Torsional impact drilling tool

A technology of percussion drilling and tools, applied in the direction of drilling with vibration, can solve the problems of broken diamond teeth, failure of drill bits, increased drilling cost, etc., and achieve the effects of short length, increase ROP, and reduce stick-slip phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

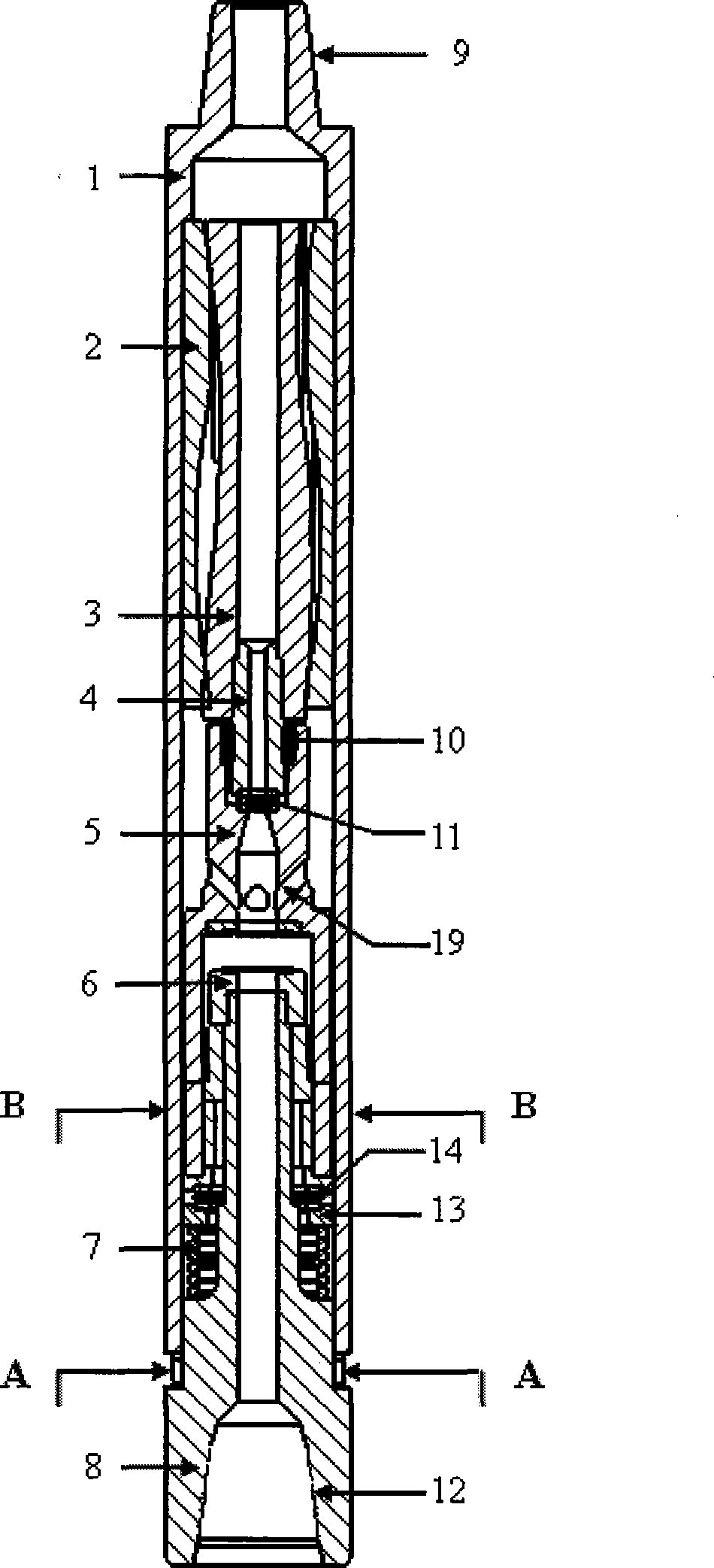

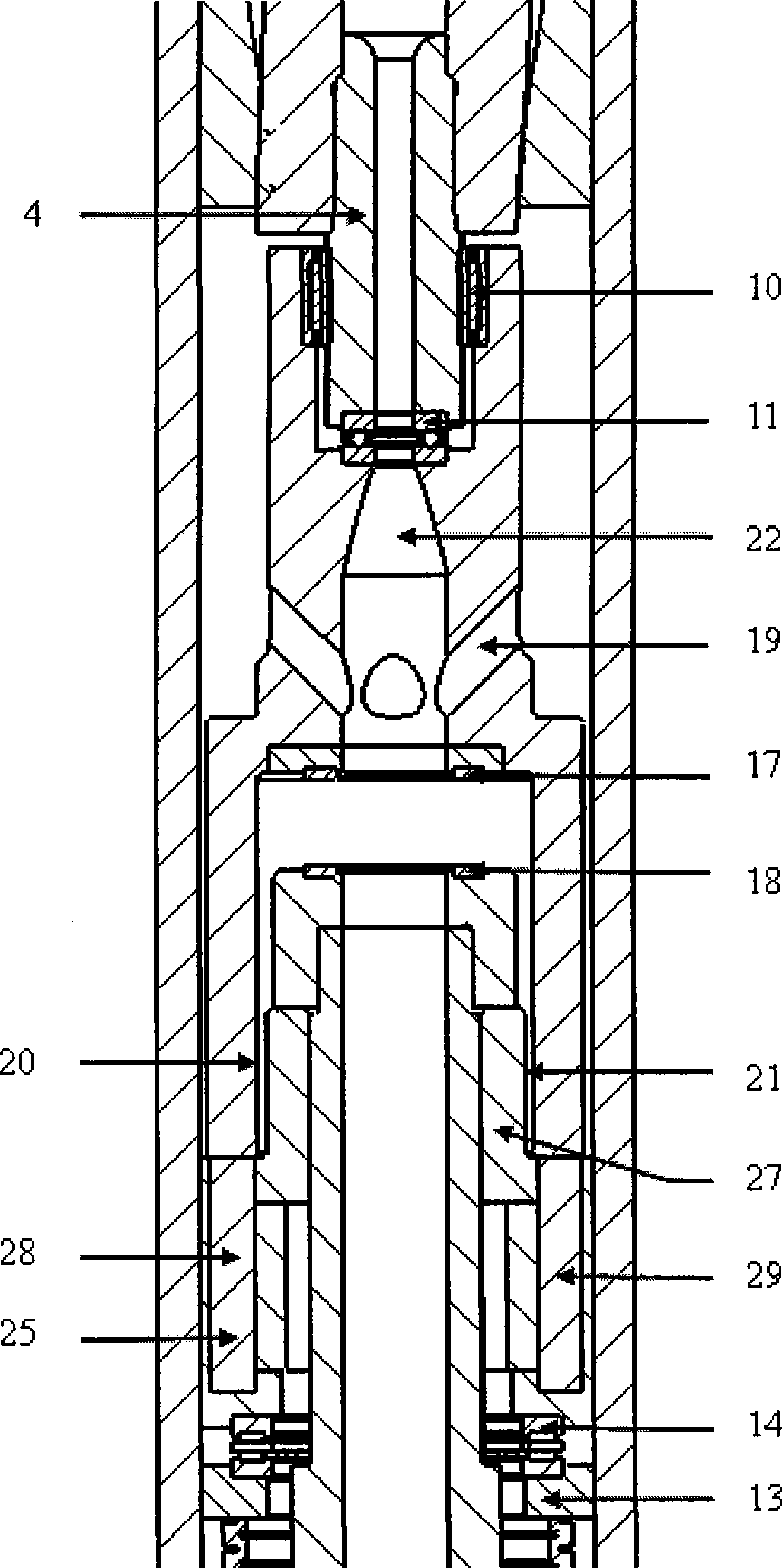

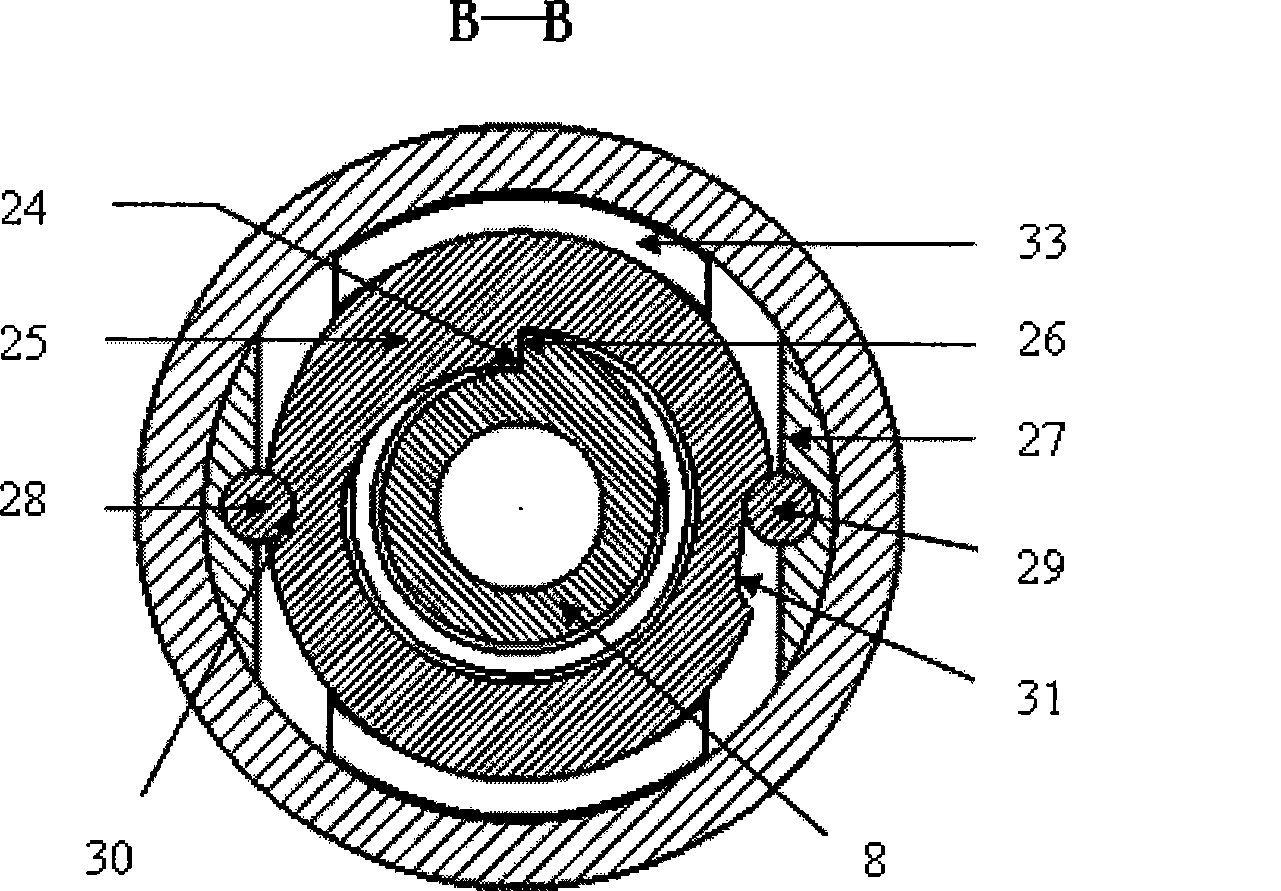

[0012] according to figure 1 , figure 2 As shown, the torsional percussion drilling tool of the present invention is composed of a housing 1, a screw motor stator 2, a screw motor rotor 3, a cardan shaft 4, a drive shaft 5, a cavity carrier 27, a sliding impactor 25 and a short drill string near the drill bit. 8 and so on, in which the housing 1 and the short joint 8 near the drill bit are connected by splines and positioned by the shaft shoulder. The joint 9 on the upper end of the housing 1 is used to connect other tools. When the housing 1 is driven, the housing 1 Cooperate with the drill string sub-section 8 near the drill bit through the spline 23 and the spline 32 to drive the drill string sub-section 8 near the drill bit; the screw motor stator 2 is fixed in the housing 1 and positioned with the inner wall; the screw motor rotor 3 and the screw motor The stator 2 cooperates to form a screw motor, which is driven by drilling fluid and provides power to drive the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com