Patents

Literature

40results about How to "Uniform film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

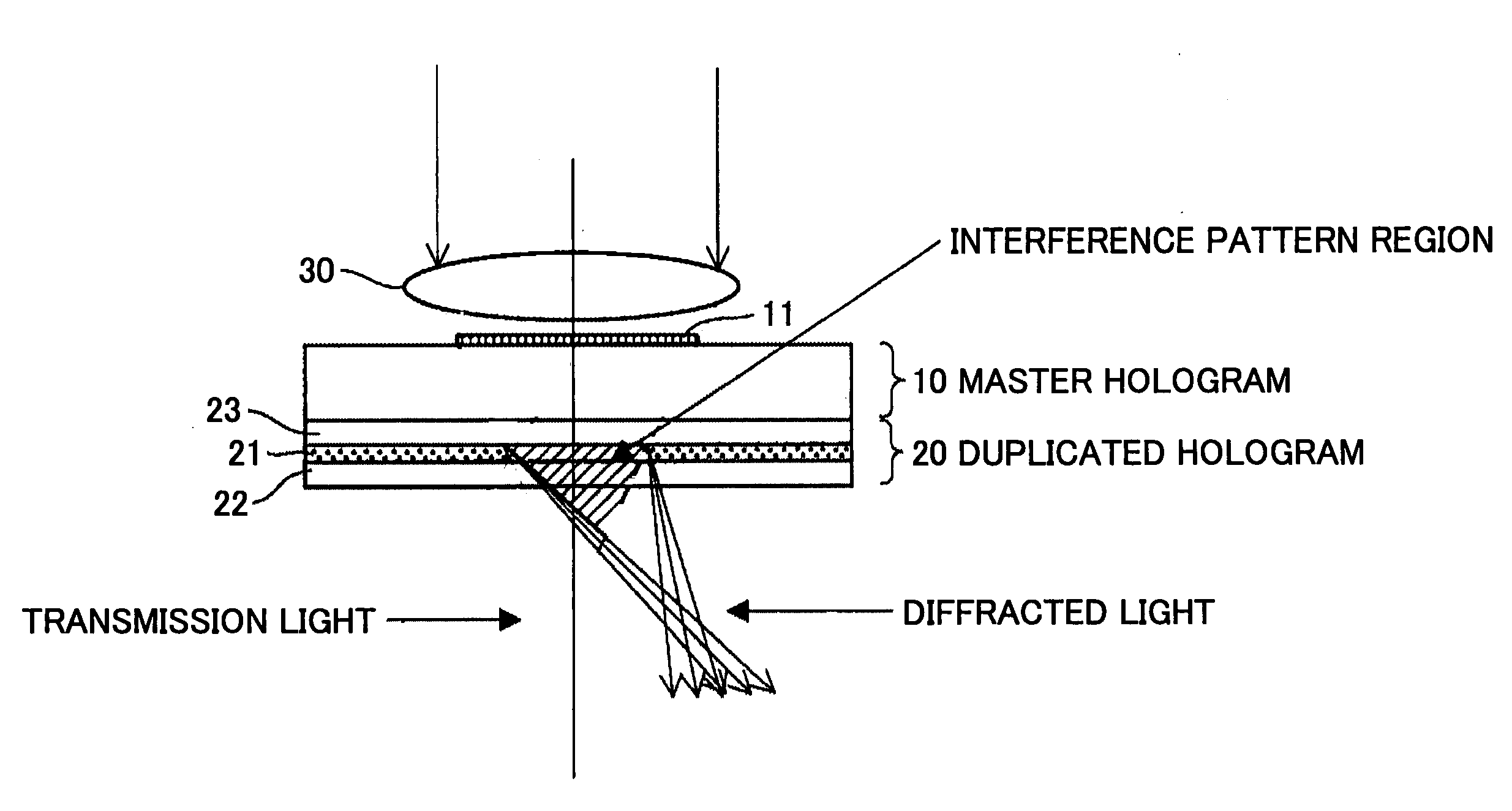

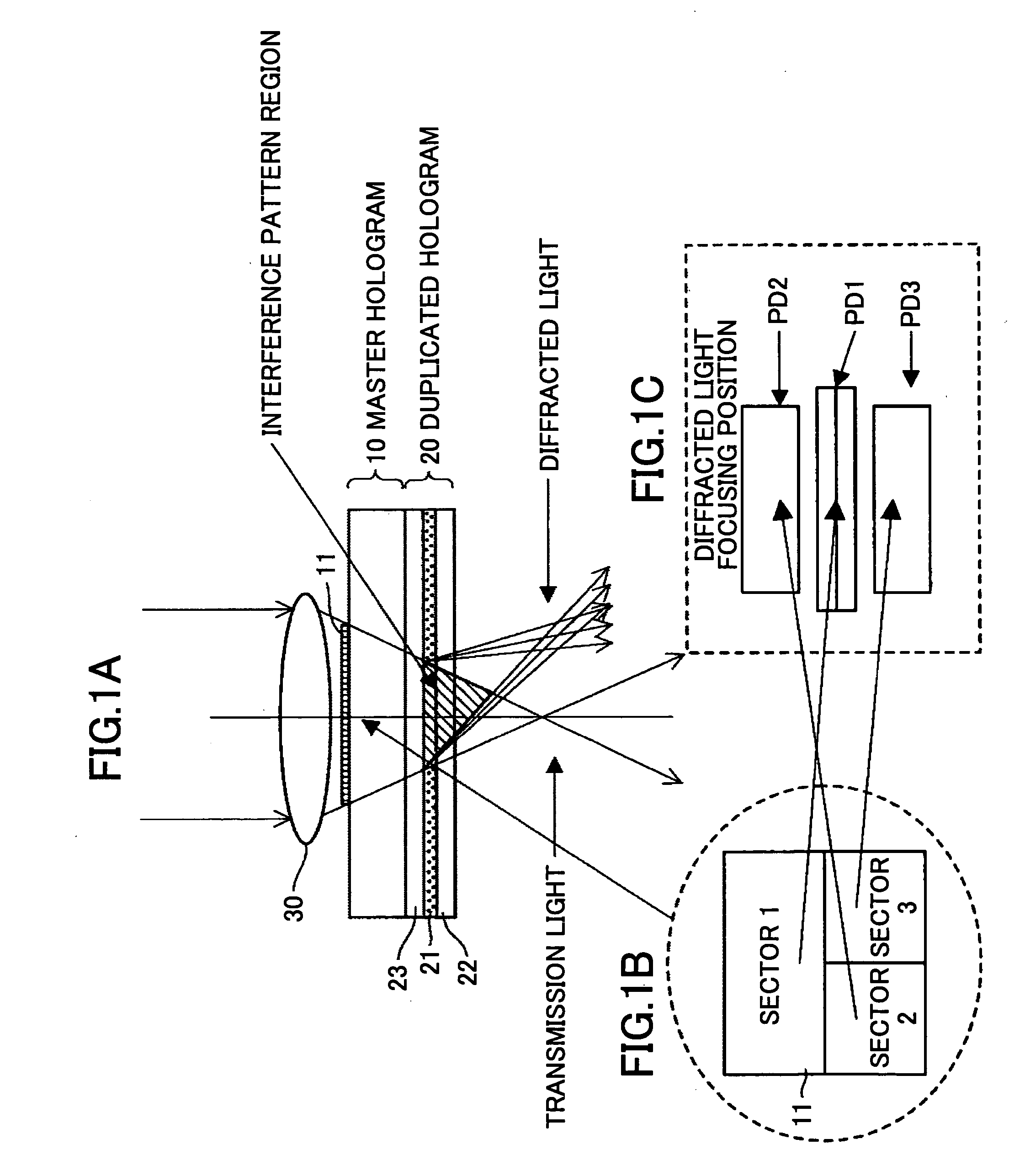

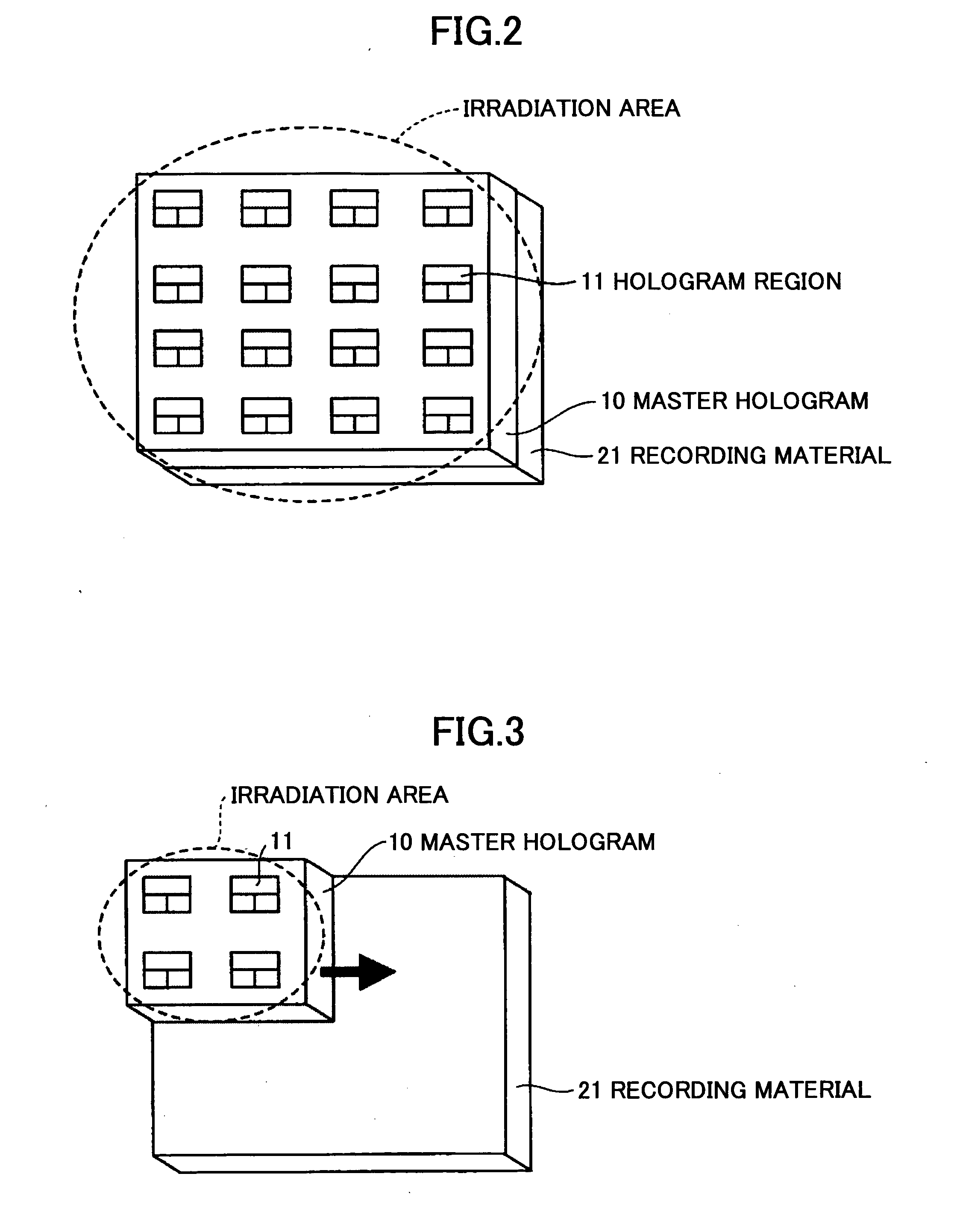

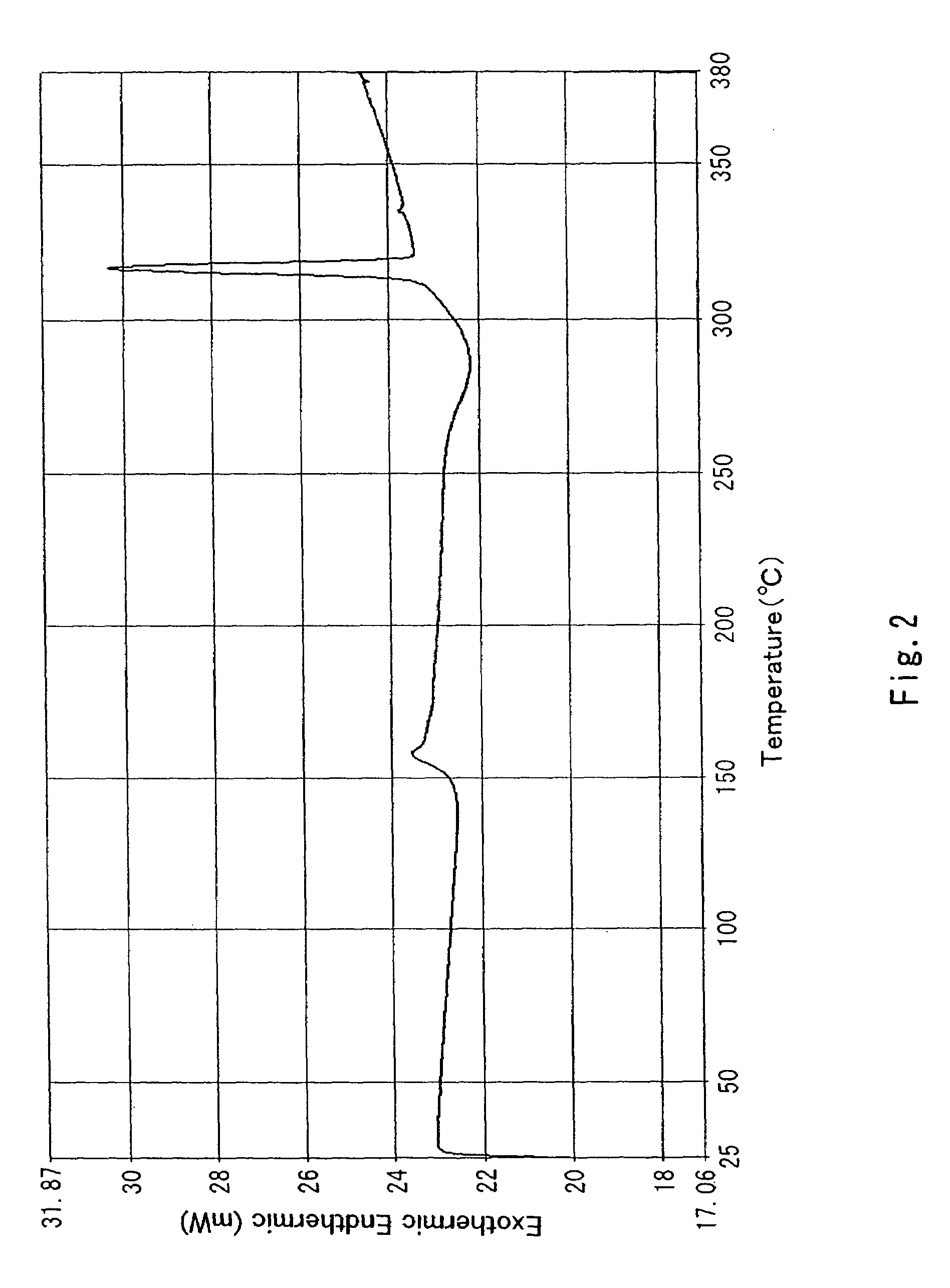

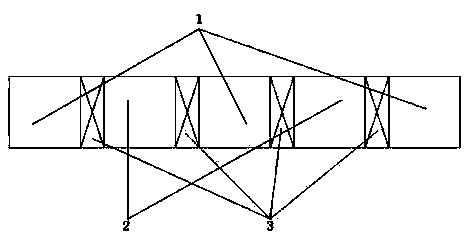

Hologram element, production method thereof, and optical header

InactiveUS20060055993A1High film thicknessImprove productivityHolographic light sources/light beam propertiesRecord information storageProduction rateLight beam

A method of producing a hologram element is disclosed that is able to prevent spread of a polymerization reaction and light leakage during exposure with interference light, and improve productivity in mass production. The hologram element is for transmitting, reflecting, diffracting, or scattering incident light, and includes a pair of substrates, an isolation member between the substrates that forms an isolated region, and a photo-sensitive recording material sealed in the isolated region. The hologram element includes a periodic structure formed by exposing the recording material to interference light. The interference light is generated by two or more light beams, or by using a master hologram. The recording material is formed from a composite material including a polymerized polymer or a polymerized liquid crystal. The periodic structure is formed by exposing the recording material to the interference light to induce the polymerization reaction and phase separation in the composite material.

