Patents

Literature

1246 results about "Temperature curve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin composition for production of optical element, the optical element, and projection screen

InactiveUS6650471B2Increase crosslink densityHigh refractive indexProjectorsOptical articlesTemperature curveProjection screen

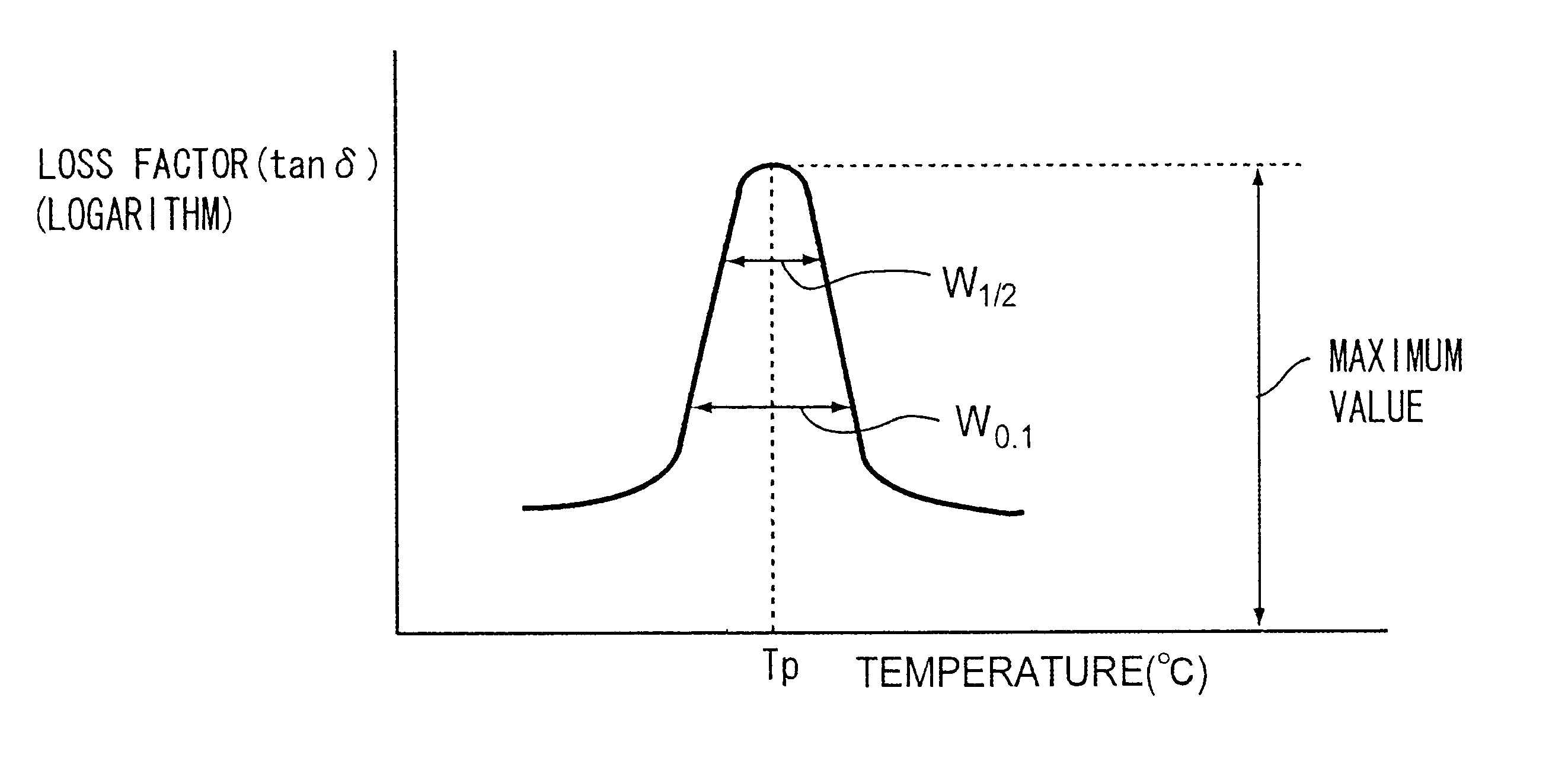

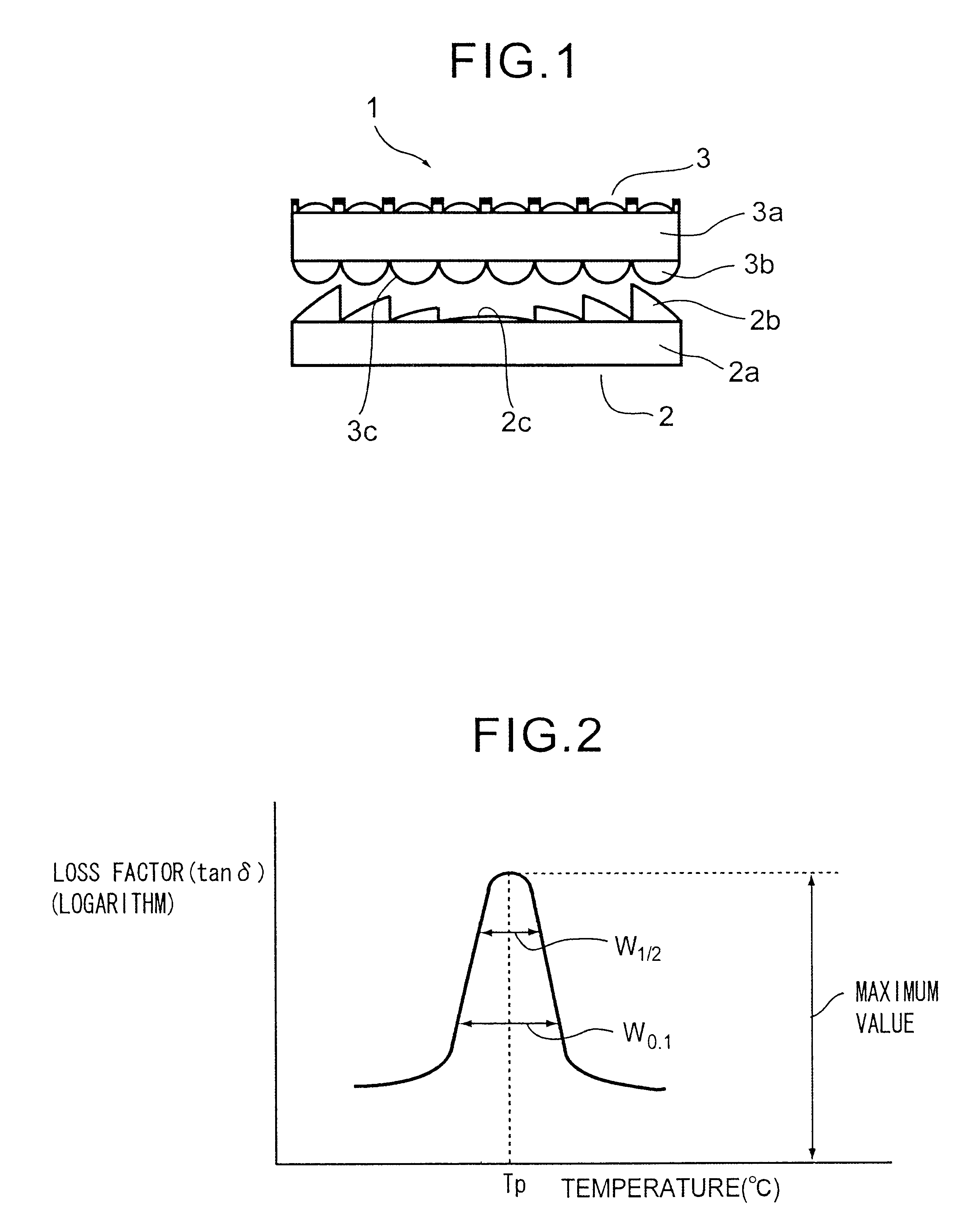

A resin composition for production of an optical element being adapted to form the optical element has a characteristics of which, when W1 / 2 (° C.) represents, regarding a crest portion in a loss factor / temperature curve obtained by measuring the loss factor of the resin composition relative to a change in the temperature, the width of the crest portion at the position of ½ of the maximum value of the loss factor in the crest portion temperature range; W0.1 (° C.) represents, regarding the crest portion, the width of the crest portion at the position of 0.1 of the maximum value of the loss factor; and DeltaW (° C.), the difference between the widths of the two crest portions, is set to be DeltaW=W0.1-W1 / 2, the DeltaW is in the range of from 16° C. to 31° C.

Owner:DAI NIPPON PRINTING CO LTD

Liquid sensor and ice detector

InactiveUS20050126282A1Difference in efficiencyRemove heat moreMachines/enginesLubrication indication devicesScreen printingLiquid temperature

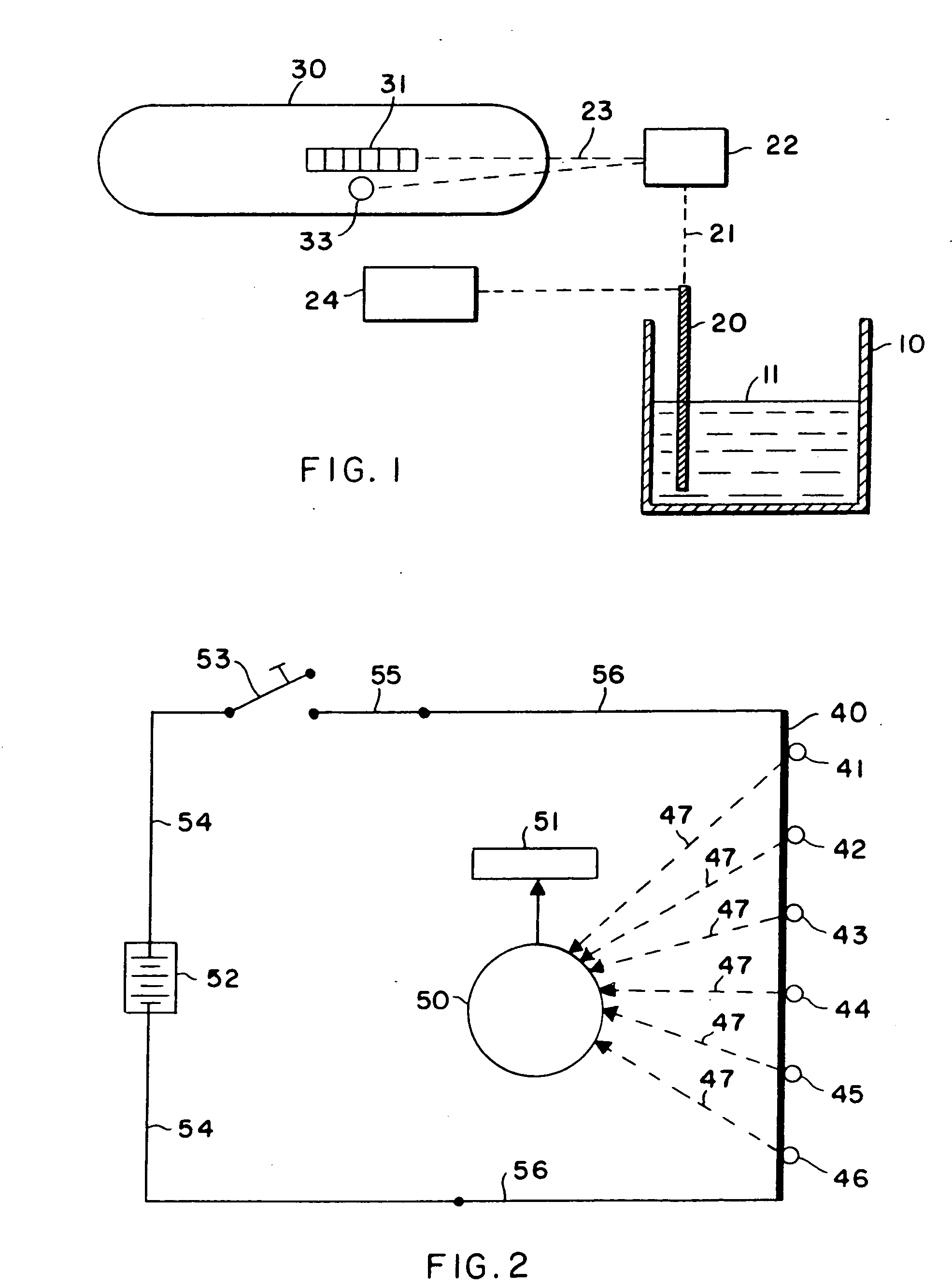

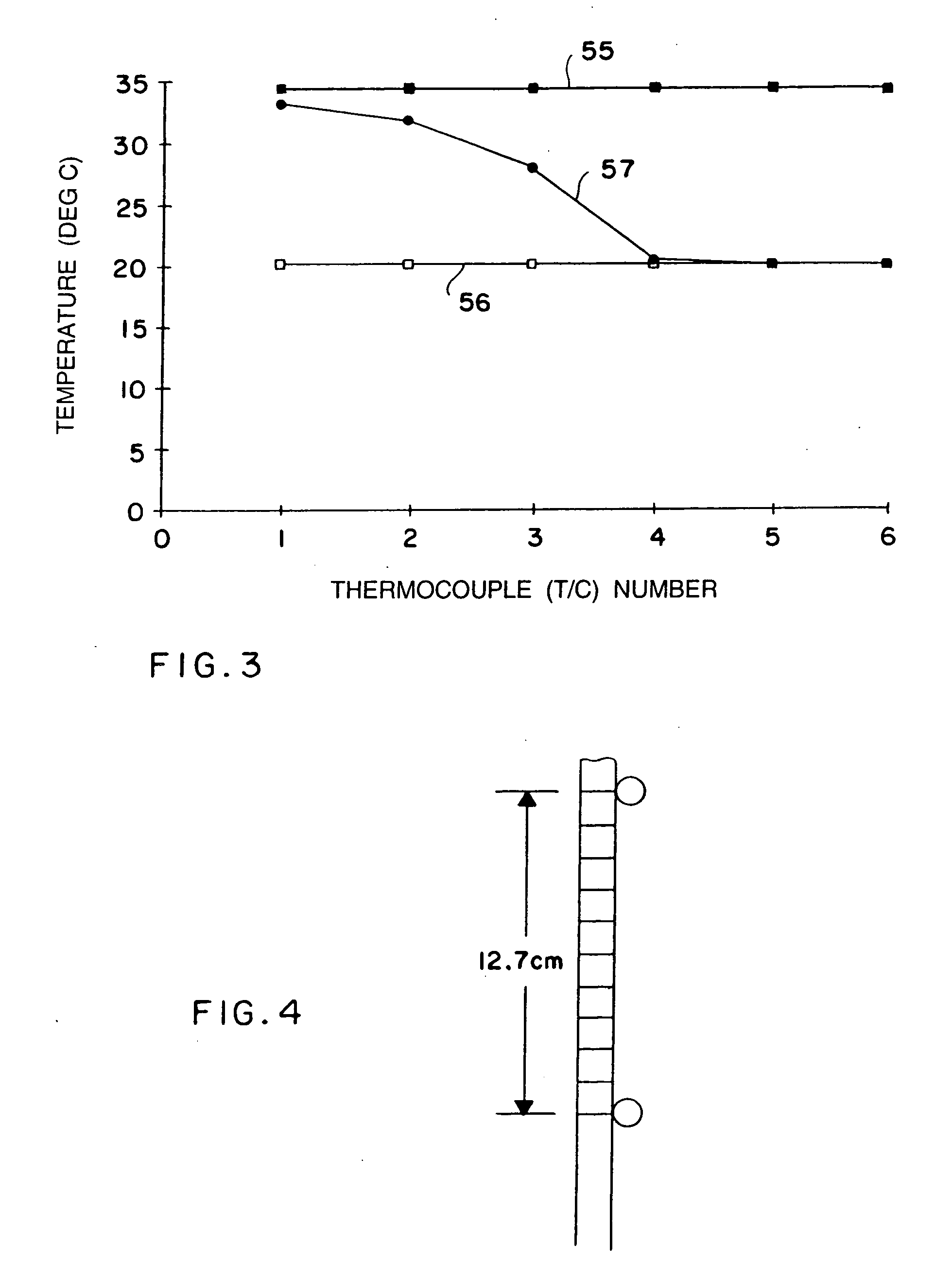

An improved apparatus and a method of measuring and interpreting reliably, simply and accurately the information on continuous liquid level, liquid temperature and other liquid properties within a vessel. The apparatus could be made of a powered heater element and temperature sensors can be screen-printed, vacuum deposited, etched, welded, soldered or plated on one or both sides of a single rigid or a flexible substrate. The geometry of the heater determines the curve shape, such as steepness or shallowness of a temperature profile along a heater. Various parallel and serial configurations of thermocouples or temperature sensors can be used to measure the temperature along a heater. Simultaneous measurements from all the temperature sensors, before and after heat is applied, are used to generate accurate temperature profiles for the entire heater. Different features of the temperature profiles will determine accurately the liquid level, liquid temperature and other liquid properties. Apparatus of the invention may also be used to detect ice formation.

Owner:MAATUK JOSEF

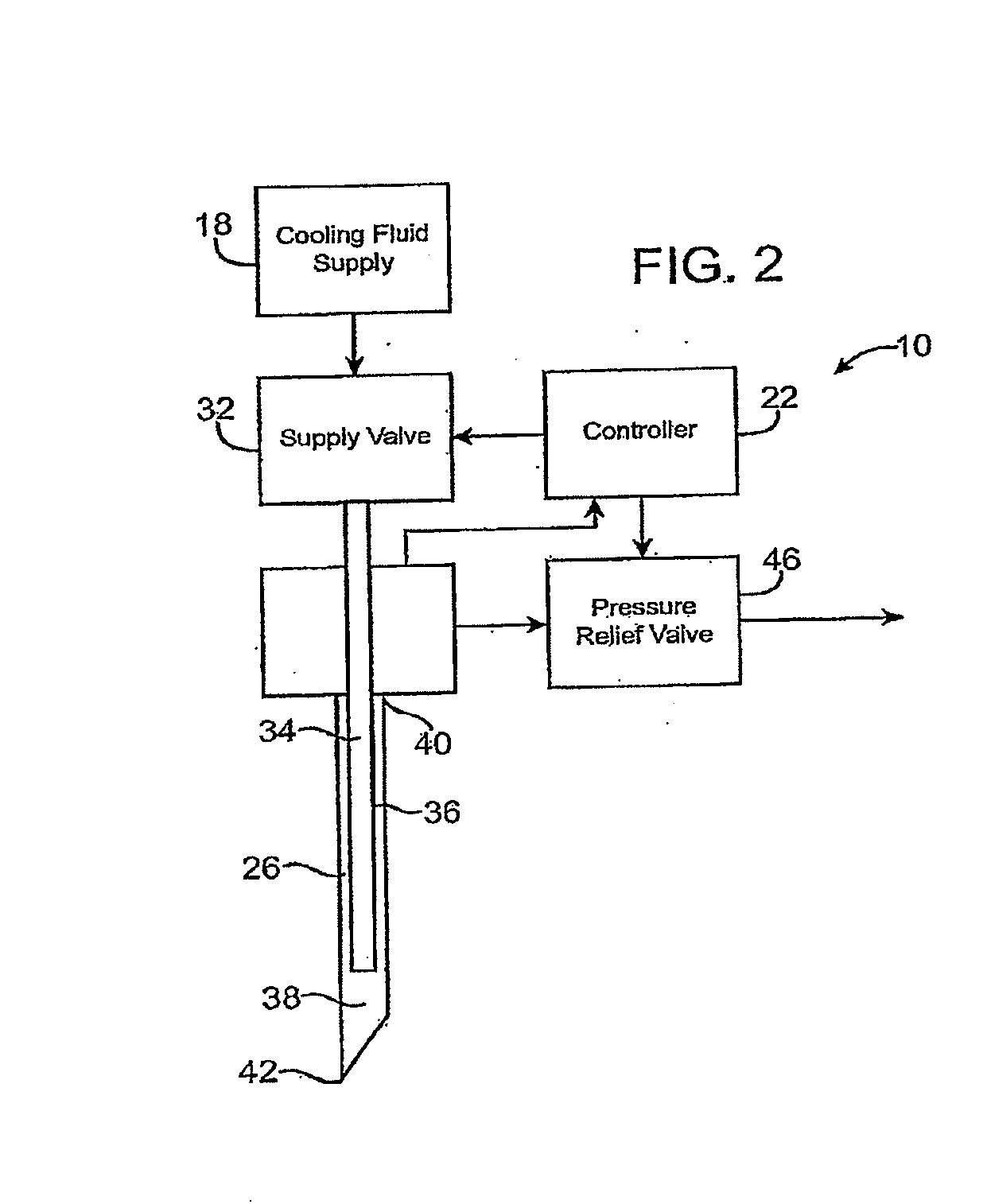

Skin protection for subdermal cryogenic remodeling for cosmetic and other treatments

InactiveUS20120259322A1Reduce appearance problemsChange shapeDevices for heating/cooling reflex pointsSurgical instruments for coolingStart timeProximal point

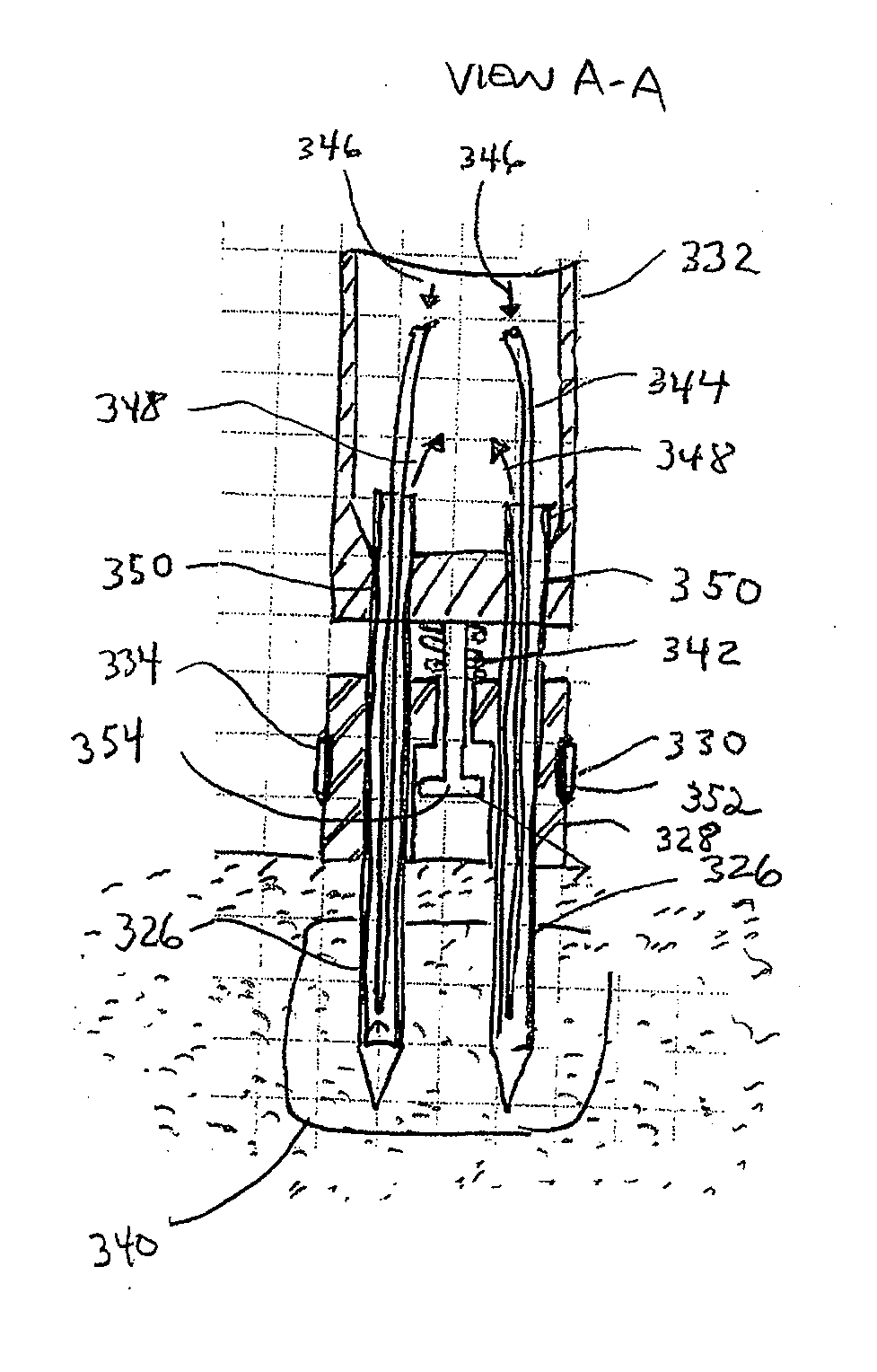

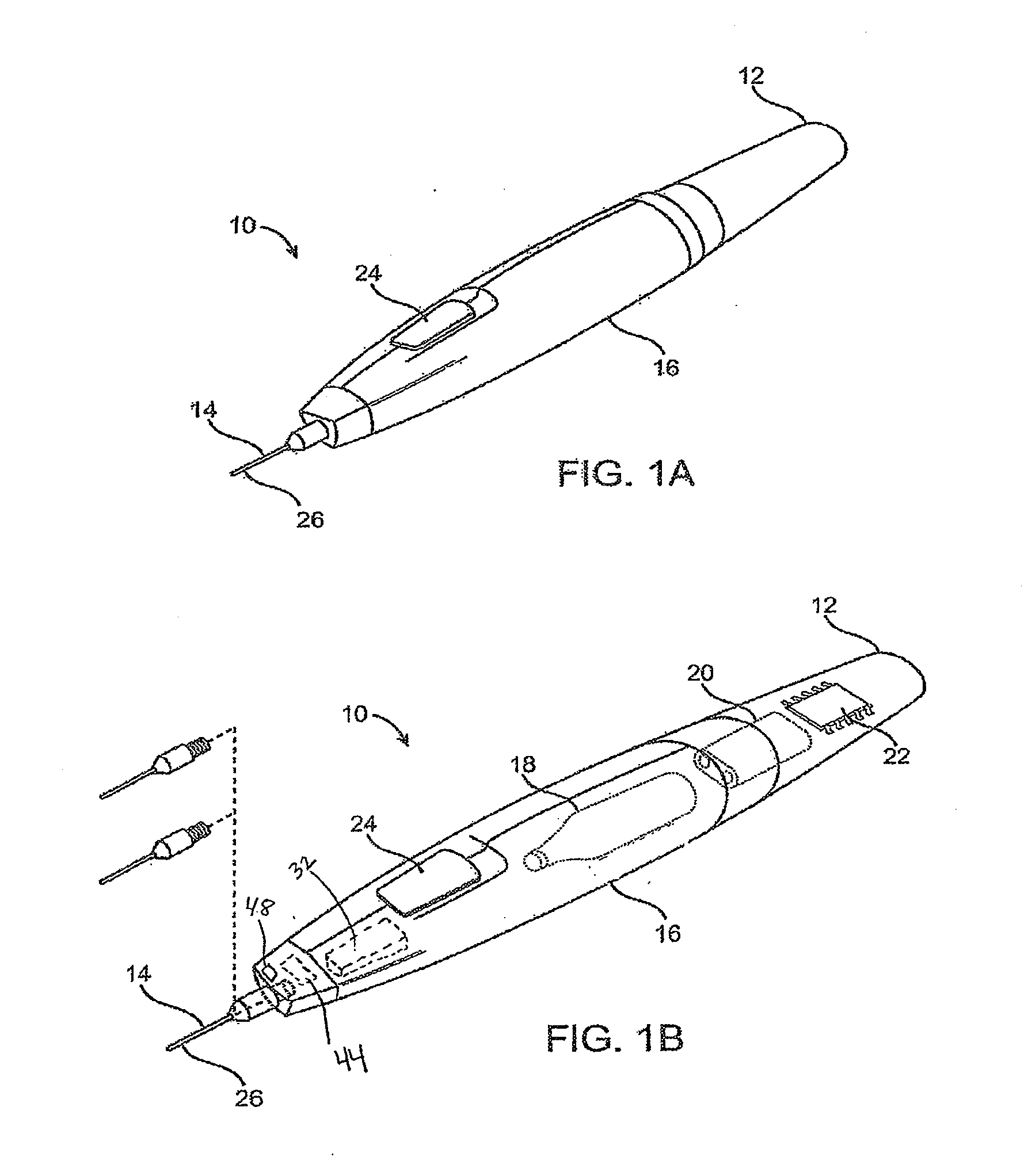

A systems and methods for controlling temperature in a cryogenic device includes providing a device having a probe and a heater element. A distal region of the probe is engaged with the target region. Measuring and recording current temperature of a proximal region of the probe and time of the measurement is used to determine slope of a temperature curve defined by two points. The first point is defined by the current temperature and time of measurement and a second point is defined by a previous measurement of proximal region temperature and time of measurement. When the slope is less than a slope threshold value a treatment flag is activated, treatment start time is recorded and the proximal region is heated with the heater element. Heating is discontinued and the treatment flag is deactivated after elapsed treatment time exceeds a duration threshold value.

