Patents

Literature

147results about How to "Small temperature deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

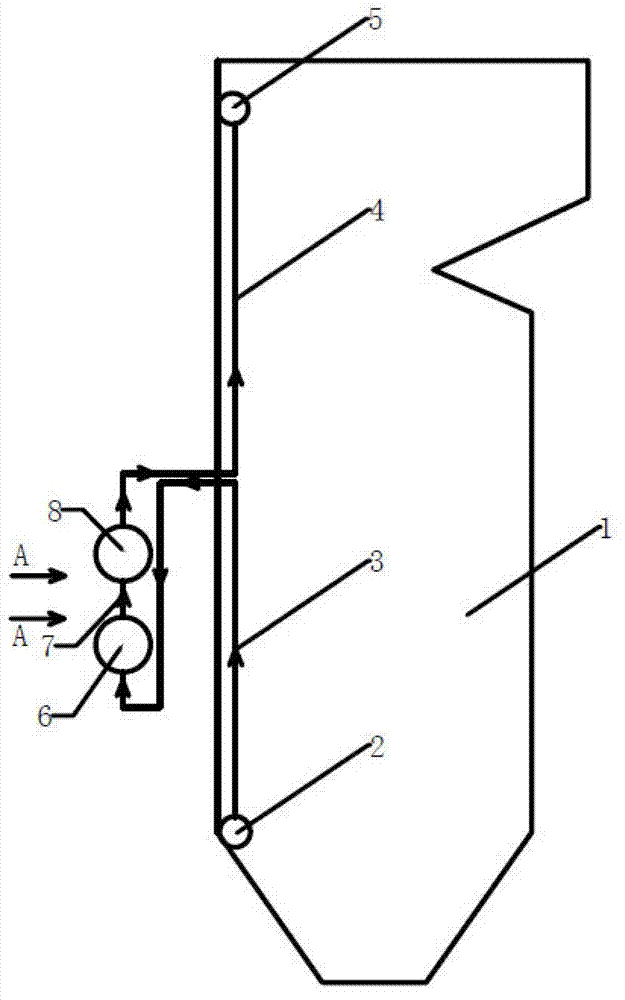

Battery system and temperature control method therefor

InactiveCN103311597ASuppress supercoolingSmall temperature deviationSecondary cellsCell component detailsTemperature controlEngineering

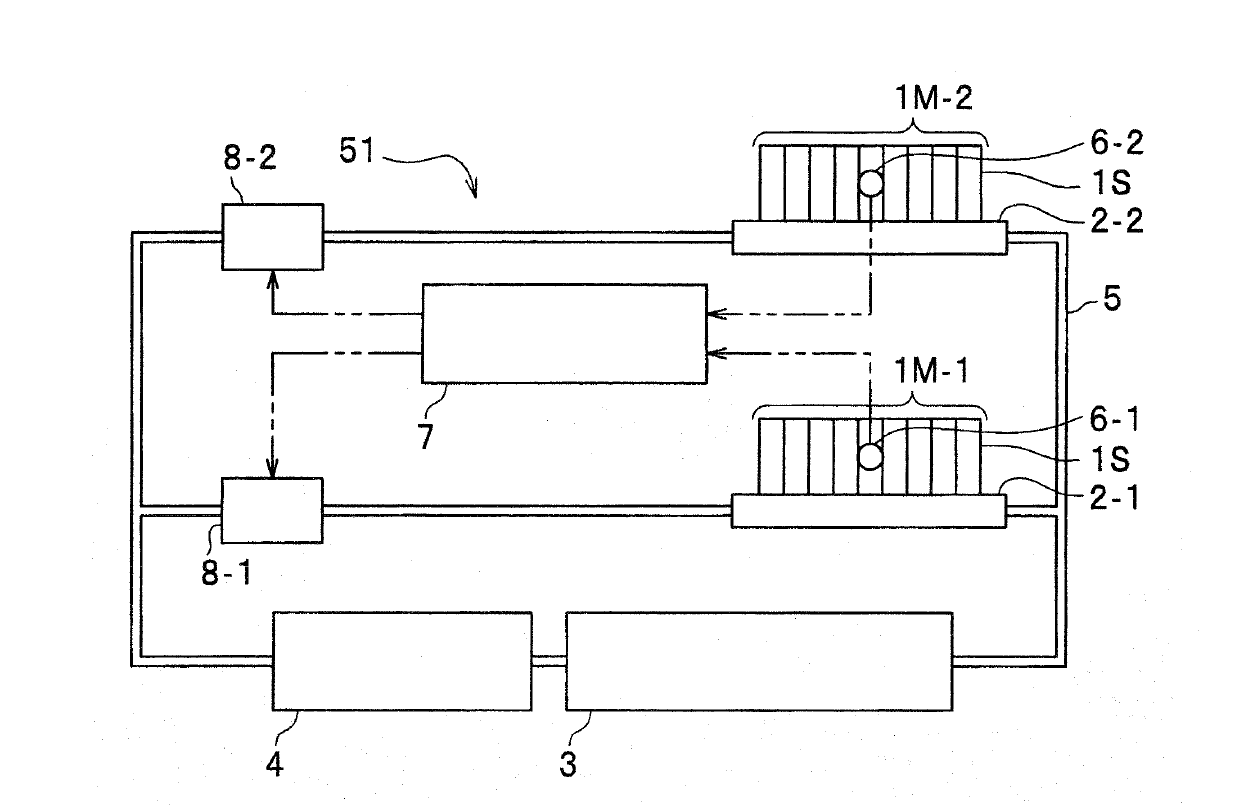

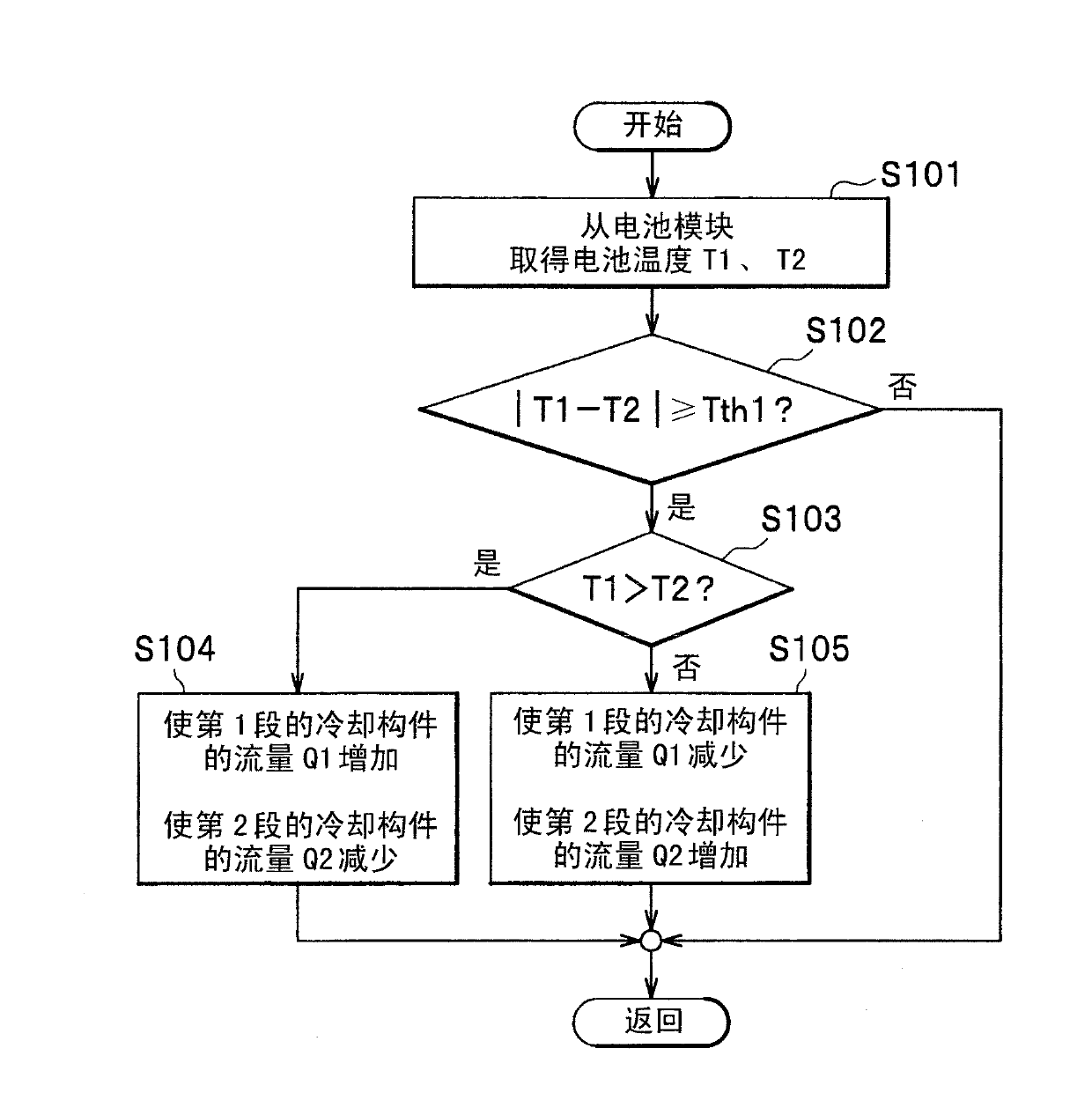

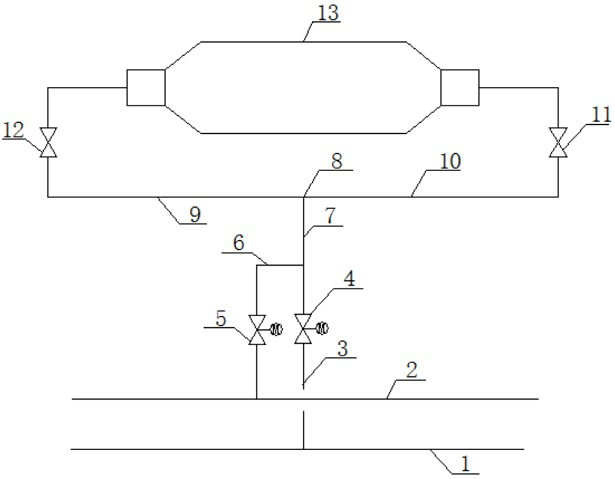

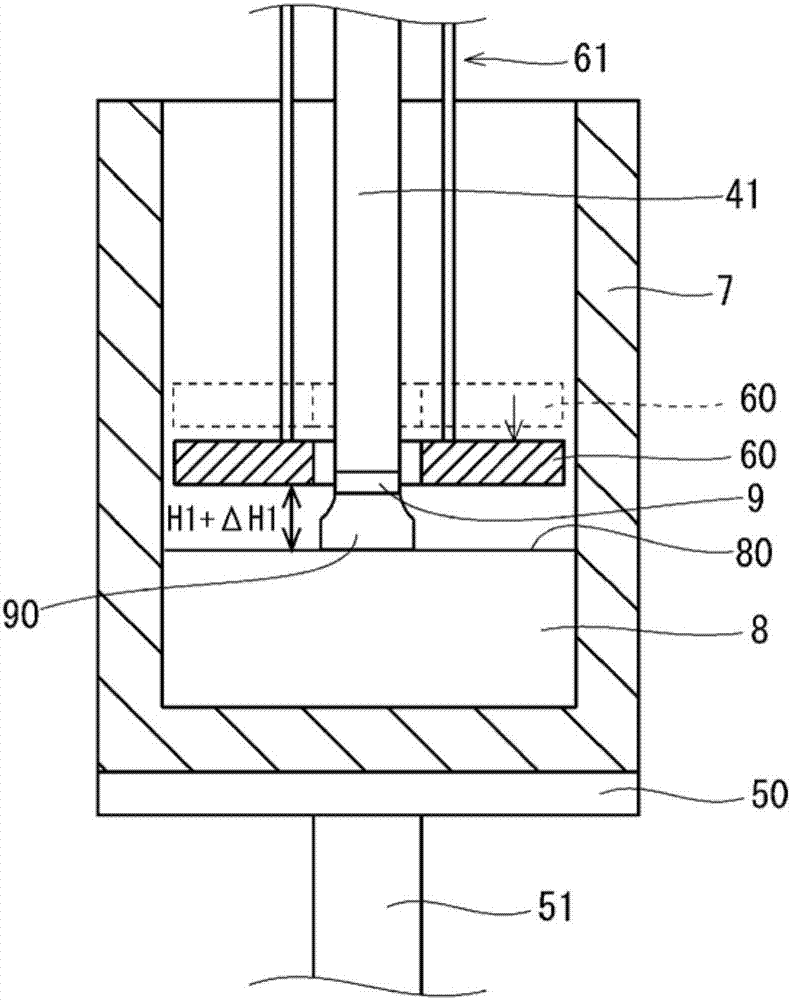

Provided are a battery system and temperature control method therefor capable of suppressing excessive cooling of a battery module, diminishing a temperature variance, and leveling the temperatures of plural battery modules. In the battery system including cooling units each of which is provided with a cooling plate (2-1, 2-2) which includes a flow channel through which a refrigerant flows and on which a battery module that is an object of temperature control (1M-1, 1M-2) is placed, and a flow rate adjustment device (8-1, 8-2) that adjusts the flow rate of the refrigerant that flows through the flow channel, temperature sensors (6-1, 6-2) that individually sense the temperatures of the battery modules, and a refrigerant circulation mechanism (4) that branches out the refrigerant into the flow channels accompanying the cooling units, and joins and circulates the refrigerants coming from the flow channels, a control unit (7) adjusts the refrigerant flow rates using the flow rate adjustment devices (8-1, 8-2) according to the temperatures, which are sensed by the temperature sensors (6-1, 6-2), for each of the cooling units.

Owner:HITACHI LTD

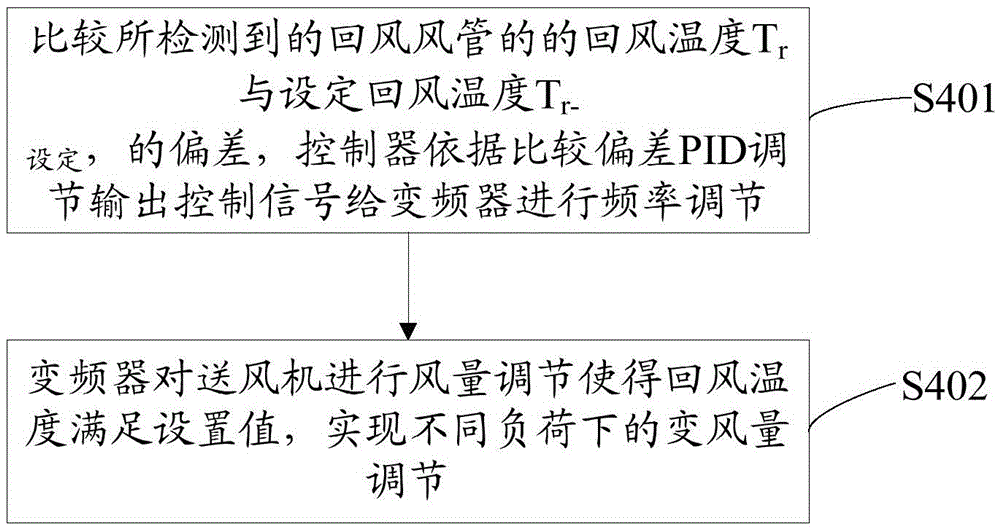

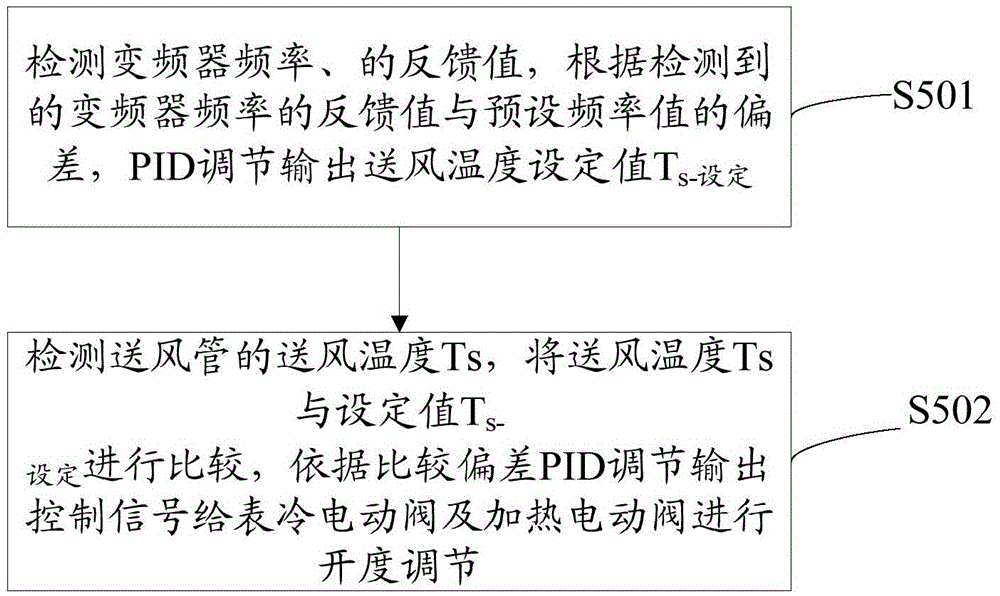

Energy-saving control method and system for constant-temperature constant-humidity air conditioning unit based on variable parameter adjustment

InactiveCN105674512ASmall temperature deviationGuaranteed qualityMechanical apparatusSpace heating and ventilation safety systemsIndoor air qualityControl system

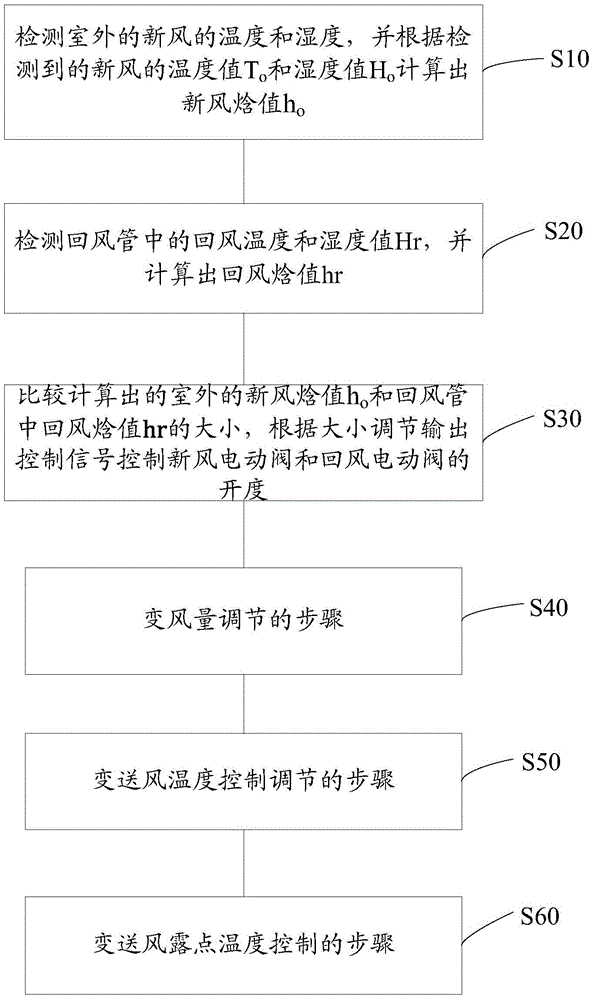

The invention discloses an energy-saving control method and an energy-saving control system for constant-temperature constant-humidity air conditioning unit based on variable parameter adjustment, and relates to the field of air-conditioning energy-saving control. The energy-saving control method comprises the following steps: detecting temperature and humidity of outdoor fresh air, and calculating a fresh air enthalpy value ho according to the detected temperature value To and the detected humidity value Ho of the fresh air; detecting a return air temperature Tr and the humidity value Hr in a return air duct, calculating a return air enthalpy value hr; comparing the fresh air enthalpy value h0 with the return air enthalpy value hr in the return air duct, and adjusting an output signal according to a size for controlling the opening degree of a fresh air electric valve and a return air electric valve; a step of adjusting an variable air rate; a step of controlling and adjusting a variable air supply temperature; and a step of controlling a variable air supply dew point temperature. By virtue of variable parameter adjustment, the system is matched with load of the tail end better, so that the temperature deviation of an air-conditioning area is reduced, and operation energy consumption required by the system is greatly reduced; and when the indoor air quality is guaranteed, the system operation is more stable and efficient.

Owner:SHENZHEN XINHUANNENG TECH

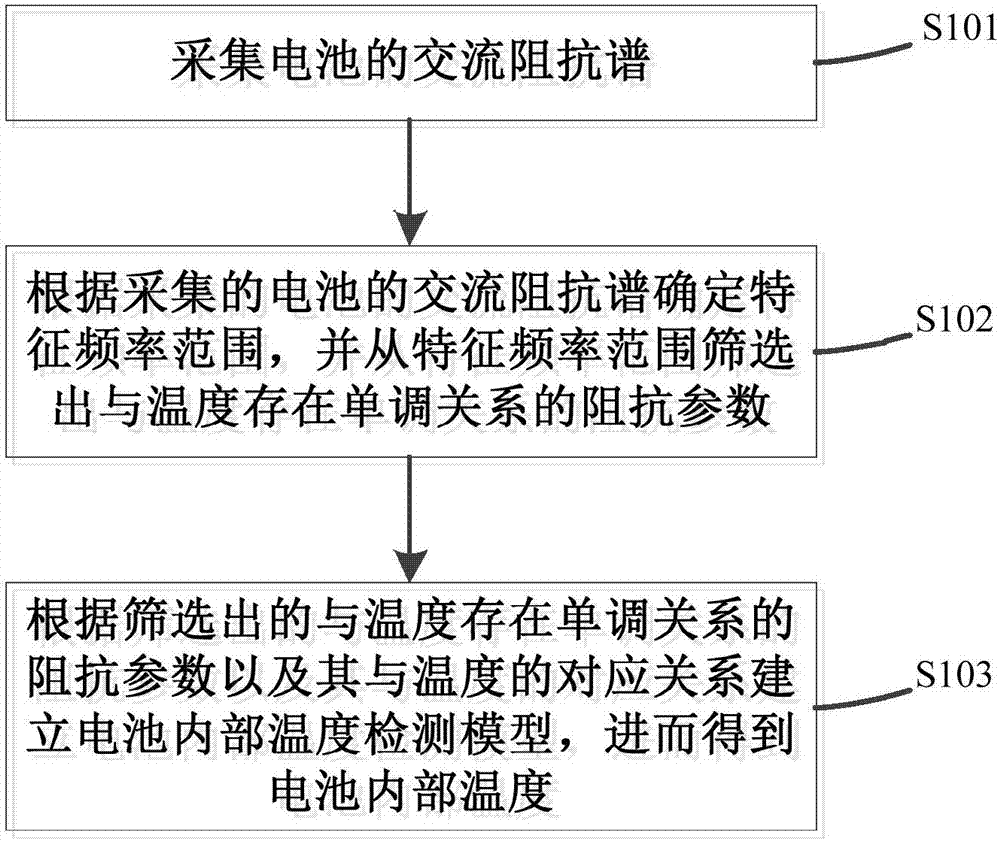

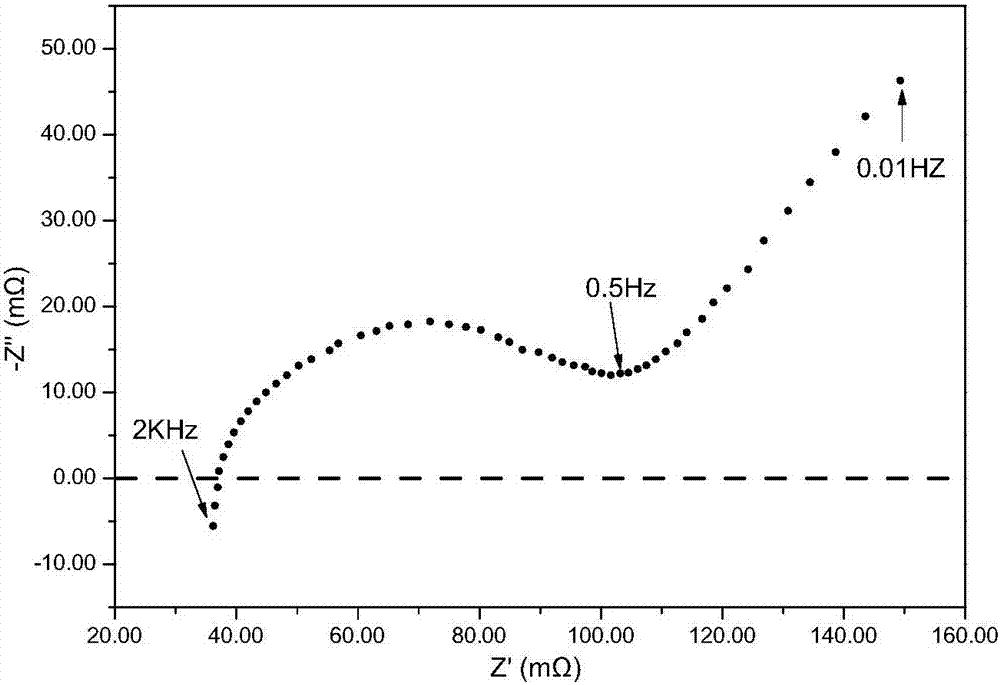

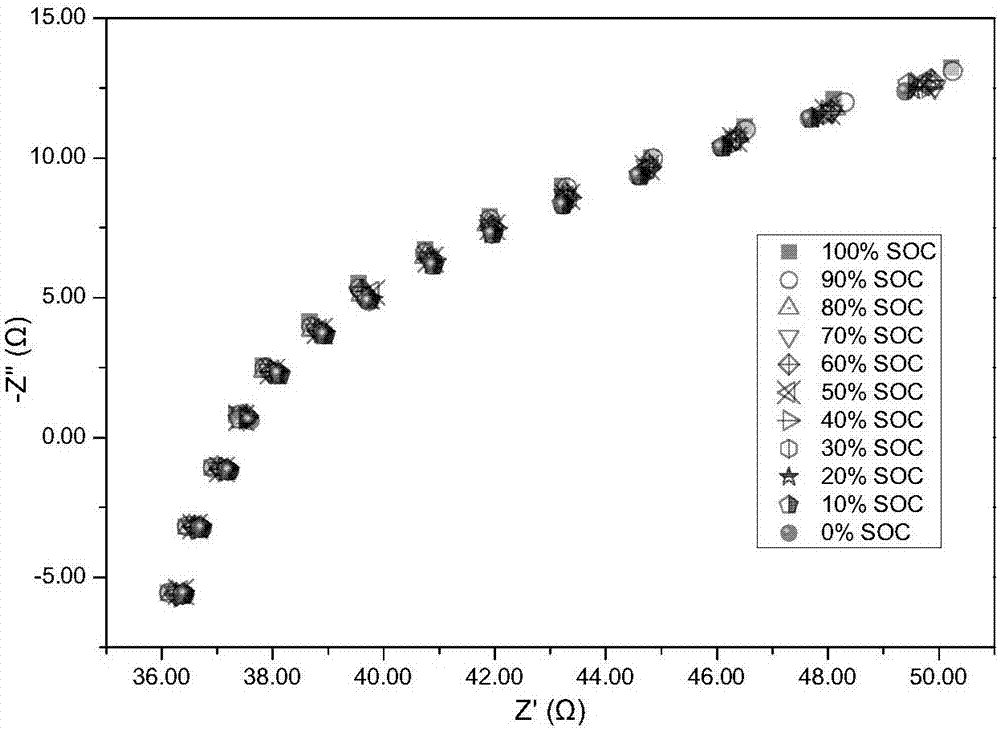

Method and device for detecting internal temperature of battery

ActiveCN107192952AAccurate detection of ambient temperatureHigh feasibilityResistance/reactance/impedenceElectrical testingAc impedance spectroscopyEngineering

The invention provides a method and a device for detecting the internal temperature of a battery. The method comprises steps: an AC impedance spectroscopy of the battery is acquired; according to the AC impedance spectroscopy of the battery, a characteristic frequency range is determined, and an impedance parameter in a monotony relationship with the temperature is selected from the characteristic frequency range; and according to the impedance parameter in a monotony relationship with the temperature and the corresponding relationship between the impedance parameter and the temperature, a battery internal temperature detection model is built, and thus, the battery internal temperature is obtained. According to the method and the device for detecting the internal temperature of the battery, the impedance characteristic parameter of the battery and the internal temperature of the battery are integrated, the internal temperature of the battery is detected on the premise of not damaging the battery structure, and the feasibility and the practicability are high.

