Patents

Literature

34results about How to "Good wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

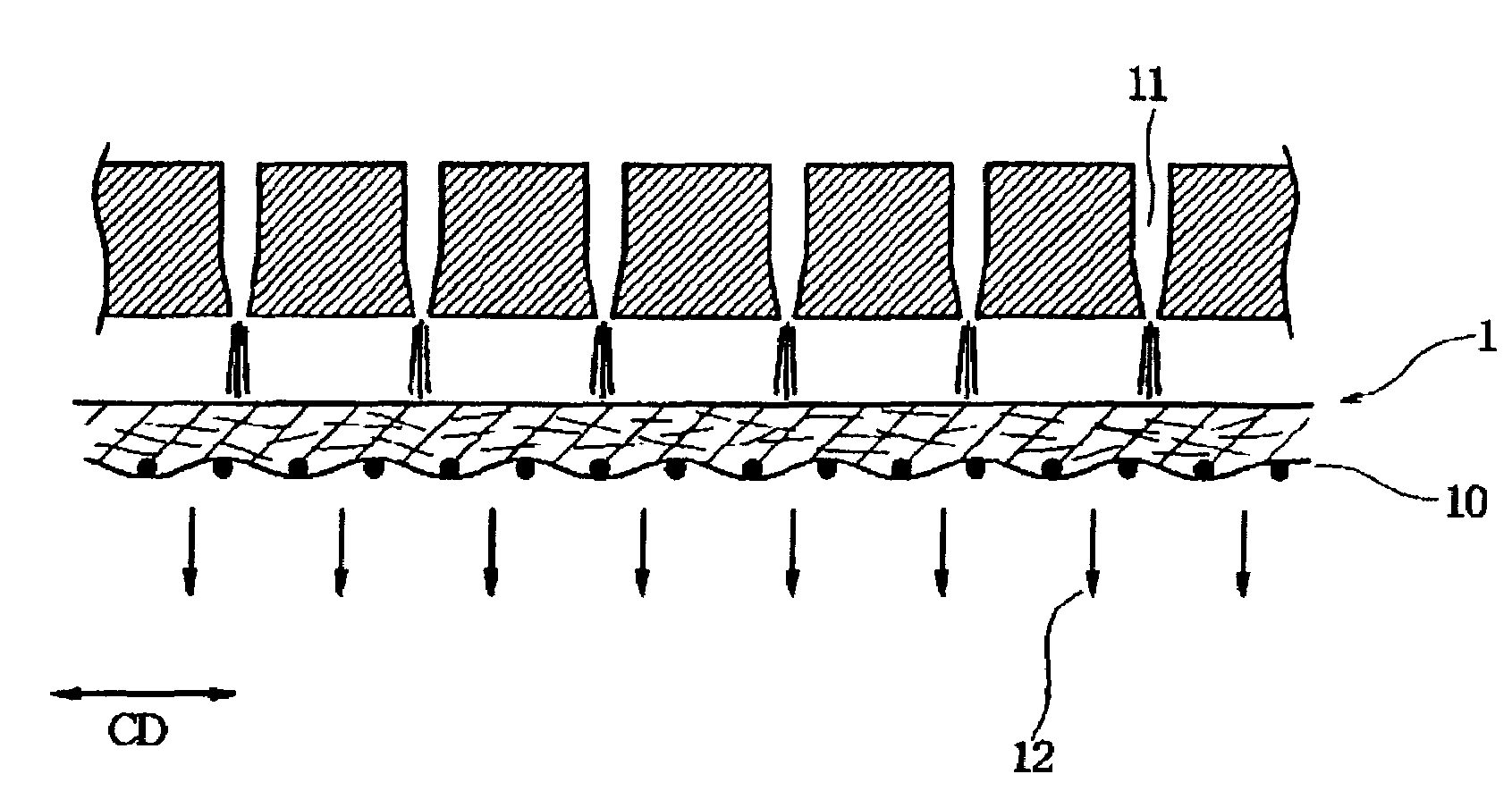

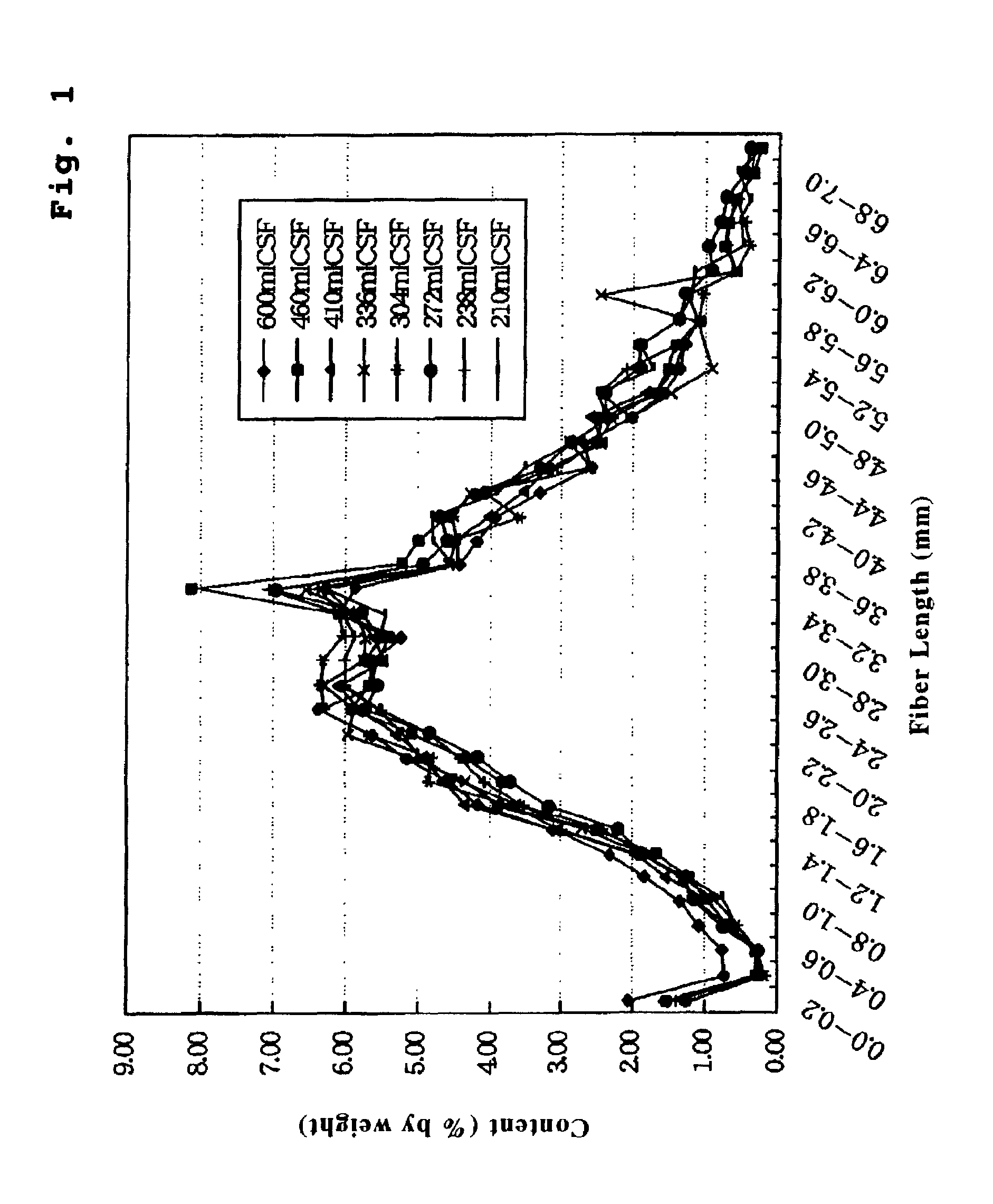

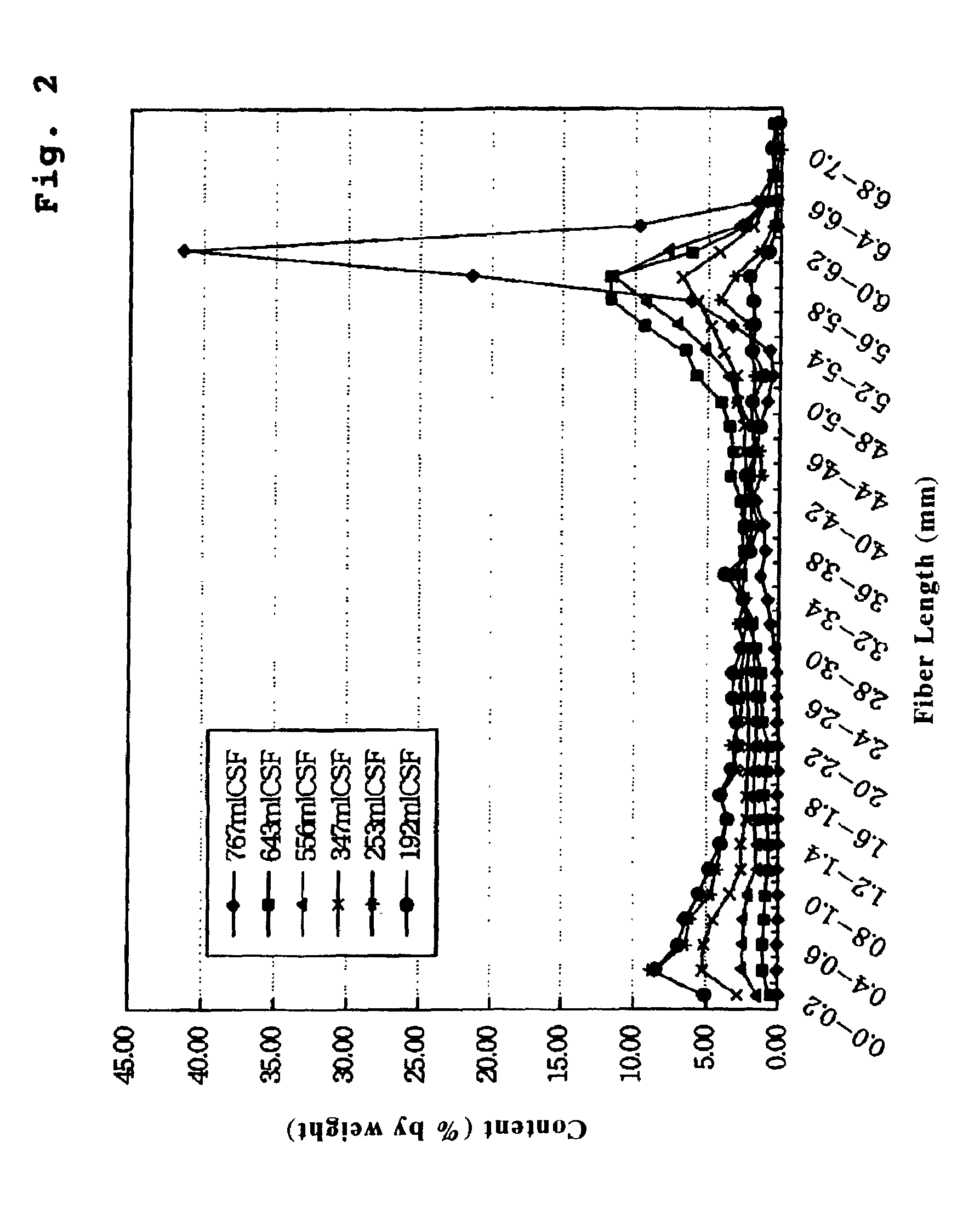

Water-disintegratable sheet and manufacturing method thereof

InactiveUS7241711B2Good wettingImprove dry strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

Disclosed is a water disintegratable sheet of which fibers are hydroentangled about each other. The water disintegratable sheet includes: at least one kind of primary fibers having a fiber length of at most 10 millimeter; and bast / leaf fibers having a Canadian Standard freeness value of at most 600 milliliter and a fiber length of at most 10 millimeter.

Owner:UNI CHARM CORP

Fluorochemical free aqueous coating compositions and methods of use thereof

InactiveUS20050215678A1Avoid healthGood wettingAqueous dispersionsPhosphorus organic compoundsOrganic phosphatesFluoride

Fluorochemical free aqueous coating compositions are disclosed. The compositions comprise a film-forming polymer and an organophosphate surfactant. The compositions exhibit superior wetting and leveling properties compared to fluoroaining sulfur based surfactants. Inventive compositions are particularly suitable for use as floor finishes. Methods of makinge aqueous coating compositions are also described.

