Patents

Literature

370 results about "Fluorinated polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

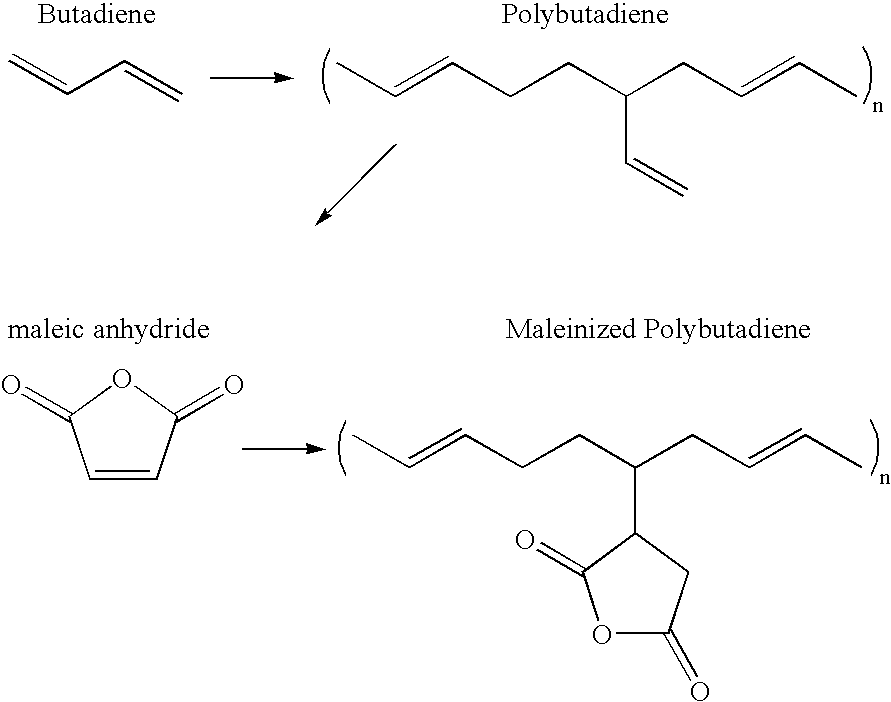

Fluorocarbon polymer, also called fluoropolymer or fluorinated polymer, any of a number of organic polymers whose large, multiple-unit molecules consist of a chain of carbon atoms to which fluorine atoms are appended.

Superhydrophobic coating composition and coated articles obtained therefrom

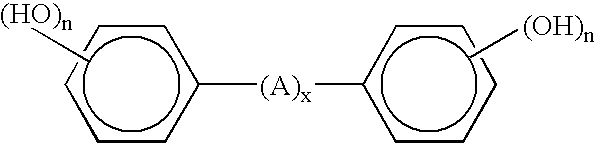

A coating composition is provided comprising: (i) a fluorinated polymer comprising (a) structural units having the formula (I):—CR1R2—CFX— (I)wherein R1 and R2 are each independently an alkyl group, a fluorine atom, a chlorine atom, a hydrogen atom or a trifluoromethyl group, and X is a fluorine atom, a chlorine atom, a hydrogen atom or a trifluoromethyl group, and (b) structural units comprising at least one type of crosslinkable functional group; (ii) a crosslinking agent; and (iii) a plurality of particles functionalized with a functional group, wherein the functional group on the particles is essentially non-reactive with the fluorinated polymer and with the crosslinking agent. Articles comprising a coating composition described in embodiments of the invention are also provided.

Owner:GENERAL ELECTRIC CO

Fluorochemical composition comprising a fluorinated polymer and treatment of a fibrous substrate therewith

InactiveUS7094829B2Easy to oilGood water repellency propertyStain/soil resistant fibresLiquid repellent fibresFiberOrganic solvent

A fluorochemical composition for rendering fibrous substrates oil repellent, water repellent, and / or stain repellent and comprising a fluorinated polymer dispersed in water or dissolved or dispersed in an organic solvent, the fluorinated polymer comprising units derived from (i) a mixture of two or more fluorinated polyether monomers that differ in at least their molecular weight, the fluorinated polyether monomers having an ethylenically unsaturated group and a perfluorinated polyether group and wherein at least 90% by weight of the mixture consists of fluorinated polyether monomers that have a perfluorinated polyether group having a molecular weight of at least 750 g / mol and (ii) one or more units derived from one or more co-monomers other than a fluorinated polyether monomer and wherein the co-monomers comprise at least one non-fluorinated monomer. Also, method for treating fibrous substrate with such composition, fluorinated polyether monomers, and fluorinated polymers derived from such monomers.

Owner:3M INNOVATIVE PROPERTIES CO

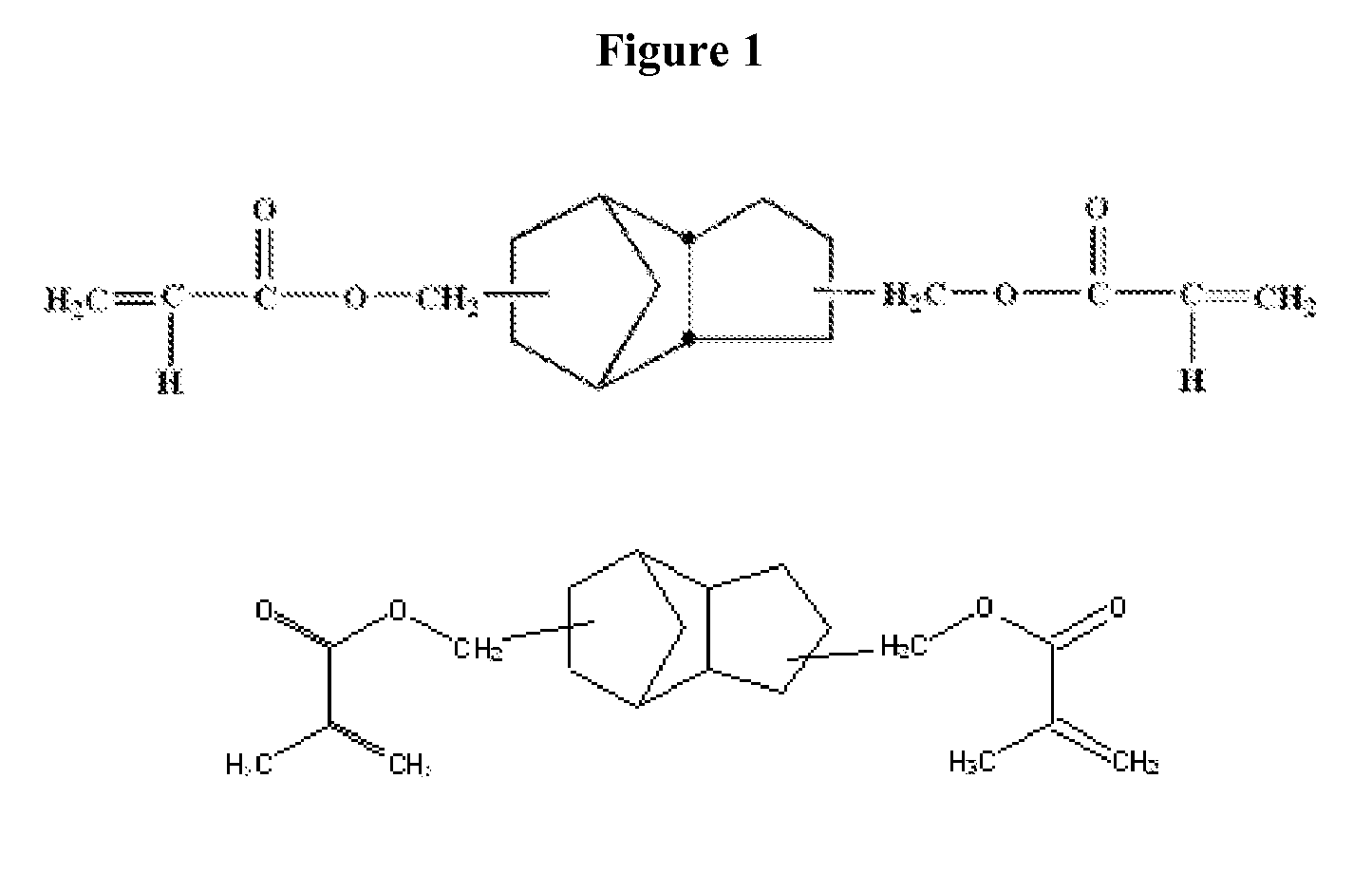

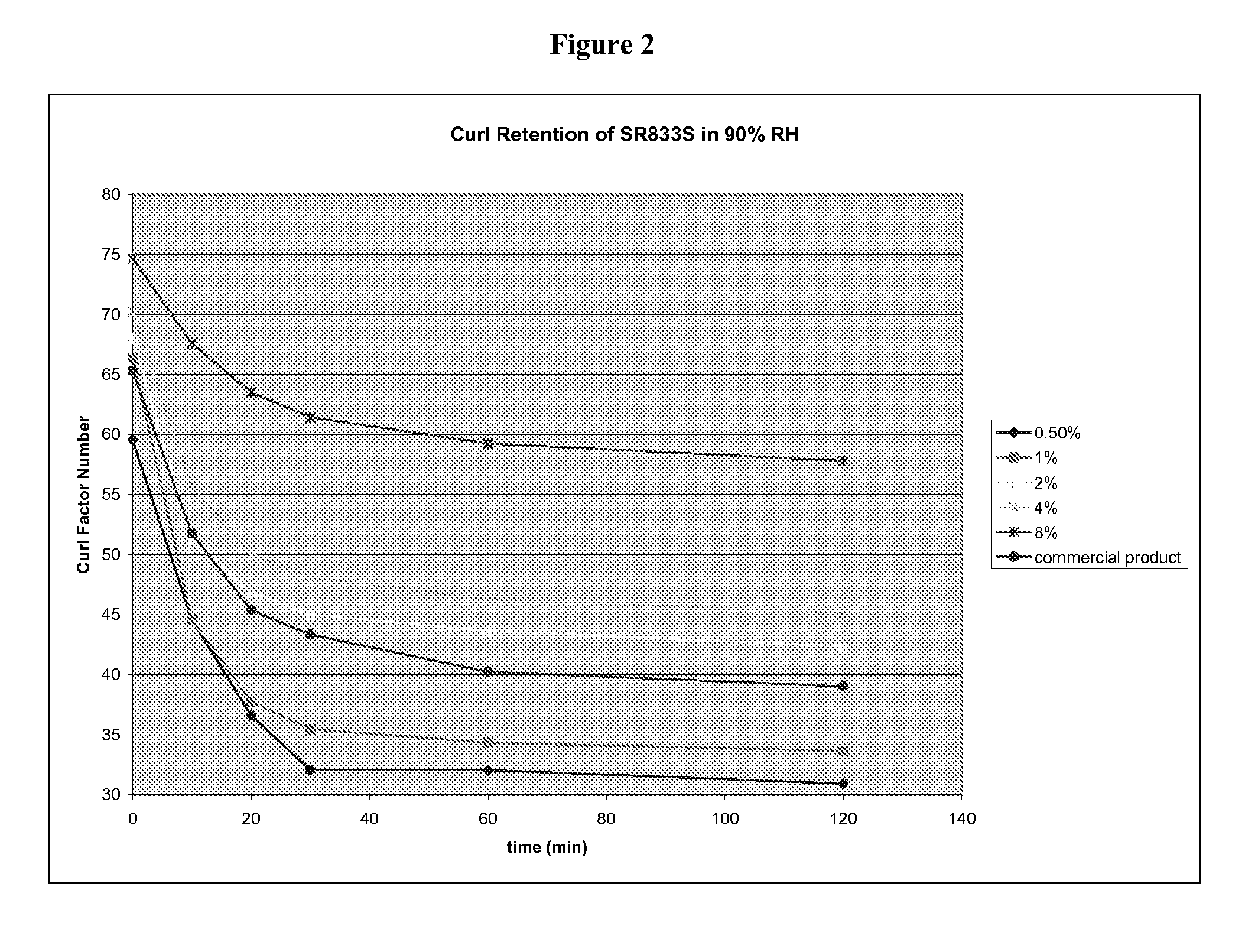

In situ polymerization for hair treatment

InactiveUS20080066773A1Effective for long period of timeImprove hair strengthCosmetic preparationsHair removalSolubilityIn situ polymerization

Hair care products represent a world-wide multi-billion dollar industry. Pre-formed polymers are commonly used in a variety of hair care products including shampoos, conditioners, gels, and hair sprays. The present invention provides technology for polymerizing monomers on hair in situ to produce desired hair characteristics. This eliminates the solubility and application issues found with some polymers. The polymerization of monomers on hair is typically initiated using a thermal or photoinitiatied free radical initiator. In certain embodiments, the monomers are fluorinated thereby producing a fluorinated polymer on the hair upon polymerization. The invention provides monomers, initiators, methods, and kits for use in treating hair with polymers.

