Patents

Literature

847results about "Vibration drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

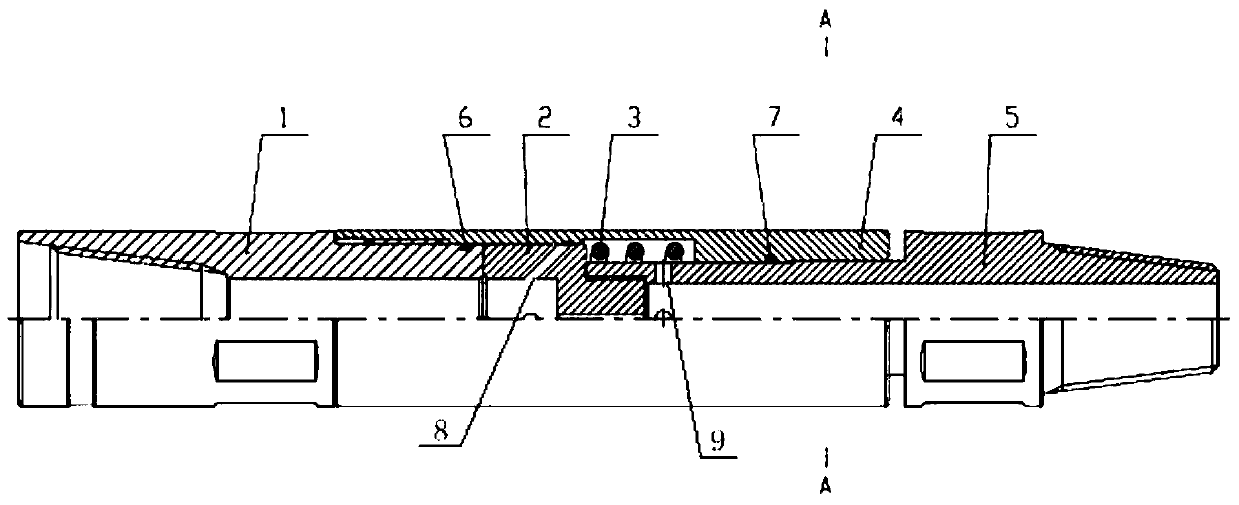

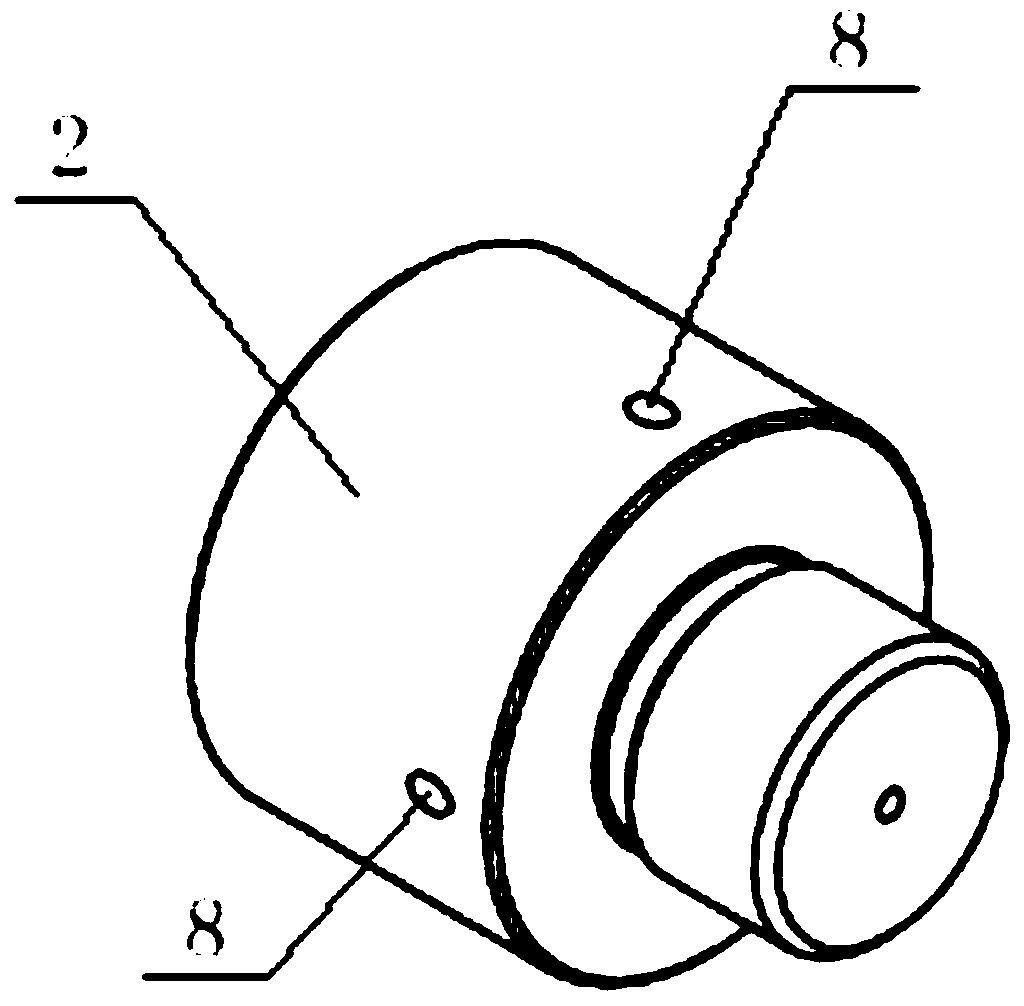

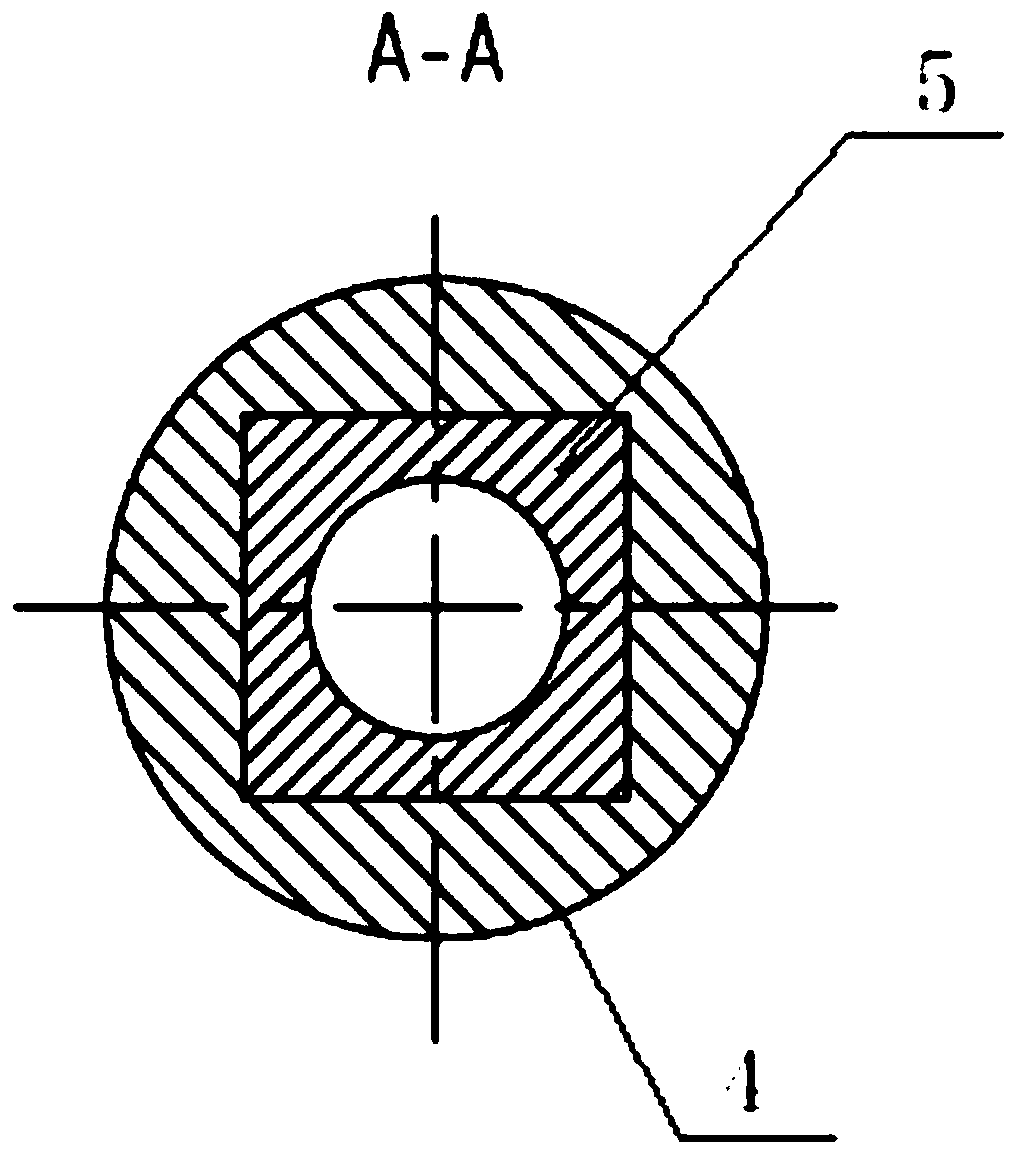

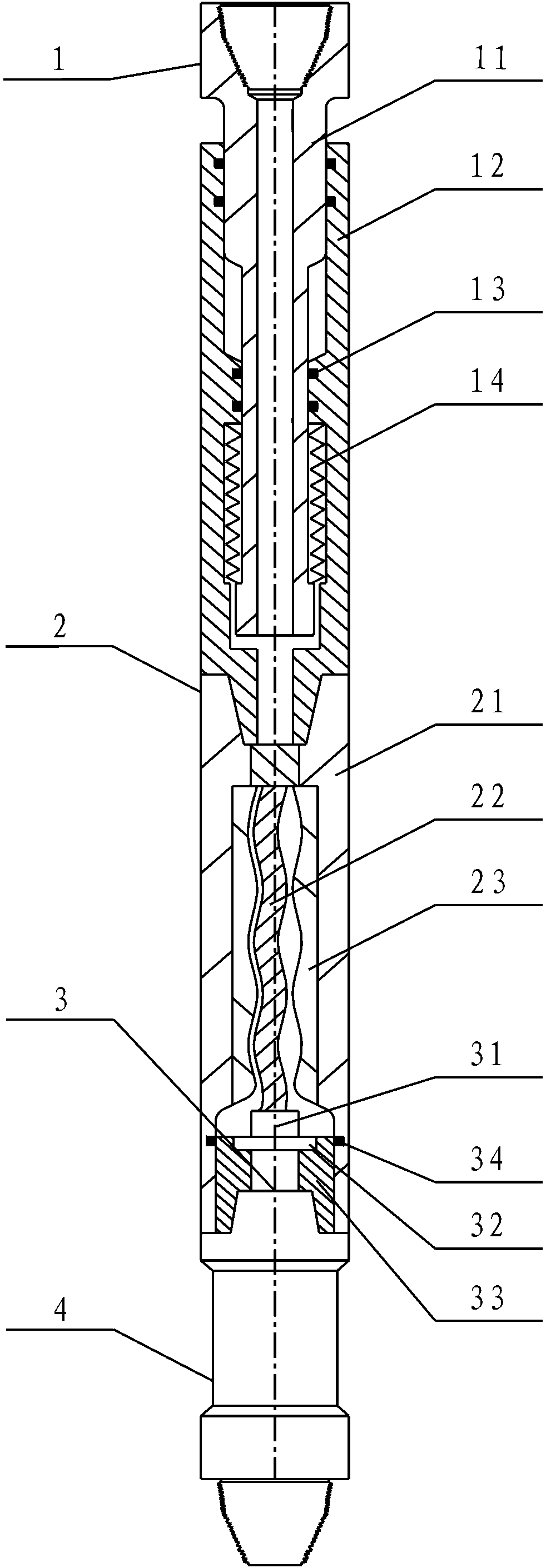

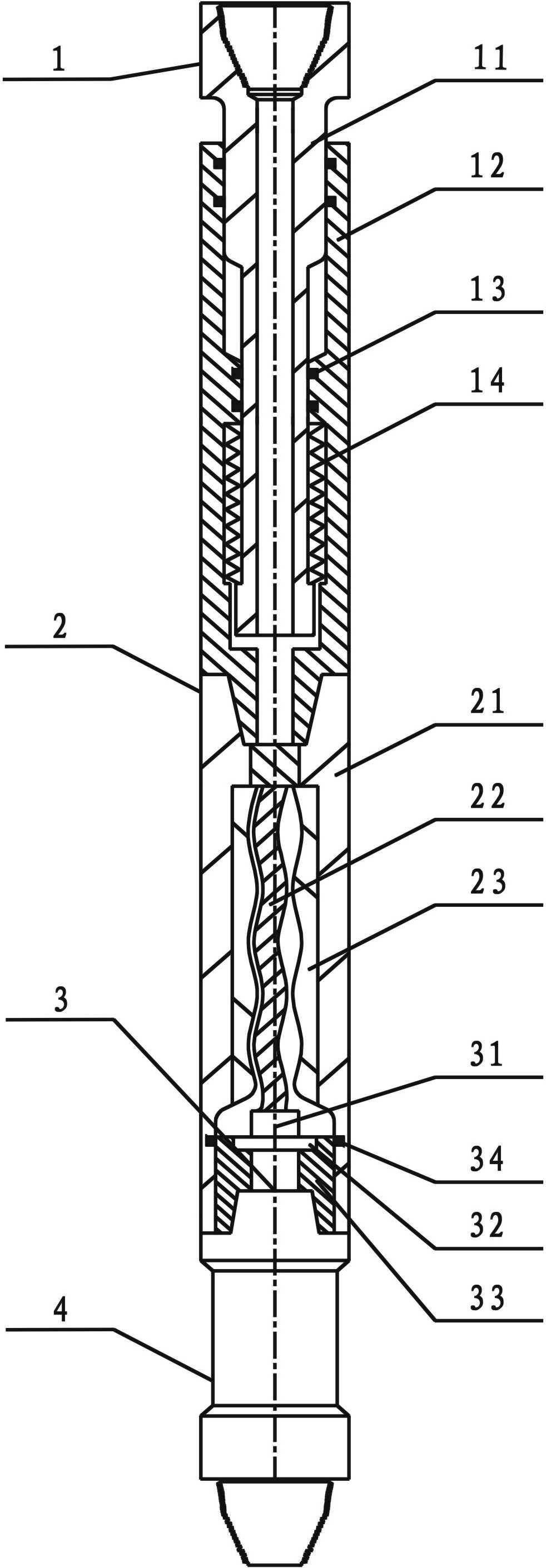

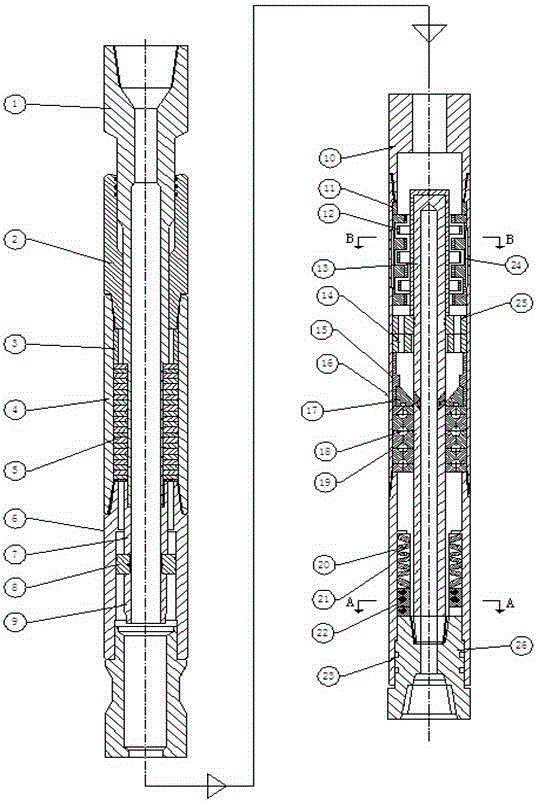

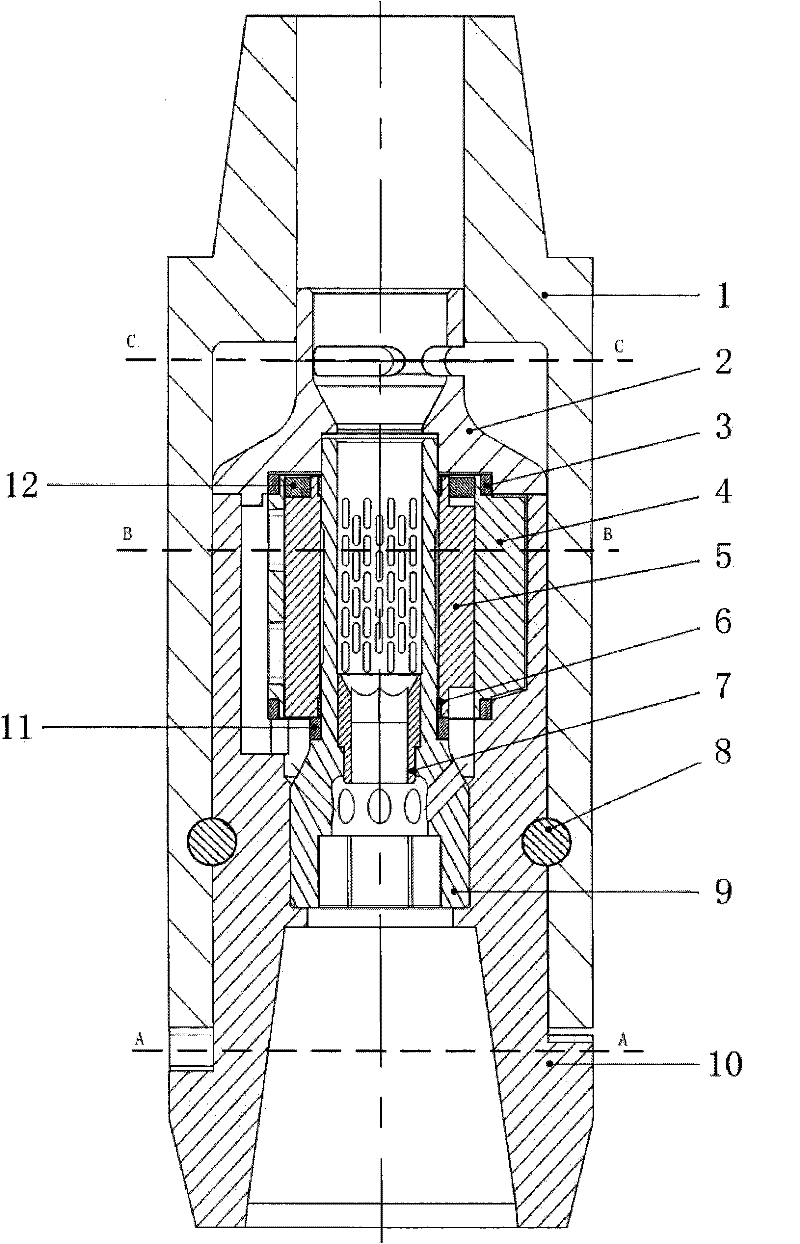

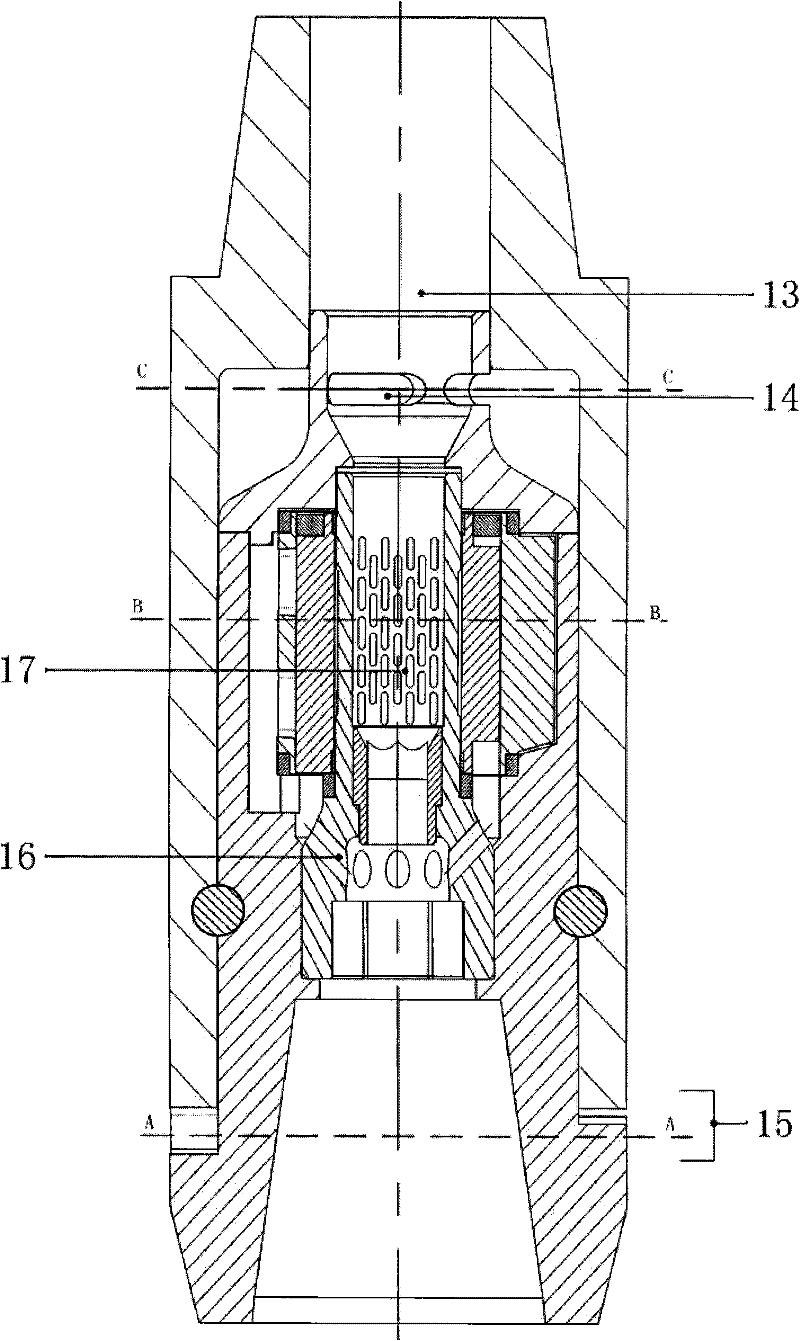

Cable-piercing hydraulic oscillator

PendingCN109555484AGuaranteed continuityImprove sealingEarth drilling toolsVibration drillingReciprocating motionEngineering

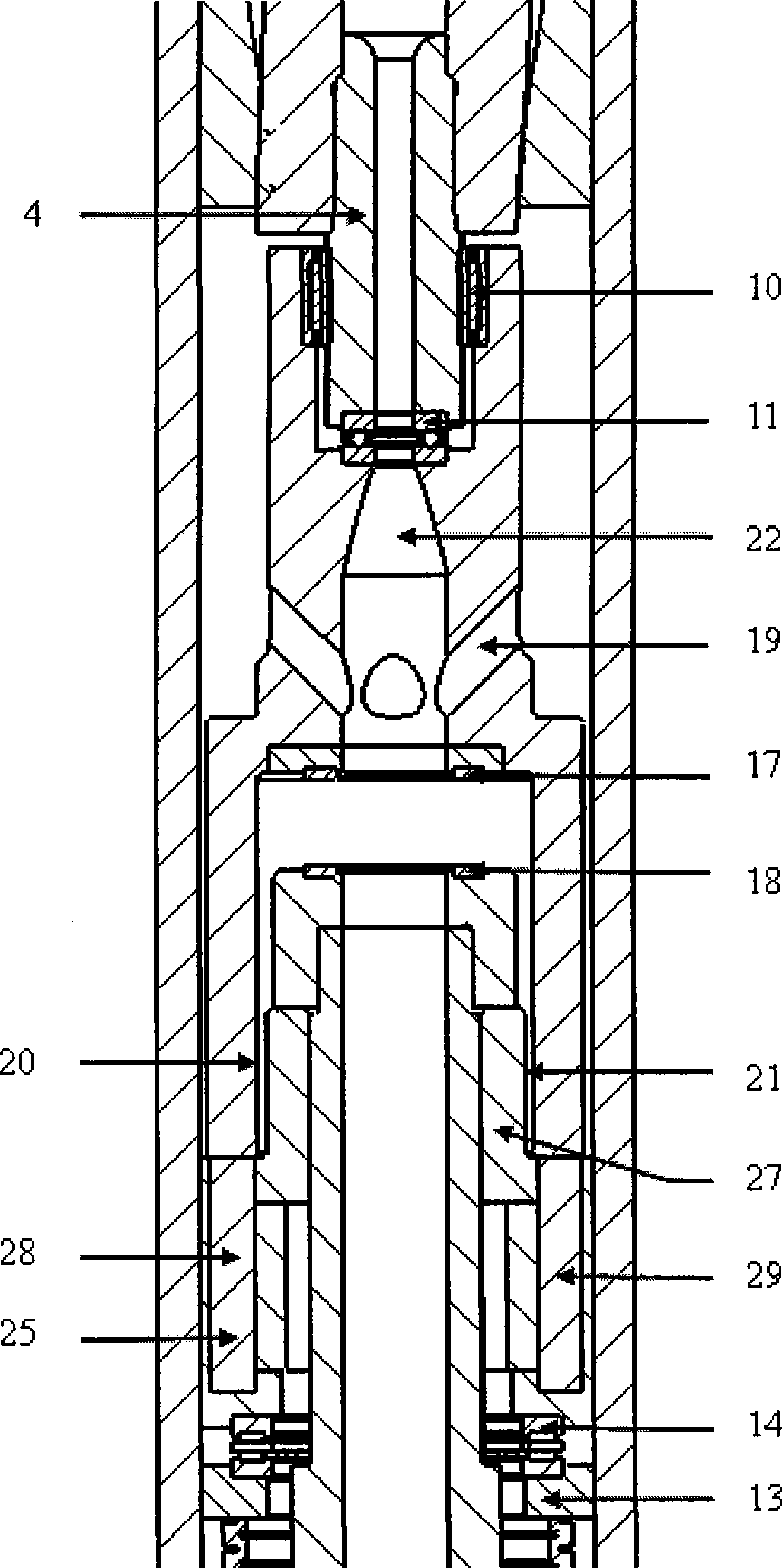

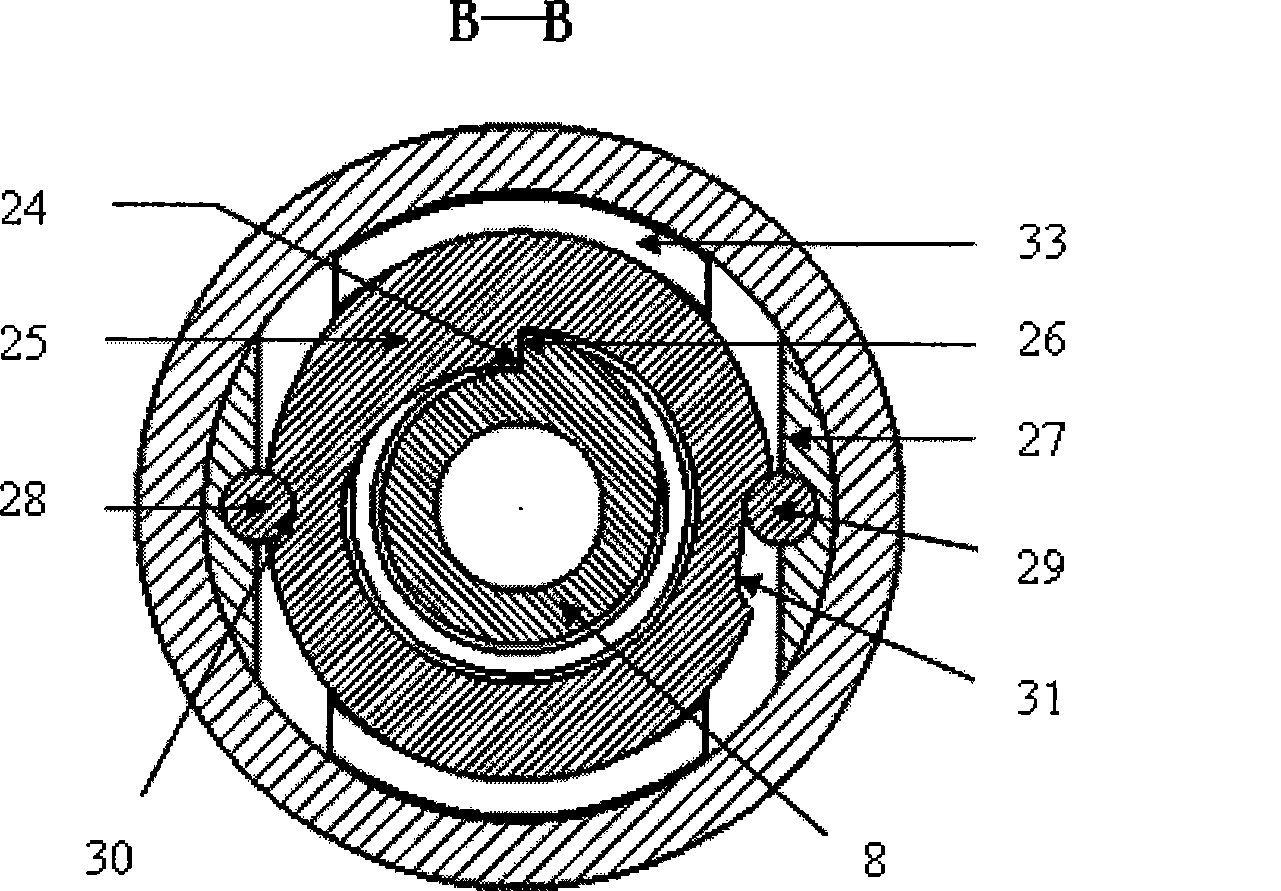

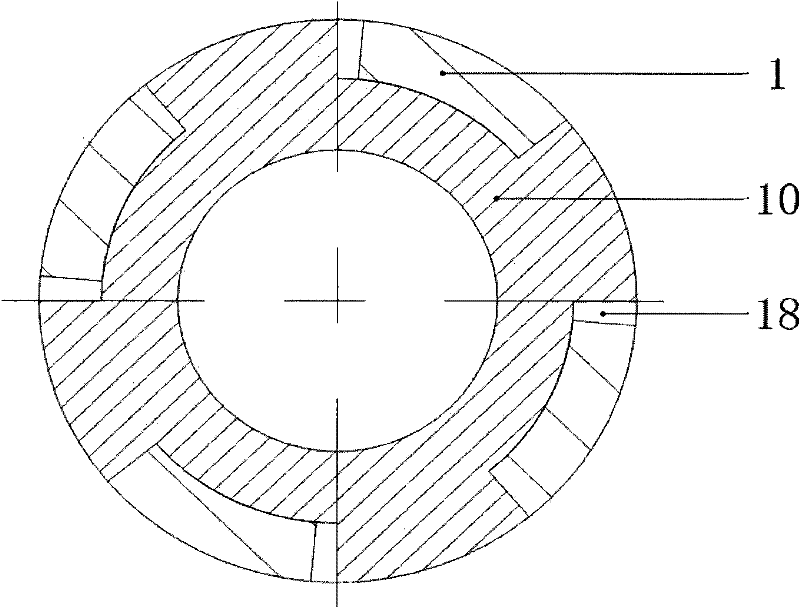

The invention discloses a cable-piercing hydraulic oscillator. The cable-piercing hydraulic oscillator comprises an upper connector, a piston, a compression spring, an outer jacket, a lower connector,a first sealing assembly and a second sealing assembly, wherein the upper connector and the lower connector are connected through the outer jacket; the outer jacket is arranged on the outer parts ofthe upper connector and the lower connector; the piston is arranged on the inner part of the outer jacket; a ring-shaped cavity is formed between the outer jacket, the piston and the lower connector;the compression spring is arranged in the ring-shaped cavity; the first sealing assembly is arranged between the upper connector and the outer jacket; the second sealing assembly is arranged between the outer jacket and the lower connector; a sealing cavity is formed between the piston and the upper connector; holes are formed in the upper end of the piston; the holes communicate with the sealingcavity; and the piston and the lower connector can move up and down in the cable-piercing hydraulic oscillator under the action of pressure difference. The cable-piercing hydraulic oscillator has thebeneficial effects that the whole hydraulic oscillator has a good sealing performance, and a flexible vibrating and rectangular limiting connection mode makes the reciprocating motion continuous well.

Owner:JEREH ENERGY SERVICES

Torsional impact drilling tool

ActiveCN101463709AReduce stick-slipReduce the possibility of failureVibration drillingRate of penetrationDrive shaft

The invention relates to a torsional impact drilling tool used for applying low amplitude high frequency torsional impact to a drill bit during a drilling process, which can increase the drilling efficiency and the service life of the drill bit and lesson the tripping operation and the drilling cost. The technical scheme of the torsional impact drilling tool is as follows: a housing is connected with a short section of a drilling column led into the drill bit by a spline, and is positioned by a shaft shoulder; a screw motor rotor and a screw motor stator form a screw motor, the screw motor rotor is eccentrically connected to a transmission shaft by a universal shaft and two bearings, and four diversion holes are arranged on the transmission shaft; the lower end of the transmission shaft is connected with a carrier with a cavity; a sliding impactor is arranged in the cavity and is fixed by pins, and an impact hammer is arranged in the sliding impactor; a falling prevention ring is connected with the housing by screw threads; and the damping shaft shoulder on the short section of the drilling column led into the drill bit is matched with the impact hammer of the sliding impactor to form a ratchet wheel structure. The torsional impact drilling tool has simple structure, and can be used in hard strata of a deep well; and as being short, the tool is also applicable to the deflecting operation and can be used in crooked well holes, thereby reducing the phenomenon of stick-slip of the drill bit and improving the rate of penetration.