Owner:JOHNSONDIVERSEY INC

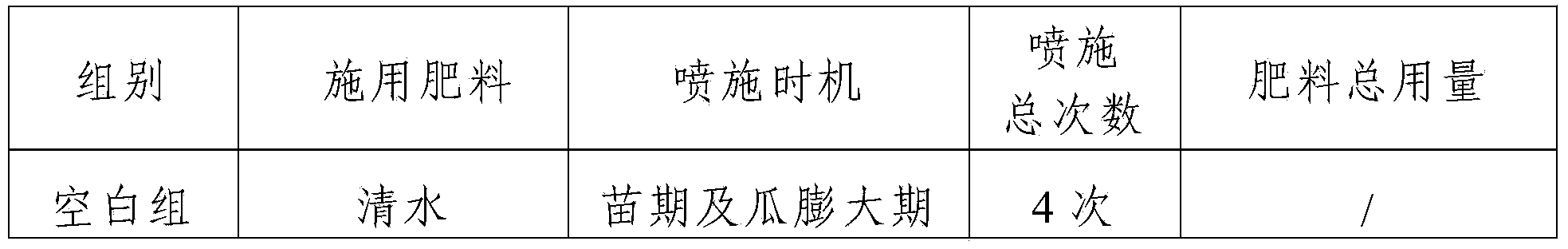

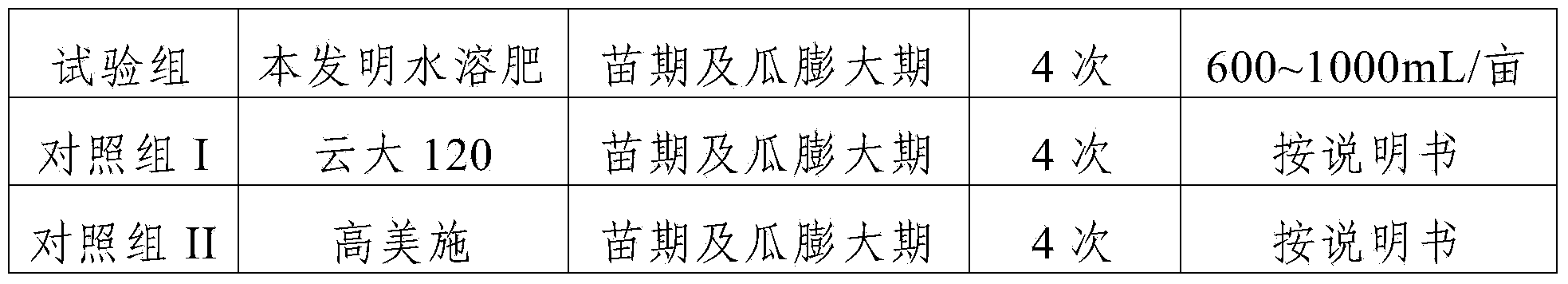

Water soluble fertilizer containing high-concentration humic acid and preparation method thereof

ActiveCN103408373AImprove buffering effectReduce heavy metal contentFertilizer mixturesDipotassium hydrogen phosphateHigh concentration

The invention provides a water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer comprises, by weight, 15-25 parts of a water soluble humic acid salt, 18-25 parts of urea, 9-15 parts of dipotassium hydrogen phosphate, 8-13 parts of potassium acetate, 0.5-2 parts of borax, 0.1-10 parts of polyglutamic acid, 1-5 parts of rhamnolipid, 5-10 parts of a hydroxymethyl cellulose aqueous solution and 30-40 parts of water. The water soluble fertilizer has humic acid content greater than or equal to 150g / L. The invention also provides a preparation method of the water soluble fertilizer containing high-concentration humic acid. The preparation method comprises the following steps of 1, carrying out heating stirring of the water soluble humic acid salt and water to obtain a humic acid salt solution, 2, adding dipotassium hydrogen phosphate, potassium acetate, borax, polyglutamic acid, rhamnolipid and urea into the humic acid salt solution, and carrying out heating stirring to obtain a mixed solution, and 3, carrying out emulsification of the hydroxymethyl cellulose aqueous solution and the mixed solution to obtain the water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer has obvious fertilizer efficiency, is environmentally friendly, stable and uniform and has a wide application range.

Owner:陕西鼎天济农腐殖酸制品有限公司

Polyesters having a controlled melting point and fibers formed therefrom

InactiveUS20030055206A1Deep dyeabilityGood printabilitySynthetic resin layered productsMonocomponent copolyesters artificial filamentYarnPolyester

The invention relates to fibers, particularly binder fibers, made from polyesters and the polyesters themselves. The polyesters are the product of a reaction between a glycol component and a dicarboxylic acid component where the glycol component contains at least 50 mole % of a four carbon diol, such as 1,4-butanediol, or a six carbon diol, such as 1,6-hexanediol or a mixture of a four carbon and six carbon diol. Typically, the polyesters of the invention are semicrystalline and / or crystalline and have a specific melting point ranging from about 140 to about 185° C. The polyesters of the invention may be formed into a variety of products, especially binder fibers for nonwoven fabrics, textile / industrial yarns and fabrics, composites and other molded articles.

Owner:EASTMAN CHEM CO

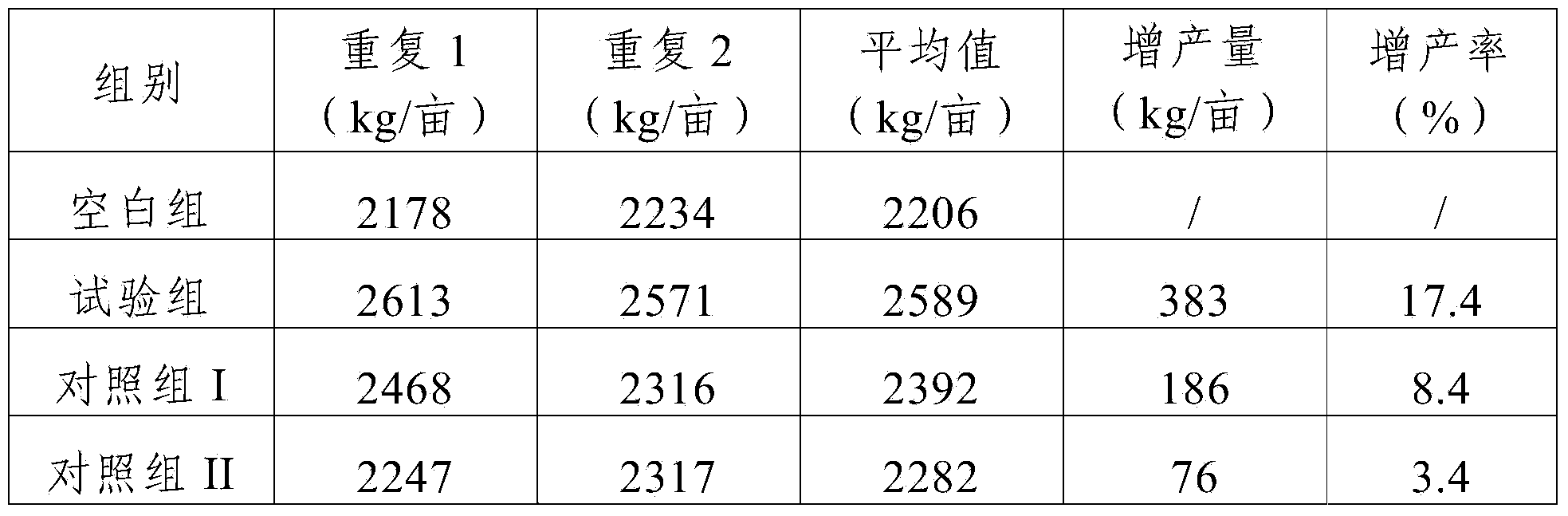

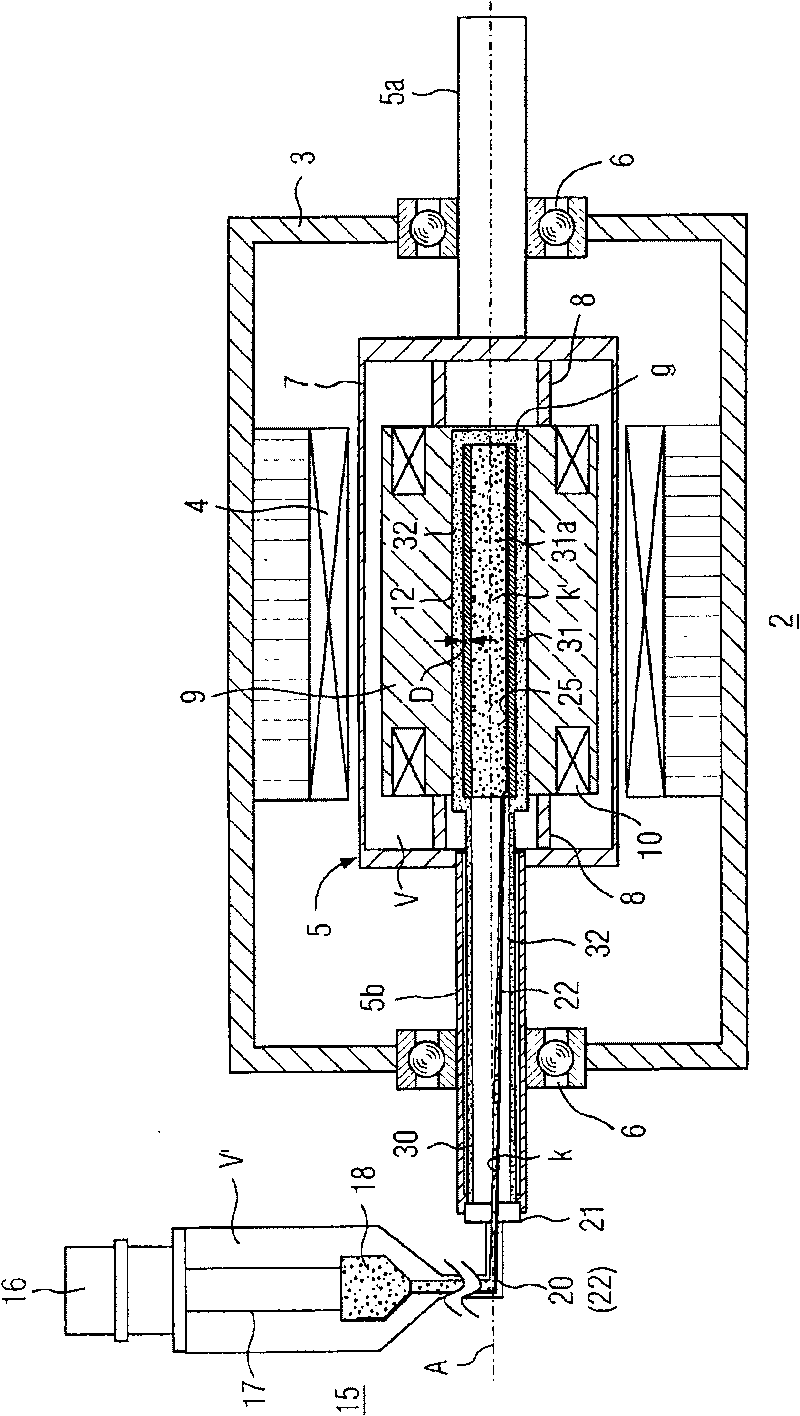

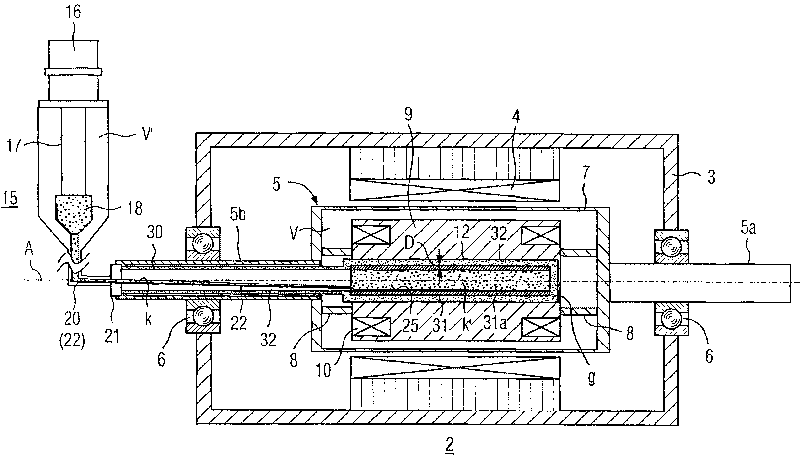

Machine system with a thermo-syphon cooled superconductor rotor winding

InactiveCN101116238AWell coupled thermallyEvenly distributedCooling/ventillation arrangementRegenerative heat exchangersThermal conductivityCooling Units

The invention relates to a machine system comprising a machine (2) with a rotor (5) rotatable about an axis (A), the superconducting windings (10) of which are passed through a winding support (9 ) and a thermal contact gas, (g) are thermally conductively coupled to a central coolant zone (31) of a heat conductor (30) that projects fixedly into a rotor cavity (12). The coolant zone (31a) is formed together with a plurality of pipe elements (22) connected to it laterally and a condenser zone (18) associated with a cooling unit (15) and located outside the machine (2). A piping system in which a coolant (k, k') circulates using the thermosiphon effect. In order to deliver coolant to the central coolant zone (31) even when the rotor (5) tilts, the coolant zone is equipped with a lining (25) made of a porous material with high thermal conductivity, so The porous material is specifically a sintered material.