Owner:RICOH KK

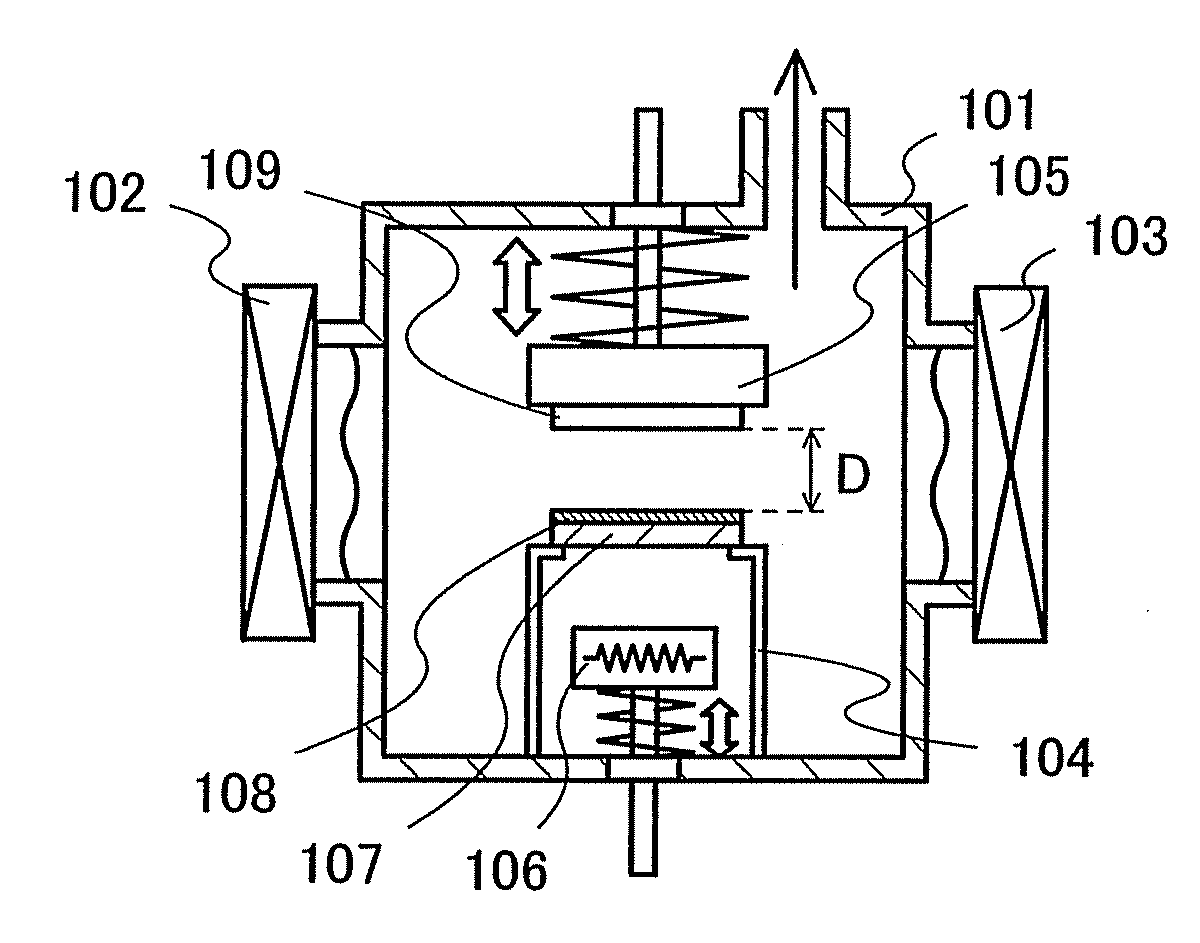

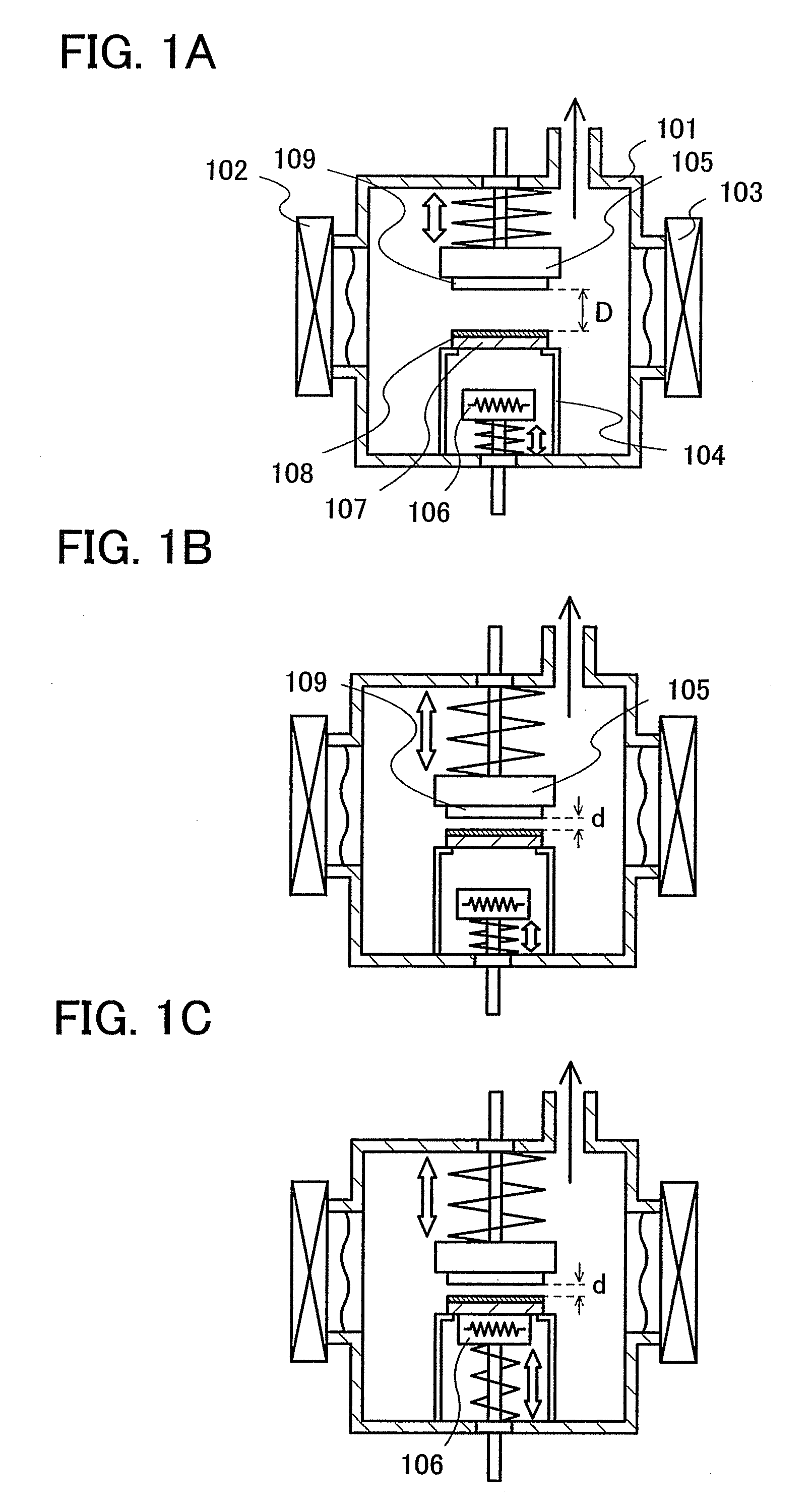

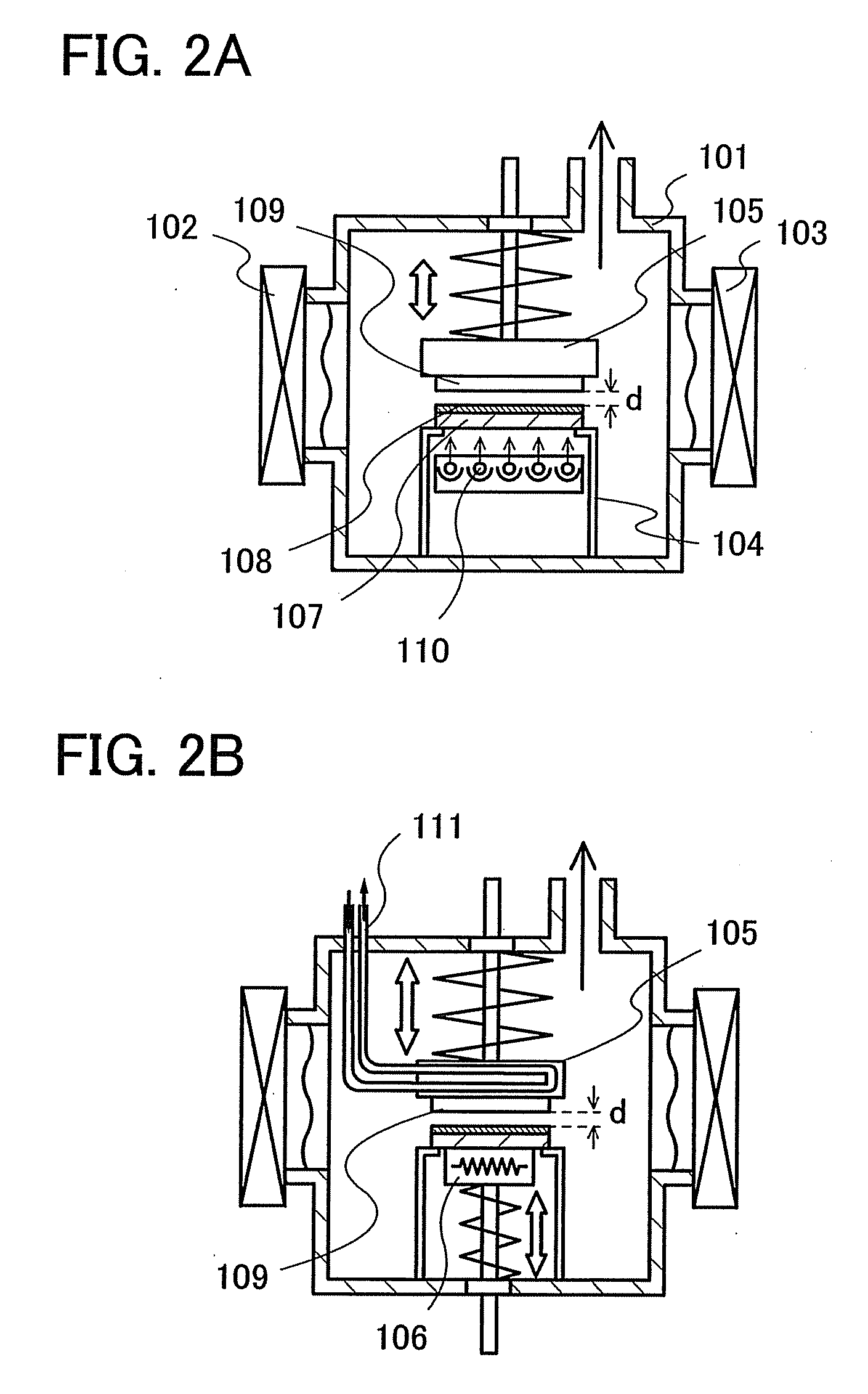

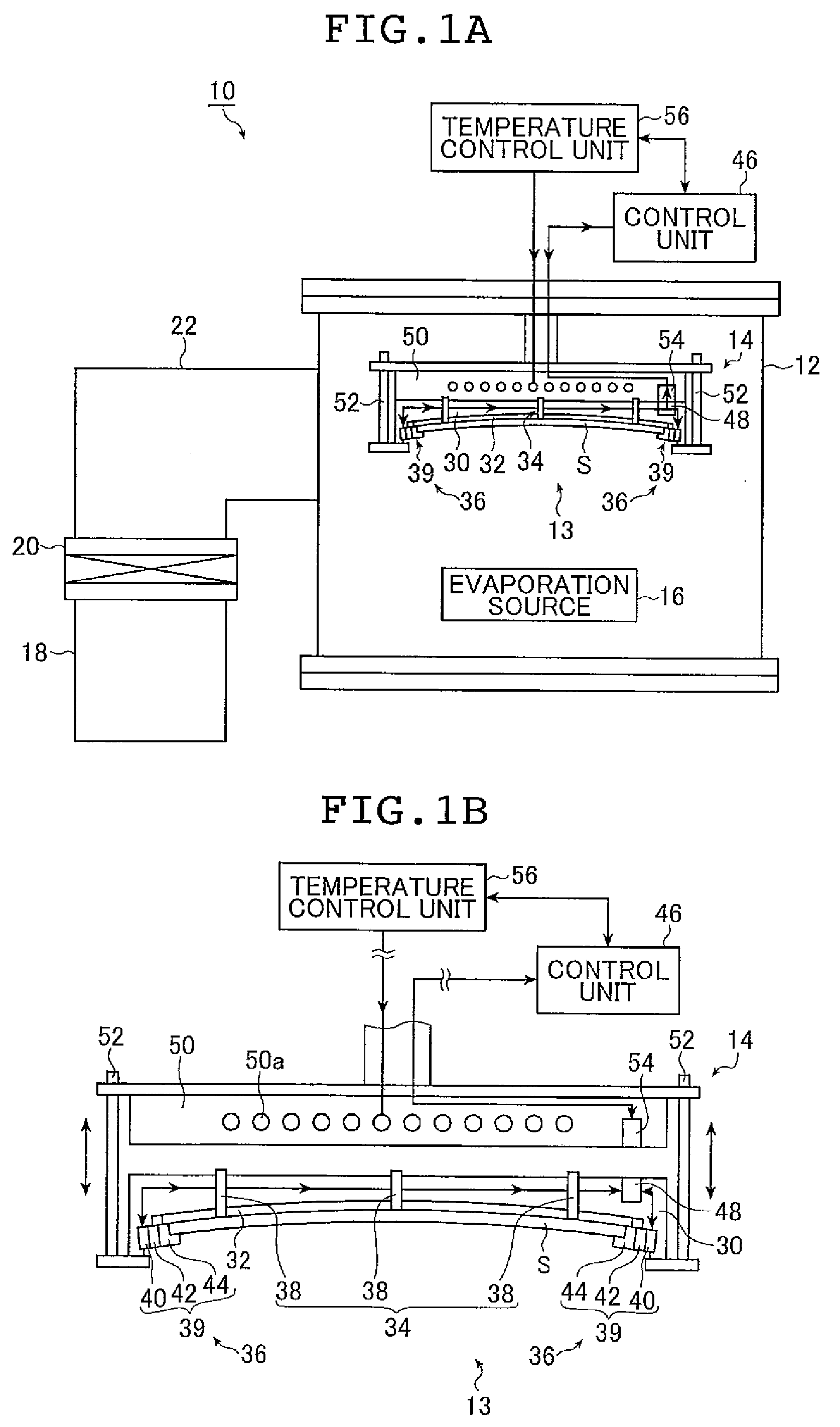

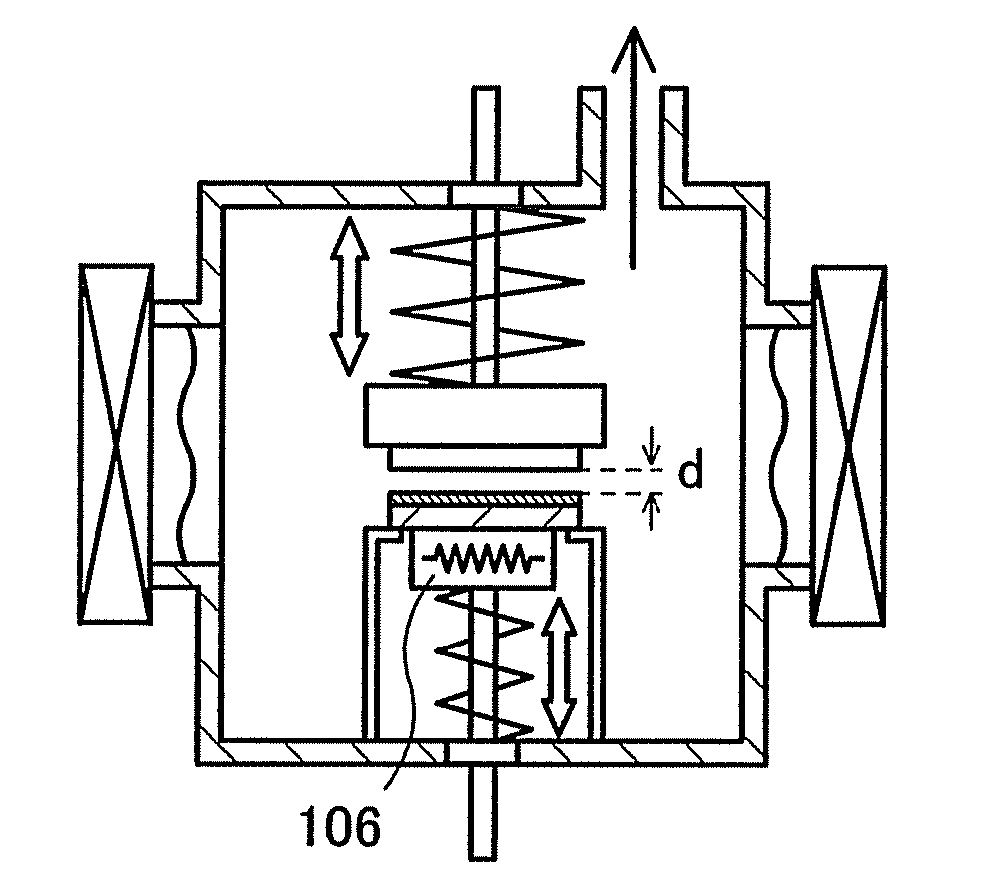

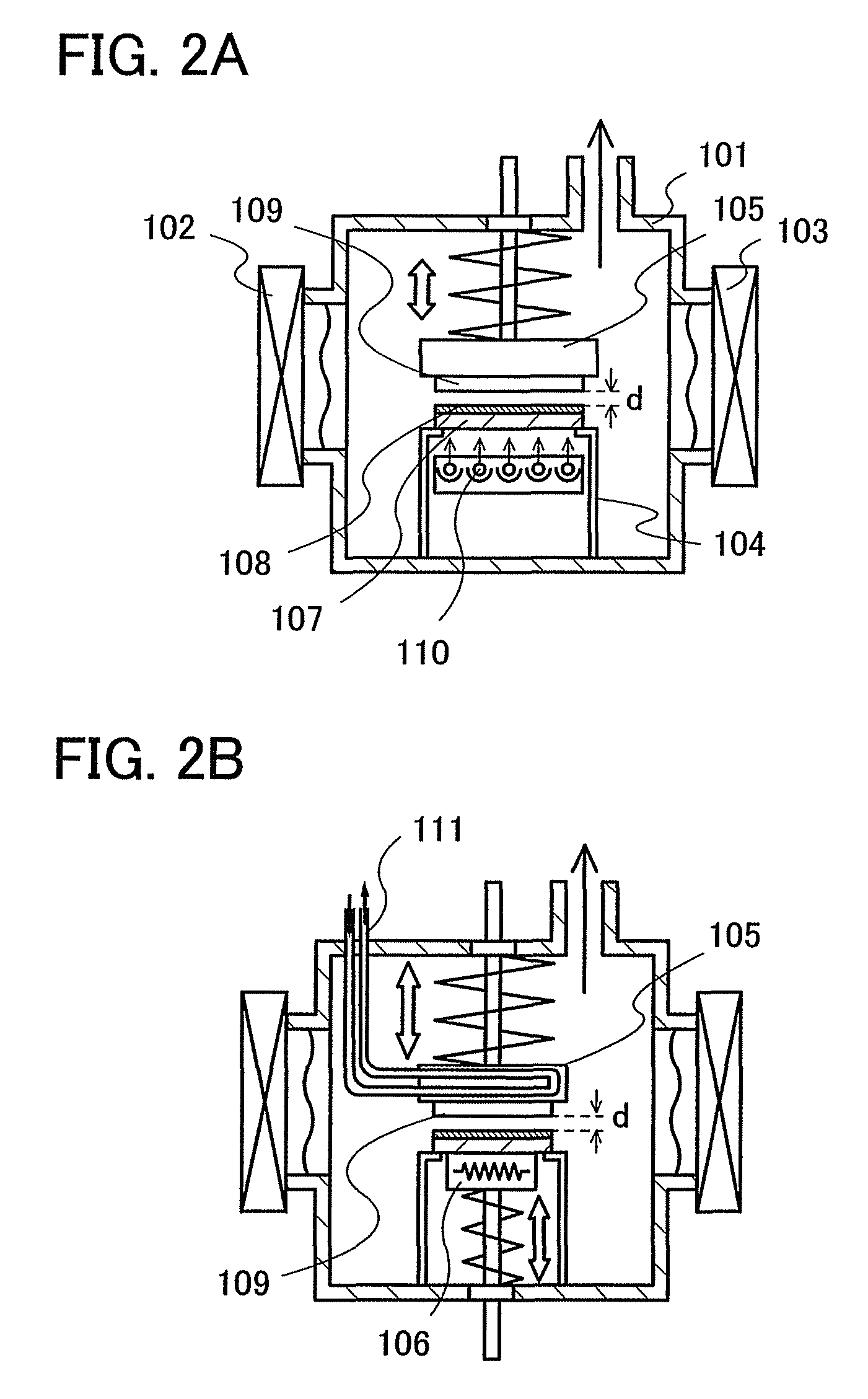

Film Formation Apparatus, Film Formation Method, Manufacturing Apparatus, and Method for Manufacturing Light-Emitting Device

InactiveUS20080260938A1Improve efficiencyImprove uniformityVacuum evaporation coatingSolid-state devicesEvaporationThermal radiation

An object is to improve use efficiency of an evaporation material, to reduce manufacturing cost of a light-emitting device, and to reduce manufacturing time needed for a light-emitting device including a layer containing an organic compound. The pressure of a film formation chamber is reduced, a plate is rapidly heated by heat conduction or heat radiation by using a heat source, a material layer on a plate is vaporized in a short time to be evaporated to a substrate on which the material layer is to be formed (formation substrate), and then the material layer is formed on the formation substrate. The area of the plate that is heated rapidly is set to have the same size as the formation substrate and film formation on the formation substrate is completed by one application of heat.

Owner:SEMICON ENERGY LAB CO LTD

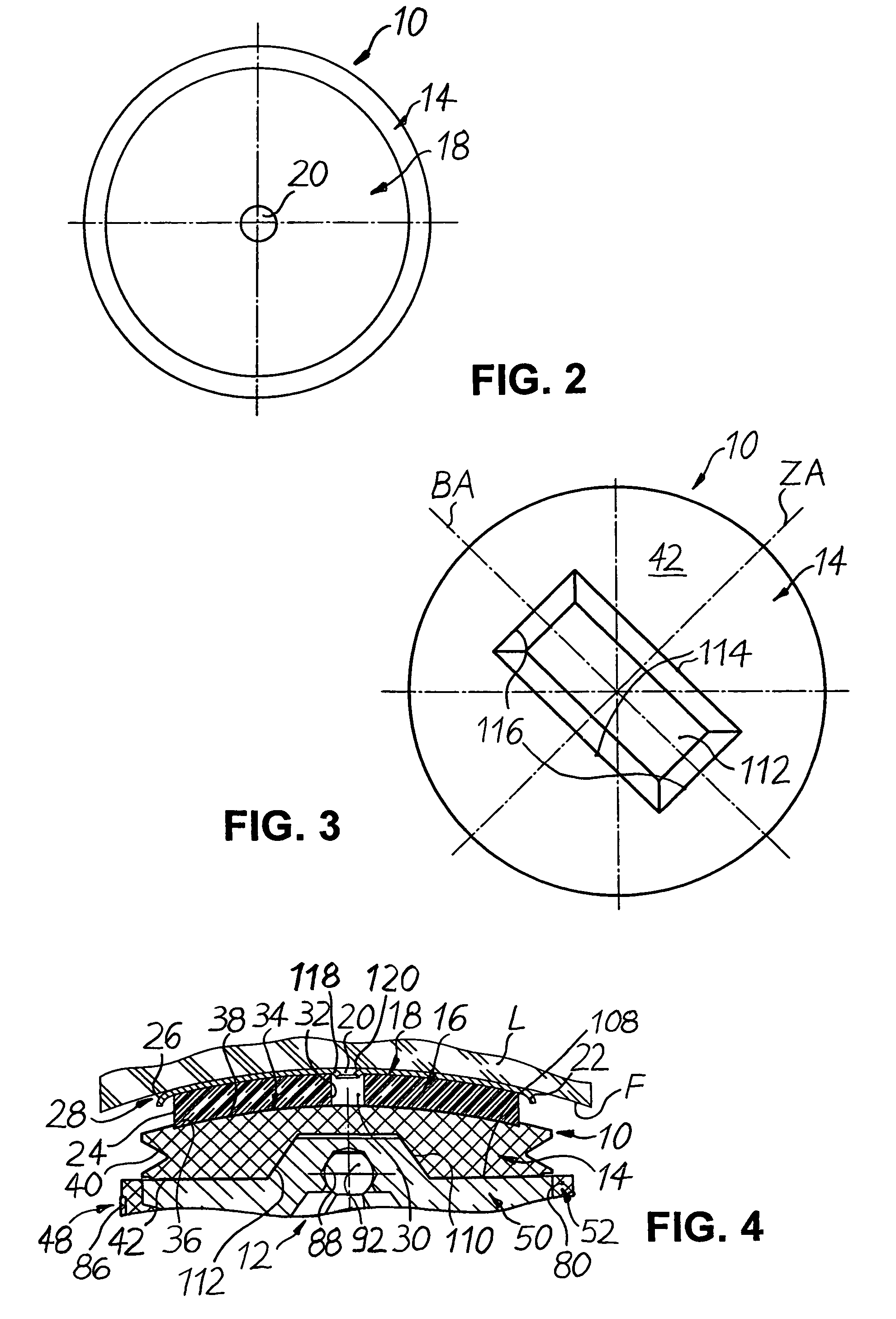

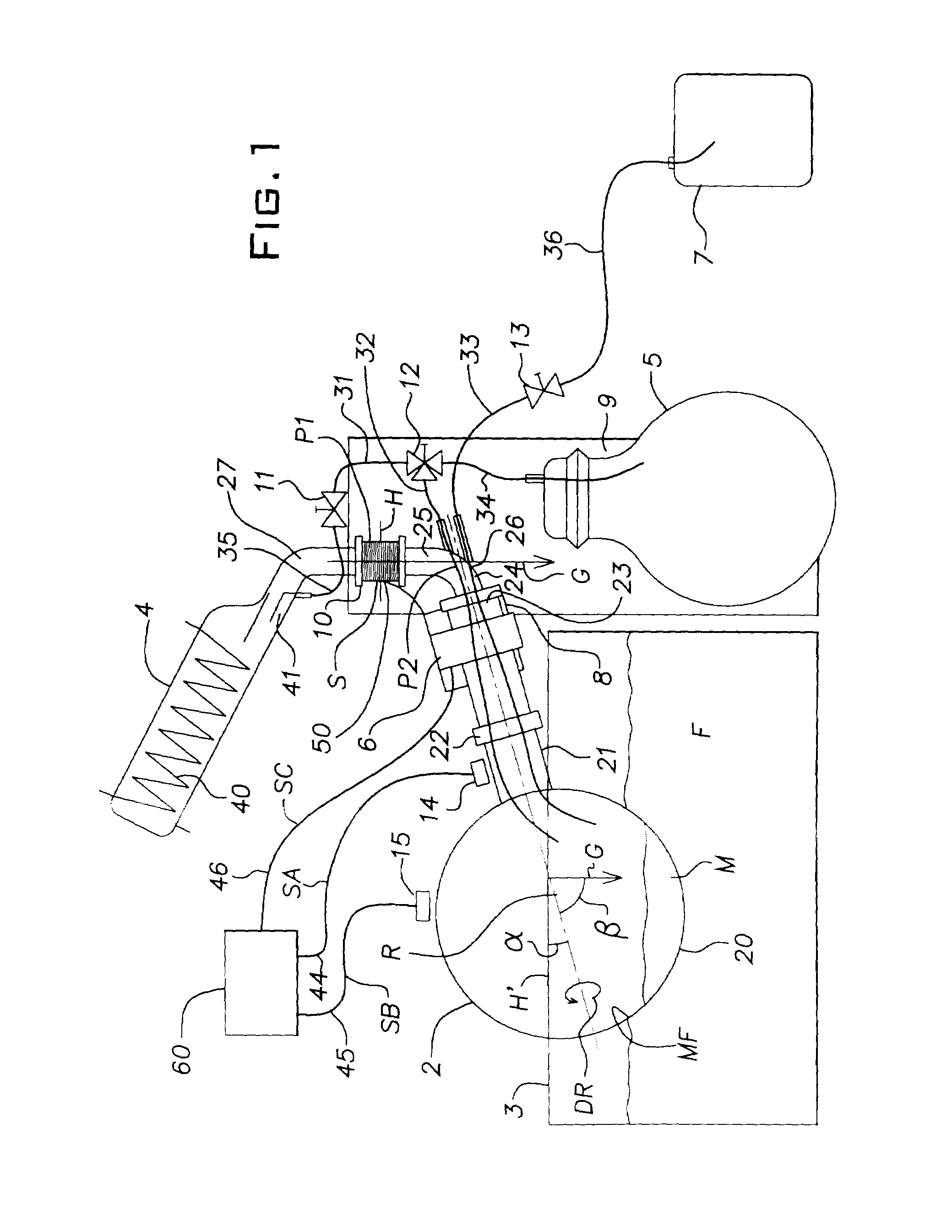

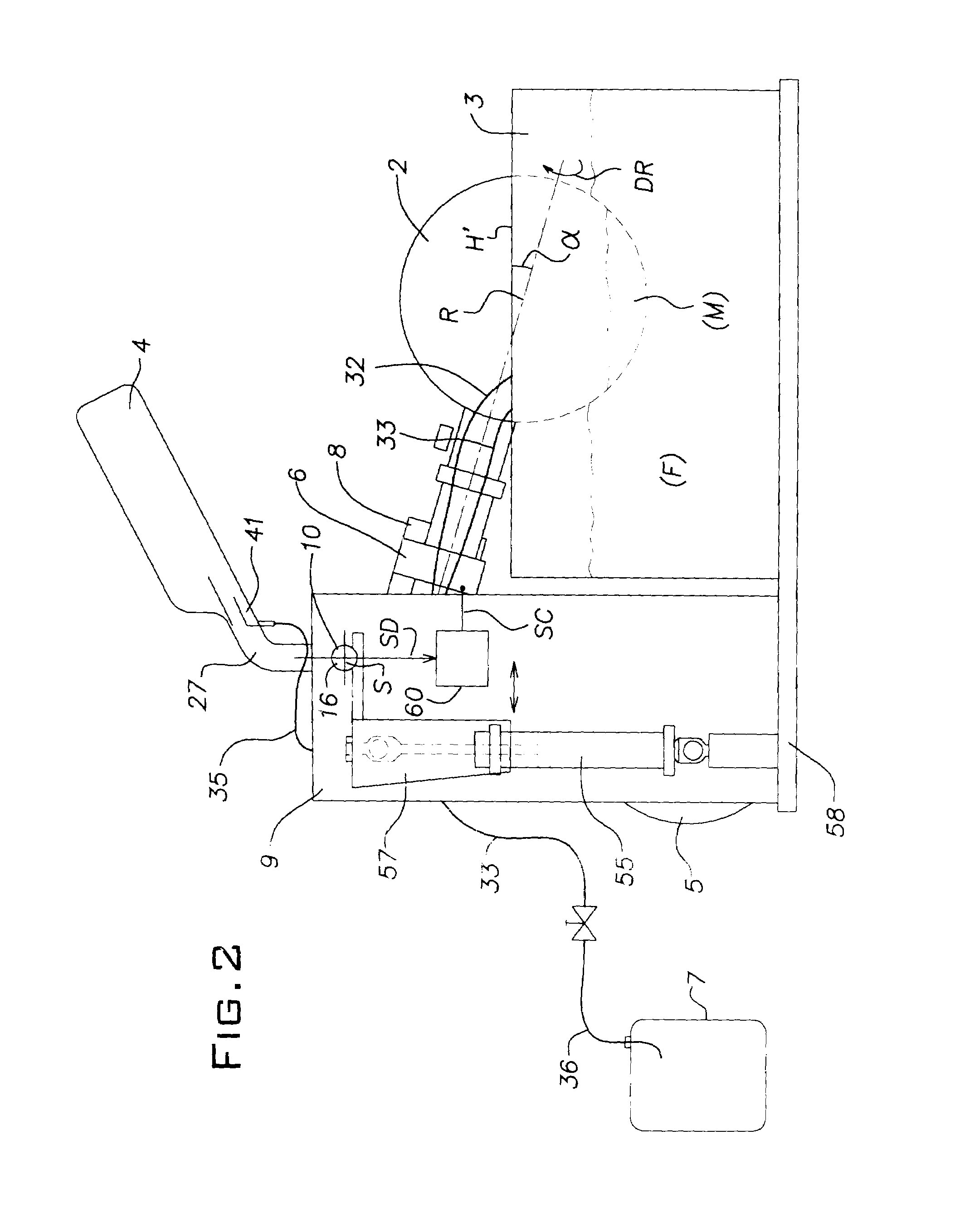

Polishing disk for a tool for the fine machining of optically active surfaces on spectacle lenses in particular

ActiveUS7278908B2Promote wettingUniform filmEdge grinding machinesPolishing machinesEngineeringHigh surface

A polishing disk for a tool for the fine machining of optically active surfaces on spectacle lenses in particular is disclosed, which comprises a support body, to which a foam layer is attached, wherein a polishing film bears against the foam layer. The polishing film is provided with at least one opening in a central region. During machining, the opening ensures pressure equalization and makes liquid polishing agent available from inside the foam layer, as a result of which better rinsing and cooling of otherwise disadvantaged regions of the polishing disk is achieved. As a result, a polishing disk of simple and cost-effective design is proposed, which is much more durable than the prior art while achieving high surface qualities.

Owner:SATISLOH GMBH

In situ polymerization for skin treatment

InactiveUS20090220436A1Long lastingResist of effectivenessCosmetic preparationsBiocideSkin treatmentsIn situ polymerization

Cosmetics represent a world-wide multi-billion dollar industry. The present invention provides technology for polymerizing monomers on skin in situ to produce desired skin characteristics. For example, the inventive system may be used to reduce the signs of aging or to protect the treated skin from UV light. The polymerization of monomers on skin is typically initiated using a thermal or photoinitiatied free radical initiator. In certain embodiments, the monomers are fluorinated thereby producing a fluorinated polymer on the skin upon polymerization. The invention provides monomers, initiators, methods, and kits for use in treating skin with polymers.

