Patents

Literature

36results about "Gas handling apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

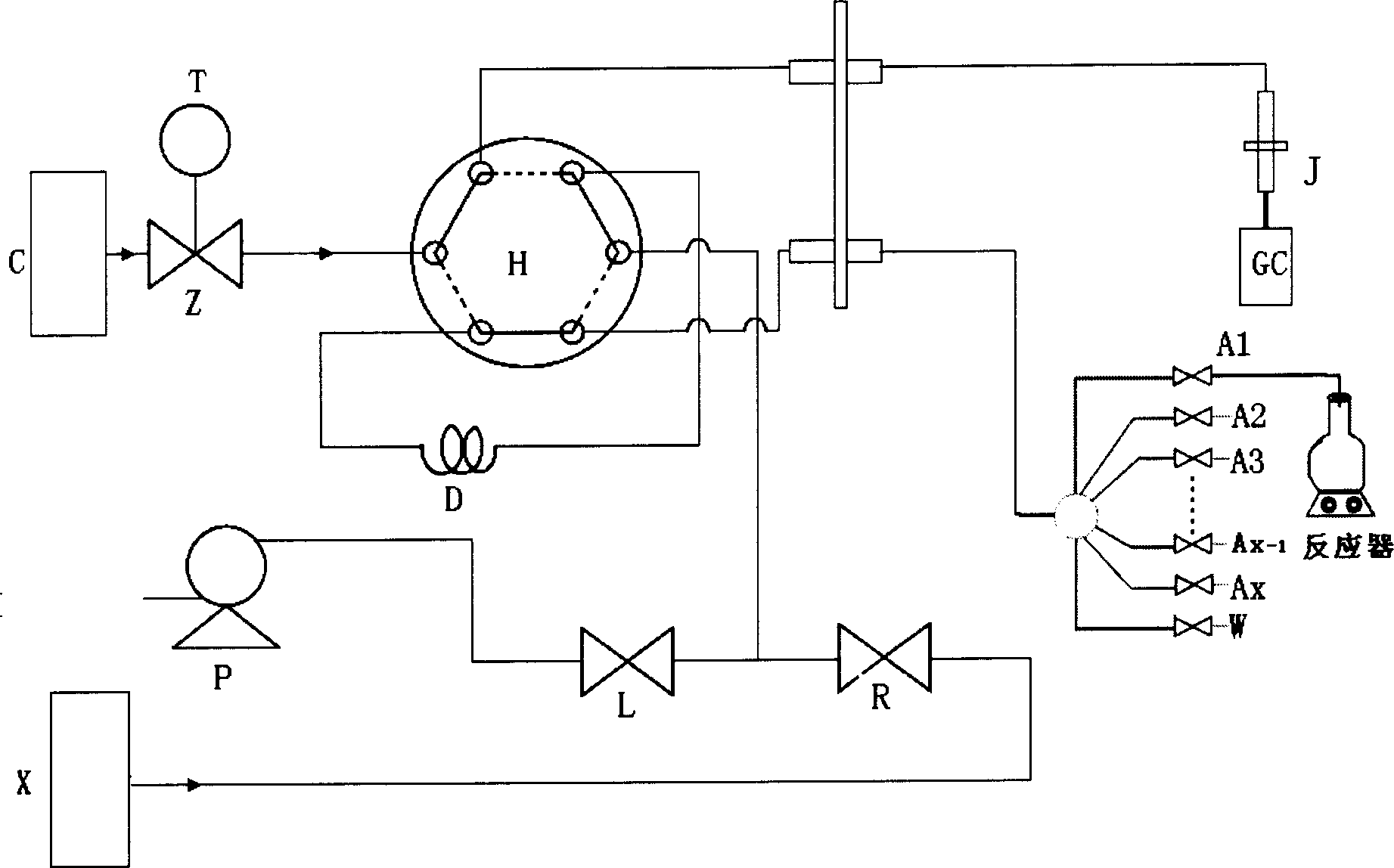

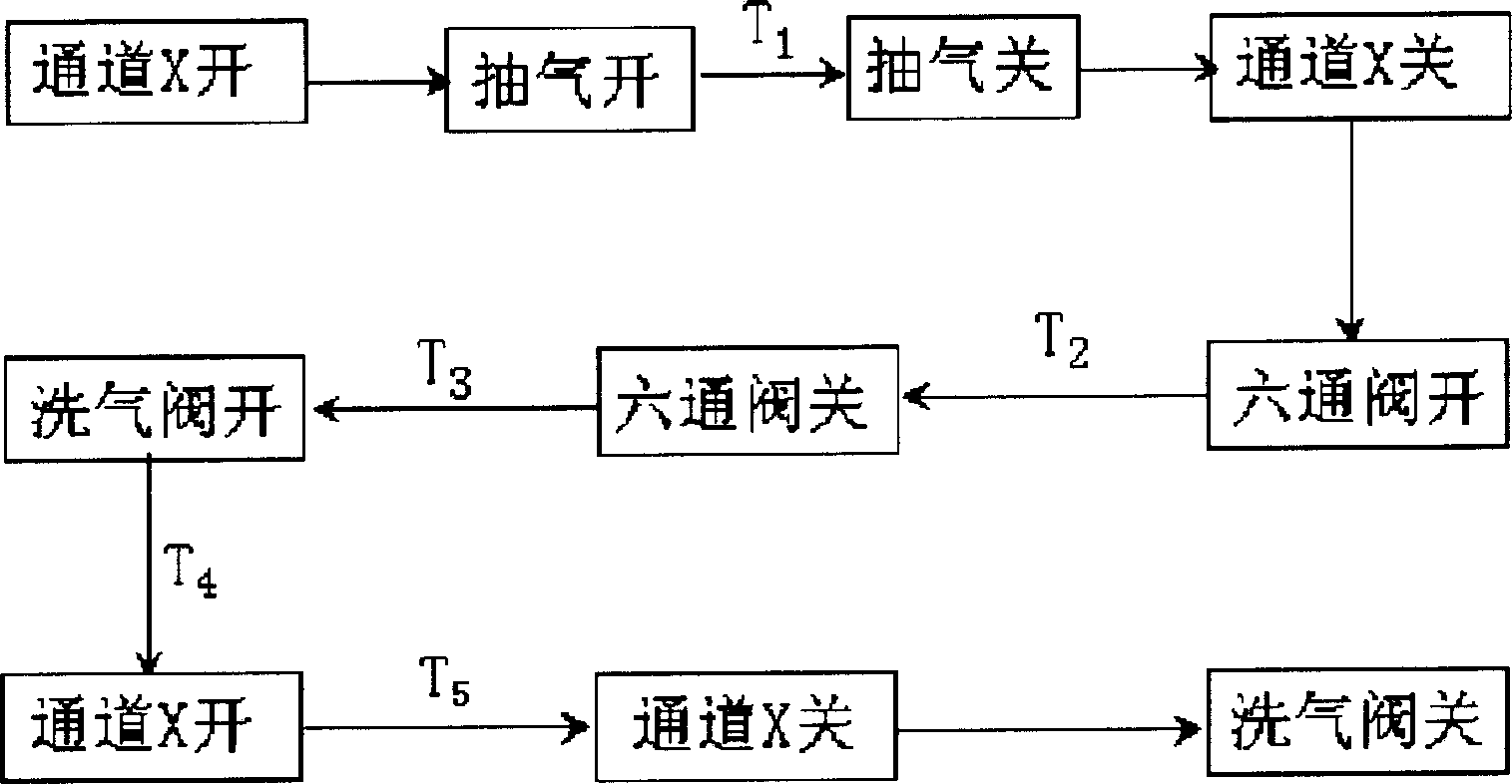

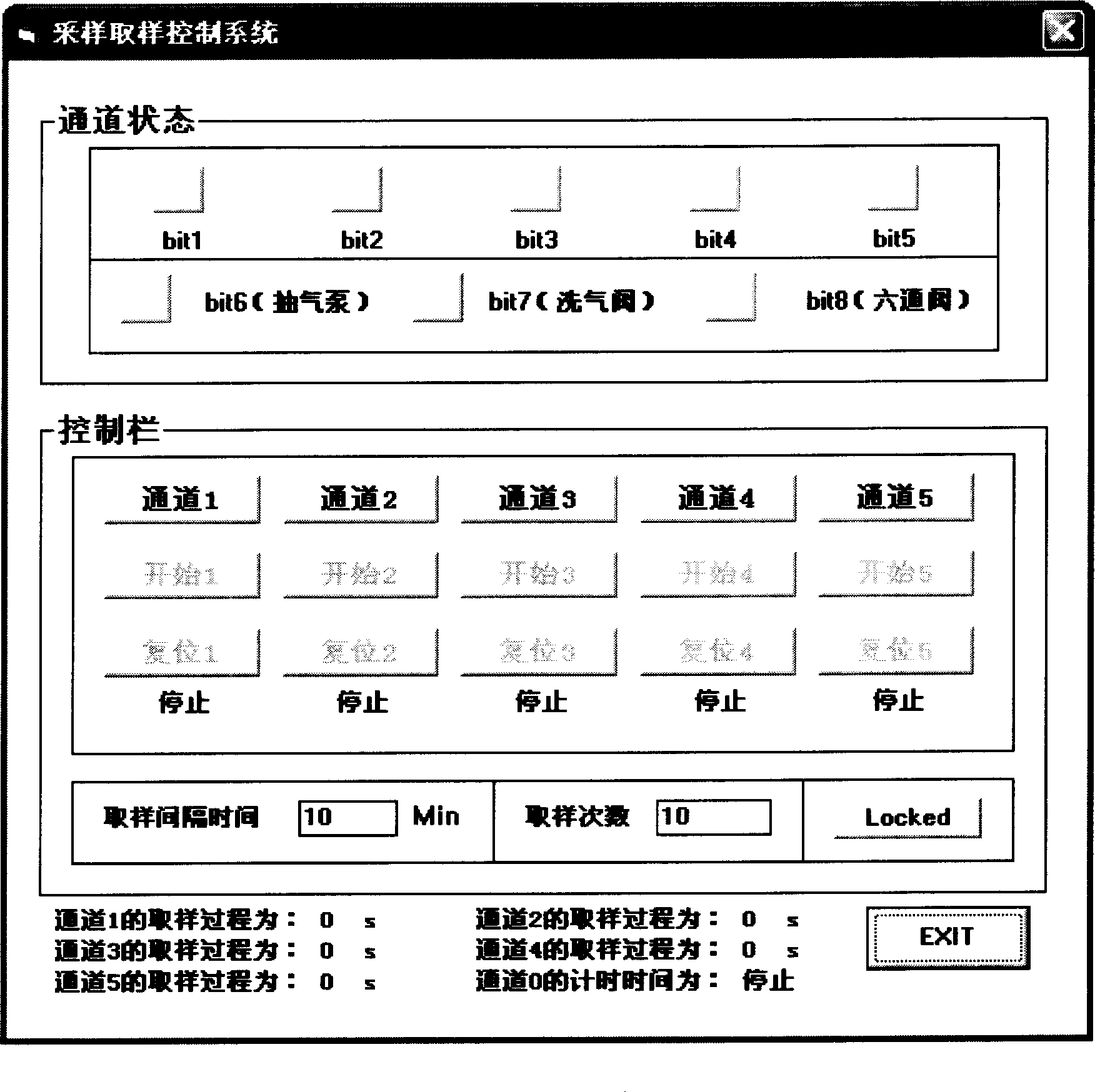

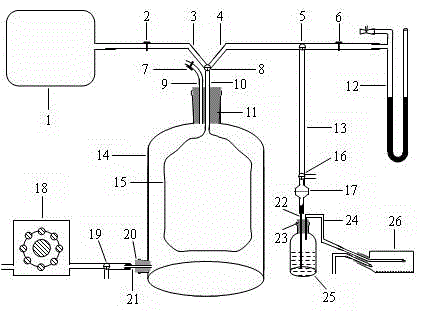

Fast On-line sampler with sample feeding for multi-channel gas and catalyst performance determining system

InactiveCN1818661AKeep the pressure constantTest accurateWithdrawing sample devicesGas handling apparatusAutomatic controlGas cylinder

An on-line quickly sampling and sample feeding device of multichannel gas consists of gas sampling unit formed by gas pipeline, multiple solenoid valves and a microdiaphragm vacuum pump; an fully-automatic six-way valve for feeding gas sample automatically; pipeline washing unit formed by a gas washing bottle and multiple solenoid valves; control unit formed by multiple switches being controlled manfully or being controlled automatically by computer .The property evaluating system of catalyst by utilizing said device is also disclosed .

Owner:XI AN JIAOTONG UNIV

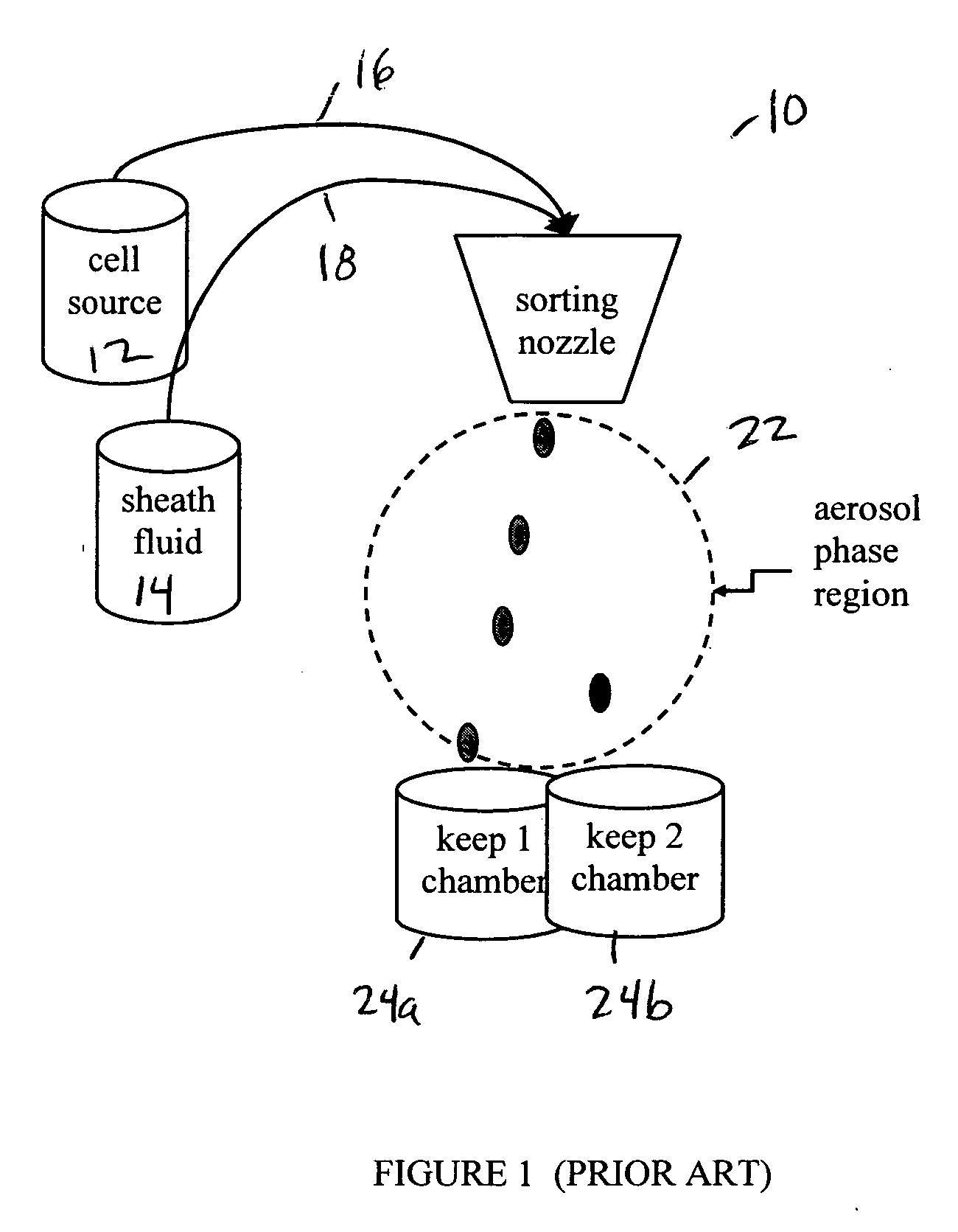

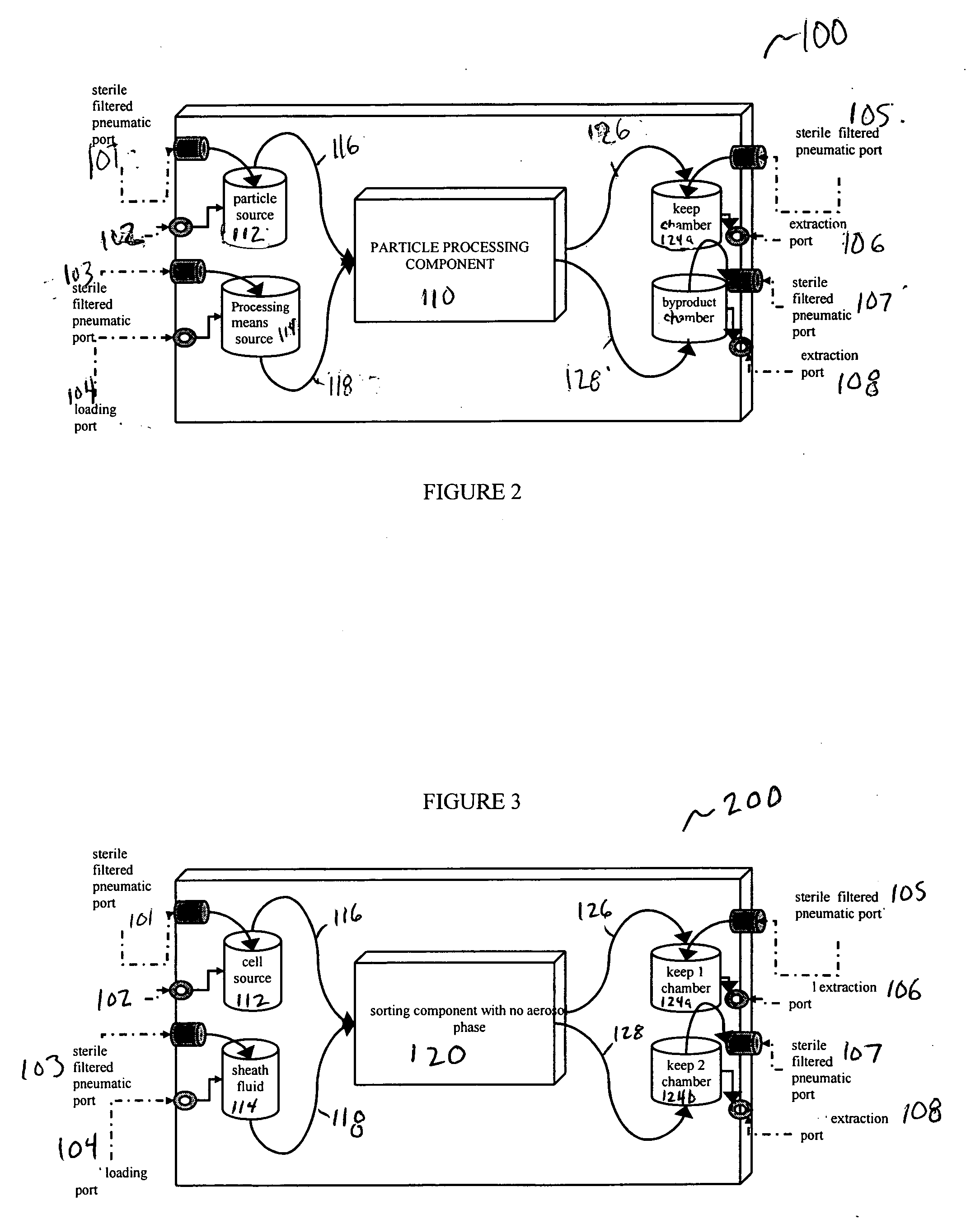

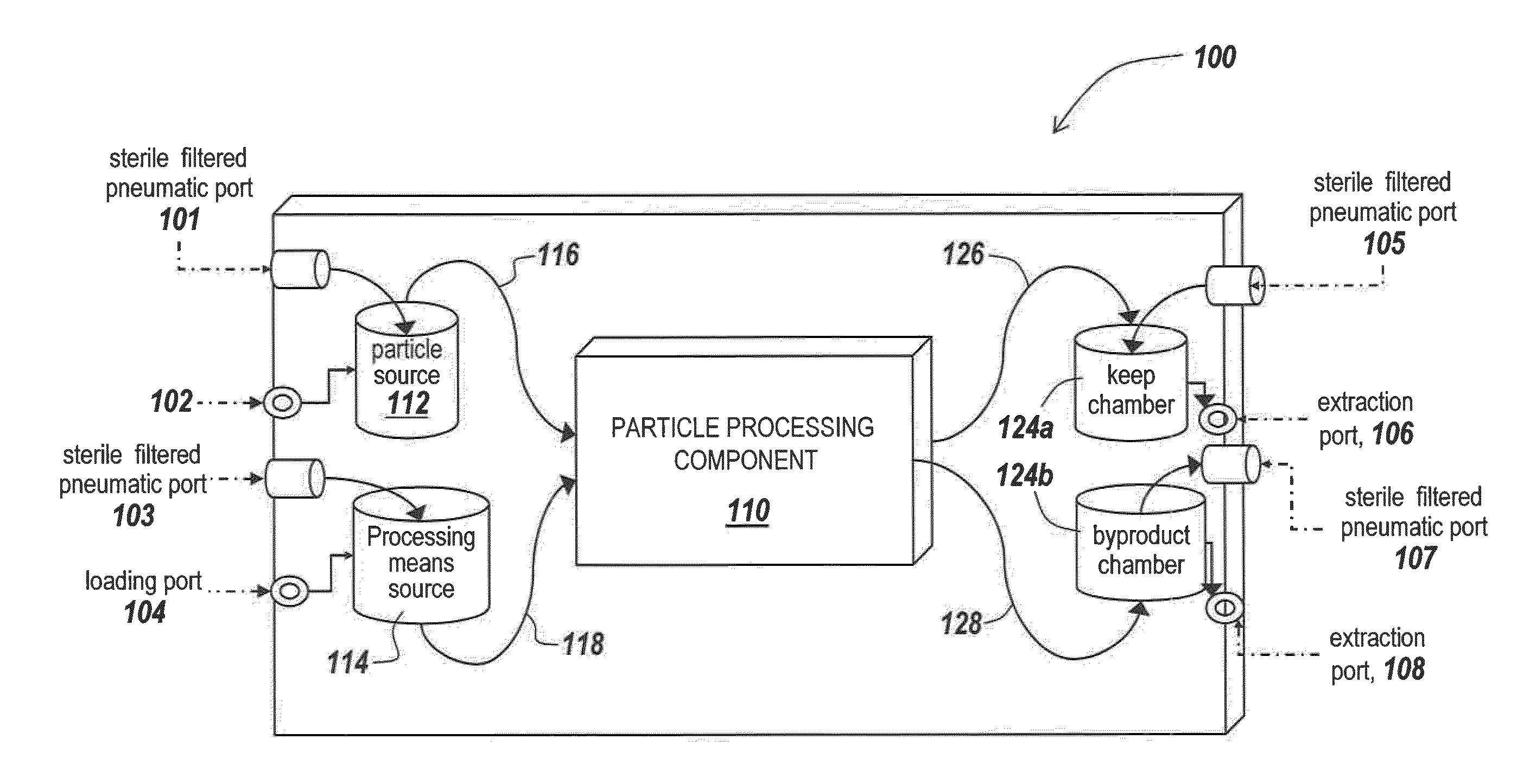

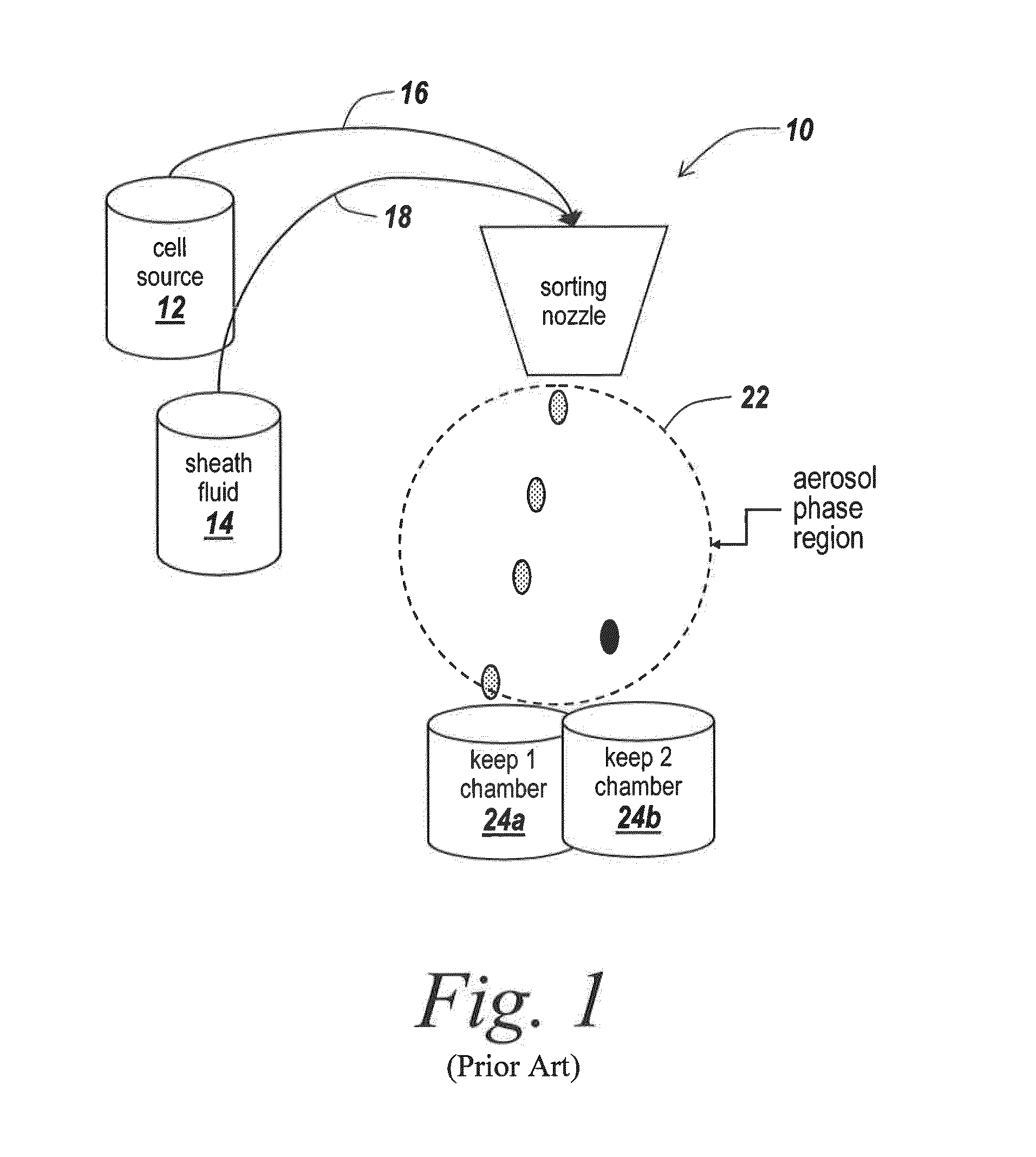

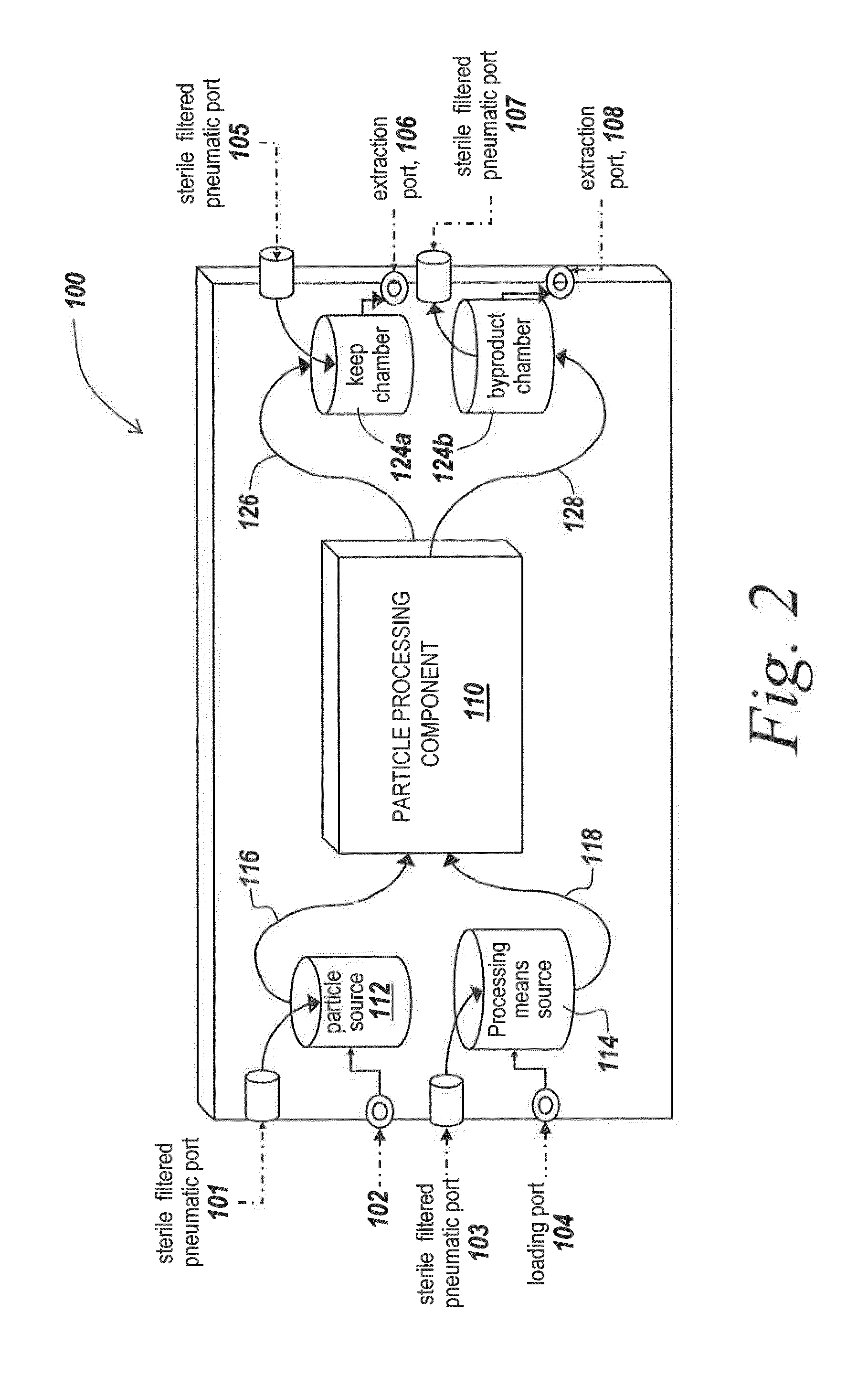

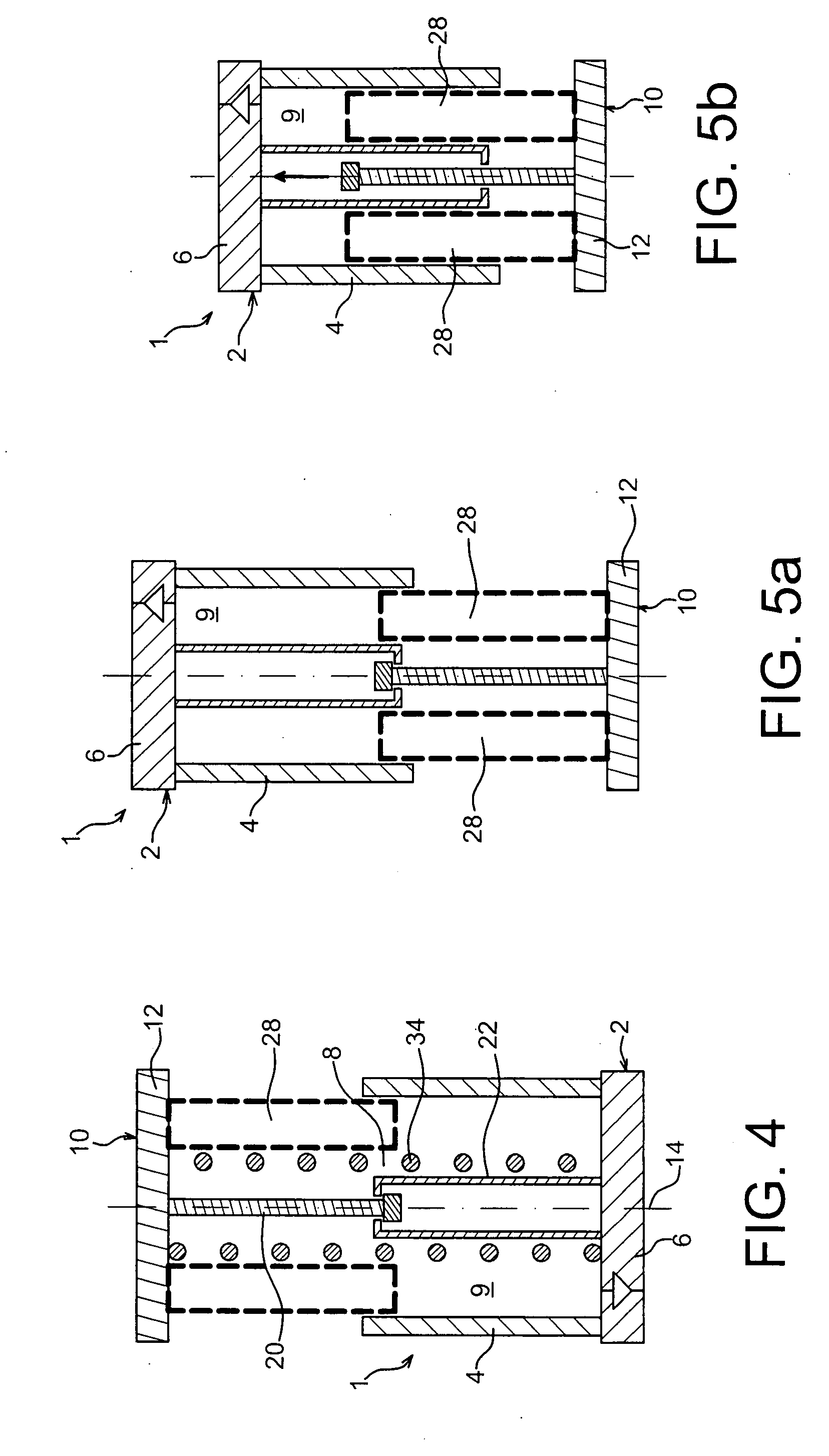

Unitary cartridge for particle processing

ActiveUS20060269446A1Improves or promotes operator isolation and/or product isolationBioreactor/fermenter combinationsBiological substance pretreatmentsOperational systemParticle sorting

A single disposable cartridge for performing a process on a particle, such as particle sorting, encapsulates all fluid contact surfaces in the cartridge for use with microfluidic particle processing technology. The cartridge interfaces with an operating system for effecting particle processing. The encapsulation of the fluid contact surfaces insures, improves or promotes operator isolation and / or product isolation. The cartridge may employ any suitable technique for processing particles.

Owner:CYTONOMEST

Unitary cartridge for particle processing

ActiveUS20120009619A1Improves or promotes operator isolation and/or product isolationBioreactor/fermenter combinationsBiological substance pretreatmentsParticle sortingEngineering

A single disposable cartridge for performing a process on a particle, such as particle sorting, encapsulates all fluid contact surfaces in the cartridge for use with microfluidic particle processing technology. The cartridge interfaces with an operating system for effecting particle processing. The encapsulation of the fluid contact surfaces insures, improves or promotes operator isolation and / or product isolation. The cartridge may employ any suitable technique for processing particles.