Owner:SIEMENS AG

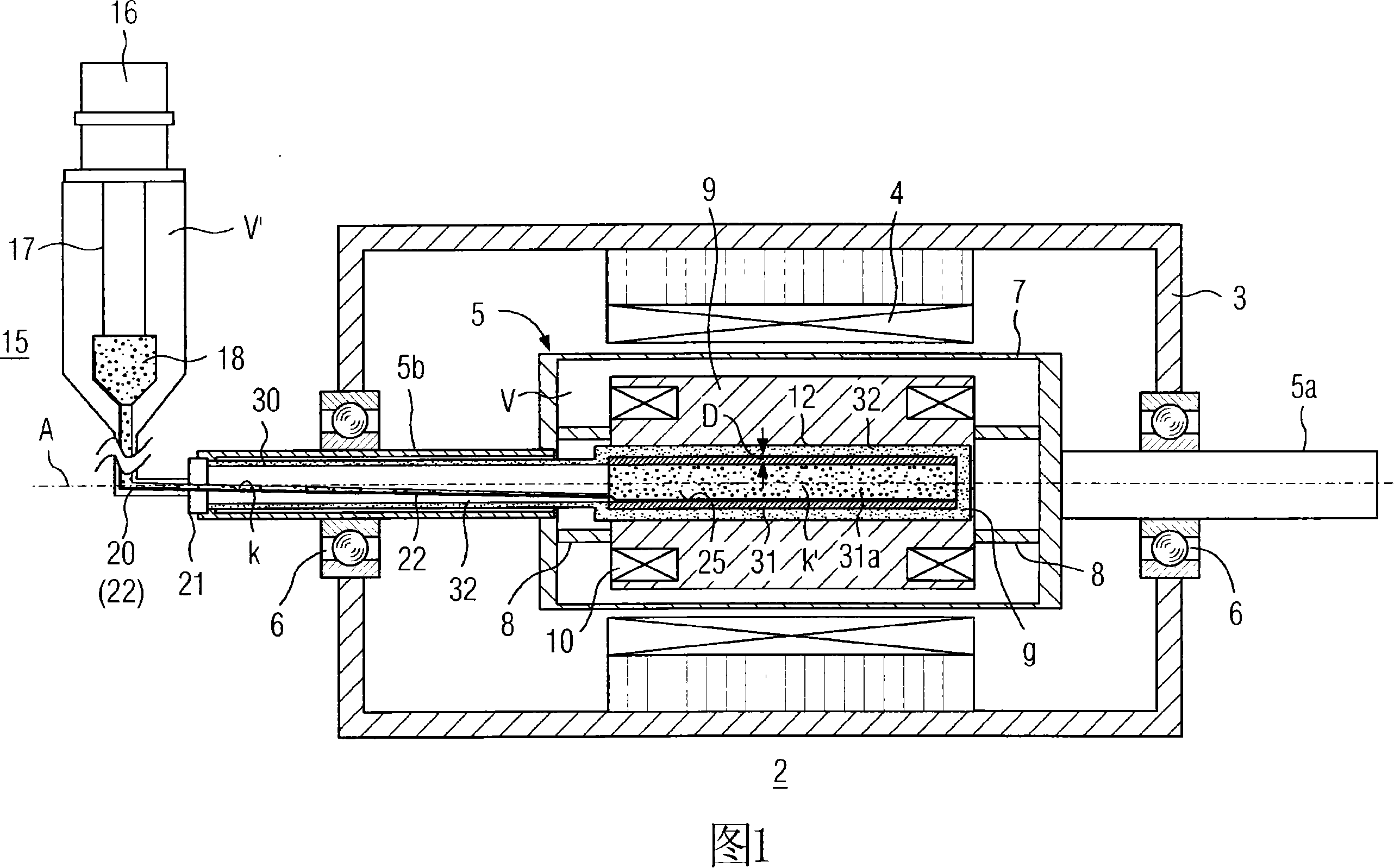

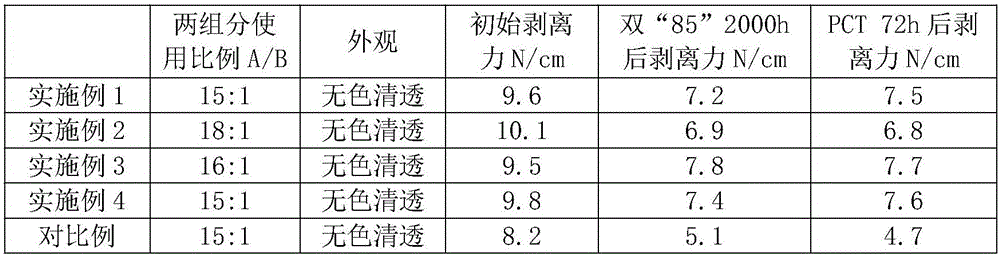

Adhesive composition for solar cell backplane and preparation method thereof

InactiveCN106244081AReduce surface tensionGood wettingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerChemistry

The invention provides an adhesive composition for a solar cell backplane and a preparation method thereof. The adhesive composition is composed of a prepolymer component and a curable component, wherein the prepolymer component contains the following raw materials: fluorine-modified resin, polyester resin, an antioxidant, an ultraviolet absorber, an anti-hydrolysis agent and ethyl acetate; and the curable component is a hexamethylene diisocyanate trimer. The preparation method of the adhesive composition comprises the step of respectively preparing the prepolymer component and the curable component. A preparation method of the prepolymer component comprises the step of uniformly mixing the above raw materials. When in use, the prepolymer component and the curable component are mixed according to the weight ratio of (15-18): 1. The invention has the following advantages: contact area is increased to raise the whole peel strength of the backplane; by adding fluororesin into the adhesive, aging resistance of the backplane can be further enhanced, and dual ''85'' test lasts over 3,000 hours.

Owner:SHANGHAI WEIKAI CHEM +2

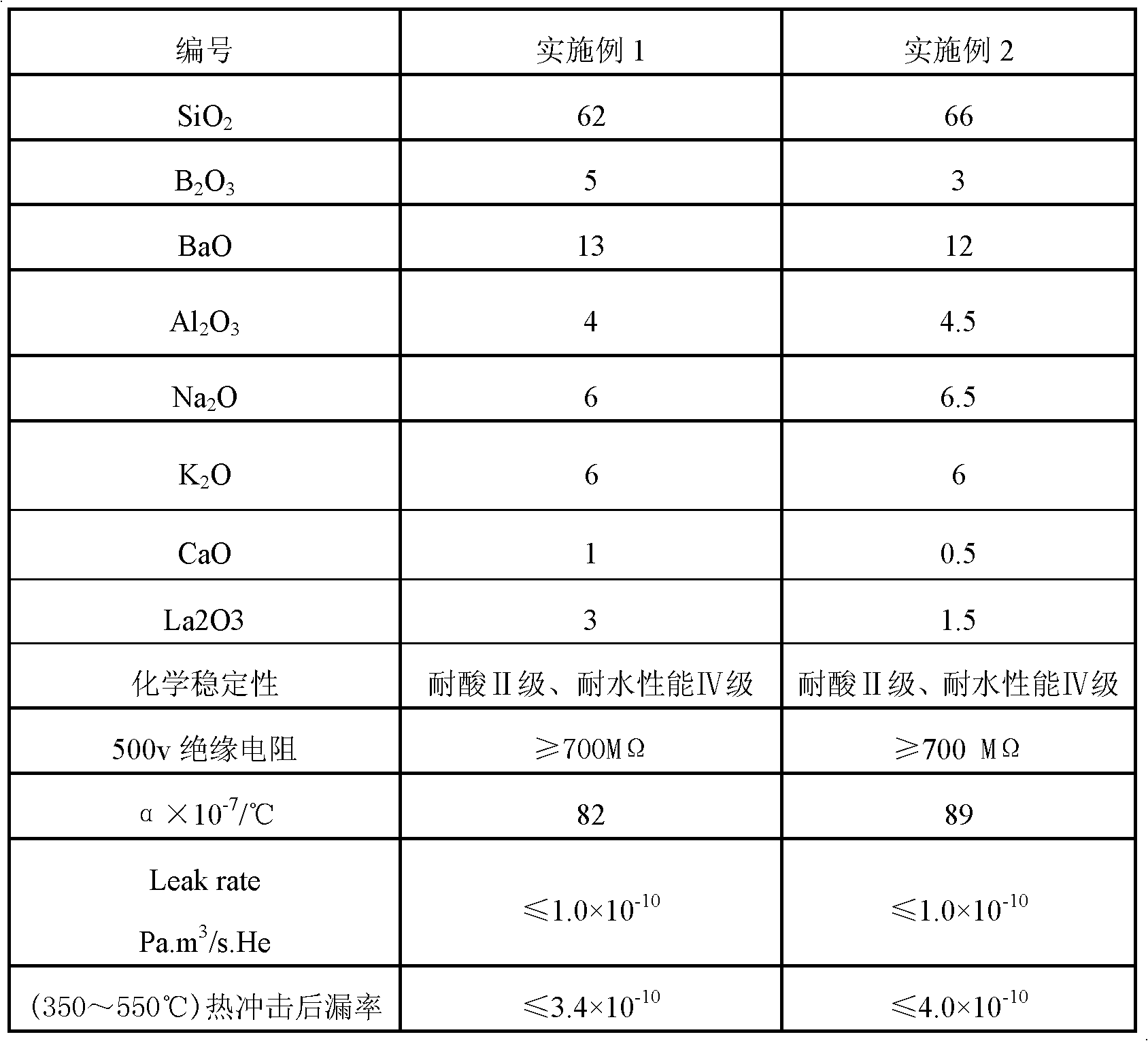

Glass sealing material for thermal battery and preparation method thereof

InactiveCN102070300AWell matched thermal expansionGood wettingInsulation resistanceMixed alkali effect

The invention discloses a glass sealing material for a thermal battery and a preparation method thereof. The invention is characterized in that the glass sealing material comprises the following components in percentage by mole : 60-80% of SiO2, 3-15% of BaO, 5-15% of Na2O, 4-15% of K2O, 0-6% of Al2O3, 0-6% of B2O3, 0-5% of Li2O, and 0-5% of La2O3. The glass sealing material disclosed by the invention basically comprises SiO2, Al2O3 and B2O3, is added with proper matching of alkali metal oxide (mixed alkali effect) so as to control a softening point and viscosity of glass, improve the flowability of the glass and improve the performance of glass powder by adding modified oxides such as La2O3 with certain content and auxiliary ingredients, so that the wetting property of the glass to a titanium battery cover is improved. In addition, the invention prepares the glass sealing material by reasonable manufacturing technologies such as smelting, clearing, pulverizing, granulating and the like, so that the leakage rate of a sealing cover of the thermal battery produced by the sealing material disclosed by the invention is less than 1.0 multiplied by 10-10Pa.m<3> / s, and the insulation resistance is improved by more than one times compared with that of the sealing cover produced by the prior art.