Owner:LIVING PROOF INC

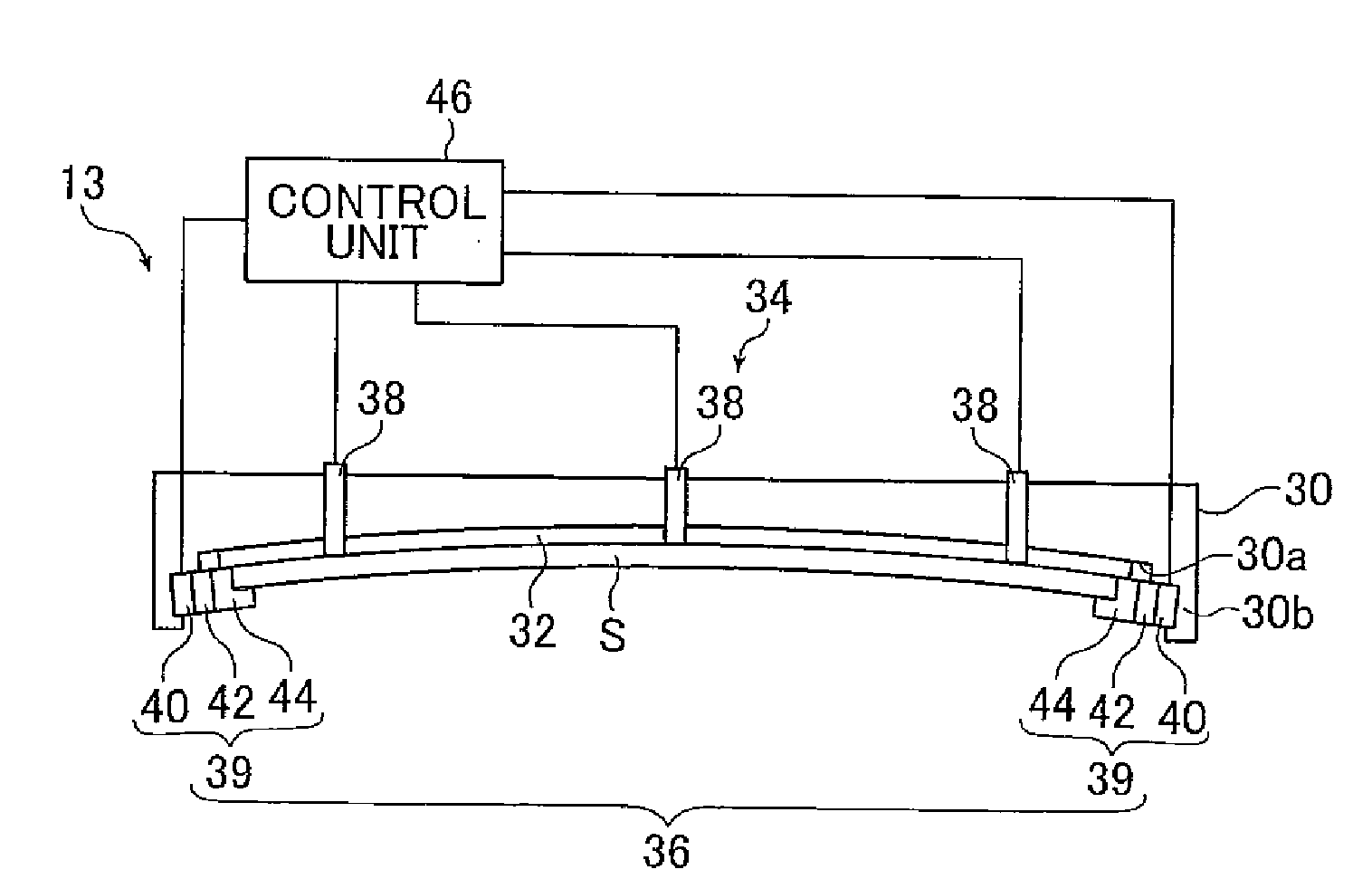

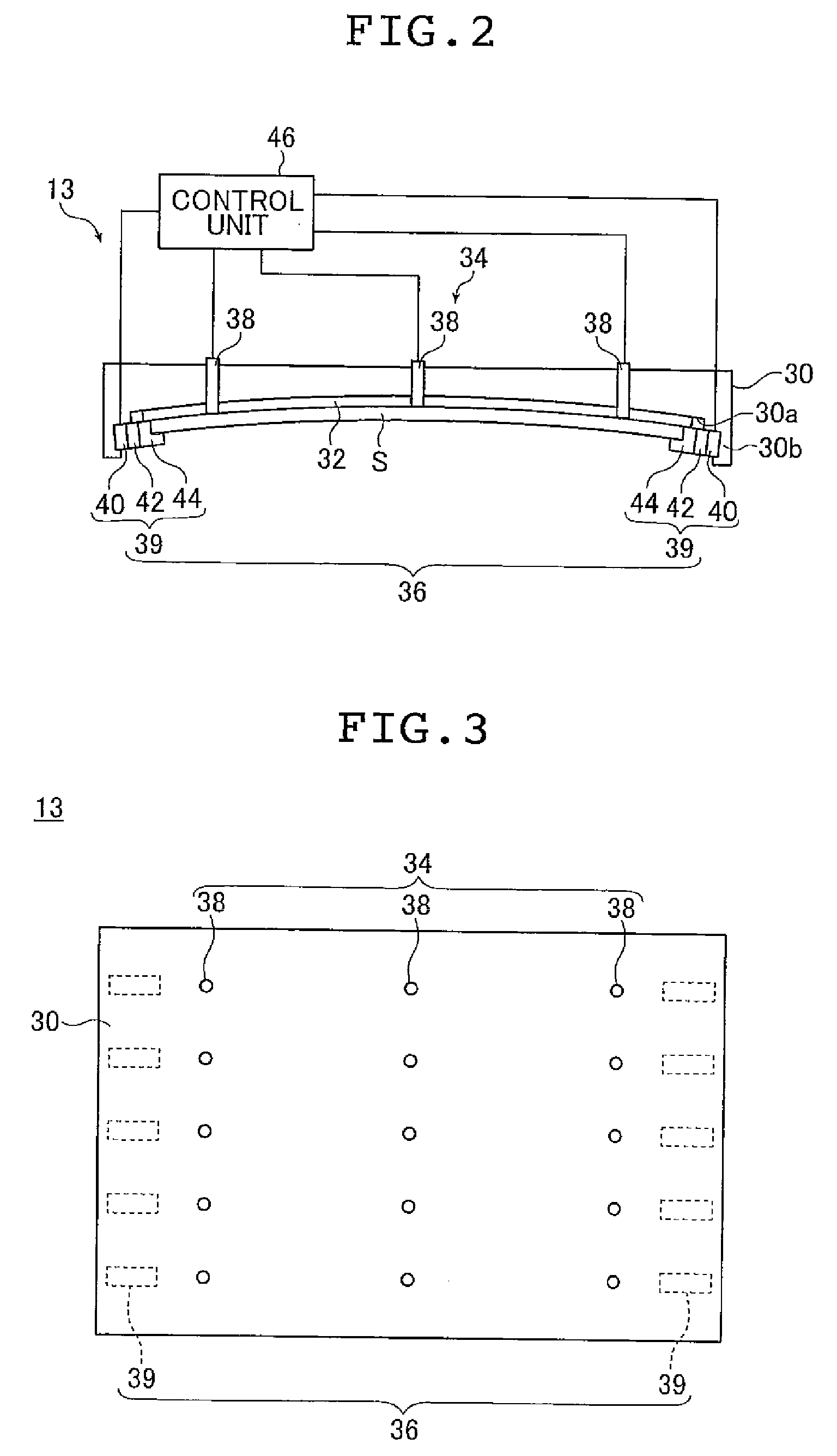

Substrate holder and vacuum film deposition apparatus

InactiveUS20090000552A1Uniform heat transferAvoid excessive loadsVacuum evaporation coatingSputtering coatingDeposition processSupport surface

A vacuum film deposition apparatus in which a film is formed on a substrate by a vacuum film deposition process includes a holder which has a substrate supporting surface which is in a curved shape and is brought into contact with the substrate. A substrate holder for holding the substrate includes a base having the substrate supporting surface. The apparatus and the substrate holder further include a contact detection mechanism which detects a state of contact between the substrate and the substrate supporting surface, a load applying mechanism which is provided outside the substrate supporting surface and supports the substrate by applying a load to end faces of the substrate and a control unit which controls the load the load applying mechanism applies to the substrate based on output from the contact detection mechanism.

Owner:FUJIFILM CORP

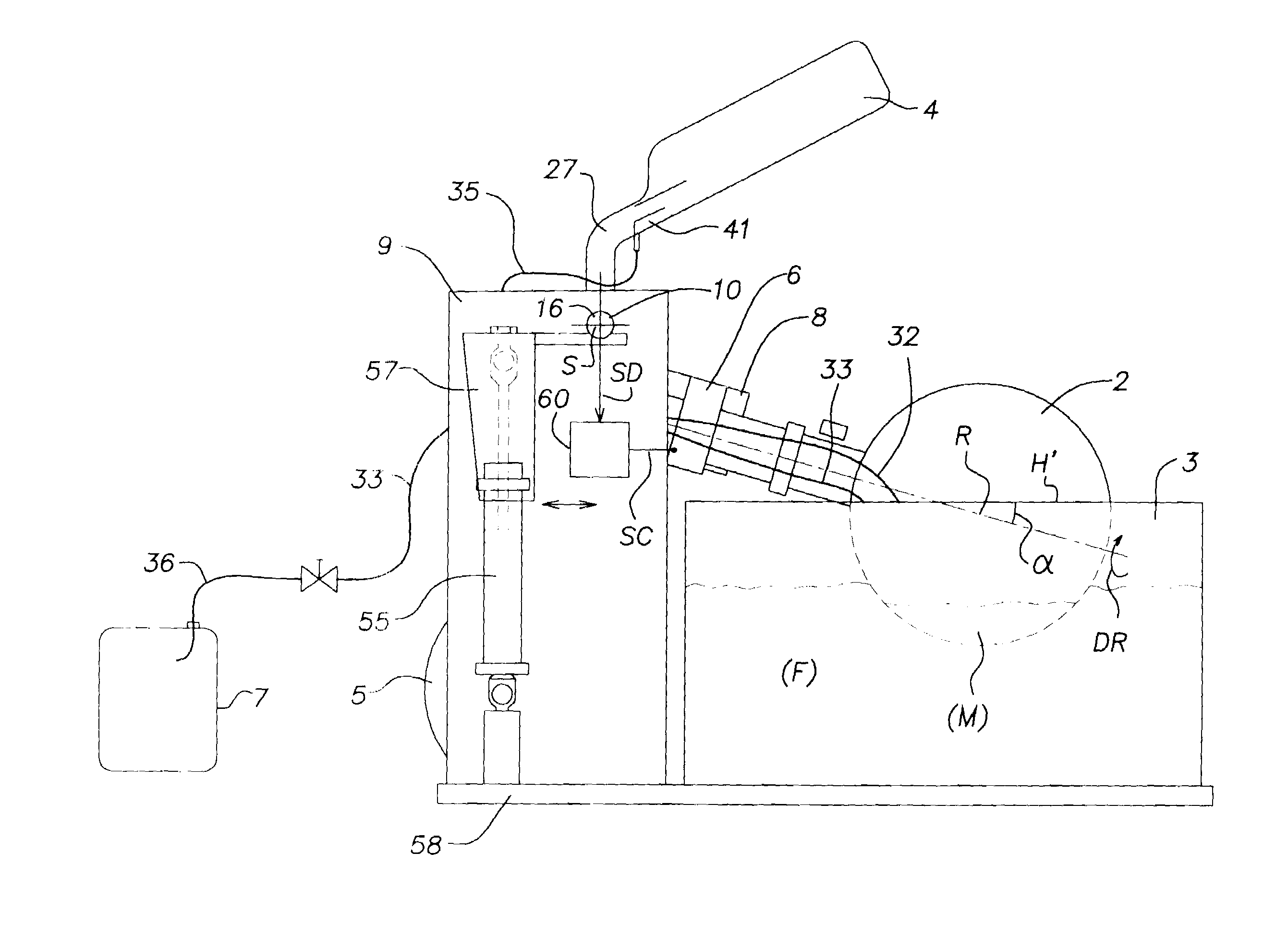

Rotating evaporator with process-dependent rotating speed regulation

InactiveUS7153396B2Enhance evaporation from surfaceUniform filmDistillation regulation/controlSpecific gravity using centrifugal effectsRotary evaporatorRotation velocity

In a rotary evaporator, the rotating speed of the rotating flask is automatically controlled or regulated dependent upon a detected process value, particularly the vibration behavior or the mass moment of inertia of the rotating flask.

Owner:GENSER HANS GEORG

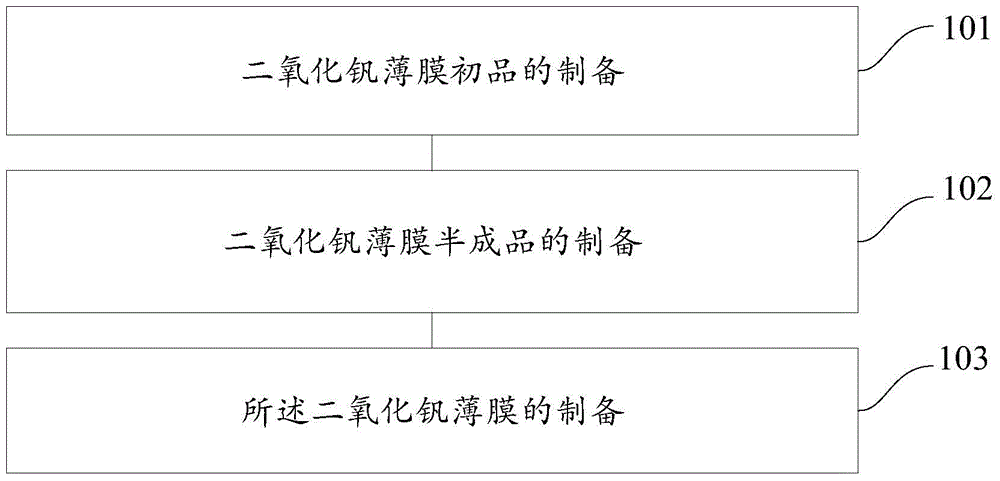

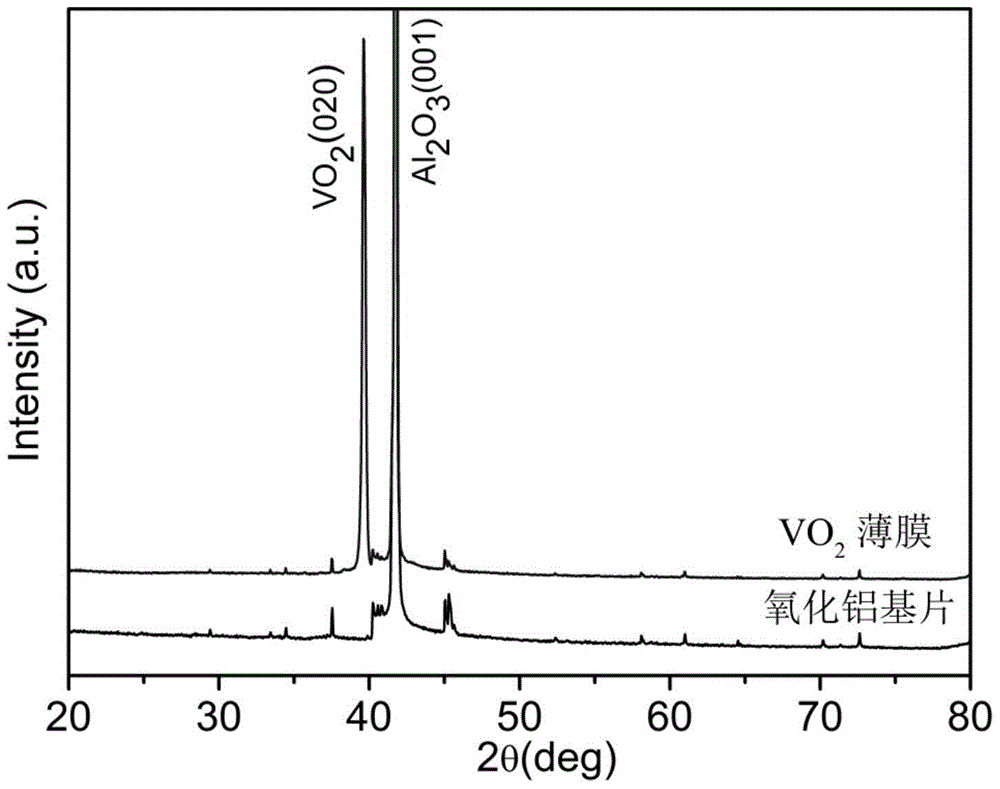

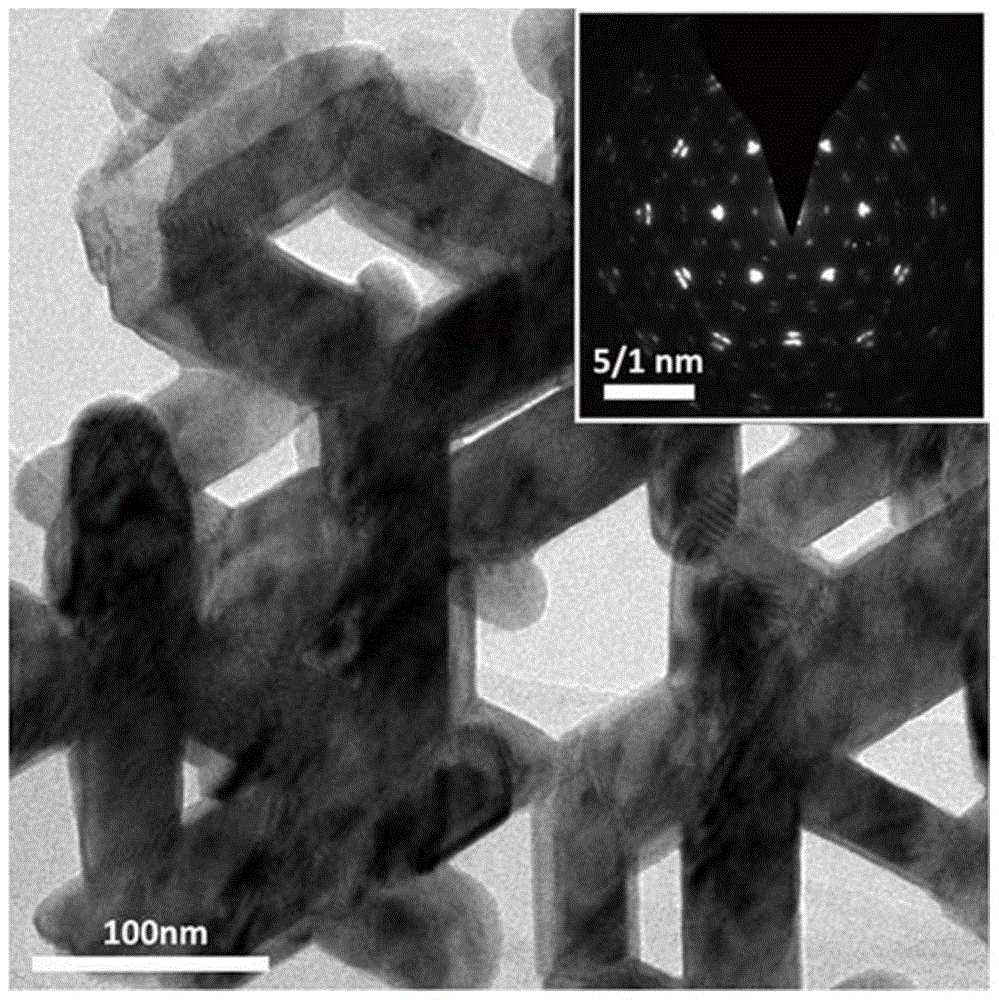

Vanadium dioxide thin film having regular truss network structure and preparation method thereof

InactiveCN105669248AUniform filmExcellent thermally induced phase change performanceChemistryTransmittance

The invention provides a vanadium dioxide thin film having a regular truss network structure and a preparation method thereof. The vanadium oxide thin film is an M phase and has the regular truss network structure formed by uniformly connecting nanorods, wherein the nanorods are each of a monocrystal structure, the length of crystal grains is 200-500 nm and the width of the crystal grains is 30-60 nm. The method includes the steps: step (1), preparation of an initial product of the vanadium dioxide thin film; step (2), preparation of a semi-finished product of the vanadium dioxide thin film, and step (3), preparation of the vanadium oxide thin film. The vanadium dioxide thin film prepared by the method provided by the embodiment of the invention has excellent thermal induced phase transition performance and excellent heat induced resistance modulation capability, and also has relatively high visible light transmittance rate and relatively strong thermal radiation modulation performance. At the same time, the thin film morphology, size and density are effectively controlled through controlling reaction conditions, and the preparation method has the advantages of simple process, large-area production, easily obtained raw materials, low cost and the like and is suitable for use in industrialization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

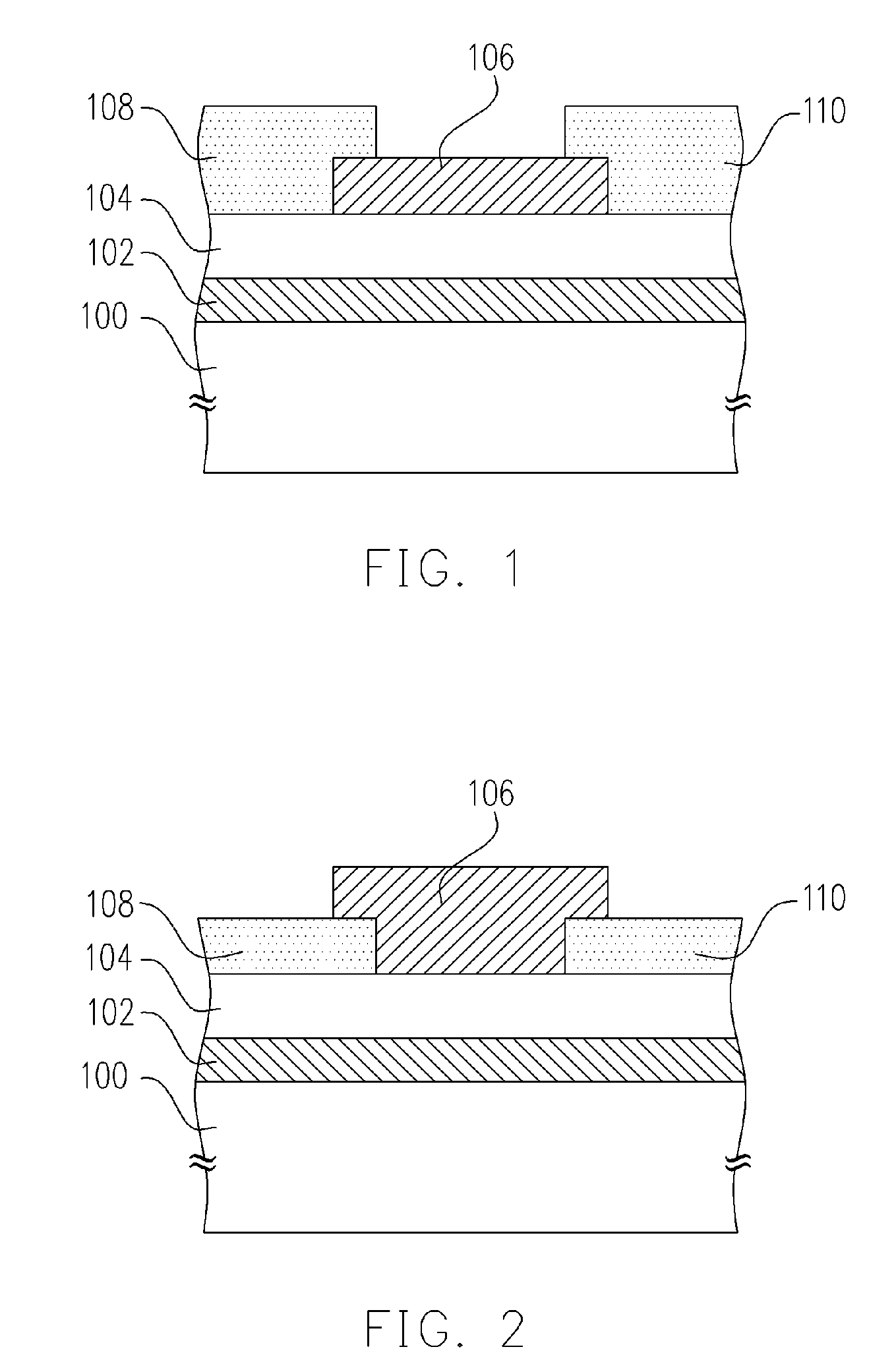

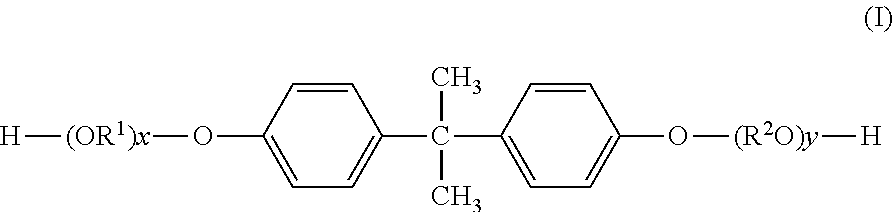

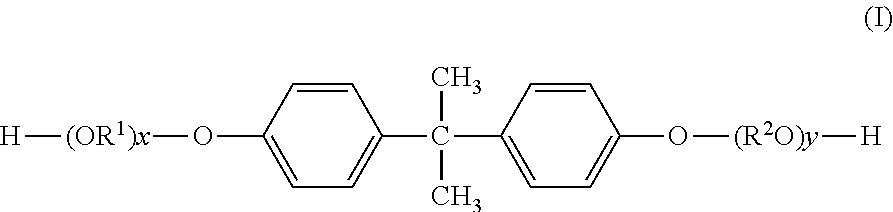

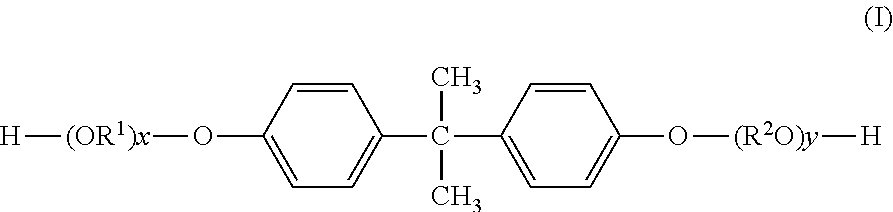

Dielectric layer, composition and method for forming the same

InactiveUS20070172583A1Improve surface roughnessReduce leakage currentSolid-state devicesPretreated surfacesPhotosensitive polymerSolvent

A composition for forming a dielectric layer includes a liquid organometallic compound serving as a precursor with high dielectric constant, a photo-sensitive polymer or a non-photo-sensitive polymer and a solvent, wherein the liquid organometallic compound includes metal alkoxide, and the metal of the metal alkoxide includes Al Ti, Zr, Ta, Si, Ba, Ge and Hf. The dielectric layer formed by the composition includes the photo-sensitive polymer or the non-photo-sensitive polymer and an amorphous metal oxide formed therein.

Owner:IND TECH RES INST

Film formation apparatus, film formation method, manufacturing apparatus, and method for manufacturing light-emitting device

InactiveUS8313603B2Improve efficiencyImprove uniformityLamination ancillary operationsDecorative surface effectsSimple Organic CompoundsEvaporation

An object is to improve use efficiency of an evaporation material, to reduce manufacturing cost of a light-emitting device, and to reduce manufacturing time needed for a light-emitting device including a layer containing an organic compound. The pressure of a film formation chamber is reduced, a plate is rapidly heated by heat conduction or heat radiation by using a heat source, a material layer on a plate is vaporized in a short time to be evaporated to a substrate on which the material layer is to be formed (formation substrate), and then the material layer is formed on the formation substrate. The area of the plate that is heated rapidly is set to have the same size as the formation substrate and film formation on the formation substrate is completed by one application of heat.