Owner:CHINA ELECTRIC POWER RES INST +2

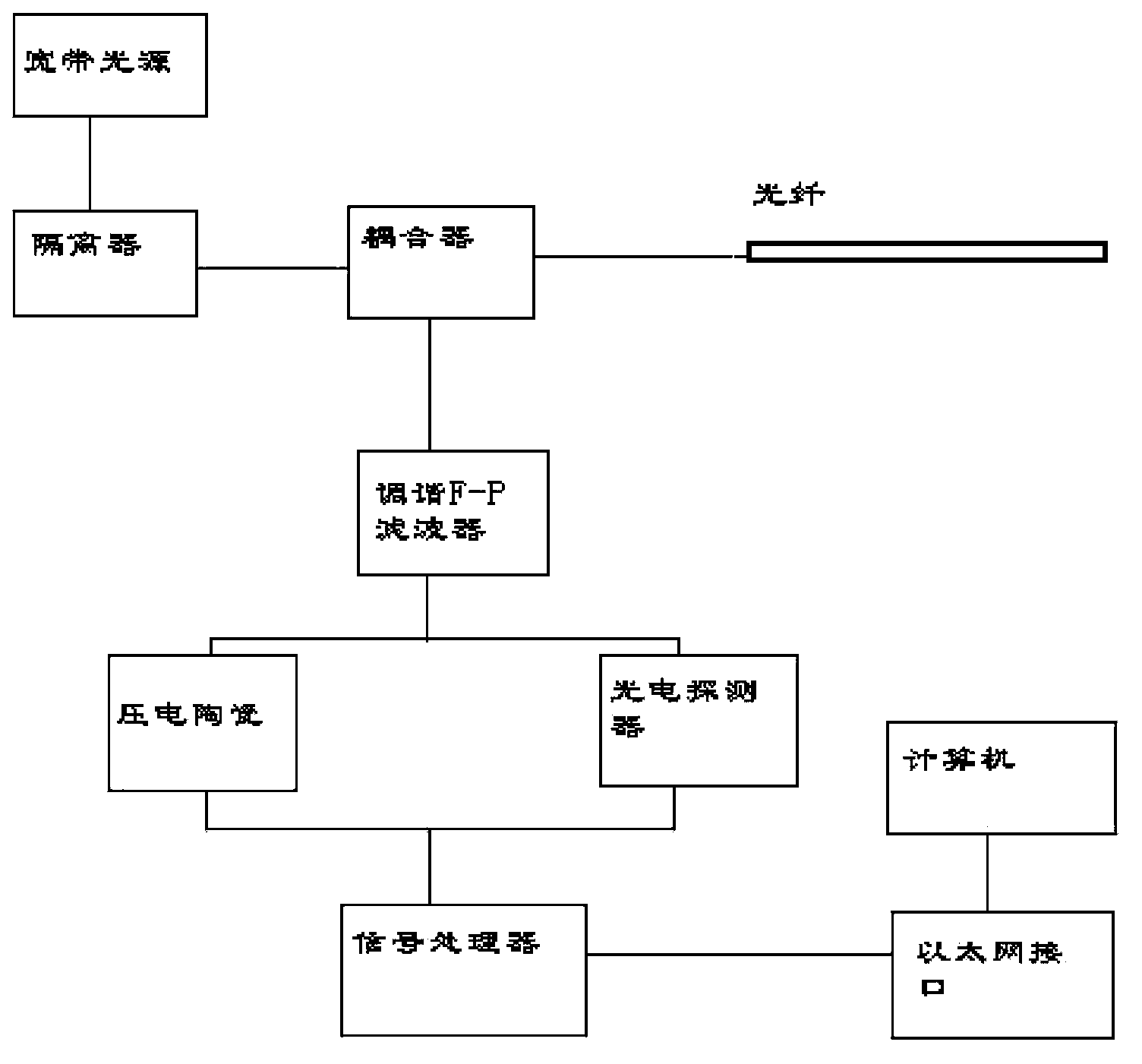

Online monitoring method for flue gas temperature of hearth outlet of power station boiler

InactiveCN101806626AGood for the economyIncrease the effective caliberRadiation pyrometryPower stationFlue gas

The invention discloses an online monitoring method for the flue gas temperature of a hearth outlet of a power boiler, comprising the steps of: placing a plurality of targets at a vertical section near a smokestack of a boiler for sensing the temperature; installing a near infrared imaging device on the side wall of a horizontal flue of the boiler for collecting the radiation energy of the targets; carrying out communication by the near infrared imaging device with a computer through a serial port and RS232, sending the collected radiation energy of the targets to the computer, calculating by the computer to obtain temperature data of the targets; and then sending the temperature data of the targets to a host computer for processing, and converting the temperature to the flue gas temperature of the position of the targets. The invention has the advantages that the average temperature at the section of the hearth outlet, the average temperature of the upper / lower and left / right side, and the highest / the lowest temperature can be continuously monitored, the distribution curve of the temperature of the section can be drawn, and a plurality of alarm functions are set; and the invention is beneficial to the safe and economic operation of a boil with a large capacity and high parameters.

Owner:四川东脑电气工程有限公司

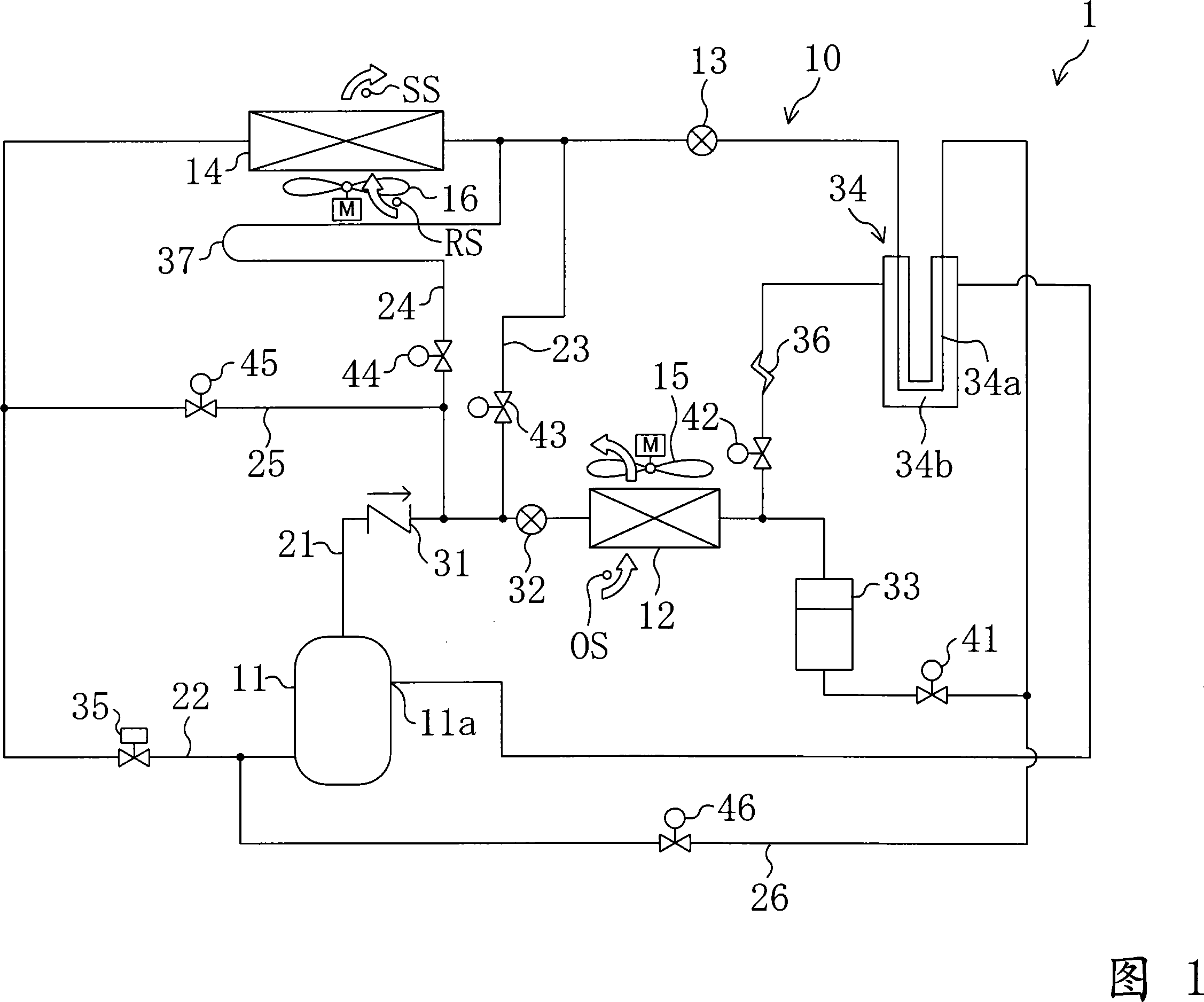

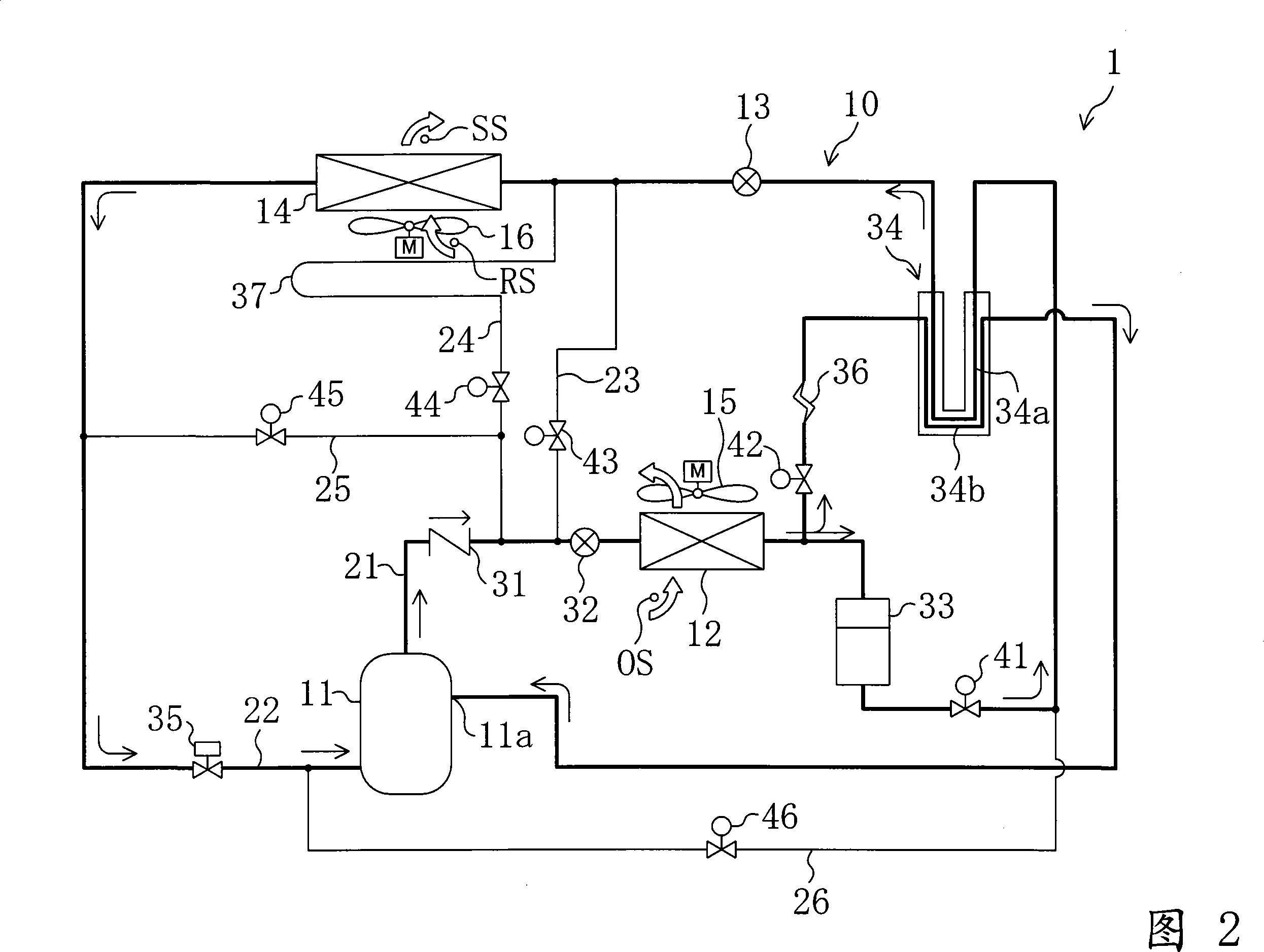

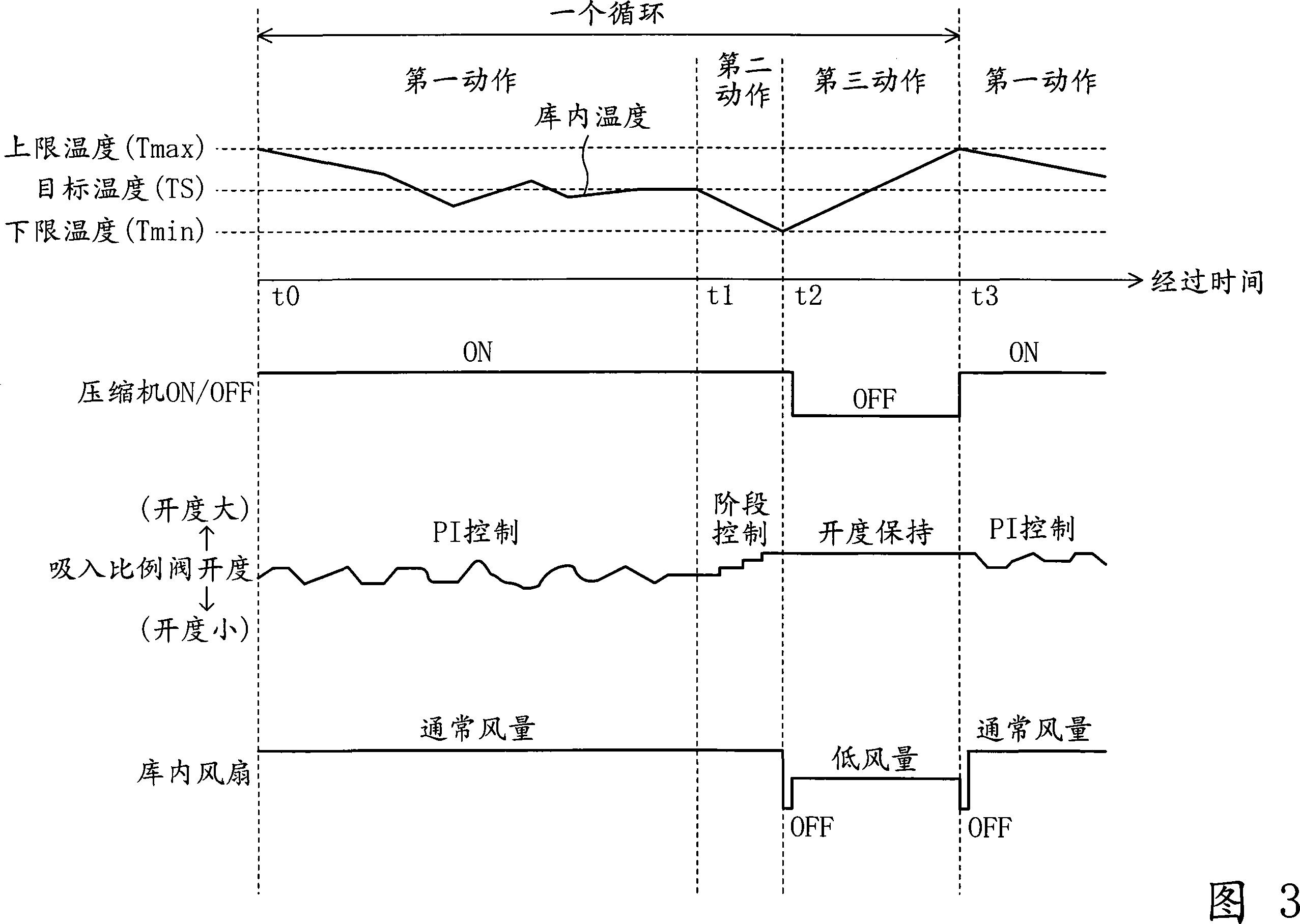

Refrigeration unit

ActiveCN101233374AExtension of timeReduce operating powerCompression machines with non-reversible cycleCooling powerEvaporator

When in the 1 operation the temperature inside is maintained at target temperature by an evaporator, the cooling power of the evaporator is increased so as to carry out the 2 operation for temperature inside lowering. When in the 2 operation the temperature inside reaches lower limit temperature (Tmin), the compressor stops so as to carry out the 3 operation. When in the 3 operation the temperature inside reaches upper limit temperature (Tmax), the compressor restarts so as to carry out the 1 operation.

Owner:DAIKIN IND LTD

A manufacturing method of whole soybean milk and soybean curd

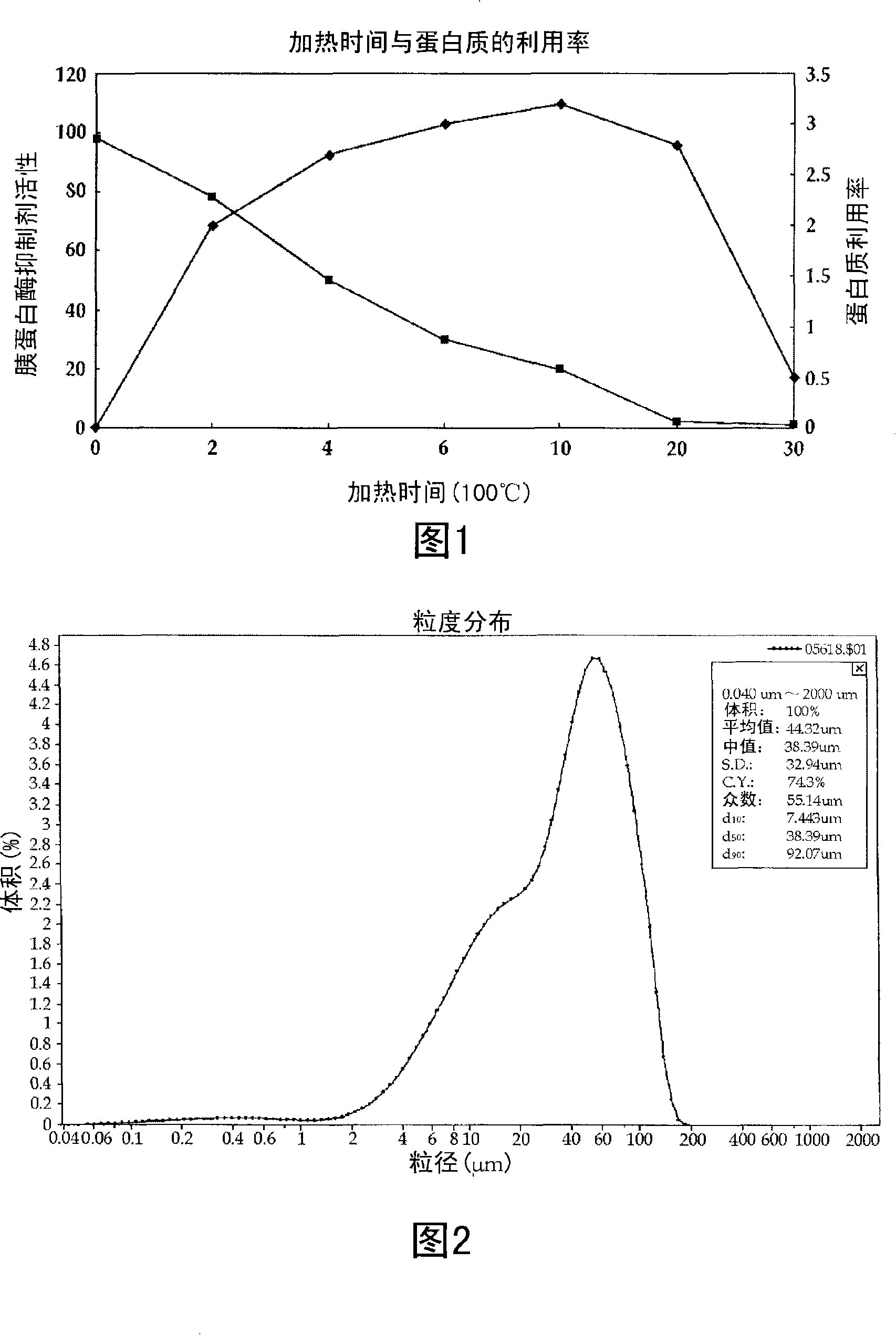

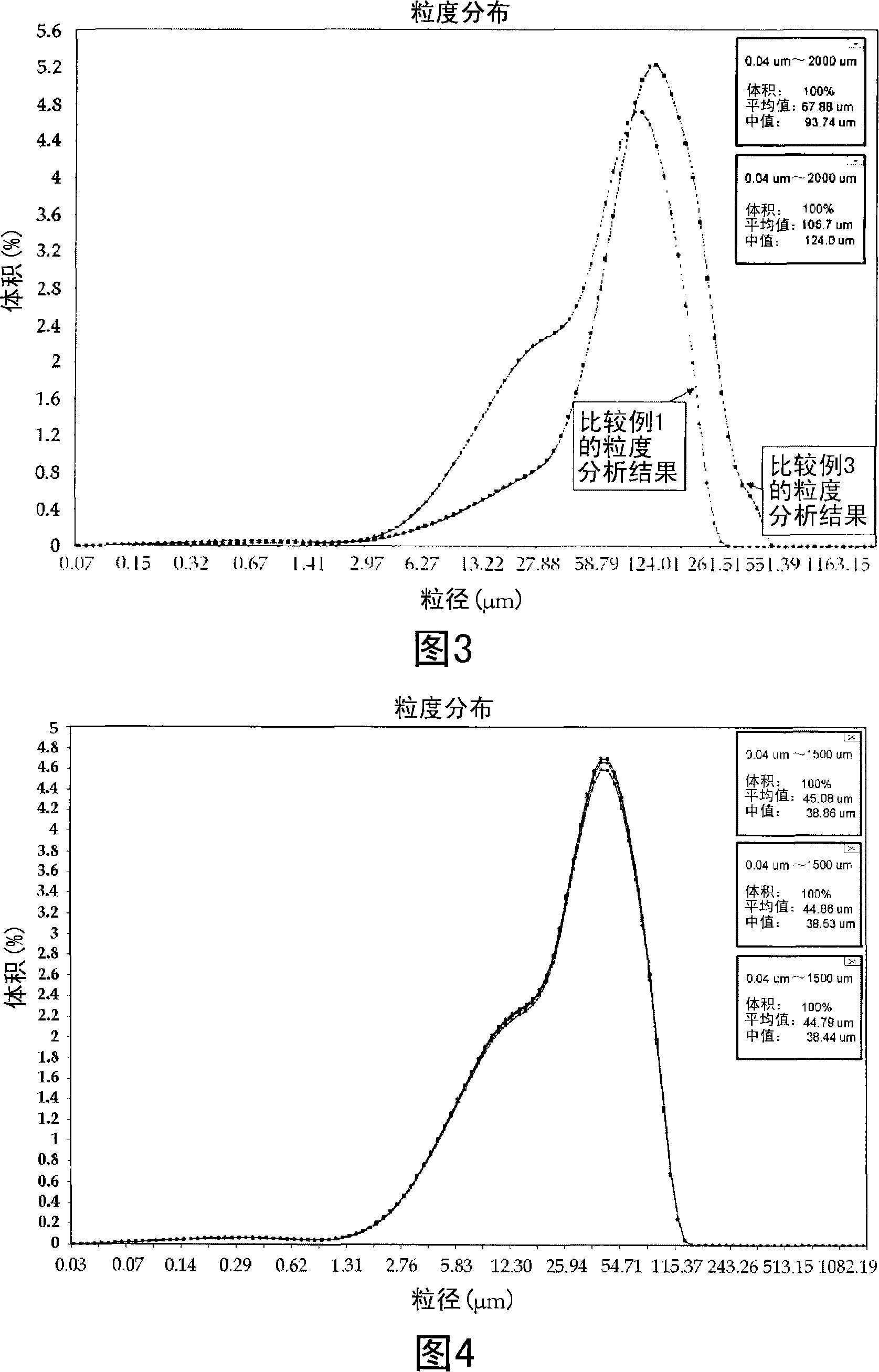

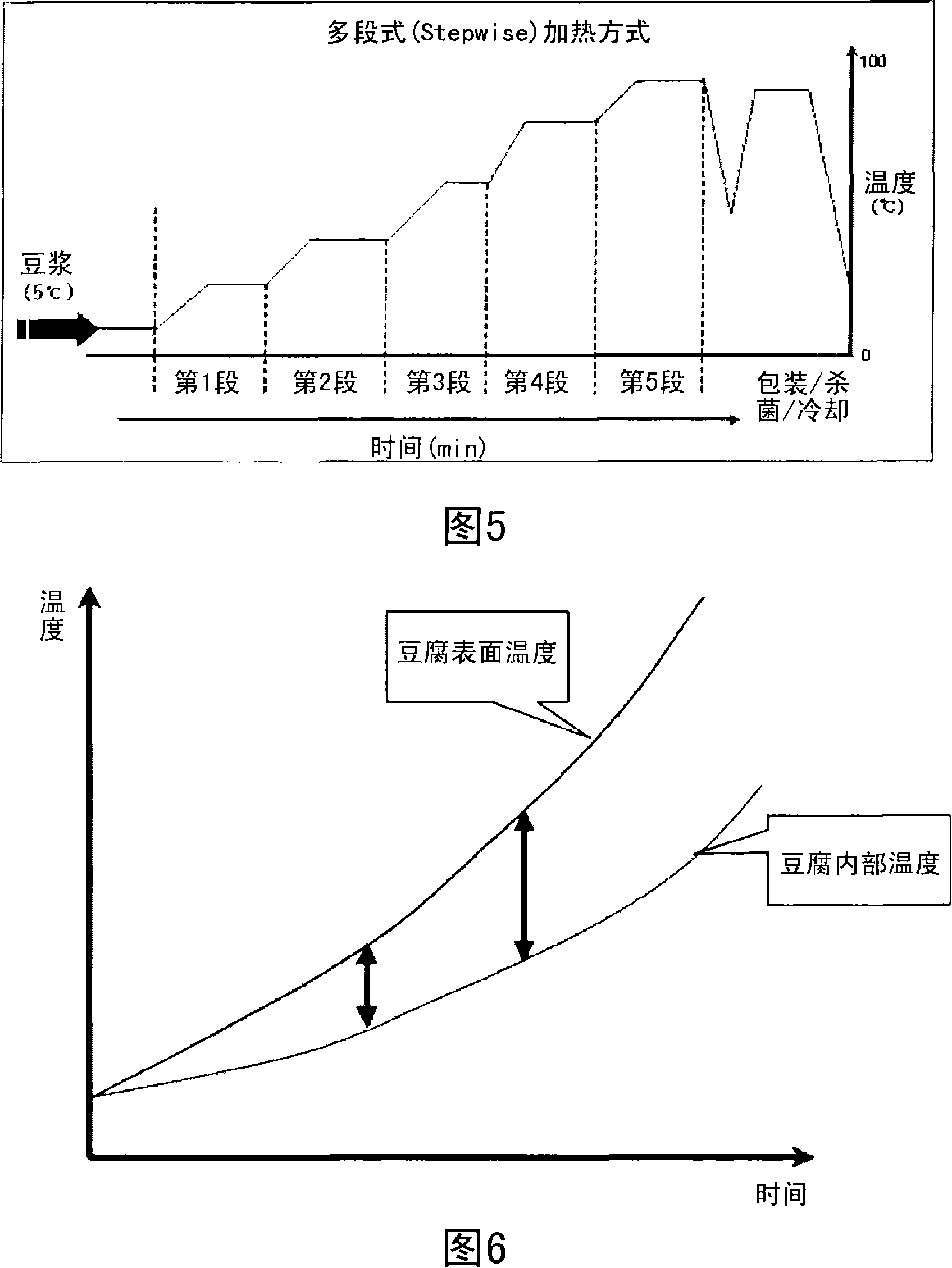

InactiveCN101155519AUnbreakableEasy to operateRigid containersFood preparationAdditive ingredientSoybean meal

The present invention relates to methods for preparing whole soybean milk and soybean curd. More particularly, it relates to a method for preparing whole soybean milk using whole soybean without separating soybean pulps, and to a method for preparing soybean curd by heating and co not agulating the prepared whole soybean milk in a stepwise manner. According to the inventive method the inventive method can effectively prepare high-quality of whole soybean milk using whole soybean without separating the soybean pulps, which contains the nutritional components of soybean pulps intact and has a very narrow and uniform particle diameter distribution so that the precipitation of soybean particles does not occur. Also, according to the method for preparing soybean curd using the whole soybean milk, soybean curd having improved sensory charac not teristics and cooking suitability can be prepared by heating the whole soybean milk in a stepwise manner so as to uniformly coagulate the soybean milk.

Owner:DAESANG FNF CORP

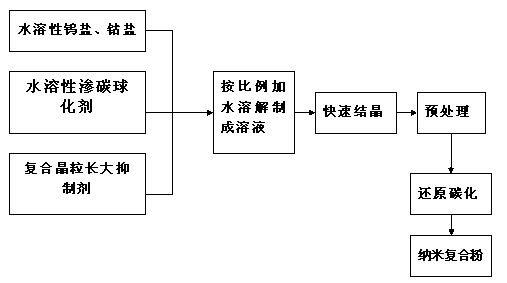

Method for manufacturing tungsten/ cobalt carbide composite powder with nanostructure

The invention discloses a method for manufacturing tungsten / cobalt carbide composite powder with a nanostructure. The method includes steps of firstly, dissolving, by mass, 55-92% of water-soluble tungsten salt, 3-40% of water-soluble cobalt salt, 3-6% of water-soluble carburizing and nodulizing agents and 0.1-2% of water-soluble composite grain growth inhibitors into water with the mass 3-5 times that of a mixture of the water-soluble tungsten salt, the water-soluble cobalt salt, the water-soluble carburizing and nodulizing agents and the water-soluble composite grain growth inhibitors to prepare mixed aqueous solution; secondly, quickly crystallizing the mixed aqueous solution obtained in the first step; thirdly, pre-treating crystalline, which is obtained in the second step, at the pretreatment temperature ranging from 500 DEG C to 700 DEG C to obtain nodular powder; and fourthly, performing reduction synthesis and carbon conditioning for powder materials, which are obtained in the third step, at the temperature ranging from 900 DEG C to 1000 DEG C to manufacture tungsten / cobalt carbide composite powder materials with nanostructures. The method has the advantages that a process is simple, and the hard alloy powder materials with the nanostructures can be produced in an industrialized manner.