Owner:LIVING PROOF INC

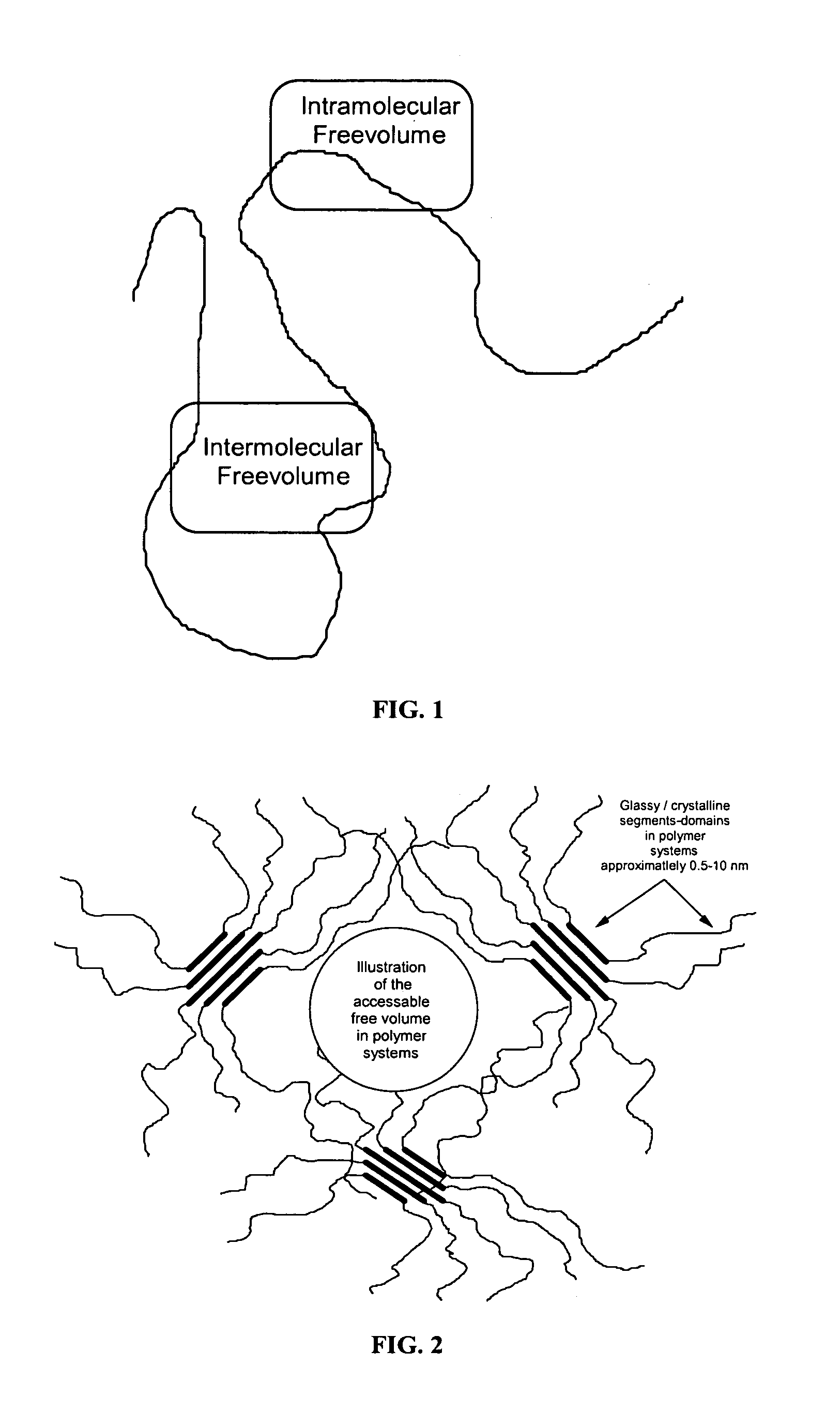

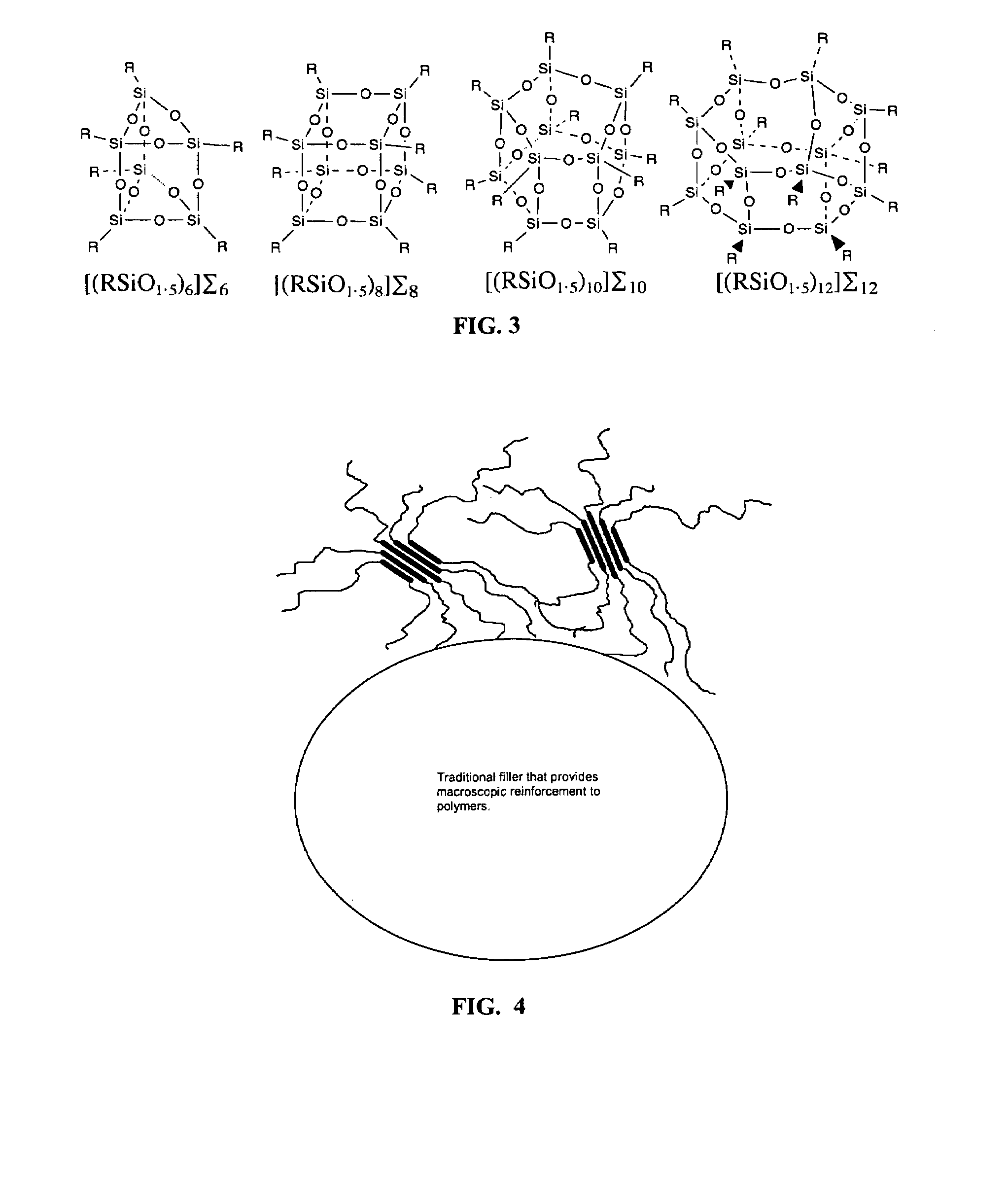

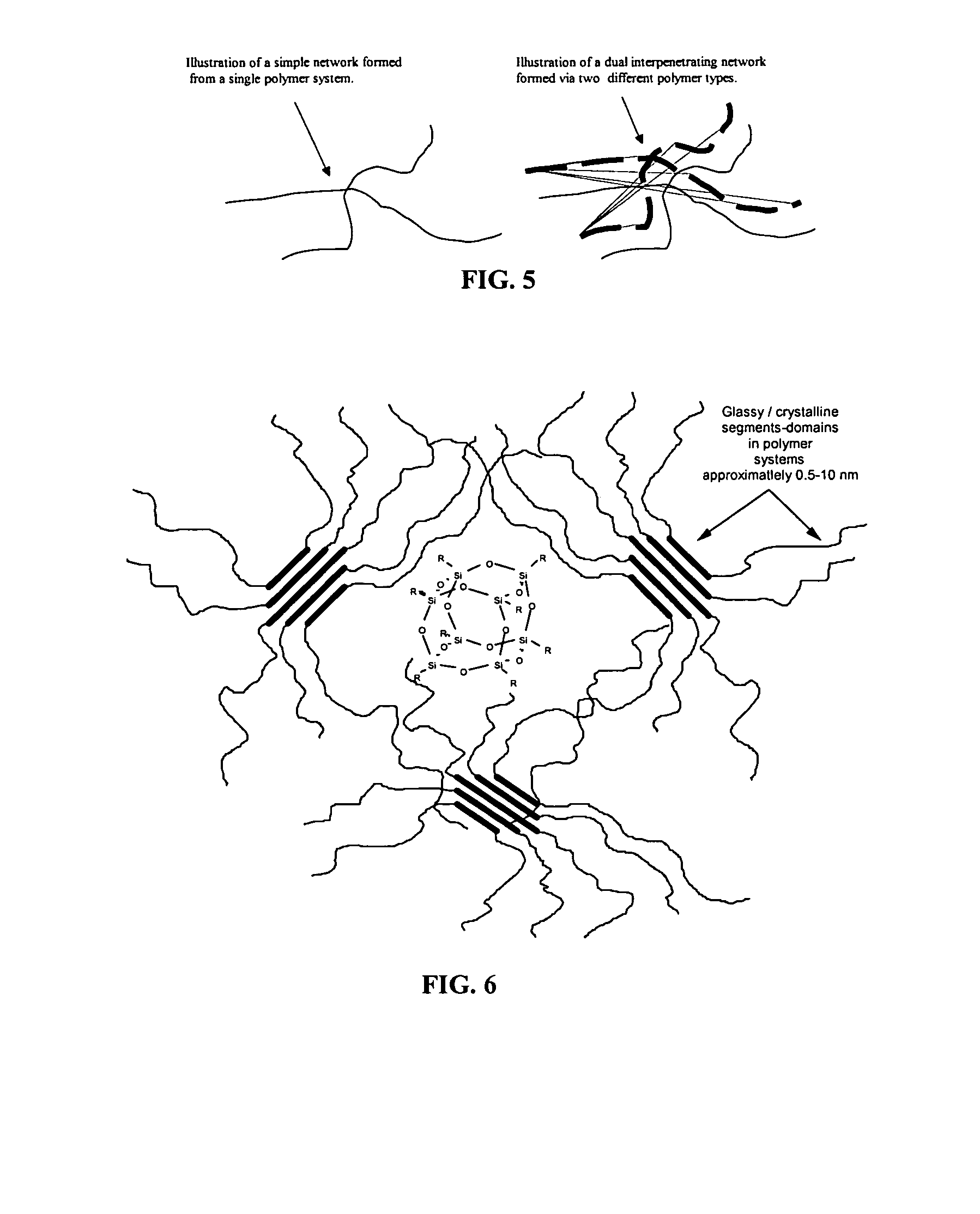

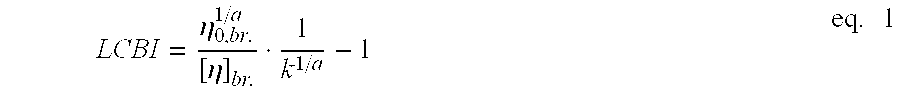

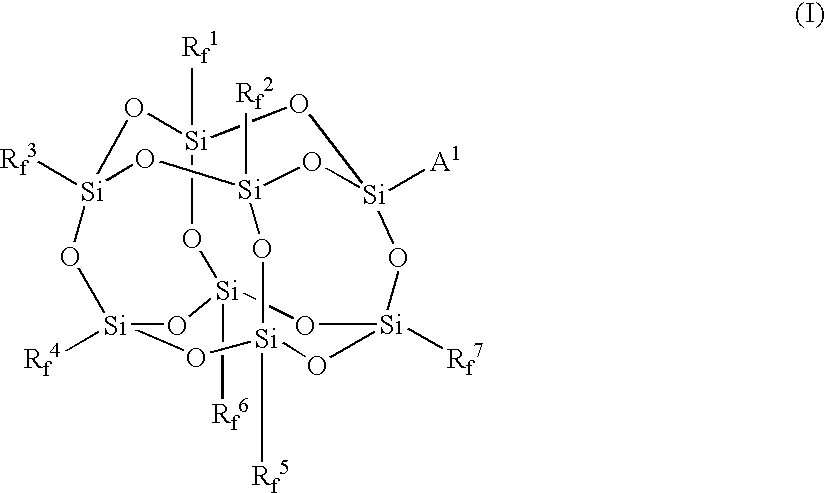

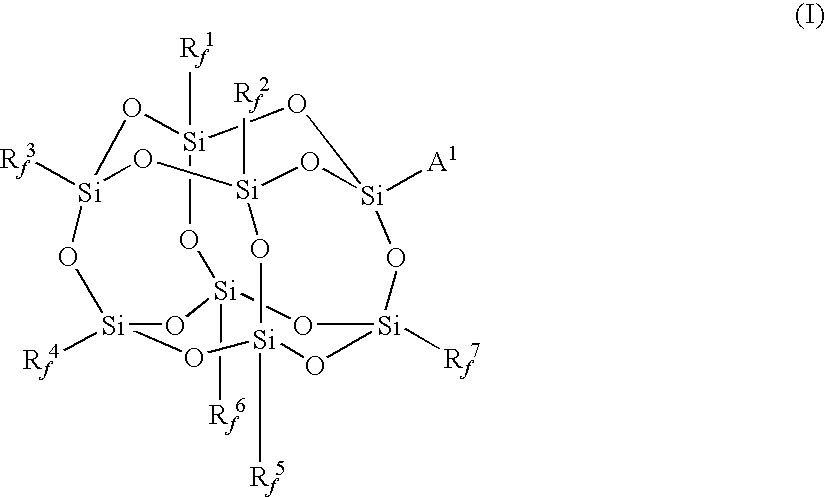

Nanostructured chemicals as alloying agents in fluorinated polymers

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

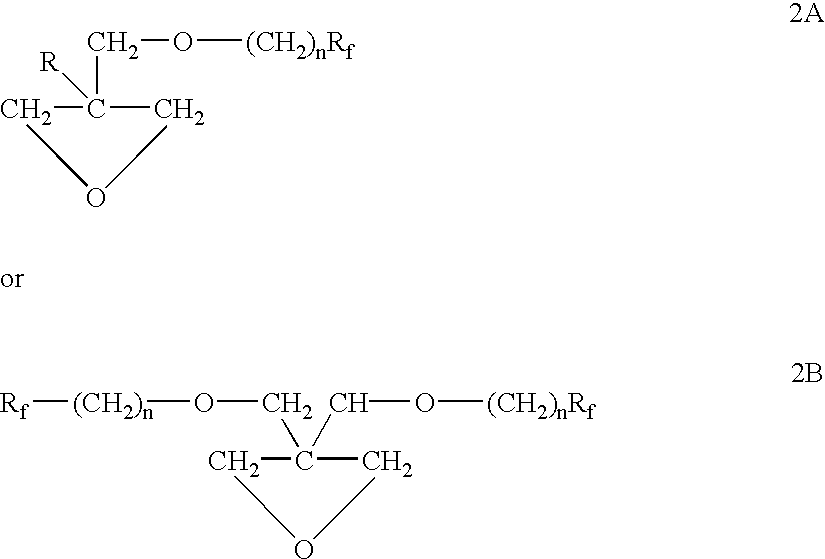

Melt-processible polymer composition comprising fluoropolymer having long chain branches

A polymer melt additive that is suitable for use as a processing aid in the extrusion of a non-fluorinated polymer. The polymer melt additive composition includes a fluoropolymer that has a long chain branching index (LCBI) of at least 0.2 and a zero shear rate viscosity at 265° C. of not more than 107 Pa's. The polymer melt additive may additionally include other compounds such as, polyoxyalkylene polymer or polycaprolactone.

Owner:3M INNOVATIVE PROPERTIES CO

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or ether side chain containing from about 1 to about 20 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:OMNOVA SOLUTIONS INC

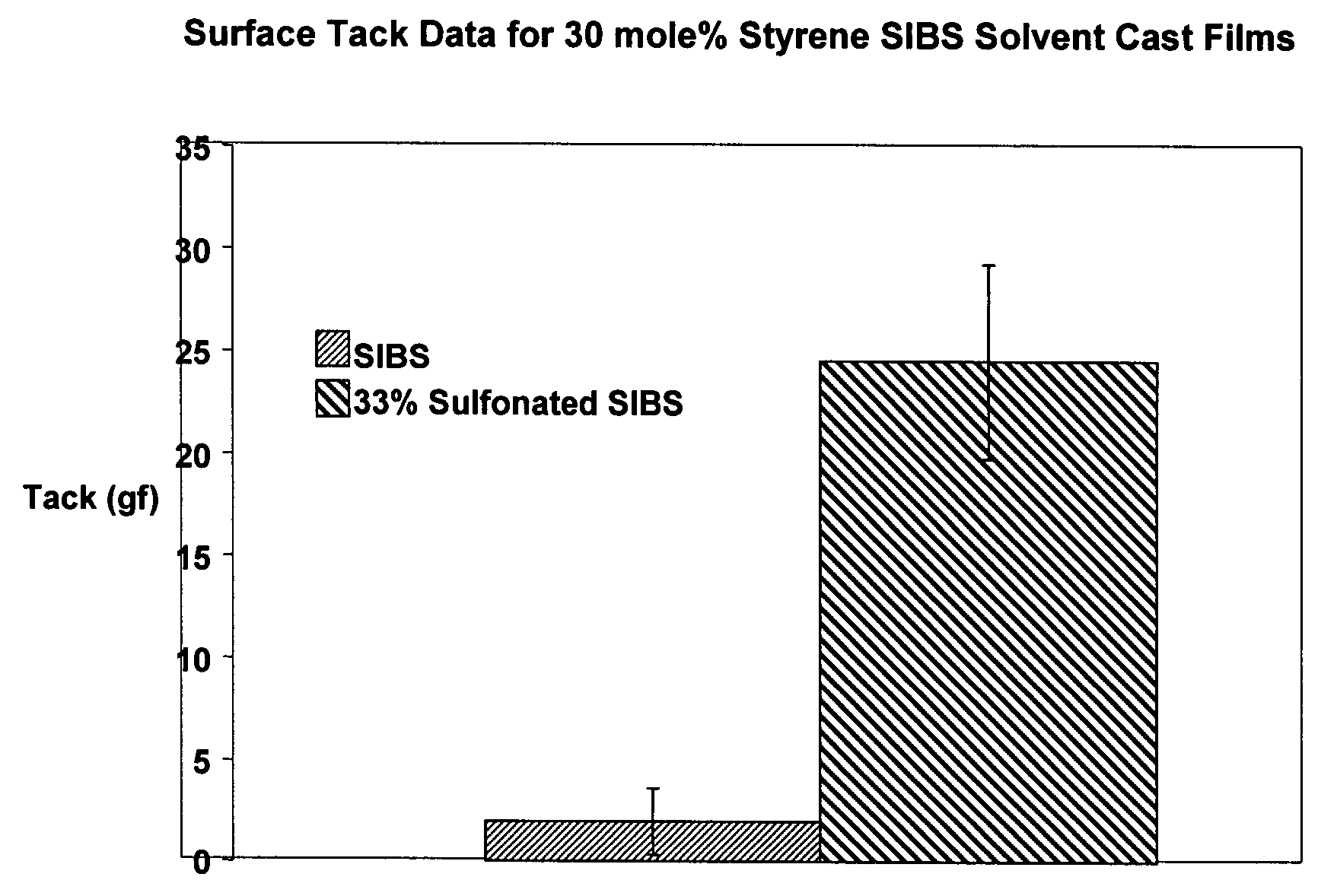

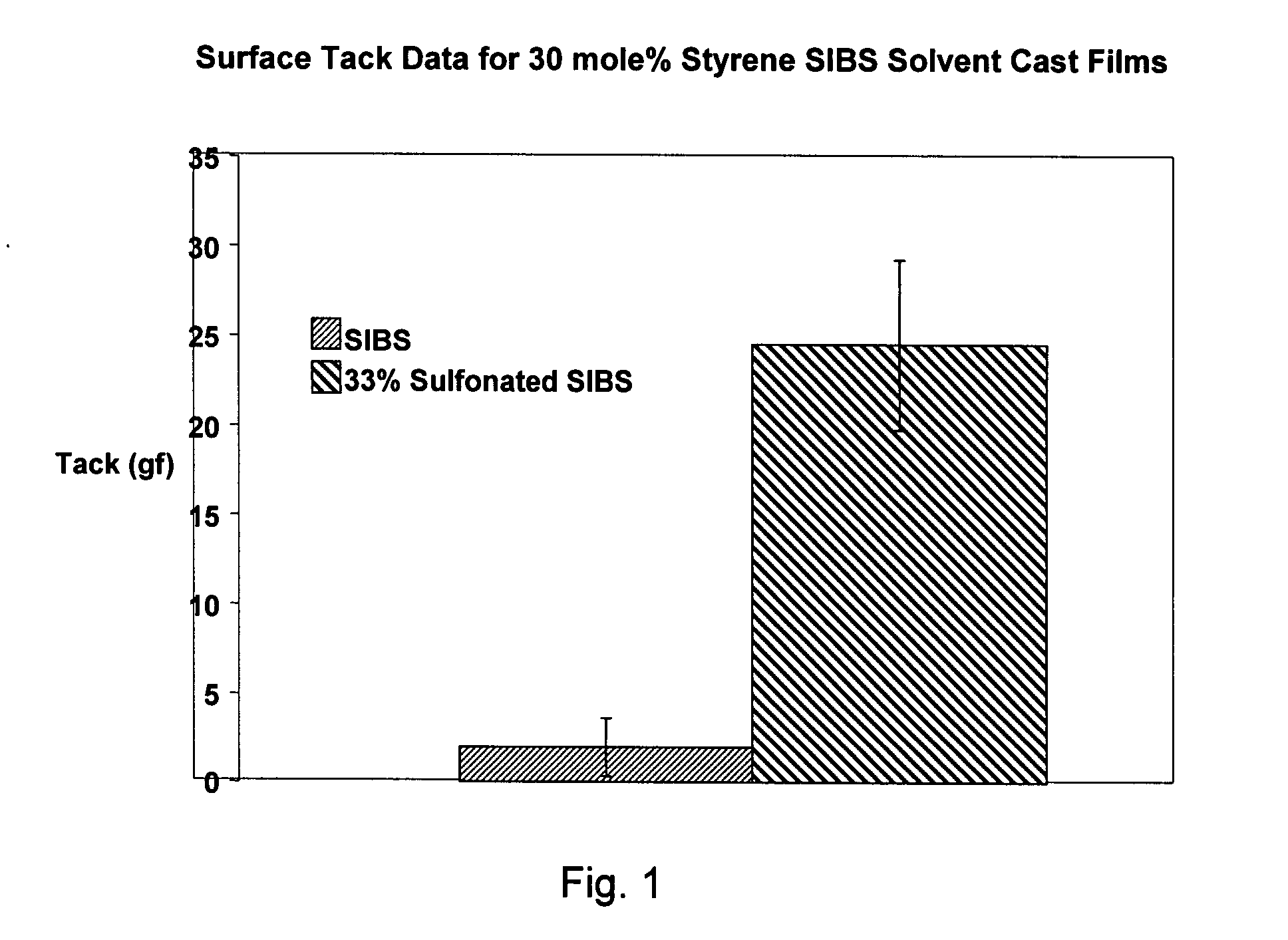

Medical devices having improved performance

In accordance with various aspects of the invention, implantable and insertable medical devices are provided, which contain one or more polymeric regions. In one aspect, the polymeric regions comprise (a) a block copolymer that comprises a polyaromatic block and a polyalkene block admixed with (b) a sulfonated high Tg polymer. In another aspect, the polymeric regions comprise a block copolymer that comprises (a) a sulfonated polymer block and (b) fluorinated polymer block.

