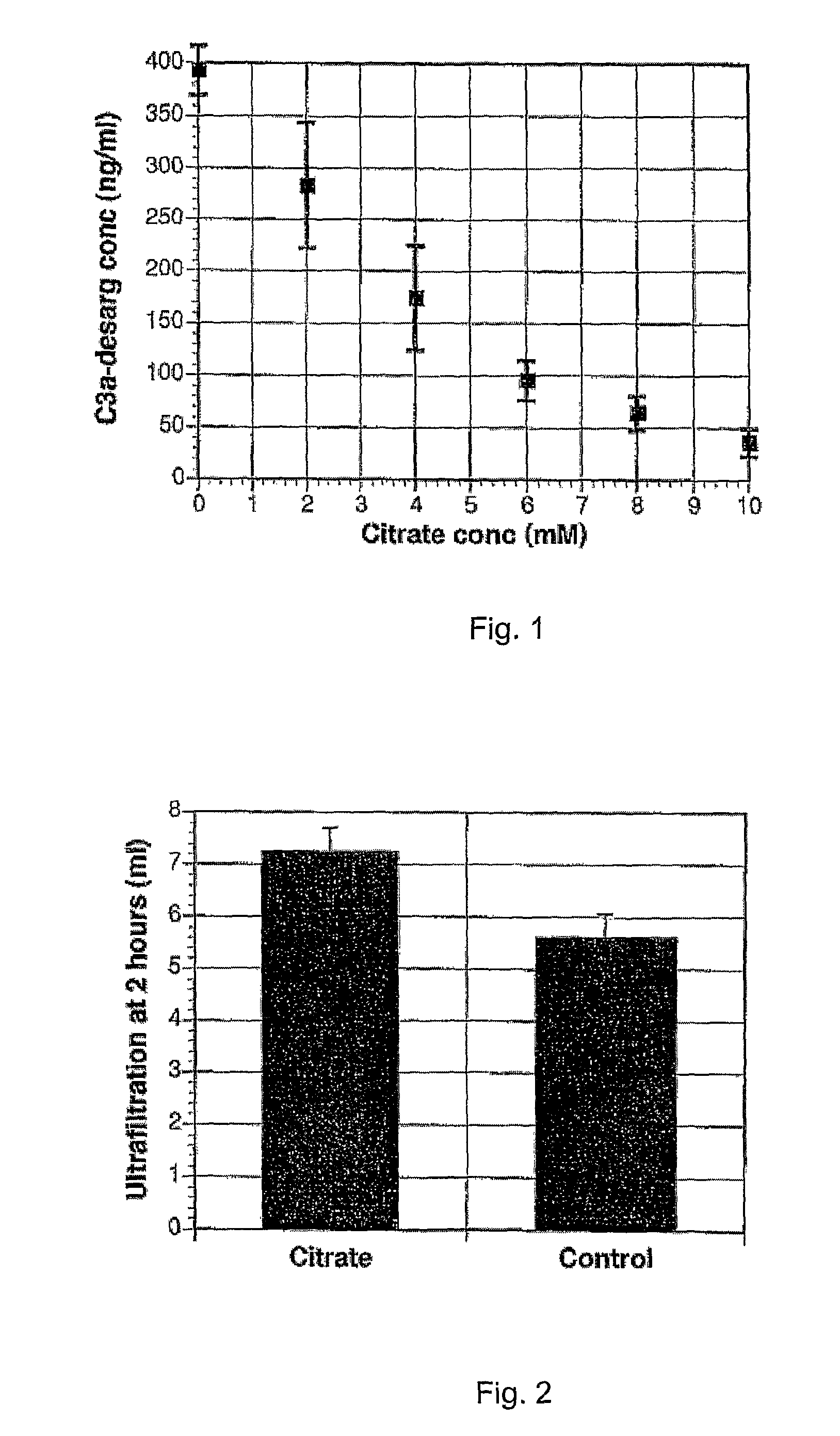

Peritoneal dialysis fluid

ActiveUS8367731B2Less tendency to become absorbedUltrafiltration during a dwell is enhancedBiocidePharmaceutical delivery mechanismCITRATE ESTERPeritoneal dialysis fluid

The present invention concerns a peritoneal dialysis fluid with enhanced ultrafiltration during the dialysis dwell period. According to the present invention this is achieved by a peritoneal dialysis fluid comprising sodium ions, osmotic agent and a buffer, characterised in that it comprises citrate at a level of 4 to 10 mM in a final solution ready for use.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com