Owner:ADVANCED FOR MATERIALS & EQUIP

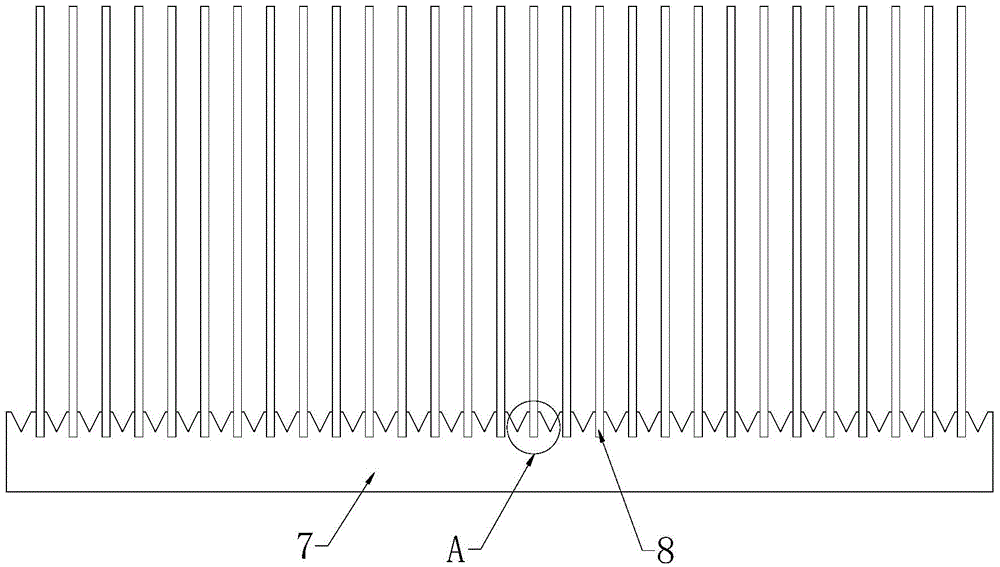

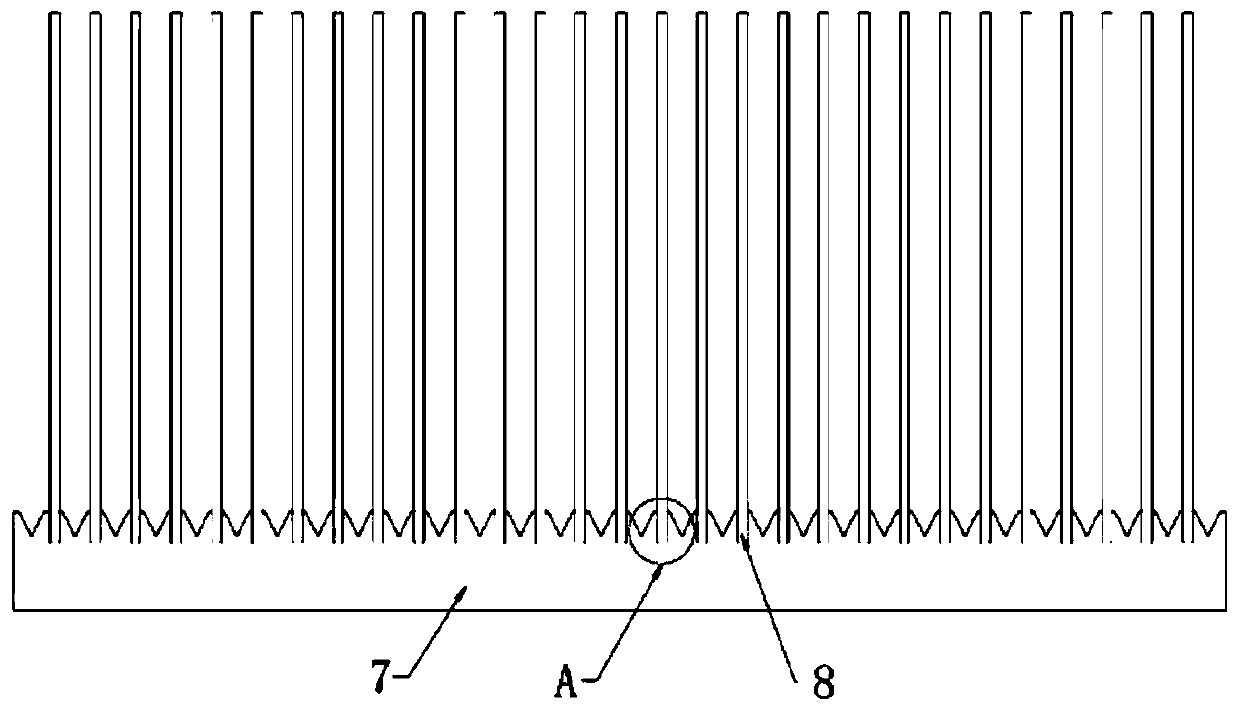

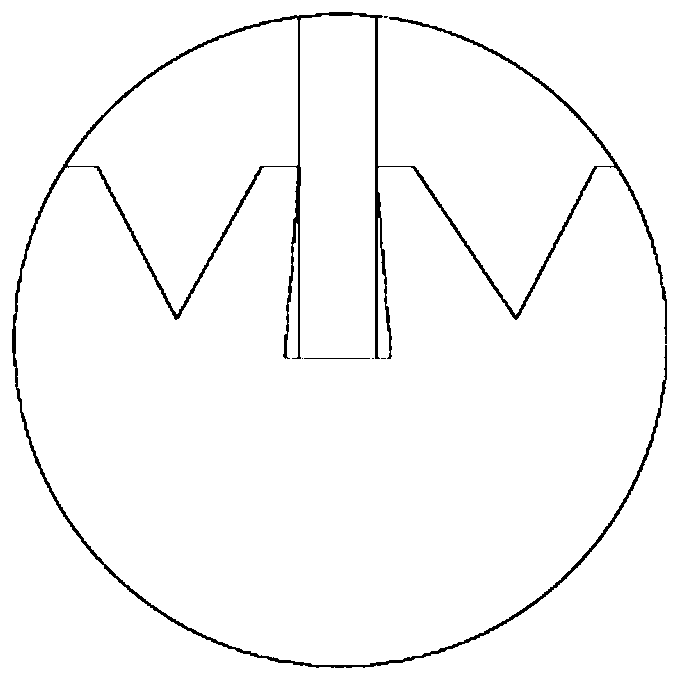

Air-cooling radiator and manufacturing method thereof

InactiveCN103987236ASmall temperature deviationReduce thermal resistanceCooling/ventilation/heating modificationsEngineeringHeat spreader

The invention discloses an air-cooling radiator and a manufacturing method thereof. The air-cooling radiator comprises a thermal conduction substrate and cooling fins. Fin insertion grooves are formed in the thermal conduction substrate. A connecting end of each cooling fin is fixed in the corresponding fin insertion groove in the thermal conduction substrate. The space between the connecting end of each cooling fin and the corresponding fin insertion groove is filled with a thermal conduction medium. An air passing passageway is further formed in each cooling fin. The space between the connecting end of each cooling fin and the corresponding fin insertion groove is further filled with the corresponding thermal conduction medium, thermal resistance between the thermal conduction substrate and the cooling fins can be reduced through the thermal conduction mediums, thermal conduction is facilitated, and the heat dissipation effect of the air-cooling radiator is improved; the cooling fins can be more tightly attached to the side walls of the fin insertion grooves, and therefore thermal resistance can be further reduced; by the adoption of the design of the air passing passageways, air from an external fan can flow through the space outside the cooling fins and the air passing passageways, so that the inner portion and the outer portion of the cooling fins are fully cooled, and heat on the cooling fins can be rapidly taken away.

Owner:深圳市华盛源机电有限公司

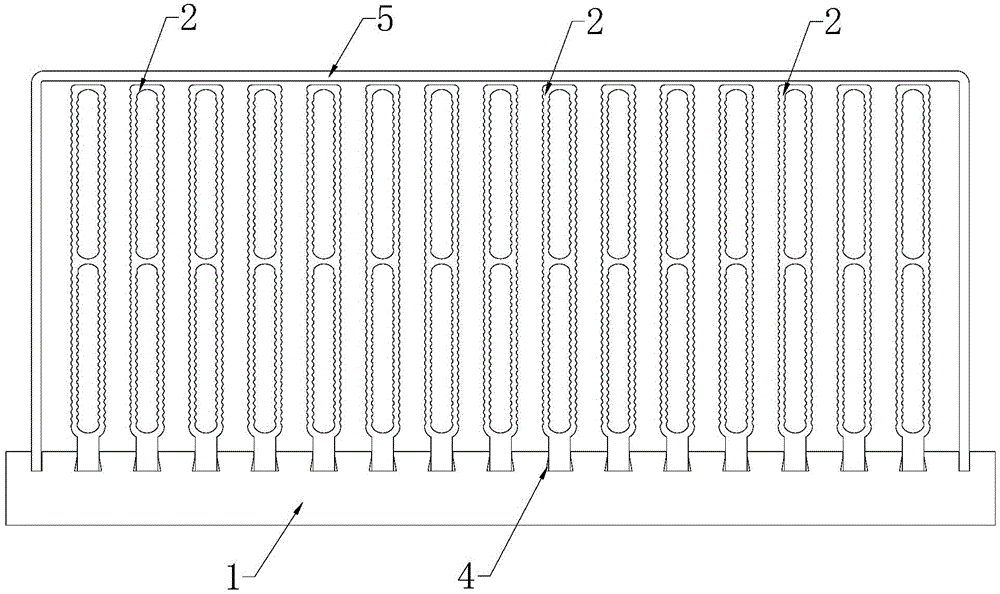

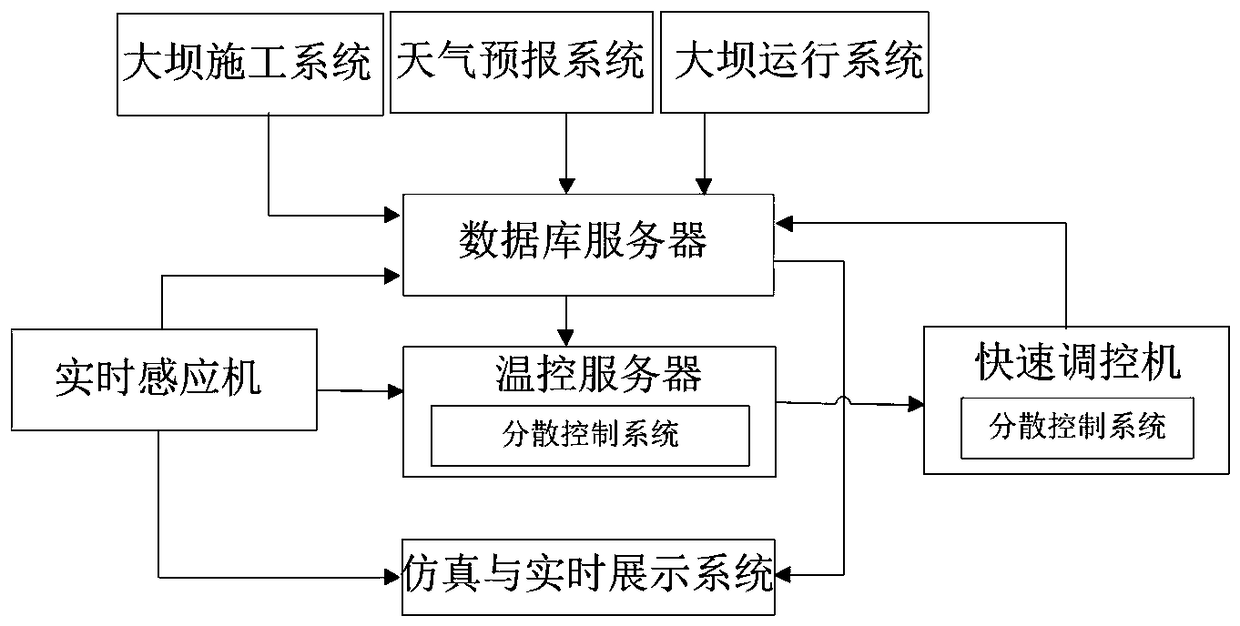

Heating-element unit, and heating device

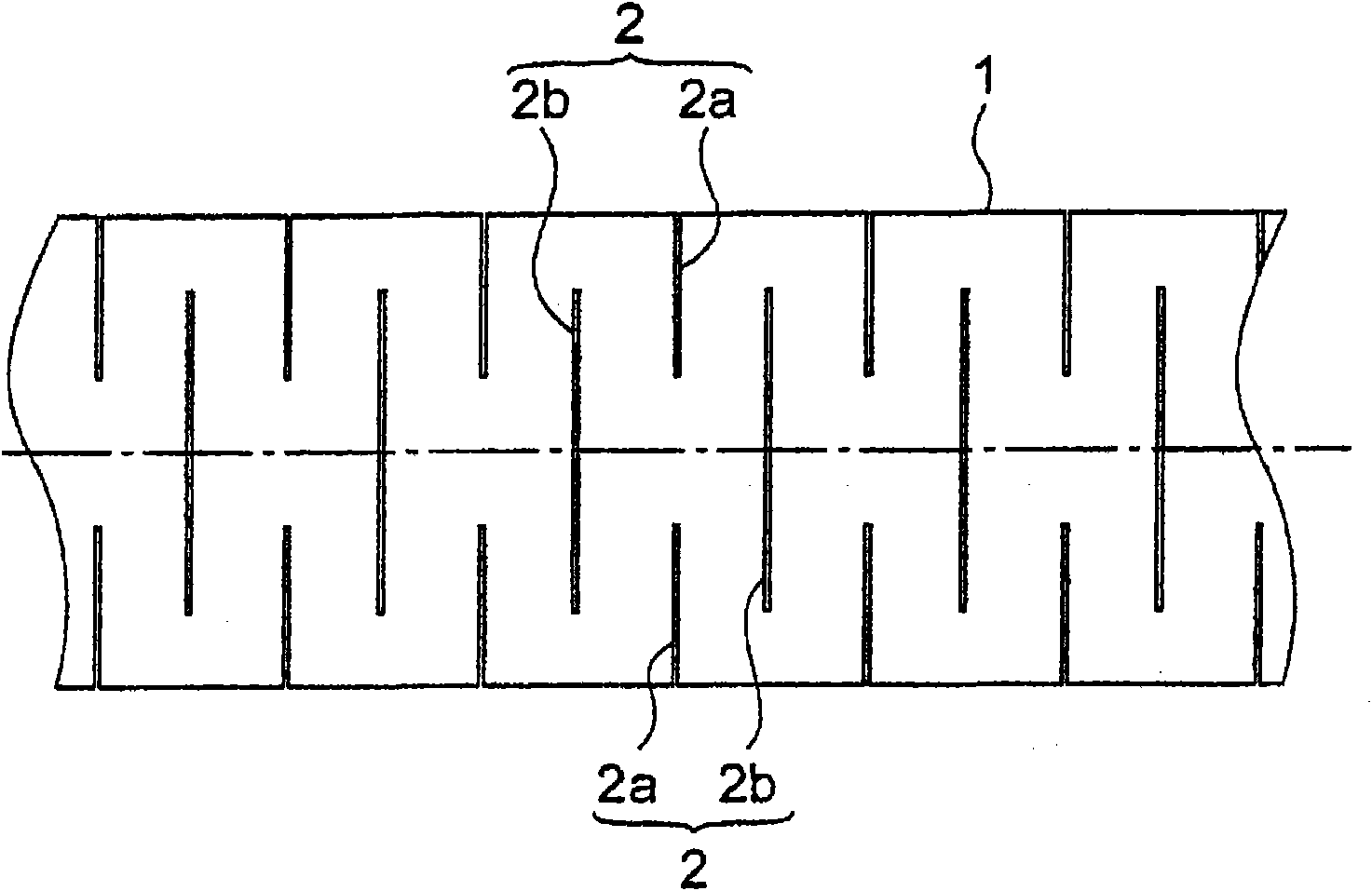

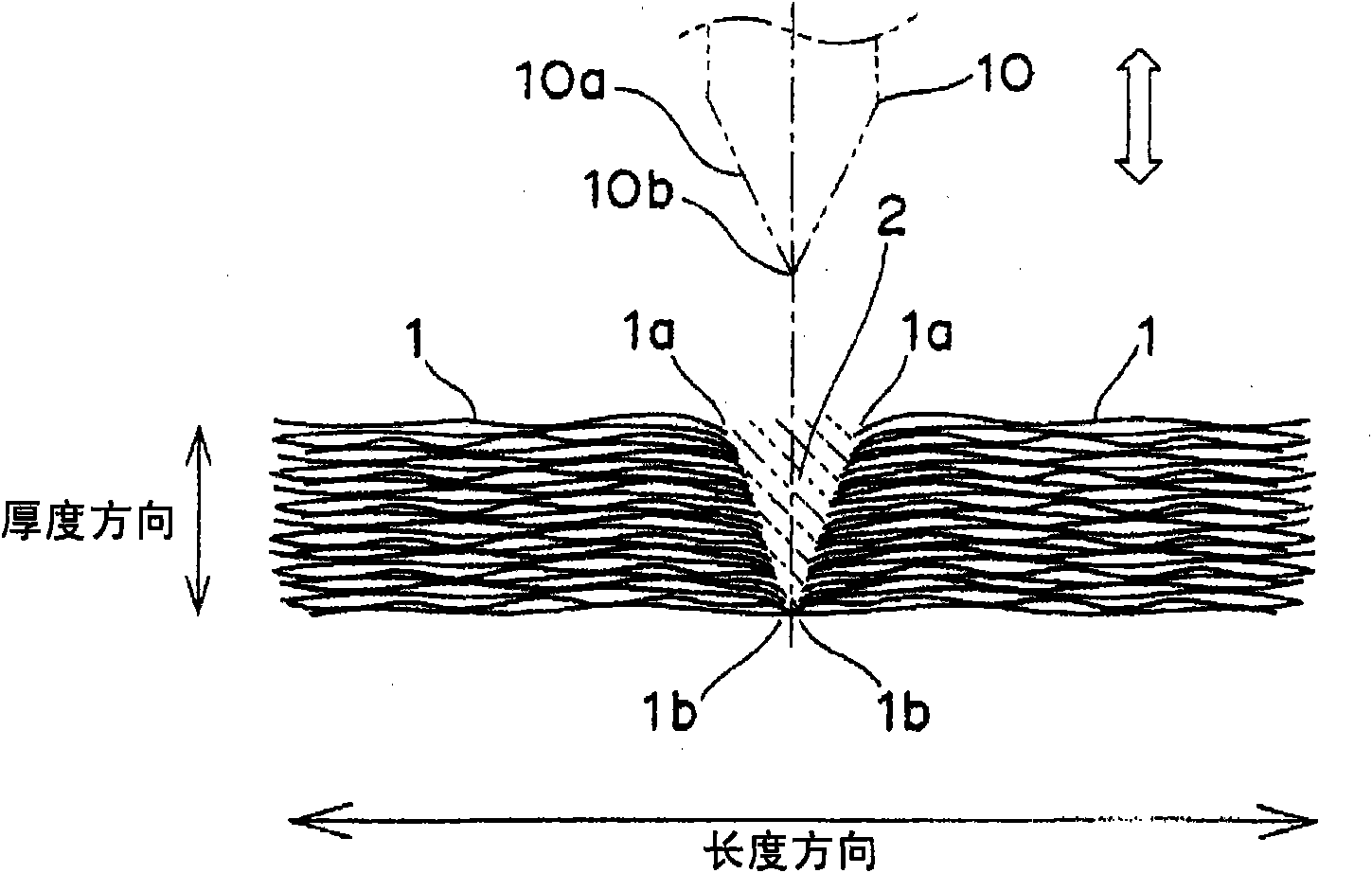

InactiveCN101861758AEasy to set resistance valueImprove cooling effectOhmic-resistance waterproof/air-tight sealsHeater elementsEngineeringCarbon group

This aims to provide a heating-element unit, in which a slender, sheet-shaped heating element (1) composed of mainly a carbon-group material has a plurality of layers laminated through gaps from each other in the thickness direction and in which current suppressing means (2) is formed to control the electric currents to flow through the individual layers laminated. The current suppressing means (2) is formed to have cuts by pushing blades in the thickness direction of the heating element (1), so that the electric current to flow in the longitudinal direction of the heating element (1) can be controlled to a desired value by forming the current suppressing means (2).