Owner:BOSTON SCI SCIMED INC

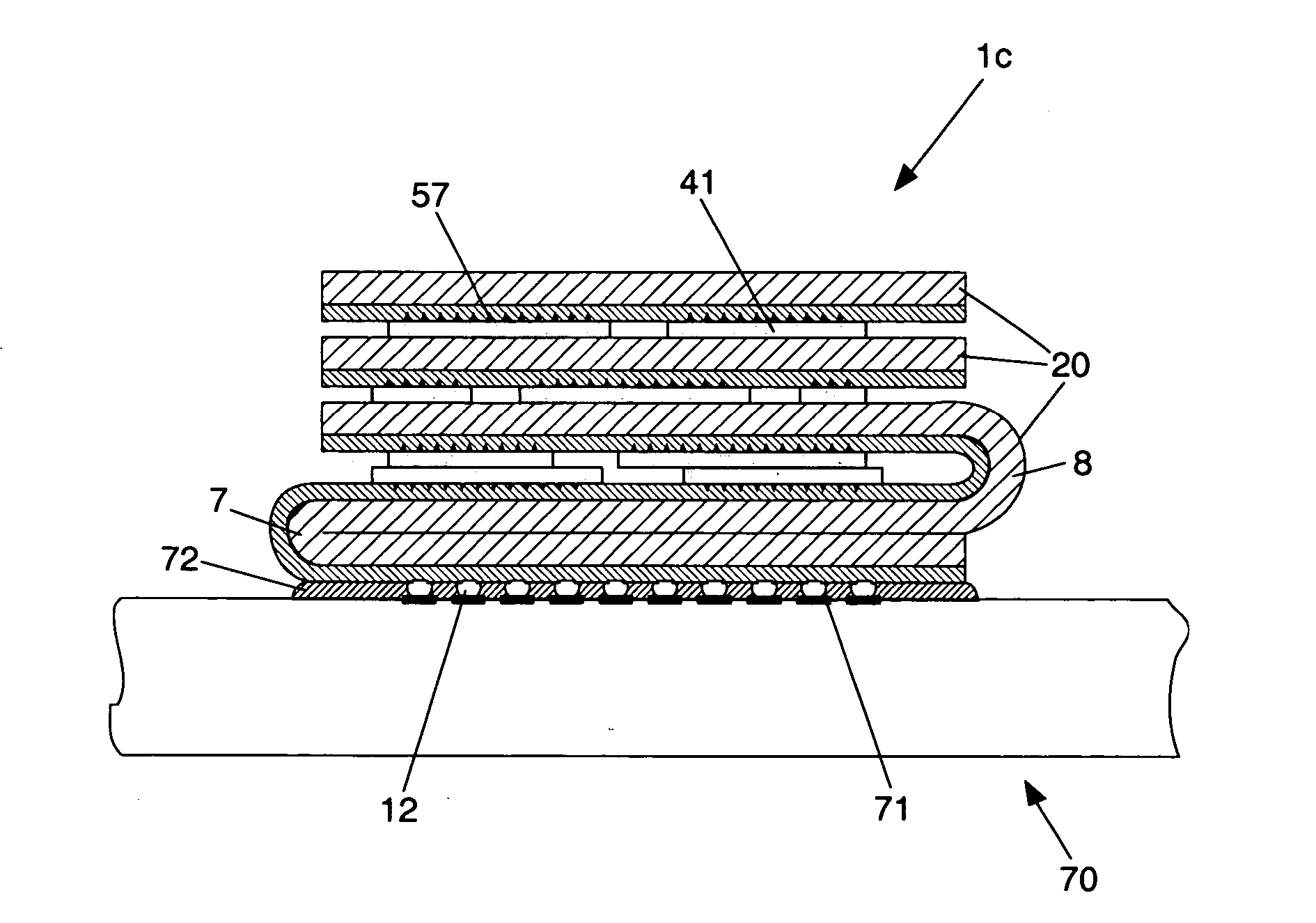

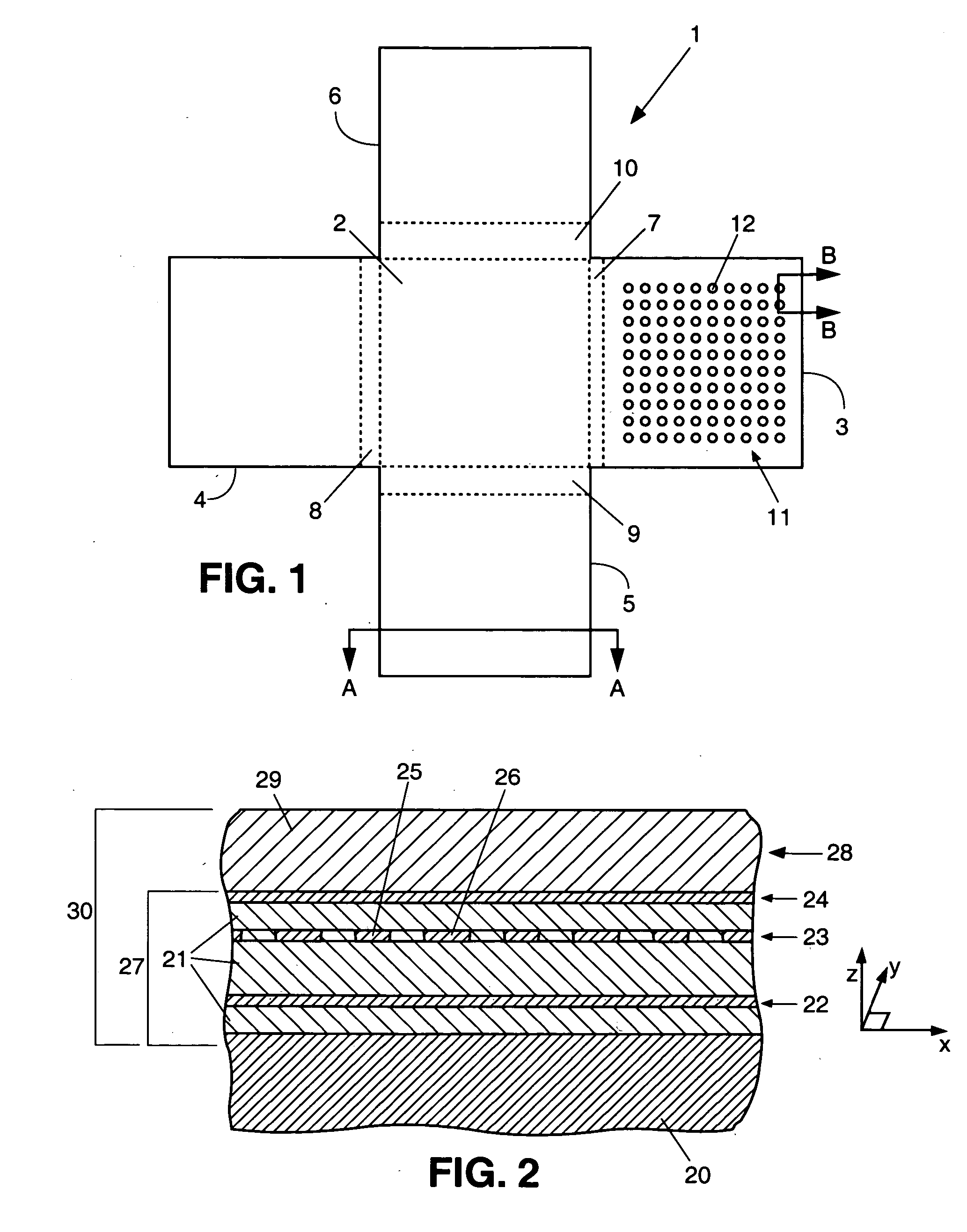

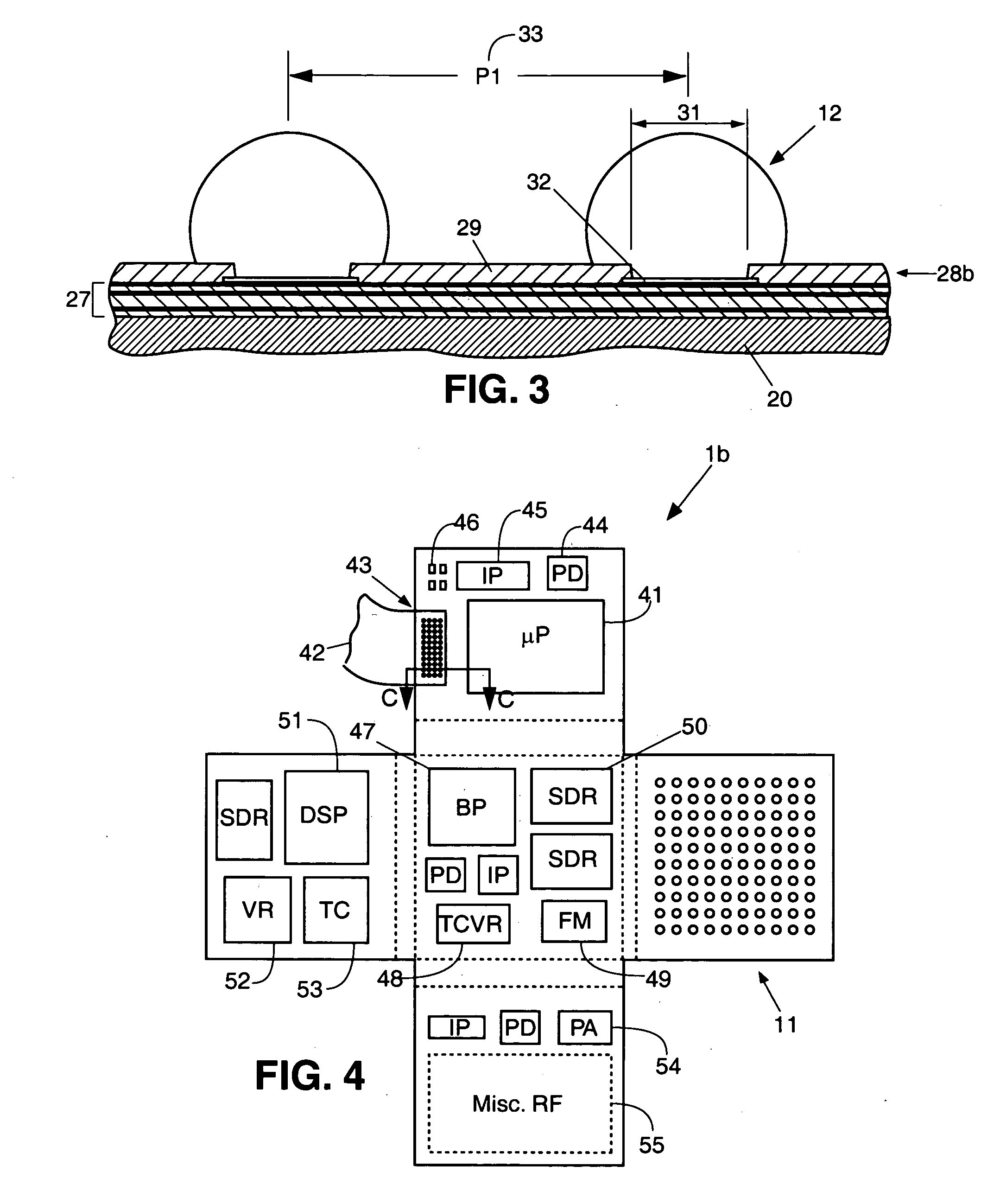

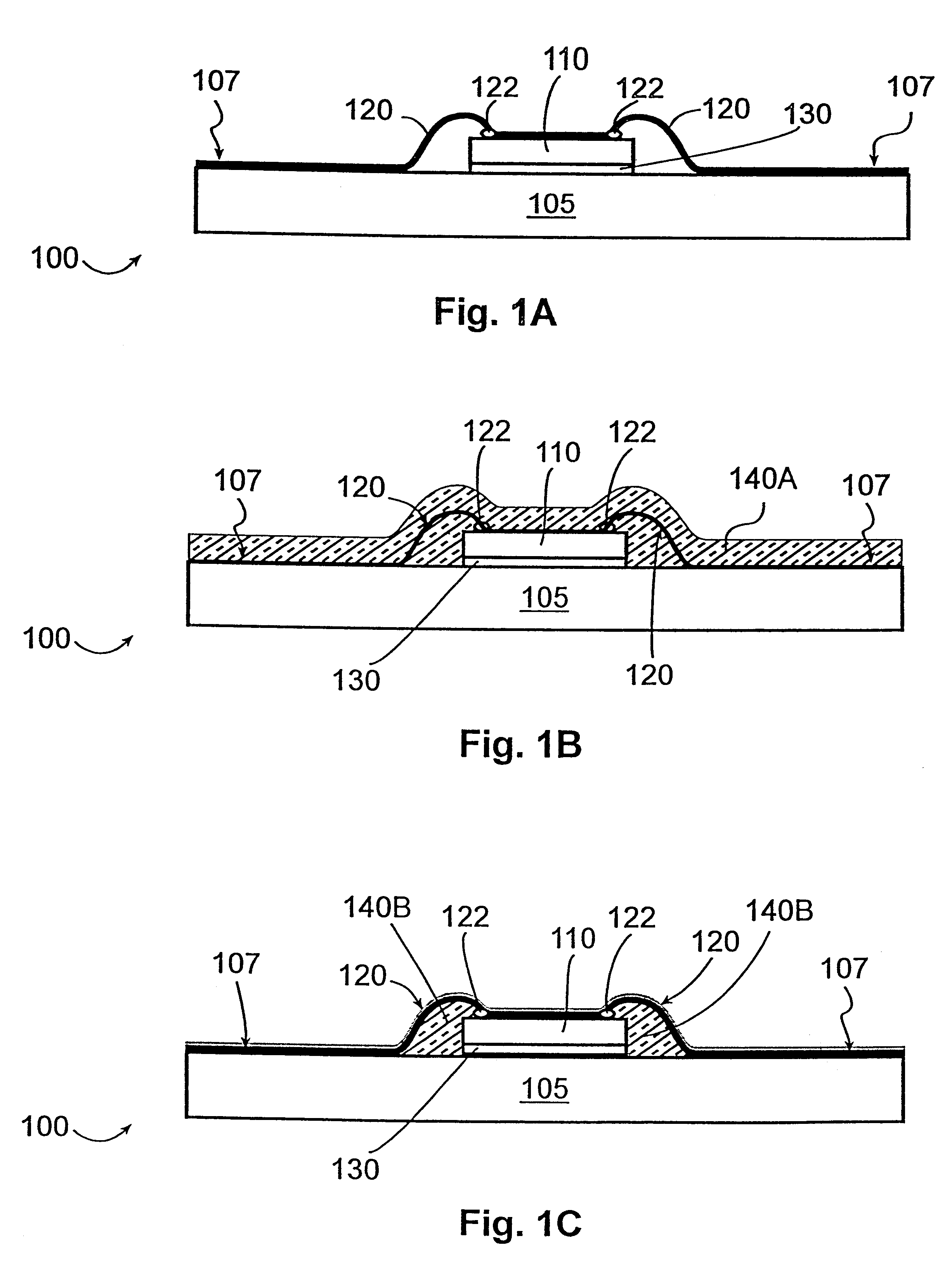

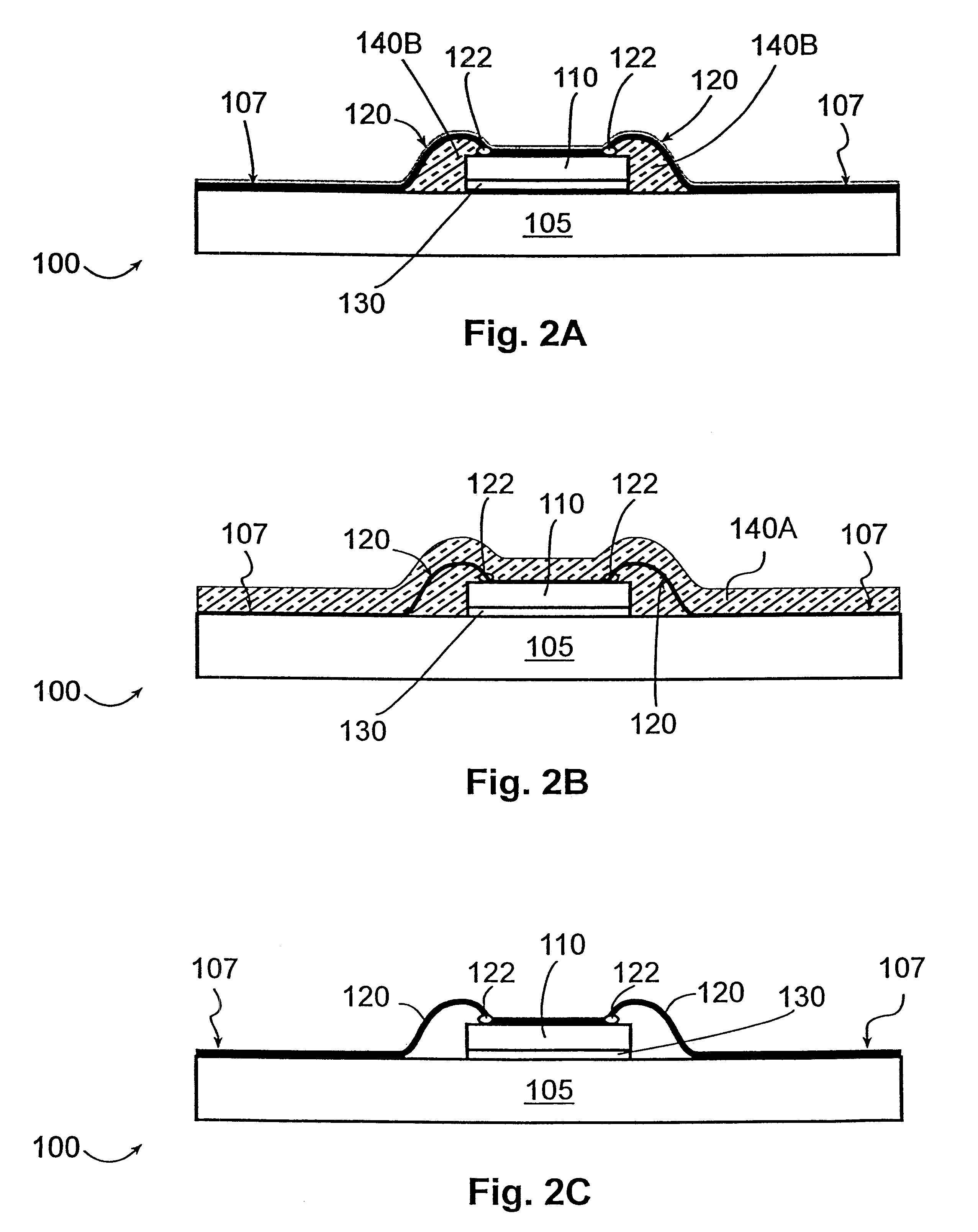

System in package

InactiveUS20050184376A1Improve cooling effectIncrease speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper conductorBand shape

A system in package (SIP) is fabricated on a sheet of copper foil. An interconnection circuit is fabricated on the foil using copper conductors and a dual damascene structure for each conductive layer. The preferred dielectric material is an amorphous fluorinated polymer called Cytop. Input / output traces of the interconnection circuit terminate in wells filled with solder. Chips are bumped and direct attached by inserting the bumps into the wells. The preferred bumps are gold stud bumps, and the preferred wells contain solder paste to a depth of approximately 15 microns. Imprinting is the preferred method for patterning; it enables 6-micron wide traces, 6-micron diameter vias, and a cost per well of around 0.02 cents. Stripline structures are described for a 4-layer stackup that can support operating frequencies of at least 10 GHz. New methods are proposed for testing the completed assembly and for rework of any chips that prove defective. After the assembly is fully tested and reworked in sheet form the copper foil is folded to form a stacked die package or system in package. 5-high and 9-high stacks are illustrated. The copper foil provides a low impedance thermal path for cooling every chip in the SIP.

