Patents

Literature

1082results about "Vibration devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

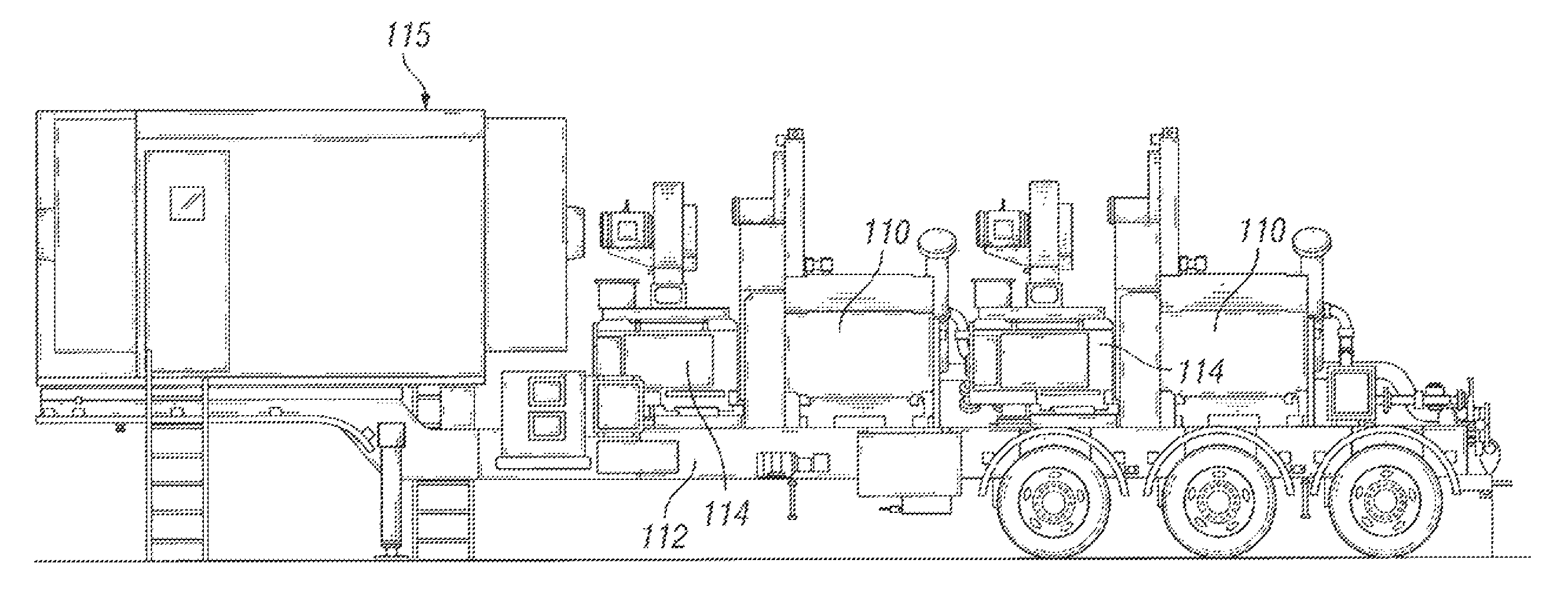

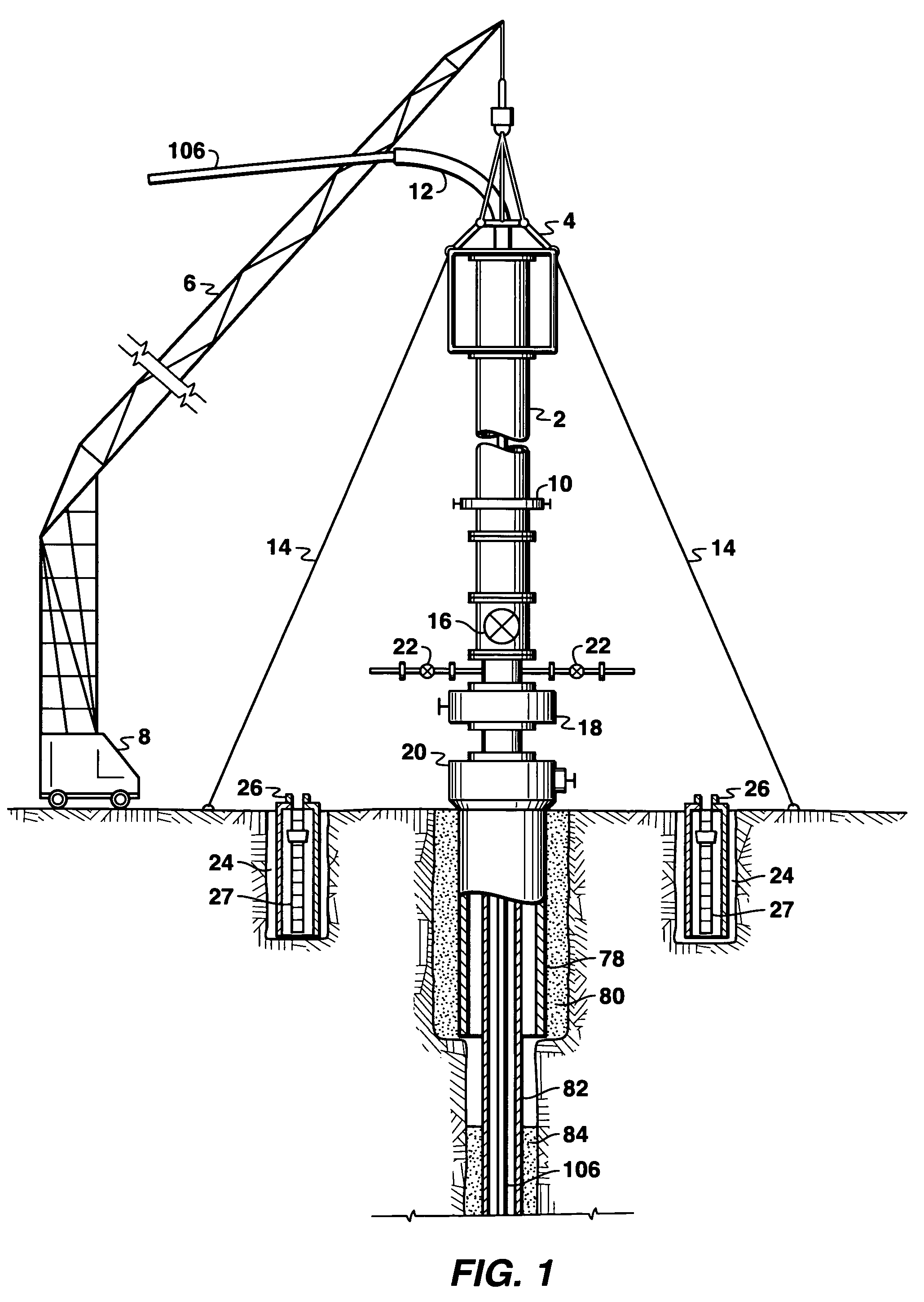

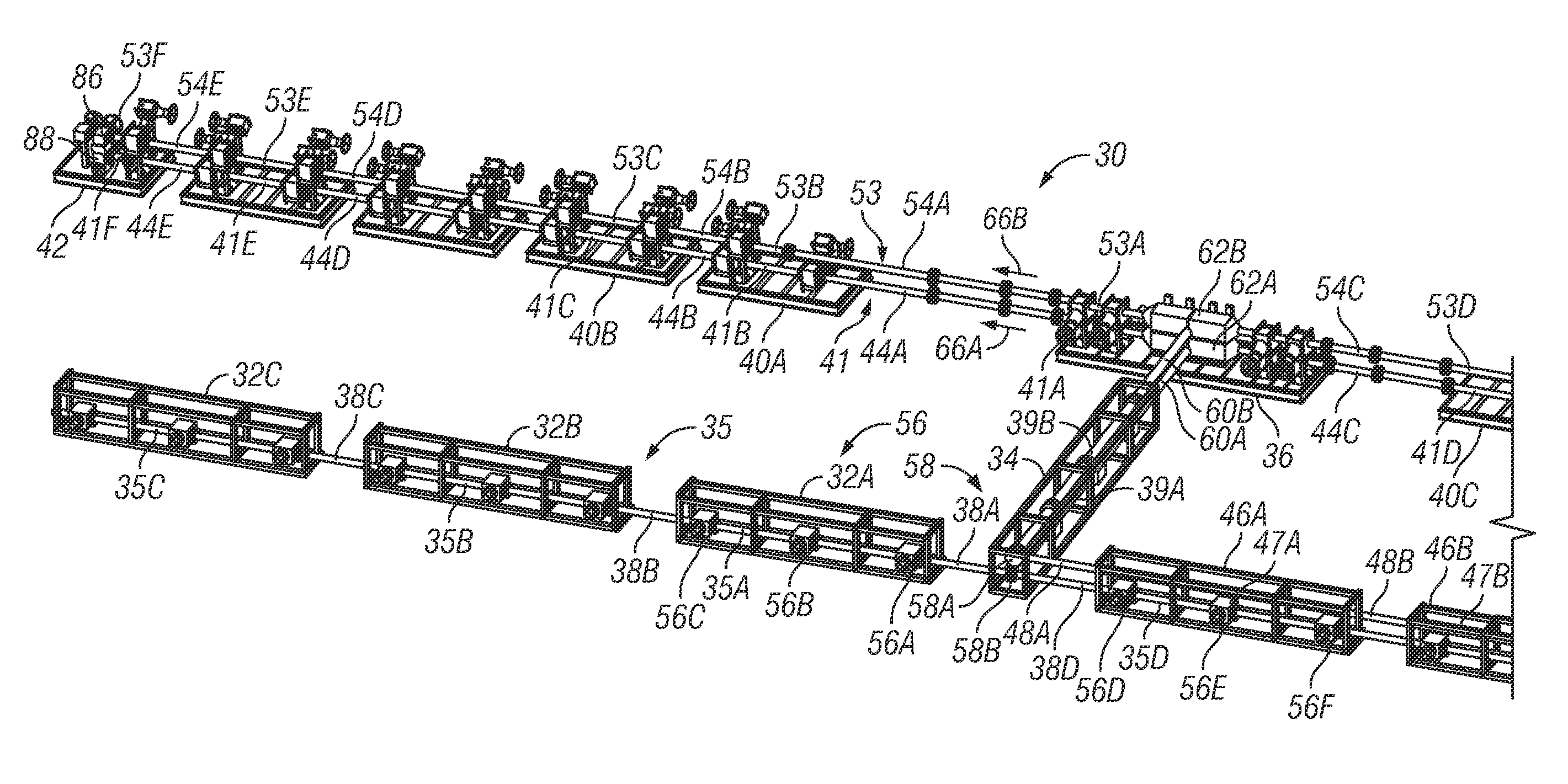

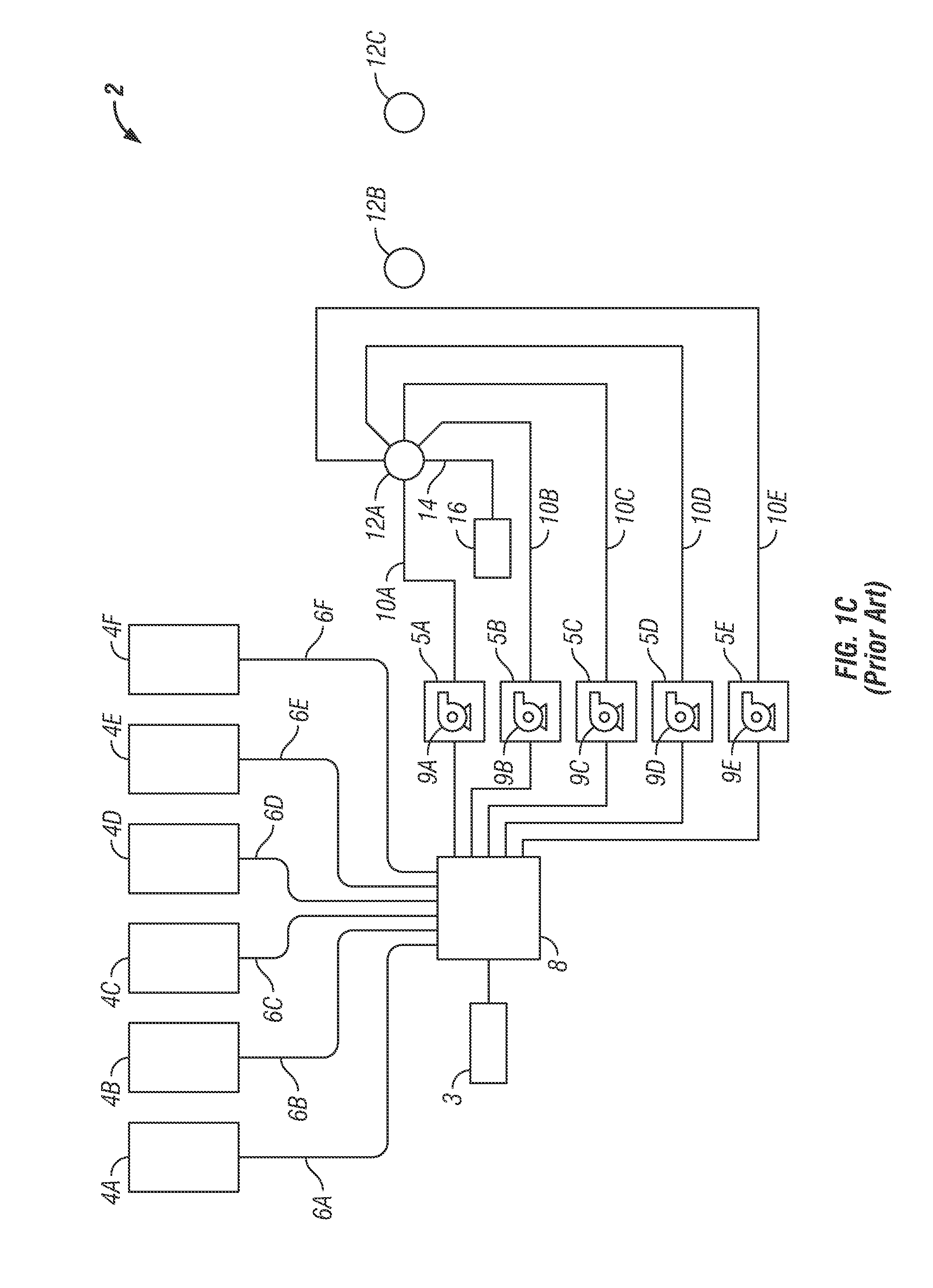

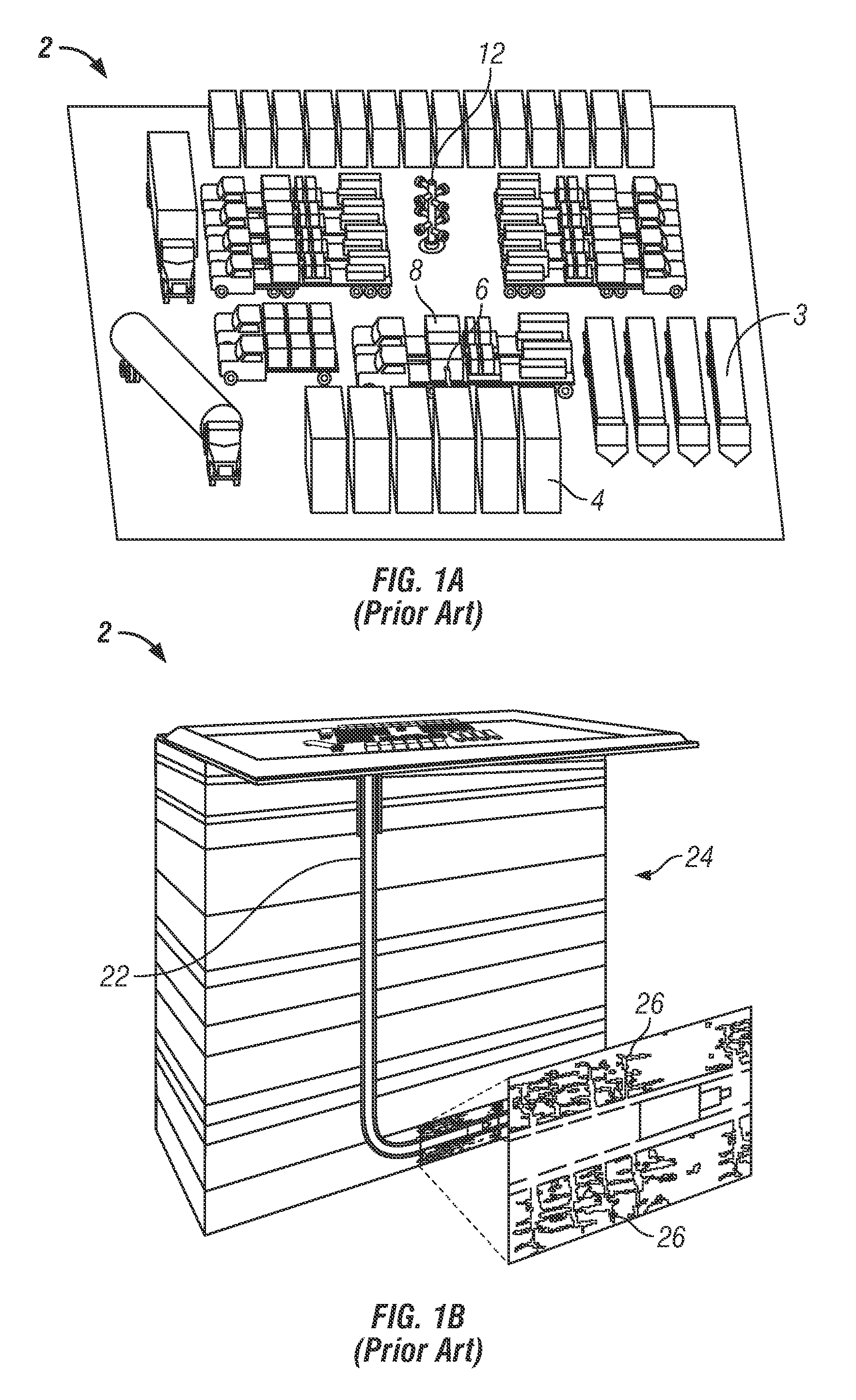

System for pumping hydraulic fracturing fluid using electric pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of pumps powered by electric induction motors and fluidly connected to the well, the pumps configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the, and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

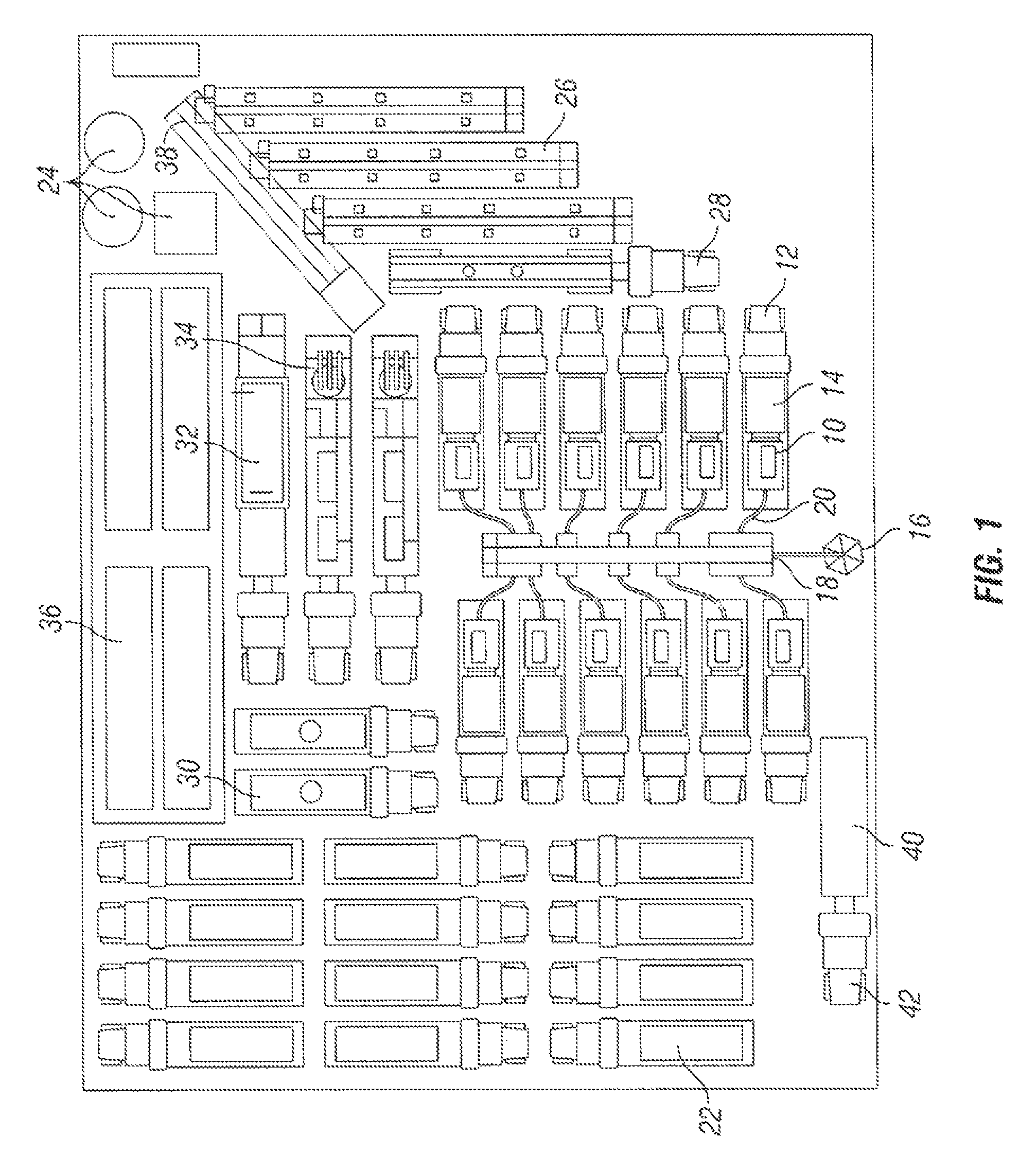

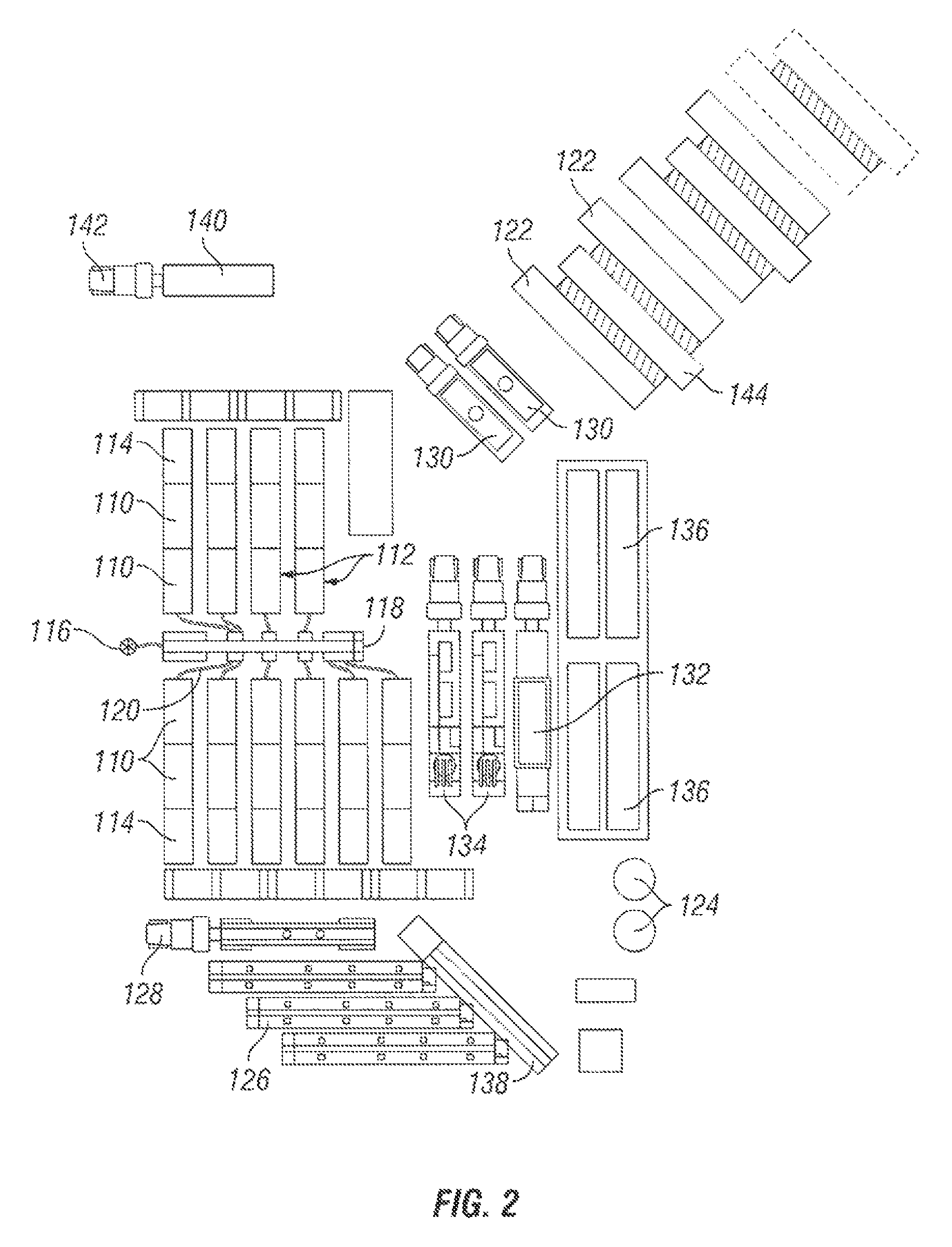

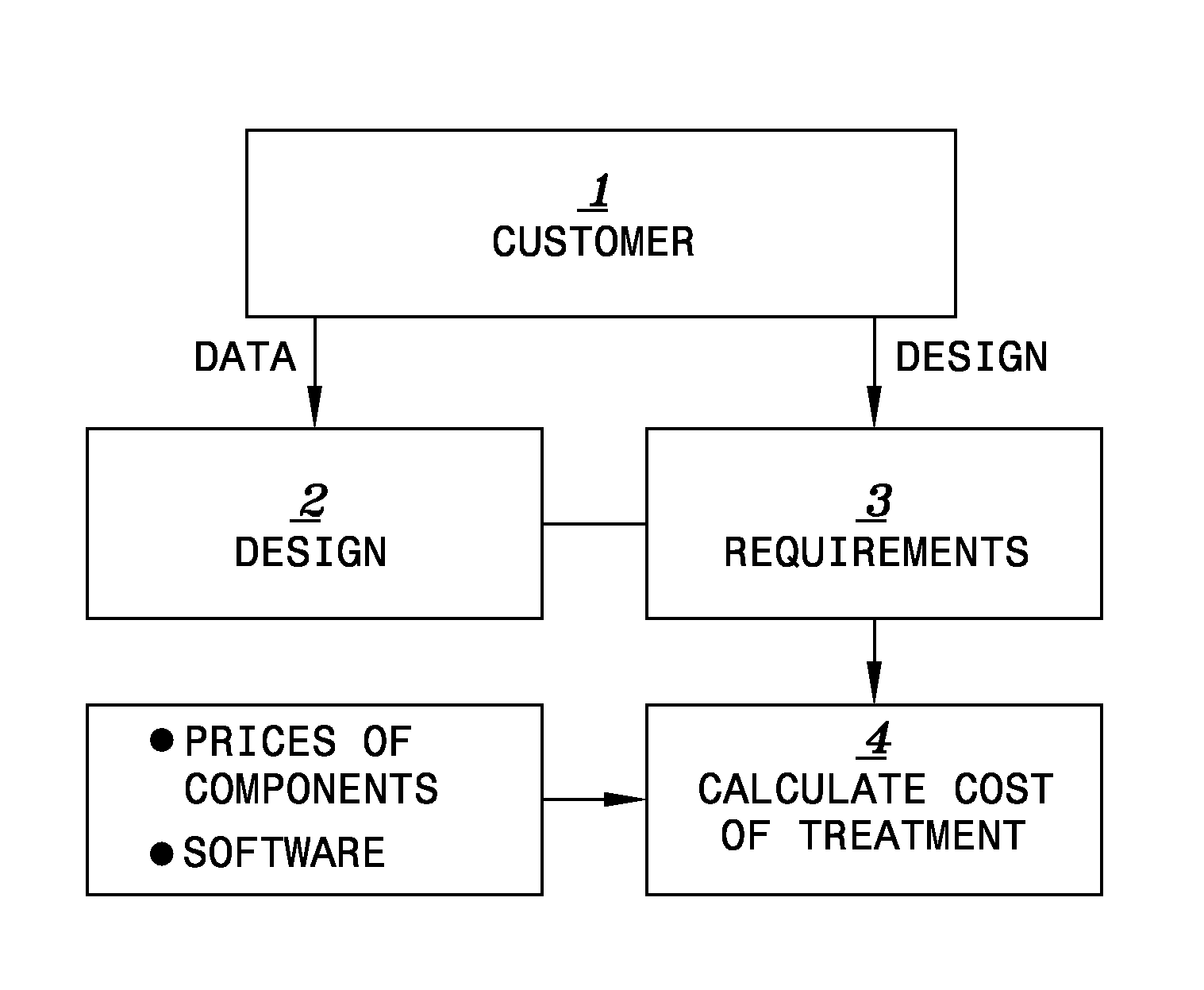

Method and Apparatus for Hydraulically Fracturing Wells

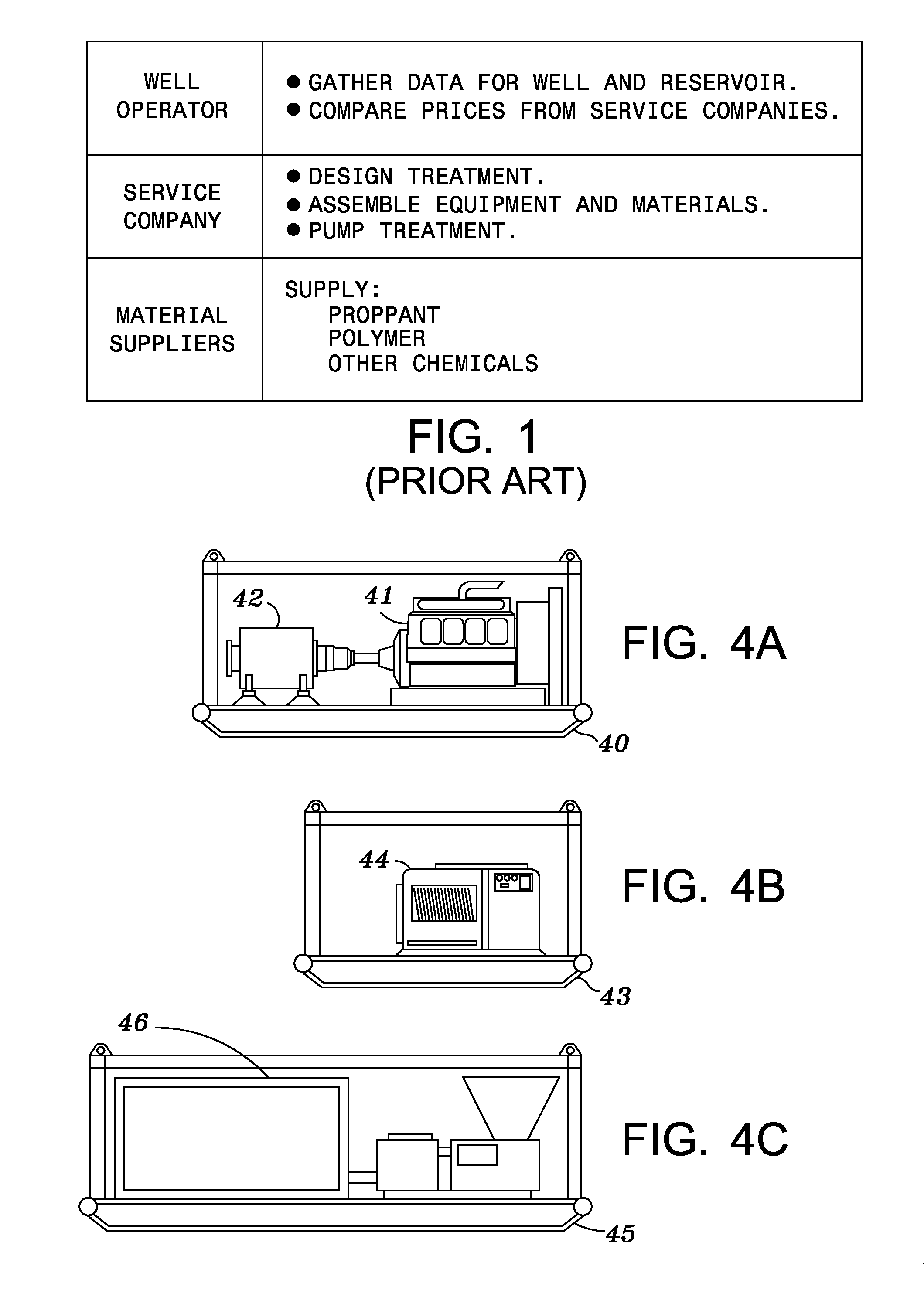

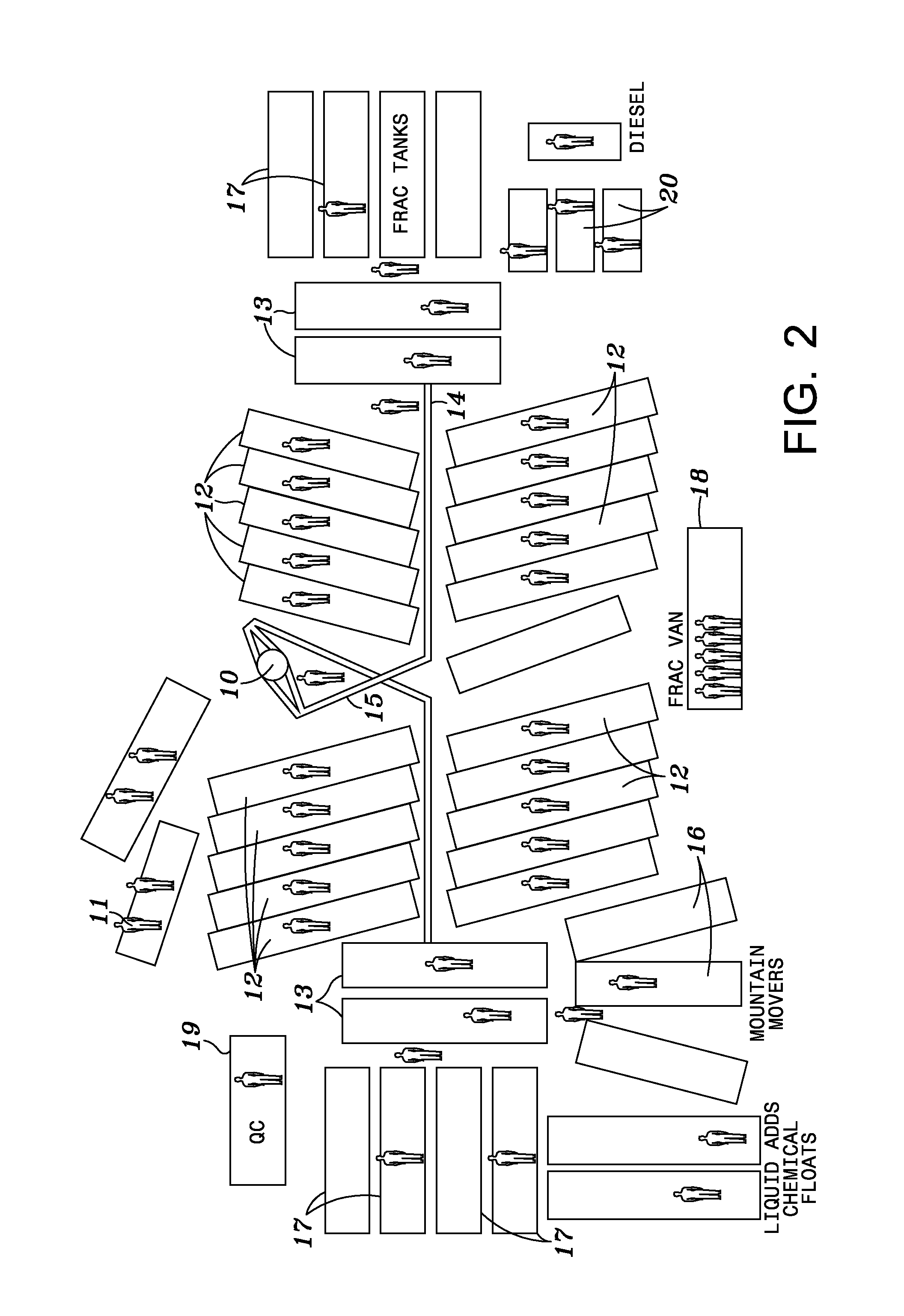

A mobile plant for supplying hydraulic fracturing service to a well is provided. The plant is particularly useful for wells that require multi-stage fracturing treatments, where the surface equipment may not be moved for longer times than when supplying conventional treatments. Skid-mounted equipment is used, so that the transport vehicle for the equipment can be released after delivery of the equipment to a well site. A method for marketing and executing fracturing treatments is also provided, wherein a customer is provided price data for each item included in the total cost of a fracturing treatment, along with software for calculating the total cost of a treatment to be purchased. The customer may calculate the cost of a treatment from computer-readable storage or over the internet. The customer may also monitor the fracturing treatment remotely and obtain a post-treatment report.

Owner:QIP HLDG

Localized fracturing system and method

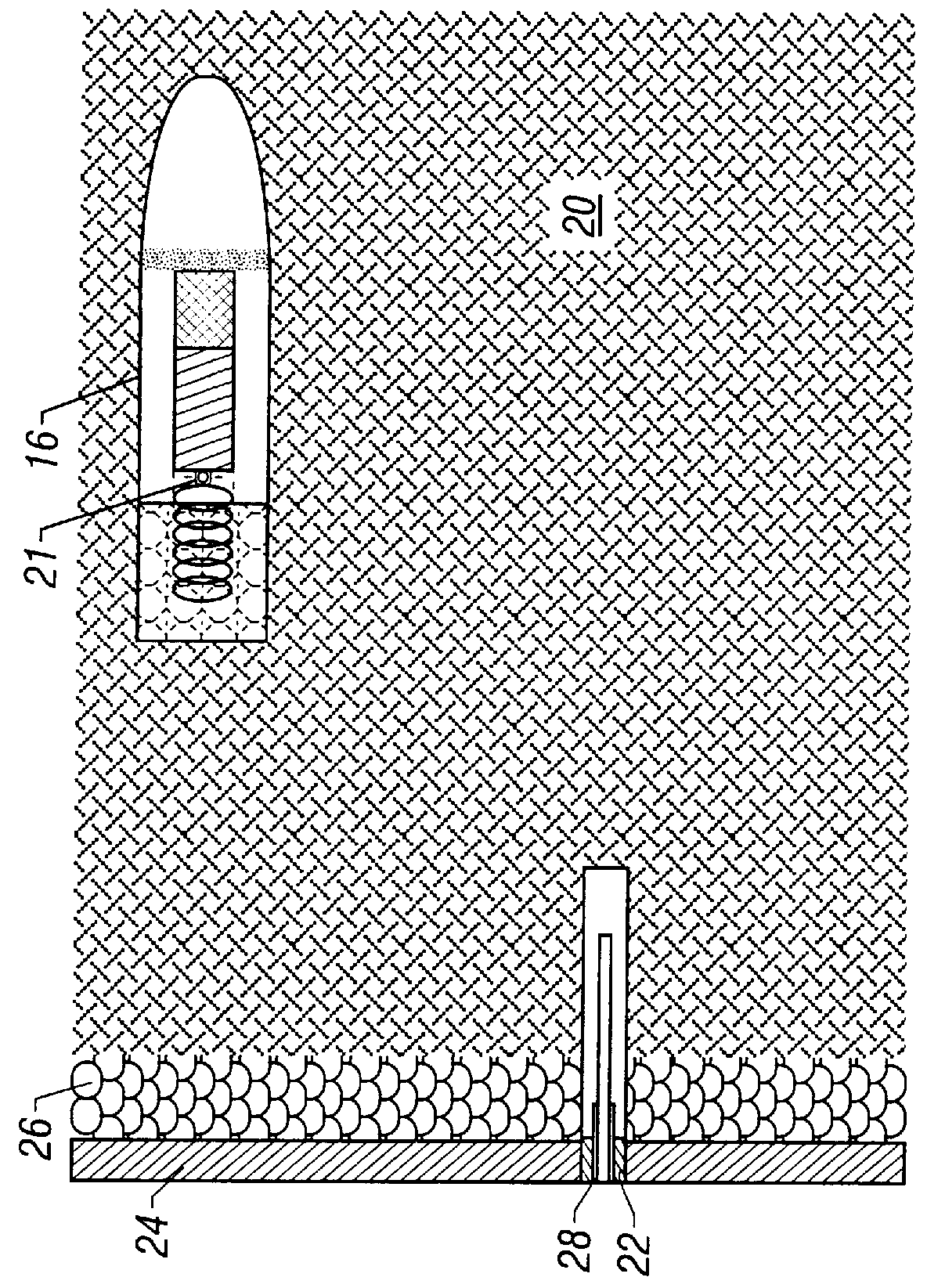

A method and apparatus useful for fracturing subterranean formations with ultra high fluid pressure. The apparatus is capable of producing isolated pressure in a formation surrounding a primary wellbore, sufficient pressure is included within the formation for creating a fracture at the edge of the perforation. The apparatus is comprised of a motor, pump, and nozzle, where the entire apparatus can be disposed within the borehole. The apparatus can be conveyed within the borehole via wireline, coil tubing, slickline, or other tubing. Alternatively, a drill bit can be included for creating the perforation just prior to the fracturing procedure.