Owner:PANASONIC CORP

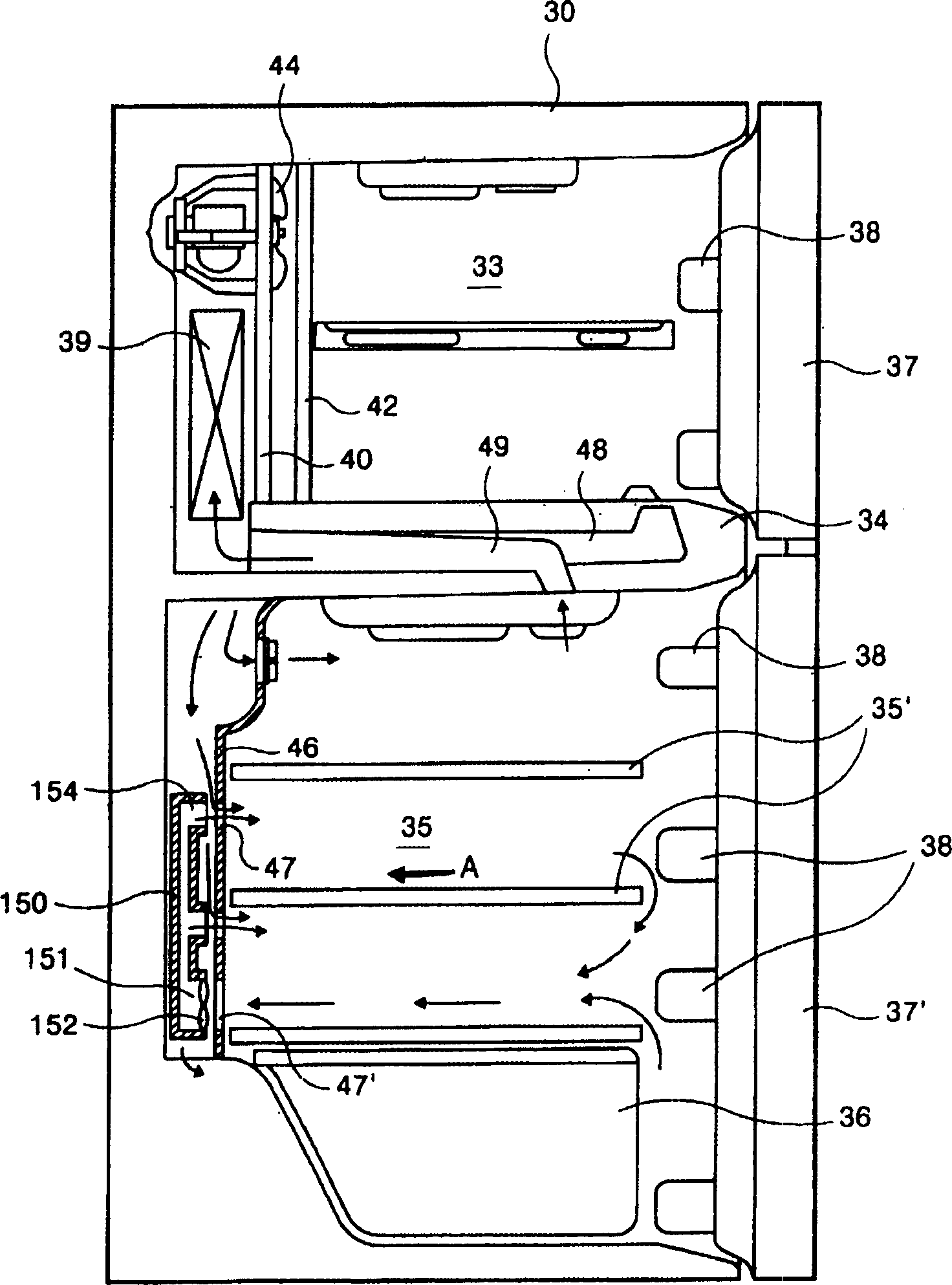

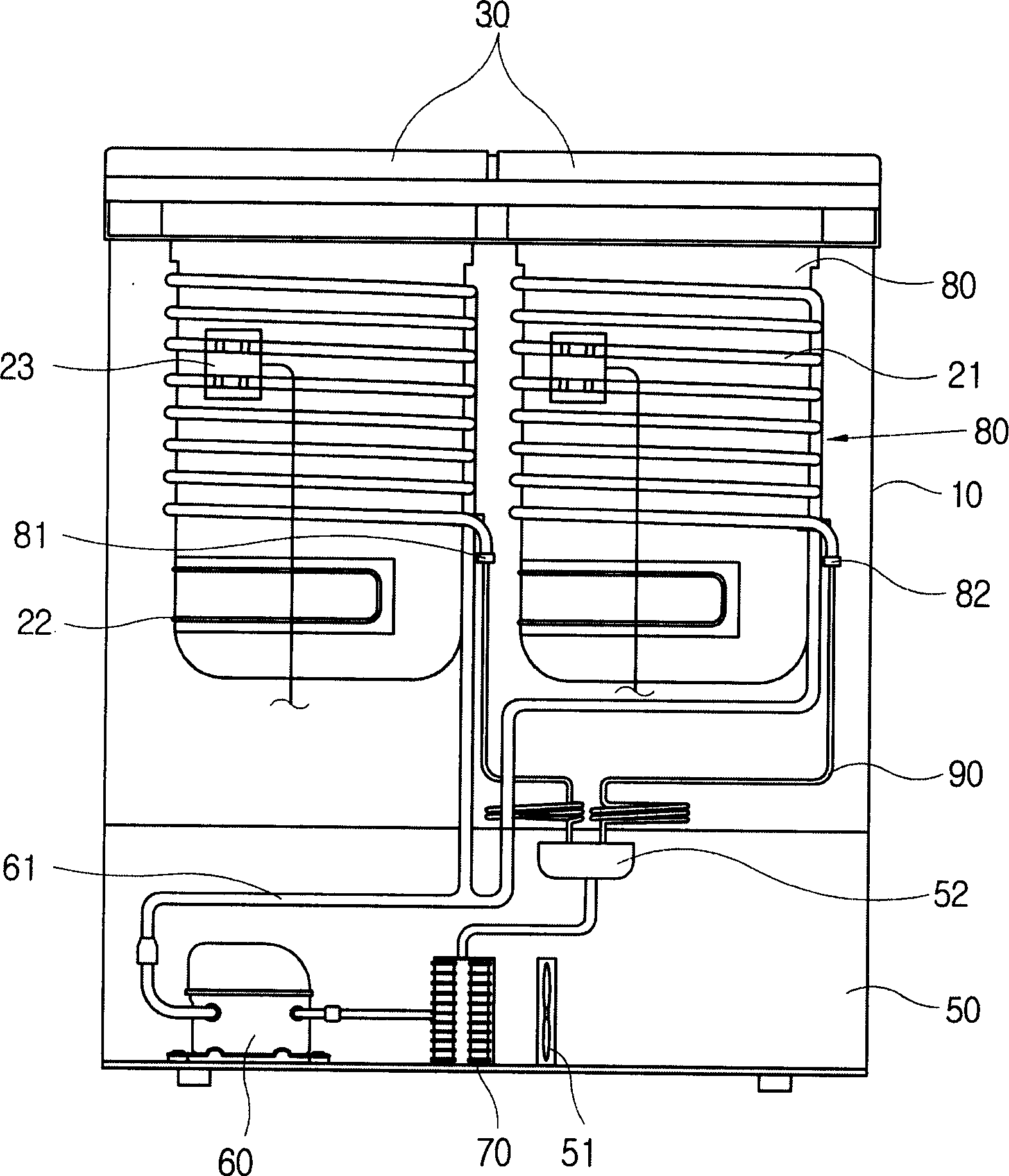

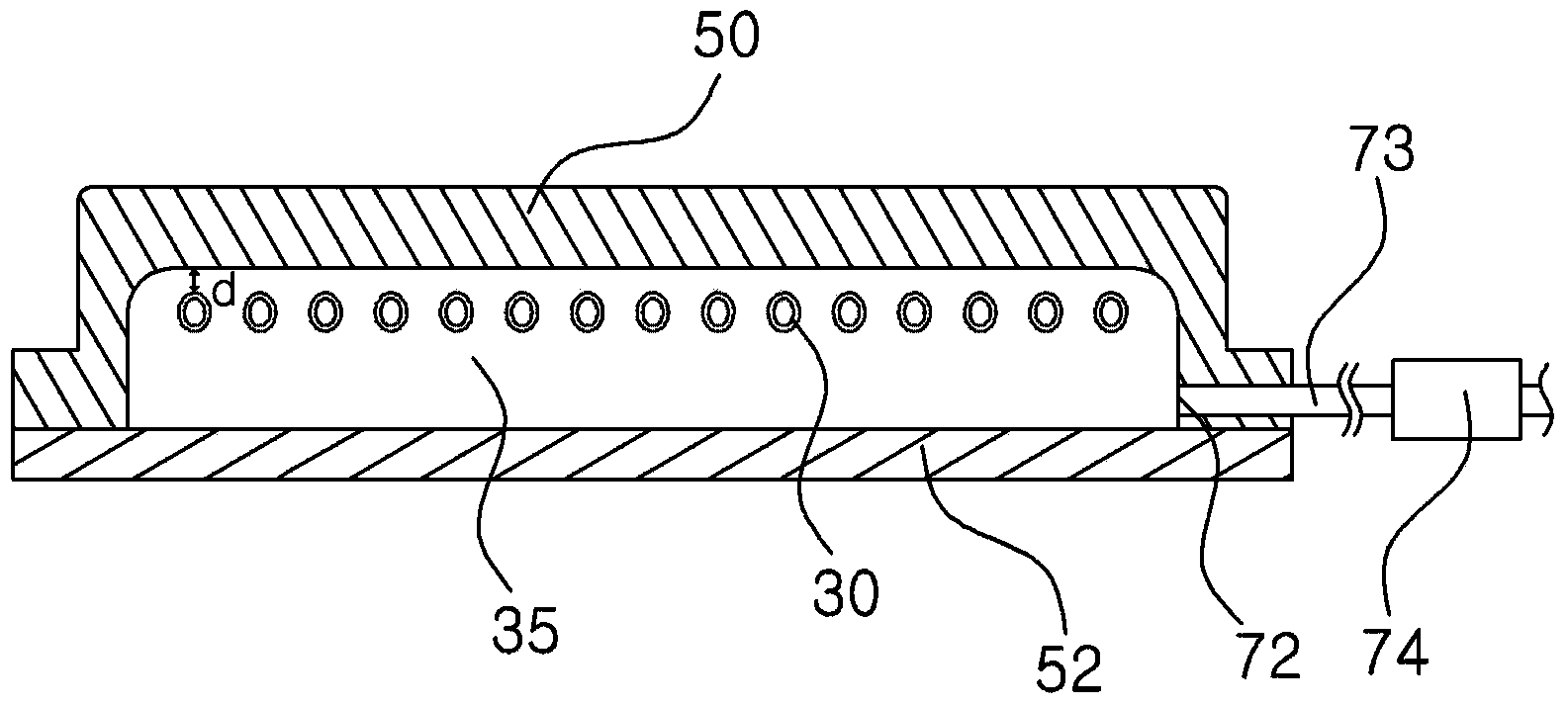

Apparatus and method for controlling cold air circulation in refrigerator

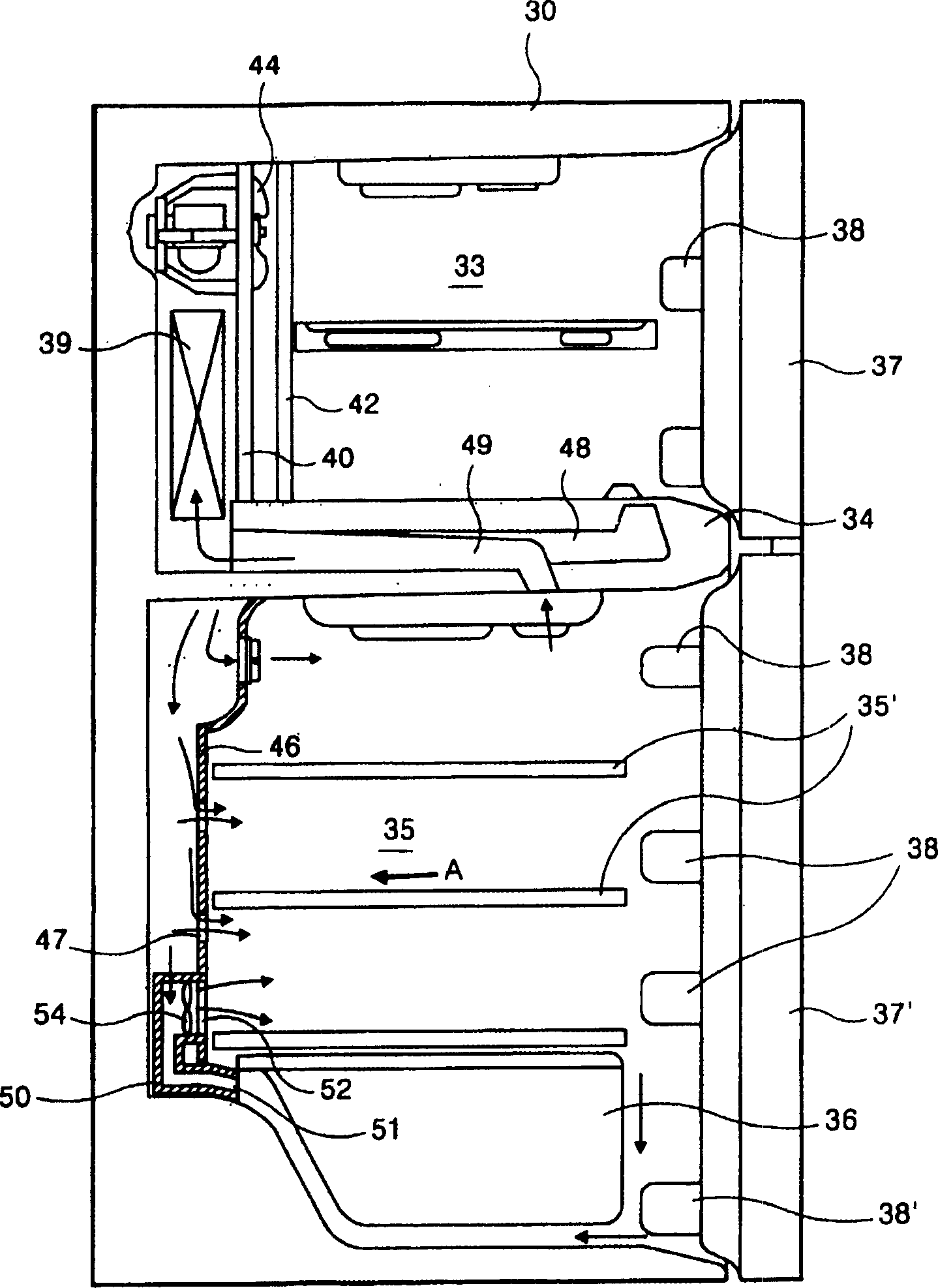

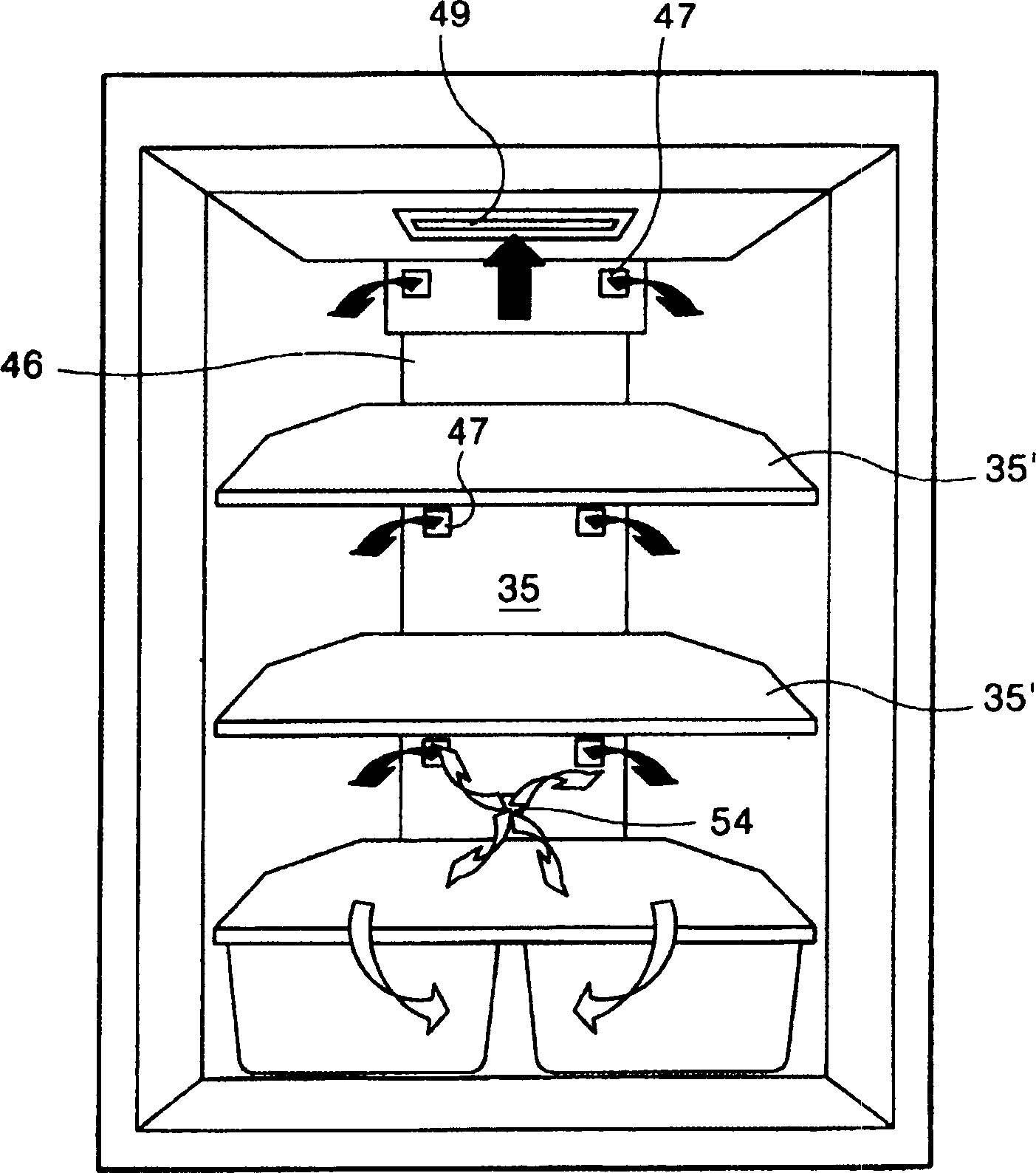

InactiveCN1531639ASmall temperature deviationLighting and heating apparatusCooling fluid circulationCold airEngineering

The present invention relates to an apparatus and method for controlling cold air circulation in a refrigerator. The present invention re-circulates cold air, which has been discharged into a refrigerating chamber (35), so that the interior of the refrigerating chamber (35) can be maintained at a substantially uniform temperature and relatively low temperature cold air is prevented from being delivered to an evaporator (39). Particularly, the present invention further facilitates the cold air circulation at a lower portion of the refrigerating chamber (35) so that the temperature of the entire refrigerating chamber (35) can be kept to be uniform and the temperature of a vegetable storage chamber (36) can be set at a desired temperature. To this end, an embodiment of the present invention includes a circulation duct (50) configured to suck the cold air around the vegetable storage chamber (36) and to discharge it to a relatively upper portion of the refrigerating chamber (35). An inlet (51) of the circulation duct (50) is installed in vicinity of a rearward lower portion of the vegetable storage chamber (36), and an outlet of the circulation duct (50) is open to above a shelf (35') corresponding to a top end of the vegetable storage chamber (36). Further, a circulation fan (54) is installed at the outlet (52).

Owner:LG ELECTRONICS INC

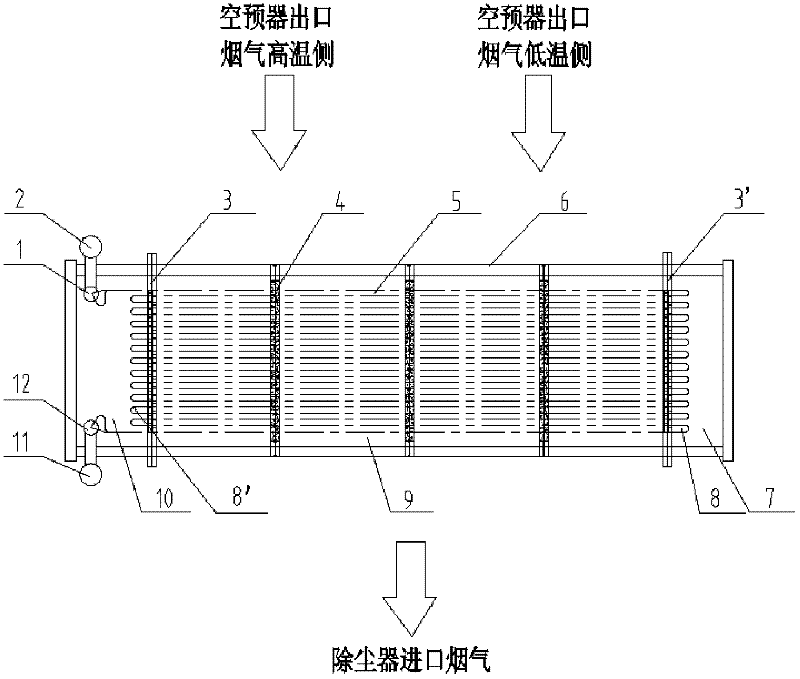

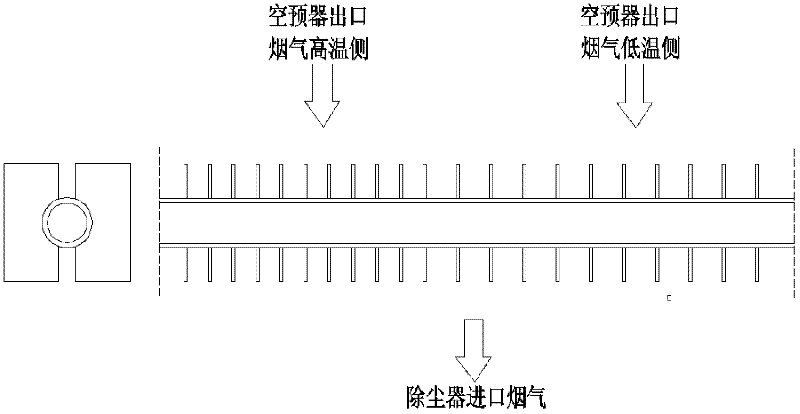

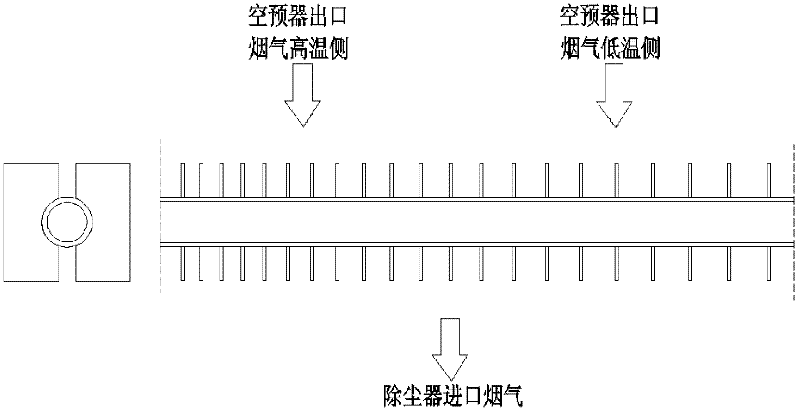

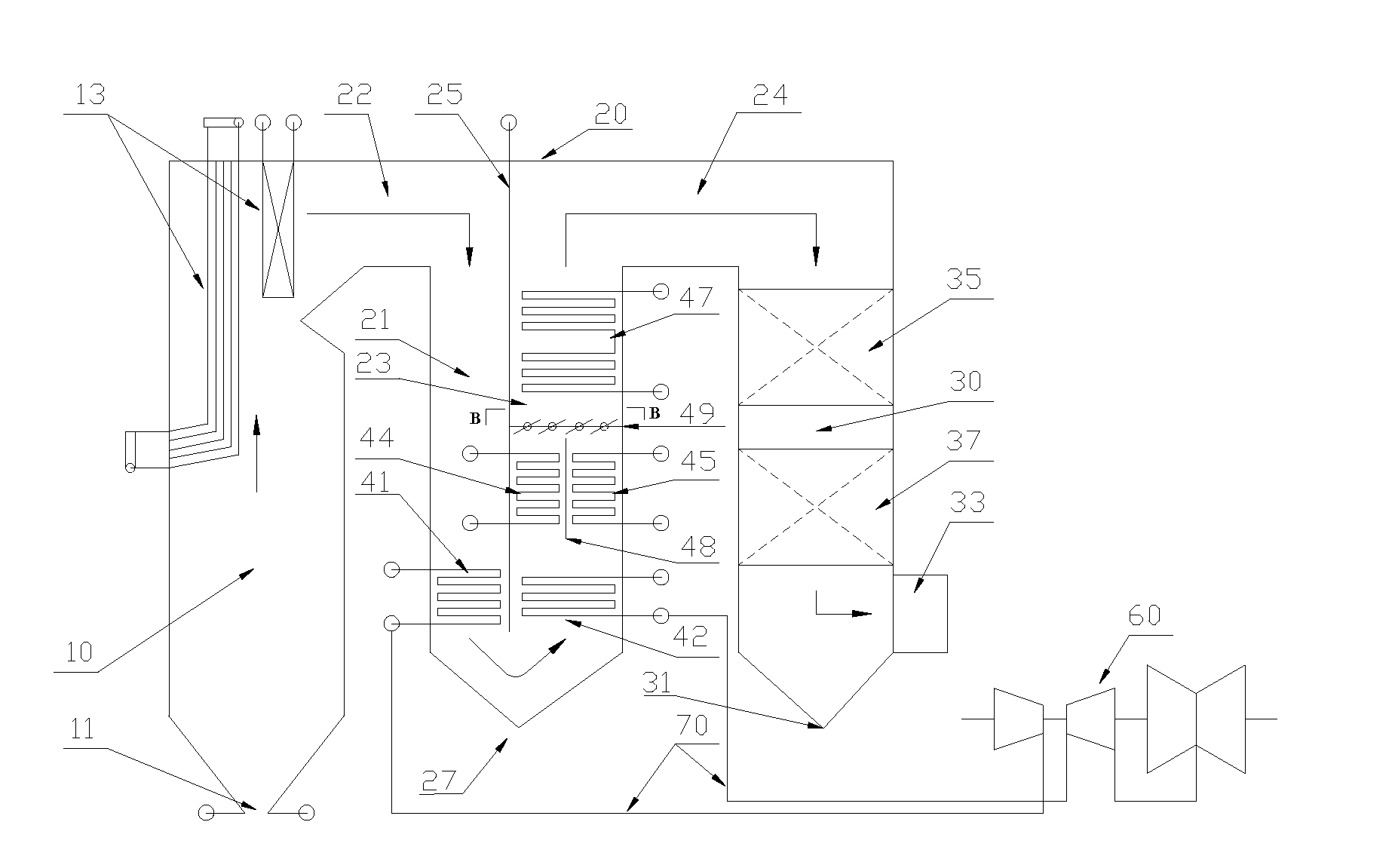

Device for eliminating flue gas temperature deviation

InactiveCN102537994AReduce flue gas temperature deviationMore exothermicLighting and heating apparatusCombustion technology mitigationFlue gasSmoke

A device for eliminating flue gas temperature deviation is arranged between an air preheater and a dust collector and comprises a circulation flue. A heat transfer fin tube bundle is arranged in the circulation flue along the width direction of the flue, the fin pitch of the heat transfer fin tube bundle is gradually changed from small to large from a high-temperature smoke zone to a low-temperature smoke zone, or the low-temperature smoke zone and the high-temperature smoke zone are of a large variable-pitch structure and a small variable-pitch structure respectively, and the heat transfer fin tube bundle comprises H-shaped fin tubes, spiral fin tubes or needle-shaped fin tubes. By the aid of the device, exhausted flue gas of a boiler is cooled, waste heat of the exhausted flue gas of the boiler is effectively recycled to heat condensed water, the flue gas temperature of an inlet of the dust collector is decreased, the internal gas temperature deviation between the flue and the dust collector is eliminated, the abnormal working condition of uneven airflow distribution caused by uneven distribution of the internal temperature of the dust collector is improved, dust collection efficiency and boiler or unit efficiency are improved, and the comprehensive targets of safe and efficient operation of the dust collector and energy conservation and emission reduction of the boiler or a unit are achieved.

Owner:XI AN JIAOTONG UNIV

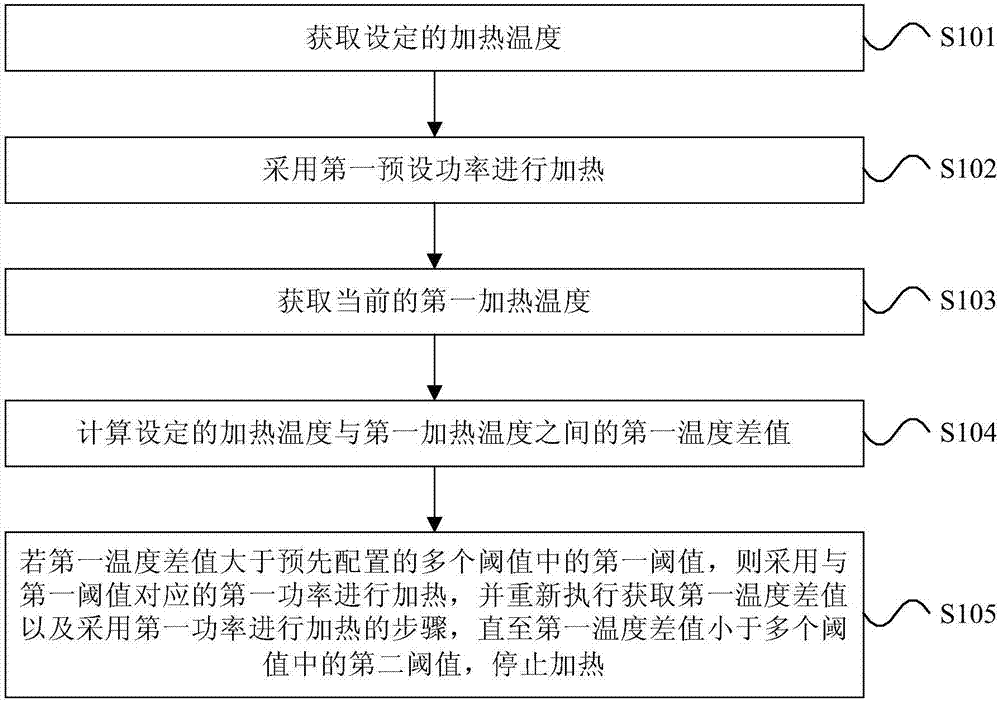

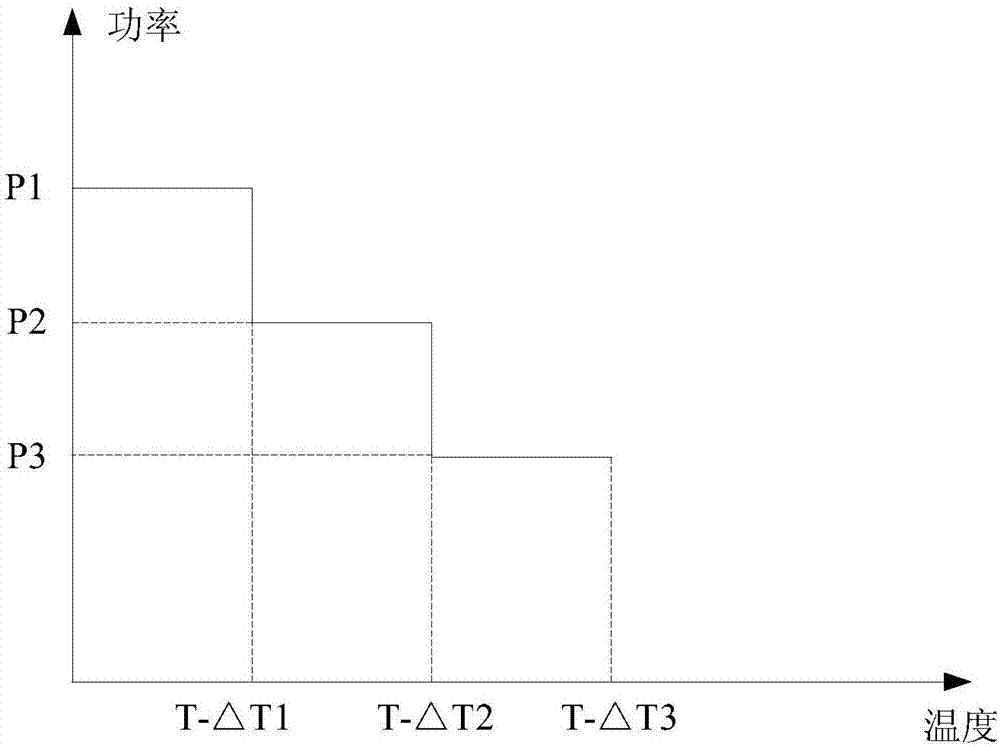

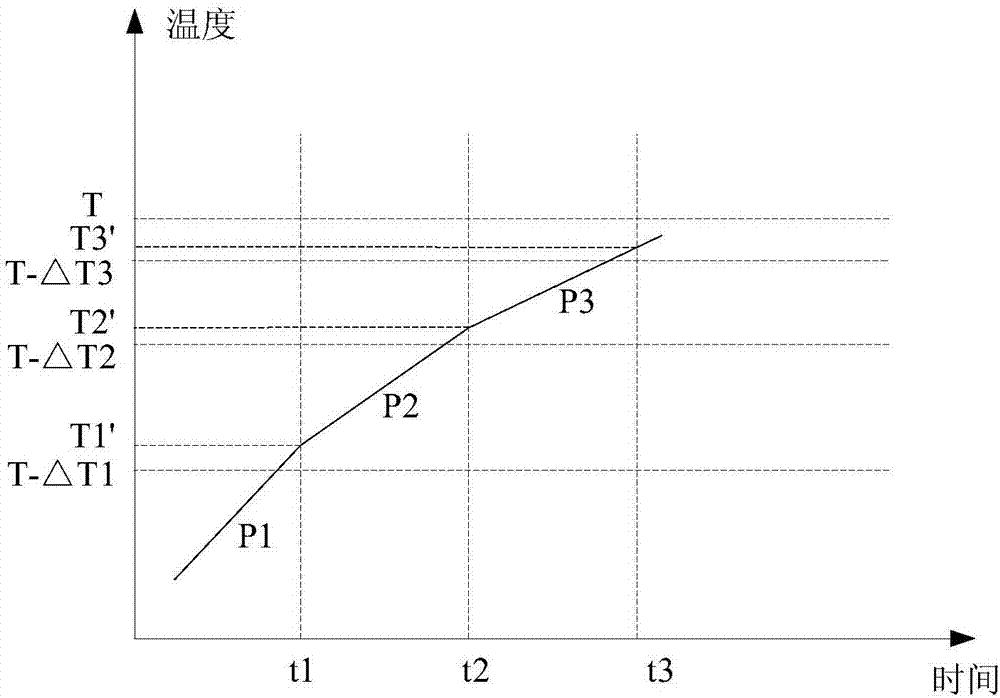

Temperature control method and device for electromagnetic heating and electromagnetic heating equipment

ActiveCN107124780AImprove accuracySmall temperature deviationInduction heating controlTemperature controlHeating time

The invention provides a temperature control method and device for electromagnetic heating and electromagnetic heating equipment. The temperature control method for electromagnetic heating comprises the following steps: acquiring a set heating temperature; carrying out heating by adopting first preset power; acquiring a current first heating temperature; calculating a first temperature difference value between the set heating temperature and the first heating temperature; if the first temperature difference value is greater than a first threshold of a plurality of pre-configured thresholds, carrying out heating by adopting first power corresponding to the first threshold, and executing the steps of acquiring the first temperature difference value and carrying out heating by adopting the first power again, and until the first temperature difference value is smaller than a second threshold in the plurality of thresholds, stopping heating. According to the temperature control method for electromagnetic heating, which is provided by the invention, accuracy of temperature control in the electromagnetic heating process can be promoted, temperature deviation is reduced, and heating time is shortened.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Water-cooled wall of boiler with double collecting boxes at middle part

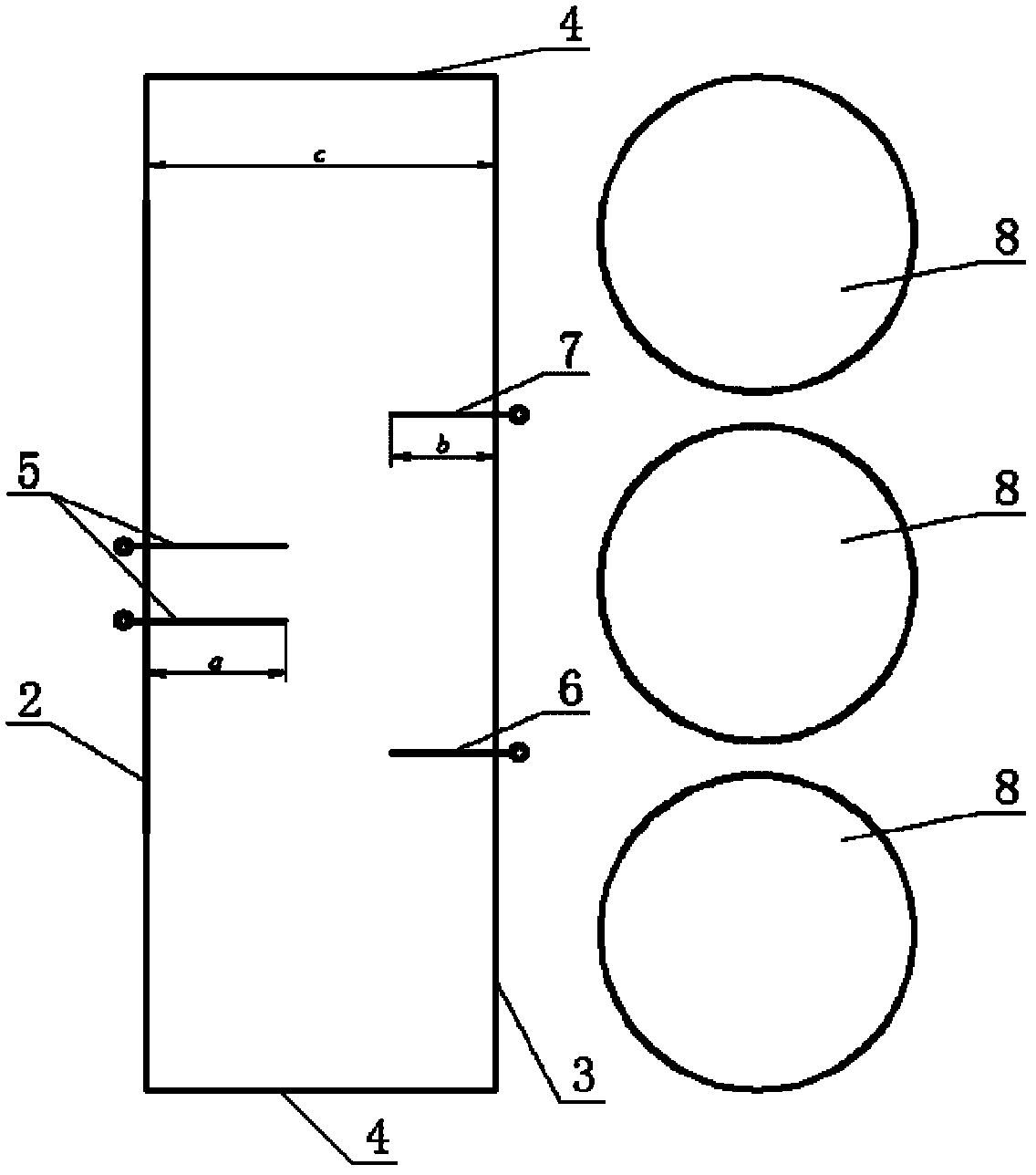

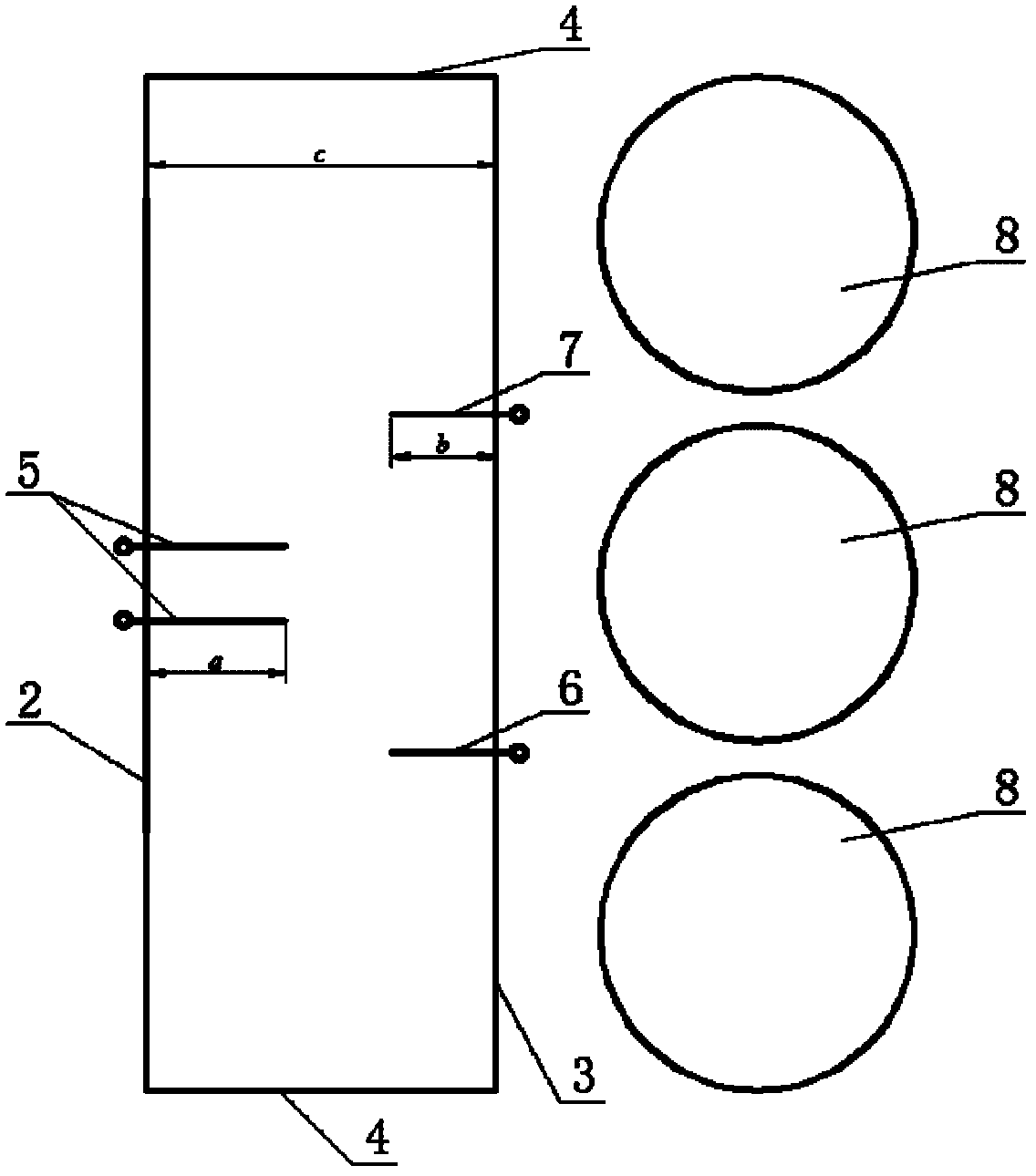

ActiveCN102734832ASolve the problem of large temperature deviation of working fluidReduce the totalCasings/liningsEngineeringDepth direction

The invention relates to a water-cooled wall of a boiler with double collecting boxes at the middle part, relating to a water-cooled wall of the boiler. The water-cooled wall is vertically arranged, and the double collecting boxes are arranged at the middle part of the boiler and consist of a distribution collecting box and a mixing collecting box. A working medium enters the mixing collecting box of the lower part of the boiler after flowing out of a water-cooled wall pipe of a lower hearth and then enters the distribution collecting box of the upper part of the boiler through a connection main pipe, the distribution collecting tank is used for distributing the working medium to a water-cooled wall of an upper hearth, and the mixing collecting box and the distribution collecting box are connected through the connection main pipe in a crossing manner. According to the water-cooled wall of the boiler, disclosed by the invention, the working medium absorbing much heat from the lower hearth is distributed to the wall-cooled wall pipe with lower thermal load in the upper hearth, thus the temperature deviation of the working mediums at outlets of water-cooled walls in width and depth directions of a hearth is effectively reduced, and the safety of boiler hydrodynamics is ensured.

