Patents

Literature

31results about How to "Prevent temperature deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

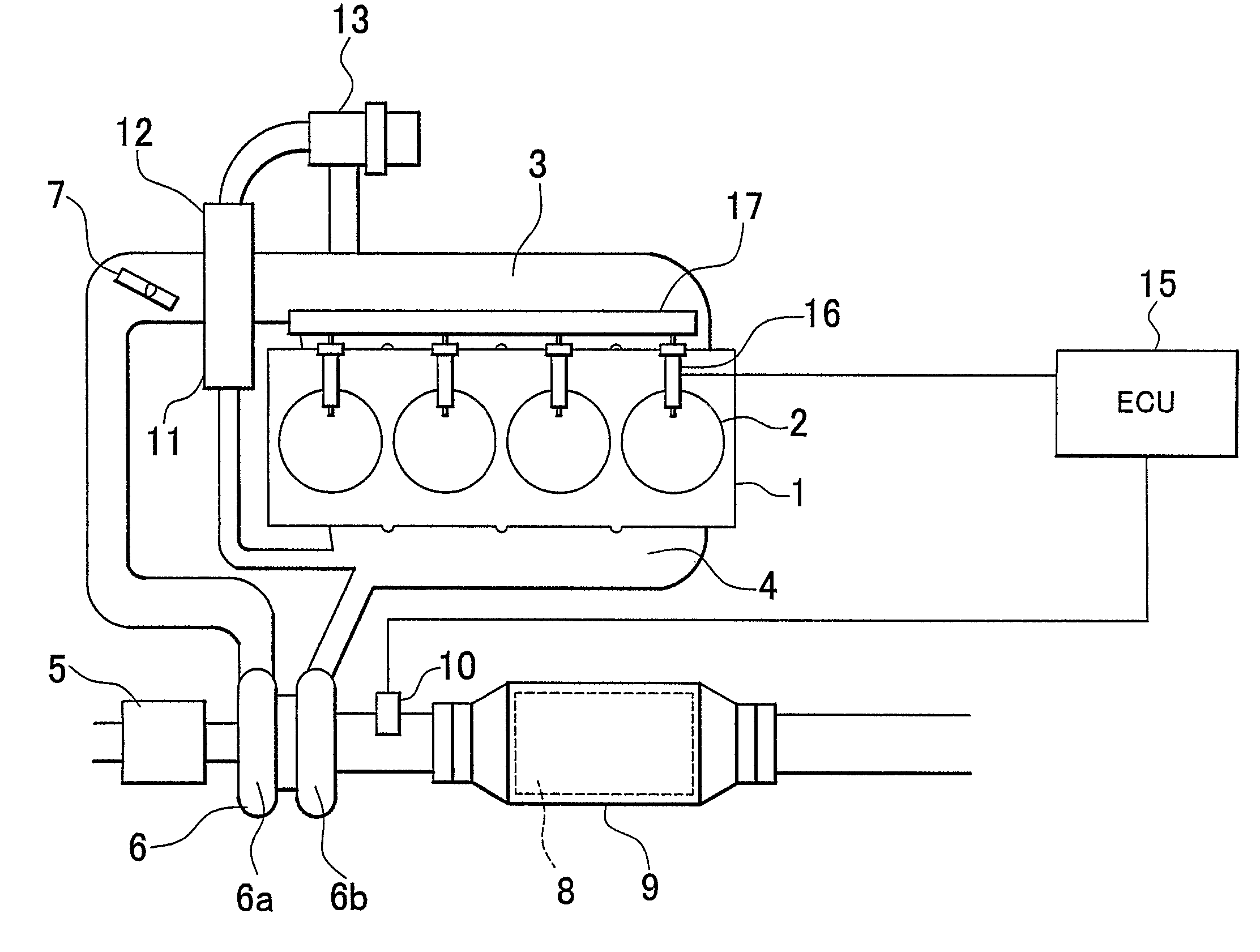

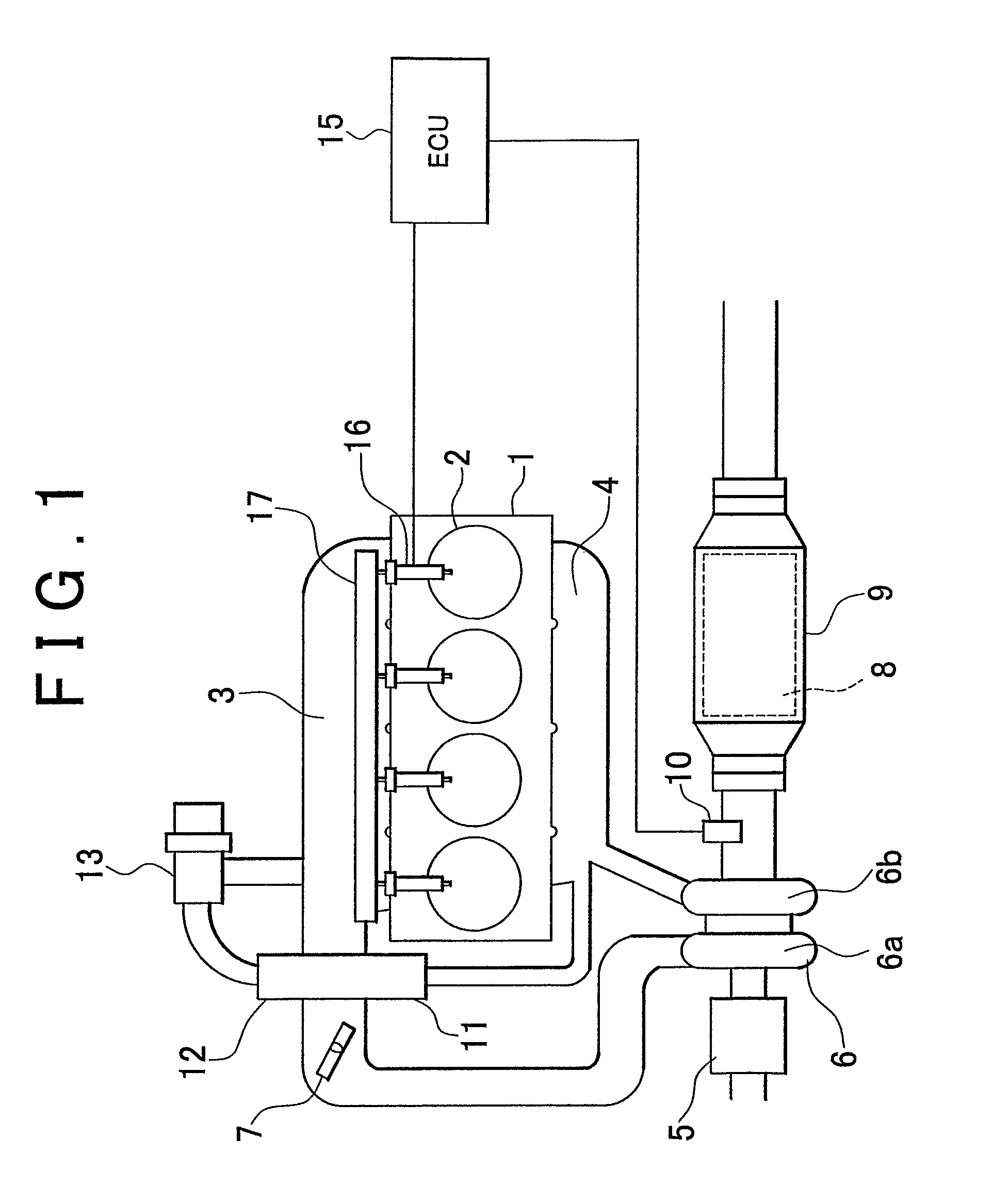

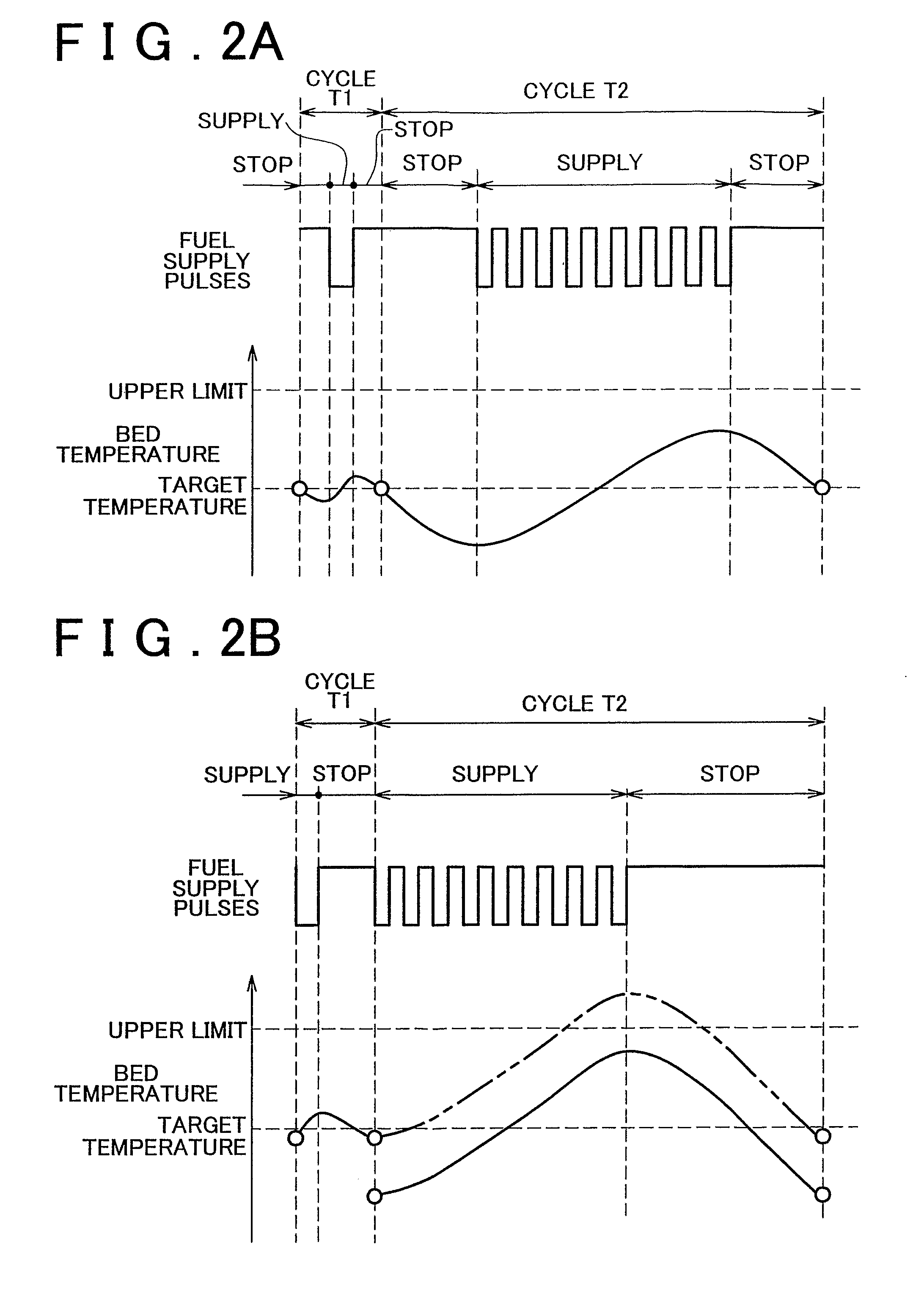

Fuel supply control method applied to exhaust gas control apparatus for internal combustion engine and exhaust gas control apparatus to which the method is applied

ActiveUS8261532B2Avoid overall overheatingPrevent temperature deviationElectrical controlExhaust apparatusPtru catalystExhaust fumes

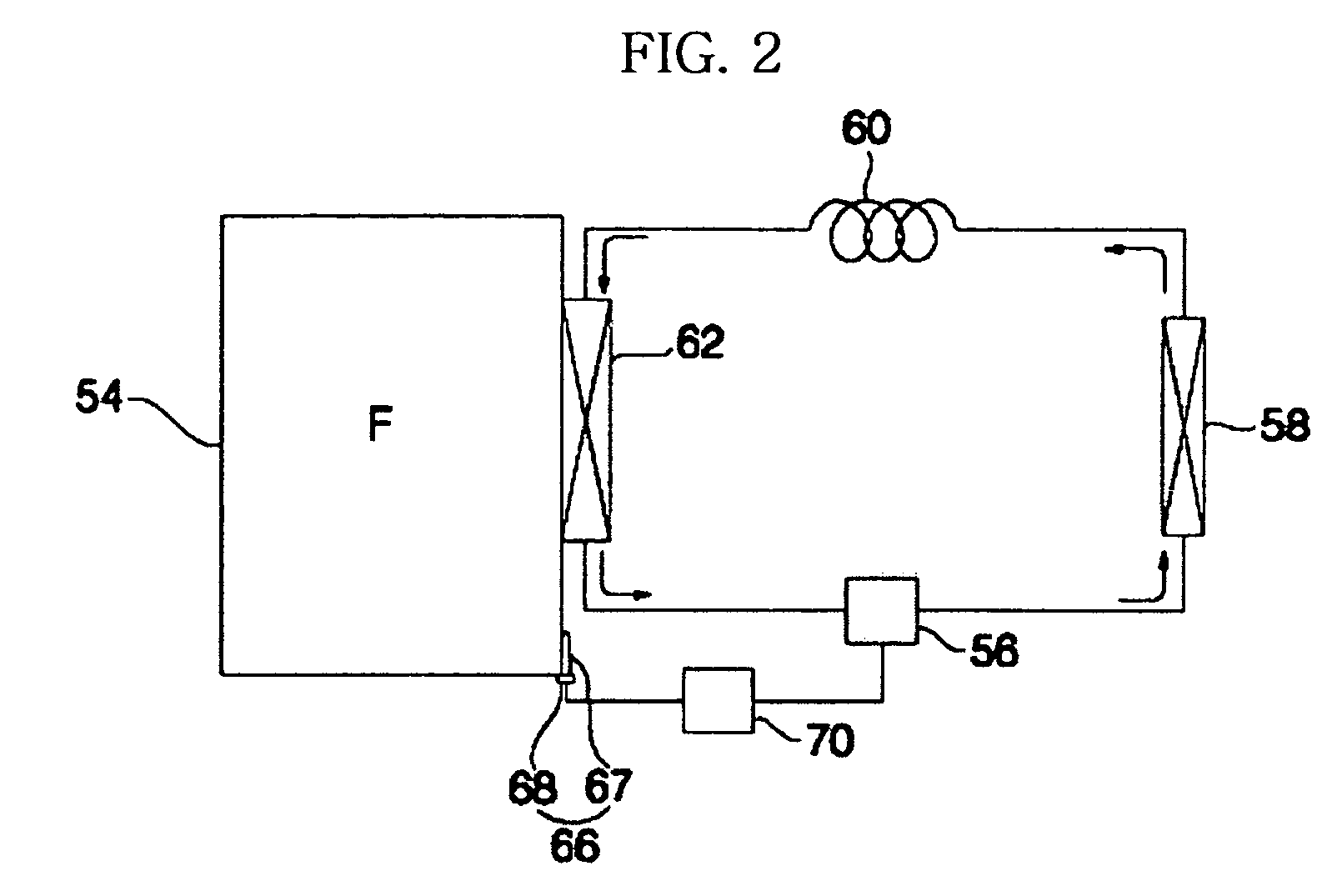

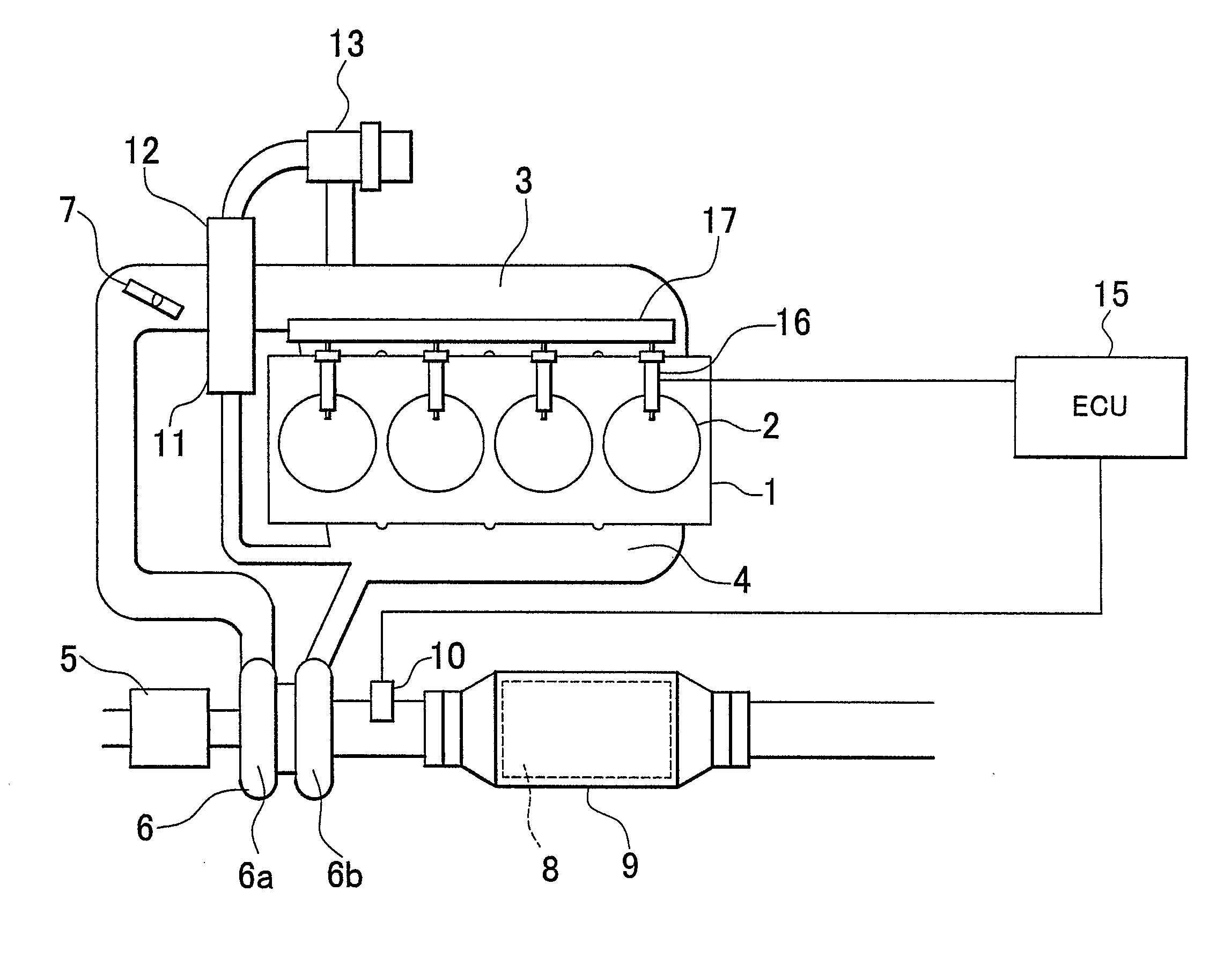

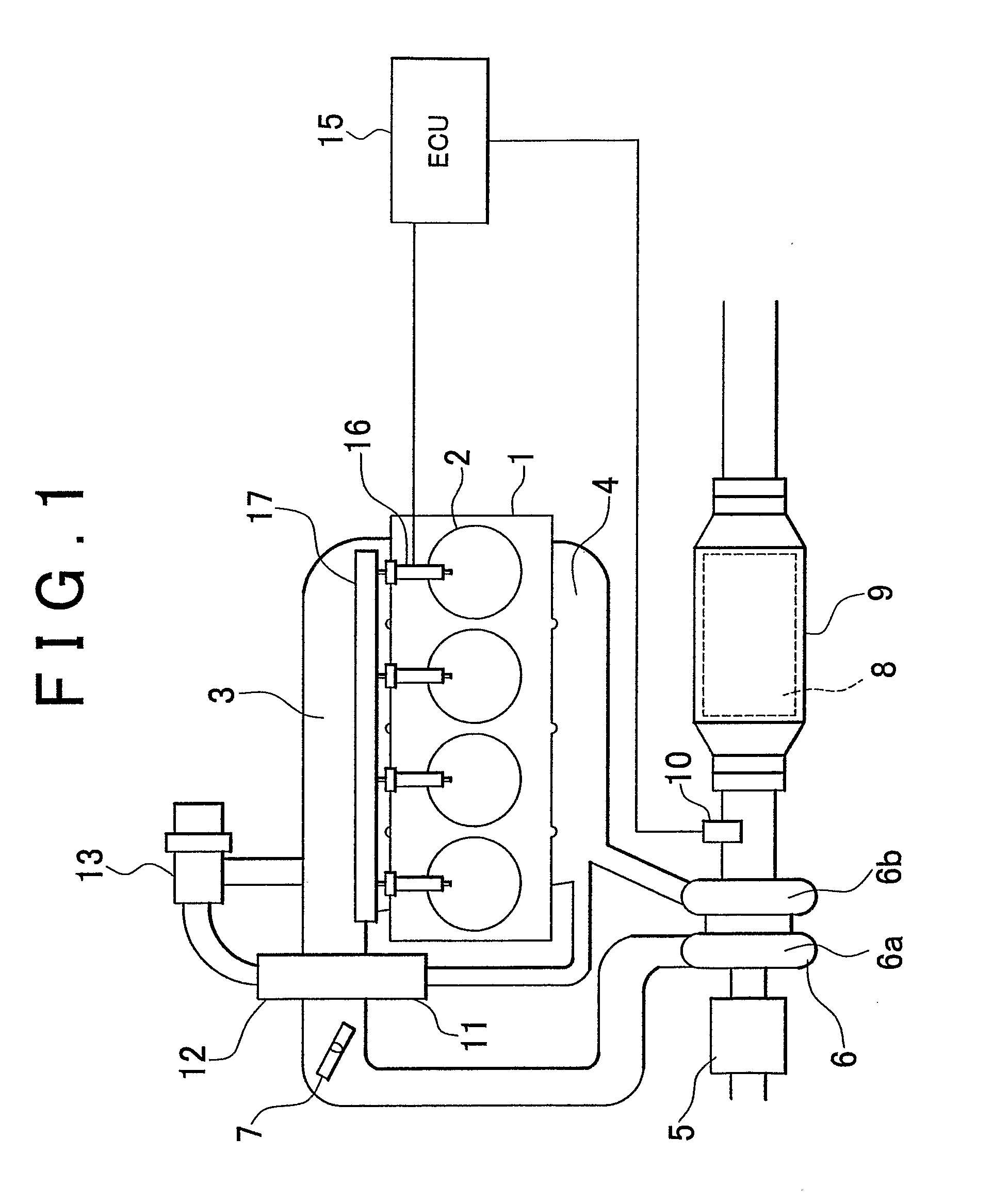

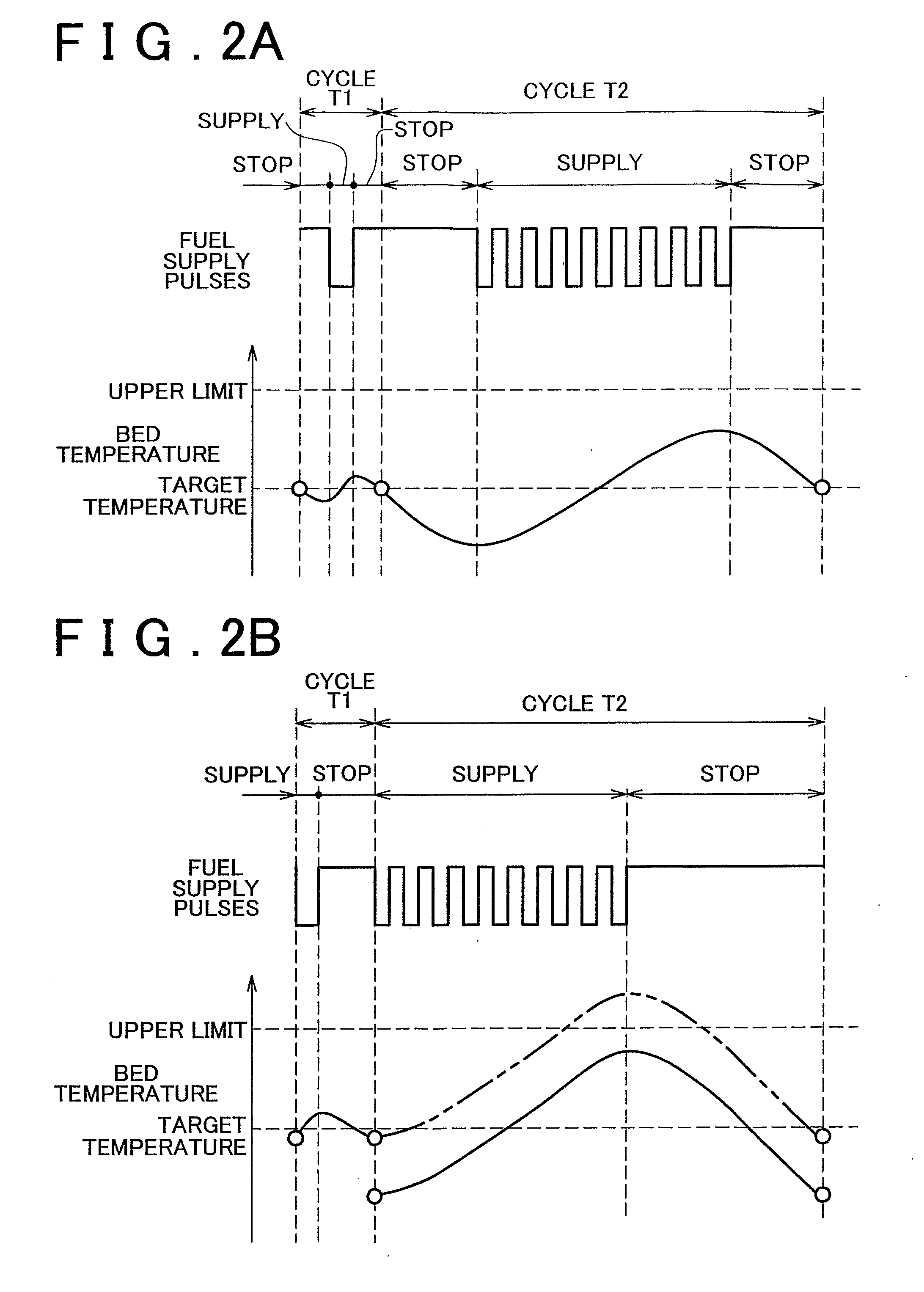

In an exhaust gas control apparatus for an internal combustion engine (1) of the invention, including an exhaust gas control catalyst (8) which purifies exhaust gas released from the internal combustion engine (1), and a fuel supply valve (10) which supplies fuel to a portion upstream of the exhaust gas control catalyst (8), the fuel supply valve (10) is operated such that a cycle formed by combining a fuel supply period in which fuel is supplied from the fuel supply valve (10) and a fuel supply stopped period in which fuel is not supplied is repeatedly performed in order to control the temperature of the exhaust gas control catalyst (8) to the target temperature. The arrangement of the fuel supply period and the fuel supply stopped period is controlled such that the temperature of the exhaust gas control catalyst (8) at each of a starting point (P1) and an ending poring (P3) of each cycle is equal to the target temperature.