Owner:西安华泰有色金属实业有限责任公司

Non-alcoholic fountain solution containing composite surfactant and preparation method of non-alcoholic fountain solution

The invention discloses a non-alcoholic fountain solution containing a composite surfactant. The non-alcoholic fountain solution comprises the following raw materials in part by weight: 70-85 parts of deionized water, 10-15 parts of kappa-carrageenan, 6-10 parts of amorophophallus konjac, 3-6 parts of tea polyphenol, 2-5 parts of sulfated caster oil, 1-3 parts of sorbitol, 3-6 parts of a pH regulator, 3-5 parts of a composite surfactant, and 1-3 parts of POP glycerin ether. Kappa-carrageenan and amorophophallus konjac are compounded to form a compound, and the compounded as a hydrophilic film former improves the water film persistence, so that the fountain solution has high wettability and permeability when used; kappa-carrageenan-amorophophallus konjac-tea polyphenol microspheres have the characteristics of small mean grain size and slow release of tea polyphenol, and the release of tea polyphenol is slowed during the using process of the fountain solution, so that the oxidation resistance of tea polyphenol is improved greatly, and the using stability of the fountain solution is ensured; and a multielement compounding system of the composite surfactant improves the surface tension reducing efficiency greatly, meets the working solution surface tension requirement of the fountain solution, and is beneficial for enabling the printing process to reach the water-ink balance quickly.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

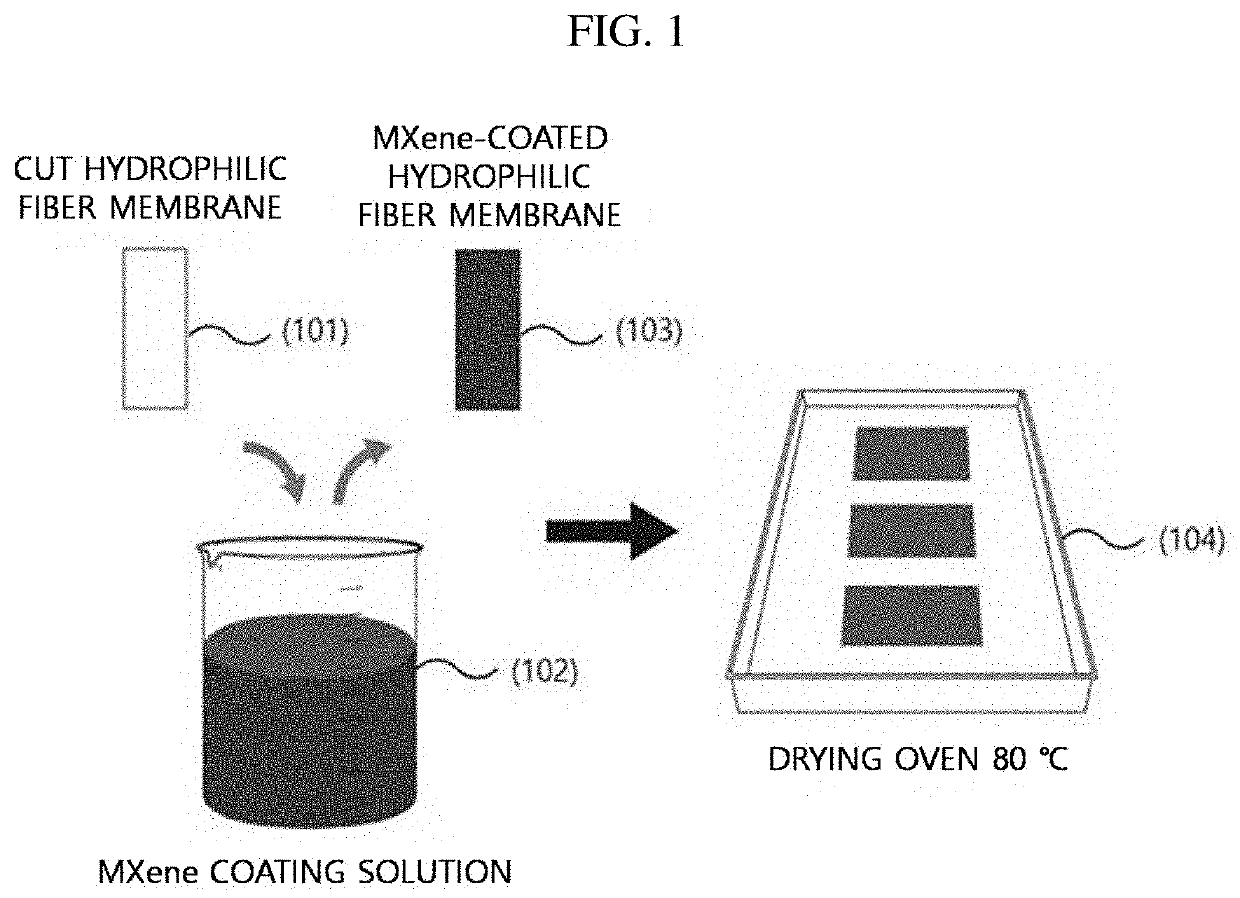

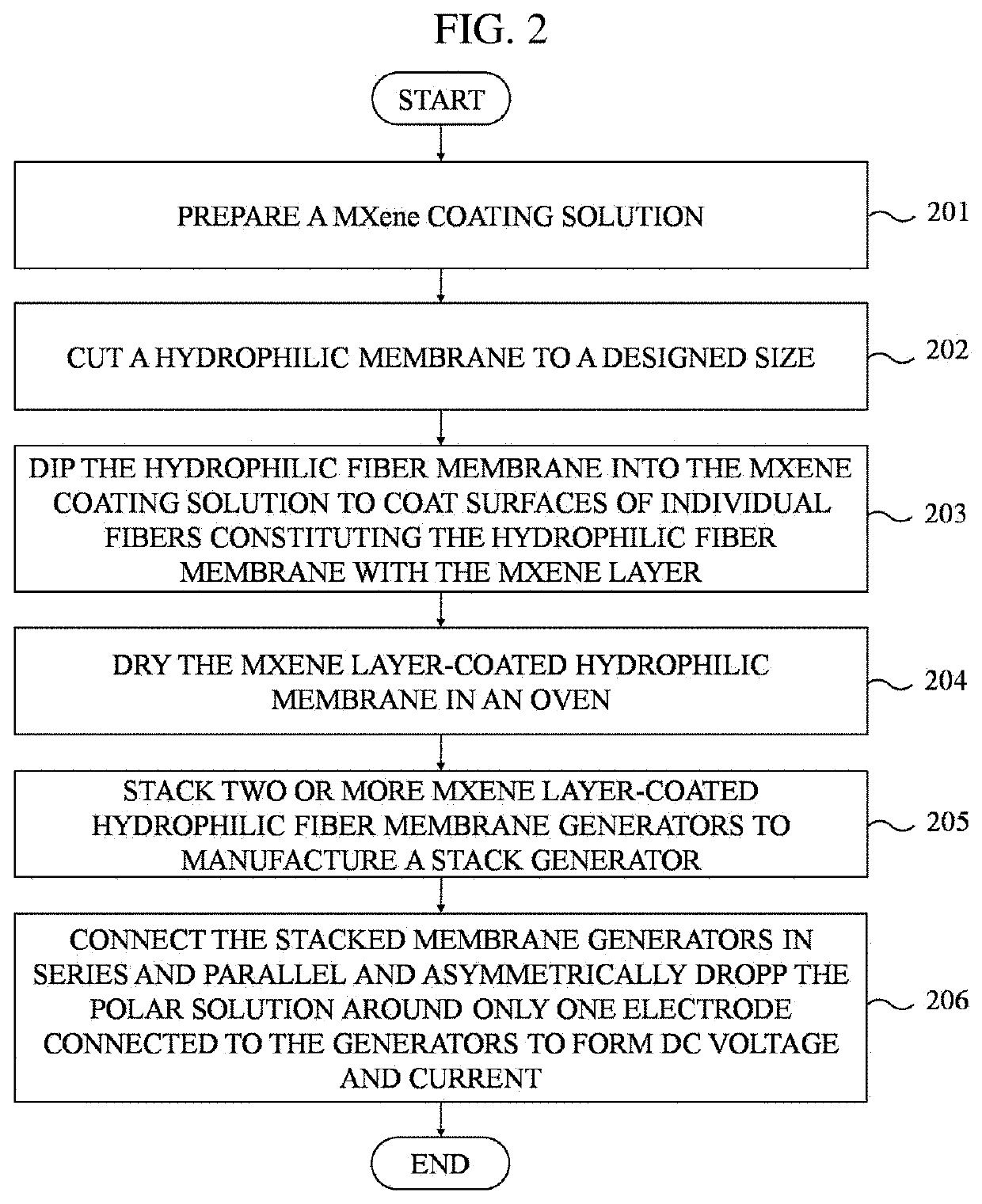

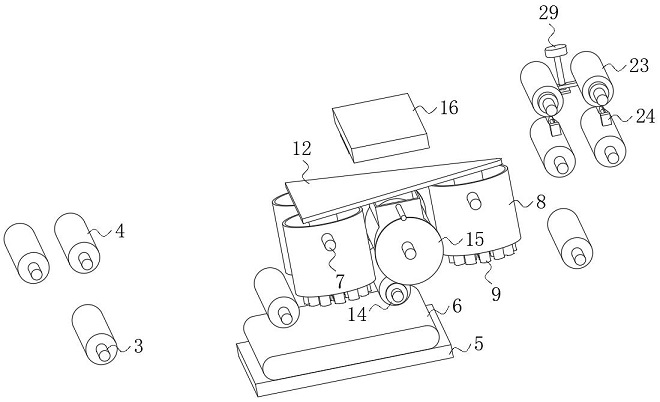

MXene COATED HYDROPHILIC FIBER MEMBRANE-BASED COMPLEX GENERATOR AND MANUFACTURING METHOD THEREOF

PendingUS20210344287A1Efficient power generationGood wettingHybrid capacitor electrolytesCarbon compoundsFiberEngineering

Embodiments of the disclosure relate to a novel concept complex generator enabling high-efficient power generation by applying a polar solution to a MXene layer-coated hydrophilic fiber membrane-based complex generator, and a manufacturing method thereof. Specifically, a MXene layer-coated hydrophilic fiber membrane-based electrical energy generation device uniformly applies MXene particles to fiber strand surfaces of hydrophilic fiber membranes through a dipping process to form a MXene layer.

