Patents

Literature

155results about How to "Shorten the concentration time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and compositions for coating pipe

InactiveUS20040191439A1Improve stabilityHigh strengthSolid waste managementPretreated surfacesUltimate tensile strengthMechanical property

The present invention includes cement compositions and methods for using such cement compositions to coat pipe surfaces, particularly usefull for providing protection from hostile conditions that may otherwise lead to corrosion of the pipe surface. These cement compositions have improved mechanical properties including tensile strength, elasticity, and ductility.

Owner:HALLIBURTON ENERGY SERVICES INC

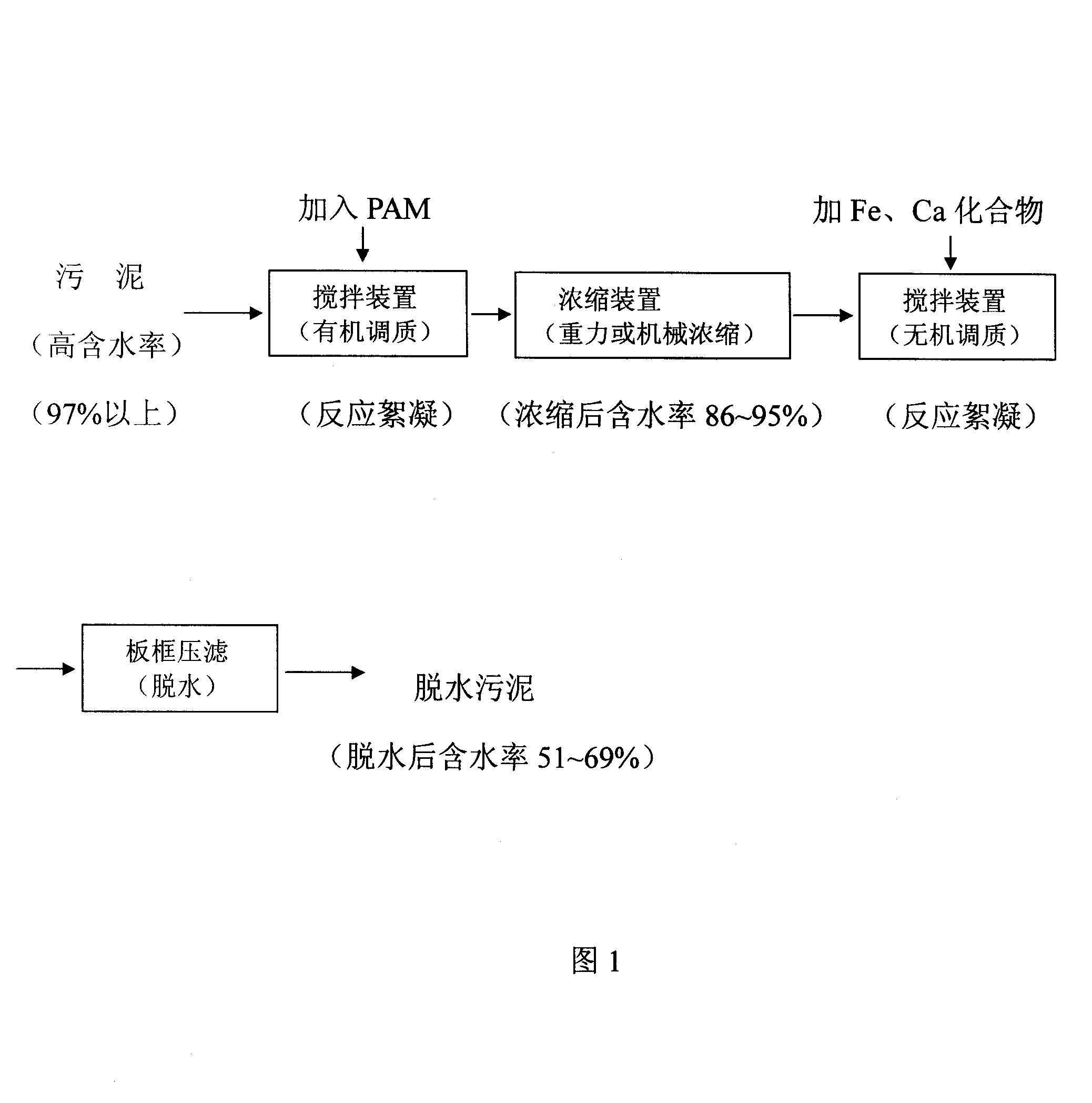

Sludge concentration dehydration method

InactiveCN101234841AReduce moisture contentEasy to handleSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSludgeEnergy consumption

The invention relates to a method of sludge concentration and dewatering which can treat sludge with different water contents and can recycle the treated sludge. The method comprises the following steps: (1) firstly the sludge is concentrated; (2) then modulating agent is added in the concentrated sludge to mix; the mixture is transported to a dewatering device to take dewatering; (3) when the dewatered sludge meets the requirement of the final disposition, the corresponding disposition can be carried out directly; the invention is characterized in that: before the sludge in the step (1) is concentrated, organic modulating agent is added to carry out a first modulating; before the concentrated sludge in the step (2) enters the dewatering device, inorganic modulating agent is added to carry out a second modulating. The method of sludge concentration and dewatering provided by the invention has high efficiency of sludge concentration and dewatering, has low energy consumption, reduces the water content at large amplitude, saves time of the operation processing, has low investment and operation cost and simple process operation.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

Method for efficiently dewatering of sludge

InactiveCN102826733AEfficient dehydrationShorten the concentration timeSludge treatment by de-watering/drying/thickeningDiaphragm pumpDry weight

The invention relates to a method for efficiently dewatering of sludge. The method comprises the following steps of: adding an organic flocculant and a physical conditioner to a gravity thickening tank, wherein the amount of the added organic flocculant is 0.2 per mill to 5.0 per mill of the dry weight of the thickened sludge, and the amount of added physical conditioner is 1% to 10% of the dry weight of the thickened sludge; tempering: adding a calcium coagulant aid to the sludge slurry based on the amount of 1% to 5% of the dry weight of the thickened sludge; and then adding a ferrum flocculant after 1 to 10 minutes based on the amount of 0.5% to 5% of the dry weight of thickened sludge; reacting for 1 to 20 minutes; dewatering: introducing the tempered sludge into a plate-and-frame filter press through a pneumatic diaphragm pump, and charging for 20 to 30 minutes, and dewatering at 0.5 to 2.5Mpa; and discharging: discharging the dewatered sludge from the plate-and-frame filter press. According to the method, the chemical and physical combination mode is adopted to condition for boosting coagulation in the sludge thickening stage; the inorganic flocculant and the coagulant aid are added for further preprocessing in the sludge tempering stage; mechanical equipment with relatively high pressure is adopted to dewater, so that the effect of dewatering can be further improved, and efficient dewatering of the sludge in the urban wastewater treatment plant can be achieved.

Owner:NANJING FORESTRY UNIV

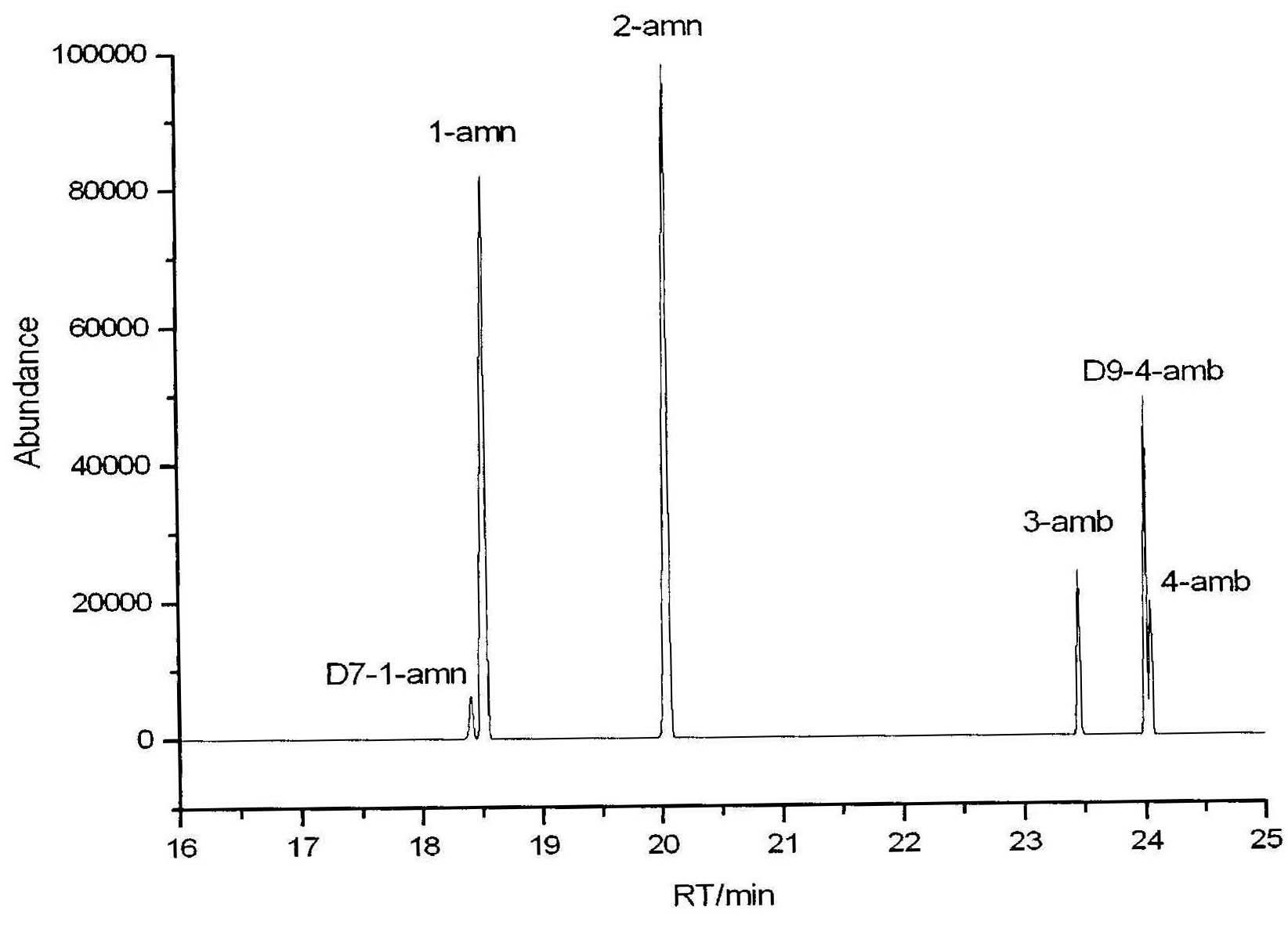

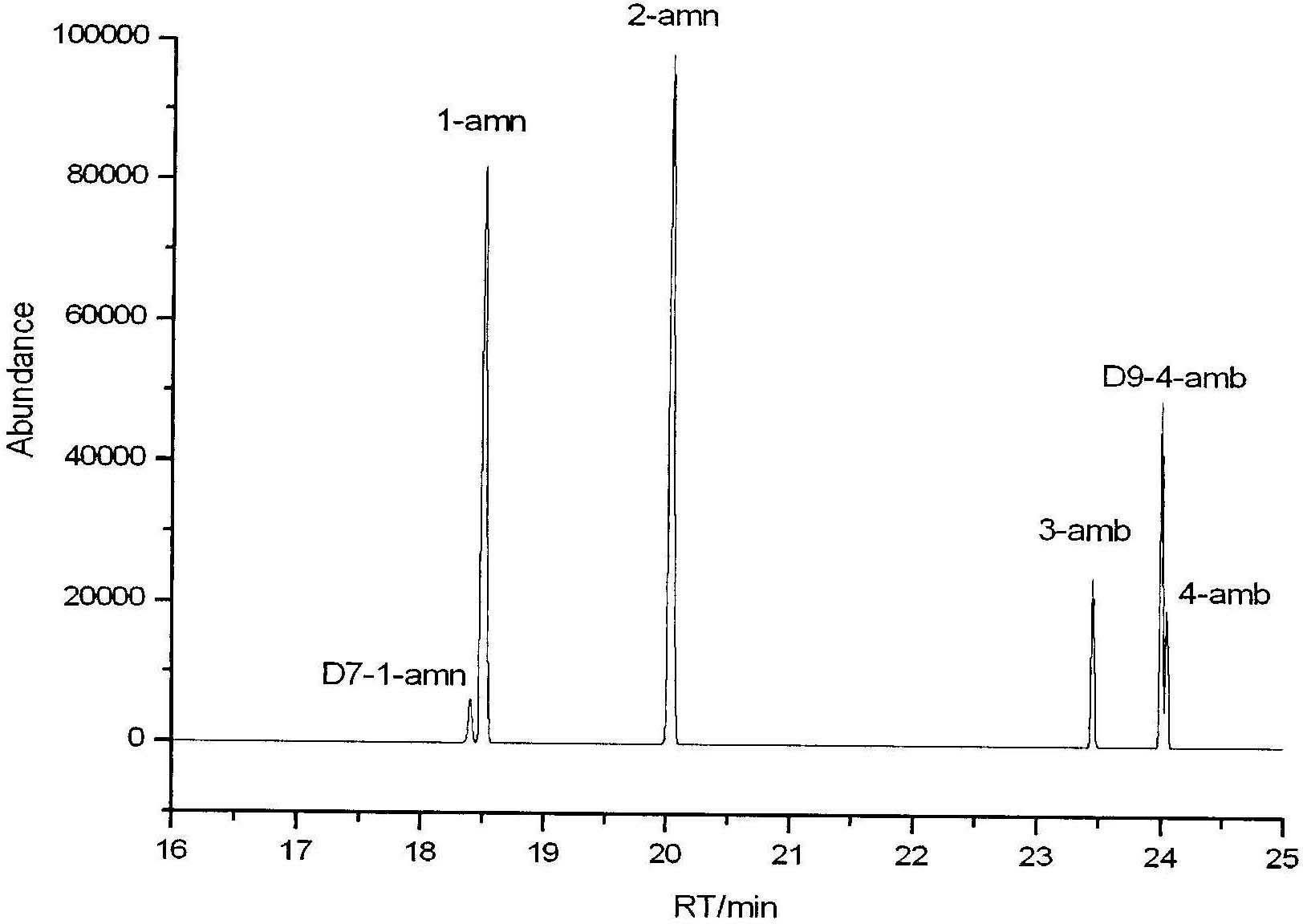

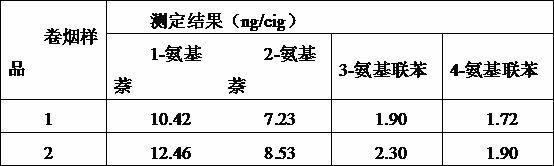

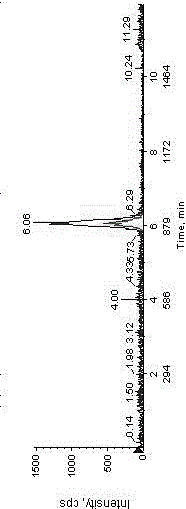

A method for the detection of aromatic amines in mainstream cigarette smoke by gas chromatography-tandem mass spectrometry

The invention discloses a method for detecting aromatic amine in cigarette mainstream smoke by using a gas chromatography-tandem mass spectrometry. The method is characterized by comprising the following steps of: catching aromatic amine compounds in a particulate matter in the cigarette mainstream smoke by using a Cambridge filter; extracting by using hydrochloric acid solution, washing by usingdichloromethane, reducing by using sodium hydroxide and then extracting by using normal hexane, and performing derivatization by using pentafluoropropionic anhydride and trimethylamine hydrochloride;and concentrating and detecting by using the gas chromatography-tandem mass spectrometer (GC-MS / MS) so as to measure the content of the main aromatic amine compounds in the cigarette mainstream smoke. Compared with the conventional method for analyzing the aromatic amine in the cigarette mainstream smoke, the analysis and measurement method has the advantage of simplifying the pretreatment of a sample along with higher sensitivity, high experimental repetitiveness and recovery rate and applicability to analysis of a large batch of samples.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation of creatine hydrochloride

InactiveCN101407478ALess side effectsHigh yieldOrganic chemistryOrganic compound preparationMedicinal chemistryGuanidine

The invention relates to a method for preparing creatine hydrochloride, which belongs to a method for preparing guanidine or derivatives thereof, wherein, hydrochloric acid and creatine water are reacted at the temperature of 25-40 DEG C and then filtered; and after concentration, crystal separation, flushing by ethanol and drying, finished product creatine hydrochloride is obtained.