Owner:TOYOTA JIDOSHA KK

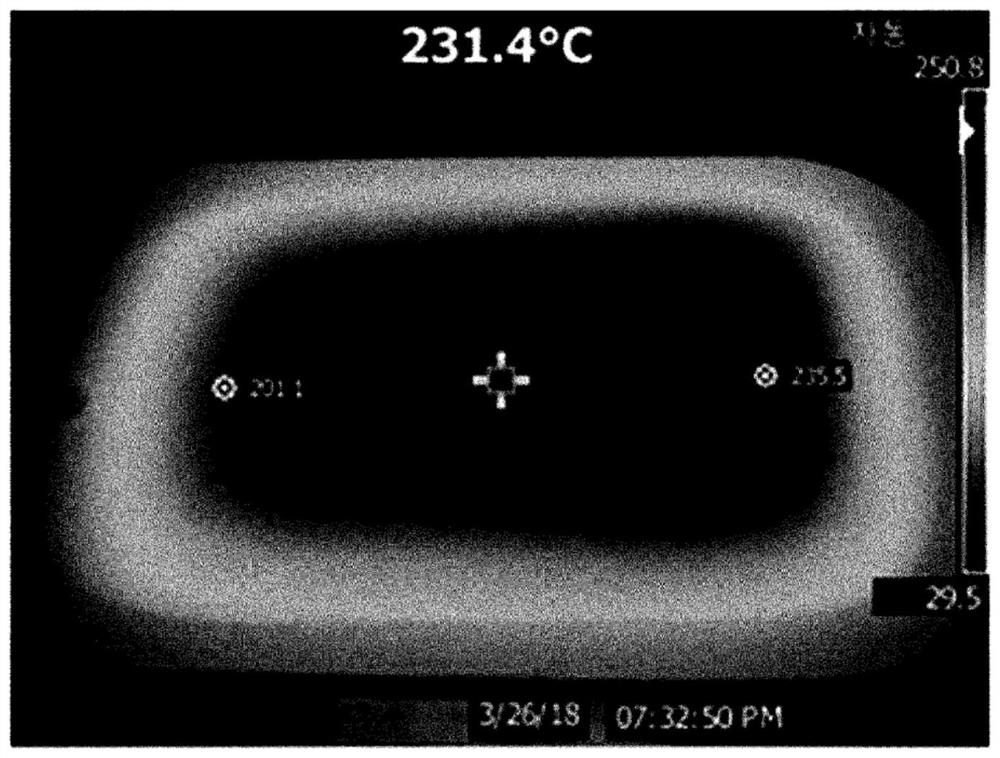

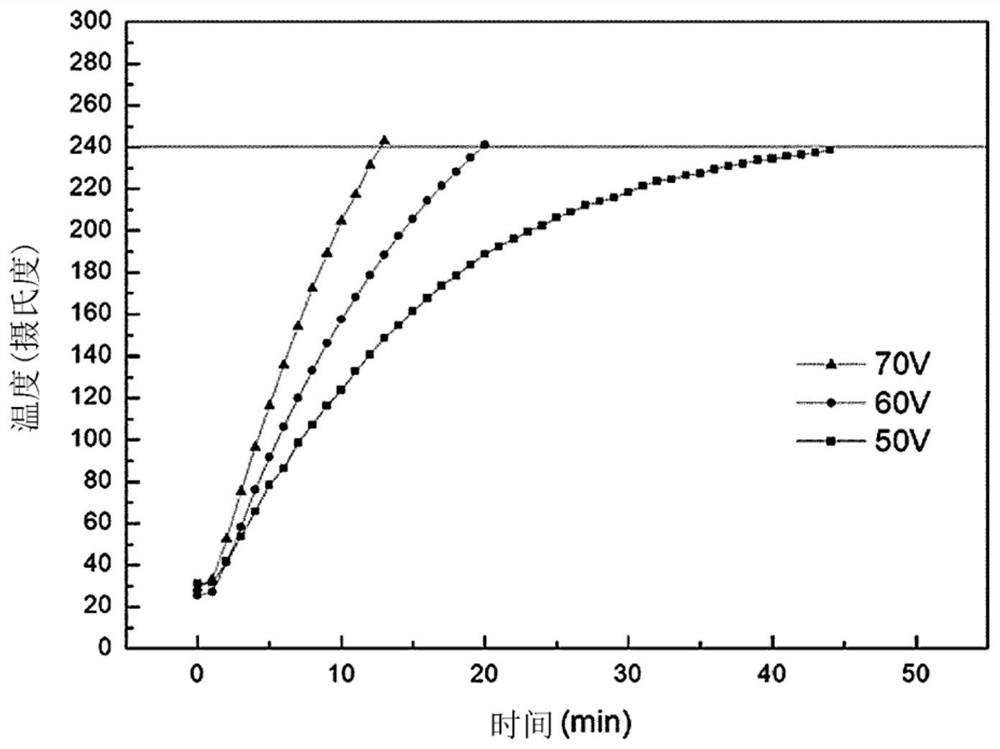

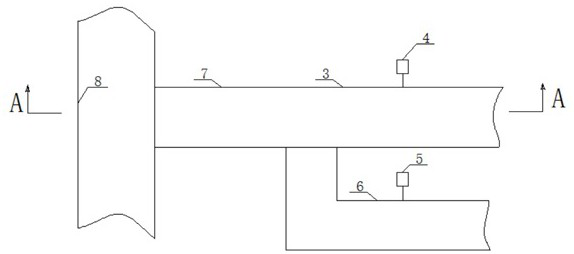

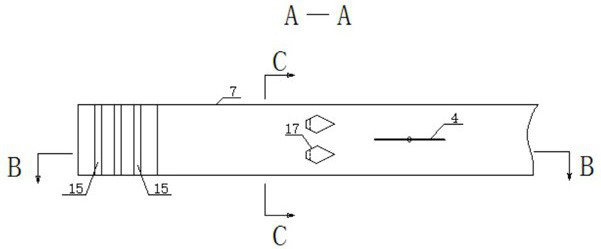

Thermal cutting shear and cutting method thereof

InactiveCN101992473ATemperature is directly measured and controlledTemperature measurement and controlMetal working apparatusRubber materialTemperature control

The invention relates to a thermal cutting shear and a cutting method thereof, and a flat arrangement type heating mode in fixture bodies is adopted to enhance the heating efficiency and the heat transfer speed and effectively control the operating temperature when the front end of a cutting edge carries out the cutting so as to enhance the cutting quality of the rubber material, and the quality of the joint and the stitching among various materials. The cutting shear comprises a group of the fixture bodies and shear bodies clamped and fixed among the fixture bodies, wherein at least one flat plate type heating plate is lined among the fixture bodies and the bases of the shear bodies; a heat source temperature sensor is arranged in the heating plate and is connected with an external power supply and a temperature control meter through a power supply wire; and a shear body temperature sensor is arranged in the cutting edge part of the shear bodies.

Owner:MESNAC

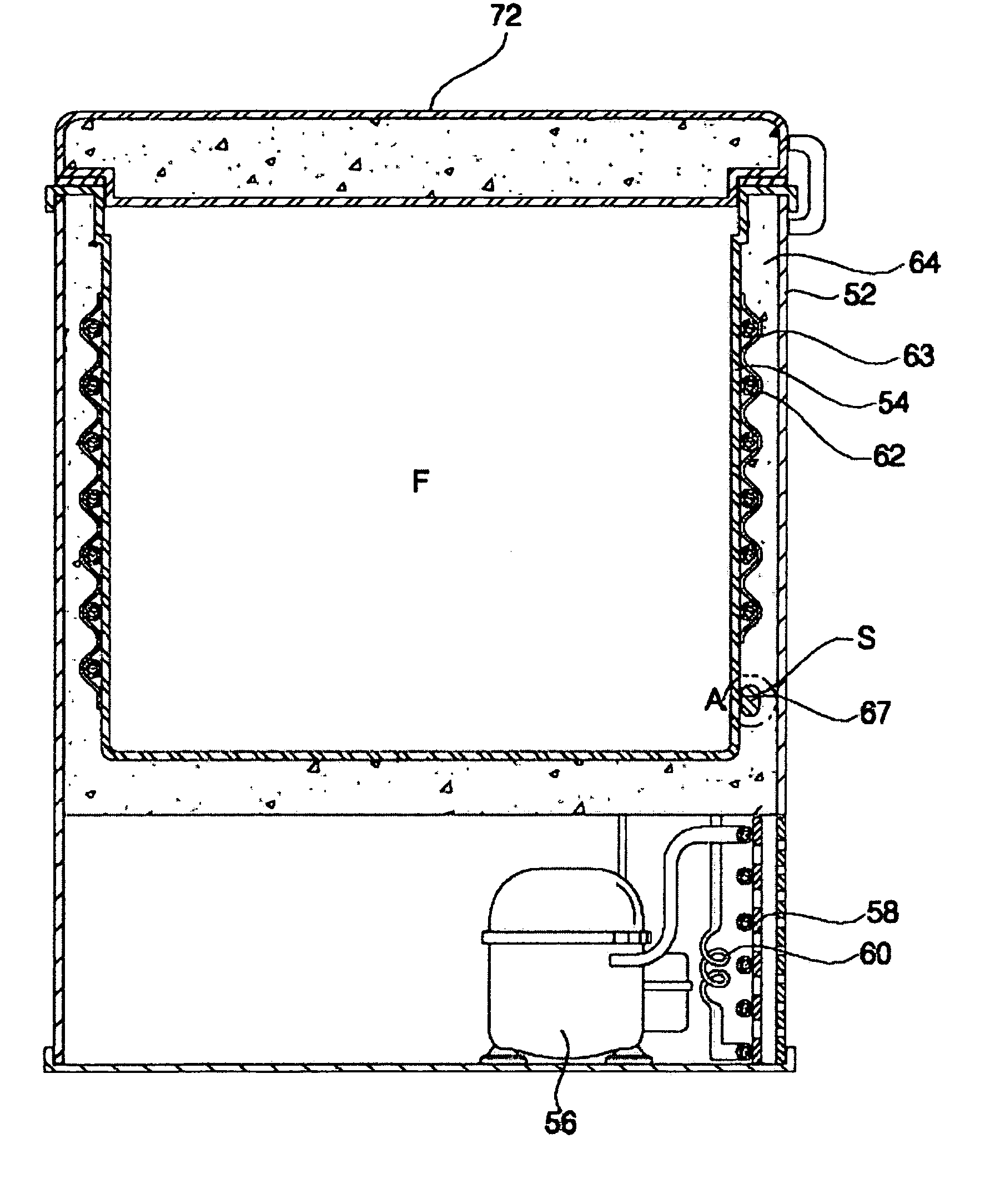

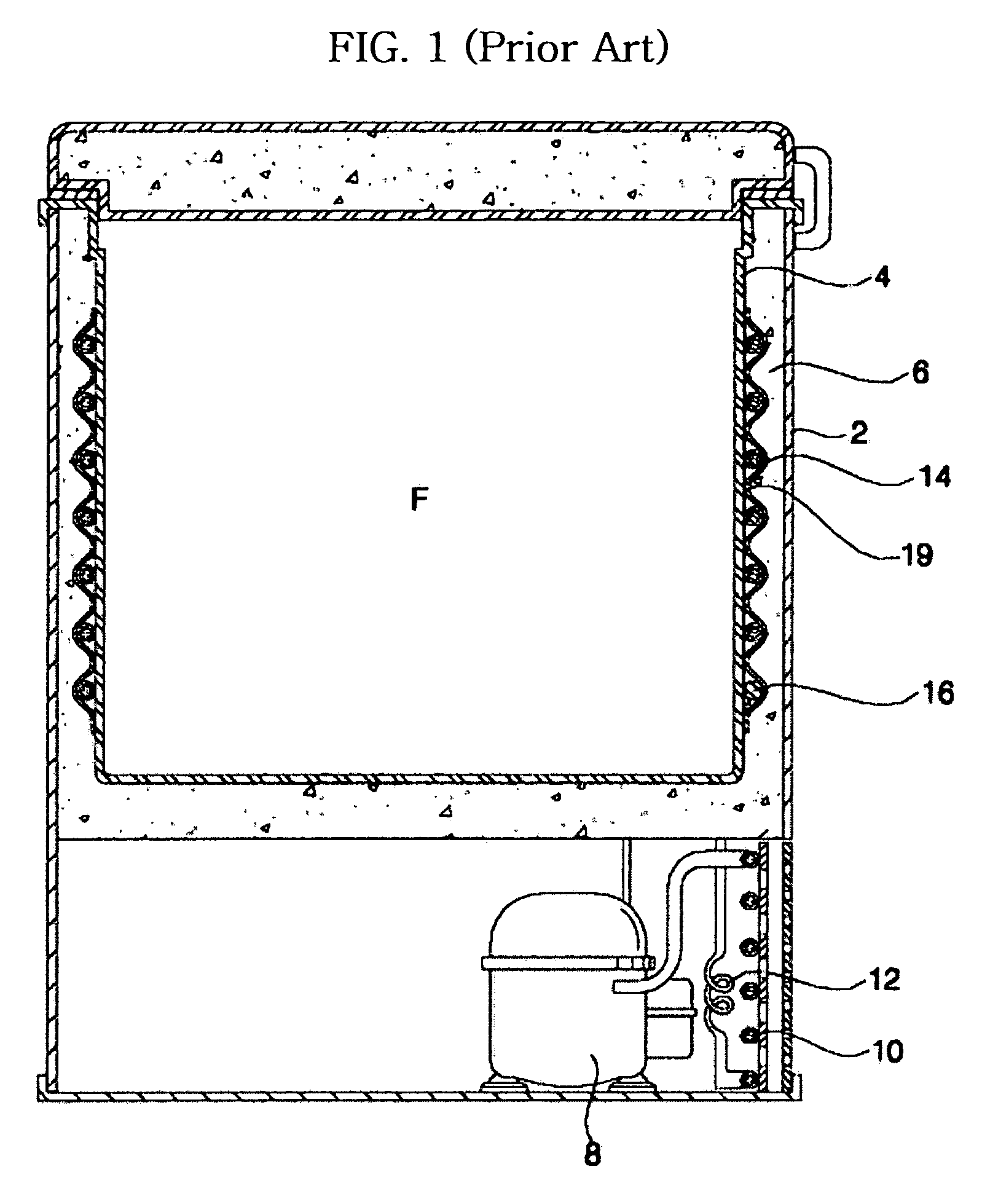

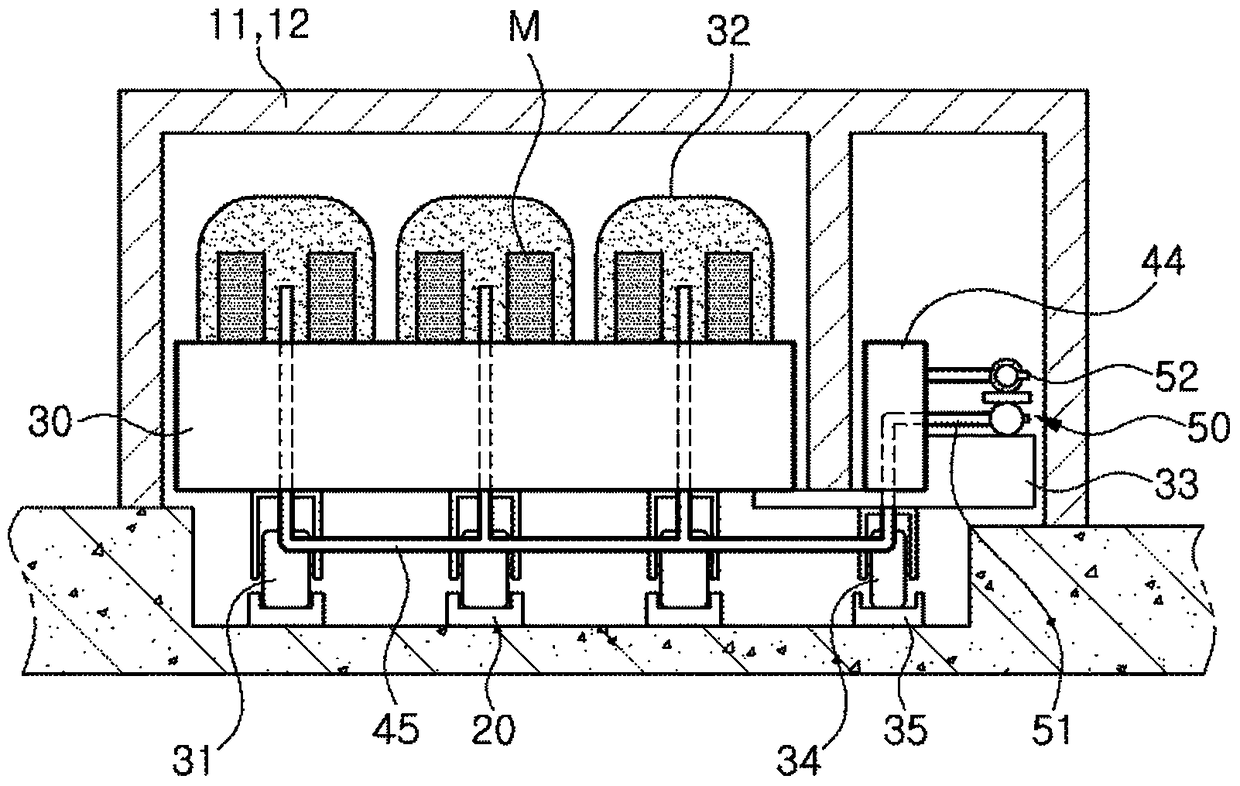

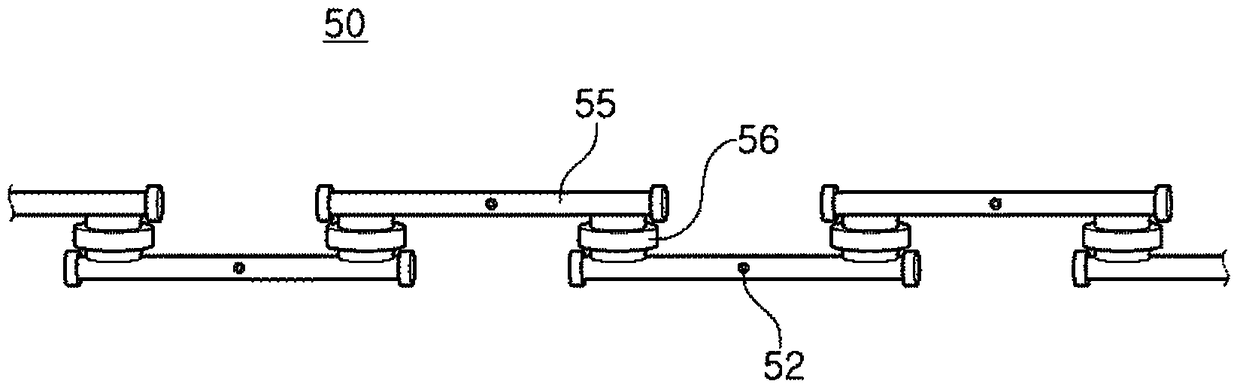

Refrigerator and temperature sensor fixing method in the refrigerator

InactiveUS7140191B2Rapidly and accurately controllingReduced on/off timeCompression machines with non-reversible cycleEvaporators/condensersTemperature controlEvaporation

A direct cooling type refrigerator capable of rapidly and accurately controlling the temperature thereof, reducing the ON / OFF time of its compressor, thereby preventing the temperature deviation of its storage compartment from increasing over a predetermined value. The refrigerator includes an outer casing defining an appearance of the refrigerator, an inner casing arranged within the outer casing, and defined with a storage compartment, an insulator interposed between the outer casing and the inner casing, a compressor for compressing a refrigerant, an evaporator arranged to be in contact with the inner casing, and adapted to cool the inner casing in accordance with evaporation of a refrigerant passing therethrough, a temperature sensor provided with a surface contact area closely contacting the inner casing, and adapted to sense a temperature of the inner casing, and a control unit for controlling the compressor in accordance with the temperature sensed by the temperature sensor.

Owner:LG ELECTRONICS INC

Fuel Supply Control Method Applied to Exhaust Gas Control Apparatus for Internal Combustion Engine and Exhaust Gas Control Apparatus to Which the Method is Applied

ActiveUS20070214769A1Avoid overall overheatingPrevent temperature deviationElectrical controlExhaust apparatusEngineeringInternal combustion engine

In an exhaust gas control apparatus for an internal combustion engine (1) of the invention, including an exhaust gas control catalyst (8) which purifies exhaust gas released from the internal combustion engine (1), and a fuel supply valve (10) which supplies fuel to a portion upstream of the exhaust gas control catalyst (8), the fuel supply valve (10) is operated such that a cycle formed by combining a fuel supply period in which fuel is supplied from the fuel supply valve (10) and a fuel supply stopped period in which fuel is not supplied is repeatedly performed in order to control the temperature of the exhaust gas control catalyst (8) to the target temperature. The arrangement of the fuel supply period and the fuel supply stopped period is controlled such that the temperature of the exhaust gas control catalyst (8) at each of a starting point (P1) and an ending poring (P3) of each cycle is equal to the target temperature.