Owner:SOUTHWEST PETROLEUM UNIV

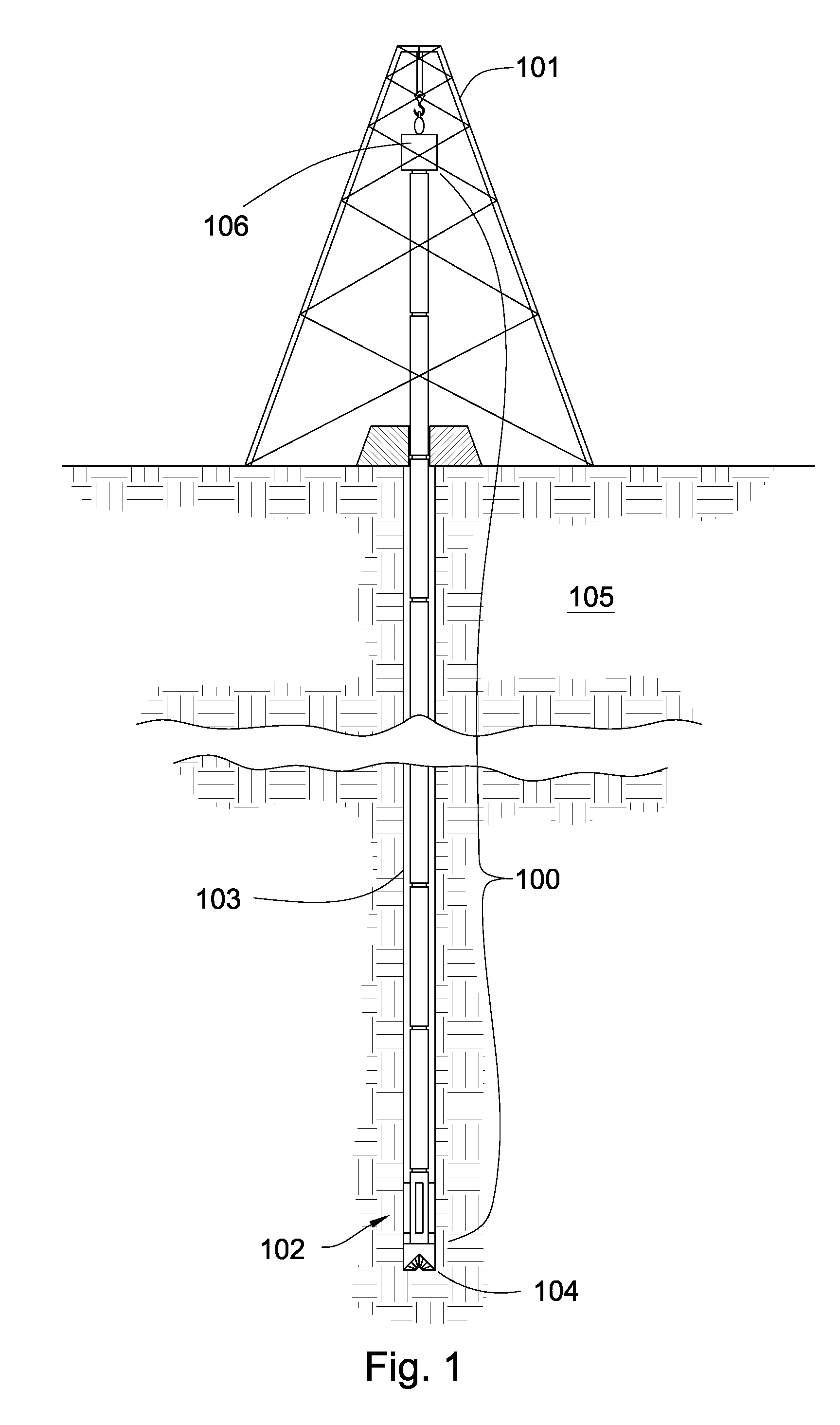

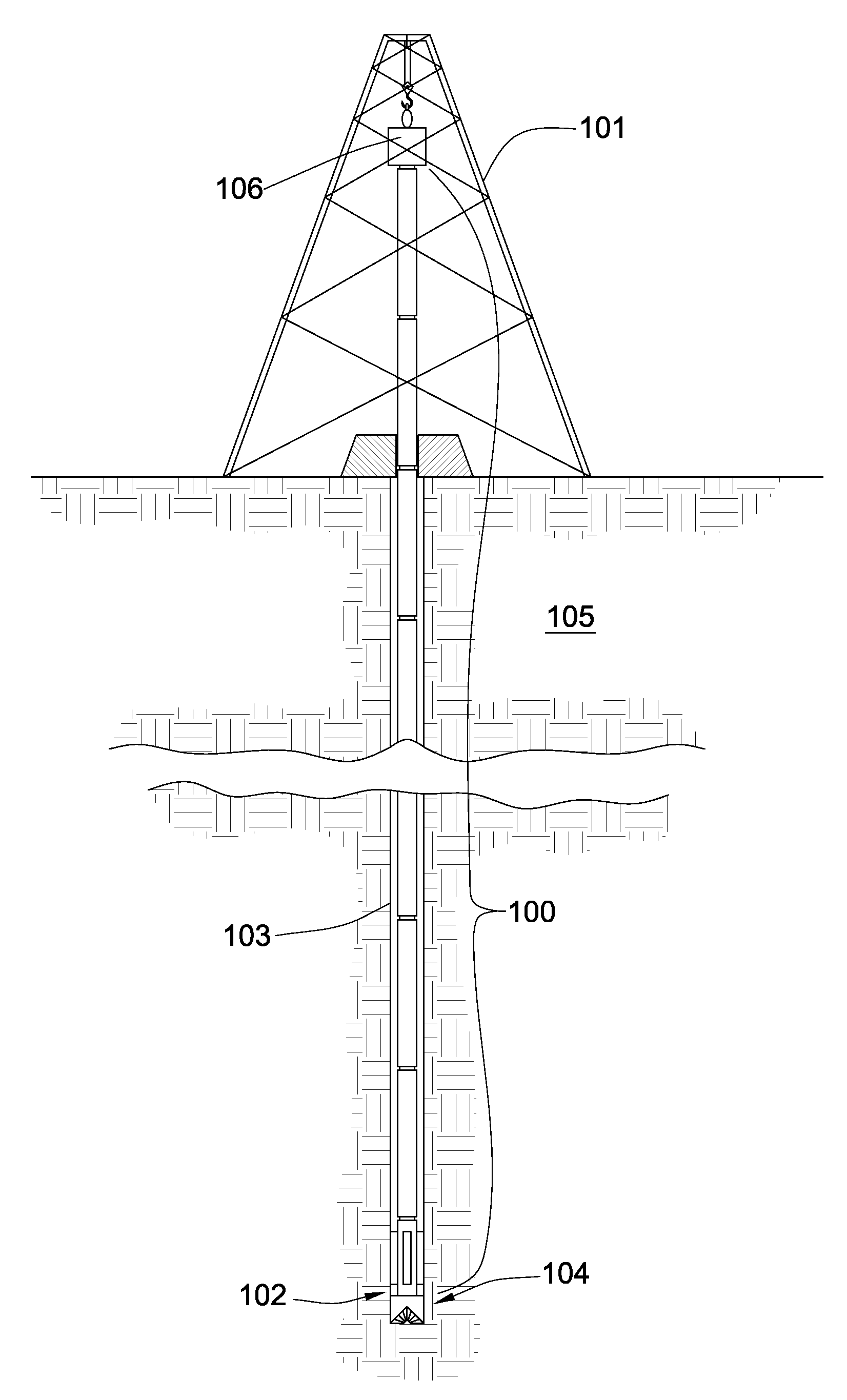

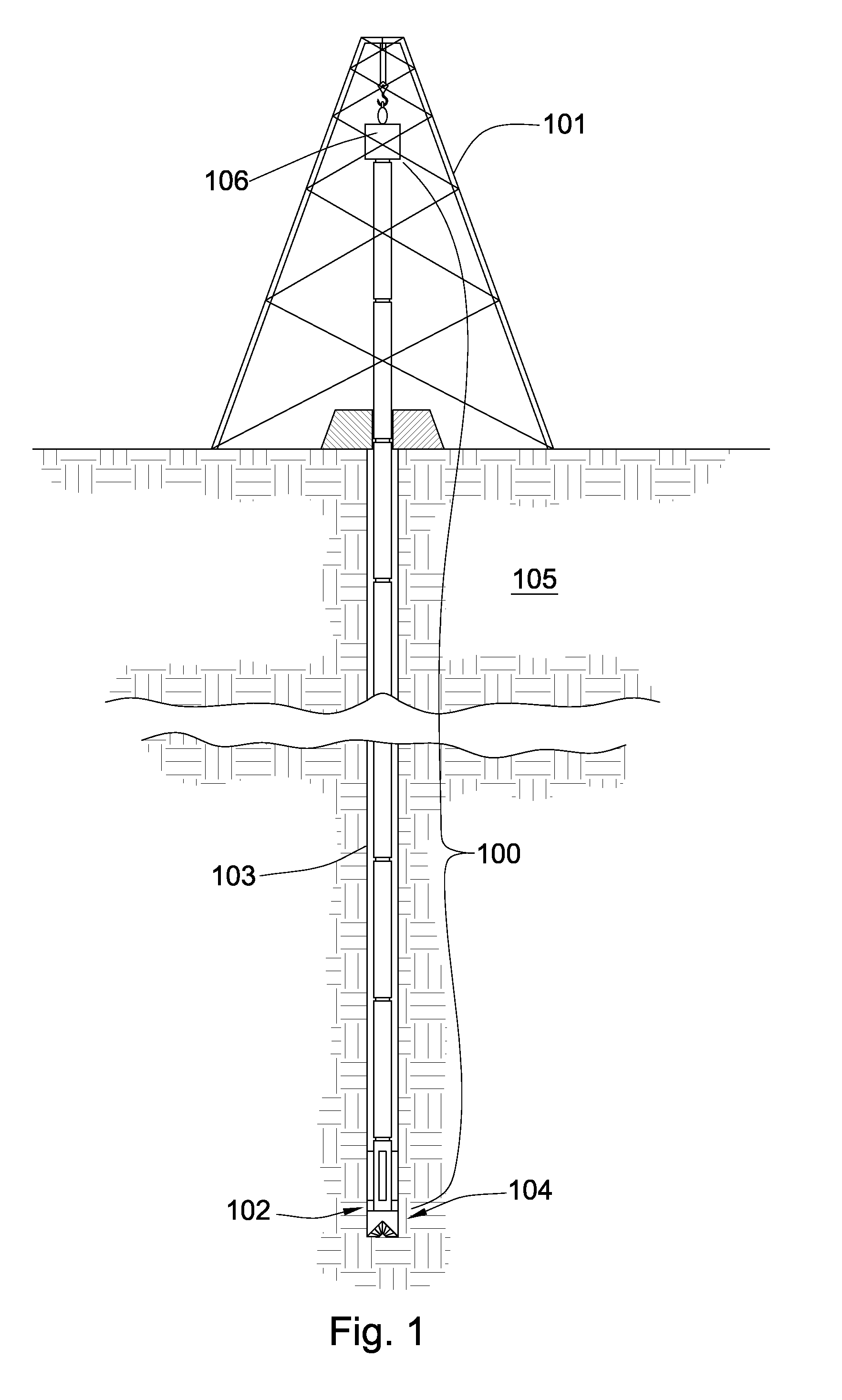

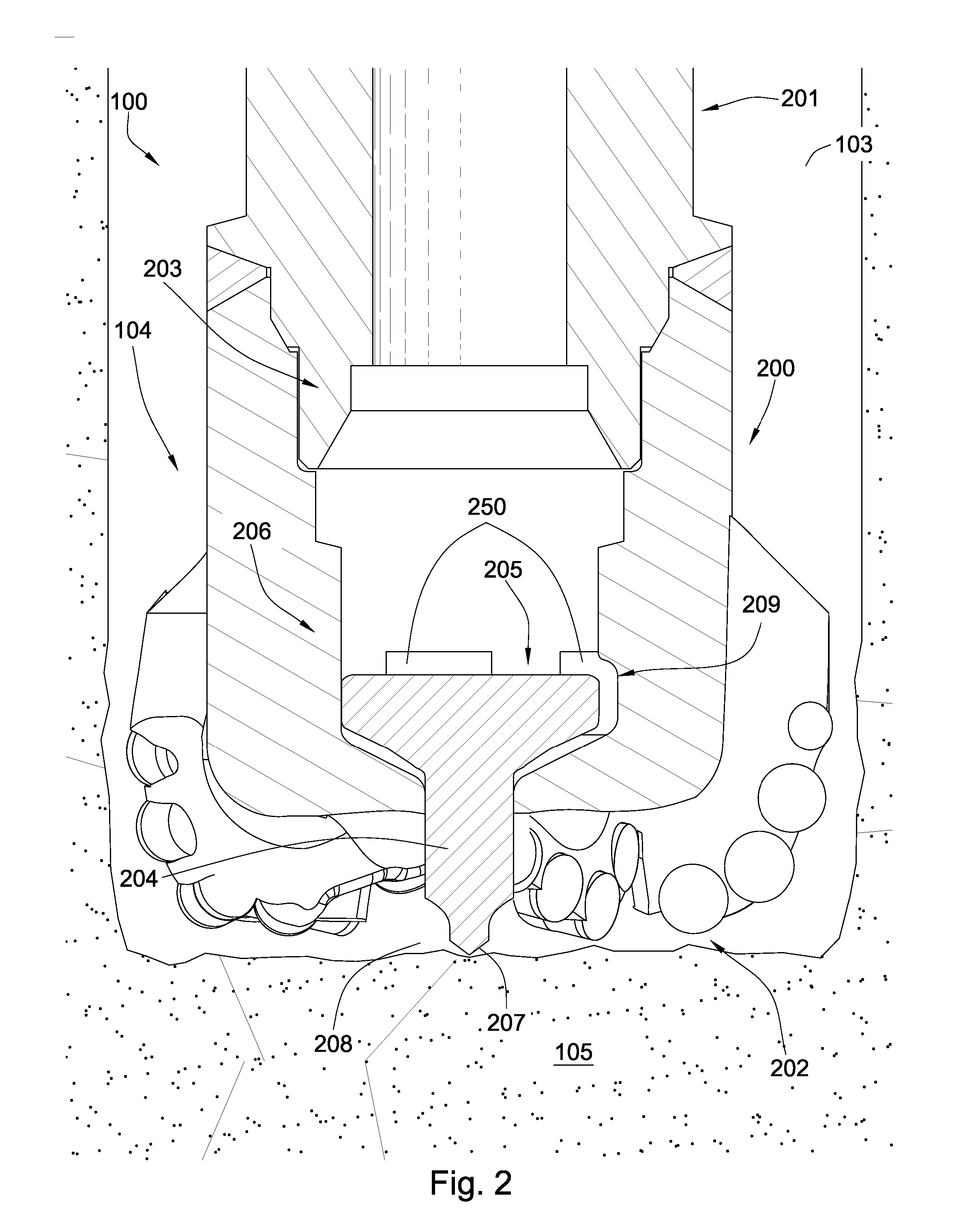

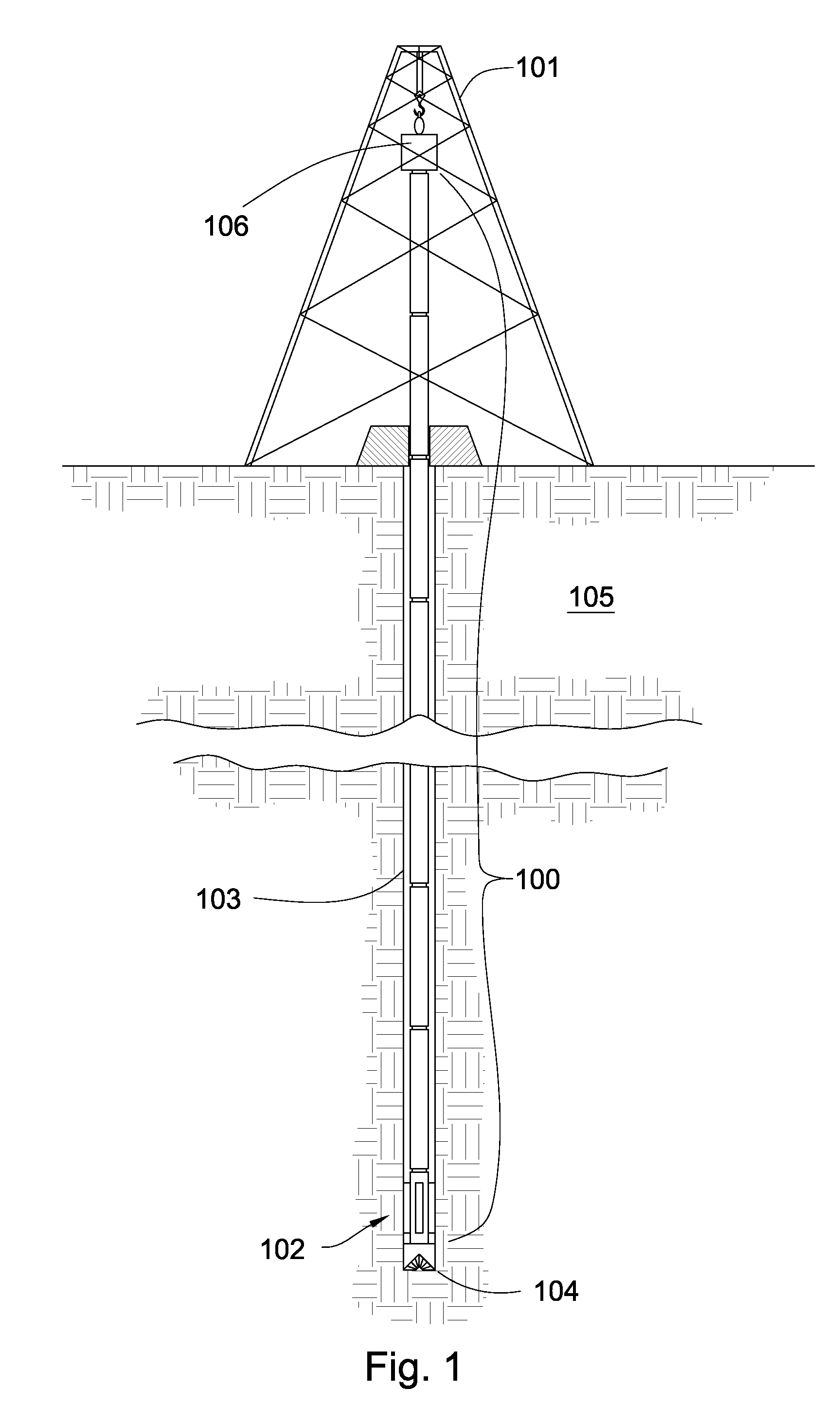

System and Method for Drilling a Borehole

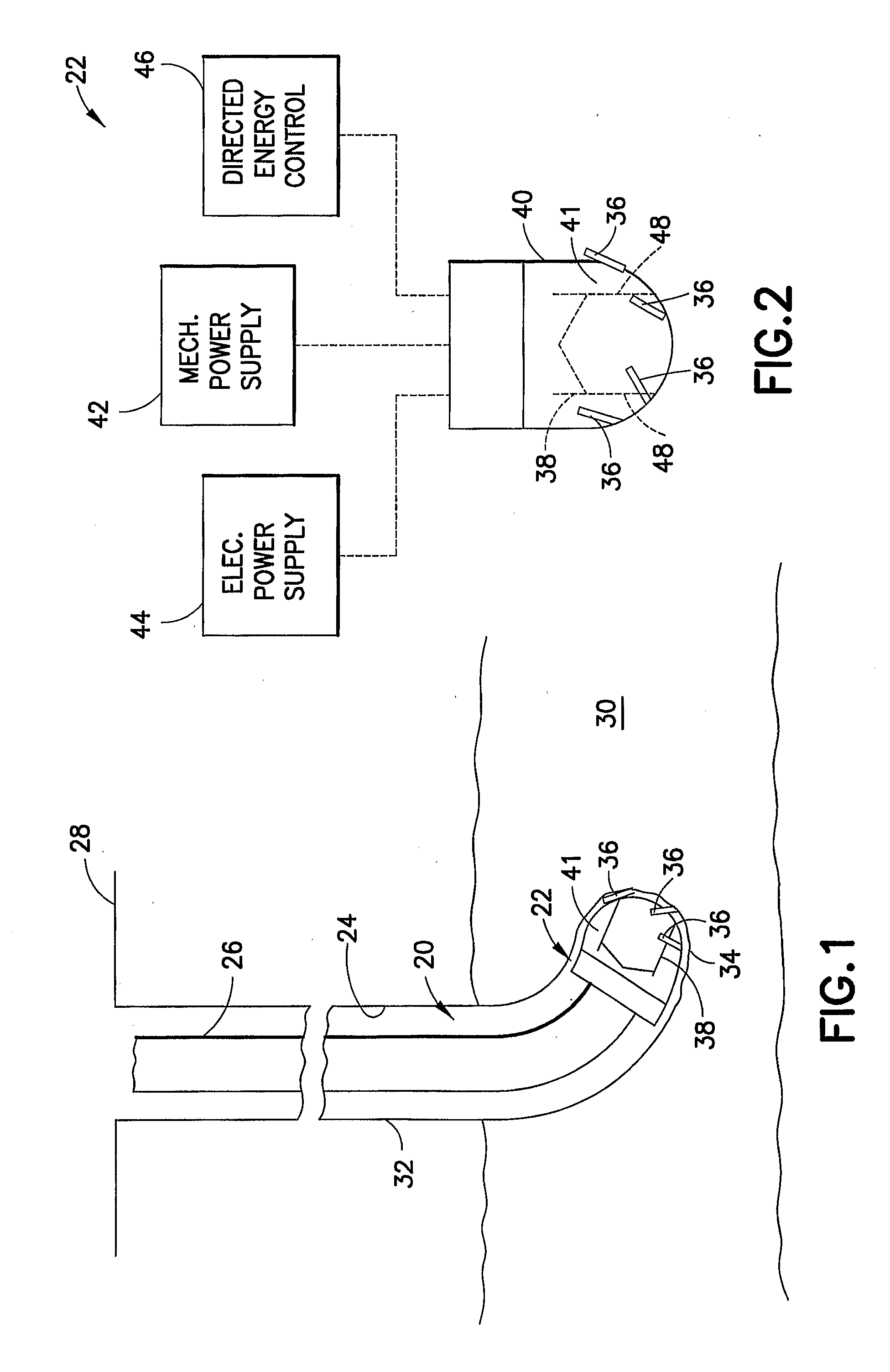

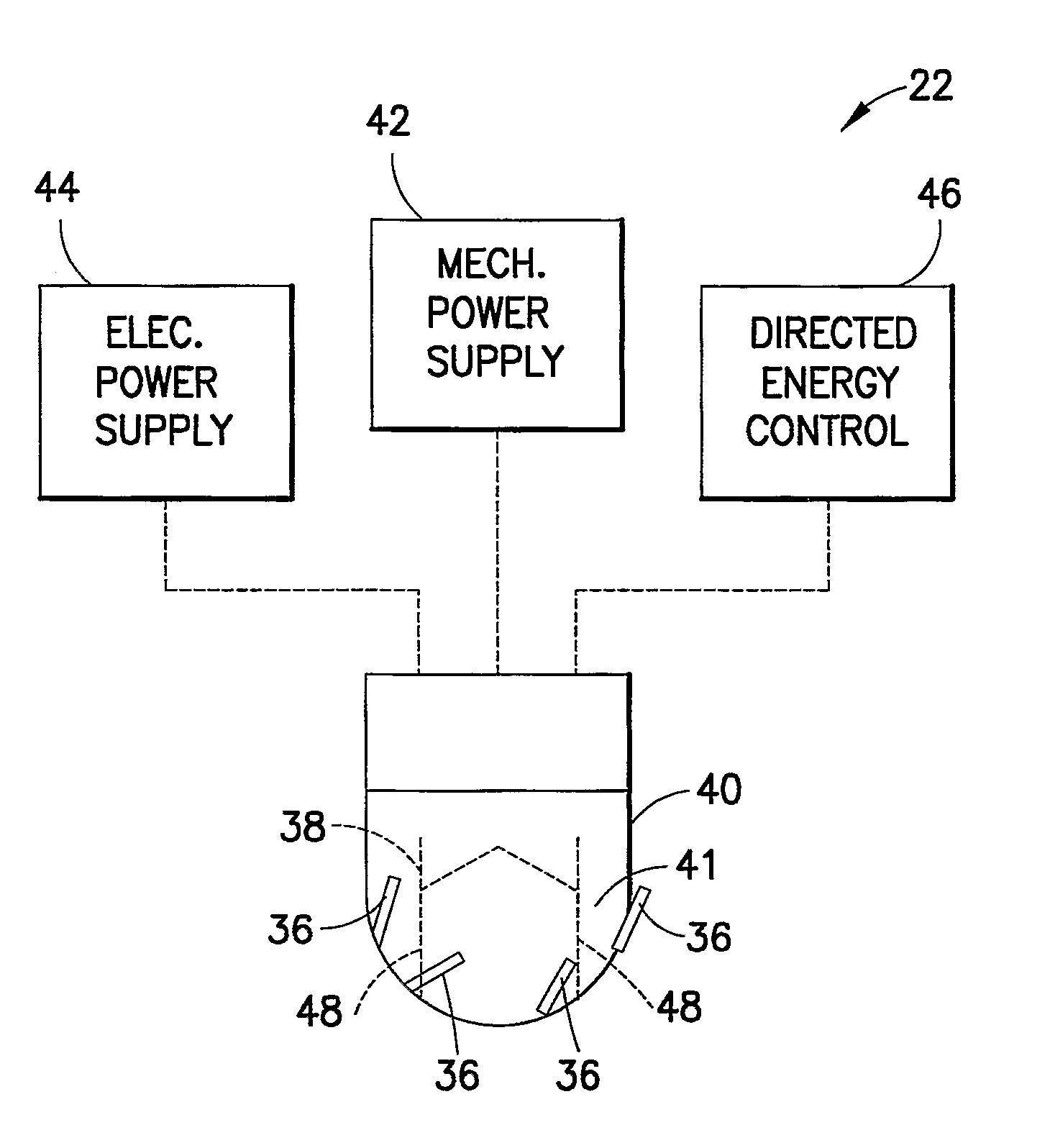

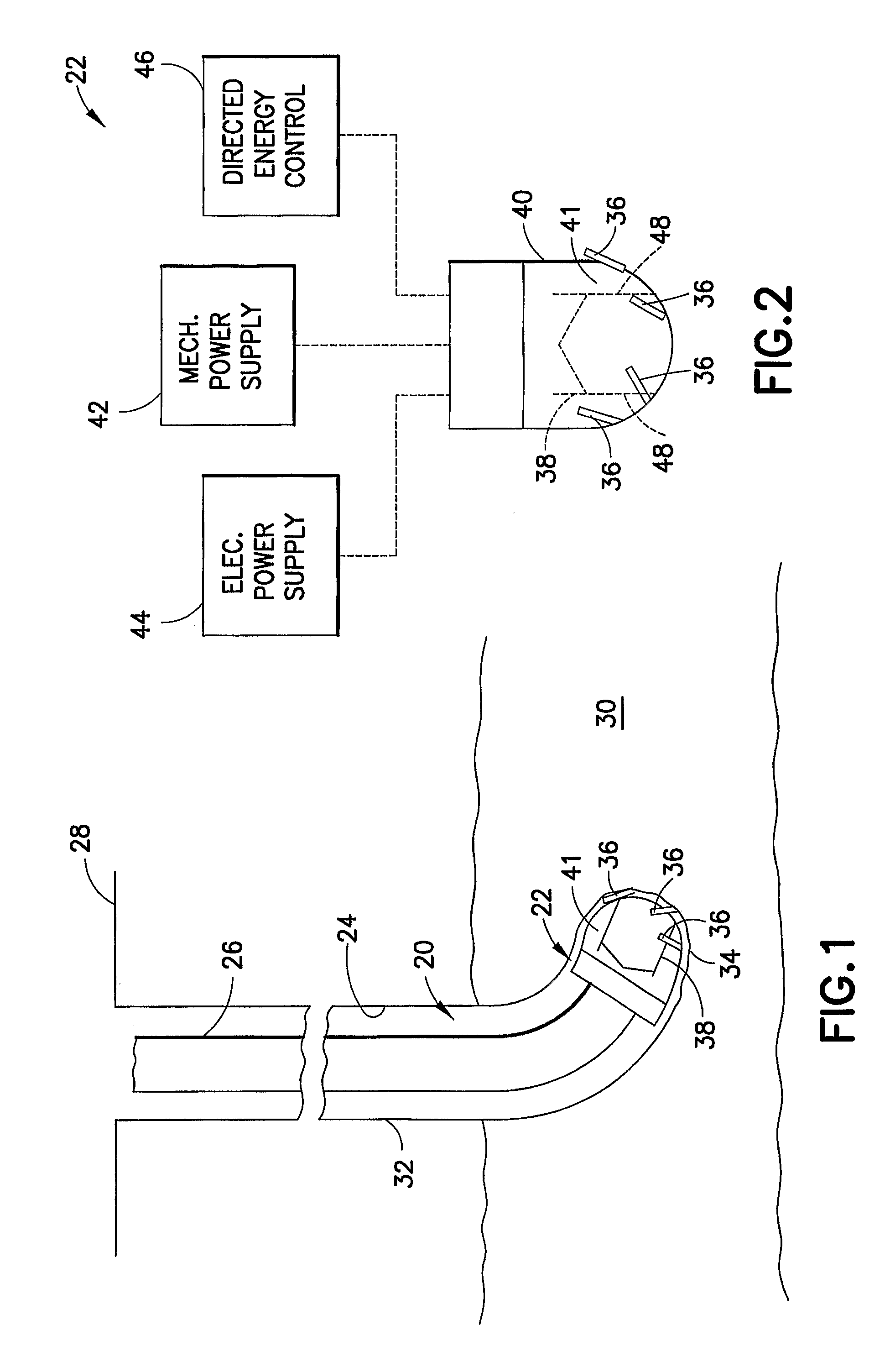

A system and method is provided for drilling a wellbore including a rotary drill bit with a bit body having a plurality of mechanical cutters to cut away formation material as the wellbore is formed; and a directed energy mechanism to direct energy into the formation such that energy from the directed energy mechanism causes fracturing of surrounding material to facilitate drilling in the direction of the directed energy.

Owner:SCHLUMBERGER TECH CORP

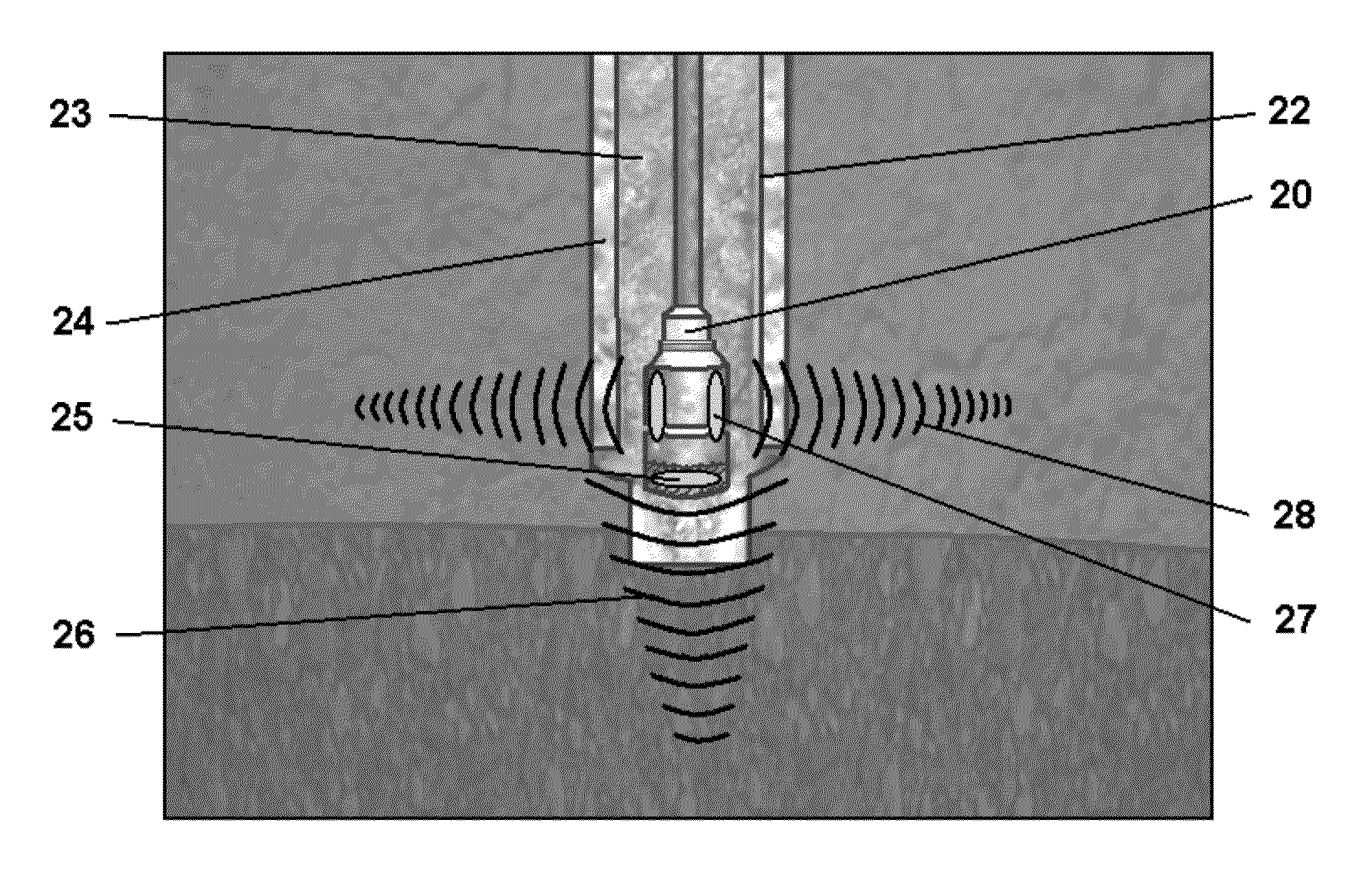

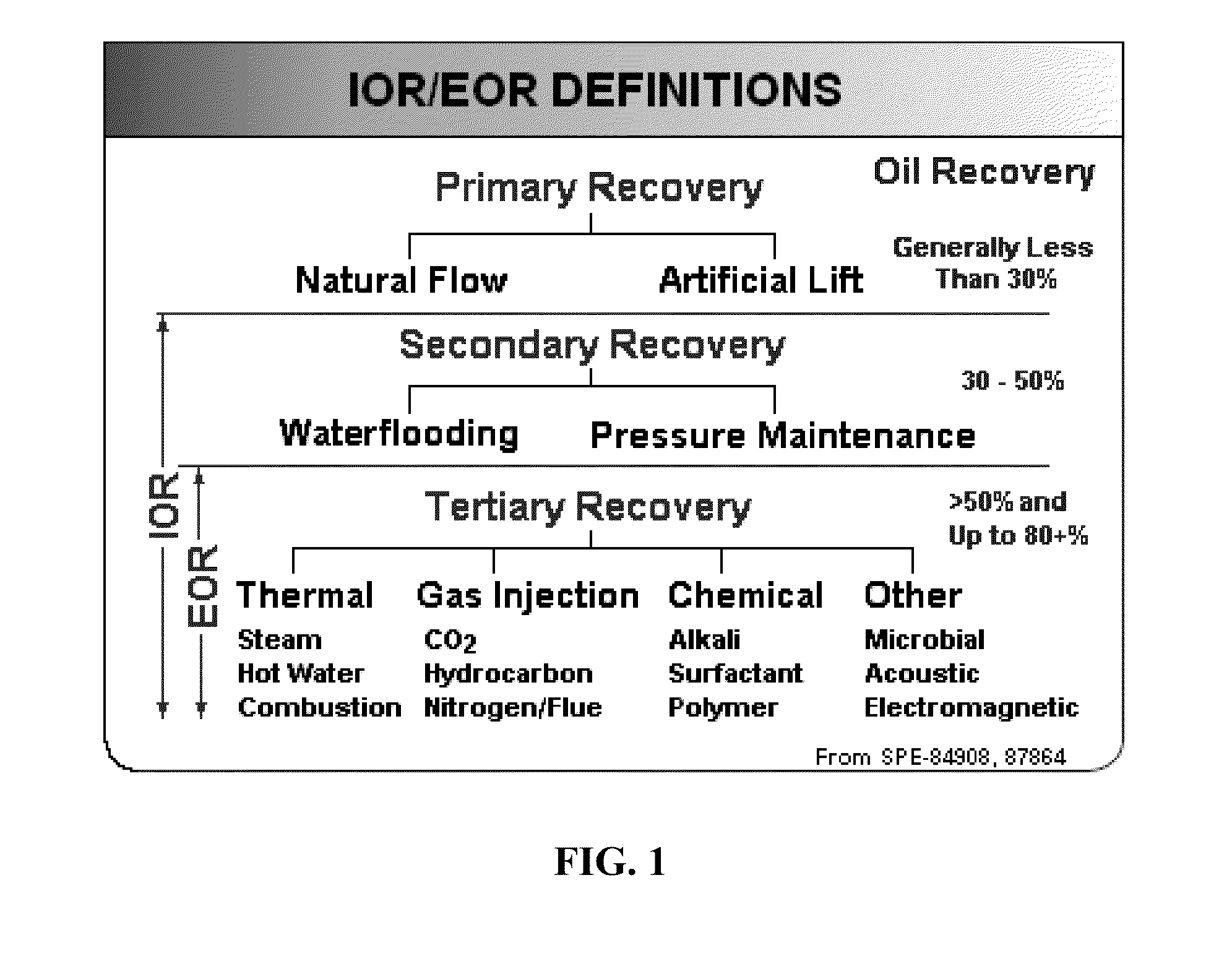

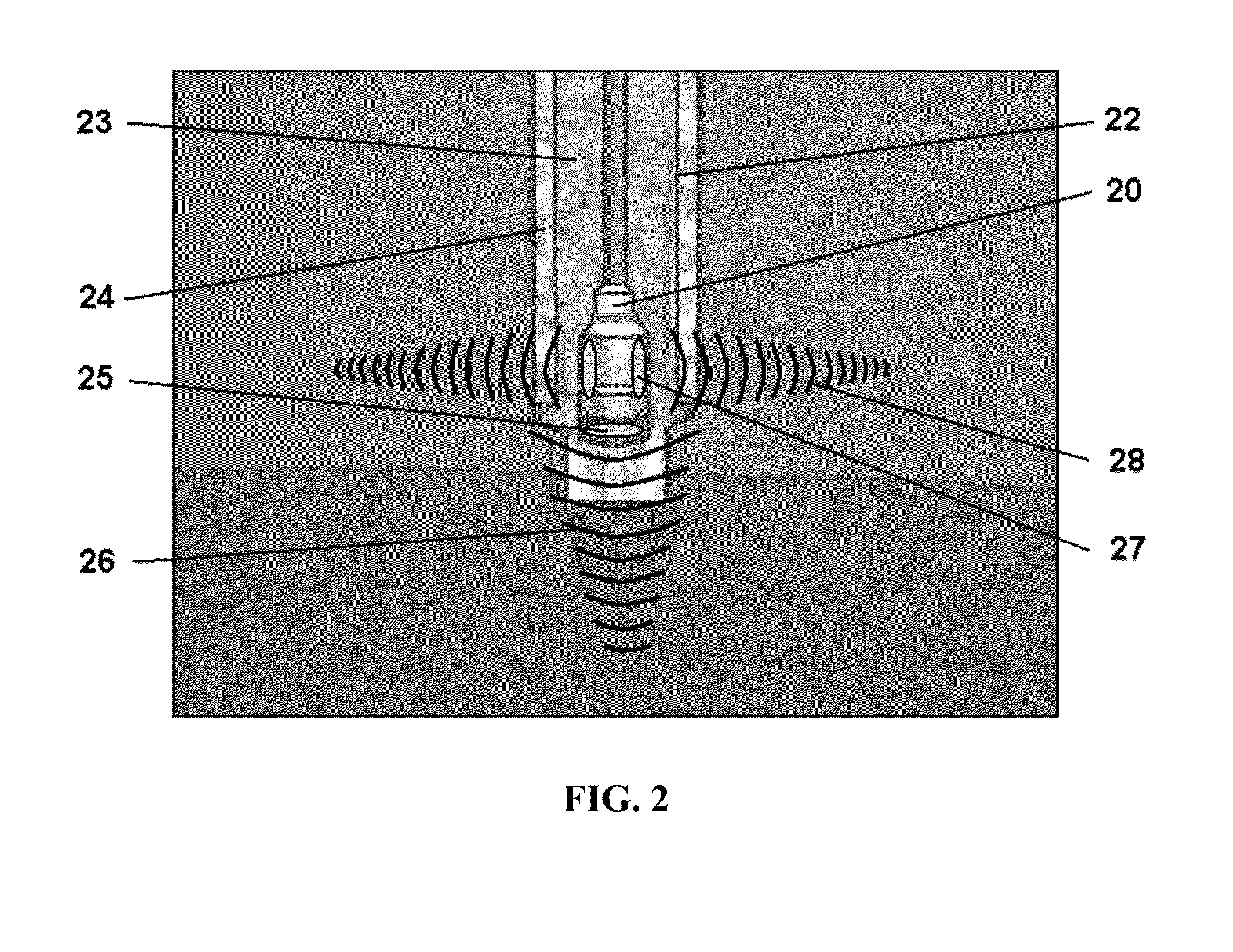

Apparatuses and methods for generating shock waves for use in the energy industry

ActiveUS20140305877A1Extend your lifeNeed can be fittedWaste water treatment from quariesFatty/oily/floating substances removal devicesShock waveFiber

Several methods and devices are provided herein to generate shock waves that are used in the oil industry for well drilling, hydrocarbon or gas exploitation, fracking process or improved oil recovery (IOR), enhanced oil recovery (EOR), cleaning of process waters, oil spills byproducts and oil pipes, which can be used as independent systems or as auxiliary systems concomitantly with other existing technologies. The different devices consist of generating shock waves utilizing either one or more laser sources, or a self-generated combustible gas supply, or a micro-explosive pellet, or piezocrystals, or a piezofiber composite structure.