Owner:TIANJIN TIANCHENG PHARMA

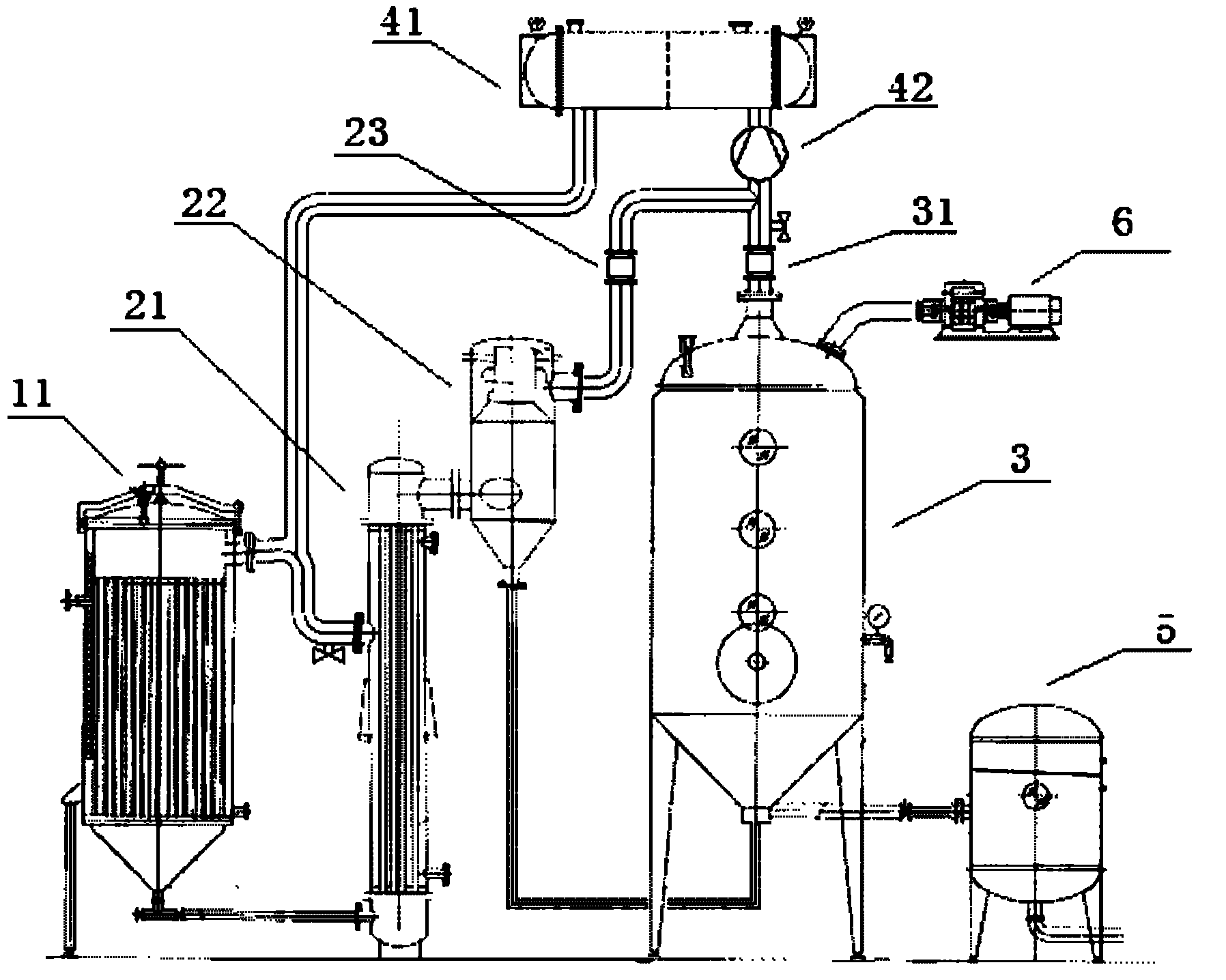

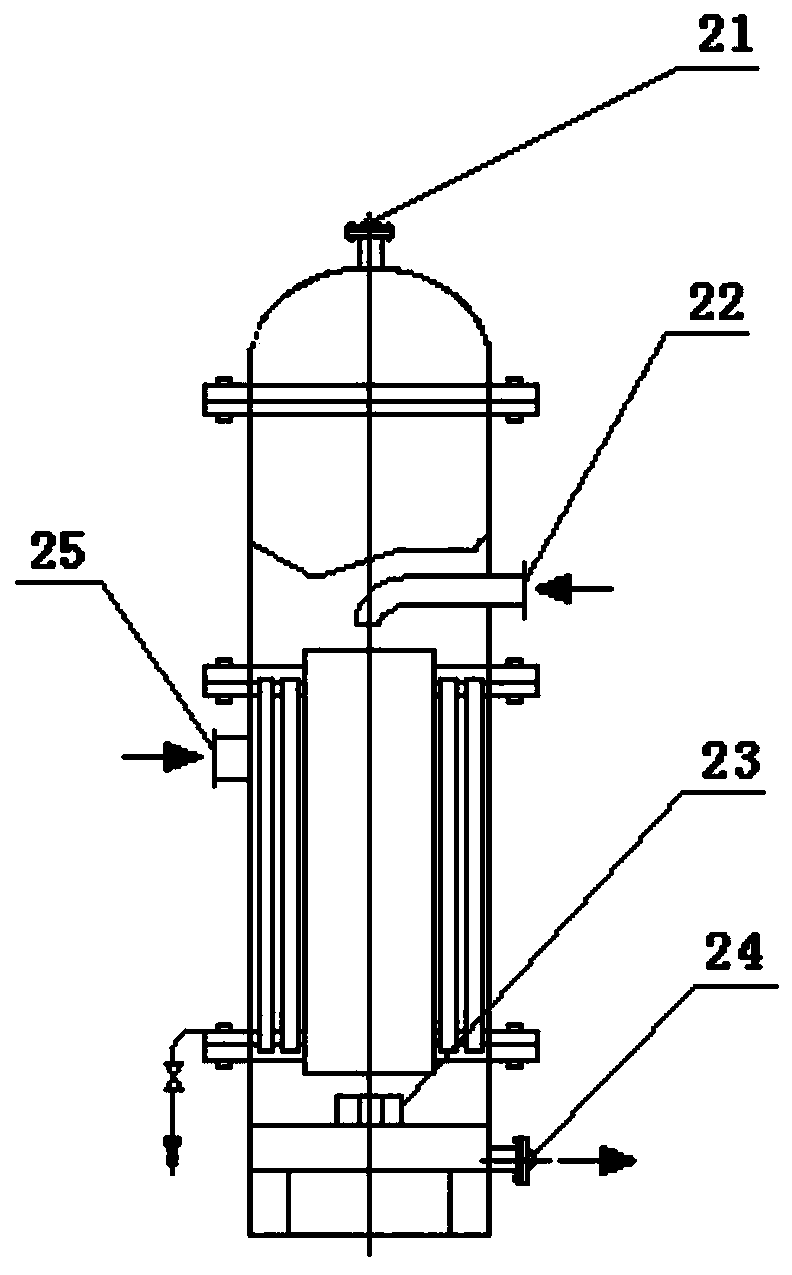

Microwave evaporation and concentration system

InactiveCN103182192AImprove evaporation effectEvaporation capacity superMultiple-effect evaporationMicrowaveEvaporation

The invention relates to the field of pharmaceutical equipment, and particularly relates to a concentration system. An evaporation and concentration system comprises a climbing film evaporator, a condenser, a cooler, a microwave heater and a flash evaporator, wherein the microwave heater is connected with the climbing film evaporator; the climbing film evaporator is connected with the flash evaporator through a high pressure plunger pump; and the flash evaporator is connected with the condenser. Due to the adoption of the above technical solution, the microwave heater is used to heat an original solution in cooperation with a stirring device, so that operation time of heating the original solution is shortened, operation modes are more convenient and consume little energy. When the original solution is evaporated, the flash evaporator is used for two-effect evaporation, the evaporation effect is substantial, evaporation speed is faster than that of other evaporators, and condensation time of the whole condensation system is shortened.

Owner:SHANGHAI JINPIBAO PHARMA

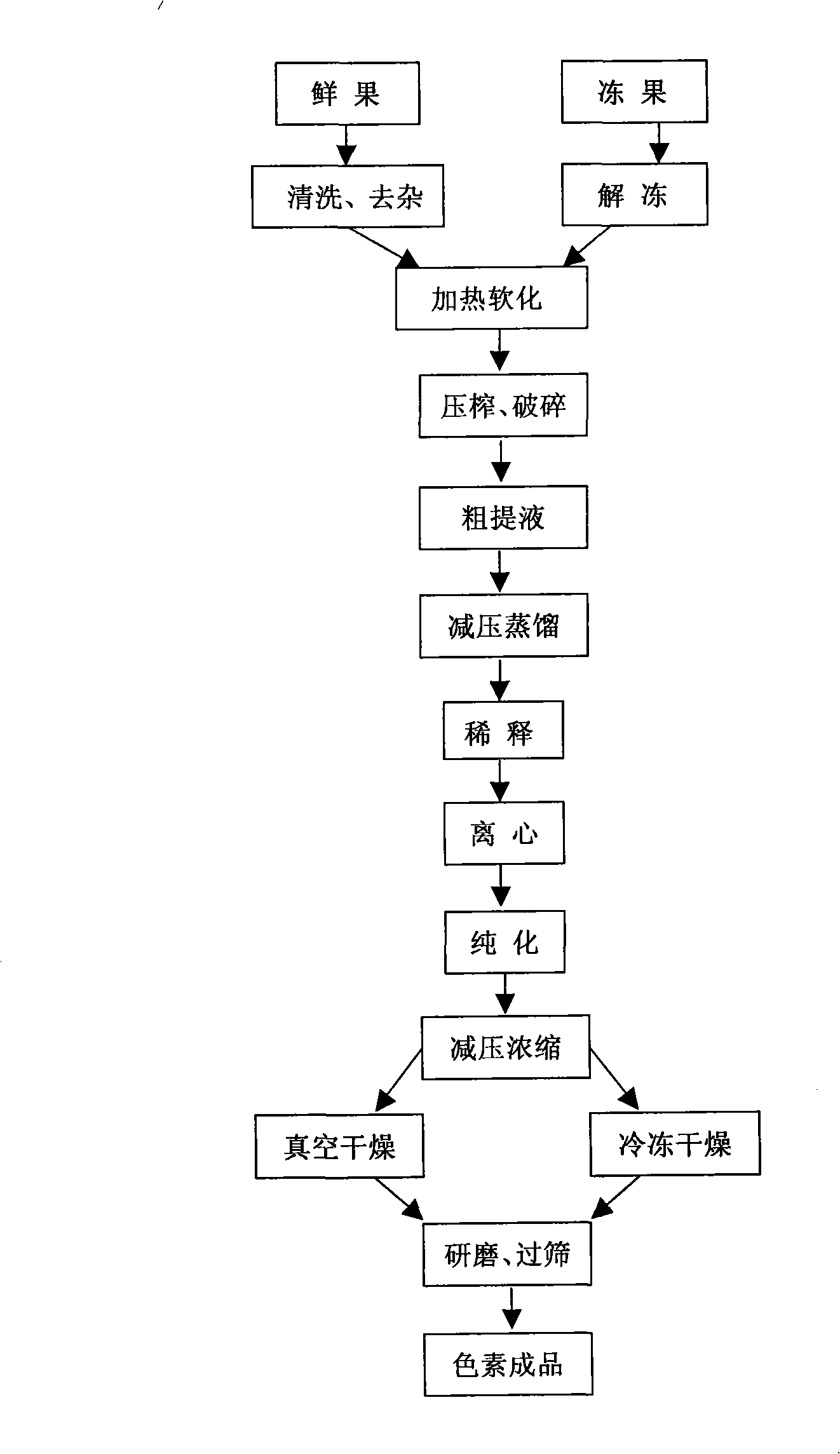

Method for extracting blackberry pigment

InactiveCN101255280AShorten the concentration timeReduce lossesNatural dyesFood preparationNutrientSolubility

An extracting method of blackberry pigment relates to a technique for producing natural blackberry pigment using fresh or frozen blackberry. The natural blackberry pigment has bright color, stable quality, rich nutrient and widely used in every field of food industry. Because the maturation period of the blackberry is centralized and the blackberry is not easy to store, the factory run is used to process the fresh blackberry into pigment powder during collection period; or the factory run is used to process the frozen blackberry into pigment powder during dead period of production. The preparation method comprises heating and softening the fresh or frozen blackberry, crushing, extracting, decompression concentrating, adjusting pH, diluting, centrifuging, purifying, decompression concentrating, drying and grinding. The invention provides a safe and effective method for extracting and purifying the blackberry pigment to obtain natural pigment with high purity, good chemical stability and strong water solubility.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

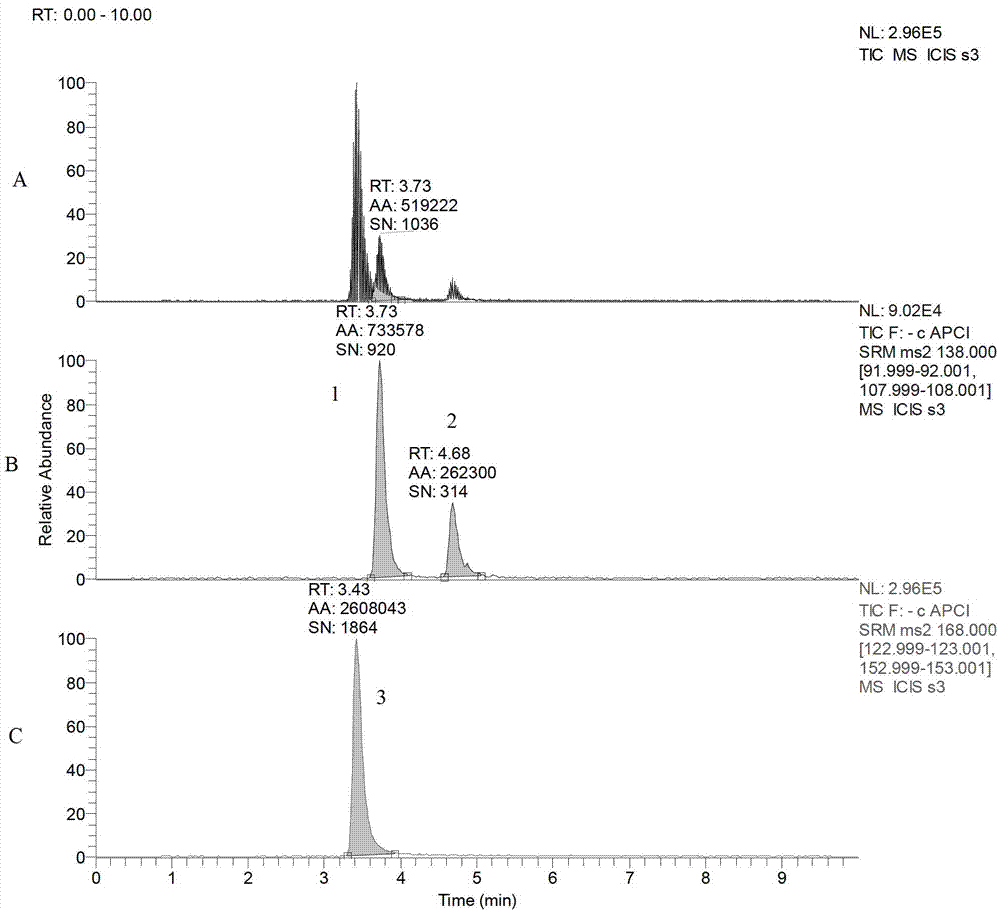

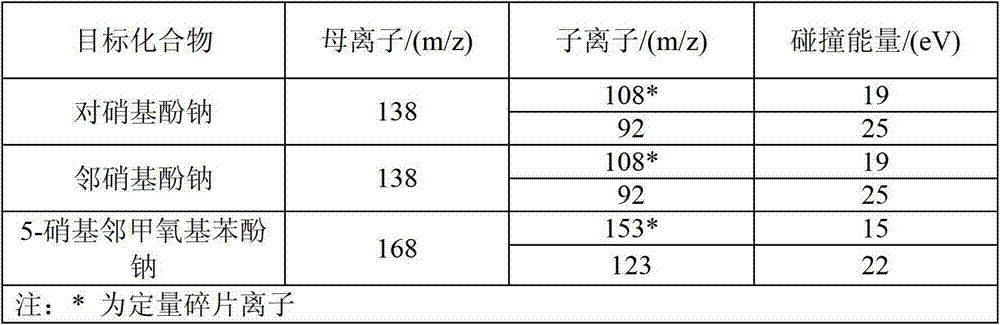

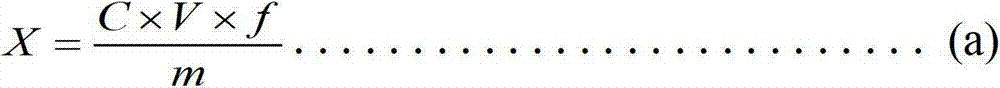

Method for detecting residual quantity of sodium nitrophenol in aquatic product

ActiveCN103091422AHigh sensitivityEasy to prepareComponent separationHazardous substancePhosphoric acid