Owner:PACIRA CRYOTECH INC

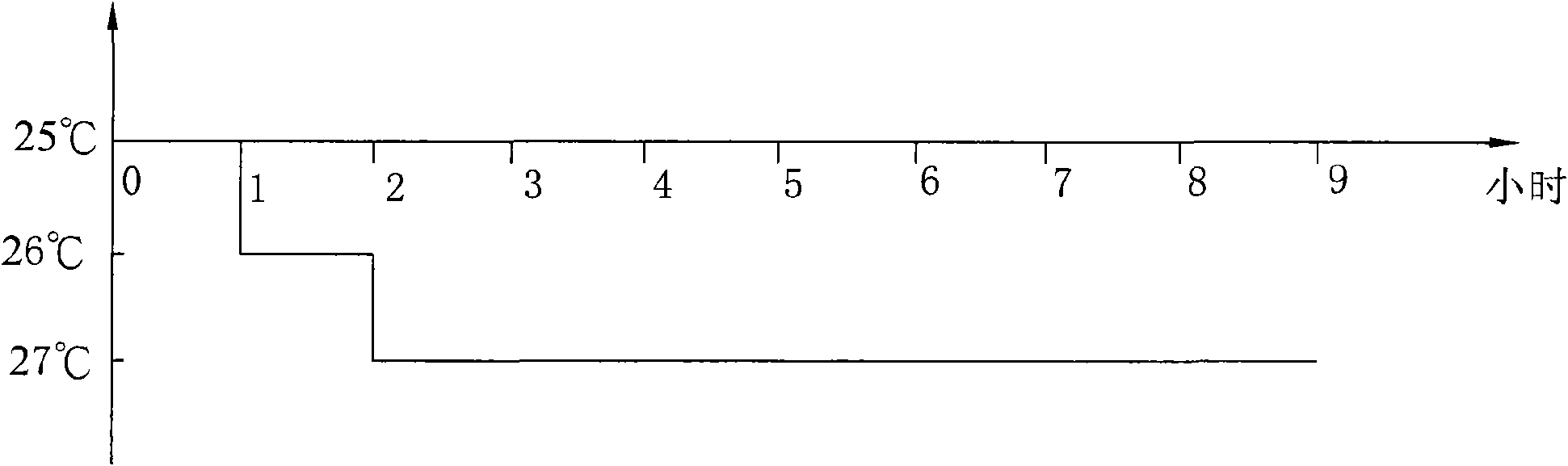

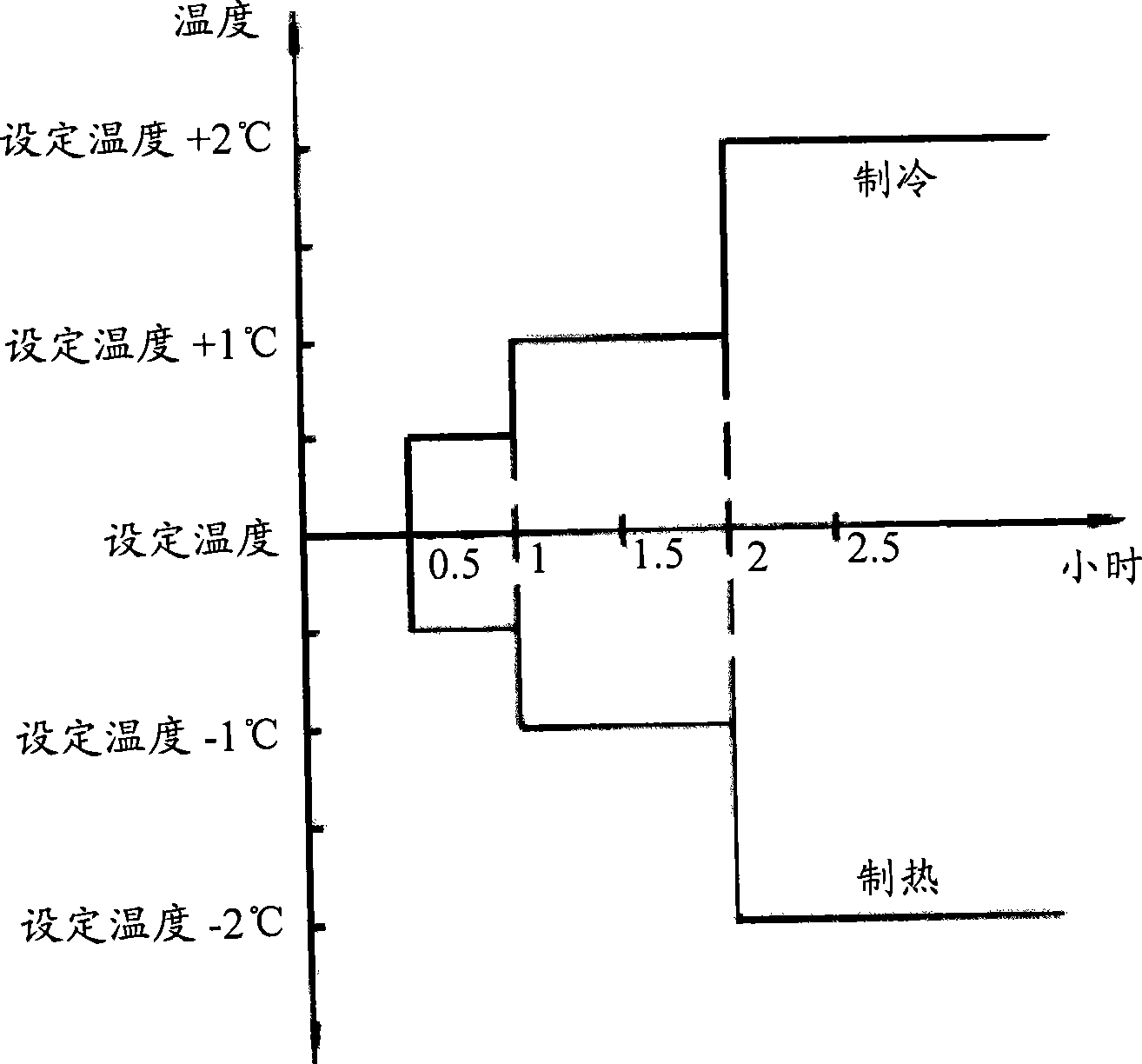

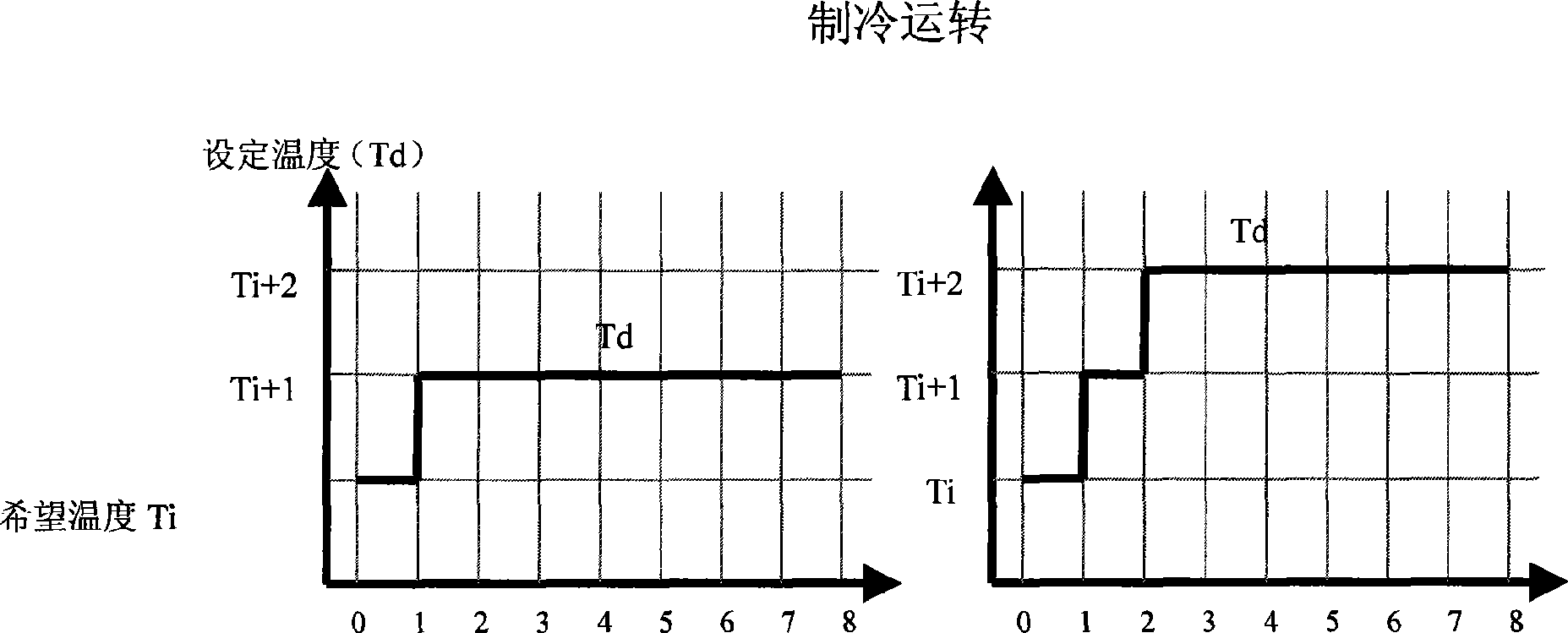

Control method of air conditioner with self-learning sleep function

ActiveCN101581489AWith self-learning sleep functionThe control method is convenient and practicalSpace heating and ventilation safety systemsLighting and heating apparatusSleep functionTemperature curve

The invention relates to a control method of an air conditioner with self-learning sleep function. The control method comprises the following steps: (a) entering a sleep operation mode; (b) adjusting indoor temperature according to a current set temperature curve and a set wind speed curve; (c) during operation, operating a system according to the changed set temperature and memorizing the changed set temperature if a user adjusts the set temperature, or operating the system according to the changed wind speed and memorizing the changed set wind speed if a user adjusts the set wind speed; and (d) modifying a sleep curve according to the set temperature-time and the set wind speed-time memorized by the system as the set temperature curve and the set wind speed curve of the current sleep mode. The control method has simple operation and can effectively increase user comfort.

Owner:MIDEA GRP CO LTD

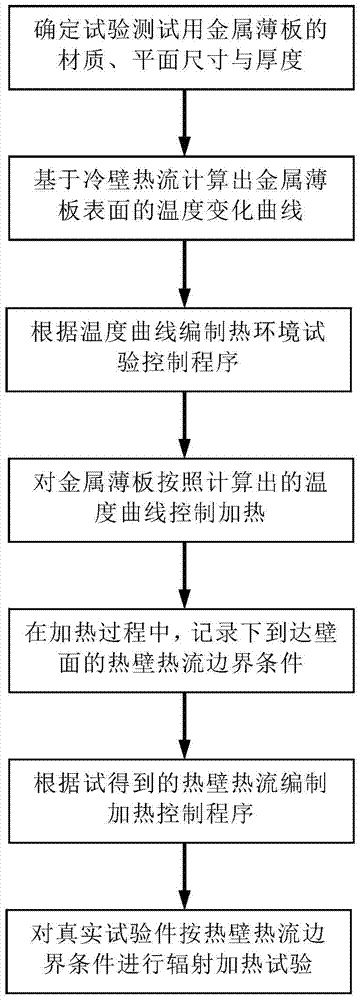

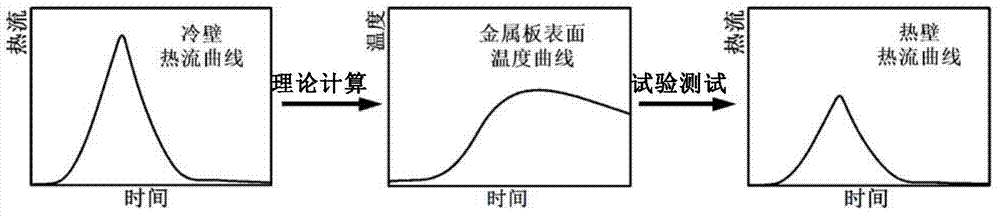

Method for converting cold wall heat flux into hot wall heat flux in aerodynamic heat simulating test

InactiveCN104267062AReliable measurementAvoid temperature measurementMaterial heat developmentThin metalHeat flow

The invention provides a method for converting cold wall heat flux into hot wall heat flux in an aerodynamic heat simulating test. The method comprises the following steps: firstly, calculating a temperature change curve for the surface of a thin metal plate according to a cold wall heat flux boundary condition; secondly, heating the thin metal plate test piece according to the calculated temperature curve, and recording a hot wall heat flux curve for the surface of a heat flux sensor in the same plane of the thin metal plate under the temperature condition, namely by a combined method of theoretical calculation and an experimental test, finally obtaining a hot wall heat flux boundary condition which corresponds to the cold wall heat flux boundary condition and is difficultly determined by a computer. The invention provides a practicable hot wall heat flux determining method for a radiant aerodynamic heat simulating test on a high-speed aircraft.

Owner:BEIHANG UNIV

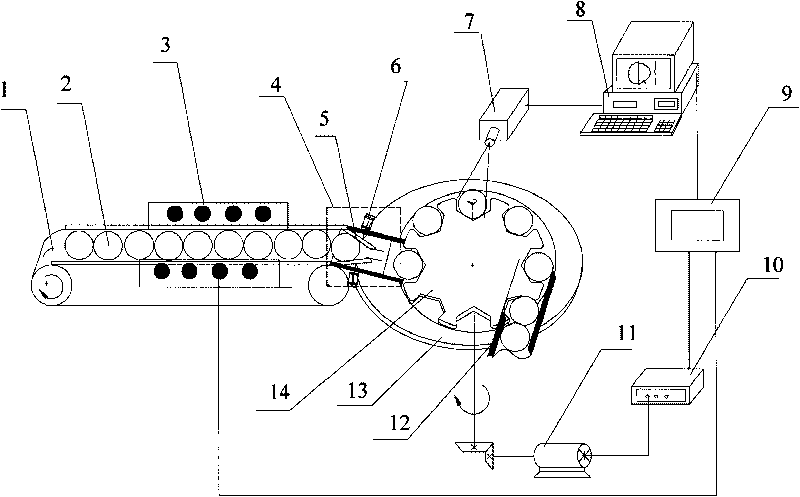

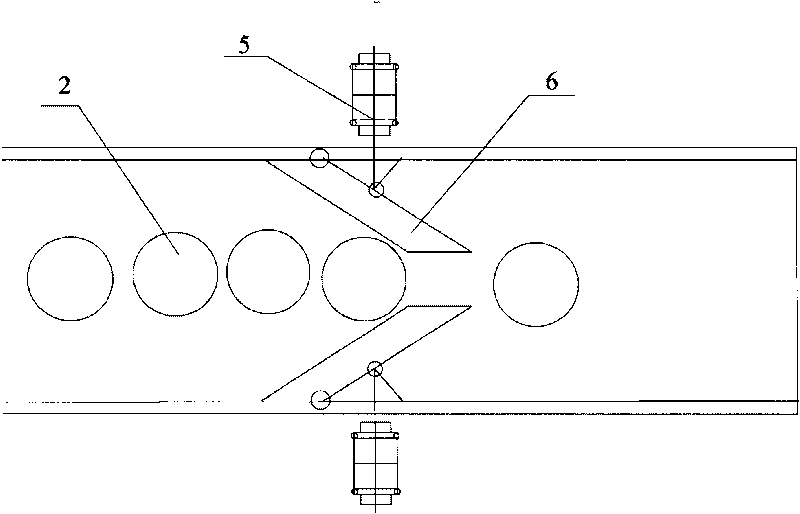

Thermal infrared imaging technology based method and device for detecting the early defect of fruit surface

InactiveCN101713747AEasy accessRadiation pyrometryOptically investigating flaws/contaminationTemperature curveInfrared lamp

The invention discloses thermal infrared imaging technology based method and device for detecting the early defects of fruit surfaces. The device comprises belt type transmission system, an infrared lamp, a beat fixing system, a dividing turnplate, a fixed bed, a step drive system, a salver, an electric motor, an thermal infrared imager, a computer and fruit defect detection software. Fruits are excited by a thermal light source of the controlled infrared lamp in transportation and rotate at constant speed during detection; a vertical temperature measuring line of the thermal infrared imager aims at the centers of the fruit surfaces and dynamically collect the temperature information of the fruit surfaces at angles of 360 degrees; and the fruit defect detection software denoises and reinforces acquired images and temperature curve information, contrasts thermal images and judges the early defects of the fruit surfaces according to waveform inference. The invention coverts the fruit surface information into one-dimensional temperature information and can well realize the detection of the early defects of the fruit surfaces by combining image information, thereby creating conditions for the refined classification of the fruits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

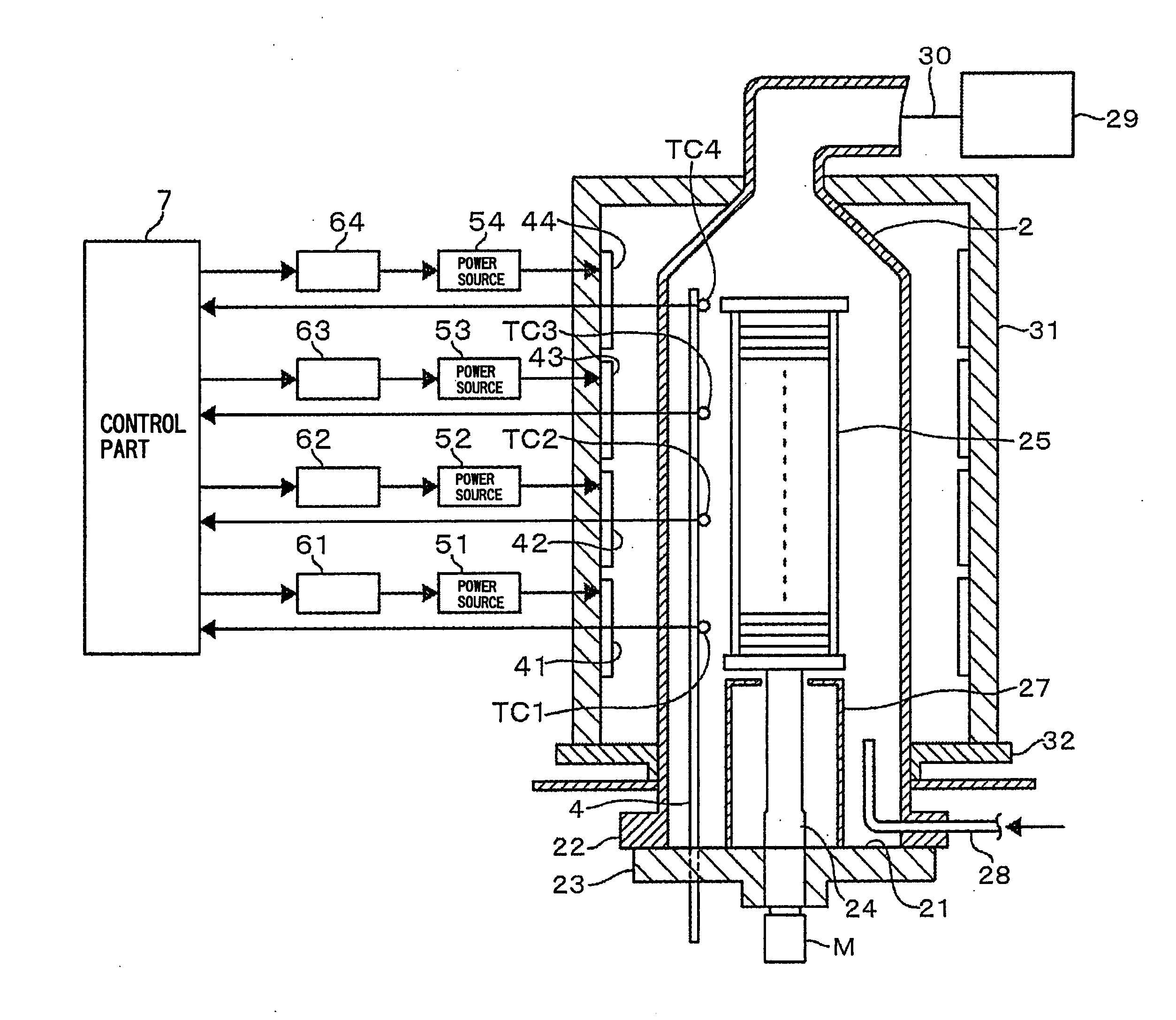

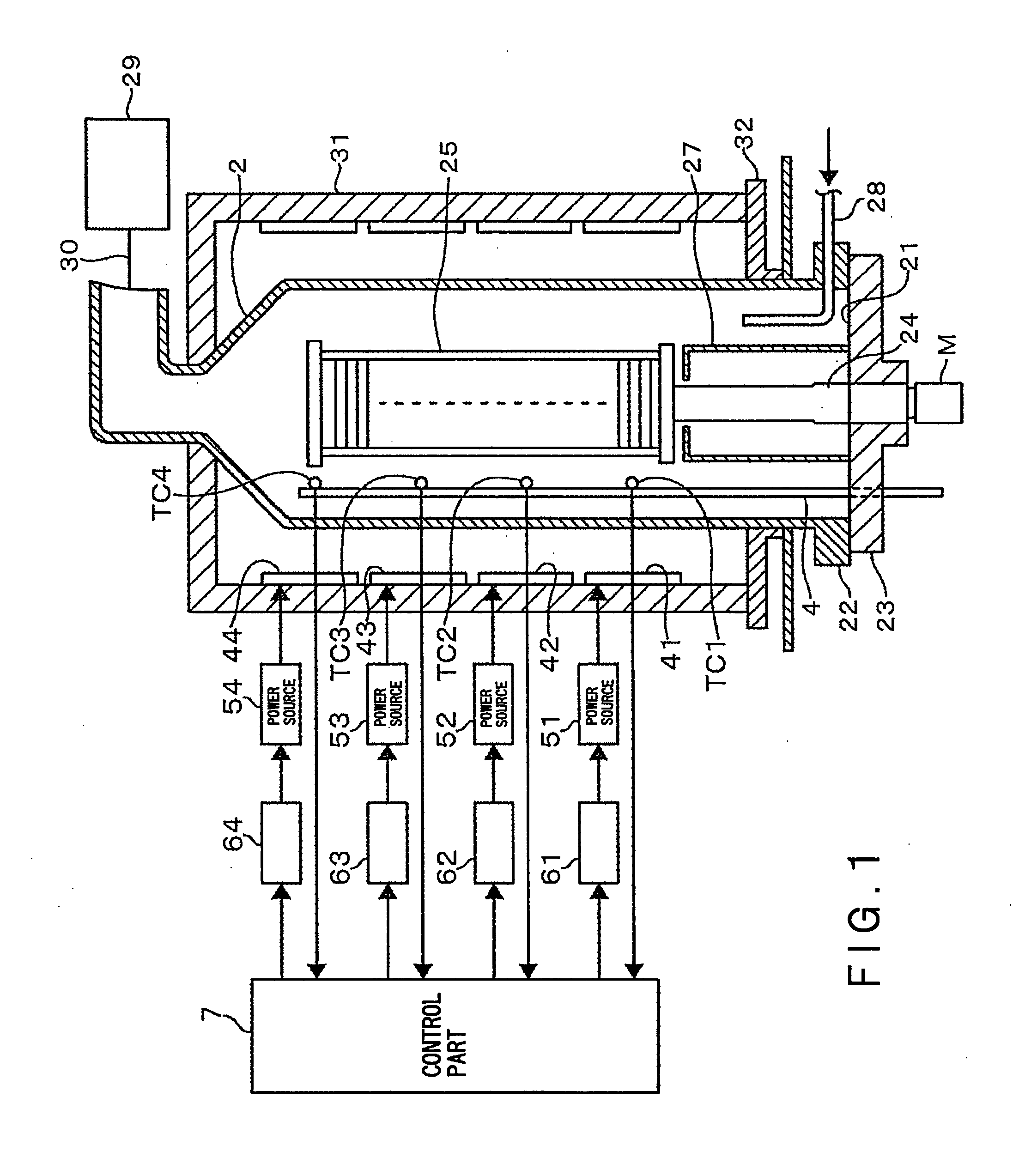

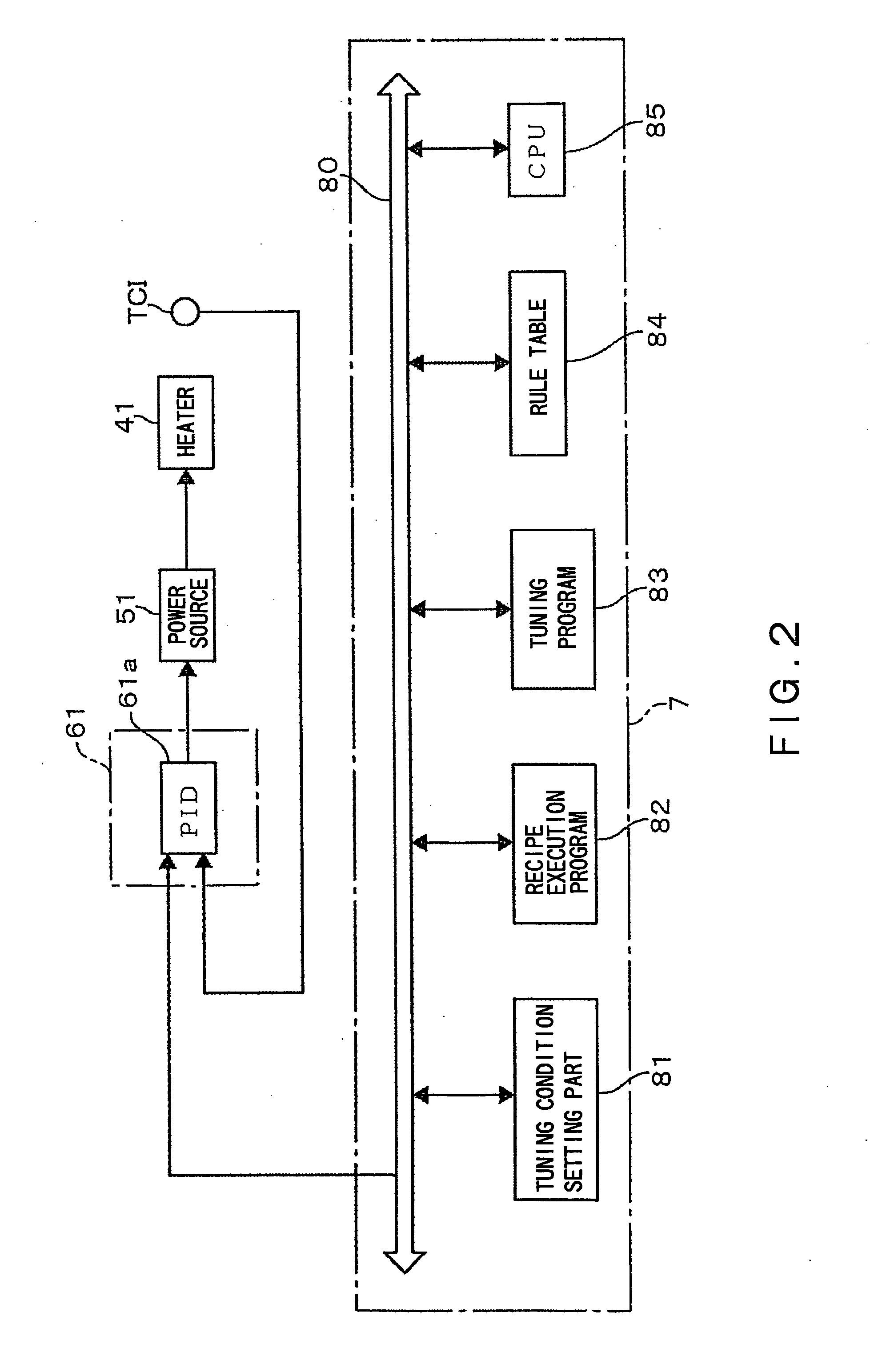

Heat processing apparatus, method of automatically tuning control constants, and storage medium

ActiveUS20080255683A1Reliable and easy mannerSemiconductor/solid-state device testing/measurementTemperatue controlTemperature curveProcess region

A heat processing apparatus comprises: a reaction vessel; a heating unit disposed in the reaction vessel and configured to heat the processing region; a temperature detection part configured to detect a temperature of the processing region; and a control part configured to control the heating unit by a PID control. The control part includes: a rule table that is prepared such that predicted change amounts of a temperature property item when a temperature of the processing region is increased up to a target value, and change ratios of PID constants are correspondingly related to each other; a performance unit configured to repeatedly perform: a step of obtaining a temperature profile based on a temperature detected value of the temperature detection part and calculating a difference between an actually measured value and a target value of the temperature property item based on the temperature profile; and a step of, when the difference is over an allowable range and larger than a prescribed value, referring to the rule table and changing the PID constants to reset new PID constants by a change ratio corresponding to an predicted change amount of the temperature property item relative to the difference; until the difference can fall within the allowable range. The control part also includes an updating unit configured to update, when there is a difference between an actually measured change amount of the temperature property item with reference to the rule table and an predicted change amount of the temperature property item that has been predicted in the preceding cycle, the corresponding relationship between the PID constants and the predicted change amounts of the temperature property item described in the rule table, based on the actually measured change amount.

