Sintering status control method in sintering process

A control method and technology for sintering state, applied in the field of iron and steel smelting, which can solve the problems of reducing the control accuracy of the sintering process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

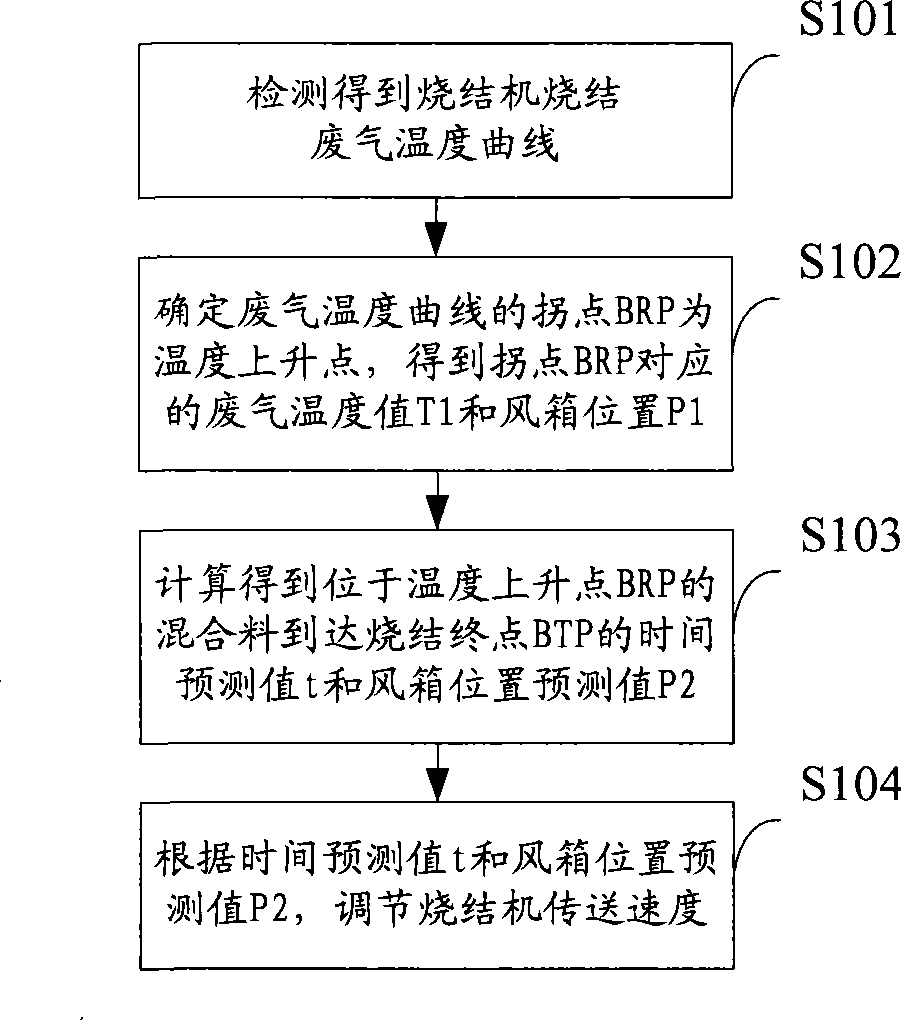

[0081] see Figure 4 , is a flowchart of the sintering state control method in the sintering process according to the first embodiment of the present invention. Described control method specifically comprises the following steps:

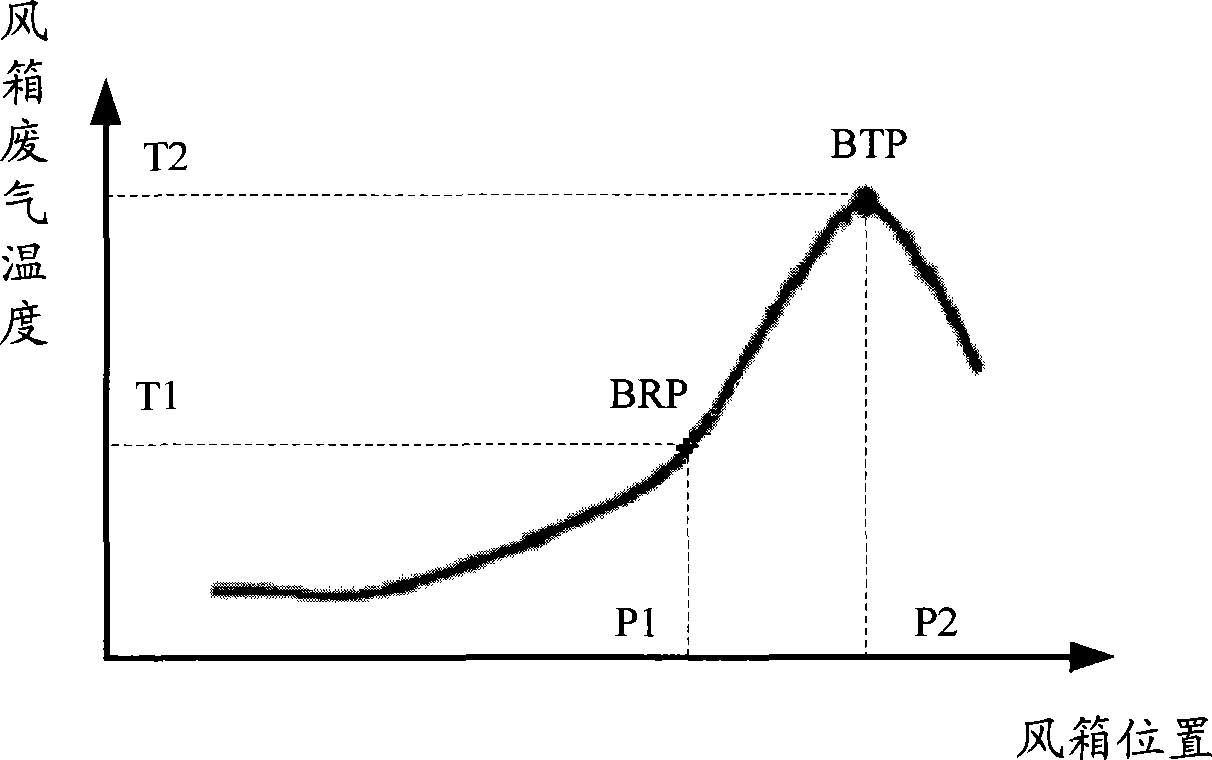

[0082] Step S401: Detect and obtain the temperature curve of the sintering waste gas of the sintering machine.

[0083] Step S402: Establish a data tracking queue corresponding to the mixed material on the sintering machine trolley.

[0084] Step S403: Use the data tracking queue, combined with the exhaust gas temperature curve, to track and count the sintering state of the mixture on the sintering machine trolley, and calculate in real time the predicted value PBTP_PRE of the sintering end point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com