Integrated sample concentrator comprising nitrogen and air generating unit

A technology of generating part and concentrator, applied in the field of combined sample concentrator of nitrogen and air generating part, can solve the problems of reduced energy efficiency, hindered appearance, cost and space waste, etc., and can reduce the concentration time and prevent temperature. Overheating, inspection and repair simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below. These examples are for illustrating the present invention more specifically, and the scope of the present invention is not limited to these examples.

[0025] First, refer to Figure 1 to Figure 10 The combined sample concentrator including the nitrogen and air generating part is explained as follows.

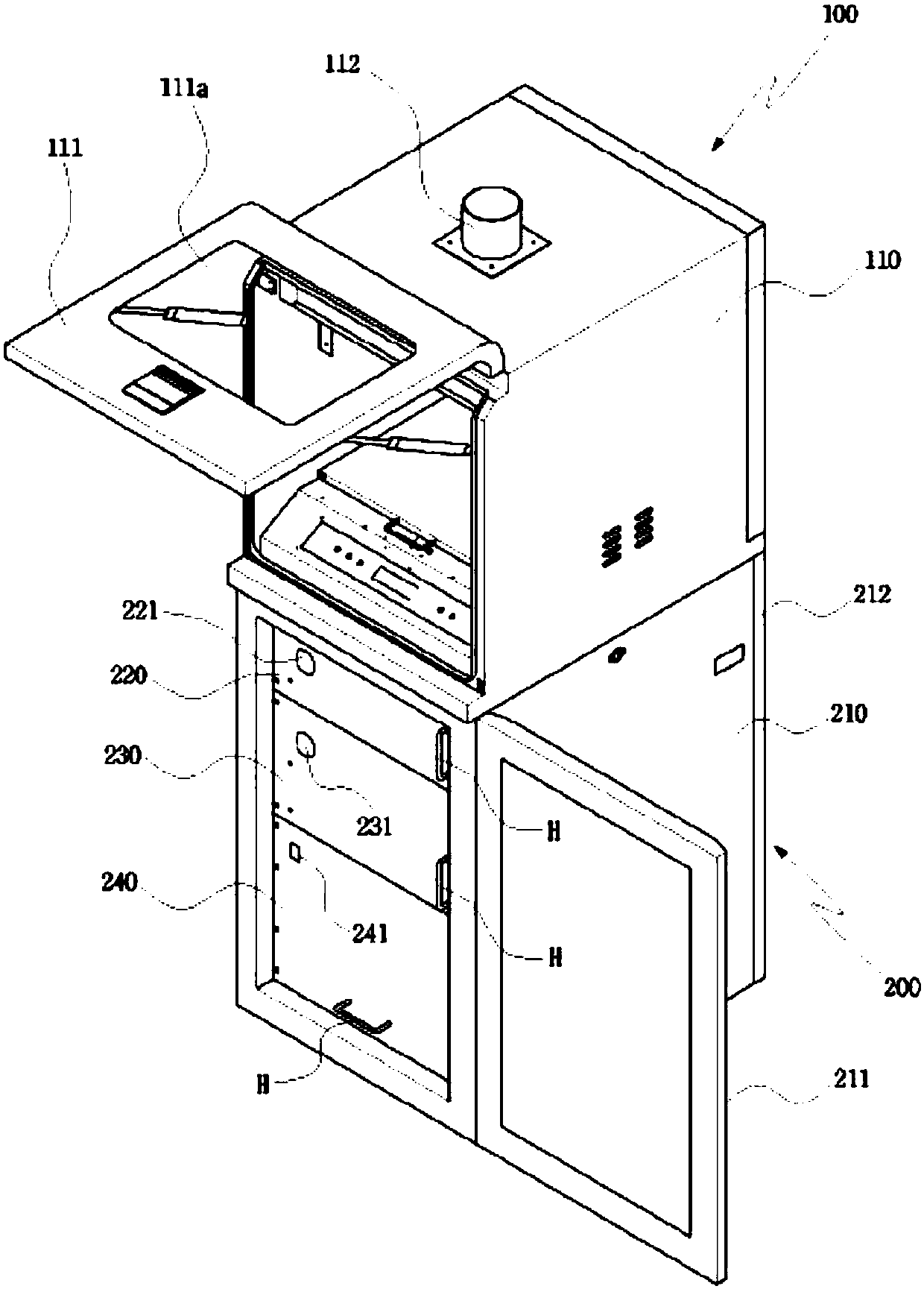

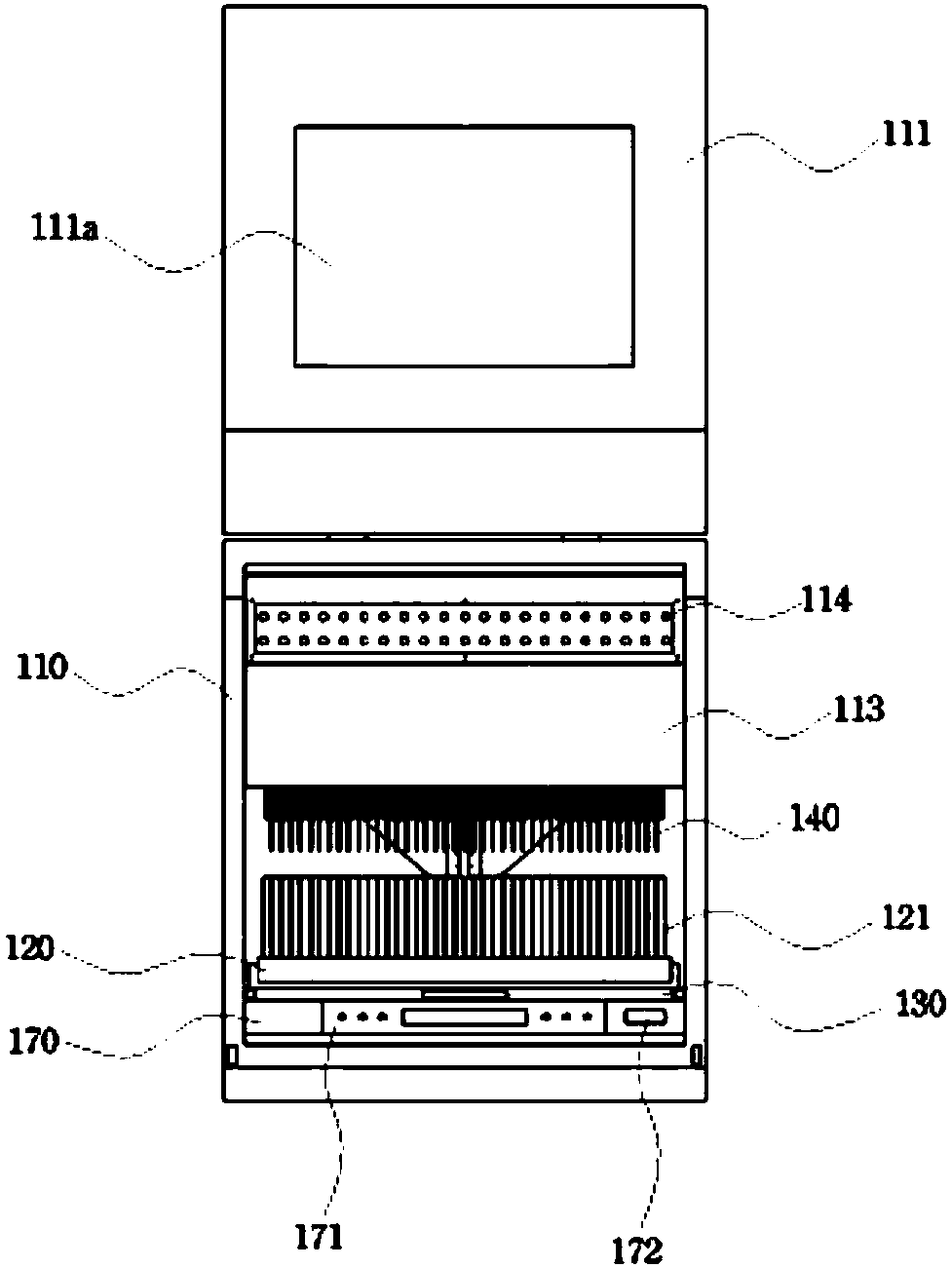

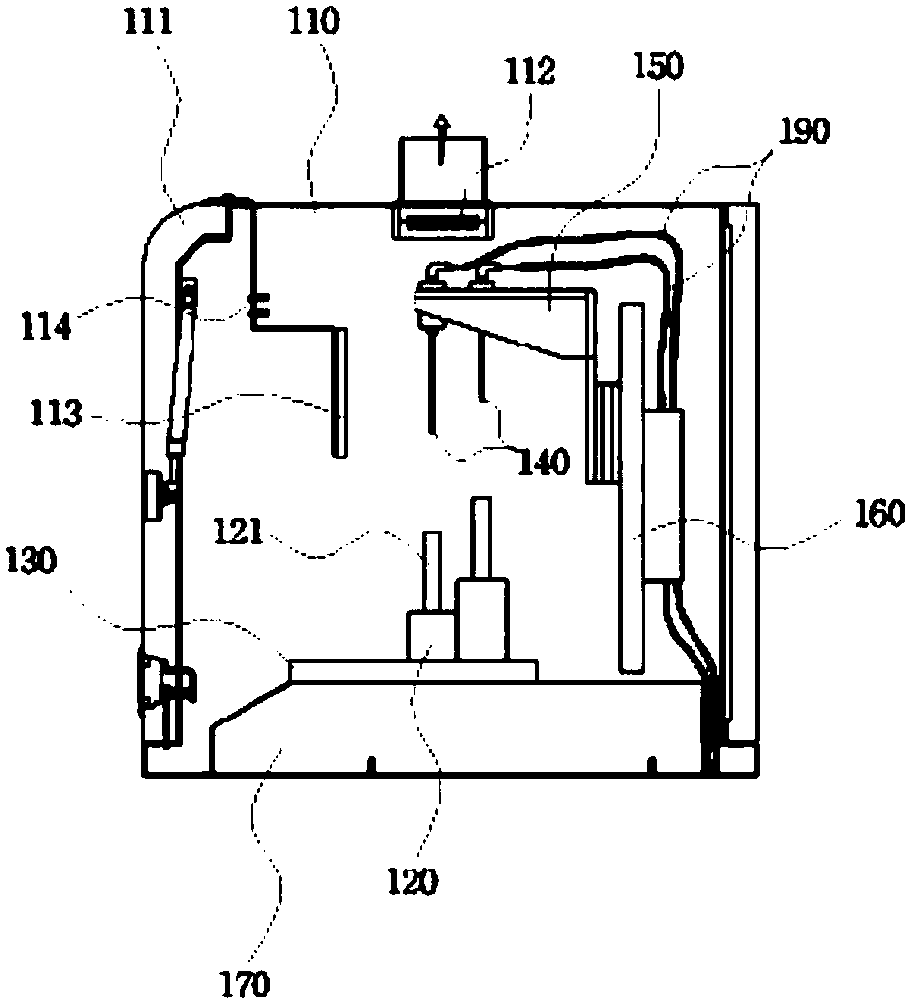

[0026] The combined sample concentrator comprising nitrogen and air generating part of the present invention comprises: sample concentrating part 100, is used for concentrating sample; And nitrogen and air generating part 200, is arranged on the bottom of above-mentioned sample concentrating part 100, It is used to supply nitrogen and air to the above-mentioned sample concentrator 100 . Specifically, the above-mentioned sample concentrating part 100 includes a sample concentrating part cover 110, a test tube fixing part 120, a shelf 130, a nozzle 140, a nozzle fixing part 150, a lifting par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com