Owner:KOREA ADVANCED INST OF SCI & TECH

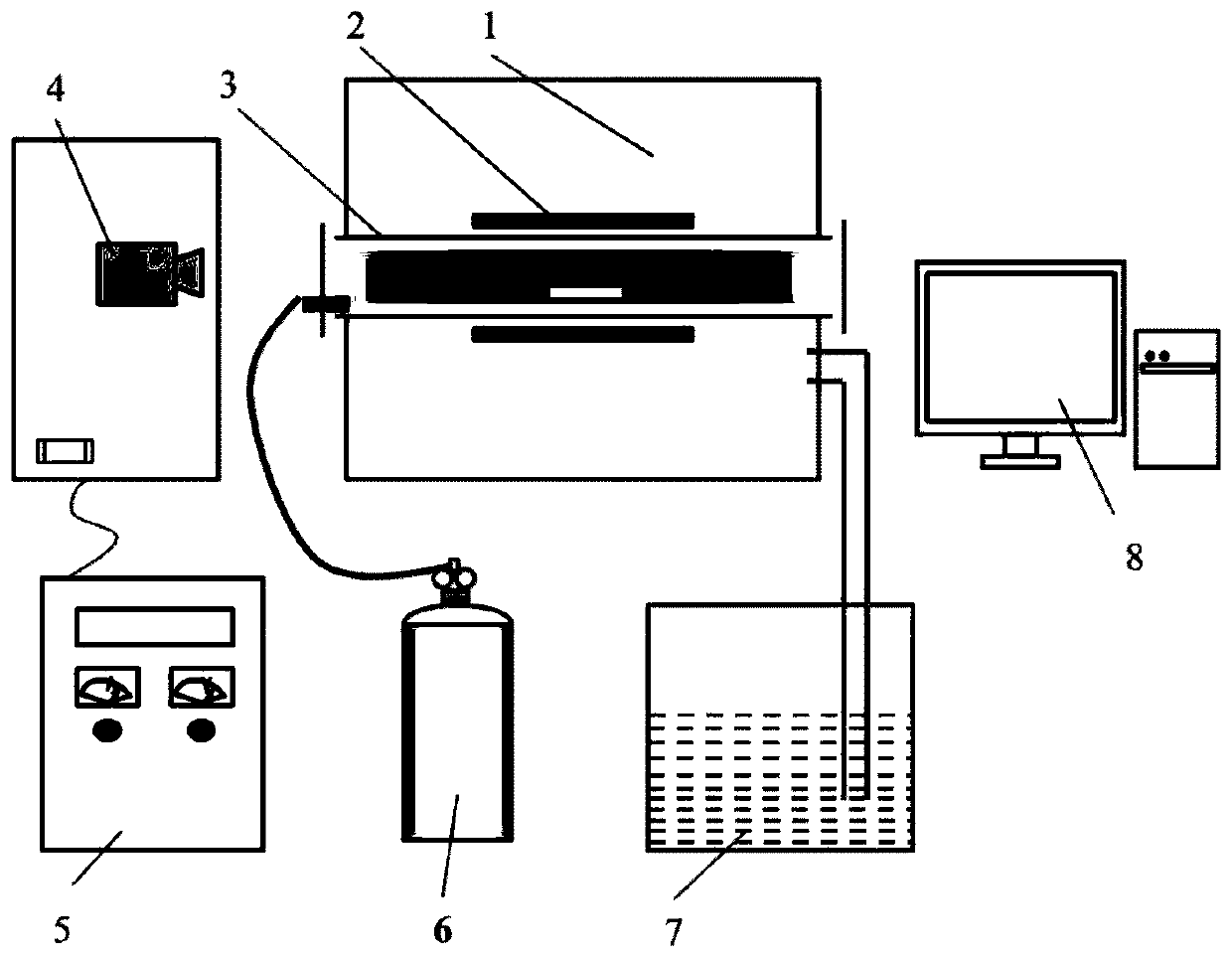

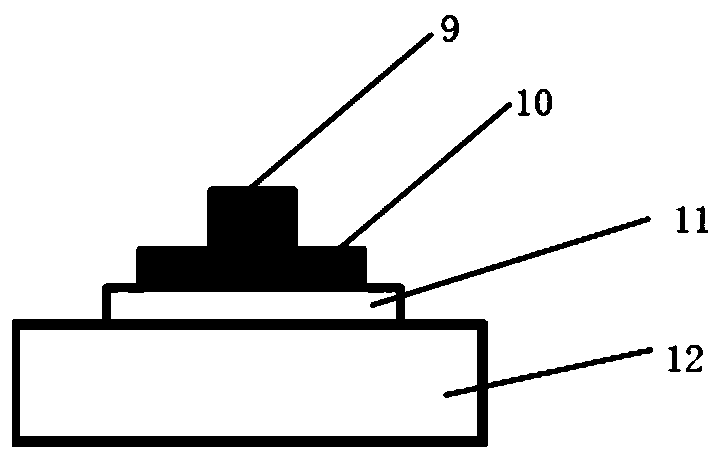

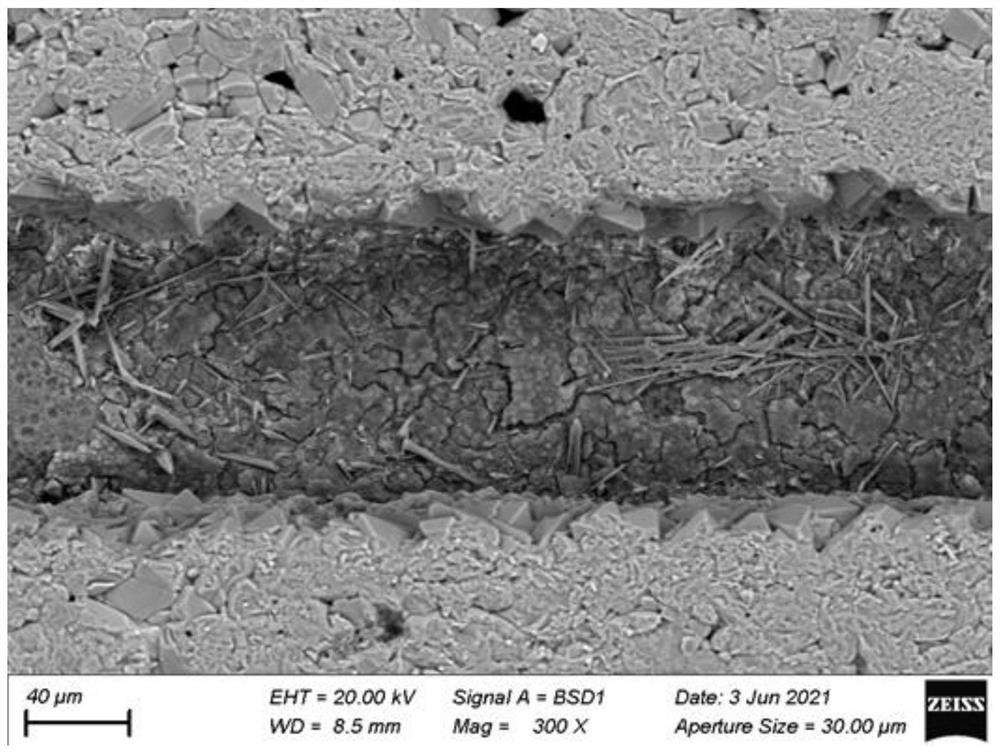

Iron mine sintering binding phase high-temperature wettability measuring method

InactiveCN110174331AGuaranteed steady stateEasy to measureSurface/boundary effectTube furnaceControllability

The invention discloses an iron mine sintering binding phase high-temperature wettability measuring method. The method comprises the following steps: preparing a substrate; putting a binding phase sample onto the prepared substrate; warming a tube furnace in advance, and after the tube furnace rise to an appointed temperature, manually feeding the sample into the furnace at a constant speed with certain rate; shooting the melting and wetting conditions of the binding phase sample on the substrate in the experimental process, carrying out analysis on images in the experimental process through special software to obtain the contact angle of the binding phase sample on the substrate for representing the high-temperature wettability. The measurement of iron mine sintering binding phase high-temperature wettability can be completed through one horizontal tube furnace with a photographic device, and the method has the advantages of wide range of application, controllability for experimentalconditions, simple and quick operation, no fluctuation for experimental data, arrangement with actual sintering process and the like.

Owner:CENT SOUTH UNIV

Kappa-carrageenan-containing fountain solution prepared from high-energy small molecule water and preparation method therefor

The invention discloses a kappa-carrageenan-containing fountain solution prepared from high-energy small molecule water. The fountain solution is composed of the following raw materials in parts by weight: 70-85 parts of water, 10-15 parts of kappa-carrageenan, 6-10 parts of konjac gum, 3-6 parts of tea polyphenol, 2-5 parts of turkey red oil, 1-3 parts of sorbitol, 3-6 parts of a pH regulator, 1-3 part(s) of polyoxyethylene fatty acid ester and 1-2 part(s) of an organic silicon defoamer. According to the fountain solution disclosed by the invention, the kappa-carrageenan and the konjac gum are compounded to be used as a hydrophilic film forming agent, so that the durability of a water film is improved, and the fountain solution has good wettability and permeability during use; and kappa-carrageenan-konjac gum-tea polyphenol microspheres have the characteristics of fine average particle size and slow release of tea polyphenol, and tea polyphenol is slowly released when the fountain solution is used, so that the oxidation resistance of tea polyphenol is greatly improved and the use stability of the fountain solution is guaranteed.

Owner:HEFEI DINGLIANG OPTICAL TECH

Compositions and methods for treatment of glaucoma

InactiveUS20120309720A1Prevent sedationEliminate and reduce rednessAntibacterial agentsBiocideDiseaseAdrenergic

The invention provides α-2 adrenergic receptor agonist compositions and methods for treating glaucoma and other intraocular conditions. The preferred α-2 agonist used in the inventive compositions and methods is dexmedetomidine.

Owner:GLAUCOMA & NASAL THERAPIES

Performance-enhanced hair treatment composition

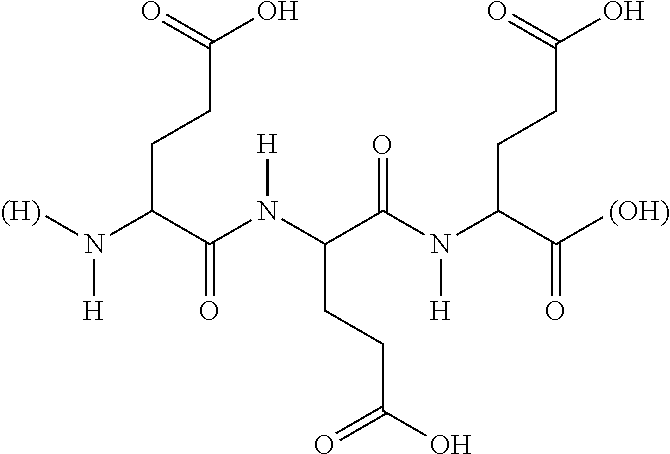

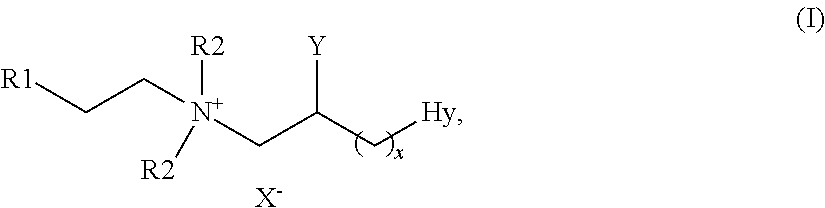

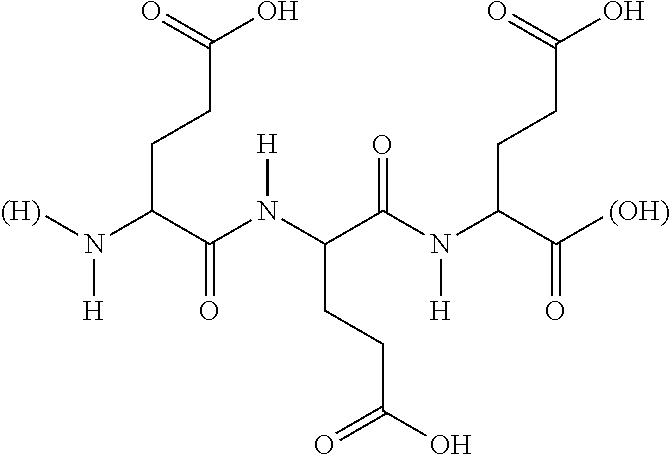

InactiveUS20160199282A1Maintain good propertiesIncrease elasticityCosmetic preparationsHair cosmeticsProtonationHydrolysate

Hair treatment compositions include—based in each case on the weight thereof—0.0001% to 10% by weight at least one oligopeptide having at least one Glu-Glu-Glu amino acid sequence, wherein the amino group may be free or protonated and the carboxyl groups may be free or deprotonated, and 0.0001% to 10% by weight at least one proteolipid of the formula (I) in which R1 is a straight-chain hydrocarbyl radical having 8 to 22 carbon atoms, R2 is (—CH2)y—CH3, with y=0 to 22, Y is —H or —OH, X− is a physiologically acceptable anion, Hy is an oligopeptide residue from keratin hydrolysate, and x has values from 0 to 22. In these compositions, proteolipids and oligopeptides have mutually enhancing positive effects on the hair and the hair follicle.

Owner:HENKEL KGAA

Low-temperature ceramic and metal composite binding agent used for grinding tool and preparing method of low-temperature ceramic metal composite binding agent

ActiveCN110509194AUniform structureImprove toughnessAbrasion apparatusGrinding devicesChemical platingCeramic metal

The invention belongs to the field of preparing of binding agents used for grinding tools and relates to a low-temperature ceramic and metal binding agent used for a grinding tool and application. A chemical plating method is adopted for introducing metal into a ceramic bonding agent, and the defects that the ceramic binding agent is large in brittleness, low in strength and poor in heat conductivity are overcome. Compared with a traditional mechanical mixing method, in the prepared composite binding agent, the uniformity and binding force of ceramic and metal are better, and the condition that the compatibility of ceramic and metal is poor is effectively improved. Compared with a ceramic binding agent, the tensile strength and impact strength of the prepared composite binding agent are obviously improved, sharpness of ceramic is achieved, and the cracking condition of the ceramic binding agent in the deep processing process is also avoided.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Light non-combustible sound insulation board and preparation method thereof

ActiveCN111517736AGood wettingLess foamingGlass/slag layered productsWater-setting substance layered productPolyurethane adhesiveCohesive strength

The invention discloses a light non-combustible sound insulation board and a preparation method thereof. The light non-combustible sound insulation board is prepared from the following raw materials in parts by weight: 10-40 parts of a magnesium compound, 35-70 parts of perlite, 15-50 parts of brine and 5-12 parts of a polyurethane adhesive. According to the invention, ketimine and PAPI are utilized to prepare the low-viscosity, solvent-free and high-wettability polyurethane adhesive, and when the polyurethane adhesive is applied to the magnesium board, the magnesium board is good in wettability, less in foaming and high in bonding strength, the critical point of the usage amount is 11-12%, the cohesion strength of the magnesium board can be greatly improved while the fire resistance of the magnesium board is kept at the non-combustible level, the waterproof and damp-proof performance is improved, and the sound insulation performance is improved.