Owner:TOKYO ELECTRON LTD

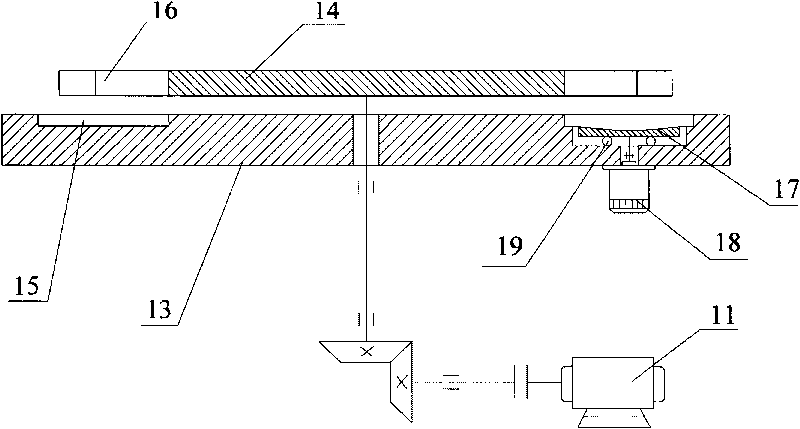

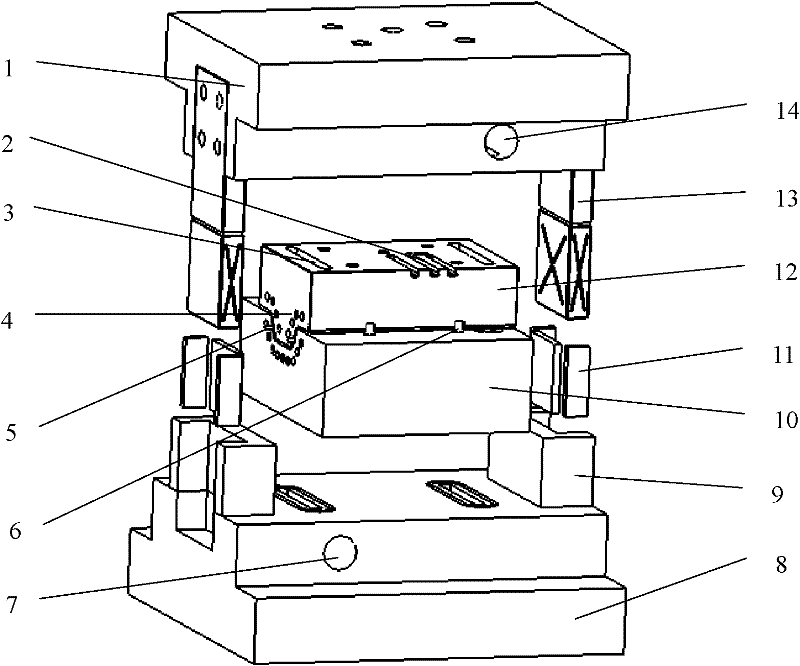

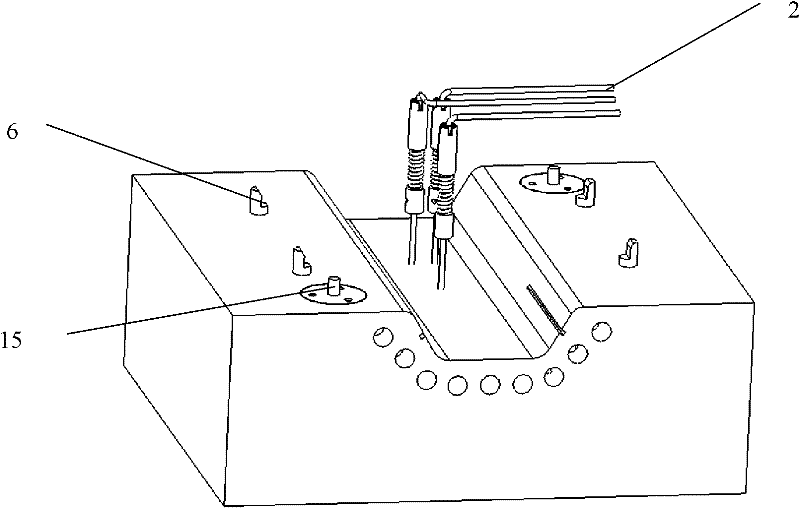

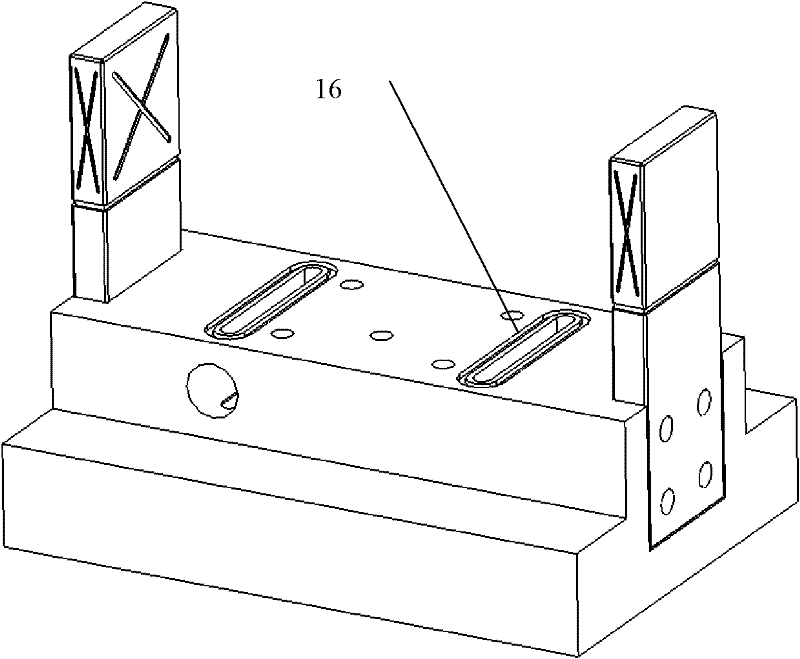

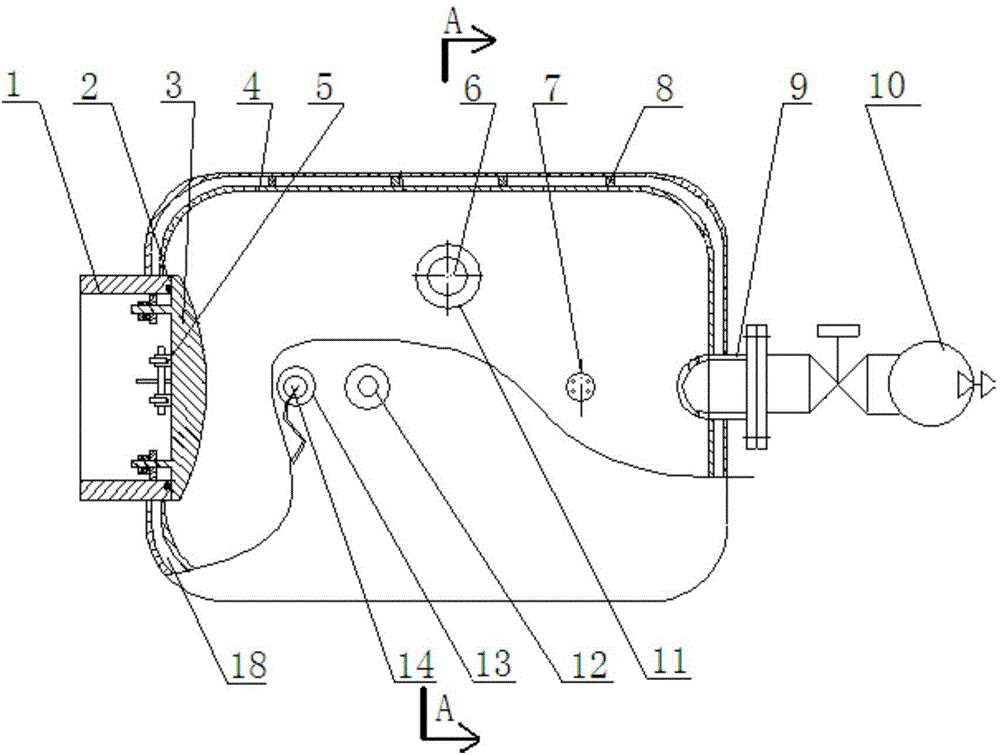

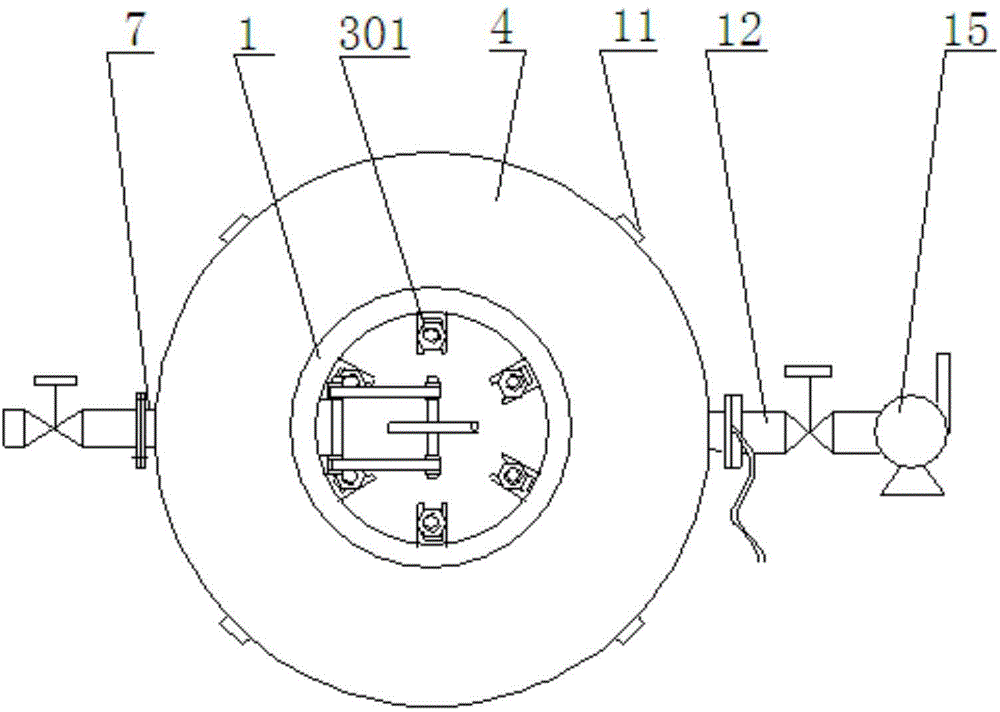

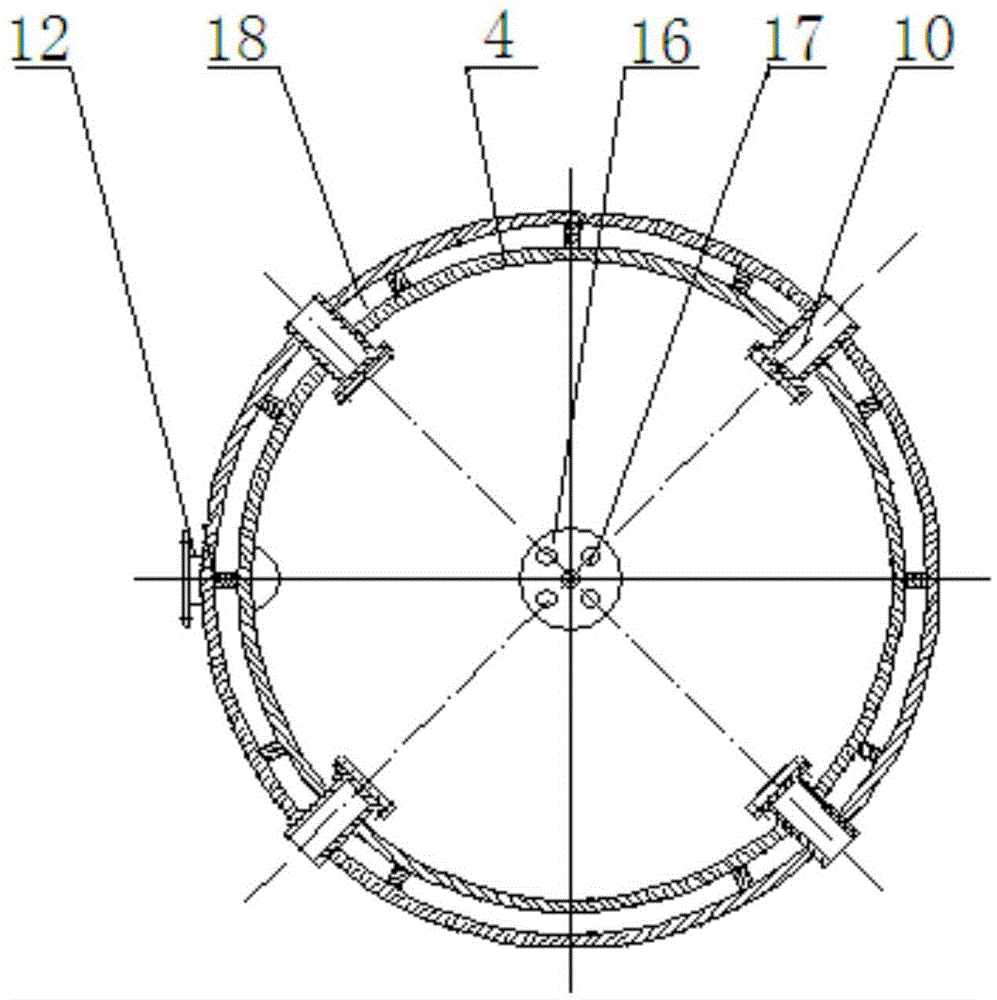

Hot stamping mould with temperature measuring system

InactiveCN102172719ARealize full cycle temperature monitoringAvoid cycleShaping toolsMetal working apparatusHot stampingTemperature curve

The invention discloses a hot stamping mould with a temperature measuring system. The hot stamping mould comprises a concave mould, a convex mould, a plate support and positioning device, a mould built-in cooling system, a mould built-in temperature measuring system and an external temperature recording device, and is characterized in that: the concave mould and convex mould are provided with a molded surface corresponding to the workpiece shape respectively; cooling pipelines are staggered in the concave mould and convex mould, and connected with a water inlet and a water outlet through a diversion groove; and multiple thermocouples are pre-embedded on specific positions on the surface of the concave mould as well as on the surface and inside of the convex mould, and connected with the multi-channel temperature recording device. The hot stamping mould disclosed by the invention realizes full-period temperature monitoring, can directly judge and predict the product quality according to a temperature curve so as to eliminate unqualified products immediately, shortens the inspection cycle and lowers the production cost.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

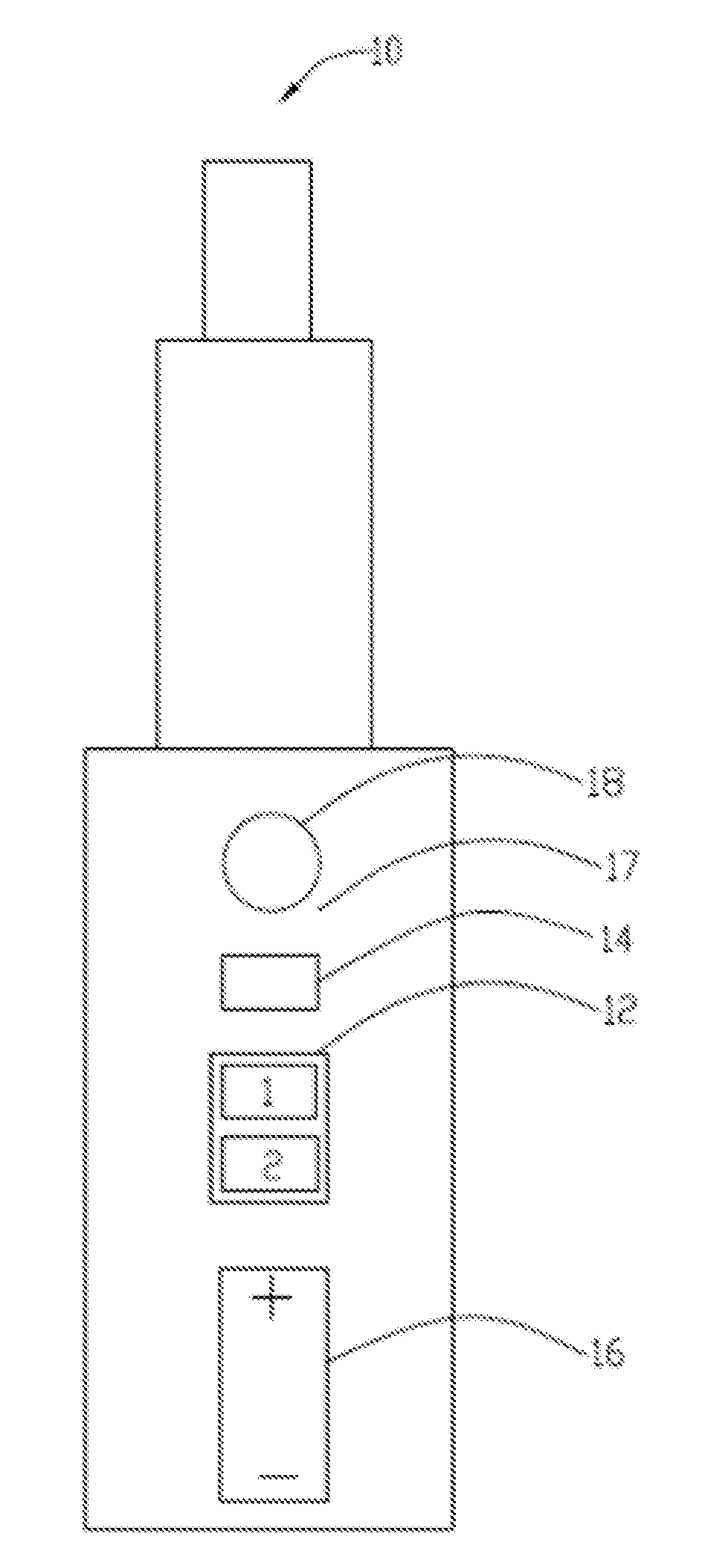

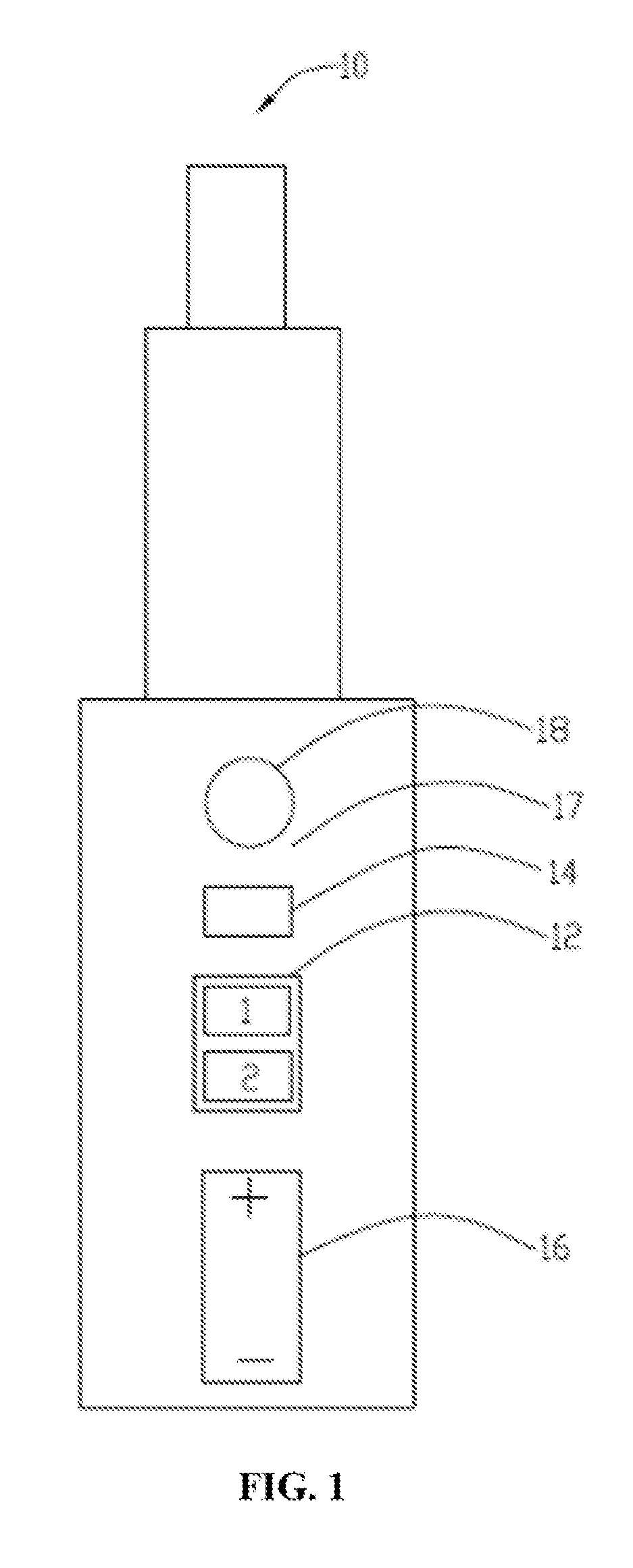

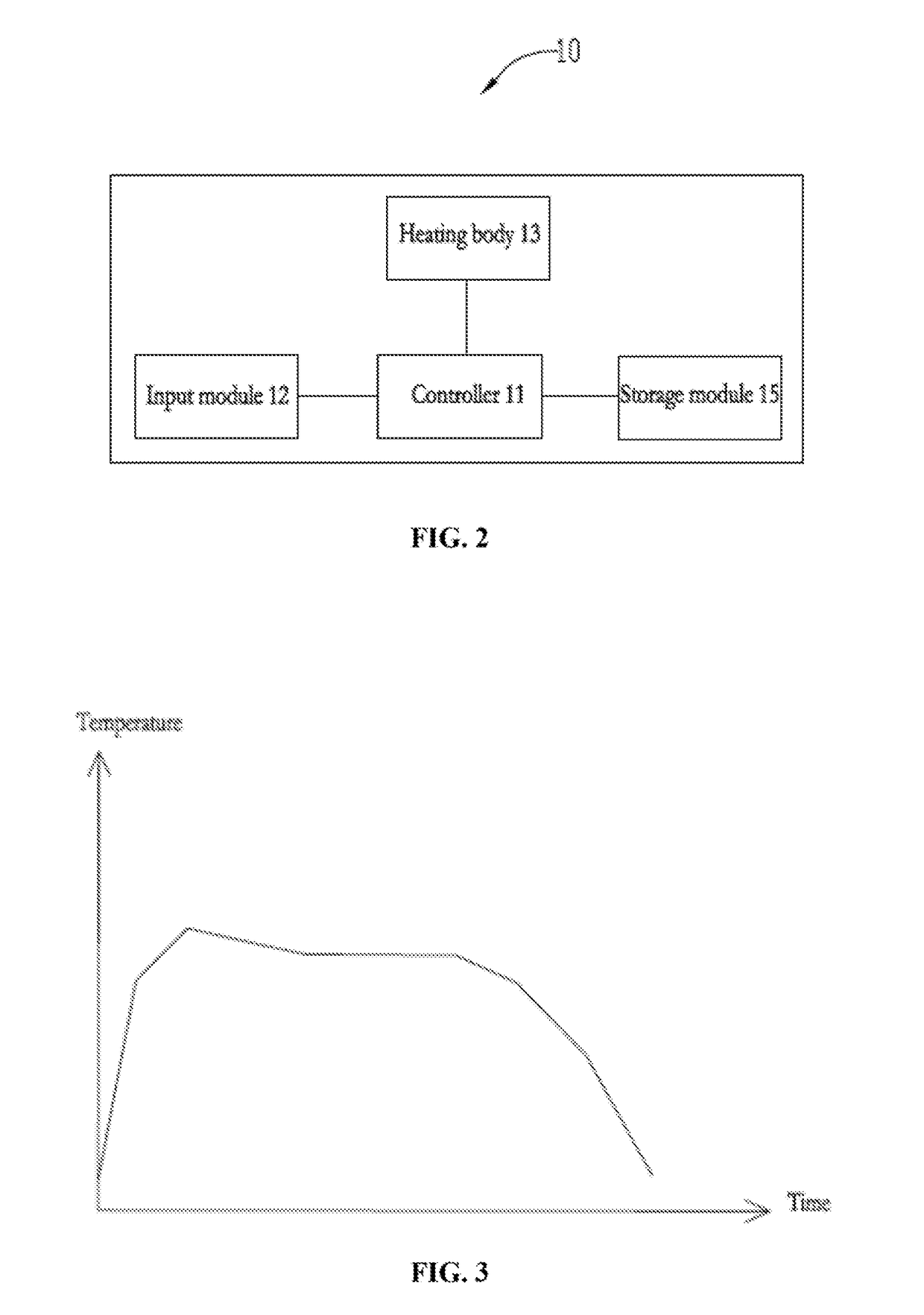

Electronic cigarette and smoking method thereof

An electronic cigarette includes a housing, a controller in the housing, an input module connected to the controller, a storage module connected to the controller, and a heating body connected to the controller. The input module is configured for inputting a type of tobacco liquid, and sending an input signal to the controller. The storage module is configured for storing a plurality of types of tobacco liquid and a plurality of temperature curves corresponding to the plurality of types of tobacco liquid. The heating body is configured for heating the tobacco liquid to form aerosol. The controller is configured for acquiring a temperature curve corresponding to the tobacco liquid based on the input signal of the input module, and controlling the heating body to heat the tobacco liquid according to the temperature curve.

Owner:SHENZHEN FIRST UNION TECH CO LTD

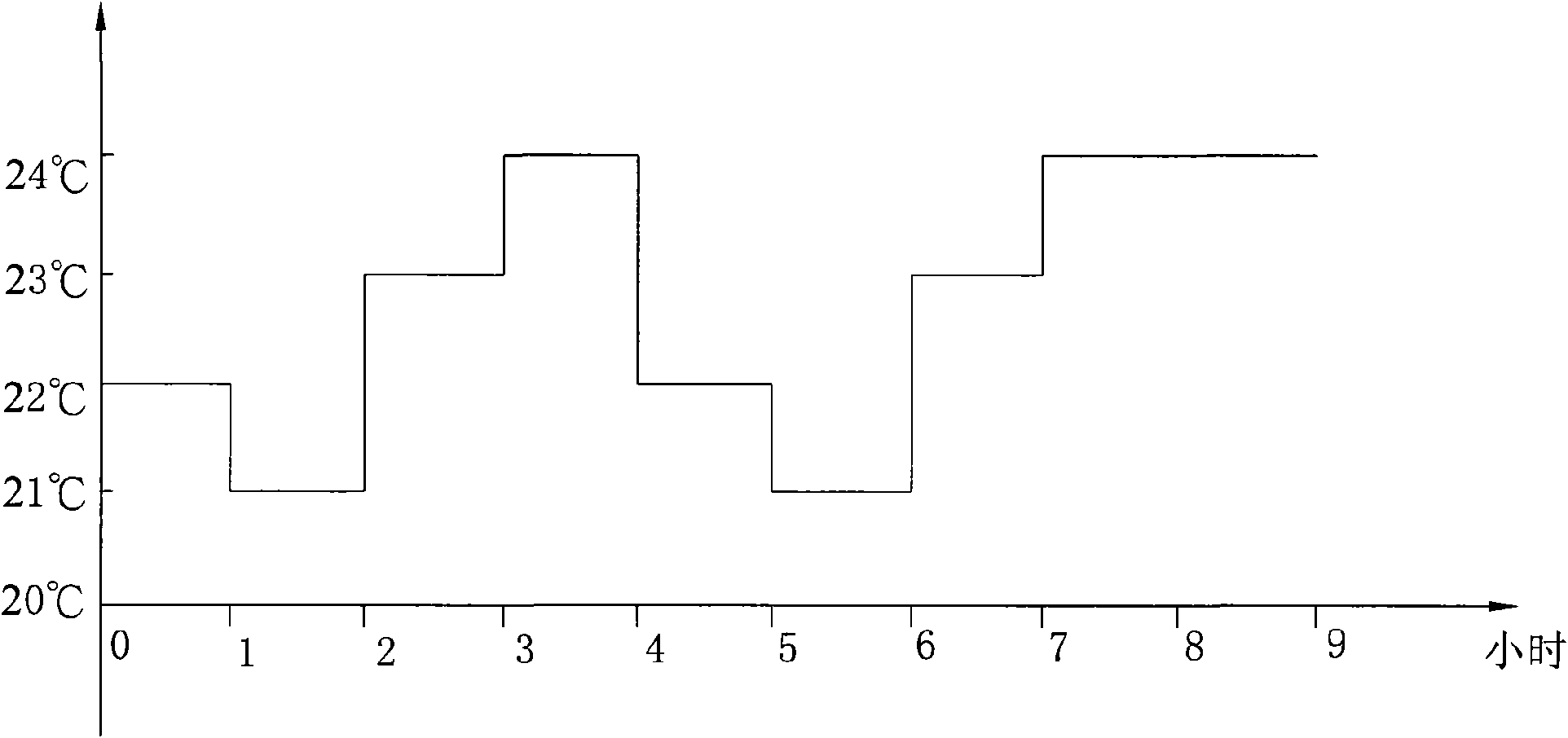

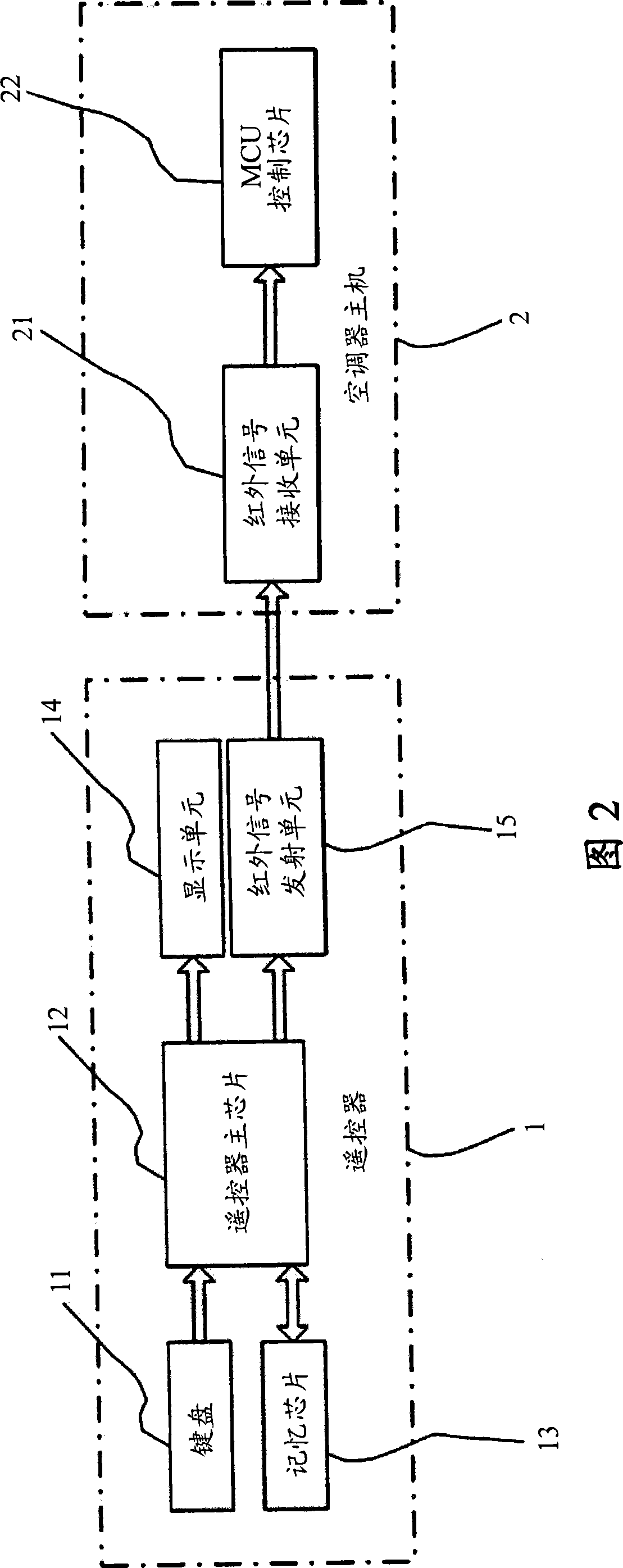

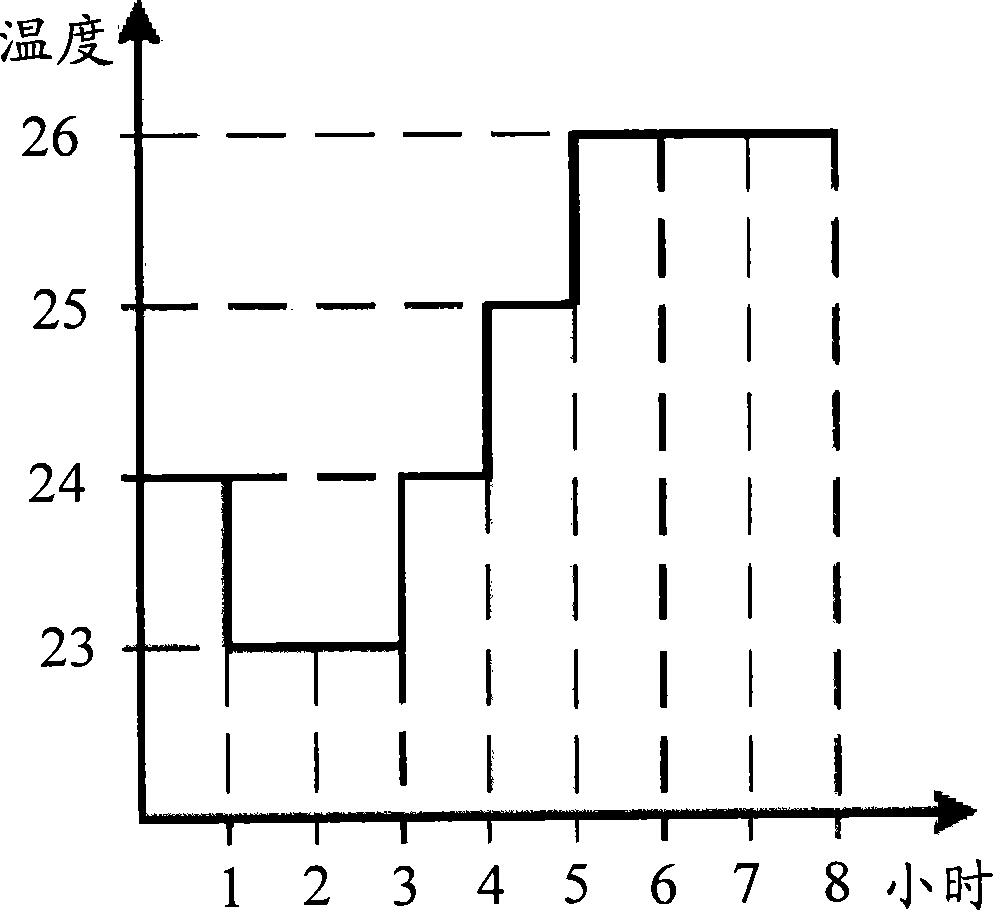

Method for controlling air conditioner to operate as custom curve

ActiveCN101382331ANon-electrical signal transmission systemsSpace heating and ventilation safety systemsMemory chipPersonalization

The invention discloses a method for controlling an air conditioner to operate according to a self-defined curve; the method comprises the following steps: the self-defined curve is set by a keyboard on a remote controller; data of the self-defined curve is stored in a memory chip; the data of the self-defined curve is sent to an infrared signal receiving unit of a main machine of the air conditioner and stored in a RAM, preset operation parameters are set in the corresponding time period according to the data of the self-defined curve, the main machine of the air conditioner is controlled to carry out the corresponding operation by the operation parameters, wherein, the step of setting the self-defined time-the temperature curve comprises: the set state is activated by entering the set mode; the start time and the operation time are set; the set temperature which is corresponding to the operation time is set and the set of a temperature point is completed; and the set of the self-defined time-the temperature curve is completed by the repeated set of a plurality of temperature points. The air conditioner can provide the personalized operation temperature and the operation mode of the air conditioner according to the needs of a user, thereby meeting the needs on the comfort of the user.