Owner:SEMICON ENERGY LAB CO LTD

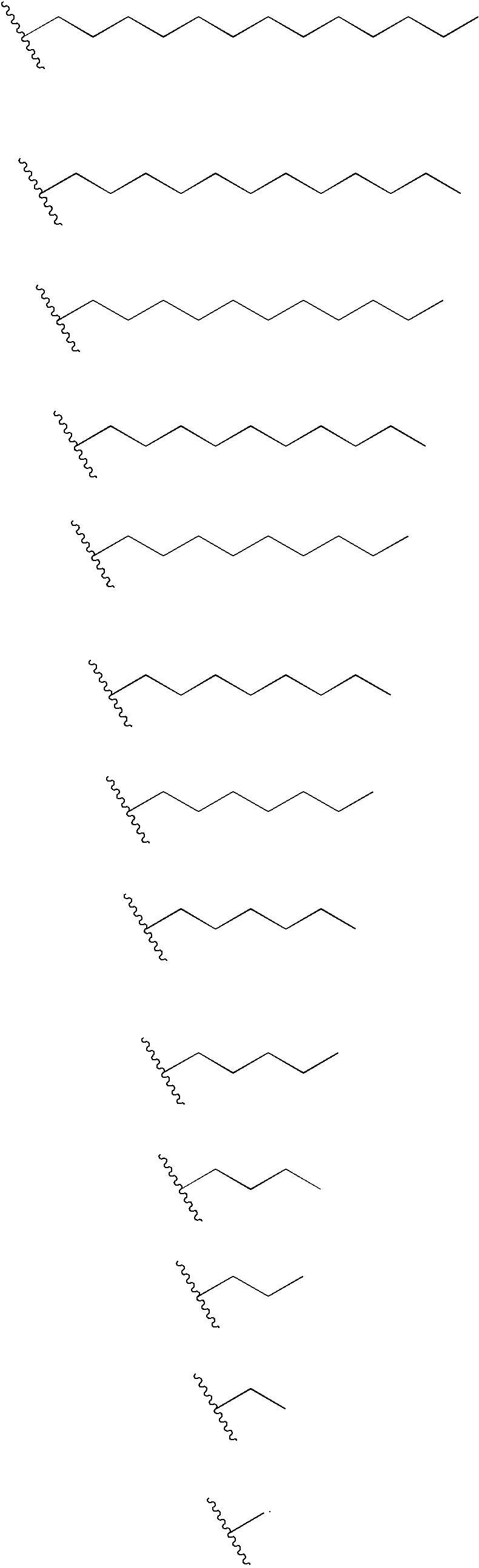

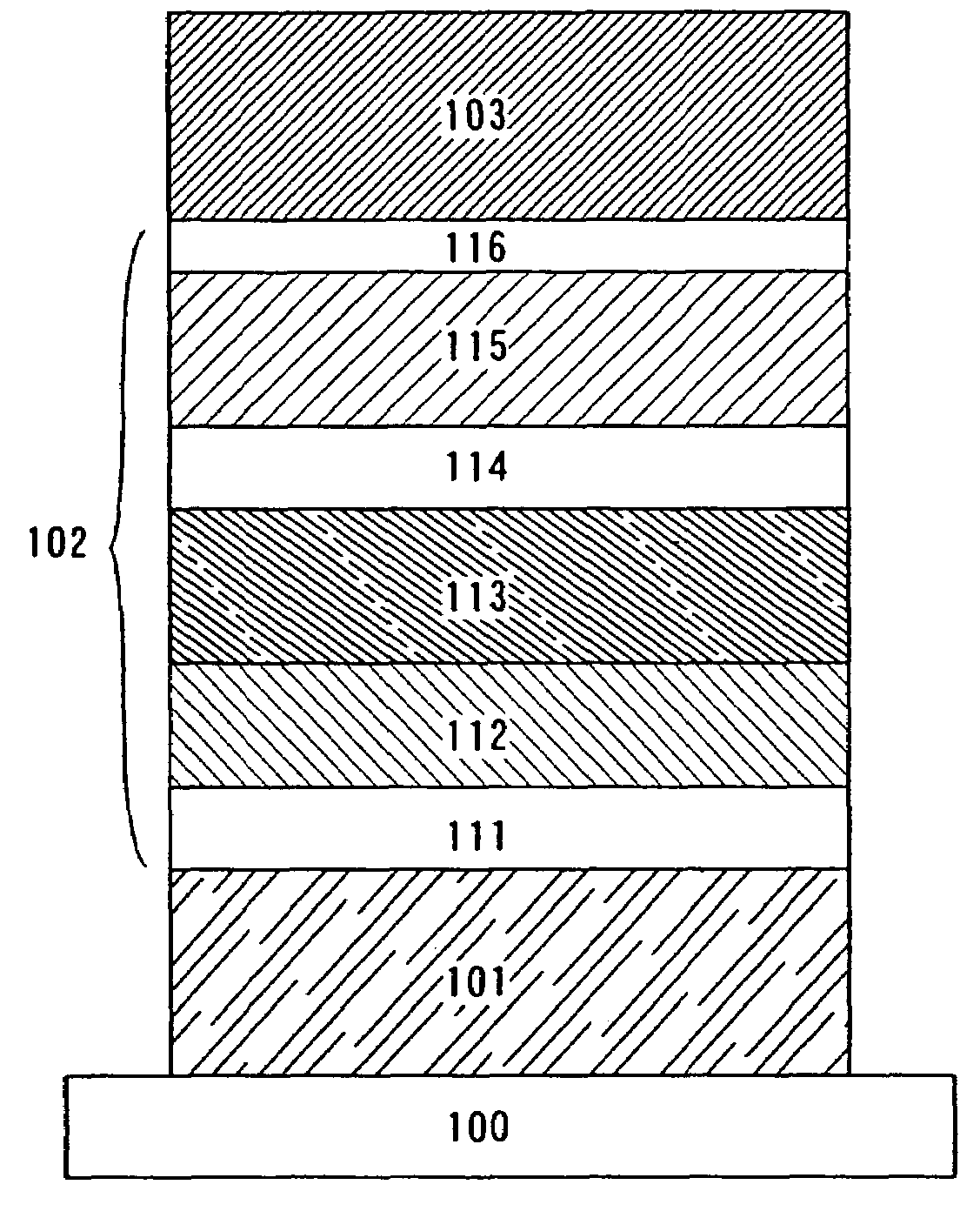

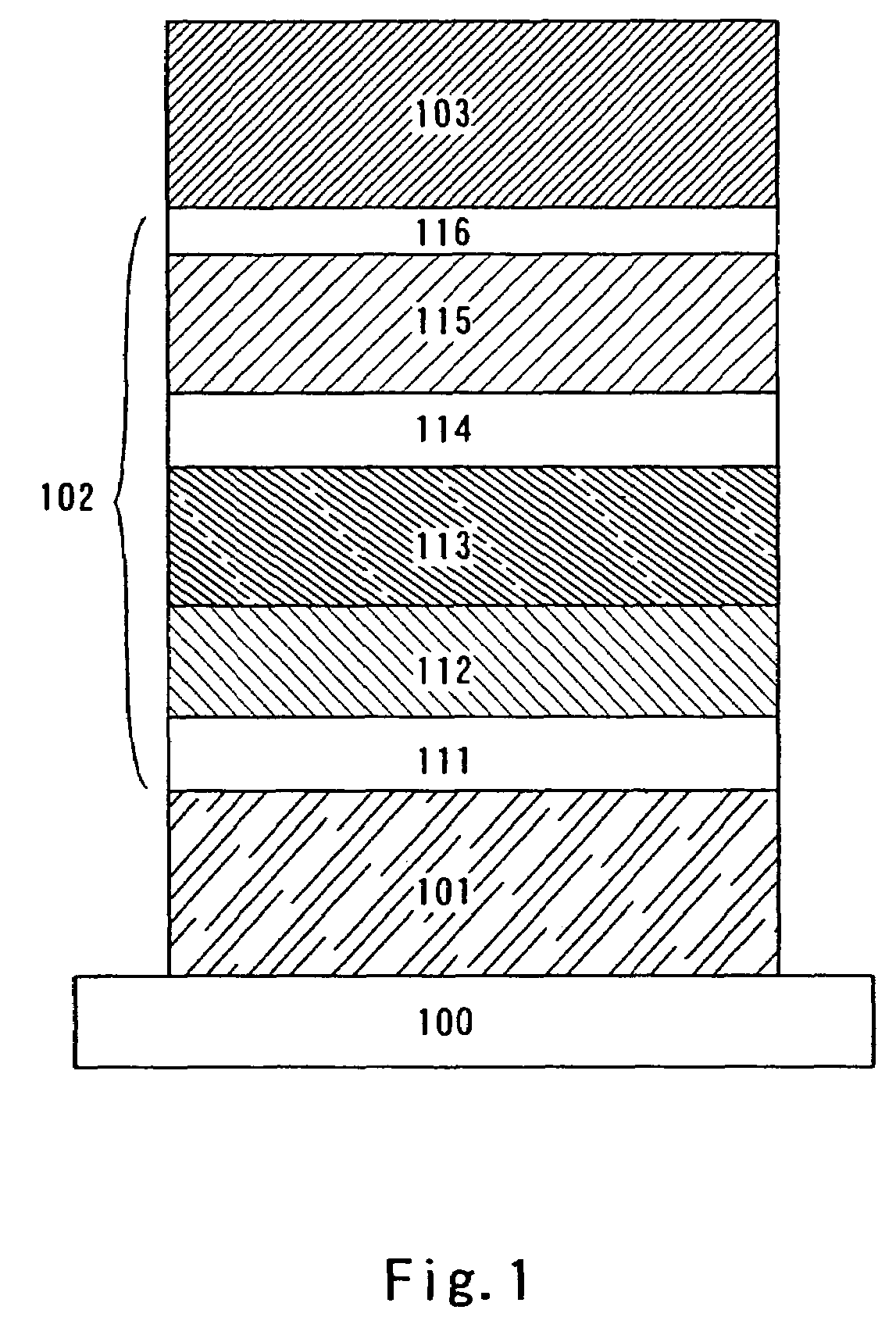

Pyrene derivative, light emitting element, and light emitting device

InactiveUS7232619B2Uniform filmHigh-efficiency luminescenceOrganic chemistryDischarge tube luminescnet screensLight emitting deviceLight-emitting diode

It is an object of the present invention to provide a pyrene derivative represented by the general formula (1) that is unlikely to crystallize and is superior in quality in the case of forming a film

Owner:SEMICON ENERGY LAB CO LTD

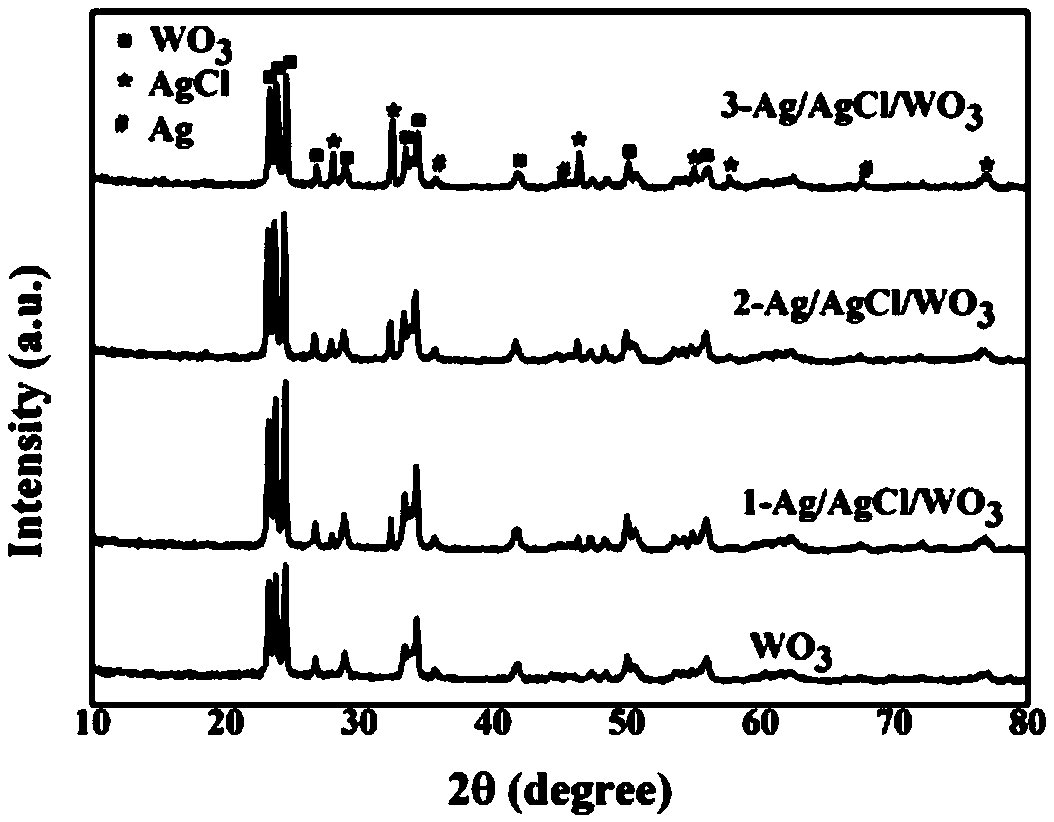

Preparation method of WO3/Ag/AgCl photocatalytic thin film material

PendingCN110732330AUniform filmGood transparencyPhysical/chemical process catalystsWater/sewage treatment by irradiationThin membraneChemistry

The invention discloses a preparation method of a WO3 / Ag / AgCl photocatalytic thin film material. According to the method, with tungstic acid as a precursor, hydrogen peroxide as a solvent and polyvinyl alcohol as an adhesive, the three components are mutually dissolved to form slurry; spin coating and high-temperature treatment technologies are adopted, a WO3 thin film is prepared on the surface of a glass substrate, the WO3 thin film material is repeatedly soaked in NaCl and AgNO3 solutions with the same concentration in sequence, drying is carried out to obtain a WO3 / AgCl thin film, and finally the thin film is illuminated to obtain the WO3 / Ag / AgCl photocatalytic thin film material. The WO3 / Ag / AgCl thin film material prepared by the method disclosed by the invention can overcome the defect that a traditional powder material is difficult to separate and recover, is good in repeatability, simple in preparation process, low in cost and relatively stable in photocatalytic performance, and is expected to be applied to the fields of sterilization, gas sensors and the like.

Owner:NANJING UNIV OF SCI & TECH

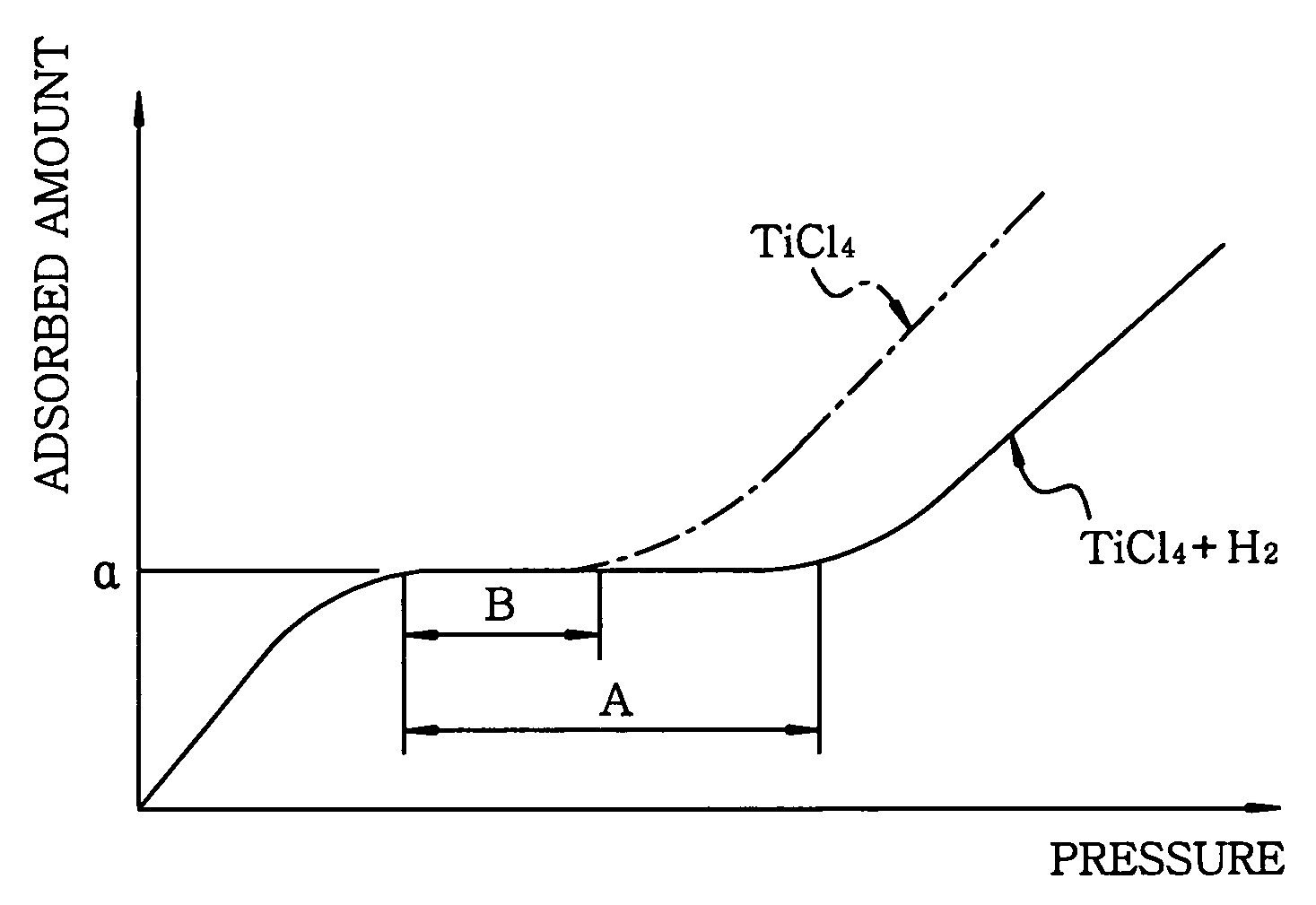

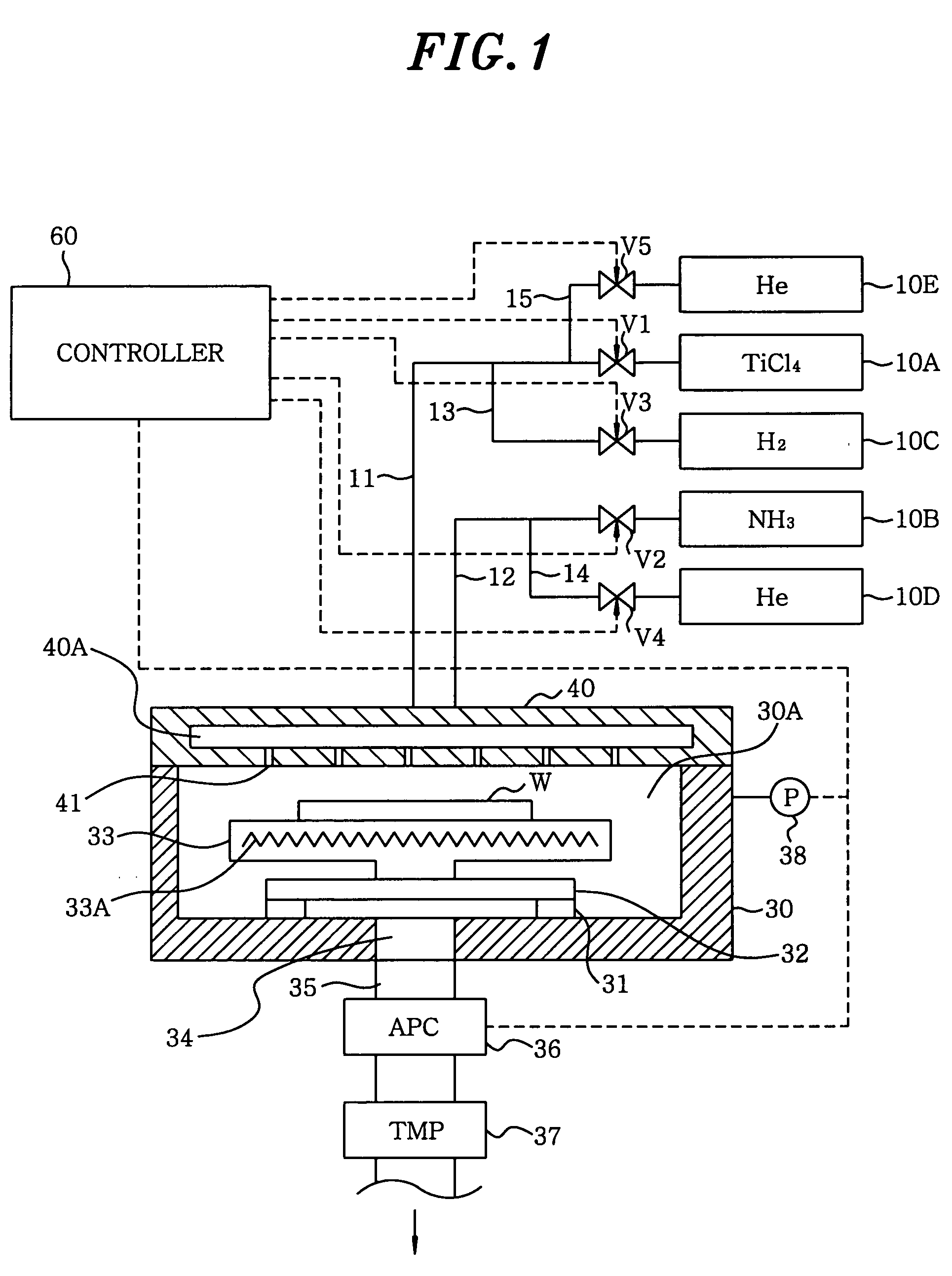

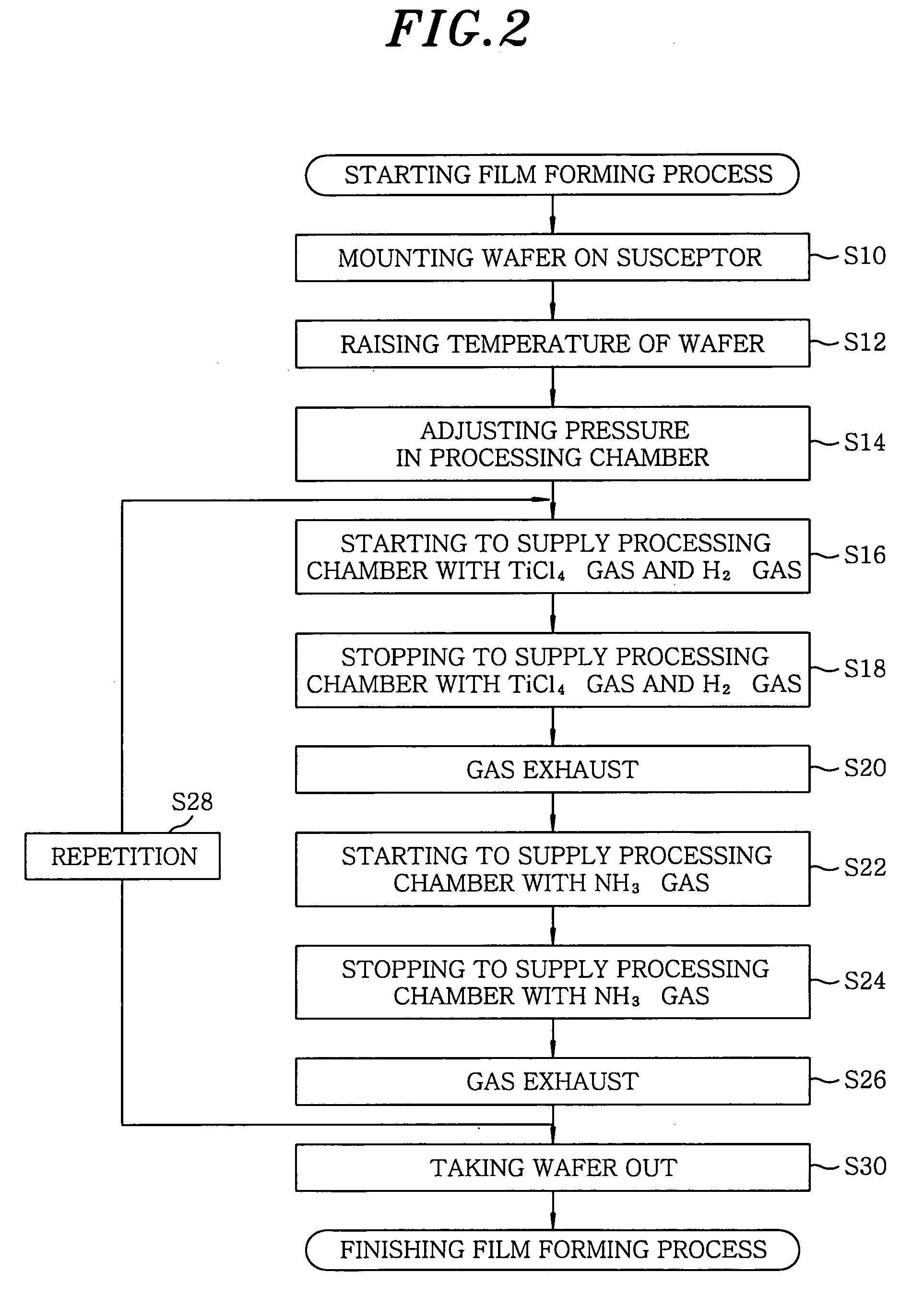

Method of Forming Thin Film, Thin Film Forming Apparatus, Program and Computer-Readable Information Recording Medium

InactiveUS20080241385A1Increase ratingsIncrease adsorption densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyPhysical chemistry

A method of rapidly forming a thin film of high quality through film formation by alternate feeding of raw gases. In particular, a method of forming a TiN thin film, comprising repeating operations including causing TiCl4 gas as a raw gas to be adsorbed on a substrate or TiCl4 molecules adsorbed on a substrate and feeding NH3 gas as a reactant gas in a treating chamber so as to effect reaction of TiCl4 and NH3 leading to formation of a TiN film, which method further comprises an operation of, prior to the adsorption of TiCl4 gas on the substrate, feeding reducing H2 gas in the treating chamber (30) so as to change TiCl4 to a state of enhanced likelihood of adsorption on the substrate (e.g., TiCl3).