Owner:BAKER HUGHES HLDG LLC

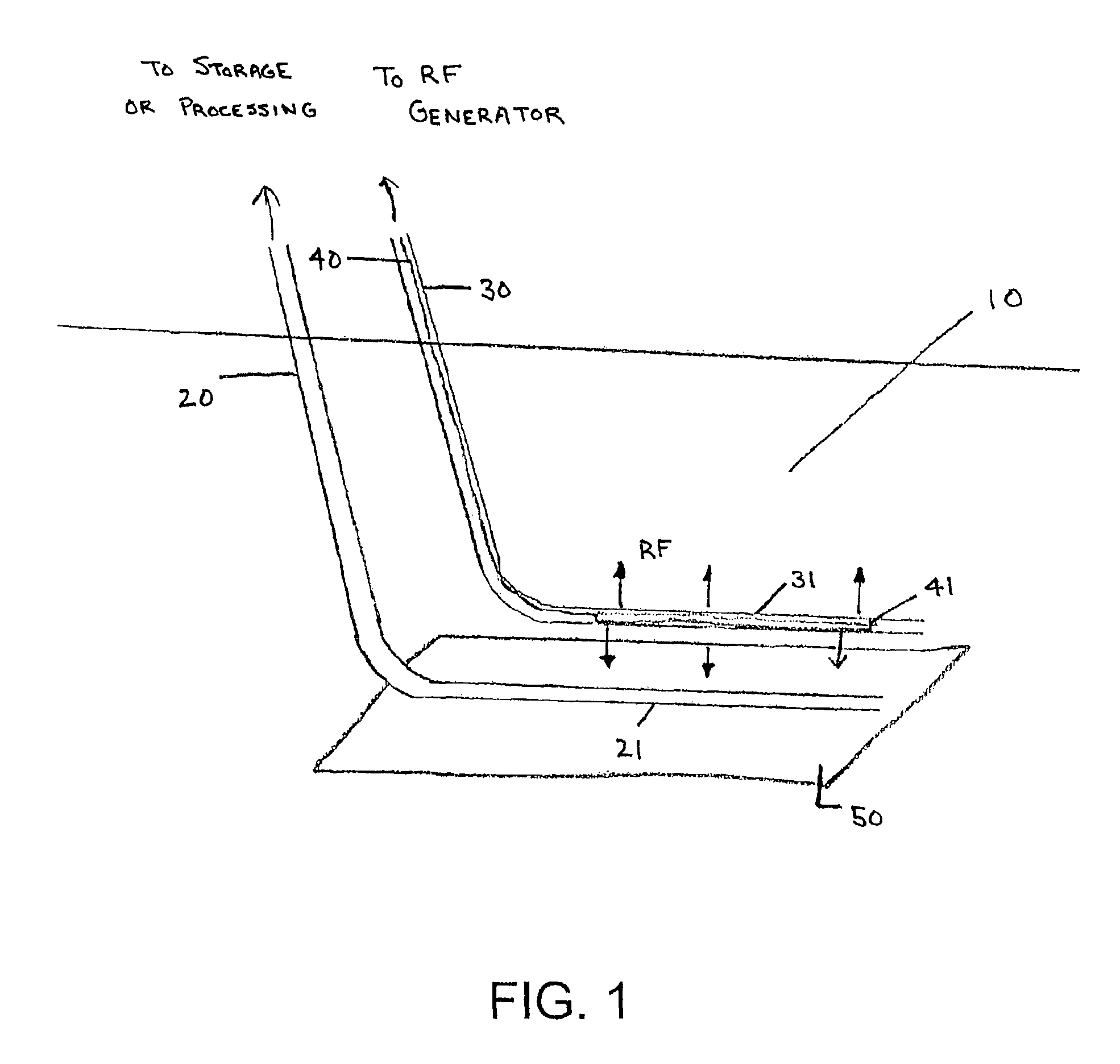

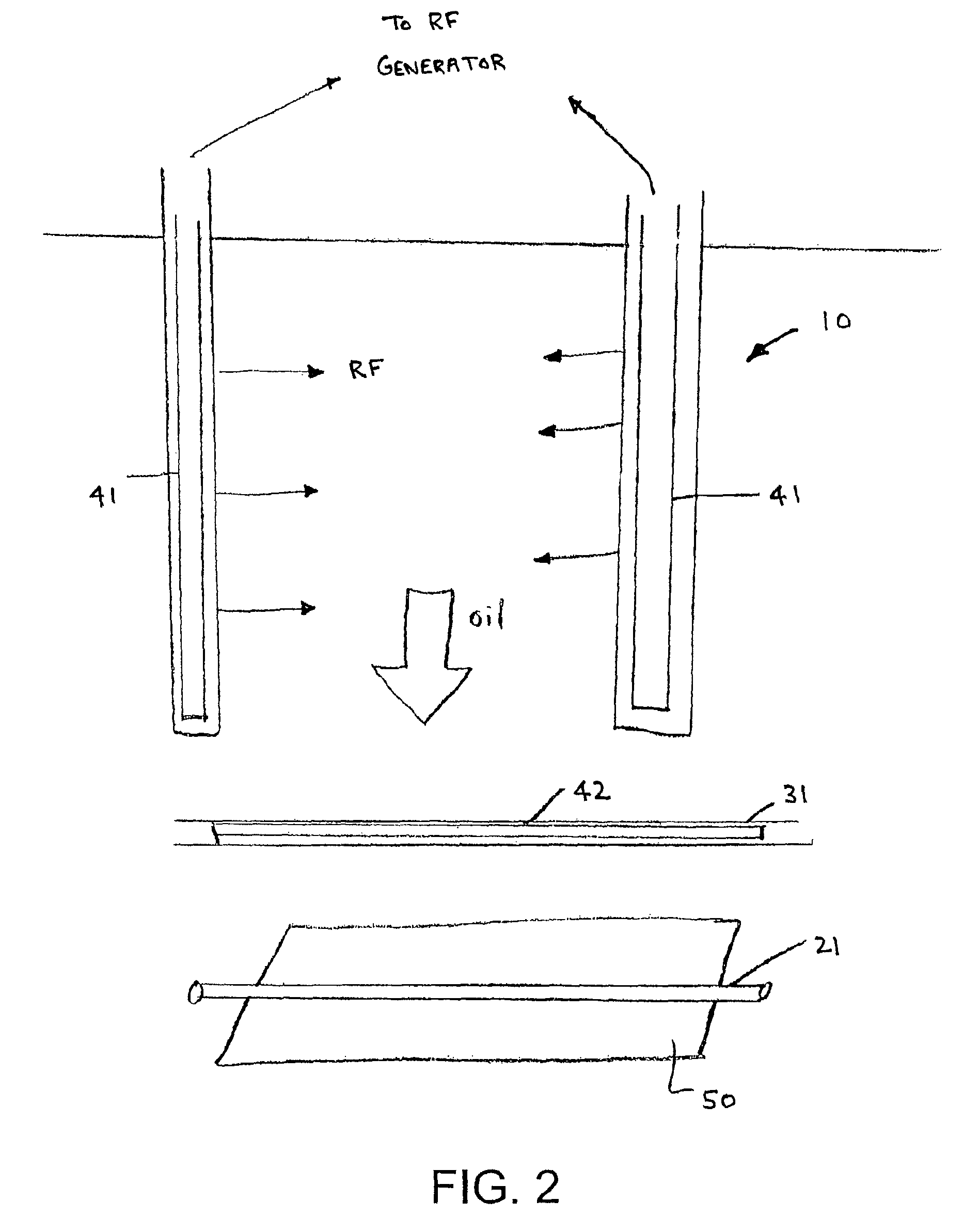

Method and apparatus for in-situ radiofrequency heating

InactiveUS7891421B2Promote recoveryEnhanced overall recoveryInsulationFluid removalElectricityNuclear engineering

Owner:TURBOSHALE INC

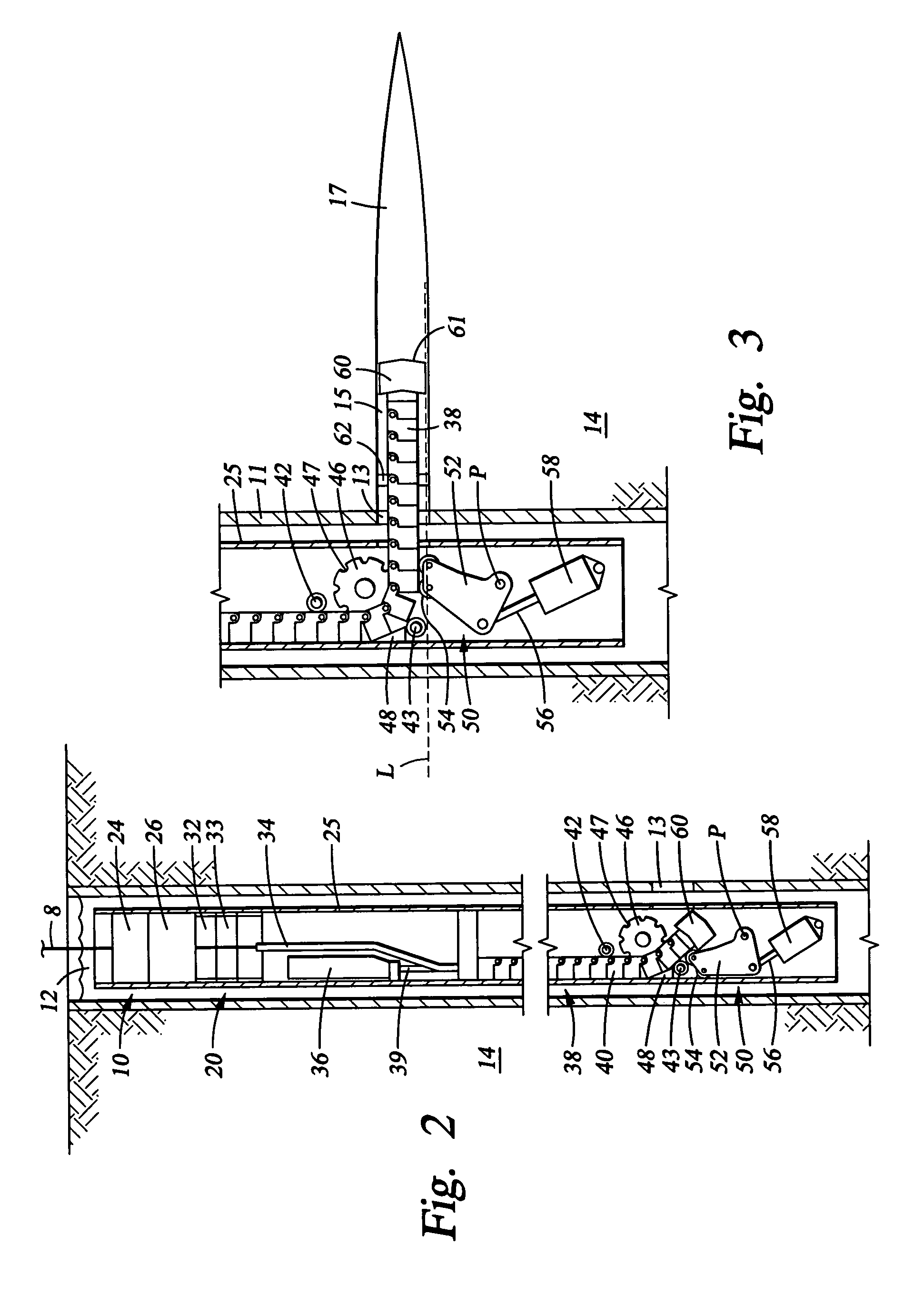

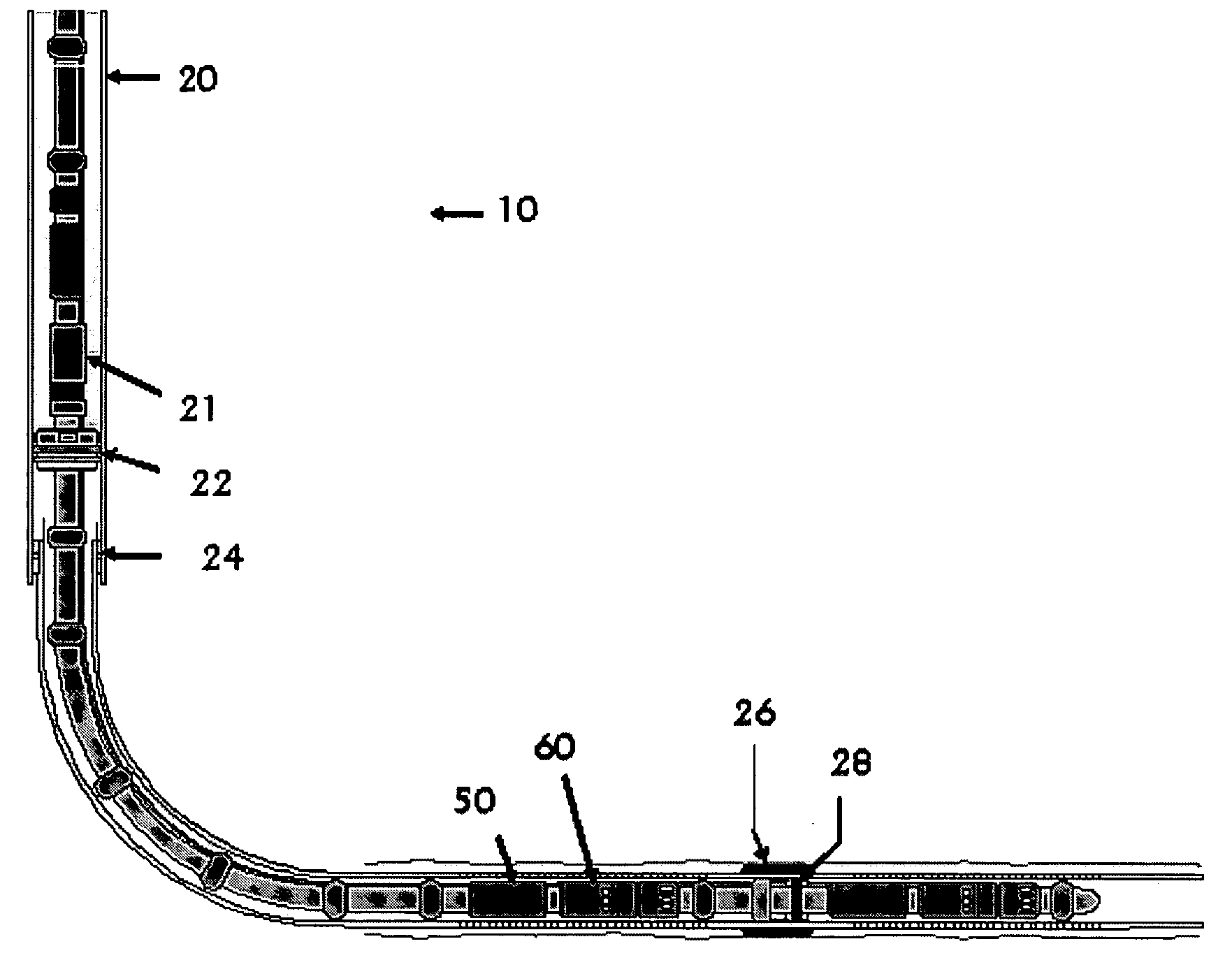

Well device for throttle regulation of inflowing fluids

A flow arrangement (10, 12) for use in a well through one or more underground reservoirs, and where the arrangement (10, 12) is designed to throttle radially inflowing reservoir fluids produced through an inflow portion of the production tubing in the well, the production tubing in and along this inflow portion being provided with one or more arrangements (10, 12). Such an arrangement (10, 12) is designed to effect a relatively stable and predictable fluid pressure drop at any stable fluid flow rate in the course of the production period of the well, and where said fluid pressure drop will exhibit the smallest possible degree of susceptibility to influence by differences in the viscosity and / or any changes in the viscosity of the inflowing reservoir fluids during the production period. Such a fluid pressure drop is obtained by the arrangement (10, 12) comprising among other things one or more short, removable and replaceable flow restrictions such as nozzle inserts (44, 62), and where the individual flow restriction may be given the desired cross section of flow, through which reservoir fluids may flow and be throttled, or the flow restriction may be a sealing plug.

Owner:RESLINK

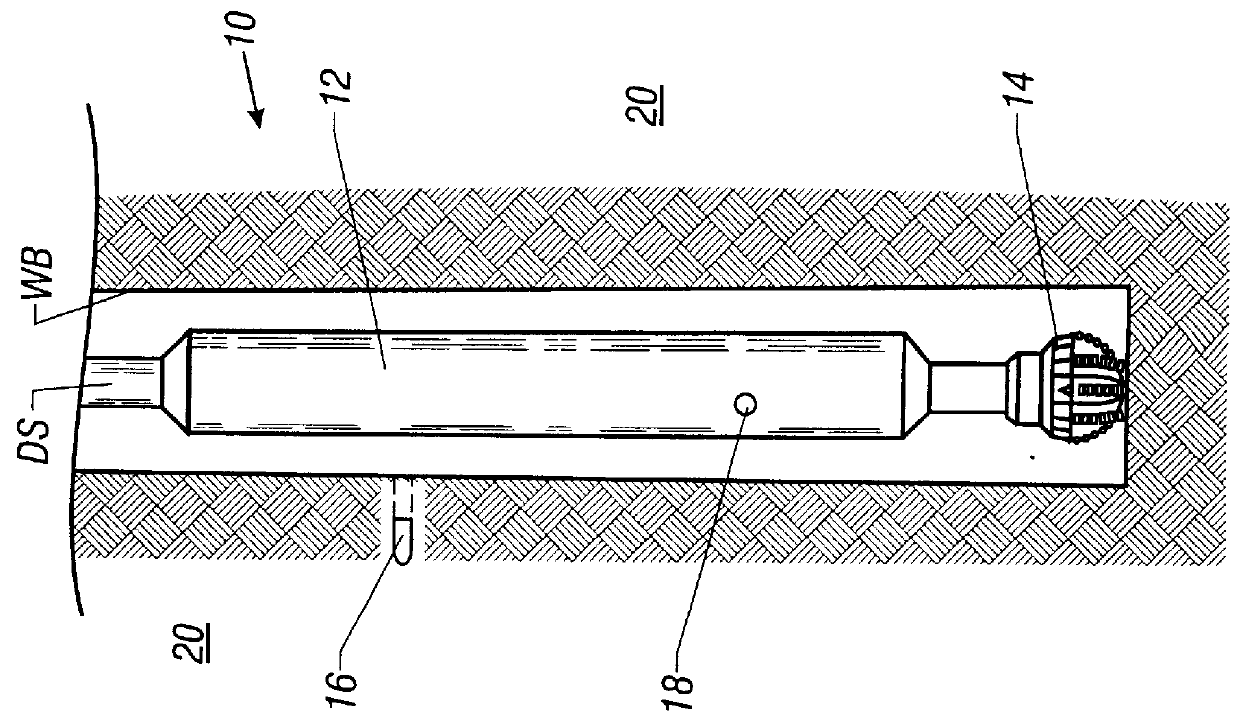

Formation pressure measurement with remote sensors in cased boreholes

The present invention relates to a method and apparatus for establishing communication in a cased wellbore with a data sensor that has been remotely deployed, prior to the installation of casing in the wellbore, into a subsurface formation penetrated by the wellbore. Communication is established by installing an antenna in an opening in the casing wall. The present invention further relates to a method and apparatus for creating the casing wall opening, and then inserting the antenna in the opening in sealed relation with the casing wall. A data receiver is inserted into the cased wellbore for communicating with the data sensor via the antenna to receive formation data signals sensed and transmitted by the data sensor. Preferably, the location of the data sensor in the subsurface formation is identified prior to the installation of the antenna, so that the opening in the casing can be created proximate the data sensor. The antenna can then be installed in the casing wall opening for optimum communication with the data sensor. It is also preferred that the data sensor be equipped with means for transmitting a signature signal, permitting the location of the data sensor to be identified by sensing the signature signal. The location of the data sensor is identified by first determining the depth of the data sensor, and then determining the azimuth of the data sensor relative to the wellbore.

Owner:SCHLUMBERGER TECH CORP

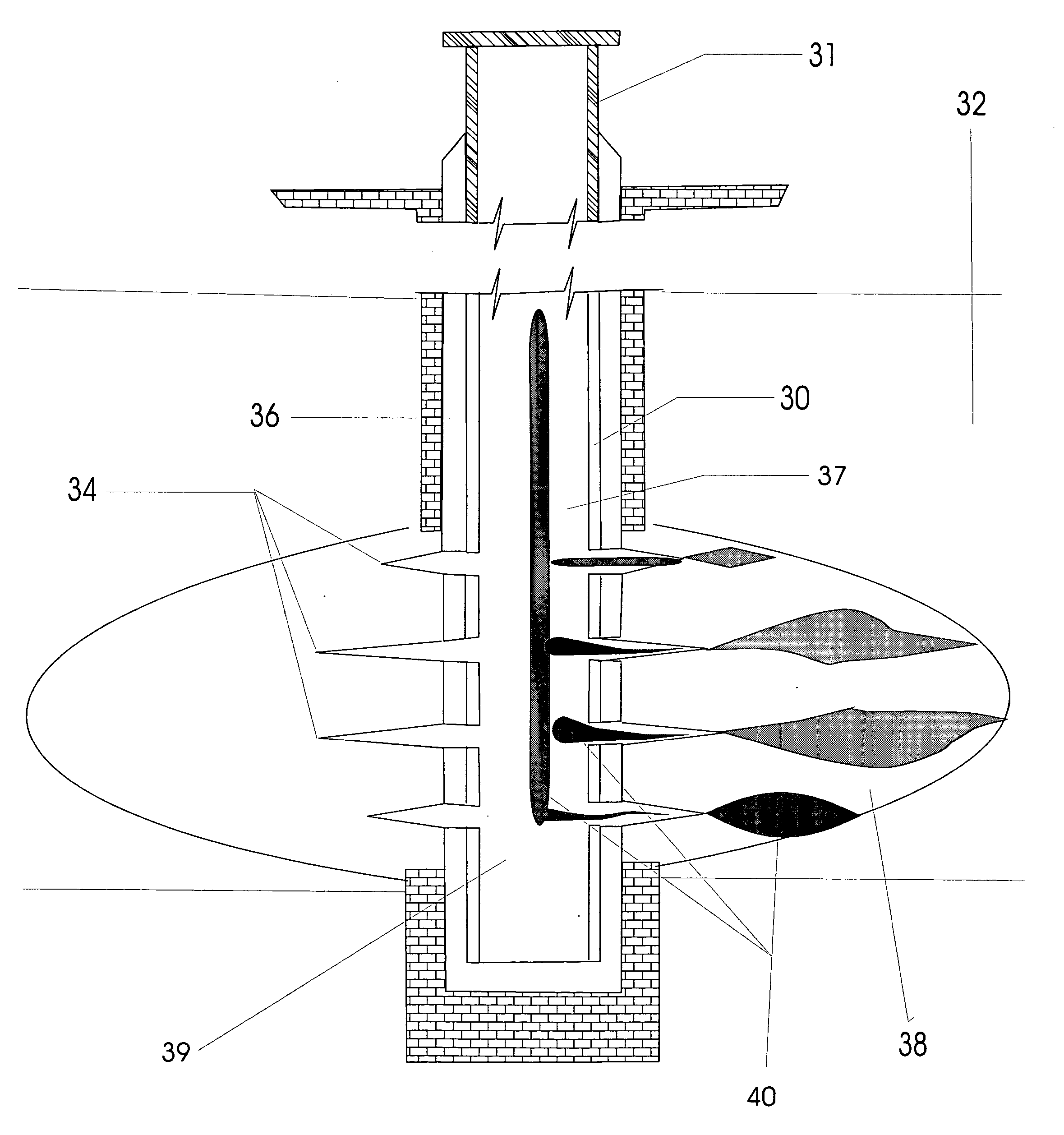

Method and apparatus for stimulation of multiple formation intervals

Owner:EXXONMOBIL UPSTREAM RES CO

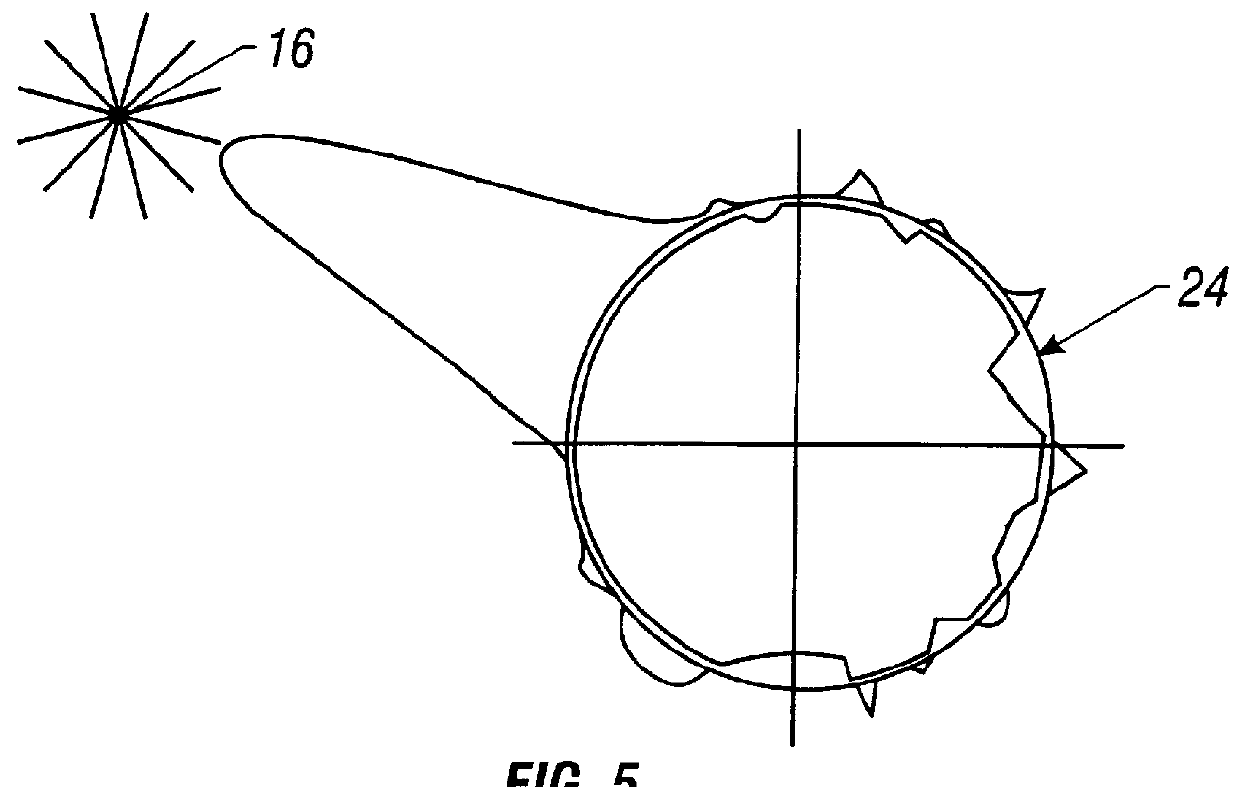

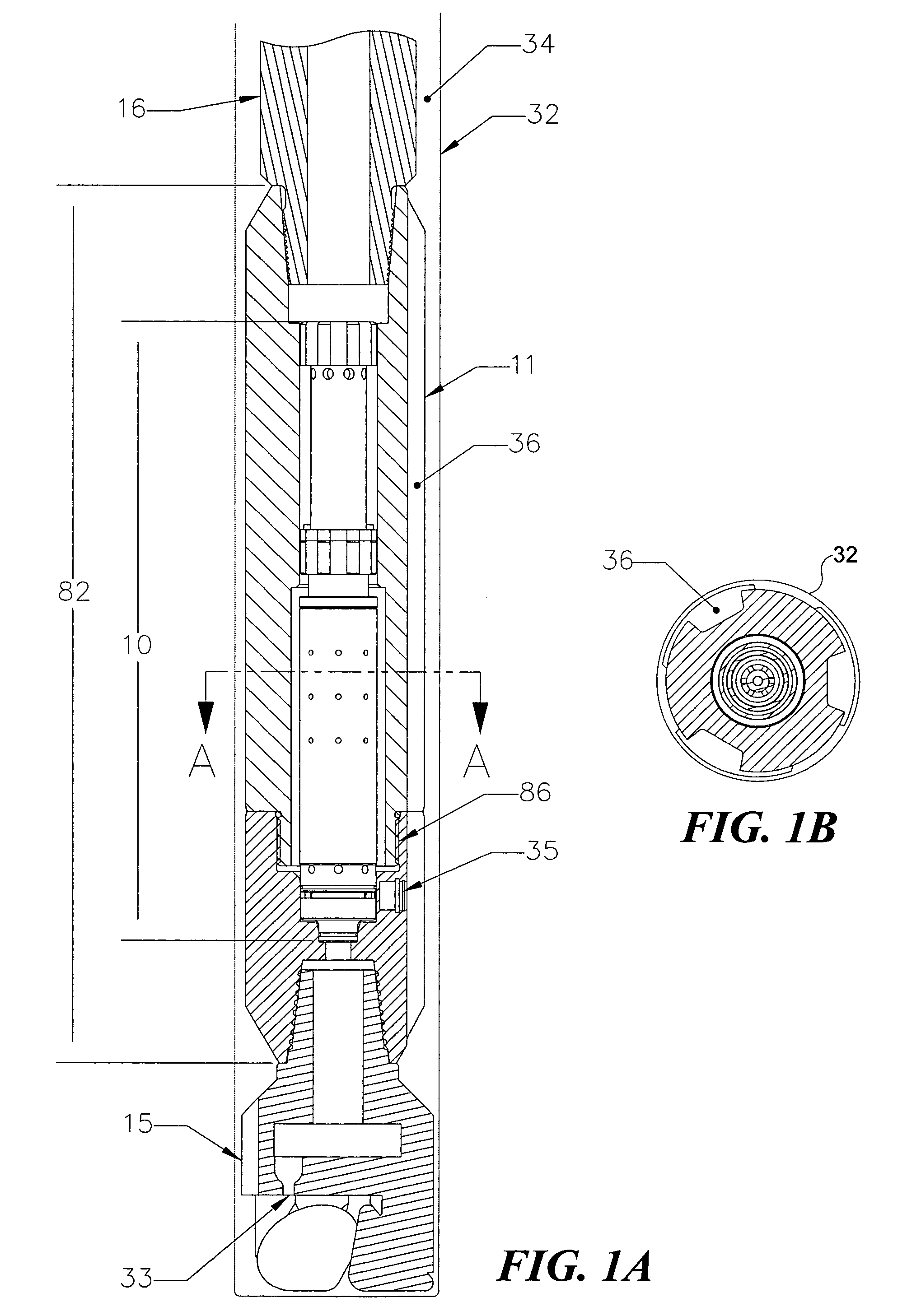

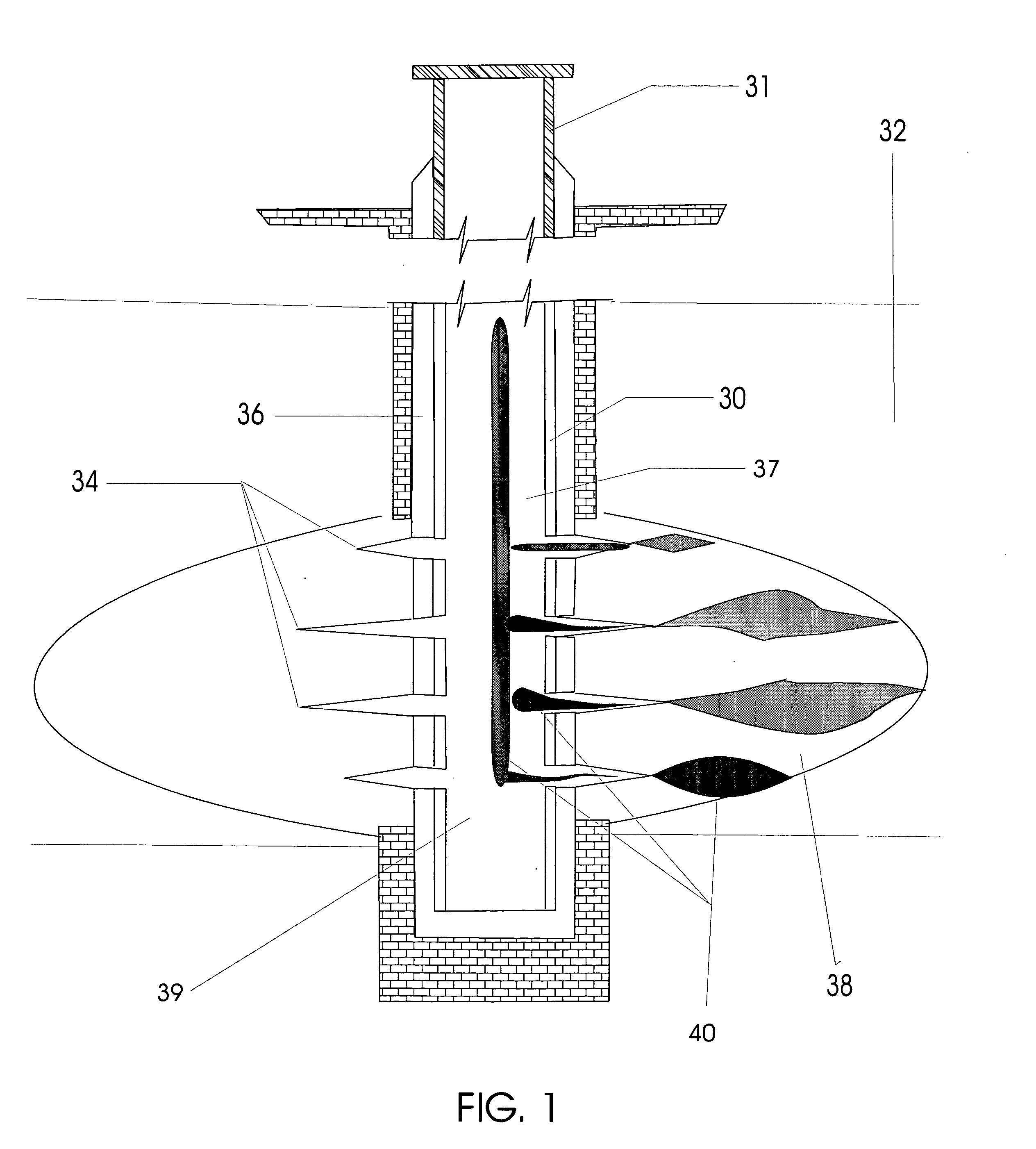

Hydraulic impulse generator and frequency sweep mechanism for borehole applications

This invention discloses a valve that generates a hydraulic negative pressure pulse and a frequency modulator for the creation of a powerful, broadband swept impulse seismic signal at the drill bit during drilling operations. The signal can be received at monitoring points on the surface or underground locations using geophones. The time required for the seismic signal to travel from the source to the receiver directly and via reflections is used to calculate seismic velocity and other formation properties near the source and between the source and receiver. This information can be used for vertical seismic profiling of formations drilled, to check the location of the bit, or to detect the presence of abnormal pore pressure ahead of the bit. The hydraulic negative pressure pulse can also be used to enhance drilling and production of wells.

Owner:WELLS FARGO BANK NAT ASSOC +1

Interventionless multi-position frac tool

Fracturing tools for use in oil and gas wells are disclosed. The fracturing tools have a run-in position and two operational positions. A sleeve disposed in the bore of the fracturing tool comprises a sleeve port alignable with a first port in the housing of the frac tool, i.e., the first operational position, during fracturing operations. A second port having a restriction member is disposed in the housing and is closed by the sleeve during fracturing operations. After fracturing operations are completed, a return member in the frac tool moves the sleeve from the first operational position to a second operational position for production operations. In this second operational position, the first port is closed and the sleeve port is aligned with the second port. Movement of the sleeve from the first operational position to the second operational position is performed without the need for an additional well intervention step.