Owner:GREE ELECTRIC APPLIANCES INC

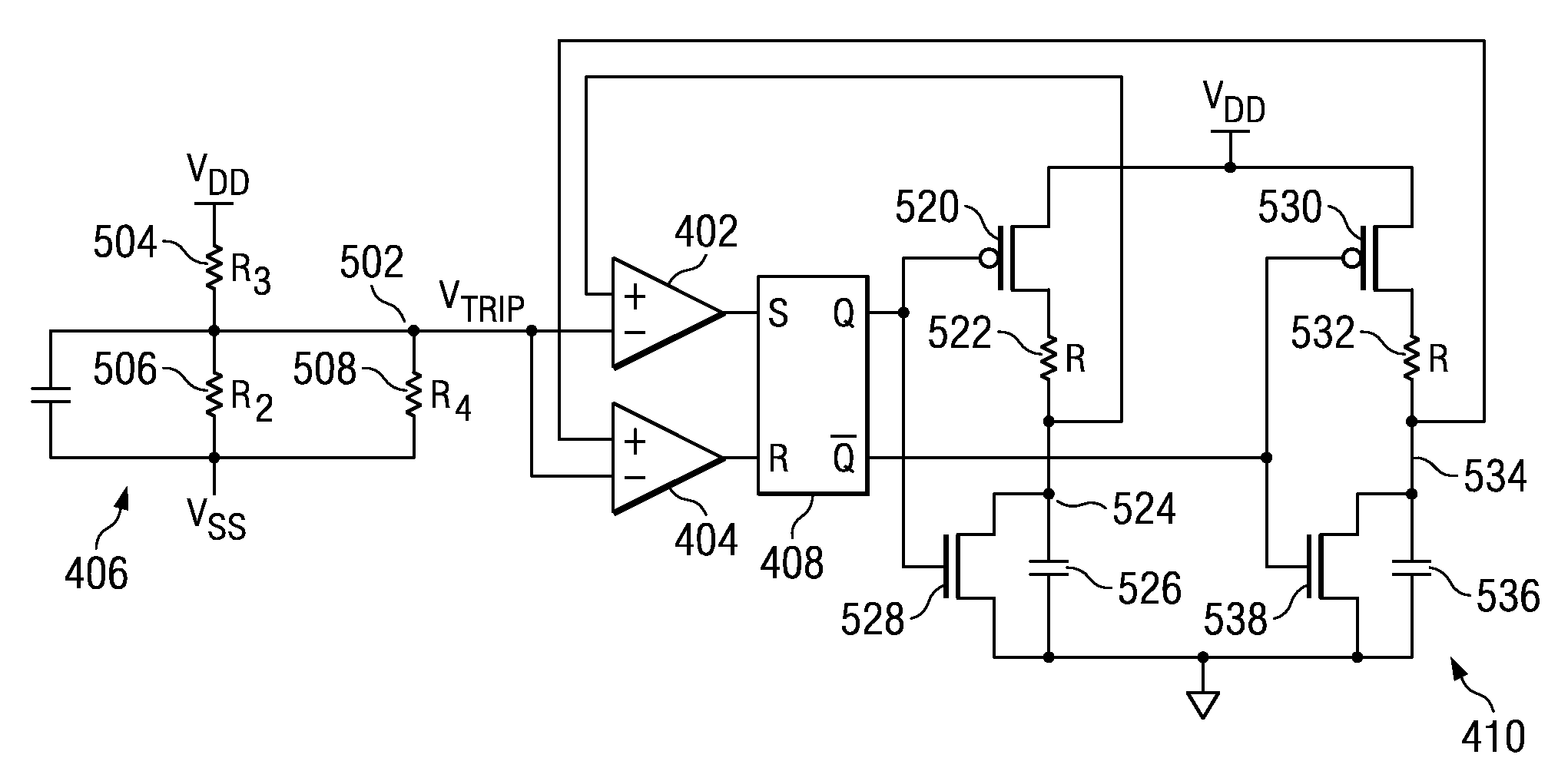

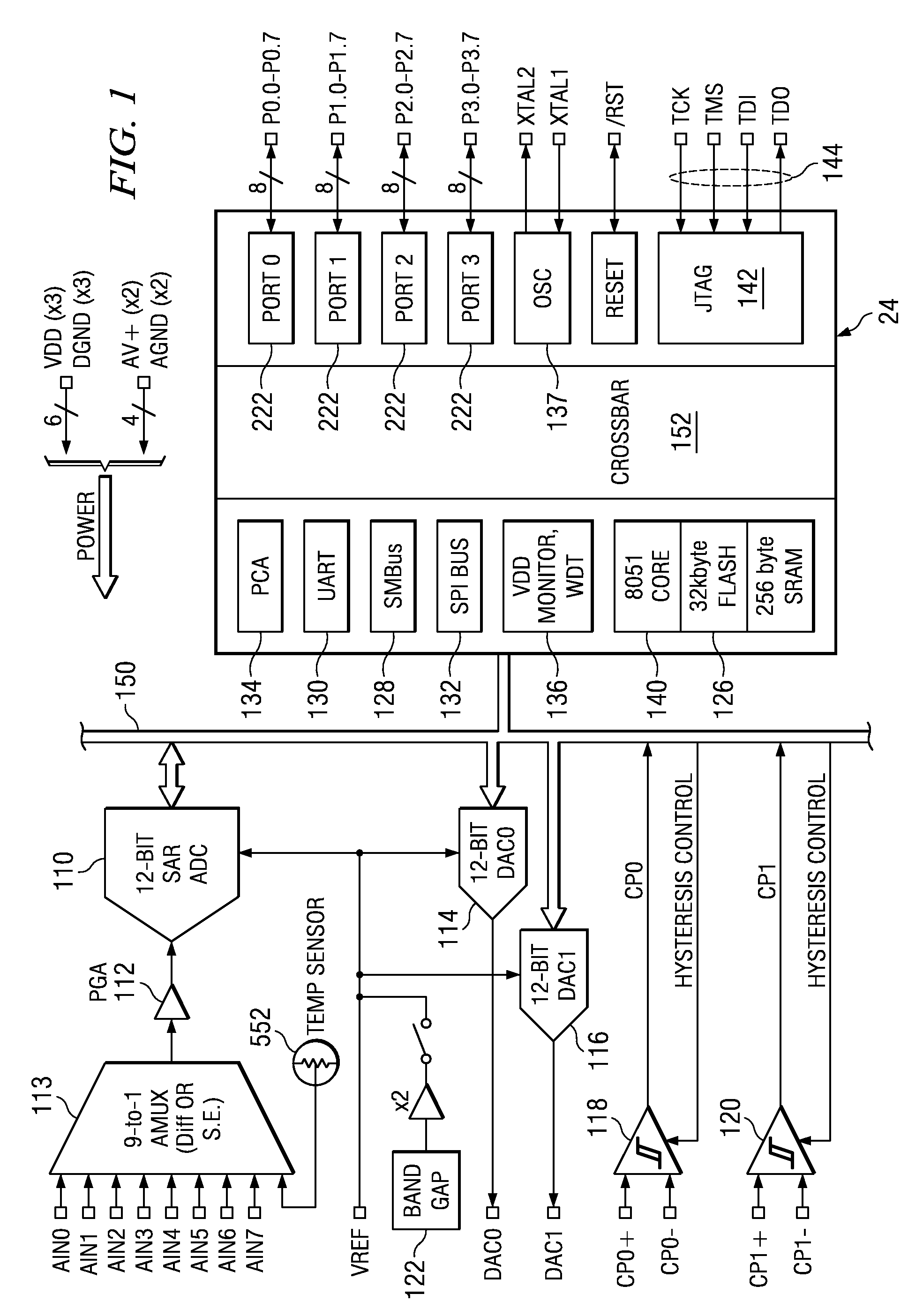

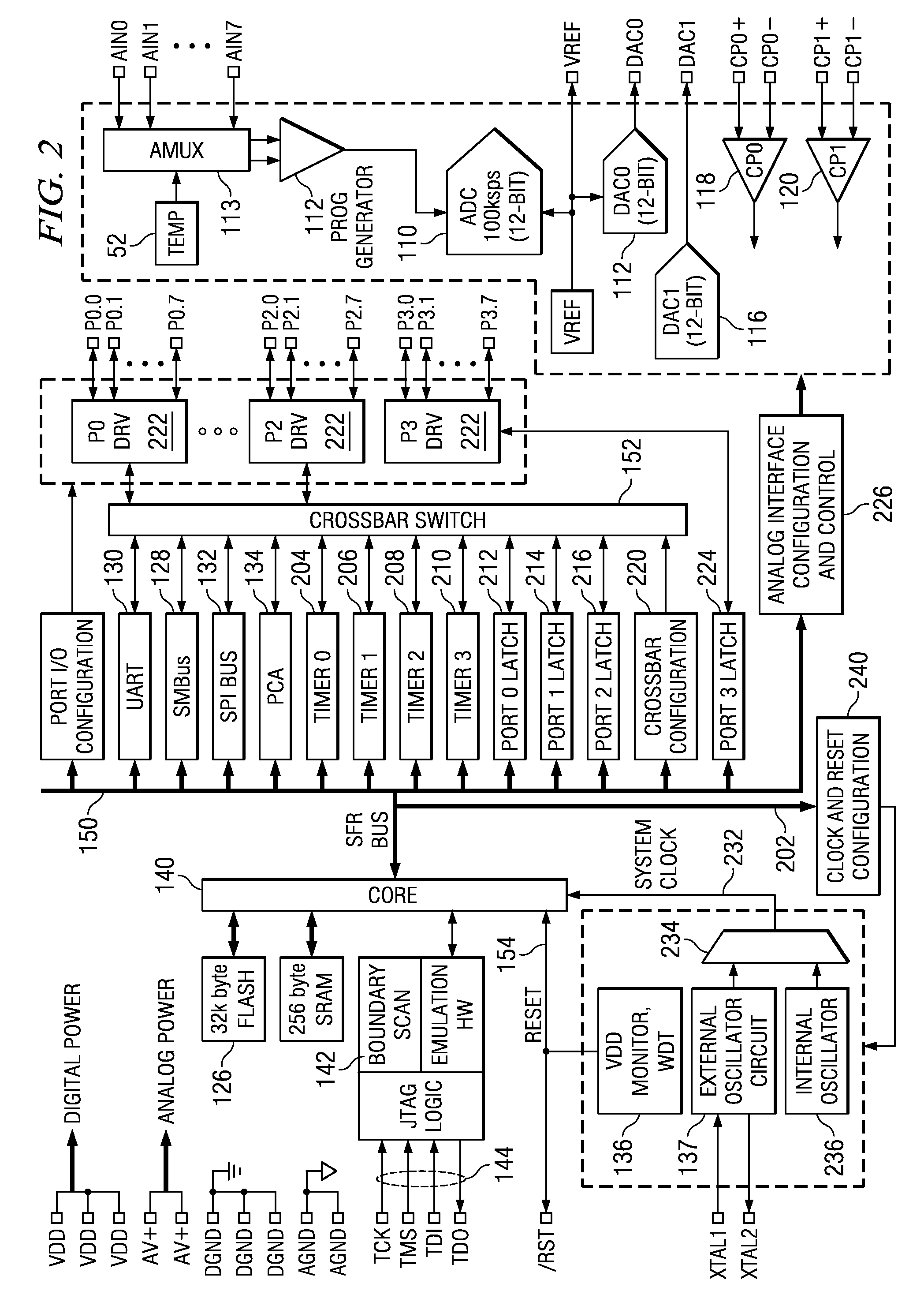

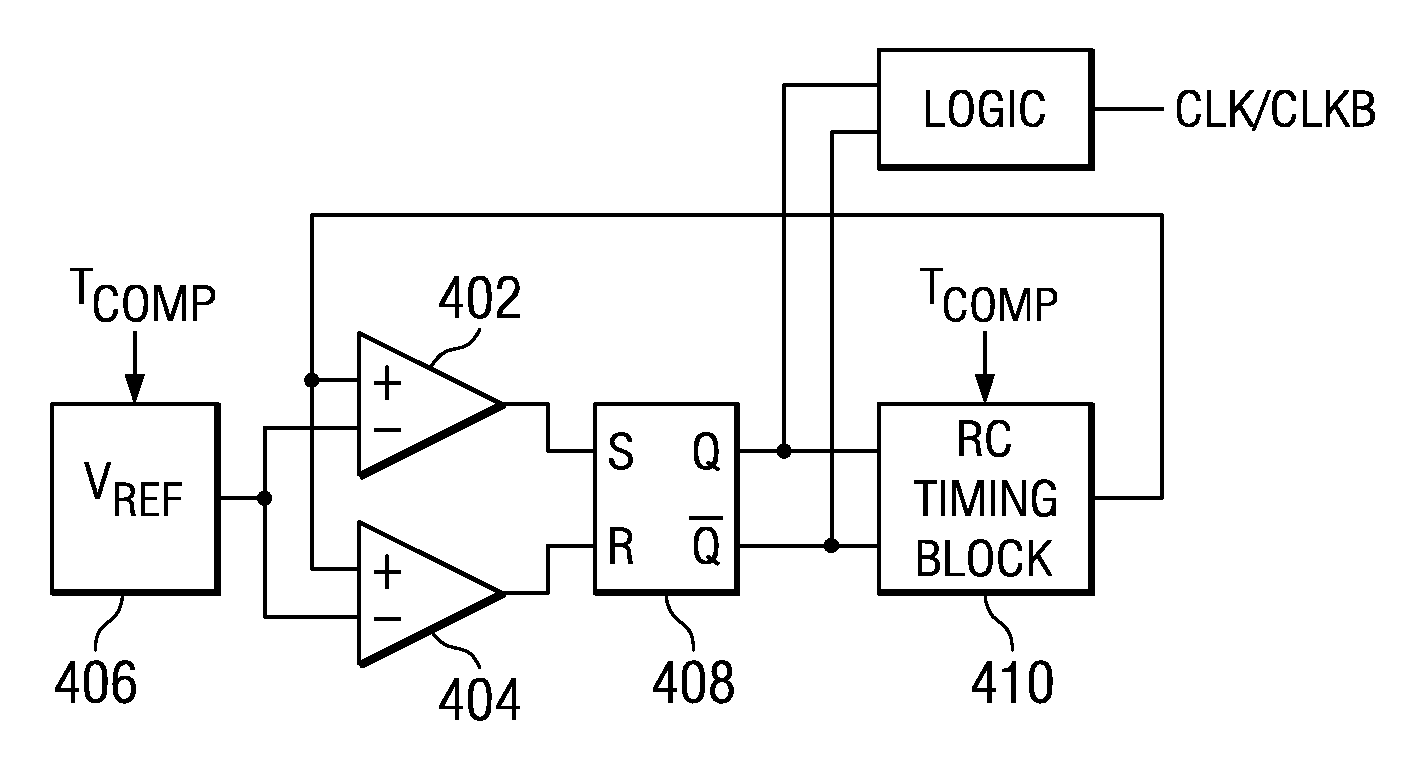

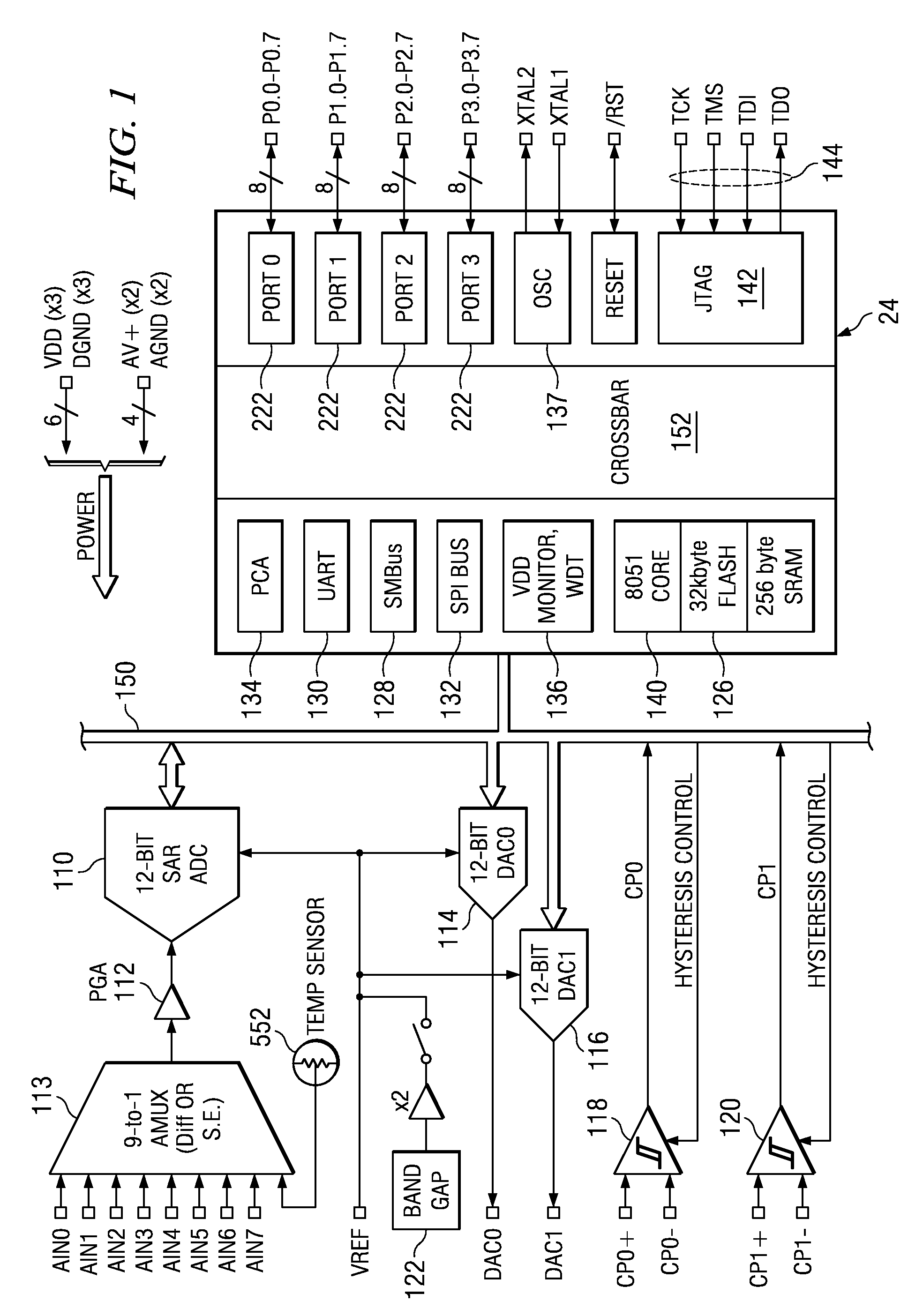

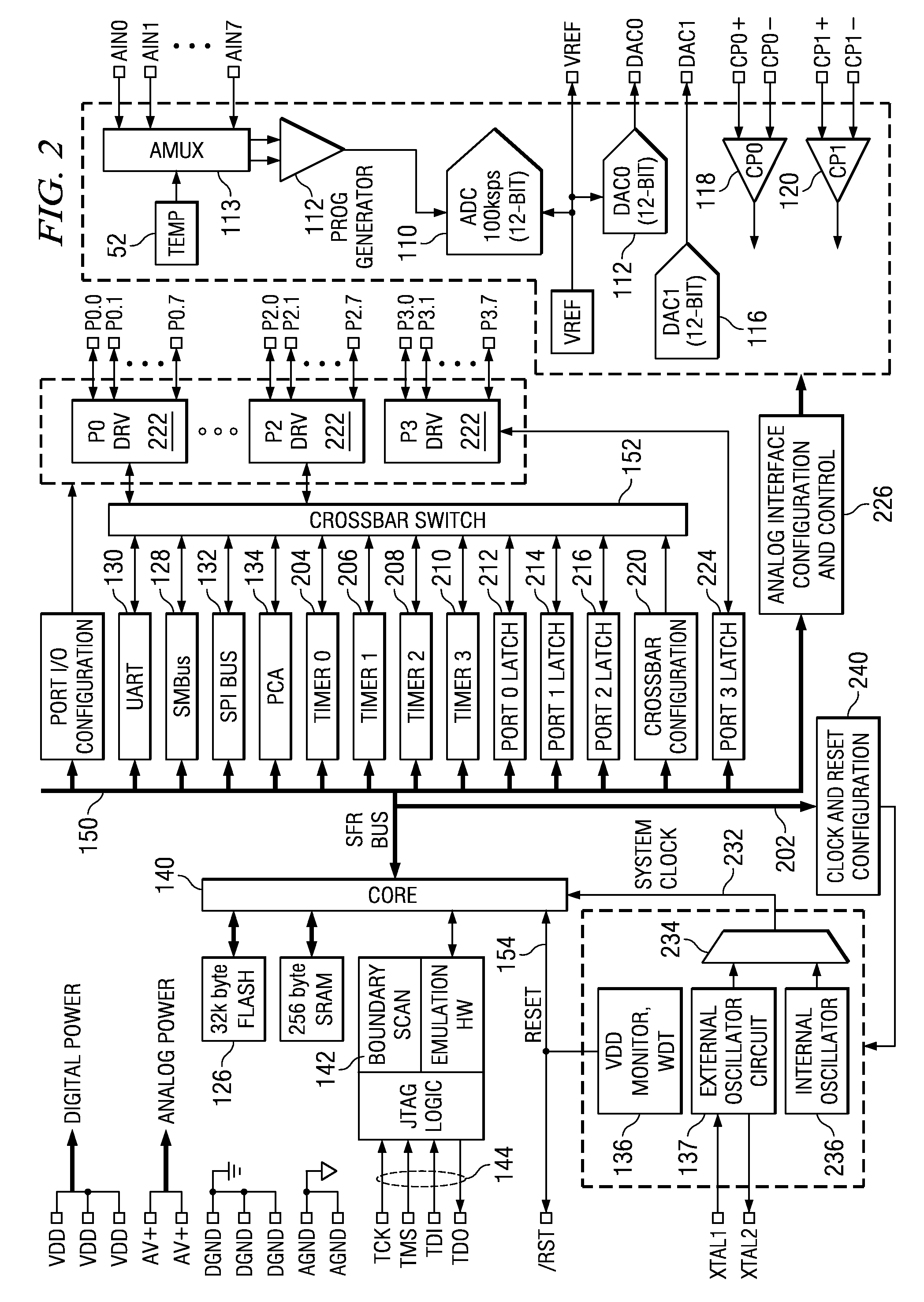

Precision oscillator having improved temperature coefficient control

InactiveUS7385453B2Angle modulation by variable impedencePulse generation by bipolar transistorsVoltage generatorTemperature curve

A free running clock circuit includes a switching circuit for switching between first and second logic states at a predetermined frequency based upon a trip voltage the switching circuit has a programmable temperature profile associated therewith. The switching circuit includes a comparator circuit that has first and second comparators. The first and second comparators have a reference input connected to receive the trip voltage, and the output of the comparators change logic states between a first logic state and a second logic state when the other input of the comparator passes the trip voltage. The first and second comparators have a programmable offset voltage enabling programming of the programmable voltage supply profile of the switching circuit. An RC timing circuit defines when the outputs of the comparators switch between the first and second logic states by providing a feedback to the other inputs of the two comparators. A temperature compensated trip voltage generator outputs a defined trip voltage that is compensated over temperature to offset the temperature profile of said switching circuit to provide an overall temperature compensated operation for said free running clock circuit.

Owner:SILICON LAB INC

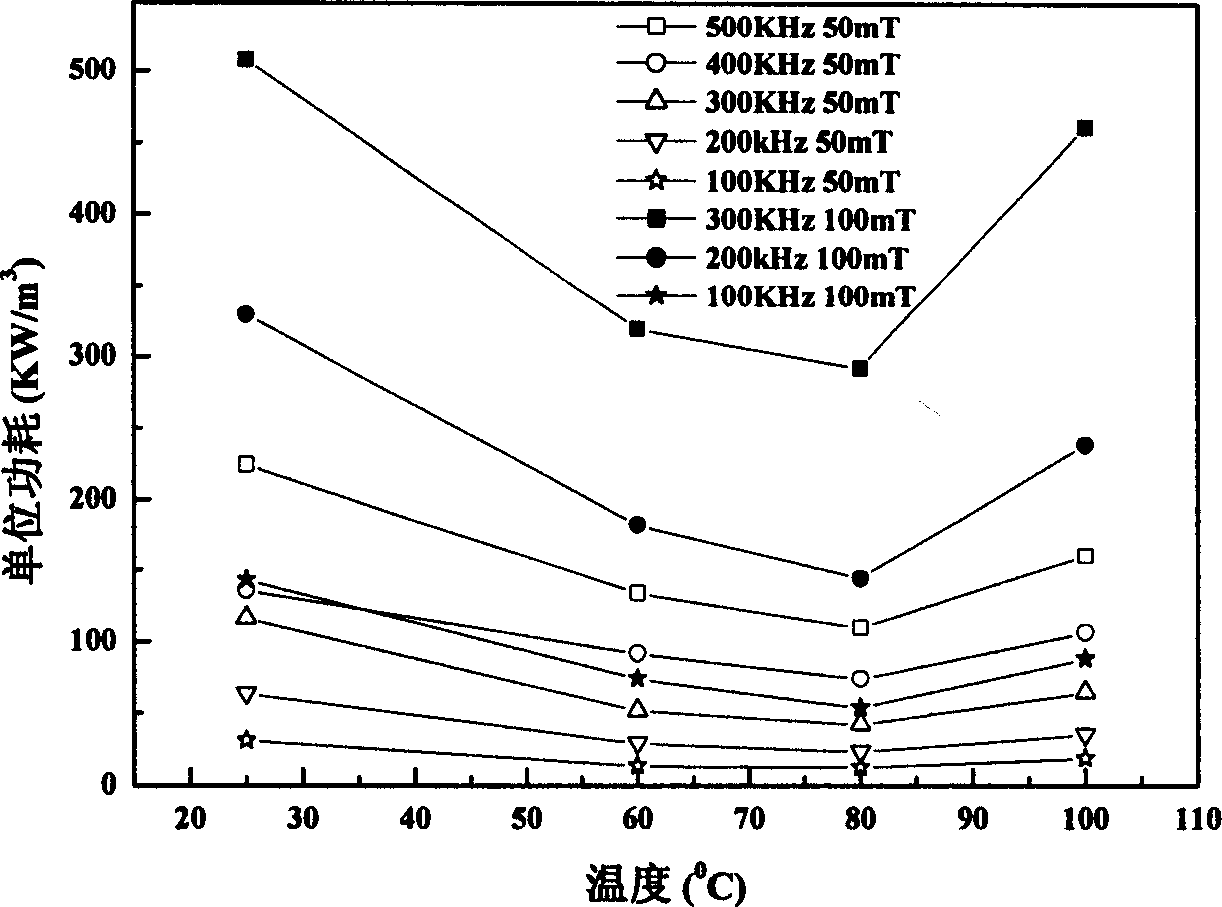

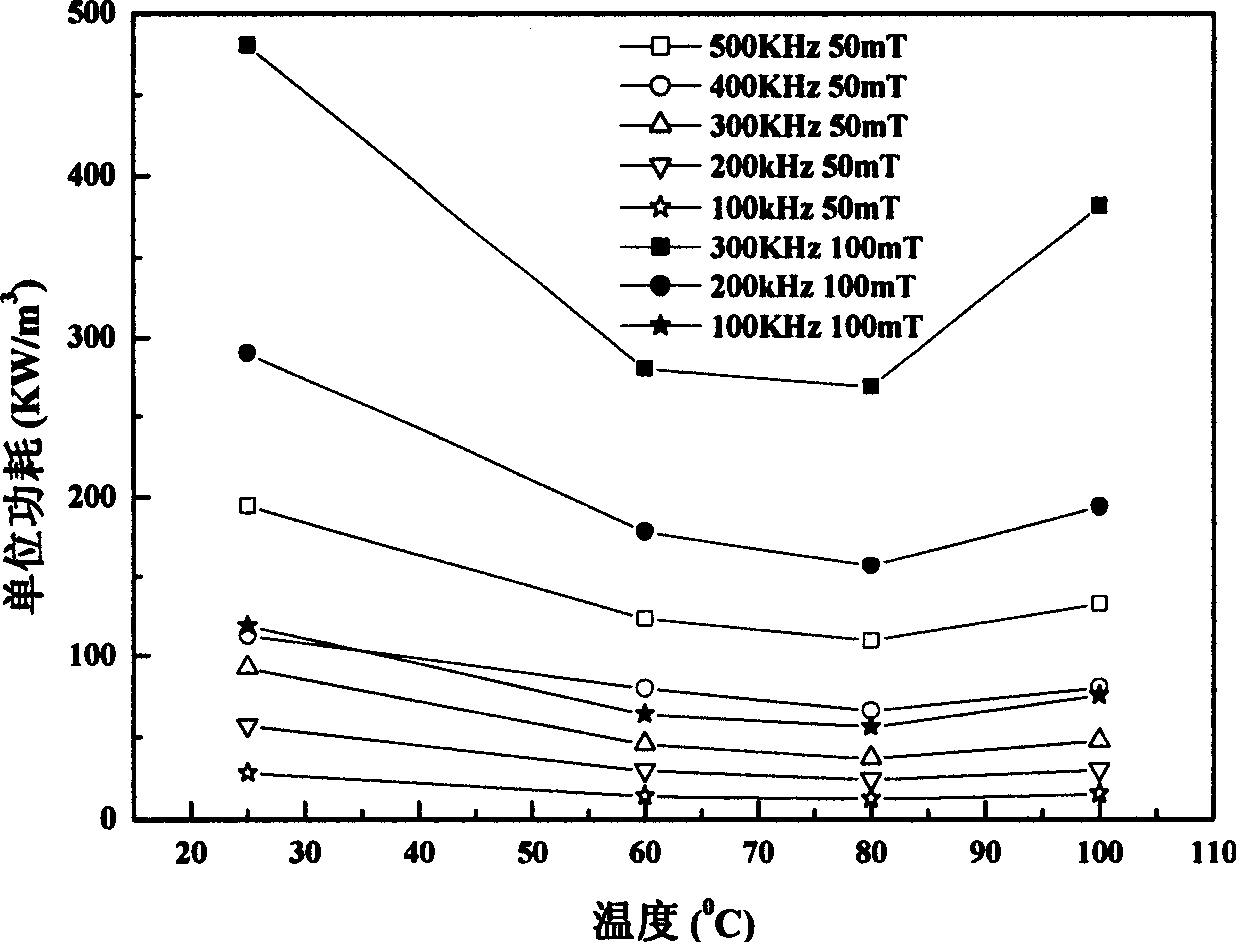

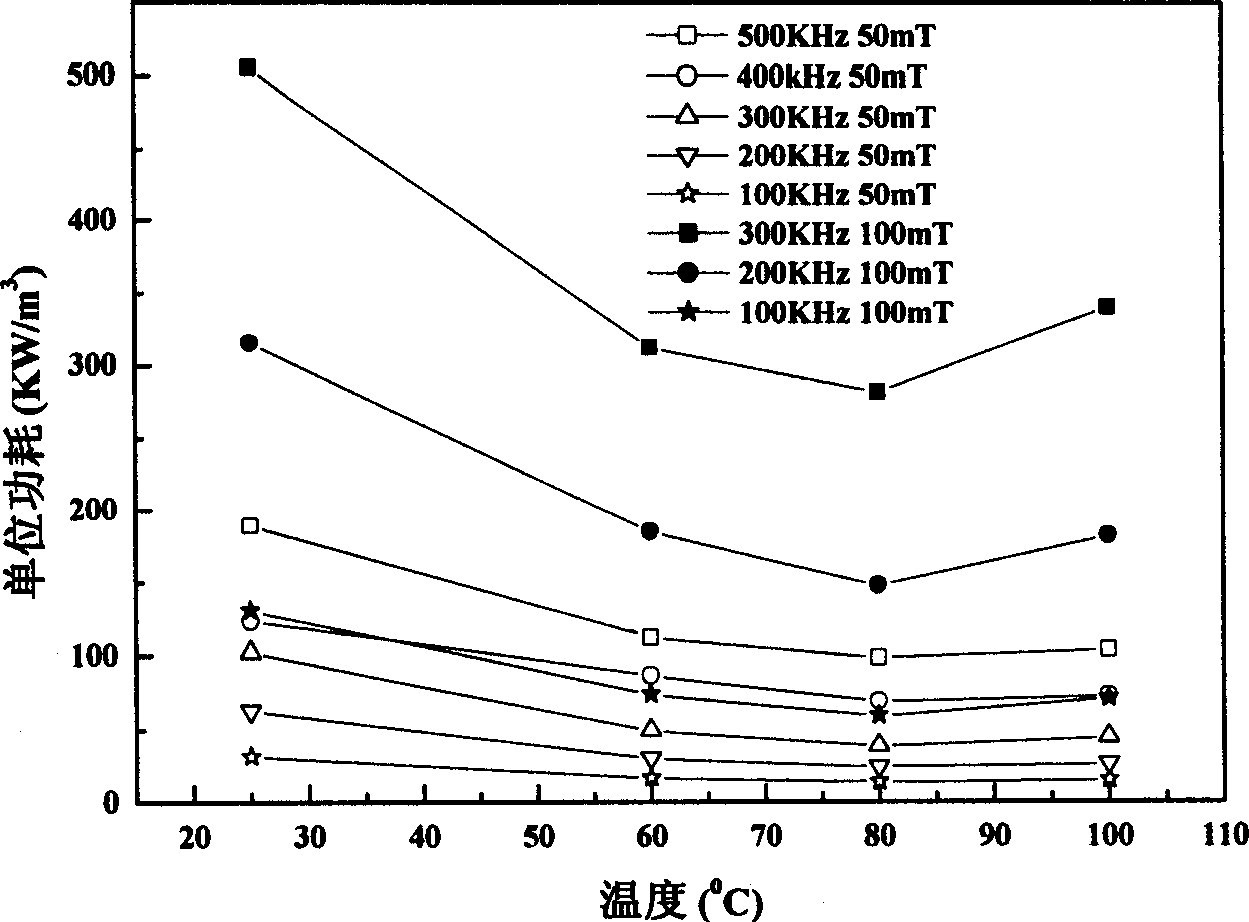

High performant low consumption manganese zine ferrite material and preparation process thereof

The invention relates to a high capacity low power consumption manganese-zinc ferrite material manufacturing method. The constituents includes 69.1-72.5wt% Fe2 O3, 22-24wt% Mn3O4, and ZnO. In the process of grinding and sintering, two or more from TiO2, Gd2 O3, SnO2, Co2O3, Ta2O5, Nb2O5, CaCO 3 could be added into the raw material. After grinding, pressure molding, sintering following certain temperature curve, the manganese-zinc ferrite material would be gained. The invention is simple and cost low. It has the feature of wide bandwidth and wide temperature.