Owner:TOKYO ELECTRON LTD

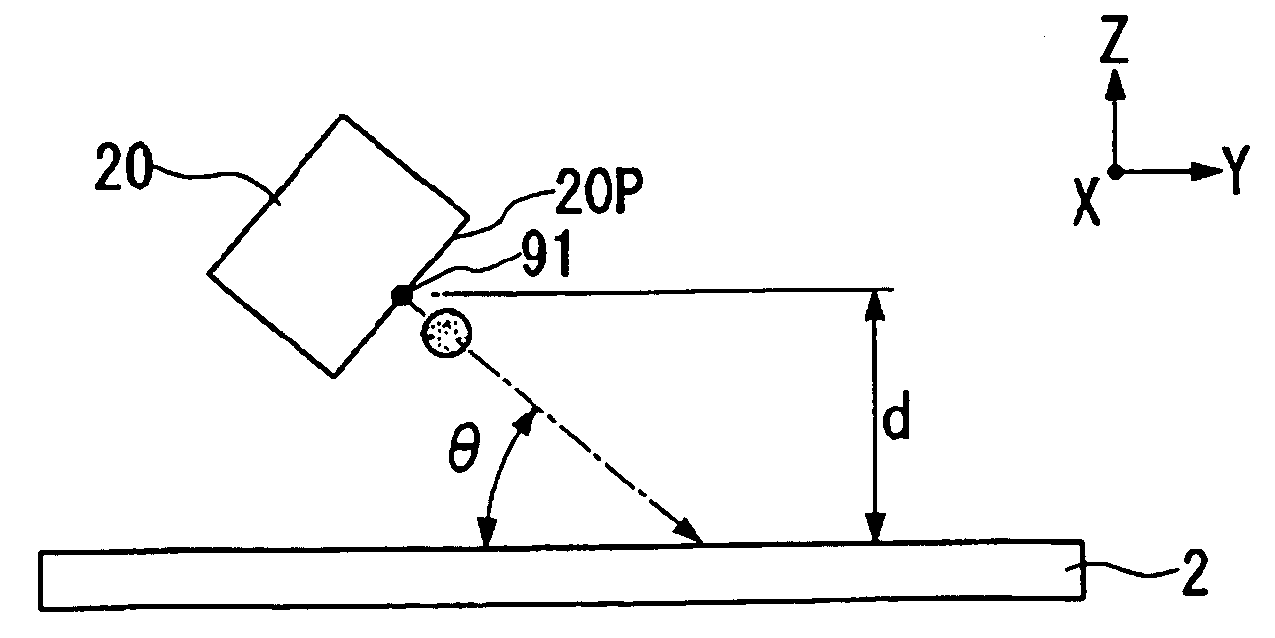

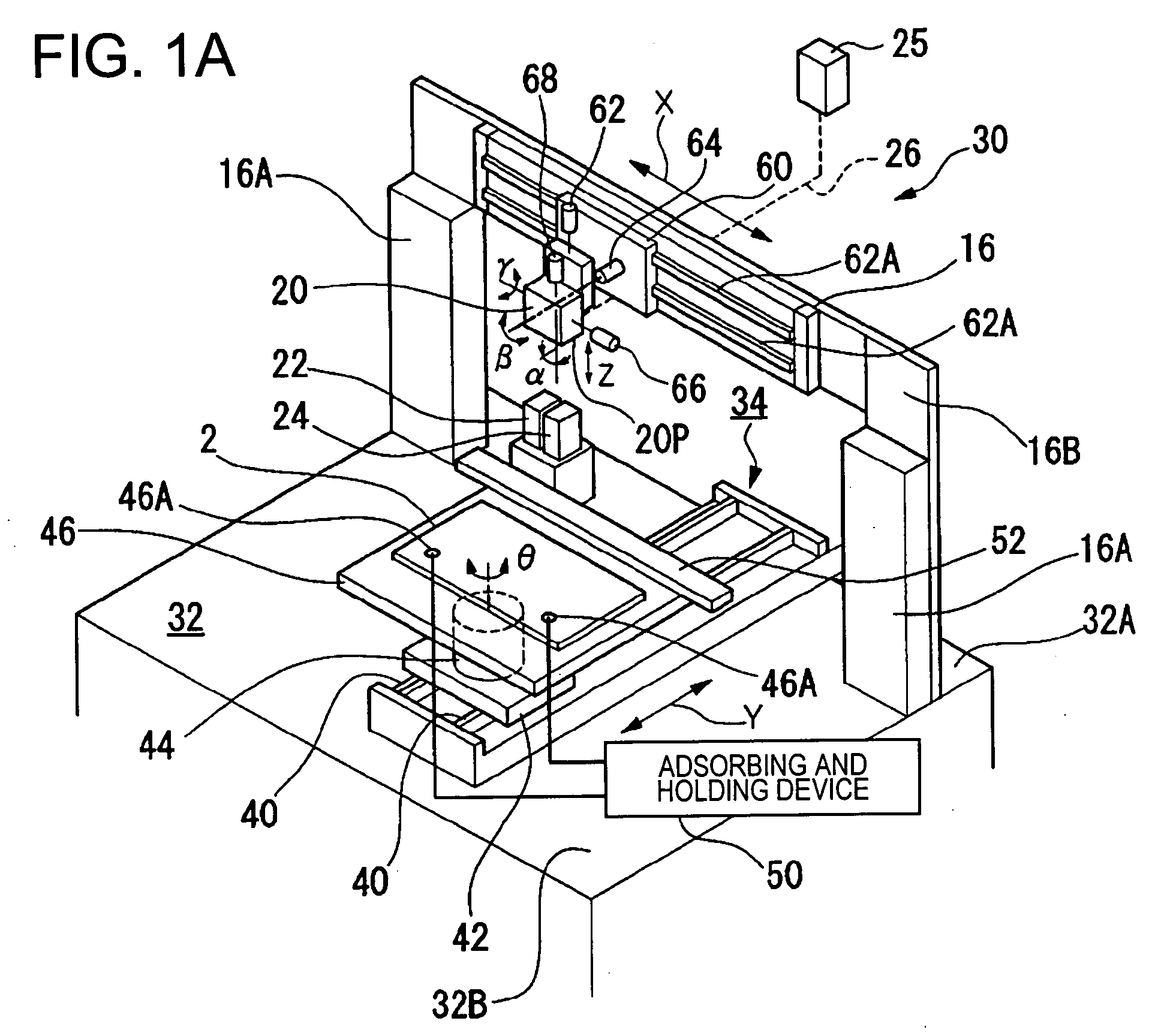

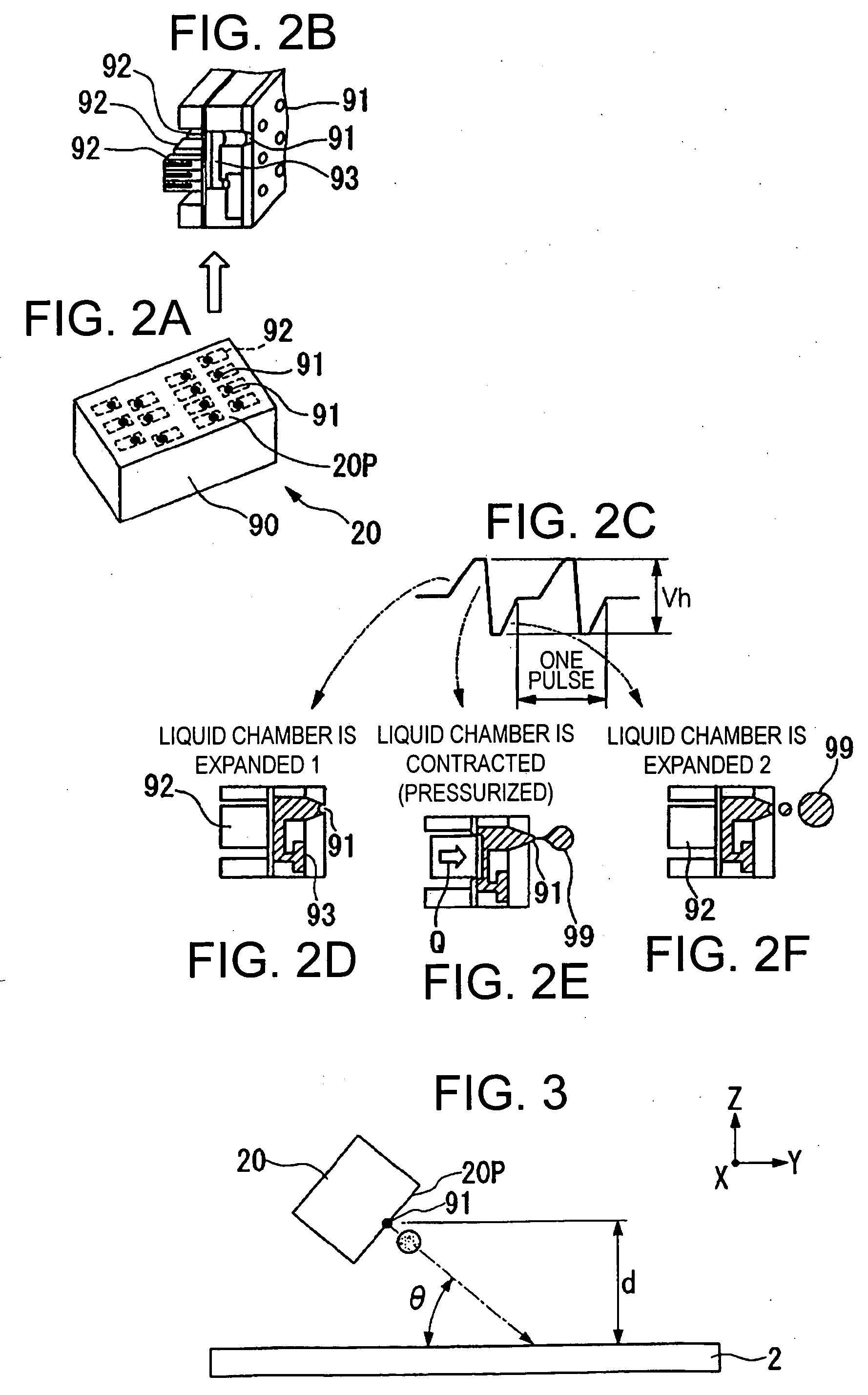

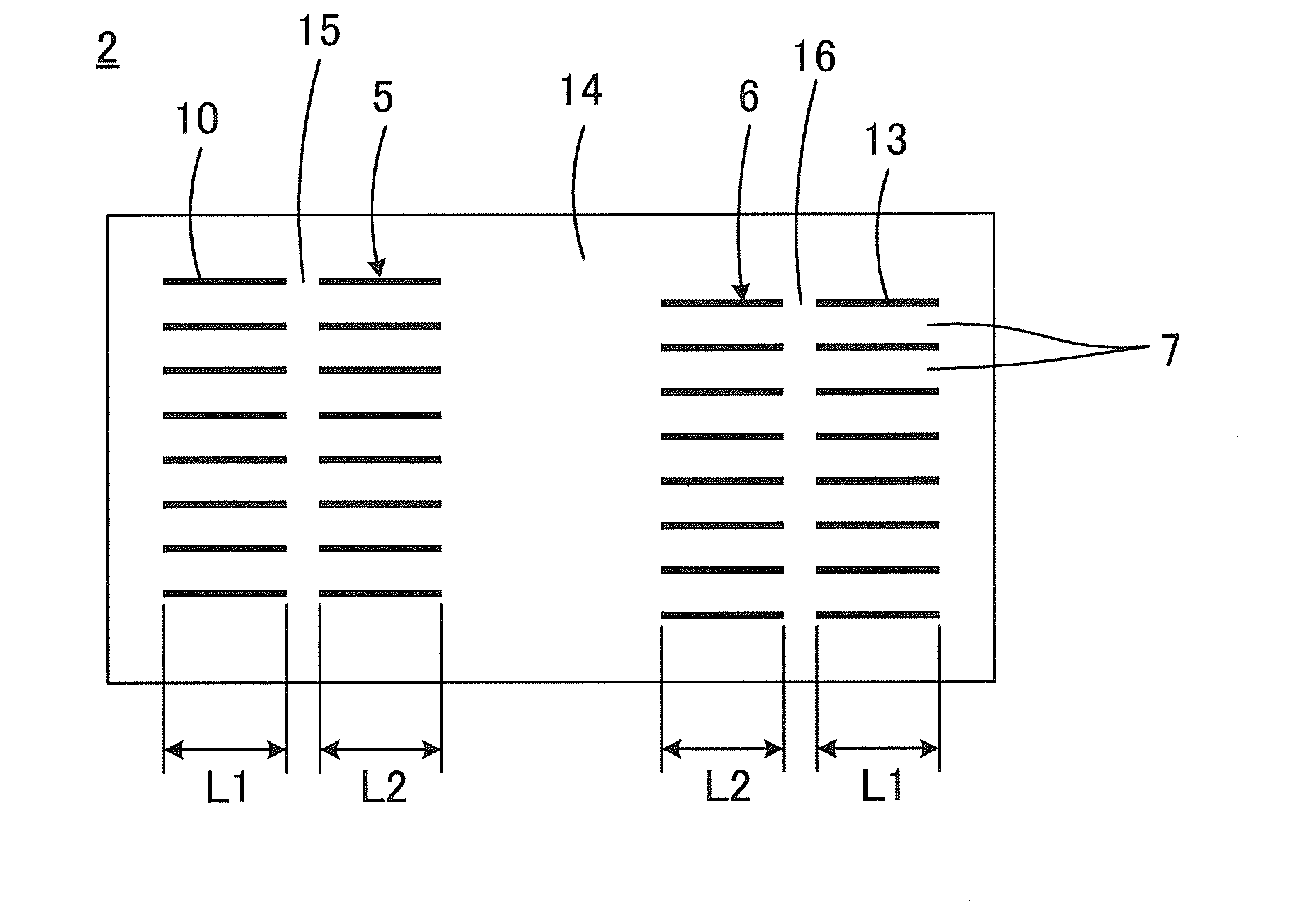

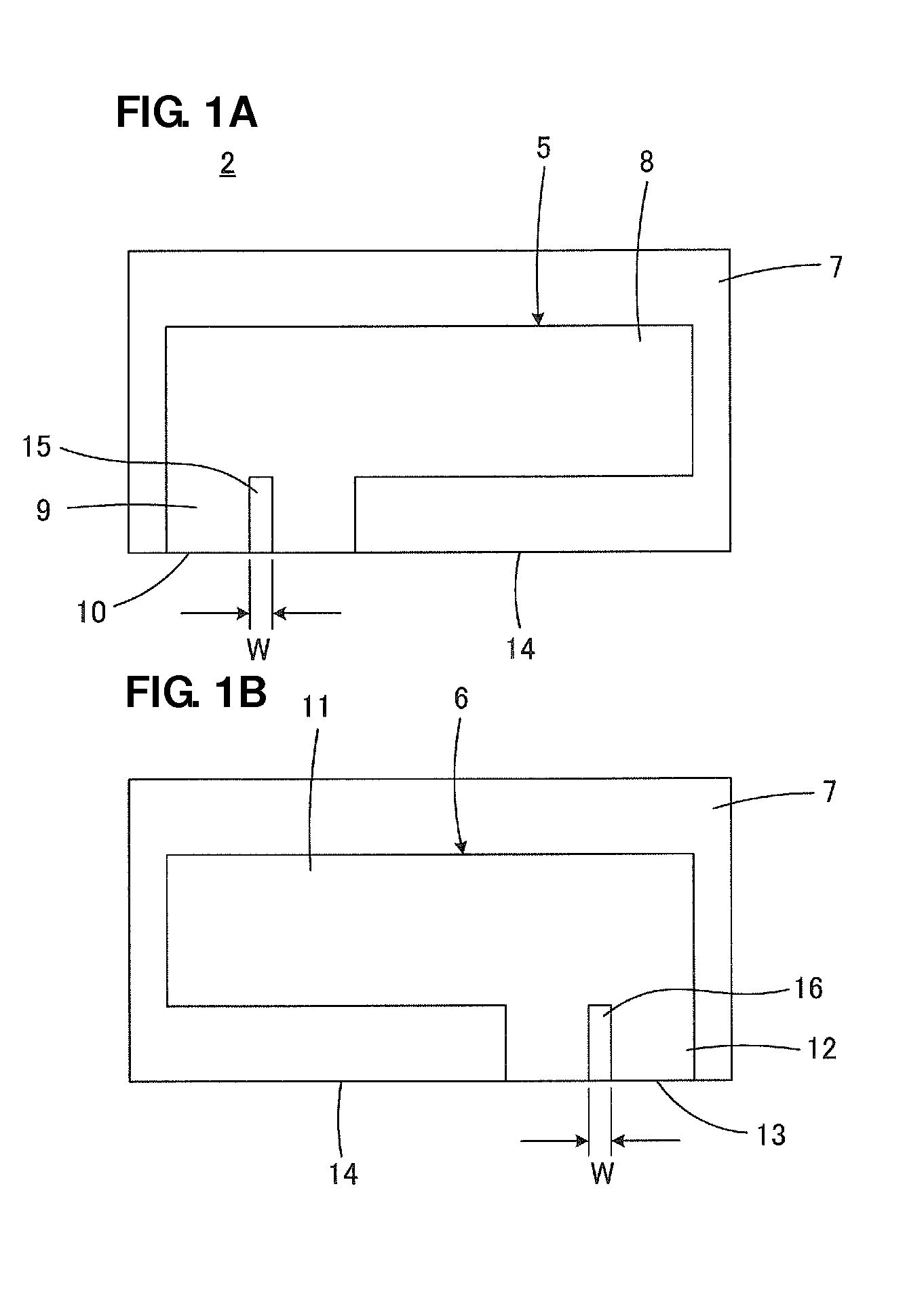

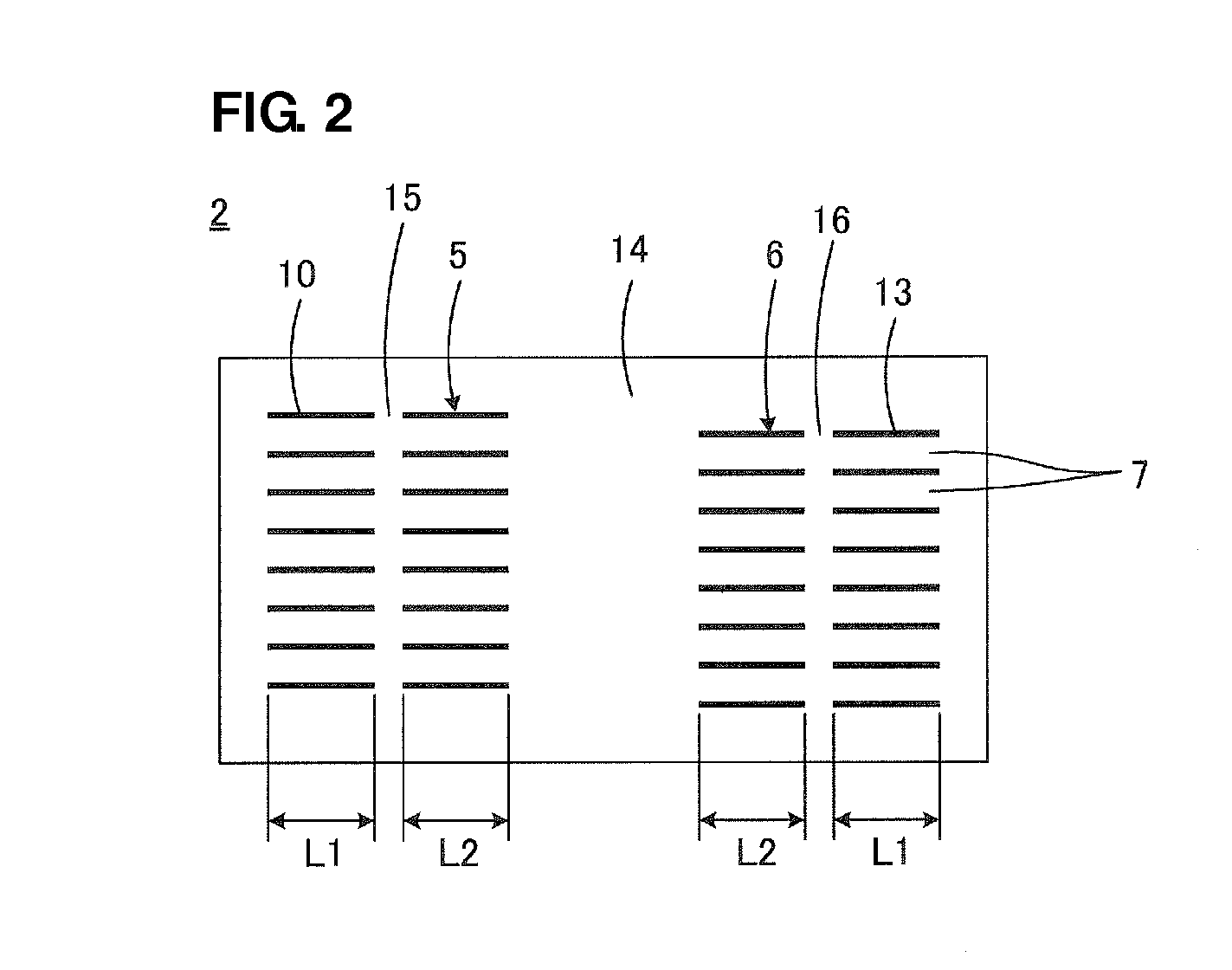

Droplet applying method and droplet applying device, and device and electronic equipment

InactiveUS20050104912A1Less irregularityUniform filmLiquid surface applicatorsSolid-state devicesEngineeringElectron

Exemplary embodiments enable formation of a uniform film and a pattern with a minute line width and generate no or substantially no quality defects, such as disconnection. A droplet is discharged from a droplet discharging head to apply in a predetermined region on a surface of a substrate while relatively moving the droplet discharging head and the substrate. The droplet is discharged with respect to the surface of the substrate in a direction intersecting with a vertical direction, and when relatively moving the droplet discharging head and the substrate to discharge the droplet, the droplet is discharged along the relative movement direction.

Owner:SEIKO EPSON CORP

Tin plating method for metal surface

InactiveCN110735132AUniform filmLight levelingLiquid/solution decomposition chemical coatingChemical reactionThiourea

The invention relates to a tin plating method for a metal surface. The method comprises the following steps: enabling a tin-free part to be in contact with a repairing solution for chemical reaction,wherein the heating temperature during chemical reaction is 30-40 DEG C; and washing and drying after the tin-free part is reacted with the repairing solution, wherein the solute of the repairing solution is tin sulfate, thiourea and sodium chloride, and the solvent of the repairing solution is water. The novel method for realizing rapid tin plating is uniform in film formation, smooth in light quantity and good in conductivity.

Owner:BEIJING SHUGUANG AERO ELECTRICAL

Laminate type electronic component and manufacturing method therefor

ActiveUS20120169180A1Promote growthImprove alignment accuracyPiezoelectric/electrostriction/magnetostriction machinesFixed capacitor electrodesEvaporationElectronic component

In a method of manufacturing a laminate type electronic component, when a heat treatment is carried out after plating films, which at least partially define external electrodes, are formed by growing plated depositions deposited on exposed ends of a plurality of internal electrodes in a component main body, the presence of the plating films may not only interfere with moisture release, but may also cause blisters or bulge defects in the plating films, while moisture such as a plating solution in the component main body is removed by evaporation. To avoid such problems, cuts to divide exposed ends into multiple sections are formed in extending sections of internal electrodes. Thus, plating films include slits extending in the stacking direction at locations corresponding to positions of the cuts.