Owner:SANUWAVE INC

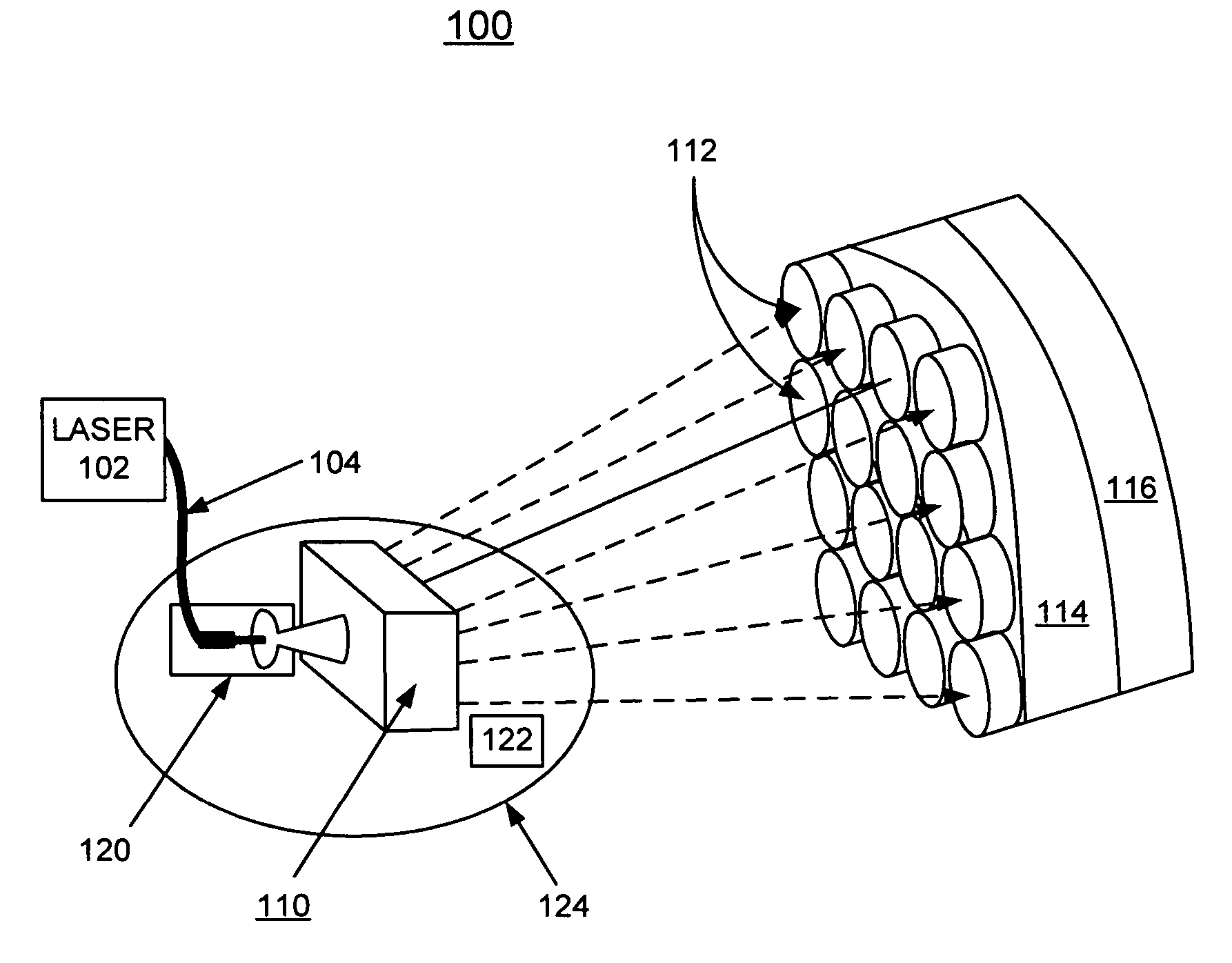

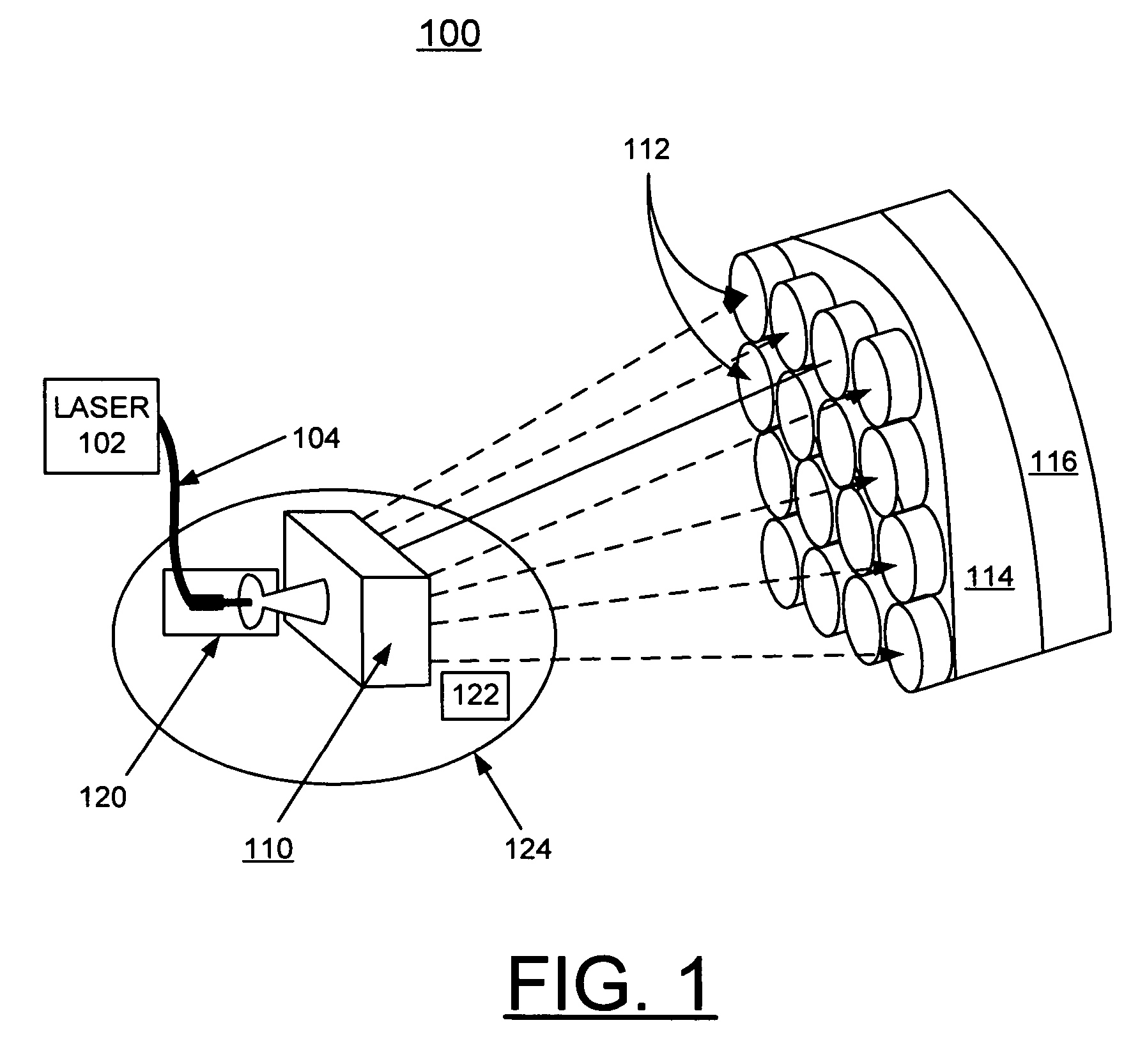

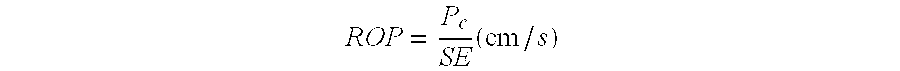

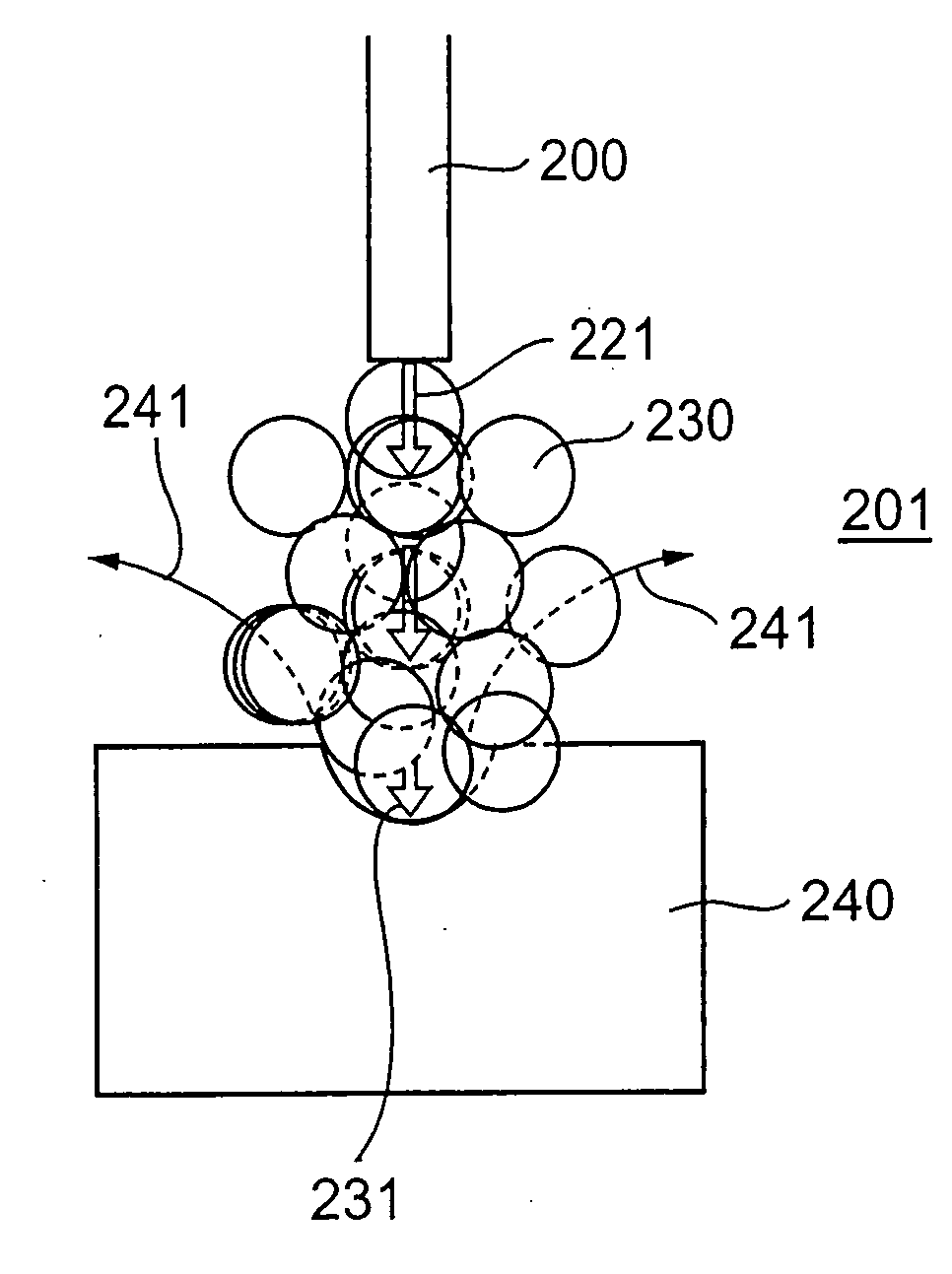

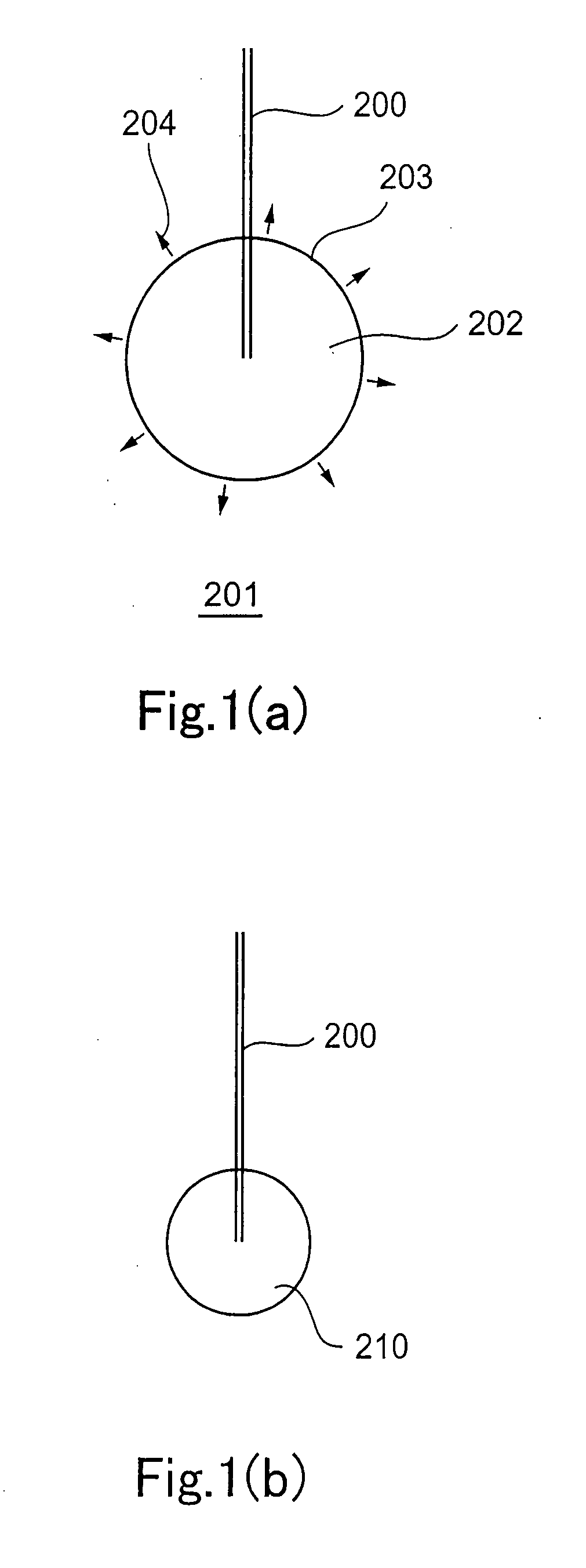

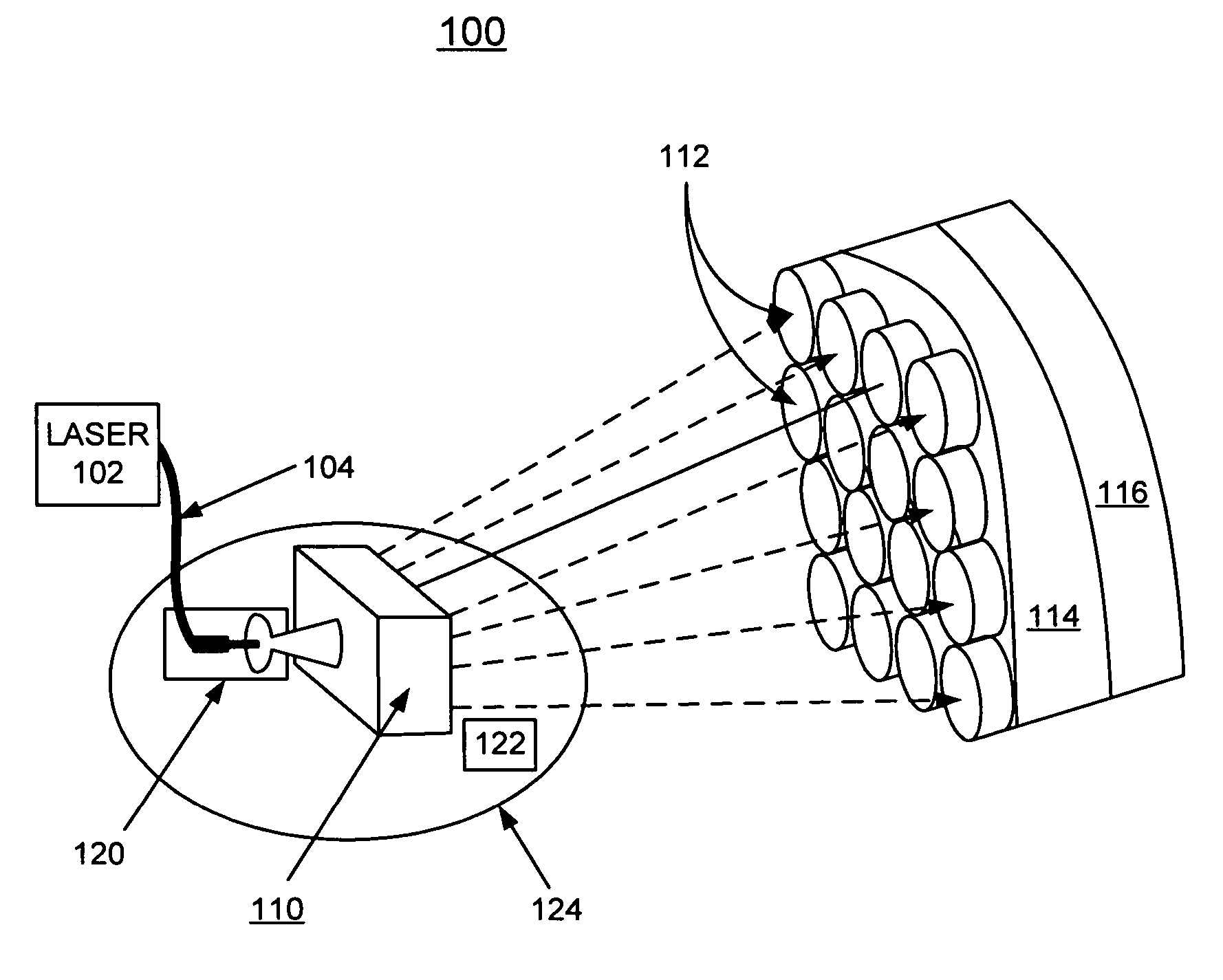

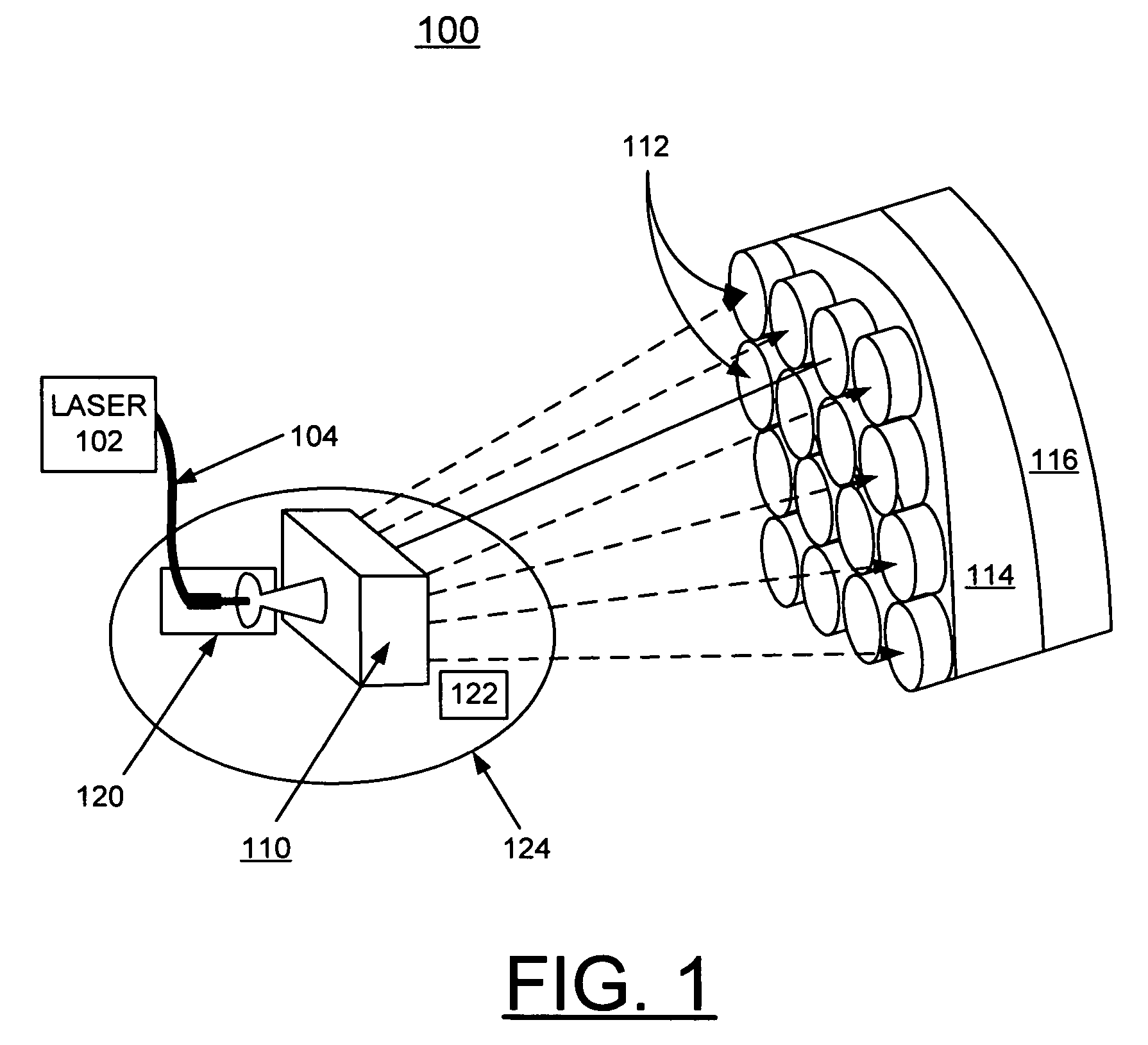

Methods of using a laser to spall and drill holes in rocks

ActiveUS20060237233A1Energy efficiencyProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

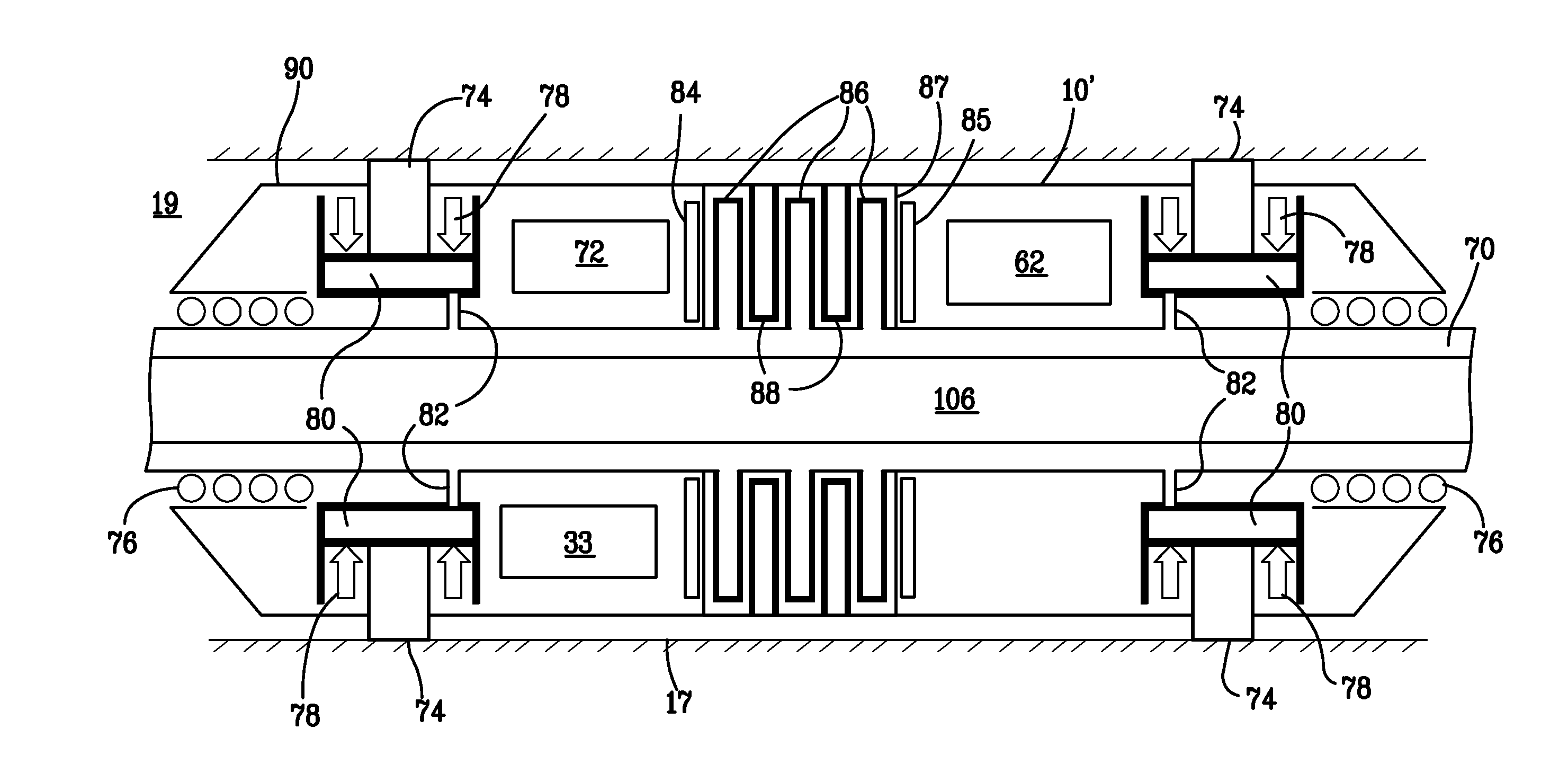

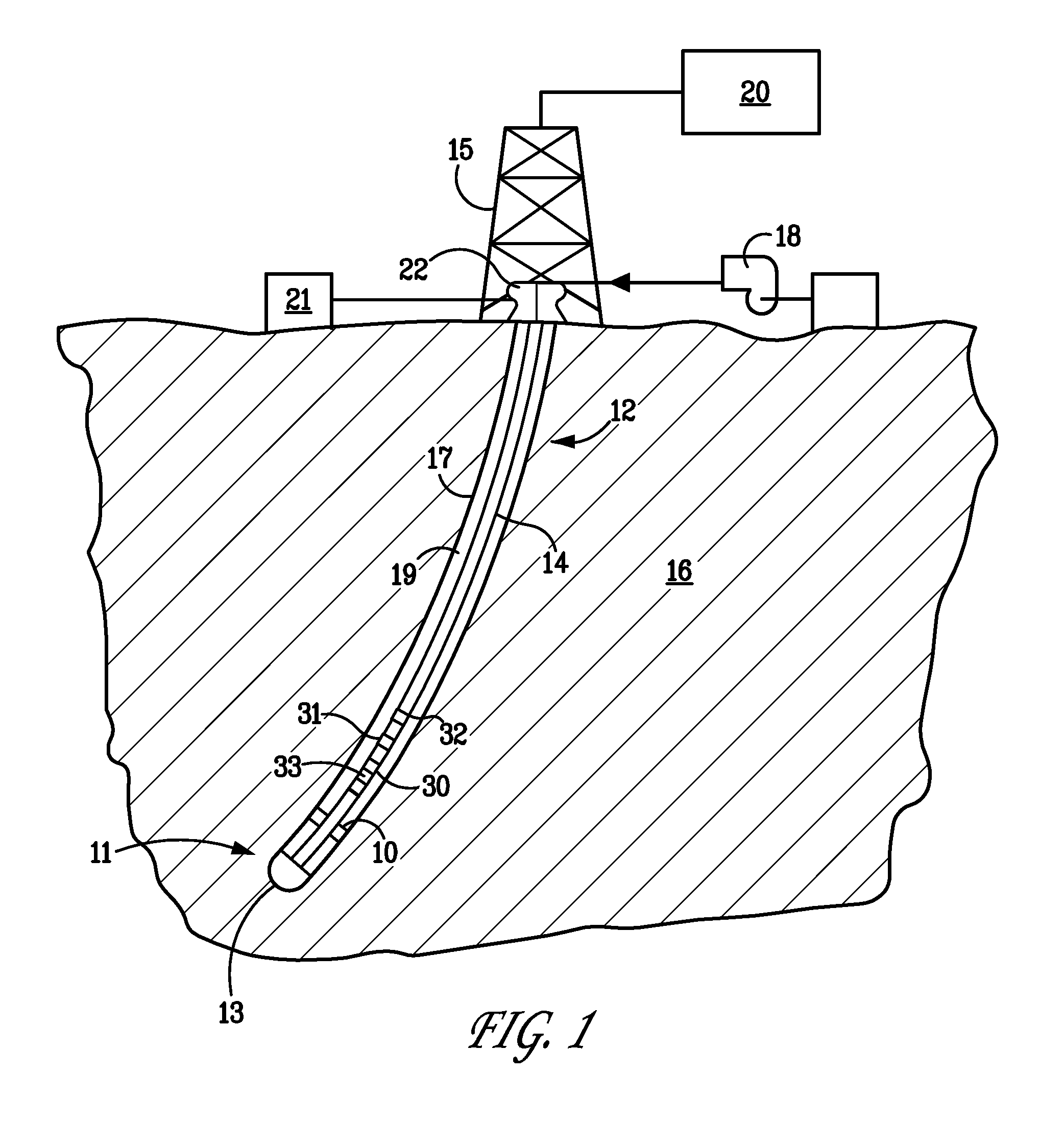

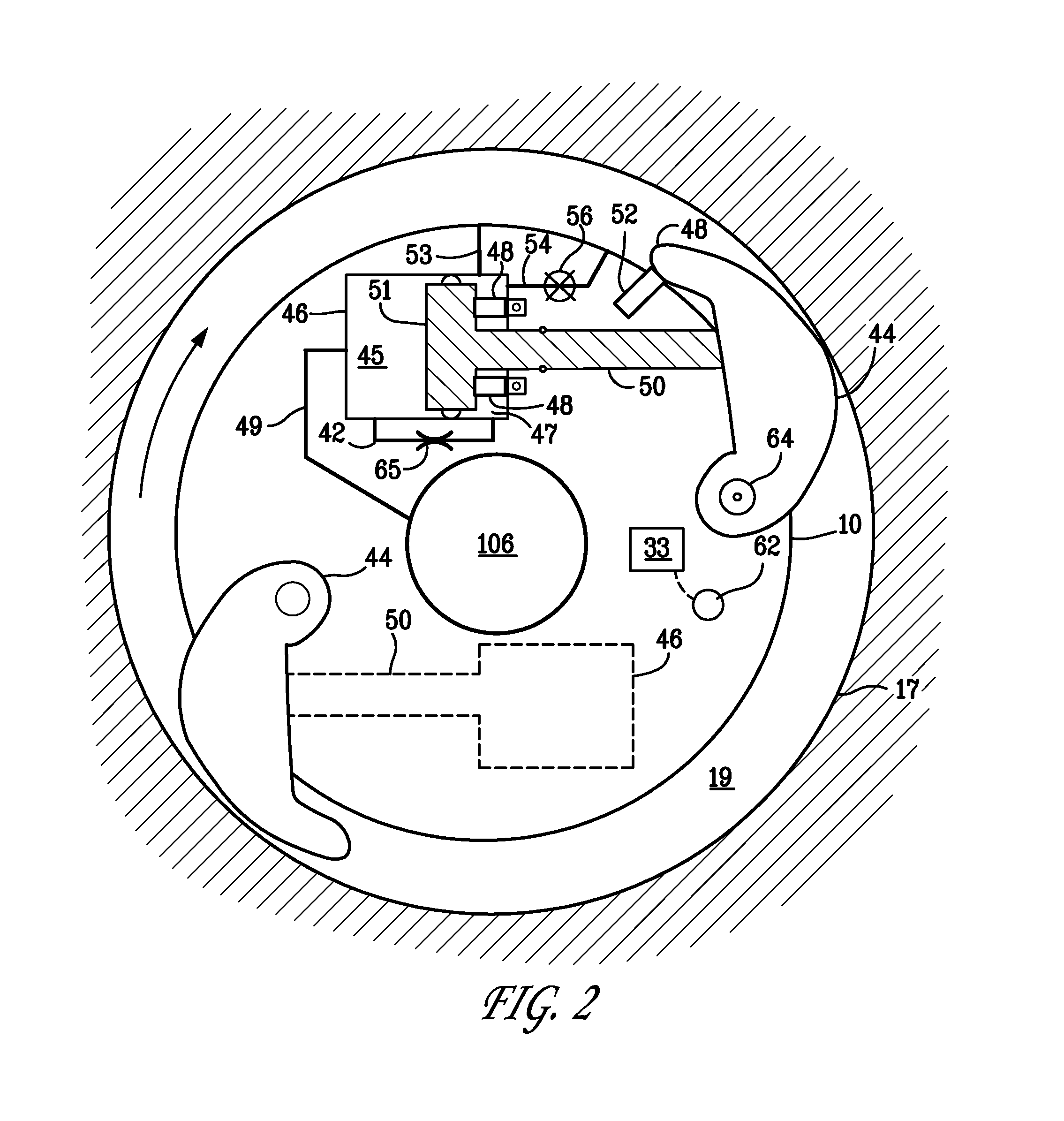

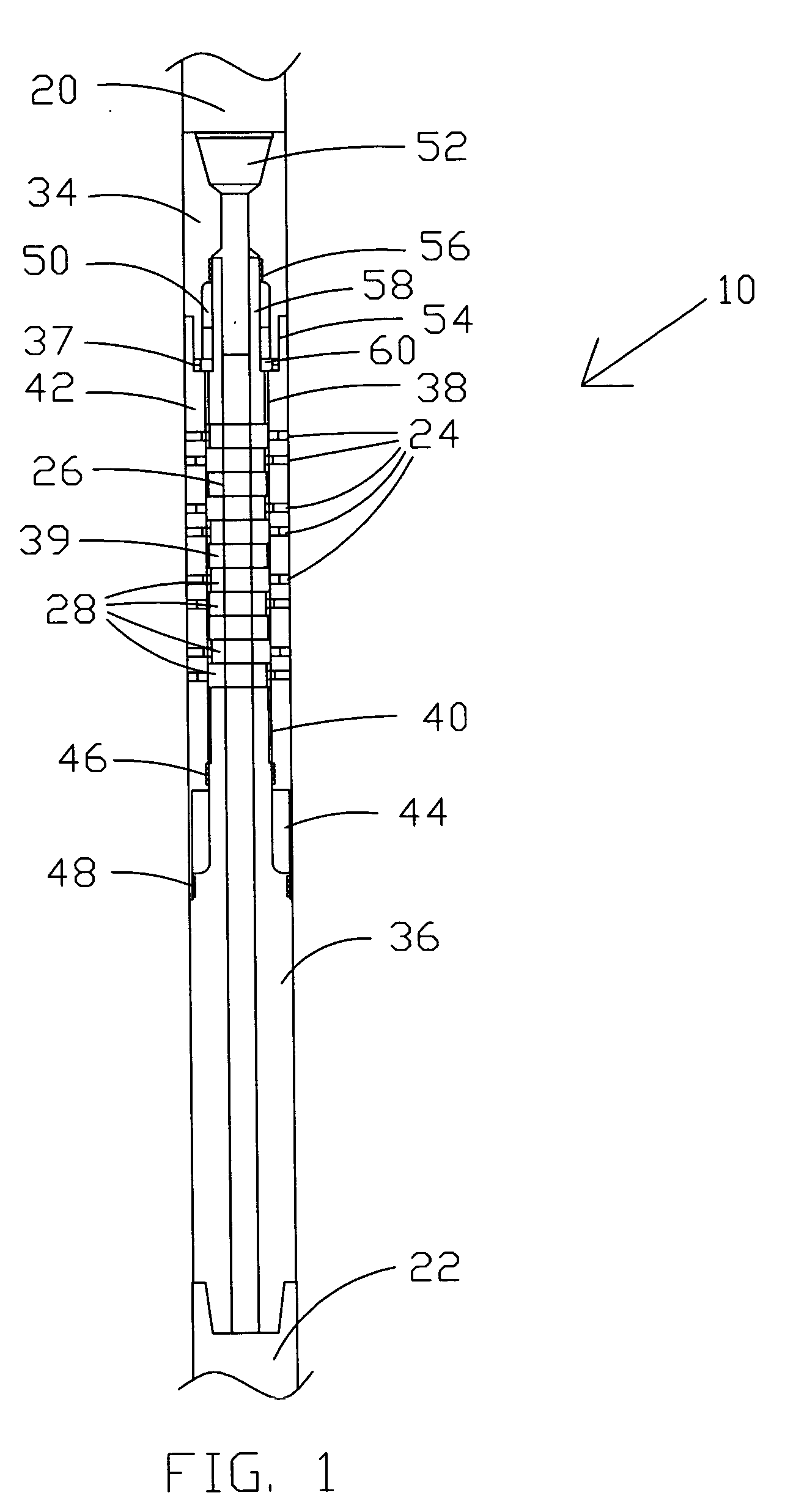

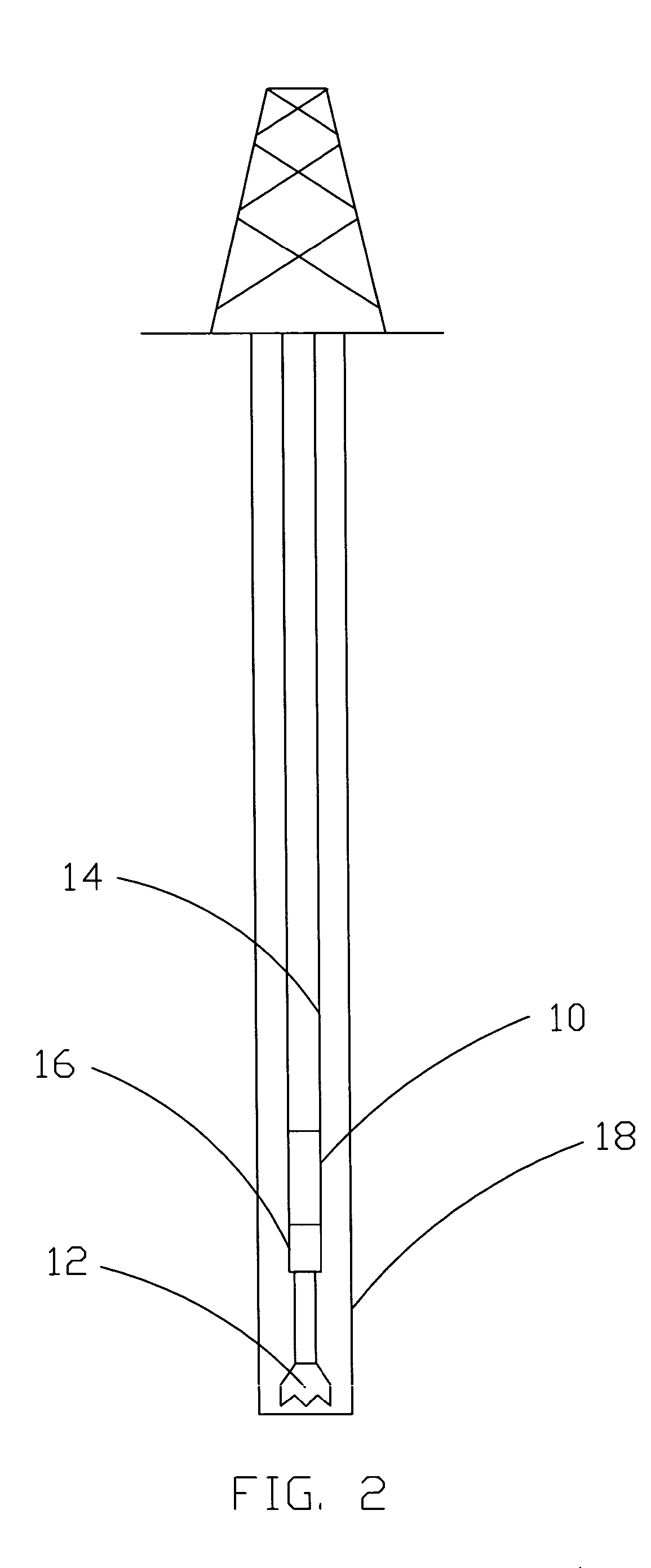

Apparatus And Method For Damping Vibration In A Drill String

ActiveUS20120228028A1Reducing drill string torsional vibrationLimiting maximum angular velocityDrilling rodsDirectional drillingMagnetorheological fluidAngular velocity

An apparatus and method for damping vibration, especially torsional vibration due to stick-slip, in a drill string, Sensors measure the instantaneous angular velocity of the drill string at one or more locations along the length of the drill string. One or more vibration damping modules are also spaced along the length of the drill string. When torsional vibration above a threshold is detected, the damping module imposes a reverse torque on the drill that dampens the torsional vibration. The reverse torque can be created by imparting a frictional resistance to the rotation of the drill string. The frictional resistance can be created externally, by extending friction pads from the damping module so that they contact the bore hole wall and drag along the bore hole as the drill string rotates, or internally by anchoring a housing mounted on the drill string to the wall of the bore hole and then imposing frictional resistance on a fluid, such as a magnetorheological fluid, flowing within the drill string.