Owner:TSINGHUA UNIV

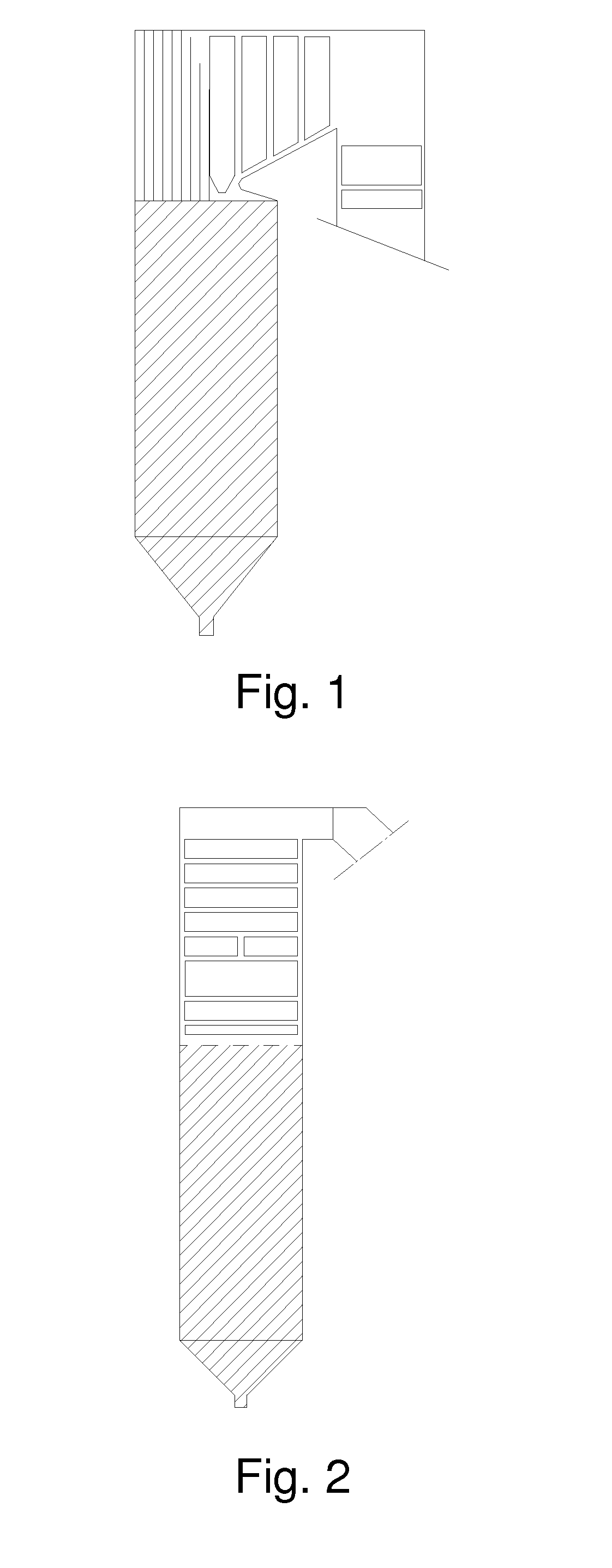

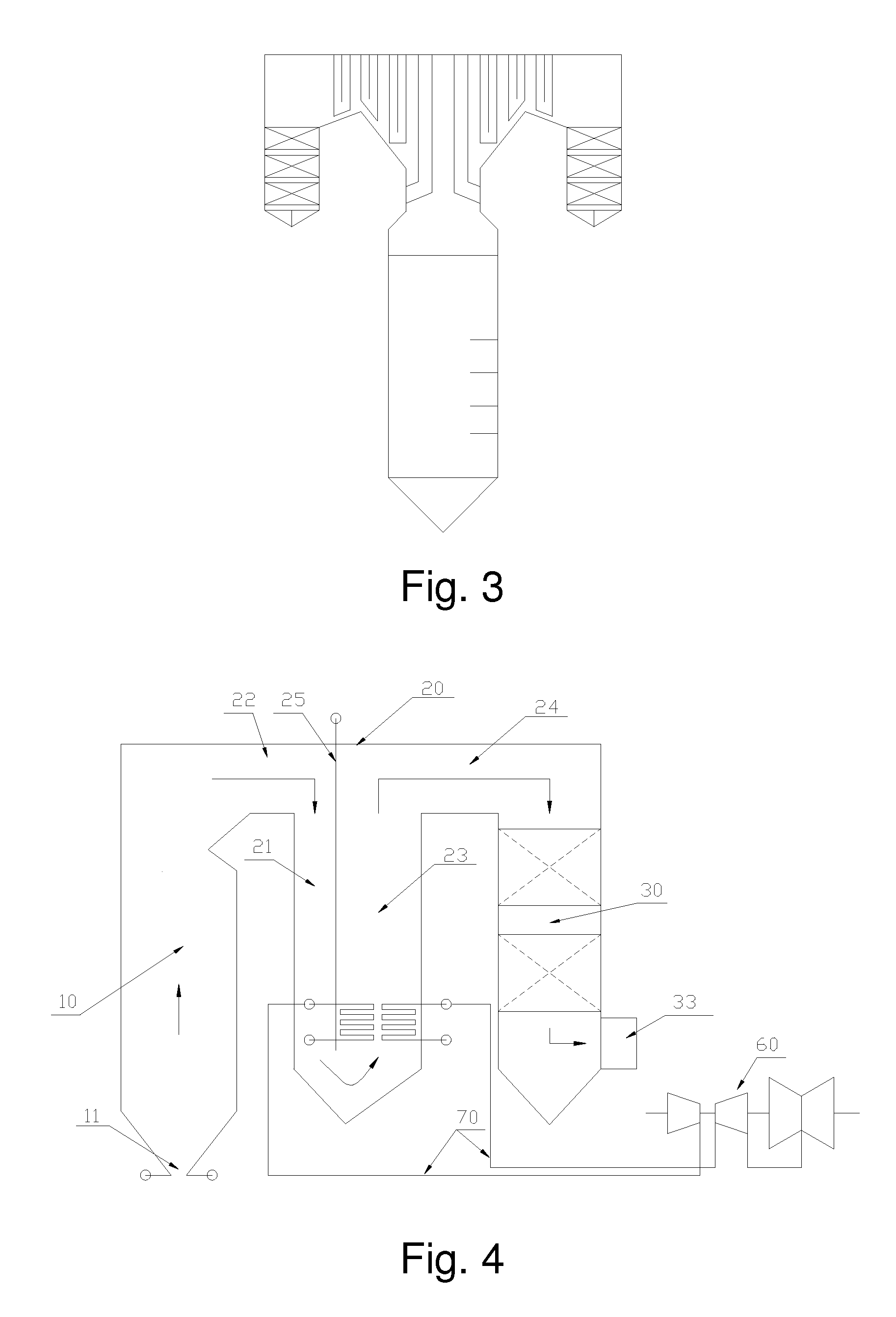

M-type pulverized coal boiler suitable for ultrahigh steam temperature

ActiveUS20140033712A1Increase manufacturing costSteam turbine can be greatly reducedWater circulationFuel injection apparatusSlagFlue gas

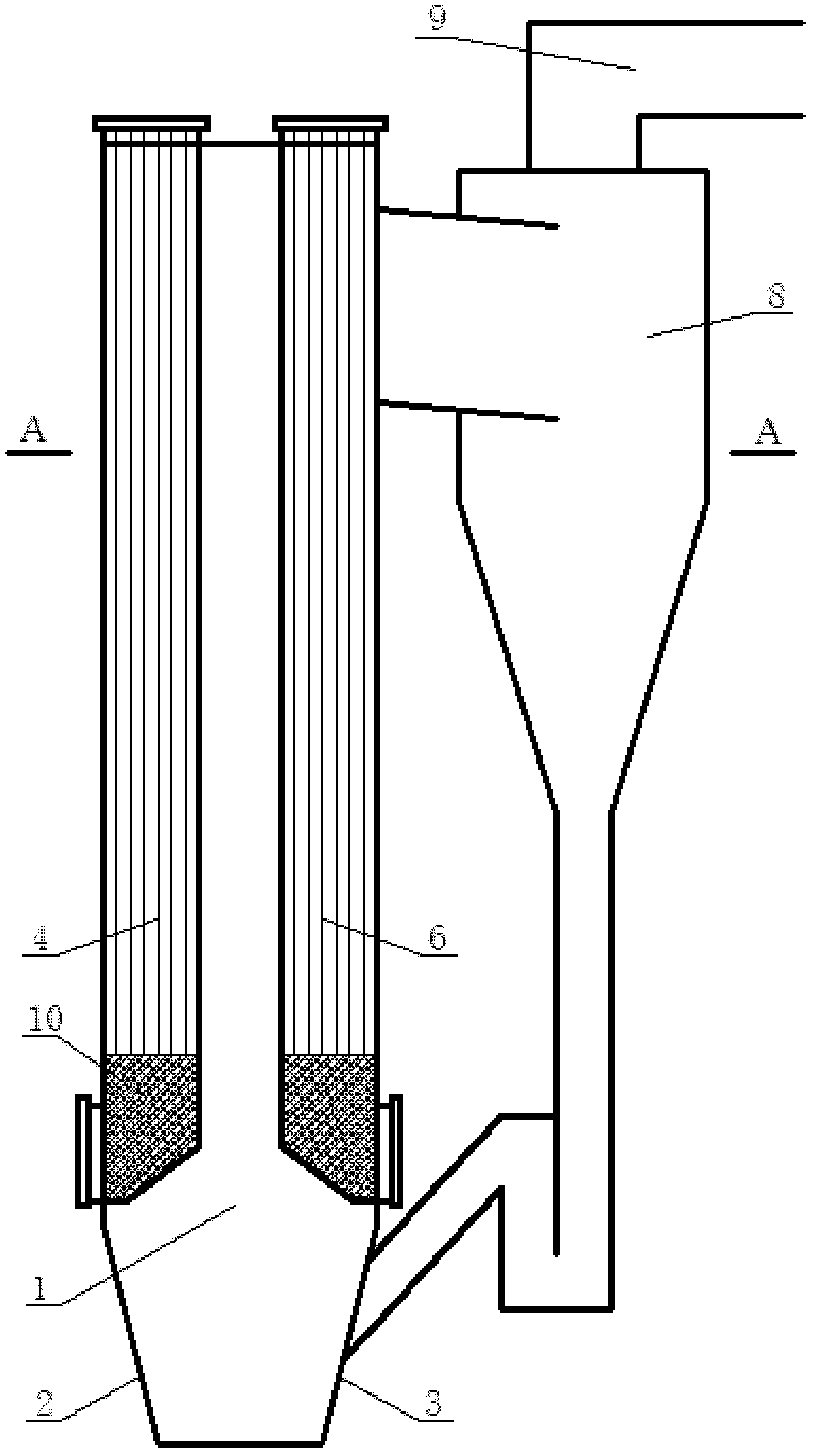

The disclosure provides an M-type pulverized coal boiler suitable for ultrahigh steam temperature. The pulverized coal boiler comprises a hearth of which the bottom is provided with a slag hole and a tail downward flue of which the lower part is provided with a flue gas outlet. The pulverized coal boiler further comprises a middle flue communicated between the hearth and the tail downward flue, wherein the middle flue comprises an upward flue and a hearth outlet downward flue of which the bottoms are mutually communicated and the upper ends are respectively communicated with the upper end of the hearth and the upper end of the tail downward flue to form a U-shaped circulation channel. In the pulverized coal boiler provided by the disclosure, the middle flue which extends downwards and can make flue gas flow along the U-shaped circulation channel is arranged between the outlet of the hearth and the tail downward flue, so that high-temperature flue gas from the hearth can be introduced into a position with low elevation through the downward flue, and final-stage convection heating surfaces (such as a high-temperature superheater and a high-temperature reheater) can be arranged at positions with low height, and the length of ultrahigh-temperature steam pipelines between the high-temperature superheater and a steam turbine, and between the high-temperature reheater and the steam turbine can be greatly reduced. Therefore, the manufacturing cost of a boiler unit is obviously reduced.