The invention discloses a method for detecting residual quantity of sodium nitrophenol in an aquatic product and belongs to the technical field of detection of aquatic products. The method comprises the following steps of: extracting and purifying a sample; drawing a standard curve; and determining and quantifying apparatus conditions. According to the method disclosed by the invention, an APCI (Atmosphere Pressure Chemical Ionization) ion source is selected by a mass spectrometer, so that the sensitivity of sodium orotho-nitrophenolate is improved by dozens of times; neutral alumina is adopted for purifying, so that interfering substances such as fat in the sample can be effectively removed, and the concentration time is shortened; sodium hydroxide is added during the concentration process, so that the sodium orotho-nitrophenolate exits in the sample in the form of sodium salt, thereby enabling the recovery rate of the sodium orotho-nitrophenolate to be more than 70%. Phosphoric acid is added after the concentration for neutralizing the excessive sodium hydroxide, so that the pH of the purifying liquid kept at about 3, and the requirements of upper solid-phase extractor column can be satisfied. The method disclosed by the invention fills up the blank that no method is provided for detecting residual quantity of sodium nitrophenol in aquatic products and other animal foods at present, and has great significance in accurately and scientifically evaluating the quality safety of the aquatic products and making the novel standards of harmful substances in the aquatic products.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

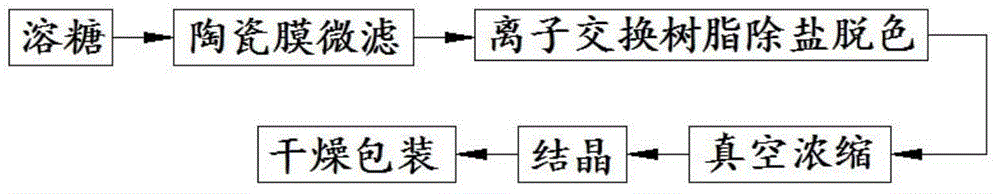

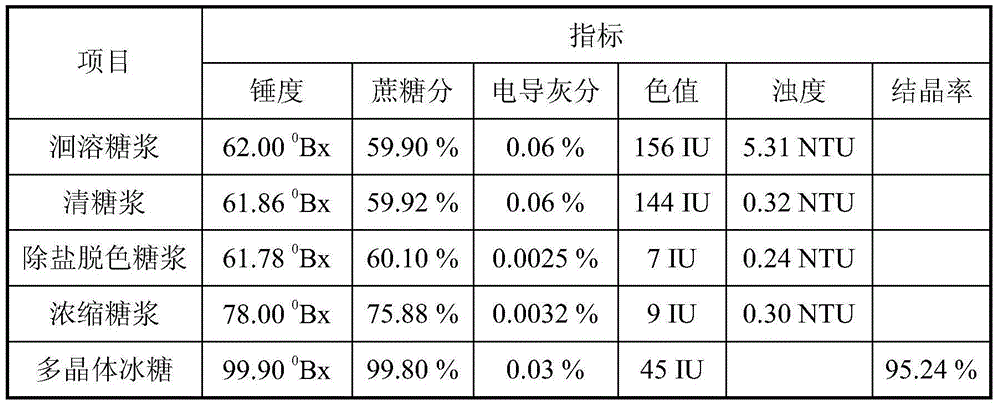

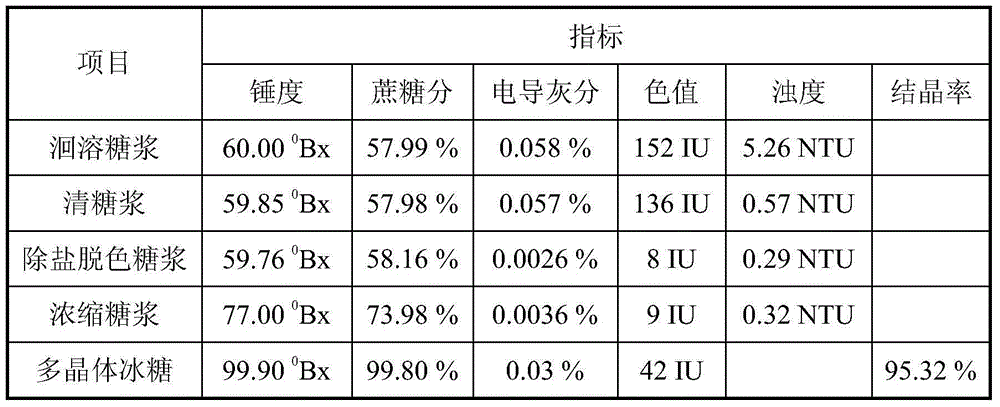

Production process of poly-crystal rocky candy

The invention discloses a production process of poly-crystal rocky candy. The production process comprises the following six steps: by taking first-grade white sugar as a raw material, dissolving the sugar, micro-filtering and clarifying, desalting and decolorizing by using ion exchange resin, concentrating in vacuum, charging seeds for crystallization, drying and packaging to produce the poly-crystal rocky candy. The poly-crystal rocky candy produced by the method disclosed by the invention is sweet and delicious in taste and white and transparent in color and luster; no sodium hydrosulfite is added for color protection during the overall production, so the product is environmental friendly and safe; the crystallization rate of the rocky candy is above 95%; the problem of low crystallization rate during production of the poly-crystal rocky candy for a long time is solved.

Owner:GUANGXI UNIV

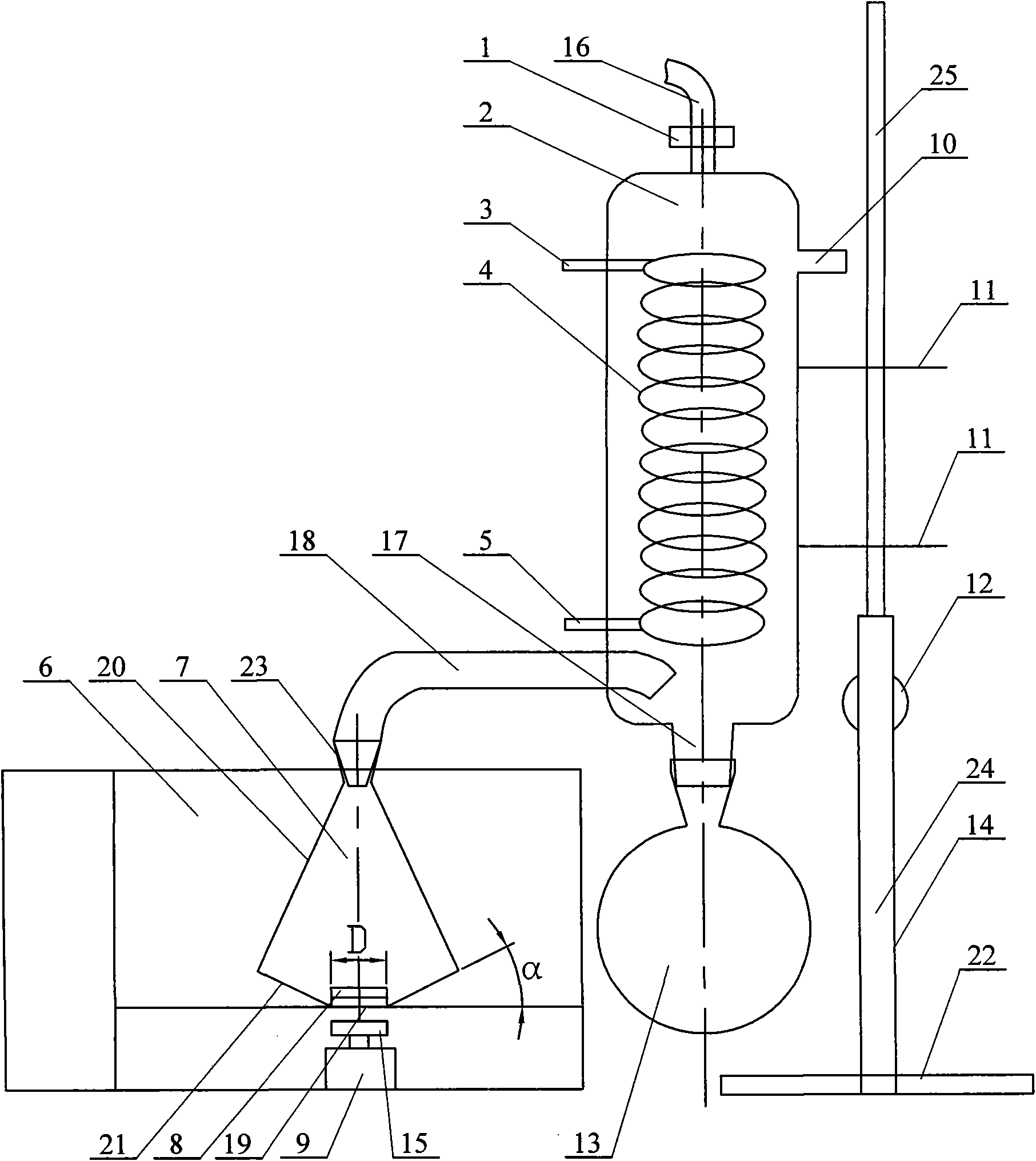

Negative pressure magnetic stirring concentrator

InactiveCN101564701AEasy to placeLow boiling pointPreparing sample for investigationLaboratory glasswaresWater bathsRotary evaporator

A negative pressure magnetic stirring concentrator relates to a concentrator and aims at solving the problems that air leaks easily at a rotating shaft, the preparation cost is high when adopting a rotary evaporator to concentrate liquid, and high purity nitrogen is wasted, air is polluted when adopting a pressure blowing concentrator to concentrate liquid, etc. A vacuum chamber is fixedly connected with a lifting support through two retaining clips, internally provided with a condense water coiled tube and provided with a pumping hole connected with a vacuum pump thereof, the upper end of the vacuum chamber is provided with a reducing valve and the lower end thereof is provided with a solution recovering bottle, two ends of a connecting tube are communicated with the vacuum chamber and a concentrating bottle that is arranged at the bottom of a thermostat water bath, a bar magnet externally coated with polyfluortetraethylene is arranged in the concentrating bottle, an electric motor is fixedly arranged below the bottom of the thermostat water bath, and an output shaft of the electric motor is connected with the lower end surface of a long-strip magnet, the upper end surface of which is magnetically connected with the lower end surface of the bar magnet externally coated with polyfluortetraethylene. The concentrator has the advantages of good air tightness, low preparation cost, no need of consuming high purity nitrogen and light environment pollution.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

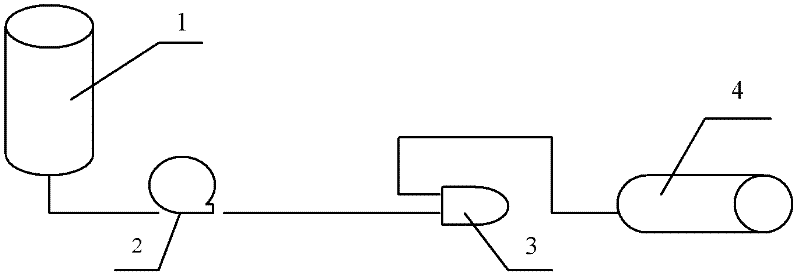

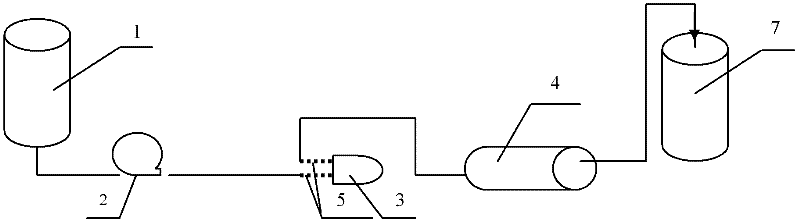

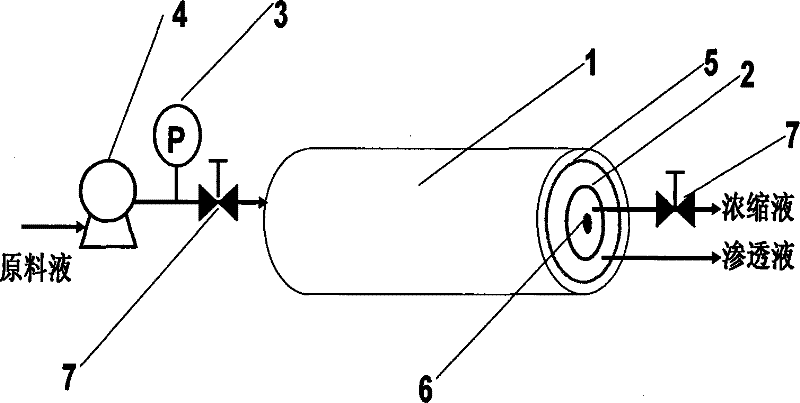

Concentrating device and concentrating method of acarbose destaining solution

InactiveCN102512957AIncreased concentration potencyIncrease drying speedSemi-permeable membranesSugar derivativesEnrichment methodsSpray drying

The invention relates to a concentration device of acarbose destaining solution, which comprises a material tank, a pre-pressurizing device, a pressurizing device and a film device which are connected in sequence by pipelines, wherein the film device is a coil type film. The invention also provides a concentrating method of the acarbose destaining solution. The concentration device and the concentration method can be used in the mass industrialized production, so that the concentration valence of the acarbose destaining solution can be obviously improved, the concentration time of the acarbose destaining solution can be obviously shortened, the production progress can be quickened, the processing amount can be greatly improved, and the speed and the efficiency of the follow-up spray drying can be quickened.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST +1