Owner:CYTONOMEST

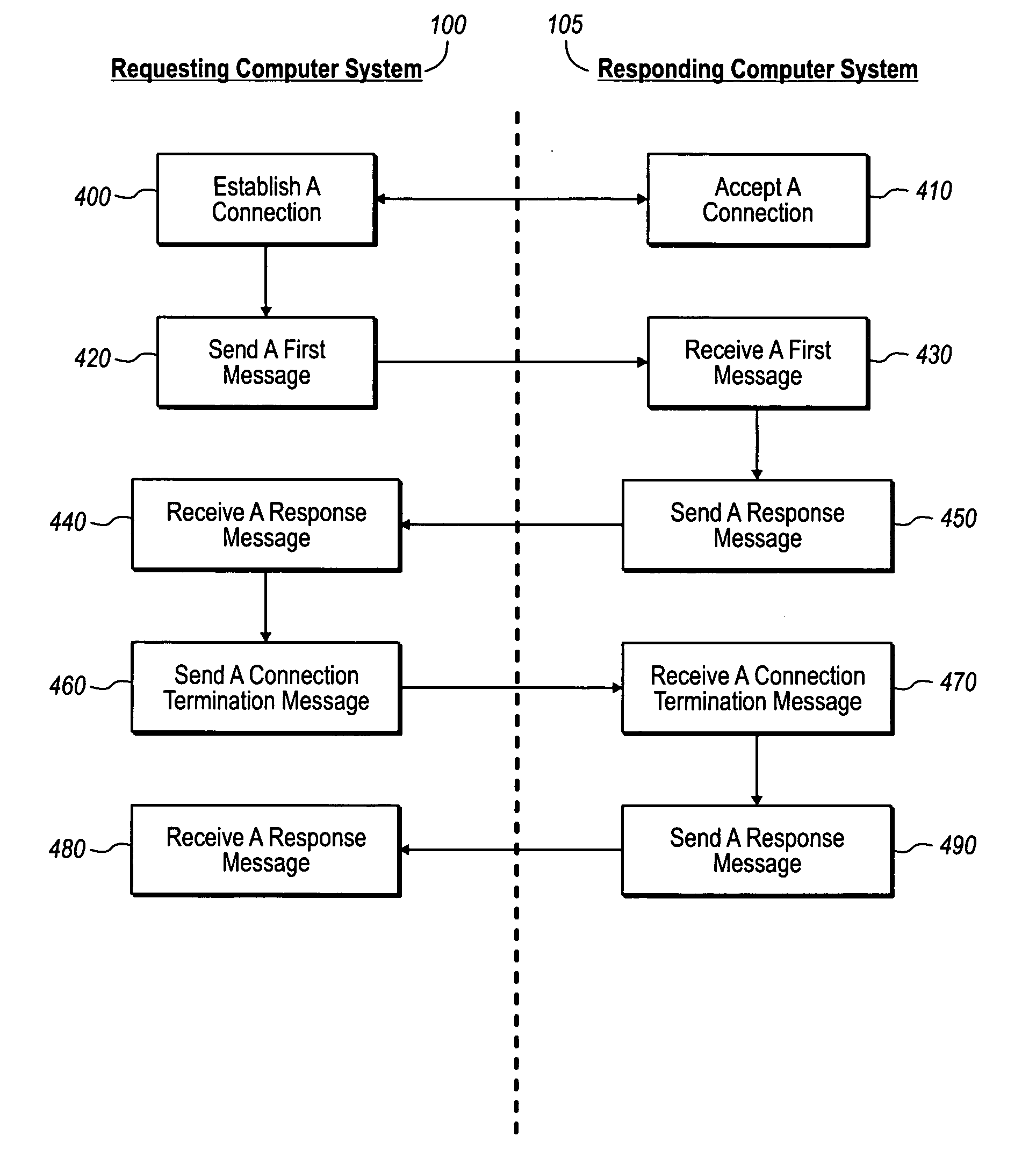

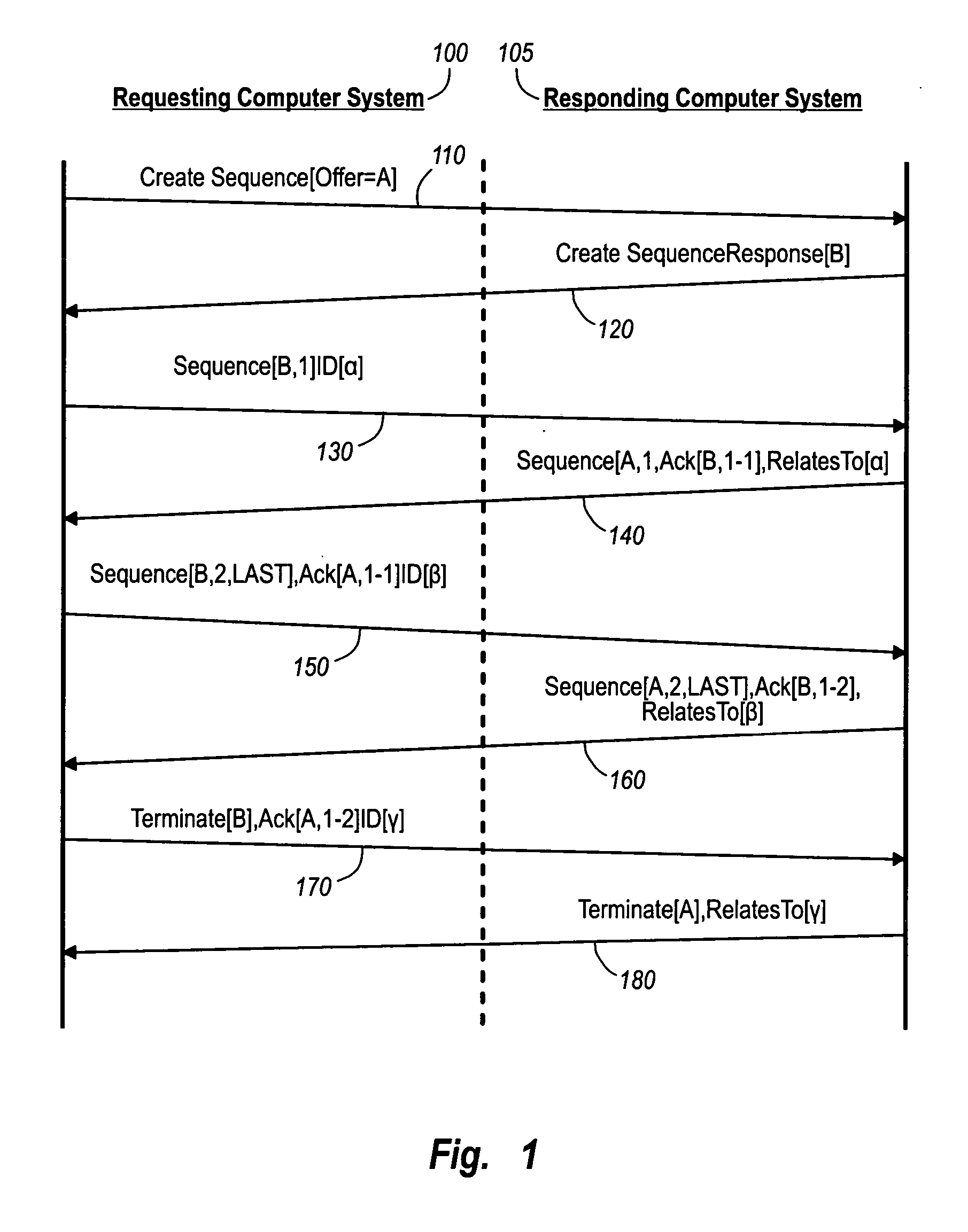

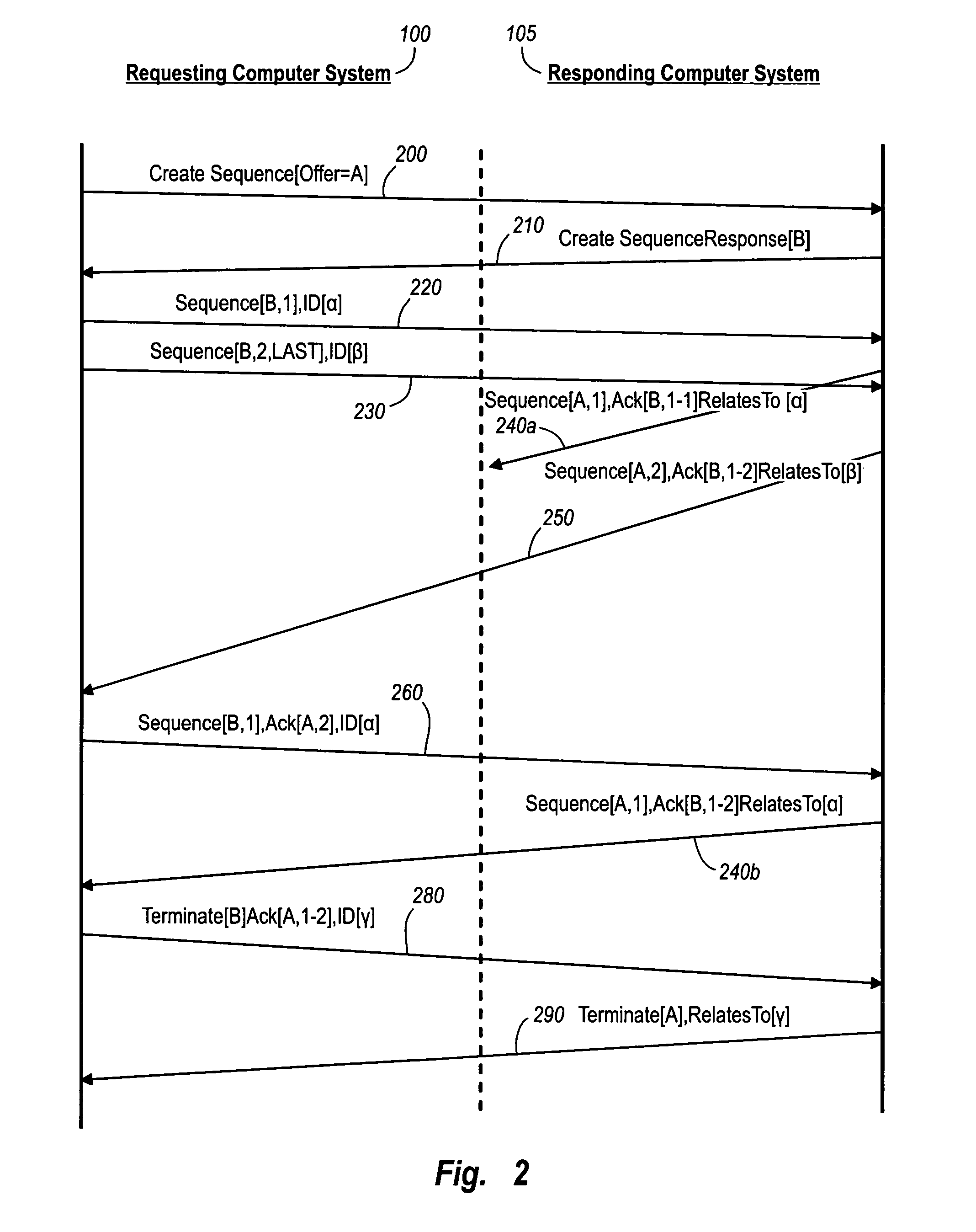

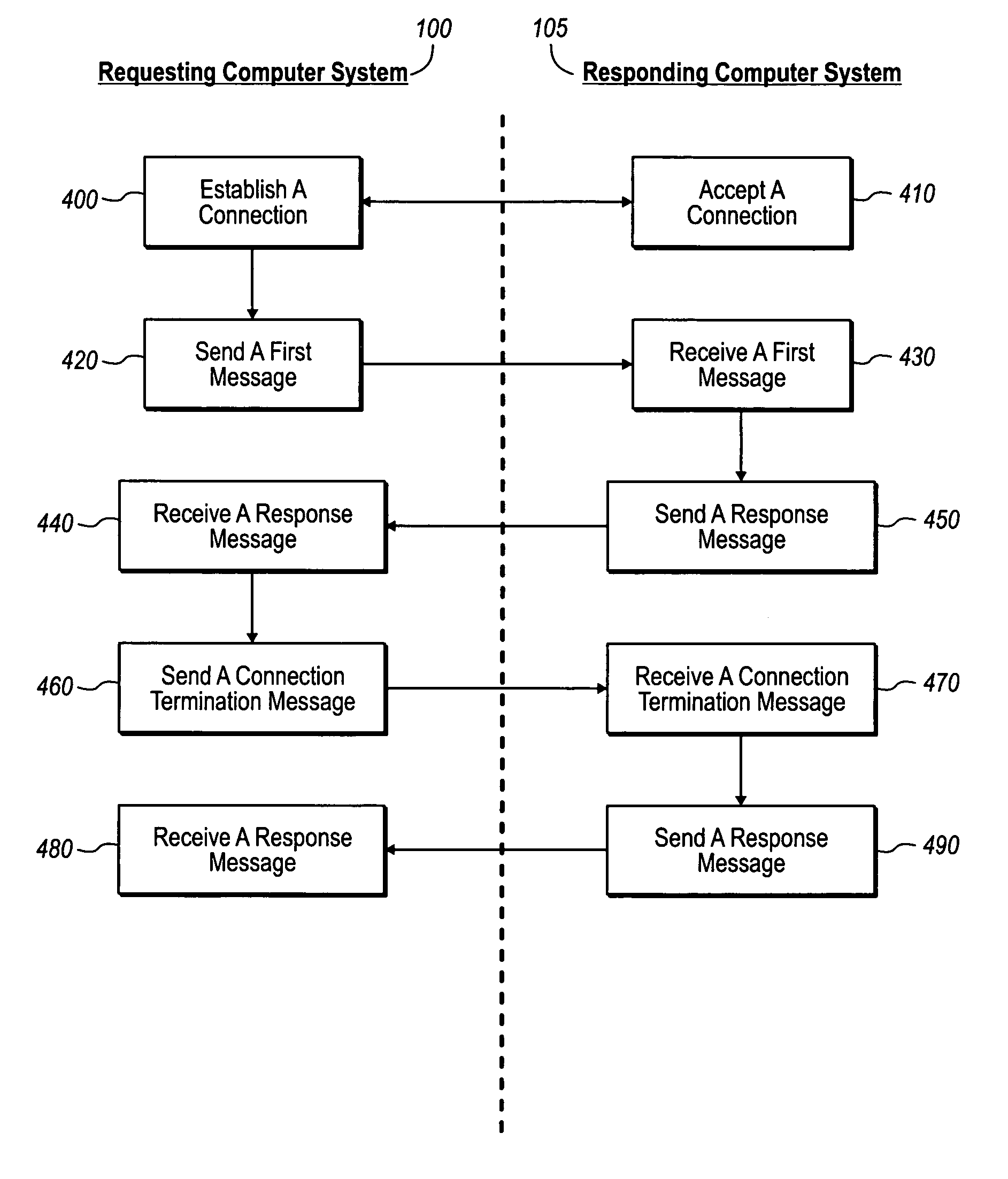

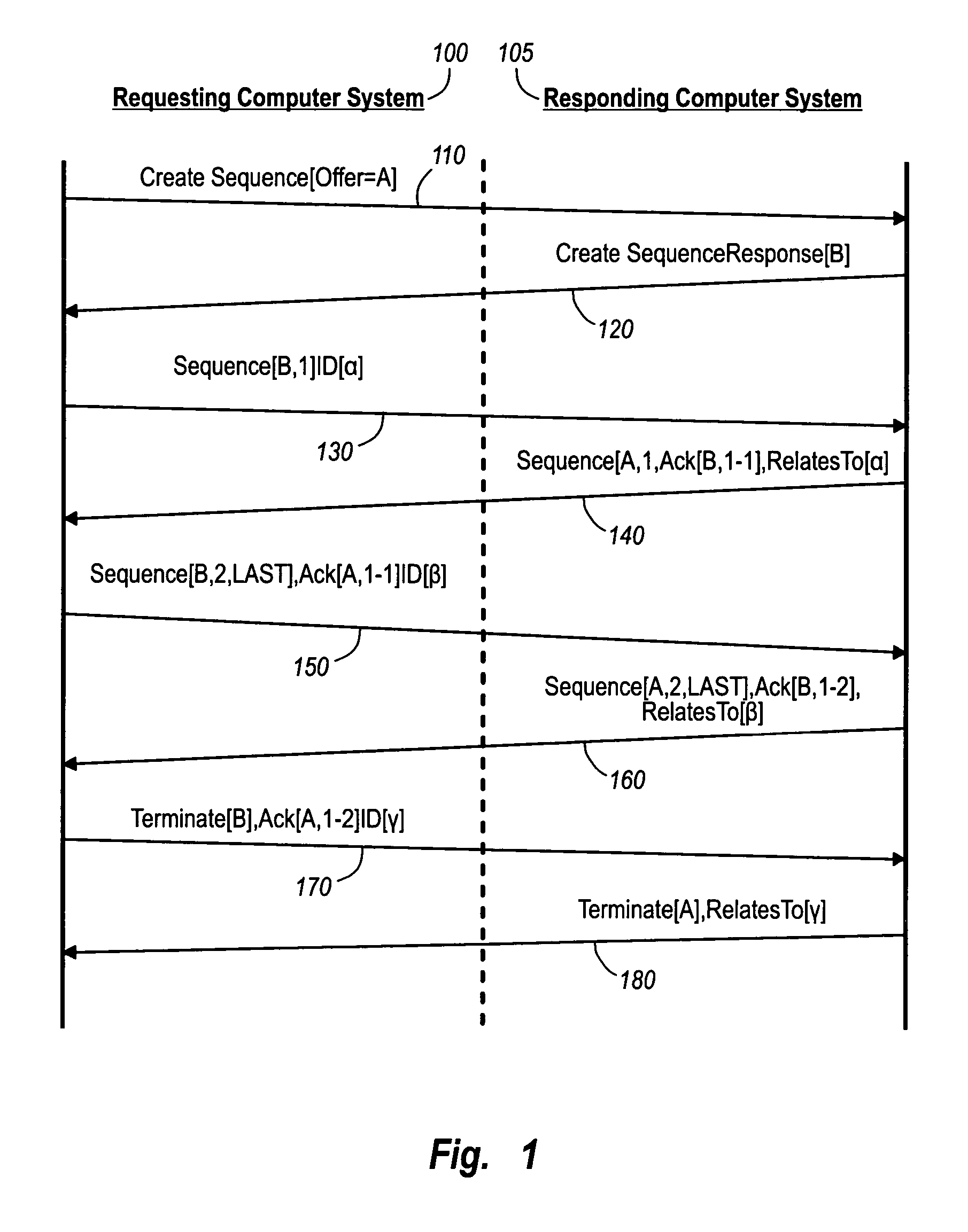

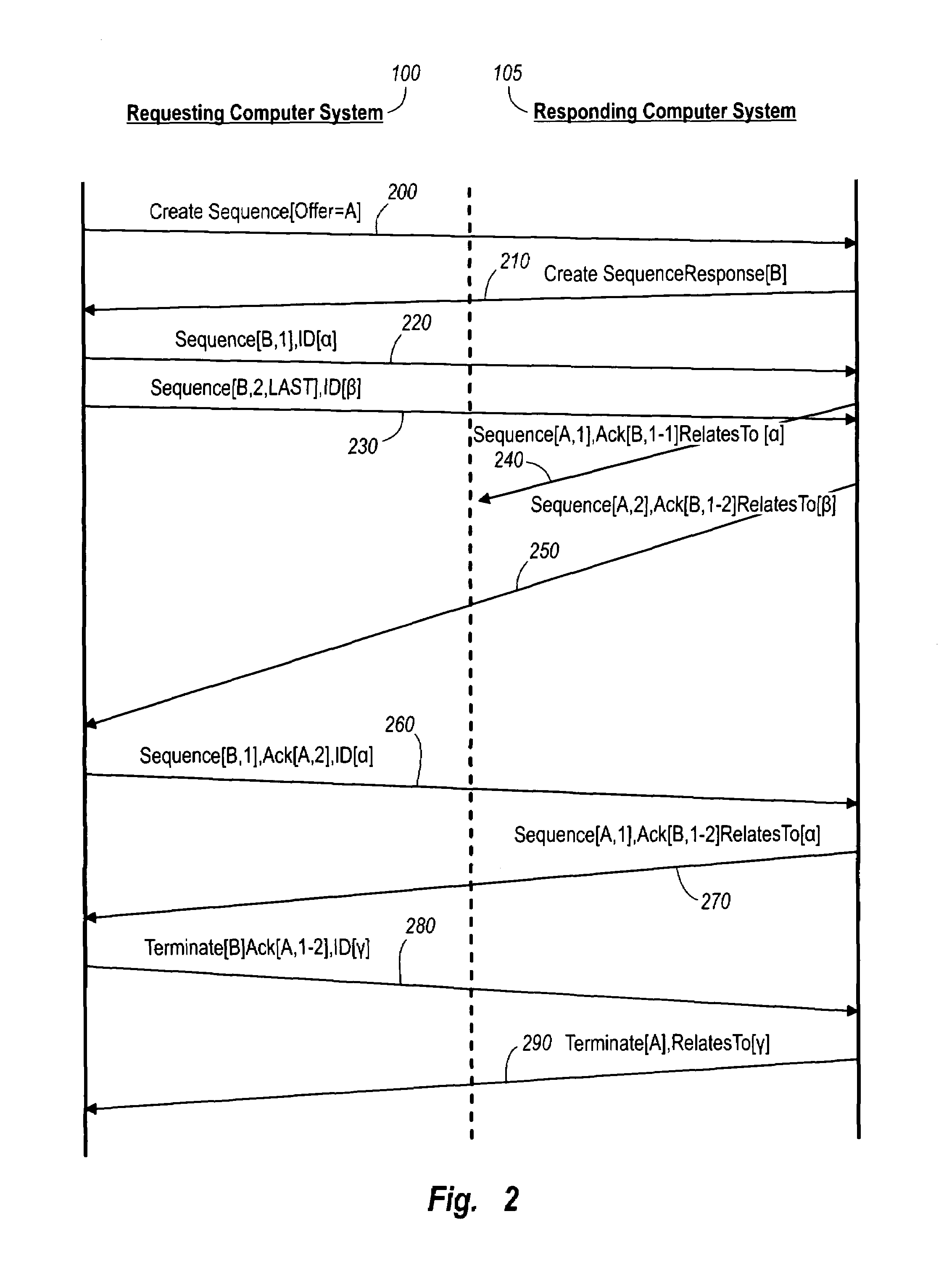

Reliable request-response messaging over a request-response transport

InactiveUS20060206558A1Data processing applicationsHeating or cooling apparatusComputer hardwareSupplicant

A reliable request-response mechanism allows a requesting computer system and a responding computer system in an established end-to-end connection to send and receive messages in a manner that the responding computer system processes a request as intended by the requesting computer system, such that all the message communication is initiated by the requesting computer system. The requesting computer system and responding computer system can accommodate a wide range of messaging failures, such as intermittent network connections or failure of a transport of SOAP intermediary by resending cached versions of previously sent messages, and by acknowledging receipt of each message received. Cached messages on either computer system are deleted after being appropriately acknowledged. After all sent messages have been acknowledged by the responding computer, and the requesting computer has received all of the response messages from the responding computer, the end-to-end connection is terminated with an exchange of connection termination messages.

Owner:MICROSOFT TECH LICENSING LLC

Reliable request-response messaging over a request-response transport

InactiveUS7359919B2Data processing applicationsHeating or cooling apparatusComputer hardwareSupplicant

A reliable request-response mechanism allows a requesting computer system and a responding computer system in an established end-to-end connection to send and receive messages in a manner that the responding computer system processes a request as intended by the requesting computer system, such that all the message communication is initiated by the requesting computer system. The requesting computer system and responding computer system can accommodate a wide range of messaging failures, such as intermittent network connections or failure of a transport of SOAP intermediary by resending cached versions of previously sent messages, and by acknowledging receipt of each message received. Cached messages on either computer system are deleted after being appropriately acknowledged. After all sent messages have been acknowledged by the responding computer, and the requesting computer has received all of the response messages from the responding computer, the end-to-end connection is terminated with an exchange of connection termination messages.