Owner:TOYOTA JIDOSHA KK

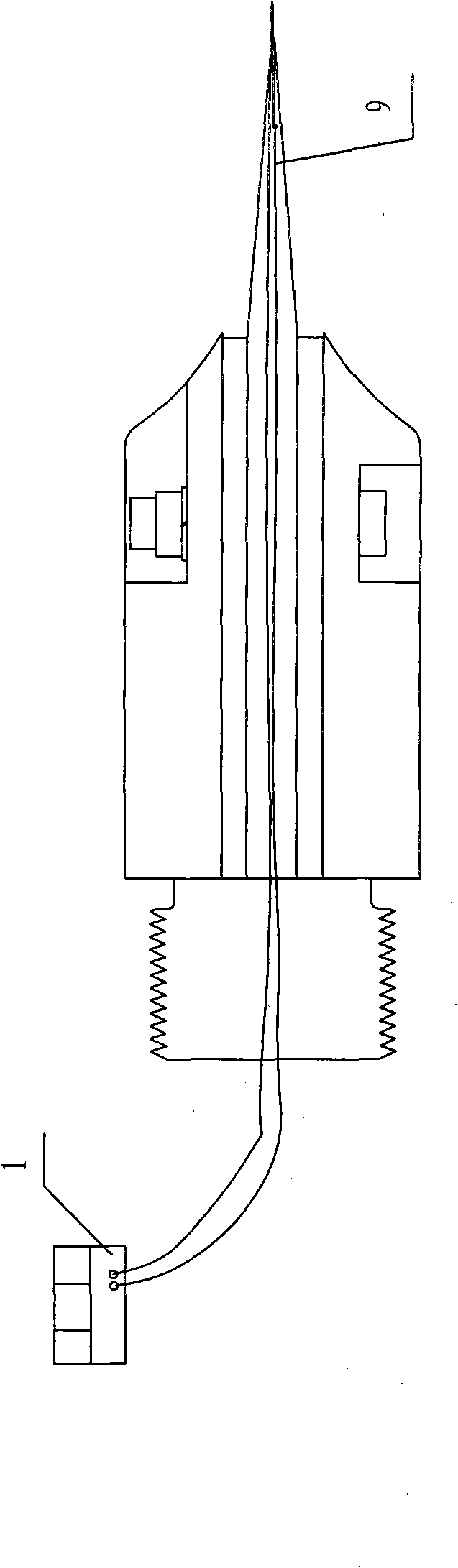

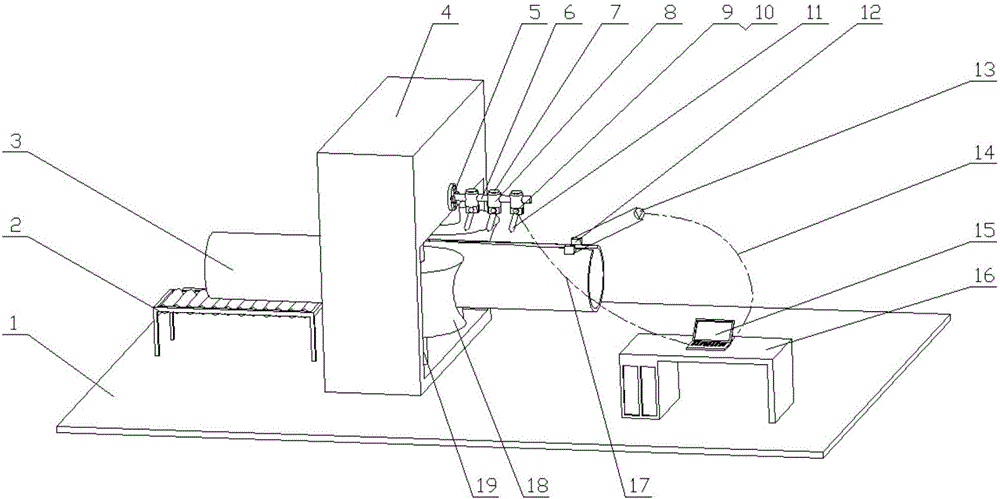

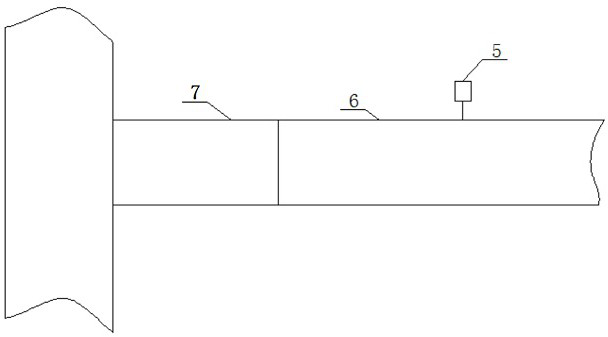

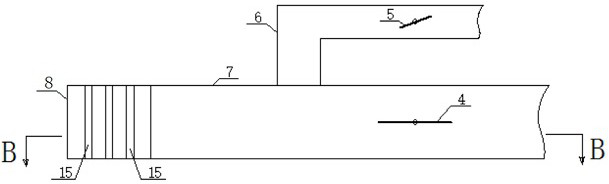

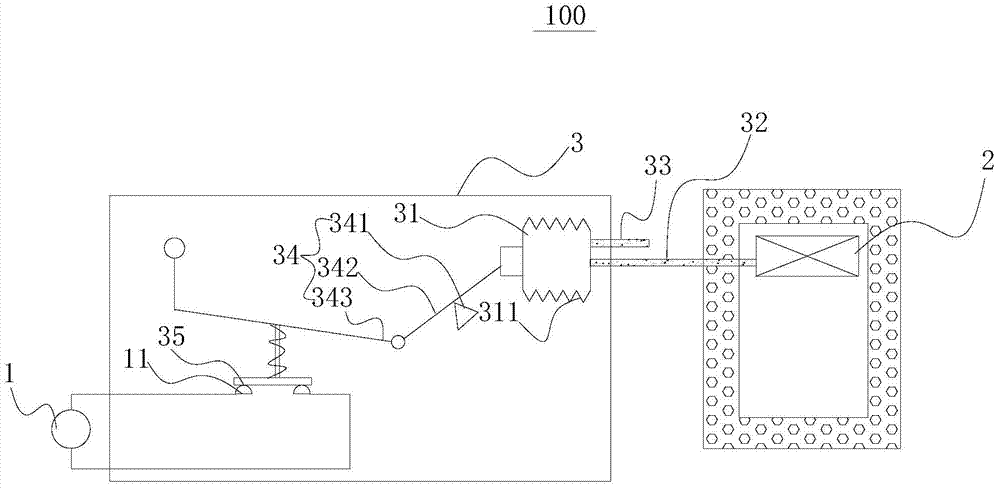

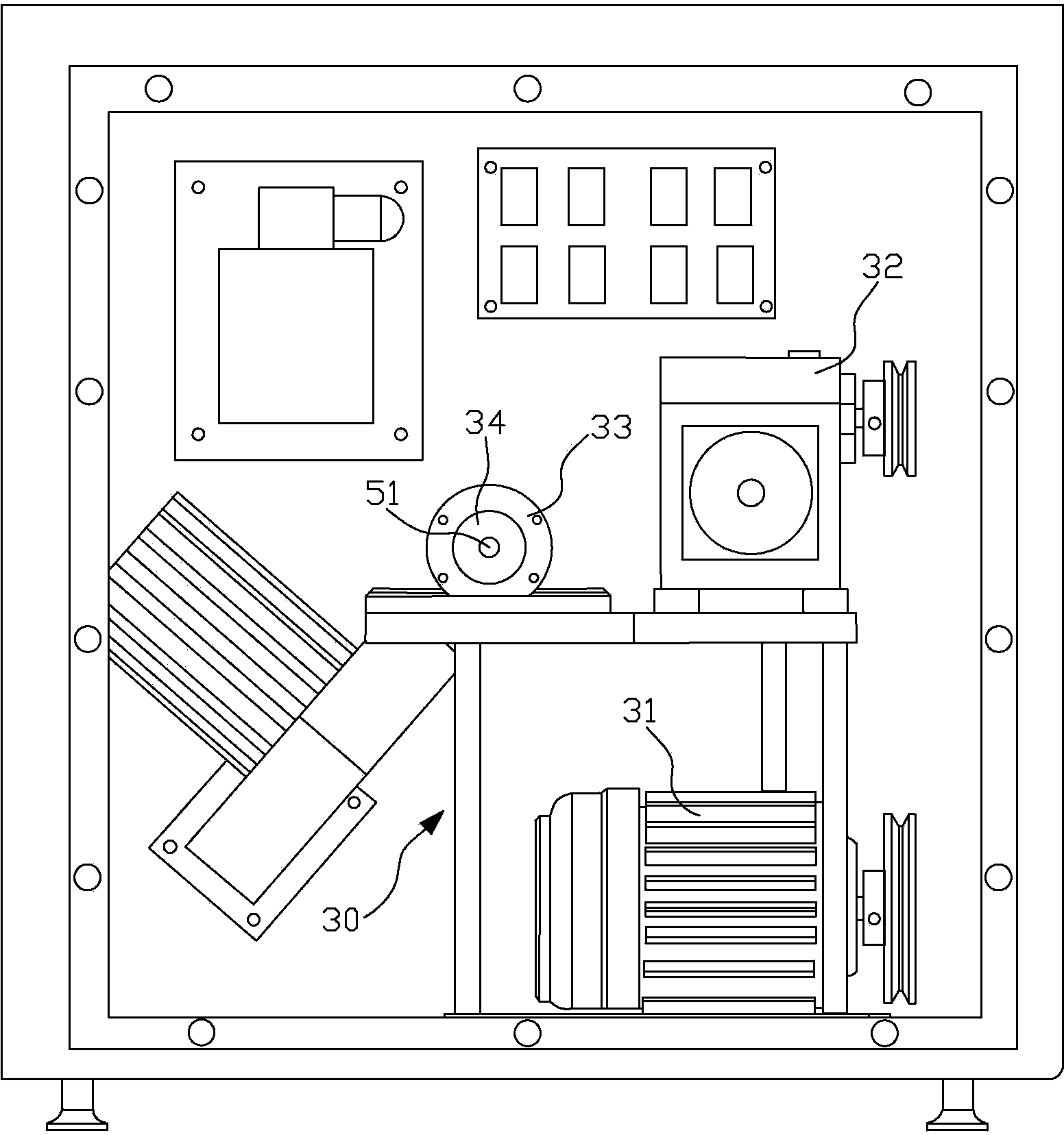

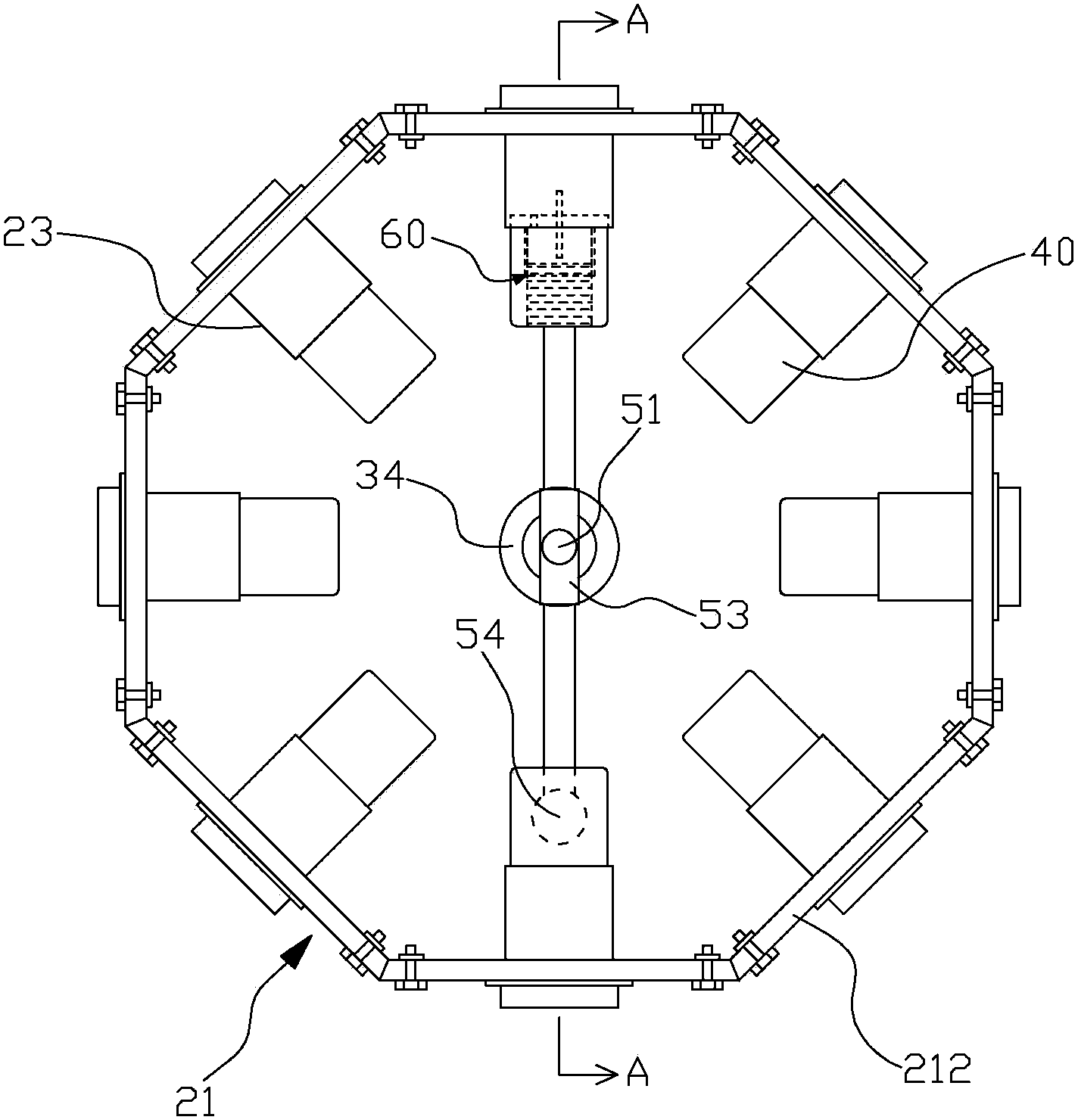

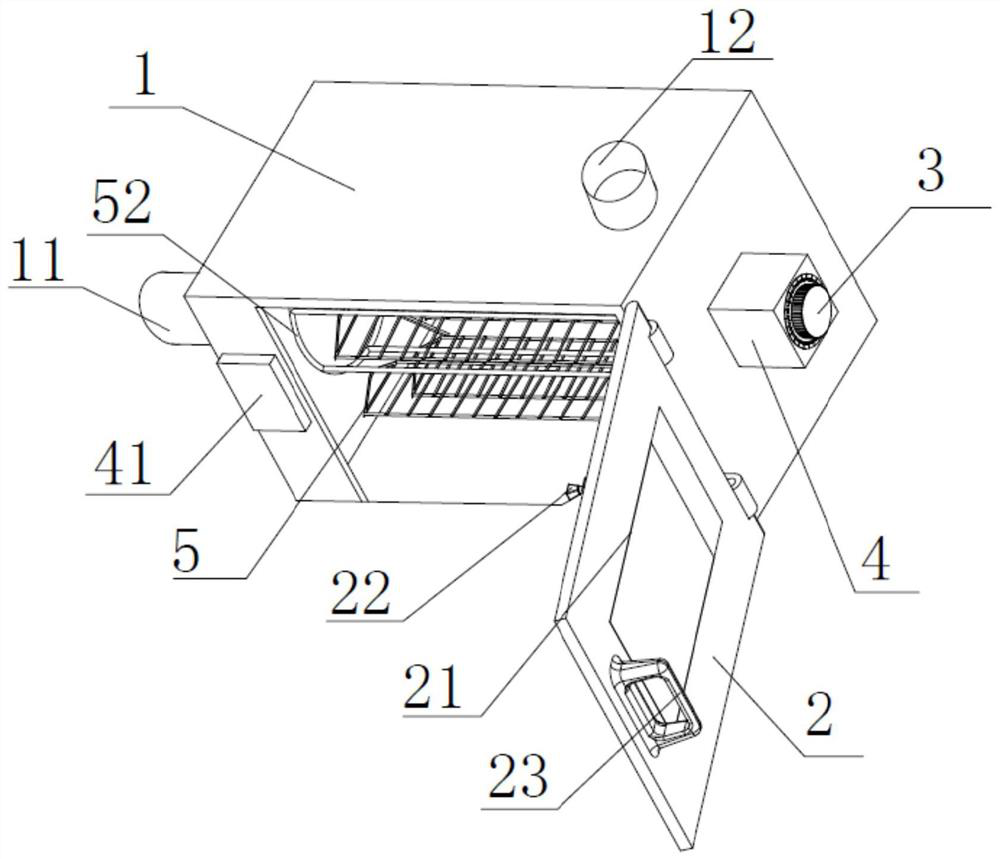

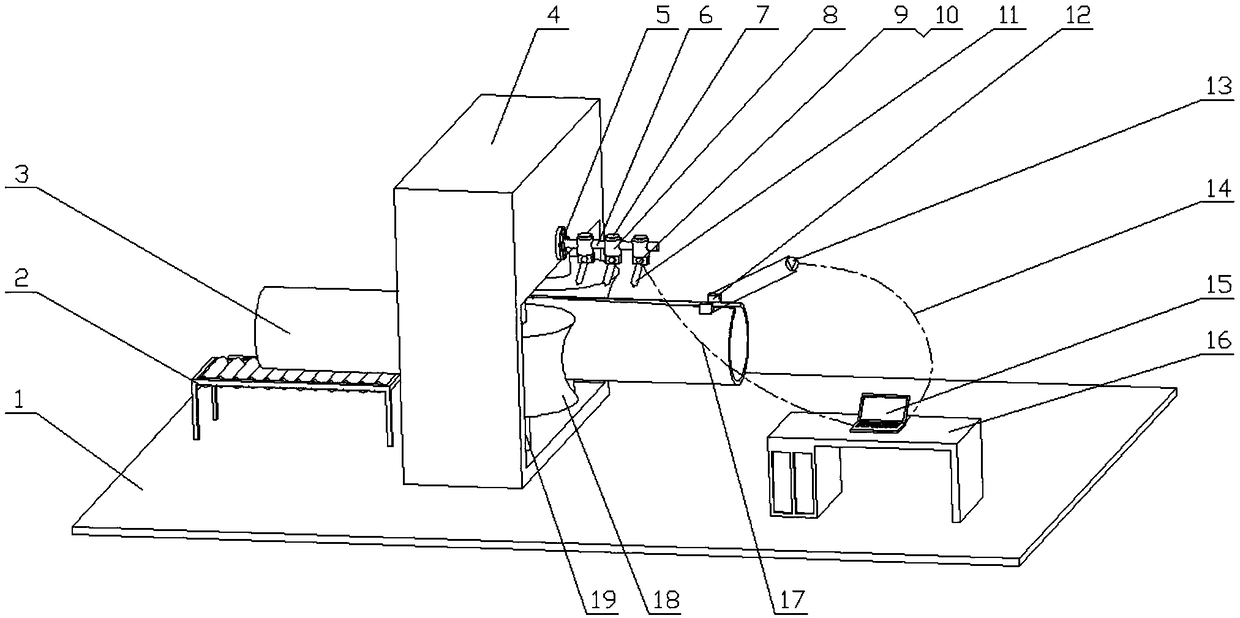

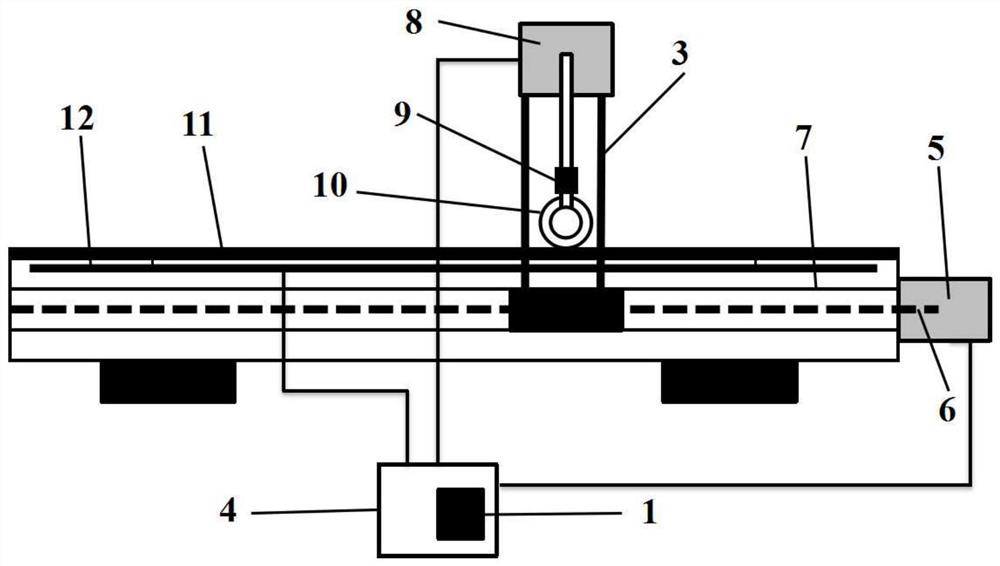

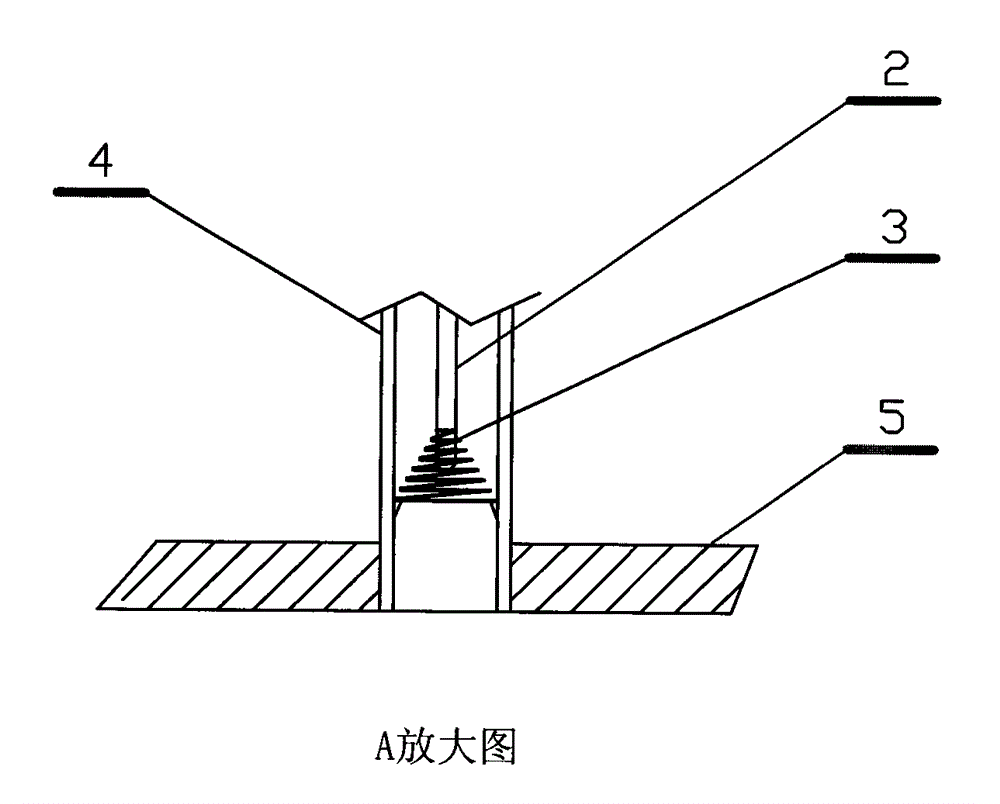

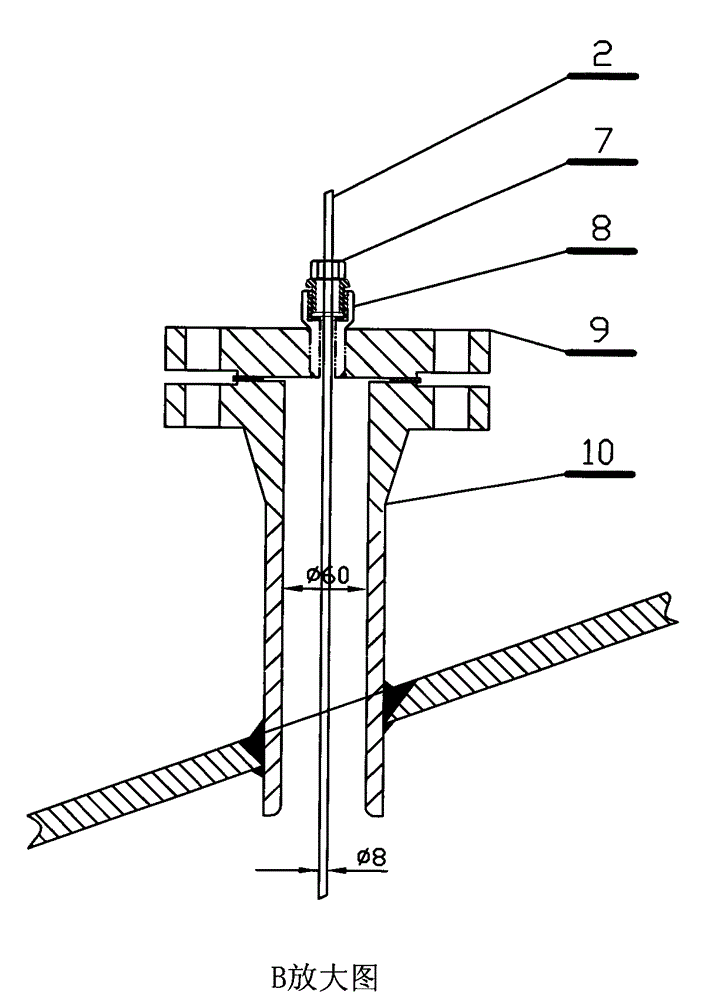

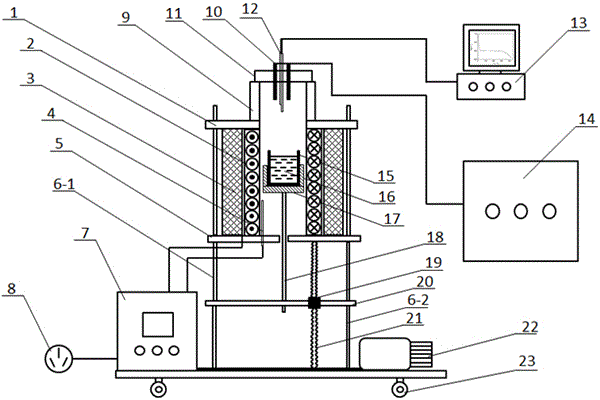

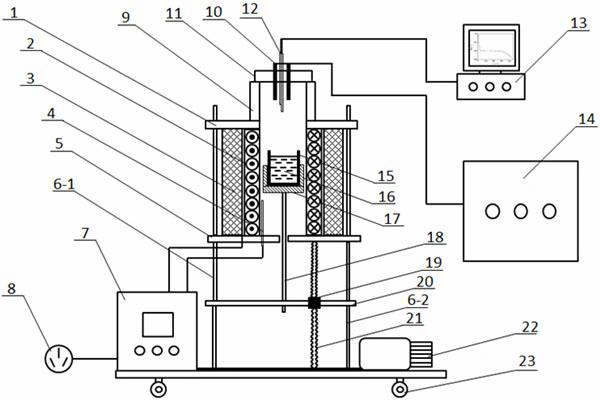

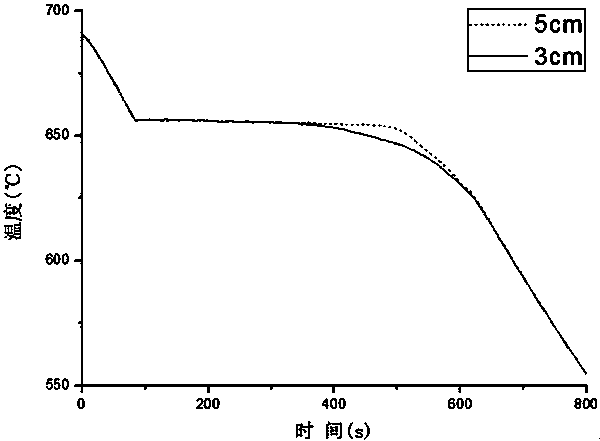

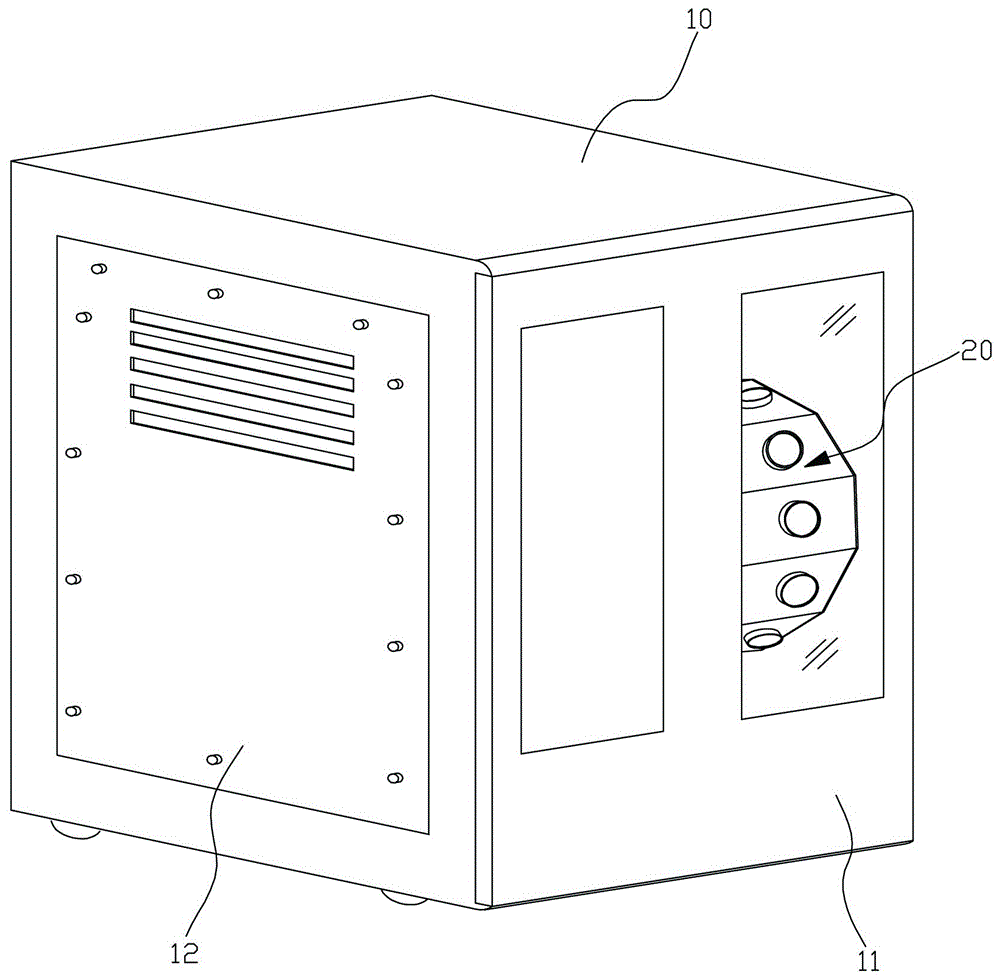

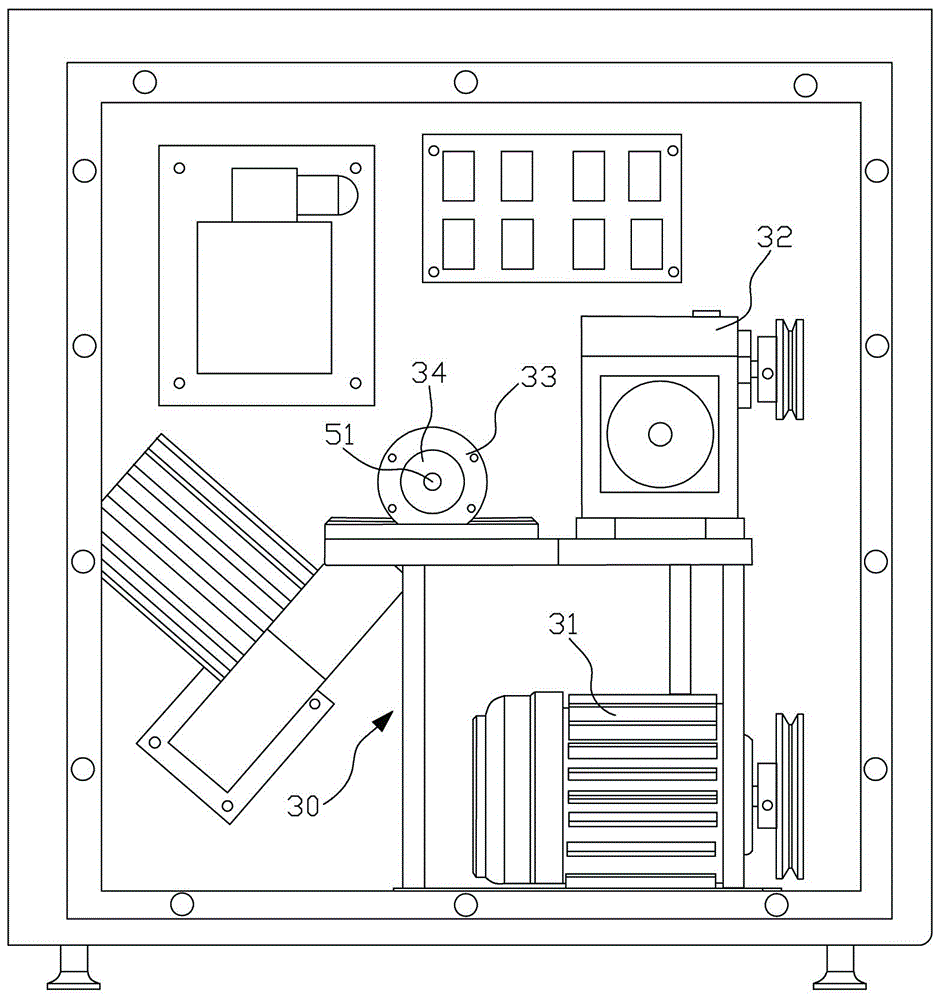

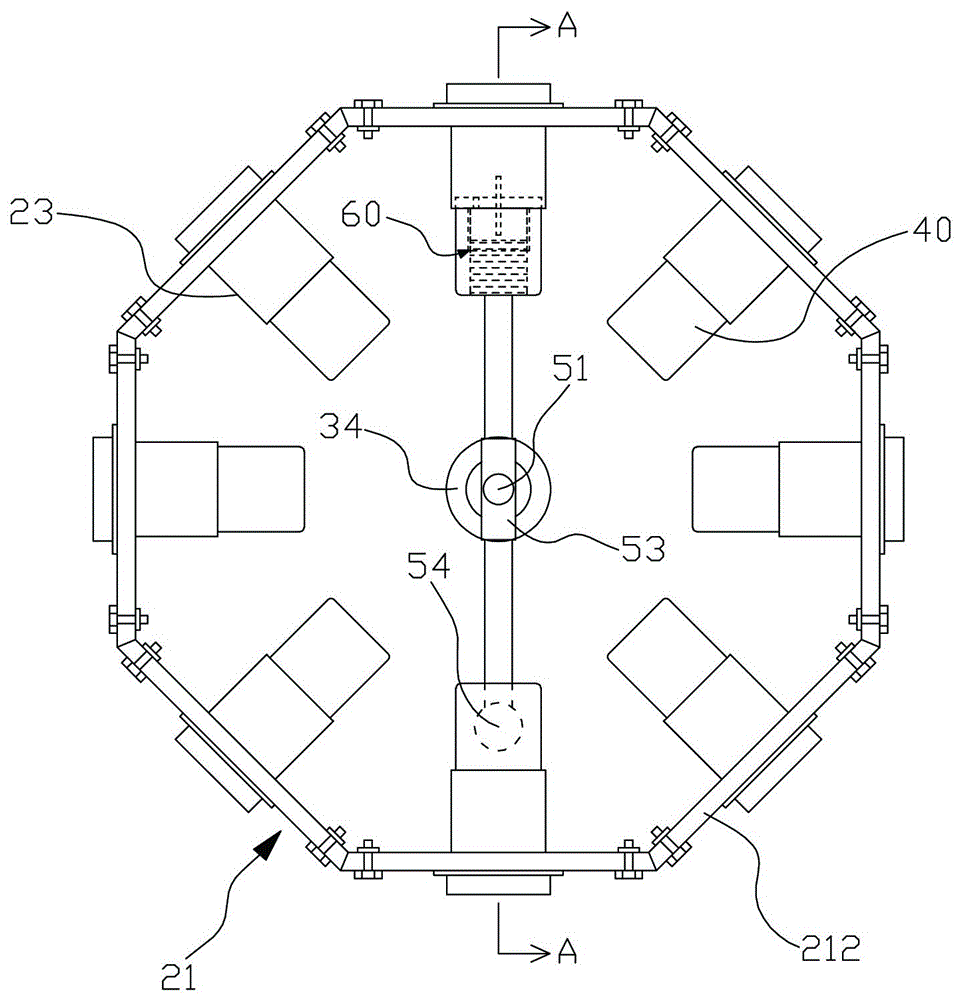

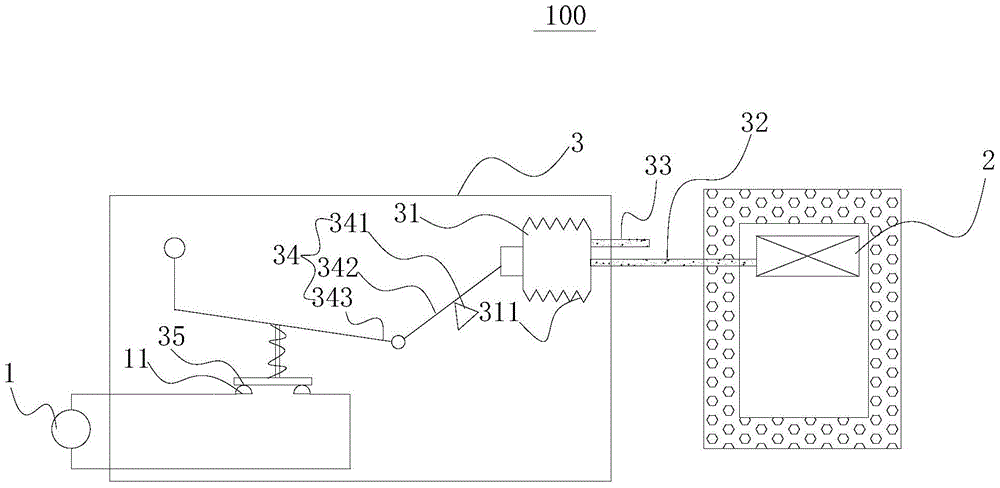

Online detection and control experimental device for welding temperature of electric resistance welding steel pipe

ActiveCN106312386AGuarantee the quality of welded pipeAccurate control of soldering temperatureWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeTemperature measurement

The invention discloses an online detection and control experimental device for the welding temperature of an electric resistance welding steel pipe. The online detection and control experimental device is mainly characterized in that the side, facing a high-frequency generator, of the upper portion of a rack is perpendicularly connected with one end of a supporting rod; connecting pieces are connected to the supporting rod at intervals in a sleeving manner; the top of each connecting piece is further provided with an upper screw hole communicating with a middle through hole, wherein a set screw is arranged in the upper screw hole; a connecting lug is arranged below each connecting piece, and a colorimetric temperature measurement device is installed on each connecting piece through the corresponding connecting lug; one set of temperature measuring assembly is composed of one connecting piece, the corresponding set screw, the corresponding colorimetric temperature measurement device, a corresponding bolt and a corresponding nut on the supporting rod, and three to six sets of temperature measuring assemblies are arranged. Each colorimetric temperature measurement device is connected with a computer through a signal line, and the computer is also connected with the high-frequency generator and an output device of the high-frequency generator through a signal line to from a closed-loop control system. According to the online detection and control experimental device for the welding temperature of the electric resistance welding steel pipe, the phenomenon that the temperature for welding the vertex of a V-shaped opening angle is directly measured is avoided, the influences of mist generated by cooling liquid on measurement of the welding temperature are reduced, the welding temperature is accurately controlled, and the quality of the welding pipe is ensured.

