Internal explosion experiment based test method for quantitative evaluation on thermobaric effect of thermobaric explosive

A temperature-pressure explosive and temperature-pressure effect technology, applied in the direction of analyzing materials and instruments, can solve the problems of inaccuracy, difficulty in calibrating static pressure effects, and incomplete evaluation of explosives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

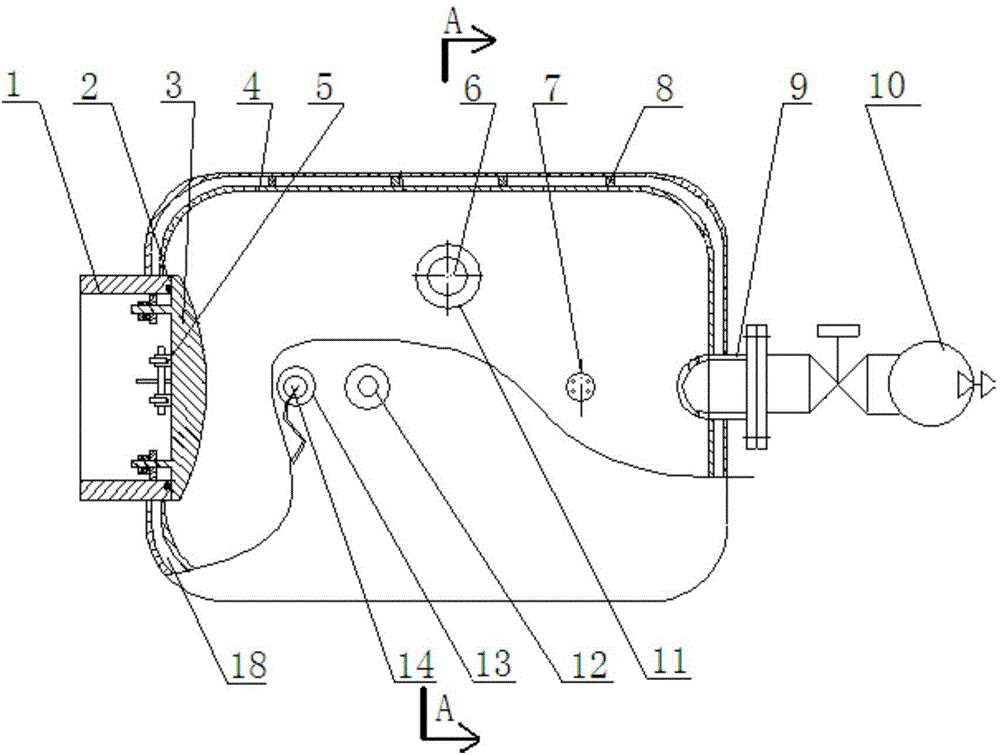

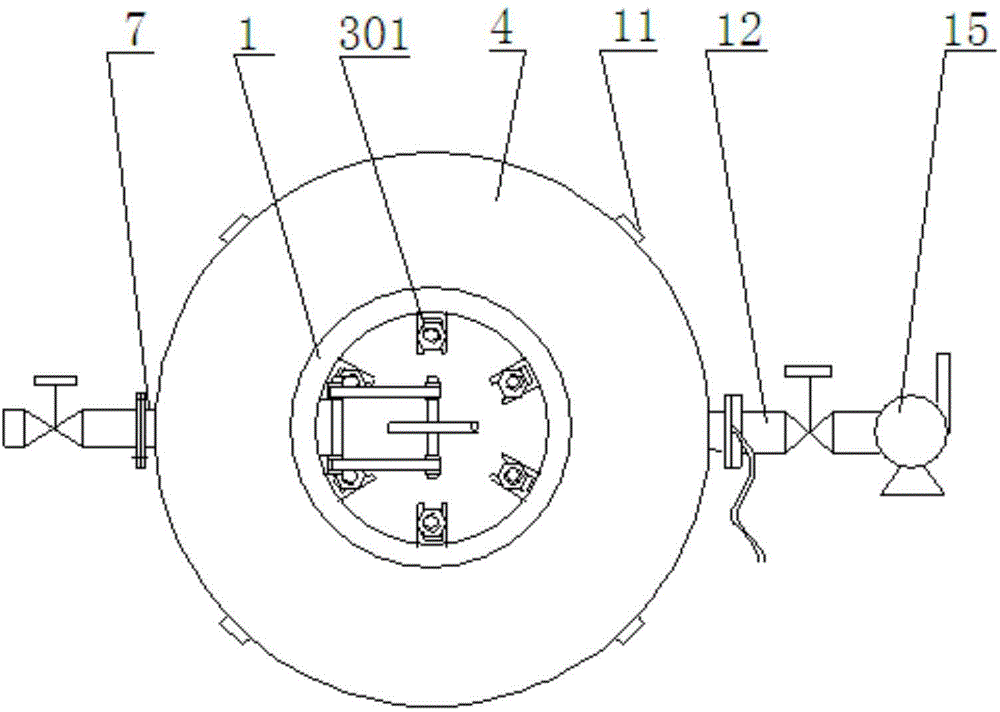

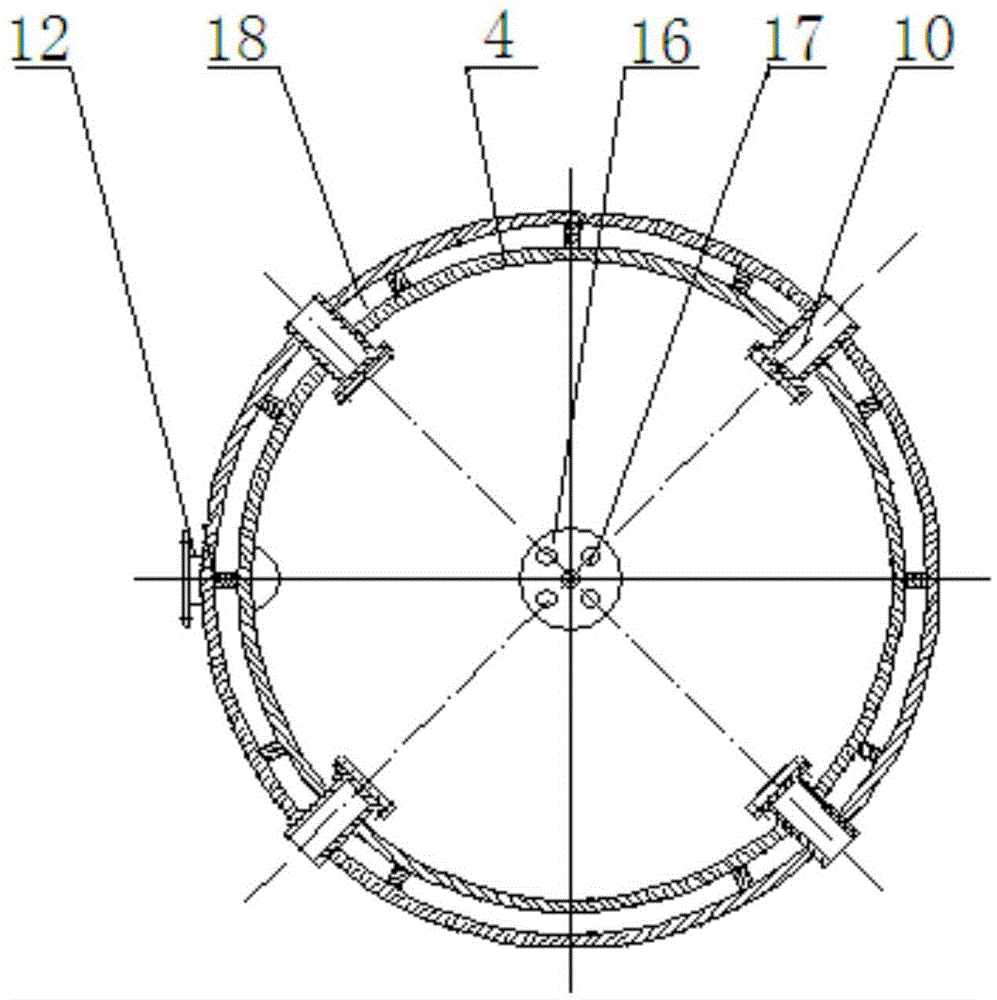

[0134] It should be noted that the inner diameter of the test explosion tank used in this example is φ2.6m, and the volume is 26m 3 , the impact resistance is less than 7kgTNT equivalent; the mass ratio of the test PMX thermobaric explosive components is 64.4% HMX, 30% Al, 1.4% fluororubber, 4.2% DOA, and the molecular formula is C 1.242 h 2.410 N 1.870 o 1.451 f 0.05226 Al 1.193 , wherein the valence of the C atom is -4, the valence of the H atom is +1, the valence of the O atom is -2, the valence of the F atom is -1, and the valence of the Al atom is +3, and the TNT equivalent coefficient of the thermobaric explosive is tested is 1.8.

[0135] This embodiment provides a kind of test method for the quantitative evaluation of the temperature-pressure effect of thermo-pressure explosives based on internal explosion test, the method comprises the following steps:

[0136] Step 1, the determination of the test device;

[0137] Use the test explosion tank to carry out the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com