Owner:SHANGHAI JIAO TONG UNIV

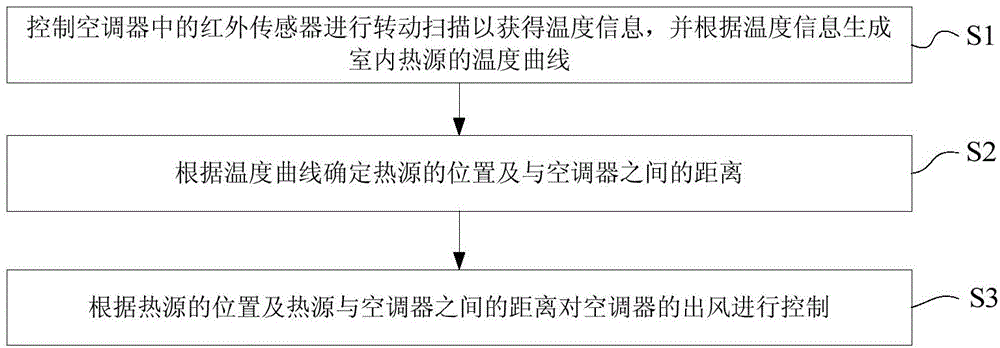

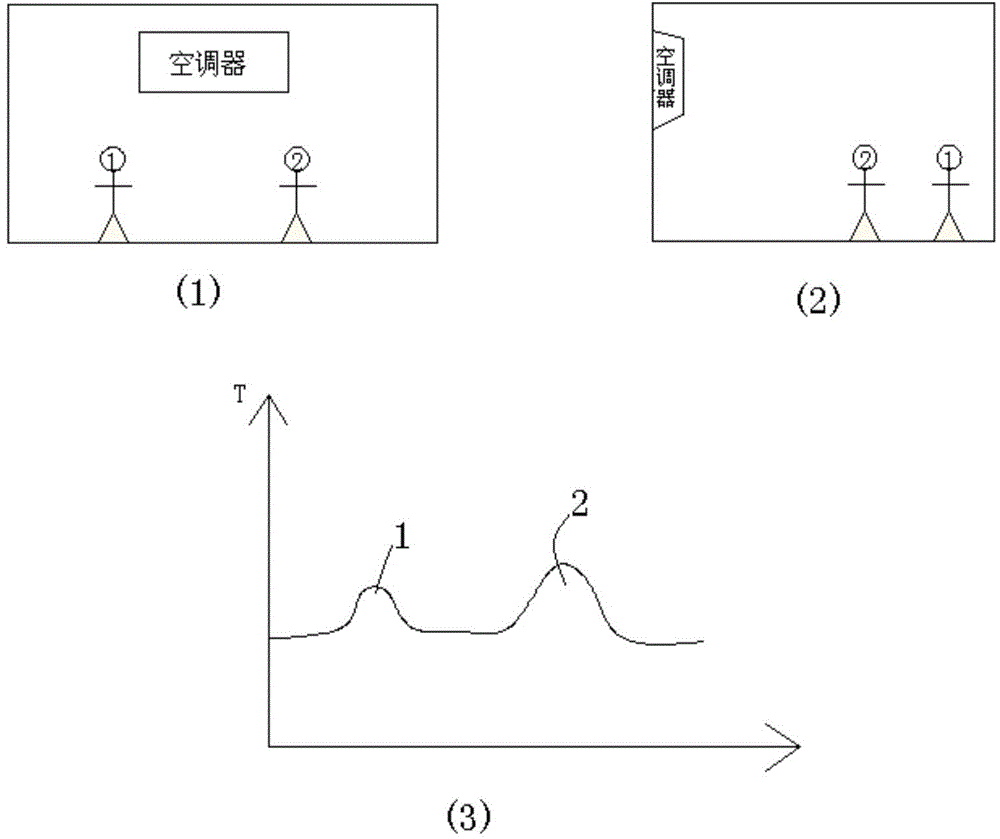

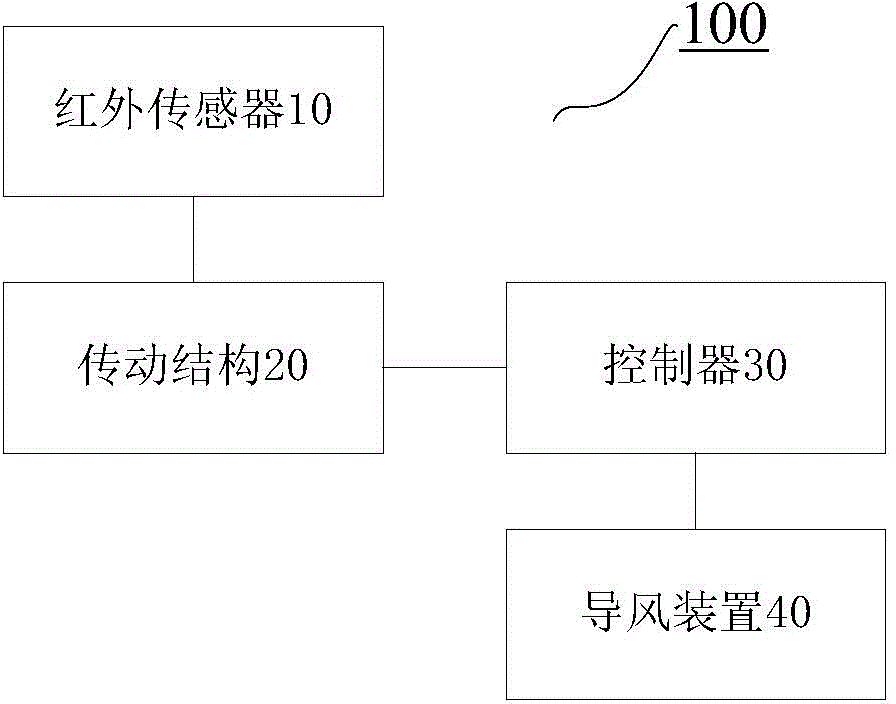

Air conditioner and air-out control method thereof

InactiveCN104833045ASimple methodData processing is simpleMechanical apparatusSpace heating and ventilation safety systemsEngineeringTemperature curve

The invention discloses an air conditioner and an air-out control method thereof. The air-out control method comprises the following steps: (1) controlling an infrared sensor of the air conditioner to carry out rotatable scanning operation with the purpose of obtaining temperature information, (2) generating the temperature curve of an indoor heat source based on temperature information, (3) determining the distance between the position of the heat source and the air conditioner, (4) performing air-out control over the air conditioner based on the position of the heat source and the distance between the heat source and the air conditioner. Without requiring an array infrared sensor, the control method is simple and easily applied. The invention further discloses the air conditioner.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

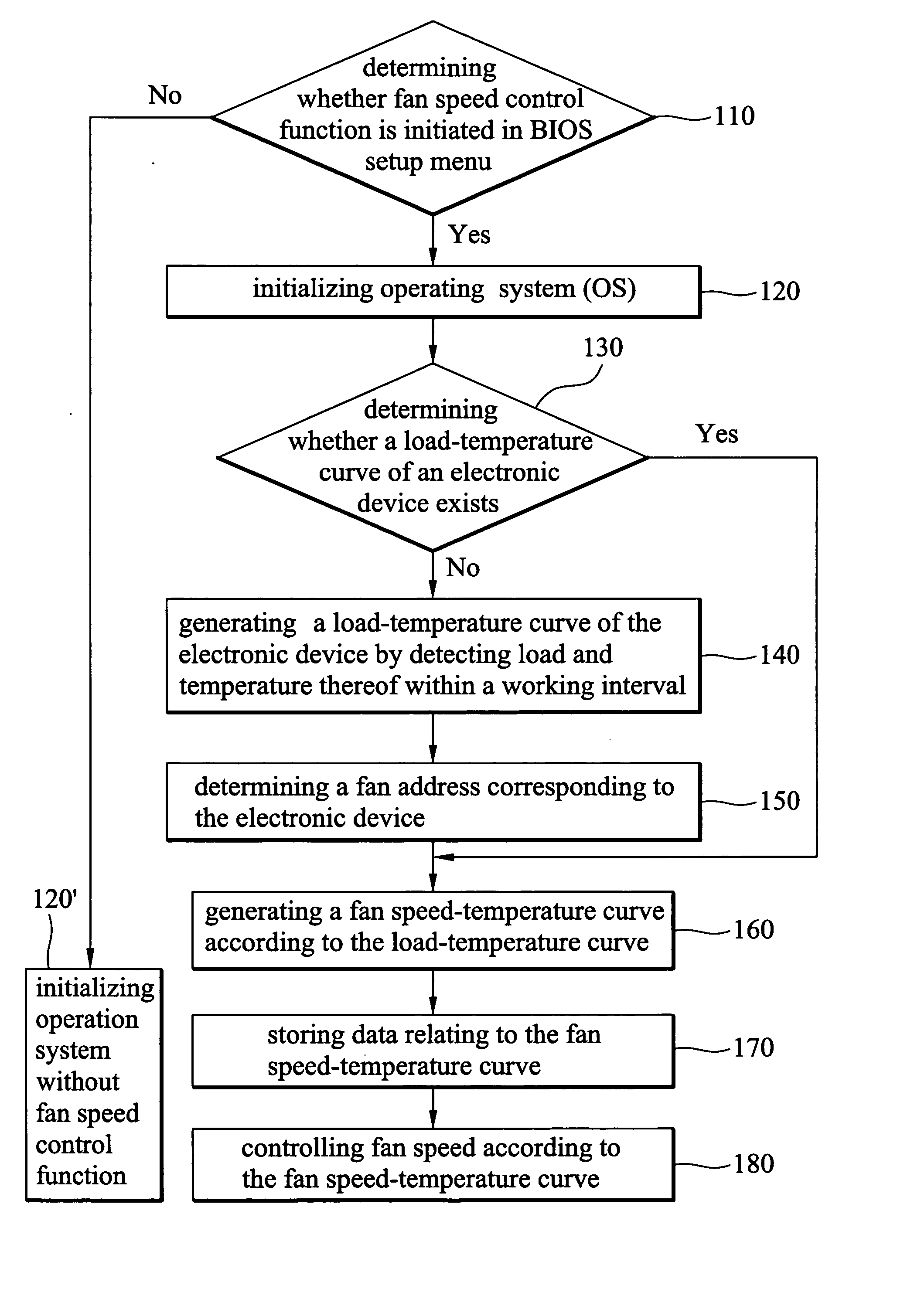

Fan speed control methods

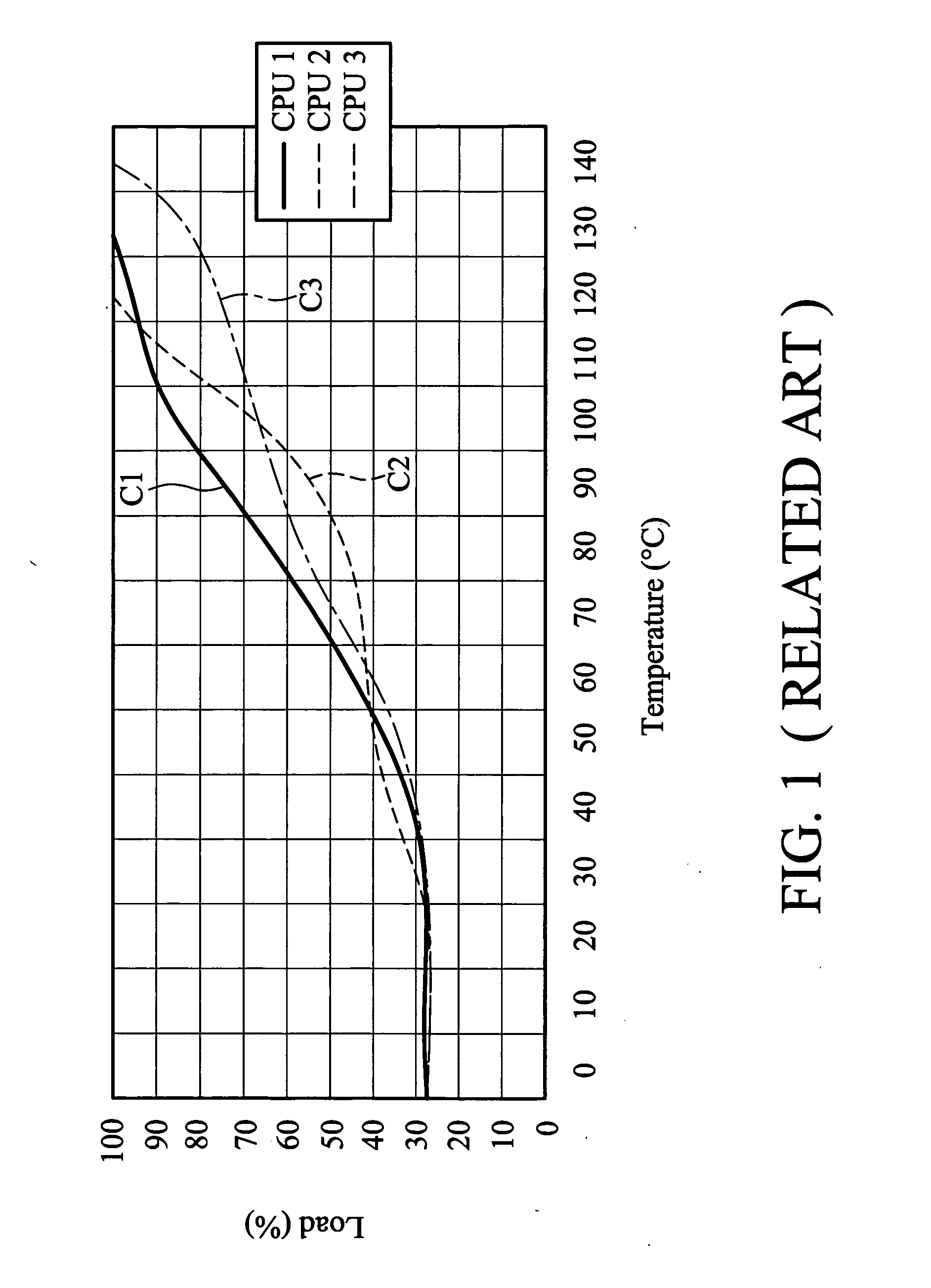

InactiveUS20070162160A1Heat dissipationEnergy efficient ICTDigital data processing detailsTemperature curveComputerized system

Fan speed control methods are provided to dissipate heat from an electric device in a computer system. A load-temperature curve of the electronic device is determined by detecting load and temperature thereof within a working interval. Subsequently, a fan speed-temperature curve is determined according to the load-temperature curve, and the fan speed is controlled according to the fan speed-temperature curve.

Owner:GIGA BYTE TECH CO LTD

Precision oscillator having improved temperature coefficient control

InactiveUS20070241833A1Pulse generation by bipolar transistorsGenerator stabilizationVoltage generatorTemperature curve

A free running clock circuit includes a switching circuit for switching between first and second logic states at a predetermined frequency based upon a trip voltage the switching circuit has a programmable temperature profile associated therewith. The switching circuit includes a comparator circuit that has first and second comparators. The first and second comparators have a reference input connected to receive the trip voltage, and the output of the comparators change logic states between a first logic state and a second logic state when the other input of the comparator passes the trip voltage. The first and second comparators have a programmable offset voltage enabling programming of the programmable voltage supply profile of the switching circuit. An RC timing circuit defines when the outputs of the comparators switch between the first and second logic states by providing a feedback to the other inputs of the two comparators. A temperature compensated trip voltage generator outputs a defined trip voltage that is compensated over temperature to offset the temperature profile of said switching circuit to provide an overall temperature compensated operation for said free running clock circuit.

Owner:SILICON LAB INC

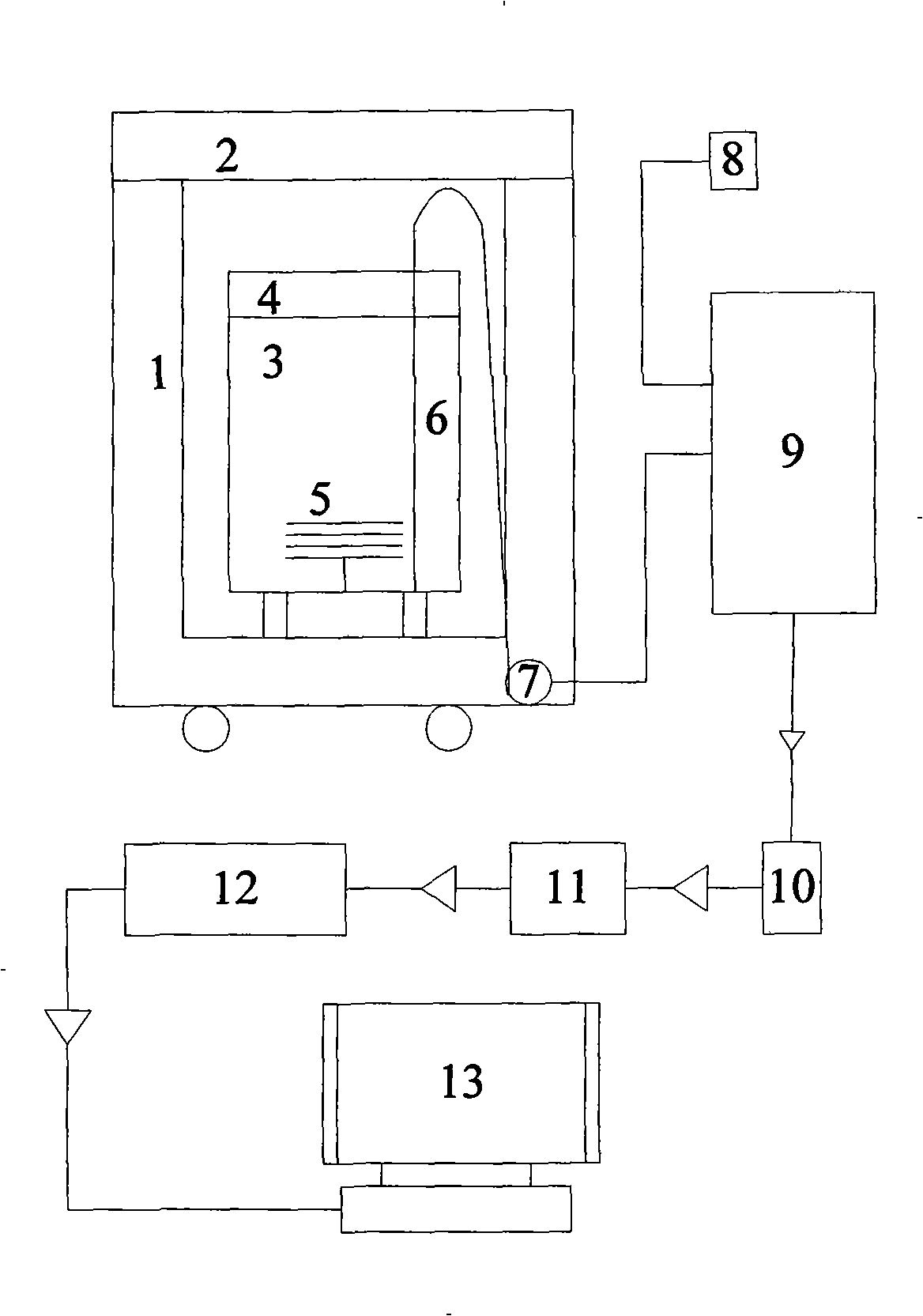

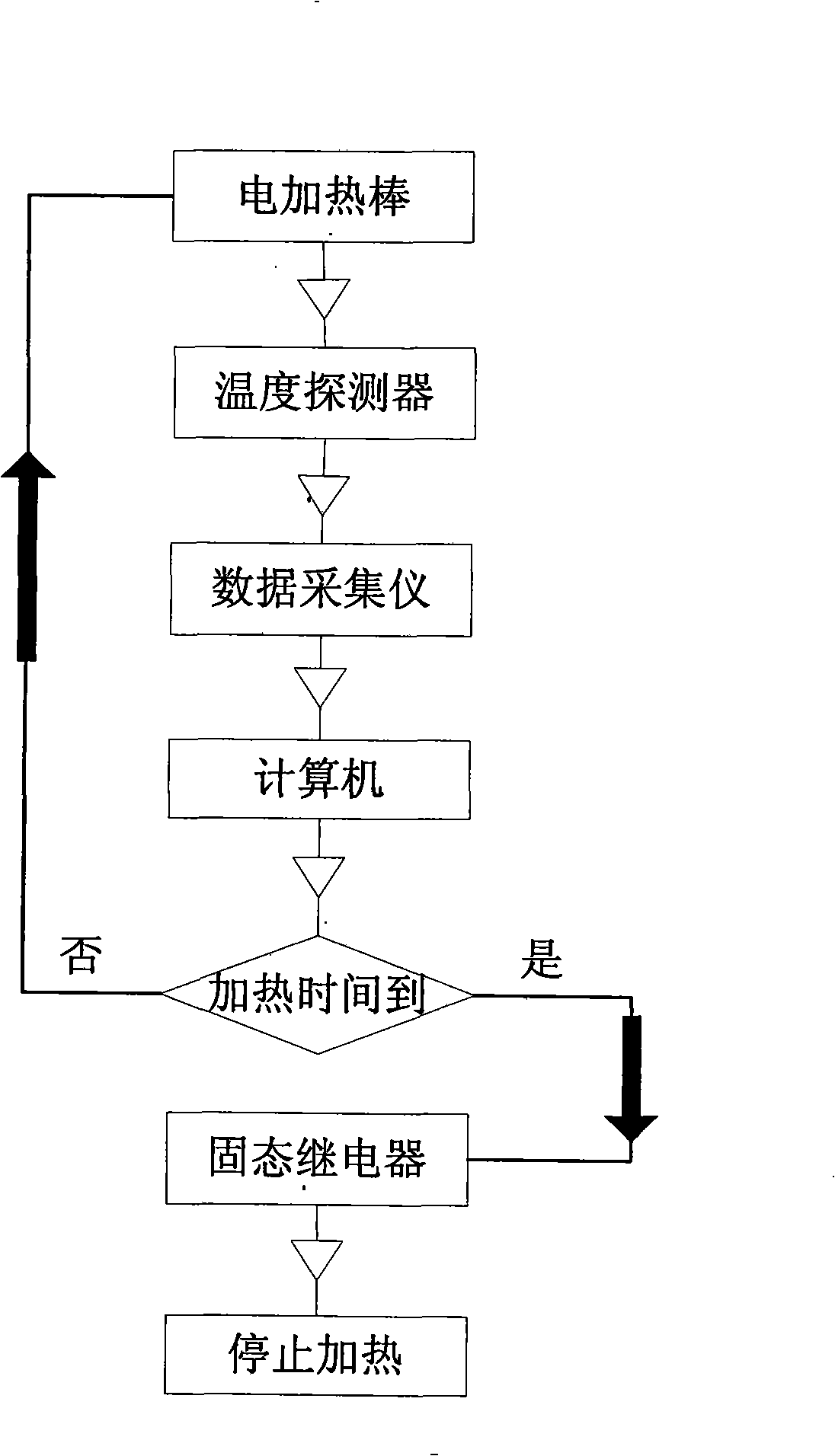

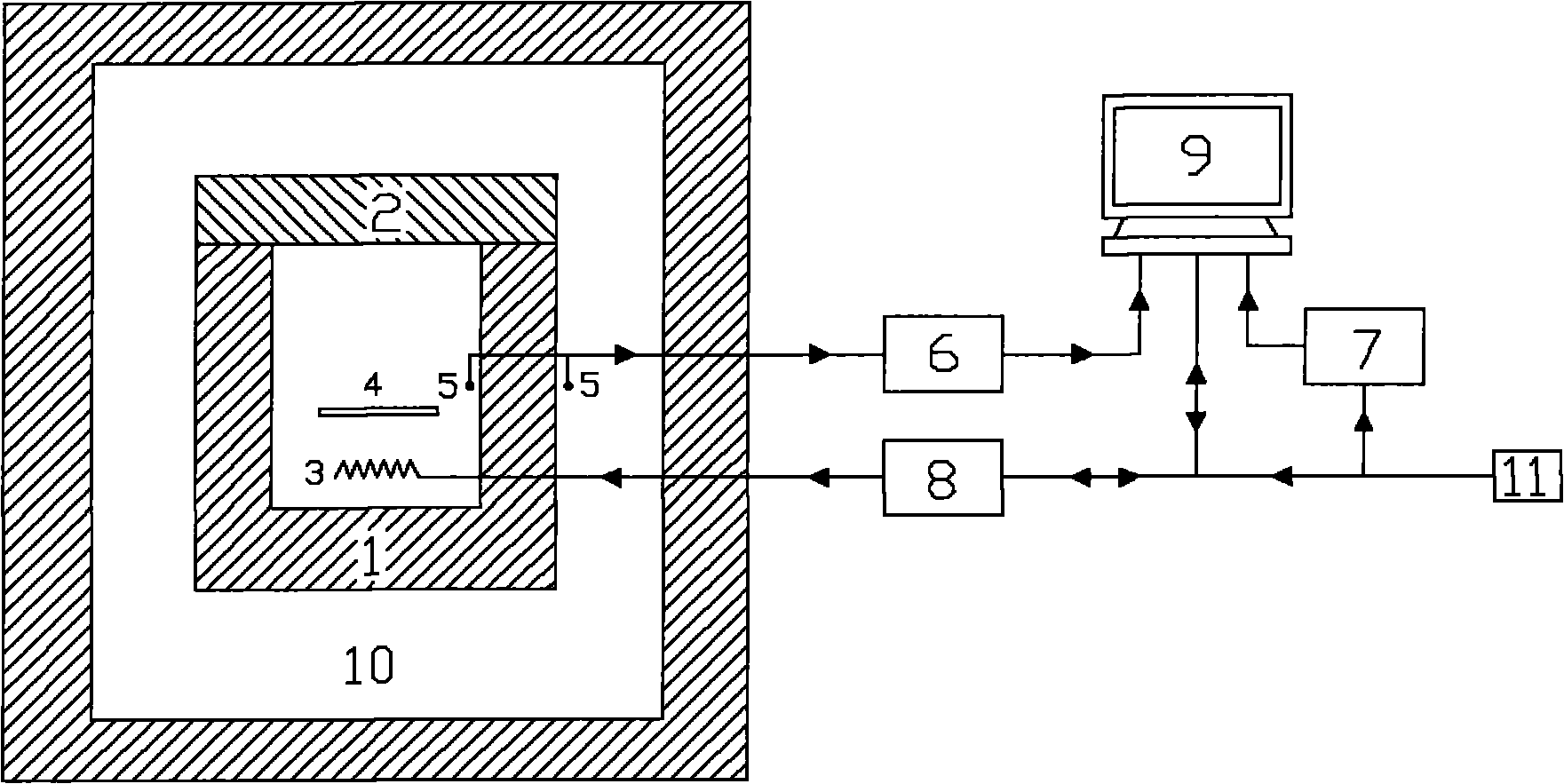

Phase change thermal storage tester

The present invention relates to a phase change thermal storage tester, and consists of a water bath, a voltage stabilizer, a solid state relay, a power converter, a temperature detector, a data acquisition instrument and a computer. The water bath consists of an internal heating barrel, an electric heating rod and an external insulating barrel. One end of the voltage stabilizer is connected with a power supply, and the other end is connected with the electric heating rod and used for providing electricity for the electric heating rod. The solid state relay, the data acquisition instrument and the computer together form the monitoring and controlling part of the whole testing process. The data collected by the data acquisition instrument is used for judging whether the heating needs stopping or starting. The computer transmits commands to connect or disconnect the solid state relay. Aiming at the defect in the existing experimental method of researching or testing phase change materials for construction, the device can heat the water bath with the phase change materials for construction, measure the temperature by the temperature sensor, map the real-time temperature curve, control the starting and stopping of the heating device, and calculate the stored heat of the phase change materials for construction according to the test data.