Owner:HUANENG CLEAN ENERGY RES INST

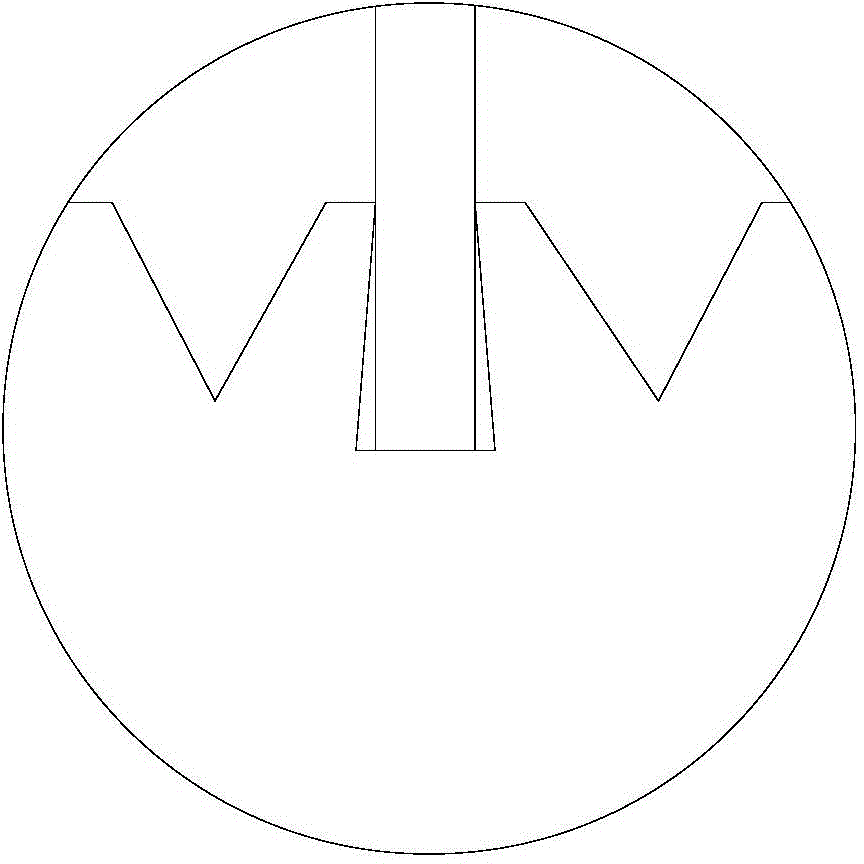

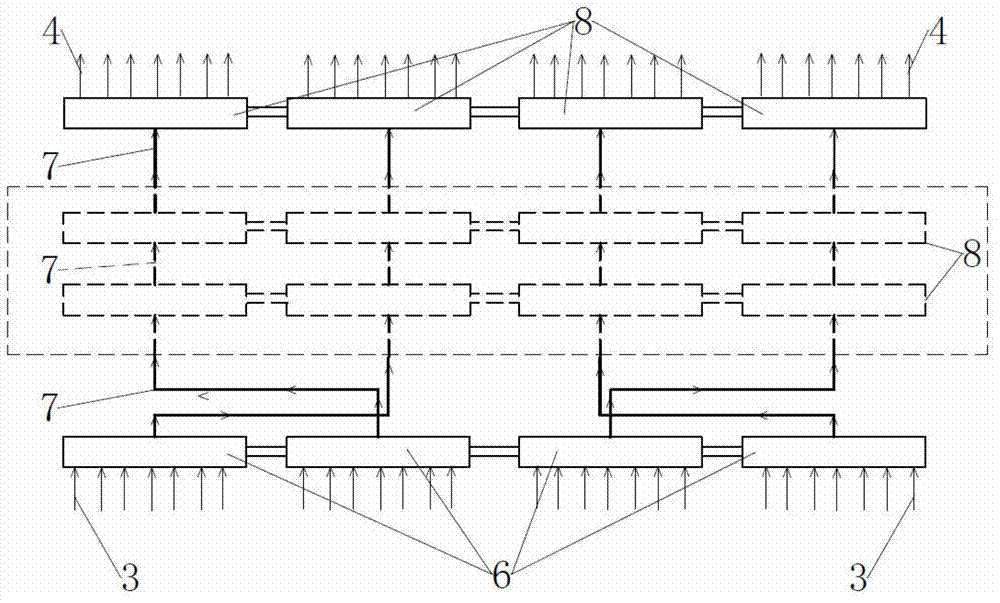

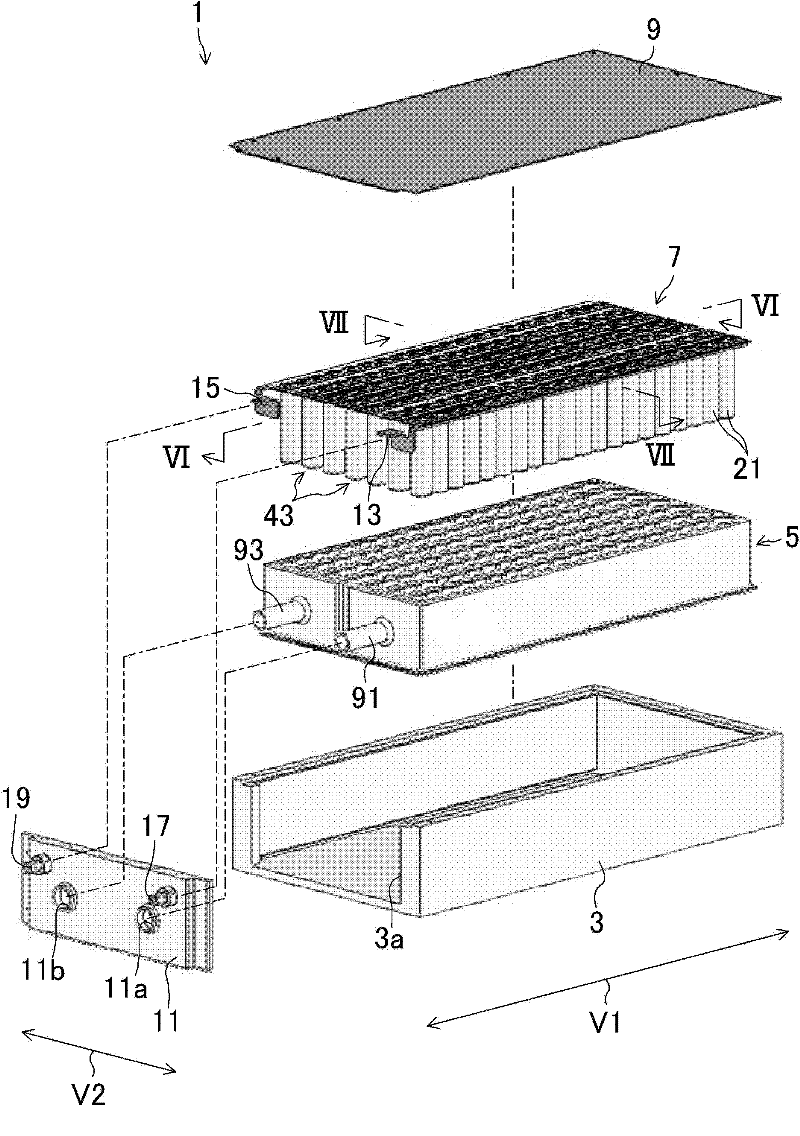

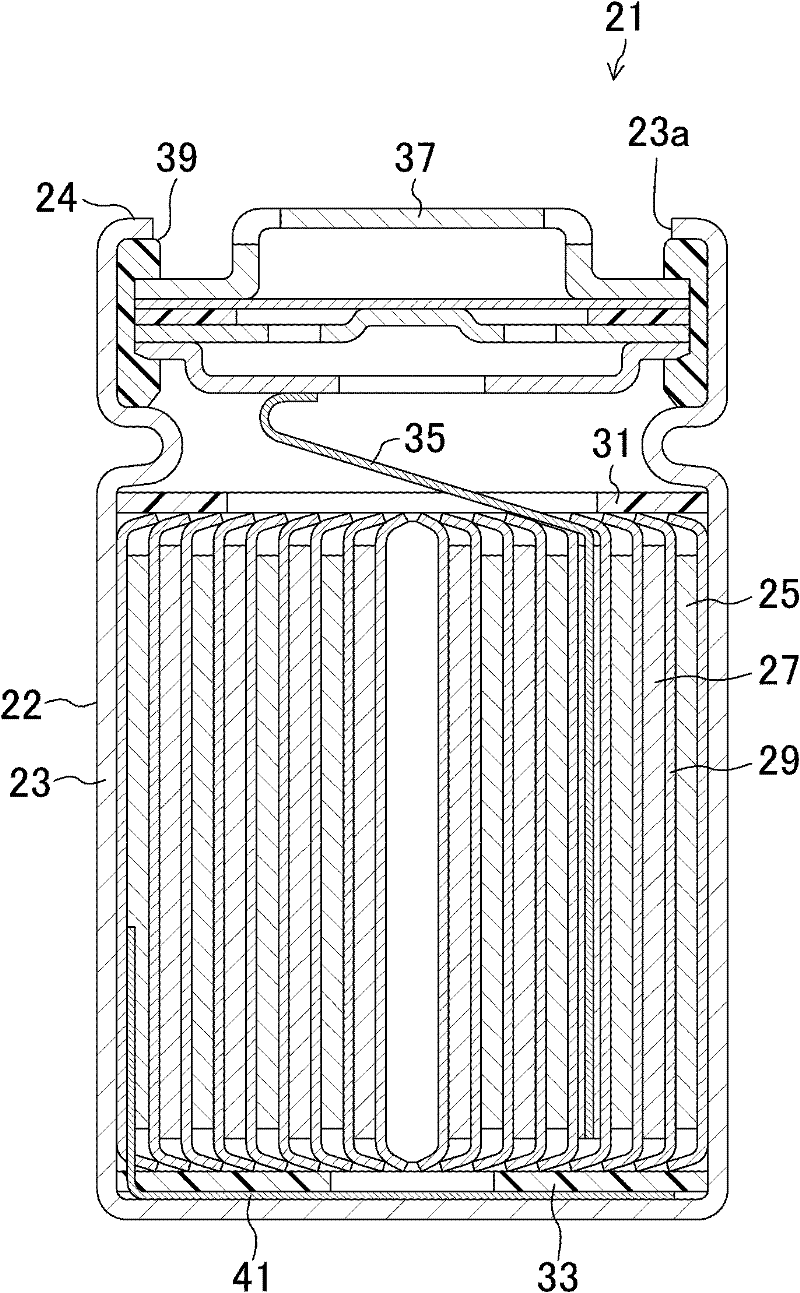

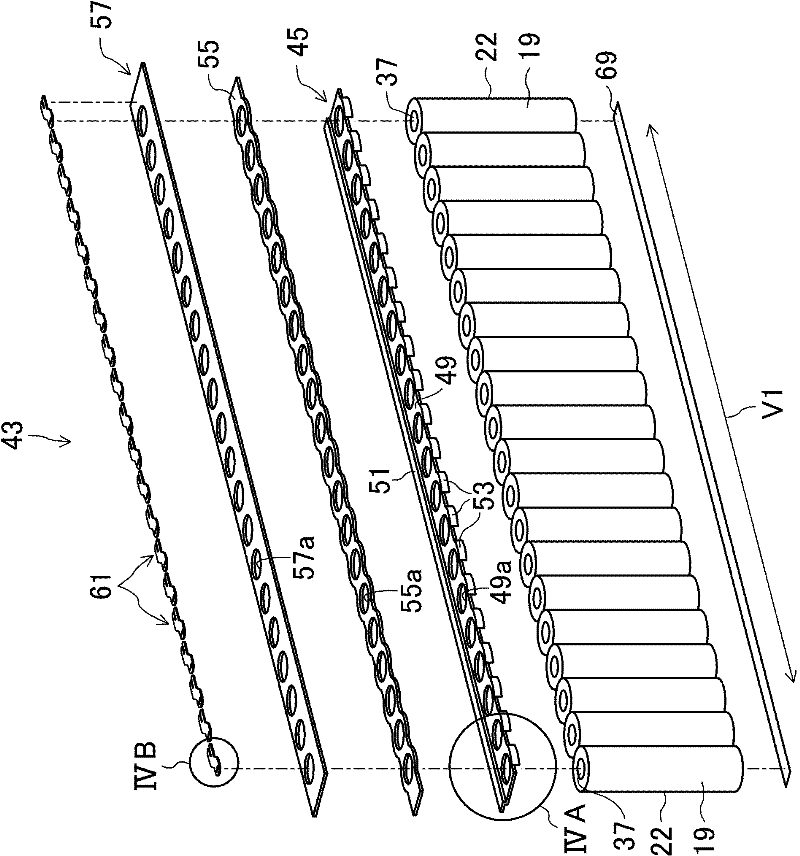

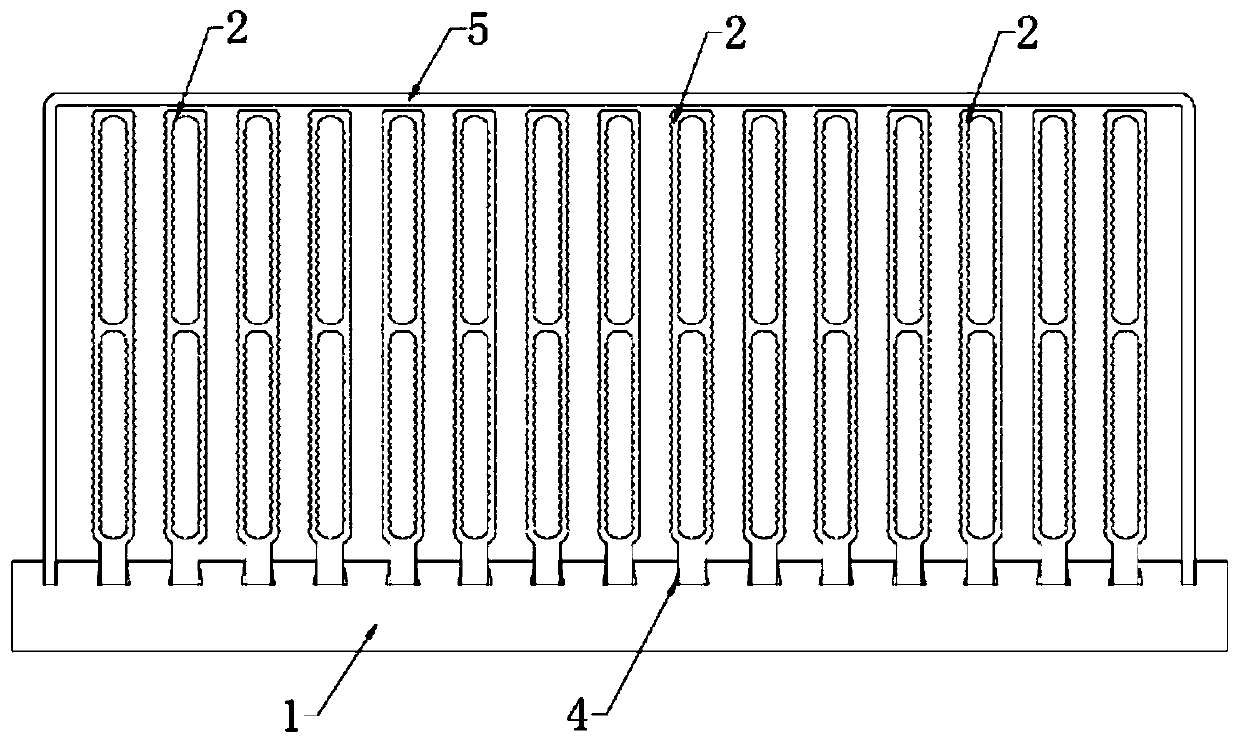

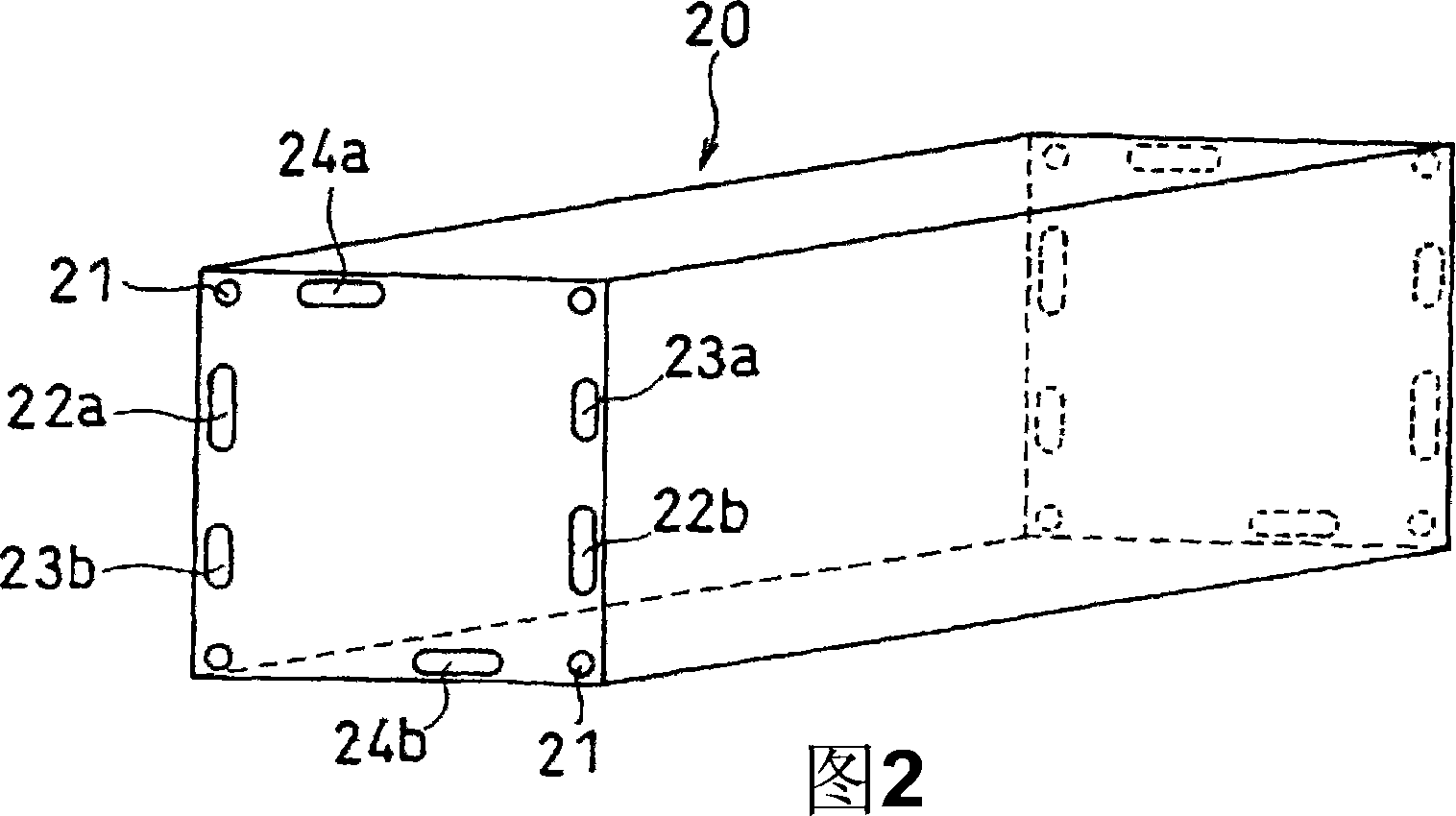

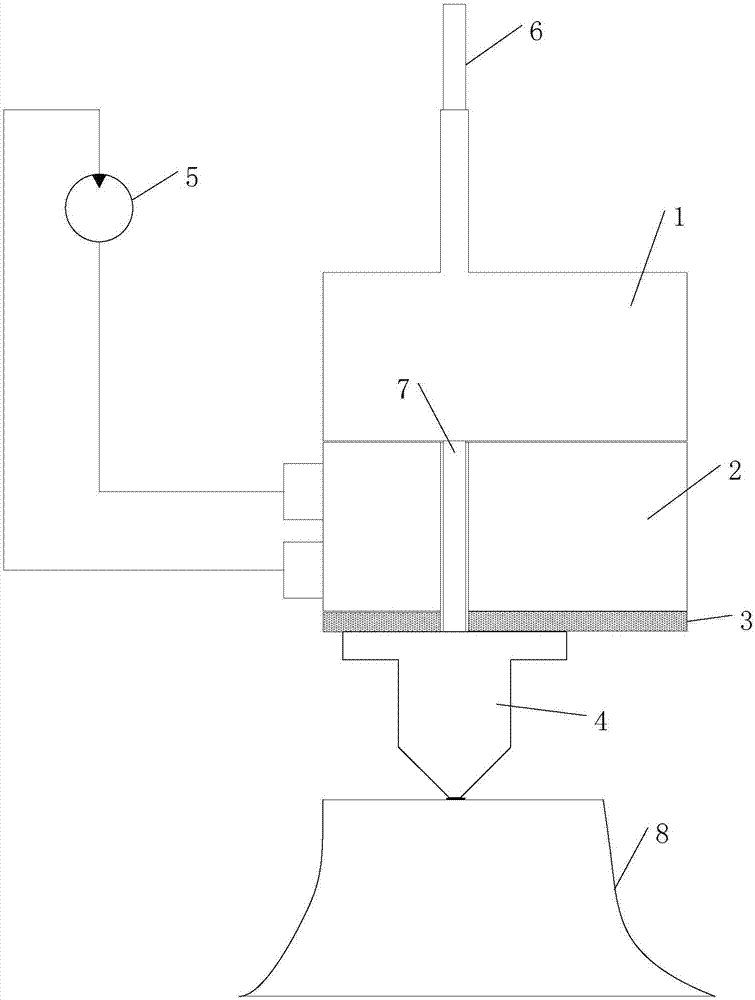

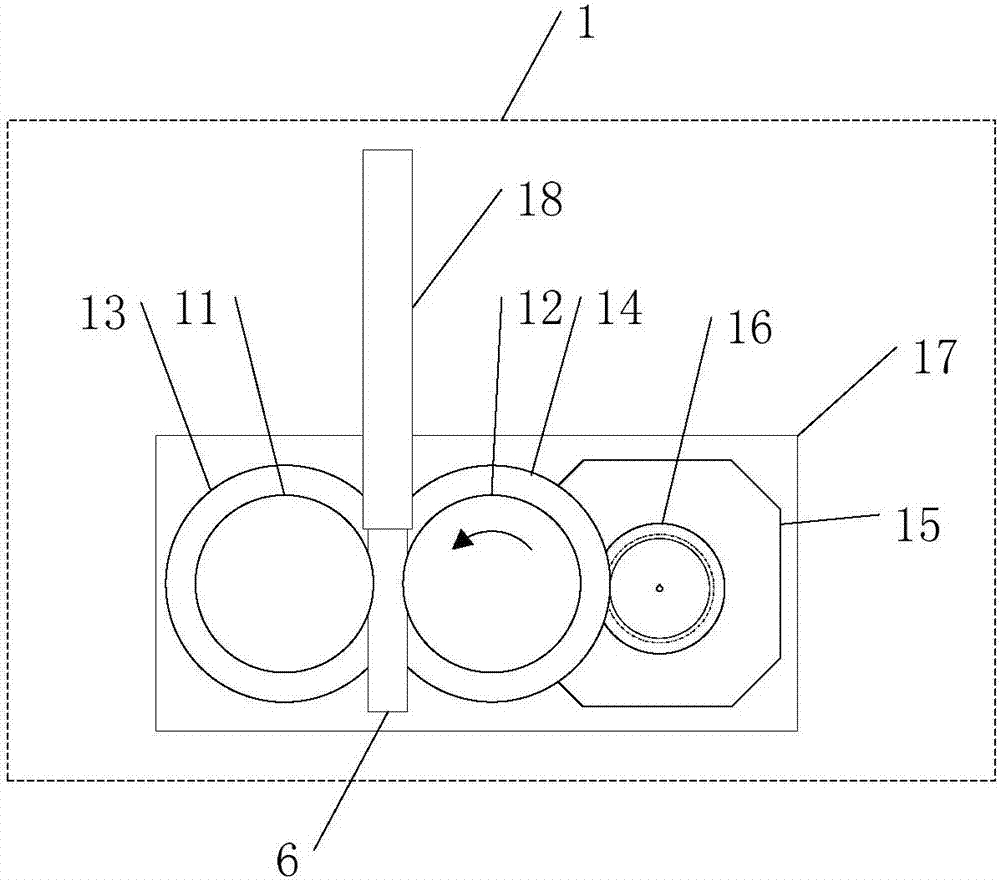

Battery module, method for manufacturing same, and temperature adjustment system

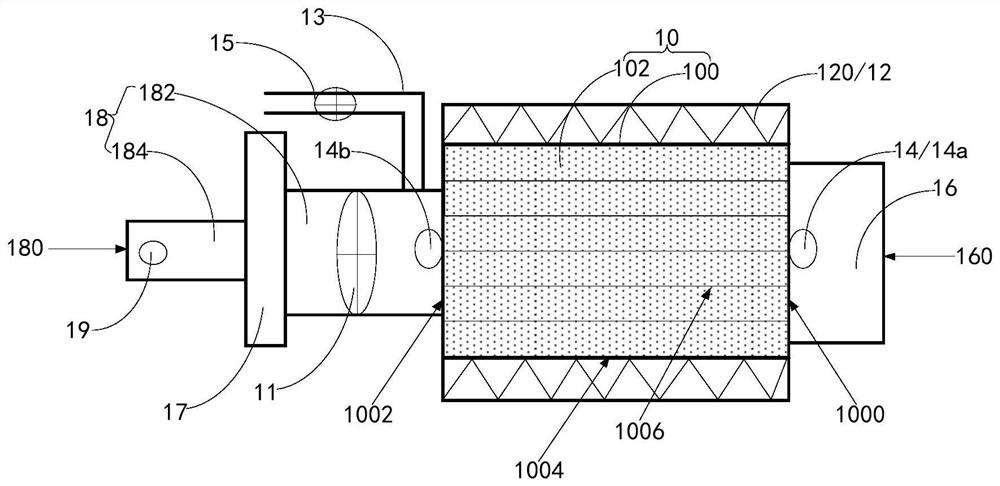

InactiveCN102227846ASmall temperature deviationLighting and heating apparatusCell temperature controlComputer moduleEngineering

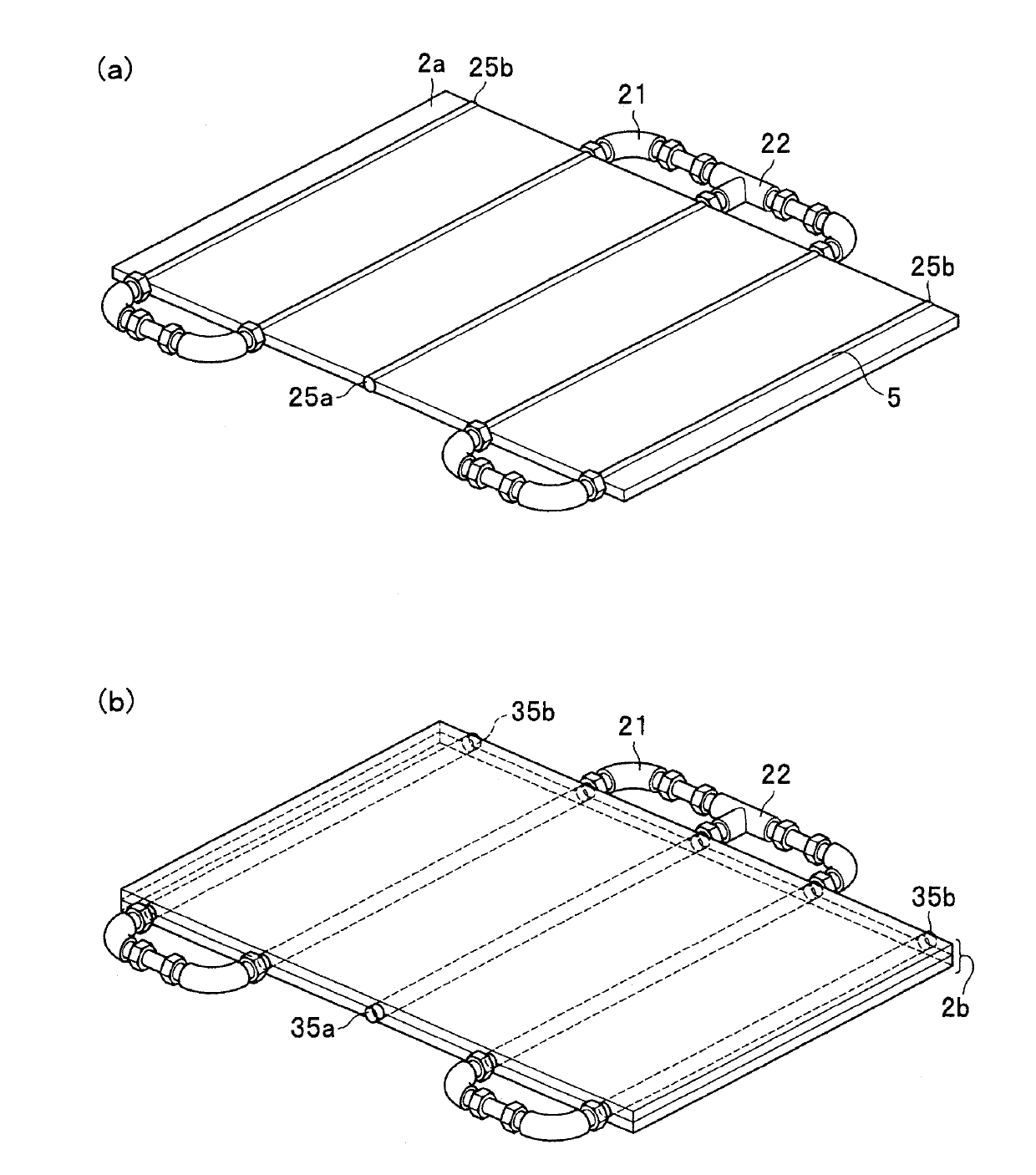

A temperature adjustment unit (5) comprises a resin molding body in which a first plane portion (73), a second plane portion (75), and a side-wall portion (77) are integrally formed, and is partitioned by the side-wall portion (77) into a holding portion (81) and a flow channel (85). A unit cell (21) is closely contacted to and held by the holding portion (81) partitioned by the side-wall portion (77).

Owner:PANASONIC CORP

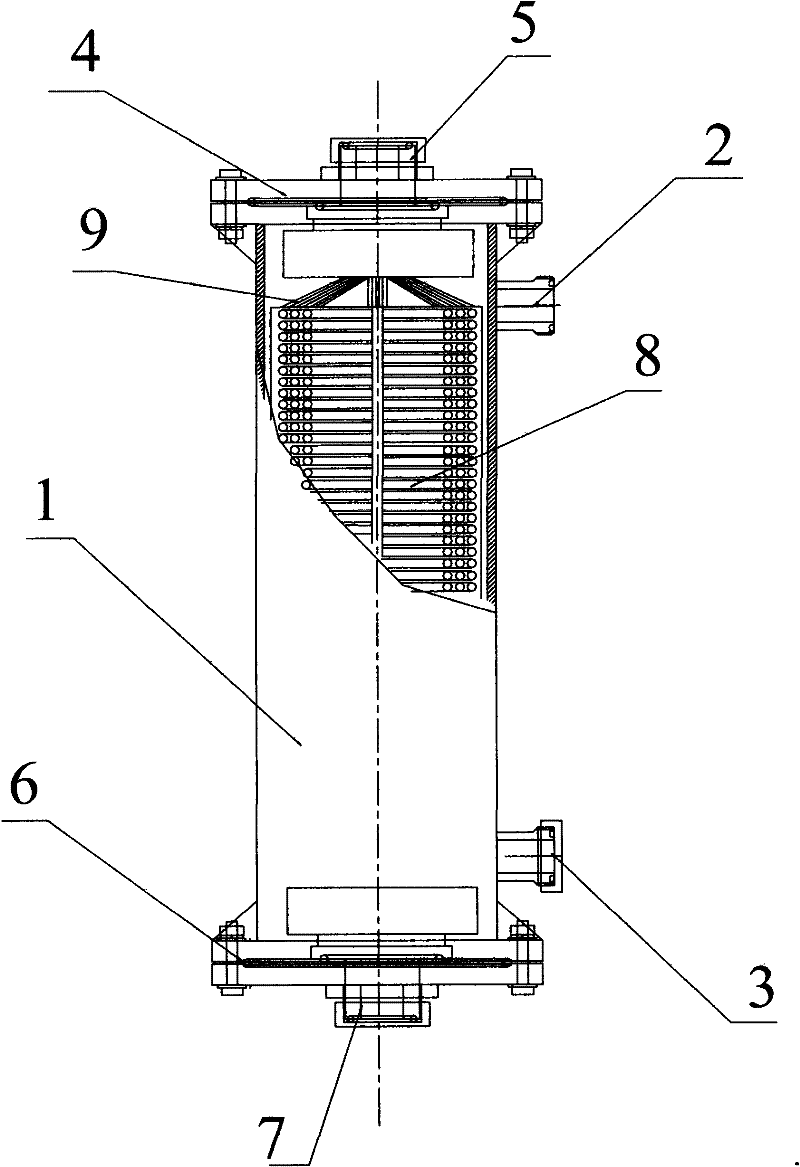

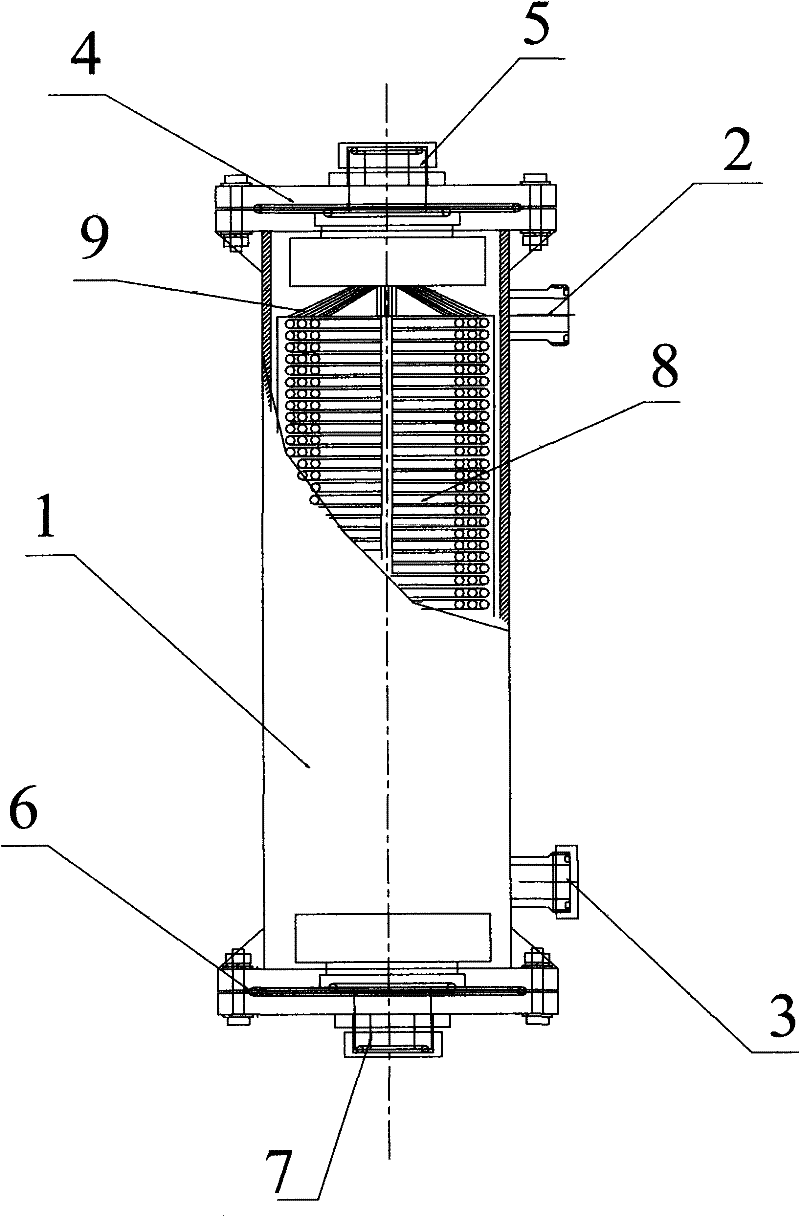

Teflon cold and heat exchanger

InactiveCN102235828AReduce volumeHigh trafficStationary tubular conduit assembliesHeat exchange apparatusEngineeringSmall deviations

The invention discloses a Teflon cold and heat exchanger comprising a pipe shell, wherein the upper end of the pipe shell is provided with a cold water and hot water outlet; the lower end of an outer pipe is provided with a cold water and hot water inlet; the cold water and hot water inlet and the cold water and hot water outlet are communicated with the inner cavity of the pipe shell; the inner cavity of the pipe shell is also internally provided with a Teflon pipe bundle; the Teflon pipe bundle is made by welding tens of or hundreds of Teflon capillaries in parallel; after being sealed, the upper end of the Teflon pipe bundle serves as an exchanged medium outlet and is fixedly connected with an exchanged medium outlet pipeline; and after being sealed, the lower end of the Teflon pipe bundle serves as an exchanged medium inlet and is fixedly connected with an exchanged medium inlet pipeline. The exchanger has the advantages of small volume, large flow, high heat transfer coefficient and light weight, and energy and materials can be greatly saved. Because the environmental temperature of the inner cavity of the external pipe is uniform, outlet temperature of exchanged liquid flowing in the Teflon capillaries has extremely small deviation, and the Teflon cold and heat exchanger can be used for precisely controlling the temperature of fluid, which can not be realized by a common exchanger.

Owner:张爱新

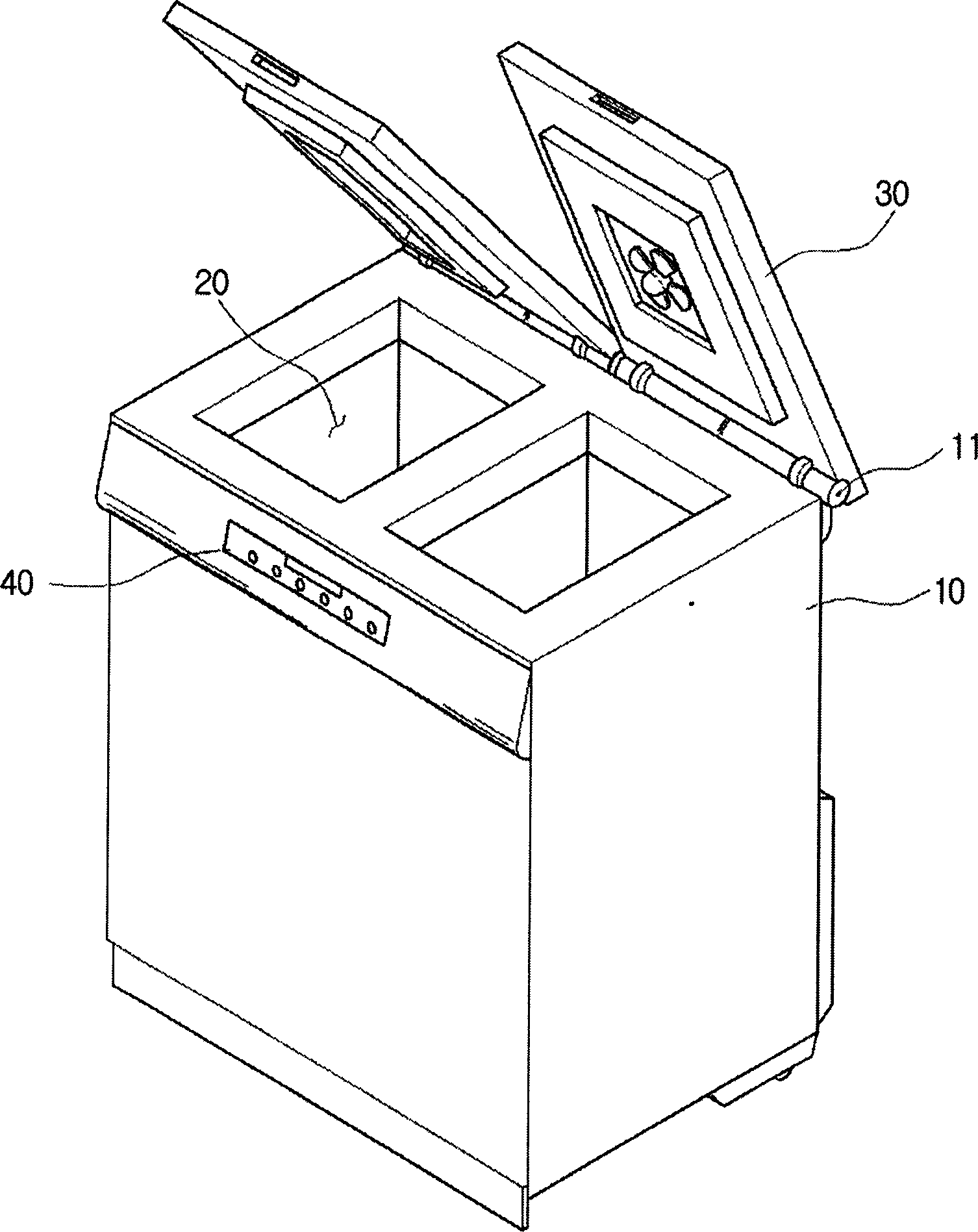

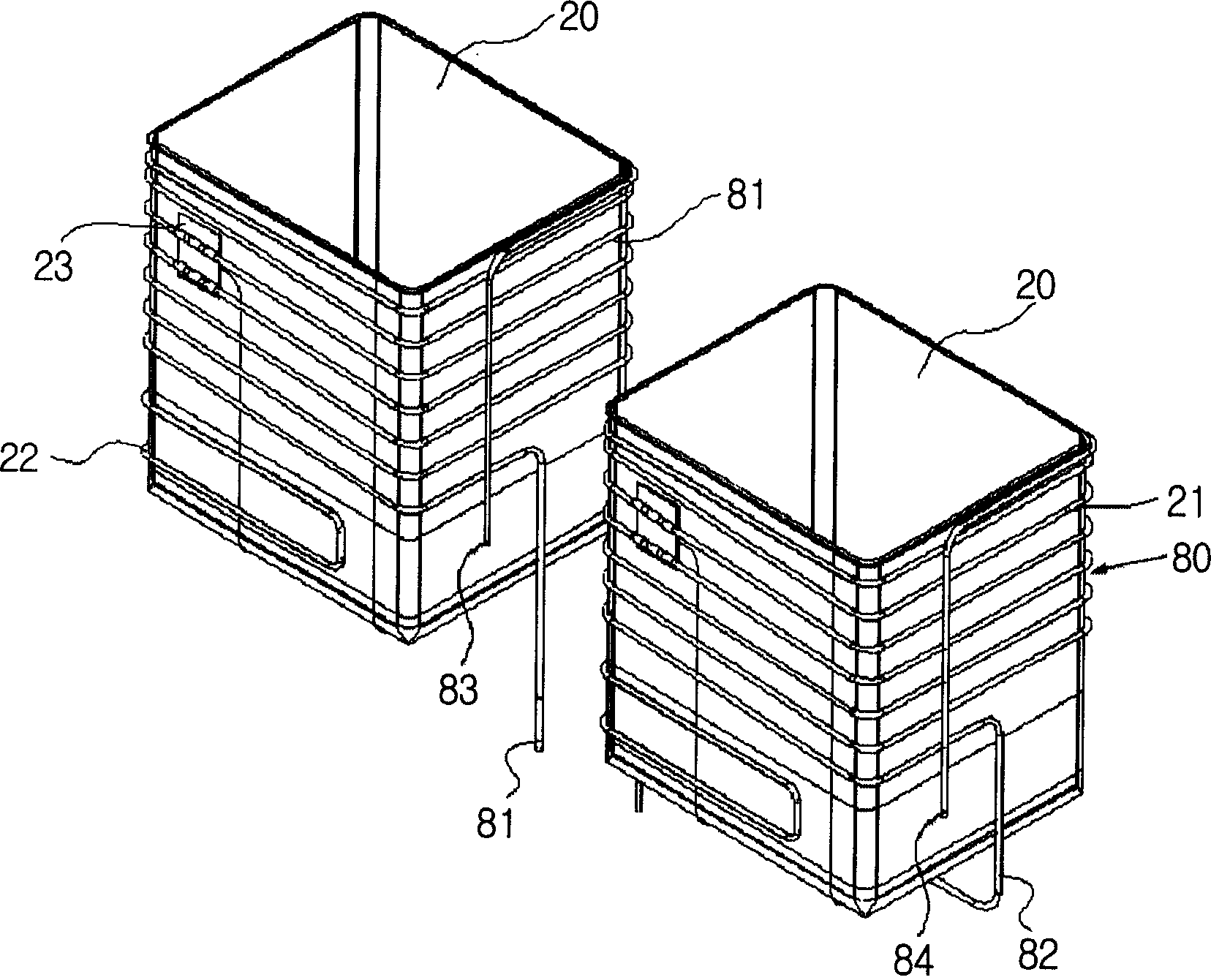

Evaporator layout structure of refrigerator

InactiveCN1880892ASmall temperature deviationImprove machinabilityDomestic refrigeratorsHeat exchange apparatusCold airTemperature difference

The layout structure of evaporator for kraut refrigerator is provided, and the evaporator is one symmetrical structure around the store chamber and thus can reduce the temperature difference inside the store chamber. The layout structure of the evaporator includes one main body to form the casing, at least one store chamber symmetrically on two sides of the main body, and one evaporator comprising the multiple turn refrigerant pipe wound around the store chamber to provide cold air. When the refrigerant pipes are wound onto the store chamber in constant interval onto the store chamber to form the evaporator during manufacture, they have opposite winding directions on the right and the left store chambers.