Owner:BAKER HUGHES INC

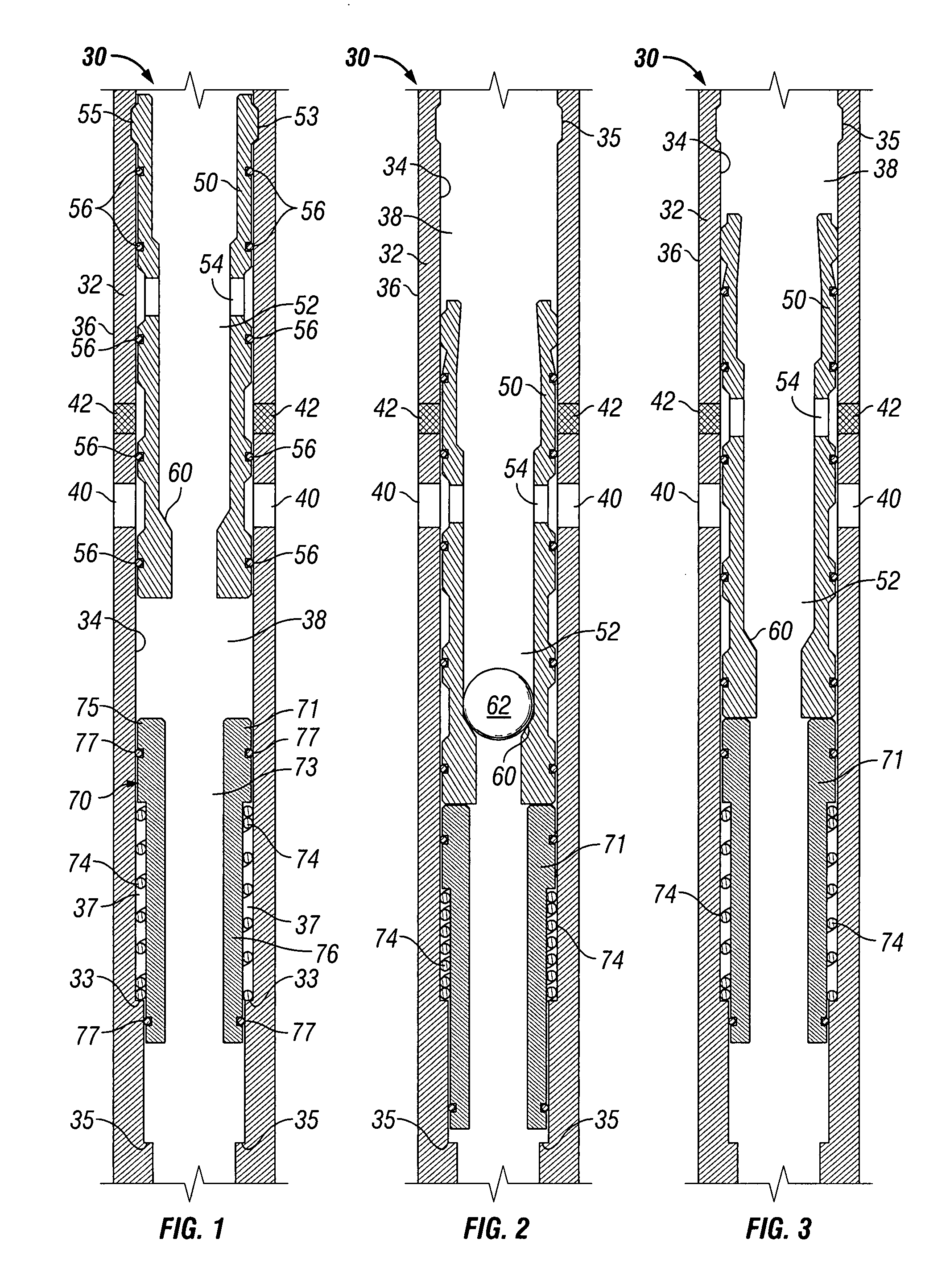

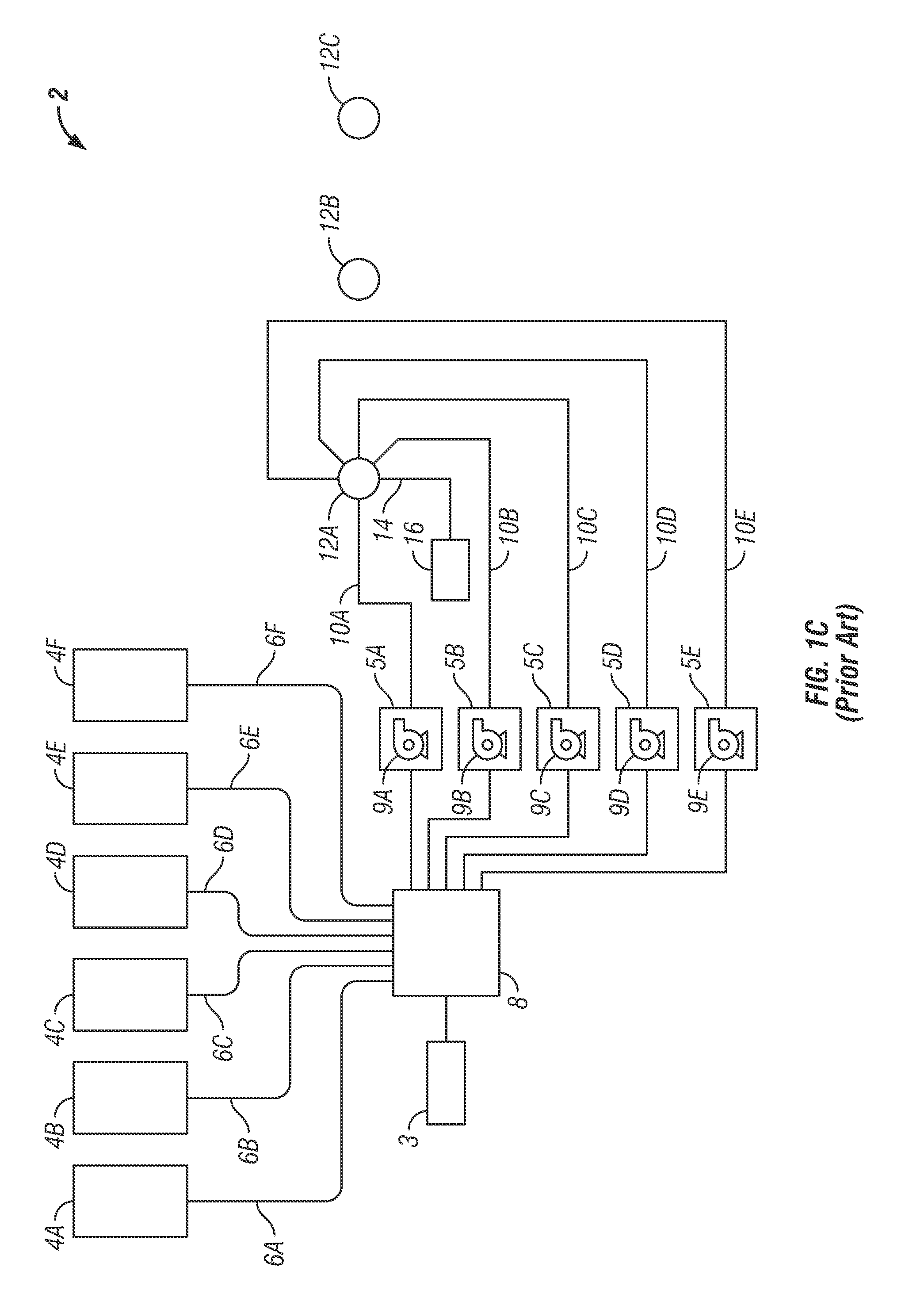

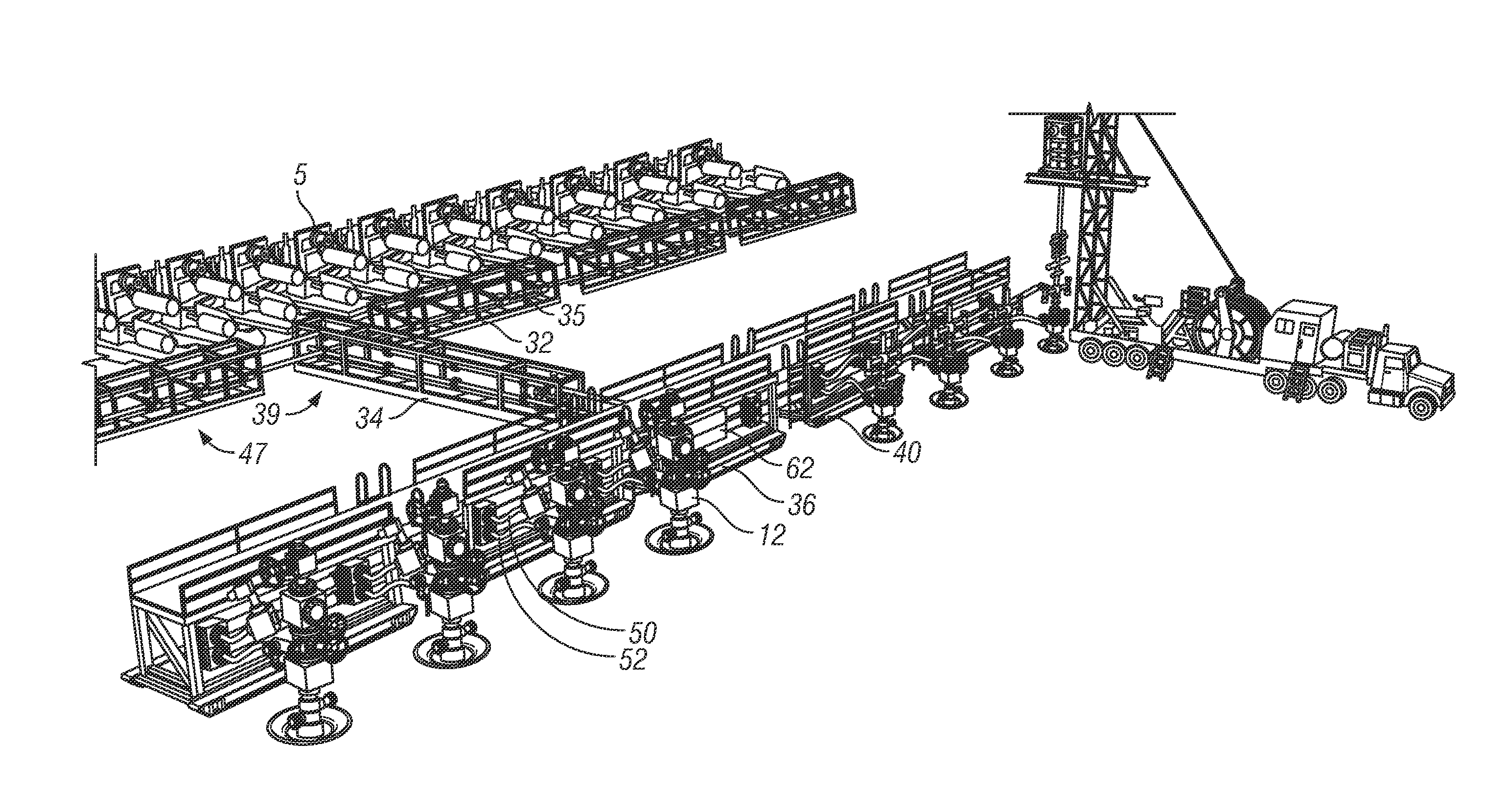

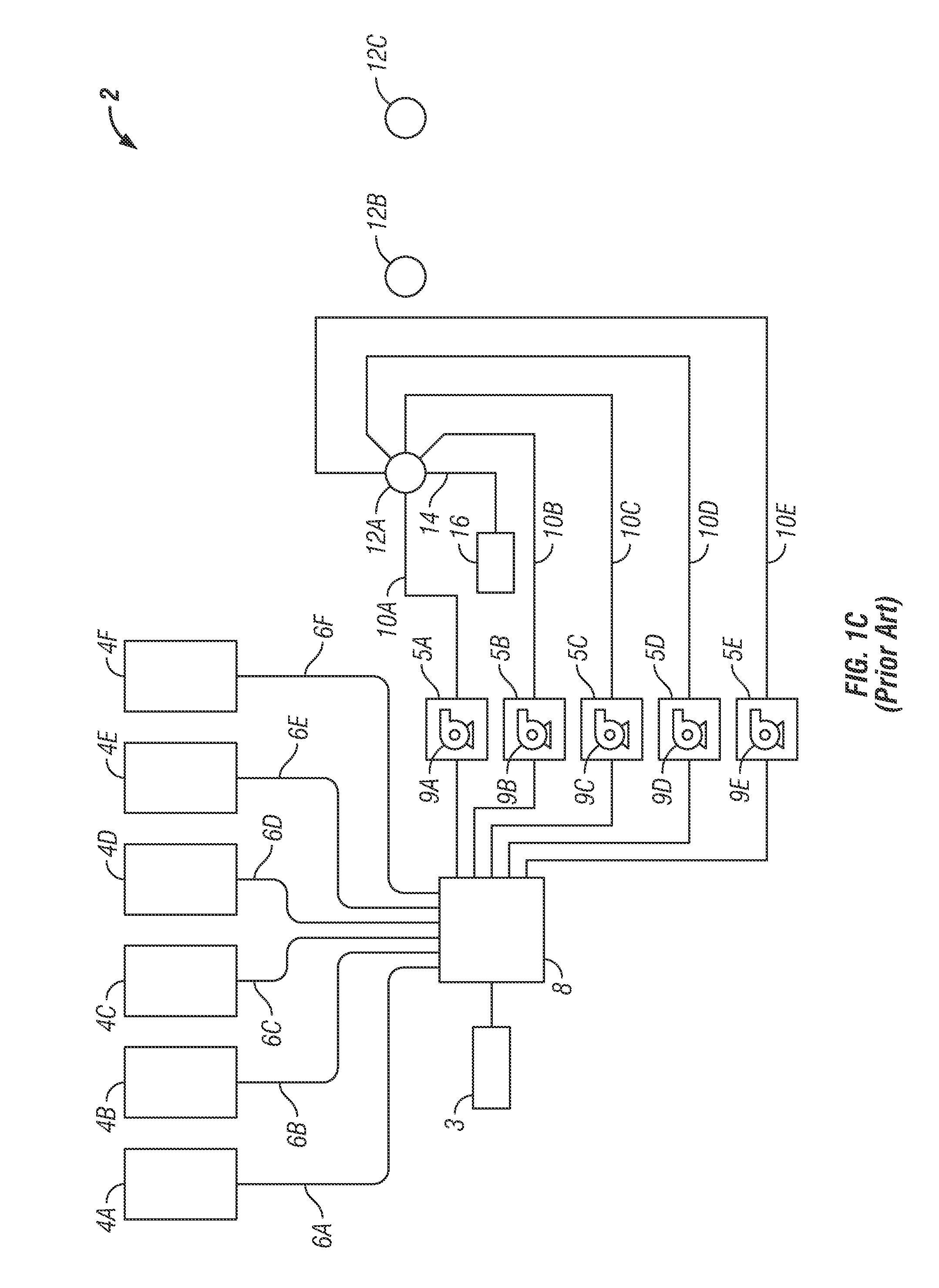

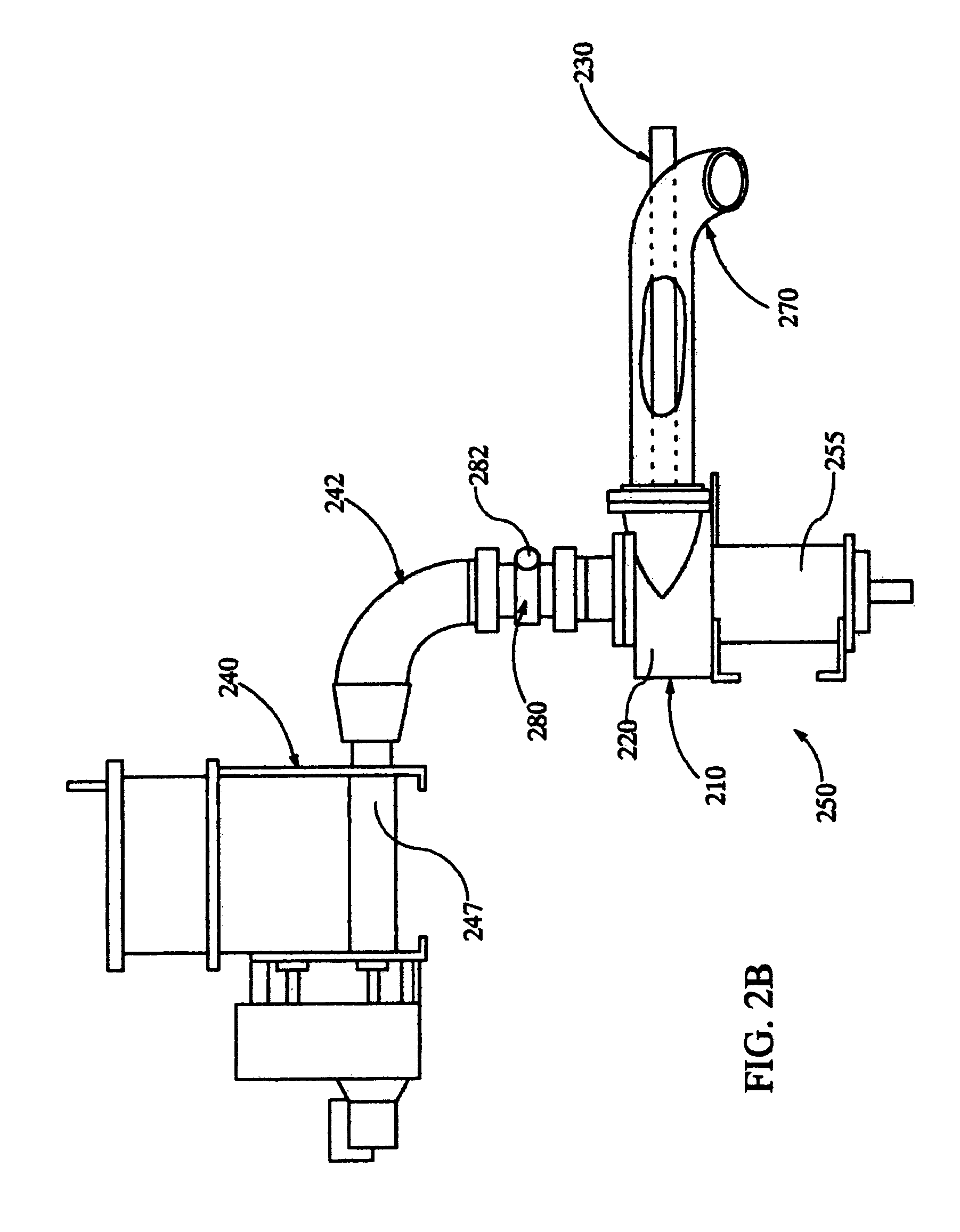

Modular skid system for manifolds

The disclosure provides an adjustable modular skid system with a plurality of skid modules having a frame to support oil field fluid components, such as manifolds, mixing blocks, collection blocks, fracturing pumps, piping and connections, and other devices used to transport water, sand slurries, gas, oil, or other fluids in oil field applications. The modules can be arranged in multiple configuration to fit a particular well site. The modules can include supply modules, transition modules, and distribution modules. The skid modules can be coupled together through piping and relevant connections at the well site. If appropriate, the skid modules can be supported on pilings or other foundational supports. The system can be assembled remotely, started and tested, partially disassembled into the skid modules, and then installed at the well site with minimal additional effort by generally providing lines and connections between the modules.

Owner:T 3 PROPERTY HLDG

Methods for enhancing treatment fluid placement in a subterranean formation

InactiveUS7114560B2Improve efficiencyControl migrationDrilling rodsFluid removalParticulatesEnvironmental geology

The present invention relates to methods for controlling the migration of unconsolidated particulates in a portion of a subterranean formation, and more particularly, to the using a pressure pulse to enhance the effectiveness of placement of a consolidation fluid in a portion of a subterranean formation. Some methods of the present invention provide methods of treating a subterranean formation comprising injecting a consolidation fluid into the subterranean formation while periodically applying a pressure pulse having a given amplitude and frequency to the consolidation fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

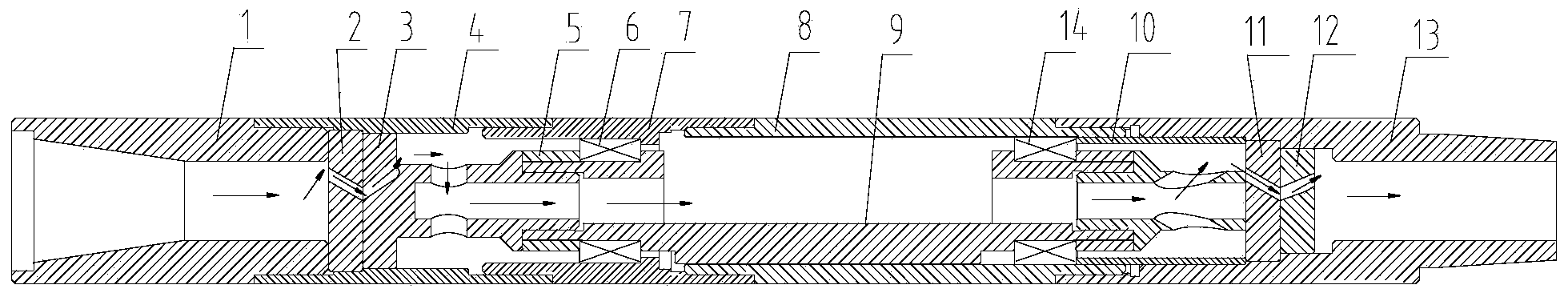

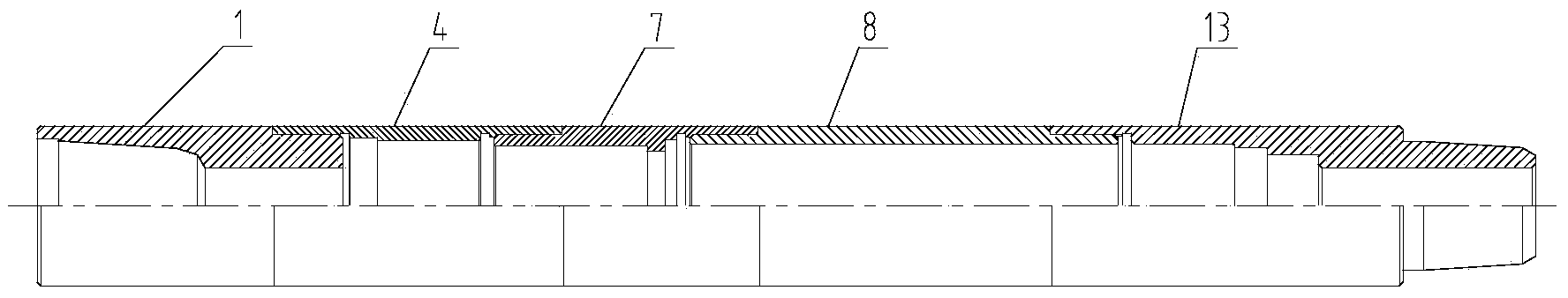

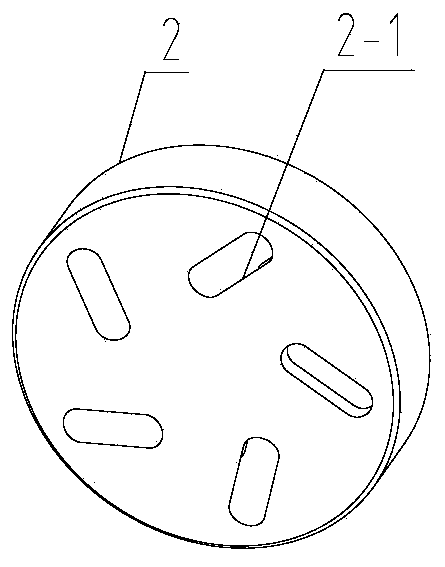

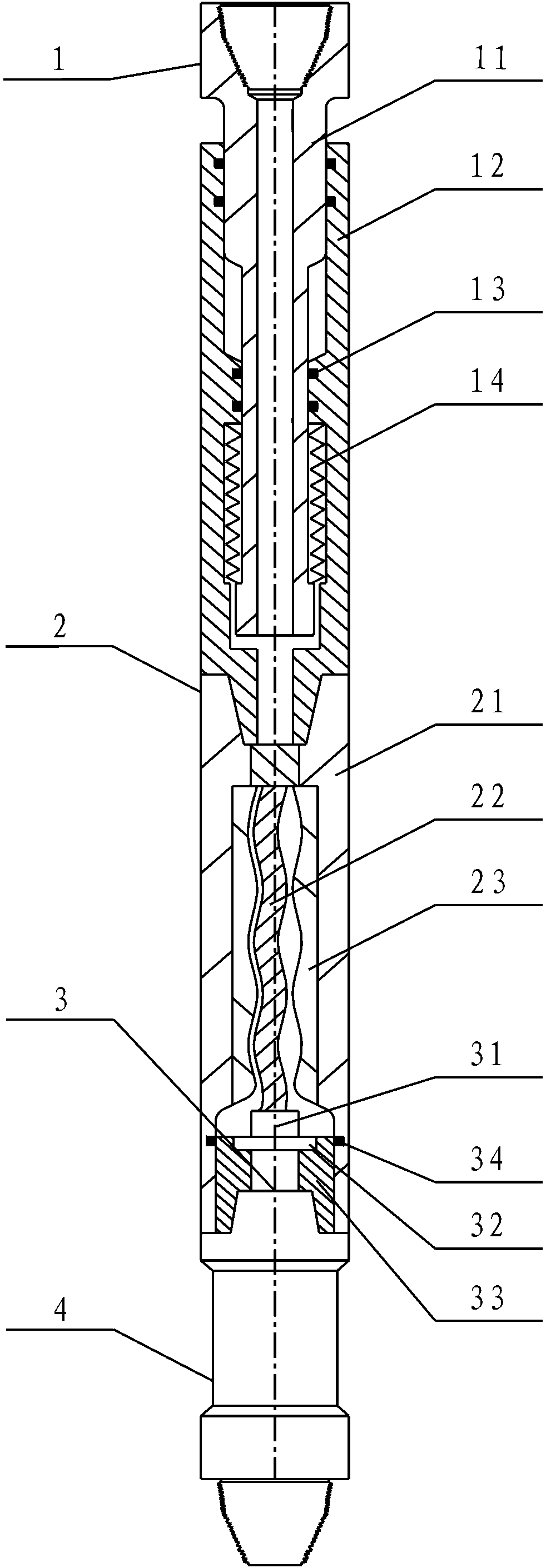

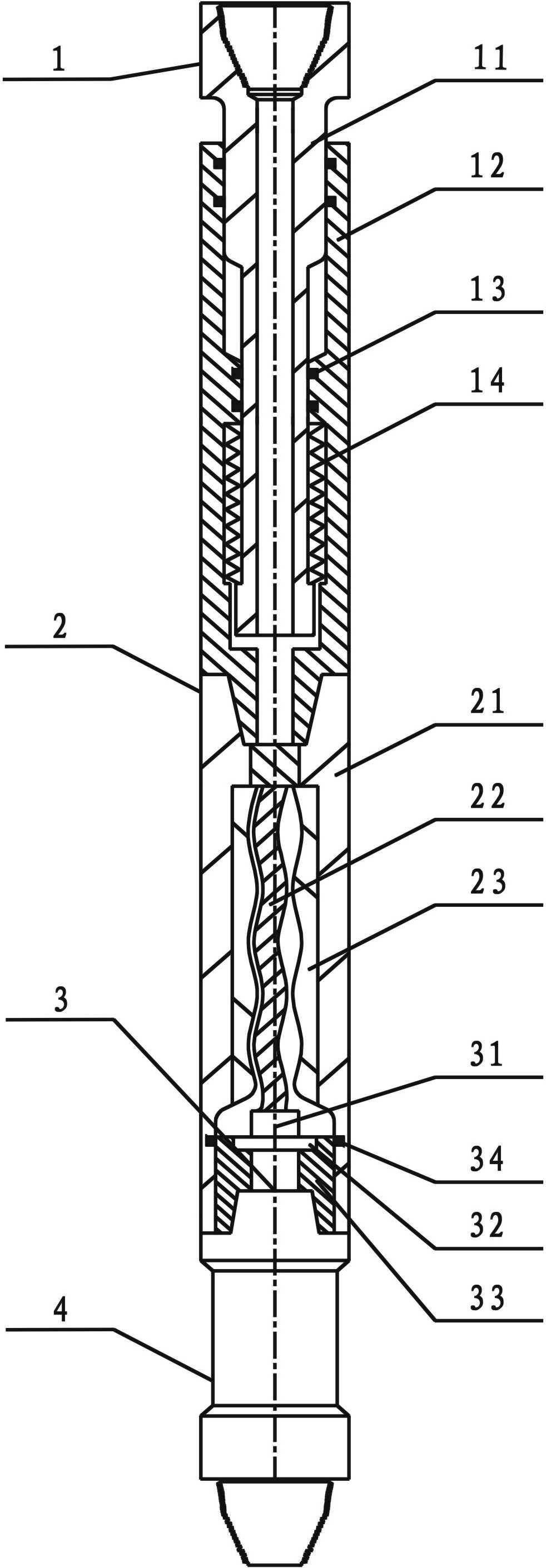

High-temperature resistant vibration tool for horizontal well

ActiveCN104234651AHigh working reliabilityImprove high temperature resistanceVibration devicesUpper jointTemperature resistance

The invention relates to a high-temperature resistant vibration tool for a horizontal well. The high-temperature resistant vibration tool for the horizontal well comprises a shell assembly and a vibration assembly arranged in the shell assembly and is characterized in that the shell assembly comprises an upper joint, an upper joint sleeve, a connection sleeve, a cover and a lower joint which sleeve from top to bottom in sequence; the vibration assembly comprises an upper end turbine, an eccentric shaft and a lower end turbine which are connected in sequence from top to bottom; the vibration assembly is arranged in the shell assembly by an upper end bearing and a lower end bearing; the upper end bearing and the lower end bearing respectively sleeve two end shafts of the eccentric shaft; an upper thrust ring and a lower thrust ring are respectively arranged at two ends of the vibration assembly and are respectively arranged in the upper joint sleeve and the lower joint; a channel for allowing fluid to flow is arranged in each of the shell assembly and the vibration assembly. The high-temperature resistant vibration tool for the horizontal well has the beneficial effects that the work reliability and high temperature resistance of the tool are improved, the deepening depth is increased, and enough drilling and pressing effects are applied.

Owner:JEREH ENERGY SERVICES

Apparatus for isolating a jet forming aperture in a well bore servicing tool

An embodiment of a well bore servicing apparatus includes a housing having a through bore and at least one high pressure fluid aperture in the housing, the fluid aperture being in fluid communication with the through bore to provide a high pressure fluid stream to the well bore, and a removable member coupled to the housing and disposed adjacent the fluid jet forming aperture and isolating the fluid jet forming aperture from an exterior of the housing. An embodiment of a method of servicing a well bore includes applying a removable member to an exterior of a well bore servicing tool, wherein the removable member covers at least one high pressure fluid aperture disposed in the tool, lowering the tool into a well bore, exposing the tool to a well bore material, wherein the removable cover prevents the well bore material from entering the fluid aperture, removing the removable member to expose a fluid flow path adjacent an outlet of the high pressure fluid aperture, and flowing a well bore servicing fluid through the fluid aperture outlet and flow path.

Owner:HALLIBURTON ENERGY SERVICES INC

Uni-bore dump line for fracturing manifold

ActiveUS20120181015A1Improve abilitiesFluid removalVibration devicesBiomedical engineeringGuide tube

Owner:T 3 PROPERTY HLDG

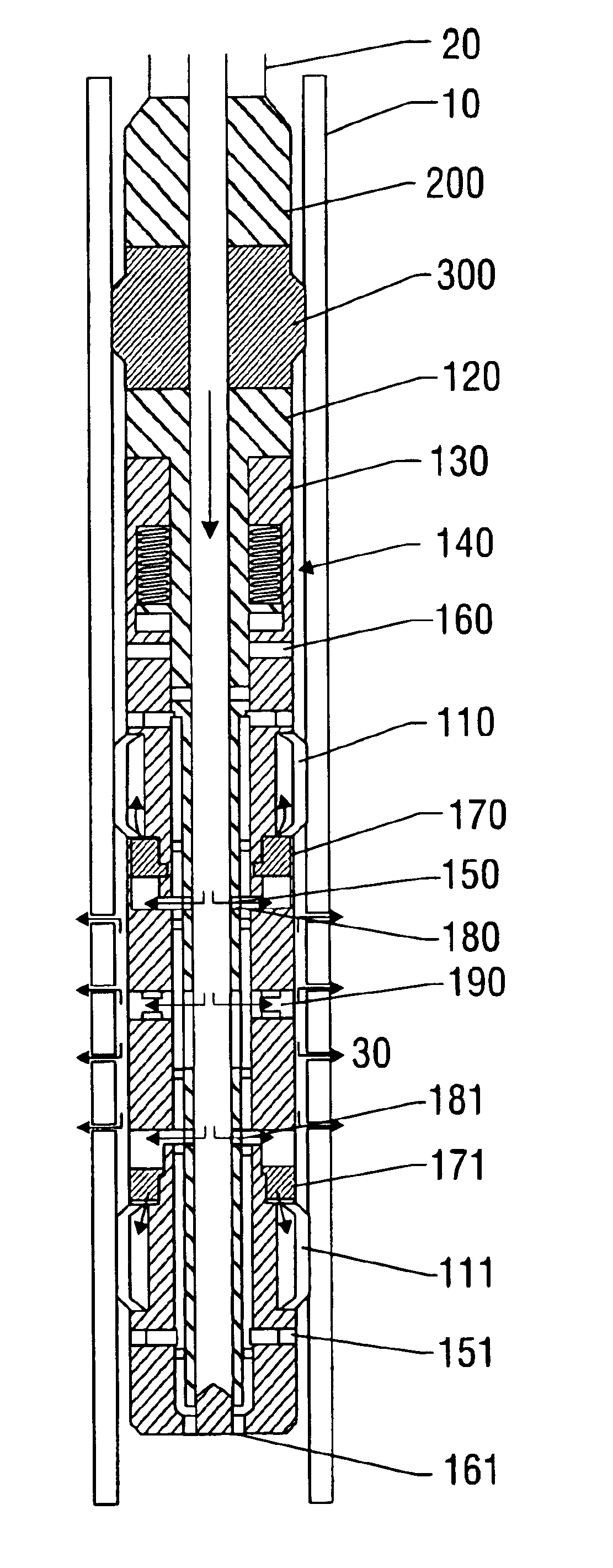

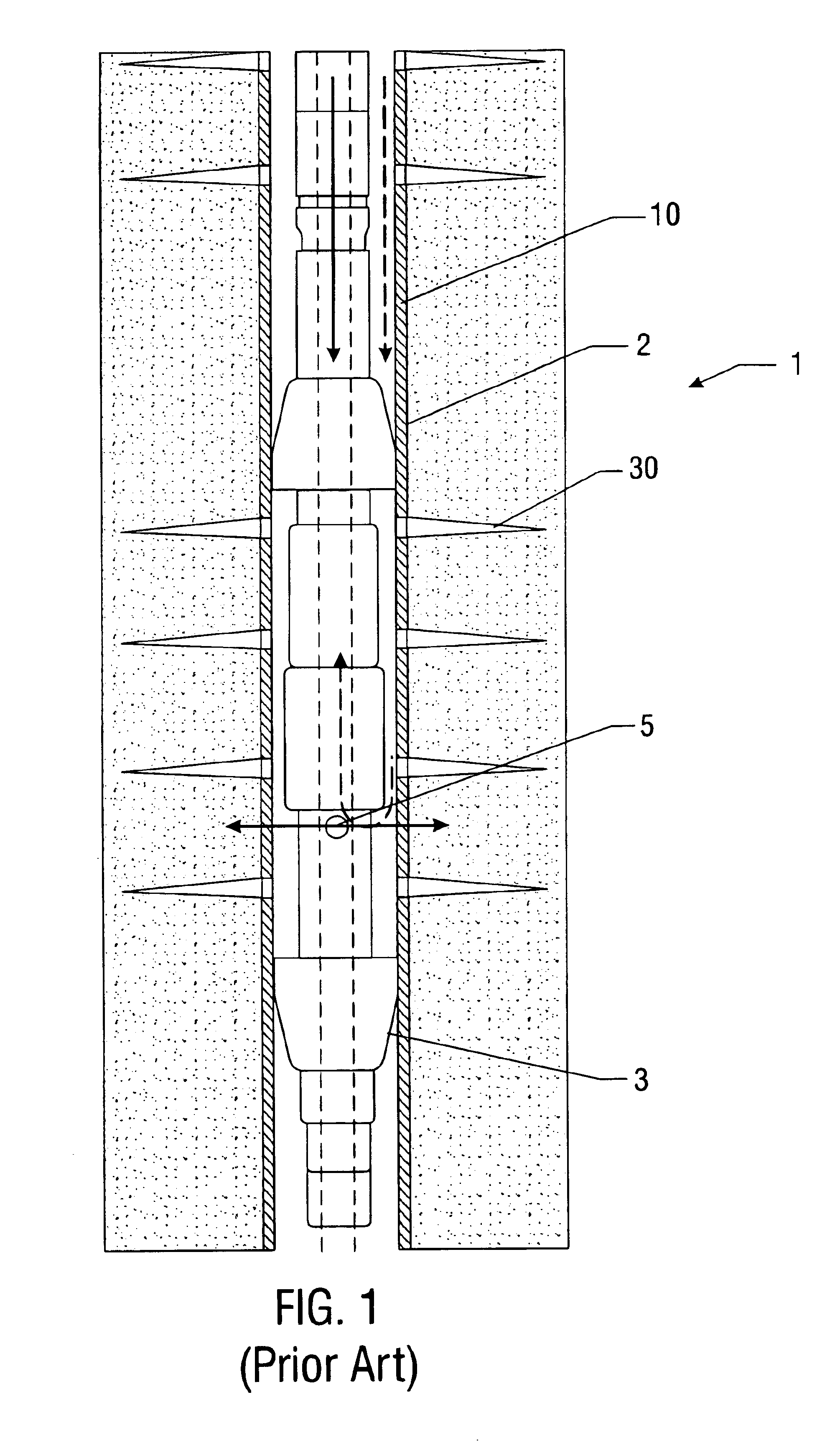

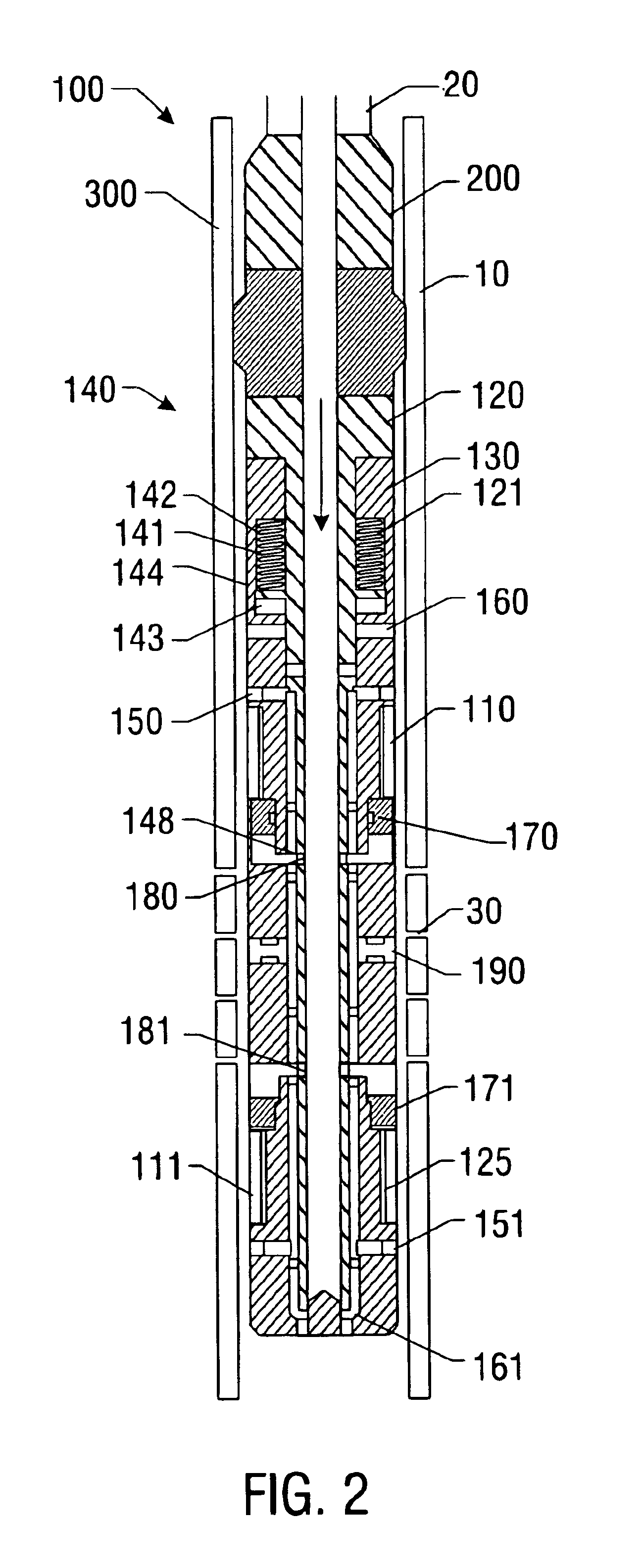

Bottom hole assembly

A bottom hole assembly for use with fracturing or fracing a wellbore using coiled tubing is described having a first packing element and a second packing on a mandrel. The bottom hole assembly may be run into the wellbore such that the packing elements straddle the zone to be fraced. Also described is a timing mechanism to prevent the closing of dump ports before the bottom hole assembly may be flushed of the sand. A release tool is described that allows an operator to apply force to the coiled tubing to dislodge a bottom hole assembly without completely releasing the bottom hole assembly. Also disclosed is a collar locator capable of being utilized in a fracing process. Methods of using the above described components are also disclosed.