Owner:廊坊市北辰创业树脂材料股份有限公司 +1

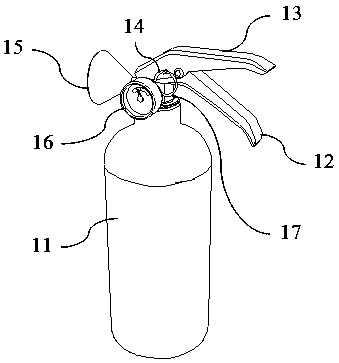

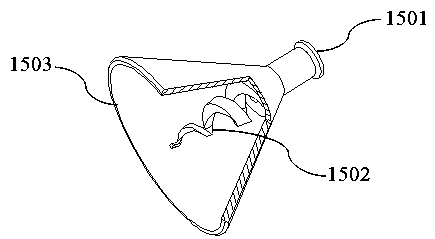

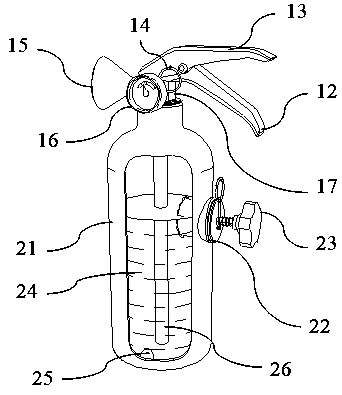

Handheld type radioactive contamination removing device

PendingCN110040370AGood wettingProtect life and propertyLiquid dispensingNuclear energy generationSpray nozzleUnderground space

The invention discloses a handheld type radioactive contamination removing device. The device comprises a bottle body, a lifting-holding handle, a pressing handle, a pressure meter, a spray nozzle anda spraying safety ring, wherein a spraying valve is mounted at a bottleneck of the bottle body; the lifting-holding handle is connected to the spraying valve; the pressing handle is in hinge connection to the lifting-holding handle, controls the spraying valve and is pressed to open the spraying valve; the pressure meter is arranged on the spraying valve and communicates with the inner part of the bottle body; the spray nozzle is arranged on the spraying valve; and the spraying safety ring is connected onto the pressing handle in an inserted mannerand blocks the pressing handle, so that the pressing handle is not capable of being downwards pressed. The handheld type radioactive contamination removing device is suitable for various places such as indoor space and underground space, in which large equipment cannot operate, realizes quick control and clear for radioactive contamination, can quickly and effectively control the diffusion range of radioactive contamination, protects life and property safety of the masses, and reduces accident harm and loss to the smallest degree.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