Owner:APS TECH

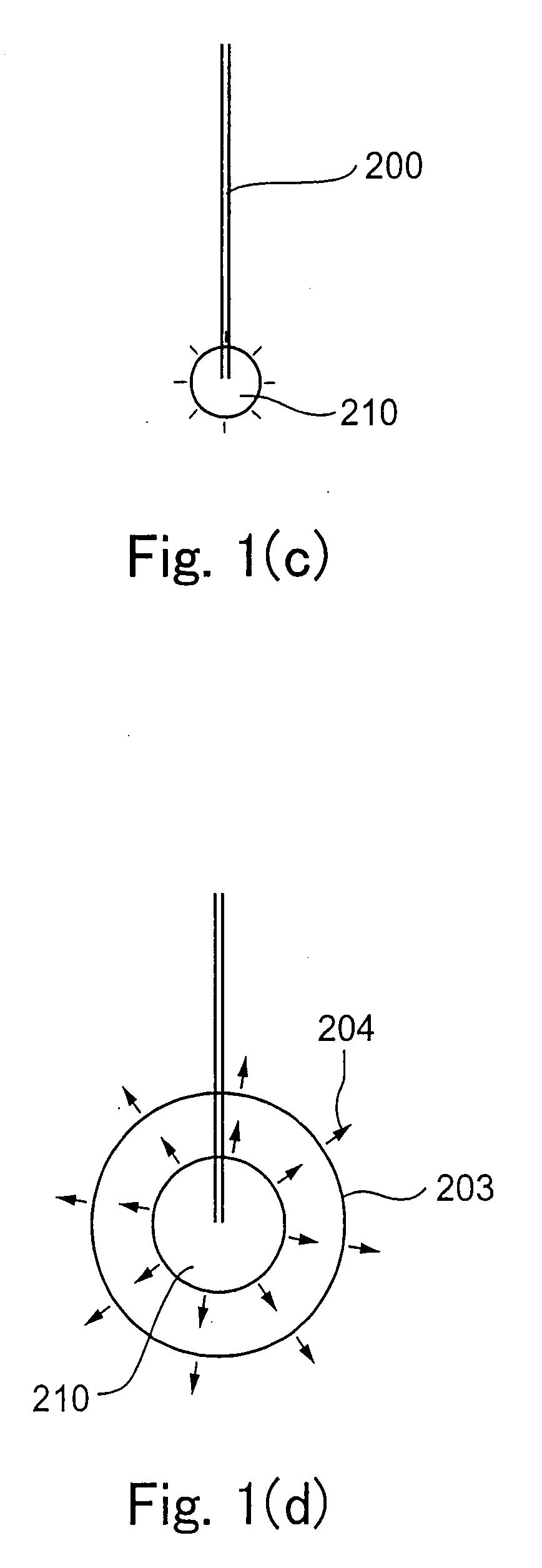

Method and device for excavating submerged stratum

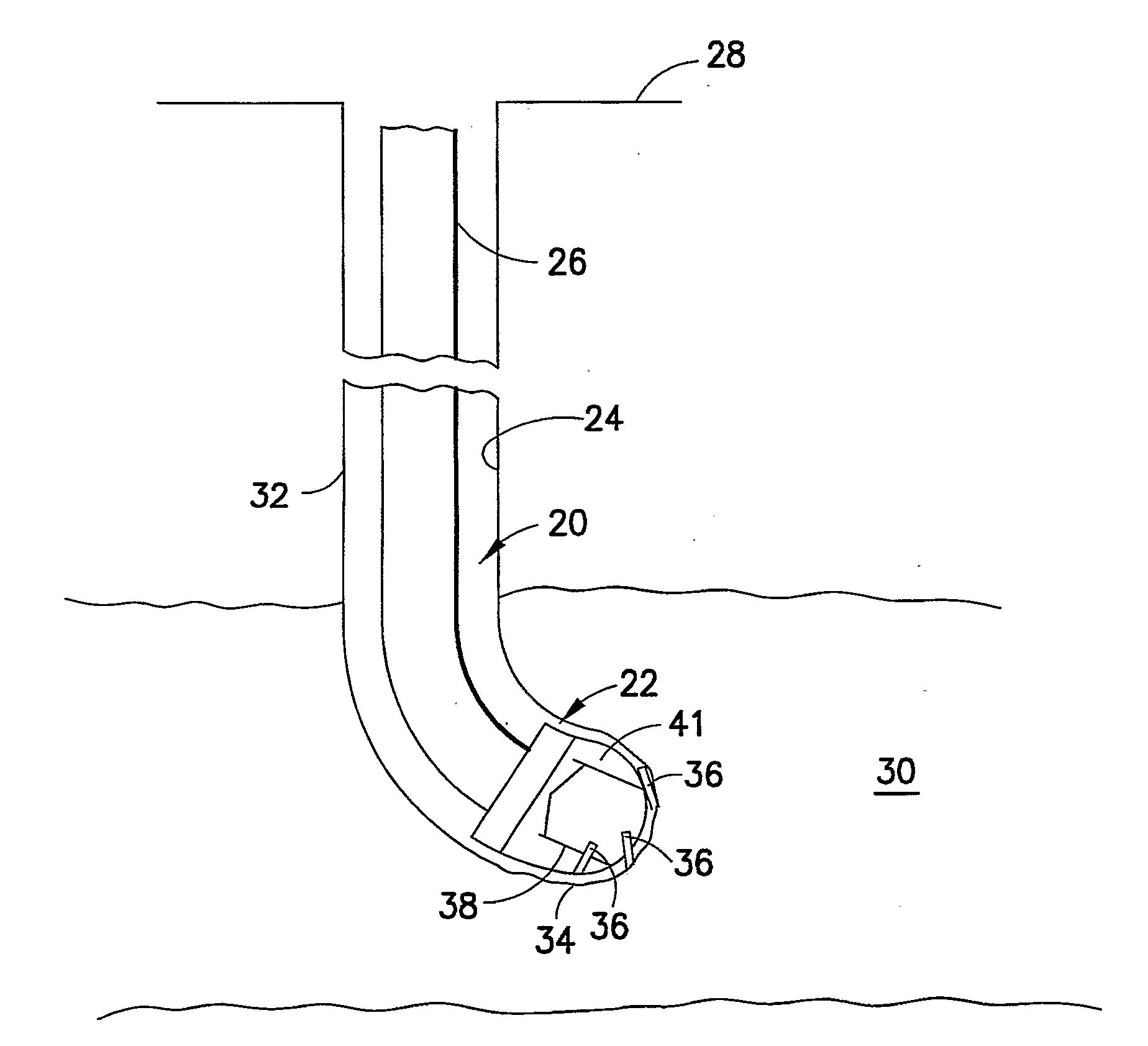

InactiveUS20090126235A1Reduce energy transferReduce loadMachines/dredgers working methodsMechanical machines/dredgersAbsorptanceLaser induced bubble

An excavation technique for a stratum capable of excavating a submerged stratum such as a layer containing an underground resource by using laser irradiation in liquid is provided. In this technique, a laser beam transmitted through laser transmission means 20 is irradiated in liquid 90 in form of a laser beam having a wavelength with high absorptance of the liquid 90 by laser-induced bubble generation means 35, generating a bubble flow 36, thus excavation of a submerged stratum may be carried out by using a laser-induced destruction effect. Moreover, a laser beam 41 having low absorptance of the liquid 90 is irradiated by laser irradiation means 39 and passed through the bubble flow 36, thereby applying a thermal effect to a stratum to destroy rock and excavate the stratum. The destruction effect and the thermal effect also may be cooperatively worked.

Owner:JAPAN DRILLING CO LTD +2

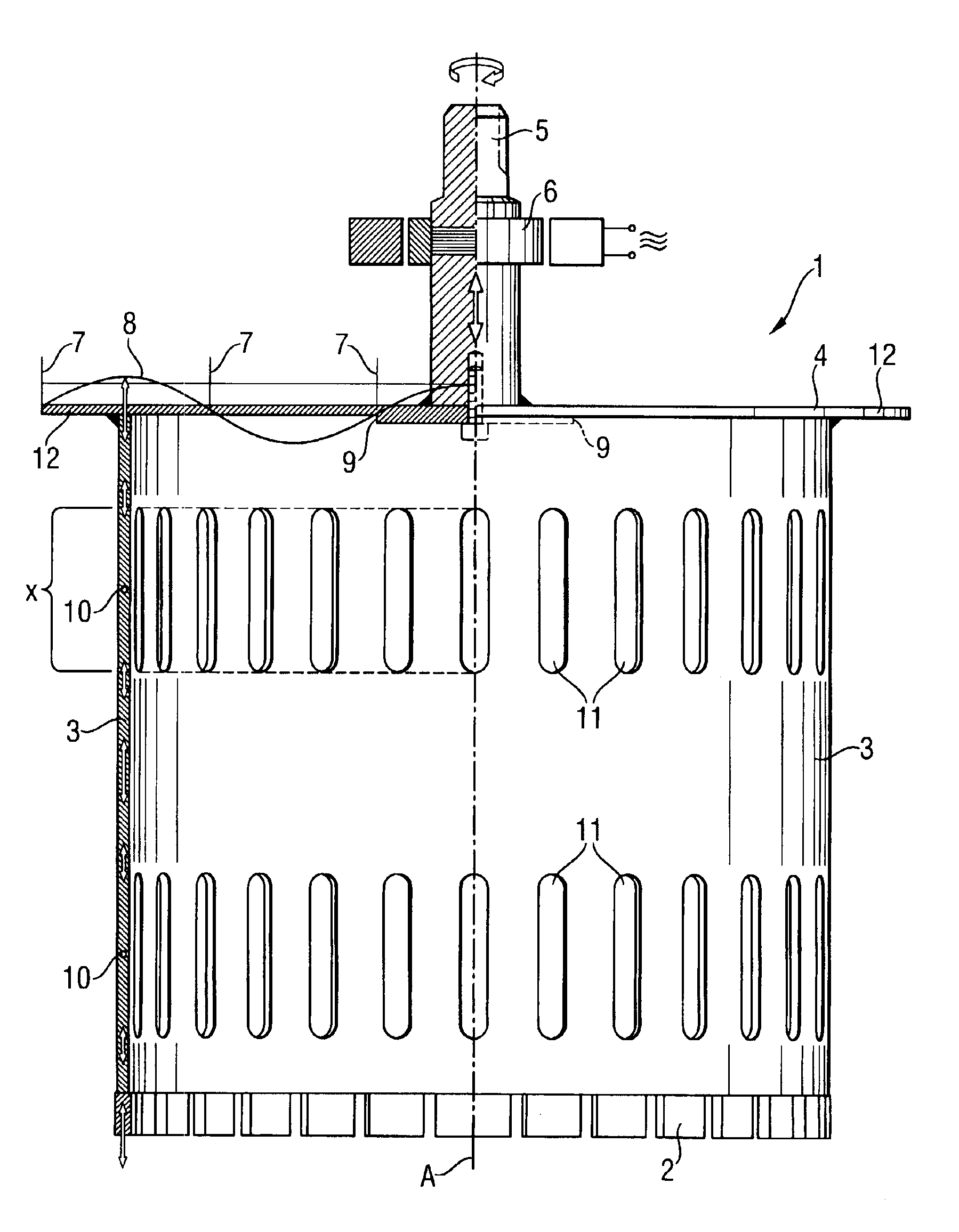

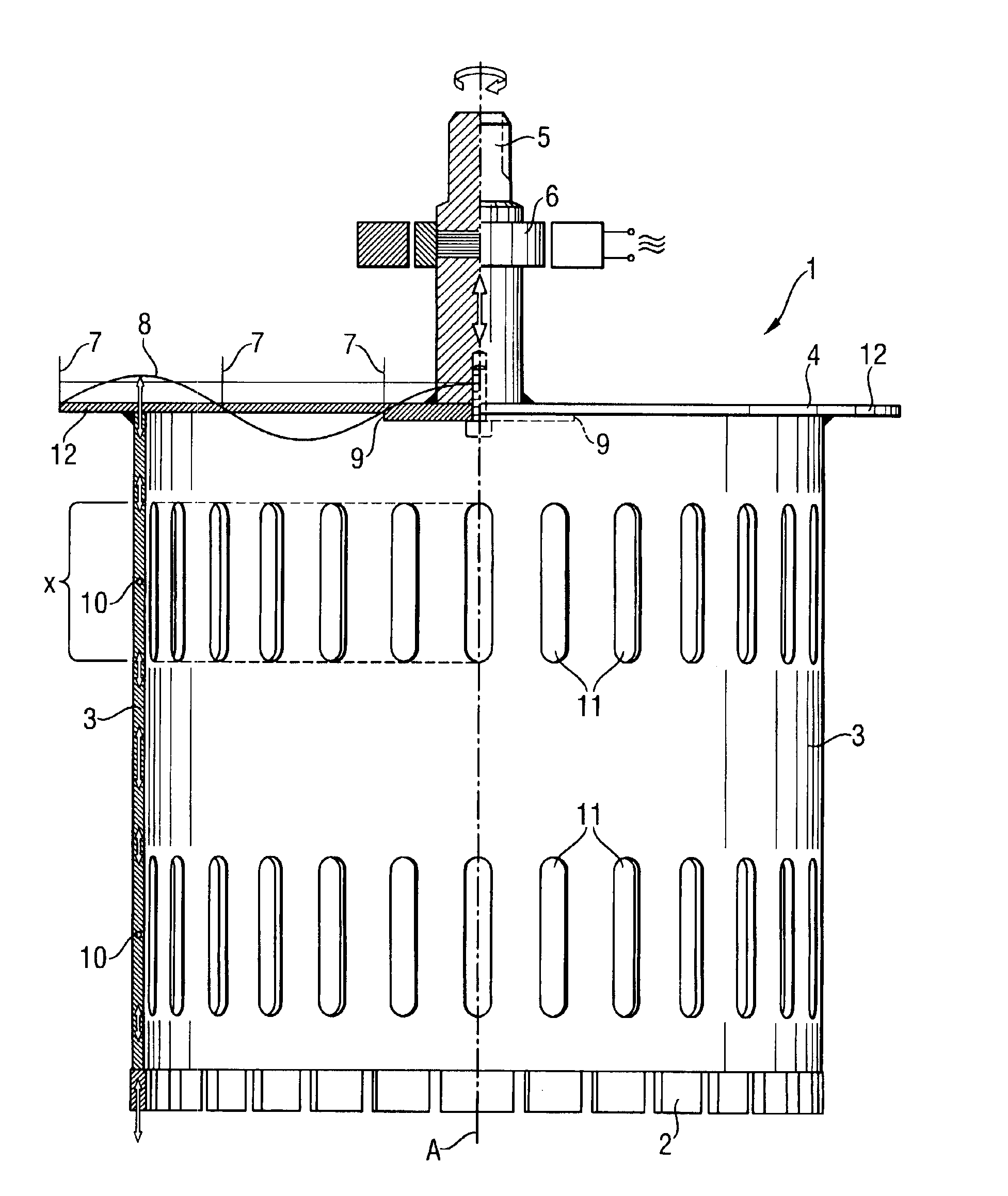

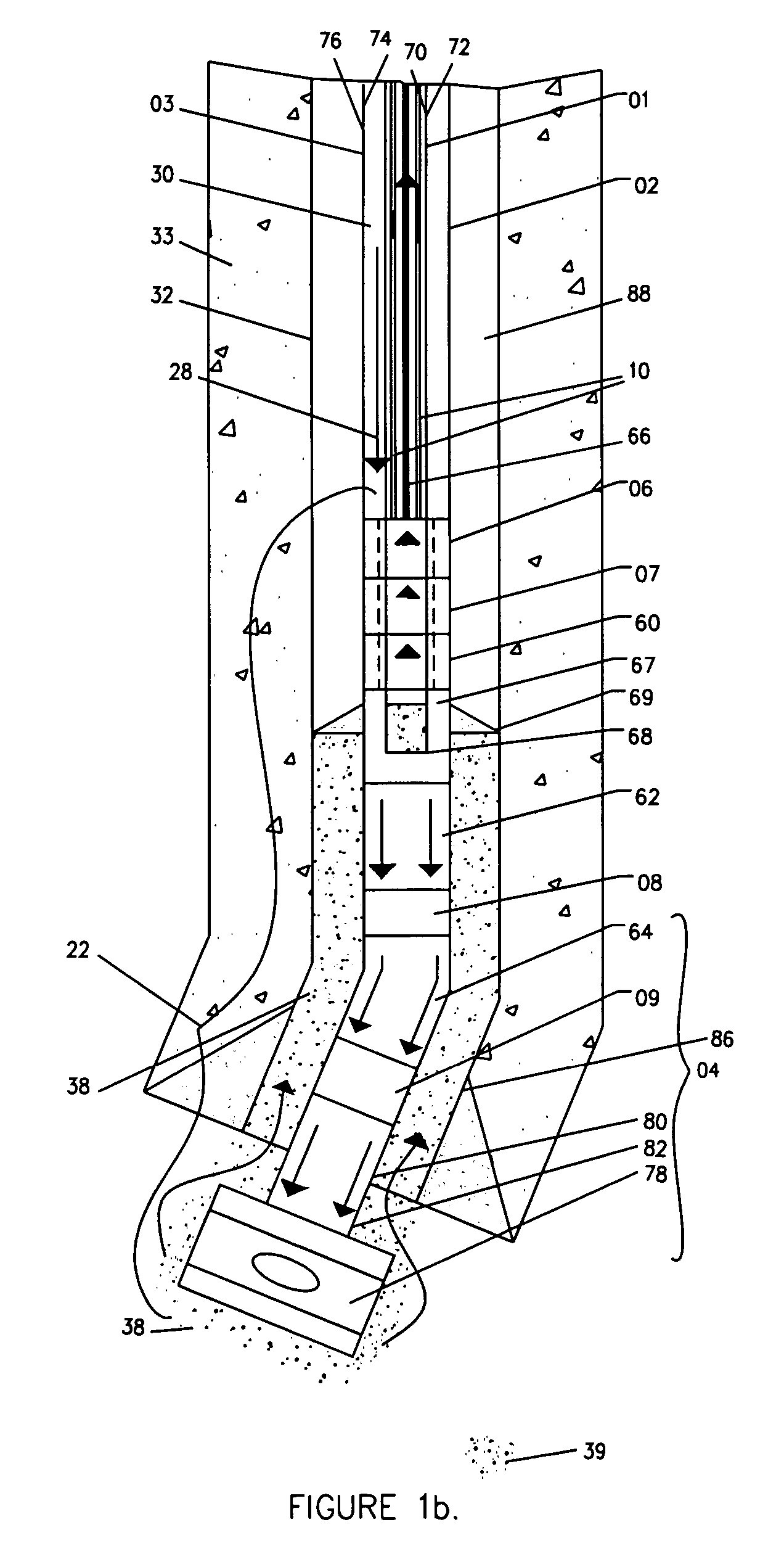

Hydro-oscillator for well drilling

InactiveCN102704842AIncrease frictional resistanceIncrease drilling speedVibration devicesVibration drillingWell drillingHarmonic vibration

The invention relates to a hydro-oscillator for well drilling. The hydro-oscillator consists of a hydraulic driving assembly, a fixed valve assembly, a bottom assembly and a vibrating pipe nipple, wherein the vibrating pipe nipple is connected with the hydraulic driving assembly; a rotor is connected with a vibrating valve; the fixed valve assembly is arranged on the bottom assembly; and a power shell is connected with the bottom assembly. A drilling fluid is used for driving the rotor to rotate, and the rotor is used for driving the vibrating valve to vibrate, so that flow holes of the vibrating valve and a fixed valve are staggered with each other, and simple harmonic pressure waves are modulated and are upwardly transmitted to a disc spring for driving the vibrating shell to perform continuous simple harmonic vibration in the axial direction, so that the friction resistance between a drilling column and a well wall is improved effectively, and the drilling speed is increased; and meanwhile, pressure waves are downwardly transmitted to drill bit jet flow, so that periodic change of rock breaking pressure is facilitated, and rocks are crushed effectively. The hydro-oscillator has the characteristics of simple structure, convenience for operating, safety, reliability, low pressure drop, high adaptability, no influence on the drilling tool structure and the like, and plays an important role in increasing the drilling speed and reducing cost.

Owner:CHINA PETROCHEMICAL CORP +1

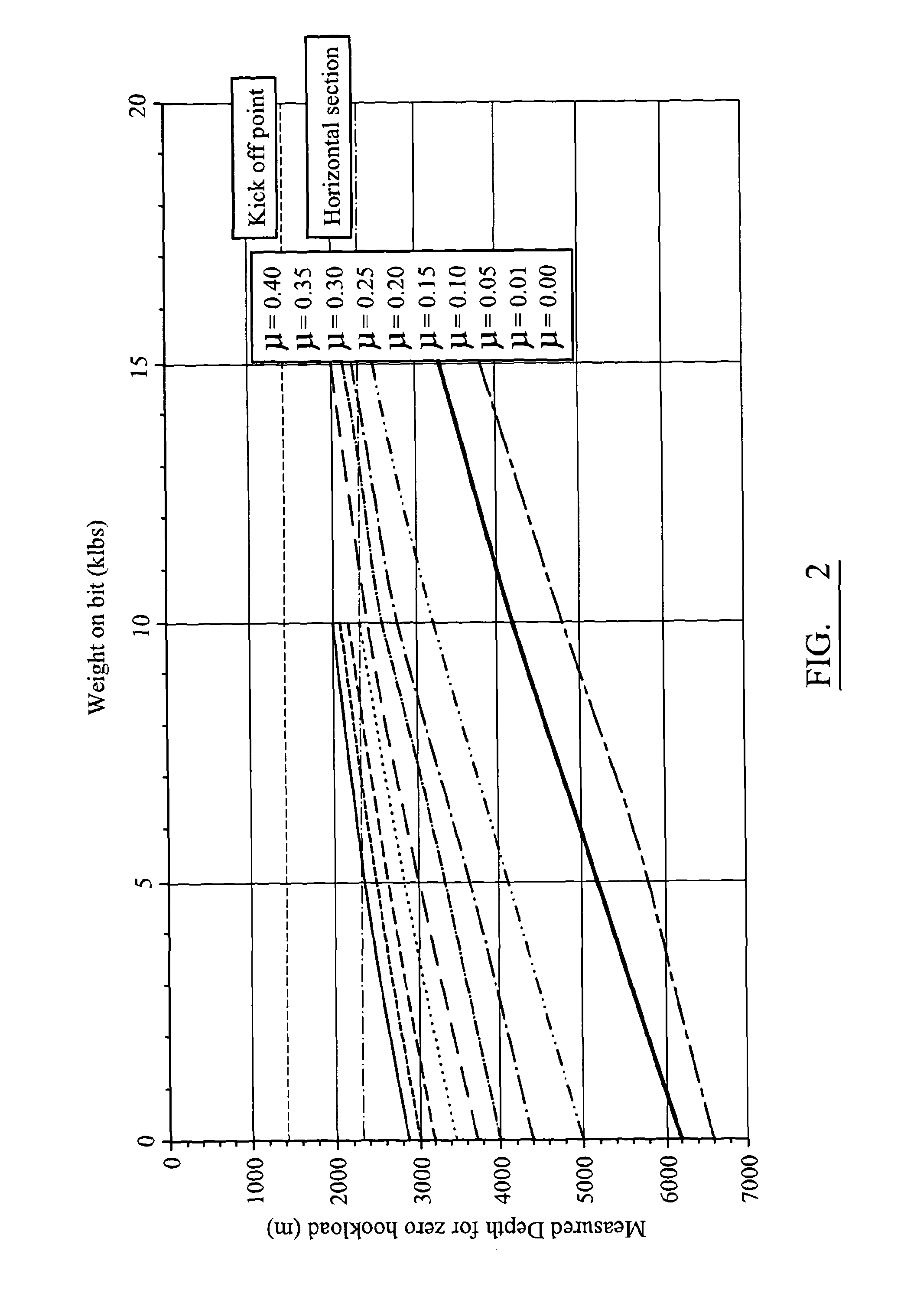

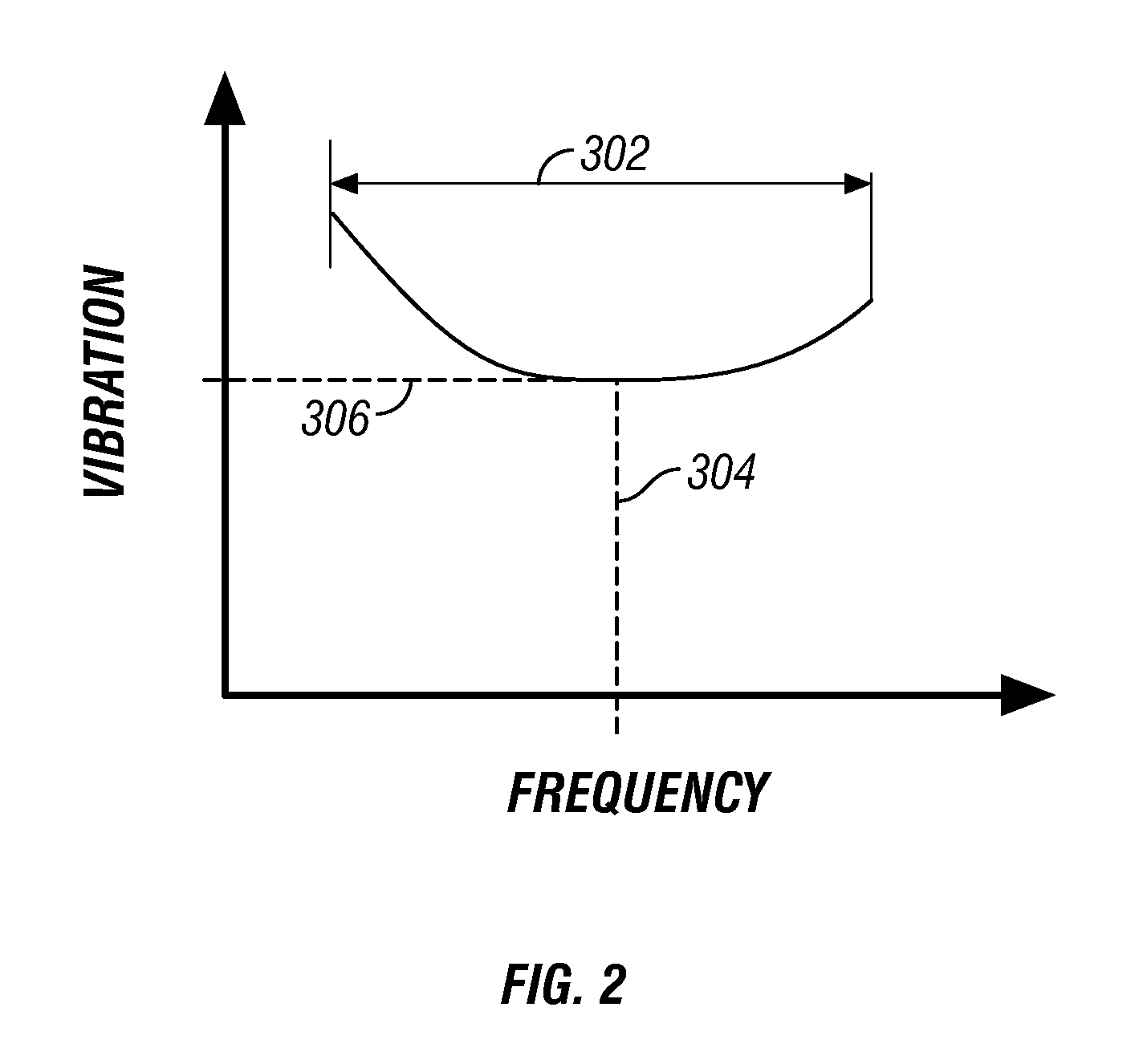

Method and apparatus for applying vibrations during borehole operations

A method of conducting borehole operations using a system including an elongate tubular conveyance that is moved through the borehole, the method comprising imposing a torsional vibration at a predetermined frequency on the tubular conveyance as it is moved through the borehole:wherein the predetermined frequency is obtained by determining the frequency-dependent mobility of the system based on the relationship between rotational velocity and torque for the system; and imposing torsional vibrations at a frequency where the relationship is optimised.

Owner:MISC

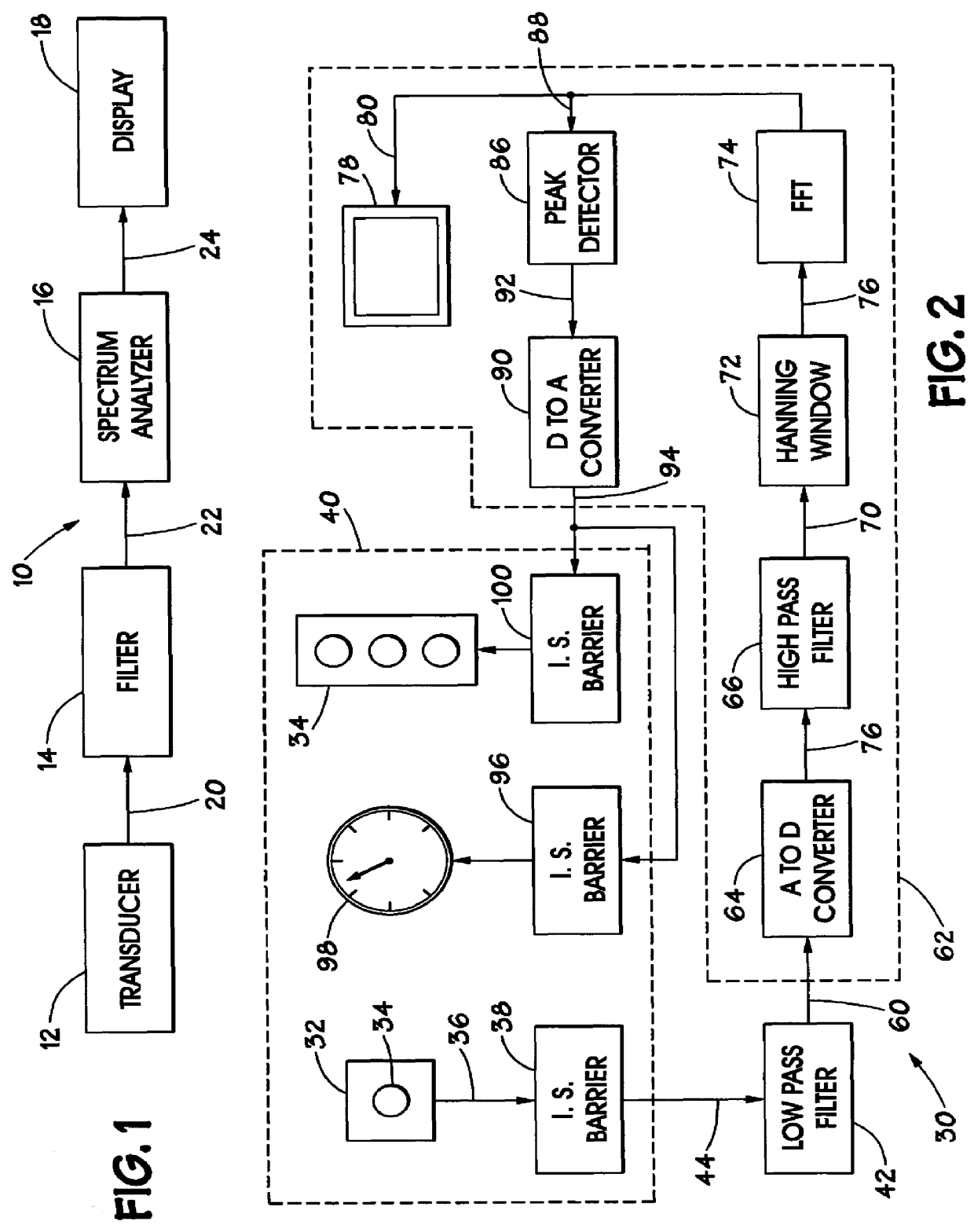

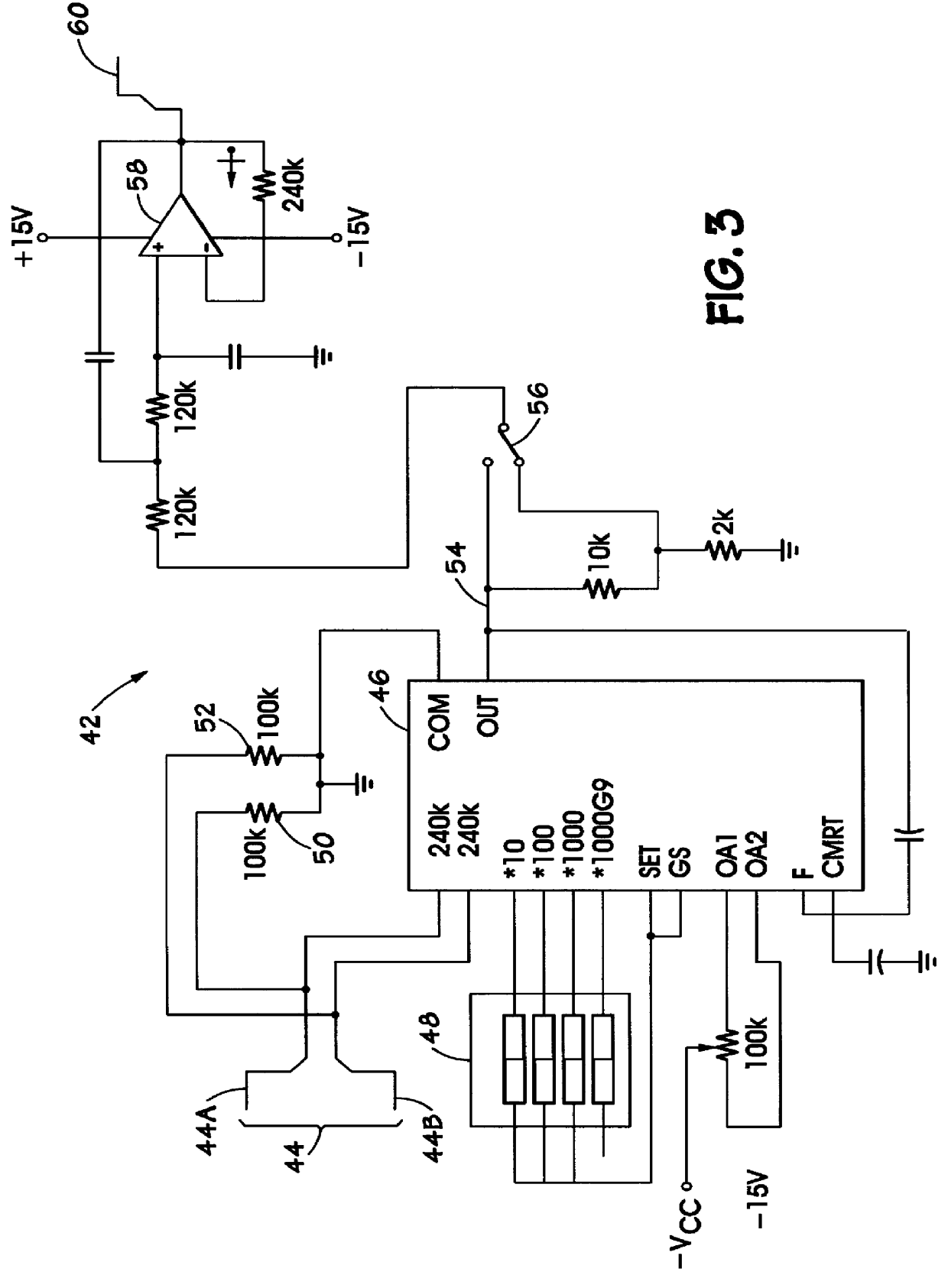

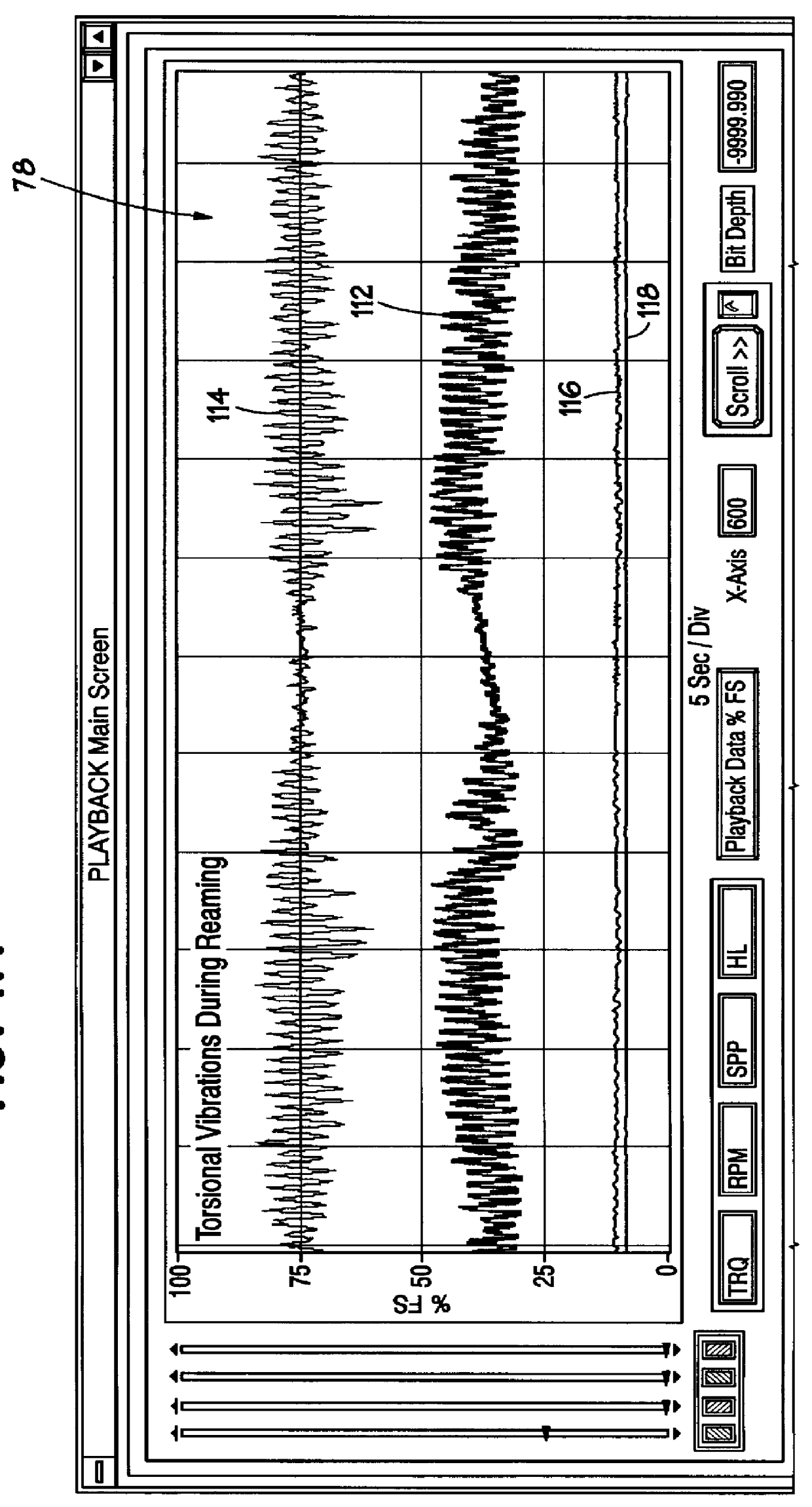

Method and apparatus for sensing and displaying torsional vibration

A method and apparatus for sensing and displaying the magnitude of torsional vibrations. A transducer provides a signal indicative of the torsional vibrations being experienced by a rotating member. The magnitude of the frequency components of the signal are determined and displayed to an operator who may take corrective action.

