Adhesive composition for solar cell backplane and preparation method thereof

A technology of solar cells and adhesives, applied in the directions of adhesives, adhesive additives, adhesive types, etc., can solve the problem of insufficient aging resistance, high humidity in the use environment, and can not fully improve the heat resistance of polyurethane adhesives. performance and hydrolysis resistance, to achieve the effect of good wetting and lower surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

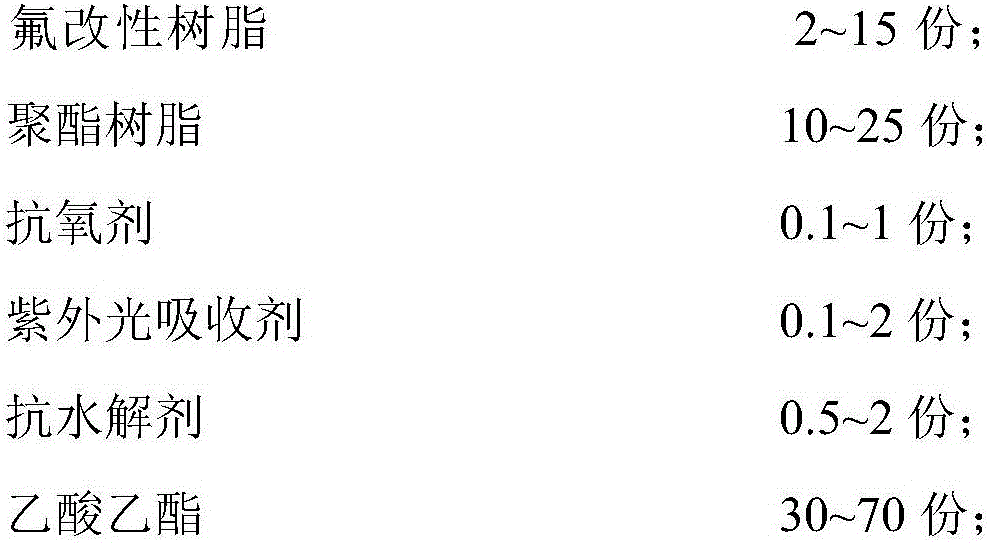

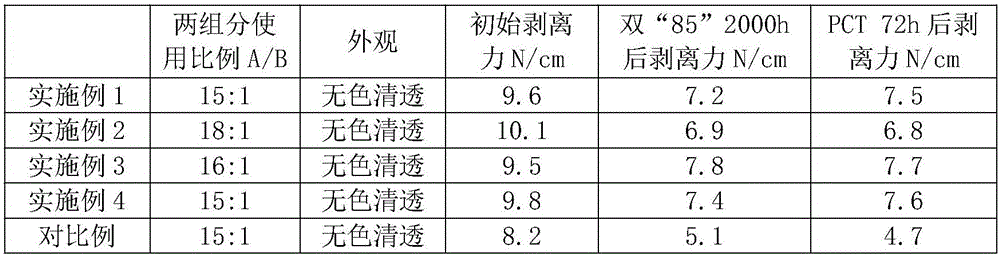

[0030] This embodiment relates to an adhesive for solar battery backsheets: it is composed of a prepolymer component and a B component, wherein the prepolymer component consists of 10wt% of fluorine-modified polyester resin and 15wt% of hydroxyl polyester. Resin, 0.5wt% antioxidant 1010, 1wt% antioxidant 168, 1.5wt% ultraviolet absorber 234, 2wt% polycarbodiimide P200 hydrolysis stabilizer, 70wt% ethyl acetate diluent mixed uniformly The curing component is hexamethylene diisocyanate trimer; after the prepolymer component and the curing component are mixed uniformly at a weight ratio of 15:1, they are uniformly coated on the bonded material through an automated continuous molding process PET film surface, sizing amount is 10g / m 2 After the solvent evaporates and dries, attach a 25μm thick PVDF film and place it in an oven in the order of 250μmPET / adhesive / 25μmPVDF film. The curing temperature is 120℃, the curing time is 3min, and it is cured in a 40℃ oven for 3 days. .

Embodiment 2

[0032] This embodiment relates to an adhesive for solar cell back sheets: it is composed of a prepolymer component and a B component, wherein the prepolymer component consists of 2wt% fluorine-modified polyurethane resin and 25wt% hydroxy polyester resin , 0.1wt% antioxidant 1076, 0.4wt% antioxidant 168, 0.5wt% UV-531, 2wt% polycarbodiimide P100 hydrolysis stabilizer, 70wt% ethyl acetate diluent mixed uniformly , The curing component is hexamethylene diisocyanate trimer; after the prepolymer component and the curing component are mixed uniformly at a weight ratio of 18:1, they are uniformly coated on the bonded material PET through an automated continuous molding process Film surface, sizing amount is 10g / m 2 After the solvent evaporates and dries, attach a 25μm thick PVDF film and place it in an oven in the order of 250μmPET / adhesive / 25μmPVDF film. The curing temperature is 120℃, the curing time is 3min, and it is cured in a 40℃ oven for 3 days. .

Embodiment 3

[0034] This embodiment relates to an adhesive for solar battery backsheets: it is composed of a prepolymer component and a B component, wherein the prepolymer component is 15wt% fluorine-modified polyethylene resin and 10wt% hydroxy polyester Resin, 1wt% antioxidant 1076, 2wt% UV-326, 2wt% monomeric carbodiimide hydrolysis stabilizer, 70wt% ethyl acetate diluent are mixed uniformly, and the curing component is hexamethylene two Isocyanate trimer: After mixing the prepolymer component and the curing component uniformly in a weight ratio of 16:1, it is evenly coated on the surface of the PET film of the bonded material through an automated continuous molding process, with a sizing amount of 10g / m 2 After the solvent evaporates and dries, attach a 25μm thick PVDF film and place it in an oven in the order of 250μmPET / adhesive / 25μm PVDF film. The curing temperature is 120℃, the curing time is 3min, and it is cured in a 40℃ oven. day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com