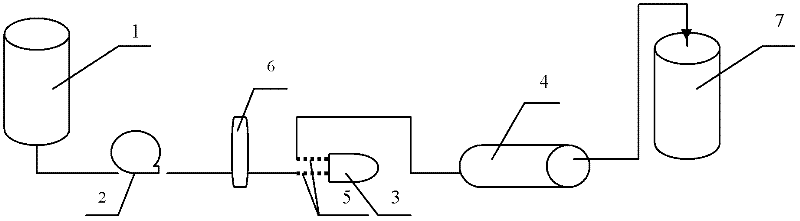

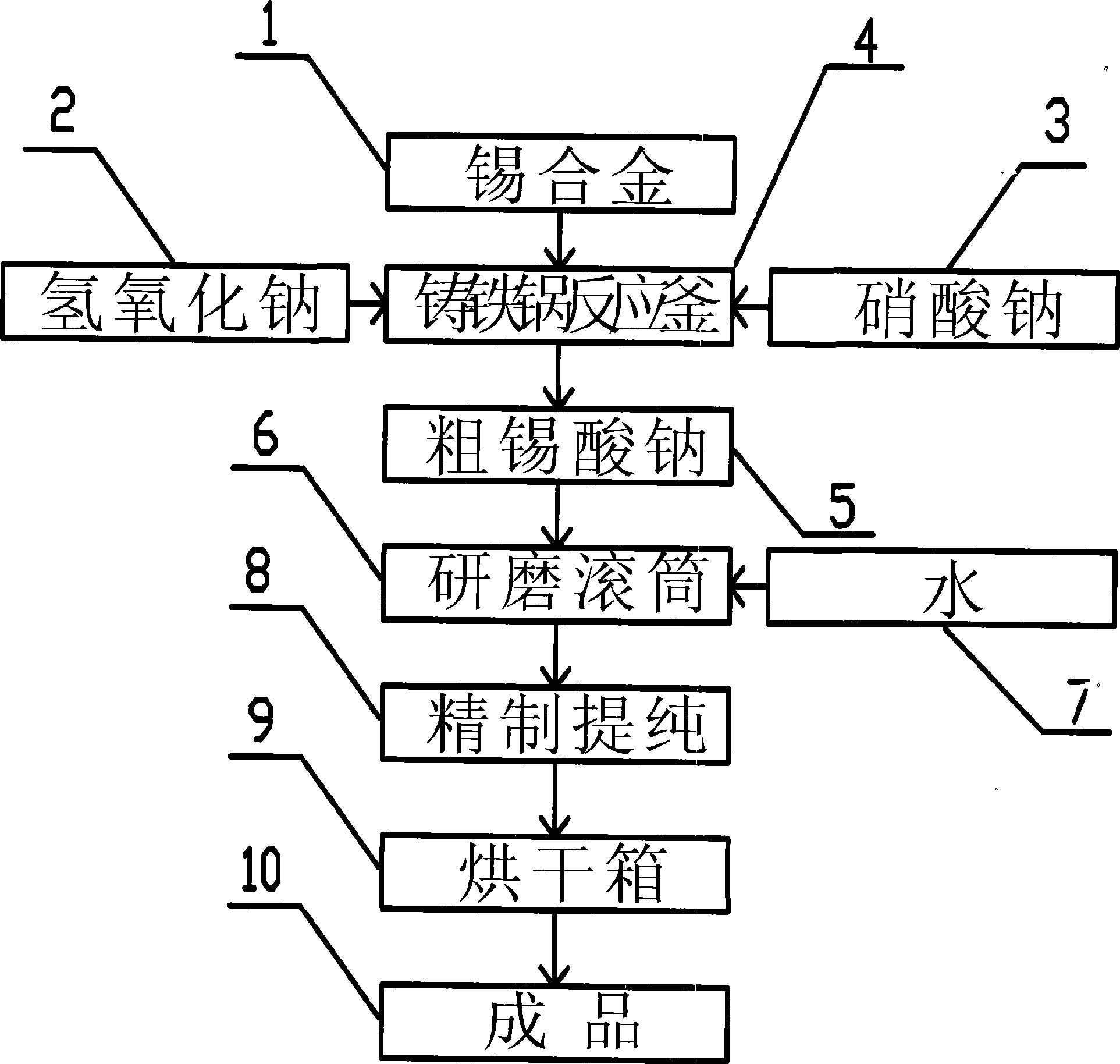

Method for producing sodium stannate by using tin and tin alloy

The invention discloses a method for producing sodium stannate by using tin and tin alloy, which comprises the following steps: (1) the tin and the tin alloy have chemical reaction with sodium hydroxide and oxidizer at a temperature of between 300 and 550 DEG C to obtain granular coarse sodium stannate; the reaction course comprises that the sodium hydroxide and the oxidizer are added to molten tin and tin alloy step by step until the reaction is completely finished; (2) the granular coarse sodium stannate is dissolved in water; (3) the solution is purified finely; and (4) the fully purified sodium stannate solution is condensed, separated and dried to obtain finished products. The method is used for producing the sodium stannate by using the tin and the tin alloy.

Owner:上饶旭日冶炼厂

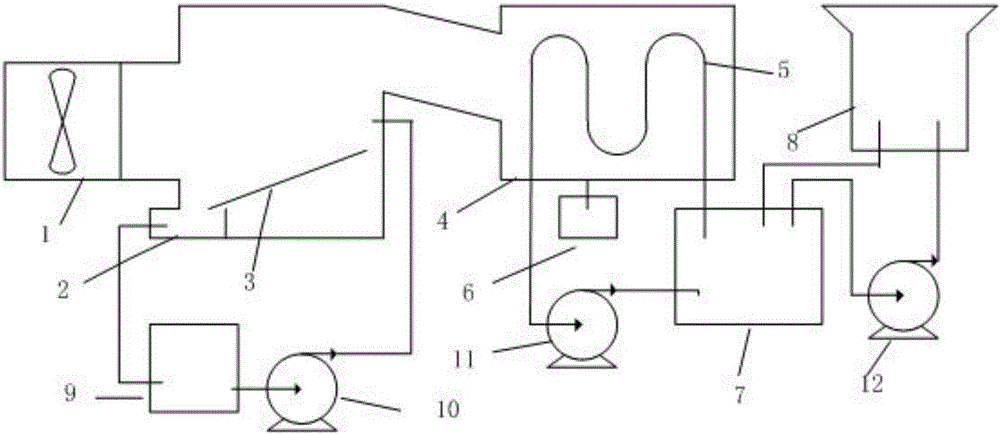

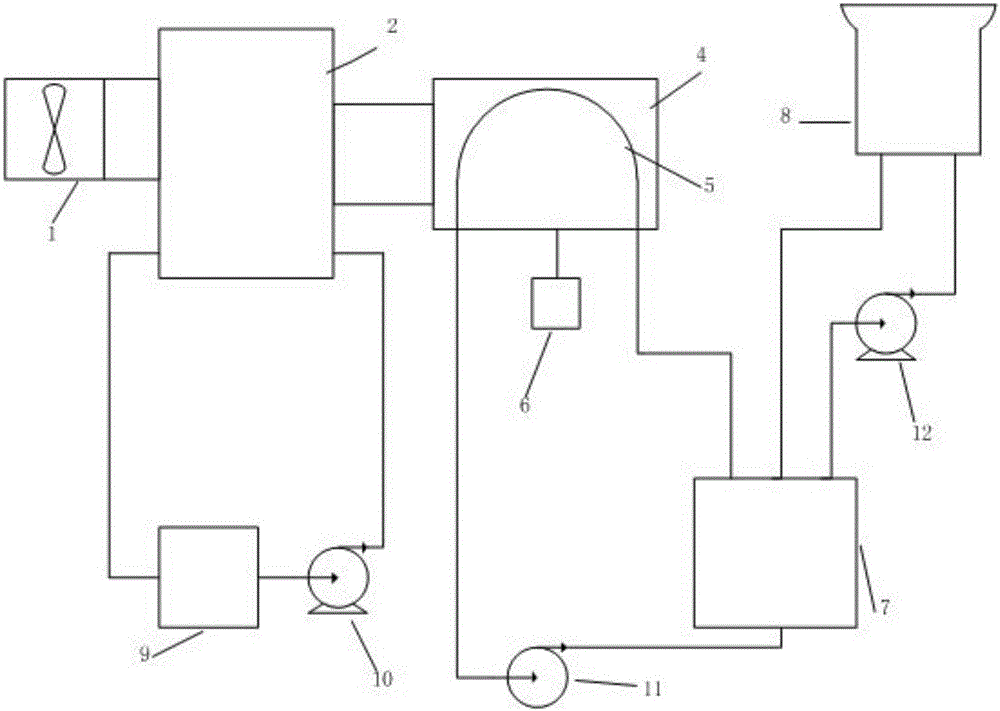

Seawater desalination device

InactiveCN105936521AFast evaporationIncrease the output speedGeneral water supply conservationSeawater treatmentEngineeringFresh water

The invention discloses a seawater desalination device, which includes an evaporator (2). The top side wall of the evaporator (2) is provided with a wind inlet, an evaporator (2) side wall that is level with and opposite to the wind inlet is provided with a damp and hot steam outlet, the top of the evaporator (2) is provided with a cold seawater inlet, the bottom of the evaporator (2) is equipped with a hot seawater outlet, the evaporator (2) is internally provided with an inclined heating plate (3), the high end of the heating plate (3) is located right below the cold seawater inlet, the damp and hot steam outlet is connected to a condenser (4), the condenser (4) is internally provided with a snakelike cooling pipe (5), the inlet and outlet of the snakelike cooling pipe (5) are respectively connected to a cooling box (7), and a fresh water collecting box (6 ) is connected below the condenser (4). The seawater desalination device provided by the invention is used for concentrated seawater desalination to produce fresh water, and can guarantee residents' drinking water supply in coastal water-deficient areas.

Owner:HOHAI UNIV CHANGZHOU

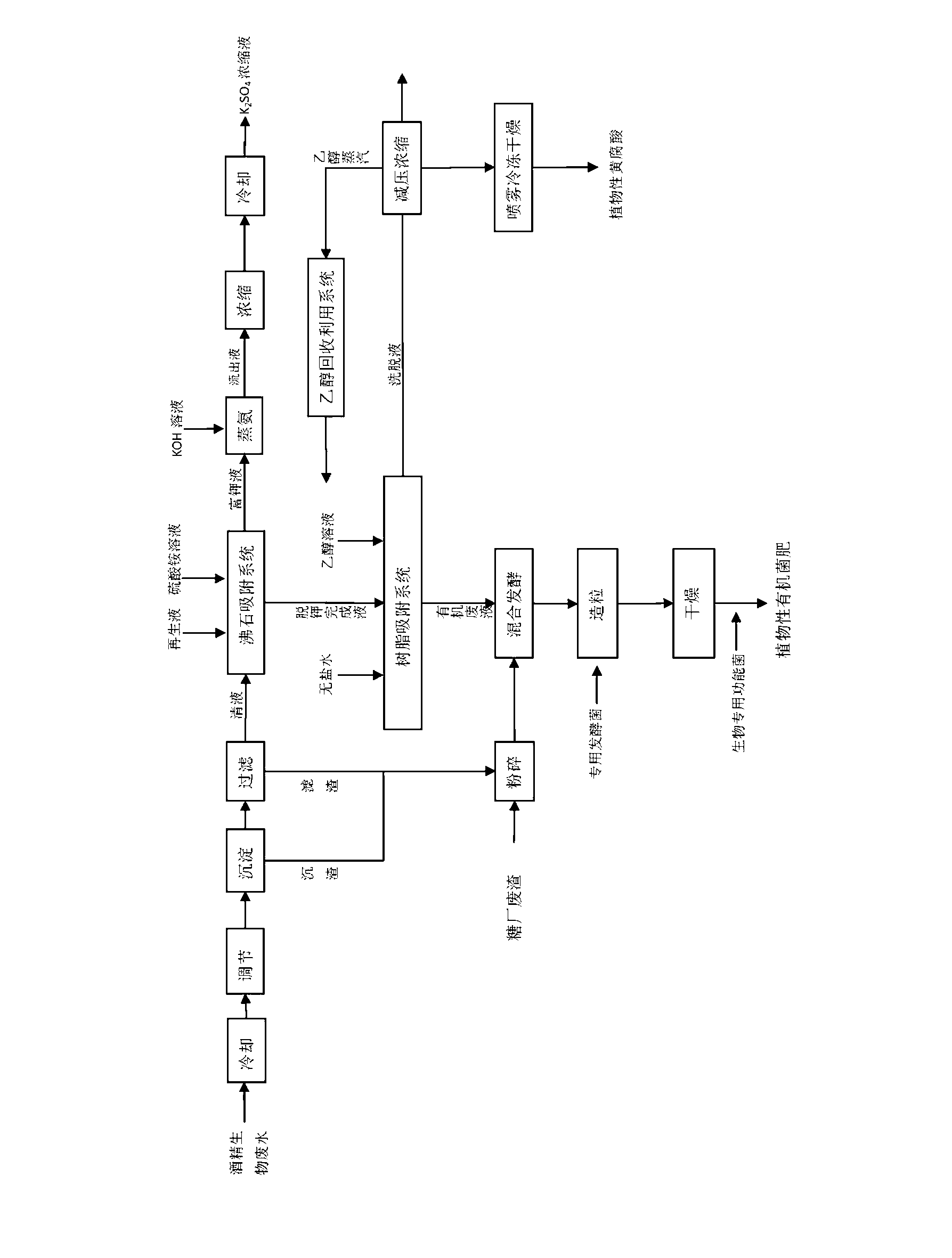

Method for producing vegetalitas fulvic acid/potassium sulfate concentrated solution/vegetalitas organic bacterial manure by utilizing alcohol biologic wastewater

InactiveCN103253686AHigh purityPromote absorptionClimate change adaptationSewage/sludge fertilisersEngineeringFermentation

The invention provides a method for producing vegetalitas fulvic acid / potassium sulfate concentrated solution / vegetalitas organic bacterial manure by utilizing alcohol biologic wastewater. The method comprises the following steps of: cooling, participating and filtering the alcohol biologic wastewater and removing potassium out of the alcohol biologic wastewater by using zeolite to obtain a potassium-removed liquid, subsequently carrying out absorption treatment on the obtained potassium-removed liquid by using a large-pore type absorption resin so that fulvic acid is absorbed onto the resin; eluting the absorption saturated resin by using an ethanol solution, carrying out vacuum concentration, spraying, freezing and drying treatment on the elution solution so as to produce high-purity vegetal fulvic acid, wherein the zeolite which is saturated through absorption in the potassium removing procedure is eluted by using an ammonium sulfate solution, the eluted potassium-enriched liquid is subjected to ammonia still, concentration and cooling so as to prepare a potassium sulfate concentrated solution; and the organic waste liquid of the resin absorption procedure is mixed with sediment, filter residue and sugar waste residue of the participation and filtering procedures, is fermented by using special fermentation bacteria, and is subjected to pelletizing and drying treatment, and special functional bacteria are added so as to prepare the vegetal organic bacterial manure. By utilizing the method, the treatment problem of alcohol biologic wastewater and sugar waste residue, which always bothers sugar plants, is solved.

Owner:佛山市顺德区弘顺达商贸有限公司

Compound camellia oil moisturizer and preparation method thereof

InactiveCN105997827AMoisturizingMoisturizing hasCosmetic preparationsToilet preparationsMugwortSweat gland

The invention relates to a compound camellia oil moisturizer, made from the following materials according to parts by weight: 30-40 parts of camellia oil, 5-10 parts of shea butter, 20-30 parts of tender bamboo leaf juice, 5-8 part of aloe gel, 8-11 parts of lemon concentrate, 7-12 parts of mugwort concentrate, 5-8 parts of loofah concentrate, 1-2 parts of trehalose, 2-4 parts of vitamin E, and 1-2 parts of an aid. The compound camellia oil moisturizer employs natural plant concentrates, uses natural plant oil in lieu of mineral oils, and is safe and reliable to use; the moisturizer is mainly specific to the skin problems such as ultraviolet injury, dryness and chapping, roughness, dullness and low elasticity, has the effects such as moisturizing, forming natural water-lock film, zero blockage to sweat glands and pores and activating skin, and is a necessary skin-care product for both male and female.