Owner:SALMON TECH

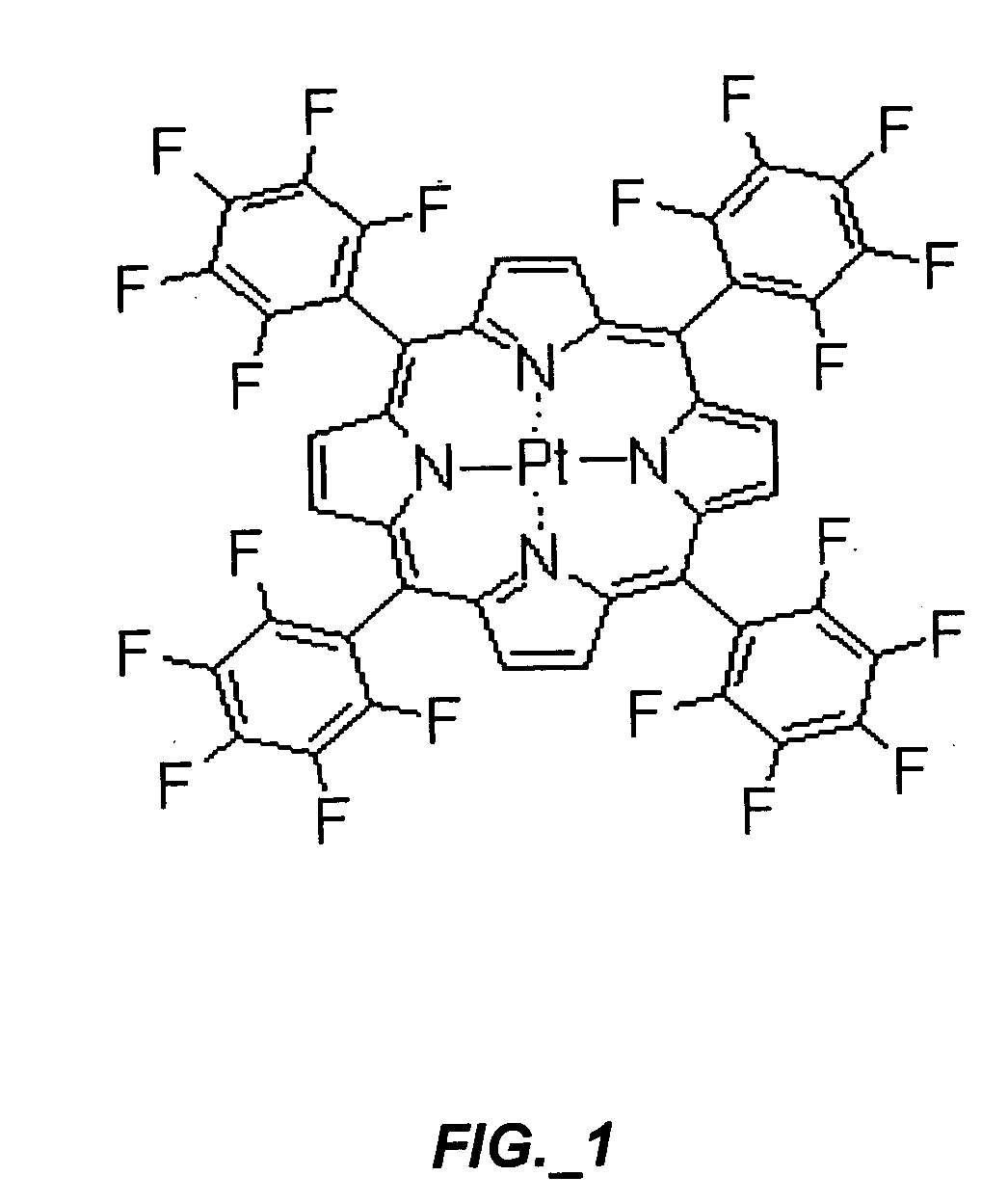

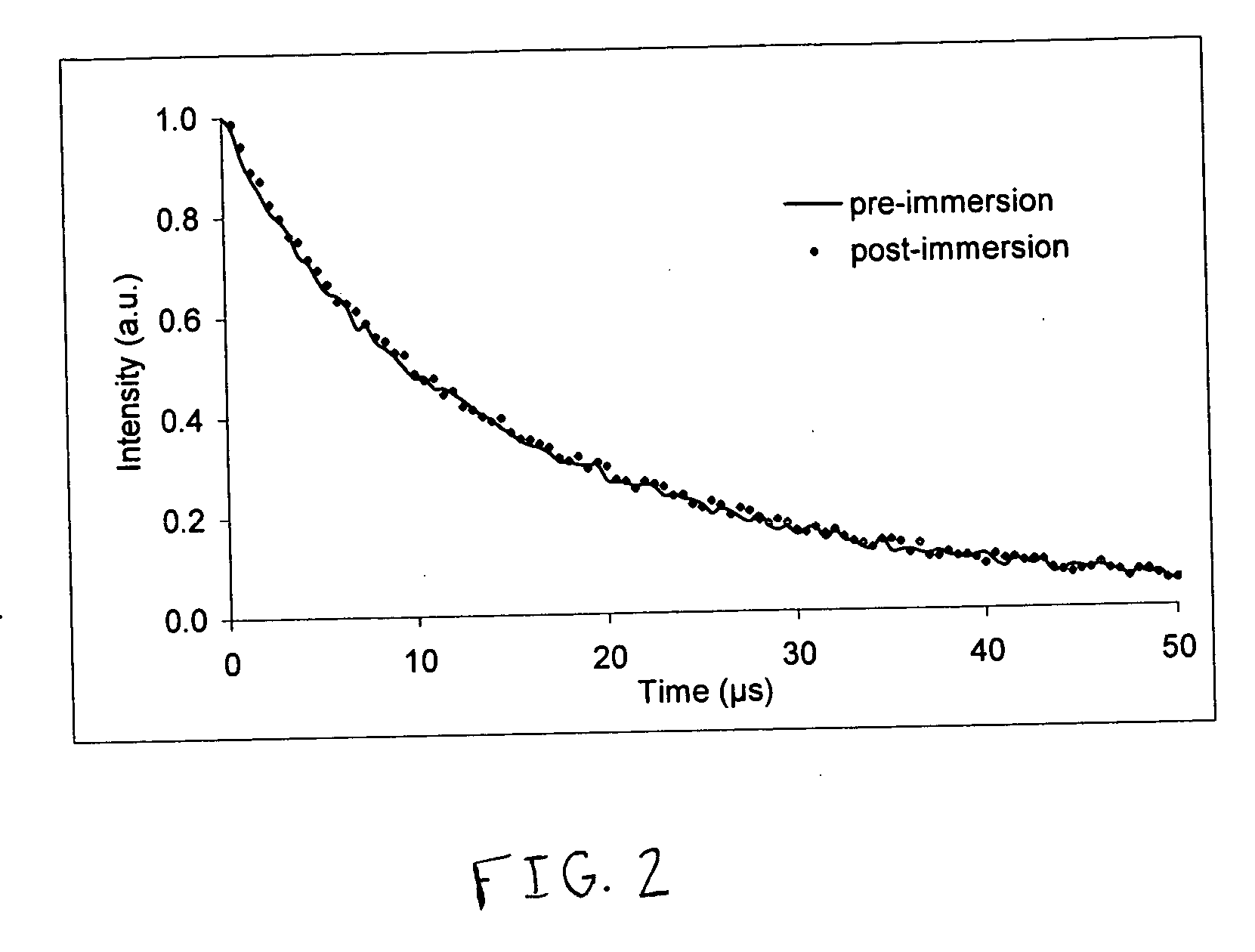

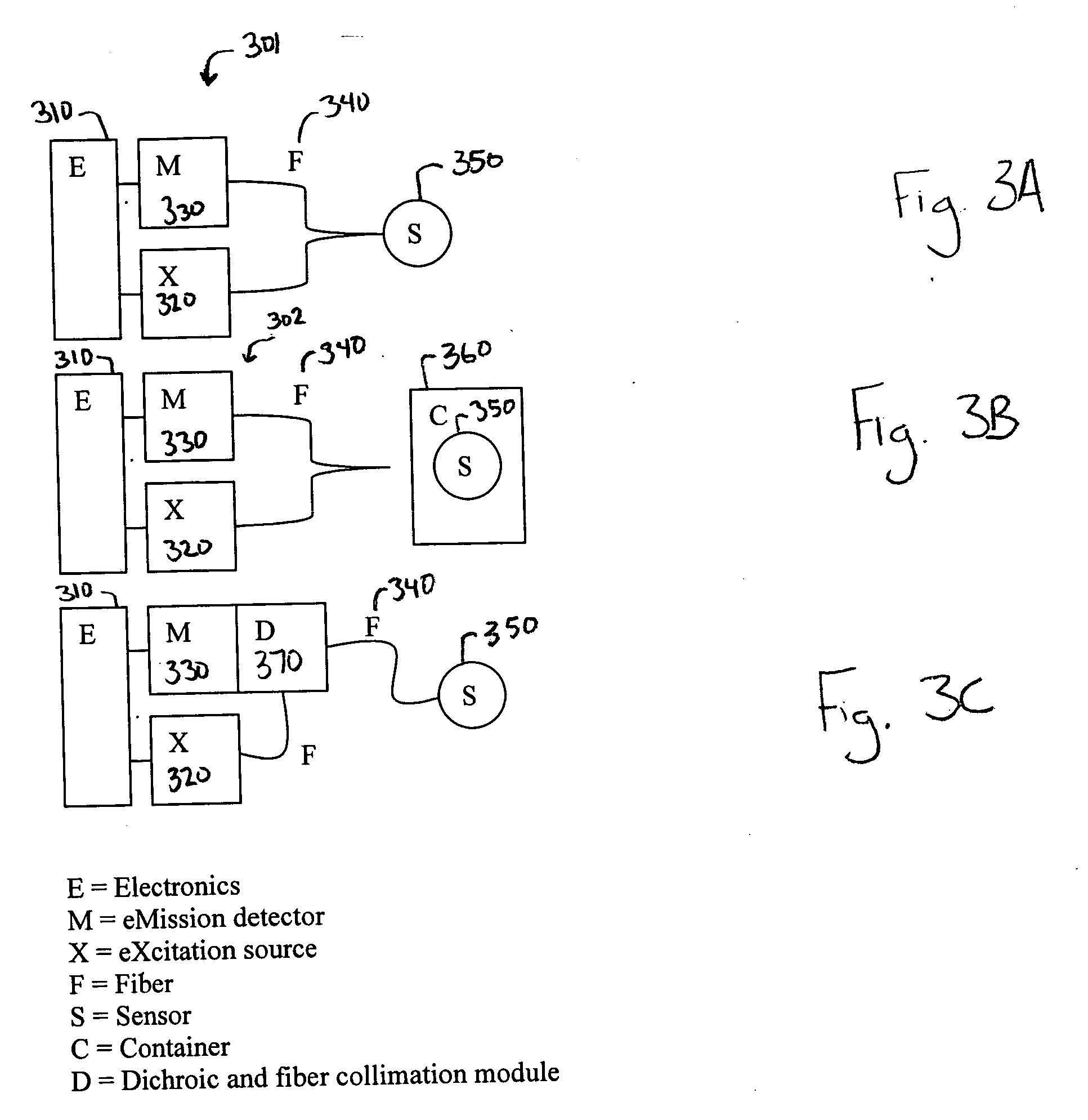

Sensors for measuring analytes

InactiveUS20060171845A1Low costImprove solubilityFuel tank safety measuresFluorescence/phosphorescenceAnalyteOrganic solvent

A sensor and system using the sensor for detecting an analyte, where the sensor includes an amorphous fluorinated polymer and a luminescent metal-ligand complex is provided. Sensor systems for monitoring oxygen in environments containing volatile organic solvents are also provided.

Owner:DAKOTA TECH

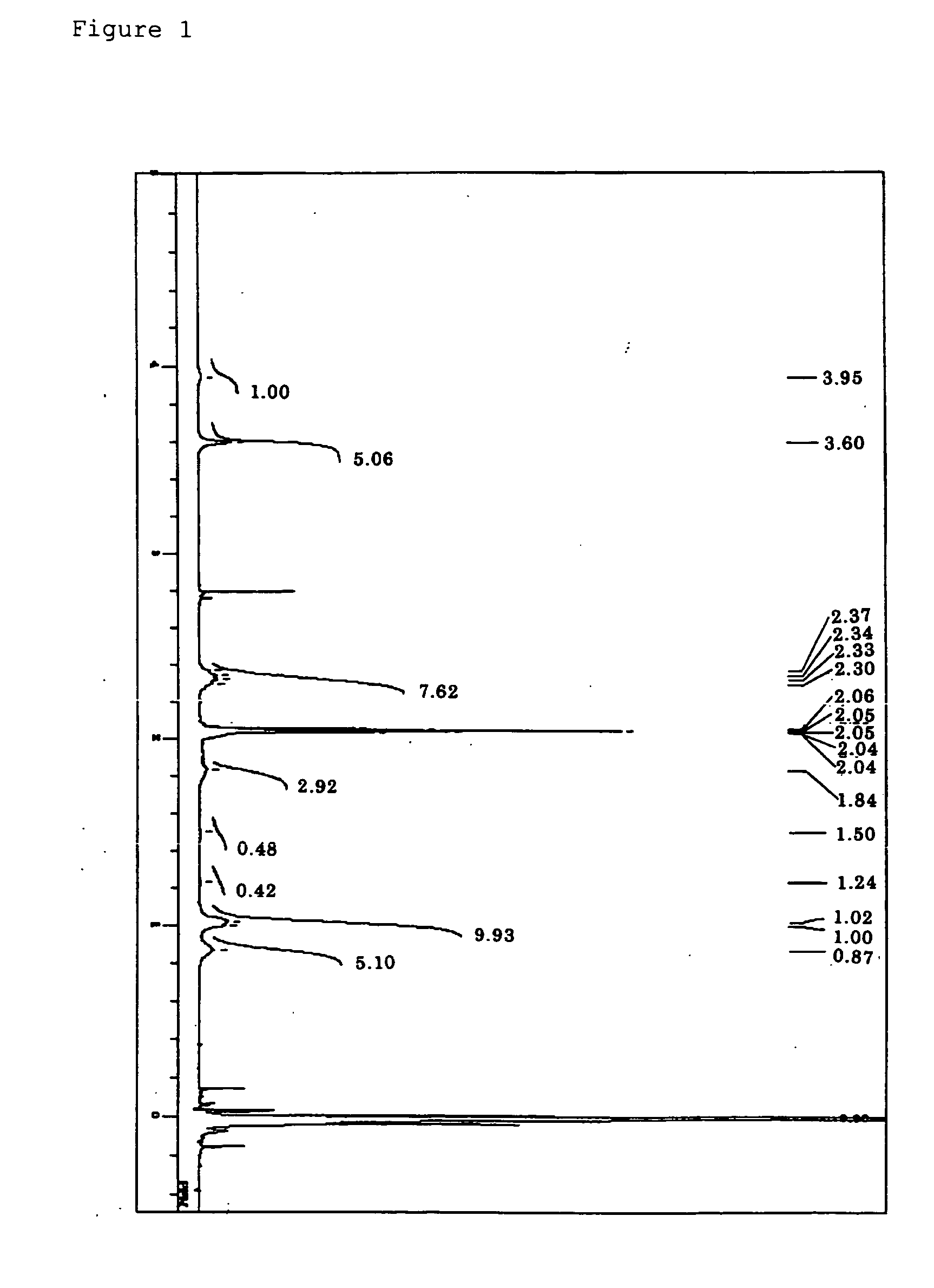

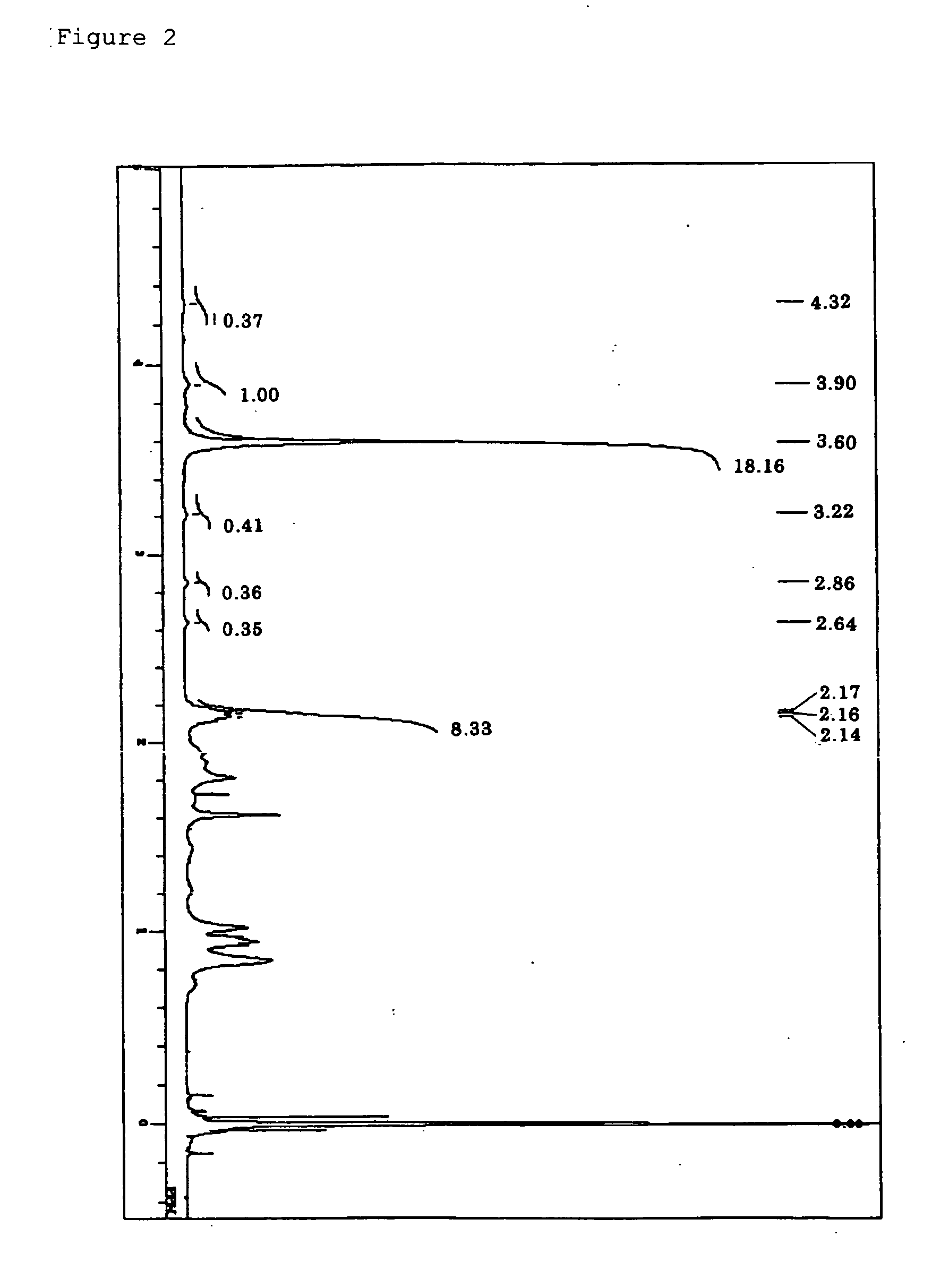

Fluorinated polymer and polymer composition

Provided are: an addition polymer of fluorosilsesquioxane (a) having one addition polymerizable functional group or an addition copolymer of the fluorosilsesquioxane (a) having one addition polymerizable functional group and an addition polymerizable monomer (b); a coating film including the polymer or the copolymer; and an addition copolymer of the fluorosilsesquioxane (a) having one addition polymerizable functional group and organopolysiloxane (c) having an addition polymerizable functional group, or an addition copolymer of the fluorosilsesquioxane (a) having one addition polymerizable functional group, the organopolysiloxane (c) having an addition polymerizable functional group, and the addition polymerizable monomer (b).

Owner:JNC CORP

Melt-processible polymer composition comprising fluoropolymer having long chain branches

ActiveUS20040260022A1Clearly detectable melting pointImprove efficiencyFibre treatmentFlotationProcedure AgentsPolymer science

A polymer melt additive that is suitable for use as a processing aid in the extrusion of a non-fluorinated polymer. The polymer melt additive composition includes a fluoropolymer that has a long chain branching index (LCBI) of at least 0.2 and a zero shear rate viscosity at 265° C. of not more than 10<7 >Pa's. The polymer melt additive may additionally include other compounds such as, polyoxyalkylene polymer or polycarprolactone.

Owner:3M INNOVATIVE PROPERTIES CO

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

InactiveUS7022801B2Good optical performanceHigh glossTransportation and packagingMixingPolymeric surfacePolymer science

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or ether side chain containing from about 1 to about 20 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:OMNOVA SOLUTIONS INC