Owner:WINIAMANDO

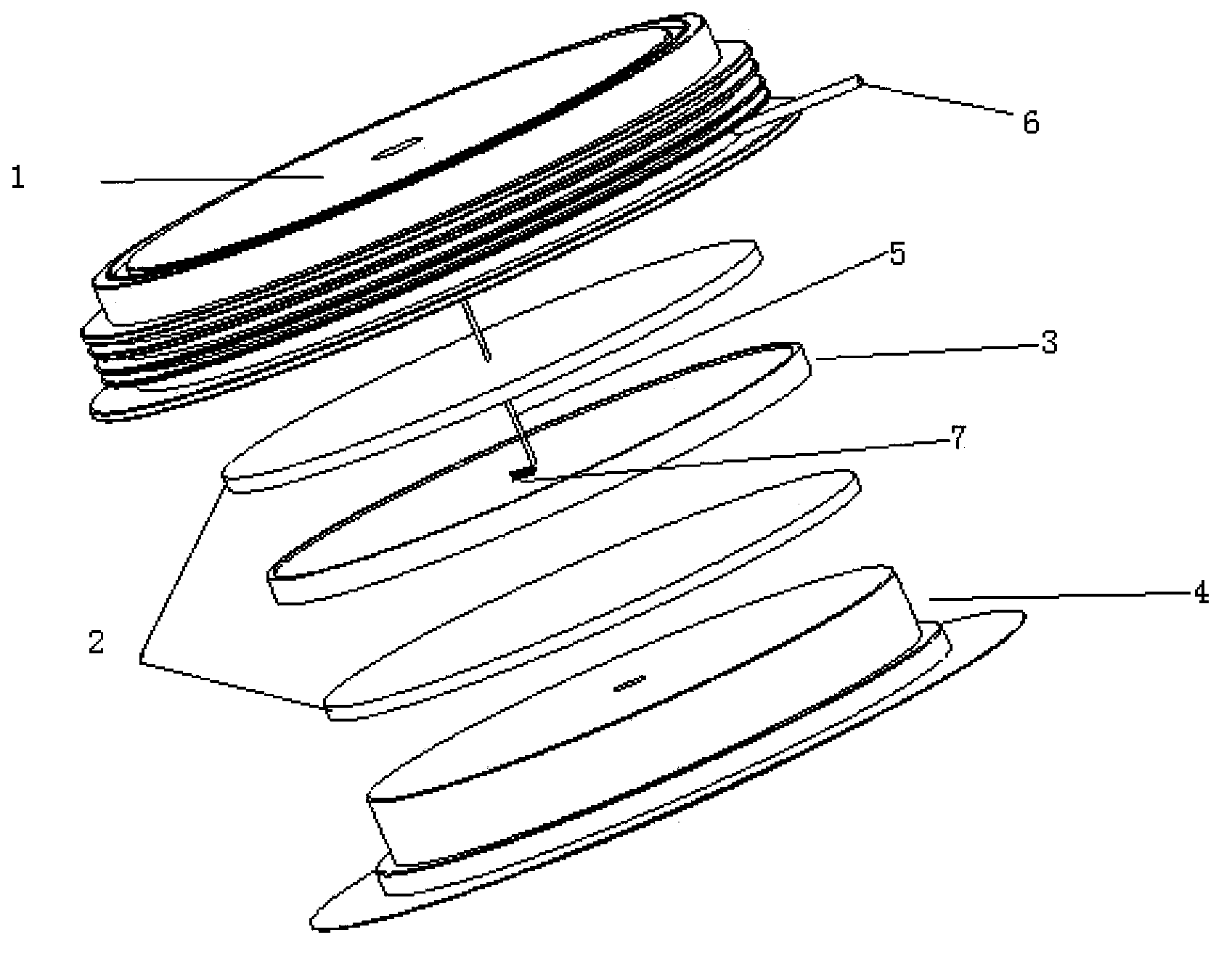

Improved high-power thyristor

InactiveCN104167437ASmall temperature deviationIntuitive real-time temperature dataThyristorSemiconductor/solid-state device detailsJunction temperatureThyratron

A high-power thyristor. The thyristor comprises a thyristor base (1), a ceramic circular shell, a protective layer (2), a chip (3) and a thyristor cover (4) which are arranged in sequence in an axial direction, wherein a rubber sleeve is wrapped around the outer edge of the chip (3); the protective layer (2) and the chip (3) are buckled into the ceramic circular shell in sequence; and a temperature sensor is arranged in the axial direction of the thyristor. By additionally installing a precise temperature sensor on the chip of the thyristor, the real-time monitoring of the temperature of the chip of the thyristor is realized, and the temperature measurement deviation can be reduced, forming intuitive real-time temperature data, and providing reliable conditions for junction temperature protection and other intellectualized functions of a direct-current converter valve.

Owner:STATE GRID CORP OF CHINA +3

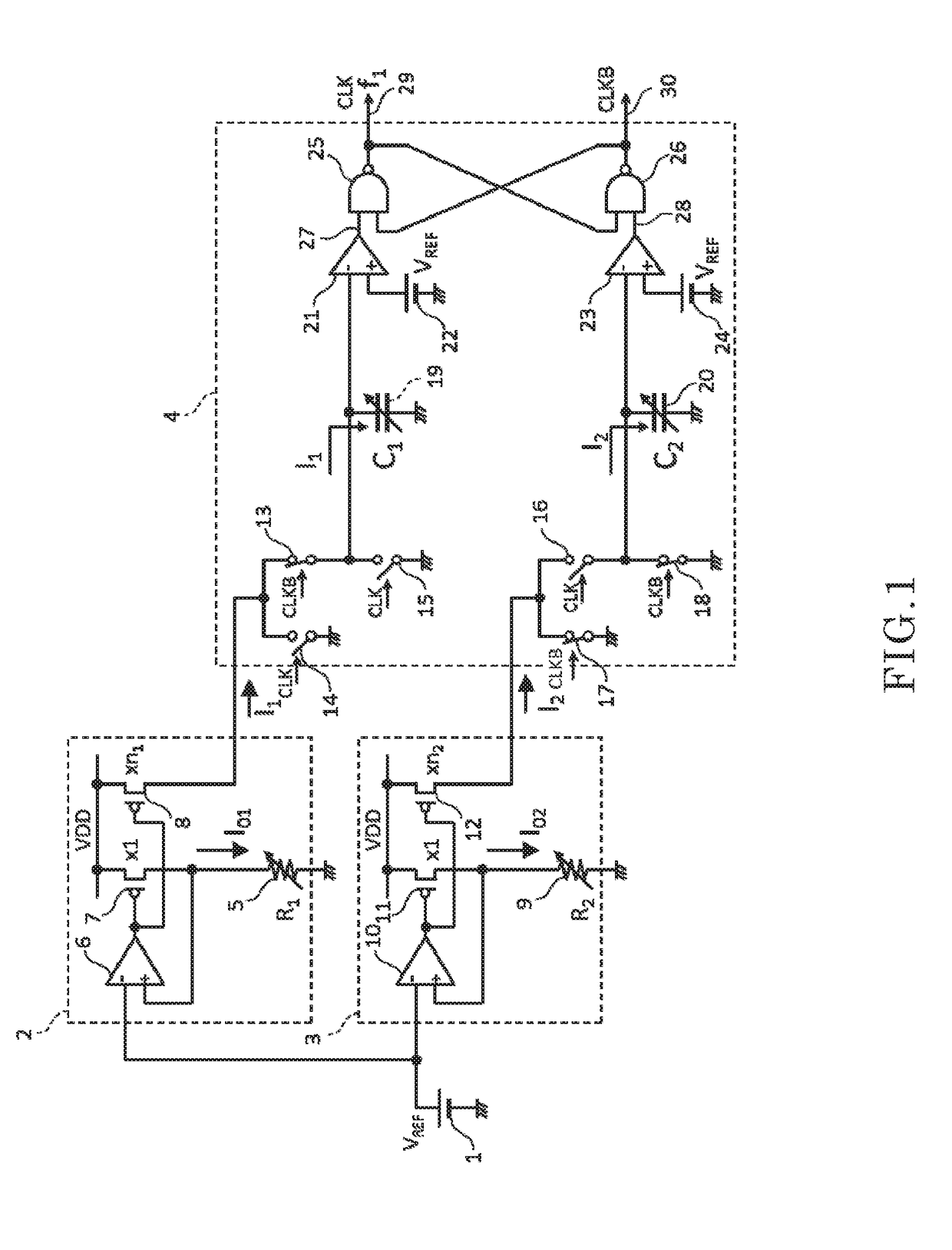

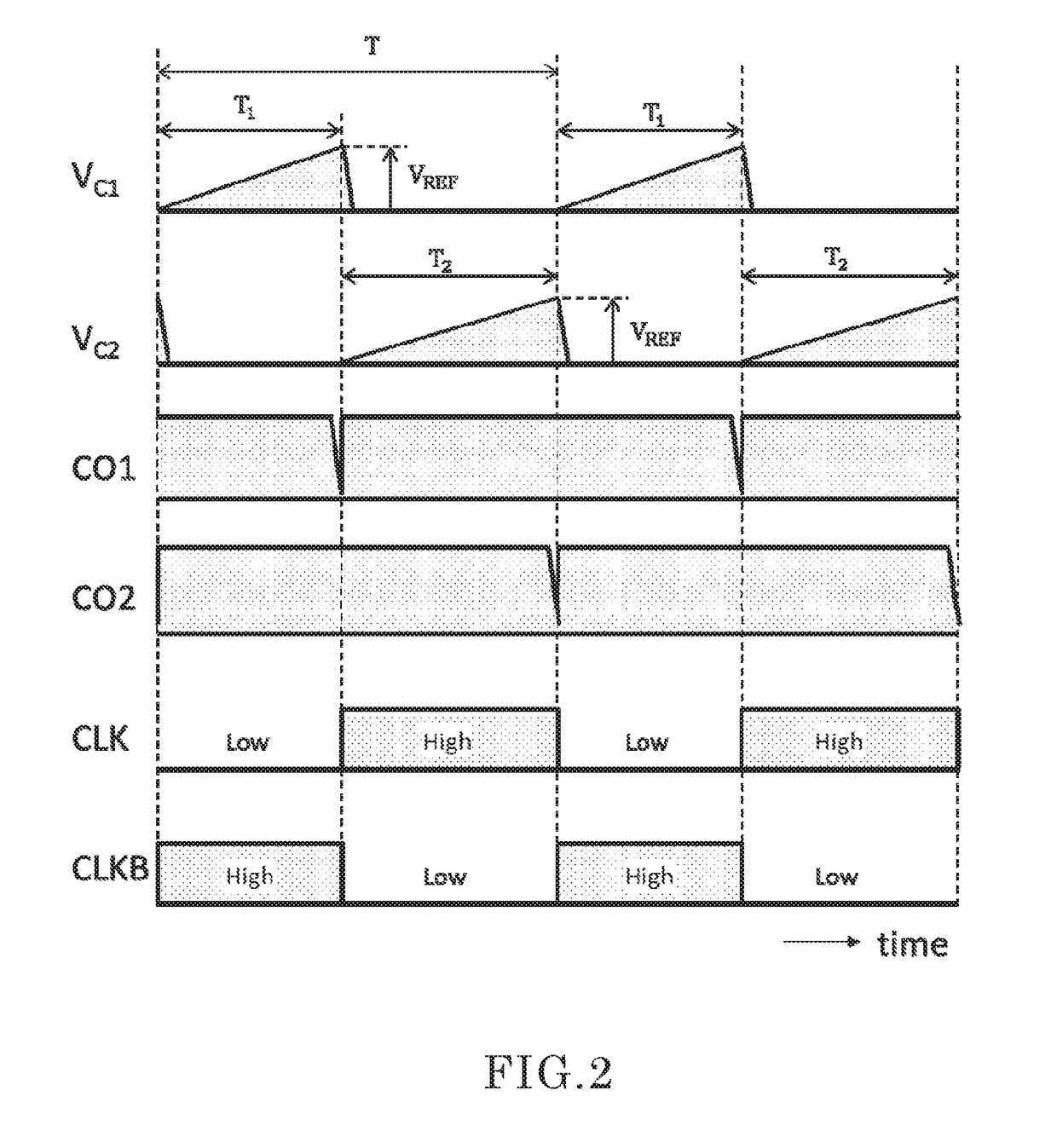

Relaxation oscillator and wireless device including relaxation oscillator

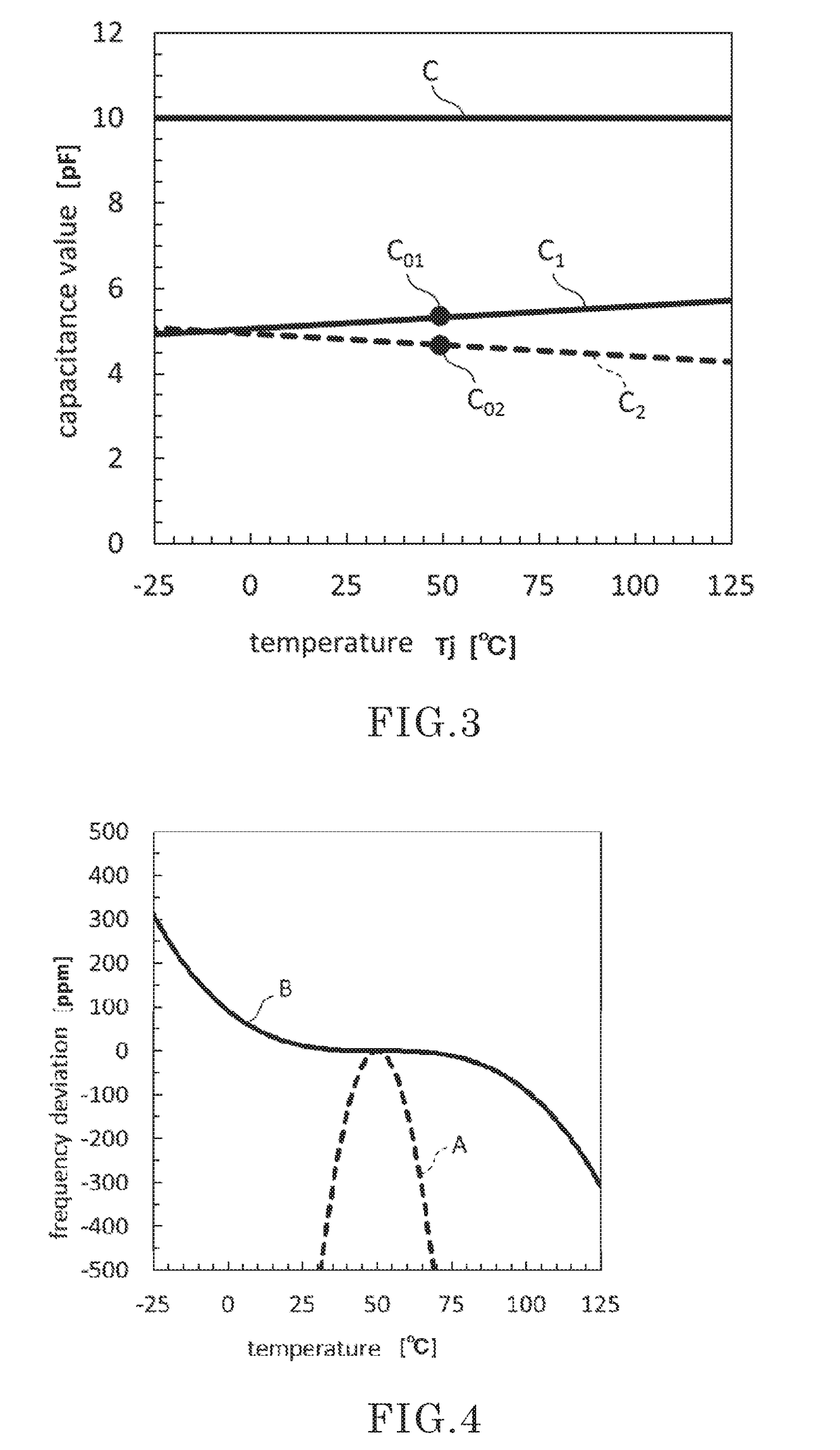

ActiveUS20180351538A1Small temperature deviationPulse generation by logic circuitsOscillations generatorsCapacitanceVoltage reference

Provided is a relaxation oscillator having an extremely small temperature deviation in oscillation frequency. A first current (I1) generated by a reference voltage source and a first resistor having a positive first-order temperature coefficient is supplied to a first variable capacitor (C1) for oscillation, and a second current (I2) generated by a reference voltage source and a second resistor having a negative first-order temperature coefficient is supplied to a second variable capacitor (C2) for oscillation. A product of a value of a ratio of a first current to a second current and a value of a ratio of a first-order temperature coefficient of the second resistor to a first-order temperature coefficient of the first resistor, and a value of a ratio of a capacitance of the first variable capacitor to a capacitance of the second variable capacitor have the same absolute value and opposite signs.

Owner:ABLIC INC

Method for reducing steam temperature deviation by using steam soot blowing for boiler of thermal power plant

ActiveCN103604115ALower heat transfer coefficientImprove economySuperheating controlSolid removalEngineeringSuperheater

The invention discloses a method for reducing steam temperature deviation by using steam soot blowing for a boiler of a thermal power plant. The method is characterized by comprising step 1 of introducing steam to a soot blowing gun under the condition of normal combustion of the hearth of the boiler; step 2 of performing differential soot blowing on heated surfaces of different regions and parts of at least a one-level super-heater and at least a one-level re-heater in the boiler based on temperature distribution so as to change surface soot formation degrees of different regions and parts of the super-heater and the re-heater; judging whether the steam temperature deviation of different regions and parts of outlets at a certain level of the super-heater and the re-heater reaches to a preset requirement; if the steam temperature of one region and one part at a certain level of the super-heater and re-heater needs to be improved, increasing the soot blowing intensity of a heated surface corresponding to the region and part at the level of the super-heater and the re-heater in the step 2 and / or reducing the soot blowing intensity of the heated surface corresponding to the other region and part at the level of the super-heater and the re-heater, and vice versa.

Owner:上海申能能源科技有限公司

Magnetic attraction type air cooling radiator

InactiveCN111372425AReduce thermal resistanceHelp conductionModifications by conduction heat transferHeat resistanceEngineering

The invention discloses a magnetic attraction type air cooling radiator. The magnetic attraction type air cooling radiator comprises a heat conduction substrate and a cooling fin. The heat conductionsubstrate is provided with a fin inserting groove, the connecting end of the cooling fin is fixed in the fin inserting groove of the heat conduction substrate, and the space between the connecting endof the cooling fin and the fin inserting groove is further filled with heat conduction media. An air passing channel is further formed in the cooling fin. The space between the connecting end of thecooling fin and the fin inserting groove is further filled with the heat conduction medium, the heat resistance between the heat conduction substrate and the cooling fin can be reduced through the heat conduction medium, heat conduction is facilitated, and therefore the heat dissipation effect is improved; in addition, the cooling fins can be more tightly attached to the side walls of the fin inserting grooves, and the thermal resistance can be further reduced; by the adoption of the design of the air passing channel, air of an external fan can flow through the outside of the cooling fins andthe air passing channel to fully cool the inside and the outside of the cooling fins, and heat on the cooling fins can be taken away quickly.

Owner:SUZHOU YONGTENG ELECTRONICS PROD

Double-inlet and double-outlet coal mill inlet cold and hot primary air mixing system and method

InactiveCN112121988AUniform flow fieldPrevent temperature deviationGrain treatmentsPower stationAir door

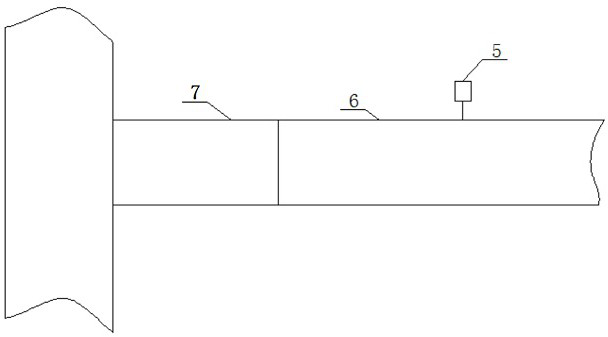

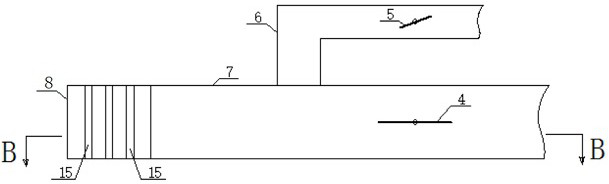

The invention discloses a double-inlet and double-outlet coal mill inlet cold and hot primary air mixing system and method, and belongs to the field of energy-saving treatment of power station boilercoal pulverizing systems. The system comprises a coal mill and further comprises a hot primary air main pipe, a cold primary air main pipe, a hot primary air pipe, a hot primary air adjusting baffle,a cold primary air adjusting baffle, a cold primary air pipe, a mixed air pipe, a flow dividing tee joint, a left-side mixed air branch pipe, a right-side mixed air branch pipe, a right-side capacityair door and a left-side capacity air door. By changing the mounting modes of the hot primary air adjusting baffle and the cold primary air adjusting baffle, structurally optimizing the pipeline structure of an airflow mixing part and structurally optimizing the flow dividing tee joint, the problem that the temperature deviation of mixed air at inlets in the two ends of the double-inlet and double-outlet coal mill is large can be thoroughly solved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Renewable adsorption material, adsorption device and household appliance

PendingCN112169533AEvenly heatedImprove efficiency and stabilityGas treatmentLighting and heating apparatusChemistryHome appliance

The invention provides a renewable adsorption material, an adsorption device and a household electrical appliance. The renewable adsorption material comprises a mixed amine substance and a magnetic conductive substance, wherein the magnetic conductive substance is uniformly distributed in the adsorption material; and the amine substance is used for adsorbing carbon dioxide in air, and the magneticconductive substance is used for heating the amine substance under the action of an alternating magnetic field, so that the adsorbed carbon dioxide is desorbed from the amine substance. In this way,the amine substance can be uniformly heated in the heating regeneration process.

Owner:GUANGDONG MIDEA WHITE GOODS TECH INNOVATION CENT CO LTD +1

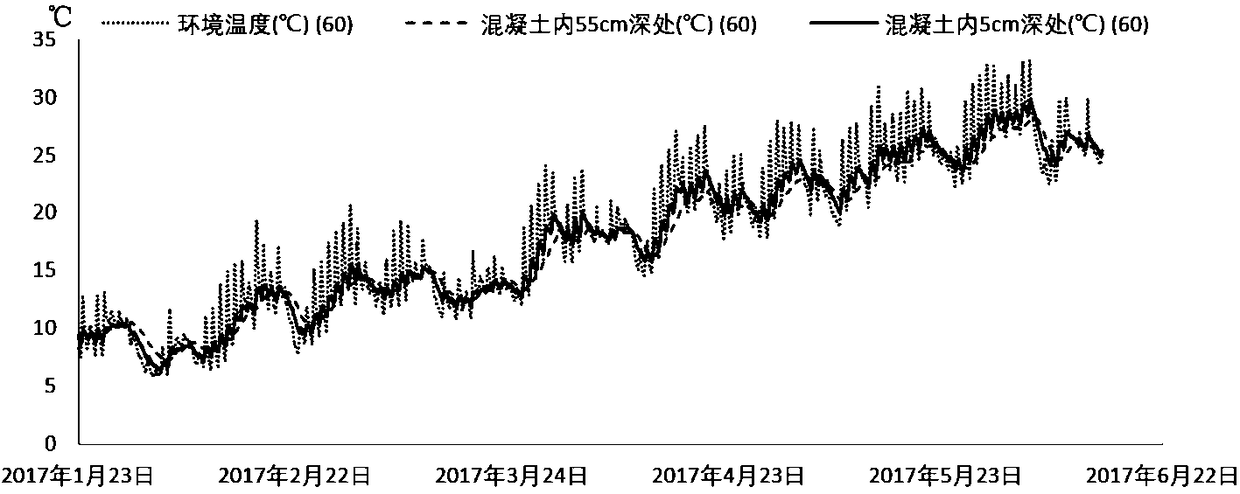

Gridded temperature control system for concrete dam

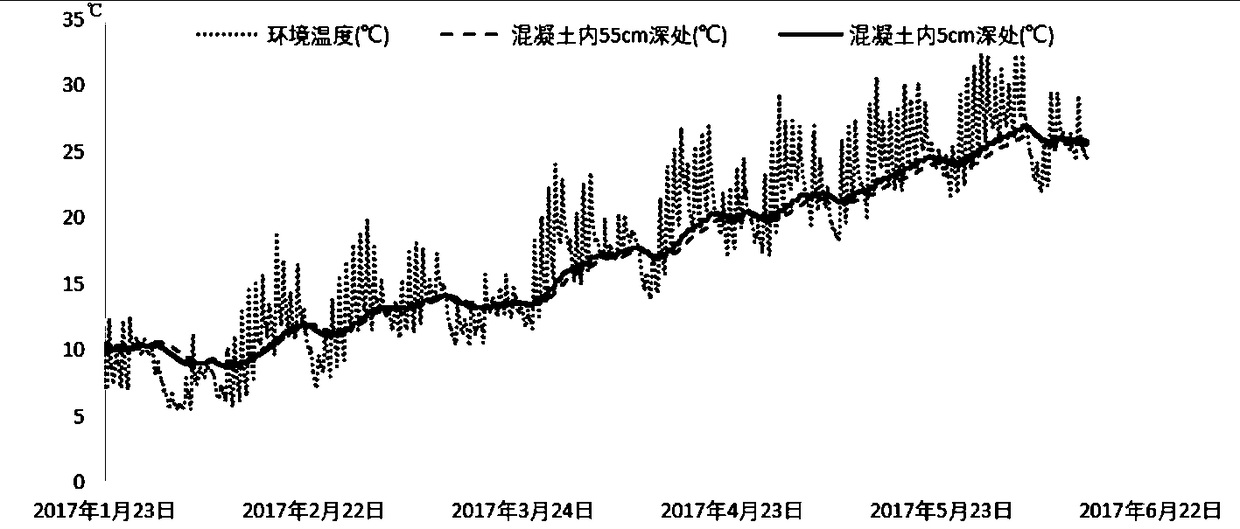

ActiveCN109024605AIncrease flexibilityImprove targetingTemperatue controlFoundation engineeringInductorMesh grid

The invention discloses a gridded temperature control system for a concrete dam. The gridded temperature control system for the concrete dam comprises a real-time inductor, a temperature control server and a rapid regulation-control machine which are sequentially connected. The gridded temperature control system for the concrete dam further comprises a database server, wherein the rapid regulation-control machine comprises a plurality of industrial personal computers, a plurality of temperature compensation sources, a plurality of PLCs, a pipe network with a variable topology structure and a wireless base station, the pipe network with the variable topology structure comprises a plurality of gridded multi-pass control units, and the temperature compensation sources, the PLCs and the wireless base station are connected with the industrial personal computers separately; the database server is connected with the real-time inductor and the rapid regulation-control machine separately; and the pipe network with the variable topology structure is arranged in a dam body. According to the gridded temperature control system for the concrete dam, a temperature control pipeline for the dam isgridded, and a sensor group is arranged around grid nodes, so that the flexibility and pertinence of temperature regulation-control for the dam are improved; and adverse factors possibly occurring inthe temperature regulation-control for the dam are predicated in advance, and a traditional passive temperature regulation-control manner is changed into active temperature regulation-control, so thatthe uncertainty of the temperature regulation-control for the dam is reduced.

Owner:宜昌天宇科技有限公司

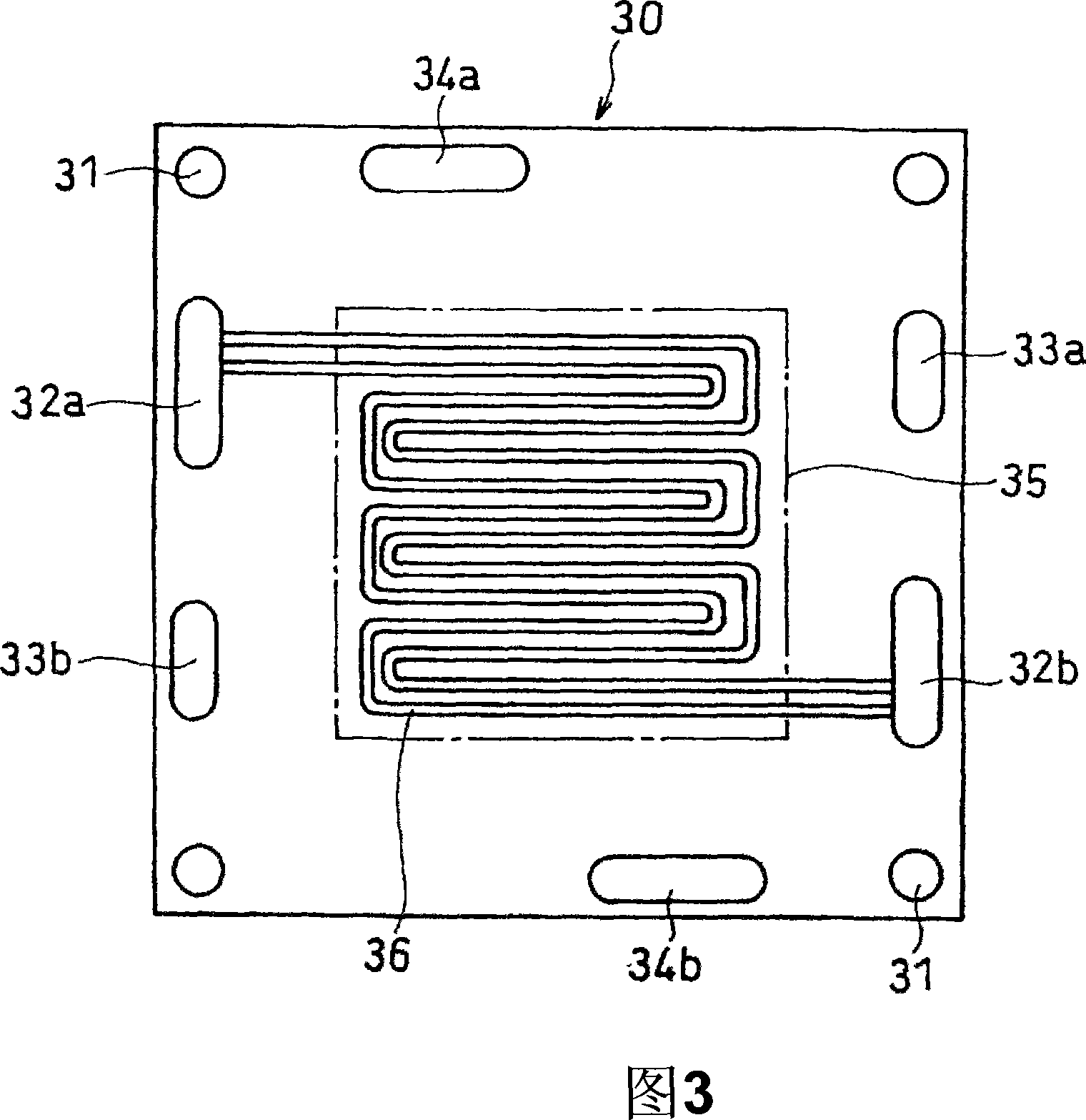

Fuel cell

InactiveCN101065871ACool evenlyStable output voltageSolid electrolyte fuel cellsFuel cell detailsFuel cellsEngineering

The temperature of cooling fluid in an entrance side manifold is raised, in power generation, by influence of the temperature of a heat generation section of a cell. This causes variation in the temperature of each single cell in a fuel cell stack, causing flooding and variation in an output voltage. The invention provides a fuel cell in which a rise in temperature of cooling fluid in an entrance side manifold is suppressed, that has high durability, and that provides a stable output voltage. The fuel cell has cooling fluid flow paths in a cathode side separator plate and an anode side separator plate, the flow paths connecting an entrance side manifold and exit side manifold for the cooling fluid. The cooling fluid flow paths are composed of first cooling sections for cooling heat generation sections that are regions corresponding to a cathode and an anode and of second cooling sections each positioned between a first cooling section and an entrance side manifold for the cooling fluid.