Owner:江苏景泰电力科技有限公司

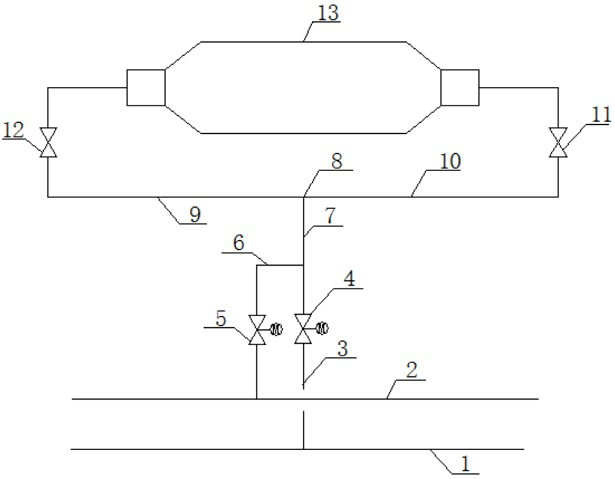

Double-inlet and double-outlet coal mill inlet cold and hot primary air mixing system and method

InactiveCN112121988AUniform flow fieldPrevent temperature deviationGrain treatmentsPower stationAir door

The invention discloses a double-inlet and double-outlet coal mill inlet cold and hot primary air mixing system and method, and belongs to the field of energy-saving treatment of power station boilercoal pulverizing systems. The system comprises a coal mill and further comprises a hot primary air main pipe, a cold primary air main pipe, a hot primary air pipe, a hot primary air adjusting baffle,a cold primary air adjusting baffle, a cold primary air pipe, a mixed air pipe, a flow dividing tee joint, a left-side mixed air branch pipe, a right-side mixed air branch pipe, a right-side capacityair door and a left-side capacity air door. By changing the mounting modes of the hot primary air adjusting baffle and the cold primary air adjusting baffle, structurally optimizing the pipeline structure of an airflow mixing part and structurally optimizing the flow dividing tee joint, the problem that the temperature deviation of mixed air at inlets in the two ends of the double-inlet and double-outlet coal mill is large can be thoroughly solved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Refrigerating system for refrigerating device

ActiveCN104501507AReduce boot timePrecise controlLighting and heating apparatusRefrigeration devicesTemperature senseEvaporator

The invention discloses a refrigerating system for a refrigerating device. The refrigerating system comprises a compressor, an evaporator and a temperature controller, wherein the temperature controller comprises a temperature sensing bag, an evaporator temperature sensing tube which is arranged on the evaporator, is used for sensing the temperature of the evaporator and is connected with the temperature sensing bag, an outer temperature sensing tube which is used for sensing the temperature in the outer environment of the refrigerating device and is connected with the temperature sensing bag, and a contact sheet, the temperature sensing bag and the contact sheet are connected, and the contact sheet is driven by the temperature sensing bag through the expansion and the contraction to switch on or off the compressor power supply loop of the compressor. According to the refrigerating system for the refrigerating device, control buttons and manual adjustment are not required, temperature control of a refrigerator is completely automatic, the compensation action is played to the changes of environment temperature through the arrangement of the outer temperature sensing tube, the accurate temperature control of the temperature in the refrigerator can be realized, and temperature deviation caused by the manual adjustment is avoided.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