Owner:HALLIBURTON ENERGY SERVICES INC

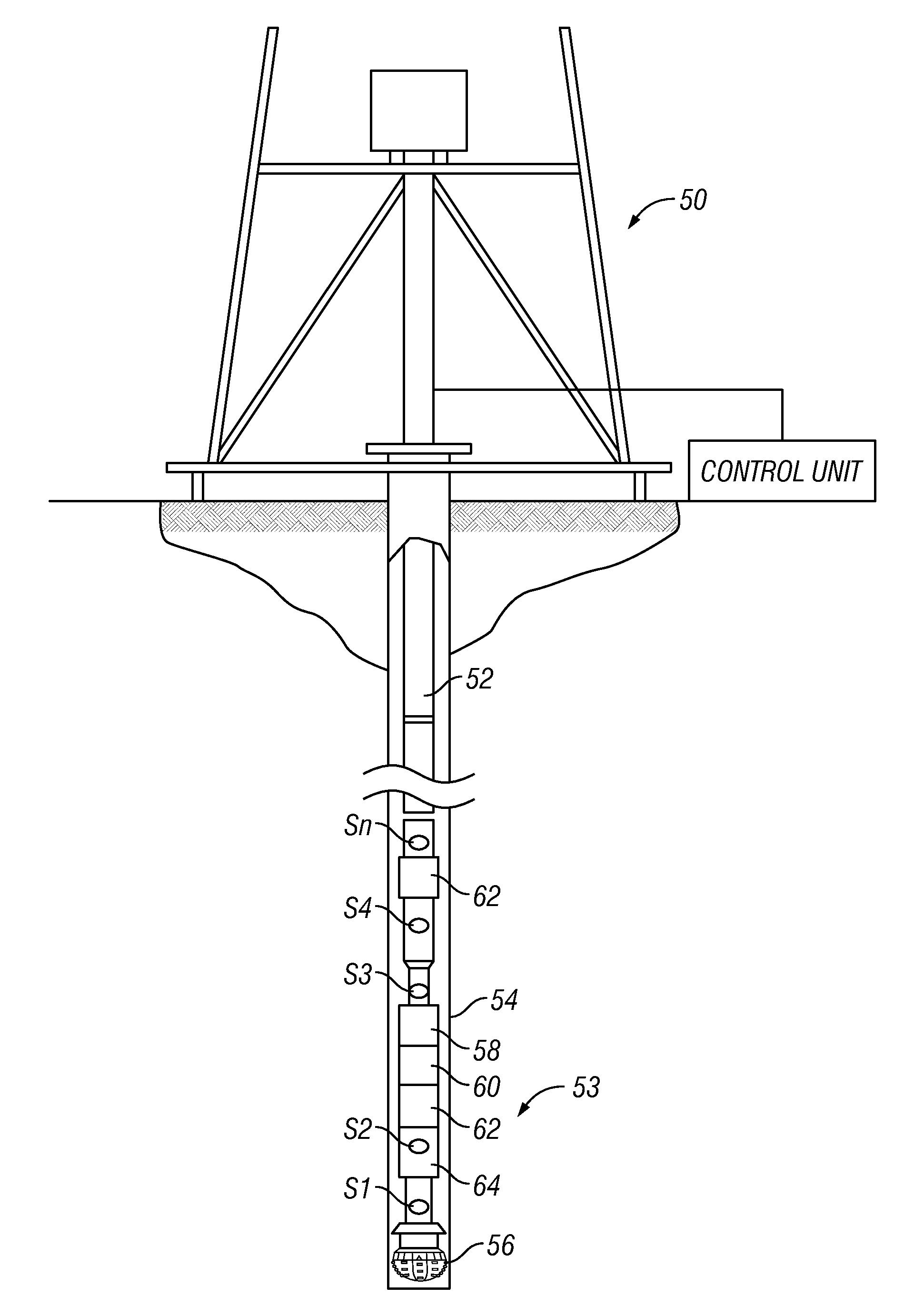

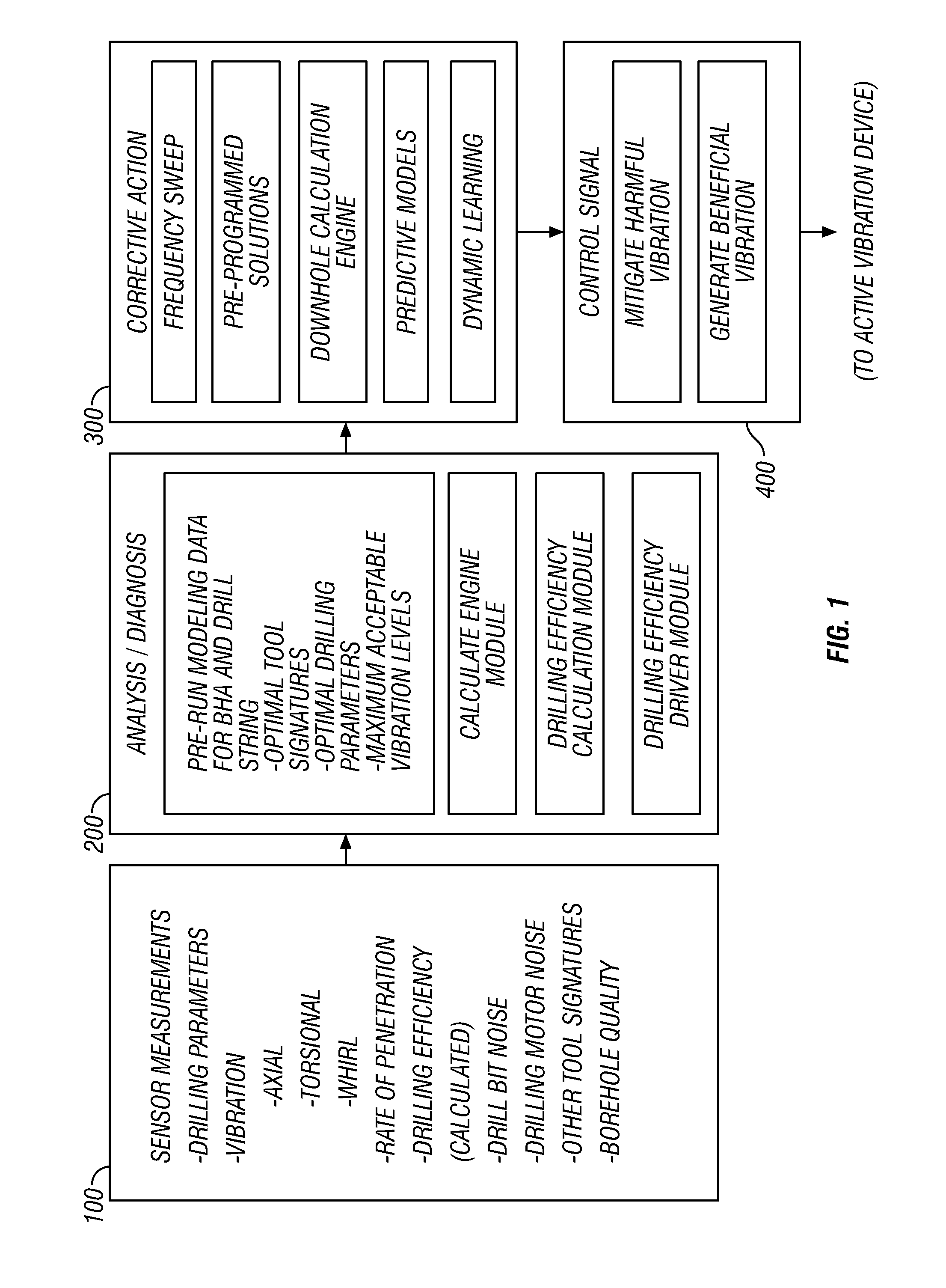

Active Vibration Control for Subterranean Drilling Operations

InactiveUS20100139977A1Prevent and minimize occurrenceImproves one and more aspectDirectional drillingVibration devicesControl signalWell drilling

An active vibration control device improves drilling by actively applying a dampening profile and / or a controlled vibration to a drill string and / or bottomhole assembly (BHA). Embodiments of the present invention control the behavior of a drill string and / or BHA in order to prevent or minimize the occurrence of harmful drill string / BHA motion and / or to apply a vibration to the drill string / BHA that improves one or more aspects of the drilling process. Measurements of one or more selected parameters of interest are processed to determine whether the undesirable vibration or motion is present in the drill string or BHA and / or whether the drill string and / or BHA operation can be improved by the application of a controlled vibration. If either or both conditions are detected, corrective action is formulated and appropriate control signals are transmitted to one or more devices in the drill string and / or BHA.

Owner:BAKER HUGHES INC

Steering Head with Integrated Drilling Dynamics Control

ActiveUS20130092441A1Reduce vibrationSampled-variable control systemsDrilling rodsEngineeringActuator

A method, apparatus and computer-readable medium for reducing a vibration of a drill string in a borehole. A sensor of the drill string obtains one or more measurements of a parameter of the vibration. A processor determines at least one force for controlling the measured vibration from the measured parameter. At least one actuator applies the determined at least one force against the borehole wall to control the vibration of the drill string.

Owner:BAKER HUGHES INC

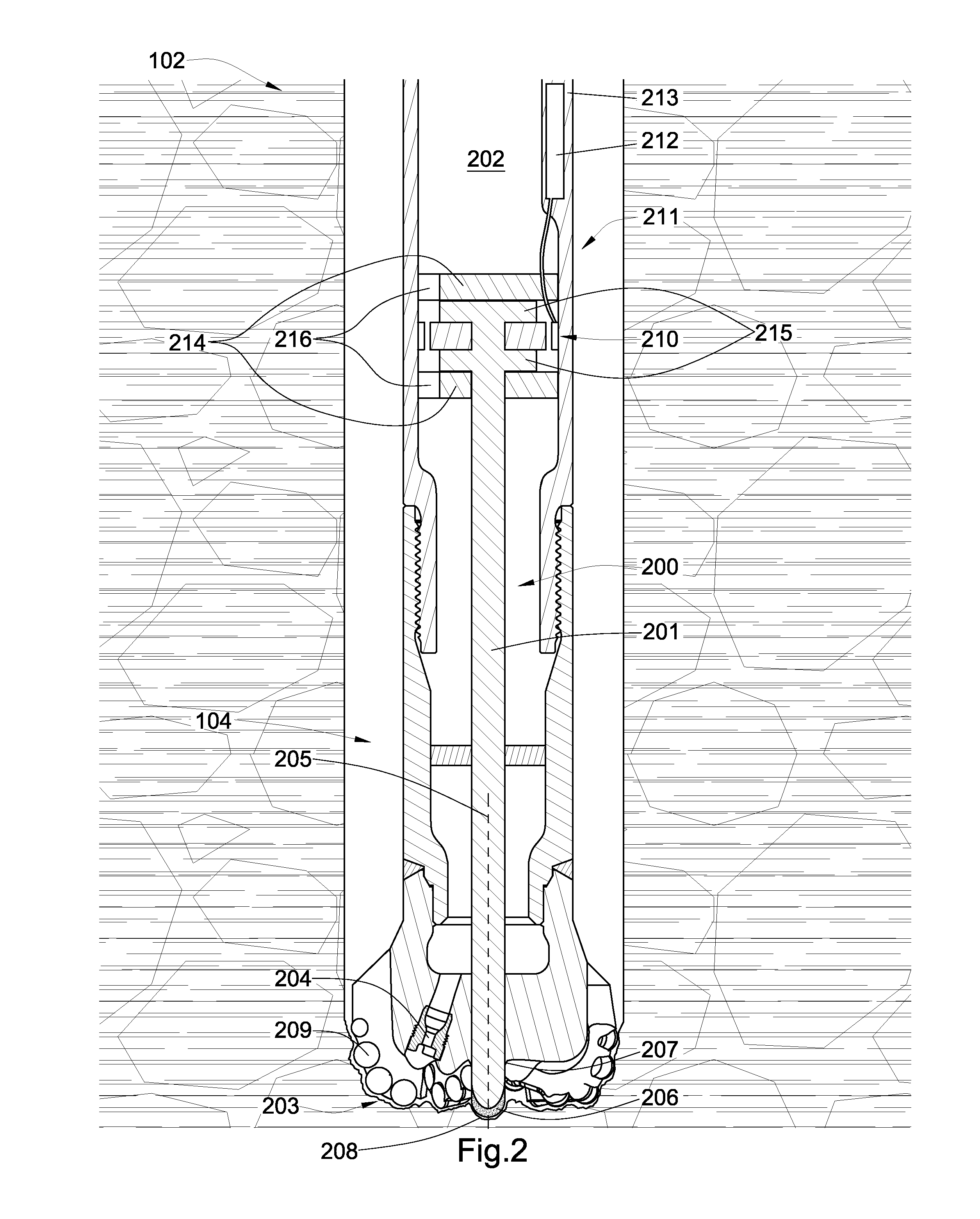

Downhole device

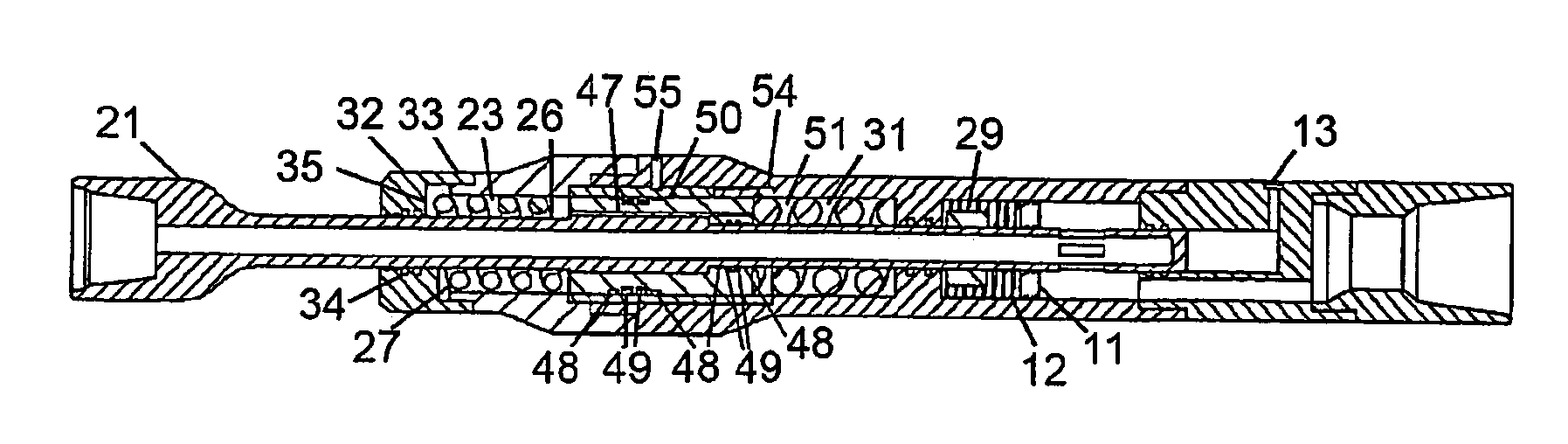

InactiveUS20110198126A1Compromising efficiencyCompromising effectivenessDrilling rodsFlushingWell drillingAxial force

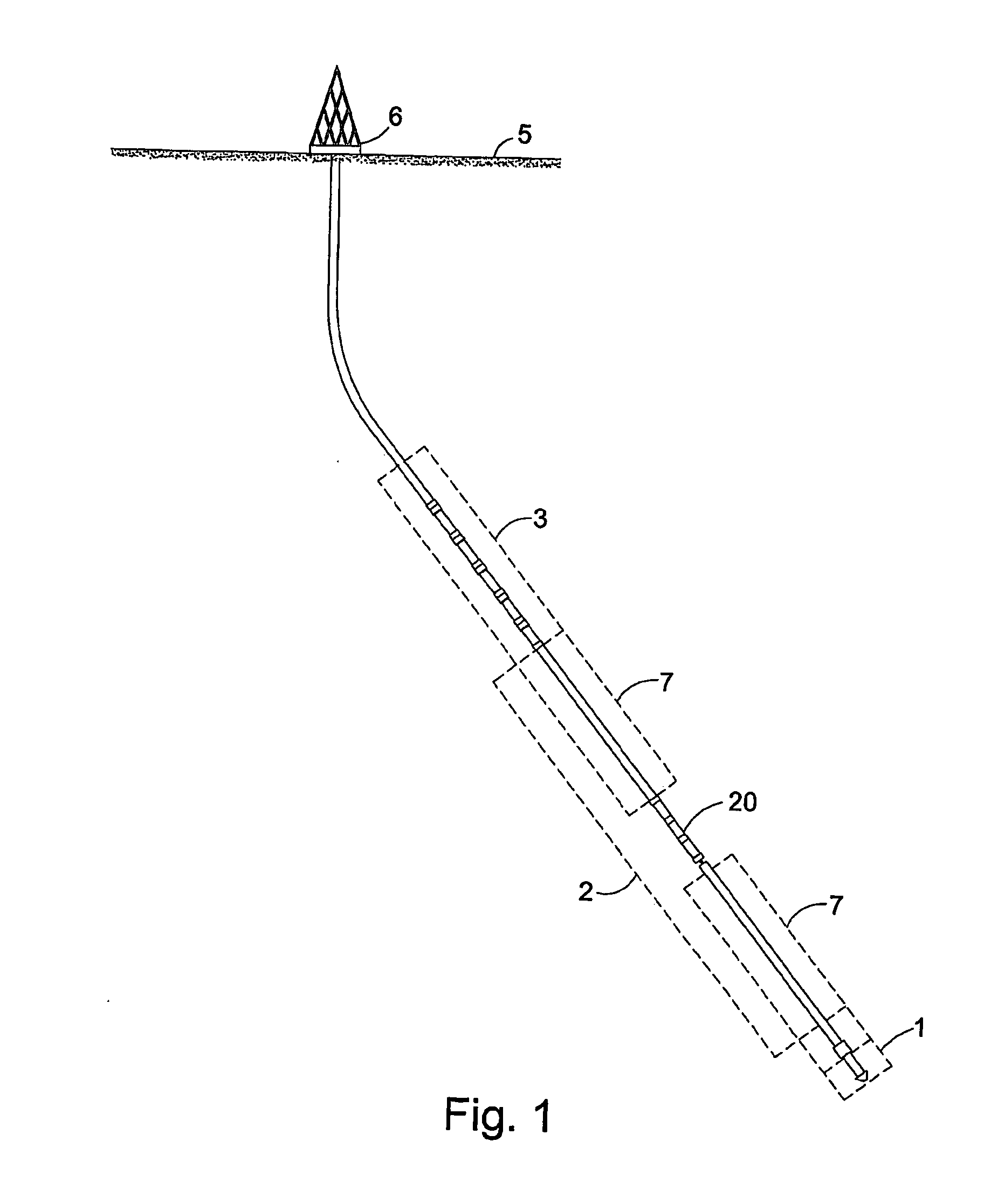

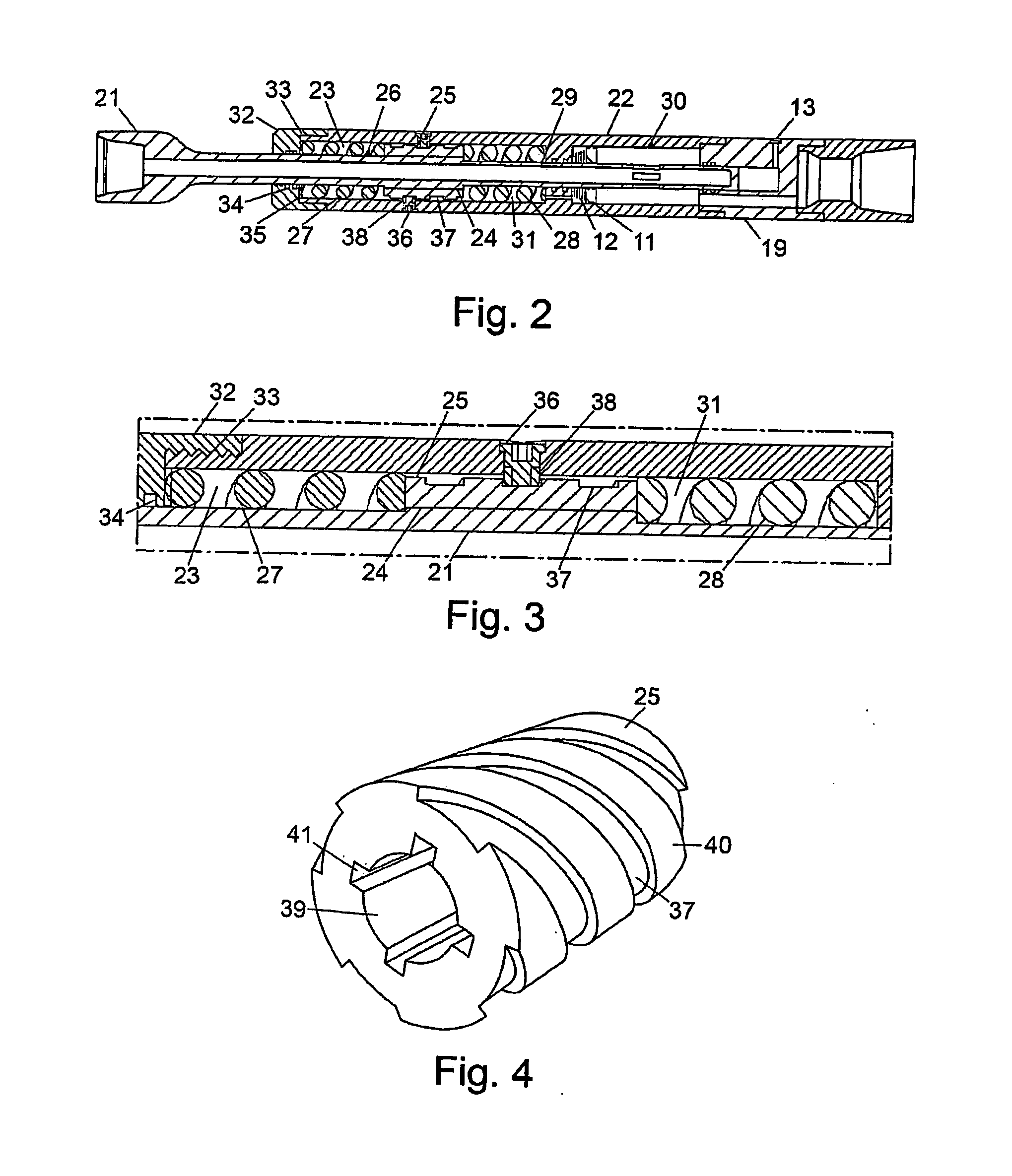

A downhole device comprising a mandrel (21) suitable for connection to a drilling assembly (3), a housing (22) surrounding said mandrel said housing being suitable for connection to the alternate end of a drilling assembly and a compensating mechanism (25) configured to adjust an axial force applied to said mandrel by changing the relative position of the mandrel with respect to the housing.

Owner:SWIETLIK GEORGE +1

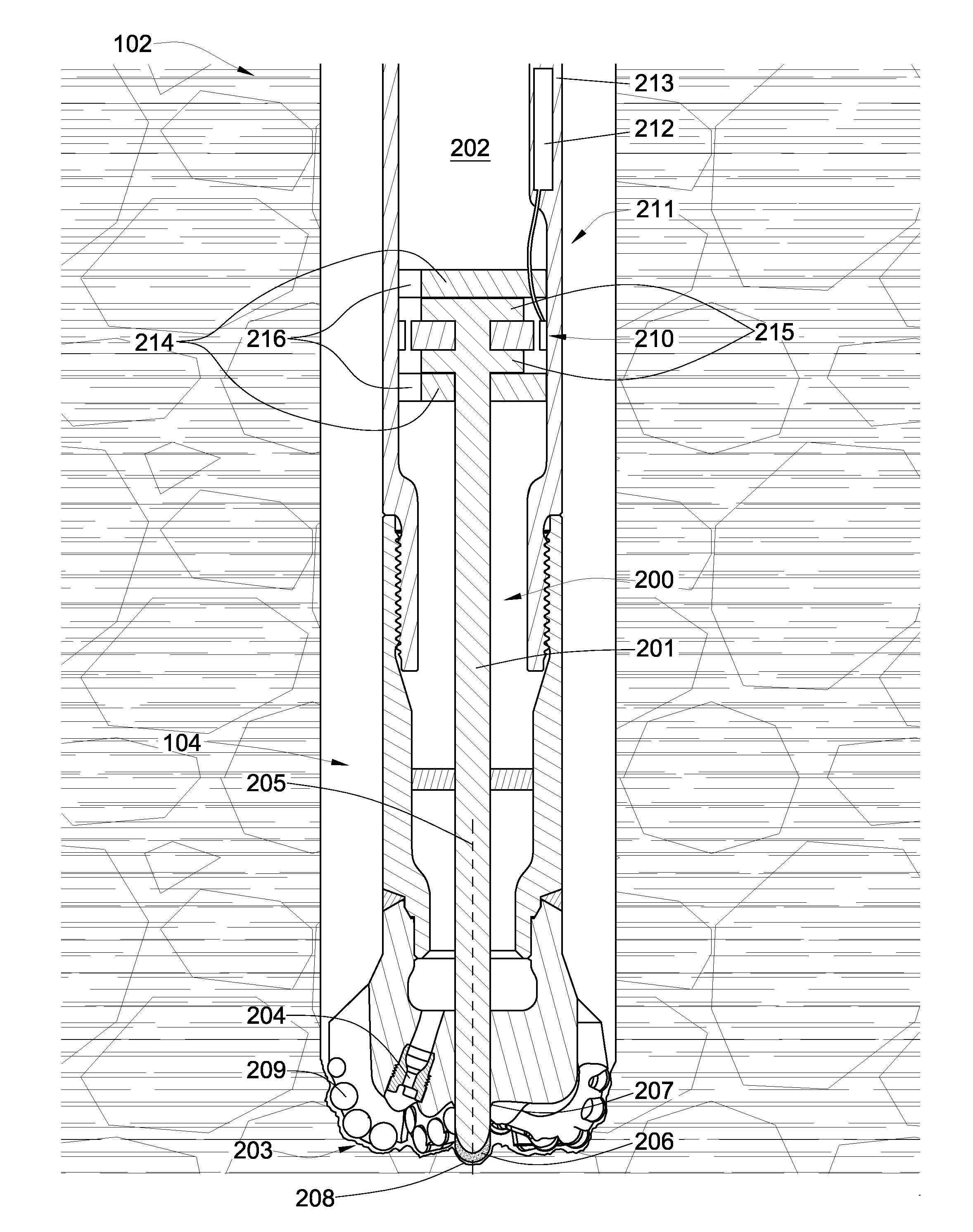

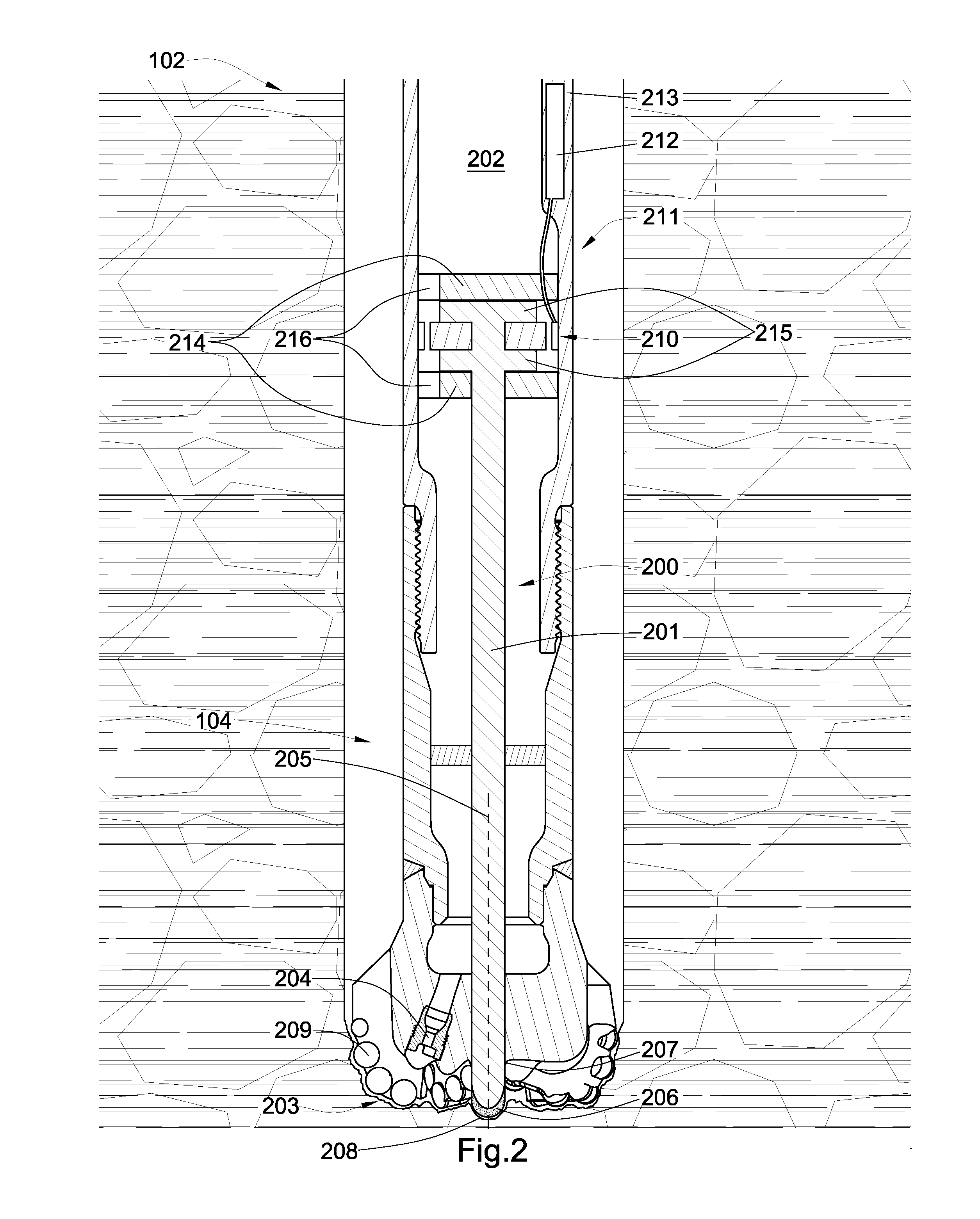

System and method for drilling a borehole

A system and method is provided for drilling a wellbore using a rotary drill bit with a bit body having a plurality of mechanical cutters to cut away formation material as the wellbore is formed and a directed energy mechanism to direct energy into the formation. The energy from the directed energy mechanism is used to enhance the cutting of the mechanical cutters by fracturing surrounding material to facilitate drilling in the direction of the directed energy.

Owner:SCHLUMBERGER TECH CORP

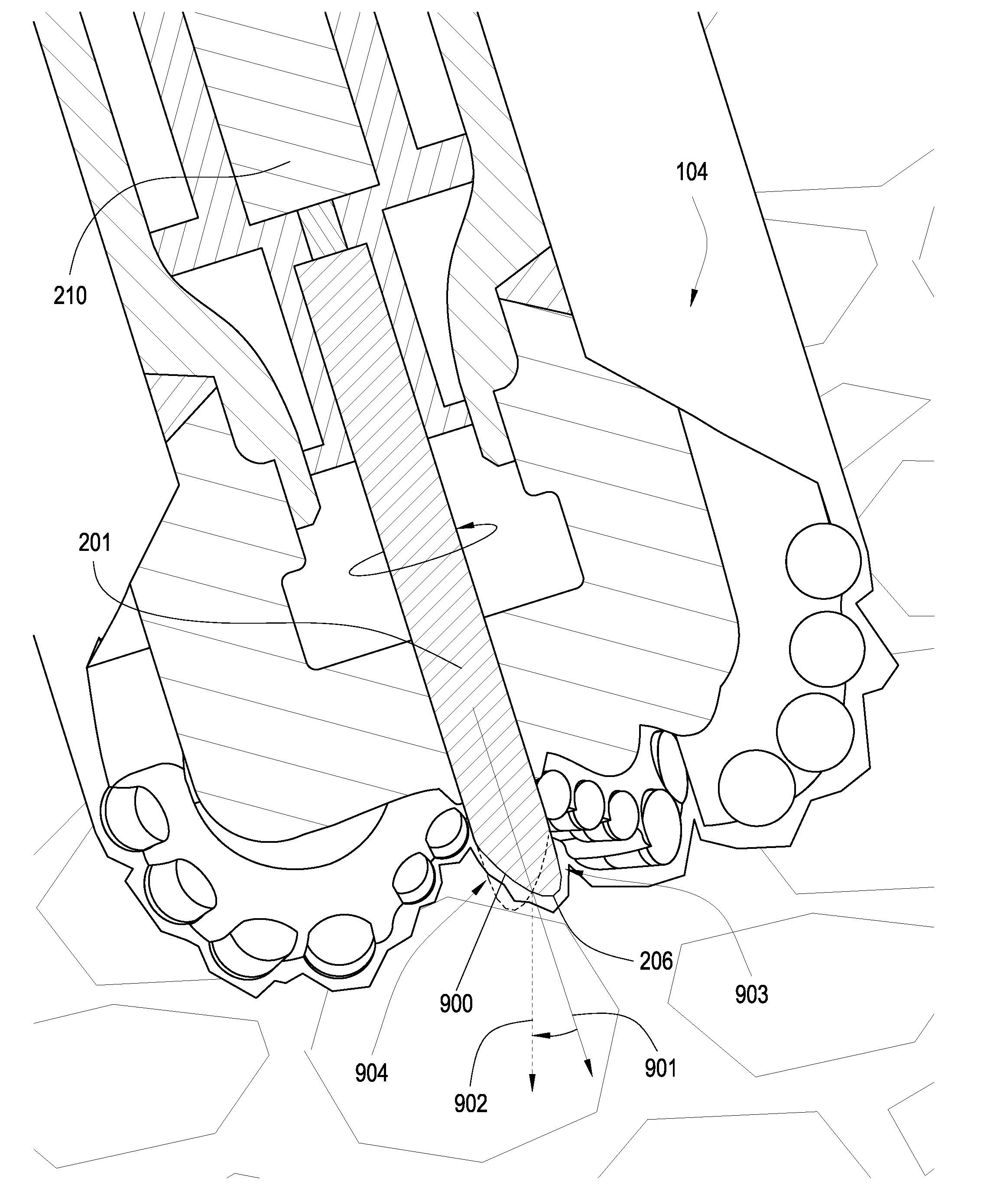

Jack Element in Communication with an Electric Motor and or Generator

A drill bit has a body intermediate a shank and a working face and has an axis of rotation. The working face has at least one cutting element and the body has at least a portion of a jack assembly. The jack assembly has at least a portion of a shaft disposed within a cavity formed in the body of the drill bit, the shaft having a distal end extending from an opening of the cavity formed in the working face. The jack assembly also has an electric motor and / or generator.

Owner:SCHLUMBERGER TECH CORP

Methods of using a laser to spall and drill holes in rocks

ActiveUS7416258B2Easy to disassembleProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

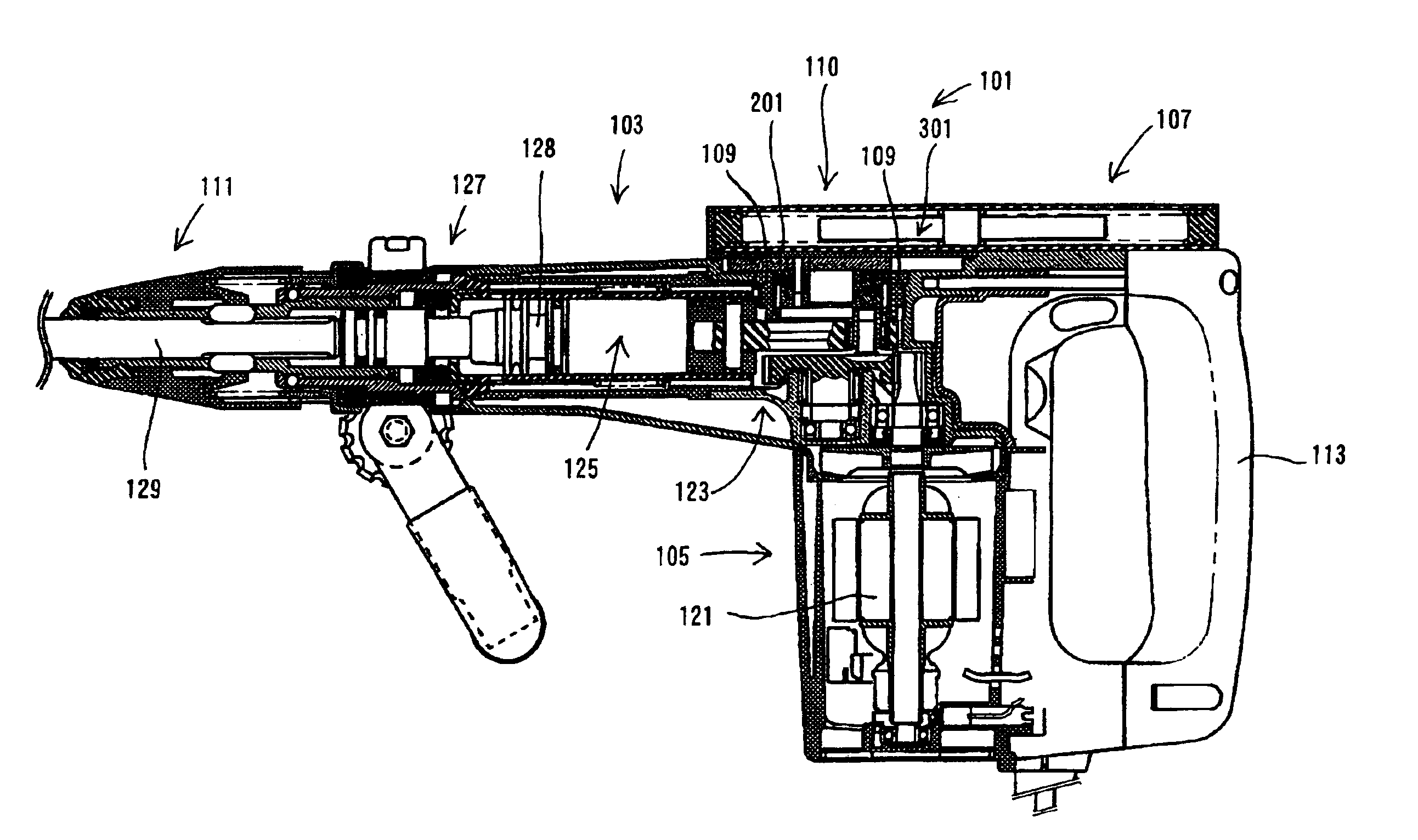

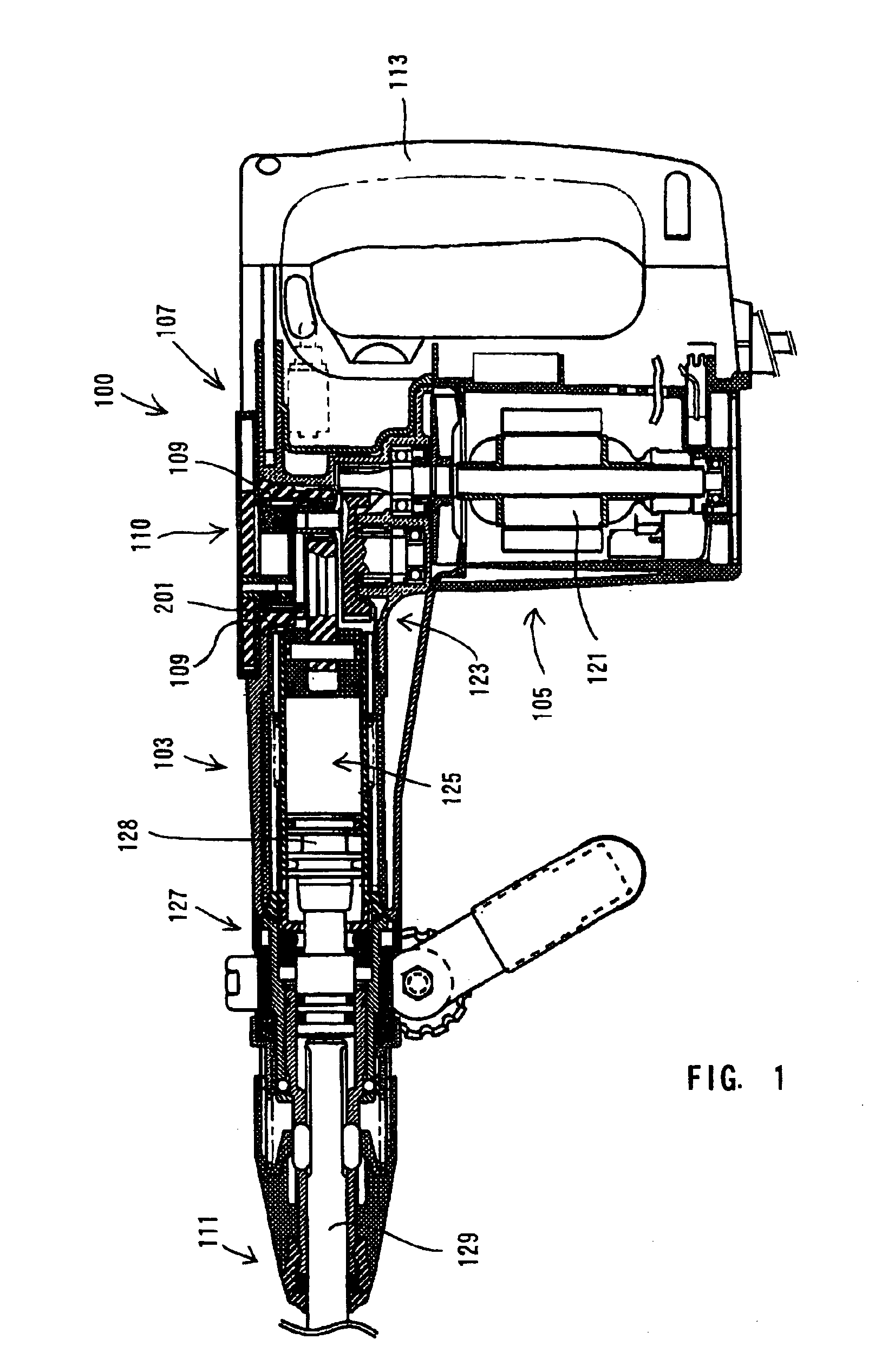

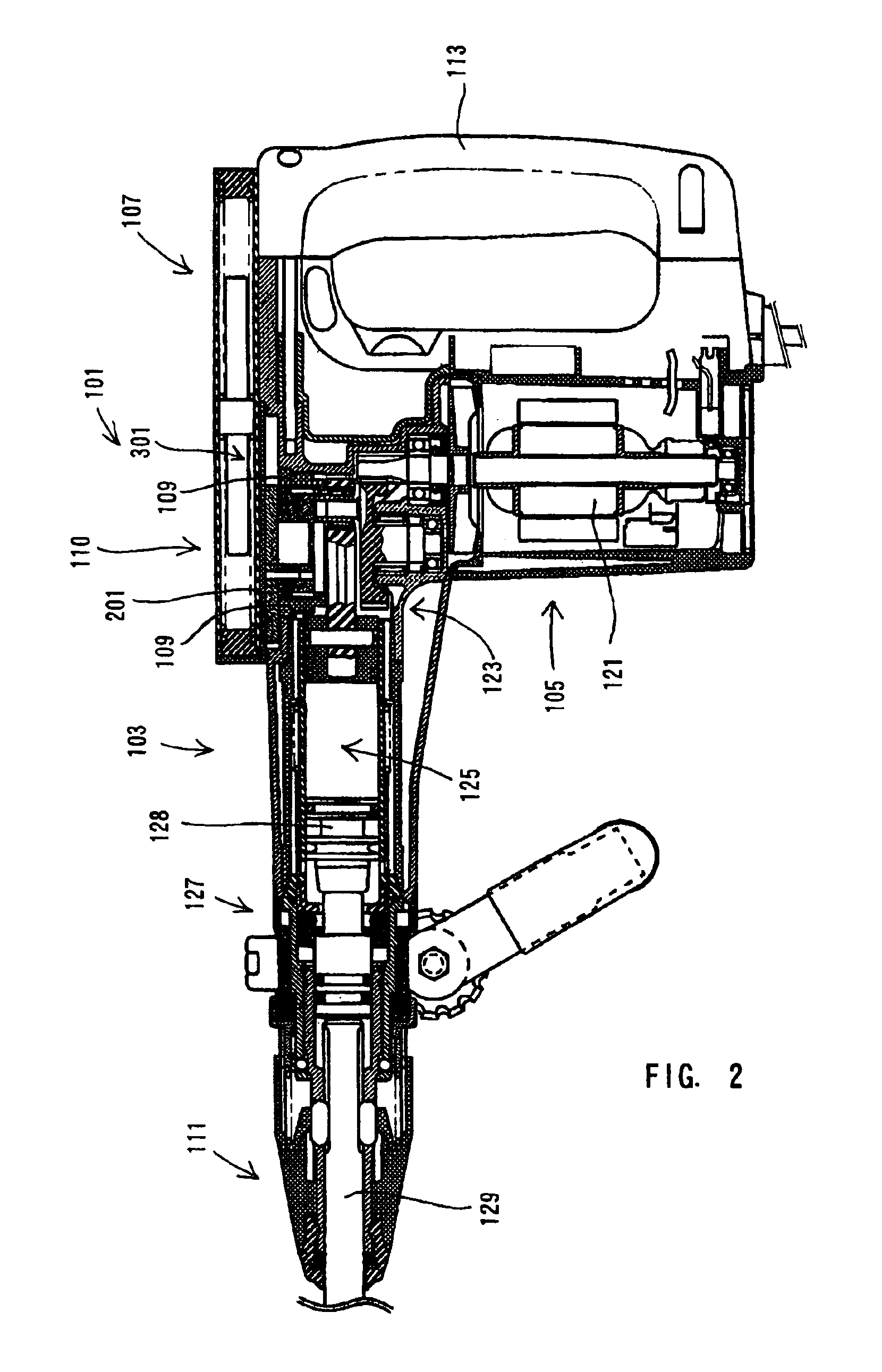

Electric hammer

ActiveUS6907943B2Easy constructionLower performance requirementsReciprocating drilling machinesPortable percussive toolsLinear motionEngineering