Owner:MICROSOFT TECH LICENSING LLC

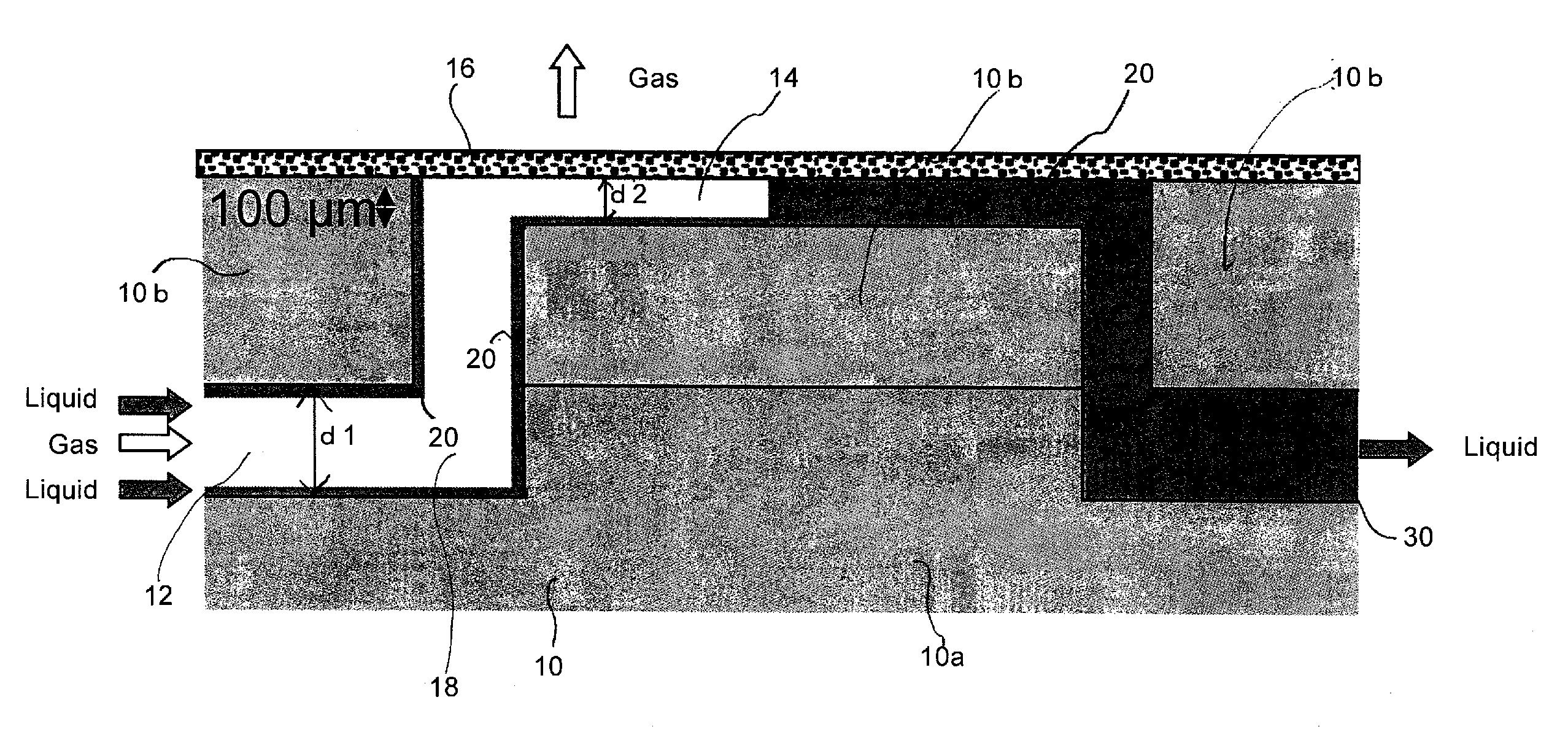

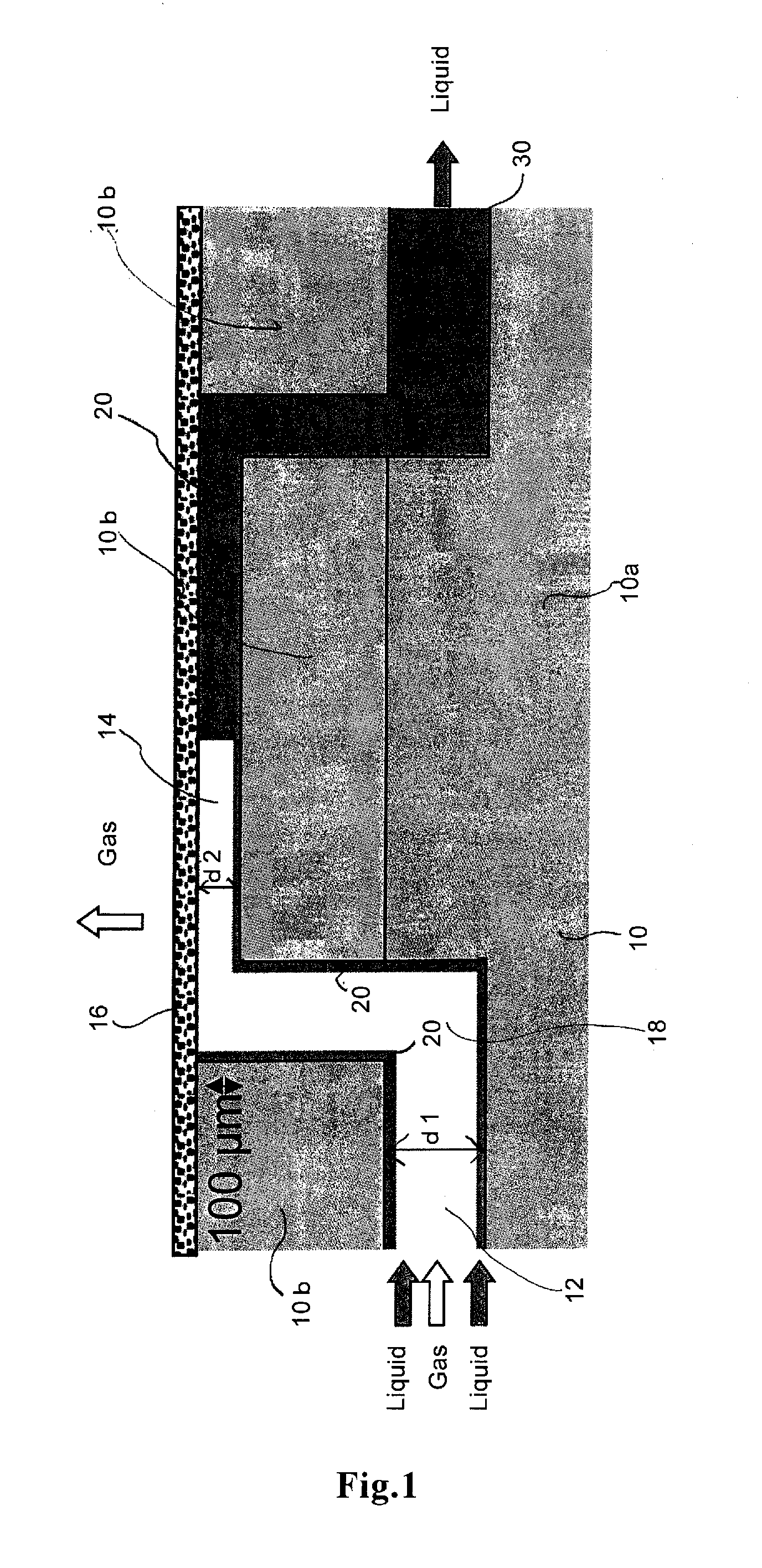

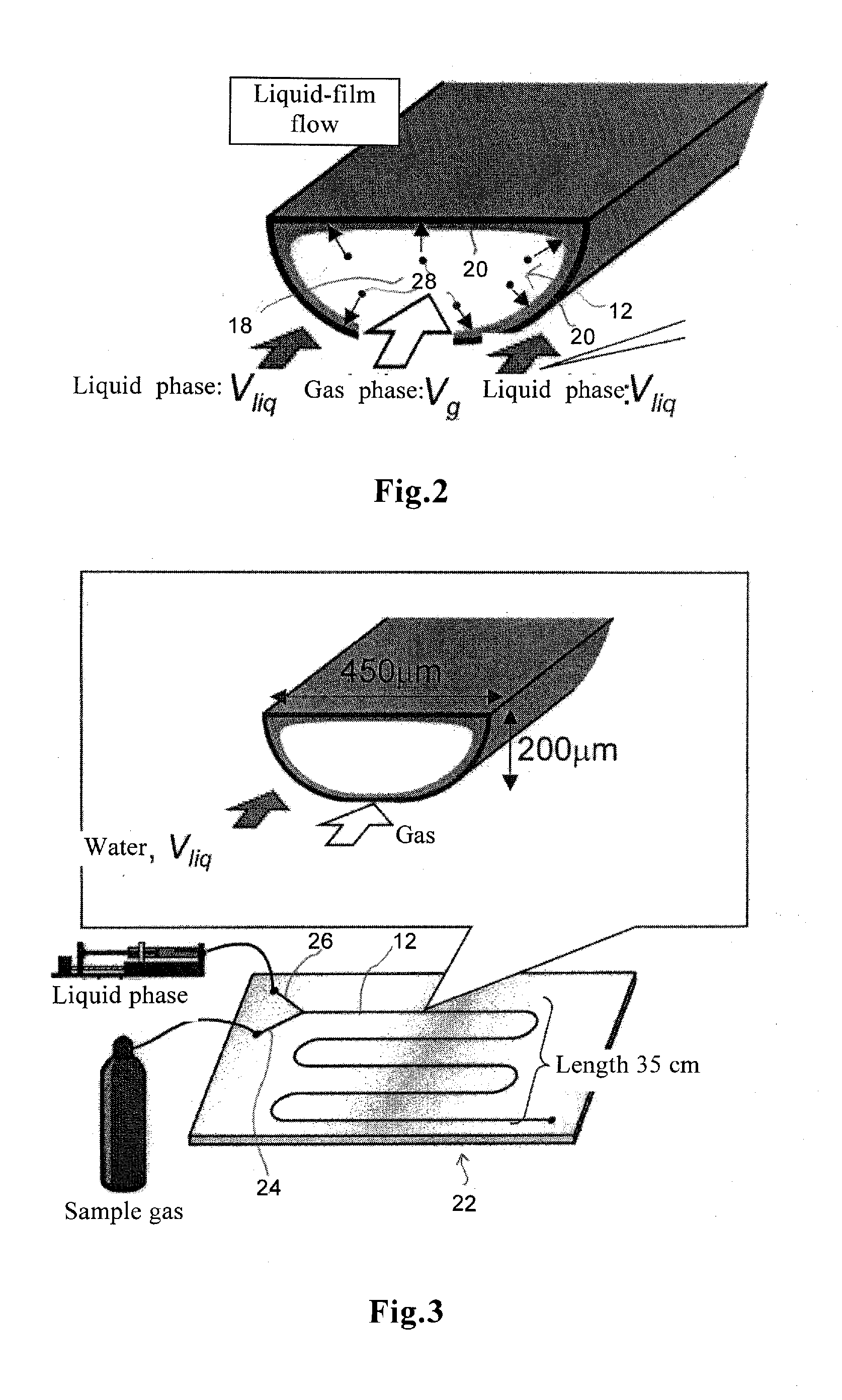

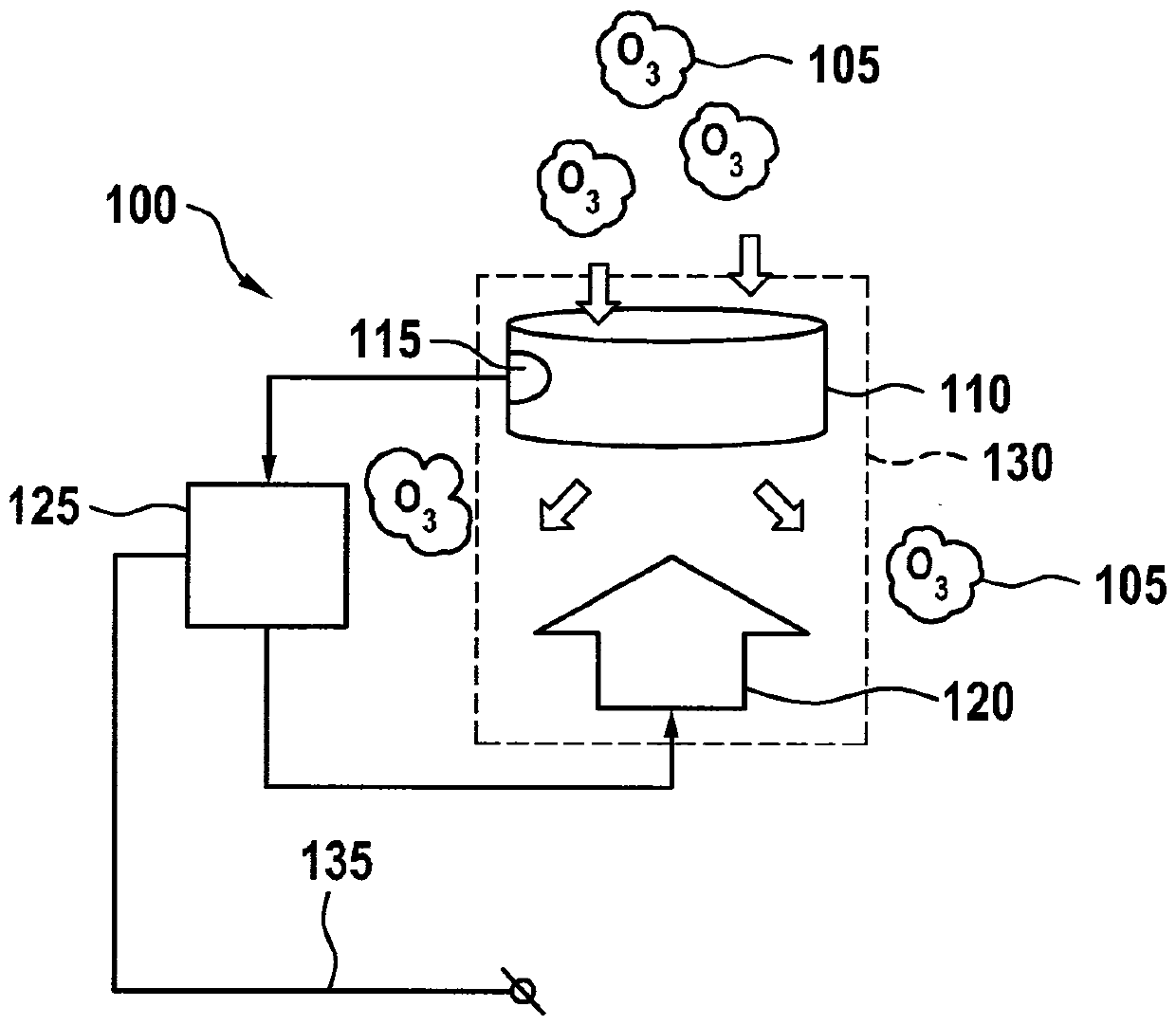

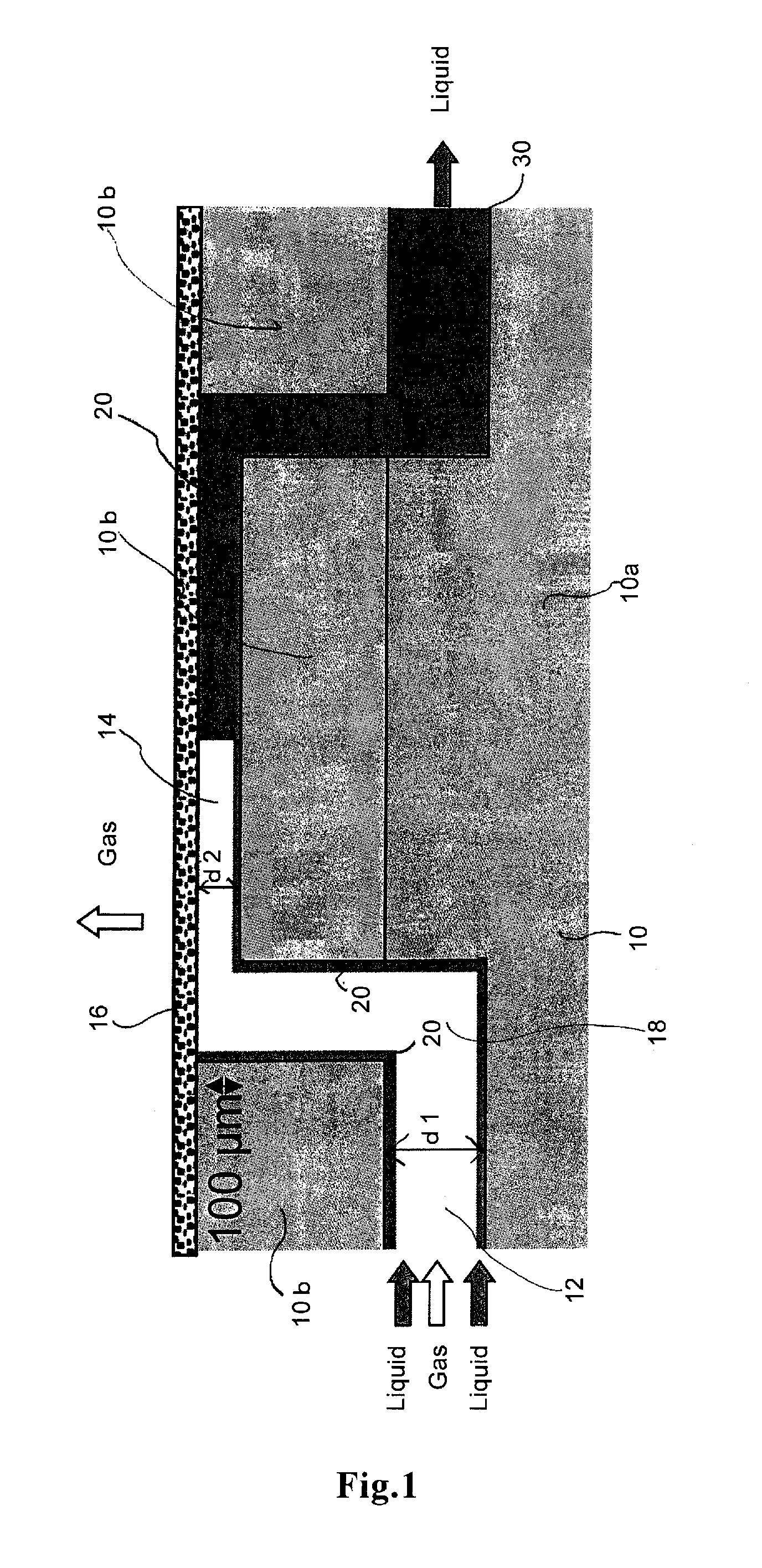

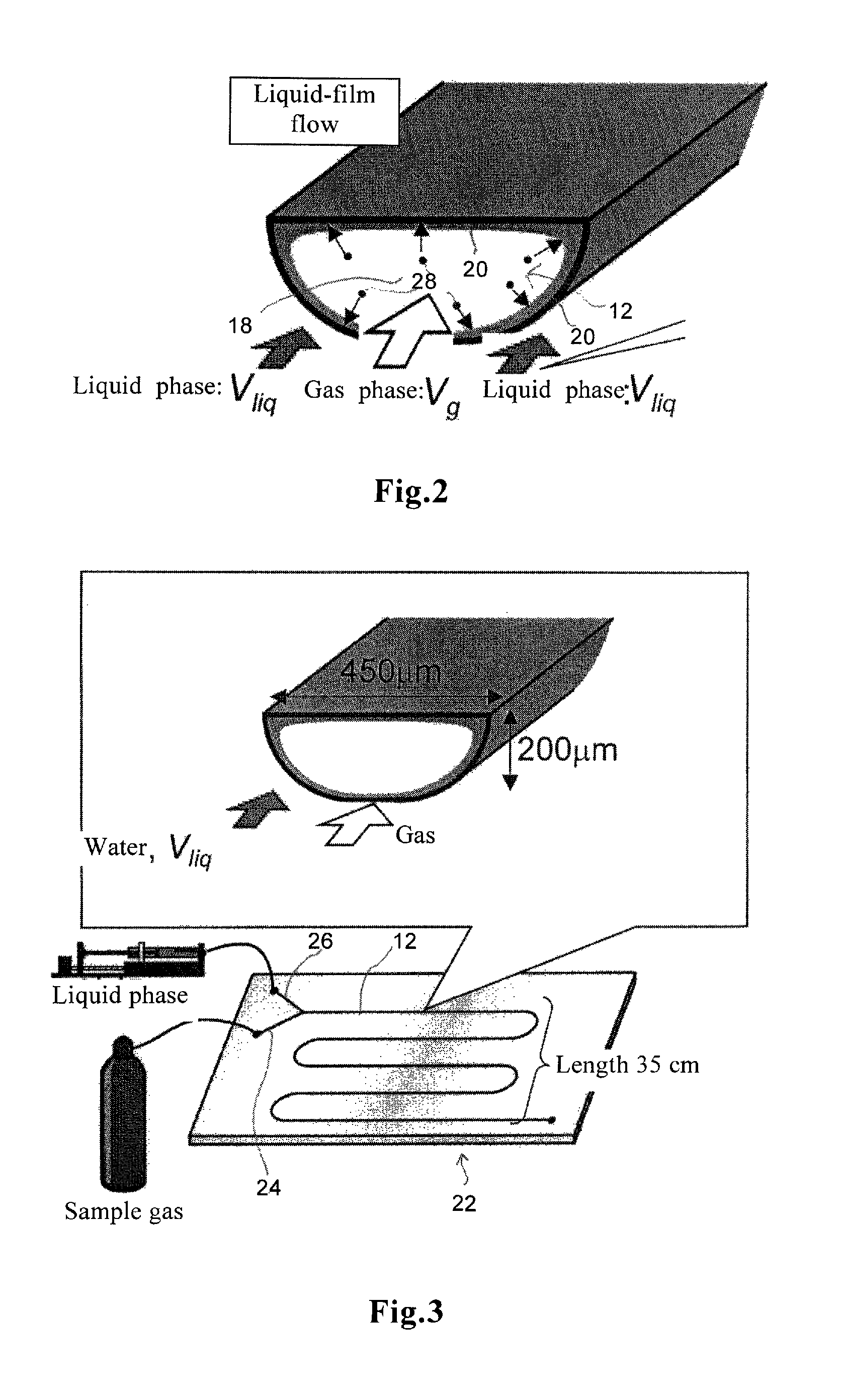

Microchannel chip and method for gas-liquid phase separation using same

ActiveUS20120164743A1High sensitivityGood reproducibilityMaterial analysis by observing effect on chemical indicatorLaboratory glasswaresGas phaseLiquid phase

A microchannel chip having a microchannel formed in a substrate and a gas-liquid phase separation microchannel whose upper part is covered with a porous film, the gas-liquid phase separation microchannel being connected to the downstream end of the microchannel and having a depth of 10 μm to 100 μm. Also, a gas-liquid phase separation method which is a method for separating a liquid-phase flow from a two-phase flow flowing through a microchannel by removing a gas phase, the two-phase flow composed of the gas phase and the liquid phase, which liquid phase flows in the periphery of the above-described microchannel and which gas phase flows interiorly of the liquid-phase flow.

Owner:KANAGAWA INST OF IND SCI & TECH +2

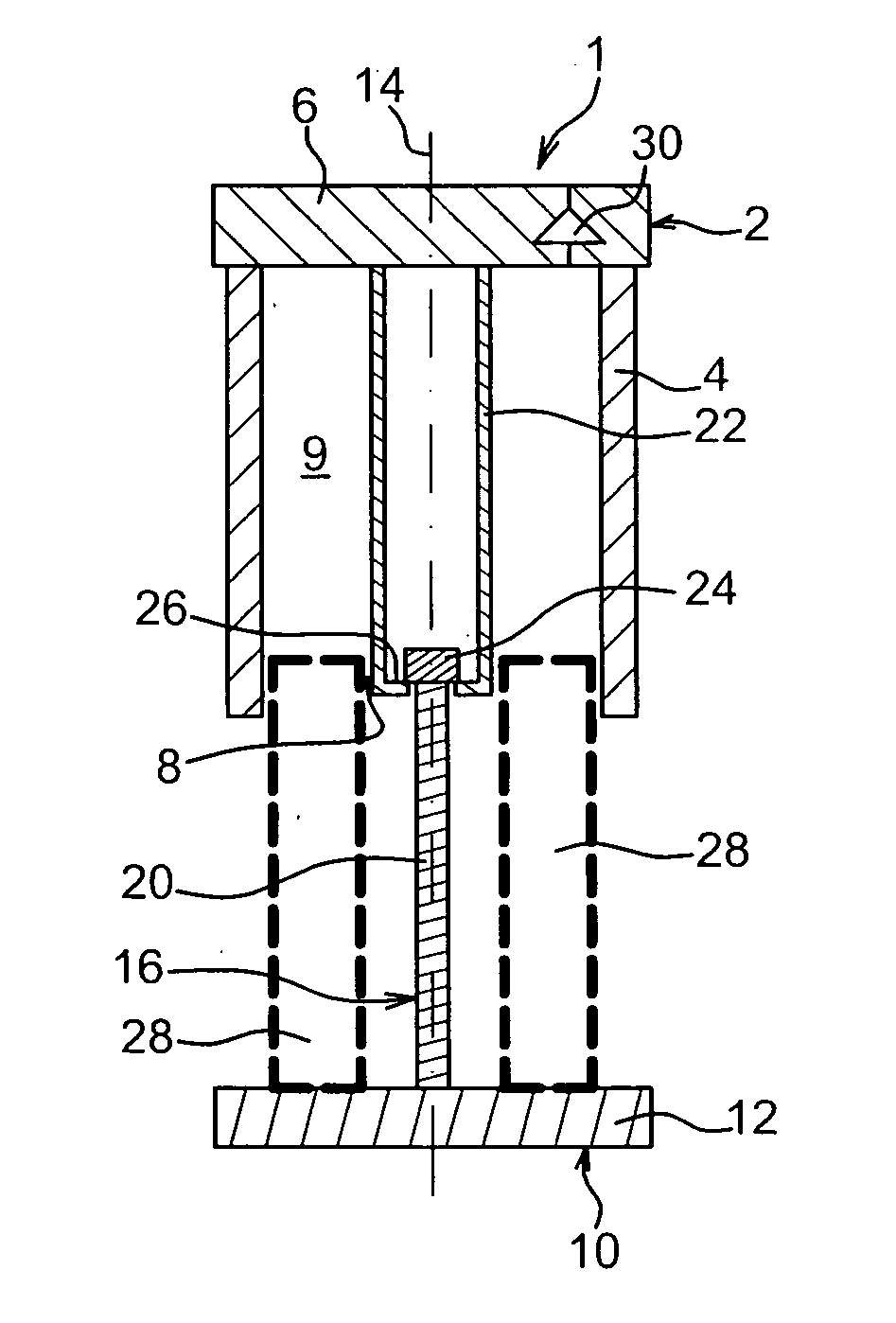

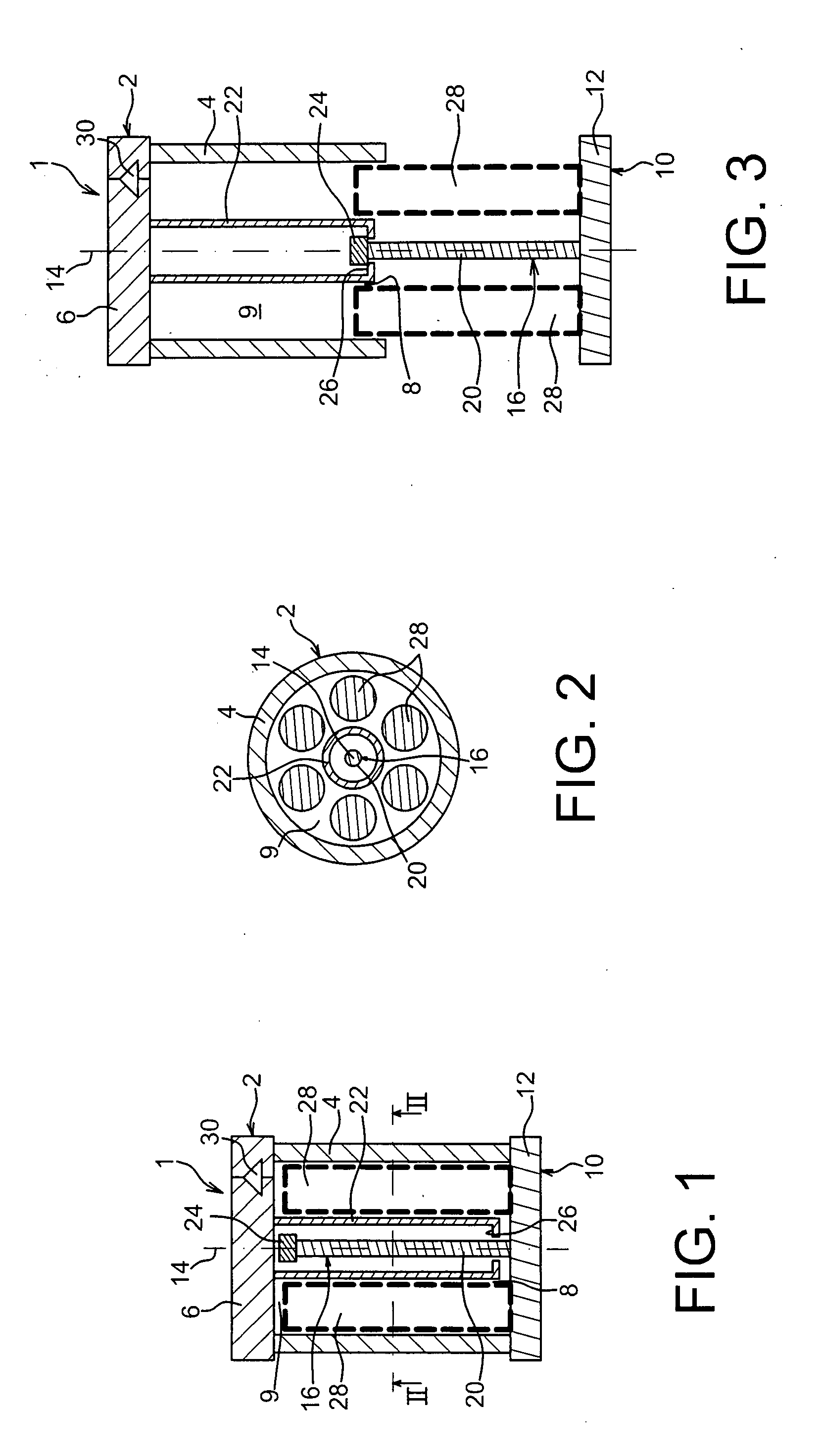

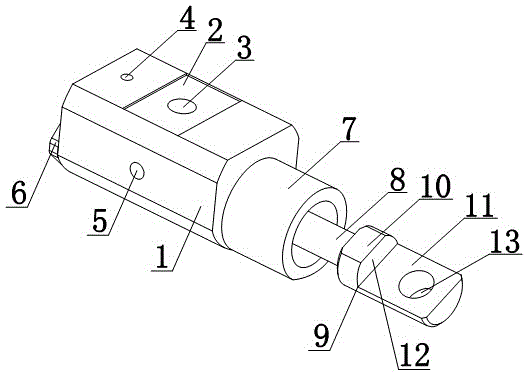

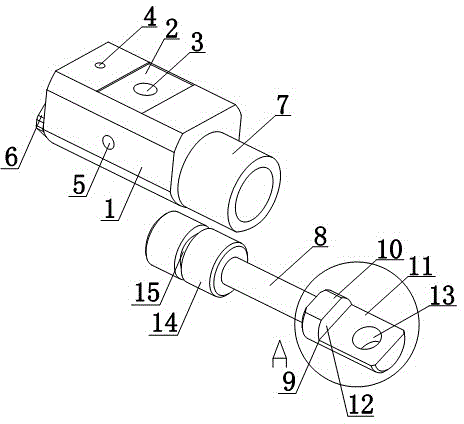

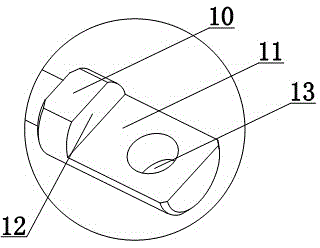

Device for Cleaning and/or Securing a Safe Containment Defined in a Device for Transporting and/or Storing Radioactive Materials

InactiveUS20070297939A1Satisfy effectivenessSimple designSafety arrangmentsLavatory sanitoryMechanical engineeringPhysics

The invention relates to a device (1) for cleaning and / or securing a safe containment defined in a device for transporting and / or storing radioactive materials, which device includes active means capable of cleaning and / or securing said safe containment, and further comprising means forming a casing (2) with an opening (8) and defining a cavity (9) as well as means for closing (10) said opening, which device is designed so that said closure means are capable of being maintained in said closed position by a pressure difference between the inside and the outside of said cavity.

Owner:TN INT (FR)

Device for measuring adsorption/desorption characteristic of surface bed sediments on contaminants and method of using the device

ActiveUS20190212318A1Simple structureEasy to makeMaterial analysis by observing effect on chemical indicatorFlow propertiesPeristaltic pumpMeasurement device

The present invention discloses a device for measuring adsorption / desorption of contaminants onto surface bed sediments and a method of using the device. The measurement device includes a sediment sample disc, a sample holder, a reaction cylinder, a liquid collection cylinder, and a liquid circulating member from inside to outside, the liquid circulating member consisting of rubber pipes and a peristaltic pump. According to the method of using the device for measuring the adsorption / desorption of contaminants onto surface bed sediments, the full contact of bed sediments with pore water and the full exchange of overlying water with pore water are realized through liquid circulation without changing the arrangement modes of the bed sediments; any thickness of bed sediments can be performed on experiments, particularly for thin-layer bed sediments; and natural permeation and accelerated permeation of pore water through bed sediments can be switched simply by adjusting the flow rates of the peristaltic pump and by opening / closing of vent holes. Adsorption characteristic parameters obtained through the device and the method provide, for water quality models, data support which conforms to the natural existing condition of bed sediments and is more scientific and reasonable, and the device and the method achieve significant environmental benefits.