Owner:陈琼燕

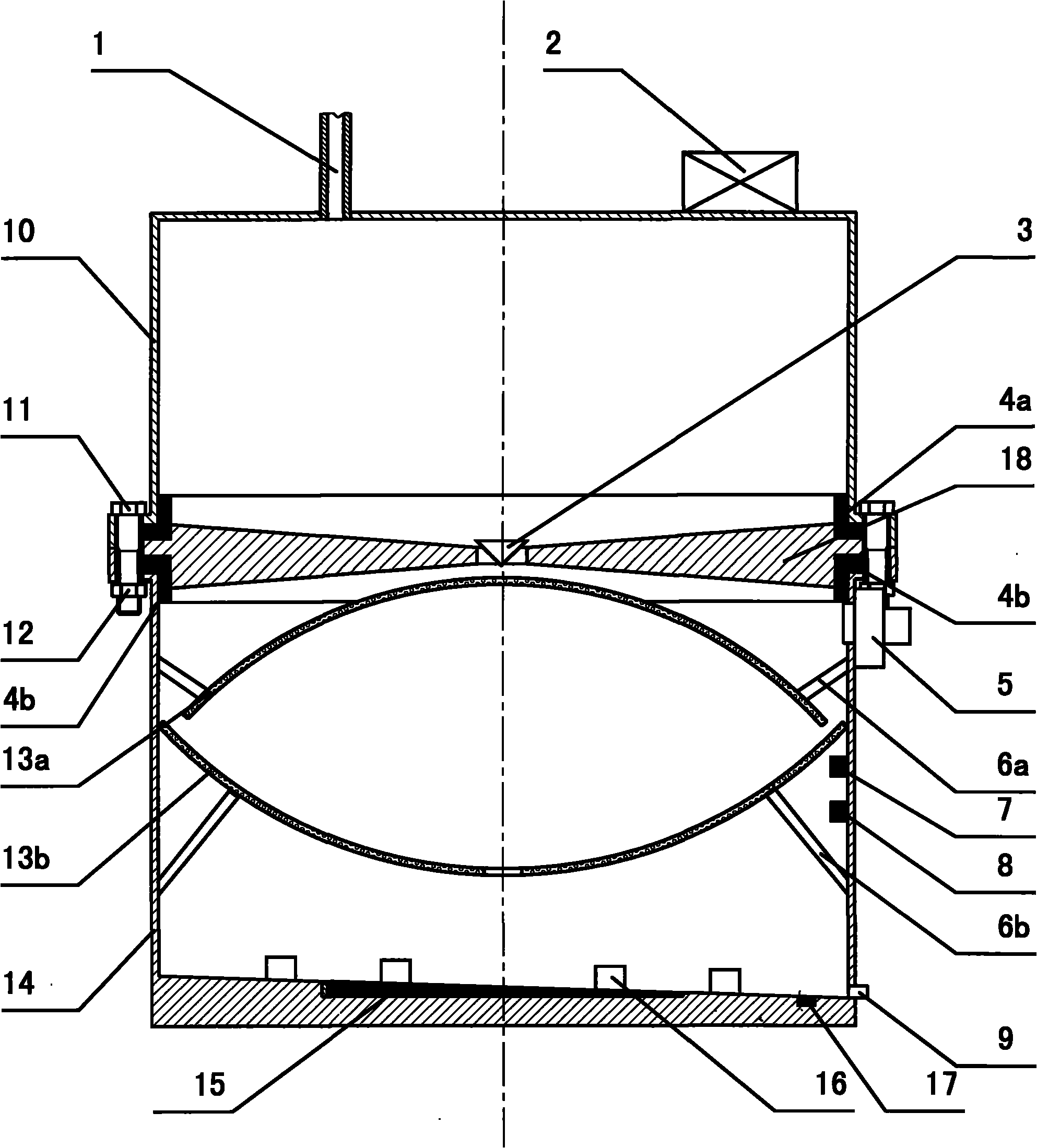

Decoction concentrating device for decocting clinical Chinese medicaments

InactiveCN101780340AReduce lossesReduce volumePharmaceutical product form changeEvaporationInternal pressureMedicine

The invention discloses a decoction concentrating device for decocting clinical Chinese medicaments, and belongs to the technical field of Chinese decoction concentration. The decoction concentrating device is characterized by comprising a decoction storage bucket and a reduced pressure concentration part, wherein the reduced pressure concentration part comprises a concentration bucket cover, a concentration bucket, upper and lower two concentration pans, an electromagnetic heater and a reducing valve; the upper and lower end faces of the concentration bucket cover are respectively connected with the decoction storage bucket and the concentration bucket; the decoction in the decoction storage bucket flows onto the inner surface of the lower concentration pan, which is in a curved-surface shape and of which the outer surface is provided with protrusions, through an outlet hole controlled by a check ball valve on the concentration bucket cover, and then flows into the concentration bucket; the electromagnetic heater is embedded on the bottom surface of the concentration bucket; the decoction in the concentration bucket can flow out through a liquid outlet pipe with an inclined surface; and the reducing valve is fixed on the outside of the upper part of the concentration bucket so as to reduce the internal pressure of the concentration bucket. The decoction concentrating device has the advantages of improving the decocting rate, reducing decocting amount and fully utilizing active ingredients of the decoction.

Owner:仝小林

Novel method for preparing double-violet injection

ActiveCN105902695AEasy accessShortened active ingredientAntibacterial agentsPharmaceutical delivery mechanismFlocculationNanofiltration

The invention provides a novel method for preparing a double-violet injection. The double-violet injection is prepared from dry whole plants of dandelion and Chinese violet as medicines, wherein the weight ratio of the dandelion to the Chinese violet is 1 to 1. The method comprises the following steps: (a) cutting the dandelion and the Chinese violet into segments, crushing the segments and adding the product to an extraction tank; (b) adding purified water to the extraction tank, heating the extraction tank to 80-85 DEG C, soaking and cooling the product 45-55 DEG C, adjusting the pH value into acidity, adding plant disintegrating composite enzyme, stirring at a constant speed, standing and decomposing the product; (c) decocting and filtering the mixture in the extraction tank to obtain final filtrate; (d) adding a flocculant to the final filtrate and carrying out centrifugal flocculation to obtain supernate; and (e) carrying out vacuum nanofiltration and concentration on the supernate by a nanofiltration membrane, wherein the end-point concentration of concentration is 0.95-1.05g / ml. According to the double-violet injection prepared by the method, effective ingredients in the dandelion and the Chinese violet can be effectively extracted and collected.