Owner:PANASONIC CORP

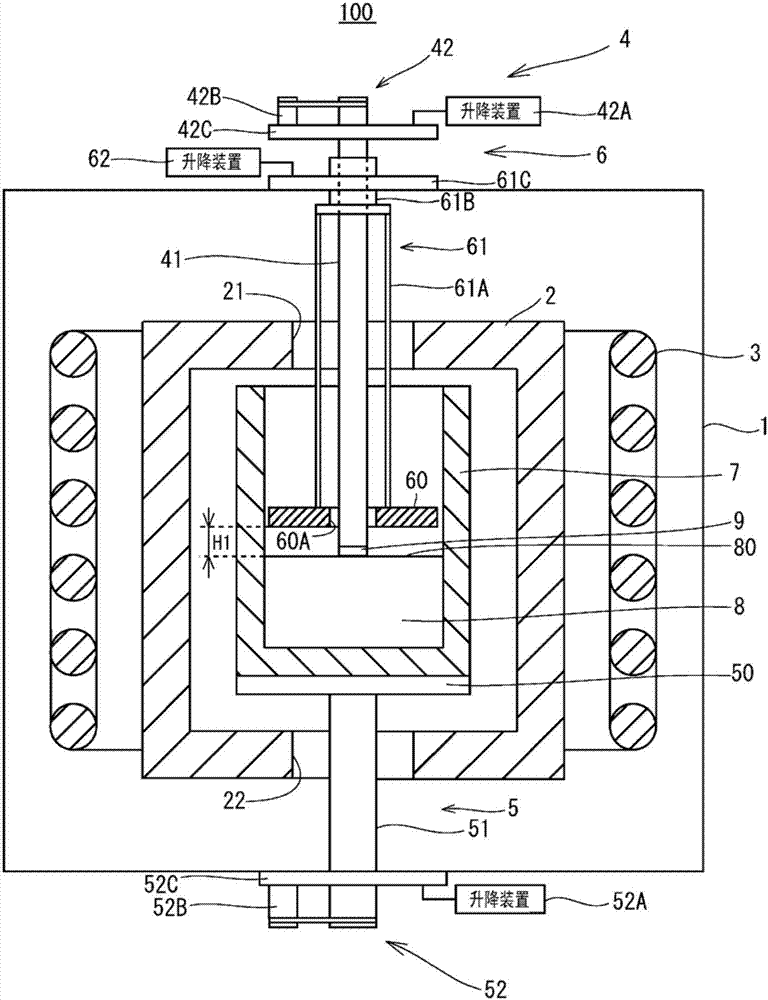

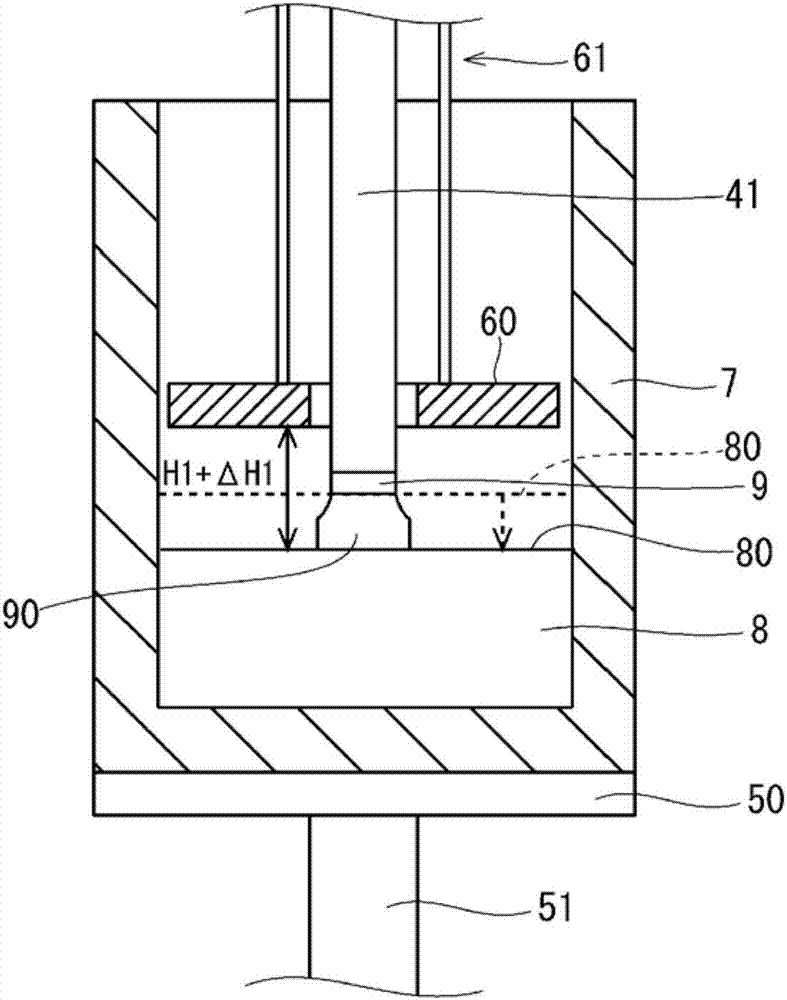

SiC single crystal production method and SiC single crystal production device

InactiveCN107075726ASmall temperature deviationPolycrystalline material growthLiquid-phase epitaxial-layer growthCrucibleEngineering

Owner:NIPPON STEEL CORP +1

Hearth structure of circulating fluidized bed boiler of 3rd-stage cyclone separator

ActiveCN102635855AEvenly distributedReduce load distribution deviationFluidized bed combustionApparatus for fluidised bed combustionCycloneFluidized bed

A hearth structure of a circulating fluidized bed boiler of a 3rd-stage cyclone separator relates to a hearth water-cooling screen arrangement of the circulating fluidized bed boiler of the 3rd-stage cyclone separator. Water-cooling screens with equal width are respectively and vertically arranged at one third position and two thirds position in width direction of the rear wall of a hearth, a water-cooling screen is vertically arranged in the middle position in the width direction of the front wall of the hearth and has a membrane type water-cooling wall structure. Under the action of three cyclone separators and the water-cooling screens on the rear wall, three relatively independently granule massing backmixing regions are formed in the hearth. According to the invention, through width of a series of water-cooling screens, area of water-cooling heating surfaces around the three regions is equal, and the temperature deviation in the width direction of wall-cooling walls of the hearth can be well reduced, thus being beneficial to safety running of the boiler.

Owner:TSINGHUA UNIV

Substrate processing method

InactiveCN101266921AHigh densityAdjustable temperatureSemiconductor/solid-state device manufacturingEngineeringProduct gas

The invention provides a substrate processing method. The substrate mounted within a processing chamber is disposed on a support anode. Then the processing chamber is isolated from outside and pressure within the processing chamber is increased to reach an established pressure under which temperature of the substrate is kept at a particular temperature, after that, pressure within the processing chamber is decreased to reach a processing pressure. The substrate is disassembled to outside of the processing chamber once the processing for substrate is accomplished in the processing chamber. The method for increasing the pressure within the processing chamber comprises the methods for provision of purification gases and processing gases.

Owner:PSK INC

Fusion control device and method for 3D printing

ActiveCN107415249ASmall temperature deviationSmall effective range requirementsAdditive manufacturing apparatus3D object support structuresEngineering3d printer

The invention provides a fusion control device and method for 3D printing. The fusion control device comprises a main controller, a heating assembly, a heating controller and a locking control assembly. The heating controller and the locking control assembly both are connected with the main controller and operate under the control of the main controller. The heating assembly is connected with the heating controller. The heating assembly comprises a first constant-temperature heating block, a second constant-temperature heating block and a heat-resistant support. The heat-resistant support is made of a heat insulation material. The first constant-temperature heating block and the second constant-temperature heating block are correspondingly arranged on the two sides of the heat-resistant support and are matched with a nozzle on a 3D printer. The temperature working point of the first constant-temperature heating block is set as the fusion extrusion temperature, the temperature working point of the second constant-temperature heating block is set as a semi-solidification temperature for preventing fusion sagging, the first constant-temperature heating block and the second constant-temperature heating block are kept in the constant-temperature state under the control of the heating controller, and the locking control assembly controls the first constant-temperature heating block and the second constant temperature heating block to be in contact with or separated from the nozzle.

Owner:金华市瑞意电气科技有限公司

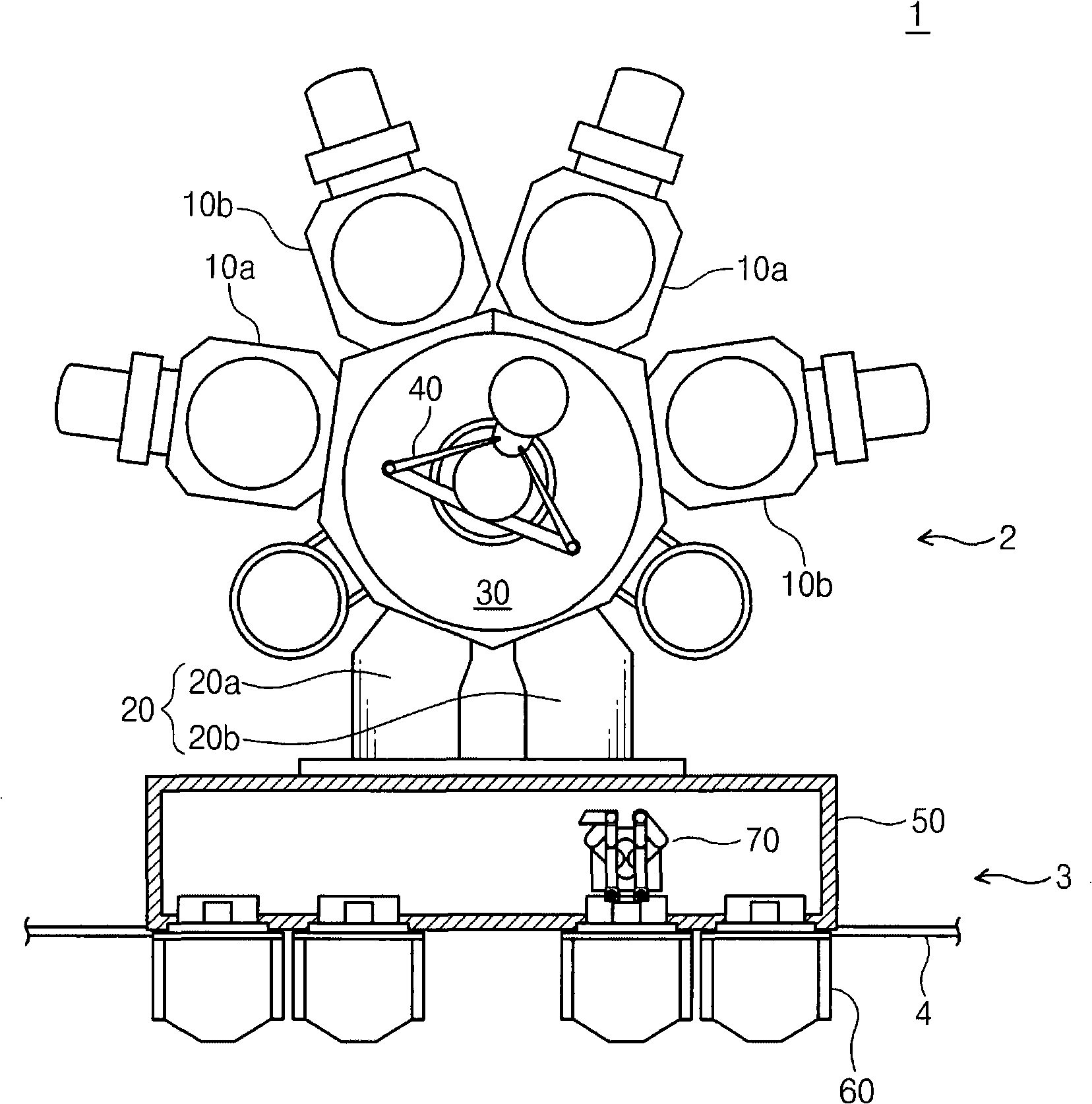

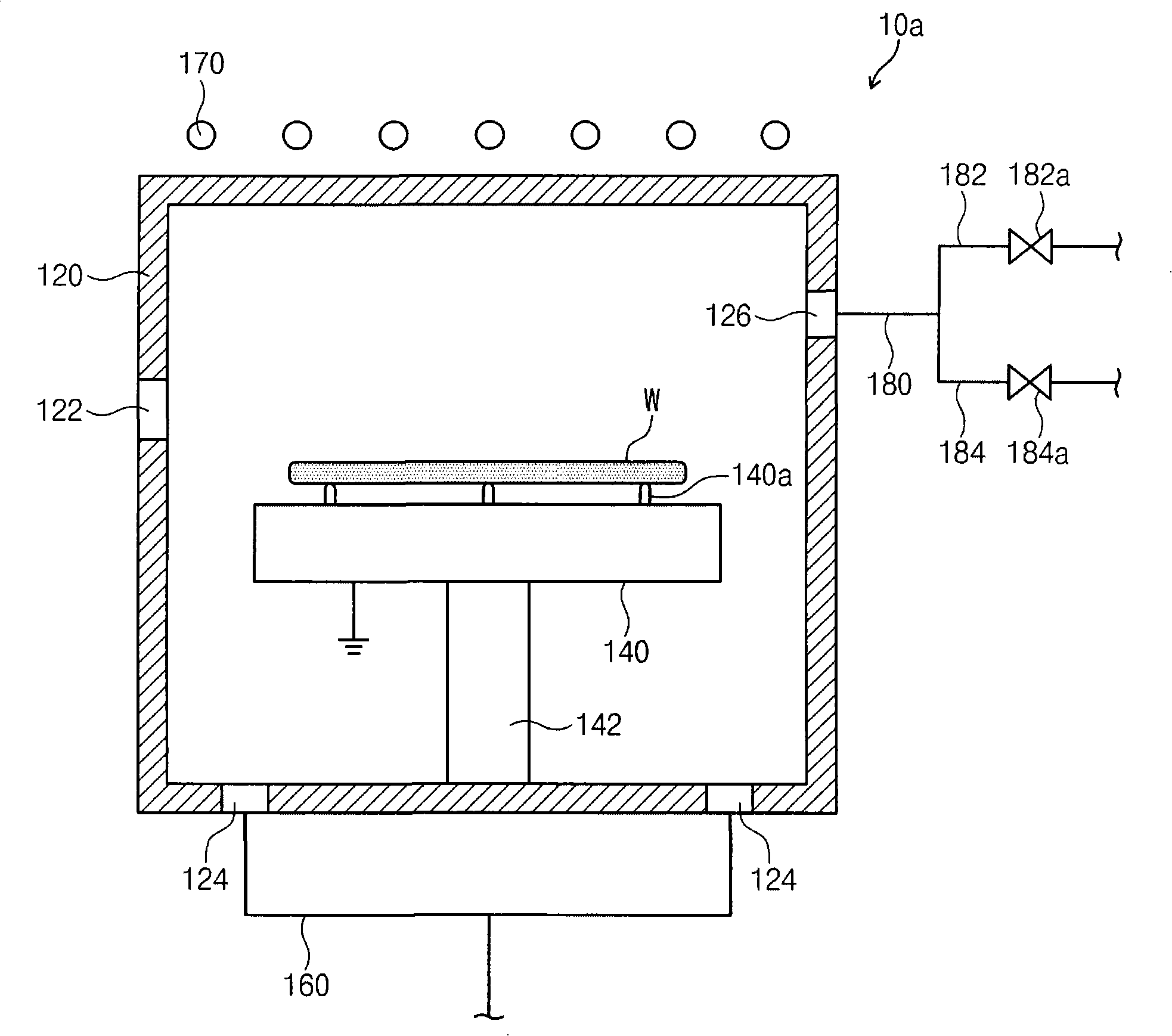

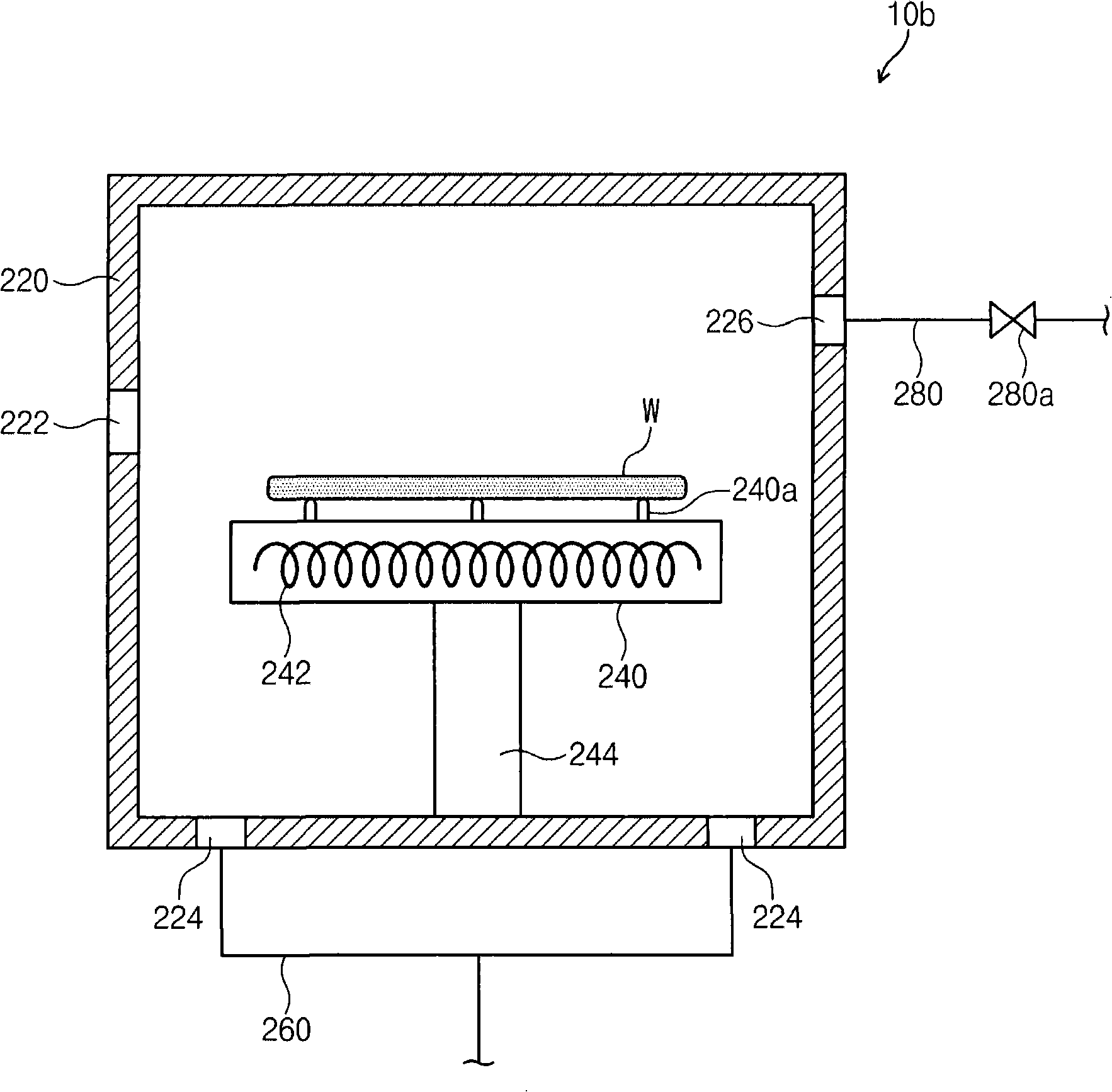

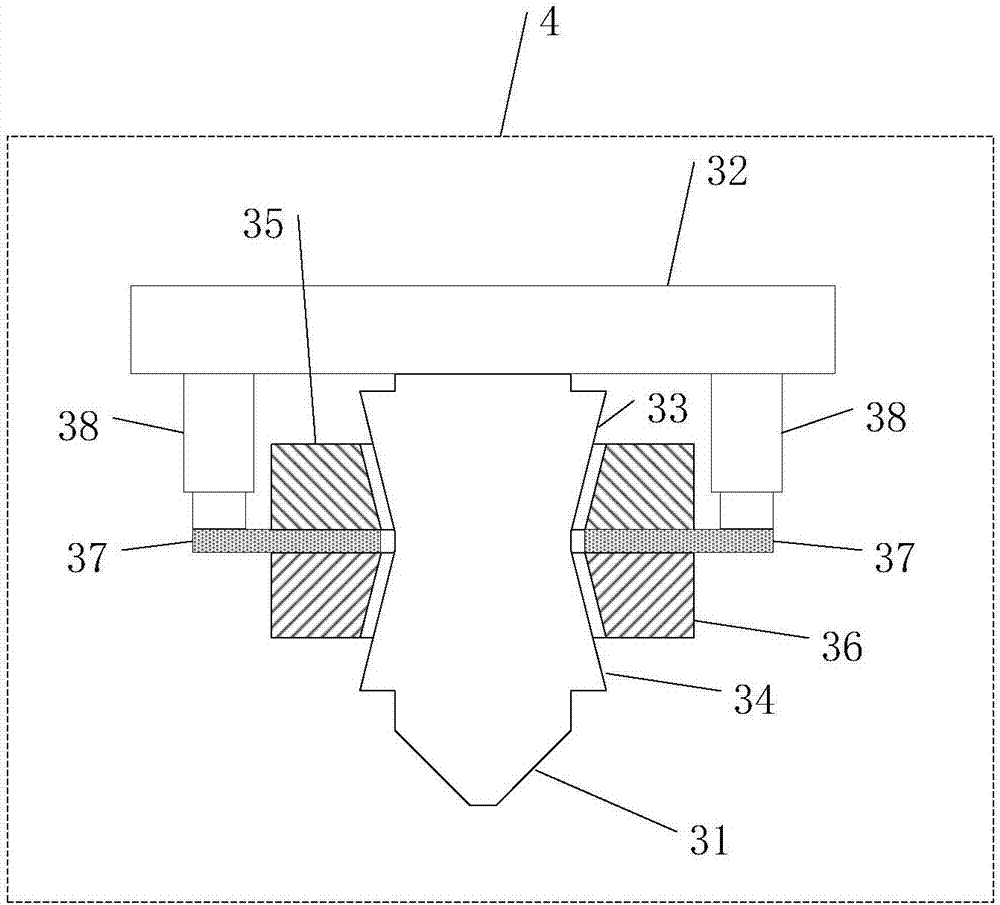

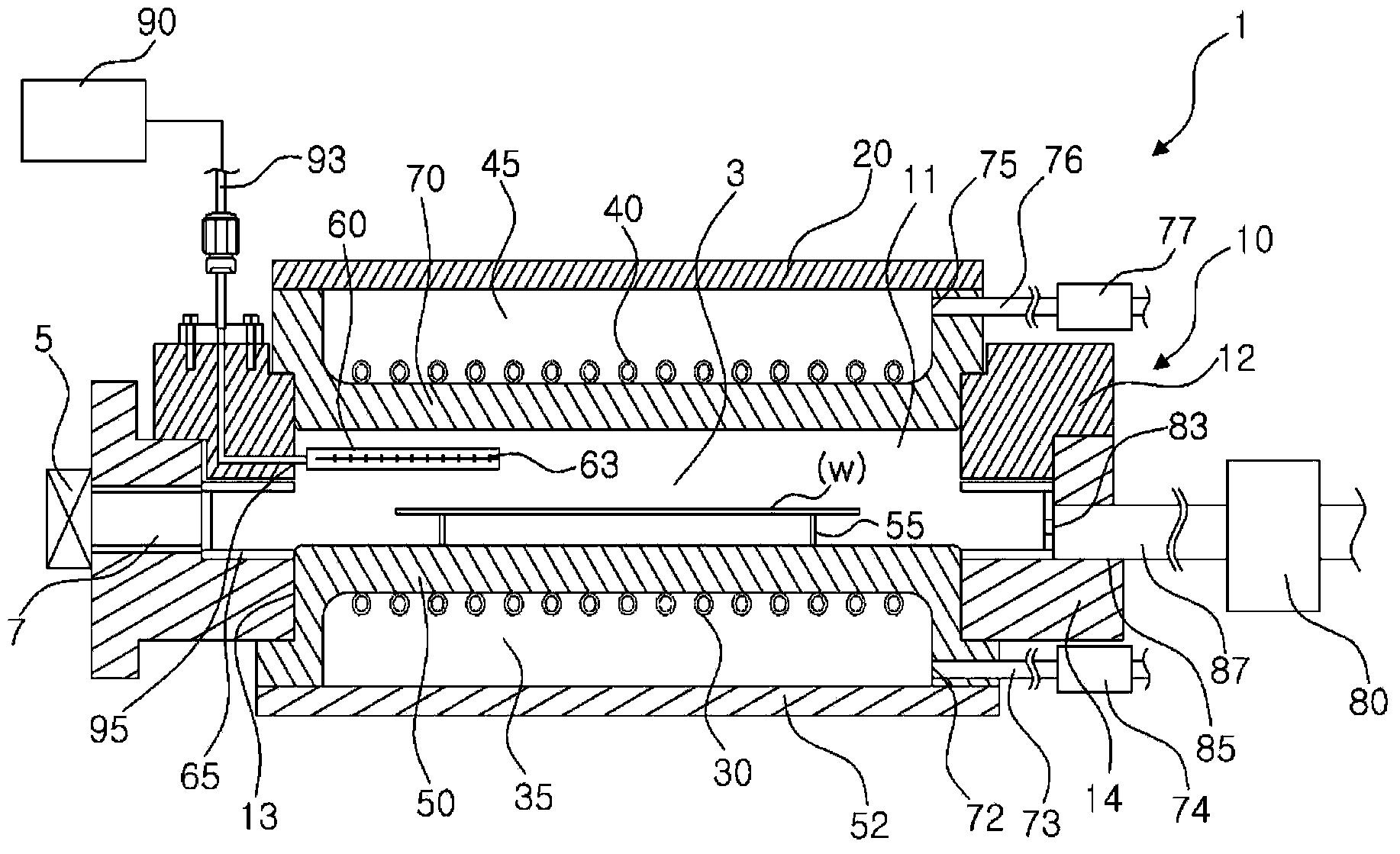

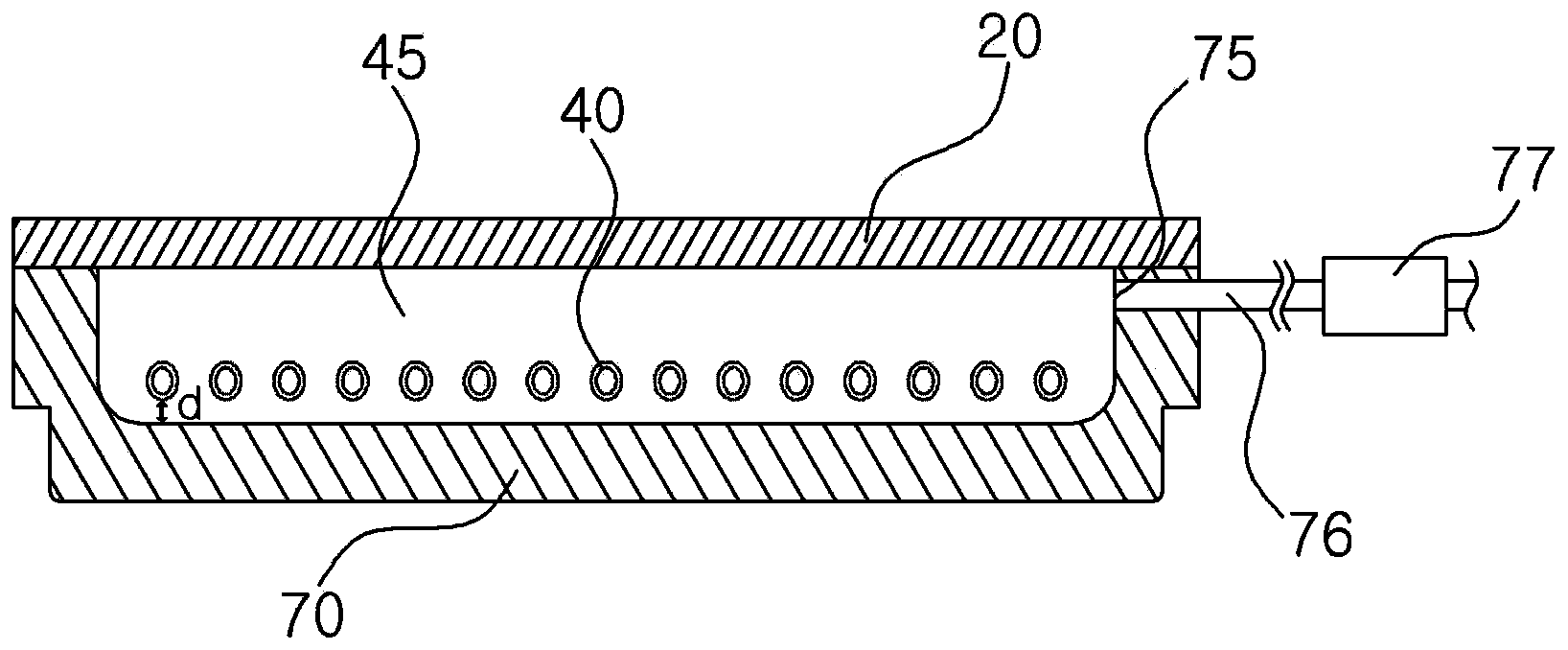

Substrate processing apparatus

ActiveCN104412363AEasy maintenanceSmall temperature deviationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A substrate processing apparatus, in which the processing of a substrate is carried out, according to one embodiment of the present invention, comprises: a main chamber having a passage which is formed on one sidewall thereof and through which the substrate moves in and out, and a top opening and a lower opening formed on the upper part and the lower part thereof, respectively; a chamber cover, which closes the top opening and forms a processing space which is separated from outside and in which the processing is carried out; a shower head which is installed in the processing space and has a plurality of injection holes for injecting processing gases; a lower heating block which is installed and fixed in the lower opening and has a lower installation space separated from the processing space, and on top of which the substrate is placed; and a plurality of lower heaters which are installed in the lower installation space in a direction parallel to the substrate and which heat the lower heating block.

Owner:EUGENE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com