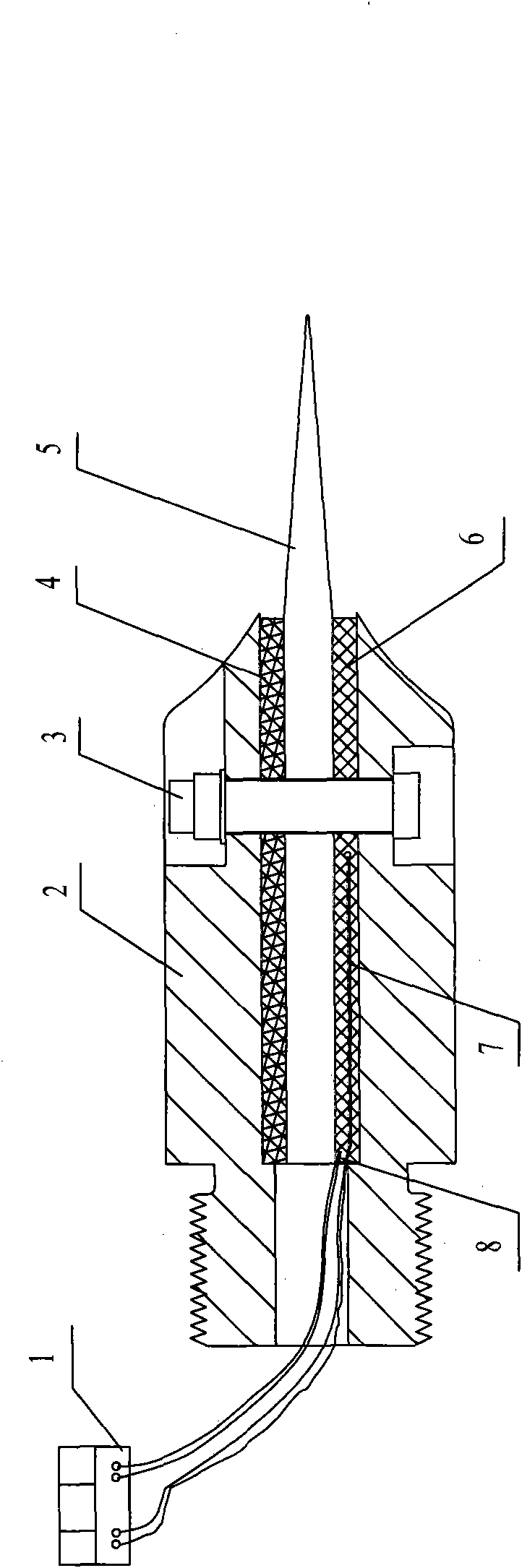

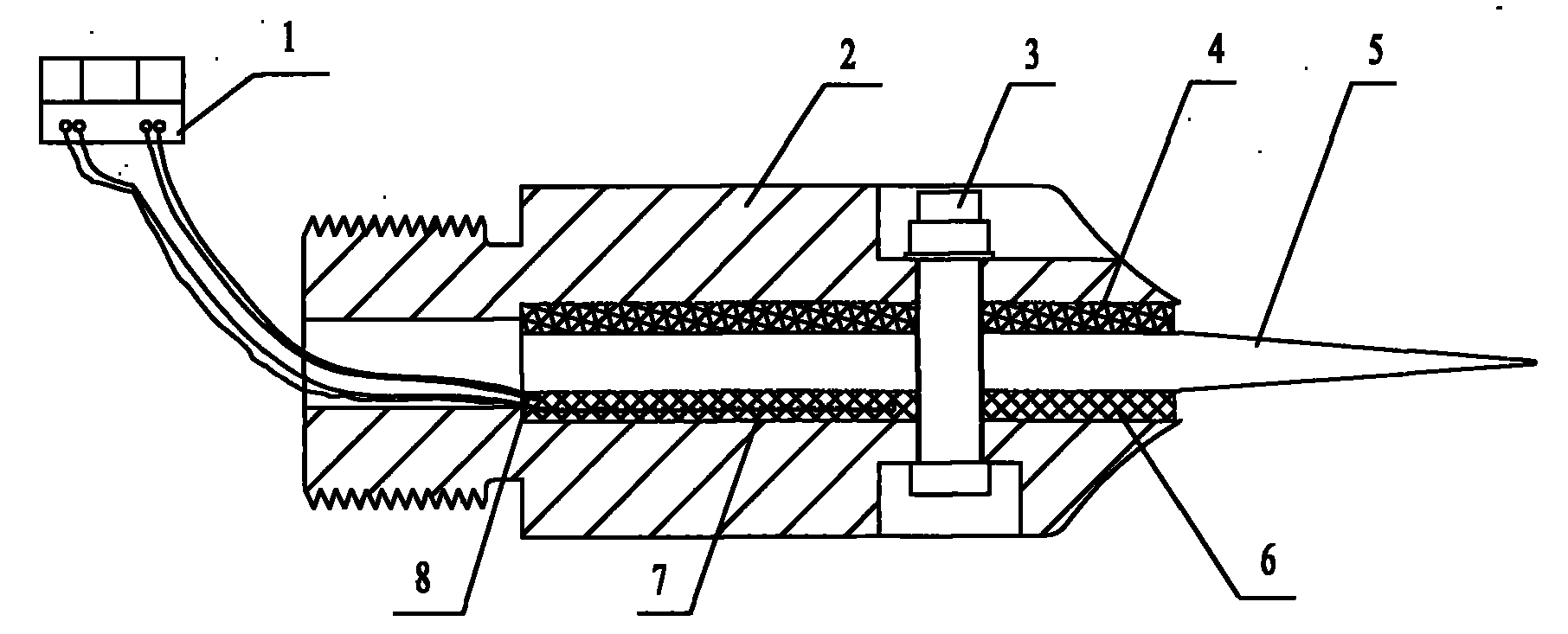

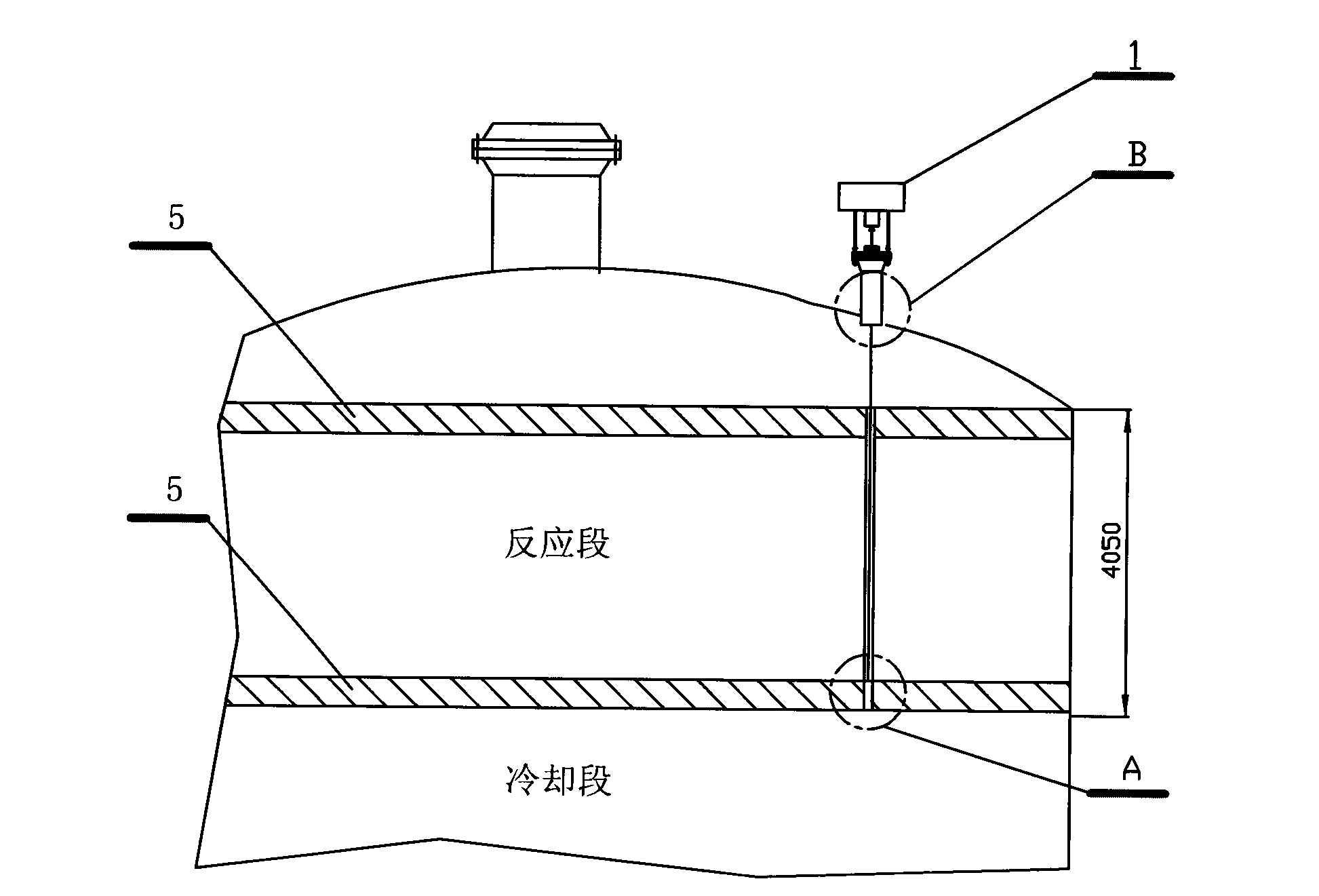

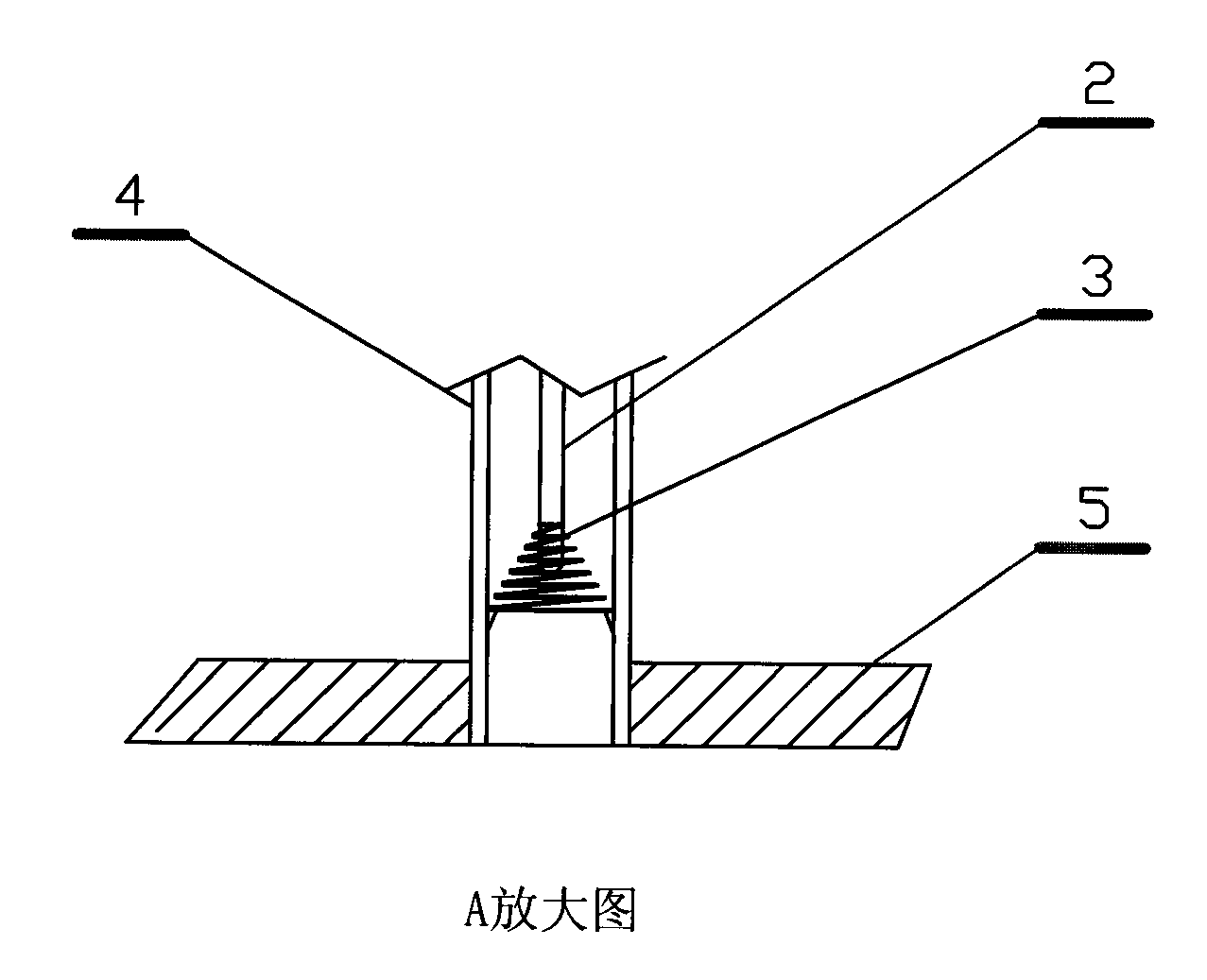

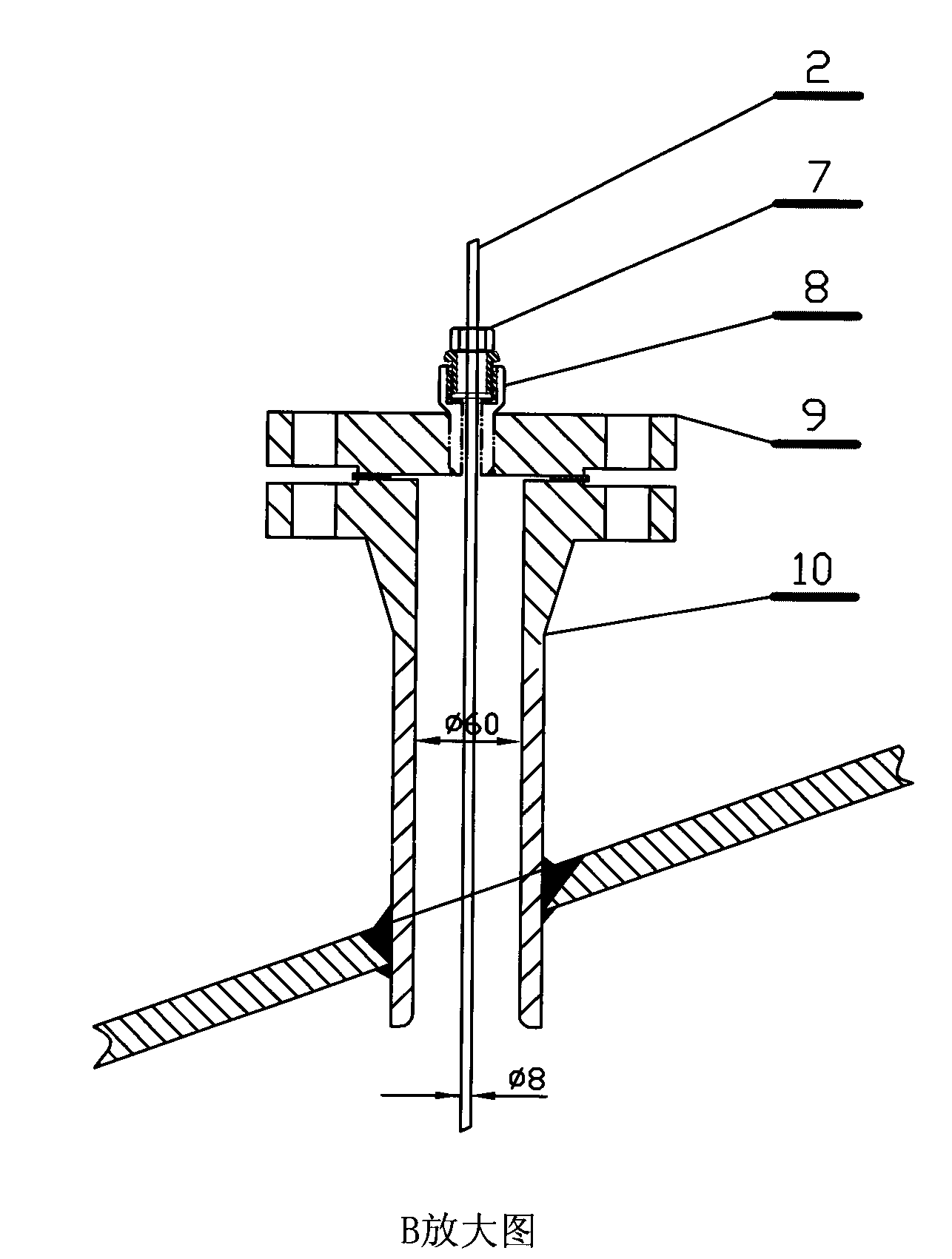

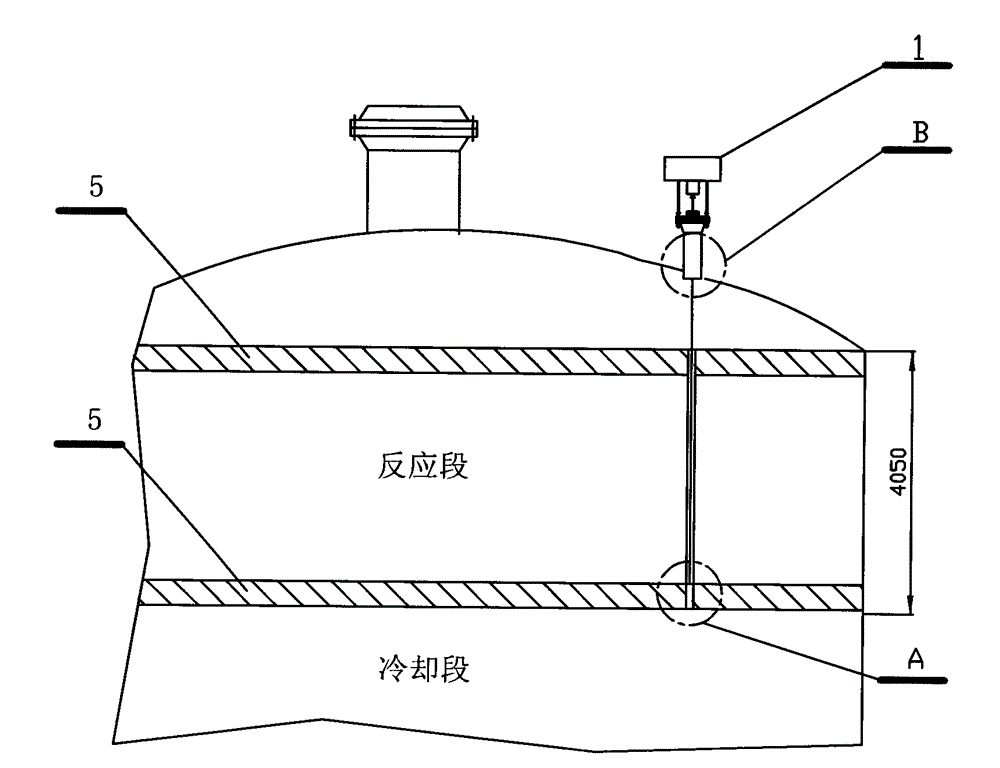

Device for installing thermocouple on reactor in propenoic acid production

ActiveCN103055767ASolve the problem of vertical installation of multi-point thermometerSolve vertical installation problemsOrganic compound preparationThermometers using electric/magnetic elementsEngineeringPetrochemical

The invention relates to a parameter measuring device in petrochemical production process. A device for installing a thermocouple on a reactor in propenoic acid production is characterized in that a short flange tube is arranged on a sealing cover of the reactor; a flange is equipped on the short flange tube; a straight connecting head is arranged on a flange cover; a movable clamping sleeve is arranged on the straight connecting head; the thermocouple is arranged inside the movable clamping sleeve; a fin is arranged on the thermocouple; and a spring is arranged at the lower end of the thermocouple. The device has the advantages of simple structure and easiness in manufacturing, solves the problem that a multi-point thermometer of a propenoic acid oxidation reactor is vertically installed, greatly reduces the difficulty in installing a catalyst, reduces the installation cost and ensures that the installation position of the thermometer is accurate; the temperature detection of the propenoic acid oxidation reactor is reliable and accurate; products in propenoic acid production are good in quality, the conversion rate of the propylene is high, the production in the oxidation process of the propylene is safe, the catalyst is prevented from cocking phenomenon in propylene production, and the service life of the catalyst is prolonged.

Owner:中石油吉林化工工程有限公司

Electric roasting pan

ActiveCN112203563AHas minimized heat lossImprove thermal efficiencyCooking-vessel materialsRefuse receptaclesCarbon nanotubeSilicone

An electric roasting pan according to the present invention comprises: a roasting pan; a heating layer being in surface contact with the roasting pan and comprising a carbon nanotube and a silicone-based adhesive; and an electrode in contact with the heating layer. The electric roasting pan has excellent thermal efficiency thanks to the minimal heat loss thereof, can reach a target temperature within a short time to reduce a preheating time, and affords excellent cooking quality. Furthermore, the electric roasting pan can substantially prevent the occurrence of temperature deviation across thearea of the roasting pan during a temperature increase and is of high durability and safety.

Owner:BIONEER

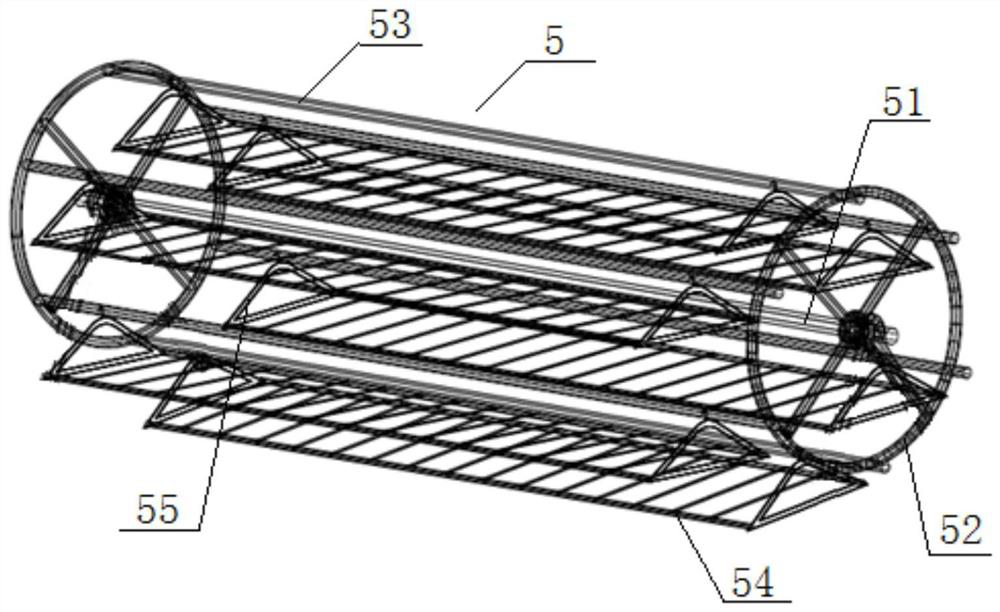

Environment-friendly heat conducting medium-free specimen stainer

ActiveCN104264404AImprove heating efficiencyReduce energy consumptionTextile treatment dyeing devicesTextile treatment machine arrangementsHeat conductingEngineering

The invention provides an environment-friendly heat conducting medium-free specimen stainer. The environment-friendly heat conducting medium-free specimen stainer comprises a rotating rack, a rotating rack driving mechanism, a heating device and dye cups; a plurality of mounting holes are formed in the peripheral surface of the rotating rack at intervals; a thermal insulating sleeve is arranged at each mounting hole and one end of the thermal insulating sleeve extends into the rotating rack; each dye cup sleeves the corresponding thermal insulating sleeve and the lower part of the dye cup extends out of the bottom of the thermal insulating sleeve; the heating device comprises heating elements which are arranged beside the middle parts of the sidewalls, extending out of the bottoms of the thermal insulating sleeves, of the dye cups; the parts, extending out of the bottoms of the thermal insulating sleeves, of the dye cups rotae along with the rotating rack and are directly heated by the heating elements. The stainer of such a structure has the advantages that the outer side walls, not covered with the thermal insulating sleeves, of the dye cups are directly heated by the heating elements, and the heating efficiency is high without heating lag time difference, the thermal insulating sleeves are used for preserving heat for the outer sidewalls of one parts of the dye cups and guaranteeing that the dye cups can be continuously heated even after leaving the heaving elements, and moreover, the dye cups in a midway into-cup test also can be preheated to prevent adverse effect on the cloth specimen due to temperature deviation resulting from too slow instantaneous heating on the dye.

Owner:广西润格电子有限公司

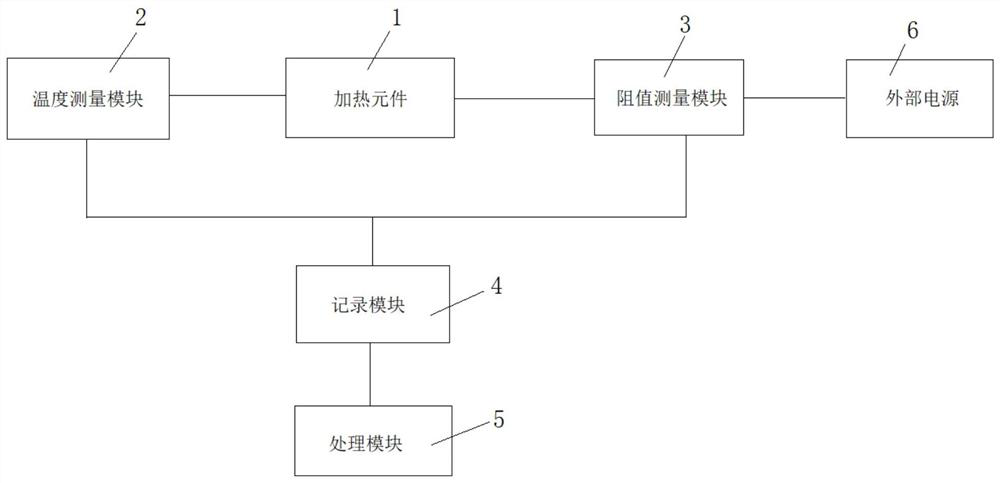

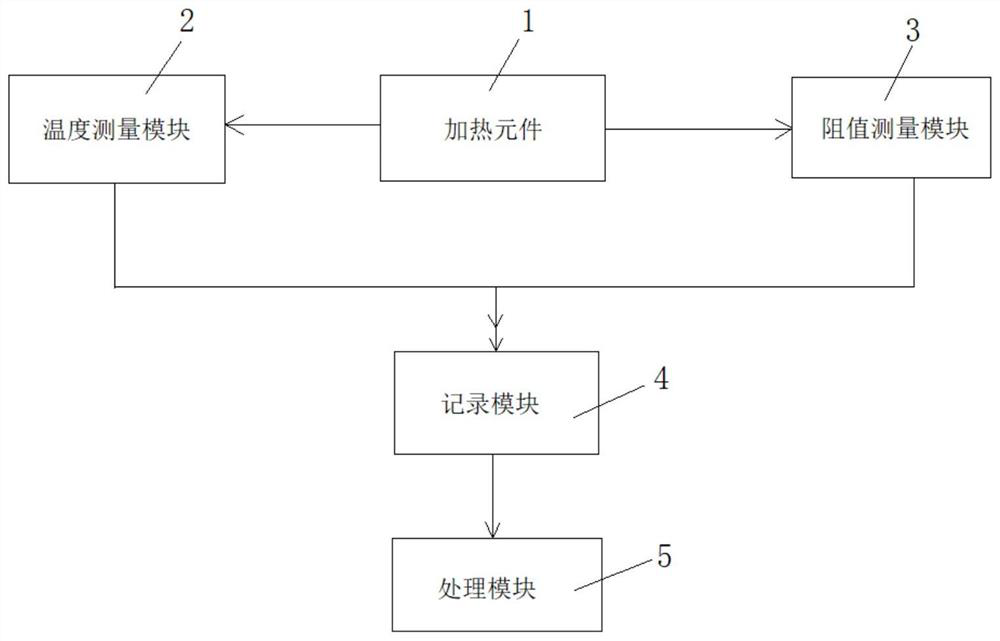

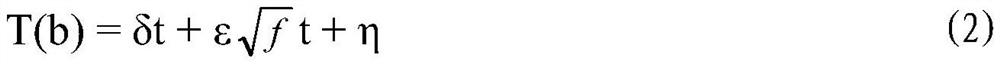

Device and method for quickly measuring resistance-temperature coefficients of heating elements

PendingCN112379166AImprove accuracyReal-time temperature controlResistance/reactance/impedenceEngineeringTemperature coefficient

The invention discloses a heating element resistance temperature coefficient rapid determination device and method, and the device comprises a heating element which is provided with a connecting end for connecting an external heat source; a temperature measurement module; a resistance measuring module which is connected with the heating element; a recording module, wherein the temperature signal output end of the temperature measurement module and the resistance signal output end of the resistance measurement module are respectively connected with the signal input end of the recording module;and a processing module which is connected with the signal output end of the recording module. The method comprises the following steps: determining a rapid determination device; controlling the heating element to be connected with an external heat source to heat the heating element; acquiring a temperature value of the heating element by using a temperature measurement module, and measuring a resistance value of the heating element by using a resistance measurement module; recording the acquired temperature value of the heating element and the measured resistance value of the heating elementby using a recording module; and processing the recorded temperature value and resistance value of the heating element by using a processing module to obtain a resistance temperature coefficient of the heating element.