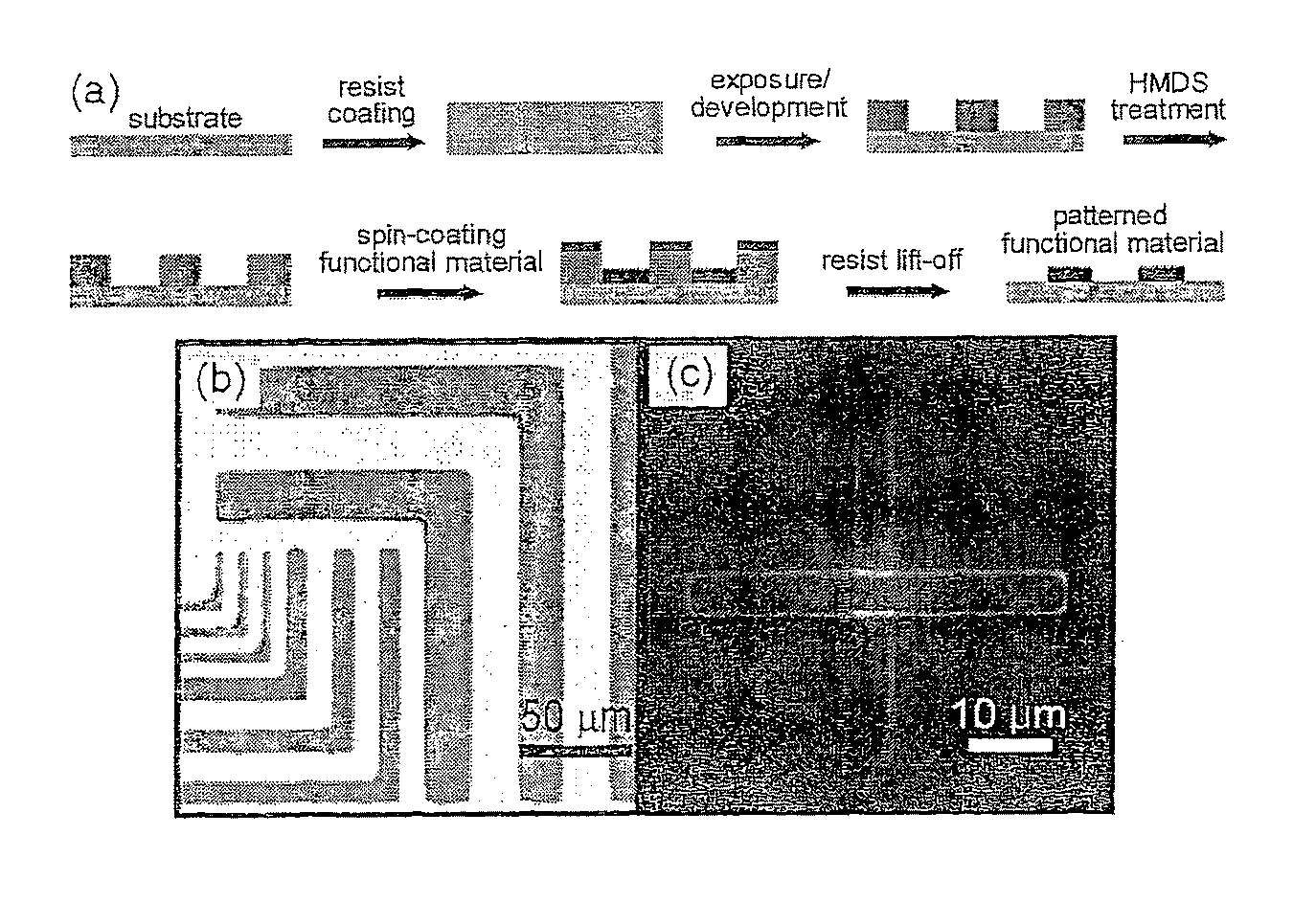

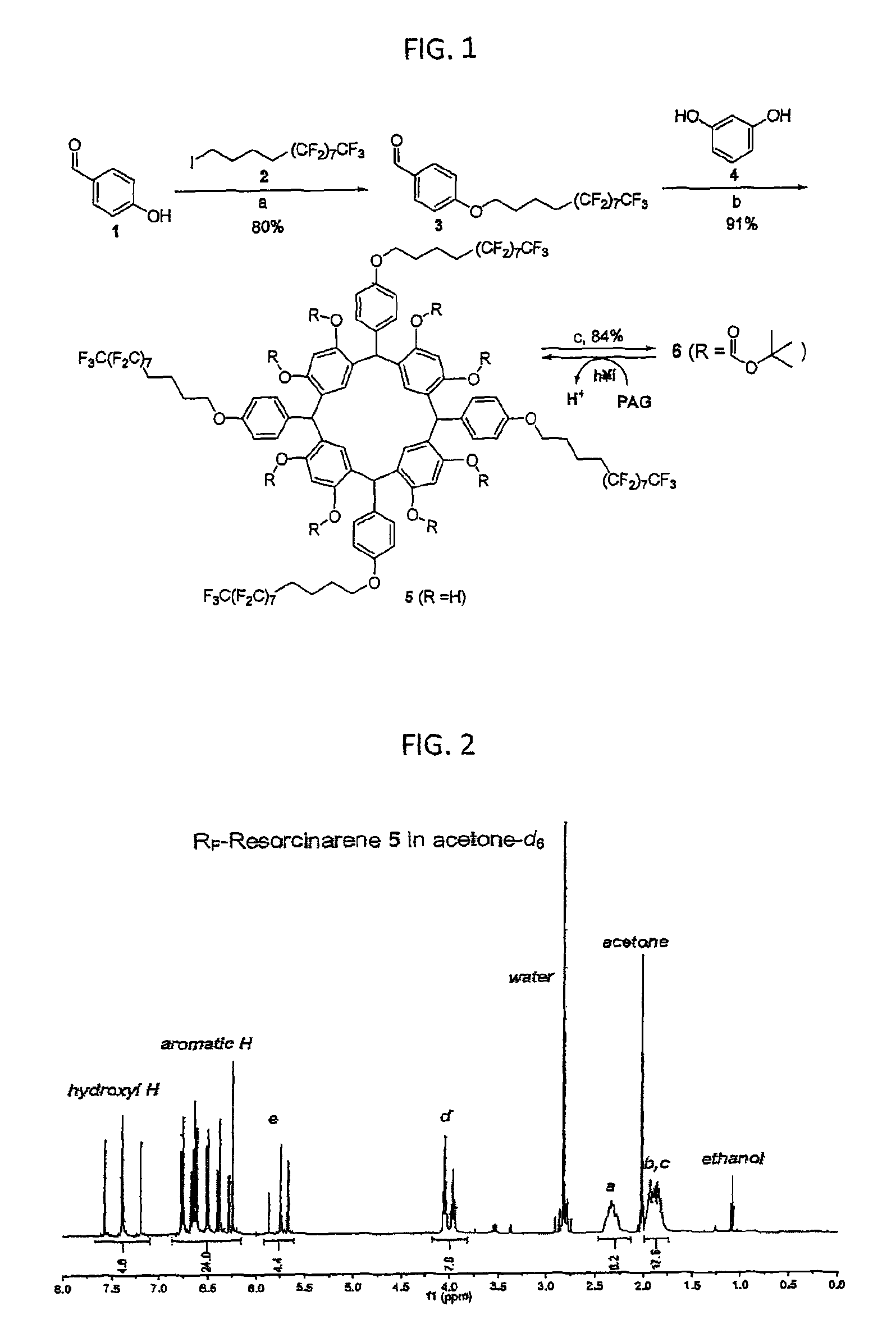

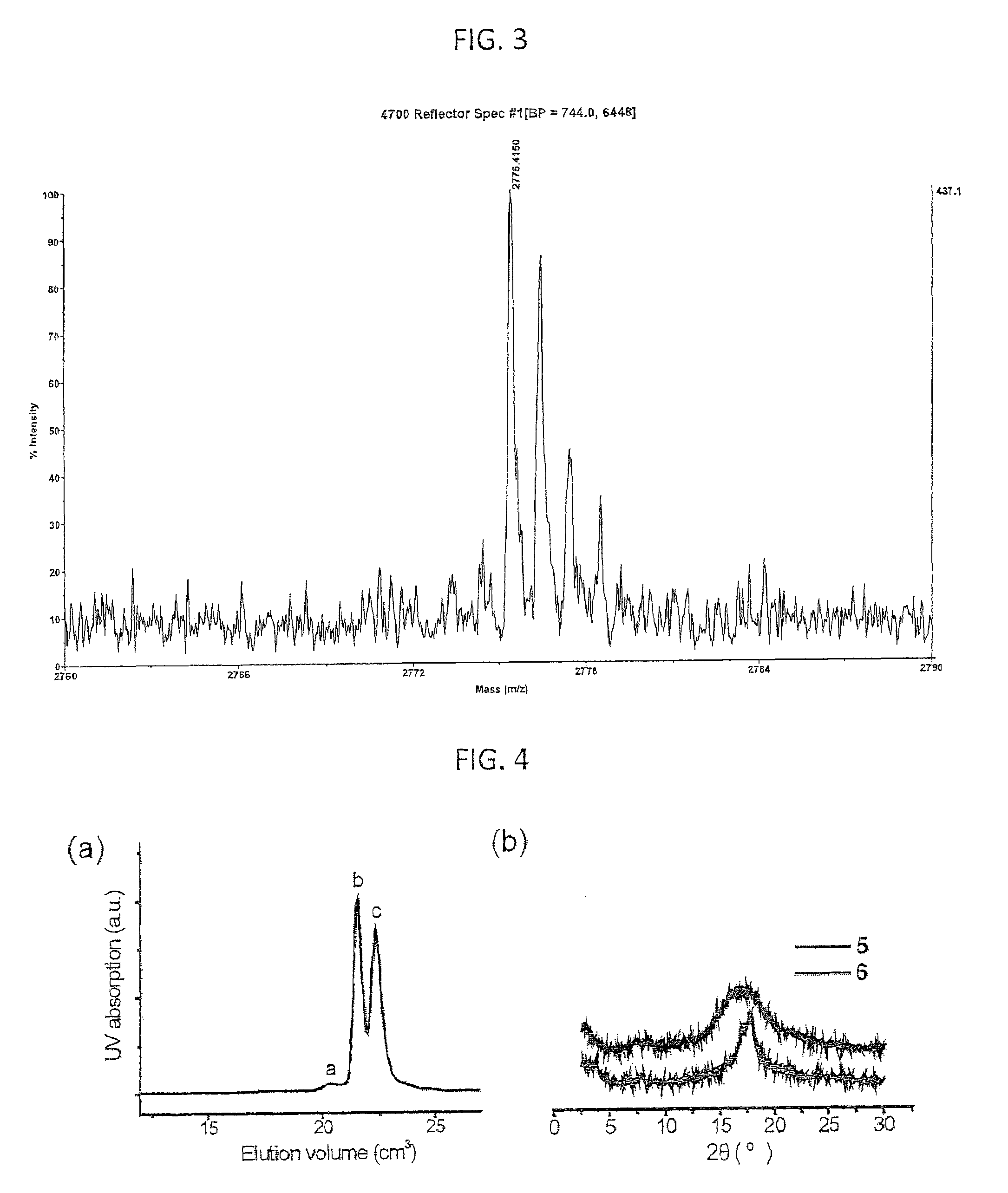

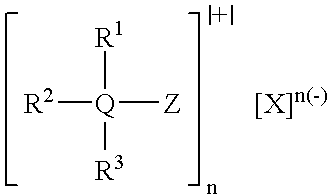

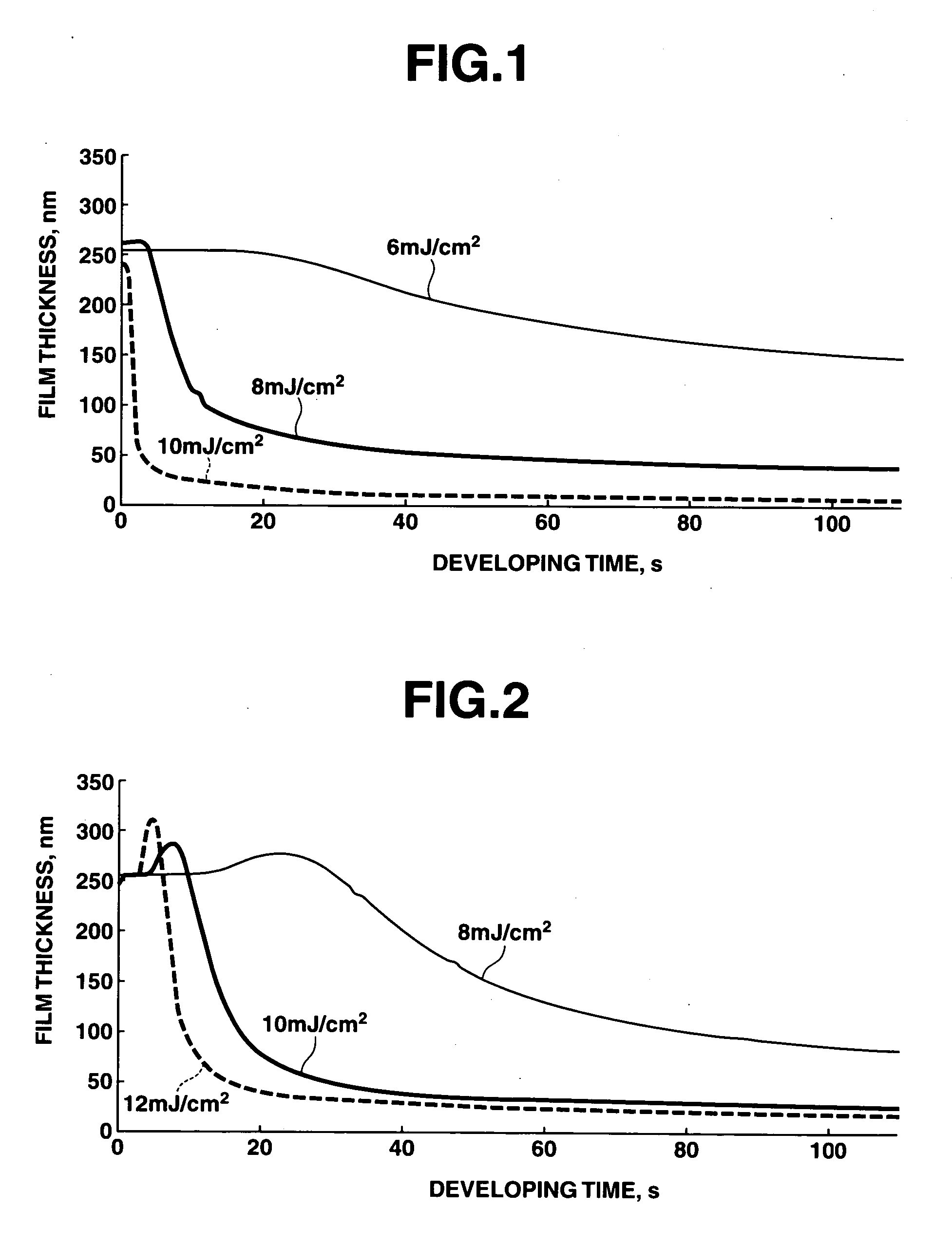

Orthogonal processing of organic materials used in electronic and electrical devices

ActiveUS8846301B2Avoid damageImprove throughputSolid-state devicesSemiconductor/solid-state device manufacturingMethacrylateOrganic structure

An orthogonal process for photolithographic patterning organic structures is disclosed. The disclosed process utilizes fluorinated solvents or supercritical CO2 as the solvent so that the performance of the organic conductors and semiconductors would not be adversely affected by other aggressive solvent. One disclosed method may also utilize a fluorinated photoresist together with the HFE solvent, but other fluorinated solvents can be used. In one embodiment, the fluorinated photoresist is a resorcinarene, but various fluorinated polymer photoresists and fluorinated molecular glass photoresists can be used as well. For example, a copolymer perfluorodecyl methacrylate (FDMA) and 2-nitrobenzyl methacrylate (NBMA) is a suitable orthogonal fluorinated photoresist for use with fluorinated solvents and supercritical carbon dioxide in a photolithography process. The combination of the fluorinated photoresist and the fluorinated solvent provides a robust, orthogonal process that is yet to be achieved by methods or devices known in the art.

Owner:CORNELL UNIVERSITY

Elastomeric compositions containing fluoropolymer blends

Processable rubber compositions contain a vulcanized fluorocarbon elastomer dispersed in a thermoplastic matrix comprising a fully fluorinated polymer and a partially fluorinated polymer. The processing temperature is below the melting point of the fully fluorinated polymer. The compositions are made by combining a curative, uncured fluorocarbon elastomer, a fully fluorinated thermoplastic, and a partially fluorinated thermoplastic material, and heating the mixture at a temperature and for a time sufficient to effect vulcanization of the elastomeric material, while mechanical energy is applied to mix the mixture during the heating step. Shaped articles such as seals, gaskets, O-rings, and hoses may be readily formed from the rubber compositions according to conventional thermoplastic processes such as blow molding, injection molding, and extrusion.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Water base dispersion of fluorinated polymer and process for producing the same

The object of the present invention is a fluoropolymer aqueous dispersion showing only a moderate viscosity increase upon temperature rise and having a low fluorine-containing anionic surfactant concentration as well as a method of producing such fluoropolymer aqueous dispersion. The present invention provides a fluoropolymer aqueous dispersion comprising a particle comprising a fluoropolymer dispersed in an aqueous medium in the presence of a nonionic surfactant, wherein a supernatant for assaying as obtained by subjecting the fluoropolymer aqueous dispersion to 30 minutes of centrifugation at 25° C. and at a gravitational acceleration of 1677 G, when subjected to high-performance liquid chromatography [HPLC] under the conditions of a flow rate of 1.0 ml / minute and a column temperature of 40° C. using an acetonitrile / 0.05 M aqueous solution of phosphoric acid (60 / 40% by volume) mixture as a developing solution, followed by detection at an absorption wavelength at which the nonionic surfactant can be identified, shows a ratio (A1 / A0), which is the ratio between the total area (A0) under the detected line and the area (A1) under the detected line over a retention time period shorter than 16 minutes, of not lower than 0.4 and the supernatant for assaying has a fluorine-containing anionic surfactant content of not higher than 100 ppm.

Owner:DAIKIN IND LTD

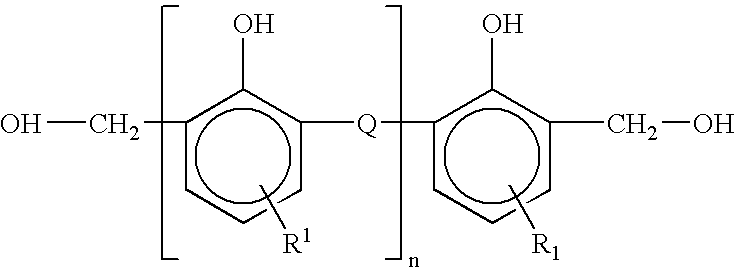

Novel fluorinated polymer

InactiveUS20090186986A1Excellent cross-linking reactivityMaintain good propertiesPolymer scienceHexafluoropropylene

The present invention provides a fluorinated polymer excellent in the crosslinking reactivity, crosslinked rubber physical properties and chemical resistance, and its crosslinked rubber.A fluorinated polymer comprising repeating units (a) based on at least one monomer selected from the group consisting of ethylenic unsaturated compounds each having a hydroxyphenyl group, repeating units (b) based on at least one fluoromonomer selected from the group consisting of tetrafluoroethylene, hexafluoropropylene, vinylidene fluoride, 3,3,3-trifluoropropene, 1,3,3,3-tetrafluoropropene, 1,1,2-trifluoroethylene, vinyl fluoride, 1,2-difluoroethylene and CF2═CF—O—Rf (wherein Rf is a C1-8 saturated perfluoroalkyl group or a perfluoro(alkoxyalkyl) group) and, if necessary, repeating units (c) based on at least one hydrocarbon monomer selected from the group consisting of ethylene, propylene and CH2═CH—O—R1.

Owner:ASAHI GLASS CO LTD

Fluorinated short carbon atom side chain and polar group containing polymer, and flow, or leveling, or wetting agents thereof

InactiveUS20030092862A1Good wettingSpeed up the flowPolishing compositions with abrasivesPolymer scienceHydrogen

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or short side chain containing from about 1 to about 7 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:OMNOVA SOLUTIONS INC

Polymer electrolyte membrane having high durability and method for producing the same

ActiveUS20050053822A1Maintain good propertiesIncreased durabilityElectrolyte holding meansIon-exchanger regenerationChemical LinkagePolymer electrolytes

A polymer electrolyte membrane comprising: (a) a fluorinated polymer electrolyte having an ion exchange group, and (b) a basic polymer, wherein, optionally, at least a part of component (a) and at least a part of component (b) are chemically bonded to each other. A method for producing the above-mentioned polymer electrolyte membrane. A membrane / electrode assembly comprising the above-mentioned polymer electrolyte membrane which is securely sandwiched between an anode and a cathode. A polymer electrolyte fuel cell comprising the membrane / electrode assembly.

Owner:ASAHI KASEI CHEM CORP

Method of reworkably removing a fluorinated polymer encapsulant

InactiveUS6306688B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPolymer scienceFluorinated polymer

The present invention provides an improved fluorinated polymer encapsulant for protectively coating electronic devices in an electronic device module. Also provided is a method for applying and reworkably removing the same to and from the electronic device module. In one embodiment, a coating of a fluorinated polymer solution is applied to at least a portion of an electronic device module. The module is then baked to operably fix to it the fluorinated polymer coating.

Owner:TERAVICTA TECH

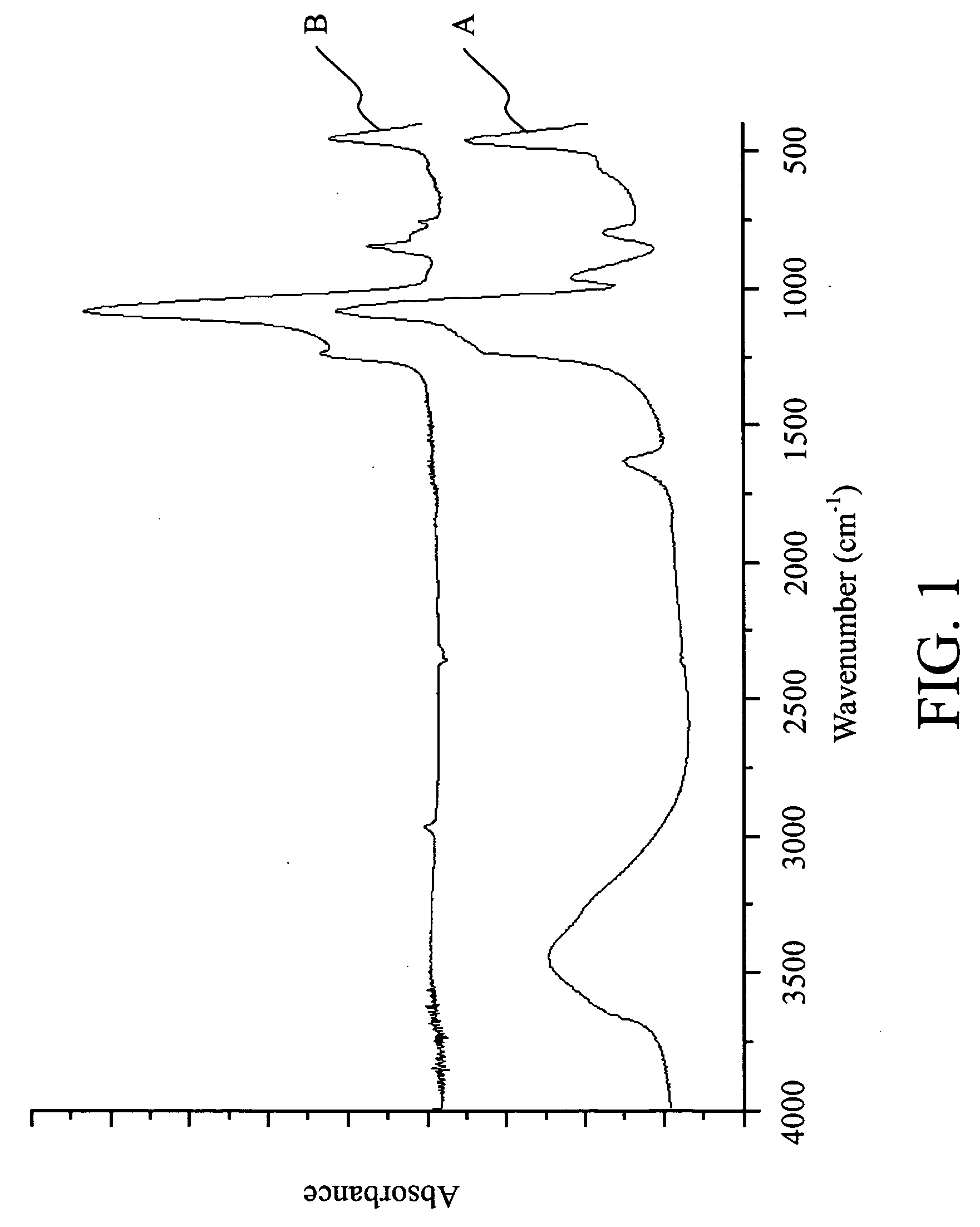

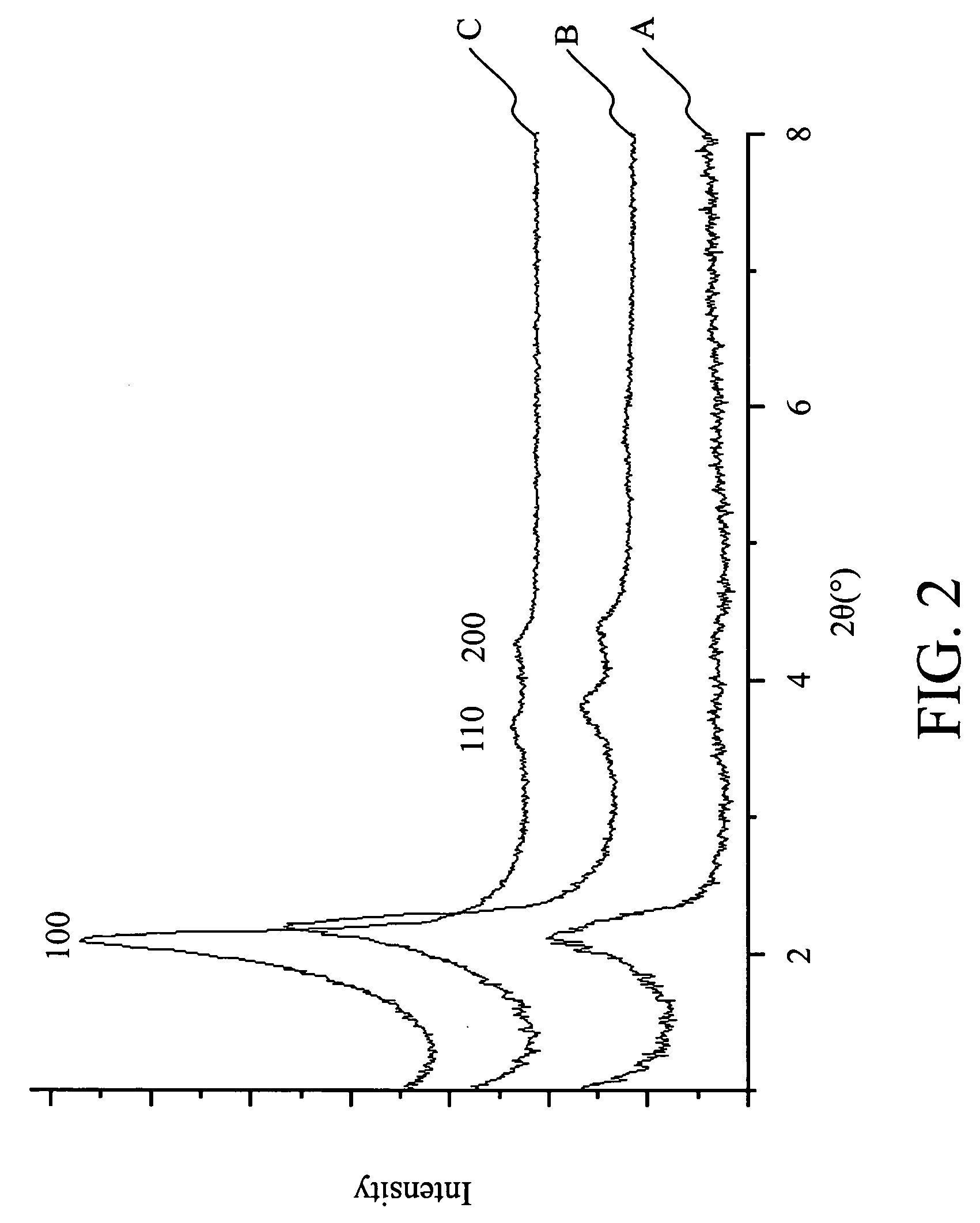

Mesoporous silica/fluorinated polymer composite material

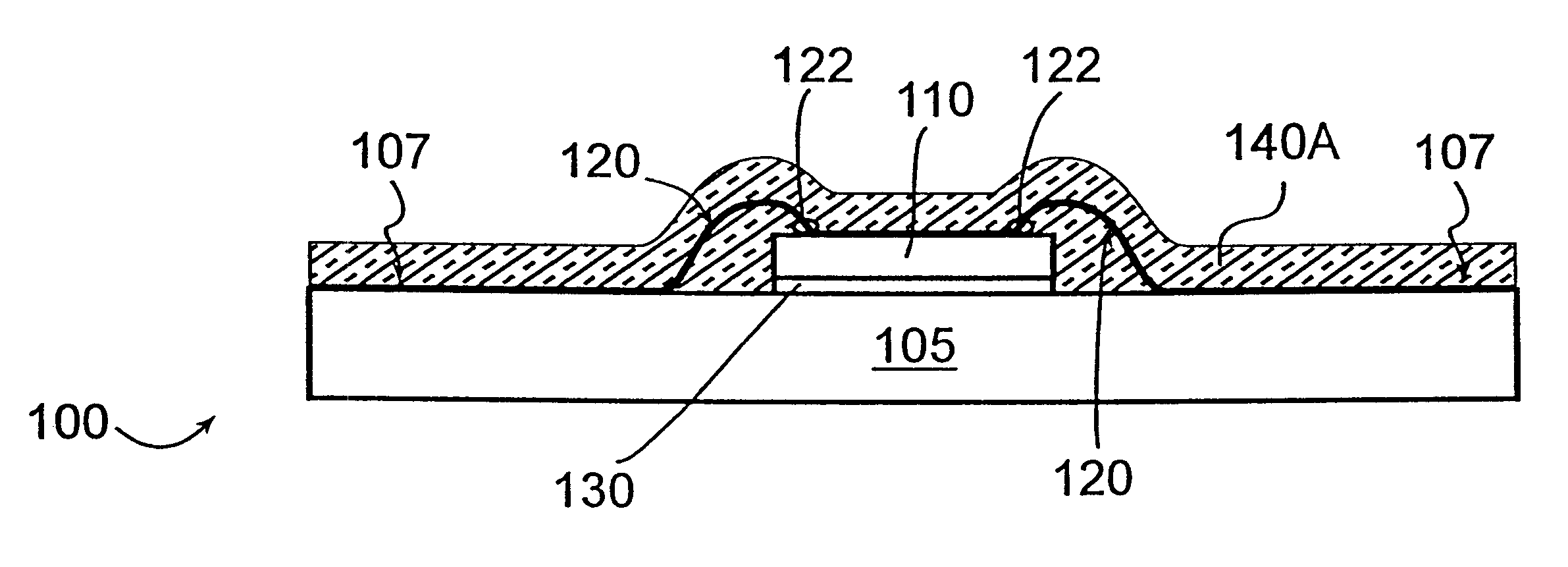

A mesoporous silica / fluorinated polymer composite material. Made up of hydrophobic modified mesoporous silica with a pore size of 0.1 to 50 nm and a fluorinated polymer, to provide Dk<4, Df<0.04, and CTE<60 ppm, the material is suitable for use in printed circuit boards or substrates in high frequency applications.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