Owner:CHINA ACAD OF BUILDING RES

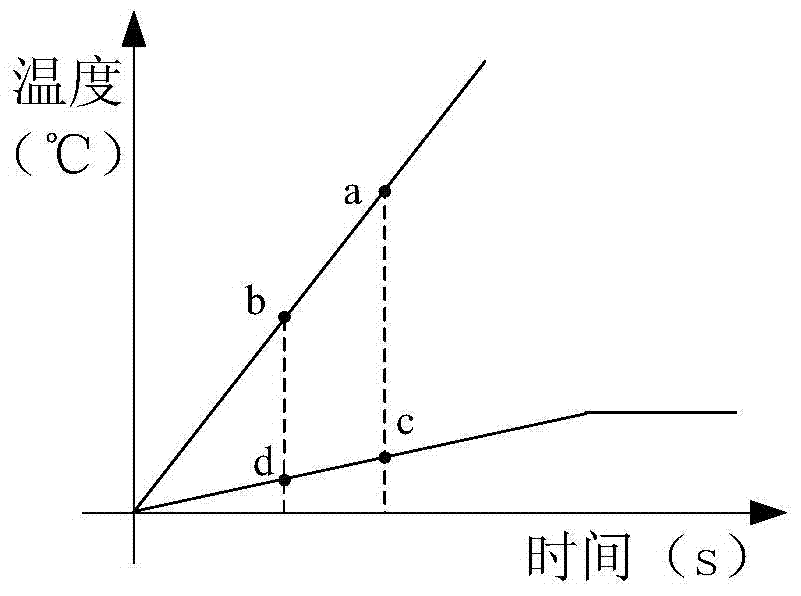

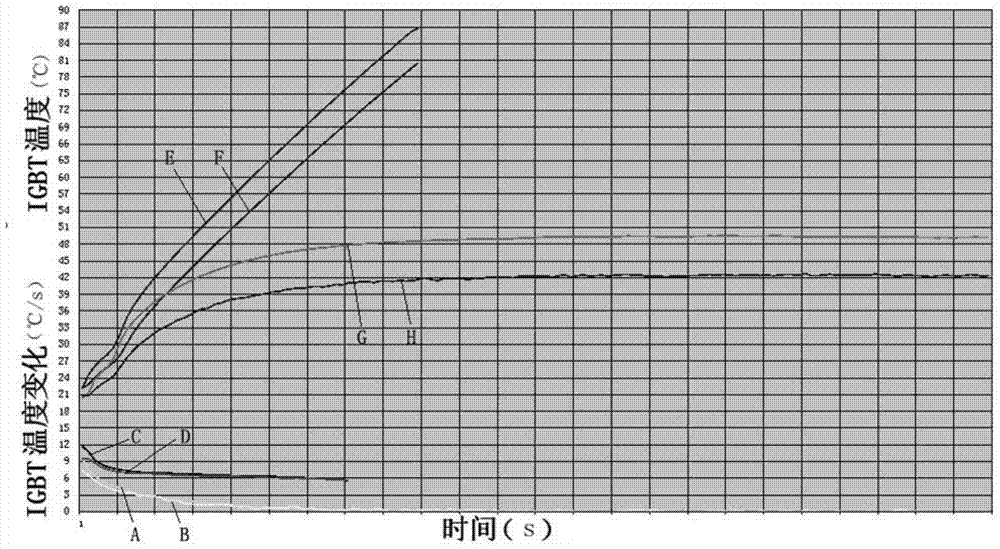

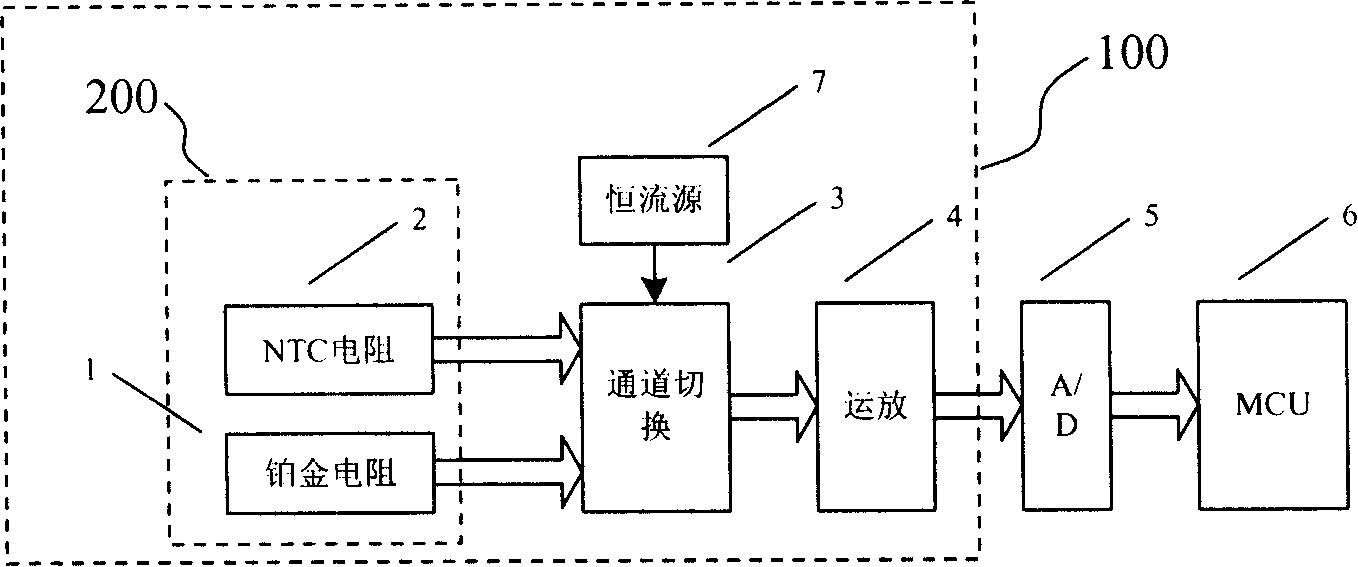

Power device over-temperature protection method based on temperature curve slope control

InactiveCN103699152AImprove reliabilityImprove the effectiveness of over-temperature protectionTemperatue controlFrequency changerThermistor

The invention discloses a power device over-temperature protection method based on a temperature curve slope control. The method comprises the following steps: a negative temperature coefficient (NTC) thermistor is added on a radiator outside a power device in an inverter and the initial temperature of the NTC thermistor can be detected when the inverter is powered on; 2) an average slope value K1 of a temperature variation curve of the NTC thermistor in an inverter operation nT time segment when the temperature value relative environment temperature of the NTC thermistor exceeds 20 DEG C is obtained after the inverter is operated, 3) in the same way, an ith nT time segment Ki is obtained; (4) when ki is not more than 1, the normal operation of a fan is judged, and an over-temperature protection set value is an over-temperature protection default value; when Ki is more than 1 for many times continuously, non-operation of the fan is judged, and the over-temperature protection set value is lowered; (5) Once the temperature of the NTC thermistor exceeding the over-temperature protection set value is detected, the inverter produces an over temperature protection fault, a PWM (Pulse-Width Modulation ) output is blockaded , and a motor is freely halted. The power device over-temperature protection method effectively solves the problem of over-temperature protection reliability, and also can judge whether the fan is operated normally or not.

Owner:WISDRI WUHAN AUTOMATION

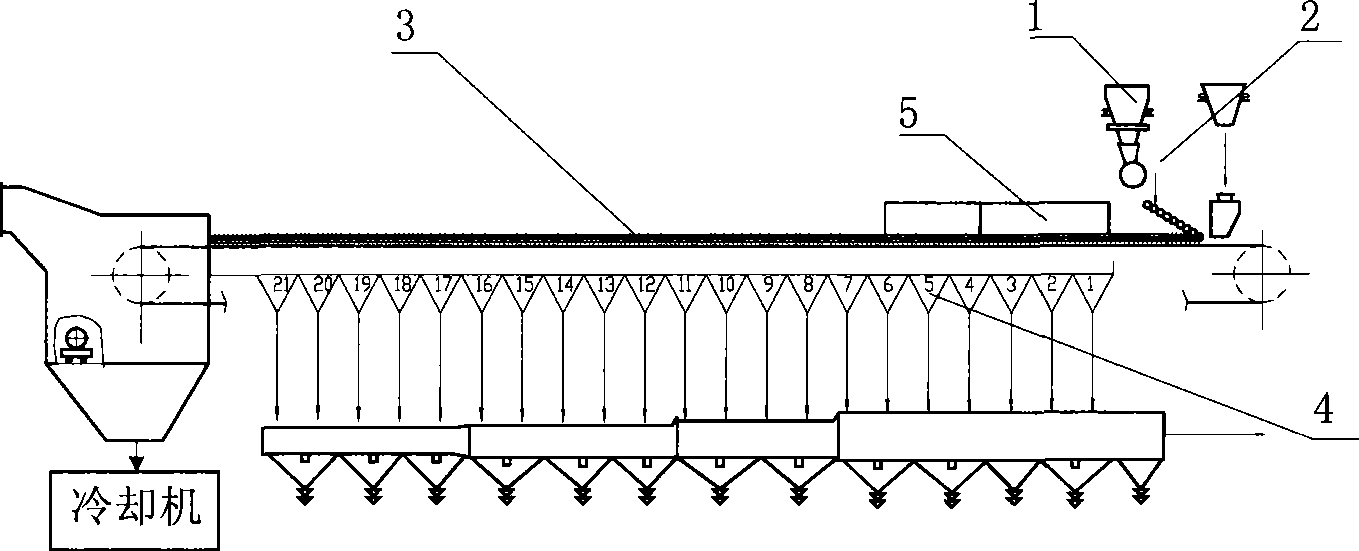

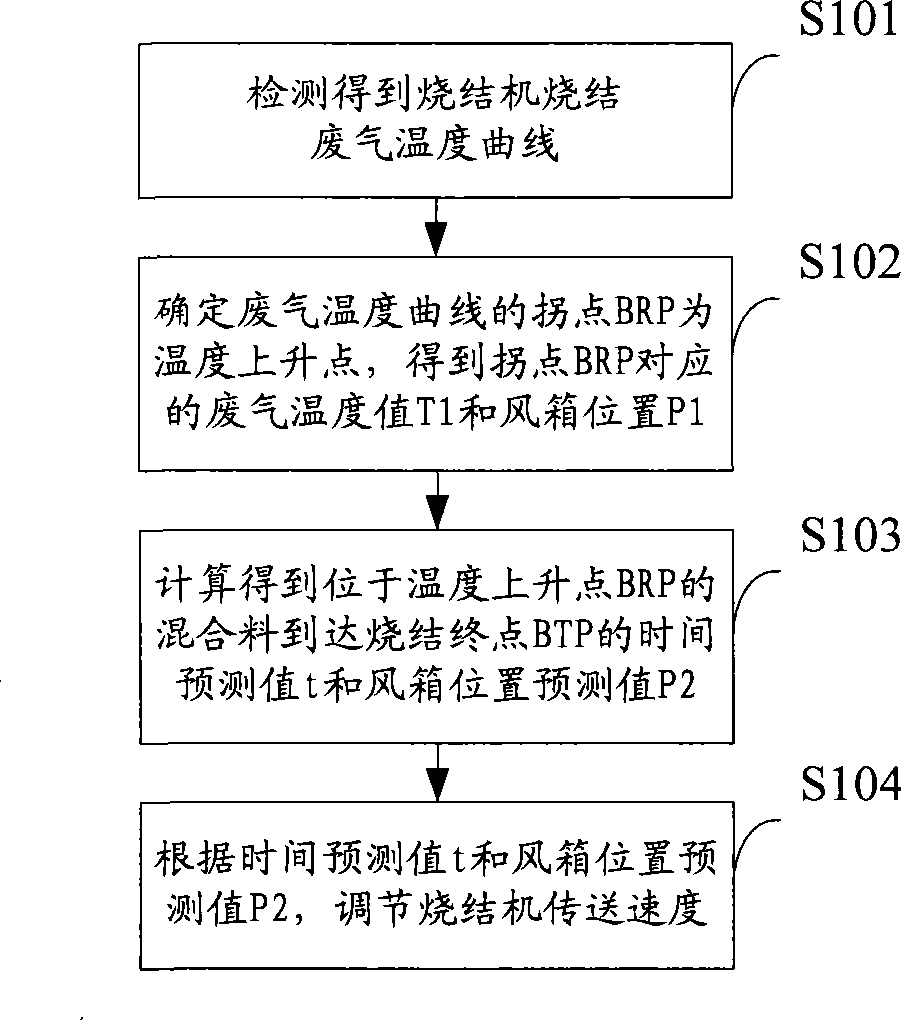

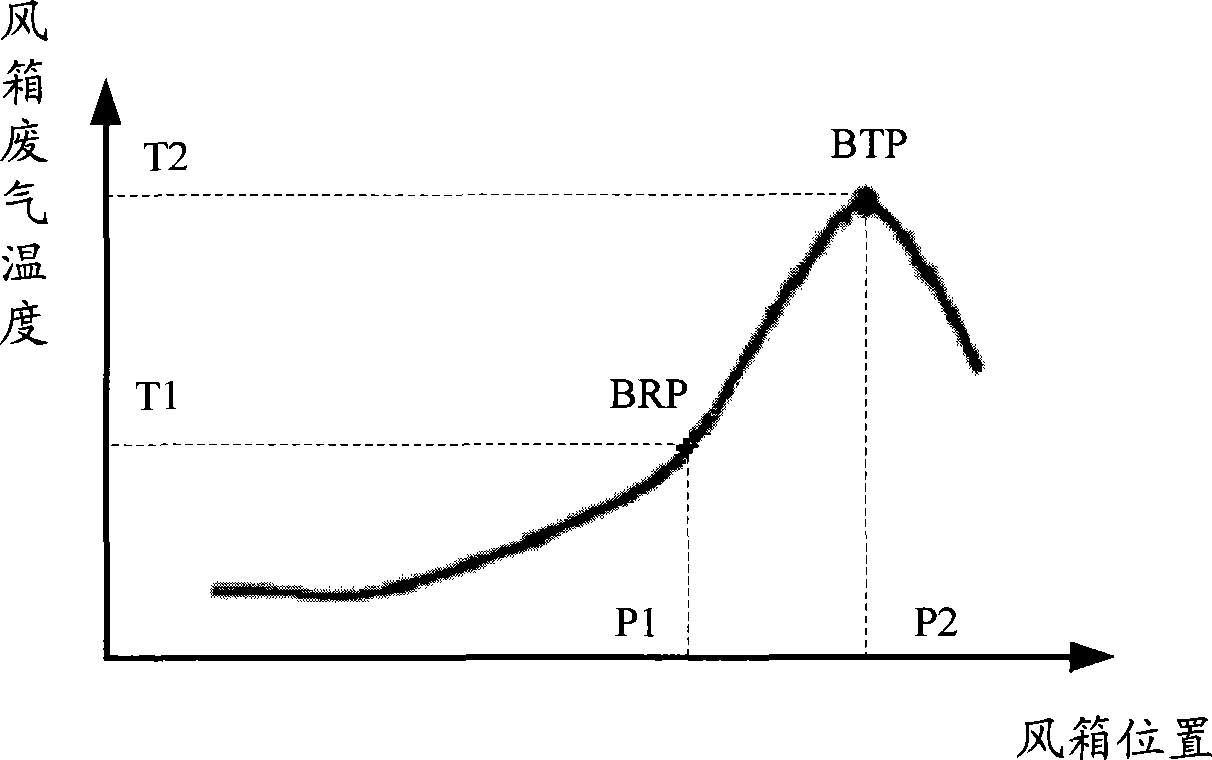

Sintering status control method in sintering process

ActiveCN101441444AEasy to controlOvercome uniformity issuesFurnace typesElectric programme controlTemperature curveMetallurgy

The invention provides a control method for the sintering status in the sintering process. The method comprises the following steps: obtaining a sintering machine sintering exhaust gas temperature curve through detection; establishing a data tracking queue corresponding to the mixture on a sintering pallet; using the data tracking queue and the exhaust gas temperature curve to track and count the sintering status of the mixture on the sintering pallet, and calculating the sintering end point predicated value P BTP_PRE of the mixture at the current temperature rise position in real time; presetting an ideal sintering end point P BTP_SP, and calculating the ideal transfer speed V of the sintering pallet through the sintering end point predicated value P BTP_PRE of the mixture at the current temperature rise position; and according to the ideal transfer speed V, adjusting the operation of the sintering pallet and controlling the sintering status of the mixture on the sintering pallet. The control method can improve the accuracy of the control on the sintering status in the sintering process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Calibration method of electrochemical sensor

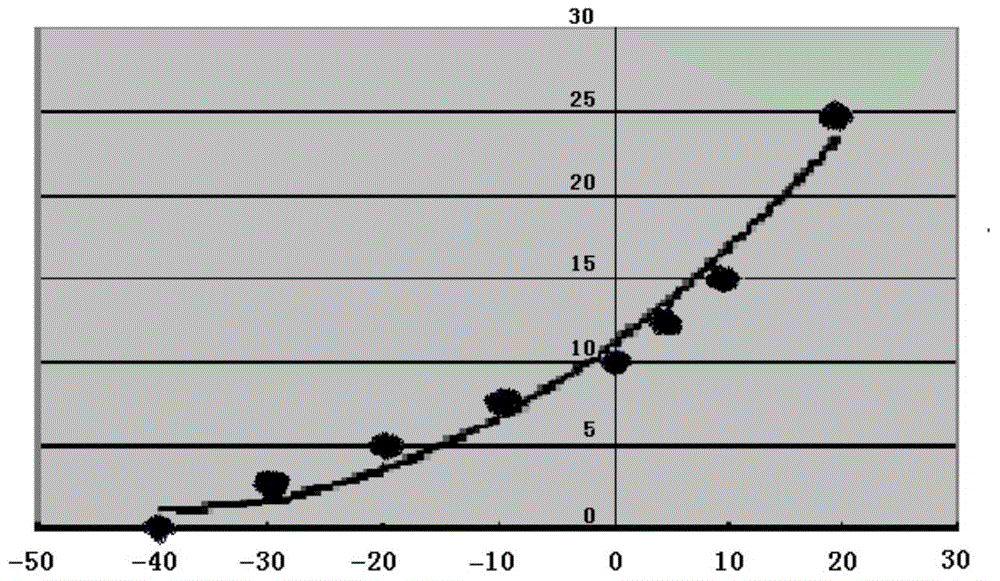

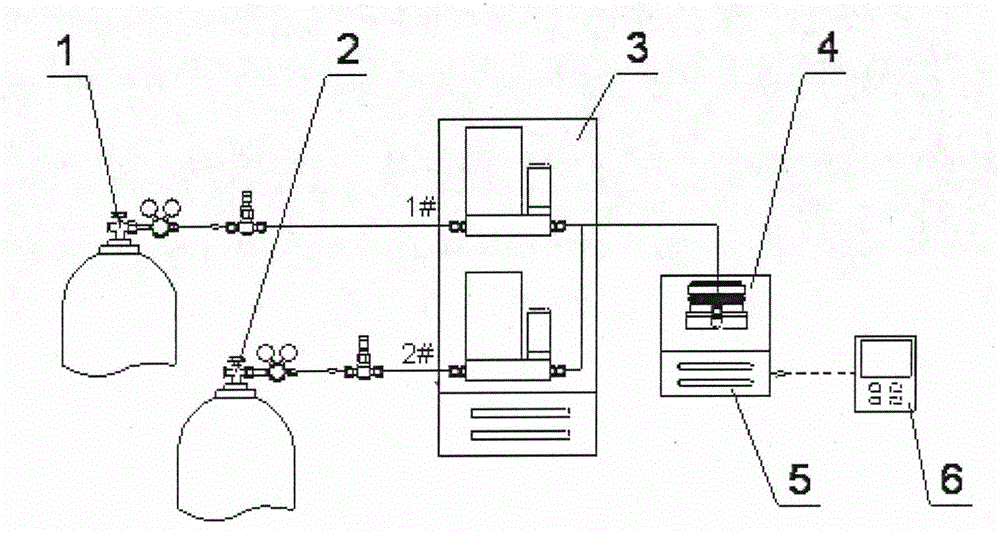

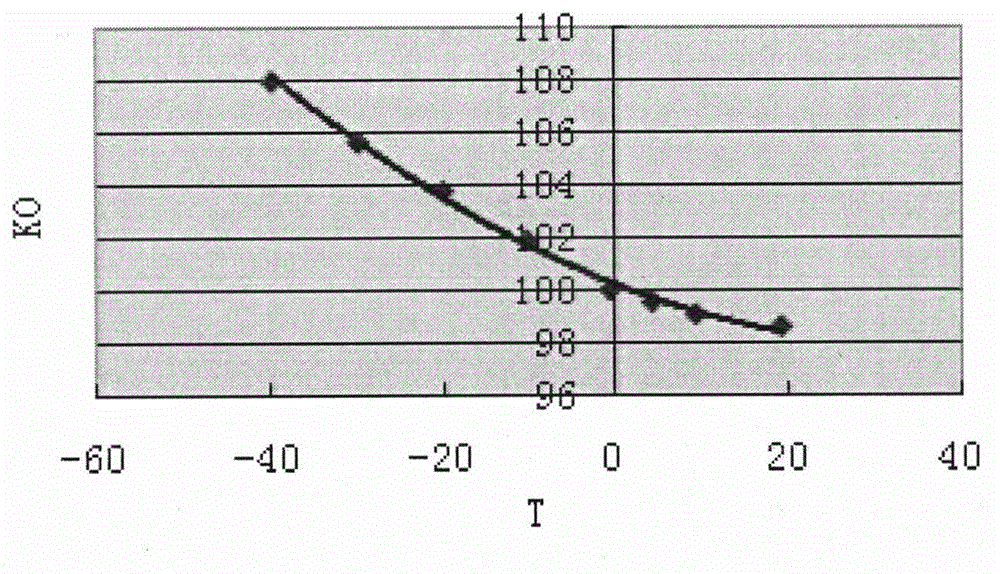

InactiveCN105628752AAccurately reflect the stateEasy accessMaterial electrochemical variablesThermodynamicsElectrochemical gas sensor

The invention provides a calibration method of an electrochemical sensor. The method comprises the following steps: inputting different concentrations of a standard gas to an electrochemical sensor to be calibrated through a dynamic gas distribution device, measuring the output value of the electrochemical sensor, and determining the calibration zero point of the sensor; and respectively fitting the zero point of the electrochemical sensor to be calibrated, the temperature curve of a measuring range and the temperature curve of cross interference in a temperature range of -20-40DEG C. The dynamic gas distribution device is adopted to carry out multi-point concentration test in order to accurately reflect the state of the sensor; a relative error value is adopted to calibrate, so the calibration result is more close to a practical condition; and a least square method quadratic polynomial fitting sensor input and output curve relationship is adopted, so the error in the calibration process is greatly reduced. The method has the advantages of wide test surface and high estimation accuracy, and can meet users' practical demands on test selection of sensors.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID QINGHAI ELECTRIC POWER COMPANY +1