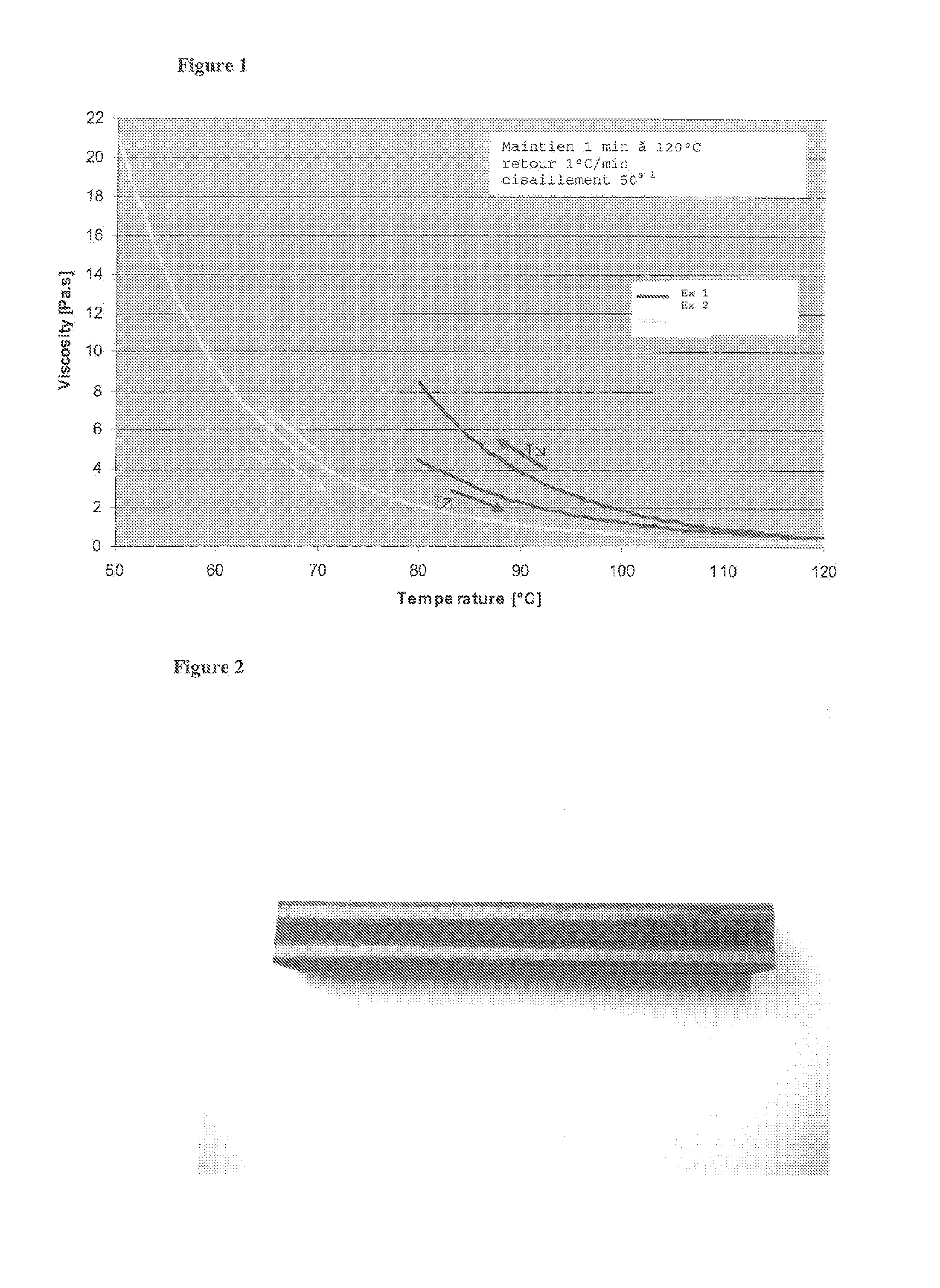

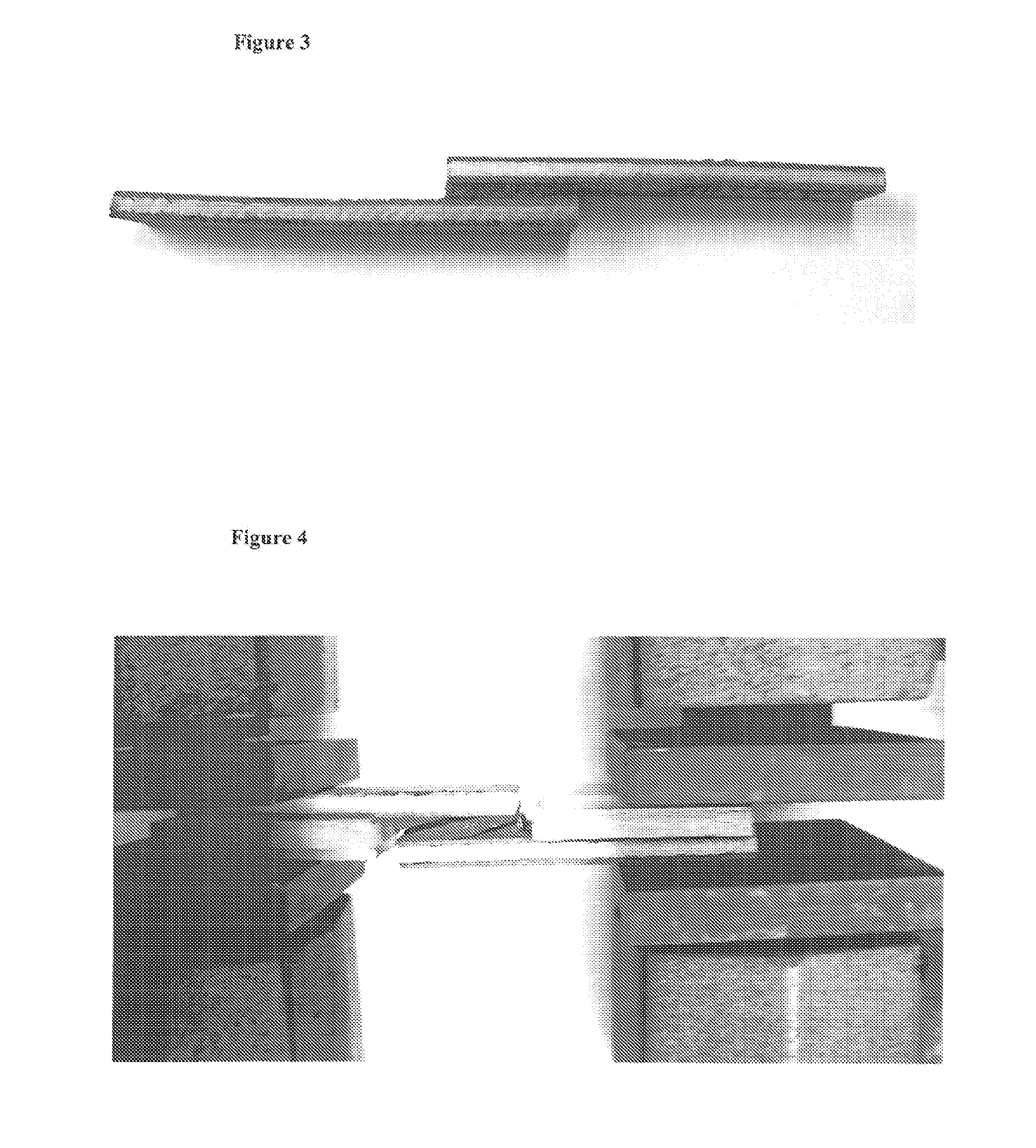

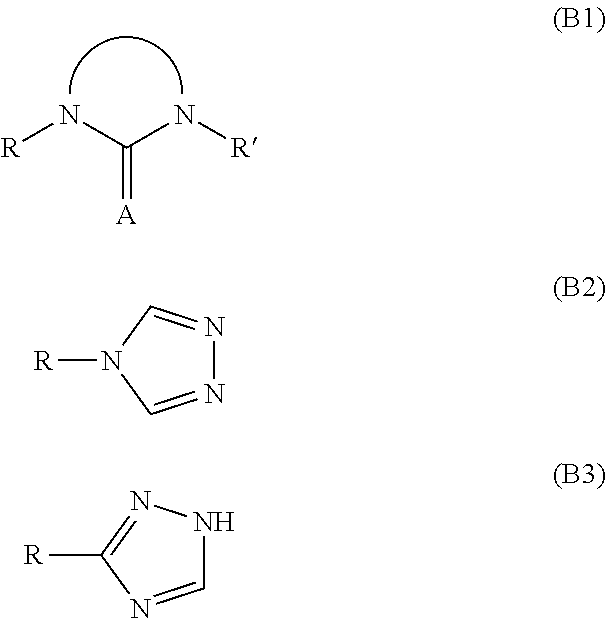

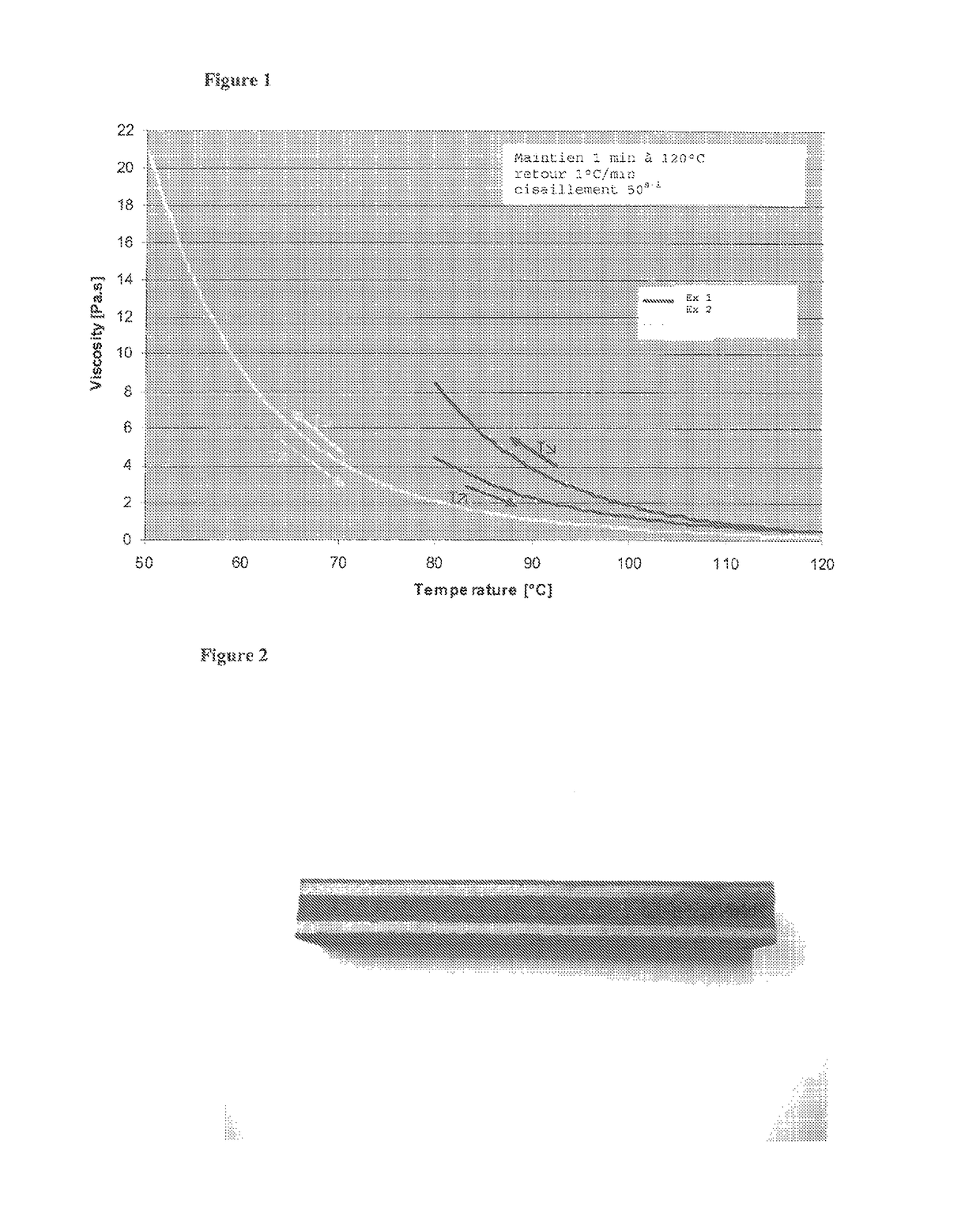

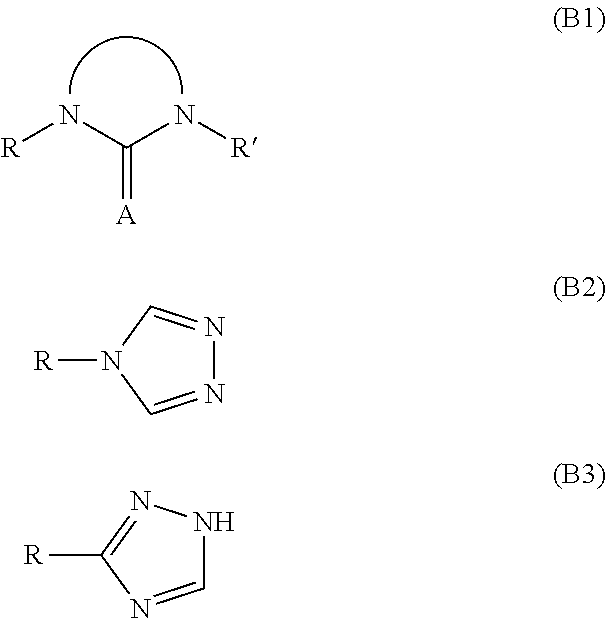

Multilayer structure comprising a layer of supramolecular material and method for the production thereof

InactiveUS20160068626A1Easy to processImprove wettabilitySynthetic resin layered productsDendritic macromolecule adhesivesAviationSound wave

The invention relates to a multilayer structure comprising at least one layer of supramolecular material and one layer of rigid material, to a method for producing such a structure by casting a composition comprising a precursor of the supramolecular material, and to the uses of the structures produced, especially for applications where a dampening of impacts, vibrations and / or sound waves is desired, for example for producing locomotion vehicles such as automotive, rail, nautical, aeronautical or aerospace vehicles, or for the construction industry.

Owner:ARKEMA FRANCE SA

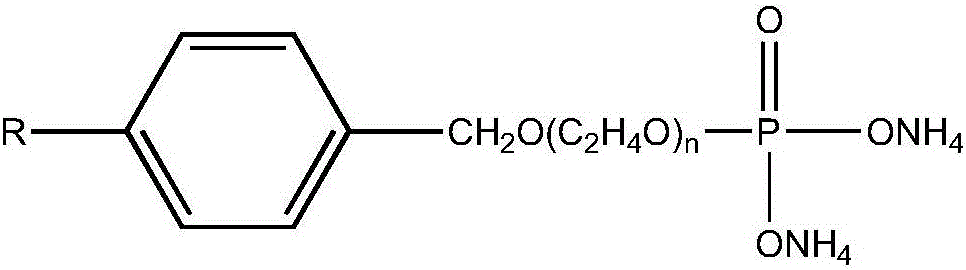

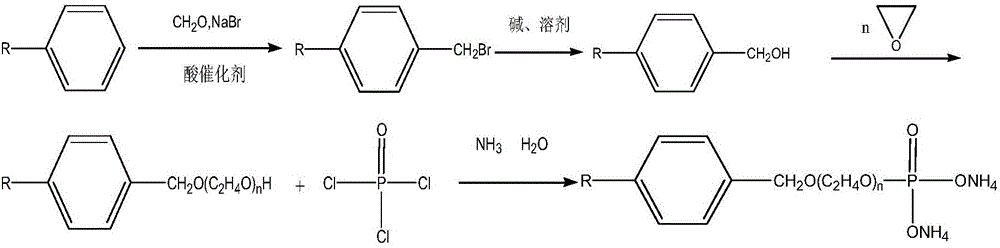

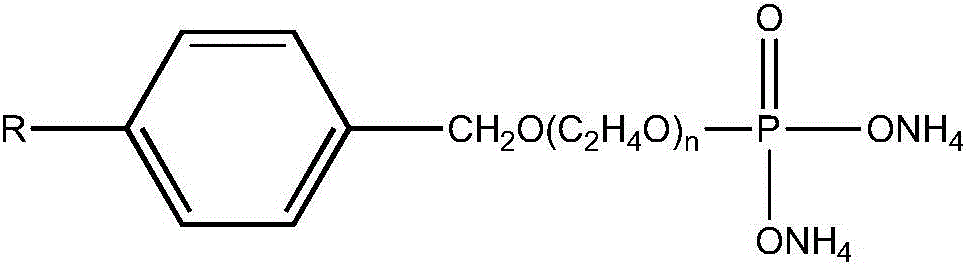

Alkyl benzoic alcohol polyoxyethylene ether ammonium phosphate and preparation method thereof

The present application discloses an alkyl benzyl alcohol polyoxyethylene ether ammonium phosphate and a preparation method thereof. The molecular structure of the alkyl benzyl alcohol polyoxyethylene ether ammonium phosphate includes a hydrophobic group and a hydrophilic group, and the molecular structure is as follows: Wherein, R in the molecular formula is an alkyl group, and n=3-50. The alkyl benzyl alcohol polyoxyethylene ether ammonium phosphate prepared by the invention does not contain APEO, has good wetting, penetrating, emulsifying, dispersing, solubilizing and washing functions, and can be used as emulsifier, textile auxiliary, detergent , dispersant, softener, etc., completely replace alkylphenol polyoxyethylene ether emulsifier, widely used in detergents, personal care products, textiles, papermaking, petroleum, pesticides, pharmaceuticals, printing, synthetic rubber, water-based emulsions, coatings, Ink, glue, plastic and other industries.

Owner:NANJING FORESTRY UNIV

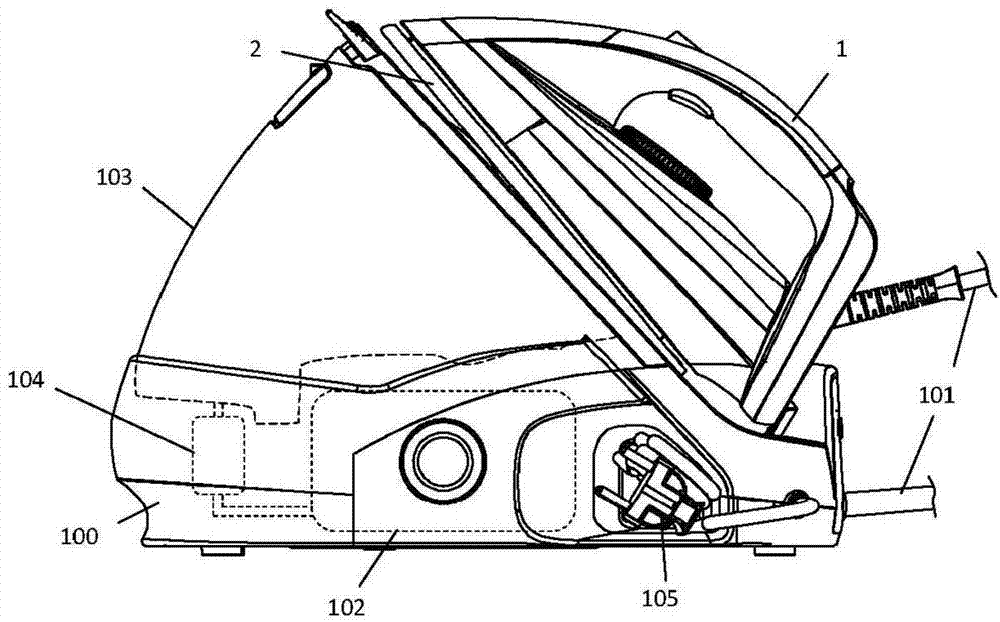

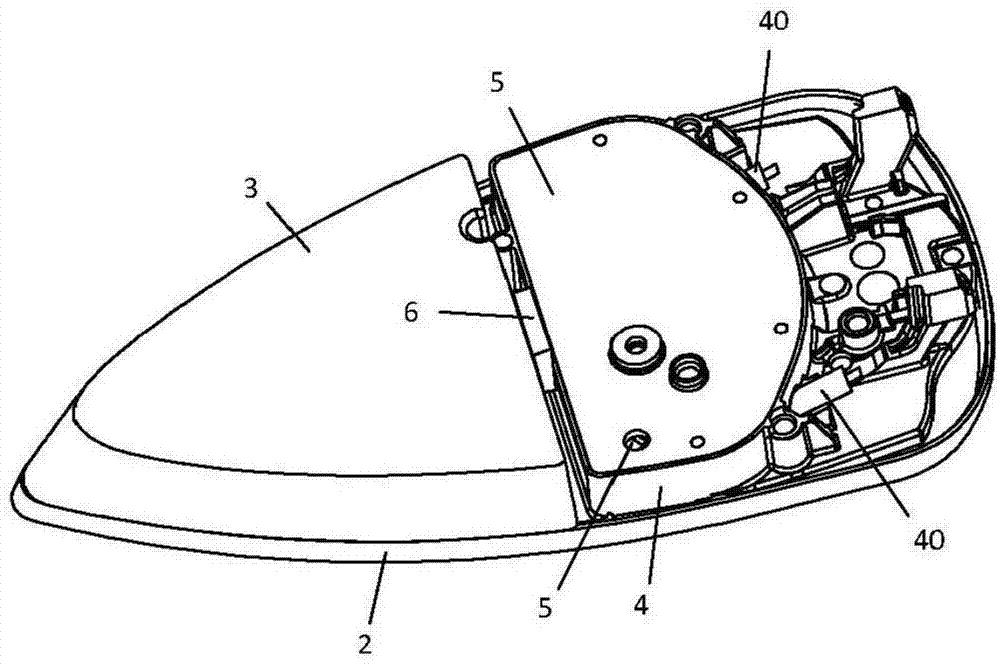

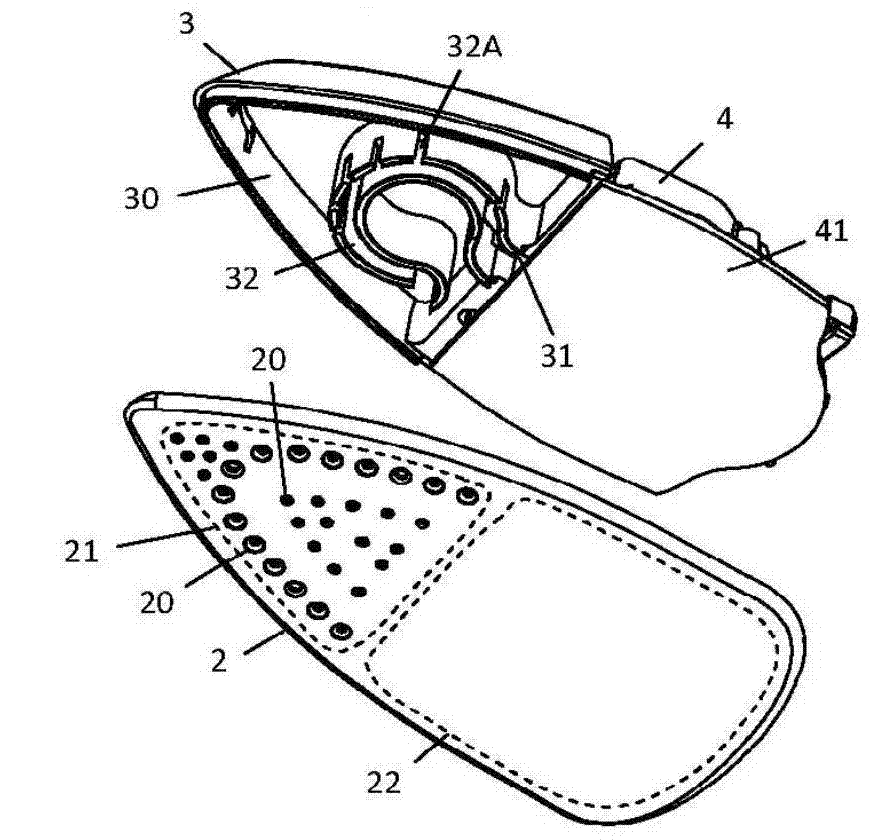

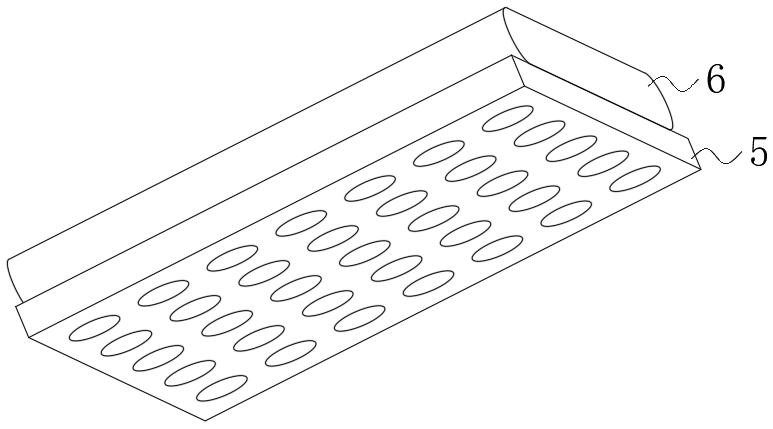

Steam ironing appliance

ActiveCN104213383AGood wettingPromote wettingHand ironTextiles and paperDiffusion chamberSteam temperature