Owner:MURATA MFG CO LTD

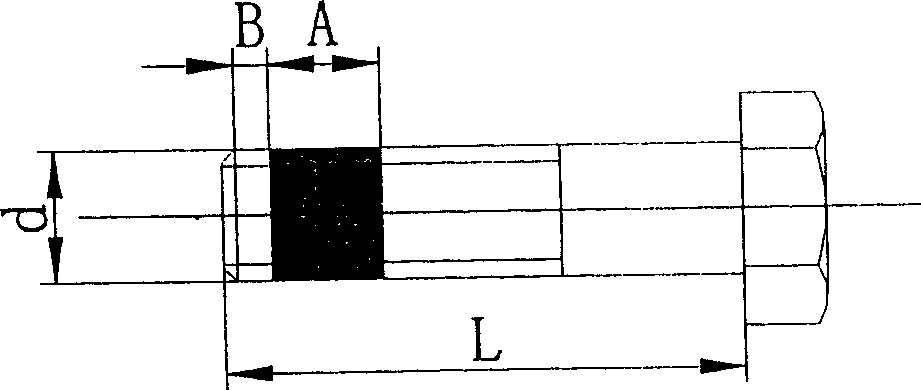

Screw thread sealing method

Owner:WEICHAI POWER CO LTD

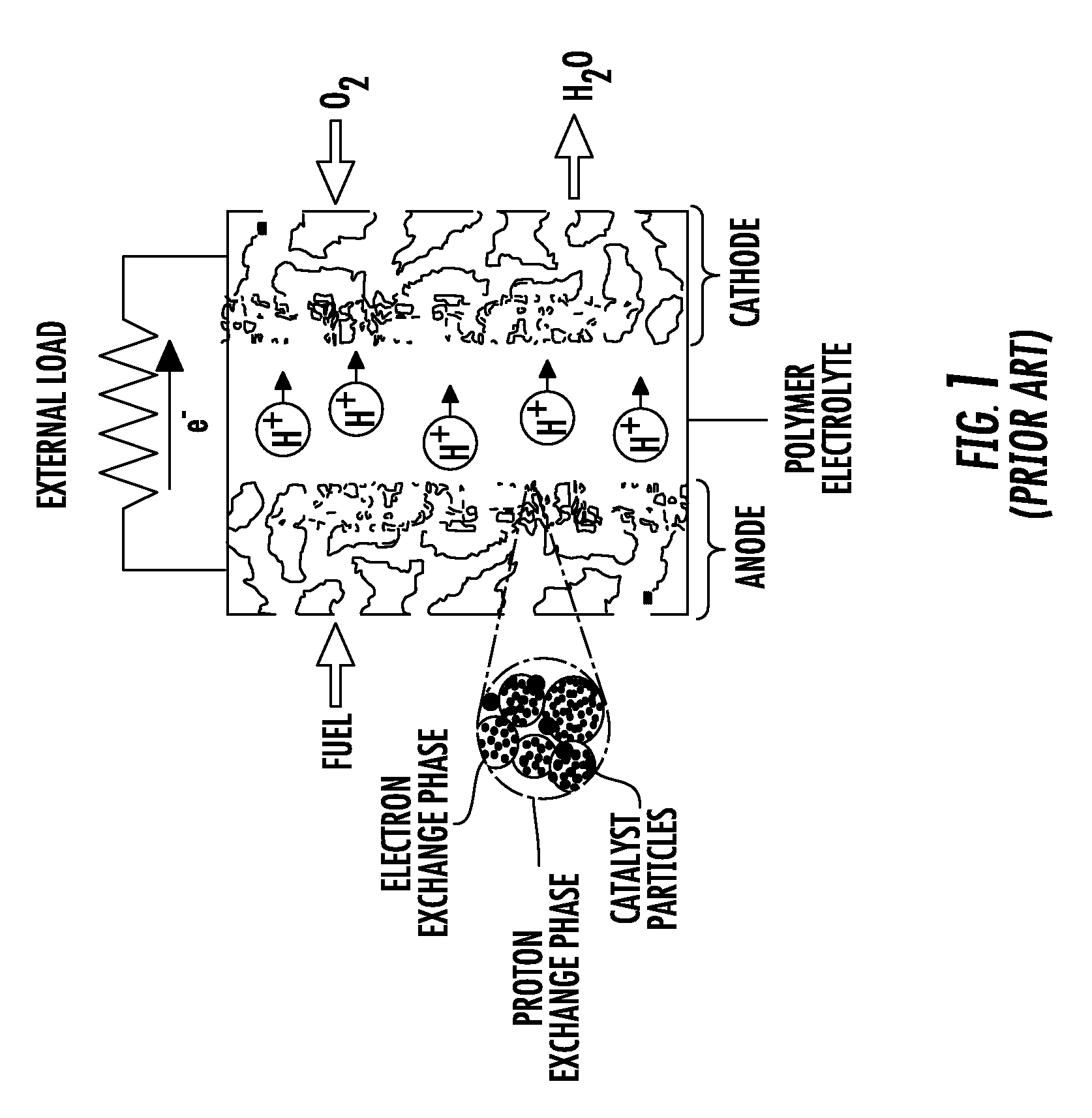

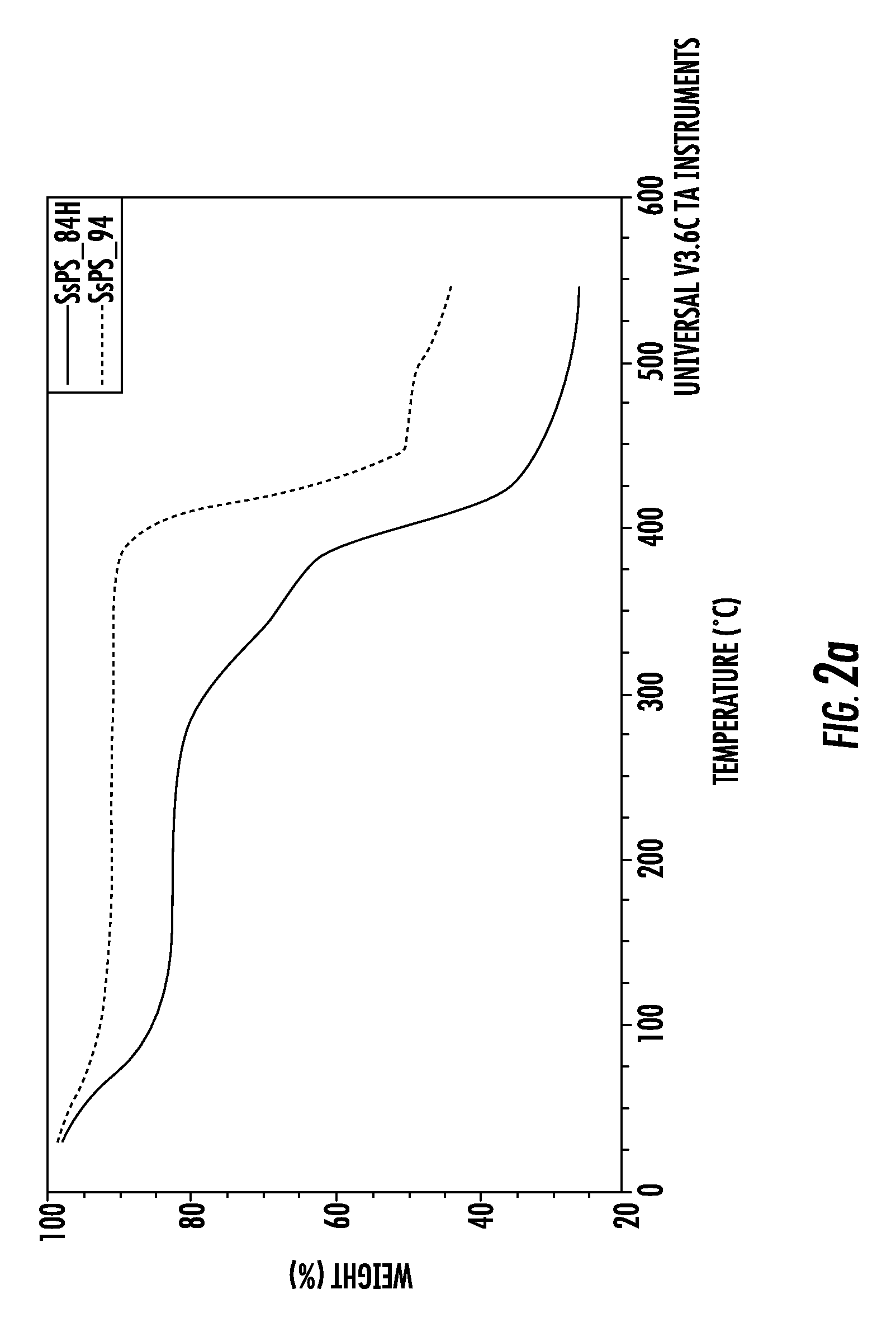

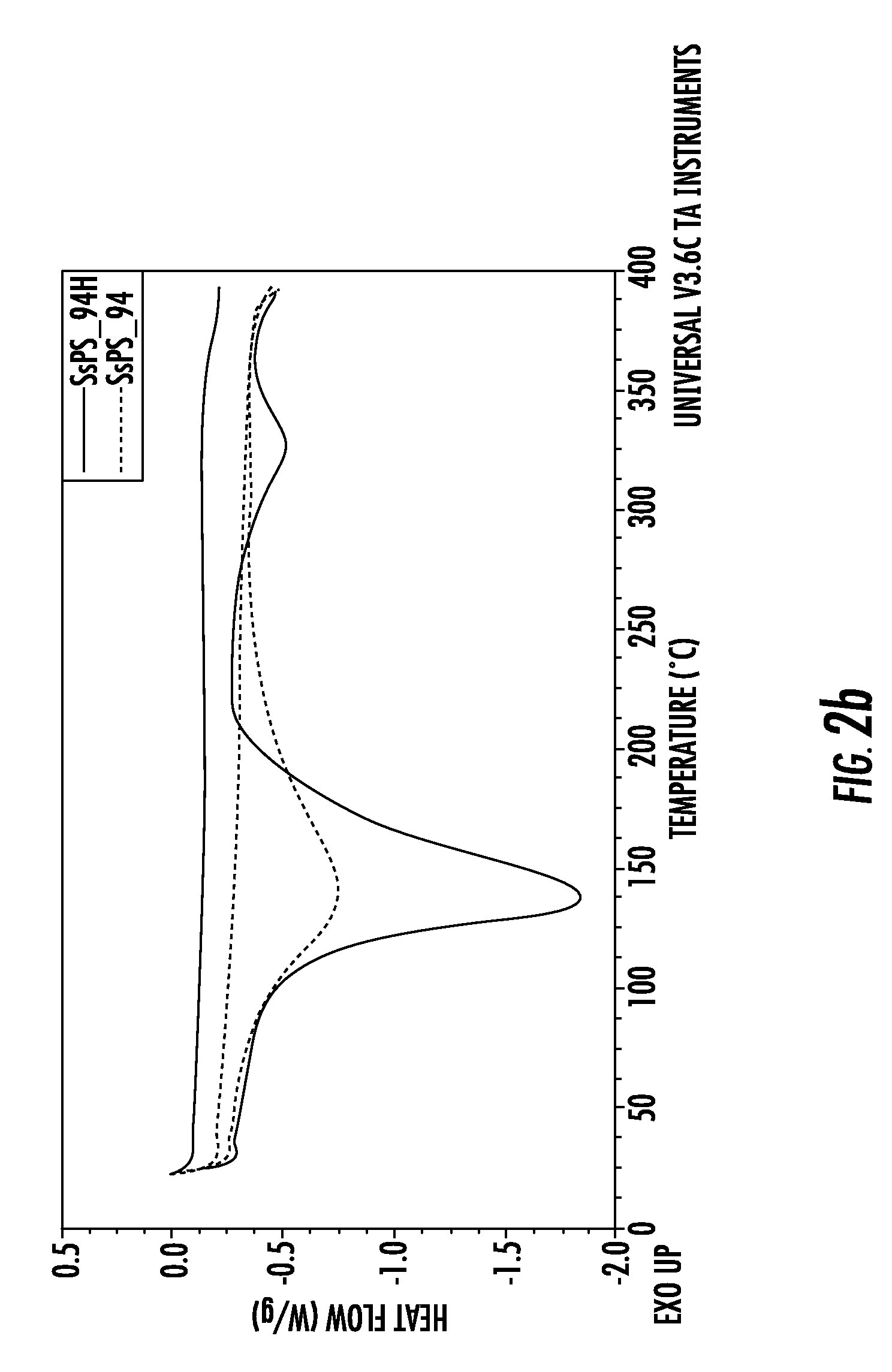

Polyelectrolyte membrane for electrochemical applications, in particular for fuel cells

InactiveUS20080299437A1Advantageously more homogenous morphologyUniform filmSolid electrolytesFinal product manufacturePolyelectrolyteElectrochemistry

A polyelectrolyte membrane may include at least one styrene polymer or copolymer having a syndiotactic configuration and having sulfonic groups. The at least one styrene polymer or copolymer may be made in the form of a film in clathrate form. The film may include less than about 0.1% sulfonate groups of —SO3−Y+ general formula, in which Y may be a monovalent metal cation.

Owner:STMICROELECTRONICS SRL

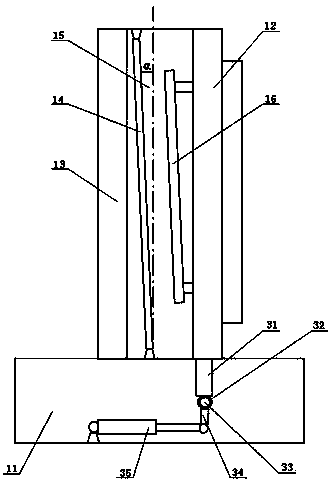

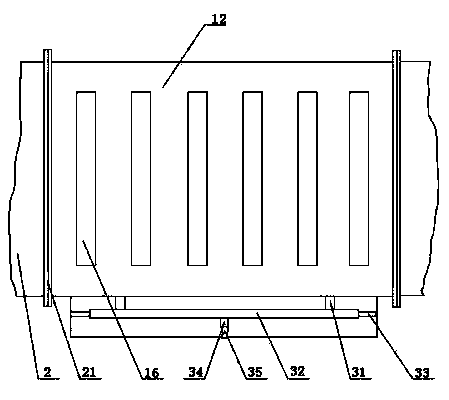

Energy-saving low-radiation glass vertical-type magnetron sputtering production device

InactiveCN103388125AUniform filmStrong adhesionVacuum evaporation coatingSputtering coatingEngineeringFilm coating

The invention discloses an energy-saving low-radiation glass vertical-type magnetron sputtering production device. The energy-saving low-radiation glass vertical-type magnetron sputtering production device comprises multiple film-coating cavity units connected in series. A process isolation cavity is arranged between each adjacent two of the multiple film-coating cavity units. An isolation valve is arranged between each one of the multiple film-coating cavity units and the process isolation cavity adjacent with the film-coated cavity unit. Each one of the multiple film-coating cavity units comprises a base, a target material frame, a backboard seat and a glass frame. The target material frame and the backboard seat are installed on the base and form a film-coating cavity. The target material frame is provided with a target material cathode. An opening / closing device is arranged between the target material frame and the base. The glass frame is arranged in the film-coating cavity, has a vertical structure and forms an angle of 0-10 degrees with a vertical plane. The opening / closing device is driven by hydraulic pressure or air pressure. The glass frame is provided with a glass conveyer. According to the energy-saving low-radiation glass vertical-type magnetron sputtering production device, in energy-saving low-radiation glass production, glass is arranged vertically so that impurities deposited on the surface of the glass are reduced, the damage produced by impurities on a film is reduced, film adhesion is improved, and arc discharge caused by deposition of impurities on the target material cathode is reduced.

Owner:YOUDU FUNCTIONAL FILM MATERIAL YANGZHOU

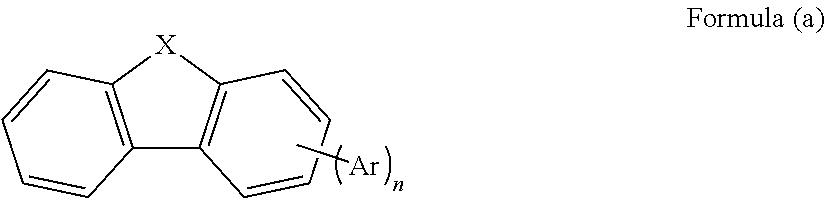

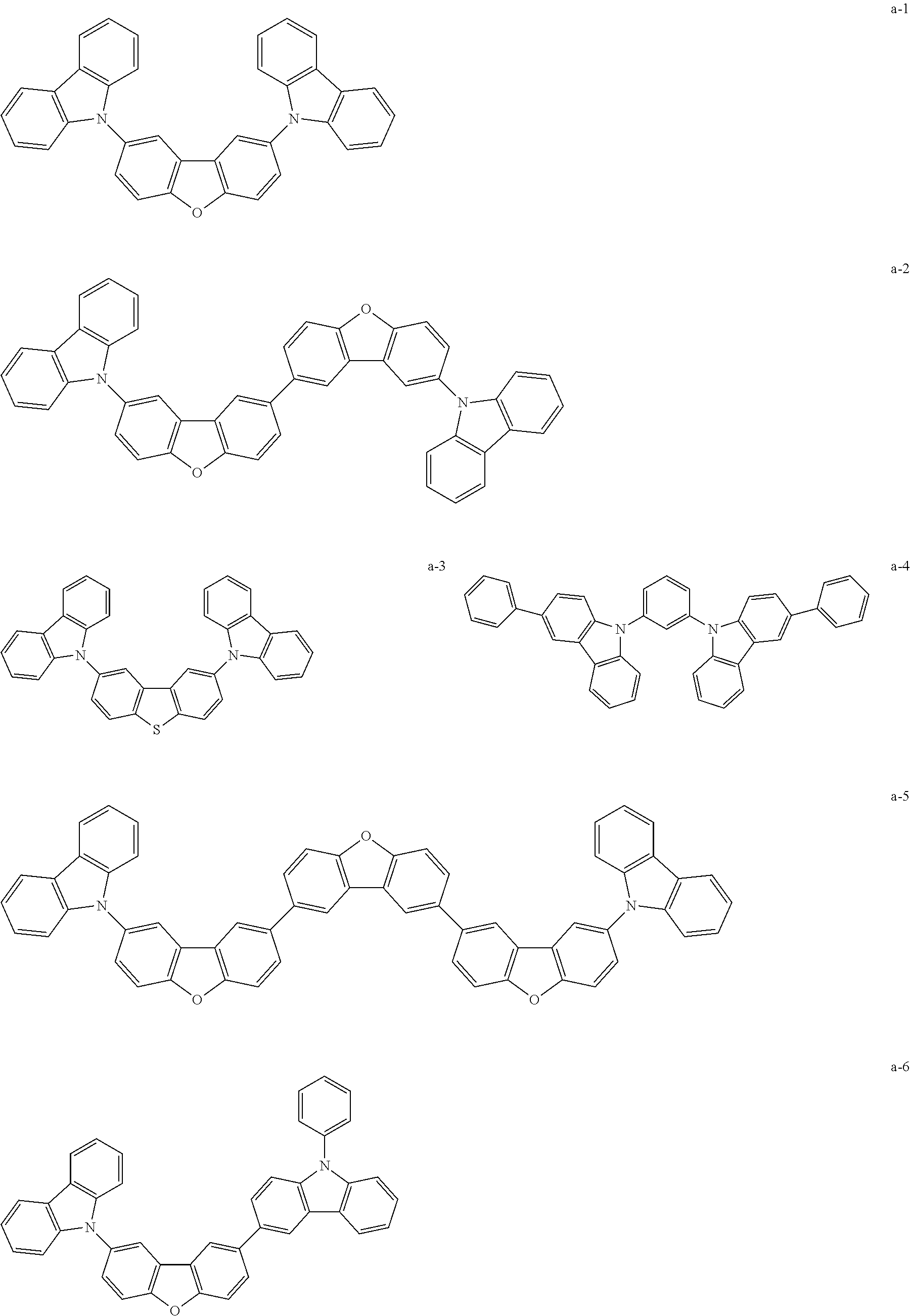

Preparation method of titanium dioxide based self-cleaning glass

The invention relates to a preparation method of titanium dioxide based self-cleaning glass, aiming at solving the problems in the preparation process of the self-cleaning glass that because the technology is complex, the requirement for manpower and material resources is high and the coating efficiency is low, large-area popularization is hard to realize. According to the preparation method disclosed by the invention, a simple sol-gel method is adopted for preparing TiO2 (B) crystal phase containing nano particle sol with uniform size and relatively small grains, glass is dipped into the sol,then the glass is drawn out from the TiO2 sol at the speed of 0.5cm / s-1.0cm / s, and a sample is subjected to annealing treatment at the temperature of 300-600 DEG C, thus obtaining the TiO2 based self-cleaning glass with large area and uniform membrane. The TiO2 based self-cleaning glass disclosed by the invention has relatively good organic matter catalytic degradation activity, and is very suitable for being popularized in the fields of external glass walls of buildings, windshields of automobiles and the like. The method disclosed by the invention is low in requirement for equipment, greatly reduces the production cost and is high in production efficiency, and membrane thickness can be flexibly mastered. The prepared glass has relatively high transmittance and is suitable for being applied to daily production and life.

Owner:NORTHEAST NORMAL UNIVERSITY

Production method for organic electroluminescent element

ActiveUS20130011951A1Solve low luminous efficiencyReduce the driving voltageElectroluminescent light sourcesSolid-state devicesOrganic electroluminescencePhotochemistry

Disclosed is a production method for an organic electroluminescent element that is provided with a substrate, an organic laminate with an organic light emitting layer that was formed by a method involving a wet process, and a pair of electrodes, wherein the method produces an organic electroluminescent element with high luminous efficiency, low driving voltage, and a minimal rise in voltage when continuously driven, by applying the coating liquid for said organic light emitting layer, and thereafter, in a drying process, heating the substrate while applying tension in a manner such that a stress that is less than the yield stress is applied to the substrate.

Owner:MERCK PATENT GMBH

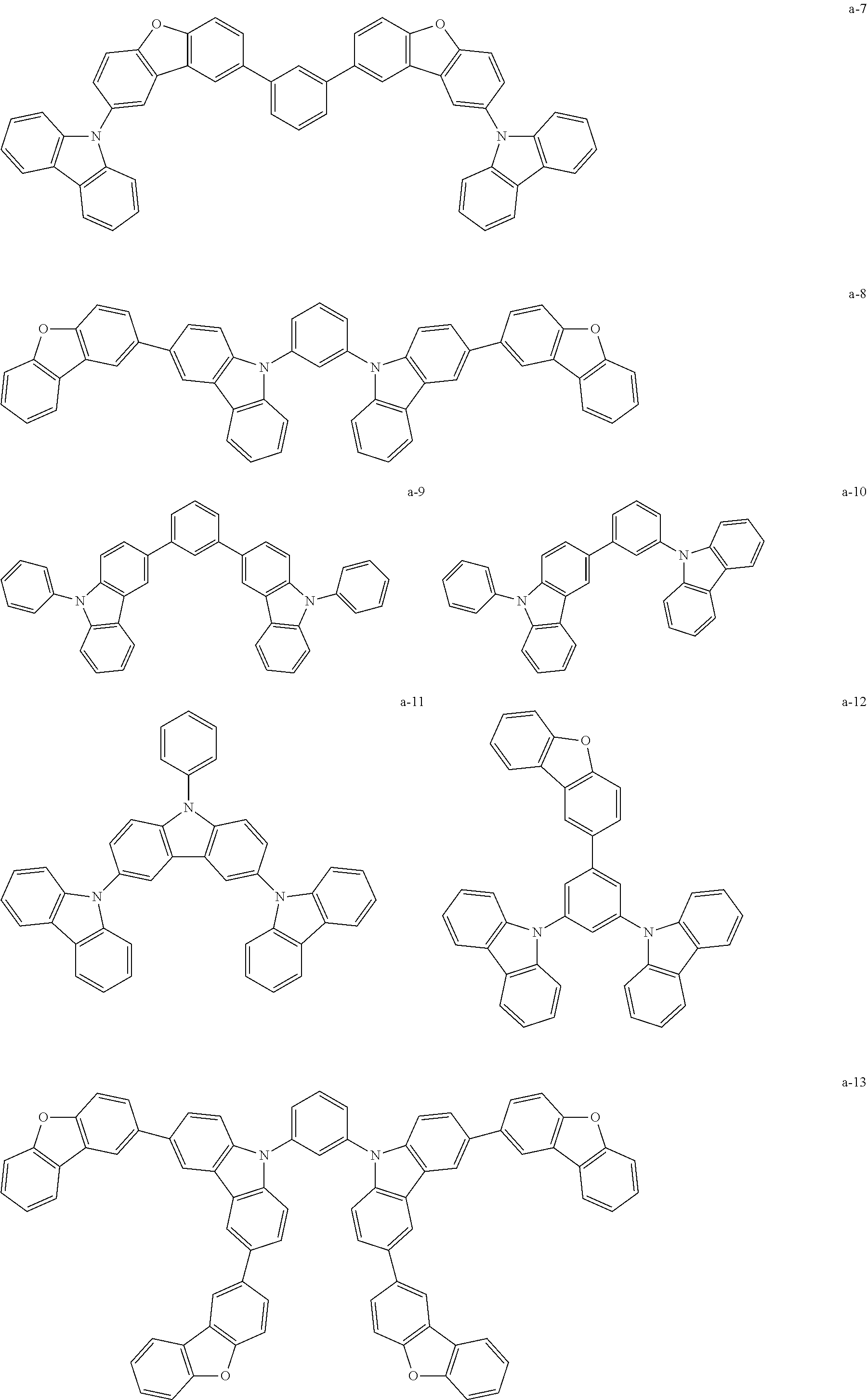

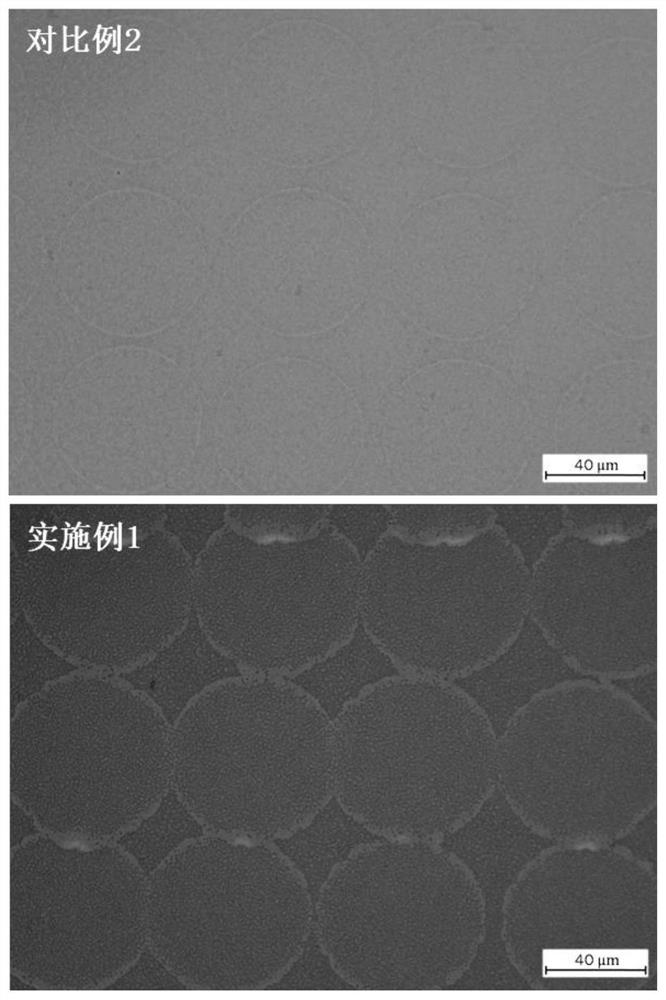

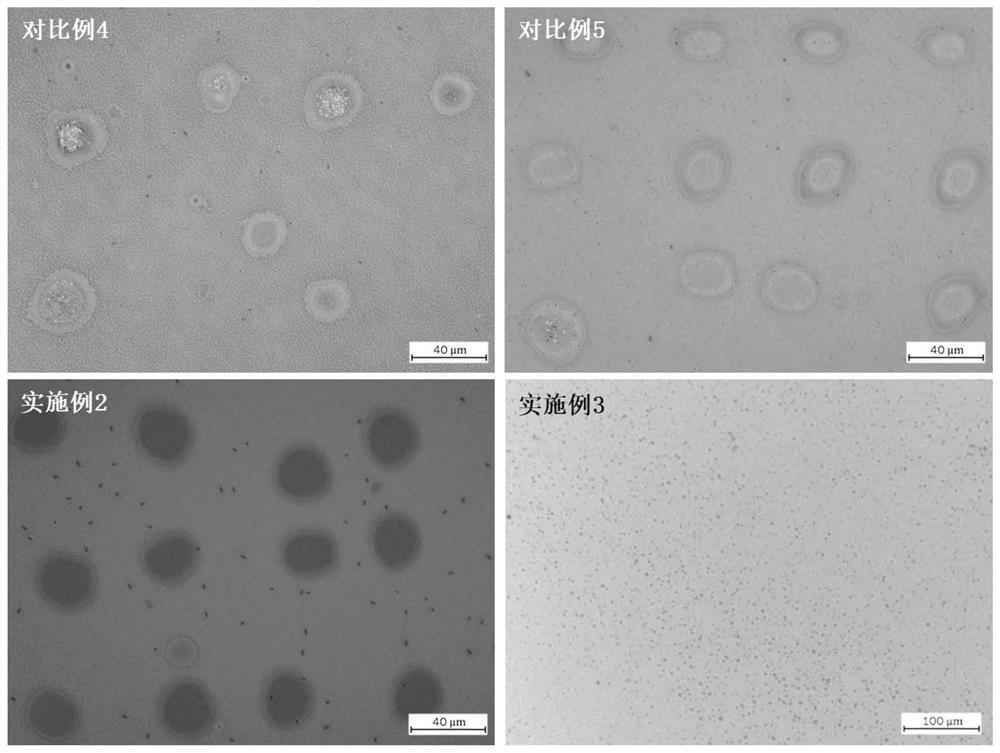

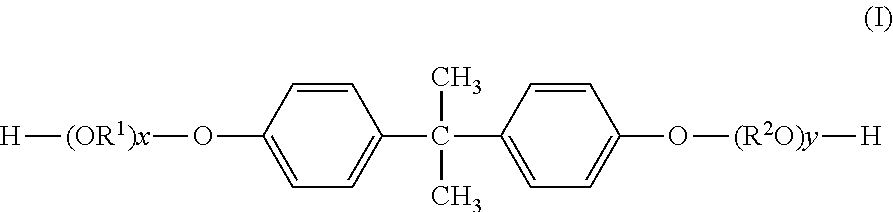

Electron transport material ink for ink-jet printing, and preparation method and application thereof

ActiveCN113234359ASolve the problem of poor spreadabilityInhibition formationSolid-state devicesSemiconductor/solid-state device manufacturingPhenyl EthersActive agent

The invention discloses an electron transport material ink for ink-jet printing, and a preparation method and application thereof. The ink comprises: a solute; solvents comprising methanol and ethylene glycol; and a surfactant being polyethylene glycol octyl phenyl ether. The solute concentration of the electron transport material ink for ink-jet printing is 2-10 mg / mL, the volume ratio of methanol to ethylene glycol is (80-99): (1-20), and the volume ratio of the surfactant to the solvent is (0.1-0.15): 100. The invention provides the electron transport material ink for ink-jet printing. The problem of mutual dissolution between layers during ink-jet printing of multiple layers of films is solved by adopting an orthogonal solvent method; and the problem of poor spreadability of ink droplets on the surface of a hydrophobic light-emitting layer film is solved by adopting a strategy of adding an activator, a uniform film is obtained, and the formation of coffee rings is inhibited.