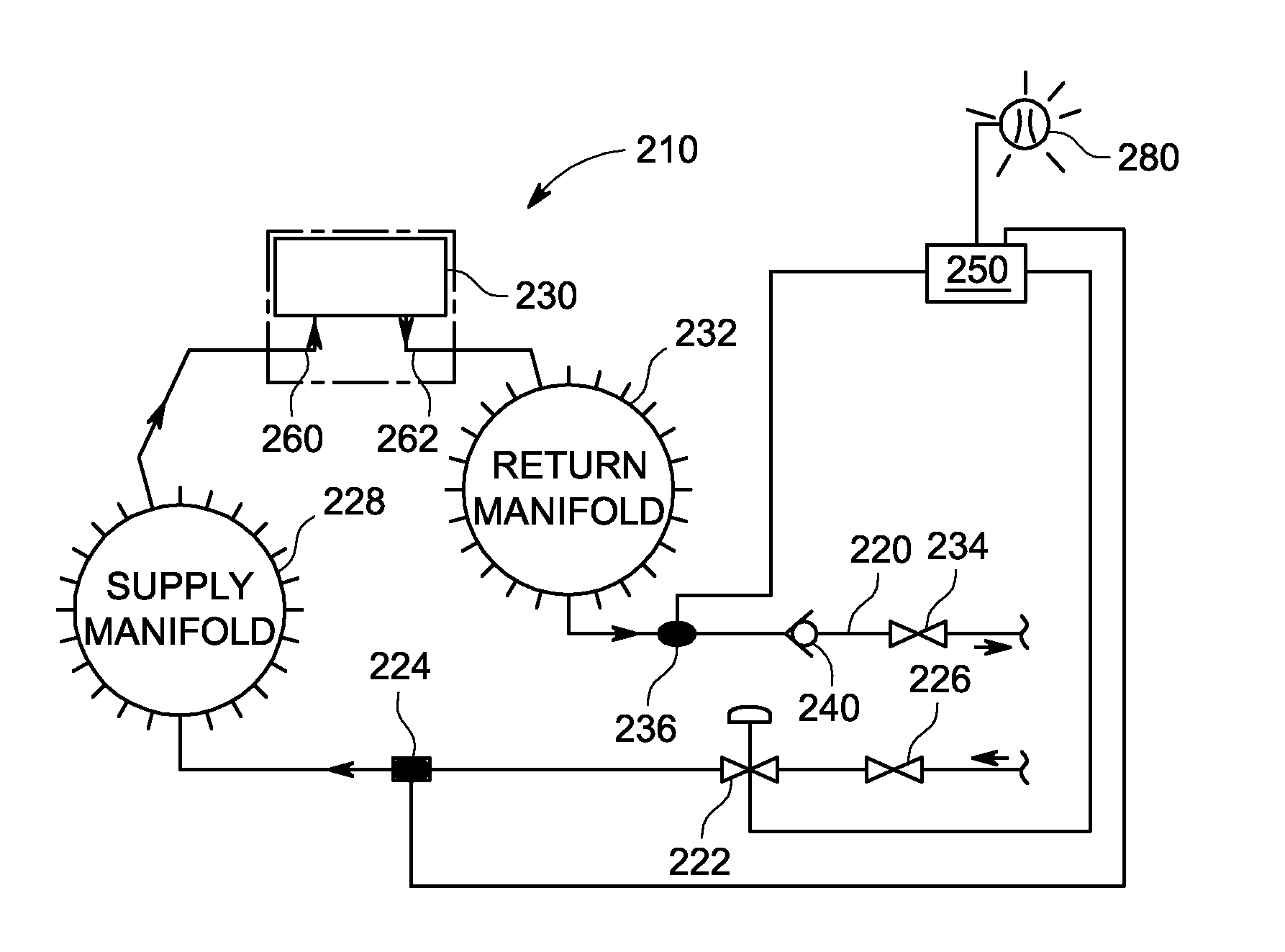

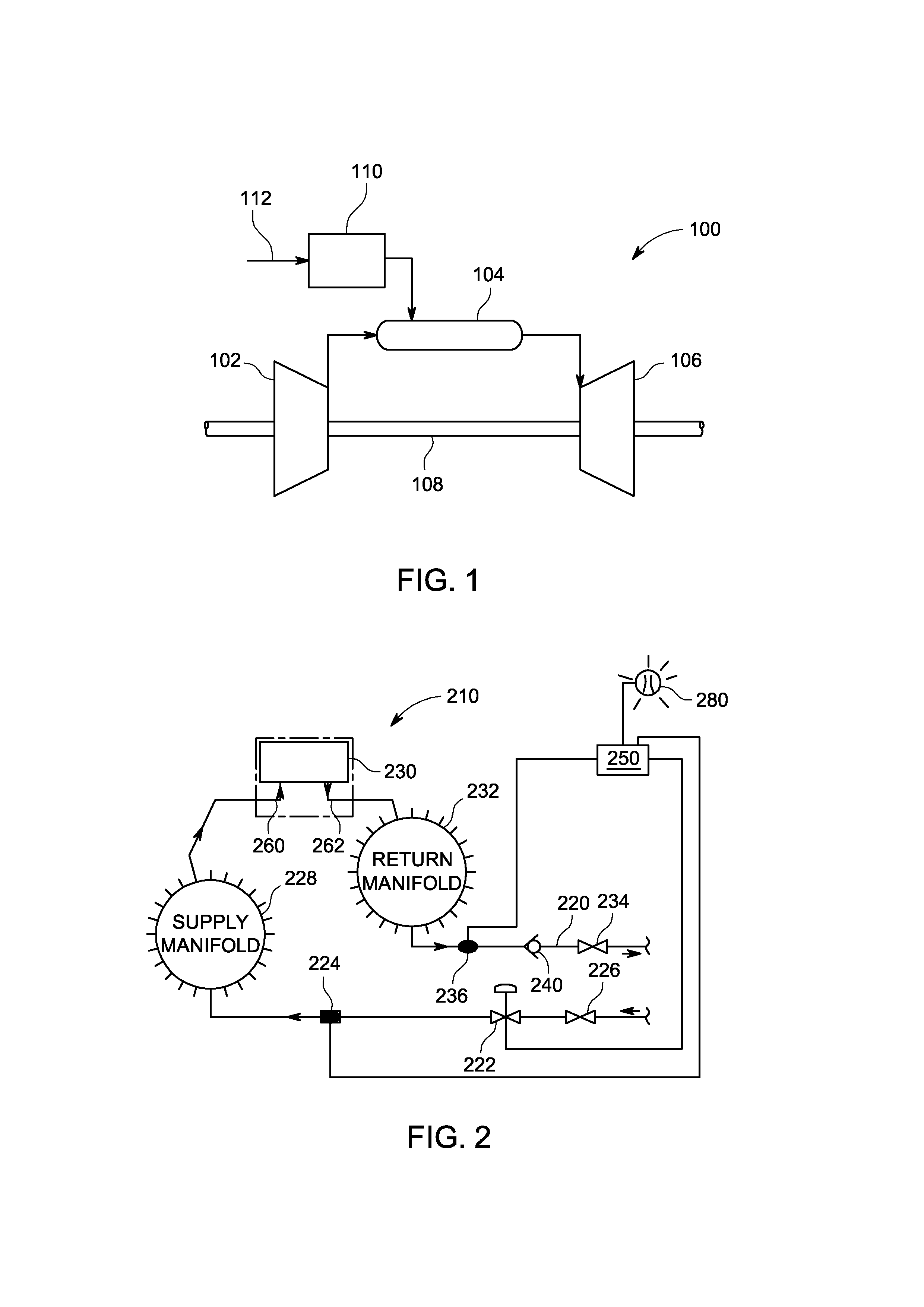

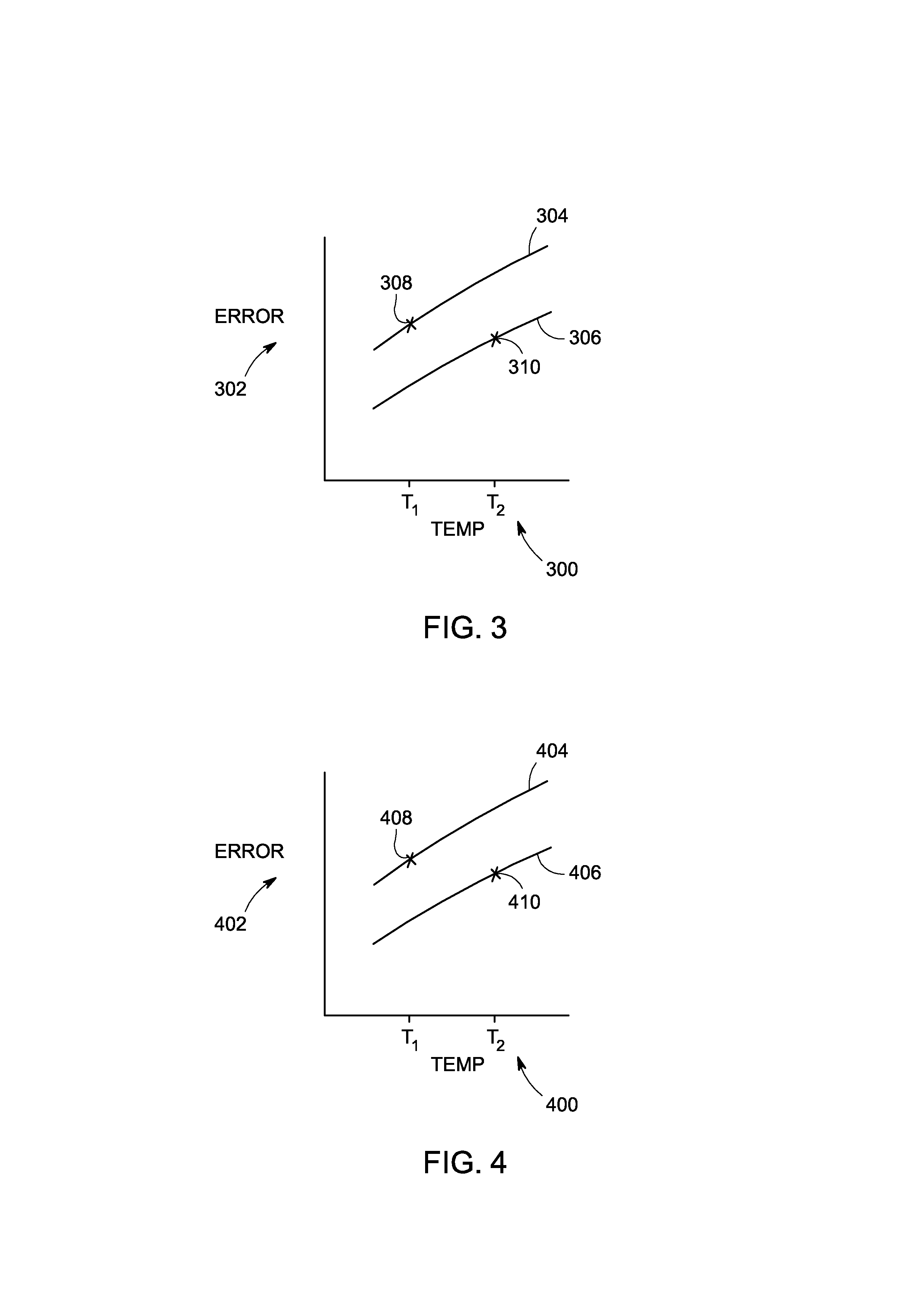

Fluid leak detection system

A fluid leak detection system is provided, and includes a fluid conduit, a fluid-cooled device having an inlet and an outlet, an inlet flow meter, an outlet flow meter, and a controller. The inlet flow meter and inlet flow meters are fluidly connected to the fluid conduit. The inlet flow meter monitors the inlet of the fluid-cooled device for an inlet temperature and an inlet flow rate. The inlet and outlet flow meters each have flow meter drift versus process fluid temperature curves as well as drift versus ambient temperature curves, wherein the curves for the inlet flow meter differ from the outlet flow meter. The outlet flow meter monitors the outlet of the fluid-cooled device for an outlet temperature and an outlet flow rate. The controller is in communication with the inlet flow meter and the outlet flow meter.

Owner:GENERAL ELECTRIC CO

Internal explosion experiment based test method for quantitative evaluation on thermobaric effect of thermobaric explosive

The invention belongs to the field of explosives, and provides an internal explosion experiment based test method for quantitative evaluation on thermobaric effect of thermobaric explosive. The method comprises the following steps: using a pressure sensor and a thermocouple to obtain benchmark TNT explosives, a curve for evaluation of shock overpressure of thermobaric explosive in an explosion tank, a thermocouple response temperature curve and a tank quasi-static pressure curve; then processing the experimental data to obtain a shock wave overpressure peak value, impulse, a thermocouple response temperature peak value and a quasi-static pressure peak value; and calculating TNT ratio of characteristic parameters of the thermobaric explosive and evaluating the thermobaric effect of the thermobaric explosive. The invention employs the explosion tank as an evaluation test carrier and uses TNT explosive with the same weight as a benchmark to quantitatively evaluate thermobaric effect of the thermobaric explosive, so as to provide technical basis for the development and power evaluation of thermobaric warhead.

Owner:XIAN MODERN CHEM RES INST

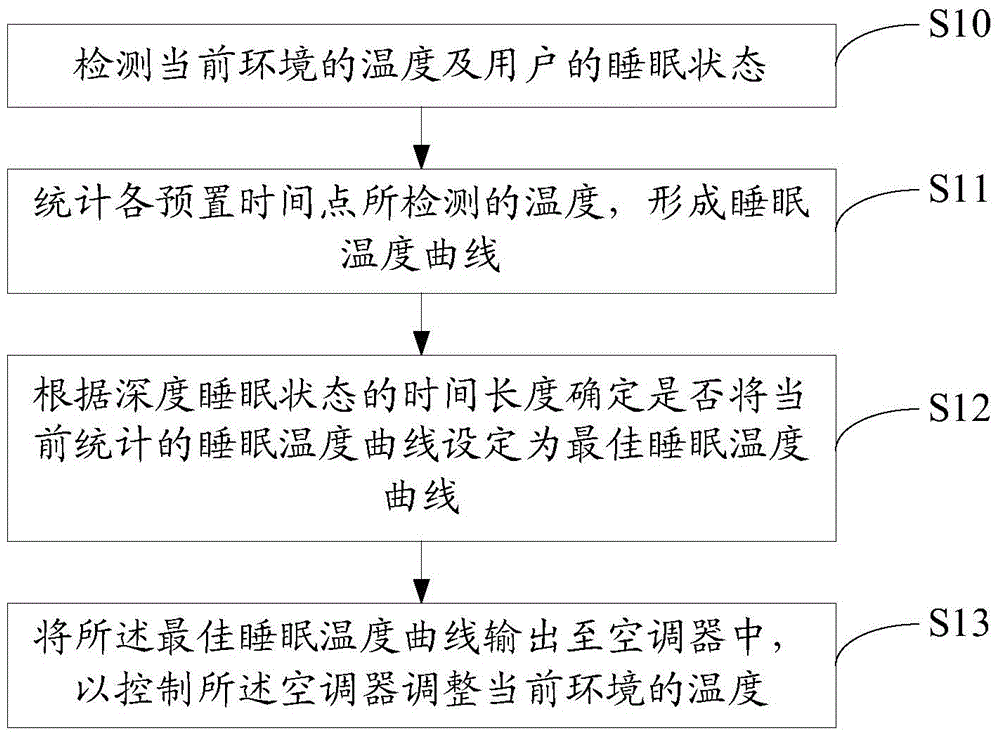

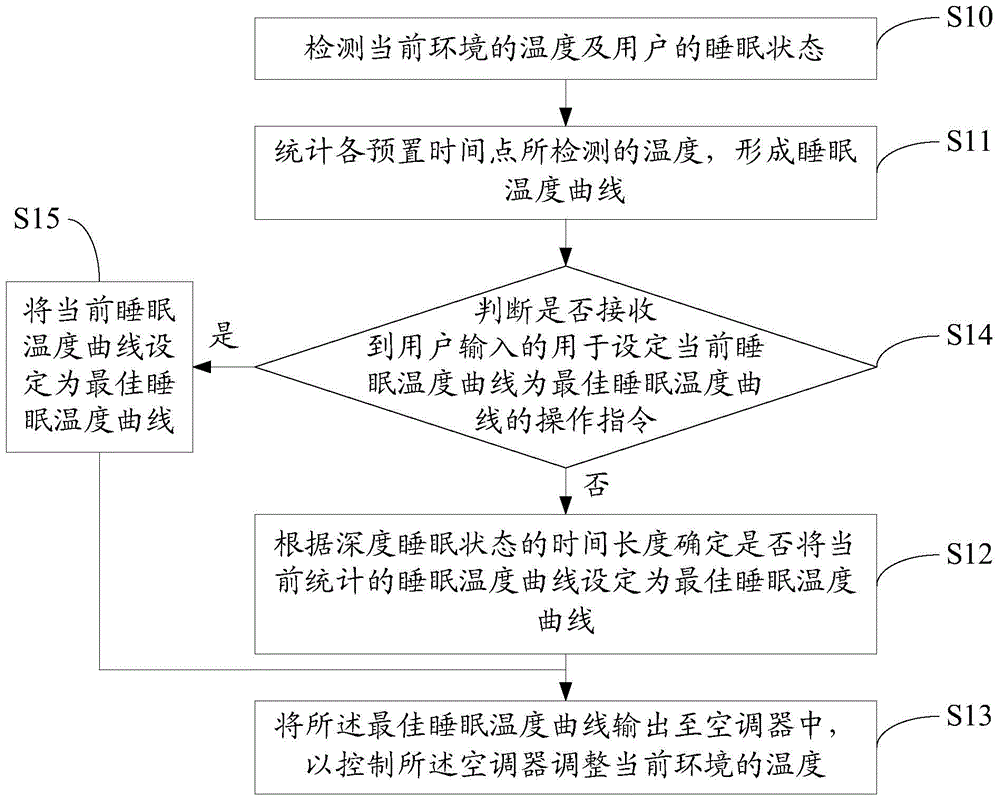

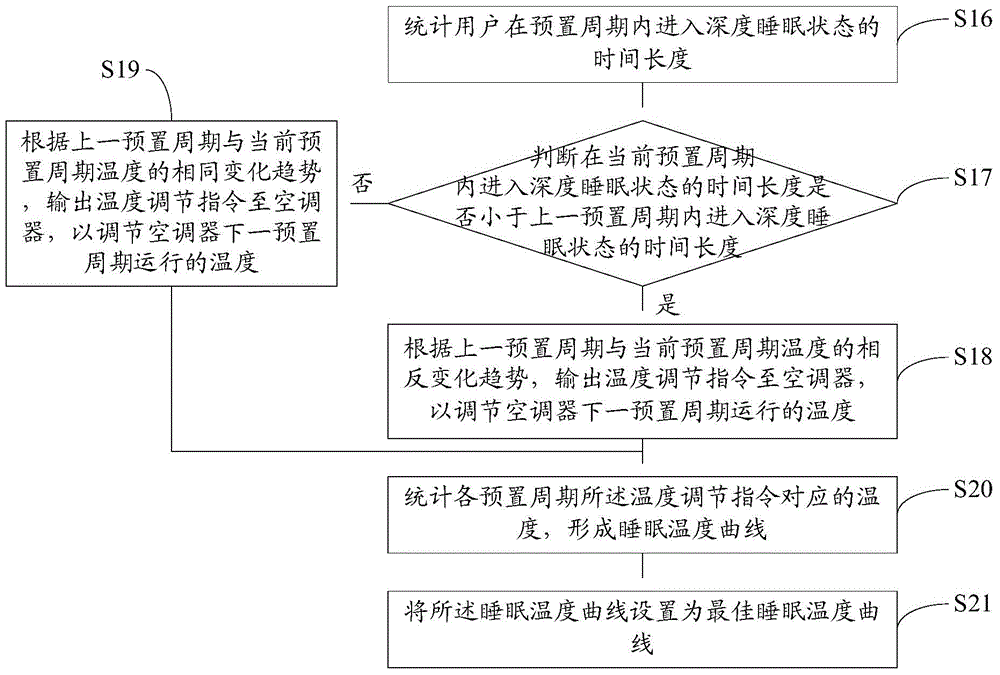

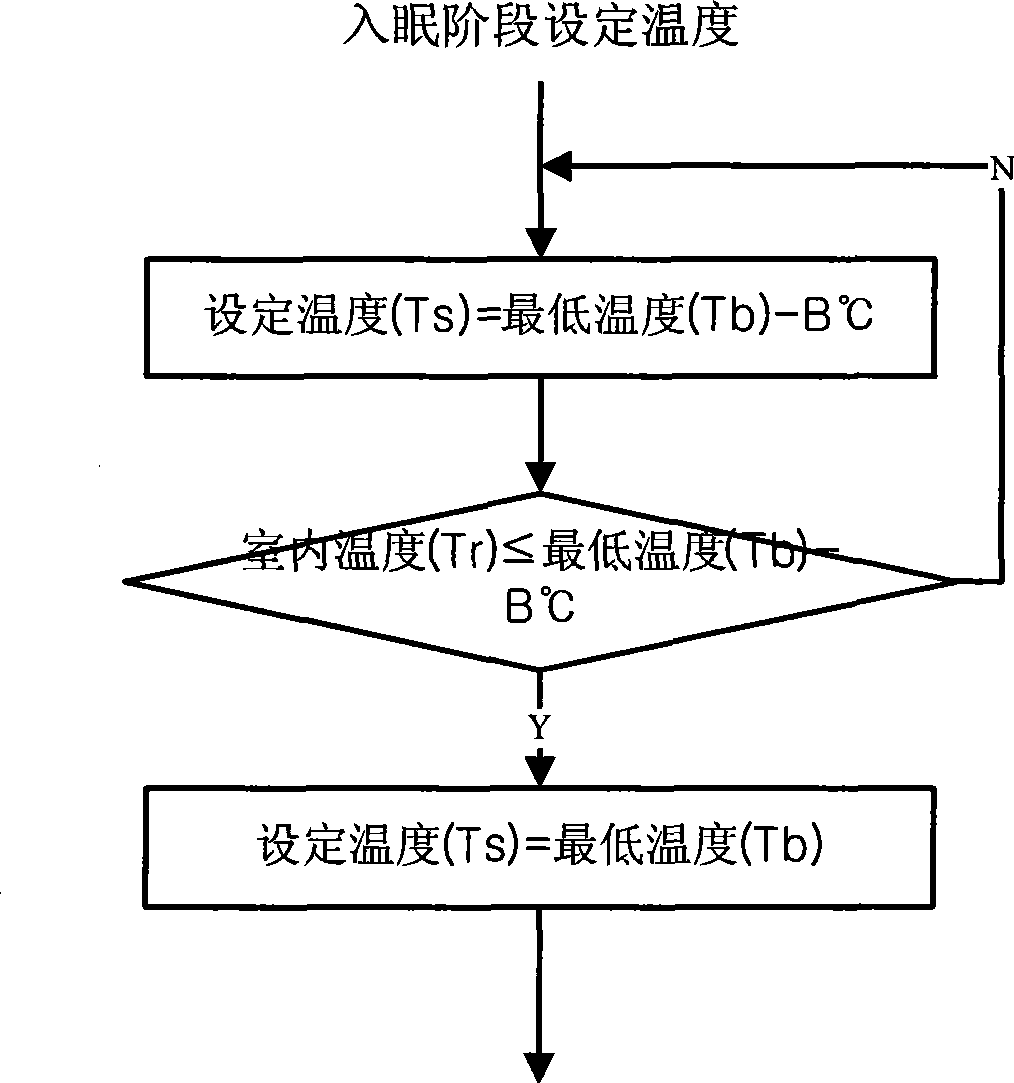

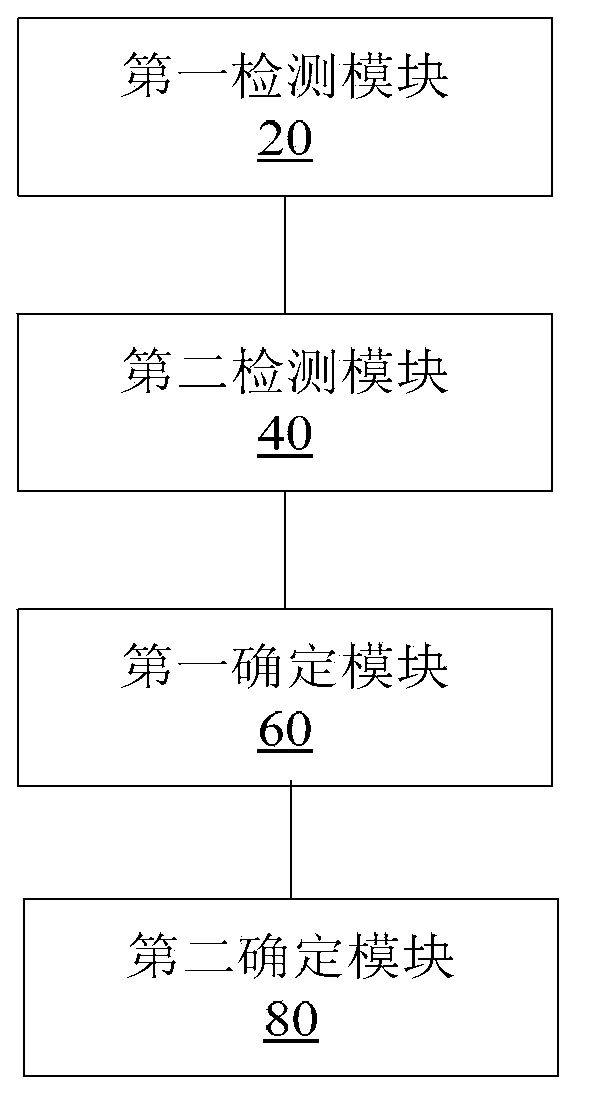

Sleep temperature control method and device

ActiveCN103982977AImprove sleep qualityIncrease flexibilitySpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlSleep state

The invention discloses a sleep temperature control method. The sleep temperature control method comprises the following steps: detecting current ambient temperature and a user sleep state, wherein the steep state comprises a deep sleep state, a light sleep state and a wake state; statistically collecting temperature detected at each preset time point to form a sleep temperature curve; determining whether to set the current statistically-collected sleep temperature curve as an optimum sleep temperature curve or not according to the time length of the deep sleep state; outputting the optimum sleep temperature curve into an air conditioner to control the air conditioner to adjust the current ambient temperature. The invention additionally discloses a sleep temperature control device. The sleep temperature control method and the sleep temperature control device improve the flexibility and the practicability of sleep temperature curve setting.

Owner:MIDEA GRP CO LTD

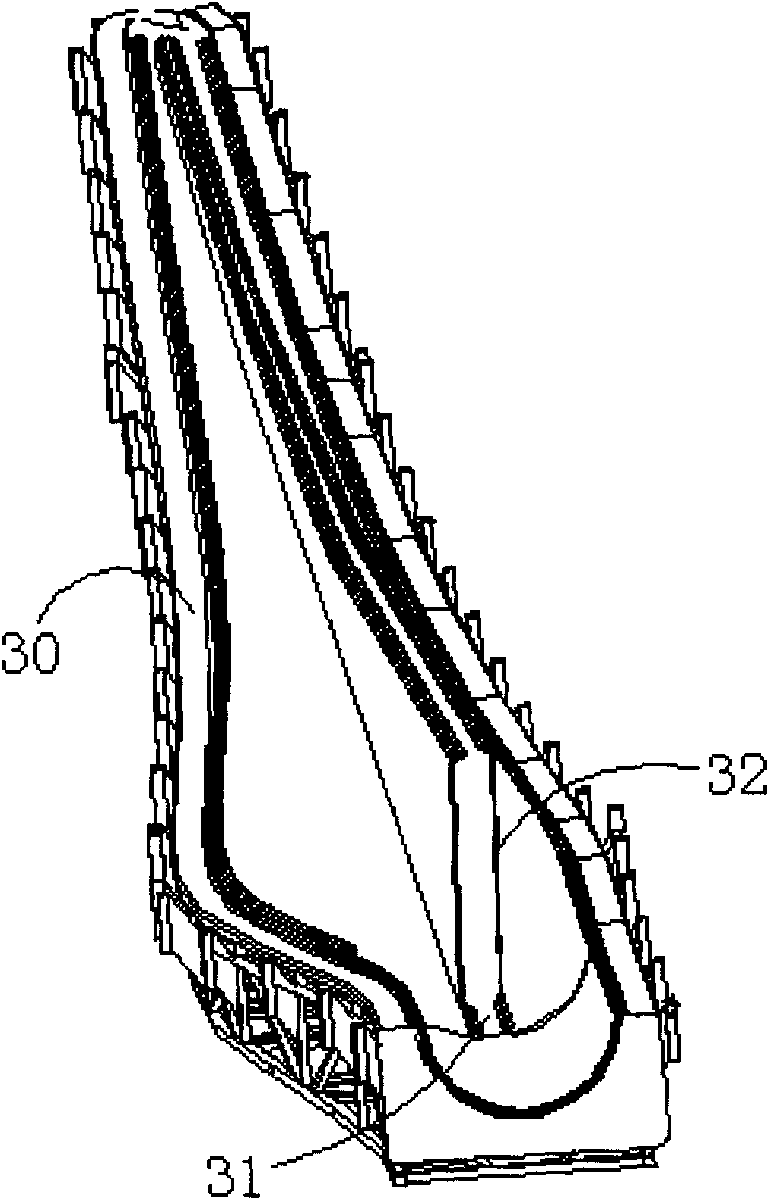

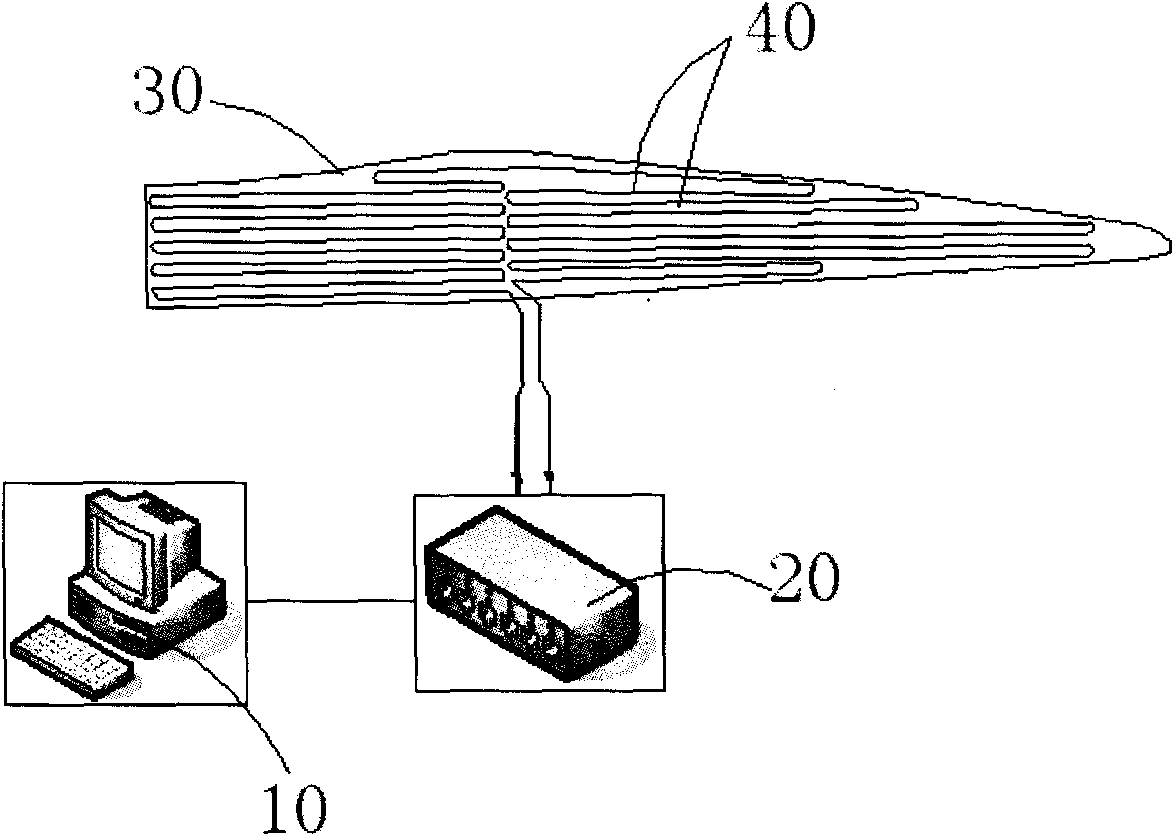

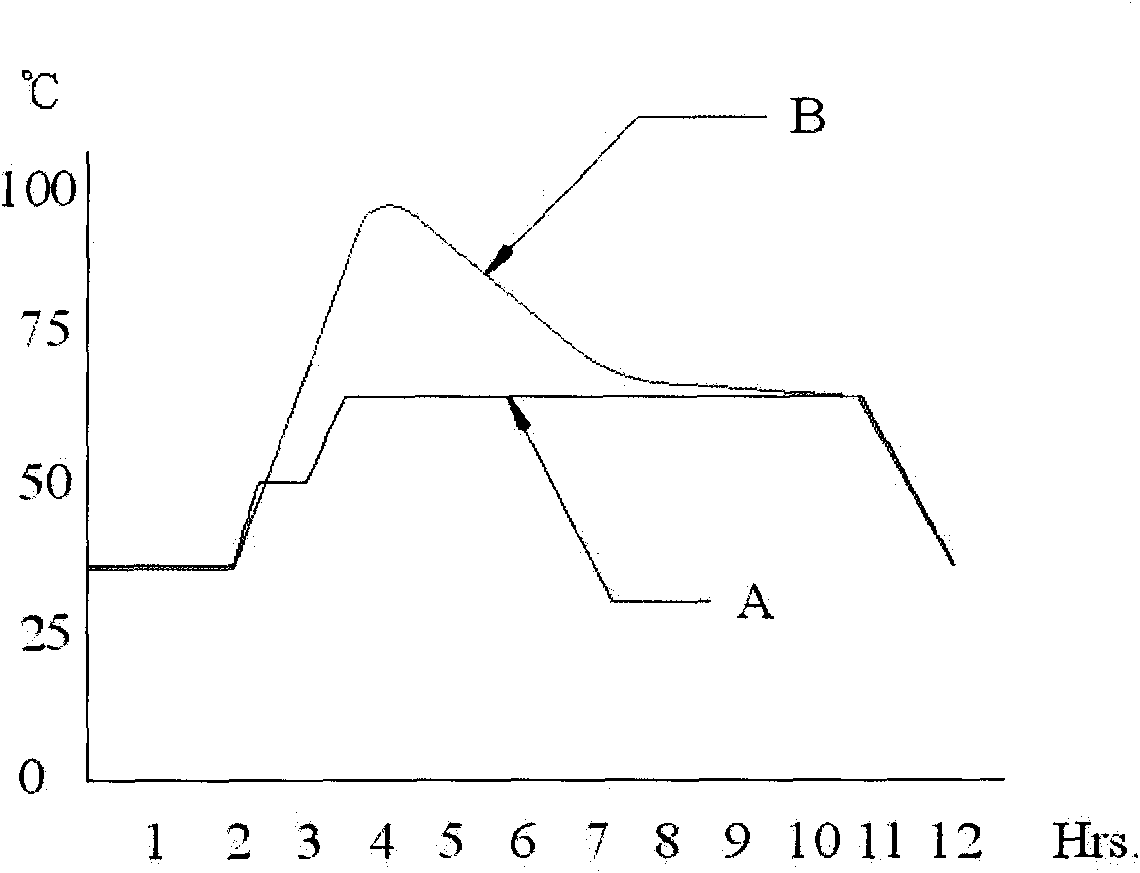

Intelligent segmental temperature control system of wind power blade die

The invention relates to an intelligent segmental temperature control system of a wind power blade die, which is provided based on the technical theory that segmental temperature control is bound to be carried out based on the differences on the formed region thickness of a designed blade structure and the energy-saving purpose can be achieved by lowering the dependence on external heating in a curing manufacturing procedure by utilizing the reaction exothermic character of a matrix material. To achieve the purpose, the invention adopts the technical measures of the construction of a die segmental temperature control pipeline, which ensures that each temperature segment can be heated or cooled independently based on requirements on thermal energy in the curing manufacturing procedure; the establishment of an intelligent temperature control system, wherein temperature and hardness data of the die and a blade shell can be captured to judge whether heating setting, exothermic peak initiating temperature and the states of completion degree, gel curing degree and the like are completed or conform to design values; and antecedent technical measures, wherein energy consumption is saved by utilizing the reaction heat of materials per se to heat and reaction and temperature control are combined to match the design of a temperature curve, which are helpful for obtaining the blades with uniform curing and excellent quality and can improve the production efficiency as a characteristic.

Owner:上海力仓实业有限公司

Soldering paste and its preparation method

InactiveCN101143407AAdaptableAvoid cleaningWelding/cutting media/materialsSoldering mediaOrganic acidOrganic solvent

The invention provides a soldering paste and a method of manufacturing the soldering paste. The composition of the soldering paste and the weight percentage of the composition are 80 to 90 per cent of ally welding power, 6 to 8 per cent of organic solvent, 2 to 10 per cent of resin and 0.2 to 2 per cent of surface active agent. The soldering paste provided by the invention has properly proportioned surface active agent, thereby making a welding point bright. The organic acid of the soldering paste of the invention is suitable for various solder-reflow temperature curves, so the soldering paste of the invention has good application, which is able to well finish the process of welding on various solder-reflow devices. As the soldering paste of the invention adopts the appropriate and well proportioned resin, with the completion of welding, no remainder is left around the welding point, which does not need to be cleaned.

