Electric roasting pan

A baking pan and electric baking technology, applied in the field of electric baking pans, can solve the problems of slow heating speed, poor cooking quality of food, cracking of slate, etc., and achieve the effect of high durability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0107]

[0108] 1.5 g of carbon nanotubes (Hanwha Nano Technology Co., Ltd.) were added to the Erlenmeyer flask, and 33.75 g of α-terpineol (α-terpineol) and 1.25 g of ethylcellulose (Ethylcellulose) were dropped into the organic solvent. 5g of silicon-based adhesive (RSN-0806, Dow Corning) and 0.75g of dispersant (DISPERBYK-192, BYK). Next, the Erlenmeyer flask was installed in a stirrer, and stirred for 60 minutes to sufficiently disperse the exothermic composition.

Embodiment 1

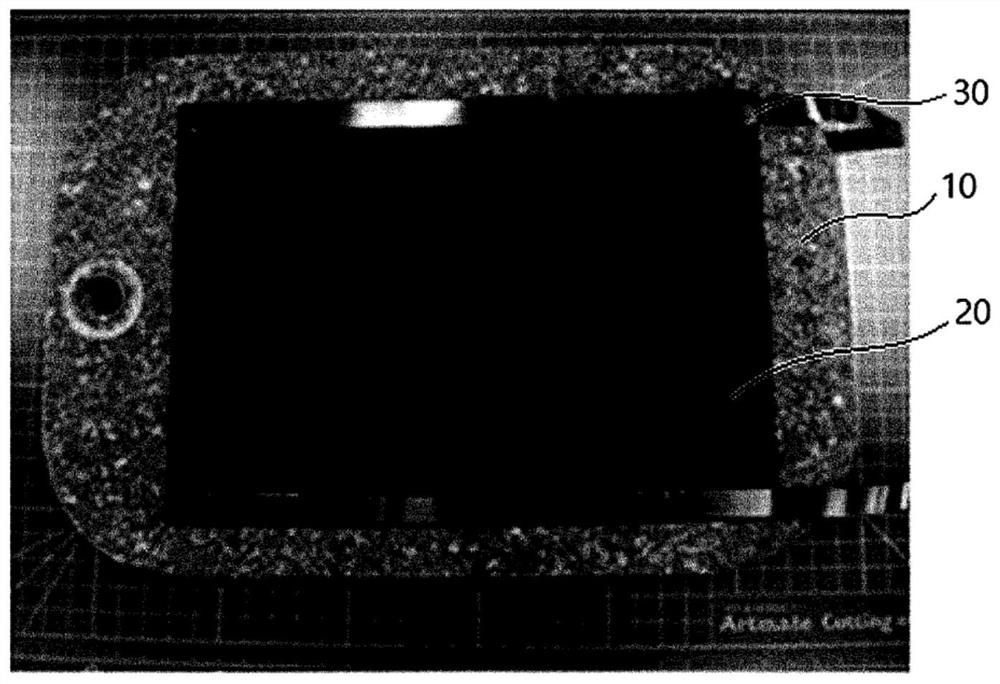

[0110] A stone plate (longevity stone) having an area of 300 mm×195 mm and a thickness of 20 mm was prepared as a baking tray. Wash the surface of the baking pan with ethanol, and perform heat treatment at 250°C for 30 minutes to remove impurities that may exist on the surface of the baking pan.

[0111] The heat-generating composition produced in Production Example 1 was coated on the lower surface of the bakeware after the above treatment with a wet thickness of 600 μm, and thermally cured at 300° C. for 30 minutes to coat the heat-generating layer on the bakeware. Such a coating process was repeated again to finally manufacture an electric grill pan coated with a heat generating layer having a wet thickness of 1.2 mm on the lower surface of the grill pan. At this time, the area of the heat generating layer was 220 mm×160 mm.