Owner:BAKER HUGHES INC

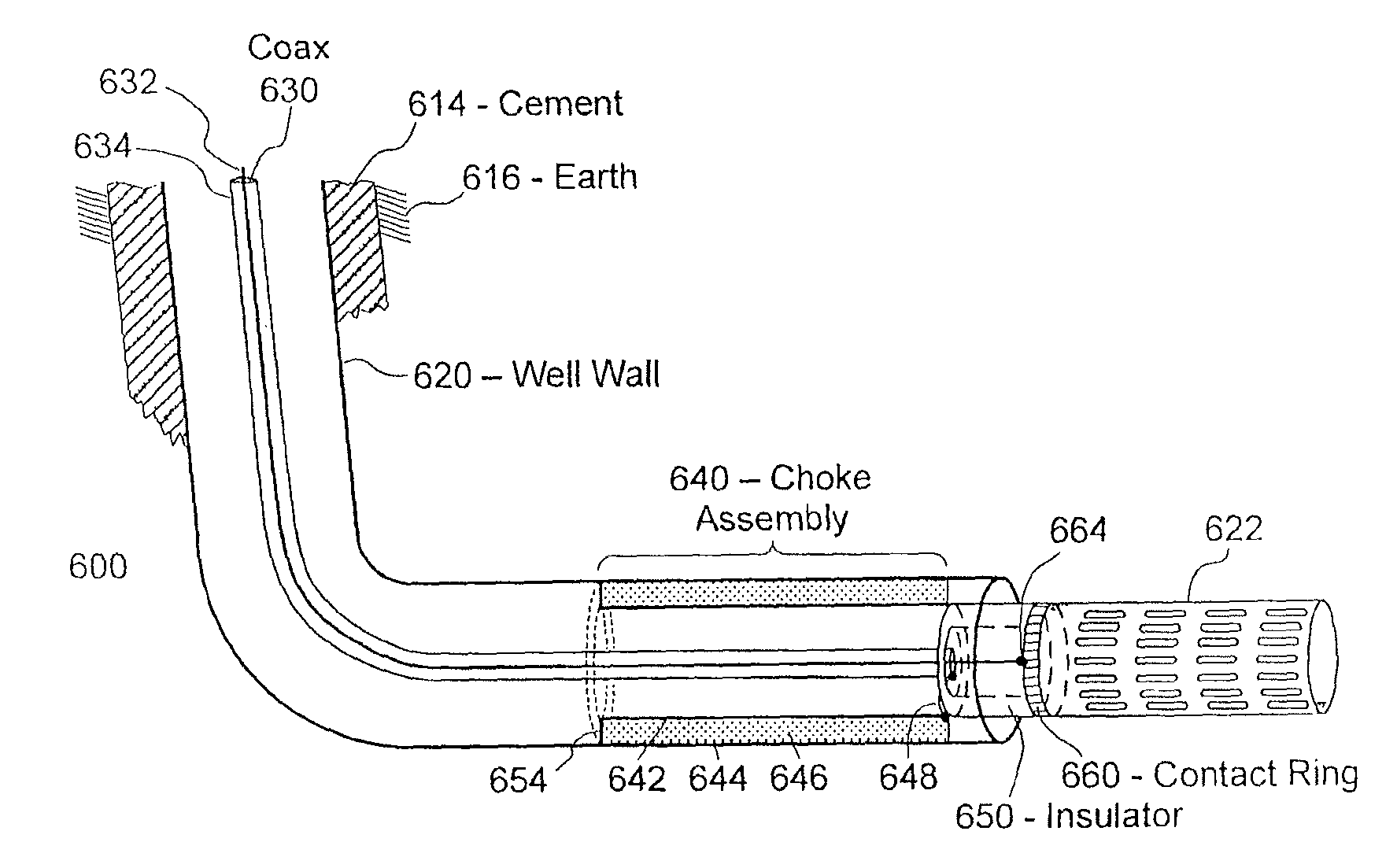

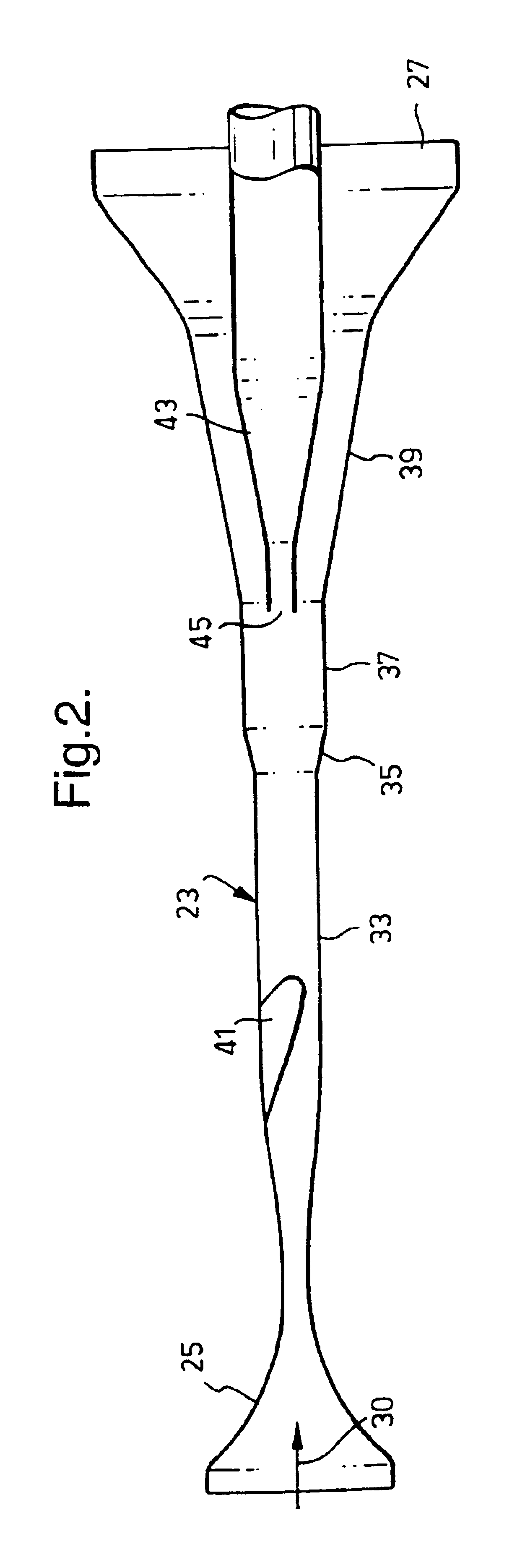

Method for removing condensables from a natural gas stream, at a wellhead, downstream of the wellhead choke

InactiveUS6962199B1Easy to separateDissipates a substantial amount of kinetic energy of the streamSolidificationLiquefactionProduct gasEngineering

The present invention relates to a method for removing condensables from a natural gas stream, at a wellhead, downstream of the wellhead choke thereof. In accordance with the invention there is provided a method for removing condensables from a natural gas stream at a wellhead, the method comprising the steps of: (A) inducing the natural gas stream to flow at supersonic velocity through a conduit of a supersonic inertia separator and thereby causing the fluid to cool to a temperature that is below a temperature / pressure at which the condensables will begin to condense, forming separate droplets and / or particles; (B) separating the droplets and / or particles from the gas; and (C) collecting the gas from which the condensables have been removed, wherein the supersonic inertia separator is part of the wellhead assembly downstream of the wellhead choke. There is also provided a device for removing said condensables from said natural gas that is part of the wellhead assembly downstream of the choke, a wellhead assembly comprising said device.

Owner:TWISTER BV +1

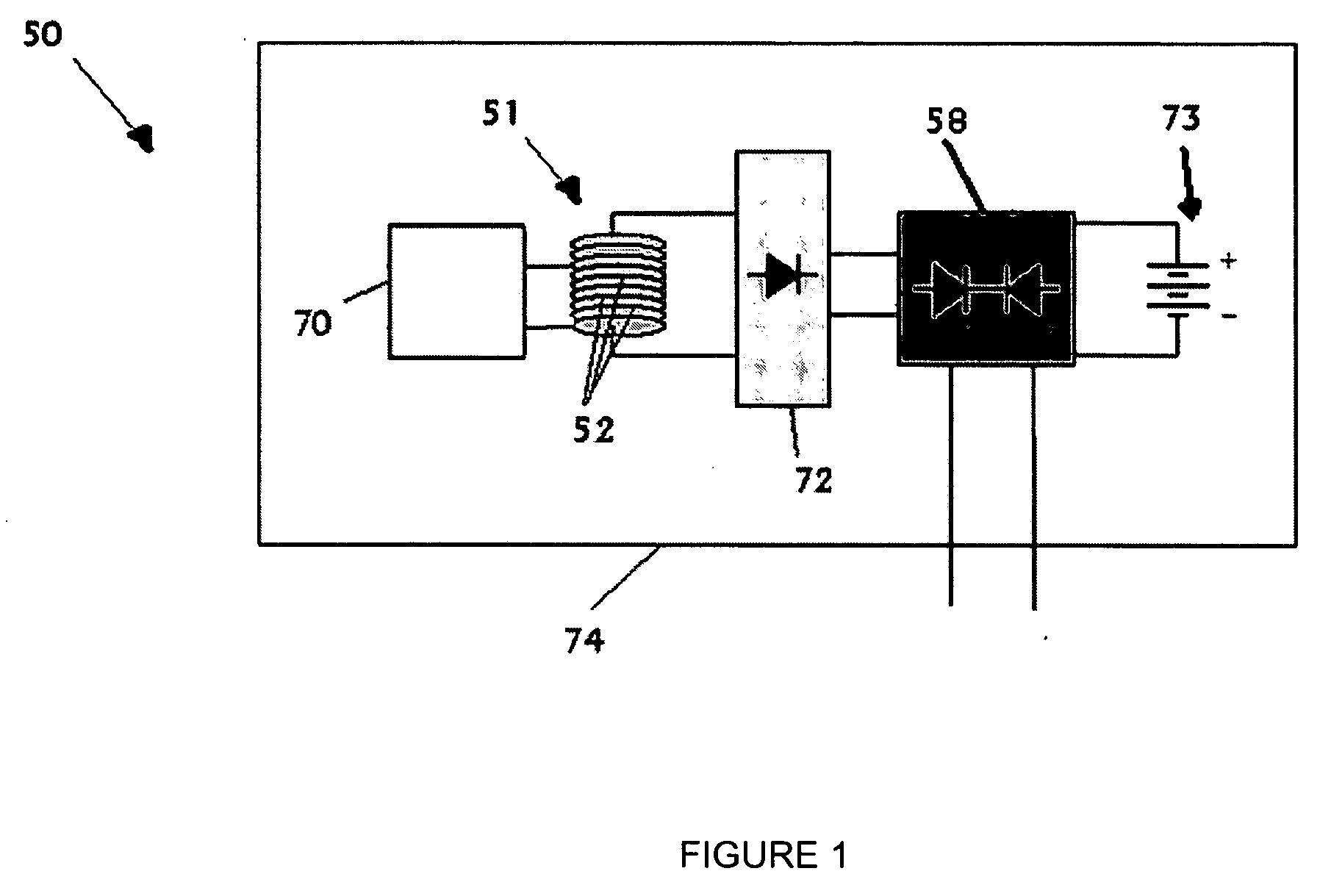

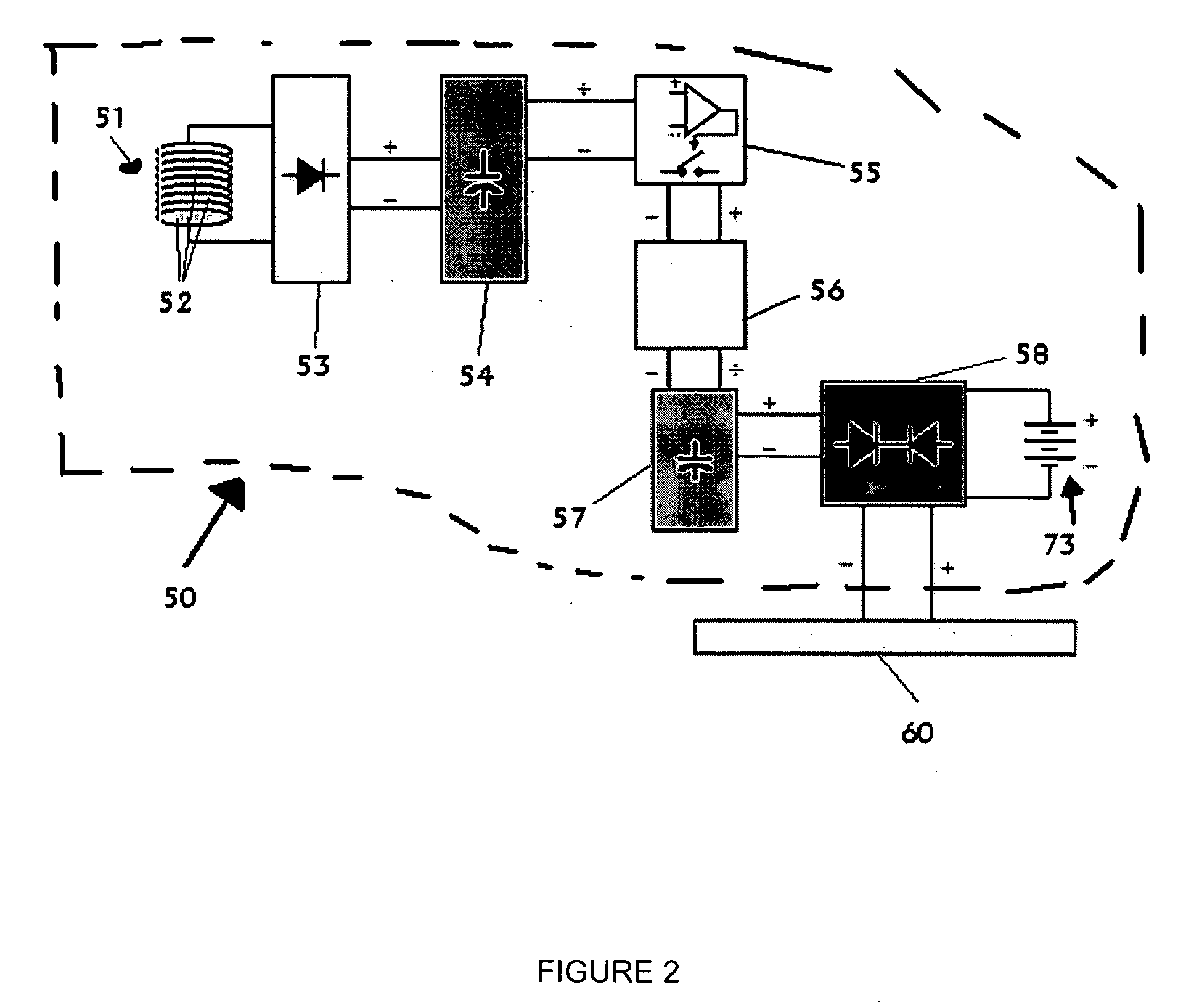

Methods and apparatus for in situ generation of power for devices deployed in a tubular

A device, system, and methods of power generation in situ in a hydrocarbon well are disclosed. A power generator for deployment in a hydrocarbon well tubular may comprise a housing adapted for deployment within a hydrocarbon well tubular; a mechanical to electrical power converter disposed at least partially within the housing, the mechanical to electrical power converter adapted to create an electric current when physically stressed; and a current converter operatively coupled to the mechanical to electrical power converter. Devices may be deployed downhole and operatively coupled to the power generator for their electrical power. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of meaning of the claims.

Owner:TUBEL TECH

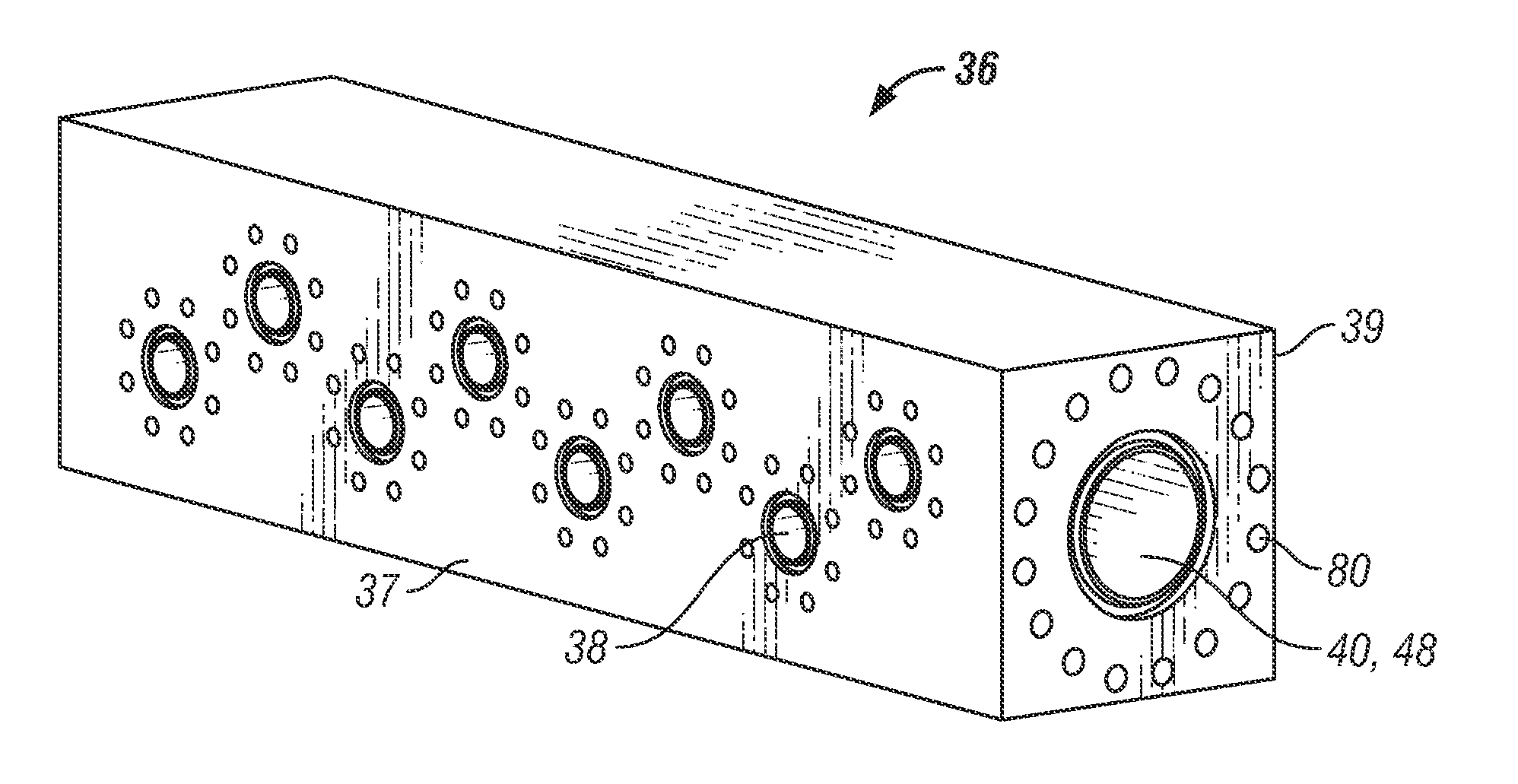

Collection block with multi-directional flow inlets in oilfield applications

The disclosure provides a collection block that aggregates multiple incoming flow lines and provides a consolidated outgoing flow path. The collection block can be remote from a given well that is being fractured to minimize safety risk in operations around the well. The collection block has dual capabilities of being connected to individual incoming flow lines as well as to manifold systems for distributing the out flowing fluids. The one or more inlets can be formed in the collection block at an offset to a centerline of a longitudinal bore through the collection block. In some to embodiments, frac trucks can connect along an extended connection zone that provides the fluids from the truck to the collection block.

Owner:T 3 PROPERTY HLDG

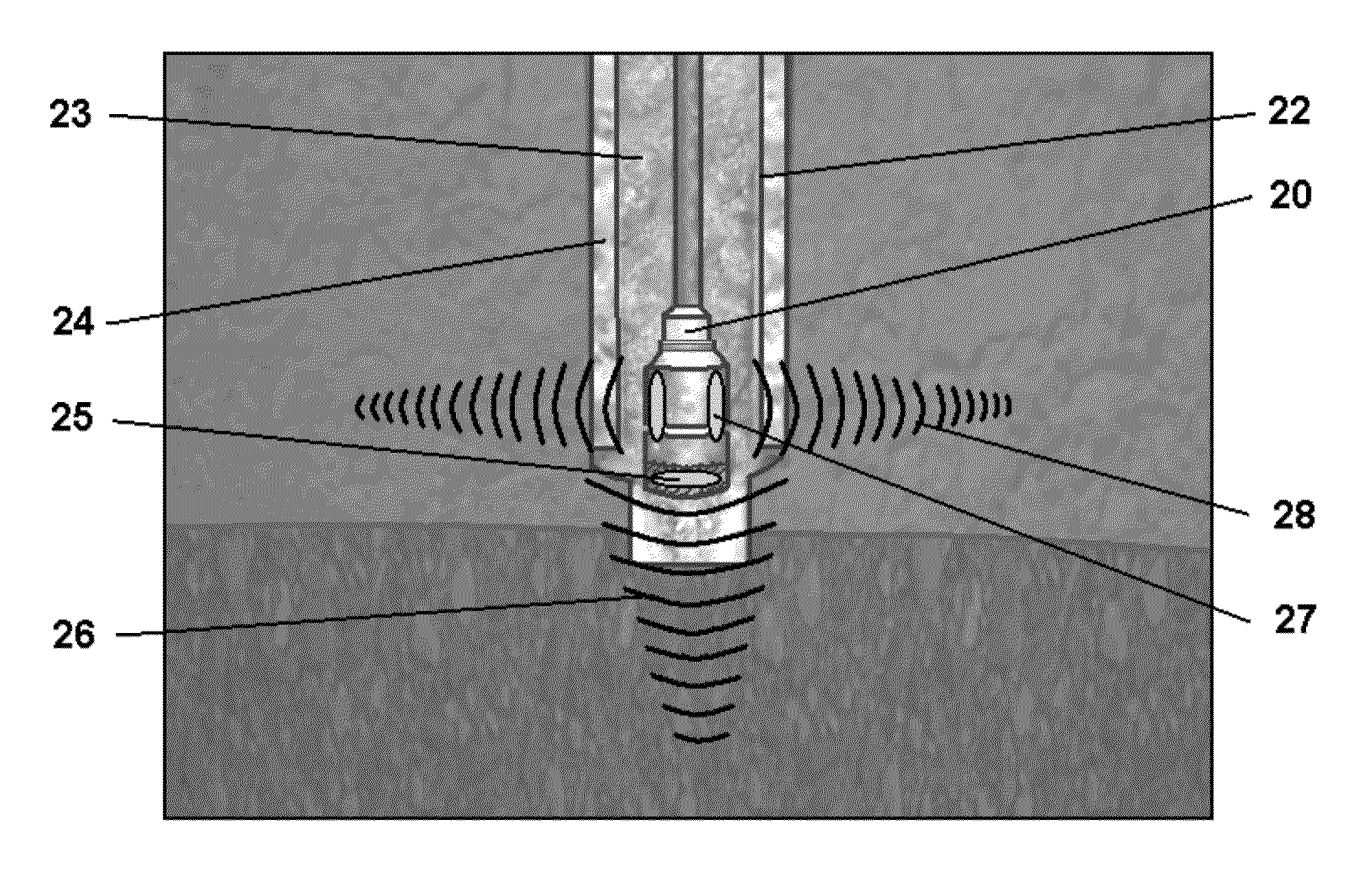

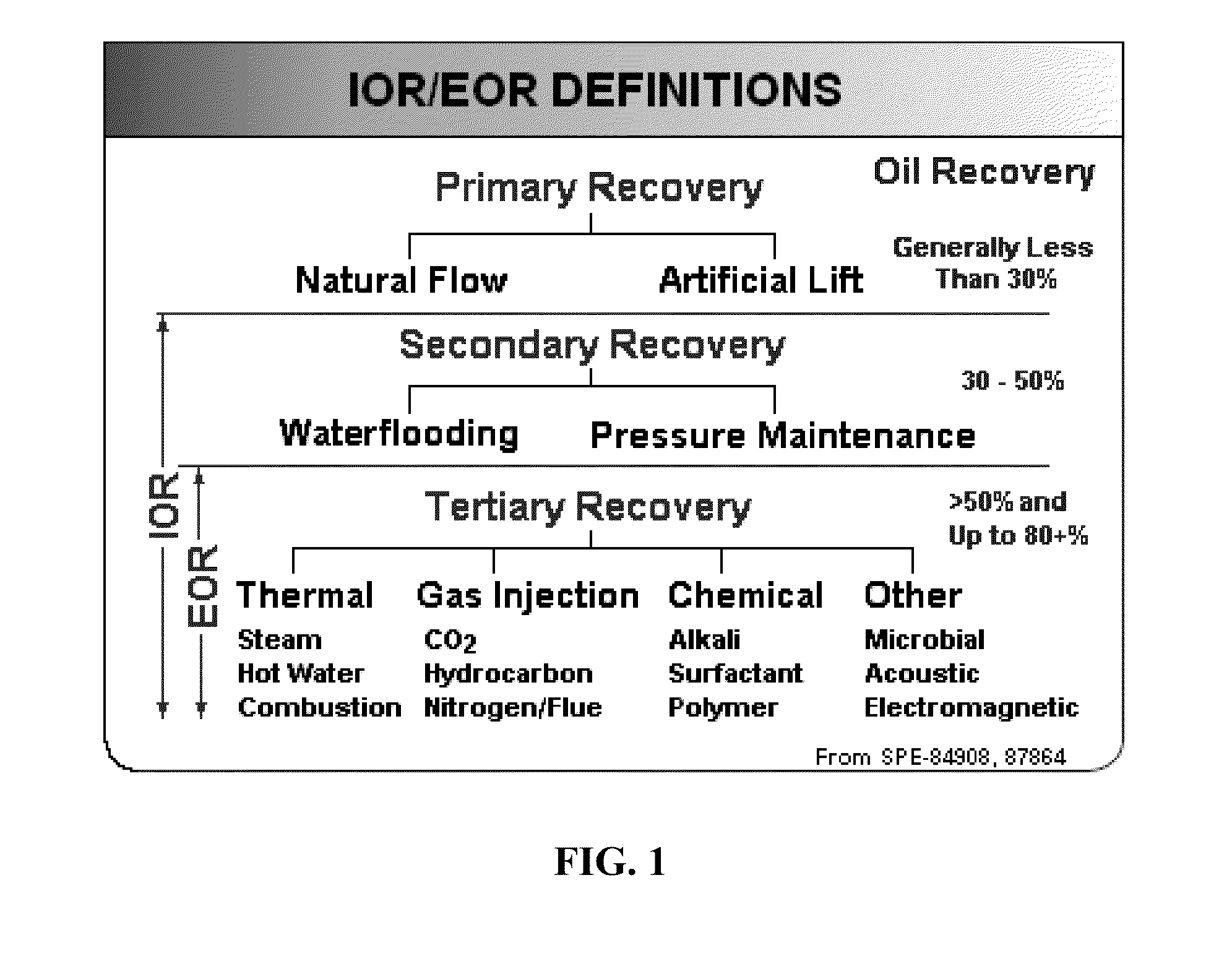

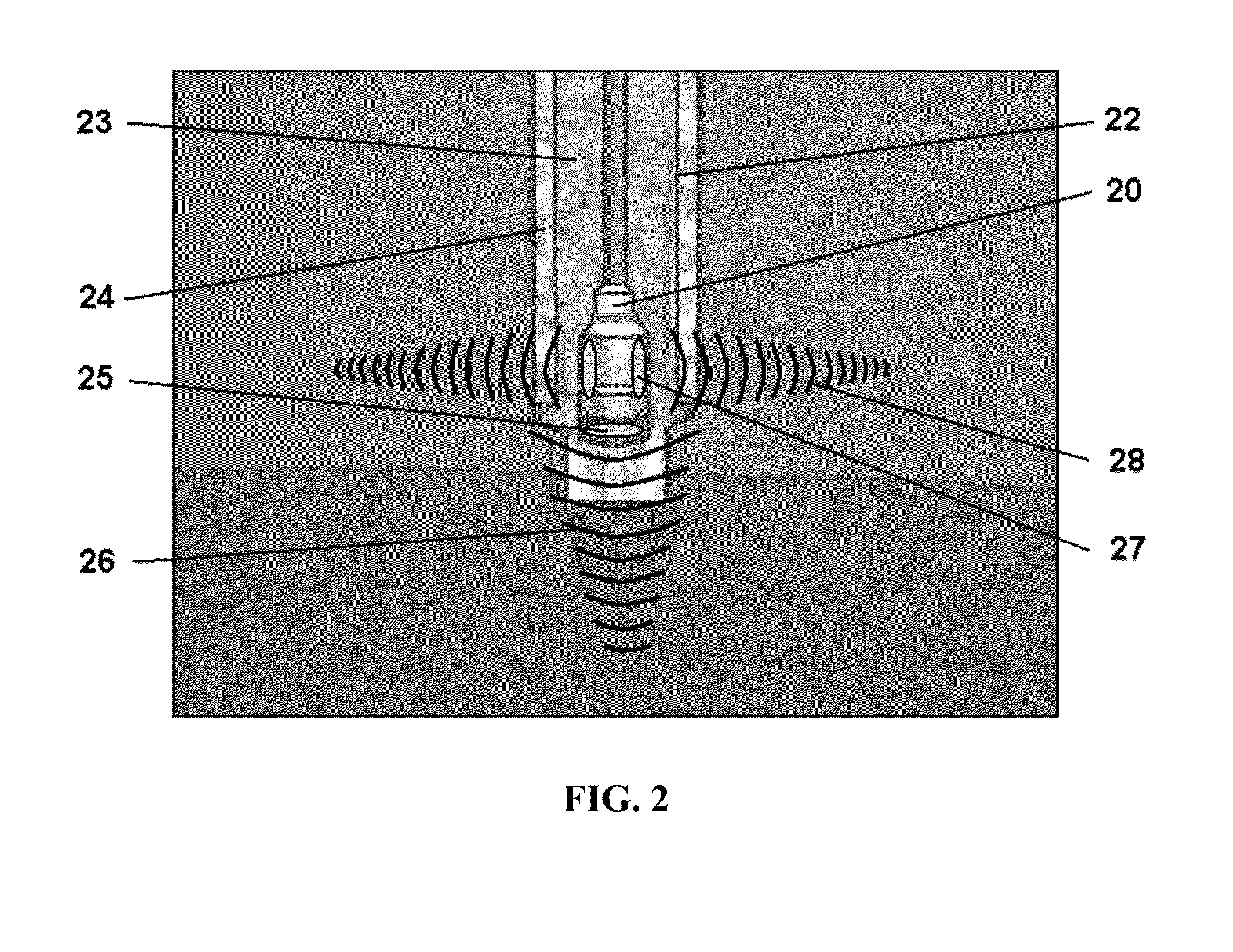

Apparatuses and methods for generating shock waves for use in the energy industry

ActiveUS20140305877A1Extend your lifeNeed can be fittedWaste water treatment from quariesFatty/oily/floating substances removal devicesShock waveFiber

Several methods and devices are provided herein to generate shock waves that are used in the oil industry for well drilling, hydrocarbon or gas exploitation, fracking process or improved oil recovery (IOR), enhanced oil recovery (EOR), cleaning of process waters, oil spills byproducts and oil pipes, which can be used as independent systems or as auxiliary systems concomitantly with other existing technologies. The different devices consist of generating shock waves utilizing either one or more laser sources, or a self-generated combustible gas supply, or a micro-explosive pellet, or piezocrystals, or a piezofiber composite structure.