STEAM IRONING DEVICE A steam clothes ironing device that includes a clothes iron (1) containing a sole plate (2; 202) that contains a front portion (21; 221) fitted with steam outlet holes (20; 220) and a back portion (22; 222) lacking steam outlet holes, the steam outlet holes (20; 220) being supplied by a diffusion chamber (30; 230) that covers the front portion (21; 221) of the sole plate, wherein the diffusion chamber (30; 230) is supplied by a steam distribution circuit that is located in a heating element (4; 204) at the thermal contact of the back portion (22; 222) of the sole plate and the diffusion chamber (30; 230) is adapted to lower the temperature of the steam coming from the steam distribution circuit so that the steam temperature at the steam outlet holes (20; 220) is between 100'C and 120'C. -- - ------------- ------ 101 100 --------z ---------------

Owner:SEB SA

Itch reliving and sebum controlling liquid foundation and preparation method thereof

InactiveCN104997687AApply evenlyGood wettingCosmetic preparationsBody powdersCetyl alcoholMethyl cellulose

The invention relates to an itch reliving and sebum controlling liquid foundation and a preparation method thereof. The liquid foundation comprises, by mass, 0.2-1.2 parts of cetyl alcohol, 5-14 parts of isopropyl myristate, 0.4-1.5 parts of ethylene glycol lauric acid ester, 1.6-3.2 parts of vaseline, 0.5-1.4 parts of methylcellulose, 0.1-0.2 part of iron oxide red, 1-4 parts of ten methyl five polysiloxane, 0.3-0.6 part of nylon powder, 0.03-0.09 part of zinc stearate, 0.3-0.6 part of glucosaminoglycan, 0.1-0.2 part of perfume, 1-5 pars of fructus cnidii, 1-5 parts of borneol and 1-5 parts of liquorice. The liquid foundation can be smeared uniformly, the moistening effect is good, the makeup is easy to put on, meanwhile, the effects of reliving itch and controlling sebum are achieved, the face is not prone itching when makeup is completed, poxes are not prone to generating, and the liquid foundation is especially suitable for being used in summer.

Owner:JIANGSU QILIKANG SKIN PHARMA

Welding flux, preparation method and application thereof, welding method and ceramic component

ActiveCN113732565AGood liquidityGood wettingWelding/cutting media/materialsSoldering mediaWettingWelding joint

The invention discloses a welding flux, a preparation method and application thereof, a welding method and a ceramic component, and belongs to the technical field of ceramic welding. The main components of the welding flux comprise 5-15% of SiO2, 40-50% of B2O3, 15-25% of Al2O3 and 15-30% of MgO. The welding flux containing the components can form microcrystalline glass containing MgAl2O4 and Al18B4O33 at high temperature, the connection reliability degree of a welding joint can be enhanced, good wetting with an Al2O3 ceramic base material can be achieved, the thermal expansion coefficient difference between the base material and the welding flux is reduced, the residual stress of the joint is reduced, and reliable connection between Al2O3 ceramic matrixes is realized. The corresponding welding method is safe in process, environmentally friendly, reliable and easy and convenient to operate, has important application value and is suitable for being widely popularized and used.

Owner:GUANGDONG INST OF NEW MATERIALS

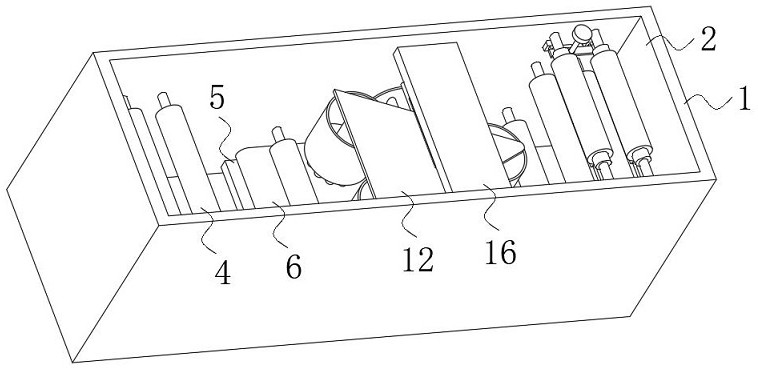

Textile cloth wetting device for spinning

InactiveCN113604998AGood wettingEasy to useLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsPolymer scienceSpinning

The invention discloses a textile cloth wetting device for spinning. The textile cloth wetting device comprises a wetting box; a wetting groove is formed in the wetting box; a plurality of first rotating shafts are rotationally installed in the wetting groove; a roller body is fixedly installed on each first rotating shaft; a supporting net plate is fixedly installed in the wetting groove; a strip-shaped sponge plate matched with each roller body is fixedly installed on the supporting net plate; and three cylinders are fixedly installed in the wetting groove through a plurality of first fixing rods. The textile cloth wetting device has the advantages that movable sealing plates are used in cooperation with the cylinders and extrusion pipes, a water flow spraying effect can be generated on textile cloth, and therefore the textile cloth can be better wetted within a relatively short time; and meanwhile, the moisture adhered to the textile cloth can be regulated and controlled by utilizing the water absorption of annular sponge rollers, and the water content of the annular sponge rollers can be regulated according to the positions of extrusion rods, so that the water absorption of the sponge rollers when the sponge rollers are in contact with the textile cloth can be regulated and controlled to a certain extent.

Owner:吴彤

Machine system with a thermo-syphon cooled superconductor rotor winding

InactiveCN101116238BEvenly distributedGood wettingCooling/ventillation arrangementRegenerative heat exchangersHeat conductingEngineering

The machine system comprises a machine (2) provided with a rotor that can be rotated about an axis (A), with a superconductor winding (10) that is coupled in a heat-conducting manner to a central coolant area (31) of a fixed heat conducting body (30) protruding into a hollow (12) of the rotor by means of a winding carrier (9) and a heat contact gas (g). The coolant area (31a) forms a line system with the line parts (22) thereof, that are laterally connected thereto, and a condenser area (18) of a cold unit (13), wherein a coolant (k,k') circulates in said line system on the basis of a thermo syphon effect. In order to maintain the supply of coolant to the central coolant area (31), even when the rotor (5) encounters difficulties, the coolant area is provided with a lining (25) that is madeof a porous material, preferably a sinter material, having higher thermal conductivity.

Owner:SIEMENS AG

Health-preserving rice wine for improving sleep

InactiveCN104004627BGood wettingGood spleenNervous disorderAlcoholic beverage preparationBiotechnologyAmnesia

Owner:辰溪香源酒庄有限公司

Flux-cored aluminum brazing filler metal and preparation method thereof

ActiveCN112621015AReduce generationLow melting pointWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses flux-cored aluminum brazing filler metal which comprises a brazing flux core and aluminum-based brazing filler metal. The brazing flux core is wrapped with the aluminum-based brazing filler metal. The flux-cored aluminum brazing filler metal comprises, by mass percent, 2.1%-9.2% of AlF3 powder, 1.7%-7.5% of CsF powder, 1.2%-5.3% of KF powder, 11%-25.3% of alloy powder, 4%-8% of Si powder and the balance aluminum-based brazing filler metal. The invention further discloses a preparation method of the flux-cored aluminum brazing filler metal. According to the flux-cored aluminum brazing filler metal, an aluminum-silicon eutectic reaction occurs in the brazing process, the melting point is low, fluidity and spreadability are good, and the brazing seam strength is high.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

Polishing solution for polishing YAG (yttrium aluminum garnet) bonding crystal and spinel bonding crystal

PendingCN114702905ASpeed up the processGood wettingPolishing compositions with abrasivesActive agentTraditional Chinese medicine

The invention discloses a polishing solution for polishing YAG (yttrium aluminum garnet) bonded crystals and spinel bonded crystals, which comprises the following components in percentage by weight: 0.5 to 2 percent of nitric acid, 10 to 15 percent of corundum, 1 to 3 percent of diamond powder, 8 to 20 percent of sodium lauryl sulfate and 68 to 80 percent of water. All the raw materials are mixed to obtain the traditional Chinese medicine composition. The principle and the advantages of the invention are as follows: nitric acid is a highly corrosive inorganic acid, and can corrode the crystal surface in the polishing process so as to accelerate the processing process; the component of corundum is AL2O3, is a powdery substance like diamond powder, and plays a role in grinding YAG in the polishing process; the sodium lauryl sulfate anionic surfactant is easily soluble in water, has good wetting, floating, decontamination and foaming properties, and can be matched with other components in the polishing solution to well improve the quality of a polished surface; the water is deionized water, so that the water is pure and impurity-free.

Owner:北京捷普创威光电技术有限公司

A kind of flux-cored aluminum solder and preparation method thereof

ActiveCN112621015BReduce interfacial energyLow melting pointWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses a flux-cored aluminum brazing filler metal including flux flux core and aluminum-based brazing filler metal, wherein the aluminum-based brazing filler metal wraps the flux flux core; 9.2%AlF 3 powder, 1.7% to 7.5% CsF powder, 1.2% to 5.3% KF powder, 11% to 25.3% alloy powder, 4% to 8% Si powder, and the balance is aluminum-based solder; the invention also discloses the flux core The preparation method of aluminum brazing filler metal; in the invention, an aluminum-silicon eutectic reaction occurs during the brazing process, the melting point is low, the fluidity and spreadability are good, and the brazing seam strength is high.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

Multilayer structure comprising a layer of supramolecular material and method for the production thereof

InactiveUS10093767B2Easy to processImprove adhesionSynthetic resin layered productsDendritic macromolecule adhesivesAcoustic waveMaterials science

The invention relates to a multilayer structure comprising at least one layer of supramolecular material and one layer of rigid material, to a method for producing such a structure by casting a composition comprising a precursor of the supramolecular material, and to the uses of the structures produced, especially for applications where a dampening of impacts, vibrations and / or sound waves is desired, for example for producing locomotion vehicles such as automotive, rail, nautical, aeronautical or aerospace vehicles, or for the construction industry.

Owner:ARKEMA FRANCE SA

A kind of low temperature ceramic metal composite bond for abrasive tool and preparation method thereof

ActiveCN110509194BUniform structureImprove toughnessAbrasion apparatusGrinding devicesChemical platingCeramic metal

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Water soluble fertilizer containing high-concentration humic acid and preparation method thereof

ActiveCN103408373BImprove buffering effectReduce heavy metal contentFertilizer mixturesDipotassium hydrogen phosphateHigh concentration

The invention provides a water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer comprises, by weight, 15-25 parts of a water soluble humic acid salt, 18-25 parts of urea, 9-15 parts of dipotassium hydrogen phosphate, 8-13 parts of potassium acetate, 0.5-2 parts of borax, 0.1-10 parts of polyglutamic acid, 1-5 parts of rhamnolipid, 5-10 parts of a hydroxymethyl cellulose aqueous solution and 30-40 parts of water. The water soluble fertilizer has humic acid content greater than or equal to 150g / L. The invention also provides a preparation method of the water soluble fertilizer containing high-concentration humic acid. The preparation method comprises the following steps of 1, carrying out heating stirring of the water soluble humic acid salt and water to obtain a humic acid salt solution, 2, adding dipotassium hydrogen phosphate, potassium acetate, borax, polyglutamic acid, rhamnolipid and urea into the humic acid salt solution, and carrying out heating stirring to obtain a mixed solution, and 3, carrying out emulsification of the hydroxymethyl cellulose aqueous solution and the mixed solution to obtain the water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer has obvious fertilizer efficiency, is environmentally friendly, stable and uniform and has a wide application range.

Owner:陕西鼎天济农腐殖酸制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com