Owner:HOHAI UNIV

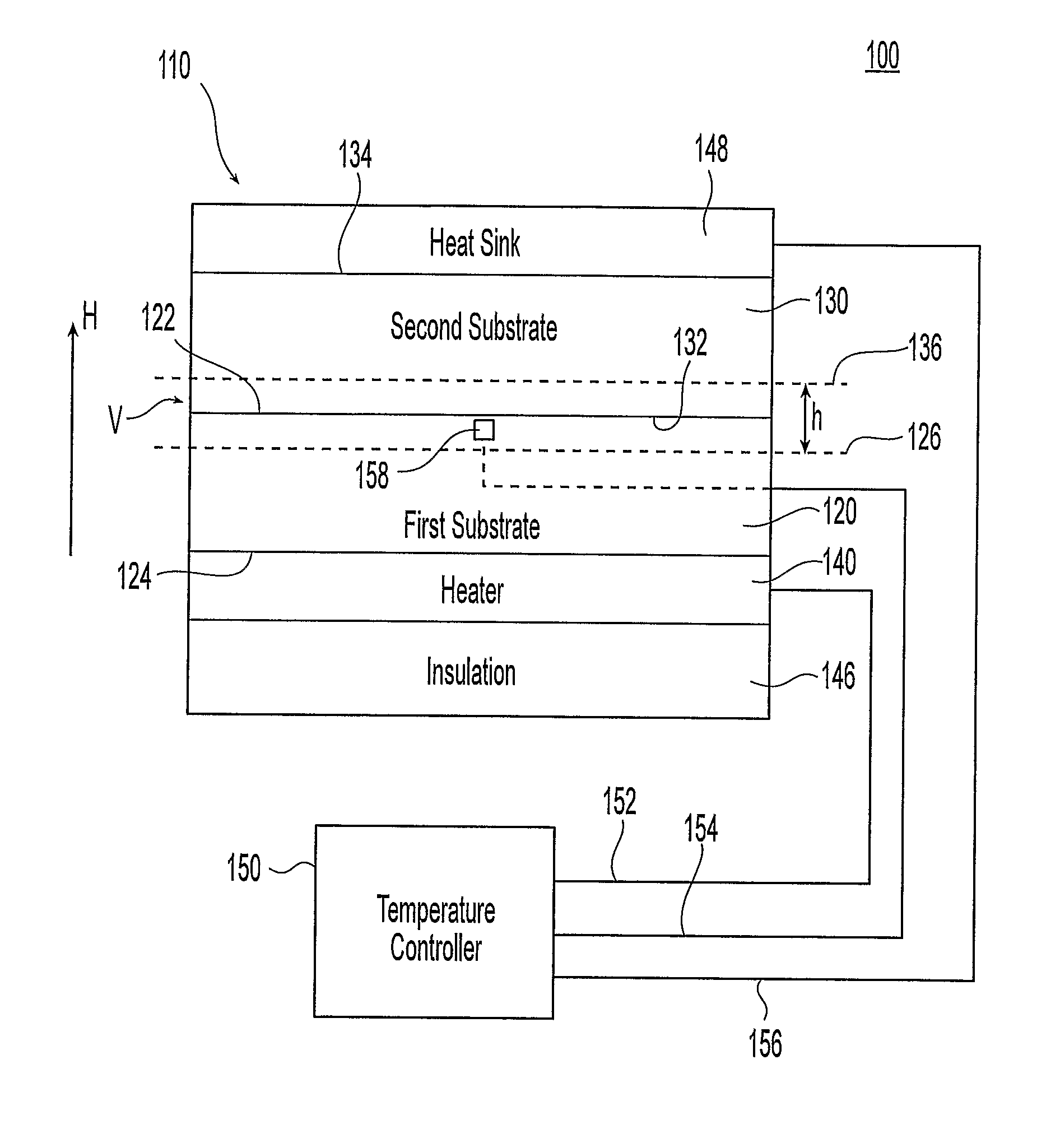

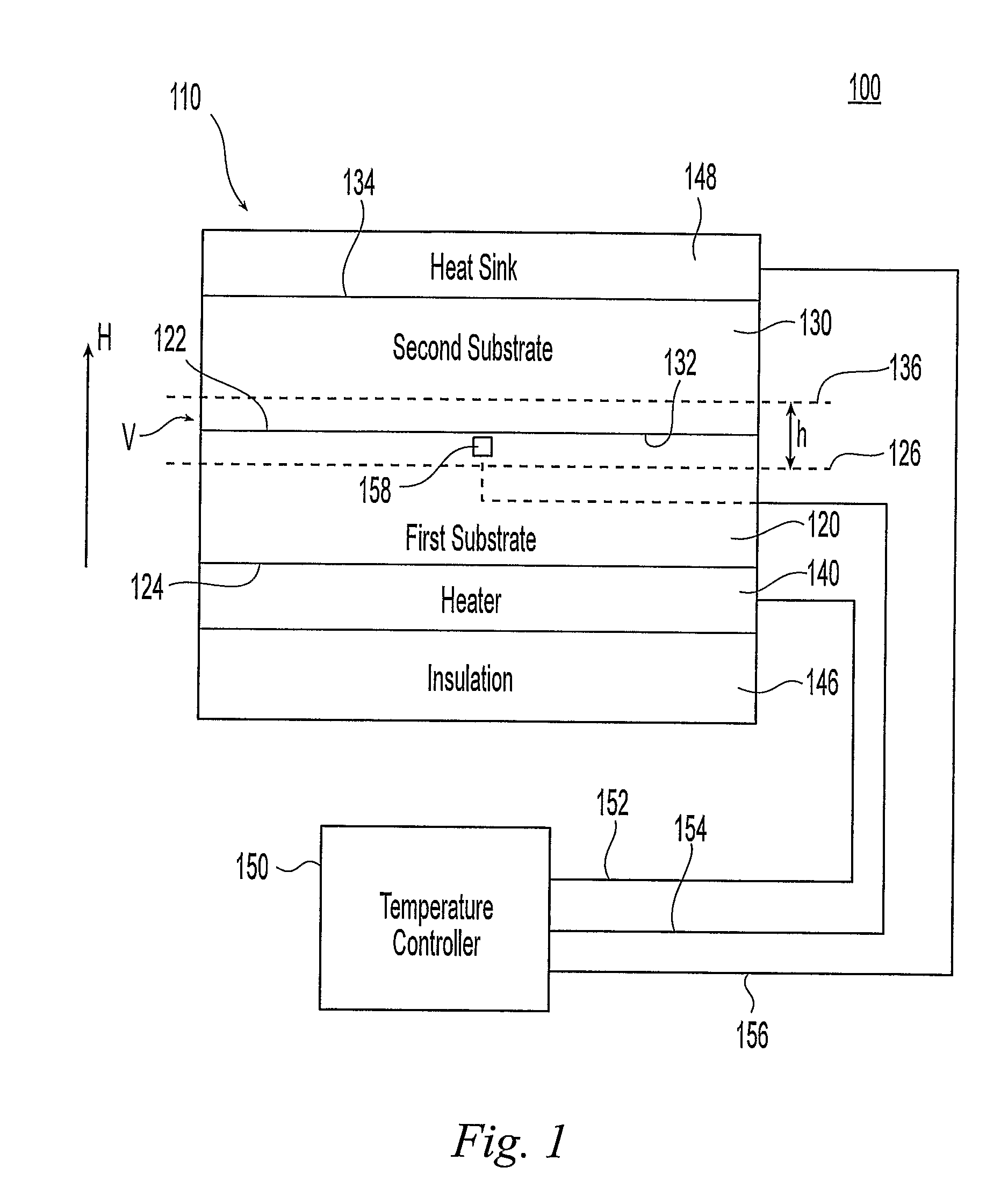

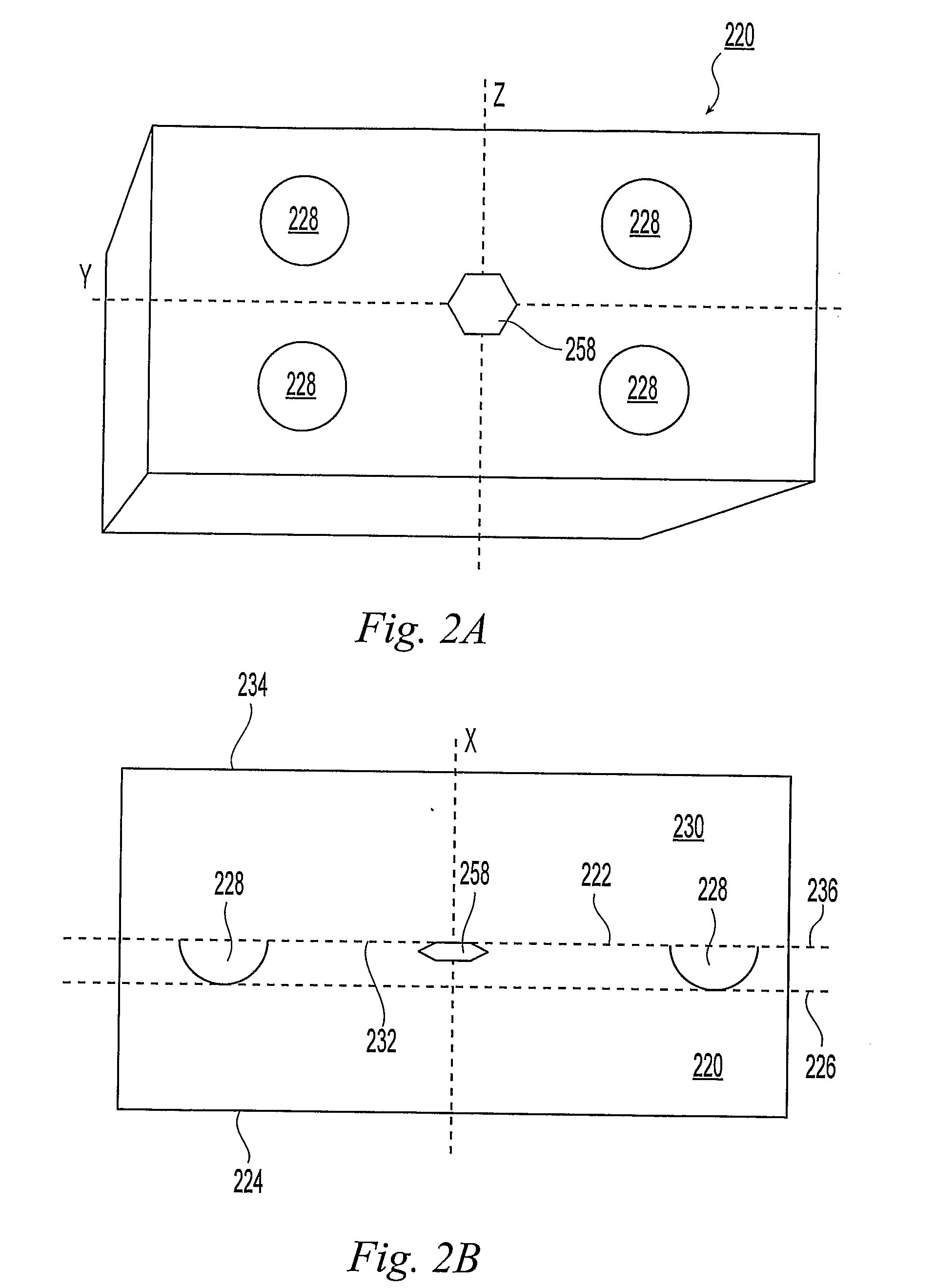

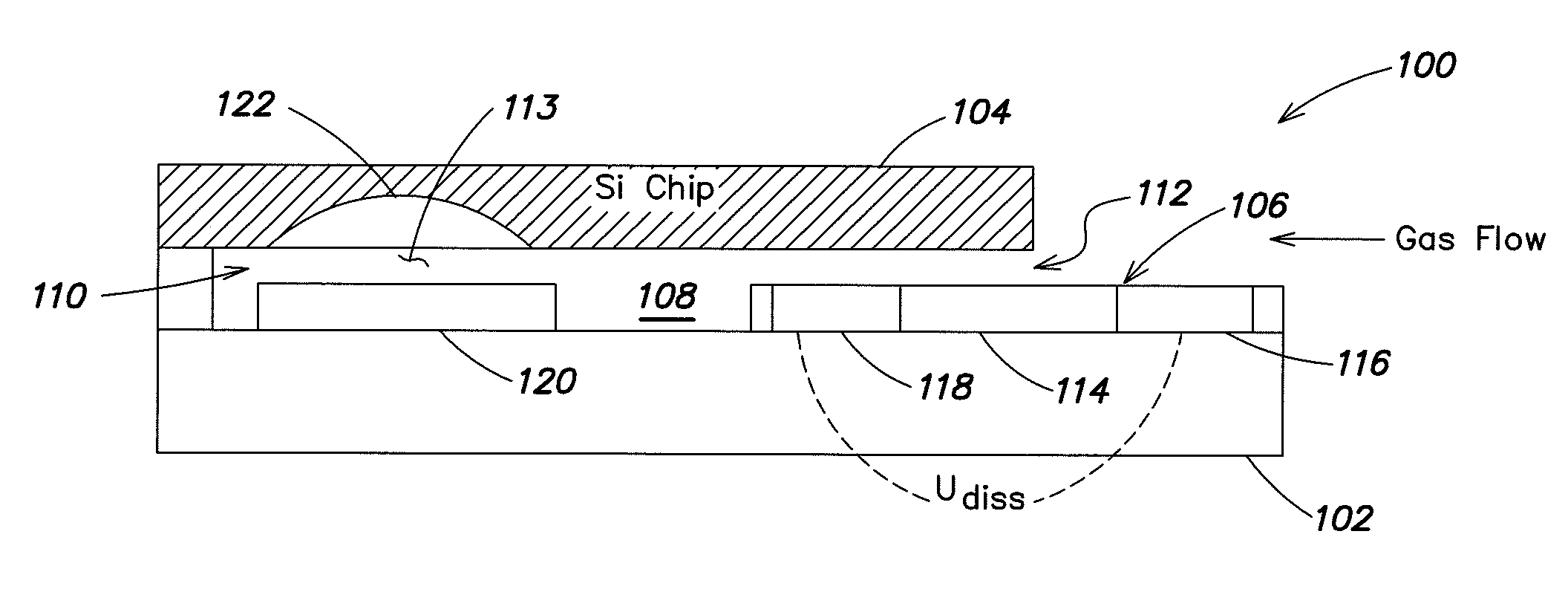

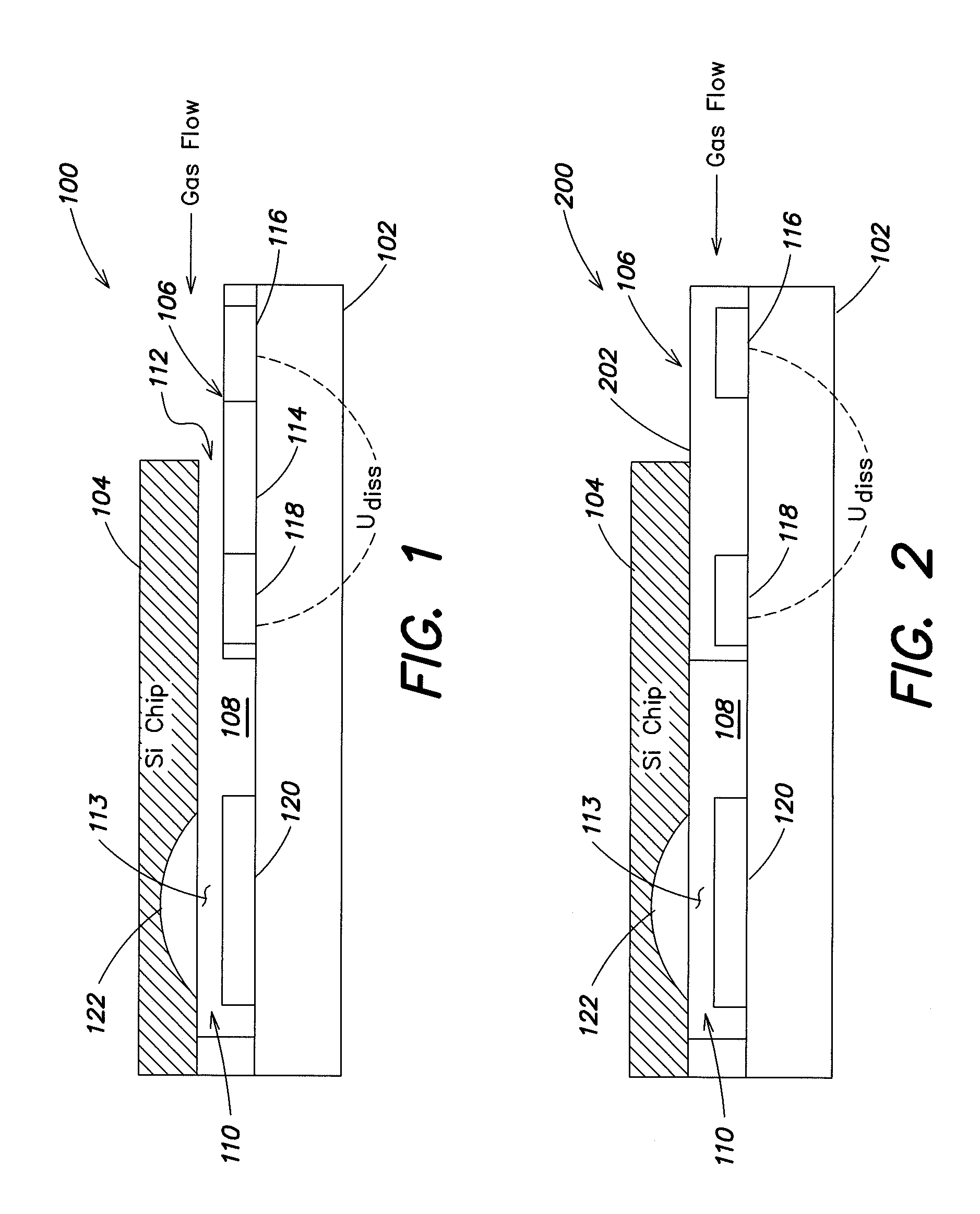

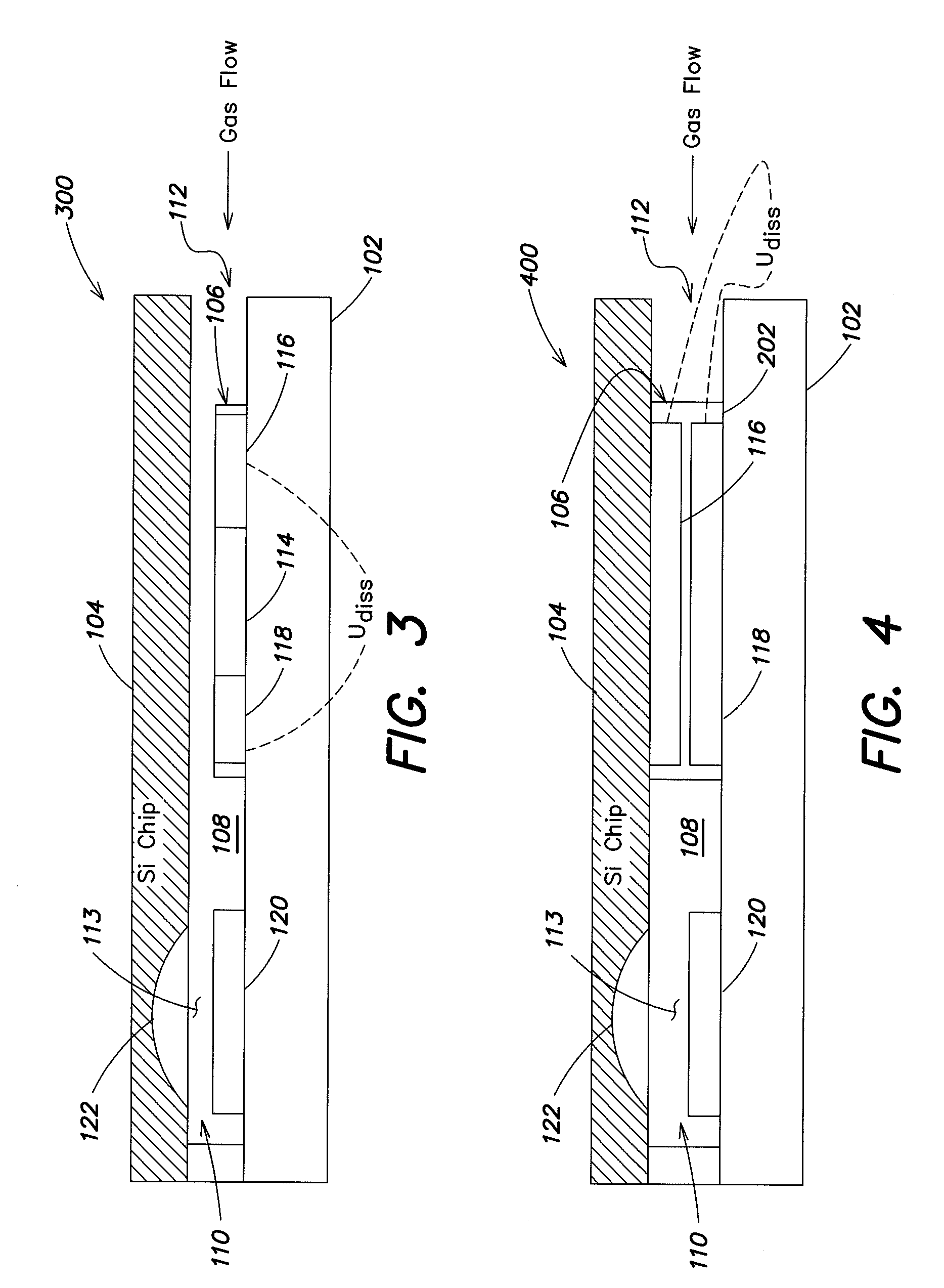

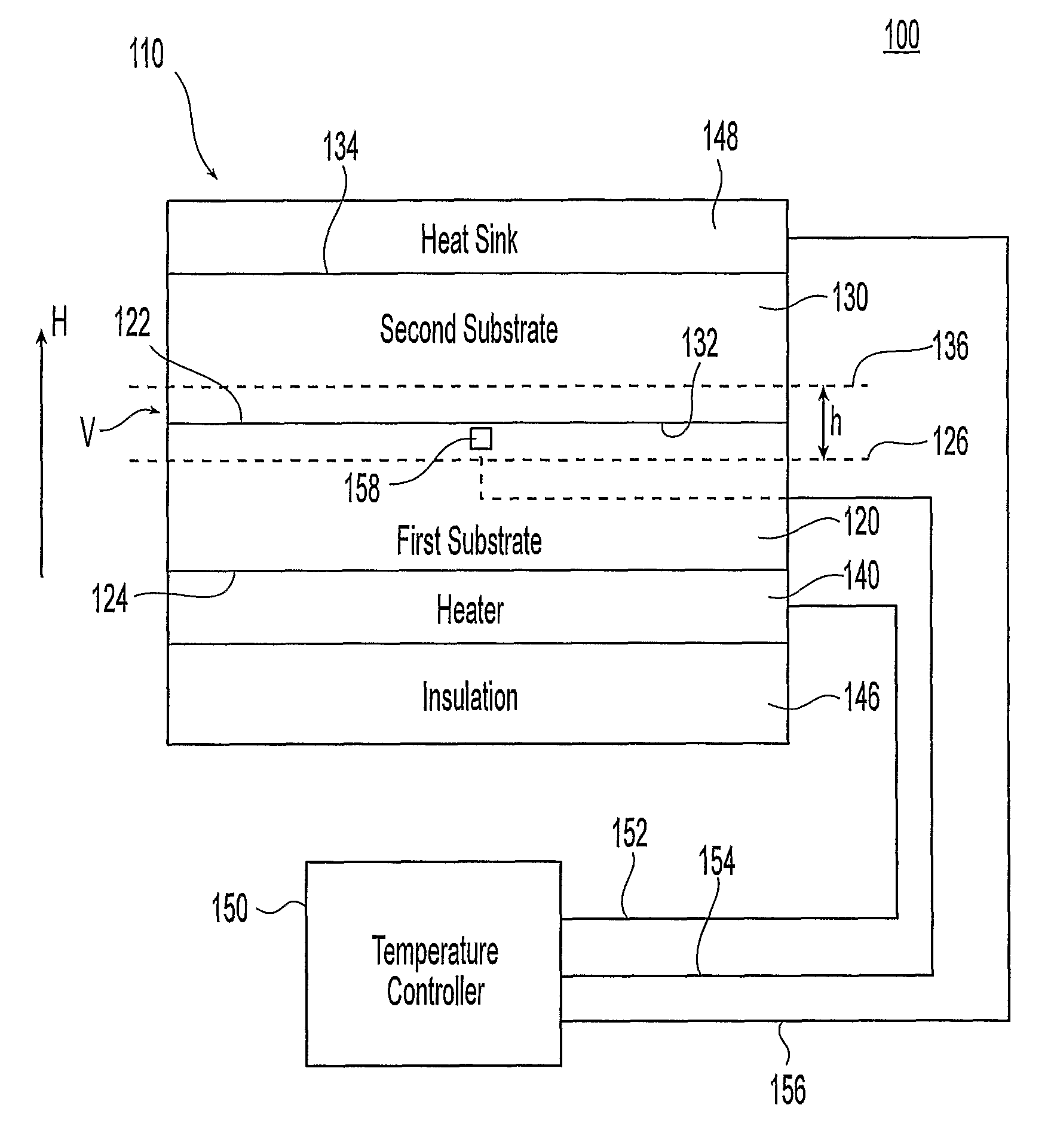

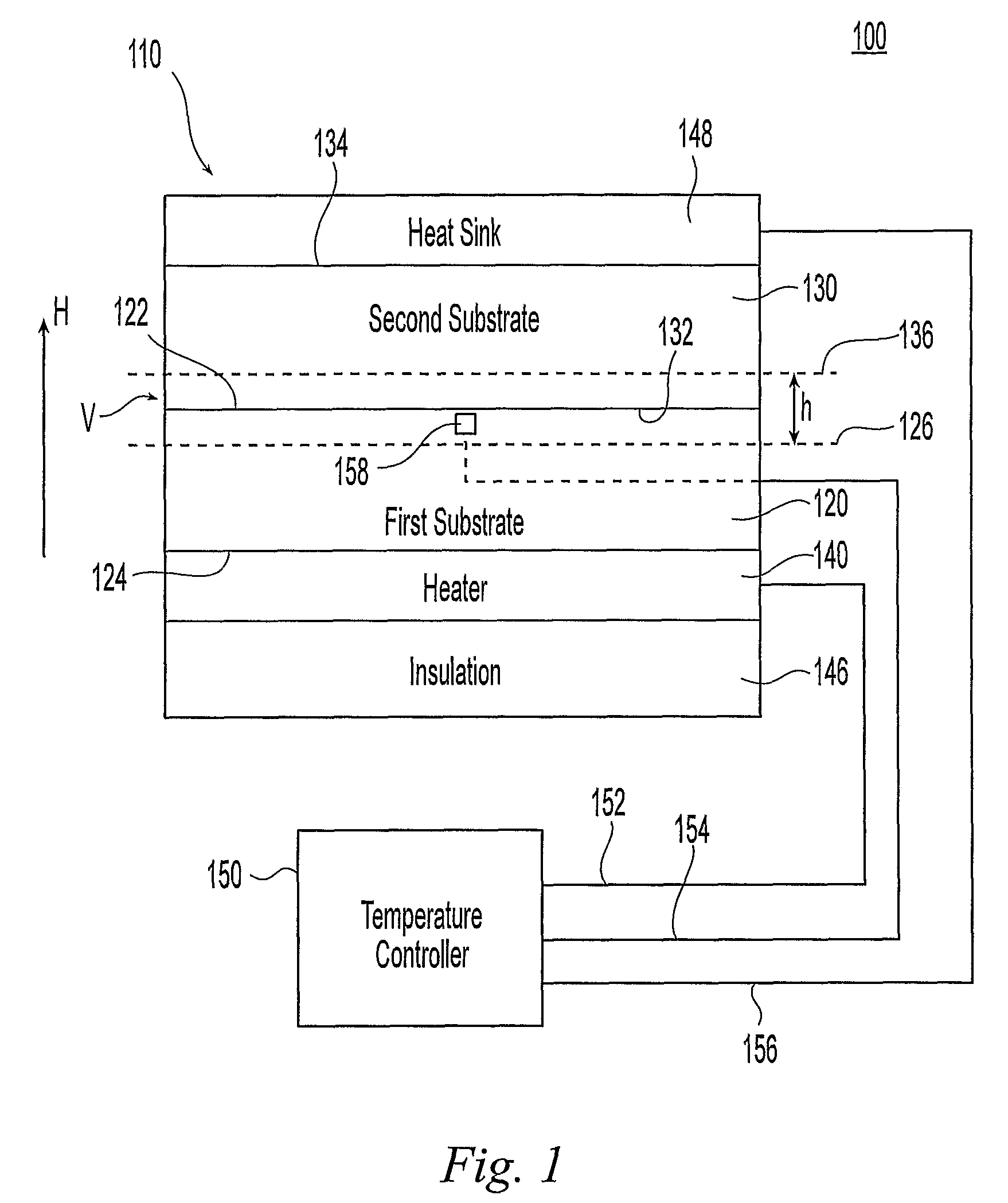

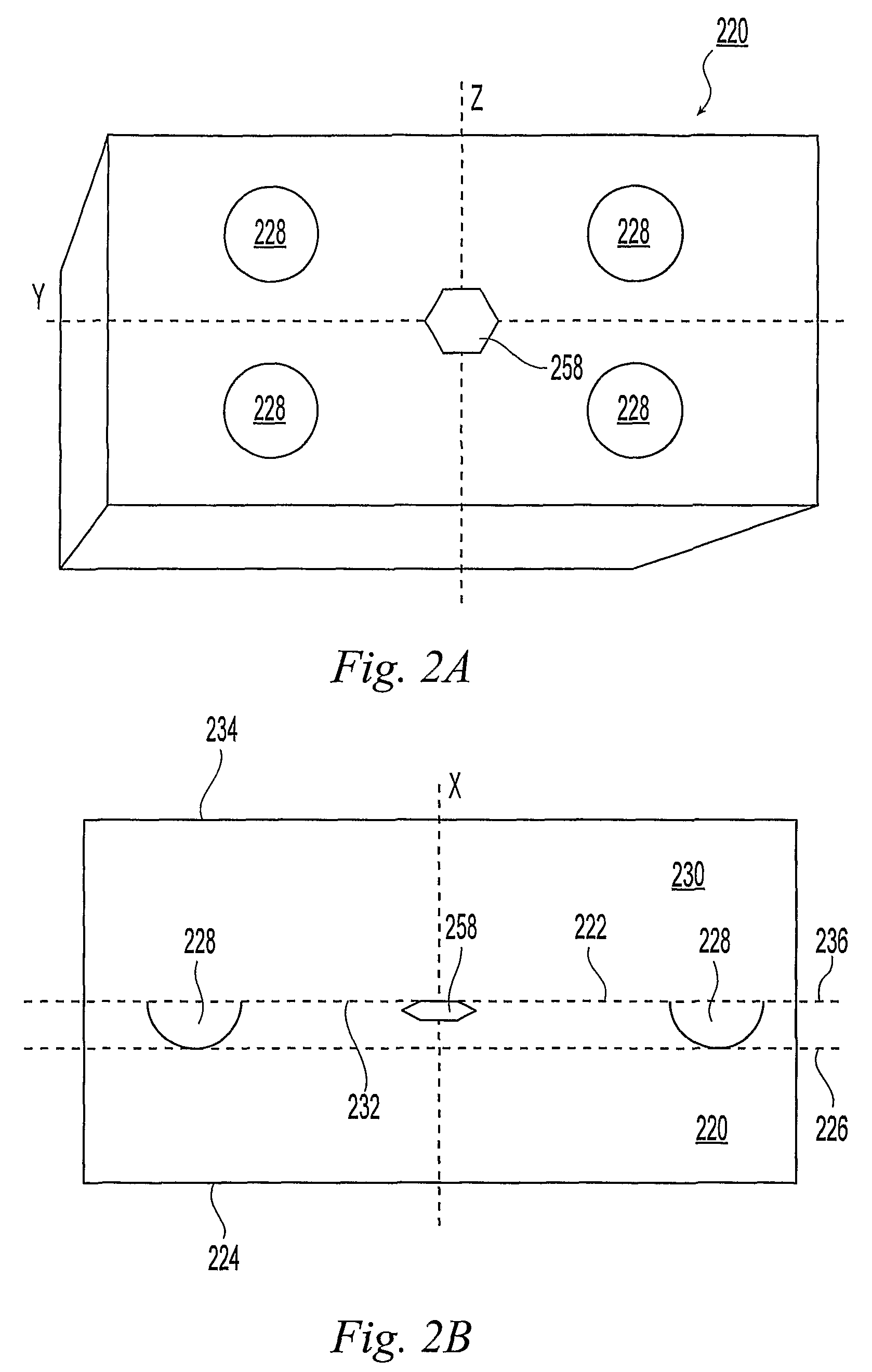

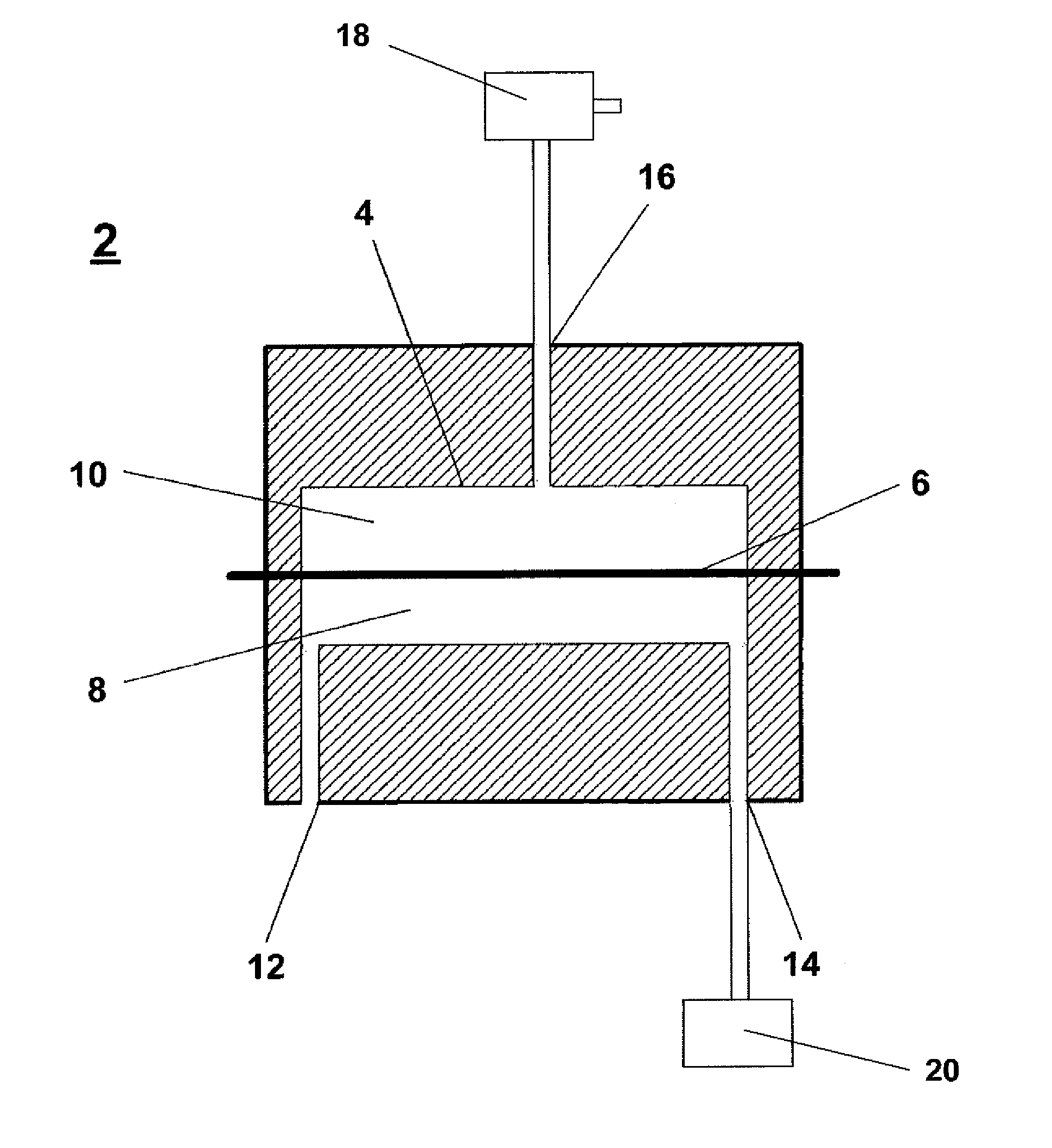

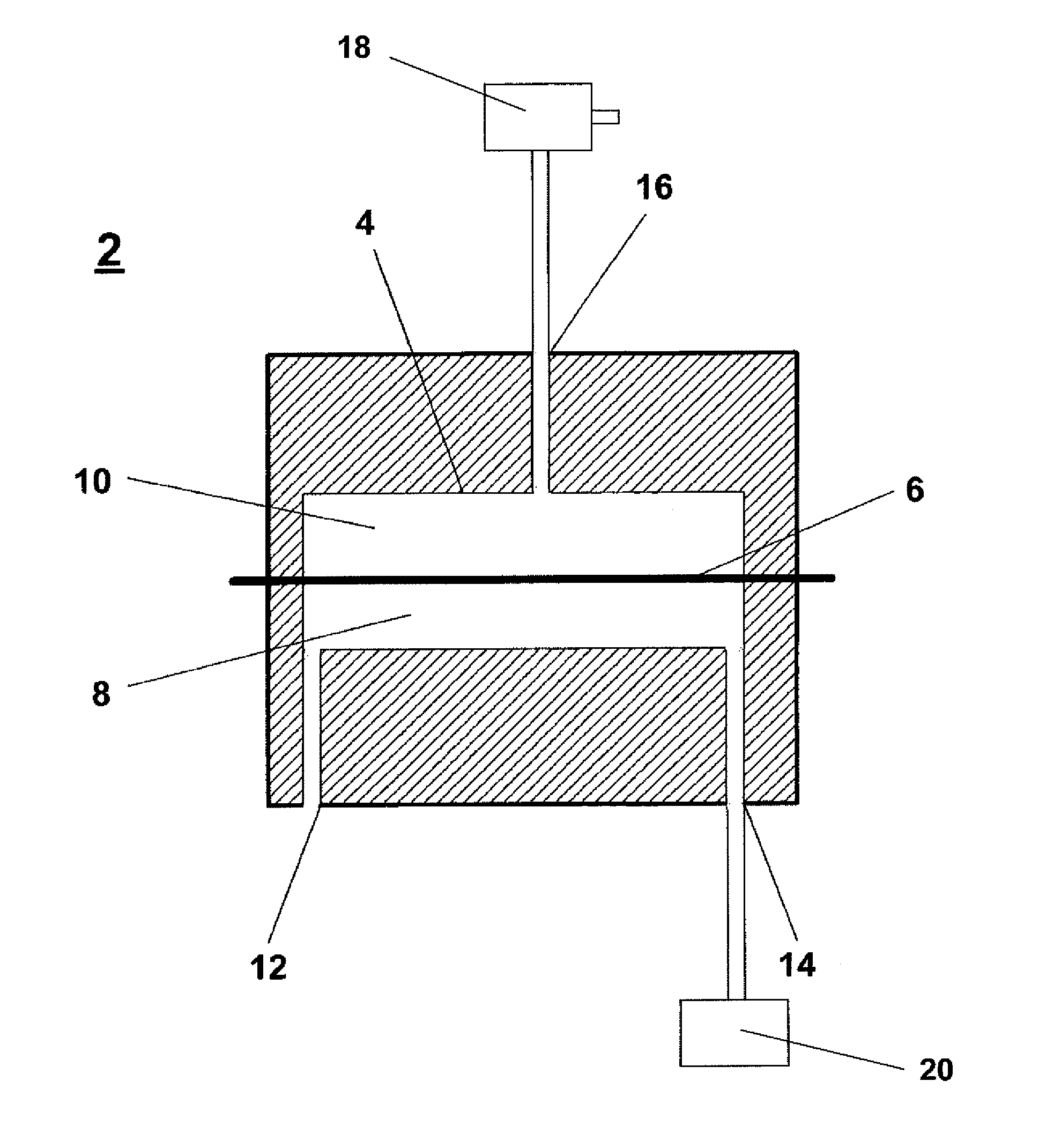

Temperature Controller for Small Fluid Samples With Different Heat Capacities

InactiveUS20080006099A1Temperature controlWithdrawing sample devicesLaboratory glasswaresTemperature controlEngineering

A system for controlling the temperature of fluidic samples includes a device having a first outer surface and a second outer surface which are parallel to one another. The interior of the device contains two or more channels suitable for accommodating samples. The channels lay on a common plane that is also parallel to the first and second outer surfaces. A temperature sensor is positioned between the channels along the common plane. A heater is thermally coupled to one of the two outer surfaces while a heat sink is coupled to the other of the two outer surfaces, thereby establishing a temperature gradient between the first and second outer surfaces. A temperature controller receives sensed temperature input from the temperature sensor and adjusts the heater in response thereto.

Owner:OSCILLOGY LLC

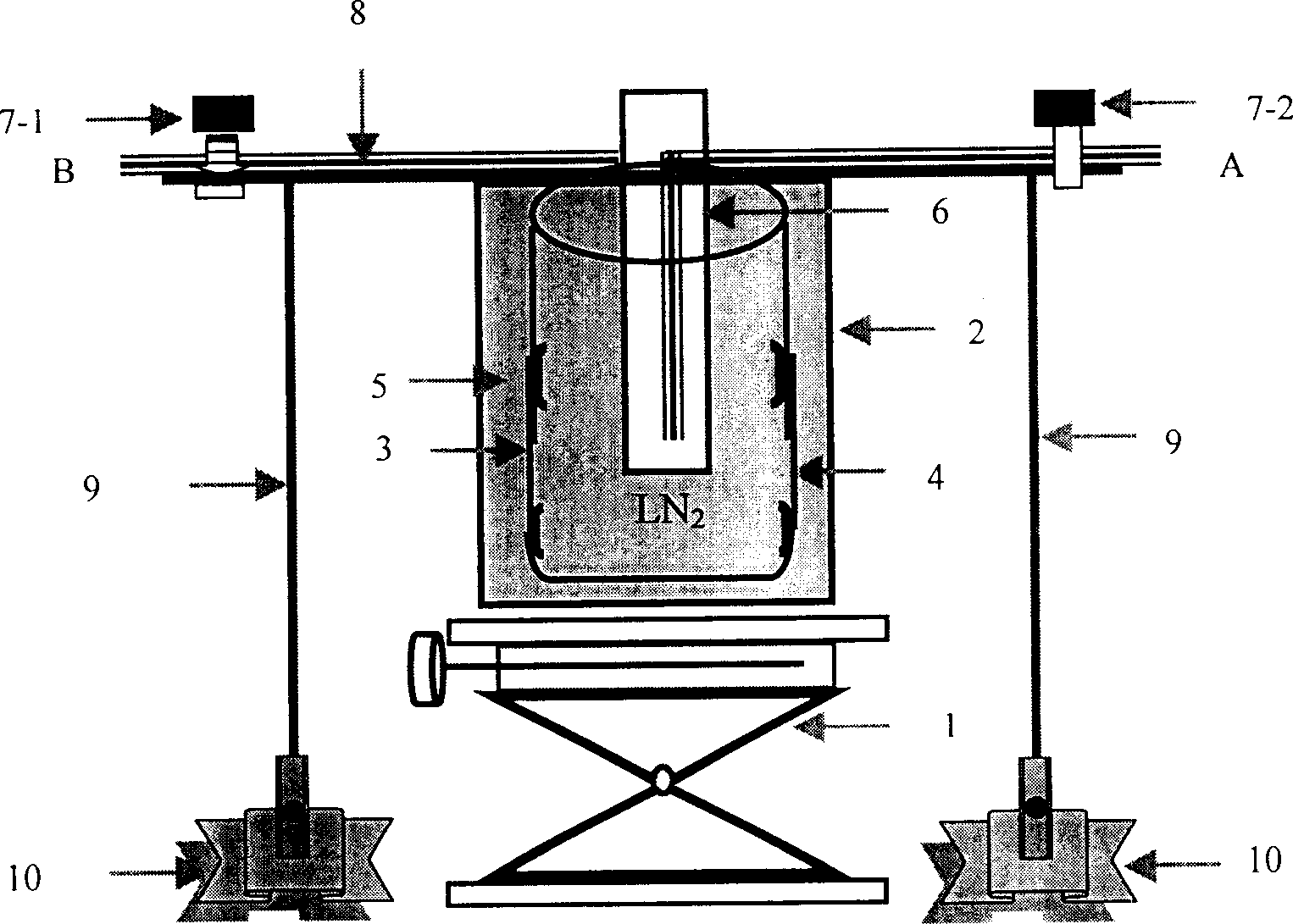

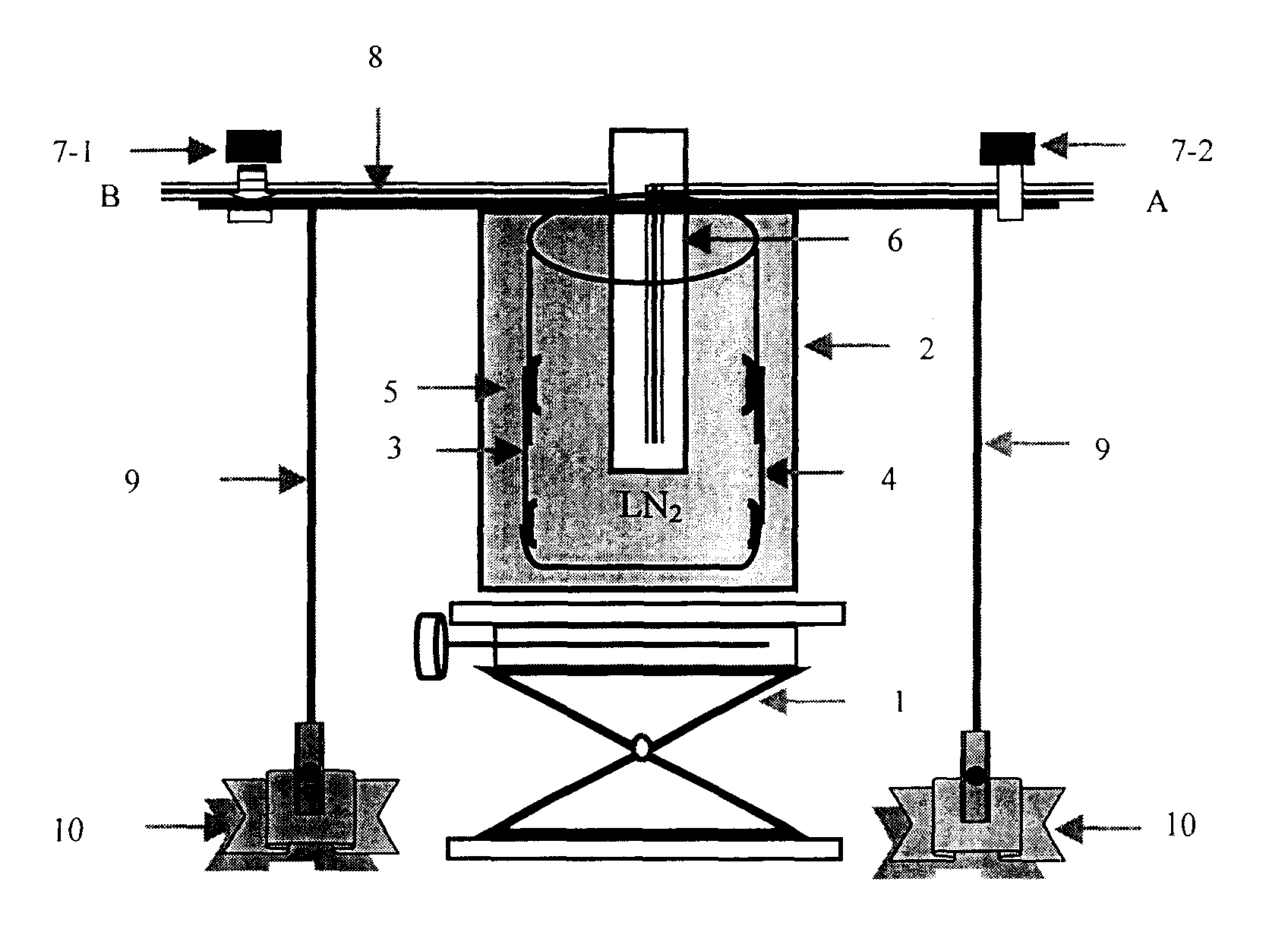

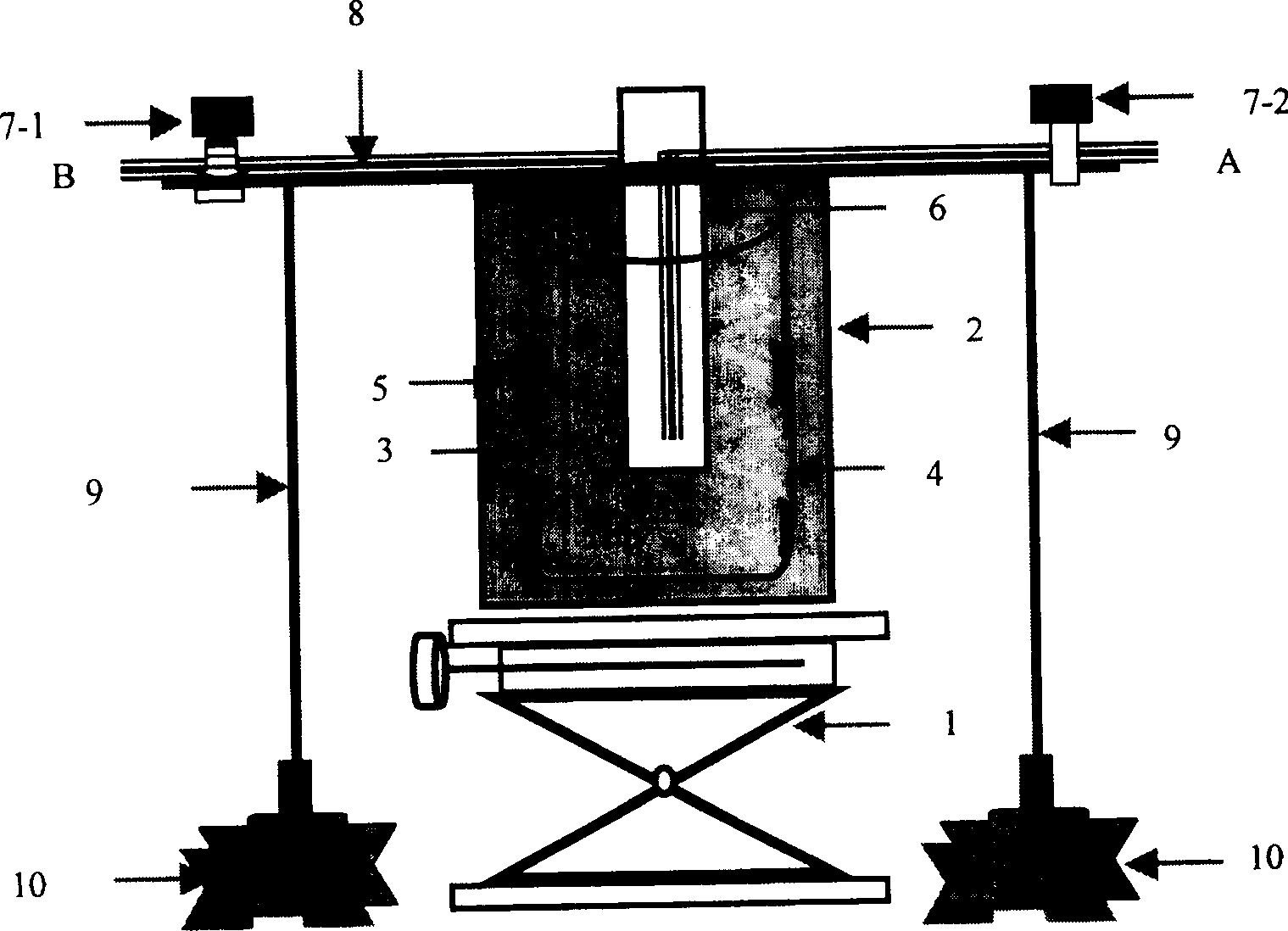

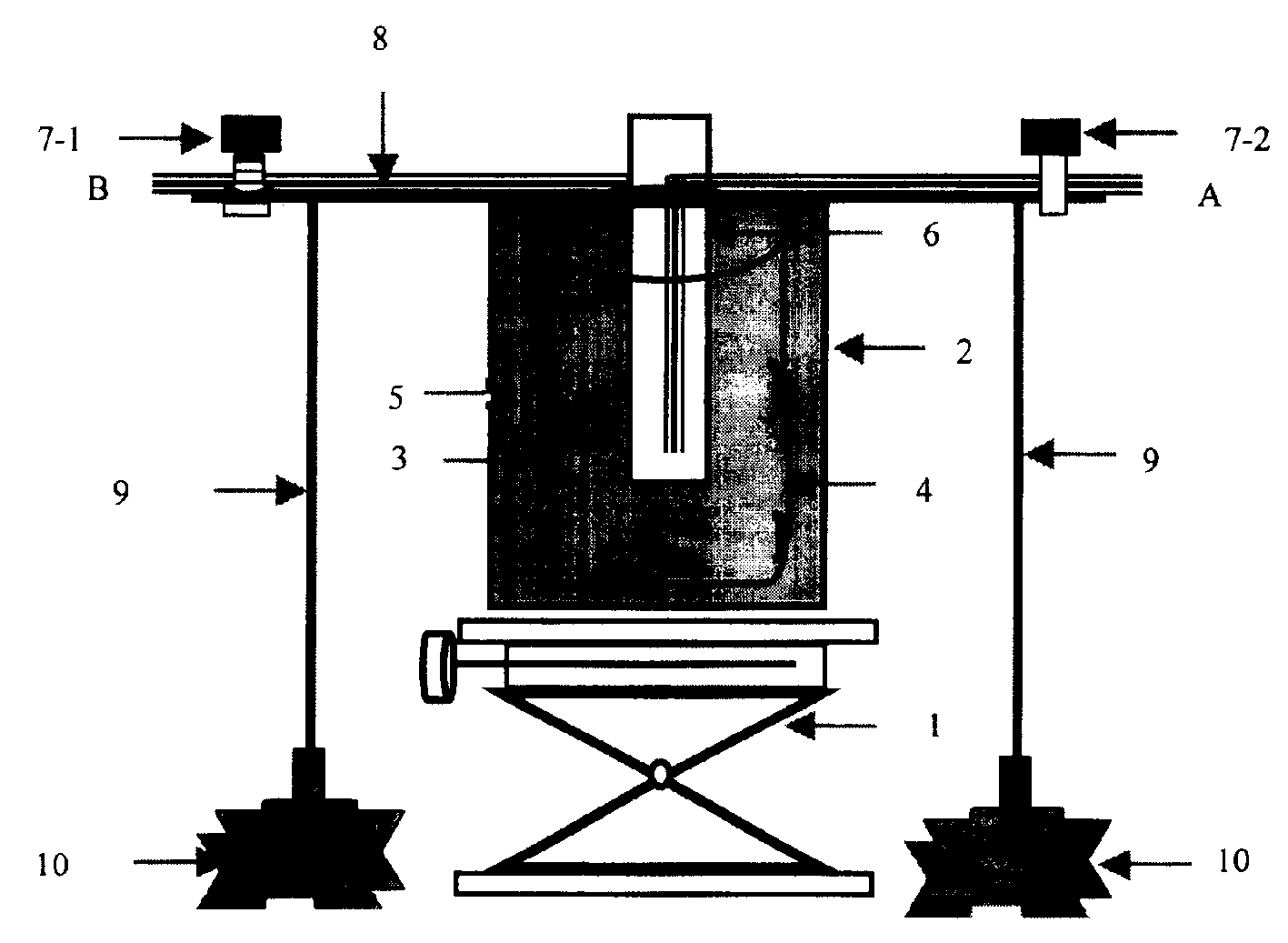

Laser polarization **Xe solid memory

ActiveCN1524620AReduce volumeEasy to carryMaterial analysis by using resonanceGas handling apparatusSignal onLiquid nitrogen