Owner:SANUWAVE INC

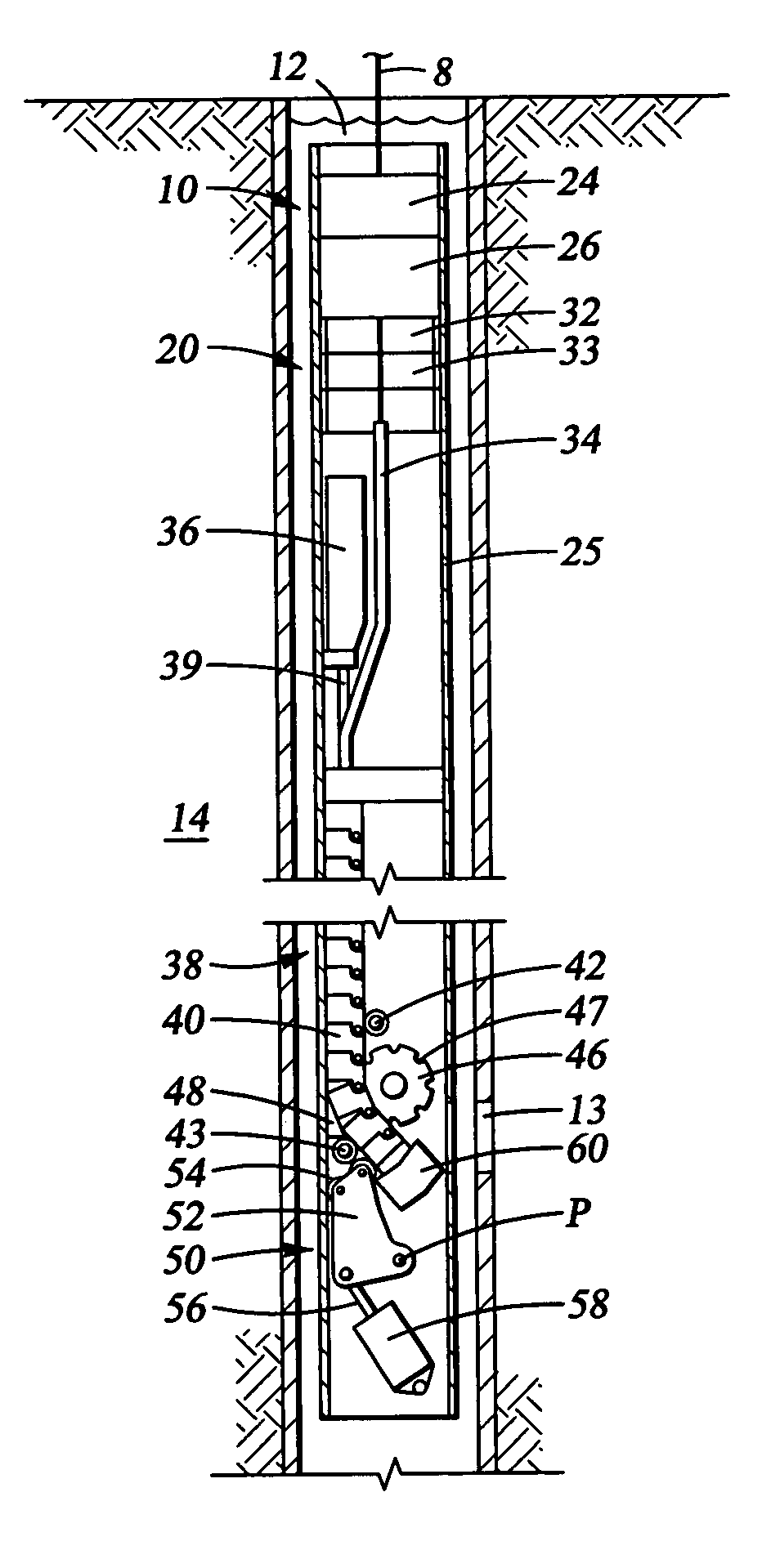

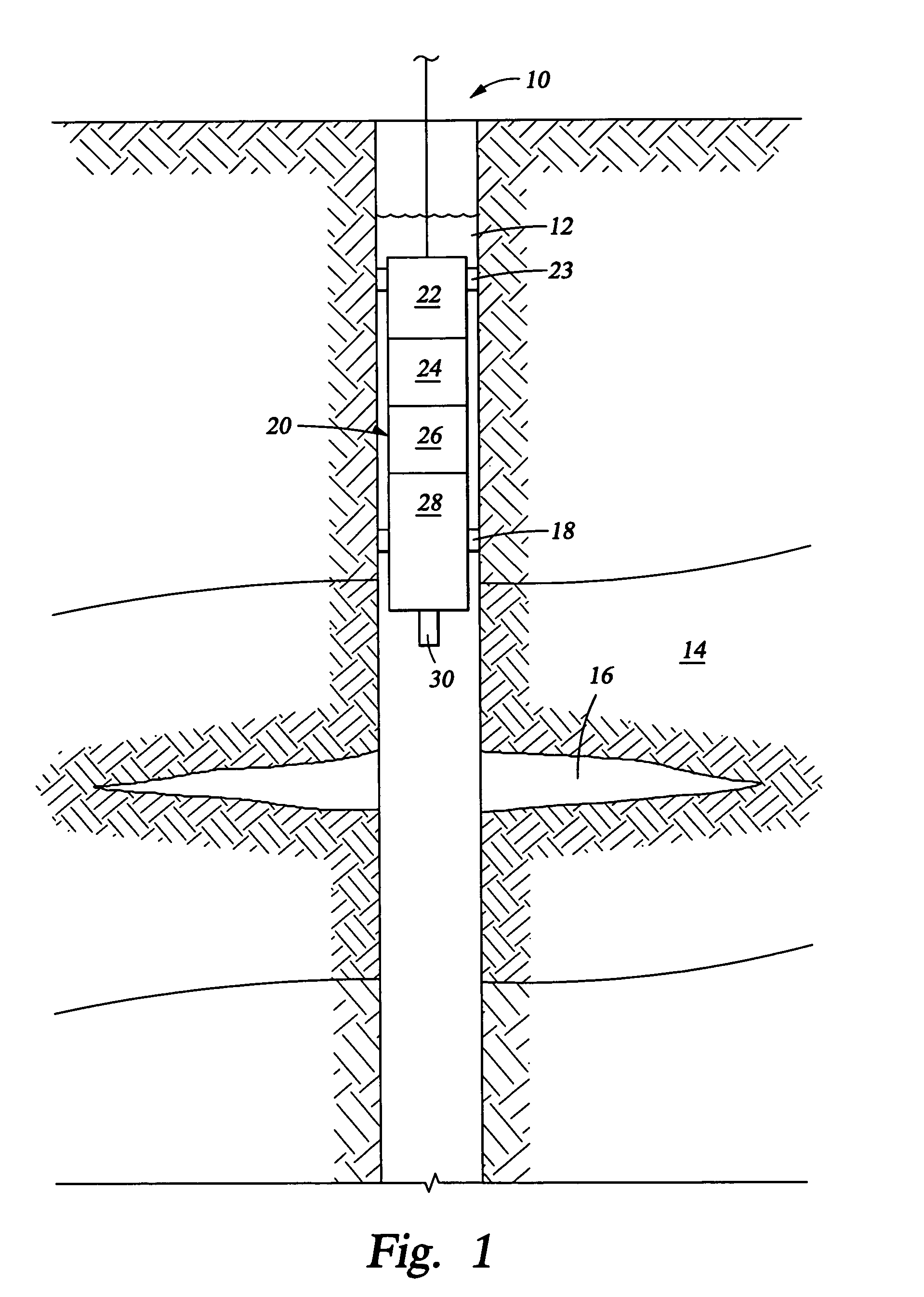

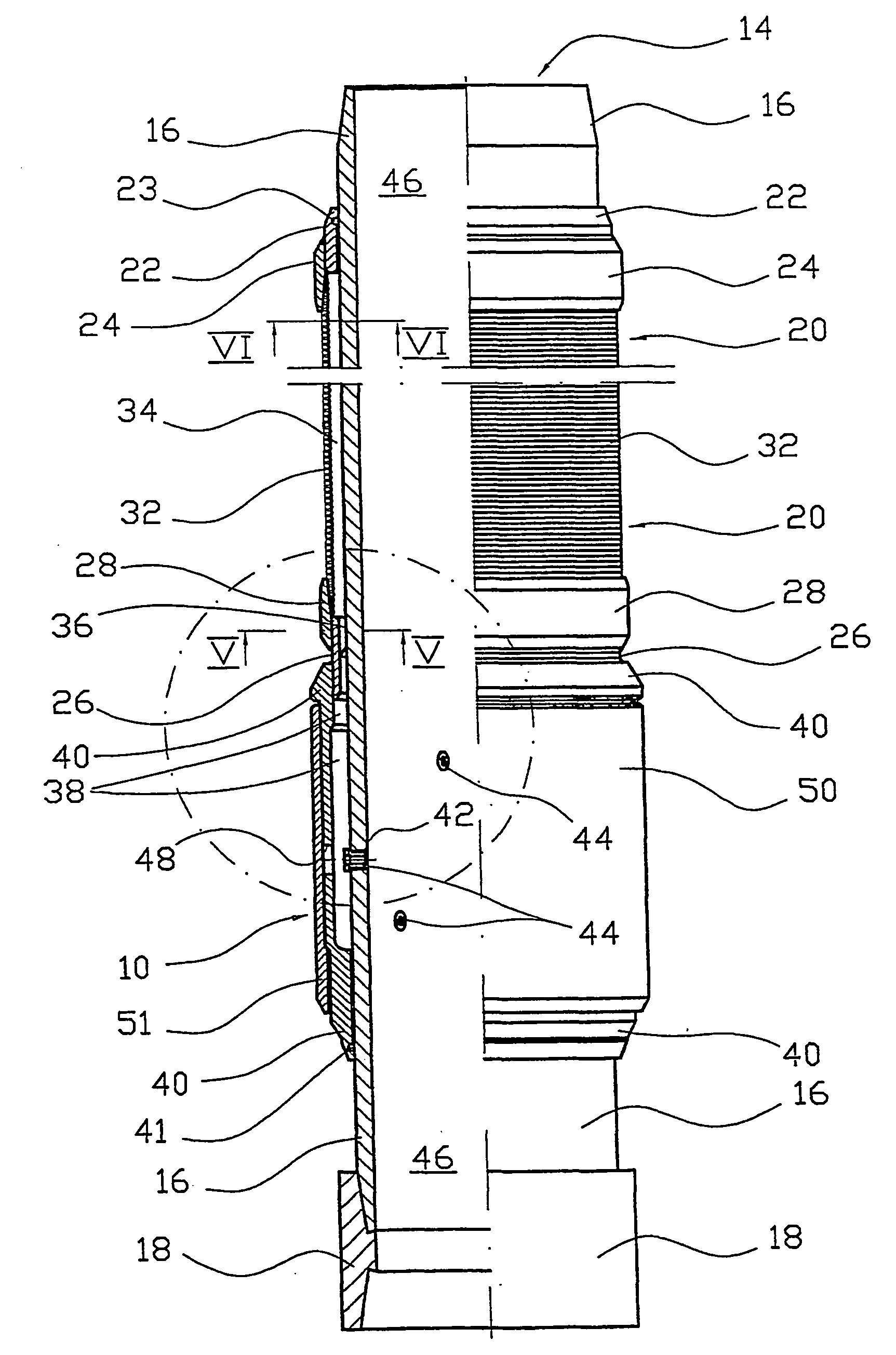

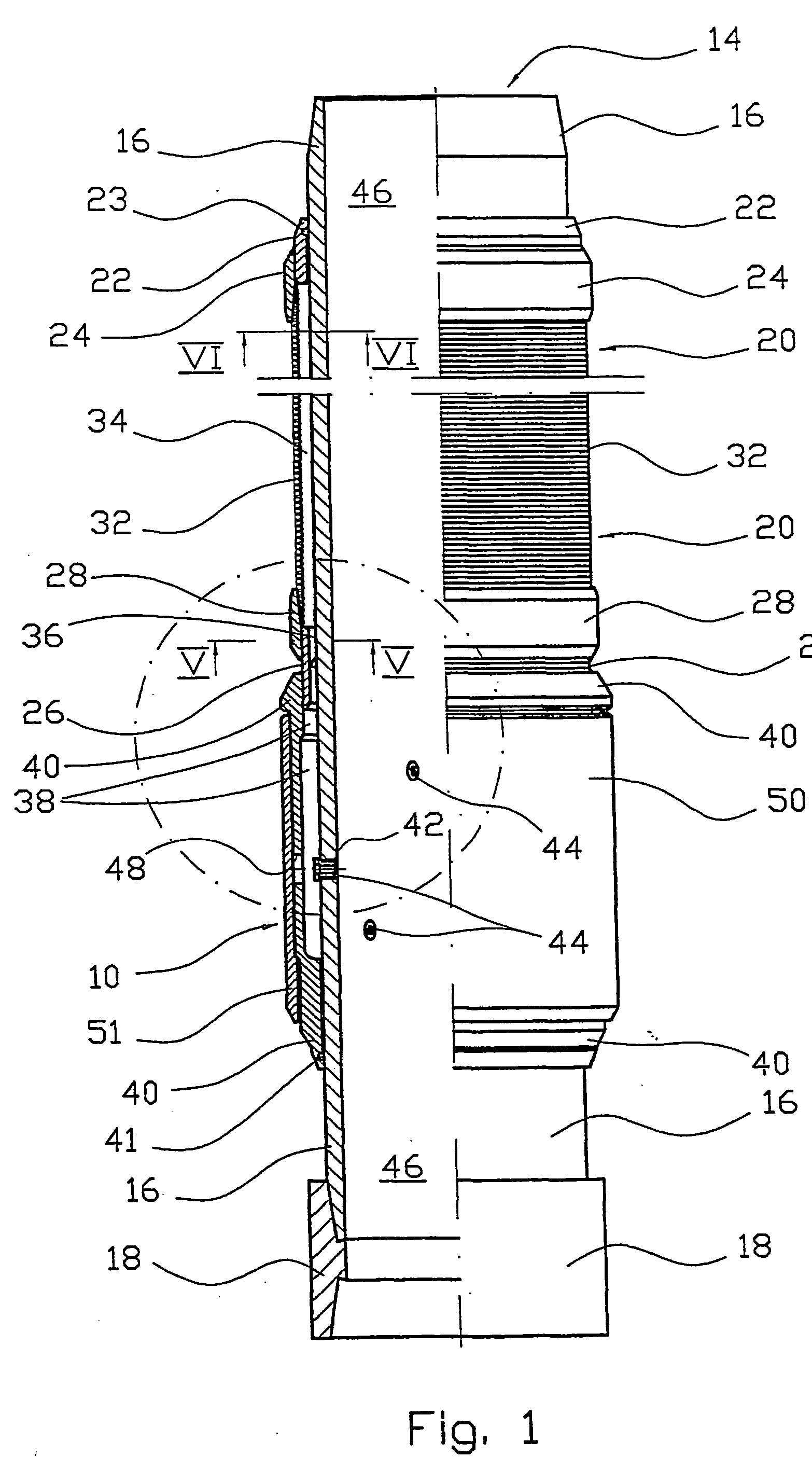

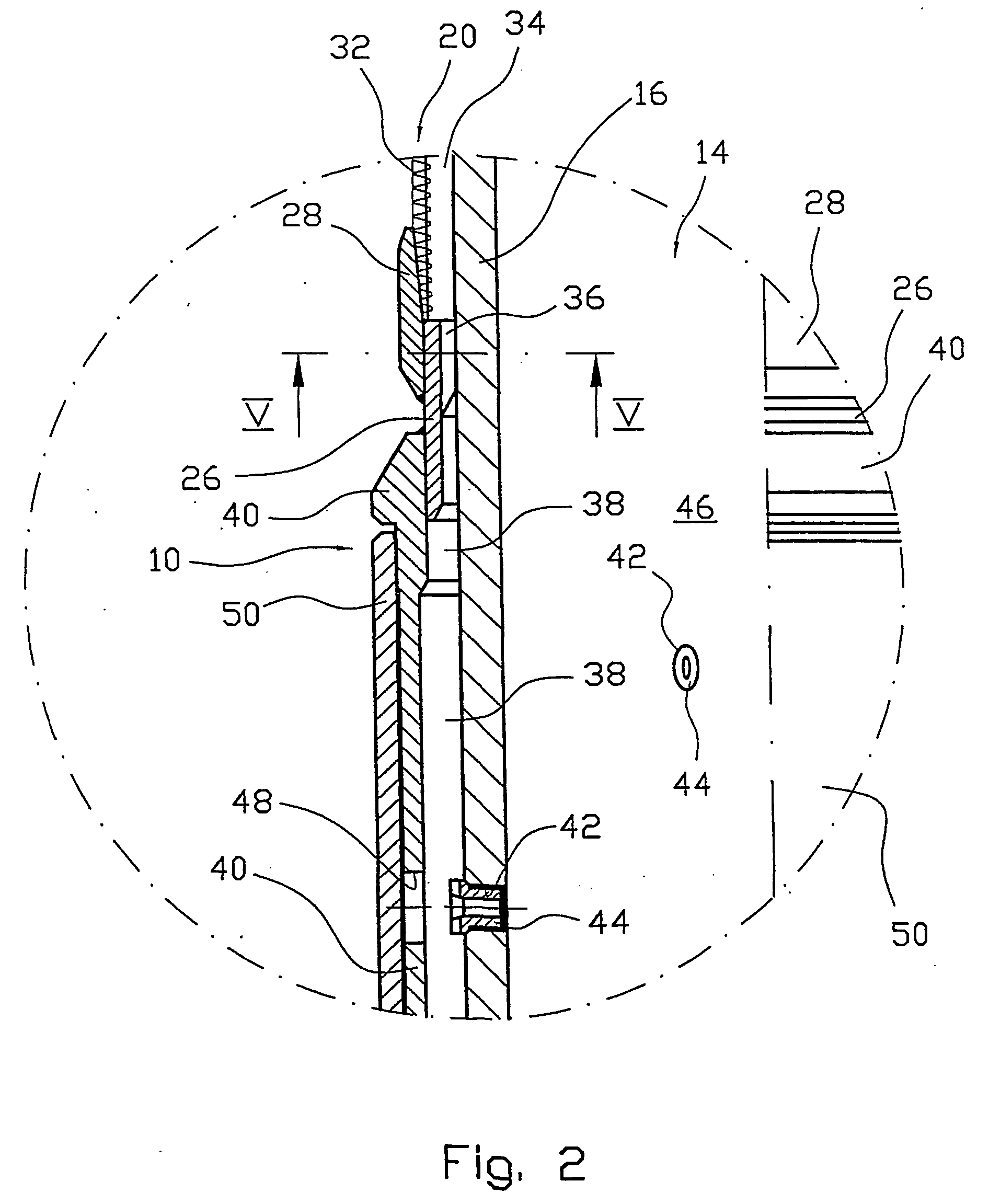

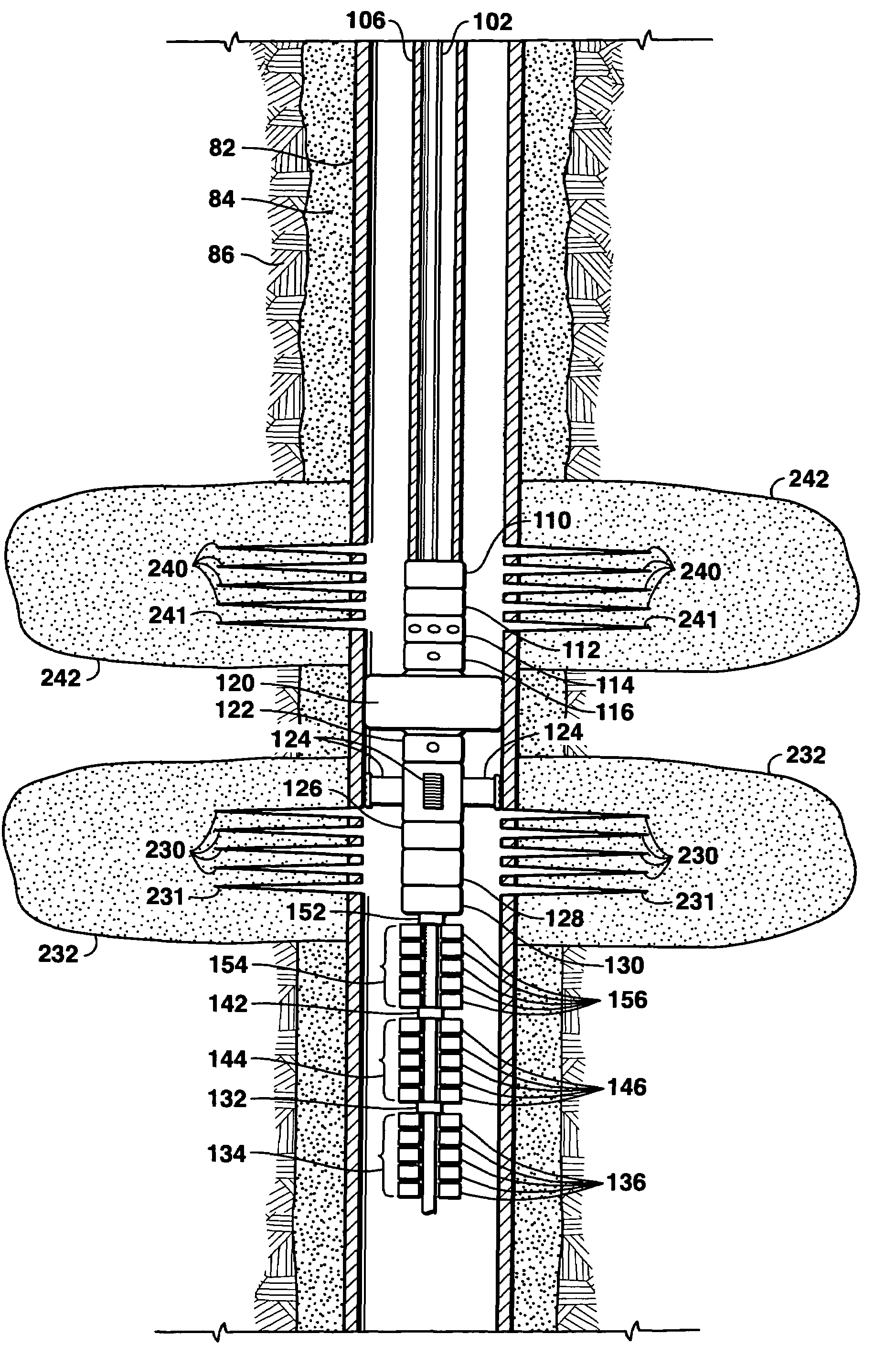

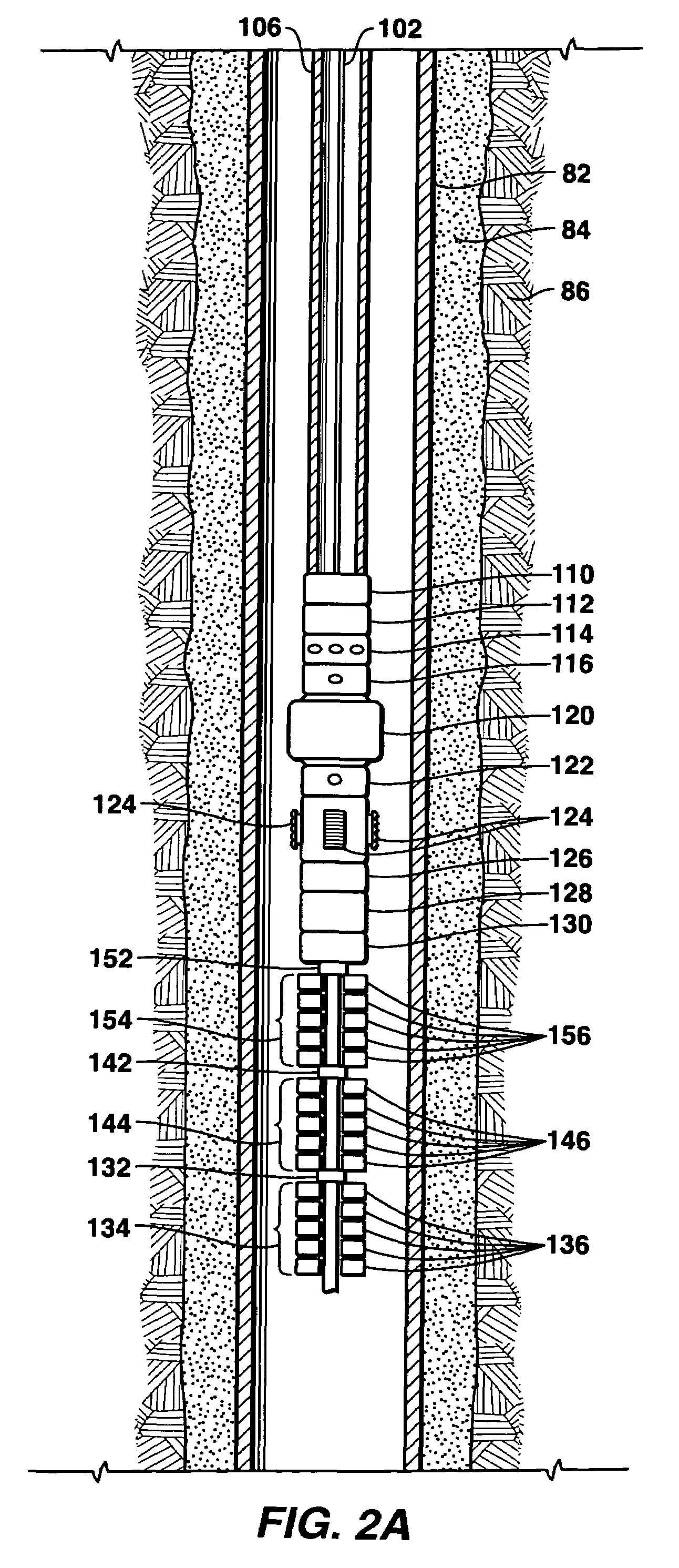

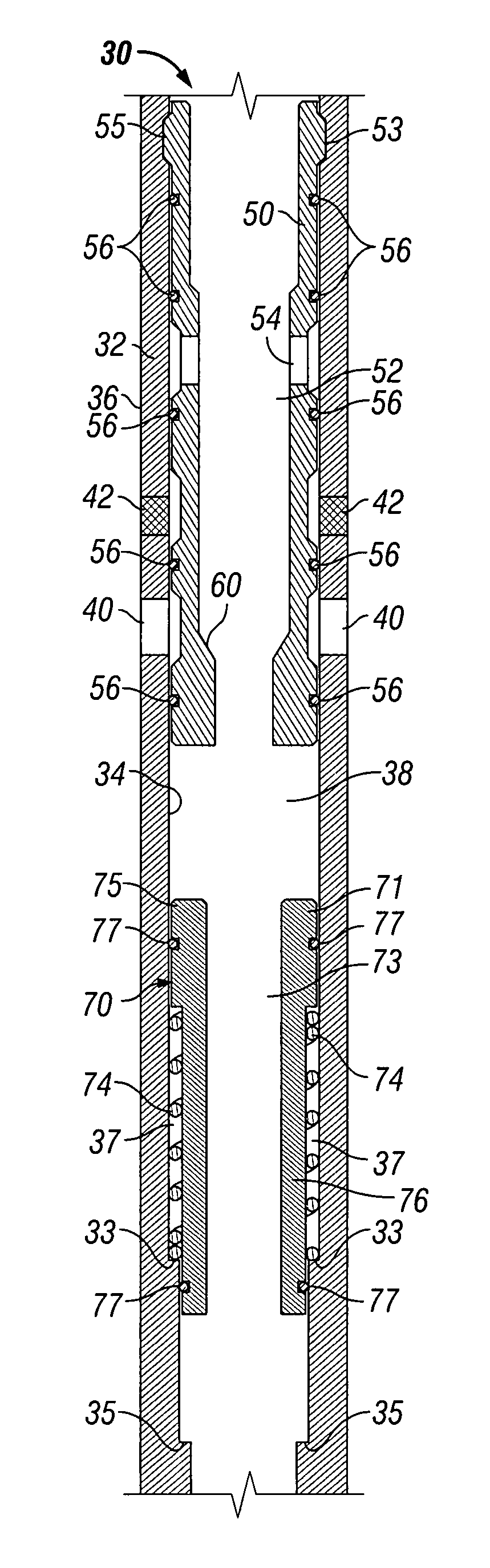

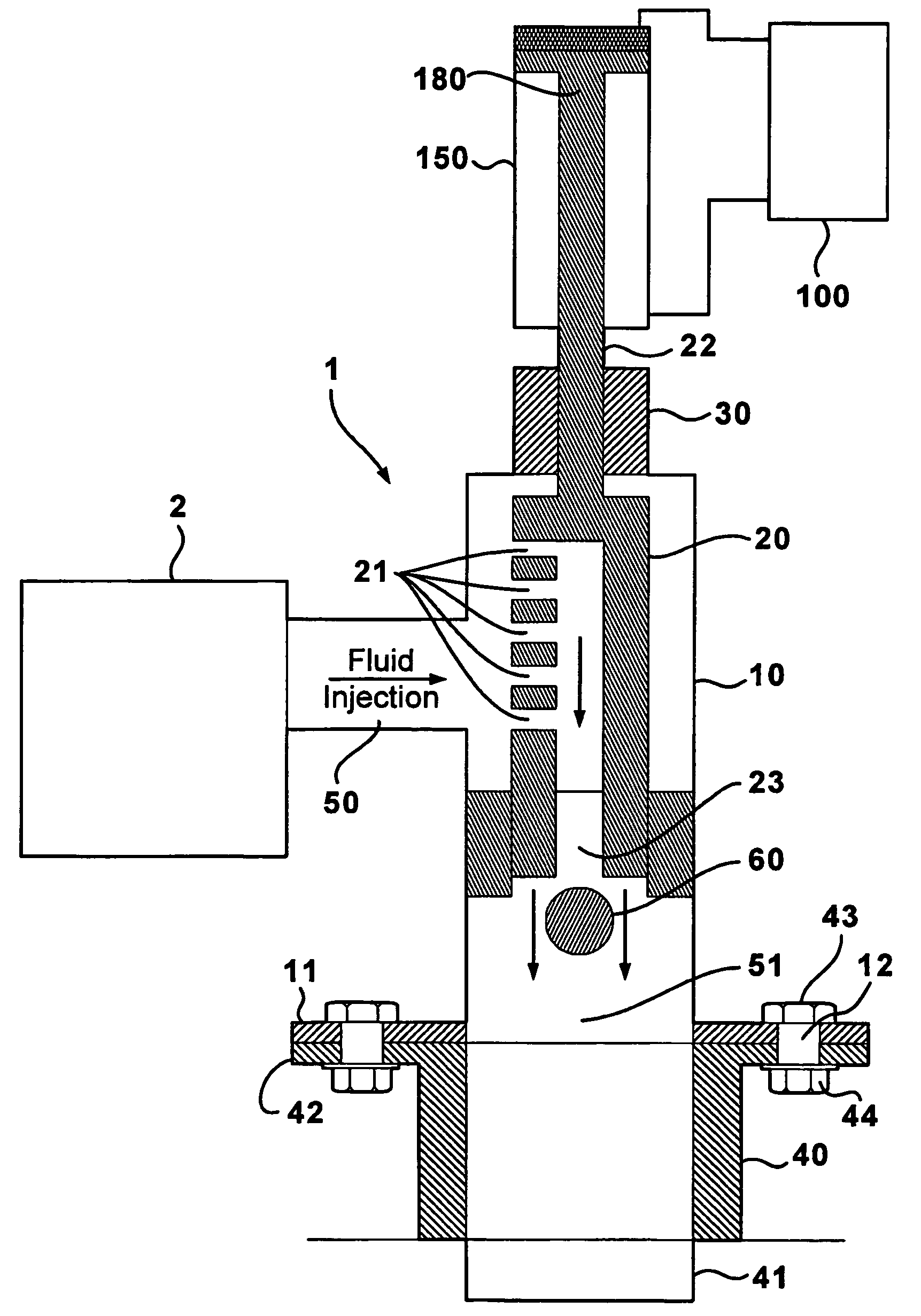

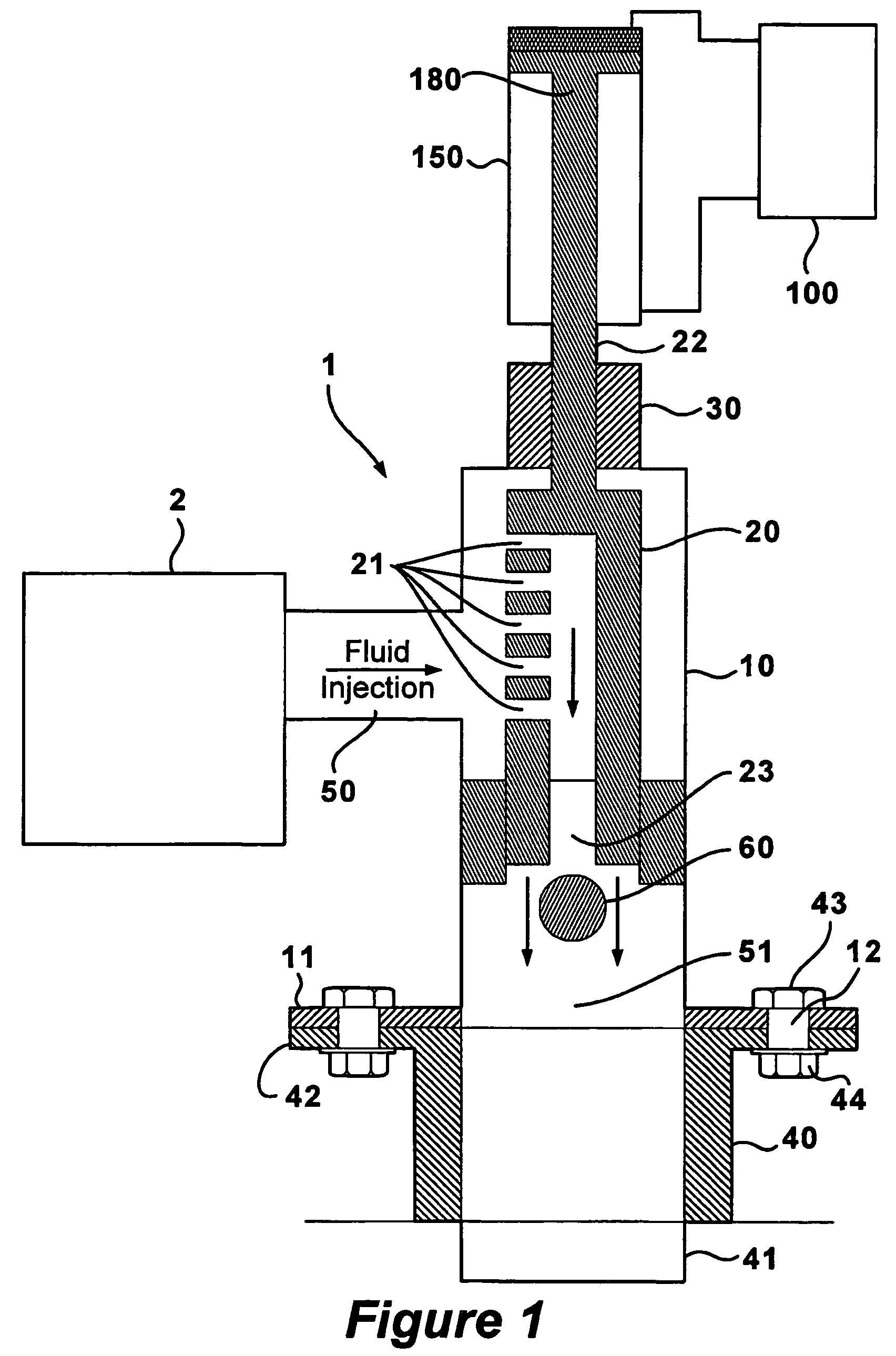

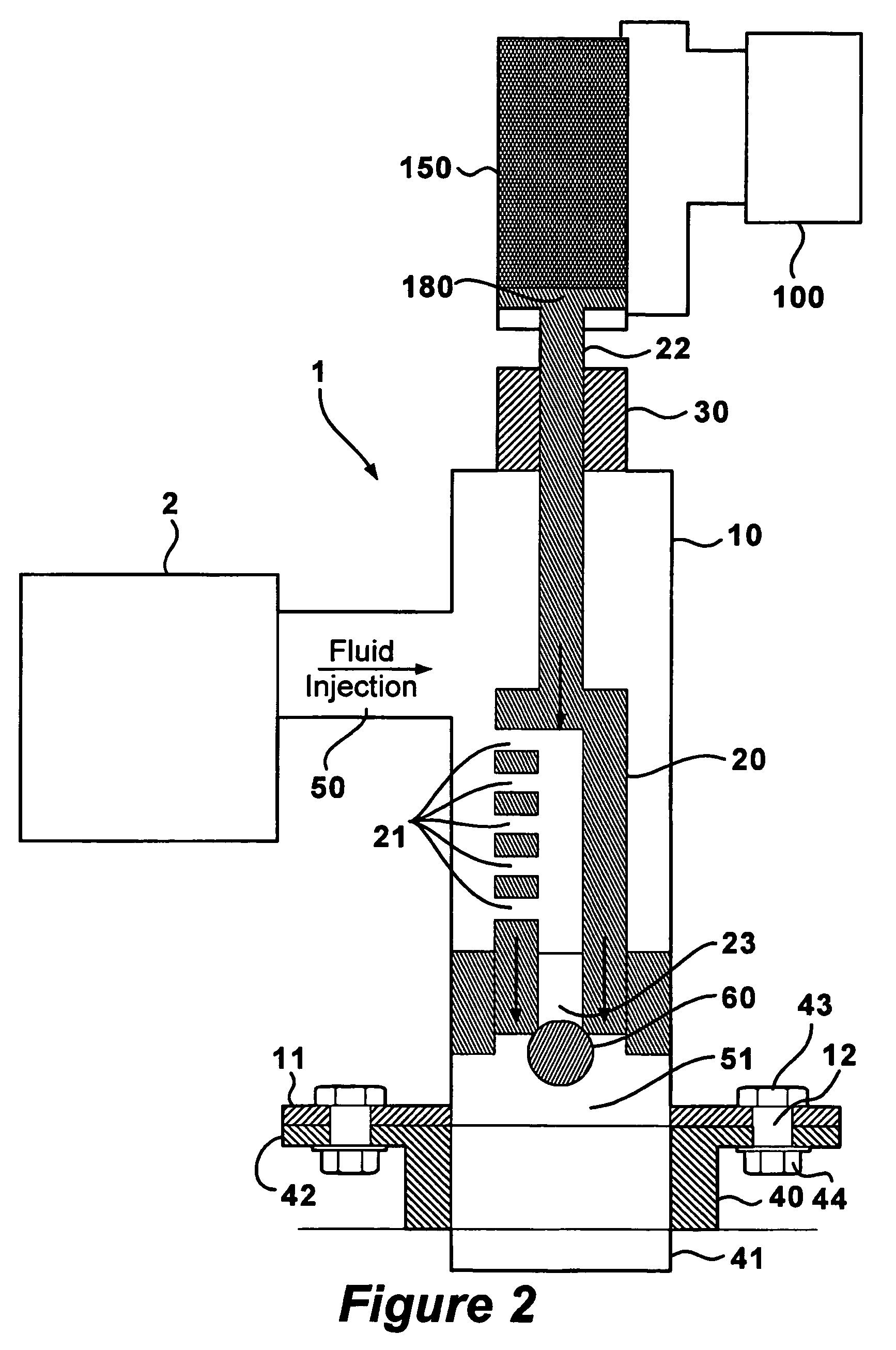

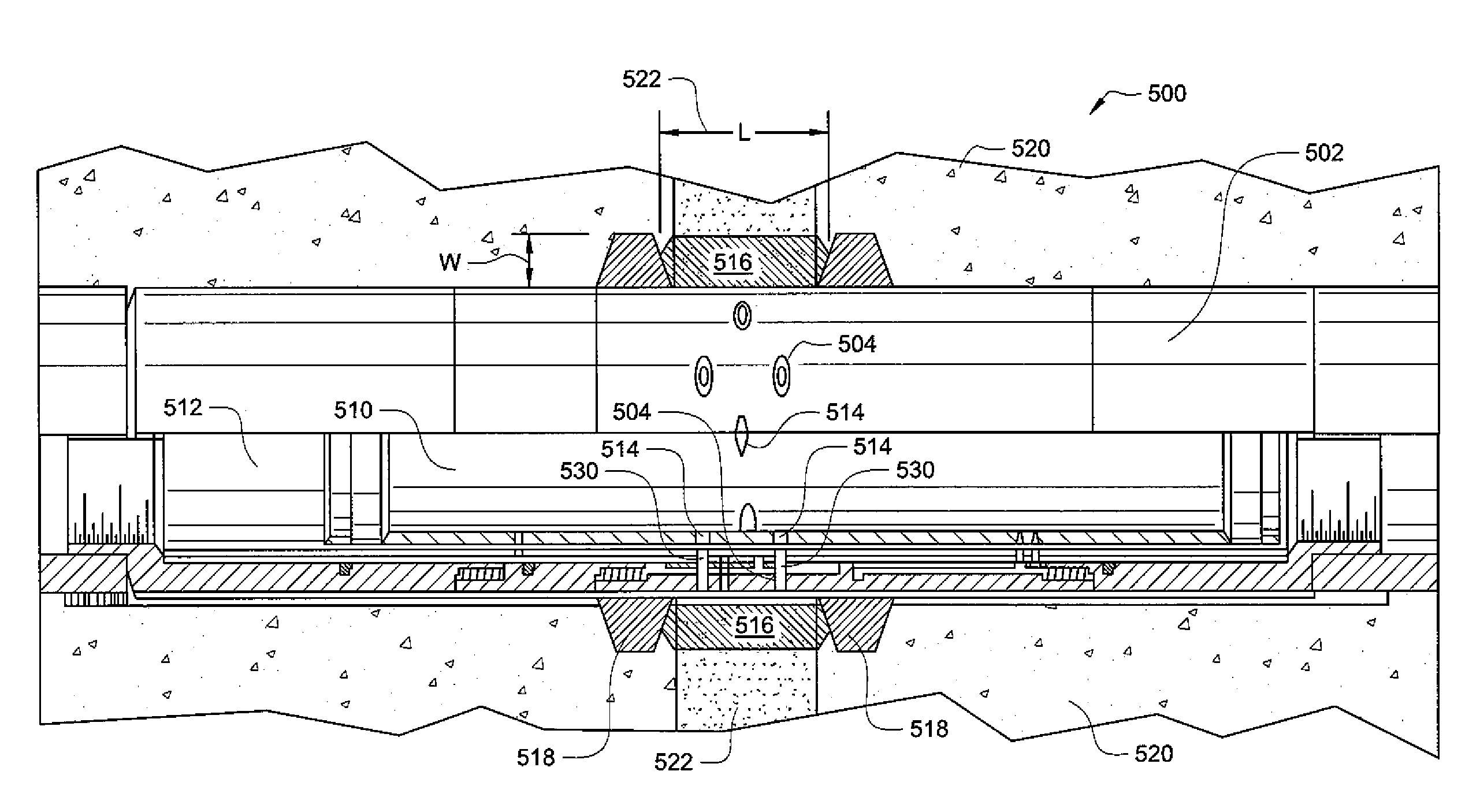

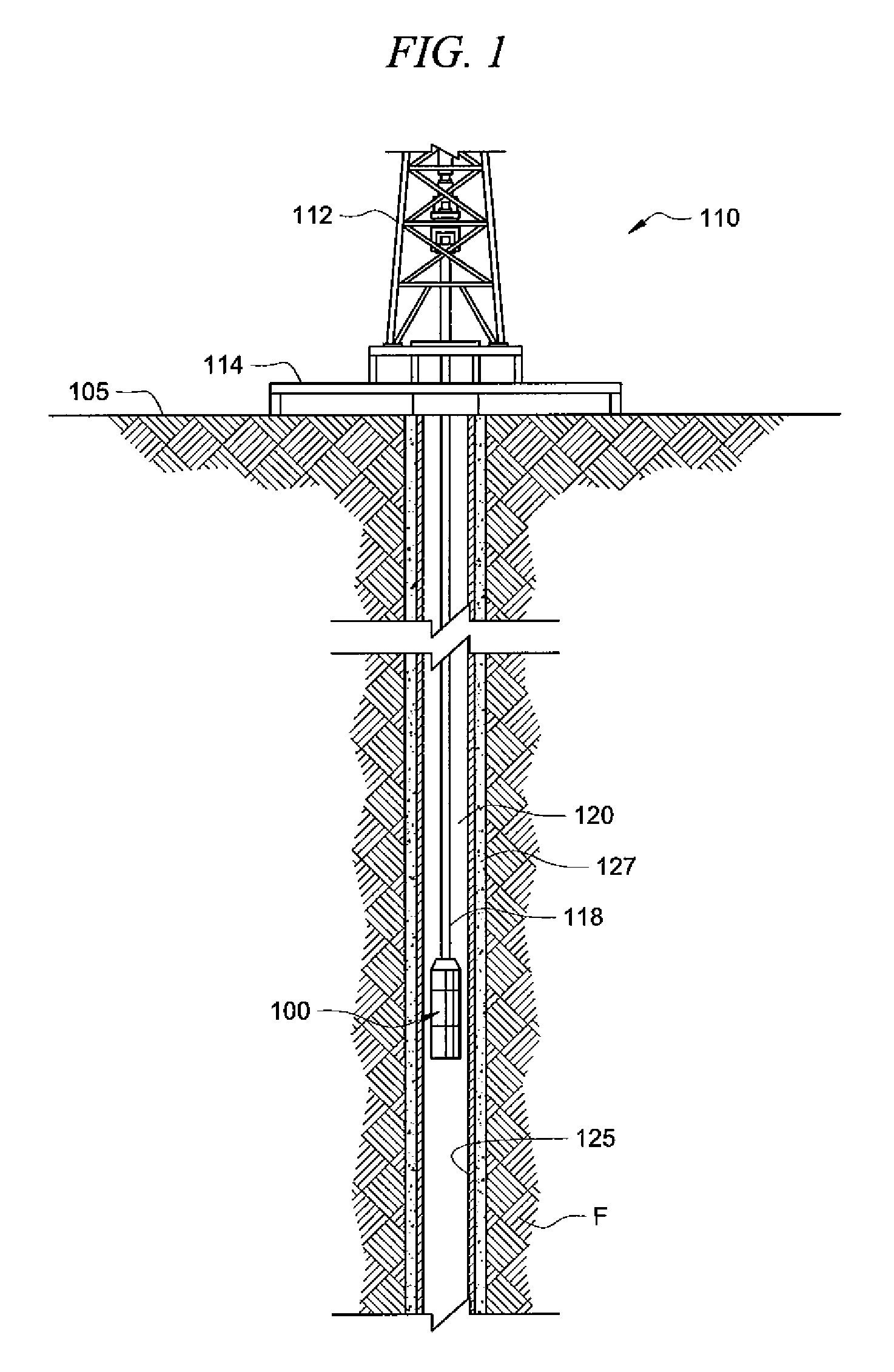

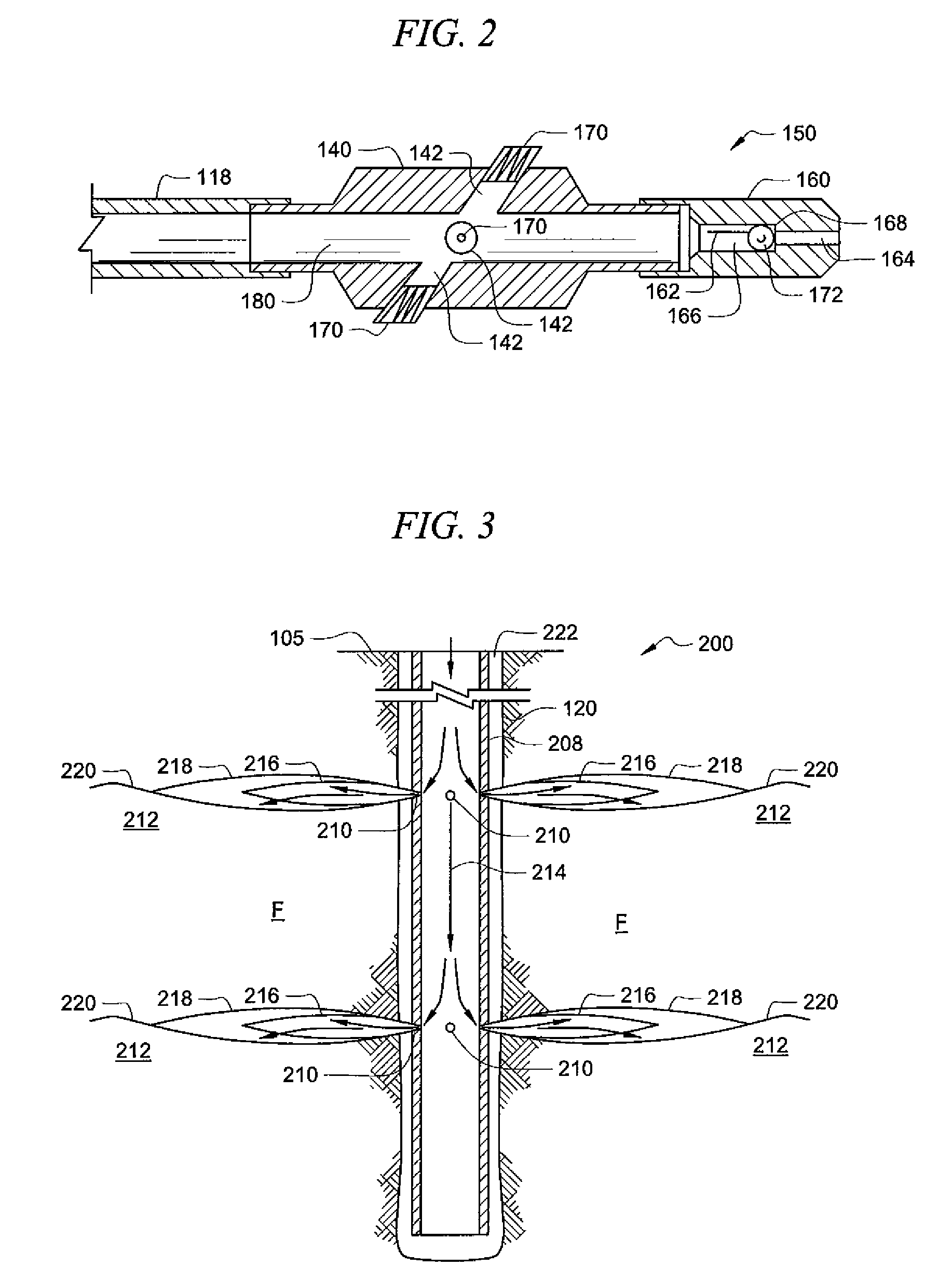

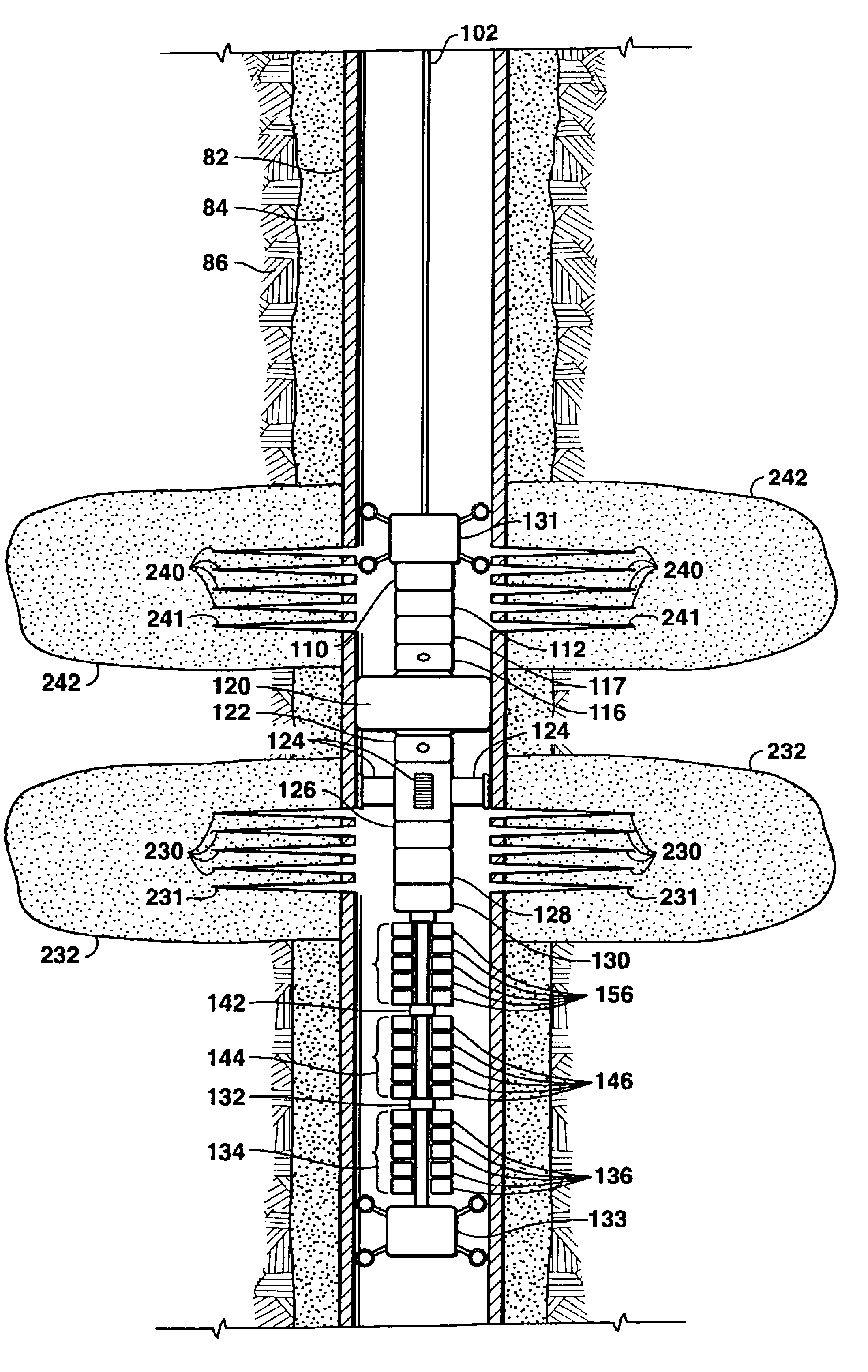

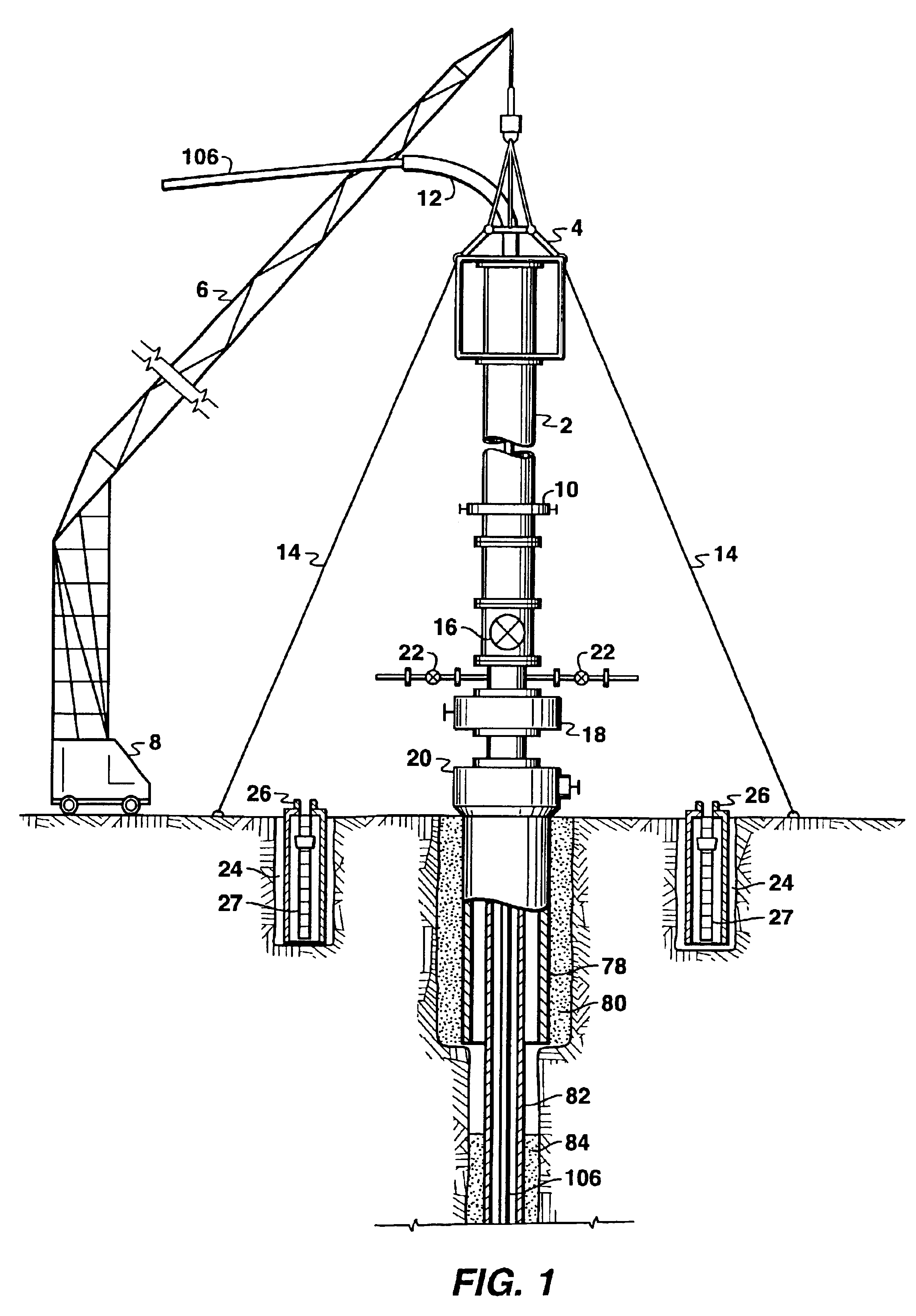

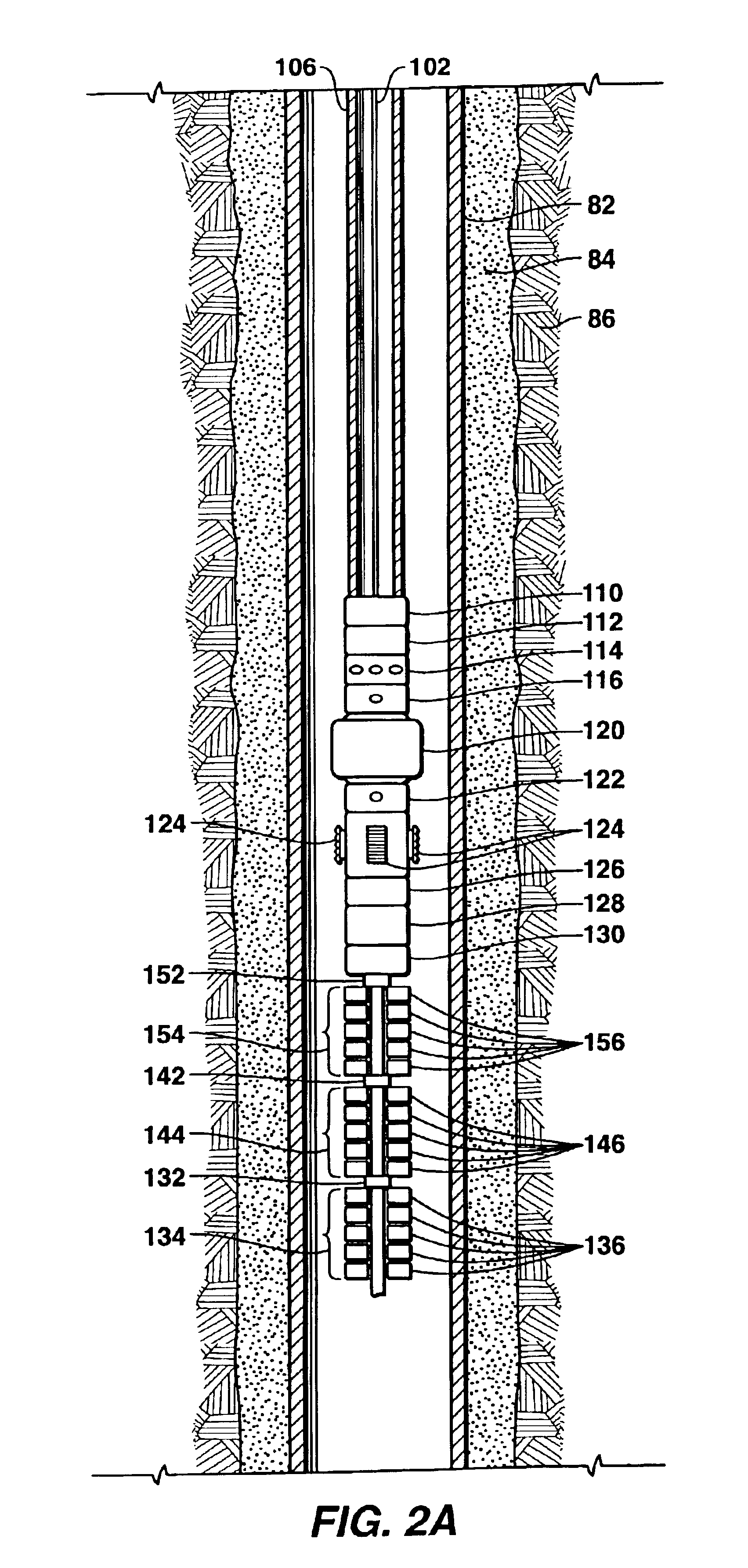

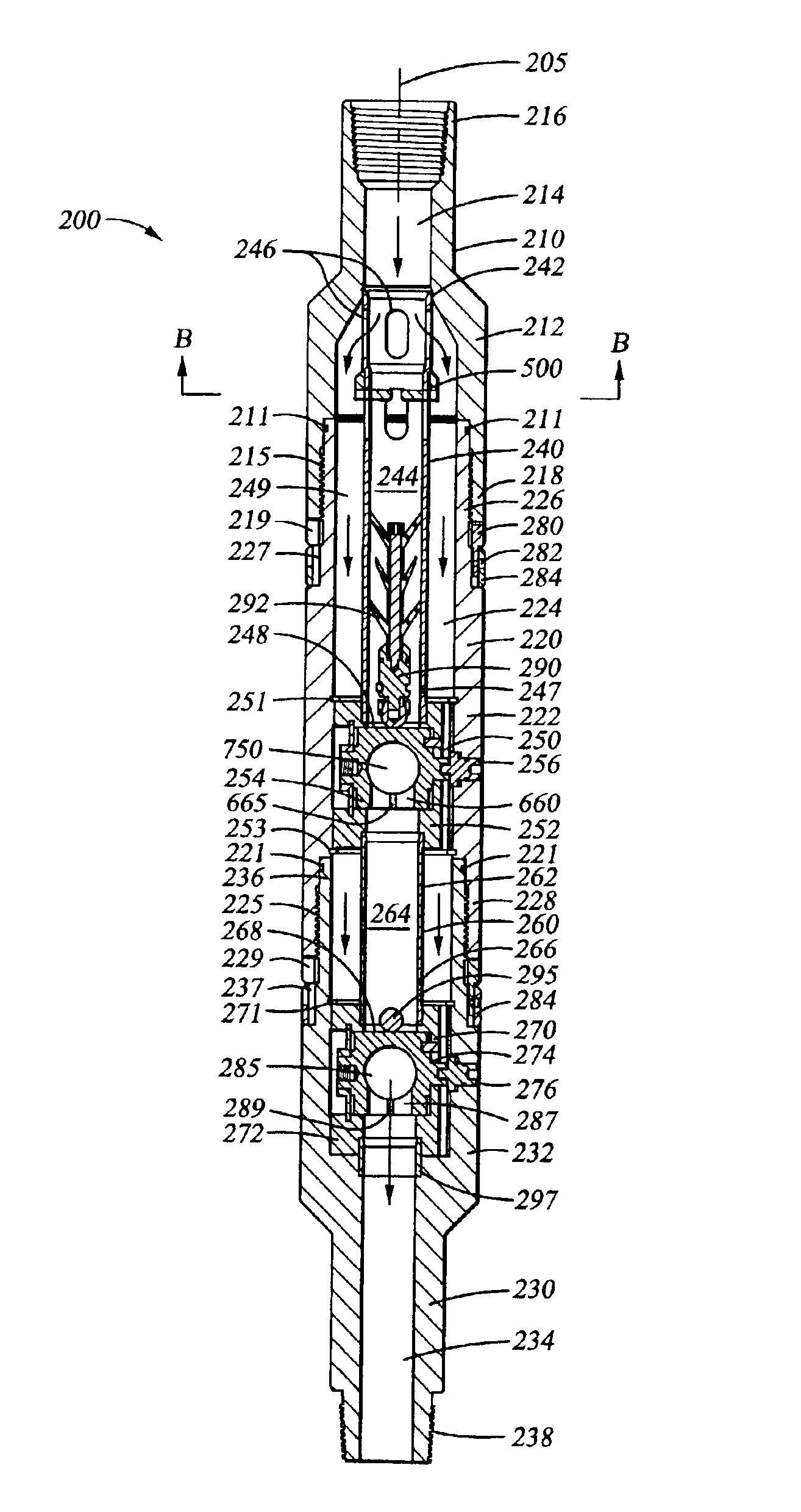

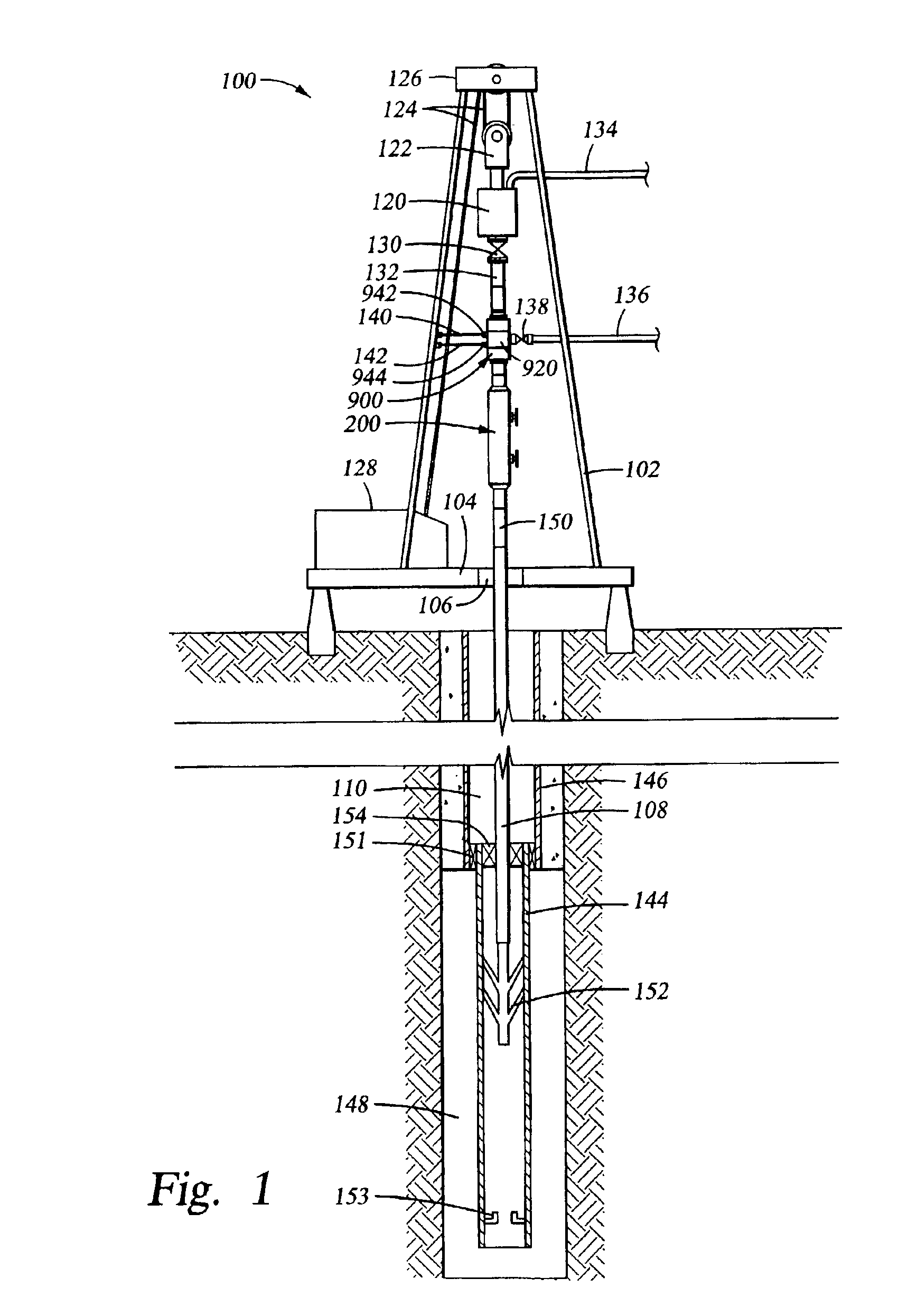

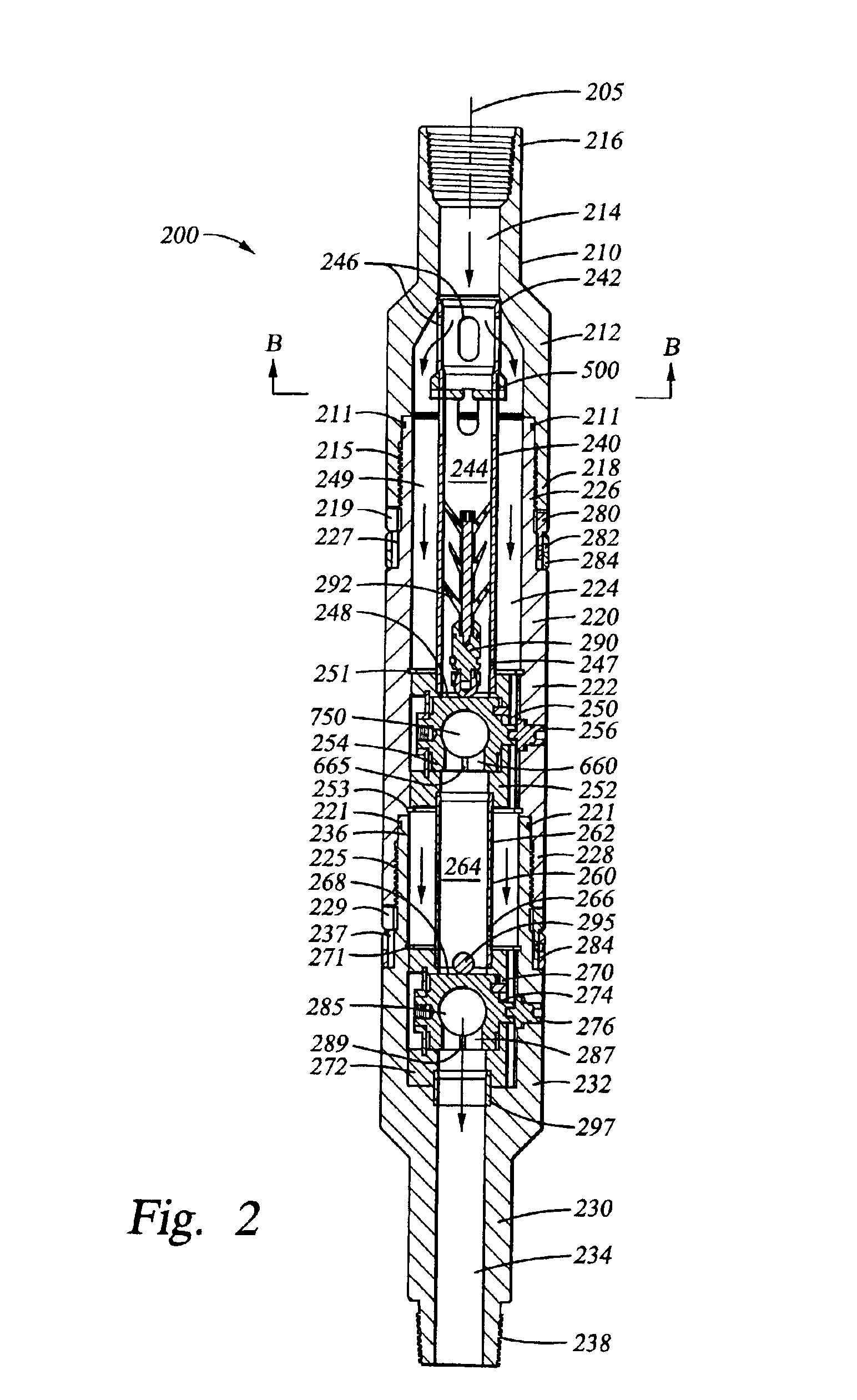

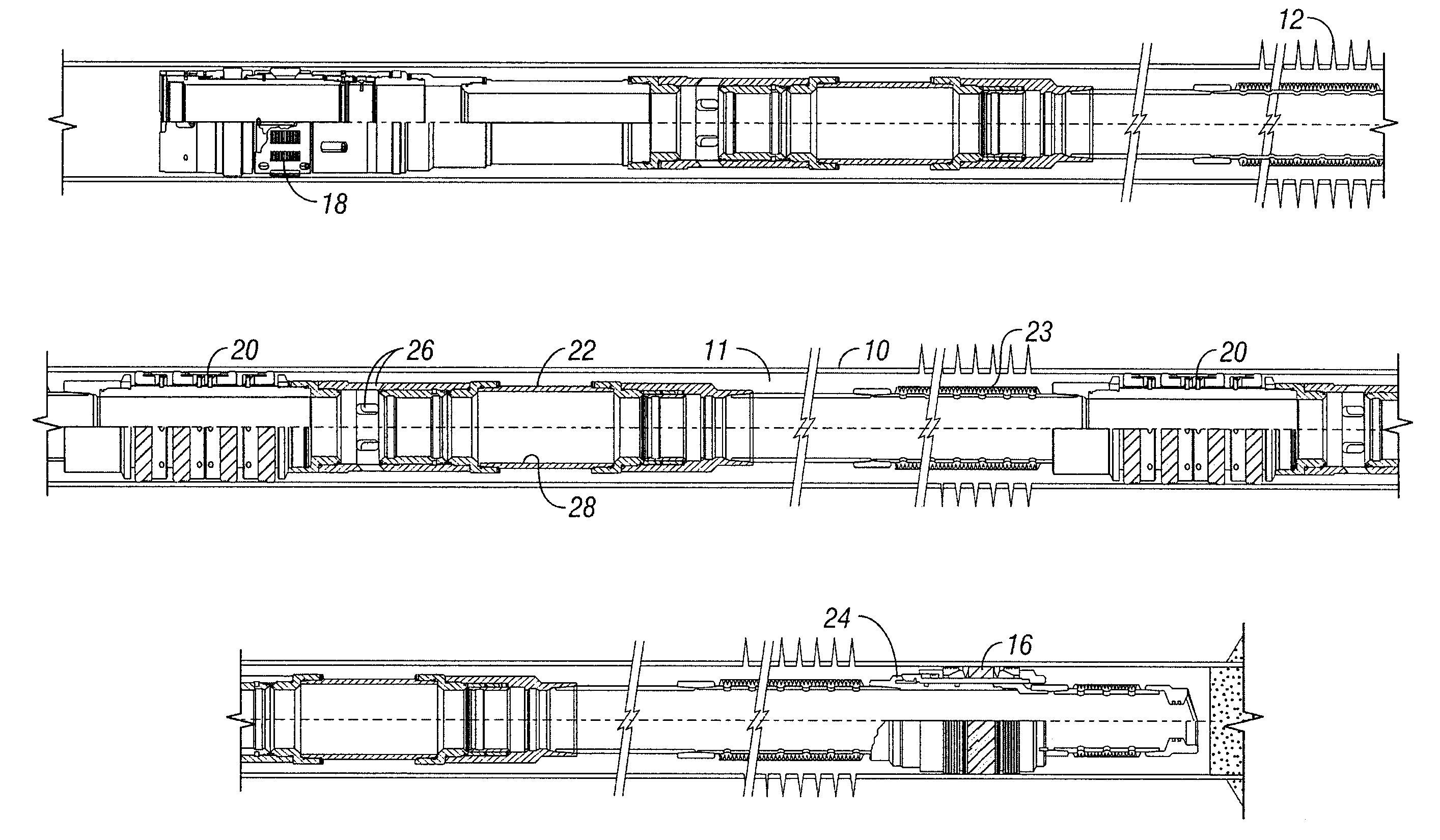

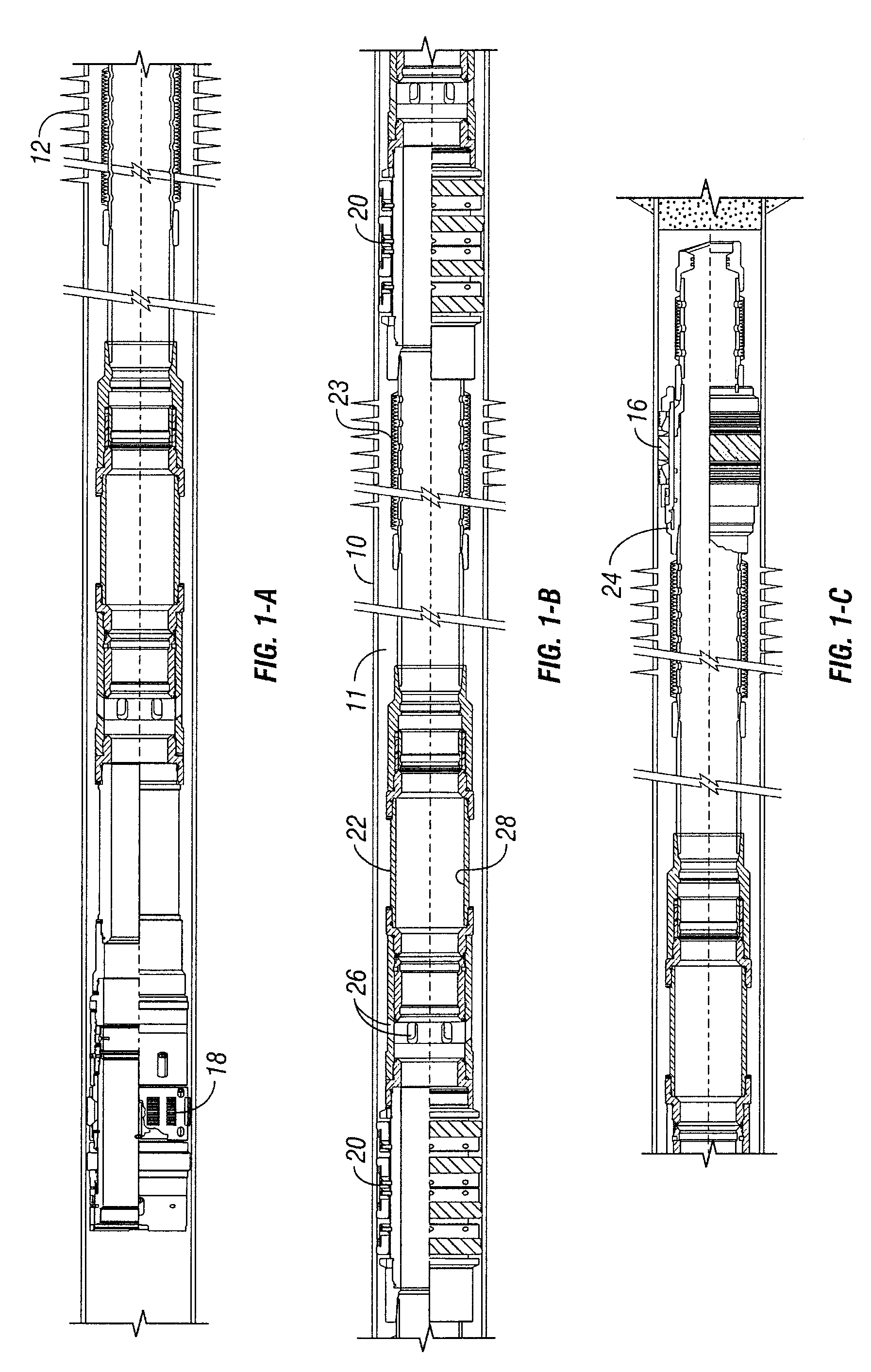

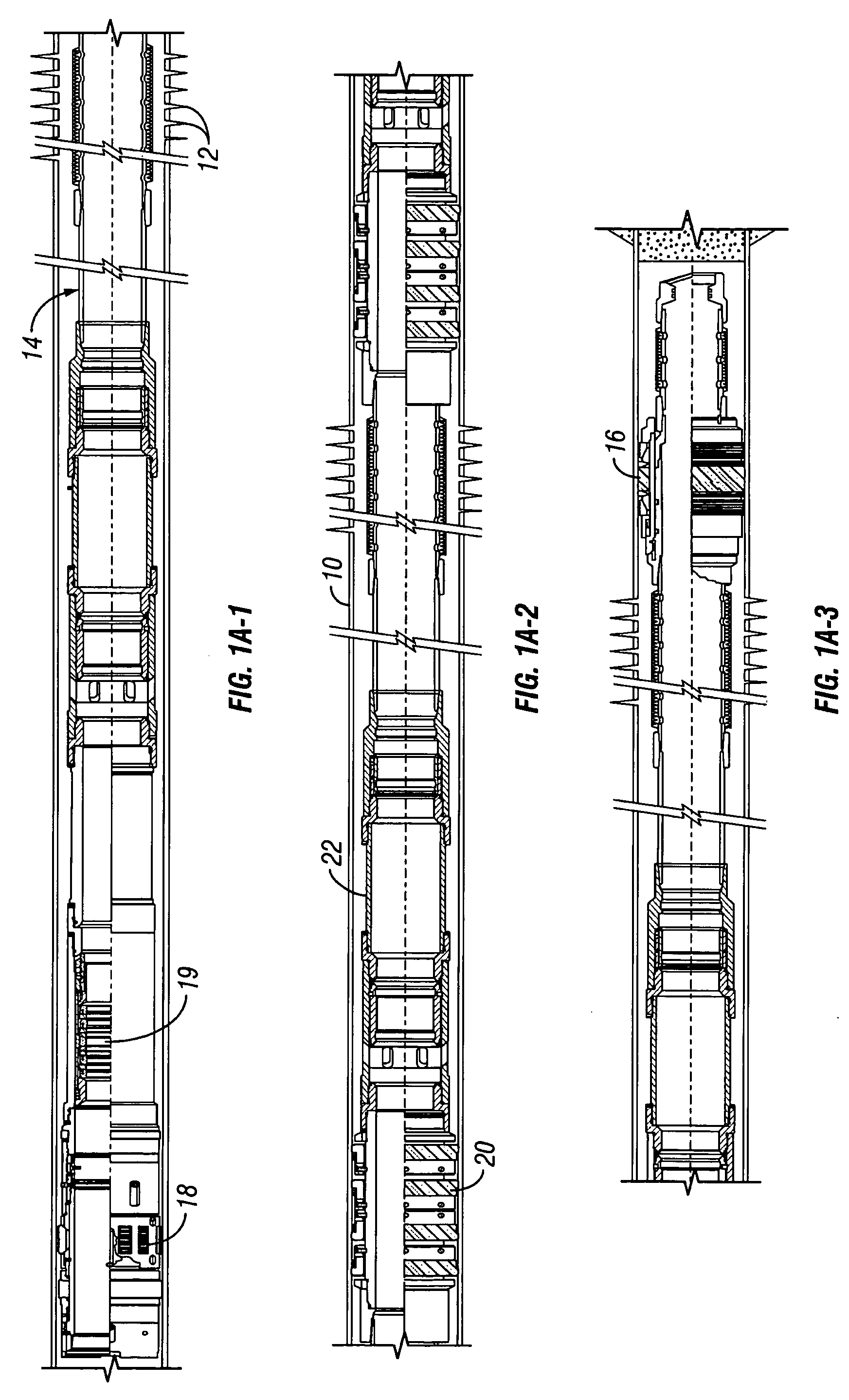

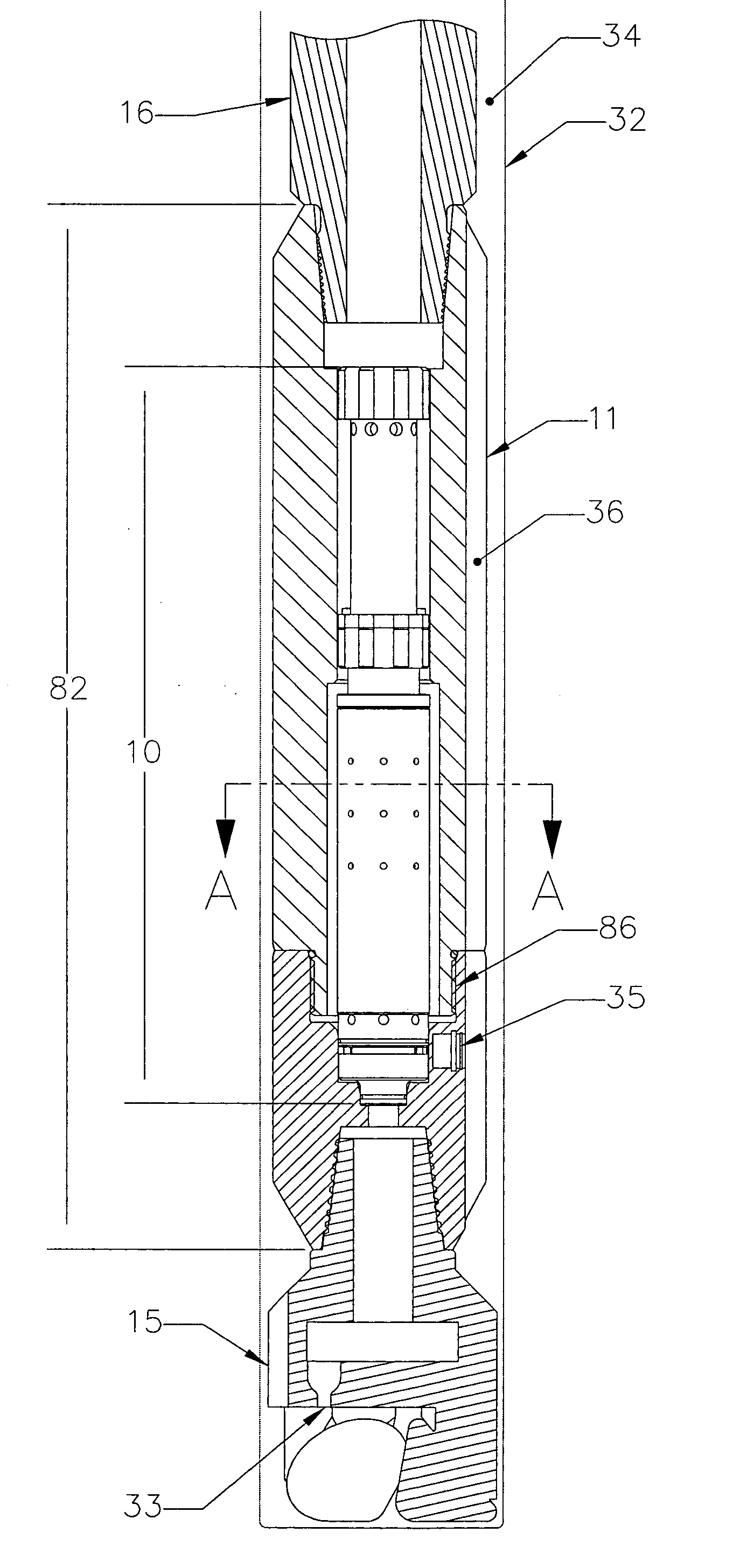

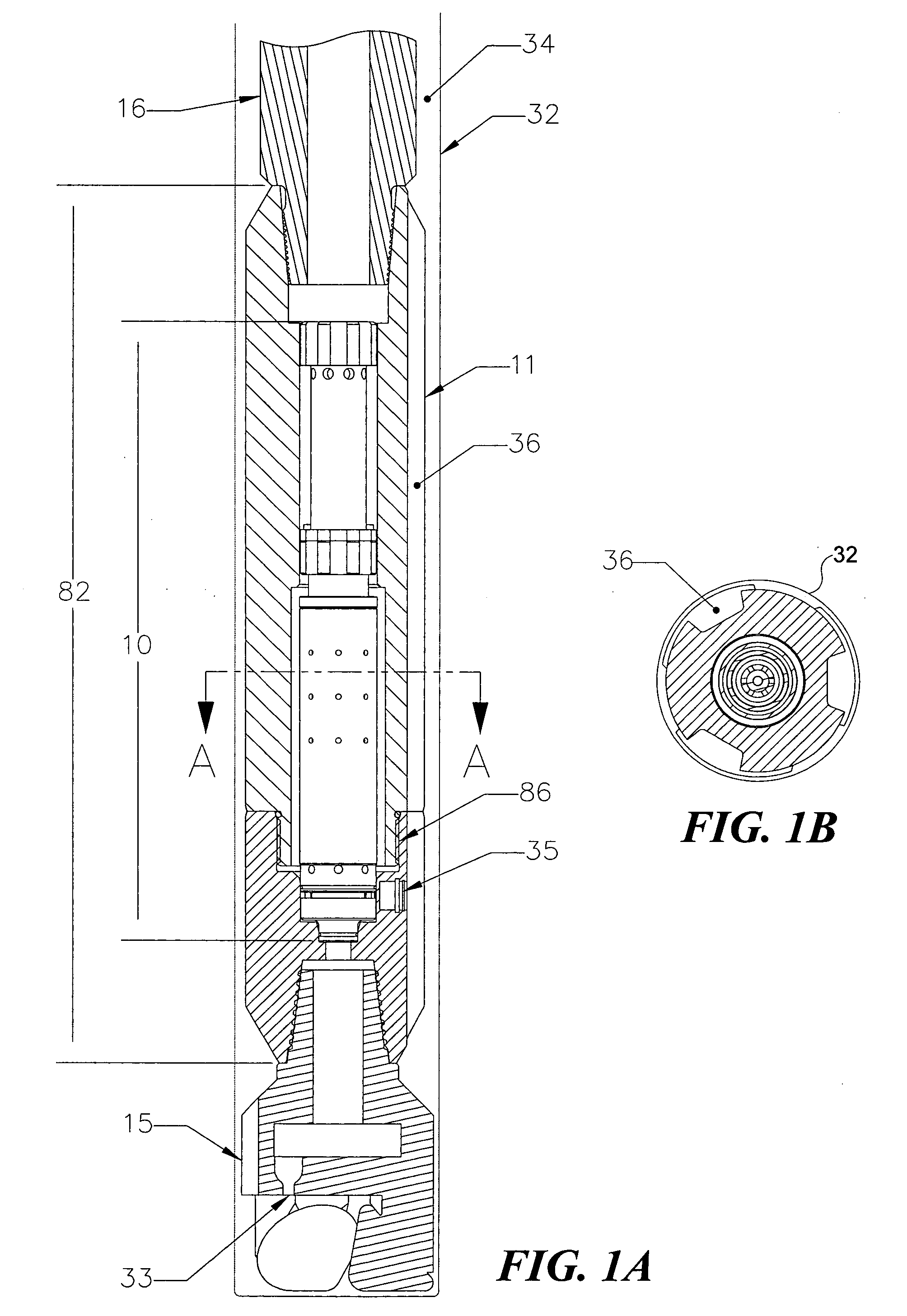

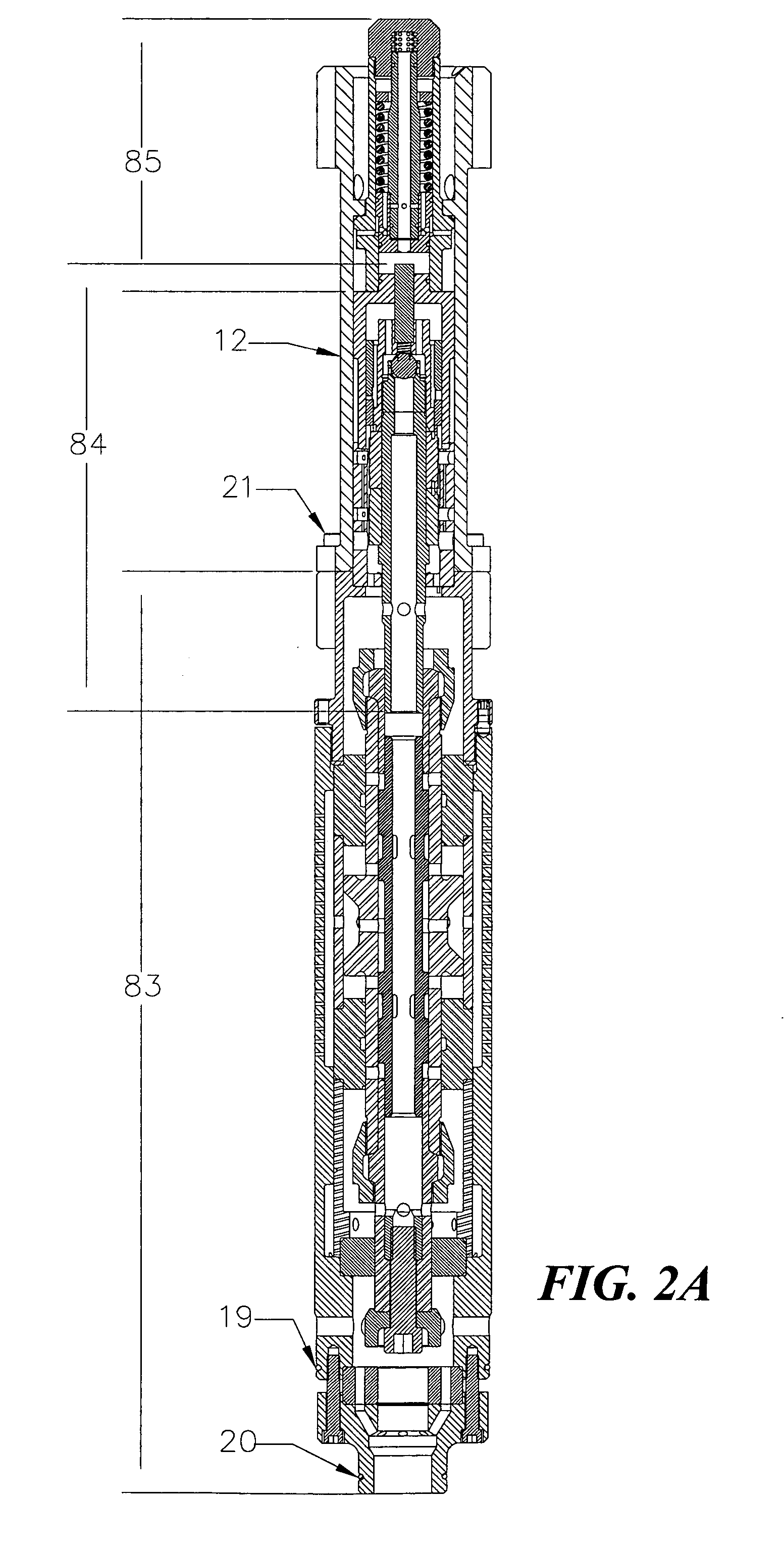

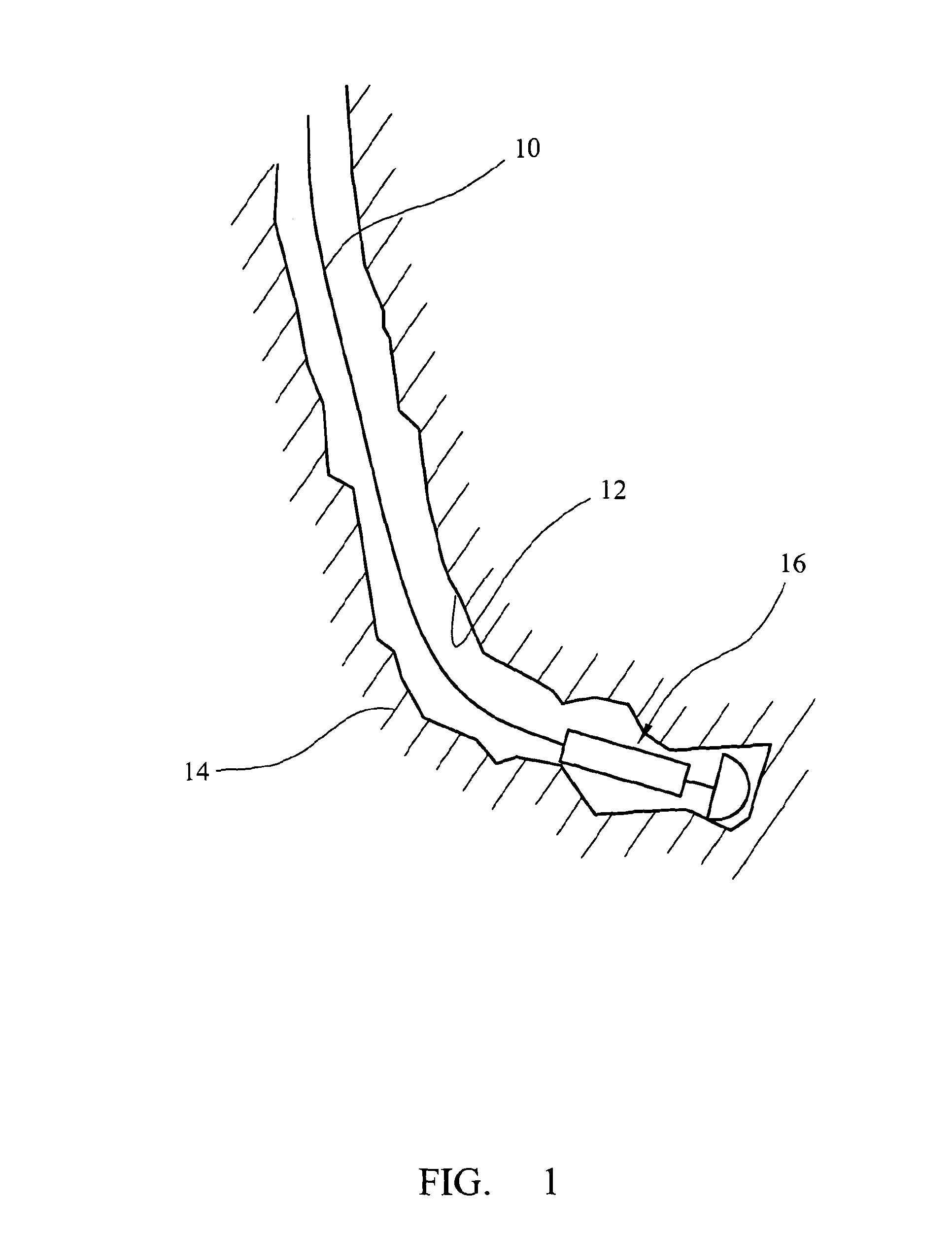

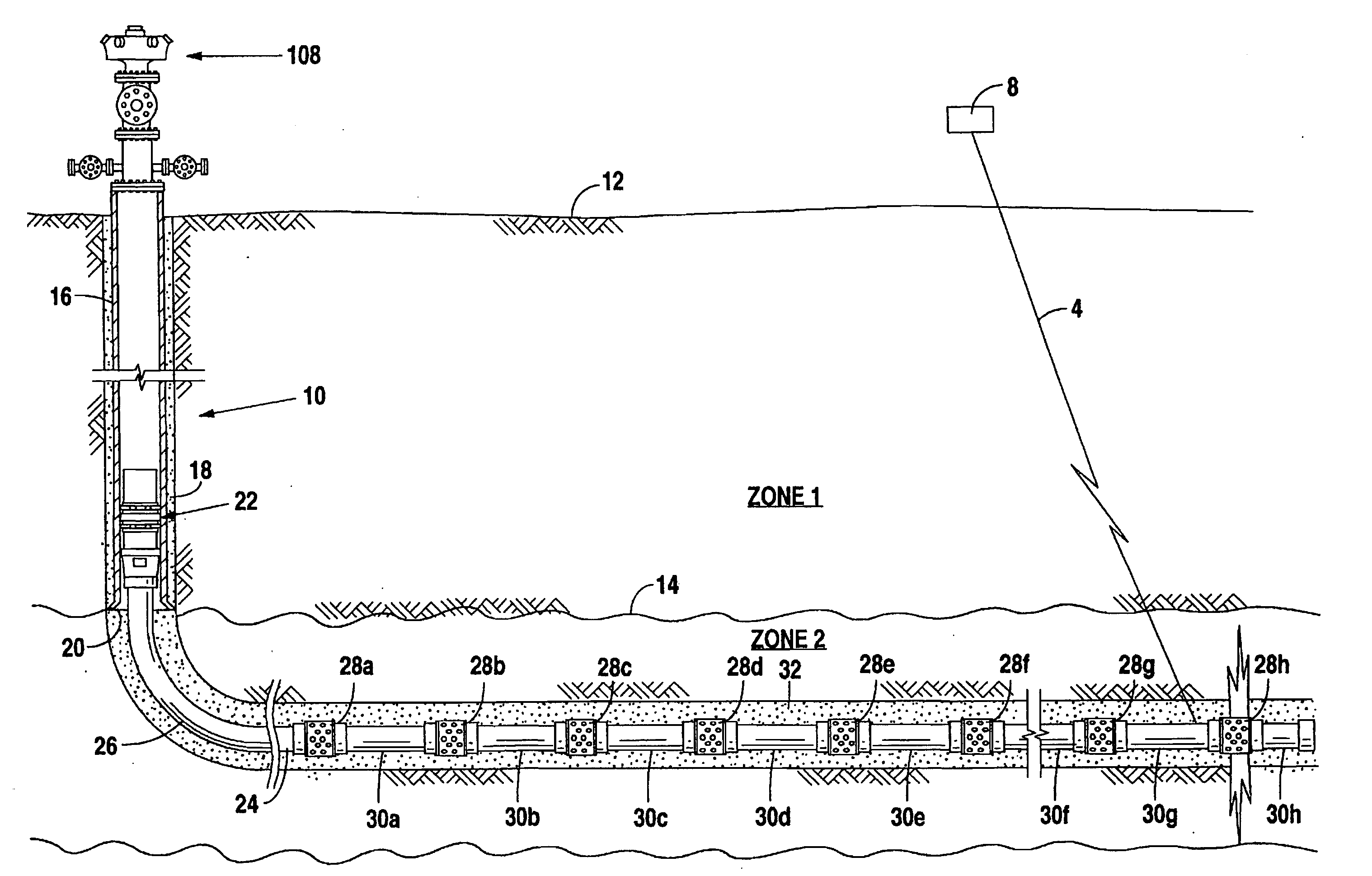

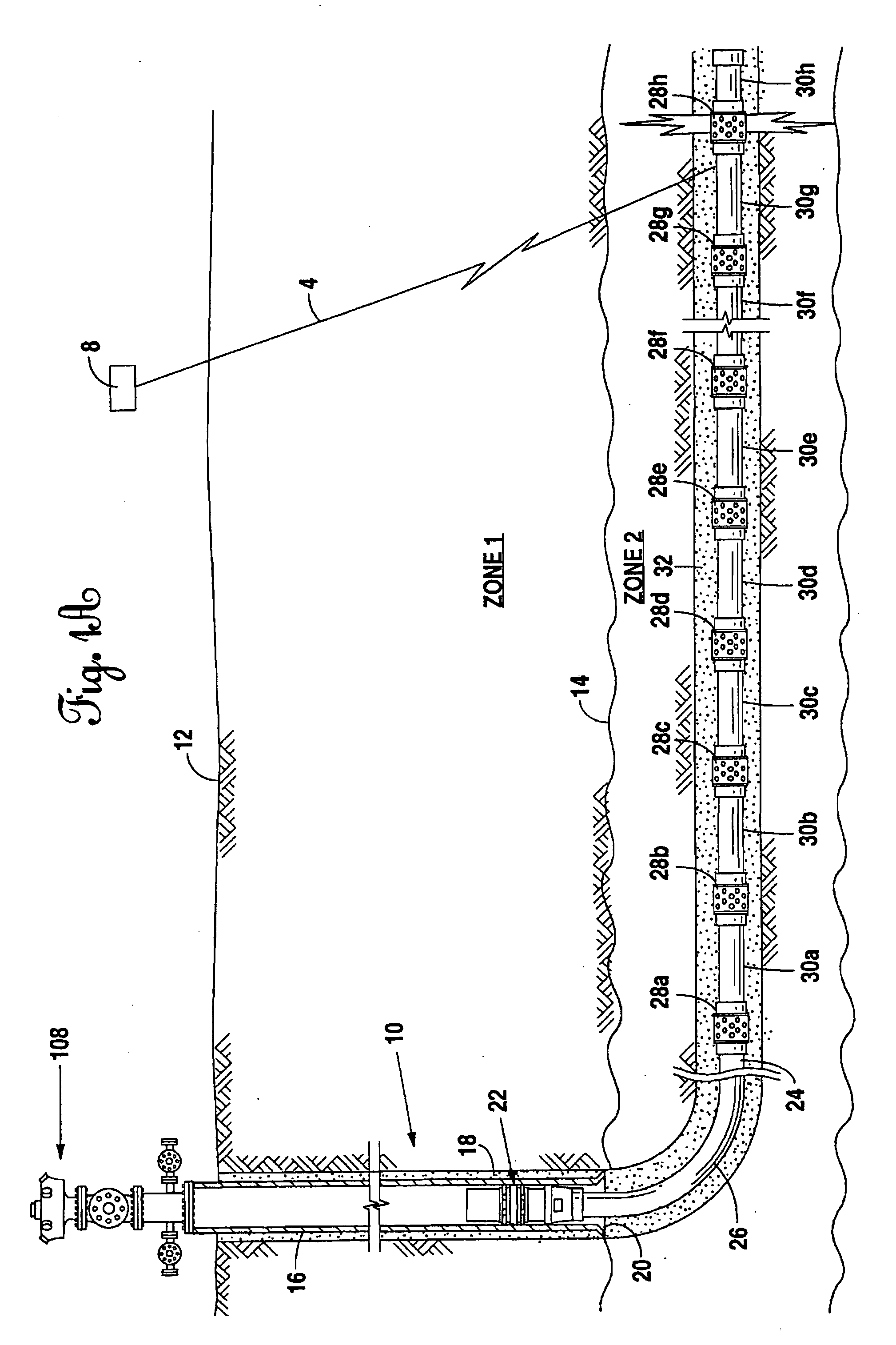

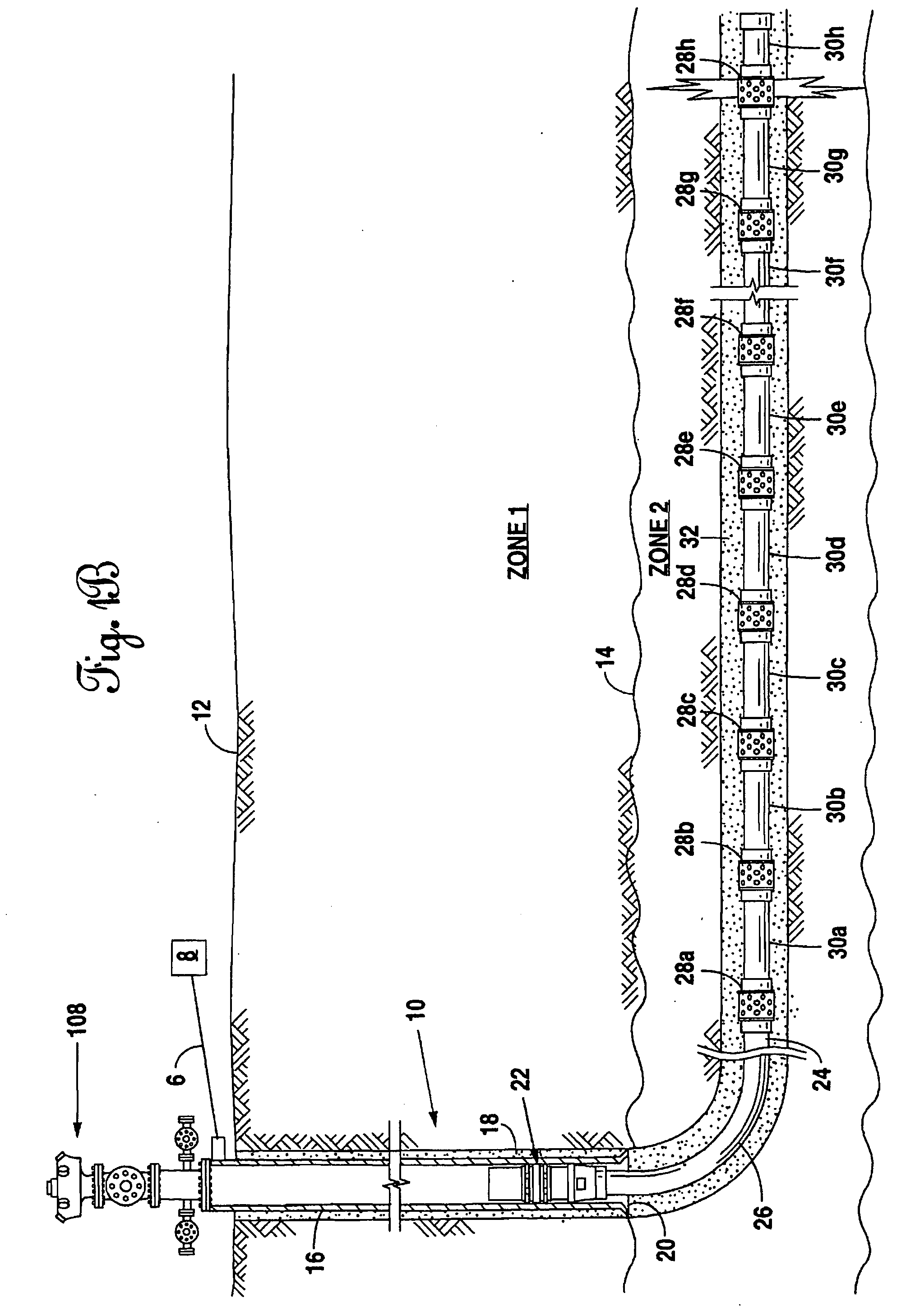

Method and apparatus for stimulation of multiple formation intervals

The invention discloses methods of, as well as apparatus and systems for, perforating and treating multiple intervals of one or more subterranean formations intersected by a wellbore by deploying within said wellbore a bottom-hole assembly (“BHA”) having a perforating device and a sealing mechanisms, wherein pressure communication is established between the portions of the wellbore above and below the sealing mechanism. The BHA is positioned within the wellbore such that the sealing mechanism, when actuated, establishes a hydraulic seal in the wellbore to positively force fluid to enter the perforations corresponding to the interval to be treated. A treating fluid is pumped down the wellbore and into the perforations created in the perforated interval. The sealing mechanism is released, and the steps are repeated for as many intervals as desired, without having to remove the BHA from said wellbore.

