Method for testing heat storage performance of building material and tester

A technology of building materials and testing instruments, which is applied in the field of measuring devices and heat storage performance testing, can solve the problems of no standards and specifications, lack of means, and restrictions on the development of the building phase change material industry, and achieve accurate phase change heat storage and operation simple interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

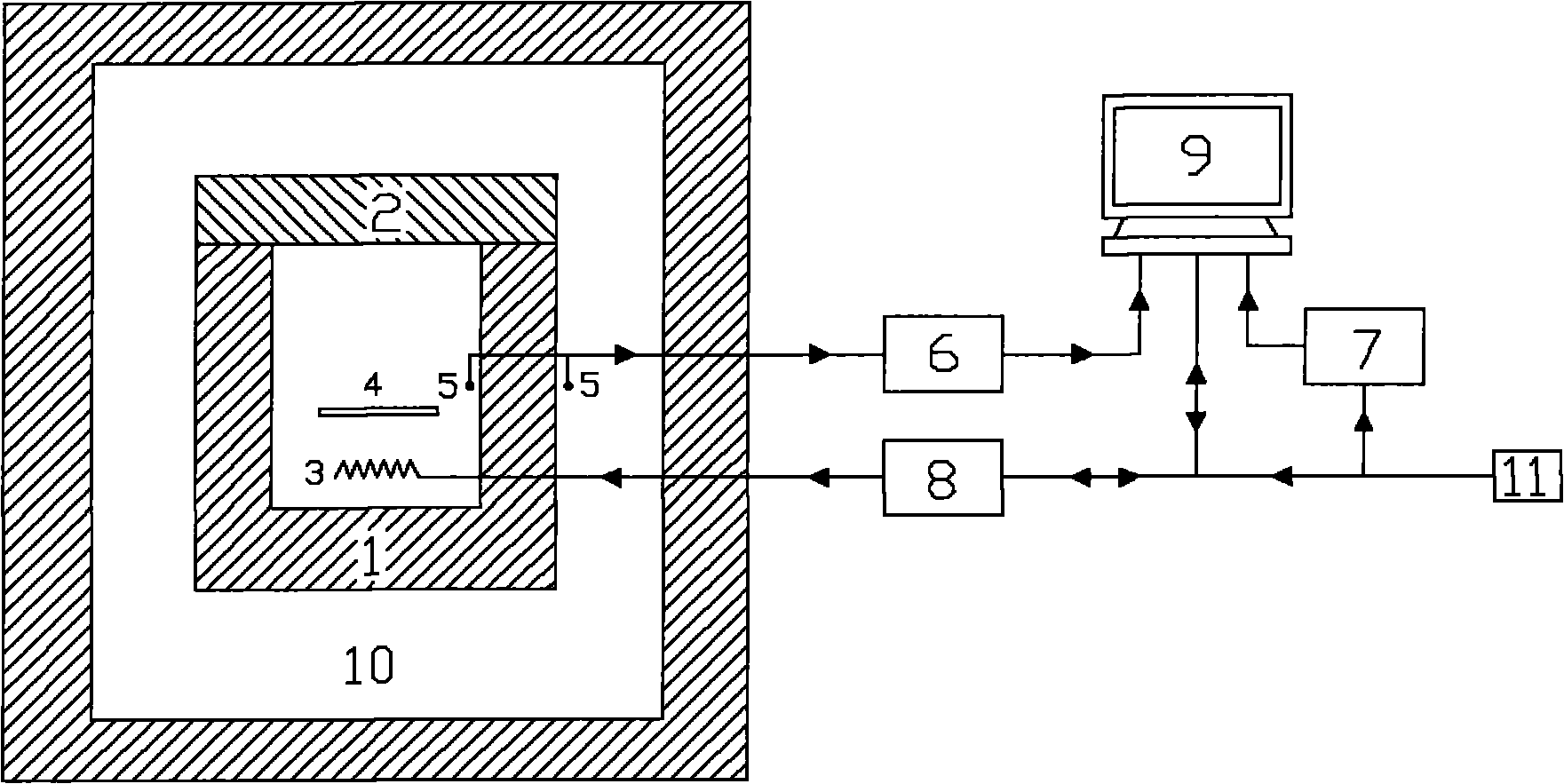

[0045] The principle, specific structure and implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0046] Fig. 1 is the schematic diagram of the structure and principle of the thermal storage performance tester for building materials. The tester includes an environmental chamber 10, a heat preservation bucket 1 with a lid 2, a temperature sensor 5, an A / D converter 6, an electric power sensor 7, D / A converter 8 and computer 9. The thermal insulation barrel is set in the environmental chamber 10, which includes a set of refrigeration system and electric heating system. When the required control temperature of the environmental chamber is lower than the ambient temperature outside the instrument, the refrigeration system operates intermittently to adjust the temperature of the environmental barrel to the required temperature. ; When the required control temperature of the environmental chamber 10 is higher than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com