Owner:HEBEI TIANYUAN PHARMA CO LTD

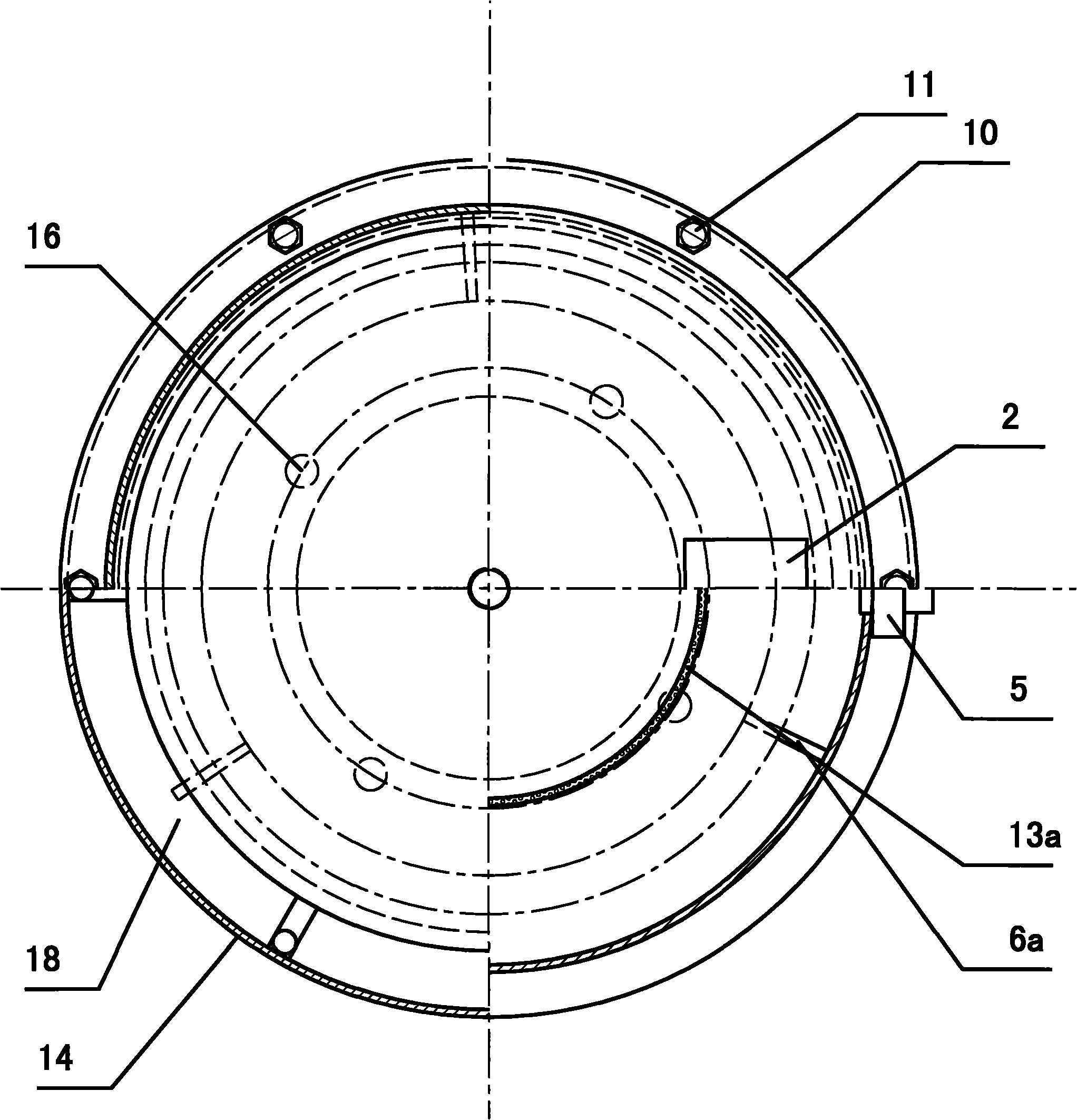

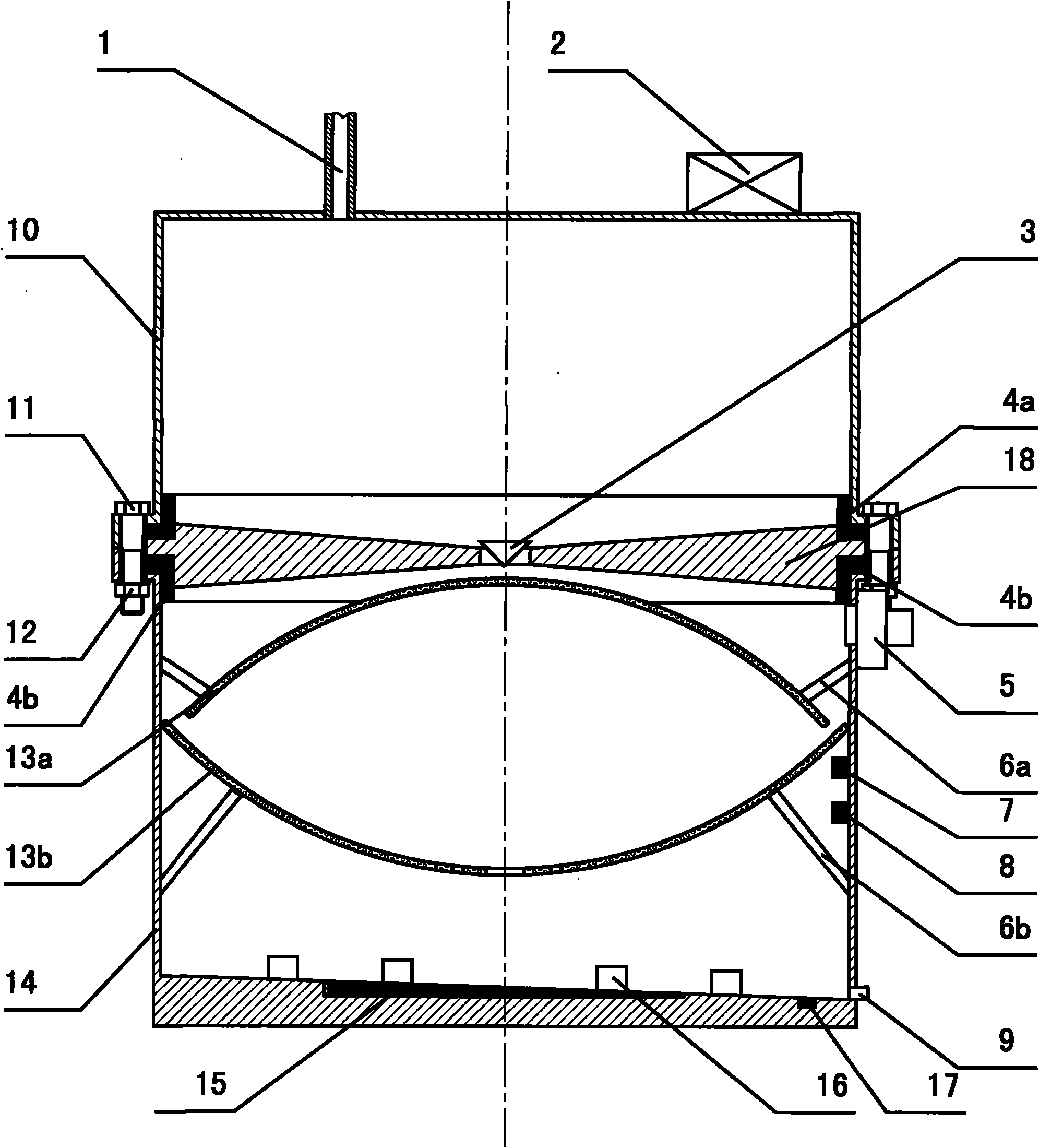

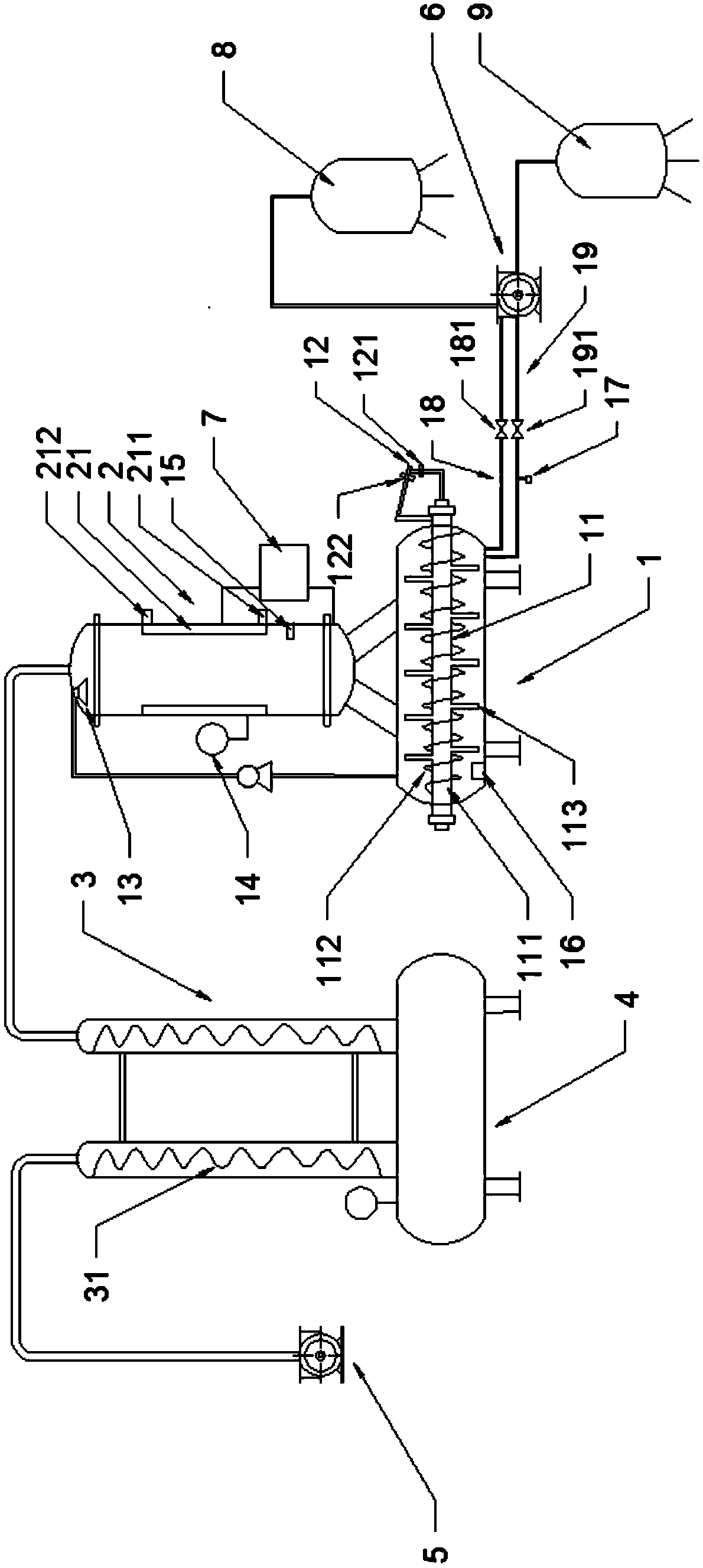

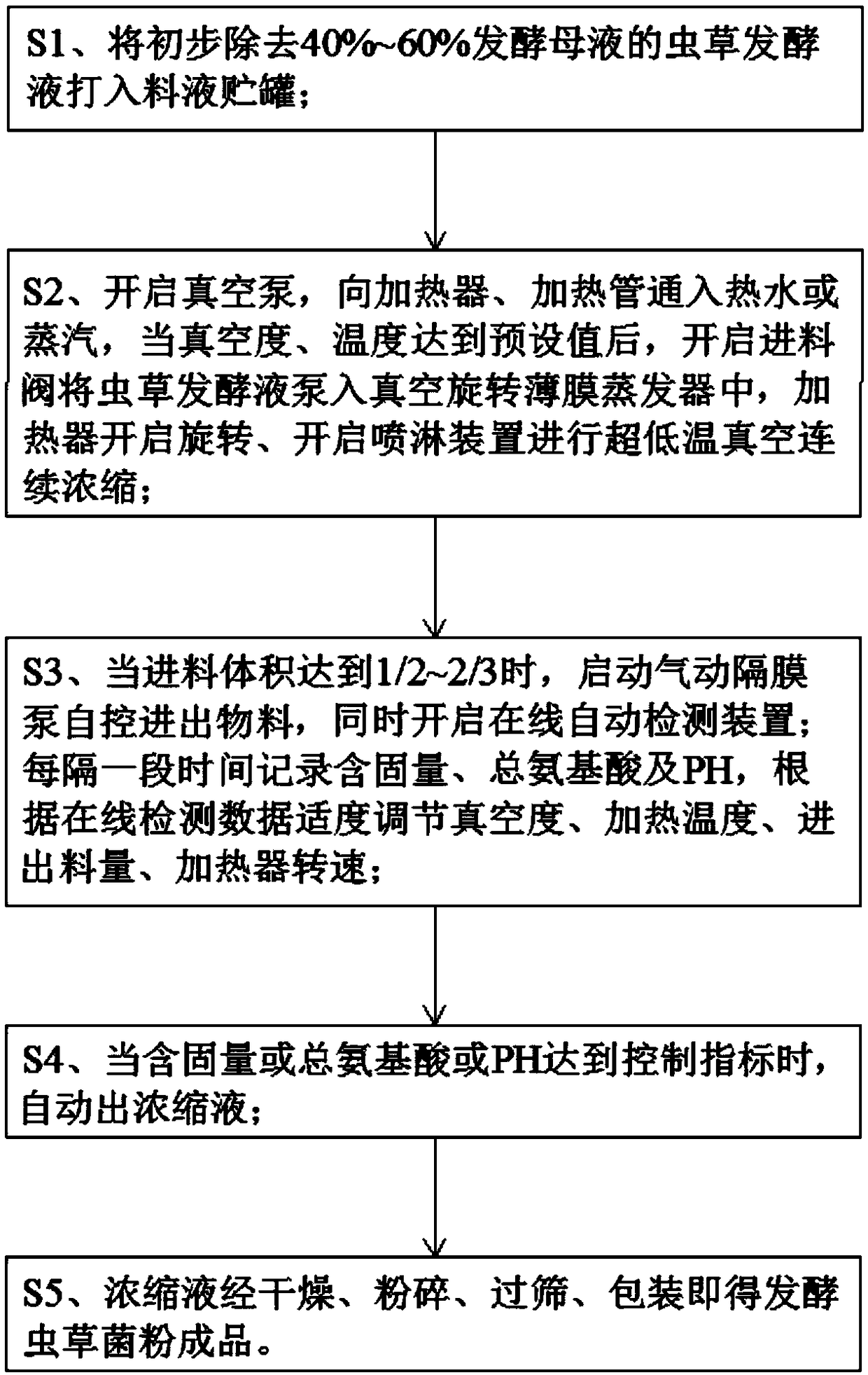

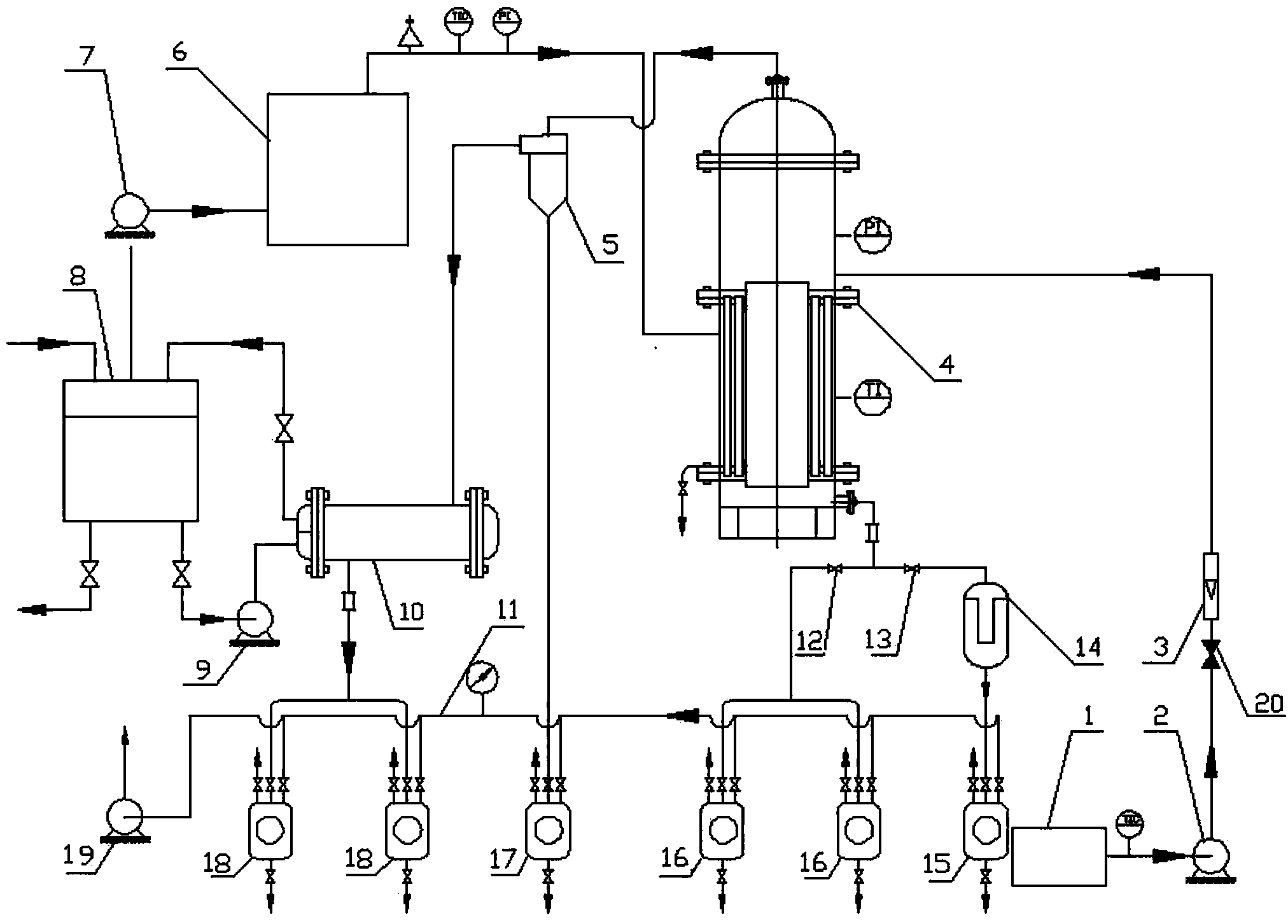

Concentration method in production process of ferment cordyceps sinensis fungus powder

ActiveCN108905240ALow boiling pointPipeliningEvaporator accessoriesEvaporator regulation/controlDiaphragm pumpEnrichment methods

The invention provides a concentration method in the production process of ferment cordyceps sinensis fungus powder. The method comprises the following steps: S1, injecting a cordyceps sinensis fermenting liquid which is subjected to the removal of 40%-60% of a fermenting mother liquid into a liquid storage tank; S2, turning on a vacuum pump, introducing hot water or water vapor into a heater anda heating pipe, pumping the cordyceps sinensis fermenting liquid into a vacuum rotary film evaporator when the vacuum degree and the temperature reach preset values, starting the rotation of the heater, and turning on a spraying device to carry out ultralow-temperature vacuum continuous concentration; S3, turning on a pneumatic diaphragm pump to automatically control the material feeding and discharging when the volume of the fed material reaches 1 / 2-2 / 3, simultaneously turning on an online automatic detecting device, recording the solid content, the total amino acids and the pH value at regular intervals, and moderately adjusting various concentration technical parameters according to the online detected data; S4, when the solid content or the total amino acids or the pH values reach thecontrol indexes, automatically discharging a concentrated liquid; and S5, drying the concentrated liquid, carrying out crushing, sieving and packaging to obtain a finished product of the ferment cordyceps sinensis fungus powder. The product provided by the invention has high quality and effective components of the product are preserved greatly.

Owner:JIANGXI GUOYAO PHARMA LLC

Method for preparing beta-D-galactoside galactose hydrolase preparation

ActiveCN101845424AHigh extraction rateSolve the problem of slow flowMicroorganism based processesEnzymesFiltration membraneGram

The invention discloses a method for preparing a beta-D-galactoside galactose hydrolase preparation. The method comprises the following steps of: 1) performing microporous membrane filtration on fermentation solution containing target enzyme to obtain clarified solution containing the target enzyme; 2) introducing the clarified solution containing the target enzyme into an ultra-filtration columnarray 1 and an ultra-filtration column array 2 in turn, and collecting the target enzyme solution; and 3) adding an aid into the target enzyme solution, and drying the mixture to obtain a target enzyme preparation, wherein the step 1) and the step 2) are performed under closed conditions. In the method, the sterile enzyme-containing classified solution filtered by a microporous membrane only needs to flow through an ultra-filtration membrane passage at one time during ultra-filtration and a circulating step is saved; therefore, compared with the prior art, the method has the advantages of avoiding the contact of the liquid and the environment, thereby ensuring that the product is not polluted during extracting and saving a re-sterilizing step. Experiments prove that the number of bacteriain the enzyme preparation finished product obtained by the method is less than 100 in every gram, and the number of bacteria in the enzyme preparation produced by the prior art is generally 1,000 in every gram.

Owner:中诺生物科技发展江苏有限公司

Toothpaste containing extract from Chinese traditional medicine as well as preparing method and application

A toothpaste containing the extract of Chinese-medicinal materials, especially the curcuma root, its preparing process and its application in beautifying, whitening and cleaning teeth are disclosed. Its advantage is high effect.

Owner:北京焦点辉煌科技有限公司

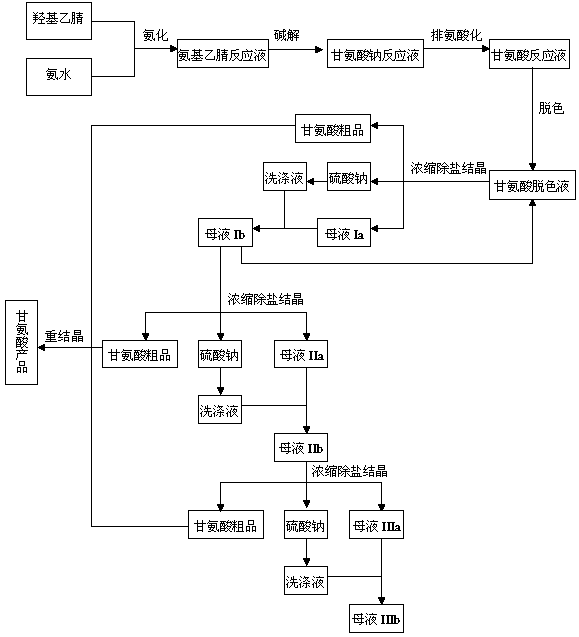

Preparation process of glycine

InactiveCN102432478BReduce pyrolysis polymerizationHigh yieldOrganic compound preparationAmino-carboxyl compound preparationReaction temperatureAlkaline hydrolysis

The invention discloses a preparation process of glycine, which comprises amination, alkaline hydrolysis, ammonia discharge acidification, decolorizing, concentration, desalting, crystallization and recrystallization steps, wherein in the amination step, hydroxyacetonitrile and ammonia water are mixed in a tubular reactor, and a reaction is undergone at the temperature of 50-100 DEG C under the pressure of 0.5-2.0 MPa for 4-10 minutes; and in the alkaline hydrolysis step, 30-50 percent of sodium hydroxide solution is added into an alkaline hydrolysis reactor in advance, an amination liquid is collected from an amination liquid outlet, a reaction is undergone at the temperature of 60-90 DEG C under the pressure of between -0.01 MPa and -0.09 MPa, and ammonia in a system is recovered simultaneously. In the process, the tubular reactor is taken as an amination reactor, so that the reaction temperature and pressure are raised, the reaction time is shortened, and raw material decomposition, pyrolytic polymerization of aminoacetonitrile and the generation of byproducts are reduced; alkaline hydrolysis is performed during the collection of the amination liquid, the concentration of an alkaline liquor and the alkaline hydrolysis temperature are raised simultaneously, and ammonia in the system is recovered under reduced pressure, so that the alkaline hydrolysis reaction is more complete, the speed is higher, and the generation of colored impurities is reduced; and a mother liquor circular utilizing mode is established, so that the treatment amount of waste mother liquor is reduced, the product yield is increased, and the production cost is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