Owner:EXXONMOBIL UPSTREAM RES CO

Cementing manifold assembly

InactiveUS6904970B2Erosion minimizationFluid removalVibration devicesWell cementingMechanical engineering

A cementing manifold is disclosed that preferably includes: modular housings that can be stacked together and interconnected to add multi-dart or multi-sphere capability; identical, interchangeable valves; internal bypass capability; a minimum number of protrusions into the pressure containing components; and no externally mounted welded or threaded components.A cementing swivel is also disclosed that preferably includes connections that are formed integrally to the housing, redundant cement connections, angled cement ports, and seal assemblies that do not require individual placement of each seal.

Owner:SMITH INT INC

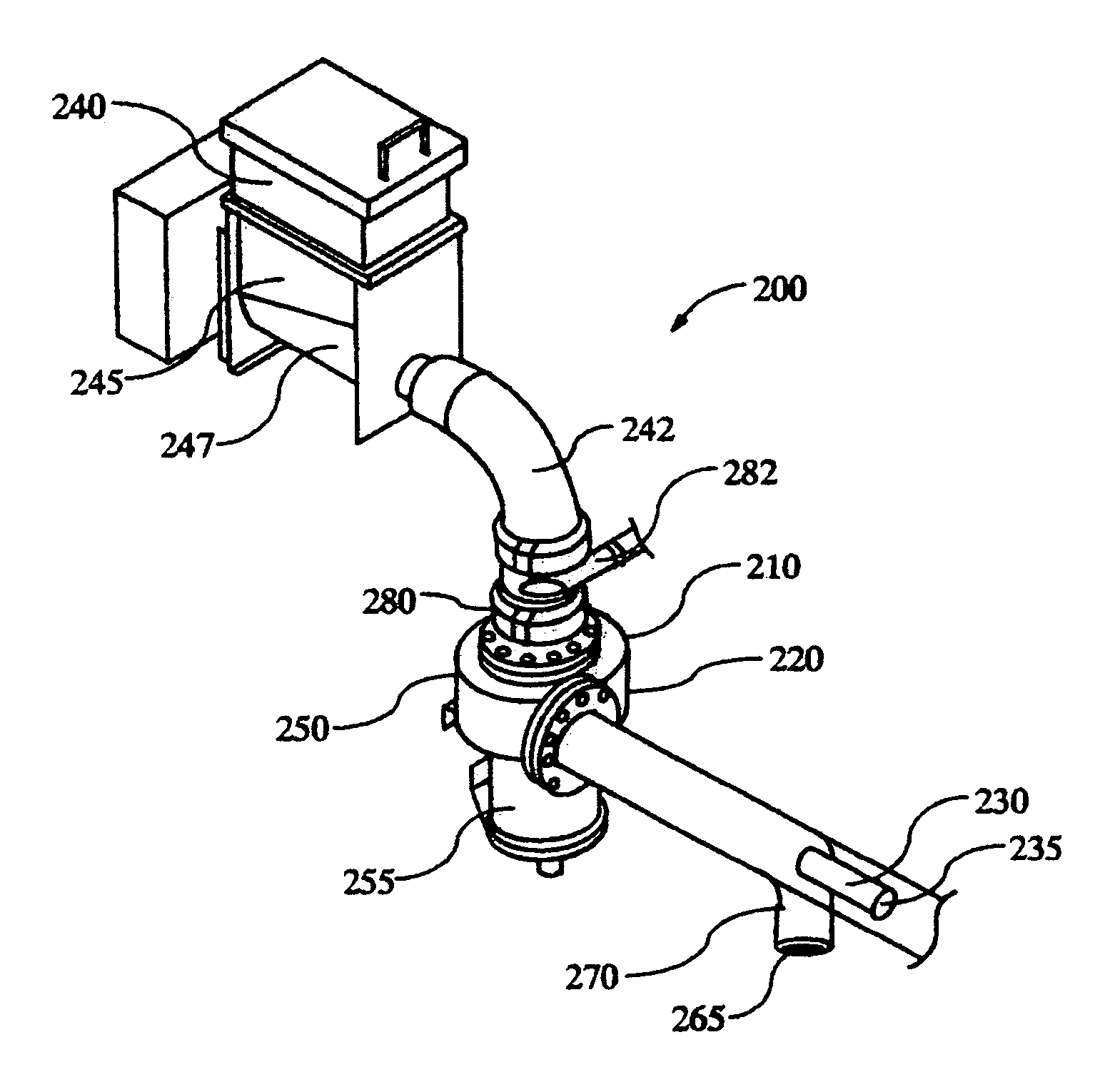

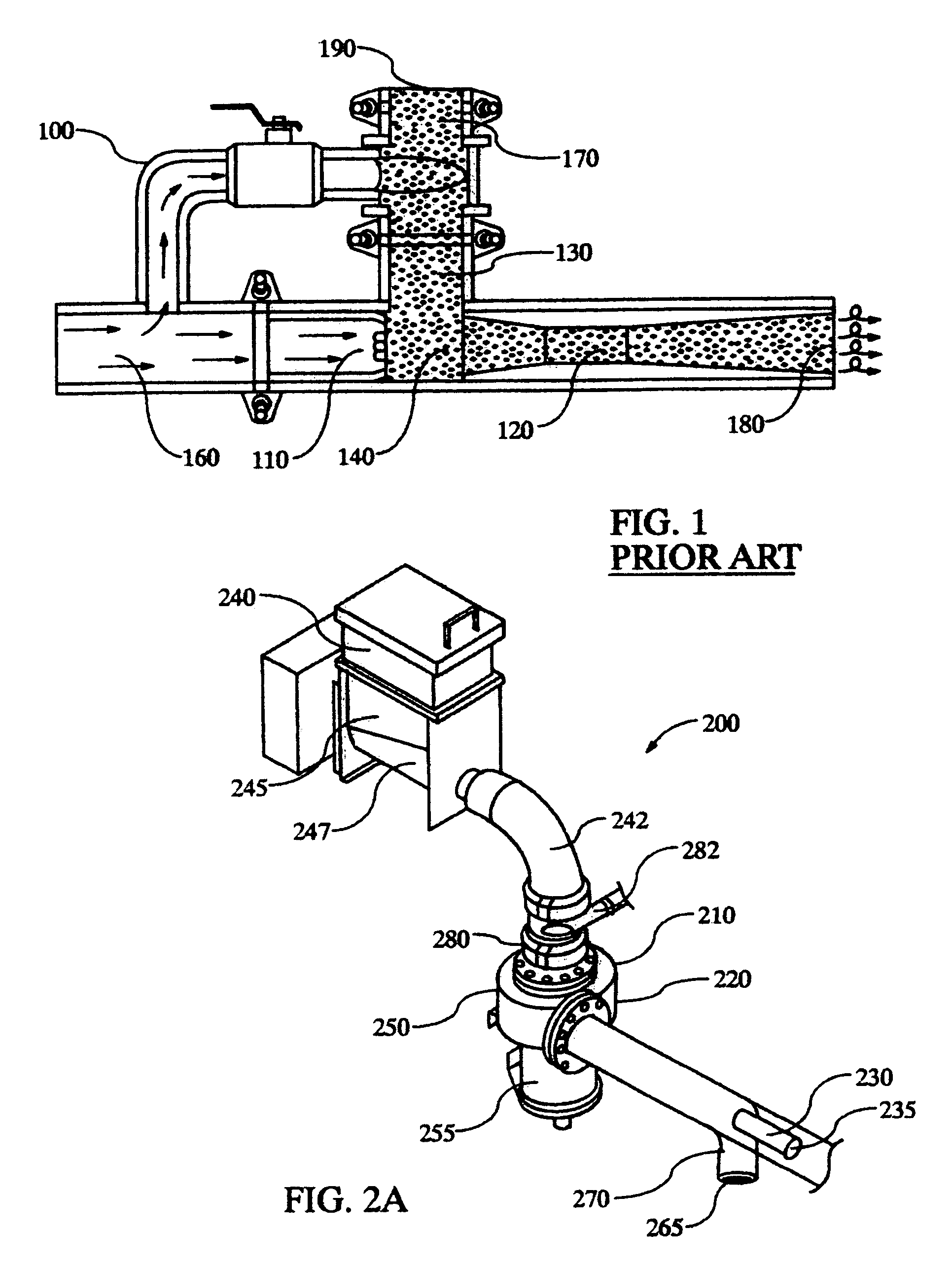

Method and apparatus for hydrating a gel for use in a subterranean formation

The present invention relates to a method and system for hydrating a gel for treating a wellbore penetrating a subterranean formation. The method includes directing a base fluid through an inlet into a mixer having an inner chamber housing a plurality of impellers extending radially from and rotating about a hub, causing a centrifugal motion of the base fluid, feeding a quantity of gel into the mixer, mixing the gel with the base fluid and discharging the now-hydrated gel from the inner chamber through an outlet of the mixer. A prewetting device may also be used. Thereafter, a variety of additives may be added to the gel fluid mix to form a fluid treatment to be introduced into a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

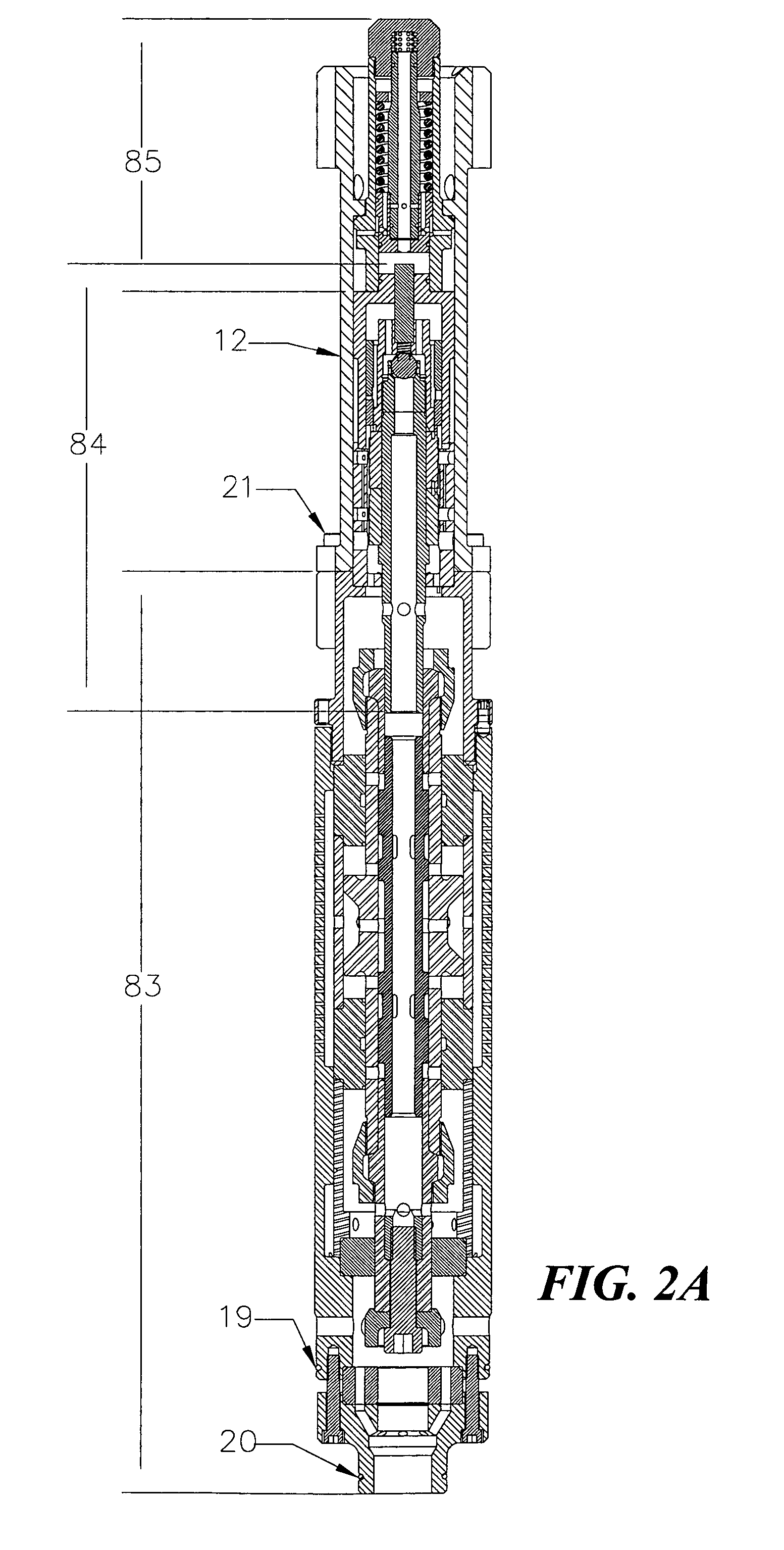

Method and apparatus for treating a subterranean formation

InactiveUS7066264B2Precise positioningMaintain positionFluid removalVibration devicesSleeve valveEngineering

