Device for measuring melt heat history curve under action of pulse magnetic liquid level oscillation

A pulsed magnetic and thermal history technology, applied in the field of material processing, can solve the problems of large difference in pouring temperature, difficult to obtain information, affecting solidification structure, etc., to avoid temperature deviation inside the melt, accurately measure, and accurately heat history curve. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

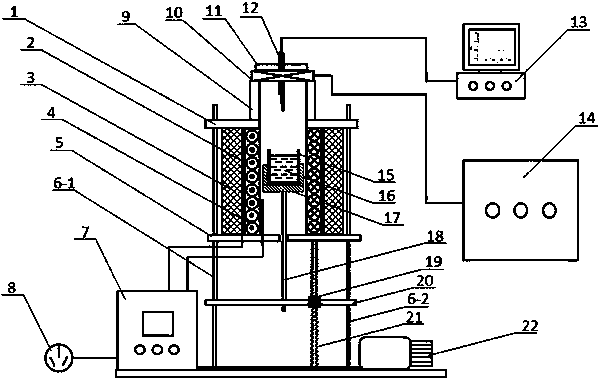

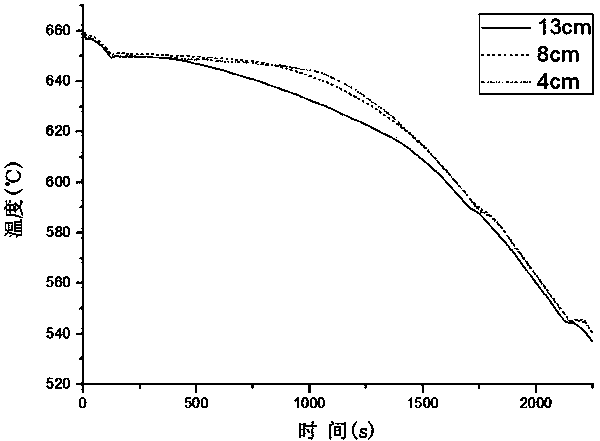

[0023] Example: Measure the thermal history curves of three points at different depths on the axis of the Al-4.5%Cu alloy melt under pulsed magneto-induced liquid level oscillation treatment.

[0024] Including: casting mold 15, casting mold fixing system 17, lifting rod 18, sliding seat 20, guide rail 6, screw rod 21, nut seat 19, motor 22, ceramic tube 9 and mosquito-repellent coil 10, etc., ceramic tube 9 is placed on On the top plate 1, the mosquito coil-shaped induction coil 10 is placed on the ceramic tube 9, and the mold 15 containing the molten metal 16 is placed in the mold fixing system 17, and the upper end of the screw rod 21 is connected to the fixed plate 5, and the screw rod 21 The lower end of the lower end is connected with the follower of the motor 22, the guide rail 6, the lifting rod 18 and the screw mandrel 21 pass through the slide seat 20 and are on the same plane, the slide seat 20 is fixed with a nut seat 19, and the nut seat 19 engages with the screw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com