Active Vibration Control for Subterranean Drilling Operations

a technology of active vibration and drilling operations, applied in vibration drilling, directional drilling, borehole/well accessories, etc., can solve the problems of reducing the life of tools, and reducing the effectiveness of cutting action, so as to prevent or minimize the occurrence of harmful drill string/bha motion, improve one or more aspects of drilling process, and improve the effect of drilling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

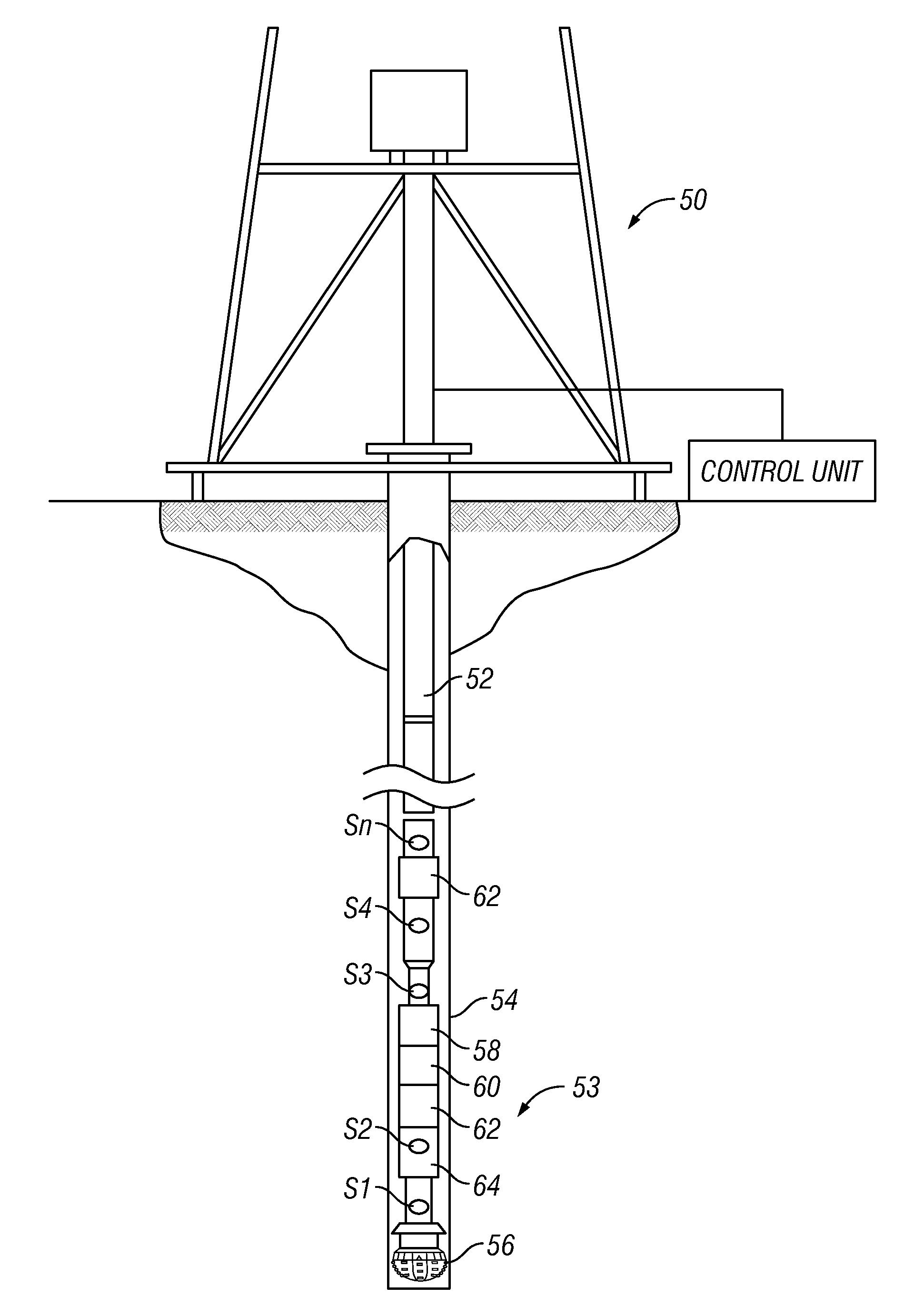

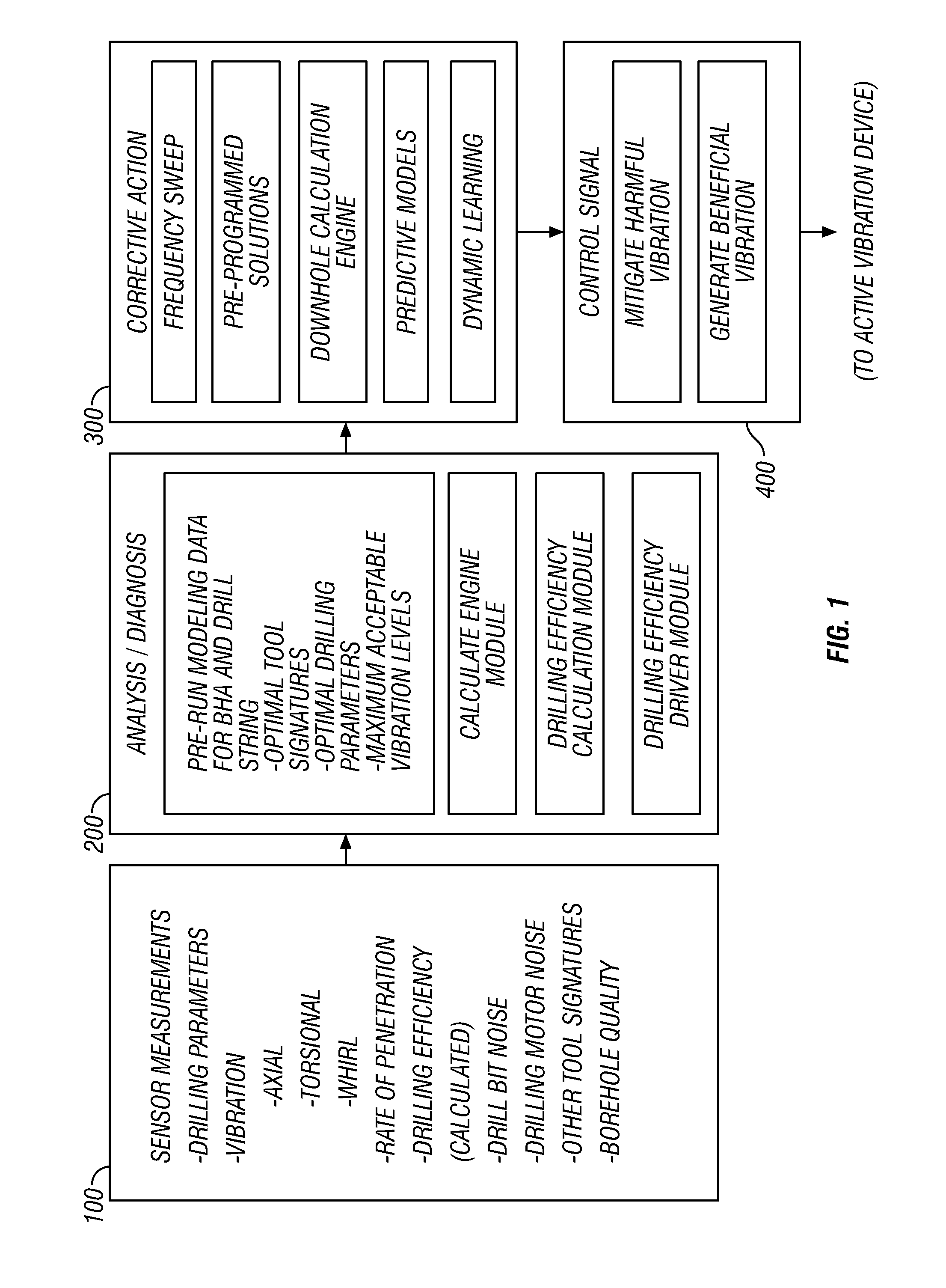

[0042]The teachings of the present invention can be applied in a number of arrangements to generally improve the drilling process by actively applying a dampening profile and / or a controlled vibration to a drill string and / or bottomhole assembly (BHA). Such improvements may include improvement in ROP, extended drill string life, improved bit and cutter life, reduction in wear and tear on BHA, and an improvement in bore hole quality. The term vibration as used herein refers generally to motion of a body but is not meant to imply an particular type of motion or time duration for the motion. The present invention is susceptible to embodiments of different forms. There are shown in the drawings, and herein will be described in detail, specific embodiments of the present invention with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention, and is not intended to limit the invention to that illustrated and described herein....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com