A service / completion liner having a plurality of downhole selectable indicating tools and being used in sand control (gravel pack) placement systems in conjunction with a straddle packer service tools or with conventional crossover type service tools. Each indicating collar has a downhole selectable indicating collar providing a robust, landing profile for precisely locating and maintaining service tool position during well treatment operations. The landing collars accommodate hydraulic and / or thermal effects commonly referred to as tubing move effects which are the principle cause of tool position error and excessive seal wear. The landing collar is downhole convertible between a pass through (Go) and non pass through (No-go) condition by simple upward and downward cycling via the tool running and treatment fluid tubing and a shifting tool, which may also be referred to as a set down collet. The shifting / set down collet is also used to open and close a downhole sliding sleeve valve and may be an integral part of an injection tool or a tool for gravel or fracture packing. A sliding sleeve valve design and a straddle packer configuration that protects the primary PBRs in the gravel pack system and also protects the sliding sleeve while sand is placed in the screen casing annulus.

Owner:SCHLUMBERGER TECH CORP

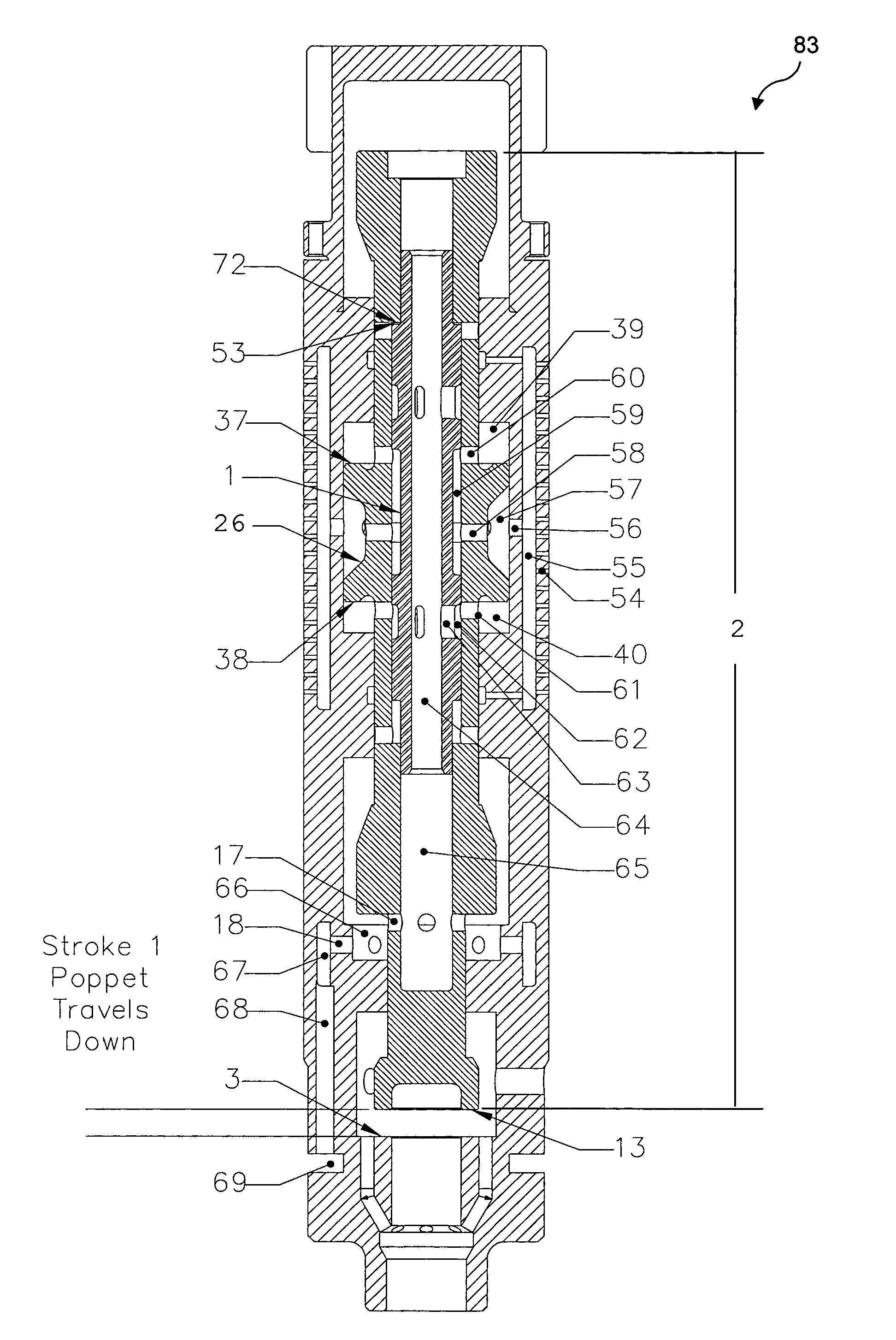

Hydraulic impulse generator and frequency sweep mechanism for borehole applications

ActiveUS20050178558A1Travel can be limitedEliminate water hammer effectSurveyOperating means/releasing devices for valvesGeophoneSeismic velocity

This invention discloses a valve that generates a hydraulic negative pressure pulse and a frequency modulator for the creation of a powerful, broadband swept impulse seismic signal at the drill bit during drilling operations. The signal can be received at monitoring points on the surface or underground locations using geophones. The time required for the seismic signal to travel from the source to the receiver directly and via reflections is used to calculate seismic velocity and other formation properties near the source and between the source and receiver. This information can be used for vertical seismic profiling of formations drilled, to check the location of the bit, or to detect the presence of abnormal pore pressure ahead of the bit. The hydraulic negative pressure pulse can also be used to enhance drilling and production of wells.