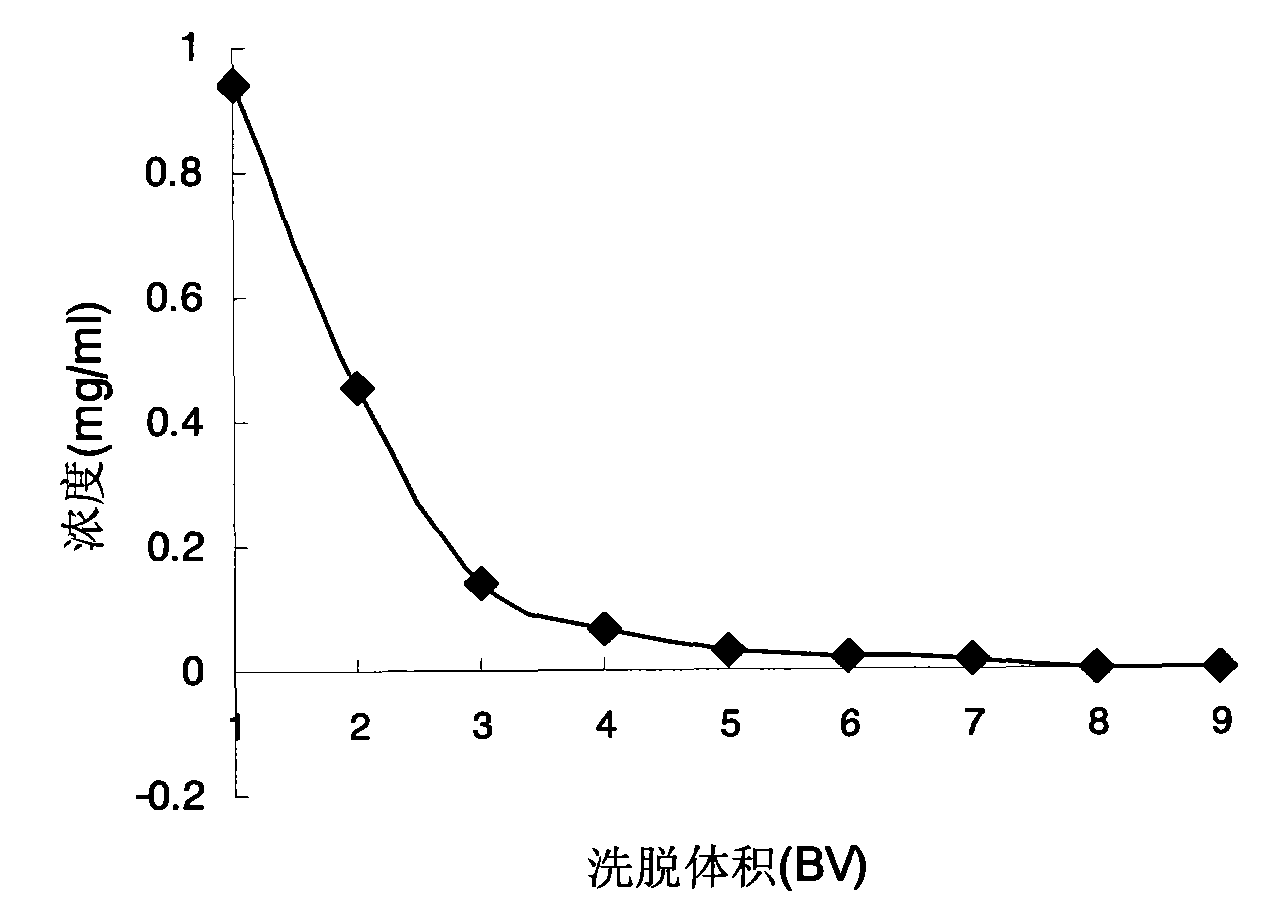

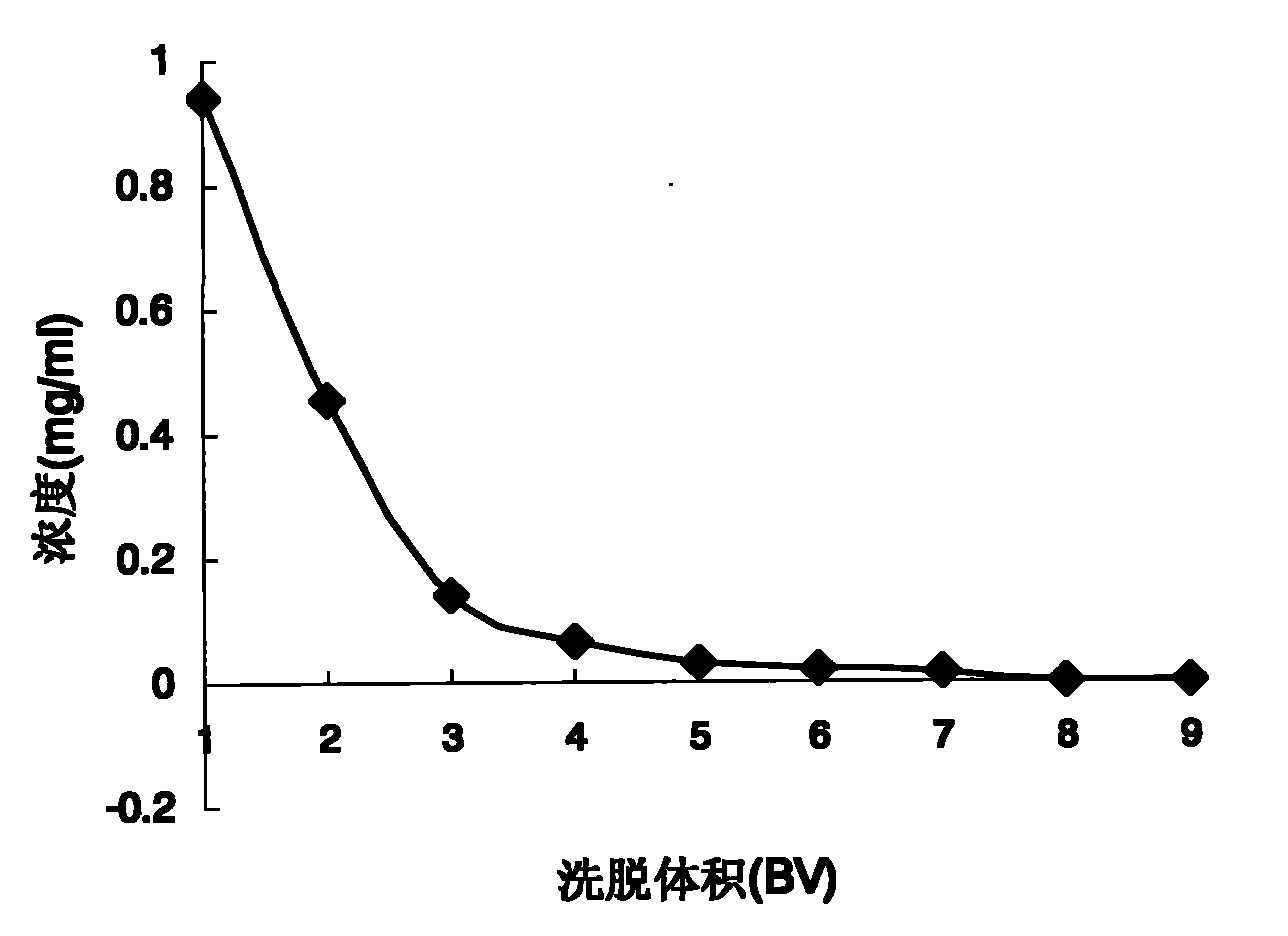

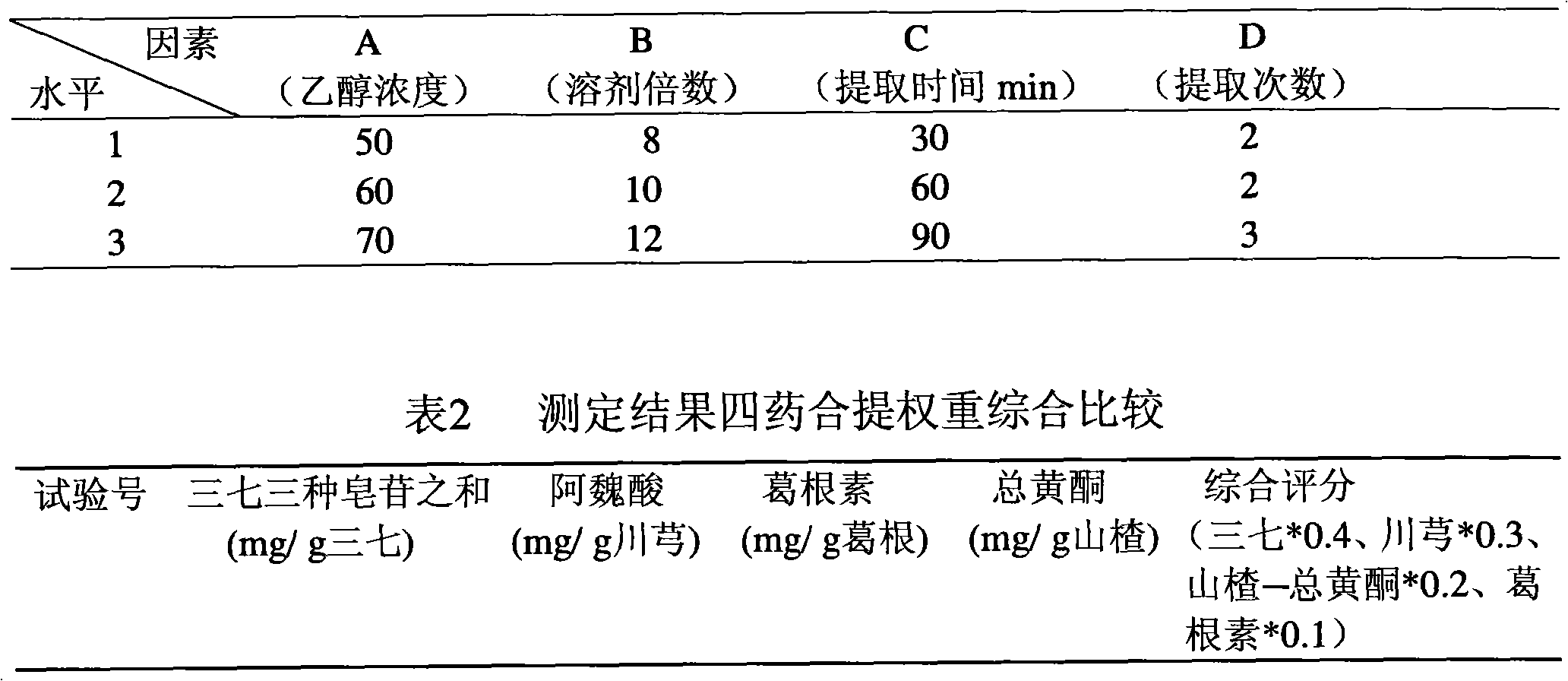

Method for purifying active ingredients of compound Naodesheng

InactiveCN101791340AHigh effective transfer rateHigh Process Comprehensive Extraction RateNervous disorderCardiovascular disorderFiltrationCurative effect

The invention discloses a method for purifying active ingredients of compound Naodesheng. The method comprises the following steps: firstly dividing raw materials of the compound Naodesheng into two parts for screening, wherein the first part comprises sanchi, kudzuvine root, hawthorn fruit and Szechuan lovage rhizome, and the second part comprises safflower; carrying out extraction, concentration, vacuum filtration, concentration, absorption by resin and elution on the two parts, then extracting and purifying for obtaining purified eluate of the two parts, merging, decompressing, concentrating and drying for obtaining the active ingredients of the compound Naodesheng. The method for purifying the compound Naodesheng can effectively remove impurities without efficacy, ensure the yield, relatively improve the content of the active ingredients, improve the efficacy of the drug and realize very high using value.

Owner:GUANGDONG PHARMA UNIV

Preparation method of passiflora edulis fruit sauce

InactiveCN106616885AFull of nutritionExtended shelf lifeSugar food ingredientsFood homogenisationFruit juicePassion fruit

The invention discloses a preparation method of passiflora edulis fruit sauce. The preparation method comprises following steps: 1, passiflora edulis fruits are selected and washed; 2, peeling is carried out, wherein the epicarp of passiflora edulis fruits is removed via a mechanical method; 3, seeds are removed, wherein fruit peel and fruit pulp juice are collected respectively, and seeds in the fruit pulp juice are removed; 4, pulping is carried out, wherein the fruit pulp juice and fruit peel are subjected to pulping so as to obtain fruit pulp; 5, flavoring is carried out, wherein a sweetening agent and / or salt is added into the fruit pulp, and pH value of the fruit pulp is controlled to be 2.0 to 4.0 at the same time; 6, reduced pressure boiling and concentration are carried out, wherein boiling is carried out for 0.5 to 30min at 40 to 100 DEG C under a pressure less than one atmosphere so as to obtain the passiflora edulis fruit sauce. According to the preparation method, the hard passiflora edulis fruit epicarp which is acerb in taste and rough in mouthfeel is removed, the passiflora edulis fruit sauce is prepared from the mesocarp, the endocarp, and pulp which are abundant in nutrients, so that the obtained passiflora edulis fruit sauce is sweet, sour, and delicious, and is abundant in nutrients.

Owner:广西欧唛果科技有限公司

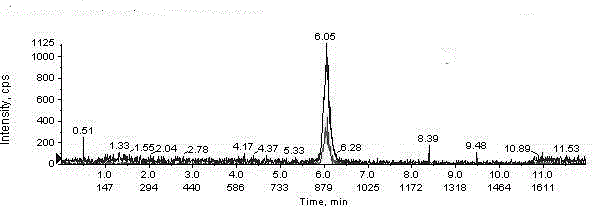

Method for rapidly detecting content of tetrodotoxin in fish flesh through liquid chromatography-mass spectrometry

InactiveCN106596790AShorten the concentration timeEasy and fast handlingComponent separationMuscle tissueAcetic acid

The invention discloses a method for rapidly detecting the content of tetrodotoxin in fish flesh through liquid chromatography-mass spectrometry. The method comprises (1) sample preprocessing and (2) chromatography-mass spectrometry detection. Diatomite is added in the preprocessing process against the effect problem of a matrix in a fish flesh sample and combining the chemical characteristics of tetrodotoxin, and the tetrodotoxin is separated from muscle tissues in an ultralow temperature freezing manner. A sample undergoes extraction by 1% acetic acid-methanol in a cell crasher at 60 DEG C, obtained extract is purified by a Carbon-GCB SPE small column, and the purified extract is directly introduced and analyzed, so the concentration time is saved. Compared with 0.2% acetic acid-water solution extraction, other SPE purification and ultrafiltration methods in the prior art, the method disclosed in the invention, adopting direct introduction and analysis of the sample, has the advantages of simplicity and low consumption in the processing process, good accuracy, convenience in operation, and good reappearance.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

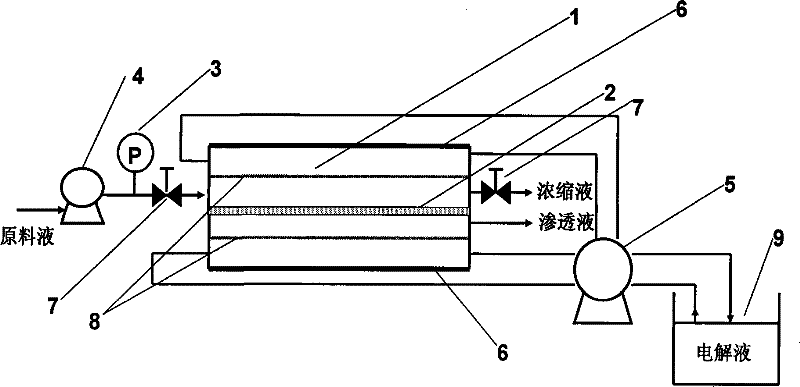

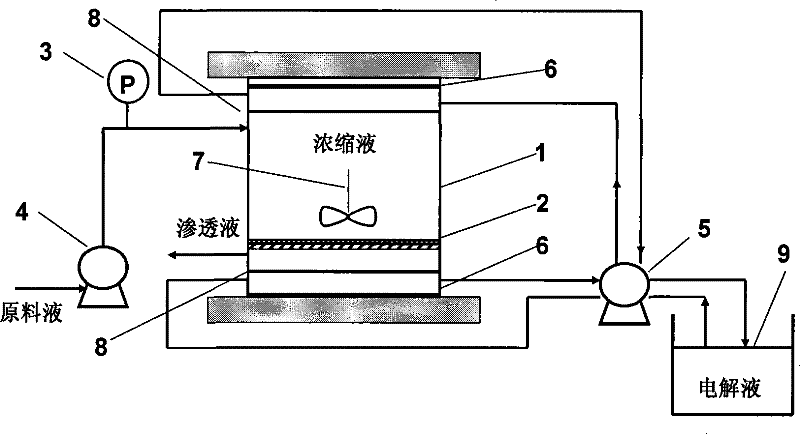

An electric field enhanced fast membrane concentration method and device

ActiveCN101596406BReduce shear forceSimple processUltrafiltrationDispersed particle separationChemical physicsMembrane technology

The invention relates to an electric field enhanced fast membrane concentration method and device, which relates to a method and a device for concentrating charged solute molecules, colloid molecules and particles in a solution by using membrane technology. Select a filter membrane with a molecular weight cut-off greater than that of the solute molecule or a pore size greater than the diameter of the particles. By applying a direct current electric field, the molecules or particles will undergo electrophoretic movement away from the membrane surface to improve the retention rate of the solute molecules and particles on the separation side of the membrane, while the solvent will penetrate quickly. Through the membrane, the rapid concentration of solute molecules or particles is realized. Compared with the conventional membrane concentration process, the invention can greatly reduce the concentration time, improve the concentration efficiency, significantly reduce the membrane pollution, and increase the service life of the membrane.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for extracting and concentrating total flavone in hawthorn

InactiveCN104138670AShorten extraction and concentration timeIncrease concentrationEvaporationEnergy based chemical/physical/physico-chemical processesHigh concentrationEvaporation

The invention relates to a process for extracting and concentrating total flavone in hawthorn. The process comprises a process for extracting total flavone in hawthorn and a process for evaporating and concentrating total flavone in hawthorn. The process is characterized in that the process for extracting total flavone in hawthorn and the process for evaporating and concentrating total flavone in hawthorn are respectively completed in integrated ultrasonic extraction, evaporation and concentration equipment. The process is scientific and reasonable in design, has the advantages of simplicity in operation, short extraction and concentration time, high concentration degree, uniformity in extraction, high circulation speed, good solution property, small possibility of scaling, convenience in equipment washing and repair and simplicity, and is relatively high in innovativeness.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