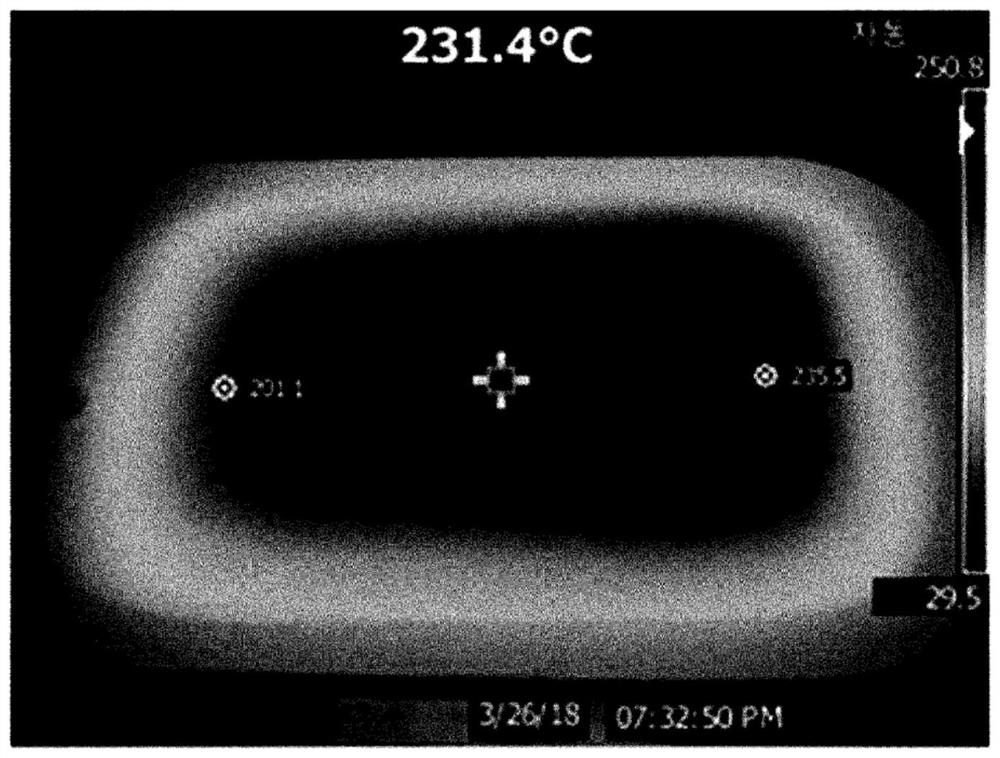

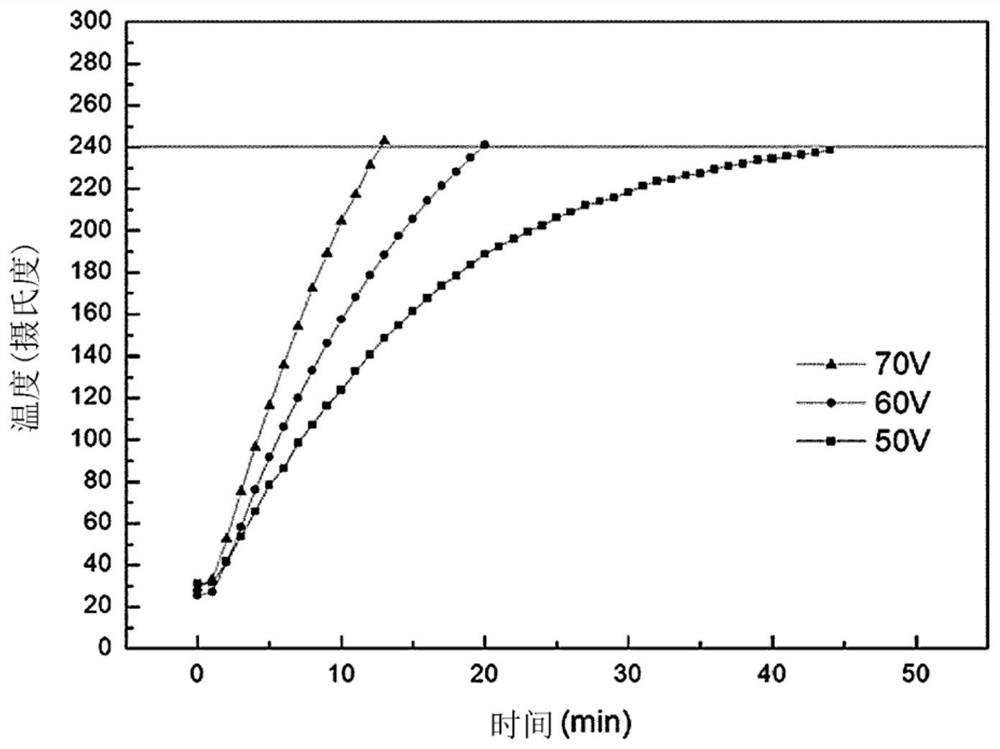

[0112] In addition, a pair of copper electrodes are respectively bonded to both ends of the heat generating layer. At this time, as Figure 7 A...

Embodiment 2

[0115] The same method as in Example 1 was implemented except that the 20 mm baking pan in Example 1 was replaced with a 15 mm thick baking pan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com