External anaerobic membrane bioreactor and waste water purification technology thereof

An anaerobic membrane biological and wastewater purification technology, applied in anaerobic digestion treatment, waste fuel, chemical instruments and methods, etc., can solve problems affecting the practicability of submerged membrane system engineering, membrane breakage and blockage, increase work intensity, etc. problems, to achieve the effect of not easy to contaminate and block, reduce the cross-flow speed, and reduce the floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

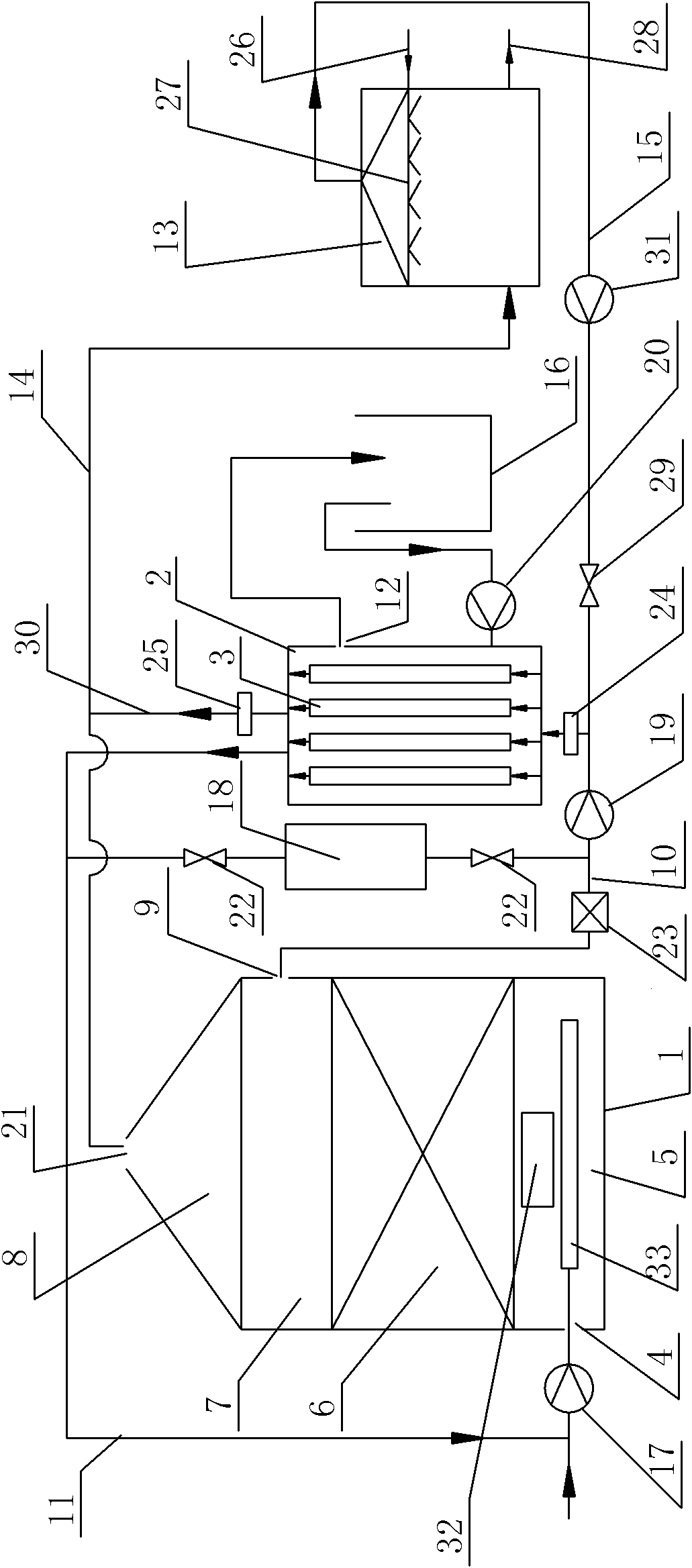

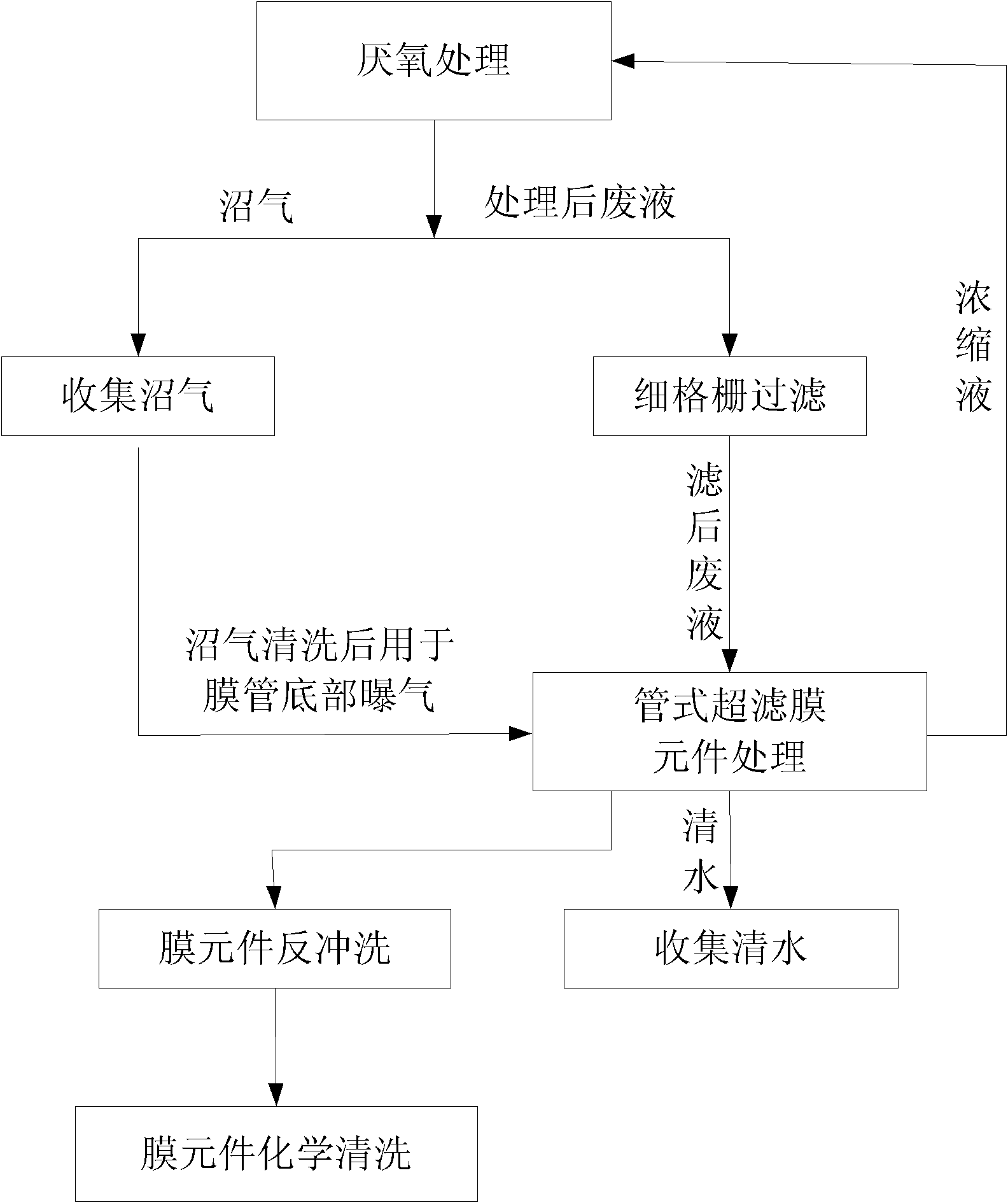

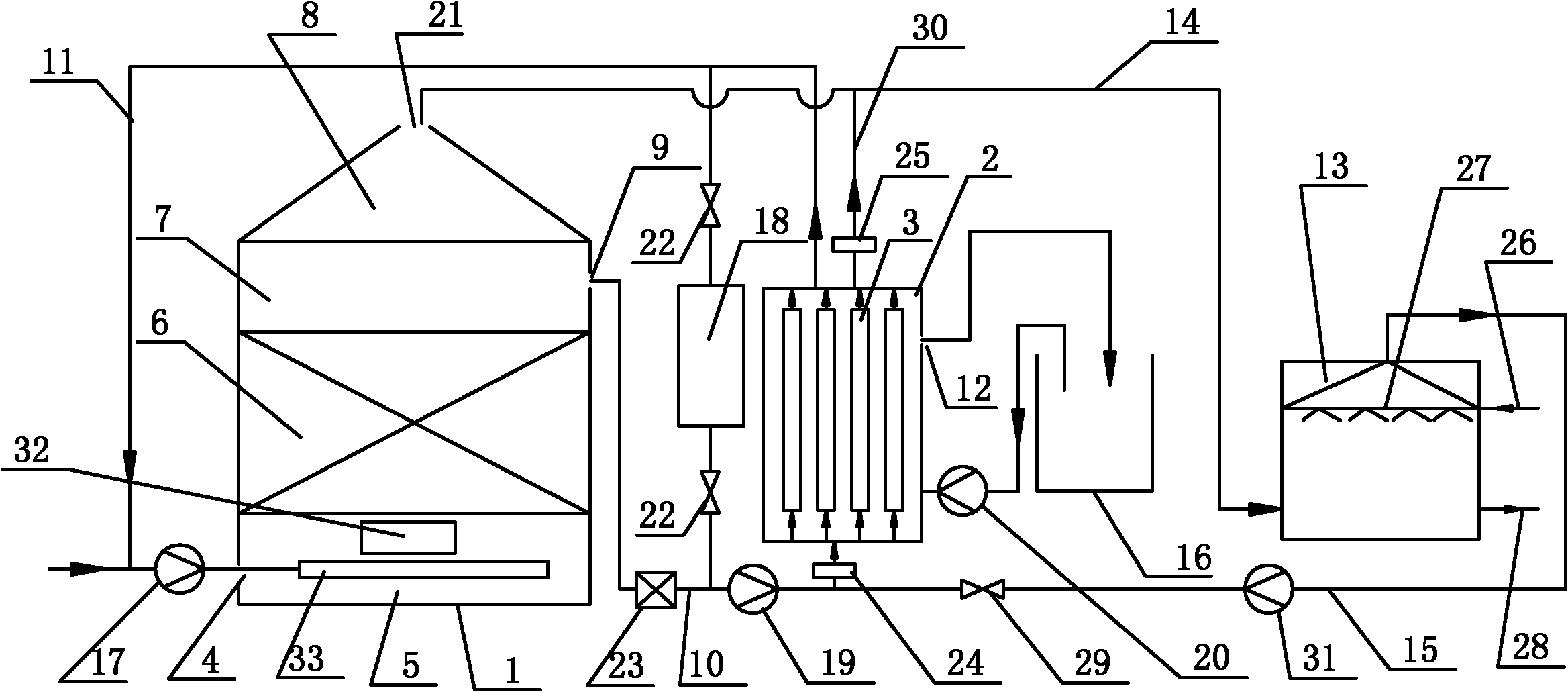

[0026] The scheme of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 The shown external anaerobic membrane bioreactor comprises an anaerobic tank 1, a tubular membrane module 2 arranged vertically (it can also be a plurality of tubular membrane modules arranged vertically in parallel), clean water The pool 16, the backwash pump 20 is connected to the tubular membrane module 2, the tubular membrane module 2 is equipped with several vertically parallel tubular ultrafiltration membrane elements 3, and the anaerobic pool 1 is sequentially arranged from bottom to top. Water area 5, packing area 6, water outlet area 7 and biogas collection area 8, sludge agitator 32 and water distributor 33 are arranged in water inlet area 5, water inlet 4 is provided on the side wall of water inlet area 5, water inlet 4 places are connected with a second water inlet pump 17, and a water outlet 9 is provided on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com