The invention discloses a laser polarized 129Xe solid memory, composed of lift table, Dewar, dual circle permanent magnet, iron sleeve, liquid nitrogen, glass casing pipe, two safety vacuum valves and regulating frame, where the dual permanent magnet is set on the iron sleeve with adjustable length to adjust magnetic field strength; there is silicon coat on the inner wall of the glass casing pipe, which is used as its storage room and sample mixing room; the lift table goes up and down to change the temperature of laser polarized 129Xe. It has the advantages of adjustable magnetic field strength, small memory volume, convenient storage and transport, etc. It is mainly applied to magnetic resonance imaging, polarization transfer, medium- and micro- aperture measurement and structure research, enhancement of NMP signal on material surface, etc.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

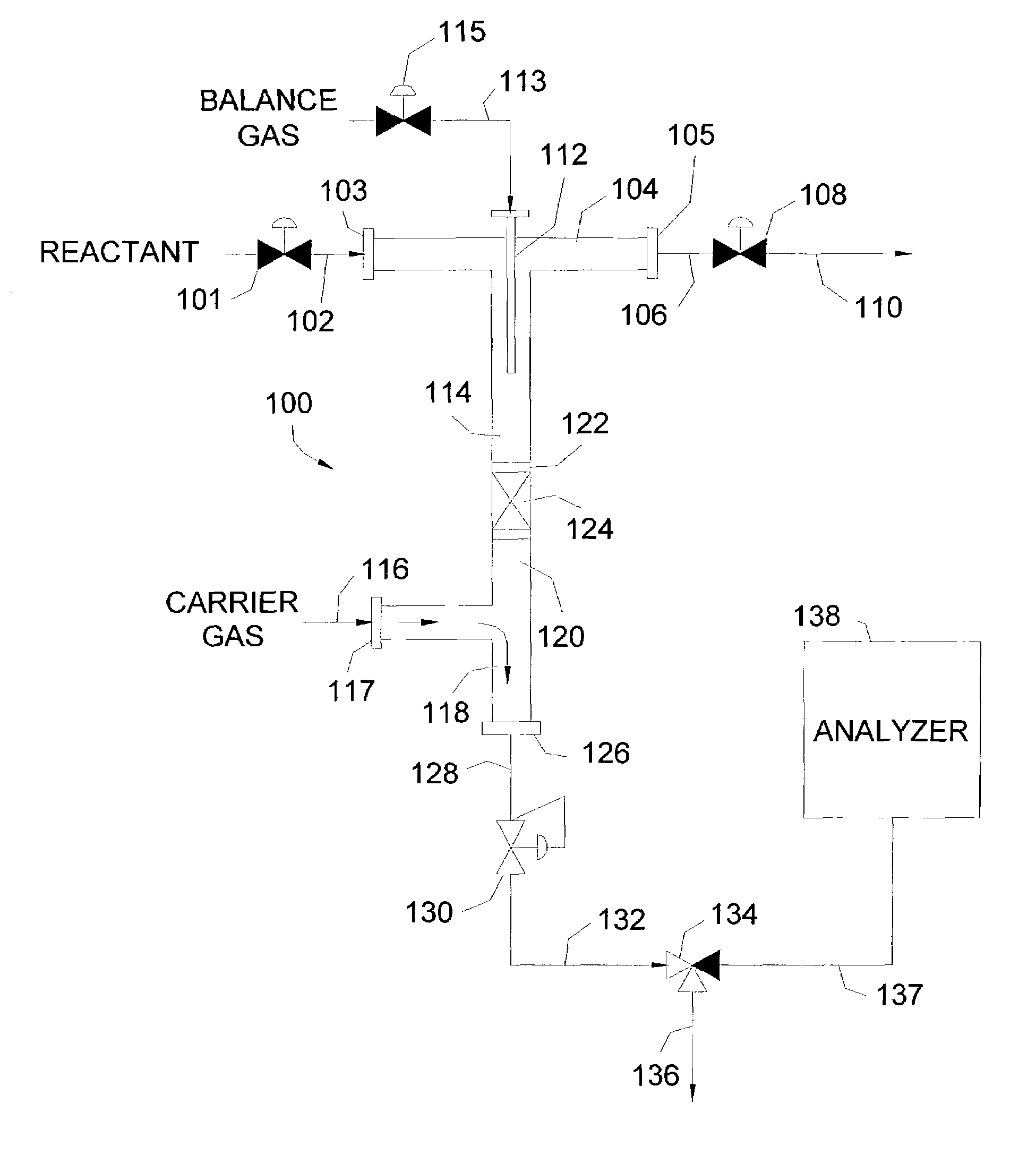

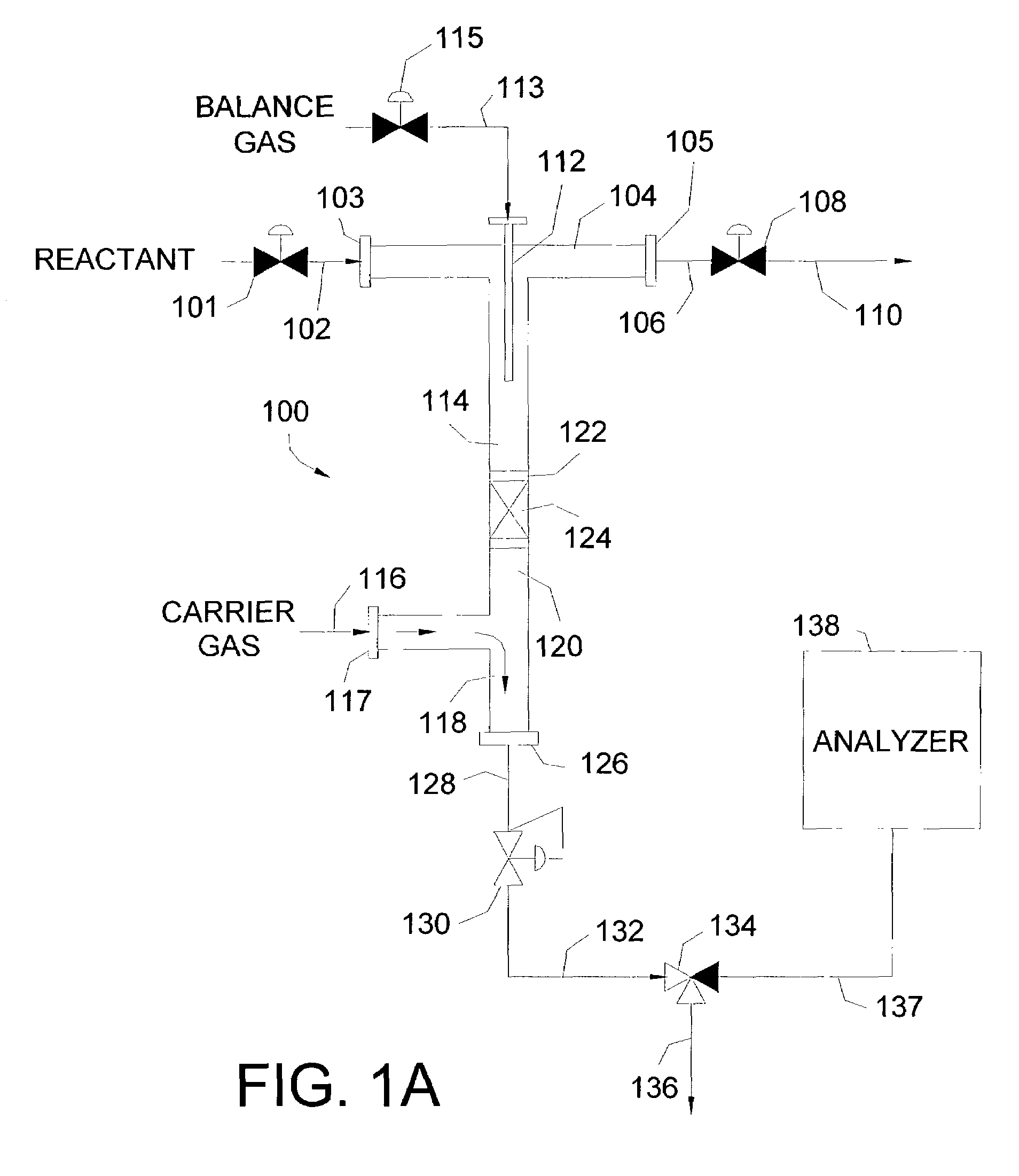

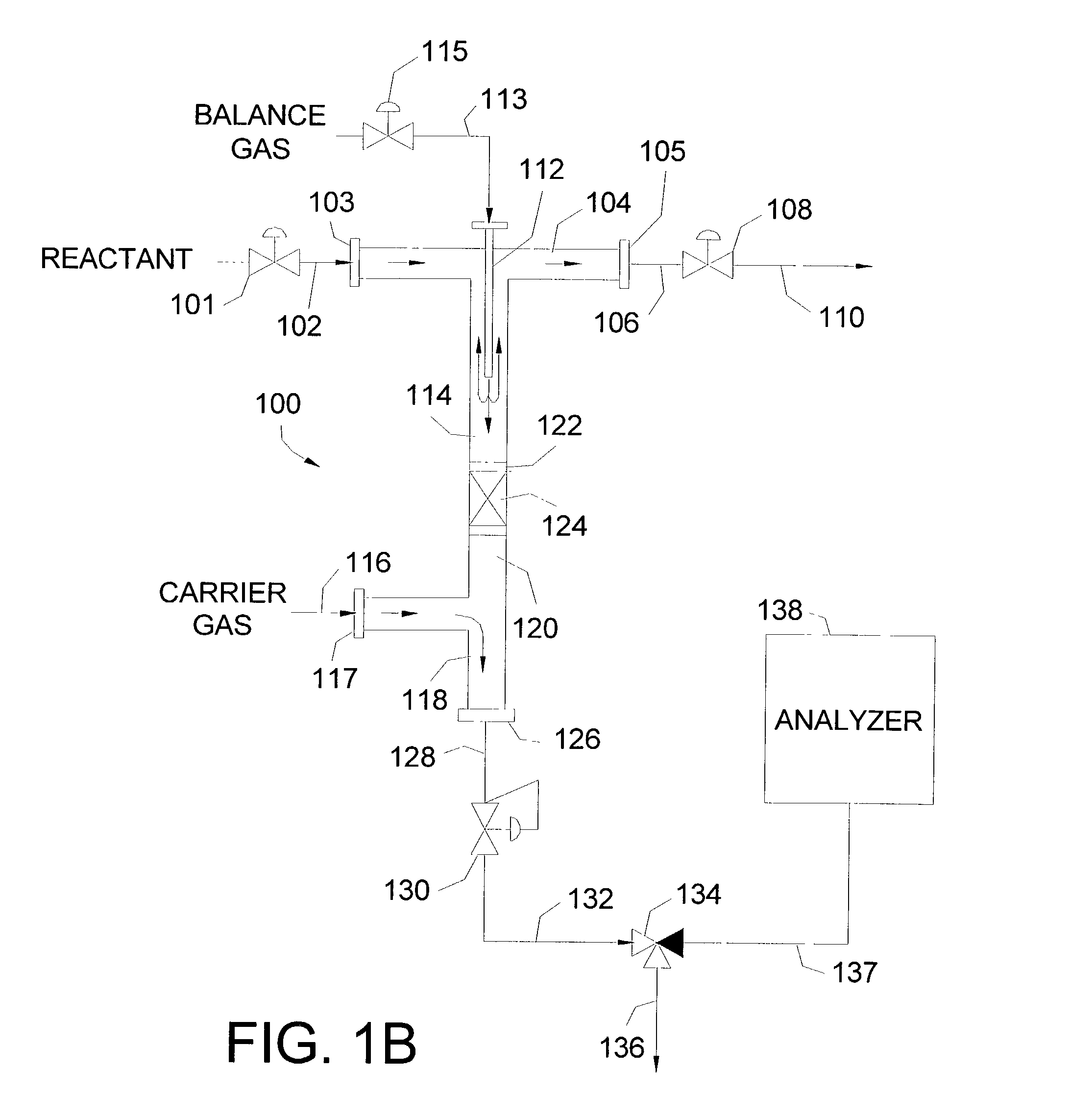

Chemical reaction and analysis system

InactiveUS7256052B2Small scaleAnalysing fluids using sonic/ultrasonic/infrasonic wavesChemical/physical/physico-chemical microreactorsMicroreactorChemical reaction

This invention is to a microreactor type of reaction and analysis system. The system includes a chemical reaction chamber having internal conduits through which a chemical reactant, such as a reaction gas, can be fed. The conduits for transporting fluids such as reactant, carrier gas and balance gas are in appropriate communication such that the amount of reactant going directly to a catalyst located in the reaction chamber can be optimally controlled. The system is highly useful for studying the kinetics of a chemical reaction.

Owner:EXXONMOBIL CHEM PAT INC

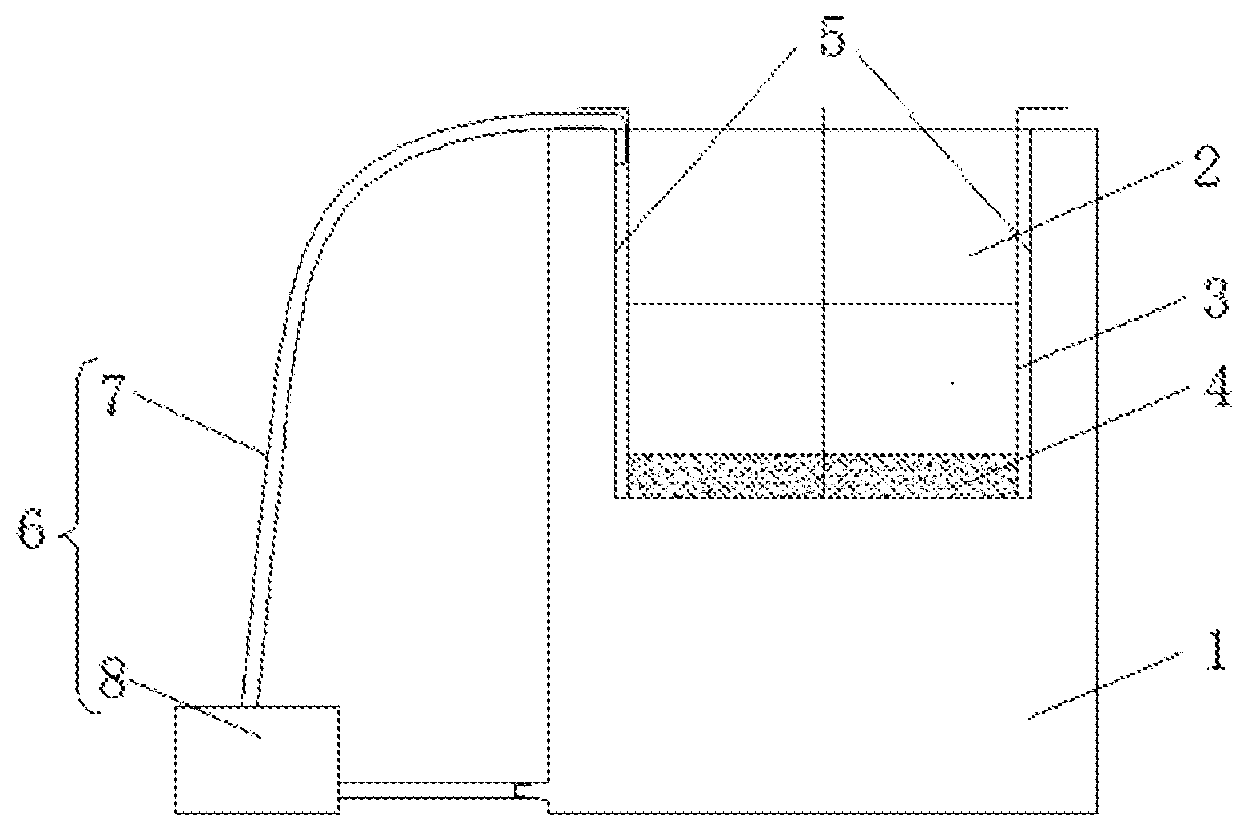

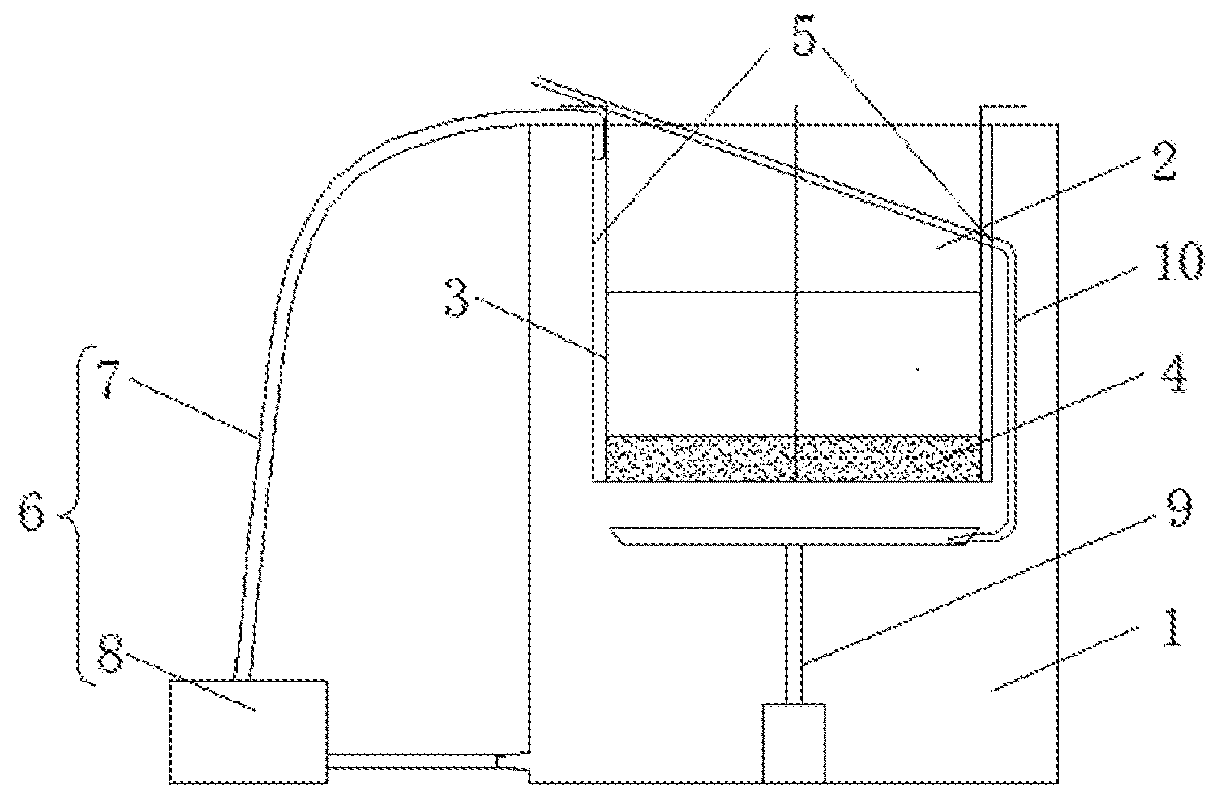

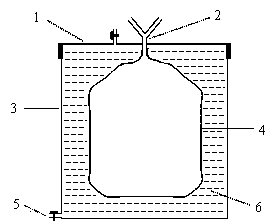

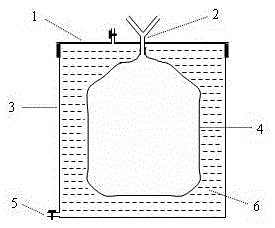

Gas quantitative blending and speed-controlled transmission method and device based on water-gas exchange technology

InactiveCN104162372ASimple structureEasy to useMixer accessoriesMixing gases with gases/vapoursWater storageDistribution method

The invention relates to a static gas distribution method and a matched apparatus thereof, and specifically relates to a gas quantitative blending and speed-controlled transmission method and device based on a water-gas exchange technology. The device comprises a rigid water storage container 3 (number for indication in the attached drawing, similarly hereinafter) provided with a sealing top cover 1 and a lower nozzle 5, the top cover is provided with an air pipe 2, a soft container 4 arranged in the water storage container 3 is arranged on the air pipe 2, the air pipe is used for introducing gas in / out of the soft container, and the lower nozzle is used for discharging / injecting water. Under a balanced pressure and a stable temperature, a certain volume of water 6 is discharged from or injected into the water storage container 3, thus the equal amount of gas is injected into or discharged out of the soft container 4, and the preparation and transmission of mixed gas are achieved. The advantages of the soft container static volume gas distribution method are preserved, and the method also has the advantages of high precision in the gas concentration, more gas production amount, and continuous gas transmission at a controllable speed.

Owner:HUNAN NORMAL UNIVERSITY

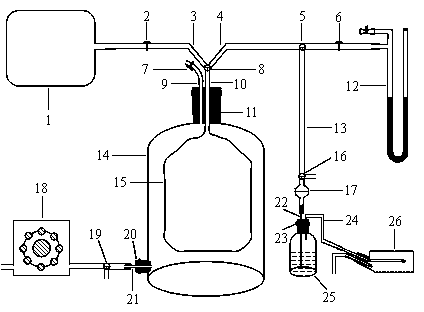

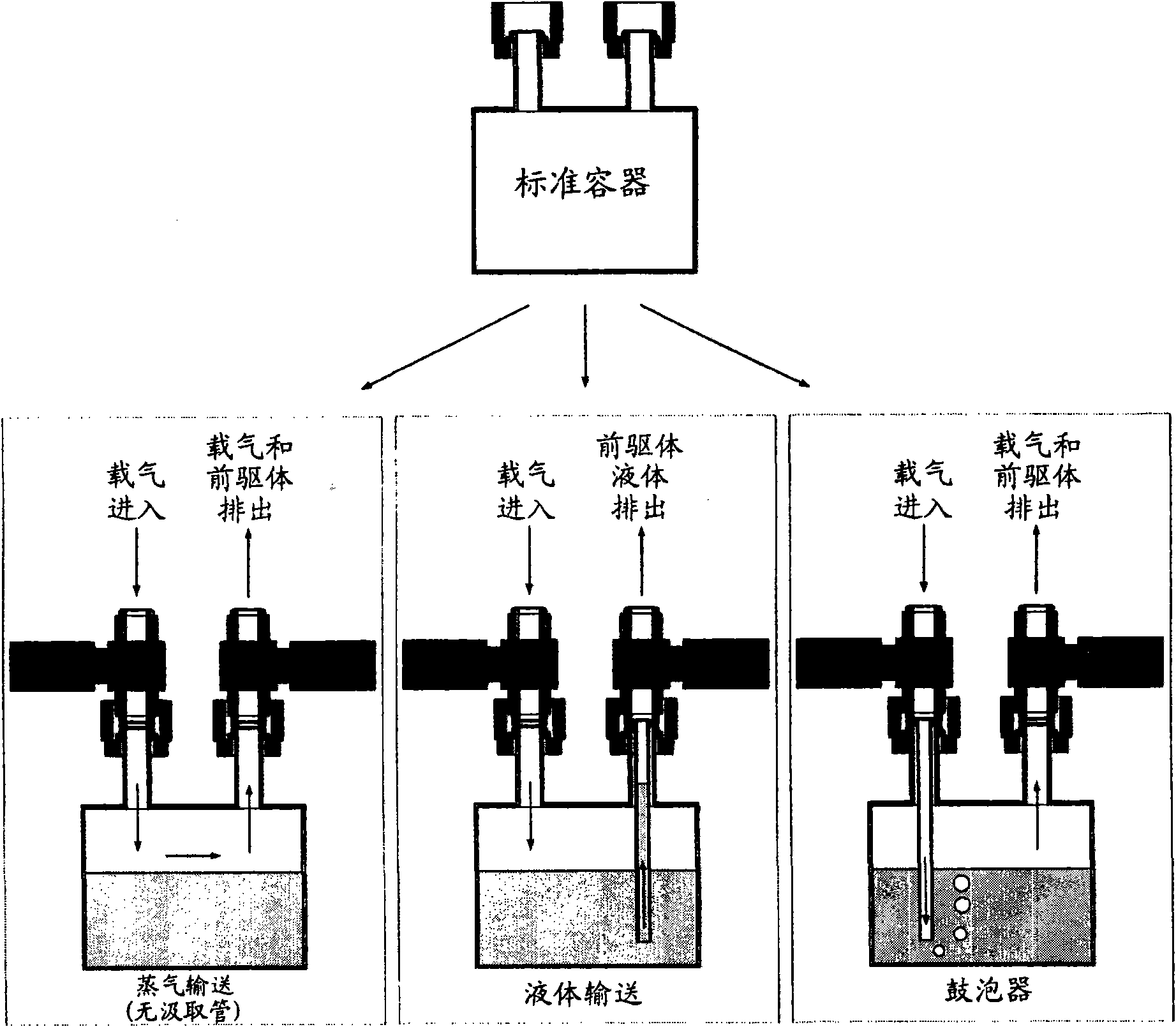

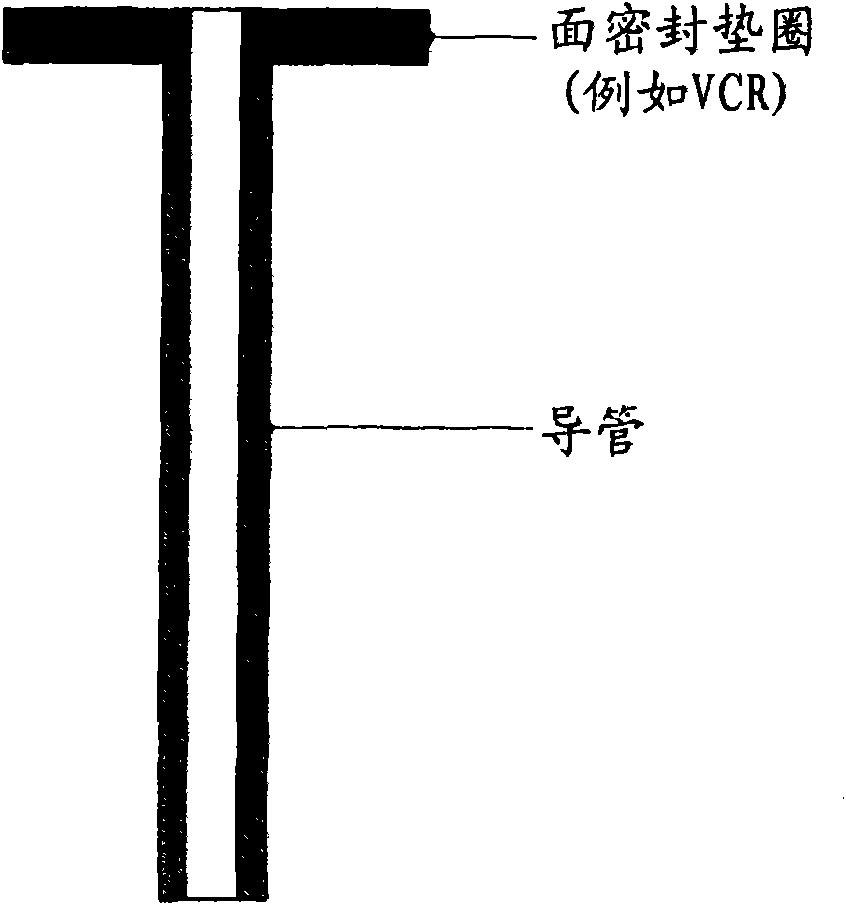

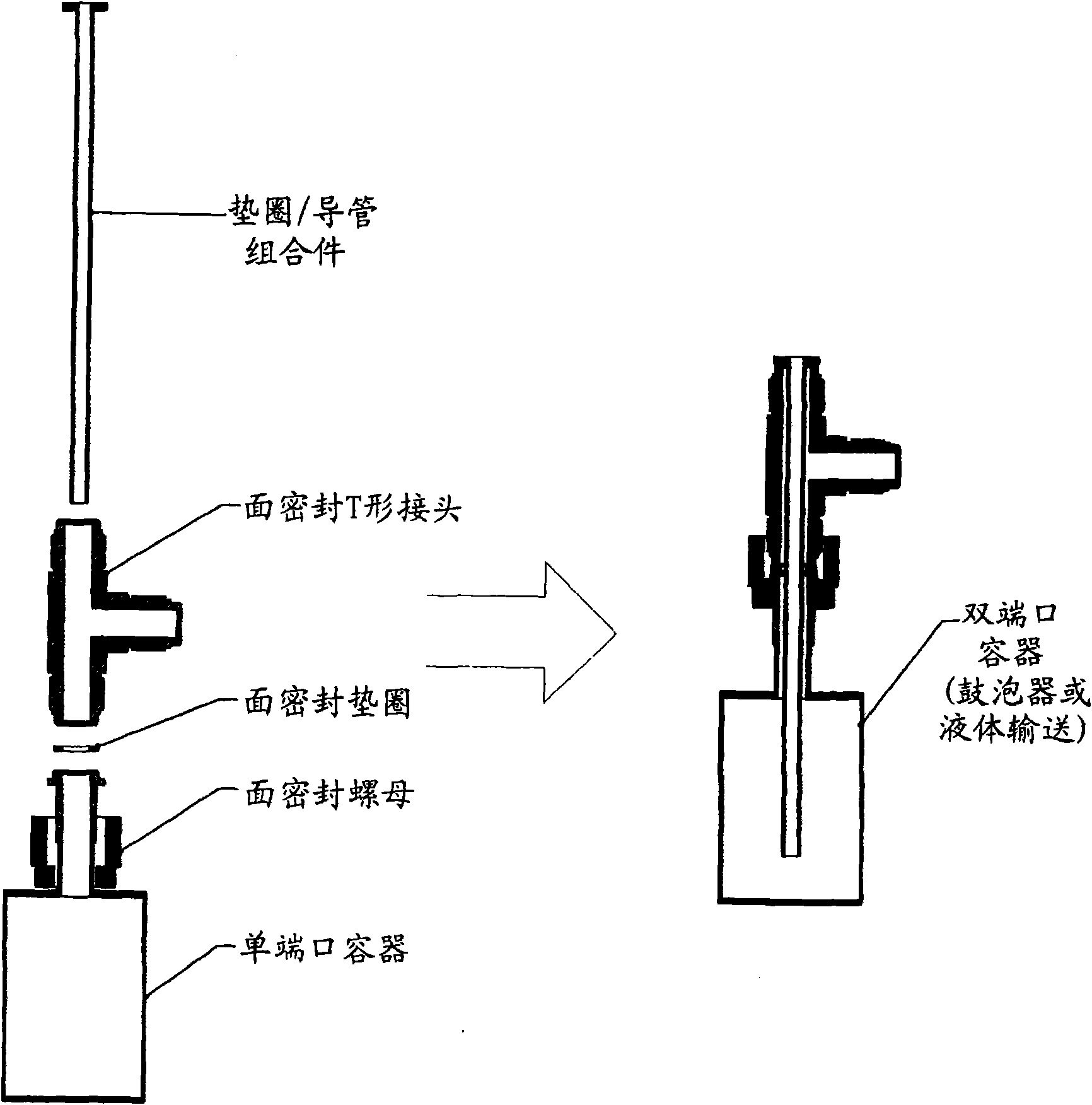

Reagent dispensing apparatus and delivery method

InactiveCN101569841AJoints with sealing surfacesLiquid transferring devicesSemiconductor materialsGas phase

The present invention relates to a reagent dispensing apparatus and a delivery method, particularly a vapor or liquid phase reagent dispensing apparatus that may he used for dispensing vapor or liquidphase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices. This invention reduces the number of container designs required to support different applications. A standard two port container without a tube can be converted to a container capable of being used in applications which require a tube (i.e., bubbler tube for gas delivery or a dip tube for liquid delivery), by inserting a gasket / tube adapter between one of the ports and the corresponding valve in accordance with this invention.

