Method for converting cold wall heat flux into hot wall heat flux in aerodynamic heat simulating test

A simulation test, aerothermal technology, applied in the field of high-speed aircraft aerothermal test, can solve the problems of inaccurate temperature data, accuracy and reliability problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

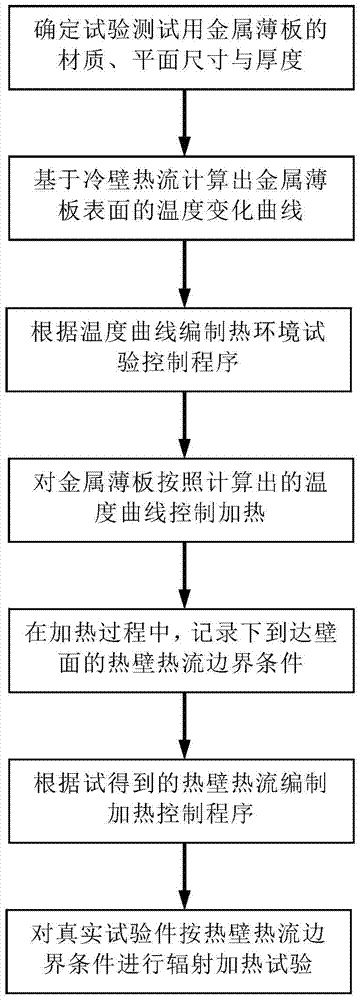

[0031] Such as figure 1 Shown, the specific embodiment of the present invention is as follows:

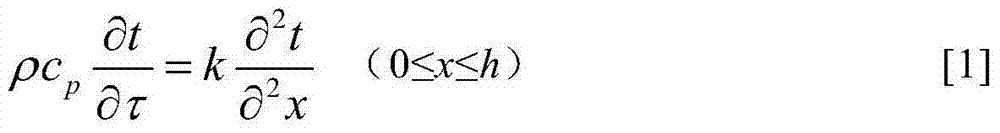

[0032] 1. The metal plate is made of high-temperature-resistant nickel-based stainless steel 1Cr18Ni9Ti, with a melting point of 1450°C. This material has better anti-deformation ability at high temperatures; the thickness range of the metal sheet is 1.0-2.0mm, because it is too thick and has a large heat capacity. The response time to the changing thermal environment is long and the thermal hysteresis is serious. It is too thin and easy to deform. After testing, it is determined that it is more suitable between 1.0-2.0mm. The plane size of the metal sheet is selected as a single side length of 100mm-120mm. Since the area is not too large, the out-of-plane deformation after heating is within the available range. The ratio of the side length to the thickness of the metal sheet is between 60:1 and 120. :1, the ratio of its width to thickness is very large, so it can be approximated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com