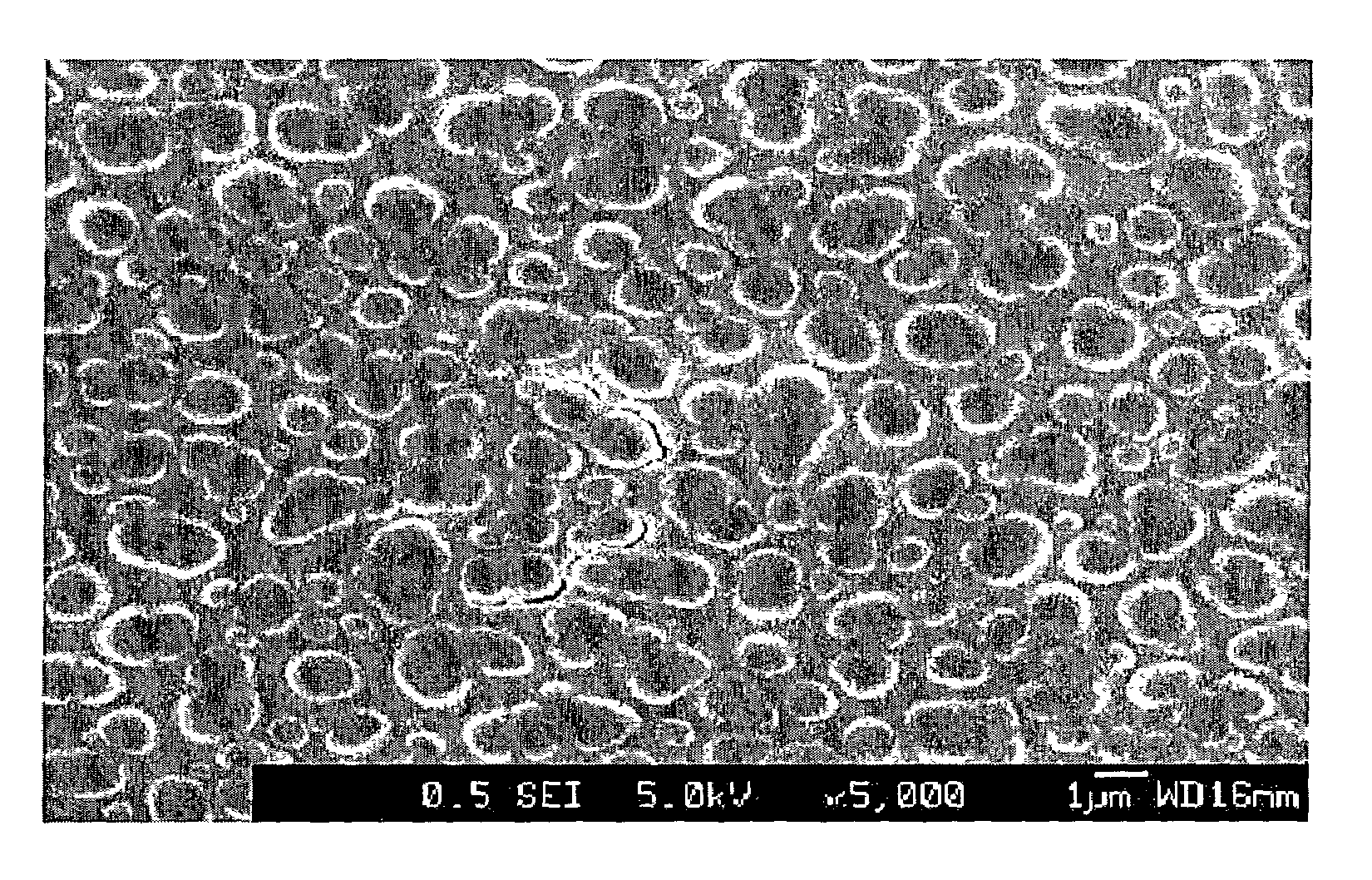

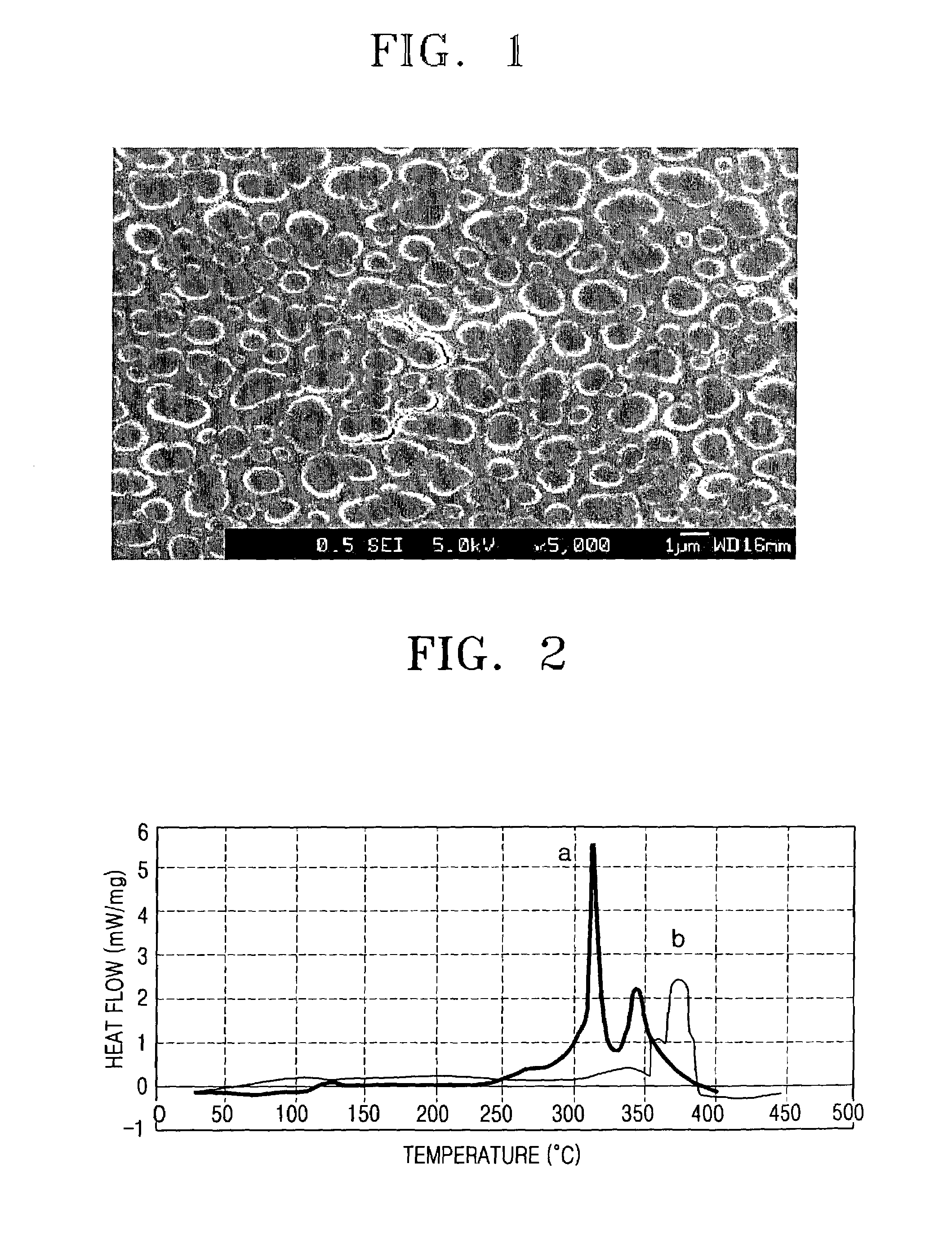

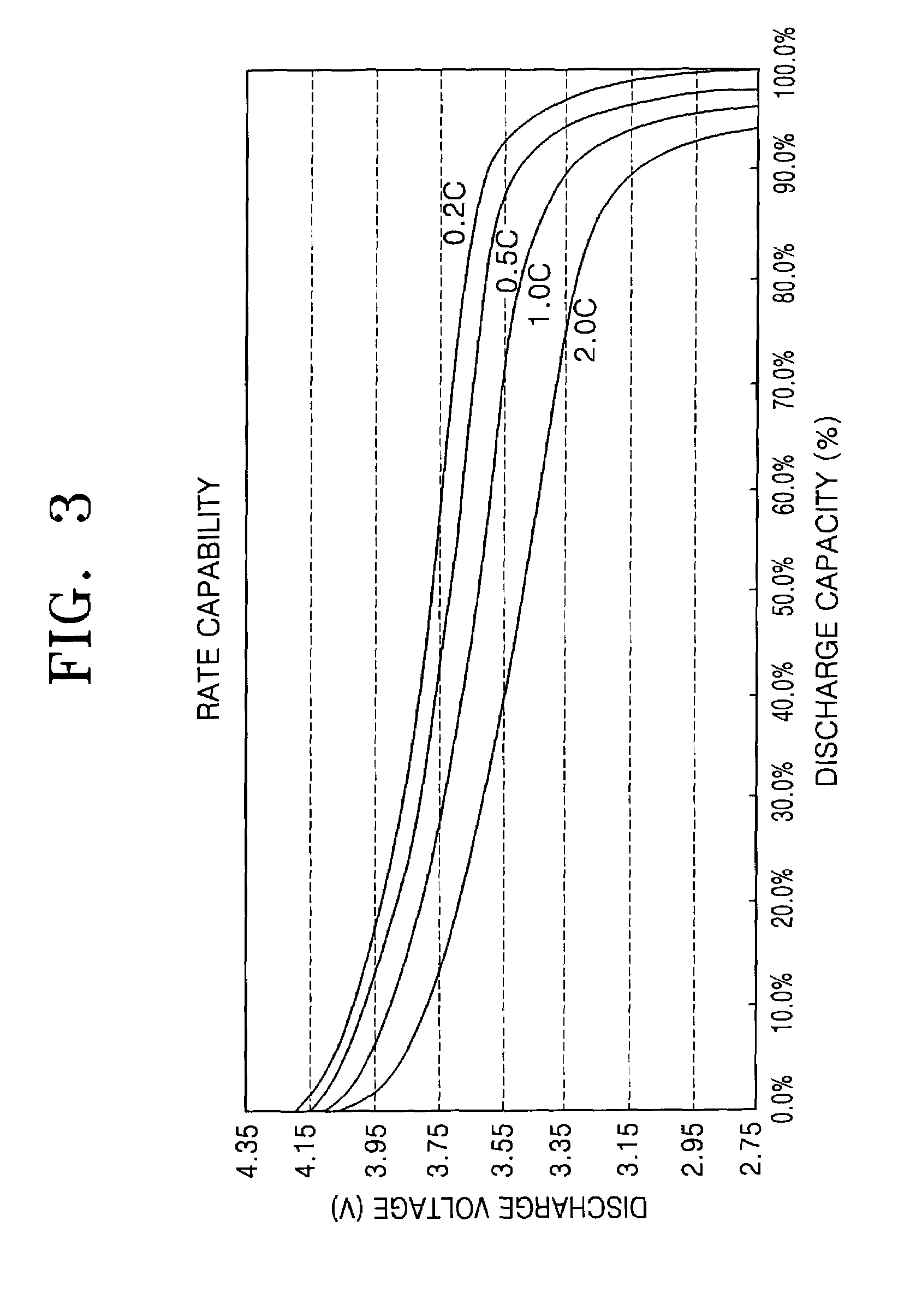

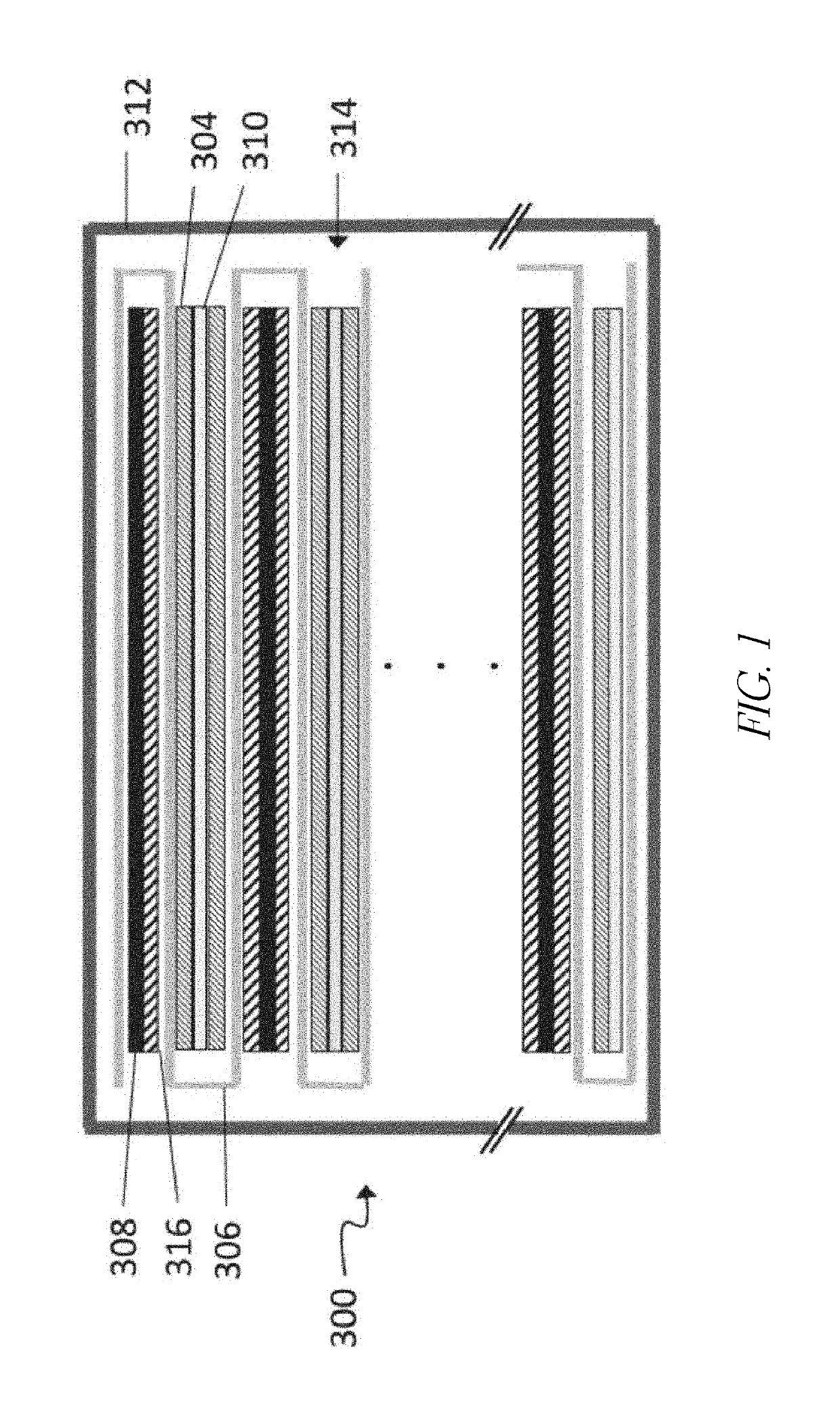

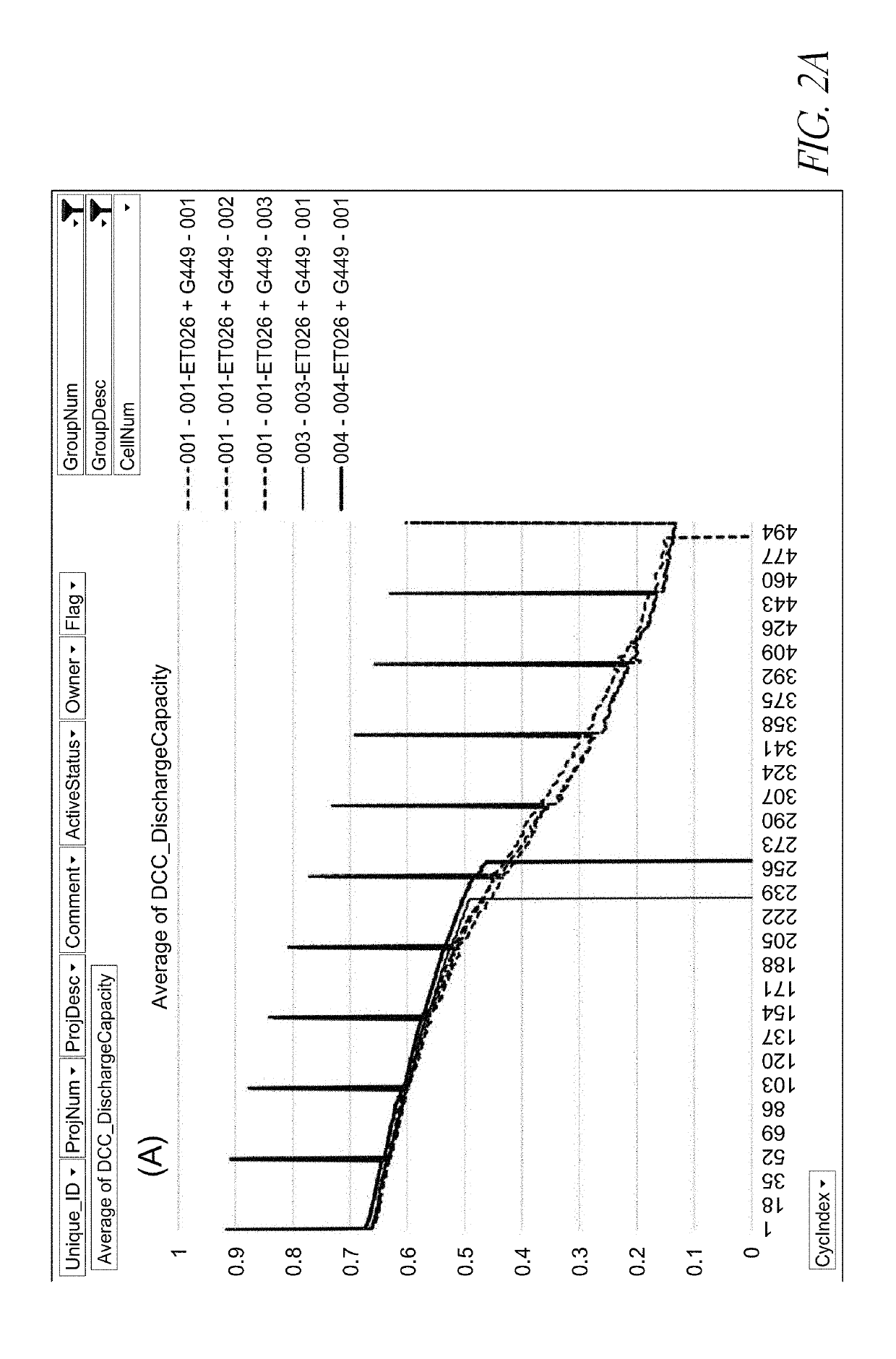

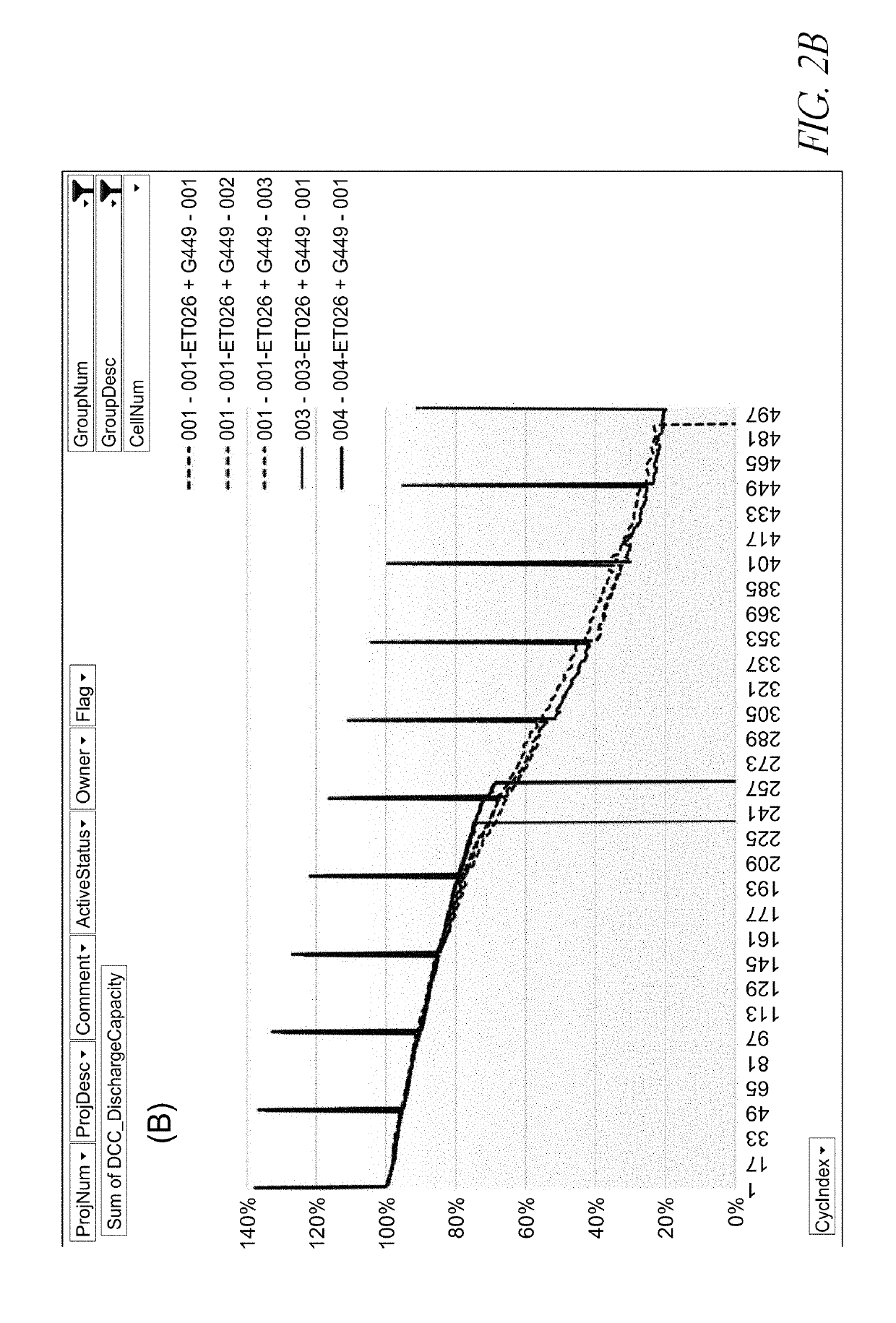

Electrode, lithium battery having the electrode, and method of manufacturing the same