Owner:PRAXAIR TECH INC

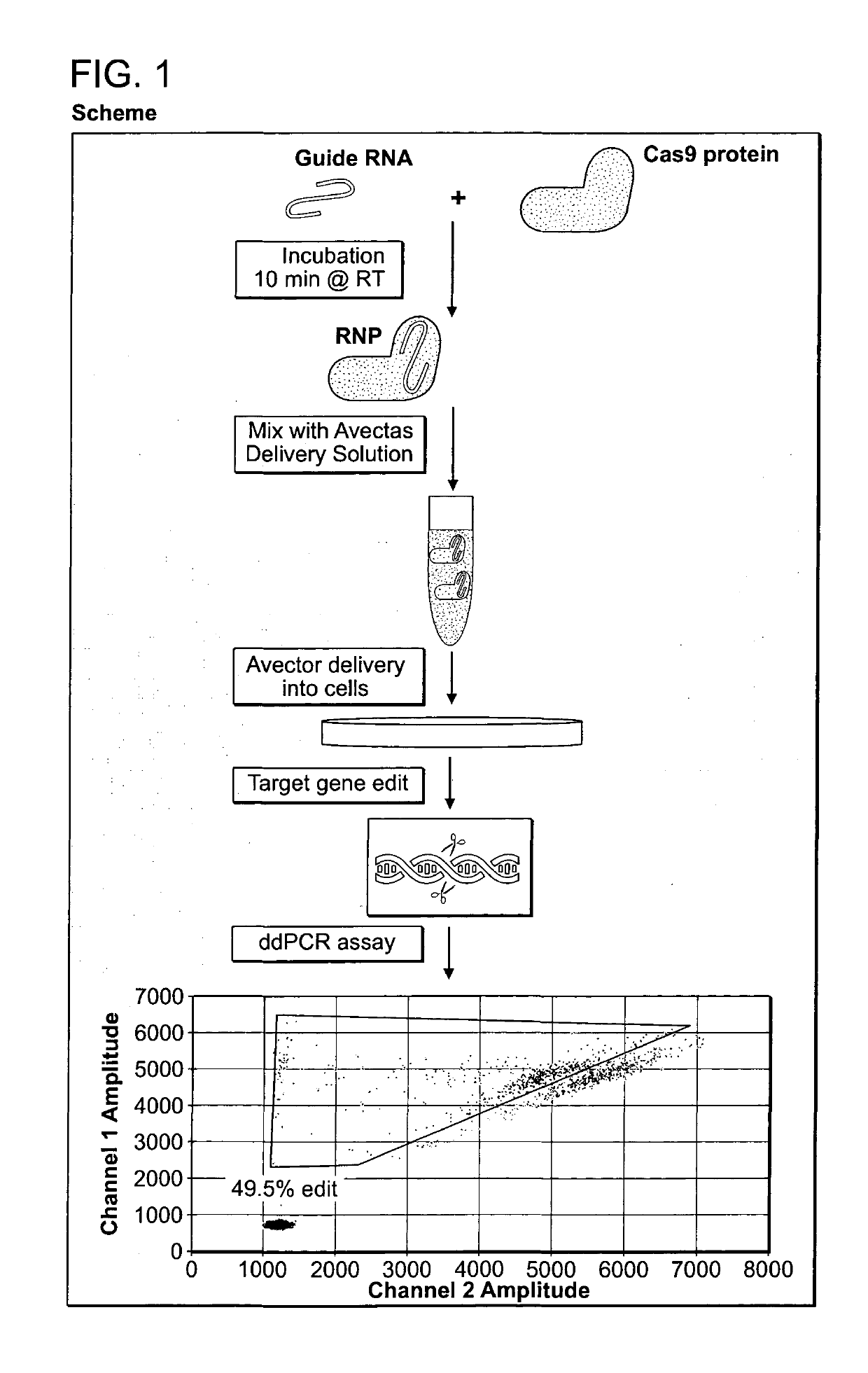

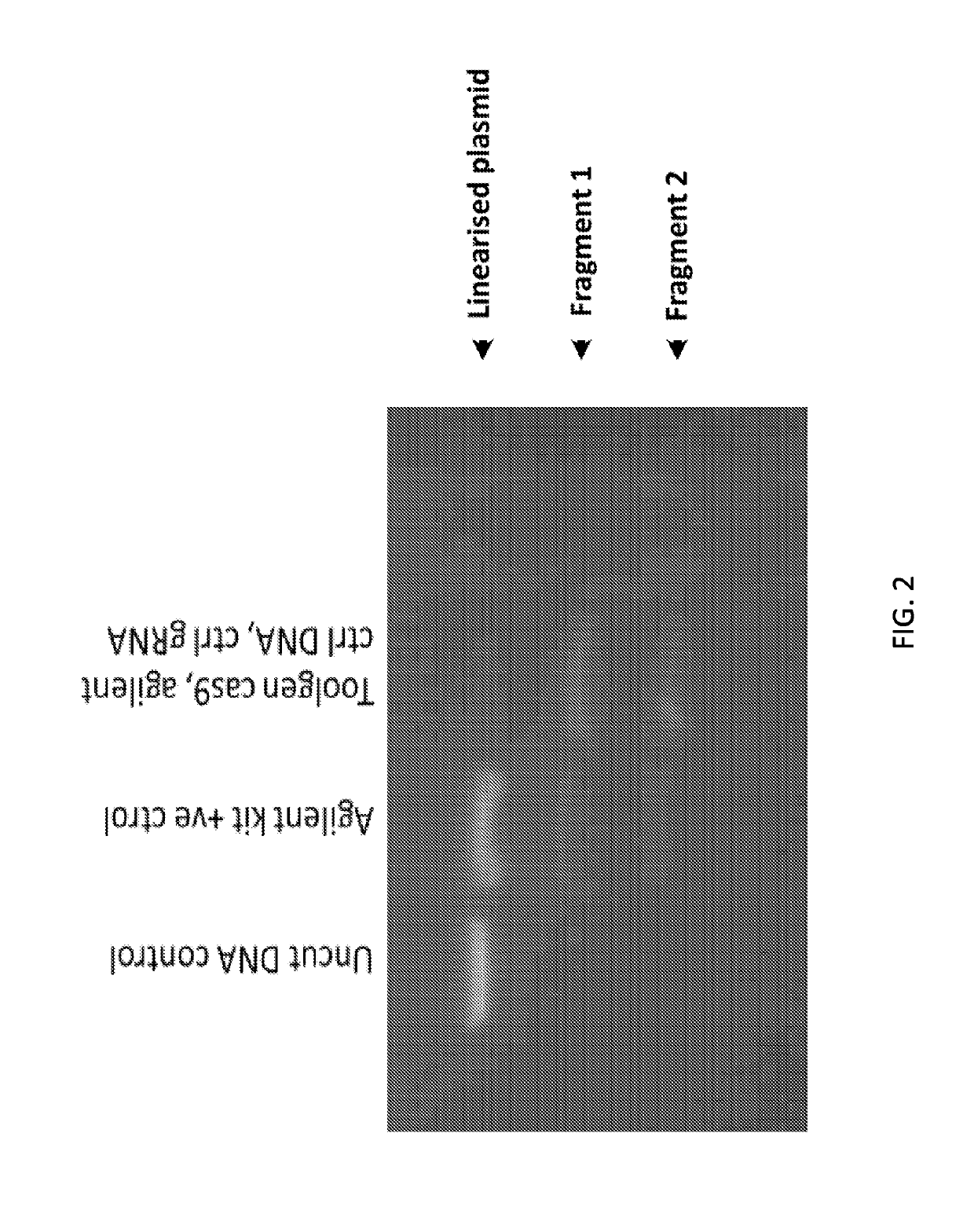

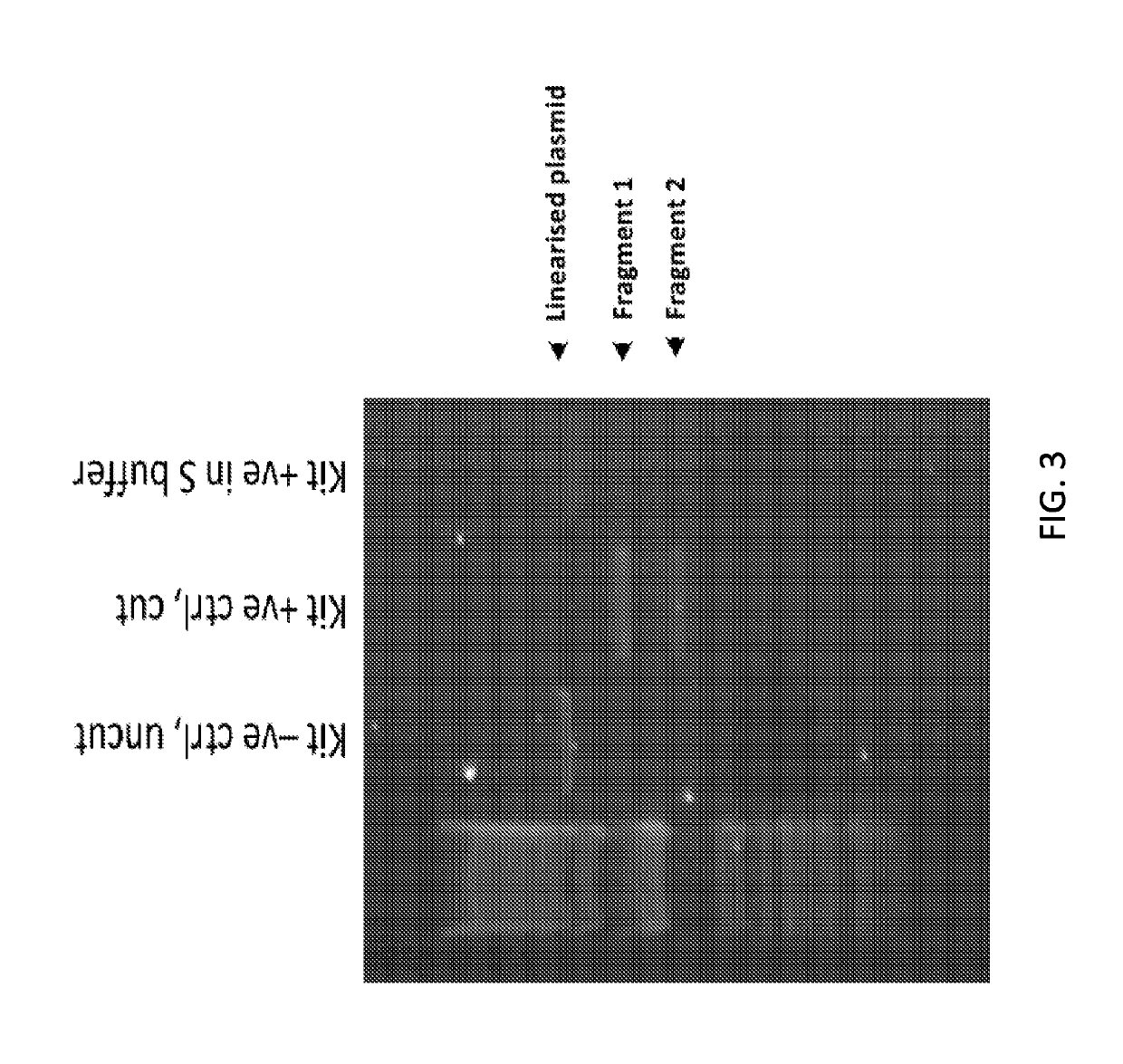

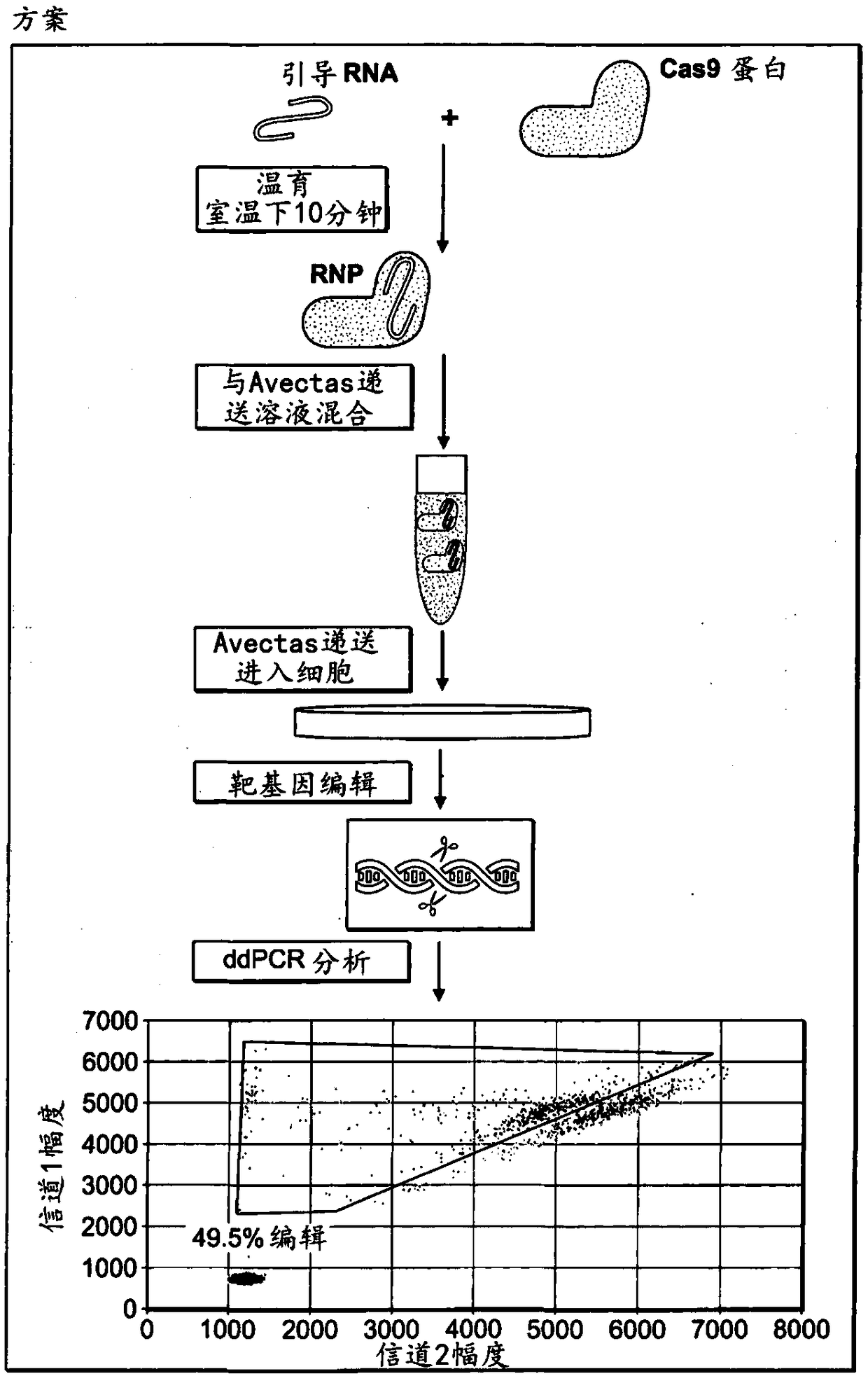

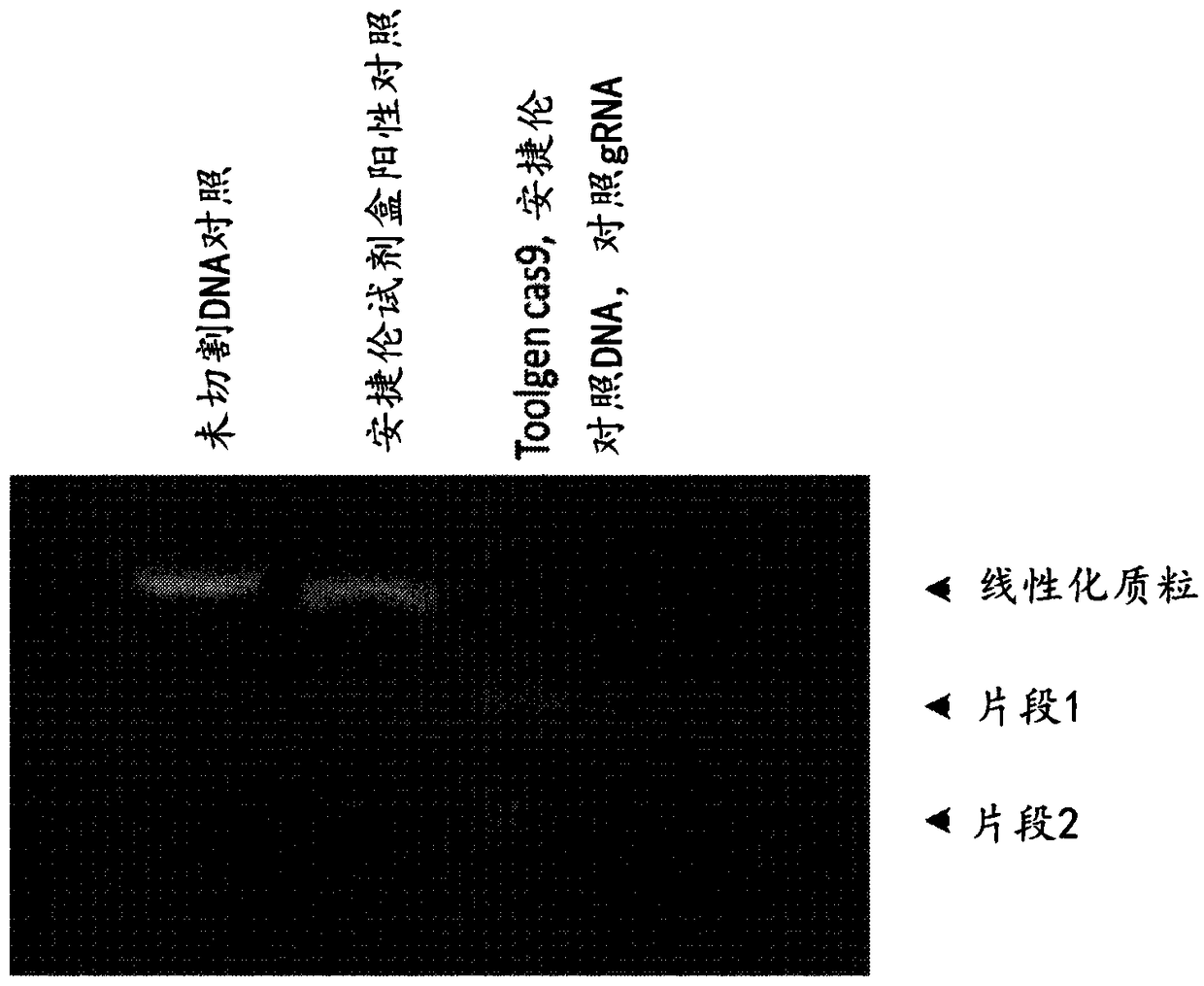

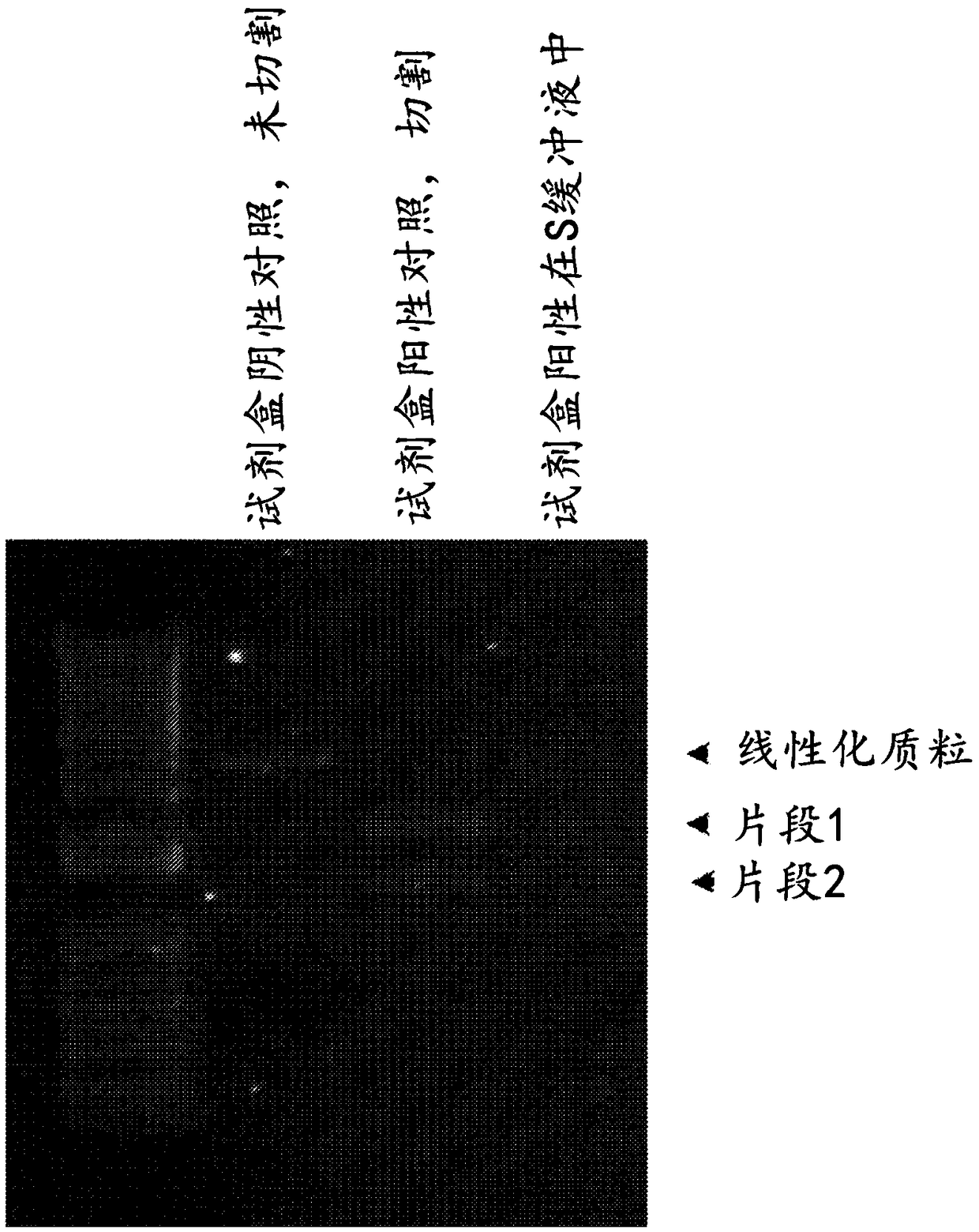

Vector-Free Delivery of Gene Editing Proteins and Compositions to Cells and Tissues

PendingUS20190194691A1Reduce functionReduced activitySpecial deliveryHydrolasesGene deliverySubject matter

The present subject matter provides a method for delivering a gene editing composition across a plasma membrane of a cell. Related apparatus, system, techniques, compositions, and articles are also described.

Owner:AVECTAS

Vector-free delivery of gene editing proteins and compositions to cells and tissues

ActiveCN109312315ADoes not delay differentiationIncrease differentiationSpecial deliveryHydrolasesGeneCell biology

Owner:AVECTAS

Quantitative gas mixing and speed-controlled delivery method and device based on water-gas replacement technology

InactiveCN104162372BSimple designSimple structureMixer accessoriesMixing gases with gases/vapoursWater storageDistribution method

The invention relates to a static gas distribution method and an applicable device thereof, in particular to a method and device for quantitative preparation and speed-controlled delivery of mixed gas based on water-gas replacement technology. It comprises a rigid water storage container 3 with a sealed top cover 1 (marking numbers in the accompanying drawings, the same below) and a lower mouth 5, the top cover is equipped with a vent pipe 2, and a soft container 4 positioned in the water storage container is installed in the vent. On the trachea 2, the vent pipe 2 is used for the air intake or air delivery of the soft container, and the lower mouth 5 is used for water discharge or water injection of the container. The present invention utilizes the principle of releasing or injecting a certain volume of water 6 from the rigid water storage container under the condition of maintaining air pressure balance and temperature stability, and then an equal volume of gas enters or outputs the soft container, and realizes the preparation of mixed gas and delivery. The invention maintains the advantages of the static volume gas distribution method of the soft container, and also has the advantages of high component gas concentration accuracy, greater gas preparation volume, and continuous speed-controlled delivery of gas.

Owner:HUNAN NORMAL UNIVERSITY

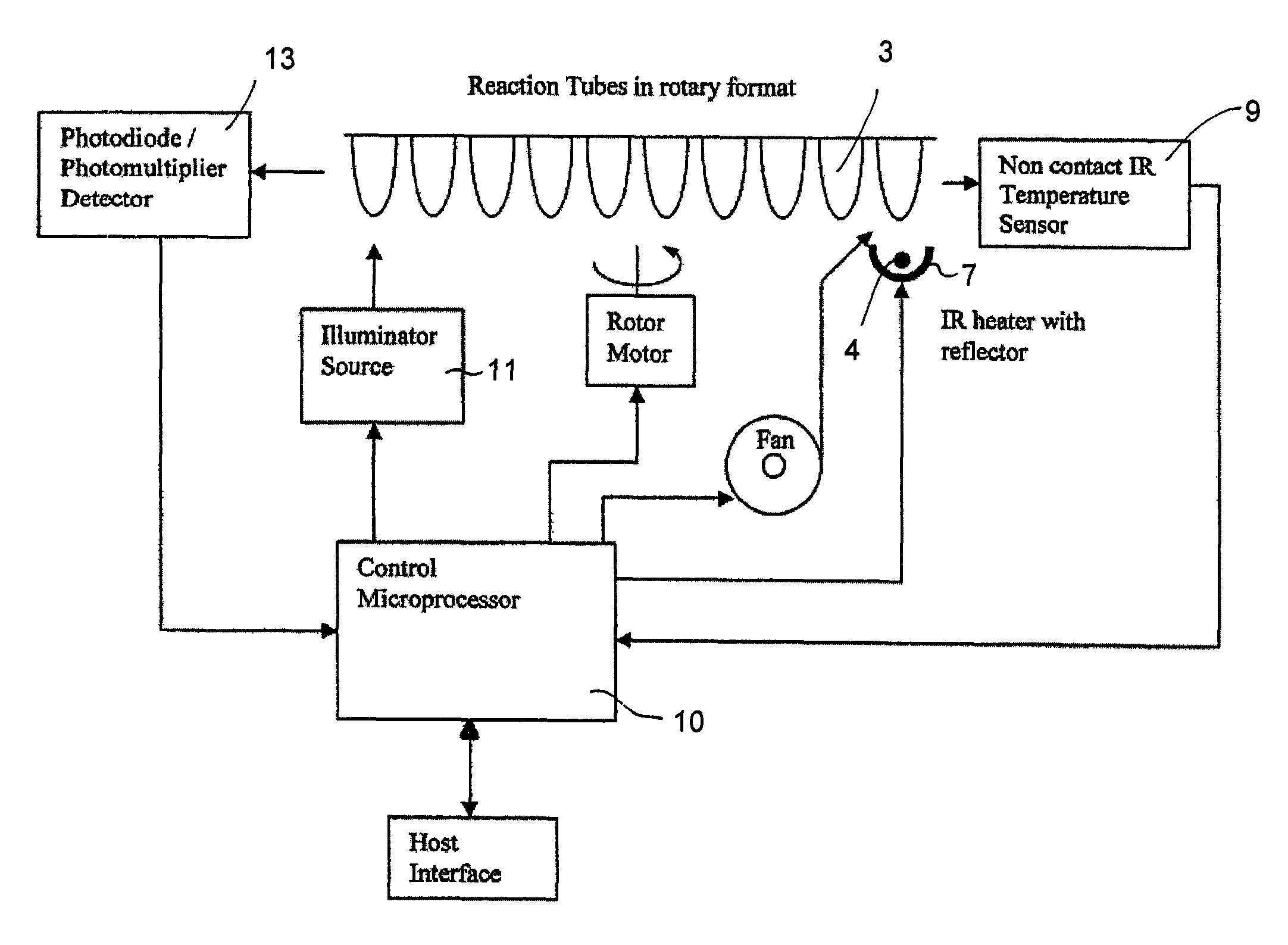

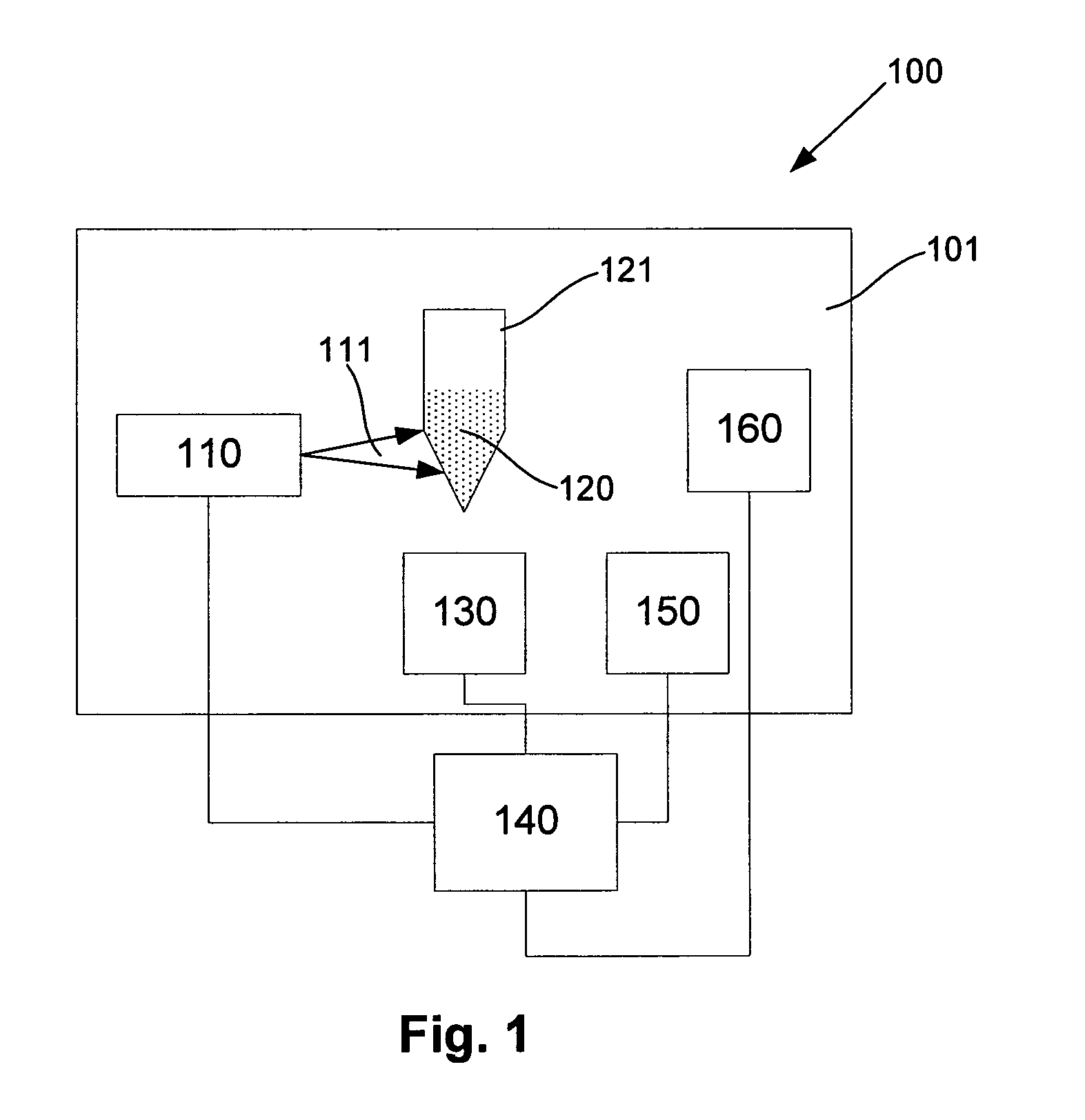

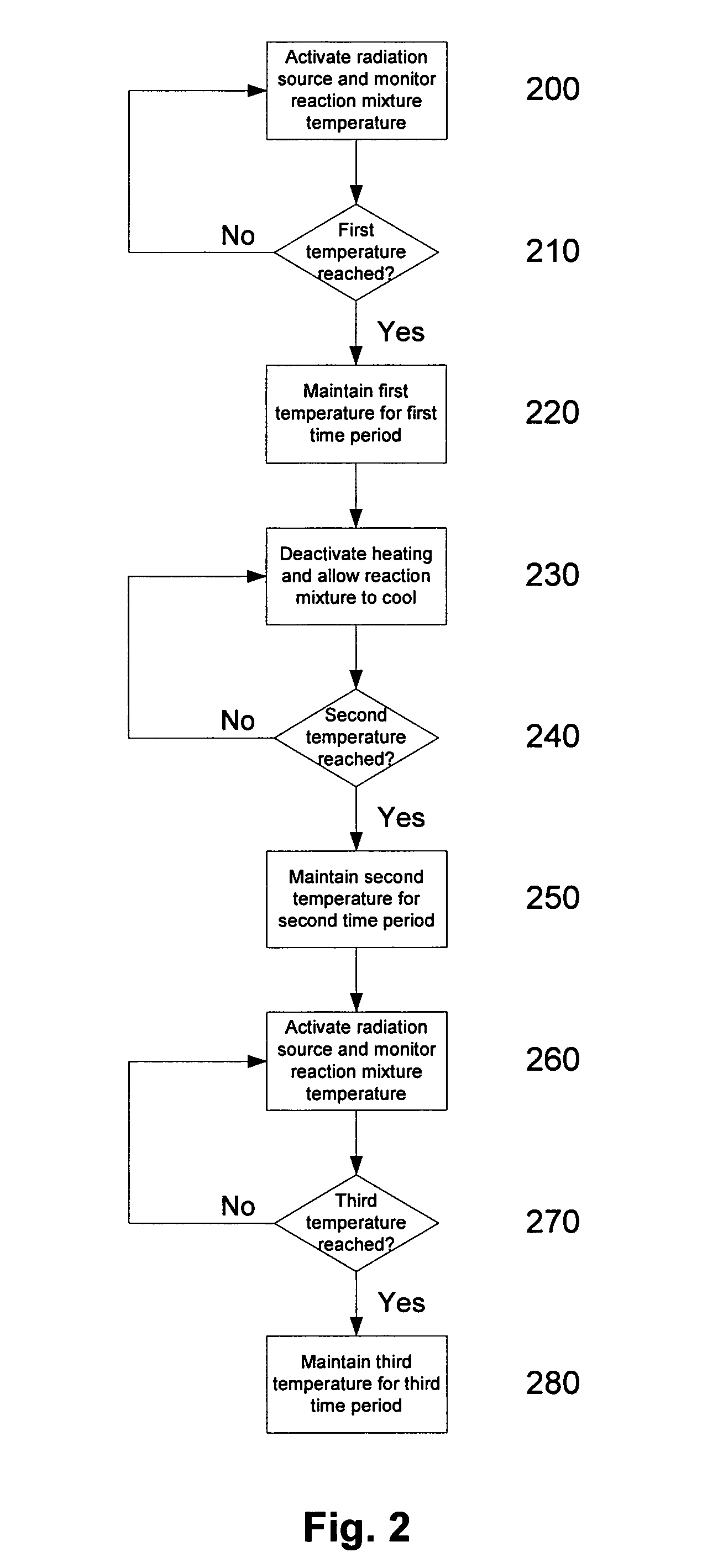

Thermal cycling device

ActiveUS9259736B2Bioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCycling

Apparatus for controlling the temperature of a reaction mixture held within a reaction container, the apparatus including a radiation source for exposing the reaction container to radiation thereby heating the reaction mixture, a temperature sensor for sensing a temperature indicative of a reaction mixture temperature and a controller for controlling the radiation source in accordance with the reaction mixture temperature to thereby selectively heat the reaction mixture.

Owner:QIAGEN GMBH

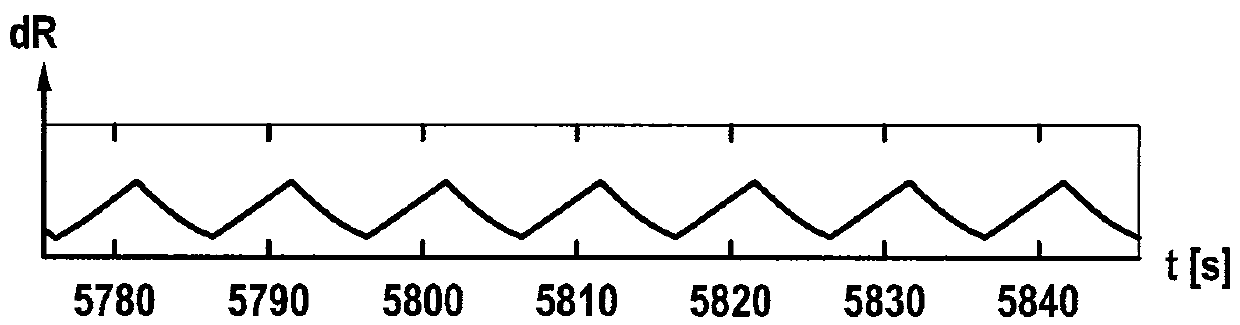

FET-based gas sensor

ActiveUS7707869B2Improve gas selectivityContinuous operationAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansProduct gasElectrochemistry

An operating method is disclosed for the selective detection of a target gas in a gas mixture to be measured by a field effect transistor with a gas-sensitive layer disposed on a carrier substrate, wherein the gas mixture to be measured is prepared by an electrochemical element such that the measured gas mixture includes minimal amounts of interfering gases that interfere with the measurement of the target gas, and / or at least one target gas is activated such that it is detected by the gas-sensitive layer.