Owner:MAKITA CORP

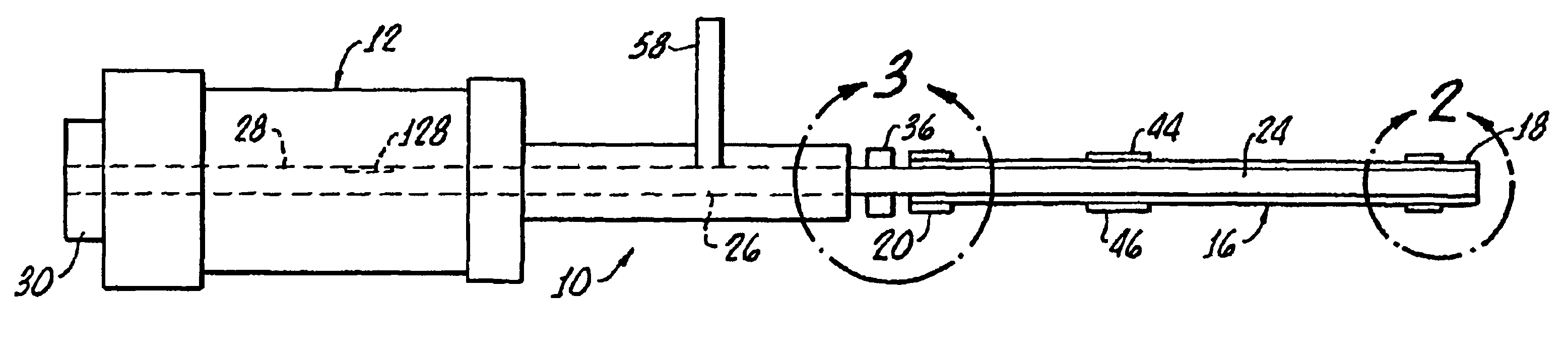

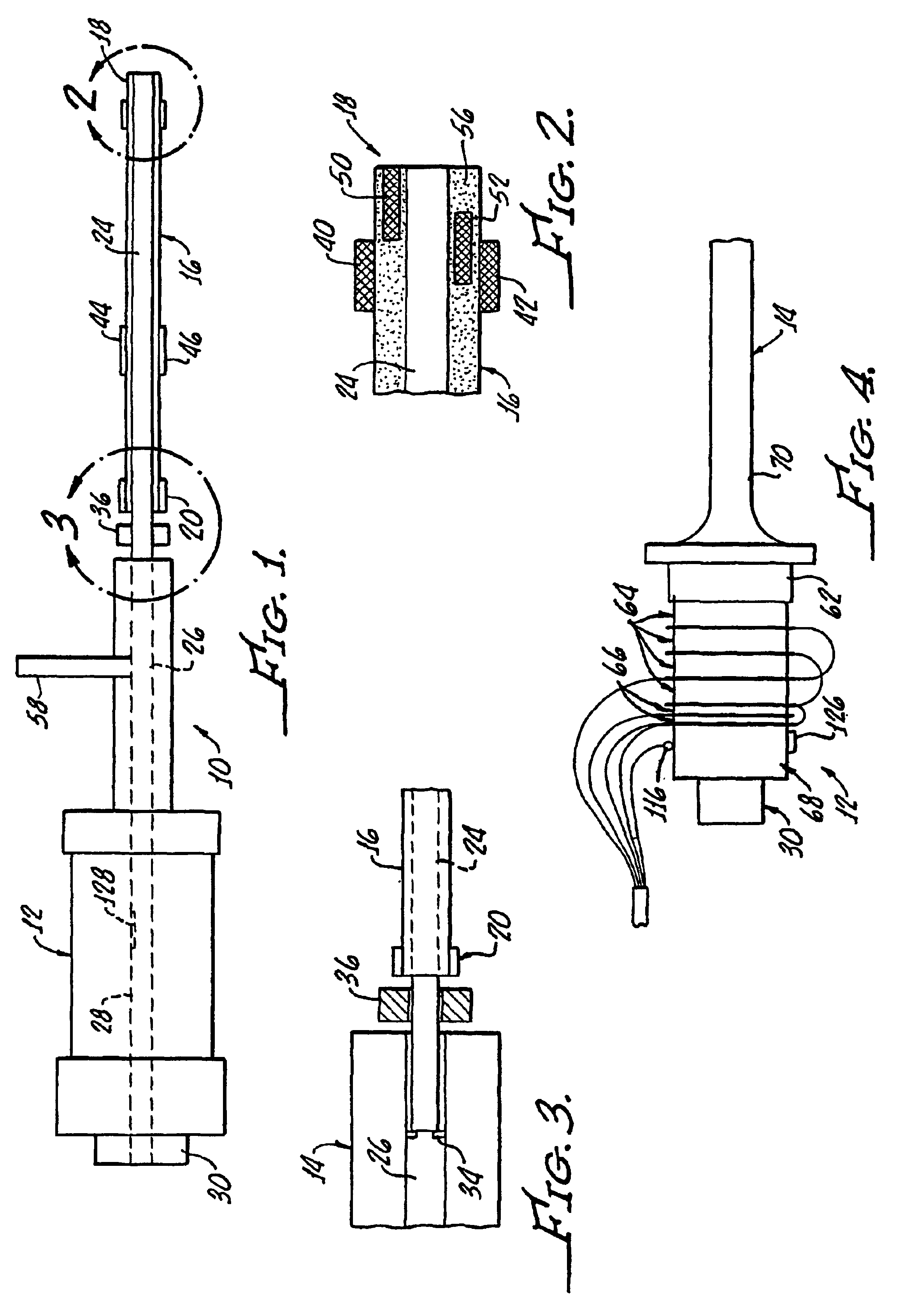

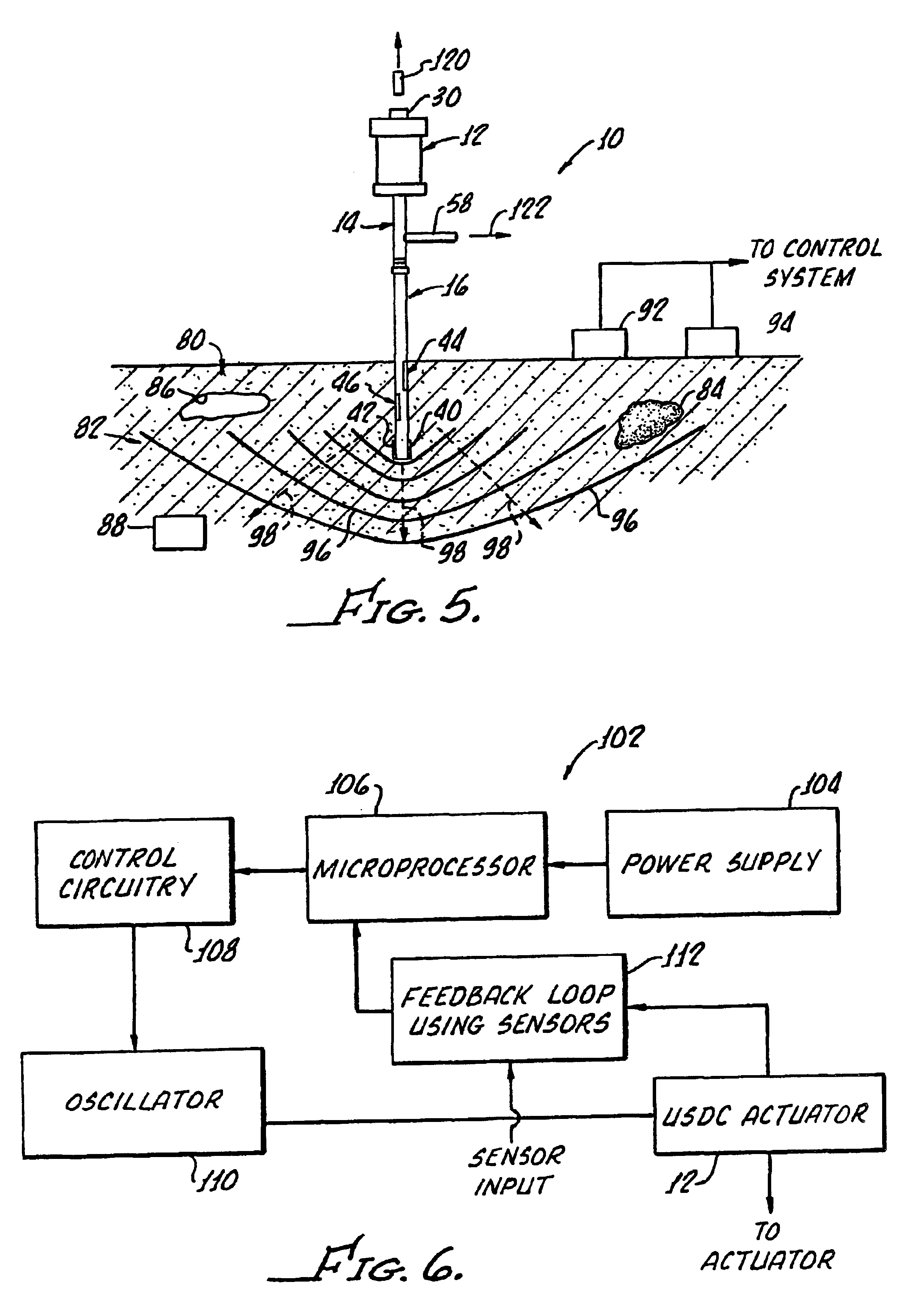

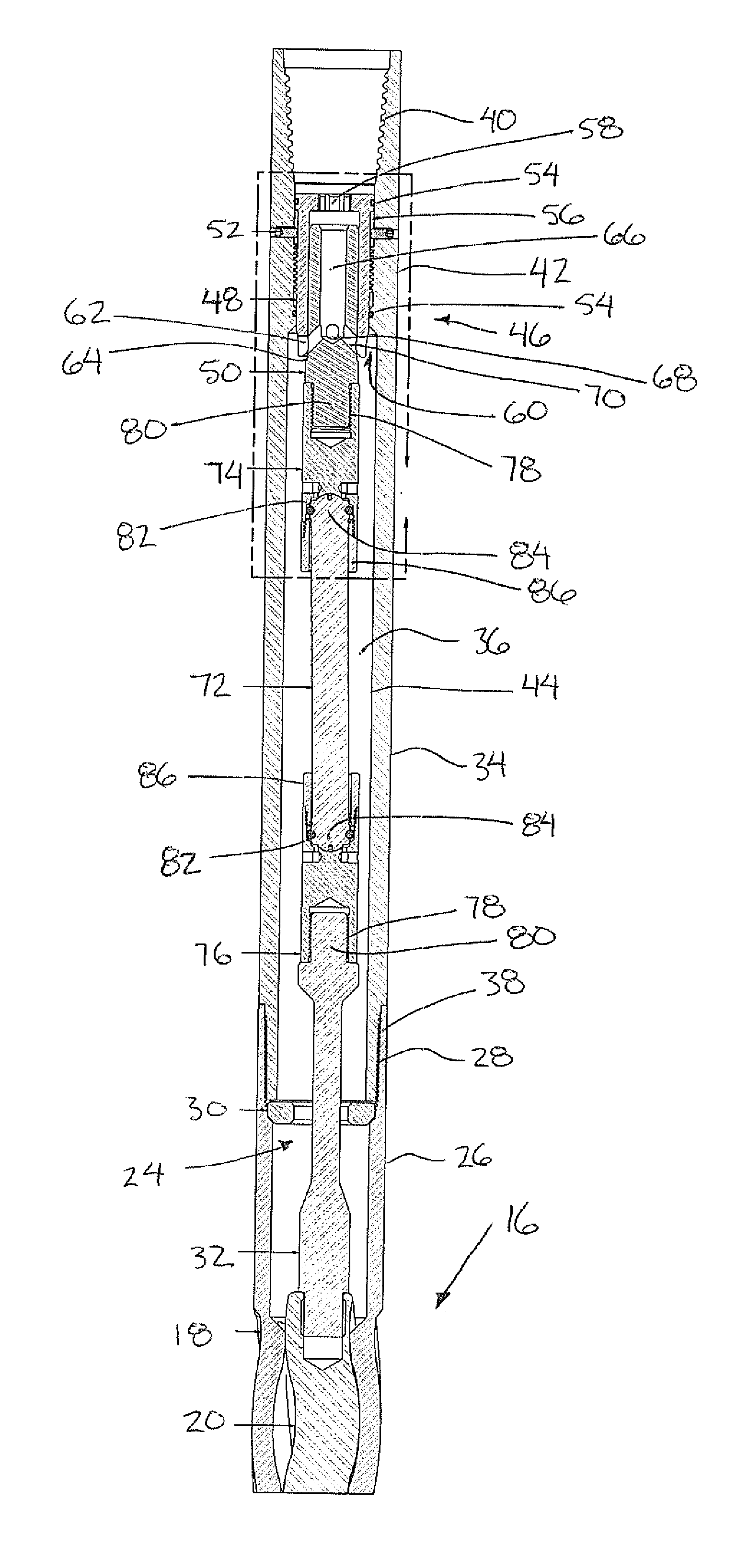

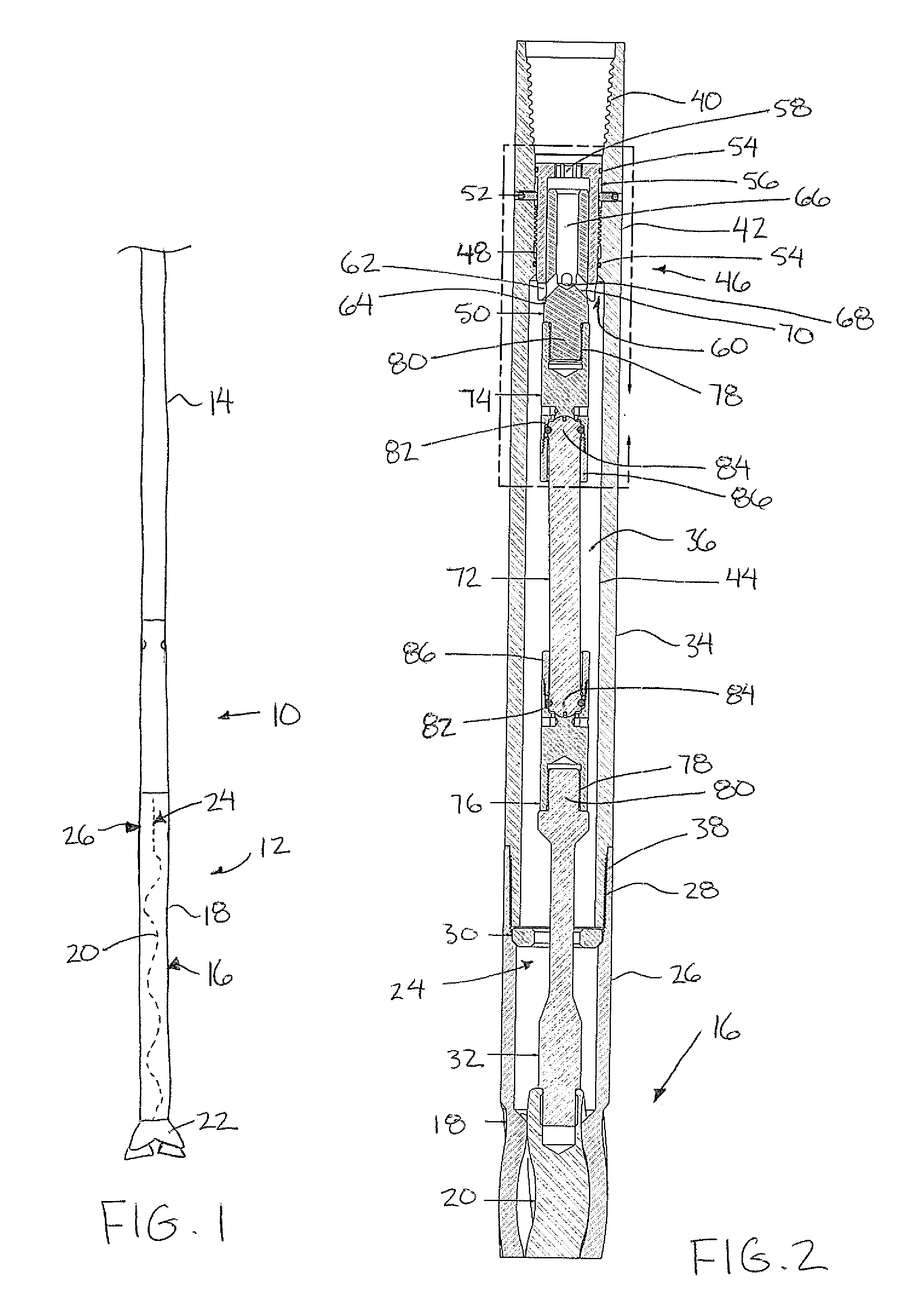

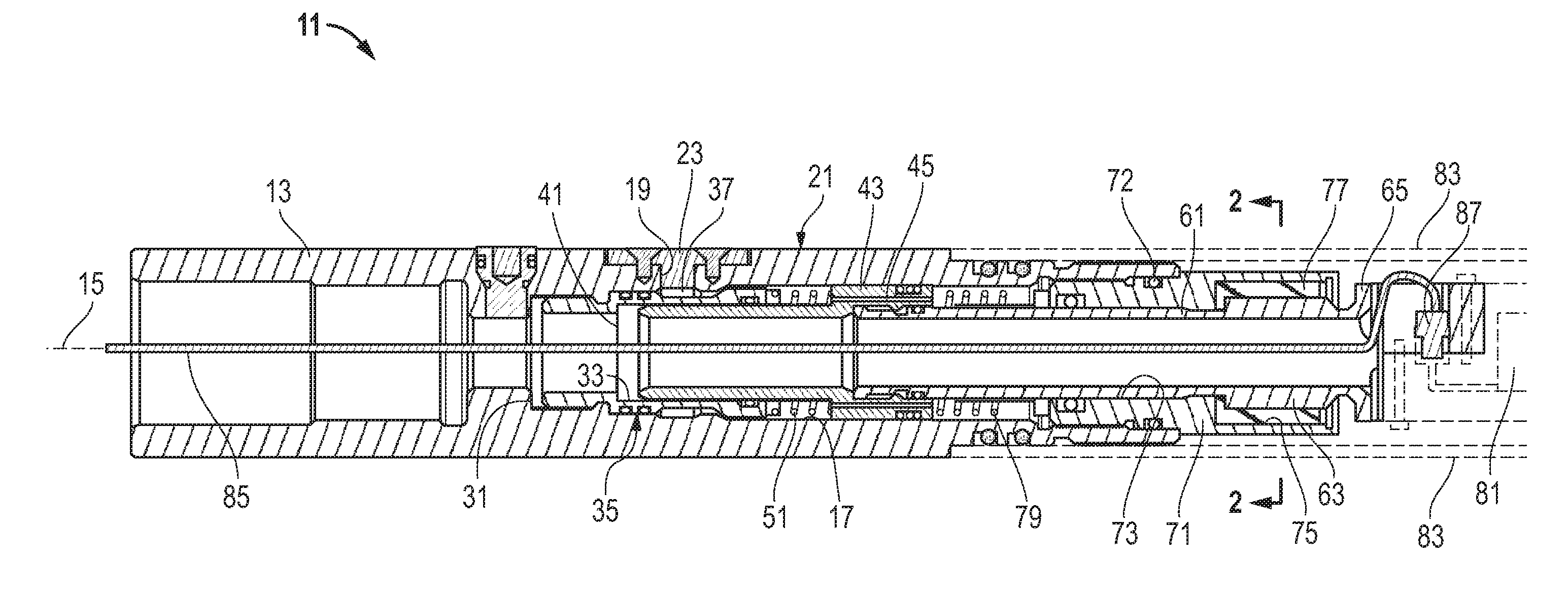

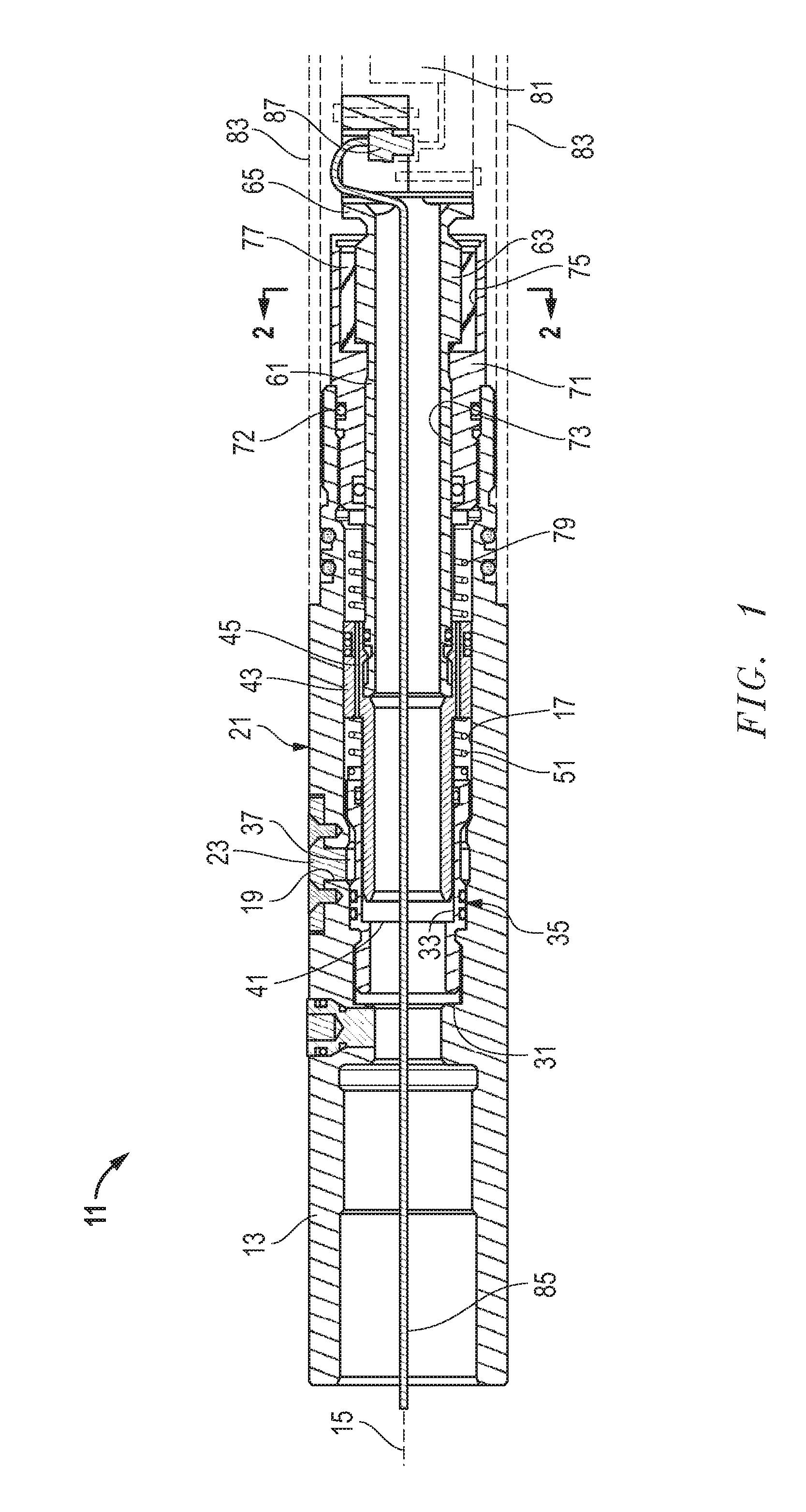

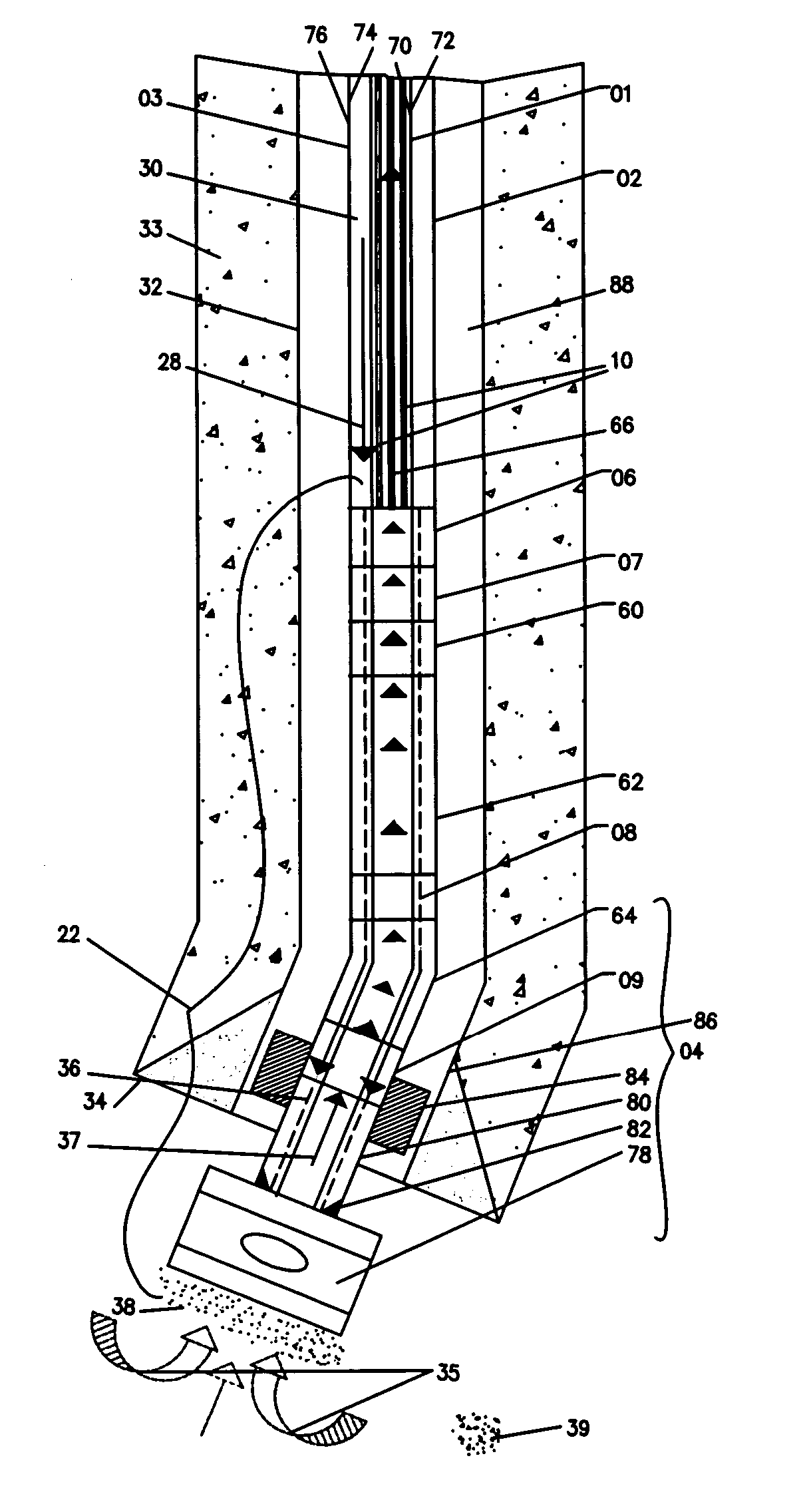

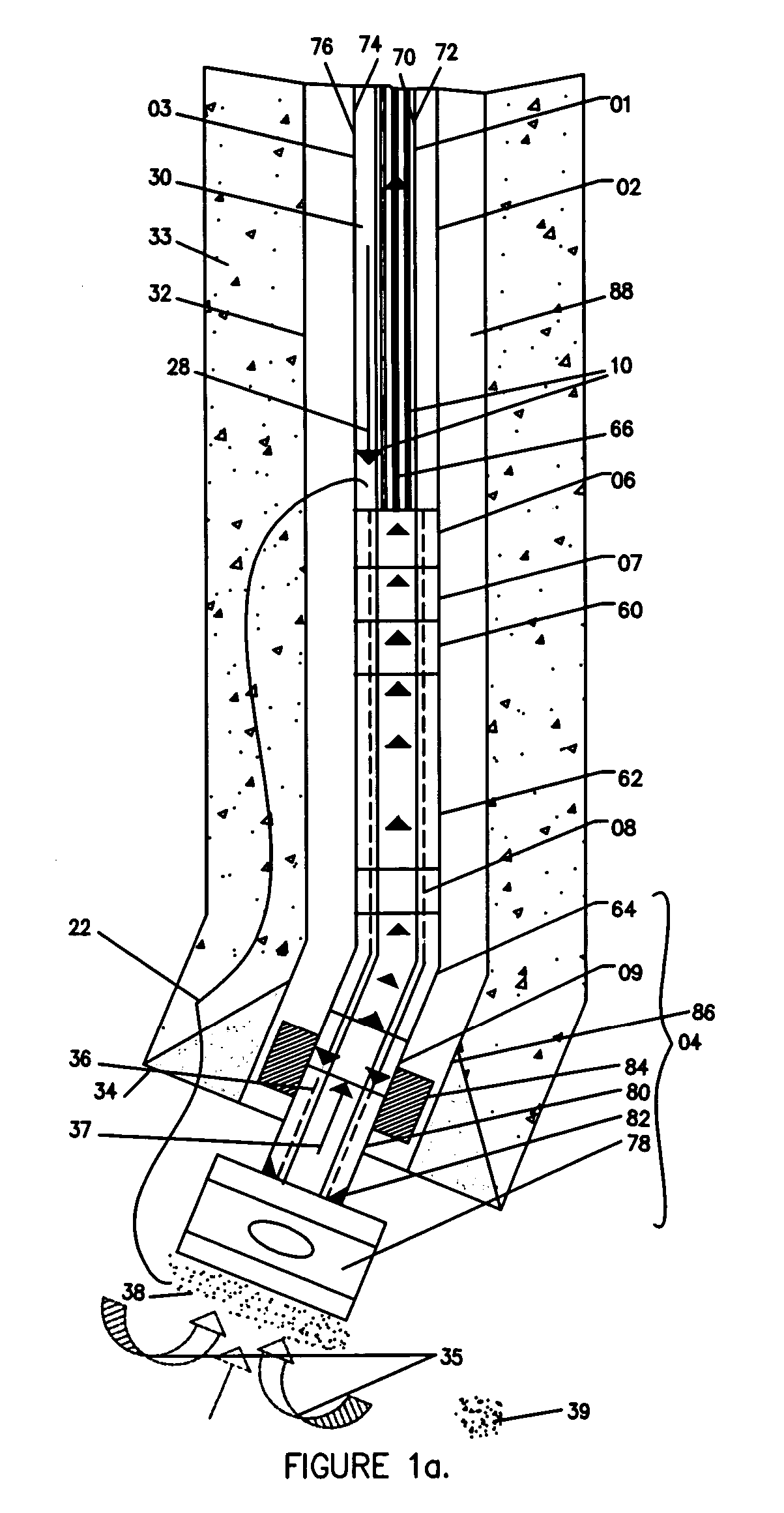

Smart-ultrasonic/sonic driller/corer

Apparatus for probing, sensing, testing penetrating and sampling a medium generally includes an actuator (12) for generating vibrations at ultrasonic frequencies and a horn (14) coupled to the actuator (12) for amplifying the actuator vibrations along with a non-rotating coring and drilling bit (16) for penetrating the medium. A bit (16) includes a drill stem (20) attached to the horn (14) and a bore (26) extends through the bit (16), horn (14) and actuator (12) for withdrawal of samples. A free mass (36) is disposed between the horn (14) and the drill stem (20) for oscillating therebetween in response to the actuator vibration for causing migration of medium debris around and through the actuator bore for effectively self-cleaning of the bit (16). The hammering action of the free mass (36) is used for penetration of the medium and for analysis of the medium though the use of spaced apart accelerometers (92 and 94).

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

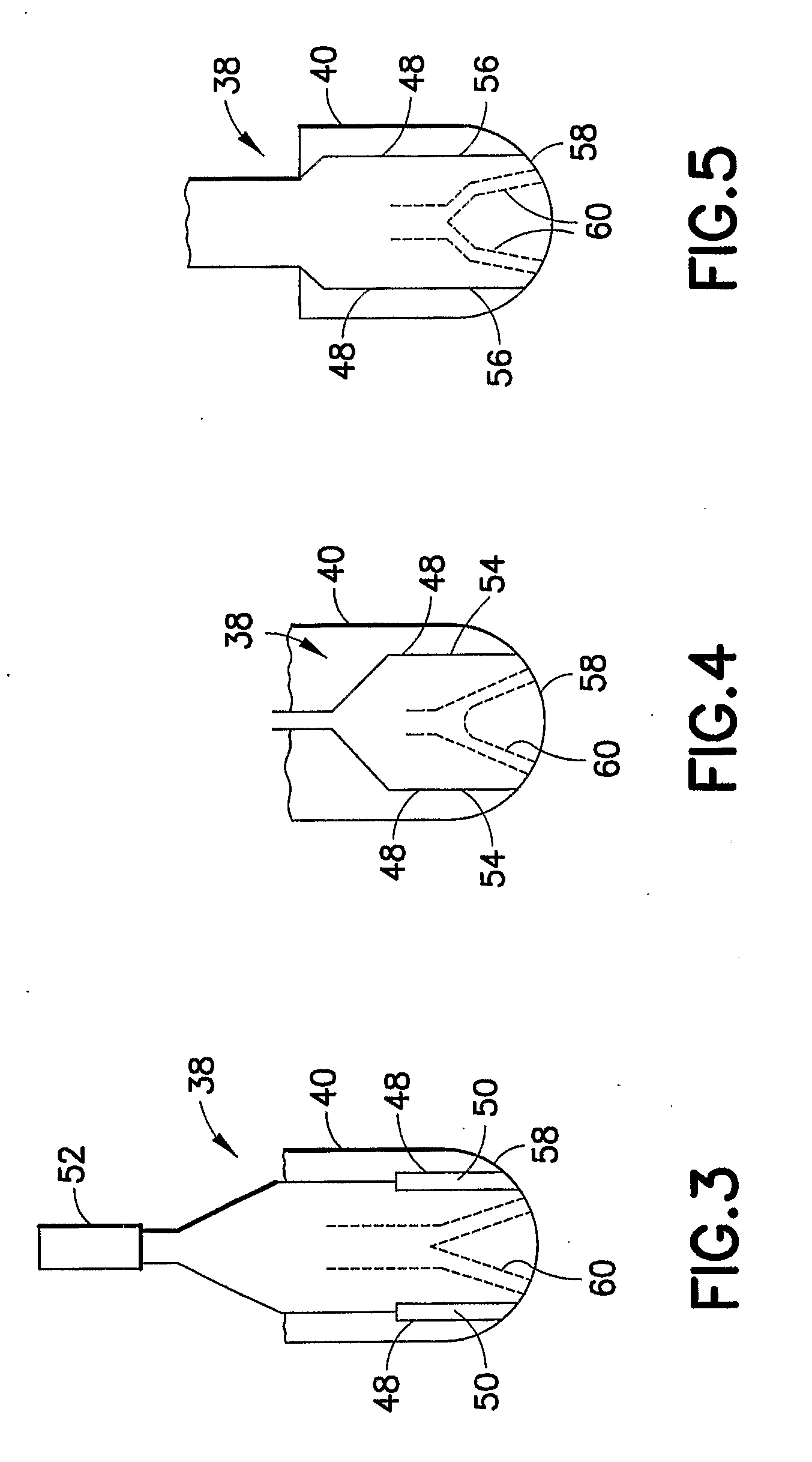

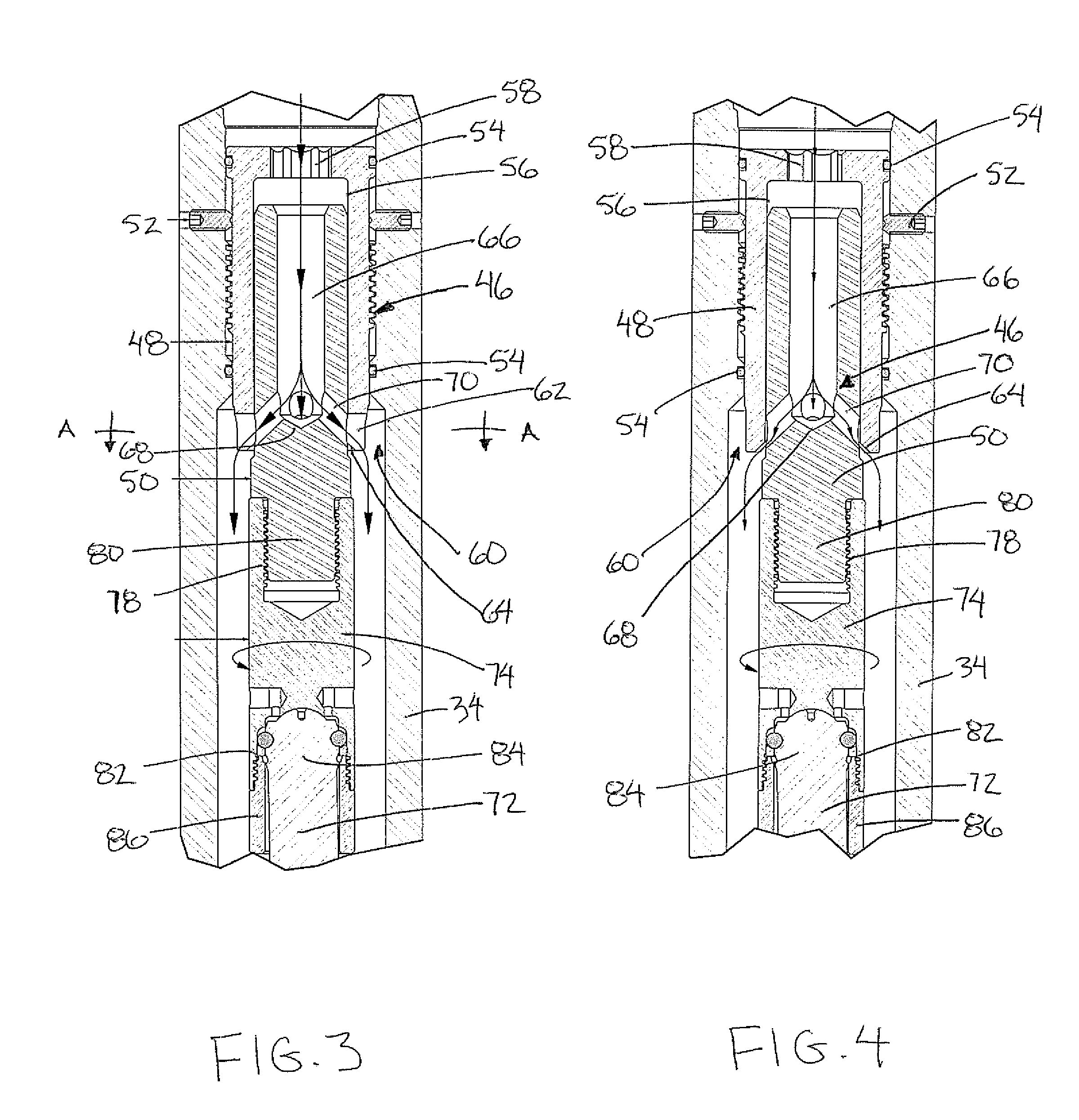

Downhole Pressure Pulse Activated by Jack Element

In one aspect of the present invention, a method has steps for forming a wellbore with a tool string bit having a body intermediate a shank and a working face. The bit body has a fluid passageway and at least a portion of a jack element is disposed within the body. The jack element also has an end forming at least a portion of a relief mechanism in the fluid passageway and a distal end substantially protruding from the working face. The bit connected to a tool string is deployed into a wellbore. Fluid is passed through the fluid passageway. A bottom of the wellbore is destructed by pulsing the fluid traveling through the passageway by opening and closing the relief mechanism.

