Microwave evaporation and concentration system

An evaporation concentration system and a microwave generator technology, applied in the field of concentration systems, can solve the problems of not being able to meet the requirements of high concentration and high quality, the concentration effect of the concentration system is not ideal, and the production time of the pharmaceutical process is affected, so that the evaporation effect is remarkable and shortens the production time. Concentration time, fast evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

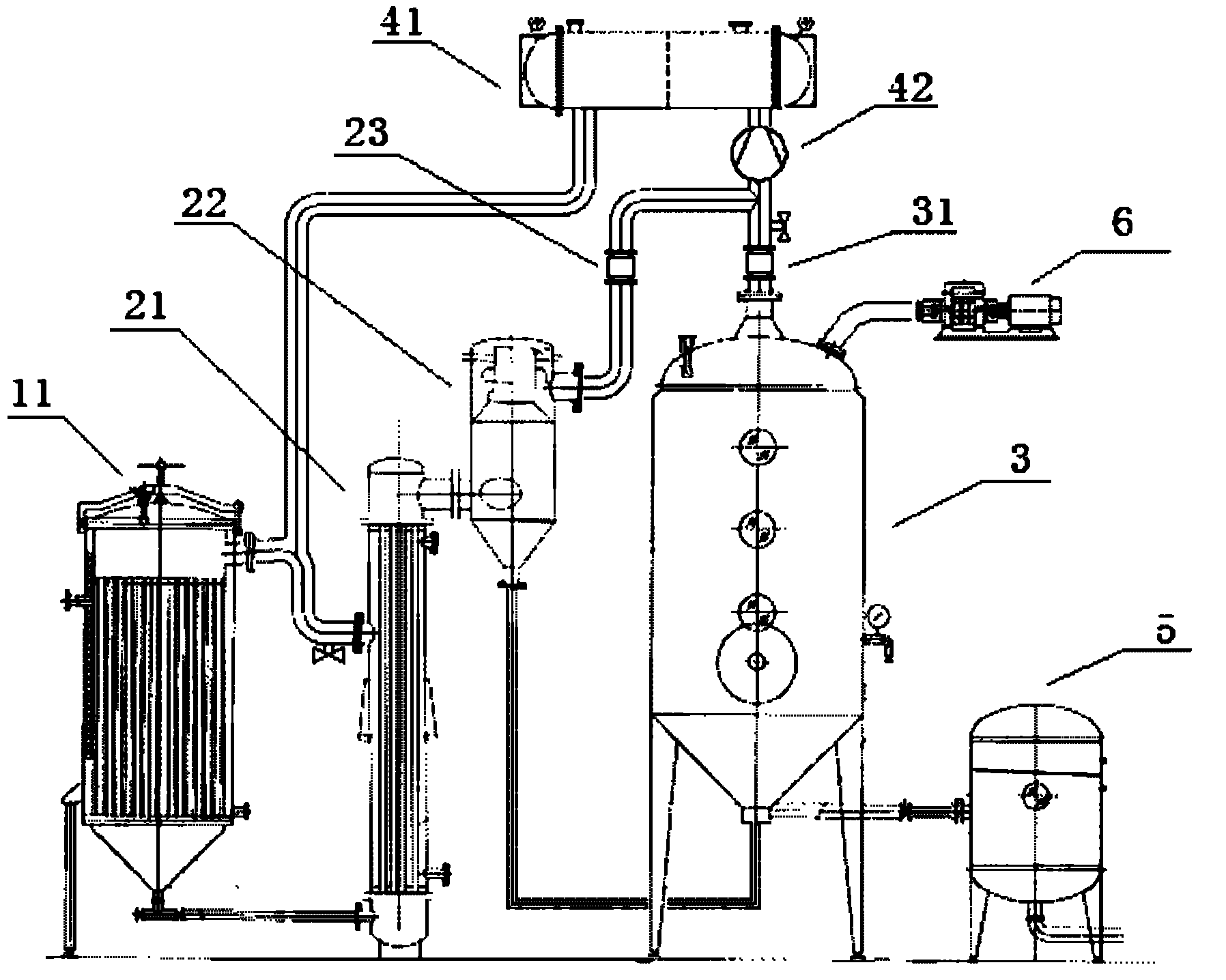

[0025] refer to figure 1 , a microwave evaporation concentration system, including a rising film evaporator, a condenser 41, a cooler 5, also includes a microwave heater 11, a flash evaporator 3, the microwave heater 11 is connected to the rising film evaporator, the rising film The evaporator is connected to the flash evaporator 3 through a high-pressure plunger pump, and the flash evaporator 3 is connected to the cooler 41 . In the present invention, the raw liquid is rapidly heated by a microwave heater, and the heated raw liquid enters a rising film evaporator for preliminary evaporation, and a large amount of excess water in the raw liquid is evaporated. With the help of the pump, the liquid compressed into high temperature and high pressure en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com