ActiveUS7005211B2Improve thermal stabilityExcellent cycle characteristicsNon-aqueous electrolyte accumulatorsFinal product manufactureEngineeringFluorinated polymer

Owner:SAMSUNG SDI CO LTD

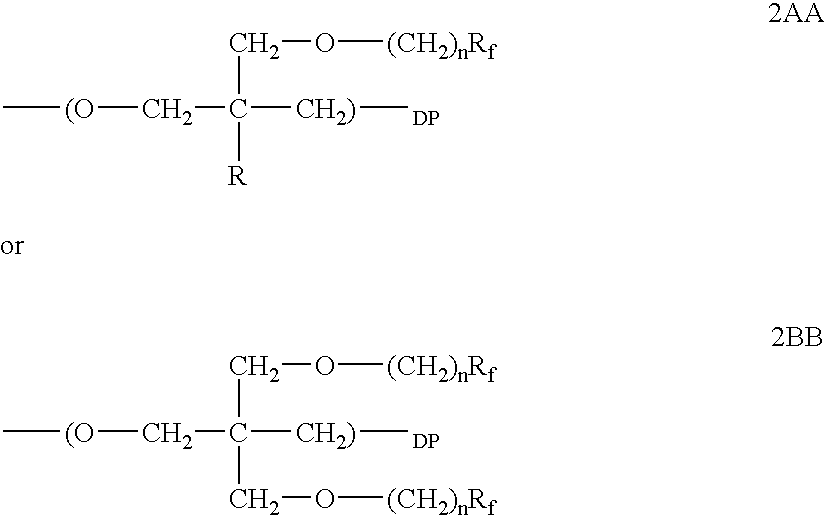

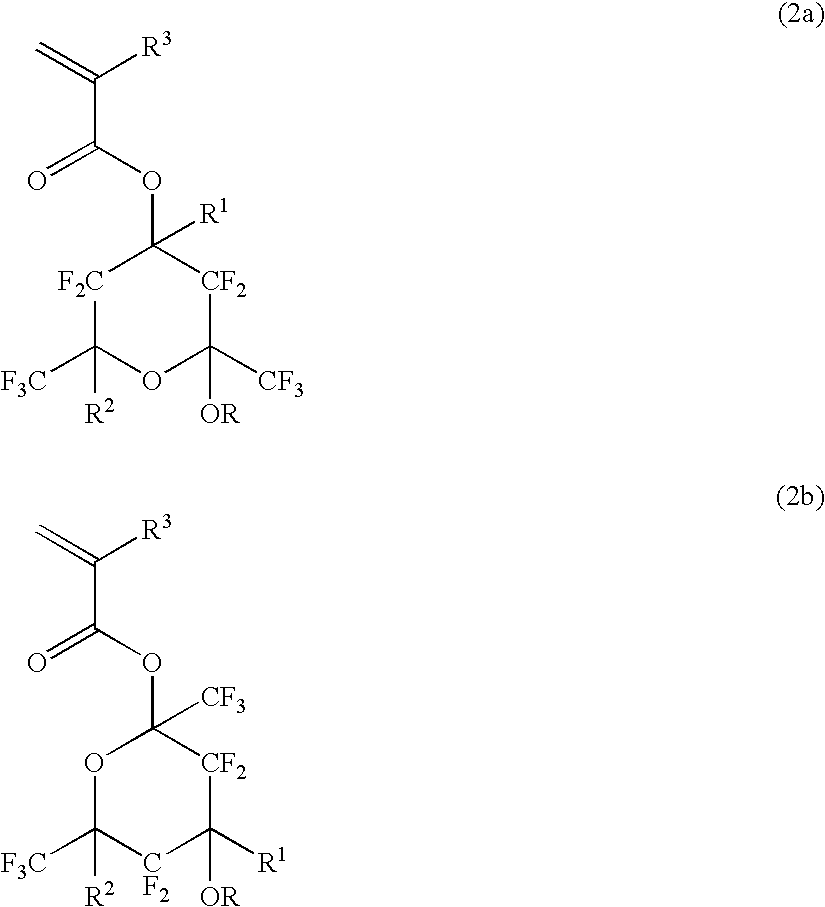

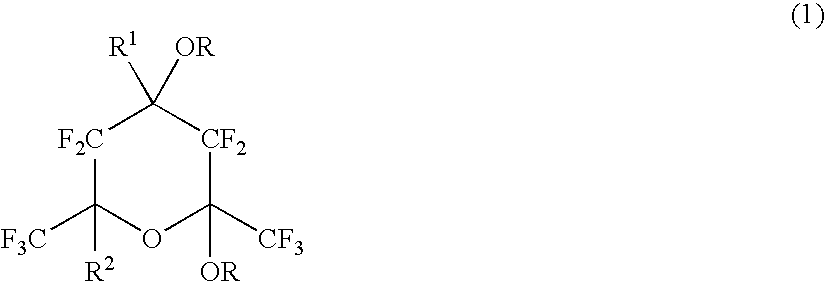

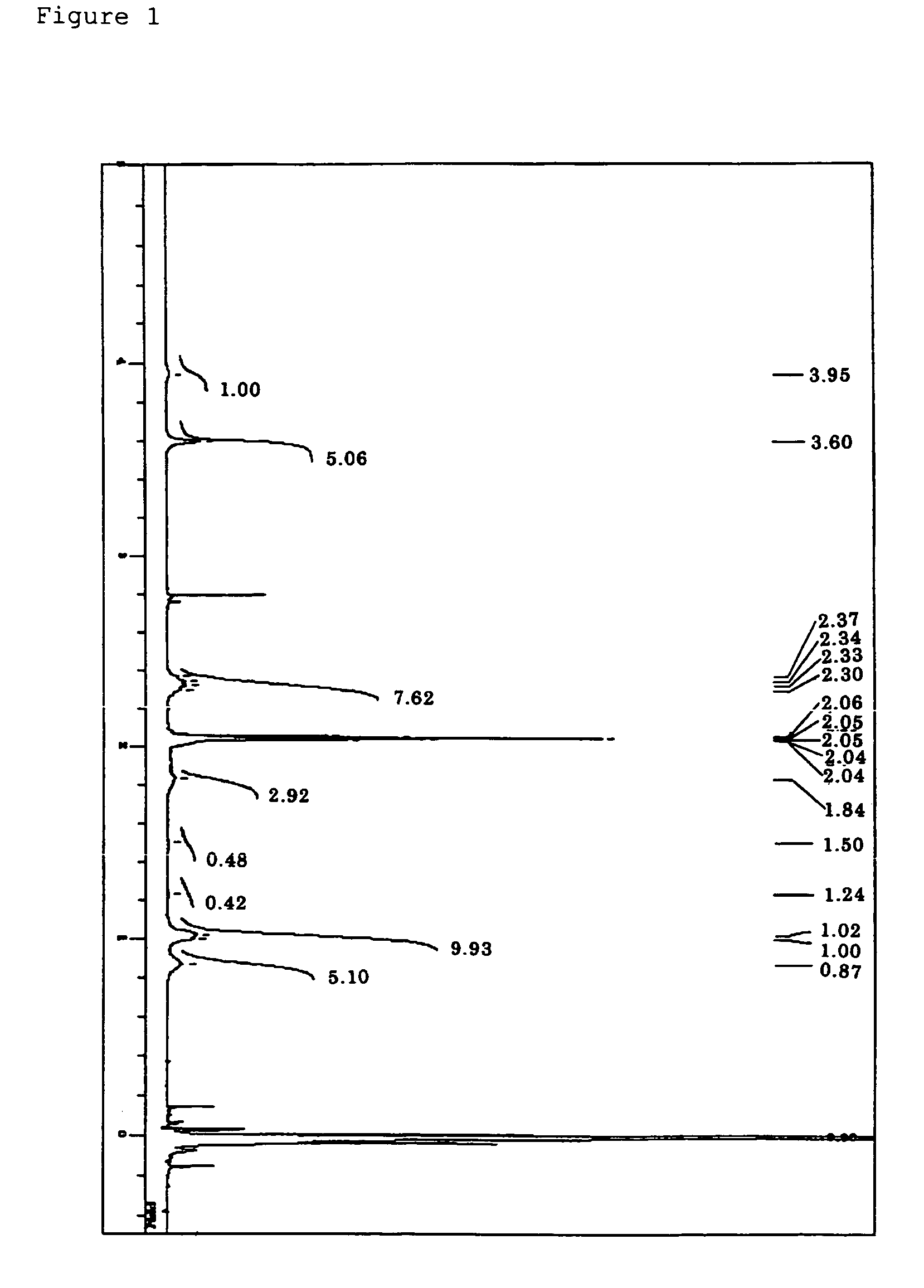

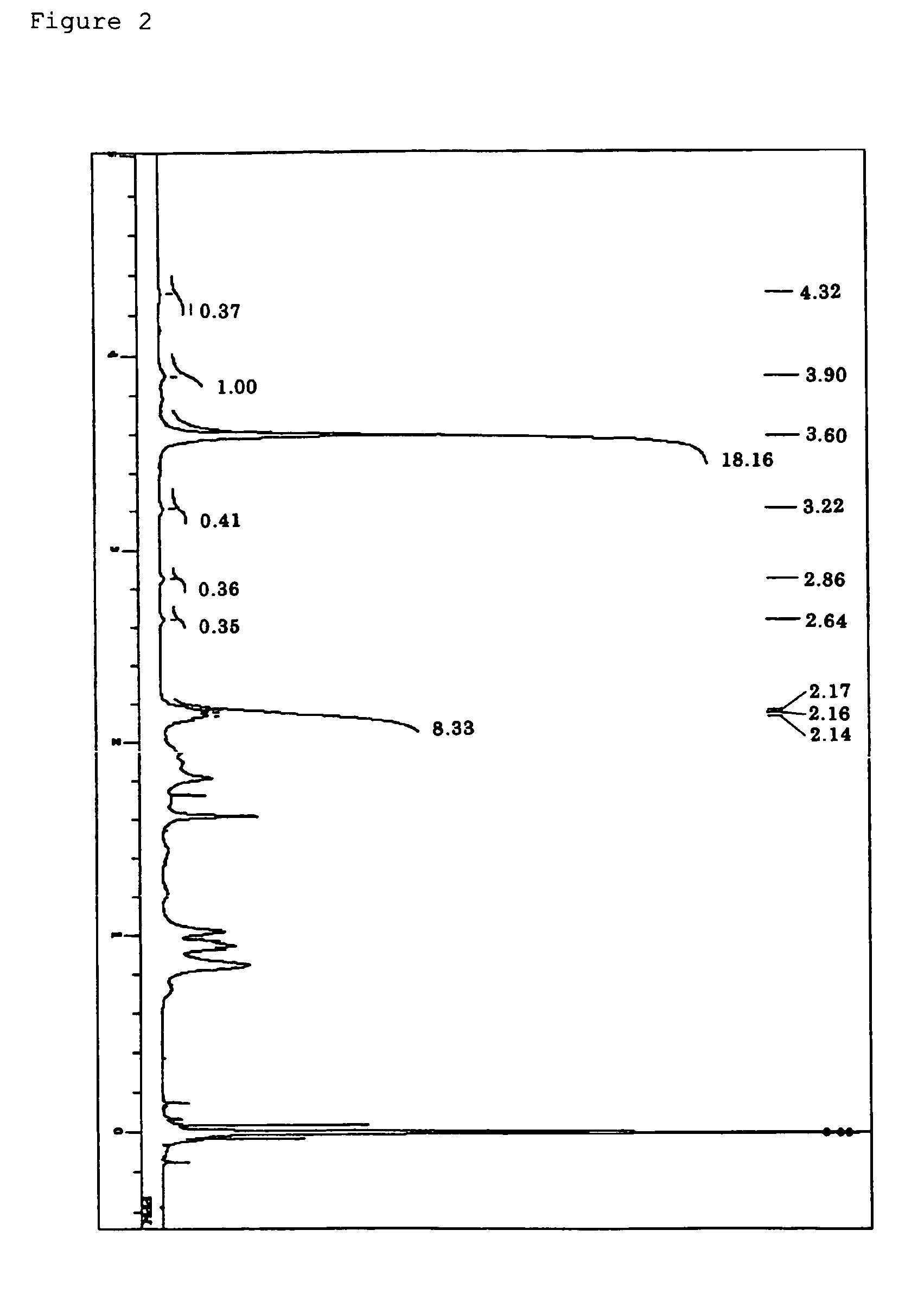

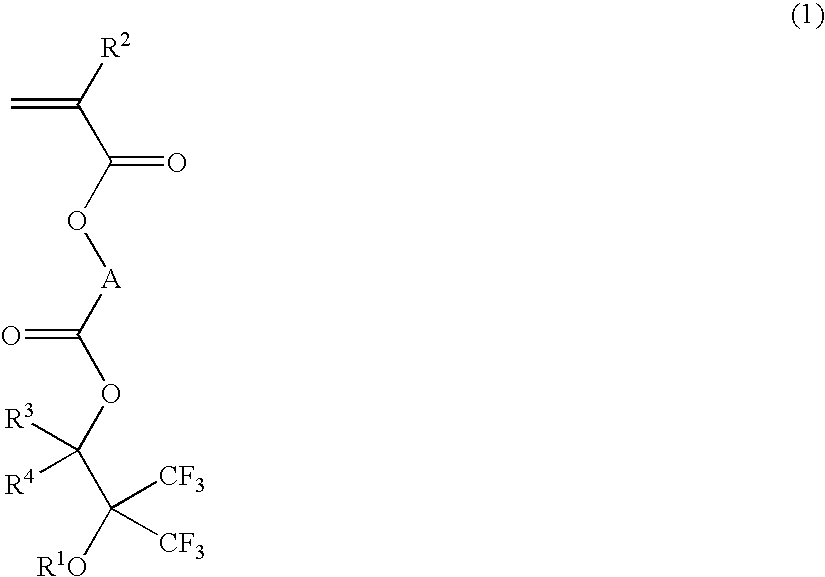

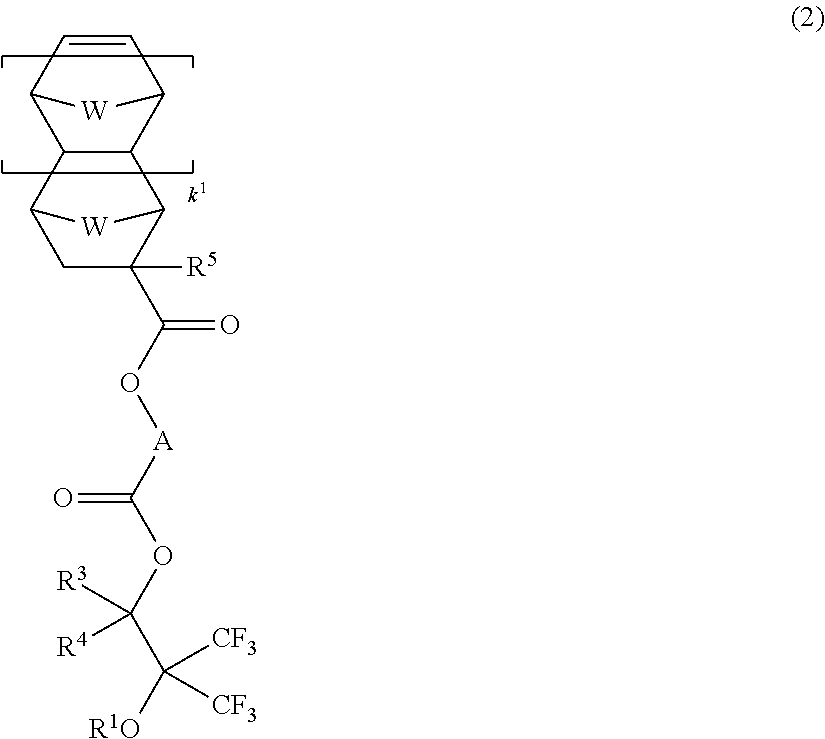

Polymerizable fluorinated compound, making method, polymer, resist composition and patterning process

ActiveUS20060094817A1High resolutionMinimized etch resistanceOrganic compound preparationPhotosensitive materialsResistPolymer science

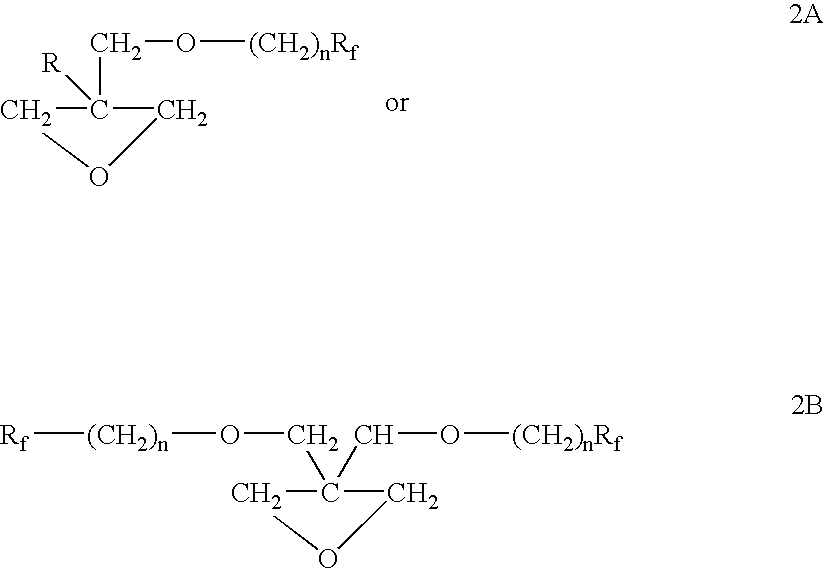

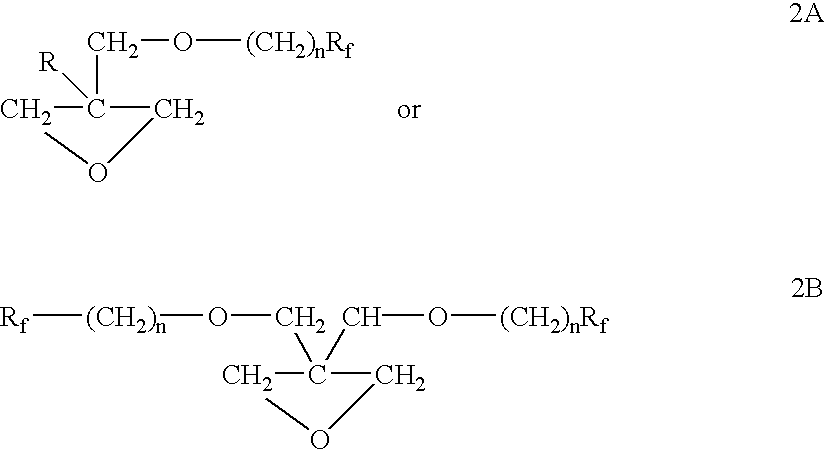

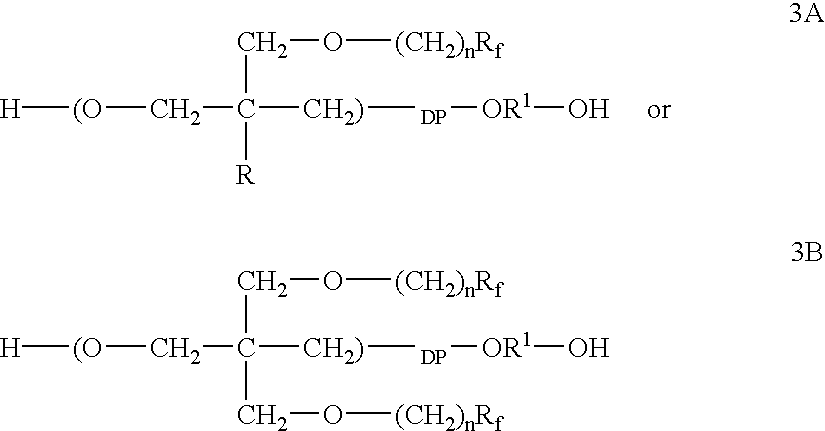

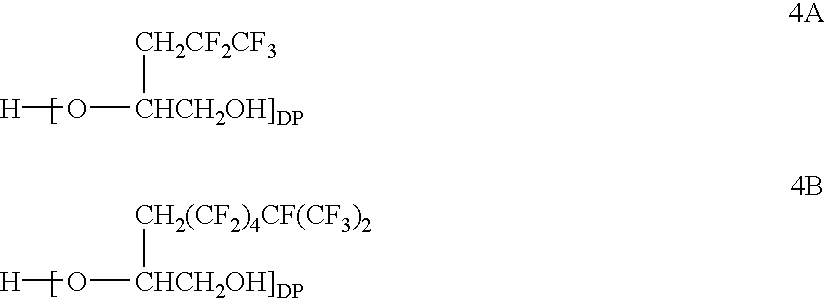

A polymerizable fluorinated compound having formula (2a) or (2b) wherein R1 and R2 are H or C1-C20 alkyl or fluoroalkyl, R3 is H, F or C1-C4 alkyl or fluoroalkyl, and R is H or a protective group is polymerized into a fluorinated polymer which is used as a base polymer to formulate a resist composition having transparency to laser light of wavelength≦300 nm, alkali development amenability, and dry etch resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Fluorinated polymer and polymer composition

Provided are: an addition polymer of fluorosilsesquioxane (a) having one addition polymerizable functional group or an addition copolymer of the fluorosilsesquioxane (a) having one addition polymerizable functional group and an addition polymerizable monomer (b); a coating film including the polymer or the copolymer; and an addition copolymer of the fluorosilsesquioxane (a) having one addition polymerizable functional group and organopolysiloxane (c) having an addition polymerizable functional group, or an addition copolymer of the fluorosilsesquioxane (a) having one addition polymerizable functional group, the organopolysiloxane (c) having an addition polymerizable functional group, and the addition polymerizable monomer (b).