Owner:SCHLUMBERGER TECH CORP

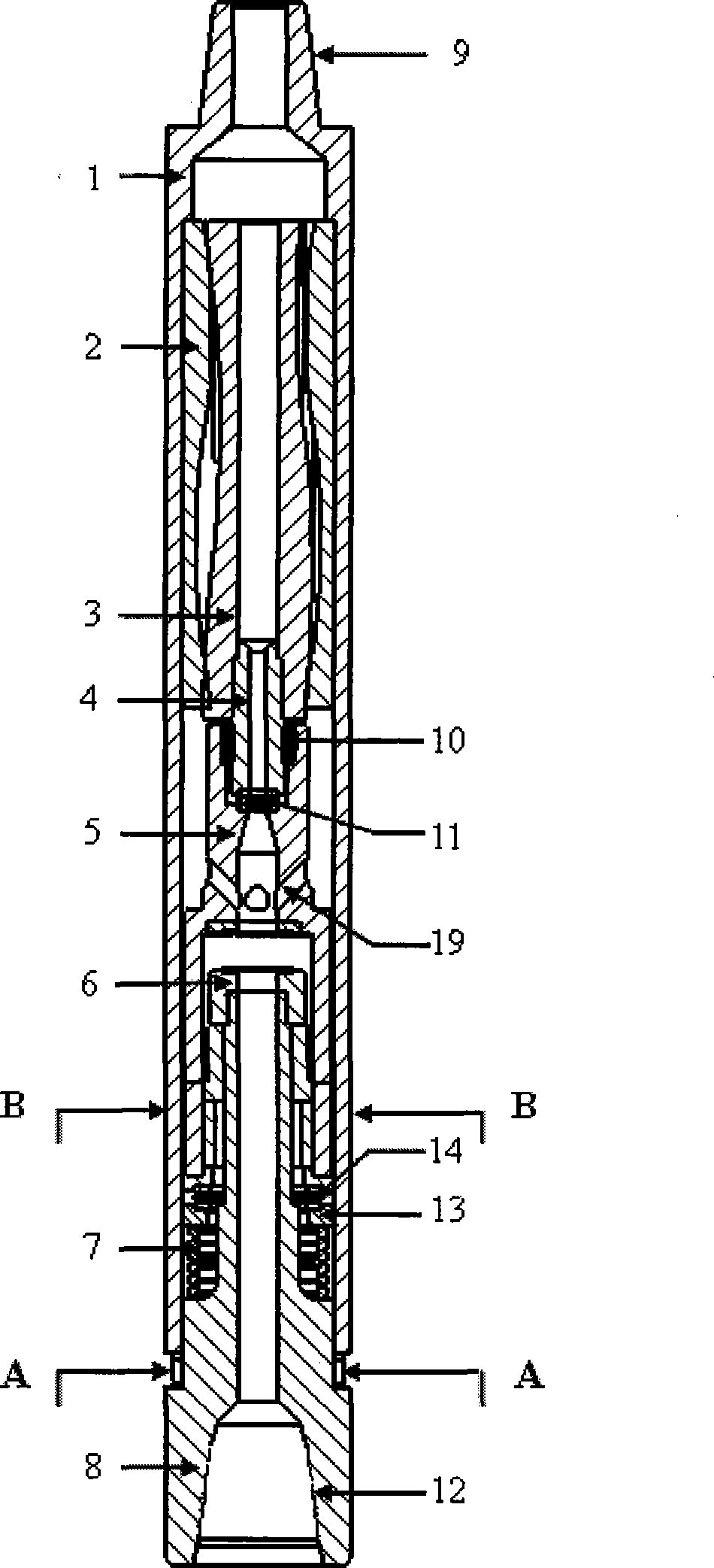

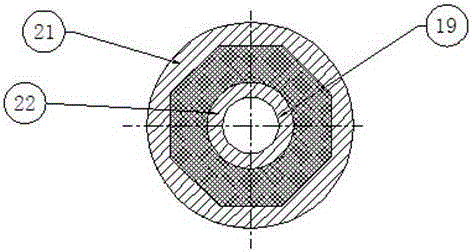

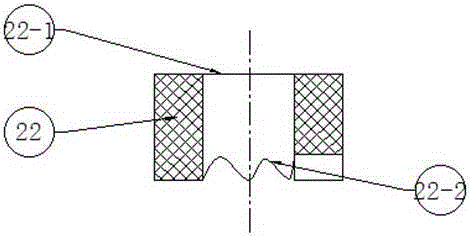

Downhole tool for achieving efficient rock breaking through spin vibration

InactiveCN105239929AQuality improvementImprove high temperature resistanceBorehole drivesVibration drillingDrive shaftSpins

The invention relates to a downhole tool for achieving efficient rock breaking through spin vibration, and belongs to the technical fields of petroleum and natural gas exploitation and drilling tools. According to the technical scheme, drilling fluid drives a turbine to rotate, a turbine rotor drives a transmission shaft to rotate to drive a disc valve set to periodically rotate, the open area changes, a periodic pressure pulse is generated to act on a vibration nipple to generate reciprocating vibration, the friction resistance between a drilling column and the well wall is effectively improved, and mechanical drilling speed is increased; the lower end of a tooth-shaped impact hammer head is provided with a tooth-shaped curved surface which is meshed with a tooth-shaped curved surface of a lower-end transmission connector, and the lower-end transmission connector is driven by a transmission shaft to generate rotating motion, so that the tooth-shaped impact hammer head is driven to rotate to generate axial reciprocating impact on the lower-end transmission connector under the joint action of the tooth-shaped impact hammer head and a force accumulating spring. According to the downhole tool, the structure is simple, the friction resistance is small, effective bit pressure and effective vibration are increased, the mechanical rotating speed is increased, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

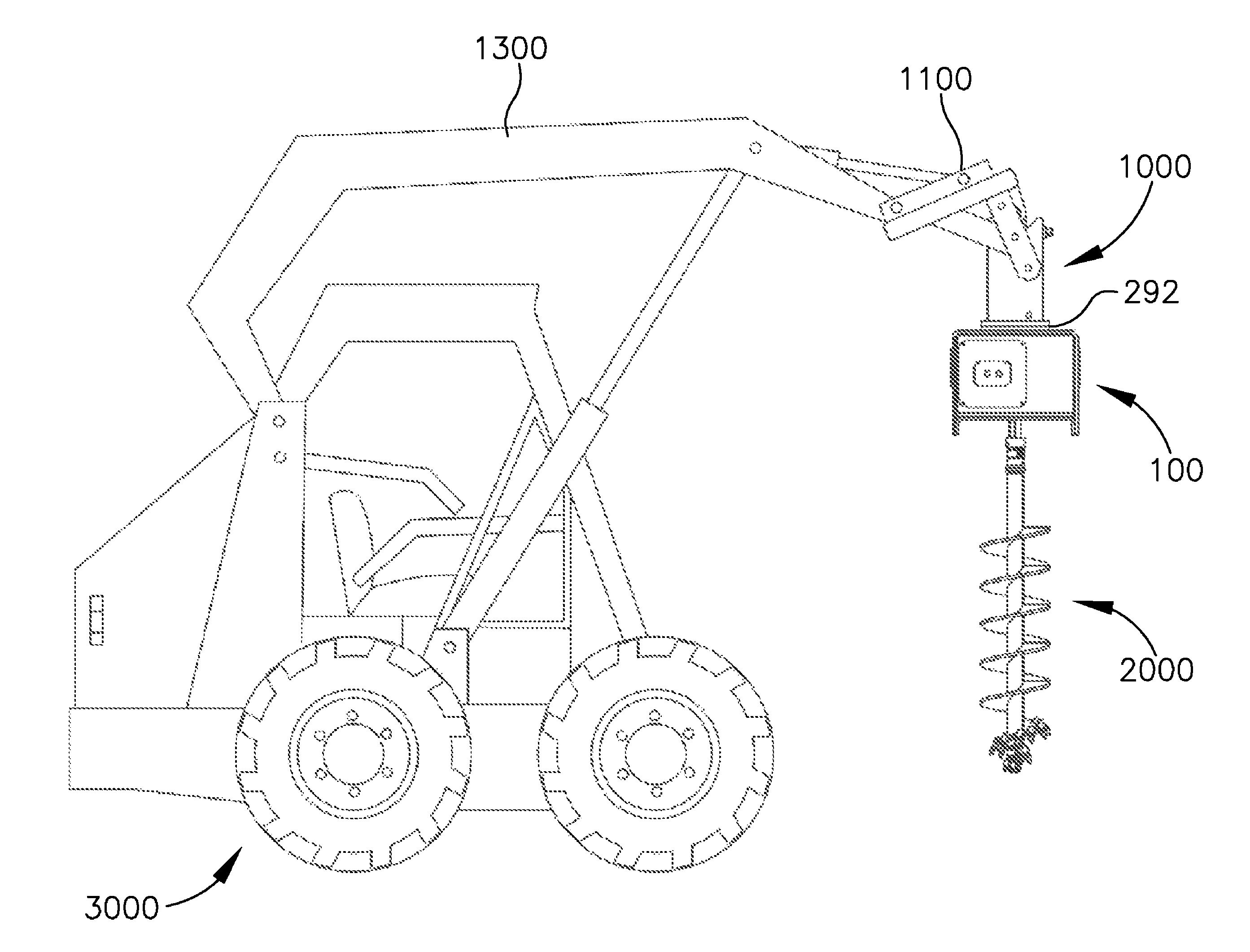

Vibratory drilling apparatus

A vibratory unit interposed between a planetary drive and earth-penetrating device, e.g., an auger, is powered by the hydraulic system of a tractor, skid loader or the like. The unit includes a housing having a base plate with a slidable striker plate mounted therein. A Kelly bar displaces the planetary drive from the auger and through the housing. A rotatable shaft with weights eccentrically mounted thereon produces vibratory forces and urges the striker plate into contact with the base plate to provide hammer-like forces on the auger.

Owner:HARLEMAN RONALD

Torsional impact drilling tool

ActiveCN102454364ATorque stability and balanceReduce torsional oscillationsVibration drillingImpact hammerPetroleum engineering

The invention discloses a torsional impact drilling tool which can apply high-frequency torsion impact to a drilling bit in the drilling engineering. The technical scheme of the torsional impact drilling tool is as follows: the torsional impact drilling tool mainly comprises a short section of a drill collar, a torsional impact generator and a connecting body, wherein the short section of the drill collar and the torsional impact generator are in clearance connection through the connecting body and are located by splines; a diversion cover is fixed on a hammer seat; a cavity is formed inside the diversion cover; a closure nozzle, a sieve tube, a locating sleeve and an impact hammer are sequentially arranged in the cavity from inside to outside; the sieve tube is fixed with the hammer seat; the impact hammer, the locating sleeve, the sieve tube and the hammer seat are provided with through holes in the circumferential direction; and an impact hammer head and a starting hammer head are processed on the impact hammer. The torsional impact drilling tool is arranged between the drill collar and the drilling bit; and the drilling bit receives the high-frequency torsional impact generated by the impact hammer under the driving of fluids while receiving the rotational torsion of a drill column. Compared with other drilling tools, the torsional impact drilling tool disclosed by the invention has the advantages that the high-frequency torsional impact can be generated, the sticking-sliding phenomenon of the drilling bit is eliminated, the mechanical drilling rate of harder or abrasive formation is increased, the service life of matched components, such as the drilling bit and the like of the drill column is prolonged, the drilling efficiency is improved and the drilling cost is reduced.

Owner:CHINA PETROCHEMICAL CORP +3

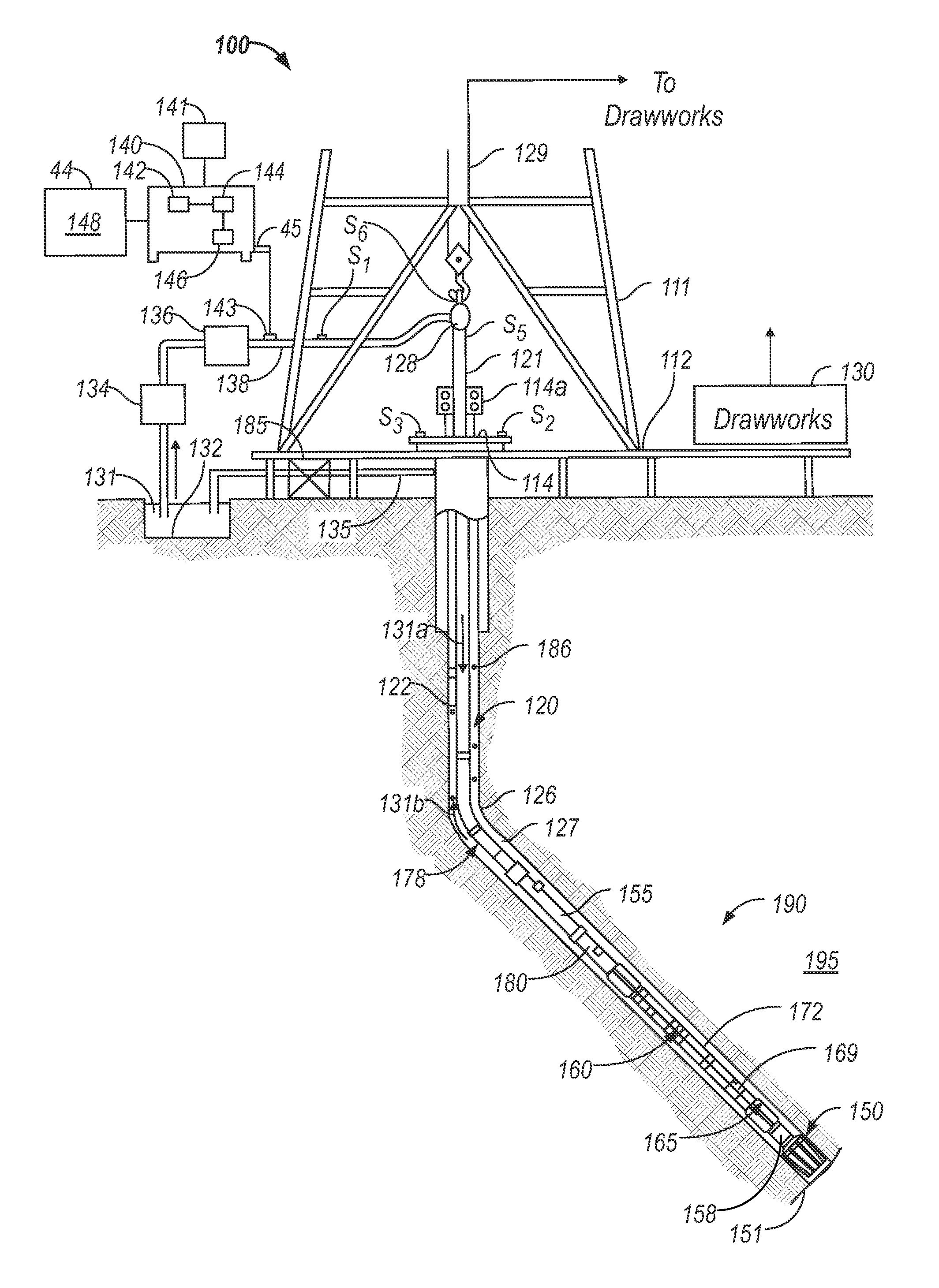

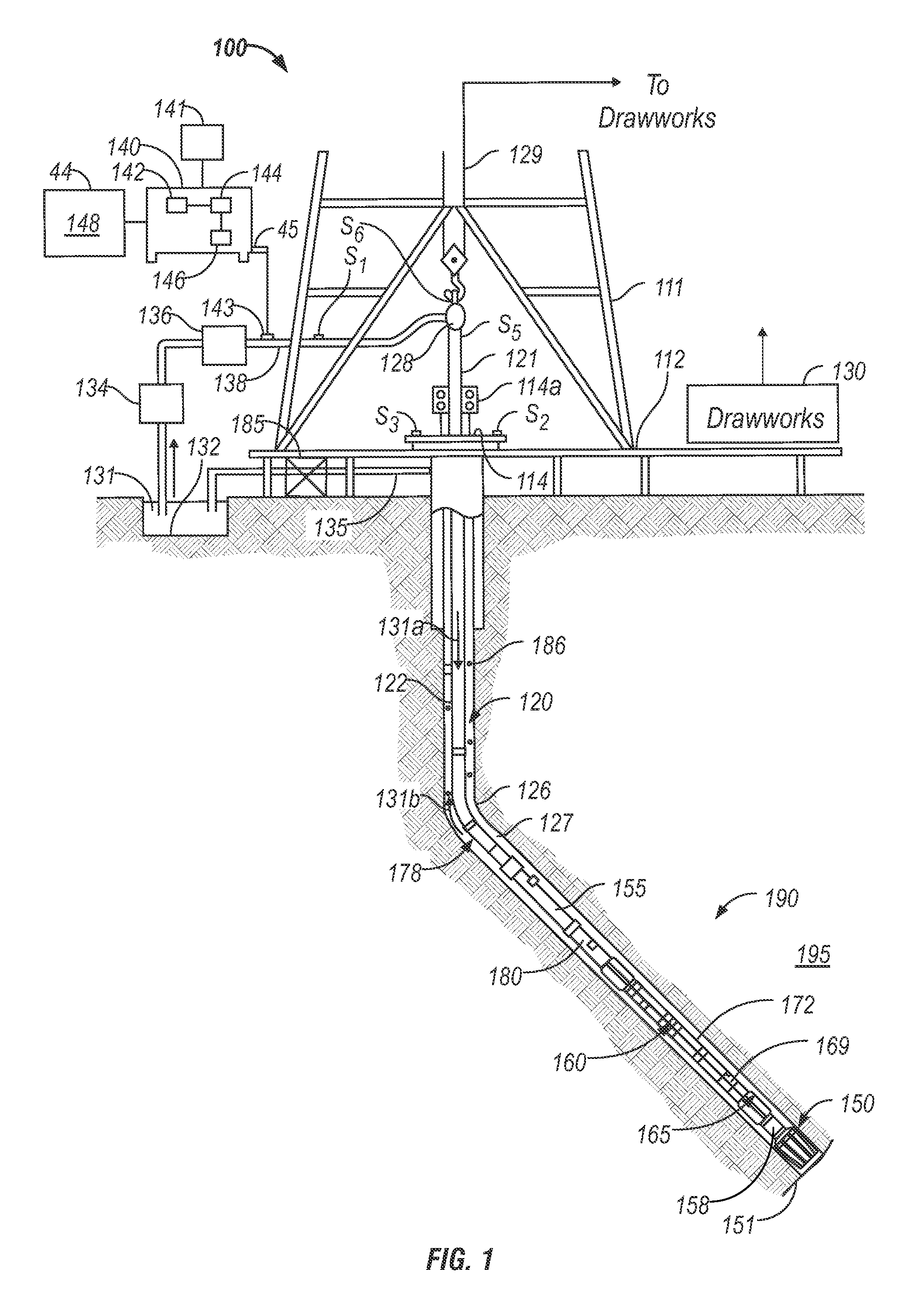

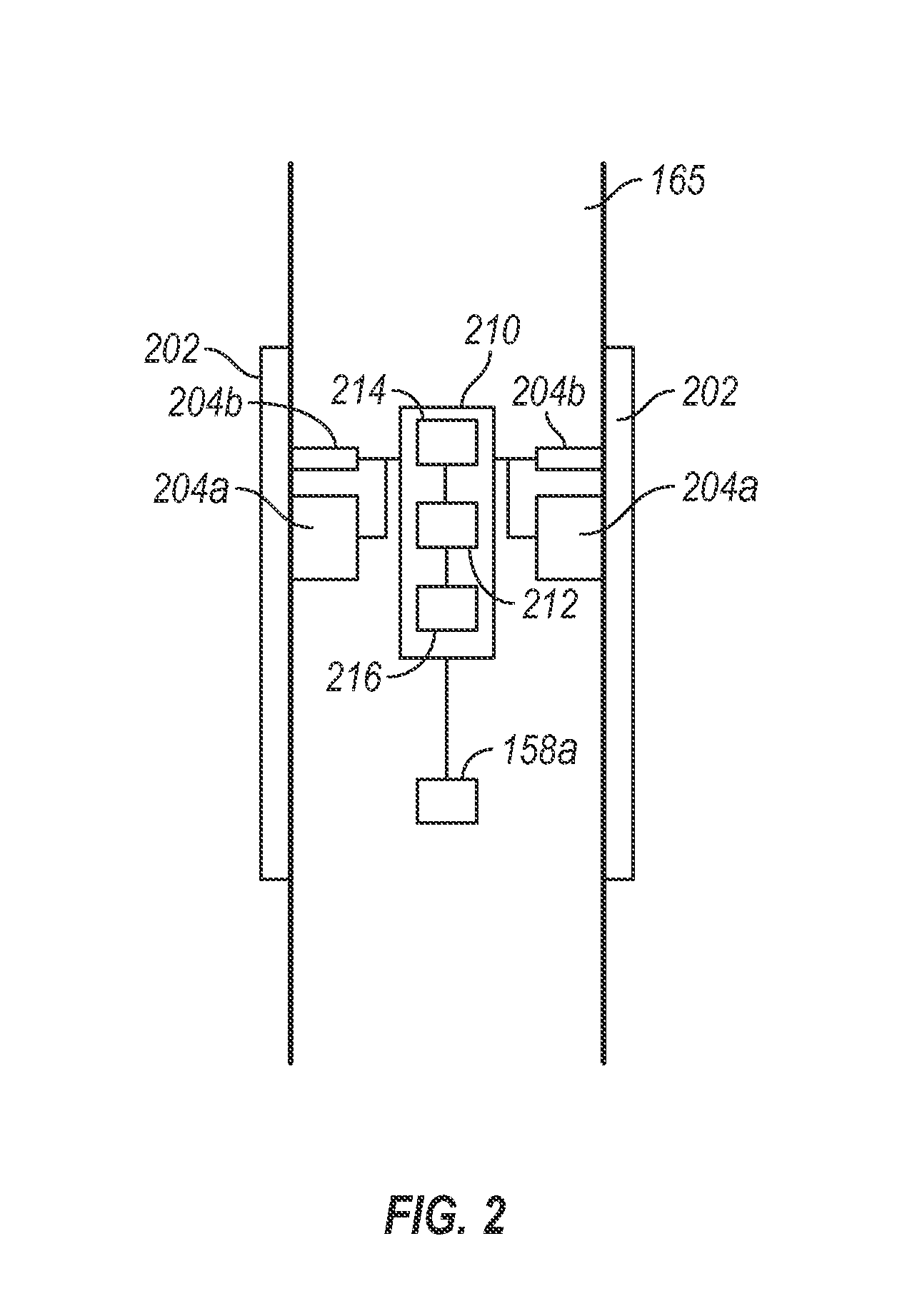

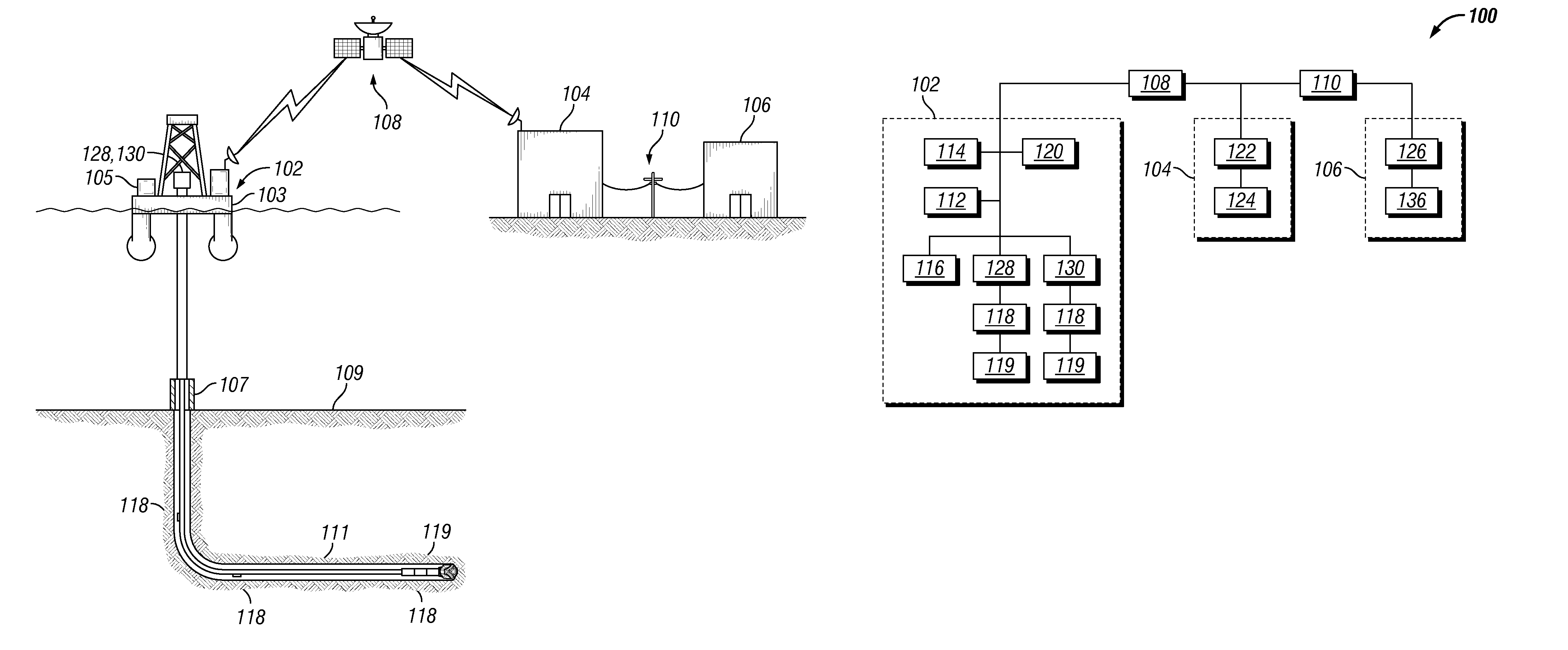

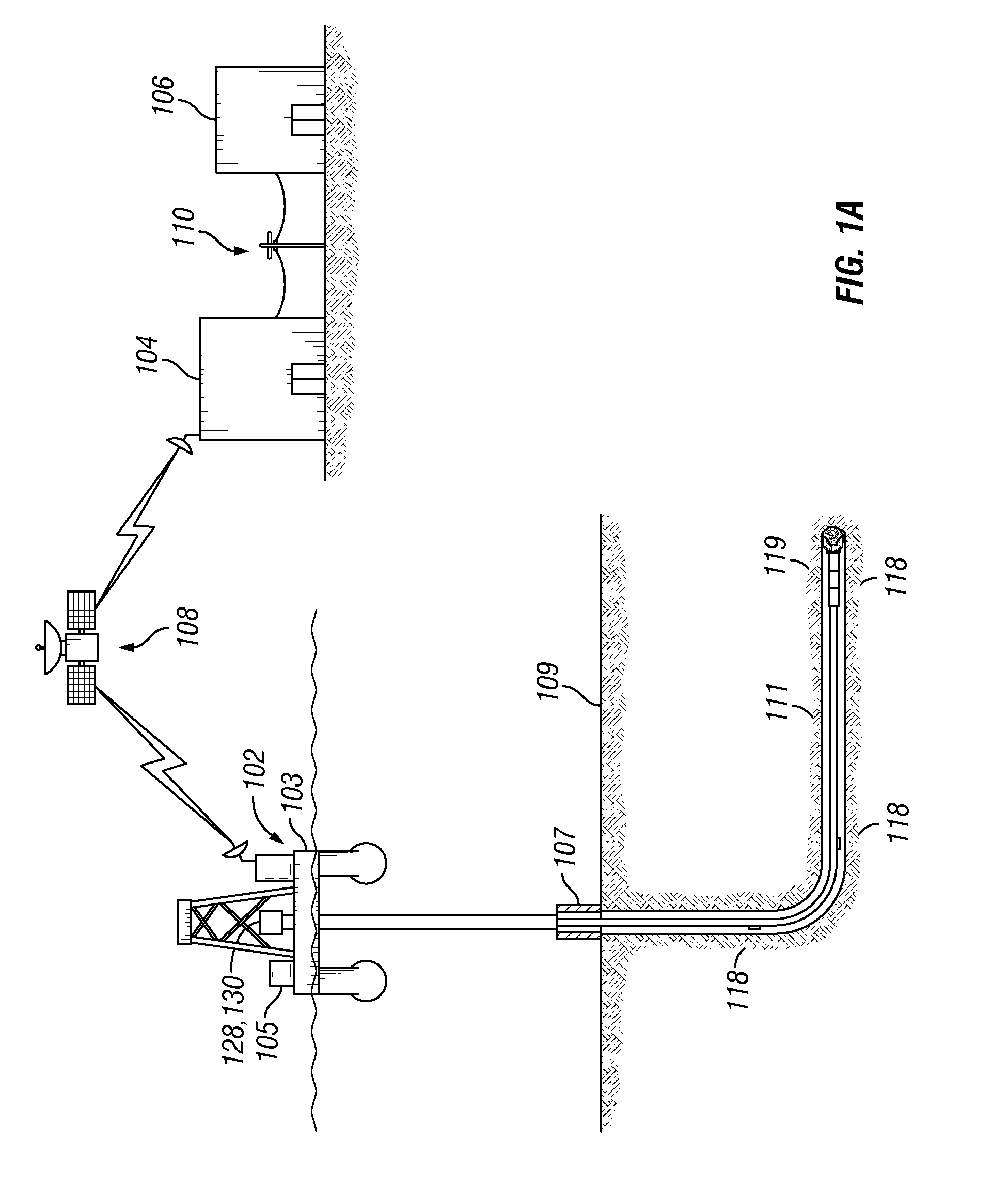

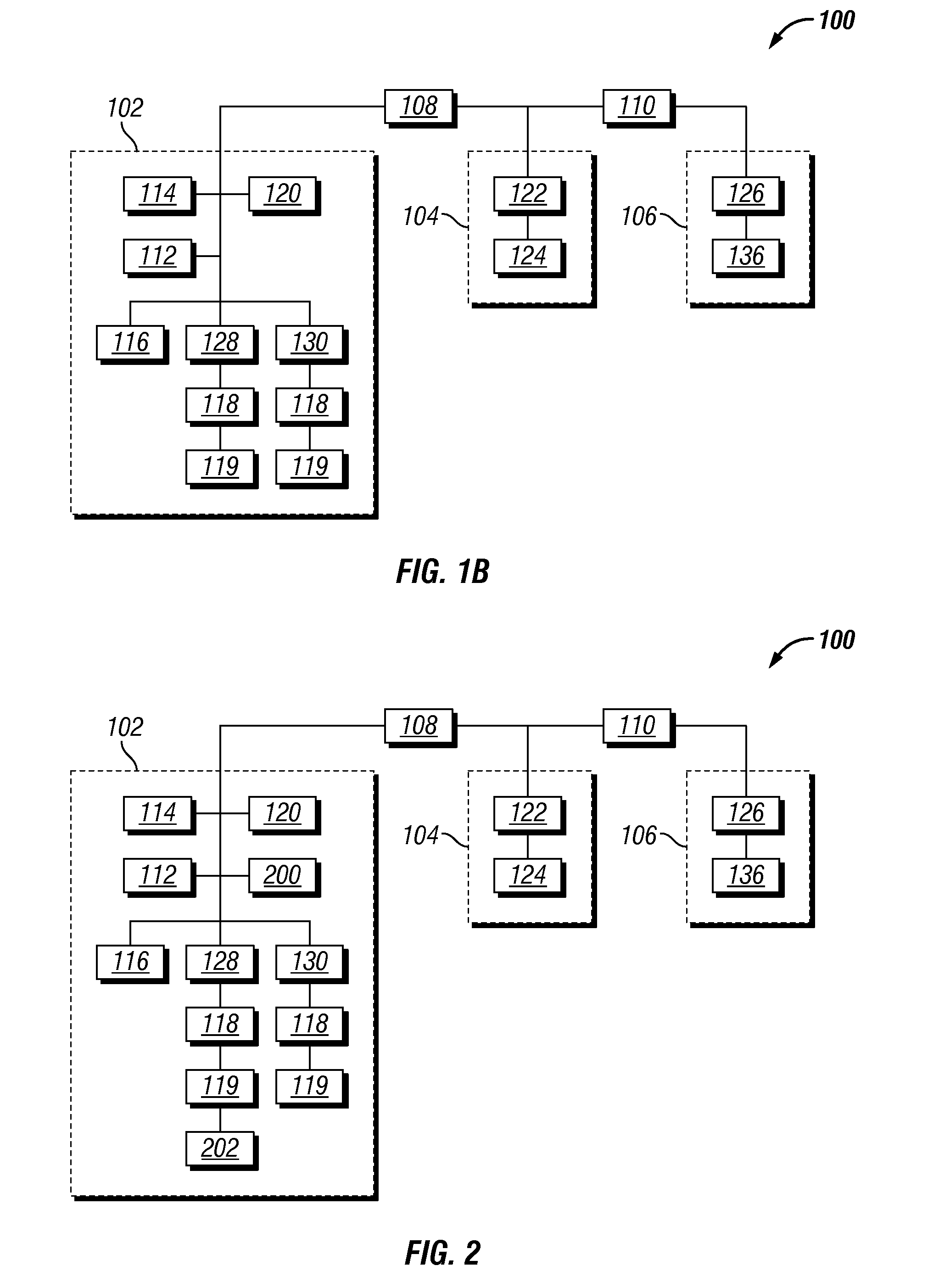

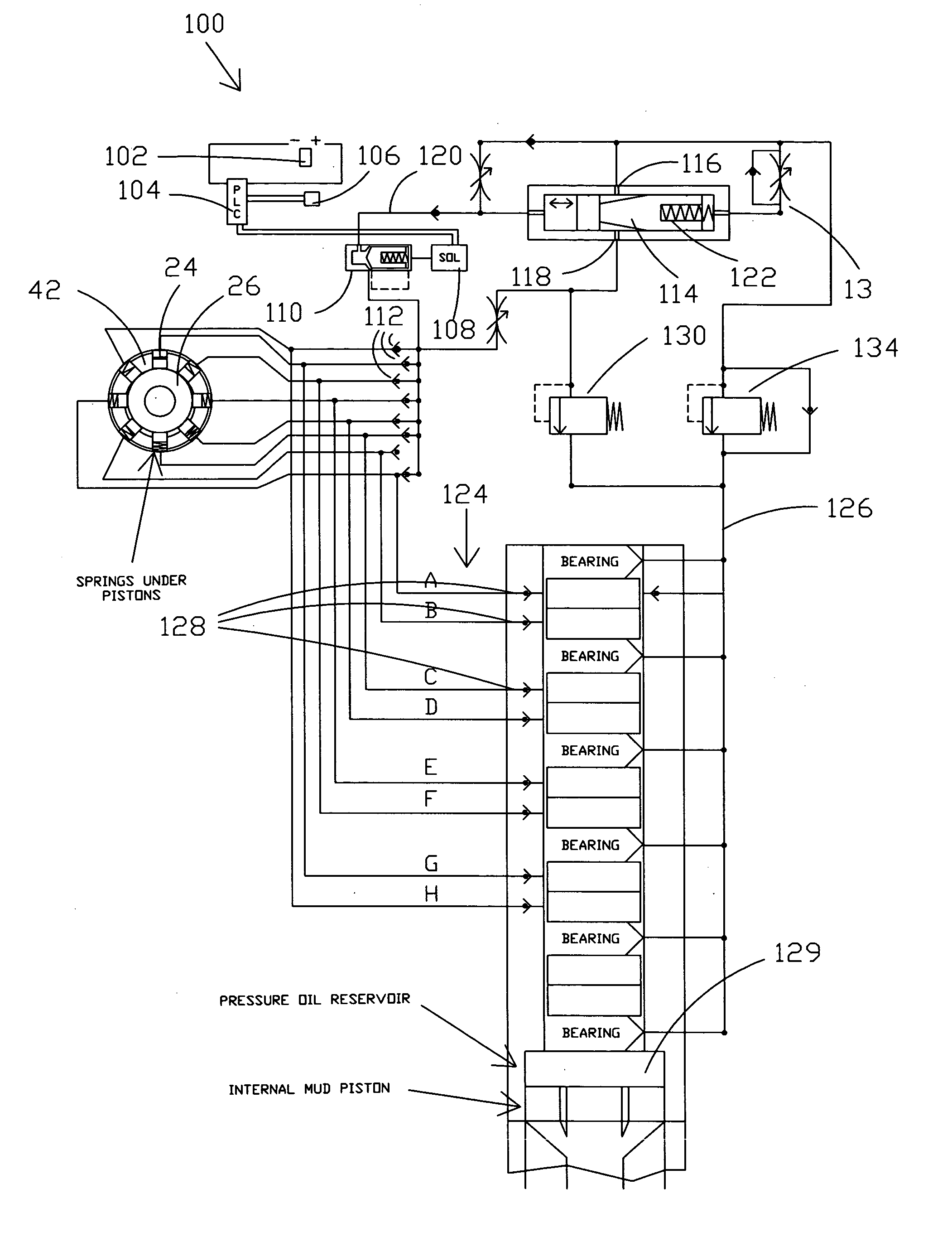

Drilling control and information system

A drilling control and information system comprising: a rig site network (102) including a drilling equipment controller (112) and a drilling parameter sensor (116); a downhole sensor (118) communicatively coupled to the rig site network; a data center (104) communicatively coupled to the rig site network; a remote access site (106) communicatively coupled to the data center; and a pressure management application (300) communicatively coupled to the rig site network, wherein the pressure management application receives pressure data from the drilling parameter sensor and the downhole sensor and issues an operating instruction to the drilling equipment controller.