Owner:WELLS FARGO BANK NAT ASSOC +1

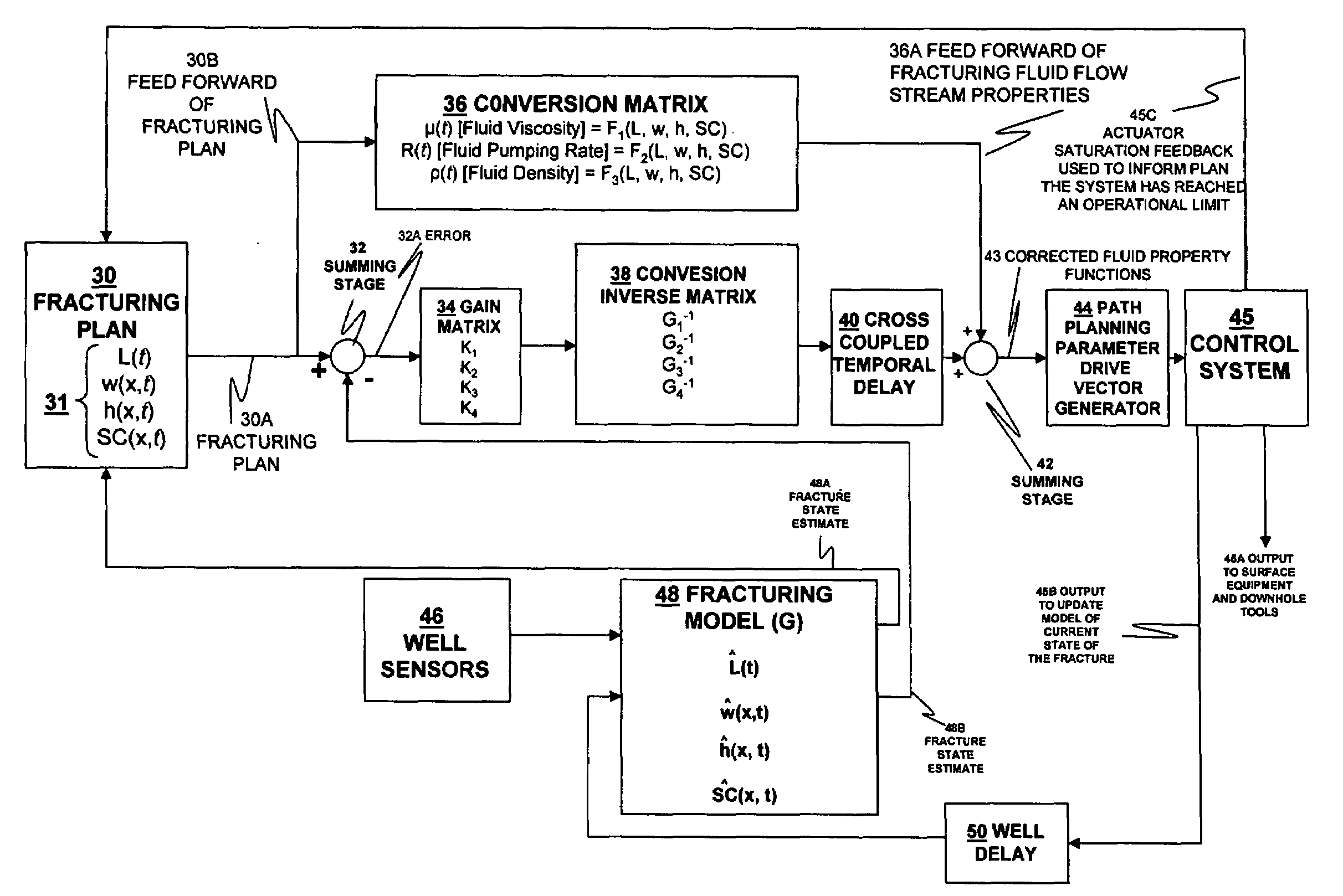

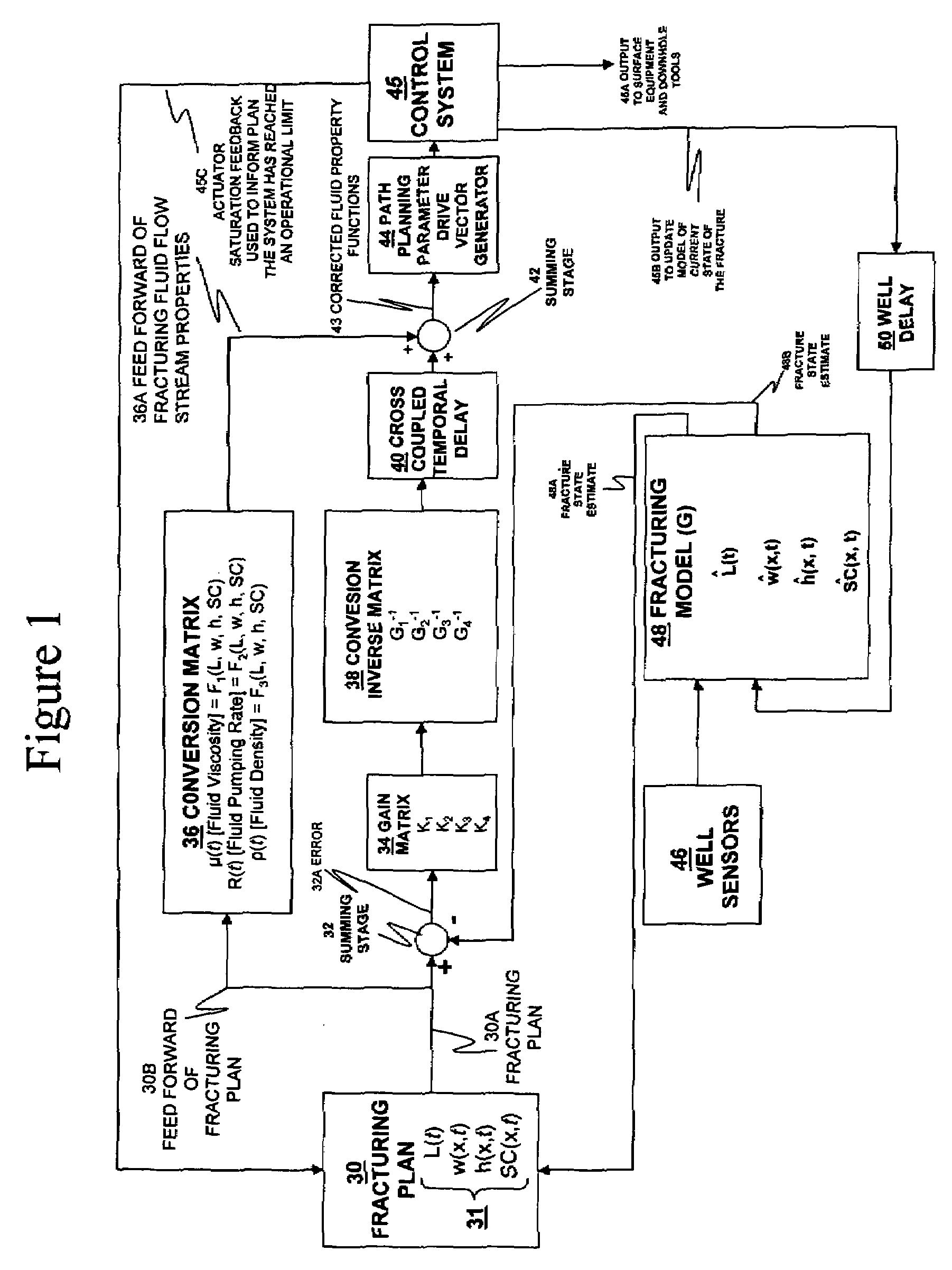

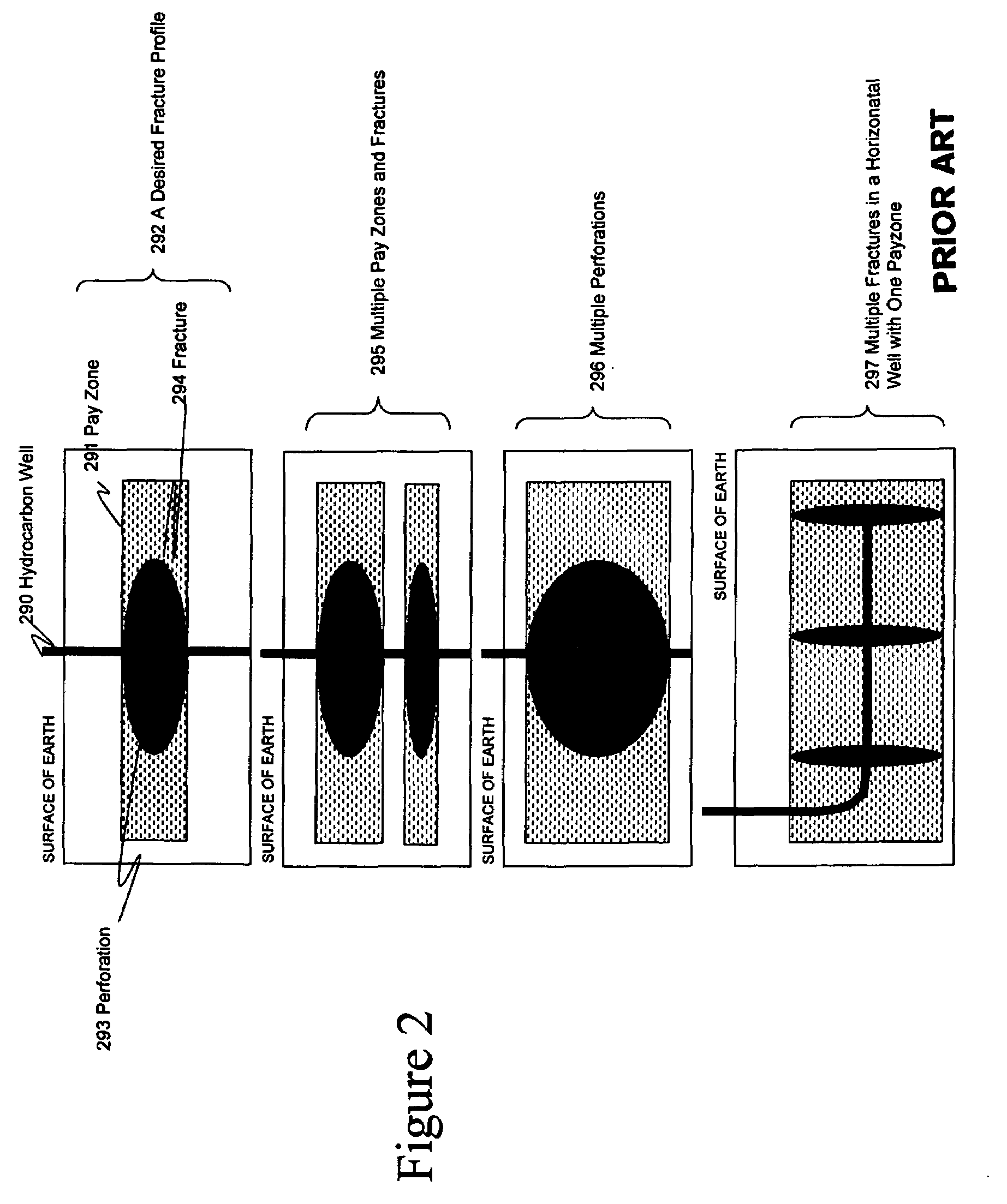

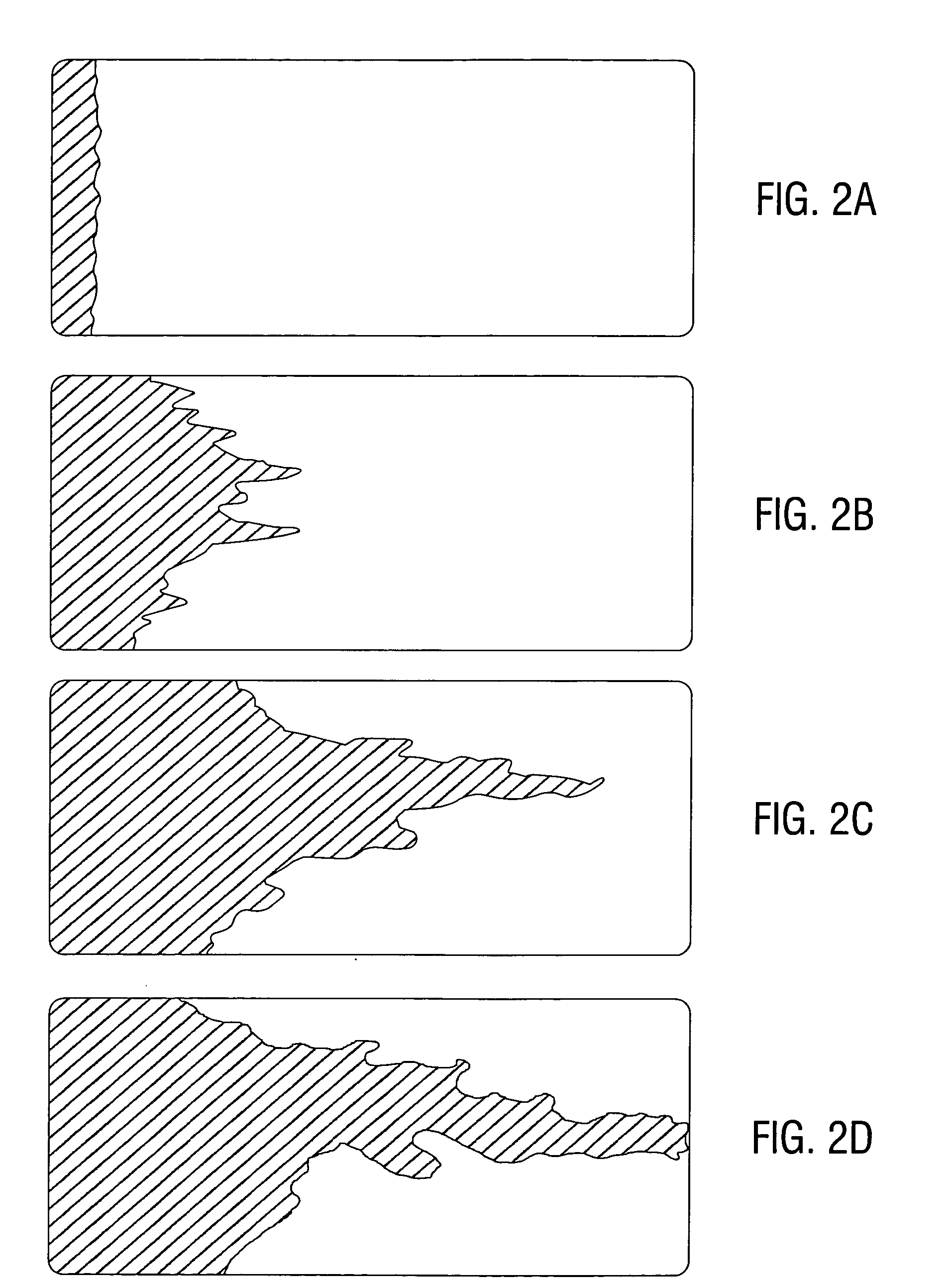

Methods and systems for fracturing subterranean wells

ActiveUS20080164021A1Reduce riskImprove permeabilitySurveyFluid removalControl flowAutomatic control

New methods and systems for subterranean fracturing for hydrocarbon wells. A plan of the fracture propagation and in-fracture proppant distribution is used with a real-time model of the status of the fracture dimensions and in-fracture proppant concentration to automatically control flow rates and properties of a fracturing fluid flow stream being used to induce and prop the fracture. Real-time measurements of the status of the fracture are made using surface and / or down-hole sensors. Real-time control over the flow rate and properties of a fracturing fluid flow stream are made by manipulating the fracturing fluid supply equipment. Real-time modifications of the fracturing model are made by comparing fracture sensor measurements of actual fracture dimensions to the predicted dimensions, and then adjusting the model for inaccuracies. Real-time updates to the fracturing plan are made by comparing actual fracture and propping results to desired results, and then adjusting to achieve optimal results.

Owner:HALLIBURTON ENERGY SERVICES INC

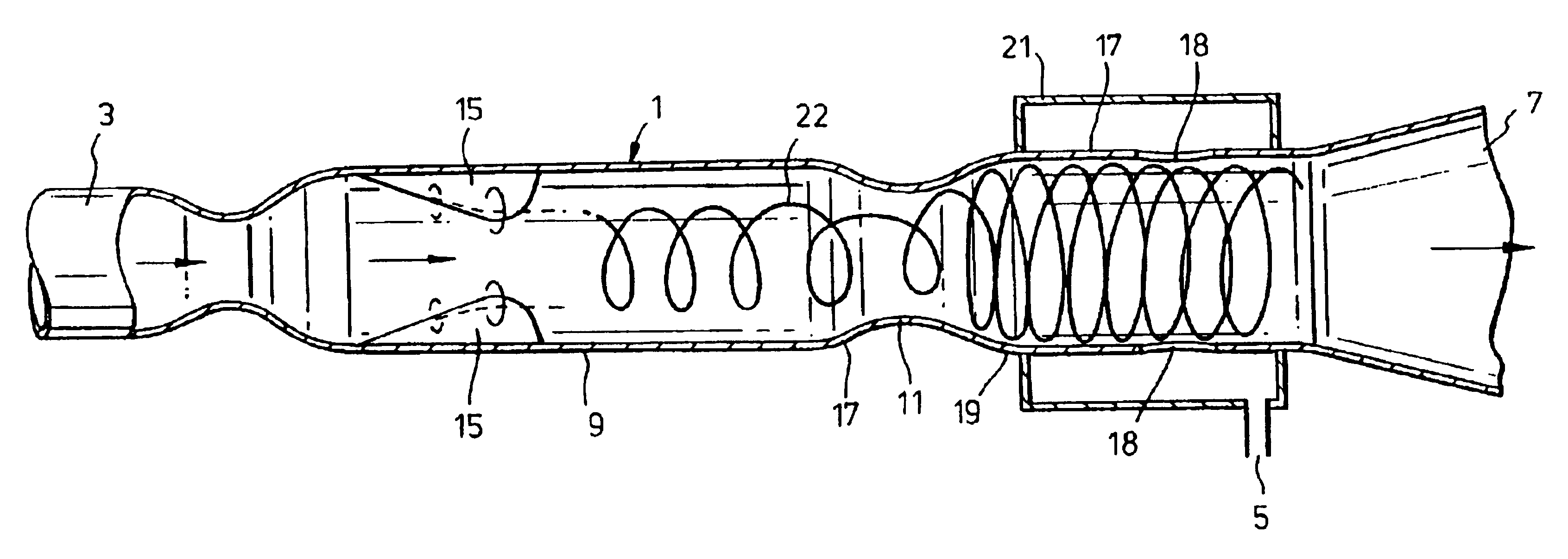

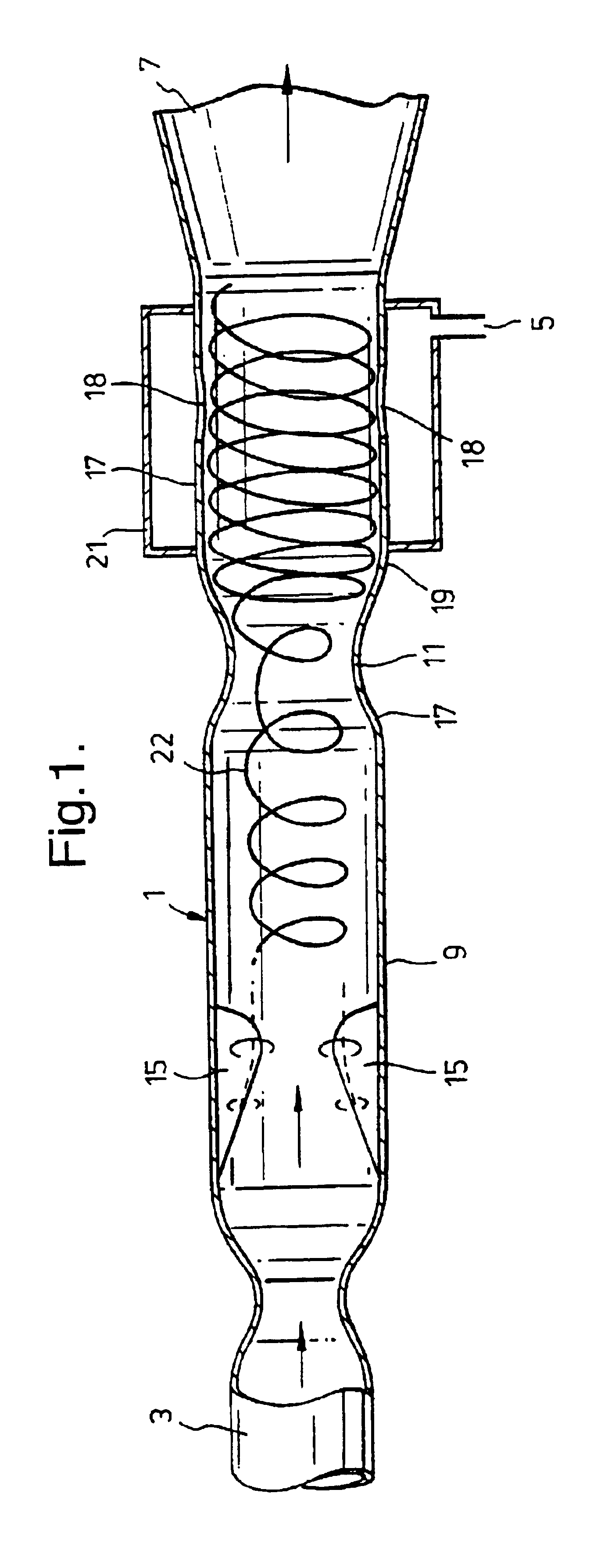

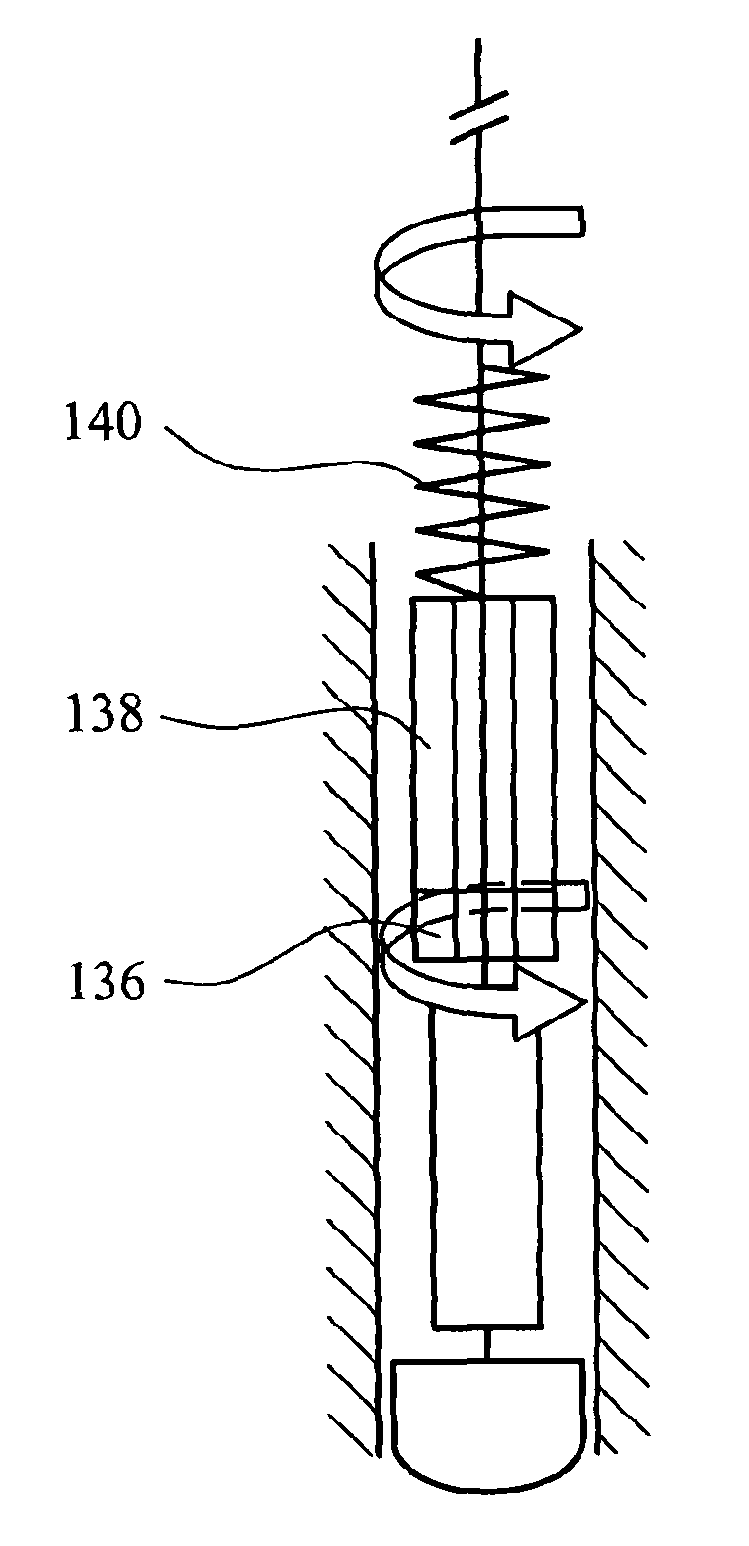

Hydro-oscillator for well drilling

InactiveCN102704842AIncrease frictional resistanceIncrease drilling speedVibration devicesVibration drillingWell drillingHarmonic vibration

The invention relates to a hydro-oscillator for well drilling. The hydro-oscillator consists of a hydraulic driving assembly, a fixed valve assembly, a bottom assembly and a vibrating pipe nipple, wherein the vibrating pipe nipple is connected with the hydraulic driving assembly; a rotor is connected with a vibrating valve; the fixed valve assembly is arranged on the bottom assembly; and a power shell is connected with the bottom assembly. A drilling fluid is used for driving the rotor to rotate, and the rotor is used for driving the vibrating valve to vibrate, so that flow holes of the vibrating valve and a fixed valve are staggered with each other, and simple harmonic pressure waves are modulated and are upwardly transmitted to a disc spring for driving the vibrating shell to perform continuous simple harmonic vibration in the axial direction, so that the friction resistance between a drilling column and a well wall is improved effectively, and the drilling speed is increased; and meanwhile, pressure waves are downwardly transmitted to drill bit jet flow, so that periodic change of rock breaking pressure is facilitated, and rocks are crushed effectively. The hydro-oscillator has the characteristics of simple structure, convenience for operating, safety, reliability, low pressure drop, high adaptability, no influence on the drilling tool structure and the like, and plays an important role in increasing the drilling speed and reducing cost.

Owner:CHINA PETROCHEMICAL CORP +1

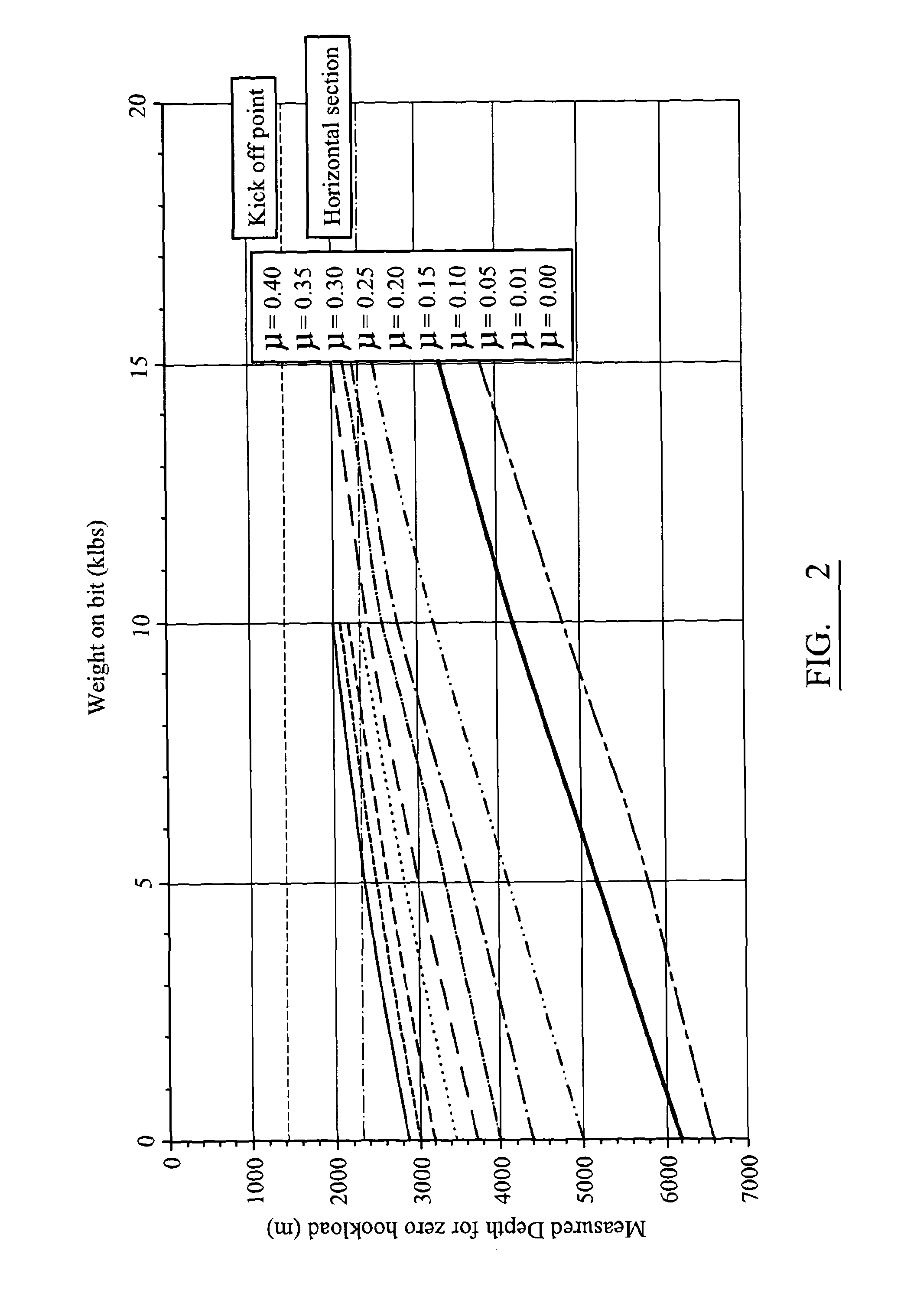

Method and apparatus for applying vibrations during borehole operations

A method of conducting borehole operations using a system including an elongate tubular conveyance that is moved through the borehole, the method comprising imposing a torsional vibration at a predetermined frequency on the tubular conveyance as it is moved through the borehole:wherein the predetermined frequency is obtained by determining the frequency-dependent mobility of the system based on the relationship between rotational velocity and torque for the system; and imposing torsional vibrations at a frequency where the relationship is optimised.

Owner:MISC

Methods and compositions for introducing conductive channels into a hydraulic fracturing treatment

InactiveUS7213651B2Affecting permeabilityAvoid flowFluid removalVibration devicesFracturing fluidVolumetric Mass Density

Owner:BAKER HUGHES INC

Remotely operated selective fracing system

InactiveUS20070204995A1Inhibit migrationOperating means/releasing devices for valvesConstructionsSupporting systemEngineering

A remotely-operated selective fracing system and valve. The valve comprises a casing with at least one casing hole; an inner sleeve nested within the casing and having at least one sleeve hole alignable with the at least one casing hole; actuator means engagable with the inner sleeve for moving the inner sleeve relative to the casing to selectively align the at least one sleeve hole with the at least one casing hole; and receiver means electrically connected to the actuator means and having a sensor for detecting a seismic or electromagnetic signal generated by a remote source. The system further includes source means for generating an acoustical signal receivable by the receiver means.

Owner:PEAK COMPLETION TECH

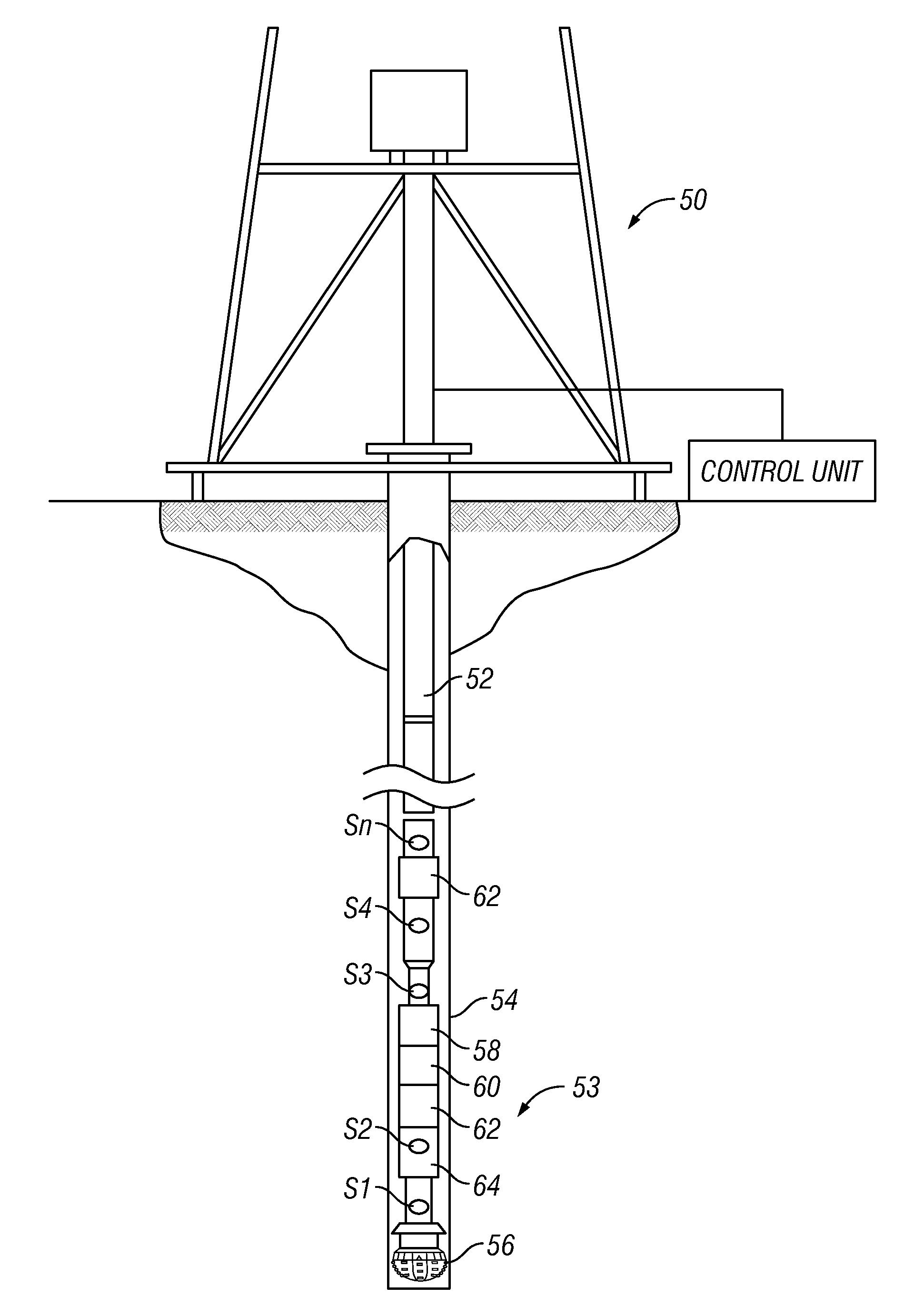

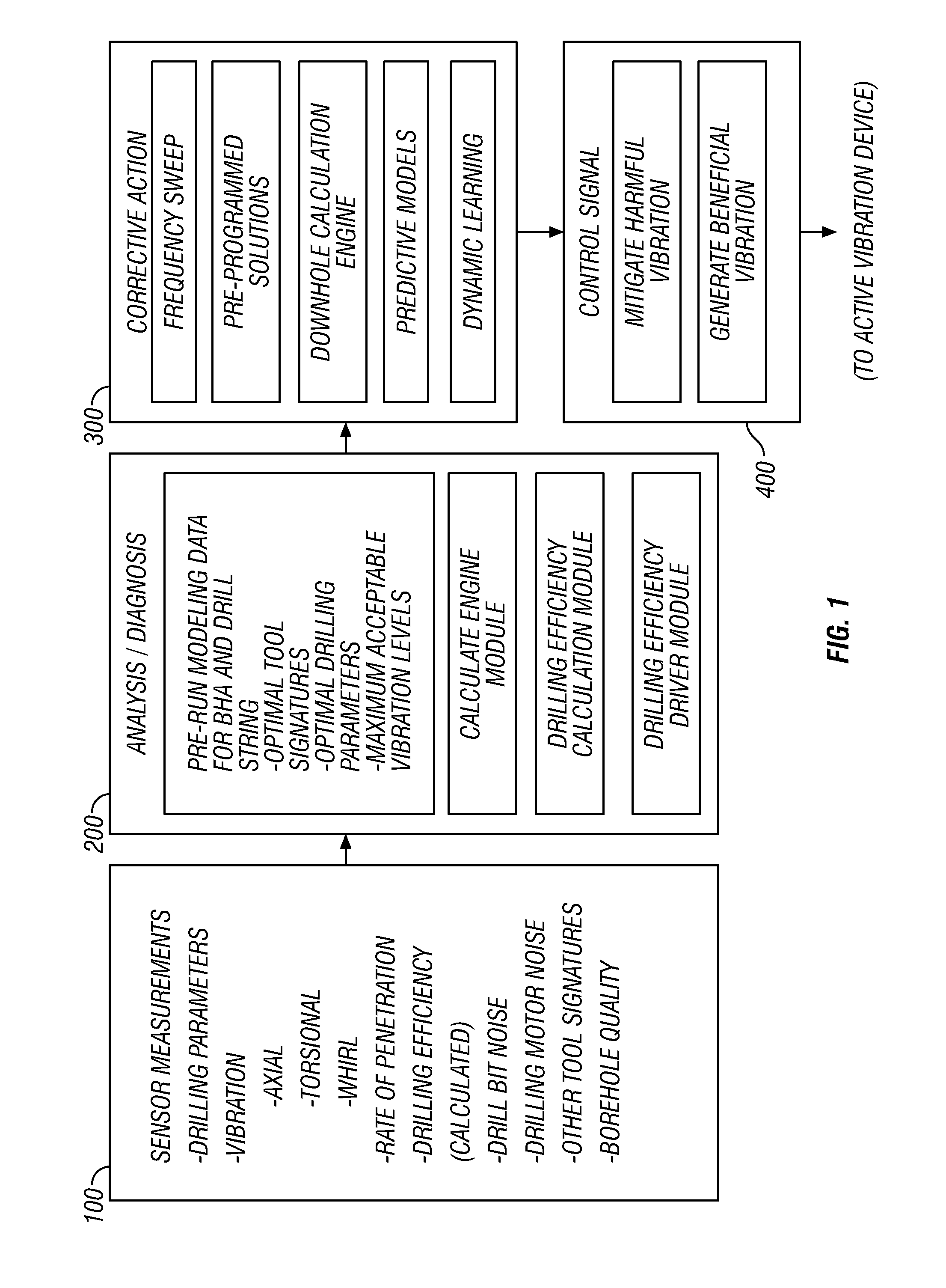

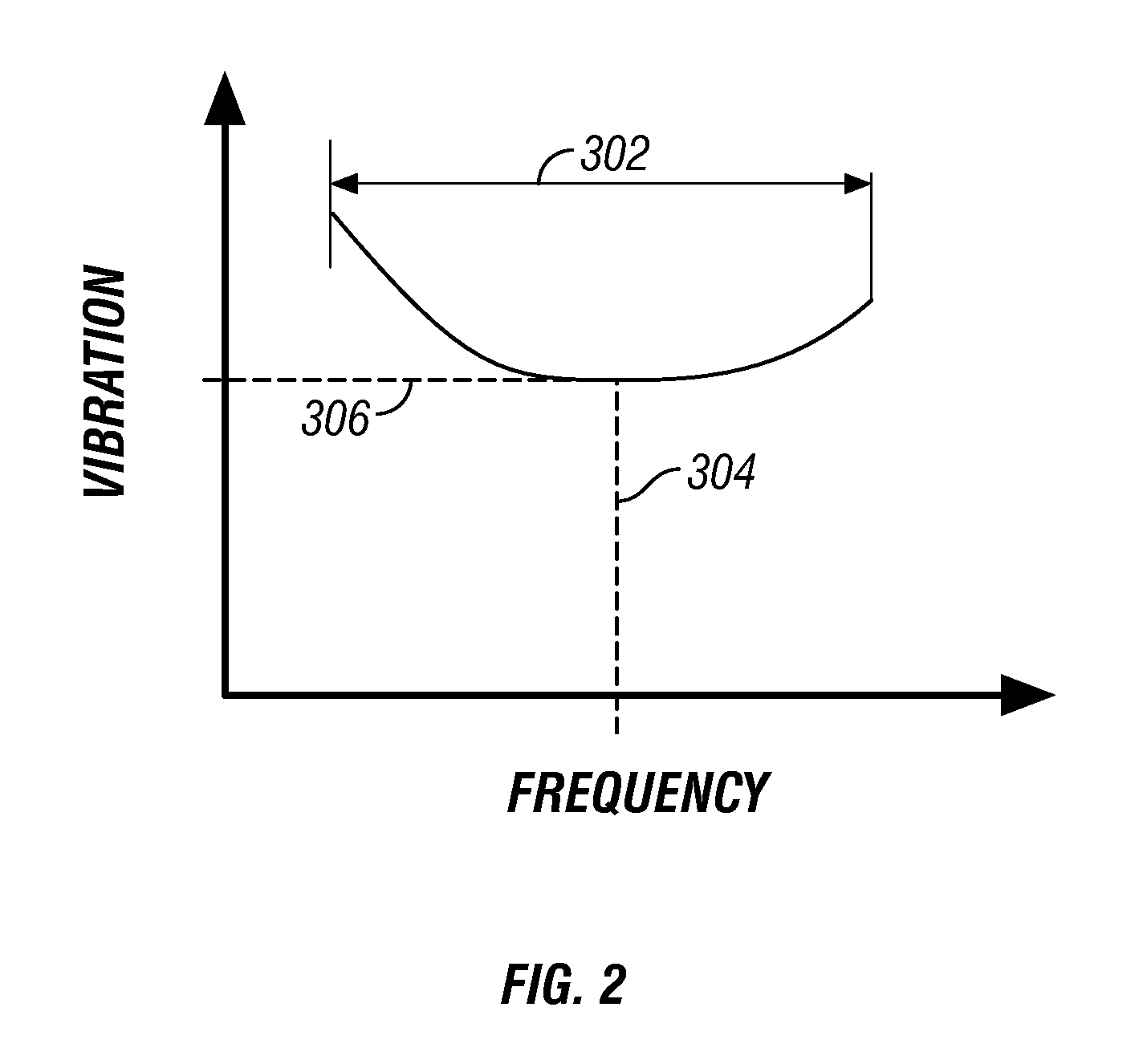

Active Vibration Control for Subterranean Drilling Operations

InactiveUS20100139977A1Prevent and minimize occurrenceImproves one and more aspectDirectional drillingVibration devicesControl signalWell drilling

An active vibration control device improves drilling by actively applying a dampening profile and / or a controlled vibration to a drill string and / or bottomhole assembly (BHA). Embodiments of the present invention control the behavior of a drill string and / or BHA in order to prevent or minimize the occurrence of harmful drill string / BHA motion and / or to apply a vibration to the drill string / BHA that improves one or more aspects of the drilling process. Measurements of one or more selected parameters of interest are processed to determine whether the undesirable vibration or motion is present in the drill string or BHA and / or whether the drill string and / or BHA operation can be improved by the application of a controlled vibration. If either or both conditions are detected, corrective action is formulated and appropriate control signals are transmitted to one or more devices in the drill string and / or BHA.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com