Vanadium dioxide thin film having regular truss network structure and preparation method thereof

A technology of vanadium dioxide and network structure, which is applied in the field of vanadium dioxide film preparation, can solve the problems of easy oxidation of organic additives, complex preparation process, and difficulty in forming large-area films, and achieve excellent thermal resistance modulation ability, strong The effect of thermal radiation modulation performance and excellent thermally induced phase transition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

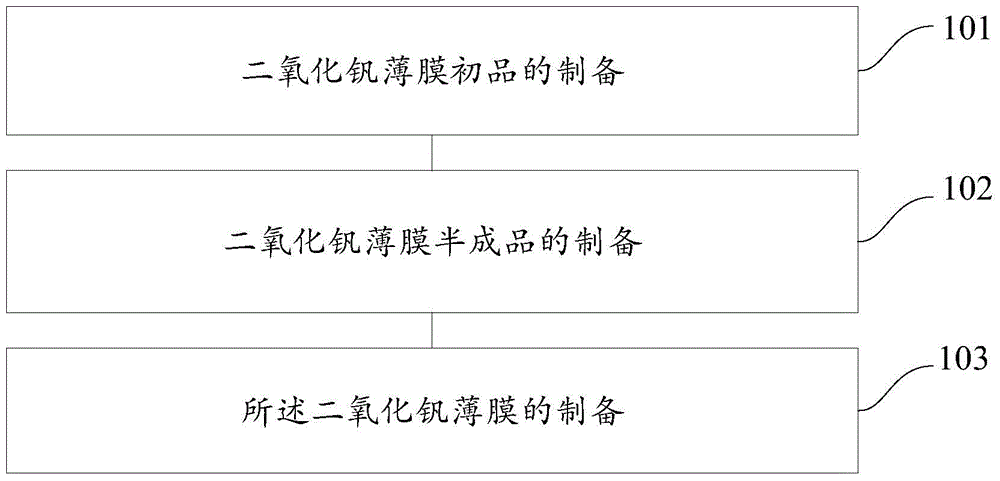

[0039]The invention provides a method for preparing a vanadium dioxide film with a regular truss network structure. refer to figure 1 , which shows a flow chart of a method for preparing a vanadium dioxide film with a regular truss network structure according to Example 1 of the present invention, the method comprising the following steps:

[0040] Step 101, preparation of the primary vanadium dioxide thin film.

[0041] Preparation of Solution 1: Heat and stir the vanadium-containing solid compound, oxalic acid and distilled water to mix until completely dissolved to obtain Solution 1.

[0042] Preparation of solution 2: add distilled water to the solution 1, and then add at least one of monohydric alcohol and dihydric alcohol to obtain solution 2; wherein, add at least one of the monohydric alcohol and dihydric alcohol in the solution 1 The volume ratio of the volume to the distilled water is 0:1 to 3:1, so that the concentration of vanadium ions in the solution 2 is 0.002...

Embodiment 1

[0070] A specific method for preparing a vanadium dioxide film with a regular truss network structure may include:

[0071] (1) Preparation of primary vanadium dioxide thin film.

[0072] Place 3.56g of V 2 o 5 powder and 2 times the V 2 o 5 The oxalic acid of mole number is mixed in 100ml distilled water, uses the water-bath magnetic stirrer to heat and stir the described vanadium-containing solid compound, the described oxalic acid and the described distilled water mixture to dissolve completely, place in the water-bath magnetic stirrer and heat and stir to dissolve, and the heating temperature is 50°C, stirred and reacted for 48 hours to obtain a dark blue solution of vanadyl oxalate, that is, solution 1.

[0073] Take 1ml of solution 1, add 99ml of deionized water (volume ratio of alcohol to water is 0:1), and make 100ml of solution 2, the vanadium ion concentration is 0.004mol / L, and the pH value of solution 2 is 1 at this time.

[0074] Take 40ml of solution 2 and p...

Embodiment 2

[0089] A specific method for preparing a vanadium dioxide film with a regular truss network structure may include:

[0090] (1) Take 1ml of the solution 1 prepared in Example 1, add 199ml of deionized water (the volume ratio of alcohol to water is 0:1), and make 200ml of solution 2, the concentration of vanadium ions is 0.002mol / L, and use ammonia water to dissolve the solution 2 The pH was adjusted to 2.4.

[0091] Take 40ml of the pH-adjusted solution 2 and place it in a reaction kettle equipped with 50ml of p-polyphenylene for hydrothermal reaction, put the C-axis oriented alumina substrate in the reaction kettle, and seal the reaction kettle well Finally, place it in a drying oven, keep it warm at 230°C for 4 hours, the upper liquid in the reaction kettle is clarified, and the hydrothermal reaction is completed;

[0092] (2) After the hydrothermal reaction is completed, the supernatant liquid in the reaction kettle is poured out, and a uniform blue-black film is obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com