Owner:NANJING UNIV OF POSTS & TELECOMM

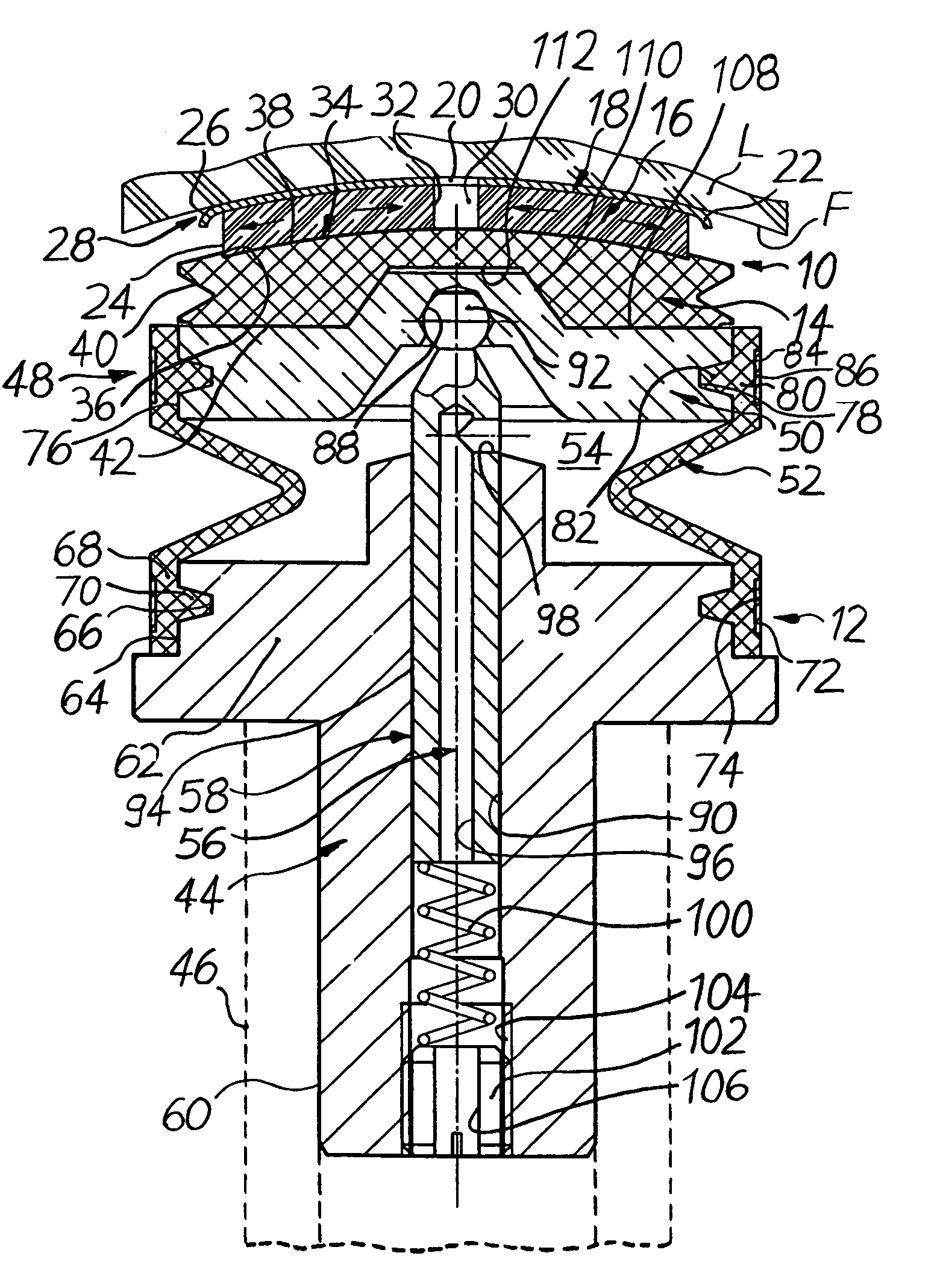

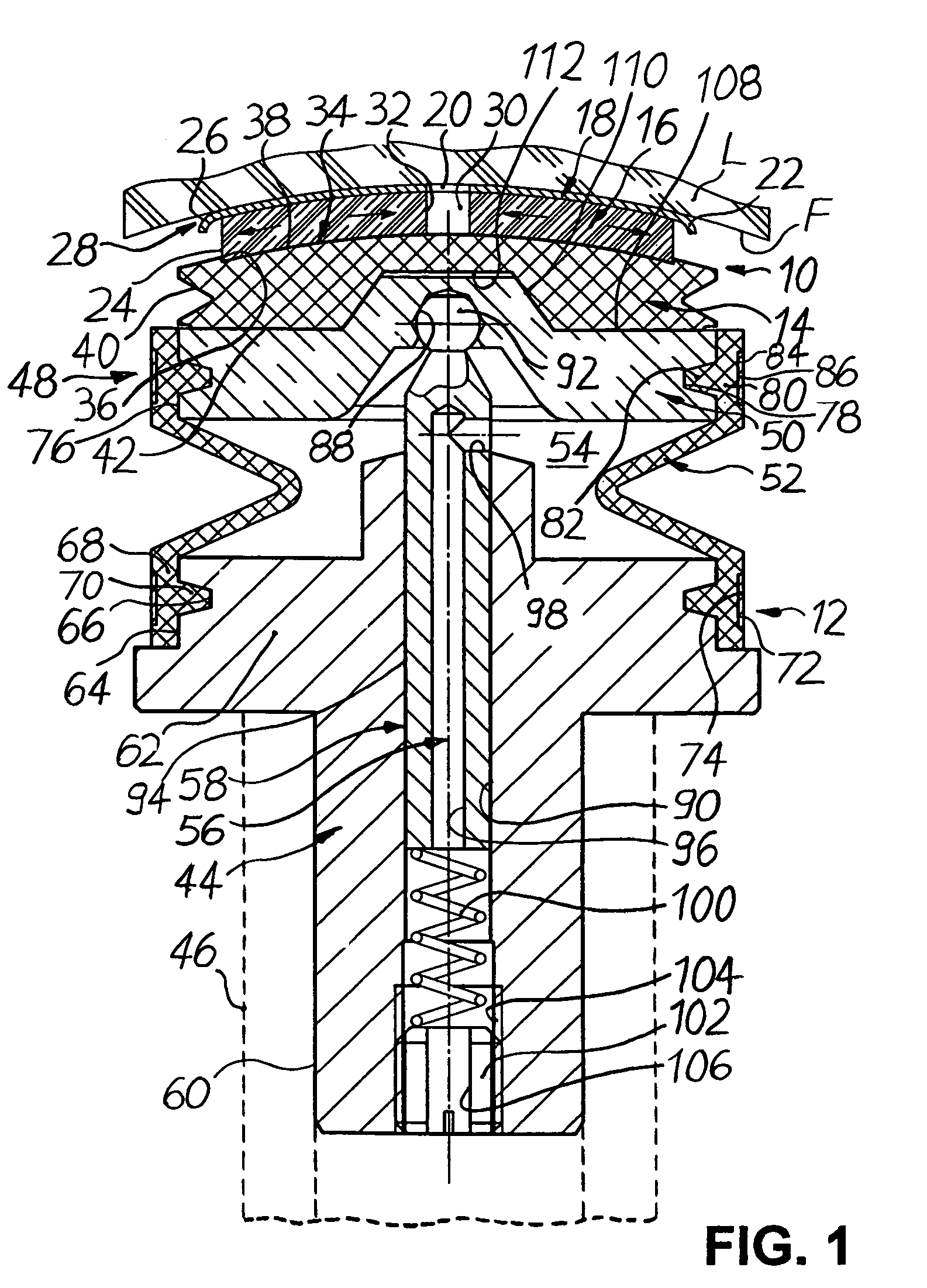

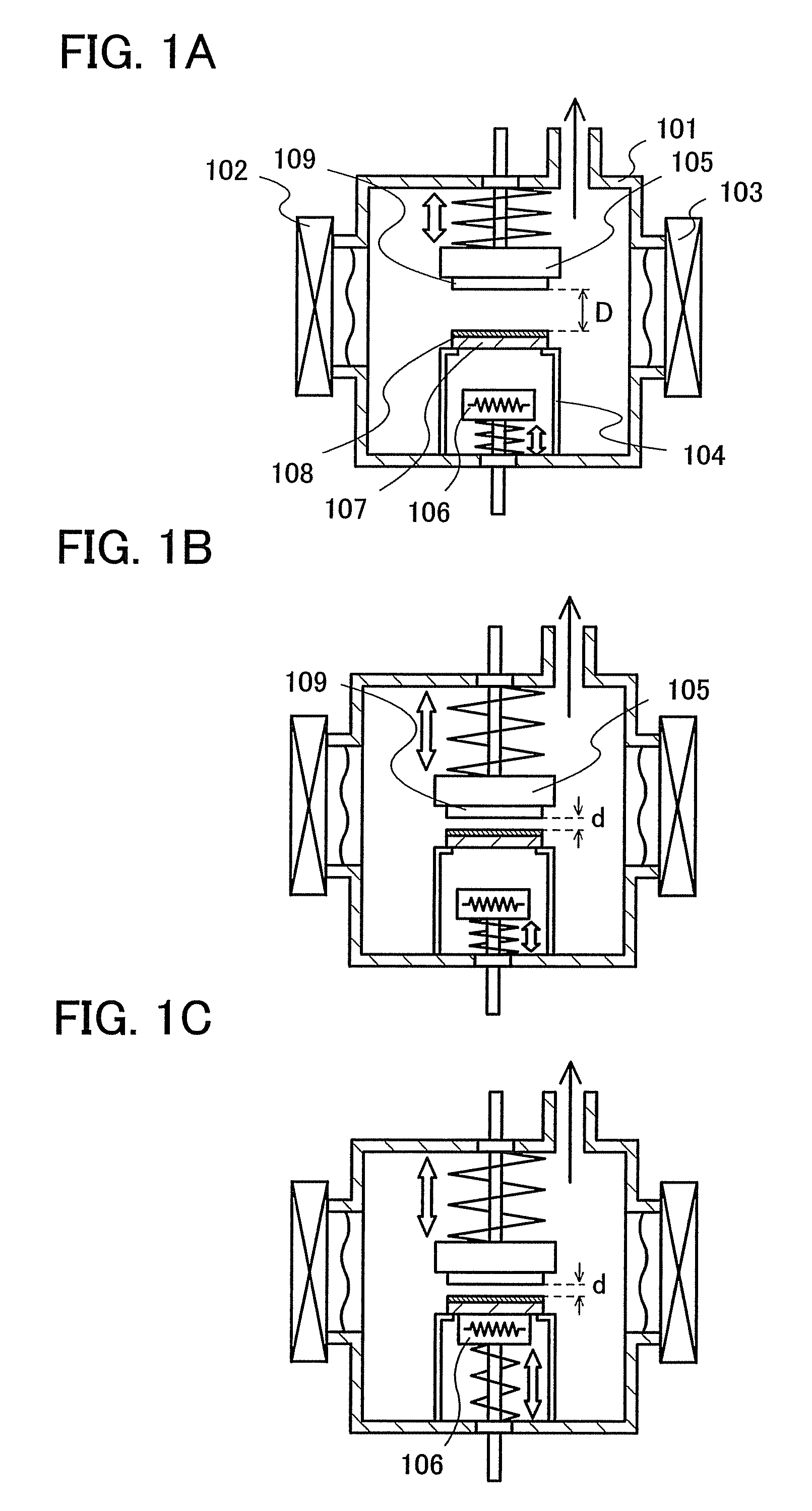

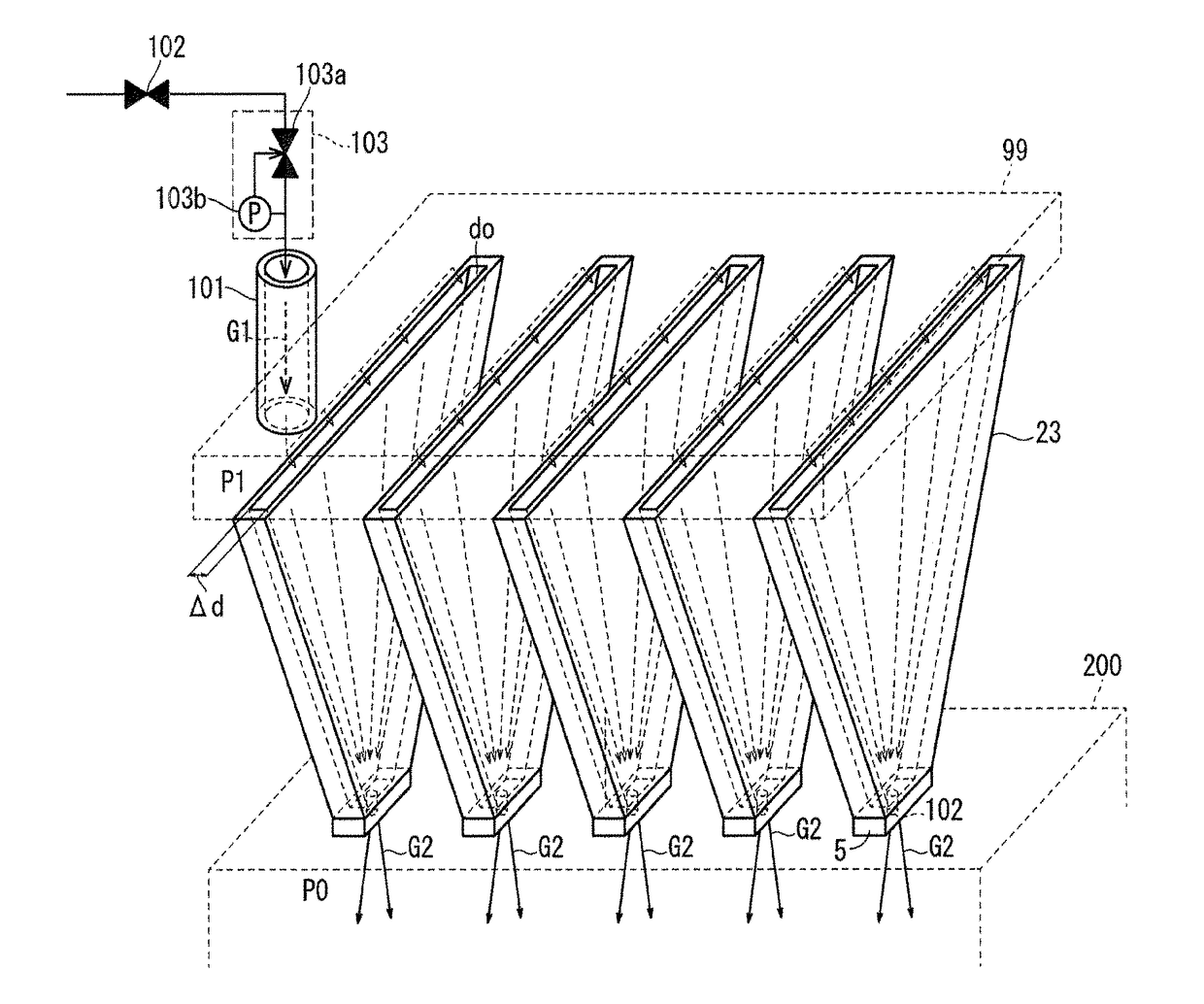

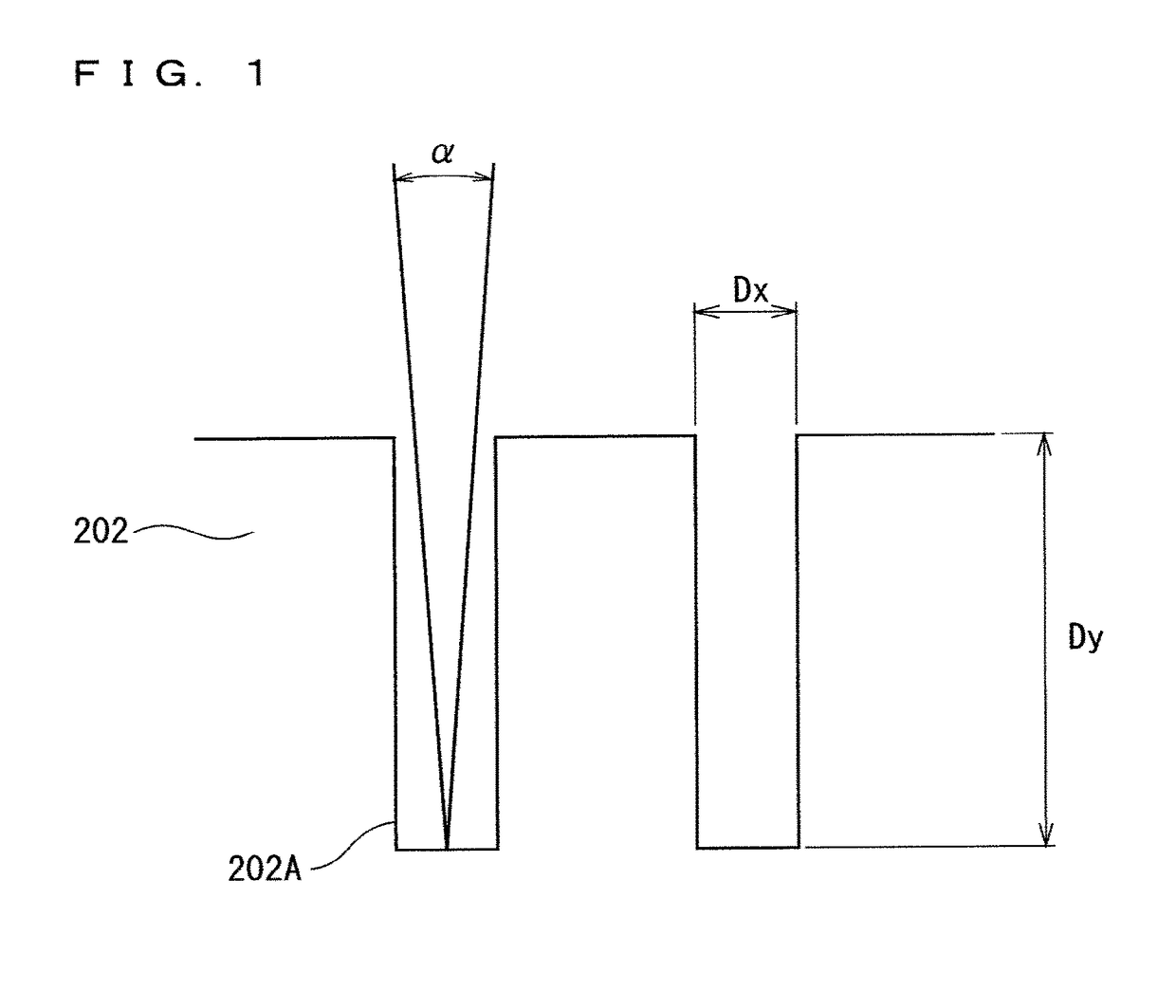

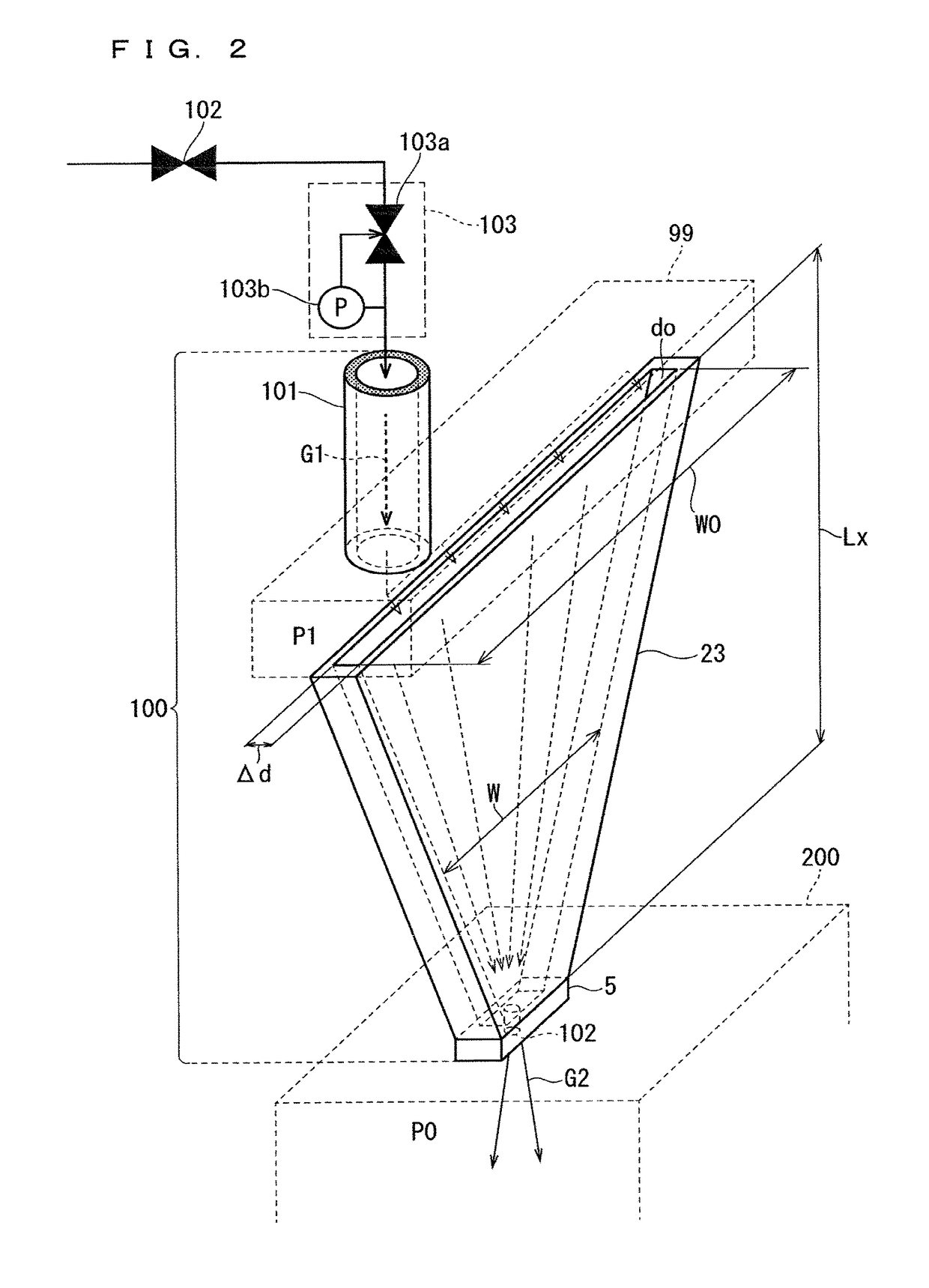

Gas jetting apparatus for film formation apparatus

ActiveUS20170275758A1Uniform filmSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTreatment targetsGas dispersion

The present invention provides a gas jetting apparatus for a film formation apparatus. The gas jetting apparatus is capable of uniformly jetting, even onto a treatment-target object having a high-aspect-ratio groove, a gas into the groove. The gas jetting apparatus (100) according to the present invention includes a gas jetting cell unit (23) for rectifying a gas and jetting the rectified gas into the film formation apparatus (200). The gas jetting cell unit (23) has a fan shape internally formed with a gap (d0) serving as a gas route. A gas in a gas dispersion supply unit (99) enters from a wider-width side of the fan shape into the gap (d0), and, due to the fan shape, the gas is rectified, accelerated, and output from a narrower-width side of the fan shape into the film formation apparatus (200).