Method for quickly detecting tetrodotoxin content in fish liver employing liquid-mass chromatography

InactiveCN106645496AMeet the technical requirements of rapid detectionEasy and fast handlingComponent separationMass Spectrometry-Mass SpectrometryMass chromatography

The invention discloses a method for quickly detecting the tetrodotoxin content in a fish liver employing a liquid-mass chromatography. The method comprises the steps of (1) sample pretreatment; and (2) chromatography-mass spectrometry detection. For the problem of a matrix effect in a fish liver sample, by combining the chemical characteristics of tetrodotoxin, kaolin is added during pretreatment, and the tetrodotoxin is separated to the maximum extent. Meanwhile, acidolysis is carried out at 60 DEG C, ultrasonic extraction is carried out by adopting a cell disruptor, and after Carbon-GCB SPE purification, a sample directly injected for analysis, so that the treatment process is simple, fast, low in consumption. The method is accurate, convenient to operate and good in reproducibility and can meet the technical requirements of fast detection of the tetrodotoxin in the fish liver.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Extraction method of small molecular rhizoma polygonati polypeptide

ActiveCN109439717AHigh extraction ratePromote dissolutionPeptide preparation methodsFermentationNeutral proteaseProteinase activity

The invention provides an extraction method of small molecular rhizoma polygonati polypeptide. The extraction method comprises the following steps: step 1, slicing rhizoma polygonati and adding purified water; uniformly stirring and decocting to obtain a decocted mixture; step 2, cooling the decocted mixture to 55 to 58 DEG C; adding cellulase, amylase and a saccharifying enzyme, and stirring andcarrying out enzymolysis to obtain a first enzymolysis solution; step 3, centrifuging the first enzymolysis solution and separating to obtain desugared rhizoma polygonati slices; adding purified waterinto the desugared rhizoma polygonati slices; raising the temperature to 50 to 55 DEG C and adding exoaspergillus oryzae neutral protease, fresh ginger protease and kiwi fruit protease; stirring andcarrying out enzymolysis to obtain a second enzymolysis solution; step 4, heating the second enzymolysis solution and raising the temperature to carry out enzyme inactivation; separating and purifyingto obtain the small molecular rhizoma polygonati polypeptide. The extraction method provided by the invention adopts a two-time enzymolysis method of a compound enzyme, and a centrifuging technologyand a nano-filtering technology are combined, so that a prepared rhizoma polygonati peptide product has high purity and the content of the peptide with a peptide molecular weight of 180 to 500 Daltonsreaches 99 percent or above.

Owner:河北肽都生物科技集团有限公司

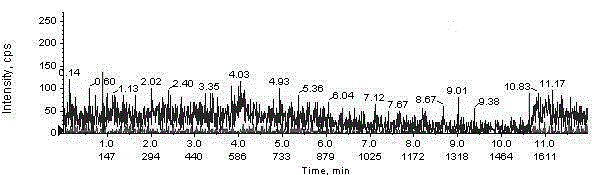

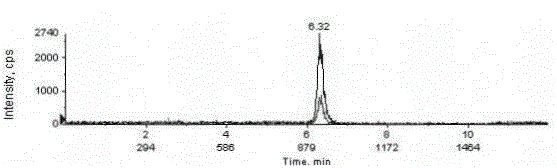

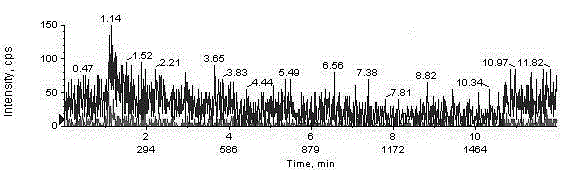

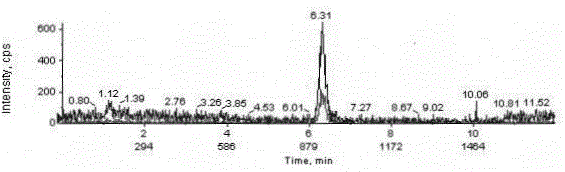

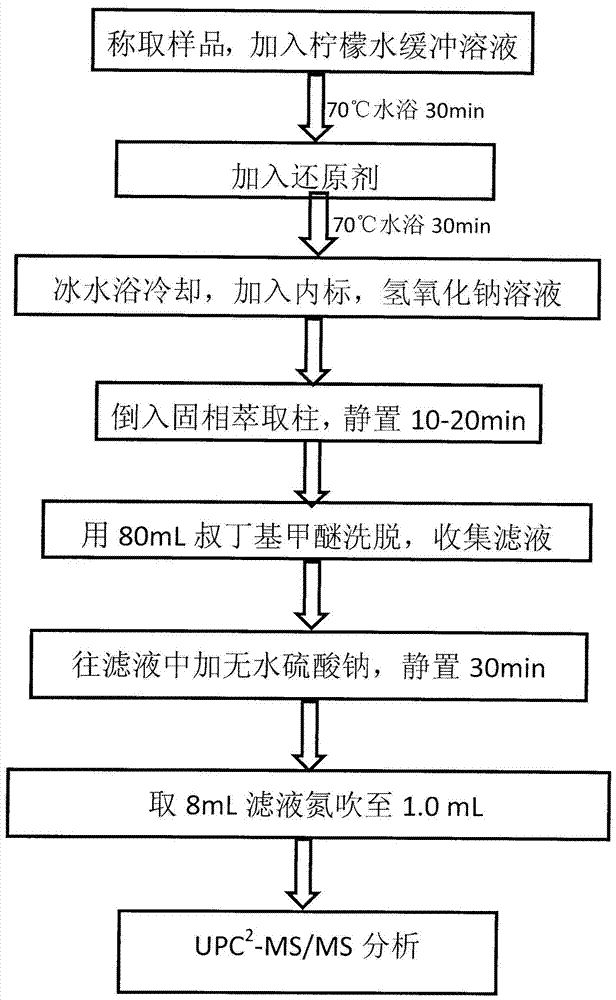

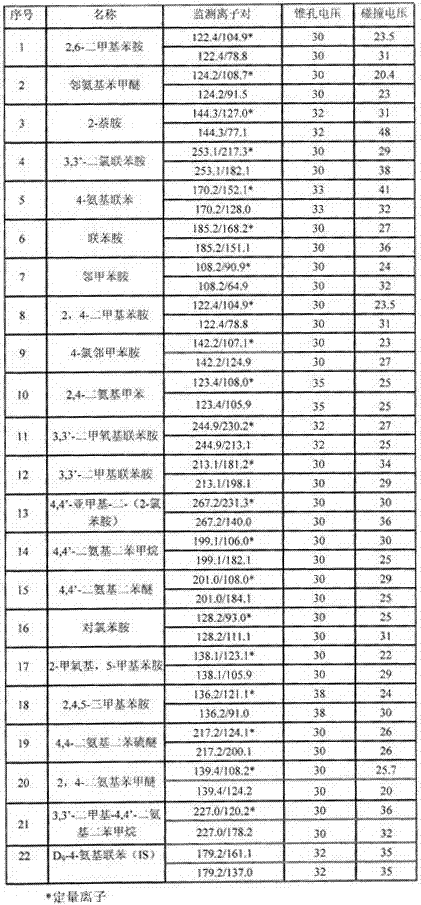

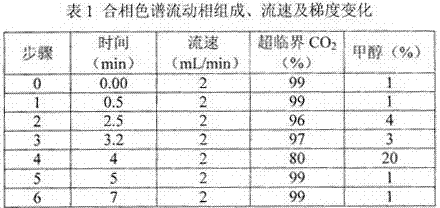

Method of determining specific aromatic amine released by azodye in cigarette paper through bonded phase chromatography-tandem mass spectrometry

InactiveCN106950317AGood effectReduce distractionsComponent separationPretreatment methodHazardous substance

The invention relates to a method of determining specific aromatic amine released by azodye in cigarette paper through bonded phase chromatography-tandem mass spectrometry, belonging to the technical field of physical and chemical inspection of residual harmful substances in paper. According to the method, the azodye is reduced to aromatic amine by using sodium hydrosulfite in a weak acidic buffer solution, then the aromatic amine is subjected to solid-phase, purification and nitrogen-blow concentration, afterwards a bonded phase chromatography-tandem mass spectrometry combination instrument is used for determination, and an internal standard method is used for fixing quantity. The method has the beneficial effects that the shortcomings of a sample treatment method in the prior art are overcome; a sample pretreatment method and instrument detection conditions are optimized according to paper samples; the disturbance of matters with similar structures to target objects can be reduced; and the method has the advantages of accurate operation, high recovery rate, short separation time, fastness, simplicity, convenience, high sensitivity and the like.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

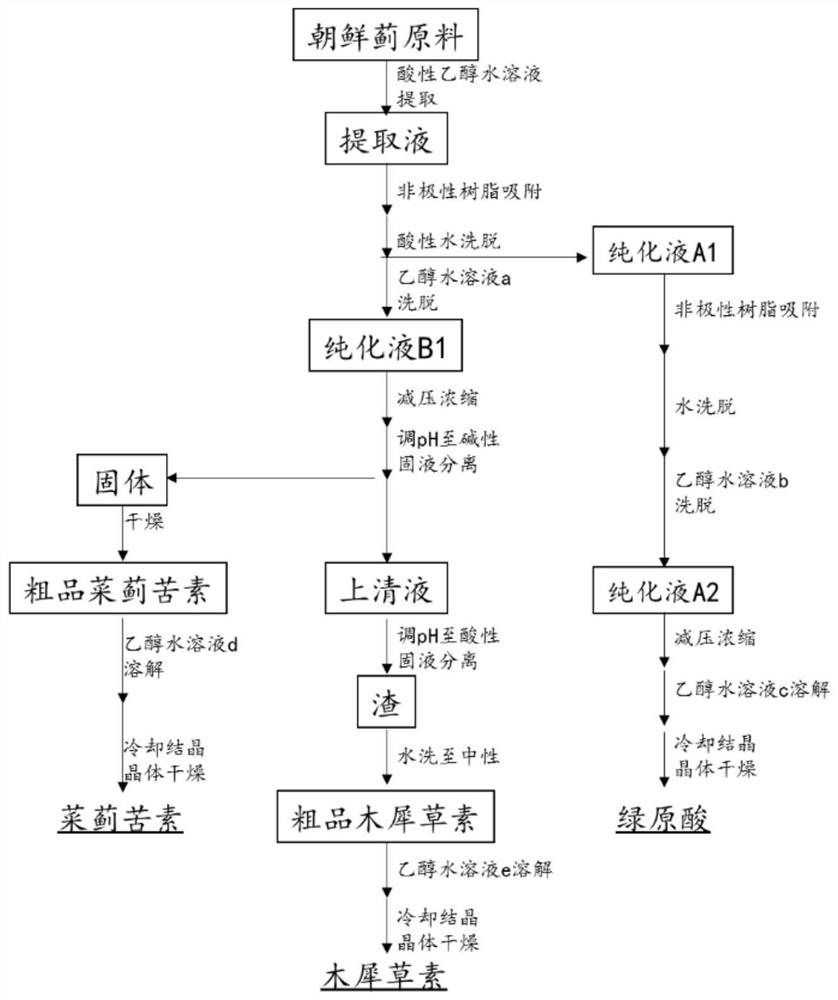

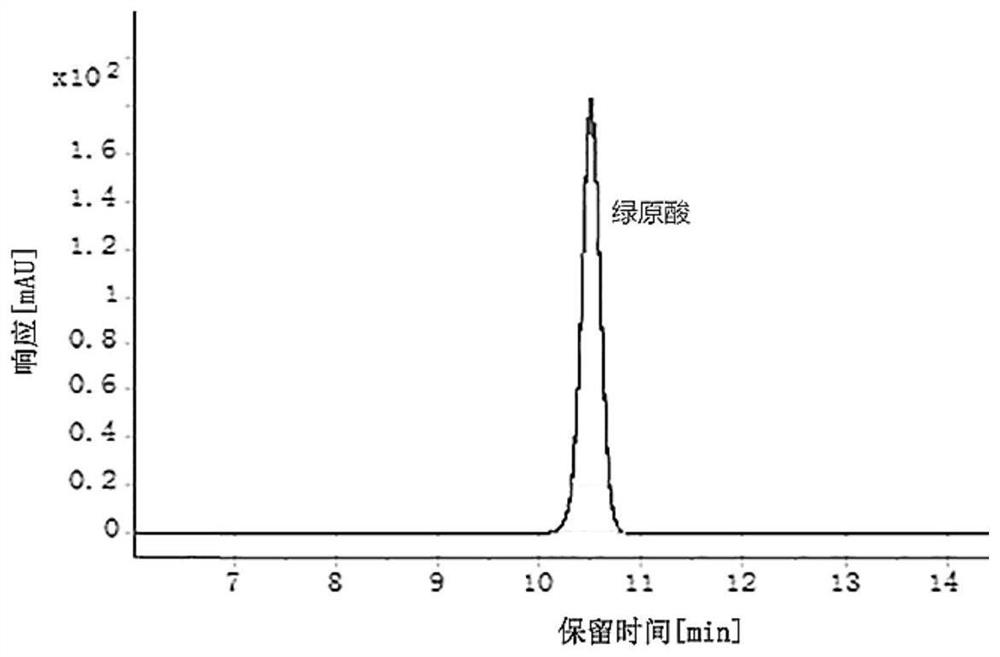

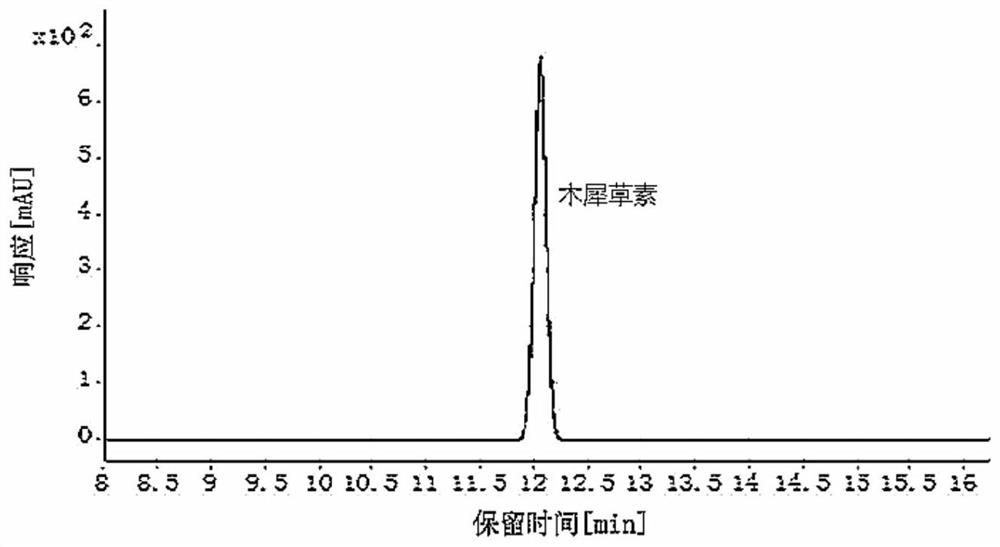

Preparation method of globe artichoke extract

ActiveCN112479881ARaise the level of developmentImprove securityOrganic compound preparationCarboxylic acid esters separation/purificationBiotechnologySocial benefits

The invention provides a preparation method of globe artichoke extract. According to the method, chlorogenic acid is separated from a mixed system of cynarin and luteolin from globe artichoke, then the cynarin and the luteolin are separated through simple pH adjustment, and finally, the chlorogenic acid, the cynarin and the luteolin are separated and extracted at the same time. Effective components in globe artichoke are fully utilized, the comprehensive development level of globe artichoke is improved, and good economic and social benefits are achieved. The extraction rate of chlorogenic acidis greater than or equal to 92.31%, the purity is greater than or equal to 93.05%, the extraction rate of cynarin is greater than or equal to 83.25%, the purity is greater than or equal to 90.10%, the extraction rate of luteolin is greater than or equal to 84.98%, and the purity is greater than or equal to 94.25%.

Owner:CHANGSHA LANGLIN BIOLOGY PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com