Owner:HUBEI CHINA TOBACCO IND

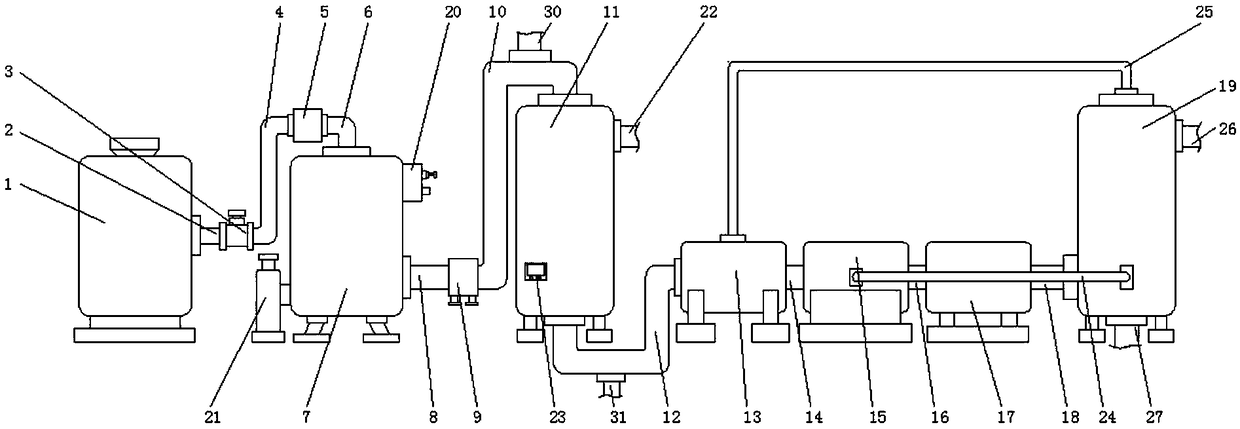

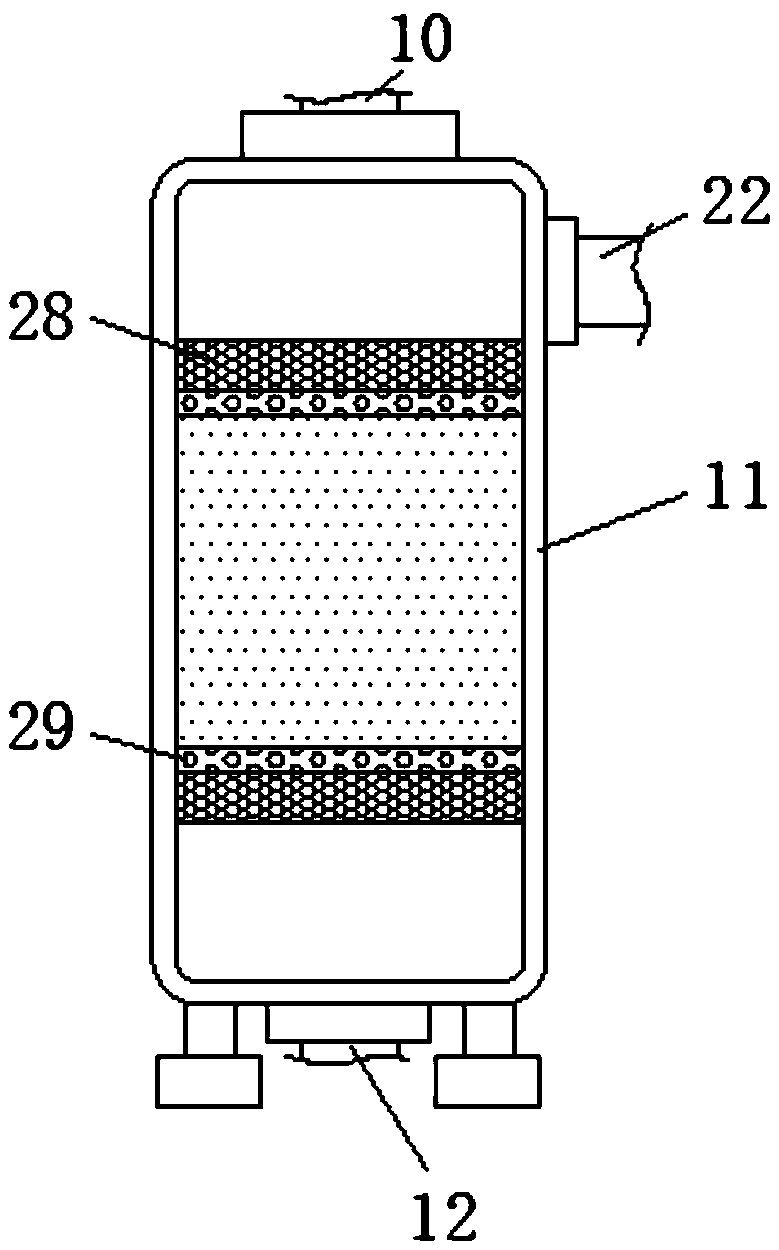

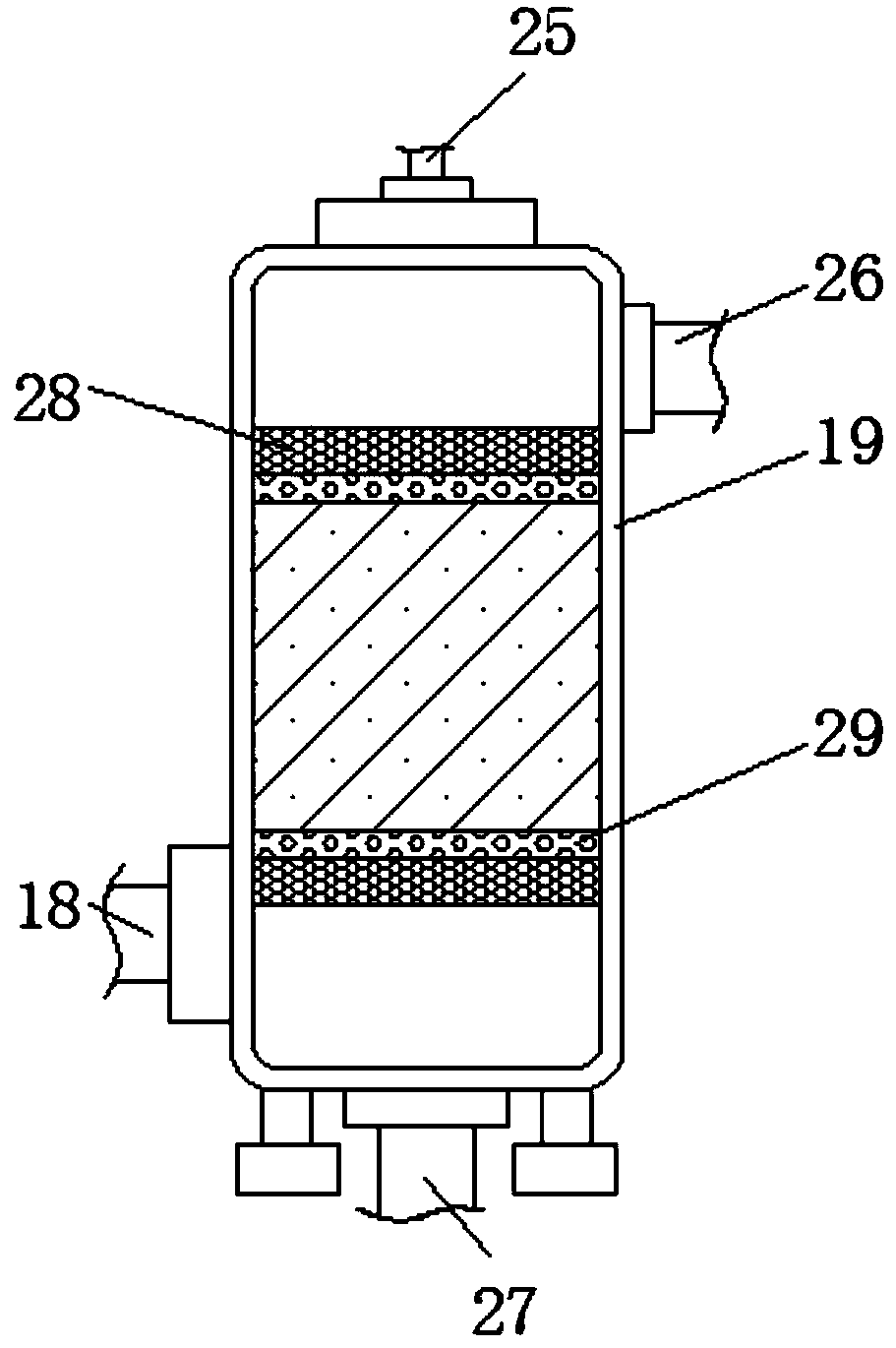

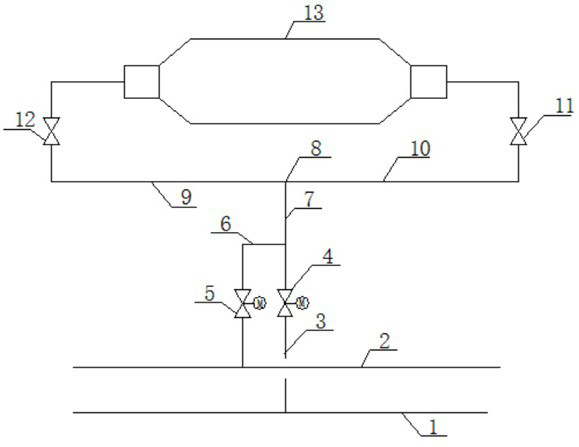

Light aromatic hydrocarbon hydrogenation transformation device and operation method thereof

InactiveCN109181751AChange temperaturePrevent temperature deviationRefining by selective hydrogenationRefining by aromatic hydrocarbon hydrogenationReboilerEngineering

The invention relates to the technical field of light aromatic hydrocarbon hydrogenation device, and discloses a light aromatic hydrocarbon hydrogenation transformation device and an operation methodthereof, wherein the device includes a raw material tank; the right side of the raw material tank is fixedly connected with a connecting pipe, the right side of the connecting pipe is fixedly equippedwith a flow control valve, and the right side of the flow control valve is fixedly connected with a through pipe; the right side of the through pipe is fixedly provided with a pre-hydrogenation heatexchanger; the right side of the pre-hydrogenation heat exchanger is fixedly connected with a right-angle pipe; the bottom end of the right-angle pipe is fixedly connected with a deweighting tower. According to the light aromatic hydrocarbon hydrogenation transformation device and the operation method thereof, by arrangement of the pre-hydrogenation heat exchanger, a reboiler and a pressure control valve, the temperature of a light aromatic hydrocarbon material is changed due to heat exchange of the pre-hydrogenation heat exchanger, and the pressure intensity and temperature inside the deweighting tower are controlled by the pressure control valve and the reboiler, so that the light aromatic hydrocarbon material can be separated to obtain light component oil in the deweighting tower, and raw materials are provided for later hydrogenation treatment.

Owner:DAQING E SHINE CHEM CO LTD

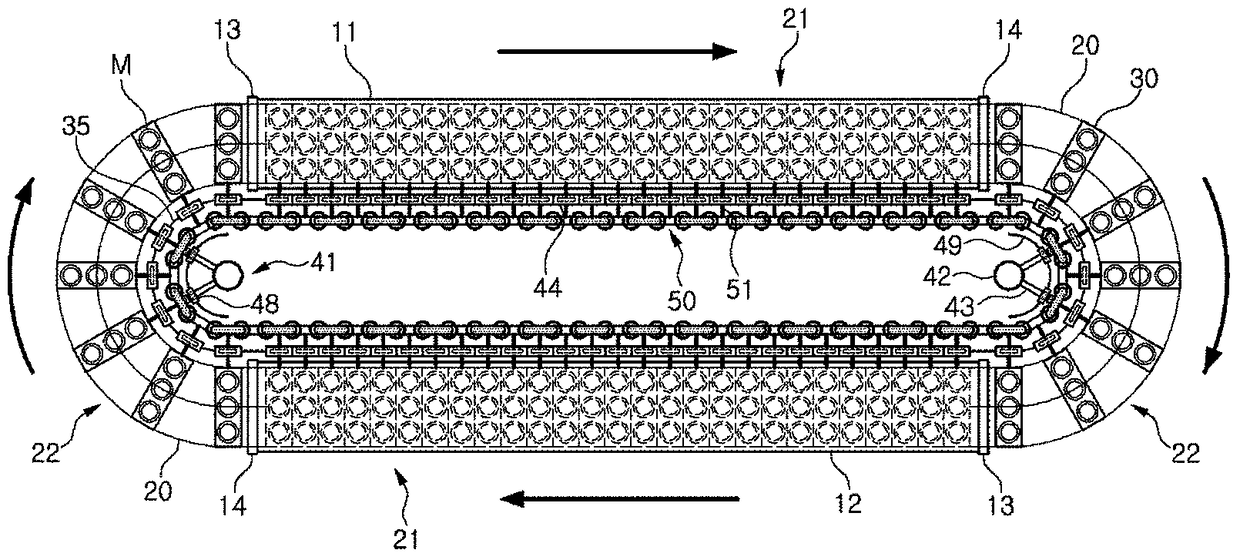

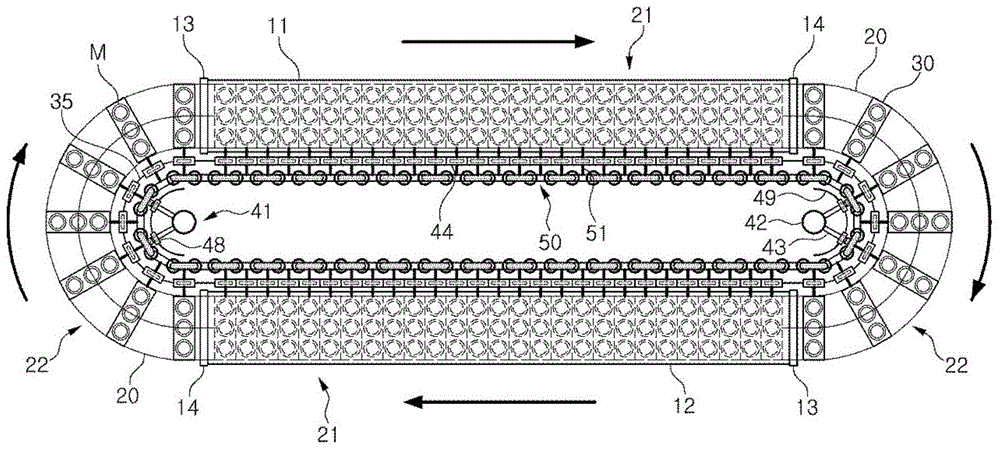

Heat treatment unit with a pair of linear furnaces and slip rings

InactiveCN106191382BEasy to usePrevent temperature deviationFurnace typesHeat treatment furnacesEngineeringHeat energy

The invention relates to a heat treatment device, which is characterized in that it comprises: a first linear furnace and a second linear furnace, respectively having an input end and a discharge end; crawlers, which run through the first linear furnace and the second connected to the linear furnace; at least one trolley, which moves along the crawler belt, can pass through the first linear furnace and the second linear furnace, and load the material to be processed; and a gas supply part, which is connected to the table The car is connected and supplied with gas. Therefore, the present invention can eliminate the area for supplying excess heat, effectively use heat energy, and prevent temperature deviation, thereby further improving product quality.

Owner:POHANG IRON & STEEL CO LTD

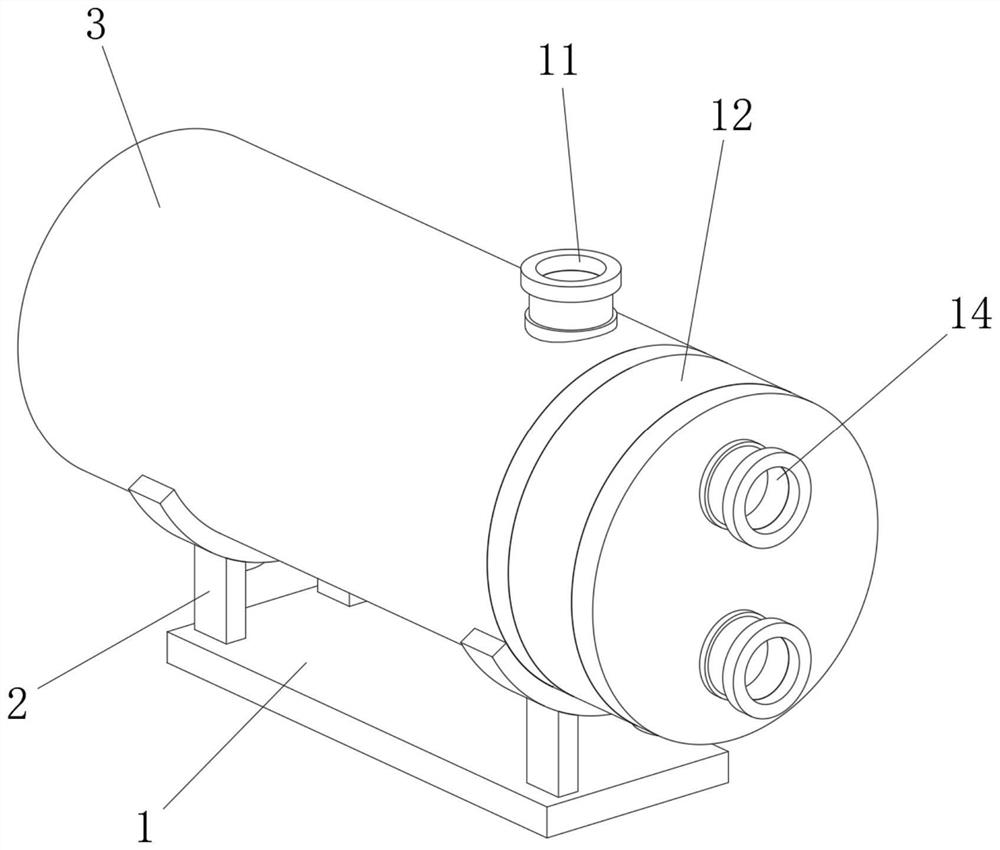

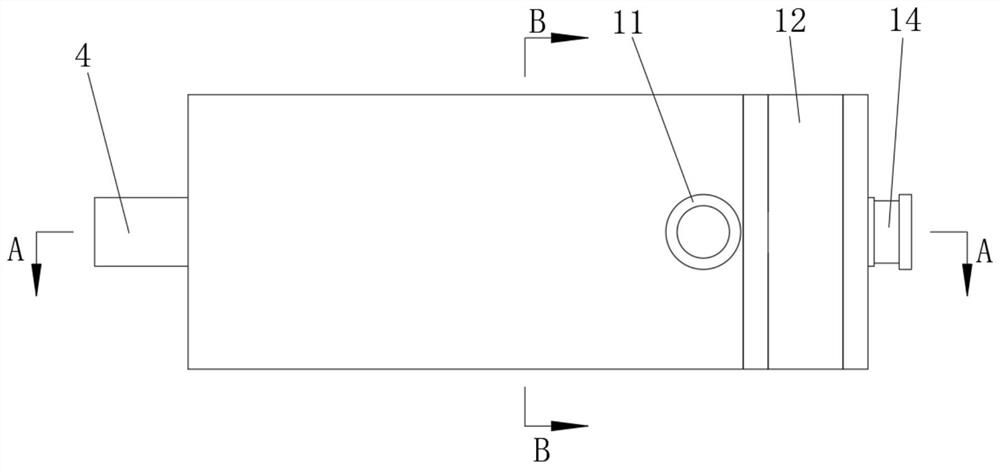

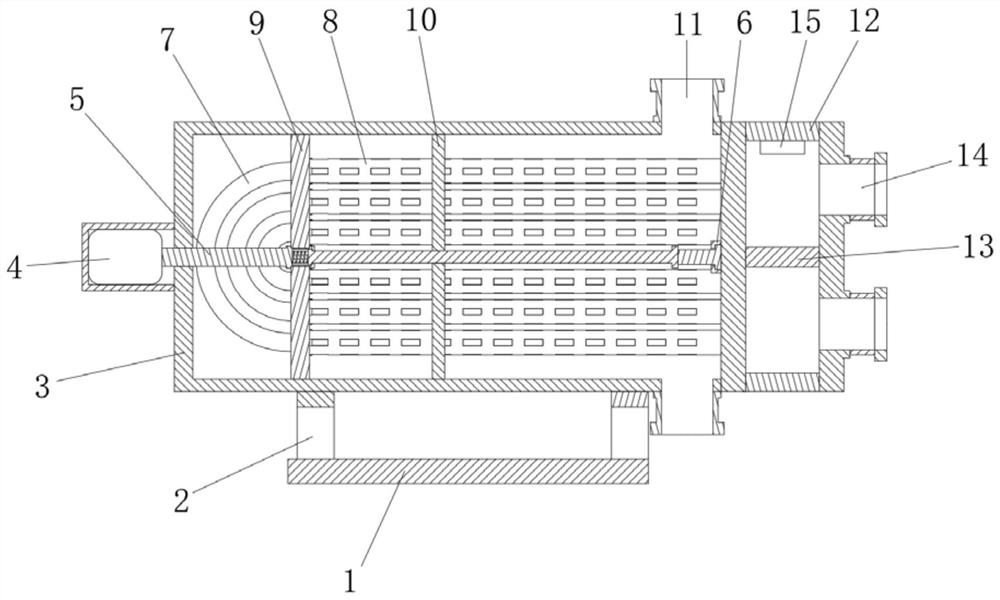

Tubular heat exchange device

PendingCN114111381APrevent temperature deviationAdjust heating temperatureHeat exchanger casingsStationary tubular conduit assembliesThermodynamicsDouble tube

The invention relates to the technical field of liquid heating, and discloses a double-tube heat exchange device which is movably sleeved with a heat conduction device through an adjusting plate and comprises a base, supporting frames are fixedly installed at the positions, close to the two ends, of the top of the base, a shell is fixedly installed at the tops of the supporting frames, and a telescopic power machine is fixedly installed at one end of the outer surface of the shell. An adjusting device is fixedly mounted at one end of an output shaft of the telescopic power machine, penetrates through the shell and extends into the shell, and a limiting sleeve is fixedly mounted at one end of the inner wall of the shell, so that liquid entering from a liquid guide flange opening cannot enter a containing cavity in the left side of the sealing plate under the common sealing effect of the sealing plate and an adjusting plate; therefore, the bending positions of the heat exchange tubes cannot be in contact with the liquid, and the problem that the temperature of the finally flowing-out liquid deviates due to uneven heat conduction caused by different total contact areas of the heat exchange tubes at different positions in the shell and the liquid due to different bending radiuses is solved.

Owner:曾吉武

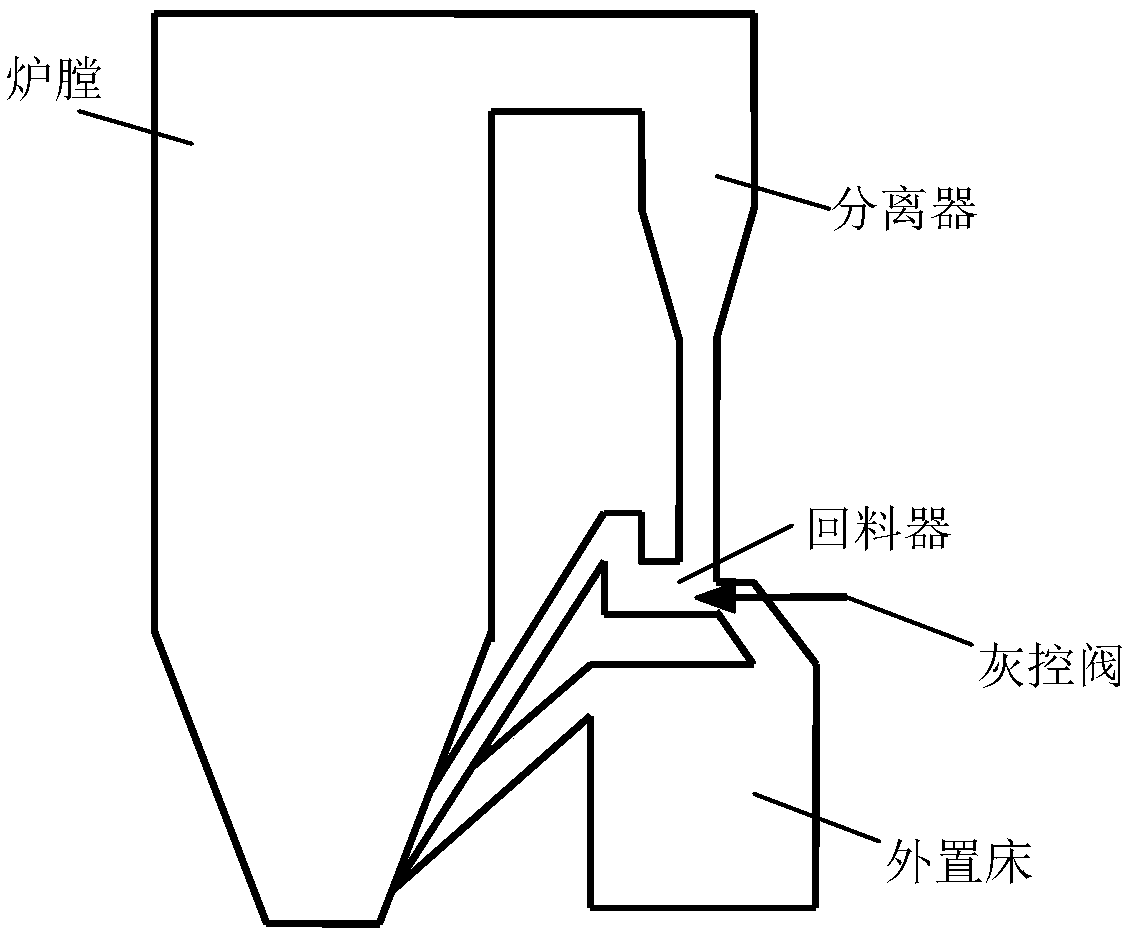

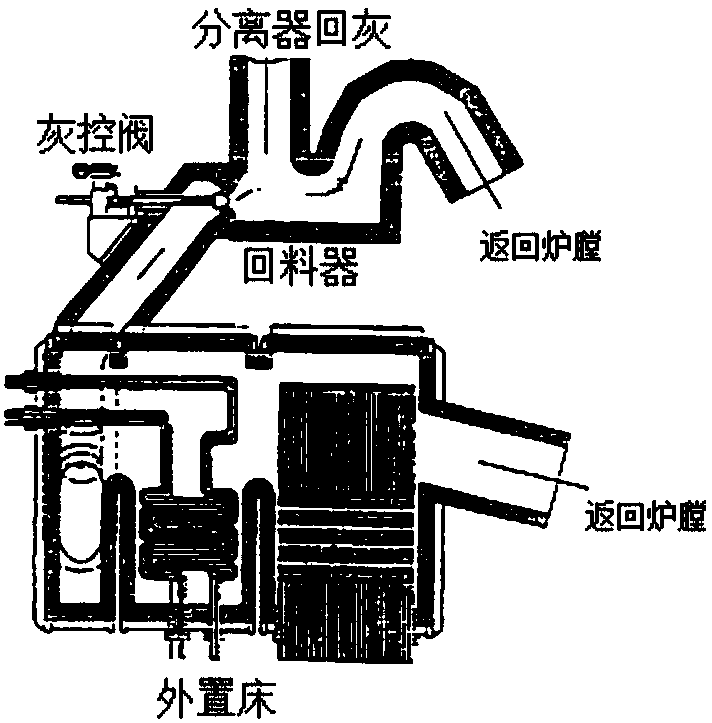

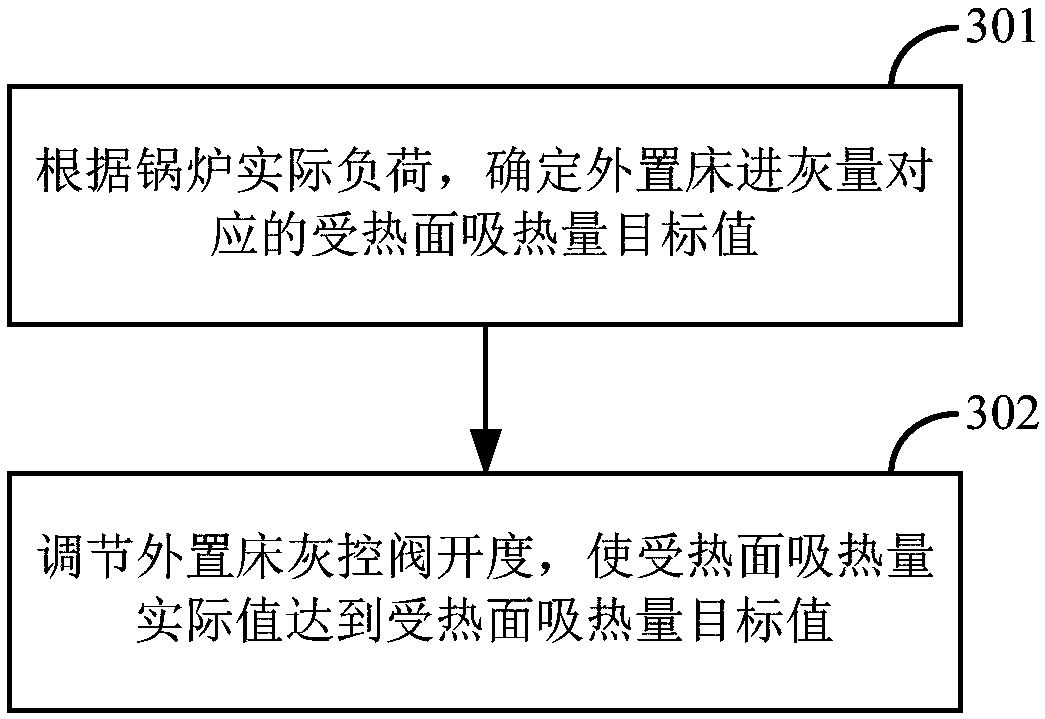

Method and device for controlling opening degree of external bed ash control valve