Owner:NAT OILWELL VARCO LP

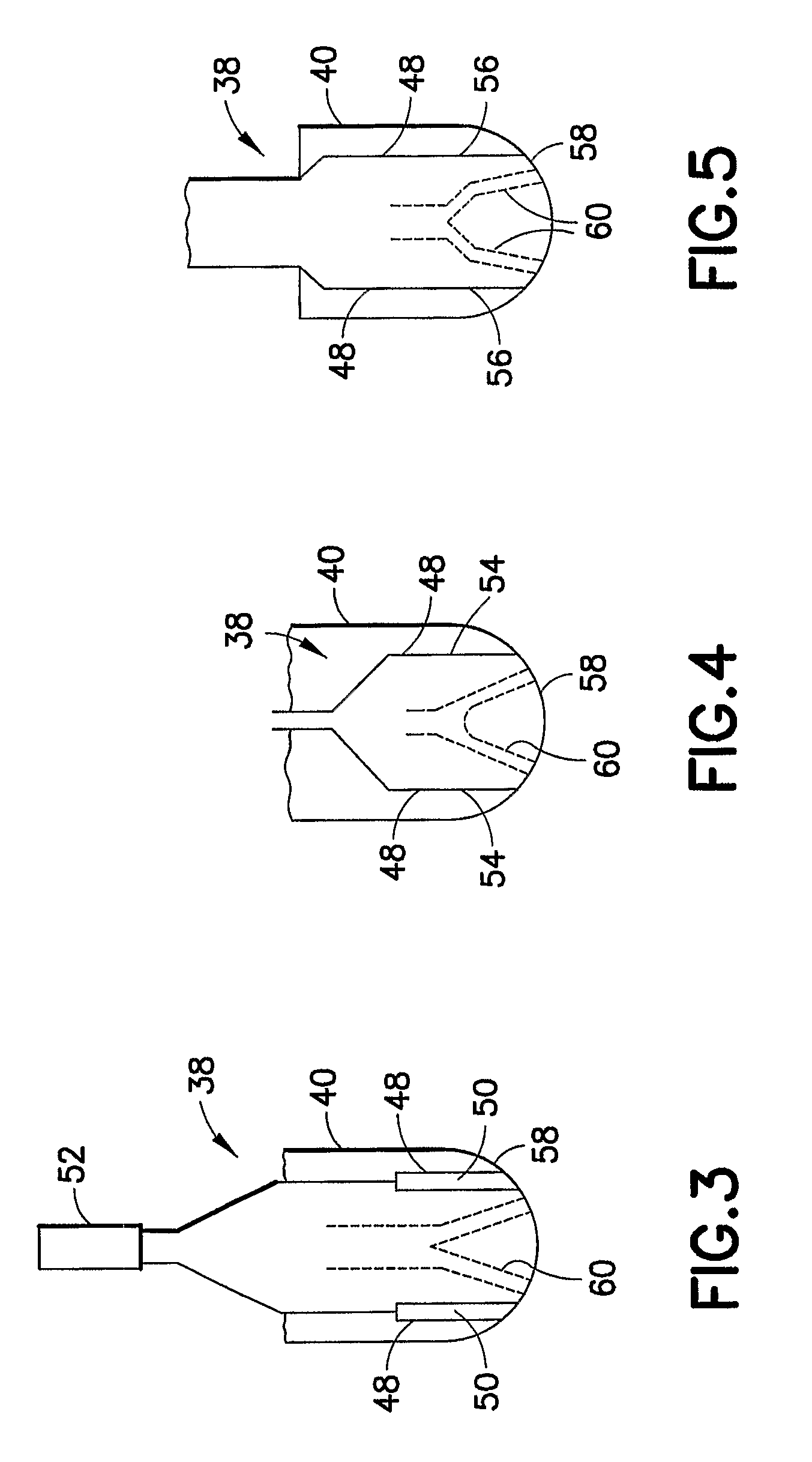

Ultrasonic annular core bit

InactiveUS6948574B2Robust excitation behaviorIncrease amplitudeDrill bitsTransportation and packagingFrequency determinationPower tool

A core bit for abrasive cutting including a cylindrical tube (3) provided at its end surface with cutting or abrasive bodies (2) and a cover (4) provided at an opposite end surface of the cylindrical tube (3) and secured thereto and having, along its central axis (A), a shank (5) to be received in a rotary power tool, with the cover (4) being dimensioned, with respect to a set excitation frequency, for forming a whole number of maximum amplitude oscillations of a concentric flexural oscillation, and the cylindrical tube (3) being dimensioned, with respect to a set excitation frequency, for forming a whole number of maximum amplitude oscillations of axial longitudinal oscillations.

Owner:HILTI AG

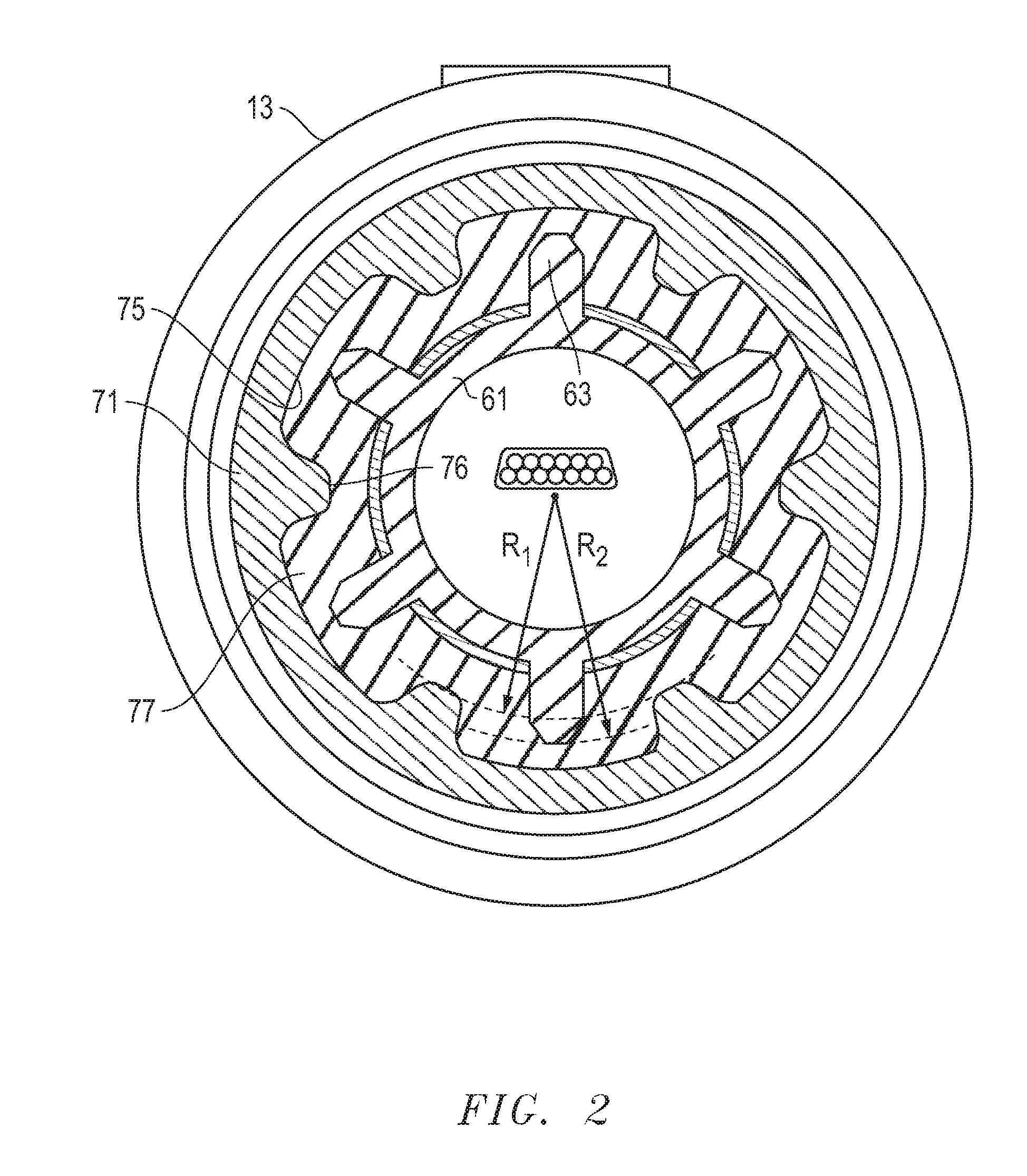

Flow Pulsing Device for a Drilling Motor

ActiveUS20110073374A1Easy to adjustEasy constructionBorehole drivesFlushingAxial displacementMotor drive

A downhole flow pulsing device comprises a housing connected in series with a drill string and a valve with a rotating portion in the housing arranged to vary an area of a flow passage through the housing. A fluid actuated positive displacement motor drives rotation of the valve. A drive link permits the rotating portion of the valve to be optionally coupled directly to the motor of the drill string. The valve includes radially oriented rotating ports intermittently communicating with surrounding fixed ports and a bypass channel. Axial displacement of the rotating ports relative to the fixed ports and bypass channel permits amplitude of the downstream fluid pulses to be adjusted. The valve includes a number of circumferentially spaced ports which differs from a prescribed number of pressure fluctuations in the fluid for each full rotation of the rotor of the drill motor.

Owner:TARTAN ENERGY GRP INC +1

Drilling string torsional energy control assembly and method

InactiveUS20040238219A1Fast penetrationProlong lifeDrilling rodsDirectional drillingEnergy controlBrief periods

The present invention provides a torsional energy control assembly and method for eliminating slip-stick and / or drill bit oscillations comprising axial and / or rotational oscillations. In one preferred embodiment, the assembly permits slippage between an upper portion of the drilling string and a lower portion of a drill string. The rotational control assembly may be installed at any desired position in the drill string. The rotational control assembly could also be utilized as a component of other drilling mechanisms such as a downhole drilling motor. The rotational control permits slippage while drilling for a selected time or selected rotational distance or other criteria to thereby release torsional energy in the drilling string which otherwise may produce damaging slip-stick torsional oscillations such as slip-stick. The rotational control assembly may, in one embodiment, comprise an on-off clutch whereby torque is either substantially completely transmitted or substantially not transmitted through the assembly for brief periods.

Owner:STRATALOC TECH PROD +1

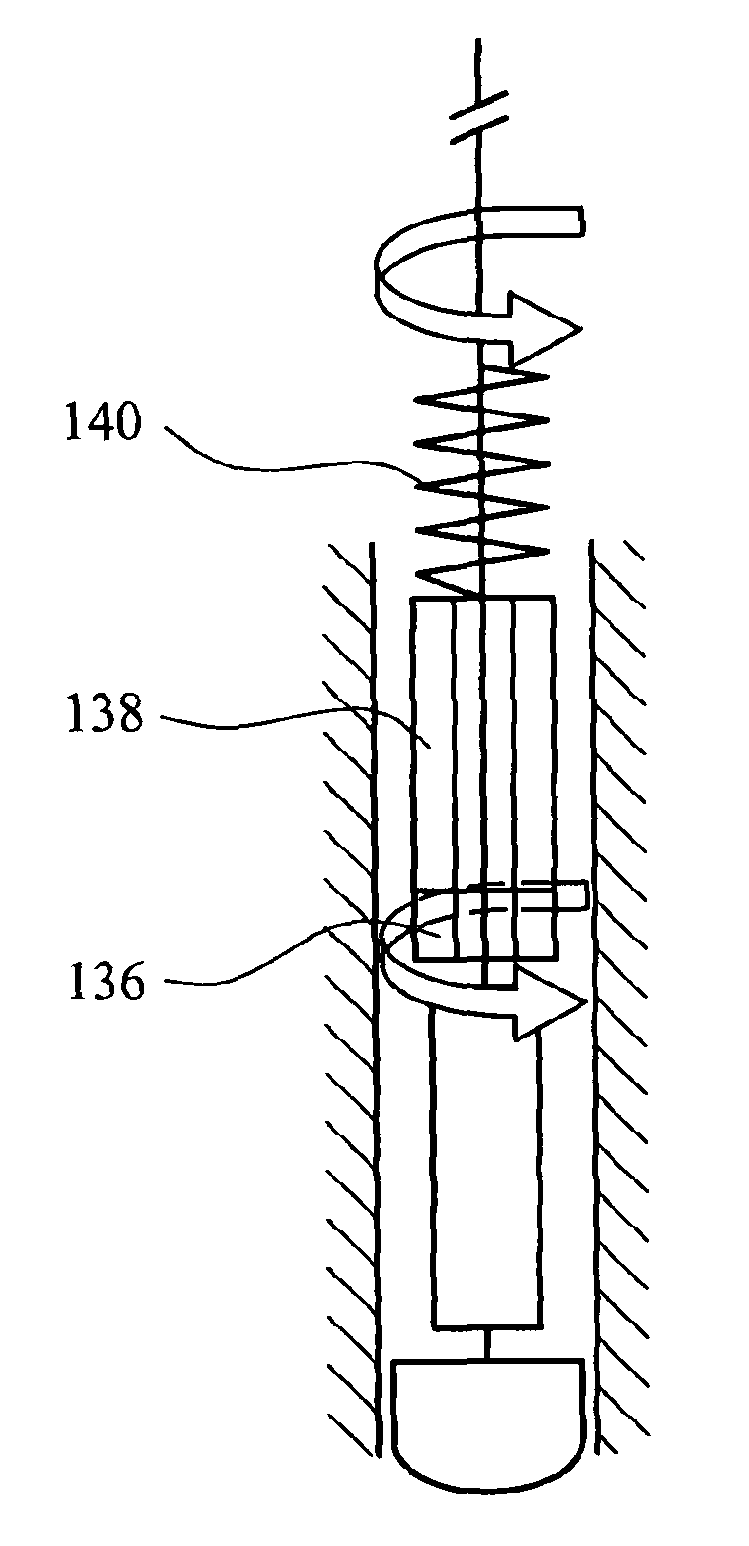

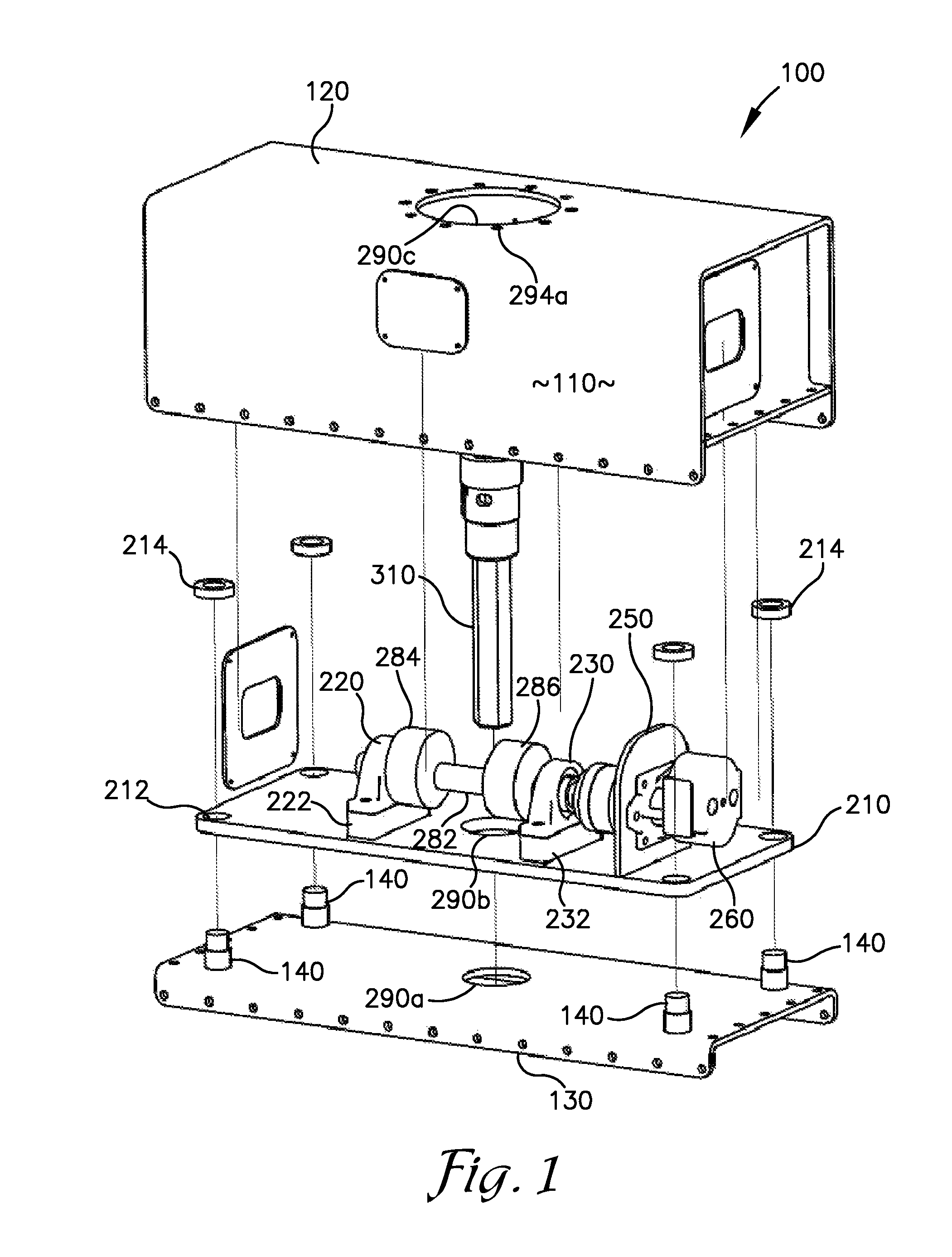

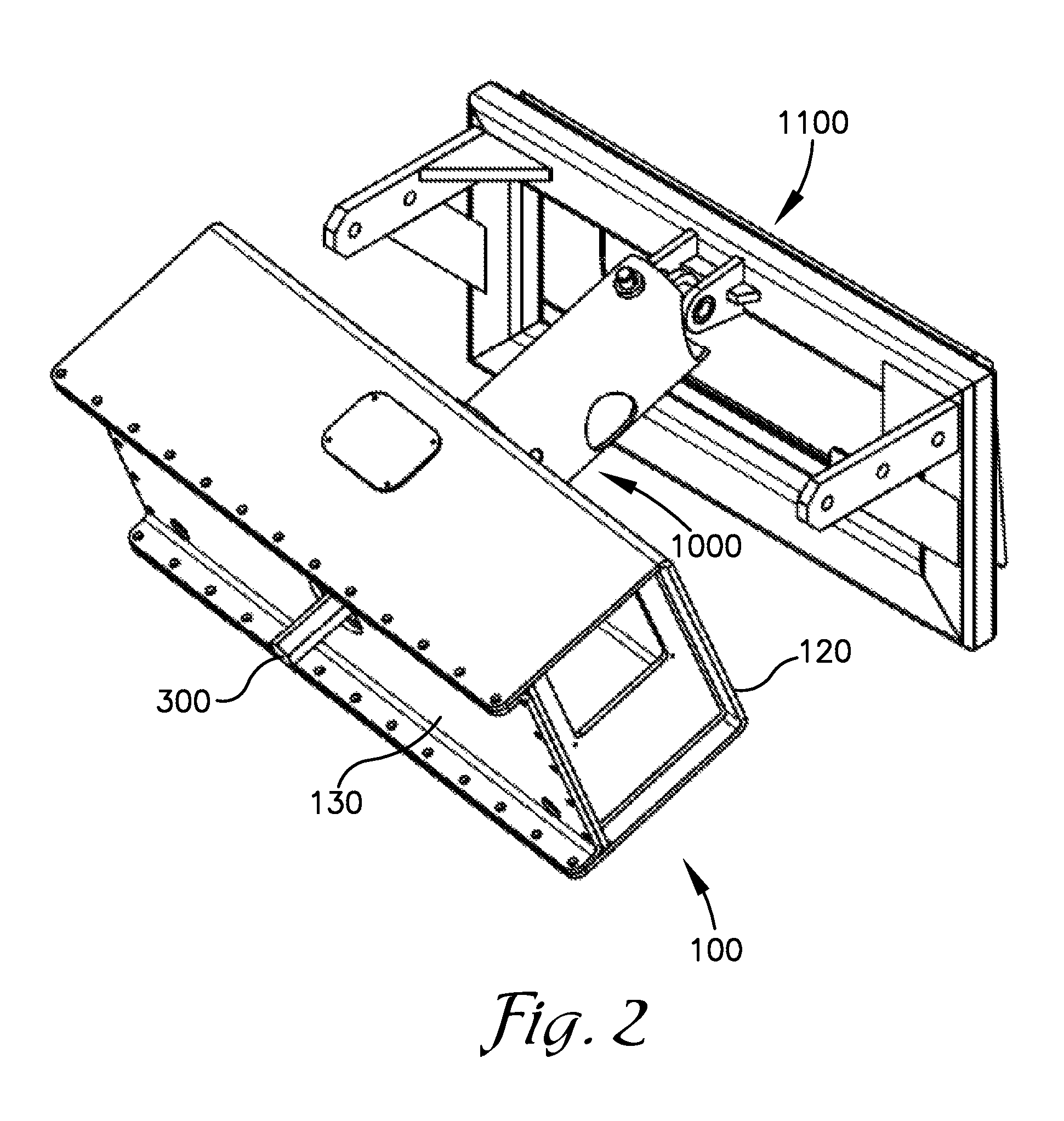

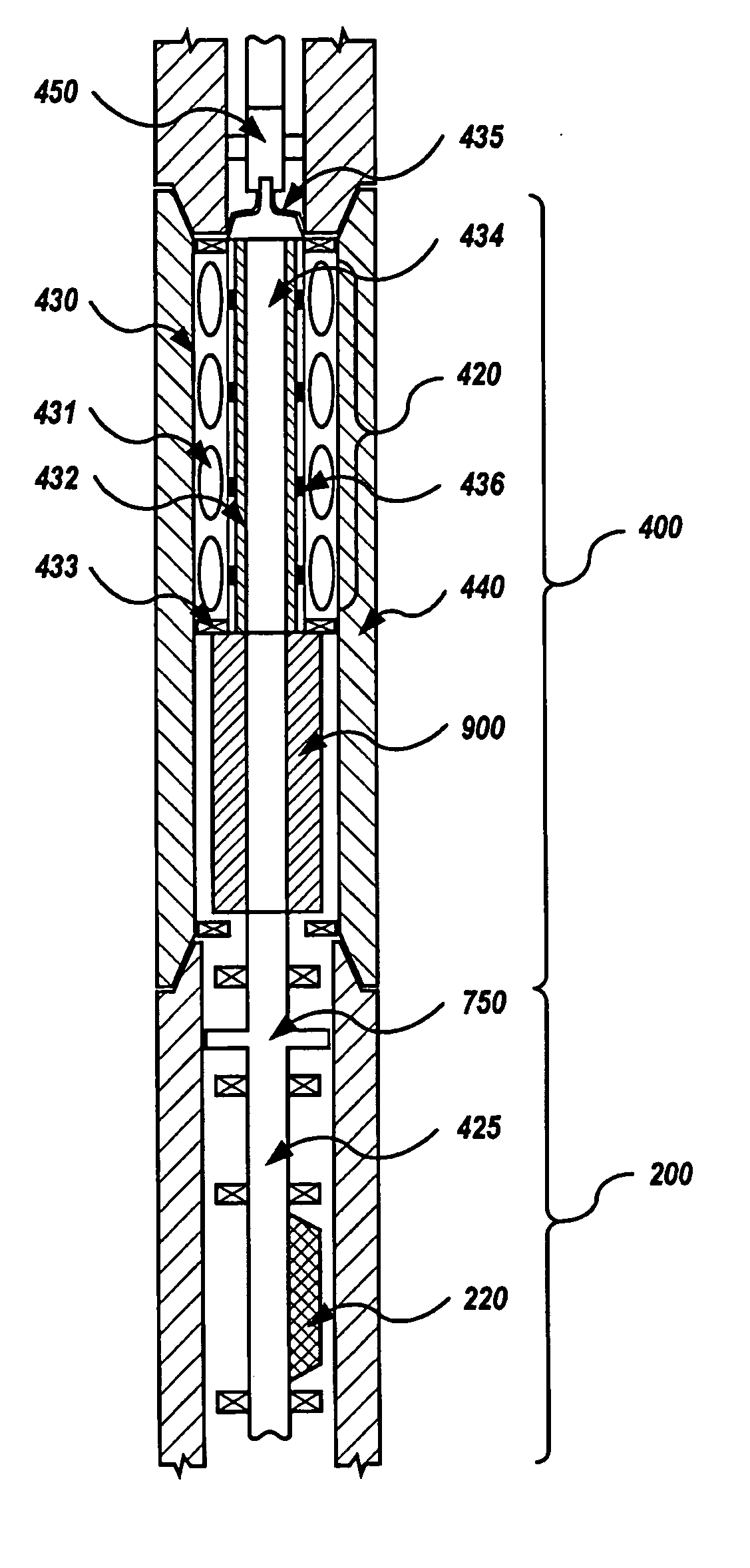

System, method and apparatus for protecting downhole components from shock and vibration

InactiveUS20120247832A1Improve permeabilityDrilling rodsConstructionsReciprocating motionEngineering

A downhole tool assembly has a component that is sensitive to shock and vibration. A reciprocating element is coupled to the component. The reciprocating element has an axial internal passage and an outer surface. A housing has an internal axial bore for receiving the reciprocating element for axial reciprocal motion therein. A retainer is mounted to the housing and seals the housing between the component and the reciprocating element. A first spring is located between the housing and the reciprocating element. A second spring is located between the reciprocating element and the retainer. A first reciprocating seal is located between the reciprocating element and the housing. A second reciprocating seal is located between the connector and the retainer. A fluid is contained by the reciprocating seals inside the housing. The reciprocating element permits a limited amount of fluid to flow between sides thereof.

Owner:PHOENIX TECH SERVICES LP

Rotating systems associated with drill pipe

Methods and apparatuses for drilling a borehole are disclosed. An electric motor electrically and mechanically coupled to a wired drill pipe is provided. The electric motor couples to a shaft that rotates when power is supplied to the electric motor. The shaft is couplable to a drill bit. The wired drill pipe transfers electricity to the electric motor from the surface. Operation of the electric motor rotates the shaft. The drill bit wears away earth to form the borehole in the earth.

Owner:HALLIBURTON ENERGY SERVICES INC

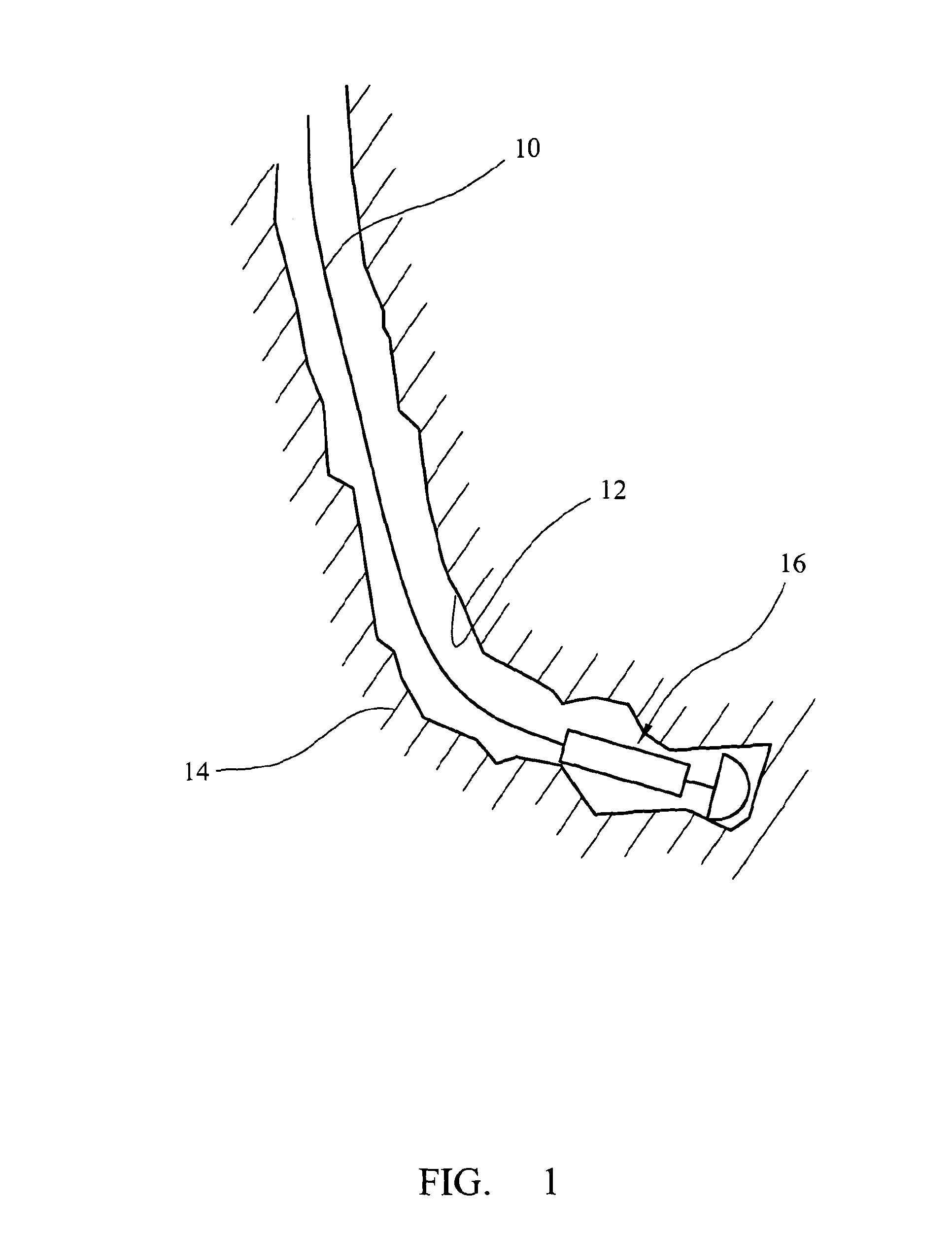

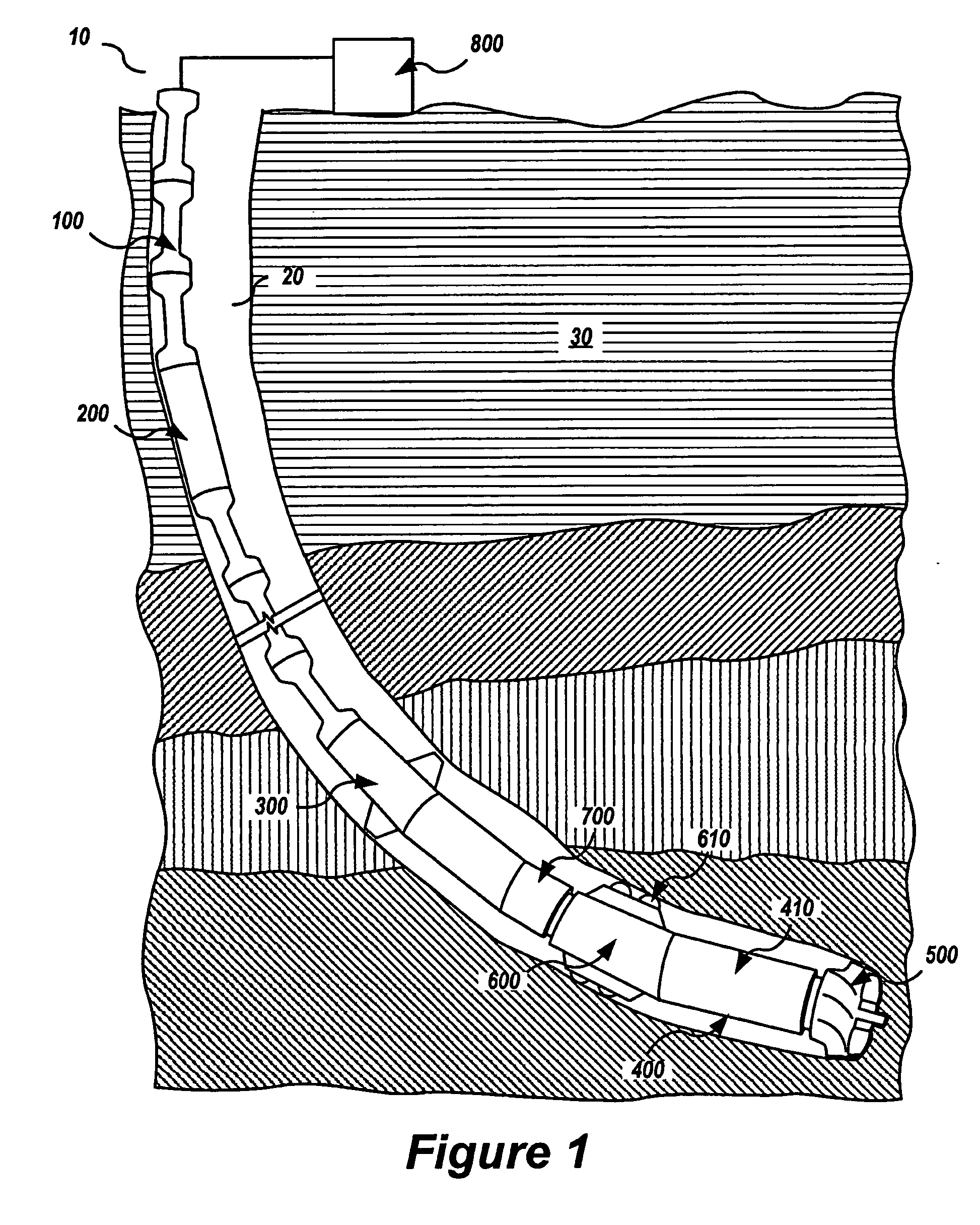

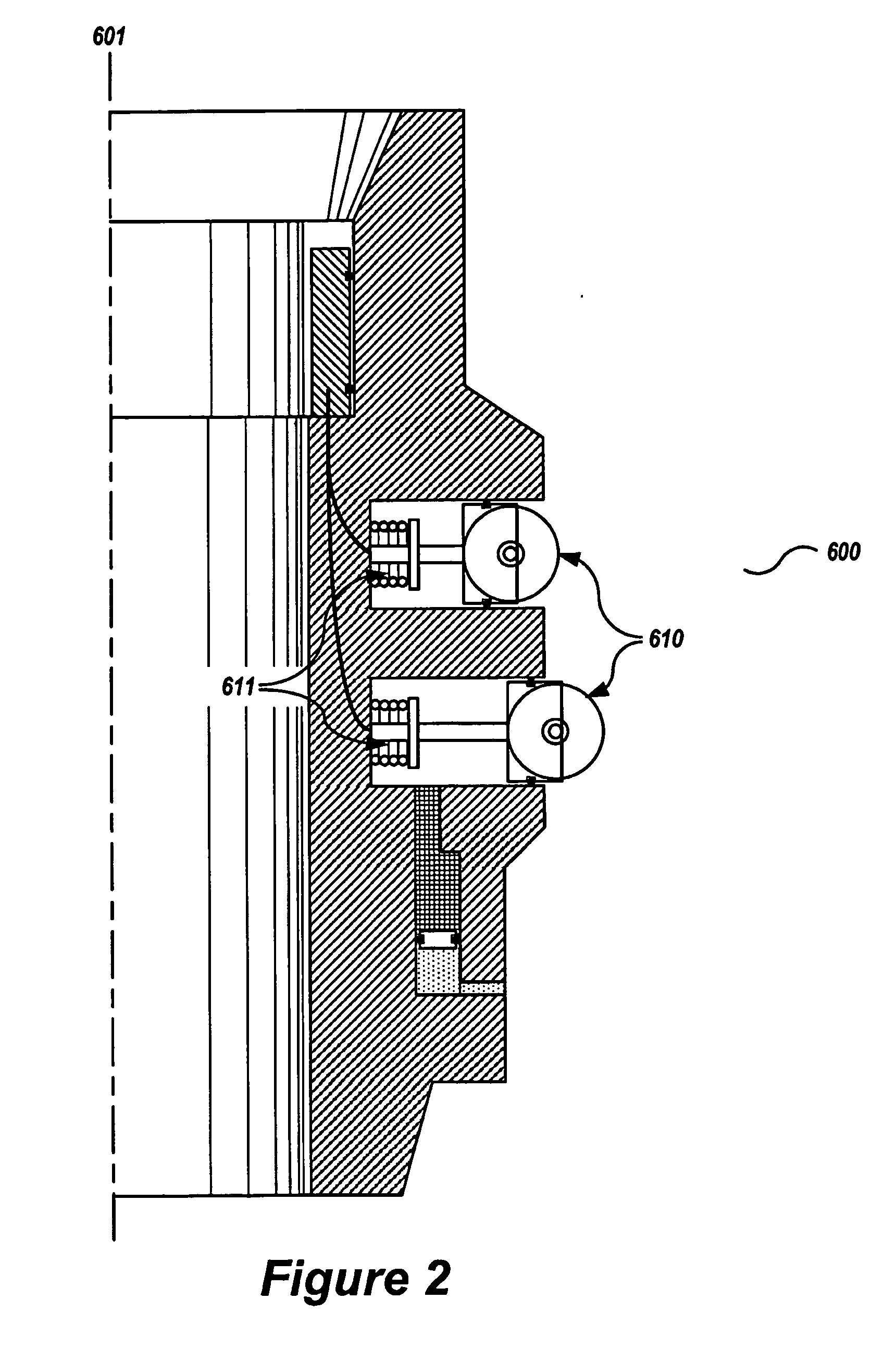

Reverse circulation directional and horizontal drilling using concentric coil tubing

InactiveUS7066283B2Less and safe mannerAvoid damageArtificial islandsDrilling rodsWell drillingCoiled tubing

Method and apparatus for drilling a directional or horizontal wellbore in a hydrocarbon formation using concentric coiled tubing drill string having an inner coiled tubing string and an outer coiled tubing string defining an annulus there between. A bottomhole assembly comprising a directional drilling means is provided at the lower end of the concentric coiled tubing drill string for reverse circulation drilling. Directional drilling means comprises a reciprocating air hammer and a drill bit, a positive displacement motor and a reverse circulating drill bit, or a reverse circulating mud motor and a rotary drill bit, and a bent sub or housing. Drilling medium is delivered through the annulus or inner coiled tubing string for operating the directional drilling means to form the directional or horizontal wellbore. Exhaust drilling medium comprising drilling medium, drilling cuttings and hydrocarbons are removed from the wellbore by extraction through the other of the annulus or inner coiled tubing string.

Owner:PRESSSOL

Jack element in communication with an electric motor and or generator

A drill bit has a body intermediate a shank and a working face and has an axis of rotation. The working face has at least one cutting element and the body has at least a portion of a jack assembly. The jack assembly has at least a portion of a shaft disposed within a cavity formed in the body of the drill bit, the shaft having a distal end extending from an opening of the cavity formed in the working face. The jack assembly also has an electric motor and / or generator.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com