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Aqueous ink

ActiveUS20190270898A1Improved in rub fastness and solvent resistanceImprove balanceDuplicating/marking methodsInksWater basedPolyester

The present invention relates to a water-based ink that contains pigment-containing polyester-based resin particles A, pigment-free polyester-based resin particles B, an organic solvent and water, in which a content of an organic solvent C having a boiling point of not higher than 235° C. in a whole amount of the organic solvent is not less than 90% by mass. The water-based ink of the present invention can be improved in rub fastness, solvent resistance and adhesion to a non-water absorbing printing medium with good balance therebetween, even when printed on the non-water absorbing printing medium.

Owner:KAO CORP

Metal surface silver plating method

InactiveCN110670053AGood restorativeUniform filmLiquid/solution decomposition chemical coatingChemical reactionPhysical chemistry

The invention relates to a metal surface silver plating method. According to the method, a non-silver-plated portion is in contact with repair liquid to make a chemical reaction. The heating temperature during the chemical reaction is 30 DEG C to 40 DEG C. After the non-silver-plated portion is reacted with the repair liquid, water washing and drying are carried out, wherein a solute of the repairliquid is silver nitrate, urea and fluoride salt, and a solvent of the repair liquid is water. The new method can achieve rapid silver plating, a film is uniform, bright and smooth, and the good conductivity is achieved.

Owner:BEIJING SHUGUANG AERO ELECTRICAL

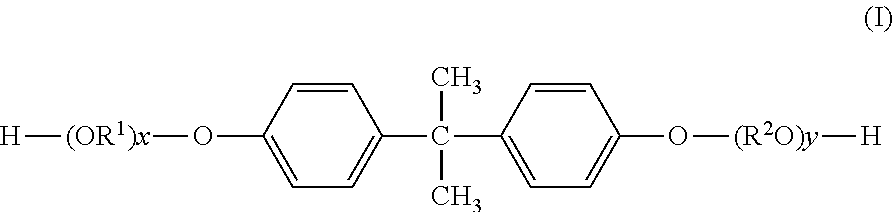

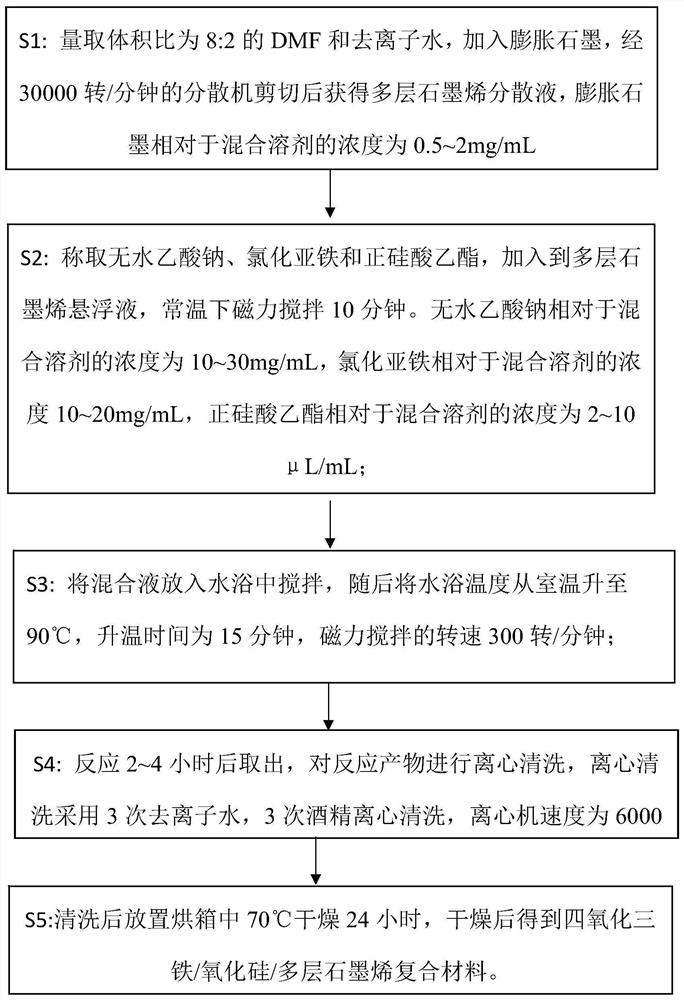

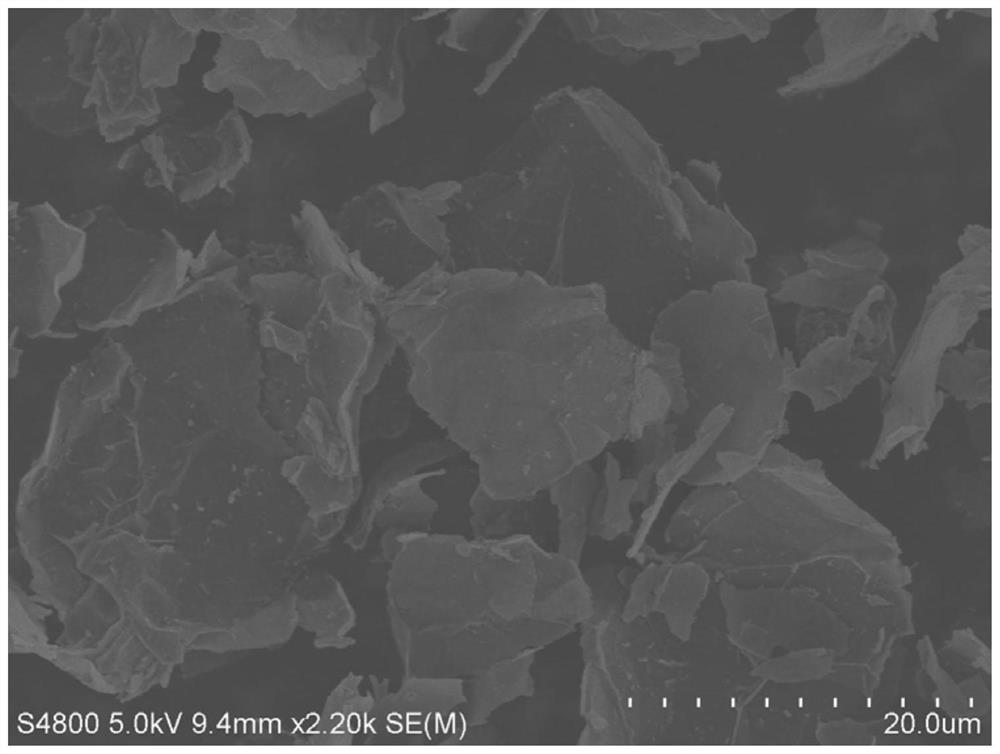

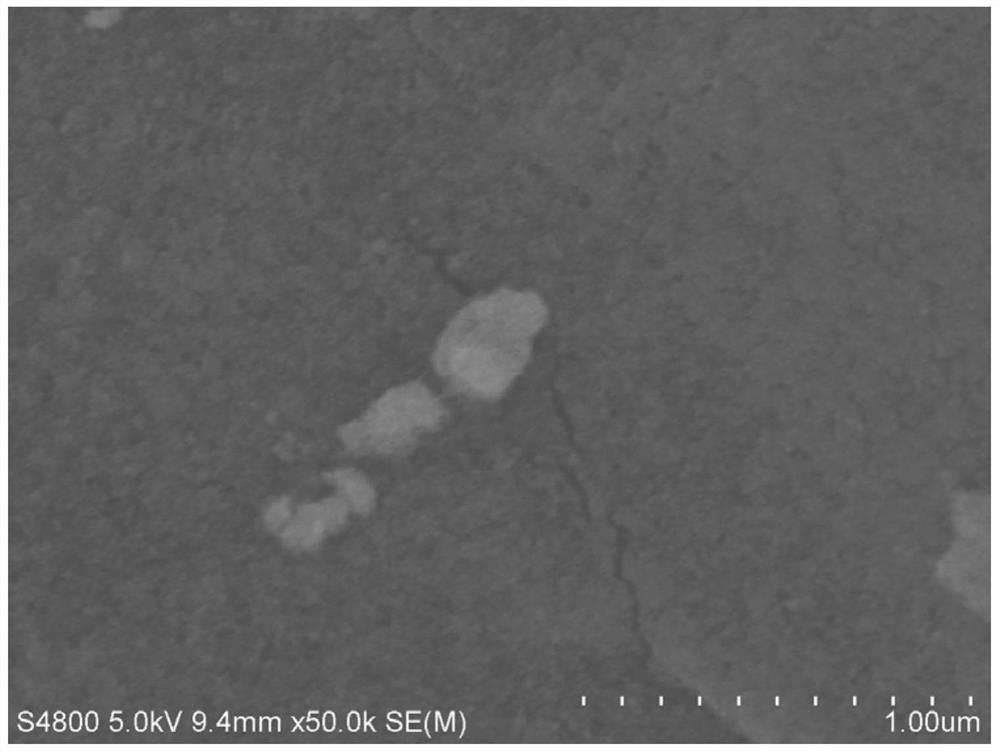

Ferroferric oxide/silicon oxide/multilayer graphene composite material and preparation method thereof

ActiveCN111769261AUniform filmSmall particle diameterSecondary cellsNegative electrodesFerriferrous OxideSilicon oxide

The invention discloses a ferroferric oxide / silicon oxide / multilayer graphene composite material and a preparation method. Multilayer graphene in the composite material is a carbon substrate material,is obtained by mechanical stripping of expanded graphite, has a thickness of less than 10nm, and has a flat surface. The ferroferric oxide and the silicon oxide form a composite film on the surface of the multilayer graphene, the ferroferric oxide and the silicon oxide are mutually isolated and uniformly distributed in the composite film, and the thickness of the film layer is less than 10nm. Thespecific preparation process of the ferroferric oxide / silicon oxide / multilayer graphene composite material comprises the following steps: putting expanded graphite into a mixed solution of DMF and water, and carrying out mechanical stripping to obtain a multilayer graphene dispersion liquid; weighing anhydrous sodium acetate, ferrous chloride and tetraethoxysilane, and adding the multilayer graphene dispersion liquid; putting into a water bath, stirring, and heating to 90 DEG C for 15 minutes at room temperature in the water bath; after reacting for a certain time, taking out, and centrifugally cleaning to obtain the ferroferric oxide / silicon oxide / multilayer graphene composite material. The preparation process is simple and suitable for industrial production.

Owner:HANGZHOU DIANZI UNIV

Magnesium plating method for metal surface

InactiveCN110885975AGood restorativeUniform filmLiquid/solution decomposition chemical coatingChemical reactionThiourea

The invention relates to a magnesium plating method for a metal surface. The magnesium plating method comprises a first magnesium plating process and a second magnesium plating process, the first magnesium plating process is different from the second magnesium plating process; the first magnesium plating process enables that magnesium plating on part of the metal surface is carried out, the secondmagnesium plating process enables that magnesium plating on the metal surface without magnesium plating is carried out; in the second magnesium plating process, the non magnesium plating part contacts with repairing liquid, the chemical reaction is carried out, the heating temperature is 30 DEG C to 40 DEG C when the chemical reaction is carried out; after the non magnesium plating part reacts with the repairing liquid, water washing and drying are carried out; the solute of the repairing liquid is magnesium sulfate, thiourea and sodium chloride, the solvent of the repairing liquid is water;the volume ratio of the magnesium sulfate to the water is 35 to 40 : 1, the unit is gram / liter; the volume ratio of the thiourea to the water is 40 to 50:1, the unit is gram / liter; and the volume ratio of the sodium chloride to the water is 2 to 6:1, the unit is gram / liter. The magnesium plating method for a metal surface realizes a new method of rapid magnesium plating, and film forming id even,the light quantity is flat and the conductivity is good.

Owner:BEIJING SHUGUANG AERO ELECTRICAL

Aqueous ink

ActiveUS10774229B2Improved in rub fastness and solvent resistanceImprove balanceLiquid surface applicatorsDuplicating/marking methodsPolyesterPolymer science

The present invention relates to a water-based ink that contains pigment-containing polyester-based resin particles A, pigment-free polyester-based resin particles B, an organic solvent and water, in which a content of an organic solvent C having a boiling point of not higher than 235° C. in a whole amount of the organic solvent is not less than 90% by mass. The water-based ink of the present invention can be improved in rub fastness, solvent resistance and adhesion to a non-water absorbing printing medium with good balance therebetween, even when printed on the non-water absorbing printing medium.

Owner:KAO CORP

Copper plating method of metal surface

InactiveCN110684969AUniform filmLight levelingLiquid/solution decomposition chemical coatingCopper platingSodium phosphates

The invention relates to a copper plating method of a metal surface. A non-copper-plated part and a repair solution are in contact to be subjected to a chemical reaction, during the chemical reaction,the heating temperature is 30 to 40 DEG C, the non-copper-plated part and the repair solution are subjected to washing and drying after the reaction, a solute of the repair solution comprises coppersulfate, thiourea and sodium hypophosphite, and a solvent of the repair solution is water. The new method of rapid copper plating can be achieved, film forming is uniform, the light intensity is flat,and the conductive property is good.

Owner:BEIJING SHUGUANG AERO ELECTRICAL

Process for preparing hot melt adhesive elastic grid by plastic uptake method

The invention discloses a process for preparing a hot melt adhesive elastic grid by a plastic uptake method. The process comprises the following steps: placing a hydrogenated styrene-butadiene block copolymer and white oil in a heating stirrer according to a specific proportion, stirring and filling oil, adding polypropylene, silicon dioxide anti-blocking master batch, an antistatic agent and an antioxidant after oil filling is completed, and continuously stirring; and casting the uniformly mixed raw materials into a film through a single-screw extruder, and meanwhile, carrying out vacuum plastic uptake on the cast film through a nickel net with square holes, so as to prepare the hot melt adhesive elastic grid. According to the invention, the hydrogenated styrene-butadiene block copolymer with low melting point and high melting index is used as a matrix material, so that the fabric can be compounded without discoloring and hardening; and the cast film is subjected to vacuum plastic uptake through the nickel net with the square holes to form a grid which is of a #-shaped structure and of which the transverse and longitudinal stems are vertical, so that the transverse and longitudinal mechanical properties can be exerted under the condition of ensuring the ventilation effect, and the cast film has higher tensile strength, thereby meeting the use requirements of the shaping clothes.

Owner:PINGHU ZHANPENG HOT MELT ADHESIVE WEB & FILM

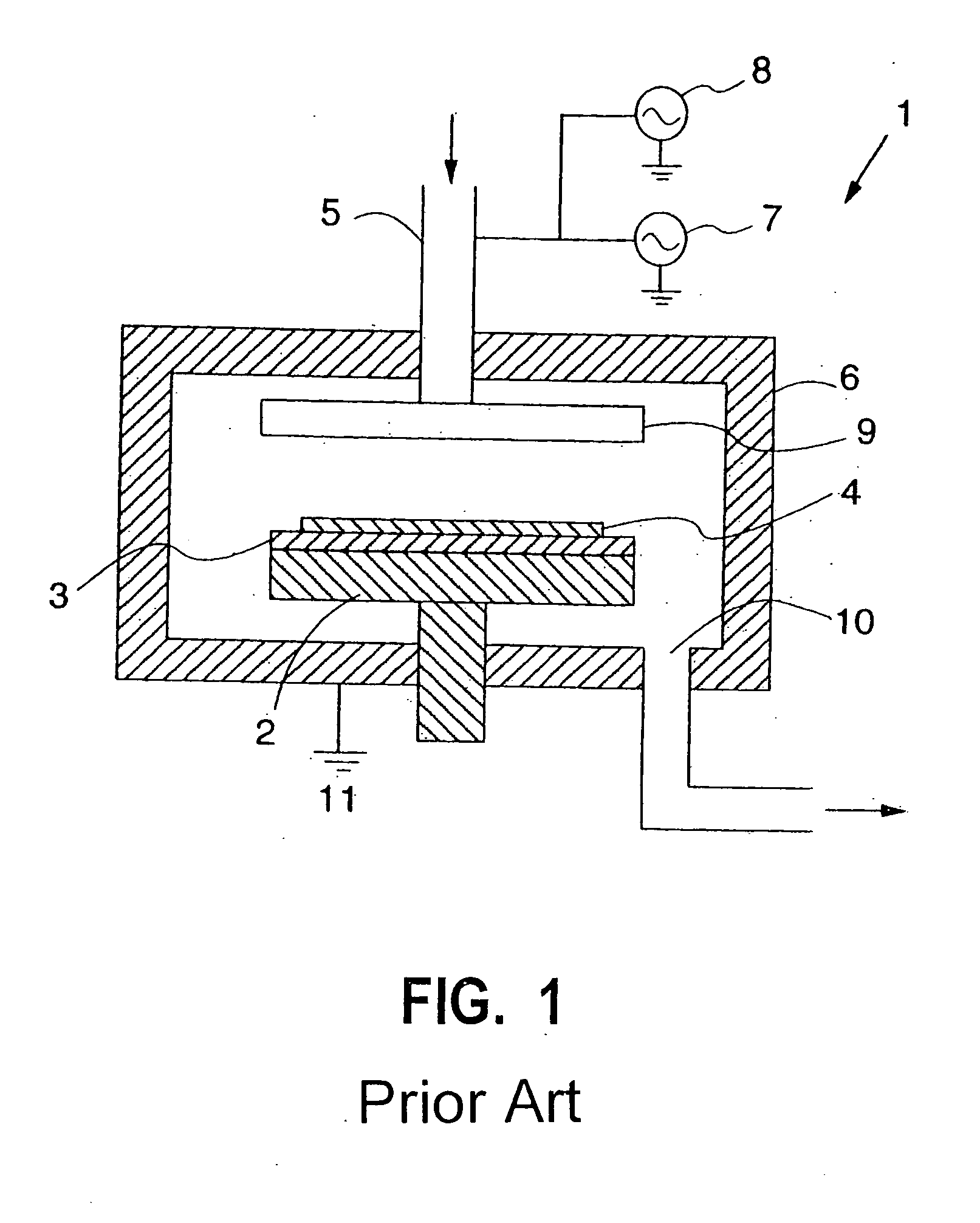

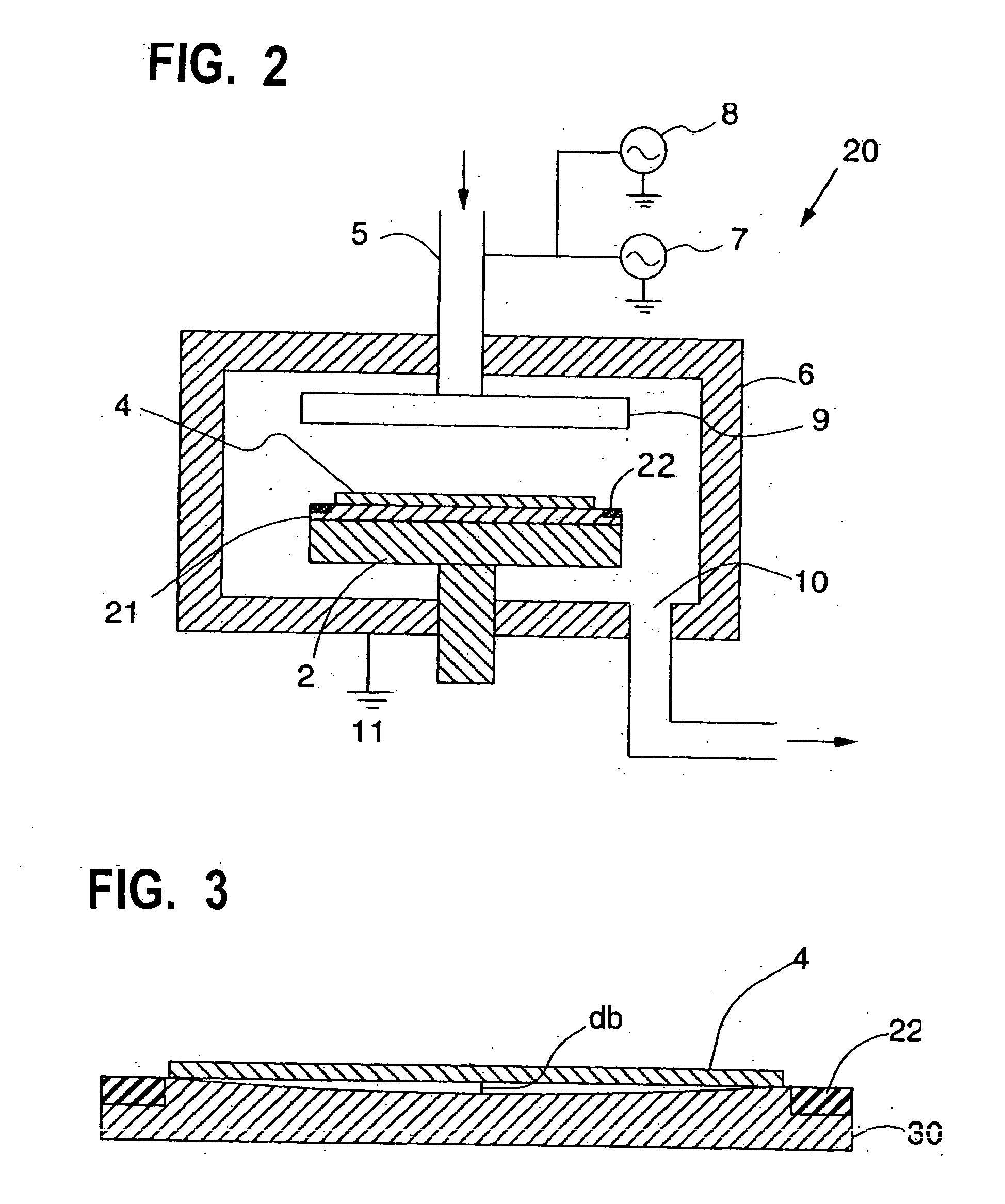

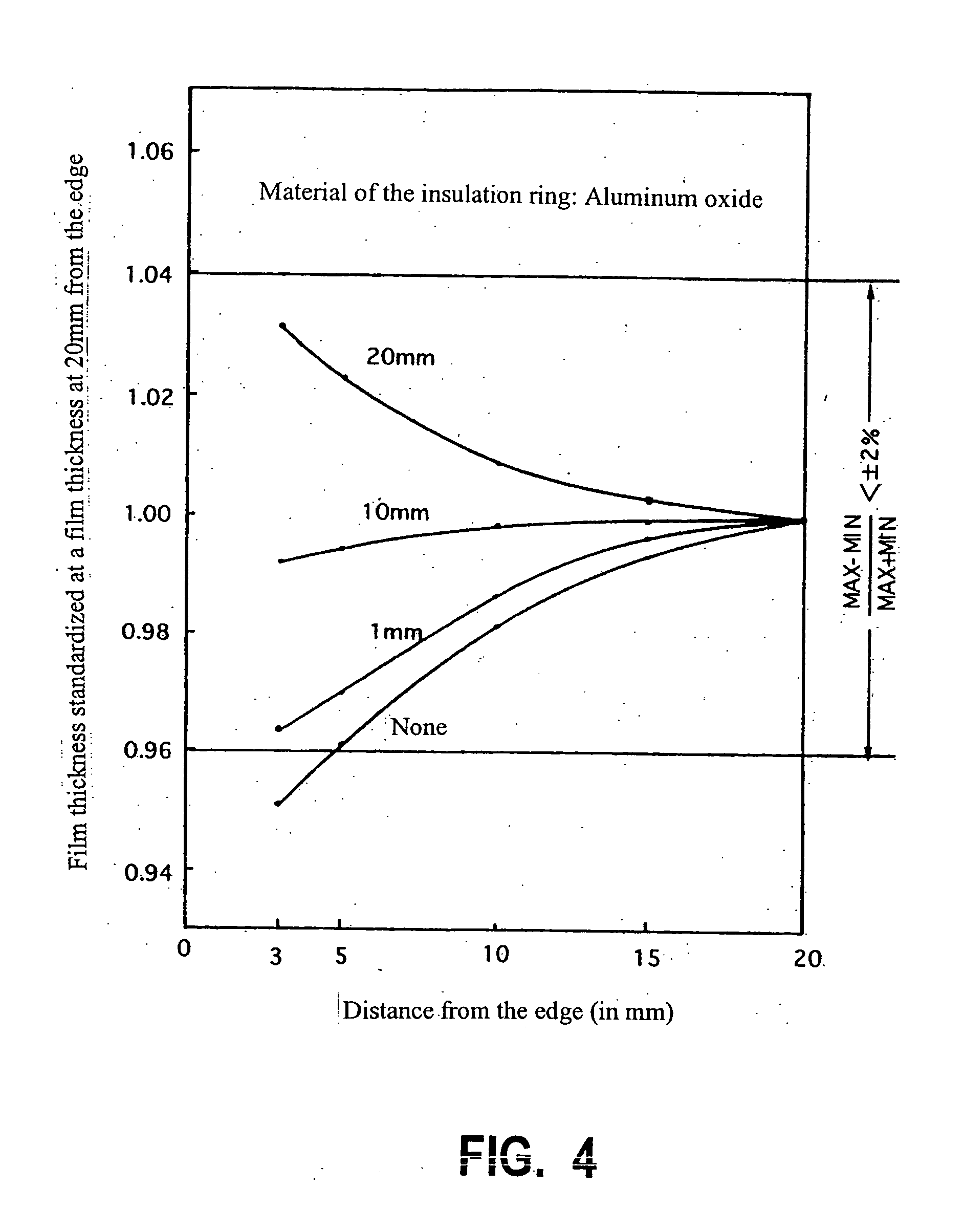

Method for depositing thin film by controlling effective distance between showerhead and susceptor

InactiveUS20070032048A1Increase effective distanceIncrease electrically effective distanceElectric discharge tubesPretreated surfacesEngineeringSusceptor

A method for depositing a thin film on a substrate by plasma CVD includes: providing a vacuum chamber including a showerhead and a susceptor entirely facing the showerhead in parallel, placing a substrate on the susceptor entirely within the inner portion; and applying an RF power between the showerhead and the susceptor to deposit a thin film on the substrate. The susceptor includes an inner portion and a peripheral portion that is defined as any portion enclosing the inner portion and defines an electrically effective distance from the showerhead greater than that defined by the inner portion.

Owner:ASM JAPAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com