ActiveCN108443871ASmall temperature deviationPrevent temperature deviationFluidized bed combustionApparatus for fluidised bed combustionAbsorption capacityFlue gas

The invention discloses a method and a device for controlling the opening degree of an external bed ash control valve. The method comprises the following steps: determining the target value of the heat absorption capacity of a heated surface, corresponding to the ash inlet amount of an external bed, according to the actual load of a boiler; and adjusting the opening degree of the external bed ashcontrol valve to make the actual value of the heat absorption capacity of the heated surface reach the target value of the heat absorption capacity of the heated surface. The heat absorption capacityof the heated surface can be used as the target value of the opening degree control of the external bed ash control valve in order to reduce a steam temperature deviation caused by a bed temperature measurement error or a tail flue gas flow deviation.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

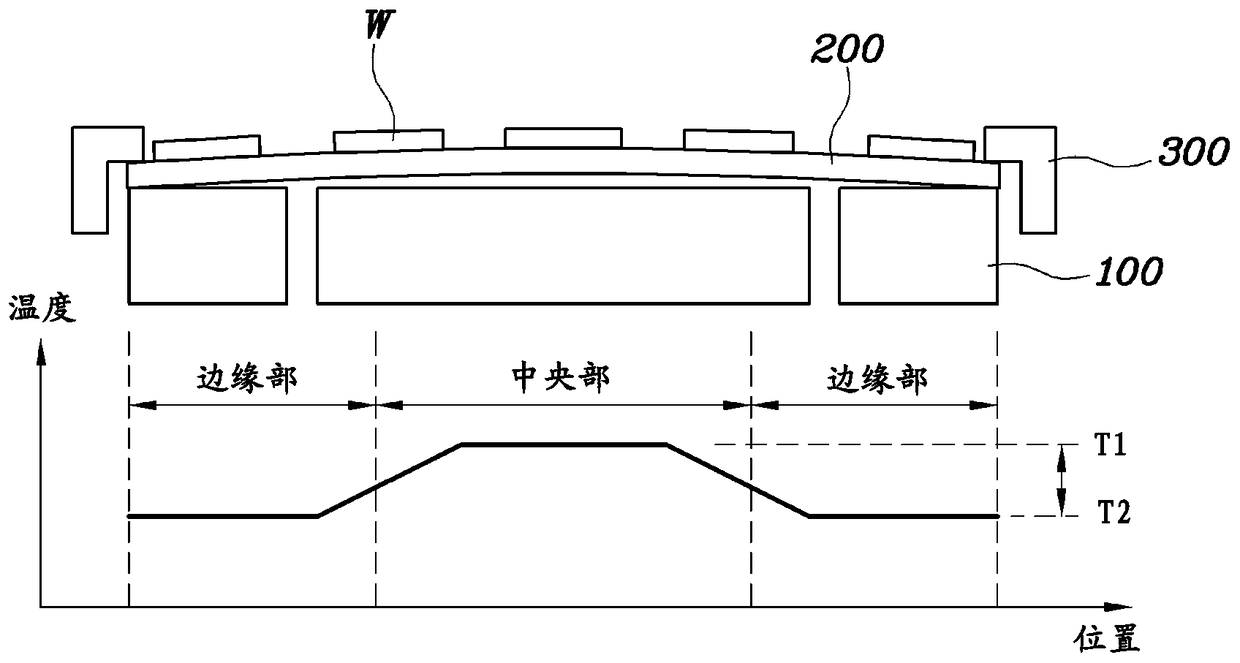

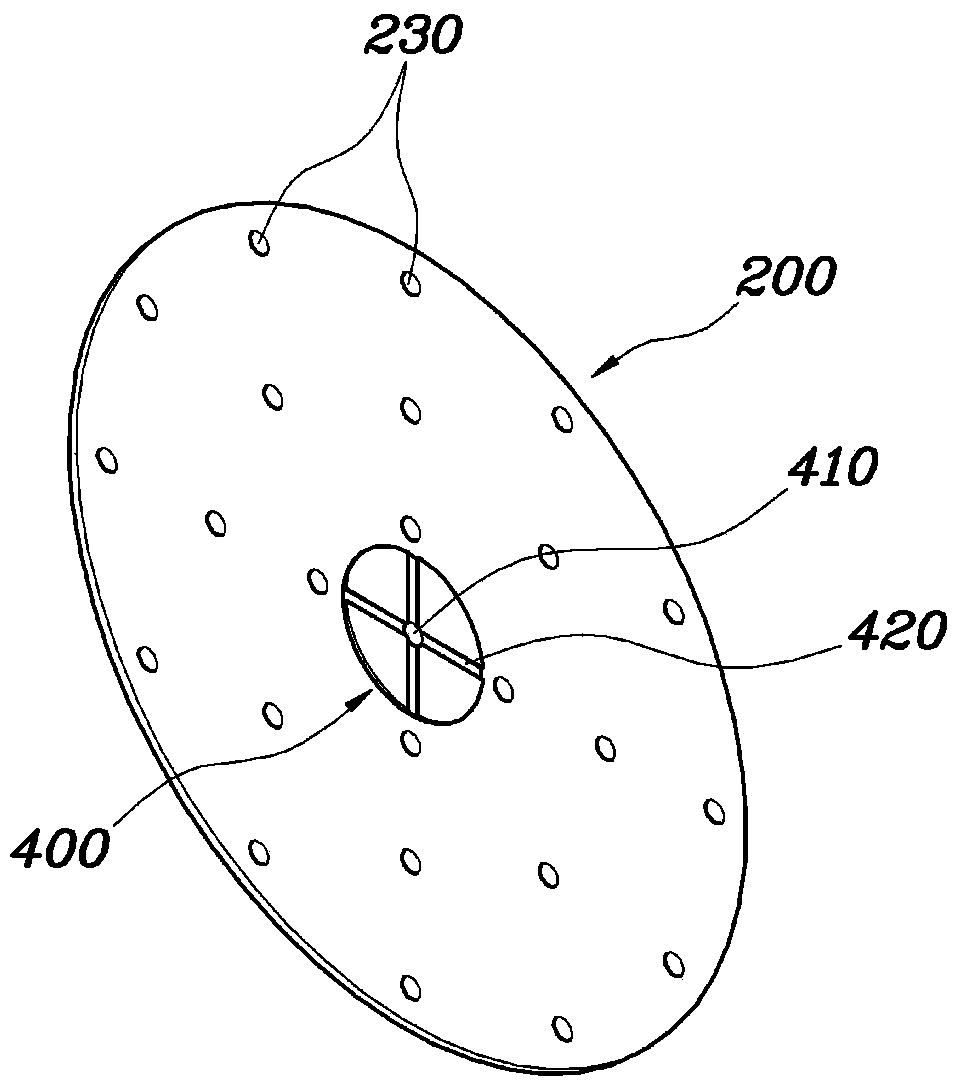

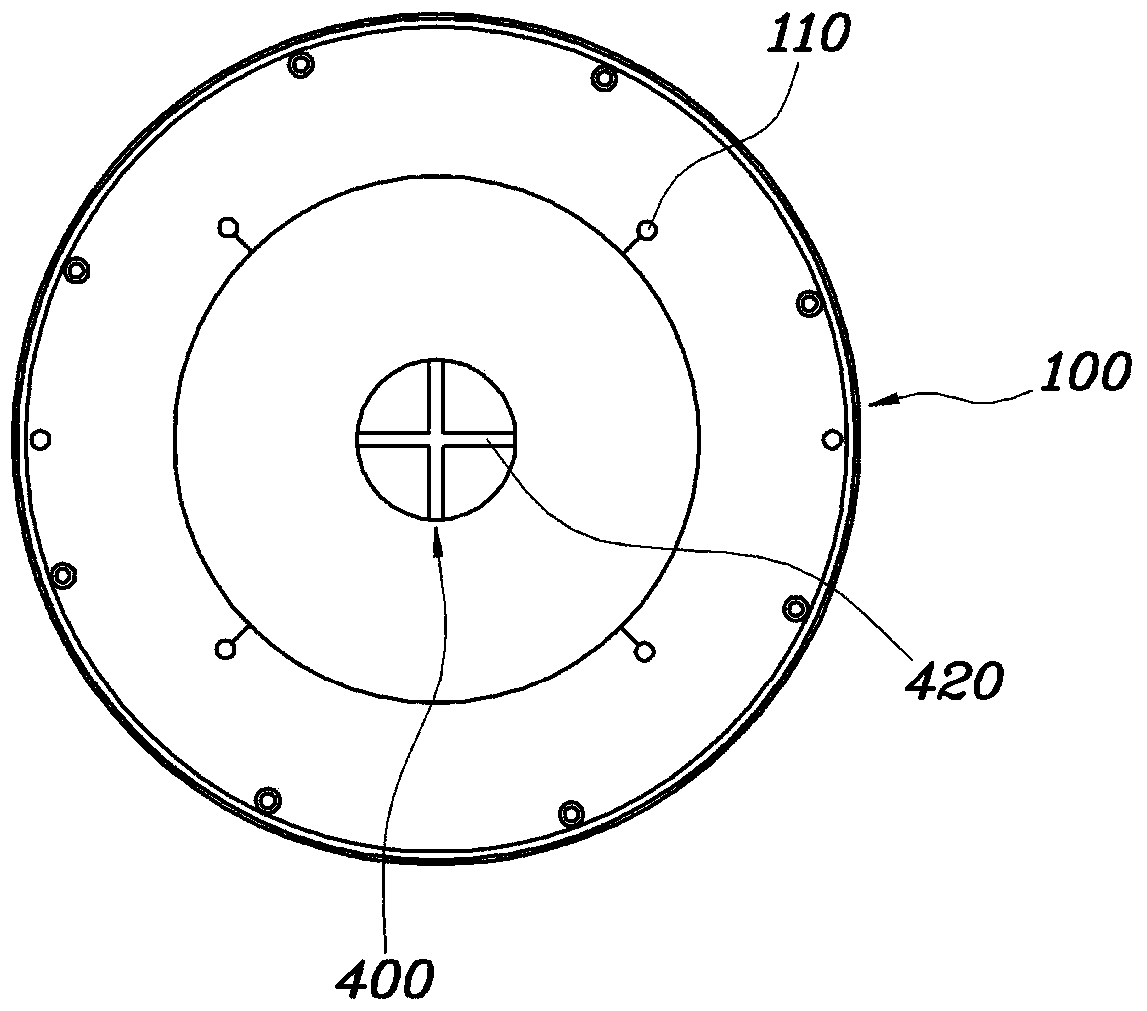

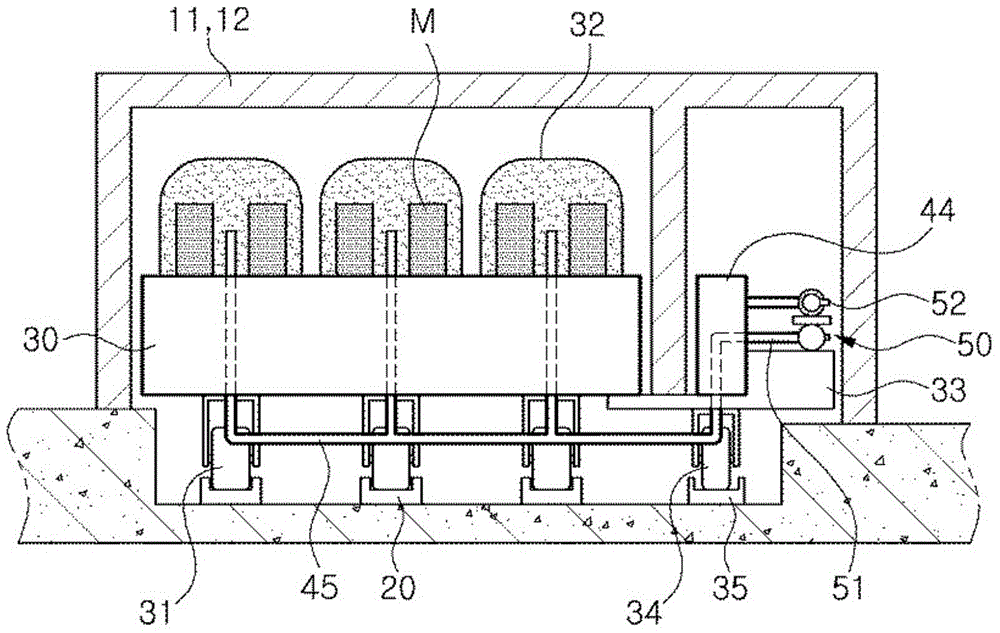

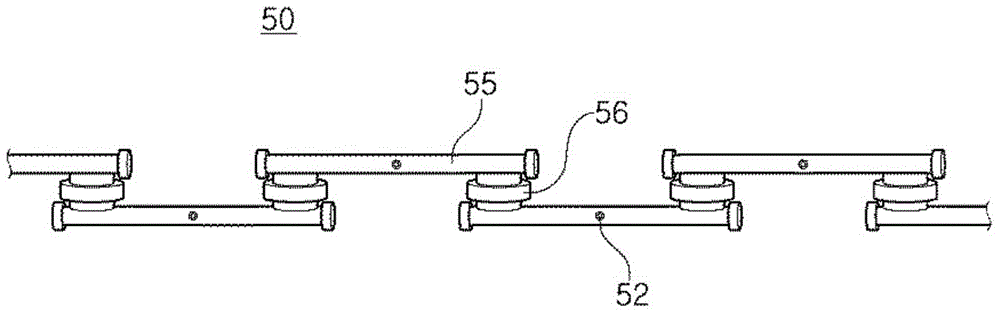

Substrate placement unit

ActiveCN105609460BImprove qualityImprove productivitySolid-state devicesSemiconductor/solid-state device manufacturingElectrical and Electronics engineering

The present invention relates to a substrate seating unit which maintains a constant distance between a tray and a chuck fixated by a clamp. According to an embodiment of the present invention, the substrate seating unit includes: the chuck installed inside a chamber of a substrate processing device; the tray having a plurality of substrate seating grooves, wherein the substrates are inserted on the surface and installed on a chuck surface; and the clamp pressurizing the edge of the chuck and the tray to fixate the edge of the chuck and the tray. A spacer is protruded from the center of a bottom surface of the tray or the center of the chuck surface.

Owner:GIGALANE CO LTD

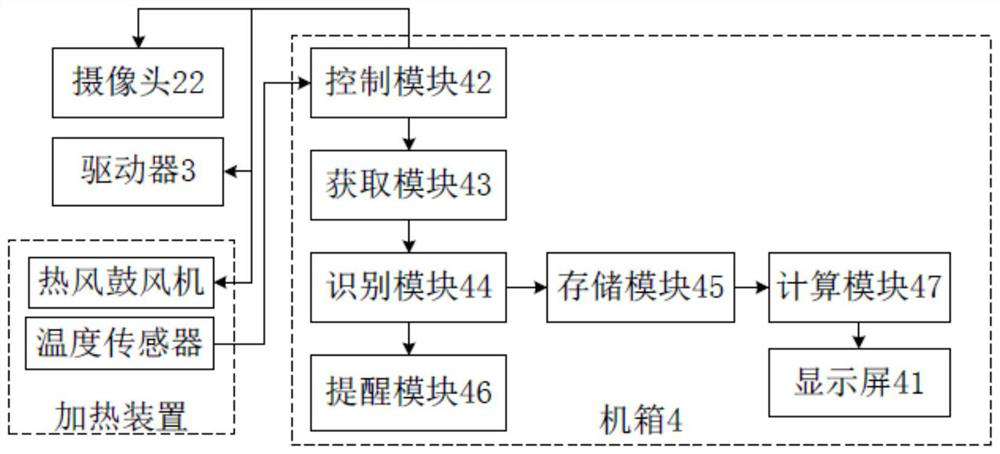

Oven and system and method for automatically measuring thermo-oxidative aging life of polymer material

PendingCN114062232AEvenly heatedPrevent temperature deviationWeather/light/corrosion resistanceMaterial heat developmentEngineeringLaboratory oven

The invention relates to the technical field of polymer material aging life testing, in particular to an oven and a system and method for automatically measuring the thermo-oxidative aging life of a polymer material. An oven body is internally provided with a heating device, the heating device can heat and age a sample placed on a sample frame, and a camera is used for shooting the sample; an identification model is utilized to judge whether the sample is aged and invalid according to the shot sample picture, frequent box opening sampling is avoided, the working efficiency is improved, temperature fluctuation in the oven caused by frequent box opening is avoided, the test stability is improved, and the reliability of automatic measurement of the thermo-oxidative aging life of the polymer material is improved.

Owner:NAT POLYMER MATERIALS IND INNOVATION CENT CO LTD

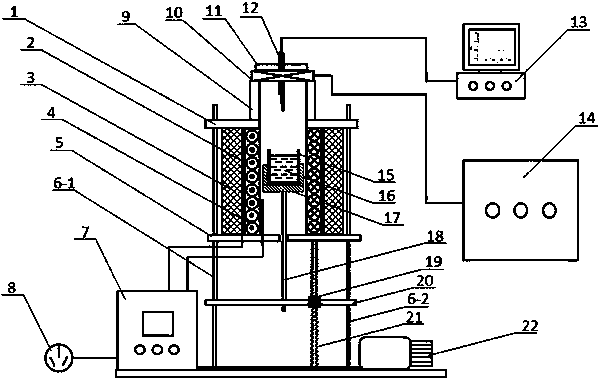

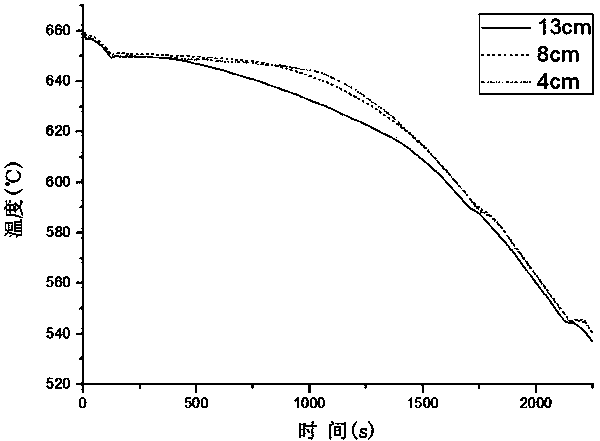

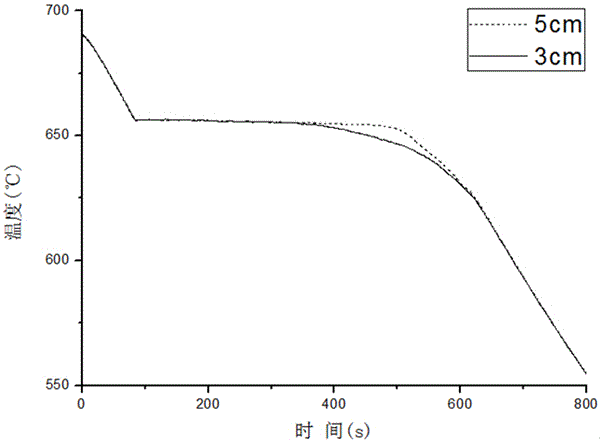

Device for measuring melt heat history curve under action of pulse magnetic liquid level oscillation

InactiveCN103994836AAccurate measurementAvoid lostThermometers using electric/magnetic elementsUsing electrical meansMagnetic liquidsElectric heating

The invention relates to a device for measuring a melt heat history curve under action of pulse magnetic liquid level oscillation, and belongs to the technical field of material machining. The device is mainly composed of a pulse power supply, a mosquito-repellent incense type induction coil, an electric heating wire, a lifting rod, a ceramic tube and a plug, wherein the electric heating wire is connected with a 220V alternating current through the plug, the mosquito-repellent incense type induction coil is connected with the pulse power supply, and a casting mold containing a metal block is placed on the lifting rod. Firstly, the electric heating wire heats to melt the metal block, then, the lifting rod ascends, the casting mold is close to the mosquito-repellent incense type induction coil, the mosquito-repellent incense type induction coil exerts pulse magnetic liquid level oscillation processing on the metal melt, a thermoelectric coupler is inserted into the melt and is fixed, and the melt heat history curve is measured. Compared with a traditional temperature measuring method, the casting process is removed, the melt heat history curve can be more stably and accurately measured, and the reliable temperature data are provided for obtaining a pulse magnetic liquid level oscillation refined metal solidification structure.