Owner:TDK MICRONAS GMBH

Temperature controller for small fluid samples with different heat capacities

A system for controlling the temperature of fluidic samples includes a device having a first outer surface and a second outer surface which are parallel to one another. The interior of the device contains two or more channels suitable for accommodating samples. The channels lay on a common plane that is also parallel to the first and second outer surfaces. A temperature sensor is positioned between the channels along the common plane. A heater is thermally coupled to one of the two outer surfaces while a heat sink is coupled to the other of the two outer surfaces, thereby establishing a temperature gradient between the first and second outer surfaces. A temperature controller receives sensed temperature input from the temperature sensor and adjusts the heater in response thereto.

Owner:OSCILLOGY LLC

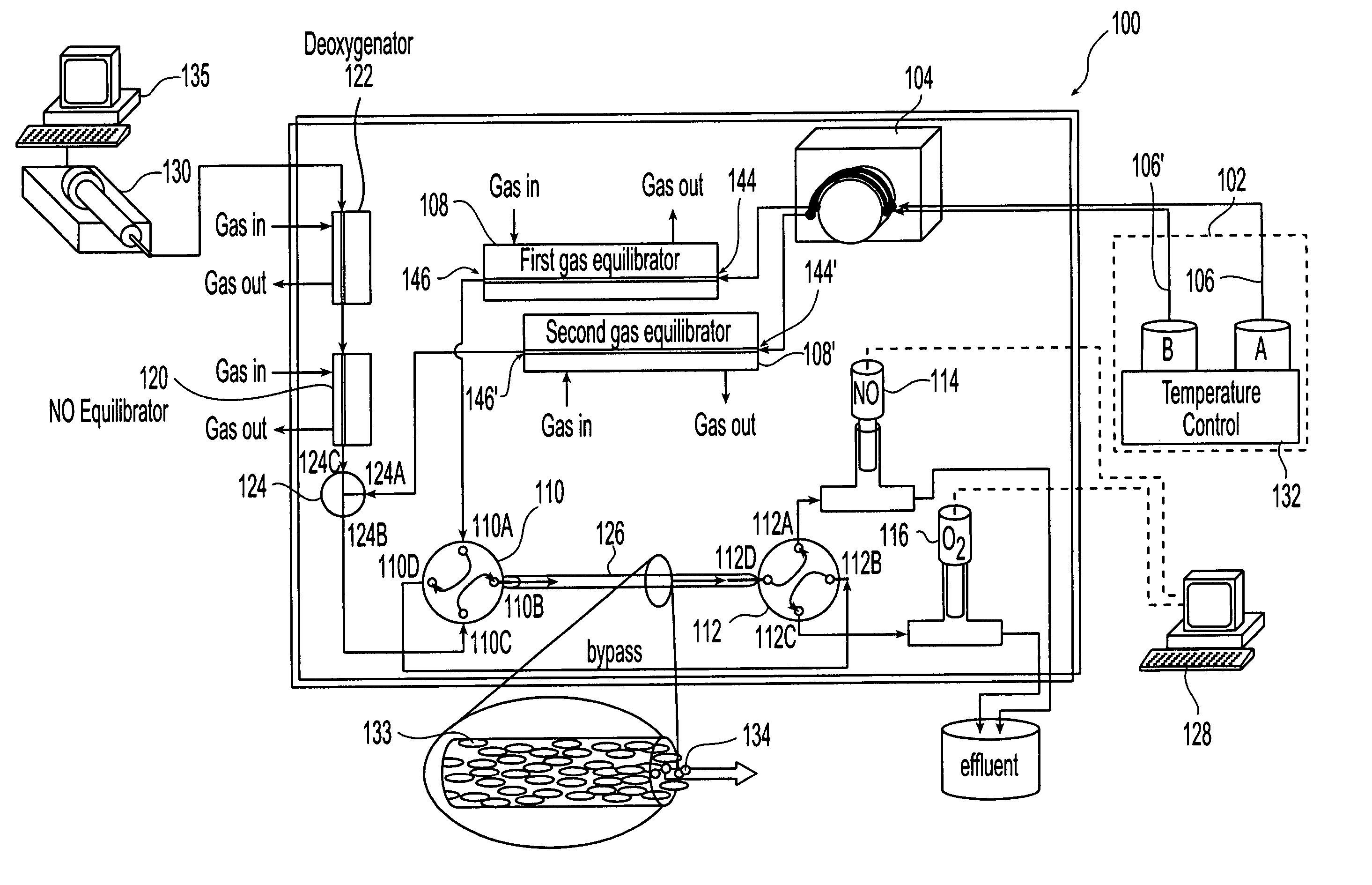

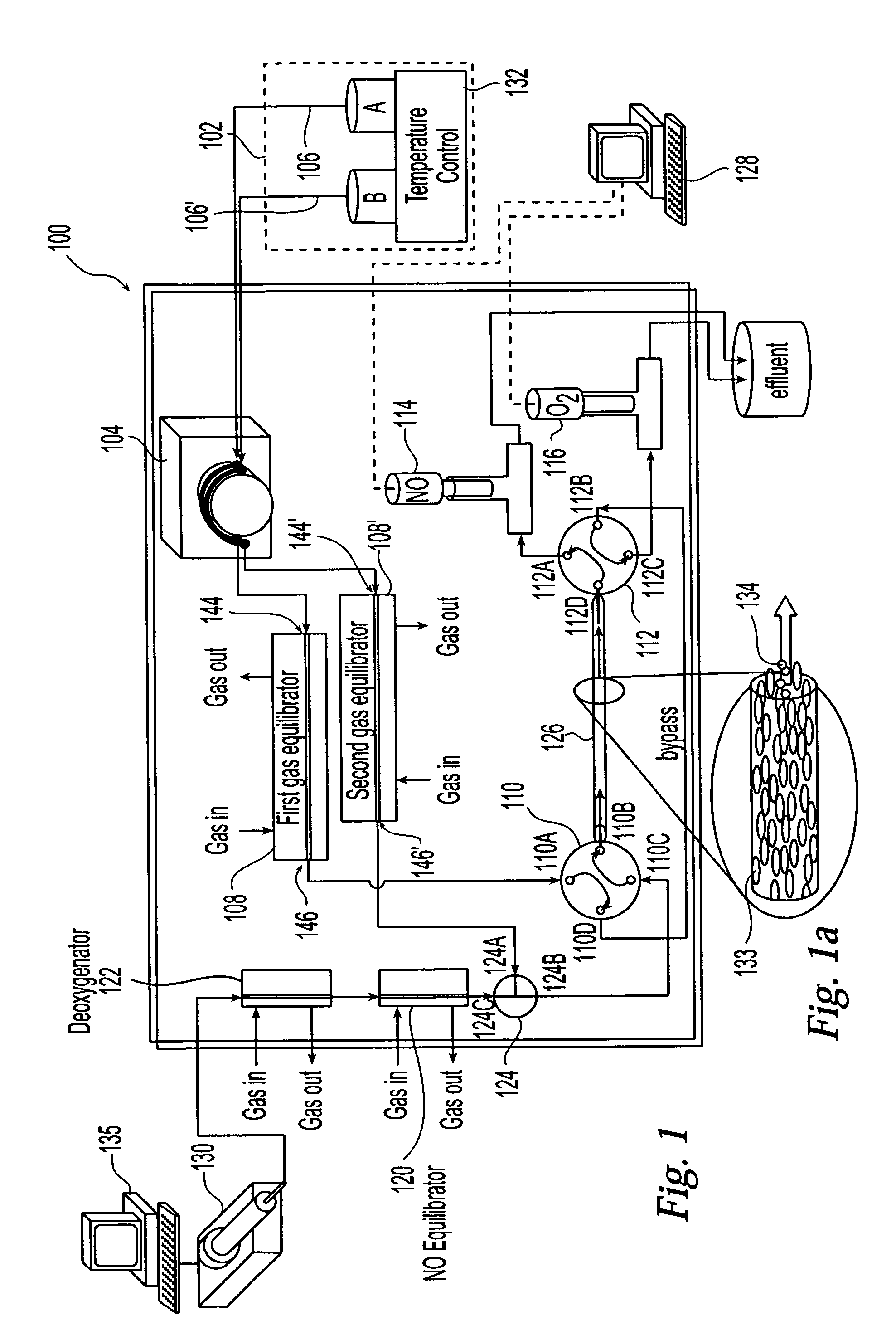

Method and apparatus for measuring nitric oxide production and oxygen consumption in cultures of adherent cells

InactiveUS7247470B2Bioreactor/fermenter combinationsBiological substance pretreatmentsCell culture mediaNitric oxide

An apparatus and method for measuring nitric oxide production and oxygen consumption in cultures of adherent cells continuously and without destroying the cells. The method involves flowing growth media through a tube having adherent cells are adhered to the inner surface thereof and then contacting the growth media with an NO or O2 sensor to detect the concentration of NO or O2 in the growth media.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Detonating gas detonation tester

InactiveCN104794971ASimple structureEasy to useEducational modelsGas handling apparatusBeak shapeGas-discharge lamp

The invention discloses a detonating gas detonation tester which is a glass product. A gas delivery pipe (1) is additionally arranged at the bottom of a flat-bottom container and provided with a gas delivery valve (2), a gas discharge pipe is additionally arranged at the top of the flat-bottom container, and a gas discharge valve (3) and a detonation beak (4) are arranged on the gas discharge pipe. The detonating gas detonation tester has the advantages of simple structure, convenience in use and obvious testing effect. The container can be used for storing gas for the convenience of use during testing anytime and anyplace.

Owner:邬苏婷

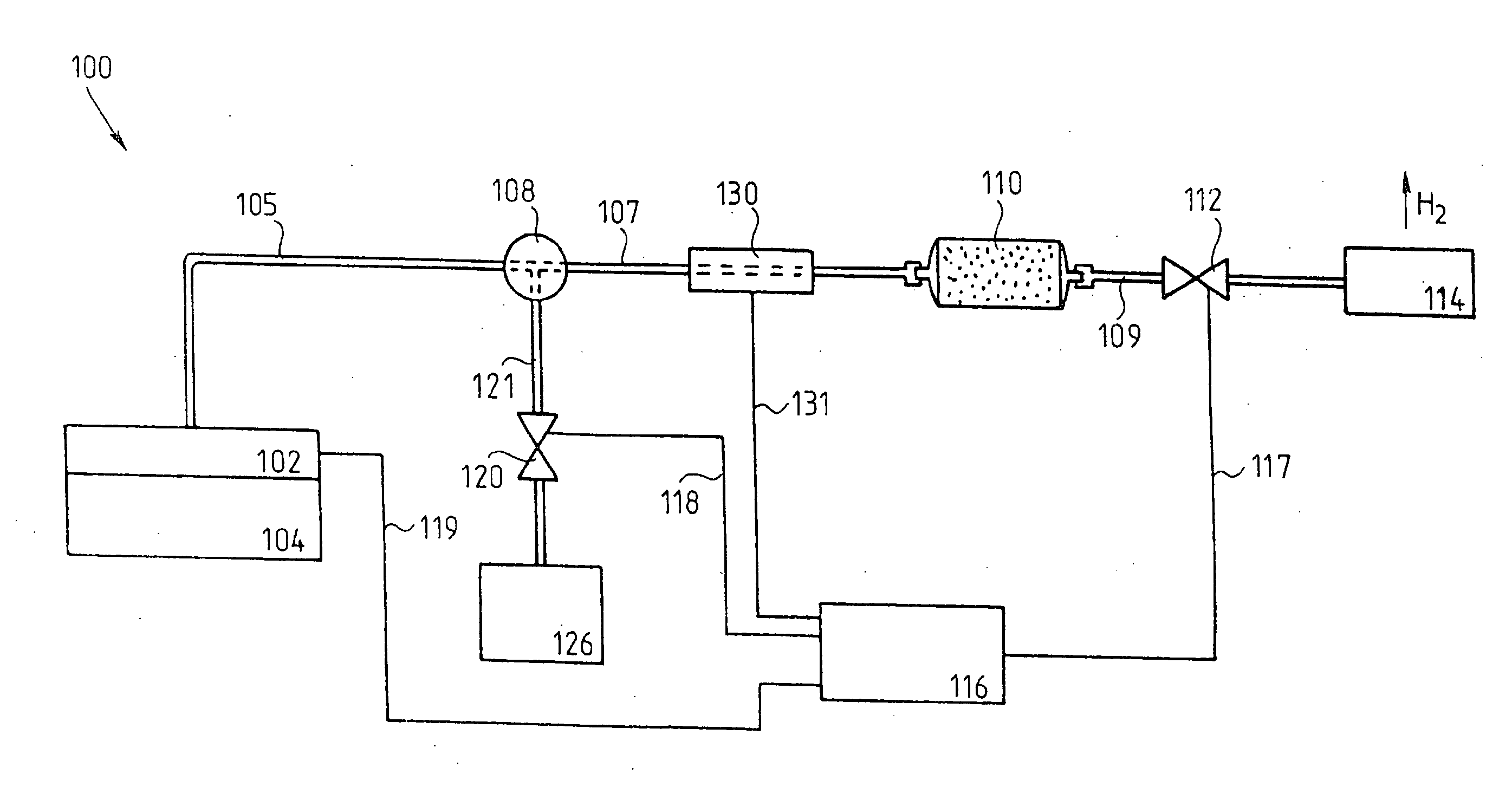

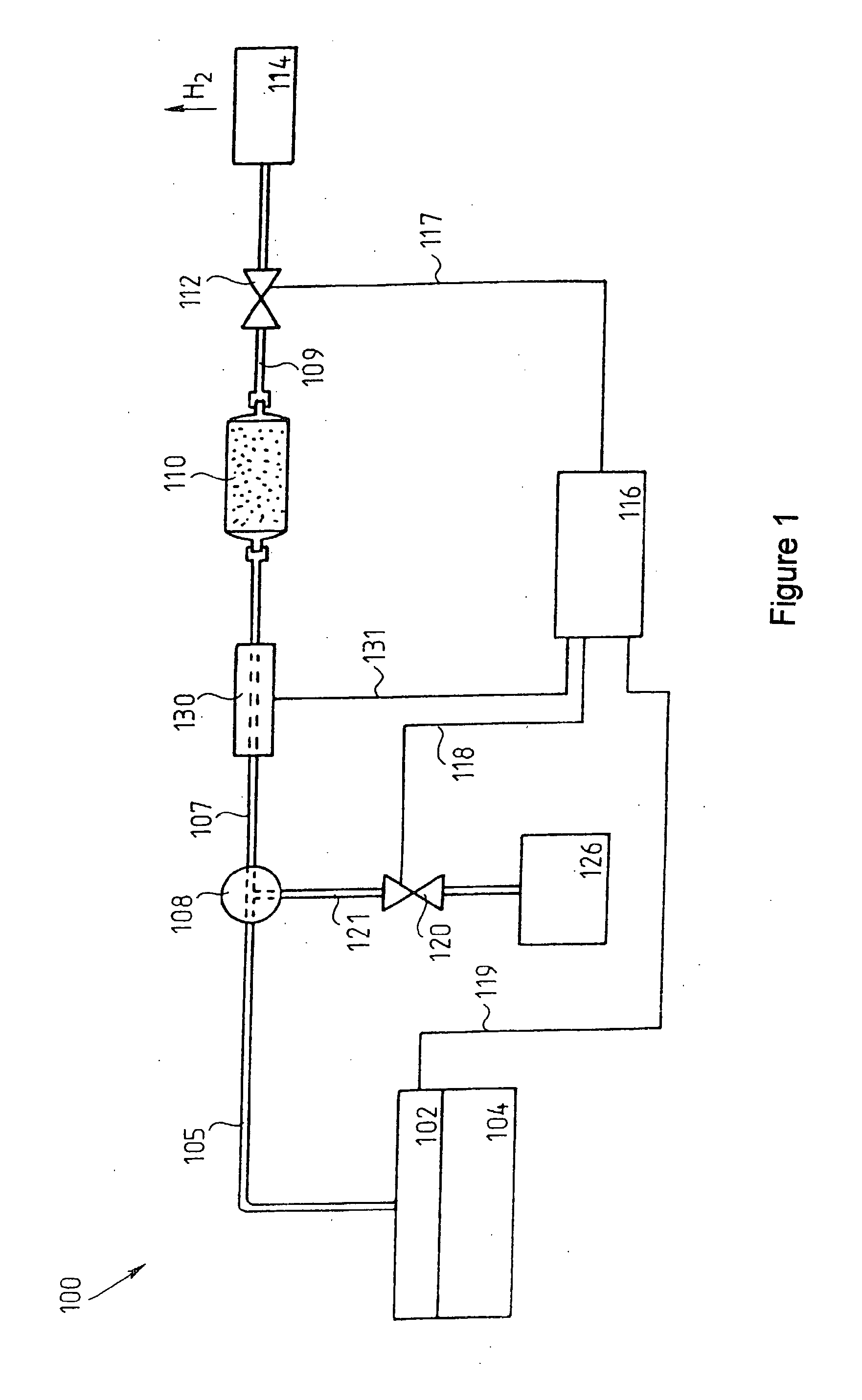

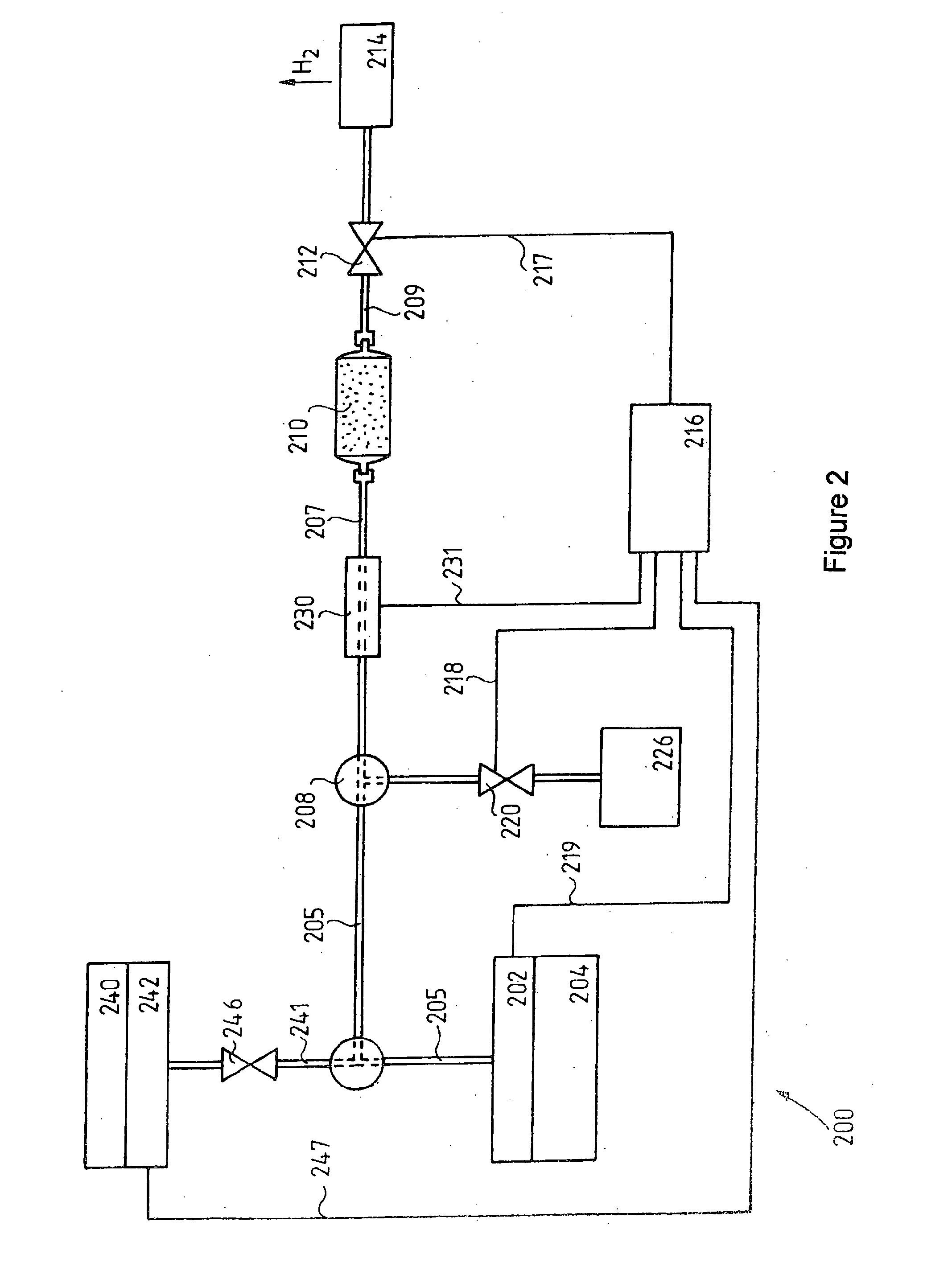

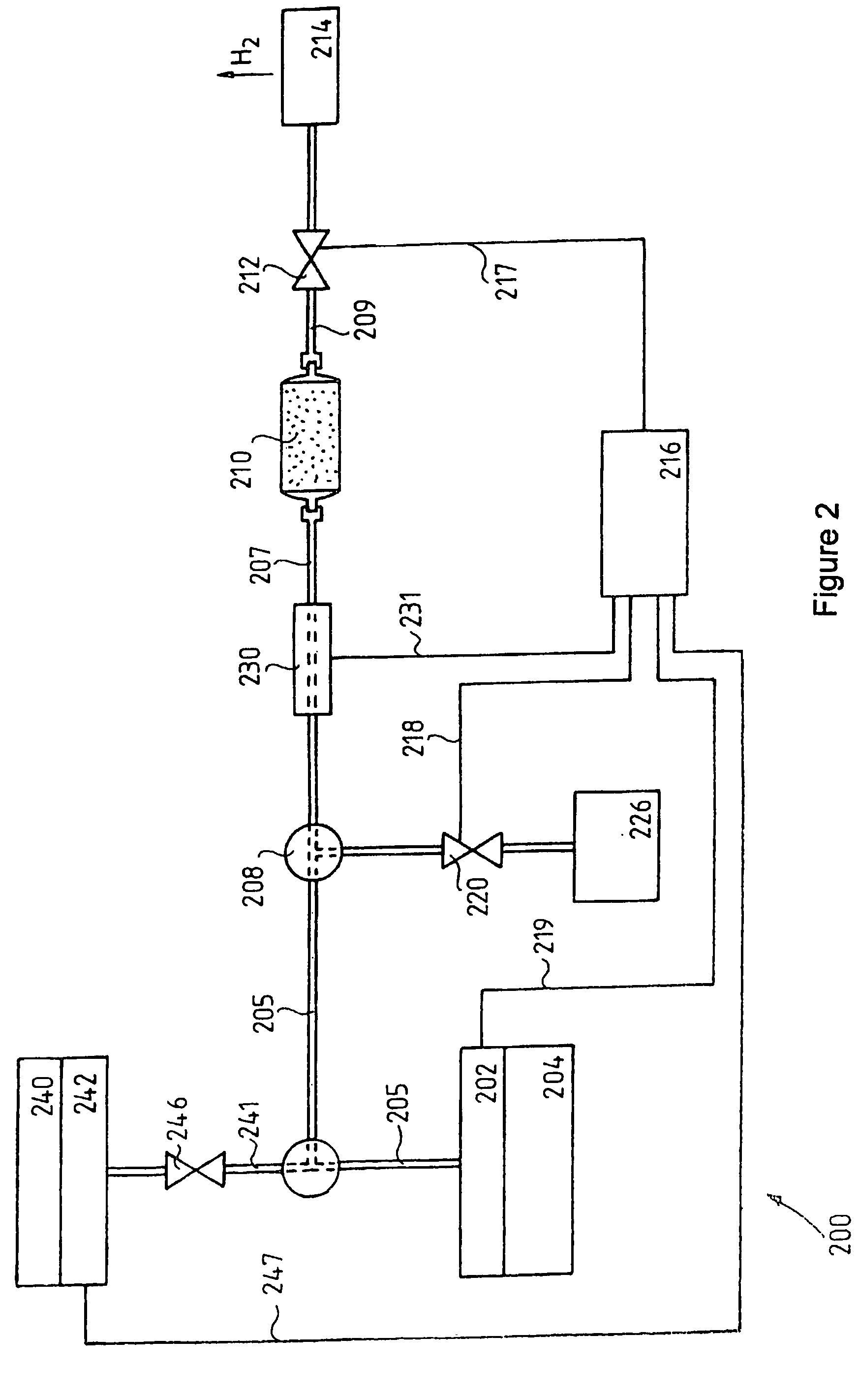

Laboratory scale continuous flow hydrogenation process

ActiveUS20110034704A1Fast and automatedChemical/physical/physico-chemical processesHydrocarbon oils refiningLaboratory scaleHydrogenation process

A process for hydrogenating a sample in a pressure range below supercritical pressure values includes supplying at least a solvent of the sample to be hydrogenated by a feed pump with a constant volume rate into a flow path to create a base solution; adding the sample being dissolved into the flow path; feeding hydrogen into the flow path through a valve configured to transmit hydrogen only into a single direction; leading the dissolved sample in the presence of a catalyst through a hydrogenation reactor, where the reactor is inserted into a section of the flow path located after the hydrogen feeding position; maintaining the pressure of the reaction in a given pressure range by element of a pressure-adjusting unit, and collecting a hydrogenate formed within the hydrogenation reactor in a product receptacle connected to the end of the flow path.

Owner:THALESNANO ZRT

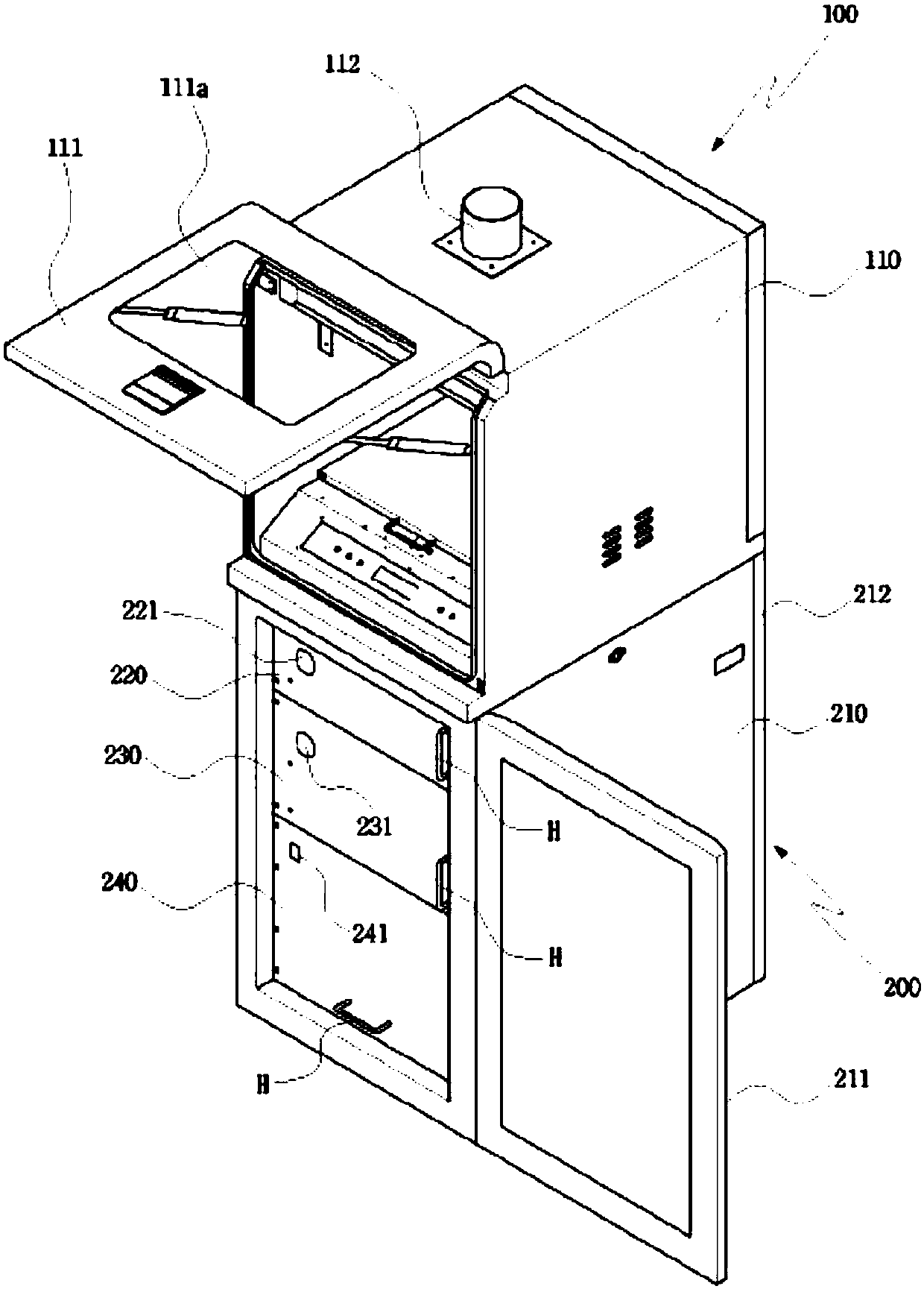

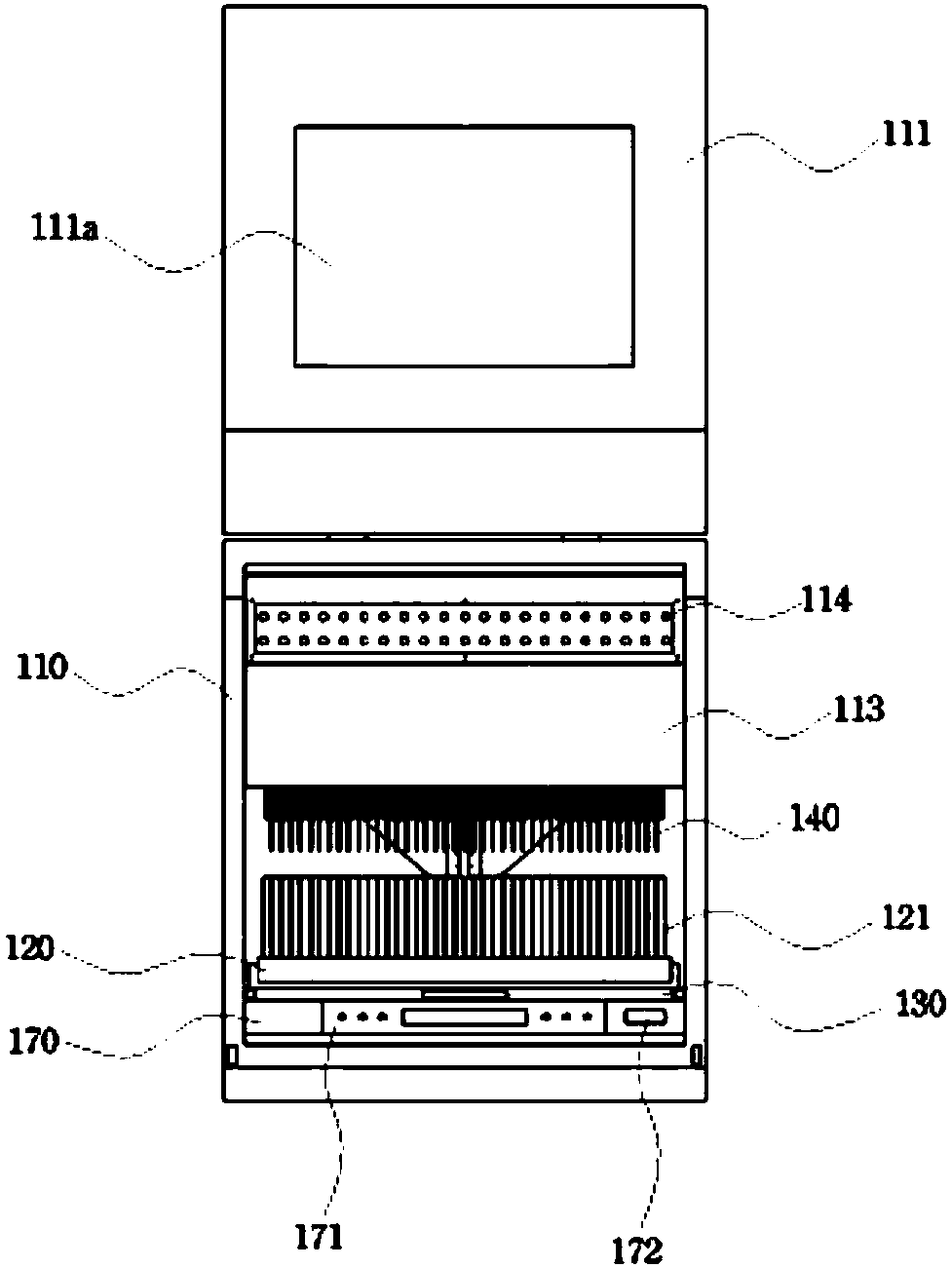

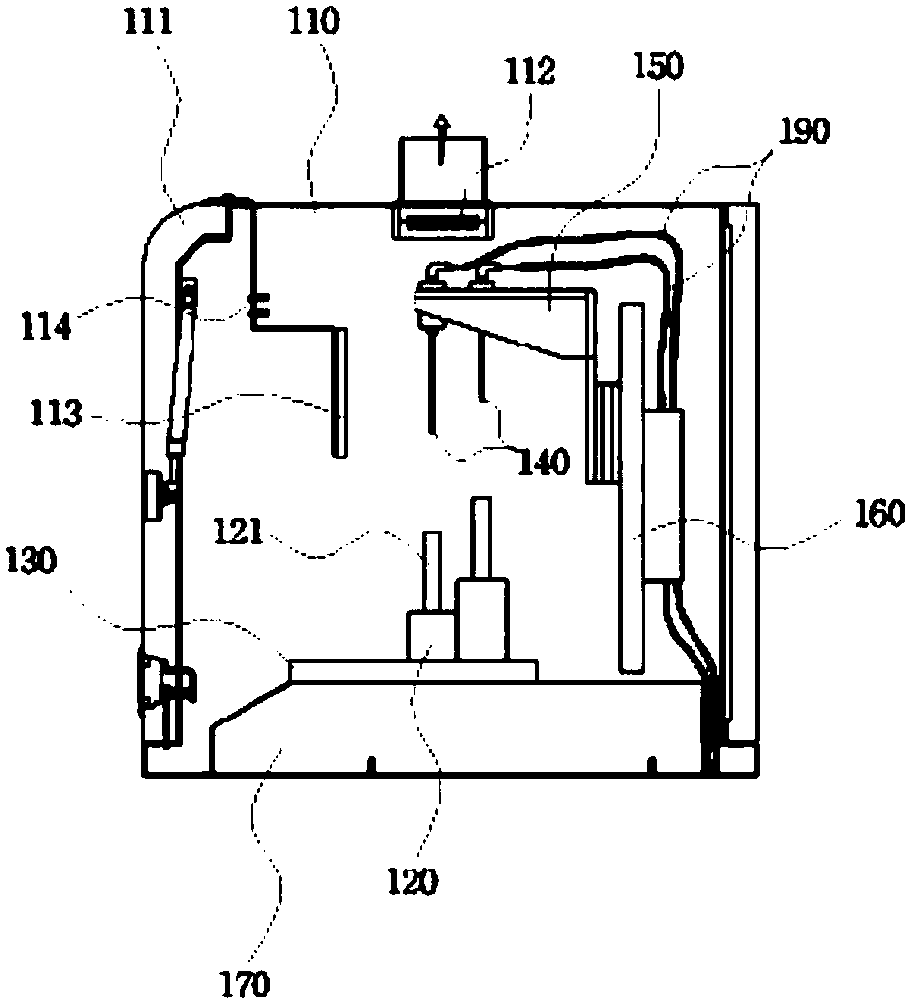

Integrated sample concentrator comprising nitrogen and air generating unit

ActiveCN107567356AAddressing Transgender IssuesAvoid overall overheatingHeating or cooling apparatusPreparing sample for investigationAtmospheric airEngineering

Provided is an integrated sample concentrator comprising a sample concentrating unit for concentrating a sample and a nitrogen and air generation unit provided below the sample concentrating unit. Thesample concentrating unit comprises: a sample concentrating unit housing provided with a glass window allowing the interior to be observed, and a fan for discharging evaporated solvent; a test tube holder for holding a plurality of test tubes; a sliding shelf provided below the test tube holder; a plurality of spray nozzles for spraying nitrogen or air into the test tubes; a spray nozzle holder for fixedly holding the spray nozzles; an elevating unit for vertically moving the spray nozzle holder; and a control unit for controlling the operation of the sample concentrator. The nitrogen and airgeneration unit comprises: a nitrogen and air generation unit housing provided with a front door and a back door, and barrier plates, with open top and bottom, installed downwardly on the left and right inner walls; a nitrogen generation module containing unit provided with a mode-switching switch to switch between a nitrogen mode and a dry air mode, and equipped with a nitrogen generation modulecomprising a nitrogen membrane for separating nitrogen when compressed air is supplied; a storage tank module containing unit provided with a first pressure gauge for indicating the pressure of nitrogen or air stored in the front, having a supply tube connected in the rear surface thereof to supply the sample concentration unit with nitrogen or air, and having a storage tank module installed in the interior thereof to store nitrogen or air; and an air compression module containing unit provided with a power switch on the front surface thereof to control the operation of the nitrogen and air generation unit, and equipped with an air compression module for suctioning in and compressing atmospheric air. Additionally, the nitrogen generation module containing unit, storage tank module containing unit, and air compression module containing unit are coupled to the nitrogen and air generation unit housing, each having rails provided on both side surfaces thereof to allow sliding, and each being provided with a handle on the front surface thereof.

