Power device over-temperature protection method based on temperature curve slope control

An over-temperature protection and power device technology, applied in temperature control, non-electric variable control, control/regulation systems, etc., can solve the problems of no temperature detection, failure of over-temperature protection, large temperature difference, etc., to achieve good results and improve reliability, improved effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

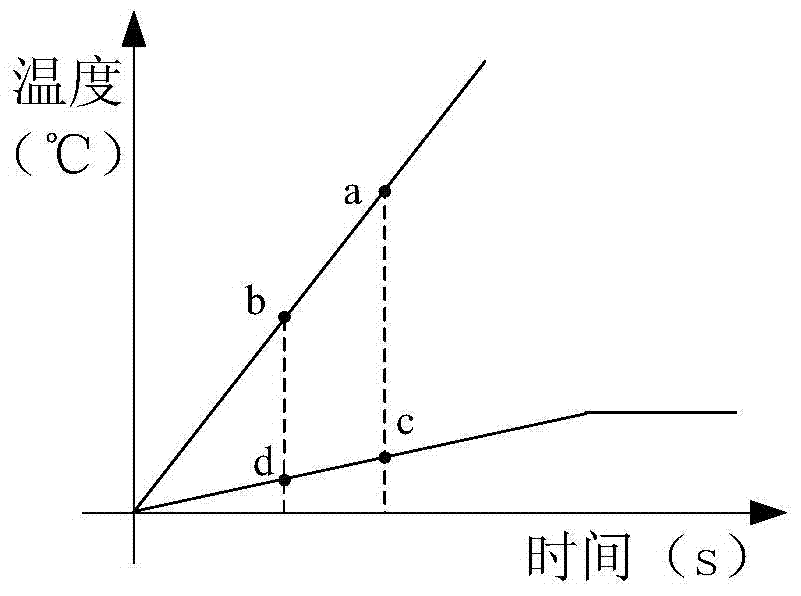

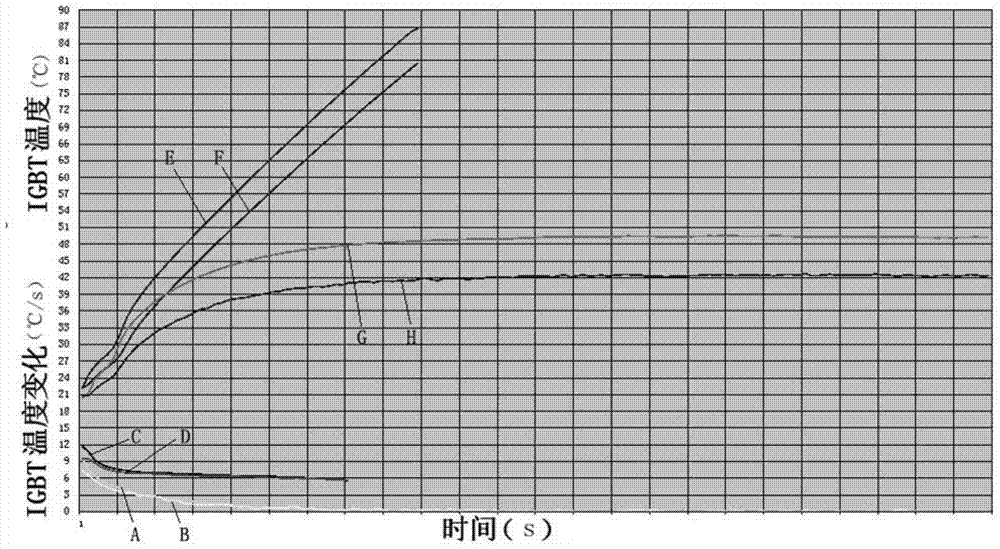

[0024] refer to Figure 1 ~ Figure 2 As shown, the power device over-temperature protection method based on temperature curve slope control in the present invention includes the following steps:

[0025] 1) Add an NTC thermistor on the radiator outside the power device in the inverter. After the inverter is powered on, detect the initial temperature of the NTC thermistor as the ambient temperature;

[0026] 2) After the inverter is running, when it is detected that the temperature value of the NTC thermistor exceeds 20°C relative to the ambient temperature, the slope of the temperature change curve of the NTC thermistor is calculated every other cycle T, and the cumulative calculation is n (n is rounded to an integer ) After the slope of the temperature change curve of the NTC thermistor at each point, calculate the average slope K of the temperature change curve of the NTC thermistor within the nT time period of the inverter running 1 ;

[0027] 3) Follow step 2 again in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com