Owner:SHANGHAI UNIV

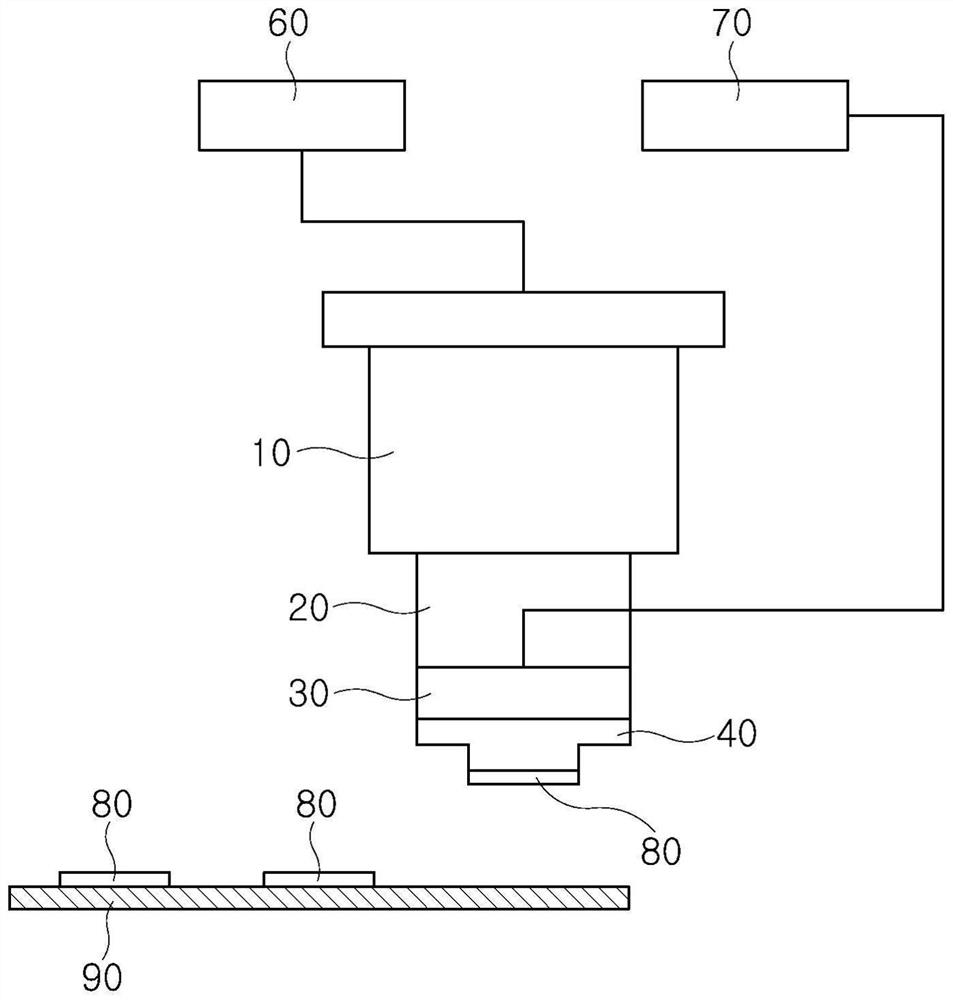

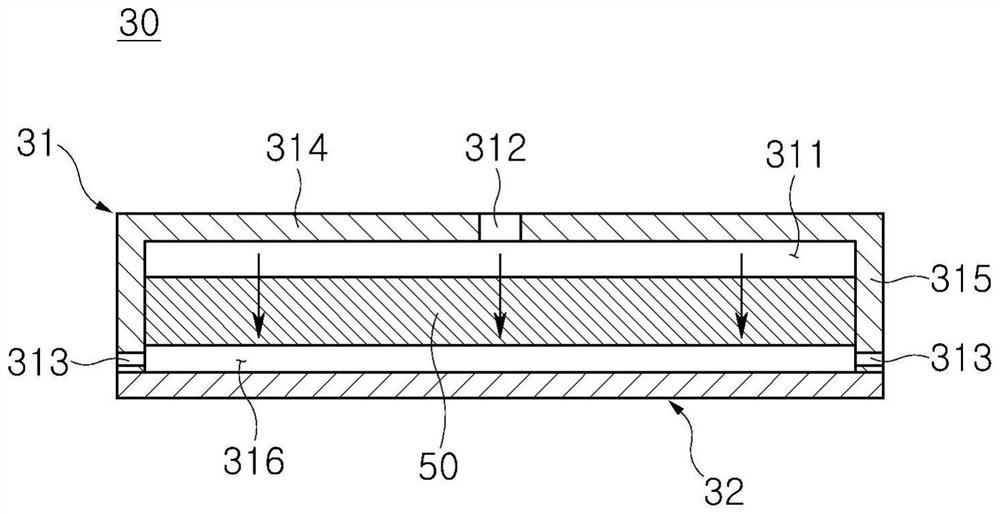

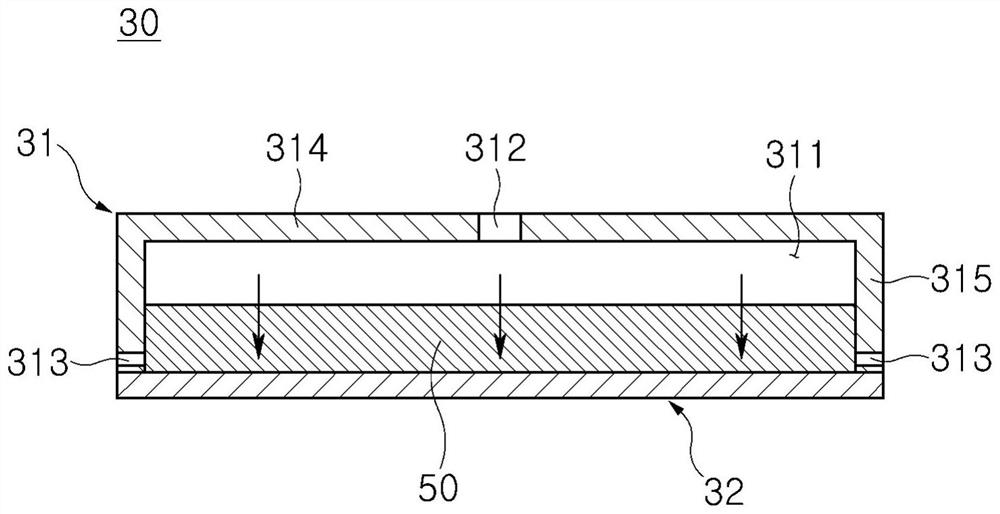

Heater assembly and joining head including same

PendingCN114582750ACool evenlyPrevent temperature deviationHeater elementsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides a heater assembly and a joint head provided with the same. The heater assembly may include: a housing, an internal accommodation space, and a cooling gas inflow port communicating with the housing; a heater coupled to the housing; and a porous block disposed in the accommodation space.

Owner:SEMES CO LTD

An experimental device for on-line detection and control of welding temperature of high-frequency straight seam welded pipes

ActiveCN106312386BAccurate control of soldering temperatureGuarantee the quality of welded pipeWelding/cutting auxillary devicesAuxillary welding devicesSet screwControl system

Owner:江苏景泰电力科技有限公司

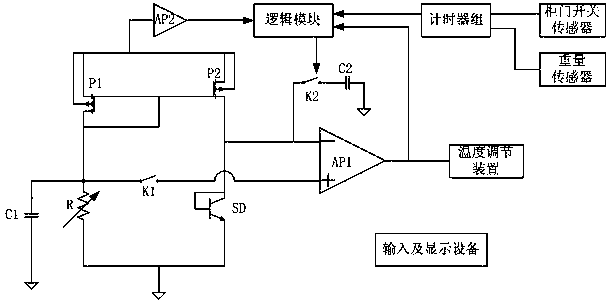

Electronic constant temperature control system for medical logistics storage device

InactiveCN106275855BPrevent temperature deviationTemperature control using electric meansContainers preventing decayCapacitanceEngineering

The invention discloses an electronic constant-temperature control system of a medical logistics storage device. The system comprises a temperature adjusting device; the temperature adjusting device includes an amplifier, and a reference voltage source and a temperature induction voltage source connected with two input ends of the amplifier; the temperature induction voltage source is a voltage source with output voltage changed along with the temperature change; the reference voltage source and the temperature induction voltage source are respectively connected with a voltage locking storage device; an output end of the amplifier is connected with an input end of an AD converter; the AD converter is in control connection with the temperature adjusting device; the voltage locking storage device includes a capacitor, and further includes a logic module and an environmental temperature sensor; the environmental temperature sensor outputs digital temperature induction signals; and the signals are input in a timer set. The system is used for logistics storage of medical objects, in particular blood products or organs, can overcome the temperature deviation caused by power supply or device faults to a certain extent, and guarantees the transported medicines or organs to reach the destination in a manner of constant temperature and quality preservation.

Owner:嘉兴飞翔医用新材料科技有限公司

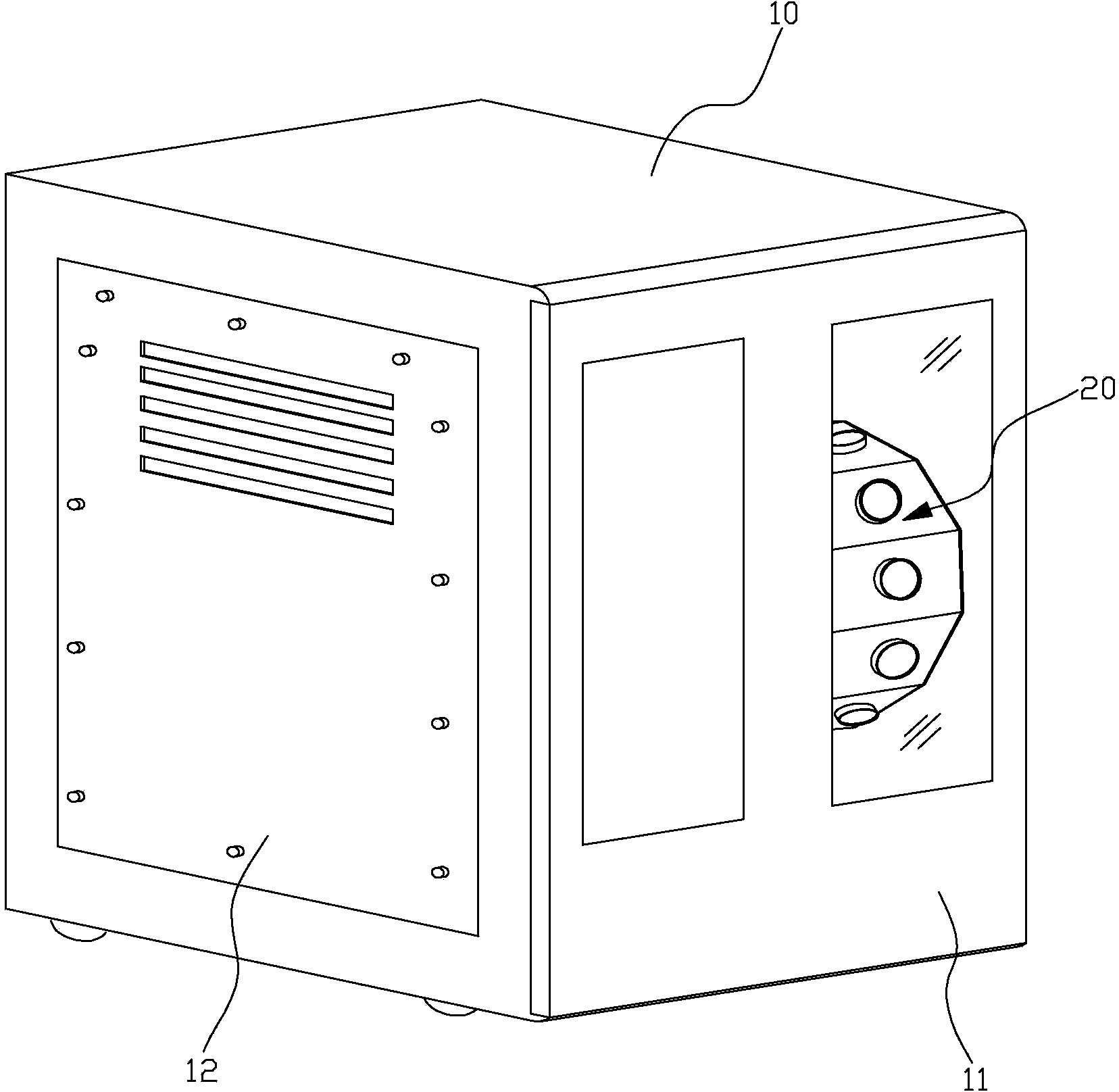

A prepreg automatic laying process parameter determination device

ActiveCN112192864BImprove research efficiencyRealize coordinated controlServomechanismIndustrial engineering

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Device for installing thermocouple on reactor in propenoic acid production

ActiveCN103055767BSolve the problem of vertical installation of multi-point thermometerSolve vertical installation problemsOrganic compound preparationThermometers using electric/magnetic elementsEngineeringPetrochemical

The invention relates to a parameter measuring device in petrochemical production process. A device for installing a thermocouple on a reactor in propenoic acid production is characterized in that a short flange tube is arranged on a sealing cover of the reactor; a flange is equipped on the short flange tube; a straight connecting head is arranged on a flange cover; a movable clamping sleeve is arranged on the straight connecting head; the thermocouple is arranged inside the movable clamping sleeve; a fin is arranged on the thermocouple; and a spring is arranged at the lower end of the thermocouple. The device has the advantages of simple structure and easiness in manufacturing, solves the problem that a multi-point thermometer of a propenoic acid oxidation reactor is vertically installed, greatly reduces the difficulty in installing a catalyst, reduces the installation cost and ensures that the installation position of the thermometer is accurate; the temperature detection of the propenoic acid oxidation reactor is reliable and accurate; products in propenoic acid production are good in quality, the conversion rate of the propylene is high, the production in the oxidation process of the propylene is safe, the catalyst is prevented from cocking phenomenon in propylene production, and the service life of the catalyst is prolonged.

Owner:中石油吉林化工工程有限公司

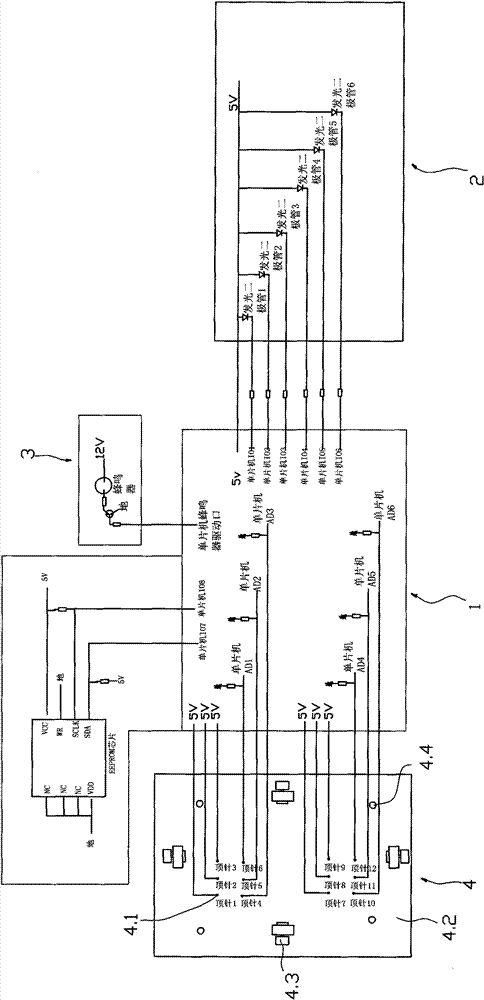

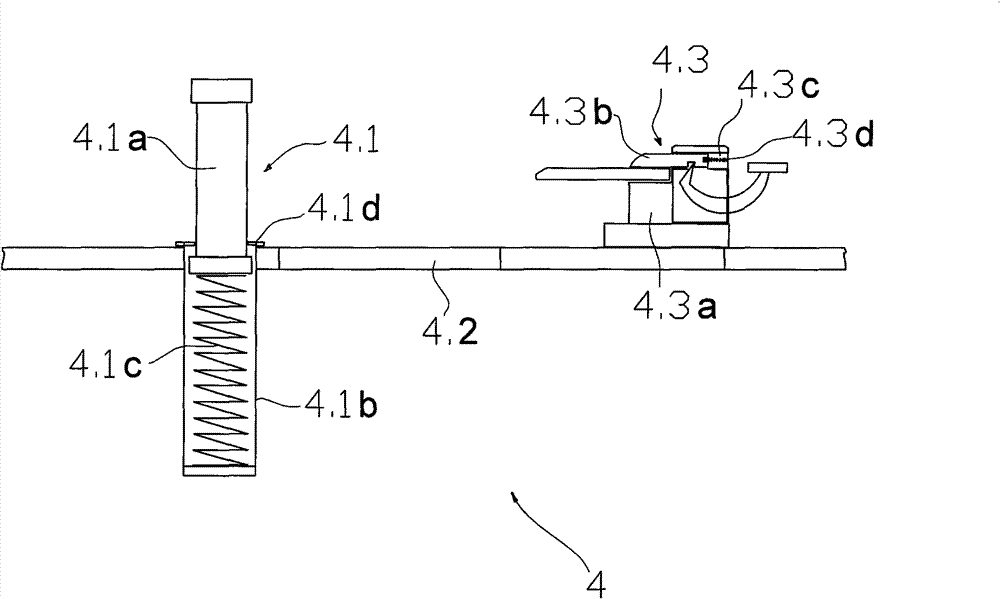

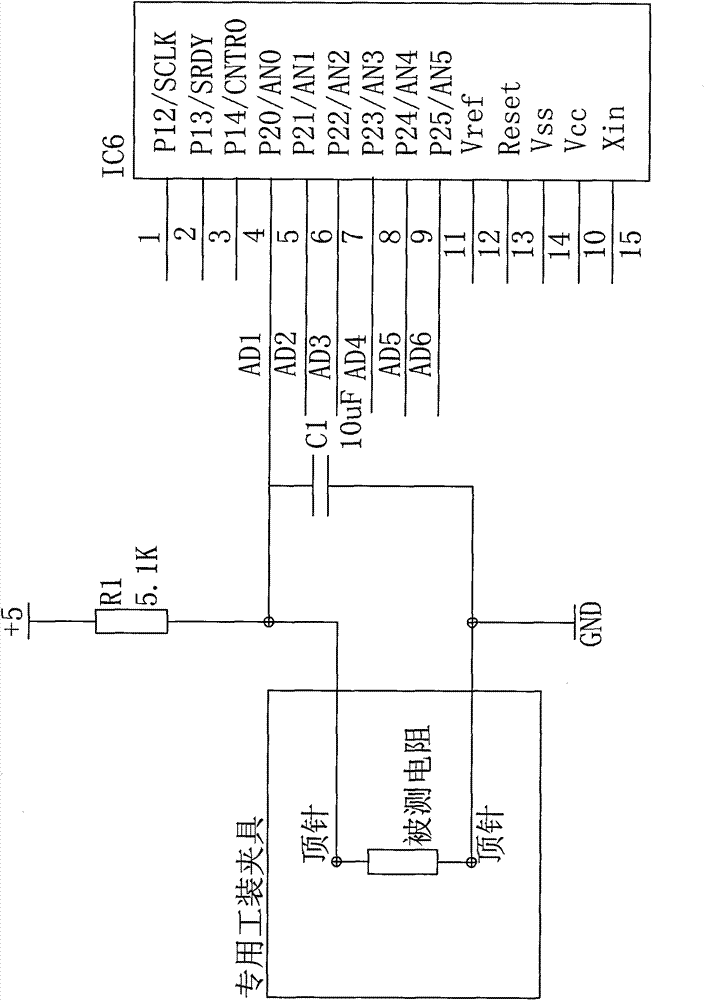

Measuring device for detecting resistors in air-condition circuits automatically

ActiveCN101930029BPrevent temperature deviationSimple structureSpace heating and ventilation safety systemsLighting and heating apparatusElectrical resistance and conductanceMeasurement device

The invention relates to a measuring device for detecting resistors in air-condition circuits automatically, which comprises a measuring main circuit module, a display module and a buzzer alarming module. The measuring device is characterized in that the measuring device comprises a clamp for clamping a measured air-condition circuit board; a plurality of pairs of thimbles on the clamp contact both ends of the resistors on the measured air-condition circuit board respectively, so that the resistors are respectively connected to the respective measured circuit; voltage signals are extracted by the thimbles and are connected to each signal input end of the main circuit module; the main circuit module calculates a value of each measured resistor according to a voltage value of each inputted signal and a line and an element parameter of each measured circuit and compares the value of each measured resistor with a design value of each resistor; and the signal output end of the main circuit module is connected to the display module and the buzzer alarming module, so that a comparison result is displayed and subjected to alarm reminding. The measuring device has the advantages of simple structure, low cost, accurate detection, convenient and quick operation and capability of improving the production efficiency.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

A device for measuring the thermal history curve of the melt in the pulse current liquid level disturbance solidification fine-grain process

ActiveCN104048780BAccurate measurementAvoid lostThermometers using electric/magnetic elementsUsing electrical meansMaterials processingPulse power supply

Owner:SHANGHAI UNIV

Apparatus for heat treating with pair of straight furnaces and collector ring

InactiveCN106191382APrevent temperature deviationImprove product qualityFurnace typesHeat treatment furnacesProcess engineeringThermal energy

The present invention relates to an apparatus for heat treatment, comprising: a first straight furnace and a second straight furnace respectively, having an input end unit and a discharge end unit; an infinite orbit connected by penetrating the first straight furnace and the second straight furnace; one or more bogie which passes through the first straight furnace and the second straight furnace by moving along an infinite orbit to load the materials to be treated; and a gas supply unit connected to the bogie to supply gas. As an area, to which an unnecessary quantity of heat is supplied, is able to be removed; the thermal energy is able to efficiently be used. The temperature deviation is able to be prevented, and the quality of the products is able to ultimately be improved.

Owner:POHANG IRON & STEEL CO LTD

Device for measuring melt heat historical curve in pulse current liquid level disturbance solidification fine-grain process

ActiveCN104048780AAccurate measurementAvoid lostThermometers using electric/magnetic elementsUsing electrical meansElectricityCasting mold

The invention relates to a device for measuring a melt heat historical curve in a pulse current liquid level disturbance solidification fine-grain process and belongs to the technical field of material processing. The device mainly comprises a pulse power supply, a parallel electrode, a heating wire, a lifting rod, a ceramic tube and a plug, wherein the heating wire is connected with a 220 V alternating current through the plug, the parallel electrode is connected with the pulse power supply, and a casting mold contained with a metal block is placed on the lifting rod. Firstly, the heating wire supplies heat to enable the metal block to be molten, then the lifting rod rises to enable the parallel electrode to be inserted into a metal melt and perform pulse current liquid level disturbance treatment on the parallel electrode. Meanwhile, a thermocouple is also inserted into the melt and fixed, and the melt heat historical curve is measured. Compared with a traditional temperature measuring method, the pouring process is omitted, the melt heat historical curve can be stably and accurately measured, and reliable melt heat historical data is provided for the pulse current liquid level disturbance solidification fine-grain process.

Owner:SHANGHAI UNIV

Environmentally friendly sample dyeing instrument without heat-conducting medium

ActiveCN104264404BImprove heating efficiencyReduce energy consumptionTextile treatment dyeing devicesTextile treatment machine arrangementsHeat conductingEngineering

The invention provides an environment-friendly heat conducting medium-free specimen stainer. The environment-friendly heat conducting medium-free specimen stainer comprises a rotating rack, a rotating rack driving mechanism, a heating device and dye cups; a plurality of mounting holes are formed in the peripheral surface of the rotating rack at intervals; a thermal insulating sleeve is arranged at each mounting hole and one end of the thermal insulating sleeve extends into the rotating rack; each dye cup sleeves the corresponding thermal insulating sleeve and the lower part of the dye cup extends out of the bottom of the thermal insulating sleeve; the heating device comprises heating elements which are arranged beside the middle parts of the sidewalls, extending out of the bottoms of the thermal insulating sleeves, of the dye cups; the parts, extending out of the bottoms of the thermal insulating sleeves, of the dye cups rotae along with the rotating rack and are directly heated by the heating elements. The stainer of such a structure has the advantages that the outer side walls, not covered with the thermal insulating sleeves, of the dye cups are directly heated by the heating elements, and the heating efficiency is high without heating lag time difference, the thermal insulating sleeves are used for preserving heat for the outer sidewalls of one parts of the dye cups and guaranteeing that the dye cups can be continuously heated even after leaving the heaving elements, and moreover, the dye cups in a midway into-cup test also can be preheated to prevent adverse effect on the cloth specimen due to temperature deviation resulting from too slow instantaneous heating on the dye.

Owner:广西润格电子有限公司

Cold and hot primary air forced mixing system and method for inlets of double-inlet and double-outlet coal mill

The invention relates to a cold and hot primary air forced mixing system and method for inlets of a double-inlet and double-outlet coal mill, and belongs to the field of energy-saving treatment of power station boiler pulverizing systems. According to the requirement of the installation mode of a hot primary air adjusting baffle and a cold primary air adjusting baffle, the transverse flow field of air flow can be kept uniform; by using a multi-layer cold primary air distribution device at the cold primary air tail end, cold primary air and hot primary air are intensively mixed; and through the design of flow guide plates and cold primary air corner flow guide plates in the system and the use of a flow distribution tee joint middle partition plate, the local flowing resistance of the air flow is reduced, and the stability of the flow field can be kept. The system is simple and reasonable in design, safe and reliable, the cold primary air and the hot primary air are intensively mixed, the stability of the flow field is kept, and the problem that the air temperature deviation of the inlets in the two ends of the double-inlet and double-outlet coal mill is large can be thoroughly solved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Refrigeration systems for refrigeration equipment

ActiveCN104501507BSimple structureFully automatedLighting and heating apparatusRefrigeration devicesTemperature controlThermal expansion

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com