Owner:彩星控股有限公司

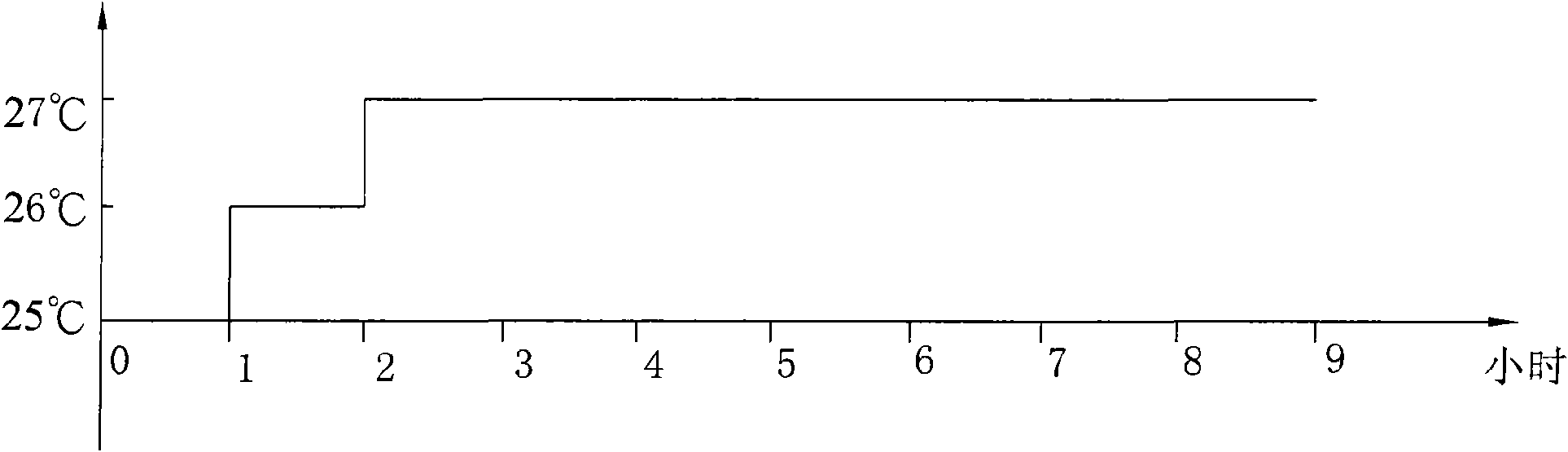

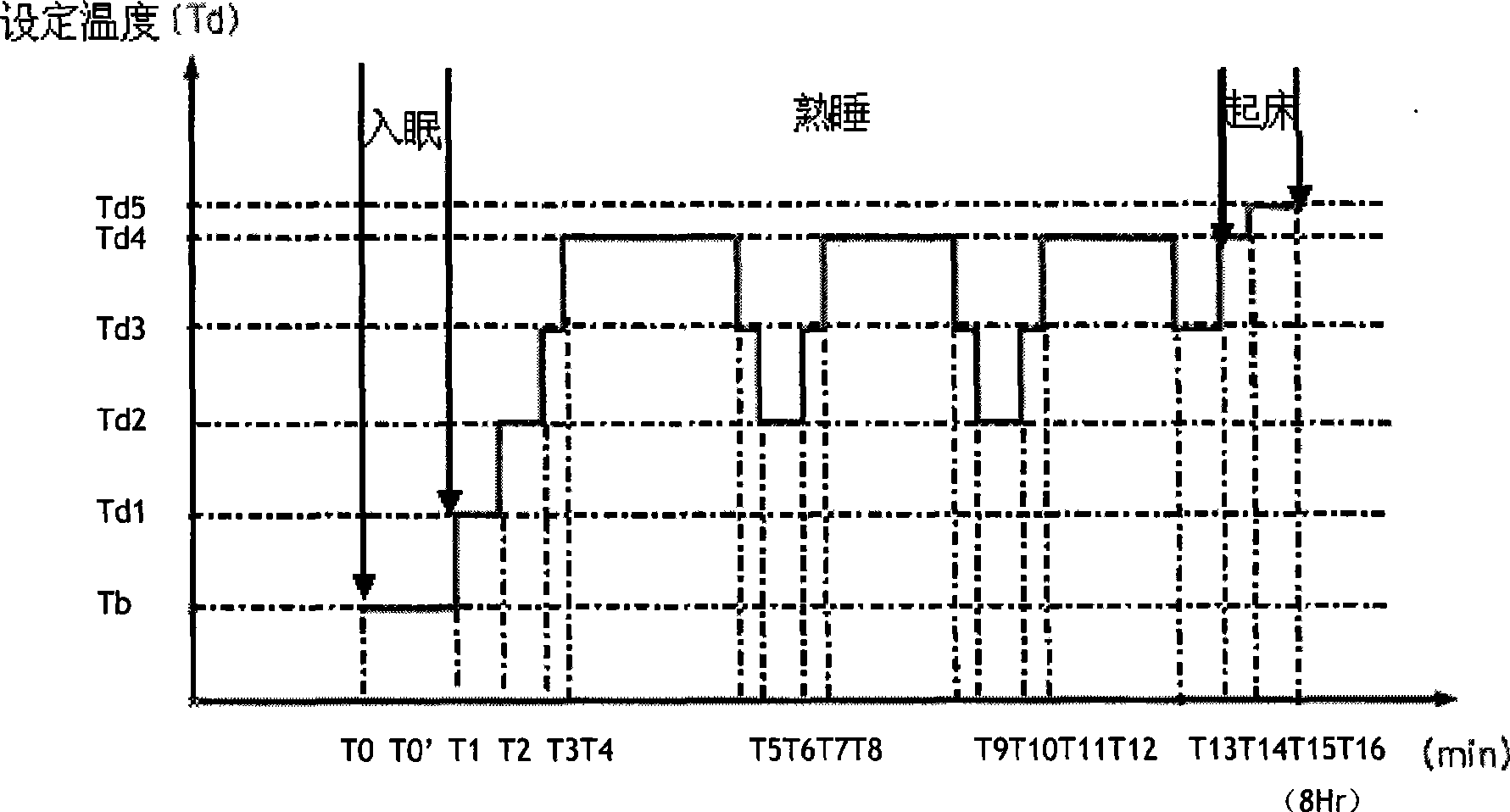

Operation control method for sleep mode of air conditioner

InactiveCN101430546AWake up easyImprove sleep qualityTemperature control using electric meansProgramme control in sequence/logic controllersHuman bodyAir volume

The invention relates to the improvement of an operational control method for a sleep pattern of an air-conditioner. The invention is characterized in that the whole sleeping process is divided into three sections of falling asleep, heavy sleep and getting up by applying the principle of human engineering, scientifically analyzing biological period, body rhythm and indoor space status of human body falling sleep; a temperature curve which can help people to enter into ideal sleeping status is set according to temperature variation requirements in different sleeping sections; users have comfortable and health sleeping by simulating and realizing the model of the temperature curve and adjusting the appropriate air quantity; the temperature curve can be widely applied to the sleep pattern of the air-conditioner.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD

Method for testing heat storage performance of building material and tester

InactiveCN101813651ATest accurateSimple operation interfaceMaterial heat developmentTemperature curveTester device

The invention discloses a method for testing heat storage performance of a building material and a tester. The tester mainly comprises a heat insulation barrel, an environment chamber, a D / C converter, an A / D converter, temperature sensors, an electric quantity sensor and a computer. The temperature sensors are arranged in the heat insulation barrel and the environment chamber respectively for measuring the temperatures of the material, the environment chamber and the inner and outer walls of the heat insulation barrel; the computer controls the heating power of a heating rod through the electric quantity sensor and the D / C converter; and temperature signals are monitored and recorded by the computer through the temperature sensors and the A / D converter. A computer program can calculate the heat storage performance of the material through a temperature curve of heating and heat release processes. Aiming at the condition that the conventional method for testing the heat storage performance of the material in the search of the building material, particularly a building phase change material, is insufficient, the method of the invention simply and quickly tests the heat storage performance of the material during change at a certain temperature interval, has the characteristics of high detection precision, strong reliability, low cost and the like, and can realize automation of the test process at the same time.

Owner:CHINA ACAD OF BUILDING RES

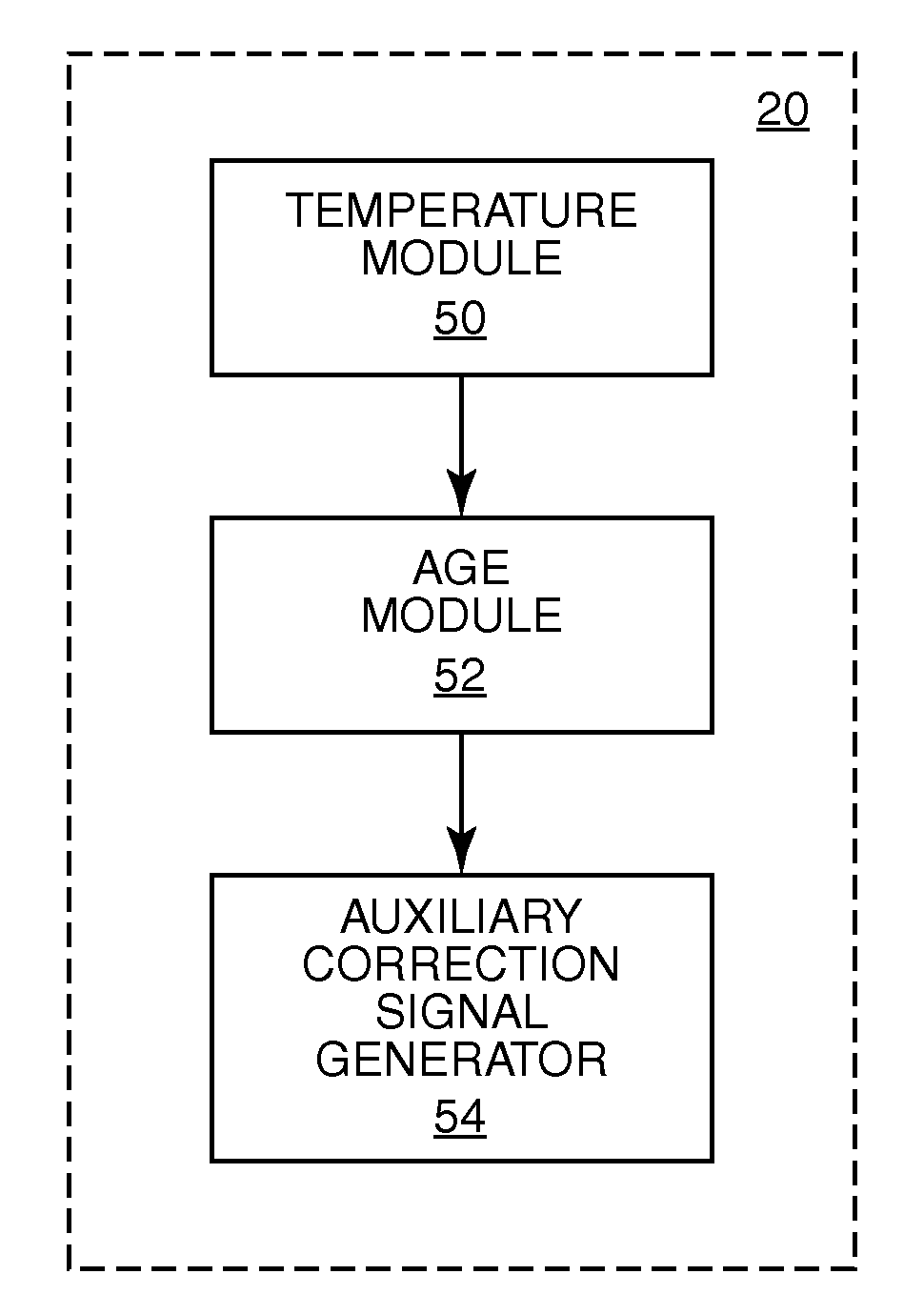

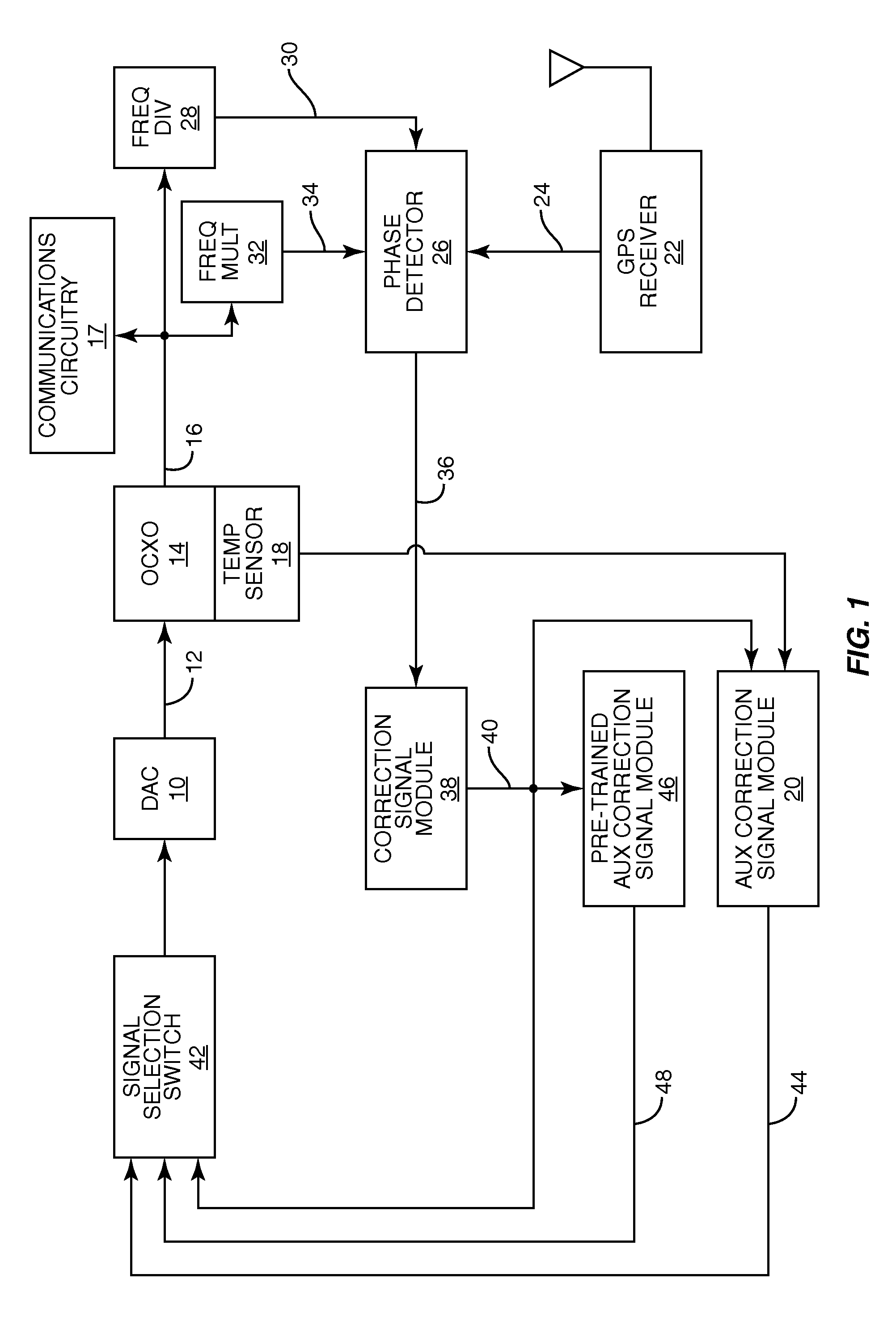

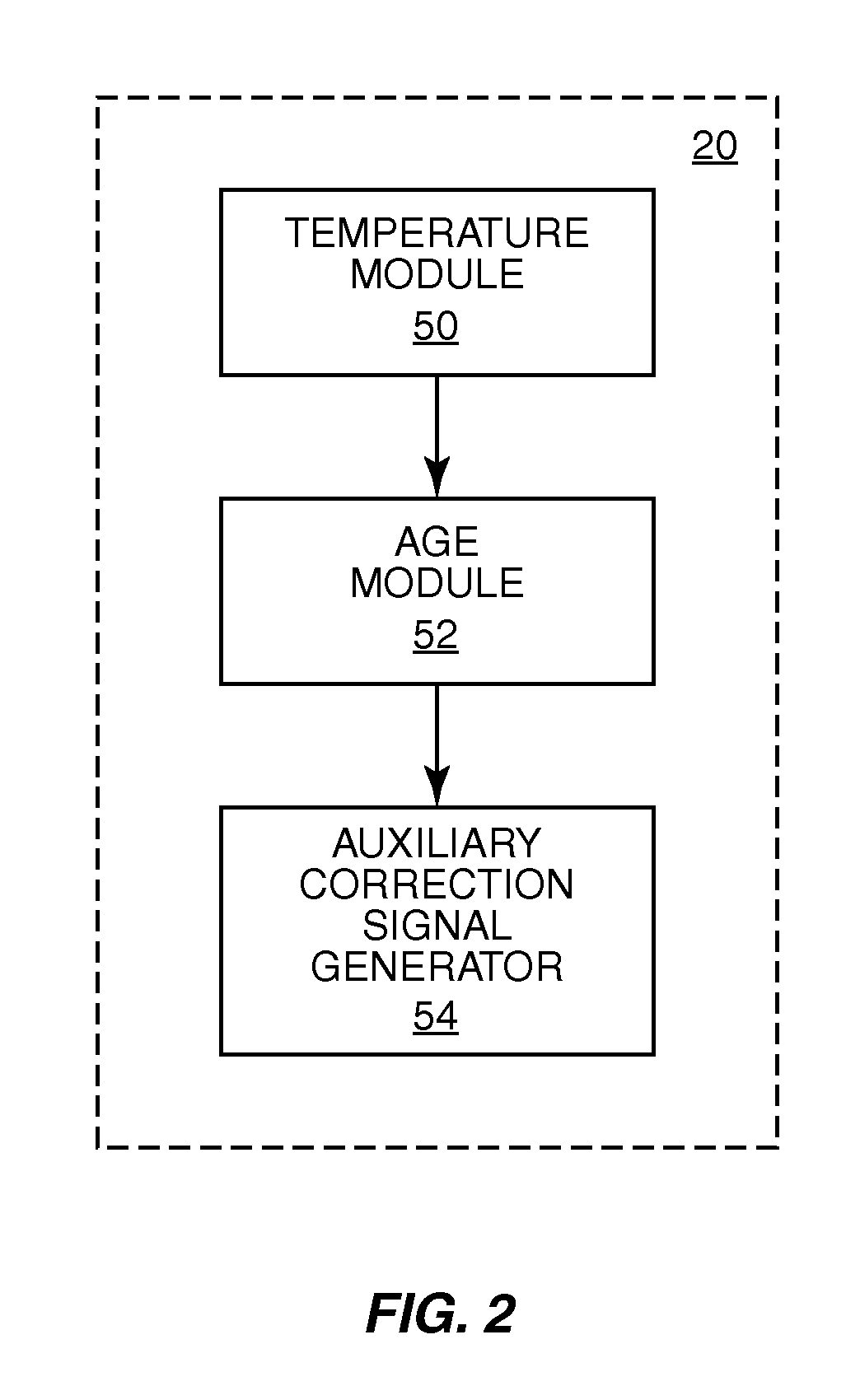

Method and system for correcting oscillator frequency drift

A method and apparatus for correcting oscillator frequency drift due to crystal aging. Correction signals that reflect a difference between an oscillator timing signal and a reference timing signal over a reference timing signal interval are modeled so that auxiliary correction signals can be generated in the event of loss of the reference timing signal. A temperature curve is generated to model how temperature variation impacts oscillator frequency drift. A rate of frequency drift due to crystal aging is also determined. During loss of a reference timing signal, auxiliary correction signals can be generated to maintain the oscillator at a desired frequency until the reference timing signal becomes available again.

Owner:APPLE INC

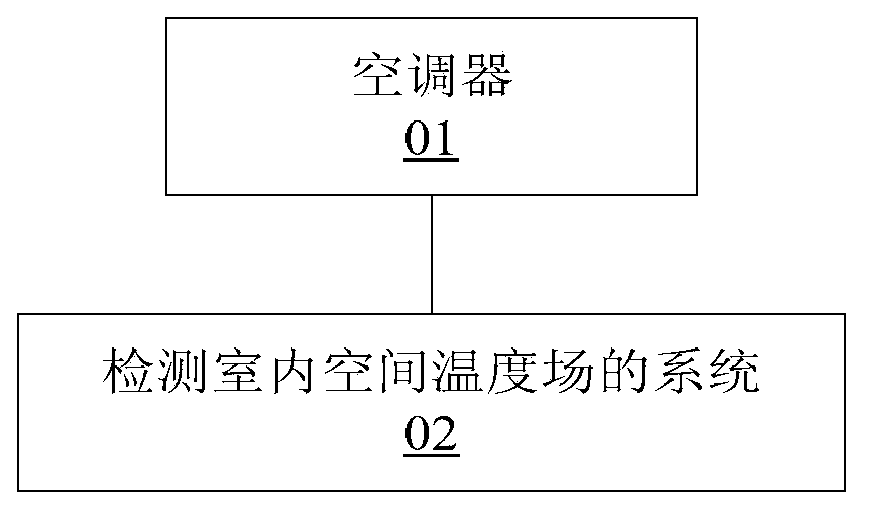

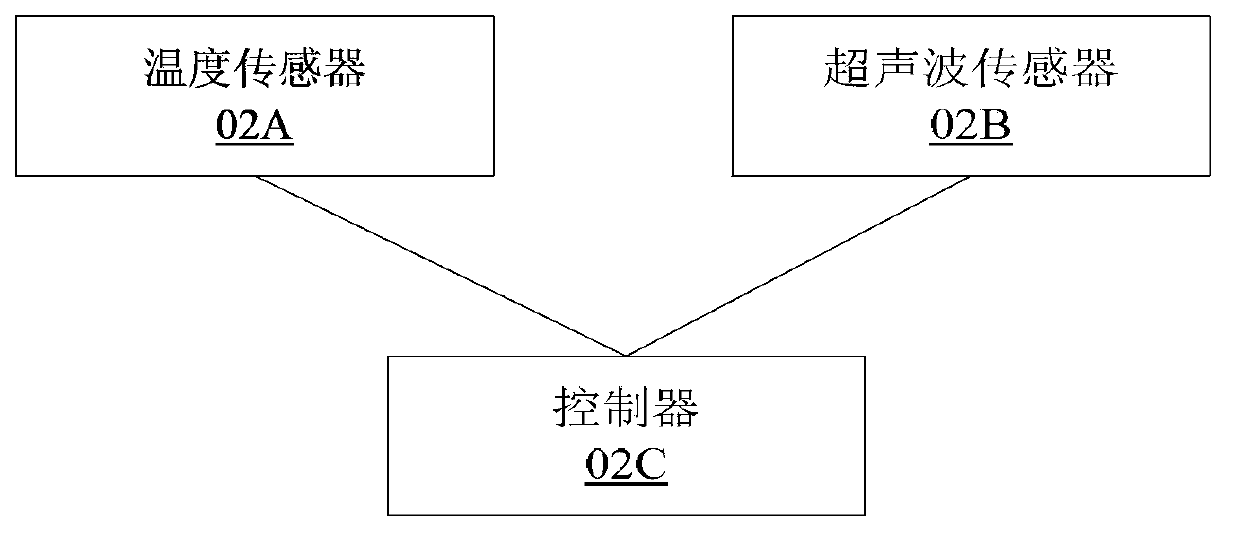

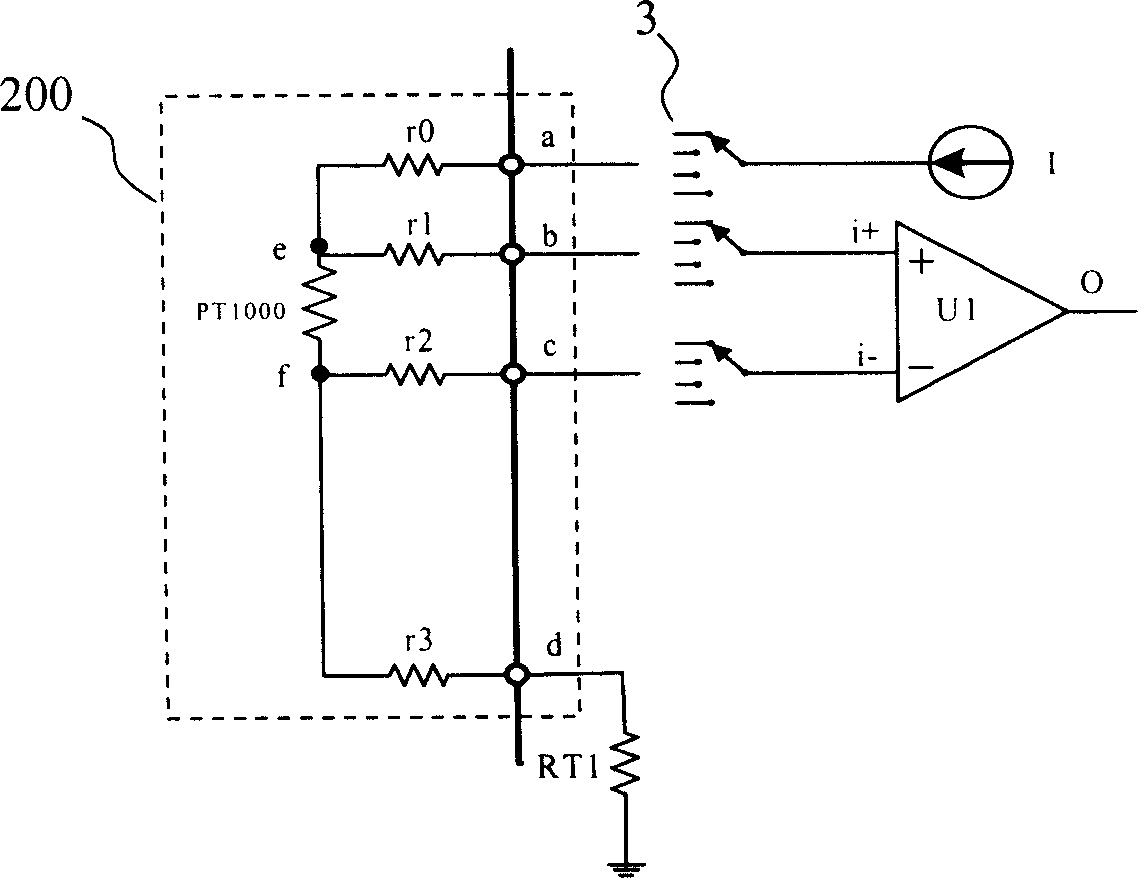

Indoor space temperature field detection method and system and air conditioner control system

ActiveCN103968967ATemperature buildEstablishment of temperature fieldThermometers using mean/integrated valuesSpace heating and ventilation safety systemsTemperature controlControl system

The invention provides an indoor space temperature field detection method and system and an air conditioner control system. The method includes detecting the temperature of the position where an indoor air conditioner locates and the temperature of the position where an indoor obstacle locates firstly; determining a temperature curve of a path between the two positions according to detected temperatures of the two positions secondly; determining the indoor space temperature field according to the temperature curve finally to acquire the temperature of the entire indoor space. The temperature control accuracy of the air conditioner can be improved by controlling the operation of the air conditioner according to the space temperature field, and accordingly the comfort of using the air conditioner is improved.

Owner:GREE ELECTRIC APPLIANCES INC

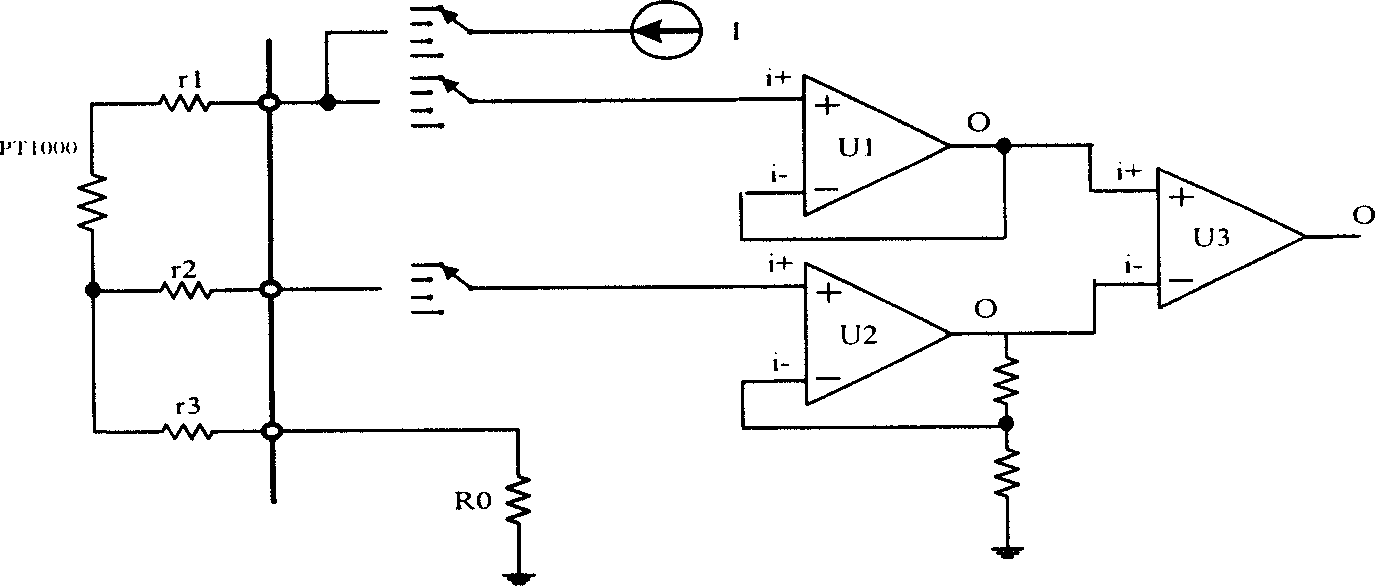

Temperature measuring circuit

ActiveCN101169341AEliminate the effects ofRealize time-division multiplexingThermometers using electric/magnetic elementsUsing electrical meansLine resistanceElectrical resistance and conductance

The invention discloses a temperature measurement circuit, which includes a temperature sensor circuit, a constant current source and a first operational amplifier. The negative pole of the power line drawn from the second end and the positive pole of the sensing lead and the negative pole of the sensing lead drawn from the first and second ends of the temperature sensor respectively, the constant current source is connected to the positive pole of the power line of the temperature sensor circuit, and the positive and negative poles of the first operational amplifier The negative input end is respectively connected to the positive electrode of the sensing lead and the negative electrode of the sensing lead of the temperature sensor circuit, the output end outputs a voltage-temperature curve, and the negative electrode of the power line of the temperature sensor circuit is coupled to the ground. The invention adopts a four-wire system, so that the positive and negative input ends of the first operational amplifier are respectively connected to the positive electrode of the sensing lead and the negative electrode of the sensing lead of the temperature sensor circuit. The effect of wire resistance on the output result.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Weld metals with superior low temperature toughness jfor joining high strength, low alloy steels

InactiveCN1529765AHigh strengthGood resistance to hydrogen induced crackingArc welding apparatusWelding/cutting media/materialsManganeseOxygen

Weld metals suitable for joining high strength, low alloy steels are provided. These weld metals have microstructures of acicular ferrite interspersed in a hard constituent, such as lath martensite, yield strengths of at least about 690 MPa (100 ksi), and DBTTs lower than about -50 DEG C. (-58 DEG F.) as measured by a Charpy energy versus temperature curve. These weld metals include about 0.04 wt % to about 0.08 wt % carbon; about 1.0 wt % to about 2.0 wt % manganese; about 0.2 wt % to about 0.7 wt % silicon; about 0.30 wt % to 0.80 wt % molybdenum; about 2.3 wt % to about 3.5 wt % nickel; about 0.0175 wt % to about 0.0400 wt % oxygen, and at least one additive selected from the group consisting of (i) up to about 0.04 wt % zirconium, and (ii) up to about 0.02 wt % titanium.

Owner:EXXONMOBIL UPSTREAM RES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com