Owner:朴钟范

Load-membrane blowing bottle

ActiveCN103977849AConvenient experimentGas handling apparatusBiochemical engineeringMicroscopic observation

The invention discloses a load-membrane blowing bottle, which comprises a blowing bottle body, the inner part of the blowing bottle body is in a cavity structure, the blowing bottle is connected to a guiding circle ring, a blowing rod capable of passing through the guiding circle ring is spliced with the blowing bottle body, a blowing push plug is arranged at one end of the blowing rod, the blowing push plug is arranged in the blowing bottle body, a push block is arranged at the other end of the blowing rod, a blowing pore is arranged at the end face of the blowing bottle body, a loading groove is arranged at the end face of the blowing bottle body, the blowing pore is arranged in the loading groove, a first auxiliary pore is arranged at the end face of the blowing bottle body, the membrane is arranged at the first auxiliary pore, a second auxiliary pore is arranged at the side surface of the blowing bottle body, the membrane is arranged at the second auxiliary pore, and the blowing pore, the first auxiliary pore and the second auxiliary pore are respectively communicated to the inner part of the blowing bottle body. According to the invention, the load-membrane cultured with microbe is placed in the loading groove for providing gas source to the load-membrane and blowing the load-membrane, so that the microbe movement status in the load-membrane can be observed by a microscope.

Owner:江苏卓燃知识产权运营有限公司

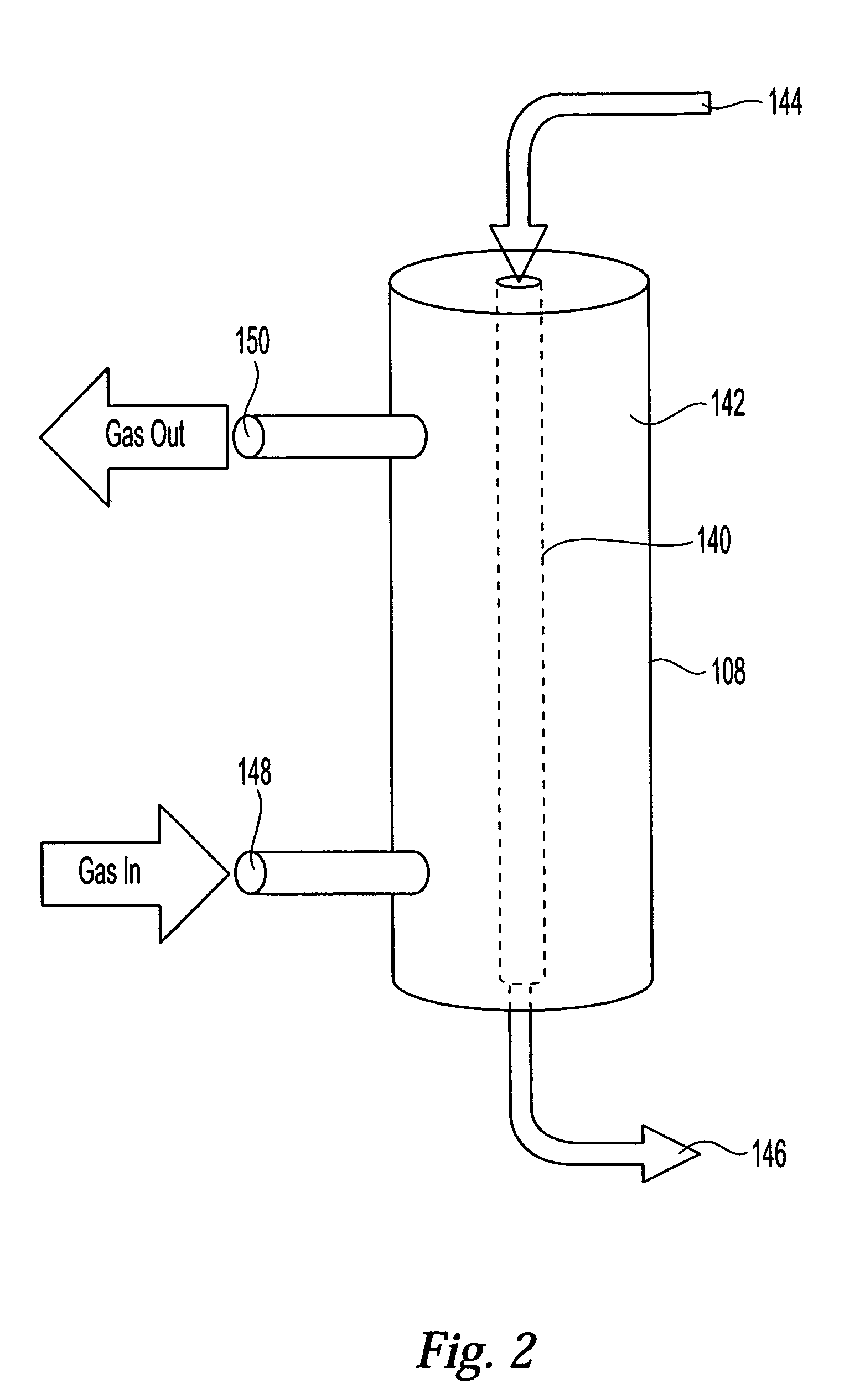

Method and apparatus for changing relative concentrations of gases present within a gaseous sample for mass spectrometry

ActiveUS9182325B2Analysis using chemical indicatorsPreparing sample for investigationAnalyteTandem mass spectrometry

An apparatus for changing relative concentrations of first and second analyte substances in an analyte sample comprises a sample cell defining a sample chamber therewithin, and a semipermeable boundary member disposed in the sample chamber to define first and second sides of the sample chamber. Sample flow input and sample flow output ducts direct an analyte sample containing respective initial concentrations of the first and second analyte substances into the first side of the sample chamber. The semipermeable boundary member permits diffusion therethrough of the first and second analyte substances to the second side of the sample chamber at different rates. An analyte sample in the second side of the sample chamber, and an analyte sample exiting the first side via the sample flow output duct, have respective concentrations of the first and second analyte substances that are different from the initial concentrations.

Owner:AGILENT TECH INC

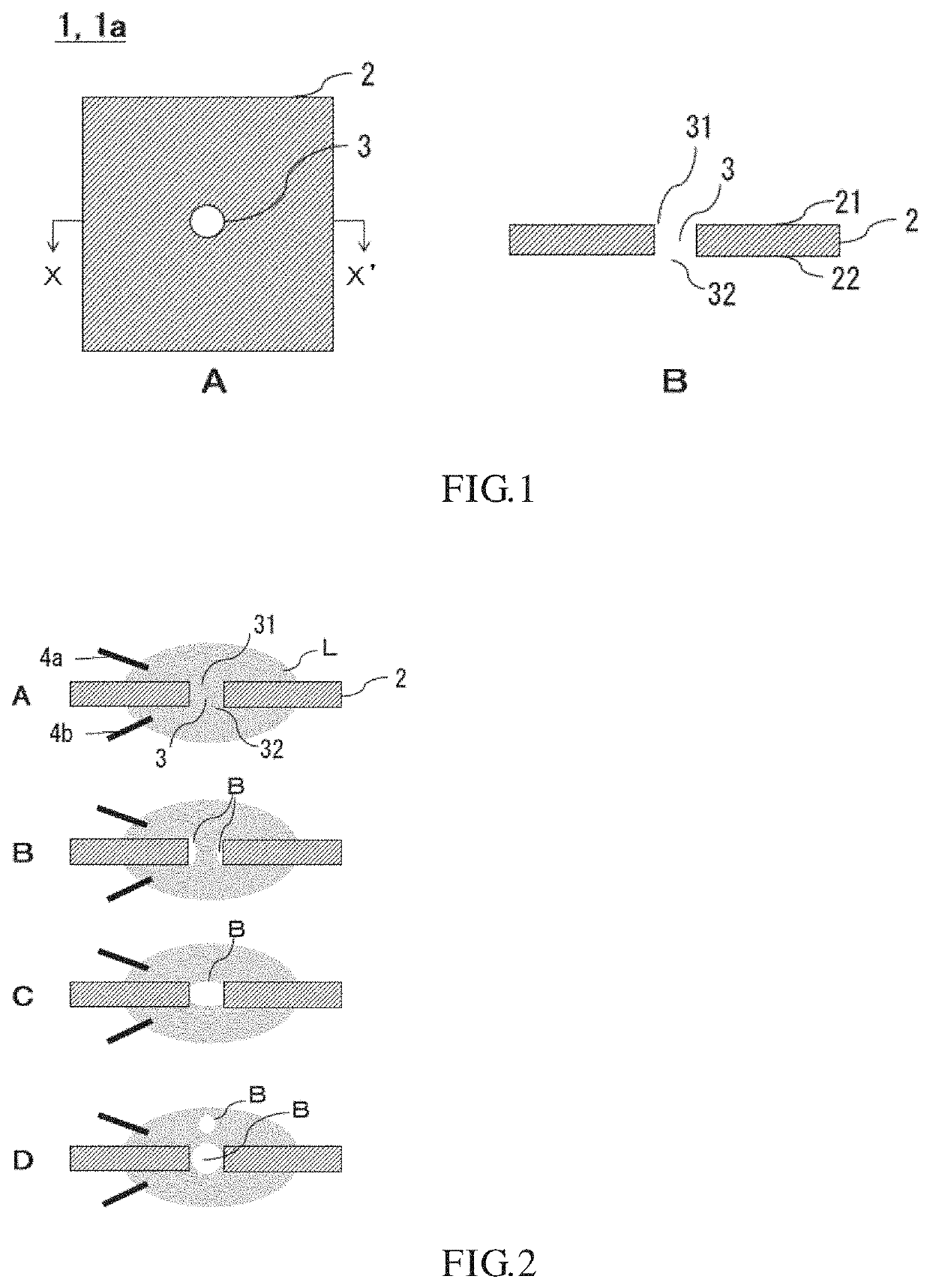

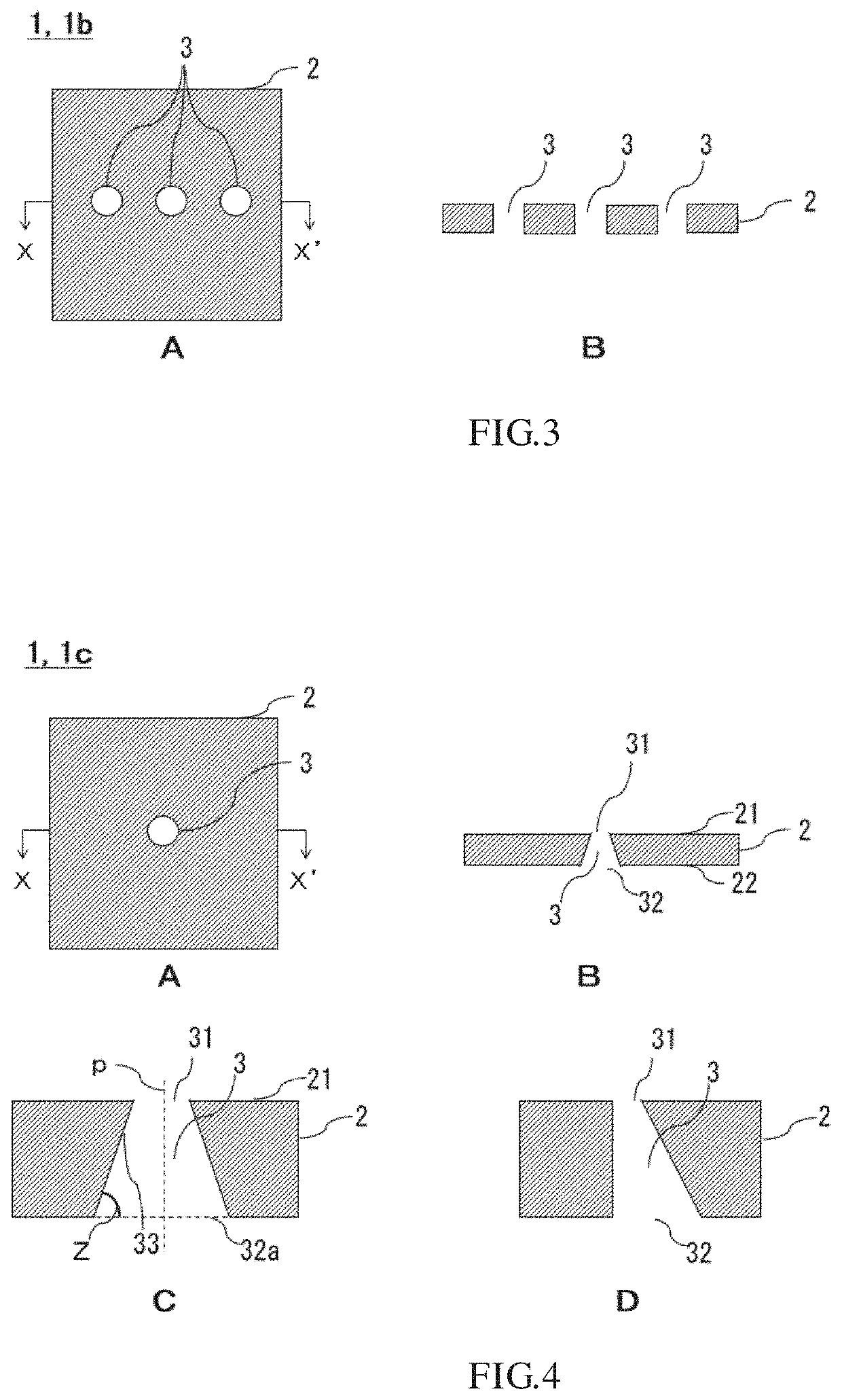

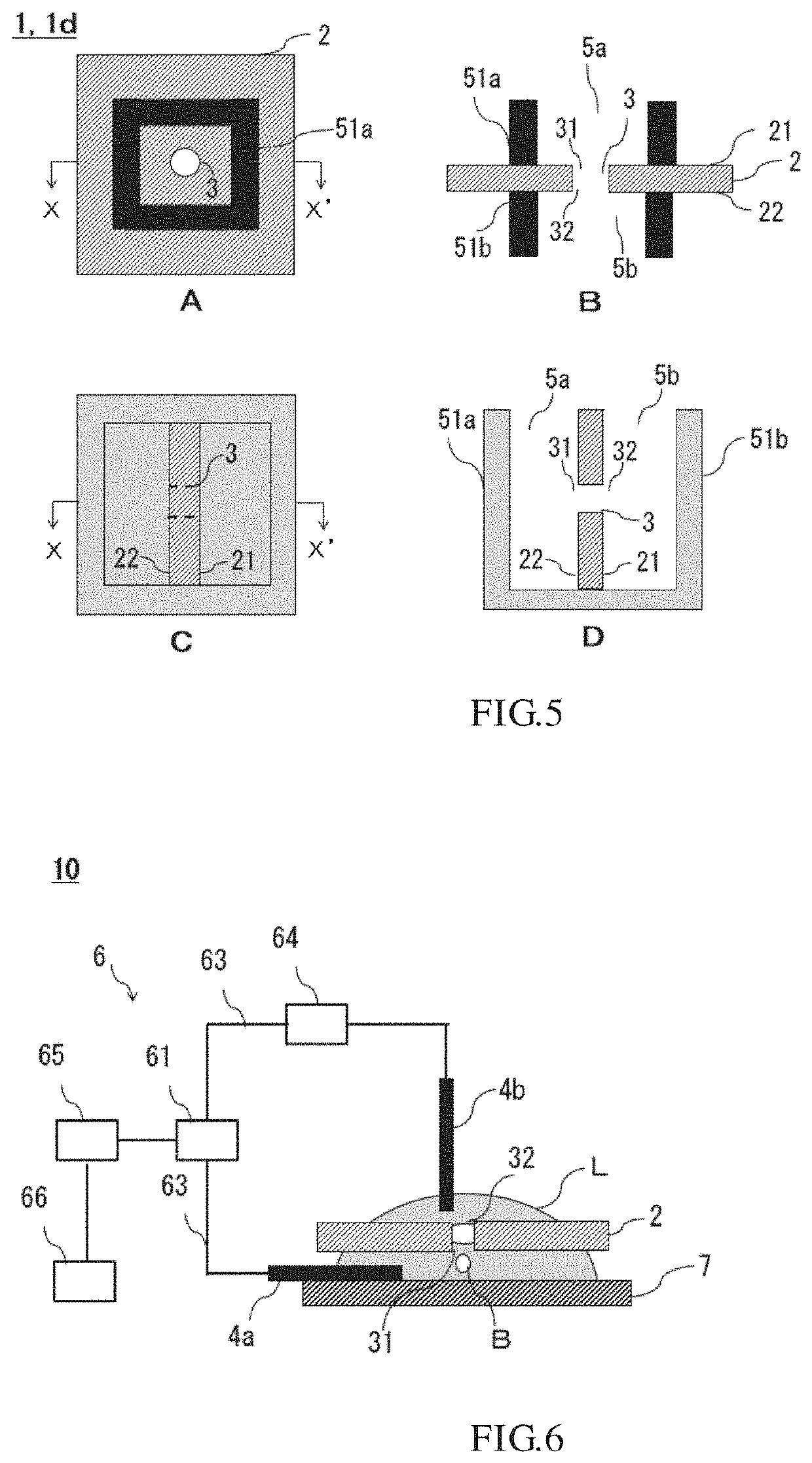

Bubble ejection method, bubble ejecting device, and bubble ejection apparatus

PendingUS20210395782A1Easy to produceImprove usabilityBioreactor/fermenter combinationsBiological substance pretreatmentsDielectricLiquid state

The present invention addresses the problem of providing a bubble ejection method based on a new principle that is different from conventional bubble ejection methods and a bubble ejecting device.To solve the problem, provided is a bubble ejection method using a bubble ejecting device, wherein the bubble ejecting device comprisesa substrate formed of a dielectric,at least one bubble ejection hole formed so as to penetrate through a first face and a second face, which is a face opposite to the first face, of the substrate,a first opening formed at a position of the first face at which the bubble ejection hole penetrates, anda second opening formed at a position of the second face at which the bubble ejection hole penetrates,the bubble ejection method comprising:a substrate-conductive liquid contact step;a conductive liquid-electrode contact step;a voltage application step; anda bubble ejection step.

Owner:KYUSHU UNIV

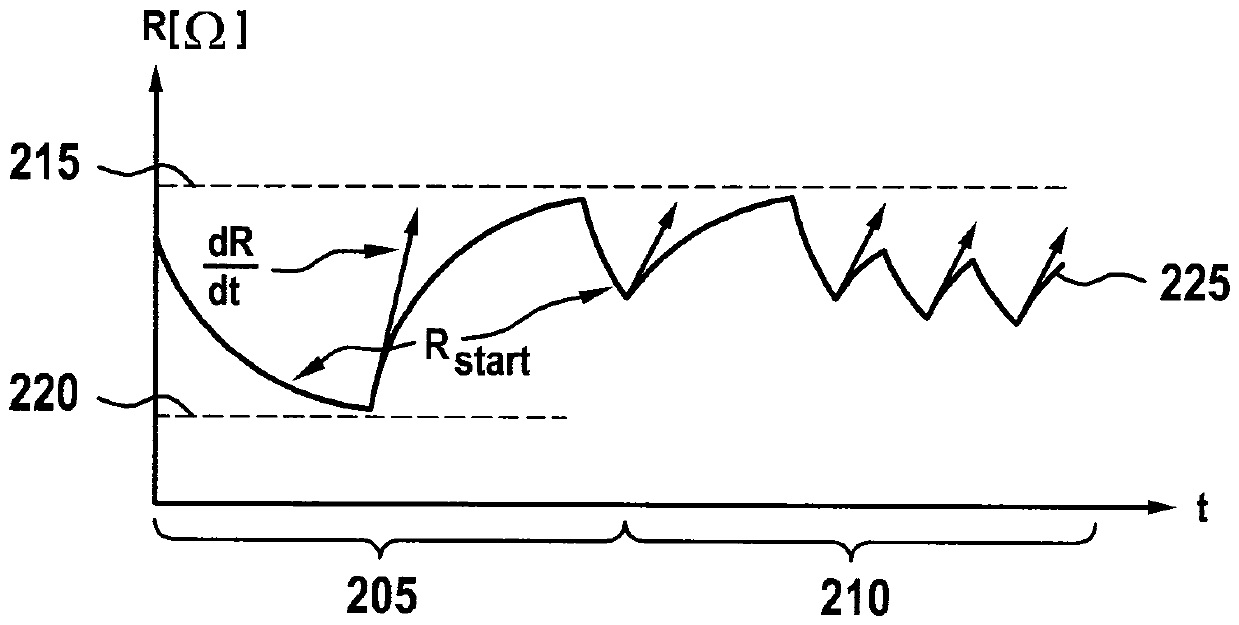

Gas sensor

A measuring device for determining a gas concentration includes a gas-sensitive element, a sensing device, a stimulation unit, and a processing unit. The gas-sensitive element is configured to absorb a gas. The sensing device is configured to determine a parameter of the gas-sensitive element in a predetermined time period, where the parameter depends on an absorbed quantity of the gas. The stimulation unit is configured to stimulate the gas-sensitive element and accelerate desorption of the gas out of the gas-sensitive element. The processing unit is configured to determine a rate of change of the parameter, to control the stimulation such that a concentration of the gas in the gas-sensitive element lies outside of an equilibrium state, and to determine the gas concentration based on the rate of change.

Owner:ROBERT BOSCH GMBH

Microchannel chip and method for gas-liquid phase separation using same

ActiveUS8815604B2Ensure sufficient separationHigh sensitivityMaterial analysis by electric/magnetic meansMaterial analysis by optical meansGas phaseLiquid phase

A microchannel chip having a microchannel formed in a substrate and a gas-liquid phase separation microchannel whose upper part is covered with a porous film, the gas-liquid phase separation microchannel being connected to the downstream end of the microchannel and having a depth of 10 μm to 100 μm. Also, a gas-liquid phase separation method which is a method for separating a liquid-phase flow from a two-phase flow flowing through a microchannel by removing a gas phase, the two-phase flow composed of the gas phase and the liquid phase, which liquid phase flows in the periphery of the above-described microchannel and which gas phase flows interiorly of the liquid-phase flow.

Owner:KANAGAWA INST OF IND SCI & TECH +2

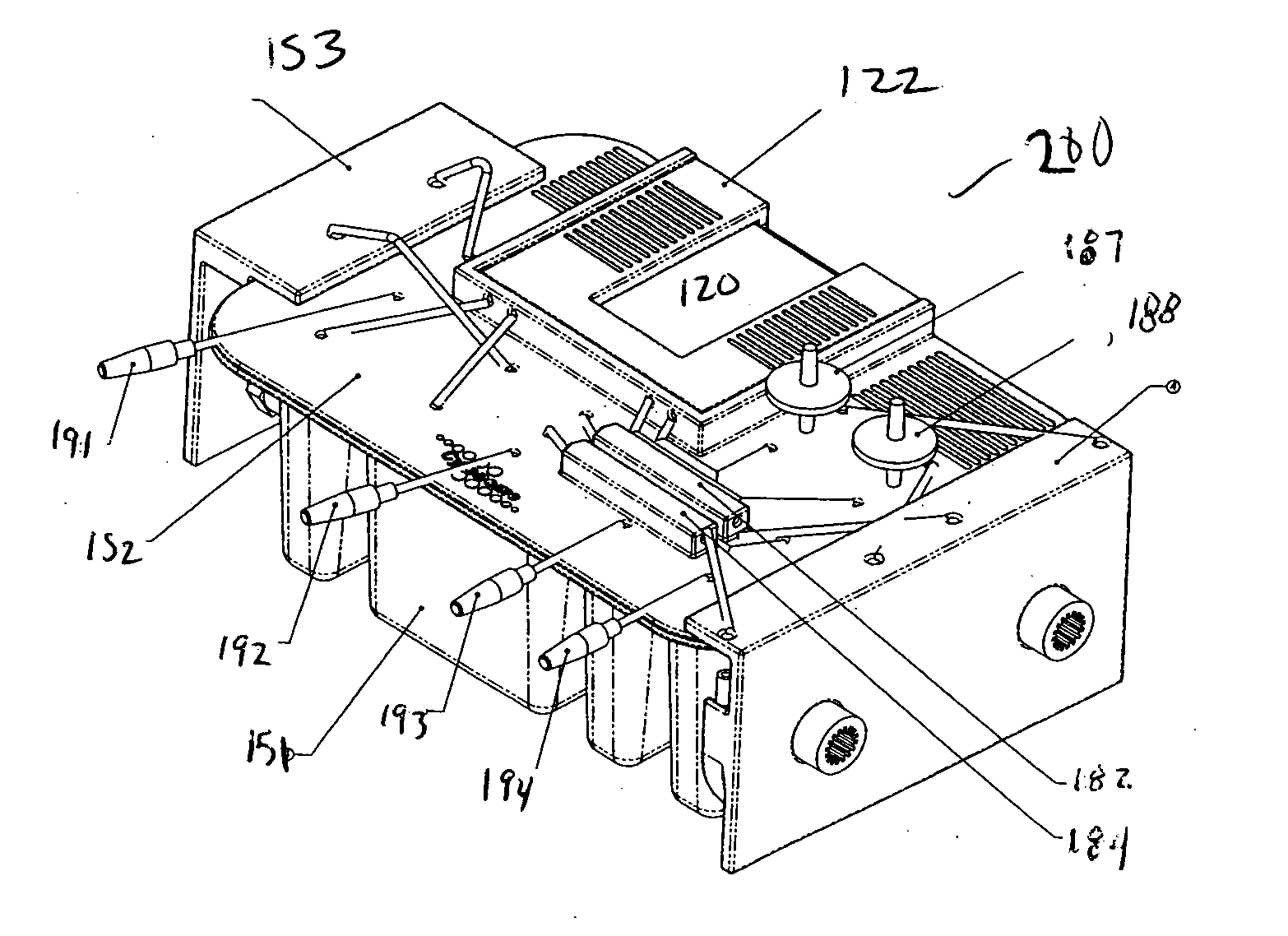

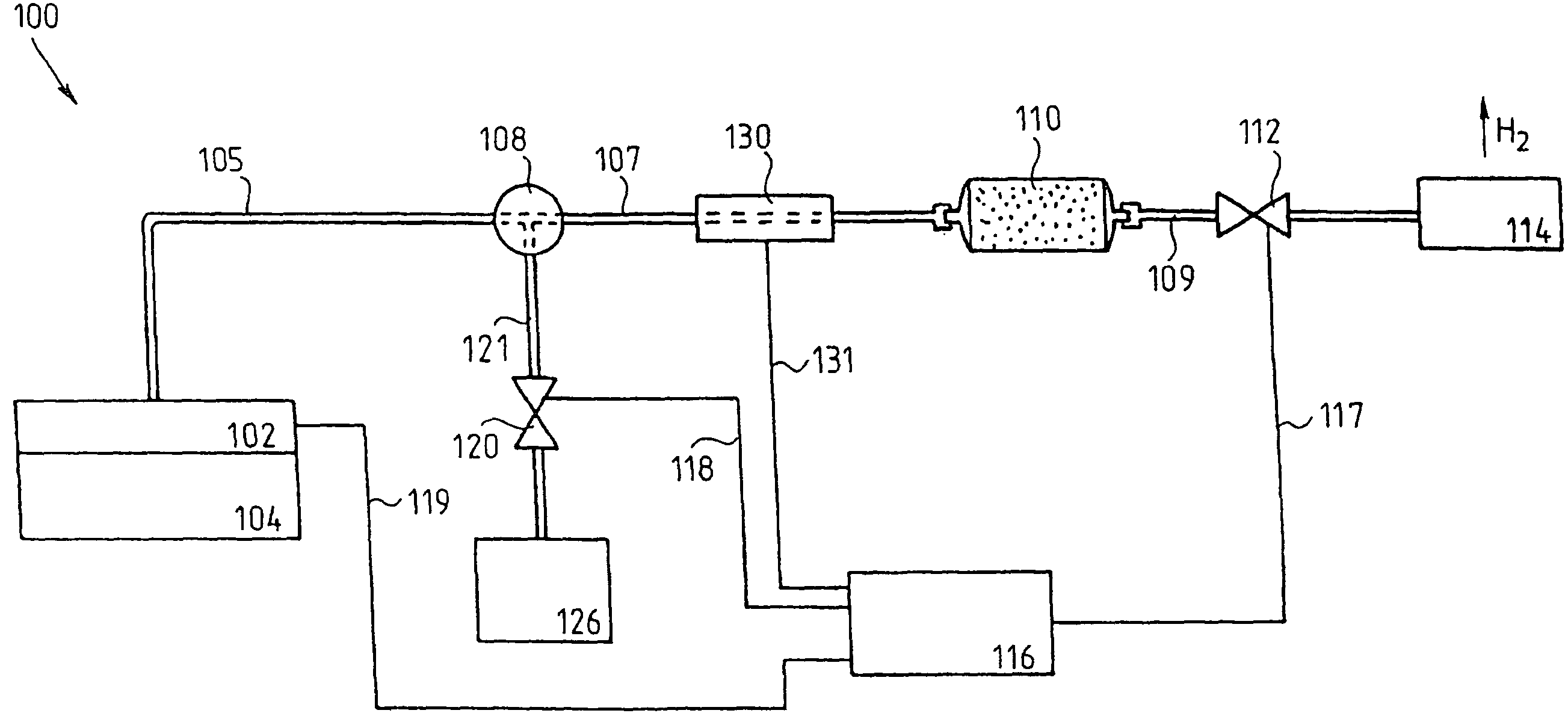

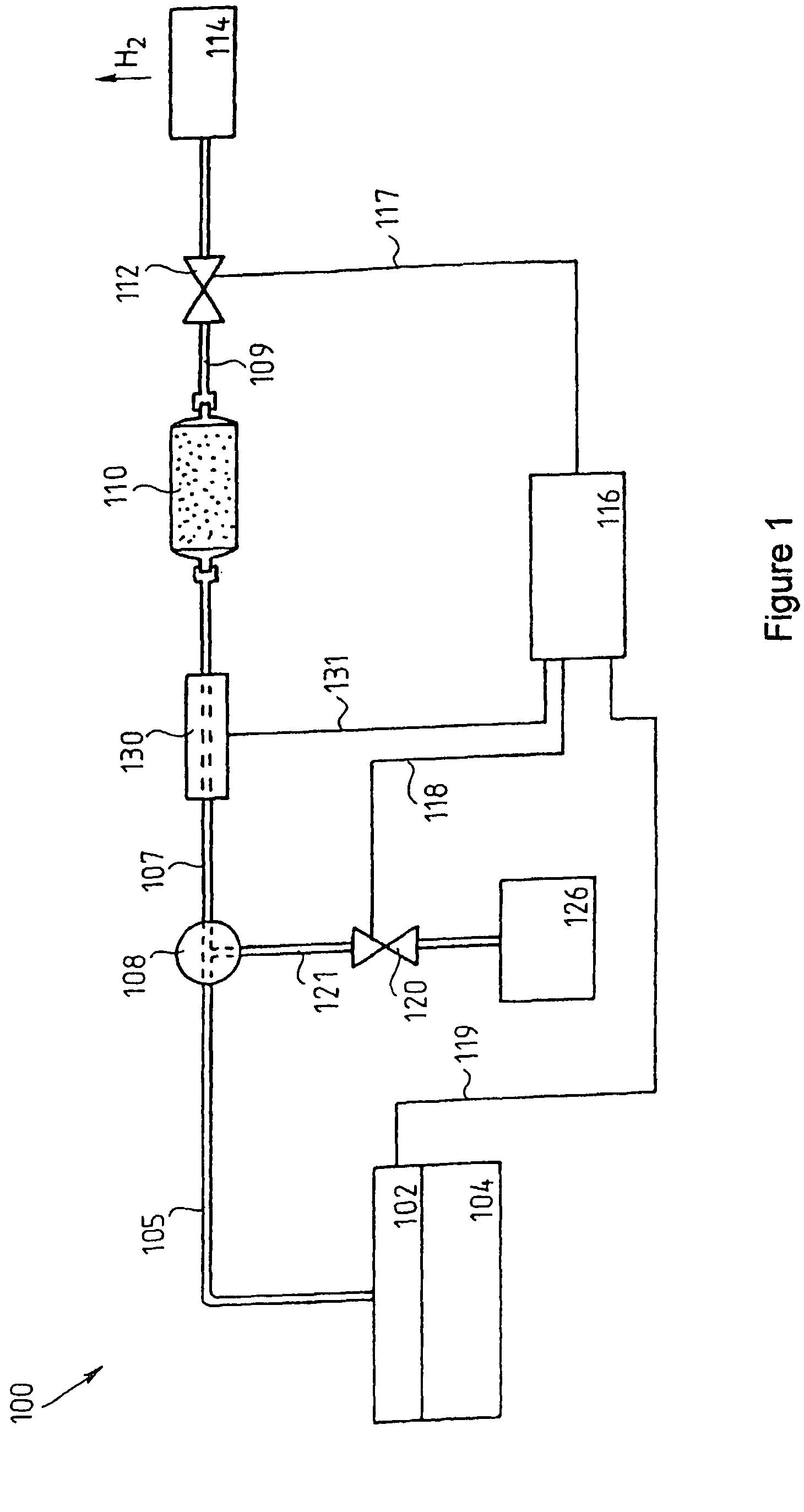

Flow-type laboratory hydrogenation apparatus and laboratory hydrogenation process using the apparatus

ActiveUS7837949B2Fast and automatedWell mixedGaseous chemical processesLiquid-gas reaction as foam/aerosol/bubblesElectricityLaboratory scale

A laboratory scale continuous flow hydrogenation apparatus (100) includes a reservoir (104), a feed pump (102), a mixing element (108) with two inlets and an outlet, a hydrogenation reactor (110) and a pressure-adjusting unit (112), all connected into a flow path. A hydrogen source (126) and a one-way valve (120) are arranged between the hydrogen source (126) and the second inlet of the mixing element (108). The feed pump (102) can provide a constant volume rate. The reservoir (104) contains at least a solvent base solution of the sample to be hydrogenated. The hydrogenation reactor (110) connects into the flow path by detachable connections and is formed as a replaceable cartridge containing a packing which increases the flow resistance and facilitates mixing. The pressure-adjusting unit (112) connects into the flow path after the hydrogenation reactor (110) and is provided with a regulation controlled electrically.

Owner:THALESNANO ZRT

Laser polarization **Xe solid memory

InactiveCN1239268CReduce volumeEasy to carryMaterial analysis by using resonanceGas handling apparatusSignal onLiquid nitrogen

The invention discloses a laser polarized 129Xe solid memory, composed of lift table, Dewar, dual circle permanent magnet, iron sleeve, liquid nitrogen, glass casing pipe, two safety vacuum valves and regulating frame, where the dual permanent magnet is set on the iron sleeve with adjustable length to adjust magnetic field strength; there is silicon coat on the inner wall of the glass casing pipe, which is used as its storage room and sample mixing room; the lift table goes up and down to change the temperature of laser polarized 129Xe. It has the advantages of adjustable magnetic field strength, small memory volume, convenient storage and transport, etc. It is mainly applied to magnetic resonance imaging, polarization transfer, medium- and micro- aperture measurement and structure research, enhancement of NMP signal on material surface, etc.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com