Owner:JNC CORP

Fluororesin powder coating composition and article having coating film

InactiveUS7414084B2Synthetic resin layered productsPowdery paintsWeather resistancePolymer chemistry

A composition which can improve impact resistance of a coating film while maintaining superior weather resistance and gloss of the coating film of a fluororesin powder coating material is provided. A fluororesin powder coating composition containing the following particles (C) in an amount of from 0.1 to 10 parts by mass per 100 parts by mass of a fluororesin. The particles (C) are particles having a core / shell structure and having an average particle size of from 0.01 to 2.5 μm, wherein the core and / or at least one shell comprises a fluorinated polymer.

Owner:ASAHI GLASS CO LTD

Silicon-based energy storage devices with fluorinated polymer containing electrolyte additives

ActiveUS20190181500A1Hybrid capacitor electrolytesHybrid capacitor electrodesPolymer scienceEnergy storage

Owner:ENEVATE CORP

Durable finishes for textiles

InactiveUS6872424B2Improve stabilityGood water solubilitySynthetic resin layered productsPretreated surfacesTextile fiberAlcohol

The present invention relates to textile treatment compositions for imparting desirable characteristics durably to textile fibers and fabrics, including softness, hydrophobicity, oleophobicity, surface lubricity, abrasion resistance, tear resistance, improved drape, and pilling resistance. More particularly, in one embodiment, the invention is directed to preparations that comprise a carboxylate-functionalized fluorinated polymer and a catalyst that is capable of forming reactive anhydride rings between carboxyl groups on the polymer. In another embodiment, the invention is directed to preparations comprising a polymeric softener having at least one anhydride functional group or at least one reactive group capable of forming an anhydride functional group, together with a catalyst for forming anhydrides from the reactive group or groups. In either embodiment, the resulting reactive anhydride rings bind to substrates, such as textiles and other webs, having free sulfhydryl, alcohol, or amine groups. The invention is further directed to the process for treating textiles and other webs with desirable finishes durable to repeated cleanings. This invention is further directed to the yarns, fibers, fabrics, textiles, finished goods, or nonwovens (encompassed herein under the terms “textiles” and “webs”) treated with the textile-reactive preparations of the invention. Such textiles and webs exhibit a greatly improved, durable characteristics, such as softness and / or hydrophobicity, even after multiple launderings.

Owner:NANO TEX

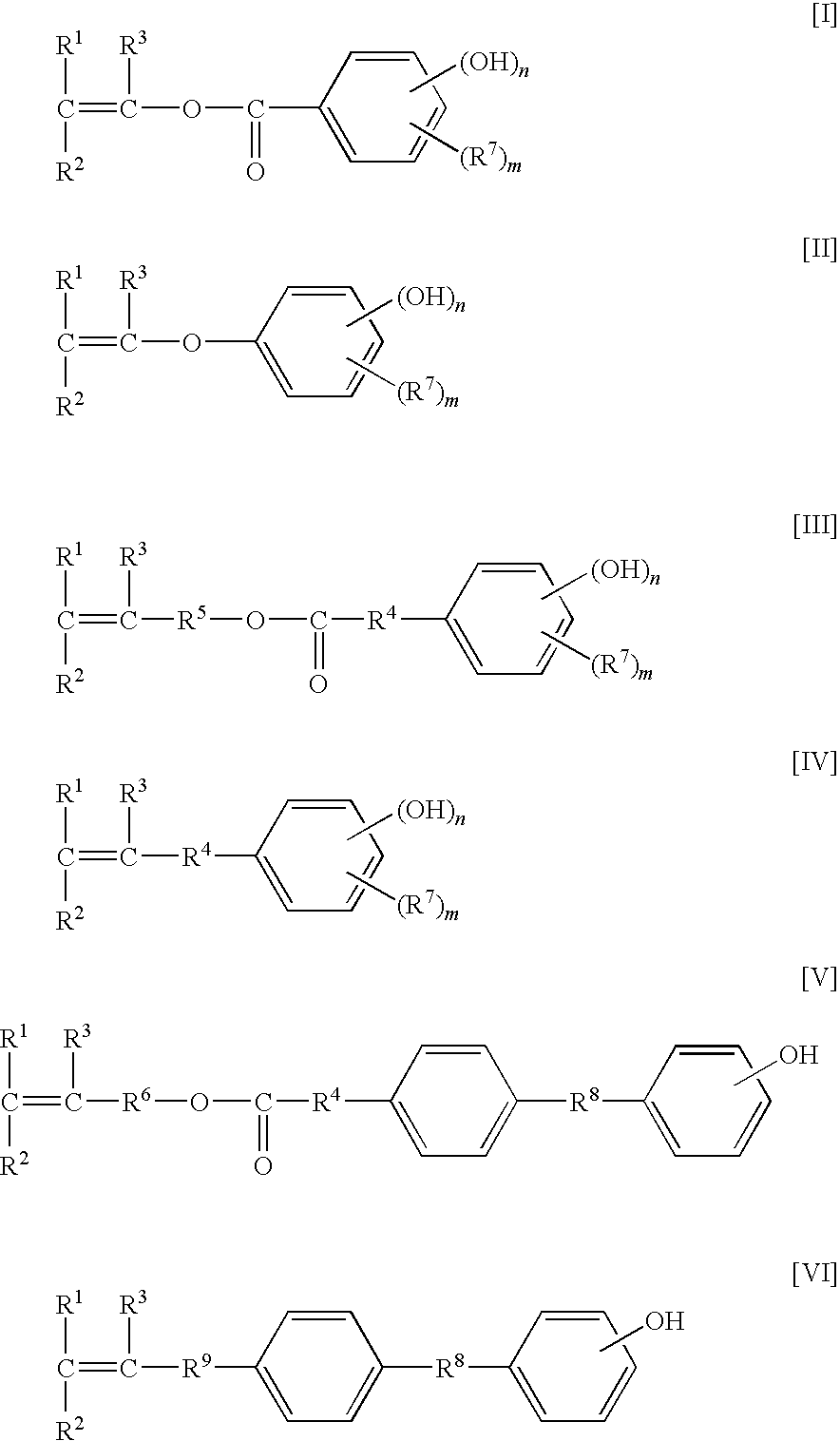

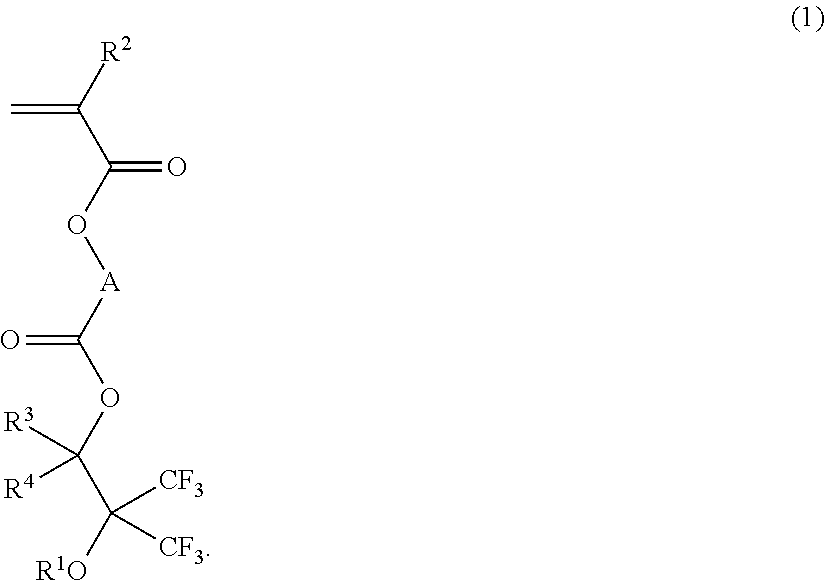

Fluorinated monomer, fluorinated polymer, resist composition and patterning process

Fluorinated monomers of formula (1) are useful in producing polymers for the formulation of radiation-sensitive resist compositions. R1 is H or monovalent C1-C20 hydrocarbon group, R2 is H, F, methyl or trifluoromethyl, R3 and R4 are H or a monovalent C1-C8 hydrocarbon group, or R3 and R4 may form an aliphatic hydrocarbon ring, and A is a divalent C1-C6 hydrocarbon group

Owner:SHIN ETSU CHEM IND CO LTD

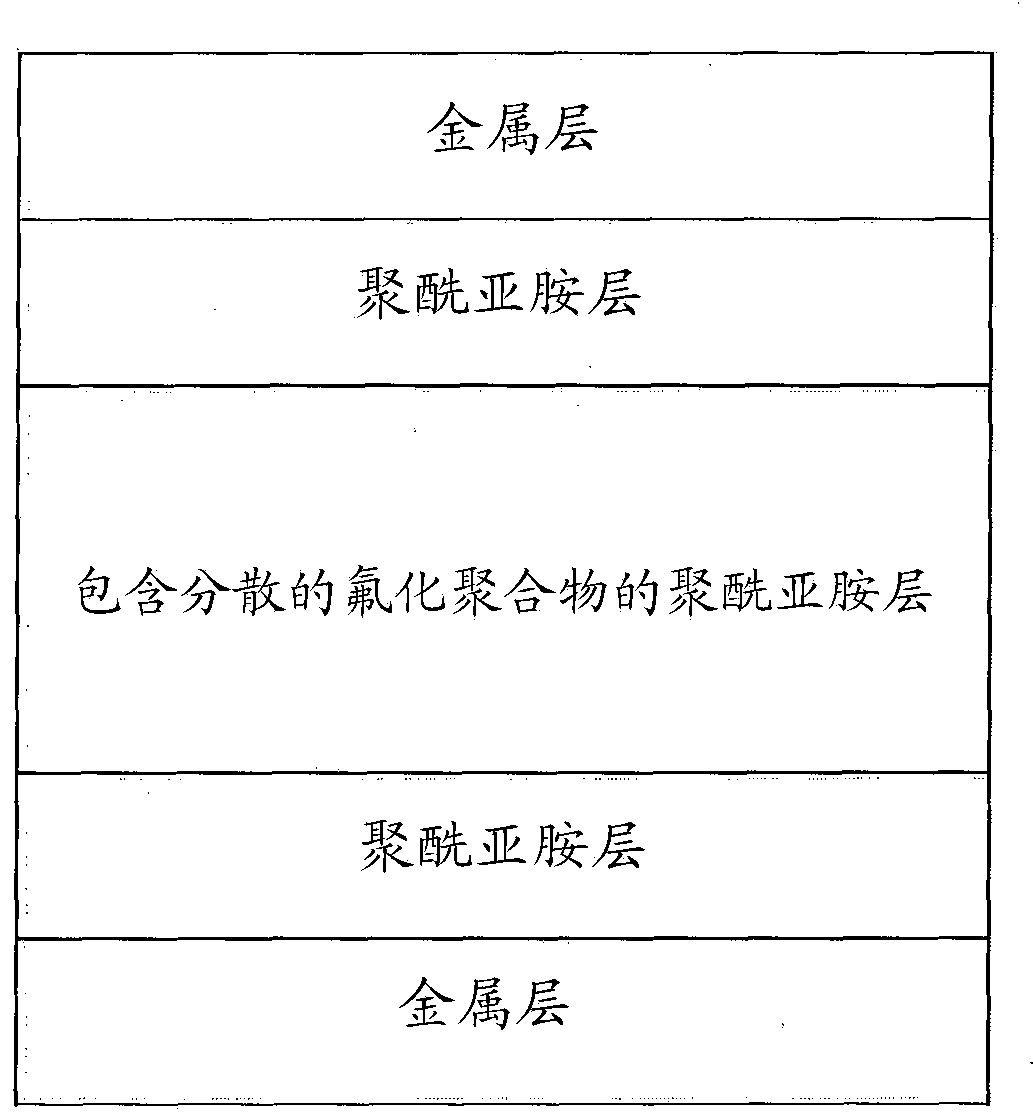

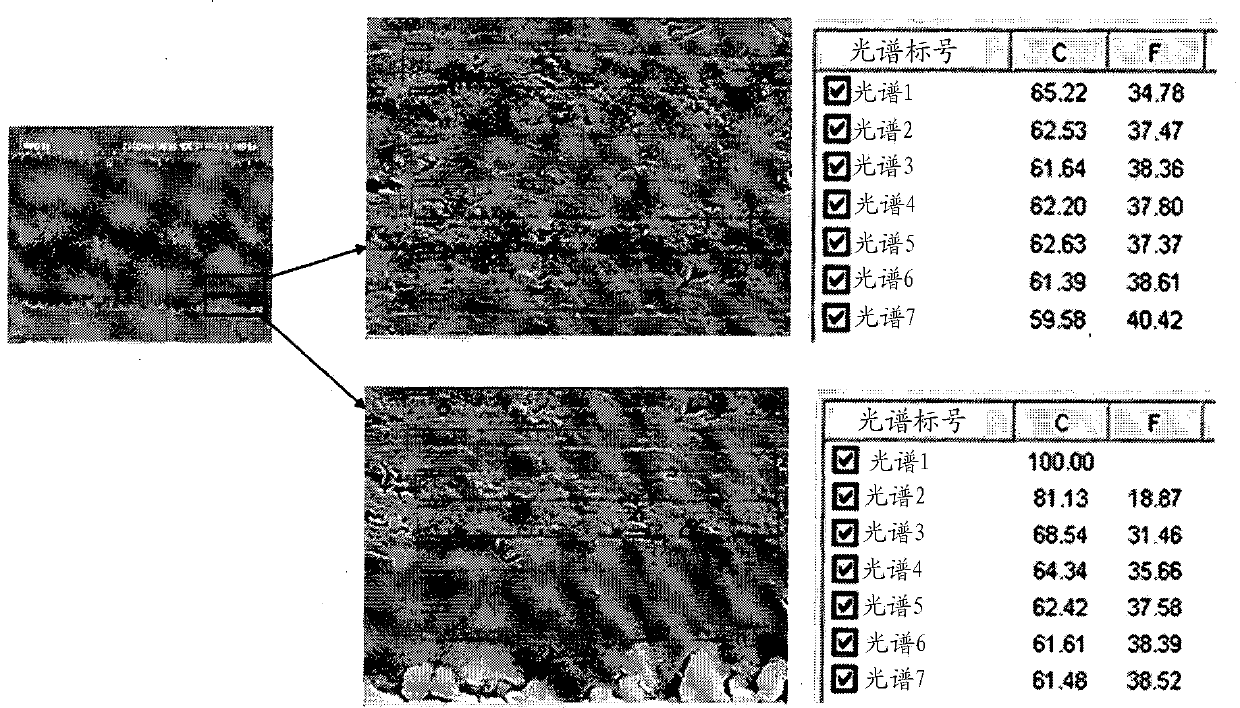

Flexible metal laminate containing fluorocarbon resin

ActiveCN103958188AEvenly dispersedImprove heat resistanceLiquid surface applicatorsSynthetic resin layered productsPermittivityTotal thickness

The present invention relates to a flexible metal laminate having low permittivity, capable of being applied to a soft printed circuit board. According to one aspect of the present invention, the flexible metal laminate comprises: a first metal layer; a first polyimide layer; a polyimide layer in which a fluorocarbon resin, which is formed on the first polyimide layer, is dispersed; and a second polyimide layer formed on the polyimide layer in which a fluorocarbon resin is dispersed, wherein the content per unit volume of the fluorocarbon resin is greater in a depth of 40-60% than in a depth of 5-10% of the total thickness from the surface of the polyimide layer in which a fluorocarbon resin is dispersed.

Owner:GUANGDONG SHENGYI SCI TECH

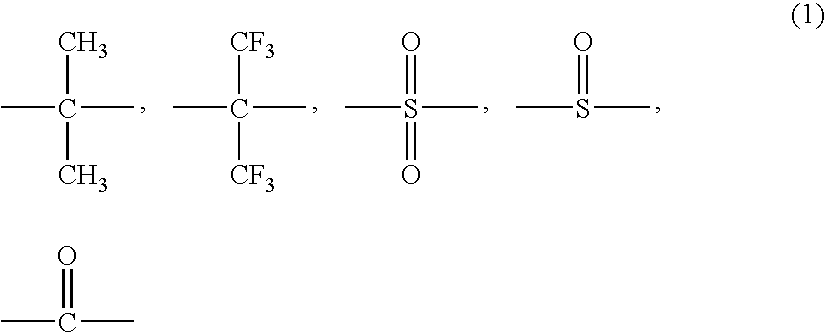

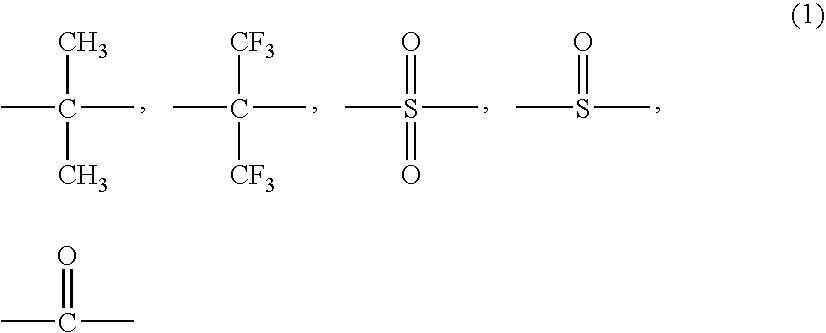

Adhesion binder containing glutarimide moieties

InactiveUS6040025AHigh mechanical strengthSufficient flexibilityHeat exhanger conduitsSynthetic resin layered productsImidePolymer science

The present invention is directed to a multilayer material having in order a layer of fluorinated polymer, a layer of binder for fluorinated polymer having a polymer A with moieties (1)-(4), and a layer of polymer which is incompatible with the fluorinated polymer. The multilayer material is useful for making a pipe which has a superior barrier properties to petroleum products and the additives thereof. The present invention also relates to a pipe having a multilayer structure having two layers of polyamide and a layer of binder comprising a polymer A with glutarimide moieties (1)-(4) in between. The pipe has superior barrier properties to petroleum products and the additives.

Owner:DECUSSA

Fluoropolymer of fluorinated short chain acrylates or methacrylates and oil and water repellent compositions based thereon

The present invention relates to compositions based on a fluoropolymer comprising repeating units derived from (i) one or more fluorinated monomers selected from the group consisting of monomers according to the general formula: Rf-X-OC(O)-C(R)=CH2 wherein Rf represents a perfluorinated aliphatic group having 3 or 4 carbon atoms, X is an organic divalent linking group and R represents hydrogen or a lower alkyl group having 1 to 4 carbon atoms; and (u) one or more non-fluorinated comonomers. The fluoropolymer has a weight average molecular weight between 3000 and 55000. The compositions may be solvent born or aqueous born and are particularly useful to provide good oil- and / or water repellency properties to the substrate.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com